Patents

Literature

256 results about "Residual magnetization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

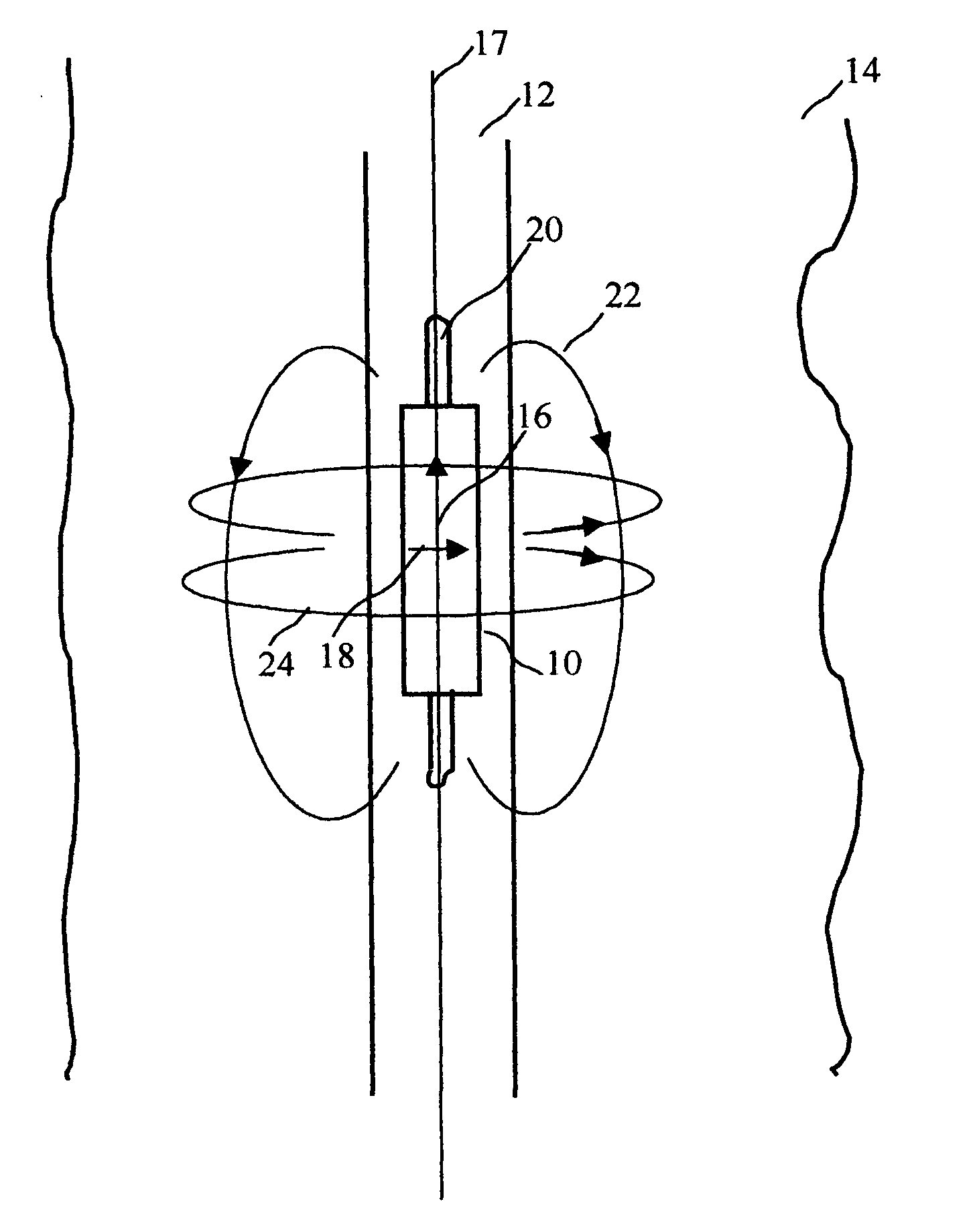

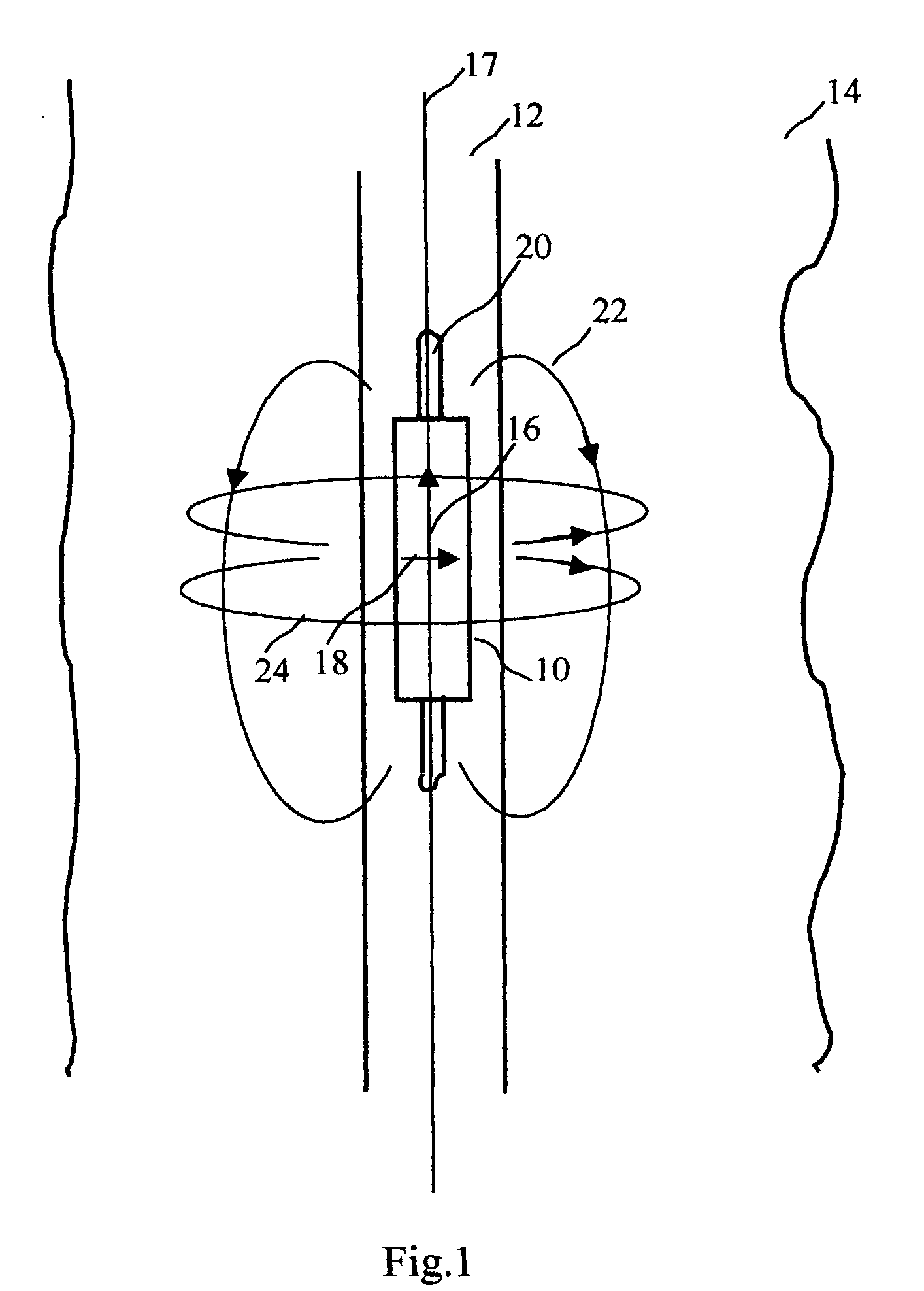

Method and apparatus of using magnetic material with residual magnetization in transient electromagnetic measurement

ActiveUS20050189945A1Facilitates highly effective generationQuick switchElectric/magnetic detection for well-loggingAcoustic wave reradiationWell loggingTransmitter antenna

Owner:BAKER HUGHES INC

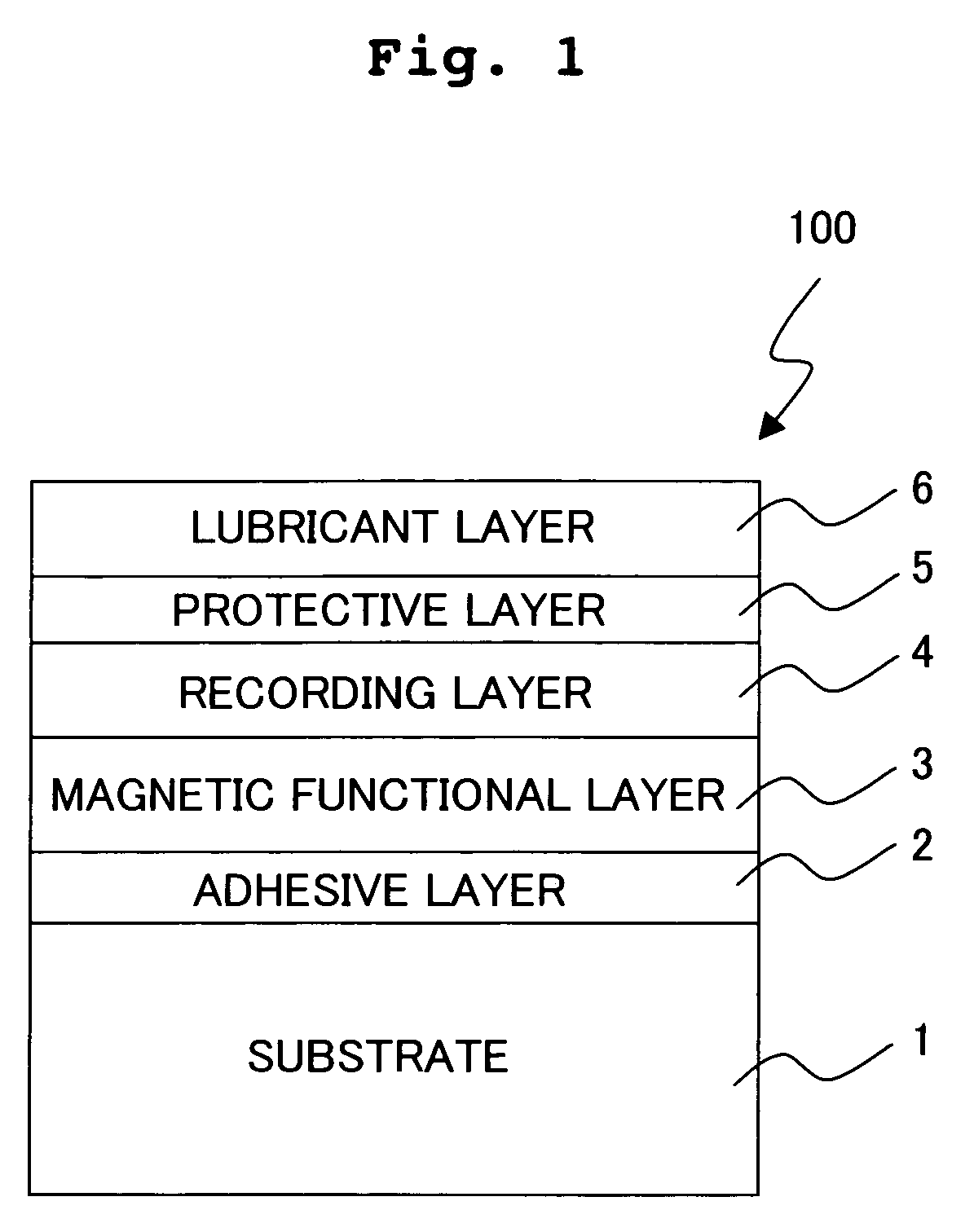

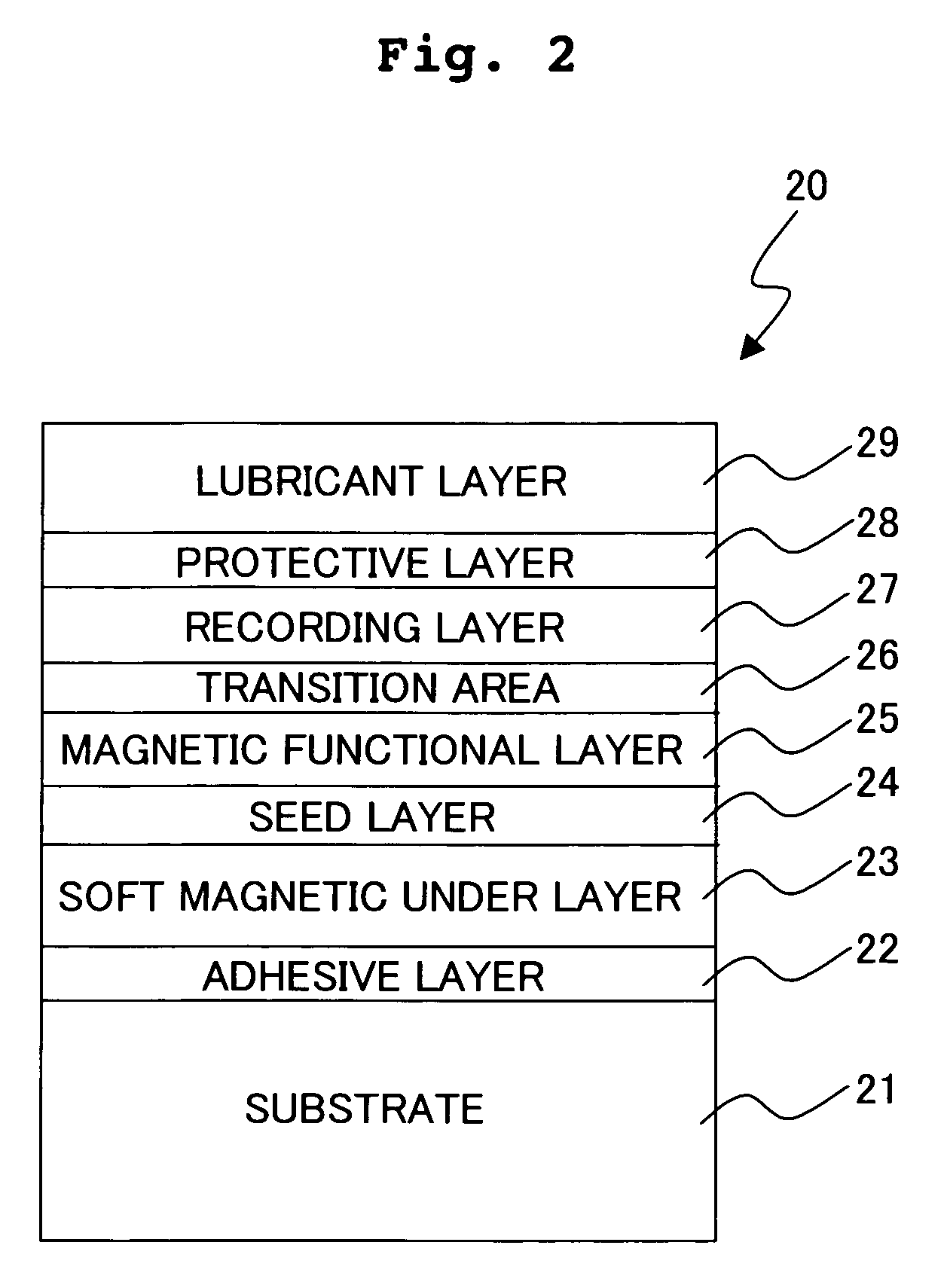

Magnetic disk and magnetic disk manufacturing method

InactiveUS7993497B2Magnetic materials for record carriersVacuum evaporation coatingMagnetic anisotropyGroup element

In a magnetic disk having at least a glass substrate, a plurality of underlayers formed over the glass substrate, and a magnetic layer formed over the plurality of underlayers, at least one of the underlayers is an amorphous underlayer containing a VIa group element and carbon and, given that the remanent magnetization in a circumferential direction of the disk is Mrc and the remanent magnetization in a radial direction of the disk is Mrr, the magnetic disk has a magnetic anisotropy in which Mrc / Mrr being a ratio between Mrc and Mrr exceeds 1.

Owner:WD MEDIA SINGAPORE PTE

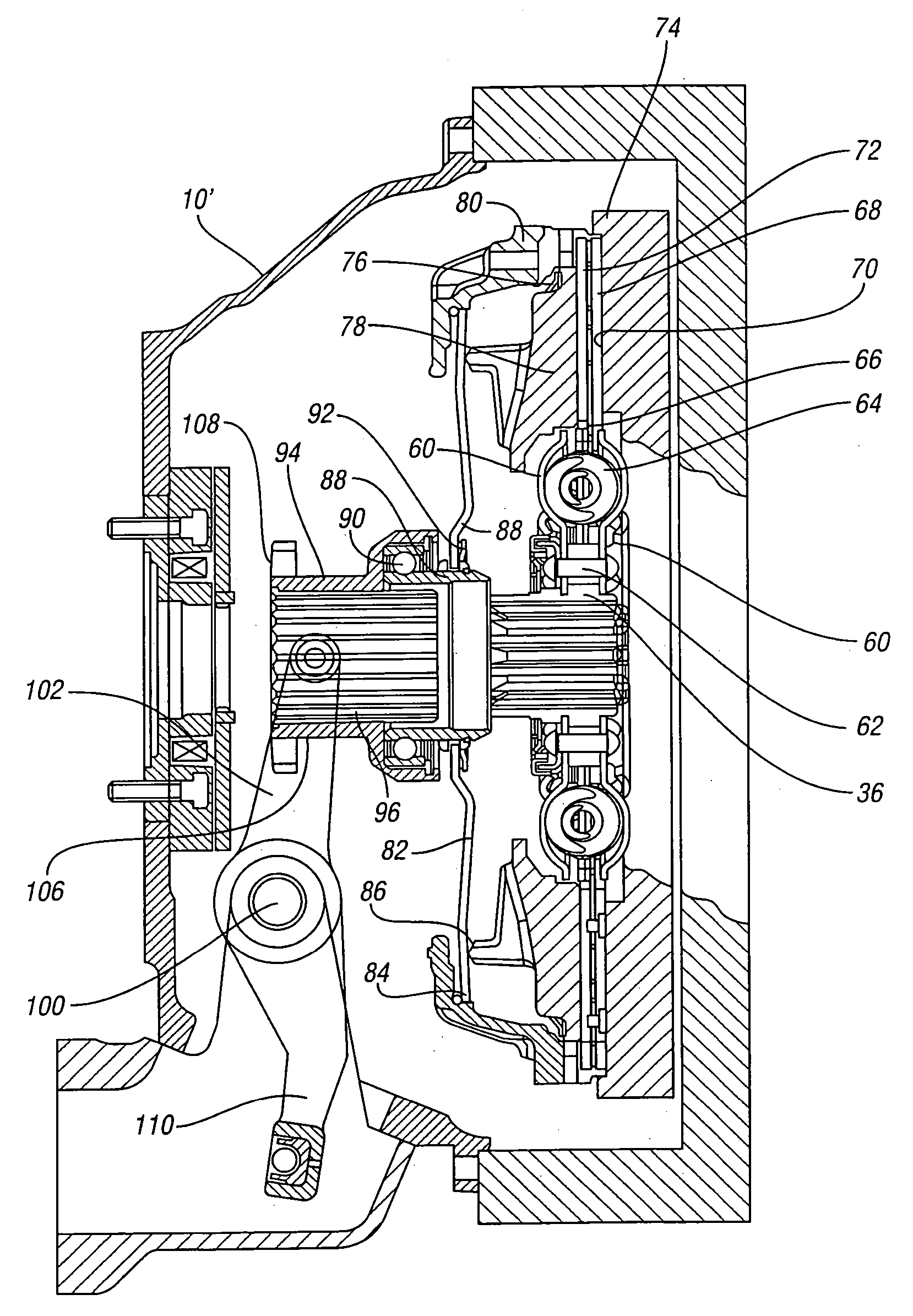

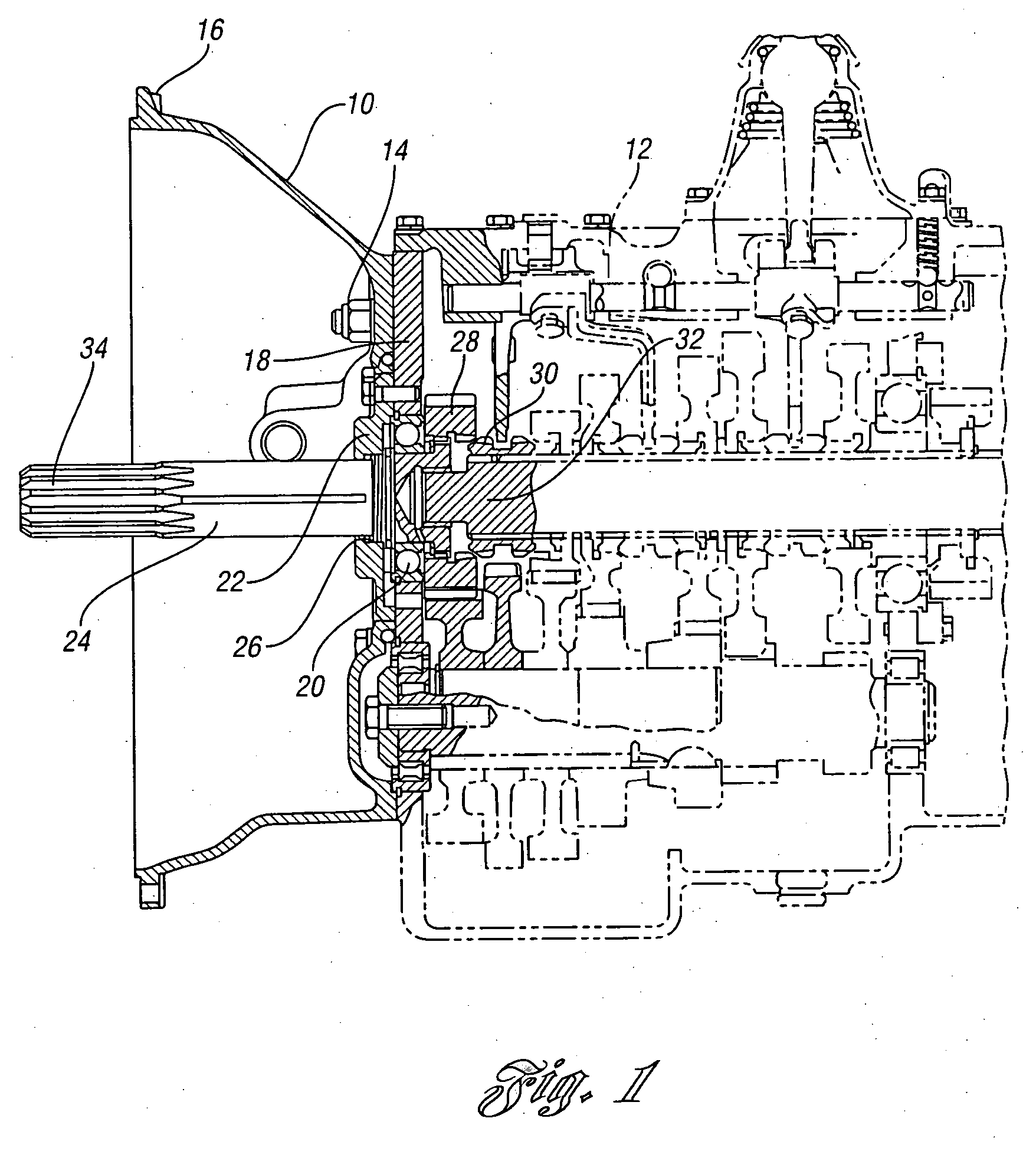

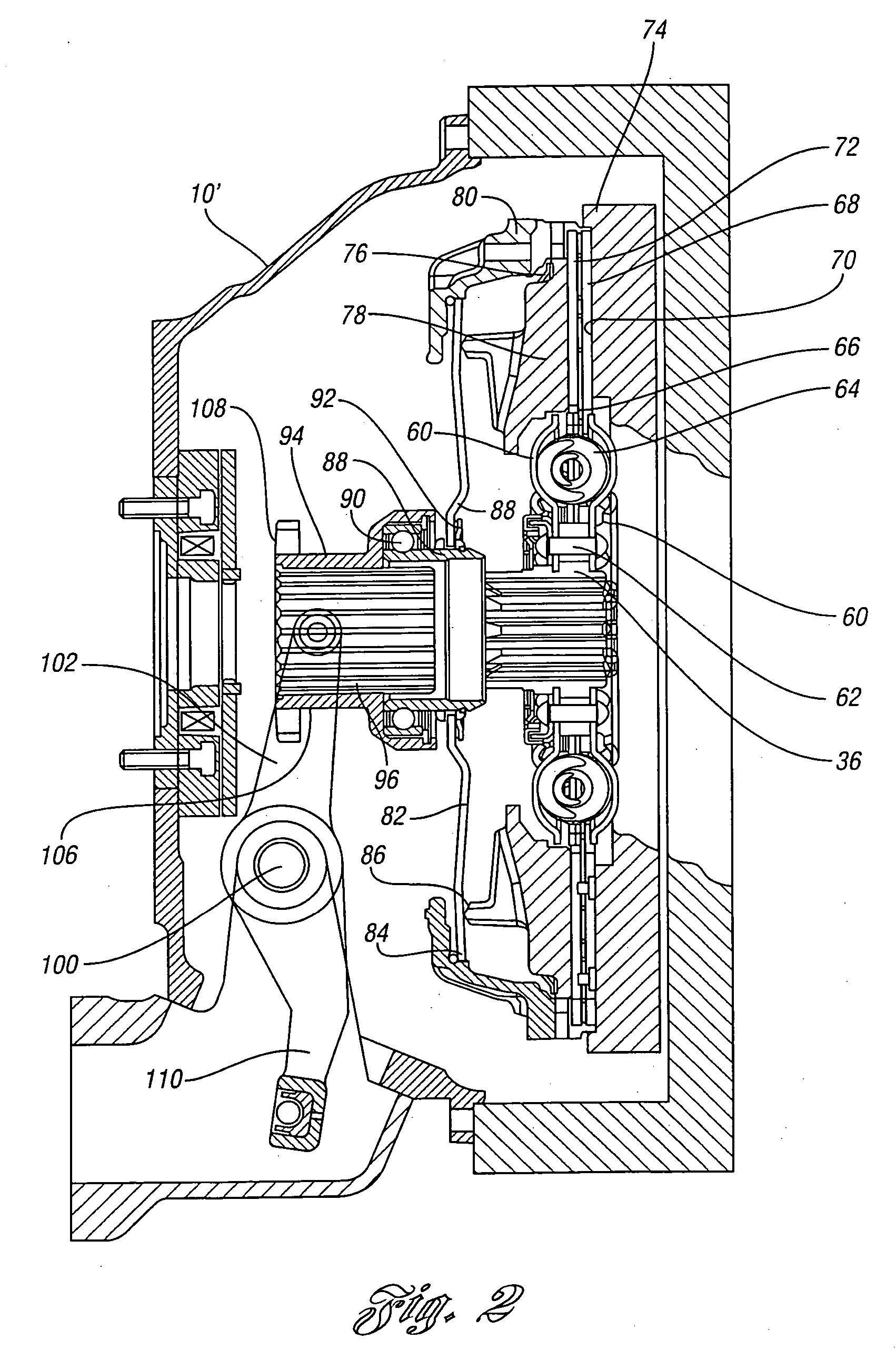

Electromagnetic brake for a multiple-ratio power transmission in a vehicle powertrain

InactiveUS20050217966A1Reduce the cross-sectional areaLimited amountBraking element arrangementsToothed gearingsActuatorControl theory

An electromagnetic brake, including an electromagnetic brake actuator coil surrounding a power input shaft for a multiple-ratio transmission in a vehicle powertrain, is disclosed. An electromagnetic flux flow path for the actuator coil is electromagnetically isolated from the power input shaft and other elements of the powertrain thereby avoiding residual magnetization.

