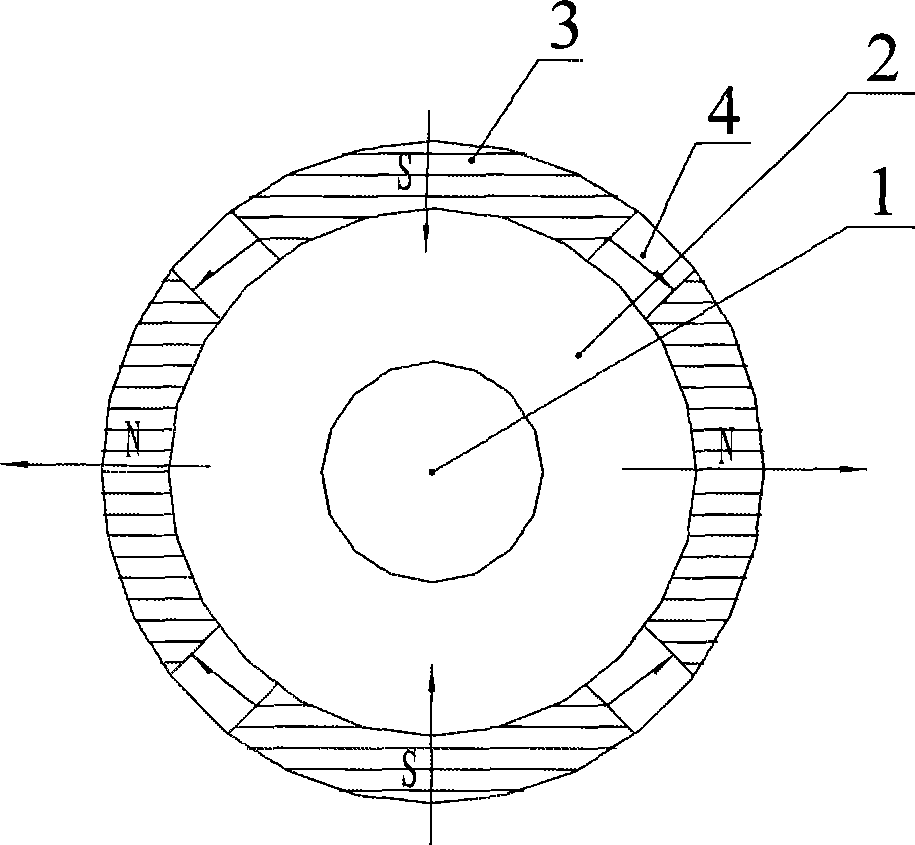

Patents

Literature

186results about How to "Increase air gap flux density" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Rotor gravity unloading type magnetic bearing composite motor

ActiveCN107222131ASolve the coupling problemReduce weightMagnetic holding devicesMagnetic bearingElectric machine

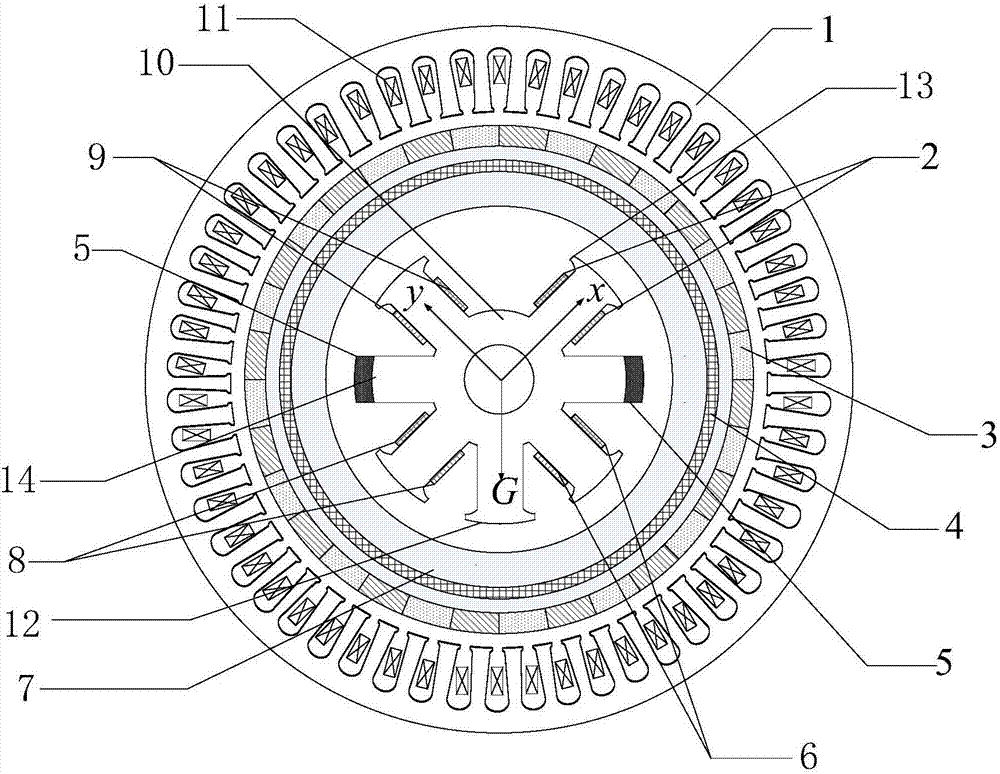

The invention discloses a rotor gravity unloading type magnetic bearing composite motor comprising an external stator, an armature winding, a permanent magnet, a rotor, a magnetic isolation aluminum ring, an internal stator and a suspension control winding. The armature winding is wound in external stator slots. The magnetic isolation aluminum ring is embedded in the rotor. A Halbach type permanent magnet array is surface-mounted on the surface of the rotor. The internal stator has seven internal stator poles including two opposite bias flux magnetic poles, four radial suspension control poles and one gravity direction rotor weight unloading pole. Radial magnetized permanent magnets are surface-mounted on the surface of the bias flux magnetic poles. The suspension control winding is wound on the four suspension control poles. Coupling between the suspension winding and the armature winding in the conventional magnetic suspension motor can be eliminated, and the influence of the rotor weight on suspension control in the conventional suspension motor can also be greatly solved so that the rotor is enabled to stably work at the central balance position without increasing suspension control current, and low power consumption and stable suspension of the magnetic bearing composite motor can be realized.

