Patents

Literature

47results about How to "Improve structural regularity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Positive Electrode Material for Secondary Battery and the Preparation Method Thereof

InactiveUS20090121179A1Well mixedDecrease material electrochemical activityCell electrodesLi-accumulatorsX-rayLithium-ion battery

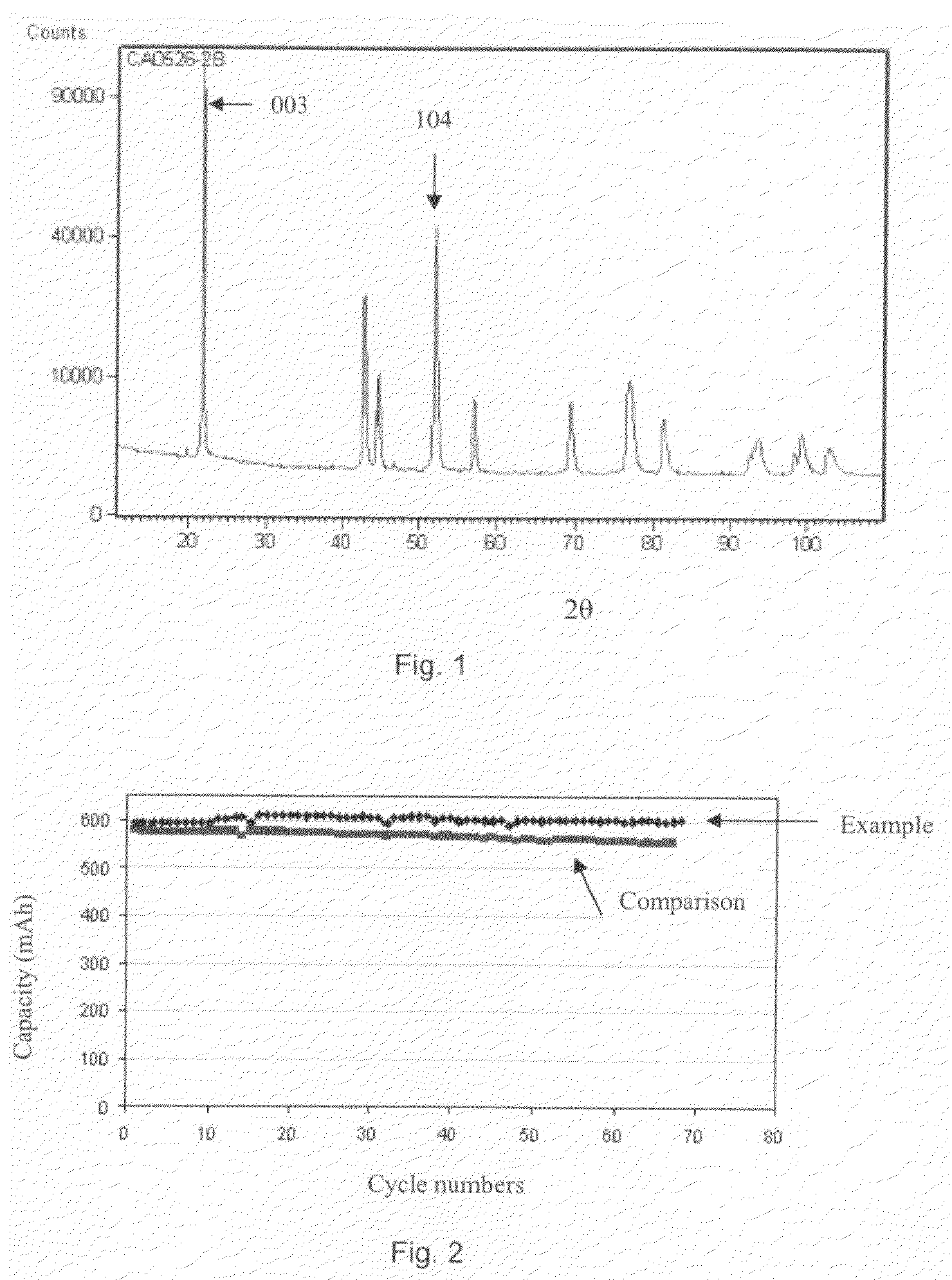

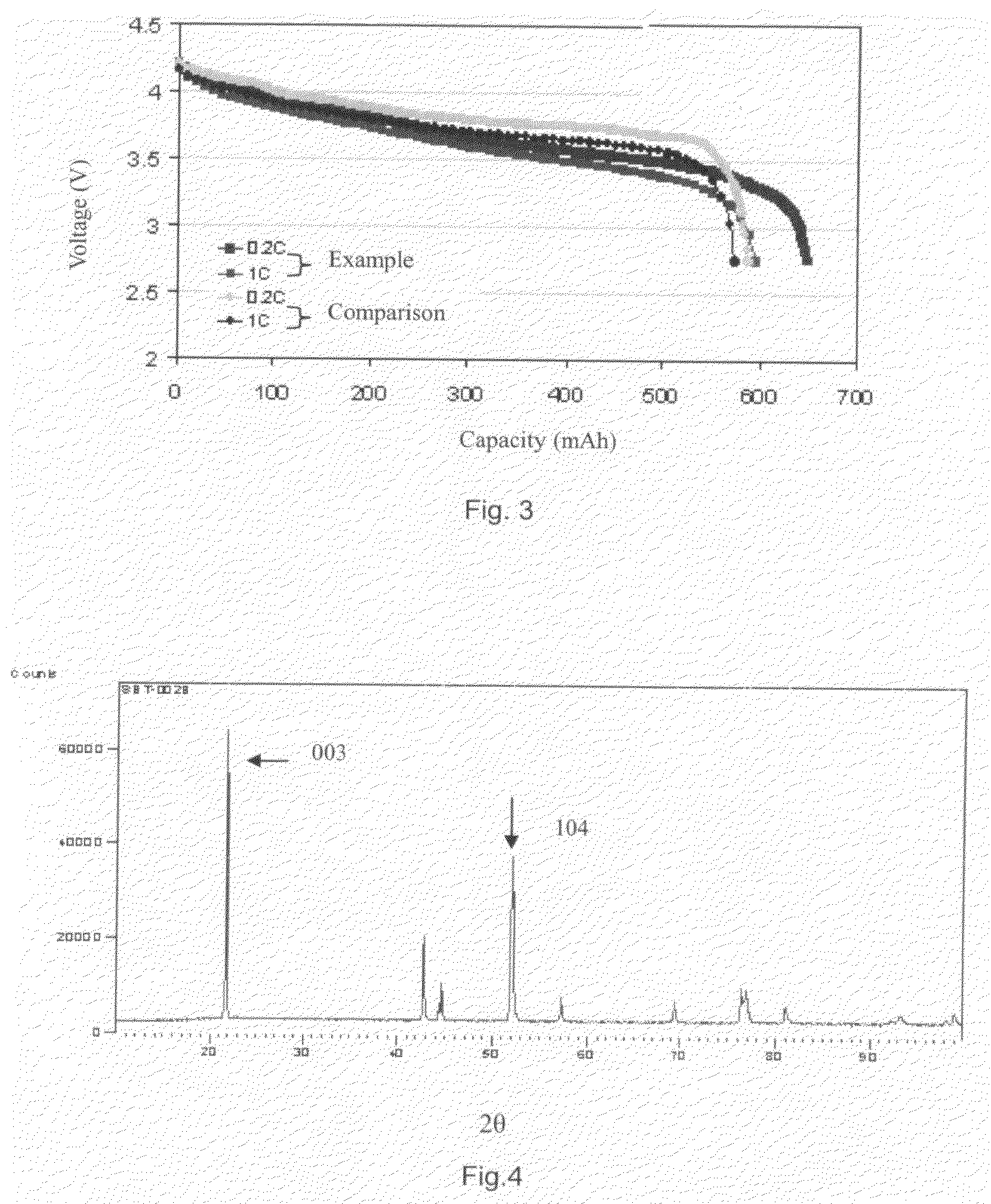

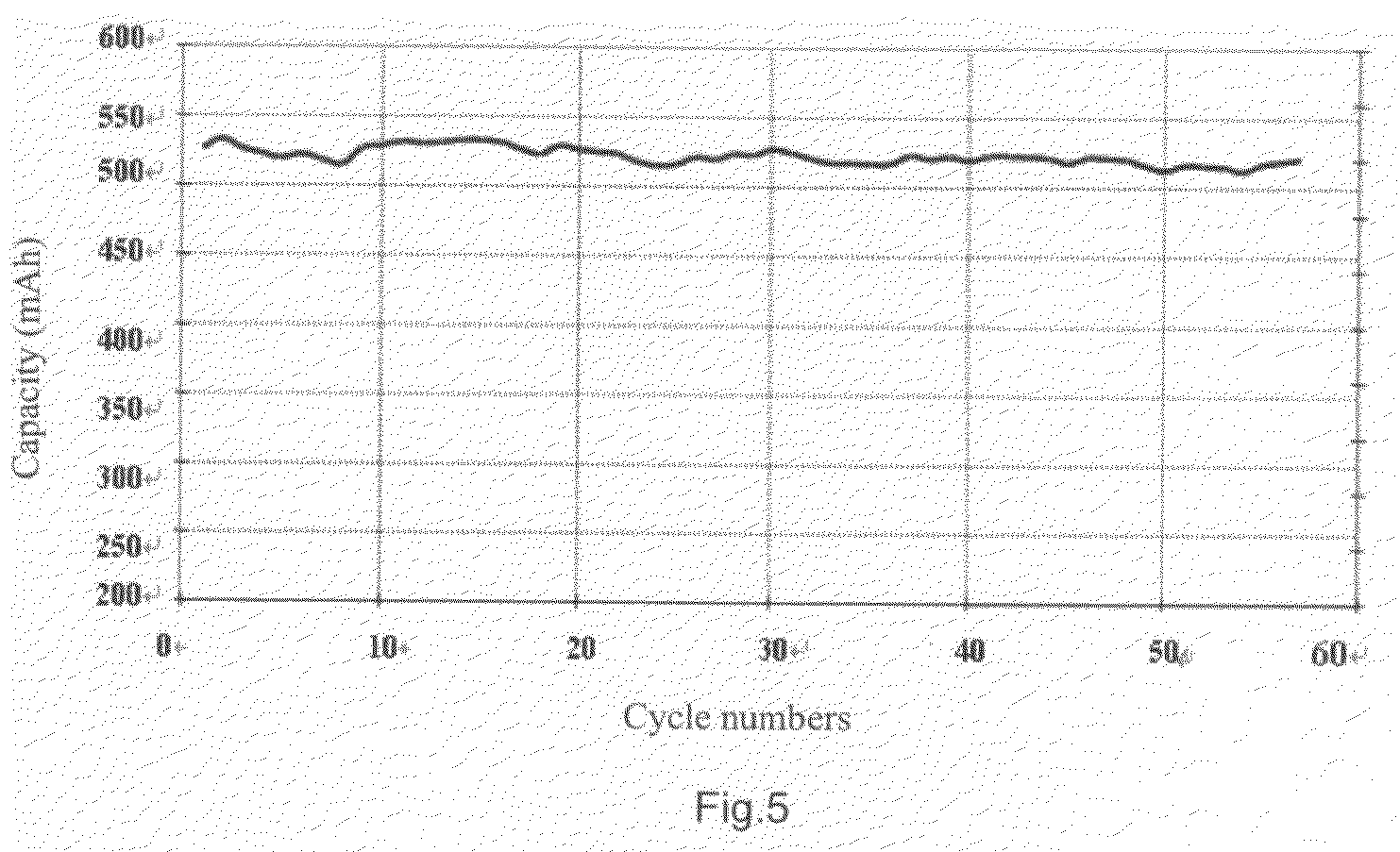

The present invention relates to a positive electrode material for secondary battery and the preparation method thereof, wherein the said positive electrode material comprises LixNi1−y−zCoyMezO2±n as the main component, 0.9≦x≦1.1, 0<y≦0.3, 0≦z≦0.1, 0≦n≦0.1 and Me is selected at least one or two elements from the group consisting of Mg, Zn, Mn, Co, Al and Ca in the formula, and LivNi1−aMe′aO2±m or LixNi1−yMe″yPO4 existed on the polycrystalline surface of the main component and / or among the crystal phase of the main component. The proportion of peak intensity ratio of (003) to (104) of the positive electrode material in the polycrystalline X-ray diffraction spectrum is 2.0≦I(003) / I(104)≦3.0. The secondary battery comprising said positive electrode material is liquid, solid or polymer lithium secondary battery or lithium ion battery.

Owner:SOBRIGHT TECH

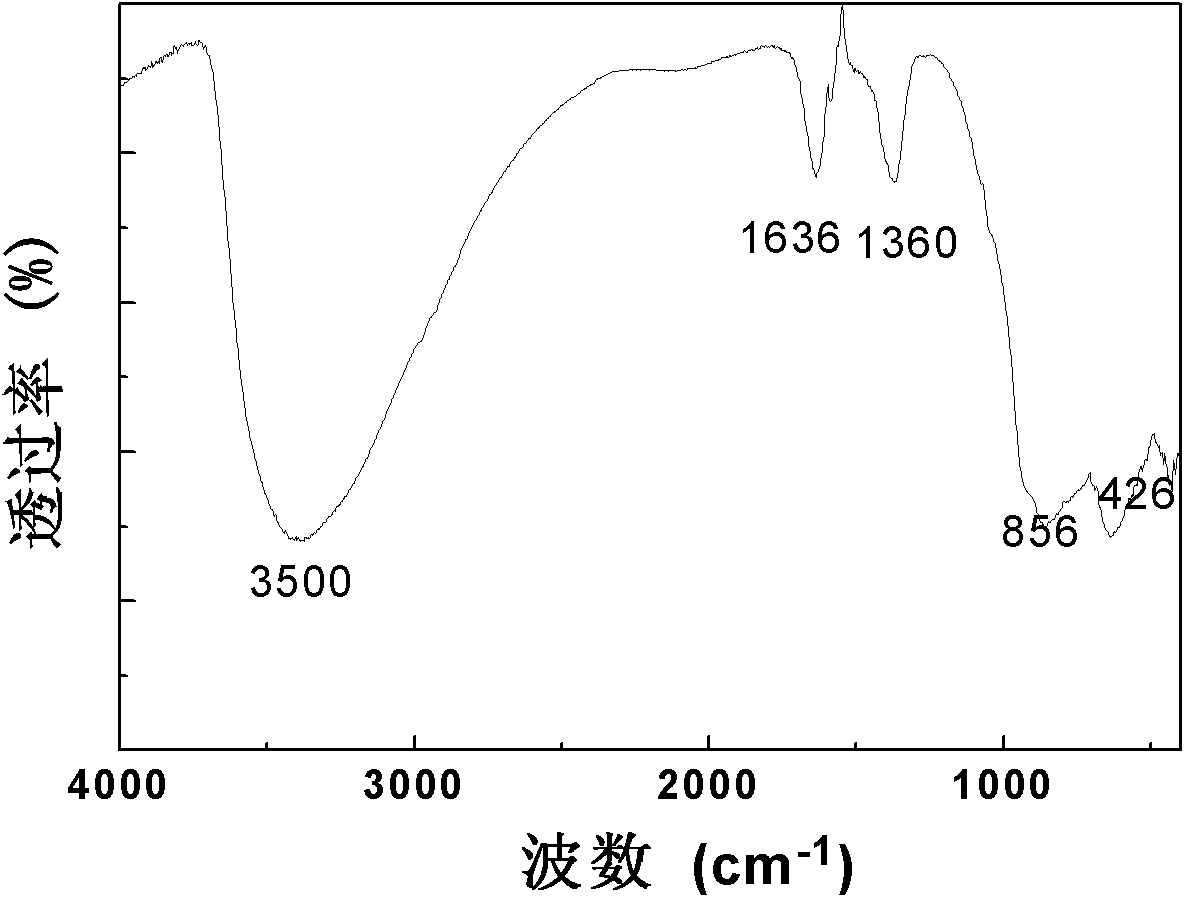

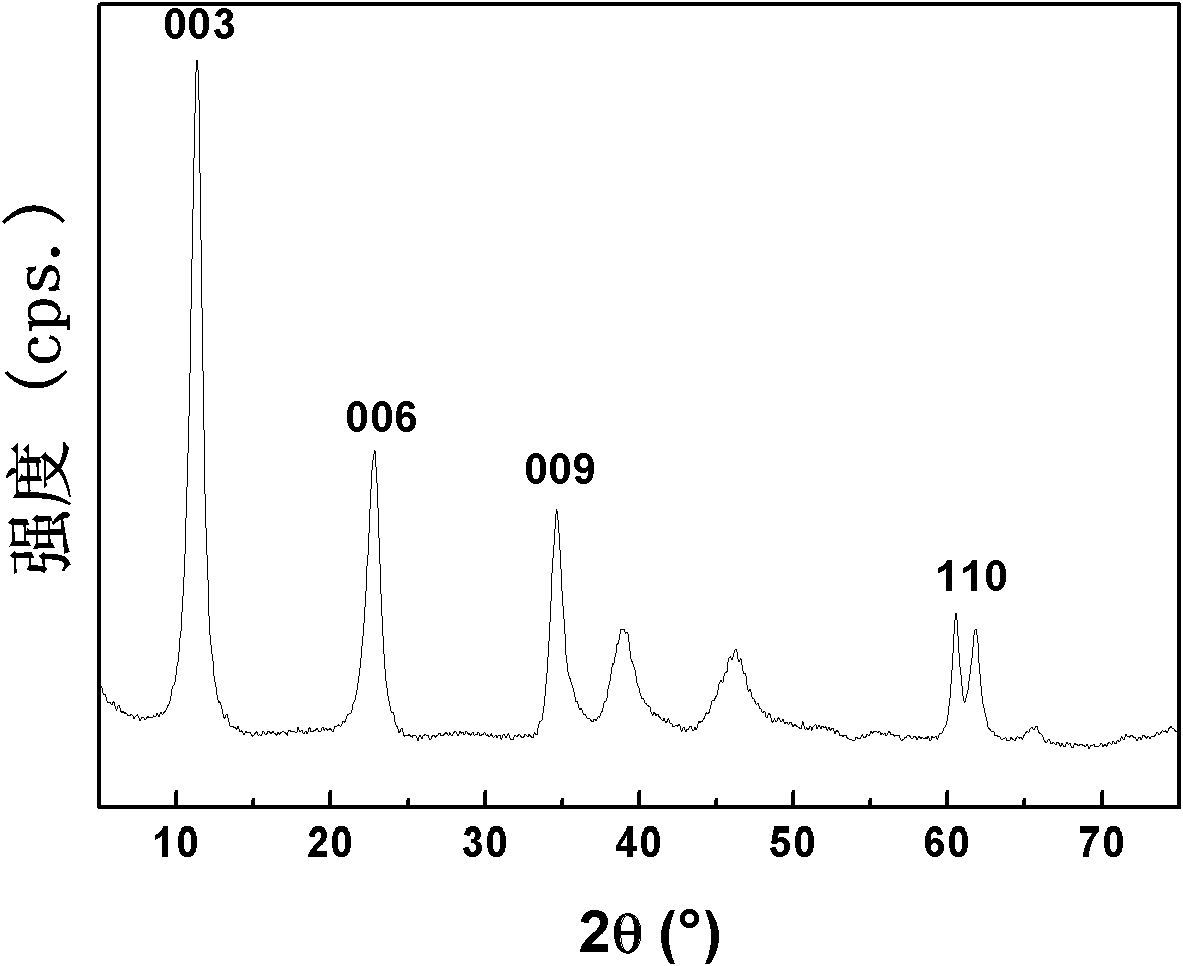

Pillared hydrotalcite and preparation method thereof

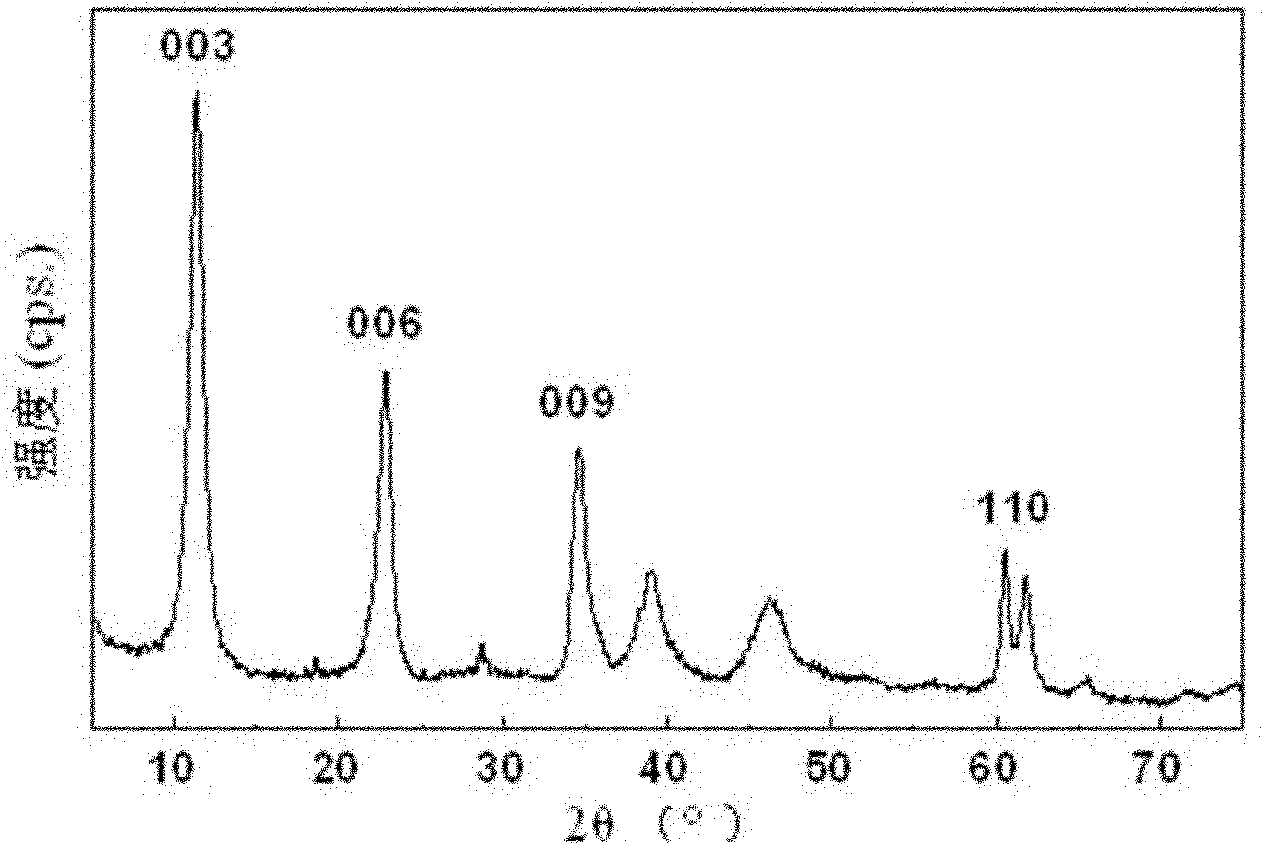

InactiveCN101913570AIncrease profitHigh crystallinityOxide/hydroxide preparationTungsten compoundsIon exchangeStructural formula

The invention discloses pillared hydrotalcite and a preparation method thereof, relates to hydrotalcite and a preparation method thereof, and solves the problems of easy agglomeration and long preparation time of the conventional pillared hydrotalcite. The structural formula of the pillared hydrotalcite is [M2+1-xM3+x(OH)2]x+[An-]x / n.zH2O, wherein M2+ and M3+ are laminar main body ions, An- is an interlayer ion, x is more than or equal to 0.20 and less than or equal to 0.34, and z is the number of crystal water. The method comprises the following steps of: dripping aqueous solution of mixed salt containing M2+ and M3+ and aqueous solution of alkali sodium carbonate into the stirring water, and obtaining a bimetallic composite oxide by microwave crystallization and sintering; and preparing reduction solution from the bimetallic composite oxide, sodium hydroxide and soluble salt of the interlayer ion An-, and performing microwave crystallization and sintering on the reduction solution to obtain the pillared hydrotalcite. The pillared hydrotalcite of the invention is difficult to agglomerate, the exchange time of the interlayer negative ions is only 10 to 20 minutes, and the pillared hydrotalcite can be used in the macromolecular flame-retardant field.

