Carrier core material and manufacturing method thereof, carrier and electrostatic charge image developing agent

A technology of electrostatic charge image and carrier core material, which is applied in developer, electrography, optics, etc., can solve the problems of insufficient mechanical strength of carrier core material particles, difficulty in obtaining long-term stable images, and cracking of carrier particles, etc. Stability balance, stable image quality, and the effect of promoting grain growth

Active Publication Date: 2013-10-23

HUBEI DINGLONG CO LTD

View PDF7 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0006] Although the resin-coated carriers disclosed in the above-mentioned patents all realize the low density of the carrier core material, due to the hollow structure, the mechanical strength of the carrier core material particles is insufficient, and the carrier core material is in the process of resin coating, and the carrier and When the toner is stirred in the developing chamber for a long time, the carrier particles are prone to breakage and fragmentation, resulting in changes in the fluidity of the carrier particles and the charge amount imparted by the carrier to the toner, making it difficult to obtain long-term stable images

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

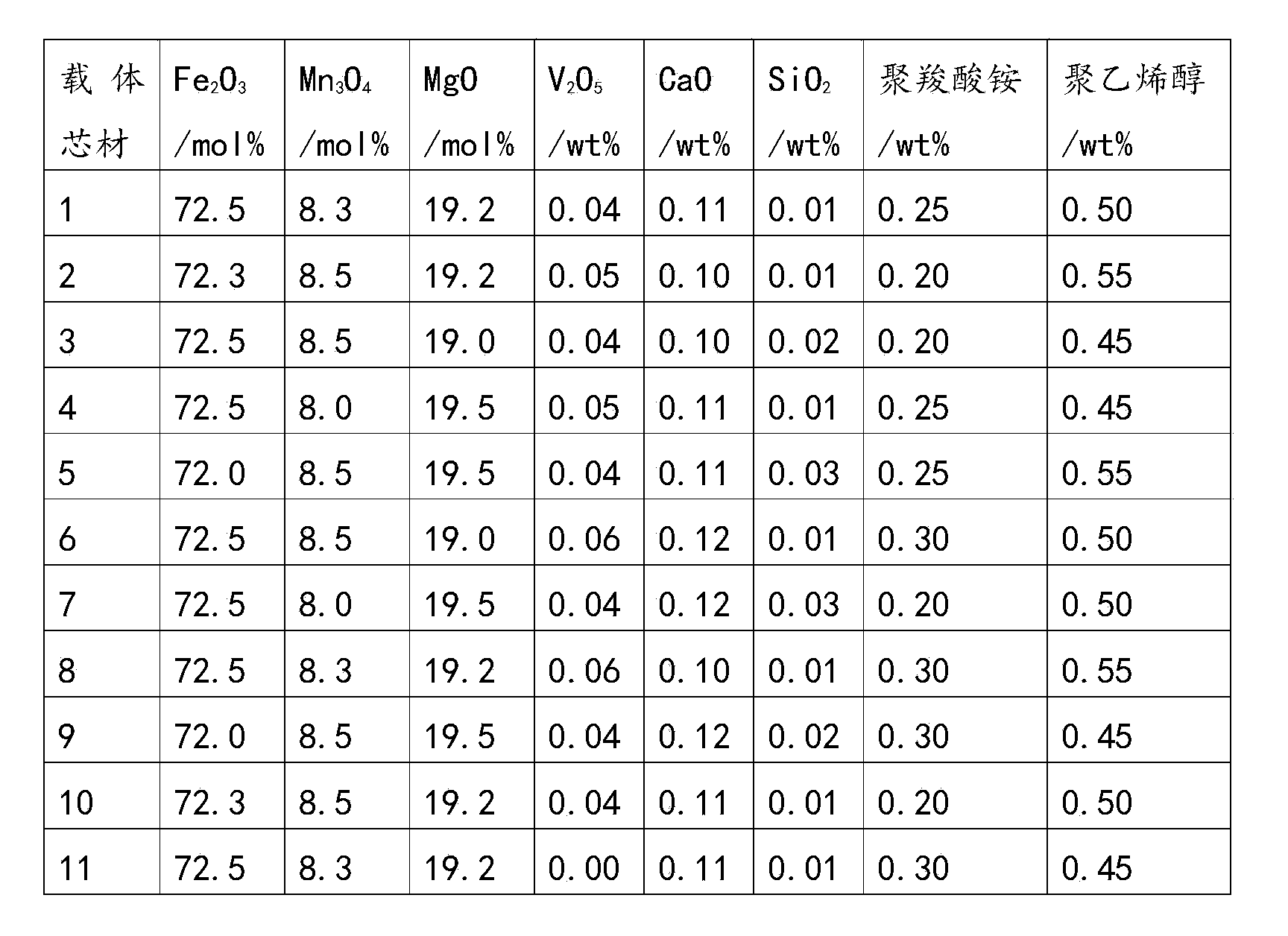

Embodiment 1~13

[0108] The above-mentioned "resin-coated carriers 1-13" and "toner" were mixed in the following manner to prepare the two-component "developers 1-13" of the example. 92 parts of carrier and 8 parts of toner were mixed in a mixer for 10 minutes to prepare a two-component developer; at the same time, 95 parts of toner and 5 parts of carrier were mixed to prepare a supplementary developer.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