Owner:EATON INTELLIGENT POWER LIMITED

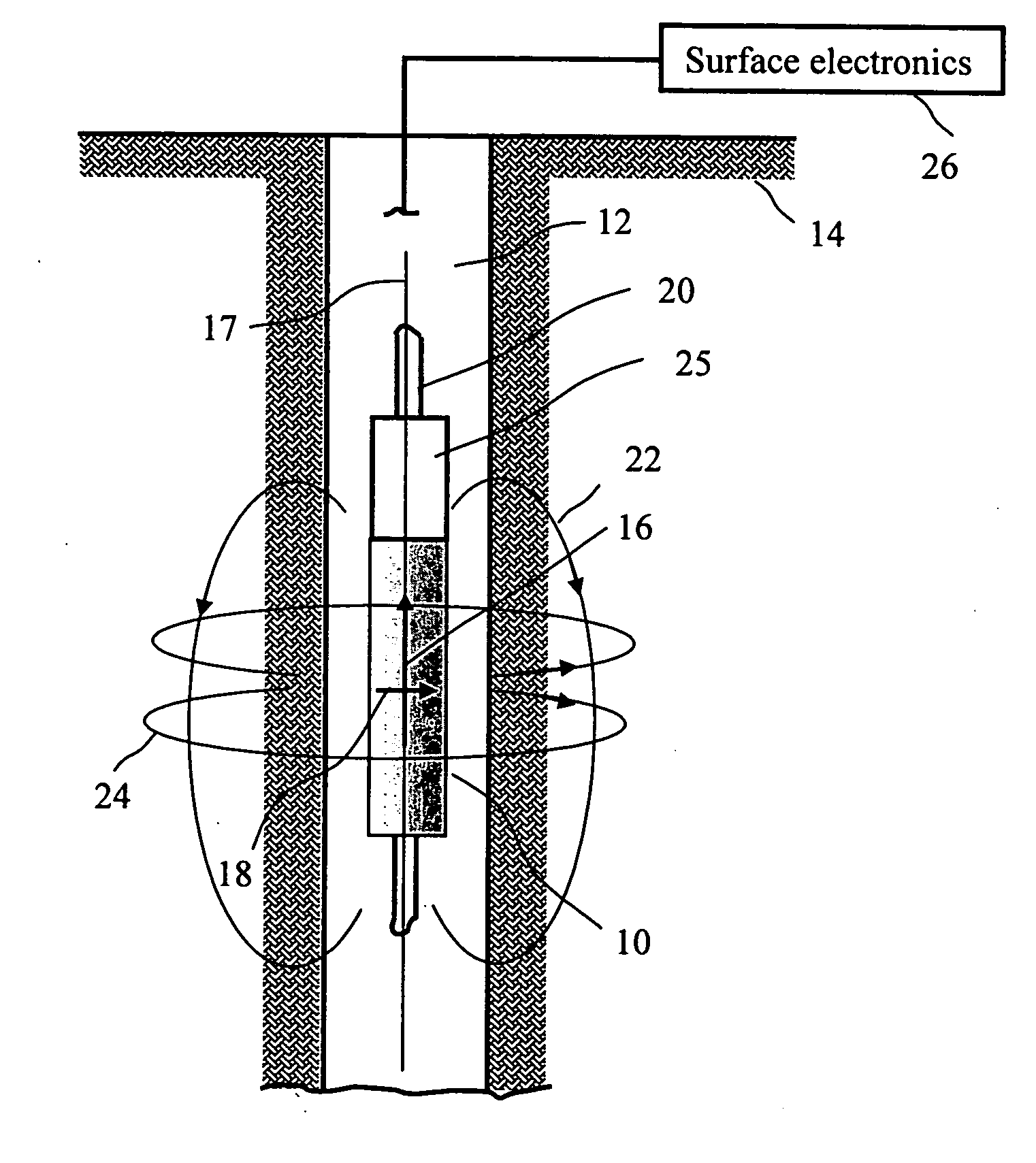

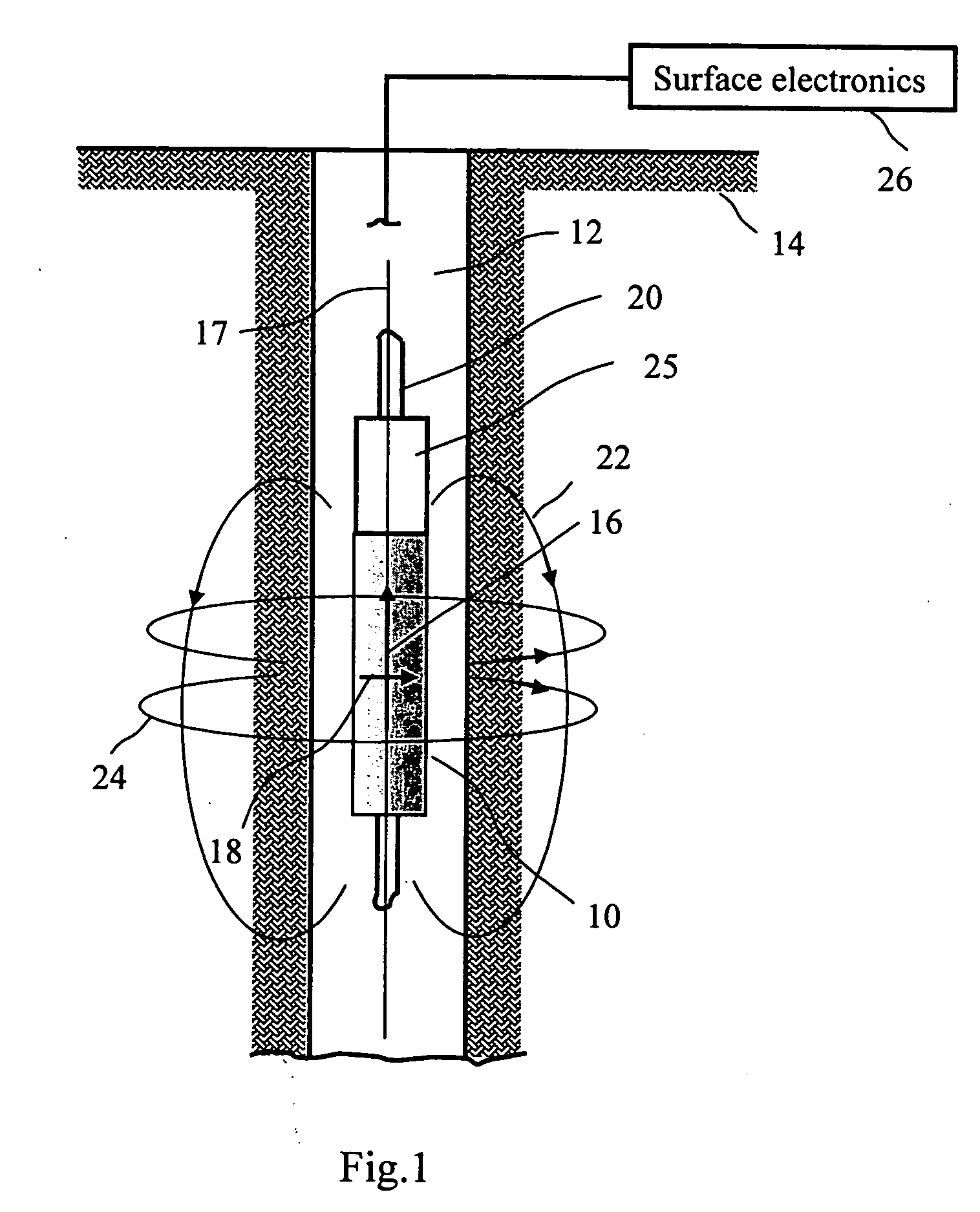

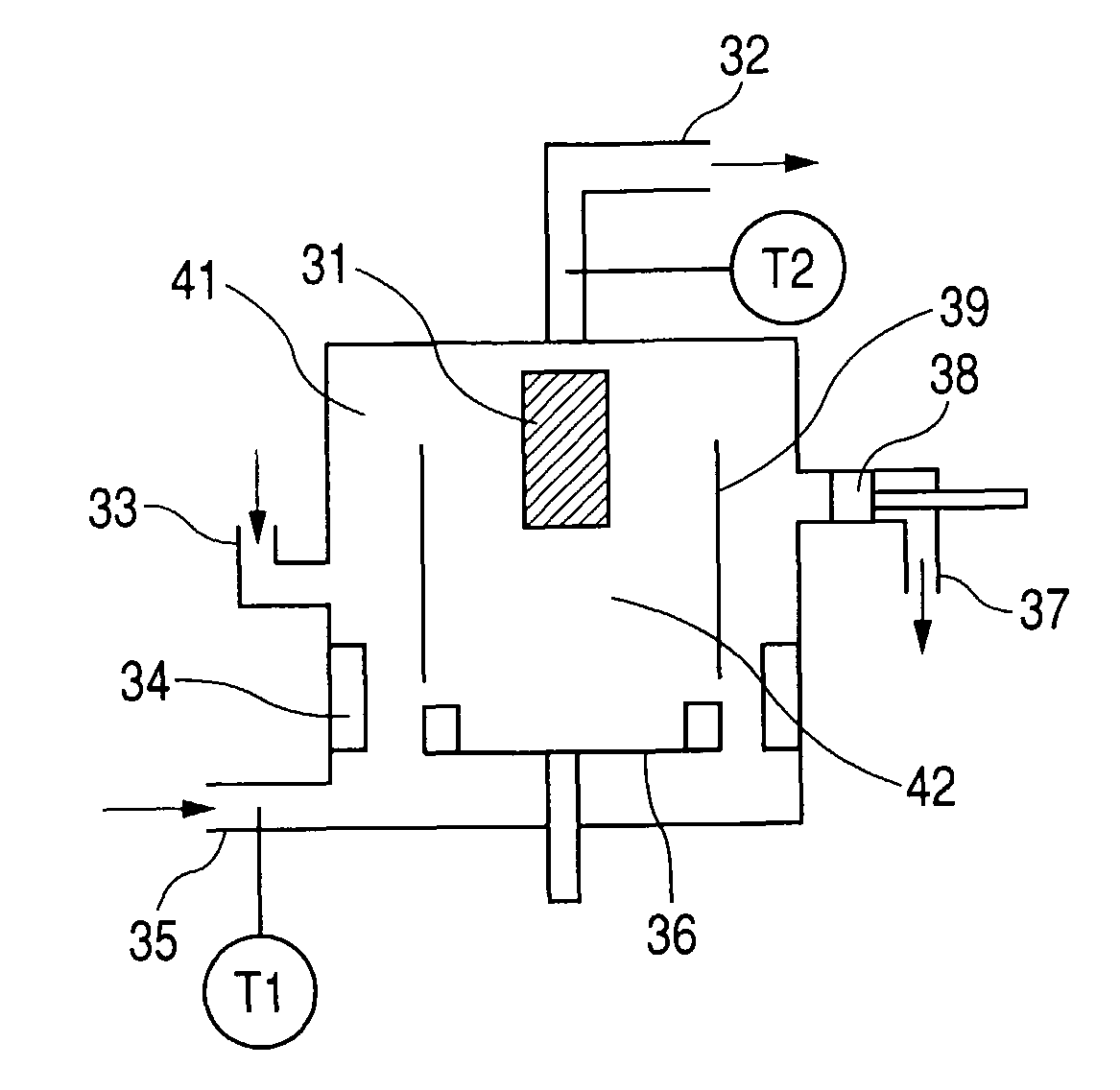

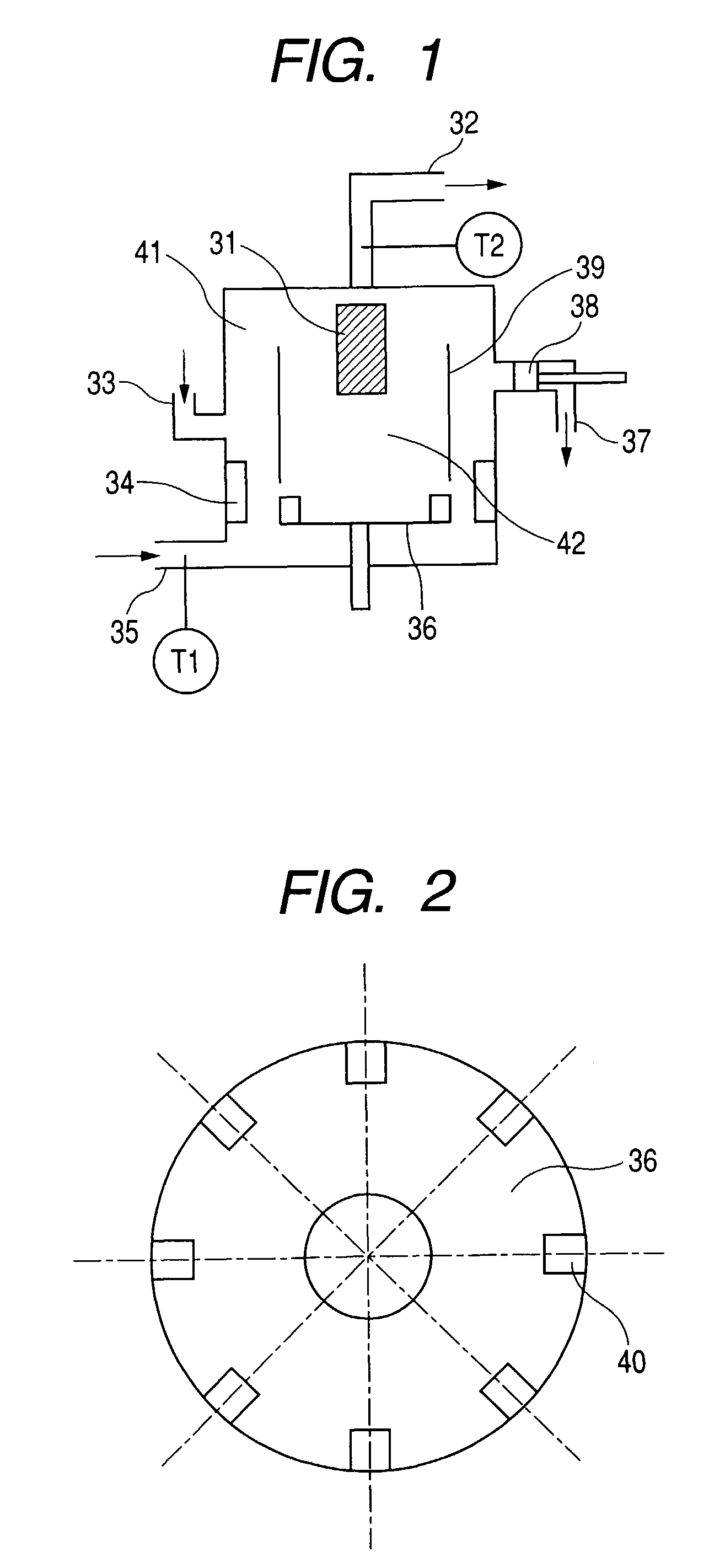

Nuclear magnetic resonance tool using switchable source of static magnetic field

ActiveUS20060255799A1Effective permeability of magneticElectric/magnetic detection for well-loggingMaterial analysis by using resonanceSolid-state nuclear magnetic resonanceSpin magnetic moment

A nuclear magnetic resonance sensing apparatus and method for operating in an earth borehole comprises a source of switchable magnetic field to polarize nuclei in the region of interest, said source comprising a coil wound on a magnetic core having controllable residual magnetization. Maintaining the magnetization of the core during a polarization interval does not require steady current in the coil. Switching intensity and polarity of magnetization of the core causes precession of spin magnetic moments of the nuclei; the precession induces a signal indicative of nuclear magnetic resonance properties of earth formations.

Owner:BAKER HUGHES INC

Magnetic carrier, two-component developer and image forming method

InactiveUS6124067AHigh-quality tonerHigh image densityElectrographic process apparatusDevelopersEngineeringPolymer

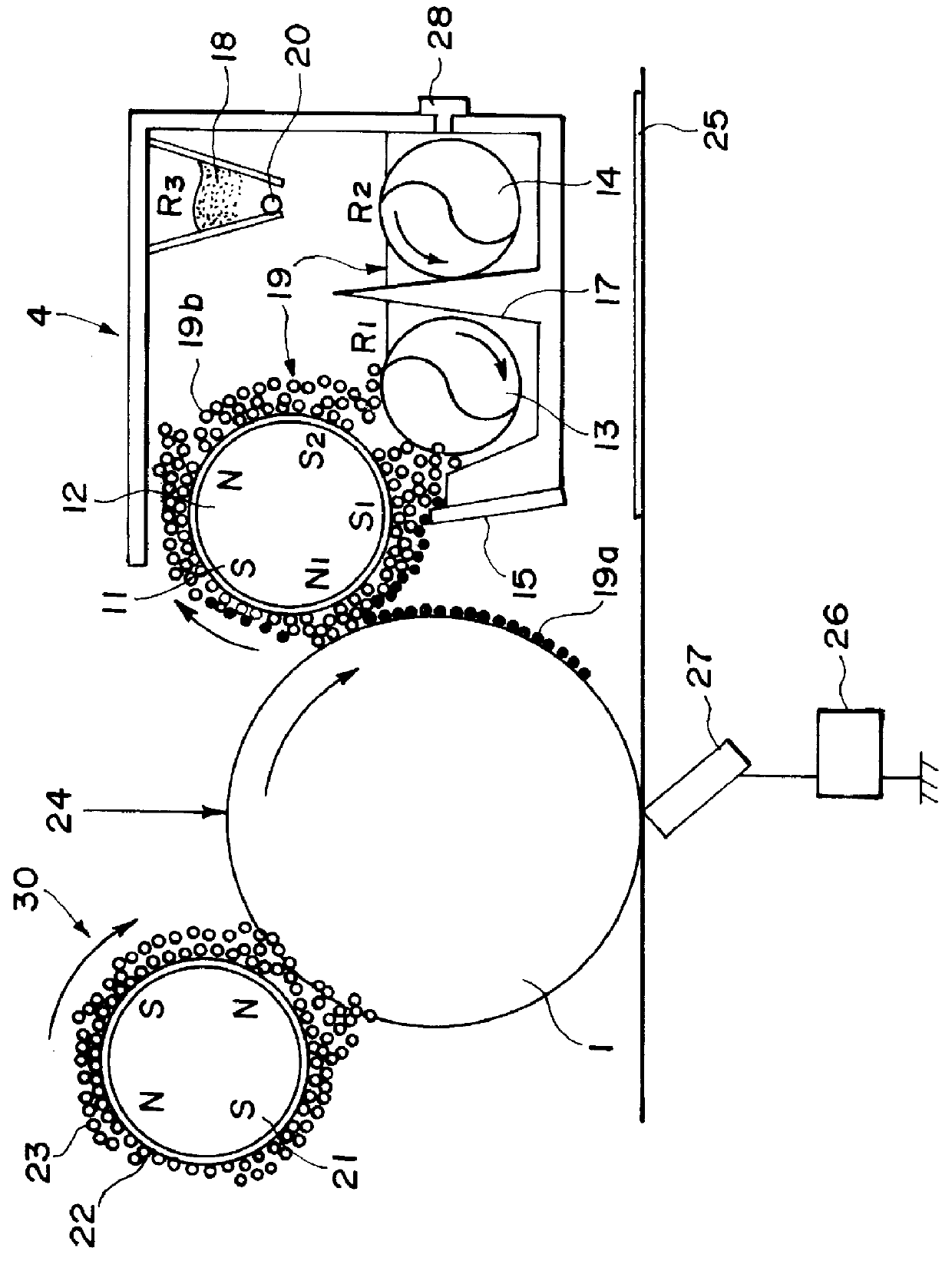

A magnetic carrier constituting a two-component developer for use in an electrophotographic image forming method is formed of a carrier core comprising a first resin and magnetic fine particles dispersed in the first resin, and a second resin surface-coating the carrier core. (a) The magnetic carrier has a true specific gravity of 2.5-4.5, a magnetization sigma 1000 as measured in a magnetic field of 1000x(103 / 4 pi )xA / m (1000 oersted) of 15-60 Am2 / kg (emu / g), a residual magnetization sigma r of 0.1-20 Am2 / kg (emu / g) and a resistivity of 5x1011-5x1015 ohm.cm. (b) The first resin has a polymer chain including a methylene unit (-CH2-). (c) The second resin has at least a fluoro-alkyl unit, a methylene unit (-CH2-) and an ester unit. (d) The carrier core is surface-coated with (i) a mixture of the second resin and a coupling agent having at least an amino group and a methylene unit, or (ii) a coupling agent having at least an amino group and a methylene unit, and then with the second resin.

Owner:CANON KK

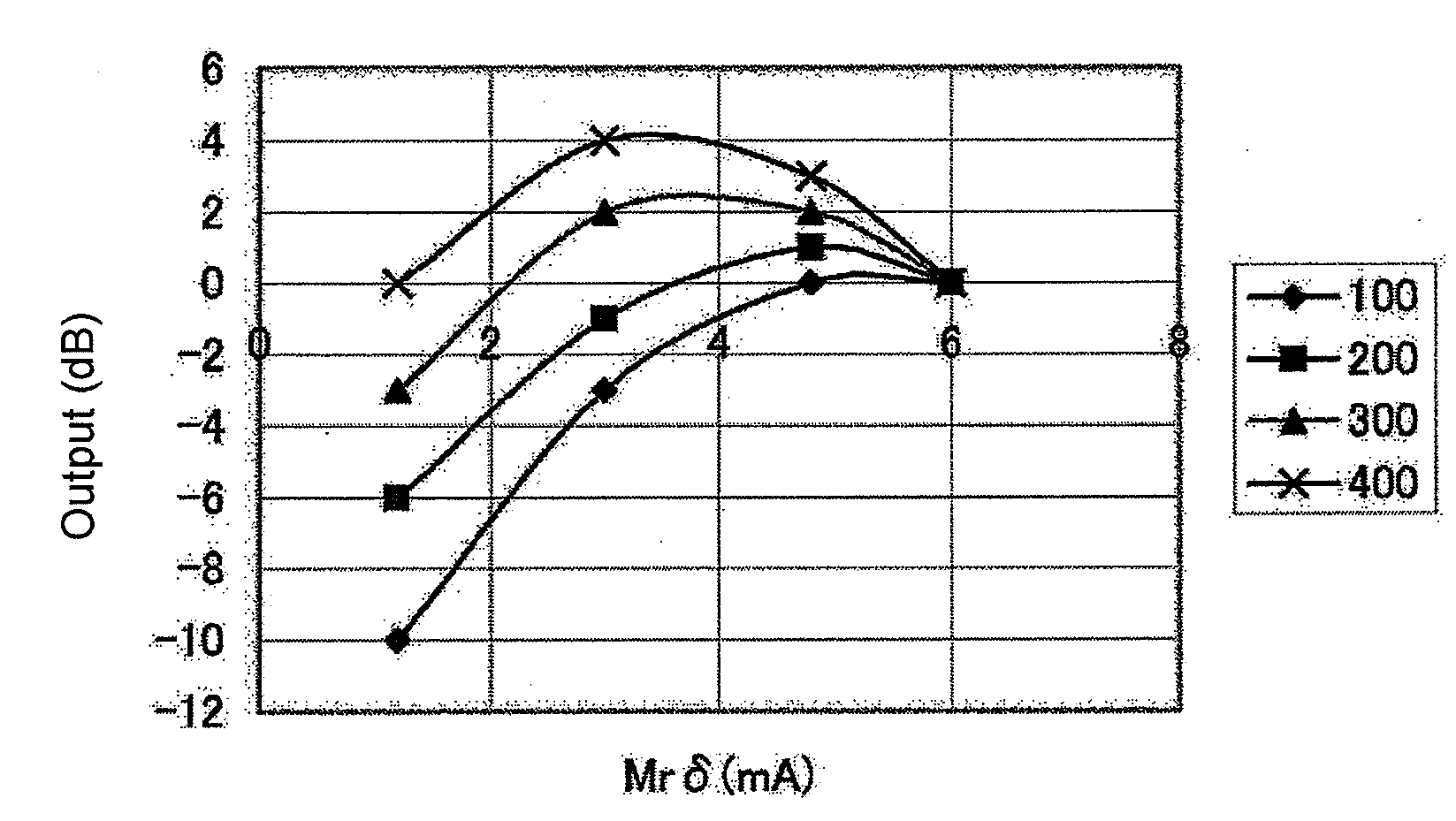

Magnetic Recording Medium, Linear Magnetic Recording and Reproduction System and Magnetic Recording and Reproduction Method

InactiveUS20090046396A1Raise the ratioIncreased durabilityDifferent record carrier formsRecord information storagePerpendicular directionUltimate tensile strength

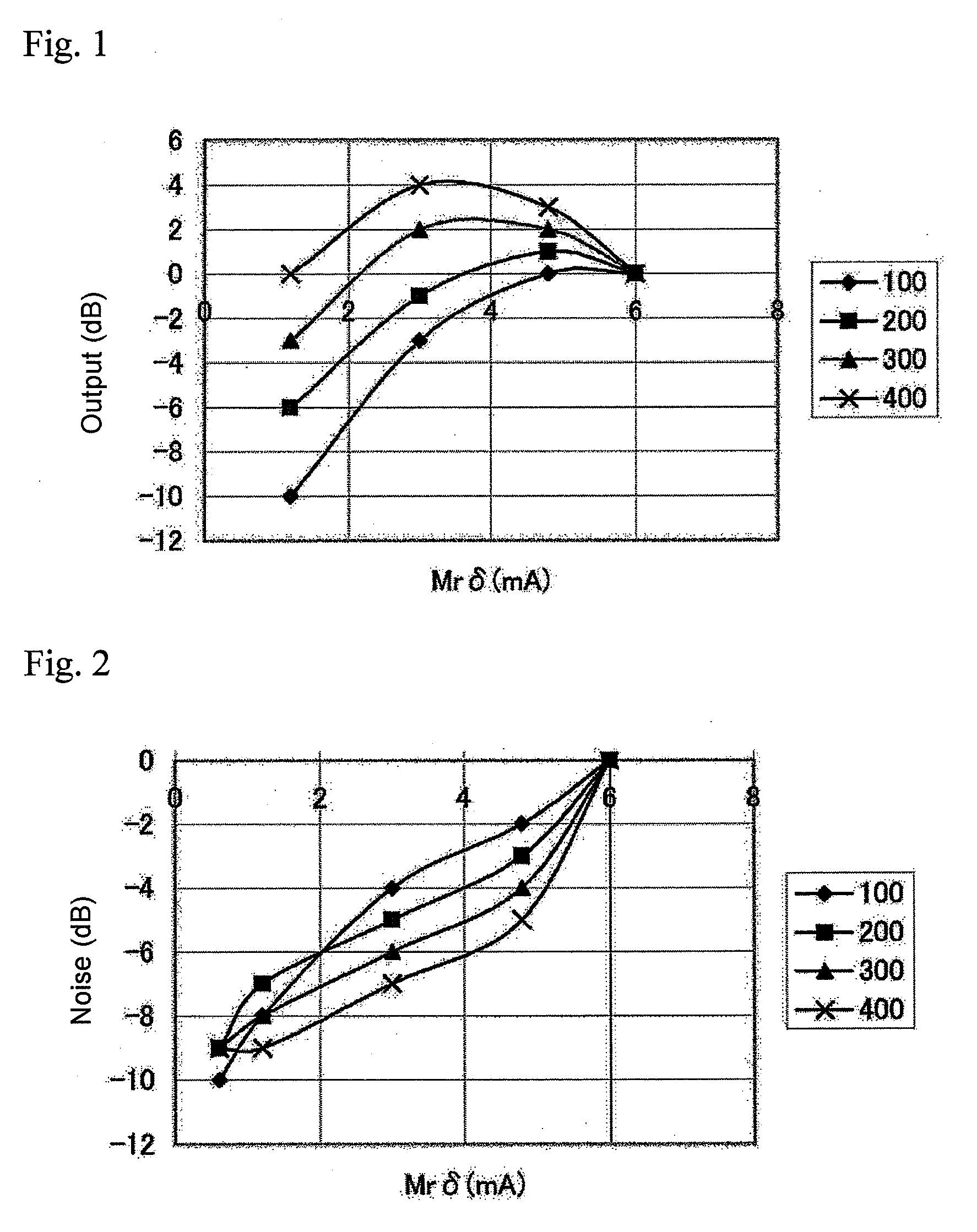

The present invention relates to a magnetic recording medium comprising a magnetic layer comprising a ferromagnetic powder and a binder on a nomnagnetic support. A product, Mrδ, of a residual magnetization Mr of the magnetic layer and a thickness δ of the magnetic layer is equal to or greater than 2 mT•μm and equal to or less than 12 mT•μm, a squareness in a perpendicular direction is equal to or greater than 0.4 and equal to or less than 0.7, and a squareness in a longitudinal direction is equal to or greater than 0.3 but less than 0.6.

Owner:FUJIFILM CORP

Magnetic toner

A magnetic toner is disclosed having magnetic toner particles containing a binder resin and a magnetic iron oxide. The magnetic toner has a specific saturation magnetization and a specific residual magnetization in ascertain magnetic field. The binder resin includes a polyester component polymerized with an aromatic carboxylic acid titanium compound as a catalyst.

Owner:CANON KK

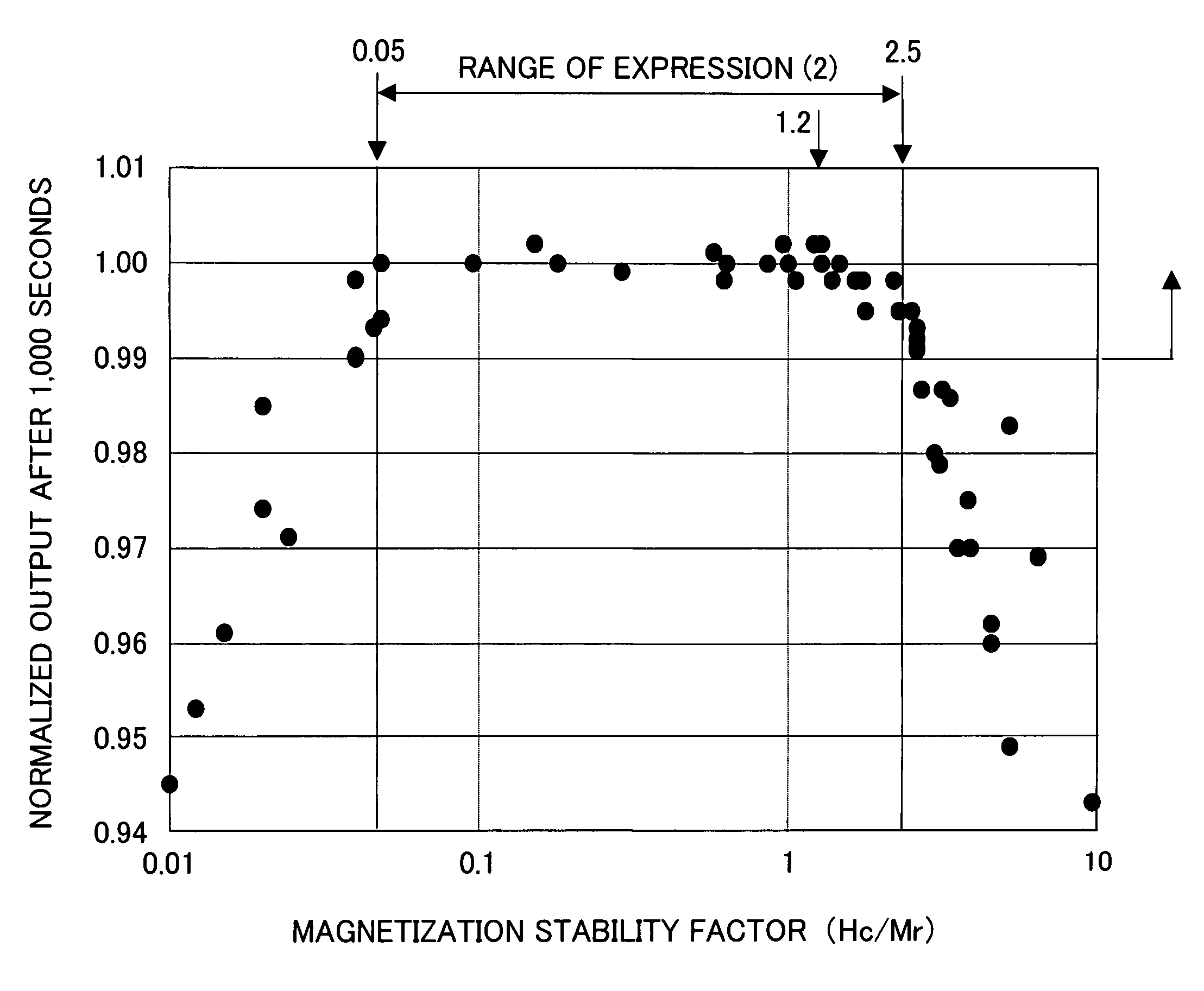

Magnetic recording medium having a specific relation of coercive force HC and residual magnetization MR in perpendicular direction to substrate surface

InactiveUS7038873B2Improve recording performanceImprove performance information retentionCombination recordingRecord information storageRecording layerUltimate tensile strength

A perpendicular magnetic recording medium has a substrate, a magnetic functional layer provided on the substrate, and a magnetic recording layer stacked in contact with the magnetic functional layer and having perpendicular magnetic anisotropy. −4×2πMs2≦Ku≦6×2πMs2 is satisfied, wherein Ku represents a perpendicular magnetic anisotropy constant of the magnetic functional layer and Ms represents a saturation magnetization. The magnetic moment of the magnetic functional layer is rotated in a direction of an applied magnetic field during the recording, and the magnetic moment acts on the magnetization of the recording layer in such a manner that the applied magnetic field is assisted thereby. Minute magnetic domains can be stably retained and excellent thermal disturbance resistance can be obtained.