Owner:NORTHEAST FORESTRY UNIVERSITY

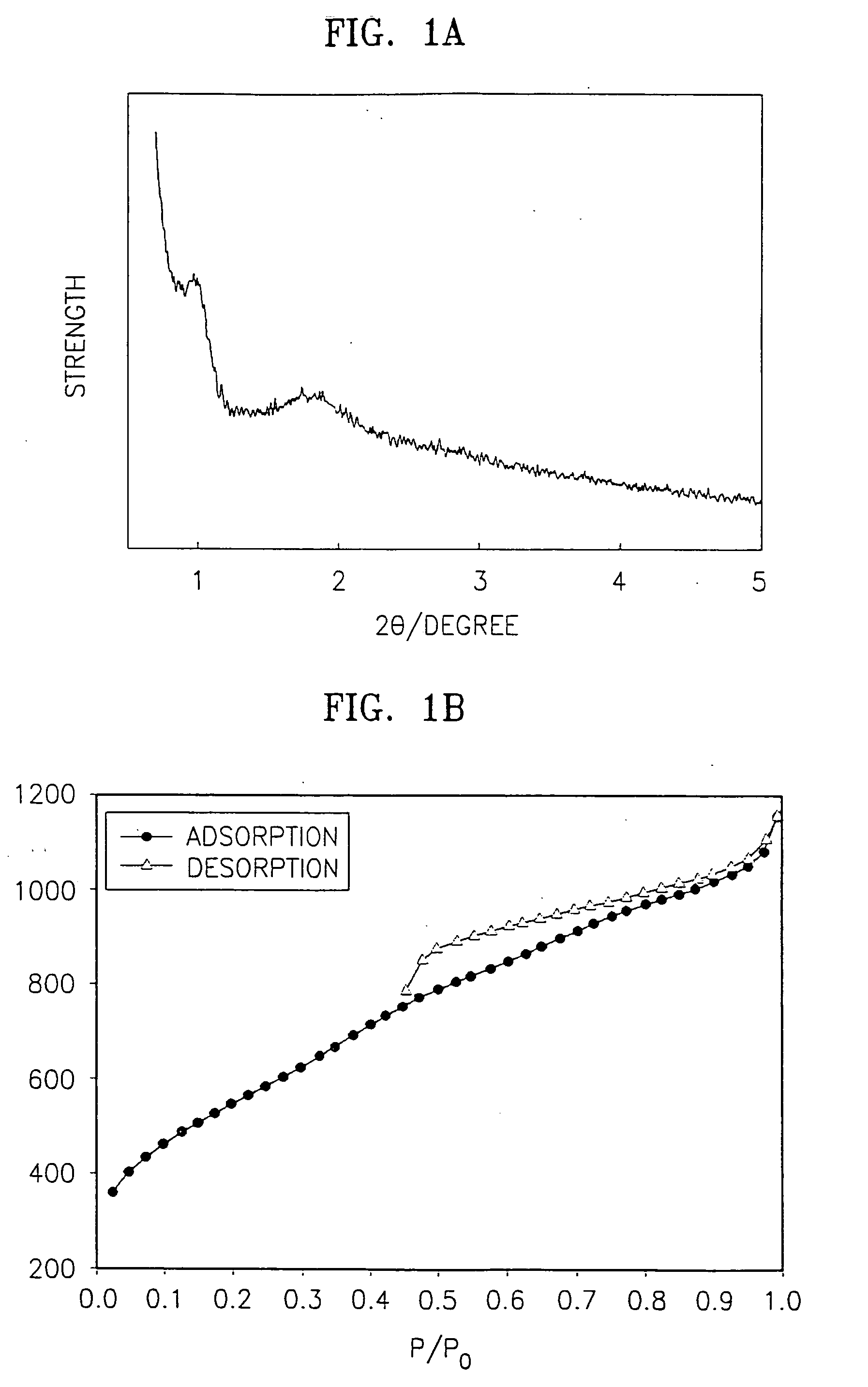

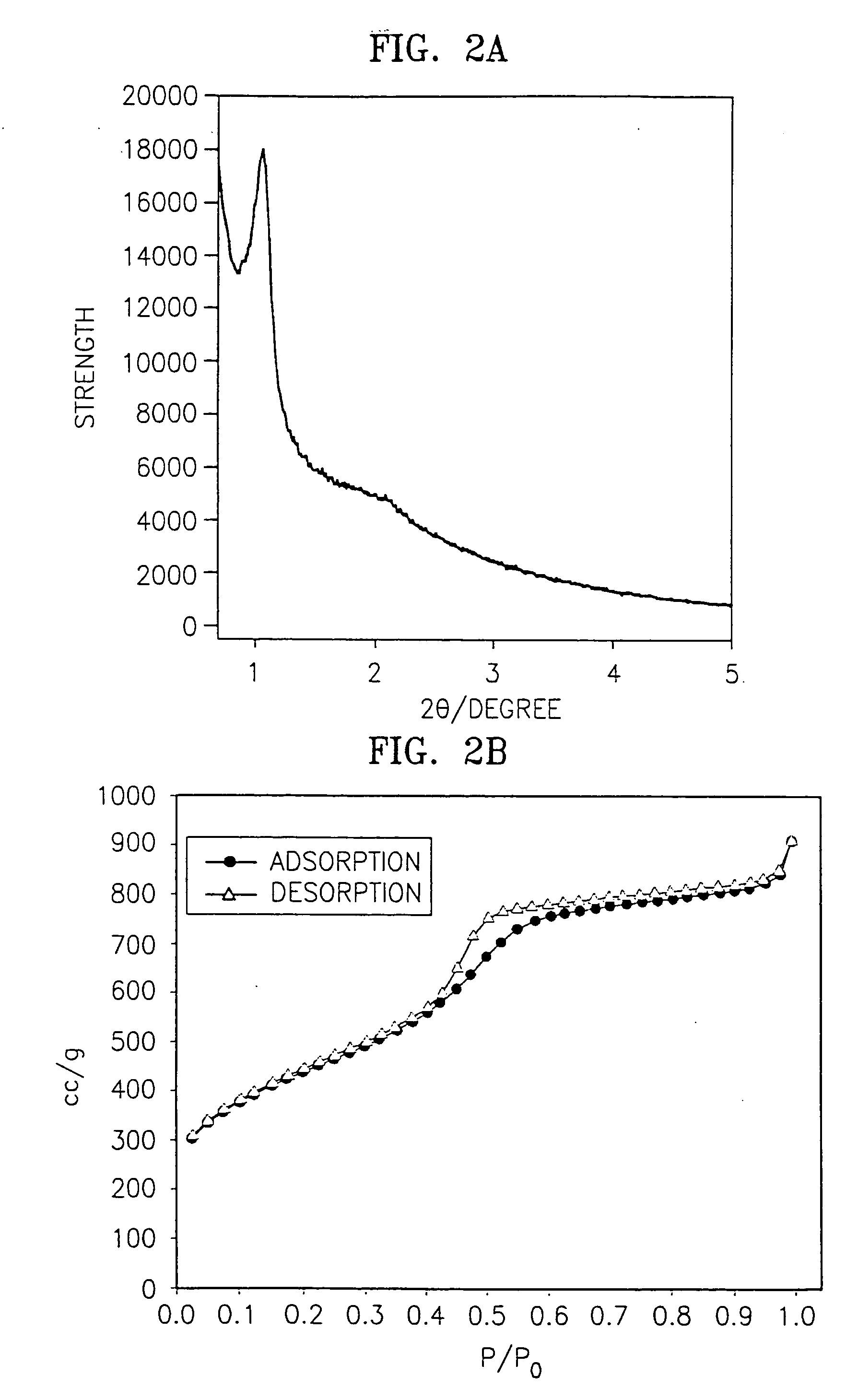

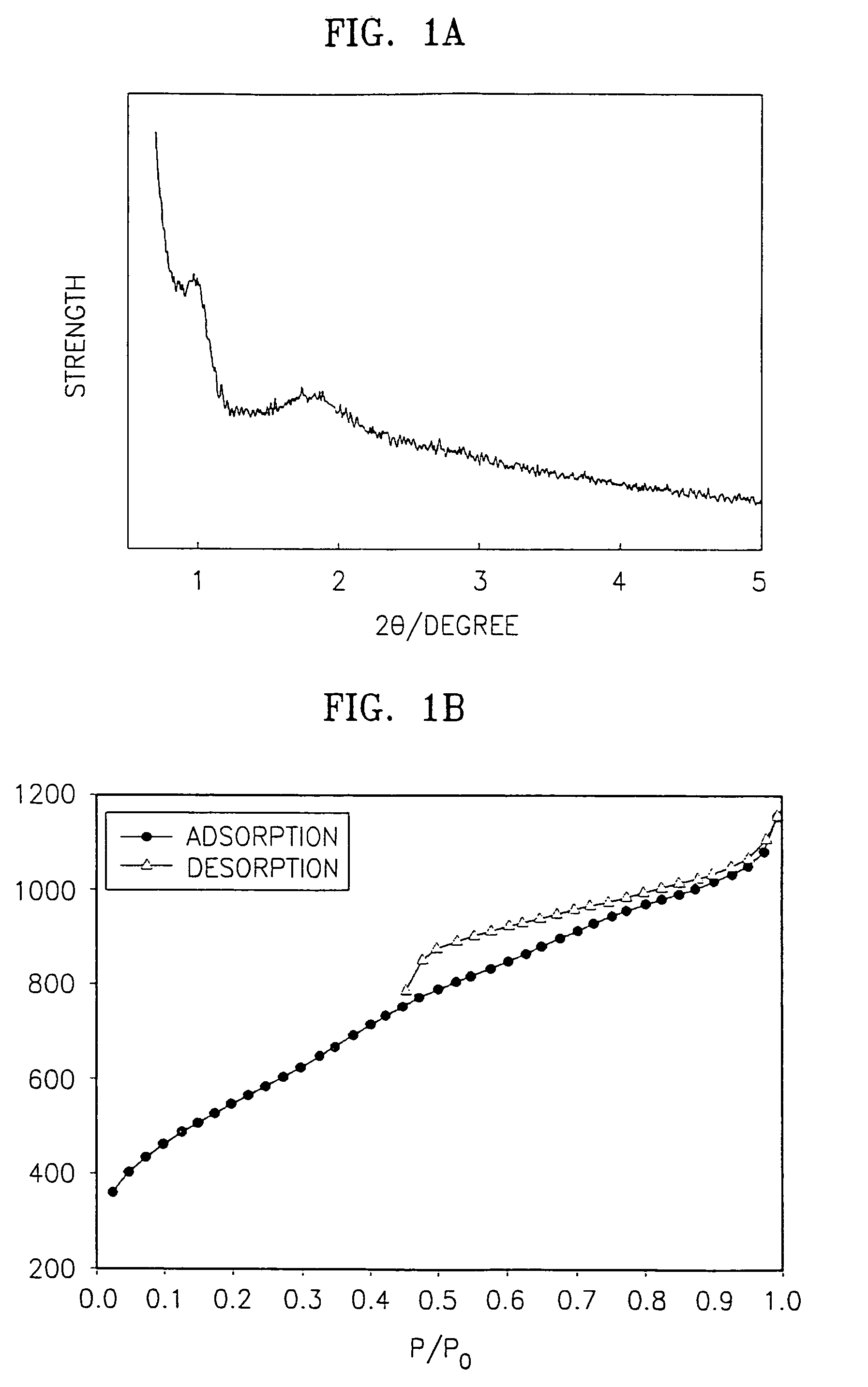

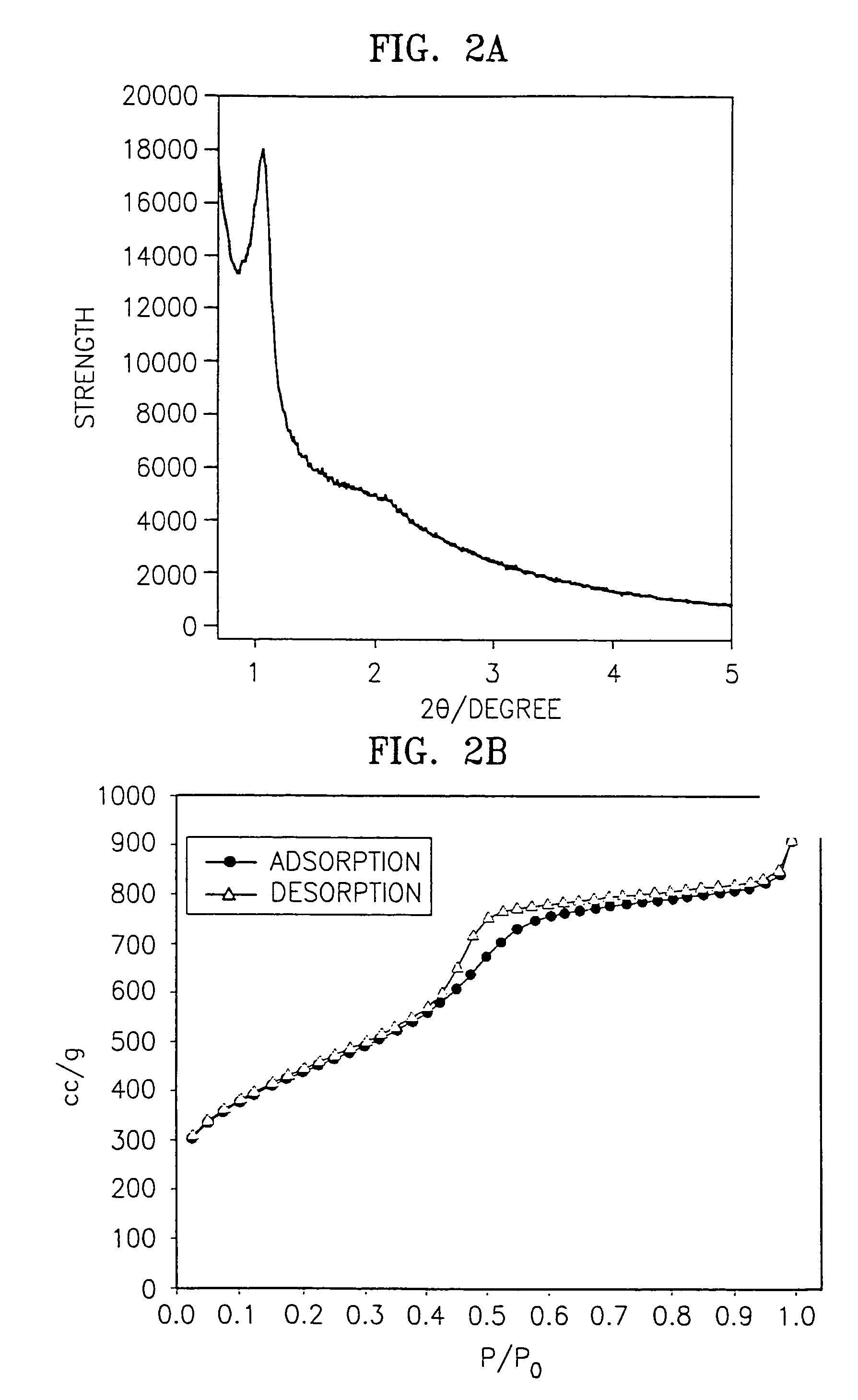

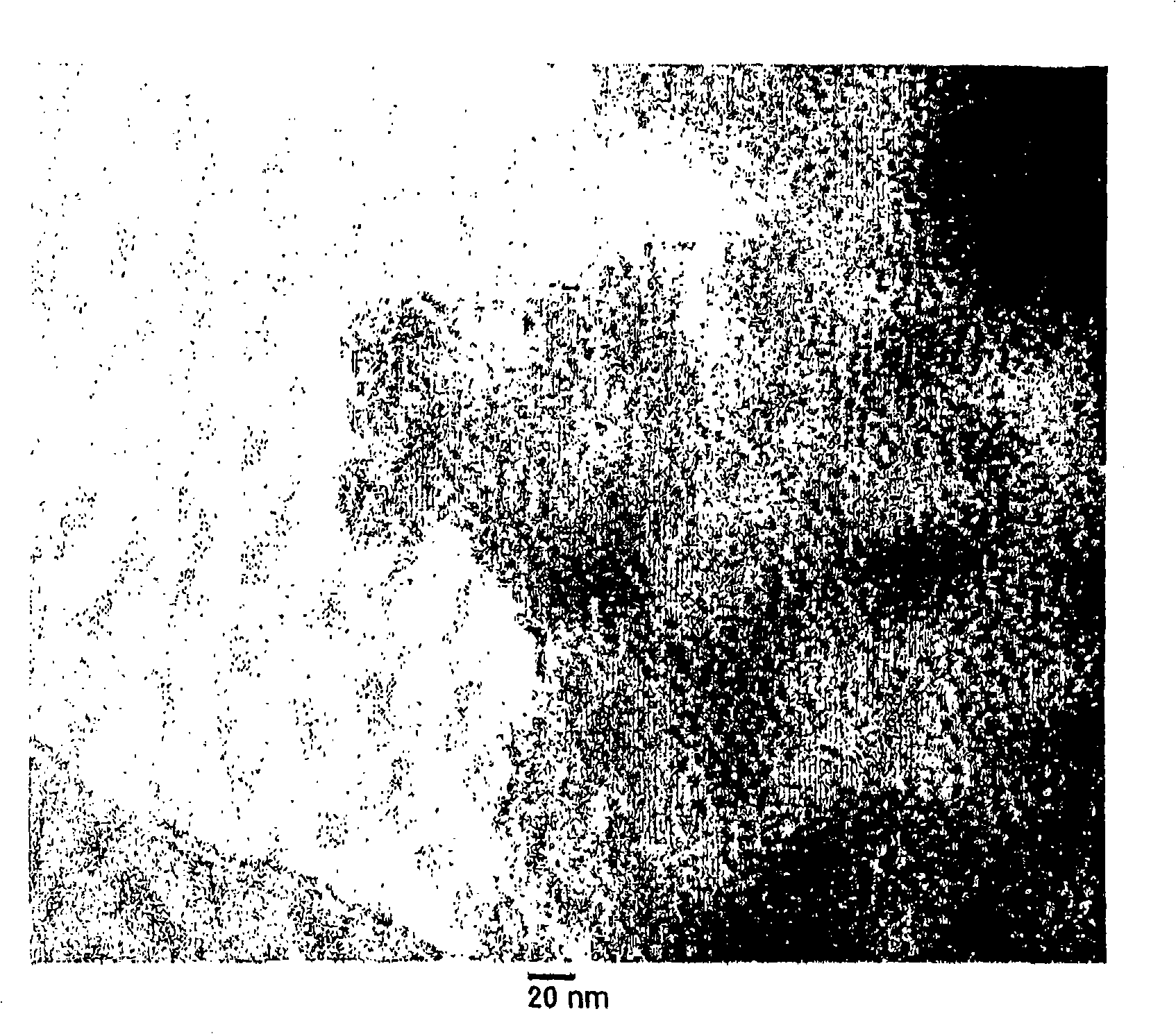

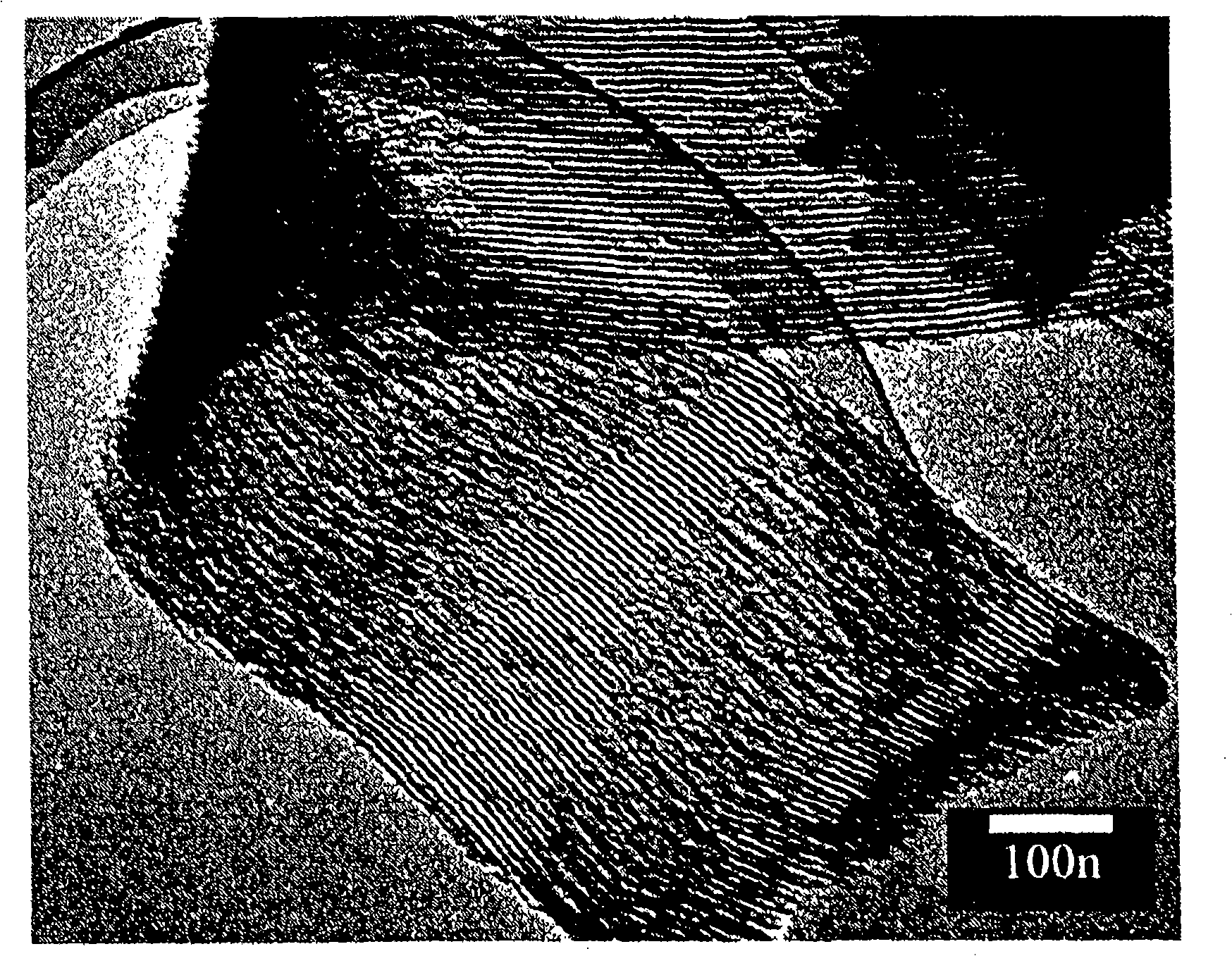

Carbon molecular sieve and method for manufacturing the same

InactiveUS20050036935A1High porosityImprove structural regularityMolecular sieve catalystsOther chemical processesMolecular sieveFuel cells

A method for manufacturing a carbon molecular sieve with increased microporosity; a method for manufacturing a carbon molecular sieve with increased