Patents

Literature

266 results about "Treatment need" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

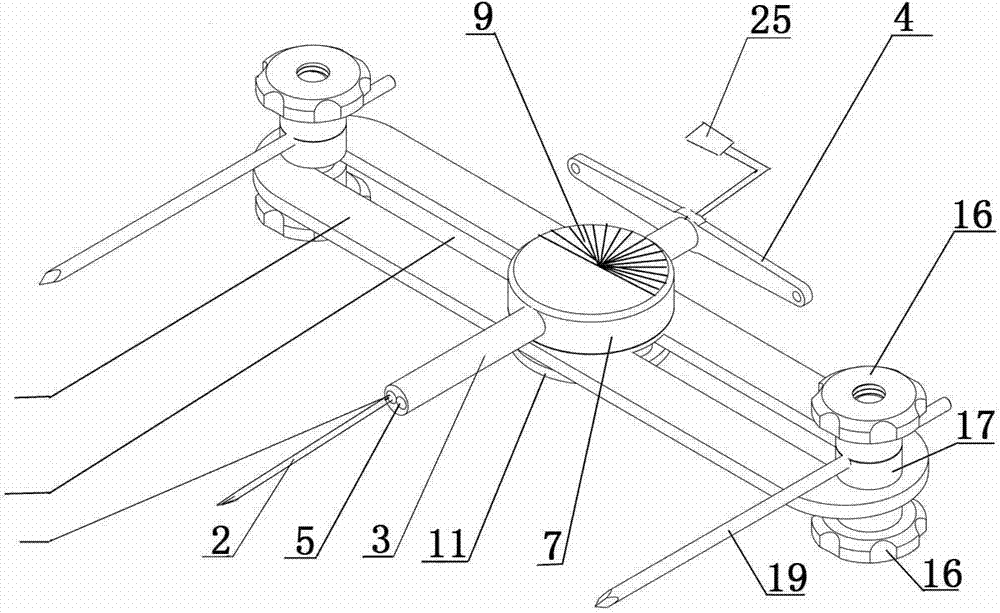

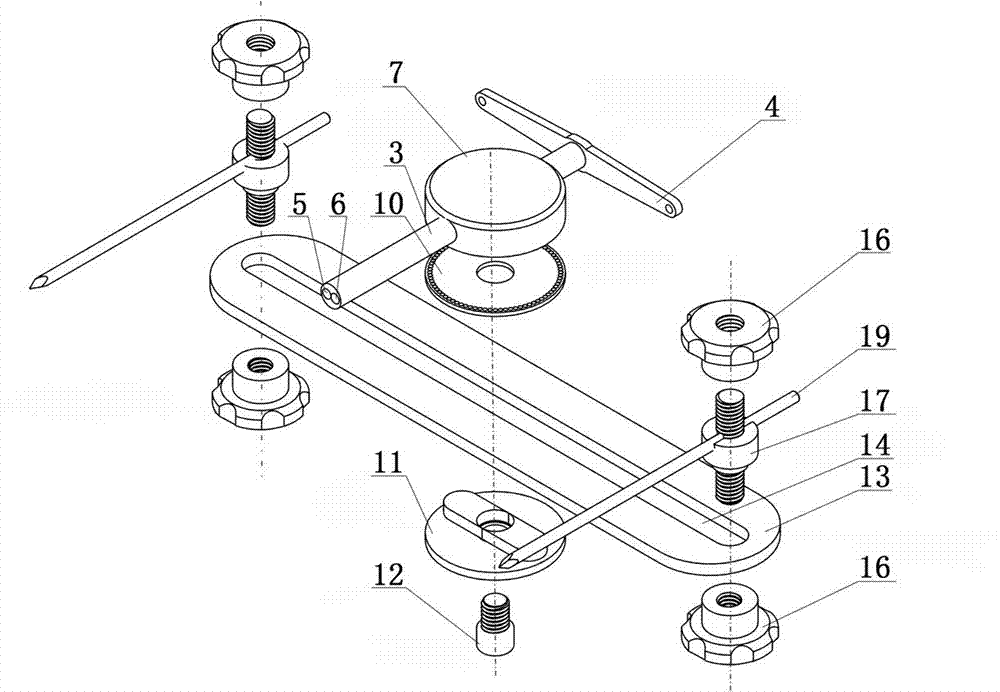

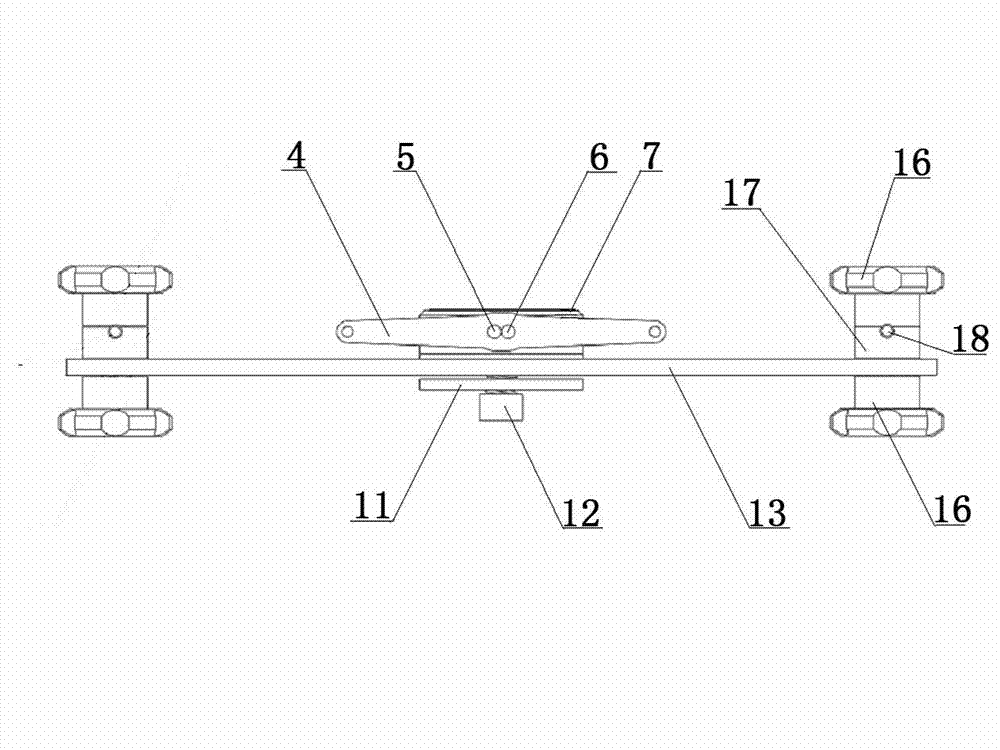

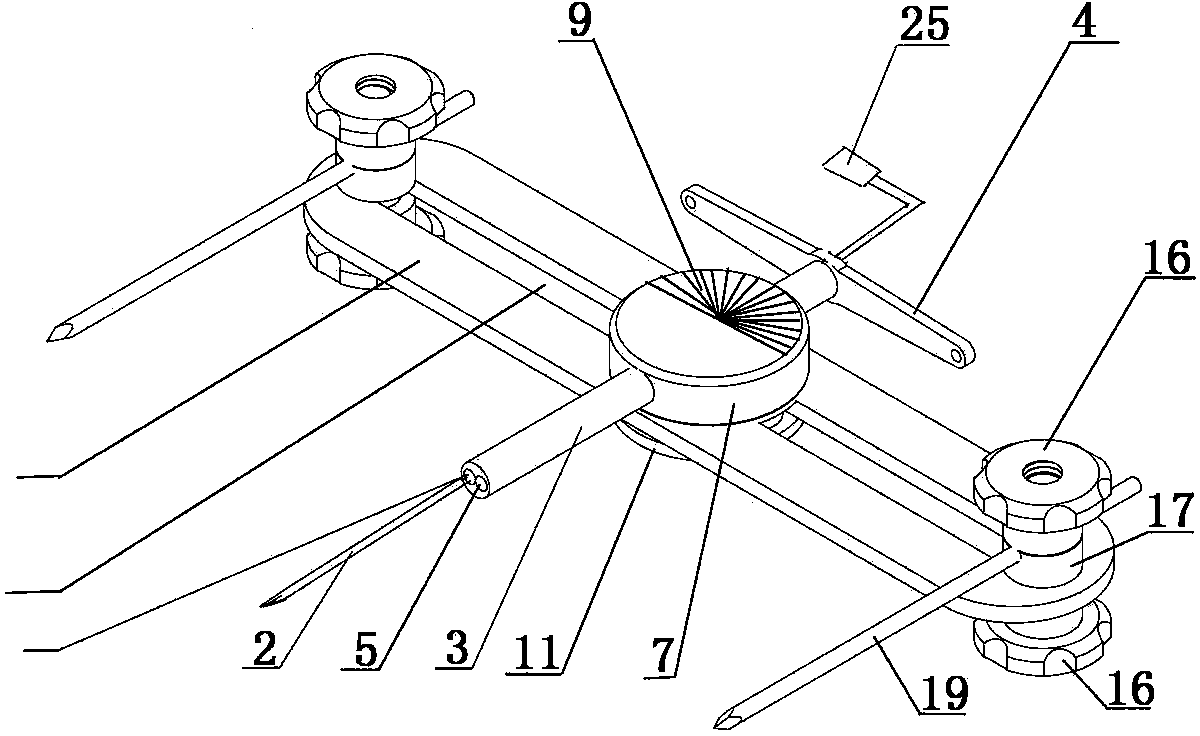

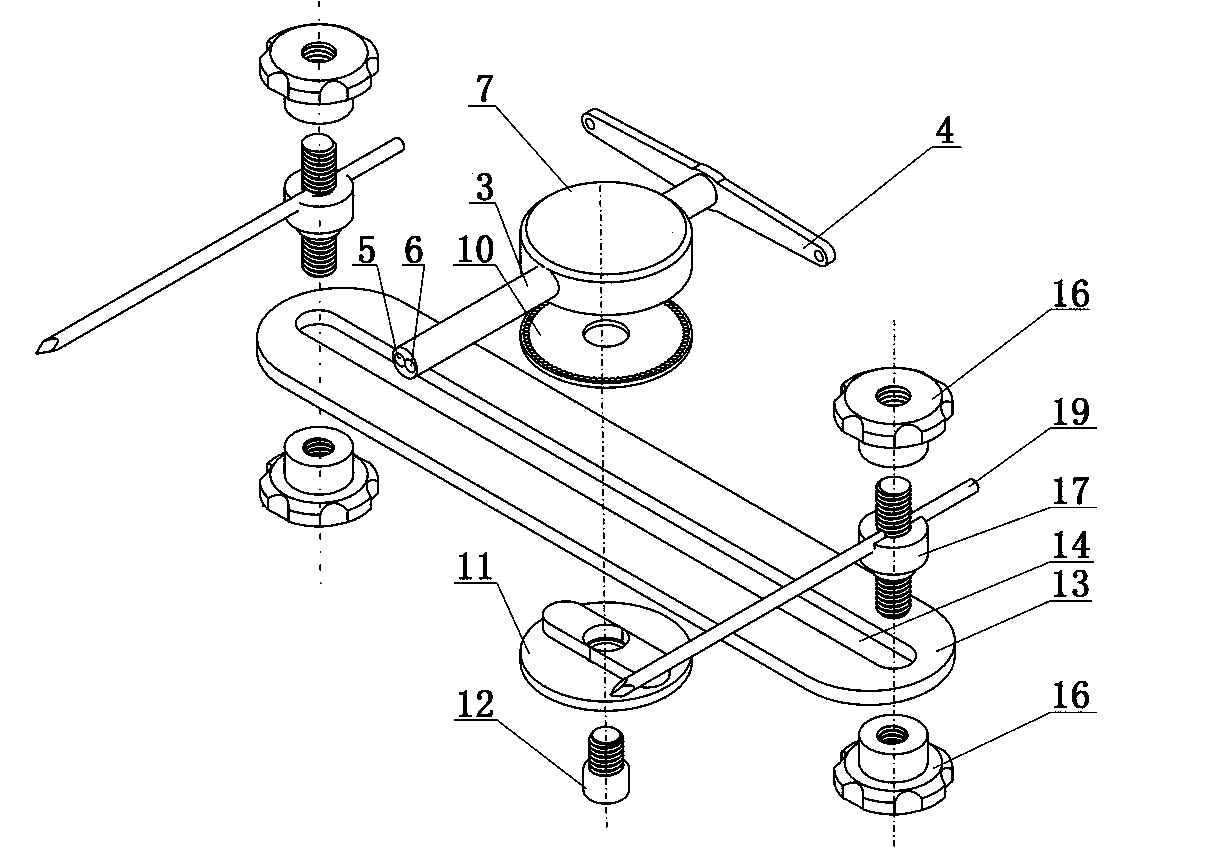

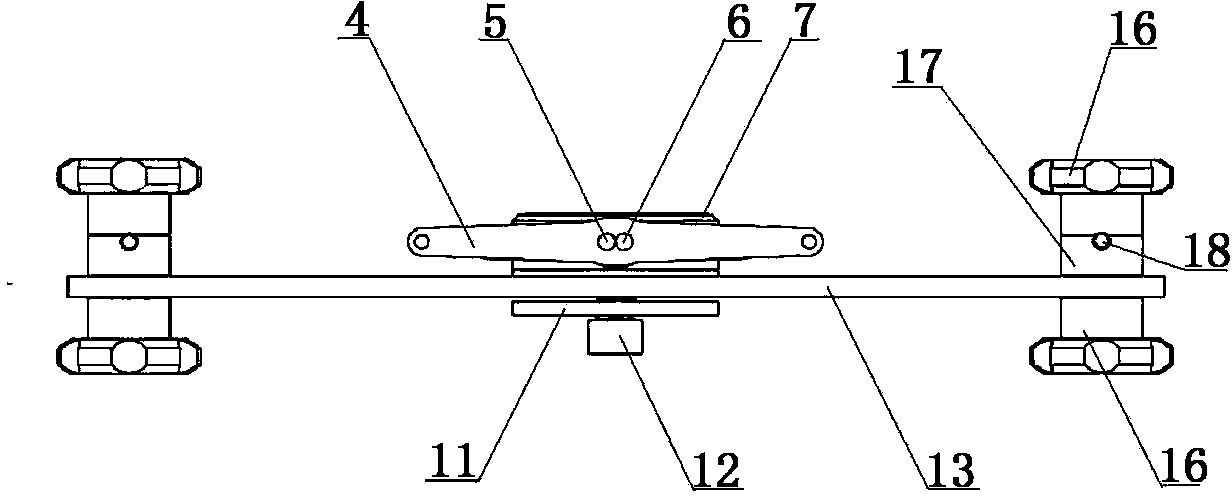

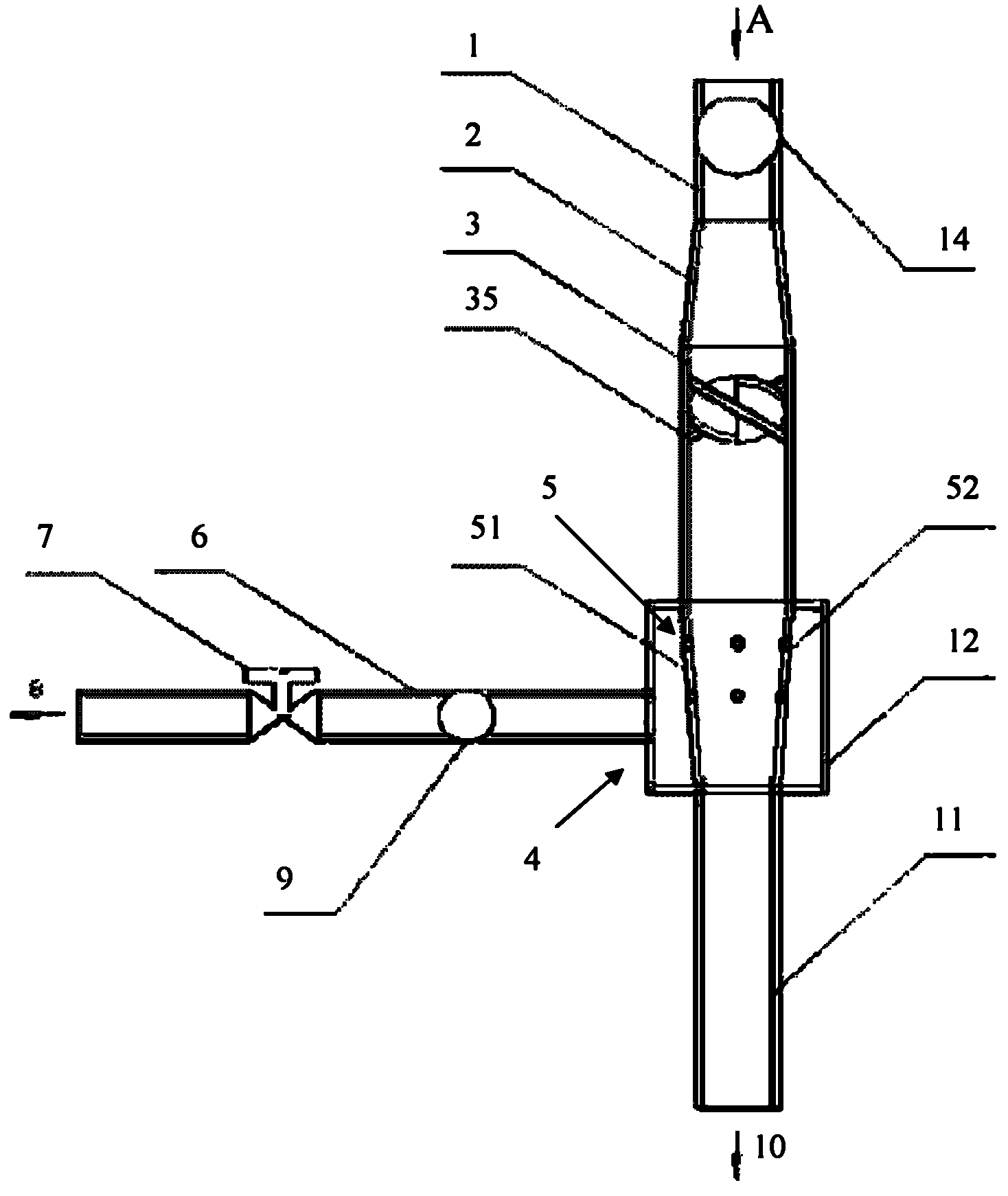

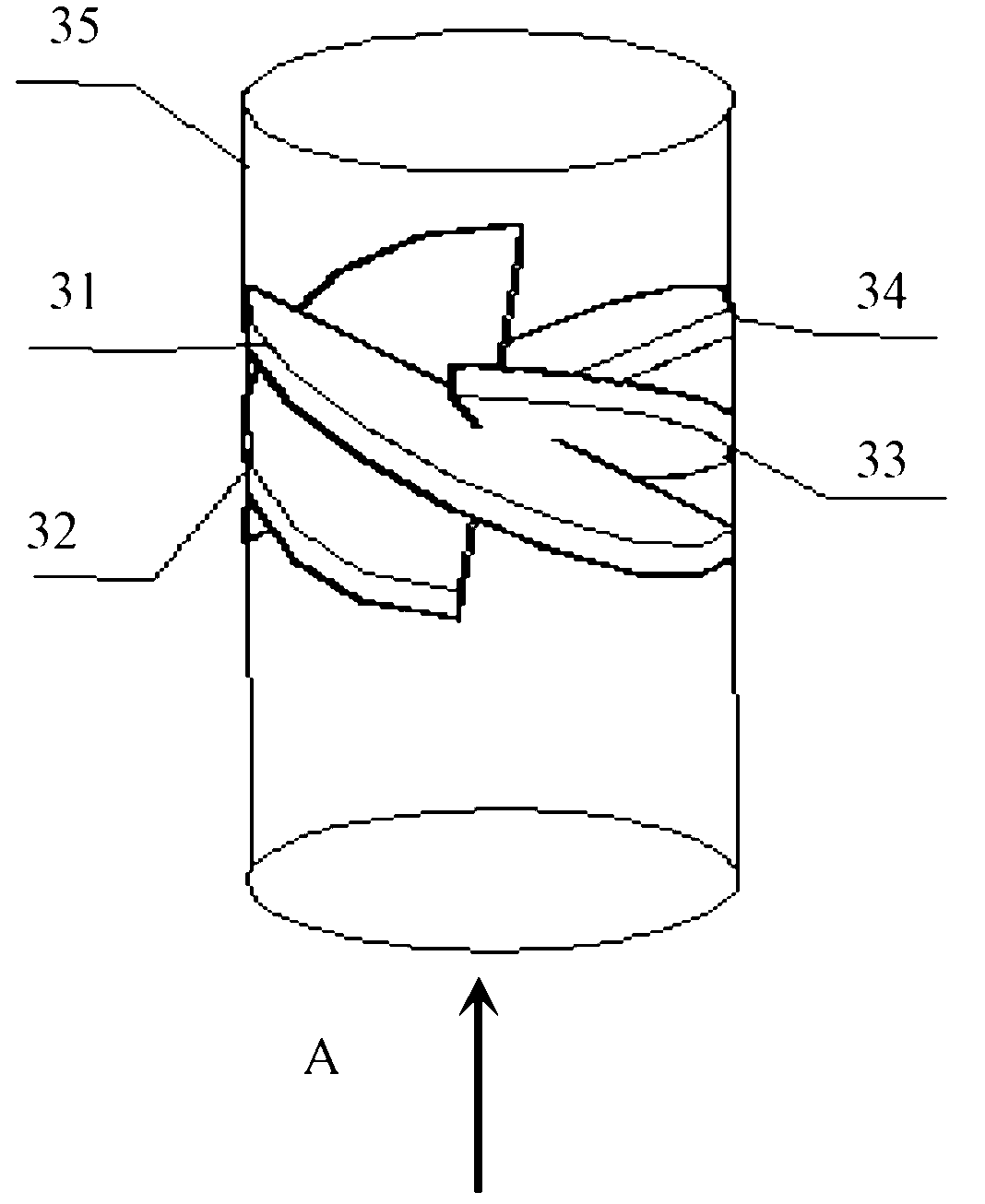

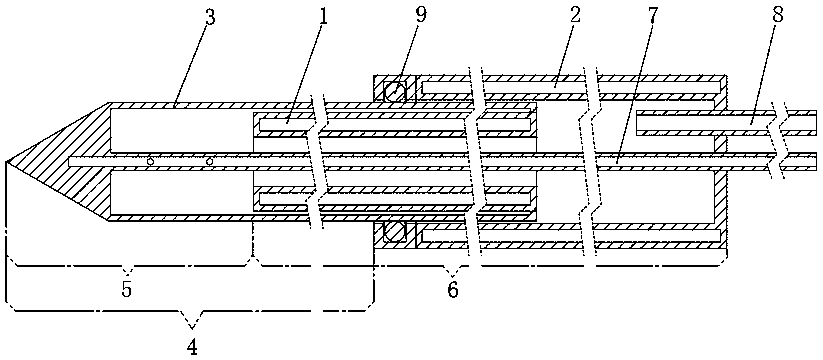

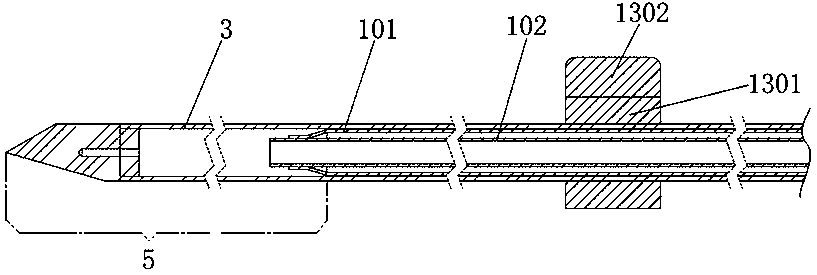

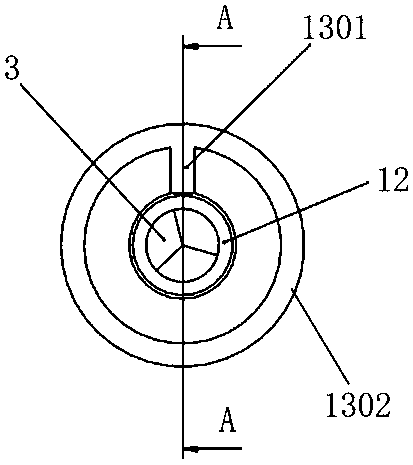

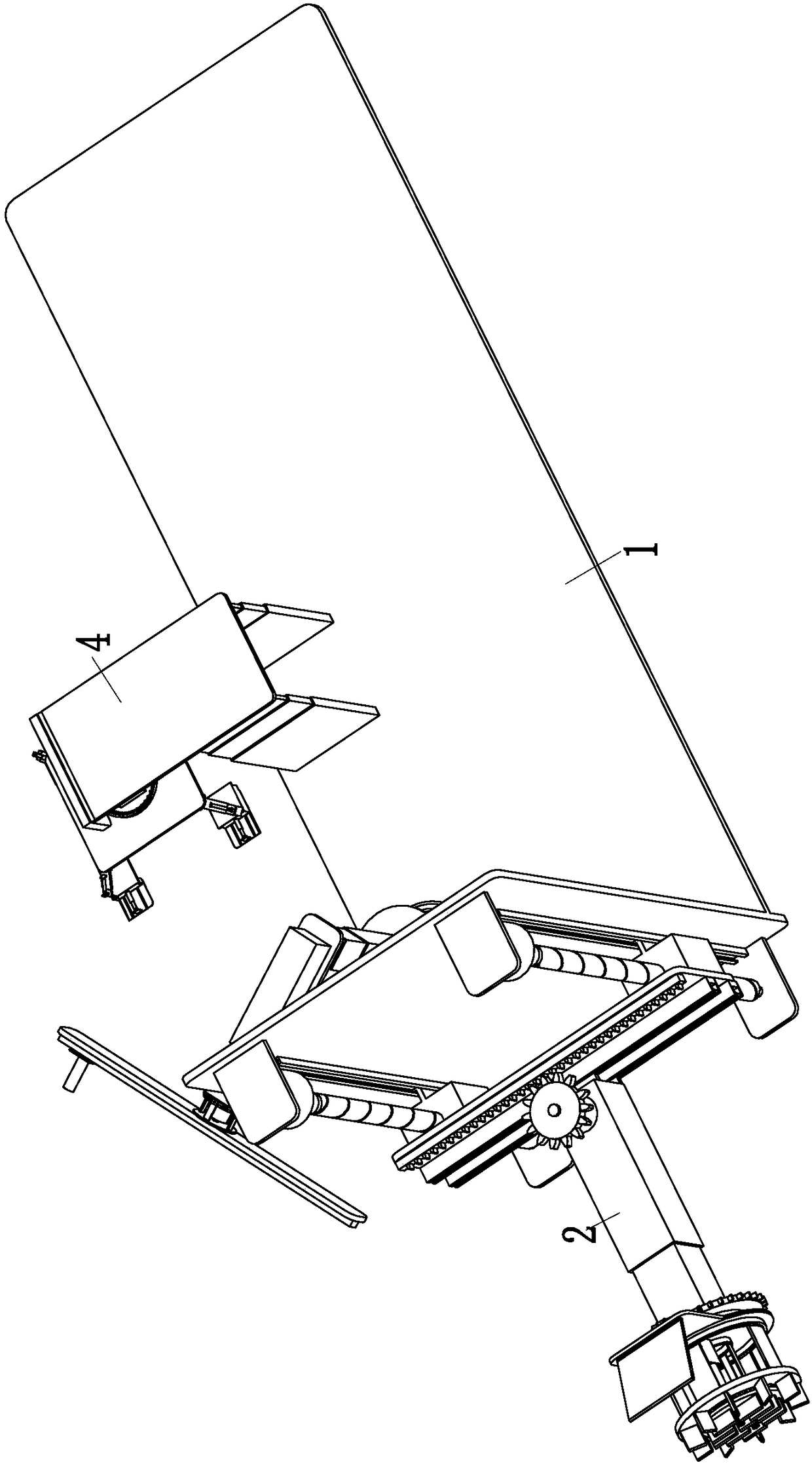

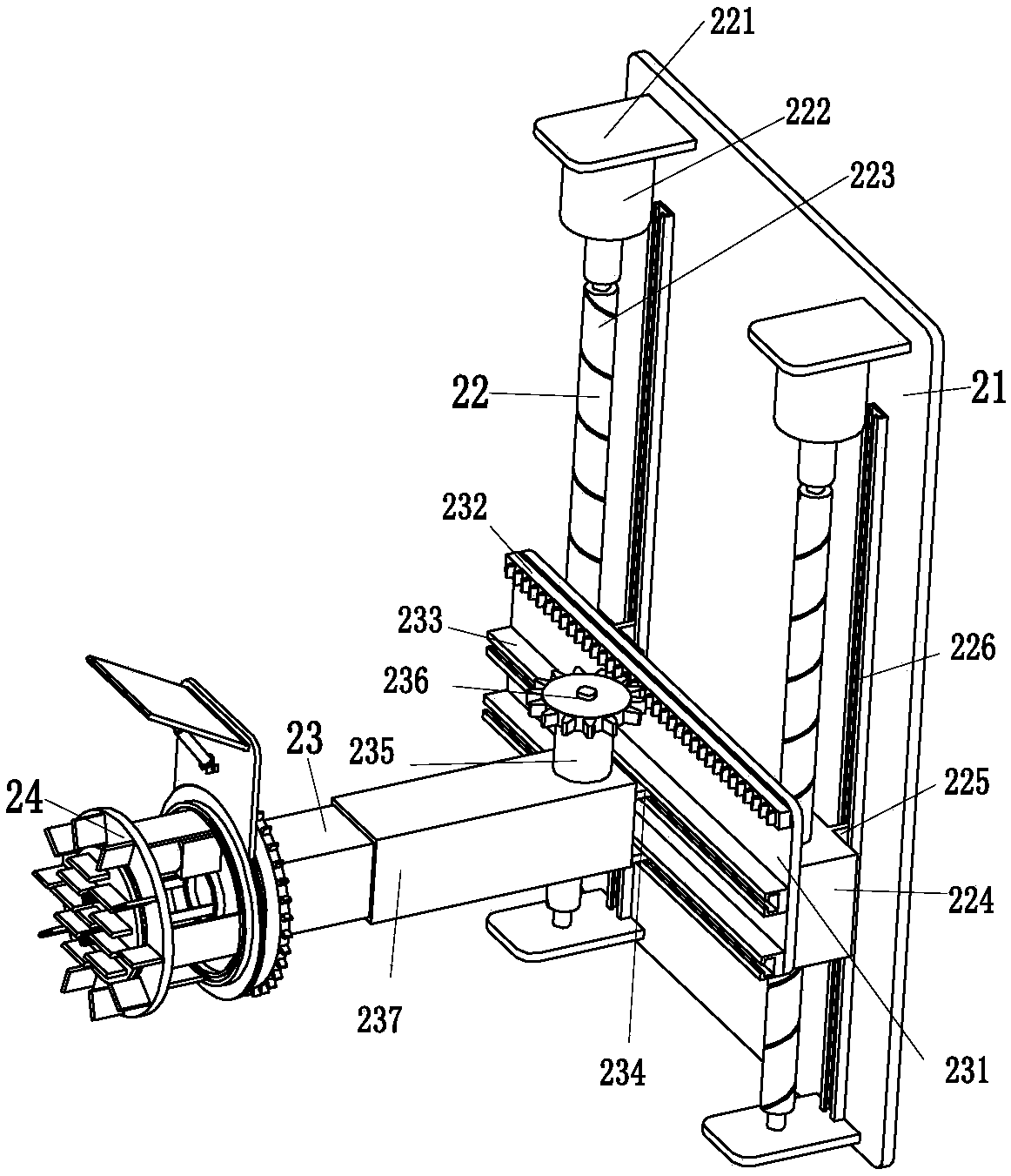

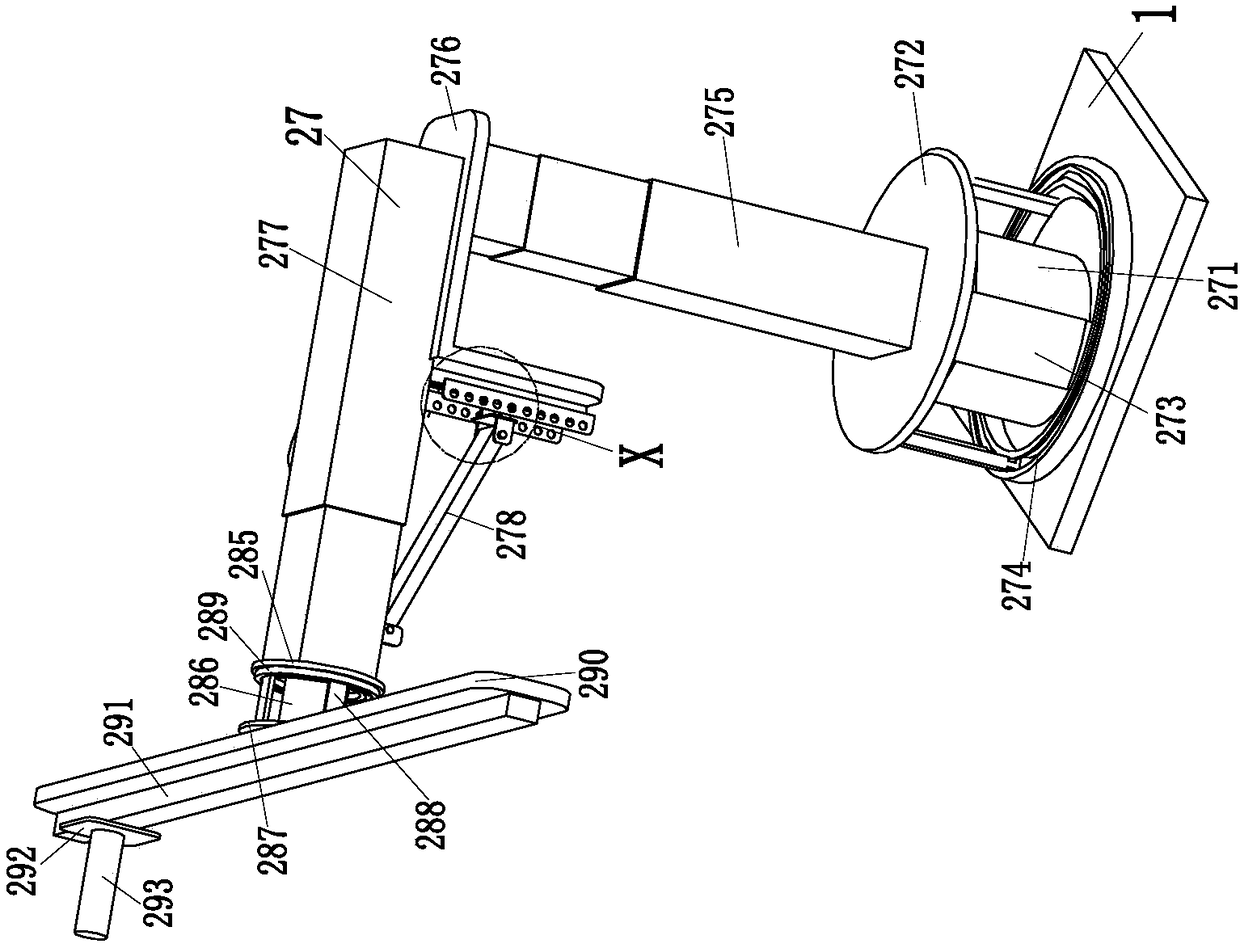

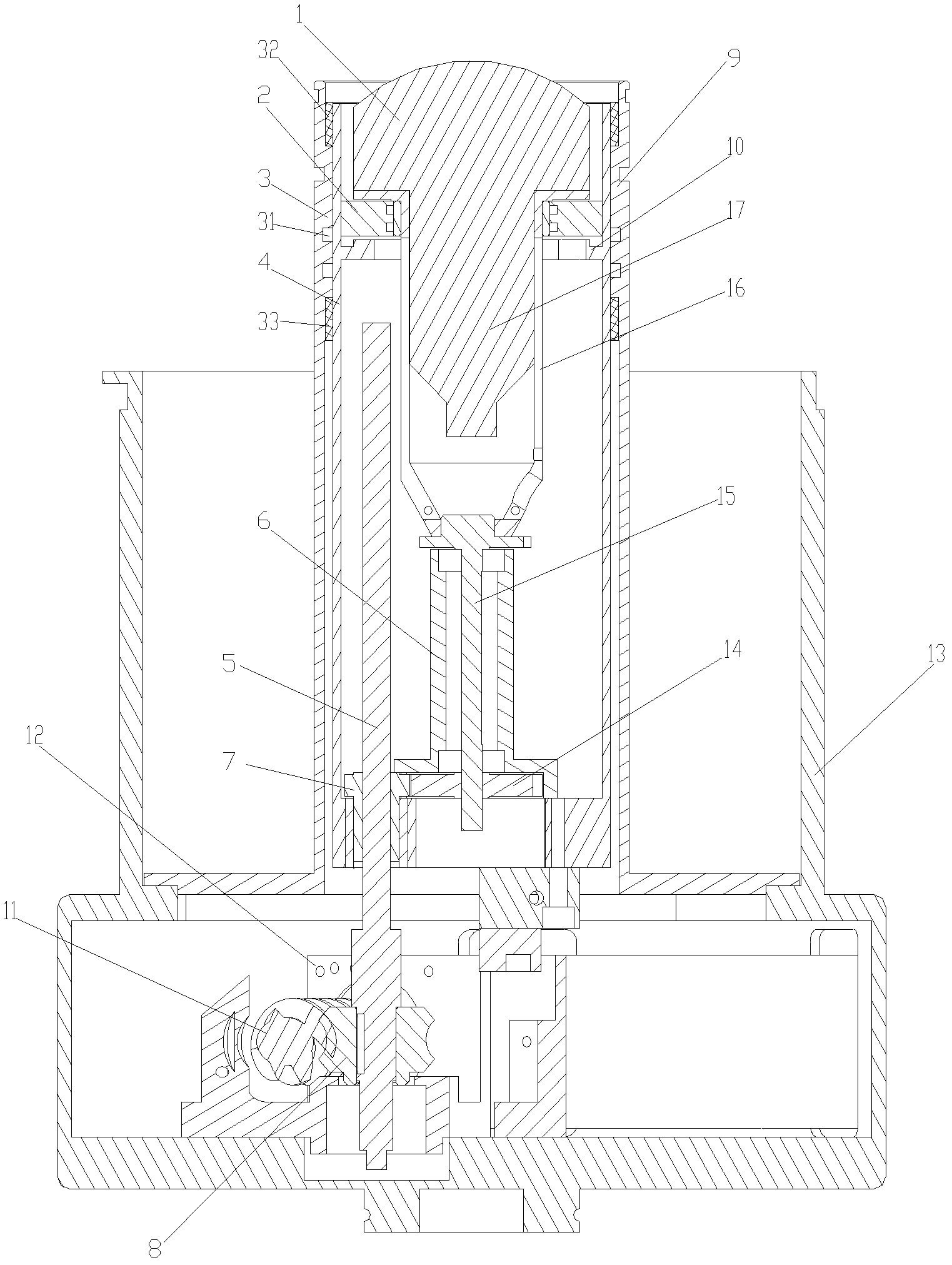

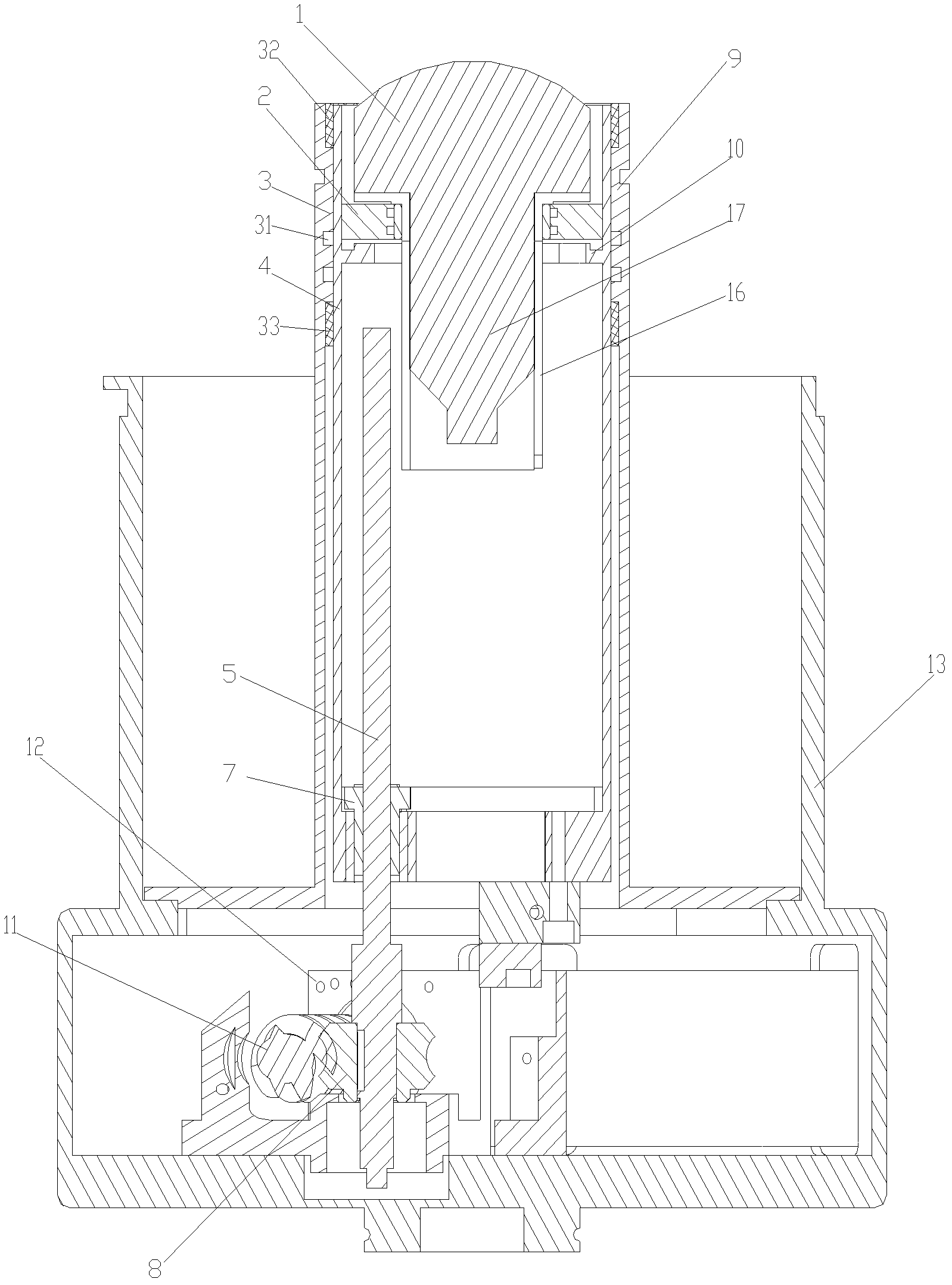

Longitudinal minimal-invasion bone cutter for tubular bones

InactiveCN102860860AFor lateral tractionFacilitates longitudinal osteotomySurgeryTraction TreatmentPeriosteum

A longitudinal minimal-invasion bone cutter for tubular bones comprises a bone cutting end bone cutting device and far end positioning devices. The bone cutting end bone cutting device is slidingly sleeved on a positioning adjusting guide rail which is in a long-strip shape, a sliding groove is arranged in the middle of the positioning adjusting guide rail along the length direction, and scales of the positioning adjusting guide rail are arranged along the sliding groove. The far end positioning devices are symmetrically sleeved at two ends of the positioning adjusting guide rail slidingly. By means of the longitudinal minimal-invasion bone cutter, medical workers can perform longitudinal bone cutting operations on the tubular bones according to treatment needs, and the longitudinal minimal-invasion bone cutter is convenient to operate. When the operations are performed, the longitudinal minimal-invasion bone cutter provides convenience for transverse traction of bone blocks and meets needs of angiitis treatment. The bone cutting operations performed by the aid of the longitudinal minimal-invasion bone cutter belong to minimal-invasion operations, do not damage nerves, blood vessels, soft tissues and periostea, have small invasion, facilitate reconstruction and union of bones, and meet needs of longitudinal traction treatment of the tubular bones. By means of the longitudinal minimal-invasion bone cutter, safety and accuracy of the longitudinal bone cutting operations of the tubular bones are improved, medical workers can conveniently perform the operations, and the operation effect is guaranteed.

Owner:JIANGSU GUANGJI MEDICAL TECH

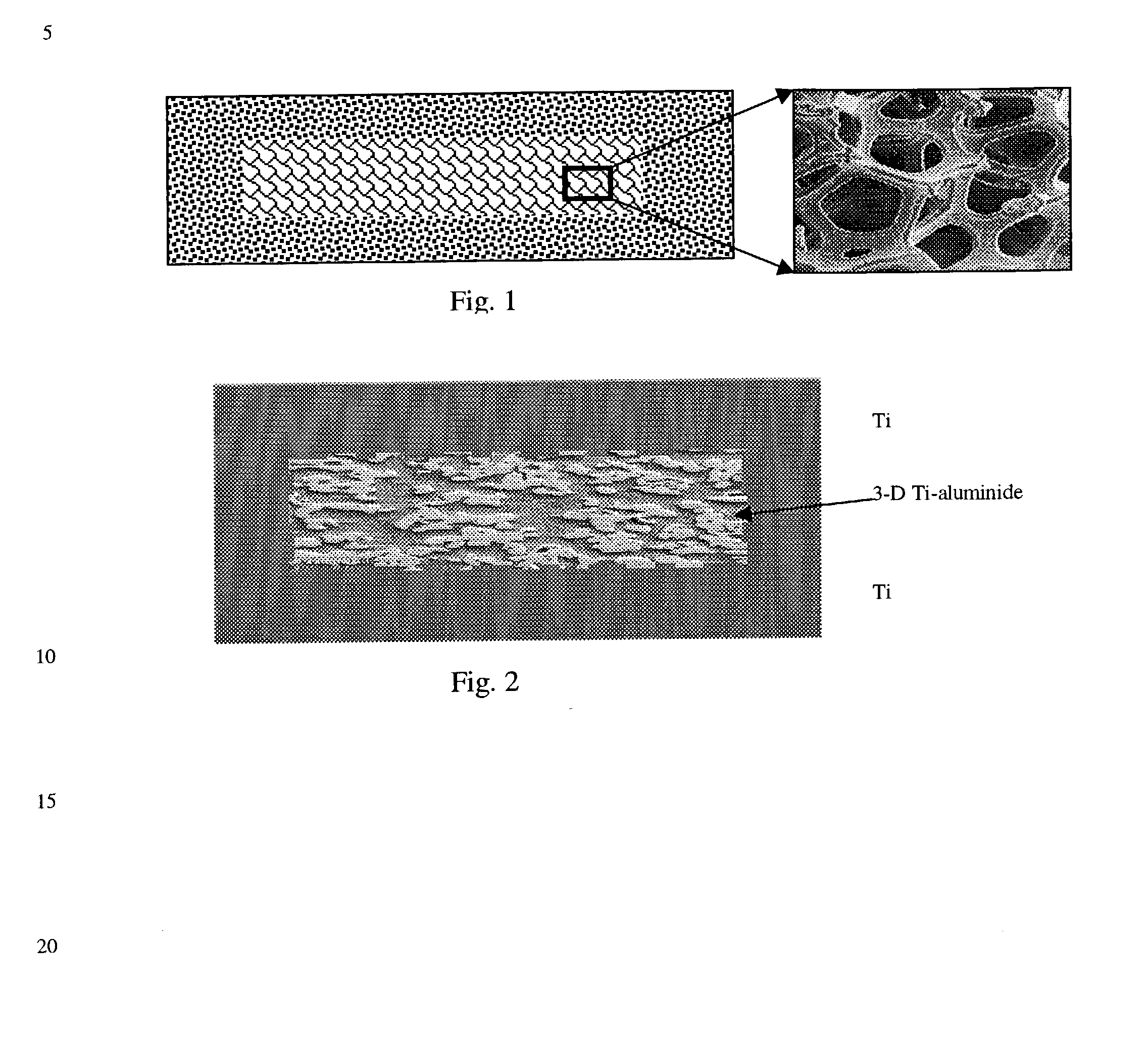

High-strength metal aluminide-containing matrix composites and methods of manufacture the same

