A method for improving the surface coating quality of wooden door electrostatic spraying

An electrostatic spraying and surface coating technology, which is applied to the device, coating, spraying device and other directions for coating liquid on the surface, which can solve the problems of reducing the adhesion of the paint film, uneven thickness of the paint film, and unstable paint rate. , to achieve the effect of low cost, improved paint film uniformity and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

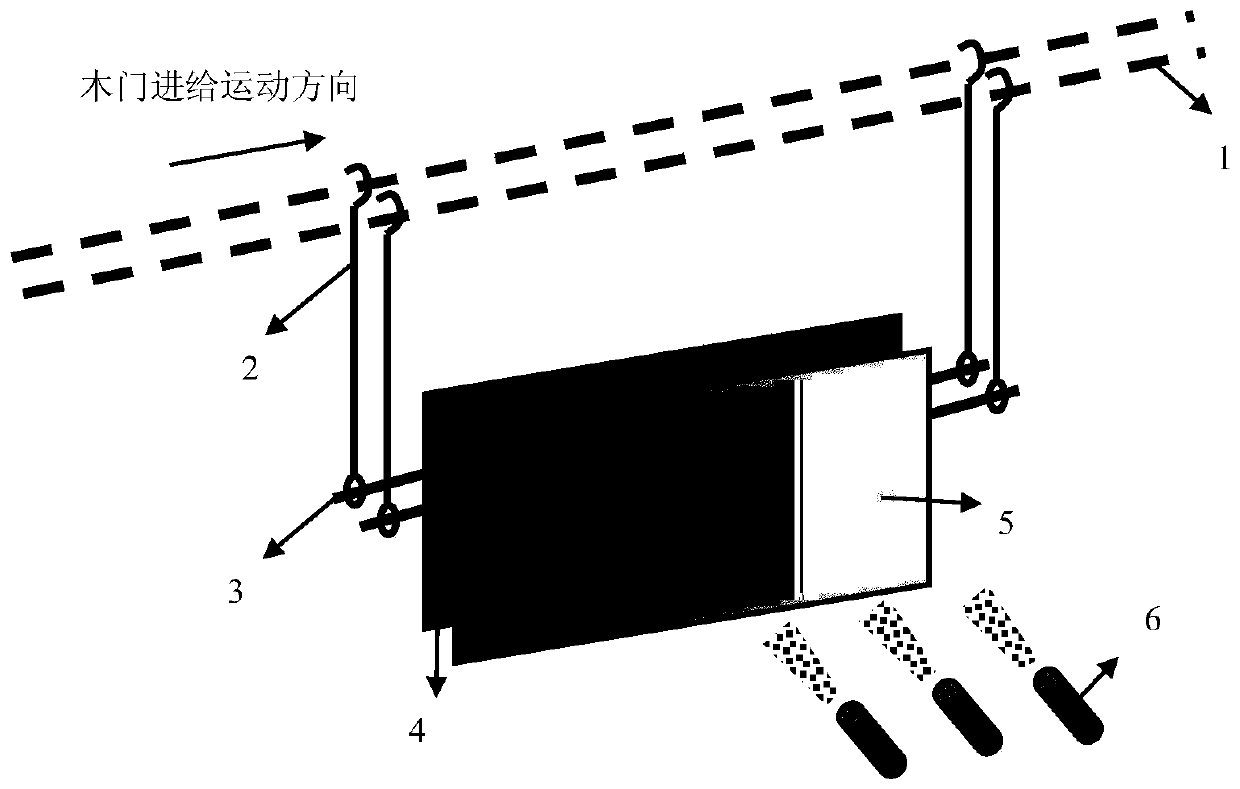

[0035] like figure 1 As shown, the method for improving the surface coating quality of wooden door electrostatic spraying of the present invention includes: 1 wooden door conveying grounding metal guide rail, 2 metal hooks, 3 metal rods, 4 grounding steel plates, 5 wooden doors, 6 electrostatic spray guns;

[0036] Before spraying, the grounding steel plate 4 welded with metal rods 3 on both sides is hung on the wooden door conveying metal guide rail 1 through the metal hook 2 . Insert the metal rod 3 in the mounting holes reserved on both sides of the wooden door 5, and hang on the wooden door conveying metal guide rail 1 through the metal hook 2. The gap between the grounding steel plate 4 and the wooden door 5 is not more than 10mm;

[0037] Three electrostatic spray guns 6 arranged horizontally at equal intervals are arranged on one side of the grounded steel plate 4 (note: the number of electrostatic spray guns on one side of the grounded steel plate is generally between...