microporosity and improved structural regularity; a carbon molecular sieve with increased microporosity; a carbon molecular sieve with increased microporosity and improved structural regularity; a catalyst for a fuel cell using the carbon molecular sieve; and a fuel cell using the catalyst are provided.

Owner:SAMSUNG SDI CO LTD

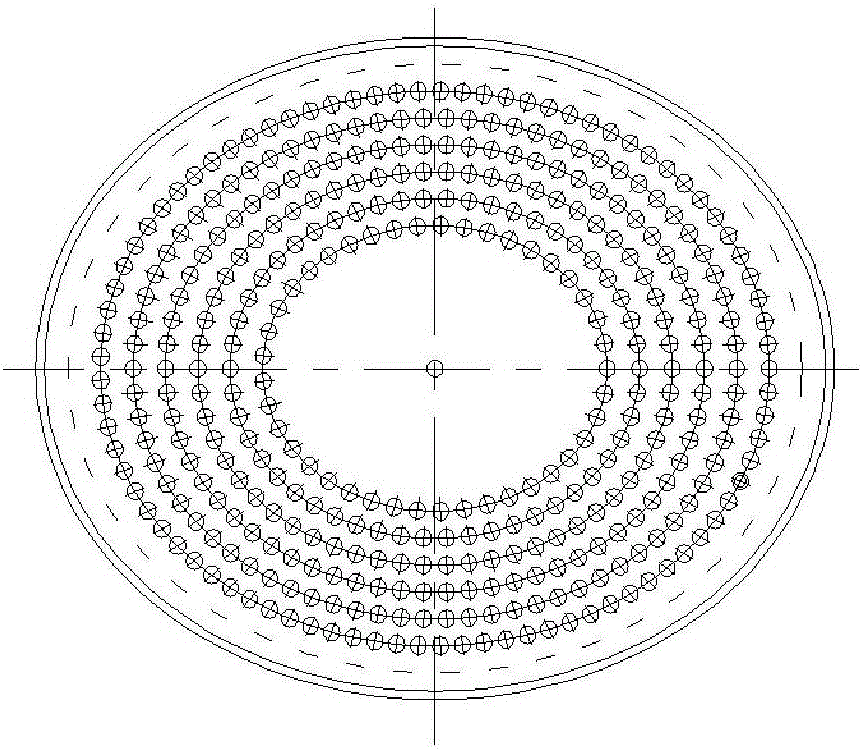

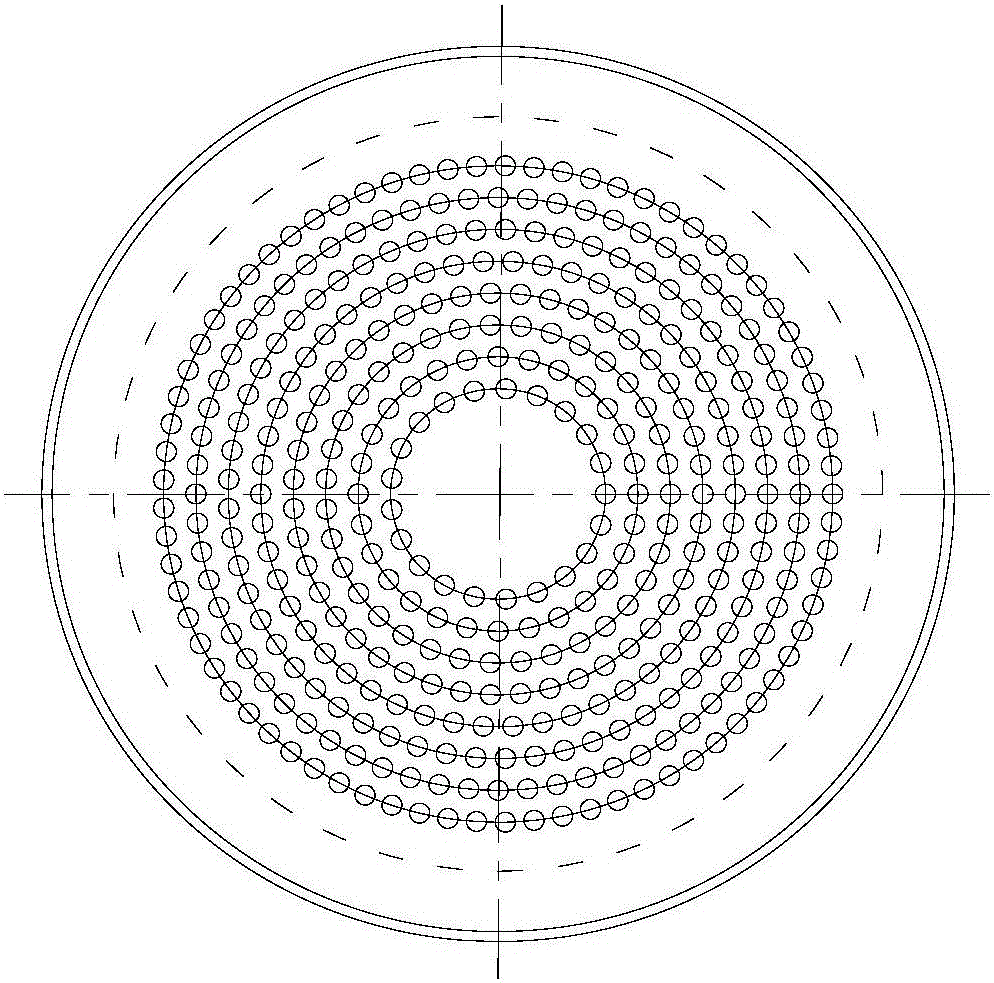

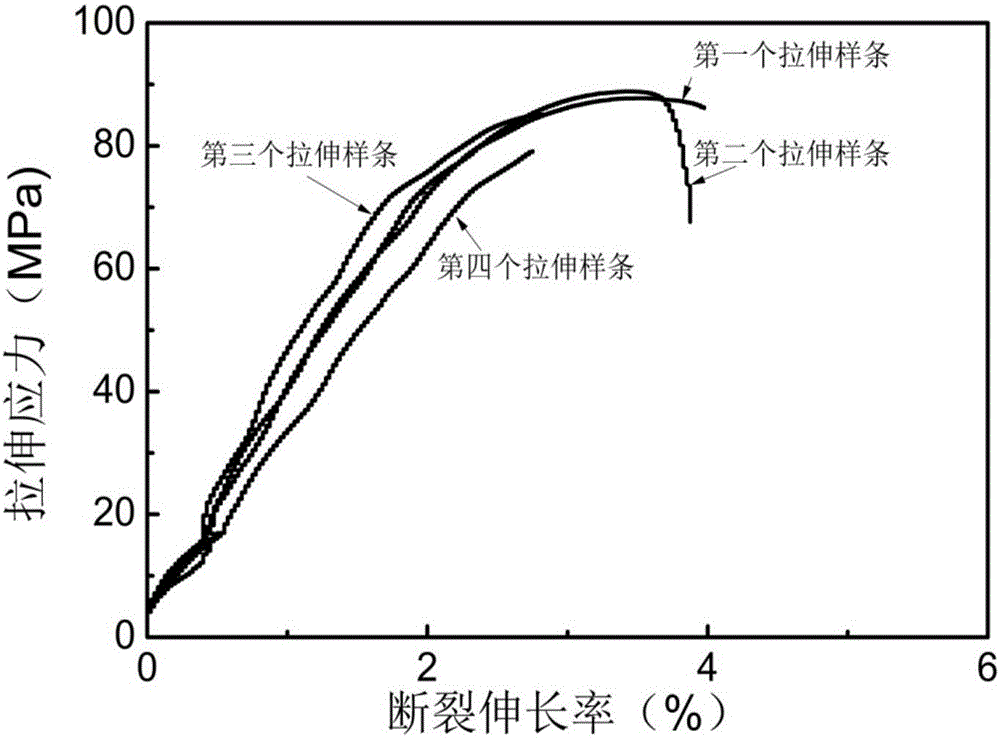

Differential shrinkage composite filament and preparing method thereof

ActiveCN106381558AImprove dyeing effectEasy to processSpinnerette packsHollow filament manufactureFiberAlcohol

