Patents

Literature

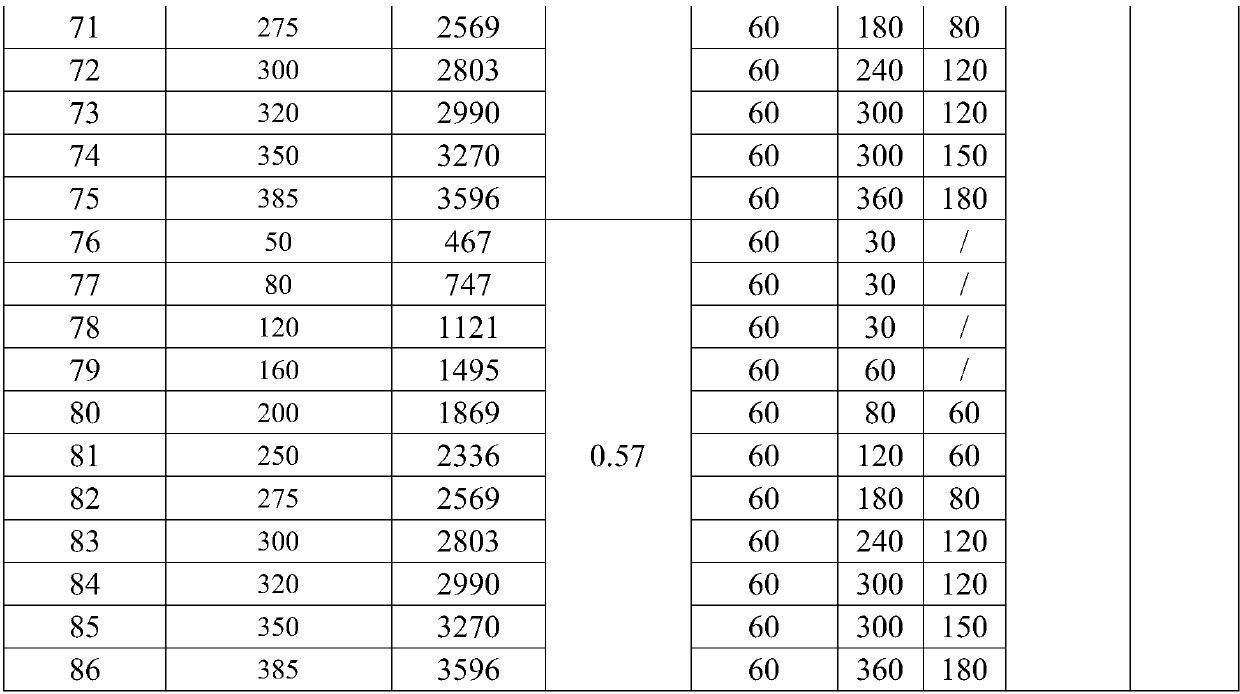

92results about How to "Frictionally stable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

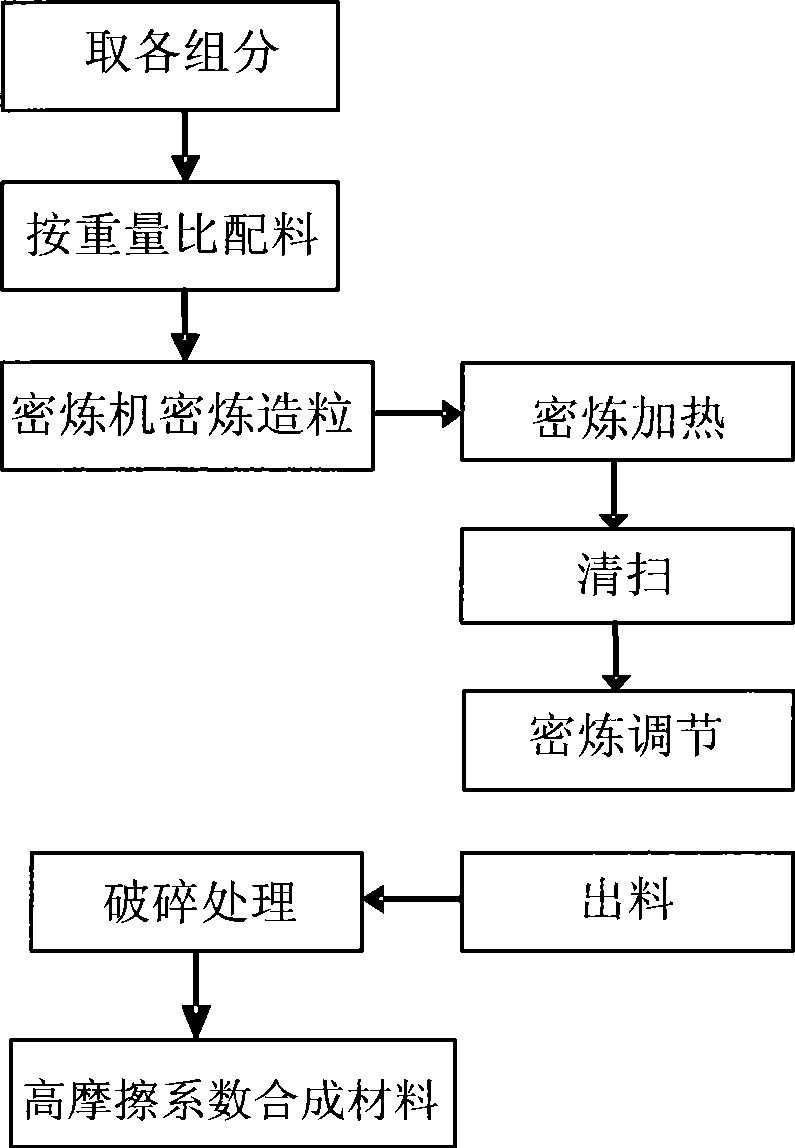

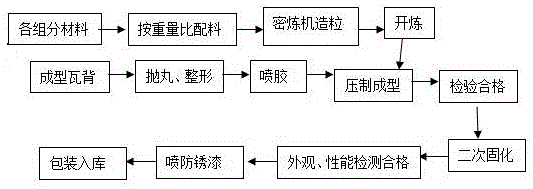

High friction coefficient synthetic materials and preparation method thereof

The invention discloses a high friction coefficient composite material and a manufacturing method thereof, wherein the material is prepared through material sealing and grain-making processing by the following compositions in weight percentage: 8 to 13 percent of butadiene-acrylonitrile rubber, 2 to 10 percent of styrene-butadiene rubber, 5 to 10 percent of cresol methyl-stage phenol-formaldehyde resin modified, 15 to 30 percent of steel fiber, 10 to 15 percent of magnesia, 5 to 10 percent of calcined petroleum coke, 2 to 5 percent of silicon carbide, 10 to 25 percent of mineral fiber, 5 to 10 percent of calcium hydroxide, 10 to 20 percent of barium sulfate, 5 to 10 percent of graphite, 1 to 5 percent of supramoly, 1 to 5 percent of carbon black, 1 to 3 percent of sulfur and 1 to 3 percent of accelerant. The material can be applied in a plurality of situations to prepare friction components, has stable friction performance and good abrasion resistance, effectively inhibits the phenomena of metal inlay, cracking, chip off-falling and so on, reduces the damage on vehicle wheels, has good impact resistance and good weathering resistance, can be used in the environment with large temperature variation for a long time, and has the application characteristics of wide application region and large difference of the regional environment.

Owner:BEIJING RAILWAY STAR FORTUNE HIGH TECH

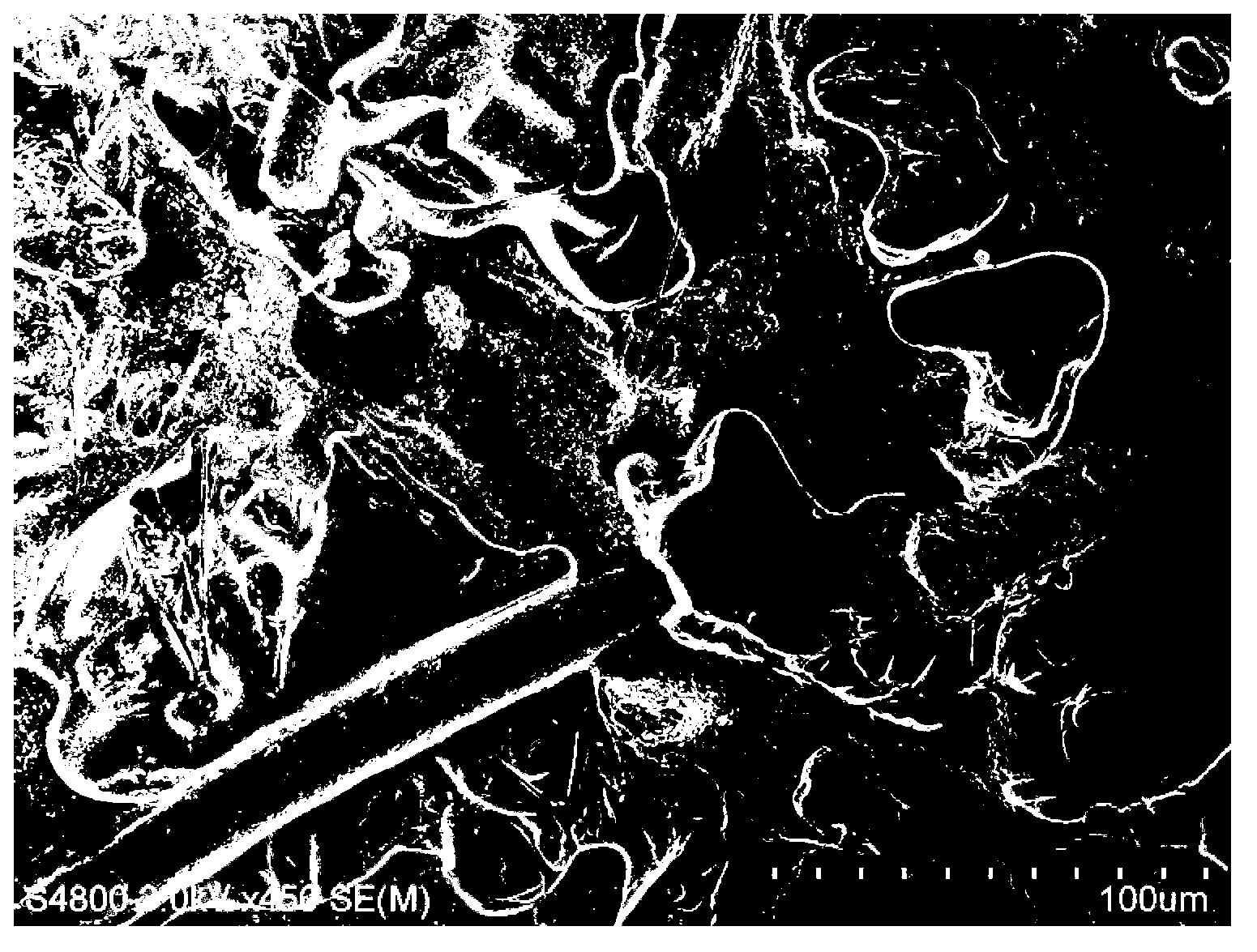

Hybrid fiber reinforced friction material for train braking and preparation method thereof

InactiveCN102191015AImprove toughnessImprove yieldOther chemical processesFriction liningFreight trainsAdhesive

The invention belongs to the technical field of materials, and particularly relates to a hybrid fiber reinforced friction material for train braking and a preparation method thereof. In the invention, a composite modified phenolic resin is used as an adhesive, and hybrid fibers, including carbon fiber, metal fiber, inorganic mineral fiber and the like, are used as the reinforcing fibers. Compared with the prior art, the invention improves the contour machining property of the organic synthetic brake, and the yield of the material is high; the brake has stable frictional property at different braking speeds, does not has obvious degradation of frictional property at high speed, and does not have the phenomena of shedding and cracking on the working surface after the braking test. The friction material provided by the invention can be widely used for manufacturing brake pads, brakes, brake shoes and the like in braking systems of passenger and freight trains, municipal rail transportation, subways and the like.

Owner:FUDAN UNIV

High-performance organic fibre brake pad

ActiveCN101555918AStable coefficient of frictionSmall thermal expansionFriction liningLow noiseCellulose

A high-performance organic fibre brake pad comprises the following components according to weight percentages: 5-9% of cashew nut oil friction powder, 4-8% of chromite, 7-10% of barite, 4-7% of calcined petroleum coke, 3-7% of crystalline flake graphite, 3-6% of sepiolite fibre, 4-7% of ceramic fibre, 1.5-3% of antimony sulphide, 4-7% of red copper fibre, 3-5% of glued aluminium silicate fibre, 1-2% of alumina fibre, 8-11% of vermiculite powder, 9-13% of organosilicone phenol-formaldehyde resin, 1-2% of carbon fibre, 5-7% of bastose, 1-2.5% of wood pulp cellulose, 3-6% of viscose fibre, 6-9% of bamboo carbon fibre, 3-5% of nitrile rubber and 0.3-0.5% of zinc oxide. The invention has the advantages of light weight, strong wear resistance, good flexibility, low noise and long service life, and the like, and the friction performance is stable at operating temperature between 100 DEG C and 450 DEG C.