(a) The metal matrix composite is suitable for the manufacture of flat or shaped titanium aluminide, zirconium aluminide, or niobium aluminide articles and layered metal composites having improved mechanical properties such as lightweight plates and sheets for aircraft and automotive applications, thin cross-section vanes and airfoils, heat-sinking lightweight electronic substrates, bulletproof structures for vests, partition walls and doors, as well as sporting goods such as helmets, golf clubs, sole plates, crown plates, etc. The composite material consists of a metal (e.g., Ti, Zr, or Nb-based alloy) matrix at least partially intercalated with a three-dimensional skeletal metal aluminide structure, whereby ductility of the matrix metal is higher than that of the metal aluminide skeleton. The method for manufacturing includes the following steps: (a) providing an aluminum skeleton structure having open porosity of 50-95 vol. %, (b) filling said skeleton structure with the powder of a reactive matrix metal, (c) compacting the aluminum skeleton / matrix powder composite preform by cold rolling, cold die pressing, cold isostatic pressing, and / or hot rolling, (d) consolidating the initial or compacted composite preform by sintering, hot pressing, hot rolling, hot isostatic pressing, and / or hot extrusion to provide, at least partially, a reaction between aluminum skeleton and matrix metal powder, and (e) diffusion annealing followed by any type of heat treatment needed to provide predetermined mechanical and surface properties of the resulting metal matrix composite. The combination of ductile matrix and metal aluminide skeletal structure results in significant improvement of mechanical properties of the composite material, especially hot strength. This high-strength aluminide-based material can also be used as a core component in multilayer metal matrix composites.

Owner:ADVANCE MATERIAL PRODS ADMA PRODS

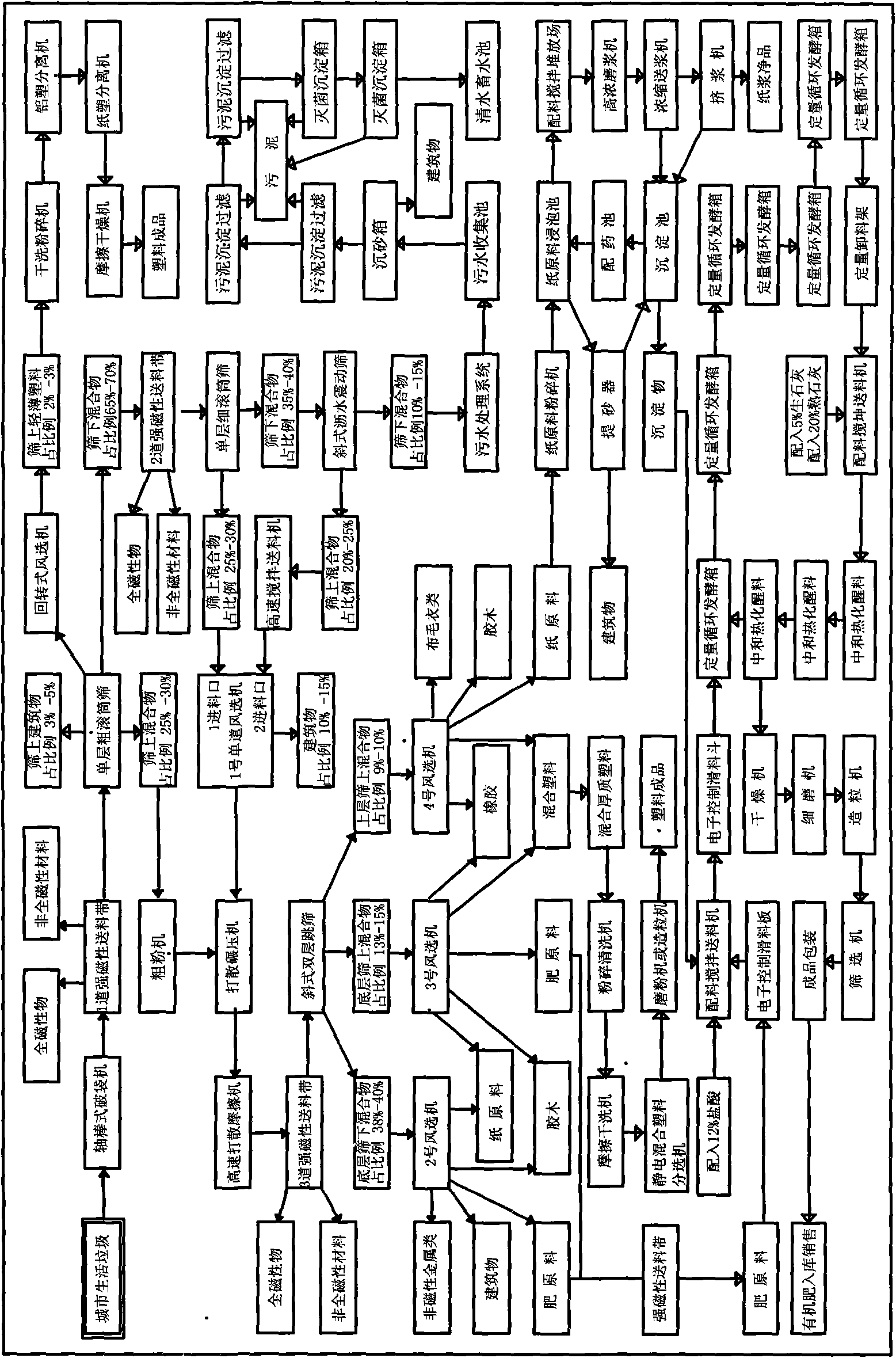

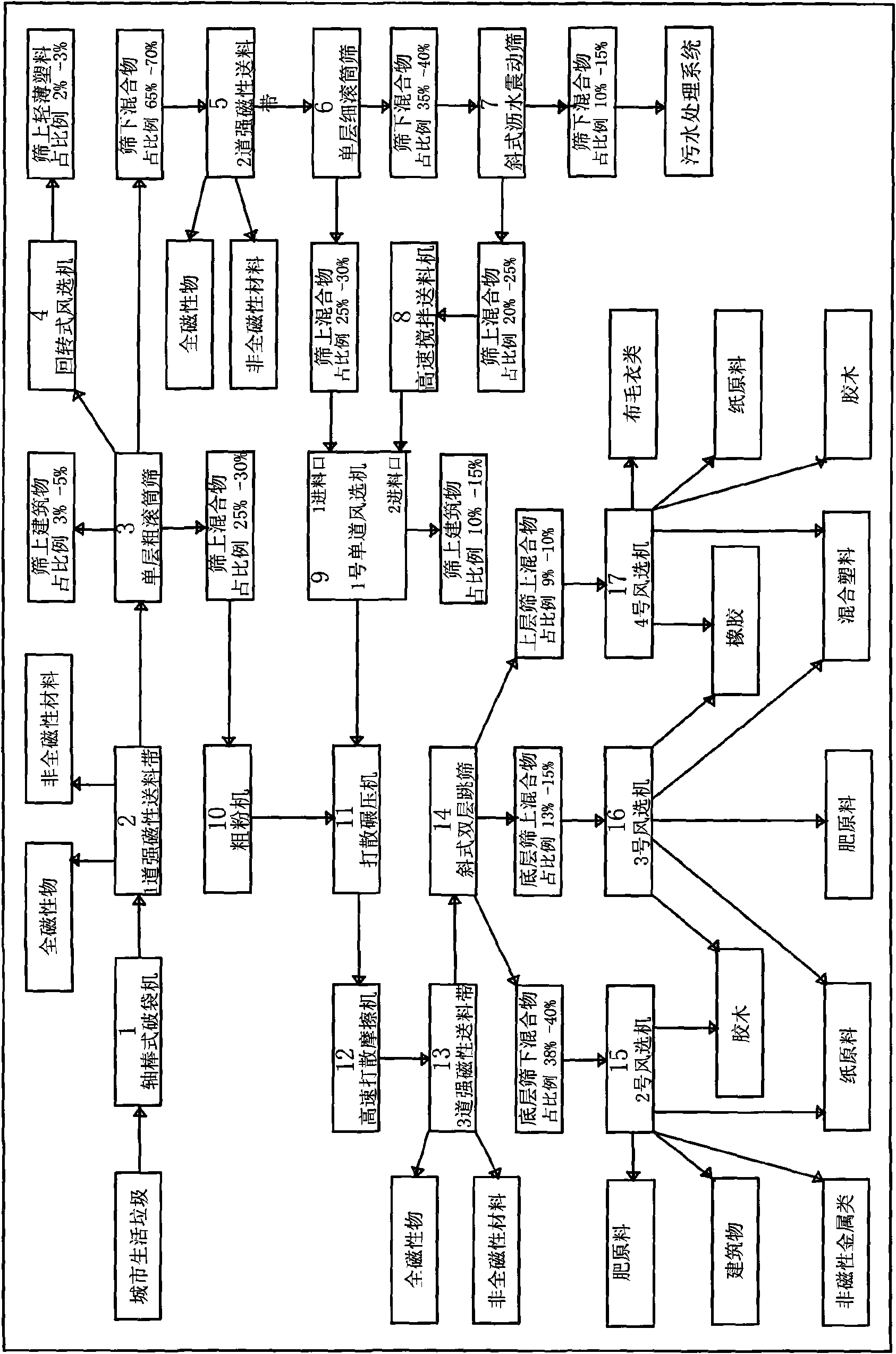

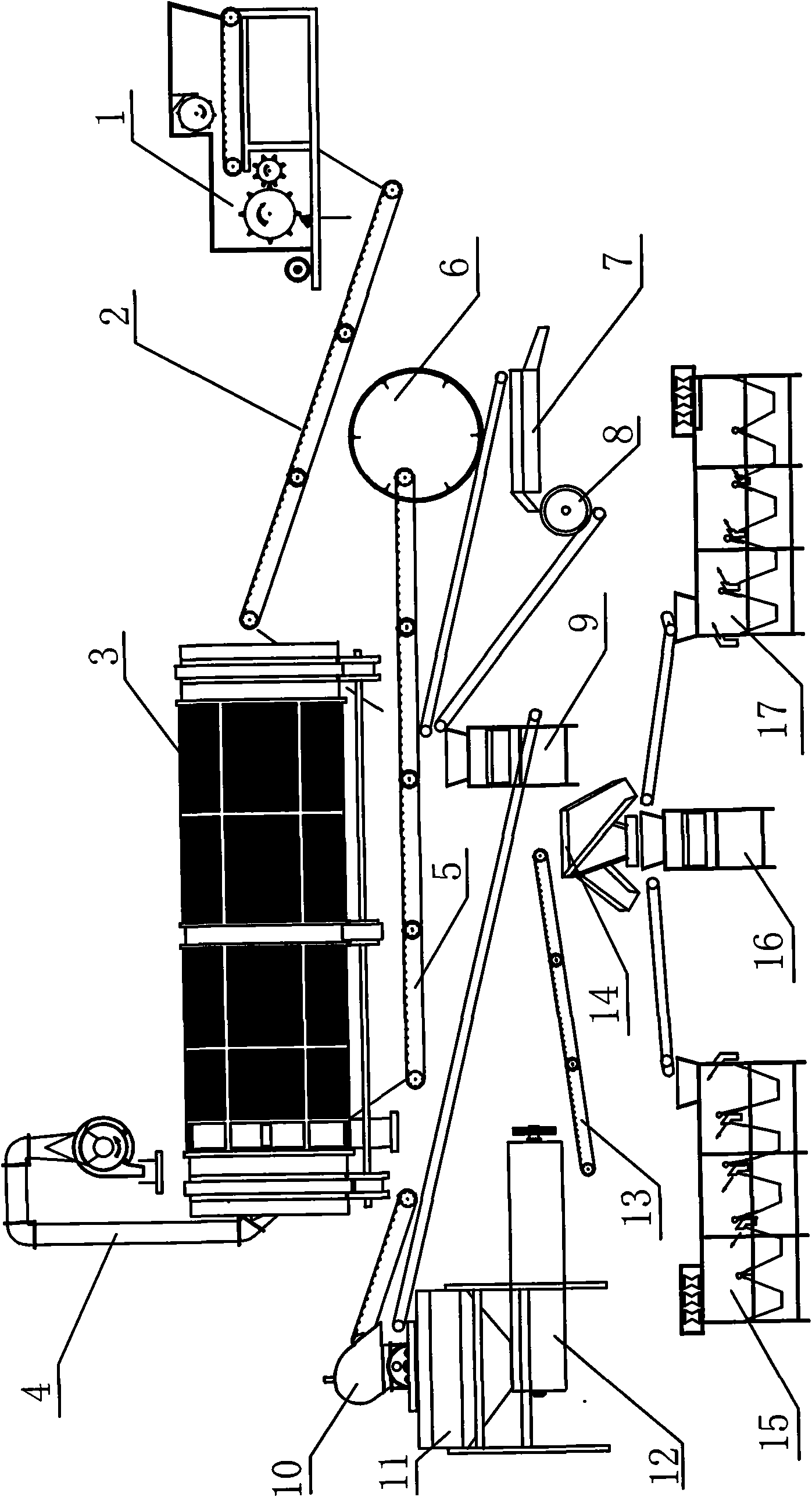

Complete system of recycling treatment of city household garbage and a method thereof

InactiveCN101579689ASolve the fragile problemSolve hanging problemsSievingGas current separationControl systemSewage treatment

The invention relates to a complete system of recycling treatment of city household garbage and a method thereof. The invention is characterized in that an electronic screen control system controls mechanical transmission and treatment condition of a garbage mechanical classification system, a fertilizer-making system, a plastic classification system, a pulping system and a sewage treatment system by a contact screen and a circuit, the recycling treatment of day treatment for day garbage, closed operation, automatic sorting, no secondary pollution and fully treatment of resources is realized finally, the city household garbage is divided into 48 types, which are combined into 15 types and seven sorts, the classification rate reaches 100 percent, the recycling rate reaches over 99 percent and the whole-range treatment needs 60 to 80 minutes.

