Preparation method of water-soluble polyaniline, water-soluble polyaniline-containing water-based high-temperature conductive primer for glass fiber reinforced plastics and preparation method thereof

A polyaniline and water-soluble technology, which is applied in the field of water-based high-temperature conductive primer and preparation of FRP, can solve the problems of poor adhesion, poor dispersion, and low painting rate of FRP, and improve flexibility and stone chip resistance. High self-condensation tendency, good wettability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1-3

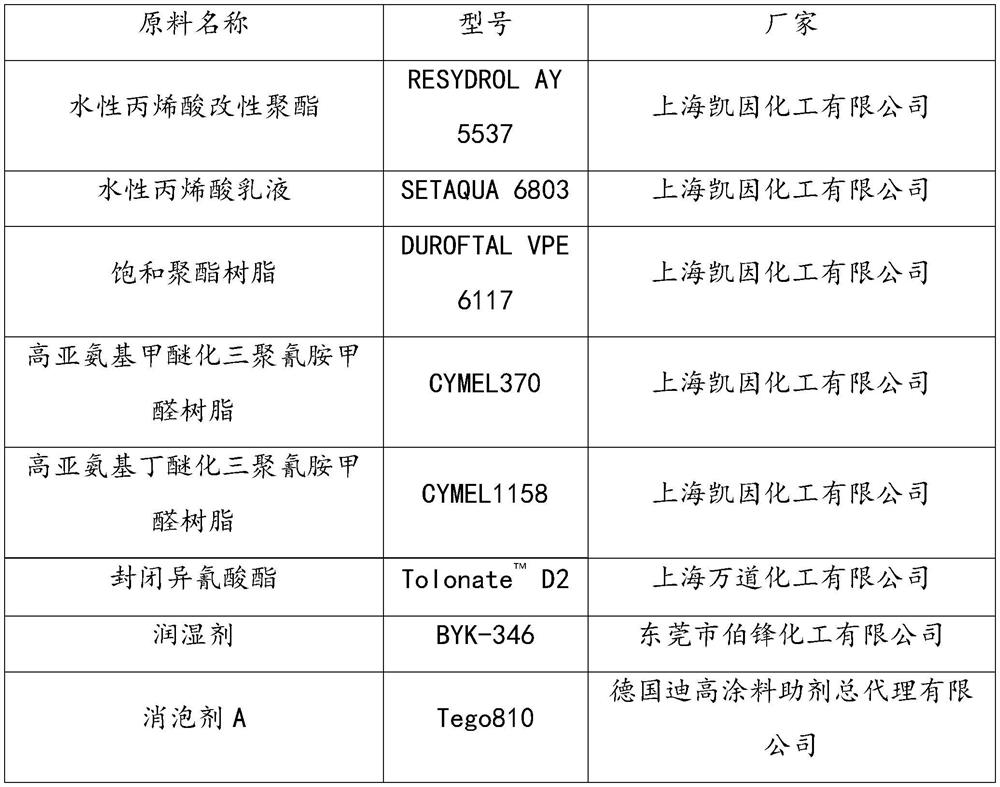

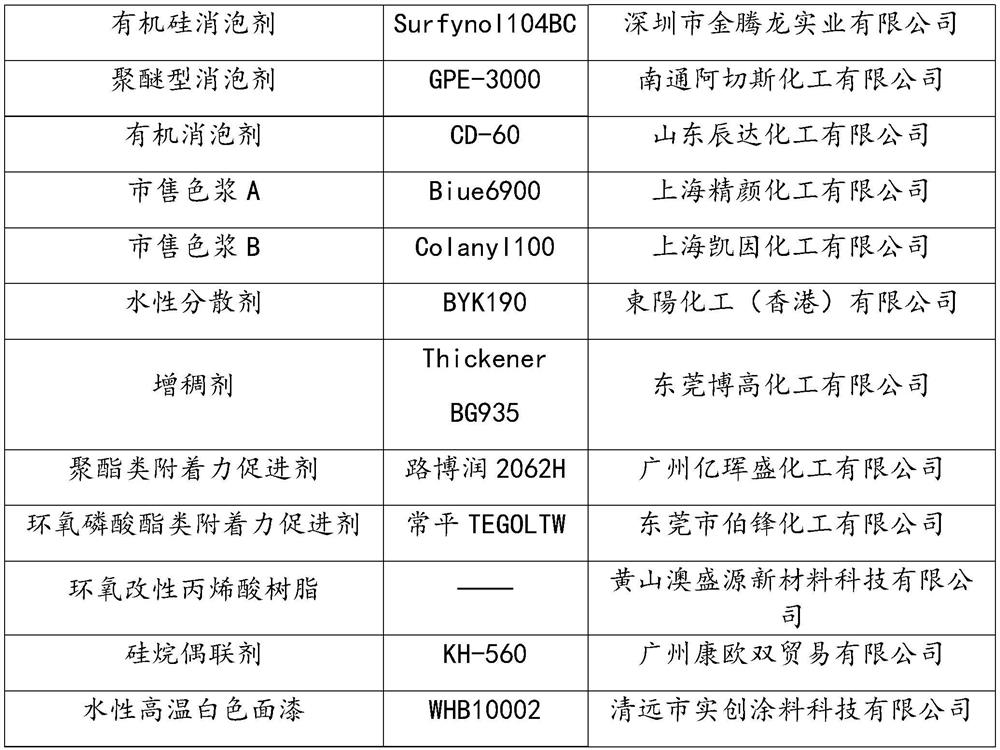

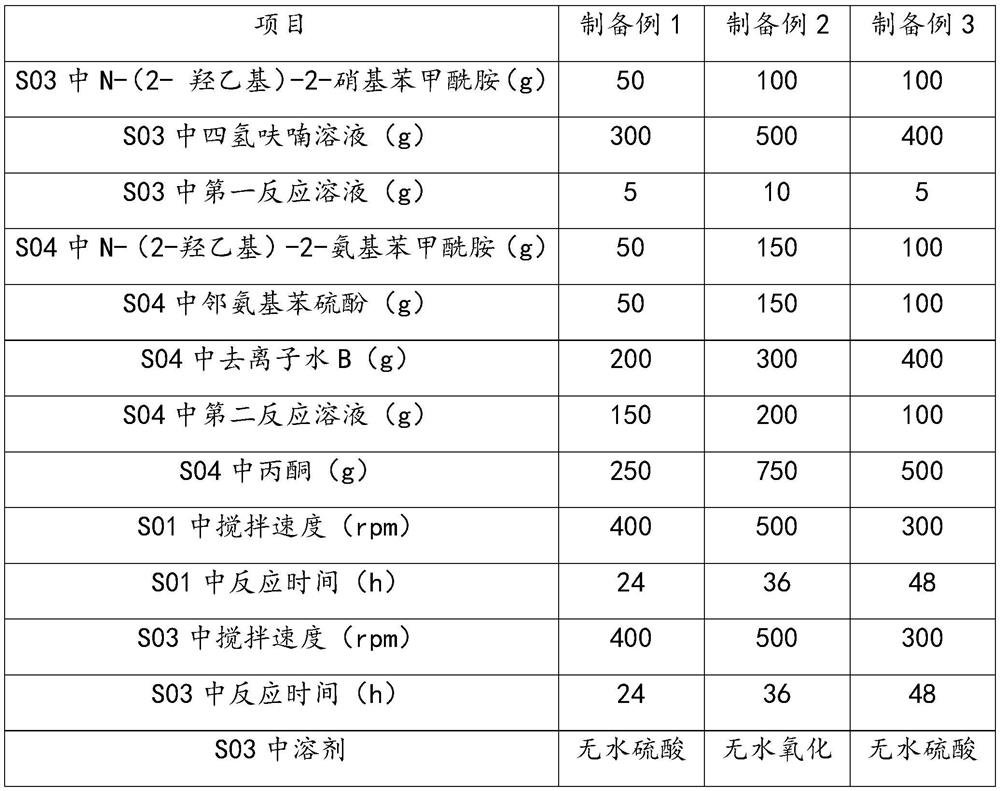

[0072] A kind of water-soluble polyaniline is prepared by following steps:

[0073] S01. Dissolve o-nitrobenzoyl chloride in dichloromethane of equal mass, stir and control the stirring speed as shown in Table 2, then add ethanolamine and o-nitrobenzoyl chloride with 5% mass of o-nitrobenzoyl chloride successively Acyl chloride quality 10% triethylamine, room temperature reaction time as shown in Table 2, obtain residue through underpressure distillation, carry out column chromatography to residue, obtain N-(2-hydroxyethyl)-2-nitrobenzene Formamide;

[0074] S02. Mix tetrahydrofuran and deionized water A at a mass ratio of 1:1 to obtain a tetrahydrofuran solution for later use, mix iron powder and concentrated sulfuric acid at a mass ratio of 1:3 to obtain a first reaction solution for later use, and Concentrated hydrochloric acid and ammonium persulfate are mixed in a mass ratio of 1:2 to obtain a second reaction solution for later use;

[0075] S03. Dissolve N-(2-hydroxyet...

preparation example 4-5

[0081] A color paste prepared by the following steps:

