Electroplating Fe-Ni alloy magnetic shielding material and preparation method thereof

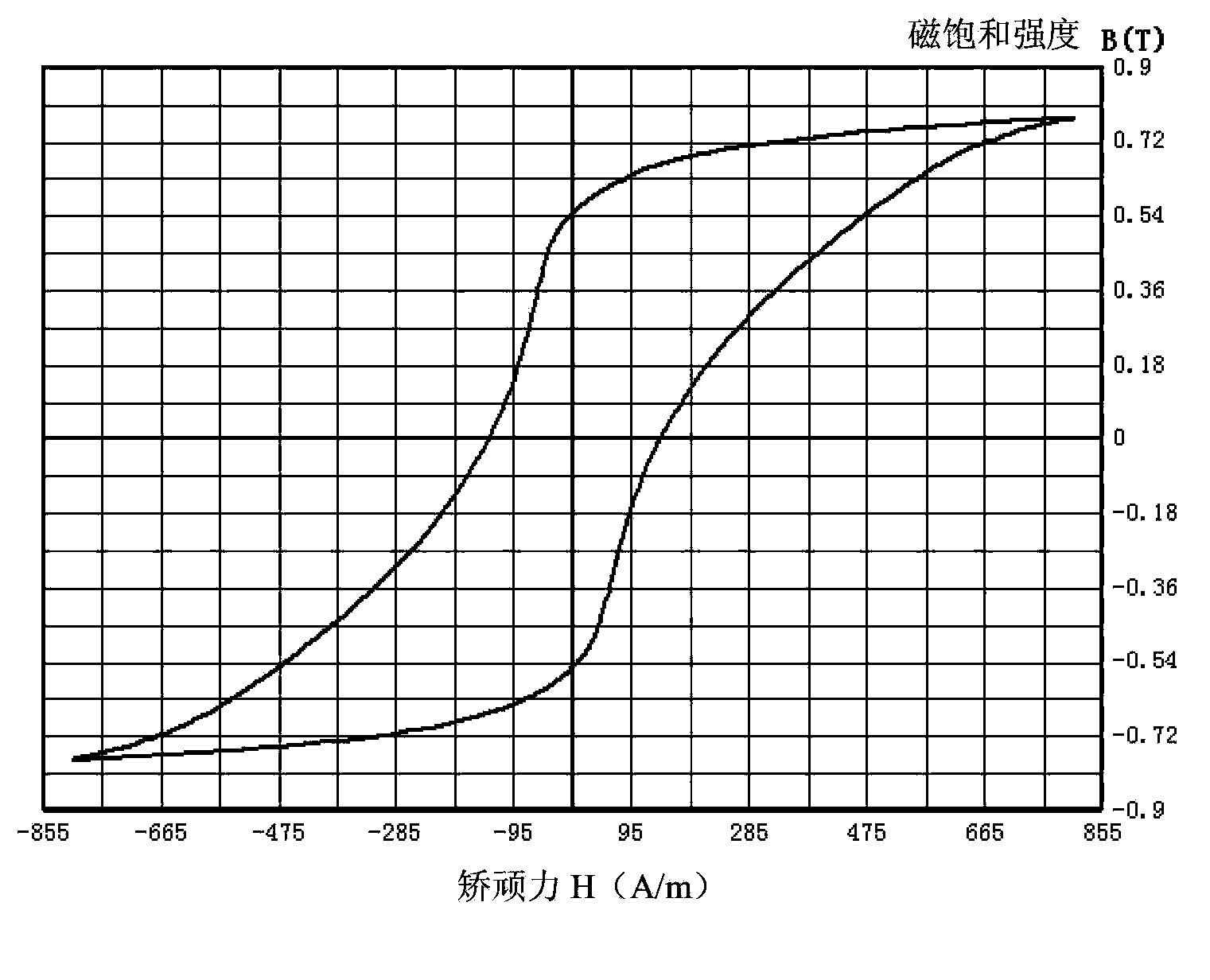

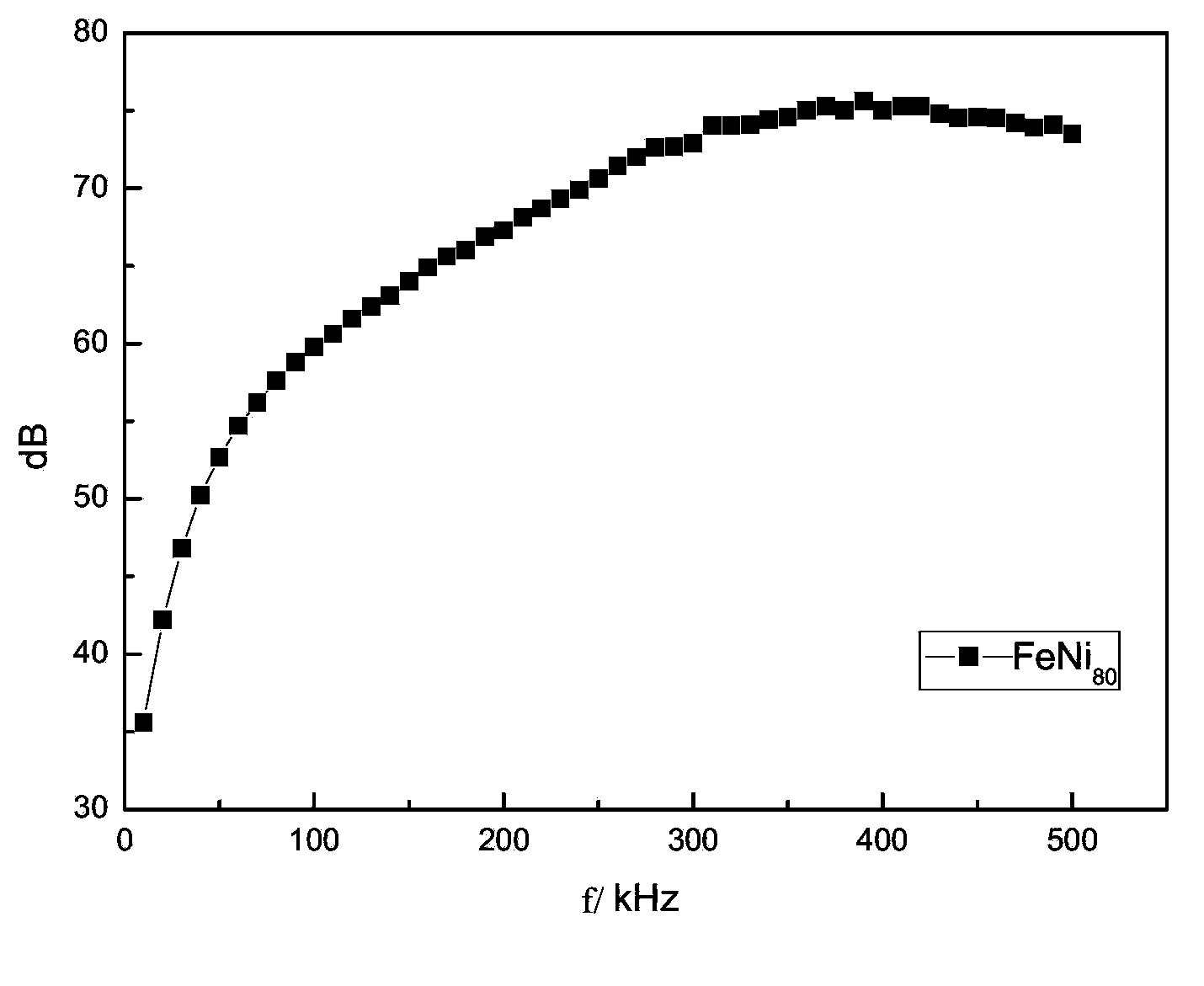

A magnetic shielding material, fe-ni technology, applied in the field of electroplating Fe-Ni alloy magnetic shielding material and its preparation, can solve the problems of reduced shielding efficiency, weak antimagnetic saturation ability, and reduced material magnetic shielding performance, and achieves low residual Magnetization and coercivity, effect of high saturation magnetization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Plating FeNi 80 Alloy plating, using copper foil (0.3mm thick) substrate.

[0029] The process route is: degreasing - water washing - pickling - water washing - primary zinc dipping solution - water washing - pickling - water washing - secondary zinc dipping - water washing - electroplating FeNi 80 Alloy Plating - Washable. The oil removal in this process route is alkaline oil removal, and 50% HNO is used for pickling 3 solution, the corresponding process conditions are carried out according to the existing process.

[0030] The electroplating solution ratio for electroplating Fe-Ni alloy coating is as follows: nickel sulfate 200g / L, ferrous sulfate 20g / L, sodium chloride 30g / L, boric acid 40g / L, sodium citrate 20g / L, saccharin 3g / L, Sodium benzenesulfinate 0.3g / L, sodium dodecylbenzenesulfonate 0.1g / L. The cathode is copper foil (0.3 mm thick), and the anode is a nickel-iron alloy with a weight ratio of nickel and iron of 6:1. Constant voltage electrodeposition is...

Embodiment 2

[0033] Plating FeNi 50 Alloy plating, copper foil (0.3mm thick) substrate