Owner:摩擦一号制动科技(仙桃)有限公司

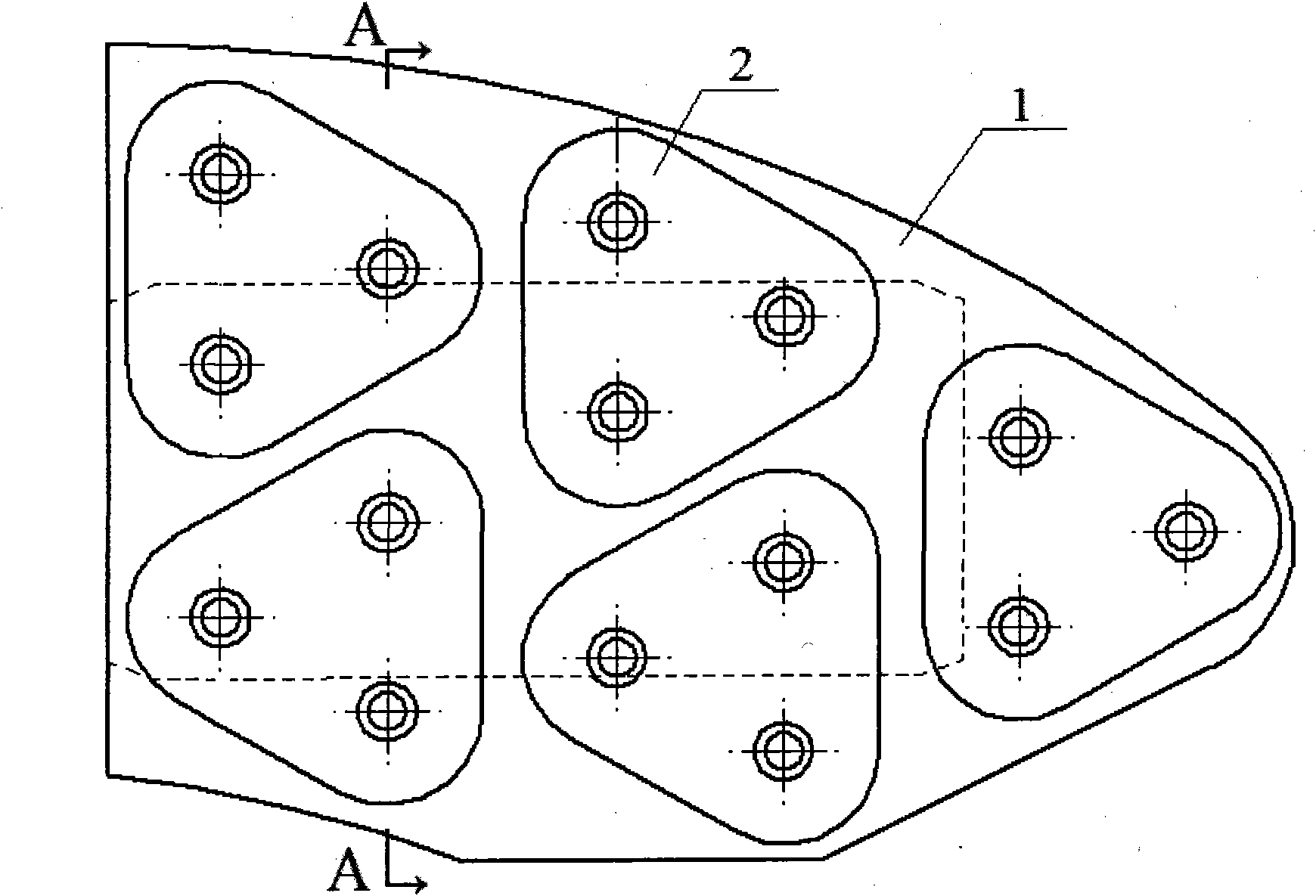

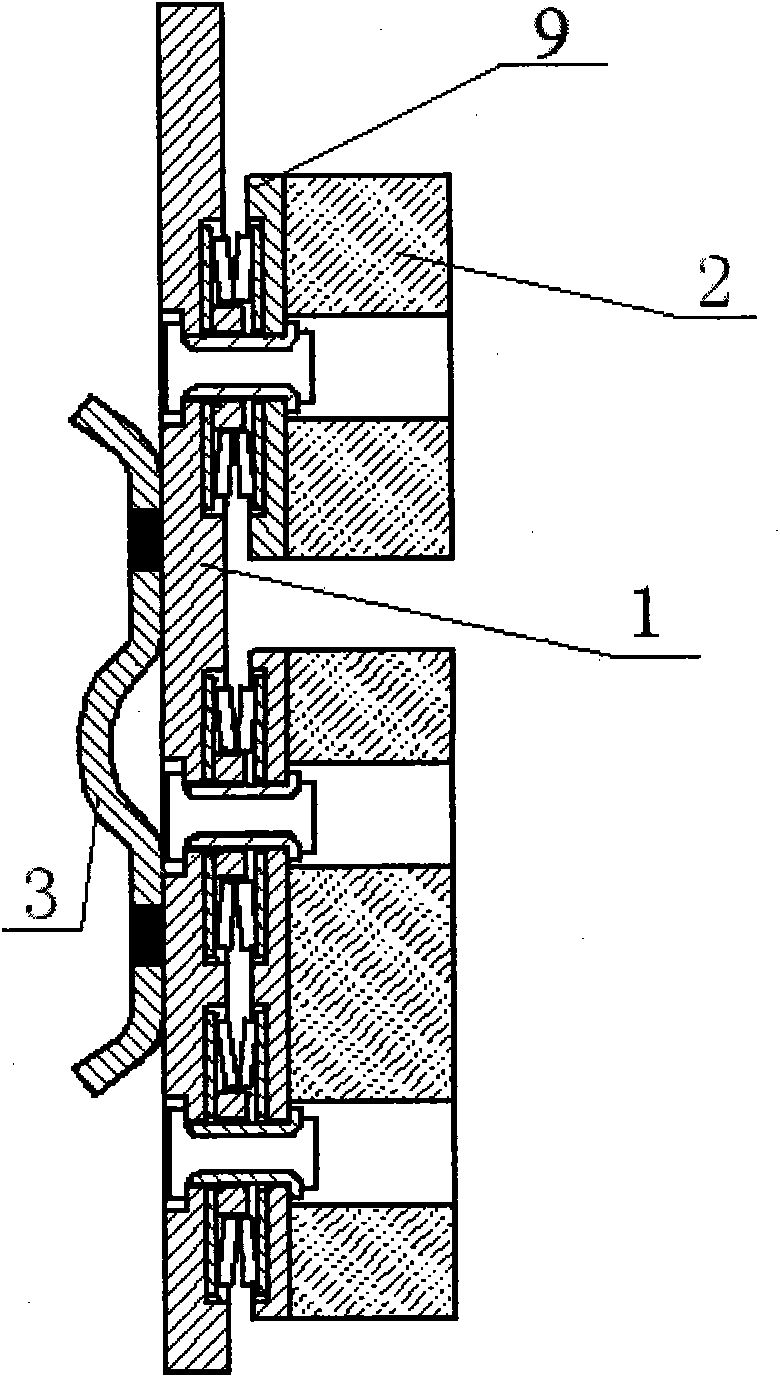

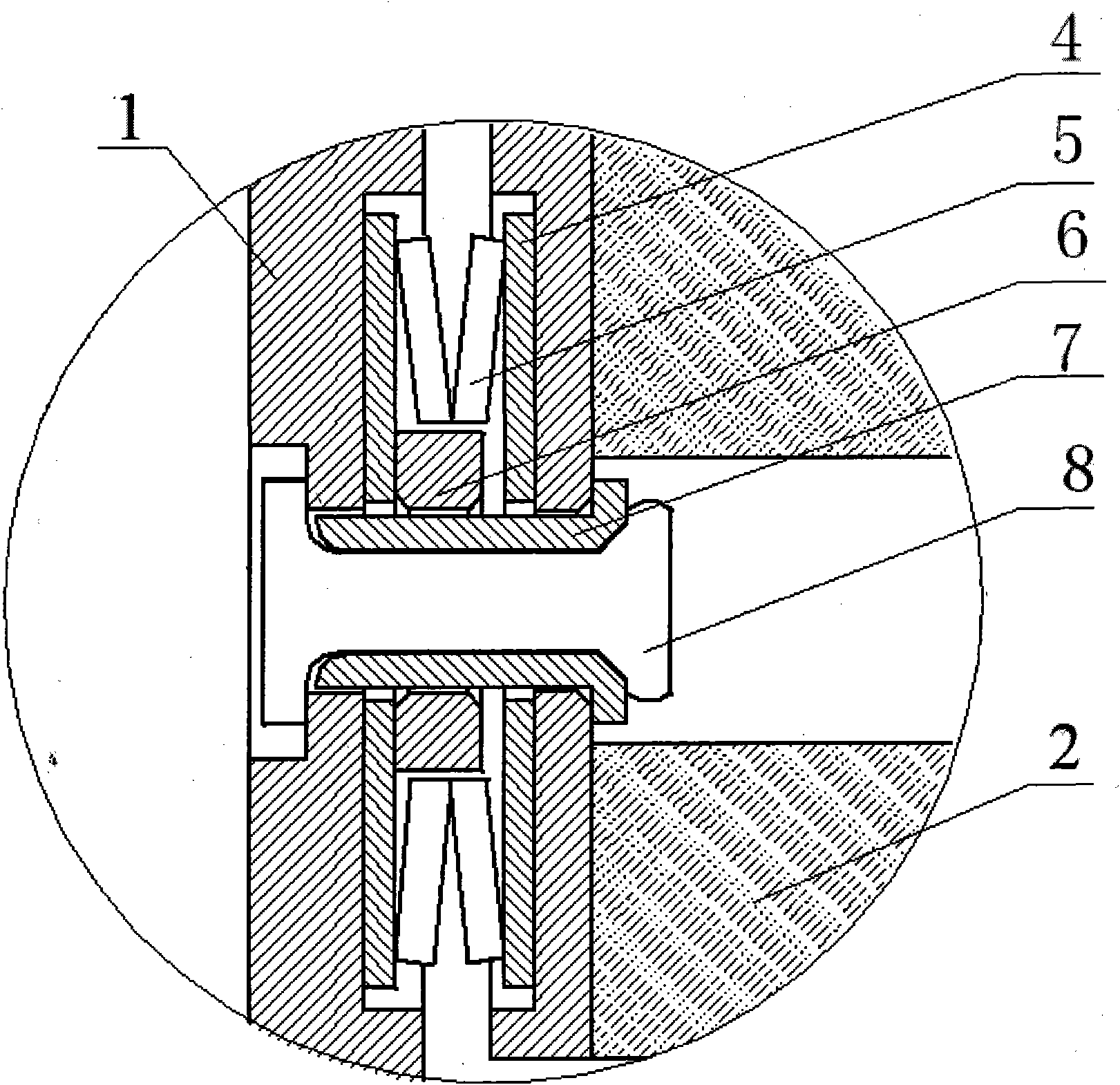

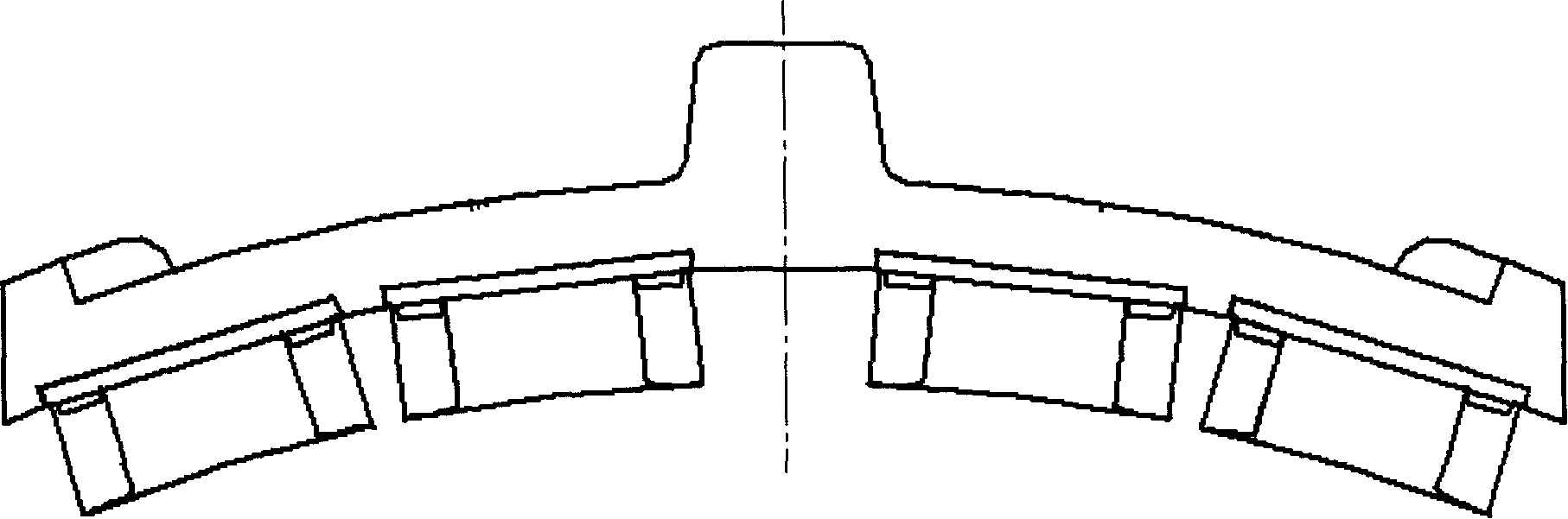

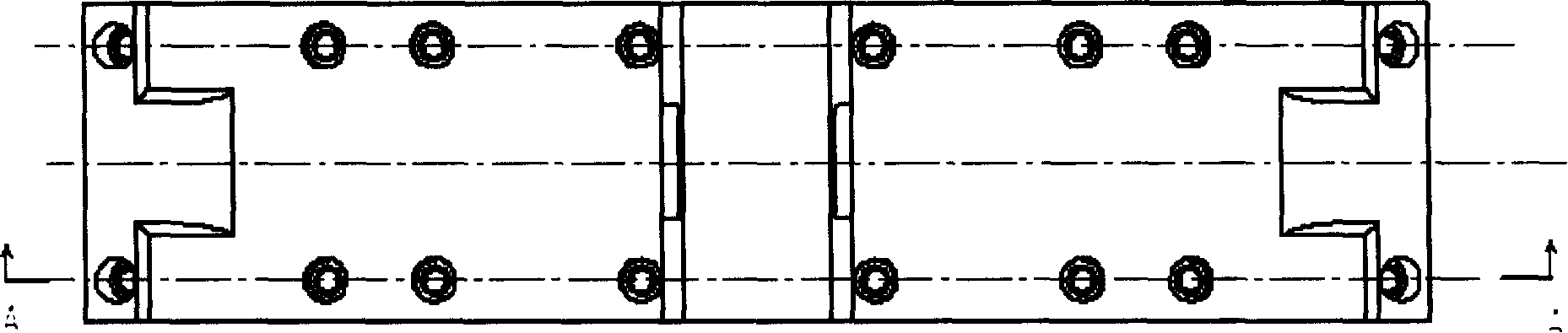

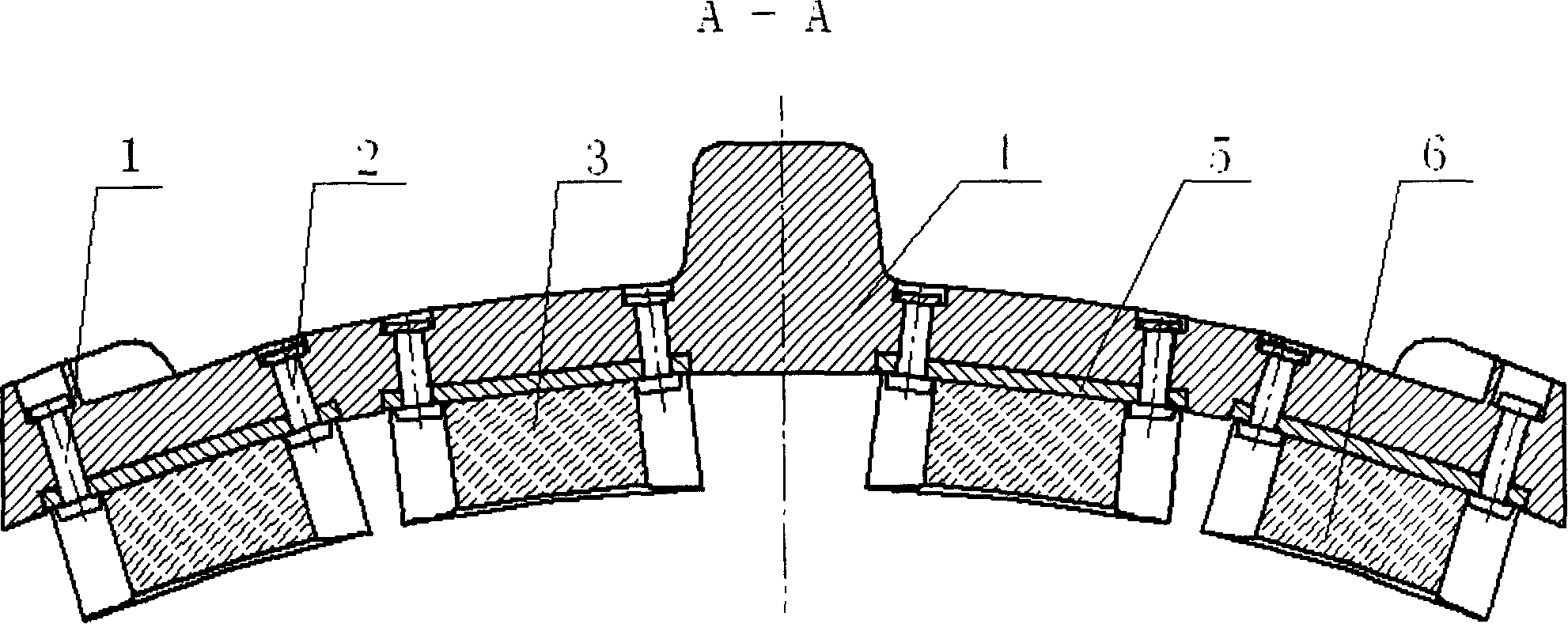

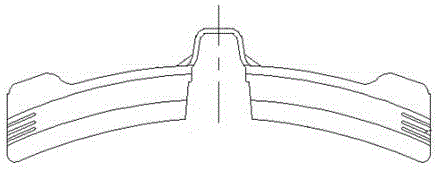

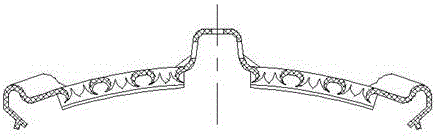

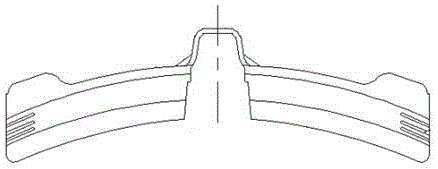

High-speed brake lining with elastic structure

ActiveCN102107665AHigh mechanical strengthReduce wearBrakes for specific applicationsEngineeringThermal stability

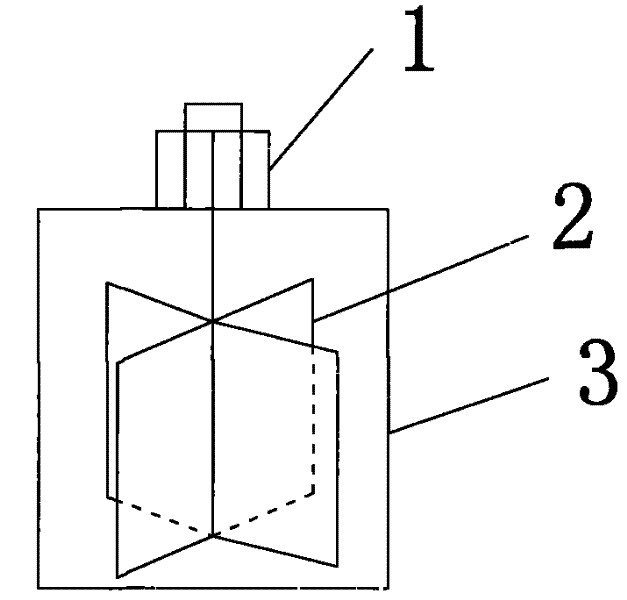

The invention provides an elastic high-speed brake lining, consisting of a steel backing (1), a brake block (2), a dovetail plate (3), a gasket (4), a disk spring (5), a guide sleeve (6), a bushing (7) and a rivet (8). The elastic structure high-speed brake lining provided by the invention has the advantages of high mechanical strength, small wearing capacity, stable friction performance, good thermal stability, good heat conductive performance, high dynamic moment and static moment, no noise, seawater corrosion resistance, sand wind prevention, excellent salt mist resistance and the like. Due to the elastic structure, the brake block of the high-speed brake lining is protected from eccentric wear caused by insufficient contact of the brake block of the high-speed brake lining and the surface of a brake disc, so that a high-speed train can brake smoothly, and the braking distance is short.

Owner:贵州新安航空机械有限责任公司

Composition brake shoe for railway freight car, and method for manufacturing same

ActiveCN102661340AHigh bonding strengthReduce wearOther chemical processesBraking membersCrazingSlag

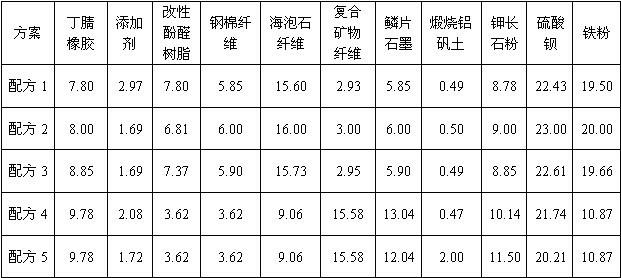

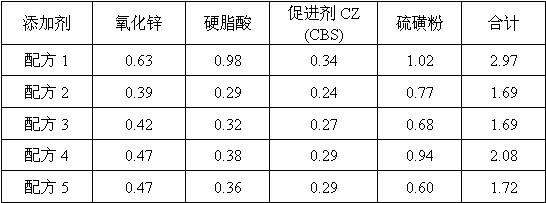

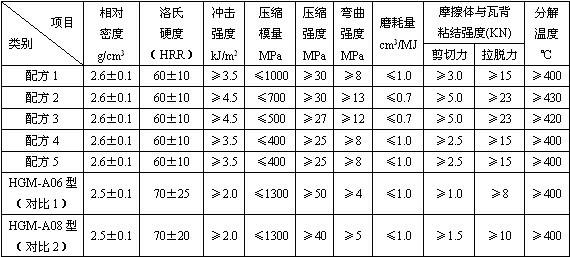

The invention discloses a composition brake shoe for a railway freight car, and a method for manufacturing the same. A friction piece of the composition brake shoe for the railway freight car is synthetised by using following materials by weight parts: 6-10 parts of nitrile rubber, 2-8 parts of modified phenolic resin, 3-6 parts of steel wool fibers, 9-16 parts of sepiolite fibers, 2-16 parts of composite mineral fibers, 5-13 parts of graphite, 0.4-2 parts of calcined bauxite, 20-24 parts of barium sulfate, 8-12 parts of potassium feldspar powder, 10-20 parts of iron powder, and 1-3 parts of additives. The friction piece of the composition brake shoe is formed through the steps of dosing, banburying or mixing, crashing, hot press molding and curing forming, and thermal processing. The composition brake shoe is capable of well satisfying various performance indexes requested in PRC (People's Republic of China) railway industrial standard TB / T2403-2010, and can be