Method for performing compatibilization treatment on vulcanized rubber powder produced by utilizing waste rubber

A technology for vulcanized rubber powder and waste rubber, applied in recycling technology, mechanical material recycling, plastic recycling, etc., can solve the problems of inoperable continuous operation, complex process, large surface tension, etc., and achieve continuous production. Process simplification and improved compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

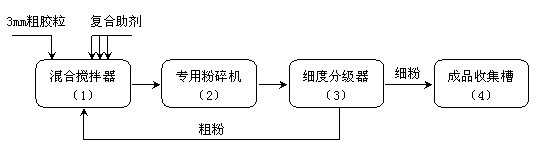

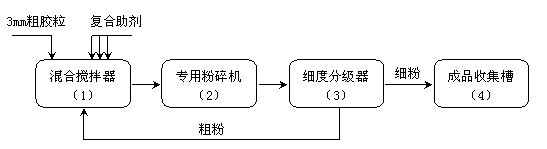

Image

Examples

Embodiment 1

[0022] Embodiment 1: Compatibilization treatment of vulcanized rubber powder mixed with rubber products

[0023] Remove impurities from waste rubber tires containing 30% (weight) of natural rubber, 35% (weight) of styrene-butadiene rubber, and 35% (weight) of butadiene rubber, and cut them into coarse rubber particles with a particle size of 2.5mm±0.5mm. Put into mixing agitator 1, drop into composite auxiliary agent according to the following proportion simultaneously: crushing auxiliary agent: hydrophobic silicon dioxide, 1.0%; Active dispersant: glyceryl monostearate, 1.0%, calcium stearate, 0.5%; The compatibilizing modifier is determined according to the blending purpose, and it is blended with non-polar rubber (such as natural rubber / NR, isoprene rubber / IR, styrene-butadiene rubber / SBR, butadiene rubber / BR, butyl rubber / IIR, Propylene rubber / EPM / EPDM), use C5 aliphatic hydrocarbon resin or C5 aliphatic hydrocarbon resin and C9 aromatic hydrocarbon resin

[0024] Polymer...

Embodiment 2

[0027] Embodiment 2: Compatibilization treatment of vulcanized rubber powder mixed with plastic products

[0028] The raw material components of waste rubber tires contain 20% (weight) of natural rubber, 30% (weight) of styrene-butadiene rubber and 50% (weight) of butadiene rubber. The process operation steps are the same as in Example 1, the difference is the kind and proportioning of compounding additives. Grinding aid: sodium salt of maleic acid-acrylic acid copolymer, 1.0%; active dispersant: glyceryl tristearate, 1.0%, zinc stearate, 0.5%; compatibilizing modifier is determined according to the purpose of blending, For non-polar plastics (such as polyethylene / PE, polypropylene / PP, polystyrene / PS), use ethylene-methyl acrylate copolymer resin, or ethylene-ethyl acrylate copolymer resin, or ethylene- Butyl Acrylate Copolymer Resin, 3.0%. For polar plastics (such as vinyl polyvinyl chloride / PVC), use styrene-butadiene copolymer resin, or styrene-methyl methacrylate copolym...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com