[0082] S001. Add deionized water D into the mobile tank, start the disperser to stir and control the speed as shown in Table 3, and add water-based dispersant, defoamer A and thickener in sequence, and the dispersion time is shown in Table 3;

[0083] S002, continue to add pigments and fillers to the mobile tank, the dispersion time is as shown in Table 3, and the color paste is obtained;

[0084] S003. Transfer the color paste in the mobile tank to a grinder, grind the color paste for 2-10 passes, and control the fineness of the color paste to be less than 25 microns.

[0085] Content and processing parameters of each component in table 3-preparation example 4-6

[0086] project Preparation Example 4 Preparation Example 5 Deionized water D(g) 20 20 Water-based dispersant (g) 2 2 Defoamer A(g) 0.5 0.5 Thickener (g) 0.2 0.2 Pigment (g) 78 78 Stirring speed in S001 (rpm)...

Embodiment 1-4

[0089] A water-based high-temperature conductive primer for FRP containing water-soluble polyaniline is prepared by the following steps:

[0090] S1. Add the color paste into the cleaned mobile tank, start the disperser to stir and control the speed as shown in Table 4, then slowly add water-based acrylic modified polyester, water-based acrylic emulsion, saturated polyester resin, amino resin, sealant Isocyanate, adhesion promoter, cosolvent, water-soluble polyaniline, auxiliary agent and deionized water C, control the dispersion time as shown in Table 4, and mix uniformly to prepare the initial mixture;

[0091] S2, use filter cloth to filter and fill the initial mixture, the filter cloth has a filter aperture of 50 microns to 100 microns, to obtain a water-based high-temperature conductive primer;

[0092] Among them, the amino resin is formed by mixing methyl etherified amino resin and butylated amino resin in a mass ratio of (7-10): 3, and the methyl etherified amino resin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com