applied to railway freight cars traveling at the highest speed of 120km / h and axle load of the composition brake shoe is not greater than 25 tons; besides, the composition brake shoe has stable friction properties and excellent friction resistance, and is low in attrition to wheels and low in braking noise; and as a result, potential quality hazards ( such as brake shoe body breakage, slag and block dropping, metal inlaying and hot cracks) endangering traveling safety are fundamentally solved.

Owner:CHONGQING YUHONG RAIL CAR ACCESSORIES CO LTD

Novel wet type method for producing surface sheet of clutch of automobile

InactiveCN1947990ASolve the problem of hard punching cracksSolve the phenomenon of surface peelingDomestic articlesGlass fiberMetal fibers

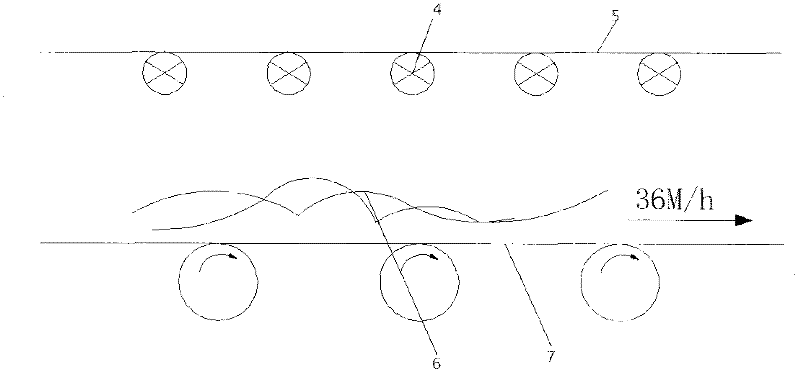

A wet method for preparing the clutch disc of car in order to eliminate the stress nonuniformity includes such steps as immersing the continuous fibers (metallic fibers, glass fibers, or mixed fibers) in the rubber solution A and then in rubber solution B, winding, sulfurizing, heat treating, grinding and dusting.

Owner:JIANGSU WEITE GROUP CORP

High speed train powder metallurgy brake pad and preparation technology thereof

ActiveCN101839295AImprove thermal conductivityImprove plasticityFriction liningSilicon dioxideLubrication

The invention embodiment discloses a high speed train powder metallurgy brake pad. The material of the brake pad comprises the following powder raw material by weight percent: 60 to 70 copper powder, 4 to 10 tin powder, 4 to 6 ferrous powder, 4 to 9 black lead, 2 to 3 silicon dioxide, 2 to 6 zinc powder, 3 to 5 molybdenum disulfide and 2 to 6 zircon. The invention further discloses the preparation technology of the powder metallurgy brake pad. The invention has the advantages that the copper with high thermal conductivity and good plasticity is used to be matrix, tin and zinc are added and alloyed in the sintering process, the sintering temperature is reduced, the abrasion performance is improved, the silicon dioxide and the zircon are added to improve friction coefficient, the black lead and the molybdenum disulfide serve as a lubrication component to protect duality and stabilize the friction coefficient. The abrasion of the brake pad produced through the method on a dual disc is small. The invention has the advantages of stable friction coefficient, small abnormal wear and noise occurrence probability and environmental protection and the brake performance thereof can meet the requirement of the high speed train.

Owner:SHANDONG GOLD PHOENIX

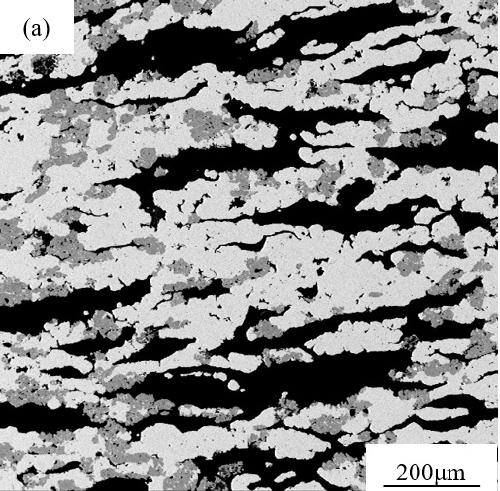

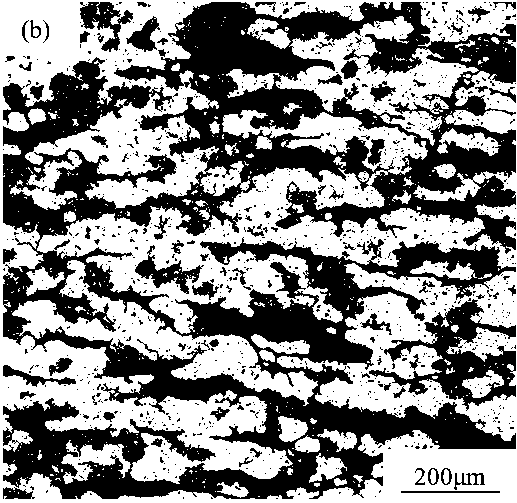

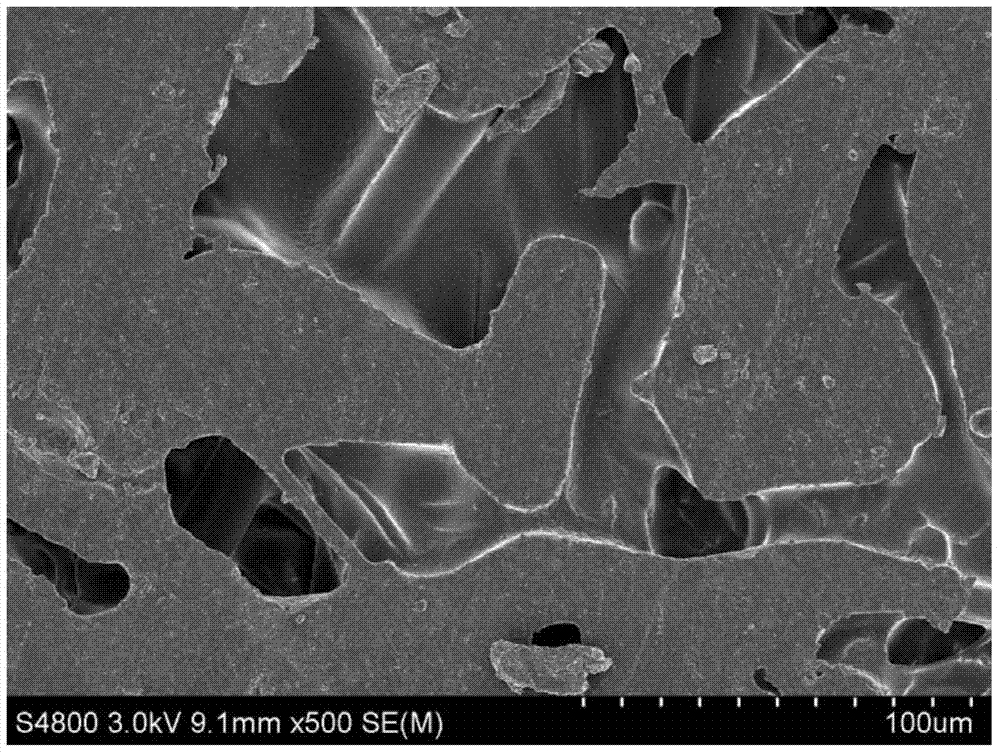

Structure function integrated C/C-Si friction material and preparation method thereof