Owner:邵道德

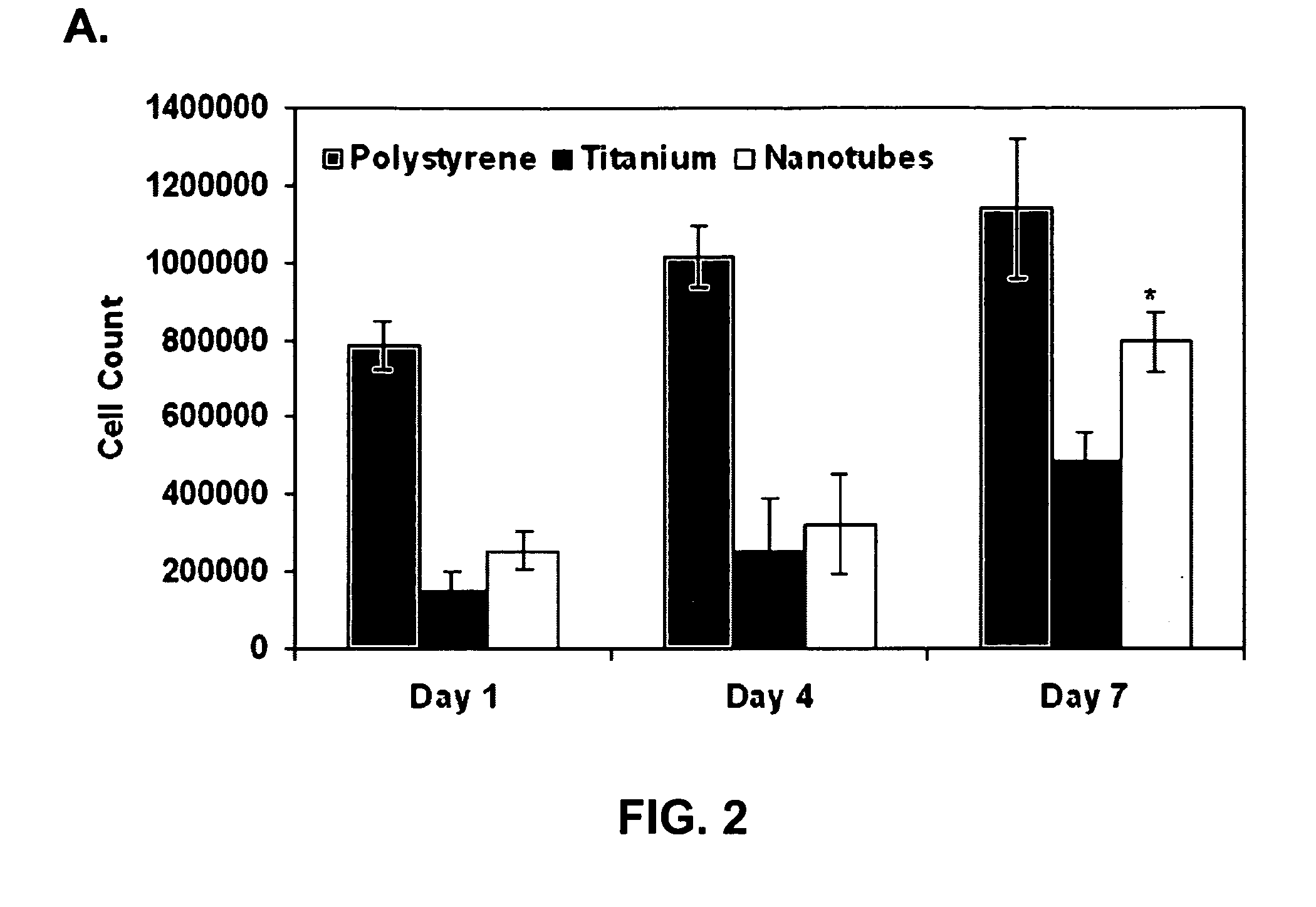

Nanostructure surface coated medical implants and methods of using the same

Compositions including a surface or film comprising nanofibers, nanotubes or microwells comprising a bioactive agent for elution to the surrounding tissue upon placement of the composition in a subject are disclosed The compositions are useful in medical implants and methods of treating a patient in need of an implant, including orthopedic implants, dental implants, cardiovascular implants, neurological implants, neurovascular implants, gastrointestinal implants, muscular implants, and ocular implants.

Owner:PENN STATE RES FOUND +1

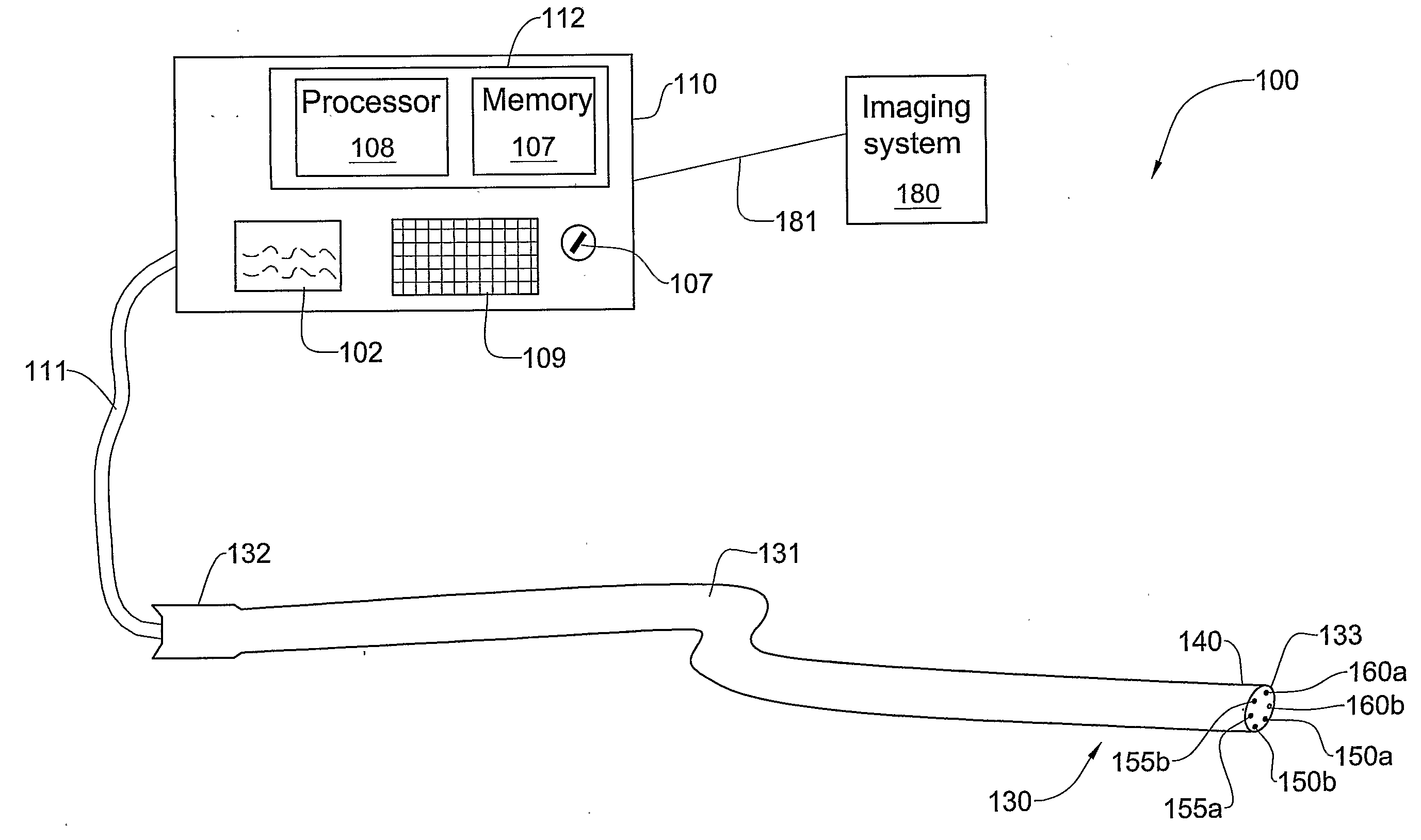

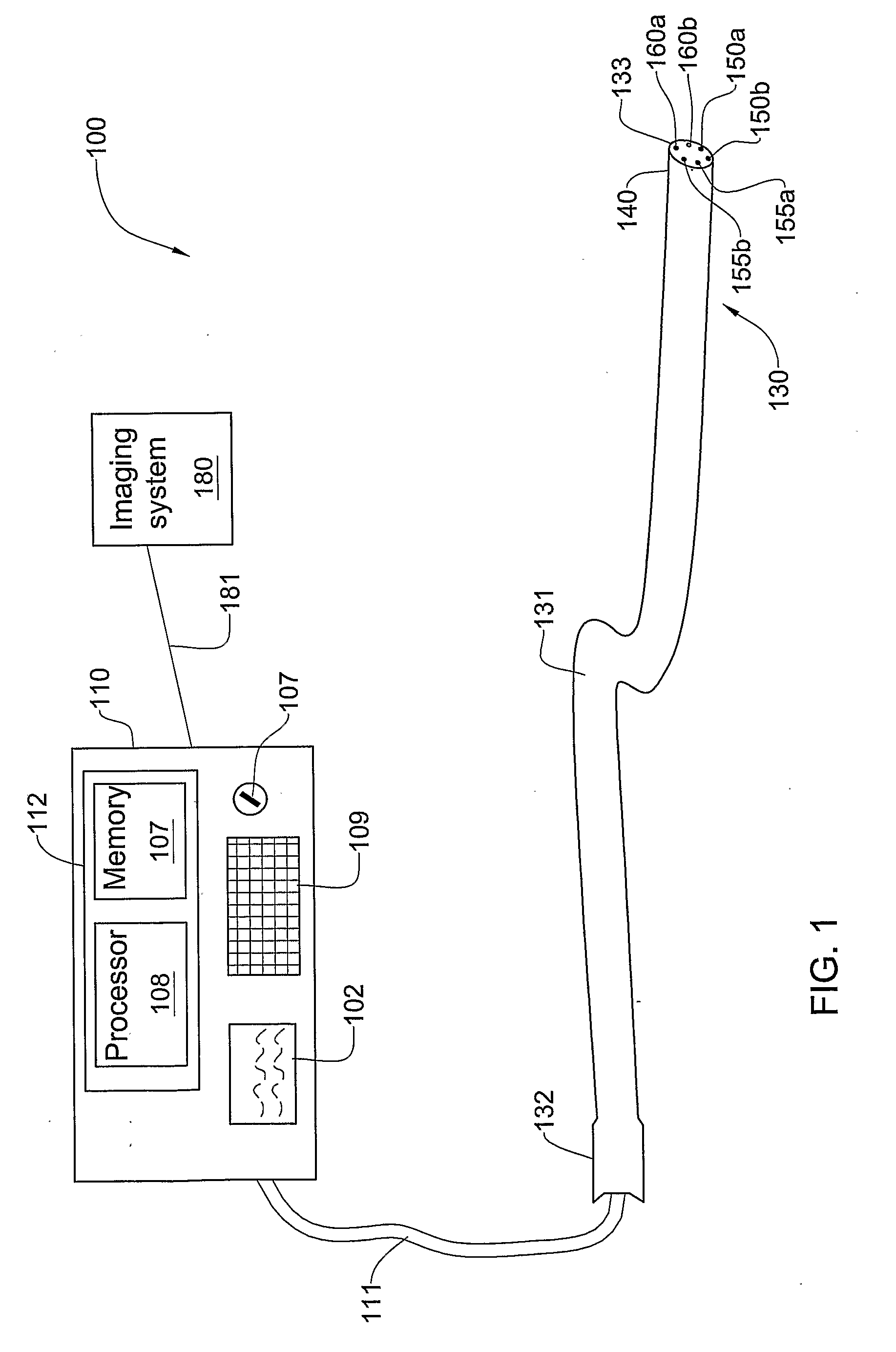

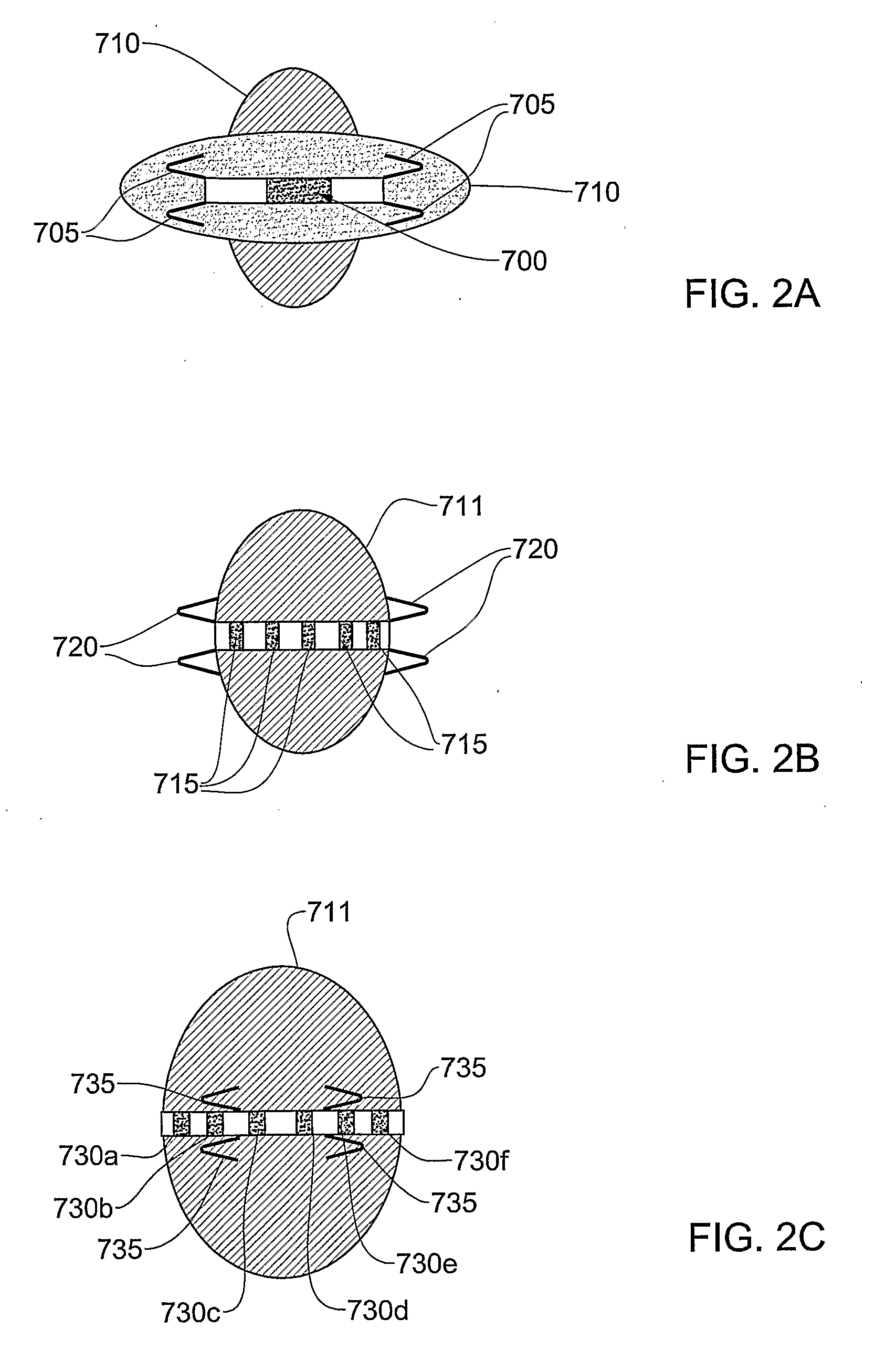

System and method for analysis and treatment of a body tissue

The invention provides a system and method for analysis and treatment of a tissue site. The system of the invention includes a probe unit containing one or more tissue sensing and monitoring probes configured to measure one or more parameters indicative of one or more states of the tissue site and one or more tissue treatment probes configured to deliver a treatment to the tissue site. A processor receives signals from the sensing and monitoring probes and determines whether the probe unit is located at the tissue site to be treated. The treatment and monitoring probes are activated in order to monitor the state of the tissue site while the treatment is being delivered to the tissue site. The processor receives signals from the sensing and monitoring probes during delivery of the treatment indicative of the state of the tissue site and determines, as the treatment is being carried out, any one or more of whether the treatment carried out so far is adequate, whether an additional treatment needs to be carried out, and whether the parameters of the treatment or the treatment targets need to be modified.

Owner:DUNE MEDICAL DEVICES

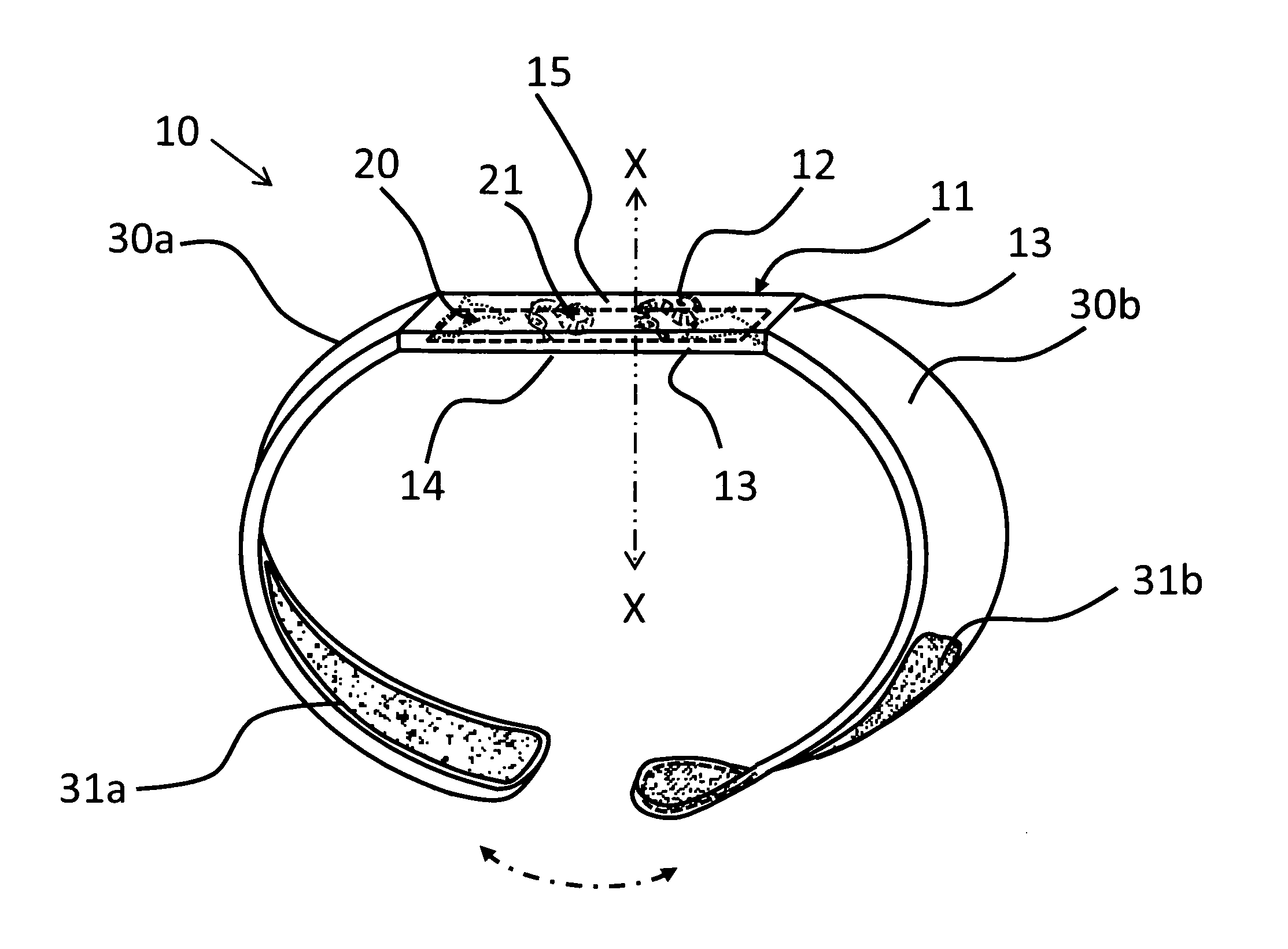

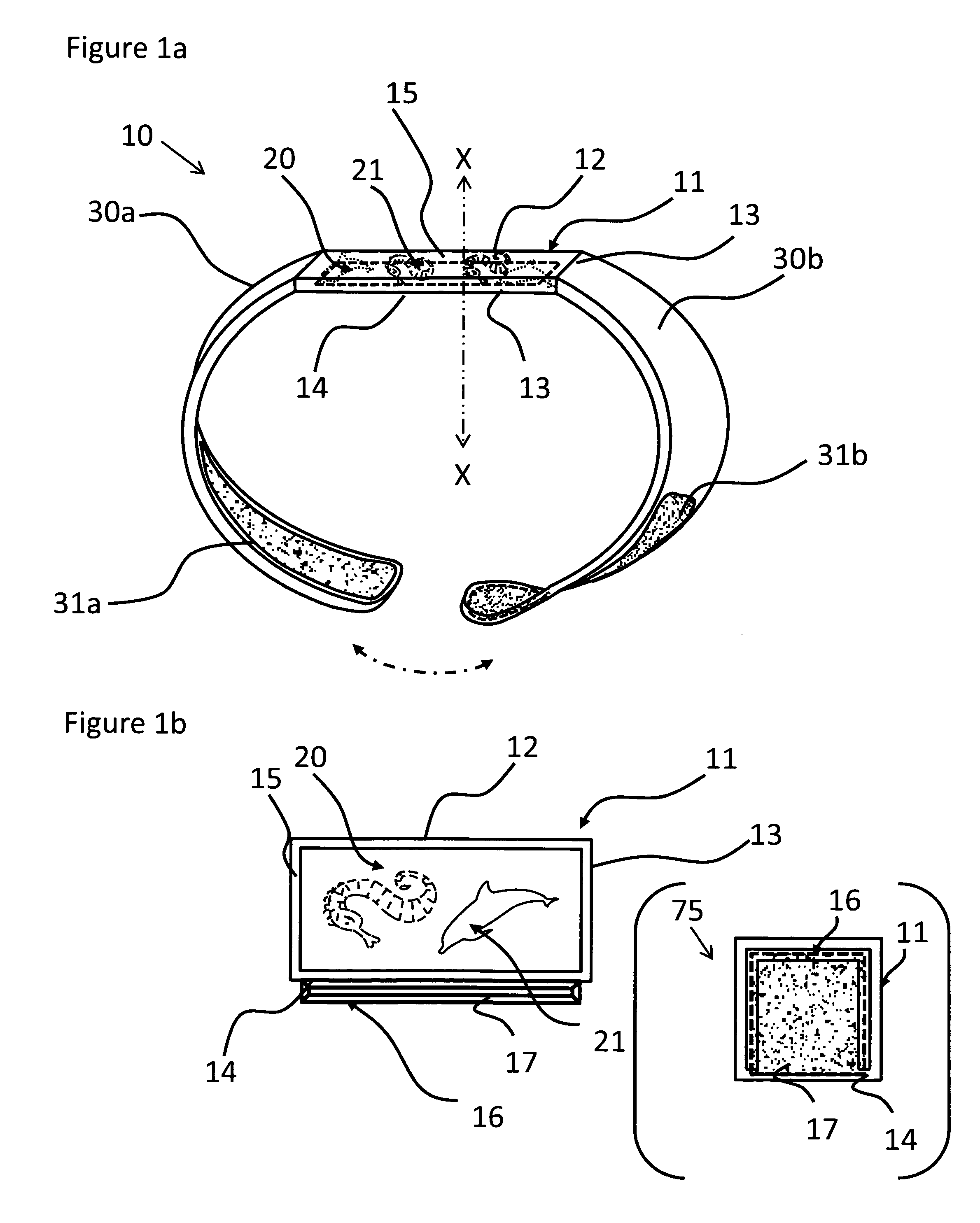

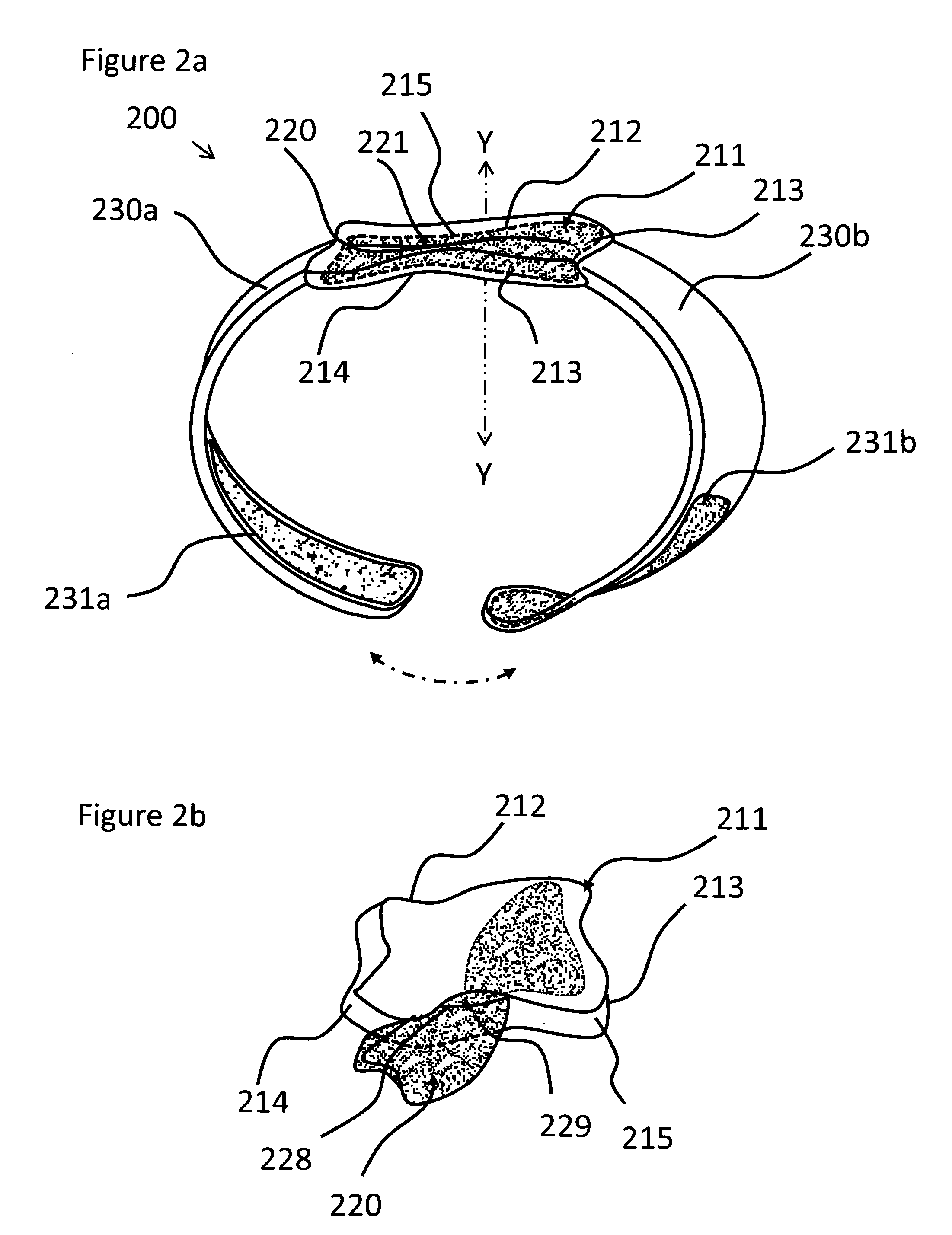

Therapeutic braceletand wrap

InactiveUS20110106227A1Healing experienceTherapeutic coolingTherapeutic heatingDistractionCold treatment

A bracelet and wrap having therapeutic properties is worn on a child's injured or sensitive wrist to facilitate healing and / or provide cold / warm treatment. The therapeutic bracelet and warp include a central portion having an internal chamber for receiving and housing a treatment pack. The therapeutic bracelet and warp further include first and second straps including mating fastener means attached to said central portion for securing the bracelet on the child's wrist. The therapeutic pack is appointed to either be a cold treatment pack or a hot treatment pack, depending on the type of treatment needed. Preferably, the treatment pack includes a transparent top wall and a liquid having a plurality of shapes suspended therein. In turn, the central portion's top side is constructed of a transparent material so that the shapes are visible. The therapeutic bracelet and wrap is appointed to be worn on an injury to facilitate healing while providing style, entertainment and distraction to the wearer.

