Patents

Literature

178results about How to "Foam stabilization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Oily cosmetic composition in aerosol form

InactiveUS20080031908A1Process stabilityHappy to useCosmetic preparationsHair cosmeticsParaffin waxSolid particle

Aerosol product containing an oily composition containing at least one oil, and at least one hydrocarbon compound having a melting point greater than or equal to 30° C., the compound being in the form of solid particles and one or more propellants. The hydrocarbon compound can notably be a paraffin or a fatty acid amide. Used for cleaning and / or make-up removal of the skin and / or of the hair, care of the skin and / or of the hair, for protecting the skin against the sun, and for make-up of the skin.

Owner:LOREAL SA

Eva recycling method

ActiveUS20140066530A1Good physical propertiesMore rubberySolesPlastic recyclingFoaming agentPetroleum resin

A method of recycling scrap ethylene-vinyl acetate (EVA) foam involves foaming and crosslinking a blend containing virgin EVA resin and scrap EVA foam, as well as a crosslinking agent and blowing agent for the EVA resin. The blend further contains a compatibilizer, which is a hydrogenated petroleum resin.

Owner:NIKE INTERNATIONAL LTD

Cosmetic and pharmaceutical foam carrier

InactiveUS20070224143A1Foam stabilizationCosmetic preparationsHair removalAlcohol freeSurface-active agents

The invention provides a quick-break, alcohol-free, cosmetic and pharmaceutical foam carrier comprising about 20%-60% hydrophobic volatile solvent, about 20%-60% water, about 3%-20% of polyol, and about 0.1%-7.5% of a surface active agent.

Owner:KAMEDIS

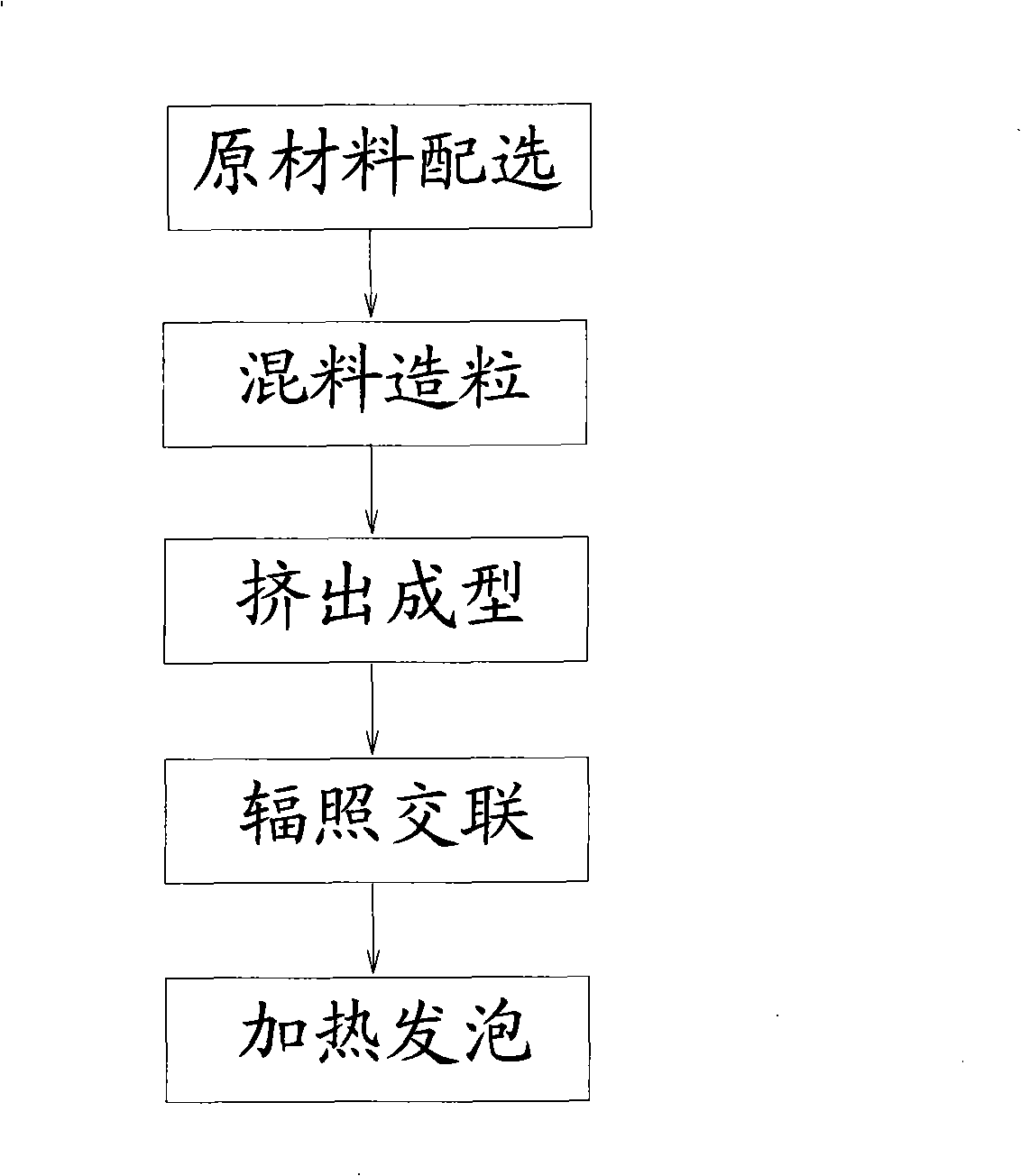

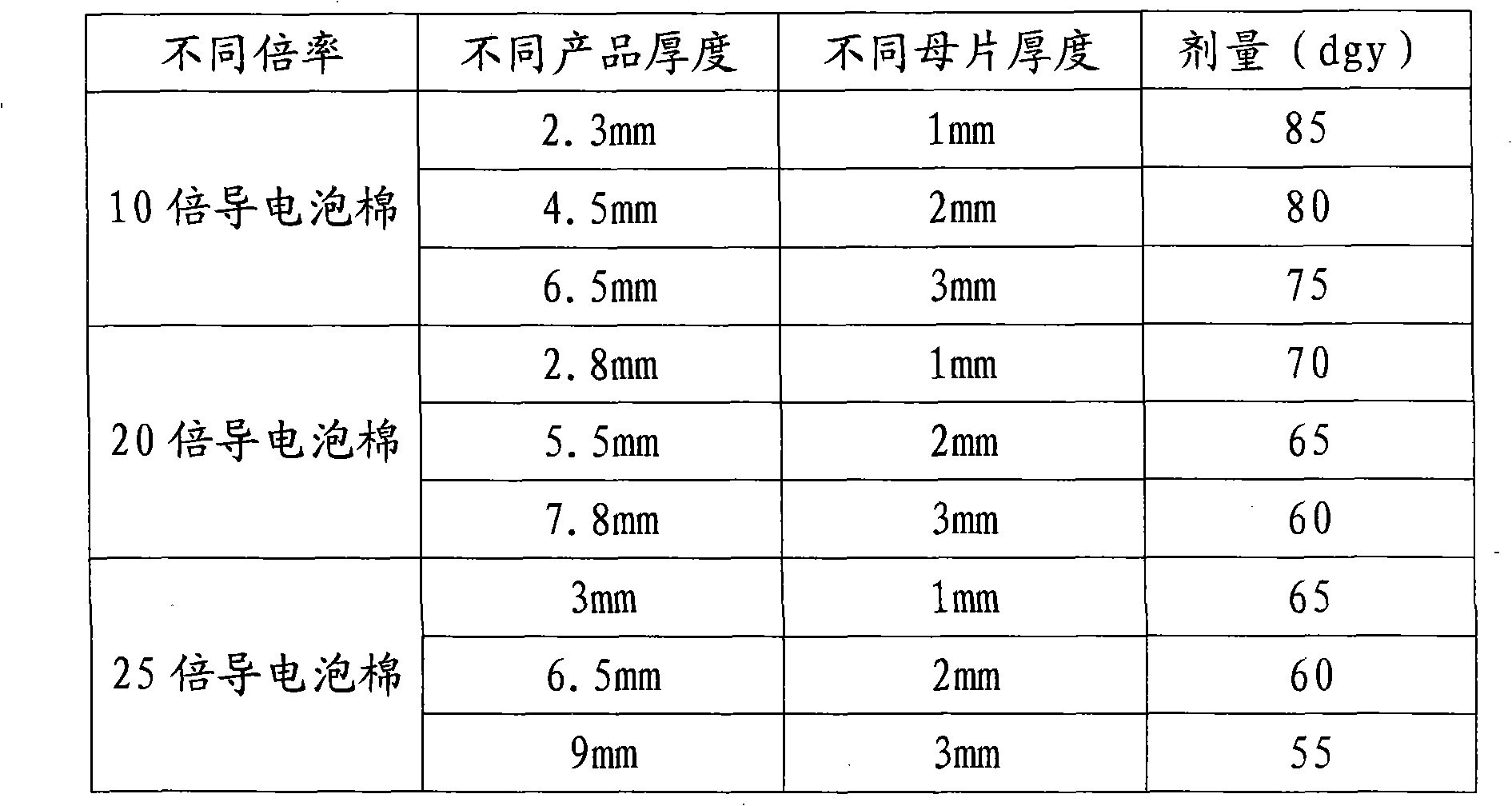

IXPE electron radiation on crosslinking polyethylene conductive foam and preparation method thereof

The invention relates to an IXPE electronic radiation crosslinked polyethylene conductive foam and a preparation method thereof. The IXPE electronic radiation crosslinked polyethylene conductive foam mainly contains the mother batch: low density polyethylene; accessories: ethylene-vinyl acetate copolymer, azodicarbonamide blowing agent, polyethylene wax lubrication additive, titanate ester coupling agent and conductive carbon black which are mixed for processing, extruded for molding, radiated for crosslinking, heated for foaming, and treated by secondary processing, etc, to produce the IXPE electronic radiation crosslinked polyethylene conductive foam. The crosslinking of the product of the invention can be easily controlled, the foaming process is stable, the foam pores are fine and even, the quality of the surface is high without unpleasant odor, the foam pores are obstructed, the production can be carried out continually, the electrical conductivity is stable, the product is lightweight, non-toxic, extremely less absorbent; the thermal conductivity is slow, aging resistant, chemical corrosion resistant, pulverization resistant, and a plurality of porous foam materials can be easily achieved; in addition, the product has good properties to be treated by the secondary processing procedures, such as bonding, machining, hot forming, etc.

Owner:SHENZHEN CHANGYUAN TEFA TECH CO LTD

Foam manipulation compositions containing fine particles

ActiveUS20090252691A1Facilitates formation of foamLower Level RequirementsCosmetic preparationsNanotechFOAM CONTROLSURFACTANT BLEND

A foam manipulation stabilizing composition for use in consumer products includes a plurality of surface-modified particles in combination with at least one surfactant. The particles have an average particle size greater than 100 nm up to about 50 μm and a hydrophobicity measured by a contact angle between about 20° to 140°. The ratio of particles-to-surfactant may be between about 1:20 to about 20:1. The surface modification may include grafting pH or temperature switching functional groups to the particles or to a composition, such as a polymer, coated on the particle. A method for reducing the level of foam in a rinse solution is also described.

Owner:THE PROCTER & GAMBLE COMPANY

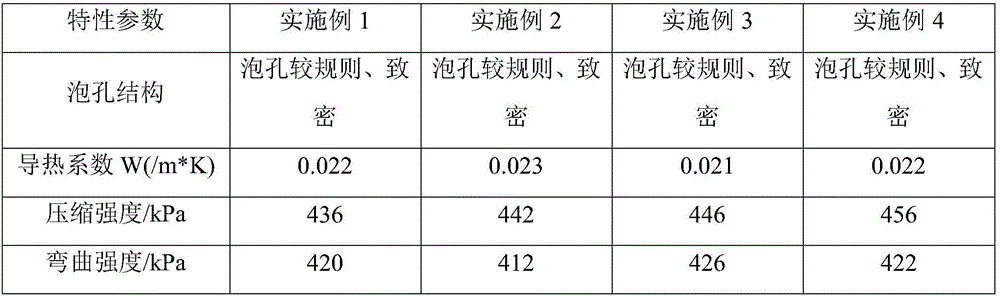

Lightweight sound-absorption heat-insulation polyimide foamed material, and preparation method thereof

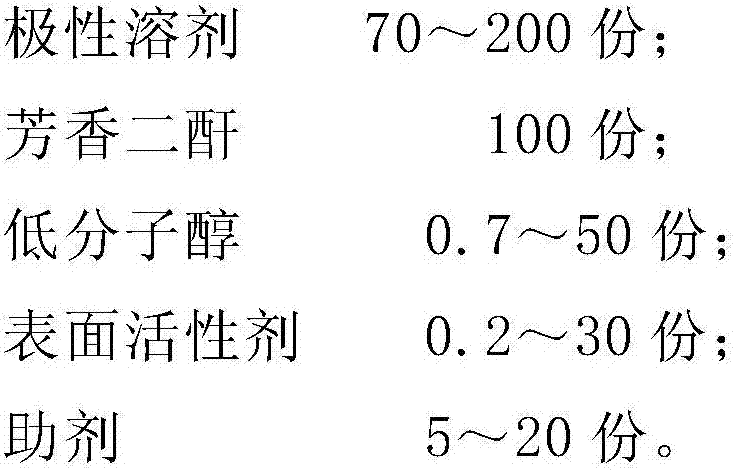

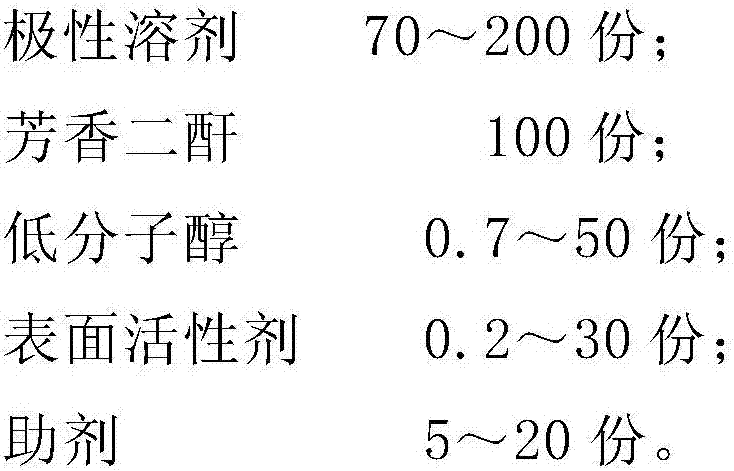

The invention discloses a lightweight sound-absorption heat-insulation polyimide foamed material, and a preparation method thereof. The preparation method comprises following steps: an aromatic dianhydride, a low molecular alcohol, a surfactant, and an auxiliary agent are mixed at a certain ratio, and are reacted in a polar solvent so as to obtain a foam precursor solution; the foam precursor solution is reacted with isocyanate in a mould, and semi-free foaming is carried out so as to obtain a foam intermediate; microwave radiation treatment, and heating curing in an aging oven are carried outso as to obtain the lightweight sound-absorption heat-insulation polyimide foamed material. The preparation route is short; the preparation method is simple; the foam precursor solution is low in viscosity and high in stability, is suitable for casting and extrusion process; the foaming process is simple, and is convenient to control; defects such as cracking, collapsing, nonuniformity, and incomplete material imidization are avoided; the obtained lightweight sound-absorption heat-insulation polyimide foamed material is high in stability and strength, is low in density, possesses excellent sound absorption and heat insulation performance, and can be widely used in fields such as aerospace, ship, automobile, refrigeration house, and other special application fields.