Owner:HITACHT MAXELL LTD

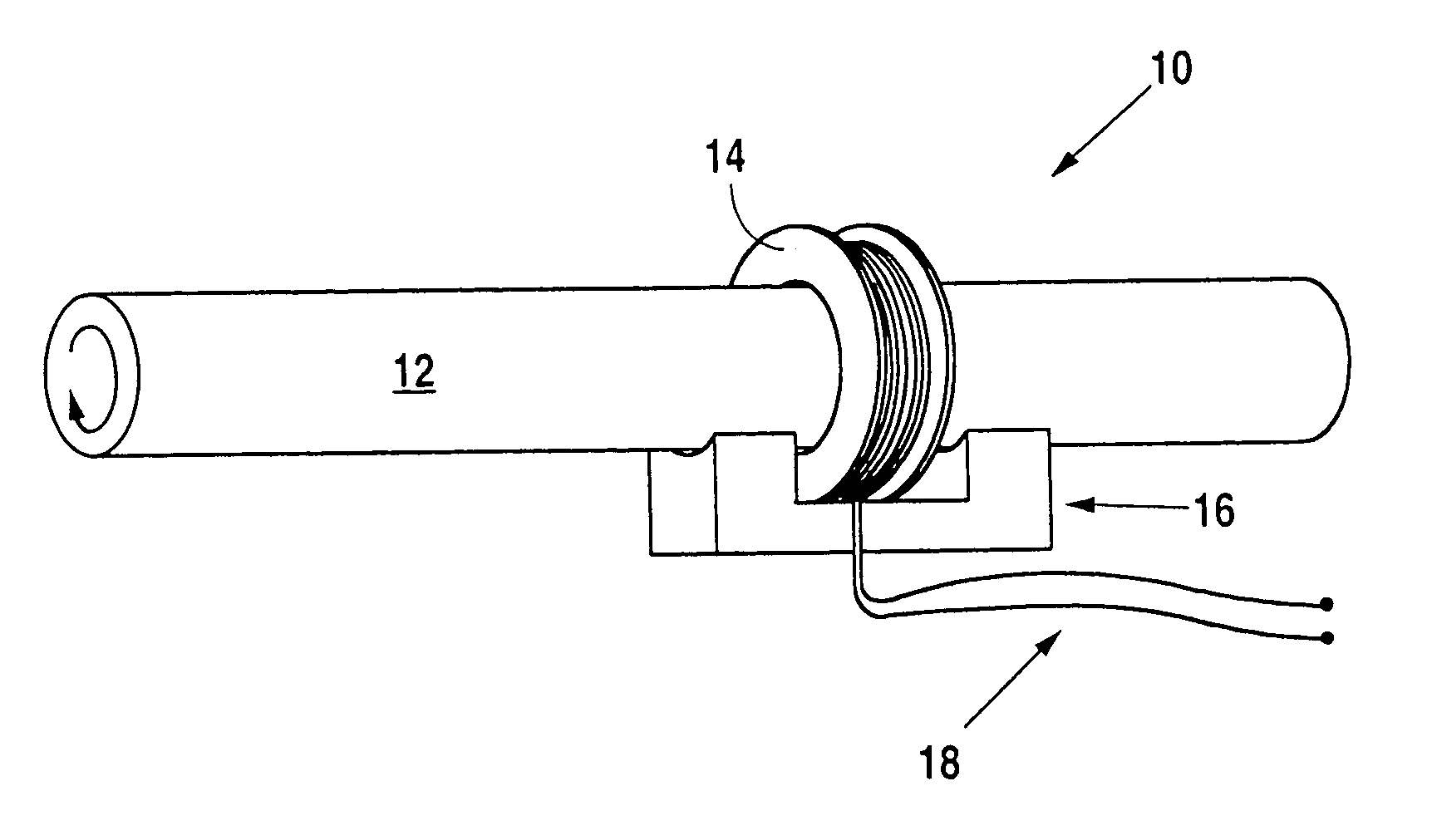

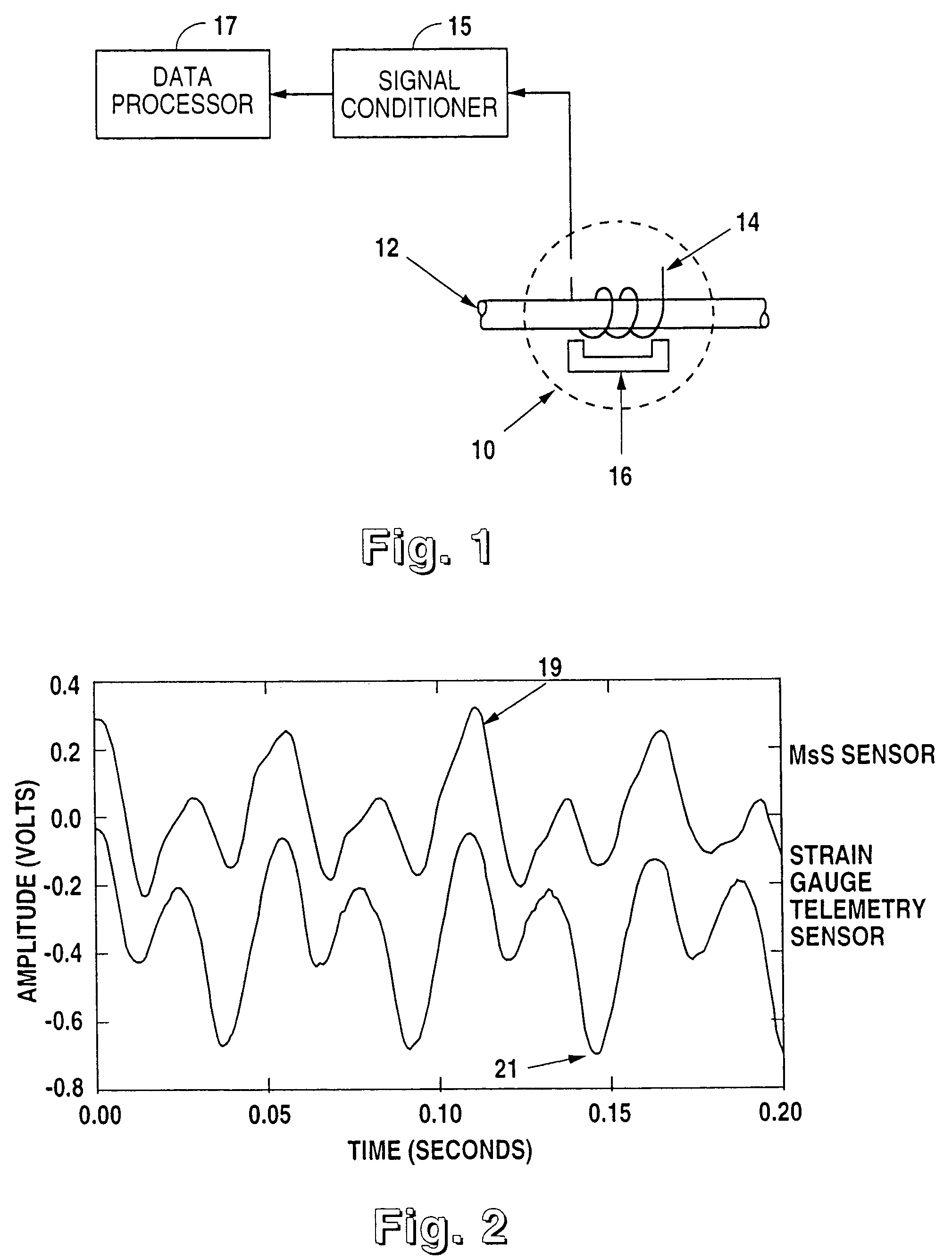

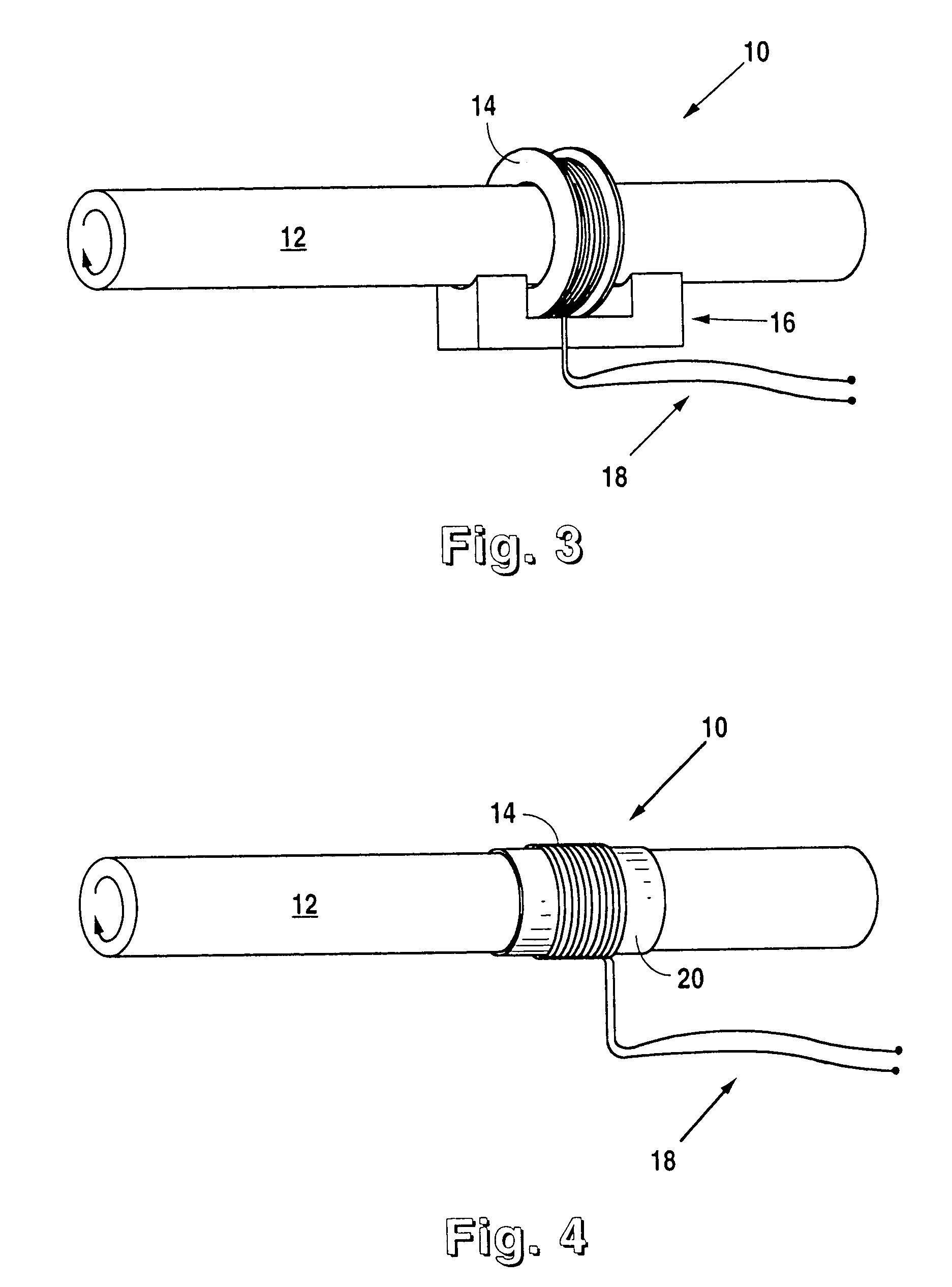

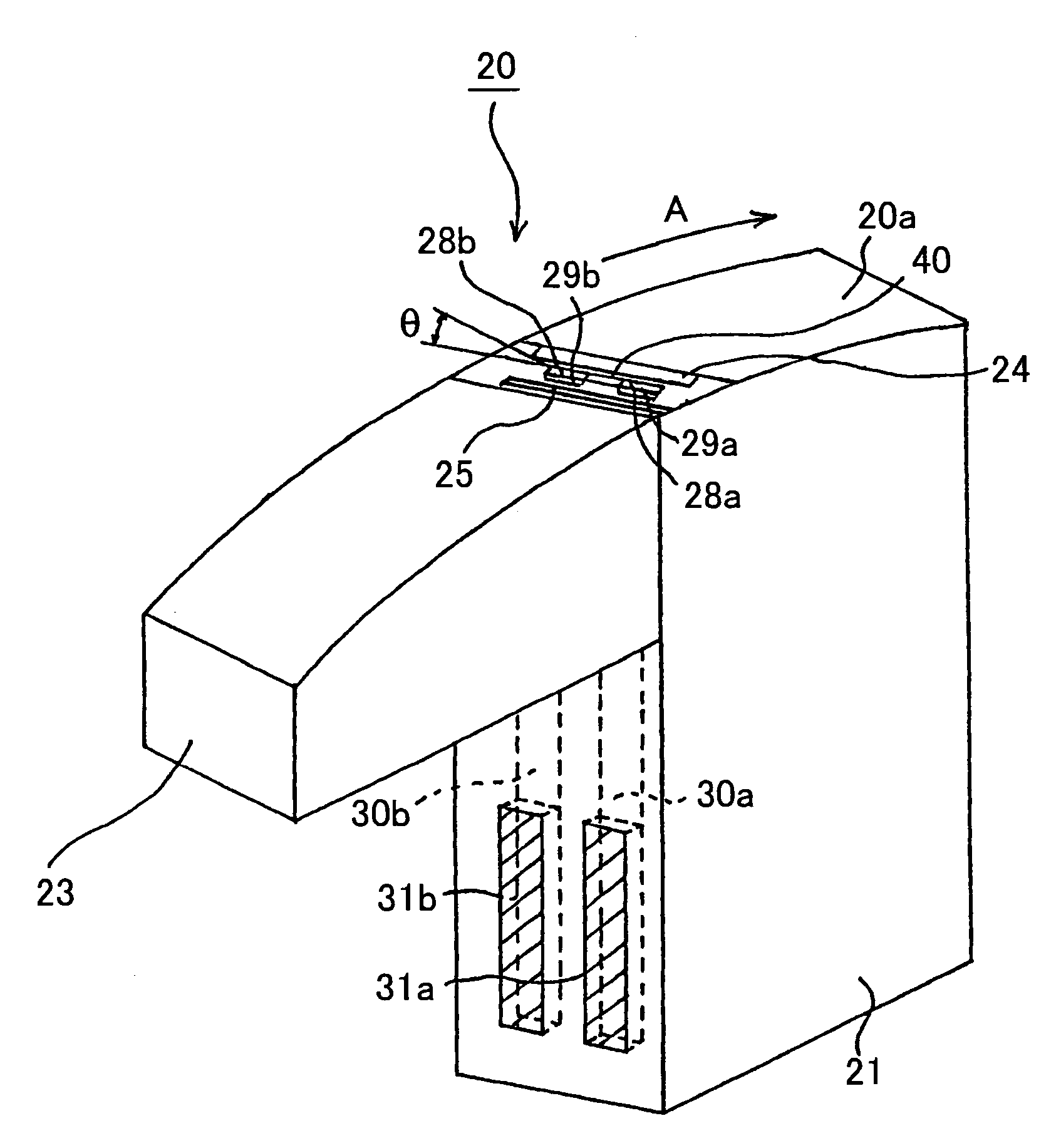

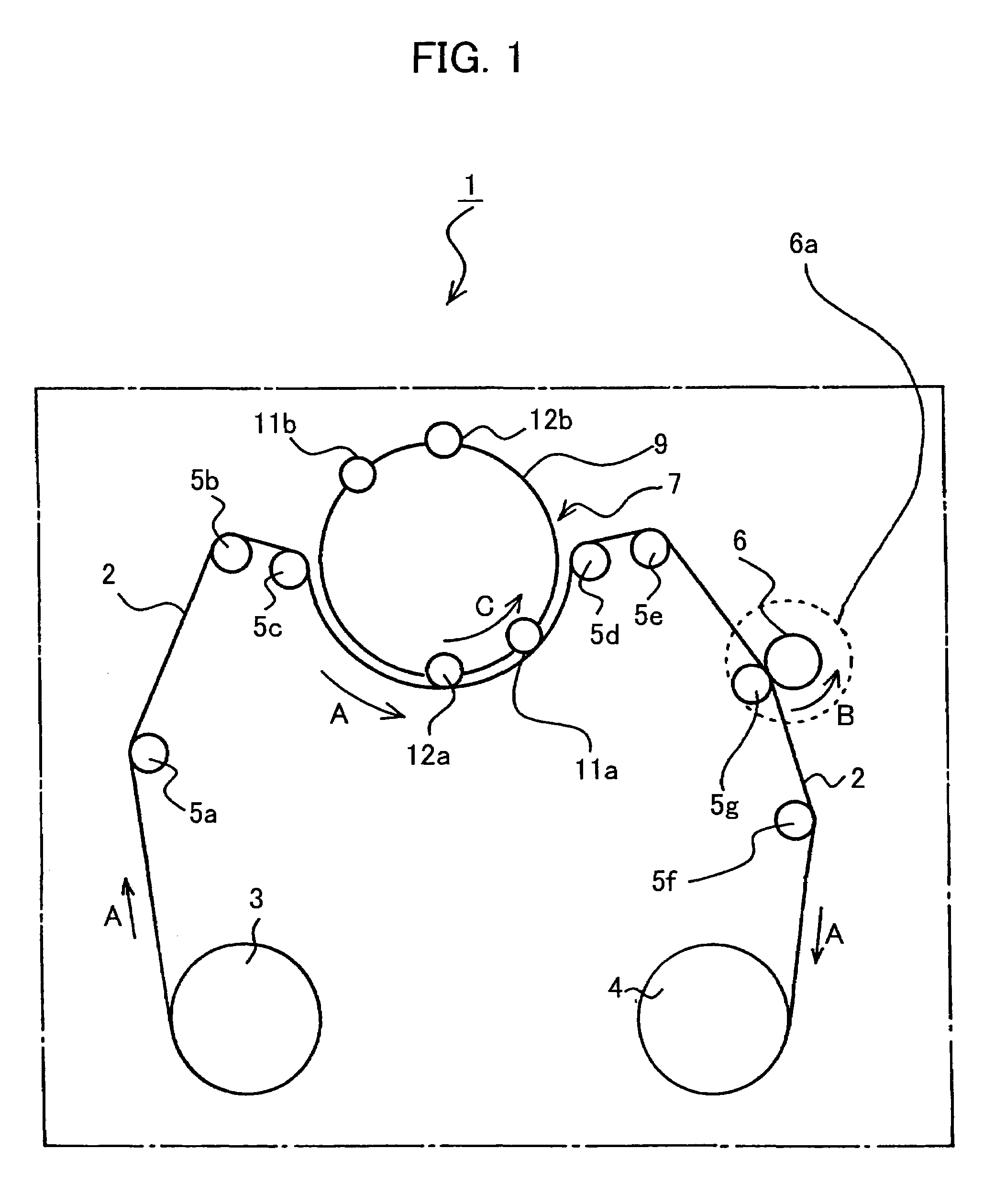

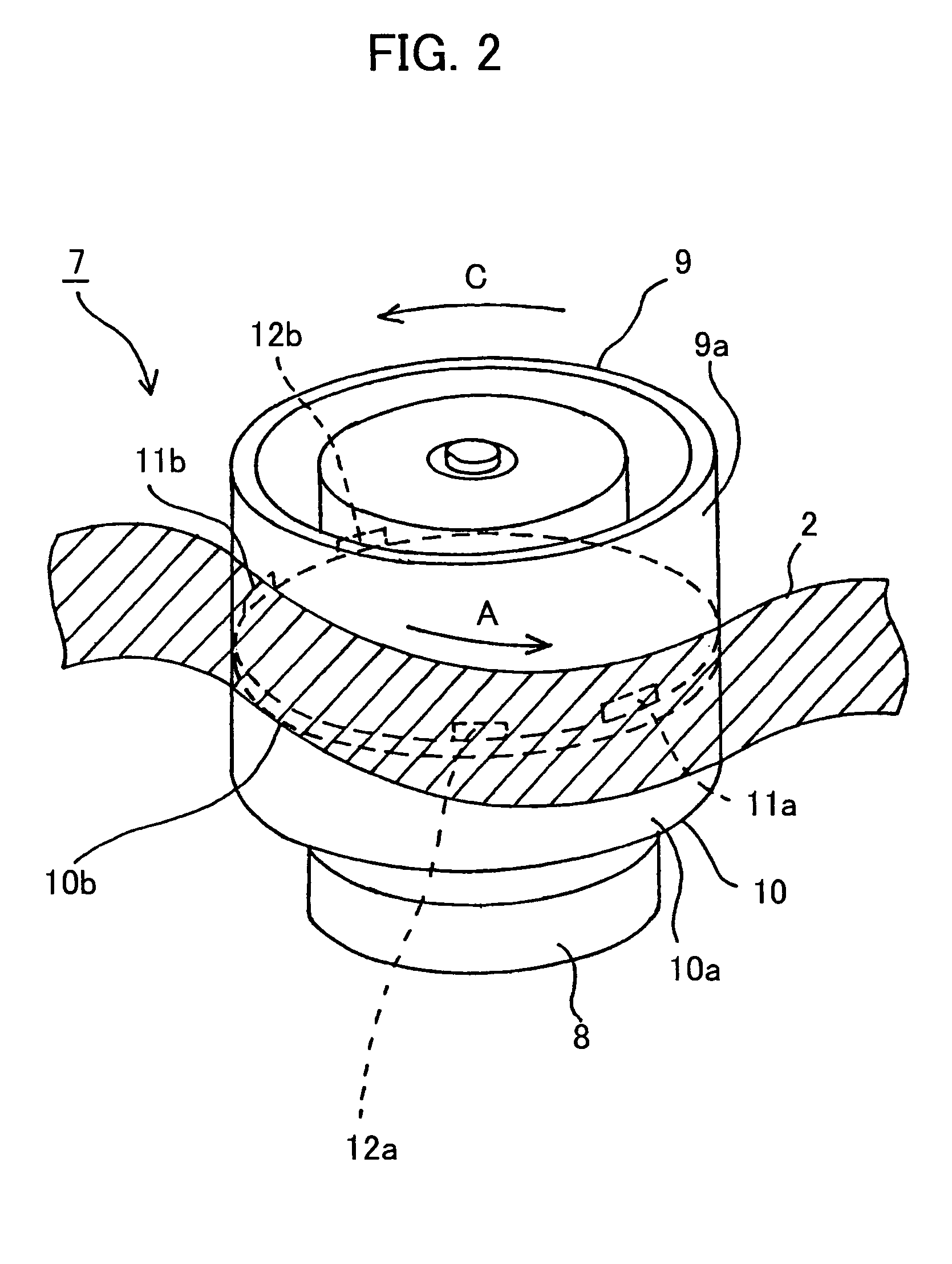

Measurement of torsional dynamics of rotating shafts using magnetostrictive sensors

InactiveUS7131339B2Low-cost and long-termWork measurementTorque measurementContact methodEngineering

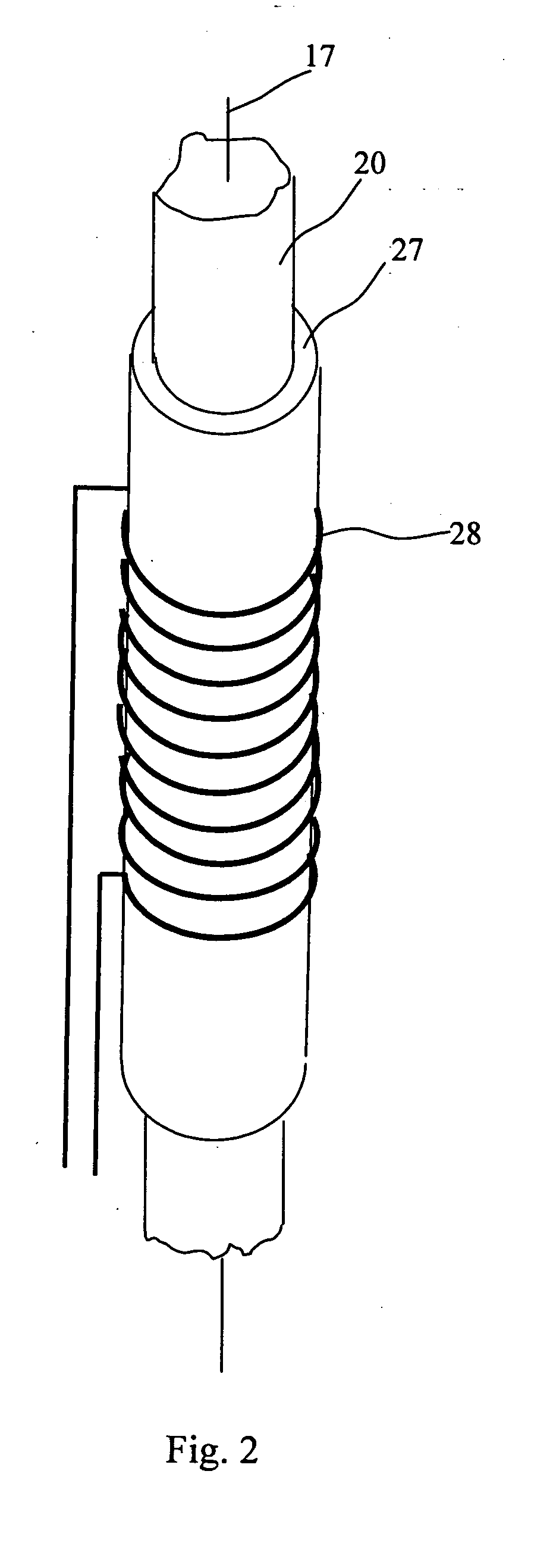

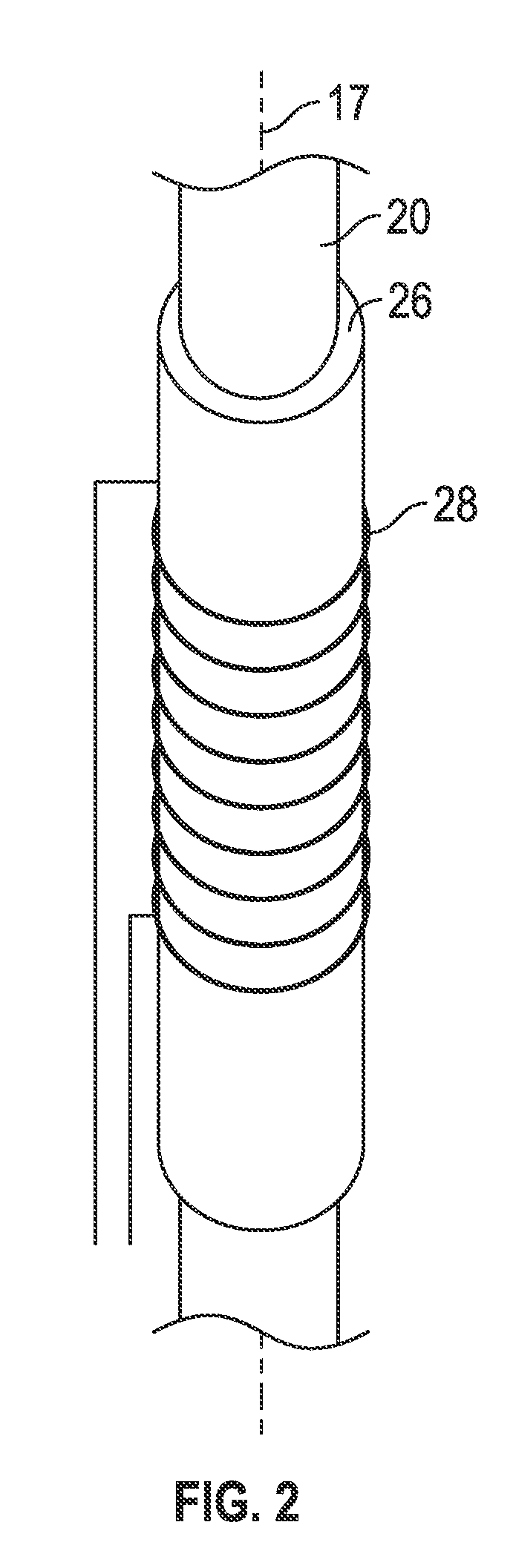

A device and method for the non-contact measurement of dynamic torsion in a rotating shaft using magnetostrictive sensors (MsS). The monitoring and detection system have specially configured magnetostrictive signal detectors that include inductive pickup coils, in which signals corresponding to localized shaft torques are induced. The non-contact method for measuring dynamic torques includes fixing a ferromagnetic strip to a ferromagnetic or non-ferromagnetic shaft and inducing a circumferential residual magnetization therein. An MsS in the form of either an encircling coil positioned around the shaft on a cylindrical substrate, or a partially encircling coil positioned on a flexible substrate and wrapped partially about the shaft.

Owner:SOUTHWEST RES INST

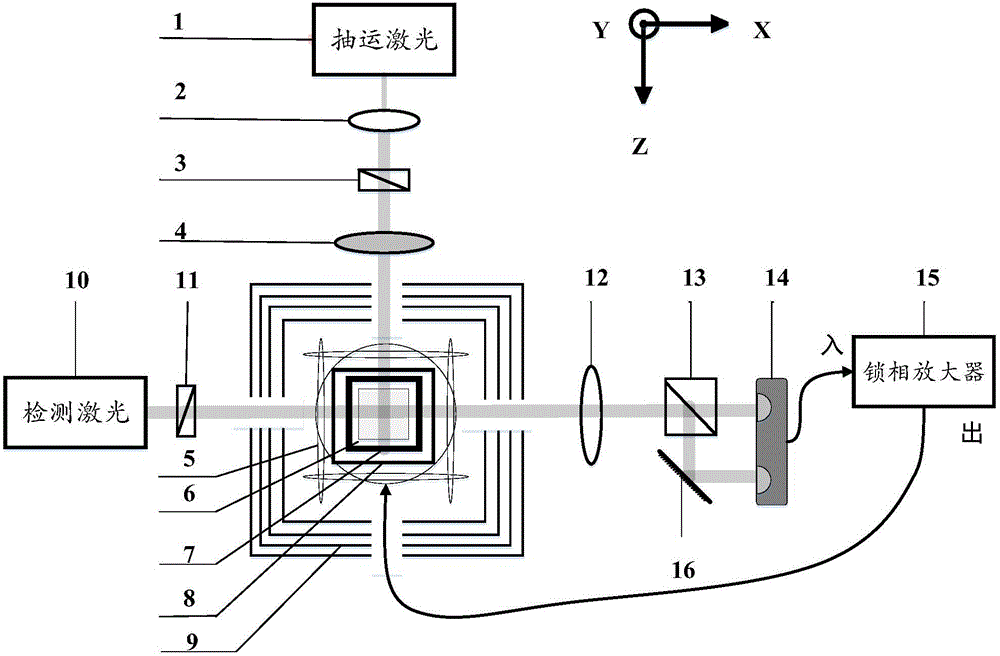

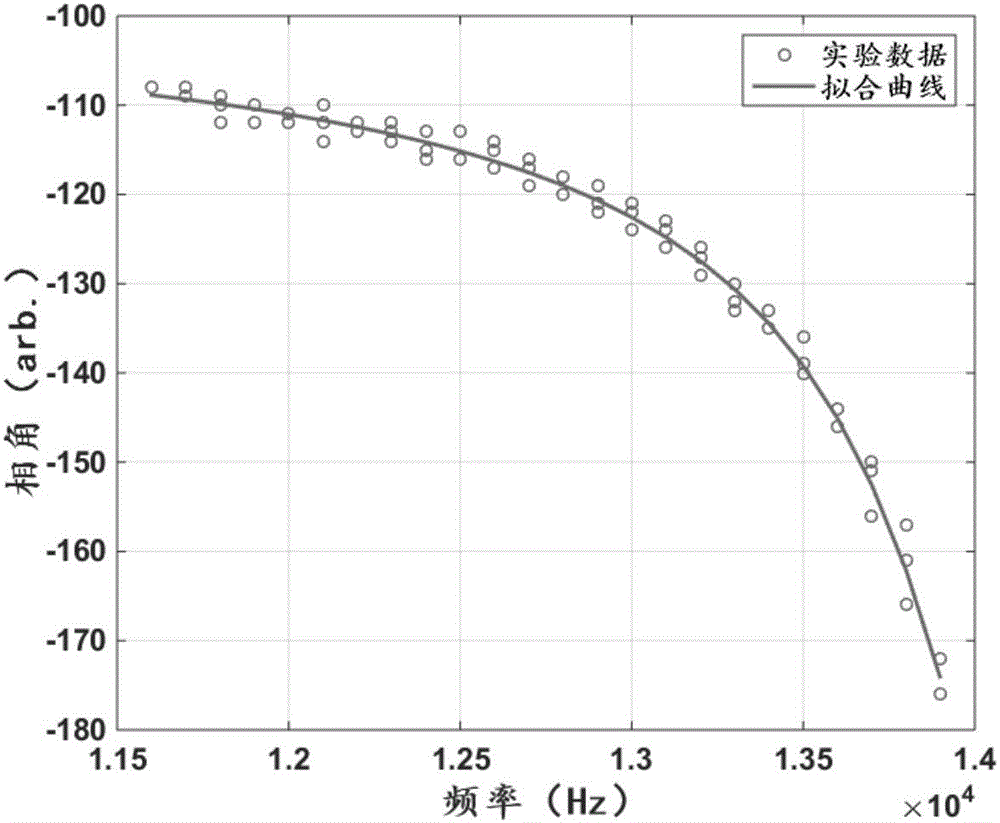

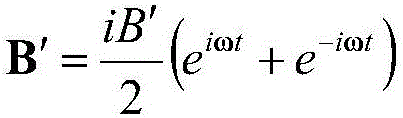

Method for measuring atomic transverse relaxation time based on electron resonance phase frequency analysis

InactiveCN106597338ASuppression of the effects of common coefficient fluctuationsExact transverse relaxation timeMeasurements using electron paramagnetic resonanceAnalysis using electron paramagnetic resonanaceFrequency spectrumTransverse magnetic field

The invention discloses a method for measuring atomic transverse relaxation time based on an electron resonance phase frequency analysis. In a strong-background magnetic field with almost neglected residual magnetization in a magnetic shielding barrel, a swept-frequency signal that has a bandwidth covering a resonance curve and has an amplitude enabling the resonance curve to have a clear curve under low polarizability is applied in a horizontal direction; an optical swing angle signal of a magnetometer is detected and a spectral analysis is carried out on an outputted signal in a polar coordinate system to obtain a phase frequency response function of the magnetometer; the phase frequency response function is fitted to a corresponding theoretical phase frequency curve of the magnetometer to obtain atomic spinning transverse relaxation time. Because the phase angle is a result obtained by quotient processing of a spinning transverse component, the influence of common coefficient fluctuation is suppressed, so that the phase frequency signal expression is more stable by being compared with amplitude-frequency signal expression. Besides, the theoretical phase frequency curve is not affected by the magnetic induction intensity of the transverse magnetic field and the atomic spinning longitudinal relaxation time, so that complexity of data processing can be reduced. Moreover, a lorenz curve widening risk caused by the transverse magnetic field can be eliminated.