Owner:DESIDERIO MARCELA N +1

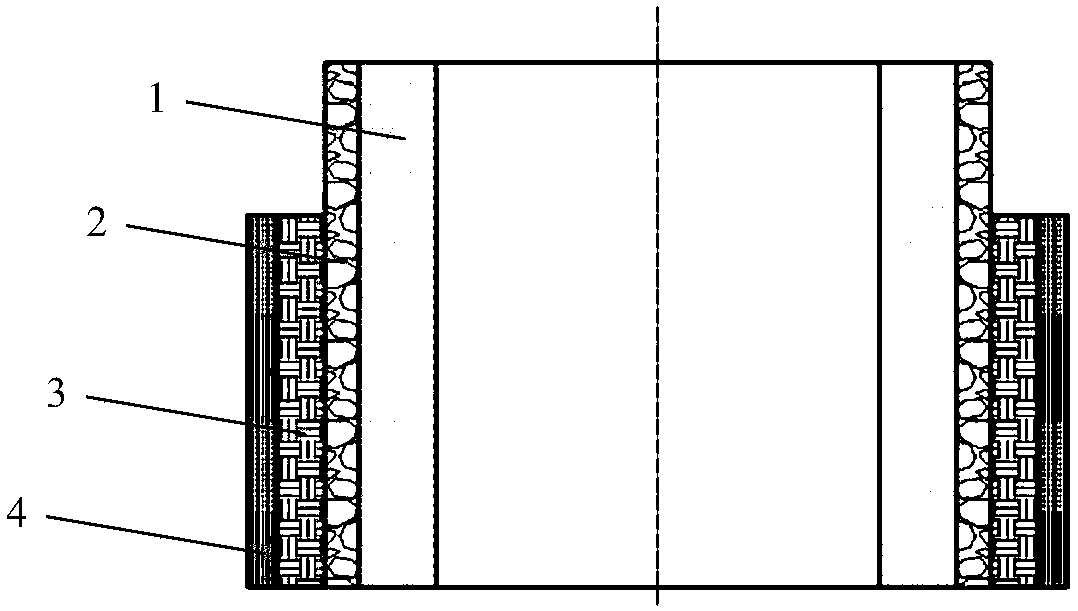

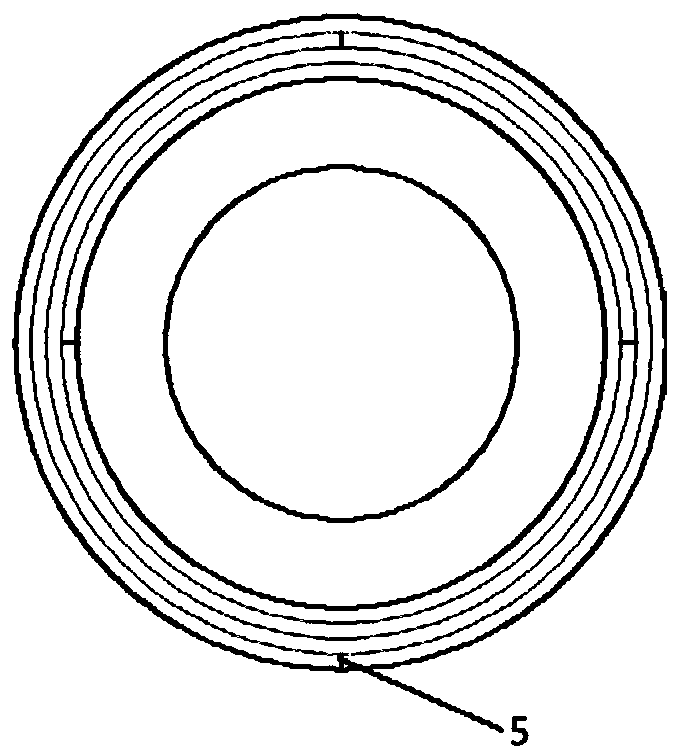

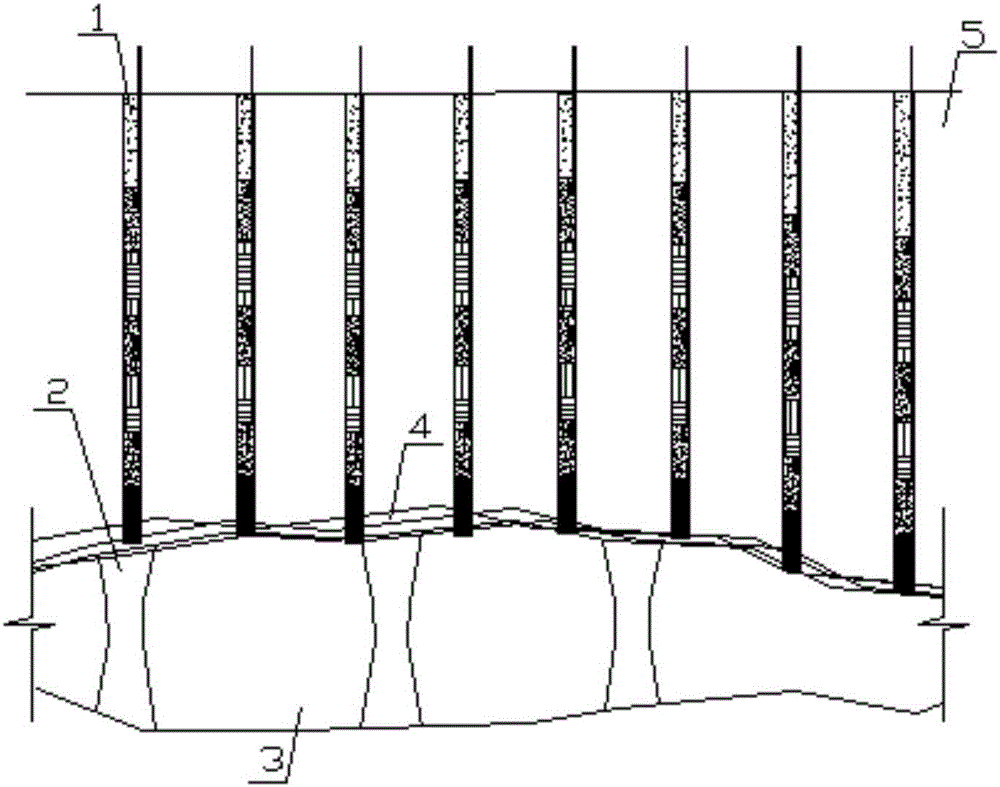

Longitudinal minimal-invasion bone cutter for tubular bones

InactiveCN102860860BFor lateral tractionFacilitates longitudinal osteotomySurgeryLess invasive surgeryEngineering

A longitudinal minimal-invasion bone cutter for tubular bones comprises a bone cutting end bone cutting device and far end positioning devices. The bone cutting end bone cutting device is slidingly sleeved on a positioning adjusting guide rail which is in a long-strip shape, a sliding groove is arranged in the middle of the positioning adjusting guide rail along the length direction, and scales of the positioning adjusting guide rail are arranged along the sliding groove. The far end positioning devices are symmetrically sleeved at two ends of the positioning adjusting guide rail slidingly. By means of the longitudinal minimal-invasion bone cutter, medical workers can perform longitudinal bone cutting operations on the tubular bones according to treatment needs, and the longitudinal minimal-invasion bone cutter is convenient to operate. When the operations are performed, the longitudinal minimal-invasion bone cutter provides convenience for transverse traction of bone blocks and meets needs of angiitis treatment. The bone cutting operations performed by the aid of the longitudinal minimal-invasion bone cutter belong to minimal-invasion operations, do not damage nerves, blood vessels, soft tissues and periostea, have small invasion, facilitate reconstruction and union of bones, and meet needs of longitudinal traction treatment of the tubular bones. By means of the longitudinal minimal-invasion bone cutter, safety and accuracy of the longitudinal bone cutting operations of the tubular bones are improved, medical workers can conveniently perform the operations, and the operation effect is guaranteed.

Owner:JIANGSU GUANGJI MEDICAL TECH

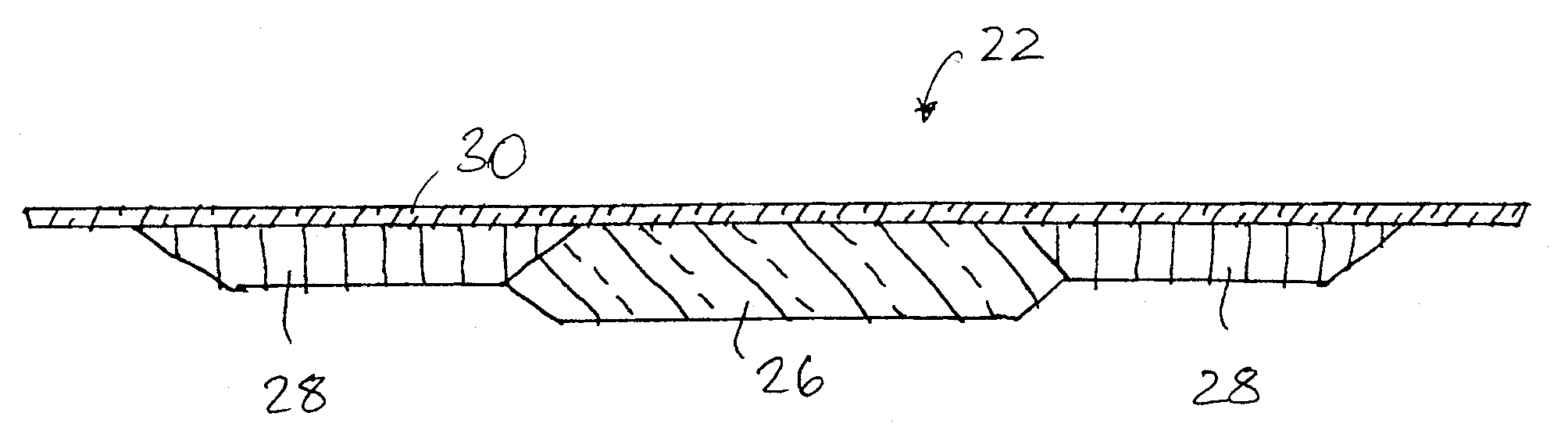

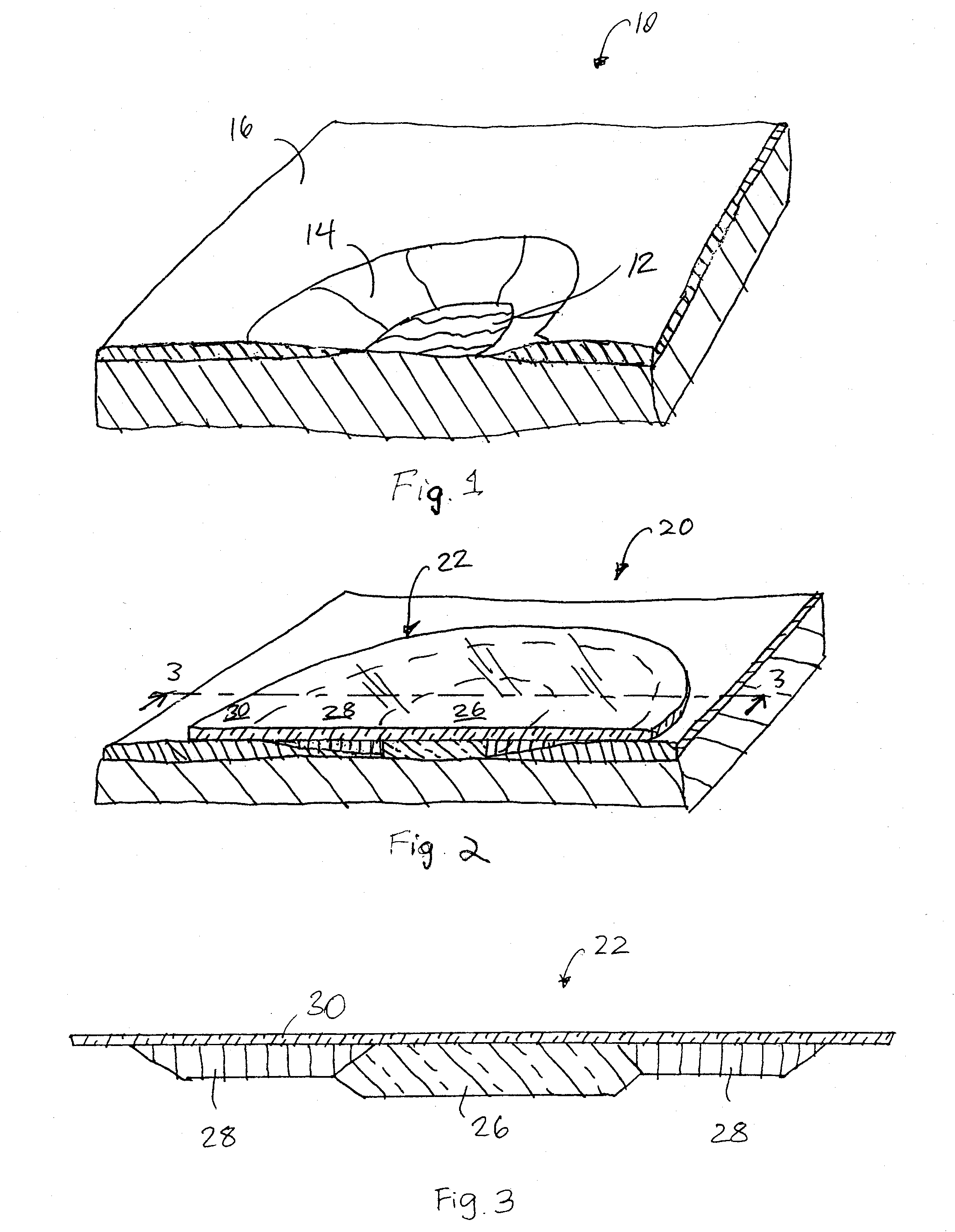

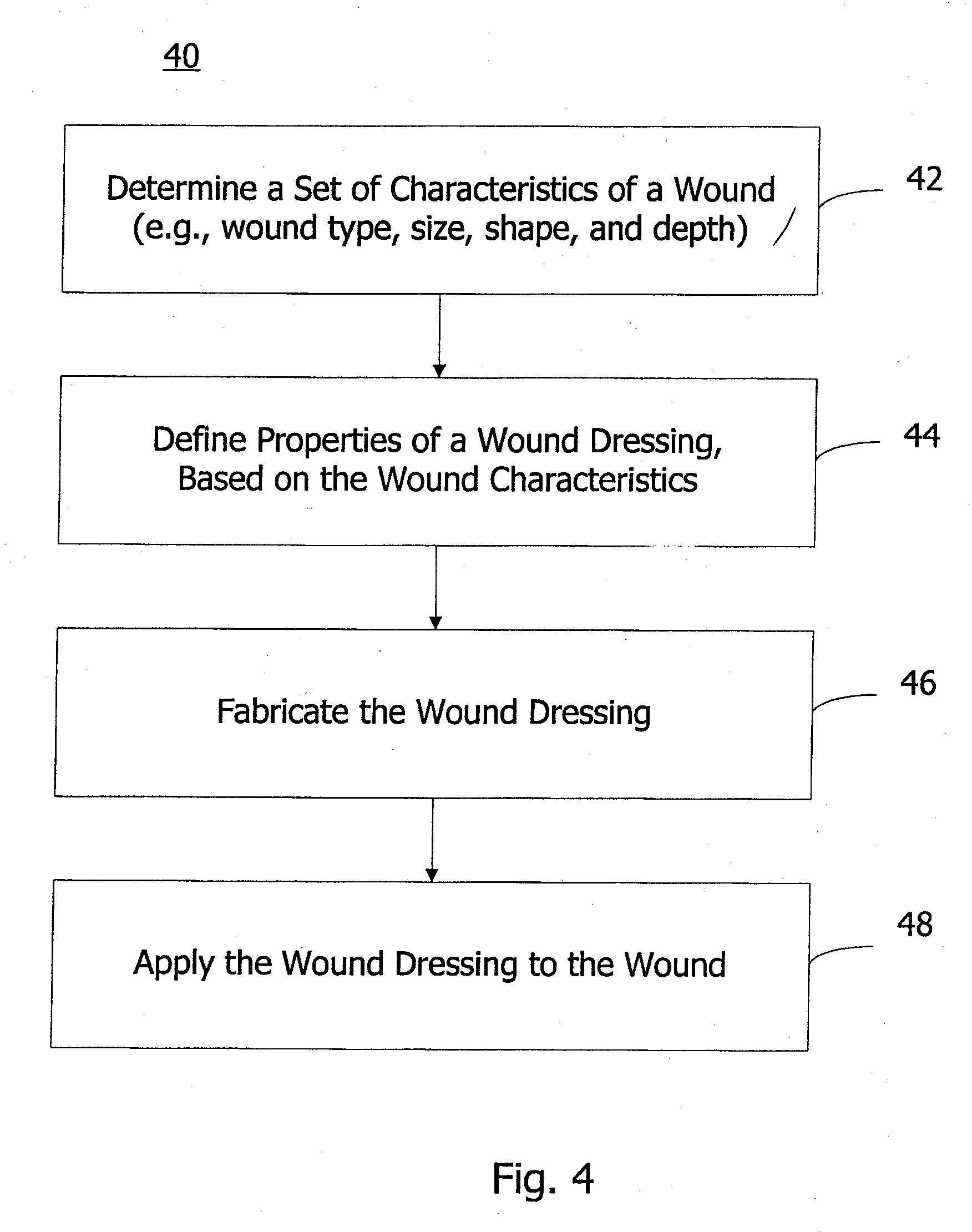

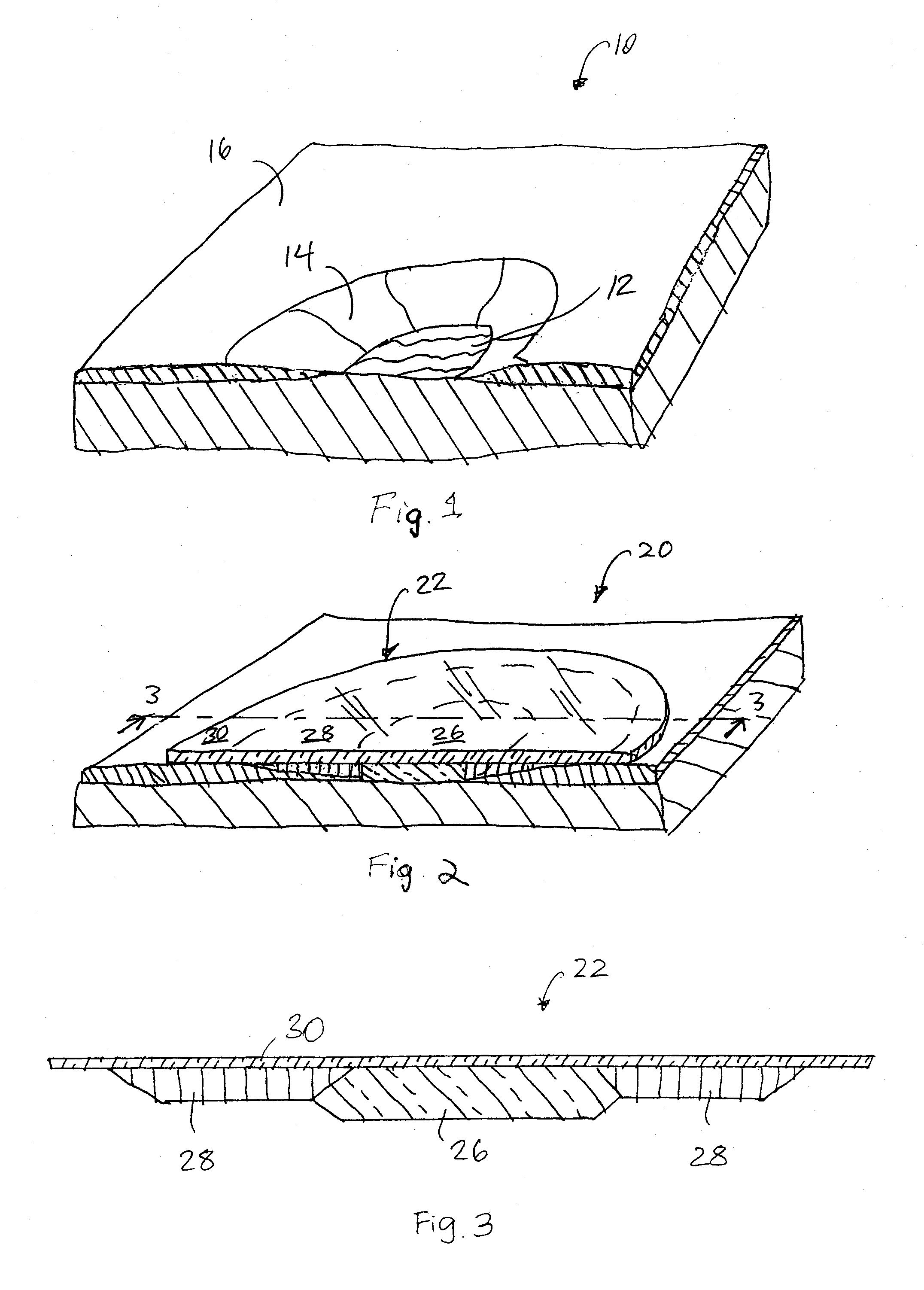

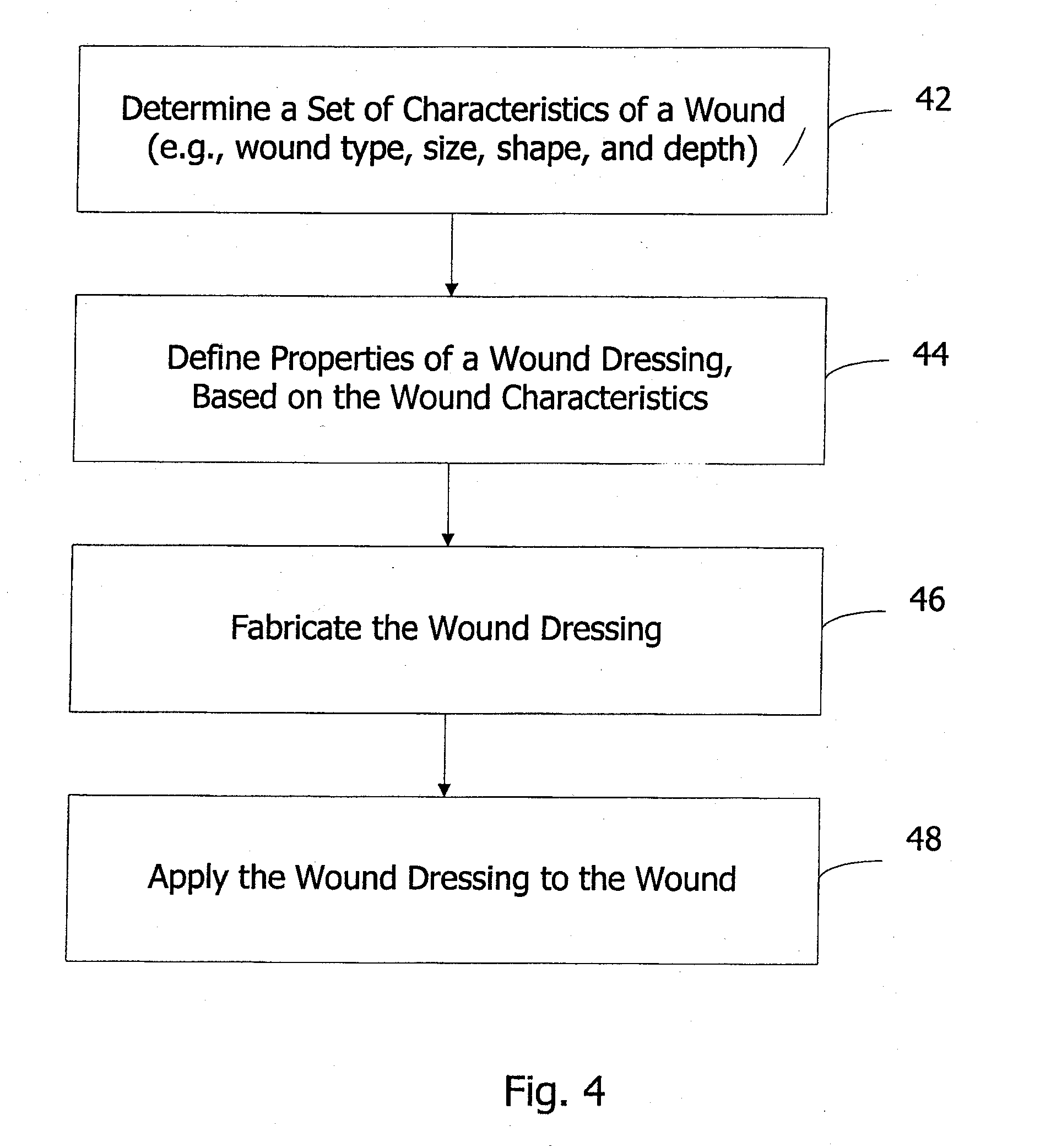

Method For Treating Wound, Dressing For Use Therewith And Apparatus and System for Fabricating Dressing

A method of treating a wound using a customized dressing. In the method, at least one wound characteristic is evaluated. A treatment need as a function of the at least one wound characteristic is determined. A dressing having a dressing characteristic responsive to the treatment need is fabricated and applied to the wound. A dressing for use therewith and an apparatus and system for fabricating the dressing are provided.

