Patents

Literature

169results about How to "Improve microporous structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Self-sealing PTFE vascular graft and manufacturing methods

InactiveUS20040193242A1Superior assimilation capabilities and resealable propertiesImprove microporous structureBlood vesselsPorosityMedicine

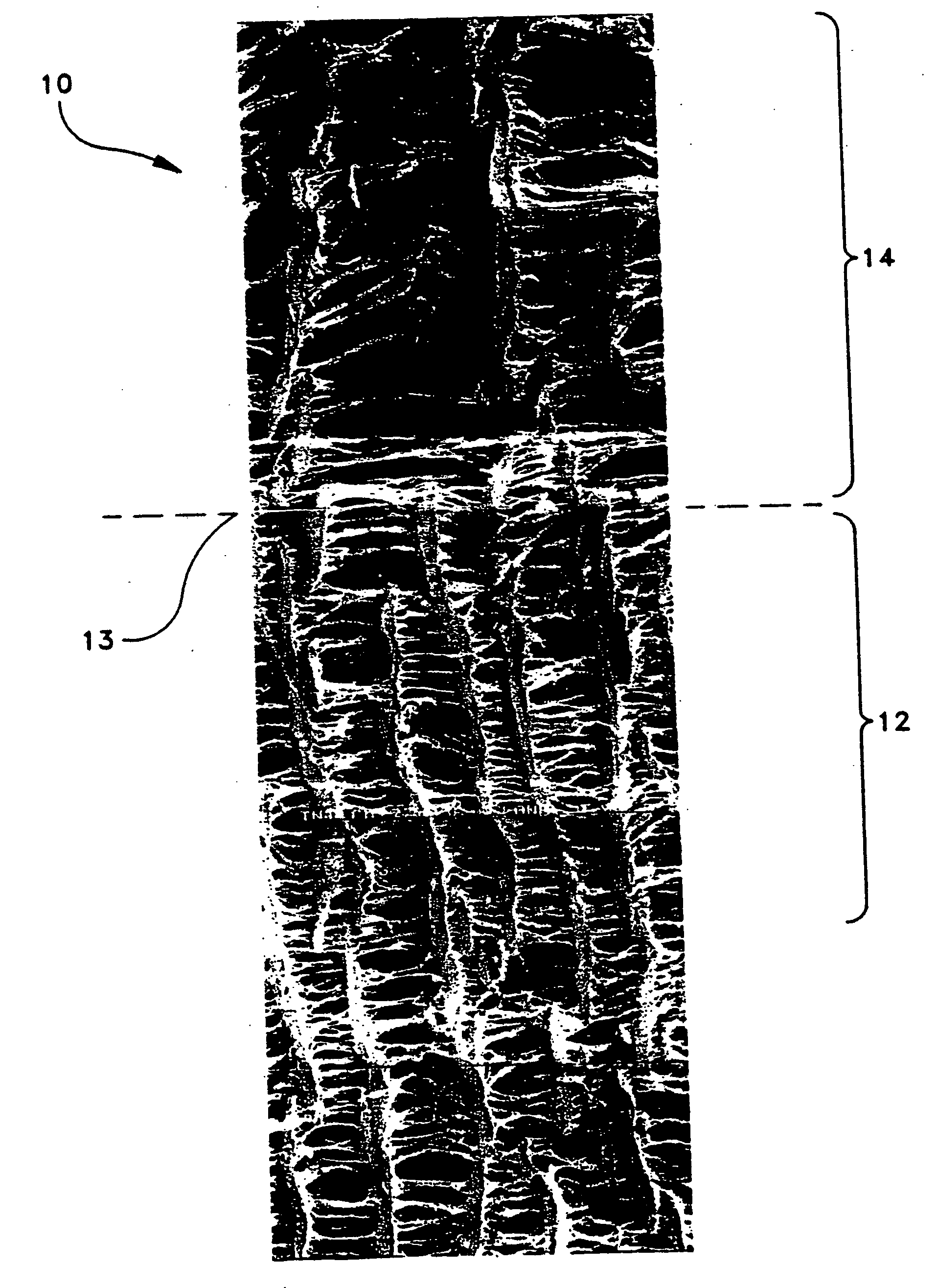

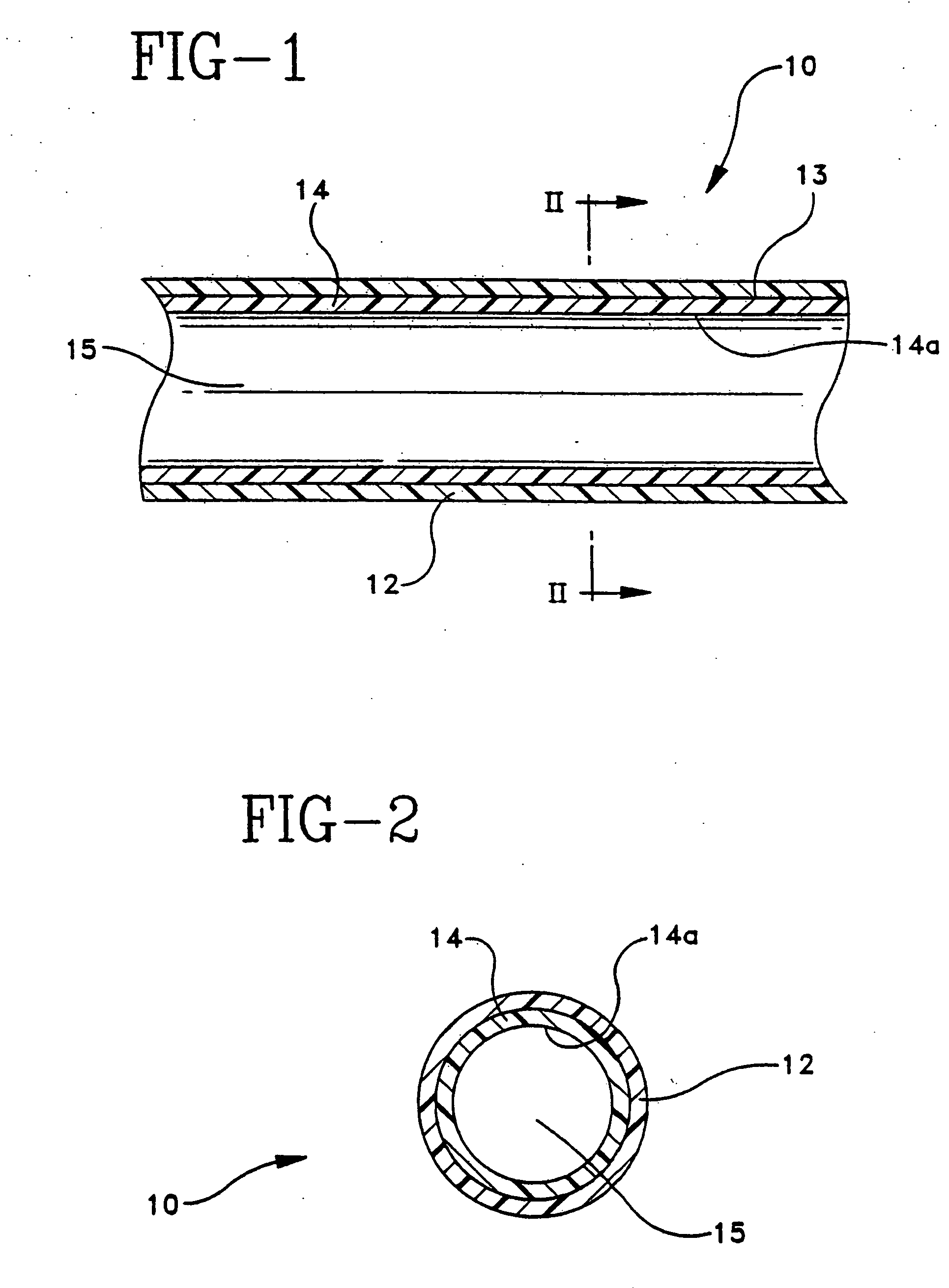

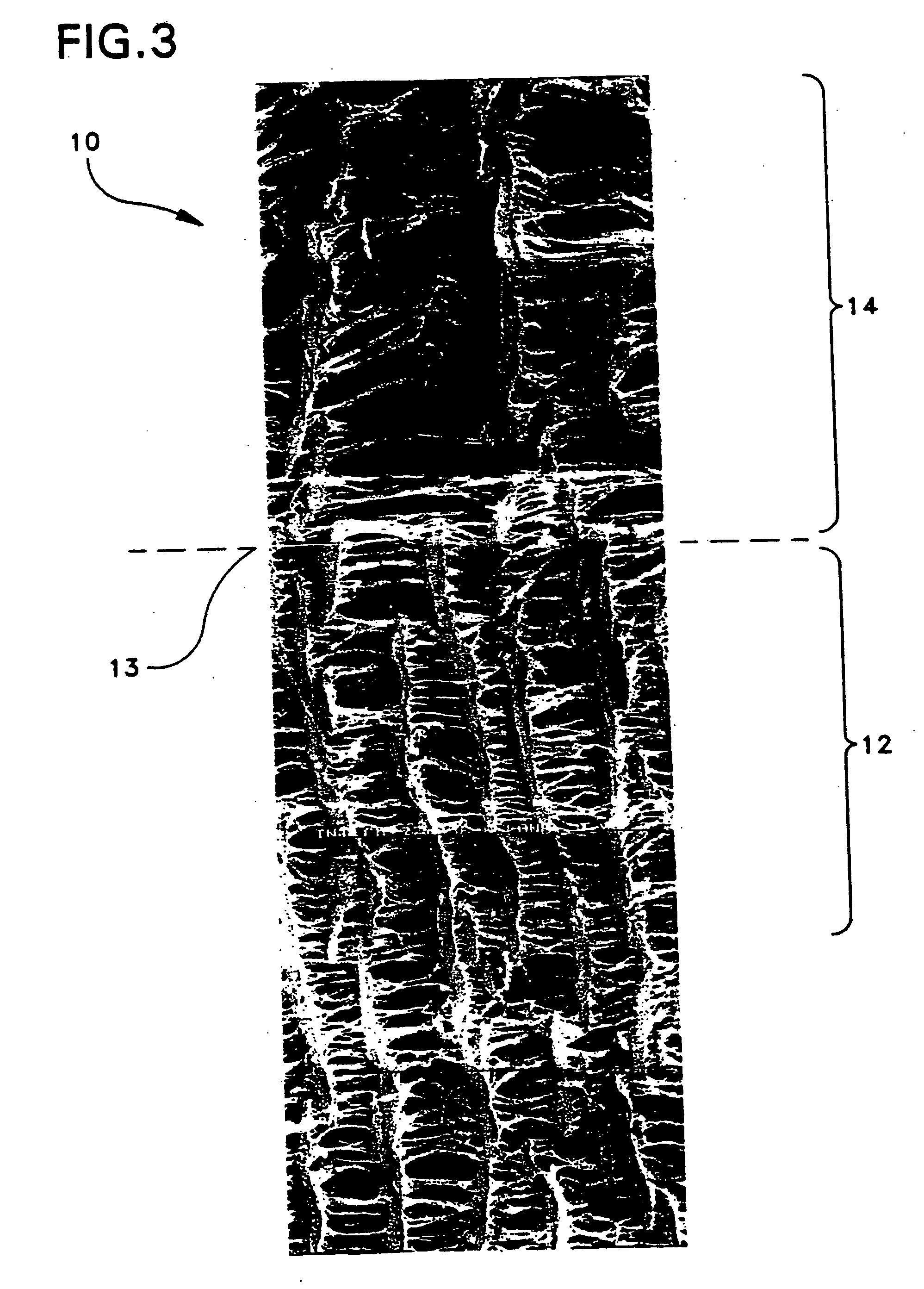

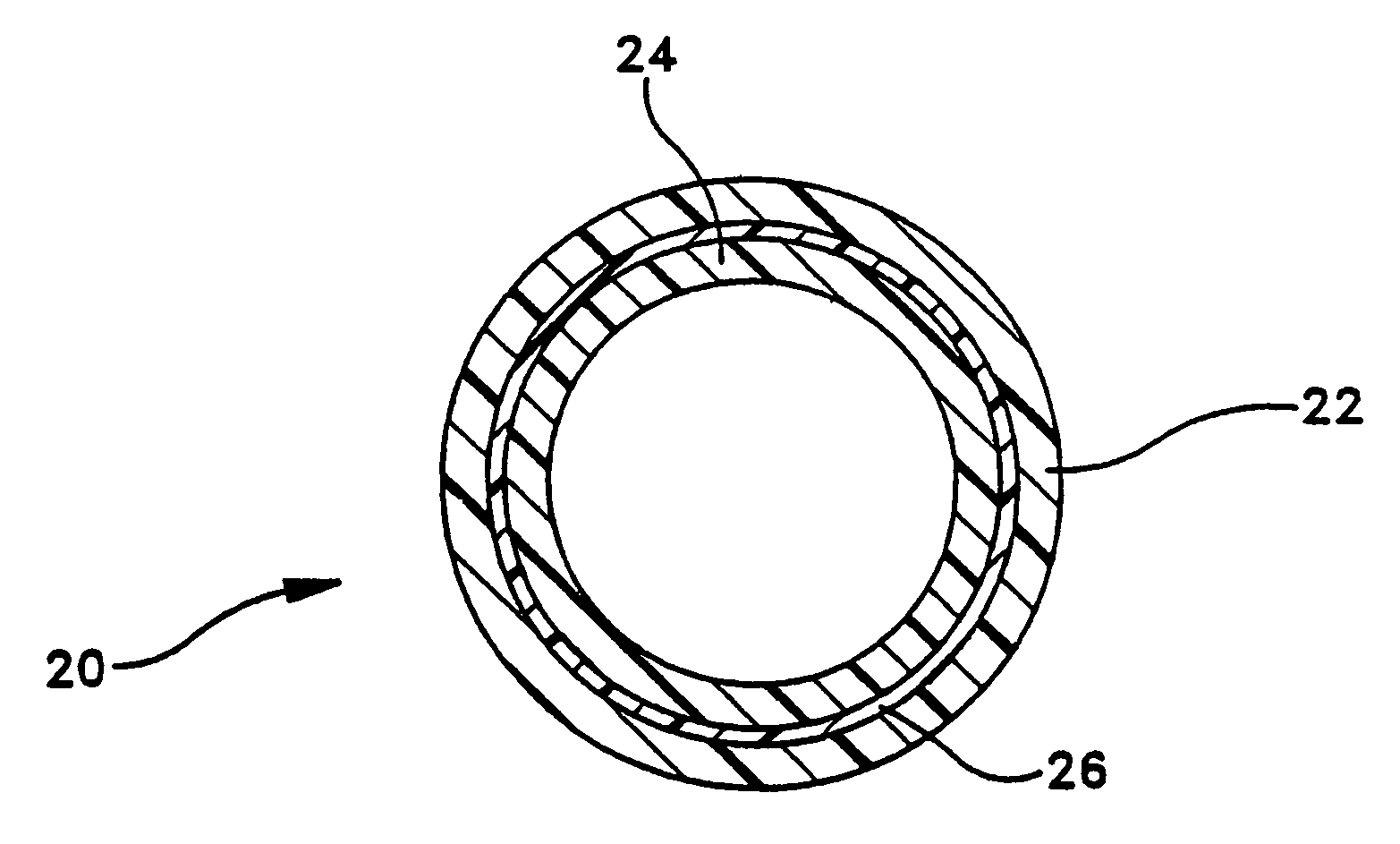

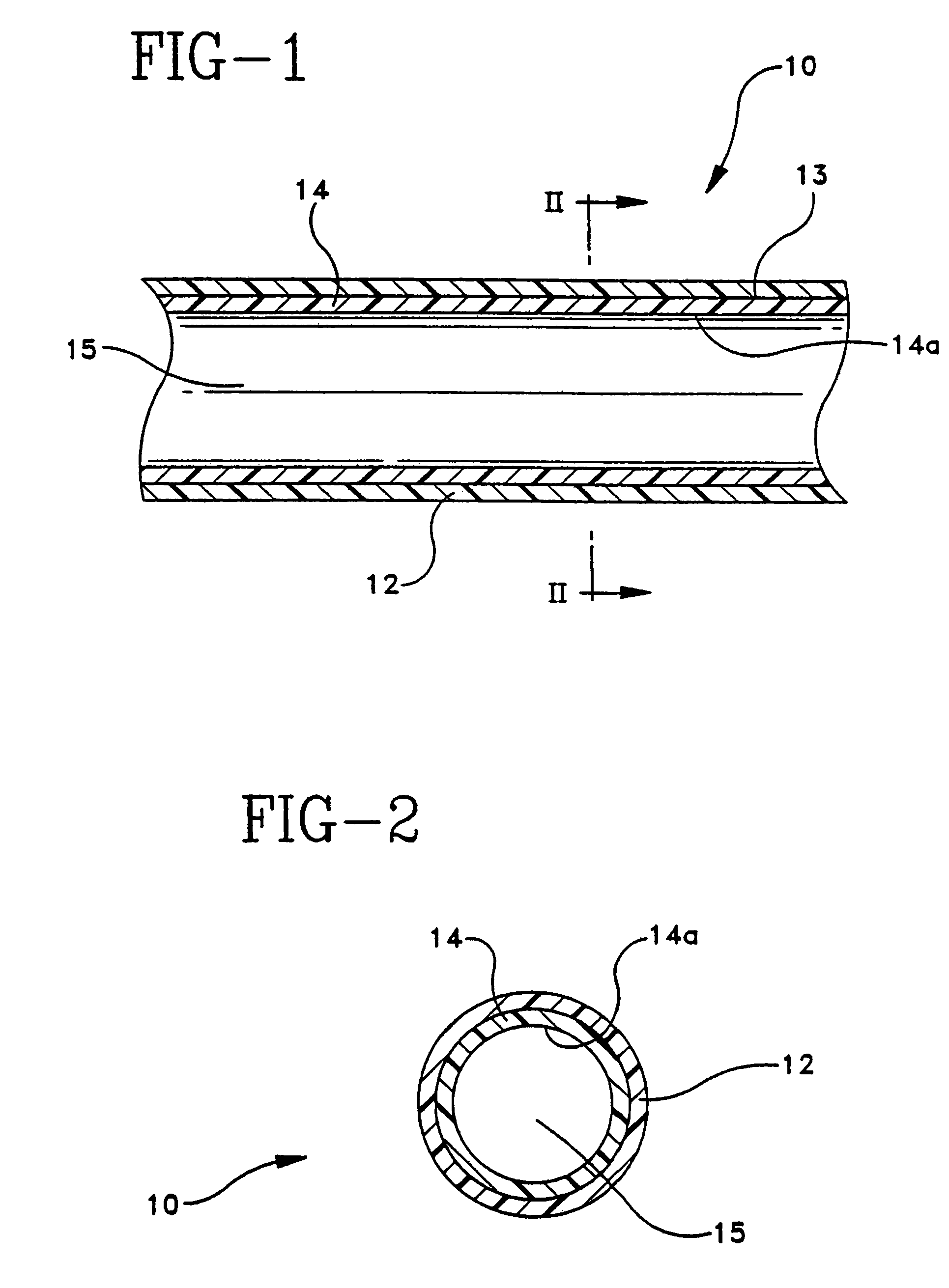

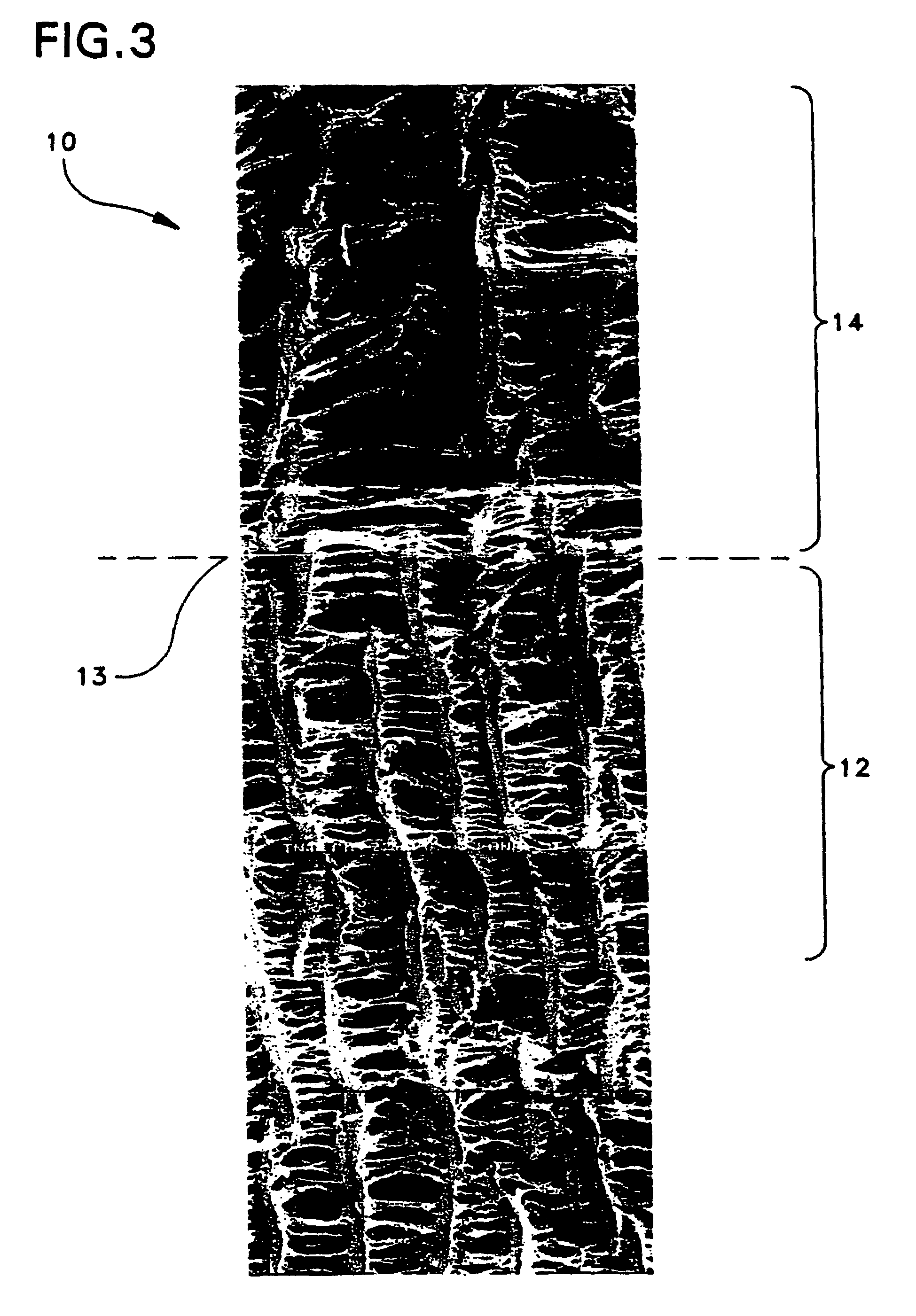

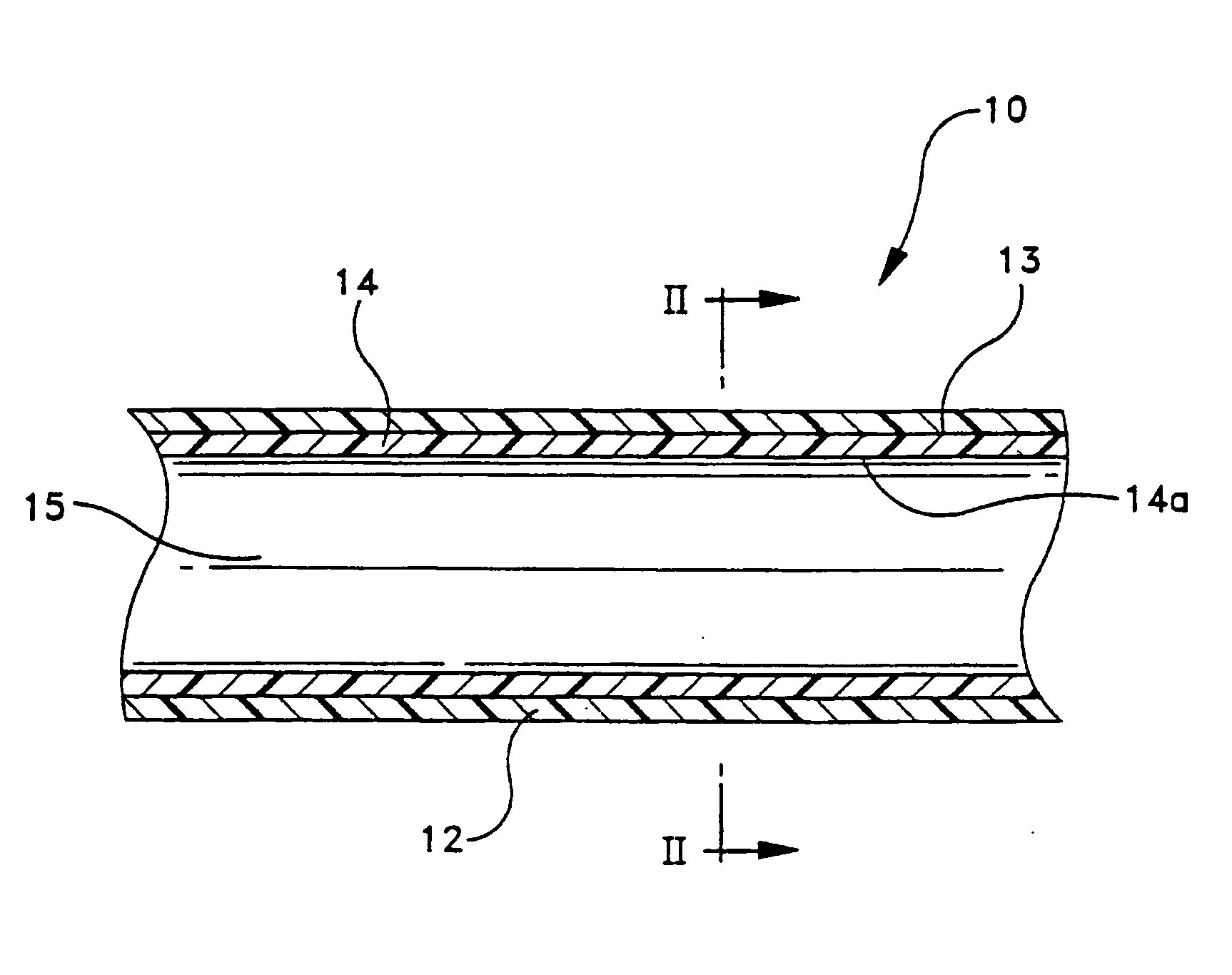

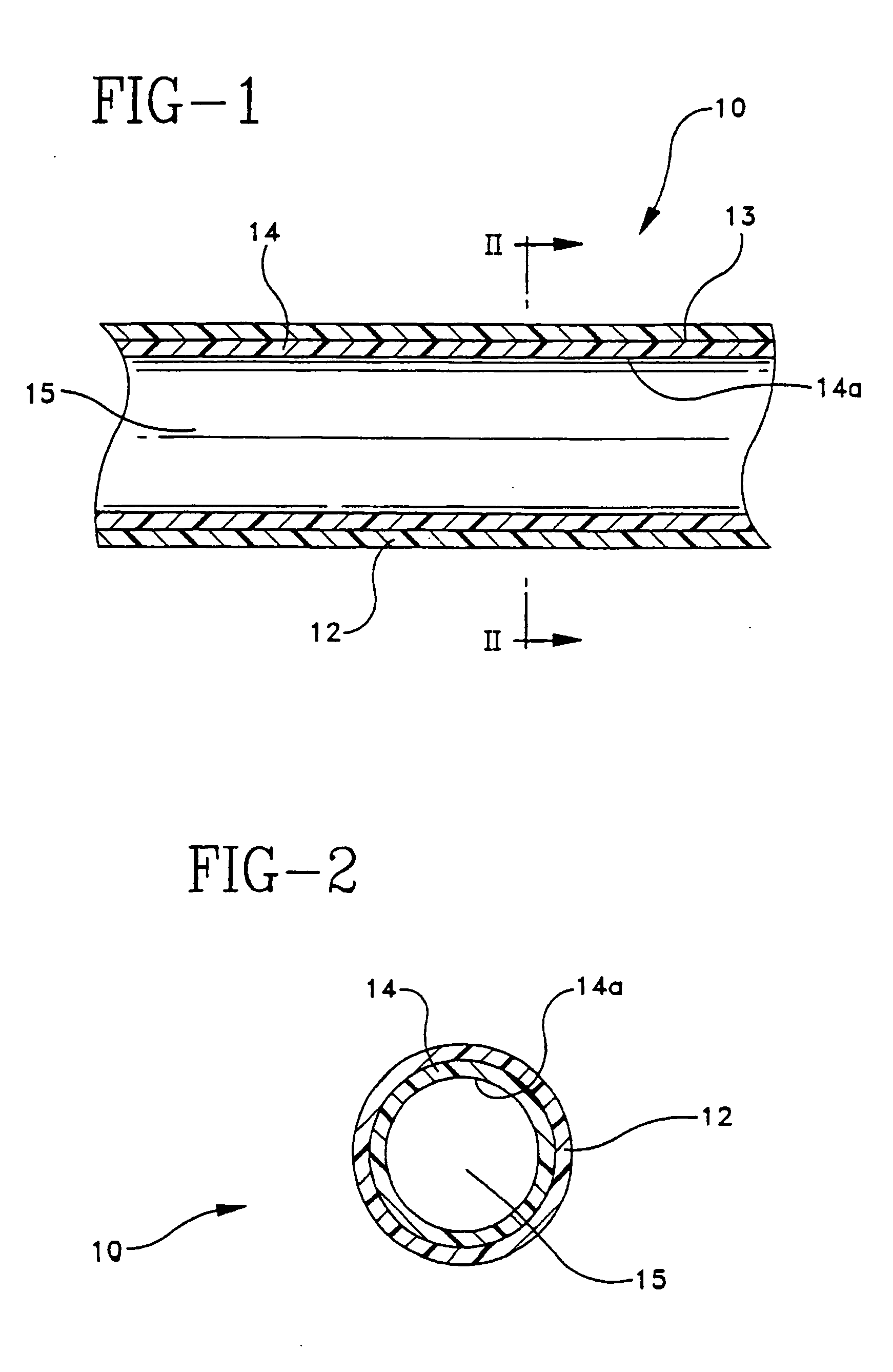

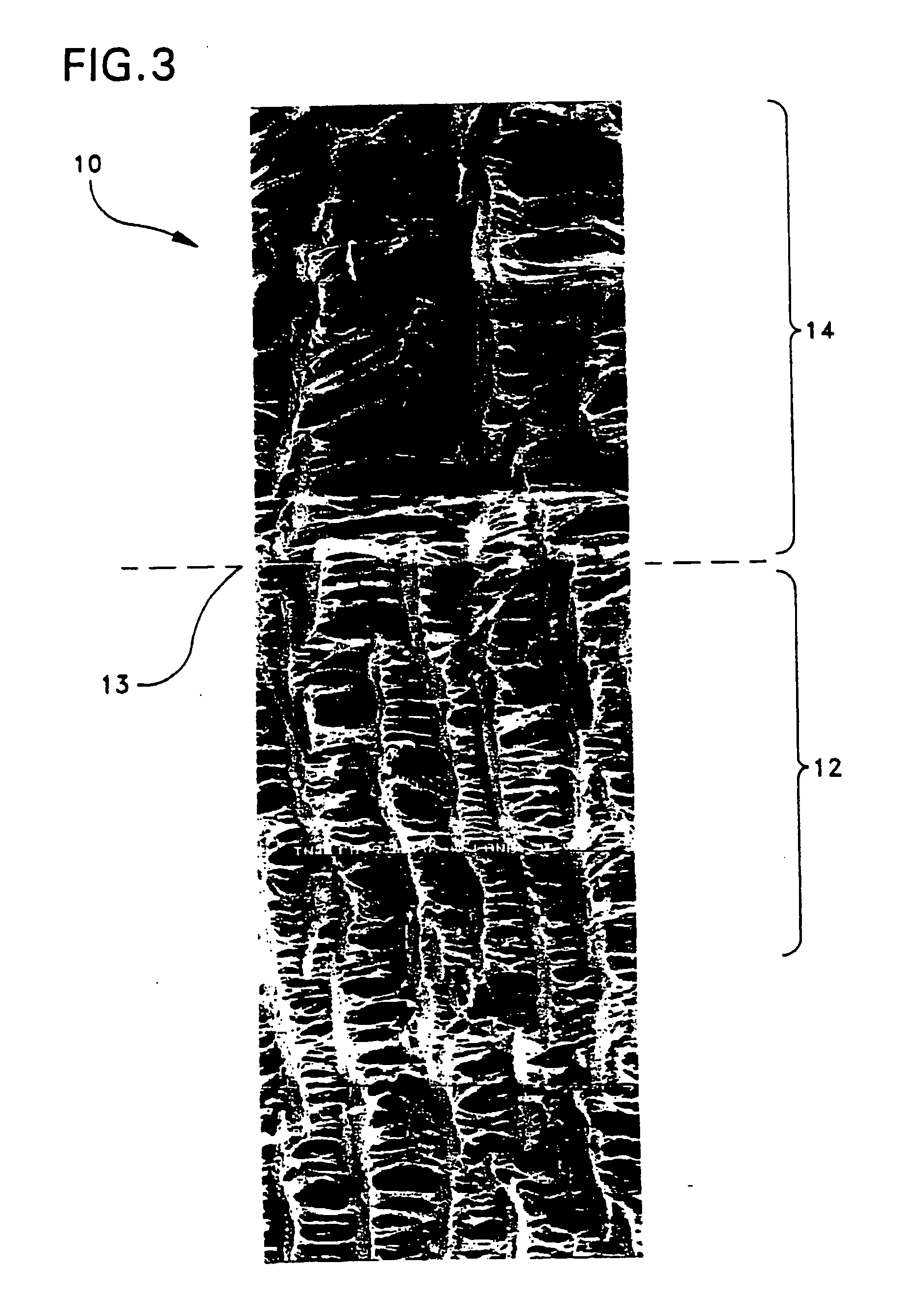

An implantable microporous ePTFE tubular vascular graft exhibits long term patency, superior radial tensile strength and suture hole elongation resistance. The graft includes a first ePTFE tube and a second ePTFE tube circumferentially disposed over the first tube. The first ePTFE tube exhibits a porosity sufficient to promote cell endothelization, tissue ingrowth and healing. The second ePTFE tube exhibits enhanced radial strength in excess of the radial tensile strength of the first tube.

Owner:LIFEPORT SCI

Self-sealing PTFE vascular graft and manufacturing methods

InactiveUS7244271B2Improve the immunityImprove rendering capabilitiesBlood vesselsPorosityVascular graft

An implantable microporous ePTFE tubular vascular graft exhibits long term patency, superior radial tensile strength and suture hole elongation resistance. The graft includes a first ePTFE tube and a second ePTFE tube circumferentially disposed over the first tube. The first ePTFE tube exhibits a porosity sufficient to promote cell endothelization, tissue ingrowth and healing. The second ePTFE tube exhibits enhanced radial strength in excess of the radial tensile strength of the first tube.