Owner:JIANGSU UNIV

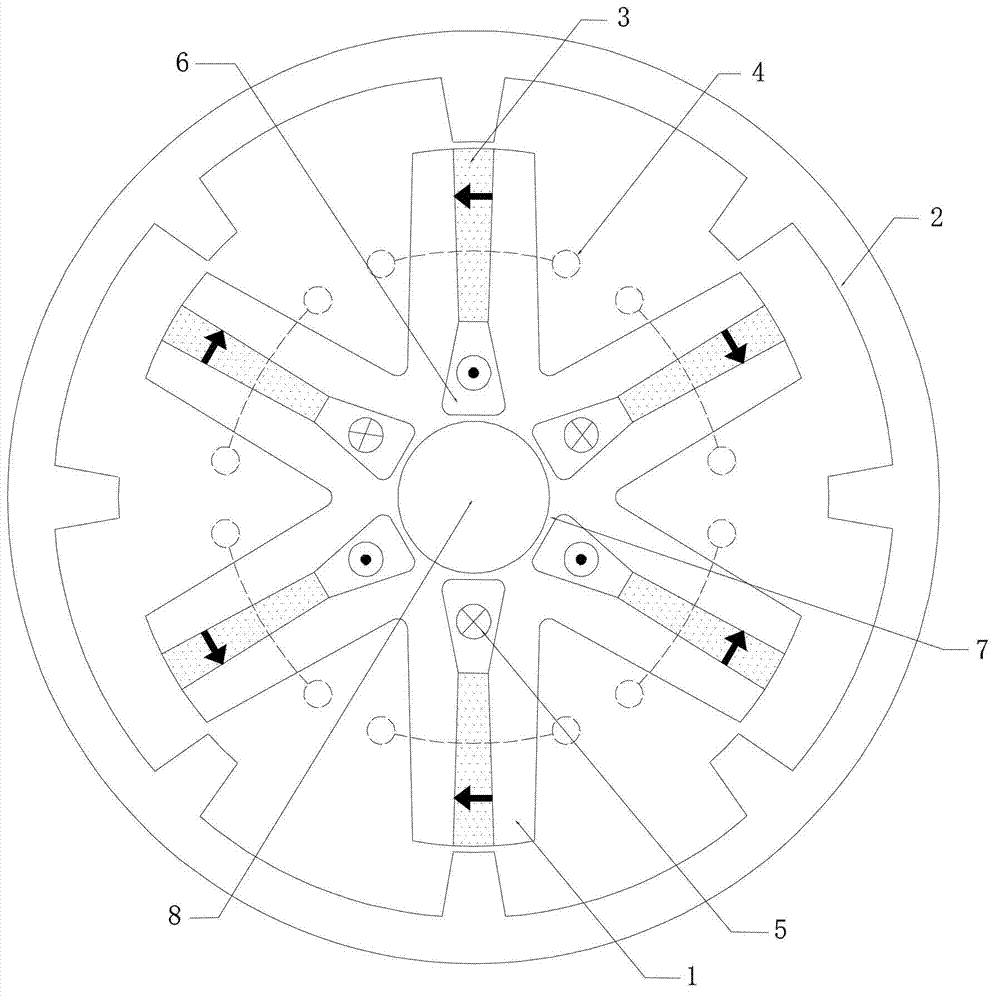

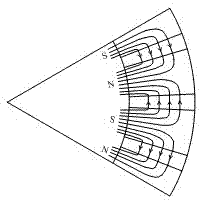

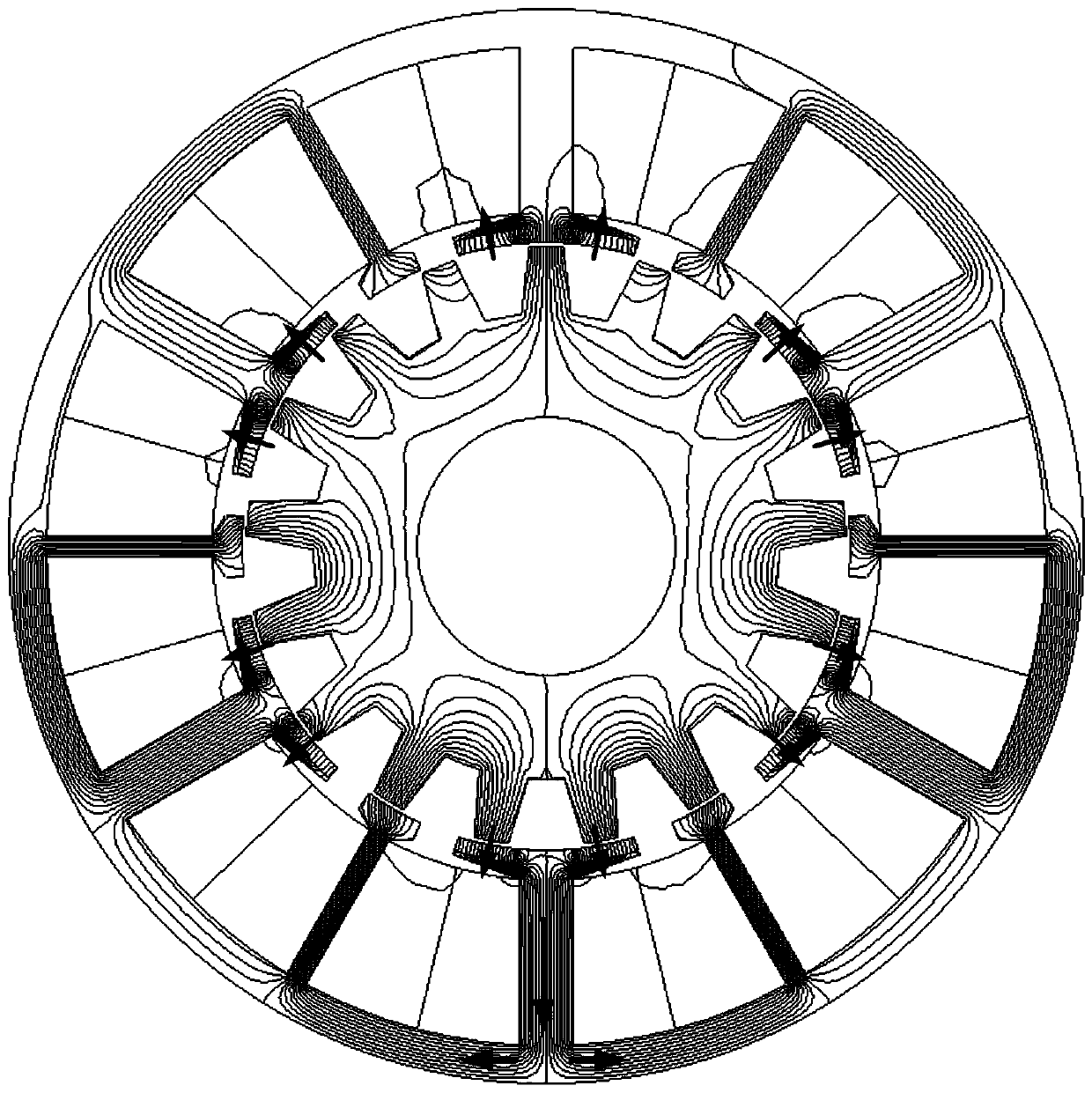

Mixed permanent magnetic pole-alternating and magnetic flux-switching memory motor and winding switching magnetism-weakening control method thereof

ActiveCN104578477ASimple structureImprove space utilizationAC motor controlMagnetic circuit stationary partsLow speedMagnetic poles

The invention discloses a mixed permanent magnetic pole-alternating and magnetic flux-switching memory motor and a winding switching magnetism-weakening control method thereof. The mixed permanent magnetic pole-alternating and magnetic flux-switching memory motor comprises a salient rotor and a stator, wherein the stator contains stator cores, aluminium-nickel-cobalt permanent magnets, neodymium-iron-boron permanent magnets, centralized armature windings and pulsed magnetism-adjusting windings; iron core edges of two adjacent outer U-shaped units and tangentially-magnetized long-stripped neodymium-iron-boron permanent magnets form a first permanent magnetic pole, while the circumferentially-inward (outward) and parallel-magnetized V-shaped embedded aluminium-nickel-cobalt permanent magnets and inner U-shaped units form a second permanent magnetic pole; mixed magnetic poles are in alternating polarity distribution; when the motor runs at a low speed, the pulsed magnetism-adjusting windings are in direct-current pulsed working state, while in a high-speed weak-magnetism area, the pulsed magnetism-adjusting windings are converted into alternating-current armature windings. Requirements on performance in a low-speed area and in the high-speed area can be met at the same time; influence of an armature reaction field on the aluminium-nickel-cobalt permanent magnets with low coercivity is small; the utilization rate of permanent magnetism, the torque density, and the reliability of system operation are high.

