An inner and outer drum structure of a washing machine with drying function

A technology of inner and outer drums and washing machines, applied in the field of washing machines, can solve the problems such as the difficulty of hot air blowing through the clothes, the blocked air path and the unsmooth dehydration rate, etc., so as to improve the drying efficiency, reduce the heat loss, increase the area and effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

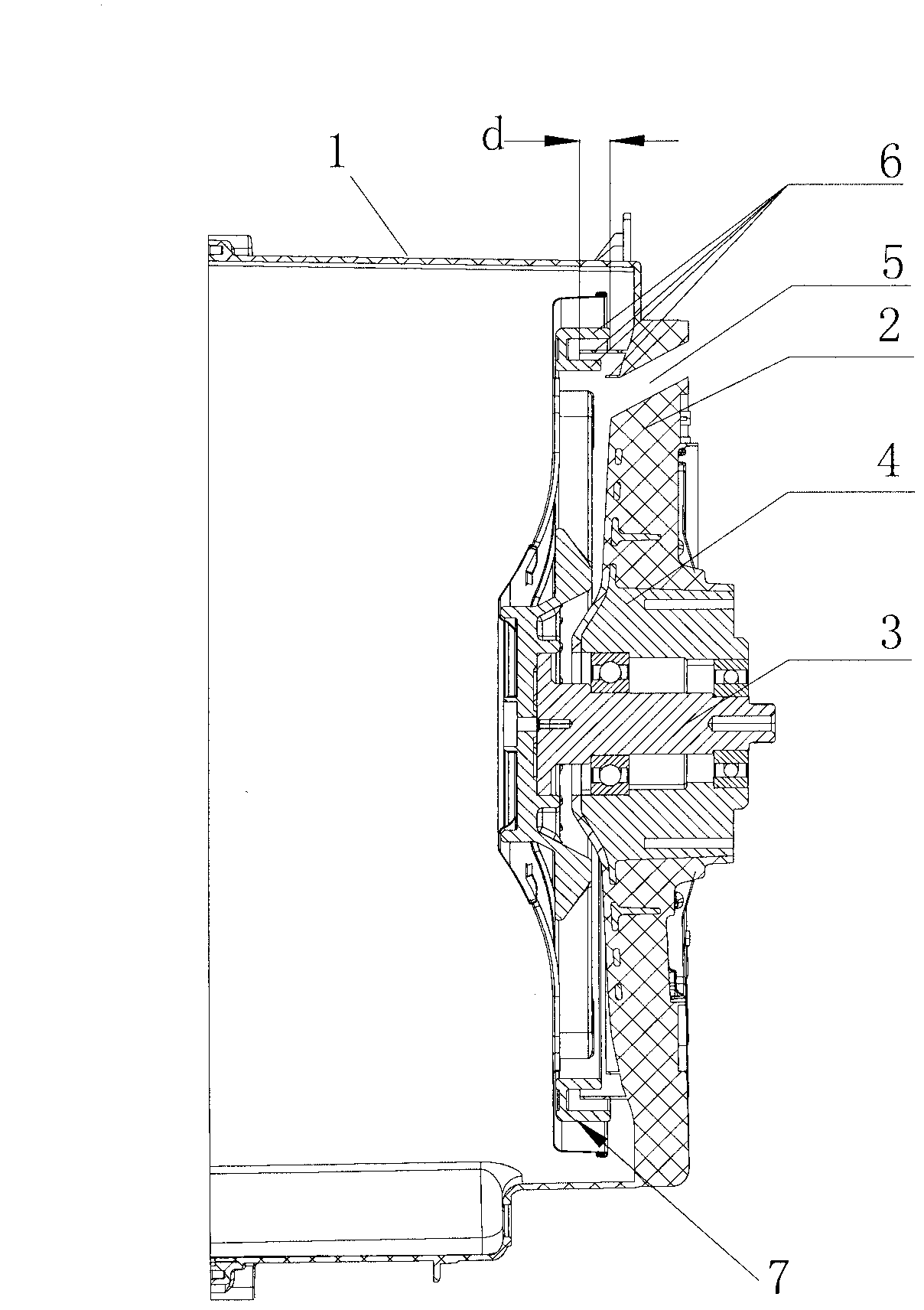

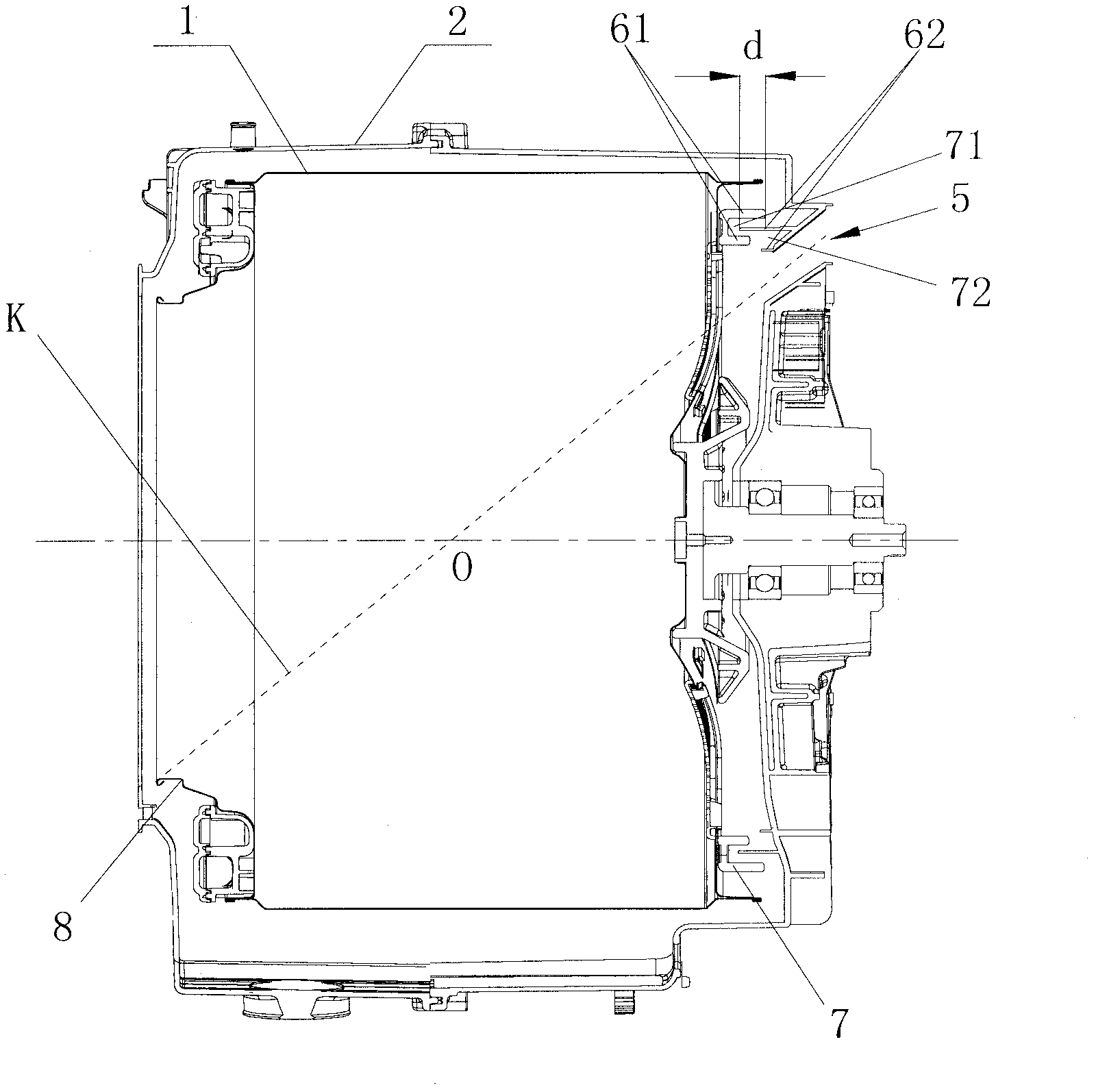

