Modified polyurethane expanded plastic and preparation method thereof

A technology of foamed plastics and polyurethane, applied in the field of plastics, can solve problems such as poor flexibility and failure to meet requirements, and achieve the effect of improving toughness, reducing raw material costs, and good toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

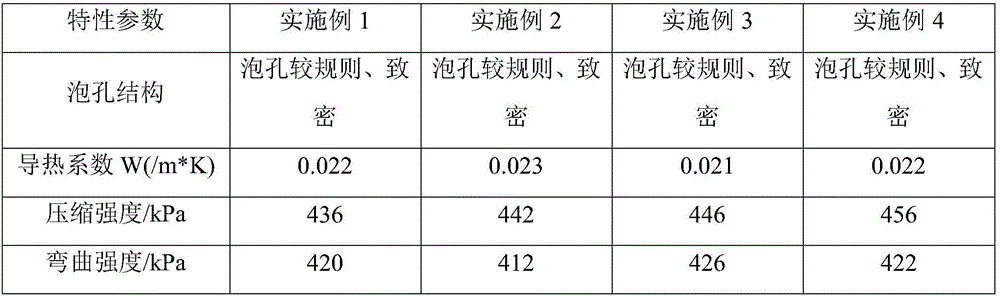

Examples

Embodiment 1

[0026] A modified polyurethane foamed plastic, the raw material for making the modified polyurethane foamed plastic includes the following components in parts by weight: 120 parts of isocyanate, 100 parts of adipate, 20 parts of glass fiber cloth, silane coupling agent 0.6 parts, 0.4 parts of titanate coupling agent, 0.6 parts of monoglyceride, 3 parts of triethanolamine, 10 parts of carbon nanotubes, 20 parts of low density polyethylene, 20 parts of aramid pulp, 10 parts of ceramic fiber, azo 1 part of dimethylamide, 0.3 part of foam stabilizer, 1 part of sodium lauryl sulfate, and 0.6 part of antioxidant.

[0027] The preparation method of described modified polyurethane foam plastics comprises the following steps:

[0028] (1) Weigh the glass fiber cloth ear material, clean it until there is no mud, dirt, etc., dry it until there is no moisture, and then send the dried glass fiber cloth ear material to the cutting machine for cutting, and cut it into lengths of 4- 5cm smal...

Embodiment 2

[0035] A modified polyurethane foamed plastic, the raw material for making the modified polyurethane foamed plastic includes the following components in parts by weight: 150 parts of isocyanate, 60 parts of adipate, 60 parts of polycaprolactone, glass fiber cloth 30 parts, 1 part of silane coupling agent, 0.8 parts of titanate coupling agent, 1 part of monoglyceride, 5 parts of triethanolamine, 20 parts of carbon nanotubes, 30 parts of low density polyethylene, 30 parts of aramid pulp, 20 parts of ceramic fiber, 2 parts of azodicarbonamide, 0.5 parts of foam stabilizer, 2 parts of sodium lauryl sulfate, and 1 part of antioxidant.

[0036] The preparation method of described modified polyurethane foam plastics comprises the following steps:

[0037] (1) Weigh the glass fiber cloth ear material, clean it until there is no mud, dirt, etc., dry it until there is no moisture, and then send the dried glass fiber cloth ear material to the cutting machine for cutting, and cut it into ...

Embodiment 3

[0044] A modified polyurethane foam plastic, the raw material for making the modified polyurethane foam plastic includes the following components in parts by weight: 135 parts of isocyanate, 110 parts of polycarbonate, 25 parts of glass fiber cloth, 0.8 parts of silane coupling agent 0.6 parts of titanate coupling agent, 0.8 parts of monoglyceride, 4 parts of triethanolamine, 15 parts of carbon nanotubes, 25 parts of low-density polyethylene, 25 parts of aramid pulp, 15 parts of ceramic fiber, azobis 1.5 parts of formamide, 0.4 parts of foam stabilizer, 1.5 parts of sodium lauryl sulfate, and 0.8 parts of antioxidant.

[0045] The preparation method of described modified polyurethane foam plastics comprises the following steps:

[0046] (1) Weigh the glass fiber cloth ear material, clean it until there is no mud, dirt, etc., dry it until there is no moisture, and then send the dried glass fiber cloth ear material to the cutting machine for cutting, and cut it into lengths of 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com