Owner:SOUTHEAST UNIV

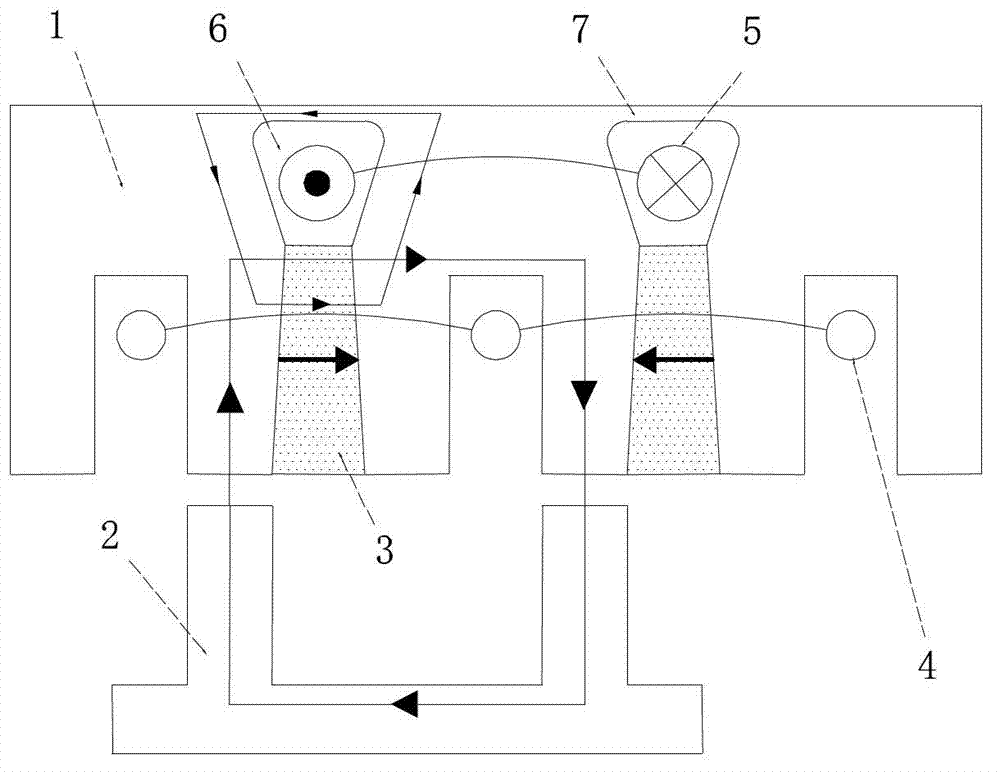

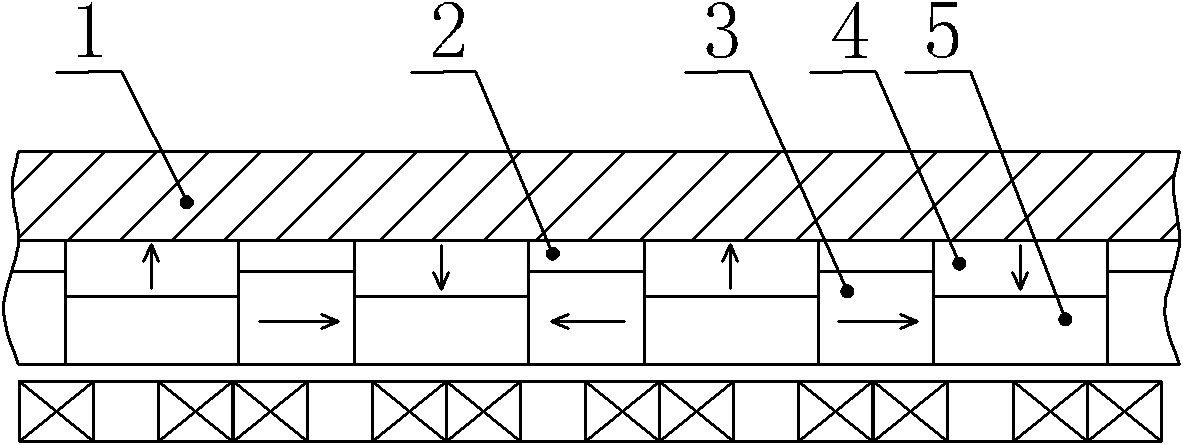

Magnetic-concentrating-type consequent-pole cursor permanent magnet motor and application thereof

ActiveCN106374718AIncrease air gap flux densityImproved Air Gap Ability to Transfer Electromagnetic PowerPropulsion systemsPower factorElectric machine

The invention discloses a magnetic-concentrating-type consequent-pole cursor permanent magnet motor, which comprises a primary core and a secondary core, wherein a plurality of open slots are formed in the primary core; armature windings are arranged in the open slots of the primary core; the secondary core and the primary core are arranged at an interval and can oppositely move; Halbach permanent magnets are arranged in notches of the open slots of the primary core, thereby forming a Halbach (Halbach) permanent magnet array; a plurality of open slots which are arranged at intervals are formed in the surface, relative to the primary core, of the secondary core and permanent magnets are arranged in the open slots, thereby forming an excitation permanent magnet array; and the magnetization direction of the Halbach permanent magnet array is matched with that of the excitation permanent magnet array. Through comprehensive application of a consequent-pole structure and a Halbach array, the air-gap flux density of the motor is significantly strengthened, the air-gap electromagnetic power transmission capacity of the motor is improved, the electromagnetic properties of the counter electromotive force, the thrust density, the power factor and the like of the motor are improved, and reduction of the volume of the motor, improvement of the acceleration performance of the motor and reduction of the capacity of a frequency converter are facilitated.

