Pillared hydrotalcite and preparation method thereof

A hydrotalcite and pillared technology, which is applied in chemical instruments and methods, oxide/hydroxide preparation, tungsten compounds, etc., can solve the problems of long synthesis time of the preparation method and easy agglomeration of pillared hydrotalcite

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

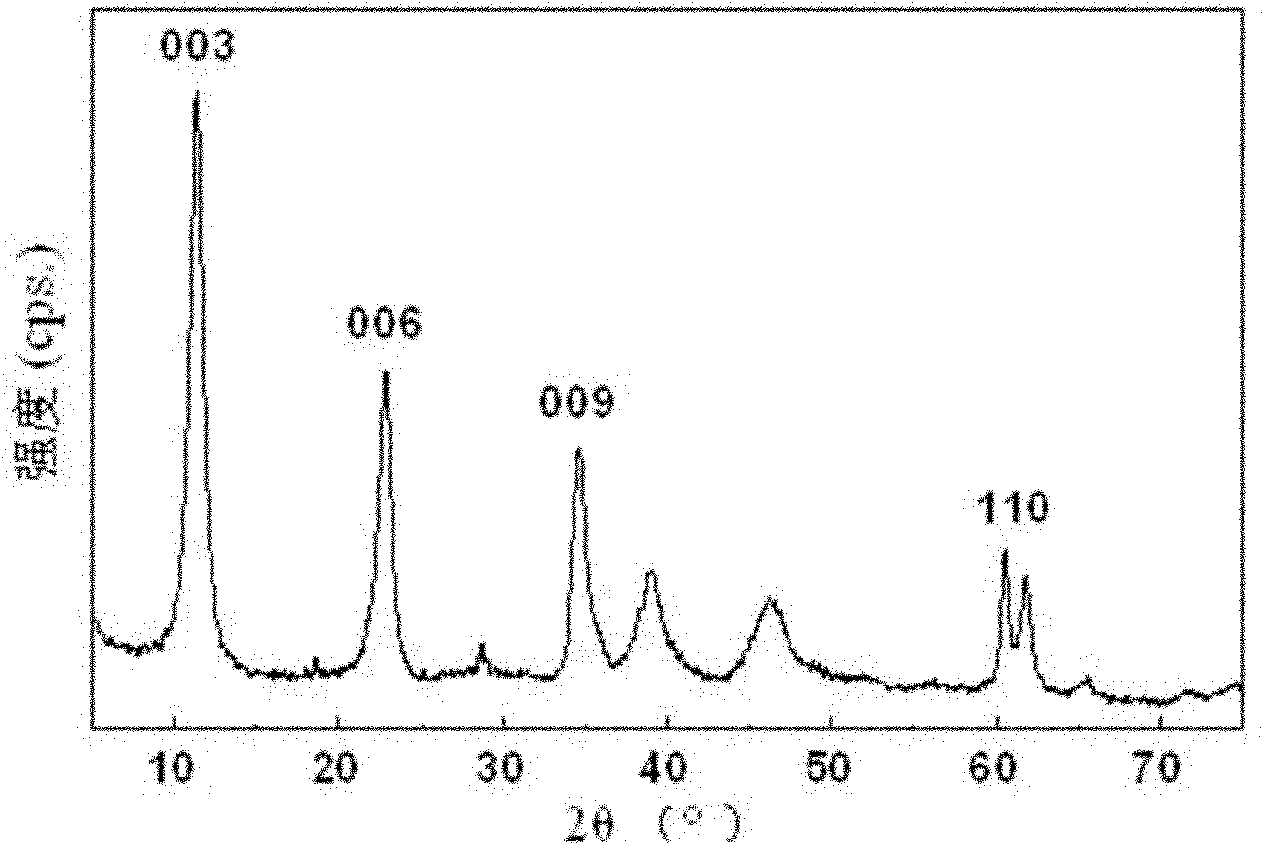

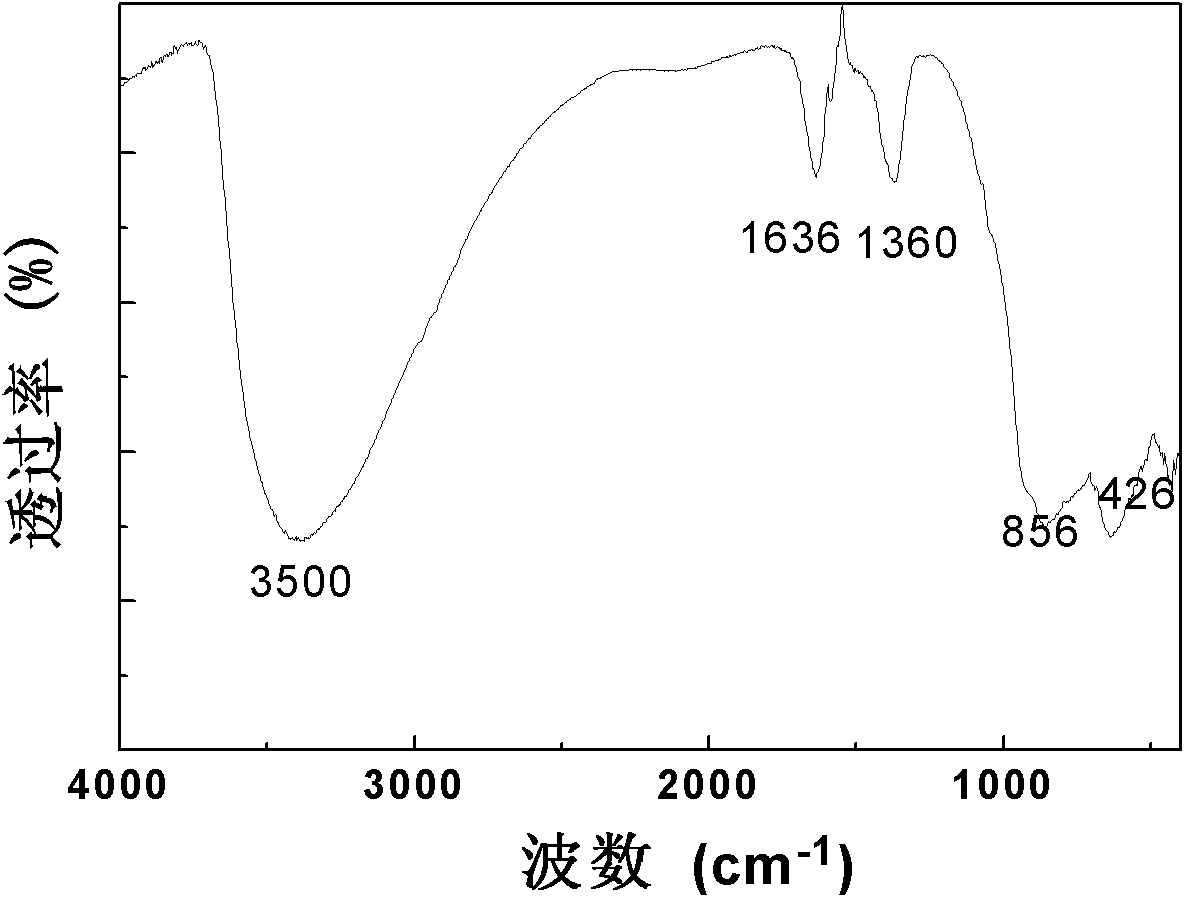

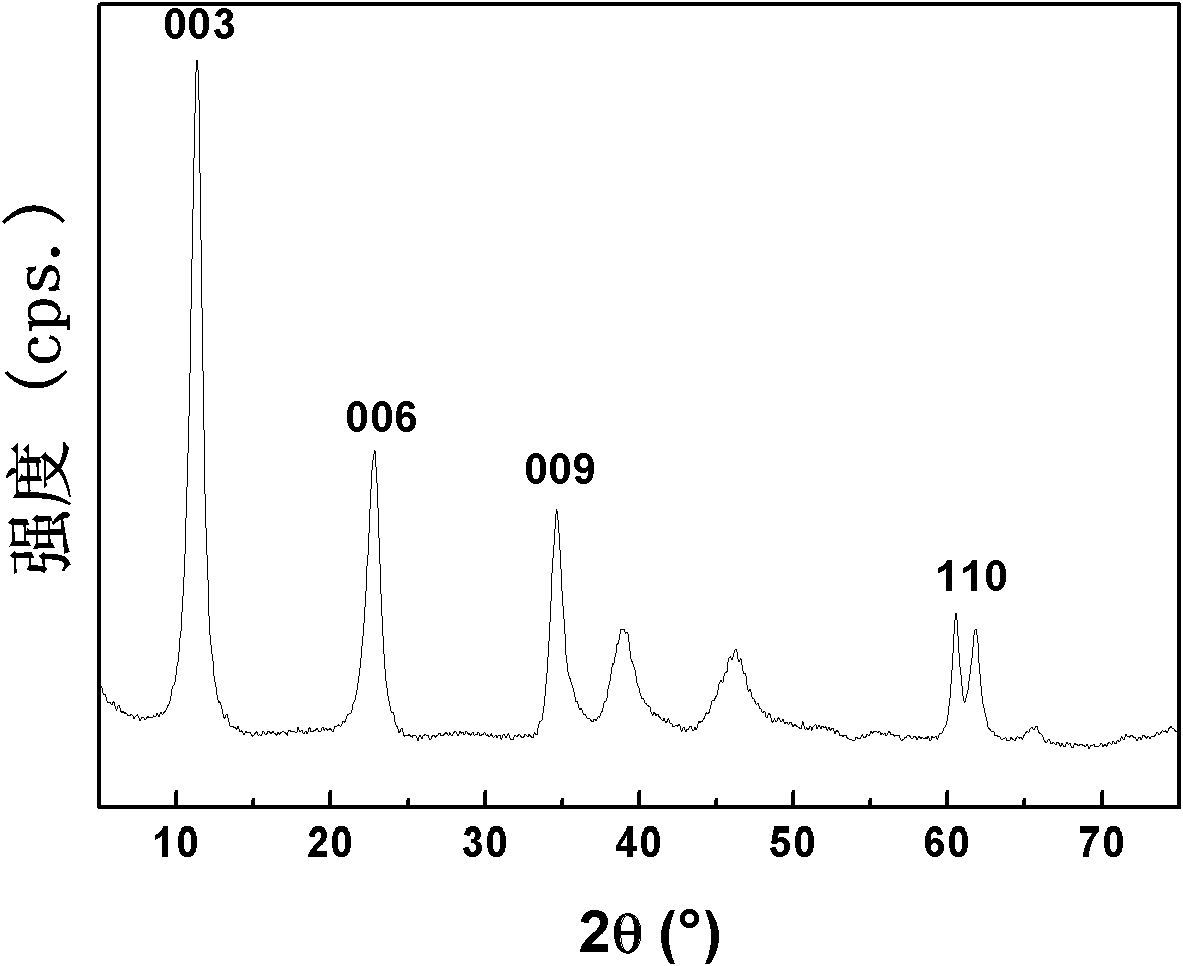

