Active nano silicon dioxide microspheres, solution, and preparation method and application thereof

A technology of nano-silica and microspheres, which is applied in the direction of silica, silicon oxide, coating, etc., can solve the problem of not being able to directly react with the modified glass, ceramics, and silicon surface, and achieve low product cost and synthetic Economic route, good aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

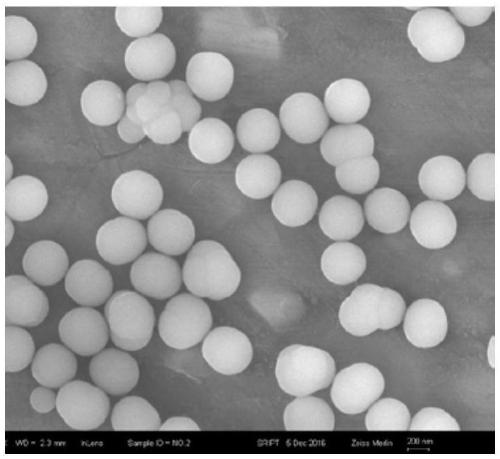

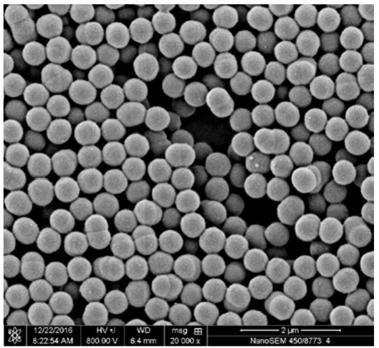

[0052] Add 10ml of n-ethyl silicate and 45ml of ethanol into a 250ml four-neck flask, heat up to 60°C, then add 15ml of ammonia water and 25ml of ethanol into the reaction flask, and react at 60°C for 5 hours to obtain nano-silica microspheres After taking 5 drops of the reaction solution and diluting it with ethanol, the diameter of the nano-silica microsphere particles was tested with a Malvern particle size meter to be 410nm. The ammonia water in the reaction solution was removed by rotary evaporation, and then 10 ml of acetic acid, 5 ml of n-ethyl silicate and 0.05 g of water were added, and the reaction was continued at 50° C. for 5 hours before the end to obtain active nano-silica microspheres. After taking 5 drops of the reaction solution and diluting it with ethanol, the average diameter of the active nano-silica microsphere particles was tested by a Malvern particle size analyzer to be 550nm.

Embodiment 2

[0054] Add 8ml of n-ethyl silicate and 45ml of ethanol into a 250ml four-neck flask, heat up to 70°C, then add 15ml of ammonia water and 25ml of ethanol into the reaction flask, and react at 70°C for 5 hours to obtain nano-silica microspheres After taking 5 drops of the reaction solution and diluting it with ethanol, the diameter of the silica particles was tested with a Malvern particle size meter to be 230nm. The ammonia water in the reaction solution was removed by rotary evaporation, and then 10 ml of acetic acid, 5 ml of n-ethyl silicate and 0.05 g of water were added, and the reaction was continued at 50° C. for 5 hours before the end to obtain active nano-silica microspheres. After taking 5 drops of the reaction solution and diluting it with ethanol, the diameter of the silica particles was tested with a Malvern particle size analyzer to be 400nm.

Embodiment 3

[0056] Add 10ml of n-ethyl silicate and 45ml of ethanol into a 250ml four-neck flask, heat up to 40°C, then add 15ml of ammonia water and 25ml of ethanol into the reaction flask, and react at 40°C for 5 hours to obtain nano-silica microspheres After taking 5 drops of the reaction solution and diluting it with ethanol, the diameter of the silica particles was tested with a Malvern particle size meter to be 508nm. The ammonia water in the reaction solution was removed by rotary evaporation, and then 10 ml of acetic acid, 5 ml of n-ethyl silicate and 0.05 g of water were added, and the reaction was continued at 50° C. for 5 hours before the end to obtain active nano-silica microspheres. After taking 5 drops of the reaction solution and diluting it with ethanol, the diameter of the silica particles was tested with a Malvern particle size analyzer to be 610 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com