Owner:HUAZHONG UNIV OF SCI & TECH

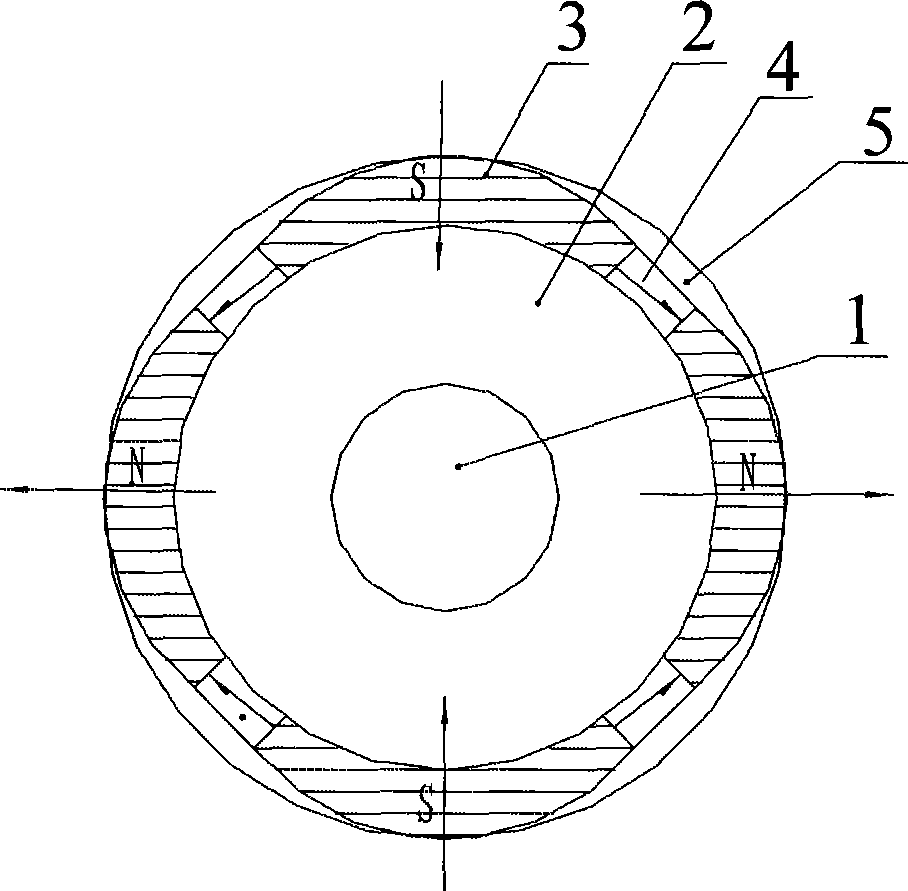

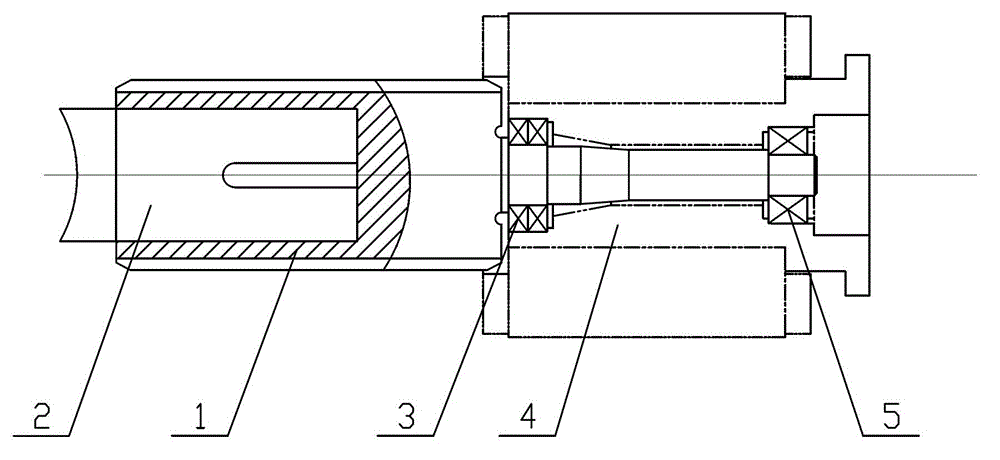

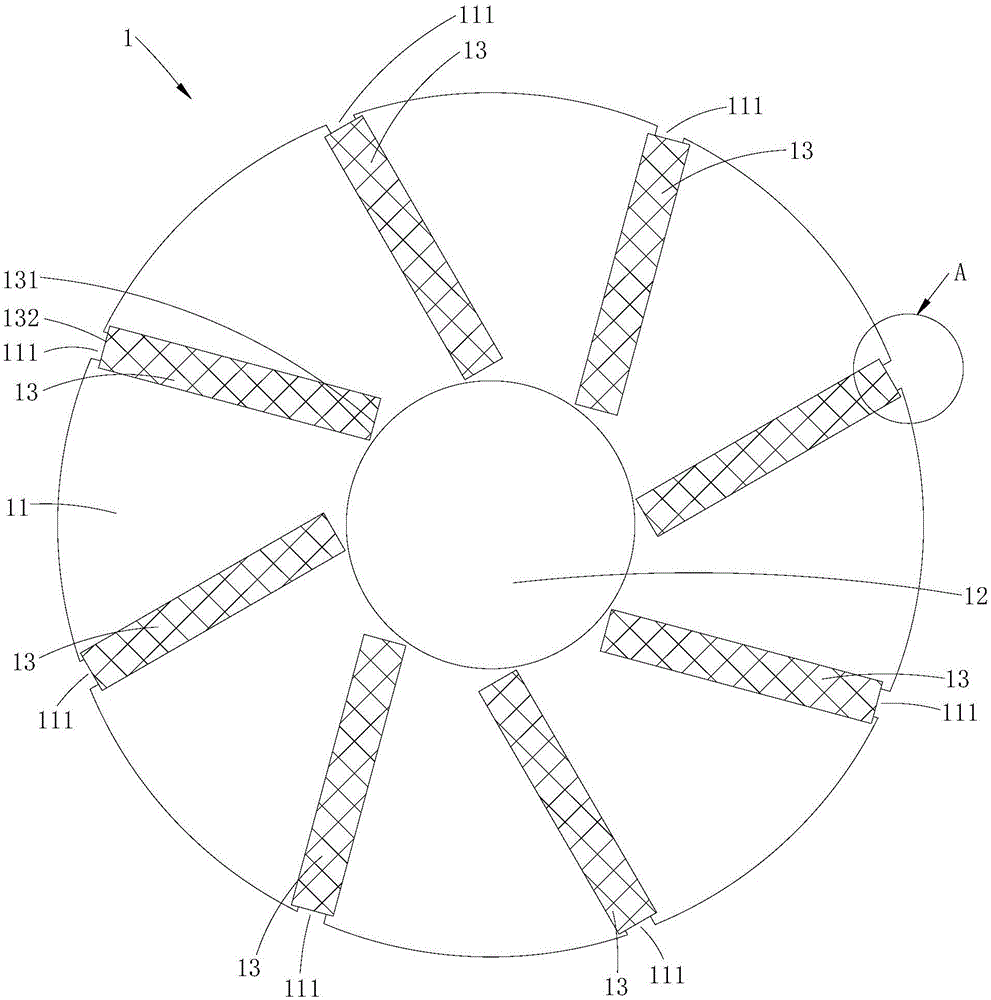

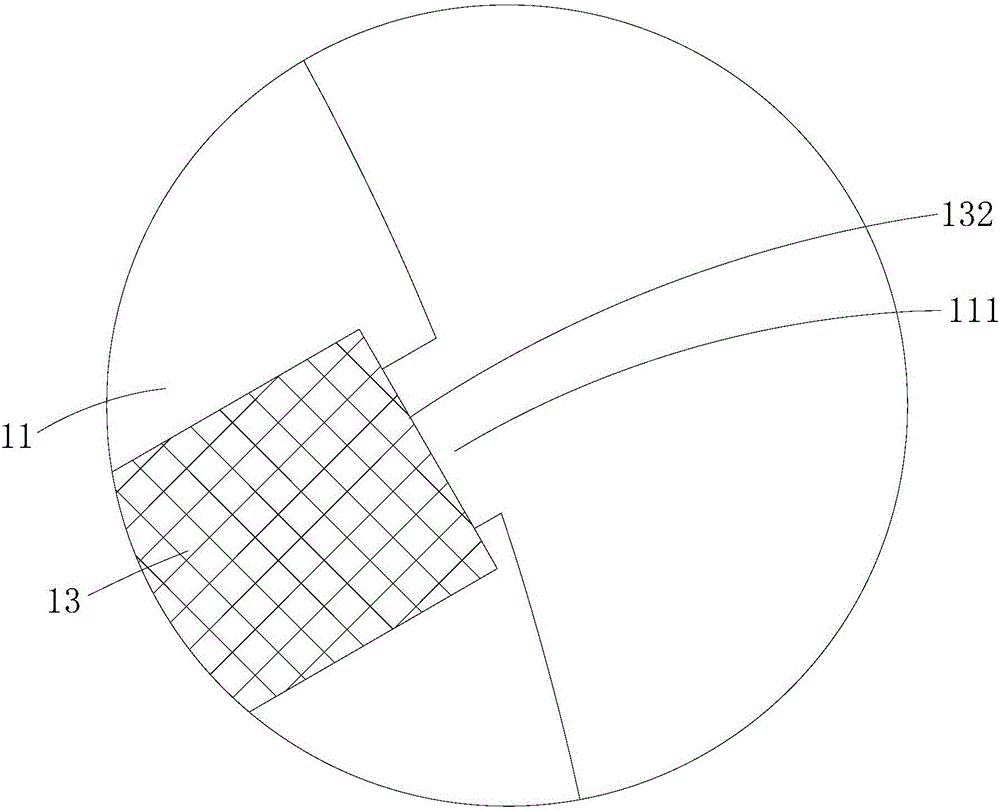

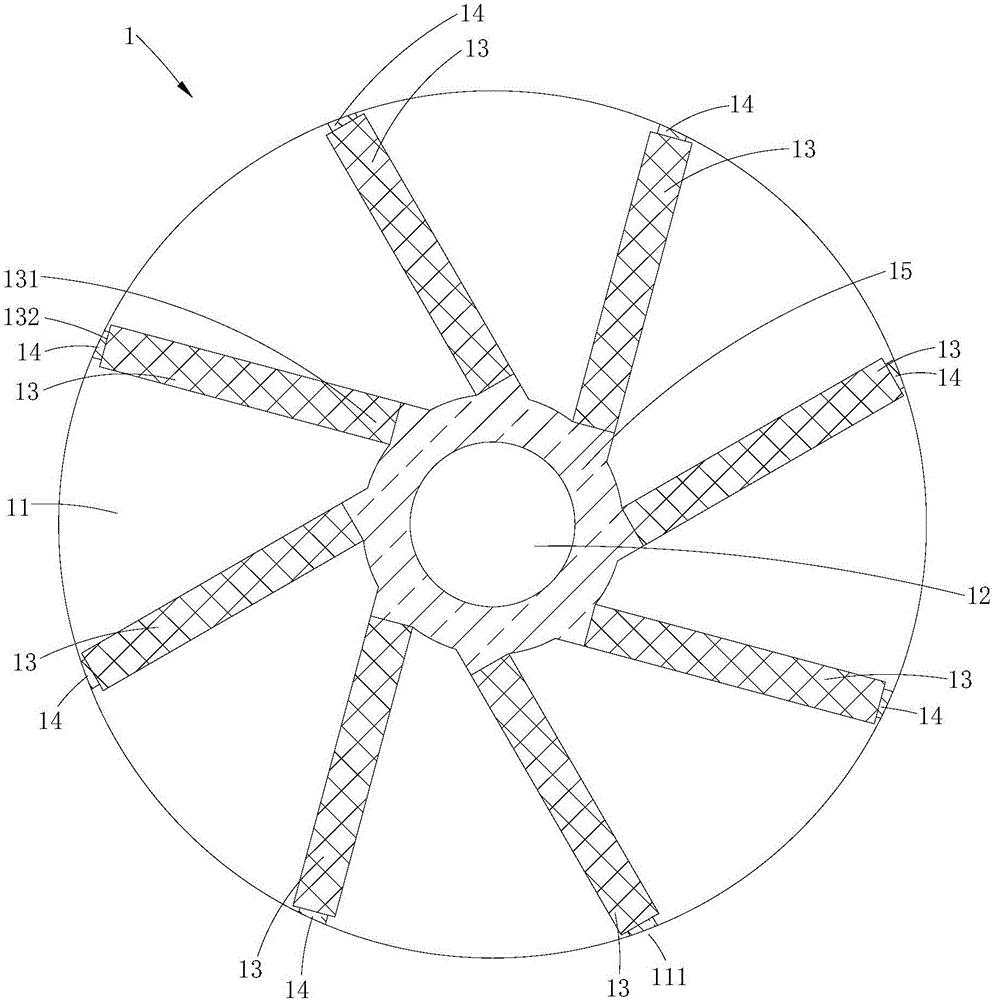

Halbach disc type magnetic coupling

InactiveCN102545538AHigh material utilizationIncrease air gap flux densityPermanent-magnet clutches/brakesMagnetEngineering

The invention provides a Halbach disc type magnetic coupling, which comprises a driving disc fixed by a driving shaft and a driven disc fixed by a load shaft. The driving disc comprises a disc body and a Halbach permanent magnet array, wherein the Halbach permanent magnet array is arranged on the surface of the disc body, and the surface faces the driven disc; and the Halbach permanent magnet array is uniformly distributed around the driving shaft, and is axially magnetized.

