Foam two-sided adhesive tape

A double-sided adhesive tape and foam technology, applied in the field of foam double-sided adhesive tape, can solve the problems of insufficient shock resistance, low adhesive performance, and insufficient strength, etc., to avoid early decomposition, excellent mechanical properties, and cellular structure regular effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

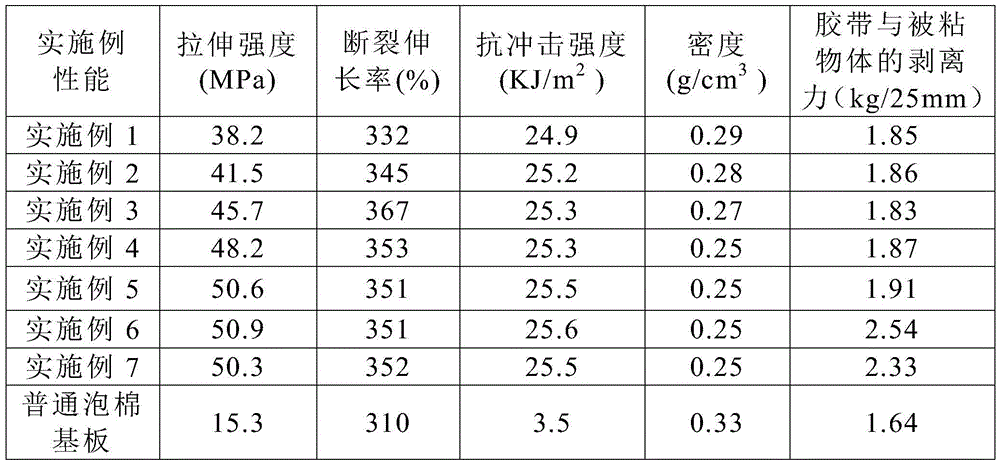

Embodiment 1

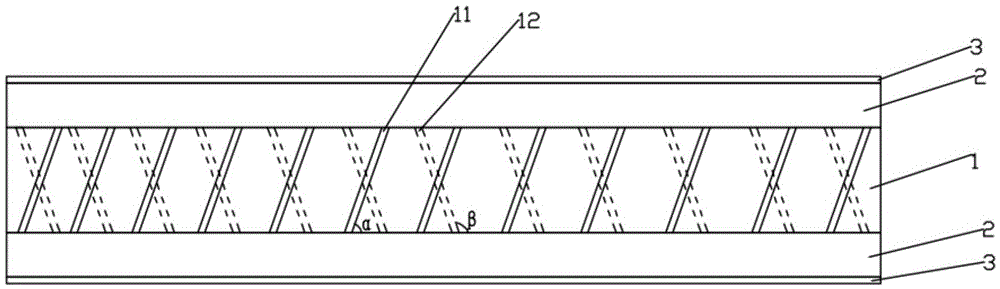

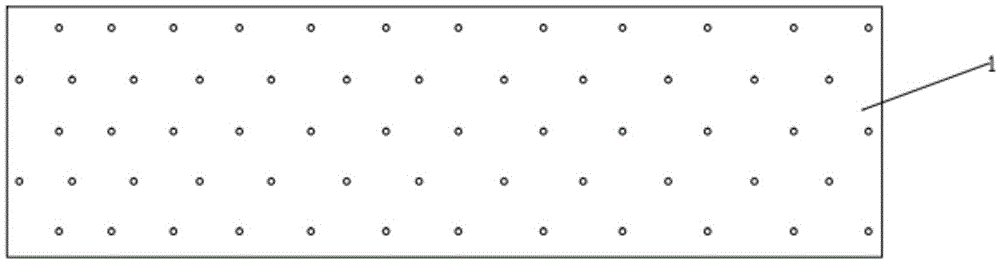

[0042] An inclined longitudinal through hole is provided between the upper surface and the lower surface of the foam substrate, the diameter of the longitudinal through hole is 220 μm, and the density on the surface of the foam substrate is 5 pieces / mm 2 . The longitudinal through hole includes longitudinal through hole I11 and longitudinal through hole II12, the angle between the longitudinal through hole I11 and the side of the lower surface of the foam substrate is α, and α is 25°, and the angle between the longitudinal through hole II12 and the side of the lower surface of the foam substrate The included angle is β, and β is 155°.

[0043] The foam substrate includes the following components in parts by weight:

[0044] 100 parts of PMMA,

[0045] 28 parts polyurethane,

[0046] 18 parts of fluorine rubber,

[0047] Light stabilizer UV-329 1.5 parts,

[0048] Mesoporous Nano TiO 2 5 copies,

[0049] Foaming agent 20 parts.

[0050] Wherein, the foaming agent is a c...

Embodiment 2

[0052] The difference from Example 1 is that,

[0053] The foam substrate includes the following components in parts by weight:

[0054] 100 parts of PMMA,

[0055] 30 parts of polyurethane,

[0056] 20 parts of fluorine rubber,

[0057] Light stabilizer GW-540 2.5 parts,

[0058] Mesoporous Nano TiO Modified by Silane Coupling Agent 2 8 servings,

[0059] Foaming agent 25 parts.

[0060] Wherein, the foaming agent is a composite powder of rare earth, sodium bicarbonate and azodicarbonamide with a weight ratio of 5:6:8.

Embodiment 3

[0062] The difference from Example 1 is that,

[0063] The foam substrate includes the following components in parts by weight:

[0064] 100 parts of PMMA,

[0065] 35 parts of polyurethane,

[0066] 23 parts of fluorine rubber,

[0067] Light stabilizer antioxidant 10103.2 parts,

[0068] Mesoporous Nano TiO Modified by Titanate Coupling Agent 2 11 copies,

[0069] 30 parts of foaming agent.

[0070] Wherein, the blowing agent is a composite powder of rare earth, sodium bicarbonate and azodicarbonamide with a weight ratio of 5:7:10.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com