Aqueous coating combination and automobile intermediate coating thereof

A technology for water-based coatings and compositions, applied in coatings, polyester coatings, etc., can solve the problems of not finding the inventor's instructions for use, poor stone chip resistance, and high baking temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0062]

[0063]

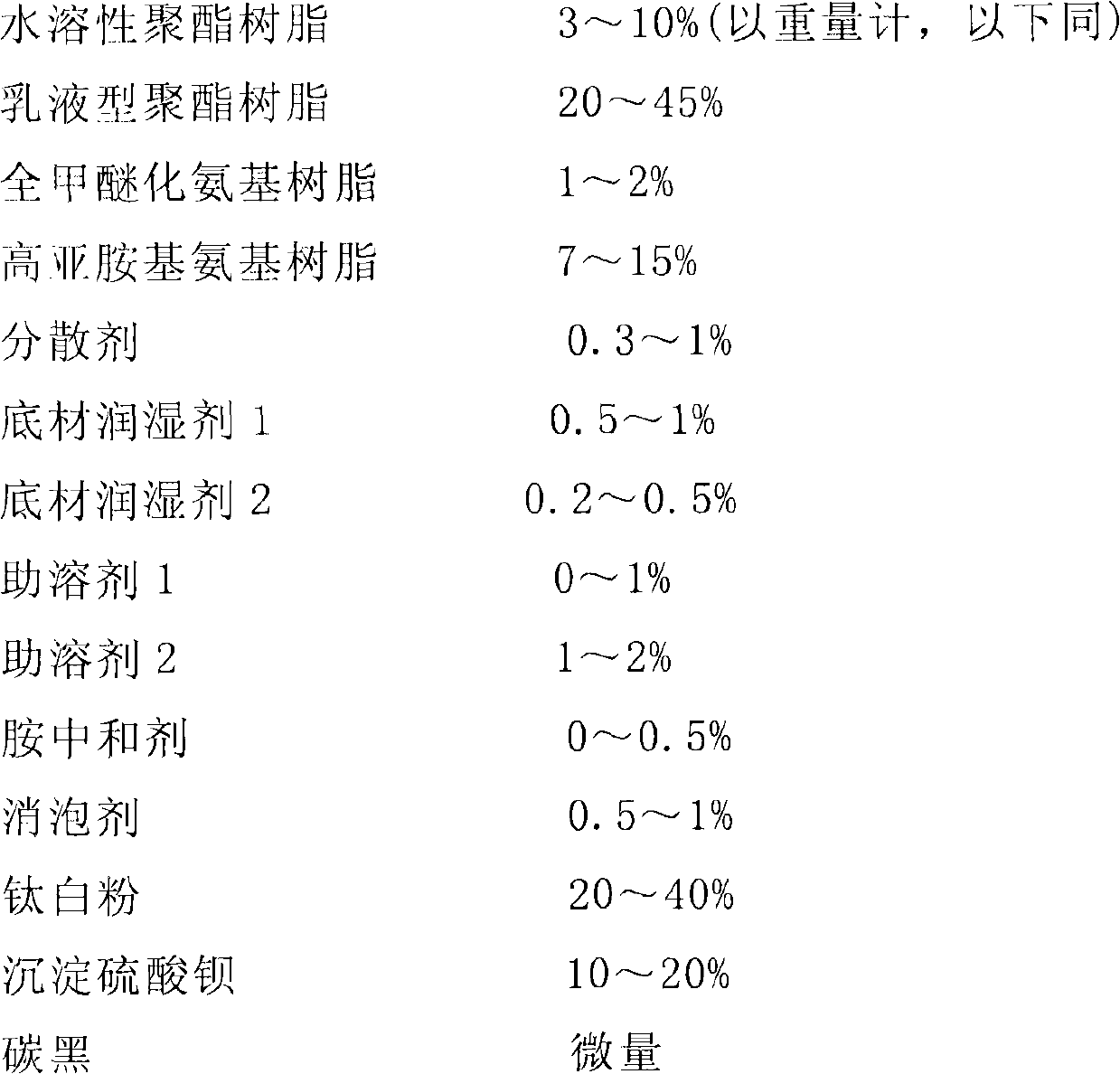

[0064] Automotive Intermediate Coating

[0065] The present invention also provides an automotive intermediate coating obtained by coating the aqueous coating composition.

[0066] The composition obtained by the invention has better stability, and various performances can reach the performances required by the current solvent-based coatings. Compared with the water-based automobile intermediate coating currently used in the market, the baking temperature of the coating obtained by applying the water-based paint composition can be reduced by 10°C. Stone chip resistance and solvent resistance are superior to similar products in the market.