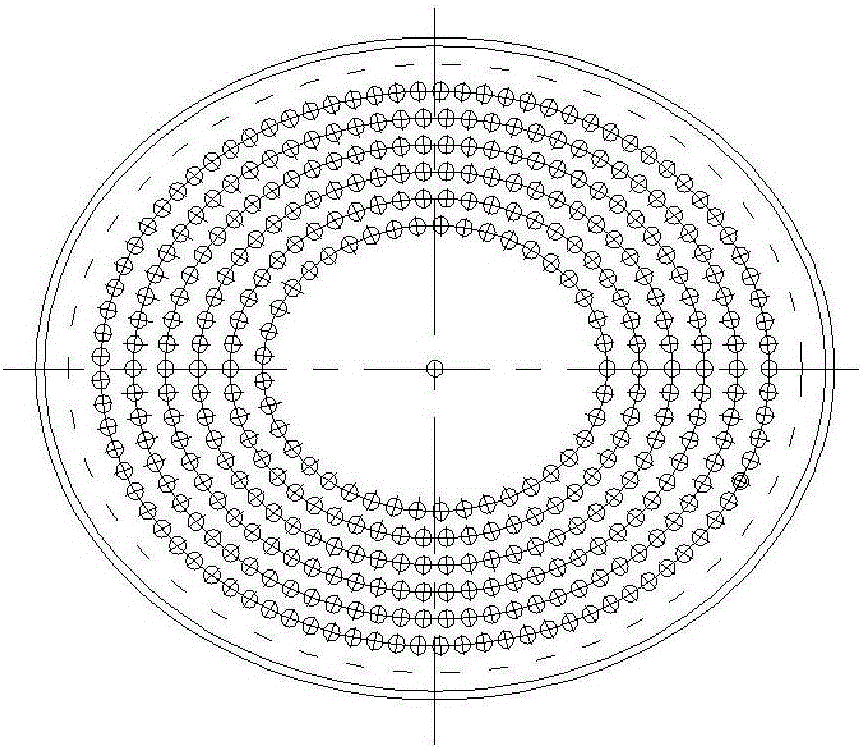

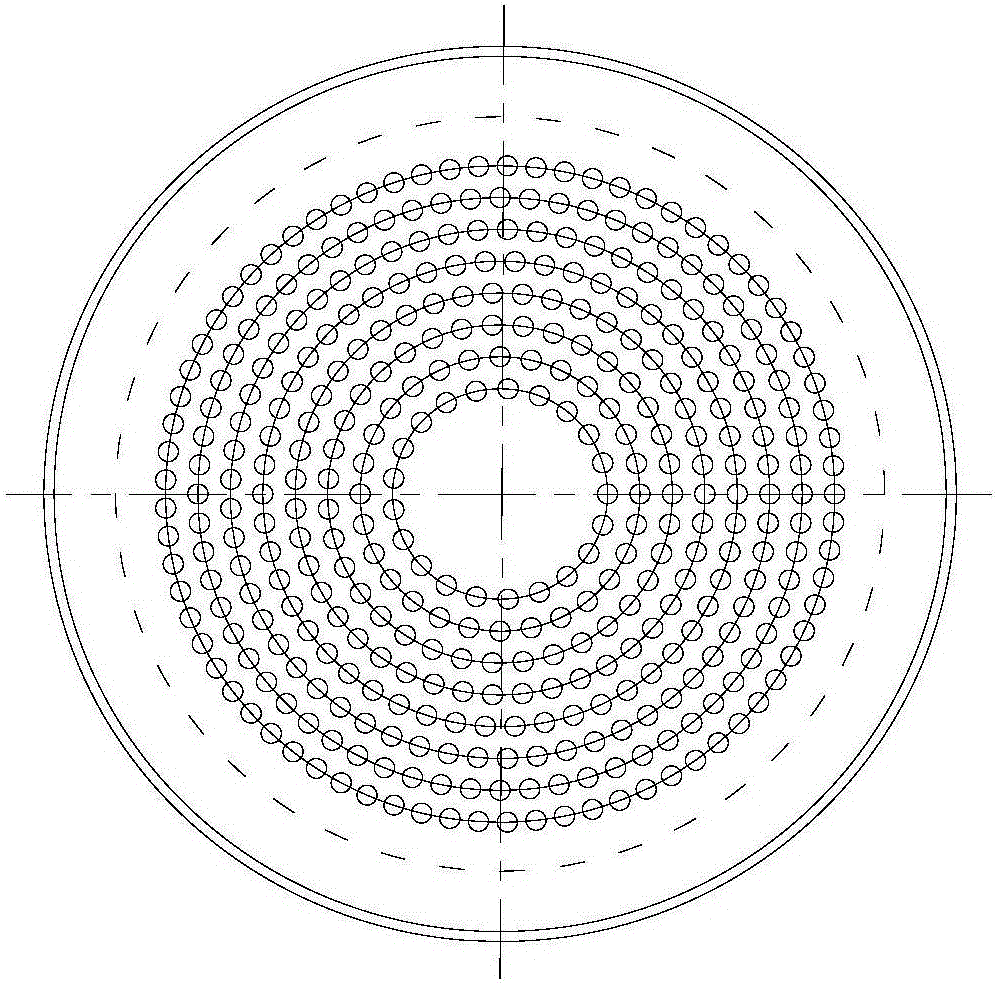

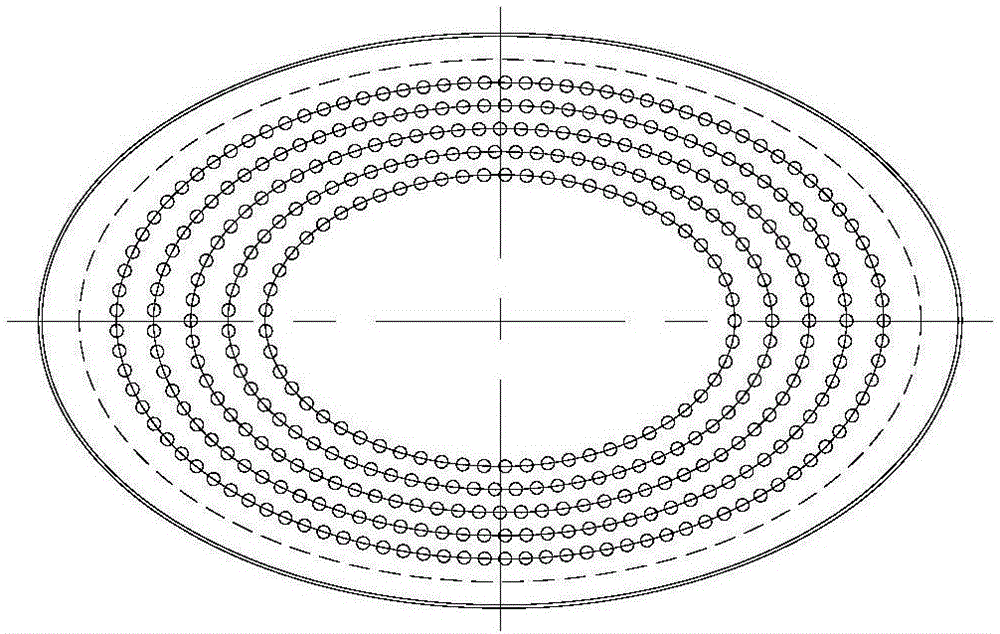

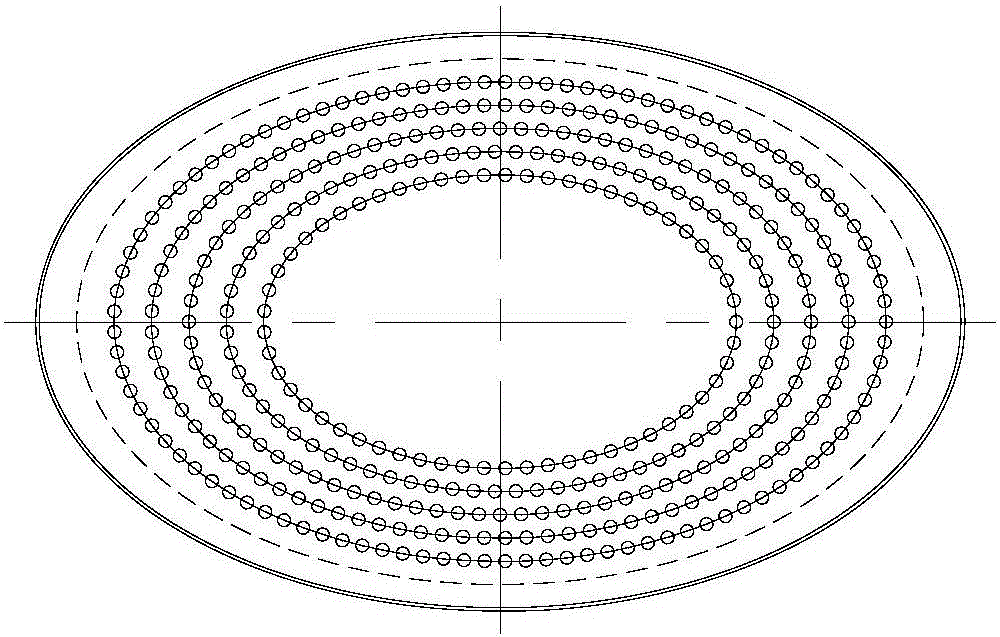

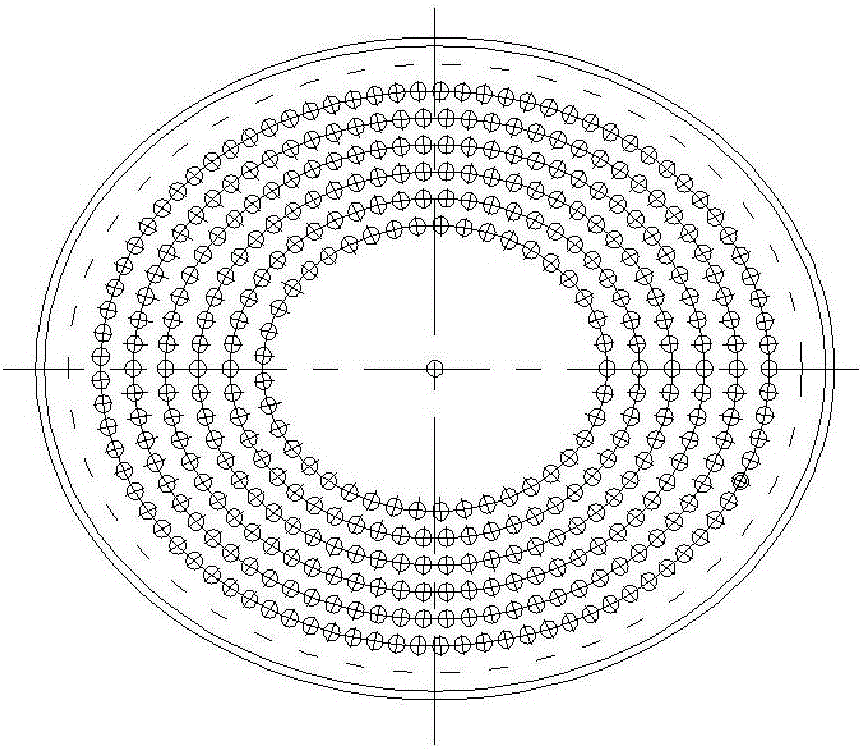

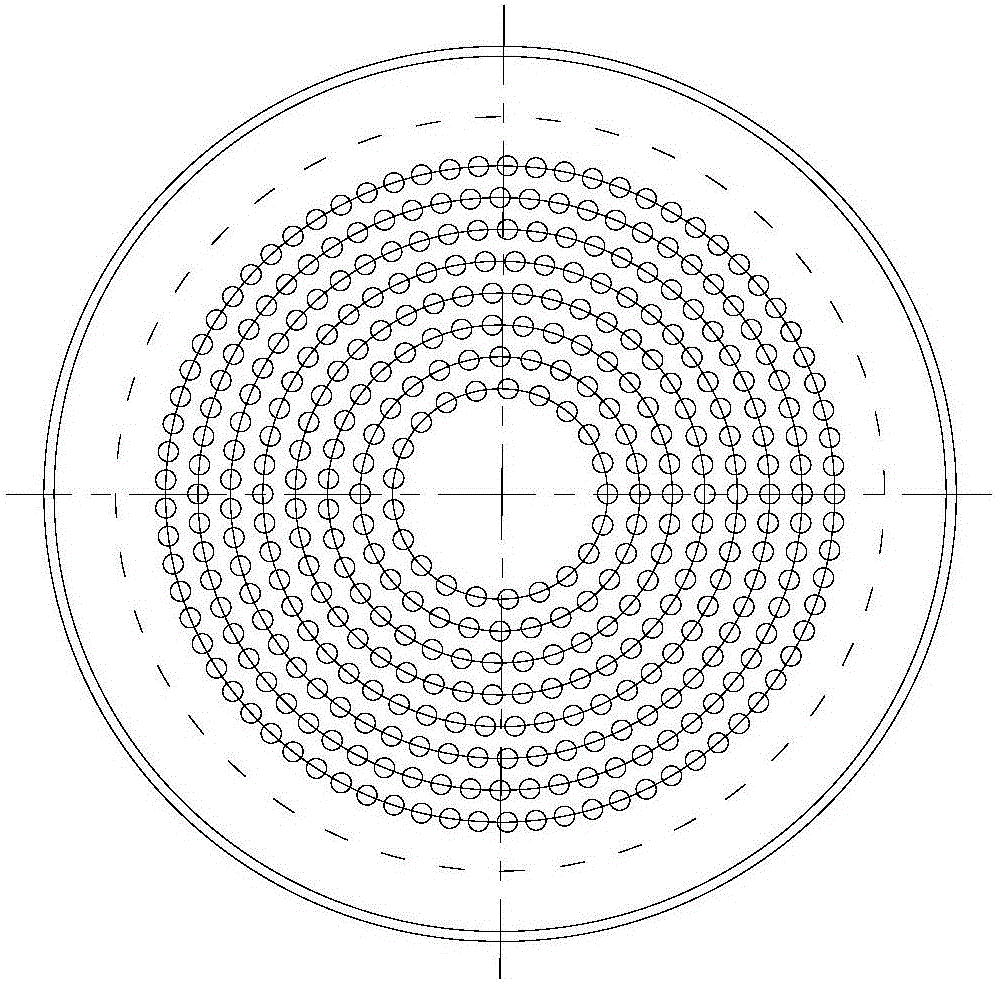

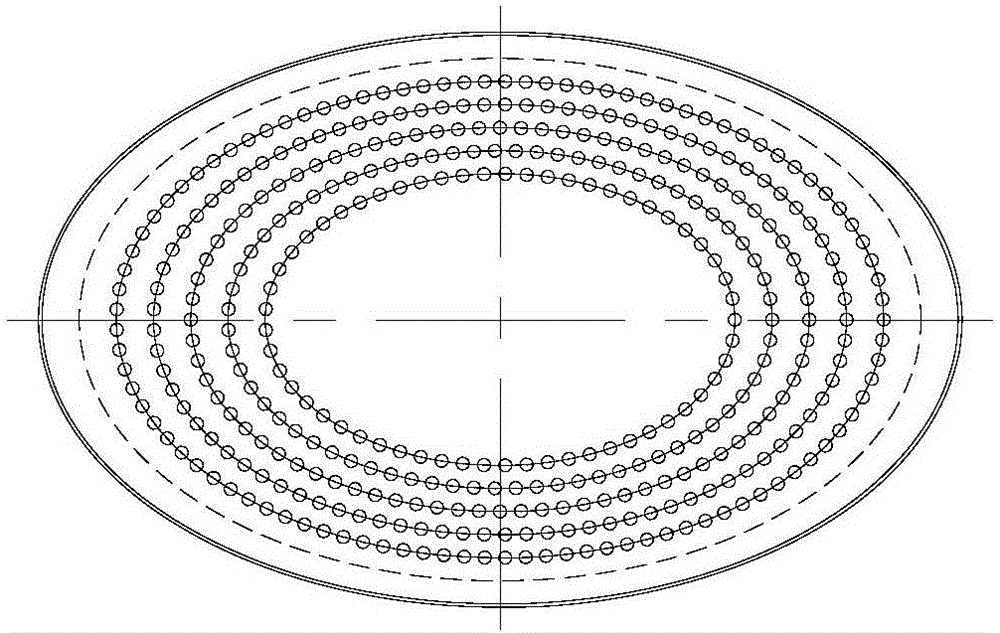

The invention relates to a differential shrinkage composite filament and a preparing method thereof. According to the invention, modified polyester employs a porous spinneret for spinning to prepare the differential shrinkage composite filament; an arrangement mode of the spinneret holes on the porous spinneret is in an elliptical shape, the aperture center of the spinneret holes is positioned on concentric ellipses, the concentric ellipses are a series of ellipses, the long shafts of all ellipses are collinear, and the short shafts are collinear. The differential shrinkage composite filament is subjected to plying and doubling by modified polyester POY filament and FDY filament, then is composited through network, and finally reeled. A preparation method of the modified polyester comprises the following steps: terephthalic acid and glycol are subjected to a reaction to prepare ethylene glycol terephthalate, terephthalic acid and branched chain-containing dihydric alcohol are subjected to a reaction to obtain terephthalic acid glycol ester, and continuous reacting is carried out on the material to obtain the product. The filament has excellent fiber performance, the linear density deviation ratio is less than or equal to 2.0%, a breaking tenacity CV value is less than or equal to 4.0%, a breaking elongation CV value is less than or equal to 8.0%, and a crimp contraction variation coefficient CV value is less than or equal to 8.0%.

Owner:JIANGSU HENGLI CHEM FIBER

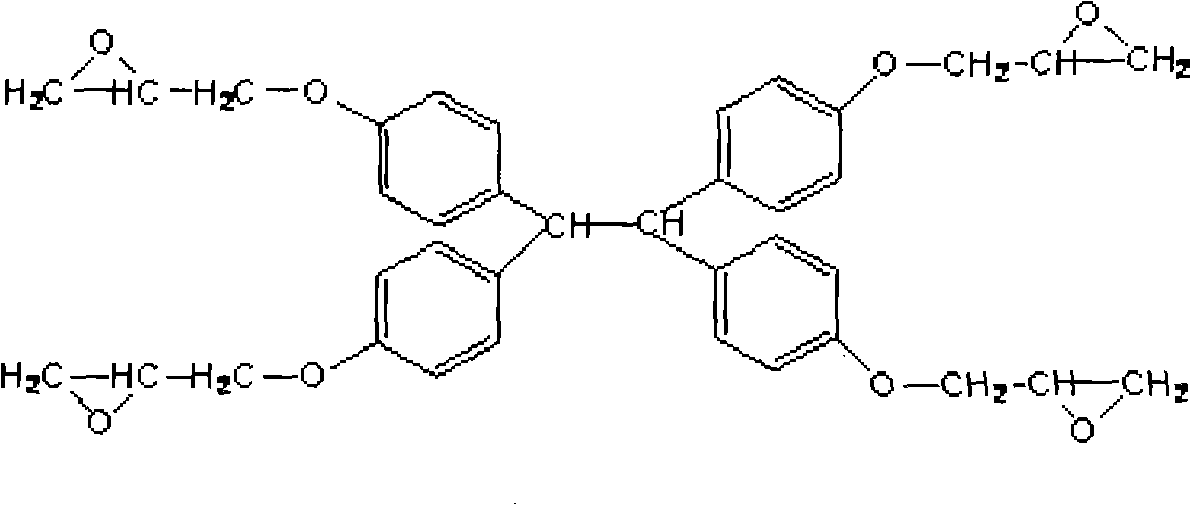

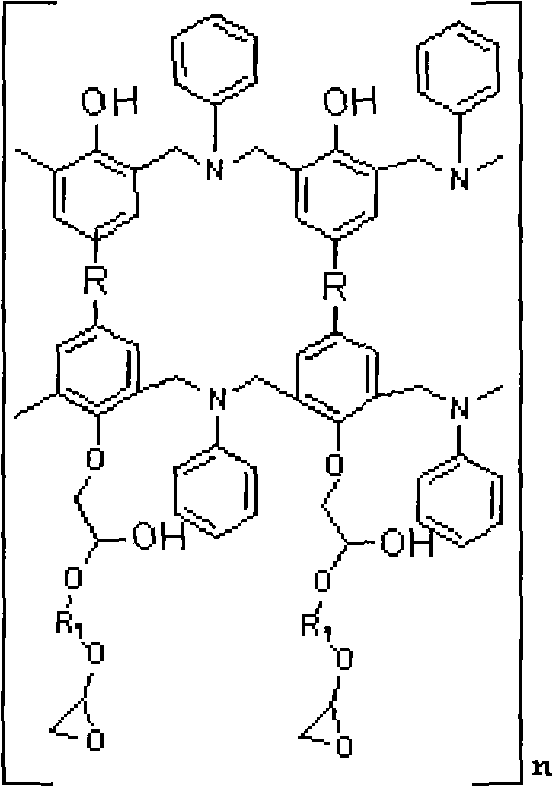

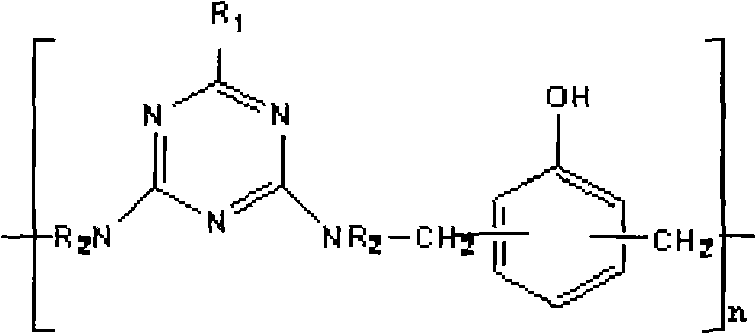

Halogen-phosphorus-free flame retardant epoxy resin composition and application thereof in bonding sheet and copper-clad plate

InactiveCN102093672AIncrease flame retardancySelf-extinguishingCircuit susbtrate materialsMetal layered productsEpoxyThermal expansion

The invention relates to a halogen-phosphorus-free flame retardant epoxy resin composition, which comprises inorganic fillers such as benzoxazine epoxy resin, a modified phenolic resin curing agent, imvite and the like, an inorganic auxiliary flame retardant material and the like, wherein the modified phenolic resin curing agent is nitrogen-containing phenolic resin; a resin condensate system has higher flame retardancy due to the self-extinguishment of the nitrogen-containing phenolic resin during combustion; and the glass-transition temperature of a condensate can be improved further by a unique structure formed by nano-level imvite and condensate molecules, and particularly the condensate has a lower thermal expansion coefficient. The resin composition does not contain halogen and phosphorus elements, and does not generate harmful substances, so a bonding sheet and a copper-clad foil layer, which are produced by the composition, for a printed circuit board have higher heat resistance and flame retardance, and are environmentally-friendly.

Owner:力森诺科电子材料(广州)有限公司

Porous soft polyester fiber FDY yarn and preparing method thereof

ActiveCN106381547AImprove dyeing effectEasy to processSpinnerette packsHollow filament manufactureYarnFiber

The invention relates to a porous soft polyester fiber FDY yarn and a preparing method thereof. According to the invention, modified polyester employs a porous spinneret for spinning to prepare the porous soft polyester fiber FDY yarn; an arrangement mode of the spinneret holes on the porous spinneret is in an elliptical shape, the aperture center of the spinneret holes is positioned on concentric ellipses, the concentric ellipses are a series of ellipses, the long shafts of all ellipses are collinear, and the short shafts are collinear. the porous soft polyester fiber FDY yarn is prepared by metering modified polyester slices, extruding, cooling, oiling, stretching, thermoforming and reeling the material. A preparation method of the modified polyester comprises the following steps: terephthalic acid and glycol are subjected to a reaction to prepare ethylene glycol terephthalate, terephthalic acid and branched chain-containing hexanediol are subjected to a reaction to obtain the terephthalic acid glycol ester, and continuous reacting is carried out on the material to obtain the product. The yarn has excellent fiber performance, the linear density deviation ratio is less than or equal to 0.5%, the breaking tenacity CV value is less than or equal to 4.0%, breaking elongation CV value is less than or equal to 8.0%, and a yarn unevenness CV value is less than or equal to 2.0.

Owner:JIANGSU HENGLI CHEM FIBER

Preparation method of high regularity mesoporous molecular sieve Fe-MCM-41

InactiveCN102198949AHigh acidityHigh activity and selectivityMolecular sieve catalystsCrystalline aluminosilicate zeolitesMolecular sieveFerric salts

The invention provides a preparation method of a high regularity mesoporous molecular sieve Fe-MCM-41. The preparation method is characterized in that an aftertreatment for a Si-MCM-41 matrix is carryed out to make the Si-MCM-41 matrix have an interaction with at least one soluble ferric salt to introduce a hetero atom Fe into the Si-MCM-41 matrix without any influence for a structure of the Si-MCM-41 matrix and thus a high regularity mesoporous molecular sieve Fe-MCM-41 is synthesized. The high regularity mesoporous molecular sieve Fe-MCM-41 has the advantages of uniform aperture sizes, big specific surface area and aperture volume, and favorable thermostability.

Owner:BEIJING UNIV OF CHEM TECH

Preparation method of polyfurandioctyl phthalate glycol ester

ActiveCN106243331AReduce dependence on petroleum resourcesGood mechanical propertiesFuranHigh selectivity

The invention discloses a preparation method of polyfuran dioctyl phthalate glycol ester. The preparation method comprises the following steps: (1) esterification or ester exchange reaction: adding furan dioctyl phthalate or furan dioctyl phthalate diester, ethylene and nitrogen-containing catalyst to a reactor, and reacting for 2-5 hours at 160-210 DEG C to obtain an esterification or ester exchange product; (2) polycondensation: reacting the esterification or ester exchange product in the conditions of pressure of less than or equal to 150Pa and temperature of 220-250 DEG C to prepare polyfuran dioctyl phthalate glycol ester. According to the invention, the efficient and high-selectivity nitrogen-containing catalyst is adopted, thus being favorable for improving the esterification or ester exchange rate, promoting polycondensation and improving molecular weight; and the prepared product is colorless or shallow in color, less in byproducts and good in structure regularity. According to the preparation method, only one nitrogen-containing catalyst is needed and is only added before reaction, adding of catalyst is not needed in the medium process, the process is very simple, the process is environmentally friendly, and realization of industrialization is facilitated.