Owner:SHANGHAI DIANJI UNIV

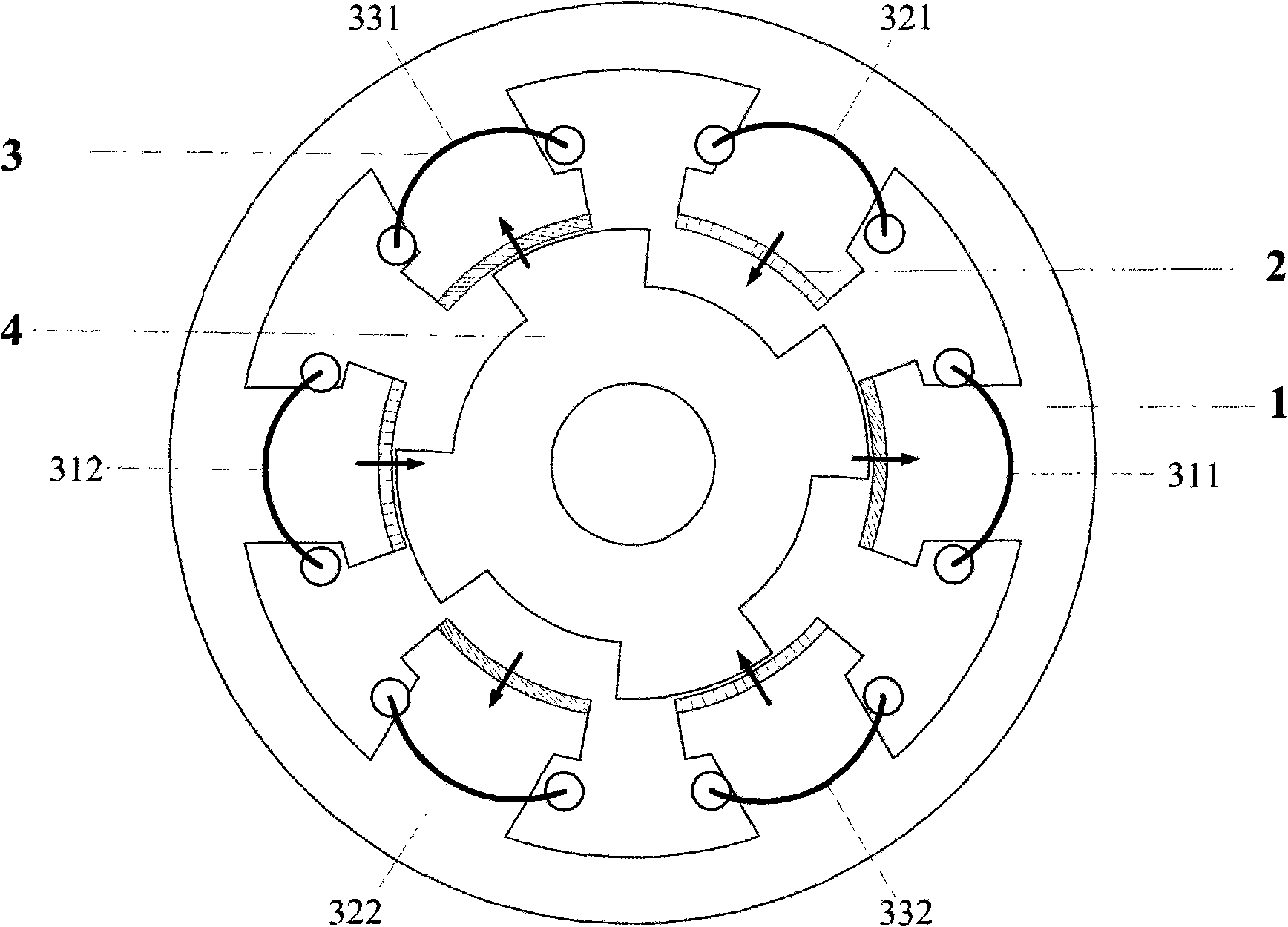

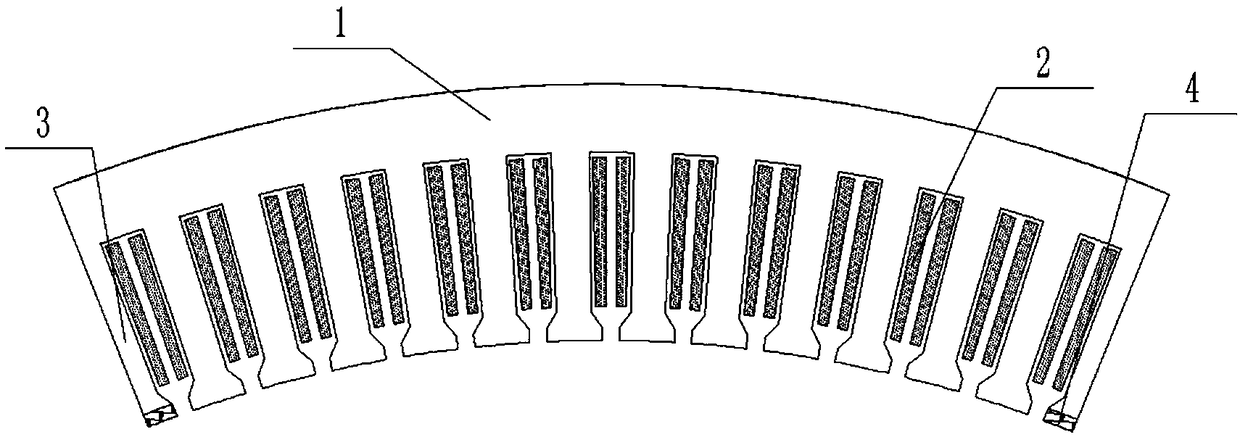

Stator surface mounted doubly salient pole permanent magnet motor

InactiveCN101662198AImprove cooling conditionsSimple and strong structureSynchronous machine detailsMagnetic circuit stationary partsSurface mountingPermanent magnet motor

The invention discloses a stator surface mounted doubly salient pole permanent magnet motor which has simple and firm structure, stronger torque output capacity and higher power density, comprises a stator (1) and a rotor (4), and is characterized in that the rotor (4) is positioned in the stator (1); the stator (1) and the rotor (4) are both in doubly salient pole structure; the stator (1) is provided with a concentrated winding (3) and a permanent magnet (2), wherein, each concentrated winding coil of any phase of the concentrated winding (3) is positioned in an iron-core groove of the stator (1), and each phase concentrated winding coil is in series connection or in parallel connection; the permanent magnet (2) is positioned on the top part of tooth of the stator (1). The motor has no-load counter-electromotive force of a high degree approximate square wave (a straight flute rotor) or a sinusoidal wave (a tapered slot rotor), stronger torque output capacity, higher power density andstronger anti-demagnetizing capacity, and is especially suitable for being used as a driving element of an alternating current governor system.

