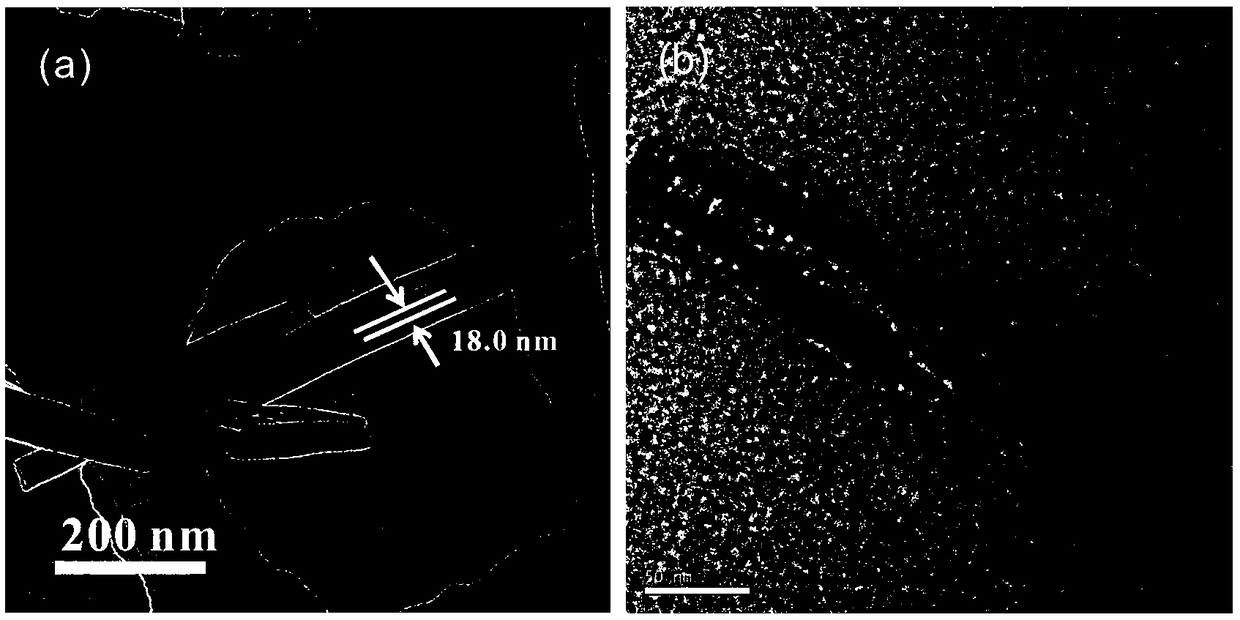

Method for preparing nanocomposite material by assembling ferriferrous oxide in halloysite tube

A nano-composite material, ferric oxide technology, applied in the direction of iron oxide/hydroxide, magnetic materials, nanotechnology, etc., to achieve the effect of improving biocompatibility and strong application advantages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A preparation of halloysite tube assembled Fe by high temperature pyrolysis 3 o 4 The method for nanocomposite material, its specific preparation steps are:

[0024] Step 1. Take 10g of halloysite and disperse it in 500mL of deionized water. Stir magnetically at room temperature for 3 hours to obtain a cloudy liquid. Suction filter it. Under drying for 8 hours, the coarse halloysite was obtained;

[0025] Step 2. Put 22mL of concentrated nitric acid, 14mL of concentrated sulfuric acid, 4g of ammonium chloride and 2g of sodium chloride into a beaker, add 714mL of deionized water into the beaker, and stir at 60°C for 0.5h with a magnetic stirrer. Obtain mixed solutions such as mixed acids and strong ionic salts for subsequent use;

[0026] Step 3: Take 750mL of the mixed solution of mixed acid and strong ionic salt prepared in Step 3 and 10g of rough-selected Halloysite obtained in Step 1 respectively, and put them into a beaker. After magnetically stirring at room te...

Embodiment 2

[0034] A preparation of halloysite tube assembled Fe by high temperature pyrolysis 3 o 4 The method for nanocomposite material, its specific preparation steps are:

[0035] Step 1, the method similar to embodiment 1, obtains the halloysite powder of purification and tube expansion;

[0036] Step 2: Weigh 1.5 g of sodium oleate and add it to 300 mL of citric acid solution (2 wt %) and stir until the sodium oleate is completely dissolved. Then add 3g of expanded HNTs powder into the sodium oleate solution and sonicate for 30min to obtain a homogeneous mixture. Stirring was continued at 60°C for 2 hours, and then collected by centrifugation to obtain oleate-modified halloysite nanotubes (BHNTs), which were washed three times with deionized water. The BHNTs were then dried at 60°C for 12 hours and ground through a 200-mesh sieve in an agate mortar;

[0037] Step 3, according to the method of embodiment 1, by Fe(acac) 3 : Oleylamine: The molar ratio of oleic acid and trioctylp...

Embodiment 3

[0041] A preparation of halloysite tube assembled Fe by high temperature pyrolysis 3 o 4 The method for nanocomposite material, its specific preparation steps are:

[0042] Step 1, the method similar to embodiment 1, obtains the halloysite powder of purification and tube expansion;

[0043] Step 2. Disperse 3 g of the tube-expanded HNTs sample obtained in Step 1 in 600 mL of deionized water to obtain a HNTs suspension (5 mg / mL). After sonication for 0.5 h the pH of the suspension was adjusted to 8.5 by tris. Then 1.2mg of dopamine powder was added to the HNTs suspension and stirred at 30°C. The gray DHNTs product was obtained after the final mixture was stirred for 3 h. The gray product was separated by centrifugation and washed repeatedly with distilled water until the filtrate became colorless and transparent;

[0044] Step 3, according to the method of embodiment 1, by Fe(acac) 3 : The molar ratio of oleylamine: oleic acid and polyvinylpyrrolidone is 1:10:4:0.5 to pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com