Split type bearing cage connection scheme

A technology of bearing frames and rolling bearings, applied in the direction of bearings, bearing assembly, shafts and bearings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

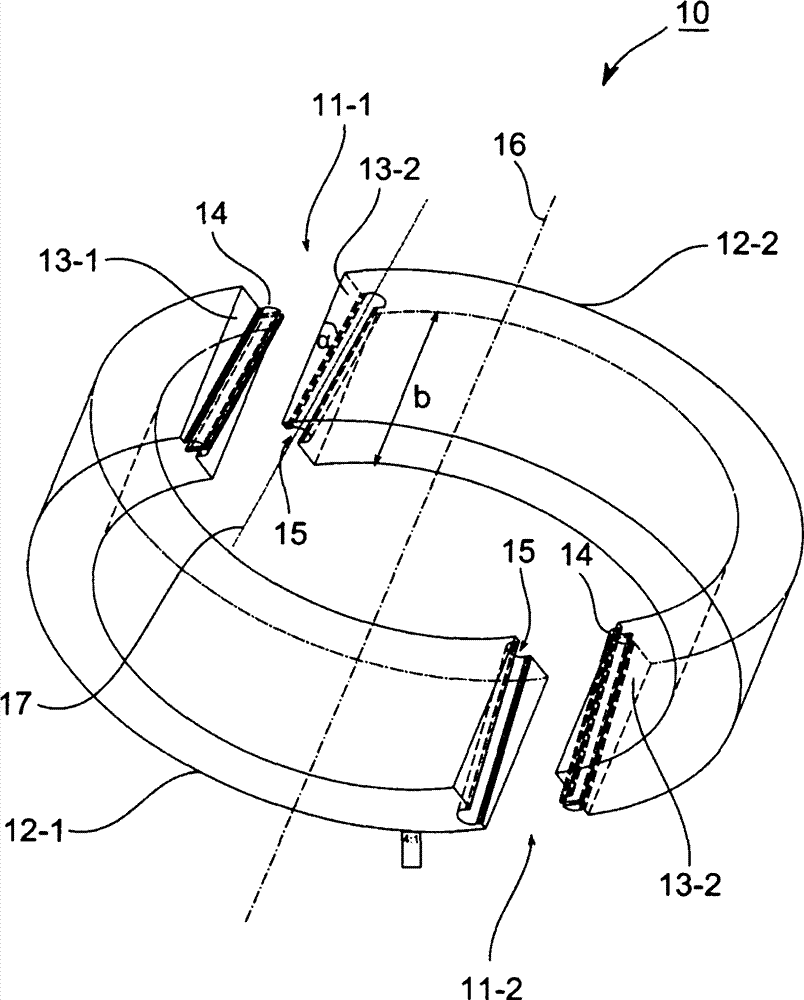

[0037] figure 1 A three-dimensional schematic diagram showing an embodiment of a split bearing frame 10 for guiding the rolling bodies of a rolling bearing.

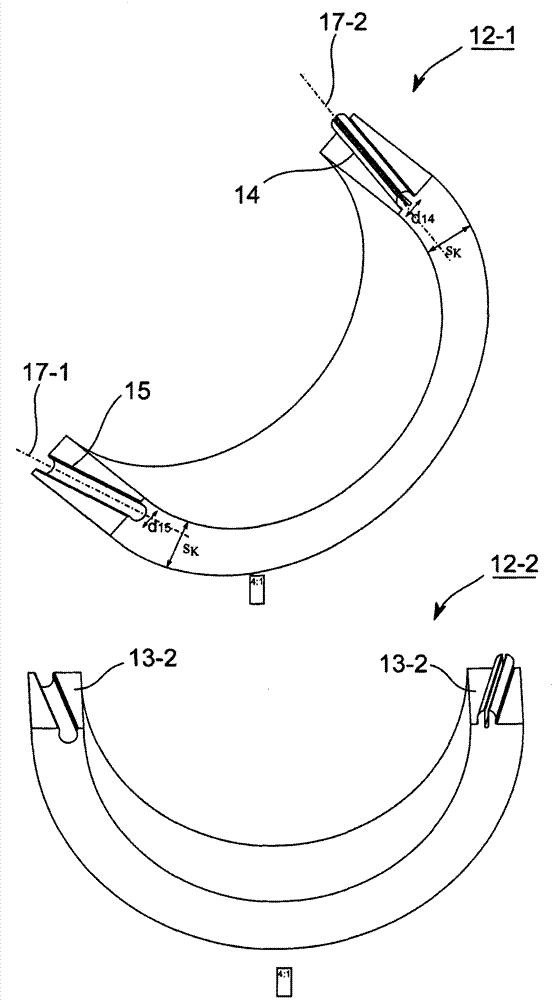

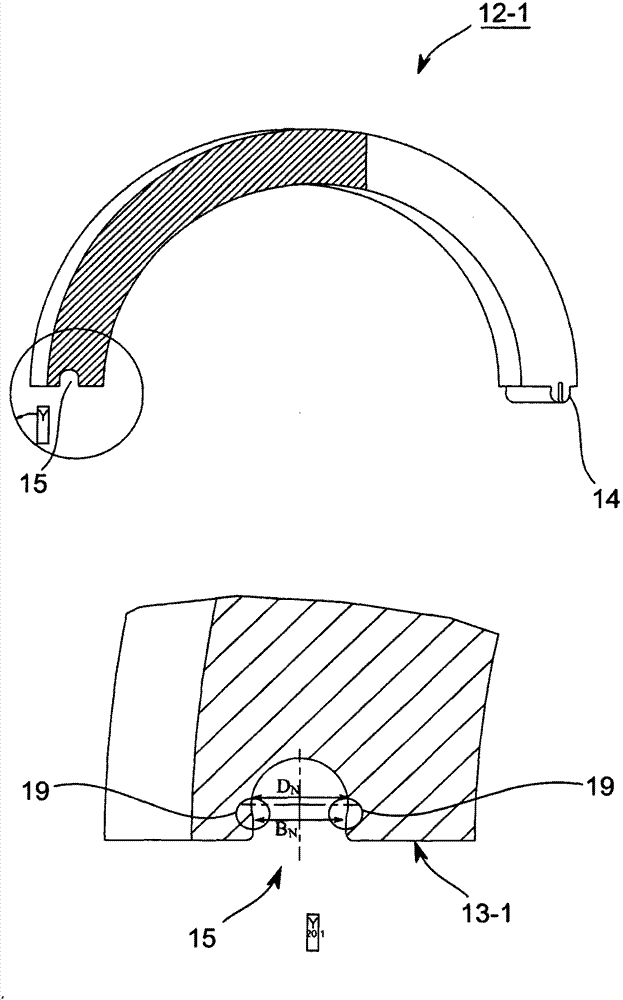

[0038] The bearing frame 10 is slit in the circumferential or tangential direction, for example at two separation locations 11-1, 11-2 between the first bearing frame section 12-1 and the second bearing frame section 12-2 or constructed separately. Formed respectively on the mutually (circumferentially) facing interface surfaces 13-1, 13-2 of the separation locations 11-1, 11-2 between the first and second bearing frame sections 12-1, 12-2 There is a pair consisting of a protrusion 14 and a corresponding and (circumferentially) opposite recess 15 for forming a contact in three directions (axial, radial and tangential) when the protrusion 14 and the corresponding recess 15 are engaged with each other. Fix or arrange the interface surfaces 13-1, 13-2 upward to each other. The protrusion 14 and its corresponding recess 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com