Owner:LIFEPORT SCI

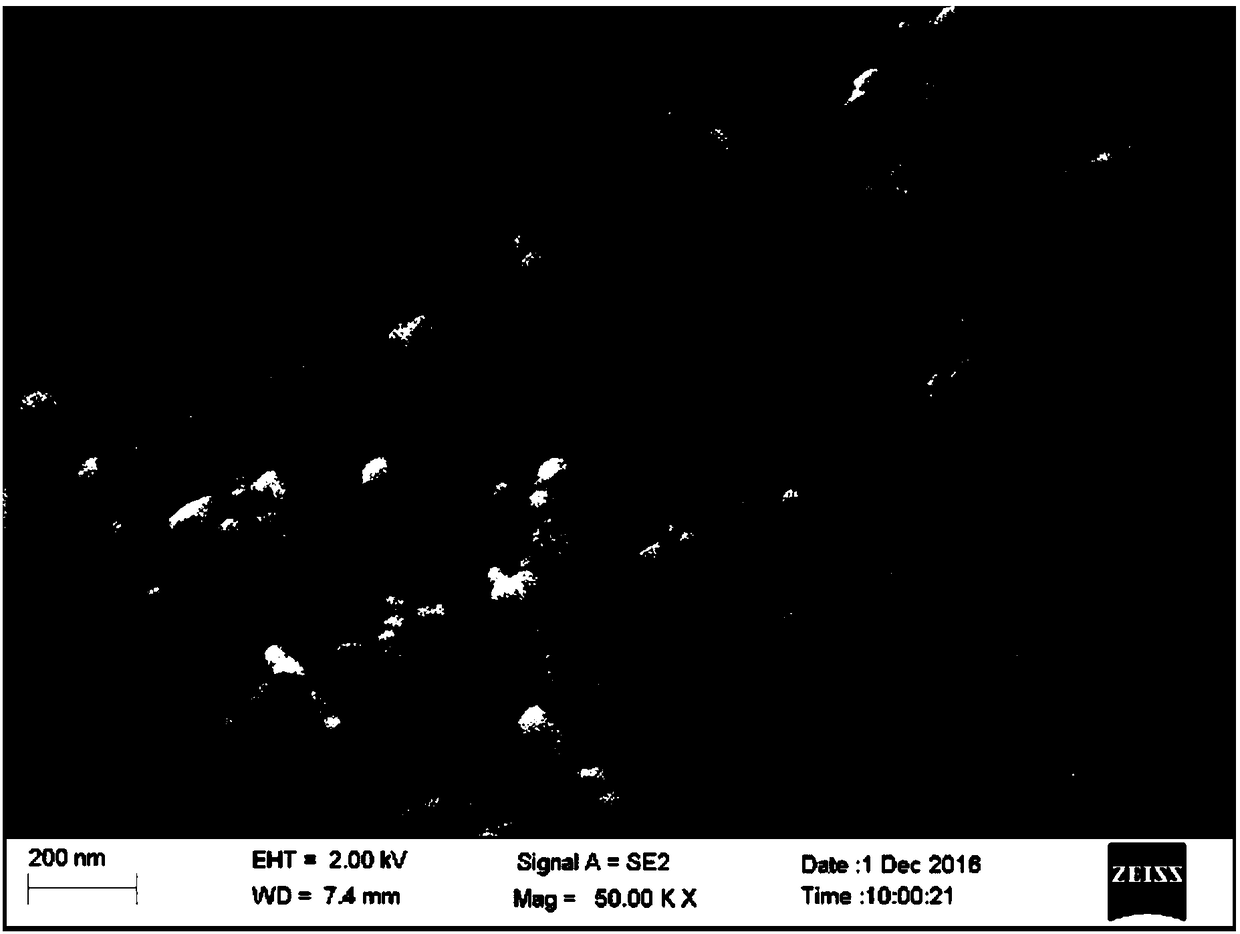

Preparation method of graphene material of supercapacitor

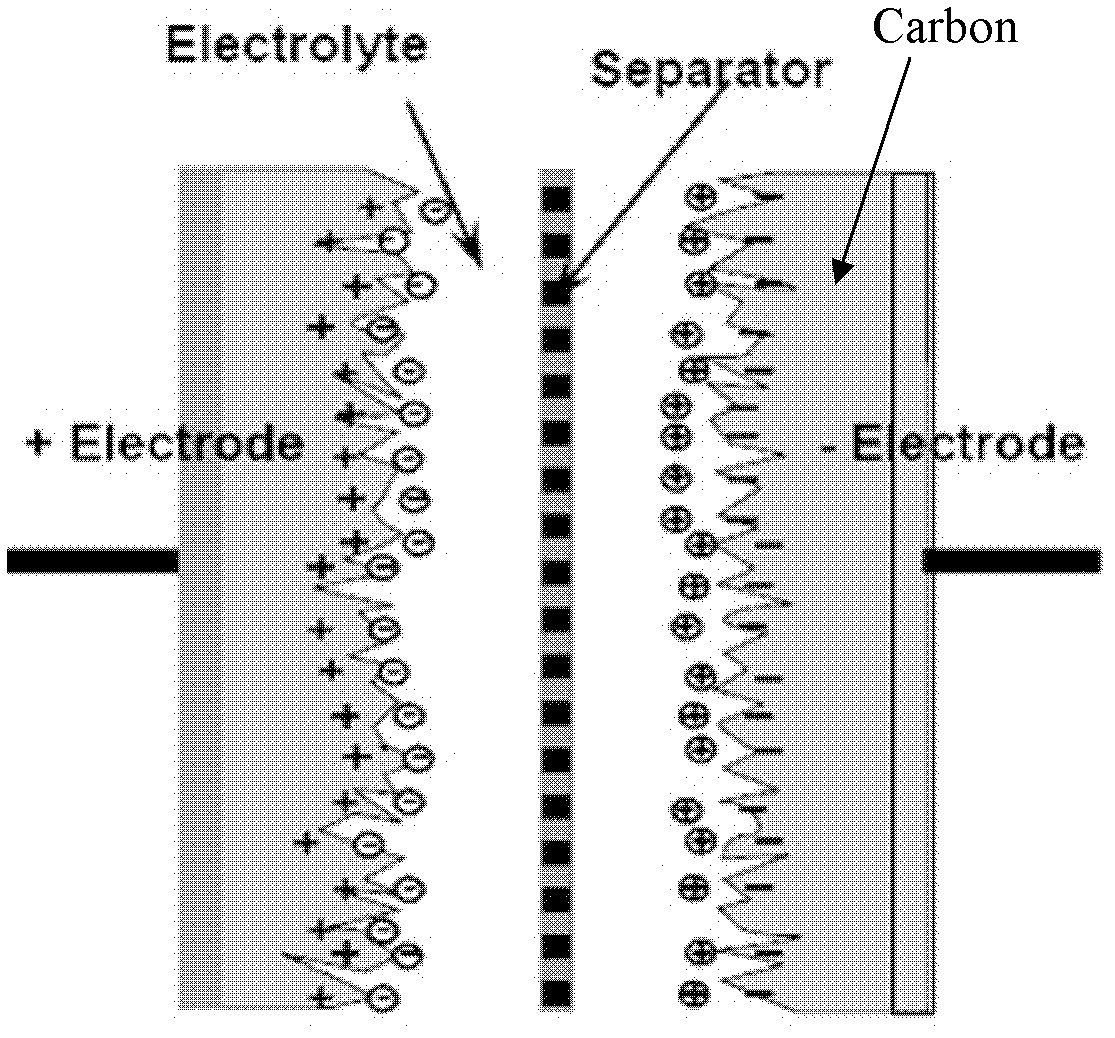

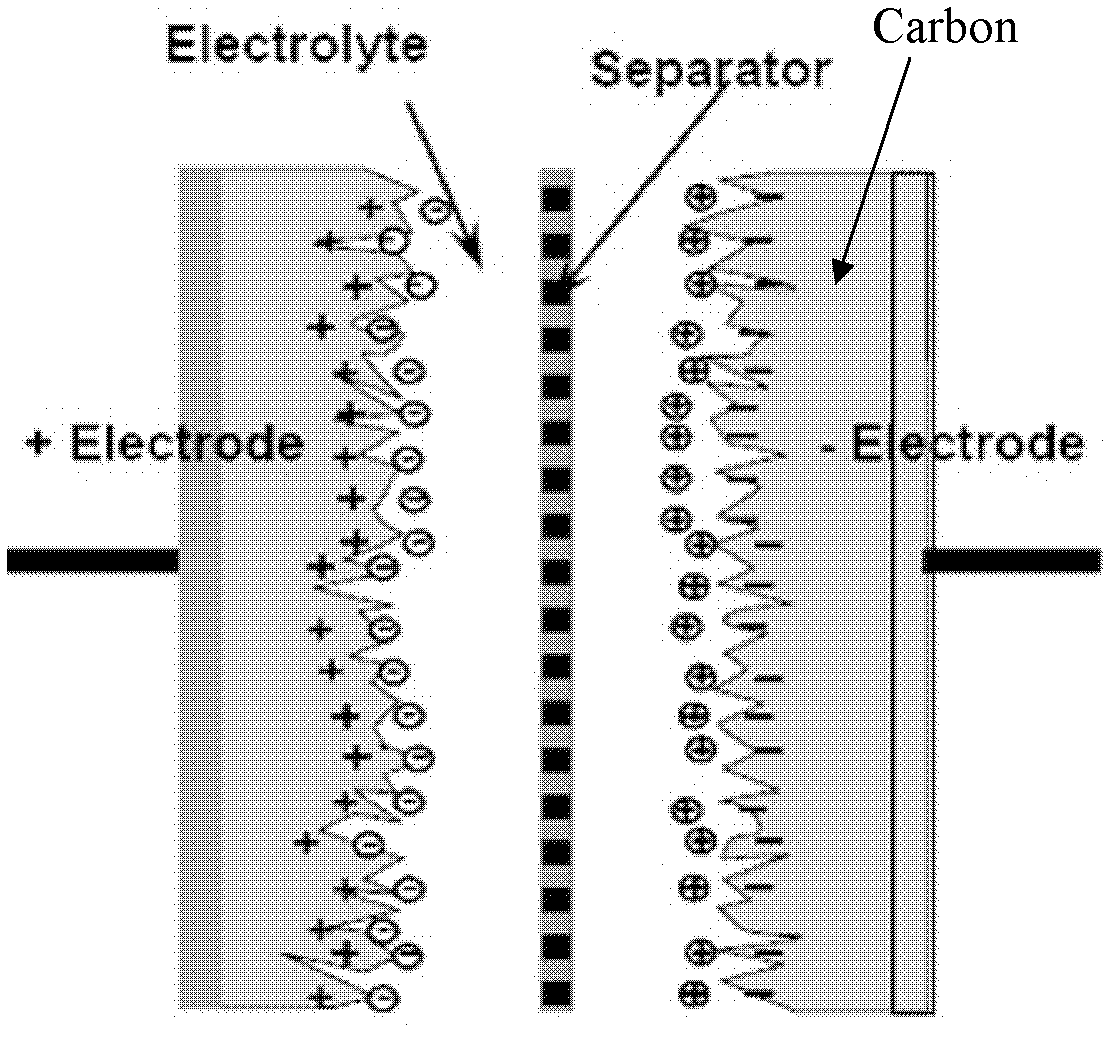

InactiveCN102543483AImprove microporous structureEasy to storeElectrolytic capacitorsHybrid/EDL manufactureSupercapacitorSpecific volume

The invention relates to a preparation method of graphene material of a supercapacitor. The preparation method comprises the following steps of: step one, preparation of expanded graphene, comprising the steps of placing 1-2 parts by weight of graphite oxide into a heating container, sealing the heating container, rapidly warming and heating for 30-120s, preparing 0.5-1 part by weight of the expanded graphene; and step two, preparation of activated graphene. The invention has the beneficial effects that the graphene material prepared by adopting the preparation method provided by the invention improves cellular structure of graphene on the basis that composition of the graphene is not changed, thus the graphene material is more beneficial to charge storage, the specific capacity of a graphene supercapacitor is improved, the specific volume of the supercapacitor in organic electrolyte reaches up to 200F / g, and energy density can reach up to 40Wh / kg; meanwhile, the preparation method provided by the invention has simple technological process and low cost.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

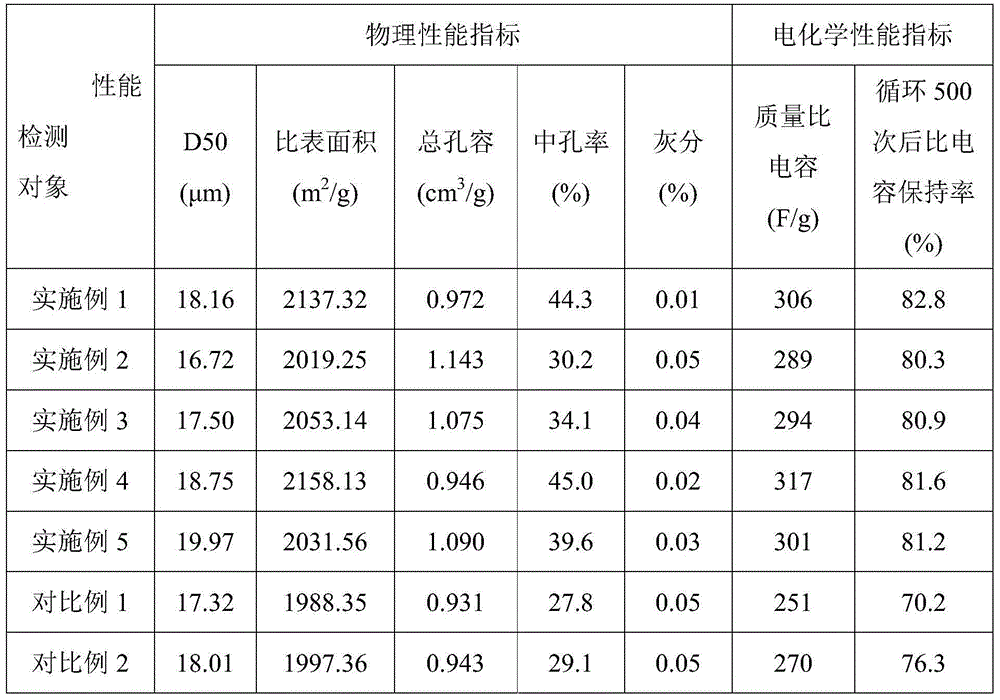

Method for preparing high specific surface area granular activated carbon by physical activation process

The invention provides a method for preparing grain active carbon with high specific surface area by a physical activation method, comprising the steps as follows: firstly, coconut shell is carbonized under high temperature; subsequently, the crushed and screened carbonization material is arranged in a microwave radiation device; by controlling activation temperature and adjusting activation time and activation gas flux, the raw material is activated so as to gain the grain active carbon product with the specific surface area more than 2200m<2> / g. The method utilizes high-temperature carbonization to improve the micro-pore structure of the carbonization material of the coconut shell, is beneficial for improving the orderly structure of the carbonization material of the coconut shell, reduces the burning of the carbon during the carbonization process and improves the yield of the active carbon product; the prepared active carbon is the grain active carbon, and the applicable range is improved.

Owner:KUNMING UNIV OF SCI & TECH

Self-sealing PTFE vascular graft and manufacturing methods

InactiveUS20070244539A1Improve the immunityImprove rendering capabilitiesStentsBlood vesselsPorosityVascular graft

An implantable microporous ePTFE tubular vascular graft exhibits long term patency, superior radial tensile strength and suture hole elongation resistance. The graft includes a first ePTFE tube and a second ePTFE tube circumferentially disposed over the first tube. The first ePTFE tube exhibits a porosity sufficient to promote cell endothelization, tissue ingrowth and healing. The second ePTFE tube exhibits enhanced radial strength in excess of the radial tensile strength of the first tube.

Owner:LIFEPORT SCI

Ceramic filter film of rare-earth modified attapulgite with nano coating and preparation method thereof

InactiveCN102614782AUniform pore size distributionLight in massSemi-permeable membranesCeramicwareRare earthPore diameter

Owner:SHANGHAI MARITIME UNIVERSITY

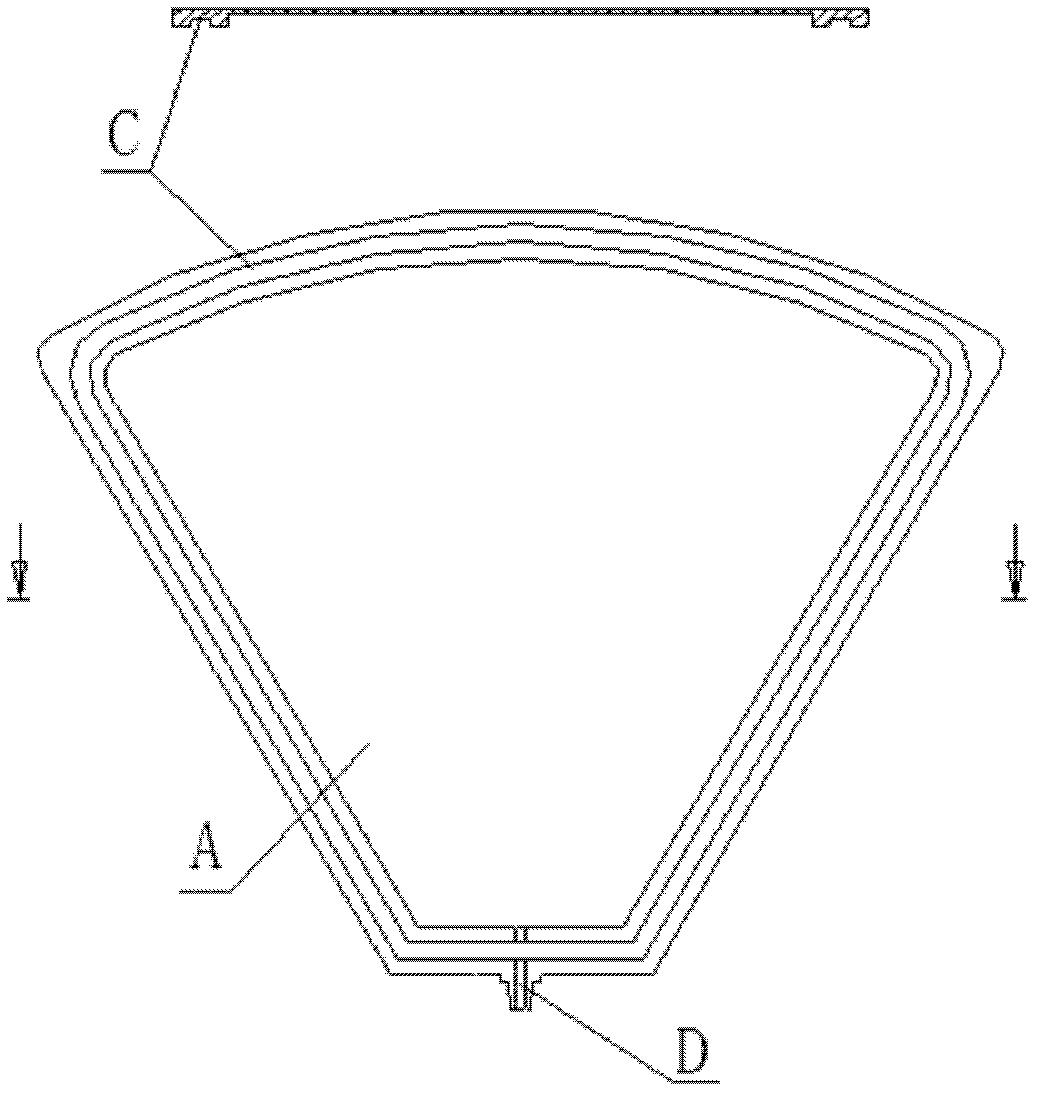

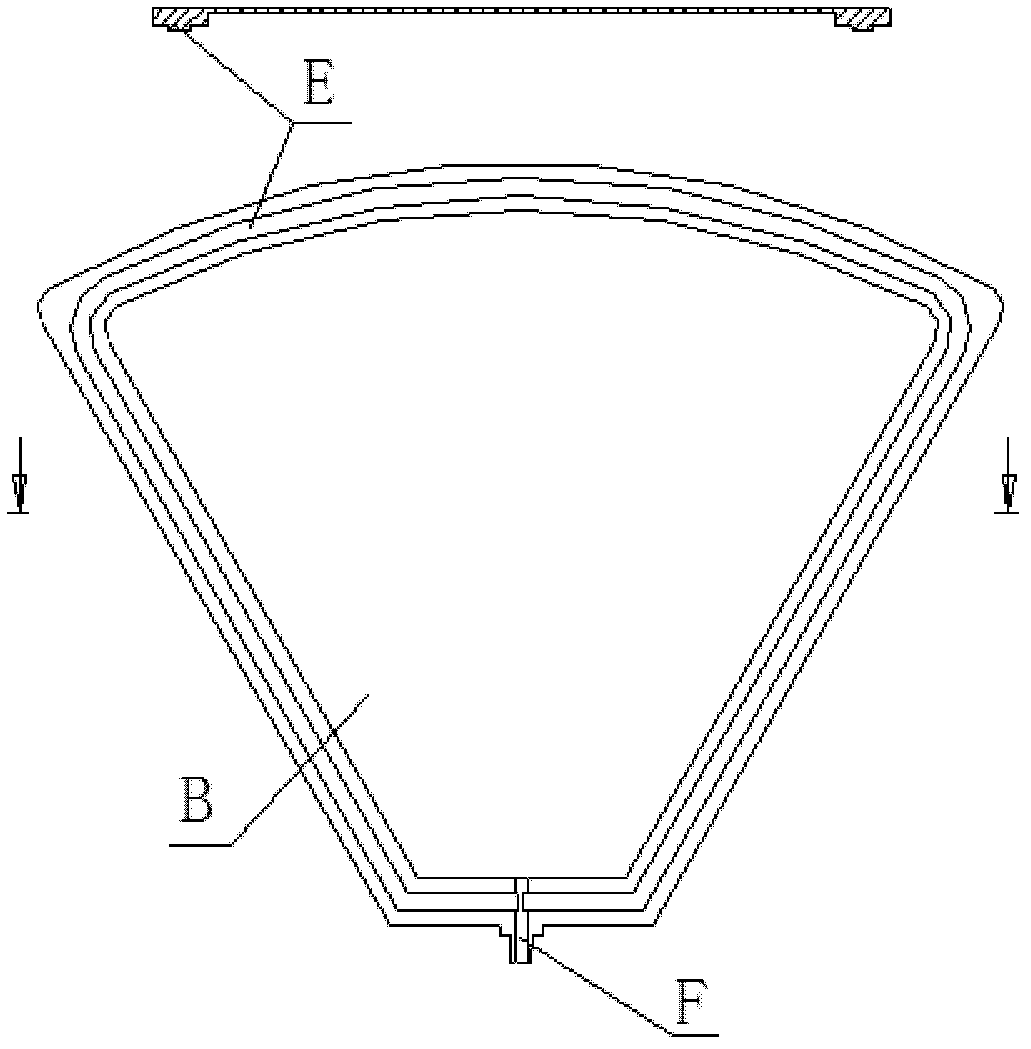

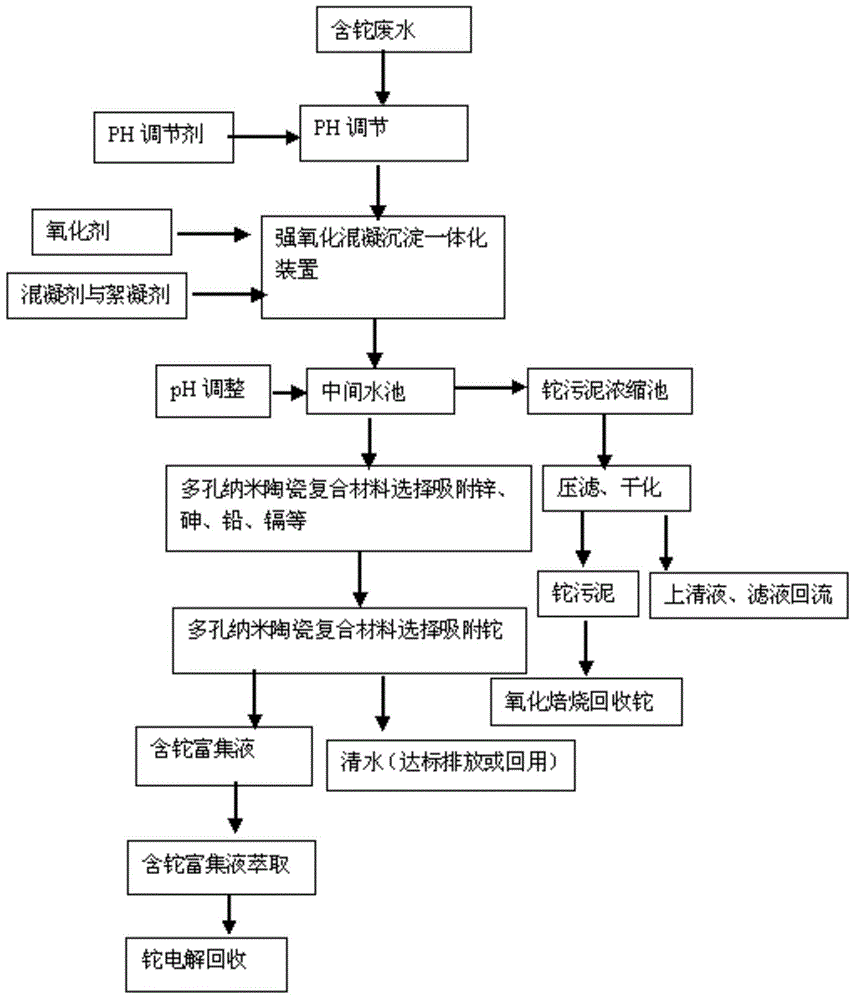

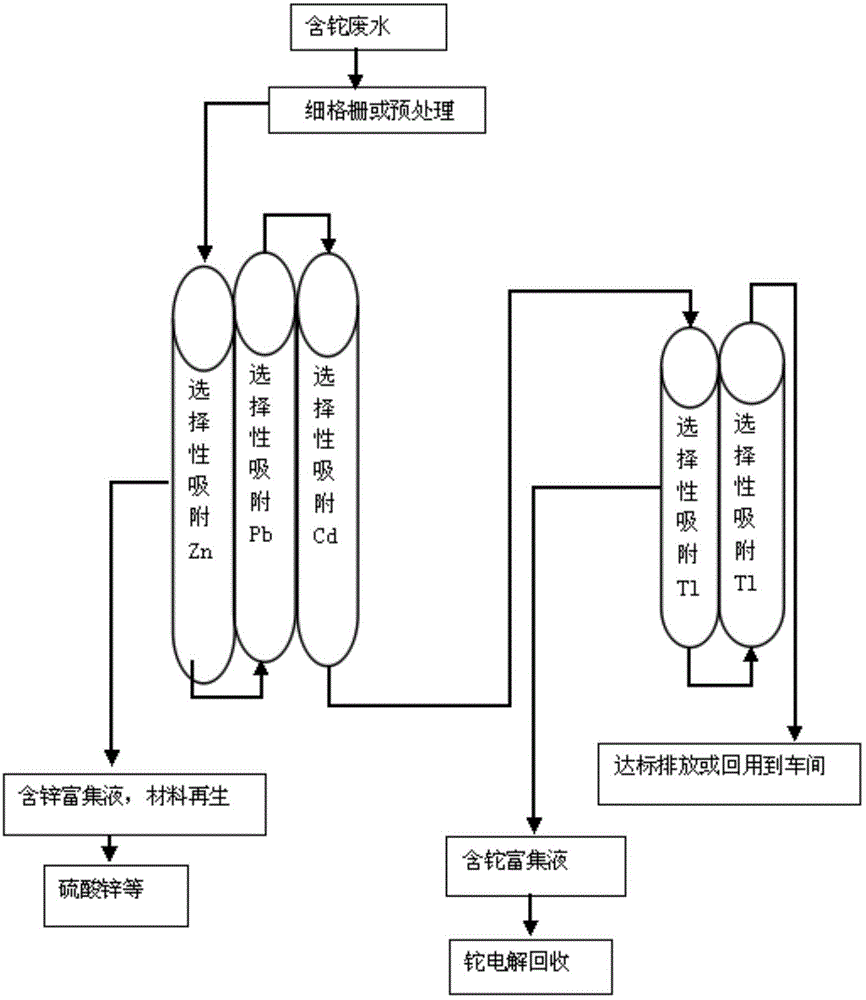

Thallium-containing wastewater strongly oxidizing, coagulating, adsorbing and recovering process

ActiveCN104310672AHighly selective adsorptionLarge specific surface areaWater treatment parameter controlSludge treatmentFiltrationSludge

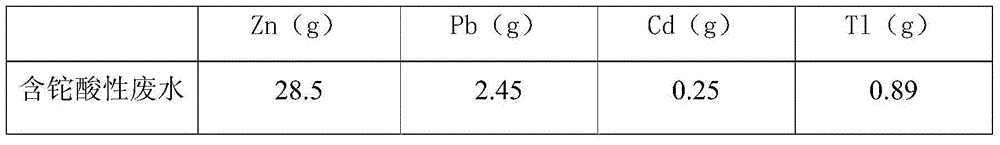

The invention provides a thallium-containing wastewater strongly oxidizing, coagulating, adsorbing and recovering process. The process includes the following procedures: thallium-containing wastewater concentration, pH regulation, strong oxidization, coagulation, flocculation, precipitated sludge treatment, pH regulation, solid impurity filtration, removal of Zn, Pb, Cd and Tl, and the like. The process has the beneficial effects that the process has the advantages of advanced technology, maturity, good effluent quality, stability in operation, conciseness in process, strong practicability, easiness in start and stop, convenience in maintenance and management, small investment, low operating cost, small floor area for construction, short construction period and large application ranges of projects; treatment of heavy metal ion polluted sewage is not limited by temperatures; the limitation that a biological method can not be used in cold regions in the north can be overcome.