Owner:BEIHANG UNIV

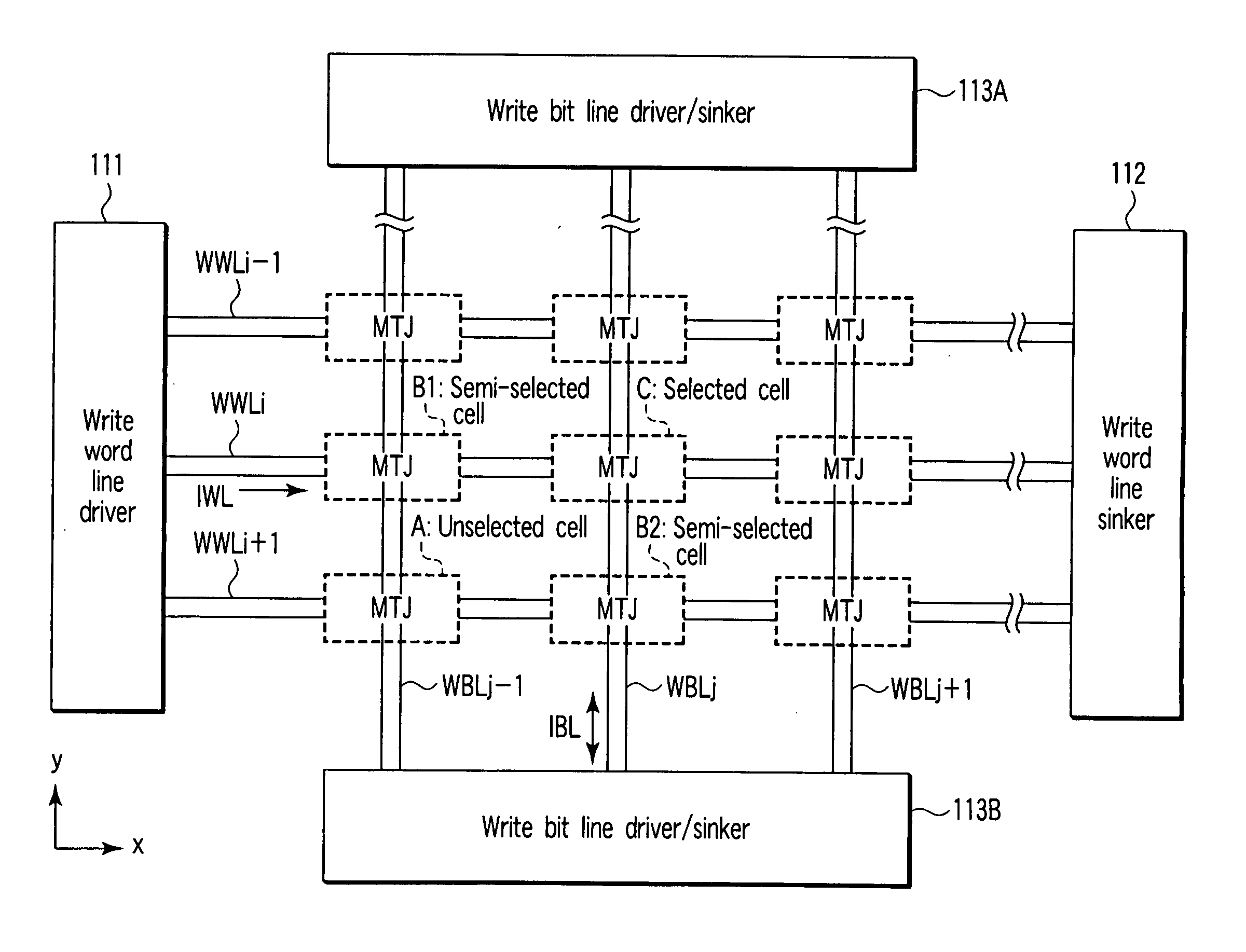

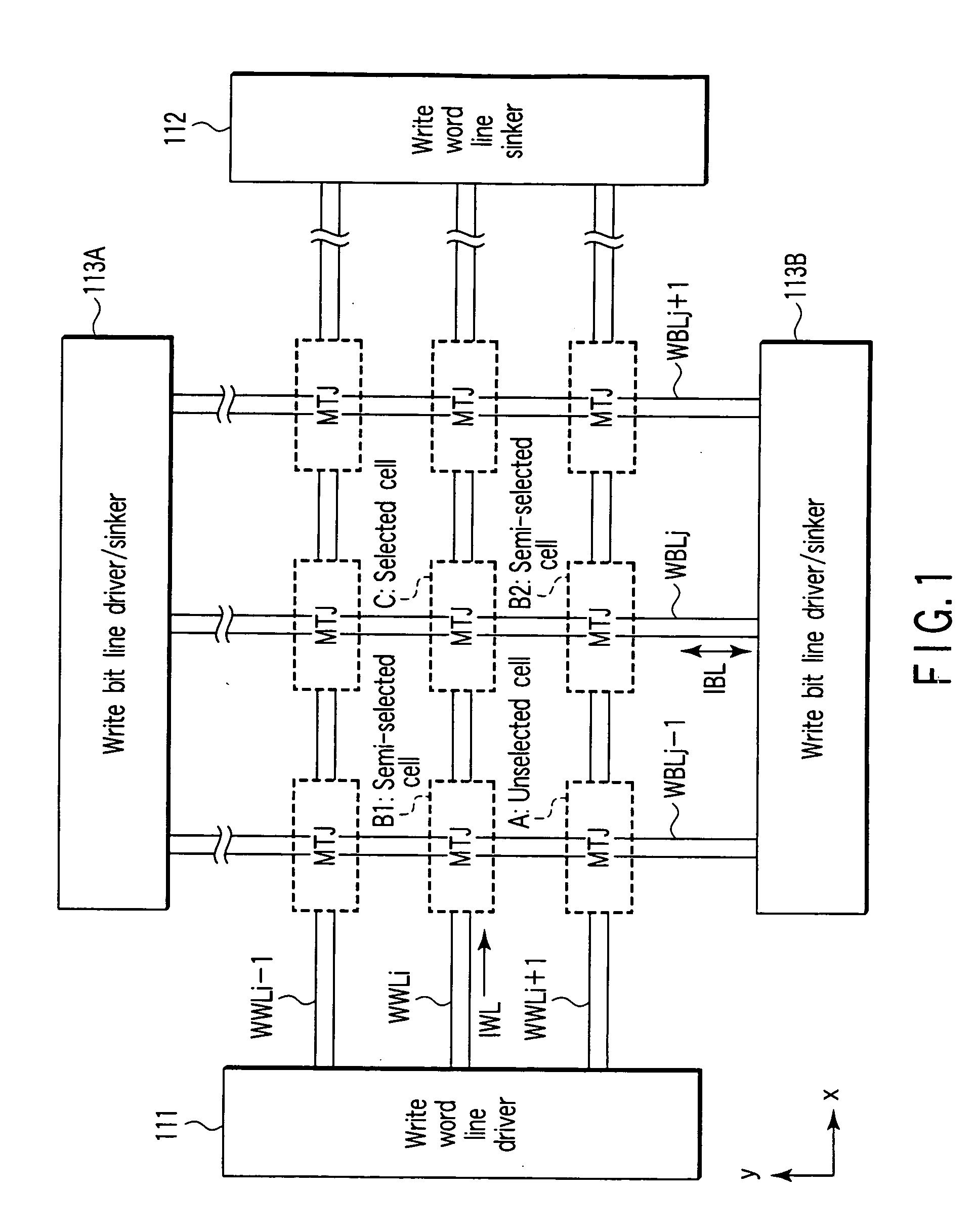

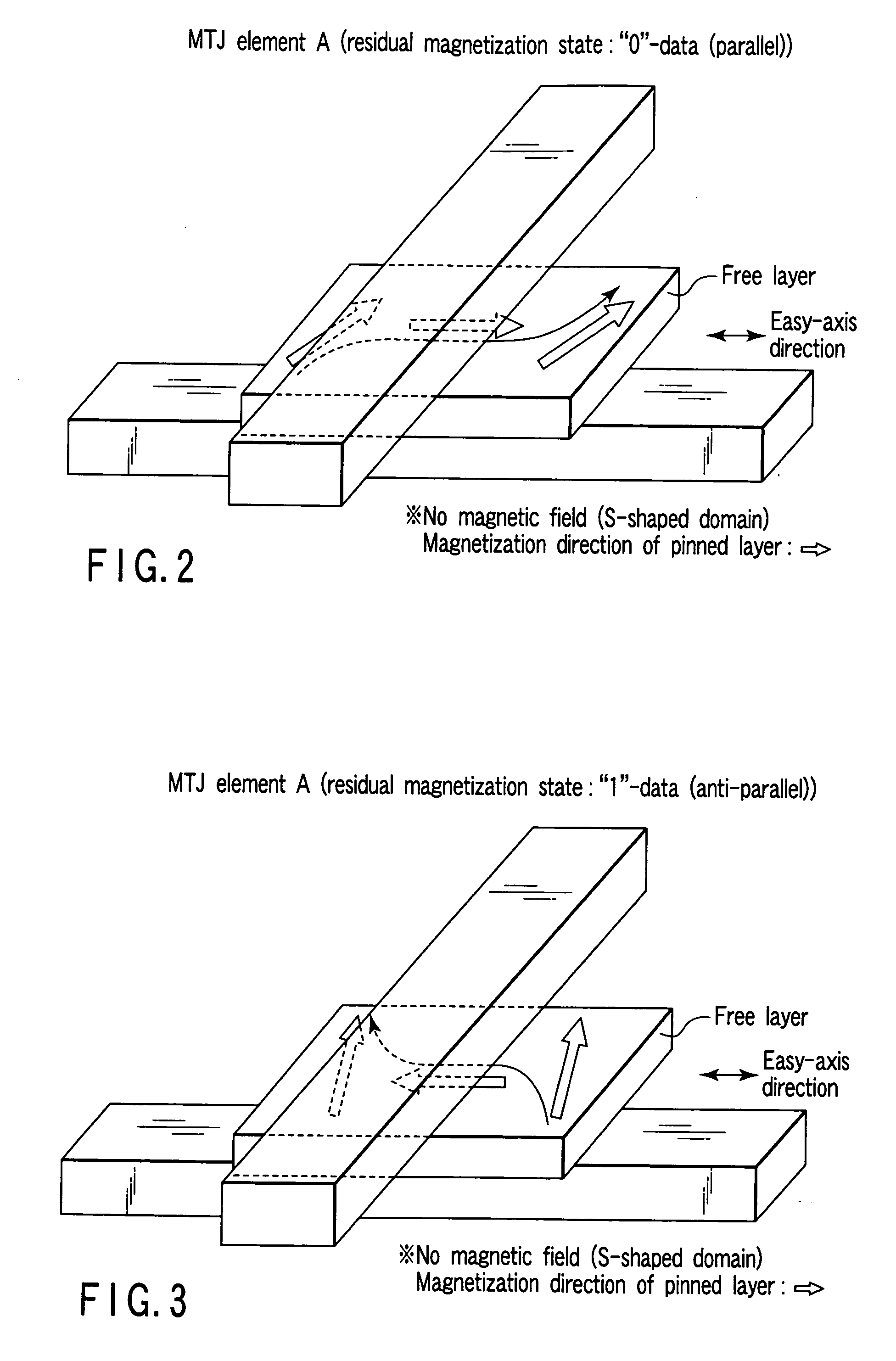

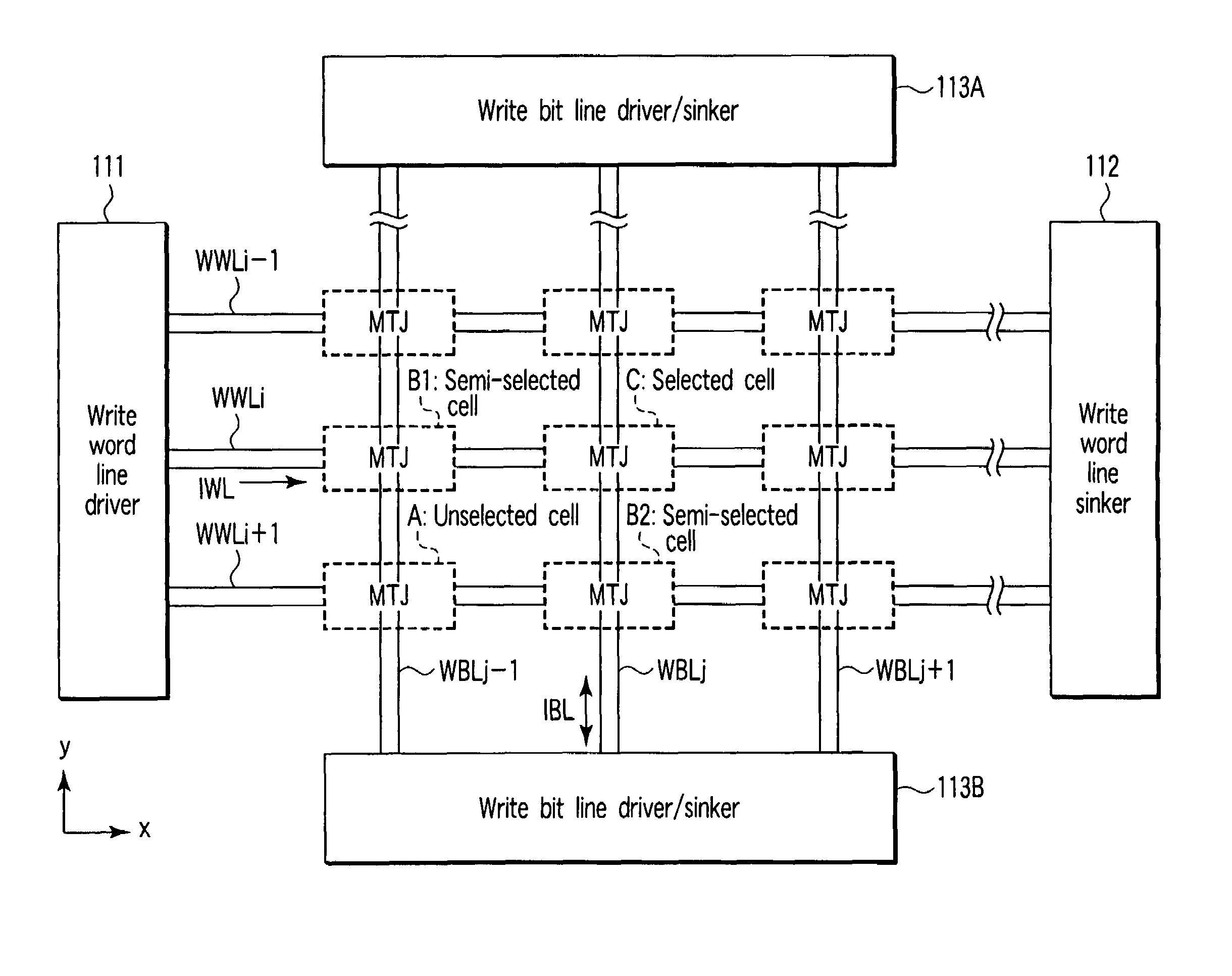

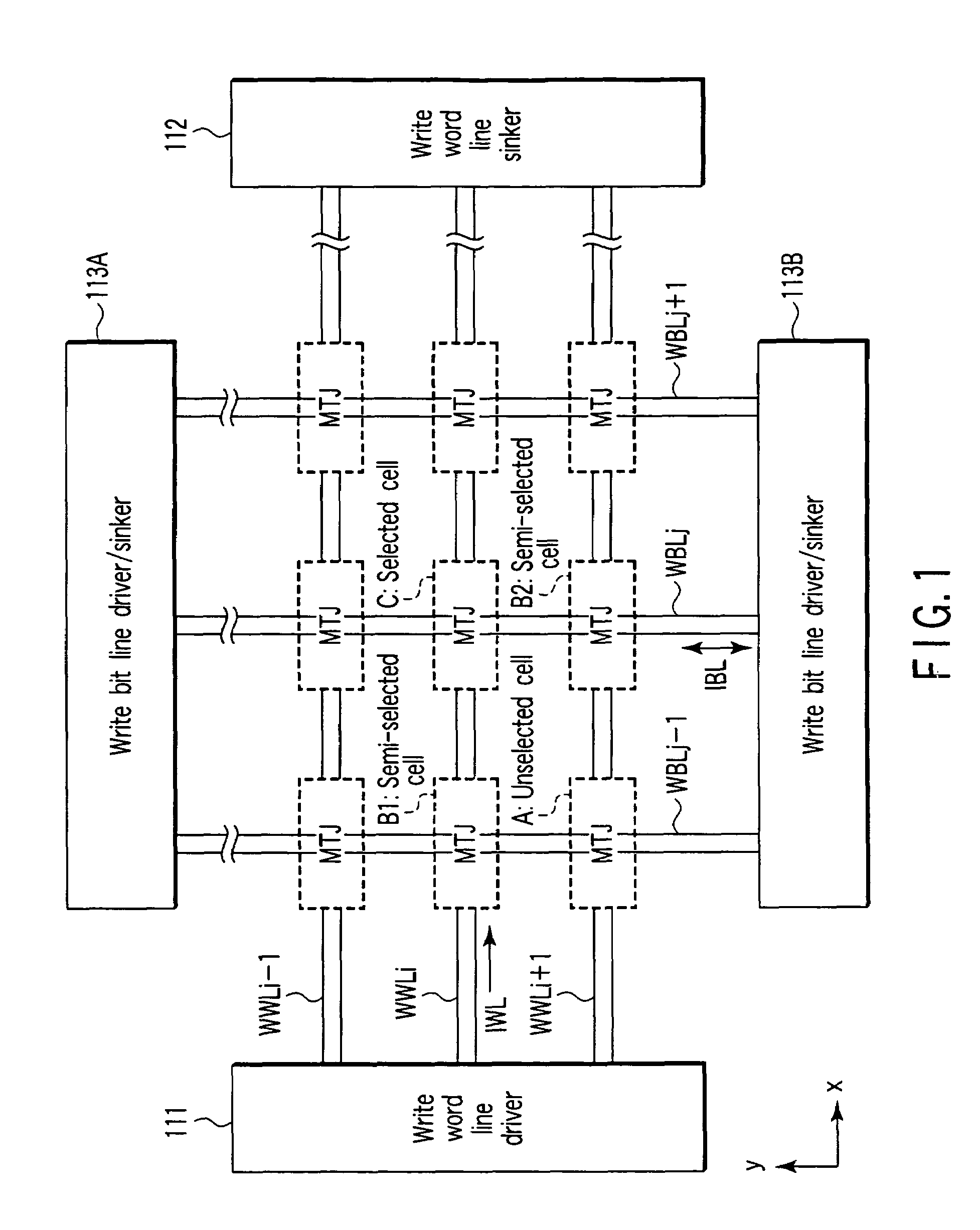

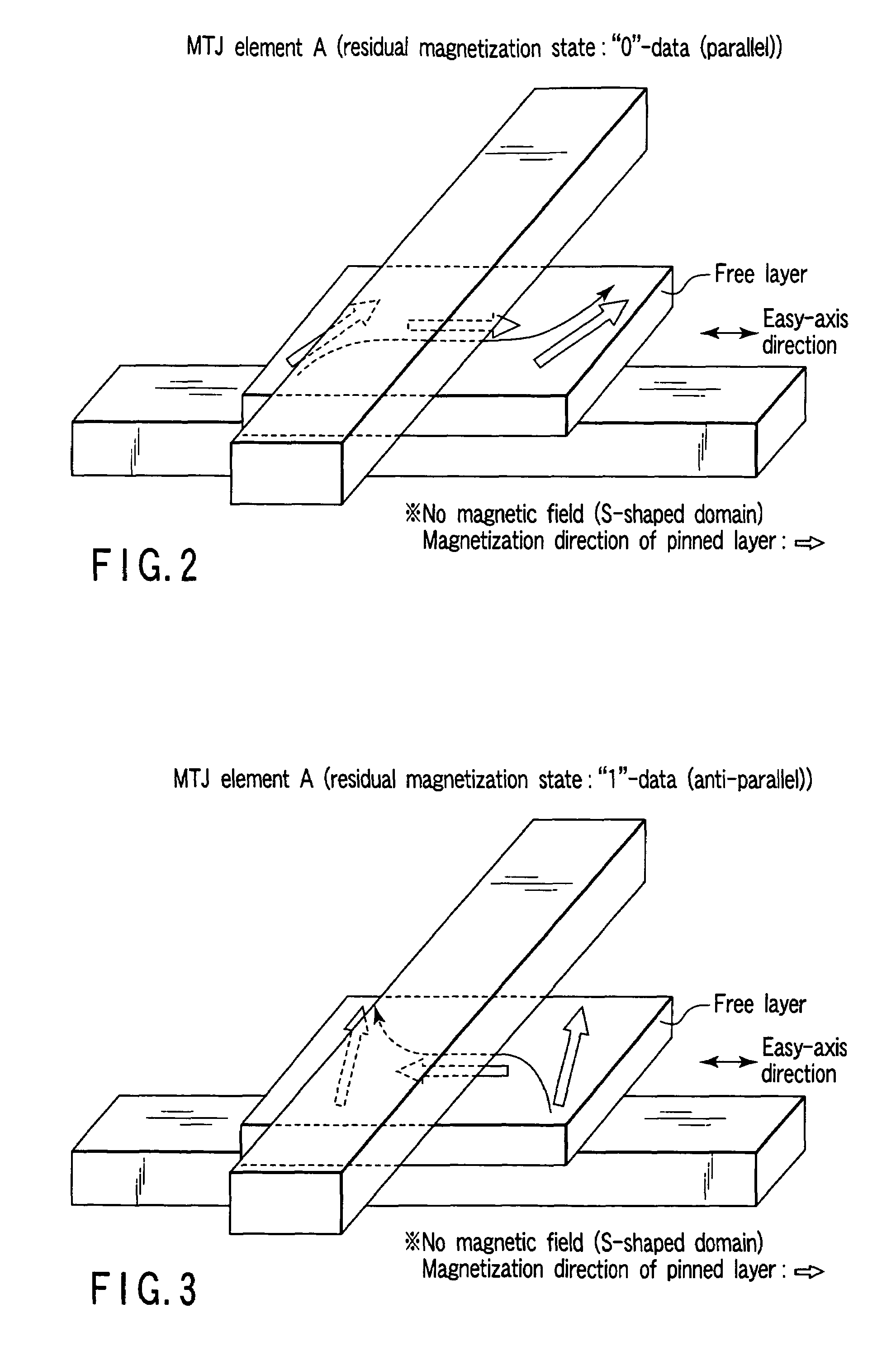

Magnetoresistive element

A magnetoresistive element includes a first ferromagnetic layer having a first magnetization, the first magnetization having a first pattern when the magnetoresistive element is half-selected during a first data write, a second pattern when the magnetoresistive element is selected during a second data write, and a third pattern of residual magnetization, the first pattern being different from the second and third pattern, a second ferromagnetic layer having a second magnetization, and a nonmagnetic layer arranged between the first ferromagnetic layer and the second ferromagnetic layer and having a tunnel conductance changing dependent on a relative angle between the first magnetization and the second magnetization.

Owner:KIOXIA CORP

Magnetoresistive element

A magnetoresistive element includes a first ferromagnetic layer having a first magnetization, the first magnetization having a first pattern when the magnetoresistive element is half-selected during a first data write, a second pattern when the magnetoresistive element is selected during a second data write, and a third pattern of residual magnetization, the first pattern being different from the second and third pattern, a second ferromagnetic layer having a second magnetization, and a nonmagnetic layer arranged between the first ferromagnetic layer and the second ferromagnetic layer and having a tunnel conductance changing dependent on a relative angle between the first magnetization and the second magnetization.

Owner:KIOXIA CORP

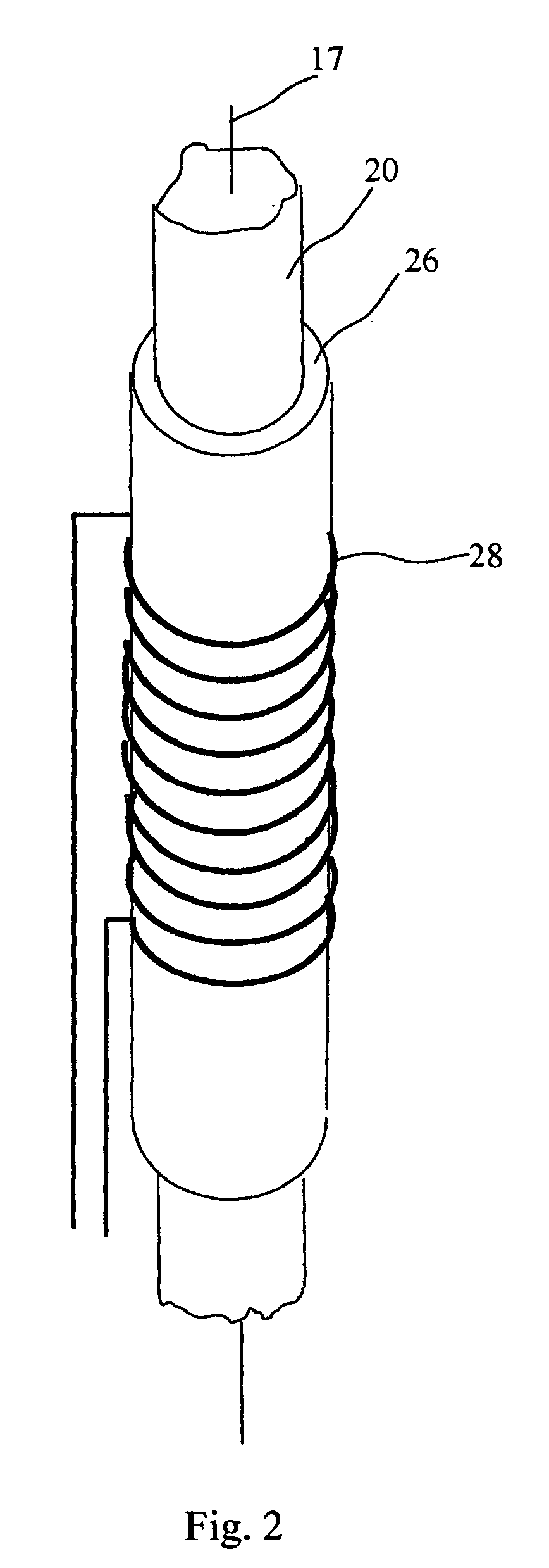

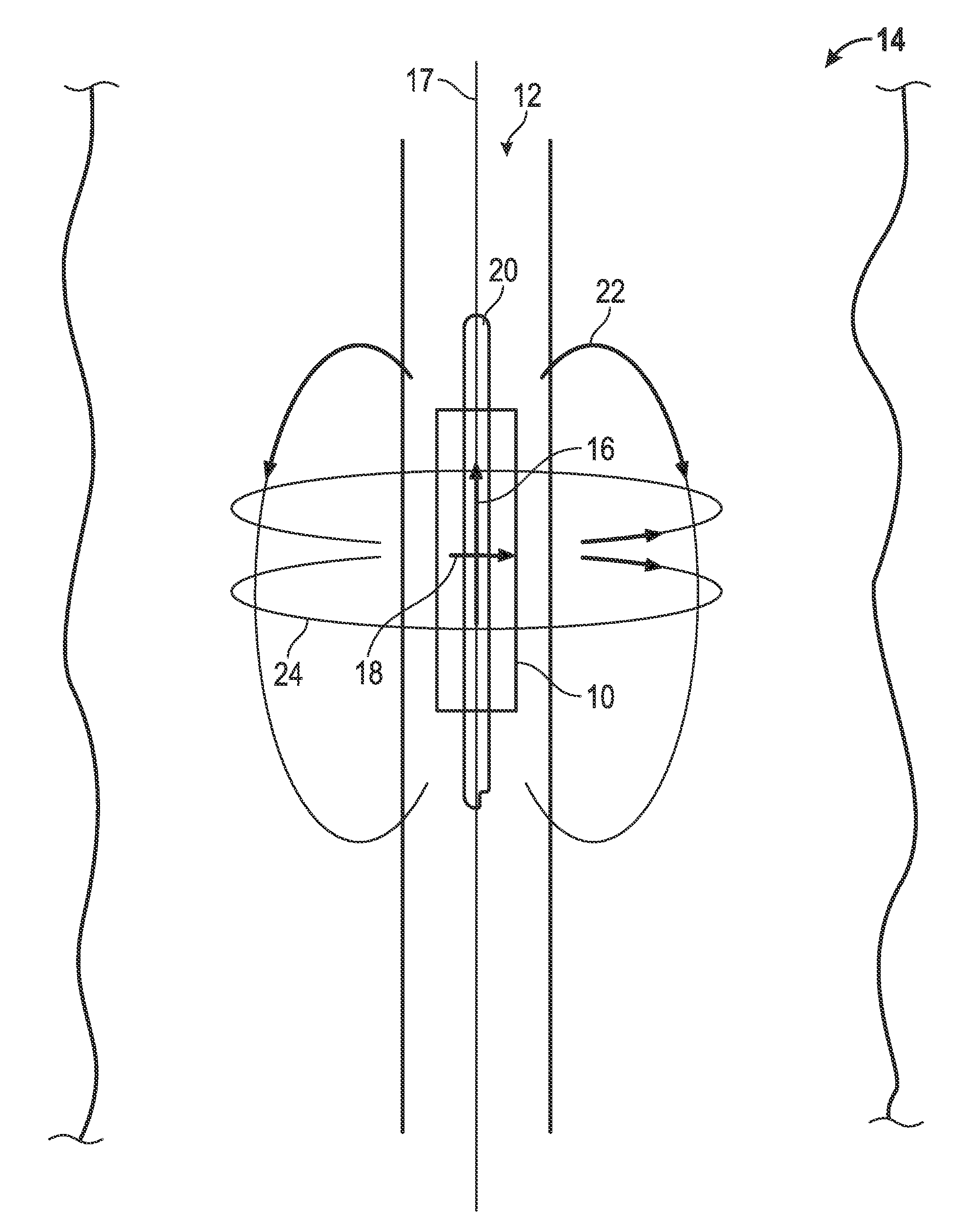

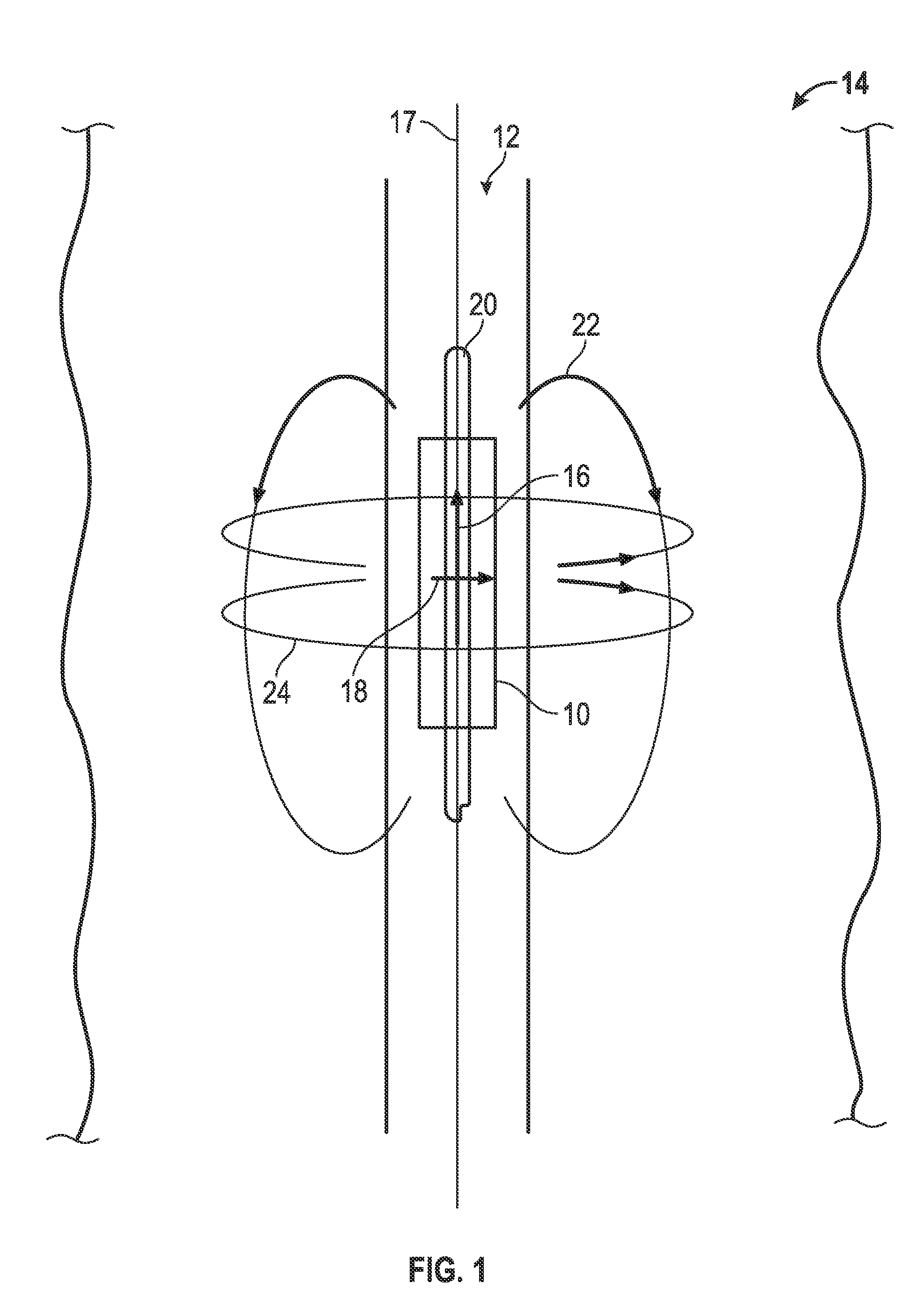

Method and apparatus of using magnetic material with residual magnetization in transient electromagnetic measurement