Owner:康达新材料(集团)股份有限公司

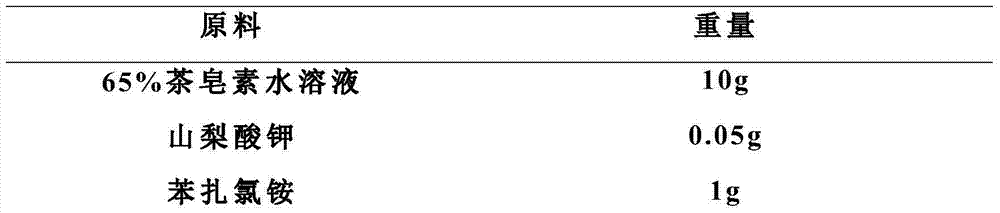

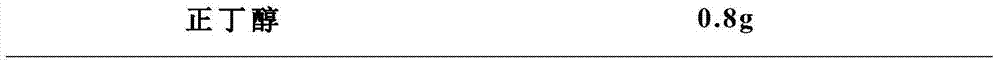

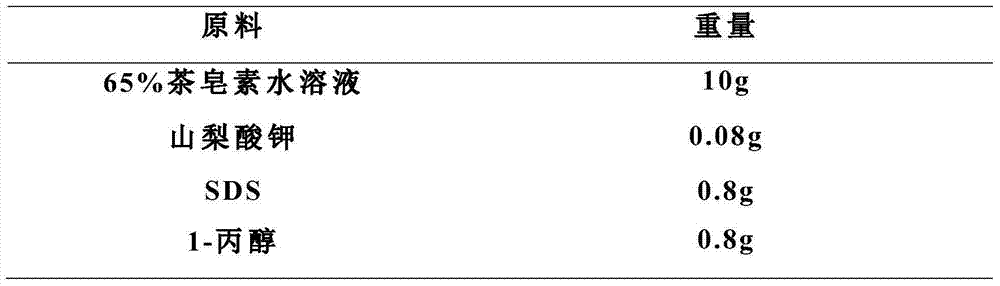

Natural tea saponin foaming agent and preparation method thereof

The invention discloses a natural tea saponin foaming agent, which is characterized by comprising the following components in percentage by mass: 50-70% of tea saponin, 0.01-2% of a preservative, 1-20% of a surfactant, 5-20% of a foam stabilizer, and the balance of water. The foaming agent is non-perishable, and stable and reliable in foaming performance, and has good economic and social benefits.

Owner:LUMIGENEX (SUZHOU) CO LTD

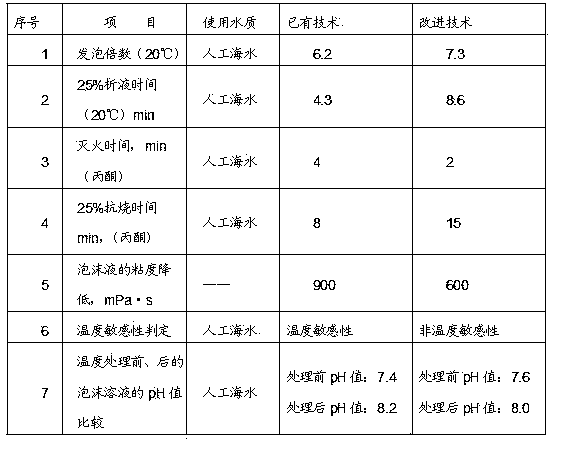

Seawater-resistant insoluble aqueous film-forming foam extinguishing agent and preparation method thereof

InactiveCN103463790AFire extinguishing speedShorten fire fighting timeFire extinguisherCocamidopropyl betaineChemistry

The invention discloses a seawater-resistant insoluble aqueous film-forming foam extinguishing agent and a preparation method thereof. The extinguishing agent comprises the following components in parts by weight: 300-400 parts of deionized water, 6-10 parts of sodium benzoate, 20-80 parts of urea, 5-9 parts of xanthan gum, 100-400 parts of Cocamidopropyl betaine, 20-60 parts of APG, 80-200 parts of ethylene glycol, 20-60 parts of ethylene glycol monobutyl ether, 10-50 parts of F1157, 10-50 parts of F1203, 10-60 parts of F1460 and 20-60 parts of a buffer agent. The seawater-resistant insoluble aqueous film-forming foam extinguishing agent is used for being mixed with seawater for fire extinguishing and has the advantages of low viscosity, high fire-extinguishing speed, high expansion rate, stable property, long storage time and the like.

Owner:江苏江亚消防科技股份有限公司

Readily-foaming emulsifying agent

InactiveCN102010275AQuality improvementControllable densityNon-explosive/non-thermic compositionsInorganic saltsEmulsion explosive

The invention provides a readily-foaming emulsifying agent. The readily-foaming emulsifying agent consists of the following components in percentage by weight: 60 to 40 percent of surfactant and 40 to 60 percent of wetting and stabilizing agent, wherein the surfactant at least comprises S-80 with high hydroxyl value. The main components and compounded products of the emulsifying agent are dissolved into oil easily; and the emulsifying agent is emulsified with aqueous solution of ammonium nitrate inorganic salt to form a latex matrix, and after the latex matrix is added into aqueous solution of sodium nitrite, bubbles are generated to sensitize the latex matrix into emulsion explosive.

Owner:GUANGDONG HONGDA BLASTING

PVC (polyvinyl chloride) foamed artificial leather and preparation method thereof

The invention discloses PVC (polyvinyl chloride) foamed artificial leather and a preparation method thereof. The PVC foamed artificial leather comprises a fabric base material, a foaming layer and a surface layer which are attached from inside to outside sequentially, wherein the foaming layer comprises components in parts by weight as follows: 95-105 parts of PVC resin, 75-85 parts of filling powder, 75-85 parts of a plasticizer, 3.5-4.0 parts of a stabilizer, 4.5-5.5 parts of a foaming agent and 9.5-10.5 parts of masterbatch; the surface layer comprises components in parts by weight as follows: 65-75 parts of PVC resin, 6-8 parts of filling powder, 46-52 parts of a plasticizer, 1.5-3 parts of a stabilizer and 4.5-5.5 parts of masterbatch. The preparation method comprises steps as follows: (1), blending; (2), mixing, open milling and filtering; (3), calendering attachment; (4), cooling; (5), foaming; (6), embossing, cooling and rolling-up to obtain a finished PVC foamed artificial leather product. The artificial leather prepared with the method feels good, and is good in texture, high in breathability and good in wear resistance.

Owner:DONGTAI FUAN SYNTHETIC MATERIAL CO LTD

Special water-based cleaning agent for aluminum magnesium alloy

The invention discloses a special water-based cleaning agent for aluminum magnesium alloy. The special water-based cleaning agent comprises the following raw materials in parts by weight: 1-6 parts of triethanolamine, 2-10 parts of sodium carbonate, 5-10 parts of sodium bicarbonate, 4-12 parts of heterogeneous alcohol ether, 6-20 parts of alkylolamides, 5-15 parts of a magnesium alloy corrosion inhibitor, 5-10 parts of an aluminum alloy corrosion inhibitor, 8-20 parts of an anionic surfactant, 3-10 parts of hydrophilic alcohol, 0-6 parts of a stabilizer and 50-100 parts of water. The special water-based cleaning agent for aluminum magnesium alloy disclosed by the invention is strong in detersive power, high in cleaning speed, few in residues after being washed, anti-static, and good in corrosion inhibition property, and can prevent the metal from being corroded.

