Water varnish and preparation method thereof

A water-based, modified technology, applied in coatings, anti-corrosion coatings, polyester coatings, etc., can solve problems such as unsatisfactory gloss and transparency, high viscosity of water-based varnishes, uneven thickness of protective film, etc., to improve gloss and appearance high degree of adhesion, high stone chip resistance and gasoline resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

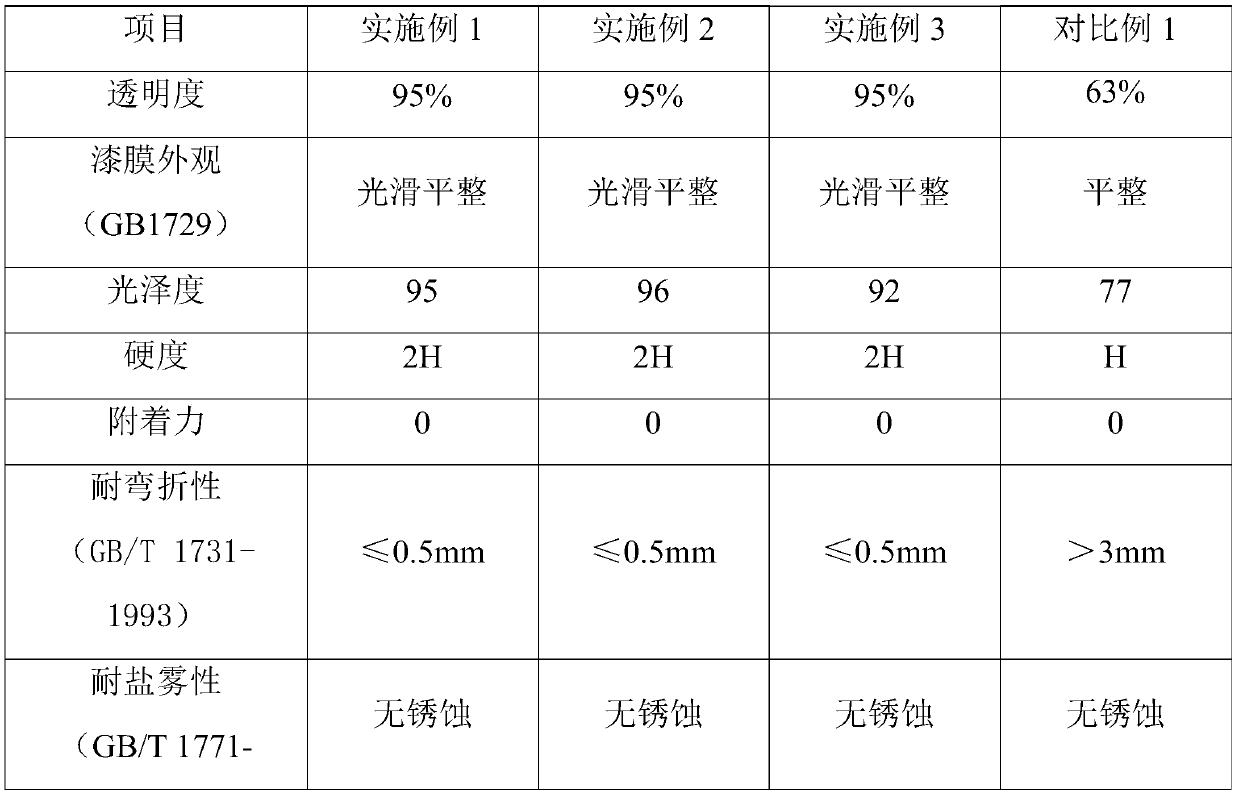

Embodiment 1

[0023] A kind of water-based varnish, comprises the component of following mass percentage:

[0024] Waterborne Acrylic Hydroxy-Functional Copolymer Emulsion 35%;

[0025] Waterborne acrylic polyester modified functional group copolymer emulsion 25%;

[0026] High imino melamine formaldehyde resin 15%;

[0027] Substrate wetting agent 0.2%;

[0028] Benzoin 1%;

[0029] Defoamer 0.2%;

[0030] Light stabilizer 0.3%;

[0031] UV absorber 0.3%;

[0032] Dispersant 0.2%;

[0033] Deionized water 22.8%.

