Patents

Literature

84results about How to "No cracking phenomenon" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

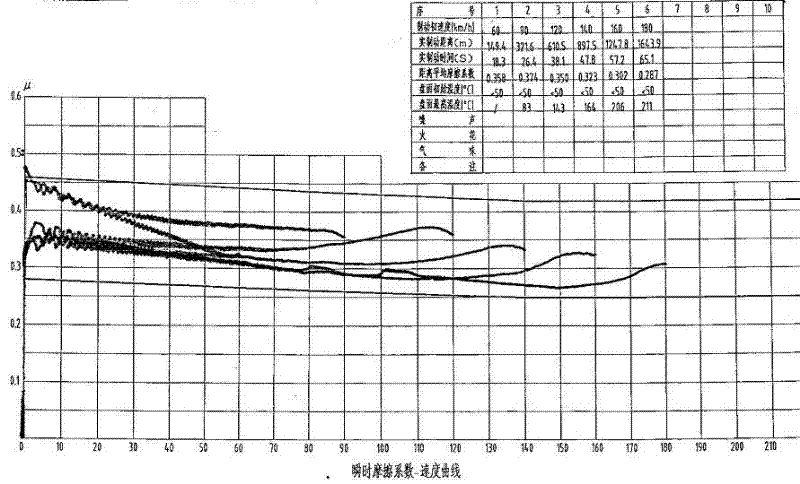

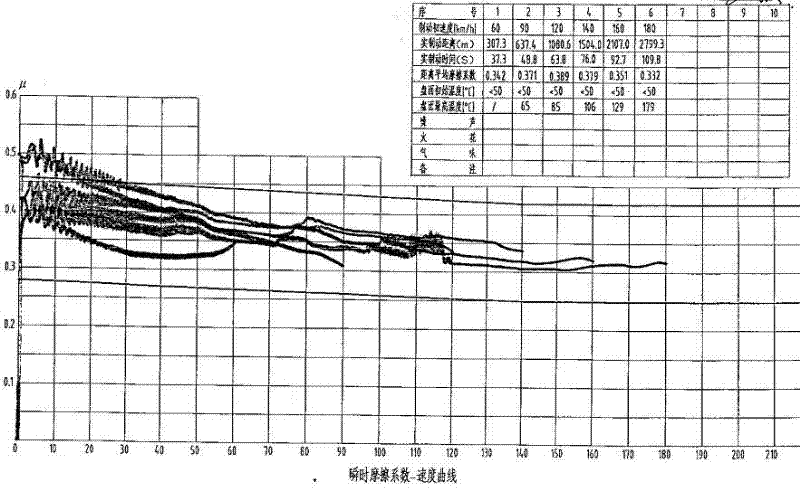

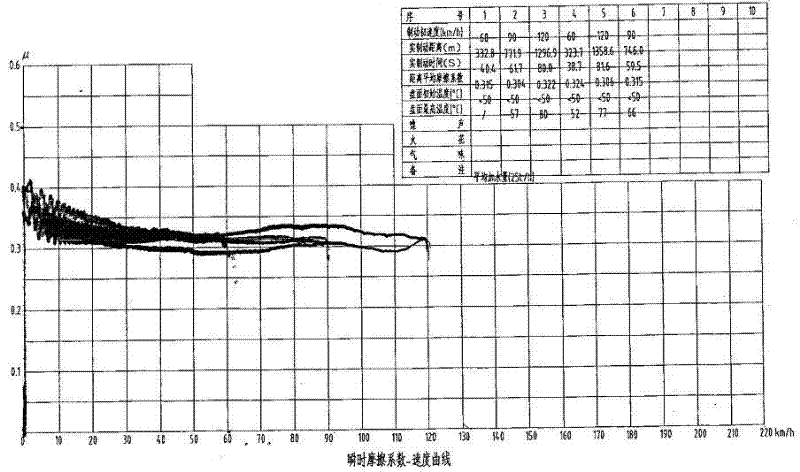

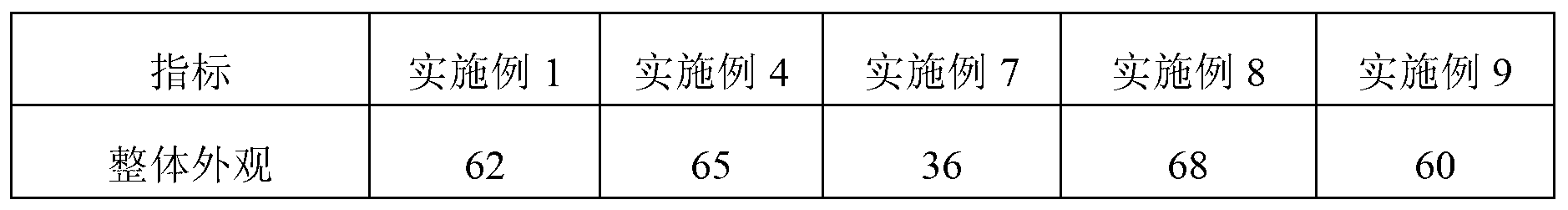

Hybrid fiber reinforced friction material for train braking and preparation method thereof

InactiveCN102191015AImprove toughnessImprove yieldOther chemical processesFriction liningFreight trainsAdhesive

The invention belongs to the technical field of materials, and particularly relates to a hybrid fiber reinforced friction material for train braking and a preparation method thereof. In the invention, a composite modified phenolic resin is used as an adhesive, and hybrid fibers, including carbon fiber, metal fiber, inorganic mineral fiber and the like, are used as the reinforcing fibers. Compared with the prior art, the invention improves the contour machining property of the organic synthetic brake, and the yield of the material is high; the brake has stable frictional property at different braking speeds, does not has obvious degradation of frictional property at high speed, and does not have the phenomena of shedding and cracking on the working surface after the braking test. The friction material provided by the invention can be widely used for manufacturing brake pads, brakes, brake shoes and the like in braking systems of passenger and freight trains, municipal rail transportation, subways and the like.

Owner:FUDAN UNIV

Method for preparing veneer ceramic-free full anatomic form zirconia dental crown

ActiveCN102302381AHigh strengthHigh transparencyTooth crownsTeeth cappingComputer assistanceTooth Preparations

The invention relates to a method for preparing a veneer ceramic-free full anatomic form zirconia dental crown. The method comprises the steps of: adopting a CAD (Computer-aided Design) / CAM (Computer-aided Manufacturing) system, and clinically fabricating an impression and a plaster model after tooth preparation; scanning by using a three-dimensional model scanner, establishing a digital model ona computer, and designing a dummy form through computer assistance; cutting a dummy form through a numerically-controlled lathe, trying wearing on the model, and adjusting the form; burnishing; painting; and glazing, and finally completing the fabrication of the dummy. The veneer ceramic-free full anatomic form zirconia dental crown provided by the invention has high strength and good light transmission, the treatment of applying ceramics is not required, and no hazard of ceramic fracture exists; the degree of precision is high due to computer control during the overall process; and the grinding amount for tooth preparation is small, and an ideal effect can be achieved with 1mm space.

Owner:SHENZHEN UPCERA DENTAL TECH

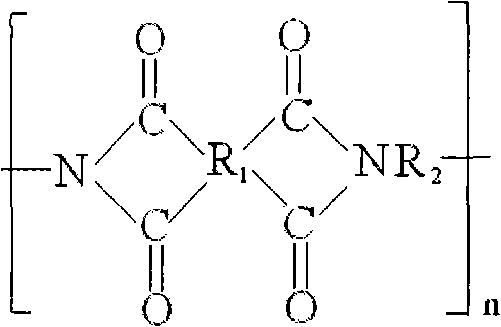

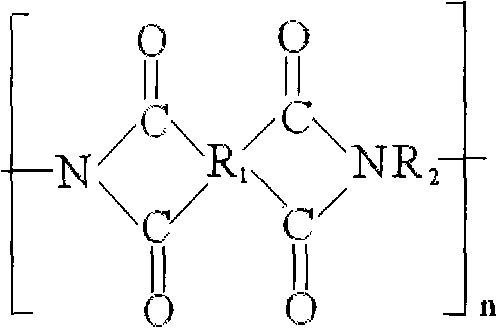

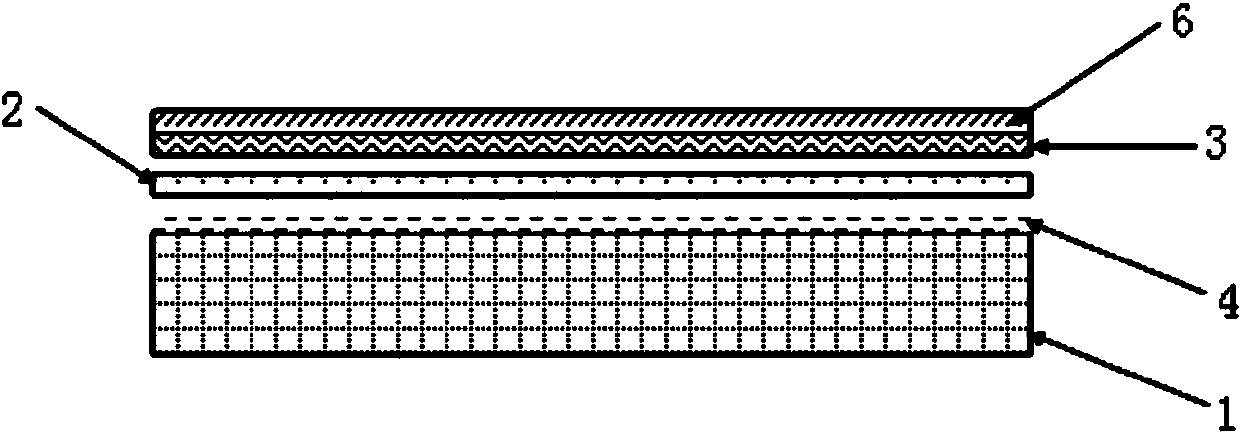

Battery separator and preparation method thereof

ActiveCN101355143AGood high temperature performanceImprove mechanical propertiesCell component detailsLithiumSubstance use

The invention provides a diaphragm for a battery, comprising a base material. The base material comprises through holes, wherein the base material contains polyimide and additives, and the additives are inorganic crystal whiskers and / or orthosilicate ester. The diaphragm prepared by the invention has excellent high-temperature performance, the heat shrinking property of the diaphragm is below 1.1 percent below 400 DEG C, and no cracking phenomenon occurs below 400 DEG C. The mechanical property of the diaphragm is excellent, the tensile-strength of the diaphragm is above 100 Mpa, while the tensile-strength of the diaphragm prepared by the prior art is only 90 Mpa. In addition, perforating substances used by the invention can effectively adjust the average diameter of a hole of the diaphragm within a better range of between 10 and 100 nanometers, thereby guaranteeing the smooth passing of lithium irons in the battery using the diaphragm, reducing the internal resistance of the battery, and having no short circuit.

Owner:BYD CO LTD

Magnesium oxide board and preparation method thereof

The invention discloses a magnesium oxide board which is prepared by extruding a reinforced material and slurry into a sheet through forming equipment, wherein the reinforced material is composed of a non-woven fabric and a fiberglass mesh or other reinforced materials; the slurry comprises the following components in parts by mass: 100 parts of magnesium oxide with the magnesium content of at least 85% and the activity degree of at least 62%, 80-90 parts of anhydrous magnesium chloride water solution with the concentration of 10-40 baume degrees, 10-15 parts of lightweight filler A, 15-20 parts of lightweight filler B, 1-5 parts of silicon dioxide and 1-10 parts of foaming agent; the particle size of magnesium oxide is 250-400 meshes; preferably, the lightweight filler A is one or more selected from perlite, polyphenyl granules, gangue and vermiculite, and the lightweight filler B is one or more selected from wood flour, straw, rice husk and bamboo fiber; more preferably, the lightweight filler A is hole-closed perlite, and the lightweight filler B is straw sawdust of 80-100 meshes. The invention also discloses a preparation method of the magnesium oxide board. The magnesium oxide board prepared according to the invention is high in strength, not easy to get damp, strong in fire resistance and free of cracks after being fired at high temperature; in addition, the preparation method of the magnesium oxide board disclosed by the invention is short in time.

Owner:SHANGHAI HUIZHUO BUILDING DECORATIVE MATERIAL

Method for dyeing all-zirconium tooth by using film

ActiveCN102512256AEasy to operateLittle impact on operationArtificial teethPolymer scienceColor printing

The invention relates to a method for dyeing an all-zirconium tooth by using a film. The method comprises the following steps of: producing a polyethylene (PE) film with stronger autohension by taking polyethylene as a main raw material by a multi-layer extrusion process; and printing or print-coloring the film, shearing the colored film of which the size is matched with that of a precolored dental crown and wrapping on the surface of the dental crown, heating to ensure that coloring particles are transferred to the surface of the dental crown to be dyed, sintering, polishing, and glazing to finish the whole dyeing process and obtain a final restoration. The invention has the advantages that: the method is easy to operate, slightly affects the transparency of zirconia dental crowns, and can meet aesthetic requirements of customers on zirconia all-porcelain teeth more easily; the coloring mode is more flexible, and the targeted color printing can be performed according to the requirements of the customers; by the method, the color difference between dental crowns can be intuitively reflected immediately, and the problem that final colors of staining fluid products can be seen only after the staining fluid products are sintered is solved; and the phenomenon of porcelain fracture is avoided, and the safety factor is high.

