3D printing scaffold material for icariin (ICA)-loaded PLGA microspheres and application of 3D printing scaffold material

A technology of icariin and 3D printing, which can be used in additive processing, medical science, tissue regeneration, etc., can solve the problems that limit the wide development and application of stem cell transplantation, the difficulty of separation and purification, and the lack of cell sources, so as to promote adhesion The effect of growth, simple operation, and no side effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

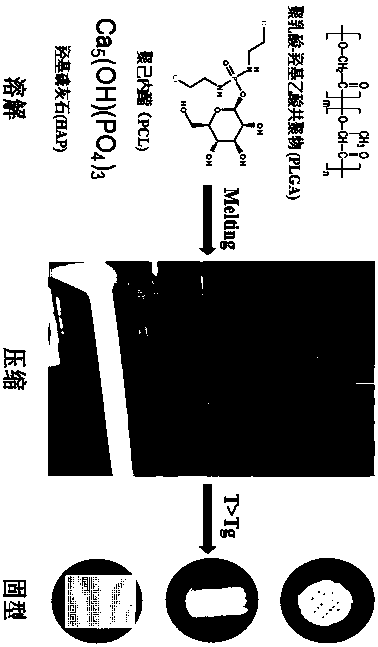

Method used

Image

Examples

Embodiment 1

[0042] (1) Prepare 250ml of polyvinyl alcohol (PVA) solution with a concentration of 0.3% and 10ml with a concentration of 4%;

[0043] The preparation method is as follows: Weigh the powder in a certain volume of deionized water, let it stand for 2 hours, heat it at 45°C for 2 hours, heat it at 60°C for 2 hours, and heat it at 90°C for 4 hours to completely dissolve it.

[0044] (2) Dissolve 0.5g PLGA in 5ml dichloromethane;

[0045] (3) Add 250ul to (2) with a concentration of 10 -5 mol / L ICA solution, ultrasonic treatment emulsion;

[0046] (4) Add 10ml of 4% PVF to (3) to form a second emulsion, vortex and sonicate to obtain a homogeneous emulsion;

[0047] (5) Add the prepared homogeneous emulsion into 250ml of 0.3% PVF solution, stir to evaporate the solvent, centrifuge, wash, and freeze-dry;

[0048] (6) Put the PLGA microspheres loaded with icariin at a mass fraction of 5%, polycaprolactone at a mass fraction of 85%, and nano-hydroxyapatite at a mass fraction of 10%...

Embodiment 2

[0050] (1) Prepare 250ml of polyvinyl alcohol (PVA) solution with a concentration of 0.3% and 10ml with a concentration of 4%;

[0051] The preparation method is as follows: Weigh the powder in a certain volume of deionized water, let it stand for 2 hours, heat it at 45°C for 2 hours, heat it at 60°C for 2 hours, and heat it at 90°C for 4 hours to completely dissolve it.

[0052] (2) Dissolve 0.5g PLGA in 5ml dichloromethane;

[0053] (3) Add 250ul to (2) with a concentration of 10 -5 mol / L ICA solution, ultrasonic treatment emulsion;

[0054] (4) Add 10ml of 4% PVF to (3) to form a second emulsion, vortex and sonicate to obtain a homogeneous emulsion;

[0055] (5) Add the prepared homogeneous emulsion into 250ml of 0.3% PVF solution, stir to evaporate the solvent, centrifuge, wash, and freeze-dry;

[0056] (6) Put the PLGA microspheres loaded with icariin with a mass fraction of 8%, polycaprolactone with a mass fraction of 82%, and nano-hydroxyapatite with a mass fraction ...

Embodiment 3

[0058] (1) Prepare 250ml of polyvinyl alcohol (PVA) solution with a concentration of 0.3% and 10ml with a concentration of 4%;

[0059] The preparation method is as follows: Weigh the powder in a certain volume of deionized water, let it stand for 2 hours, heat it at 45°C for 2 hours, heat it at 60°C for 2 hours, and heat it at 90°C for 4 hours to completely dissolve it.

[0060] (2) Dissolve 0.5g PLGA in 5ml dichloromethane;

[0061] (3) Add 250ul to (2) with a concentration of 10 -5 mol / L ICA solution, ultrasonic treatment emulsion;

[0062] (4) Add 10ml of 4% PVF to (3) to form a second emulsion, vortex and sonicate to obtain a homogeneous emulsion;

[0063] (5) Add the prepared homogeneous emulsion into 250ml of 0.3% PVF solution, stir to evaporate the solvent, centrifuge, wash, and freeze-dry;

[0064] (6) Put the PLGA microspheres loaded with icariin at a mass fraction of 10%, polycaprolactone at a mass fraction of 80%, and nano-hydroxyapatite at a mass fraction of 10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com