Owner:CHAOHU GUANGFENG METAL PROD

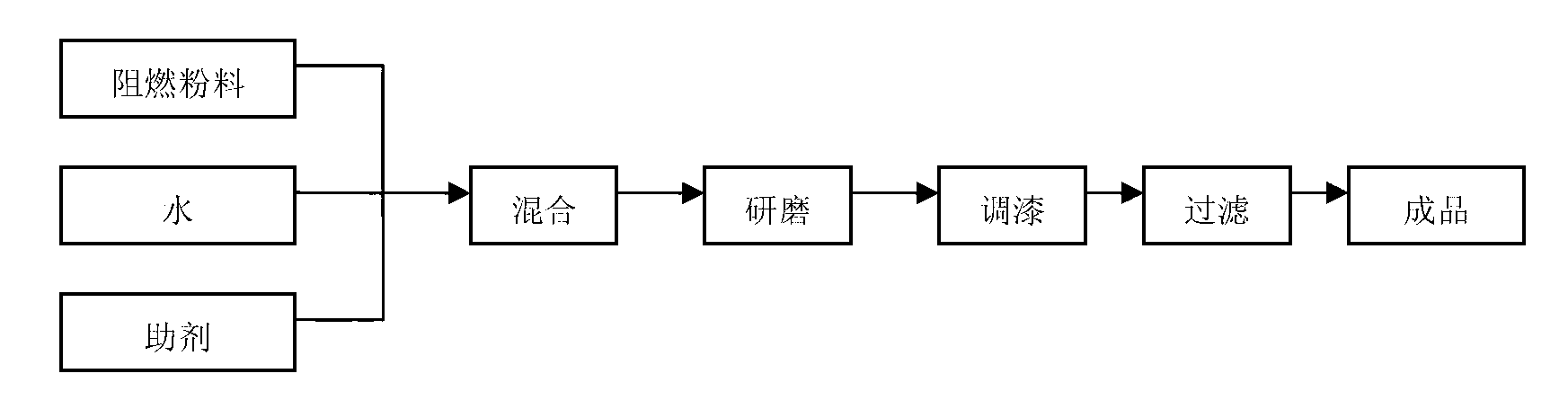

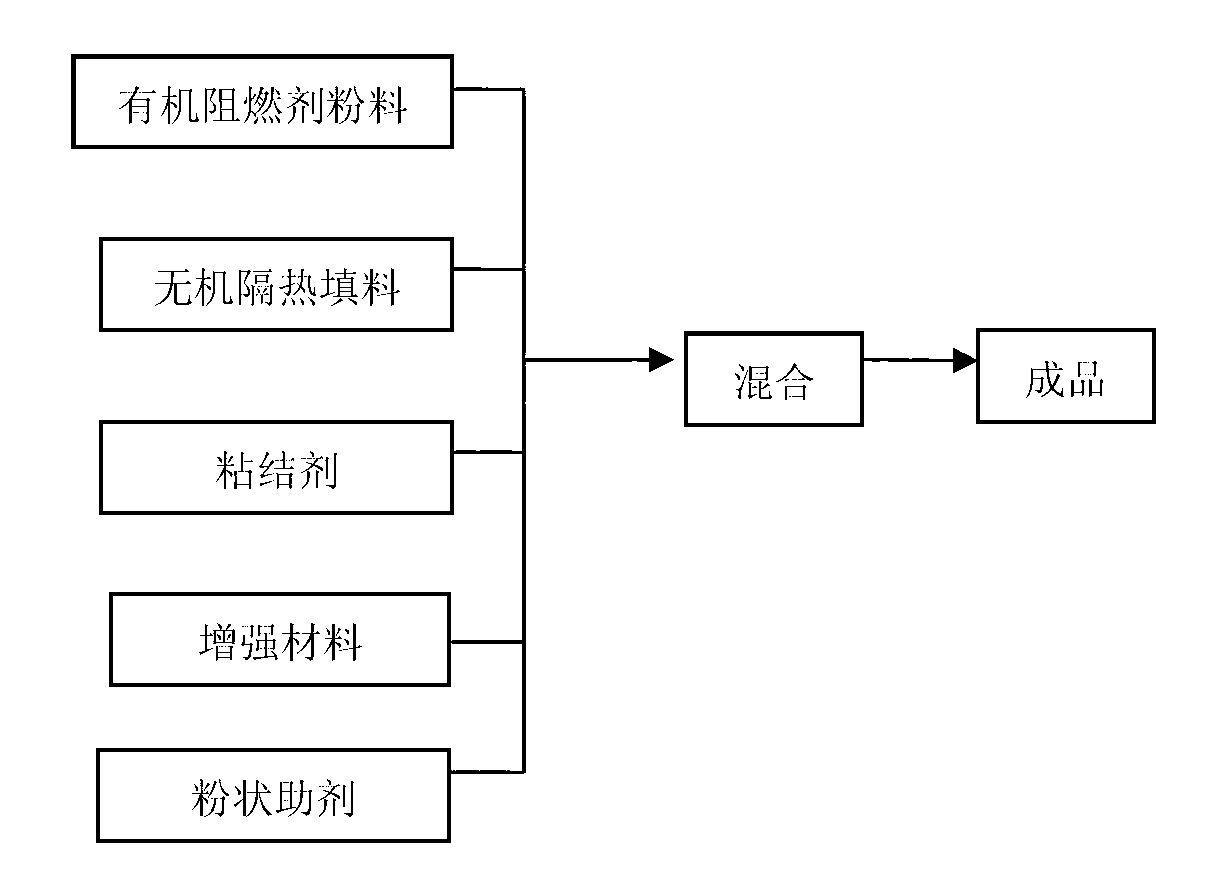

Fireproof coating primer of single-mass-system indoor thin steel structure

The invention relates to a fireproof coating primer of a single-mass-system indoor thin steel structure. The fireproof coating primer comprises the following components in parts by mass: 9-12 parts of adhesive powder, 0.1-0.5 part of powder dispersant, 0.1-0.3 part of powder antifoam agent, 20-24 parts of inorganic insulating filler, 0.0-20.06 parts of coating reinforcing material and 24-28 parts of mixture composed of dehydration catalyst, foaming agent and charcoal forming agent. The fireproof coating is produced by one-step dry powder mixing method, therefore, the production efficiency is improved; the problems that the fireproof coating primer of the emulsion-based double-mass-system thin steel structure is easy to mildew in summer and has unstable foaming performance; and meanwhile, the product cost of package, storage, transport and the like is saved.

Owner:江苏兰陵钢结构工程有限公司

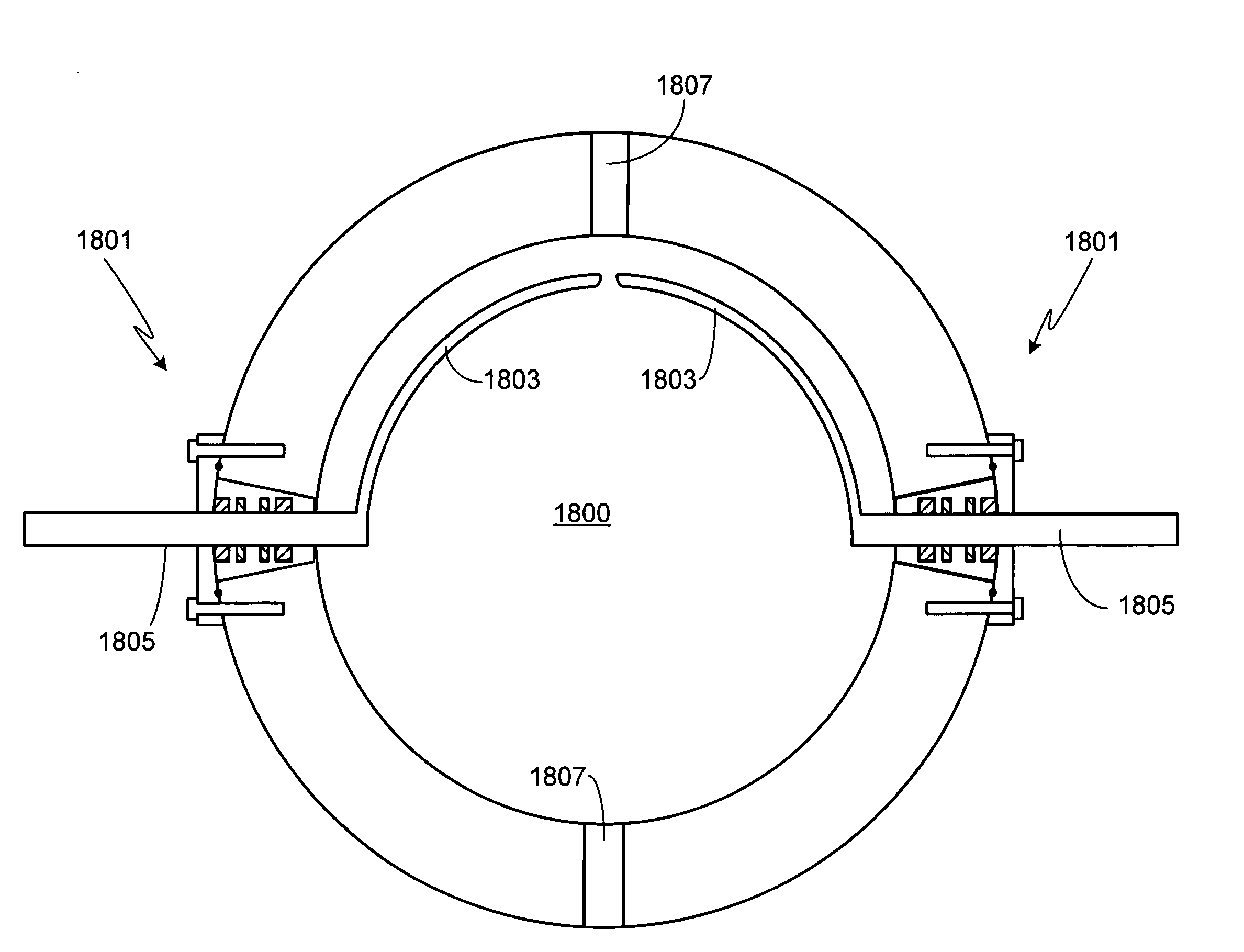

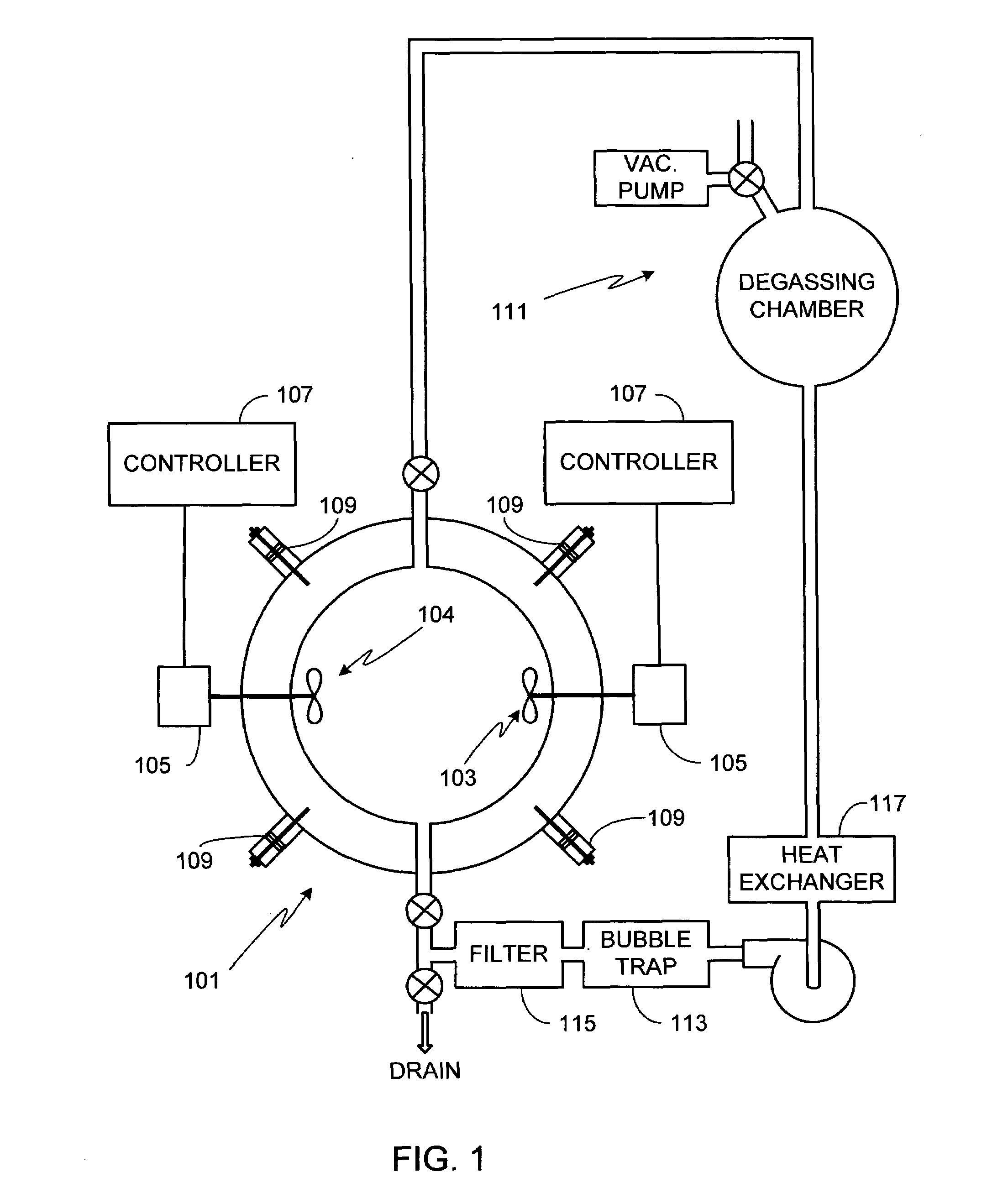

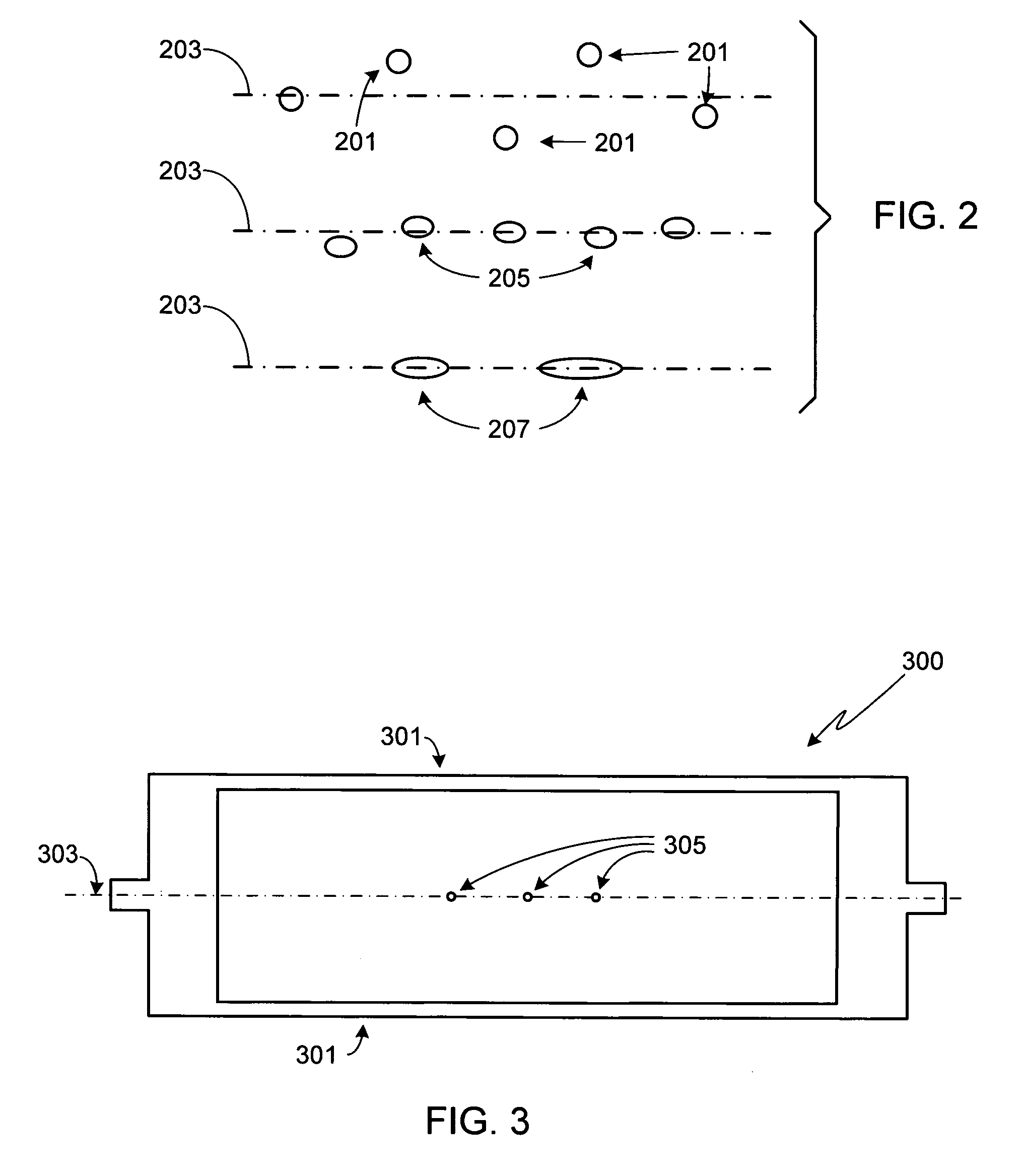

Fluid rotation system for a cavitation chamber

InactiveUS7677790B2Foam stabilizationInterference minimizationShaking/oscillating/vibrating mixersPositive displacement pump componentsImpellerCavitation

A system for achieving bubble stability within a cavitation chamber is provided. The system includes an impeller assembly, the impeller assembly having at least one impeller located within the cavitation chamber. A motor, coupled to the impeller by a drive shaft, rotates the impeller thereby causing bubbles within the cavitation chamber to move toward the impeller's axis of rotation. As a consequence, the bubbles become more stable. Preferably the axis of rotation of the impeller is positioned in a substantially horizontal plane, thus allowing the rotating impeller to counteract the tendency of the bubbles to drift upward and to accumulate on the upper, inner surfaces of the cavitation chamber. The impeller can be rotated continuously throughout the cavitation process or stopped prior to cavitating the bubbles within the cavitation chamber. In the latter scenario, the impeller can be stopped, and if desired locked, at a specific rotational position, thus minimizing possible interference between the impeller and the source of the cavitation energy. The impeller can be shaped to correspond to the inner surface of the cavitation chamber, for example spherically or cylindrically, and can utilize multiple impeller blades.