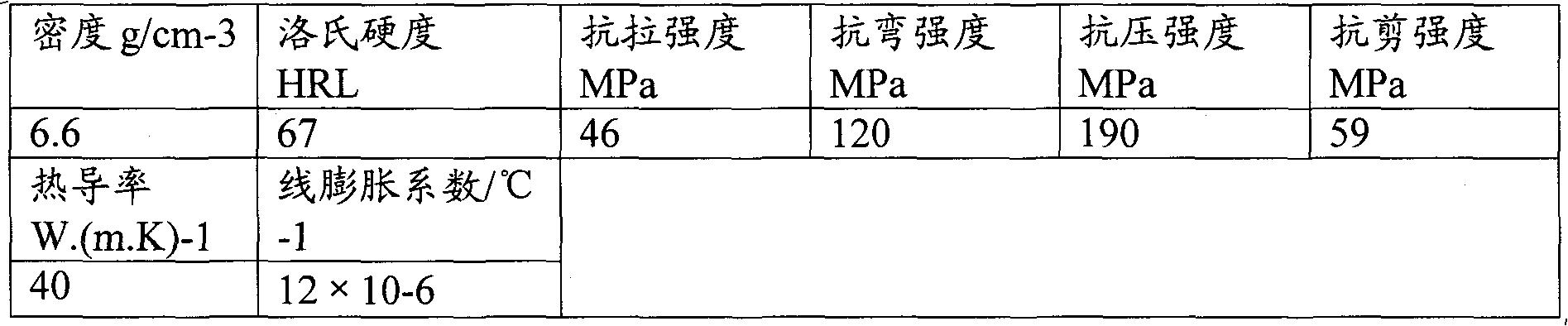

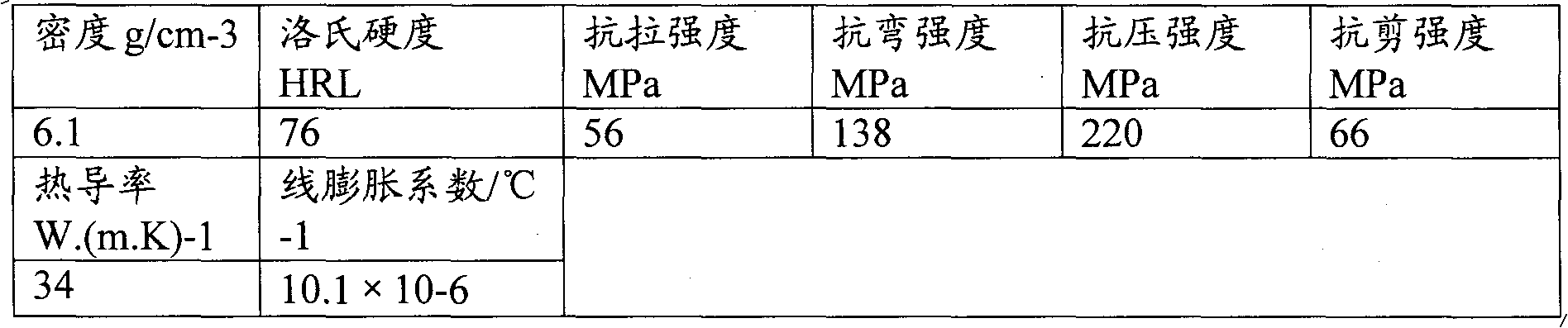

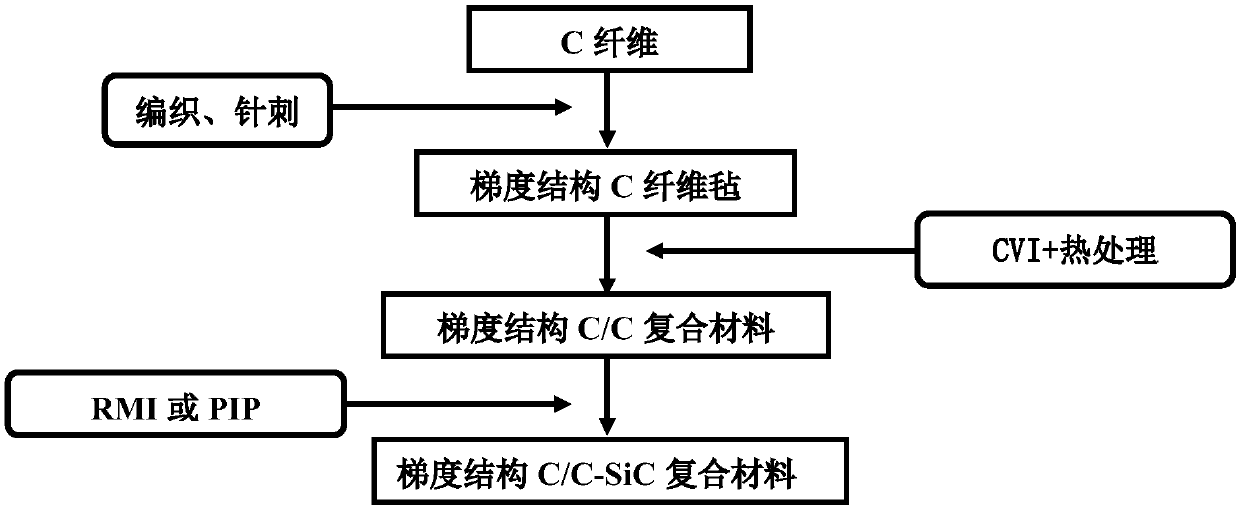

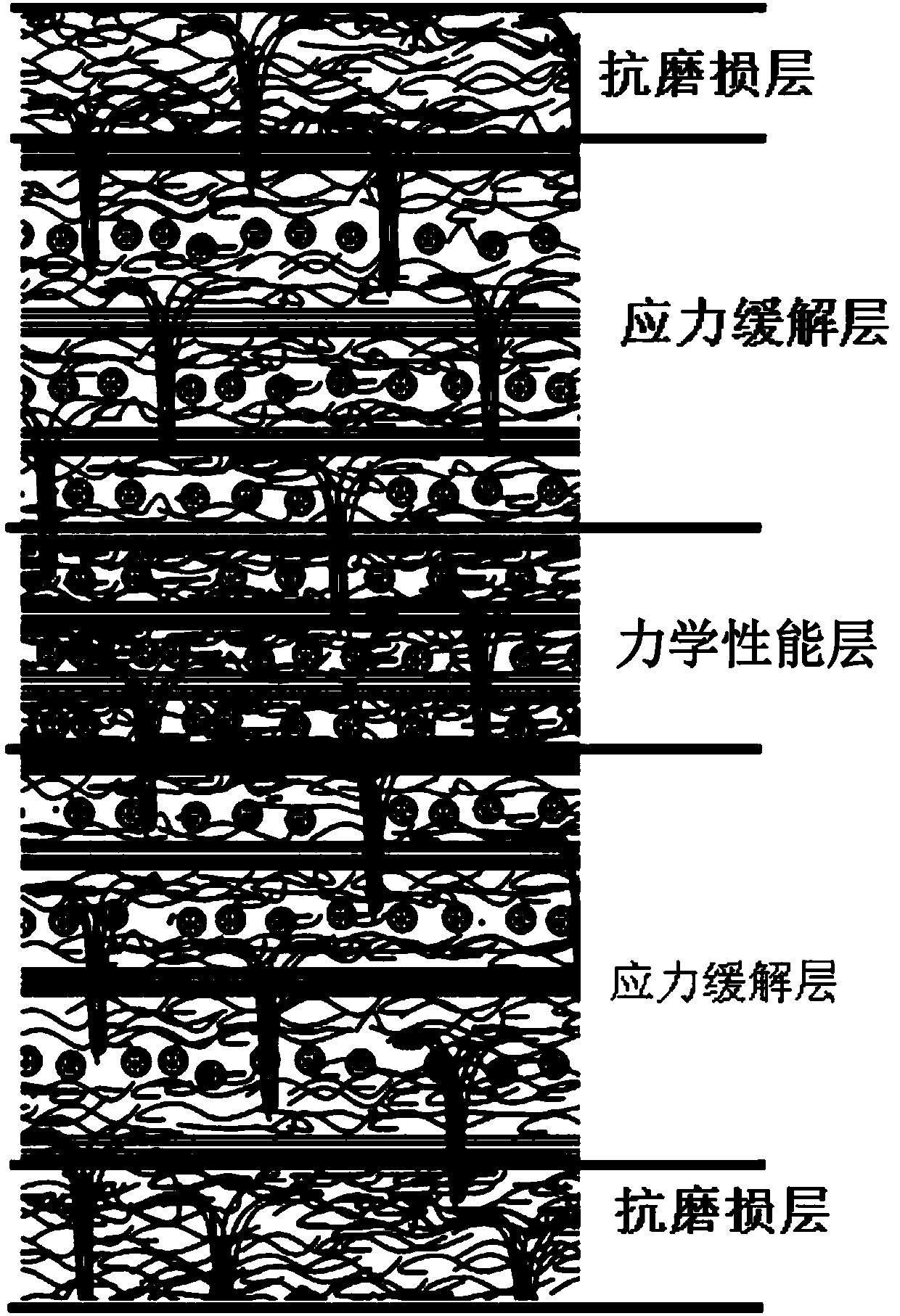

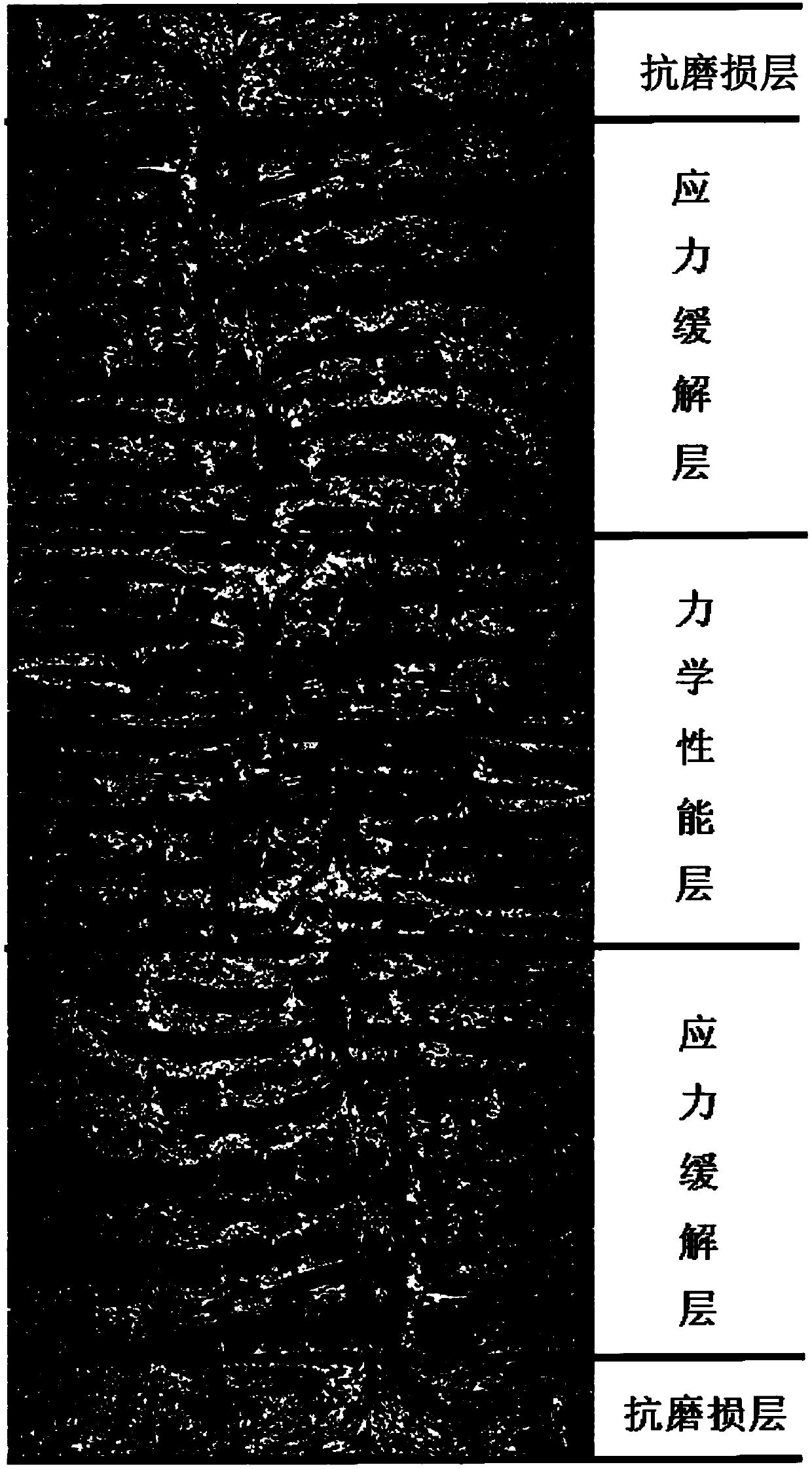

The invention relates to a structure function integrated C / C-Si friction material and a preparation method thereof. The C / C-Si friction material comprises a mechanical structure layer, stress relief layers, and abrasion resistant layers. The mechanical structure layer contains a lot of laid fabric long fiber, and can improve the structural strength of the material; the abrasion resistant layers contain evenly distributed chopped carbon fiber, SiC, Si and a pyrolytic carbon phase, and can improve the wear resistance and friction performance stability of the material; the stress relief layers contain laid fabric long fiber in gradient distribution along a vertical ply direction, can relieve the thermal mismatch problem of the abrasion resistant layers and the mechanical structure layer during material preparation, and ensure the material structural integrity. The method provided by the invention is free of crusting phenomenon in preparation of a low density carbon / carbon composite material by chemical vapor deposition, can greatly reduce the preparation cycle of low density carbon / carbon composite material by chemical vapor deposition, and then reduces the preparation cycle and costof carbon ceramic friction material, and improves the friction performance stability. The technological method is suitable for industrial production.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Hemp fiber doped saloon car brake pad and preparation process thereof

InactiveCN102408671AEnvironmentally friendlyWith noise reductionFriction liningHemp fiberEnvironmentally friendly

The invention relates to a hemp fiber doped asbestine organic group free saloon car brake pad. The brake pad has the characteristics of stable friction coefficient, strong heat decay resistance, small abrasion rate, small vibration noise, low cost and the like, and is environmentally-friendly. According to the invention, the hemp fiber is subjected to combined treatment of microwave, ultrasonic wave and laser, and the hemp fiber is subjected to alkaline treatment before microwave treatment, thus on the basis of maintaining the advantages of the hemp fiber, the flexibility of the hemp fiber isenlarged, the friction property and heat resistance of the hemp fiber are improved, and the cohesiveness of the hemp fiber is improved. The invention also provides a preparation process of a saloon car brake pad.