Owner:SHENZHEN UPCERA DENTAL TECH

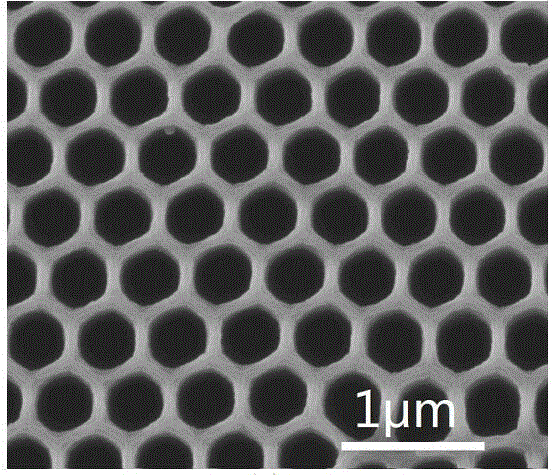

Porous film and preparation method thereof

ActiveCN105854629ANo cracking phenomenonAdequate responseSemi-permeable membranesDispersed particle filtrationAlloySlurry

The invention discloses a porous film which has high porosity, is simple and practical to prepare and has good formability during preparation, and a preparation method thereof. The porous film is a slice composed of solid-solution alloy and a metal porous material with elemental metal of a face-centered cubic structure or a body-centered cubic structure as a matrix phase, and has a thickness of 5 to 3000 [mu]m, an average pore size of 0.05 to 100 [mu]m and porosity of 40 to 85%. The preparation method comprises the following steps: 1) acquiring a support body which is foam metal; 2) preparing slurry which contains raw material powder used for producing the porous film; 3) loading the slurry on the support body to prepare a film body; 3) rolling the film body; and 5) sintering the rolled film body and then carrying out cooling so as to obtain the porous film.

Owner:CHENGDU INTERMENT TECH

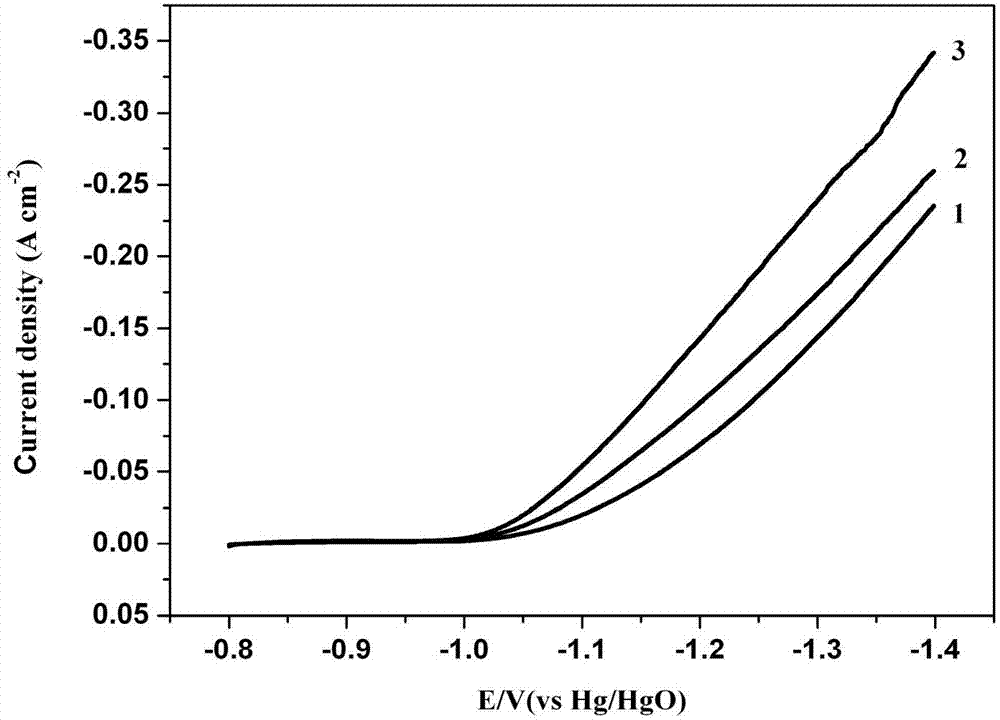

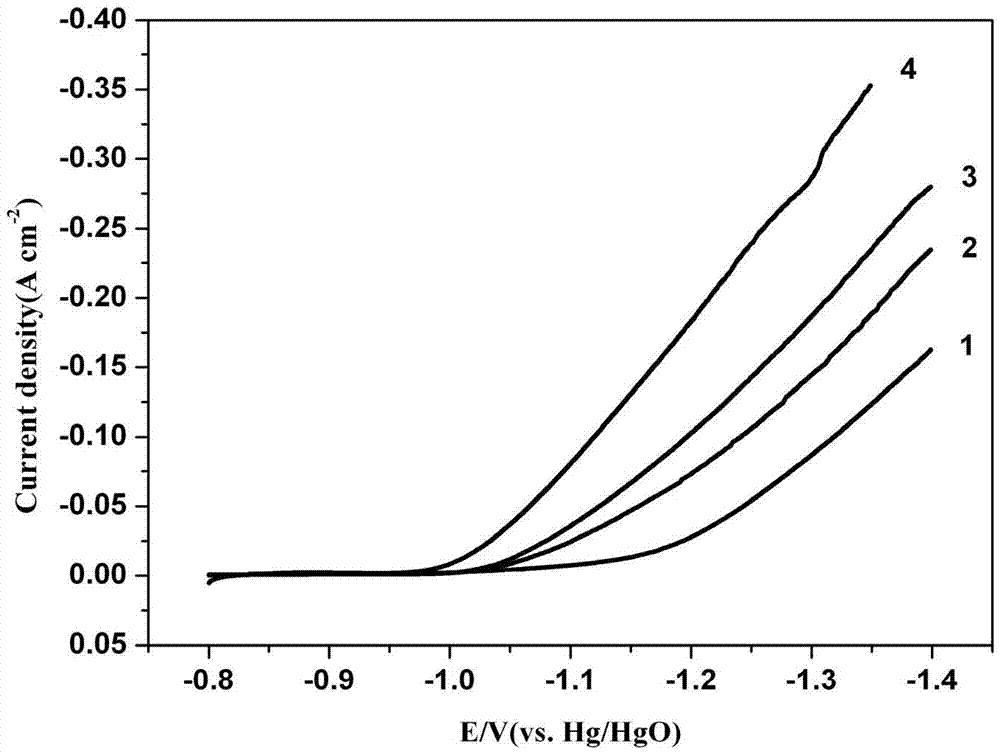

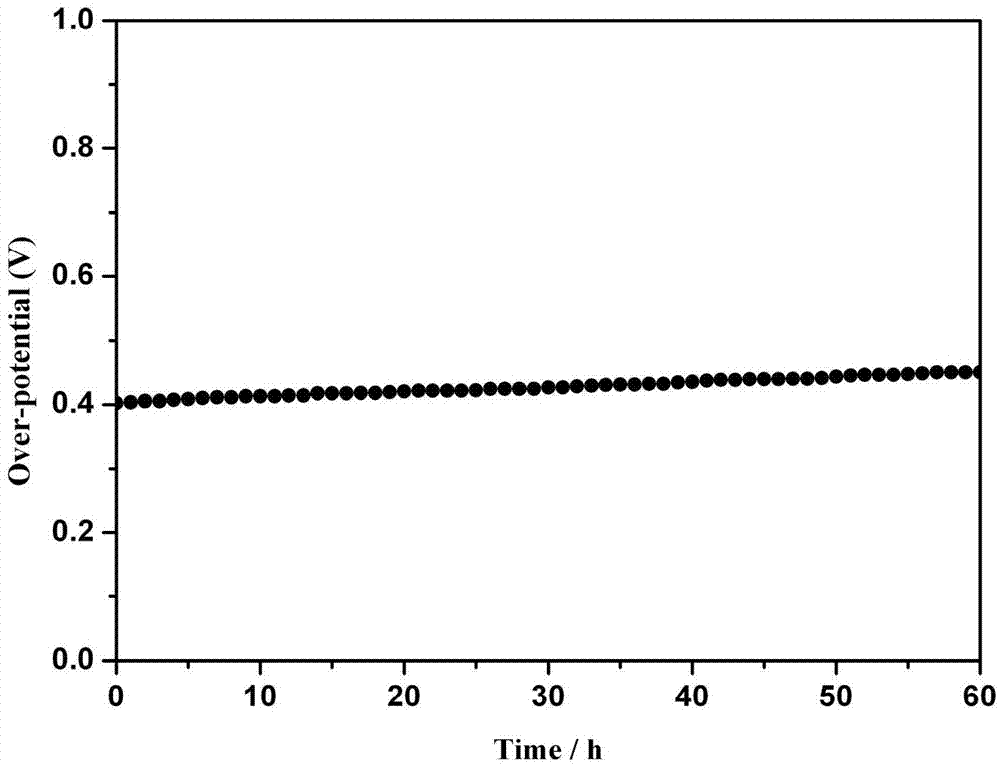

Preparation method of high-performance nickel-based ruthenium-containing compound oxide hydrogen evolution electrode

InactiveCN103924263ALarge specific surface areaFully exposedLiquid/solution decomposition chemical coatingElectrodesElectrolysisSynthesis methods

The invention provides a preparation method of a high-performance nickel-based ruthenium-containing compound oxide hydrogen evolution electrode, and belongs to the field of electric catalytic hydrogen evolution in chlorine alkali industry. The method comprises the following steps: firstly, putting a foam nickel substrate into an acetone solution and carrying out ultrasonic concussion for 15 minutes so as to perform chemical degreasing; then, soaking the foam nickel substrate in a 3mol / L hydrochloric acid aqueous solution for 0.5 hour so as to remove oxides from the surface of the foam nickel substrate; finally, carrying out in-situ growth of nickel ruthenium oxide nanorods on the surface of the pretreated foam nickel substrate by virtue of a solvent thermal synthesis method, thereby obtaining the hydrogen evolution electrode with good catalytic performance and high stability. The method is simple and novel and is convenient and feasible to operate. The prepared nickel-based ruthenium-containing compound oxide hydrogen evolution electrode has a unique nanorod structure; the coating surface of the electrode is flat and flawless without a fracturing phenomenon. Thus, the electrode provided by the invention can be widely taken as a hydrogen evolution electrode material for alkaline electrolysis water.

Owner:CHONGQING UNIV

Method for culturing non-pollution Dongzao Chinese date trees with increased prodn.

A method for culturing winter jujube with high yield and no environmental pollution preparing the bactericide from long-term bactericide, therapeutic bactericide and Ca-contained nutrients, spraying it onto the surface of each winter jujube fruit three times for loosening fruits, and putting the chosen jujube fruits in bags one in one.

