A kind of water-based composite paint and its composite film coating method

A composite coating, water-based technology, applied in the field of coatings, can solve the problems of stone chip resistance reduction, composite coating film damage, peeling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

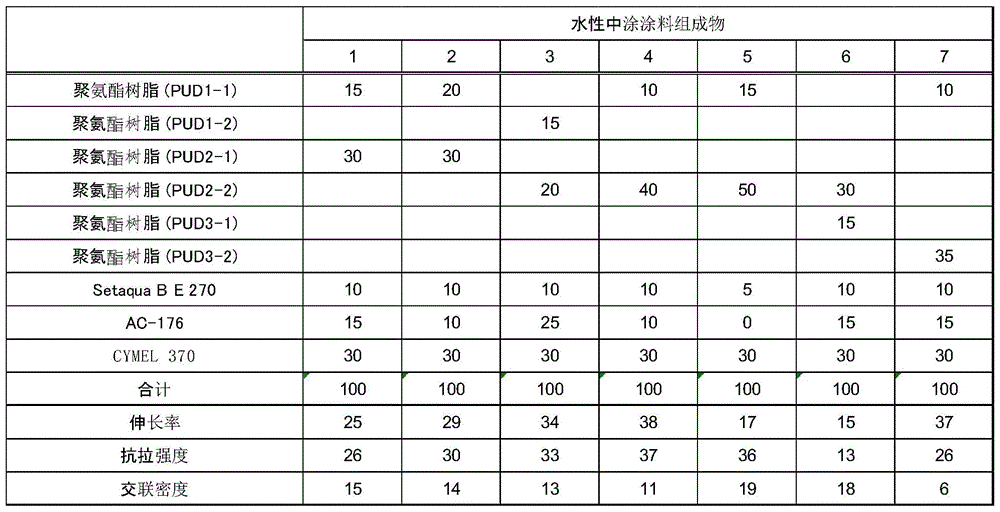

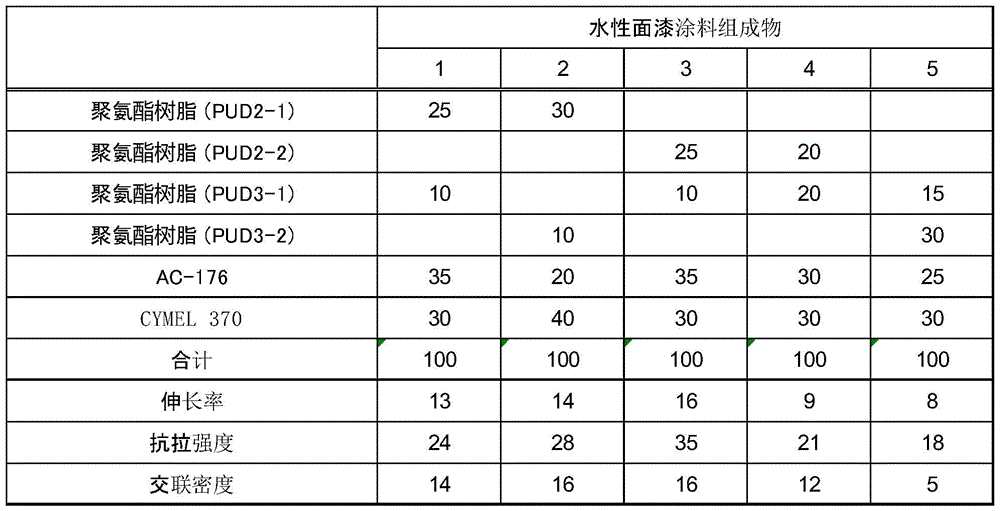

Examples

manufacture example 1

[0053] Production Example 1, Preparation of Polyester Polyol 1-1 (PE1-1)

[0054] Neopentyl glycol (7.5 parts), 1,6-hexanediol (38.5 parts), 1,6-hexanediol and Acid (54 parts) was added, and the temperature was raised to 120° C. After the raw materials were dissolved, the temperature was raised to 160° C. with continuous stirring. After keeping at 160°C for 1 hour, the temperature was raised to 230°C for 5 hours. Test the acid value at regular intervals at 230°C until the acid value of the resin reaches 1mgKOH / g. Then cool to below 80°C to obtain polyester polyol 1-1 (PE1-1) with an acid value of 1 mgKOH / g, a hydroxyl value of 36 mgKOH / g and a number average molecular weight of 3000.

manufacture example 2

[0055] Production Example 2, Preparation of Polyester Polyol 1-2 (PE1-2)

[0056] Neopentyl glycol (13 parts), 1,6-hexanediol (33.5 parts), 1,6-hexanedioic acid (53.5 parts) were put in, using the method of Production Example 1, the acid value was 1 mgKOH / g, and the hydroxyl value was 55mgKOH / g, polyester polyol 1-2 (PE1-2) with a number average molecular weight of 2000.

manufacture example 3

[0057] Production Example 3, Preparation of Polyester Polyol 2 (PE2)

[0058] Neopentyl glycol (5.8 parts), 1,6-hexanediol (29.9 parts), trimethylolpropane (13.2 parts), 1,6-adipic acid (51.1 parts) were put in, using the method of Production Example 1 , Obtain the polyester polyol 2 (PE2) of acid value 1mgKOH / g, hydroxyl value 136mgKOH / g, number average molecular weight 1500.

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com