Device for purifying exhaust gases of a motor vehicle and method for the production thereof

An exhaust gas purification device and exhaust gas technology, which can be applied to exhaust devices, mufflers, machines/engines, etc., can solve problems such as uneven quality of welds, and achieve the effect of accurate adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

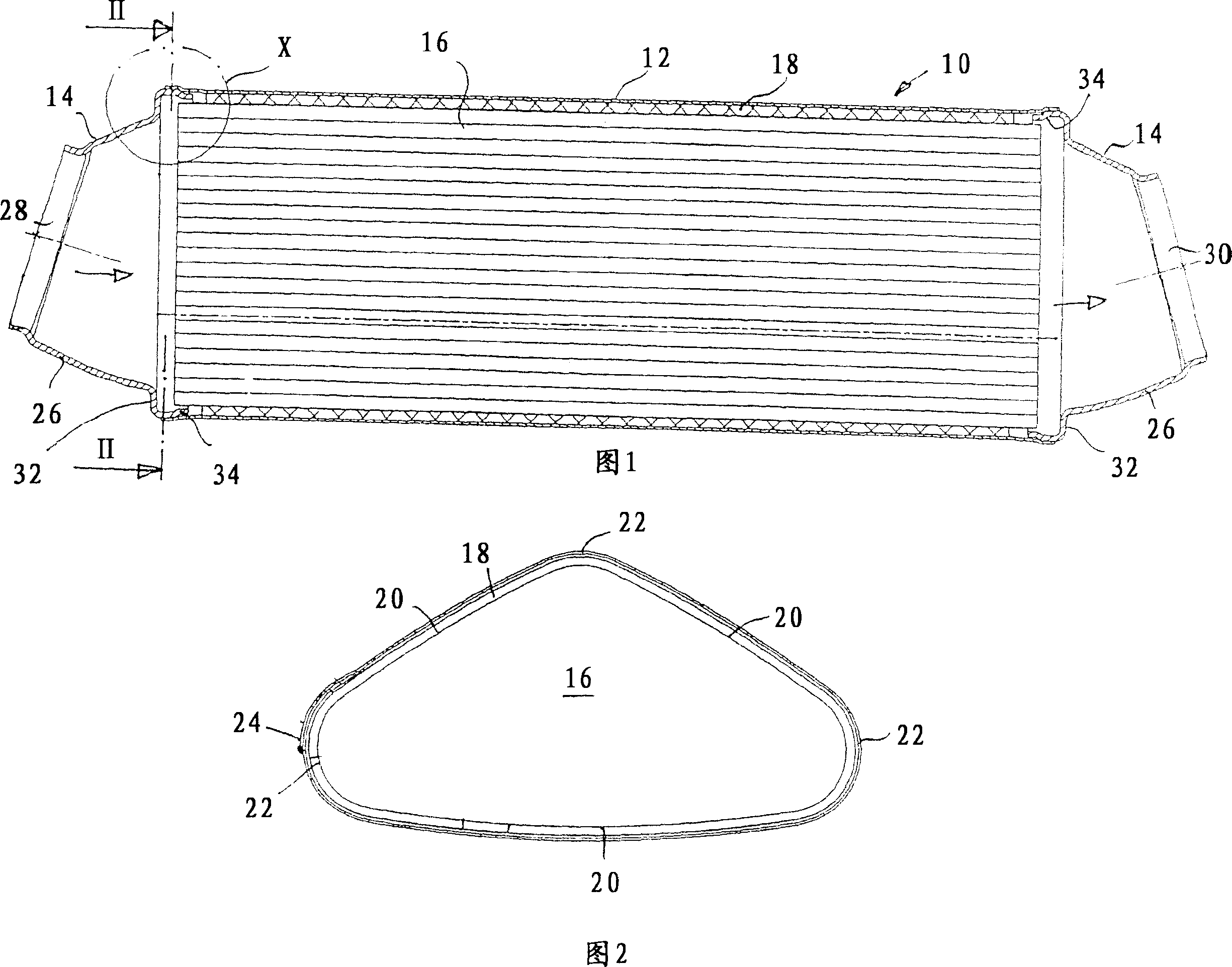

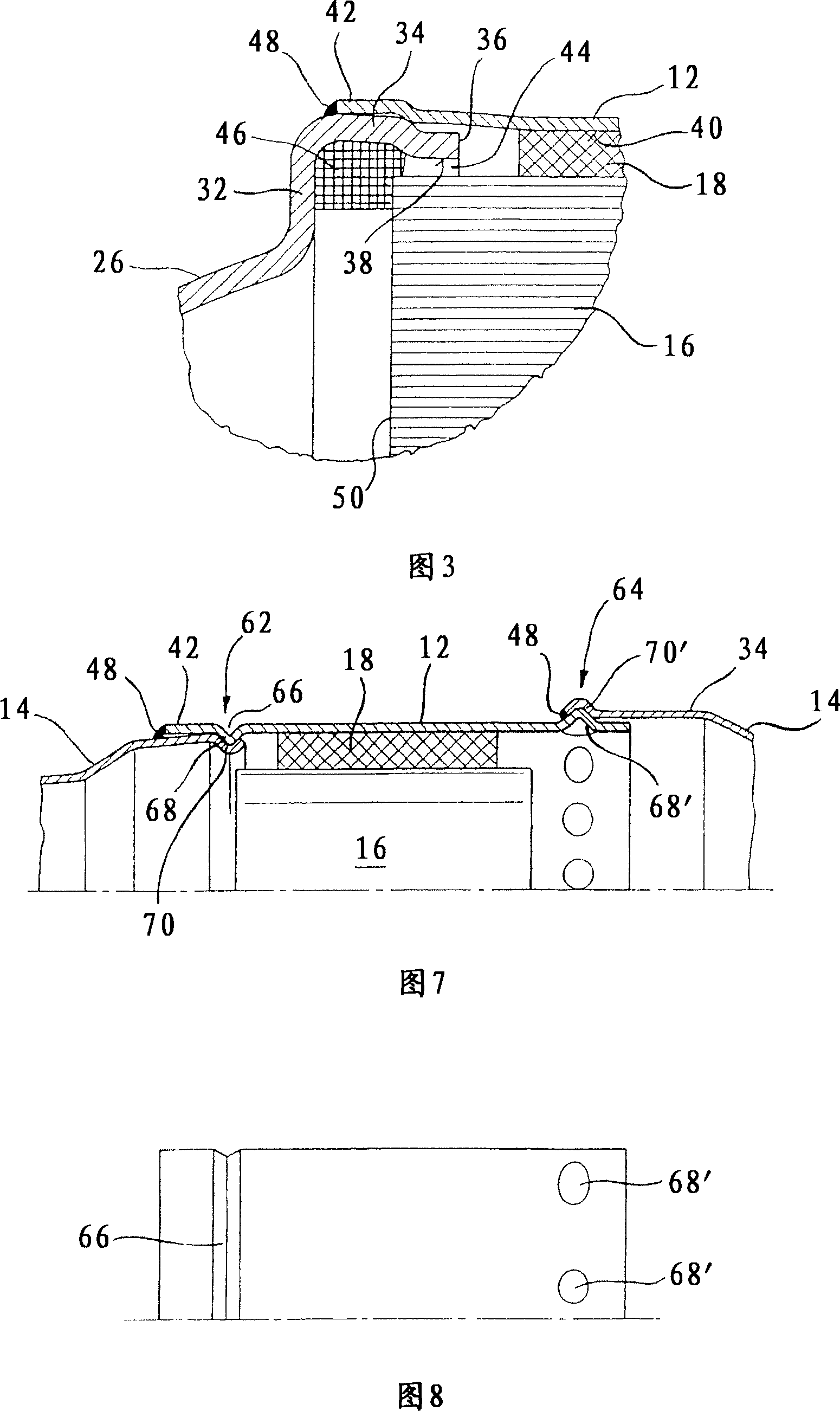

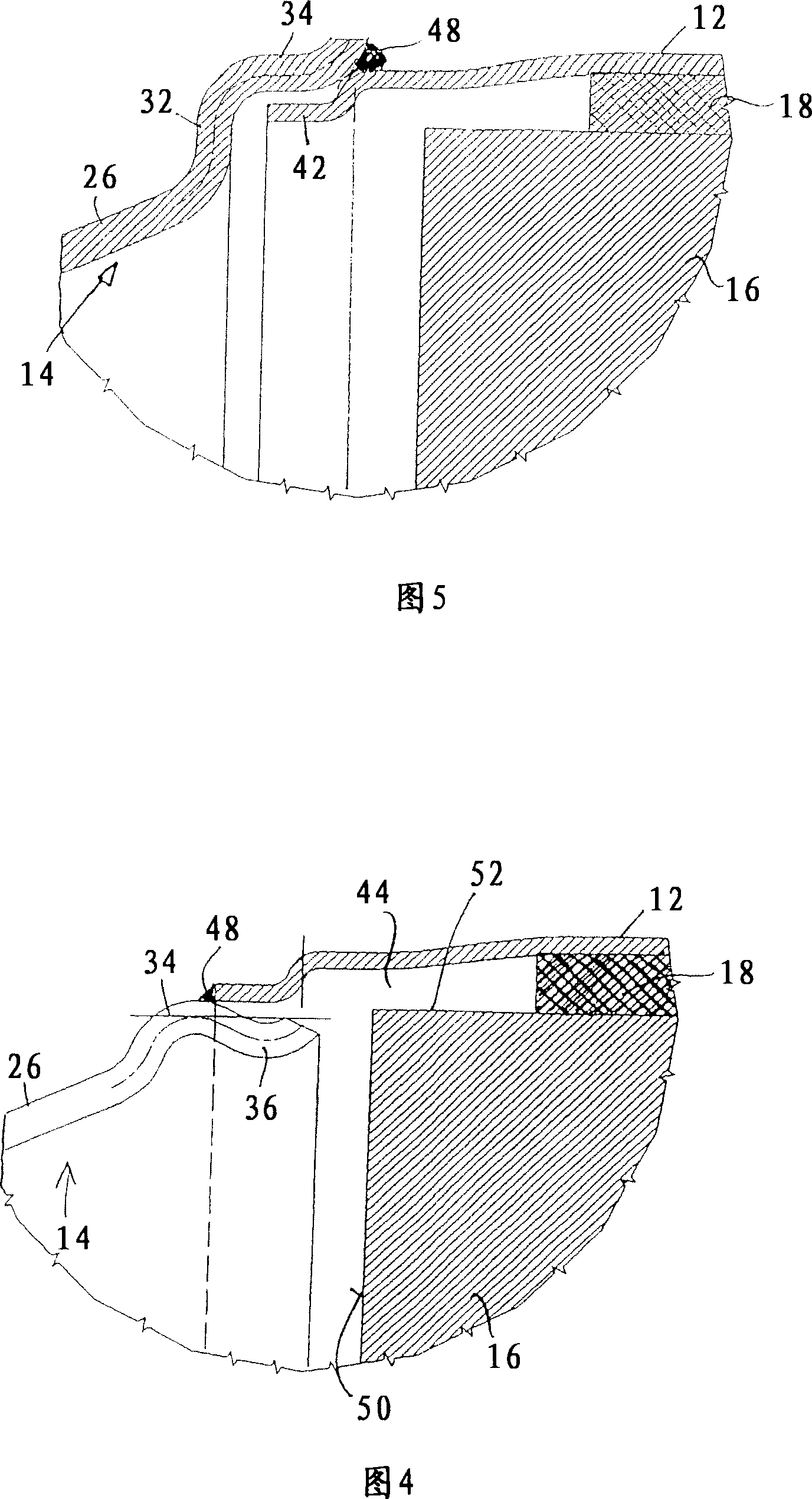

[0035] Figure 1 shows a vehicle exhaust purification device installed in the exhaust system. The device has a three-part housing 10 comprising a tube 12 longitudinally welded from sheet metal forming a surrounding sheath, and an end wall 14 mounted on the open end face of the tube 12 . A filter body 16 through which the exhaust gas flows is inserted into the housing 10 in the form of an integral diesel particulate filter or a catalytic converter (see arrow). The filter body 16 is surrounded by an insulating or intumescent pad 18 which supports the filter body 16 in the housing 10 with a non-positive fit. The pads 18 also function to compensate for tolerances and limit the deflecting forces exerted by the housing 10 on the filter body 16 .

[0036] Both the filter body 16 and the tube 12 have a geometry different from that of a circular ring and are delimited by three sections 20 that are planar or not curved at all and three relatively very curved sections 22 of the connectin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com