Owner:HUNAN JINGYUAN ENVIRONMENTAL ENG

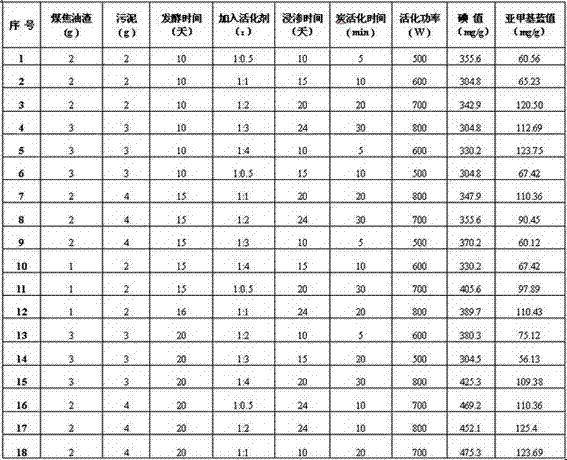

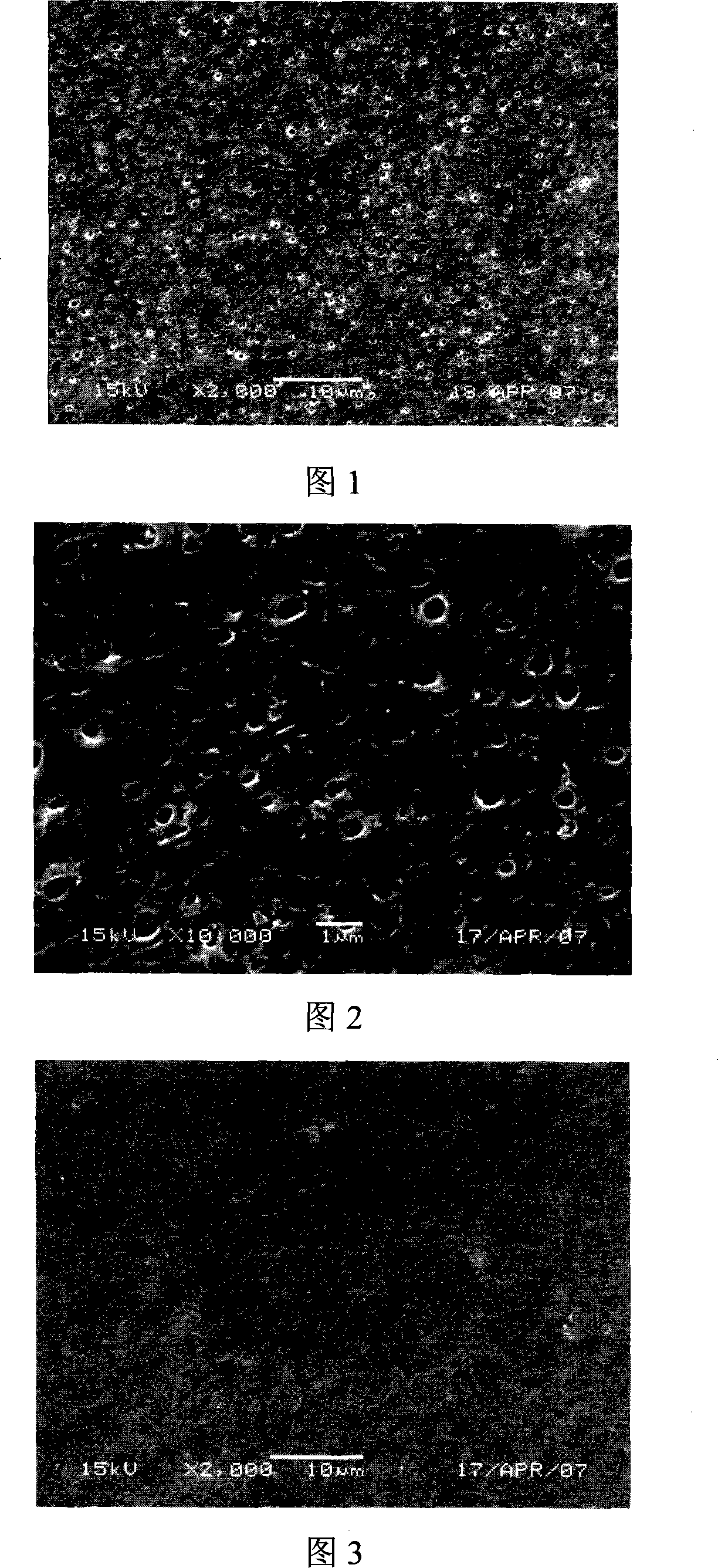

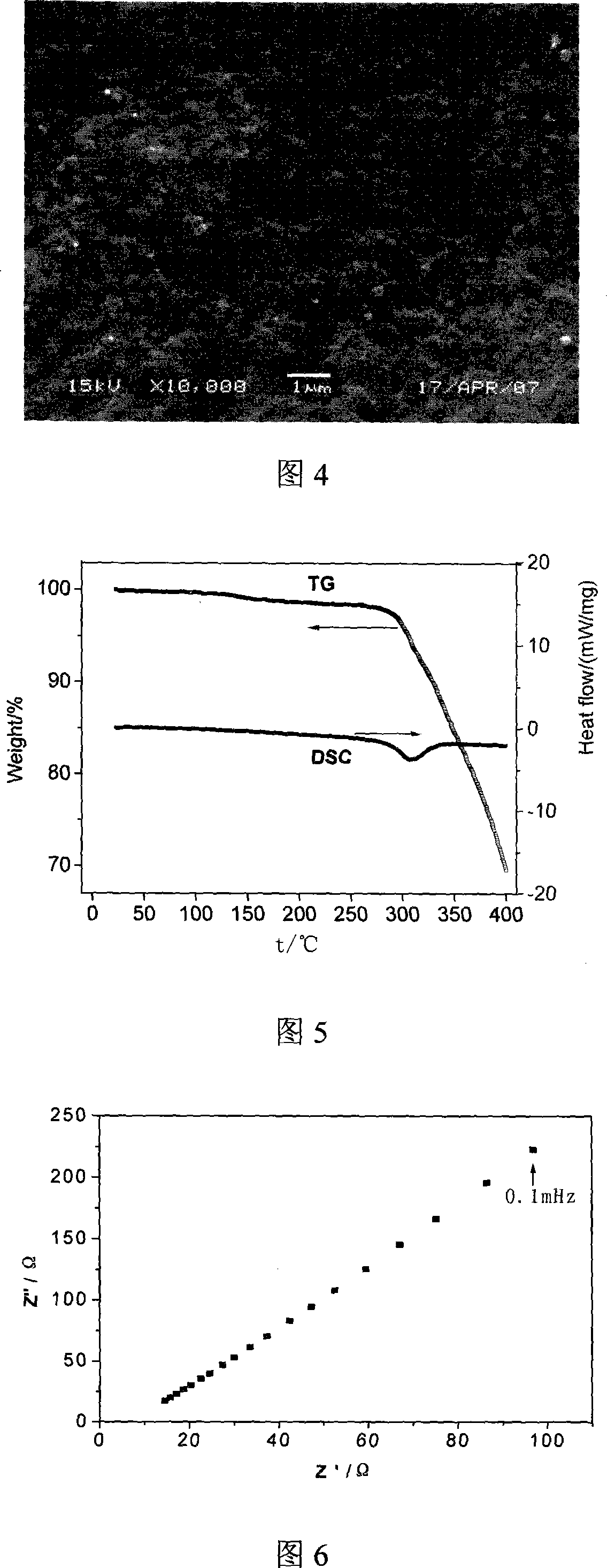

Method for producing activated carbon by thermally activating coal tar dreg/ sludge fermentation body by using microwaves

ActiveCN102381705ALower activation energyReduce manufacturing costActivated carbonIndustrial effluent

The invention discloses a method for producing activated carbon by thermally activating a coal tar dreg / sludge mixed fermentation body by using microwaves. The method comprises the steps of: firstly crushing and grinding coal tar dreg into more than 200 meshes, then, mixing the ground coal tar dreg with sludge, and performing aerobic fermentation for 10-20 days; then, adding zinc chloride servingas an activator into the mixed fermentation body, and infiltrating for 12-24h at 70-80 DEG C, wherein the added zinc chloride is 0.5-4 times more than the mixed fermentation body in mass; and finally, carbonizing and activating for 30-120min in a microwave carbonization furnace under a N2 protection condition to obtain coal tar dreg / sludge mixed activated carbon, washing with water till a neutralcondition is achieved, and drying to obtain a product disclosed by the invention. The method disclosed by the invention has the advantages of simplicity and convenience for operation, easiness for control, low cost, high product synthesis rate and favorable product performance, and can be widely applied to industrial wastewater treatment, refractory wastewater treatment, sound insulation, noise reduction, deodorization, oil absorption, lipid suction and other industries.

Owner:SOUTHWEAT UNIV OF SCI & TECH

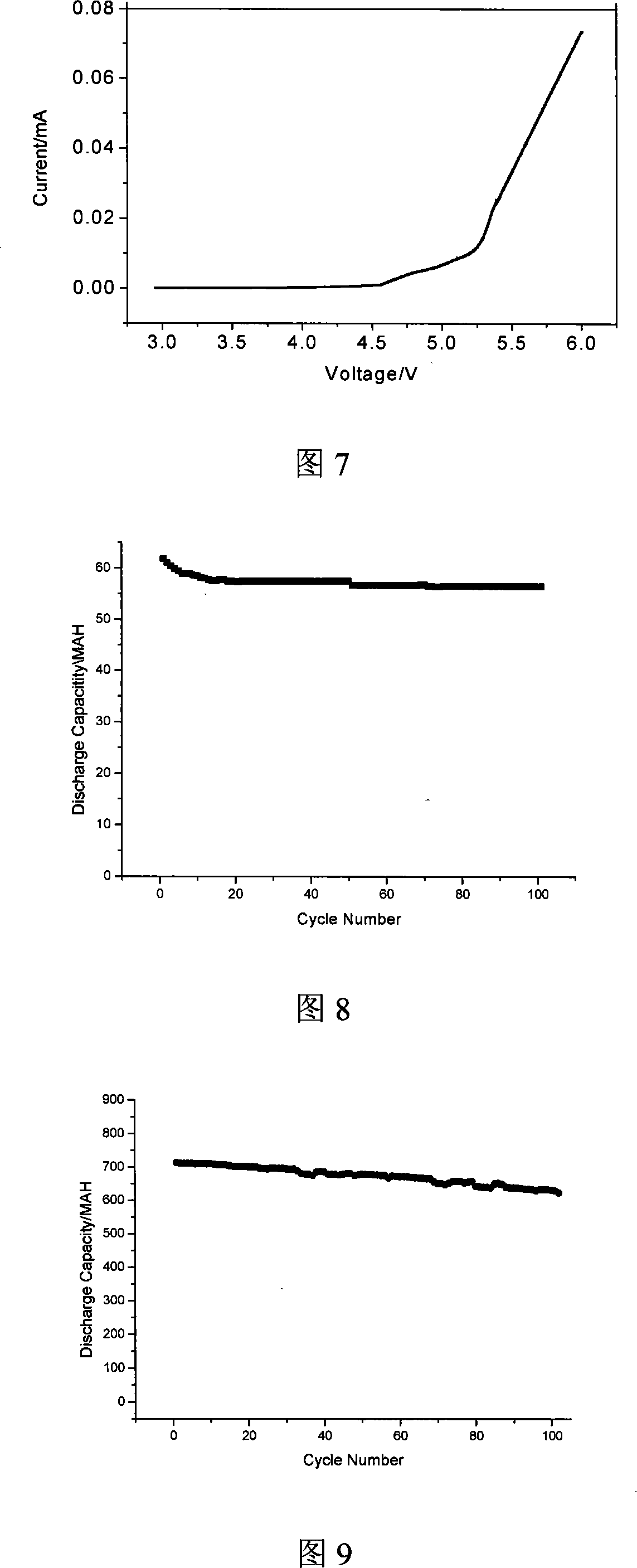

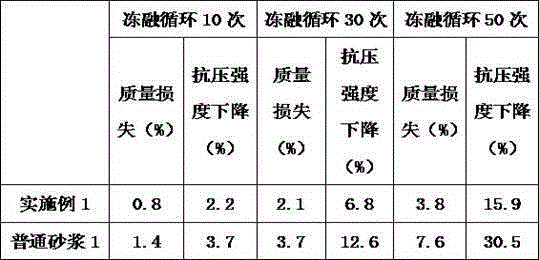

Micro joint gel state lithium ion battery polymer electrolyte film and its making method

ActiveCN101127408AIncrease polarityImprove ionic conductivitySolid electrolyte cellsSecondary cellsAcrylonitrileElectrochemistry

The utility model relates to a polymer electrolyte film for a micro cross-linking gel state lithium-ion battery and a preparation method, which is used for making the battery. The utility model discloses the poly-acrylonitrile-methyl methacrylate with the cross-linking degree of 0.1 to 0.4 % is obtained after suspension polymerization with the monomer component mass ratio of a methyl methacrylate and an acrylonitrile of 1:9 to 4:6, then the poly-acrylonitrile-methyl methacrylate is dissolved by a polar organic solvent and coated on a formed die, finally the micro cross-linking degree polymer electrolyte film is obtained when the film is removed from the formed die, the thickness of the film is 20 to 50um, the tensile strength is 7 to 22Mpa, and the average hole diameter is 0.1to 3um. The utility model has advantages of good conductivity, good absorbing capability, good heat stability, good electrochemical stability and good mechanical property under the ambient temperature, and simple manufacturing operation, high transforming rate of polymer, economy and environmental friendliness.

Owner:GUANGZHOU TINCI MATERIALS TECH

Doped lithium titanate adsorption agent and preparation method thereof

ActiveCN109317087AImprove adsorption capacityHigh selectivityOther chemical processesZirconium compoundsLithiumSorbent

The invention relates to an adsorption material for separating and extracting lithium from brine, in particular to a doped lithium titanate adsorption agent and a preparation method thereof. The dopedlithium titanate adsorption agent HxLi4-xMyTi5-yO12 is obtained by doping M into crystal lattices of Li4Ti5O12 to form precursors Li4MyTi5-yO3 and then removing lithium by acid pickling, where M is one or a mixture of several of Ce, Sn, Nb, Zr, Mo, Ta, W, Mn and Hf; the value range of x is 0.0 to 4.0; the value range of y is 0.0 to 2.0. A titanium source, the lithium source and M salts are uniformly mixed, dried, roasted, cooled and are subjected to acid pickling to obtain the doped lithium titanate adsorption agent. The doped lithium titanate adsorption agent prepared by the method is used for performing adsorption lithium extraction on brine with the magnesium-lithium ratio being greater than 100; the lithium absorption rate is greater than 75 percent; the magnesium removal rate is greater than 99 percent; the stripping liquid acidity is high; the lithium enriching times is about 1 to 7 times; the titanium dissolution damage rate is low; the industrialized application prospects arerealized.

Owner:四川泛宇锂能新材料科技有限公司

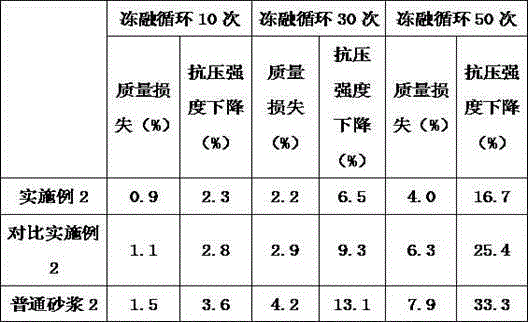

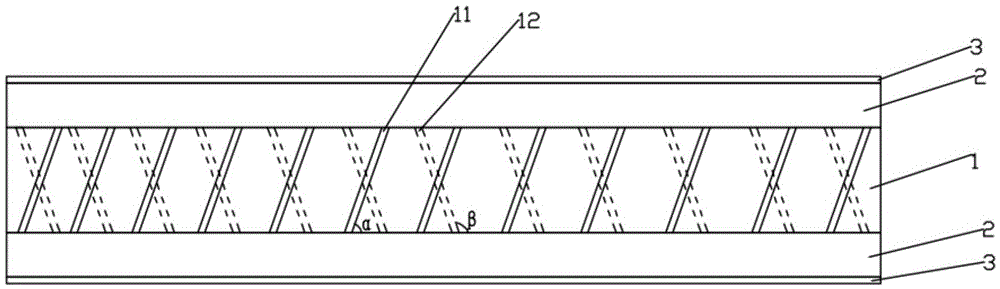

Anti-freezing mortar special for aerated bricks

The invention discloses anti-freezing mortar special for aerated bricks, made from, by weight, 30-40 parts of mineral residue, 30-35 parts of cement, 25-30 parts of river sand, 0.5-1 part of a water reducing agent, 0.5-1 part of an air entraining agent, 1-2 parts of an anti-freezing agent, 4-6 parts of vitrified micro bubbles, 3-5 parts of Kapok fiber, 2-4 parts of rare-earth oxide, and 5-8 parts of modified attapulgite. Unique components are selected, their contents are reasonably matched, and the mortar and its products are good in strength, cracking resistance, water permeation resistance and temperature resistance and excellent in anti-freezing performance, are applicable to cold areas and areas having great temperature differences and have excellent performance, and potential safety hazards are decreased.

Owner:ANHUI KUNLONG BUILDING MATERIALS CO LTD

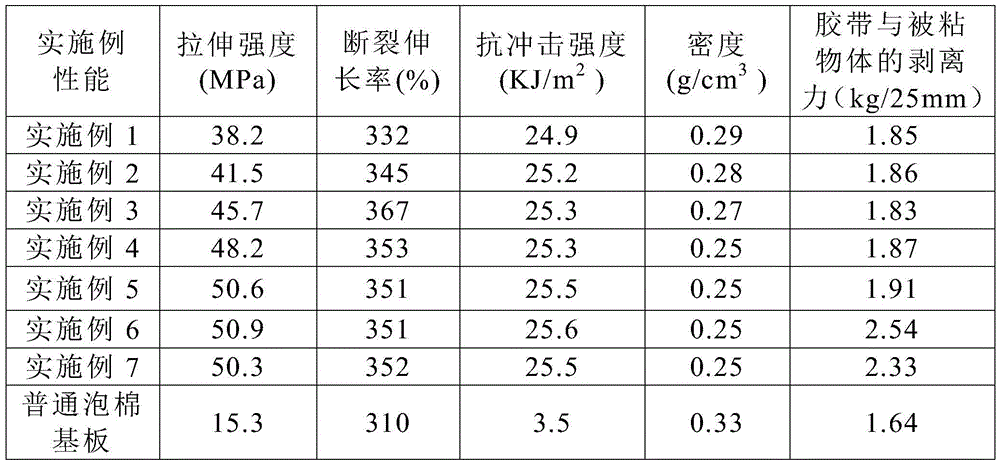

Foam two-sided adhesive tape

ActiveCN105542674AIncrease connection forceStop dislocationFilm/foil adhesivesFoaming agentShock resistance

The invention relates to a foam two-sided adhesive tape, which belongs to the technical field of an adhesive tape. The foam two-sided adhesive tape comprises a foam basal plate, an adhesive coating and a release film, wherein longitudinal through holes are formed between the upper surface and the lower surface of the foam basal plate, the foam basal plate comprises the following components in parts by weight: 100 parts of PMMA, 28 to 35 parts of polyurethane, 18 to 23 parts of fluorine rubber, 1.5 to 3.2 parts of light stabilizer, 5 to 11 parts of mesoporous nano TiO2 and 20 to 30 parts of foaming agents. The longitudinal through holes are formed in the foam basal plate, so that adhesive forms a complete lattice system, the connection performance of the adhesive tape is improved, and the connected object is more stable and reliable. The foam basal plate which is light in weight, good in shock resistance and excellent mechanical performance is adopted as the base material of the adhesive tape, so that the prepared adhesive tape is high in strength, good in flexibility, high in impact resistance and applicable to the manufacturing of more precise instruments and equipment.

