Submersible aerator impeller

A technology of aerator and water impeller, applied in biological water/sewage treatment, water/sludge/sewage treatment, sustainable biological treatment, etc., can solve the problem of reducing aerator efficiency, reducing air intake, fragmentation Unsatisfactory effect and other problems, to achieve the effect of high aeration efficiency and oxygenation efficiency, and small bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

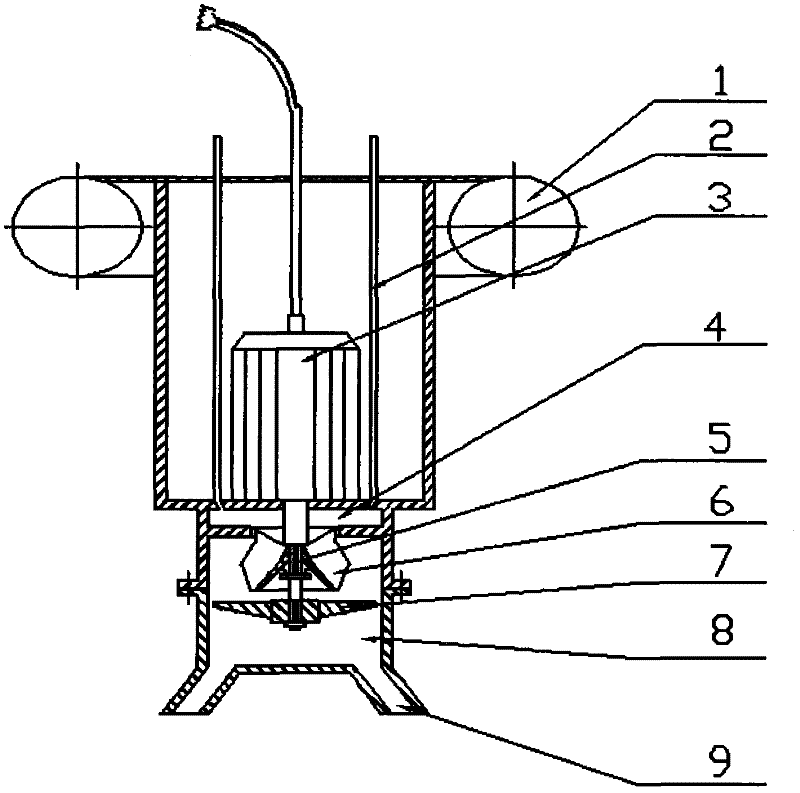

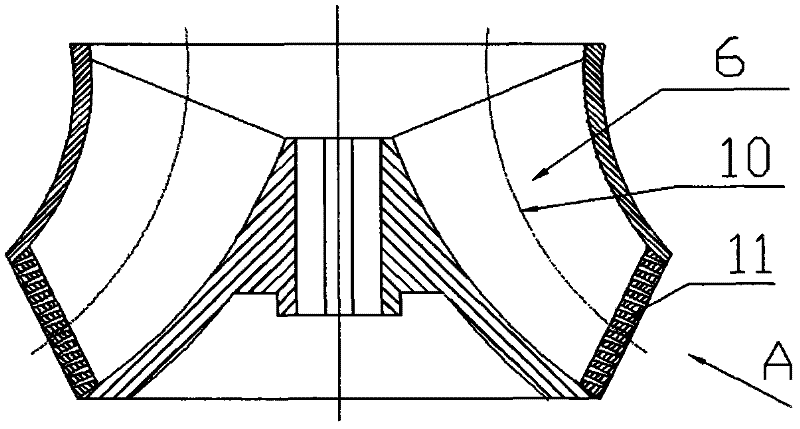

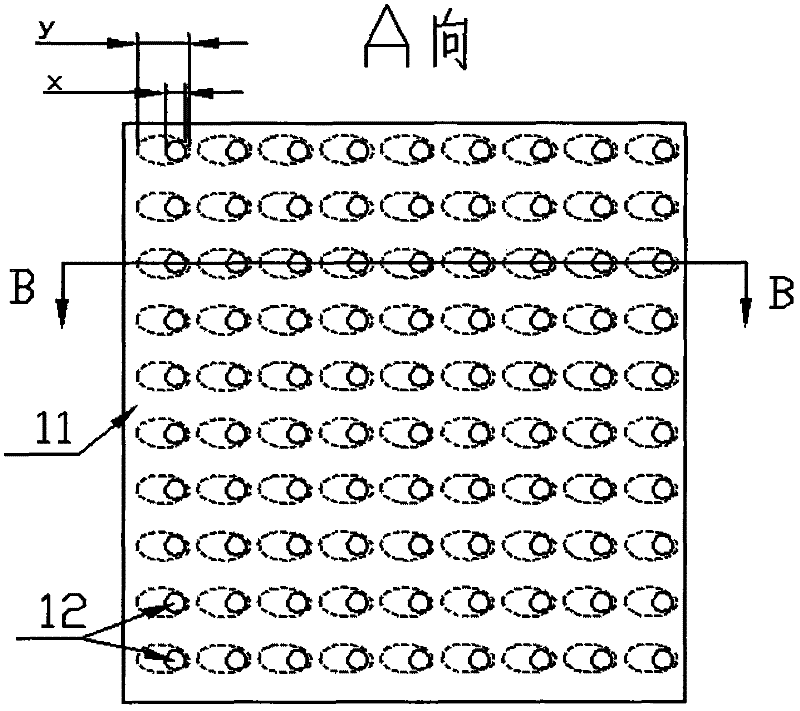

[0019] See Figure 1~6 As shown, in the present embodiment, when the aerator is submerged into a deeper depth (less than 4m), the submersible motor (3) drives the wind impeller (6) and the water impeller (7) to rotate at a high speed after the submersible motor (3) is energized, and the wind impeller (6) has two A wind impeller blade (13), the water impeller (7) has two water impeller blades (15), and the structure is as Figure 5 (a) and Figure 6 As shown in (b), the wind impeller (6) is a mixed-flow impeller, which has the characteristics of large flow rate and low head, and can transport a large amount of fluid per unit time compared with ordinary wind impellers. After the wind impeller (6) rotates at high speed, a negative pressure is formed in the bellows (4), and a large amount of outside air will enter the bellows (4) along the intake pipe (2), and the air passes through the outlet arc baffle (11) of the wind impeller. The structure is as follows: figure 2 , as show...

Embodiment 2

[0021] This embodiment is basically the same as Embodiment 1, and the difference is that when the aerator submerged deeply (when greater than 4m), the wind impeller (6) had three wind impeller blades (13), and the water impeller (7) had Three water impeller blades (15), structure such as Figure 5 (b) and Figure 6 (b) shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com