Owner:张景友

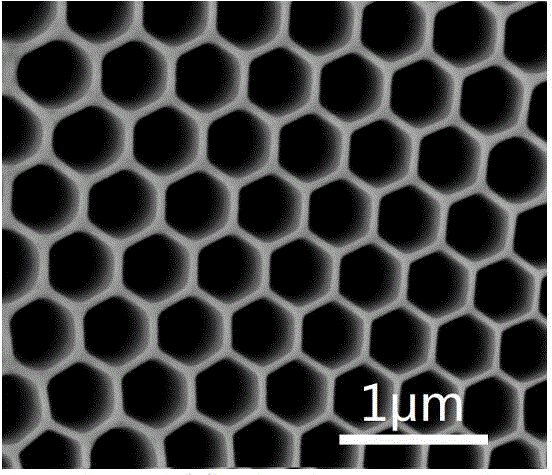

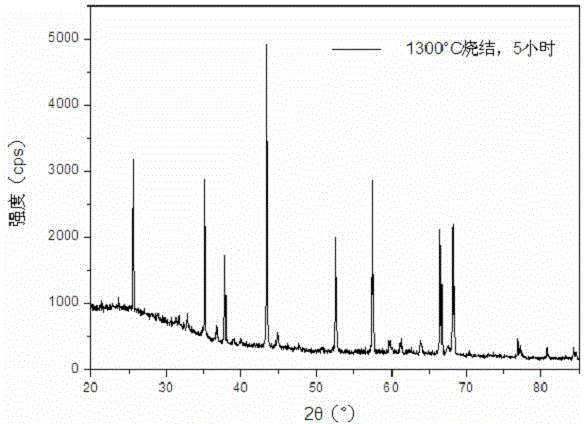

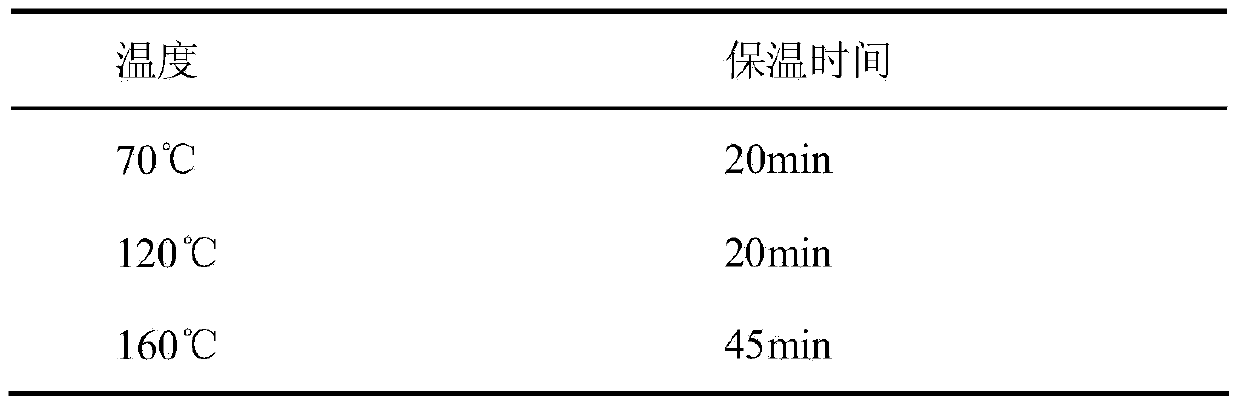

Preparation method of porous alpha-alumina membrane

A preparation method of a porous alpha-alumina membrane comprises the following steps: carrying out an annealing and electric polishing pretreatment on a high purity aluminum foil; taking the processed aluminum foil as the positive electrode, and graphite as the negative electrode, then carrying out two-step positive electrode oxidation in a mixed solution of phosphoric acid and aluminum oxalate to obtain an aluminum-base-containing porous anodic alumina membrane; subjecting the obtained aluminum-base-containing porous anodic aluminum membrane to a pore enlarging treatment; then subjecting the pore-enlarged aluminum-base-containing porous anodic alumina membrane to a water boiling treatment or a hydrothermal treatment; then removing the aluminum base from the aluminum-base-containing porous anodic alumina membrane, which has been treated by water boiling or a hydrothermal treatment; using a sodium citrate solution to remove the baffle layer and alumina hydrate on the external layer of the porous alumina membrane from the aluminum-base-free porous anodic alumina membrane so as to form a periodical hexahedral densely-arranged alumina through hole structure finally; and sintering the prepared alumina membrane with a periodical hexahedral densely-arranged alumina through hole structure in a muffle furnace at a high temperature so as to obtain porous alpha-alumina membrane.

Owner:常毅

Repair technology for leather clothing with coating cracks

ActiveCN102994662ASolve crackingSolve problems that are difficult to repair and refurbishPolyurea/polyurethane coatingsLeather surface finishingAcrylic resinMechanical engineering

The invention discloses a repair technology for leather clothing with coating cracks. The repair technology comprises steps such as cleaning, filling, sizing and the like. The key process of the repair technology is the filling process, which is the key to solve the cracks of the coating. In the filling formula, excellent filling ability and permeability of filling type acrylic resin are utilized to radically realize the purpose of filling cracks and solving chromatic aberration. Meanwhile, the excellent penetrating quality of the filling fluid enables the formed resin film to form an extremely thin three-dimensional netted structure on the surface layer and inner part of the lather, so that the bonding firmness of the film is very high. The lather clothing treated by the repair technology has uniform, smooth and flat surfaces and bright color, and solves a problem that the leather clothing is difficult to repair due to cracks of coating after being worn for a long time. The repair technology provided by the invention can be used for repairing the leather clothing with coating cracks.

Owner:JIHUA 3514 LEATHER & FOOTWARE

Canned ginkgo nut and processing method thereof

InactiveCN103300377AGuaranteed freshnessGuaranteed brightnessSugar food ingredientsEdible seed preservationForeign matterTinning

The invention provides a canned ginkgo nut. The canned ginkgo nut is prepared from the following materials in parts by weight: 5.5-6% of gingkgo, 3-4% of water, 0.1-0.5% of salt and the like. The processing method comprises the steps of grading and selecting ginkgo materials, and also comprises the following steps of packaging and putting into a refrigeration house at 0-5 DEG C for use after grading the ginkgo materials; drying and cooking the ginkgo; precooking the ginkgo, entering a dryer to dry; decladding and peeling, re-cooking by the effect of a high-pressure water torch of which the pressure is 0.2-0.3 Mpa; cooling, choosing and checking; selecting the ginkgo, cleaning and detecting by a foreign matter remover; checking and accepting empty cans; sterilizing the empty cans, tinning, preparing soup, injecting, sealing, sterilizing and cooling. The canned ginkgo nut has the advantages that the freshness, the brightness and the mouthfeel of pulp are ensured to the maximal extent; most of all, no fruit crack phenomenon appears after sterilization; and the quality guarantee period can achieve 3-4 years without a change.

Owner:桂林日盛食品有限责任公司

Processing technology for plastic decorated board

ActiveCN102320102ASolve the phenomenon of high stressNo cracking phenomenonFlat articlesInjection pressureInjection molding machine

The invention discloses a processing technology for plastic decorated boards, which comprises the following steps of: adding dried raw materials into a heated injection machine; and obtaining a final qualified product by setting injection pressure, speed, injection time and injection glue amount of different sections of the injection machine and setting that the final pressurized pressure and pressurized speed reach the optimal injection technology. According to the technology, the phenomenon that a product water gap (gap inlet) has big possibility of generating appearance defects, such as cold charge speckles, silver marks, blow marks and the like when injection moulding plastic decoration boards are shaped can be eliminated. Meanwhile, the processing technology has good stability, the obtained product has stable quality, production efficiency is improved, and production cost is lowered.

Owner:ANHUI APPROPRIATE WANFENG ELECTRIC APPLIANCE

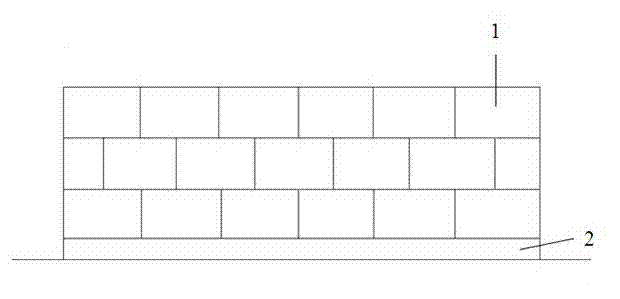

Gypsum block masonry and construction method thereof

InactiveCN102352660AUnique structureHas breathing functionWallsBuilding material handlingLap jointSlurry

The invention discloses a construction technology for gypsum block masonry. The gypsum block masonry has a simple structure and attractive appearance, is convenient to construct, environment-friendly, fire-resistant and quake-proof, and saves manufacturing cost. The construction technology comprises masonry of the gypsum block masonry and construction of decorative layers. The invention has the technical key point that: a wall cushion is arranged on the lower part of the gypsum block masonry; gypsum blocks of the gypsum block masonry are in lap joint with one another in an up-and-down staggered mode and are constructed by using binding slurry; the gypsum block masonry is provided with tie bars equidistantly on each gypsum block along a main body structural column or a wall height direction; and the tie bars extend into the masonry. By the construction technology for the gypsum block masonry, the technical problems of low efficiency, long construction period, large pollution, large occupied space of heavy walls and non-low-carbon and non-environment-friendly building materials in the traditional partition wall construction technology are solved.

Owner:NANTONG CONSTR PROJECT GENERAL CONTRACTING

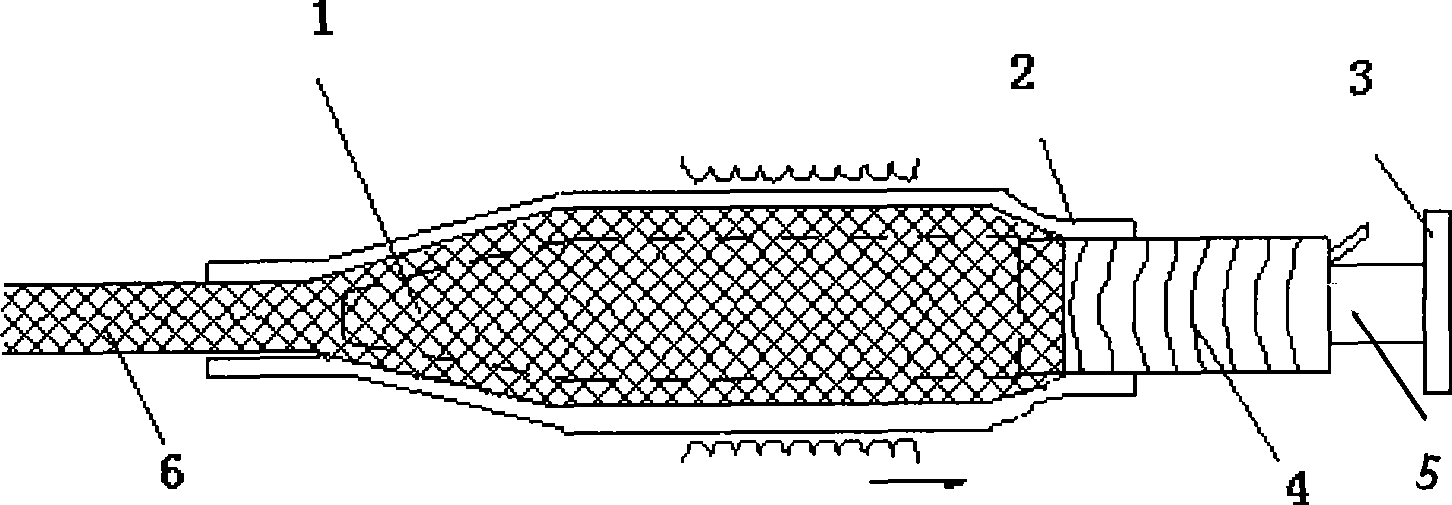

Silicon rubber sleeve expansion method and device

The invention relates to a silastic bushing expansion method and a device thereof. The invention is characterized in that the tail end of an expansion head is provided with an empty cavity; a spiral supporting pipe is inserted into the empty cavity and is provided with a top rod; the top rod can support a spiral supporting strip winding pipe; the top rod and a support saddle thereof are connected in an inserting way; a net sleeve is arranged between a silastic tube and a steel stick as a spacer. The air clearance formed after a nylon sleeve is sheathed on the expansion head can reduce much resistance in the silastic tube and hauls a silastic piece on a plastic spiral pipe by proper force. The silastic bushing expansion method and the device thereof have the advantages of clean expansion, non-large mechanical power and being suitable for the expansion of a short and thick pipe.

Owner:CHANGCHUN UNIV OF SCI & TECH

Field patching method after damage of zinc coating of in-service power transmission tower

InactiveCN103272752AGood film formingStrong adhesionPretreated surfacesCoatingsAngle grinderSurface oxidation

The invention relates to a field patching method after damage of a zinc coating of an in-service power transmission tower. The field patching method comprises the following steps of: (1) surface polishing treatment of using an angle grinder to oxidize a surface of angle steel which damages the zinc coating and removing a corrosive layer, rusty spots and oxidized spots to expose metallic luster of a metal material; (2) surface refining treatment of using an abrader to grind the surface gradually with abrasive paper from coarse to fin until the surface is like a mirror surface; (3) surface cleaning and drying of cleaning the surface by using a cotton ball containing absolute ethyl alcohol to remove sand particles and dust on the surface, then using acetone to wipe the surface, and removing oil grease to enable the surface to be dried rapidly; (4) spraying Subaru cold galvanized coating until a thickness of a film is up to 80-100 microns; and (5) finishing drying. As the method is used for dealing with the damaged zinc coating, good film-forming effects of the Subaru cold galvanized coating, strong adhesive force and no aging and fracturing phenomenon are achieved, and an original service life of a lightning rod tower is kept.