ActiveUS8432167B2Facilitates highly effective generationQuick switchElectric/magnetic detection for well-loggingAcoustic wave reradiationWell loggingTransmitter antenna

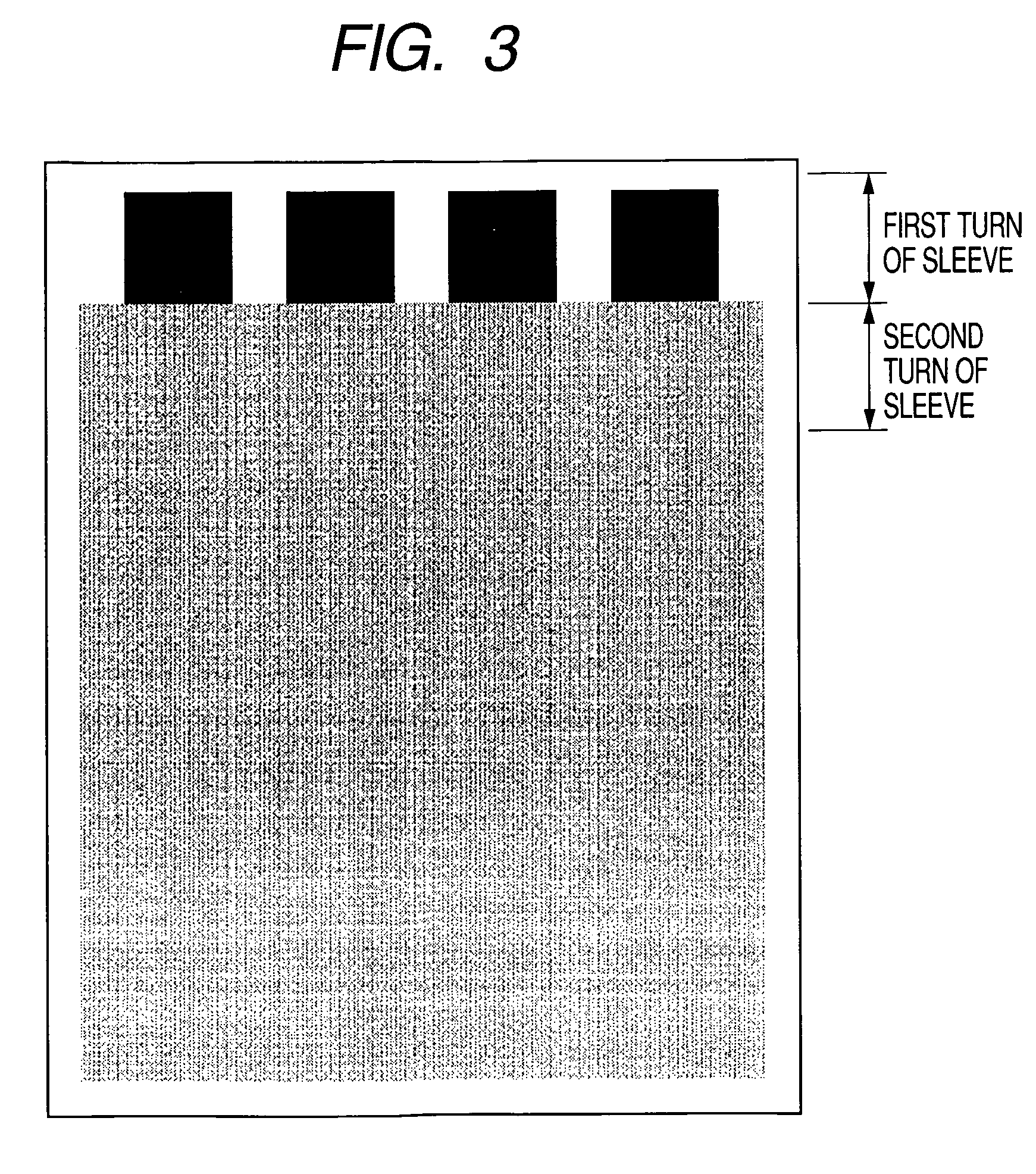

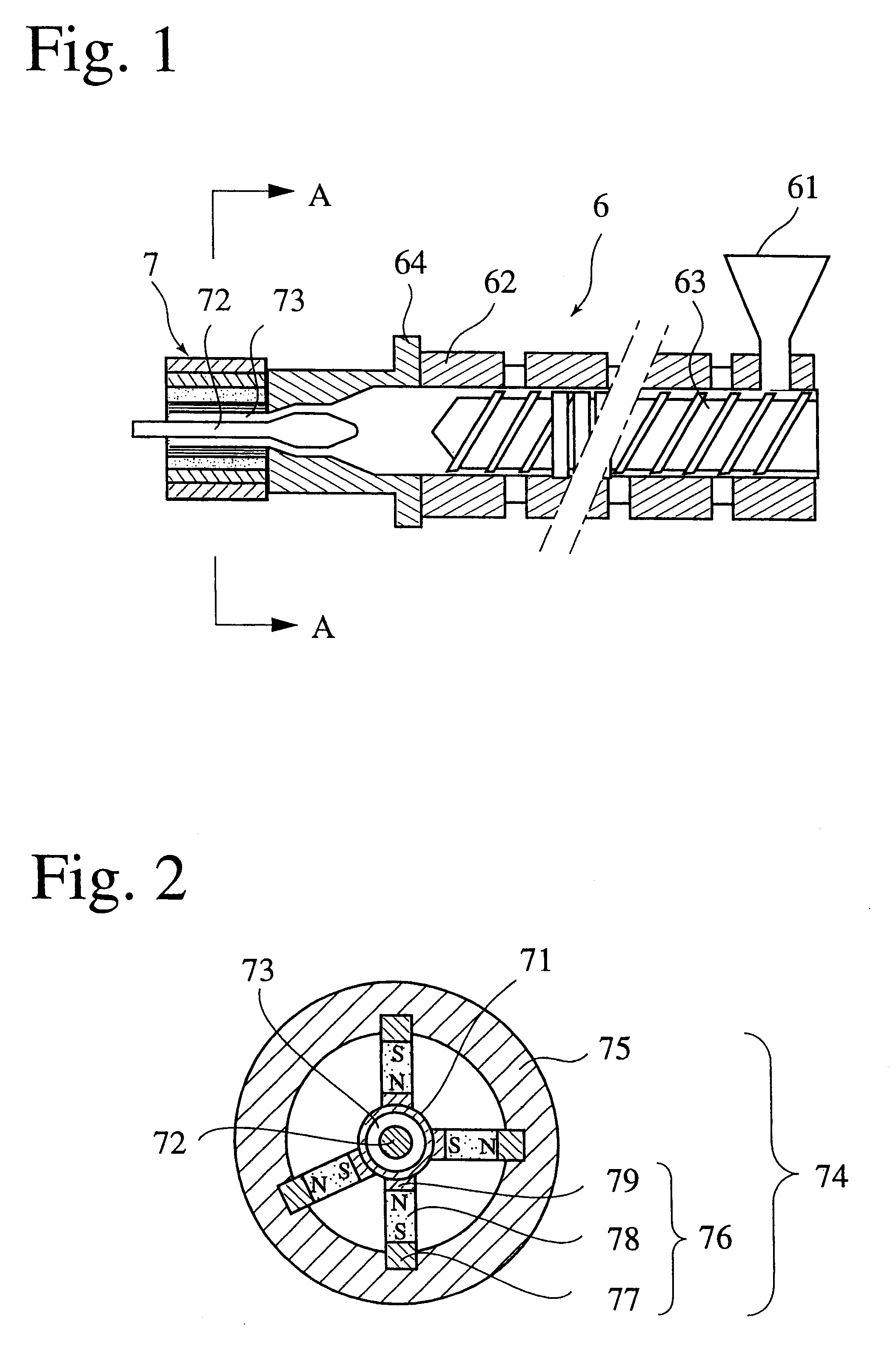

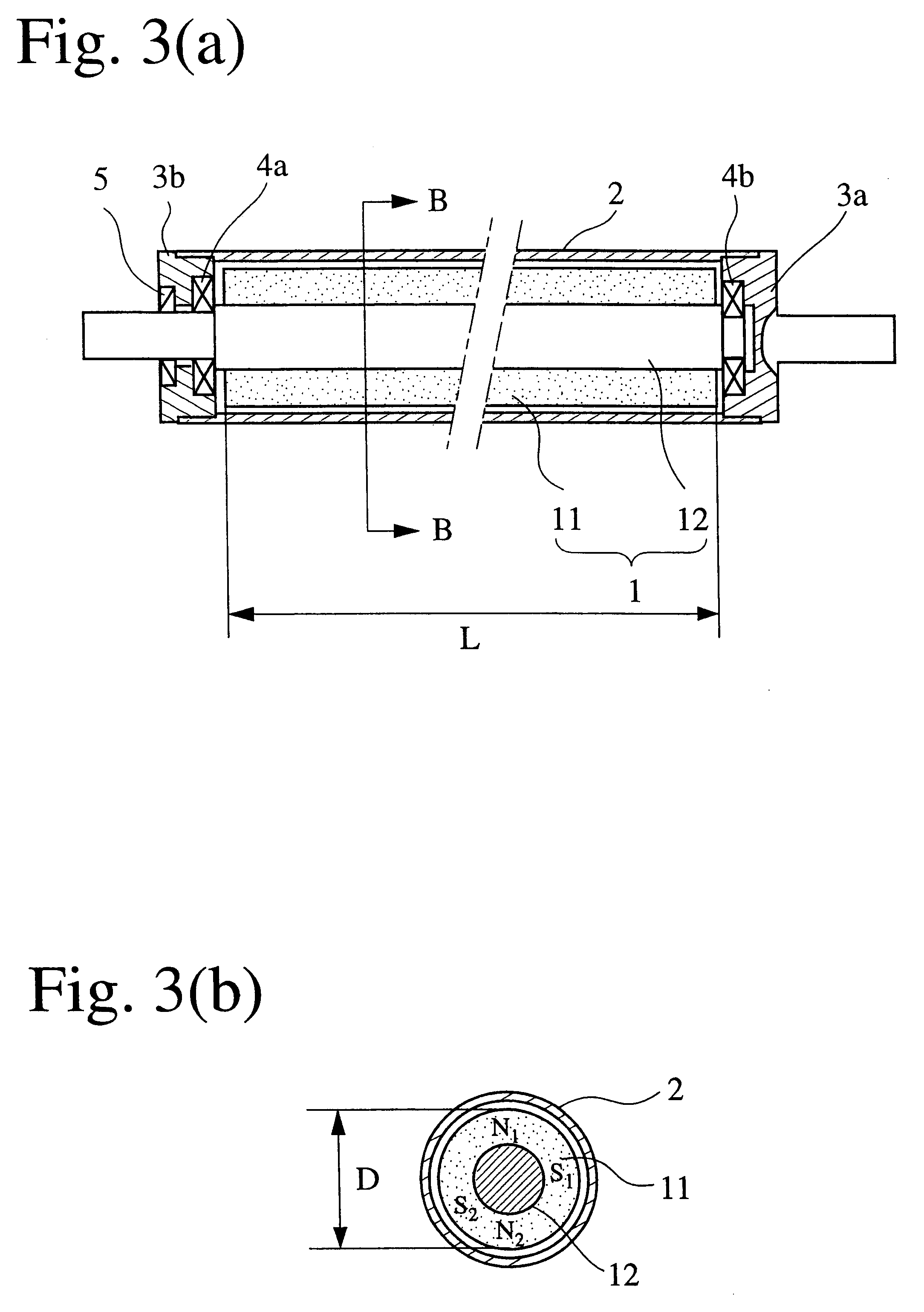

A transmitter antenna assembly for transient electromagnetic well logging instrument comprises an antenna coil coupled with a current source and a magnetic core having residual magnetization. Switching current in the antenna coil results in magnetization reversal in the magnetic core and change in magnetic dipole moment of the antenna. After the magnetization reversal is complete the current is removed and the new vector of magnetic dipole of the antenna maintains constant (steady-state phase of the antenna dipole) due to magnetic hysteresis of magnetic material employed for the magnetic core. No power expenditure during the steady-state phase of the magnetic dipole facilitates highly effective generation and fast switching of a large magnetic dipole. The magnetic core also serves as a shield between the antenna coil and any conductive part of the antenna assembly. Embodiments suitable for measurement-while-drilling or measurements through casing make use of residual magnetization of magnetic drill collar or magnetic casing respectively.

Owner:BAKER HUGHES INC

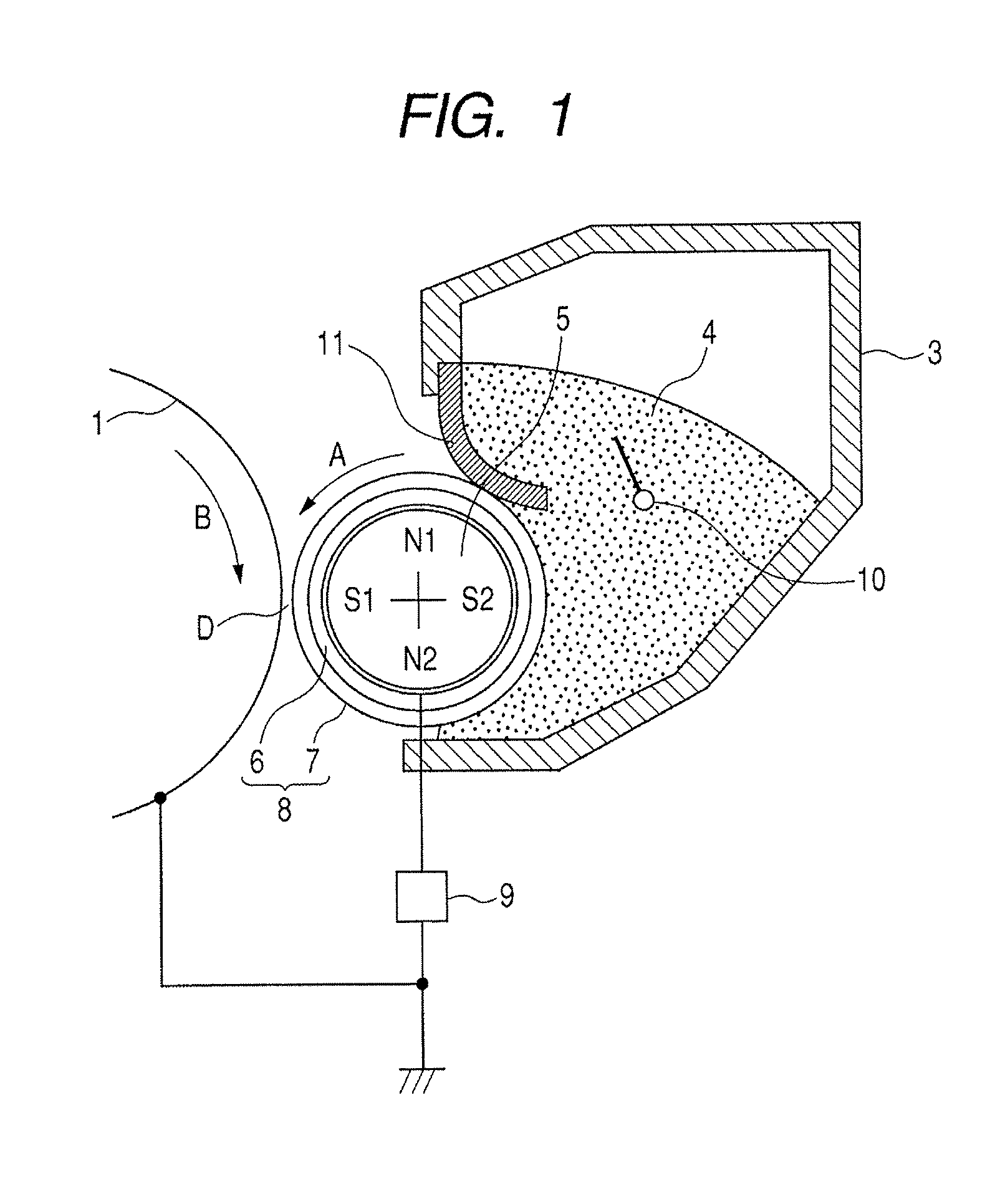

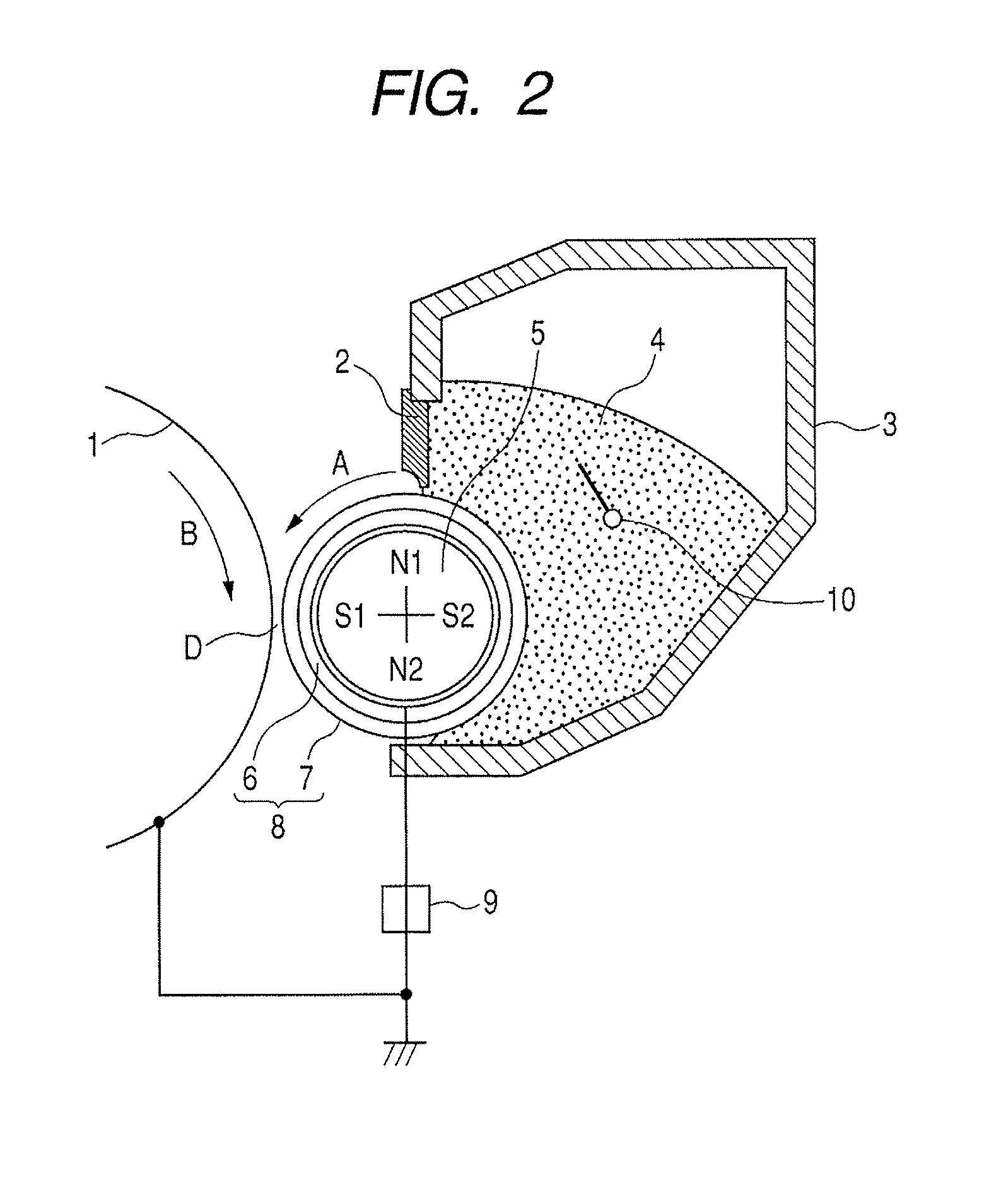

Magnetic sensor and method of producing the same

InactiveUS6904669B2Easy to produceNanostructure applicationElectrical transducersSingle chipMagnetic layer