Owner:SINYAGIN DMITRIY

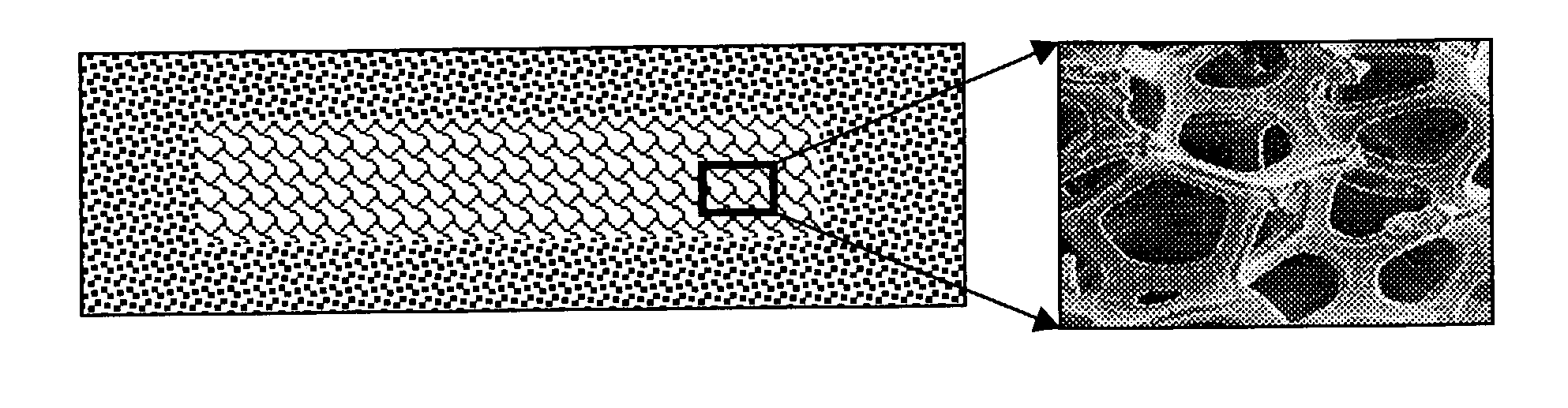

Humanization active forging bone and preparation method thereof

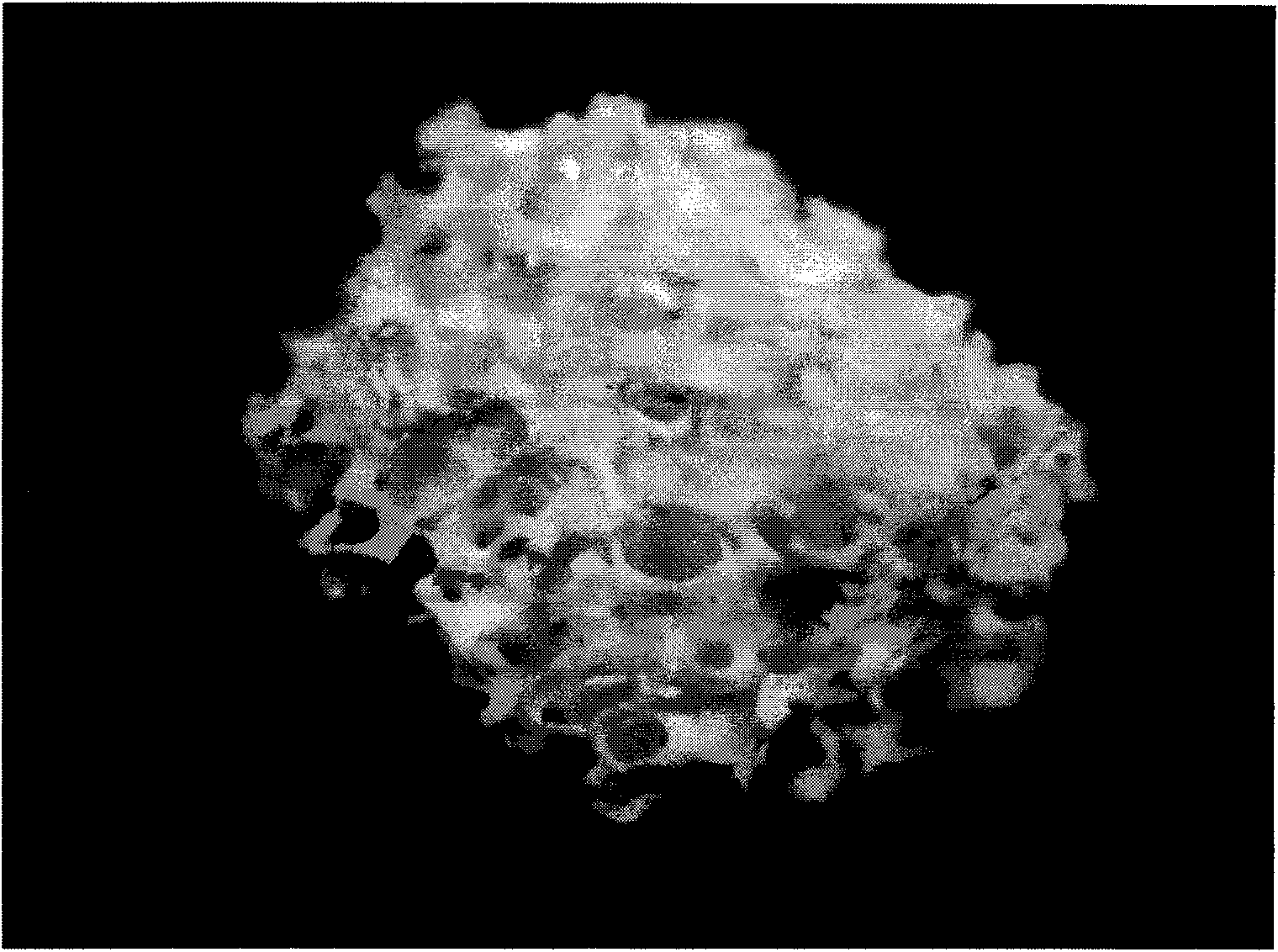

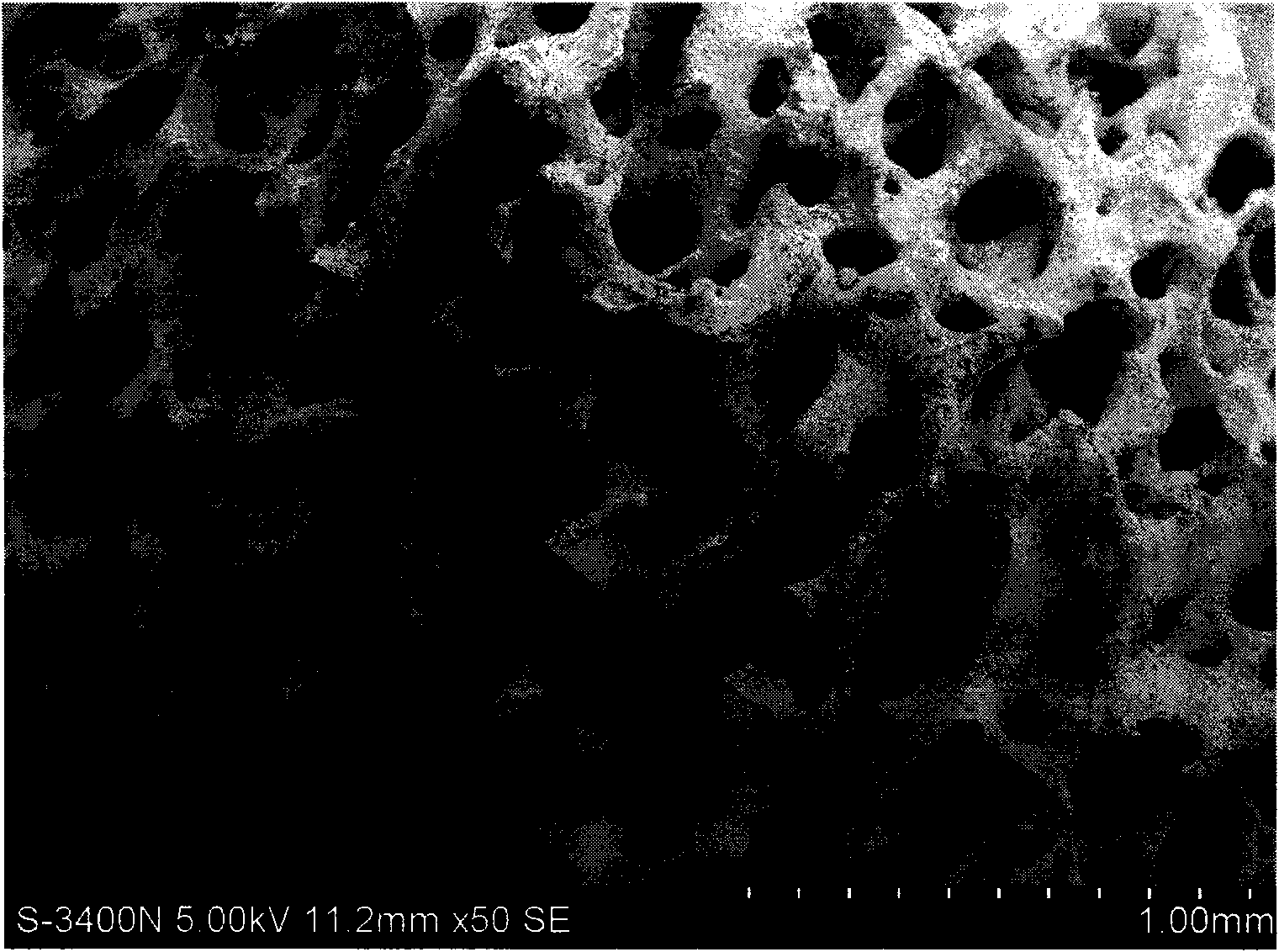

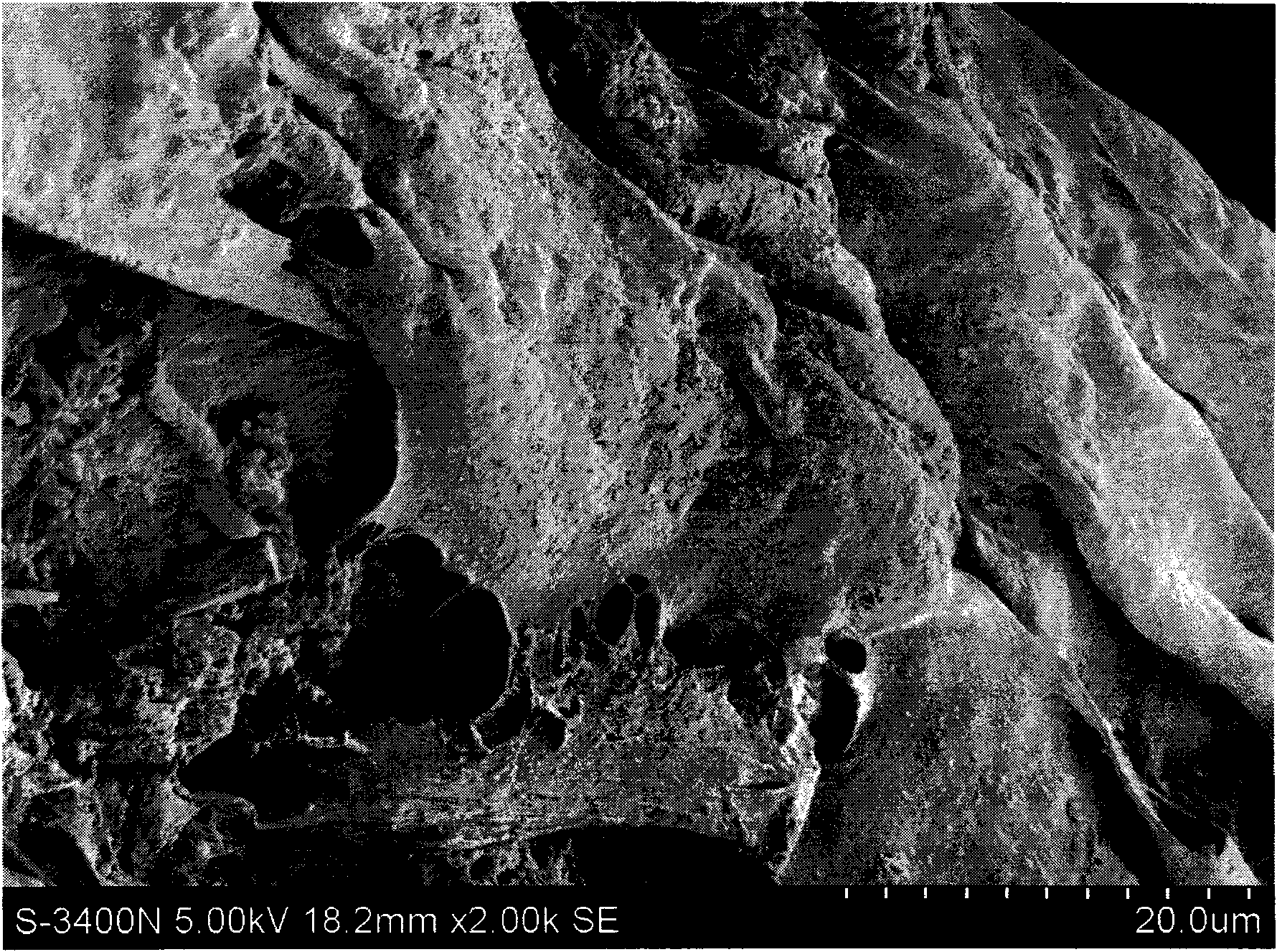

ActiveCN101564553APromotes Adhesive GrowthPromote ingrowthProsthesisBone structureCell-Extracellular Matrix

The invention discloses a humanization active forging bone and a preparation method thereof. The humanization active forging bone has main components of hydroxyapatite crystal, natural animal cancellous bones, particles of which the particle size is between 0.1 and 5 millimeters and having three-dimensional netlike porous structures, and a coating of which the pore-size distribution is between 50 and 600 microns and the surface is compounded with extracellular matrix synthesized and excreted by human cells. The forging bone not only has a similar structure with a human bone and is advantageous for cell ingrowth, formation of new bones, and bone structure reconstruction at a transplantation position, but also can be firmly combined with the coating of which the surface is coated with the extracellular matrix synthesized and excreted by the human cells and cell growth factors, promotes the attached growth of in vivo osteoblasts, and accelerates the formation of the new bones; and simultaneously, the forging bone has the advantages of molding randomly and not causing immunological rejection reactions, and can satisfy treatment needs of clinical bone defect and nonunion.

Owner:SHAANXI RUISHENG BIOTECH

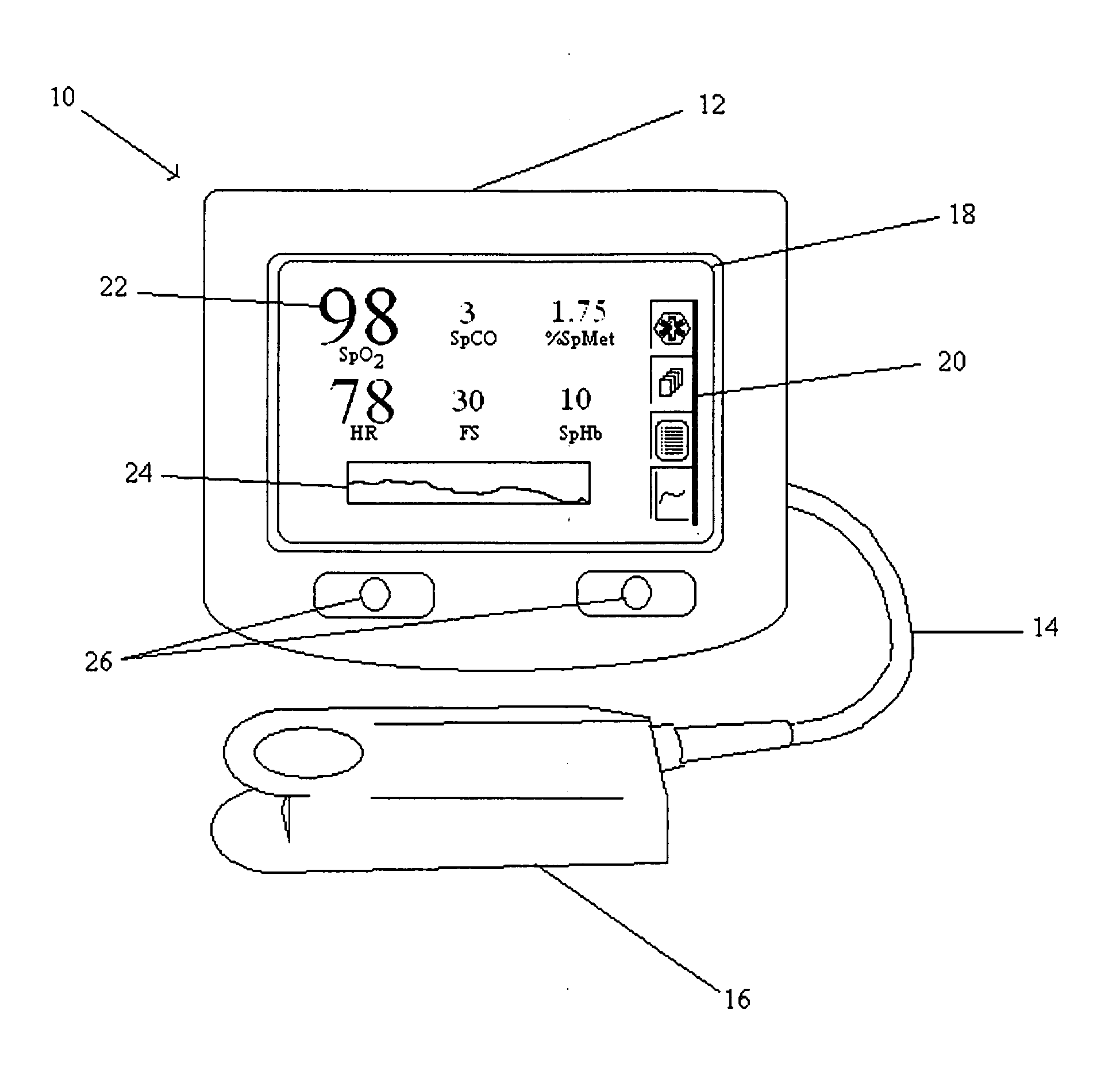

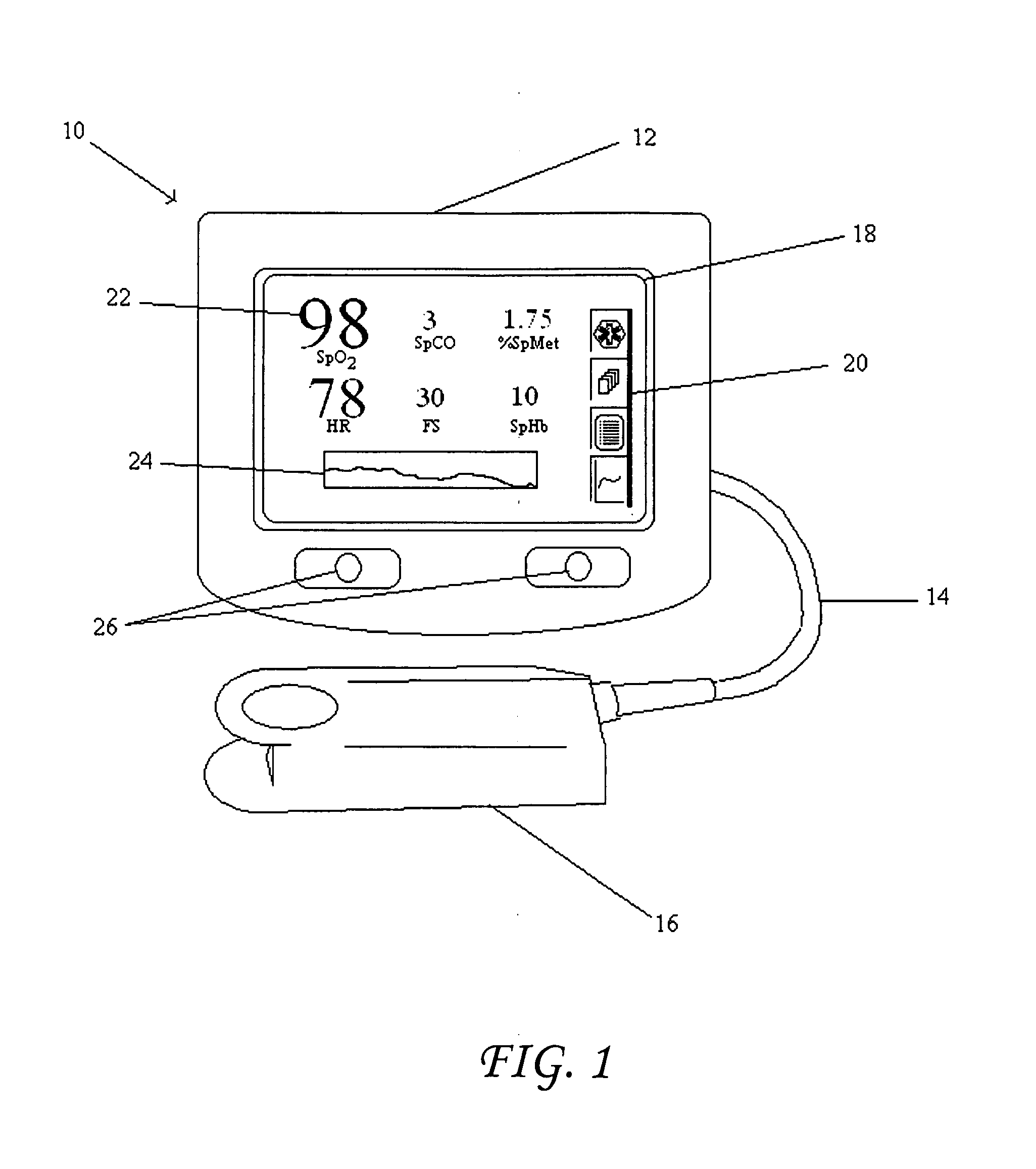

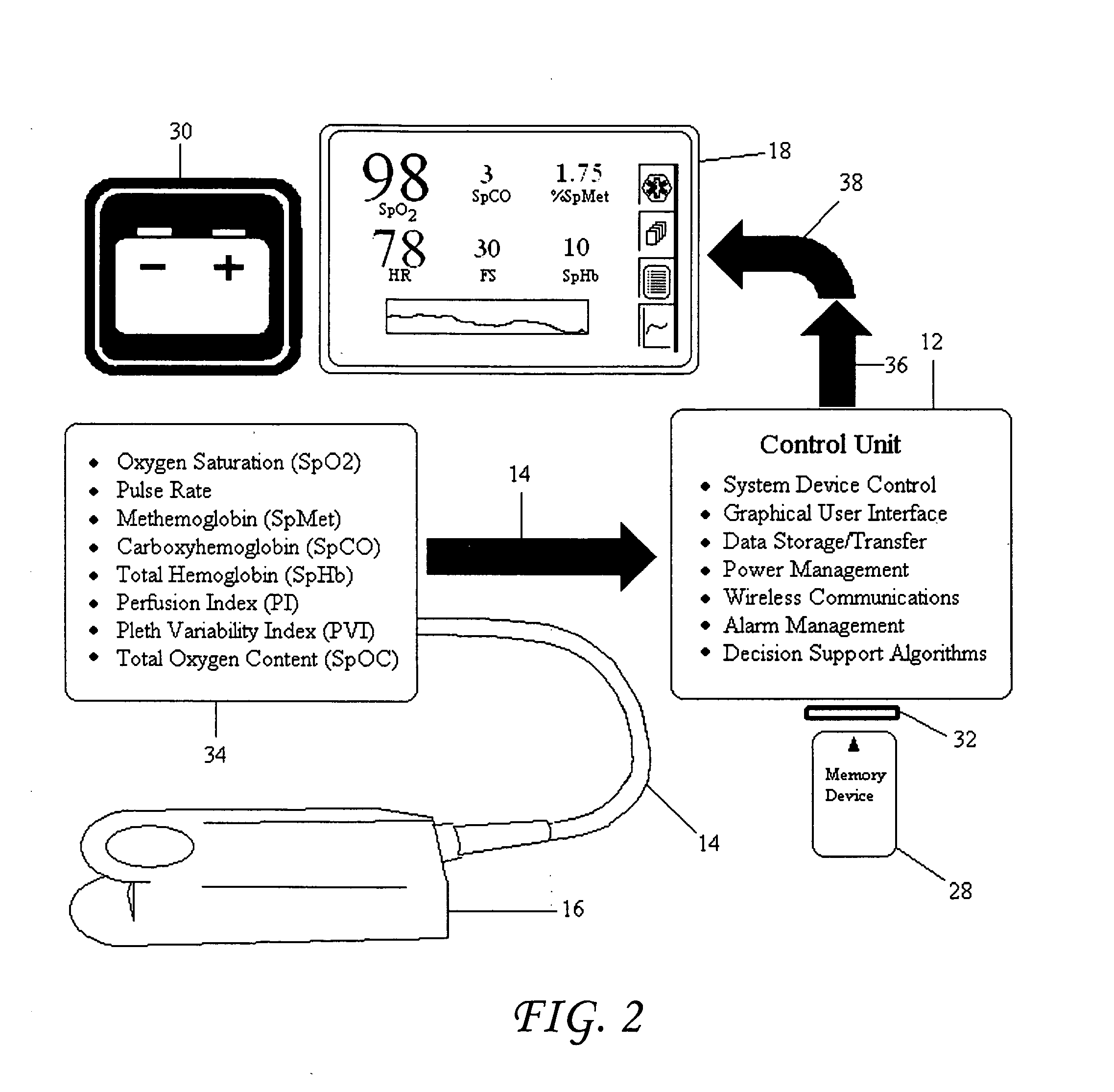

Decision support method for casualty treatment using vital sign combinations

InactiveUS20110201905A1Continuous monitoringConfirm and improve uponDiagnostic recording/measuringSensorsTreatment demandWhole blood product

A device and control software and system capable of accepting patient vital sign readings from an oximeter and applying a predetermined decision algorithm that incorporates unique combinations of vital signs and will allow the care giver to continuously monitor and have continuous feedback regarding certain patient vital functions, body trauma status, and immediate treatment needs, such as the patient's likelihood of the onset of shock and the advisability of introducing blood or blood products to the patient.

Owner:OFFICE OF THE GOVERNOR

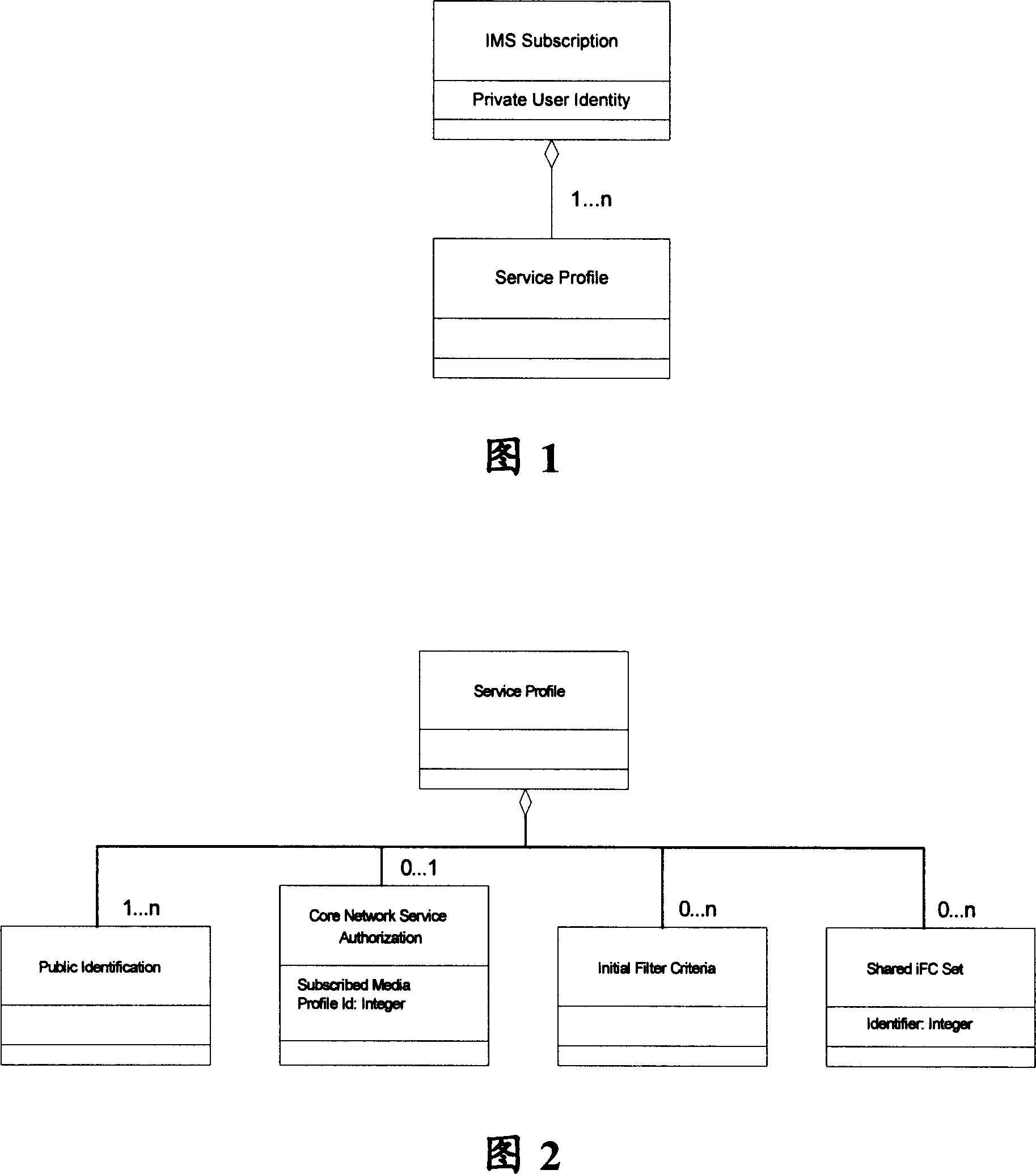

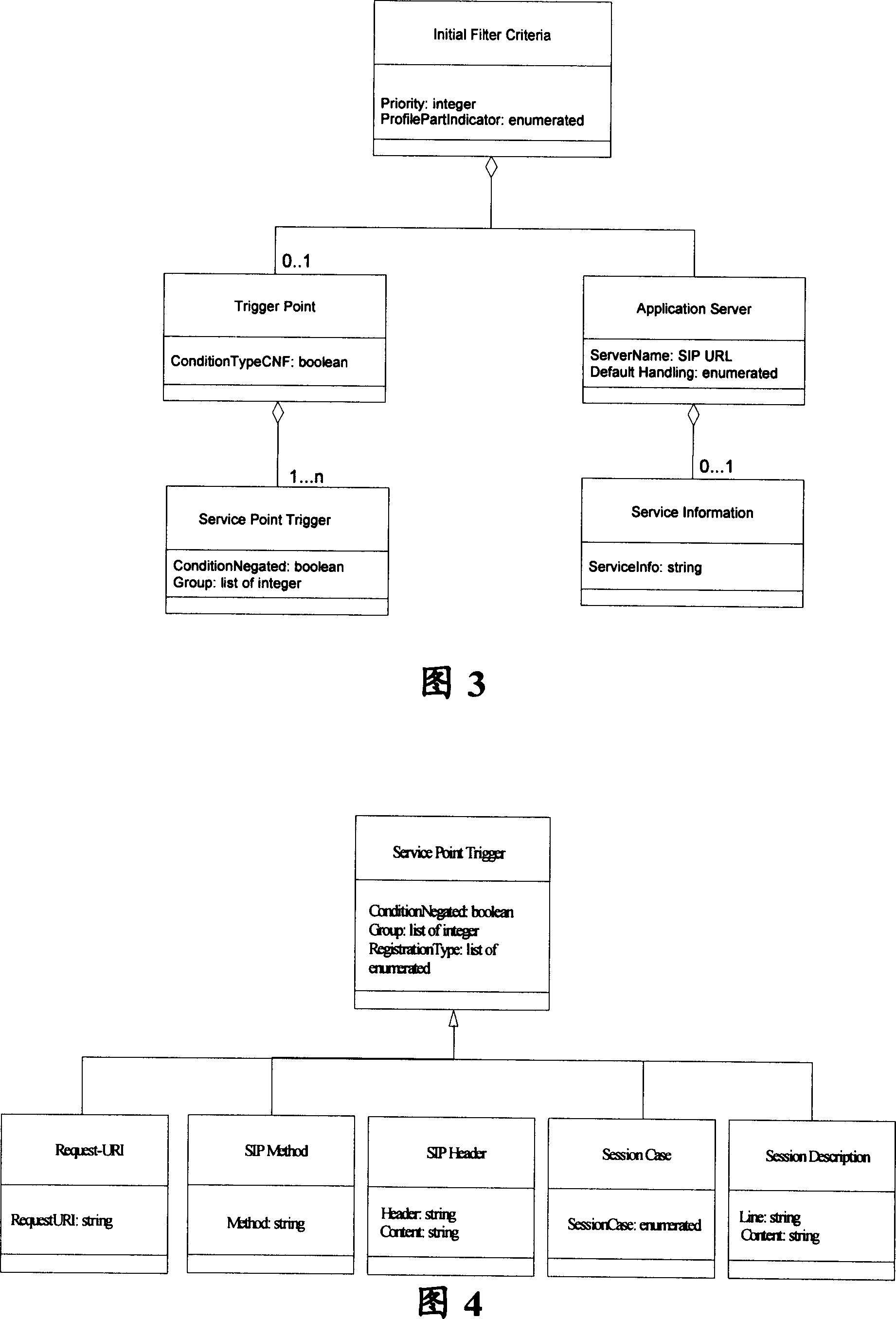

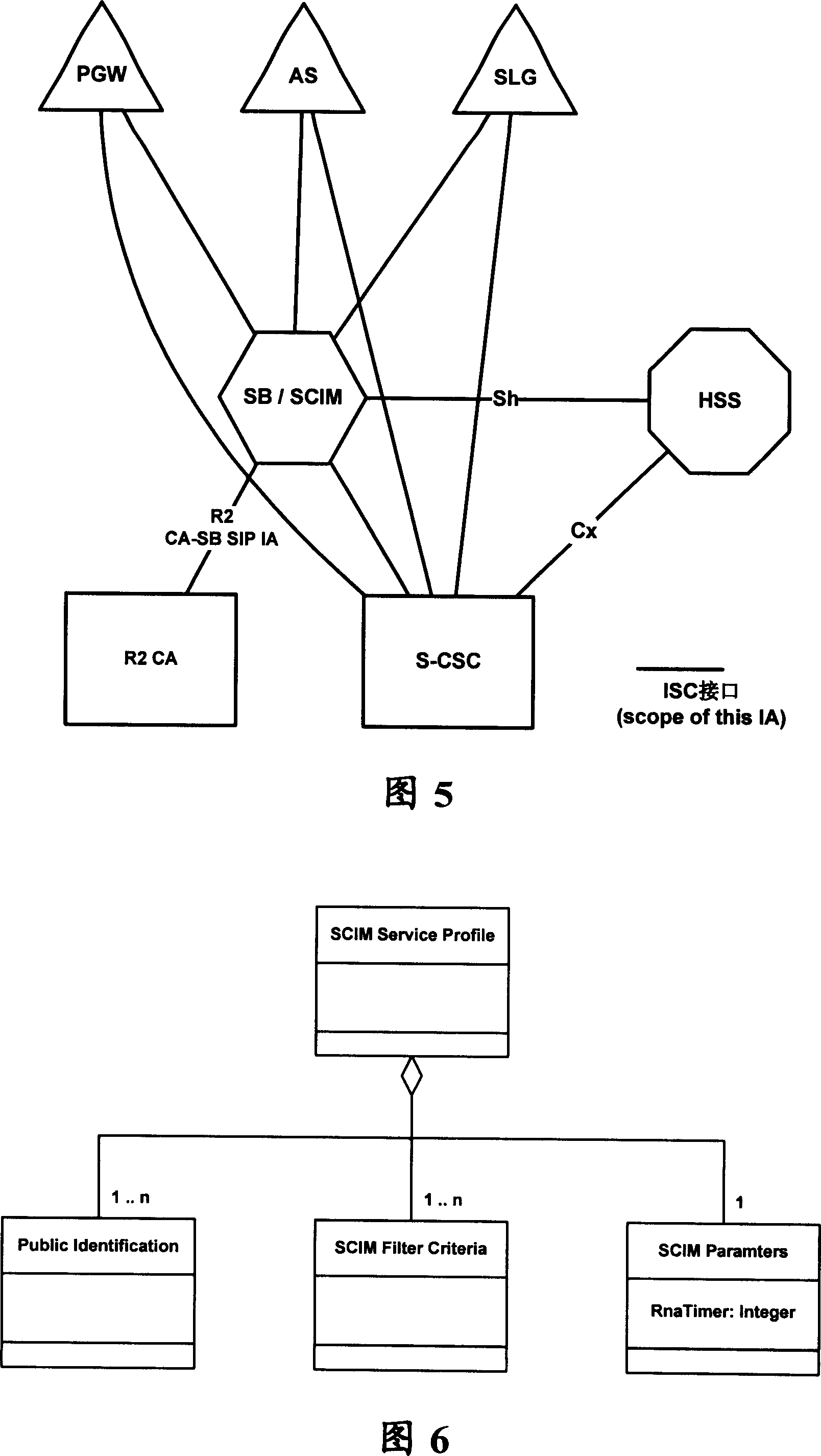

Packet network with enhanced service filtering rule and its implementation method

