A waterborne automobile coating composition and a preparing method and applications thereof

A composition and water-based technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of insufficient stone chip resistance, high cost of coating energy consumption, high cost of raw materials, etc., to achieve improved resistance, regular structure, The effect of excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

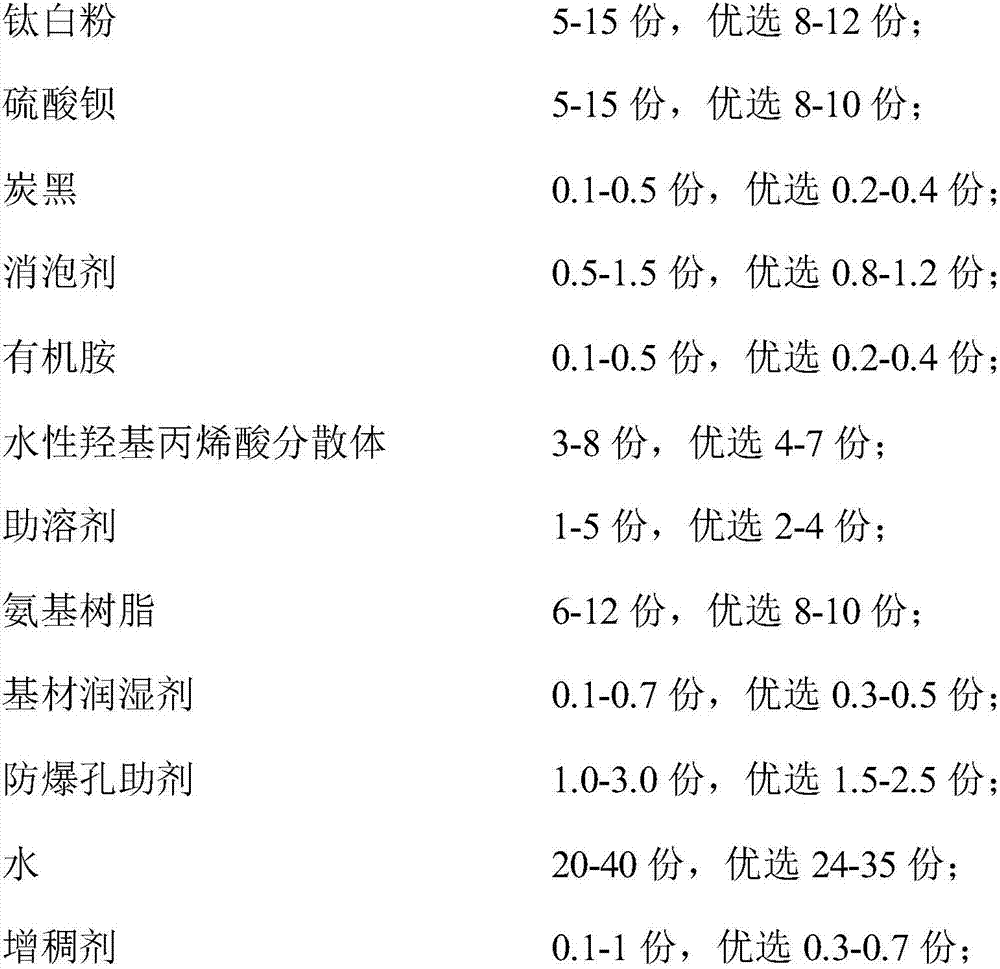

Method used

Image

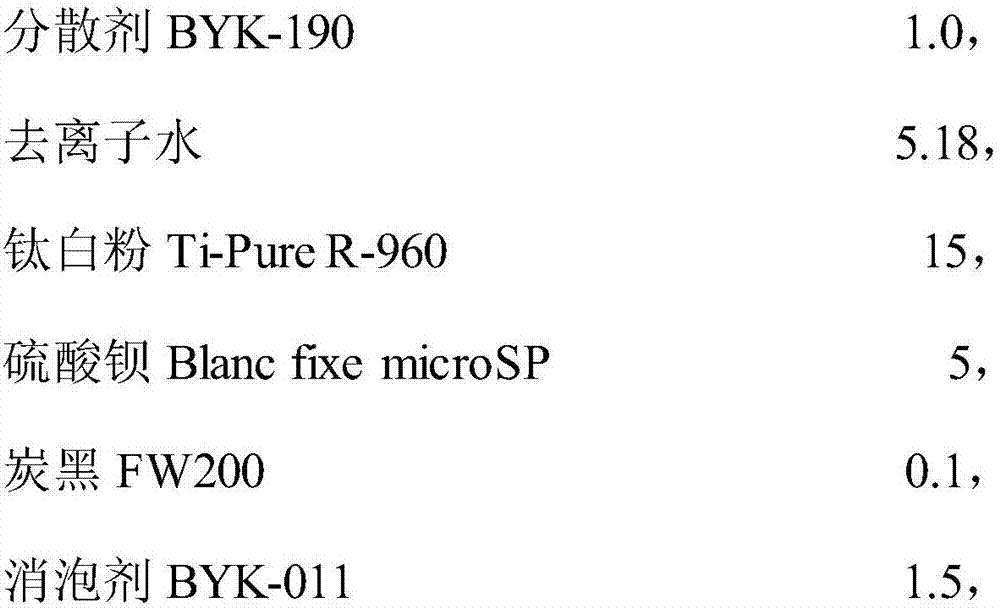

Examples

Embodiment 1

[0074] Preparation of polycarbonate polyurethane dispersion 1: 189 parts of polycarbonate polyol 980R (parts by weight, the same below), 7.2 parts of dimethylolpropionic acid DMPA, 3 parts of trimethylolpropane TMP and 4,4' -Add 42 parts of dicyclohexylmethane diisocyanate HMDI into the reaction bottle, react at 80~120°C to the end point, add an appropriate amount of solvent (such as acetone, methyl ethyl ketone) to reduce the viscosity, then lower the temperature to below 40°C and add 4.52 parts of triethanolamine TEA Neutralize, then add deionized water to disperse under strong stirring, adjust the solid content after removing the solvent, the solid content is 35%, and the hydroxyl content is about 1%. Based on the weight of the solid components in the dispersion, the weight average molecular weight is about 10000 Polycarbonate Polyurethane Dispersion 1.