Owner:NINGBO JIXIANG PLASTIC PROD CO LTD

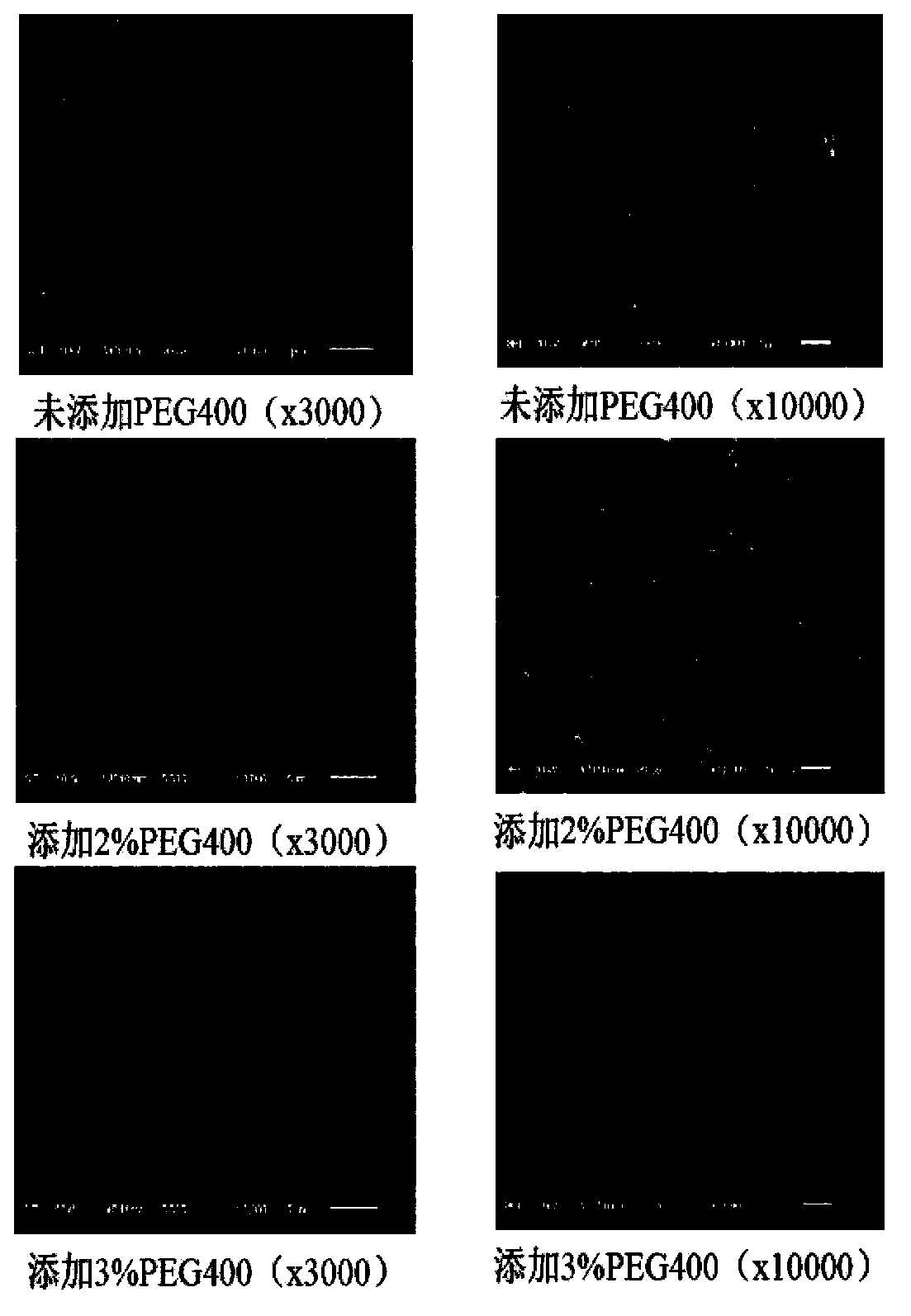

Preparation method of functionalized multiwalled carbon nanotube blended ultrafiltration membrane

ActiveCN105478018AThe phenomenon of reunion is obviousGood dispersionMembranesUltrafiltrationSilanesUltrafiltration

The invention provides a preparation method of a functionalized multiwalled carbon nanotube blended ultrafiltration membrane, comprising the following steps: putting dried MWCNT after acidized modification into thionyl chloride for reaction for 7-8h; drying a product and then adding the dried product into ethanol water, carrying out ultrasonic dispersion and then adding 3-aminopropyl triethoxy silane, continuing to carry out ultrasonic dispersion and then carrying out backflow for 1h at the temperature of 80 DEG C, filtering and drying to obtain the functionalized multiwalled carbon nanotube; adding the functionalized multiwalled carbon nanotube to an N, N-dimethylacetamide solution, carrying out ultrasonic dispersion and then adding polyvinylpyrrolidone and polyvinylidene fluoride, heating and stirring, cooling and then defoaming to prepare a casting film solution; pouring the casting film solution to a glass plate and scraping to form a membrane; pre-evaporating in air and then immersing into pure water; and taking out after the membrane falls out and then soaking with deionized water, and drying to obtain the functionalized blended ultrafiltration membrane. The hydrophilia, the anti-fouling performance and the mechanical performance of the functionalized multiwalled carbon nanotube blended ultrafiltration membrane are all enhanced, and the manufacture cost is low.

Owner:成都恒固新材料科技有限公司

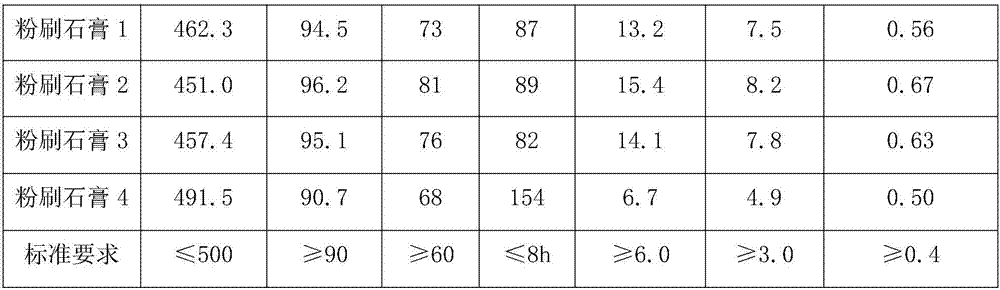

High-strength energy-saving type surface layer plastering gypsum and preparation process thereof

The invention discloses high-strength energy-saving type surface layer plastering gypsum and a preparation process thereof. The plastering gypsum is prepared from the following raw materials in parts by weight: 30 to 50 parts of desulfurized hemihydrate gypsum, 25 to 35 parts of modified diatomite, 20 to 30 parts of fly ash, 15 to 25 parts of heavy calcium carbonate powder, 10 to 20 parts of attapulgite powder, 8 to 12 parts of polypropylene fiber, 5 to 15 parts of starch binder, 1 to 5 parts of retarder, 1 to 3 parts of water-reducing agent, 1 to 3 parts of water-retaining agent, 1 to 3 parts of foaming agent and 1 to 3 parts of foam stabilizer. The preparation process comprises the steps: feeding part of raw materials such as desulfurized hemihydrate gypsum and modified diatomite into a mixing machine, adding a proper amount of water to mix, so as to obtain gypsum slurry; then feeding all the remaining raw materials into the gypsum slurry and stirring evenly. The plastering gypsum disclosed by the invention has the advantages of simple preparation process, low cost, high strength, strong adhesive property, good water retention performance and excellent construction performance, and can absorb harmful gases such as formaldehyde and benzene in a room to a certain extent, thereby realizing energy conservation and environmental protection; the plastering gypsum has a broad market prospect.

Owner:明光市泰丰新材料有限公司

Method for preparing polyurethane polishing disc

The invention relates to a method for preparing a polyurethane polishing disc, in particular to a proportioning and a preparing process of the polyurethane polishing disc. The method comprises the following steps: taking toluene diisocynate, polyether polyol, a chain extender, a cross-linking agent, a copolymer of polysiloxane and polyalkoxy-ether and cerium oxide as raw materials based on the weight ratio of 100:200-240:45-60:16-25:1.5-2.5:90-110; and pre-polymerizing the toluene diisocynate and the polyether polyol to form component A, mixing the chain extender, the cross-linking agent, the copolymer of polysiloxane and polyalkoxy-ether and the cerium oxide to form component B, adding the component A and the component B to a vacuum closed mixing vessel to mix quickly for 5-15 seconds, infusing the components into a die, cooling and curing into polyurethane blank, and then cutting the blank into slices to finally obtain the polyurethane polishing disc. The polyurethane polishing disc obtained by the method of the invention has good elasticity and good microcellular structure and can be used in high-precision grinding and polishing process of various lenses, glasses, prisms, mirror surfaces, optical parts and other glass products. The method of the invention has the advantages of good wear resistance, high polishing efficiency, high polishing precision, high cutting rate, no passivation, simple and convenient operation, low cost and the like.

Owner:张海龙

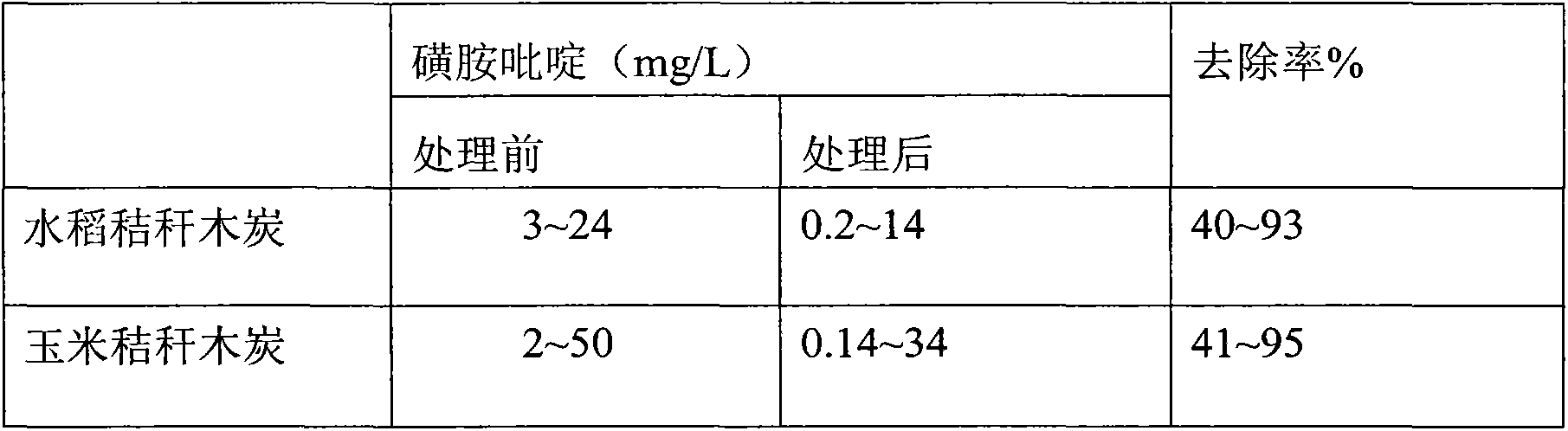

Method for removing sulfapyridine in water bodies with straw charcoal through adsorption and application of straw charcoal in removing sulfapyridine in water bodies

InactiveCN103523847AImprove adsorption capacityEfficient removalOther chemical processesCarbon compoundsAdsorption equilibriumSorbent

The invention discloses a method for removing sulfapyridine in water bodies with crop straw charcoal through adsorption. The method is characterized by comprising a step of putting crop straw charcoal into water bodies containing sulfapyridine as an adsorbent to adsorb and remove sulfapyridine in the water bodies, wherein the adsorption temperature is 20-30 DEG C; the adsorption time is 72-75 hours; the pH value of solution after adsorption equilibrium is 5.8-6.0; the initial concentration of sulfapyridine in the water bodies is 2-50mg / L; the mass ratio of the crop straw charcoal to the water bodies containing sulfapyridine is 1:(2000-4000). Under the condition of room temperature, after adsorption for 3 days, the crop straw charcoal shows a high antibiotics adsorption removal rate. Besides, the method has the beneficial effects that the materials are simple to prepare; the method is convenient to operate; the cost is low; the raw materials are accessible; medicine pollution is effectively eliminated; the current technical gaps are filled in.

Owner:NANJING UNIV

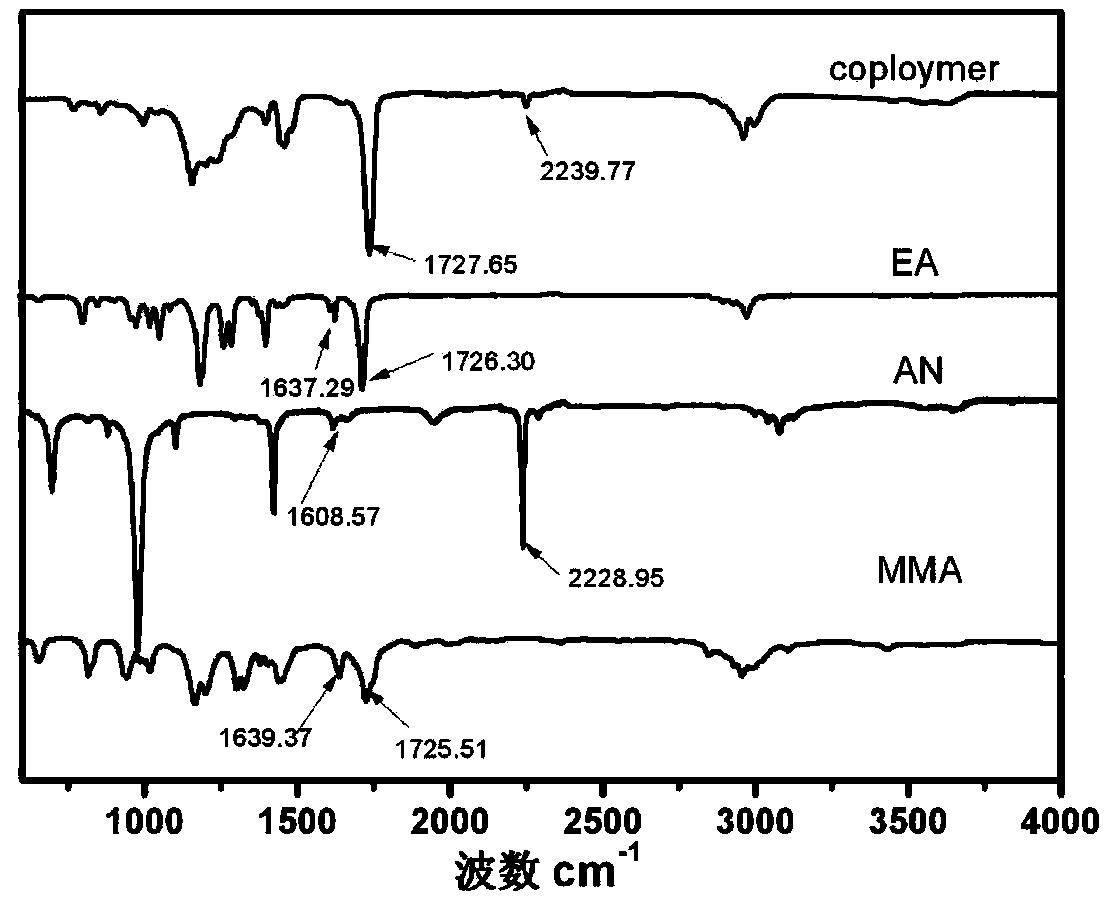

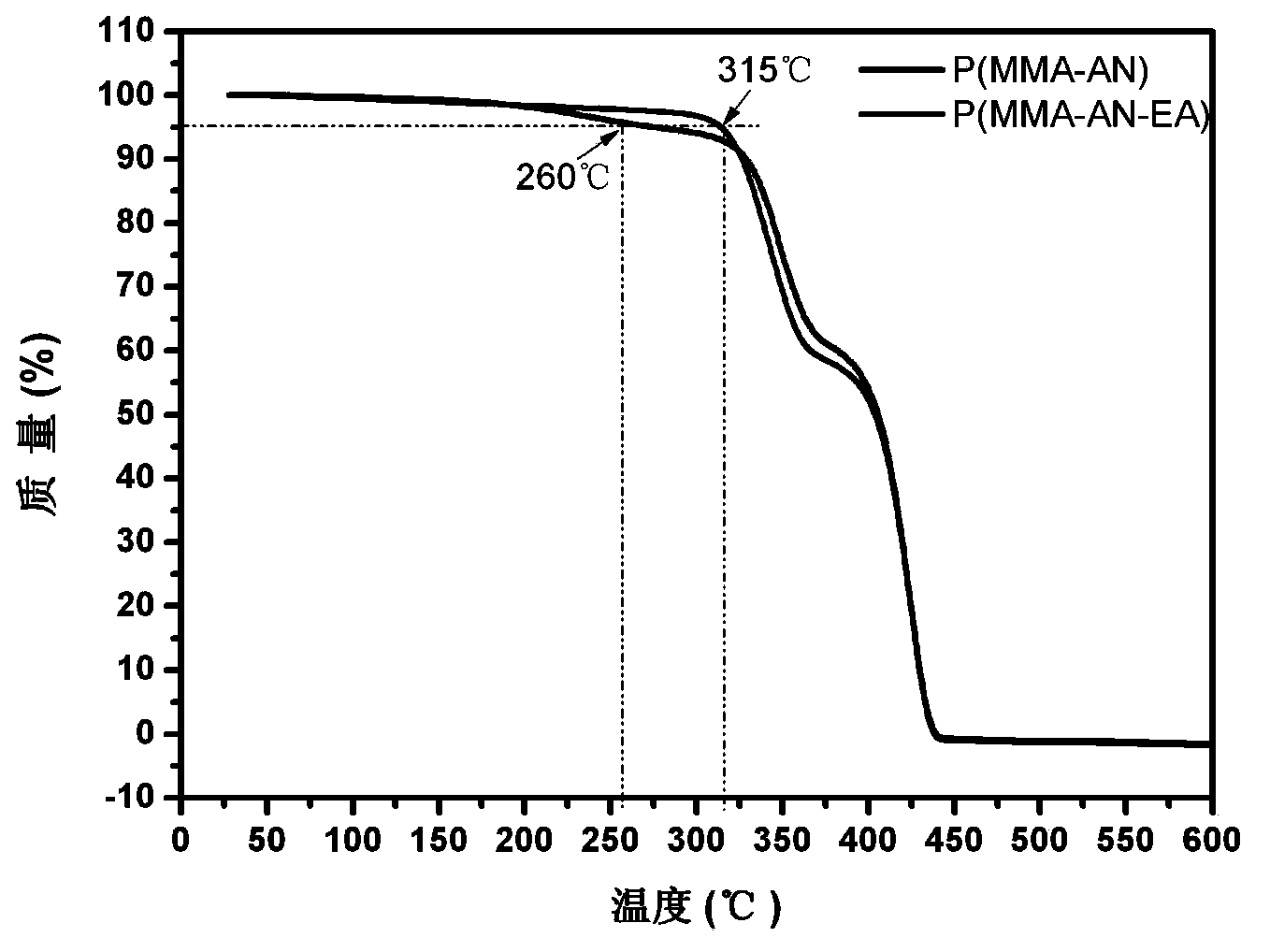

Preparation method of lithium ion battery gel polymer electrolyte

ActiveCN103413974AImprove microporous structureImprove mechanical propertiesFinal product manufactureElectrolyte accumulators manufactureElectrolytic agentFunctional monomer

The invention discloses a preparation method of a lithium ion battery gel polymer electrolyte. The preparation method comprises following steps: poly(methyl methacrylate-acrylonitrile-ethyl acrylate) is prepared by taking methyl methacrylate, acrylonitrile and ethyl acrylate as functional monomers; an appropriate amount of a pore forming agent is added; lithium ion battery gel polymer films supported by different supports are prepared by phase-transfer method; and the lithium ion battery gel polymer films are immersed into an electrolyte so as to obtain the lithium ion battery gel polymer electrolyte. The lithium ion battery gel polymer films possess excellent mechanical properties, liquid absorption capability and liquid retention capability. The lithium ion batteries assembled by using the lithium ion battery gel polymer electrolyte possess high ionic conductivity and electrochemistry stability. Deionized water is used as a solvent in the preparation, and no volatile organic solvent is used, so that no pollution on the environment is caused, and protection cost is low.