InactiveCN101106521AReduce loadImprove effectivenessData switching networksApplication serverFiltering rules

The invention provides a packet network with increased business filtering rule, which includes a user sign database, used to preserve user business filtering rule; a business control point, used to provide user with business; and a business trigger point, obtaining business filtering rule from user sign database and deciding whether SIP communication in current treatment need to trigger business control point or need local treatment, according to business filtering rule. The business filtering rule at least includes one of the following: the message body content other than SIP message conversation description, conversation state, message event other than SIP request message, time, user presentation message, user roaming state, business transfer message, other relevant rule message, and virtual application server address. The invention also provides a business trigger method, which is used to realize the business trigger of packet network.

Owner:HUAWEI TECH CO LTD

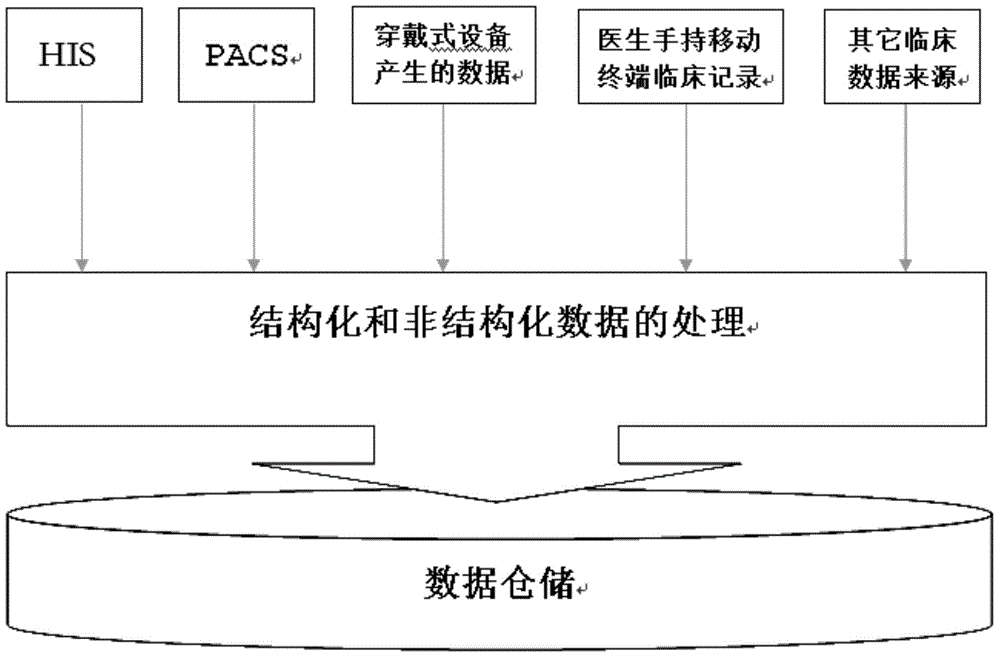

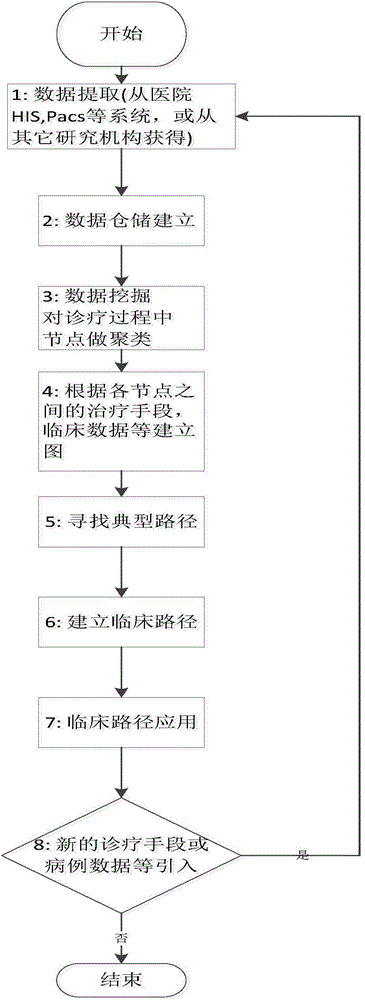

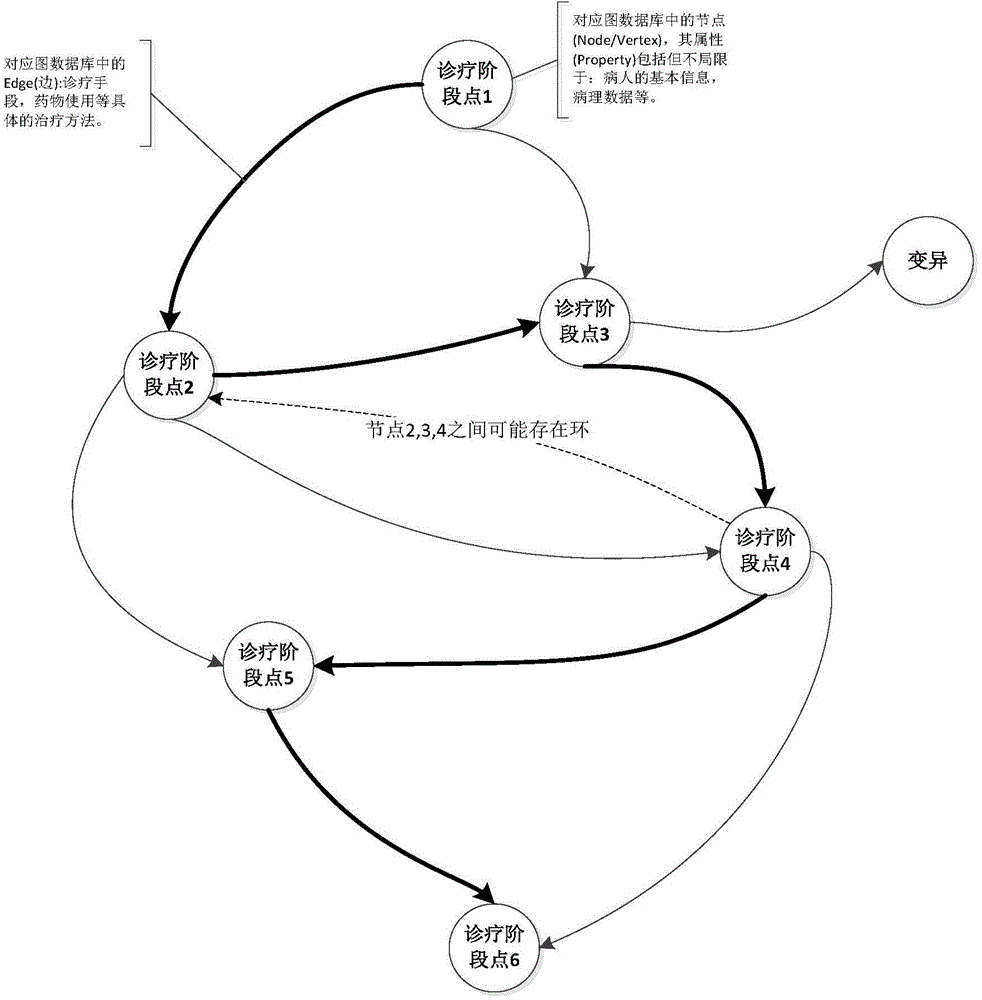

Clinical path establishing and optimizing method and system based on data mining and graph theory technology

ActiveCN104834826ABig amount of dataFast growthSpecial data processing applicationsDiseasePhases of clinical research

The invention discloses a clinical path establishing and optimizing method and system based on data mining and a graph theory technology. The method includes the steps that S1, data are extracted for different diseases; S2, data in a distributed database are analyzed, and all diagnosis and treatment stage points of a complete treatment course are set for different diseases respectively; S3, based on the graph theory technology, the diagnosis and treatment stage points are stored and at least include diagnosis and treatment stages, information of treatment needing to be performed between the diagnosis and treatment stages and clinical pathology data included in each diagnosis and treatment stage; S4, by the utilization of the related algorithm of the graph theory, a typical path for the disease is searched for; S5, according to each diagnosis and treatment stage pint and the diagnosis and treatment activity of each diagnosis and treatment stage point, a clinical path is established and stored in a clinical path database; S6, the result and variation of applying the clinical path are recorded, and if variation exists, the clinical path is optimized again.

Owner:NANJING PLASO NETWORK TECH CO LTD

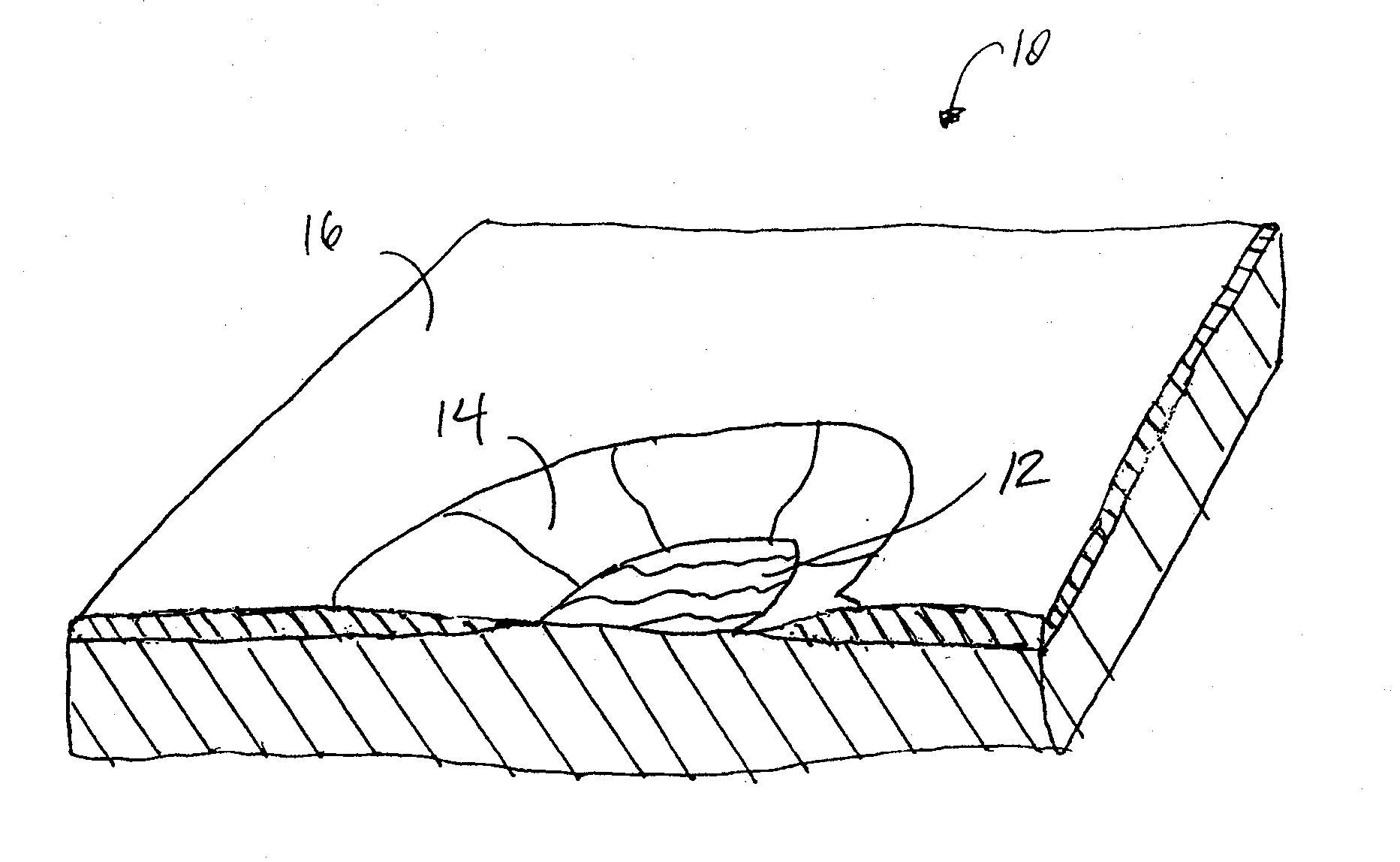

Method For Treating Wound, Dressing For Use Therewith Apparatus And System for Fabricating Dressing

A method of treating a wound using a customized dressing. In the method, at least one wound characteristic is evaluated. A treatment need as a function of the at least one wound characteristic is determined. A dressing having a dressing characteristic responsive to the treatment need is fabricated and applied to the wound. A dressing for use therewith and an apparatus and system for fabricating the dressing are provided.

Owner:SINYAGIN DMITRIY

Processing method for high-purity titanium sheet for coating titanium anode base material

Provided is a processing method for a high-purity titanium sheet for a coating titanium anode base material. O-stage sponge titanium with the average particle size being 3-25.4 mm is placed in an electron beam cold hearth and melted in a vacuum state so that a high-purity titanium slab can be obtained through purification; a hot coil which is 2.5-5 mm thick is manufactured through rolling of a steckel mill, and annealing is performed; shot blasting and pickling treatment need to be performed after annealing; the hot coil is placed on a reversible cold rolling machine to be subjected to many times of rolling; finally, a cold coil which is 0.5-2 mm thick can be obtained; the deformation rate is controlled to be 40-60% during each time of rolling; then the cold coil is subjected to degreasing treatment; then complete recrystallization annealing is performed in the vacuum state or the argon protection state, wherein the annealing temperature is controlled to be 600-720 DEG C and a titanium coil is obtained. As is detected, the average grain size of the titanium is controlled to be 15-30 microns, and the high-purity titanium sheet for the coating titanium anode base material is obtained after the titanium coil is straightened. The unevenness of the high-purity titanium sheet is smaller than or equal to 3 mm / m, and no strip-shaped flow direction lines exist after the high-purity titanium sheet is used as a coating.

Owner:LUOYANG SUNRUI TI PRECISION CASTING

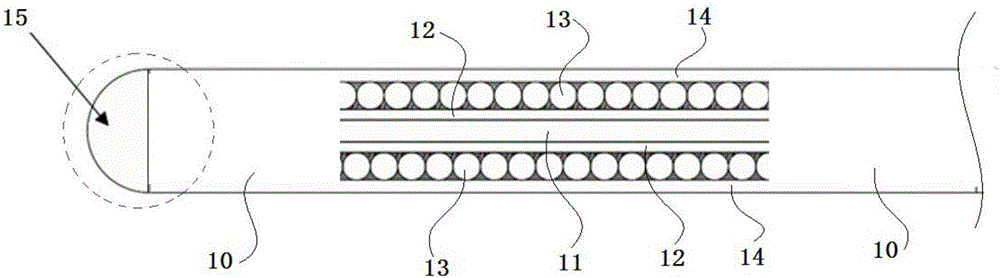

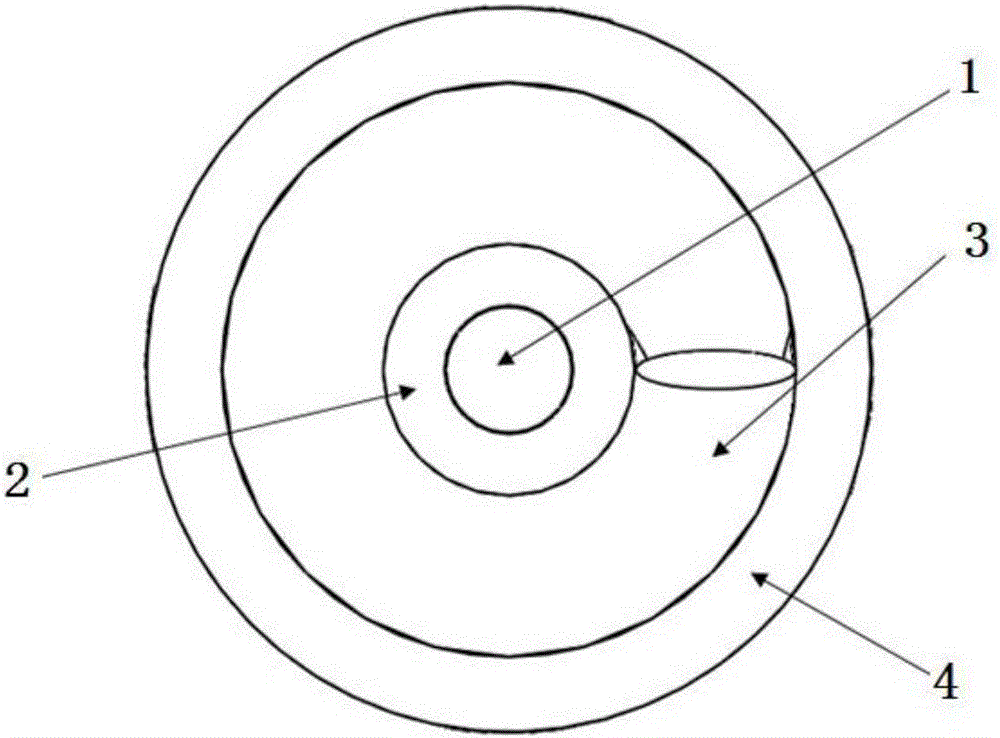

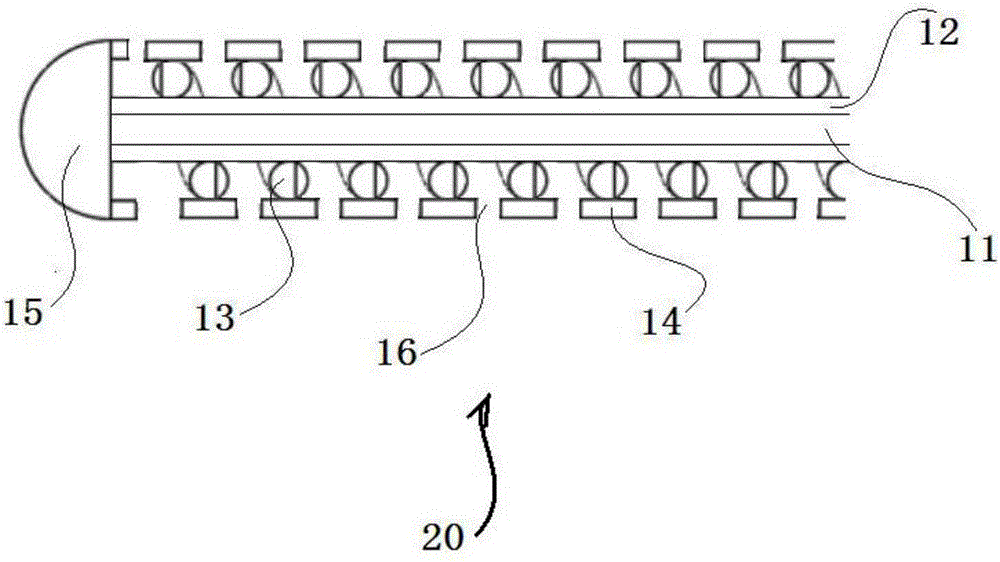

Axial type inlet oil-water cyclone separator

The invention discloses an axial type inlet oil-water cyclone separator comprising a liquid inlet pipe section, a cyclone generation pipe section and a water outlet pipe section, which are sequentially connected, wherein the cyclone generation pipe section further comprises a cyclone pipeline and more than two diversion sheets which can be fixed and obliquely mounted in the cyclone pipeline, and the diversion sheets are uniformly distributed along the circumferential direction of the cyclone pipeline and sequentially superposed in the axial direction of the cyclone pipeline; when oil-water mixed flow liquid flows through the diversion sheets, a centrosymmetric cyclone field is formed and the centrifugal separation of oil and water in the cyclone field is further realized. The axial type inlet oil-water cyclone separator is an oil-water separation device utilizing the cyclone principle, the inner diameters of the liquid inlet pipe section and the water outlet pipe section are the same, only one section on a liquid collecting pipeline which needs the treatment needs to be cut off for mounting the separator, the pipe flow direction is not changed and the applicability is good; compared with a traditional gravity settling separation device, the treatment efficiency is obviously improved and the occupied space is smaller.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

Non-contact type flexible explosion-proof method and non-contact type flexible explosion-proof device design method

ActiveCN108627062AImprove impact performanceImprove the protective effectProtective equipmentSynthetic resin layered productsExplosion protectionContact type

The invention discloses a non-contact type flexible explosion-proof method and a non-contact type flexible explosion-proof device design method, and relates to the field of social public security andexplosive disposal. The structure destroying explosion-proof theory is adopted, and in the explosion-proof process, an explosion-proof device is broken up, crushed and flied apart to absorb explodingenergy; multiple nonmetal flexible materials are composited, during explosion-proof operation, an impact wave protection layer is placed on the side close to the explosive, impact wave strength generated by exploding is weakened, and exploding heat is absorbed; a fragment protection layer is placed on the periphery of the impact wave protection layer, impact wave strength is further weakened, andthe fragment speed generated by explosion is weakened; during structural design, on the basis of the design principle of temporal and spatial variation of explosive main loads and non-contact type treatment needs and on the basis of main load decomposing protection size design and the material positioning connection principle of non-secondary-additional-damage needs, the explosion-proof structureis high in explosion protection capacity, small in self weight, flexible in treatment manner, high in safety and free of secondary additional damage.

Owner:湖南艾尔防务技术有限公司

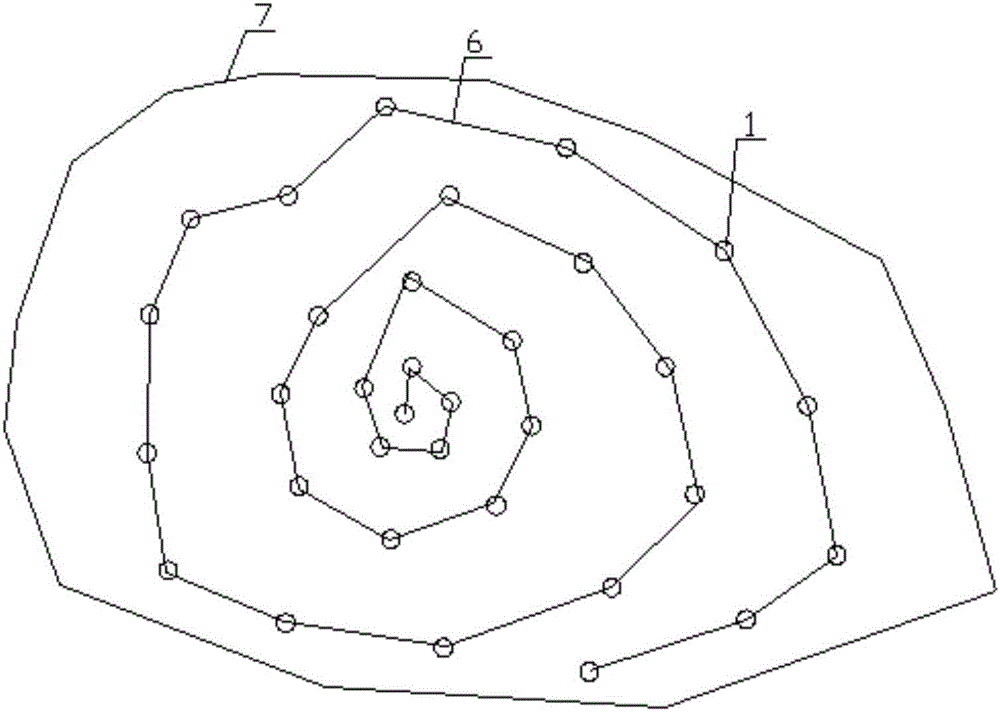

Method for hole-by-hole blasting explosion treatment of abandoned mined-out area

The invention discloses a method for hole-by-hole blasting explosion treatment of an abandoned mined-out area. The method comprises the steps that the dangerousness of the abandoned mined-out area is evaluated, the range of the abandoned mined-out area and explosion parameters are determined, and the treatment effect of the abandoned mined-out area is evaluated, specifically, the above rock thickness H of the abandoned mined-out area is smaller than or equal to the above rock thickness Hs of the abandoned mined-out area (namely H is smaller than or equal to Hs), the residual gap height of the abandoned mined-out area is larger than or equal to the product of the above rock thicknesses of the abandoned mined-out area and the rock hulking coefficient (namely Hk is larger than or equal to KsH), and explosion treatment needs to be carried out on the above rock of the abandoned mined-out area; according to the step of determining the range of the abandoned mined-out area, milling data are collected, the actual range of the abandoned mined-out area is surveyed and mapped, and drilling inspection is conducted; the hole-by-hole blasting explosion parameters are composed of adjusting hole net parameters, the charging constitution, the connection way and the blasting sequence; and the treatment effect of the abandoned mined-out area is verified by determining whether an expected effect is reached or not through comparison of the actually measured collapse depth with the theoretically calculated collapse depth.

Owner:ANHUI UNIV OF SCI & TECH

Method for treating circulating cooling water

ActiveCN1796307ASolve processing problemsImprove control abilityWater softeningPhosphateWater quality

This invention involves a process for treating circulating cooling water, comprising the steps of adding a first part compound inhibitor and an optional second part compound inhibitor into the circulating cooling water. The said first part compound inhibitor comprises organic phosphonate acid, phosphonate carboxylic acid, copolymers containing carboxyl and sulfonic groups, and optional zinc and polyphosphate salts. The second part compound inhibitor comprises zinc and polyphosphate salts, copolymers containing carboxyl and sulfonic groups, and optional phosphate salts, phosphonate carboxylic acid and organic phosphonate acid. This invention can solve such problems as agent treatment needed in the processes of acid-preset operation and acid-free operation brought about by the wide-range fluctuation of the quality of the circulating water. This invention also strengthens the controllability over the circulating water system, controlling the amount of the released agents in both parts according to different conditions of corrosion and scaling.

