Humanization active forging bone and preparation method thereof

A calcined bone and humanized technology, applied in medical science, prosthesis, etc., can solve the problems of difficult immunogenicity, difficult combination, and limited application, achieving non-carcinogenic and teratogenic effects, convenient clinical operation, The effect of moderate degradation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

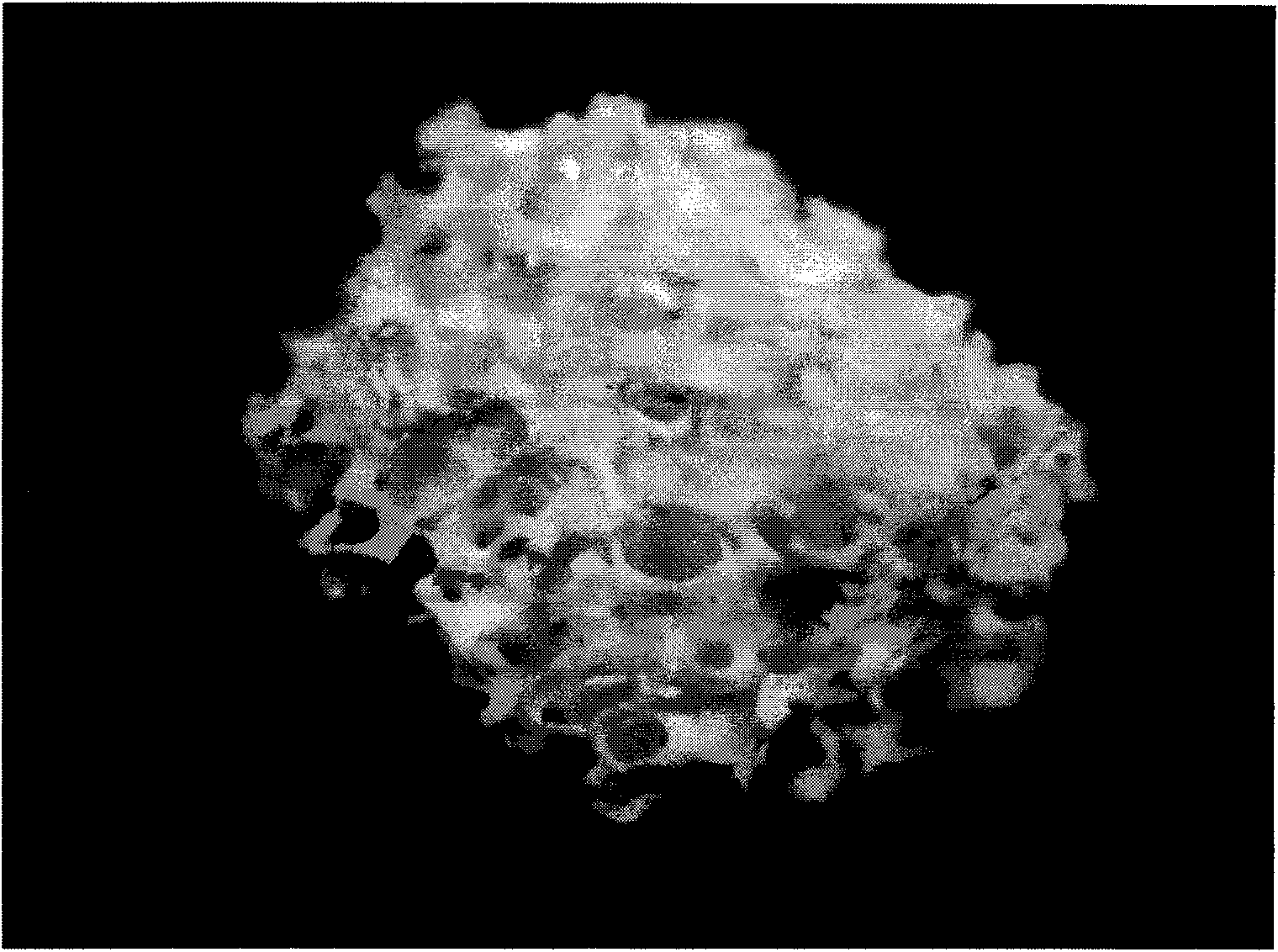

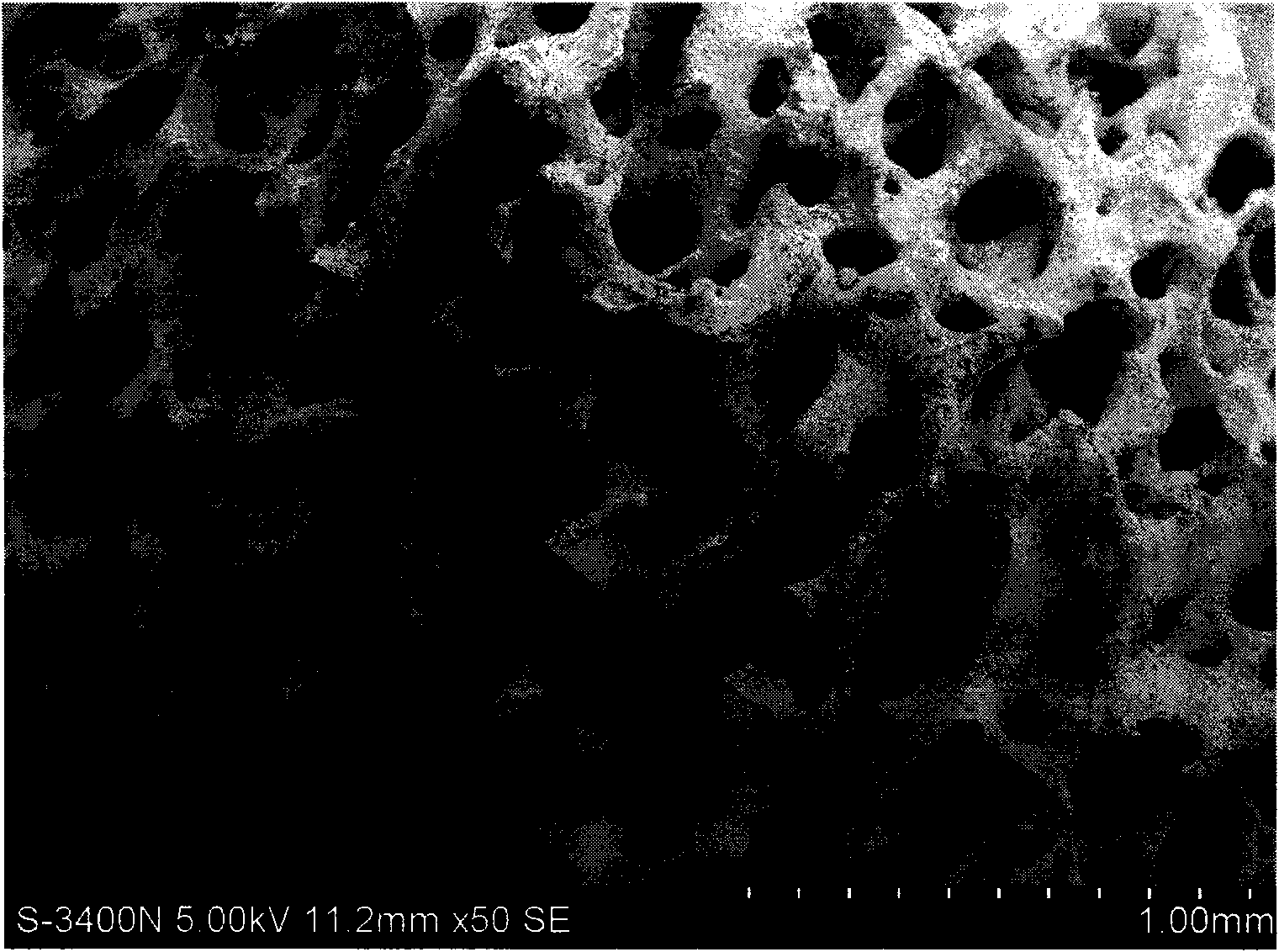

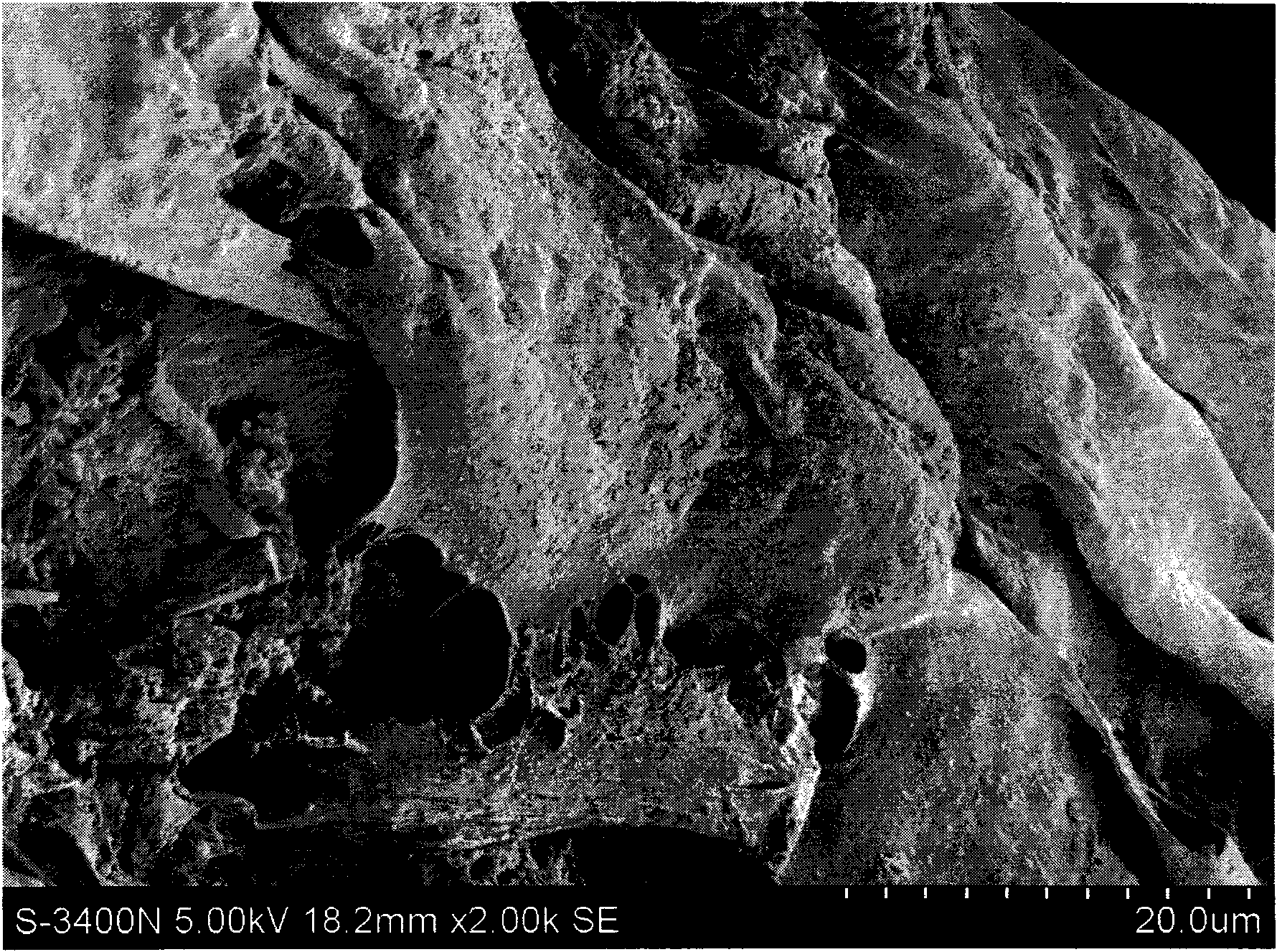

Image

Examples

Embodiment 1

[0022] 1. Removal of organic matter: take bovine femoral epiphyseal cancellous bone, remove the soft tissue on the surface, machine it into broken bone pieces with a particle size of 5mm, stir and wash them with pure water for 30 minutes; put the broken bone pieces at a concentration of 0.5g / L trypsin solution was digested at room temperature for 24 hours, stirred and washed with pure water, then ultrasonically cleaned in 1M NaOH solution for 2 hours, the solution was changed every half hour, stirred and cleaned with pure water until neutral; 2 o 2 The solution was treated at room temperature for 40 minutes, stirred and washed with pure water, and dried in a 37°C oven until dry.

