Method for hole-by-hole blasting explosion treatment of abandoned mined-out area

A goaf-by-hole technology, applied in blasting, data processing applications, instruments, etc., can solve problems such as casualties, buried workers, road surface fractures and subsidence, and achieve the effect of preventing secondary disasters caused by earthquakes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

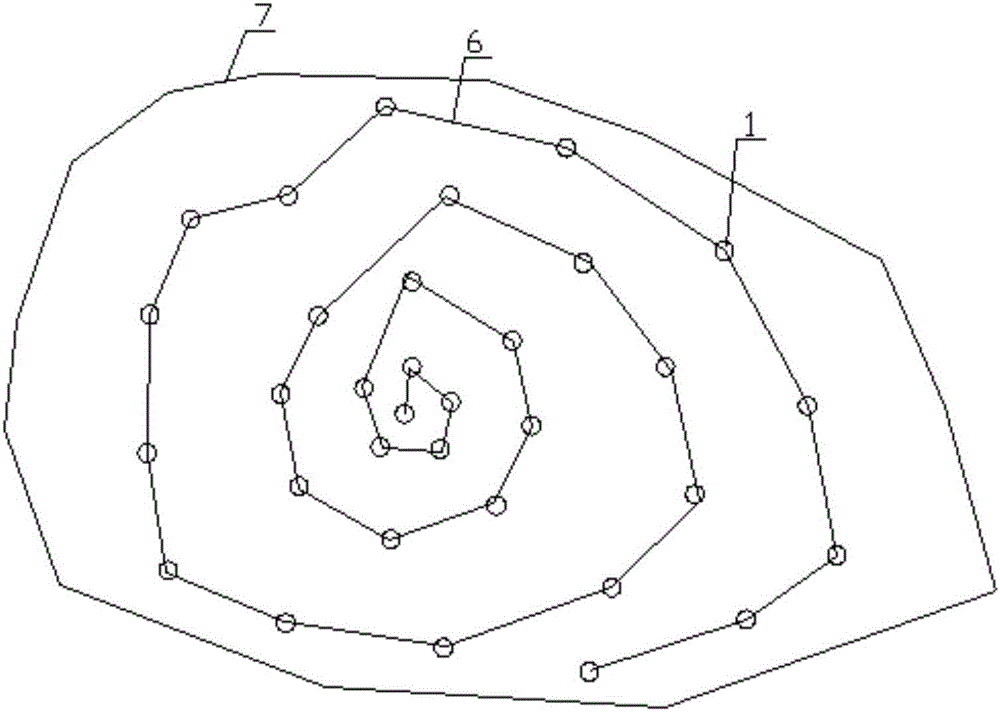

[0040] The present invention will be further described below in conjunction with the accompanying drawings.

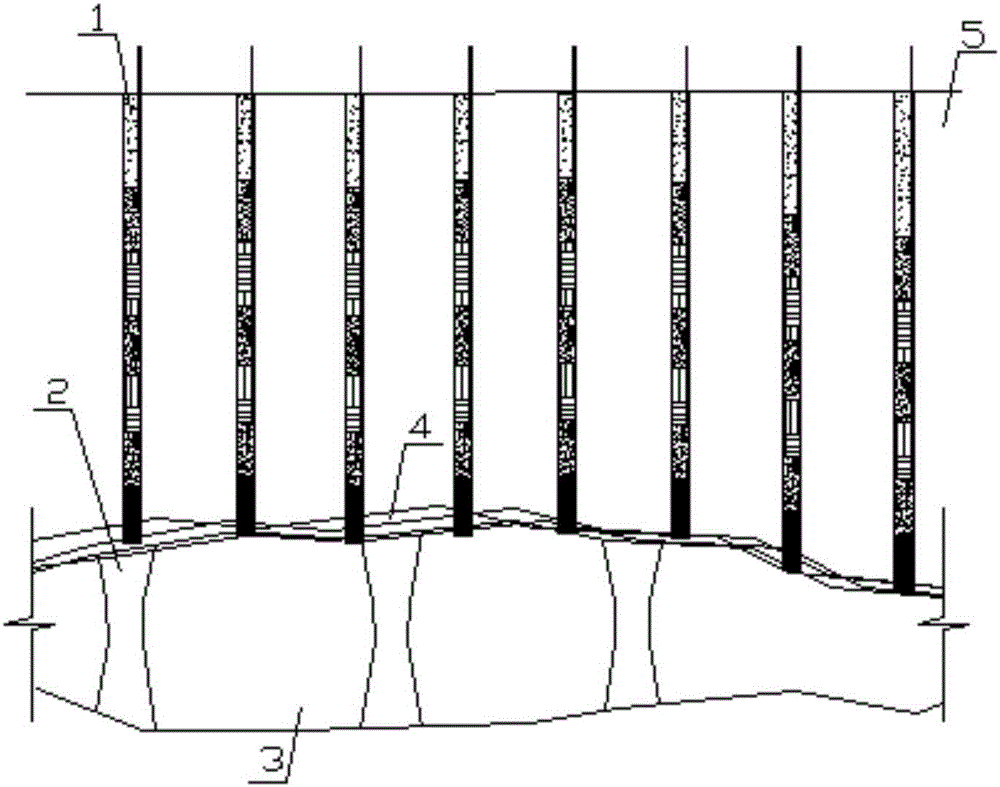

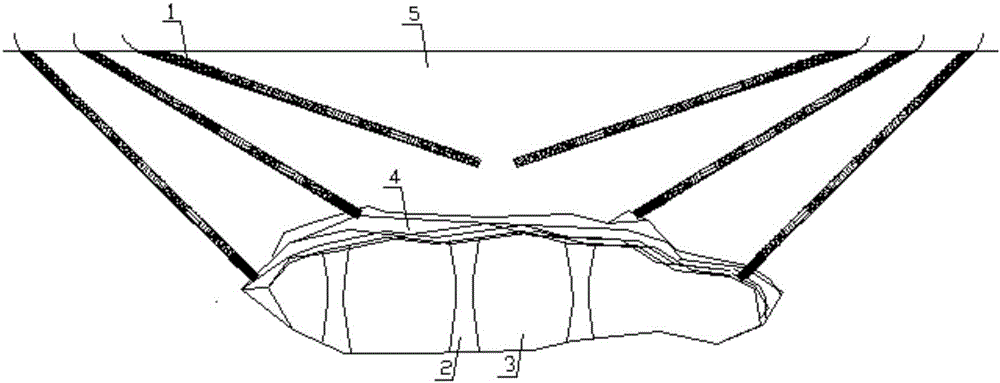

[0041] Disaster Formation of Abandoned Goaf

[0042] As the underground ore is mined, a goaf is formed under the natural surface, and at the same time the original stress balance state of the surrounding rock is changed, the surrounding rock (5) above the goaf (3) will be deformed and damaged to varying degrees. The exposed area of the goaf (3) reaches a certain range, the overlying surrounding rock (5) is affected by mining, the softening of the overlying surrounding rock (5) by groundwater, etc., and the remaining pillars (2 ) and the overlying rock mass (5) will cause the movement and deformation of the overlying rock mass to spread to the surface. The overall collapse of the overlying rock mass in the goaf (3) destroys the surface buildings and causes environmental problems, and the impact caused by a large amount of rocks falling into the abandoned goaf (3) cau...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com