Owner:BEIJING YANHUA PETRO CHEM

Method for preparing burdock granules for conditioning through combined even drying of radio frequency pretreatment and microwave pulse spouting

ActiveCN103461462AStrong aromaImprove brittlenessFruits/vegetable preservation by heatingFood preparationMicrowaveEngineering

The invention relates to a method for burdock granules for conditioning through combined even drying of radio frequency pretreatment and microwave pulse spouting, belonging to the field of a fruit and vegetable food processing technology. The method comprises the steps of performing pretreatment (washing, unpeeling and slicing) on fresh burdocks, protecting color, pre-drying by radio frequency, drying through microwave pulse spouting and packaging; the color and the luster of a product are greatly improved after color protection, the radio frequency pre-drying treatment is only performed for 20 minutes, but hot air drying treatment for removing moisture on the surface is performed for 60 minutes, so that the method has short drying time and high efficiency; the sectional type microwave pulse spouting treatment only needs 60 minutes totally, while the complete hot air drying treatment needs 400 minutes, so that the drying time of the method is greatly shortened, and the drying is uniform; furthermore, a sample after microwave pulse spouting drying has strong fragrance; the method has the characteristics of having convenience in operation and high nutrition and safety, saving drying time and having low energy consumption.

Owner:NINGBO HAITONG FOOD SCI & TECH CO LTD +1

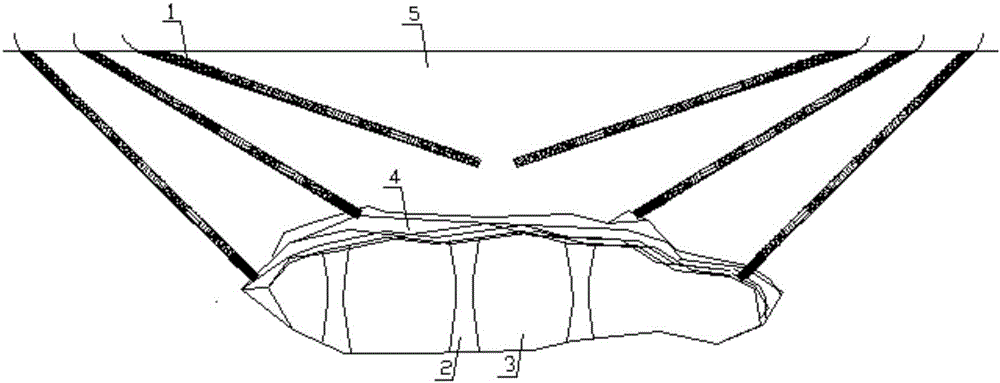

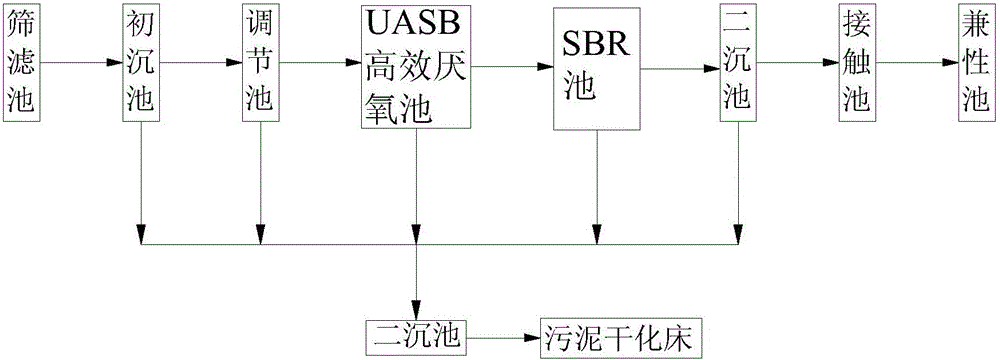

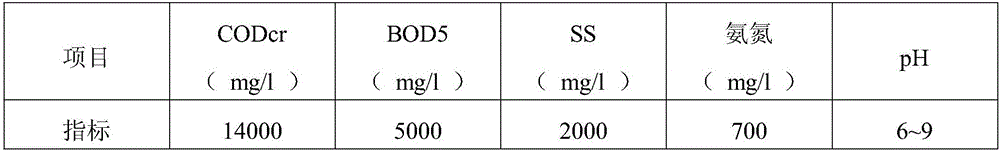

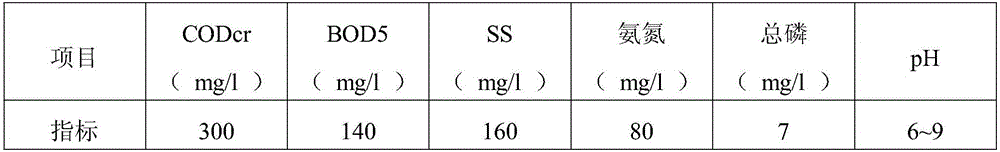

Farm waste water treatment method

InactiveCN106007211AReduce concentrationImprove impact performanceWater treatment parameter controlWater contaminantsOxygenPre treatment

The invention provides a sewage treatment method for farms, which comprises the following steps: sending the waste water from the farms into a sieve filter tank through a sewage pipe, sending the waste water after removing solid matter into a primary sedimentation tank through a lifting pump, and separating fine particles of waste water Enter the regulating tank, the wastewater in the regulating tank is sent into the UASB high-efficiency anaerobic tank through the lifting pump, and the effluent of the UASB high-efficiency anaerobic tank flows into the SBR tank for biological oxidation, and the mud-water mixture is exported, and the mud-water mixture is sent into the The secondary sedimentation tank separates the mud and water in it, sends the separated sludge into the sludge thickening tank, and discharges the clarified water; the clarified water is sent into the contact tank through the lifting pump, and ozone is used for disinfection, and the clarified water after the treatment of the contact tank Water is fed into facultative pools. The treatment method system in the present invention has low energy consumption and low operating costs; this scheme strengthens the effect of pretreatment and anaerobic treatment, so that the pollution is greatly removed before the aerobic treatment that requires energy consumption, thereby reducing the load of aerobic biochemical treatment and saving energy consumption.

Owner:佛山杰致信息科技有限公司

Vascular optical fiber guide wire

InactiveCN106512232APlay a therapeutic rolePlay a diagnostic roleLight therapyTreatment needHydrophilic coating

The invention relates to a vascular optical fiber guide wire. The vascular optical fiber guide wire comprises at least one optical fiber core wire, a wire winding layer and a hydrophilic coating capable of improving body fluid compatibility and reducing resistance, wherein the optical fiber core wire is arranged at an axial position of the optical fiber guide wire; the wire winding layer is composed of at least one winding wire or winding piece which coats and surrounds the optical fiber core wire; and the hydrophilic coating is painted on the periphery of the wire winding layer. The vascular optical fiber guide wire can enter an artery blood vessel of a human body to arrive at a predetermined position, and lead light into and / or out of a lesion part to realize photodynamic therapy for in-vivo tumors and the like, so as to satisfy the diagnosis and treatment needs in biological, medical fields and the like.

Owner:尚华

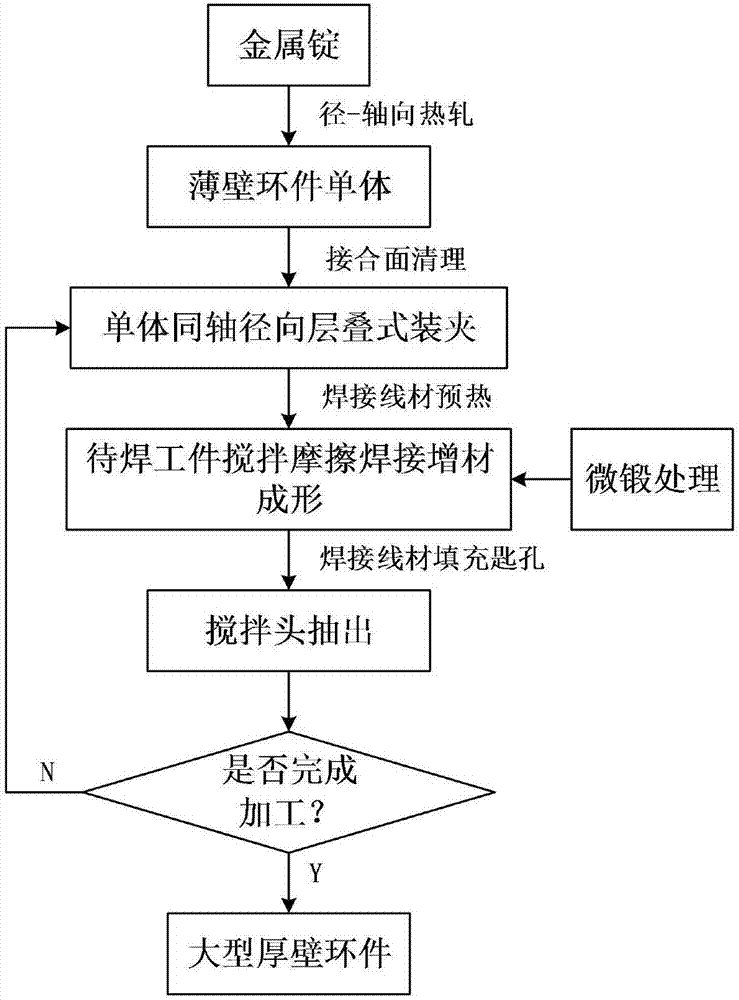

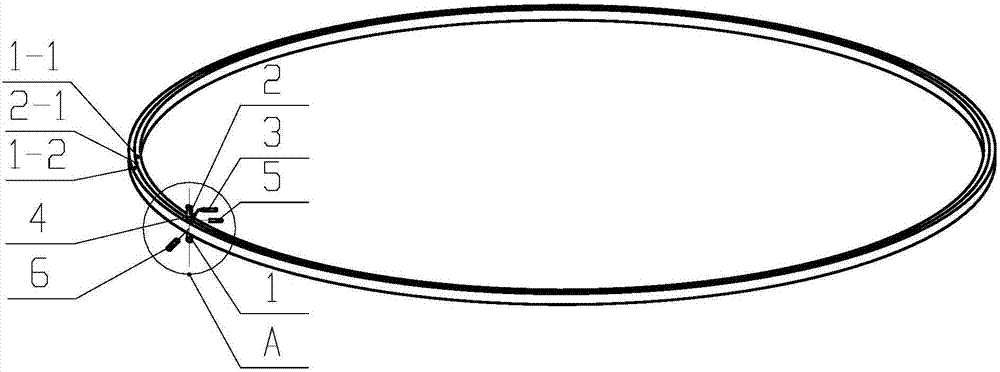

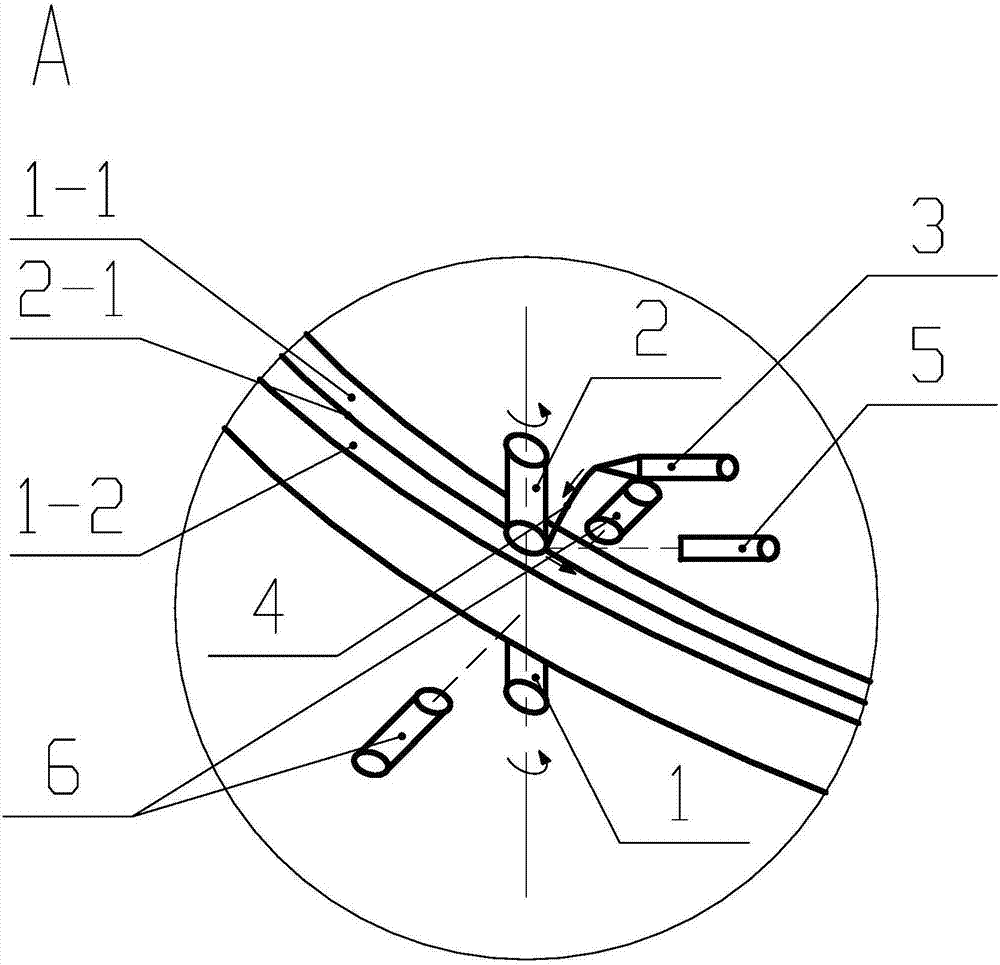

Radial stacking type friction-stir welding material adding forming process for large thick-wall ring part

InactiveCN106925883ASmooth and uniform appearanceIncrease profitNon-electric welding apparatusMetal formingEngineering

Disclosed is a radial stacking type friction-stir welding material adding forming process for a large thick-wall ring part. A sheet-shaped thin-wall ring part single body is prepared through radial-axial hot rolling technology, and radial stacking type double-shaft friction-stir welding material adding forming of the thin-wall ring part single body is conducted through double-shaft friction-stir welding material adding forming technology. A welding wire used by welding needs to be preheated by a laser heater, and plasticizing of the welding wire during welding is convenient. Meanwhile, during welding, micro forging treatment needs to be conducted on plasticized metal through an ultrasonic vibration exciter, and the effect that the texture form of the metal forming a weld joint approximately completely forms a welding core is ensured. One week after welding is conducted along the weld joint, a keyhole is filled with the welding wire constantly, meanwhile, a stirring head is drawn out of a workpiece slowly, and thus welding of the first ring of thin-wall ring part single body is completed. Finally, radial stacking type friction-stir welding material adding forming of the thick-wall ring part is conducted. Through the radial stacking type friction-stir welding material adding forming process, the utilization rate of materials can be increased significantly, energy consumption is reduced, and the overall performance of the product is improved.

Owner:XI AN JIAOTONG UNIV

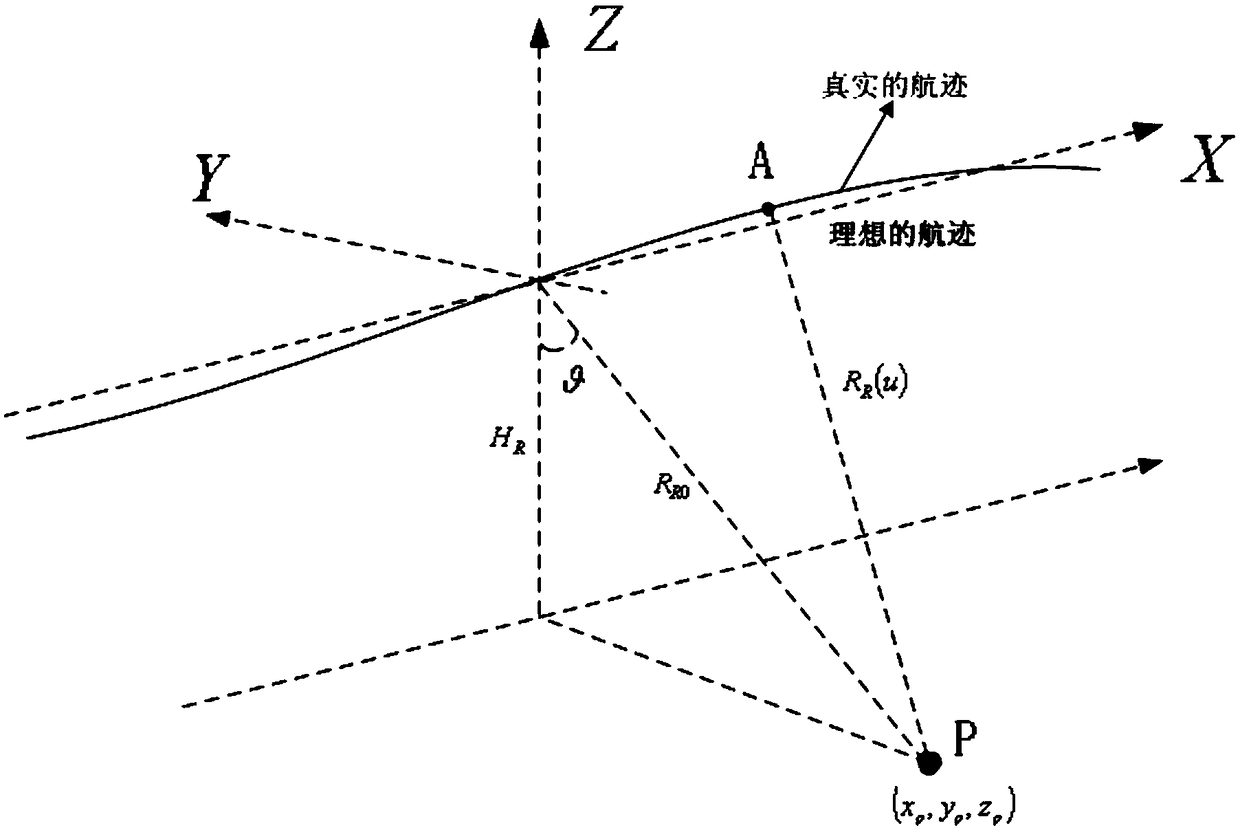

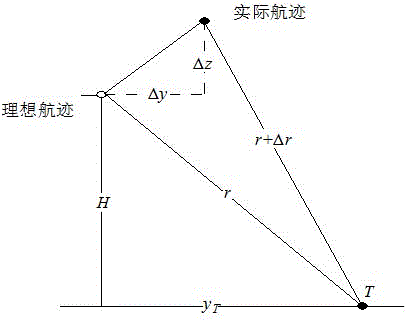

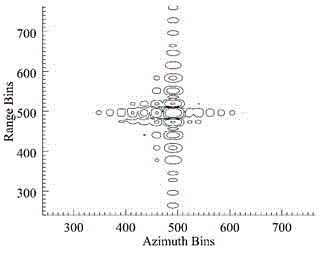

Dual-station SAR receiver kinematic error compensating method based on navigation satellite signals

ActiveCN109507667AEffective estimateEffective compensationRadio wave reradiation/reflectionKinematicsMotion error

The invention provides a dual-station SAR receiver kinematic error compensating method based on navigation satellite signals. The method includes the steps of establishing a Doppler rate and kinematicerror relation model, estimating and compensating for receiver method planar kinematic errors, and estimating and compensating for receiver cruise direction kinematic errors. The method has the advantages that according to the structural characteristics of a dual-station SAR based on the navigation satellite signals, the method based on the instantaneous Doppler rate is put forward to correct thekinematic errors of a receiving platform; the real model of three-dimensional movement errors is sufficiently considered in the method, and the kinematic error estimating and compensating can be effectively conducted; no interpolation or iteration treatment needs to be conducted in the method, the processing efficiency is high, and a good imaging result is obtained.

Owner:曲卫

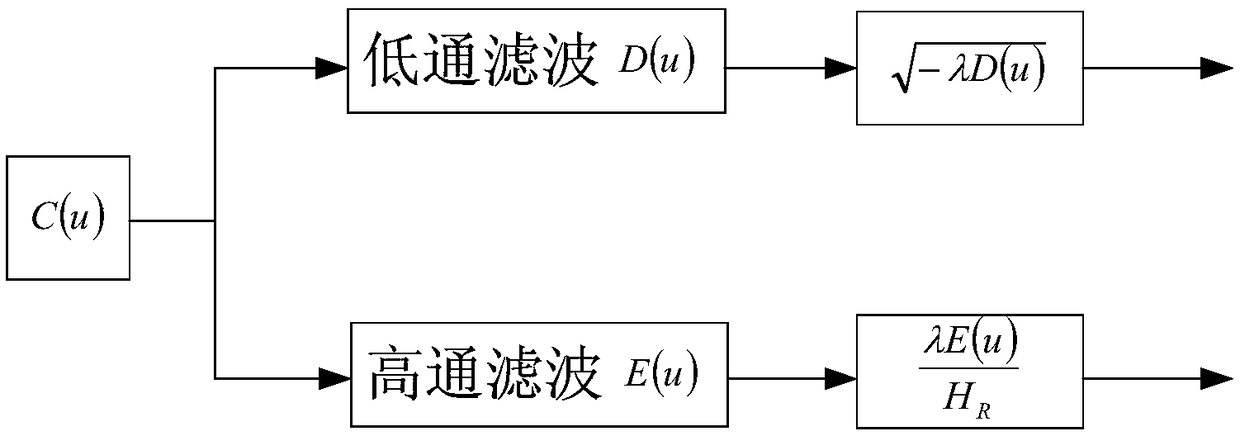

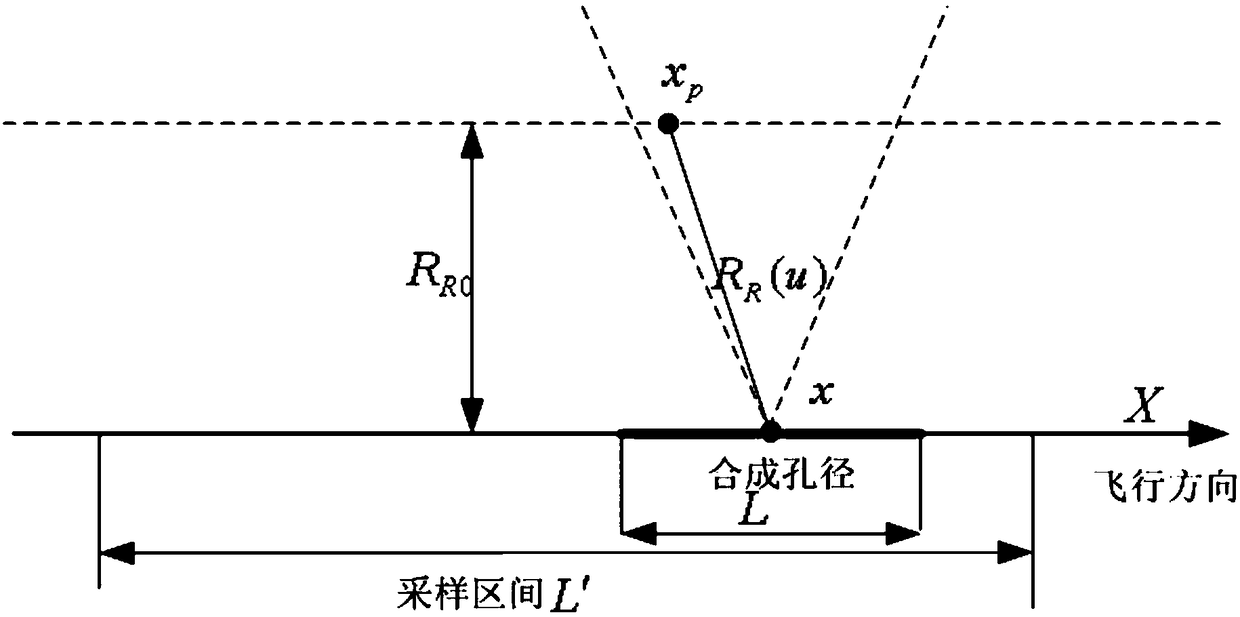

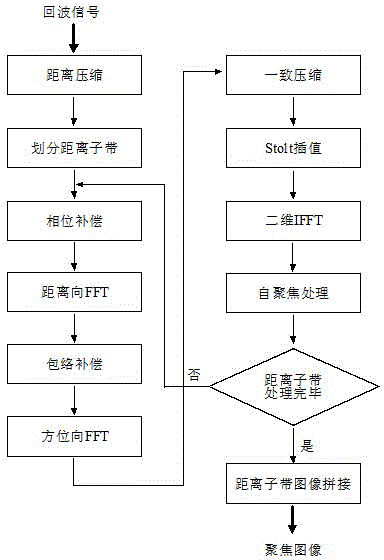

High-resolution wide-swath onboard SAR (synthetic aperture radar) real-time motion compensation algorithm

InactiveCN104808182AImprove real-time processing performanceGuaranteed Phase AccuracyRadio wave reradiation/reflectionImage resolutionSynthetic aperture radar

The invention discloses a high-resolution wide-swath onboard SAR (synthetic aperture radar) real-time motion compensation algorithm which mainly includes an envelop compensation portion and a phase compensation portion. A traditional phase compensation algorithm is improved, and phase compensation can be finished before envelop compensation. Envelop compensation approximate treatment needs to divide distance sub-bands for echo signals after distance compression, so that motion error space varying is reduced. Therefore, interpolation operation of a traditional envelop compensation algorithm is avoided, and envelop compensation is finished by directly multiplying distance frequency domain with linear phase. Finally, distance sub-band images are spliced to obtain an imaging result of a whole swath. By the aid of an improved phase compensation algorithm, signal phase precision is ensured, so that the interpolation operation with large calculating amount can be more effectively avoided by rapid envelop compensation based on the distance sub-bands, and the real-time treatment performance of the algorithm is improved without affecting resolution.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Adjustable cryoablation needle

ActiveCN110251224AAvoid bendingAvoid constantDiagnosticsSurgical instruments for coolingAbnormal tissue growthEngineering

The invention provides an adjustable cryoablation needle, comprising a shank, a front heat-insulating tube, a rear heat-insulating tube and an intake structure penetrating the shank and the front heat-insulating tube; the shank can move along the axis of the rear heat-insulating tube relative to the rear heat-insulating tube so as to adjust a first axial distance between the front end of the rear heat-insulating tube and the front end of the shank; the front heat-insulating tube can move along the axis of the rear heat-insulating tube relative to the rear heat-insulating tube so as to adjust a second axial distance between the front end of the front heat-insulating tube and the front end of the rear heat-insulating tube. The adjustable cryoablation needle helps prevent the inconveniences caused by surgeons selecting cryoablation needle types, can adapt fully to different entering depths, allows the length of the exposed shank to be as small as possible to prevent bending of the shank and prevent the injury risks, such as tear of human tissues. The adjustable cryoablation needle herein can also further meet conveniently the treatment needs of tumors of different sizes at the premise of satisfying different entering depths.

Owner:ACCUTARGET MEDIPHARMA (SHANGHAI) CO LTD

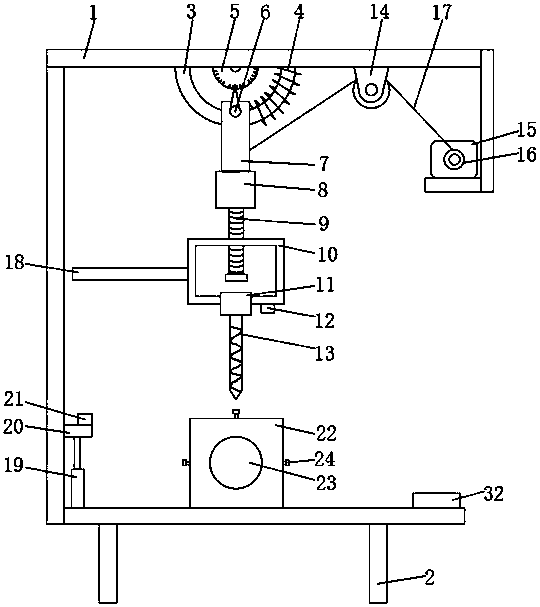

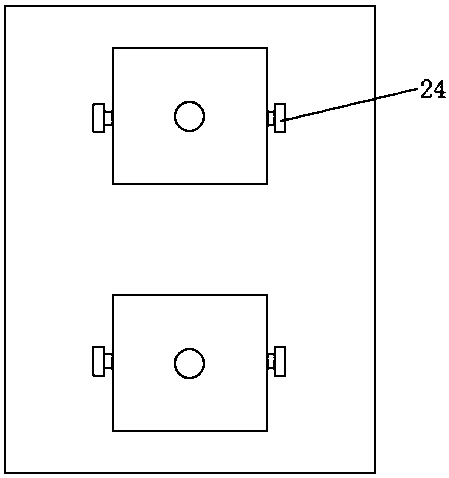

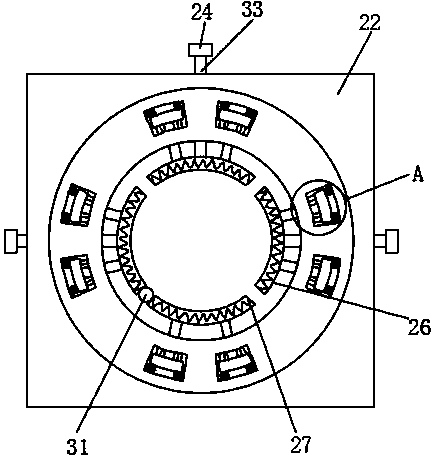

Orthopedics department positioning and punching device

InactiveCN108420502AAids in post-recoveryPrevent tamperingInstruments for stereotaxic surgeryBone drill guidesTemperature controlPunching

The invention discloses an orthopedics department positioning and punching device, comprising a body, wherein the inner top wall of the body is fixedly connected with an arc-shaped slide bar, one sideof the arc-shaped slide bar is provided with a rotation device, the middle of the arc-shaped slide bar is connected with a rotary block, a first spring sleeves the arc-shaped slide bar located between one side wall of the rotary block and the inner top wall of the body, and the inner top wall of the body is further fixedly connected with an angle scale. The orthopedics department positioning andpunching device has the advantage that an infrared sighting device is arranged to sight and punch an affected part, thus realizing accurate punching; the device can incline by a certain angle throughthe rotation device to punch the affected part, thus solving the problem that sometimes two or three holes are needed to meet the treatment need, reducing the workload, and facilitating later restoration of a patient; a fixing device is arranged to avoid involuntary movement of the patient due to pain or nervousness caused by punching, thus reducing punching difficulty; the temperature of a fixedpart is controlled to create a good hospital environment for the patient.