Owner:STATE GRID CORP OF CHINA +1

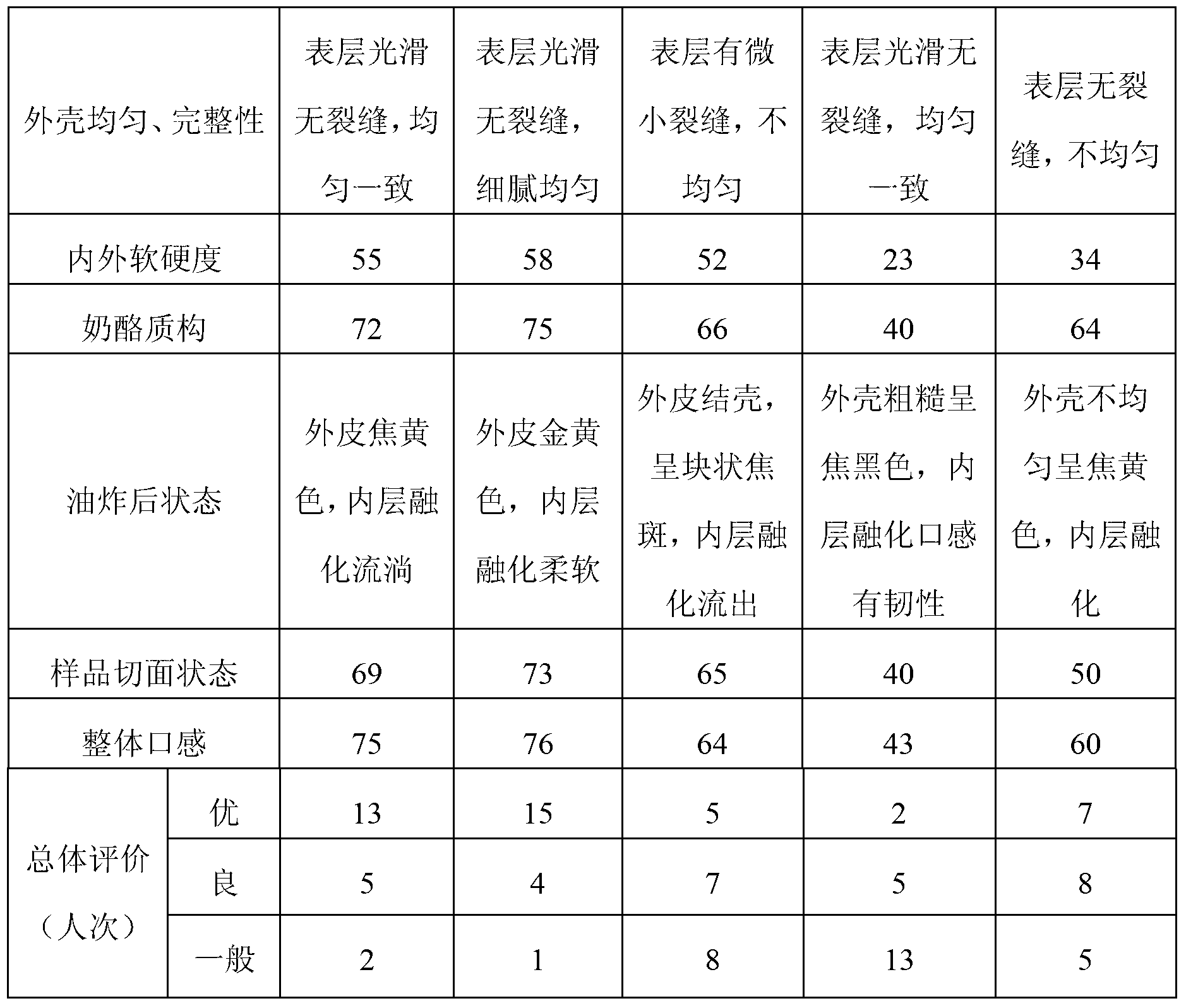

Reproduced cheese ball and preparation method thereof

The invention discloses a reproduced cheese ball and a preparation method thereof. The preparation method comprises the following steps of: (1) melting and mixing raw materials, wherein the raw materials comprise natural cheese, milk fat, albumen powder, emulsifier, stabilizer and water; (2) sterilizing, and emulsifying so as to obtain an outer shell material; (3) molding and forming the outer shell material so as to obtain a formed outer shell; (4) performing core injection: injecting core material in the formed outer shell; and (5) demolding, and cooling so as to obtain the reproduced cheese ball. The reproduced cheese ball disclosed by the invention can be eaten directly, and also can be eaten after being fried; and the reproduced cheese ball after being fried is scorched outside but tender inside, the outer shell cannot be dissolved by hot flow, and the inner core is melted; and moreover, the reproduced cheese ball has high nutrition value, and is rich in protein and fat which are easily absorbed by human body.

Owner:BRIGHT DAIRY & FOOD

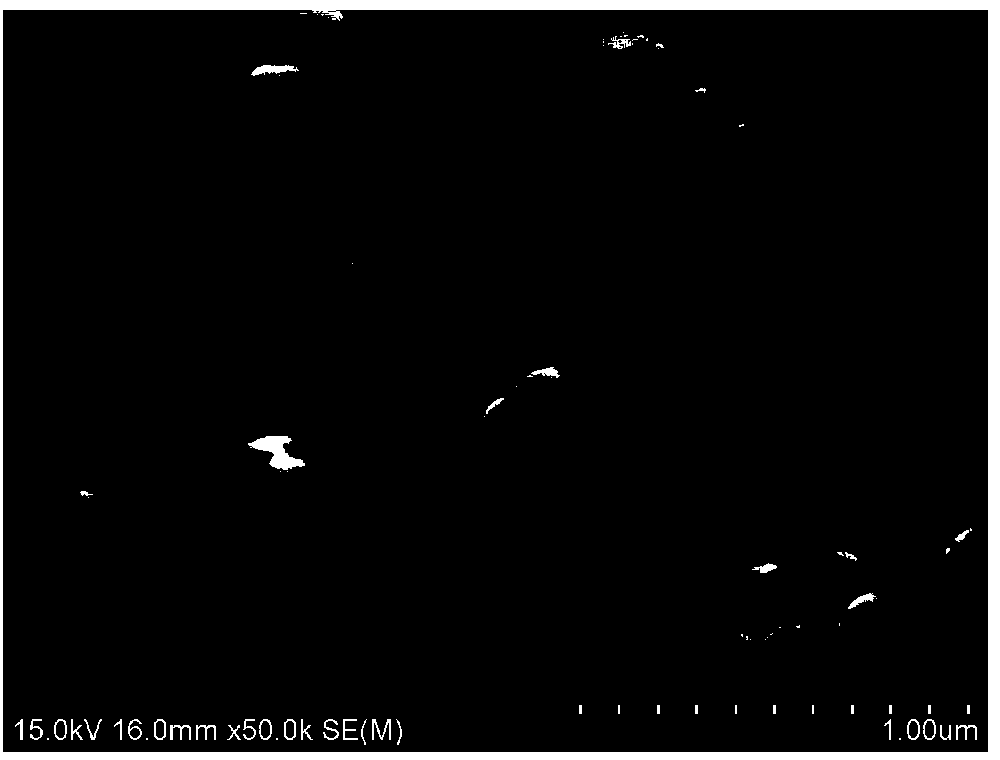

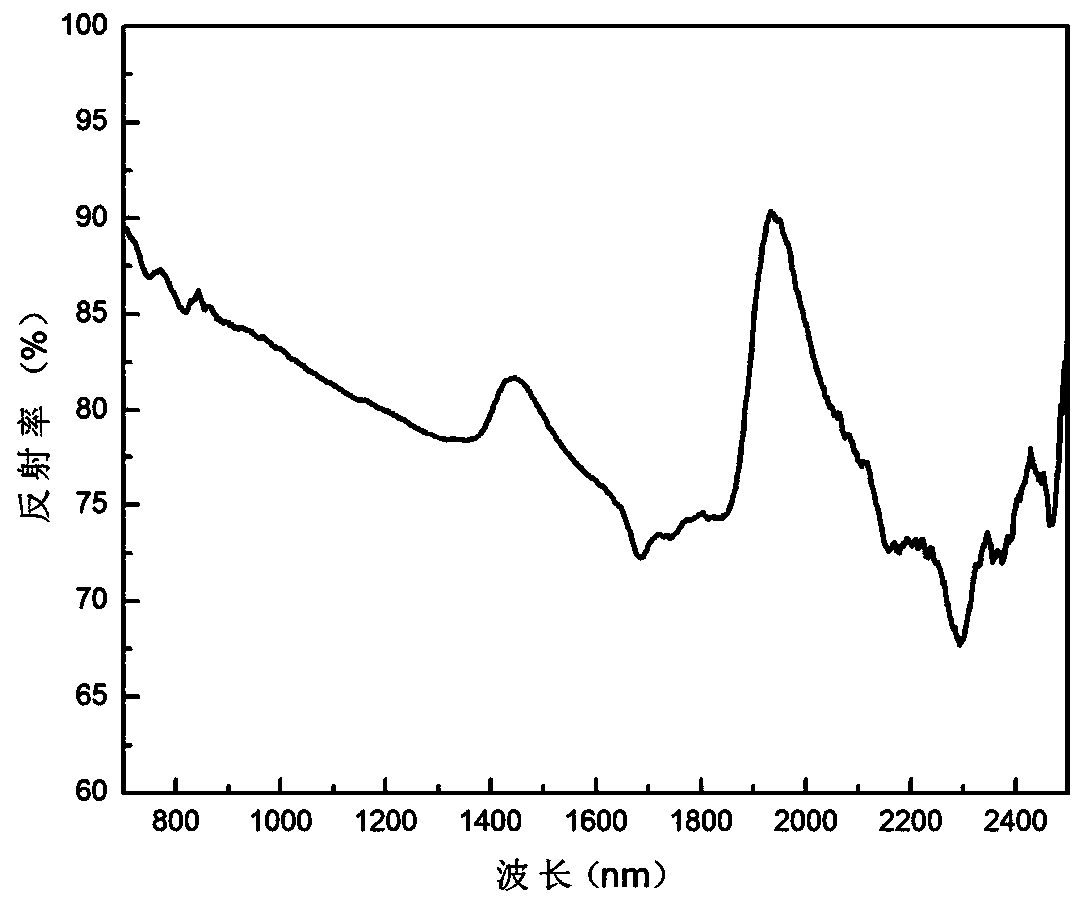

Yellow near-infrared high reflective coating and preparation method thereof

InactiveCN104194624AGood thermal stabilityPrevent reflocculationReflecting/signal paintsAlcoholSolvent

The invention relates to a yellow near-infrared high reflective coating and a preparation method of the yellow near-infrared high reflective coating. The yellow near-infrared high reflective coating comprises the following components in percentage by weight: 20 to 50% of yellow near-infrared reflective pigments, 10 to 50% of a film-forming matter, 30 to 60% of a solvent and 4 to 30% of an additive. The film-forming matter is organic silicon resin, and the solvent is water or C1-C4 alcohol. The invention further provides the preparation method of the yellow near-infrared high reflective coating. The yellow near-infrared high reflective coating is high in reflectivity, bright in yellow chrominance and good in mechanical properties, and applied to outer surfaces of building exterior facades and top layers or oil storage tanks, vehicles and aircraft shells and ship decks to obviously lower temperature inside a coating material.