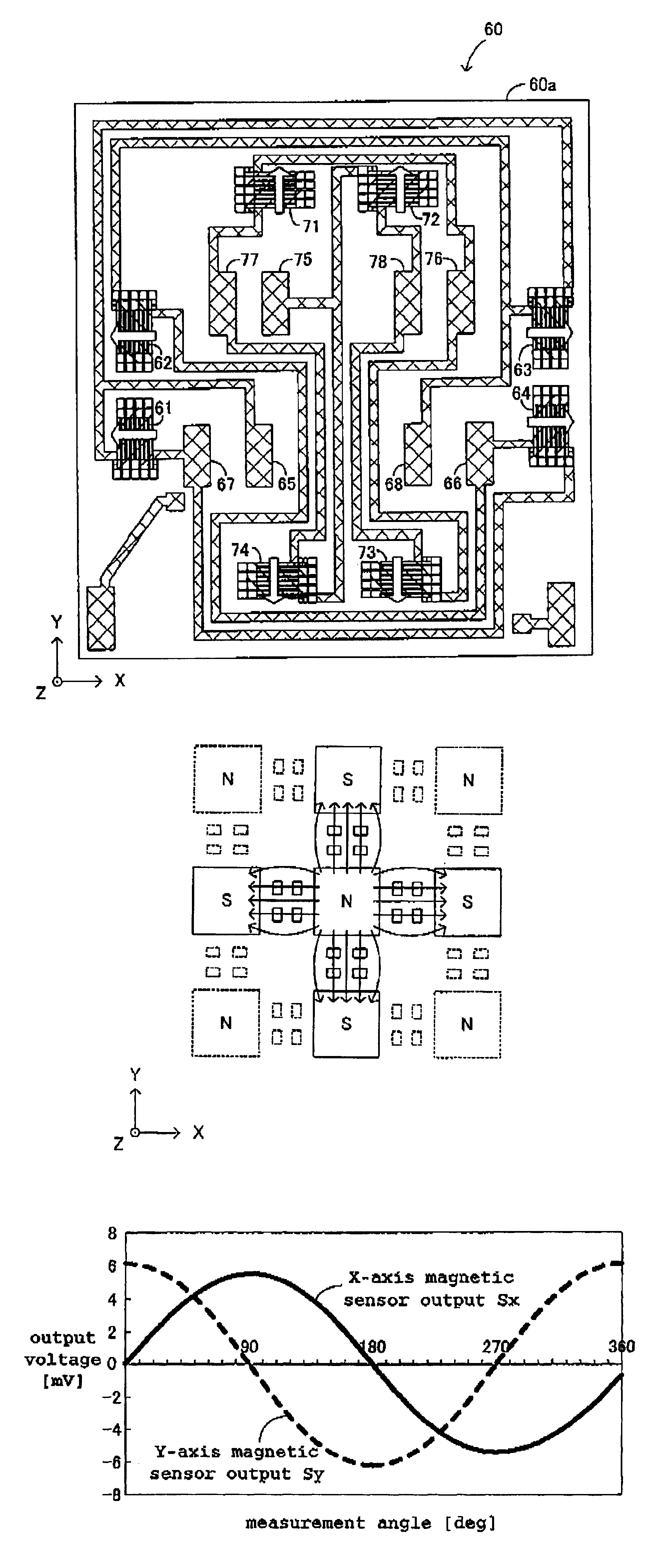

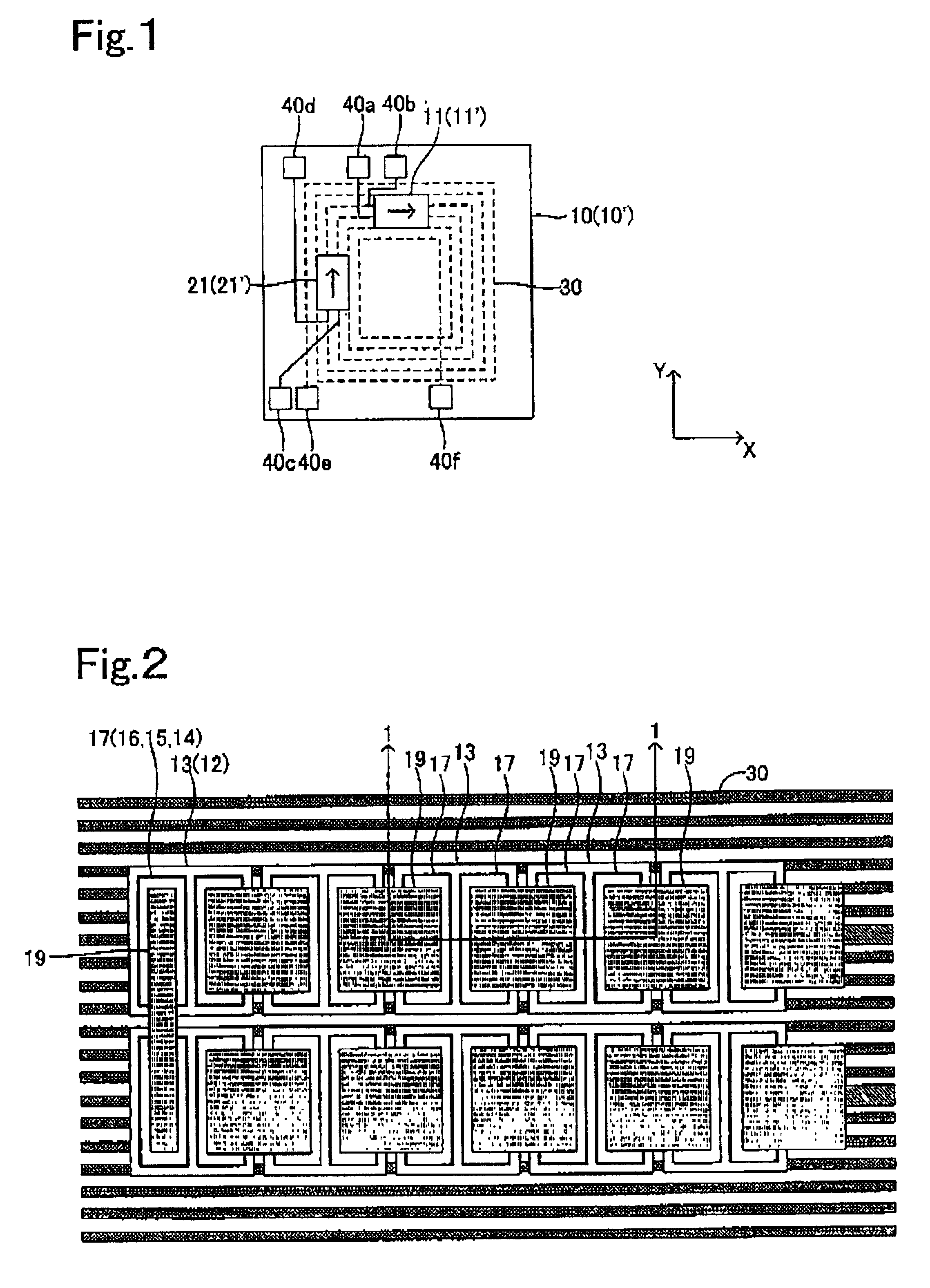

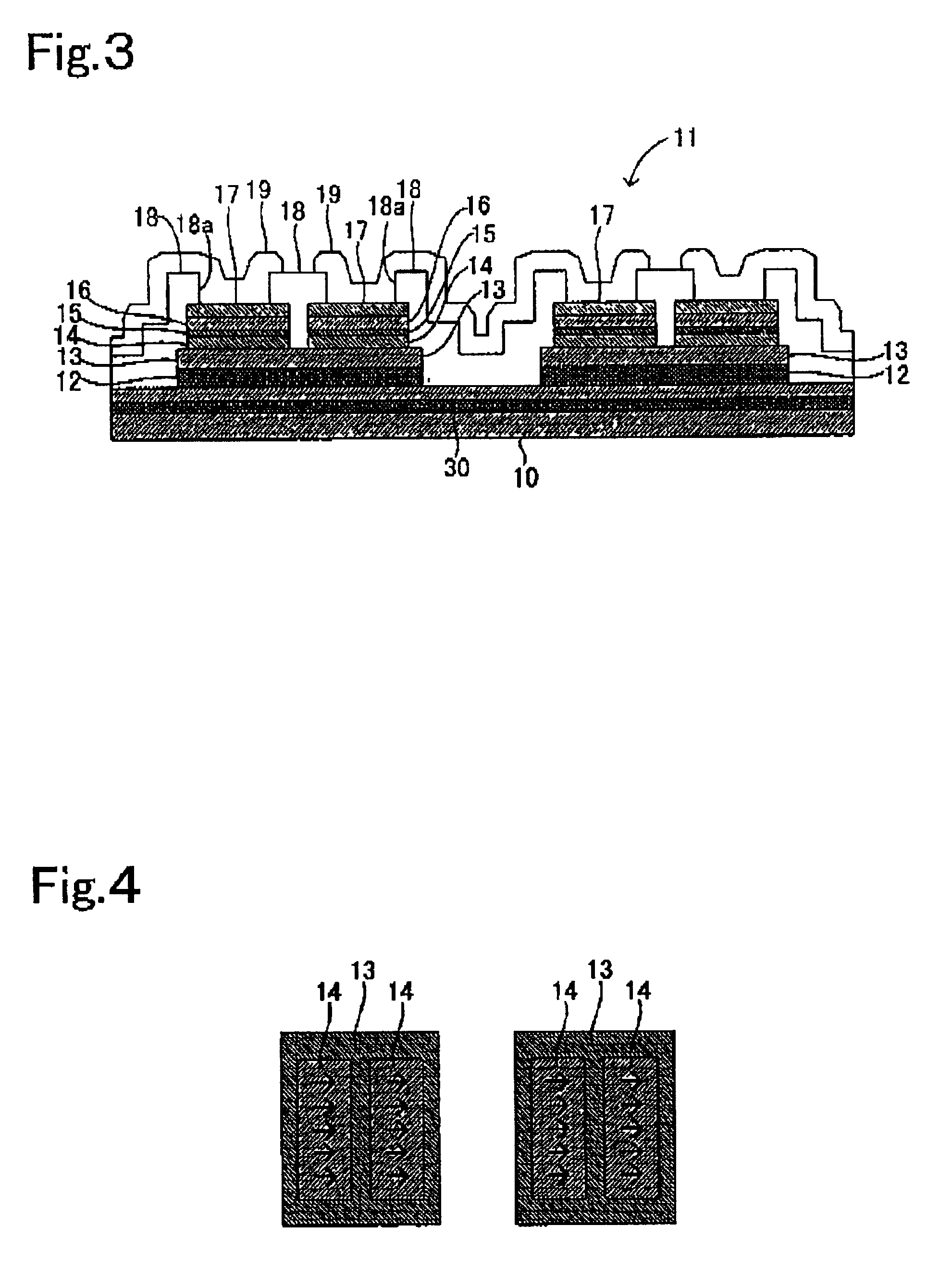

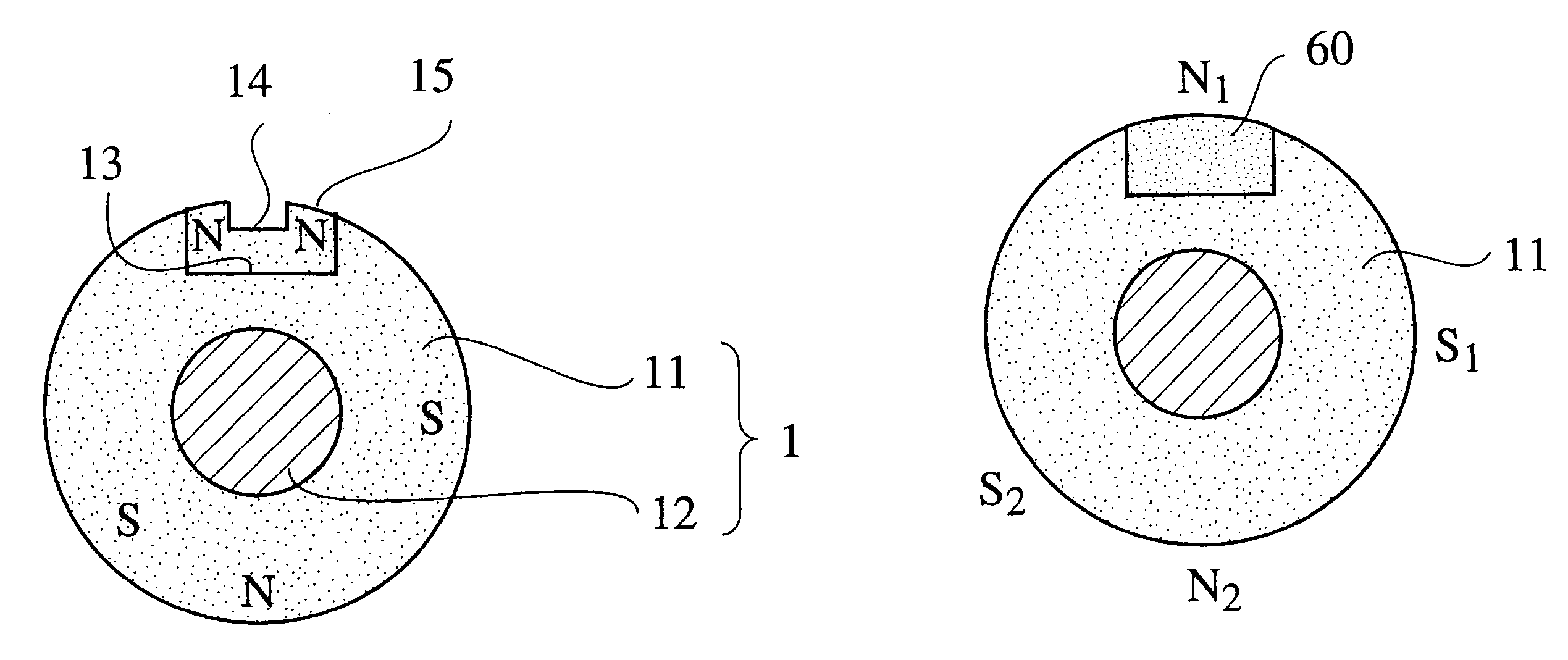

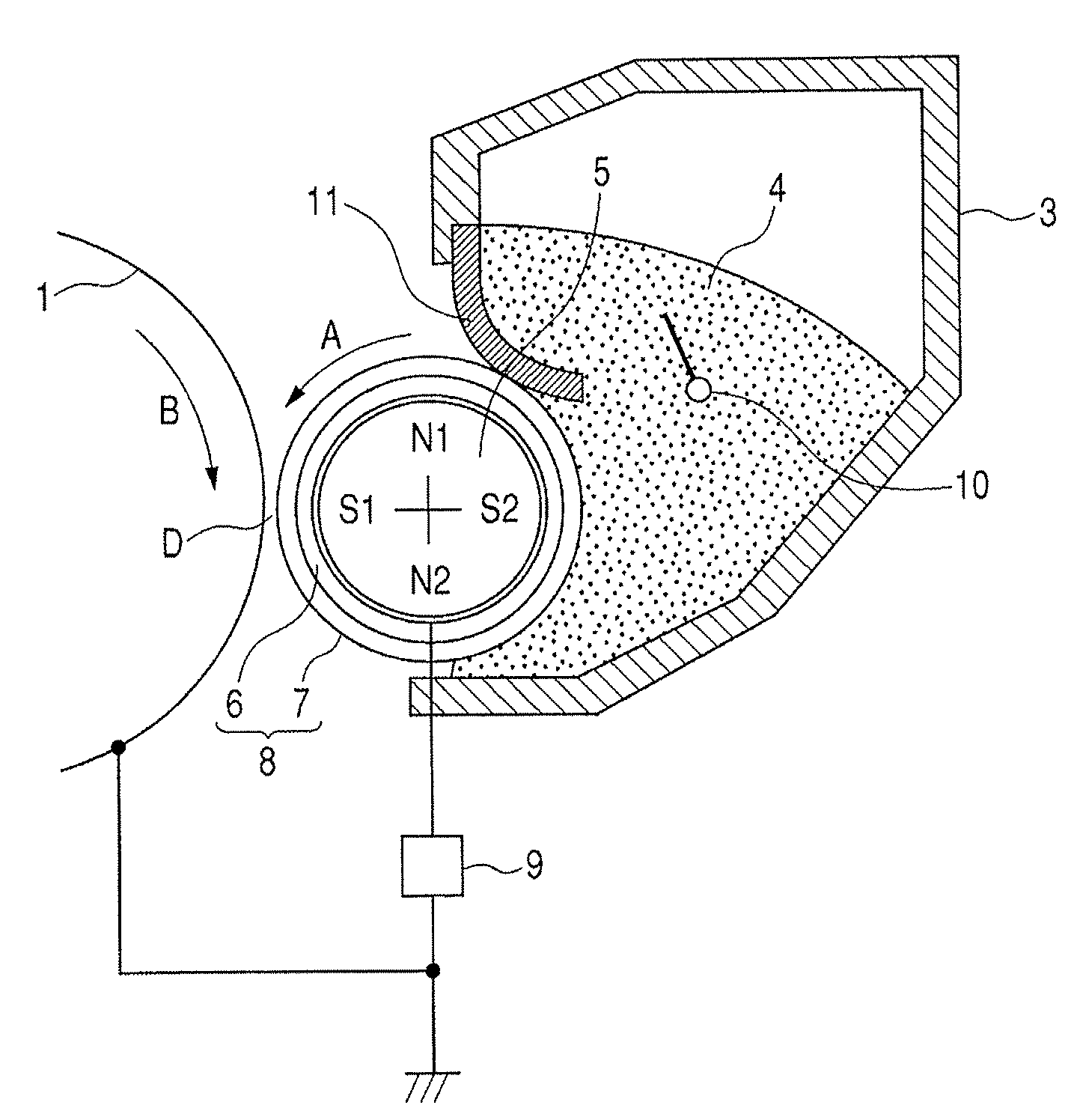

On a single chip are formed a plurality of magnetoresistance effect elements provided with pinned layers having fixed magnetization axes in the directions that cross each other. On a substrate 10 are formed magnetic layers that will become two magnetic tunnel effect elements 11, 21 as magnetoresistance effect elements. Magnetic-field-applying magnetic layers made of NiCo are formed to sandwich the magnetic layers in plan view. A magnetic field is applied to the magnetic-field-applying magnetic layers. The magnetic field is removed after the magnetic-field-applying magnetic layers are magnetized in the direction shown by arrow A. As a result of this, by the residual magnetization of the magnetic-field-applying magnetic layers, magnetic fields in the directions shown by arrows B are applied to the magnetic layers that will become magnetic tunnel effect elements 11, 21, whereby the magnetization of the pinned layers of the magnetic layers that will become magnetic tunnel effect elements 11, 21 is pinned in the directions shown by arrows B.

Owner:YAMAHA CORP

Magnet roll having an anisotropic bonded magnet portion containing rare earth-iron-nitrogen magnet powder

InactiveUS6421519B1High and uniform surface magnetic flux densityEasy to usePermanent magnetsMagnetic materialsRare-earth elementMetallurgy

Owner:HITACHI METALS LTD +1

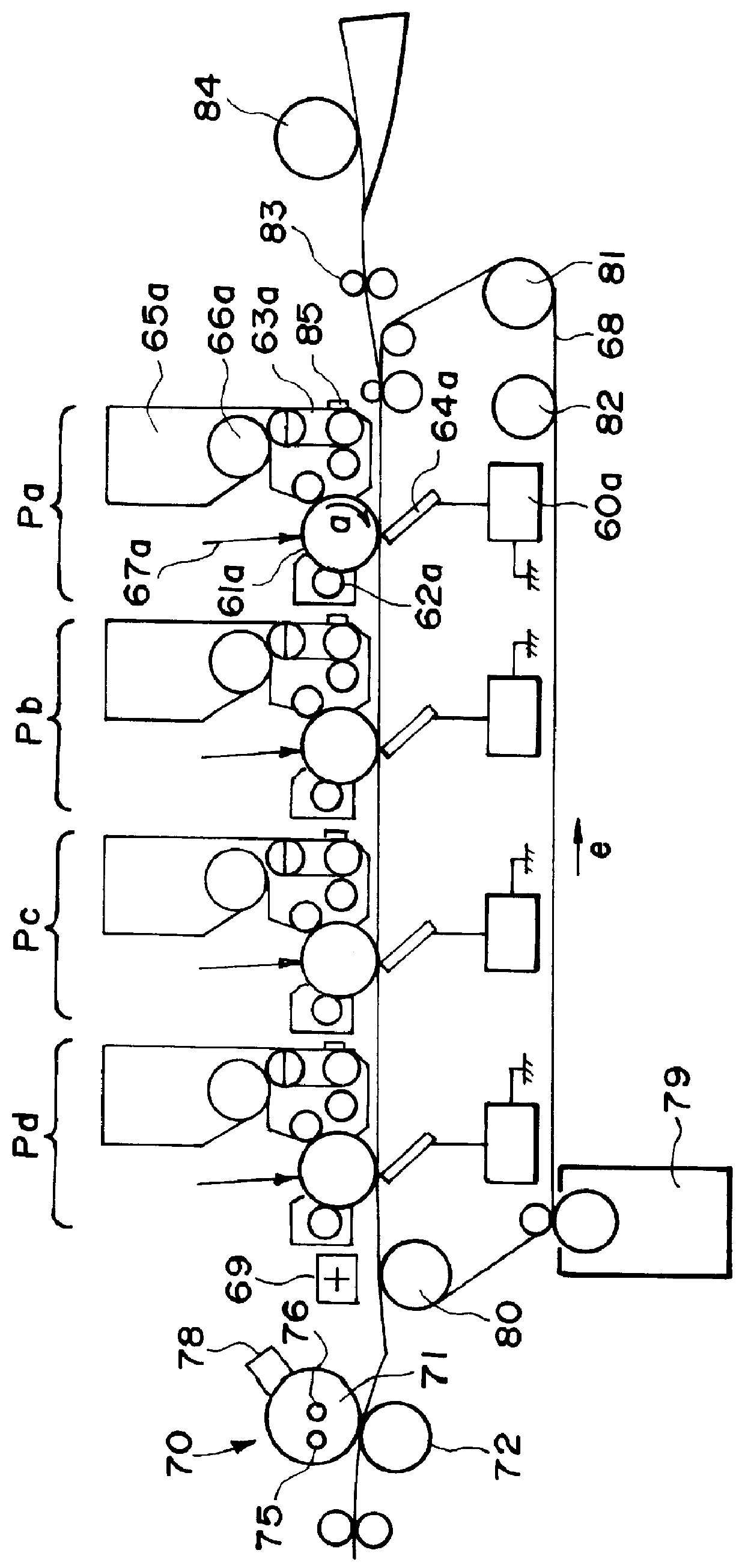

Developing method and developing assembly

A developing method is provided in which a developer is carried on a developer carrying member, a thin layer of the developer is formed thereon and a latent image on a latent image bearing member is developed with a developer. The developer is composed of magnetic toner particles containing a binder resin and a magnetic powder. The magnetic powder has a saturation magnetization of 67.0 Am2 / kg to 75.0 Am2 / kg in a magnetic field of 79.6 kA / m (1,000 oersteds) and has a residual magnetization of 4.5 Am2 / kg or less. In the surface profile of the conductive resin coat layer of the developer carrying member, the relationship 1.00≦S / A≦1.65 is satisfied where S is a surface area of regions zoned by an area A of microscopic unevenness regions from which parts exceeding a reference plane by 0.5×r (r: weight average particle diameter (μm) of a toner used) or more have been excluded.

