Magnetic gear type double-stator hybrid permanent magnet memory motor

A hybrid permanent magnet and memory motor technology, applied in electrical components, electromechanical devices, magnetic circuit static parts, etc., can solve the problems of limited application, difficult adjustment, large hysteresis loss and eddy current loss, etc., to achieve high space utilization. , The effect of small copper consumption, improving power density and torque capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing and embodiment mode, the patent of the present invention is described in further detail:

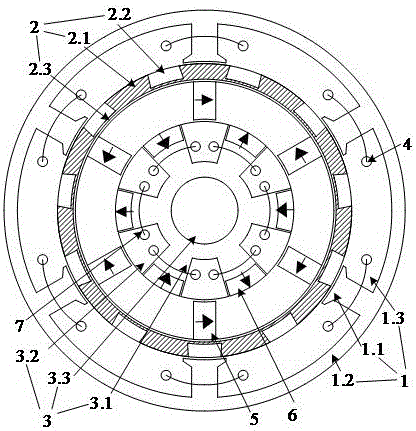

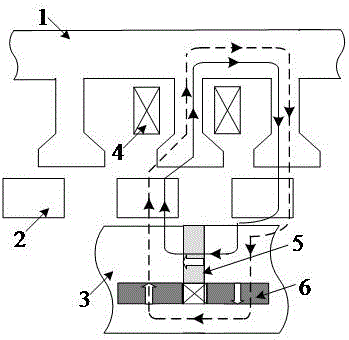

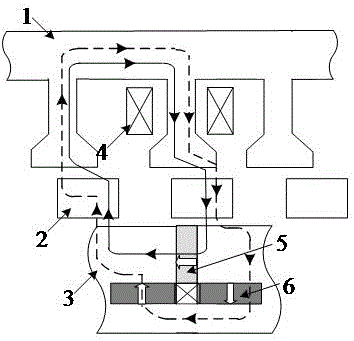

[0027] Such as Figure 1-6 As shown, the present invention discloses a magnetic gear type double-stator hybrid permanent magnet memory motor, which includes an outer stator 1, a rotor 2 and an inner stator 3 that are sequentially socketed from outside to inside and arranged coaxially;

[0028] The outer stator 1 comprises armature core teeth 1 .1 , an annular stator yoke 1 .2 and an armature winding 4 . The armature core teeth 1.1 are arranged between the stator yoke 1.2 and the rotor 2, and an interspace 1.3 is formed between adjacent armature core teeth 1.1 for placing the armature winding 4 wound on the armature core teeth 1.1;

[0029] The rotor 2 is in the shape of a cylindrical cup as a whole, and more than one rotor iron block 2.1 made of magnetically conductive silicon steel is arranged at intervals in the circumferential dir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com