Owner:SHANDONG UNIV

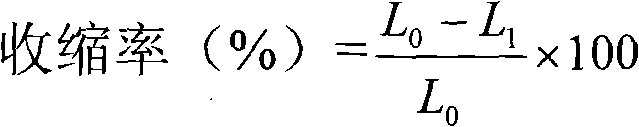

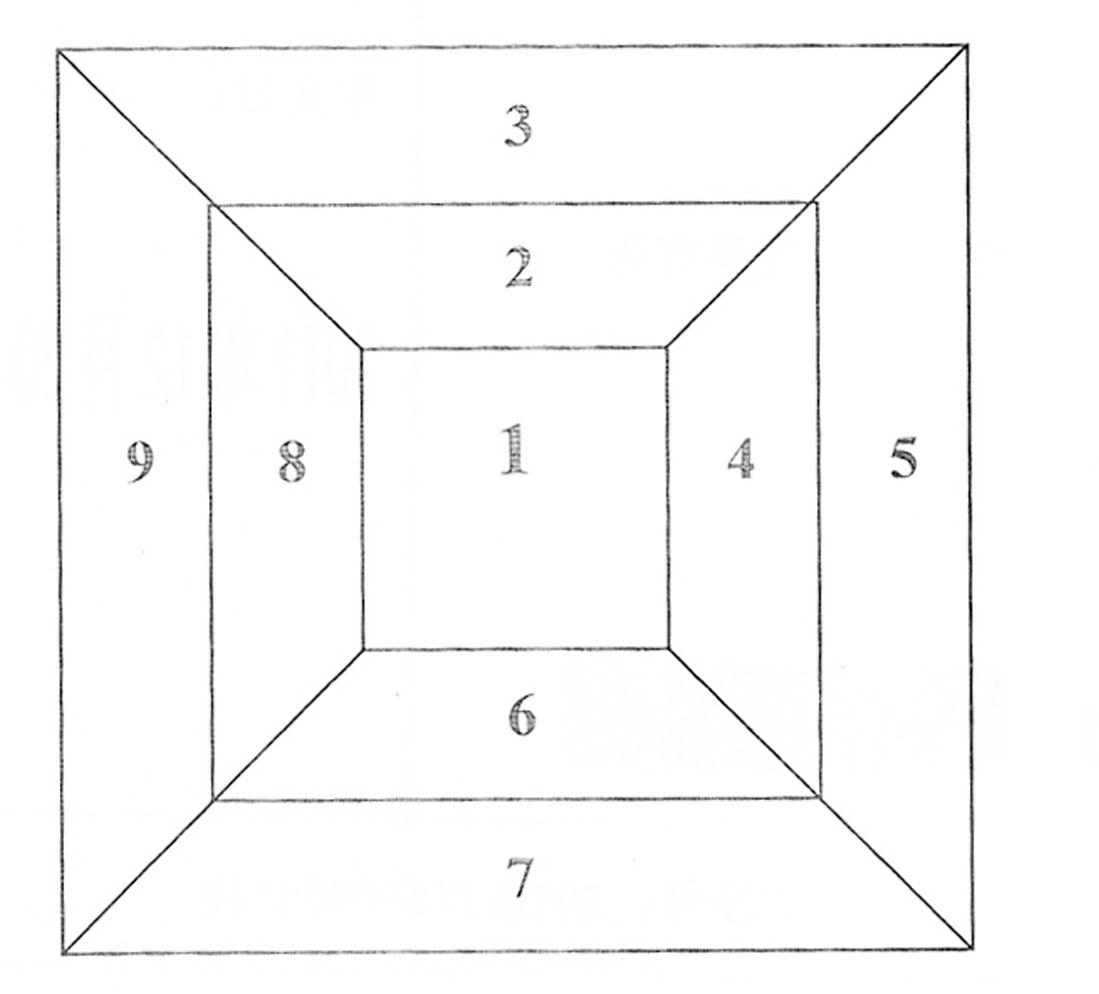

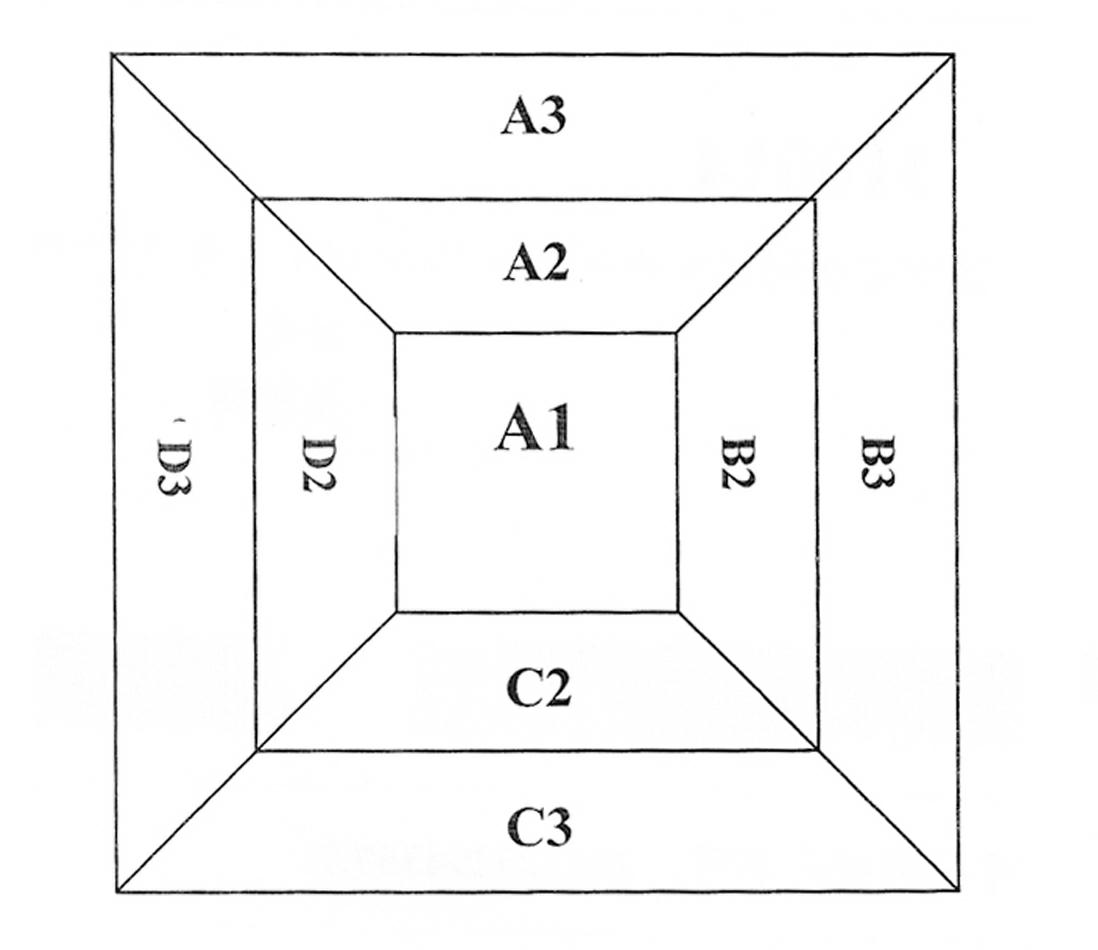

Layer-to-layer registration control method for inner layers of HDI (High Density Interconnector) board

InactiveCN106061139AOvercome the disadvantages of the production processNovel and reasonable designMultilayer circuit manufactureHigh densityInterconnector

The invention discloses a layer-to-layer registration control method for inner layers of an HDI (High Density Interconnector) board. The method comprises the following steps: performing earlier-stage detection on a film used for making inner layer lines and patterns, wherein the earlier-stage detection of the film includes earlier-stage compensation of the film, and detection and picking of the used film in order to ensure that the rising and shrinking of the used film are within + / -1MIL, and the rising and shrinking of a diagonal line of the used film are within + / -1MIL; setting a monitoring point on the picked and used film which is proved to be qualified by detection; and repeatedly measuring rising and shrinking numerical values of the film by 200PNL / time and recording the rising and shrinking numerical values during making of the inner layer lines and the patterns with the film, and measuring rising and shrinking data of the film and recording the rising and shrinking data after the inner layer lines and the patterns are made. The technical scheme has the advantages that the defects of a current production flow can be overcome, and the design is reasonable and novel.

Owner:奥士康精密电路(惠州)有限公司

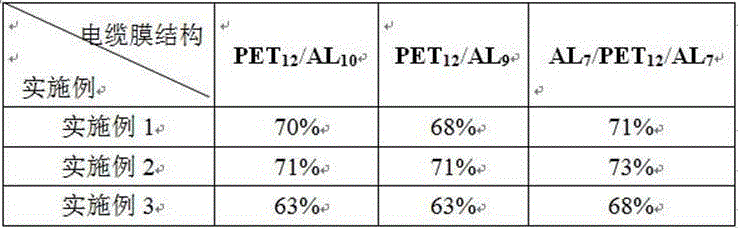

High-stretching-ratio-resisting adhesive for cable shielding film

InactiveCN106367014AStrong rotationGood flexibilityPolyureas/polyurethane adhesivesChemistryAluminium

The invention discloses a high-stretching-ratio-resisting adhesive for a cable shielding film. The high-stretching-ratio-resisting adhesive is prepared from a main agent and a curing agent, wherein the mass part ratio of the main agent to the curing agent is 100 to 3; the main agent is a polyurethane macromolecule; the molecular weight of the polyurethane macromolecule is 19000 to 25000, a hydroxyl value is 4.5mgKOH / h to 6mgKOH / g and the solid content is 48 percent to 52 percent; the rotary viscosity at 25 DEG C is 1000mPa.S to 1500mPa.S. The adhesive provided by the invention has excellent flexibility and high bonding strength on an aluminum layer; when the high-stretching-ratio-resisting adhesive is used for adhering the cable shielding film, the aluminum layer is not broken and has no cracks under a stretching ratio which is smaller than or equal to 70 percent, so that the shielding effect of the cable shielding film is guaranteed.

Owner:中山市康和化工有限公司

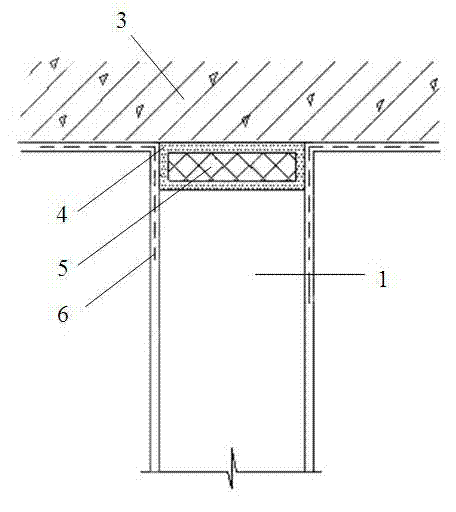

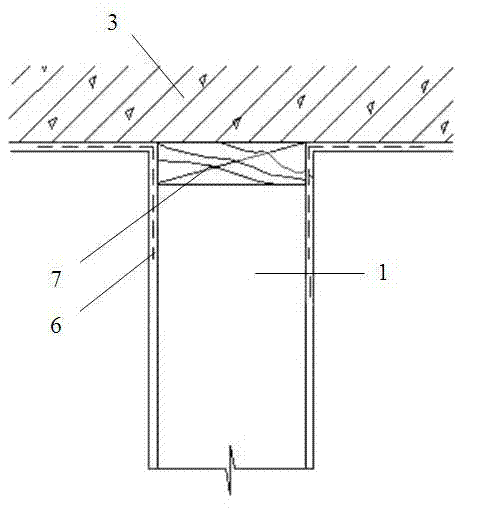

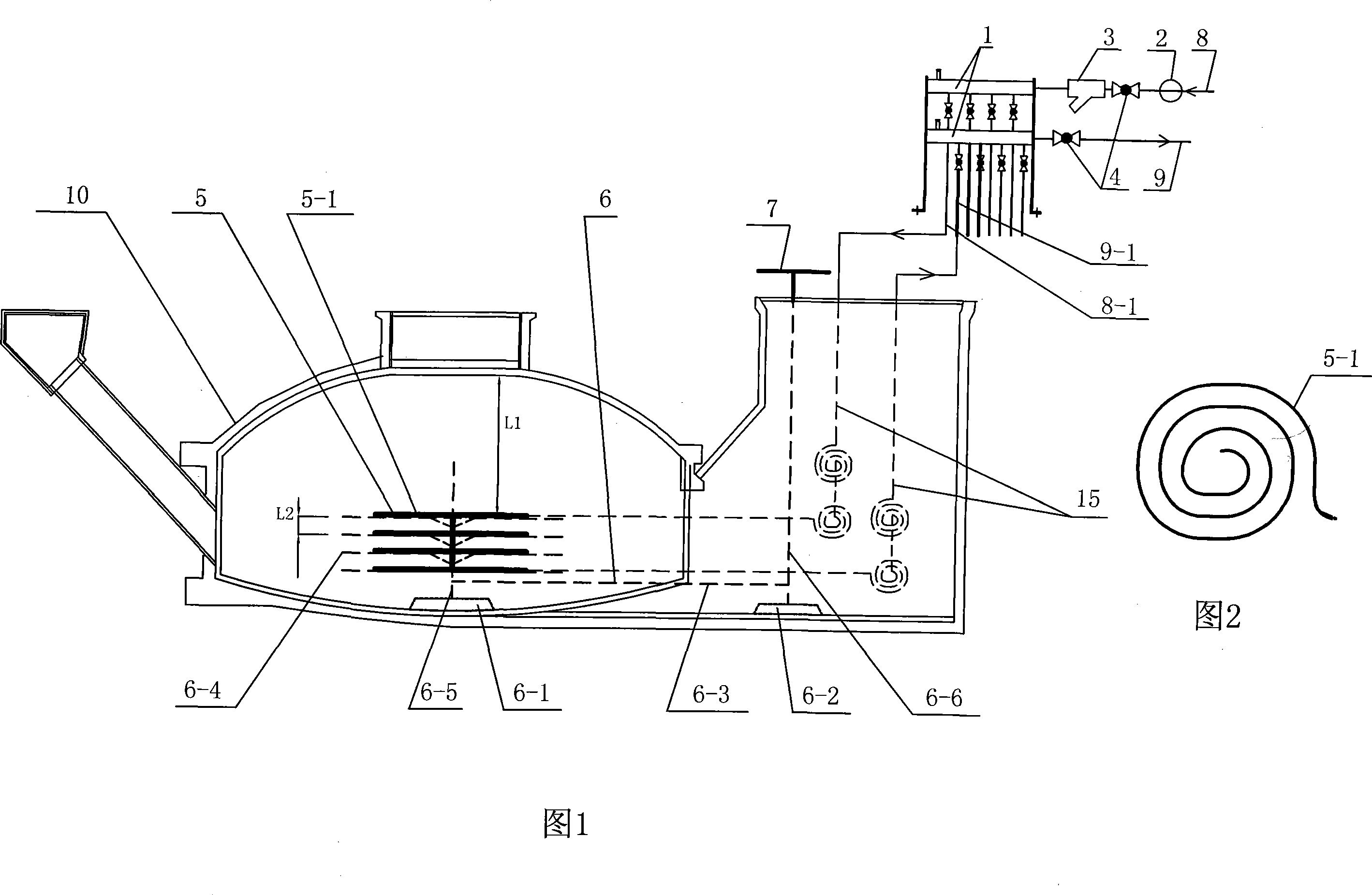

Mobile heating device having shell breaking function inside methane pool and shell breaking method

InactiveCN101182460AGuaranteed uptimeIncrease profitBiological substance pretreatmentsGas production bioreactorsEngineeringHeat pipe

A mobile heating device with shell breaking function, which is provided in a methane pool, and a shell breaking method are disclosed. The invention relates to a heating device and a shell breaking method. The invention effectively solves the problem that the methane pool in cold mountain areas generates no marsh gas in winter and can not be used normally, which is caused by unavailability of the heating device; the invention also solves the problem that the shell breaking function is not combined with the heating function. The invention comprises at least one set of heating pipe body (5) and a base frame (6) of the heating pipe and a control handle (7); a set of heating pipe body (5) is arranged on the base frame (6) of the heating pipe; the control handle (7) is fixed and connected with the base frame (6) of the heating pipe. The steps of the method are that: the mobile heating device with shell breaking function is installed in the methane pool; the distance L1 between an upper end of the heating pipe body and a top end of the methane pool is 0.5m to 5m; the base frame (6) of the heating pipe and the heating pipe body are moved up and down by the mobile control handle. The invention combines the heating function with the shell breaking function; the invention has the advantages of a simple structure, a low cost and convenient operation.

