Manufacturing method for display screen and display screen

A technology for display screens and adhesive materials, which is applied in semiconductor/solid-state device manufacturing, electrical components, and electric solid-state devices, etc. problems, to achieve the effects of flexible folding display, improvement of adverse effects, and reduction of bending stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

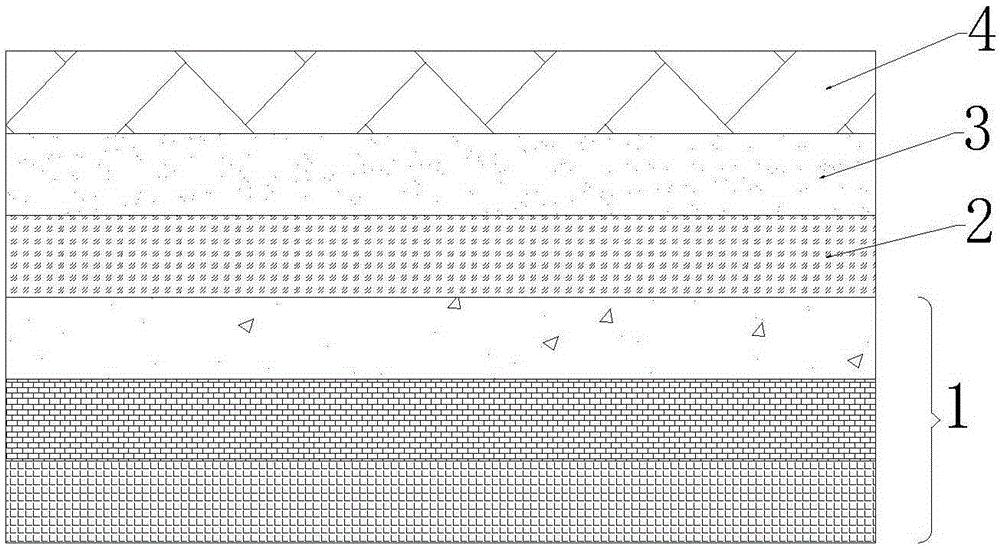

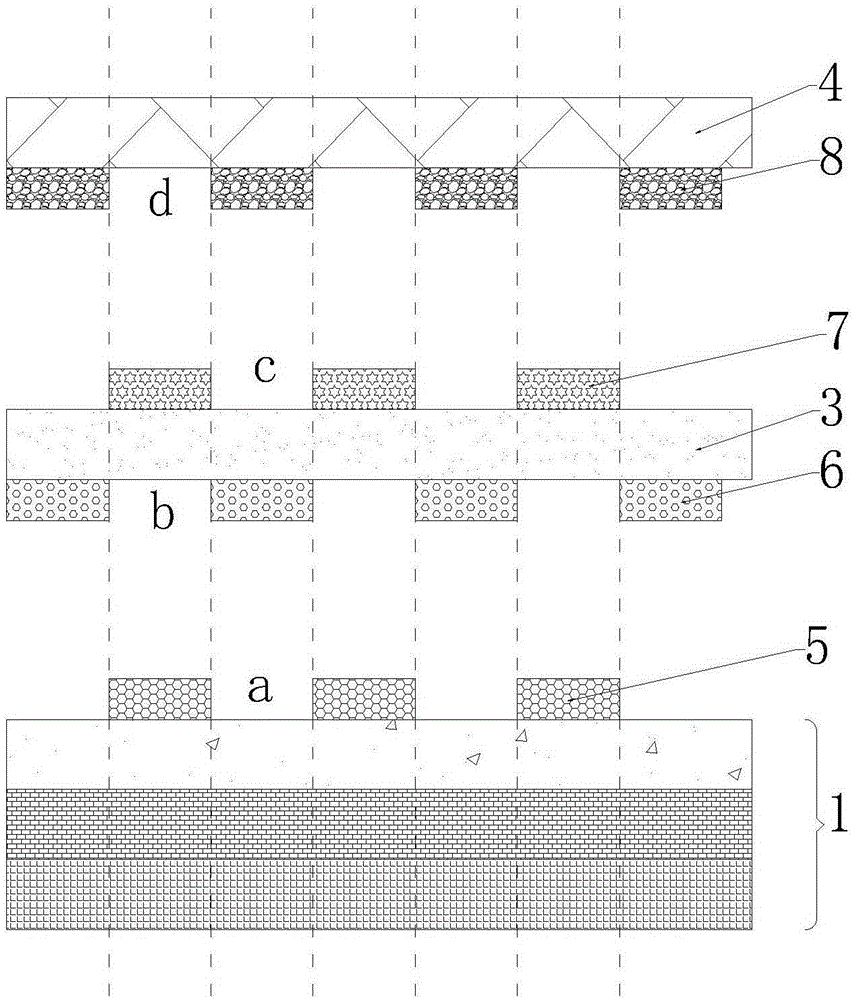

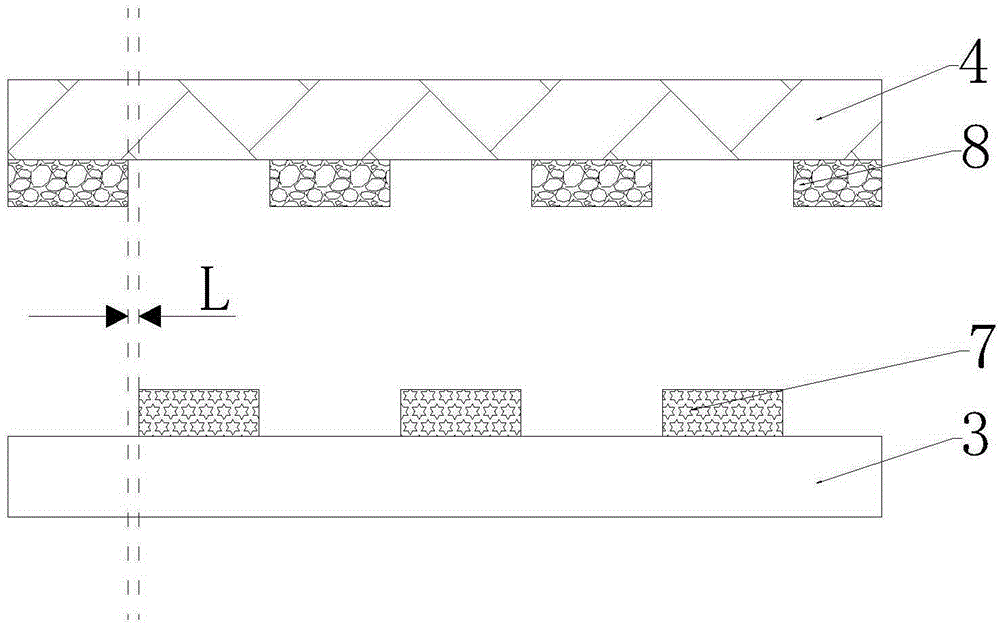

[0065] Such as Figure 1 to Figure 6 As shown, an AMOLED panel 1 , encapsulation layer 3 and functional layer 4 are provided, similar to the AMOLED panel 1 , encapsulation layer 3 and functional layer 4 in the existing display screen. After providing such AMOLED panel 1, encapsulation layer 3 and functional layer 4, it is necessary to bond the AMOLED panel 1, encapsulation layer 3 and functional layer 4 together. All of them are coated on the lower surface of the encapsulation layer and the functional layer, or a layer of adhesive material is completely coated on the upper surface of the AMOLED panel and the encapsulation layer, but the disadvantages of such an arrangement have been described in the first embodiment above. I won't go into details here.

[0066] Therefore, in order to overcome the adverse effects caused by the original bonding method, the present invention is to arrange a number of adhesive material units at intervals on the AMOLED panel 1, the encapsulation l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com