[0067] The coating method can adopt a method in the art. Usually, water-soluble polyester resin and water-soluble additives are uniformly stirred; sand milling; then add emulsion polyester resin, high imine amino resin and water-dispersible additives, and then adjust the pH with amine neutralizer; The coating is...

preparation Embodiment 1

[0098] (1) Mix the following components (the following components are all in parts by weight):

[0099]

[0100] The above components are dispersed at a high speed to a dispersion with a fineness of 15um.

[0101] (2) Add the following components:

[0102]

[0103]

[0104] The pH value is 8.2 and the viscosity is 60s.

preparation Embodiment 2

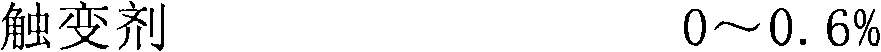

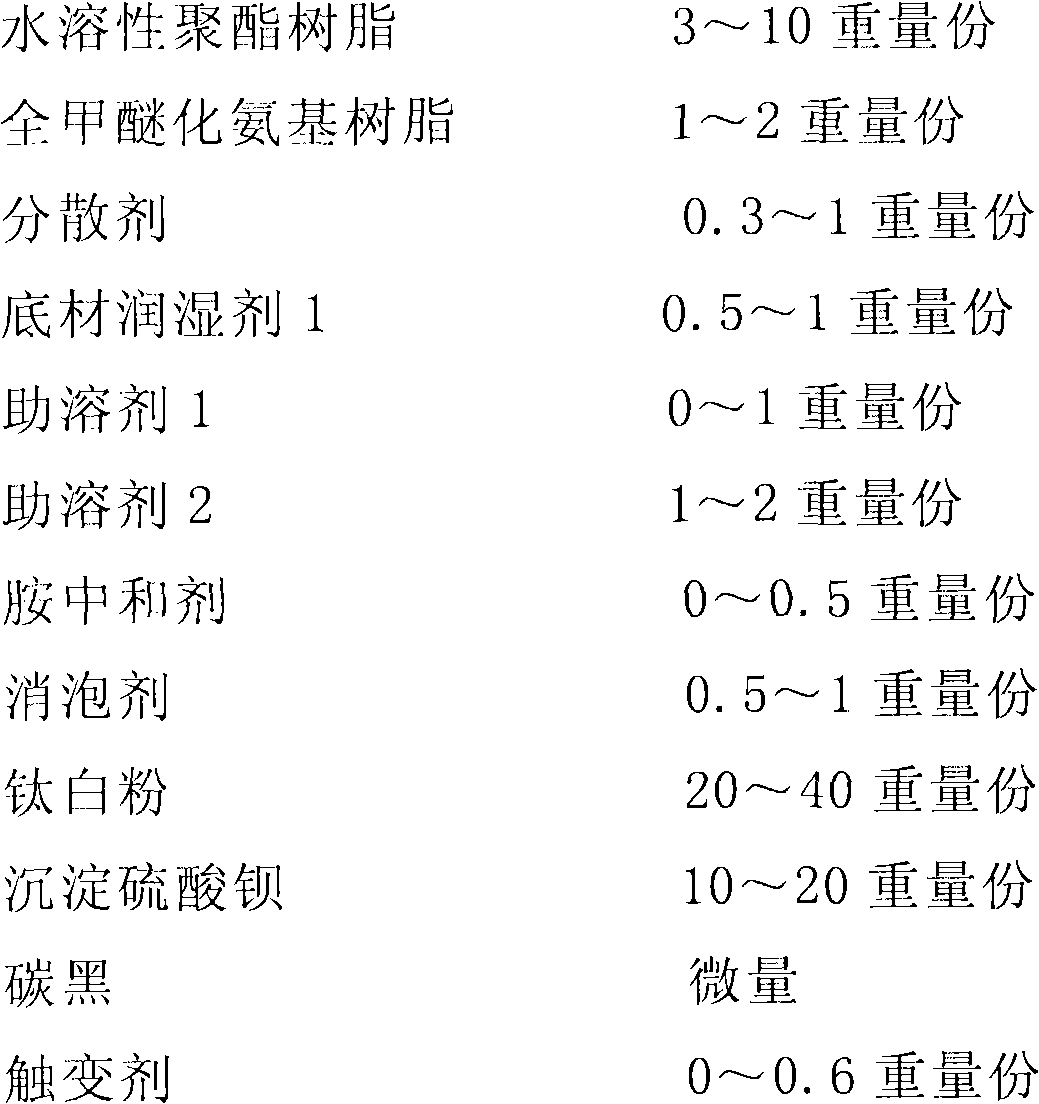

[0106] (1) Mix the following components (the following components are all in parts by weight):

[0107]

[0108] The above components are dispersed at a high speed to a dispersion with a fineness of 15um.

[0109] (2) Add the following components:

[0110]

[0111] The pH value is 8.2 and the viscosity is 60s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com