Owner:高德广

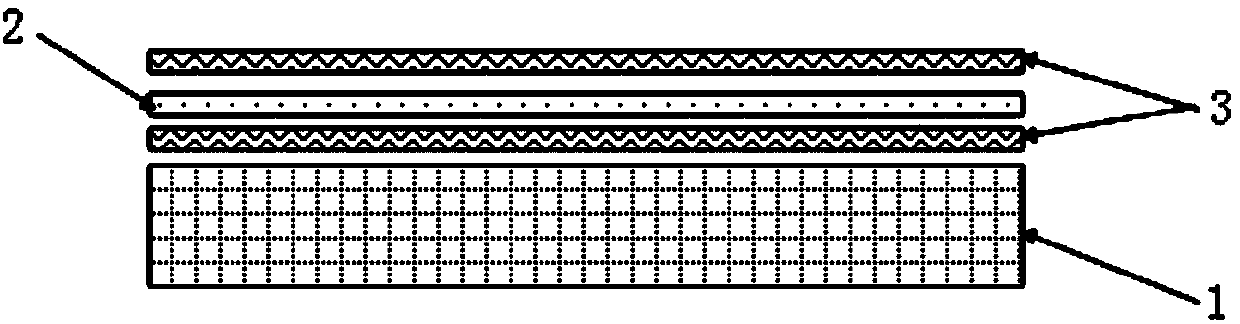

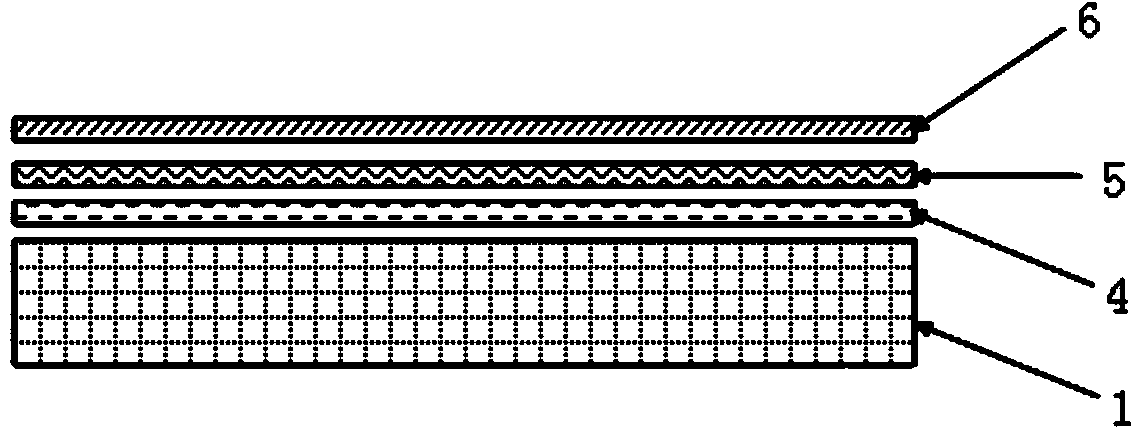

Anti-fracturing solid wood composite board and processing method thereof

InactiveCN104191470AWon't crackAvoid crackingSynthetic resin layered productsLaminationSolid woodFiber

The invention provides an anti-fracturing solid wood composite board and a processing method thereof. At least one non-impregnated fiber layer is arranged on a base material, the upper face and the lower face of the non-impregnated fiber layer are respectively provided with at least one impregnated layer, the non-impregnated fiber layer, the upper impregnated layer and the lower impregnated layer form an anti-fracturing fiber buffering layer, and the fiber buffering layer and the base material are composited in a hot-press mode to form the anti-fracturing solid wood composite board. The anti-fracturing solid wood composite board has the advantages that the fracturing phenomenon caused by different expansion factors is avoided, and surface resin can not fracture due to expansion or shrinkage of the base material; production cost is not increased, the processing method is simple and practical, and the anti-fracturing solid wood composite board can be suitable for industrial mass production.

Owner:濮亮

Method for manufacturing plastics hods special for building

InactiveCN101108905AGood aging resistanceImprove aging resistanceCans/barrels/drumsBuilding material handlingRebarUv absorber

The invention relates to a manufacture method of a plastic hod special for construction. The technical solution of the invention is that the polymer is weighed and is added with color mother materials (containing antioxidant and anti UV absorber) to stir uniformly with the detailed mixture ratios of polymer amount (98 to 99) per cent, color mother materials amount (1 to 2) per cent, and then is processed to the hod via an injection machine and is arranged with a carrying rope and a reinforcement handle. The hod suitable for invention and manufacture is free from fading and weathering when shining by sun and free from breaking when falling freely from 10m height.

Owner:YANCHENG XINGDA WAVE OSCILLATOR

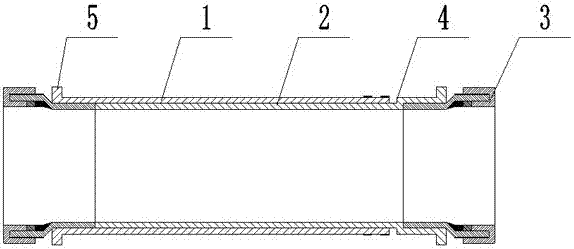

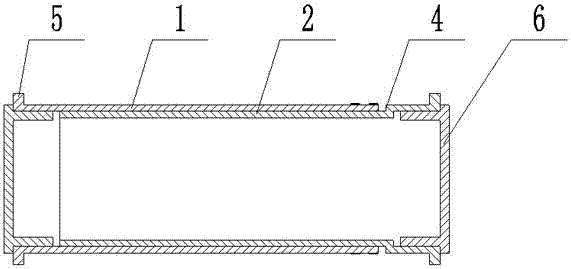

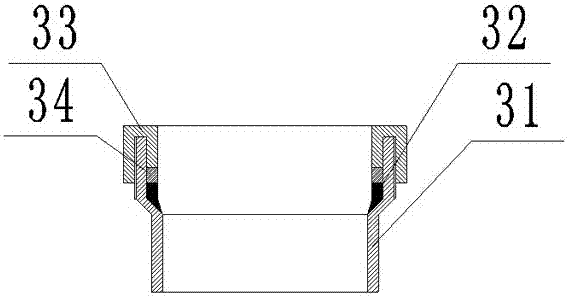

Wall bushing embedding device with extension function

The present invention overcomes the deficiencies of the prior art, and provides a pre-embedded device for the wall-piercing casing with a telescopic function, which prevents the phenomenon of cracking caused by the reserved holes in the wall, and at the same time plays the role of sealing the connecting pipe and making the wall beautiful; In order to solve the above-mentioned technical problems, the technical solution adopted in the present invention is: a pre-embedded device for wall-piercing casing with telescopic function, including an outer casing, an inner casing and a sealing module, the outer casing and the inner casing are both cylindrical structure, the outer sleeve is movably fitted on the inner sleeve, and a positioning boss is provided on the outside of one end of the inner sleeve, the outer sleeve and the inner sleeve cooperate to form a telescopic sleeve, and the sleeve The parts are pre-buried in the wall, and the two ends of the set are provided with sealing modules, and the sealing modules are used for positioning the plug-in external pipes and wires, and can seal the plug-in parts; the present invention can be widely used in The field of wall bushings.