[0034] Process route: degreasing - water washing - pickling - water washing - primary zinc immersion - water washing - pickling - water washing - secondary zinc immersion - water washing - electroplating Fe-Ni alloy coating - water washing. The oil removal in this process route is alkaline oil removal, and 50% HNO is used for pickling 3 solution, the corresponding process conditions are carried out according to the existing process.

[0035] The electroplating solution proportion of electroplating Fe-Ni alloy coating is as follows: nickel sulfate 60g / L (electroplating FeNi 50 ), ferrous sulfate 20g / L, sodium chloride 30g / L, boric acid 40g / L, sodium citrate 20g / L, saccharin 3g / L, sodium benzenesulfinate 0.3g / L, dodecylbenzenesulfonic acid Sodium 0.1g / L. The cathode is copper foil (0.3 mm thick), and the anode is a nickel-iron alloy with a nickel-iron ratio of 6:1. Using constant voltage electrodepo...

Embodiment 3

[0038] Plating FeNi 50 / FeNi 80 Double-layer alloy coating, aluminum alloy substrate

[0039] Process route: degreasing-water washing-alkali-pickling-water washing-primary zinc dipping solution-water washing-pickling-water washing-secondary zinc dipping-water washing-electroless nickel plating-FeNi electroplating 80 Alloy coating - washing - heat treatment - degreasing - washing - copper plating - FeNi plating 50 Alloy Plating - Washable.

[0040] In the above-mentioned route, lye is caustic alkali, removes the oxide (Al 2 o 3 ). The treatment time should not be too long, otherwise it is easy to dissolve the surface of the aluminum substrate; pickling uses 50% HNO 3 Solution, electroless nickel plating is to put the aluminum alloy substrate into the nickel plating solution at 80 ℃ for 30 minutes, so that the surface is uniformly plated with a layer of nickel. The electroplating solution ratio of the electroplating Fe-Ni alloy coating is as follows: Nickel sulfate 200g / L...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com