Owner:ADVANCED ELECTRONICS ENERGY LIMITED GUANGDONG +1

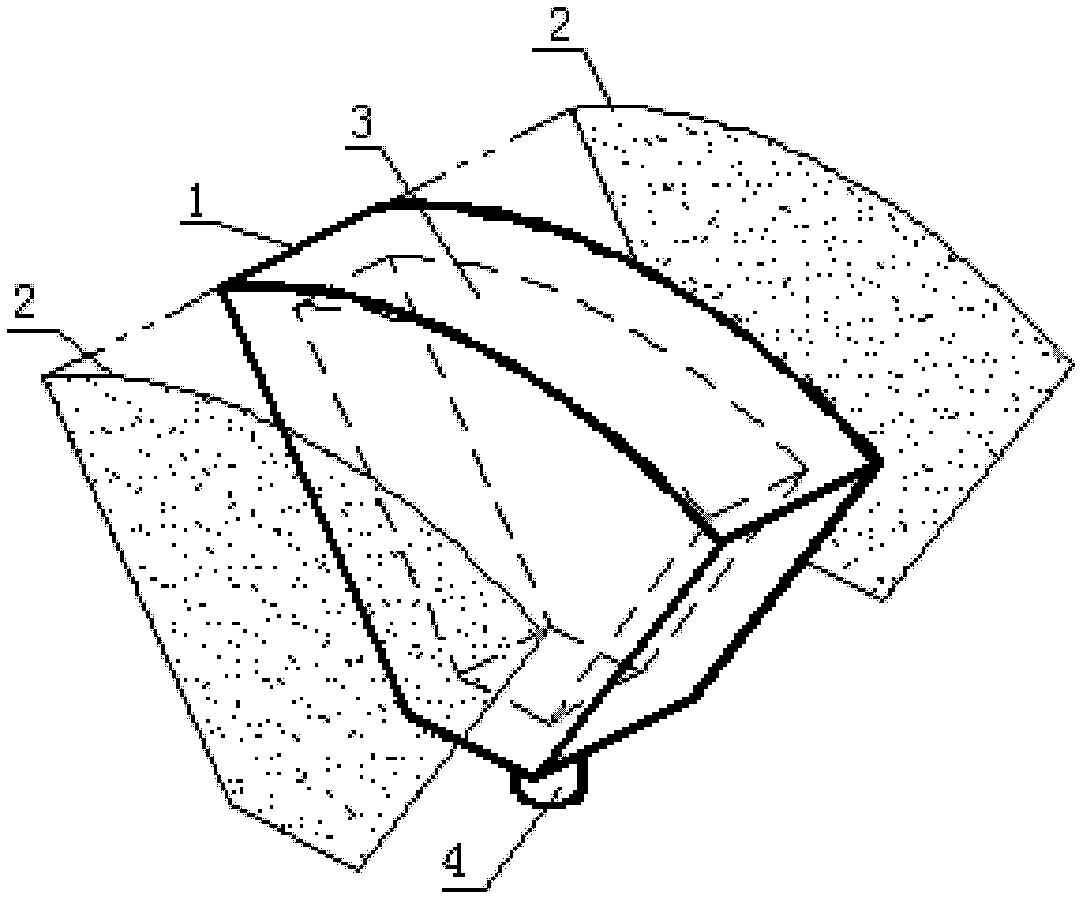

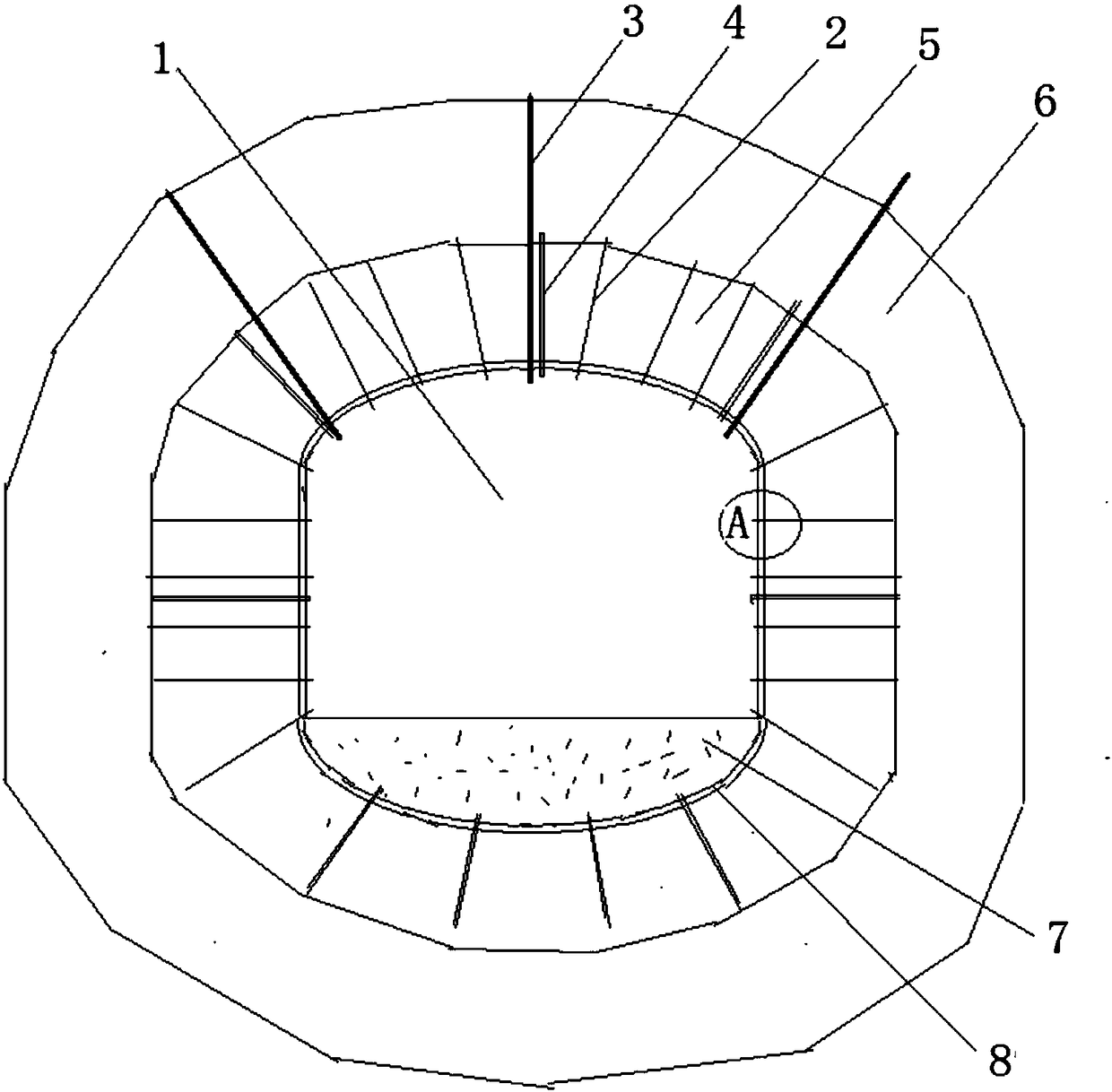

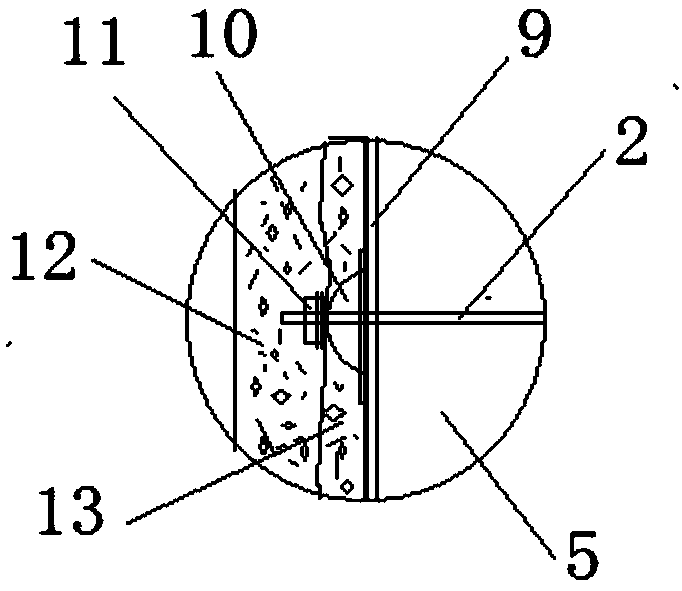

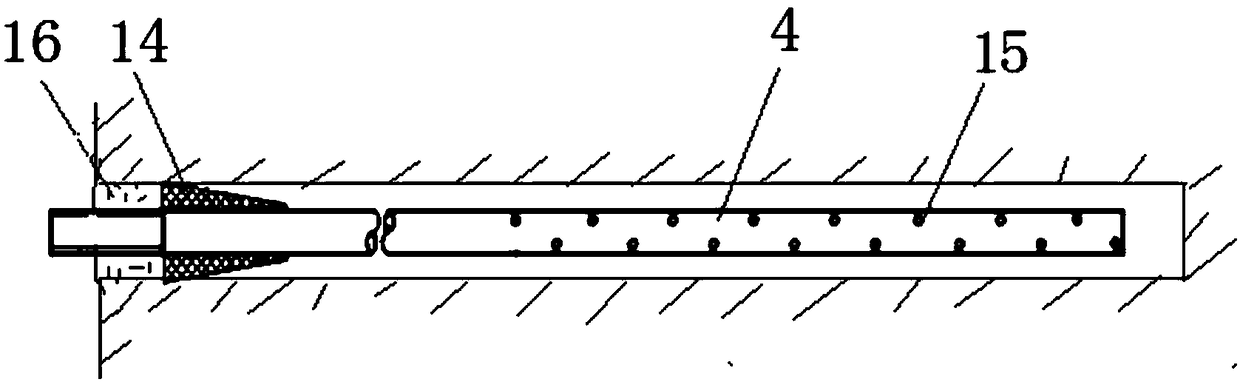

Fracture coal-rock mass quasi-three dimensional prestressed reinforcement method

InactiveCN108194100AEasy to controlEffectively closedUnderground chambersTunnel liningShotcreteSlurry

The invention discloses a fracture coal-rock mass quasi-three dimensional prestressed reinforcement method. The fracture coal-rock mass quasi-three dimensional prestressed reinforcement method comprises the steps that initial support of anchor net cables is conducted, tunneling and concrete spraying are conducted simultaneously, yielding anchor rods are mounted on the two sides and a roof of a roadway, and yielding anchor cables are mounted on the central line and the arch corner parts on the two sides of the roof correspondingly; secondly, slurry-injecting reinforcement is conducted, specifically, expansible slurry is injected into coal-rock mass on the two sides and the roof of the roadway; thirdly, concrete with the thickness being 100 mm is sprayed again; and fourthly, reverse arch reinforcement is conducted. The coal-rock mass subjected to slurry-injecting reinforcement is in a quasi-three dimensional stress state, and the bearing capability is improved obviously.

Owner:SHANDONG UNIV OF SCI & TECH

Vanadium-tungsten denitration catalyst and preparation method thereof

ActiveCN103638921BIncrease the areaImprove microporous structureDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsActivated carbonBULK ACTIVE INGREDIENT

The invention discloses a vanadium-tungsten denitration catalyst and a preparation method thereof. The catalyst is characterized in that active carbon is taken as a carrier, vanadium pentoxide is taken as a main active ingredient, and an organic binding agent and a forming addition agent are simultaneously added to assist the forming of the catalyst. Compared with the prior art, the preparation method disclosed by the invention has the advantages that the cost is low; as the specific surface area of the active carbon is large, the active ingredient can be well dispersed at the surface of the carrier, the contact area between gas and the catalyst is increased, and the denitration efficiency is improved; the denitration efficiency of the denitration catalyst can reach above 95% in a temperature range of 350-400 DEG C.

Owner:ANHUI YUANCHEN ENVIRONMENTAL PROTECTION SCI & TECH

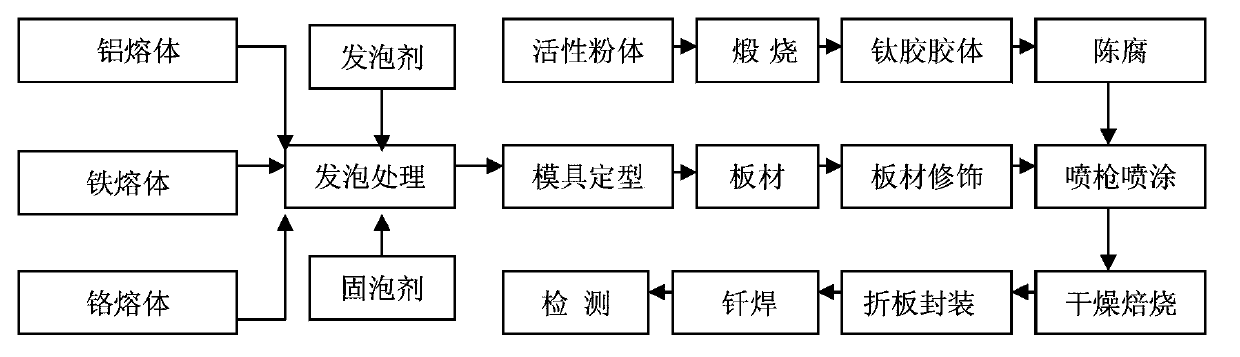

Preparation method of foaming stainless steel plate, and preparation method of heat-engine plant denitration catalyst

InactiveCN103866151AImprove microporous structureIncrease the areaCatalyst carriersDispersed particle separationFoaming agentPolyvinyl alcohol

The invention discloses a preparation method of foaming stainless steel plate, and a preparation method of a heat-engine plant denitration catalyst, and belongs to the technical field of denitration catalyst. The preparation method of the denitration catalyst is capable of solving problems of existing denitration catalysts that carrier open pore area is small, and ash clogging resistance is poor. The preparation method of the foaming stainless steel plate comprises following steps: a hydride foaming agent and polyvinyl alcohol are added into aluminum alloy melt for uniform stirring; an obtained mixture is delivered into a mould, and is subjected to foaming treatment so as to obtain the foaming stainless steel plate. The foaming stainless steel plate is large in open pore area, and excellent in ash clogging resistance. The foaming stainless steel plate is taken as the carrier of the denitration catalyst, and the preparation method of the denitration catalyst comprises following steps: step 1, titanium gel is prepared; step 2, humic acid is added into the titanium gel for staling; step 3, the surface of the foaming stainless steel plate is coated with the titanium gel via spraying, and is dried and roasted; and step 4, the heat-engine plant denitration catalyst monomer is obtained via plate folding, brazing, and packaging. The denitration catalyst is wide in use temperature range, and low in use cost.

Owner:SHANGHAI LANGT ELECTRIC POWER ENVIRONMENTAL PROTECTION TECH +1

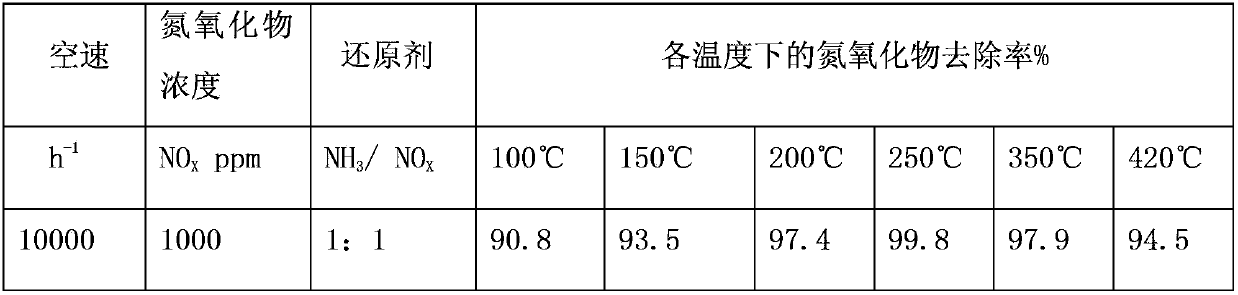

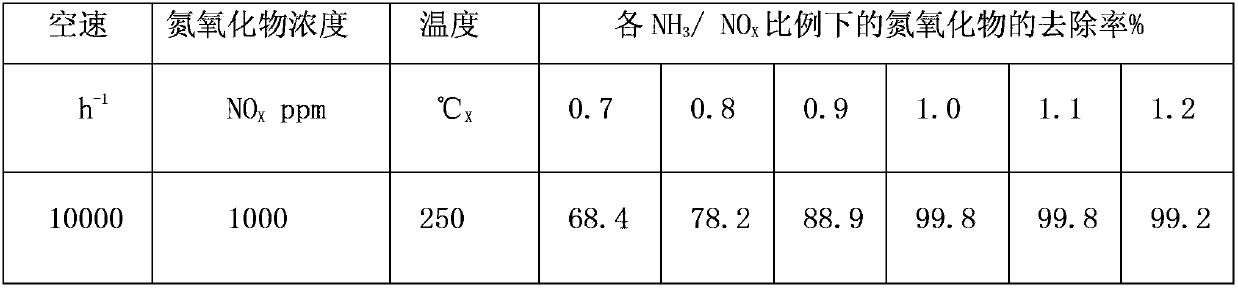

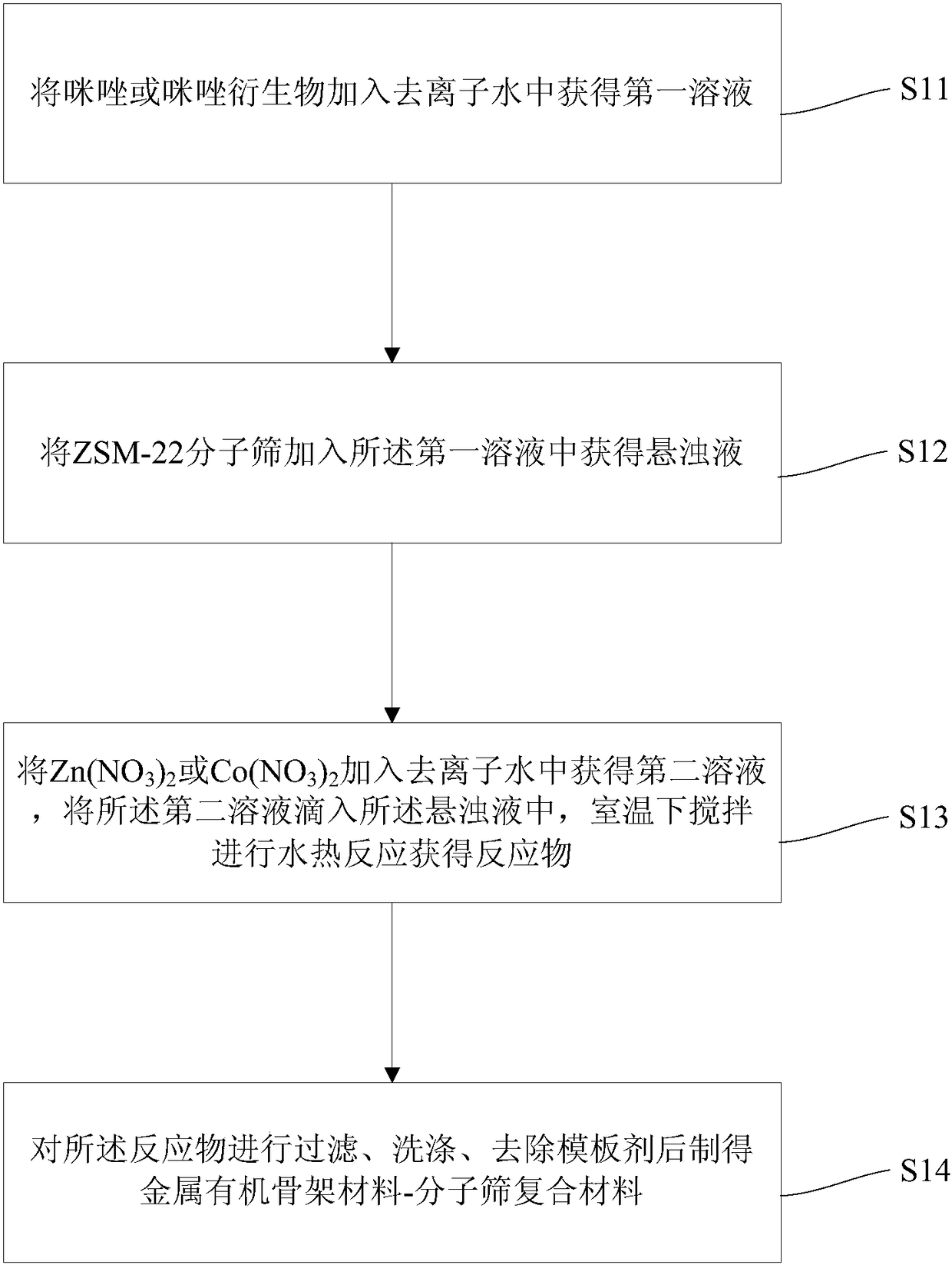

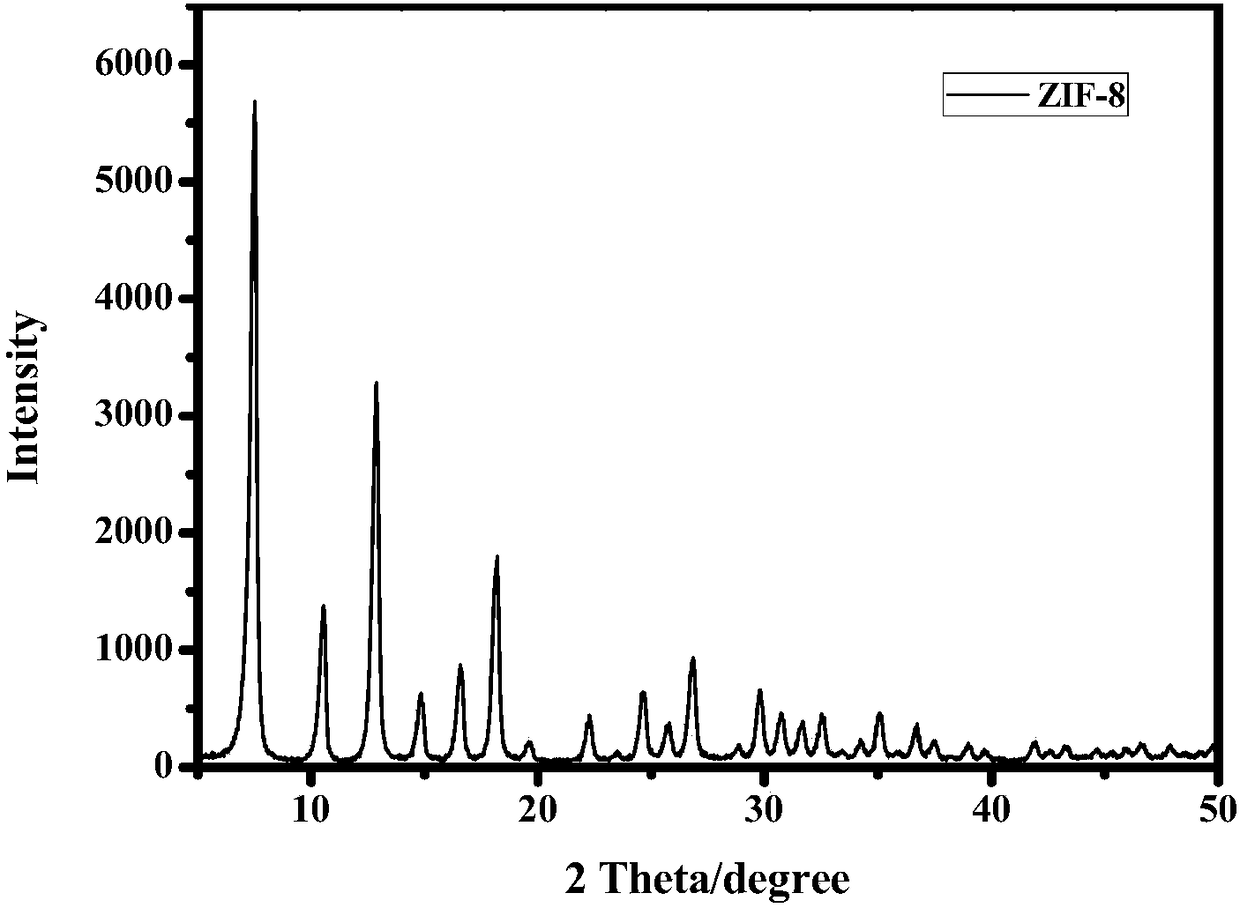

Metal organic framework material-molecular sieve composite material and preparation method thereof