Owner:CANON KK

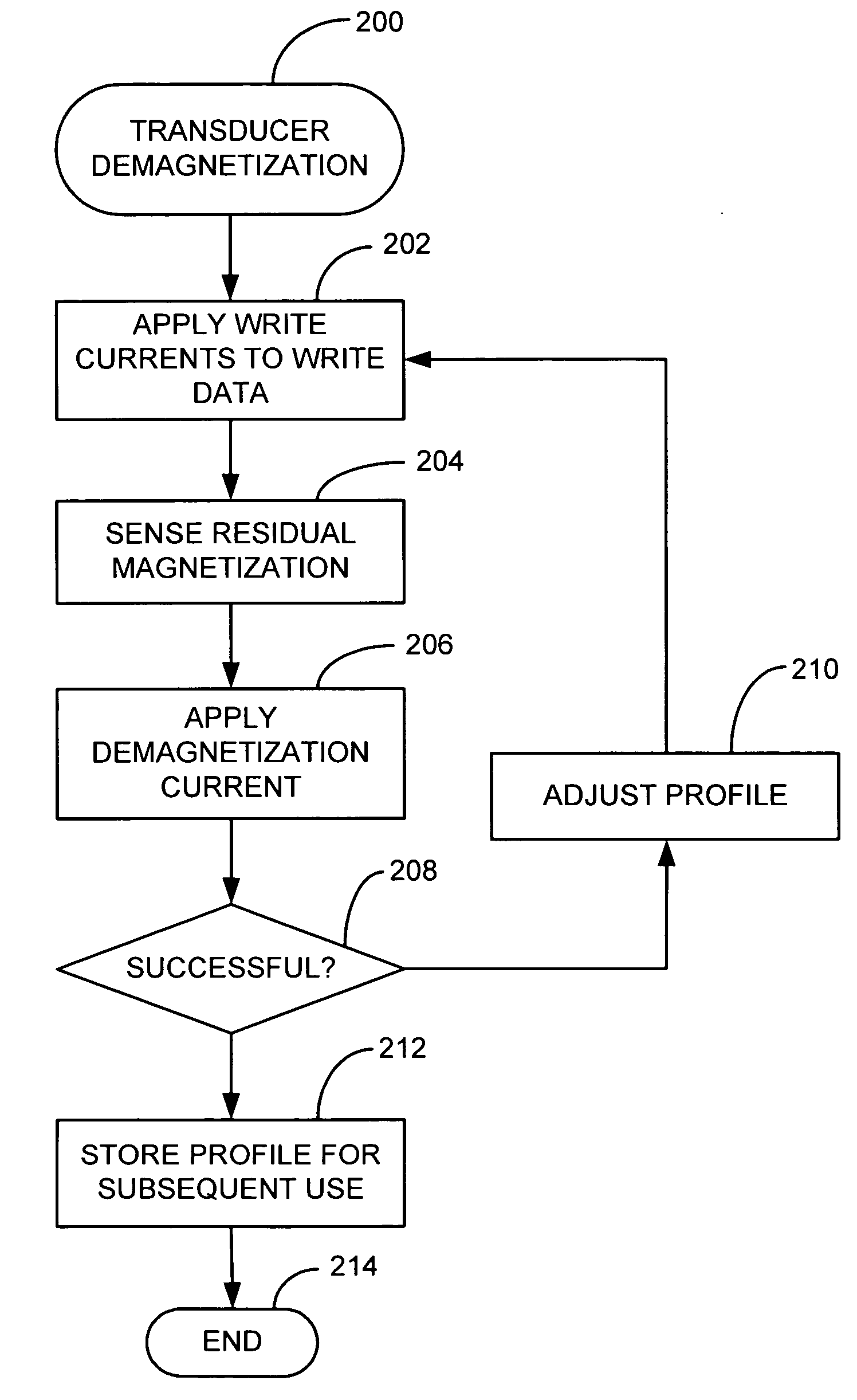

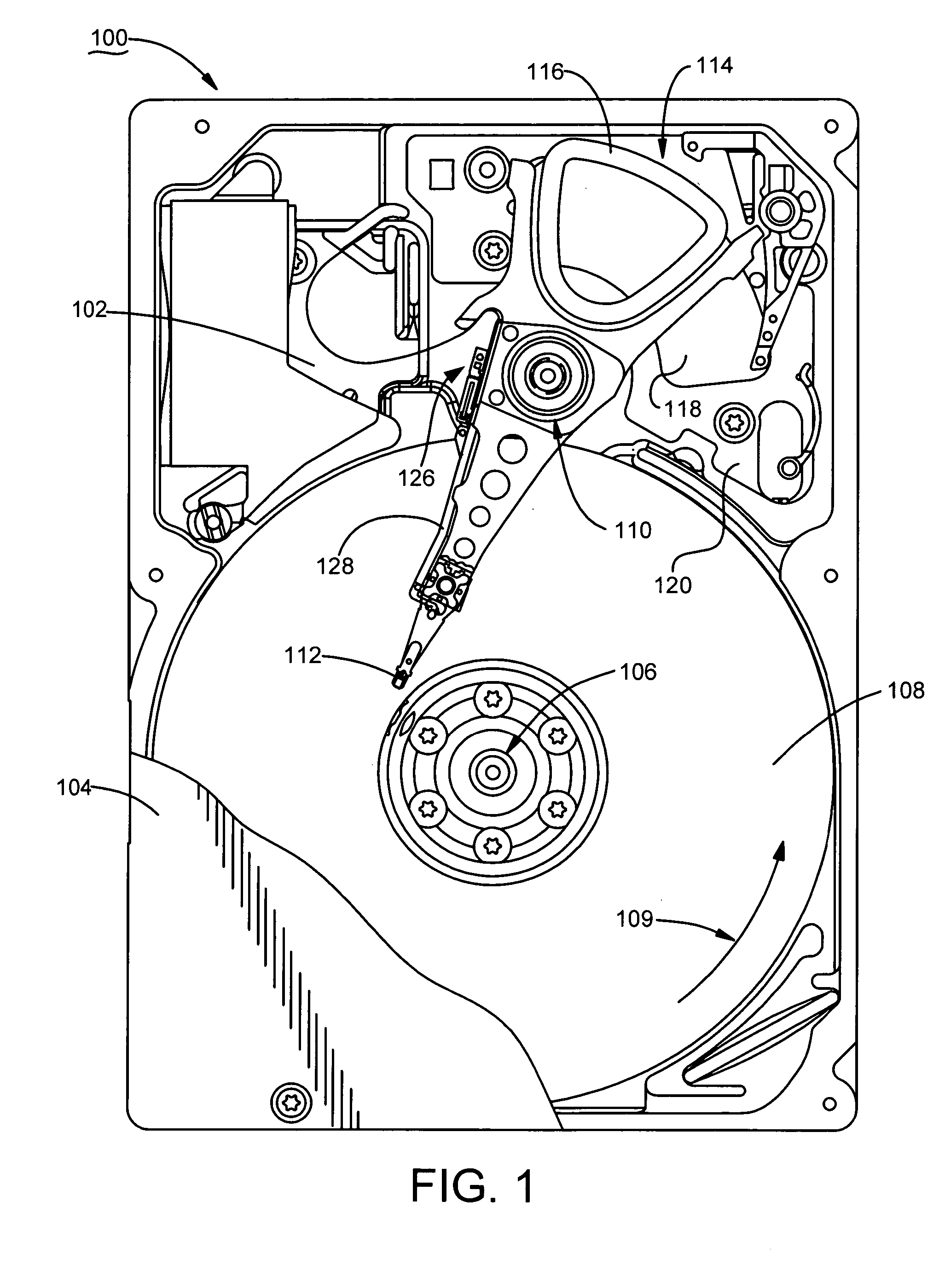

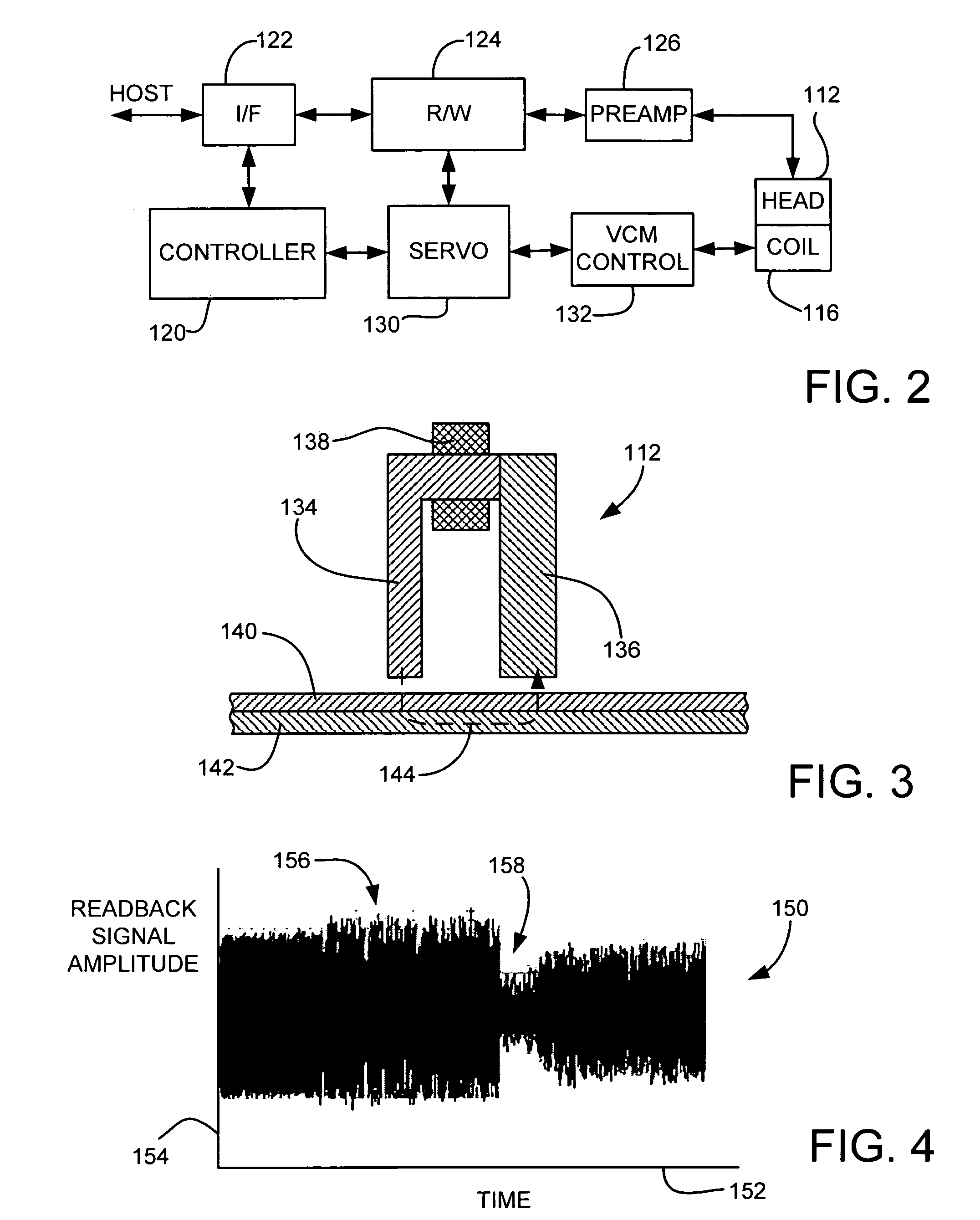

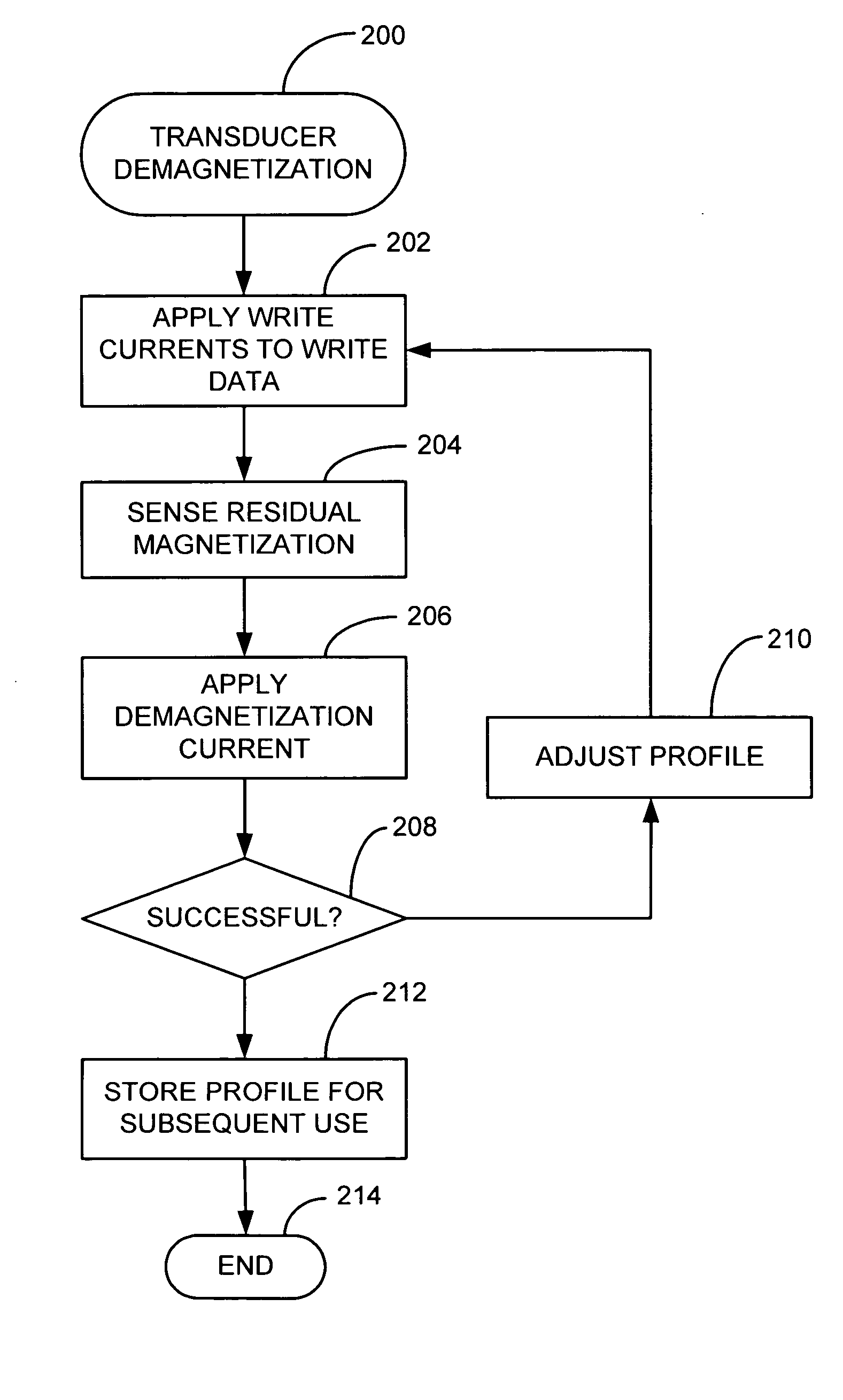

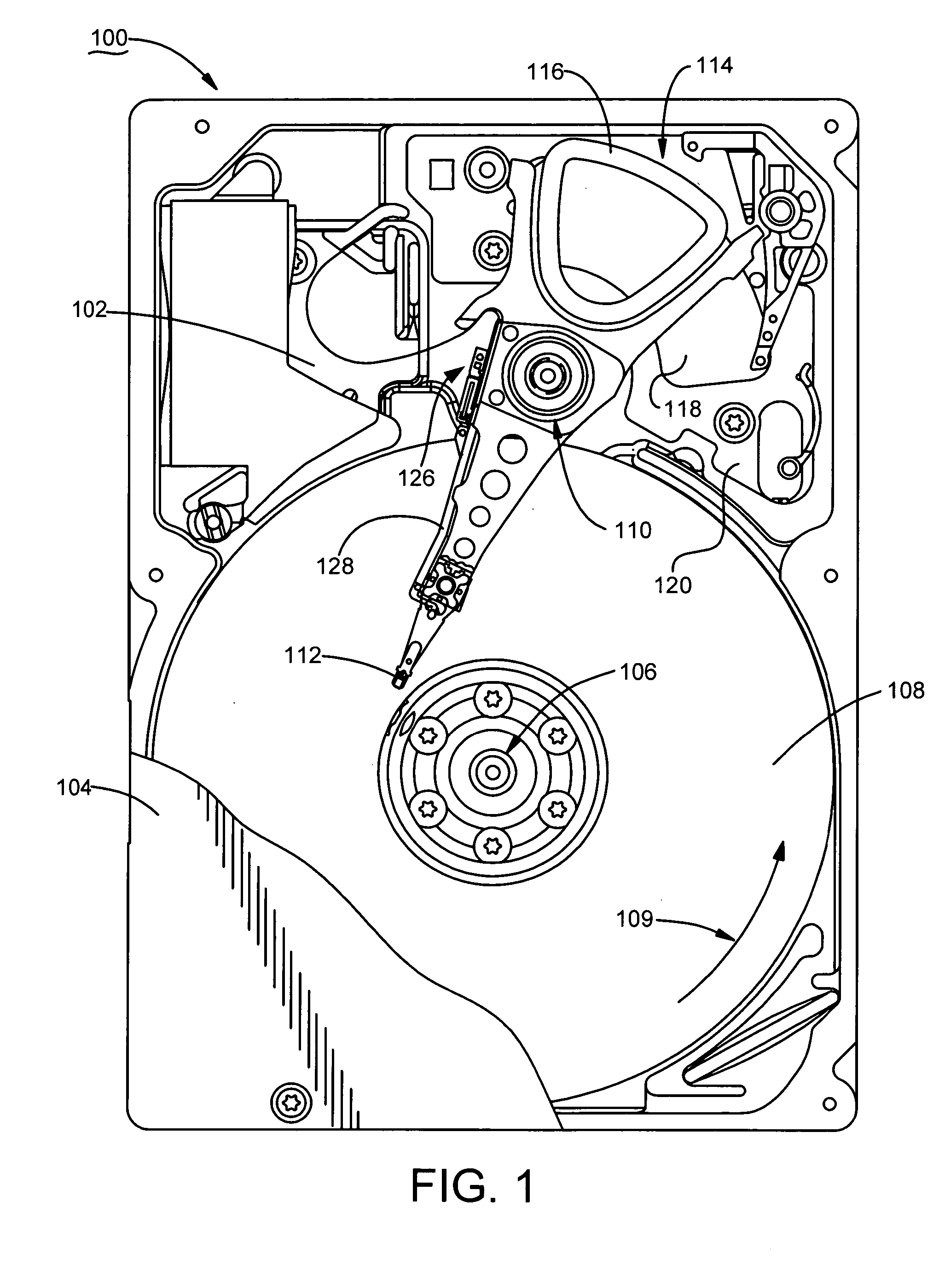

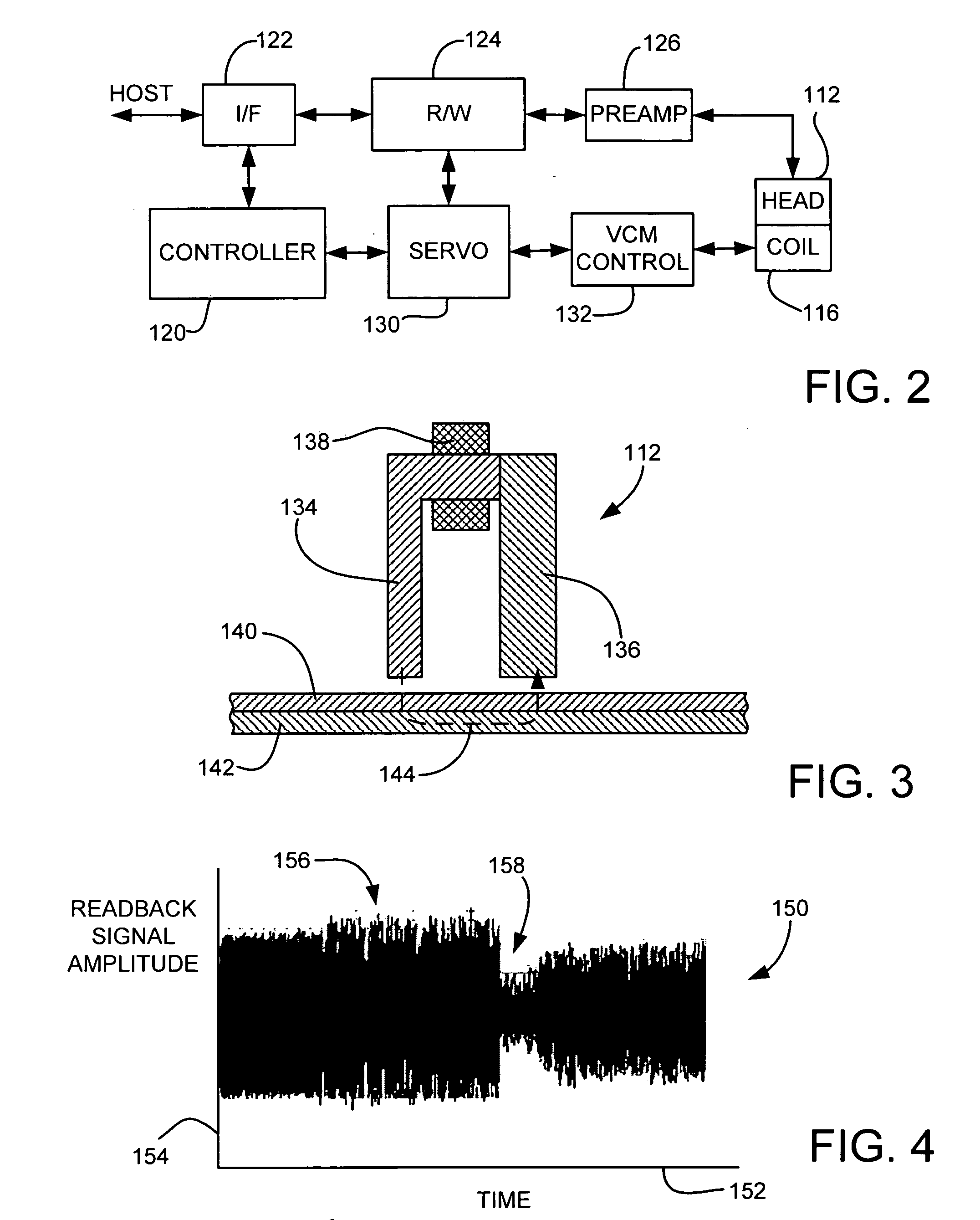

Removing residual magnetization in a data transducer

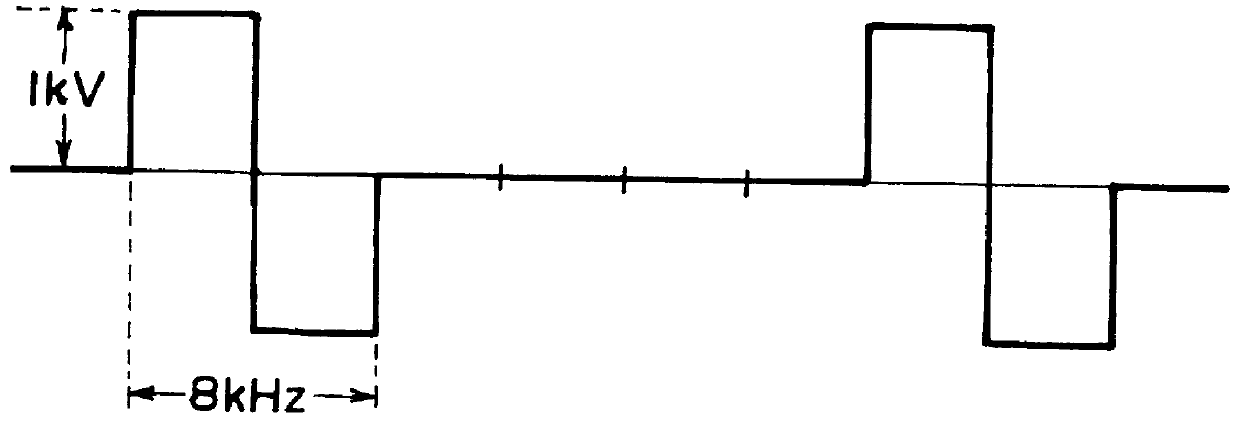

ActiveUS7088537B2Driving/moving recording headsDemagnetisation of recording headsDriver circuitSensing data

Method and apparatus for removing residual magnetization in a data transducer, such as a recording head used to write data to a recording medium in a data storage device. A residual magnetization sense circuit senses a residual magnetization of a pole of the data transducer as a result of the application of a data transmission current to the transducer. A demagnetization current generator removes the residual magnetization by supplying the transducer with a demagnetizing current that decreases to a final magnitude in accordance with a selected profile. The demagnetization current preferably comprises a bi-directional, time varying current of selected frequency to the transducer that tapers linearly, exponentially or in a step-wise fashion to the final magnitude. The demagnetization profile is preferably continuously adapted during operation. Preferably, the sense circuit and demagnetization current generator are incorporated into a preamplifier / driver circuit which performs the demagnetization operation in a self-contained fashion.

Owner:SEAGATE TECH LLC

Method of raising permanent magnetic ferrite residual magnetization by adding additive

InactiveCN1414575AImprove remanenceHigh energy productInorganic material magnetismStrontiumSilicon dioxide

An additive to be used for raising the residual magnetism of ferrite in permanent magnetism adds an additive of raising the residual magnetism with the molecular formula of MxSiyO2, where X=1=4, y=0-2, Z=2-6 in addition to add calcium carbonate and 1-4 additives of kaolin silica, aluminium oxide and boracic acid to increase its coercive force in the secondary process during production course of strontium ferrite or barium ferrite, where X, Y and Z can be decimal and M is one or more kinds of mixtures of Fe, Pr, Nd, Mn, Sr and C. With the same raw material, by use of the additive of MxSiyO2 ofthe present invention, the residual magnetism can be raised by 50-150 Gs based on 3600-4100 Gs.

Owner:BGRIMM TECH CO LTD +2

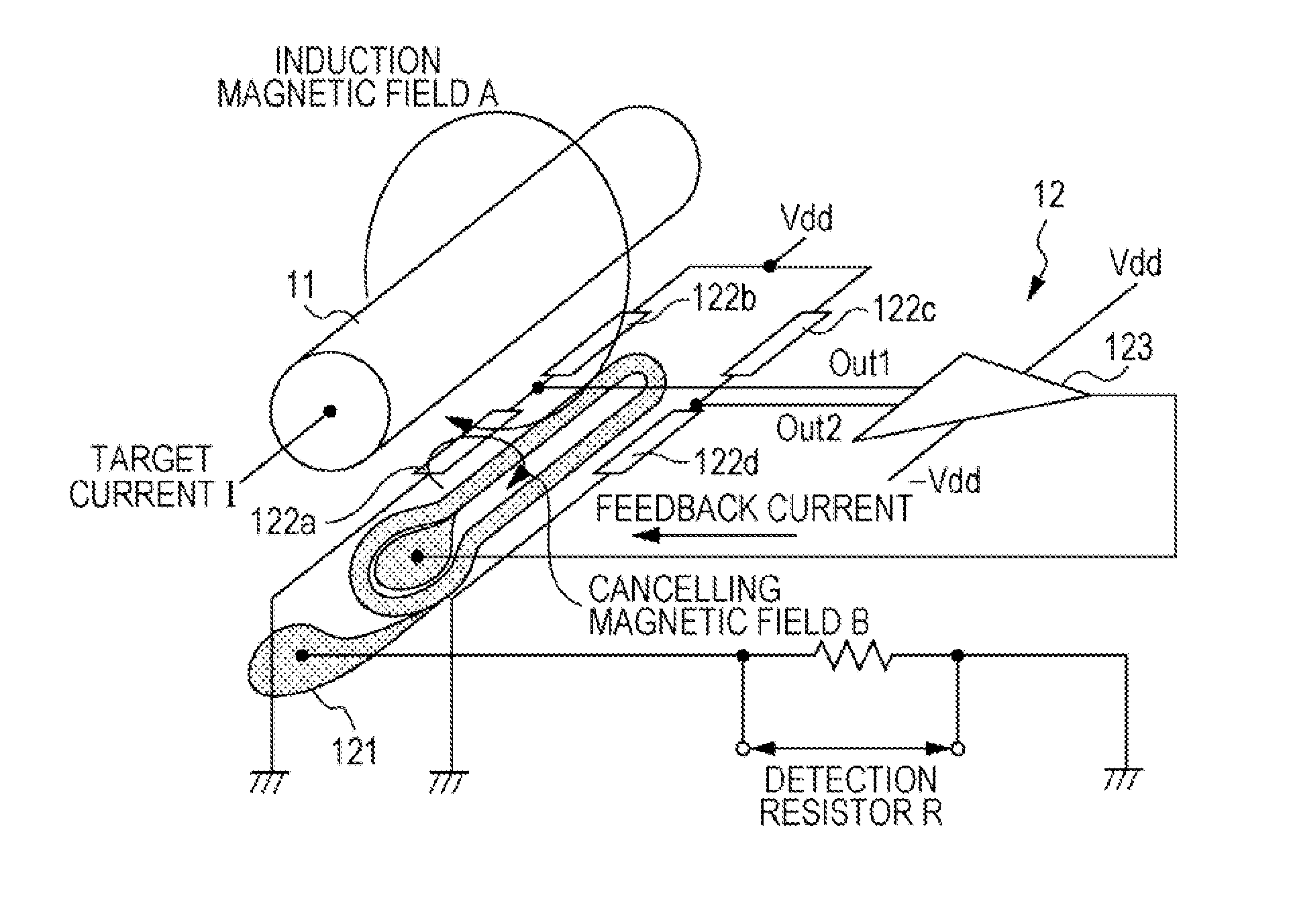

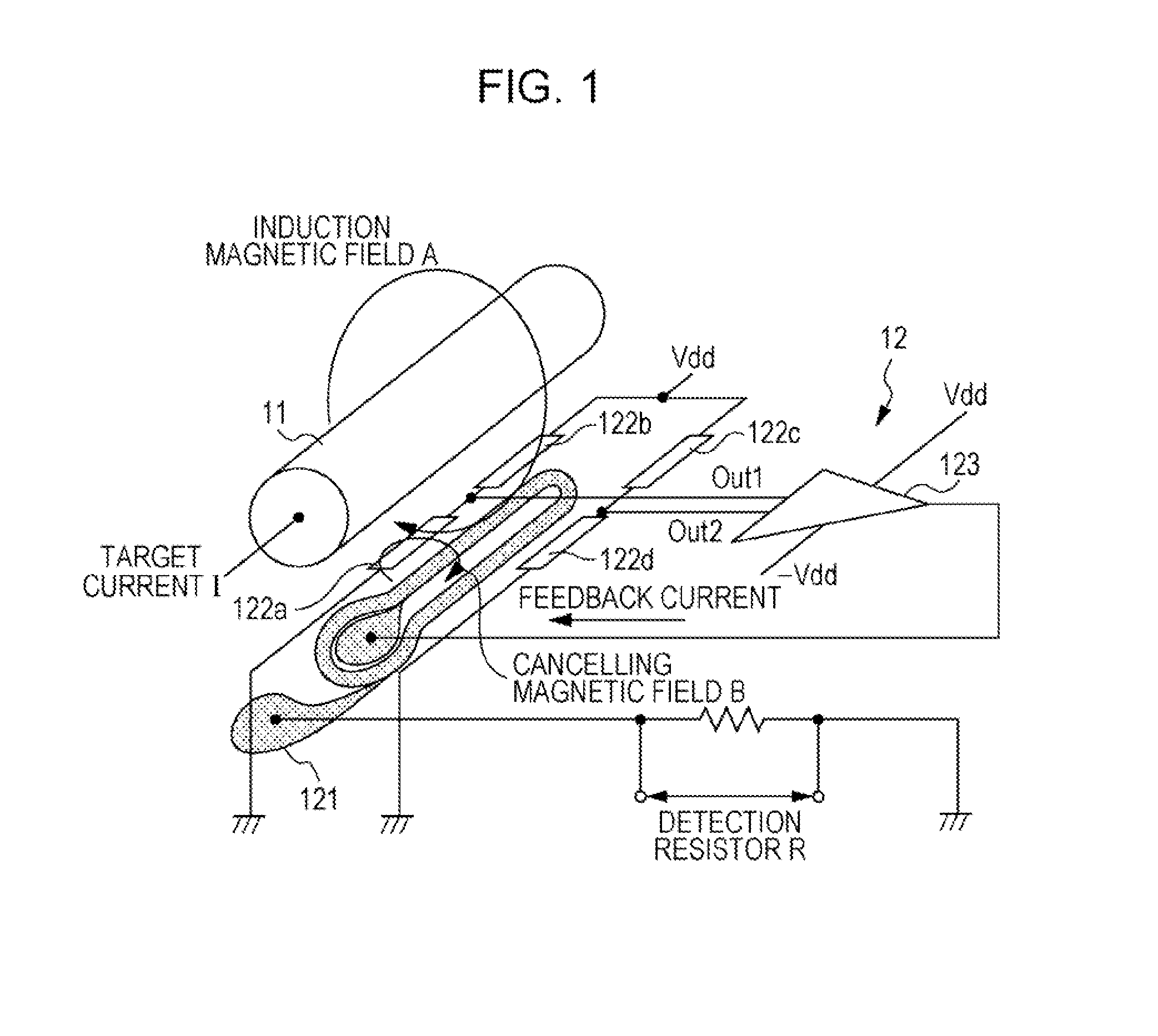

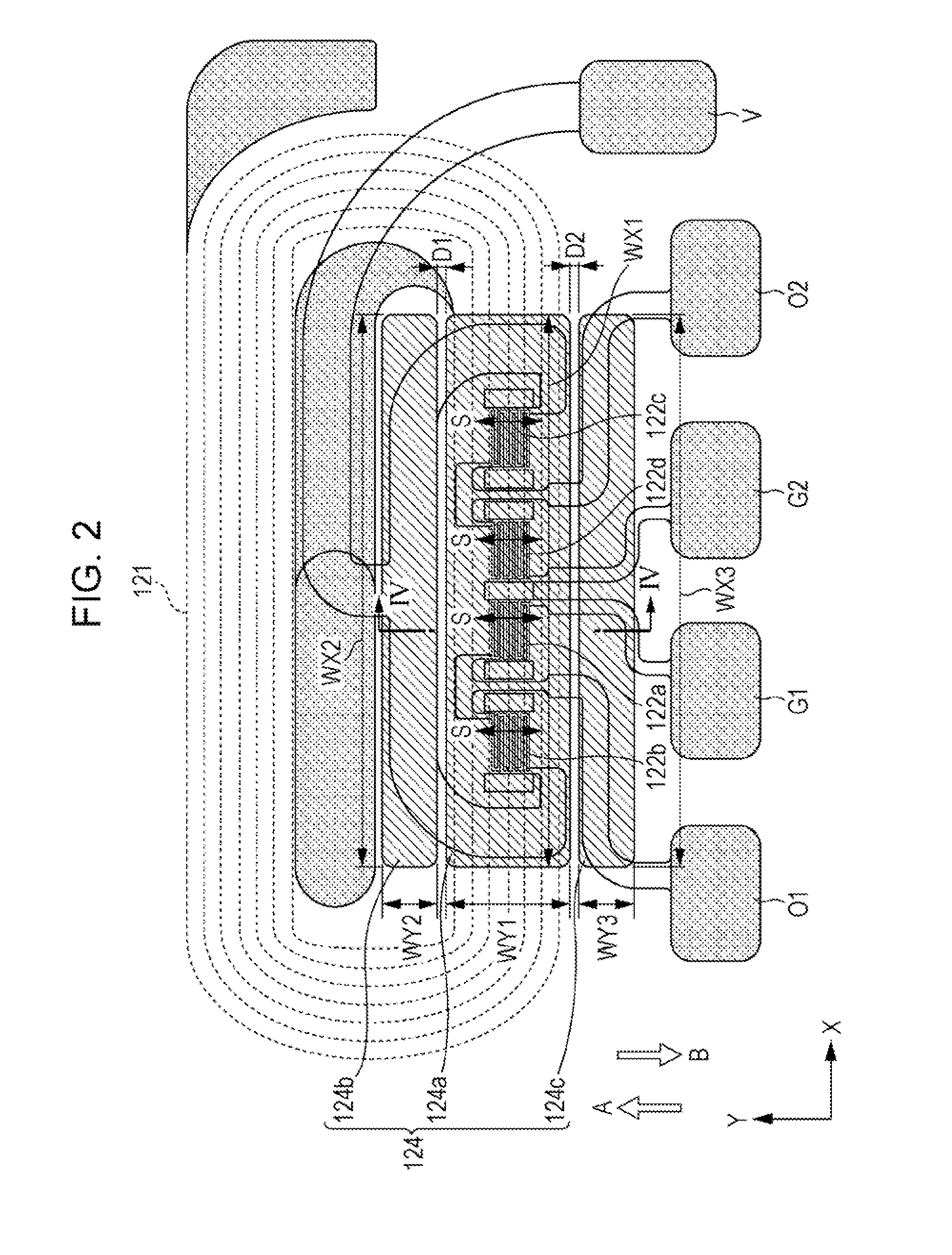

Current sensor

InactiveUS20130057273A1Reduce decreaseInhibition effectMagnitude/direction of magnetic fieldsIn planeCurrent sensor

A current sensor includes a magnetoresistive element and magnetic shields arranged between a current line and the magnetoresistive element. The magnetic shields include a flat first magnetic shield placed so as to attenuate the strength of an induction magnetic field applied to the magnetoresistive element and a flat second magnetic shield placed apart from the first magnetic shield in a direction in-plane with the main surface of the first magnetic shield so as to attenuate the strength of the induction magnetic field applied to the magnetoresistive element and reduce the influence of residual magnetization in the first magnetic shield.

Owner:ALPS GREEN DEVICES

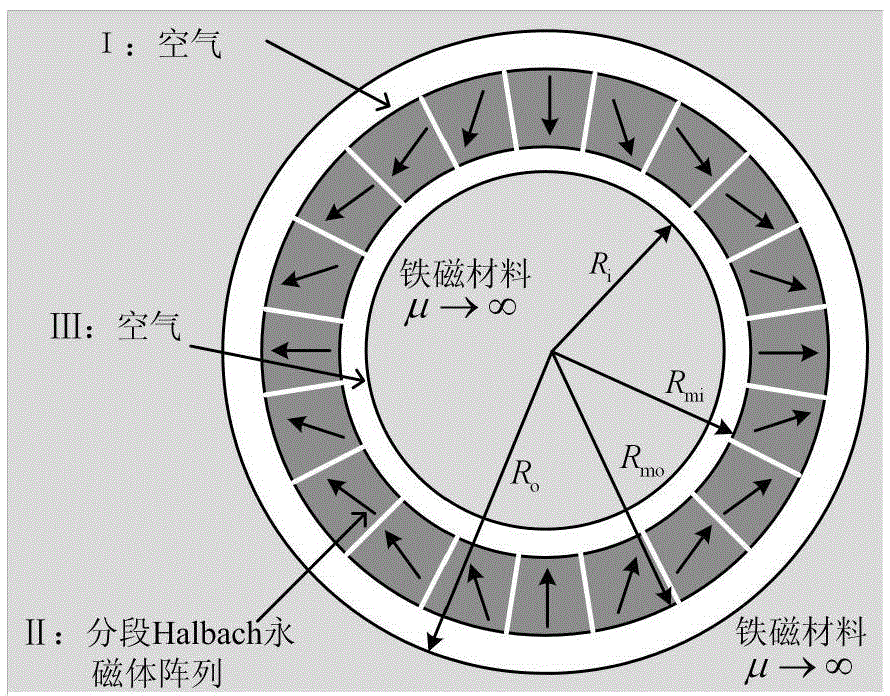

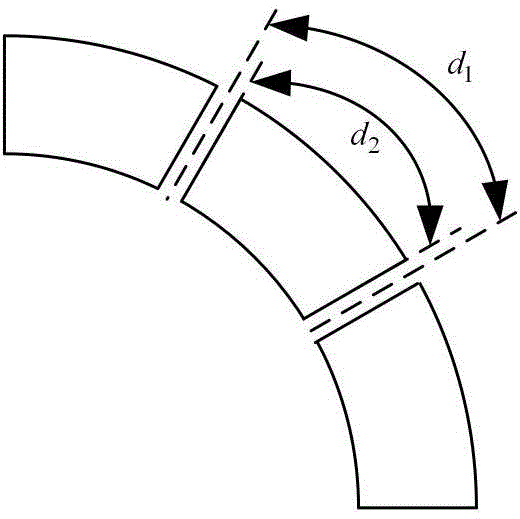

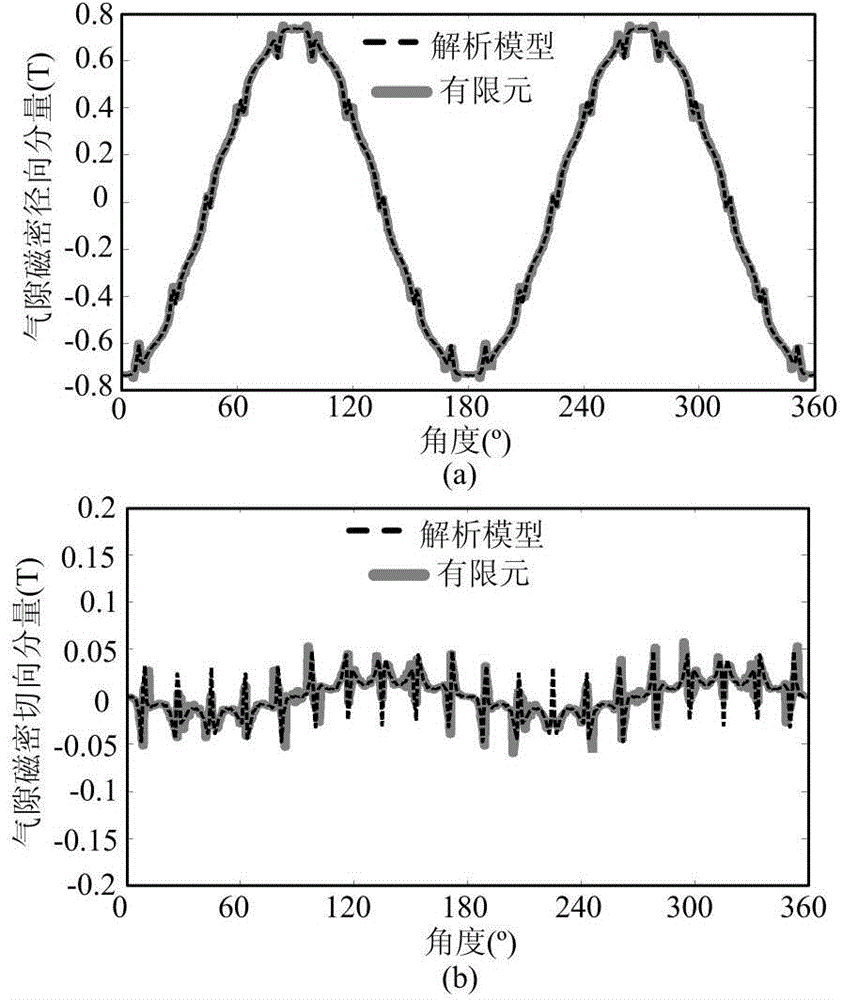

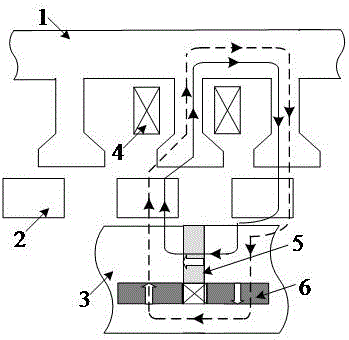

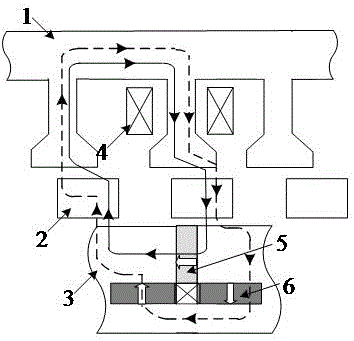

Sectional type Halbach array permanent magnet motor magnetic field calculation method

ActiveCN104091060AAccurate distributionSpecial data processing applicationsHarmonicPermanent magnet motor

The invention relates to a sectional type Halbach array permanent magnet motor magnetic field calculation method. The sectional type Halbach array permanent magnet motor magnetic field calculation method comprises the steps of determining solution areas, respectively building Laplace's equations or Poisson's equations for the different solution areas, calculating the interval between magnetic blocks of a sectional type Halbach array, solving the radial and tangential component amplitudes under each order of harmonic waves of residual magnetization intensity of a permanent magnet, solving the built Laplace's equations or Poisson's equations, obtaining an expression of a scalar magnetic potential in the solution areas, and further obtaining radial and tangential components of flux densities of the areas. The sectional type Halbach array permanent magnet motor magnetic field calculation method can accurately solve the magnetic field of an inner and outer rotor sectional type Halbach array permanent magnet motor with any magnetic block number of each pole and any number of pole pairs.

Owner:TIANJIN UNIV

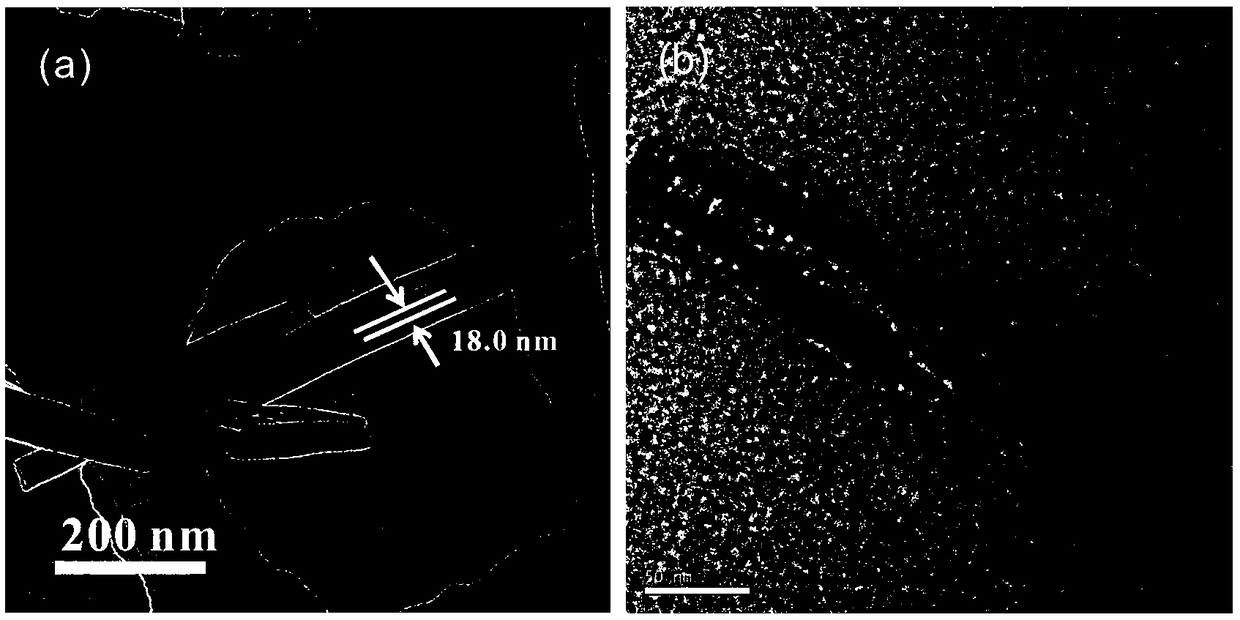

Method for preparing nanocomposite material by assembling ferriferrous oxide in halloysite tube

ActiveCN108059193AGood biocompatibilityStrong Application AdvantageMaterial nanotechnologyAluminium silicatesHalloysiteBiocompatibility Testing

The invention provides a method for preparing a nanocomposite material by assembling ferriferrous oxide in a halloysite tube, and belongs to the technical field of deep processing of nonmetallic minerals. The method comprises the following four steps: (1) pretreatment, tube expansion and purification of the halloysite minerals; (2) modification in the halloysite tube; (2) preparation of Fe3O4 magnetic nanoparticles through a mixed hydrothermal solution technology; and (4) vacuum impregnation for obtaining the compoiste material with the nano-Fe3O4 assembled in the halloysite tube. The halloysite / Fe3O4 composite material prepared in the invention has no residual magnetization or coercive force, and has a typical paramagnetic performance. The material prepared through the method has good biocompatibility, and broadens the application prospect of mineral magnetic materials in the fields of biomedicines and composite magnetic materials.