[0023] 2. Calcination: Put the dried bone fragments into a corundum crucible and calcinate in a muffle furnace; raise the temperature to 800°C, continue calcination at a constant temperature for 4 hours, lower the temperature in the furnace to room temperature, and take out the calcined bone;

[0024...

Embodiment 2

[0030] 1. Remove organic matter: Take the cancellous bone of the bovine vertebrae to remove the soft tissue on the surface, machine it into broken bone pieces with a particle size of 10mm, stir and wash them with pure water for 90 minutes; put the broken bone pieces into 1.5g / L trypsin solution at room temperature Digested for 48 hours, thoroughly stirred and cleaned with pure water, then ultrasonically cleaned in 1M NaOH solution for 3 hours, the solution was replaced every 1 hour, fully stirred and cleaned with pure water until neutral; 2 o 2 The solution was treated for 50 minutes, thoroughly stirred and washed with pure water, and dried in a 37°C oven until dry.

[0031] 2. Calcination: put the dried bone fragments into a corundum crucible, and calcinate in a muffle furnace; raise the temperature to 600°C, continue to calcine at a constant temperature for 3 hours, lower the temperature in the furnace to room temperature, and then raise the temperature to 1000°C, and keep t...

Embodiment 3

[0038] 1. Removal of organic matter: Take porcine femoral epiphyseal cancellous bone to remove the soft tissue on the surface, process it into broken bone pieces with a particle size of 20mm, stir and wash with pure water for 60 minutes; add 2g / L trypsin solution to digest the broken bone pieces at room temperature for 72 hours , after stirring and cleaning with pure water, put it in 1M NaOH solution and ultrasonically clean it for 4 hours, replace the solution every 1 hour, and ultrasonically clean it with pure water until it is neutral; 2 o 2 The solution was treated for 60 minutes, stirred and washed with pure water, and dried in a 37°C oven until dry.

[0039] 2. Calcination: put the dried bone fragments into a corundum crucible, and calcinate in a muffle furnace; heat up to 700°C, and calcine at a constant temperature for 4 hours, then lower the temperature in the furnace to room temperature, and then heat up to 1100°C, and calcine at a constant temperature After 3 hours...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com