Owner:JIANGSU ANJIE AUTO PARTS

Weaving method of carbon fiber preform of automobile brake disc

ActiveCN109795180AReduce wasteImprove thermal efficiencyLayered productsNon-woven fabricsGraphiteMaterials science

The invention relates to a weaving method of a carbon fiber preform of an automobile brake disc, and belongs to the technical field of carbon fiber composite material reinforcement weaving. The methodincludes the following steps: (1) preparing a carbon fiber plain cloth; (2) preparing a carbon fiber net tire; (3) sewing the carbon fiber plain cloth of step (1) and the carbon fiber net tire of step (2) together to form a plain-mesh tire cloth; and (4) winding the plain-mesh tire cloth obtained in the step (3) for a plurality of circles along the circumferential direction of a graphite sleeve,and needling once in each winding circle until the size requirement of the carbon fiber preform is met to form the carbon fiber preform, wherein the weight percentage of the carbon fiber plain cloth in the carbon fiber preform is more than or equal to 67%, and the weight percentage of the carbon fiber net tire is less than or equal to 33%. The preparation method is safer, the fiber waste quantityis less, the thermal conductivity in the thickness direction of the product can be ensured to be higher, the internal phase of the material is more uniform, and the friction surface is smoother and more beautiful.

Owner:山东道普安制动材料有限公司

Iron powder and steel fiber free ceramic friction material

InactiveCN102363724AFrictionally stableStable coefficient of frictionOther chemical processesEnvironmental resistanceCorrosion

The invention discloses an iron powder and steel fiber free ceramic friction material. The invention is characterized in that the ceramic friction material comprises the following components in percentage by weight: 5 to 15 percent of adhesive, 15 to 35 percent of reinforcing material, 15 to 30 percent of friction agent, 5 to 15 percent of friction reducer, 10 to 25 percent of filler and 10 to 20 percent of other mixture. Because the ceramic friction material does not contain metals, a brake block made of the ceramic friction material comprises a brake block and a braking disc instead of the conventional metal brake block and mating plate, avoids metal sound caused by friction, and eliminates the adhesion between the brake block and the braking disc. As the ceramic material is more capable of resisting high temperature than a metal material and has a small temperature sensitivity, the friction factor of the brake block produced by using the ceramic friction material is stable, free from corrosion to hub and braking noises and environment-friendly, has less dust and long service life. The ceramic friction material is suitable for manufacturing brake blocks for high-speed automobiles and heavy load automobiles.

Owner:湖南常德嘉达摩擦材料有限公司

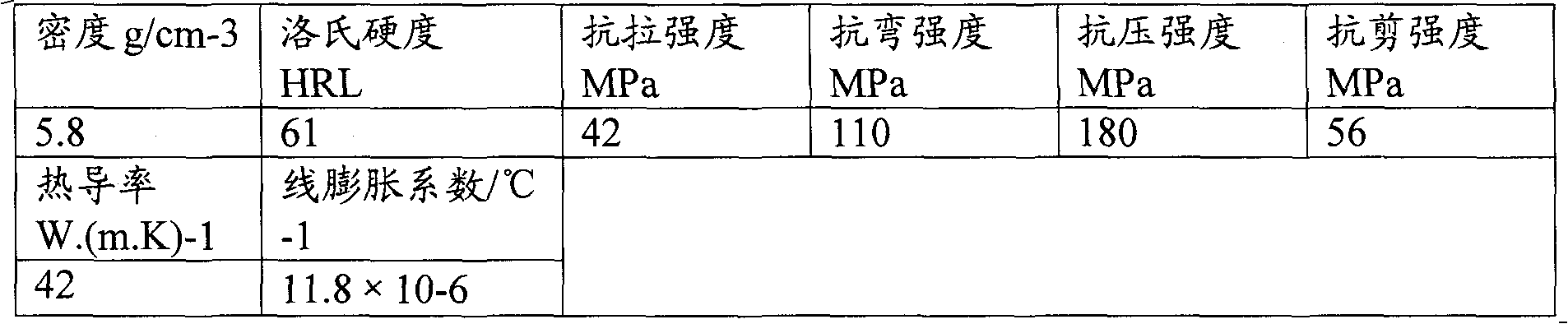

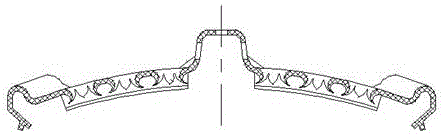

Freight car compartment powder metallurgy brake block

InactiveCN101162033AReasonable shape and structure designStable friction performanceFriction liningTruckPowder metallurgy

The invention relates to a powder metallurgy brake block for a boxcar, composed of a brake shoe back (4) and a shoe block (3) which are connected with each other, wherein, the brake shoe back (4) adopts the material of QT400-18 and is shaped by casting once; the shoe block and the brake shoe back adopt the connection structure of welding or riveting; a powder metallurgy friction block (6) on the shoe block (3) adopts powder metallurgy friction materials, takes iron as matrix, is added with lead, graphite, supramoly, copper and aluminium sesquioxide and so on, all of which are mixed uniformly pro rata, and is formed by chill pressing and compression sintering. The invention is characterized by reliable structure, stable drag friction performance, low surface temperature rise, small relative dispersion and good wearing resistance, etc., and is suited to starting or towing a car on a railway with speed at or below 160km / h.

Owner:贵州新安航空机械有限责任公司

Tungsten carbide enhanced copper-based powder metallurgy friction material and preparing method thereof

ActiveCN109468487AImprove adverse effectsIncrease coefficient of frictionTransportation and packagingMetal-working apparatusMatrix strengthMaterials science

The invention discloses a tungsten carbide enhanced copper-based powder metallurgy friction material. The friction material comprises following raw materials including, by weight percent, 50%-70% of copper powder, 10%-20% of iron powder, 1%-5% of tin powder, 6%-11% of graphite and 0.01%-15% of tungsten carbide. Compared with similar materials, the novel tungsten carbide enhanced copper-based powder metallurgy friction material has the advantages that the matrix strength is high, hardness is high, the friction coefficient is high, the friction performance is stable, the abrasion amount is low,the preparing technology is simple, and the production cost is low; the comprehensive performance of the material is improved, and it is guaranteed that the material has stable friction performance, the high friction coefficient and good abrasion resistance; few microelement kinds exist, lead, asbestos and other components doing harm to health are not contained, the requirements for health safetyand environment protection are met; and in the preparing technology, the technology is simple, large-batch production is conveniently achieved, and the manufacturing cost is low.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

Clean ceramic brake material and manufacturing method thereof

The invention discloses a clean ceramic brake material and a manufacturing method of the brake material. The clean ceramic brake material comprises the following compositions in percentage by weight: 3-6% of phenolic resin, 5-10% of silicone / alkyne resin, 15-30% of red copper / brass powder, 4-10% of inorganic binders, 7-12% of hexagonal boron nitride, 15-25% of reinforcing fibers, and the balance of packing, wherein the total weight is 100 parts. The clean ceramic brake material prepared according to the technical scheme of the invention has good high-temperature resistant performance, and canbe used for a long time at a temperature of 800 DEG C; the clean ceramic brake material is extremely stable in friction performance and good in abrasion resistance; especially in the process of application, nearly no black dust is produced, therefore, the cleaning of auto hubs can be maintained; and the braking is comfortable and smooth, and no vibration and brake noise is produced.

Owner:上海华化摩擦材料有限公司

Manufacturing process and method of abrasion-resisting lining part

The invention relates to an abrasion-resisting part and a preparation method thereof, belongs to the field of new material science and relates to a braking and abrasion-resisting frictional material widely used in the industries of mining, oil extraction, ships, automobiles, metallurgy, paper making, wind power, bullet trains, nanomaterial sanding machines, ore grinding equipment and the like and a manufacturing technology thereof, in particular to a manufacturing technology for forming the abrasion-resisting part containing a macromolecular environmentally-friendly nano-composite ceramic material through vacuum pressing, and a formula includes a macromolecular adhesive, a structure reinforcement fiber and abrasion-resisting nano ceramic material and a friction performance regulator.