Owner:BURST ENERGIES INC

Infection Mediated Foam Dissolution Rate Measurement

InactiveUS20110059460A1Foam stabilizationLess-stable foamMicrobiological testing/measurementPreparing sample for investigationBiotechnologyMedicine

The subject invention concerns methods and materials for determining the presence or absence of bacterial or fungal infection in a blood sample. In one embodiment, a method of the invention comprises exposing an anticoagulant treated blood sample to freezing the sample to a solid, followed by thawing of the sample and then agitation of the sample to develop foam and then observing the rate that foam dissolves.

Owner:IMIGENE

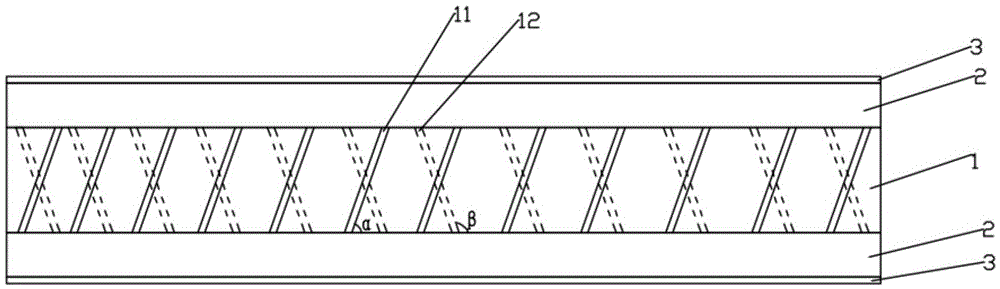

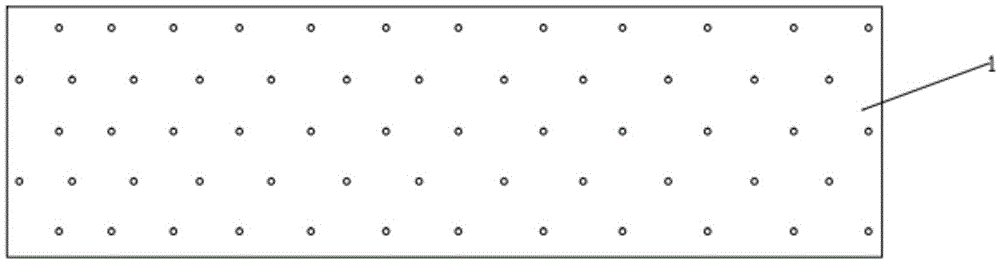

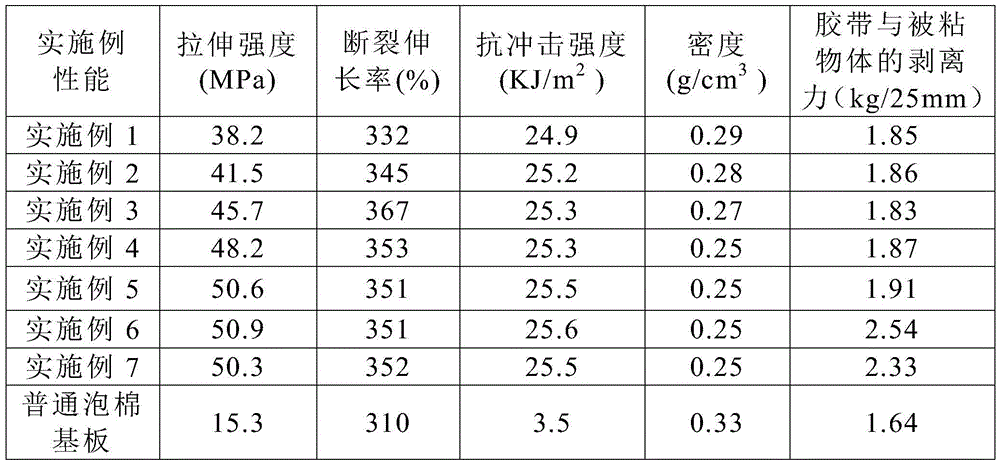

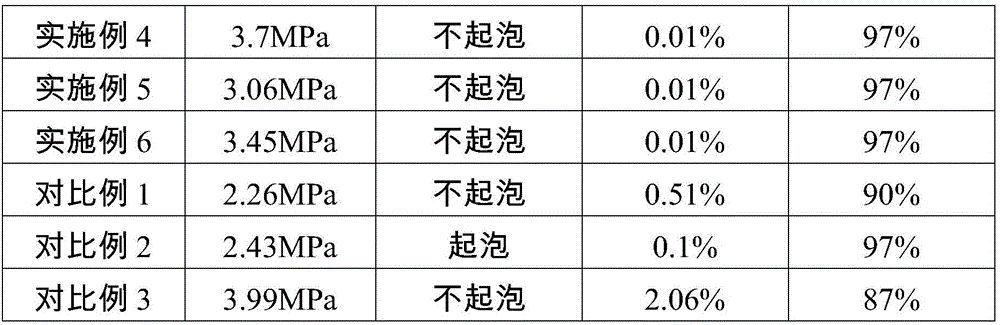

Foam two-sided adhesive tape

ActiveCN105542674AIncrease connection forceStop dislocationFilm/foil adhesivesFoaming agentShock resistance

The invention relates to a foam two-sided adhesive tape, which belongs to the technical field of an adhesive tape. The foam two-sided adhesive tape comprises a foam basal plate, an adhesive coating and a release film, wherein longitudinal through holes are formed between the upper surface and the lower surface of the foam basal plate, the foam basal plate comprises the following components in parts by weight: 100 parts of PMMA, 28 to 35 parts of polyurethane, 18 to 23 parts of fluorine rubber, 1.5 to 3.2 parts of light stabilizer, 5 to 11 parts of mesoporous nano TiO2 and 20 to 30 parts of foaming agents. The longitudinal through holes are formed in the foam basal plate, so that adhesive forms a complete lattice system, the connection performance of the adhesive tape is improved, and the connected object is more stable and reliable. The foam basal plate which is light in weight, good in shock resistance and excellent mechanical performance is adopted as the base material of the adhesive tape, so that the prepared adhesive tape is high in strength, good in flexibility, high in impact resistance and applicable to the manufacturing of more precise instruments and equipment.

Owner:NINGBO JIXIANG PLASTIC PROD CO LTD

Environment-friendly polyurethane prepolymer and preparation method thereof

The invention belongs to the field of fine chemical engineering, and particularly relates to an environment-friendly polyurethane prepolymer and a preparation method thereof. Polypropylene carbonate polylol and isocyanates are used as raw materials to prepare a polyurethane adhesive, and the polyurethane adhesive is subjected to termination modification by organosilane to obtain the environment-friendly polyurethane prepolymer, thereby lowering the release of free isocyanates and other substances harmful to the human body, and implementing no pollution. The prepolymer has the advantages of high strength, hydrolysis resistance, low bubbling tendency and stable performance, and can be widely used in the fields of traditional production of adhesives, sealants, paints and elastomers and the like.

Owner:GUANGDONG UNIV OF TECH

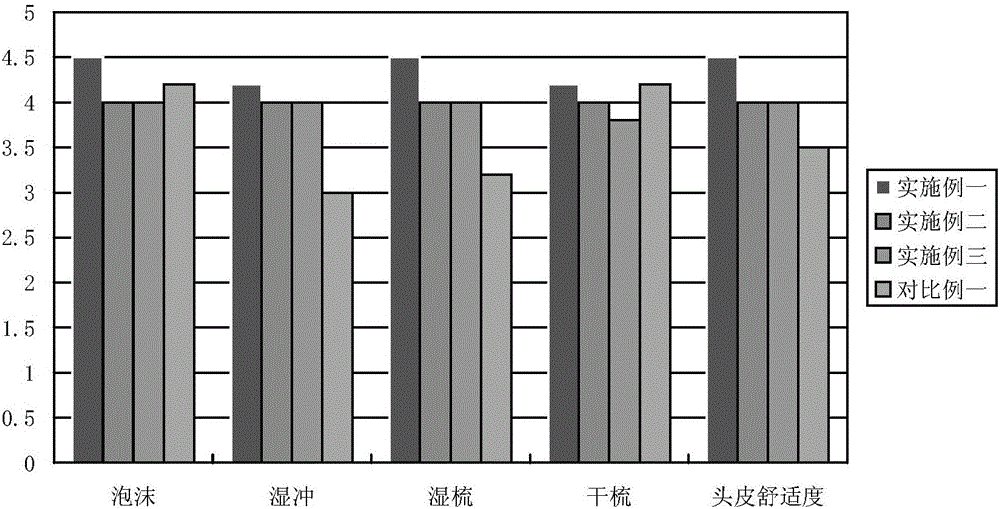

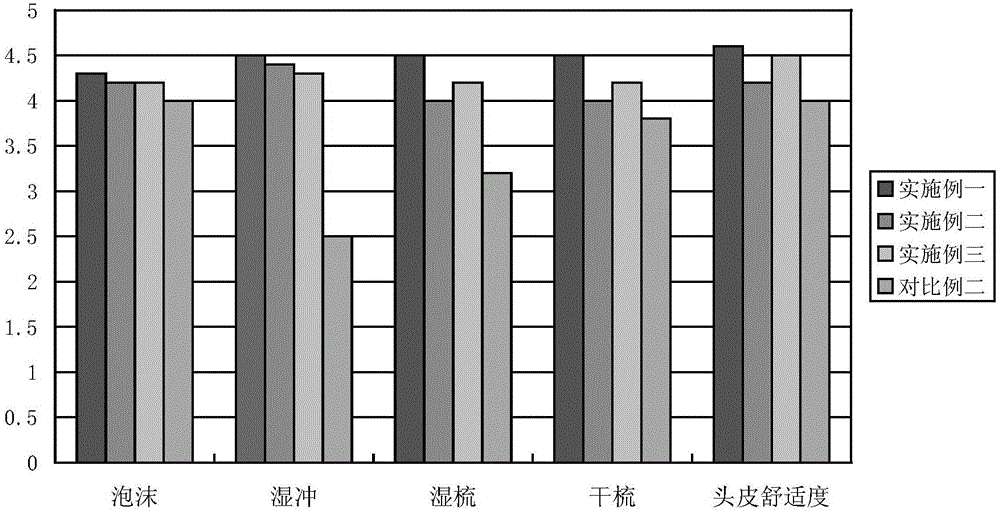

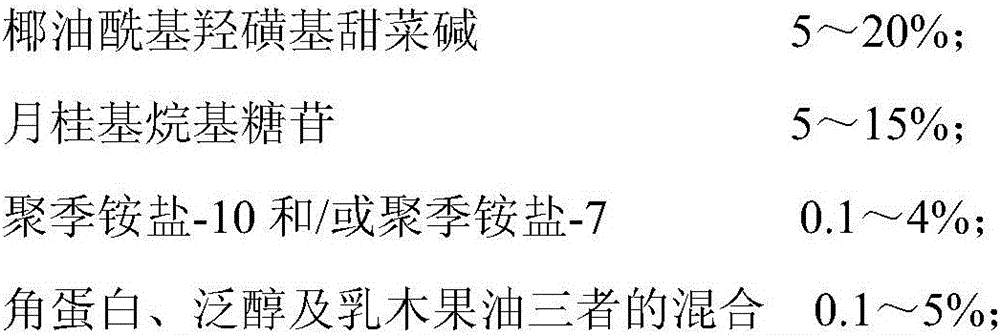

Sulfate-anionic-surfactant-free silicone-oil-free shampoo composition

ActiveCN106361660AAvoid damageGood compatibilityCosmetic preparationsHair cosmeticsDISODIUM LAURYL SULFOSUCCINATEAdhesive

The invention discloses a sulfate-anionic-surfactant-free silicone-oil-free shampoo composition. The shampoo composition is composed of 10-45% of anionic surfactant, 8-20% of zwitterionic surfactant, 5-15% of nonionic surfactant, 0.1-3% of conditioner, 0.1-3% of plant extract, 0-1% of preservative, 0.1-1.0% of essence and the balance of deionized water. The shampoo composition comprises one or two of disodium lauryl sulfosuccinate, sodium cocoyl glutamate and sodium lauroyl sarcosine as the main surfactant which is compounded with cocoyl hydroxyl sulfobetaine, lauryl alkyl glycoside and isostearamide monoisopropanolamine. A polyquaternary ammonium salt-10 and a polyquaternary ammonium salt-7 are used as the conditioner; keratin, panthenol and shea butter grease adhesive are matched with the plant extract nutrient; and hexamidine (hydroxy-ethyl sulfonic acid) salt is used as one of the anti-dandruff bactericides. The shampoo composition is free of sulfates and silicone oil, and is capable of well cleaning and conditioning the hair and scalp.