Embodiment 2

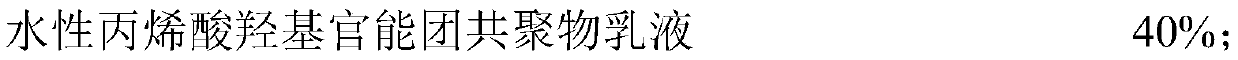

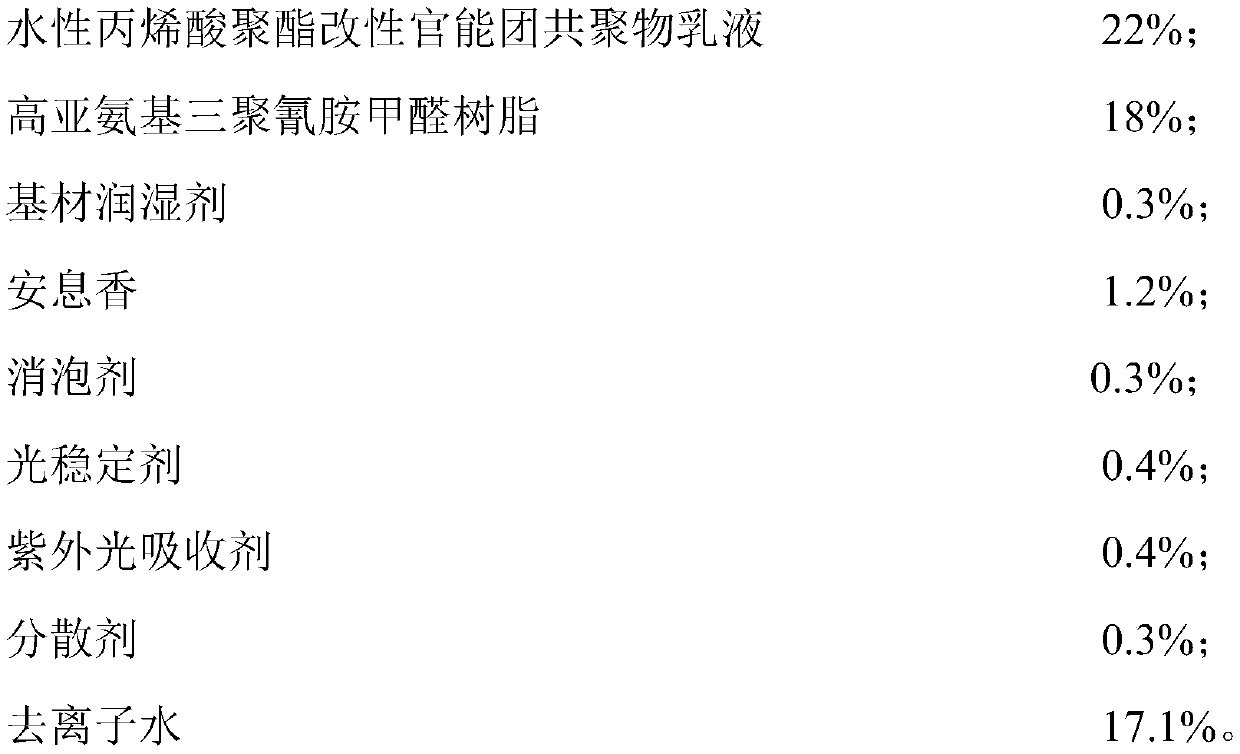

[0035] A kind of water-based varnish, comprises the component of following mass percentage:

[0036]

[0037]

Embodiment 3

[0039] A kind of water-based varnish, comprises the component of following mass percentage:

[0040] Waterborne Acrylic Hydroxy-Functional Copolymer Emulsion 45%;

[0041] Waterborne acrylic polyester modified functional group copolymer emulsion 20%;

[0042] High imino melamine formaldehyde resin 20%;

[0043] Substrate wetting agent 0.5%;

[0044] Benzoin 1.5%;

[0045] 0.5% defoamer;

[0046] Light stabilizer 0.6%;

[0047] UV absorber 0.6%;

[0048] Dispersant 0.5%;

[0049] Deionized water 10.8%.

[0050] In embodiment 1-3, water-based acrylic acid hydroxyl functional group copolymer emulsion uses allnex's VSC6800W / 47WA; waterborne acrylic polyester modified functional group copolymer emulsion uses allnex VSC6276w / 44WA; GK-19 for benzoin; tego280 for substrate wetting agent; BYK011 for defoamer; TINUVIN 123 for light stabilizer; TINUVIN 400 for UV absorber; BYK190 for dispersant.

[0051] The preparation method of the water-based varnish described in embodim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com