Tungsten carbide enhanced copper-based powder metallurgy friction material and preparing method thereof

A friction material and powder metallurgy technology, applied in the field of friction material manufacturing and powder metallurgy, can solve the problems of unstable friction performance, large amount of wear, low friction coefficient, etc., and achieve the effects of low manufacturing cost, high hardness and high friction coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

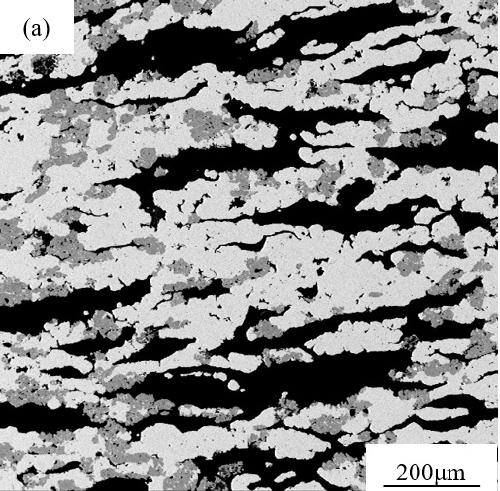

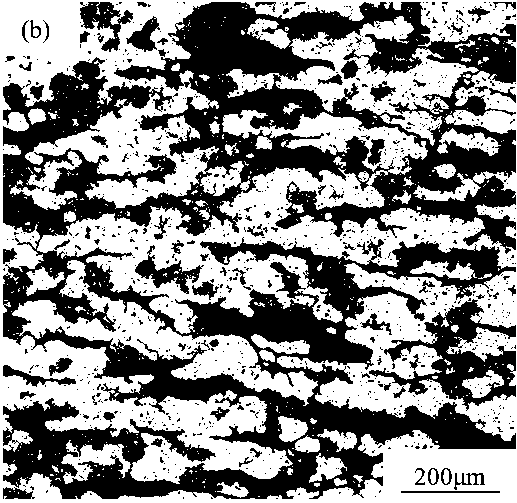

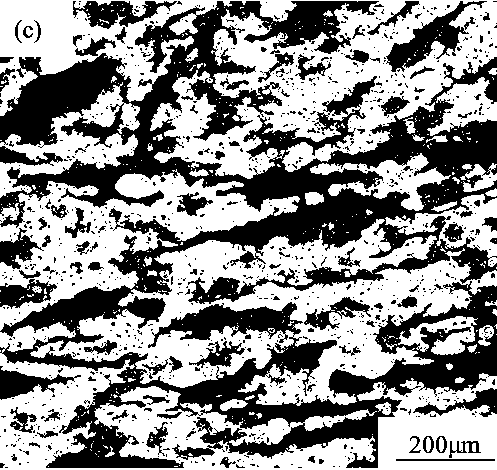

[0028] A tungsten carbide reinforced copper-based powder metallurgy friction material, which is composed of the following raw materials in weight percentages, copper powder is 50% to 70%, iron powder is 10% to 20%, tin powder is 1% to 5%, and graphite is 6% %~11% and 0.01%~15% for tungsten carbide.

[0029] For the above raw materials, copper is the matrix, which utilizes the characteristics of soft copper and high plasticity to reduce the wear of self-lubricating materials on the key parts in contact with it, and utilizes the high thermal conductivity of copper to absorb and export the heat generated during the braking process. Heat; iron is the same as the matrix phase, which can make up for the shortcomings of the strength of the copper matrix. Iron can be strengthened by graphite to improve hardness and strength. From the perspective of friction materials, iron powder is selected as the matrix reinforcement phase. Under the action of graphite, the strength of iron and hard...

Embodiment 2

[0042] A tungsten carbide reinforced copper-based powder metallurgy friction material is made of the following raw materials in the weight ratio: 0.01% tungsten carbide, 8% graphite, 18% iron powder, 4% tin powder, and 69.99% copper powder.

[0043] The particle size of tungsten carbide is 200 mesh, graphite is 100 mesh, iron powder is 280 mesh, tin powder is 280 mesh, copper powder is 200 mesh.

[0044] Concrete preparation process is as follows:

[0045] Weigh each raw material powder according to the above ratio, first put copper powder, iron powder, tin powder and tungsten carbide into the V-shaped mixer and mix for 2 hours, then add graphite powder and mix for 3 hours to make a uniformly mixed powder ;Put an appropriate amount of material powder into a regular hexagonal cold-pressing mold, and perform cold-pressing with a pressure of 400MPa, and hold the pressure for 3 minutes; put the sample after cold-pressing into a hot-pressing mold, and heat it in an argon atmosphere...

Embodiment 3

[0049] A tungsten carbide-reinforced copper-based powder metallurgy friction material is made of raw materials in the following weight ratio: 5% tungsten carbide powder, 8% graphite, 20% iron powder, 4% tin powder, and 63% copper powder.

[0050] The particle size of tungsten carbide is 150 mesh, graphite is 100 mesh, iron powder is 260 mesh, tin powder is 280 mesh, and copper powder is 180 mesh.

[0051] Concrete preparation process is as follows:

[0052] Weigh each raw material powder according to the above ratio, first put copper powder, iron powder, tin powder and tungsten carbide into the V-shaped mixer and mix for 2 hours, then add graphite powder and mix for 2 hours to make a uniformly mixed powder ; Add appropriate amount of material powder into a regular hexagonal cold-pressing mold, cold-press with a pressure of 300MPa, and hold the pressure for 15 minutes; put the cold-pressed sample into a hot-pressing mold, and heat it in an argon atmosphere Pressing and sinteri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com