Owner:SOUTHEAST UNIV

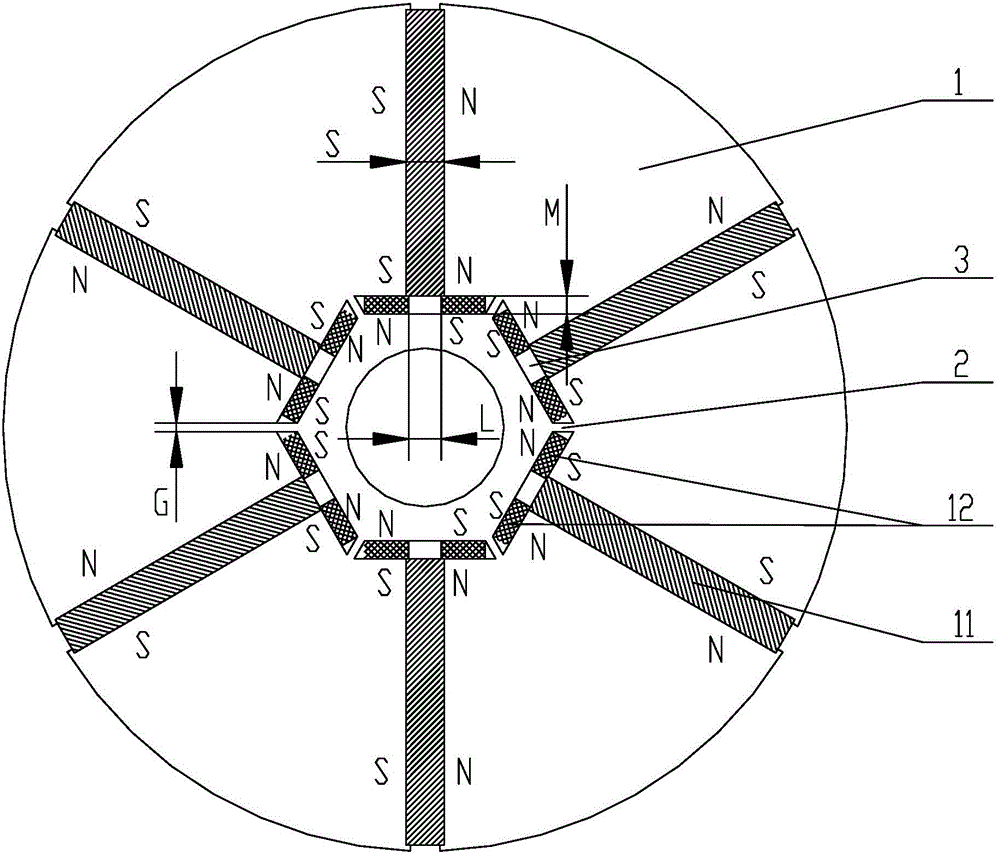

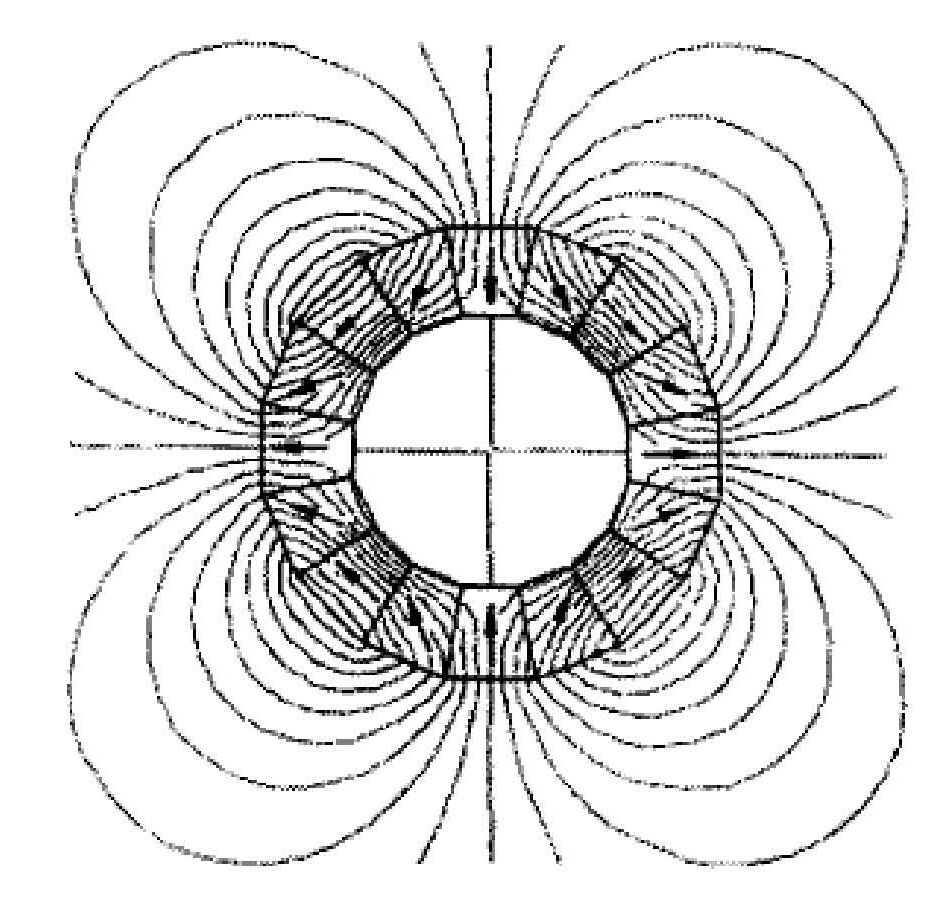

Rotor of permanent magnet synchronous motor and permanent magnet synchronous motor provided with same

ActiveCN104485762AHigh mechanical strengthReduce Flux LeakageSynchronous machine detailsMagnetic circuit rotating partsPermanent magnet synchronous motorPermanent magnet synchronous generator

The invention discloses a rotor of a permanent magnet synchronous motor and the permanent magnet synchronous motor, which belong to the technical field of the permanent magnet synchronous motors, and are designed in order to solve the problems of high leakage flux, low permanent magnet utilization rate, influence on motor performance and efficiency and the like in existing rotor of the permanent magnet synchronous motor. The rotor of the permanent magnet synchronous motor comprises a rotor core, wherein an even number n of tangential permanent magnets are distributed evenly in radial direction on the rotor core, and the same polarities of two adjacent tangential permanent magnets are opposite; radial permanent magnets are arranged symmetrically on two sides of one end of each tangential permanent magnet close to the inner side of the rotor core respectively; every two radial permanent magnets sandwiched between two adjacent tangential permanent magnets have the same polarity in the direction facing to a stator, and a magnetic isolating bridge is arranged between every two radial permanent magnets. The invention further discloses a permanent magnet synchronous motor provided with the rotor. By utilizing the rotor, the leakage flux of the tangential permanent magnets on the inner side of the rotor is reduced, the utilization rate of the permanent magnets is improved, and the motor efficiency and the motor structural intensity are enhanced.