ActiveCN108686623AImprove adsorption capacityIncrease the areaMolecular sieve catalystsOther chemical processesMolecular sieveChemical industry

The invention provides a metal organic framework material-molecular sieve composite material and a preparation method thereof. The preparation method comprises: adding a ZSM-22 molecular sieve to a solution containing Zn(NO3)2 or Co(NO3)2, and imidazole or an imidazole derivative, stirring at a room temperature, carrying out a hydrothermal reaction to obtain a reactant, filtering the reactant, washing, and removing the templating agent to obtain the metal organic framework material-molecular sieve composite material. According to the present invention, the material with high adsorption performance is prepared by compounding the organic framework material with excellent adsorption performance and the ZSM-22 molecular sieve, wherein the specific surface area and the microporous structure ofZSM-22 can be substantially improved through the compounding of ZIF-8, and the high hydrothermal stability of the silicon-aluminum molecular sieve can be combined; and the product has the excellent adsorption performance of the organic framework material, and can be widely used in the fields of medicine, chemical industry, environmental protection and the like.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI

Porous zeolite air purification material and preparation method thereof

InactiveCN107537451AImprove microporous structureGood film formingOther chemical processesDispersed particle separationPolyvinyl alcoholPhosphate

The invention discloses a porous zeolite air purification material. The material comprises, by weight, 37-40 parts of porous stone powder solution, 20-30 parts of acrylamide, 0.4-1 part of sodium diacetate, 3-4 parts of borax, 2-4 parts of aluminum dihydrogen phosphate, 1-2 parts of HEDP, 0.7-1 part of polydimethylsiloxane, 1-2 parts of calcium propionate, 2-4 parts of polyvinyl alcohol and 0.7-0.8 part of ammonium persulfate. Acrylamide serves as a monomer, HEDP is doped, and polymerization is conducted under the effect of an initiator, so that polymer emulsion is obtained; then the polymer emulsion is mixed and reacts with the polyvinyl alcohol solution of porous stone powder, the compatibility between the compound stone powder and the polymer is effectively improved, and then the stability of a finished product material is improved. The porous material has a good adsorption effect and is high in repeating utilization rate.

Owner:国投盛世承德科技股份有限公司

Oyster-shell soil conditioner, preparation method thereof and application of oyster-shell soil conditioner in rice planting

PendingCN108822863AImprove microporous structureImprove efficacyAgriculture tools and machinesOther chemical processesBiologyCalcination

The invention relates to an oyster-shell soil conditioner, a preparation method thereof and application of the oyster-shell soil conditioner in rice planting. Step-wise high temperature calcination isconducted on oyster shells, wherein the step-wise high temperature calcination comprises two calcination temperatures: a first calcination temperature and a second calcination temperature, the firstcalcination temperature is 300-550 DEG C, and the second calcination temperature is 900-1200 DEG C. According to the oyster-shell soil conditioner, by adopting step-wise high temperature calcination,the effect of soil modification by oyster shell can be improved significantly, the content of effective cadmium in rice soil can be reduced, the pH value of the soil can be improved, and the content of cadmium in the rice can be reduced significantly.

Owner:JIMEI UNIV

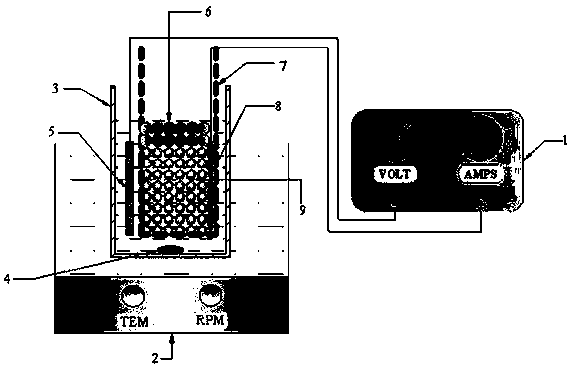

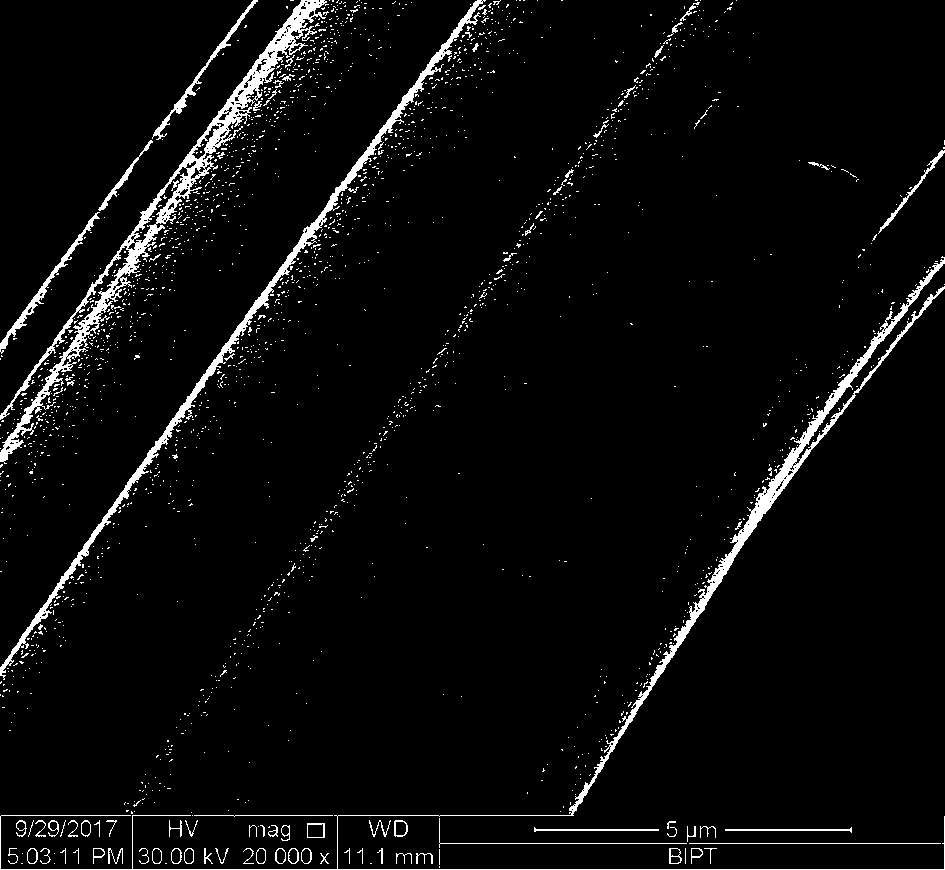

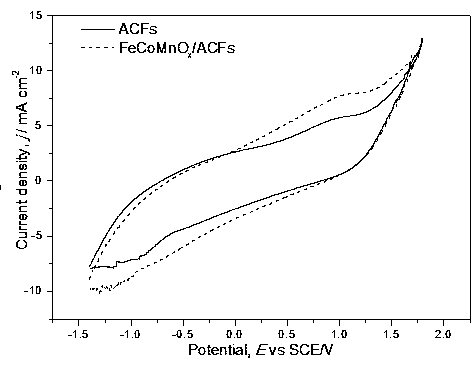

Active carbon fiber three-dimensional particle electrode catalyst and preparation method thereof

InactiveCN108212161AEfficient removalImprove adsorption capacityWater contaminantsCatalyst activation/preparationFiberWastewater

The invention discloses an active carbon fiber three-dimensional particle electrode catalyst and a preparation method thereof, and belongs to the technical field of electrocatalytic oxidation treatment of organic wastewater. The carrier of the particle electrode catalyst is activated active carbon fibers, and an activation technology comprises the steps of removal of ash from the active carbon fibers and surface modification of the active carbon fibers by an electrochemical reduction technique; and one or any combination of oxides of Fe, Co, Mn and Sn is supported on the active carbon fiber carrier to form the particle electrode catalyst. The preparation method comprises the following steps: removal of the ash from the active carbon fibers, addition of the activated active carbon fibers toa metal impregnation solution, and catalyst loading using an isopyknic impregnation technology. The catalyst has the advantages of high efficiency in removal of organic pollutants from the wastewater, no additional oxides in the reaction process, reduction of the process operation risk, simple required device, strong oxidation capability and low production cost, and can be applied to the treatment of the organic wastewater.

Owner:山西晋环科源环境资源科技有限公司 +1

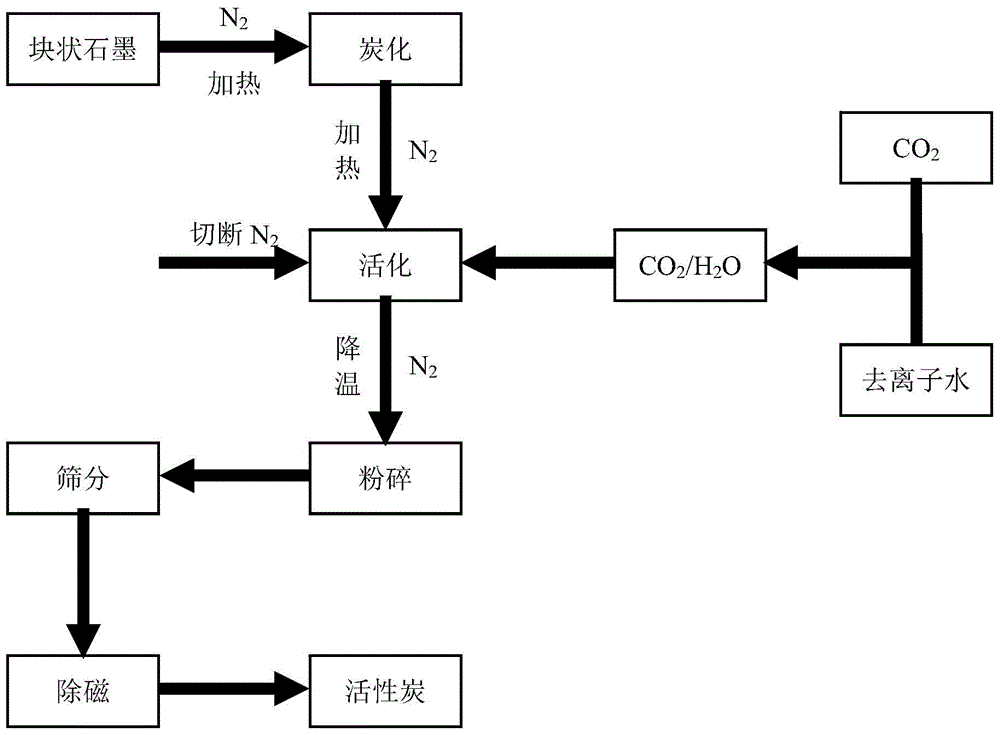

Activated carbon material and preparation method thereof and supercapacitor

ActiveCN104609419ALow costLarge specific surface areaCarbon compoundsHybrid capacitor electrodesPorosityCapacitance

The invention discloses an activated carbon material and a preparation method thereof and a supercapacitor, which belong to the technical field of electrode materials. The activated carbon material is prepared by taking blocky graphite as a raw material through heating the blocky graphite to 500-700 DEG C at a heating rate of 10-20 DEG C / min; carbonizing the blocky graphite, and heating the blocky graphite to 700-900 DEG C at a heating rate of 0-20 DEG C / min; and feeding activation gas for activating the obtained object, so that an activated carbon material with large specific surface area, large total pore volume and high porosity is obtained. Because the blocky graphite is taken as a raw material, the activated carbon material is wide in source and low in price, thereby saving cost. The preparation method disclosed by the invention is mild in activation conditions, small in energy consumption, environmentally friendly, easy to operate, wide in raw material sources, low in cost, and suitable for large-scale industrial production. The supercapacitor disclosed by the invention takes the activated carbon material prepared according to the invention as an electrode material, so that the specific capacitance and charge-discharge cycle performance of the supercapacitor are improved, and the requirements of the supercapacitor on high specific capacitance and excellent large current properties are met.

Owner:LUOYANG YUEXING NEW ENERGY TECH

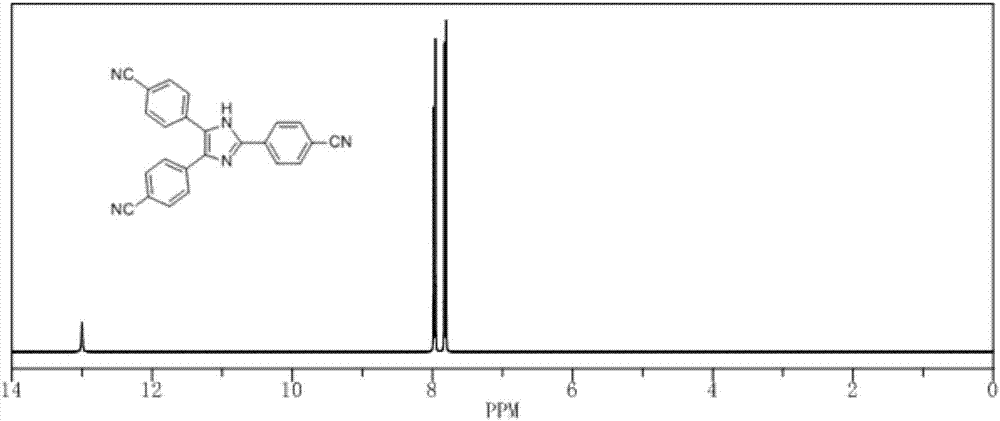

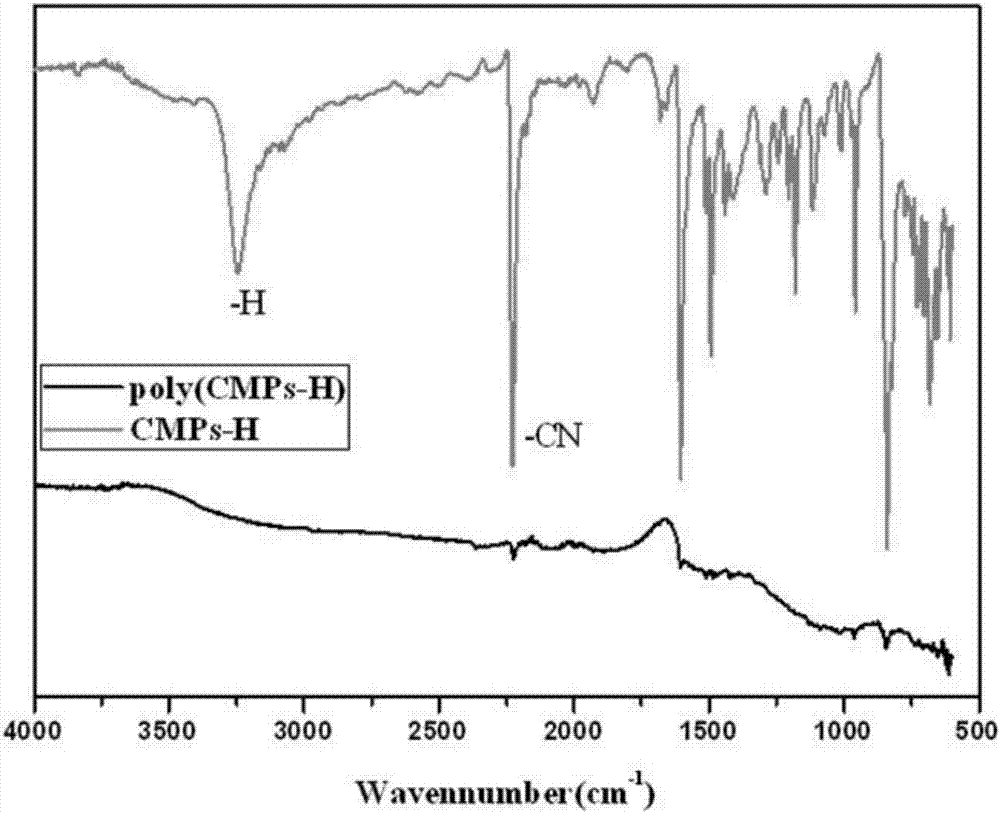

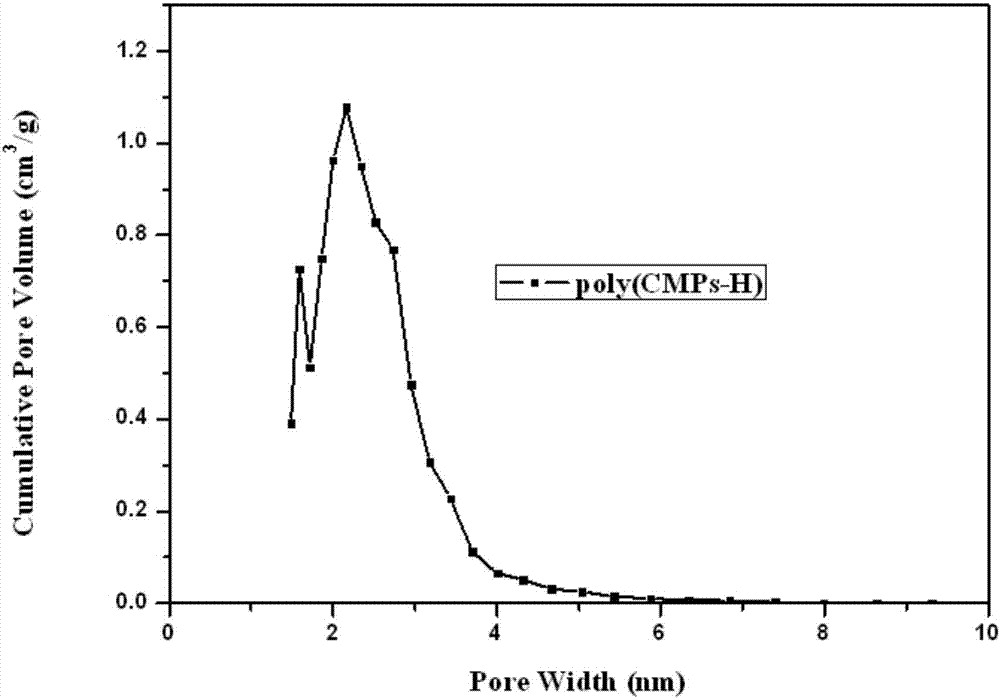

Rigid porous framework polymer with gas adsorption performance, preparation method of polymer and application

InactiveCN106905526AHas gas adsorption propertiesHigh nitrogen contentOther chemical processesDispersed particle separationPolymer scienceNitrogen

The invention provides a rigid porous framework polymer with gas adsorption performance. A monomer is triaryl tricyano imidazole of R substitution, and R is hydrogen or alkyl with 1-5 carbon atoms. The invention provides a preparation method of the porous polymer and application of the porous framework polymer to the field such as oxygen reduction, hydrogen storage, adsorption and separation. The porous polymer materials have high nitrogen content and a micro-pore structure, the contact area between gas and the polymer is greatly increased, adsorption efficiency is improved, and the rigid porous framework polymer has good oxygen reduction performance under the carbon-forming condition and has good application prospects in the field such as oxygen reduction, hydrogen storage, adsorption and separation.

Owner:XIANGTAN UNIV

Environment-friendly ceramic tile and manufacturing method thereof

InactiveCN105601321AGood structural strengthGood microporous structureCeramicwareTalcEnvironmental resistance

The invention provides an environment-friendly ceramic tile. The environment-friendly ceramic tile is prepared from components in parts by weight as follows: 60-80 parts of diatomaceous earth, 5-10 parts of pyrophyllite, 1-5 parts of ball clay, 3-9 parts of spodumene, 5-10 parts of albite and 2-5 parts of talc. The environment-friendly ceramic tile is light in mass and high in structural strength and has functions of dehumidification, deodorization, indoor air purification and the like; with the adoption of a manufacturing method of the environment-friendly ceramic tile, the best structural strength and the best cellular structure of the ceramic tile can be guaranteed.