Owner:GUANGZHOU OUSIA IND CO LTD

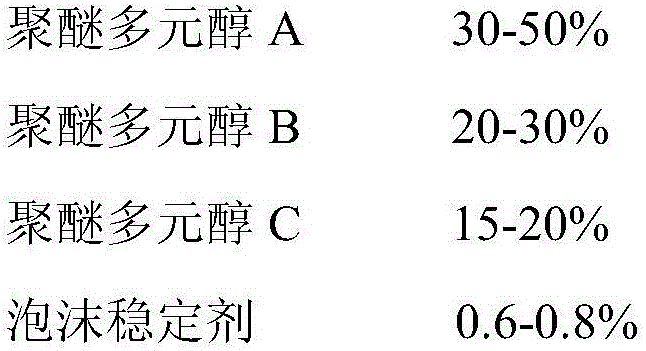

Polyurethane foam material for packaging and preparation method thereof

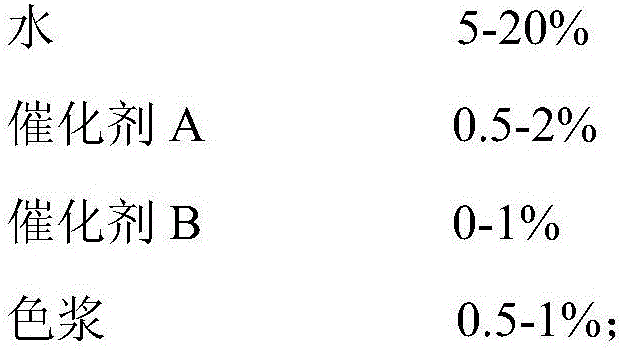

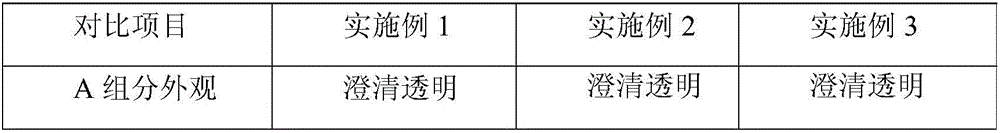

Belonging to the technical field of chemical materials, the invention in particular relates to a polyurethane foam material for packaging and a preparation method thereof. The polyurethane foam material for packaging is composed of a component A and a component B, the component A consists of: polyether polyol A, polyether polyol B, polyether polyol C, a foam stabilizer, water, a catalyst A, a catalyst B, and a color past, and the component B is polymethine polyphenyl polyisocyanate. The method provided by the invention is carried out under normal temperature and atmospheric pressure, the process is simple and easy to operate, is low in volatilization, and has no three wastes, also the product quality is stable.

Owner:SHANDONG INOV NEW MATERIALS CO LTD

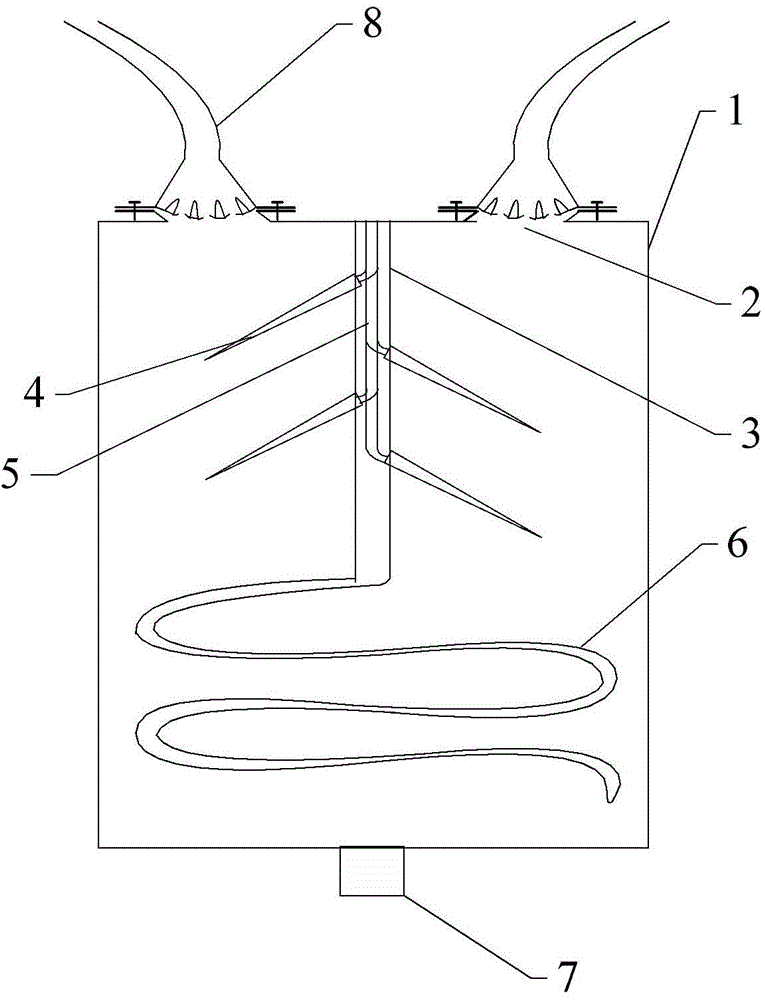

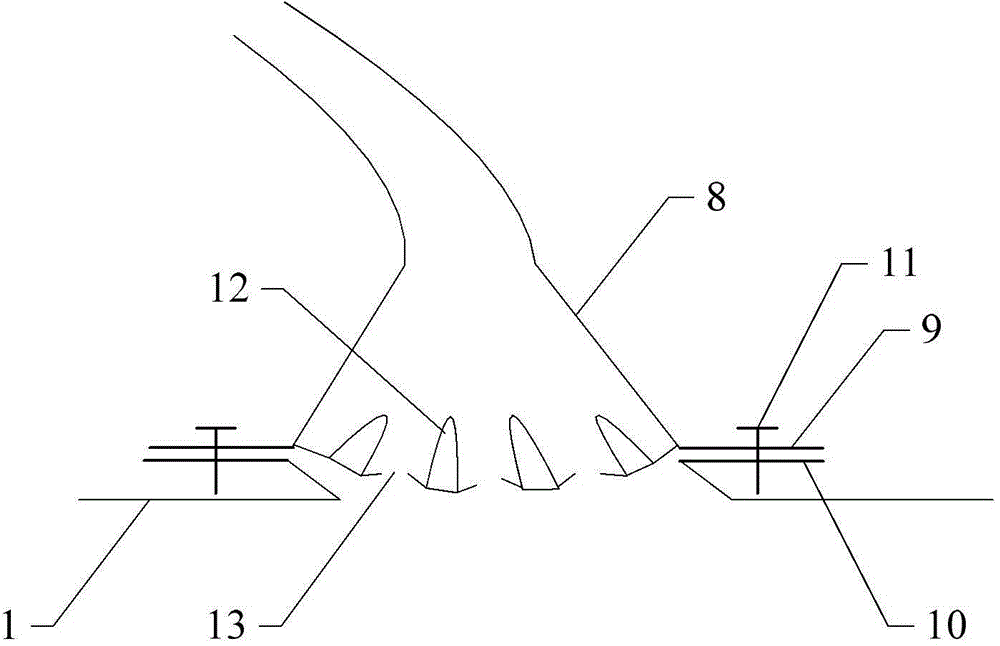

Polyurethane foaming machine

InactiveCN104476713AAchieve the purpose of productionLow costRotary stirring mixersSprayerEngineering

The invention discloses a polyurethane foaming machine which comprises a shell, a feeding device and injection holes, wherein the feeding device is an umbrella-shaped sprayer; the umbrella-shaped sprayer comprises a cone; the lower end surface of the cone is fixedly arranged on the inner side surface of the spraying surface of the umbrella-shaped sprayer; the tip end of the cone extends to the opposite direction of the spraying surface of the umbrella-shaped sprayer; the cross section of the cone is a triangle of which the side length has a radian; and the injection holes are uniformly distributed in the spraying surface at the periphery of the cone. The polyurethane foaming machine disclosed by the invention is simple in structure, stable in foaming process, full in stirring and uniform and moderate in bubble size and is applied to large-scale production of multiple polyurethane foaming materials.

Owner:东莞市程辉实业投资有限公司

Collecting agent for separating gold from auriferous pyrite and preparation method for collecting agent

ActiveCN103657870AFoam stabilizationStrong harvesting abilityFlotationChemistryNitrilotriacetic acid

A collecting agent for separating gold from auriferous pyrite is prepared by the following raw materials in part by weight: 30-34 parts of xanthate, 12-14 parts of glycerin, 4-7 parts of sodium hexametaphosphate, 18-22 parts of terpenic oil, 10-12 parts of black powder, 2-3 parts of dimer acid, 1-2 parts of phthalic acid ester, 12-14 parts of diltiazem nitrile ester, 2-3 parts of 3-aminopropyltrimethoxysilane, 4-5 parts of nitrilotriacetic acid and 10-12 parts of activating agent. The collecting agent has a collecting function and a foaming function; foams are stable; the collecting ability is high, so that the recycling rate of the gold ores is high, the selectivity is high, and the grade of the gold ore is also high; and moreover, by using the collecting agent, the affinity of gold and iron can be reduced, collection on iron can be restrained, and then the grade of gold is improved. By using the activating agent, the surface hydrophobicity of the gold ore is changed, the internal structure is activated, and the gold collecting performance of the collecting agent is improved.

Owner:ANHUI CHAOSHAN NEW MATERIAL

Polyurethane foam caulking agent

Owner:苏州健能新材料科技有限公司

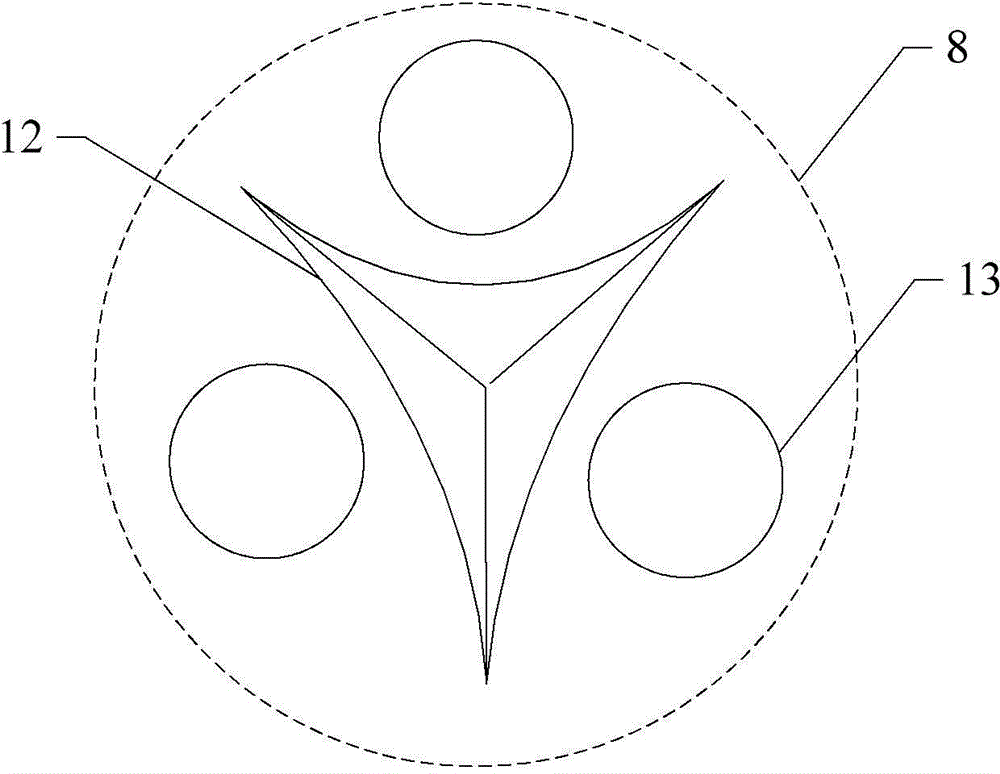

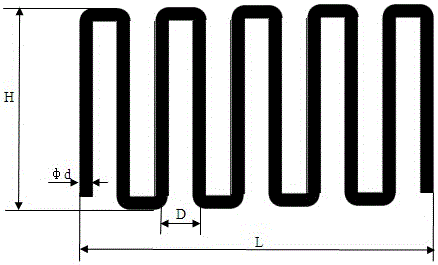

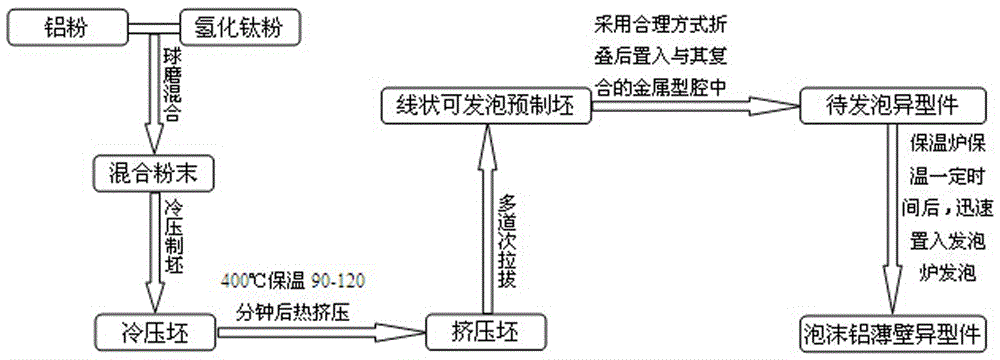

Preparation method of novel thin-walled and special-shaped foamed aluminum part

The invention relates to a preparation method for a novel thin-walled and special-shaped foamed aluminum part, and belongs to the technical field of porous metal materials. A three-step forming technique is adopted based on preparation of a foaming preformed blank, namely a multi-pass drawing procedure is added based on traditional cold-pressing and hot-extruding procedures, and the linear foaming preformed blank with the diameter being 2-5 mm is prepared. In the preparation process of the thin-walled and special-shaped part, the linear foaming preformed blank with the proper diameter is selected according to the wall thickness of the special-shaped part and the density requirement for a core foam body, the linear foaming preformed blank with the proper diameter is placed in a metal cavity combined with the linear forming preformed blank after being folded in a reasonable folding way, and then the linear foaming preformed blank with the proper diameter and the metal cavity are placed into a holding furnace together for heat-preservation foaming; and the procedure of preparing a plurality of small-size foaming preformed blanks required by a multi-blank foaming method by consuming a large amount of time is not needed any more. By adoption of the preparation method for the novel thin-walled and special-shaped foamed aluminum part, the production efficiency is greatly improved, the production cost is reduced, and the preparation method has extremely positive significance for promoting the industrialization process of thin-walled and special-shaped foamed aluminum parts.