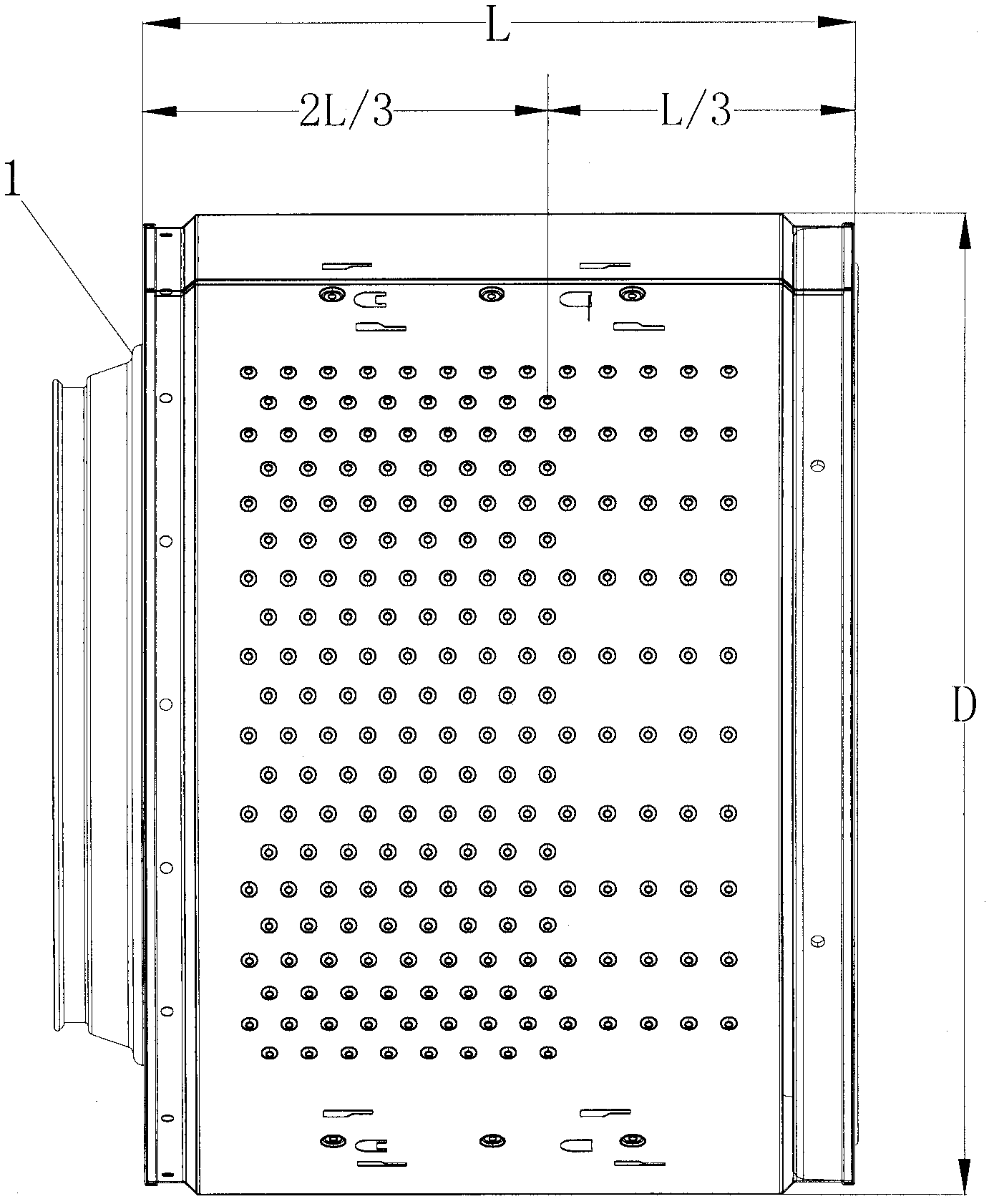

[0025] The washing machine with drying function according to the present invention comprises a casing, an outer cylinder, a driving device and a heating device arranged in the casing, an inner cylinder is arranged coaxially inside the outer cylinder, a drying air inlet is provided at the rear of the outer cylinder, and a drying air inlet is arranged at the front of the outer cylinder. There is an air outlet at the top, the heating device of the present invention can be a heater arranged in the air duct, the heater is heated, and the air blown by the fan enters the inner tube to heat the clothes, and the heated humid air is discharged to the outside or outside through the front air outlet. After passing through the lint filter, it enters the air duct to condense and dehumidify, and then the heater heats the air to circulate and dry the clothes, or the heating device is a heat pump system, and the air heated by the condenser in the heat pump is sent into the inner cylinder, from t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com