Owner:CHONGQING LEHU TECH CO LTD

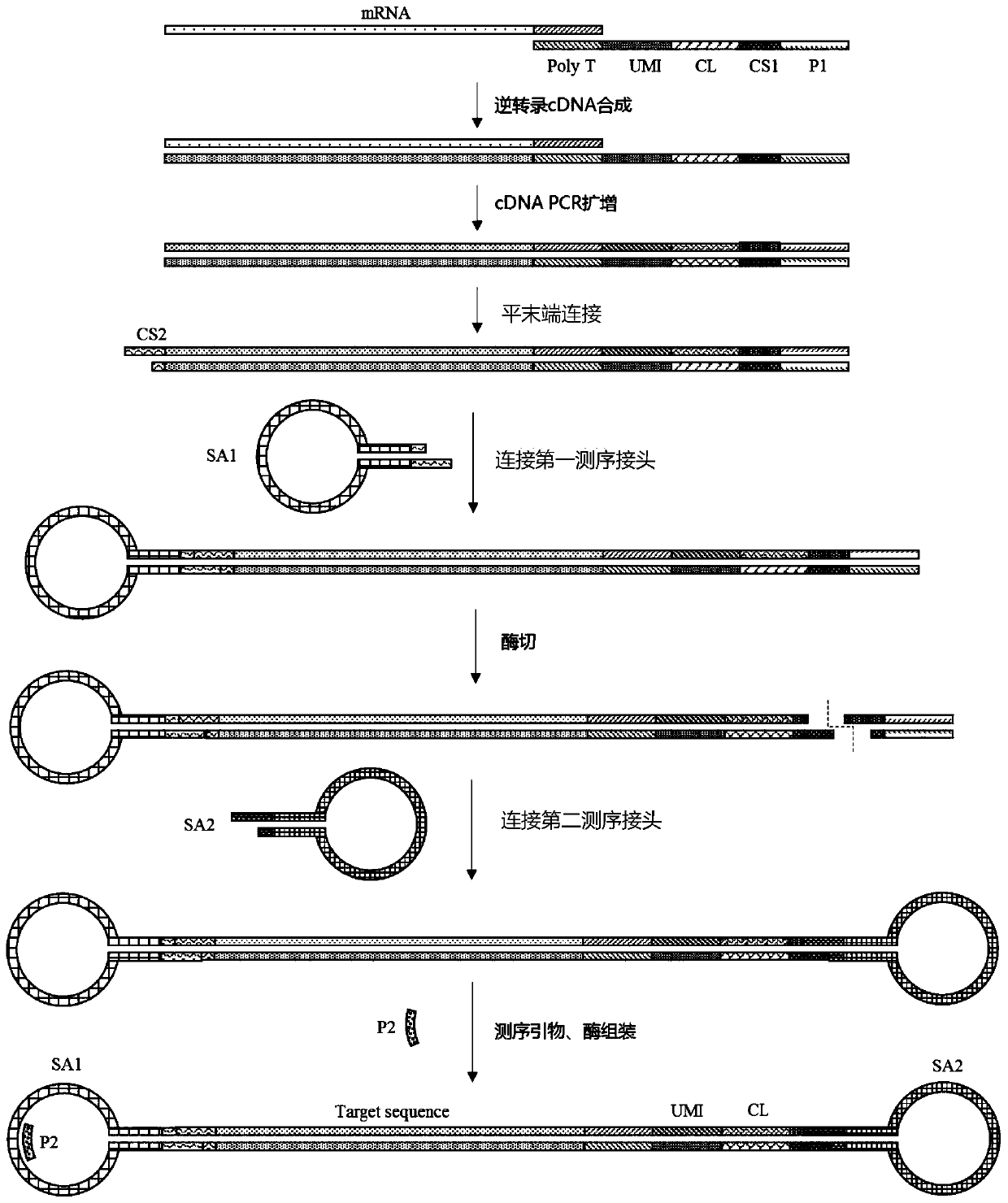

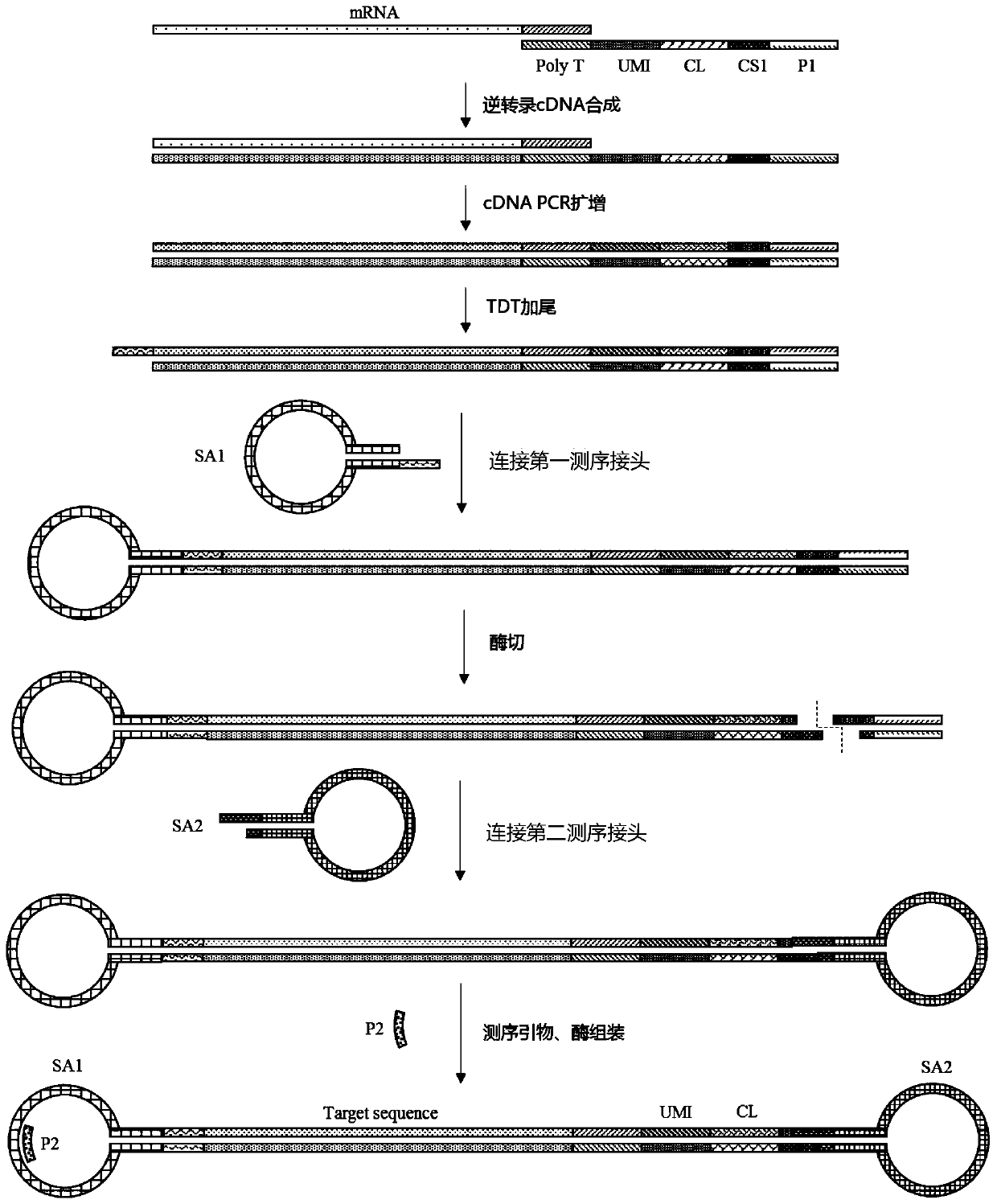

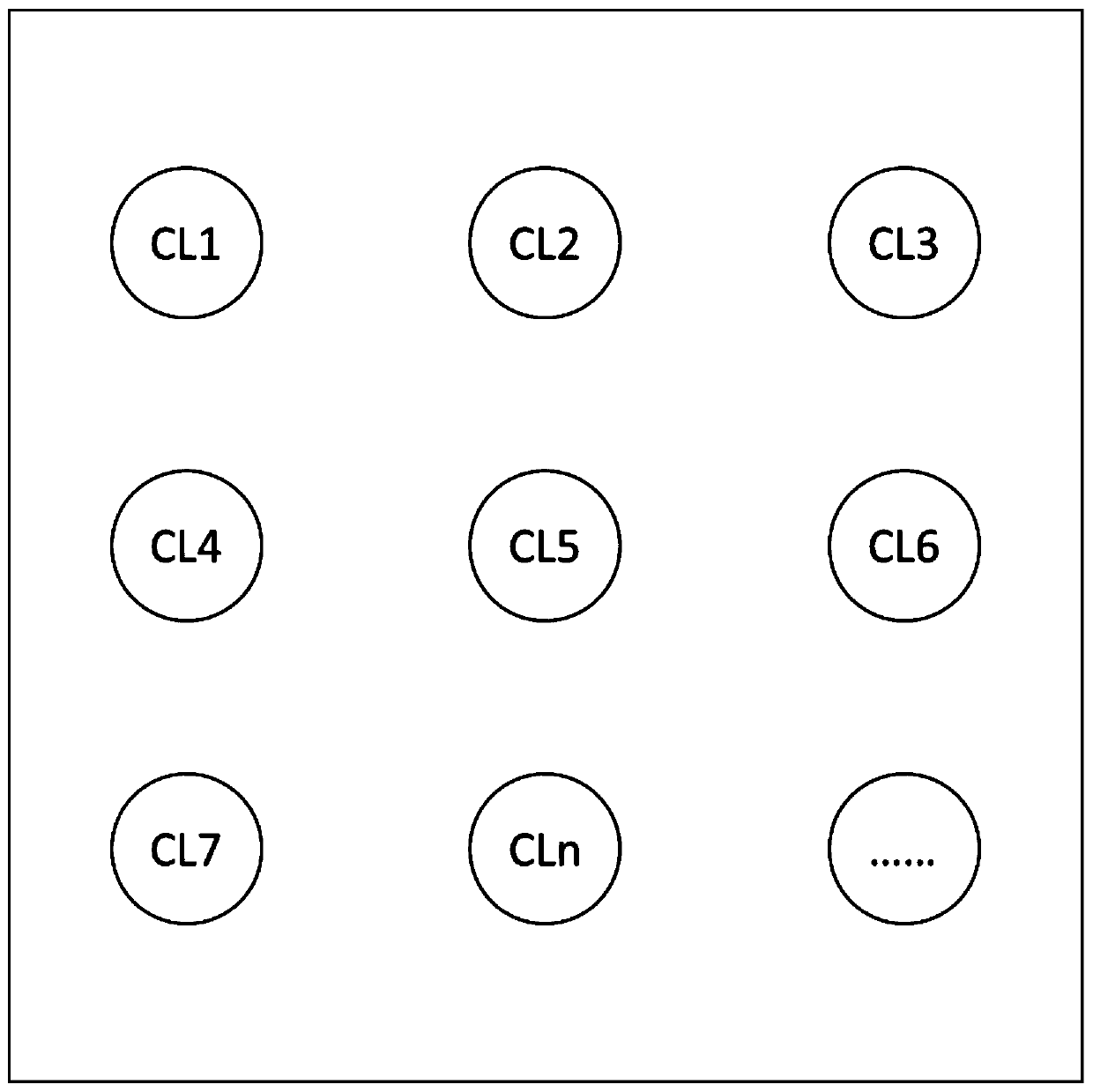

MRNA capture sequences, synthesis method of capture carrier and production method of high-throughput single-cell sequencing library

ActiveCN111088250AImprove capture efficiencySequencing guaranteeMicrobiological testing/measurementLibrary creationNucleotideCell trapping

The invention provides mRNA capture sequences. The mRNA capture sequences comprise universal primers, rare enzyme cutting sites, cell tags, random molecular tags and PolyT sequences, wherein by introducing rare enzyme cutting site sequences, sticky ends are provided for subsequent sequencing connector connection, so that two ends of a cDNA double strands are connected with two different sequencingconnectors. A synthesis method of a capture carrier used for mRNA capture and a production method of a high-throughput single-cell sequencing library are further provided. According to the provided capture carrier, by synthesizing the mRNA capture sequences of the rare enzyme cutting site sequences in situ and introducing the mRNA capture sequences of the rare enzyme cutting site sequences on a base material, the provided capture carrier is adopted for preparing the single-cell sequencing library, the single-cell capture efficiency and the labelling efficiency of oligonucleotide tags are improved, a process of constructing the library is simplified, and the two ends of the produced cDNA double strands are connected with the two different sequencing connectors, so that it is guaranteed that one dumbbell-shaped sequencing library is only assembled with a primer and DNA polymerase, and one-to-one correspondence of the dumbbell-shaped sequencing library, the primer and the DNA polymeraseis the premise of guaranteeing single-cell real-time sequencing.

Owner:SUZHOU INST OF BIOMEDICAL ENG & TECH CHINESE ACADEMY OF SCI

Polyurethane foam base adhesive tape

InactiveCN105838275AUniform and fine cell structureIncrease elasticityFilm/foil adhesivesPolyesterCross-link

The invention relates to a polyurethane foam base adhesive tape and belongs to the technical field of adhesive tapes. The polyurethane foam base adhesive tape comprises a polyurethane foam base plate, a glue coating and a release film. The polyurethane foam base plate comprises, by weight, 100 parts of polyester polyol, 11.5-28.3 parts of diisocyanate, 8-12 parts of a chain extender, 5-13 parts of a cross-linking agent, 1.0-2.5 parts of a light stabilizing agent and 5-11 parts of mesoporous nano-TiO2. The polyurethane foam base adhesive tape has high strength, good toughness, good impact resistance and small thickness and can be used for precision apparatus manufacture. The mesoporous nano-TiO2 heterogeneous nucleation effects improve a polyurethane foam base plate microporous structure and improve strength, toughness and shock resistance. Supercritical CO2 is used for polyurethane foam base plate foaming so that safety and environmental friendliness are obtained. The foam has uniform and fine pores. The polyurethane foam has any thickness and is suitable in different fields.

Owner:NINGBO JIXIANG PLASTIC PROD CO LTD

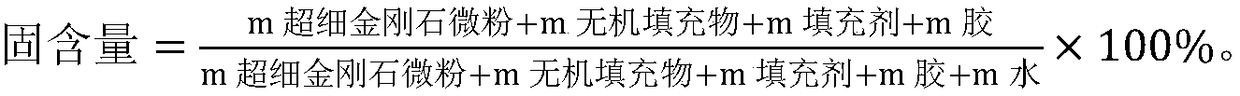

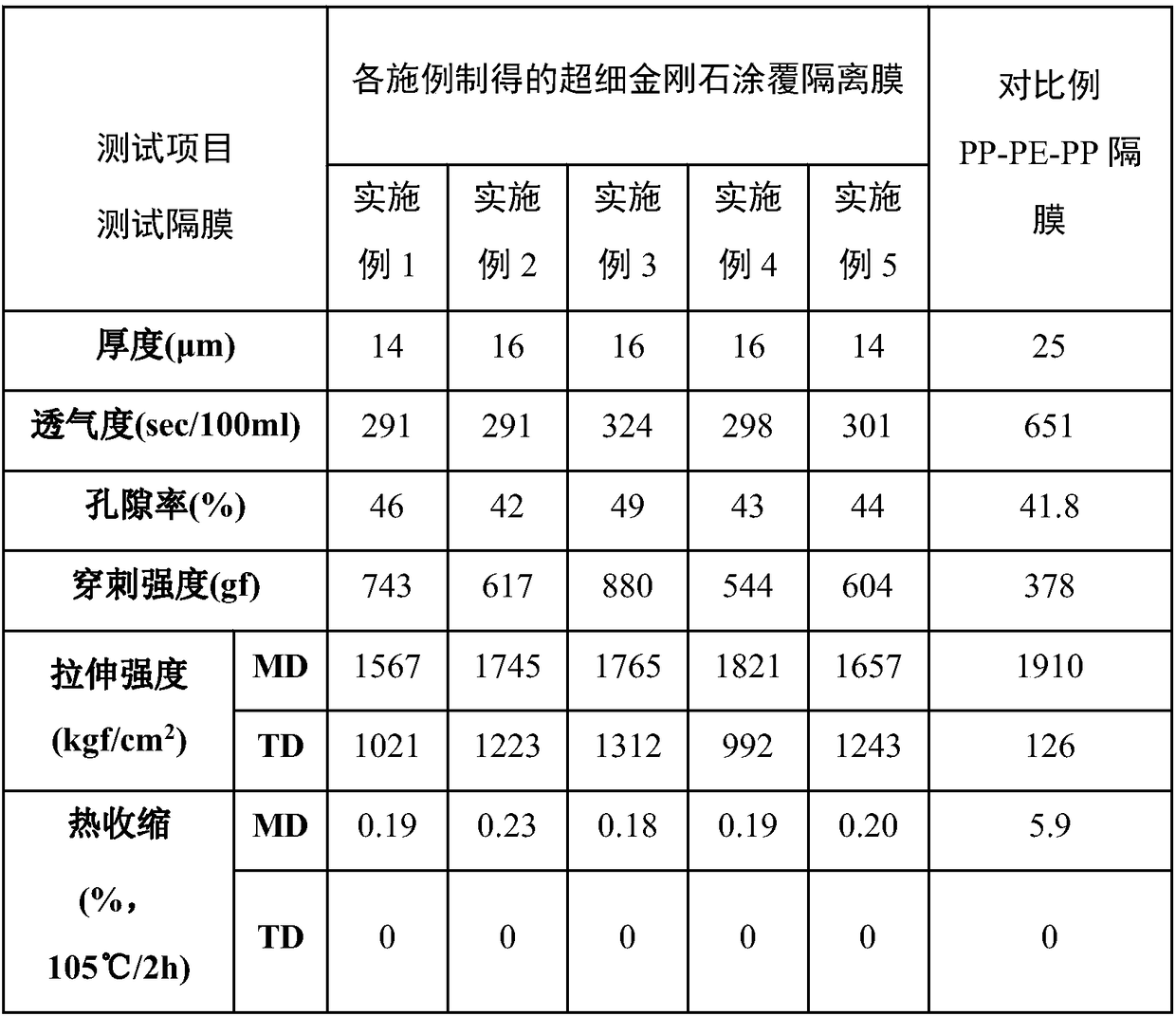

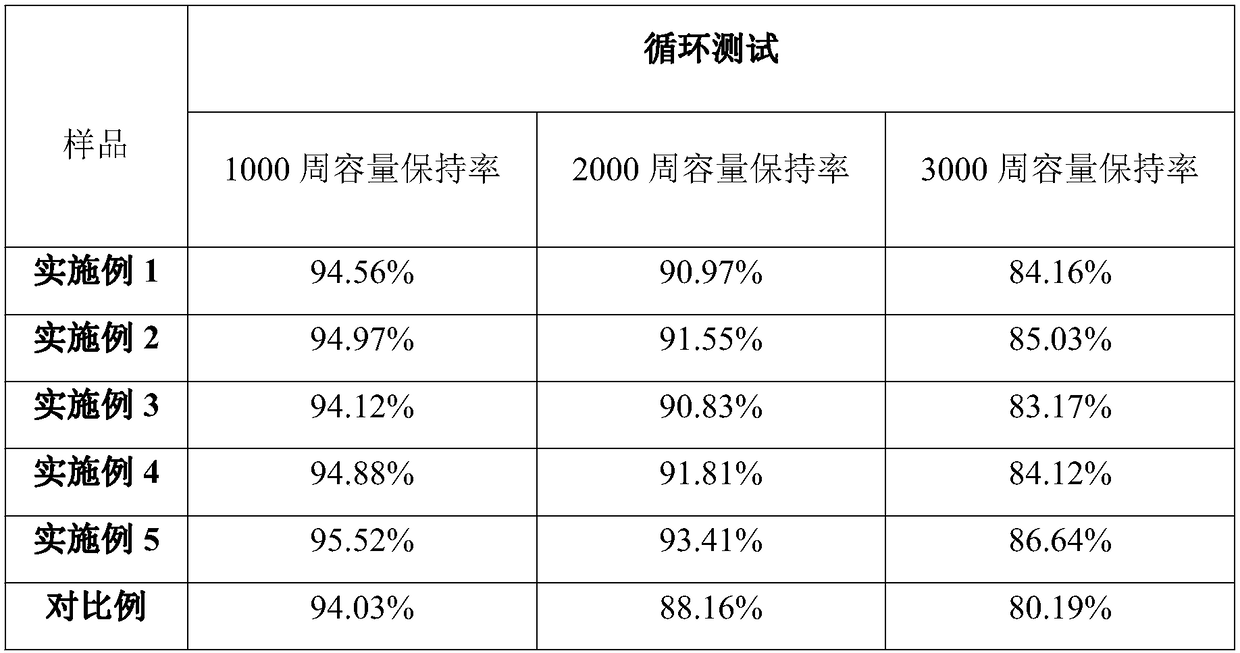

Ultrafine diamond coated diaphragm and lithium ion battery using diaphragm

ActiveCN108550764AImprove microporous structureExcellent heat shrinkage resistanceSecondary cellsCell component detailsLithium electrodeInorganic filler

The invention belongs to the technical field of lithium ion batteries, and relates to an ultrafine diamond coated diaphragm, a preparation method thereof, and a lithium ion battery using the diaphragm. The ultrafine diamond coated diaphragm is prepared through the following steps: coating a base film with a slurry, and drying the coated base film, wherein the slurry contains, by mass, 65-85% of ultrafine diamond micro-powder and am inorganic filler, 10-25% of a filler and 3-15% of glue; and the mass of the ultrafine diamond micro-powder is 0.5-100% of the total mass of the ultrafine diamond micro-powder and the inorganic filler. The diaphragm makes micron-sized diamond crystal particles uniformly dispersed on the surface of the base film, so the micro-porous structure of the diaphragm is effectively strengthened, and the heat shrinkage resistance and the puncture strength are improved. The lithium ion battery using the diaphragm improves the transfer state of lithium ions in an electrode sheet interface, inhibits the lithium ions from accumulating into lithium element dendrite after the lithium battery is repeatedly circulated, and improves the safety and the cycle performances ofthe battery.

Owner:河南力旋科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com