Owner:SHENYANG POLYTECHNIC UNIV

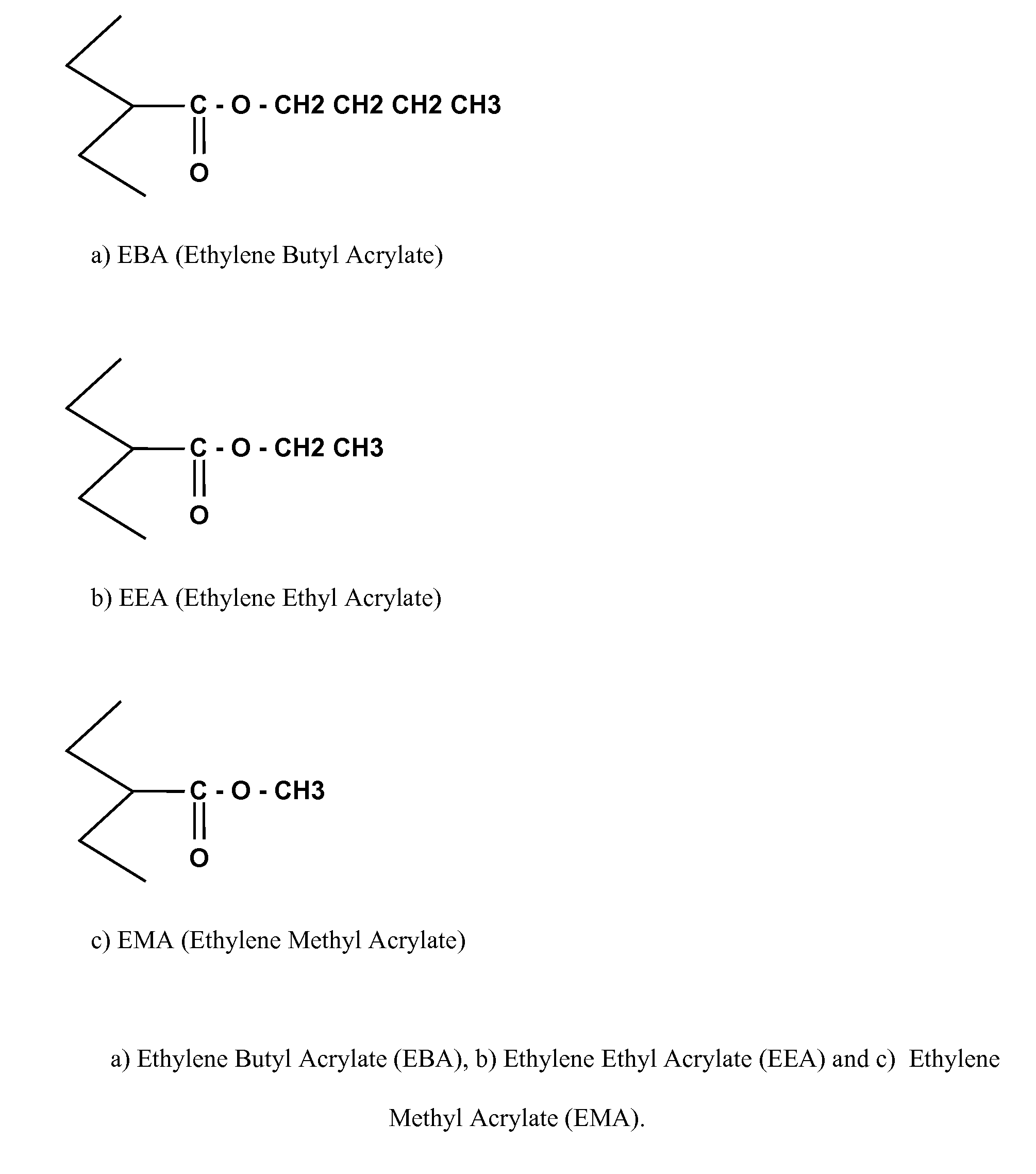

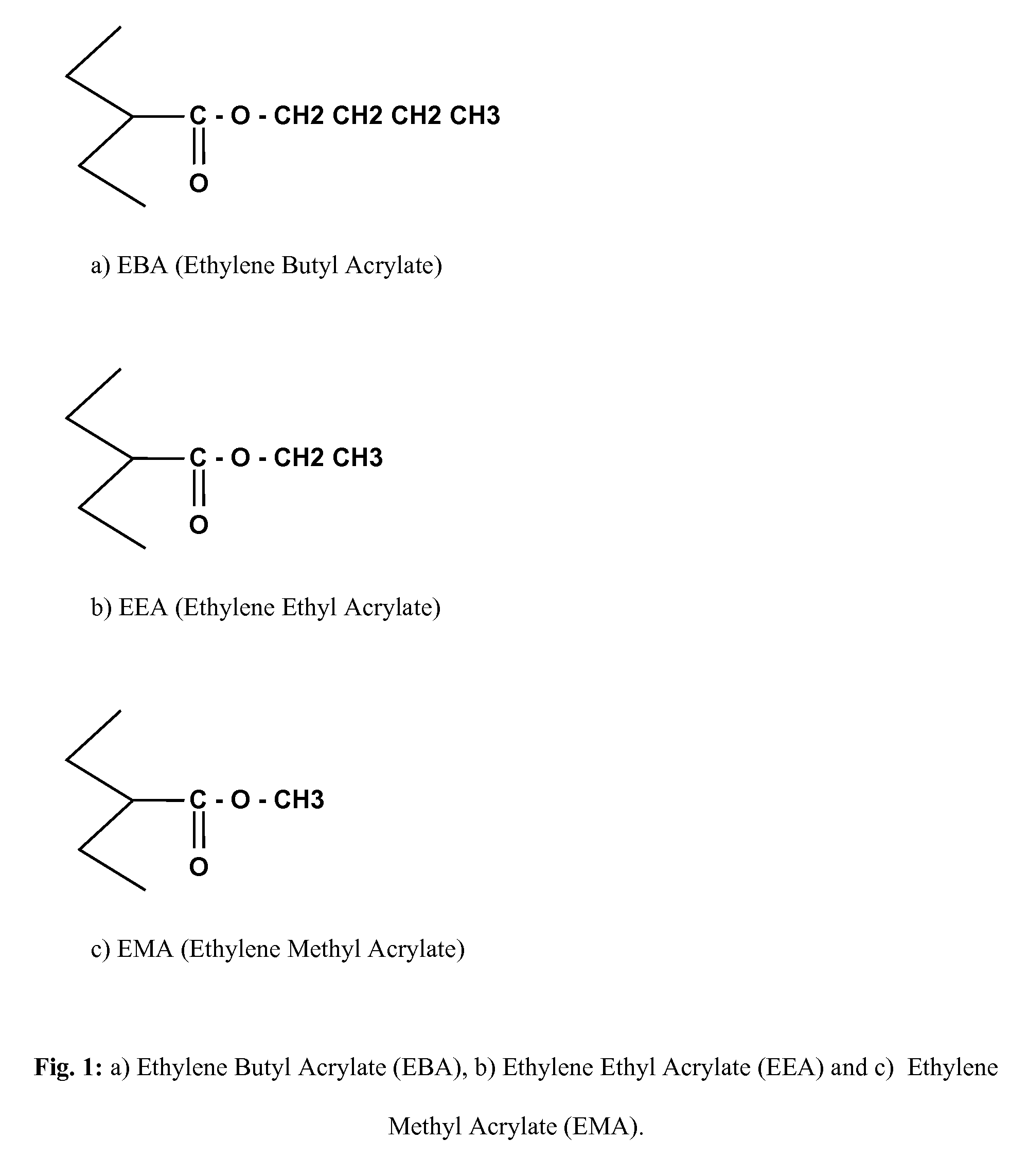

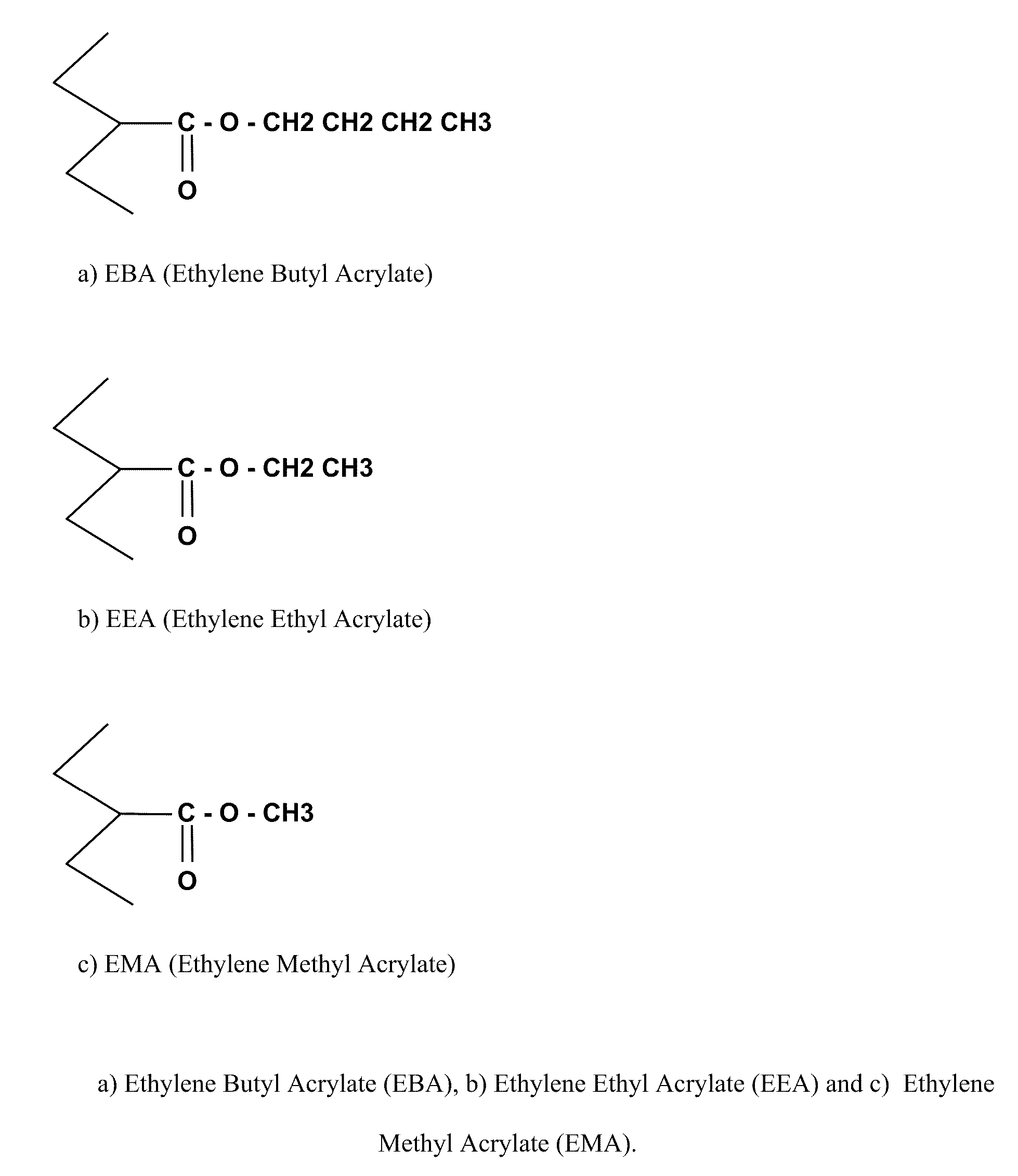

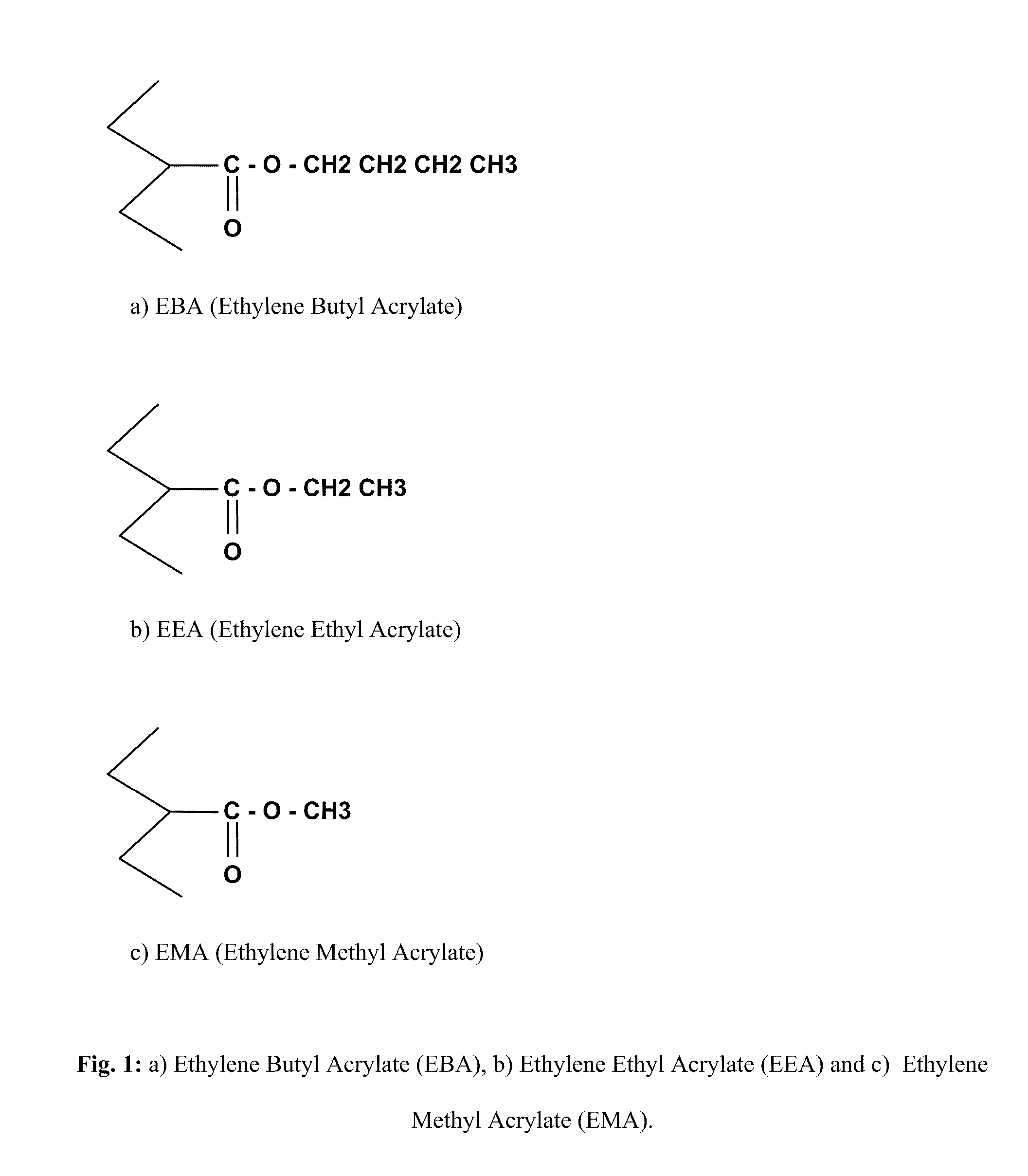

Preparation and application of chain-extending concentrates for polyester foaming process

The composition and the preparation of a chain-extending concentrate for production of foamed cellular materials of aromatic polyesters is disclosed in this invention. The chain-extending concentrate includes an ethylene-acrylate copolymer, a high-temperature thermoplastic and a multifunctional compound. The preparation process includes two steps: 1) Mixing and melt blending the multifunctional compound and the HT thermoplastic resin into the matrix of the ethylene-acrylate copolymer in an internal mixer and 2) extrusion of the mixture at a temperature below the melting point or reaction temperature of the multifunctional compound.

Owner:ARMACELL ENTERPRISE GMBH & CO KG

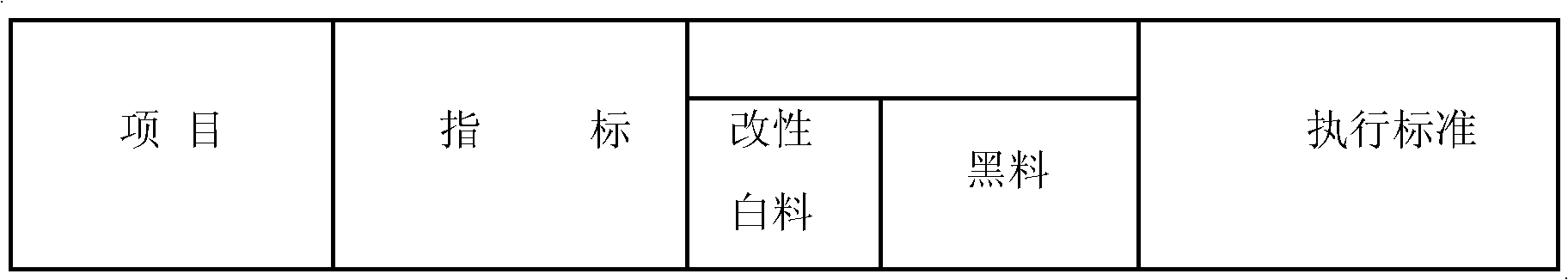

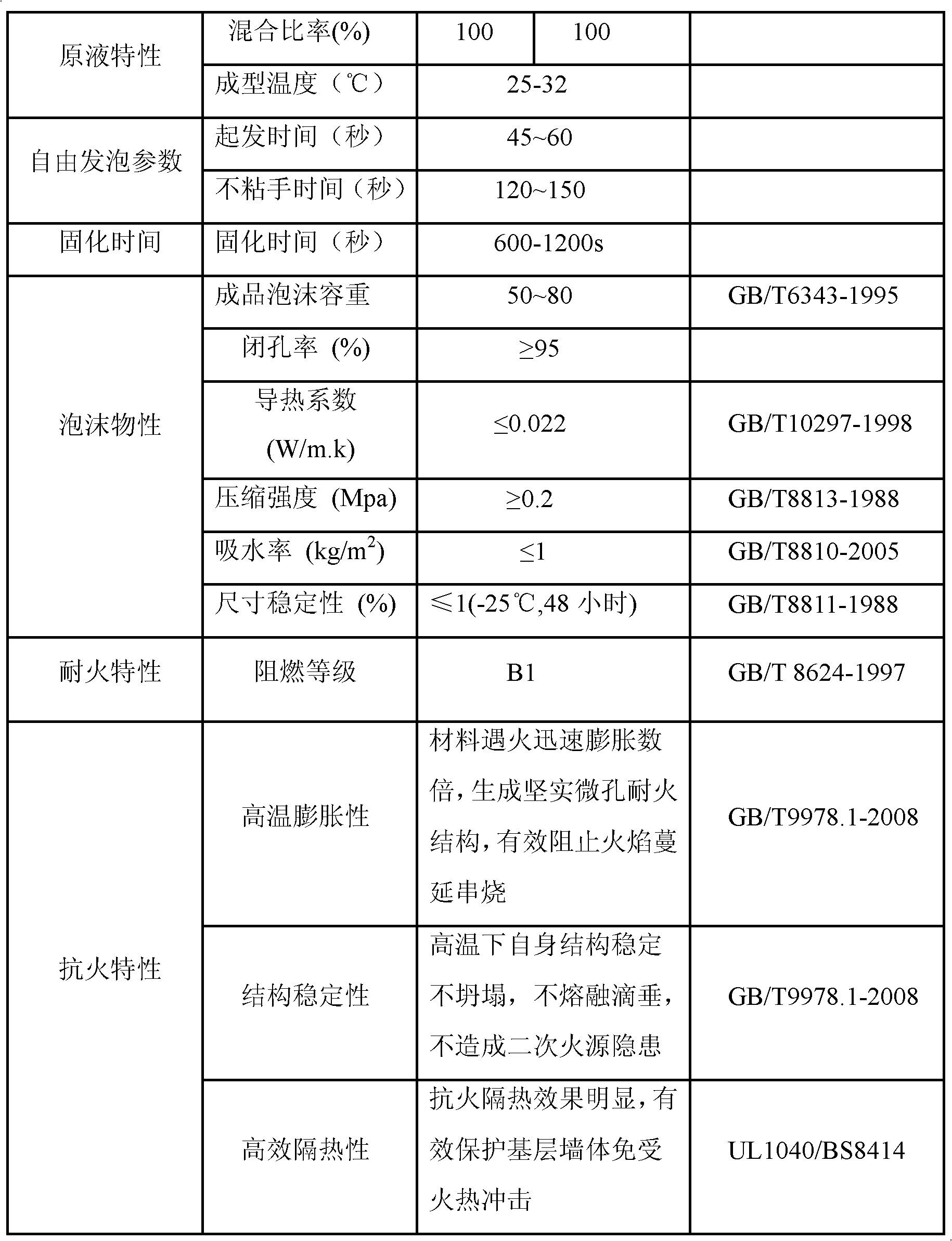

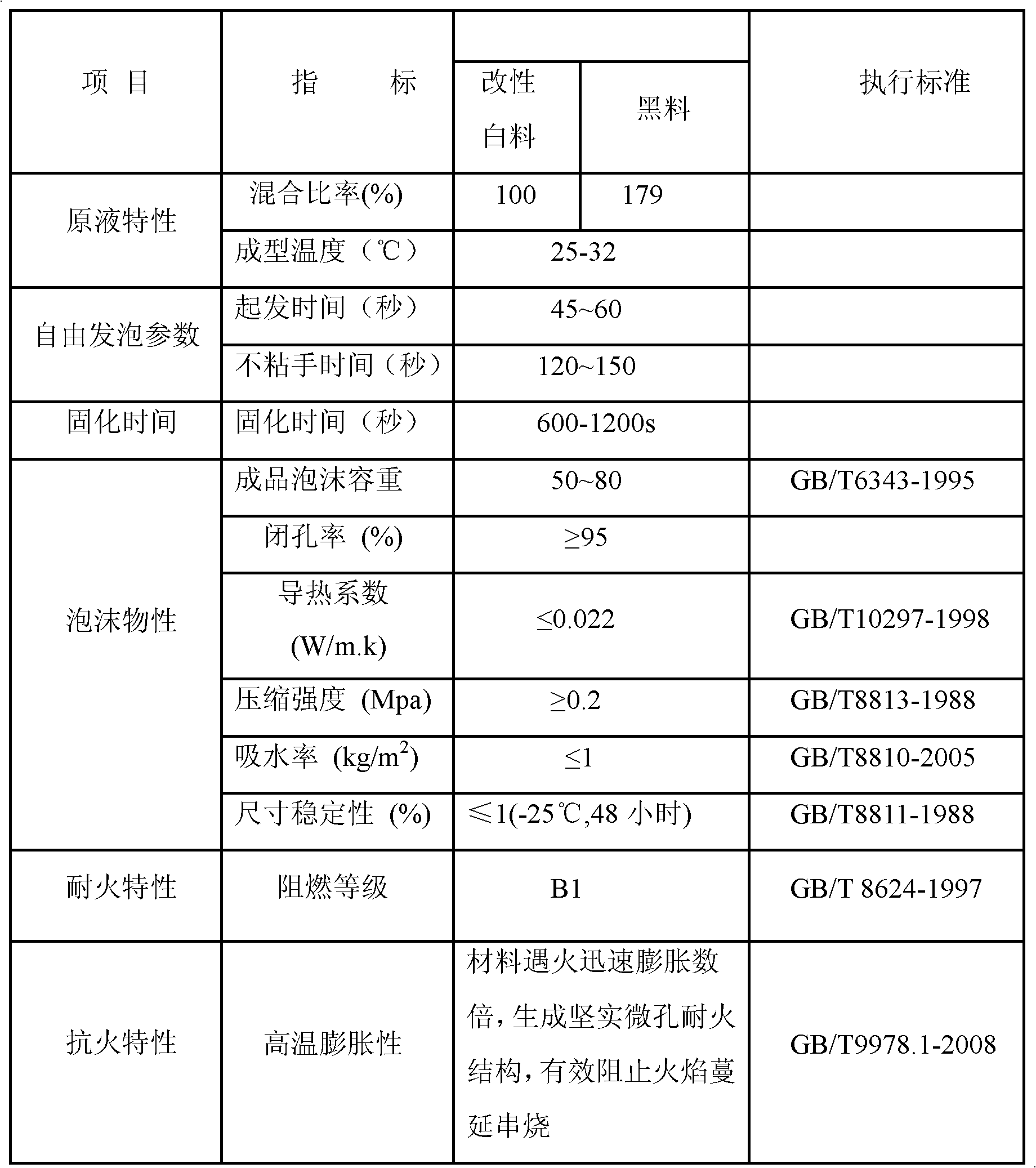

High flame-retardant rigid polyurethane foam and its preparation method

ActiveCN102276974AStop the flame from spreading skewersObvious effect of fire resistance and heat insulationAmmonium polyphosphateBuilding material

The invention provides high-fire-resistance rigid polyurethane foam plastic and a preparation method thereof and relates to a fireproof building material and a preparation method thereof. The high-fire-resistance rigid polyurethane foam plastic has the fire resistance of B1 grade, stable foaming and curing reaction time, and brand new flame-retardant and fire-resistant characteristics. The high-fire-resistance rigid polyurethane foam plastic consists of a polyurethane modified white material and a polyurethane black material, wherein the mass ratio of the polyurethane modified white material to the polyurethane black material is 1:(1-1.8); the polyurethane modified white material consists of the following components in part by mass: 5 to 15 parts of expanded graphite with the grain size of 150 to 300 meshes, 1 to 6 parts of aluminium hydroxide with the grain size of 100 to 500 meshes, 2 to 10 parts of ammonium polyphosphate, 0.5 to 1 part of zinc borate and 40 to 45 parts of polyurethane white material; the polyurethane white material refers to Elastopor CH1141C-A in BASF Company; the polyurethane black material refers to the black material of M20S in the BASF Company; the molecular formula of the ammonium polyphosphate is (NH4PO3)n; and the weight mean polymerization degree n is 500 to 1,200.