Owner:ZHEJIANG UNIV

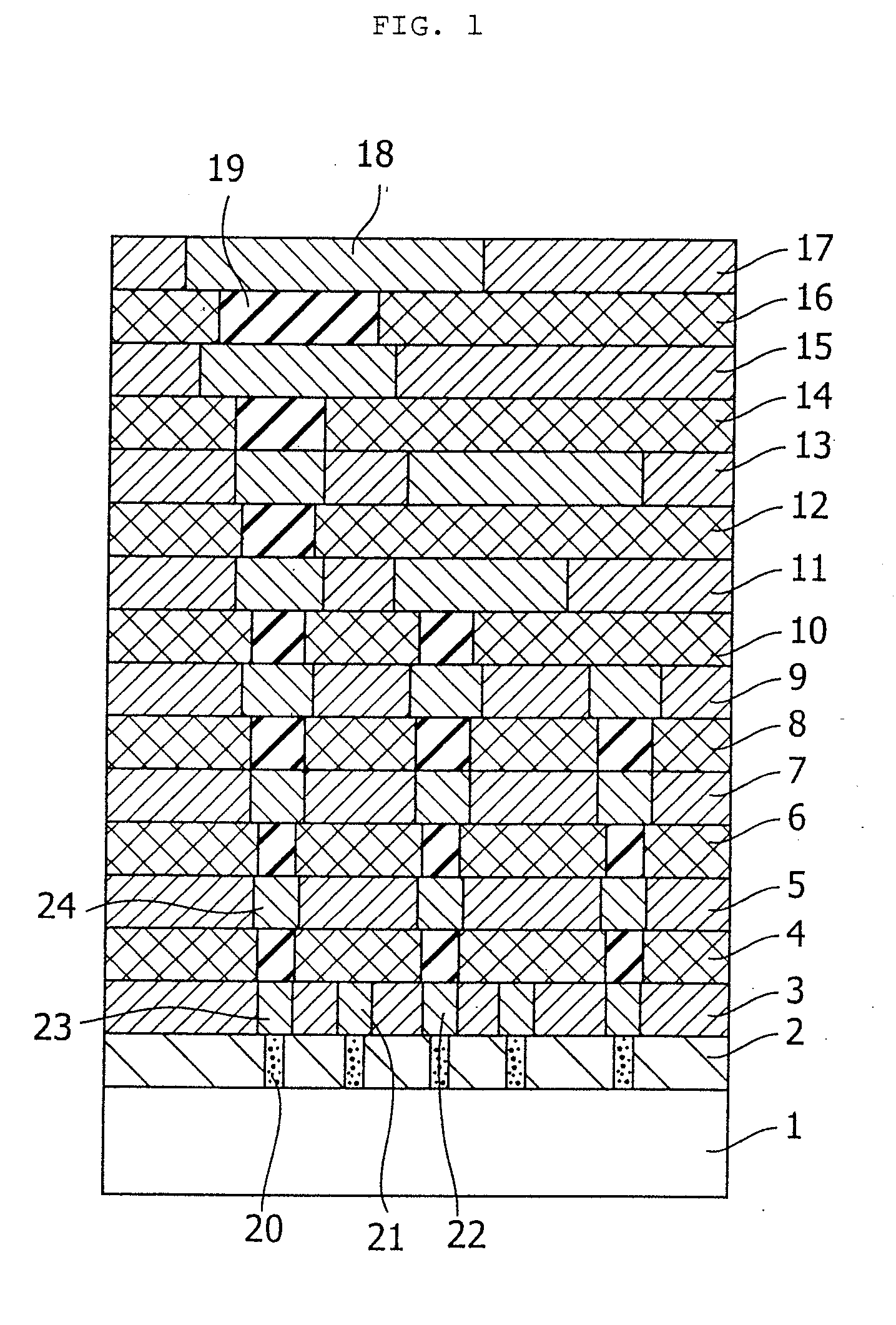

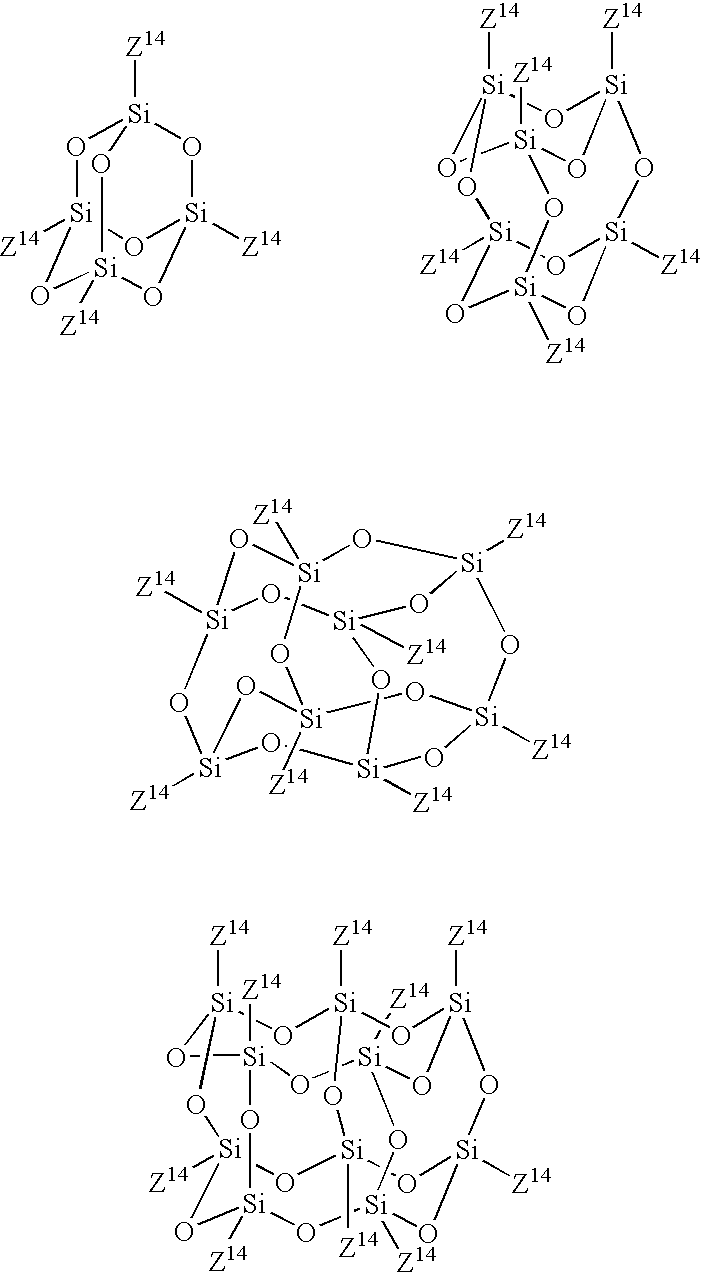

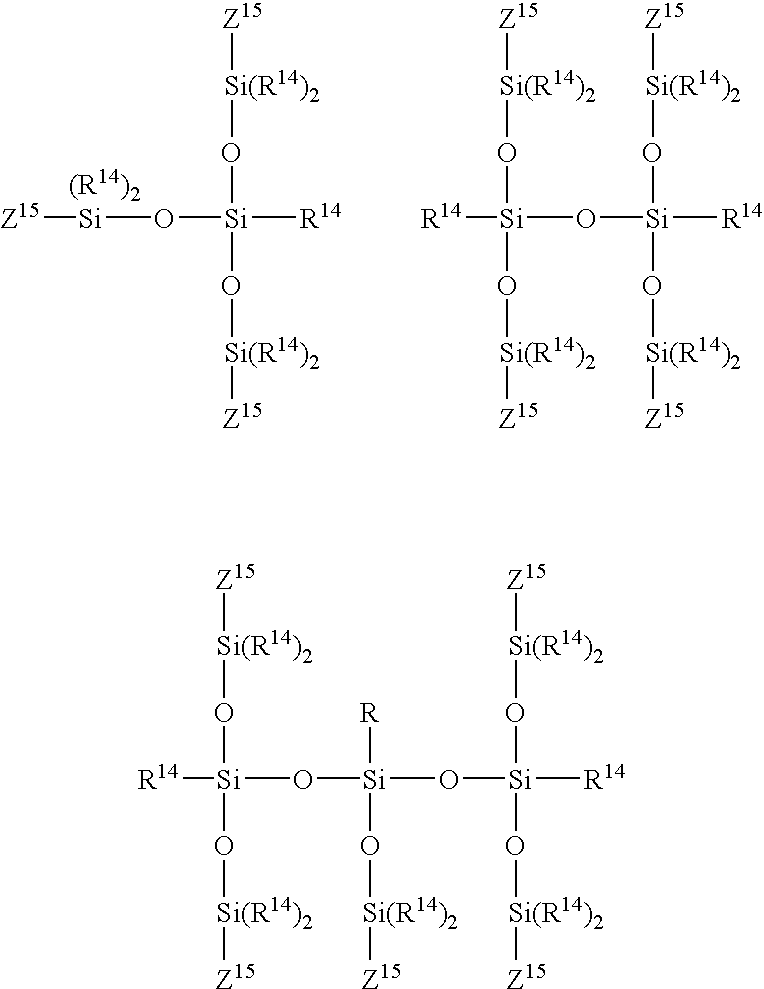

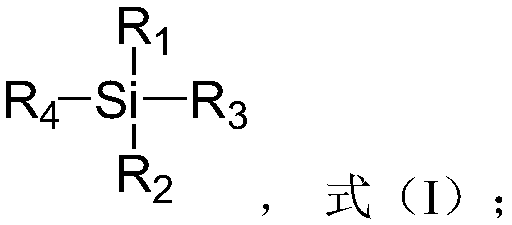

Composition for forming porous film, porous film and method for forming the same, interlevel insulator film, and semiconductor device

InactiveUS20070178319A1Hygroscopic property be decreaseDecrease parasitic capacitanceLayered productsSemiconductor/solid-state device detailsOligomerSemiconductor

The present invention is a composition for forming a porous film obtainable by hydrolysis and condensation, in an acidic or alkaline condition, of a mixture of 100 parts by weight of one or more compounds selected of the group consisting of hydrolysable silicon compounds represented by Formulas (1) and (2) as described herein and partially hydrolyzed and condensed products of the hydrolysable silicon compounds represented by Formulas (1) and (2), and 0.1 to 20 parts by weight of one or more cross-linking agents selected from the group consisting of structure-controlled cyclic or multi-branched oligomers represented by Formulas (3) to (8) as described herein.

Owner:PANASONIC CORP

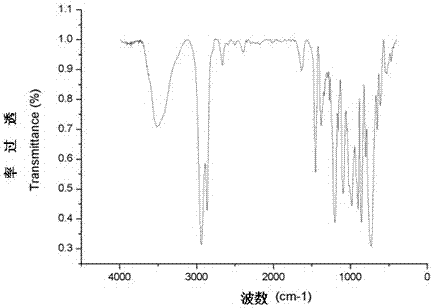

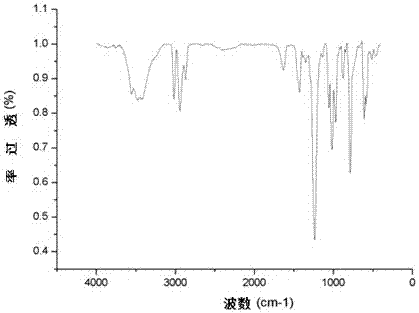

Preparation method of sulfur dioxide and epoxide copolymer

The invention discloses a preparation method of a sulfur dioxide and epoxide copolymer. According to the method, a novel polysulfone material is prepared through copolymerization of sulfur dioxide and epoxide under the catalytic action of SalenMX, epoxide and SalenMX are sequentially added to a high-pressure reaction kettle, sulfur dioxide is introduced and has a reaction at the temperature of 50-100 DEG C for 8-48 h, then, a product, namely, the sulfur dioxide and epoxide copolymer is obtained, the product is dissolved with chloroform, a hydrochloric acid and methanol mixed solution is used for precipitation, amber precipitates are filtered and repeatedly washed with methanol for 2-4 times, the washed product is transferred to a vacuum drying box and dried in vacuum at the room temperature for 8-24 h, and the sulfur dioxide and epoxide copolymer with higher stereoregularity can be obtained. The preparation method is simple, few catalysts are used, the reaction temperature is mild, the yield is high, the structure regularity of the product is good, the cost is low, and industrial production is easy to realize.

Owner:KUNMING UNIV OF SCI & TECH

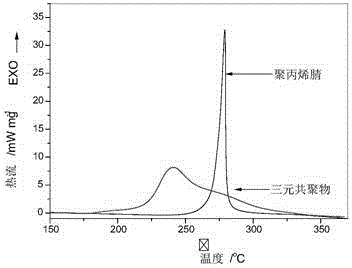

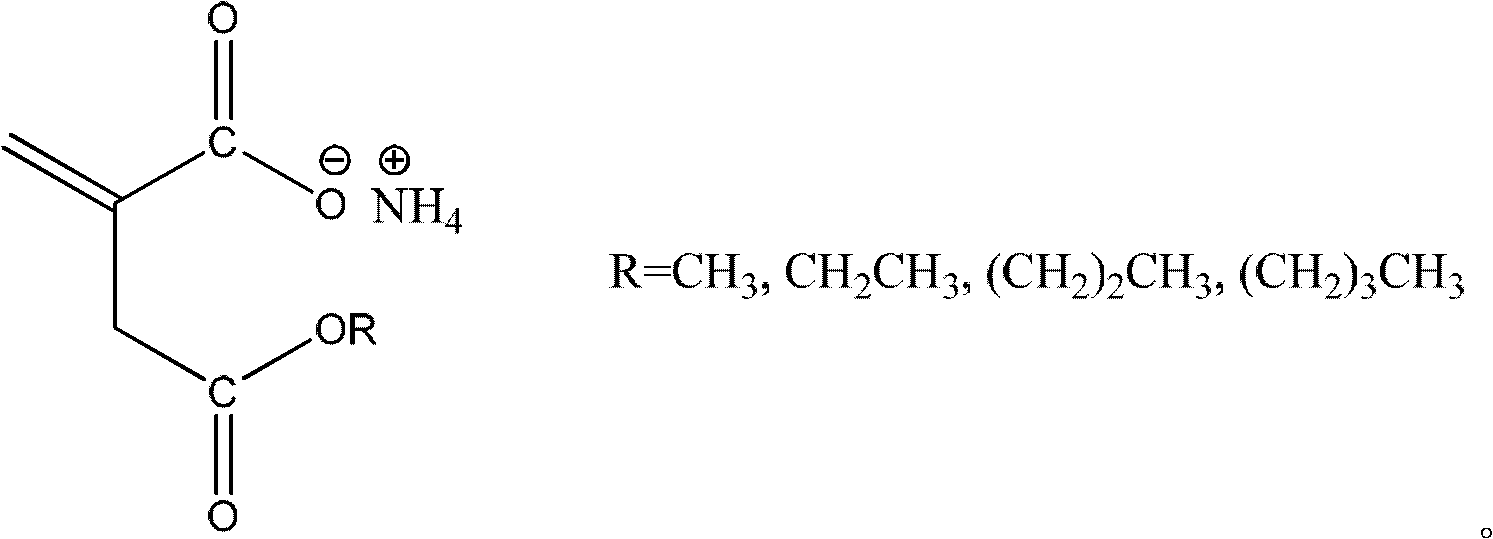

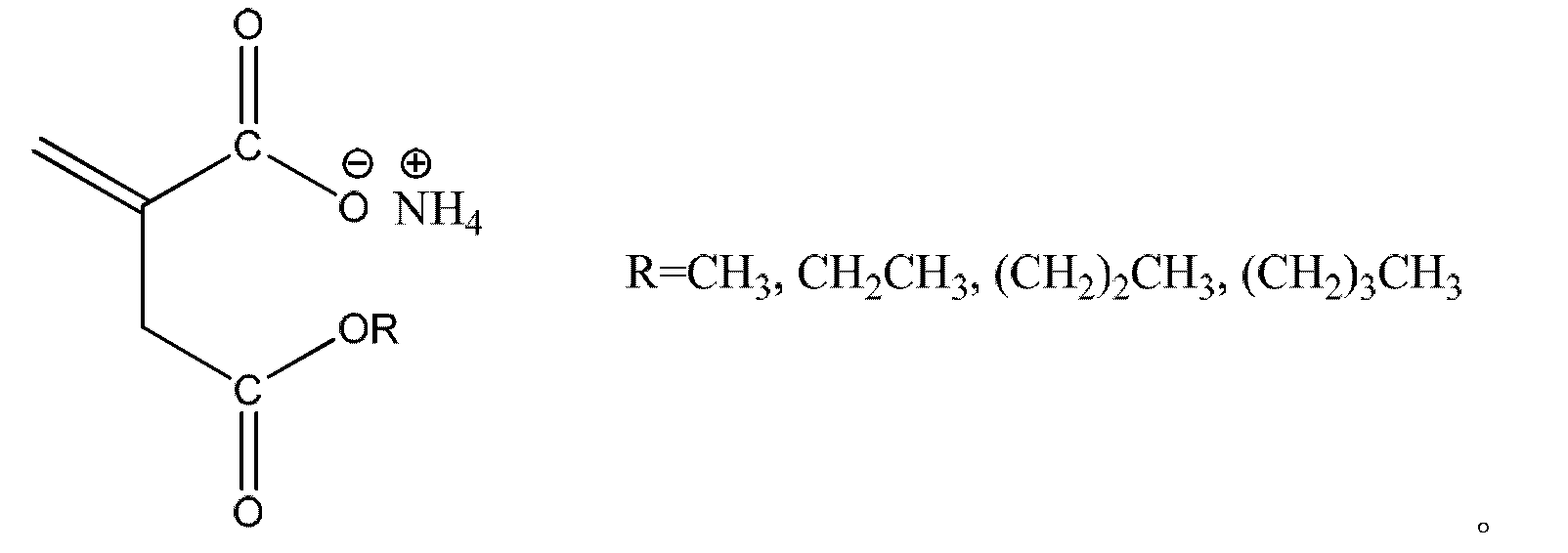

Preparation method of binary polyacrylonitrile carbon fiber precursor

InactiveCN103614800AReduce dosageImprove structural regularityFibre typesArtificial filament heat treatmentStructural regularityCarbon fibers

The invention relates to a preparation method of a binary polyacrylonitrile carbon fiber precursor. The method comprises the following steps: mixing acrylonitrile, a second comonomer beta-itaconic acid ester amide and a solvent in the presence of nitrogen, and adding an initiator; reacting for 22-38 hours under the condition of 35-75 DEG C, so as to obtain an acrylonitrile polymer; then filtering, taking off and defoaming, so as to prepare a spinning solution; spinning the spinning solution by virtue of a dry-jet wet process, stretching, oiling, drying, densifying, drawing by hot steam, and thermoforming, so as to obtain the binary polyacrylonitrile carbon fiber precursor. By adopting the preparation method, double functional group beta-itaconic acid ester amide is adopted as a comonomer, and a polyacrylonitrile macromolecule for the carbon fiber precursor is prepared by binary copolymerization and substituted ternary copolymerization. Thus, the dosage of the comonomer is reduced, meanwhile, the structural regularity of the polyacrylonitrile macromolecule is improved, and the prepared carbon fiber precursor is even in structure, small in fineness and high in strength.

Owner:DONGHUA UNIV

Preparation method of sulfur dioxide, carbon dioxide and epoxide copolymer

The invention discloses a preparation method of a sulfur dioxide, carbon dioxide and epoxide copolymer. According to the method, epoxide, SalenCr<III>Cl and PPNCl are sequentially added to a high-pressure reaction kettle, sulfur dioxide and carbon dioxide are introduced and have a reaction at the temperature of 50-100 DEG C for 8-48 h, then, a product is dissolved with chloroform, a hydrochloric acid and methanol solution is used for precipitation, amber precipitates are filtered and repeatedly washed with methanol, the washed product is dried in vacuum at the room temperature, and the sulfur dioxide, carbon dioxide and epoxide terpolymer with higher stereoregularity can be obtained. The sulfur dioxide, carbon dioxide and epoxide terpolymer has structural characteristics of polycarbonate and polysulfone and has a wide application prospect in the fields of packaging, filtration and the like; the preparation method is simple, few catalysts are used, the reaction temperature is mild, the yield is high, the structure regularity of the product is good, the cost is low, and industrial production is easy to realize.

Owner:KUNMING UNIV OF SCI & TECH

Preparation method and application of metal organic framework MIL-101-V with three-dimensional mesoporous structure

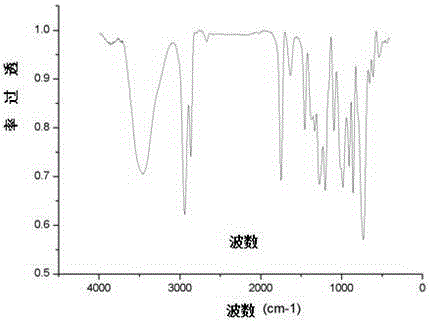

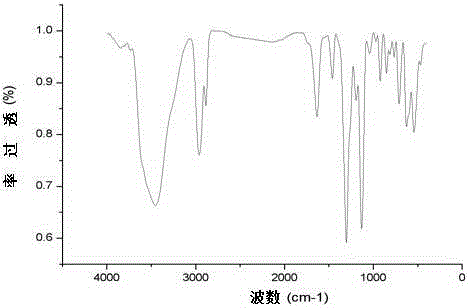

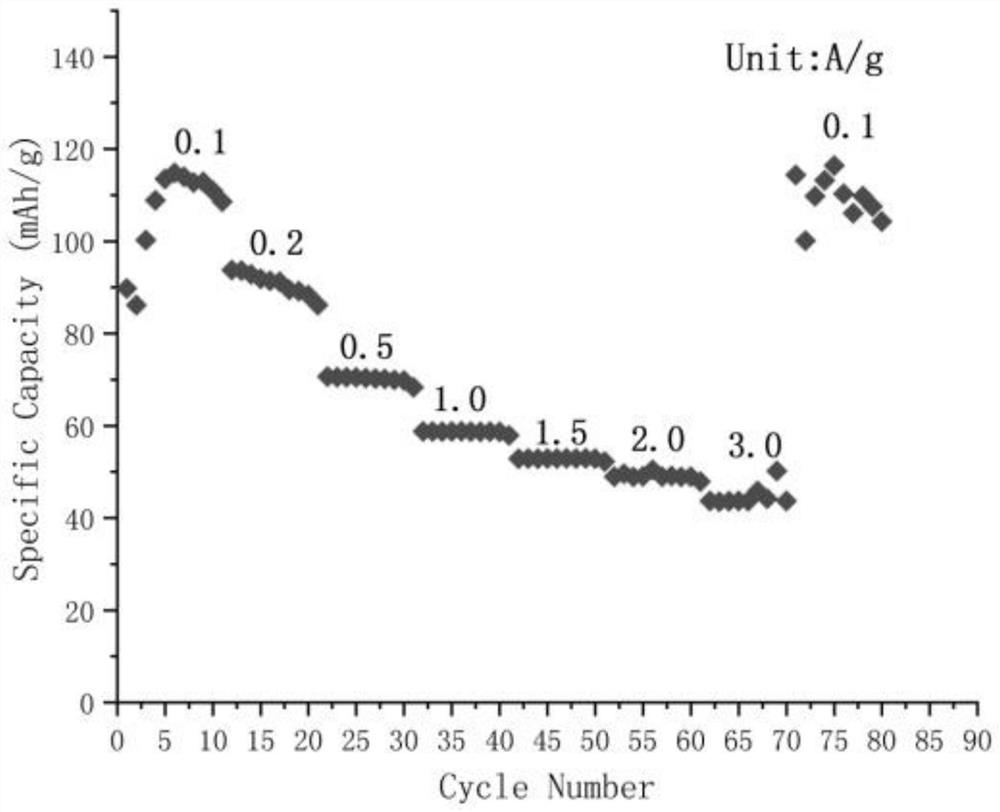

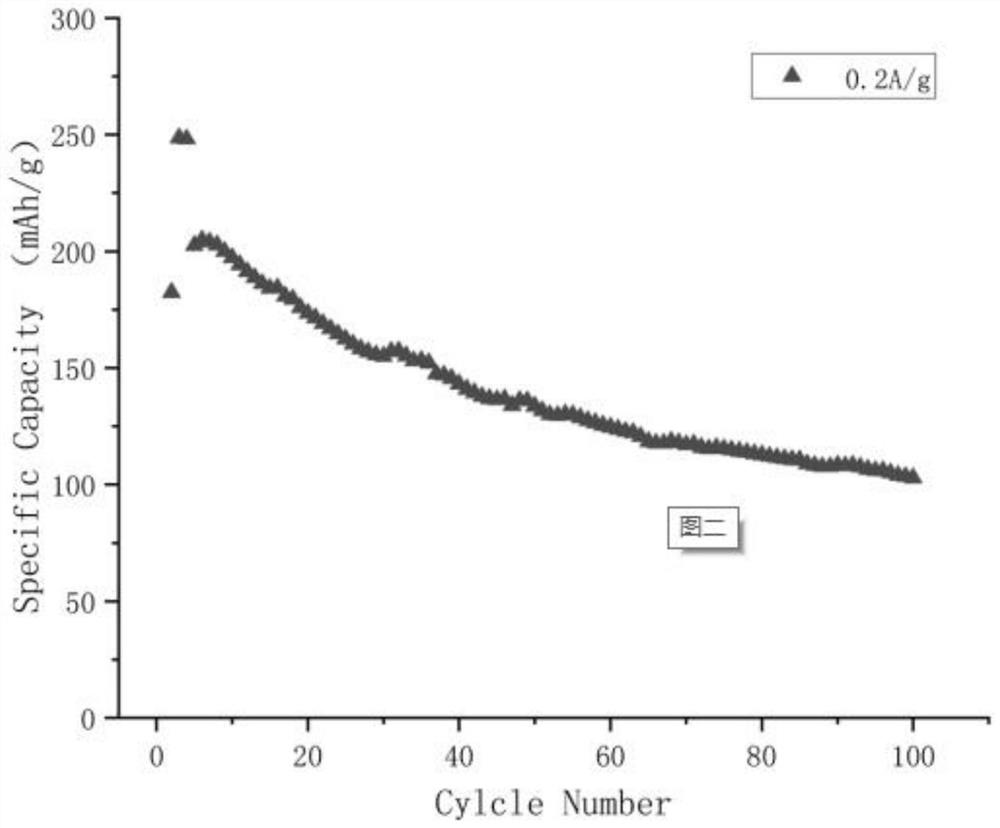

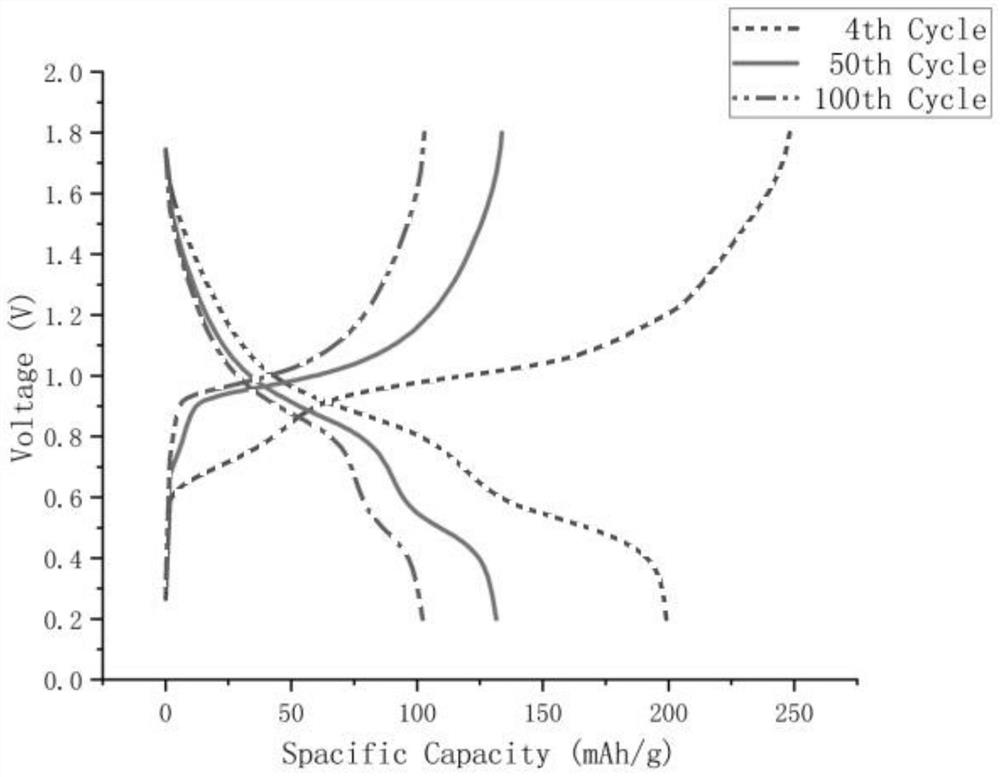

PendingCN113583246AImprove electrochemical performanceThe synthesis method is simpleCell electrodesSecondary cellsElectrical batteryMetal-organic framework

The invention discloses a preparation method and application of a metal organic framework MIL-101-V with a three-dimensional mesoporous structure, and an MIL-101-V composite material with a three-dimensional porous structure is obtained through a simple hydrothermal reaction. When the composite material is used as a positive electrode of a zinc ion battery, the composite material shows excellent electrochemical performance and still has the specific discharge capacity of 102.94 mAh / g after 100 cycles. The raw materials used in the method are renewable and environment-friendly, the operation is simple, and the method has a good application prospect in the aspect of large-scale energy storage of the aqueous zinc ion battery.