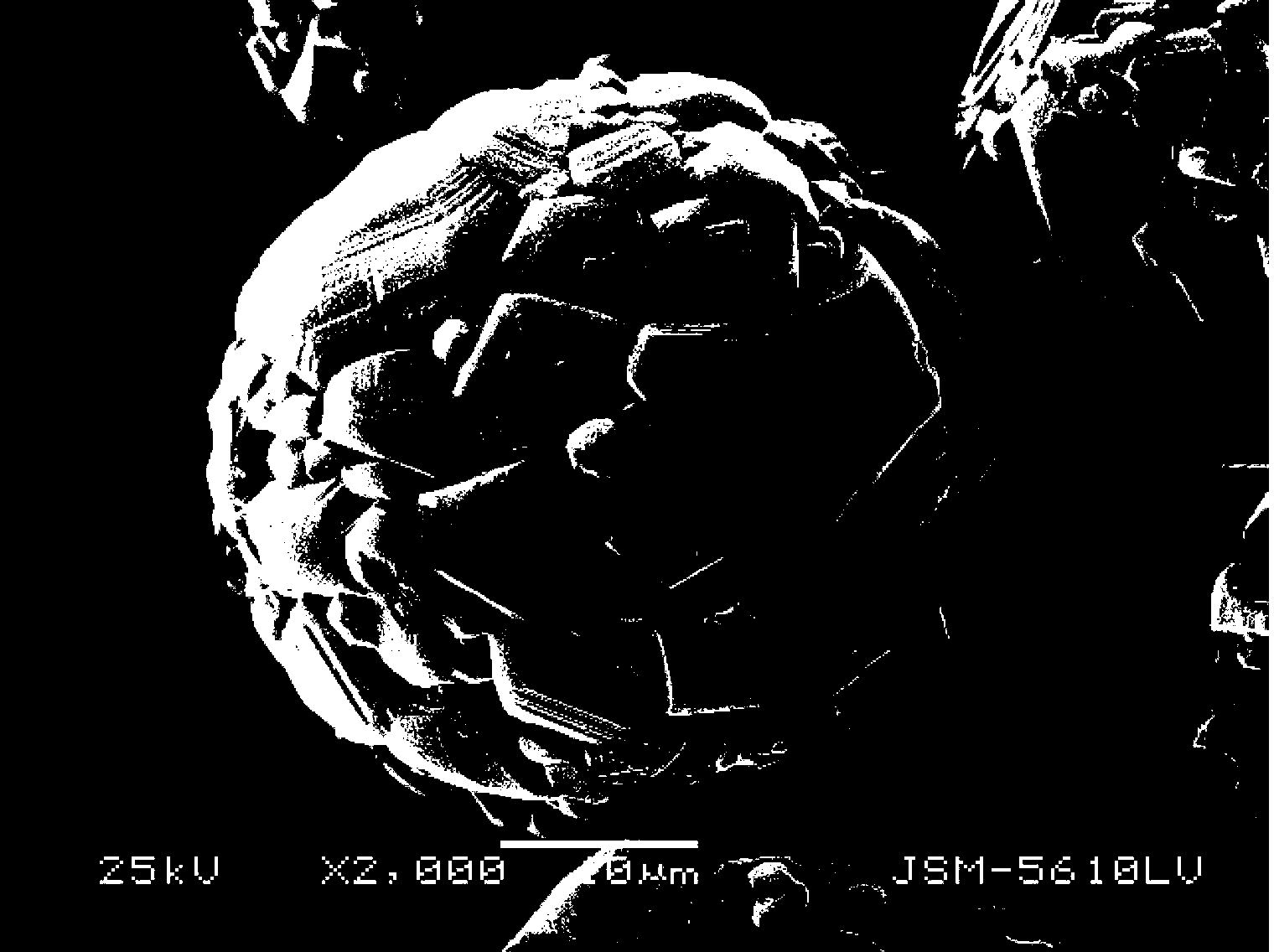

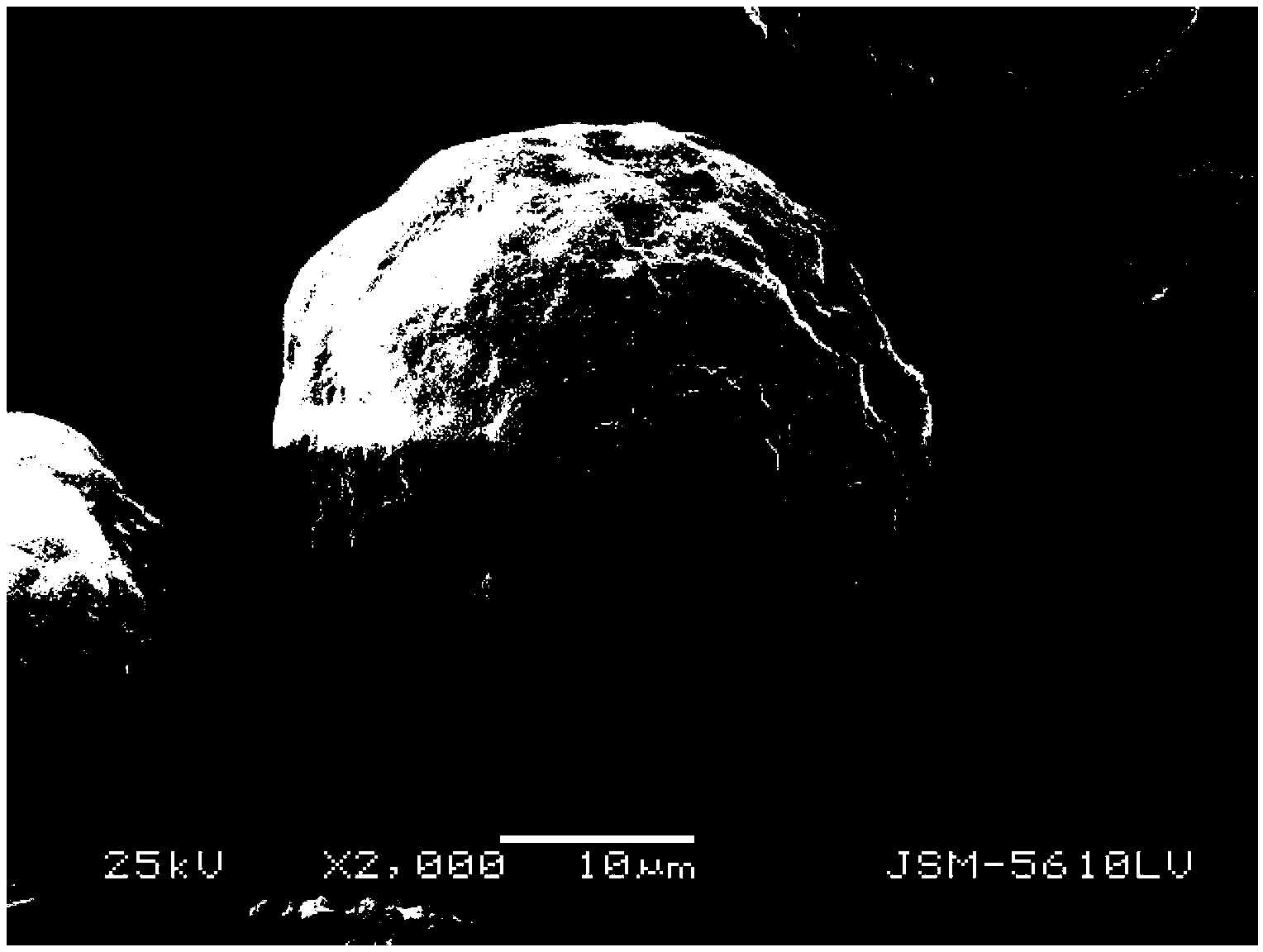

The invention relates to a carrier core material and a manufacturing method of the carrier core material, a carrier and an electrostatic charge image developing agent. The carrier core material comprises the following main components and auxiliary components, wherein the main components comprise 72.0-72.5 mol% of Fe2O3, 8.0-8.5mol% of Mn3O4, and 19.0-19.5mol% of MgO; the additive amounts of the auxiliary components are as follows (by weight percent of the main components): 0.04-0.06wt% of V2O5, 0.10-0.12 wt% of CaO, and 0.01-0.03wt% of SiO2. A carrier particle containing the carrier core provided by the invention has good mobility, the electric quantity of a color matching agent is stable, a fracture phenomenon and fragments are not generated for long time use, the developing agent is used for an image forming device and can control the degradation of image quality.

Description

technical field [0001] The invention relates to the field of manufacturing an electrostatic charge image developer, in particular to a carrier core material for an electrostatic charge image developer and a manufacturing method thereof, a carrier containing the carrier core material, and an electrostatic charge containing the carrier core material. image developer. Background technique [0002] In recent years, with the automation of office equipment and the popularization of image forming devices such as high-speed printers, copiers, and multi-function machines that use electrostatic charge image forming methods, the market has demanded high image quality, long life of developers, and devices. The requirements for high speed and miniaturization are also getting higher and higher. As the image-forming developer corresponding to the image forming apparatus, a one-component developer composed of only toner or a two-component developer composed of carrier and toner can be used...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G03G9/107G03G9/10G03G9/113

Inventor 黎文部朱双全

Owner HUBEI DINGLONG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com