Owner:TIANJIN BAITE WEIER NANO POWER SCI & TECH CO LTD

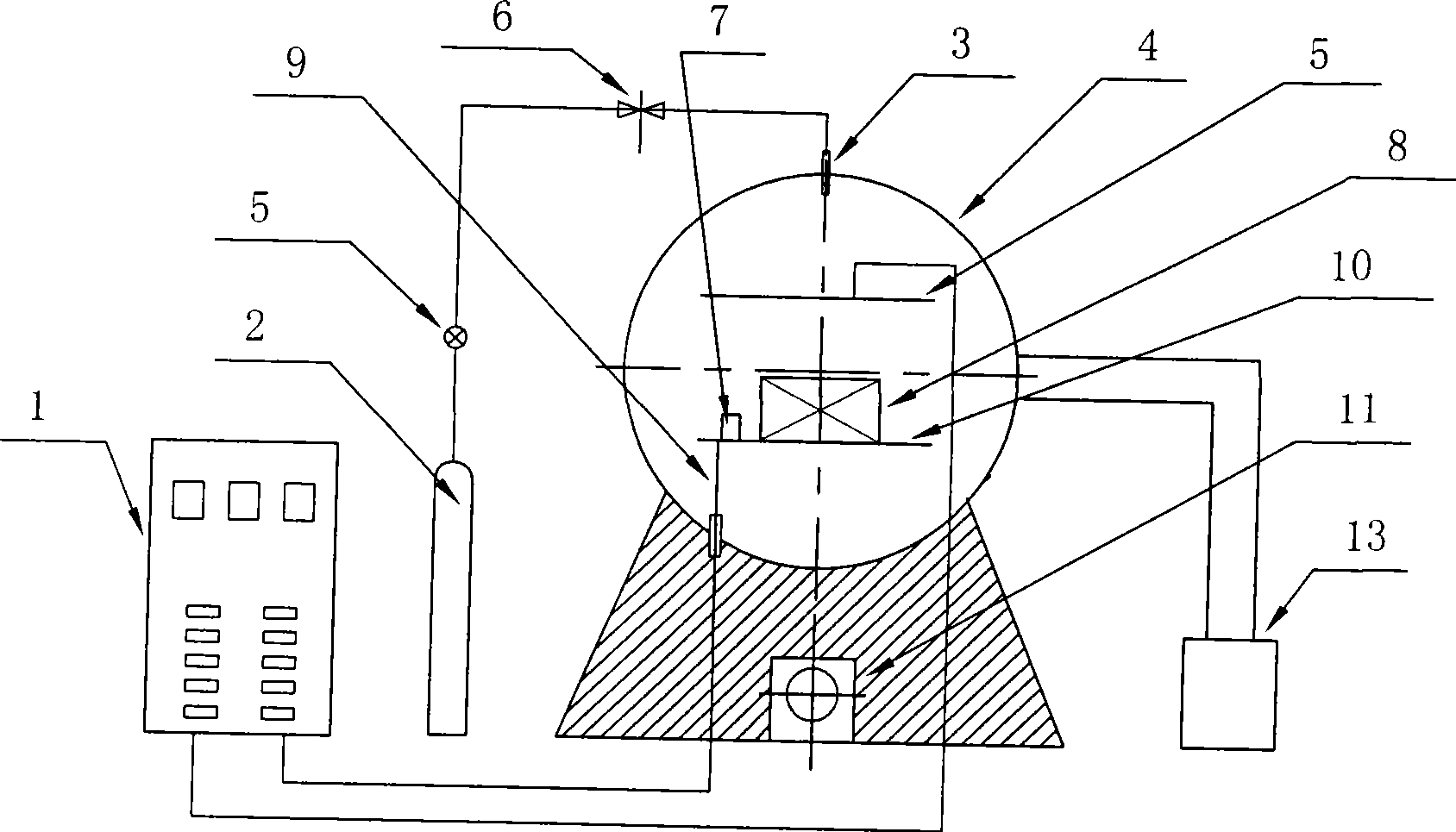

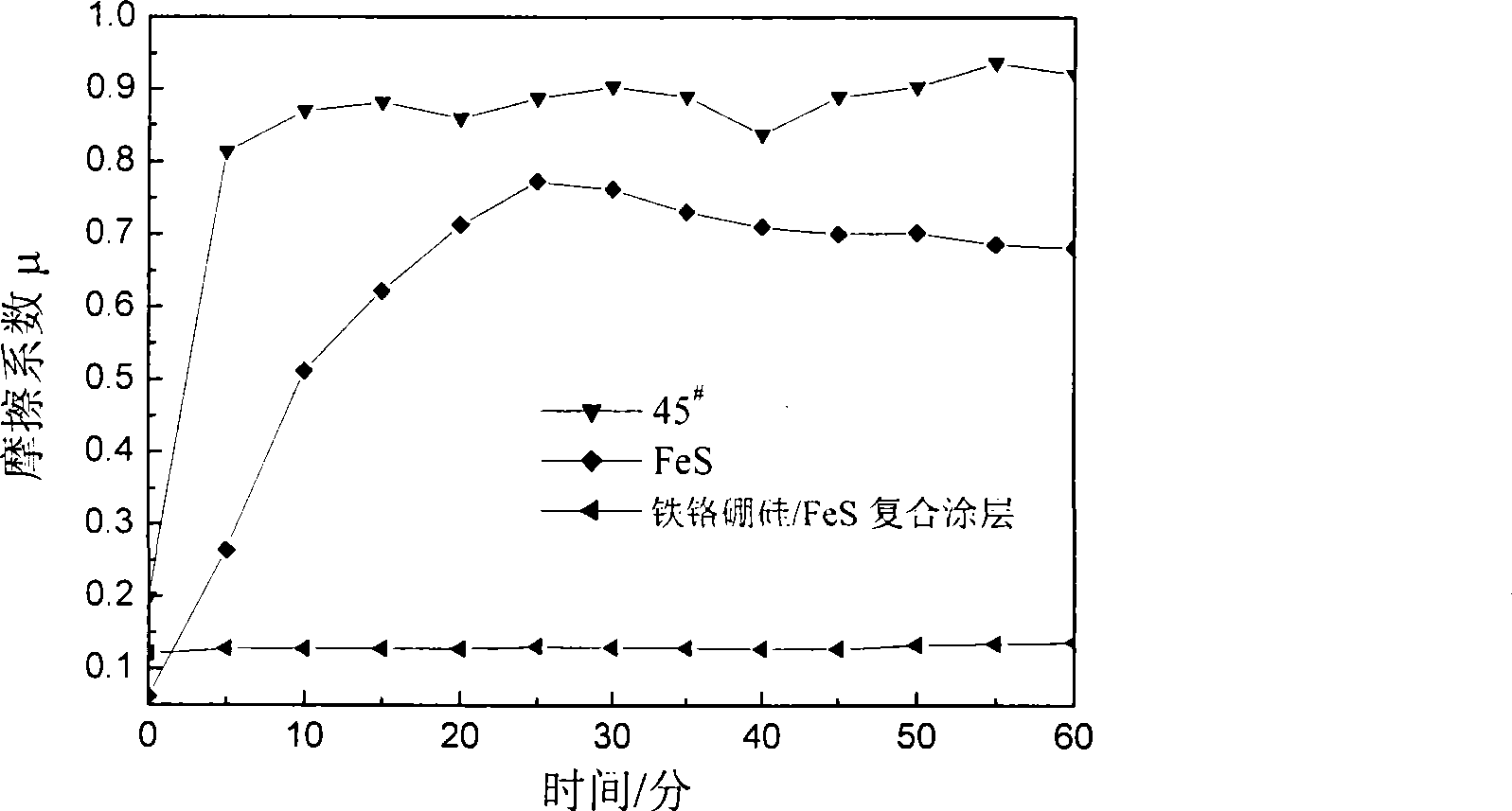

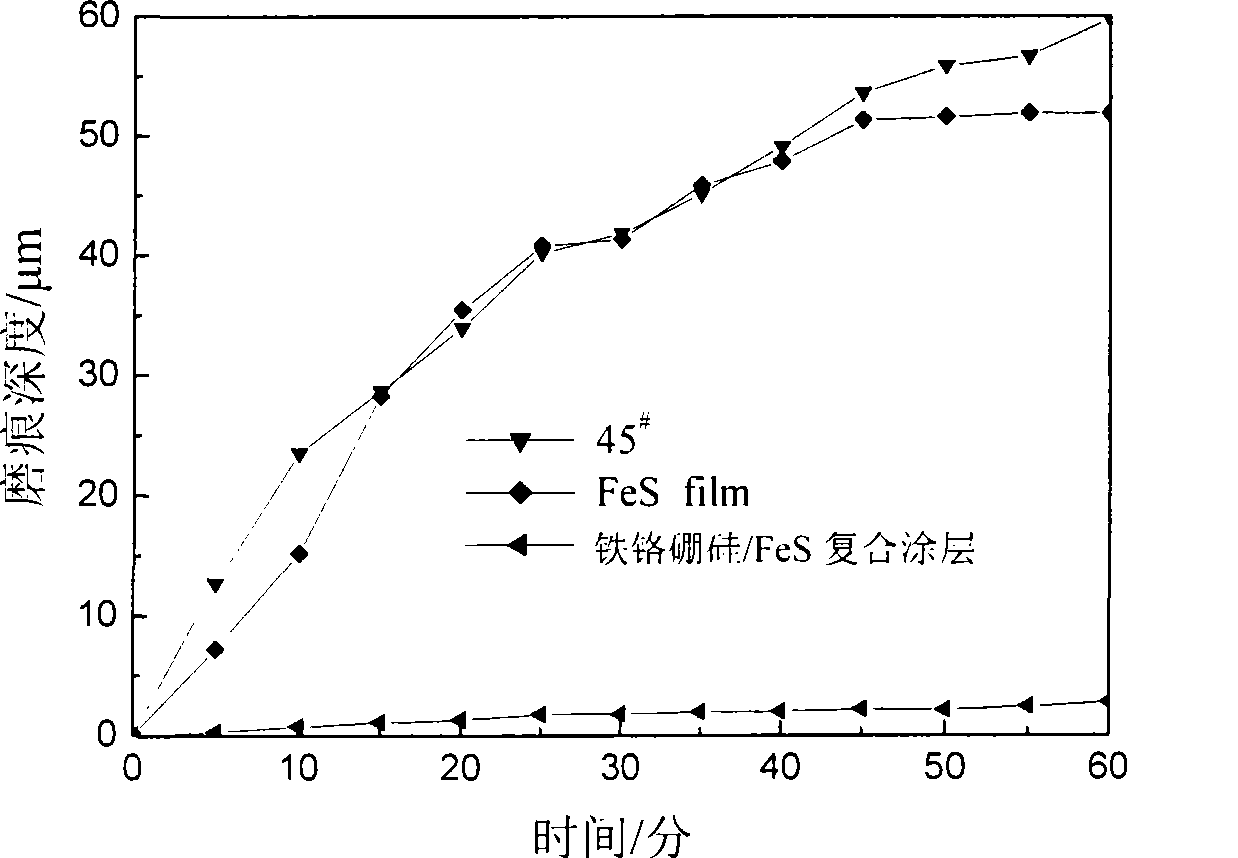

Iron-chromium-boron-silicon/FeS composite solid lubrication thin film and method for making same

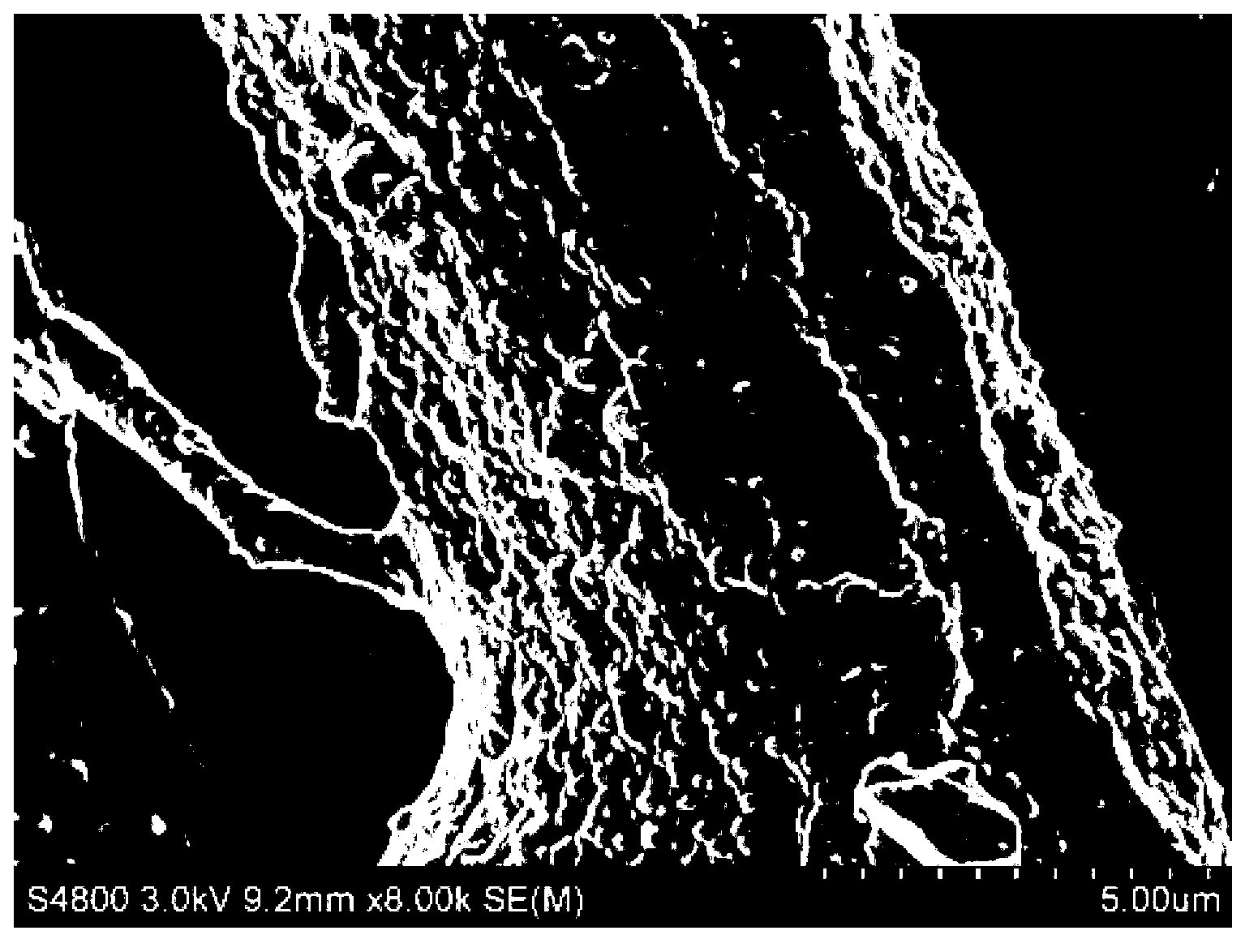

ActiveCN101398122ANovel structureImprove bindingMolten spray coatingEngine lubricationSurface layerSulfur

The invention discloses an Fe-Cr-B-Si / FeS composite solid lubricating film and a preparation method thereof, which firstly uses ultrasonic plasma for spray painting an Fe-Cr-B-Si coating on a substrate and then low temperature ion sulfurizing treatment is carried out to the Fe-Cr-B-Si coating and the Fe-Cr-B-Si / FeS composite solid lubricating film is prepared. The Fe-Cr-B-Si / FeS composite solid lubricating film is characterized in that: the Fe-Cr-B-Si coating is firstly painted and then the sulfurizing treatment is carried out to the coating so that the surface layer of the coating reacts with sulfurous steam to form an FeS layer, and finally, the upper part of the Fe-Cr-B-Si coating turns out to be an FeS solid lubricating layer. The invention has a novel structure and no obvious boundary exists on the FeS layer of the Fe-Cr-B-Si coating and the FeS layer has good binding capacity with the substrate. Compared with the prior art, the invention has good nano mechanical properties with an anti-friction capacity better than the prior art by more than 20 times. As the invention is the FeS layer obtained from sulfurizing on the surface of the Fe-Cr-B-Si coating, thus having a compact structure; besides, the friction property of the Fe-Cr-B-Si / FeS composite solid lubricating film is stable and the anti-friction property thereof is much better under the conditions of either dry friction or oiling.

Owner:ACADEMY OF ARMORED FORCES ENG PLA

Wear-resistant brake-shoe friction body for railway truck and brake-shoe

InactiveCN106402219AFrictionally stableImprove wear resistanceFriction liningActuatorsCrazingStearic acid

The invention discloses a wear-resistant brake-shoe friction body for a railway truck and the brake-shoe. The wear-resistant brake-shoe friction body for the railway truck is composed of 8-12% of nitrile rubber, 2-7% of cashew nut shell oil-modified phenolic resin, 5-9% of steel fibers, 16-19% of sepiolite fibers, 10-20% of composite fibers, 15-25% of barium sulfate, 14-19% of iron powder, 8-13% of graphite, 5-10% of feldspar powder, 1-3% of calcined bauxite, 1-3% of an accelerant, 1-3% of stearic acid and 1-3% of sulfur. The wear-resistant brake-shoe friction body for the railway truck is prepared by the steps of: performing mill mixing; performing plastifying; and performing crushing. The invention relates to the brake-shoe friction body which is stable in friction performance, good in wear resistance and small in environmental pollution. The brake-shoe friction body can be used in a railway high-speed truck, has a stable friction coefficient and relatively good wear resistance, and can satisfy the operating requirements that the highest operating speed is 120km / h and the axle load is not greater than 25t, of the truck; the friction body has relatively high compression strength, bending strength, impact strength and relatively low elastic modulus, and can prevent phenomena such as cracks, drop-dregs and drop-blocks, fracture and the like.

Owner:CHONGQING YUHONG RAIL CAR ACCESSORIES CO LTD

High friction coefficient rubber composite brake shoes

InactiveCN1439673AFrictionally stableExtended service lifeOrganic active ingredientsCosmetic preparationsBrake shoeAluminium

A composite rubber crystal brake shoe with high friction coefficient for locomotive and train is disclosed. Its advantages are high friction coefficient, high antiwear performance, and long service life.

Owner:吴有站 +2

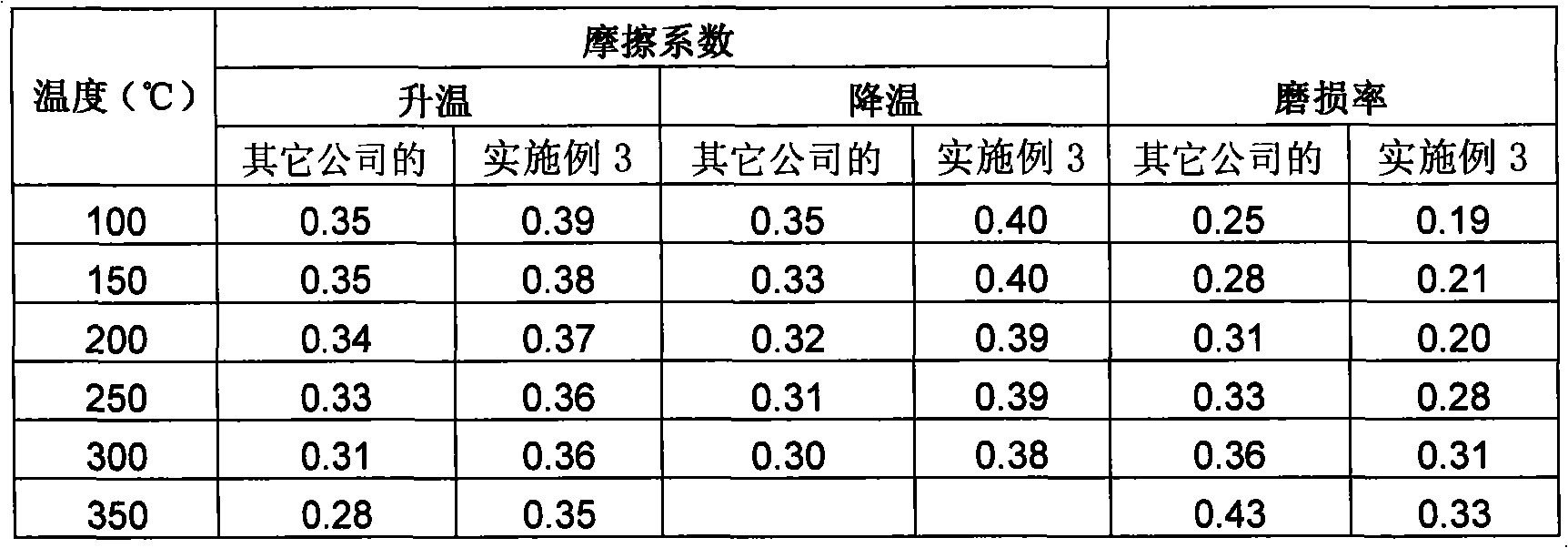

A kind of brake pad with high friction coefficient and preparation method thereof

ActiveCN106238722BIncrease coefficient of frictionSmall fluctuationOther chemical processesFriction liningSulfideSilicon dioxide

The invention provides a brake pad with high friction coefficients and a preparation method of the brake pad. A raw material formula of the brake pad comprises components as follows: a copper source, eutectoid steel ground powder, copper-coated graphite powder, ferrous sulfide, a nickel source, silicon dioxide and molybdenum oxide; the components of raw materials are sufficiently mixed, pressed and formed, a blank body is subjected to hot pressed sintering and constant-temperature cooling, and the brake pad is prepared. Through adoption of the reasonable proportion of the raw materials, strict control of heating temperature and proper constant-temperature cooling treatment, the density of the produced material can be substantially improved, the texture and the structure of the materials are more stable, and the brake pad can adapt to the high-temperature condition produced during braking of a high-speed train and also always has stable high friction coefficient and low wear in the use process. The brake pad prepared with the method has the advantages of high friction coefficients, little wear, stable friction performance, long service life and the like under the high-speed braking condition.