Owner:安徽理工大学环境友好材料与职业健康研究院(芜湖)

Method for preparing carbon fiber precursor by polymerization from mixed solvent

InactiveCN104695036ANarrow molecular weight distributionReduce dosageWet spinning methodsMonocomponent synthetic polymer artificial filamentPolymer scienceCarbon fibers

The invention relates to a method for preparing a carbon fiber precursor by polymerization from a mixed solvent. The method for preparing the carbon fiber precursor by polymerization from the mixed solvent comprises the following steps: (1) initiating copolymerization on acrylonitrile, 3-carboxyl-3 butylene amide and itaconic acid diester at the temperature of 50-80 DEG C while dimethyl sulfoxide / deionized water or N,N-dimethyl formamide / deionized water is taken as the solvent and azodiisobutyronitrile is taken as an initiating agent; and (2) dissolving an acrylonitrile polymer obtained in the step (1), defoaming, filtering, carrying out dry jet wet spinning, drawing, oiling, compacting by drying, drawing in superheated steam, and carrying out heat setting, so that the carbon fiber precursor is obtained. The method for preparing the carbon fiber precursor by the polymerization from the mixed solvent has the advantages that the characteristic that the chain transfer constant of the deionized water is zero is utilized, the molecular weight of the polymer is regulated and controlled by regulating the ratio of the deionized water to the organic solvent, the molecular weight of the prepared polymer is more than 1.5 times of the molecular weight of the polymer obtained by the polymerization from the traditional solvent, and the prepared carbon fiber precursor is uniform in structure, low in fineness and high in strength; meanwhile, water is adopted for substituting part of the organic solvent, the environment protection can be facilitated, and the production cost is effectively reduced.

Owner:JIANGNAN UNIV

Carbon molecular sieve and method for manufacturing the same

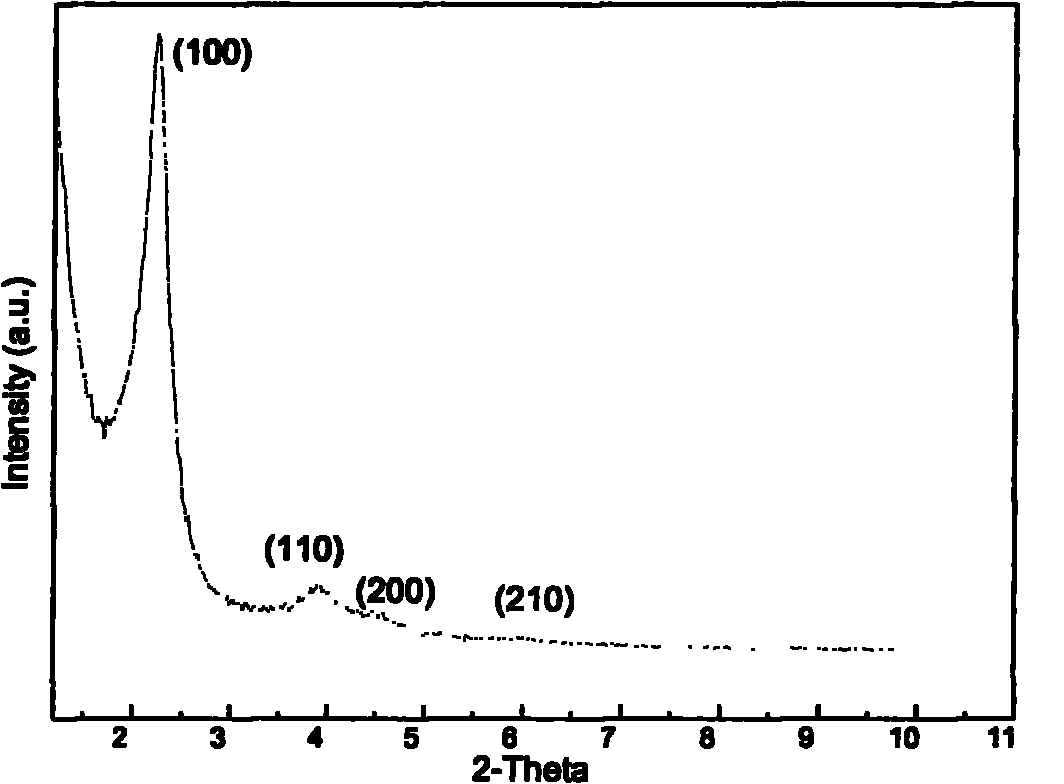

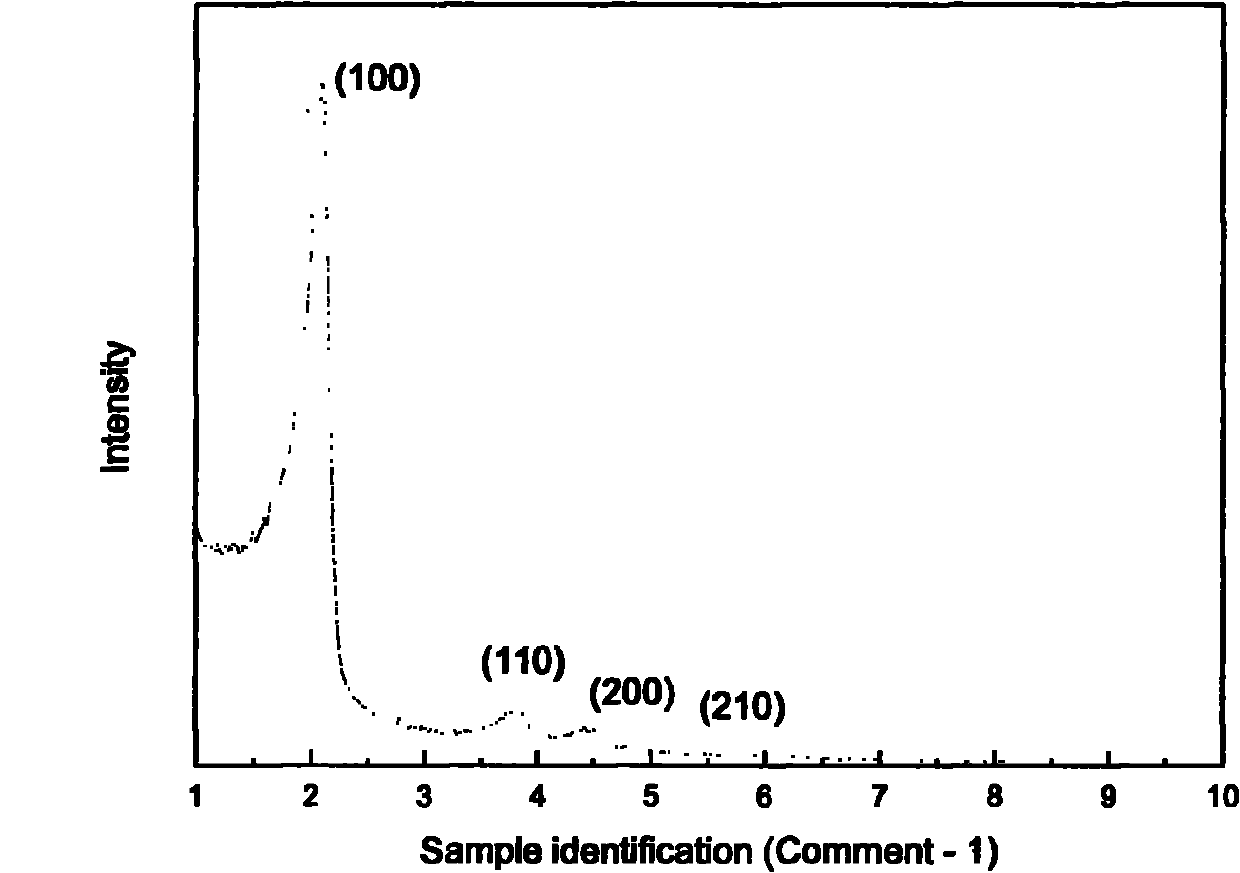

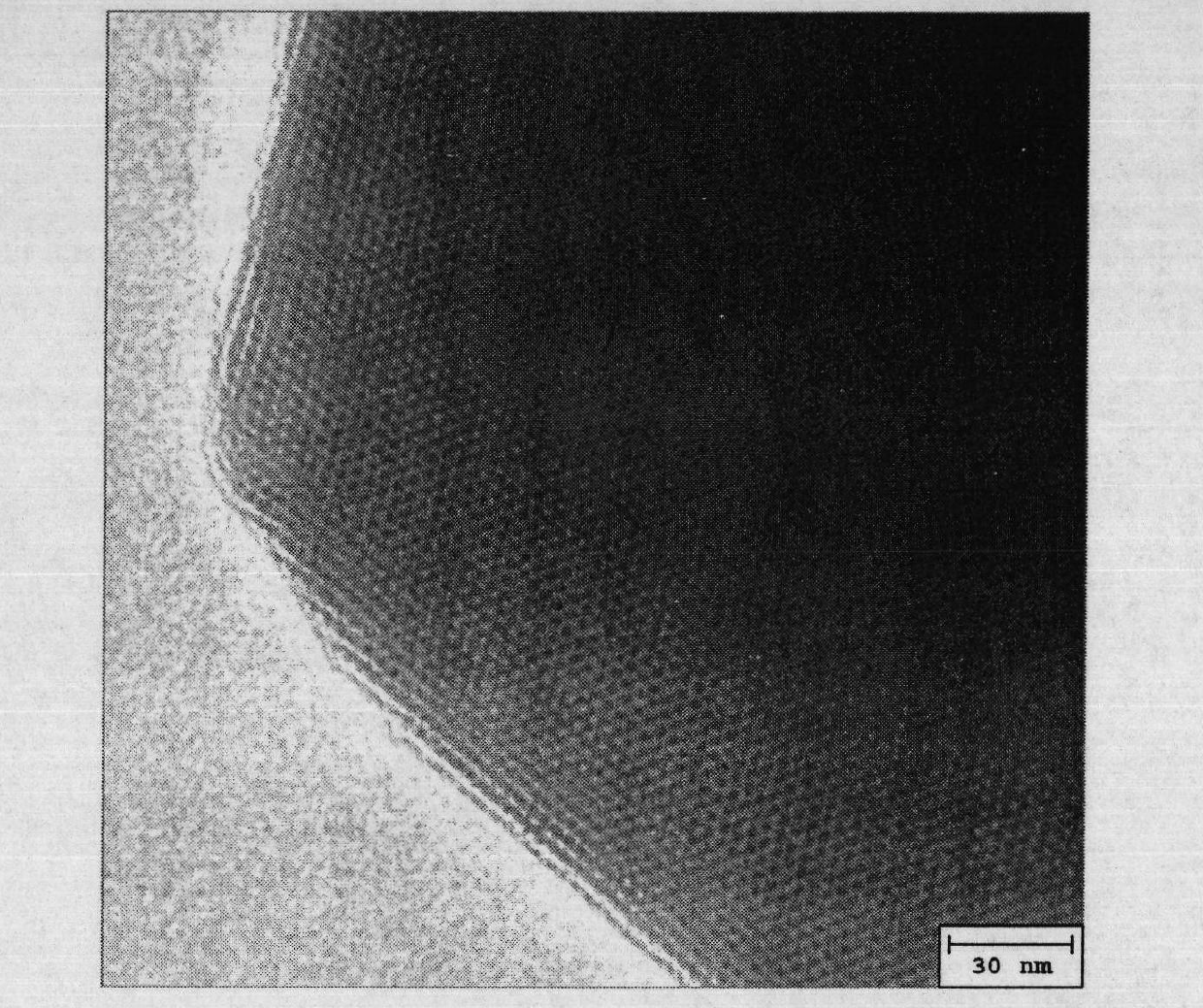

InactiveUS7718570B2High porosityImprove structural regularityMolecular sieve catalystsOther chemical processesMolecular sieveStructural regularity

A method for manufacturing a carbon molecular sieve with increased microporosity; a method for manufacturing a carbon molecular sieve with increased microporosity and improved structural regularity; a carbon molecular sieve with increased microporosity; a carbon molecular sieve with increased microporosity and improved structural regularity; a catalyst for a fuel cell using the carbon molecular sieve; and a fuel cell using the catalyst are provided.

Owner:SAMSUNG SDI CO LTD

Preparation method of ternary polyacrylonitrile copolymer

InactiveCN104710565AImprove structural regularityImprove thermal stabilityMonocomponent synthetic polymer artificial filamentFiltrationAcrylonitrile

The invention relates to a preparation method of a ternary polyacrylonitrile copolymer, which comprises the steps of heating an aqueous solution of maleic anhydride, acrylamide and a dispersing agent to 55-75 DEG C under a nitrogen shielding condition, adding acrylonitrile to keep constant temperature for 20-30min, adding an initiator solution for reaction for 3-12h, and carrying out washing, demonomerisation, filtration and drying. The method employs a mixed solvent precipitation polymerization method for polymerization and has the advantages of high reaction yield, high viscosity average molecular weight, narrow distribution, easiness in temperature control, stable product quality and the like. The thermal property of the polyacrylonitrile copolymer prepared by the method can be effectively improved, and the copolymer has certain practical application prospects.

Owner:DONGHUA UNIV

Method for preparing binary polyacrylonitrile-based carbon fiber protofilament

InactiveCN102605476AReduce dosageImprove structural regularityArtificial filament washing/dryingArtificial filament heat treatmentStructural regularityCarbon fibers

The invention relates to a method for preparing a binary polyacrylonitrile-based carbon fiber protofilament. The method comprises the following steps of: (1) performing copolymerization reaction on acrylonitrile and beta-ammonium itaconate for 10 to 30 hours at the temperature of between 50 and 70 DEG C by using dimethyl sulfoxide as a solvent and using azodiisobutyronitrile as an initiator, filtering, removing residual monomers, and defoaming to obtain a spinning solution; and (2) sequentially performing dry-spray wet spinning, drawing, oiling, drying densification, hot steam drawing and heat setting on the spinning solution, and thus obtaining the carbon fiber protofilament. By the method, the consumption of copolymerization monomers is reduced, and the structural regularity of polyacrylonitrile macromolecules is improved; and the prepared carbon fiber protofilament is uniform in structure, low in fineness and high in strength, and is suitable for preparing high-performance carbon fibers.

Owner:DONGHUA UNIV

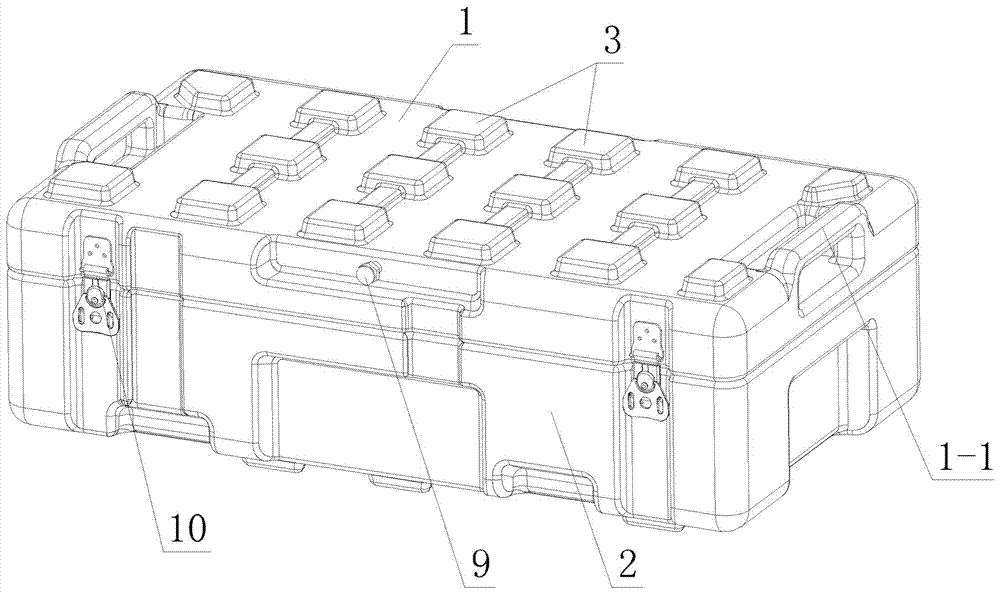

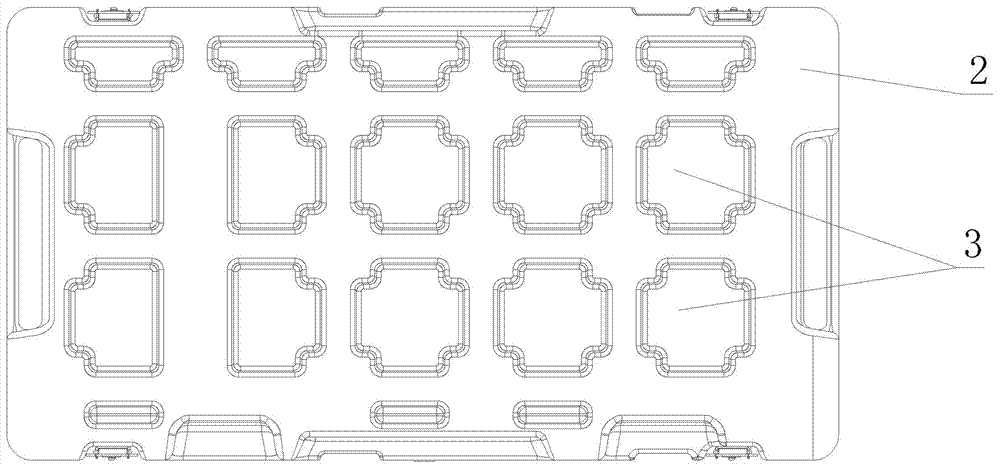

Air-drop type storage-transportation packaging box convenient to stack and preparation method of packaging box

ActiveCN107383579ANot easy to damageImprove toughnessCoatingsRigid containersLinear low-density polyethyleneLow-density polyethylene

The invention relates to an air-drop type storage-transportation packaging box convenient to stack and a preparation method of the packaging box, belonging to the package and transportation fields. The packaging box comprises a box body and a box cover which are mutually buckled, wherein the box body and the box cover are prepared from the following raw materials in parts by weight through rotational molding: 50-70 parts of linear low density polyethylene, 50-70 parts of low density polyethylene, 40-80 parts of high density polyethylene, 10-30 parts of medium density metallocene polyethylene and 1-6 parts of a coupling agent; and rig grids are arrayed at the bottom of the box body or the top of the box body or the box cover in a matrix manner, the rig grids at the top of the box body or the box cover are mutually seamed and clamped with the rig grids at the bottom of the box body on an upper layer so as to form embedding and splicing type anti-dislocation stacking structure. The packaging box is produced from the polyethylene materials with different densities through mixing and rotational molding, and modularized rid grid structures are arranged at the top and the bottom of the packaging box, so that the strength, impact resistance and packaging efficiency of the packaging box are improved, and the mutual stable stacking of different specifications of packaging boxes is realized.