Owner:山东华德隆建材科技有限公司

EVA recycling method

ActiveUS9074061B2More rubberyIncrease rubber like natureSolesPlastic recyclingPetroleum resinBlowing agent

A method of recycling scrap ethylene-vinyl acetate (EVA) foam involves foaming and crosslinking a blend containing virgin EVA resin and scrap EVA foam, as well as a crosslinking agent and blowing agent for the EVA resin. The blend further contains a compatibilizer, which is a hydrogenated petroleum resin.

Owner:NIKE INTERNATIONAL LTD

Modified polyurethane expanded plastic and preparation method thereof

The invention belongs to the plastic field and discloses modified polyurethane expanded plastic and a preparation method thereof. The modified polyurethane expanded plastic is prepared from 120 to 150 parts by weight of isocyanate, 100 to 120 parts by weight of polyester polyol, 20 to 30 parts by weight of a glass fiber cloth, 0.6 to 1 part by weight of a silane coupling agent, 0.4 to 0.8 parts by weight of a titanate coupling agent, 0.6 to 1 part by weight of monoglyceride, 3 to 5 parts by weight of triethanolamine, 10 to 20 parts by weight of carbon nanotubes, 20 to 30 parts by weight of low-density polyethylene, 20 to 30 parts by weight of aramid pulp, 10 to 20 parts by weight of ceramic fibers, 1 to 2 parts by weight of azodicarbonamide, 0.3 to 0.5 parts by weight of a foam stabilizer, 1 to 2 parts by weight of sodium dodecyl sulfate and 0.6 to 1 part by weight of an antioxidant. The modified polyurethane expanded plastic has the advantages of uniform bubbles, light weight, good toughness, wear resistance, anisotropy and excellent thermal insulation performances.

Owner:QINGDAO HAIZHIYUAN INTELLIGENT TECH

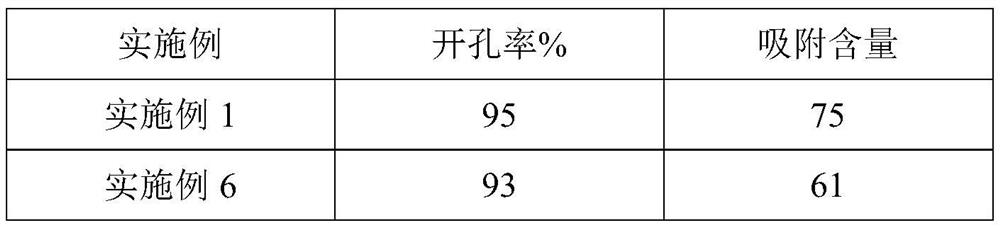

Microporous polymer carrier as well as preparation method and application thereof

InactiveCN111808368AFoam stabilizationAdsorption efficiency is controllableOther chemical processesPolyolefinPolymer chemistry

The invention relates to the technical field of porous polymers, and provides a microporous polymer carrier which comprises the raw materials in parts by weight: 100-150 parts of polyolefin resin, 5-25 parts of a modifier and 0.1-5 parts of a nucleating agent, wherein the raw materials further comprise a foaming agent, and the addition amount of the foaming agent is 1-25% of the mass of the polyolefin resin. The microporous polymer carrier is suitable for adsorbing various assistants; the loading application range of the high-stability polymer carrier material is expanded; the microporous polymer carrier can be used for adsorbing substances such as an antibacterial agent, a plasticizer, a phase-change material, a light stabilizer, an antibacterial agent, an antioxidant, dry silane, an antistatic agent, color paste, a deodorant, spice and a catalyst, the foaming performance of the microporous polymer carrier is relatively stable, the foaming efficiency is improved, and micropores with uniform sizes can be formed.

Owner:安徽星贝达新材料科技有限公司

Sparkling alcoholic beverage and process for producing the same

The present invention provides an alcoholic beverage with improved a foam stability. A processing method of an alcoholic beverage with improved foaming properties comprising a process for processing a pre-fermentation, wherein a pea protein which was extracted and was obtained from green peas is added to a pre-fermentation liquid. The alcoholic beverage with improved foaming properties can be applied to the processing method of the alcoholic beverage with improved foaming properties by fermenting the pre-fermentation liquid which created raw materials containing malts or by fermenting the pre-fermentation liquid created using a syrup containing sources of carbon, sources of nitrogen, hops, a coloring matter, an improving substance for a generating of foam and for the foam stability and water as raw materials with a brewers' yeast.

Owner:SAPPORO BREWERIES

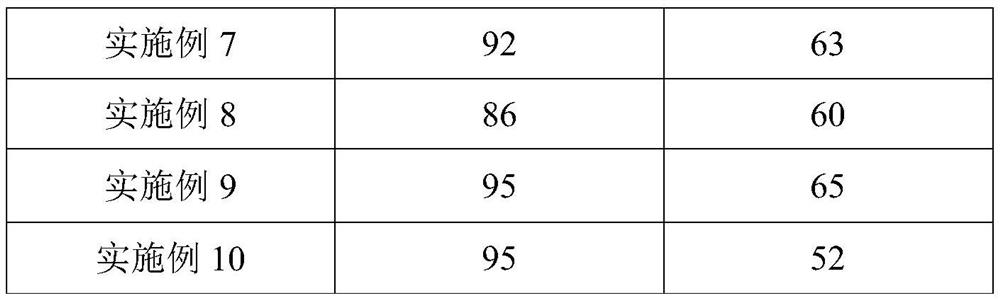

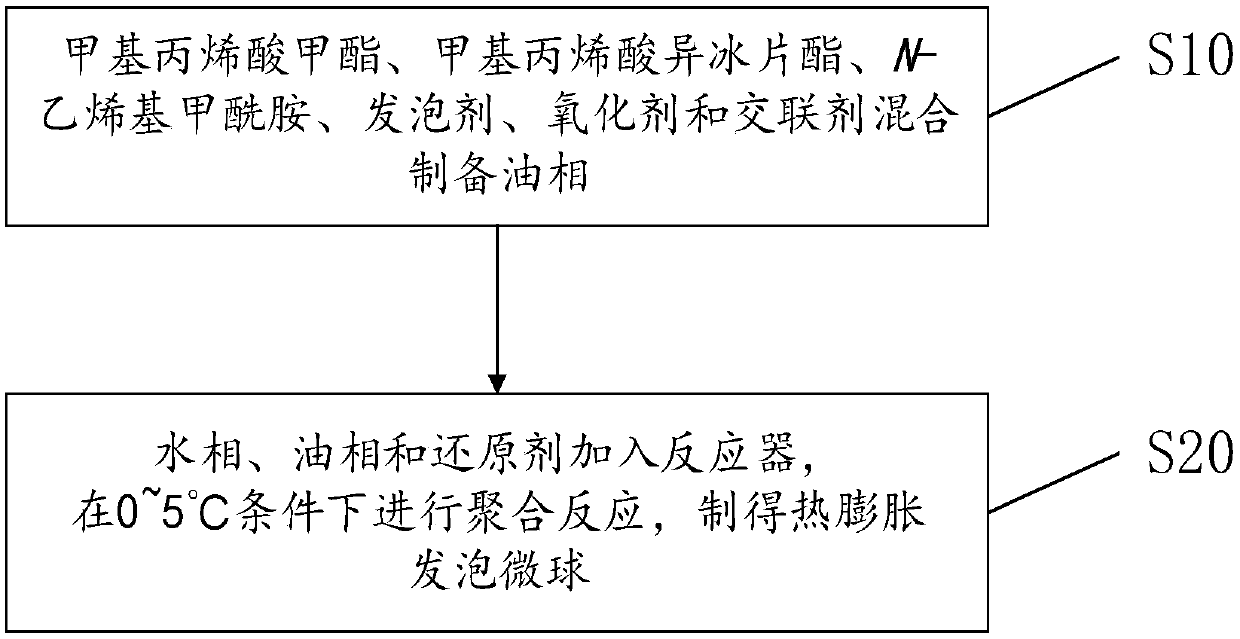

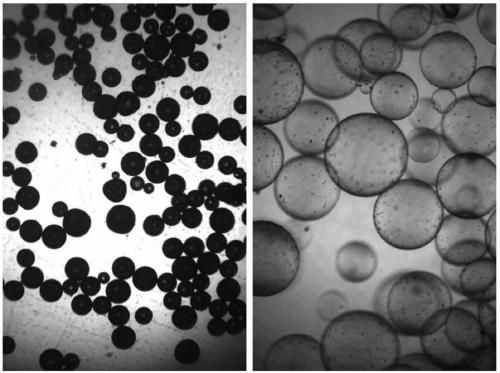

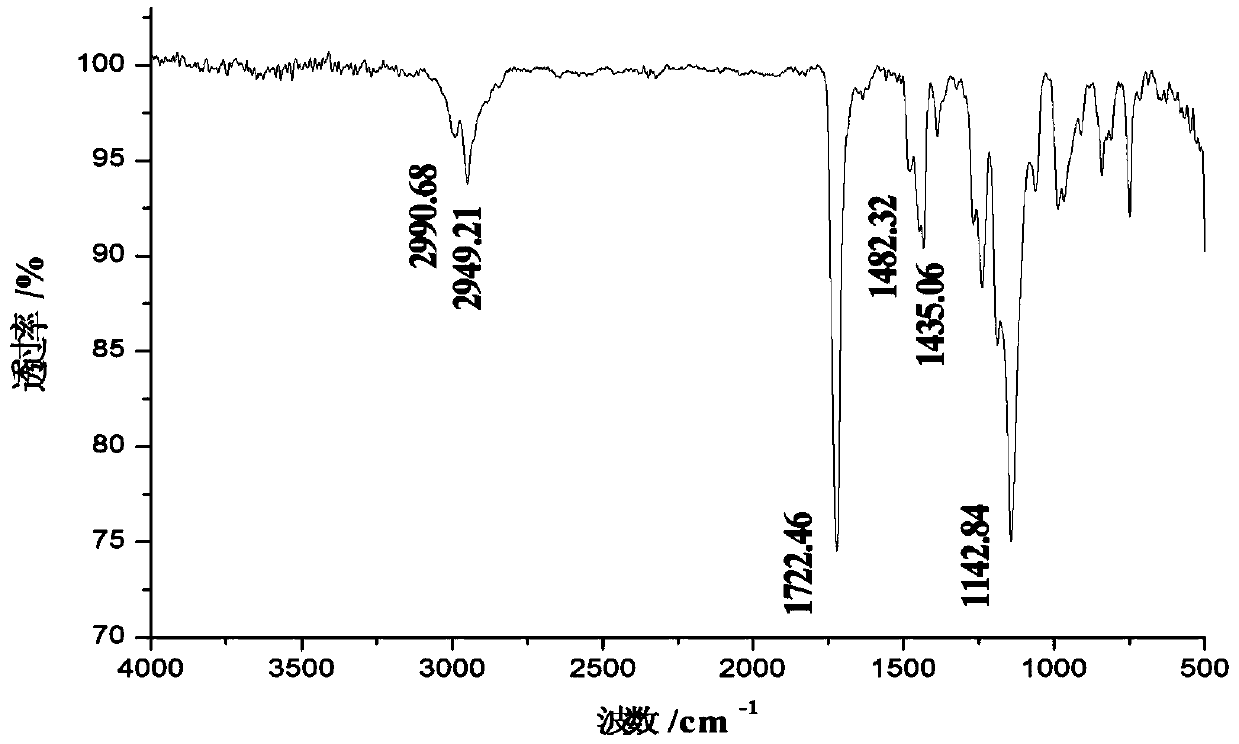

Acrylic resin thermal expansion foaming microspheres and preparation method thereof

The invention relates to the technical field of high polymer materials. The invention provides a preparation method of acrylic resin thermal expansion foaming microspheres. According to the method, methyl methacrylate is used as a main monomer and is subjected to suspension copolymerization with isobornyl methacrylate and N-vinylformamide monomers under the normal pressure at 0-5 DEG C to preparethe thermal expansion foaming microspheres. The production process is simple, safe, low in energy consumption and low in equipment requirement, and then the production cost can be reduced. The invention also provides a formula composition for preparing the thermal expansion foaming microspheres, the microsphere product produced according to the formula does not contain nitrile group and halogen component, the microsphere product has the advantages of high expansion ratio, moderate foaming temperature, stable foaming performance and the like, and the microsphere shell has good mechanical property and sealing property.

Owner:ZHEJIANG HAIHONG HLDG

Preparation and application of chain-extending concentrates for polyester foaming process

The composition and the preparation of a chain-extending concentrate for production of foamed cellular materials of aromatic polyesters is disclosed in this invention. The chain-extending concentrate includes an ethylene-acrylate copolymer, a high-temperature thermoplastic and a multifunctional compound. The preparation process includes two steps: 1) Mixing and melt blending the multifunctional compound and the HT thermoplastic resin into the matrix of the ethylene-acrylate copolymer in an internal mixer and 2) extrusion of the mixture at a temperature below the melting point or reaction temperature of the multifunctional compound.

Owner:ARMACELL ENTERPRISE GMBH & CO KG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com