Owner:BEIJING TIANYISHANGJIA NEW MATERIAL

Pumping filtration-based preparation method of paper-based friction material

ActiveCN103541266AIncrease frictionReduce wear ratePaper/cardboardSynthetic cellulose/non-cellulose material pulp/paperFiberWater use

The invention discloses a pumping filtration-based preparation method of a paper-based friction material. The pumping filtration-based preparation method comprises the following steps of dissolving cashew nut shell oil-modified phenolic resin in anhydrous ethanol to obtain a solution A, dispersing multi-walled carbon nanotubes in a sodium dodecyl sulfate aqueous solution to obtain a suspension liquid B, dispersing short carbon fibers, bamboo fibers, diatomite and the solution A in anhydrous ethanol, adding the suspension liquid B into the mixed solution to obtain a solution C, carrying out defibering on the solution C, carrying out suction filtration and drying to obtain a sample sheet, soaking the sample sheet in the solution A, taking out the sample sheet, carrying out drying in air, carrying out hot press molding to obtain the paper-based friction material obtained based on pumping filtration. The pumping filtration-based preparation method utilizes a pumping filtration process to replace a sheet making machine for friction material sheet formation, can prepare the single-layer paper-based friction material, has easily controlled processes, solves the problem that the existing paper-based friction material preparation technology can be carried out only in a water phase, is free of water use in the whole sheet formation process, greatly improves the friction performances of the paper-based friction material, and effectively reduces a wear rate.

Owner:盐城大数据资产经营管理有限公司

Rail wagon high-friction-coefficient brake shoe friction body and brake shoe

InactiveCN106704422AFrictionally stableImprove wear resistanceOther chemical processesBraking membersFiberSlag

The invention discloses a rail wagon high-friction-coefficient brake shoe friction body and brake shoe. The brake shoe friction body is composed of 9%-12% of butyronitrile rubber, 7%-10% of cashew nut shell oil modified phenolic resin, 4%-7% of steel fiber, 15%-23% of sepiolite fiber, 22%-27% of barium sulfate, 19%-22% of reduction iron powder, 5%-9% of graphite, 8%-12% of feldspar powder, 0.4%-1.3% of calcined bauxite, 0.26%-1% of accelerants, 0.3%-1% of stearic acid, 0.4%-1% of zinc oxide and 0.67%-1.2% of sulfur and is obtained through open mill, plastication and crushing. The brake shoe friction body is stable in friction performance, good in abrasion resistance and small in environmental pollution, can be used in rail high-speed heavy-load wagons, has stable friction coefficient and good abrasion resistance, can meet the operating requirements of wagons of which the maximum operating speed is 120 km / h and the axle weight is not larger than 25 t, has high compression strength, bending strength and impact strength as well as low elastic modulus, and can prevent cracking, slag falling, block falling, fracturing and other phenomena.

Owner:CHONGQING YUHONG RAIL CAR ACCESSORIES CO LTD

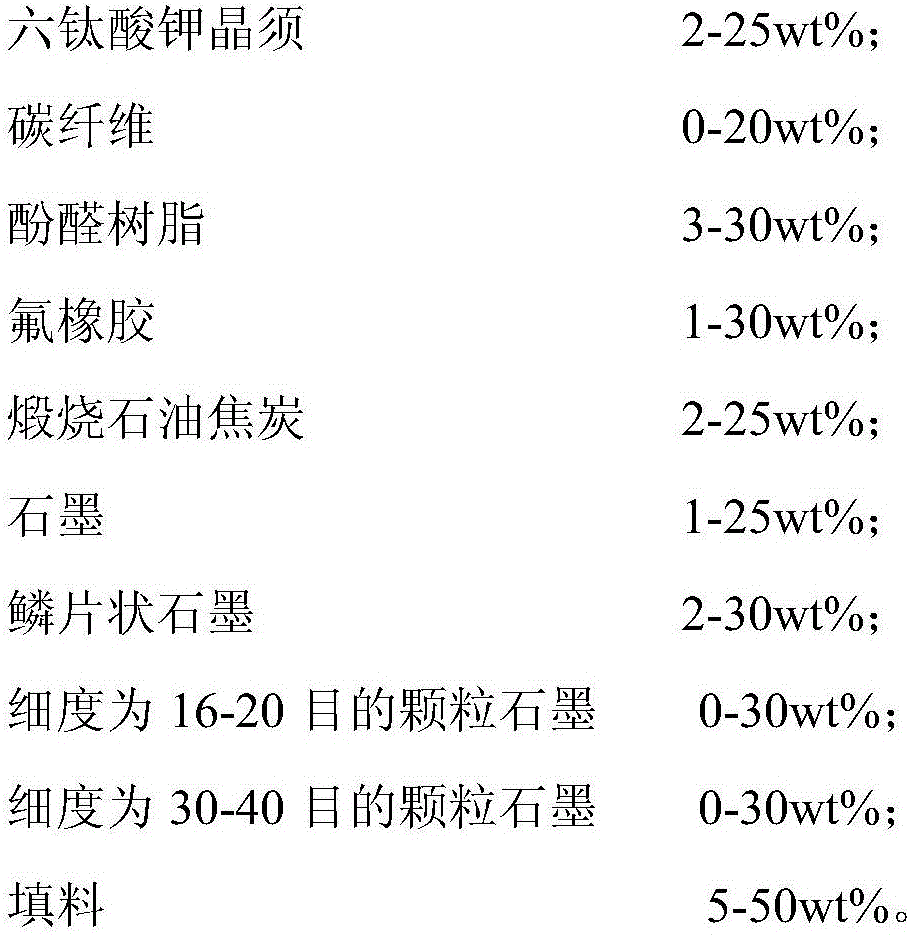

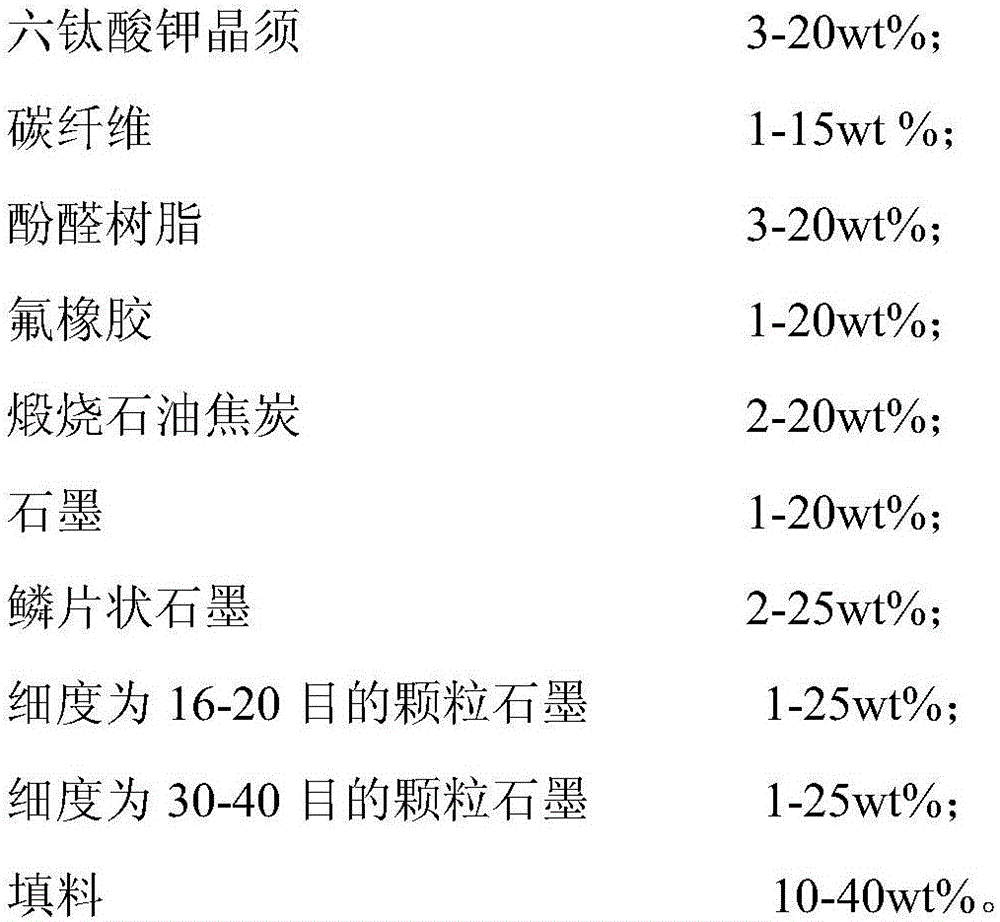

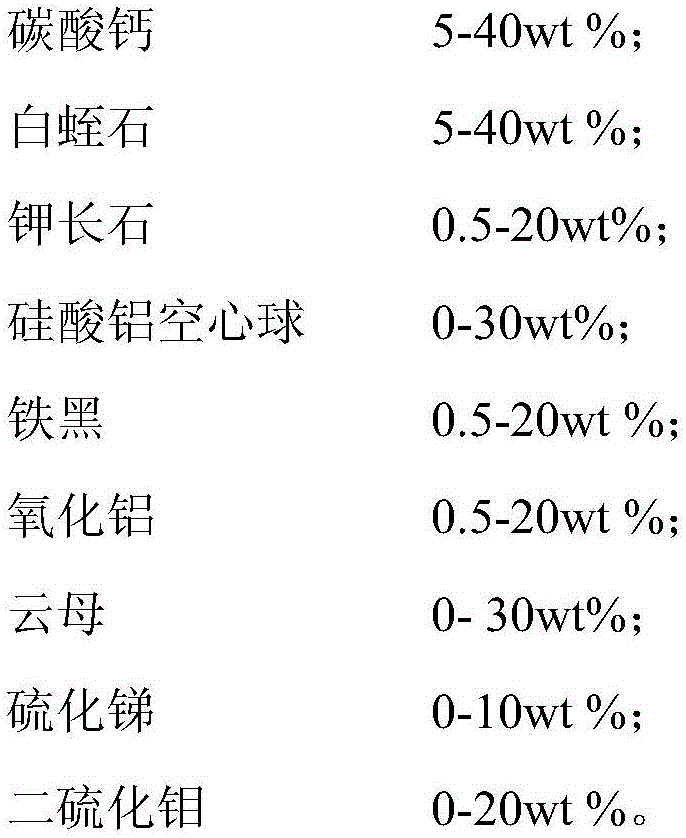

Automotive brake pad with high graphite content and high friction property and stability and preparation method

InactiveCN106763362AFrictionally stableReduce wear rateOther chemical processesFriction liningFiberCooking & baking

The invention provides an automotive brake pad with high graphite content and high friction property and stability. The automotive brake pad is prepared from potassium hexatitanate whisker, carbon fiber, phenol formaldehyde resin, fluorine rubber, calcined petroleum coke, graphite, flake graphite, grain graphite with the fineness of 16 meshes to 20 meshes, grain graphite with the fineness of 20 meshes to 40 meshes and filling. The invention further provides a preparation method of the automotive brake pad; the preparation method comprises the following steps after metering all the components in percentage by weight, putting the components into a stirrer and stirring and sufficiently mixing; weighing and adding raw material powder into a mold and putting the mold into a hot press; carrying out mold pressing and molding, pressure keeping and cooling; after de-molding, putting a product into a baking oven and carrying out heat treatment; carrying out heat treatment for 6h to 10h at the temperature of 120 DEG C to 160 DEG C; grinding through a grinding machine and spraying to obtain the automotive brake pad with the high graphite content and the high friction property and stability. The automotive brake pad provided by the invention has the characteristics of low noises, low heat fading, extremely stable friction coefficient, extremely low abrasion rate, uneasiness of damaging coupled parts and the like.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

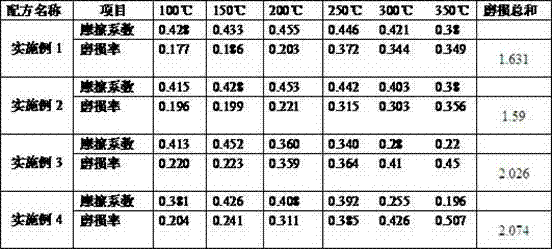

Flexible grease-proof paper-based friction plate and manufacturing method thereof

InactiveCN110118234AGuaranteed oil resistanceConsistent frictionOther chemical processesFriction liningNitrile rubberAdhesive

The invention provides a flexible grease-proof paper-based friction plate and a manufacturing method of the flexible grease-proof paper-based friction plate. The flexible grease-proof paper-based friction plate comprises, by mass, 0.8-1.2 parts of compounding agent; 2.5-5.5 parts of sulfur; 44-73 parts of filler; 8-12 parts of flexible adhesive; 10-20 parts of brittle adhesive; 10-14 parts of nitrile rubber; 0.3-1 part of flexible reinforcing fiber and 0.5-2 parts of carbon fiber. By the adoption of the flexible grease-proof paper-based friction plate and the manufacturing method of the flexible grease-proof paper-based friction plate, the grease resistance of a friction material can be guaranteed, the friction performance existing after oil immersion of the friction plate is identical with that of the friction plate without oil immersion, and a stable friction performance and a high friction coefficient of the paper-based friction plate can be guaranteed; the flexible reinforcing fiber and the carbon fiber with good friction performance are used as reinforcing fiber, the flexible adhesive and the brittle adhesive are used as adhesive, the flexible reinforcing fiber and the carbonfiber are complementary in performance, so that the flexibility of the paper-based friction material is improved, and the friction wear resistance of the paper-based friction material is also improved.

Owner:NANTONG WANDA FRICTION MATERIAL

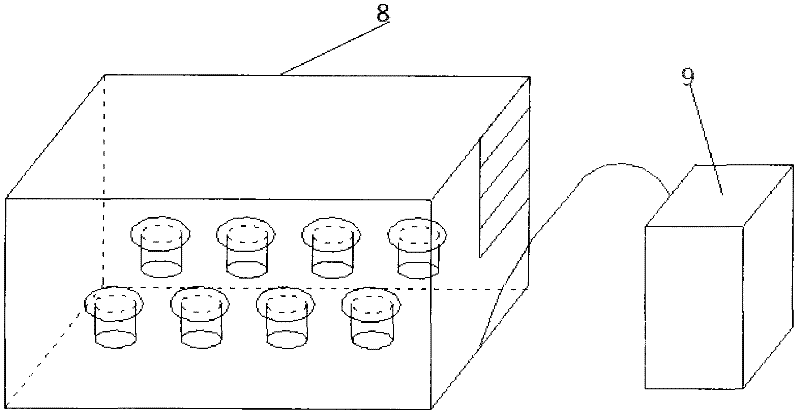

Preparation method of powder metallurgy brake pad friction block for high-speed train

ActiveCN107448525ASimple processEasy to operateOther chemical processesFriction liningPowder metallurgyHardness

The invention discloses a preparation method of a powder metallurgy brake pad friction block for a high-speed train. The preparation method comprises the following steps that 1, friction body raw materials are placed into a drying machine to be dried, the corresponding weight parts of raw materials are placed into a mixing machine to be mixed, the mixture is transferred into an ultrasonic apparatus for ultrasonic treatment, and mixed friction body powder is obtained, wherein the friction body is prepared from Cu, Fe, MoS2, graphite, chromite powder, hematite powder and mullite powder; 2, the mixed friction body powder obtained in the step 1 is placed into an automatic powder pressing machine to be pressed and formed; and 3, the pressed friction block, a steel back and a welding pad are placed into an atmosphere sintering furnace to be sintered, and therefore the finished product is obtained. According to the preparation method, the process is simple, operation is easy, the cost is low, the prepared brake pad friction block is stable in friction performance, the friction coefficient can reach 0.35 or above, the abrasion rate is low, the hardness is moderate, cracking resistance and wear resistance are high, and the service life is long.