Owner:河北金后盾塑胶有限公司

Method for preparing porous graphene silicon negative electrode material

ActiveCN110112384AImprove structural regularityAvoid irreversible damageCell electrodesSecondary cellsPorous grapheneLithium

The invention relates to a method for preparing a porous graphene silicon negative electrode material. For the problem that the volume expansion of a current silicon negative electrode material seriously causes structural collapse to cause rapid collapse to cause the quick attenuation of energy, a metal oxide-graphene composite material is prepared by using a graphite intercalation method, a liquid phase stripping method and an in-situ growth method, the surface of a silicon material is coated with the metal oxide-graphene composite material, then the metal oxide is etched away with an acid solution, and the porous graphene silicon negative electrode material is obtained by the principle of carbothermal reaction. The excellent conductivity and porous structure of high-quality graphene facilitate the rapid transmission of electrons and lithium ions, a variety of pore graphene structures can be obtained by controlling heat treatment time and temperature, the flexible adjustment can be carried out according to conditions needed by an actual negative electrode material, the etched metal oxide leaves a buffer space, and a series of negative effects caused by the volume expansion of thesilicon material are alleviated.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

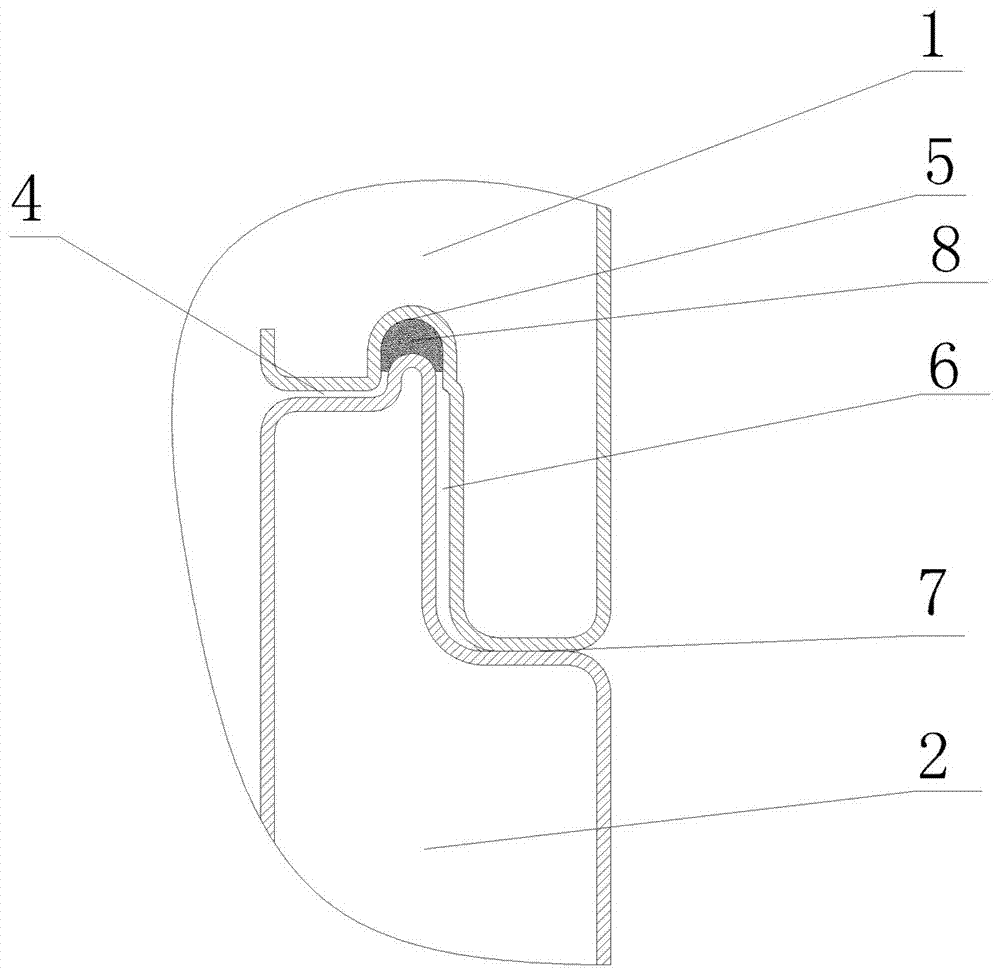

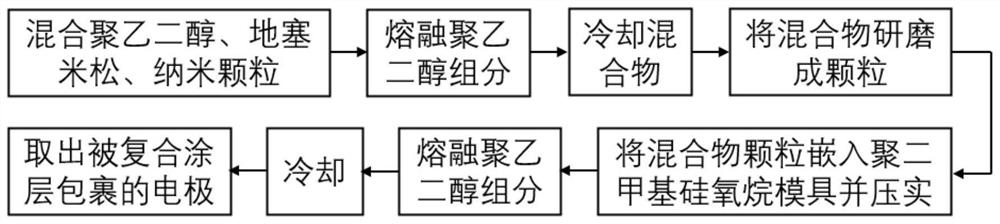

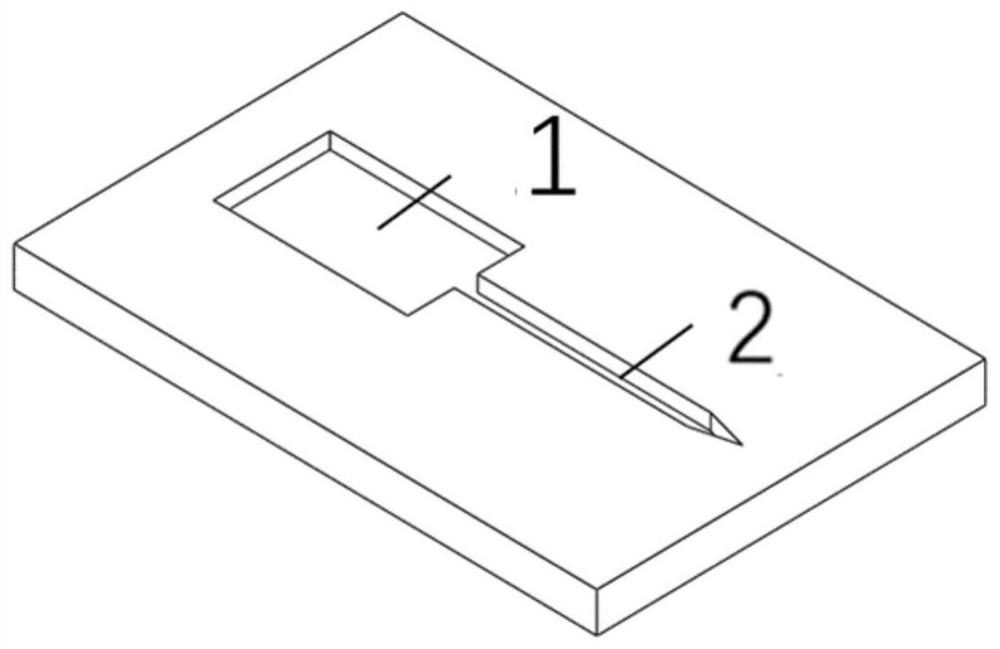

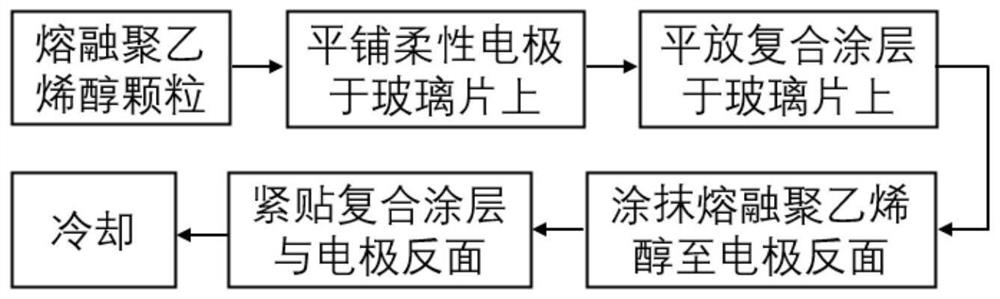

Preparation method of flexible brain nerve electrode coating and electrode assembled by flexible brain nerve electrode coating

ActiveCN112999432ASuccessfully implantedImprove the success rate of implantationSurgeryDiagnostic recording/measuringMetallic electrodePolyvinyl alcohol

The invention discloses a preparation method of a flexible brain nerve electrode coating and an electrode assembled by the flexible brain nerve electrode coating, and relates to the field of implantable medical device. Polyethylene glycol, medicinal dexamethasone and polylactic acid-glycolic acid copolymer loaded medicinal dexamethasone nanoparticles are mixed in a beaker to form a mixture, and a composite coating is prepared in a specific mold and is connected with the flexible brain nerve electrode through polyvinyl alcohol. The flexible brain nerve electrode composite coating which has relatively high mechanical hardness and strength and can continuously release anti-inflammatory drugs can be rapidly, simply and conveniently prepared, and implantation of the flexible brain nerve electrode is assisted. Polyvinyl alcohol can be completely hydrolyzed within 1 min, the composite coating can be rapidly separated from the neural electrode after implantation, no polymer adheres to the metal electrode site of the neural electrode, normal recording of the electrode on the bio-electricity signal is not affected, and the slow-release anti-inflammatory drug can relieve the inflammatory response of tissue.

Owner:SHANGHAI JIAO TONG UNIV

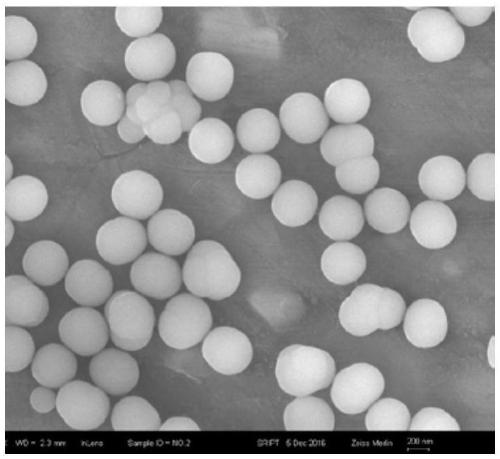

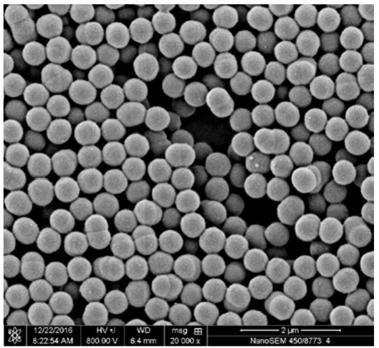

Active nano silicon dioxide microspheres, solution, and preparation method and application thereof

ActiveCN111099597AGood structural regularityRegular structureSilicaCoatingsNano siliconNano structuring

The invention relates to active nano silicon dioxide microspheres, a solution and a preparation method and application thereof, and mainly solves the problem that the nano silicon dioxide microspheresprepared by using an existing method cannot be directly subjected to chemical reaction with the surfaces of modified glass, ceramic and silicon, so that a coating with a micro-nano characteristic structure is difficult to prepare. According to the technical scheme, the active nano silicon dioxide microspheres are adopted; the active nano silicon dioxide microspheres comprise nano silicon dioxidemicrospheres and an active layer on the surfaces of the nano silicon dioxide microspheres, and the active layer contains condensable siloxane, so that the problem is better solved, and preparation ofcoatings with micron or nano structure characteristics on the surfaces of glass, ceramics and silicon can be realized.

Owner:CHINA PETROLEUM & CHEM CORP +1

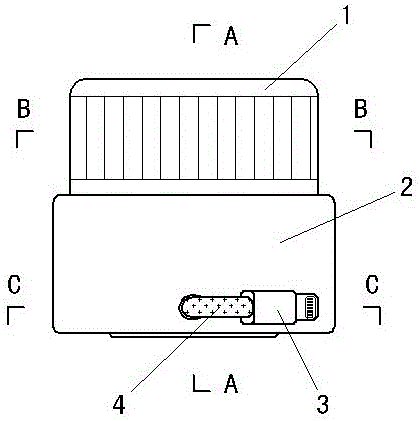

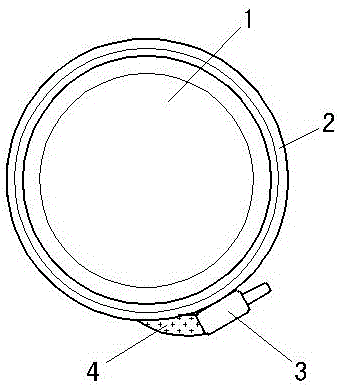

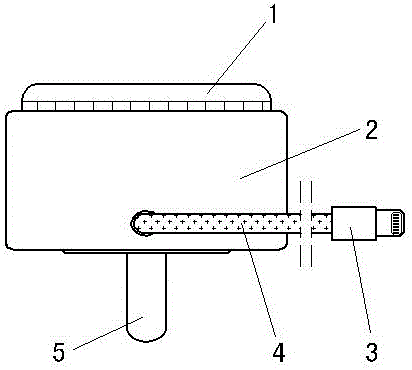

Portable charger

ActiveCN105914525AImprove structural regularityEasy to carryBatteries circuit arrangementsElectric powerElectricityBattery charger

The invention provides a portable charger. An electric appliance box is arranged in a housing. An upper end head of the electric appliance box is connected to the central position of a housing top plate. A certain interval exists between the outer wall of the housing and the outer wall of the electric appliance box. An external thread is formed in the outer wall of the electric appliance box. A plurality of electric plugs are connected to the lower end of the electric appliance box. A telescopic cylinder is arranged in a storage box. A lower end port of the telescopic cylinder is in abutted connection with a central hole in a bottom plate of the storage box. An internal thread is formed in the inner wall of the telescopic cylinder. The storage box is connected with the thread of the electric appliance box in the housing through the telescopic cylinder. A power supply wire is arranged in the storage box and is wound on the telescopic cylinder. One end of the power supply wire penetrates through the interval to be connected with the electric appliance box, and the other end of the power supply wire penetrates out through a through hole in the outer wall of the storage box to be connected with a charging head. A hand holds the storage box and pulls the power supply wire out from the storage box, and the power supply wire can drive the electric appliance box to rotate around the telescopic cylinder. When the electric appliance box moves downwards with the rotation along the thread, the electric plugs on the electric appliance box are enabled to extend out from the central hole in the storage box.

Owner:深圳市蓝能世通电子有限公司

Ecological multifunctional ternary copolymerization PETG (Polyethylene Terephthalate Glycol) polyester, preparation method of polyester, and method for preparing unidirectional stretching heat-shrinkable film from polyester

ActiveCN102558517BRaw materials are cheapLow priceStructural regularityPolyethylene terephthalate glycol

The invention discloses an ecological multifunctional ternary PETG (Polyethylene Terephthalate Glycol), a preparation method of the polyester, and a method for preparing a unidirectional stretching heat-shrinkable film from the polyester. The ecological multifunctional ternary copolymerization PETG polyester is formed by ternary monomer copolymerization of terephthalic acid, neopentyl glycol and glycol, wherein the molar ratio of terephthalic acid to neopentyl glycol to glycol is 1: (0.1-0.65):(1.2-1.75). The preparation method comprises esterification reaction and polymerization, wherein the temperature of the esterification reaction is 200 DEG C to 255 DEG C, the temperature of the polymerization is 270 DEG C to 280 DEG C, and the vacuum degree of the polymerization is 0.098 MPa to 0.1 MPa. The price of raw materials of the ecological multifunctional ternary copolymerization PETG polyester is low, so that the manufacturing cost is reduced, and the structural regularity of the PETG polyester is good, so that the strength is high. The heat-shrinkable film prepared from the obtained ecological multifunctional ternary copolymerization PETG polyester according to the invention is high in strength, transparency and heat shrinkage.

Owner:河南银金达新材料股份有限公司

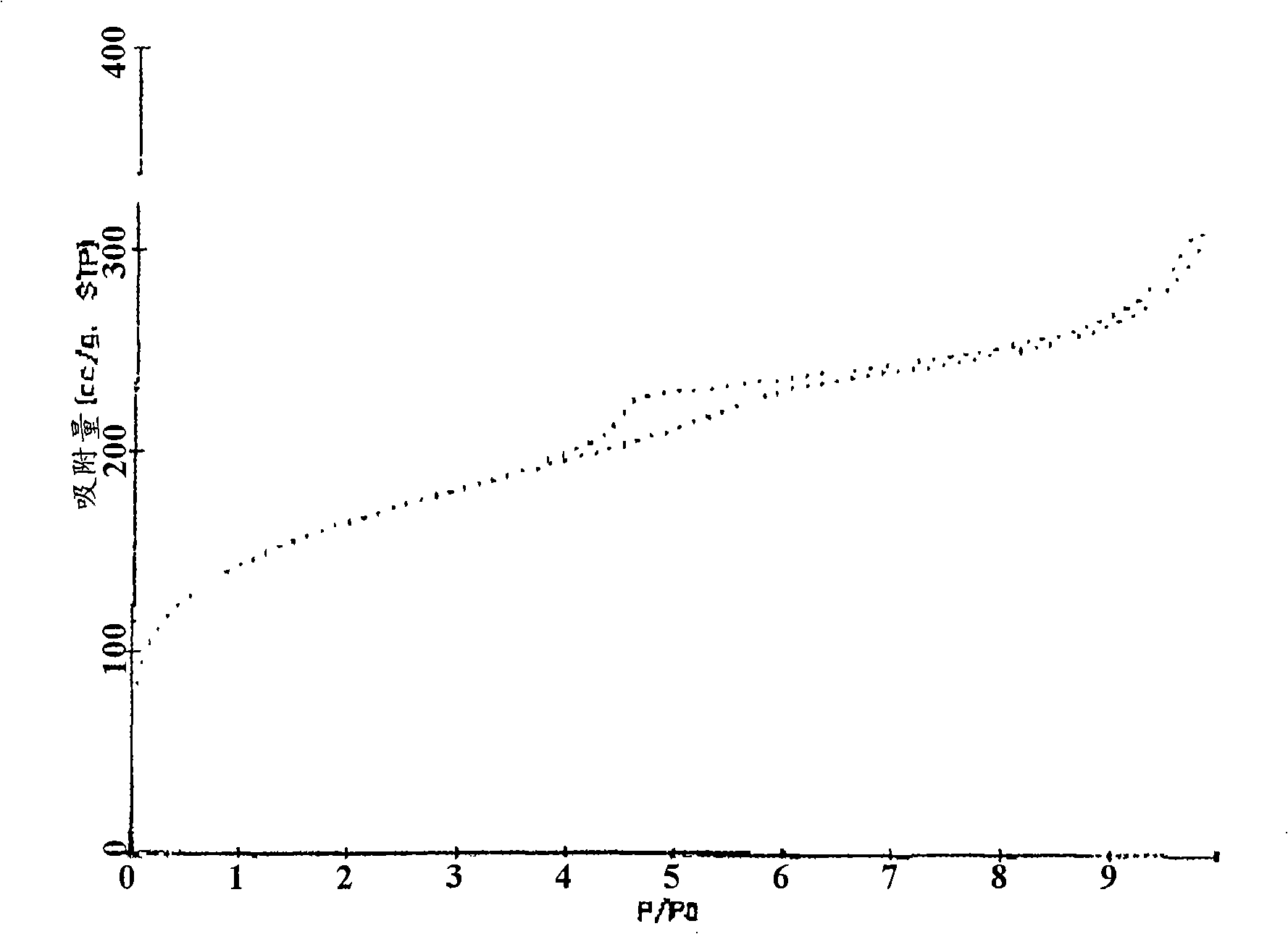

Method of manufacturing mesoporous silica and method of manufacturing the same

InactiveCN101272987AImprove structural regularityIncrease changeSilicaMolecular-sieve silica-polymorphsChemistryWater soluble

Disclosed is a method for production of a mesoporous silica under electrolyte-free conditions by using a surfactant aggregate structure as a template. Also disclosed is a mesoporous silica having a novel geometrical structure which has not been produced heretofore. A mesoporous silica can be produced under electrolyte-free conditions by reacting a nonionic surfactant with a water-soluble silicate monomer having a specific structure under neutral conditions. A nonionic surfactant may be used which can form a ribbon phase or nematic phase at appropriate temperature range and concentration range when dissolved in water. By using the nonionic surfactant, a sheet-like mesoporous silica can be prepared.