Owner:SHANXI GAOYANG SANITARY SAME FLOOR INSTALLATION ENG

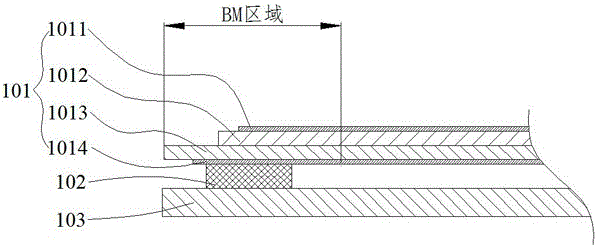

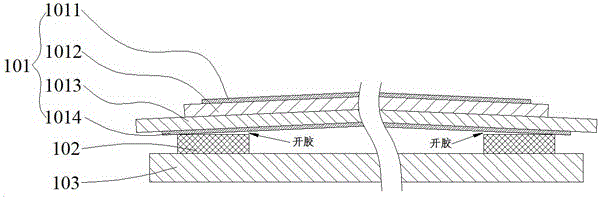

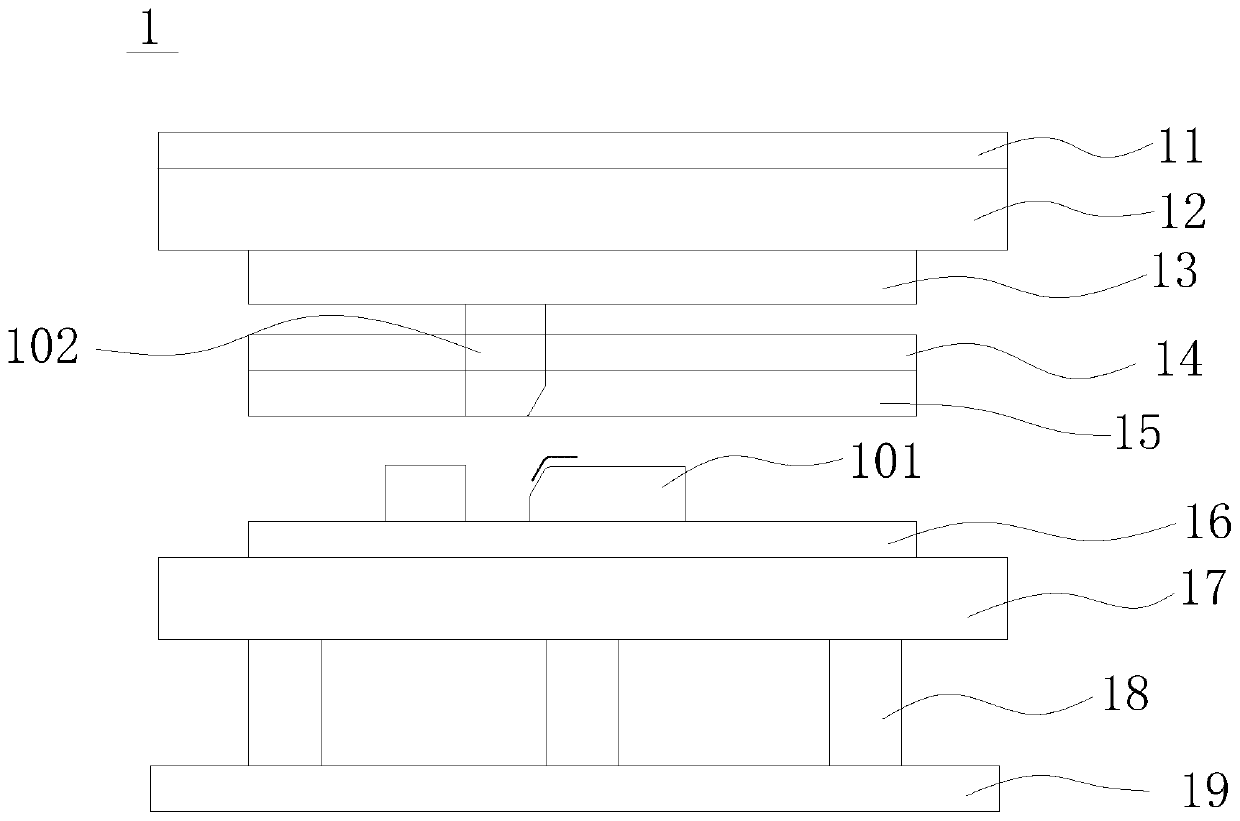

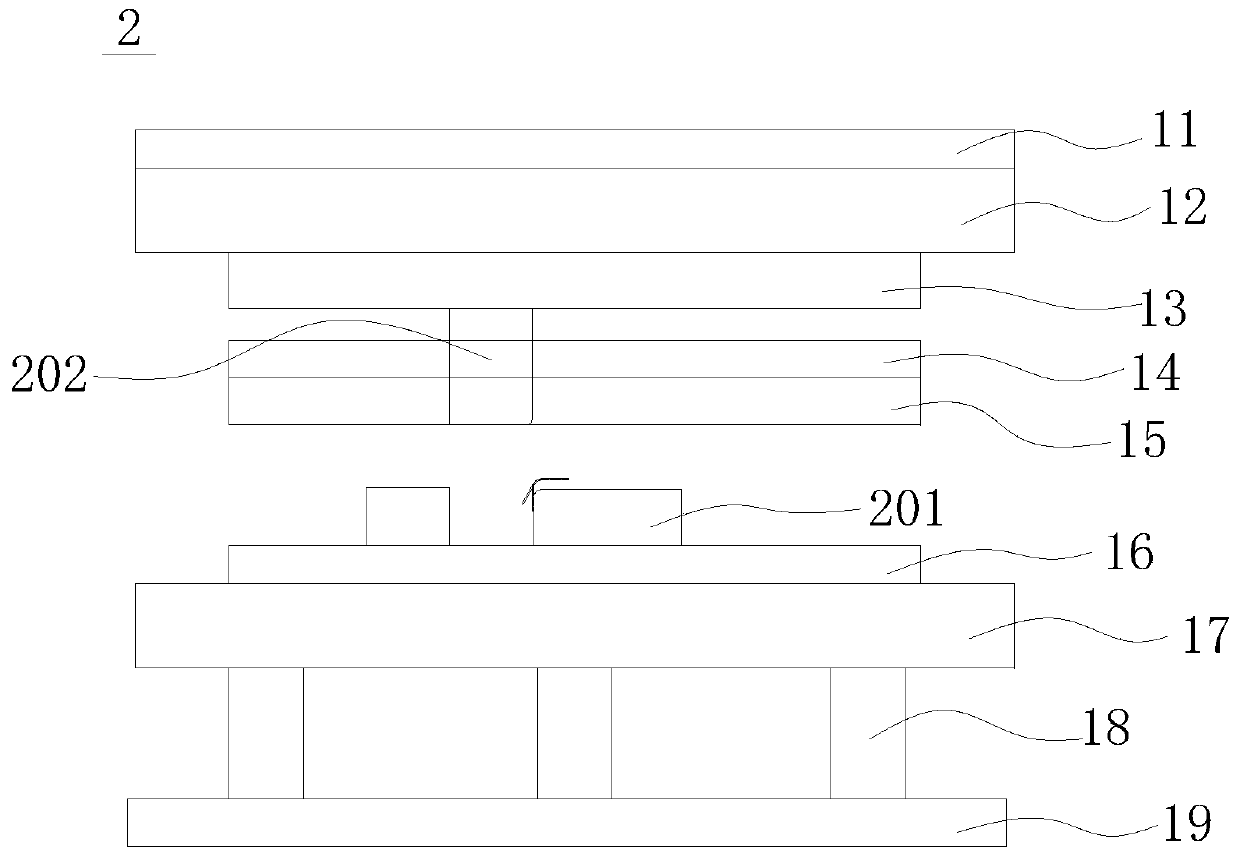

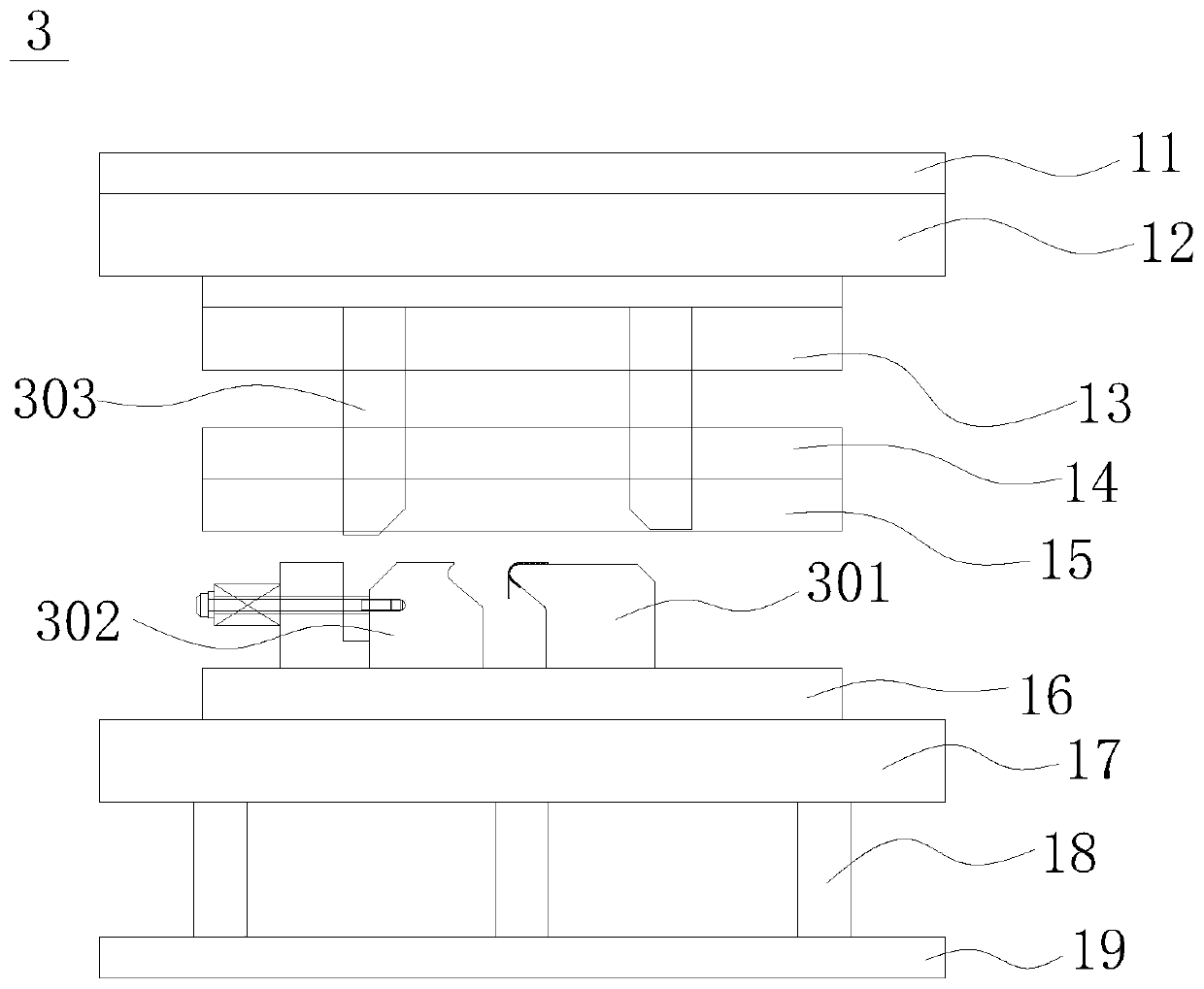

Liquid crystal display device

ActiveCN106292034ANo cracking phenomenonGuaranteed stabilityNon-linear opticsLiquid-crystal displayWorking temperature

The invention provides a liquid crystal display device which comprises a panel, an adhesive layer and an adhesive medium, wherein the panel comprises a glass layer and a lower polarizing film; the lower polarizing film is bonded and fixed to the lower surface of the glass layer; the surface area of the lower polarizing film is smaller than that of the glass layer; the adhesive layer is arranged on the lower surface of the glass layer along an outer contour edge of the lower polarizing film; the lower surface of the glass layer is fixedly bonded to the surface of the adhesion medium through the adhesive layer. For the fixation of the panel and the adhesive medium, the glass layer and the adhesive medium are fixedly bonded through the adhesive layer in the invention; when a working temperature of the liquid crystal display device changes, the deformation quantity generated by the glass layer under the change of temperature is insufficient to deform or crack the panel, so as to avoid the occurrence of panel cracking phenomenon due to excess deformation quantity of the lower polarizing film, to ensure the panel working stability, and to be beneficial to the frameless design of the liquid crystal display device.

Owner:HISENSE VISUAL TECH CO LTD

Cell preservation solution and method of cell preservation by using cell preservation solution

The invention discloses a cell preservation solution, which is characterized by comprising, by weight, the following materials: 15.00-35.00% of methanol, 0.20-0.35% of proclin300, 0.10-0.52% of EDTA,0.10-0.23% of NaCl, 53.20-68.70% of acetic acid, 2.30-25.0% of albumin, 0.10-1.00% of glucose, 0.5-0.9% of normal saline and 0.1-1% of chromium chloride. By using the method, the collected cells can be well preserved in practice, and the morphology, activity and structure features of the original cells can be kept completely without the phenomenon of autolysis or burst of the cells. In addition, the cell preservation solution is simple in composition, low in cost, simple in use and convenient to operate. The cell preservation solution is suitable for promotion and used.

Owner:合肥诺森医学检验有限公司

Conductive antiaging ABS (acrylonitrile-butadiene-styrene) composite plastic and preparation method thereof

The invention discloses a conductive antiaging ABS (acrylonitrile-butadiene-styrene) composite plastic and a preparation method thereof. The ABS composite plastic comprises the following components in parts by weight: an ABS resin, chlorinated polyether, ethylene-propylene monomer, nano titanium dioxide, carbon fibers, zinc sulfide powder, nano bismuth meal, carrageenin, acetic acid-cellulose butyrate, sodium diethylhexyl sulfosuccinate, a compatilizer, a coupling agent and an antiaging agent. The ABS composite plastic disclosed by the embodiment of the invention has the advantages of favorable conductivity, favorable aging resistance, high use safety and long service life, and has market application prospects.

Owner:合肥圆融新材料有限公司

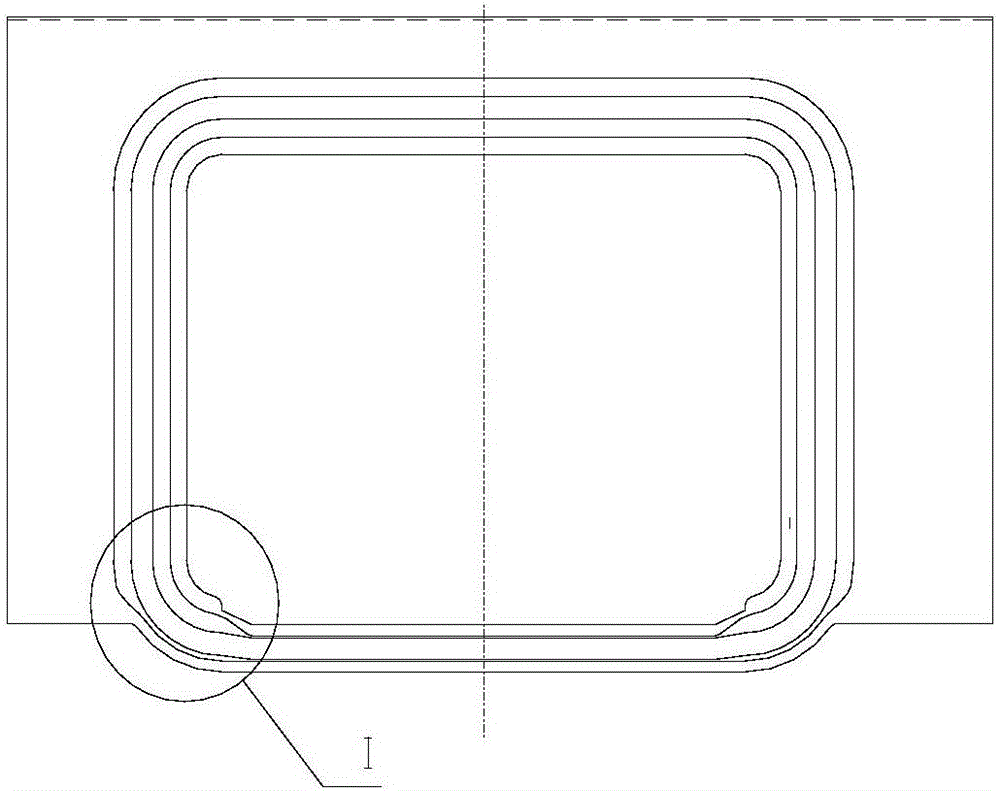

Notebook computer shell inward buckling and round wrapping forming method

ActiveCN111545616AImprove yield rateReduce economic lossShaping toolsMechanical engineeringIndustrial engineering

The invention belongs to the technical field of notebook computer shell equipment, and particularly relates to a notebook computer shell inward buckling and round wrapping forming method. Dies are included and each comprises an upper support plate, an upper die base, an upper clamping plate, a stop plate, an upper stripper plate, a lower cushion plate, a lower die base, lower foot pads and a lowersupport plate. The six dies are adopted and include the first die, the second die, the third die, the fourth die, the fifth die and the sixth die. The method comprises the first step, the second step, the third step, the fourth step, the fifth step and the sixth step. The notebook computer shell inward buckling and round wrapping forming method has the beneficial effects that the fact that a goodinward buckling and round wrapping method is not formed in the prior art is filled up; in addition, through mutual cooperation of the multiple dies in the notebook computer shell inward buckling andround wrapping forming method, notebook computer shell inward buckling and round wrapping are conducted step by step, the phenomenon of product cracking cannot happen to notebook computer shells in the round wrapping and inward buckling process through the multiple steps, the yield of the notebook computer shells is effectively improved, and economic losses of enterprises are reduced.