Embodiment 2

[0076] Preparation of polycarbonate polyurethane dispersion 2: 189 parts of polycarbonate polyol 980R, 7.8 parts of dimethylolpropionic acid DMPA, 4.8 parts of trimethylolpropane TMP and 4,4'-dicyclohexylmethane diisocyanate HMDI42 Add 5.88 parts of triethanolamine TEA to neutralize after cooling down to below 40 ℃, and then stir vigorously Add deionized water to disperse, and adjust the solid content after removing the solvent to obtain a polycarbonate polyurethane dispersion 2 with a hydroxyl content of 2%, a solid content of 35%, and a weight average molecular weight of about 15,000.

Embodiment 3

[0078] Preparation of polycarbonate polyurethane dispersion 3: 150 parts of polycarbonate polyol 980R, 7.0 parts of dimethylolpropionic acid DMPA, 7.5 parts of trimethylolpropane TMP and 4,4'-dicyclohexylmethane diisocyanate HMDI Add 42 parts into the reaction bottle, react at 80-120°C to the end, add an appropriate amount of solvent (such as acetone, methyl ethyl ketone) to reduce the viscosity, then cool down to below 40°C, add 5.28 parts of triethanolamine TEA to neutralize, and then Add deionized water to disperse under stirring, and adjust the solid content after removing the solvent to obtain a polycarbonate polyurethane dispersion 3 with a hydroxyl content of 3%, a solid content of 35%, and a weight average molecular weight of 3000.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com