Embodiment 2

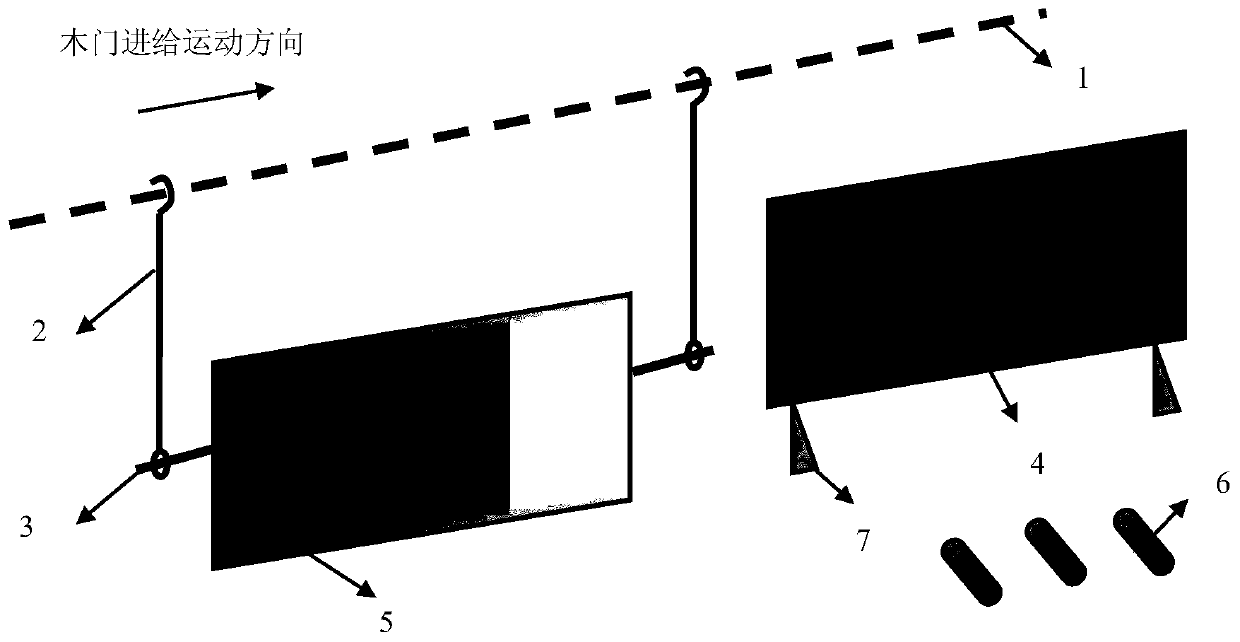

[0041] like figure 2 As shown, the method for improving the surface coating quality of wooden door electrostatic spraying of the present invention comprises: 1. Wooden door conveys metal rail (grounding), 2. Metal hook, 3. Metal bar, 4. Grounding steel plate, 5. Wooden door, 6. Electrostatic spray gun, 7. base;

[0042] Before spraying, fix the grounding steel plate 4 directly in front of the electrostatic spray gun 6, and realize grounding through the base 7;

[0043] Insert the metal rod 3 in the mounting holes reserved on both sides of the wooden door 5, and hang it on the wooden door conveying metal guide rail 1 through the metal hook 2;

[0044] Three electrostatic spray guns 6 arranged horizontally at equal intervals are arranged on one side of the grounded steel plate 4 (note: the number of electrostatic spray guns on one side of the grounded steel plate is generally between 1 and 3, and there are 3 in this figure). And the joint action of the control system, synchro...

Embodiment 3

[0048] The electrostatic spray gun is placed vertically on the ground and sprays downward in the vertical direction. The large surface of the wooden door to be sprayed is perpendicular to the spraying direction.

[0049]With this spray gun arrangement, the grounded steel plate can be fed and moved synchronously with the wooden door, so that the wooden door is between the electrostatic spray gun and the grounded steel plate during the electrostatic spraying process; the grounded steel plate can also be fixed directly below the electrostatic spray gun, and when the wooden door is fed When moving to the bottom of the electrostatic spray gun, the wooden door is just between the grounded steel plate and the electrostatic spray gun.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com