Owner:CENT SOUTH UNIV

Porous ferrite core material for electrophotographic developer, resin-filled ferrite carrier and electrophotographic developer using the ferrite carrier

InactiveUS20110129772A1Increased durabilityIncreased operating lifeDevelopersUltimate tensile strengthFerrite core

A porous ferrite core material for an electrophotographic developer, the porous ferrite core material including Mg in a content of 0.3 to 3% by weight, Ti in a content of 0.4 to 3% by weight and Fe in a content of 60 to 70% by weight, and the porous ferrite core material having a pore volume of 0.04 to 0.16 ml / g, a peak pore size of 0.4 to 1.6 μm, a saturation magnetization of 40 to 80 Am2 / kg, a remanent magnetization of less than 7 Am2 / kg and a coercive force of less than 43 A / m; a resin-filled ferrite carrier for an electrophotographic developer obtained by filling a resin in the voids of the porous ferrite core material; and an electrophotographic developer using the ferrite carrier.

Owner:POWDERTECH

Titanium-doped barium ferrite ceramic material and preparation method thereof

The invention discloses a titanium-doped barium ferrite ceramic material and a preparation method thereof. Densification sintering of the ceramic material is achieved through titanium doping, and electron hopping and a nonuniform conduction structure are formed through the replacement of iron ions to titanium ions. The ceramic has high residual magnetization, and great dielectric constant can be produced by utilizing the nonuniform conduction structure. The preparation method of the titanium-doped barium ferrite ceramic comprises the following steps of: preparing a ceramic precursor through a citrate sol-gel method, and then molding and sintering at high temperature to obtain the titanium-doped barium ferrite ceramic, wherein the molar ratio of titanium to barium is controlled between 0.4 and 0.8; and the molar ratio of iron to barium is between 11.6 and 11.2. According to the titanium-doped barium ferrite ceramic material and preparation method thereof, the process is simple, the cost is low, and meanwhile extremely high dielectric constant, high saturation magnetization and residual magnetization can be obtained. The residual magnetization acts as an important multifunctional material and can be used for developing preparation of relative electronic components.

Owner:ZHEJIANG UNIV

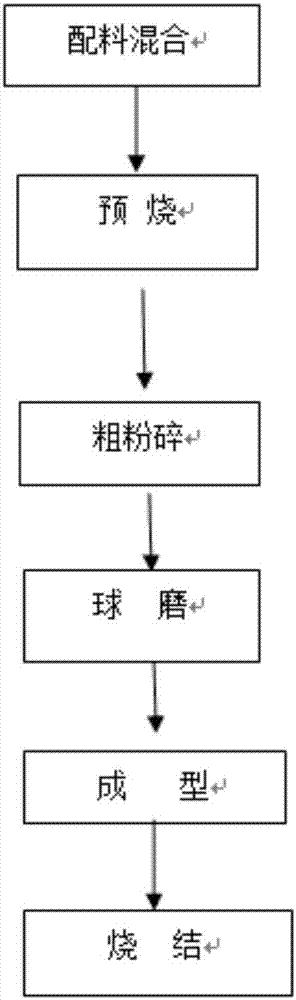

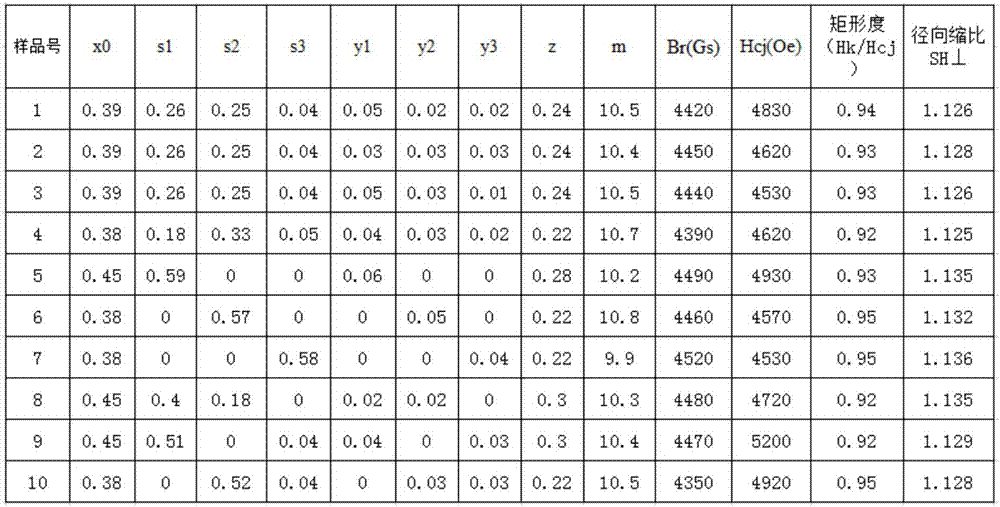

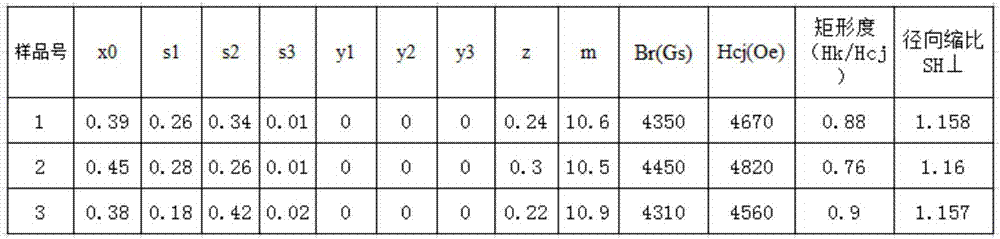

Hexagonal sintered permanent magnetic ferrite magnet and preparation method thereof

ActiveCN107056270AHigh residual flux densityImprove performanceInorganic material magnetismInductances/transformers/magnets manufactureAlkaline earth metalPotassium

The invention discloses a hexagonal sintered permanent magnetic ferrite magnet and a preparation method thereof and belongs to the field of permanent magnetic ferrite magnets. The composition formula of the hexagonal sintered permanent magnetic ferrite magnet is represented as A<2+>(1-x-y)B<1+>yLa<3+>xFe<3+>(n-z)Co<2+>zO<2->19, A is at least one of divalent alkaline earth metal Ca, Sr and Ba, B is at least one of univalent alkali metal Li, Na and K, x, y, z and n represent adding proportions of elements respectively, wherein x is 0.24-0.45, y is 0.03-0.10, z is 0.20-0.33, n is 10.0-12.0, x is larger than or equal to 1.1z and smaller than or equal to 1.8z, and the sum of y and z is smaller than or equal to x. The preparation method of the hexagonal sintered permanent magnetic ferrite magnet comprises steps as follows: material mixing, pre-sintering, coarse crushing, ball milling, forming, sintering and the like. The magnet has an M type magnetoplumbite structure basically and has higher residual magnetization and higher intrinsic coercivity / squareness ratio (Hk / Hcj) than a traditional permanent magnetic ferrite magnet, and the magnetic performance is remarkably optimized.

Owner:马鞍山市鑫洋永磁有限责任公司

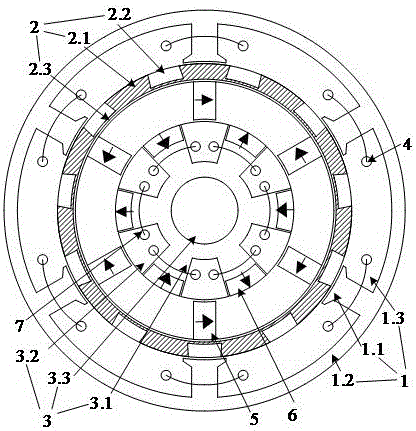

Magnetic gear type double-stator hybrid permanent magnet memory motor

InactiveCN105141092ASimple structureImprove space utilizationMagnetic circuit rotating partsMagnetic circuit stationary partsEpoxyElectric machine

The invention discloses a magnetic gear type double-stator hybrid permanent magnet memory motor. The motor comprises an external stator, a rotor and an internal stator which are coaxially arranged and sleeved from outside to inside in turn. The external stator comprises armature iron core teeth, stator yokes and armature windings which are arranged on the armature iron core teeth. The internal stator comprises an internal stator iron core provided with internal slots, neodymium iron boron permanent magnets, aluminum nickel cobalt permanent magnets and pulse magnetic regulating windings which are arranged in the internal slots of the internal stator. The two types of co-excitation permanent magnets are arranged in a "U" shape. The number of single permanent magnets on the internal stator is equal to that of external stator armature teeth. The whole rotor has an annular cup-shaped structure. Rotor iron blocks are fixed in a non-magnetic-conductive epoxy resin sleeve. The rotor iron blocks are connected via magnetic conductive bridges. Disadvantages that a conventional single stator has multiple internal excitation sources which are mutually hindered in space and torque density is relatively low can be solved. Besides, high power density is realized by arrangement of double-stator hybrid permanent magnets, and residual magnetization intensity and magnetization direction of the permanent magnets are regulated by applying pulse current so that motor magnetic field high-efficiency regulation is realized, and rotating speed operation range is enhanced.

Owner:SOUTHEAST UNIV

Magnetic recording/reproducing apparatus using a GMR head

InactiveUS6989974B2Improve corrosion resistanceHigh sensitivityNanoinformaticsHeads using thin filmsMagnetic reluctanceSpin valve

A highly reliable magnetic recording / reproducing apparatus is provided. In the magnetic recording / reproducing apparatus, a spin-valve film is used as a magnetic sensor element for detecting magnetic signals. By defining the corrosion potential of this spin-valve film, and further by specifying the residual magnetization of a magnetic recording medium used as well as the product of the residual magnetization and the thickness of the magnetic layer to a range that is numerically optimal, the occurrence of corrosion on the surface of a magnetoresistive head that contacts the medium is prevented, and the occurrence of electromagnetic discharge is avoided. Further, by numerically specifying the surface resistivity of the metal magnetic thin film of the magnetic recording medium, as well as the roughness of the surface on which the metal magnetic thin film is formed, electrostatic discharge preventing effects and wear resistance are improved.

Owner:SONY CORP

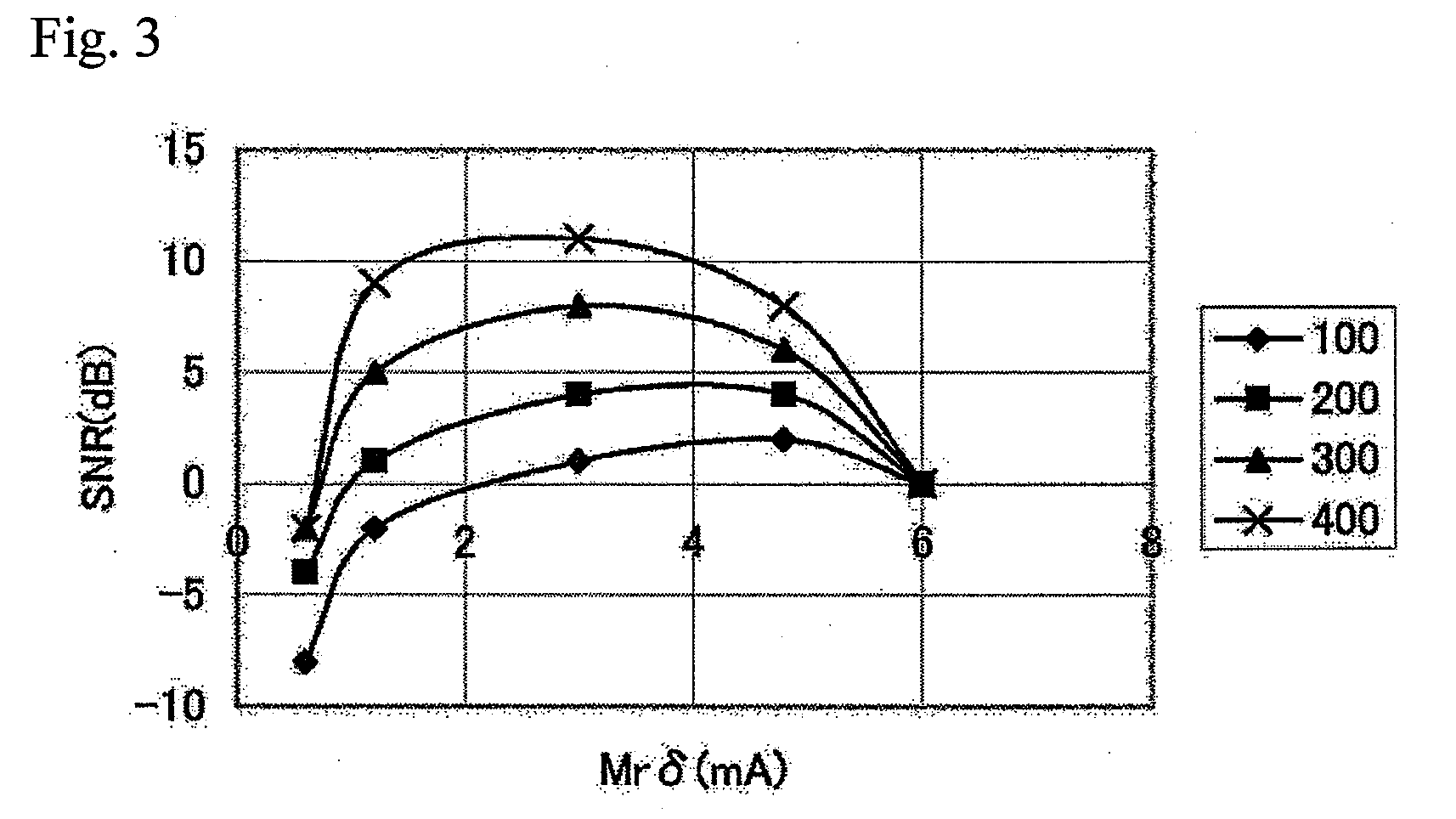

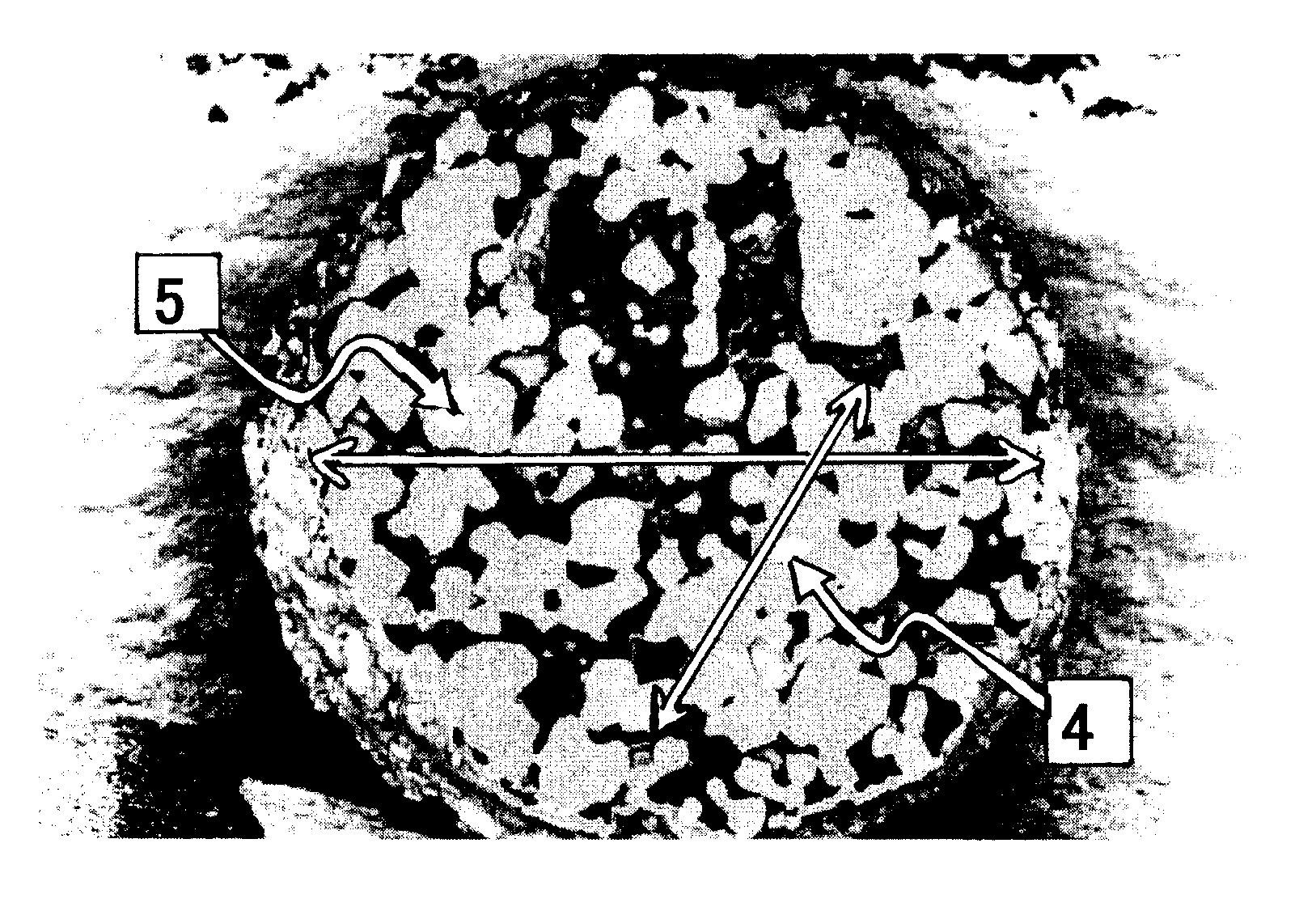

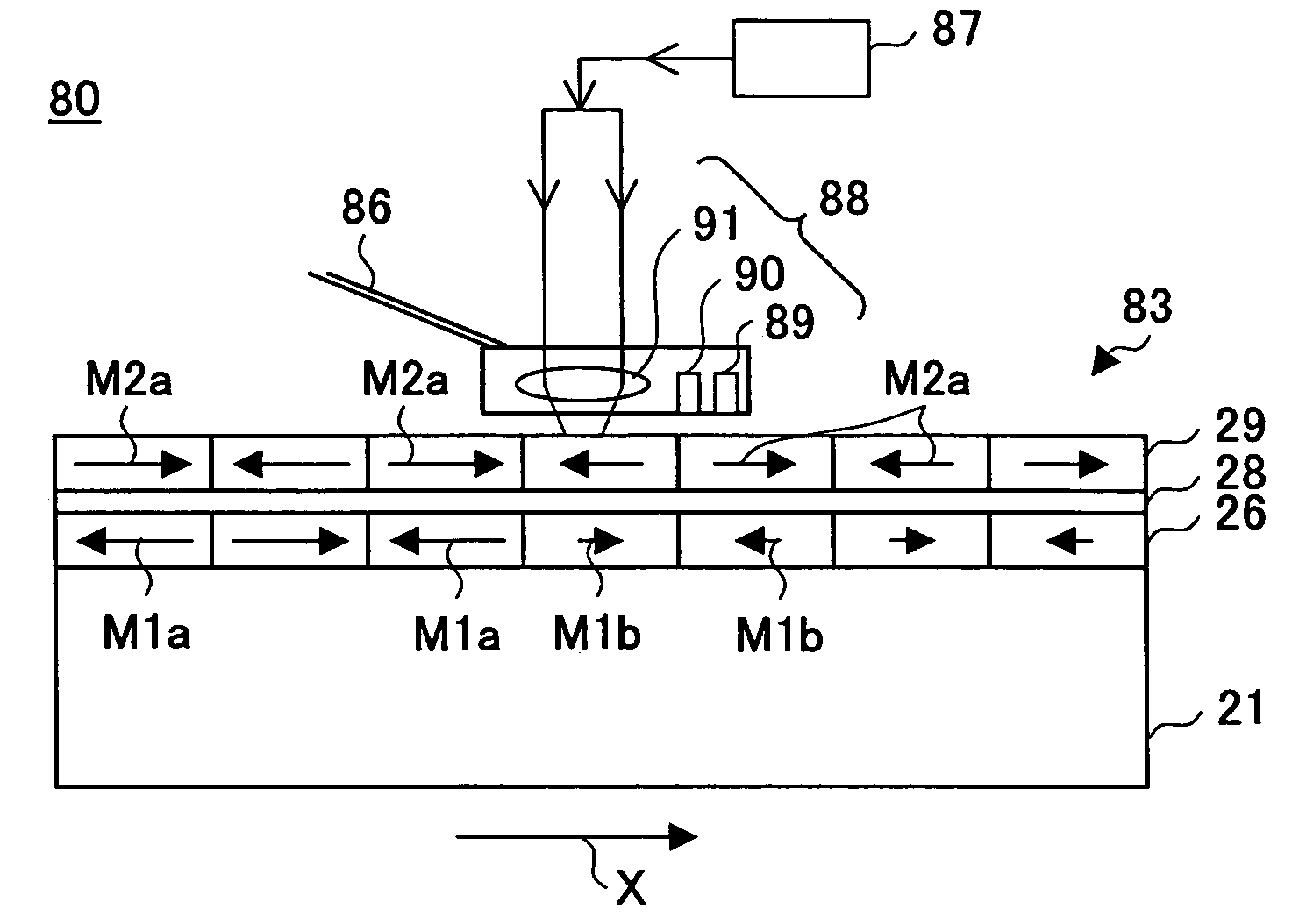

Magnetic recording medium, magnetic signal reproduction system and magnetic signal reproduction method

InactiveUS20090174969A1Good electromagnetic propertiesReduce noiseRecord information storageManufacture of flux-sensitive headsMagnetic force microscopeNon magnetic

The present invention relates to a magnetic recording medium comprising a magnetic layer comprising a ferromagnetic powder and a binder on a nonmagnetic support, wherein the magnetic layer has a thickness δ ranging from 10 to 80 nm, a product, Mrδ, of a residual magnetization Mr of the magnetic layer and the thickness δ of the magnetic layer is equal to or greater than 1 mA but less than 5 mA, a ratio, Sdc / Sac, of an average area Sdc of magnetic clusters in a DC demagnetized state to an average area Sac of magnetic clusters in an AC demagnetized state as measured by a magnetic force microscope, MFM, ranges from 0.8 to 2.0.

Owner:FUJIFILM CORP

Two-component developer

ActiveUS9034551B2Good reproducibilityImprove the development effectDevelopersUltimate tensile strengthFerric

Provided is a two-component developer containing: a magnetic carrier obtained by coating a magnetic core with a resin; and toner, in which: the magnetic core contains at least a ferrite component and at least one kind of an oxide selected from the group consisting of SiO2 and Al2O3; the content of the oxide is 4.0 mass % or more and 40.0 mass % or less with respect to the magnetic core; the magnetic core has a specific resistance of 5.0×104 Ω·cm or more and 5.0×108 Ω·cm or less at the time of the application of 1,000 V / cm; the magnetic carrier has an intensity of magnetization in 79.6 kA / m of 40.0 Am2 / kg or more and 65.0 Am2 / kg or less, and a residual magnetization after the application of an external magnetic field of 79.6 kA / m of 3.0 Am2 / kg or less; and the toner has a weight-average particle diameter (D4) of 3.0 μm or more and 10.0 μm or less and an average circularity of 0.940 or more and 0.990 or less.

Owner:CANON KK

Removing residual magnetization in a data transducer

ActiveUS20050200997A1Driving/moving recording headsDemagnetisation of recording headsDriver circuitAudio power amplifier

Method and apparatus for removing residual magnetization in a data transducer, such as a recording head used to write data to a recording medium in a data storage device. A residual magnetization sense circuit senses a residual magnetization of a pole of the data transducer as a result of the application of a data transmission current to the transducer. A demagnetization current generator removes the residual magnetization by supplying the transducer with a demagnetizing current that decreases to a final magnitude in accordance with a selected profile. The demagnetization current preferably comprises a bi-directional, time varying current of selected frequency to the transducer that tapers linearly, exponentially or in a step-wise fashion to the final magnitude. The demagnetization profile is preferably continuously adapted during operation. Preferably, the sense circuit and demagnetization current generator are incorporated into a preamplifier / driver circuit which performs the demagnetization operation in a self-contained fashion.

Owner:SEAGATE TECH LLC

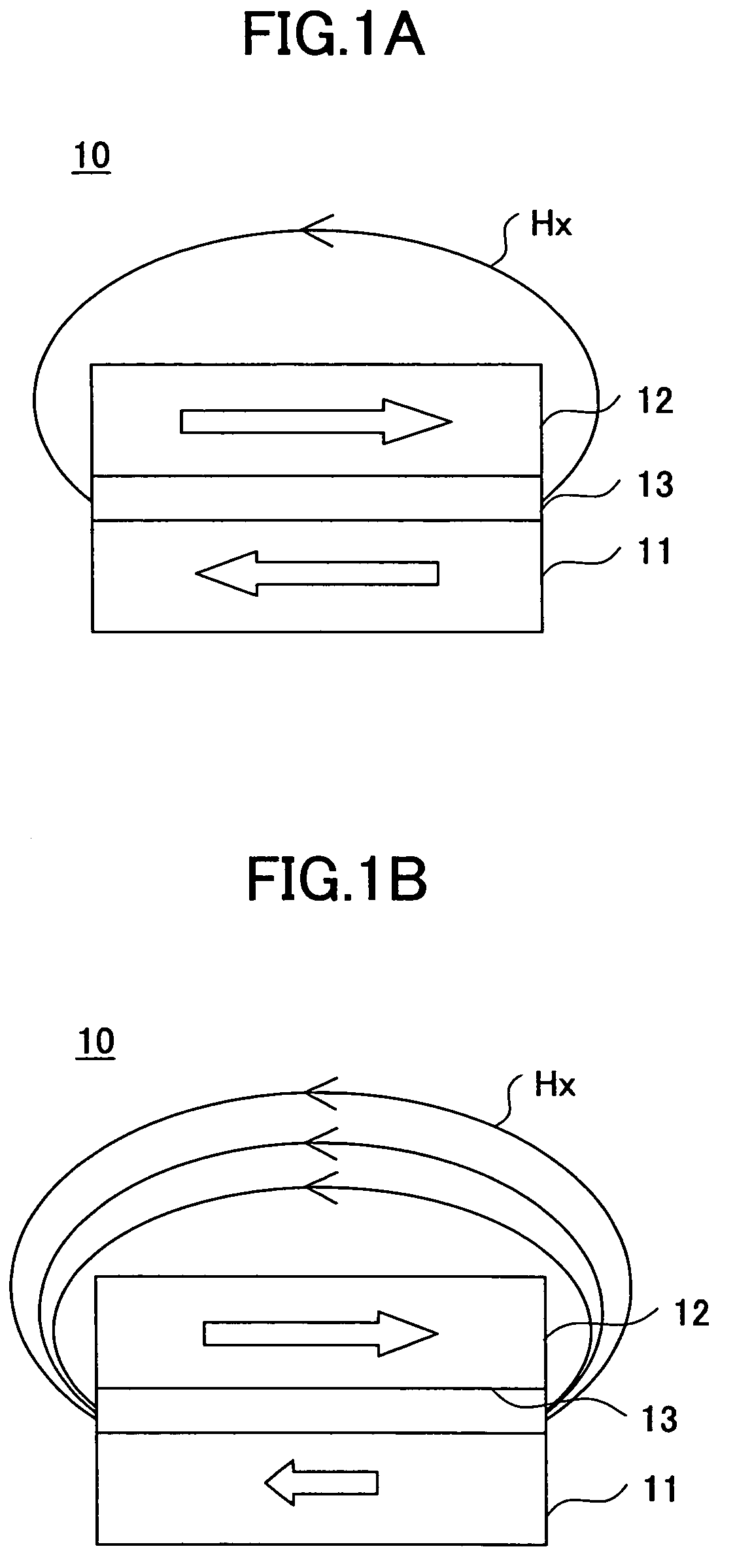

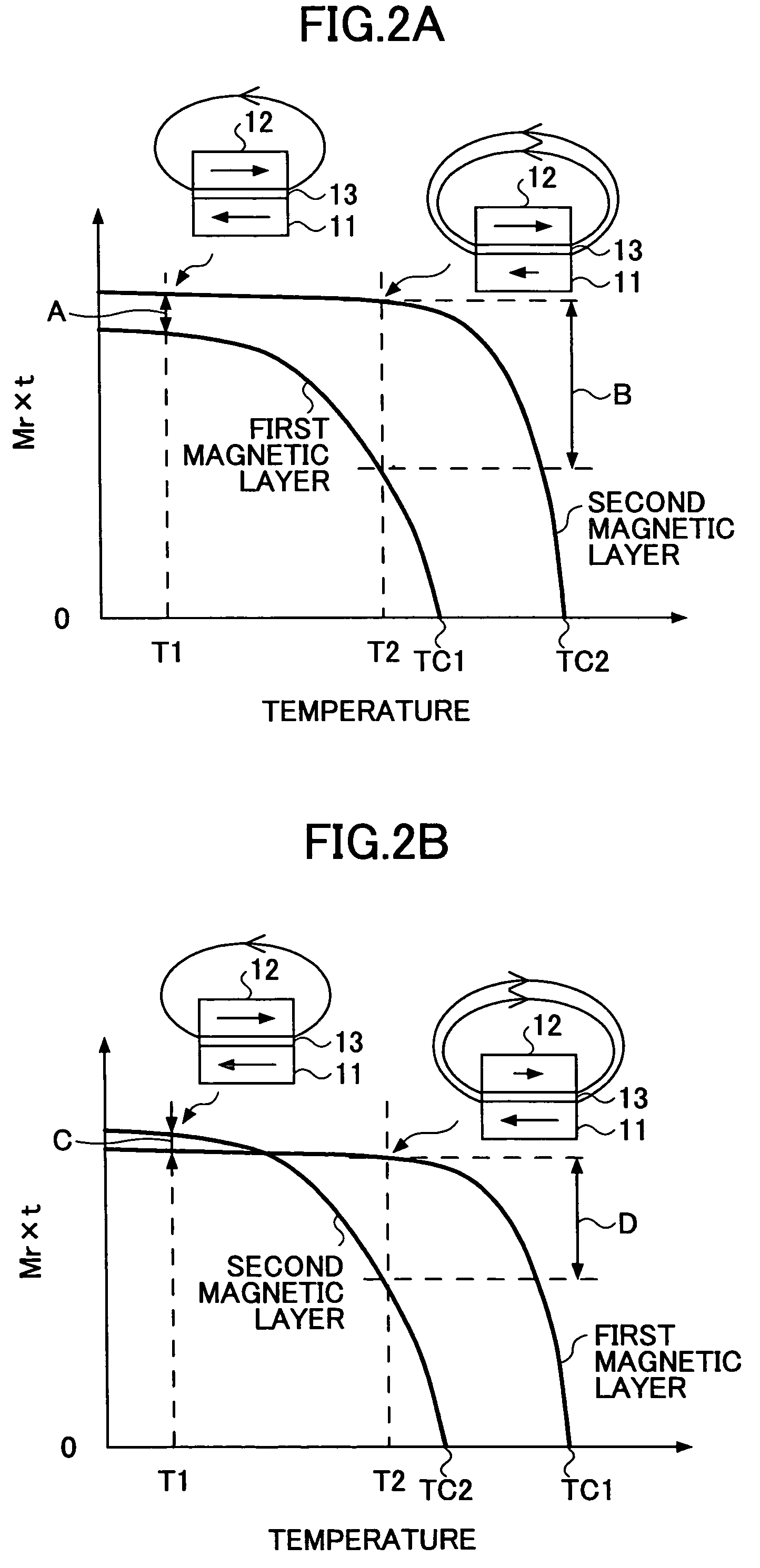

Magnetic recording medium, magnetic storage and method for reproducing information from magnetic recording medium

InactiveUS7502188B2Improve recording densityRaise the ratioRecord information storageRecording/reproducing/erasing methodsCouplingMagnetic storage

A magnetic recording medium includes a first magnetic layer; and a second magnetic layer formed on the first magnetic layer. The first magnetic layer and the second magnetic layer make exchange coupling therebetween and also, have their magnetizing direction in anti-parallel to one another. A net residual area magnetization of the first magnetic layer and the second magnetic layer is expressed by the following formula: |Mr1×t1−Mr2×t2| where Mr1 and Mr2 denote respective residual magnetizations of the first magnetic layer and the second magnetic layer, and t1 and t2 denote respective film thicknesses of them; and the net area magnetization at a first temperature is larger than the net area magnetization at a second temperature lower than the first temperature.

Owner:SHOWA DENKO KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com