Owner:赵训明

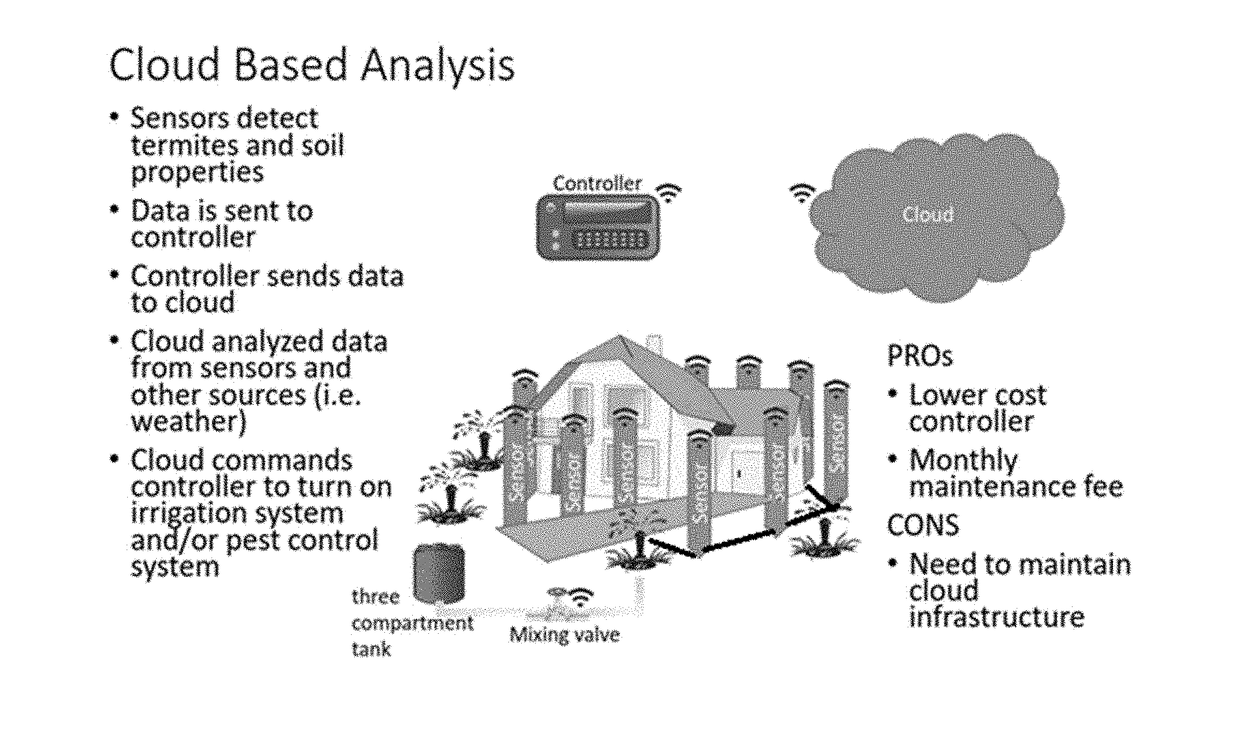

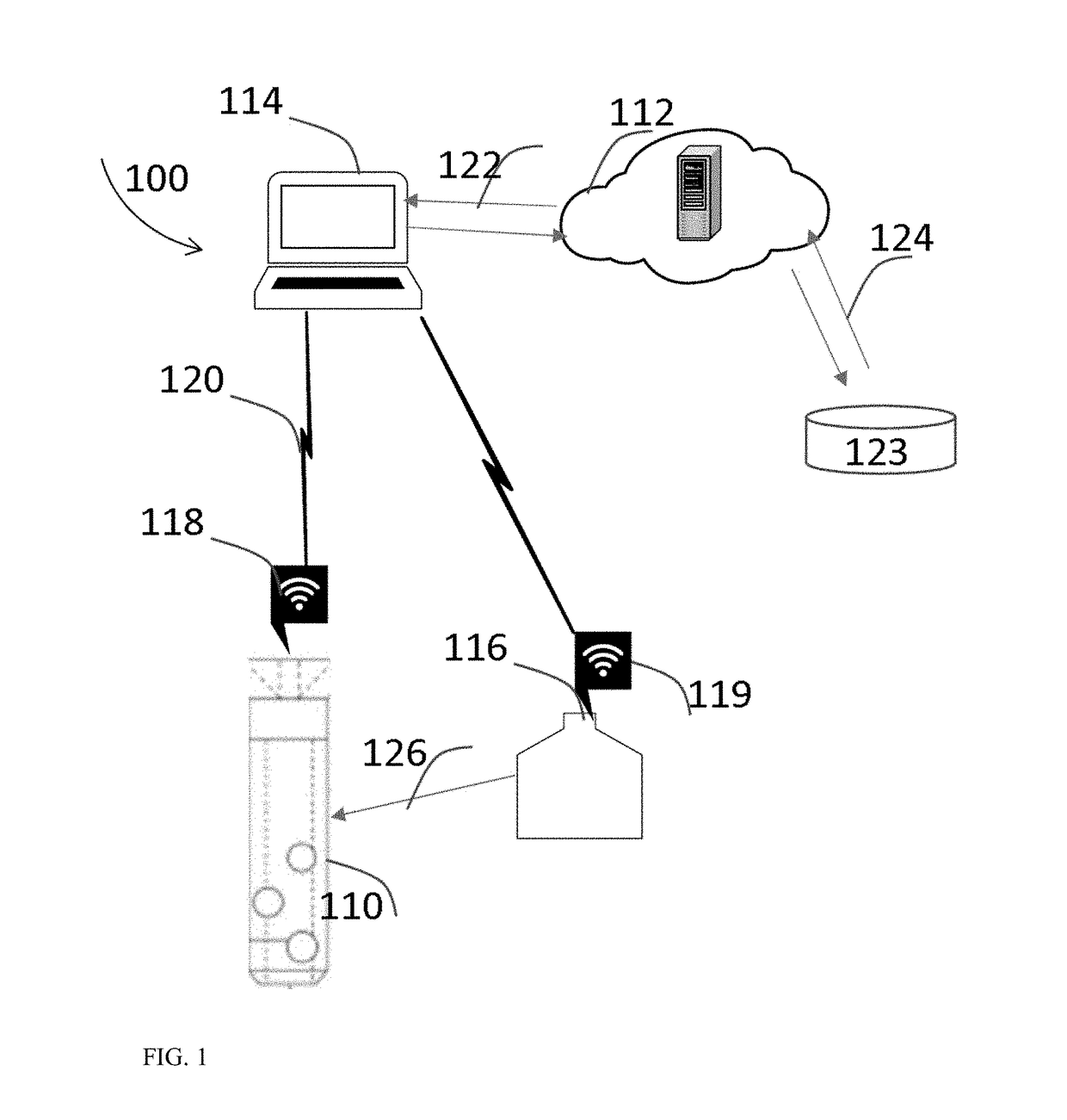

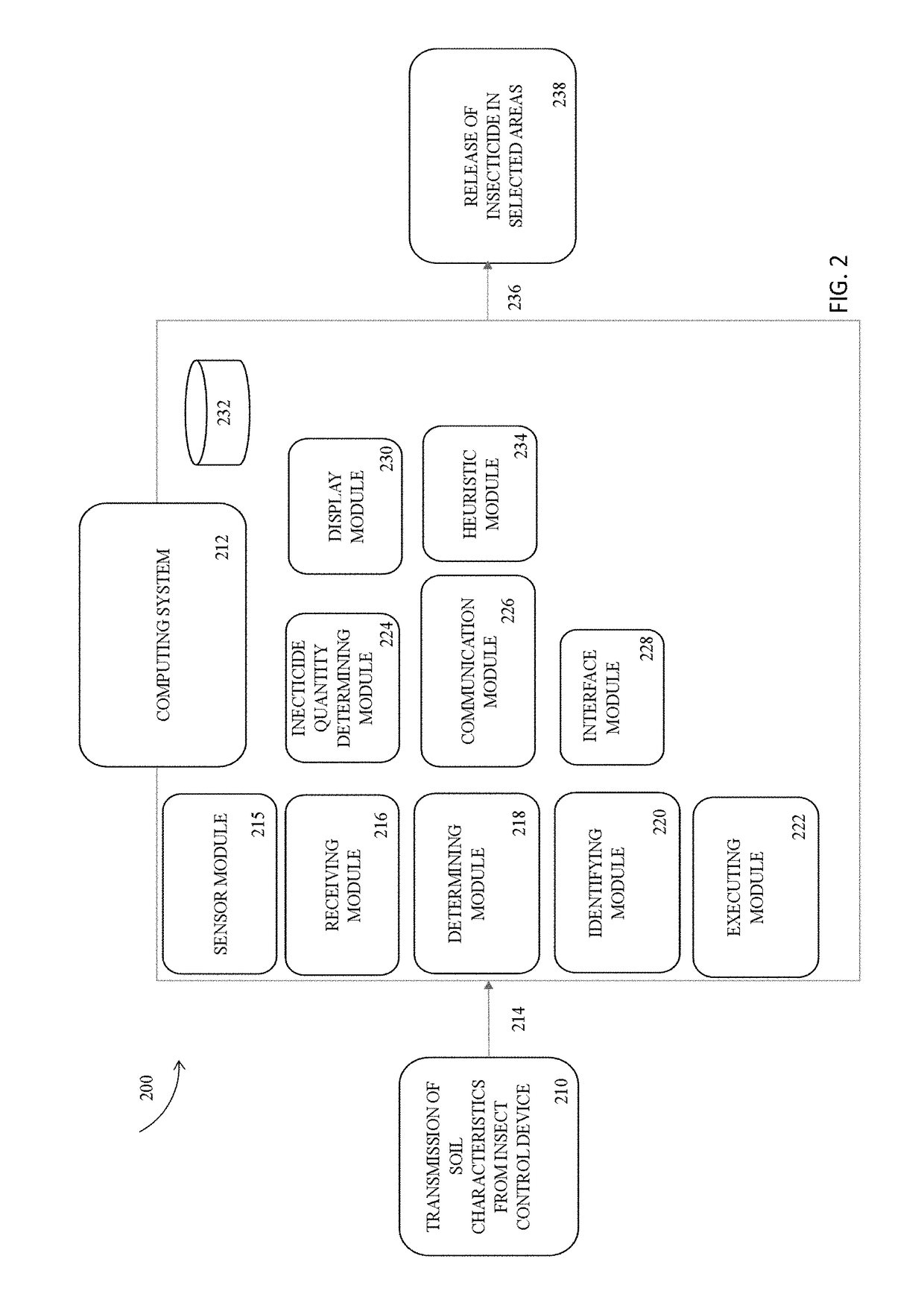

System, apparatus, and method for subterranean termite control

A system, apparatus, and method for use in controlling subterranean insect population and for use in irrigation is provided. Characteristics are monitored in a plurality of under and above soil level regions. The characteristics may include, for example, thermal heat or moisture level characteristics; seismic-type, vibrational, or acoustic characteristics indicative of air pockets or tunnels created by a subterranean insect population; or sound or acoustic levels produced by a subterranean insect population. It is determined whether one or more of the characteristics in one or more of the soil regions are indicative of a subterranean insect population exceeding a threshold or have a need for irrigation. Based on the determining, a treatment need is identified for the one or more soil regions. The treatment need is executed at regions corresponding to the one or more soil regions.

Owner:FRUDAKIS TONY NICK +1

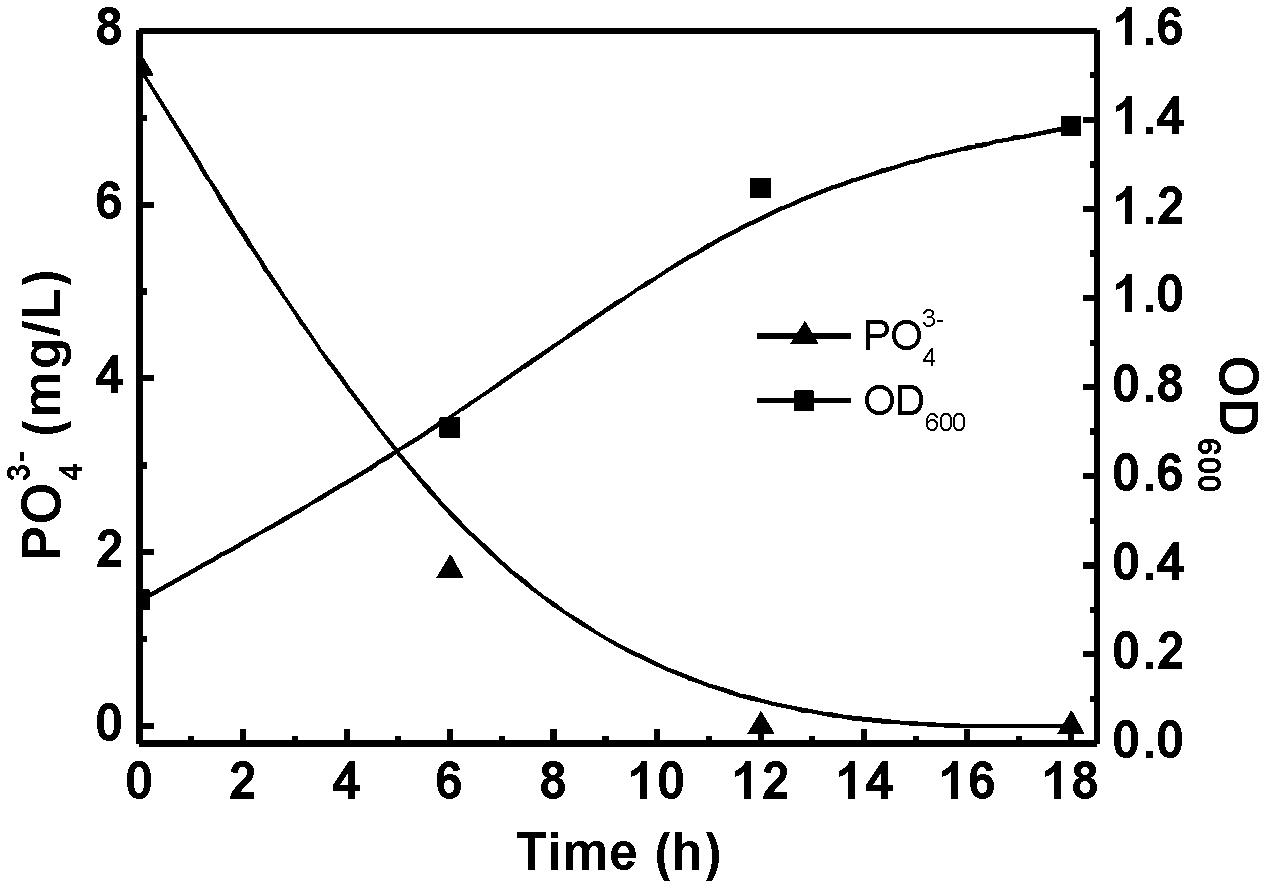

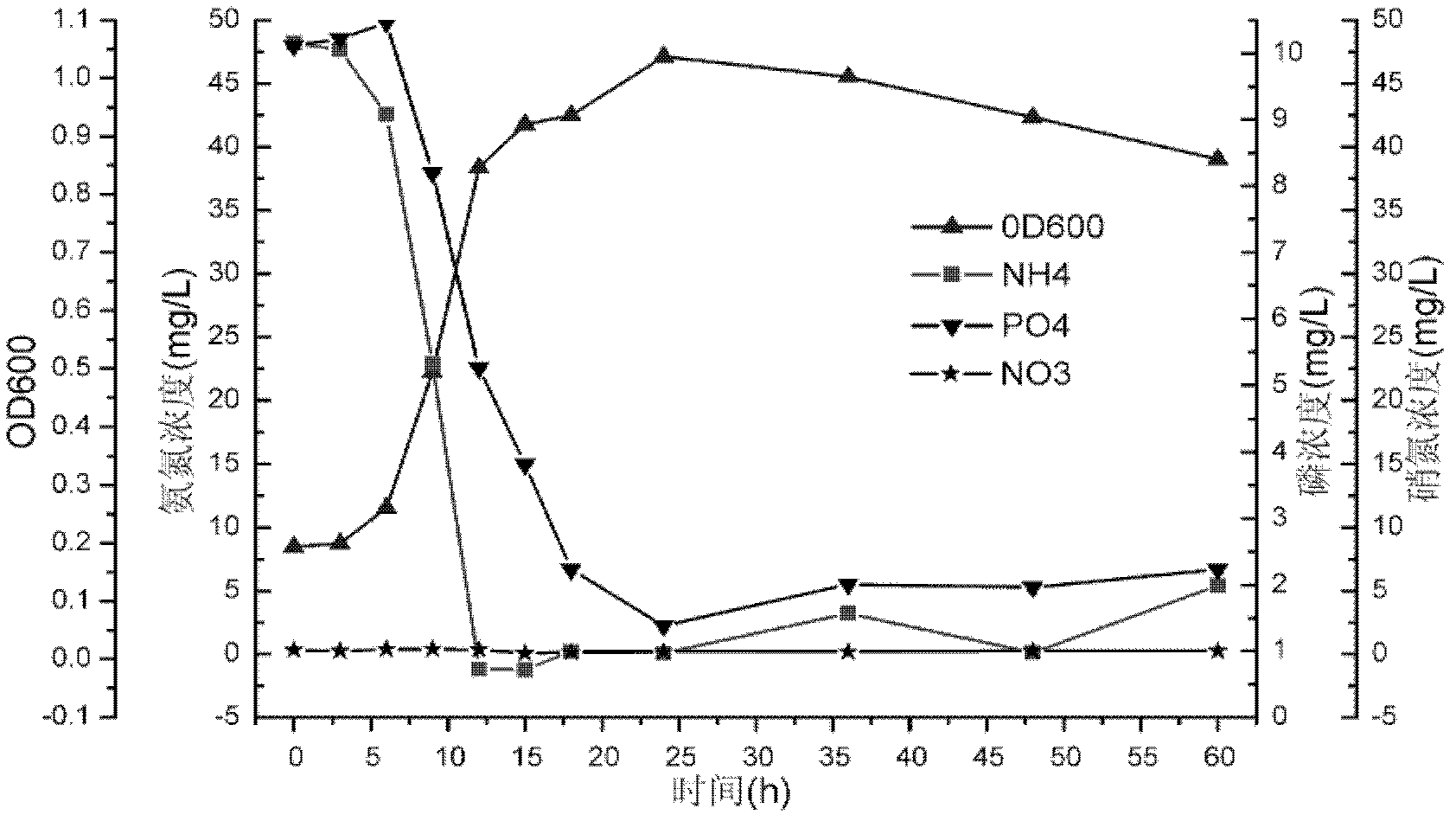

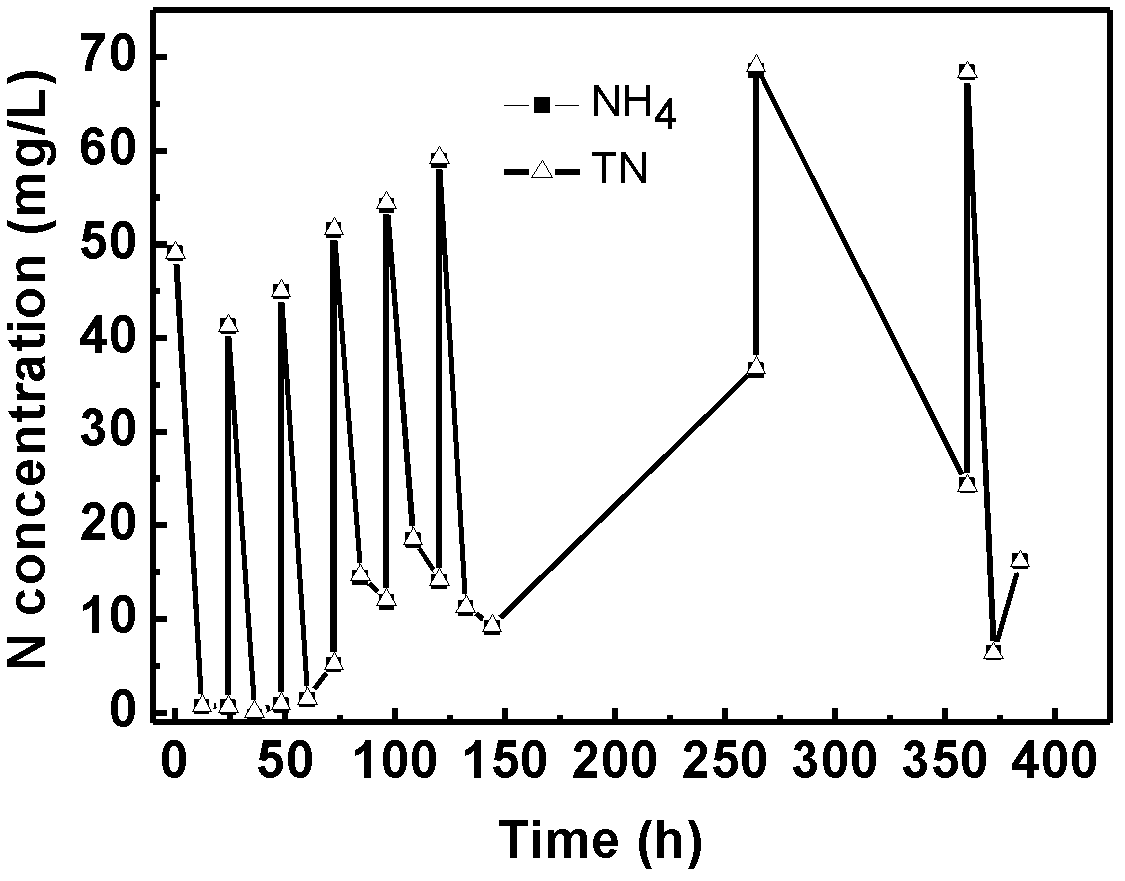

Achromobacter xylosoxidans with denitrification and dephosphorization function and application of Achromobacter xylosoxidans

ActiveCN102533623ARealize synchronous removalSolve bottlenecksBacteriaTreatment using aerobic processesPhosphateInorganic phosphorus

The invention relates to application of Achromobacter xylosoxidans with a heterotrophic nitrification-aerobic denitrification and dephosphorization function in wastewater treatment. The Achromobacter xylosoxidans can metabolize by using organic carbon as a unique carbon source and using ammonia nitrogen as a unique nitrogen source and can directly convert the ammonia nitrogen into gas products through the action of heterotrophic nitrification-aerobic denitrification so as to achieve the aim of denitrification, can also take nitrate nitrogen as a unique nitrogen source and convert the nitrate nitrogen into gas products through the action of aerobic denitrification, and can further ingest inorganic phosphorus and convert the inorganic phosphorus into a tissue of the Achromobacter xylosoxidans under an aerobic condition so as to achieve the aim of removing phosphorus from wastewater. The Achromobacter xylosoxidans are applied to the wastewater treatment, the simultaneous removal of nitrogen and phosphorus can be achieved under the single aerobic condition, and the difficult problem that the biological denitrification and dephosphorization in the traditional wastewater treatment need to adopt the segmented treatments of anaerobic phosphate release, anoxic denitrification and aerobic nitrification and phosphorus absorption, is better solved, so that the Achromobacter xylosoxidans have broad application prospects.

Owner:PEKING UNIV

Building floor cement outer wall construction machine with functions of automatic grinding and cement fiber plate mounting

InactiveCN108149933AGuaranteed smoothnessEnsure safetyBuilding material handlingPlane surface grinding machinesFiberCement

The invention relates to a building floor cement outer wall construction machine with functions of automatic grinding and cement fiber plate mounting. The building floor cement outer wall constructionmachine comprises a moving platform, a grinding and scribing device and a face plate mounting device. The grinding and scribing device is mounted at the front end of the moving platform, and the faceplate mounting device is mounted at the left end of the moving platform. The problems that in the existing cement fiber plate mounting process, grinding and scribing of an outer wall and mounting ofa face plate need to be conducted manually; during grinding and scribing of the outer wall, grinding and scribing treatment needs to be conducted by people with the help of a ladder, when the next position is ground, people needs to carry the ladder manually and then climb onto the ladder again for working, and therefore, the process is tedious and complicated; during mounting of the face plate, cooperation division of multiple people is needed, the difficulty of cooperation of multiple people is high, and when multiple people work on the same ladder, the falling-down accident is likely to occur, and consequently potential safety hazards are caused can be solved, and the functions of automatic grinding of the cement outer wall and fixed mounting of the face plate can be achieved.

Owner:黄正秀

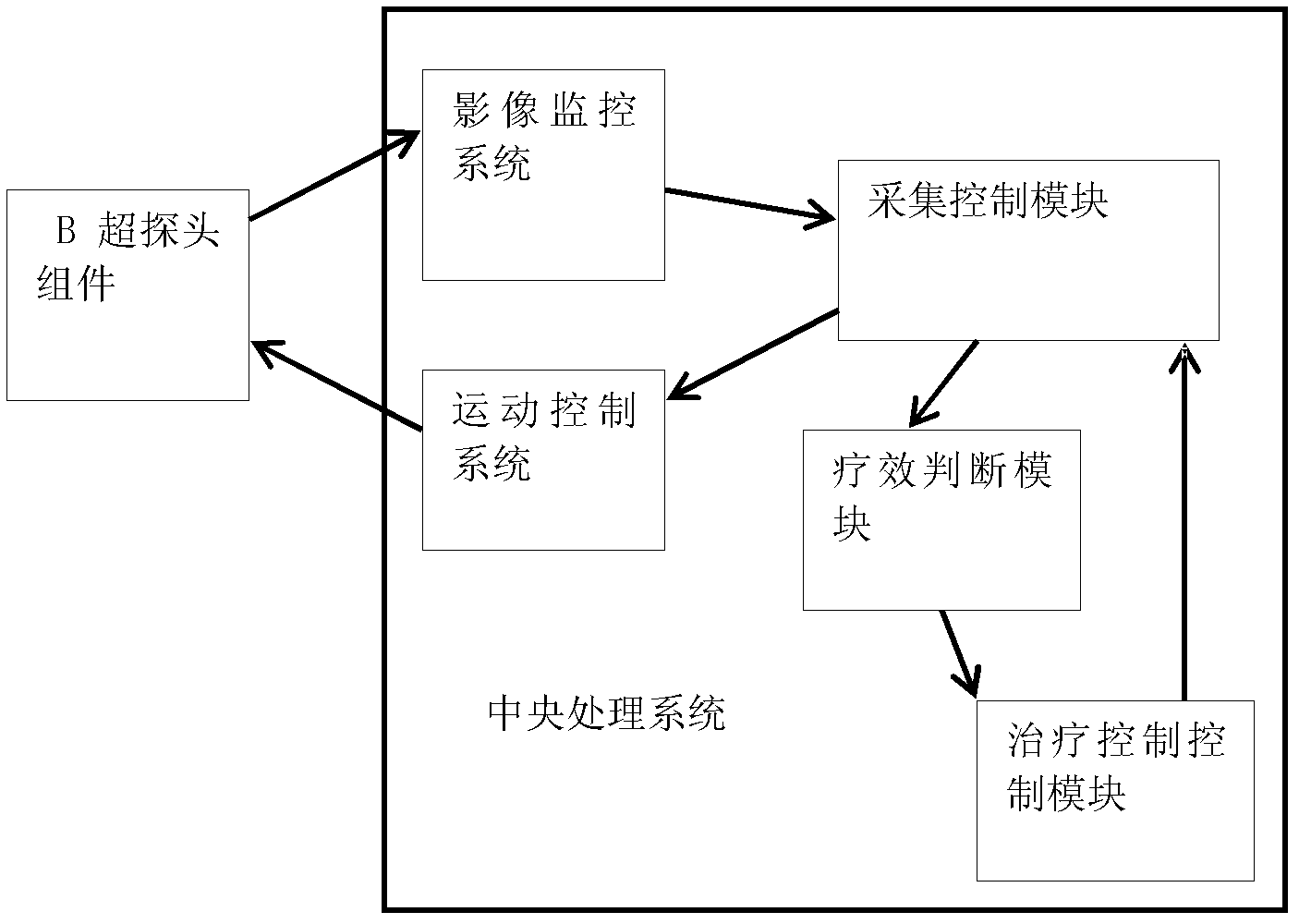

Ultrasound collection and treatment control system and image acquisition method thereof

The invention discloses an ultrasound collection and treatment control system and an image acquisition method thereof. The system comprises a treatment head and a type-B ultrasound probe which can rapidly revolve 360 degrees around the probe axis and is used for acquiring a primary section image and orthogonal section images. A rotation driving component for driving the type-B ultrasound probe to revolve around the probe axis is adopted; a collection control module is adopted to control a type-B ultrasound probe rotating component of an ultrasound treatment device to acquire an image of any angle from 0 degree to 360 degrees (particularly two orthogonal images); the two images are displayed in a three-dimensional manner on a screen, and an HIFU ((High Intensity Focused Ultrasound)) focal points and sound channels are drawn in a three-dimensional window, so as to provide safe auxiliary diagnosis for doctors. A treatment efficacy judgment module is adopted to judge treatment efficacy according to comparison of the orthogonal images of two angles before and after treatment. The judgment results are the basis for automatically controlling the treatment process and judging whether the treatment is effective and whether the treatment can be stopped, or judging whether a danger exists and the treatment needs to be stopped or interrupted.

Owner:CHONGQING HAIFU MEDICAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com