Tire-inner-liner rubber composition and preparing method thereof

A technology of rubber composition and airtight layer, which is applied in special tires, tire parts, transportation and packaging, etc., can solve the problems of high cost, poor processing performance, poor vulcanization and adhesion performance, etc., so as to reduce transportation transit and reduce The effect of rubber sticking to the cold roll and slowing down the vulcanization speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

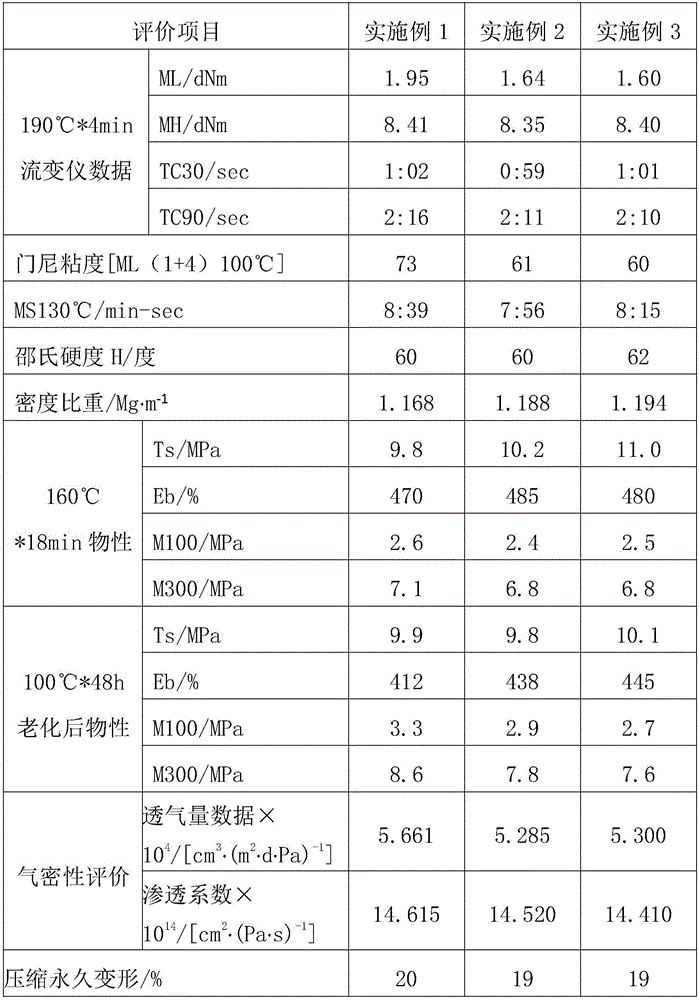

Examples

Embodiment 1

[0017] The tire inner liner rubber composition involved in this embodiment, the raw material components and the parts by weight of each component are: 30 parts of SMR20 type natural rubber, 70 parts of BIIR-2030 type brominated butyl rubber, 62 parts of N660 type carbon black , 35 parts of Qiangwei powder, 10 parts of TDAE environmental protection aromatic oil, 2 parts of stearic acid, 3 parts of zinc oxide, 2 parts of tackifying resin, 2 parts of 40MS type dispersant, 0.3 part of magnesium oxide, 0.3 part of DM type accelerator, 0.7 parts of TB710 accelerator, 1.2 parts of sulfur.

[0018] The preparation method of the tire inner liner rubber composition that this embodiment relates to, its specific preparation process comprises the following steps:

[0019] (1) One-stage internal mixing: send natural rubber, bromobutyl rubber, carbon black, Qianwei powder, tackifying resin, 40MS type dispersant, DM type accelerator, stearic acid and magnesium oxide into the internal mixer P...

Embodiment 2

[0025] The tire inner liner rubber composition involved in this embodiment, the raw material components and the parts by weight of each component are: 32 parts of SMR20 type natural rubber, 68 parts of BIIR-2030 type brominated butyl rubber, and 60 parts of N660 type carbon black , 38 parts of Qiangwei powder, 12 parts of TDAE environmental protection aromatic oil, 2 parts of stearic acid, 3.5 parts of zinc oxide, 2 parts of tackifying resin, 2 parts of 40MS type dispersant, 0.4 part of magnesium oxide, 0.4 part of DM type accelerator, 0.7 parts of TB710 accelerator, 1.2 parts of sulfur.

[0026] The preparation method of the tire inner liner rubber composition involved in this embodiment is the same as that in Embodiment 1.

Embodiment 3

[0028]The tire inner liner rubber composition involved in this embodiment, the raw material components and the parts by weight of each component are: 25 parts of SMR20 type natural rubber, 75 parts of BIIR-2030 type bromobutyl rubber, 60 parts of N660 type carbon black , 35 parts of Qiangwei powder, 12 parts of TDAE environmental protection aromatic oil, 2 parts of stearic acid, 3 parts of zinc oxide, 2 parts of tackifying resin, 2 parts of 40MS type dispersant, 0.3 part of magnesium oxide, 0.4 part of DM type accelerator, 0.7 parts of TB710 accelerator, 1.1 parts of sulfur.

[0029] The preparation method of the tire inner liner rubber composition involved in this embodiment is the same as that in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com