Owner:SHISEIDO CO LTD

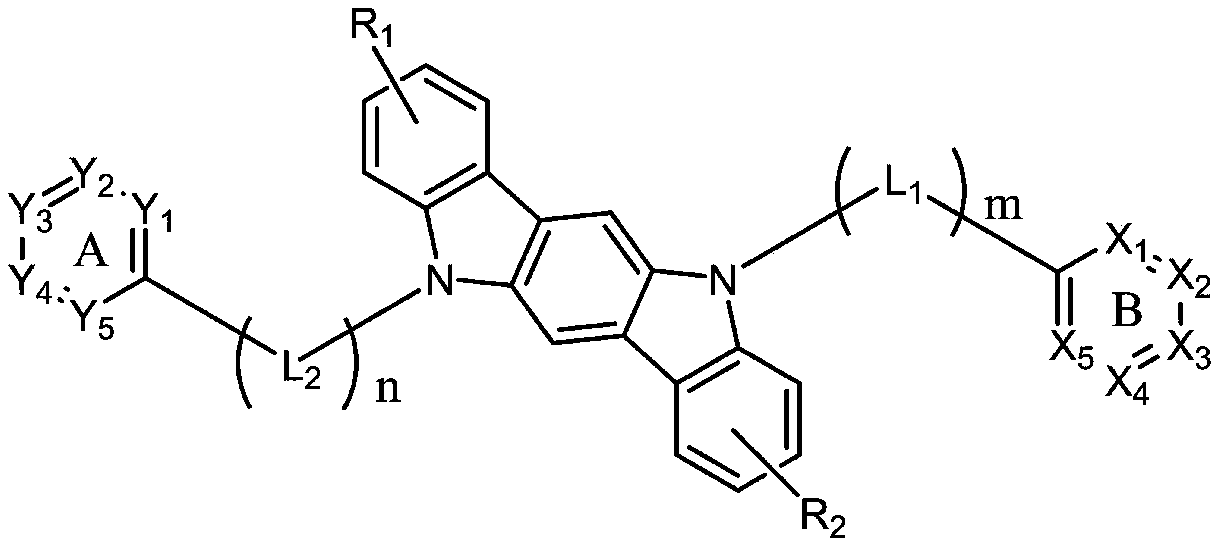

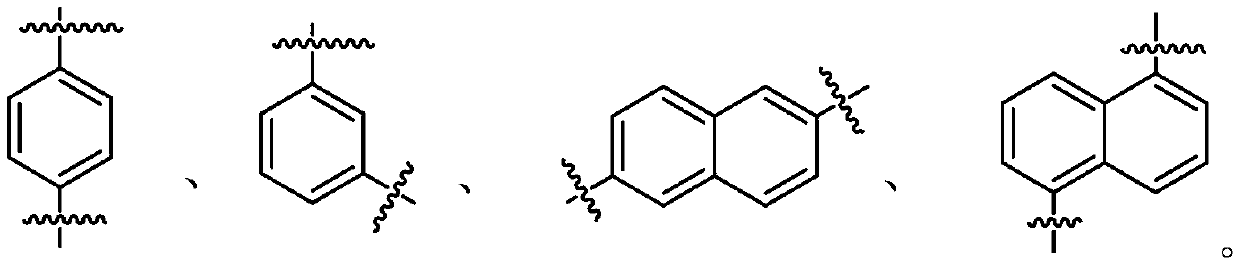

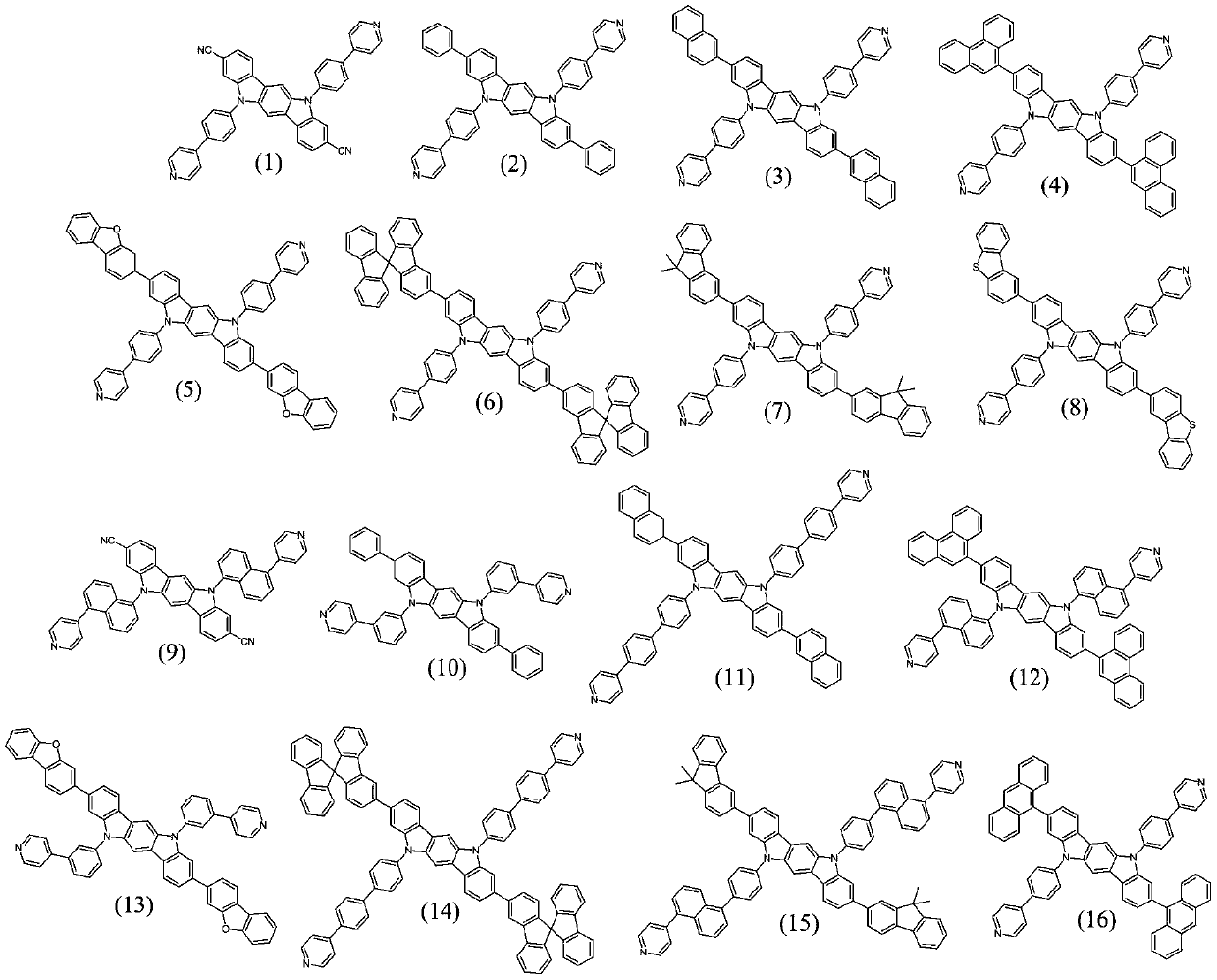

Organic compound based on nitrogen-containing heterocyclic ring and preparation method and application of organic compound

InactiveCN110804060AImprove structural regularityImprove performanceOrganic chemistrySolid-state devicesSimple Organic CompoundsOrganic light emitting device

The invention provides an organic compound based on a nitrogen-containing heterocyclic ring and a preparation method and application of the organic compound and relates to the field of OLED (organic light emitting diode) materials. The organic compound has a structural formula shown in the description. The organic compound provided by the invention has a high neat degree, high luminous efficiencyand heat stability, enables carrier transmission to be balanced, is applied to organic light emitting devices, especially used as a blue light emitting material in an OLDE light emitting layer, has high luminous efficiency, has a good application effect in OLED devices, has a good industrialization prospect.

Owner:HEZE UNIV

Porous soft polyester fiber POY and preparation method thereof

ActiveCN106381548AImprove dyeing effectEasy to processSpinnerette packsHollow filament manufactureFiberBreaking strength

The invention relates to porous soft polyester fiber POY and a preparation method thereof. Modified polyester undergoes spinning by a porous spinneret plate to prepare porous soft polyester fiber POY. The arrangement mode of spinneret orifices on the porous spinneret plate is elliptical arrangement. That is to say, the centers of the spinneret orifices are positioned at concentric ellipses which are series ellipses. Long axis of all the ellipses is collinear, and minor axis is collinear. According to the porous soft polyester fiber POY, modified polyester undergoes grain-sized dicing to obtain modified polyester chip; and the modified polyester chip undergoes metering, extrusion, cooling, oiling and winding so as to prepare the product. A preparation method of the modified polyester comprises the following steps: letting terephthalic acid and glycol react to prepare ethylene glycol terephthalate, adding terephthalic acid and dihydric alcohol containing branched chain and reacting to prepare terephthalic dibasic alcohol ester, and continuously reacting to the modified polyester. The prepared fiber has excellent properties. Deviation ratio of linear density is less than or equal to 0.2%; breaking strength CV value is less than or equal to 2.5%; and breaking elongation CV value is less than or equal to 5.0%.

Owner:JIANGSU HENGLI CHEM FIBER

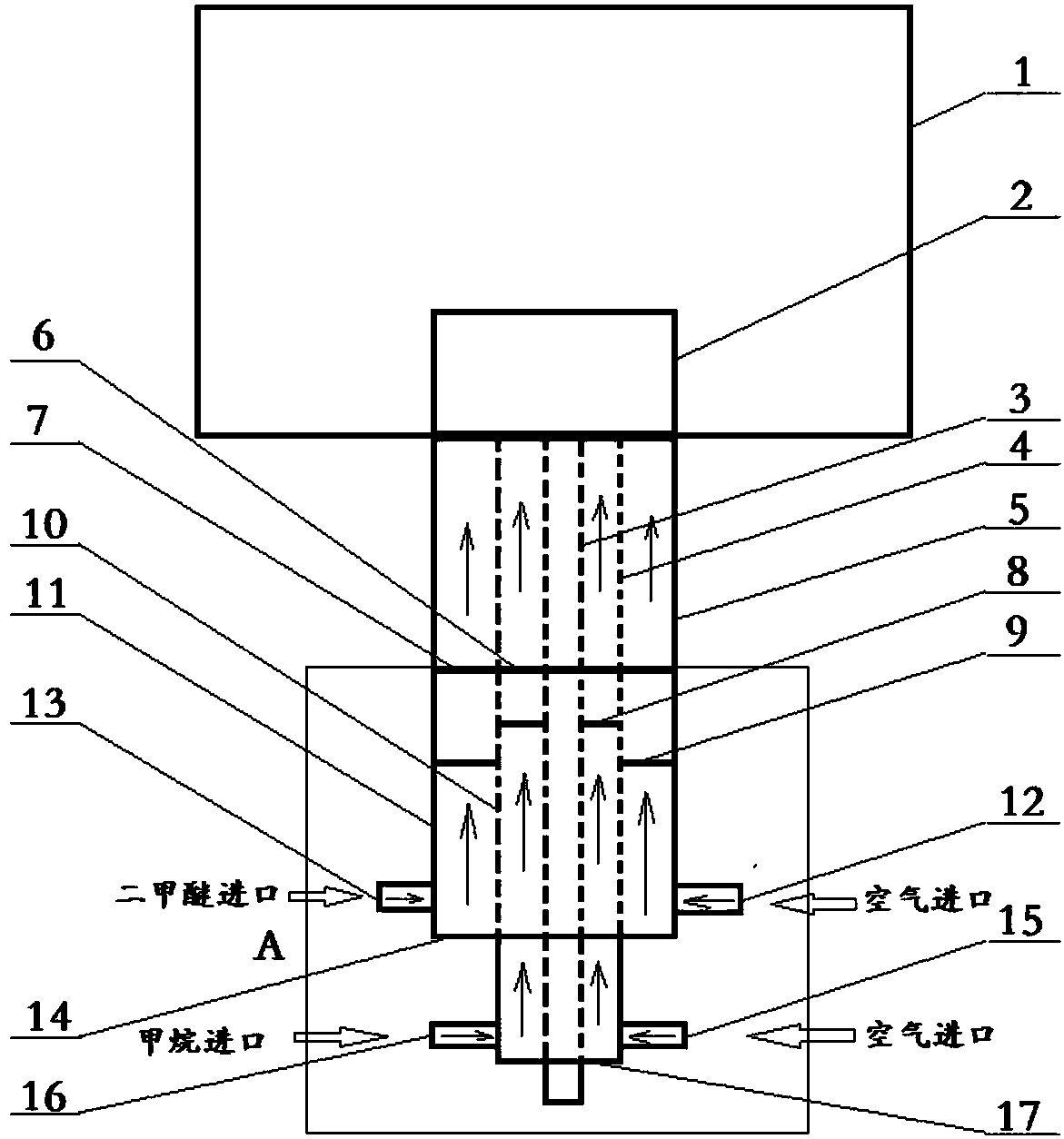

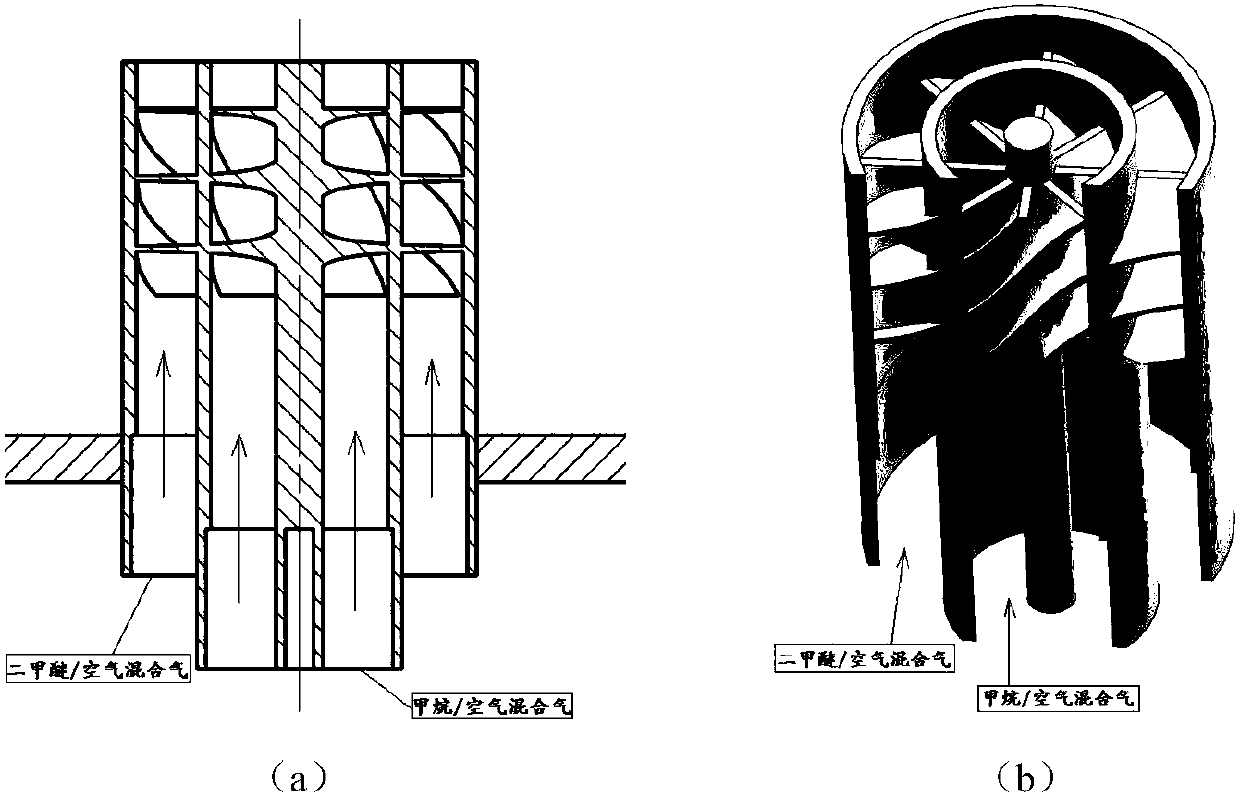

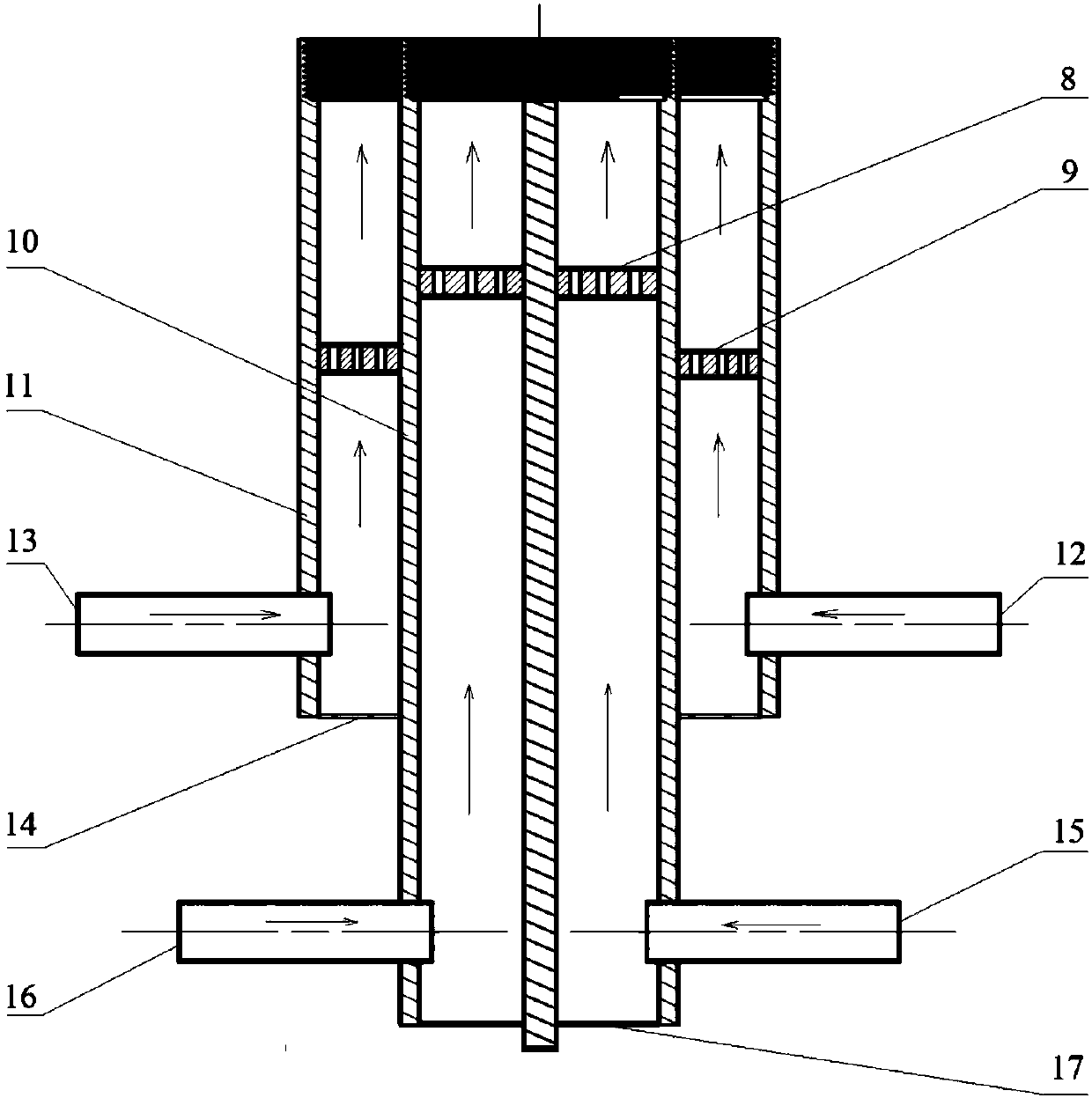

A combustor with double swirling inflow channels can be used for the study of multi-fuel blending combustion phenomena

The invention discloses a combustor which is provided with double rotation inflow channels and capable of being used for a multi-fuel mixing combustion phenomenon research. The combustor comprises a visualization square combustion chamber, a fuel full premixing and rotating flow generation device and a fuel and air inflow mixing device. The whole combustor is arranged in a vertical mode. When the combustor works, air and fuel enter the combustor through an air inlet pipe and are premixed in a pipeline; full premixing of the fuel and the air can be facilitated through a metal hole plate embedded in the pipeline; then the premixed mixture forms stable rotating airflow through a double-layer whirlcone; and finally, the rotating airflow enters the square combustion chamber and is ignited, so that a stable combustion flame is formed. According to the combustor which is provided with the double rotation inflow channels and capable of being used for the multi-fuel mixing combustion phenomenon research, the double-layer structure design is adopted; an inner-layer structure and an outer-layer structure are very similar; single-layer or double-layer flame experiments can be designed according to the actual requirements; mixing combustion experiments with two kinds of different fuel can be conducted at the same time; the combustor can be well used cooperatively with other measuring and detecting instruments; and the combustor is capable of reaching excellent premixing and rotating flow effects, novel in design, easy to process and reliable in work.

Owner:蓝色火焰能源科技(镇江)有限公司

Antiskid permeable pavement

ActiveCN112195711AExtended service lifeImprove structural regularityIn situ pavingsPaving gutters/kerbsAdipic acidMaterials science

The invention discloses an antiskid permeable pavement which comprises a pavement base layer and an adhesive stone surface layer paved on the surface of the pavement base layer, the adhesive stone surface layer is prepared from the following raw materials in parts by weight: 2-5 parts of a component A, 3-7 parts of a component B and 95-105 parts of aggregate; the component A is prepared from the following raw materials: polyester of aliphatic dicarboxylic acids, polyether polyol, dipropylene glycol, neopentyl glycol, linoleic acid, castor oil, 2,2,3,3,4, 4,5,5-octafluoro-1-amyl alcohol, epoxyresin E-44, epoxy resin E-14, diphenyl-methane-diisocyanate, hexamethylene diisocyanate, nano silicon dioxide, nano calcium carbonate, boron carbide and modified lignin; the component B is prepared from the following raw materials: 1,8-diazacyclo[5,4,0]undecene-7 and triethanolamine. The anti-skid permeable pavement provided by the invention has the advantages of good skid resistance and water permeability, excellent aging resistance, short curing time and long service life.

Owner:江苏固迈新材料技术有限公司

A kind of preparation method of ternary polyacrylonitrile copolymer

InactiveCN104710565BImprove structural regularityImprove thermal stabilityMonocomponent synthetic polymer artificial filamentPAN copolymerAcrylonitrile

The invention relates to a preparation method of a ternary polyacrylonitrile copolymer, which comprises the steps of heating an aqueous solution of maleic anhydride, acrylamide and a dispersing agent to 55-75 DEG C under a nitrogen shielding condition, adding acrylonitrile to keep constant temperature for 20-30min, adding an initiator solution for reaction for 3-12h, and carrying out washing, demonomerisation, filtration and drying. The method employs a mixed solvent precipitation polymerization method for polymerization and has the advantages of high reaction yield, high viscosity average molecular weight, narrow distribution, easiness in temperature control, stable product quality and the like. The thermal property of the polyacrylonitrile copolymer prepared by the method can be effectively improved, and the copolymer has certain practical application prospects.

Owner:DONGHUA UNIV

A kind of preparation method of sulfur dioxide and epoxy compound copolymer

The invention discloses a preparation method of a copolymer of sulfur dioxide and epoxy compounds; a novel polysulfone material is prepared by using SalenMX to catalyze the copolymerization of sulfur dioxide and epoxy compounds, adding epoxy compounds and SalenMX into a high-pressure reactor in sequence, and then injecting sulfur dioxide into the React at 50~100°C, react for 8~48 hours to obtain the product, namely sulfur dioxide and epoxy compound copolymer, dissolve the product in chloroform and precipitate with hydrochloric acid methanol mixture, filter the amber precipitate and wash it repeatedly with methanol for 2~4 times , the washed product is moved to a vacuum drying oven for 8 to 24 hours at room temperature and vacuum-dried to obtain a copolymer of sulfur dioxide and epoxy compounds with higher tacticity; the preparation method involved in the present invention is simple, the catalyst consumption is small, and the reaction The temperature is mild, the yield is high, the structure of the product is good, the cost is low, and industrial production is easy to realize.

Owner:KUNMING UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com