Owner:广德竹昌电子科技有限公司

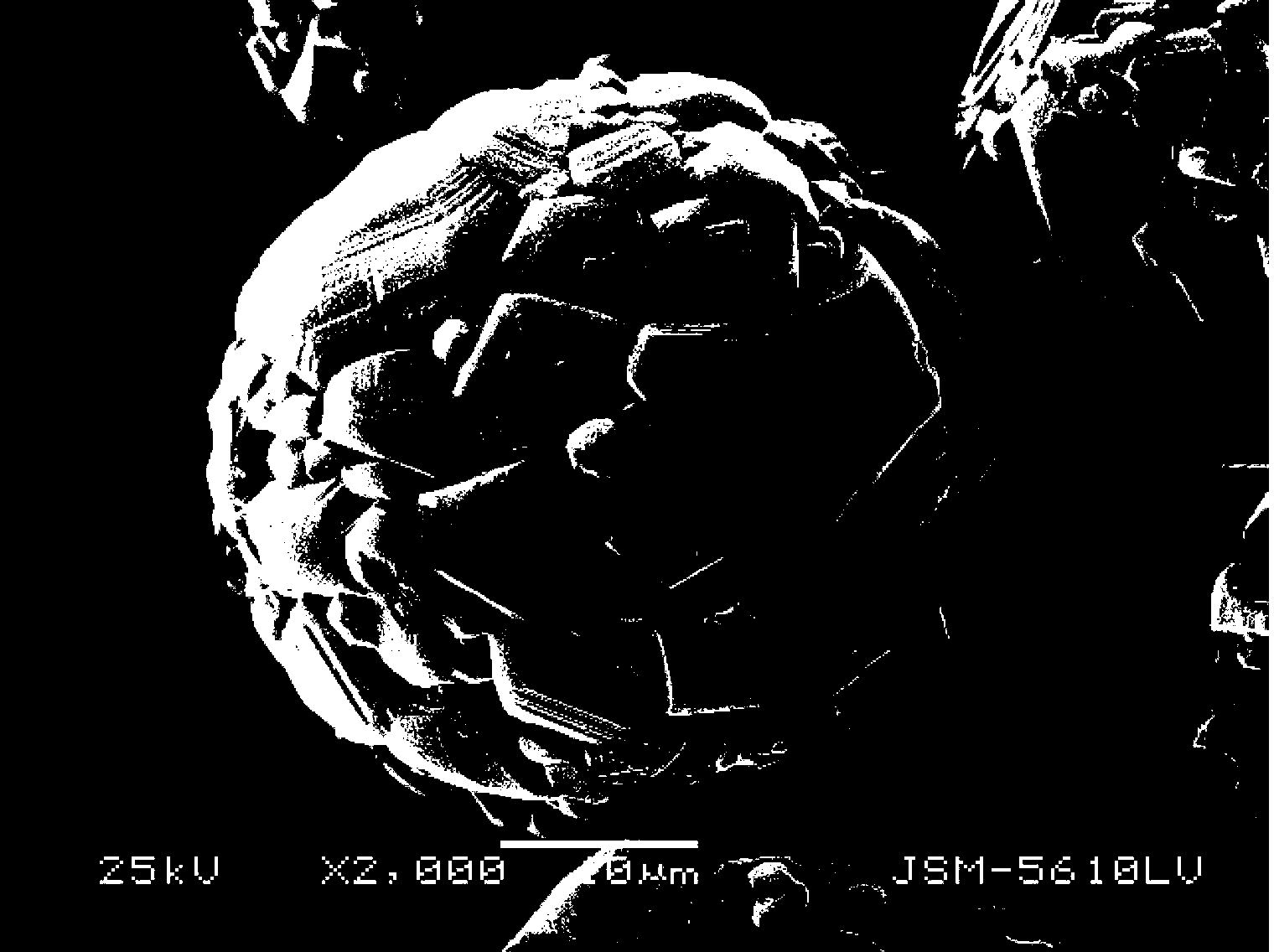

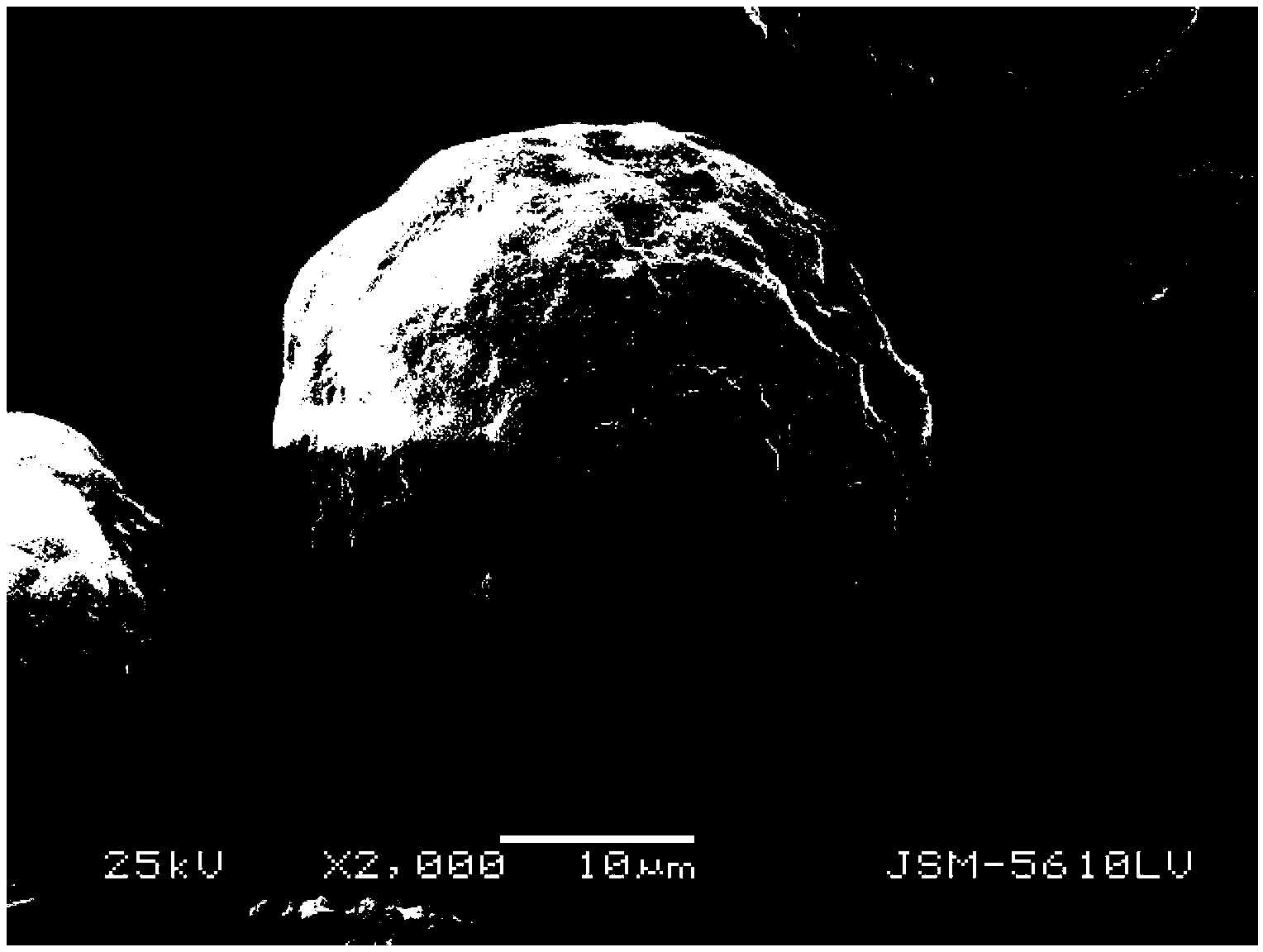

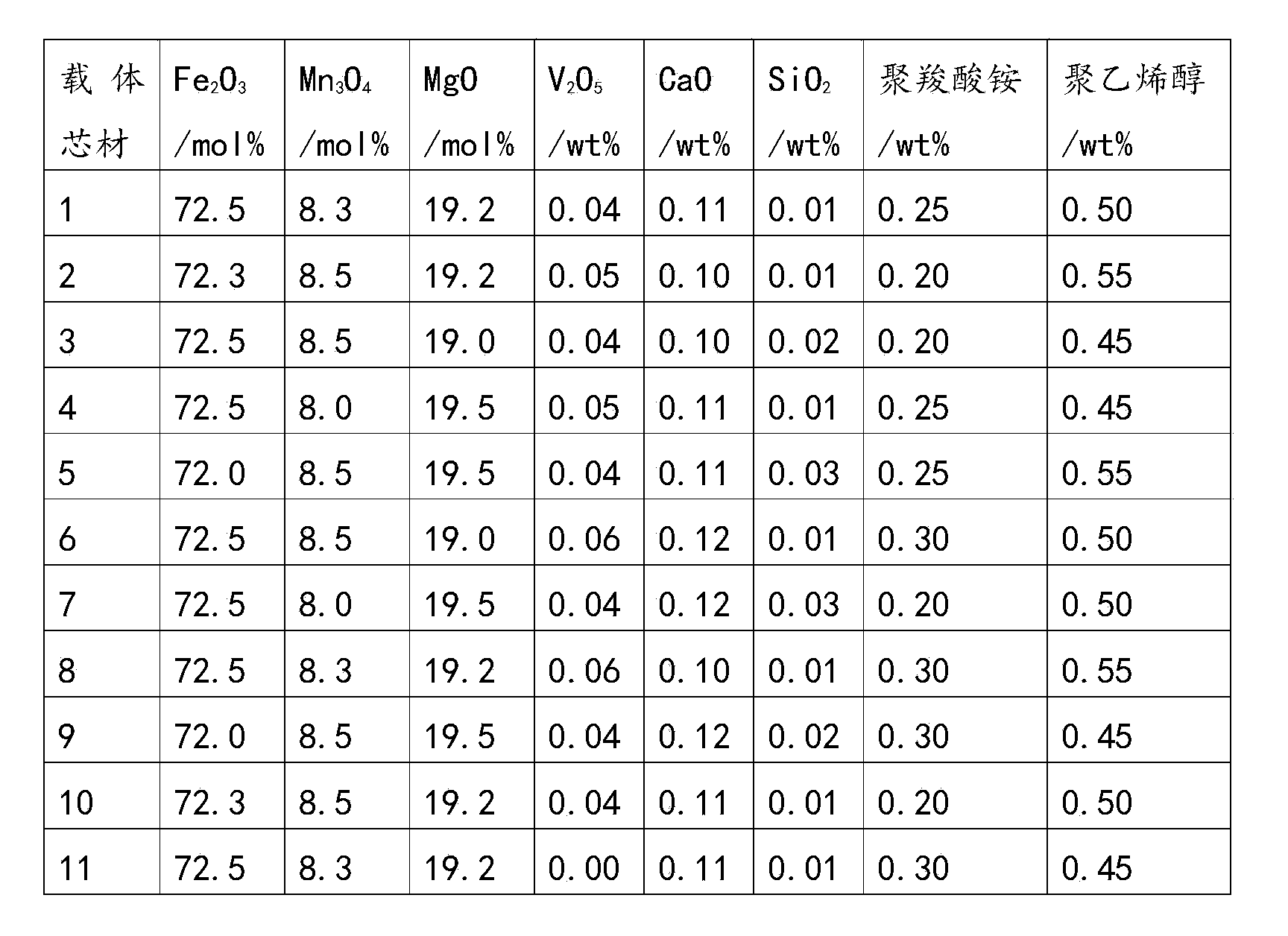

Carrier core material and manufacturing method thereof, carrier and electrostatic charge image developing agent

The invention relates to a carrier core material and a manufacturing method of the carrier core material, a carrier and an electrostatic charge image developing agent. The carrier core material comprises the following main components and auxiliary components, wherein the main components comprise 72.0-72.5 mol% of Fe2O3, 8.0-8.5mol% of Mn3O4, and 19.0-19.5mol% of MgO; the additive amounts of the auxiliary components are as follows (by weight percent of the main components): 0.04-0.06wt% of V2O5, 0.10-0.12 wt% of CaO, and 0.01-0.03wt% of SiO2. A carrier particle containing the carrier core provided by the invention has good mobility, the electric quantity of a color matching agent is stable, a fracture phenomenon and fragments are not generated for long time use, the developing agent is used for an image forming device and can control the degradation of image quality.

Owner:HUBEI DINGLONG CO LTD

Manufacturing method of flyback transformer

InactiveCN103779057BImprove the ability to withstand pressure agingIncrease productivityTransformersInductancesKnot tyingCopper wire

The invention discloses a manufacturing method of a flyback transformer. The manufacturing method comprises steps as follows: (1), the winding number of coils is set; (2), a to-be-wound primary magnetic bar is fixed on a jig; (3), a wire head with required length by a product is reserved; (4), the wire head winds tightly along the edge of the jig for one circle counterclockwise, and a wire tail presses the wire head which winds for one circle in a 1 / 2 position of a reverse side of the magnetic bar, is parallelly attached to the first circle of copper wire which finishes winding, and is fixed; (5), the wire head is perpendicularly guided out to the tail end of the magnetic bar along the surface of the magnetic bar and is fixed, and equipment is started for winding; (6), the wire tail is tightly attached to the tail end of a winding, a knot is tied in a cross manner, and the wire tail is cut off according to the required length after winding to form a semi-finished product for standby application; (7), during later process production, the knot tied on the primary magnetic bar is untied in the direction opposite to the tying direction, and the wire head or the wire tail is connected to the corresponding position according to requirements of a product; and (8), potting is performed. With the adoption of the manufacturing technology, the voltage withstanding property and the anti-ageing property of the product are improved, the production efficiency is high, and the service life of the product is prolonged remarkably.

Owner:佛山市顺德区铭派电子有限公司

Machining method for large high-strength stamping part with inner hole

The invention relates to a machining method for a large high-strength stamping part with an inner hole. According to the specific method, sample putting and spreading, blank part size determining, blank part cutting, stamping, inner hole cutting, external straight side shearing, external curve side cutting and leveling are sequentially carried out according to the material performance, the plate thickness, the part shape, the size and related technical requirements of the large high-strength stamping part with the inner hole. Thus, the machining method has the following beneficial effects that equipment with the cut fracture surface quality being relatively high is adopted to machine the size of the inner hole and the size of an outer hole of a stamped blank part, and it can be ensured that no pull crack phenomenon or an extremely small number of pull crack phenomena of the part appear during profiling; and by means of the machining manners of manufacturing an explorator for manual cutting and manufacturing a shearing sample plate for shearing a straight side, the cost of manufacturing a large number of dies can be saved, the die manufacturing time and the die testing and repairing time can be saved, the production cost can be greatly reduced, and timeliness of production is guaranteed.

Owner:CRRC YANGTZE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com