[0009] Specific embodiment one: the pillared hydrotalcite of the present embodiment, the general molecular formula of hydrotalcite is: [M 2+ 1-x m 3+ x (OH) 2 ] x- [A n- ] x / n ·zH 2 O, where the laminate body M 2+ for Mg 2+ 、Ni 2+ , Zn 2+ 、Co 2+ 、Cd 2+ 、Cu 2+ or Mn 2+ , laminate body M 3+ for Al 3+ , Fe 3+ 、Cr 3+ , Ga 3+ or Co 3+ , the interlayer anion A n- for WO 4 2- , B 4 o 7 2- , SiO 3 2- , (PO 3 ) 6 6- 、PO 4 3- 、C 6 h 5 SO 3 - 、C 2 o 4 2- 、C 4 h 4 o 6 2- 、C 6 h 5 o 7 3- or H 5 P(W 2 o 7 ) 8 2- ; 0.20≤x≤0.34, n is the interlayer anion A n- The number of charges, the value of crystal water z=1-3x / 2+d, where d=0.125.

[0010] The pillared hydrotalcite of this embodiment is surface-modified by introducing larger inorganic ions, organic anions and heteropolyacid ions to passivate the surface, which can effectively prevent the generation of hard agglomerates and improve The physical and chemical properties of its surface ca...

specific Embodiment approach 2

[0011] Embodiment 2: This embodiment differs from Embodiment 1 in that: 0.23≤x≤0.30. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0012] Embodiment 3: This embodiment is different from Embodiment 1 or Embodiment 2 in that: x=0.26. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com