Owner:山东百德瑞轨道交通科技有限公司

Preparation method of zirconium boride modified paper base friction material

ActiveCN103321093AReduce coefficient of frictionReduce wear ratePaper/cardboardSynthetic cellulose/non-cellulose material pulp/paperBorideDispersion stability

A preparation method of a zirconium boride modified paper base friction material comprises the following steps: dissolving cashew hull modified phenolic resin in absolute ethyl alcohol to obtain a solution A; dispersing multiwalled carbon nanotube in a sodium dodecanesulphonate aqueous solution to obtain a fluid suspension B; dispersing zirconium boride in PMAA to obtain a zirconium diboride dissolving pulp C with good dispersion stability; dispersing short carbon fiber, bamboo fiber and diatomite in water and adding the fluid suspension B and the dissolving pulp to obtain a solution D; pouring the solution D into a fluffer for dispersion, making sheets by a sheet-making machine and drying to obtain a sample wafer E; and uniformly smearing the solution A on the sample wafer E and naturally airing, and carrying out hot briquetting by a vulcanizer so as to obtain the zirconium boride modified paper base friction material with stable friction performance. According to the invention, zirconium boride is used as a raw material to be added in a carbon fiber reinforced resin matrix wet-type friction material, and a single-layer paper base friction material is prepared to endow zirconium boride (ZrB2) with good electroconductibility and thermal conductivity, corrosion resistance, resistance to heat shocks, oxidation resistance at high temperature and wear resistance.

Owner:盐城大数据资产经营管理有限公司

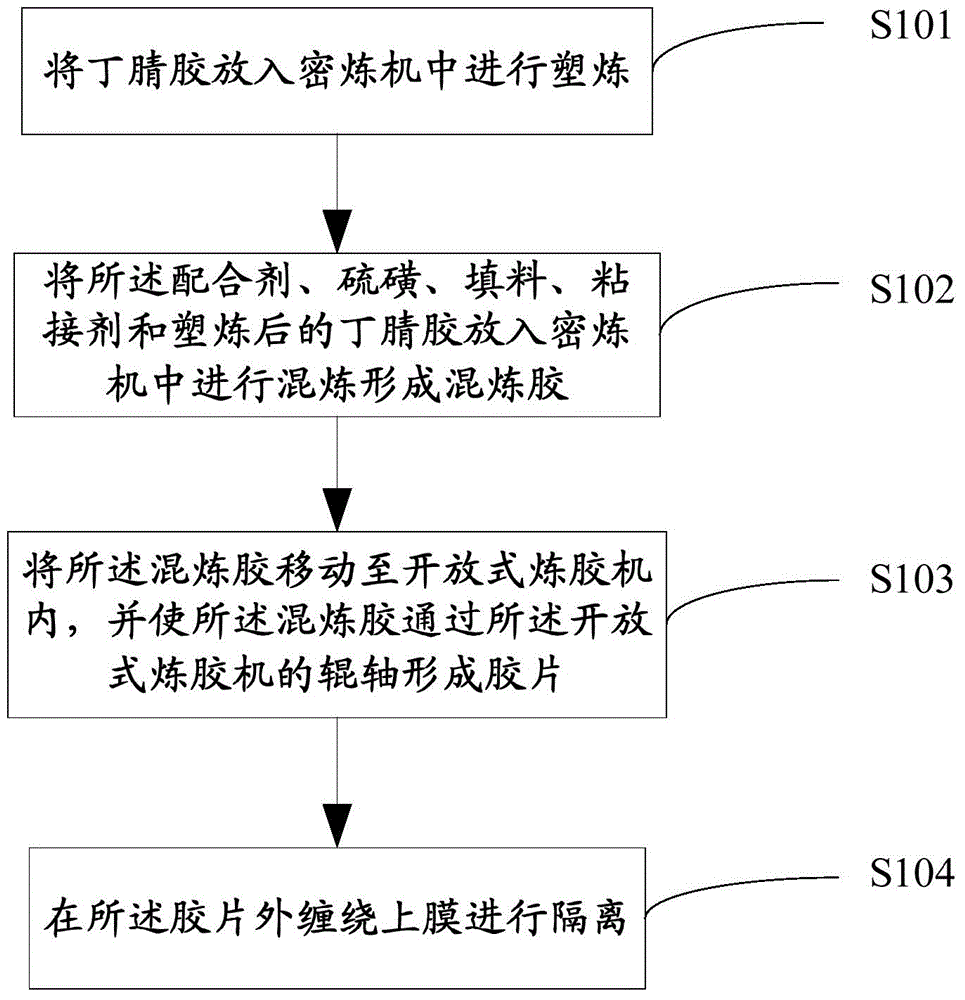

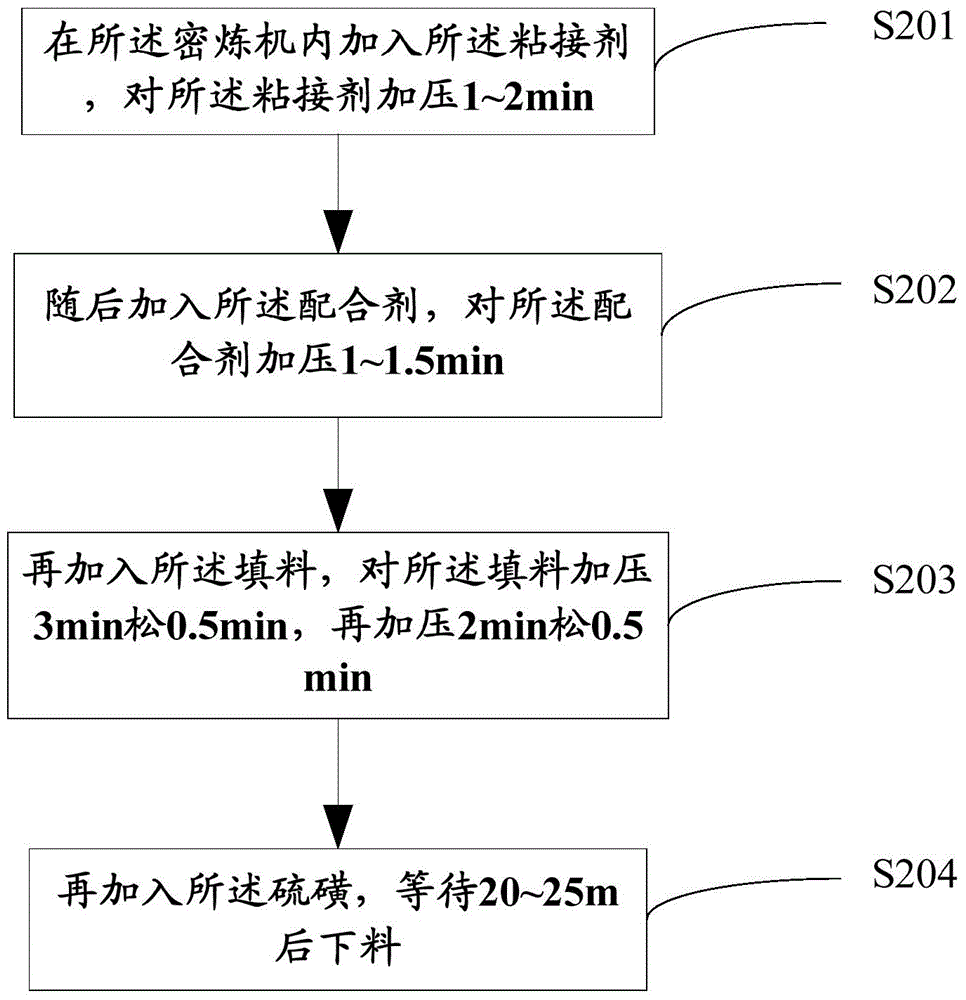

Oil-resistant paper-base friction plate and production method thereof

The invention relates to an oil-resistant paper-base friction plate and a production method thereof. The oil-resistant paper-base friction plate comprises the following materials in parts by weight: 0.8-1.2 parts of compounding agent, 2.5-5.5 parts of sulfur, 44-73 parts of filler, 20-28 parts of adhesive and 10-14 parts of butadiene-acrylonitrile rubber. The method comprises the following steps: S101: plastifying the butadiene-acrylonitrile rubber in a Banbury mixer; S102: adding the compounding agent, sulfur, filler, adhesive and plastified butadiene-acrylonitrile rubber into the Banbury mixer, and compounding to form the compounded rubber; S103: moving the compounded rubber into an open rubber mixing mill to form a rubber plate; and S104: winding a film outside the rubber plate for isolation. The production method can ensure the oil resistance of the friction material. The frictional property of the friction plate subjected to oil impregnation is the same as before oil impregnation, thereby simultaneously ensuring the stable frictional property and higher friction factor of the paper-base friction plate.

Owner:NANTONG WANDA FRICTION MATERIAL

Brake gasket with bundle-type acrylic fibers and preparation method thereof

InactiveCN103174780AFrictionally stableLow wear resistanceOther chemical processesFriction liningPolymer sciencePolymer chemistry

The invention provides a brake gasket with bundle-type acrylic fibers. The brake gasket is prepared by components which comprise, by weight, 8% to 20% of resin, 5% to 15% of bundle-type acrylic fibers, 20% to 40% of friction strengthening agents, 7% to 15% of friction reduction agents, and 15% to 45% of padding. The brake gasket with the bundle-type acrylic fibers has the advantages of being stable in friction coefficient, small in heat fading, small in abrasion and light in weight, and therefore the bundle-type acrylic fibers are novel good strengthening materials which can replace asbestos and be used for the automobile brake gasket, and have a good application prospect.

Owner:LIAONING JIUTONG FRICTION MATERIALS

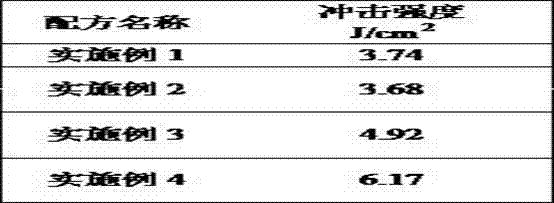

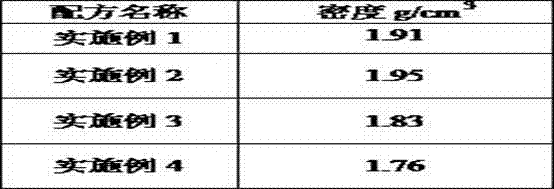

Boron carbide reinforced paper-based friction material and preparation method thereof

ActiveCN103741542AImprove wear resistanceImprove thermal conductivityOther chemical processesPaper coatingFiberCarbon fibers

The invention discloses a boron carbide reinforced paper-based friction material and a preparation method thereof. The preparation method comprises the following steps: dissolving cashew nut shell oil modified phenolic resin into absolute ethyl alcohol to obtain a solution A; dispersing multiwalled carbon nanotubes into a sodium dodecyl sulfate water solution to obtain a suspending liquid B; dispersing chopped carbon fiber, bamboo fiber and boron carbide into water, and then, adding the suspending liquid B to obtain a solution C; defibering the solution C, then, making sheets and drying to obtain a sample sheet D; and spraying the solution A on the sample sheet D, airing and carrying out hot press molding to obtain the boron carbide reinforced paper-based friction material, wherein the boron carbide reinforced paper-based friction material has the dynamic friction coefficient of 0.139-0.147 and the wear rate of 4.5*10<-8>. According to the invention, the paper-based friction material is prepared by adding boron carbide as reinforcing phase into the raw materials, so that the process is simple and easy to control, the braking stability and friction coefficient of the paper-based friction material can be greatly improved, the friction performance can be greatly improved, and the wear rate can be effectively reduced.

Owner:盐城大数据资产经营管理有限公司

Preparation method of carbon ceramic automobile brake disc

ActiveCN110372389ALow costFrictionally stableFriction liningActuatorsCeramic compositeAmorphous silicon

The invention discloses a preparation method of a carbon ceramic automobile brake disc. The preparation method comprises the following steps that a C / C composite material with the density being 0.8-1.0 g / cm<3> is taken as a green body and sequentially subjected to PIP treatment, high-temperature treatment and RMI treatment, and namely a carbon ceramic composite material with the density being 1.9-2.0 g / cm<3> is obtained; penetrative low melting point metal treatment is conducted on the carbon ceramic composite material to obtain the carbon ceramic automobile brake disc, and the melting point of the low melting point metal is less than 1200 DEG C; and the process of the RMI treatment includes the steps the high-temperature treated green body is placed in a graphite mold paved with silicon powder and amorphous silicon carbide powder, under the vacuum condition, a siliconizing reaction is conducted, and the amorphous silicon carbide powder is obtained by sintering a silicon carbide ceramics precursor at 800-1000 DEG C. The preparation method of the carbon ceramic automobile brake disc with low cost, stable friction performance and excellent heat dispersion is provided.

Owner:HUNAN BOWANG CARBON CERAMIC CO LTD

Method for preparing carbon pottery aircraft brake disc

The invention discloses a method for preparing a carbon pottery aircraft brake disc. The method comprises the following steps: by taking a C / C composite material of which the density is 1.0-1.5g / cm<3>as a blank, performing PIP (precursor infiltration and pyrolysis) treatment, high temperature treatment and RMI (reaction siliconing process) on the blank in sequence so as to obtain a carbon potterycomposite material of which the density is 2.0-2.2g / cm<3>; and soaking the carbon pottery composite material into silica sol for multiple times in vacuum, performing drying till the weight gain rateof the carbon pottery composite material is 1-4%, and performing thermal treatment, so as to obtain the carbon pottery aircraft brake disc, wherein the RMI treatment comprises the following steps: putting the blank after high temperature treatment into a graphite mold with silicon powder and amorphous silicon carbide powder, and performing a siliconing reaction under a vacuum condition, wherein the amorphous silicon carbide powder is obtained by sintering a silicon carbide ceramic precursor at 800-1000 DEG C. The brake disc has stable friction performance, has adjustable friction coefficients,has a small friction amount, has no conspicuous vibration in the brake process, has a brake curve which is rectangular, stable without wash back, and is applicable to aircraft brake discs expected bybrake of high / low movement loading systems such as an airplane and a helicopter.

Owner:HUNAN BOWANG CARBON CERAMIC CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com