Owner:GREE ELECTRIC APPLIANCES INC +1

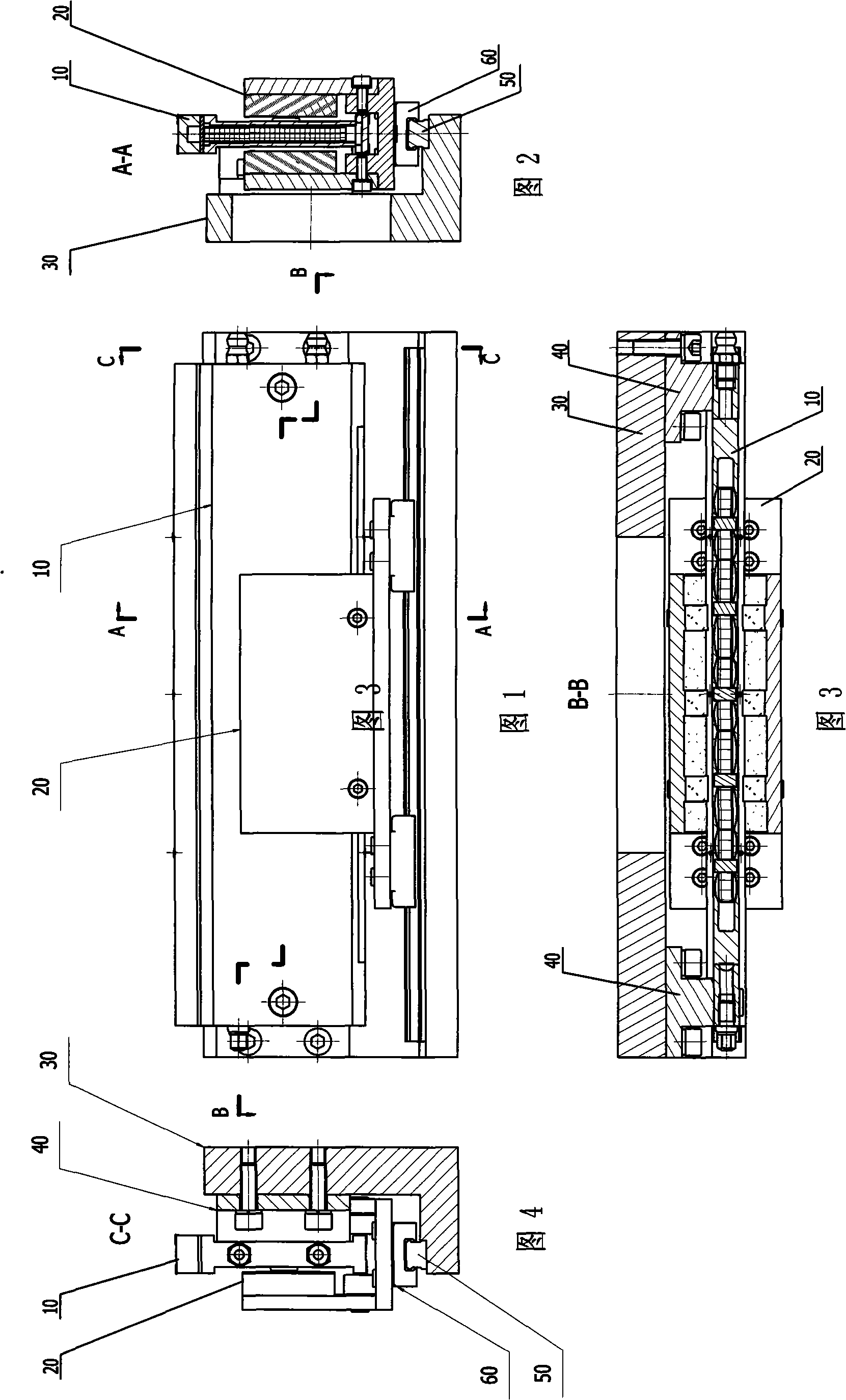

High-thrust short-travel voice coil motor

ActiveCN101404438AIncrease air gap flux densityHigh speedDynamo-electric machinesThermal radiationUnit volume

The invention discloses a high thrust short stroke voice coil motor and relates to the motor field, solving the defects of low thrust, relatively large thrust fluctuation and the like, in the existing voice coil motors. Two stator interpole coils of the motor are arranged at the two sides of three stator coils and fixed in the groove of a coil rack by a positioning key, the five coils are connected in series; the magnetic steel of a active cell of the motor adopts the structure of bilateral series permanent magnet and consists of the magnetic steels with three different lengths, and the magnetic steels with the first length, the third length and the second length are sequentially arranged towards two sides by taking the middle first steel with the third length as the symmetry axis; along magnetizing direction, the distribution takes Halbach array structure; the length relation between the magnetic steel and the coil meets the following conditions: s1 is equal to 1<2> plus 2d and s2 is equal to 1<1> plus 2d minus s1 and s3 is equal to 1<3> minus 2d. The invention is mainly applied to accurate positioning servo systems, improves the thrust of unit volume and the reliability of the voice coil motor and reduces thrust fluctuation as well as the heat radiation toward the external environment.

Owner:HARBIN INST OF TECH

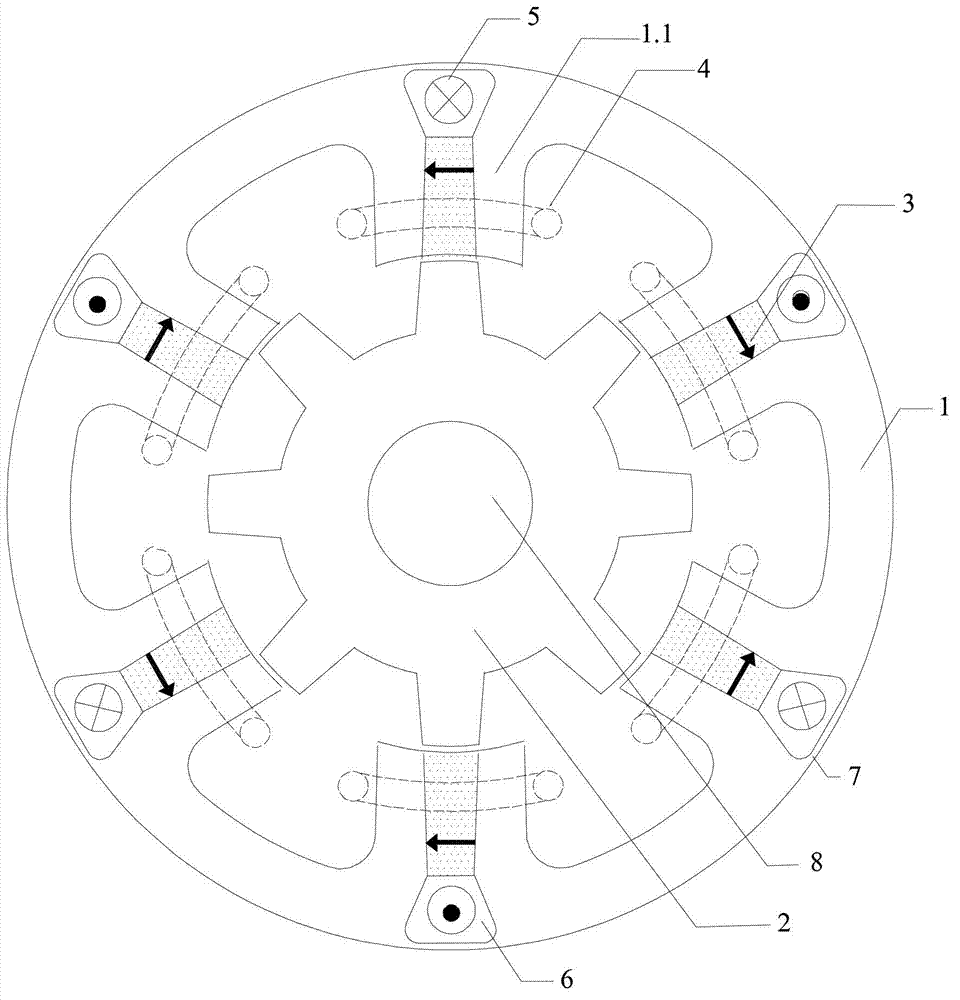

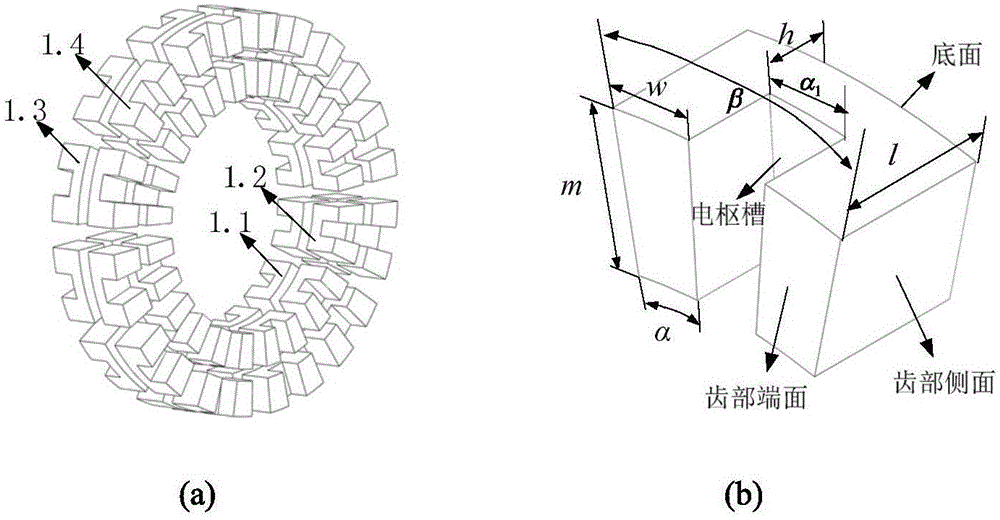

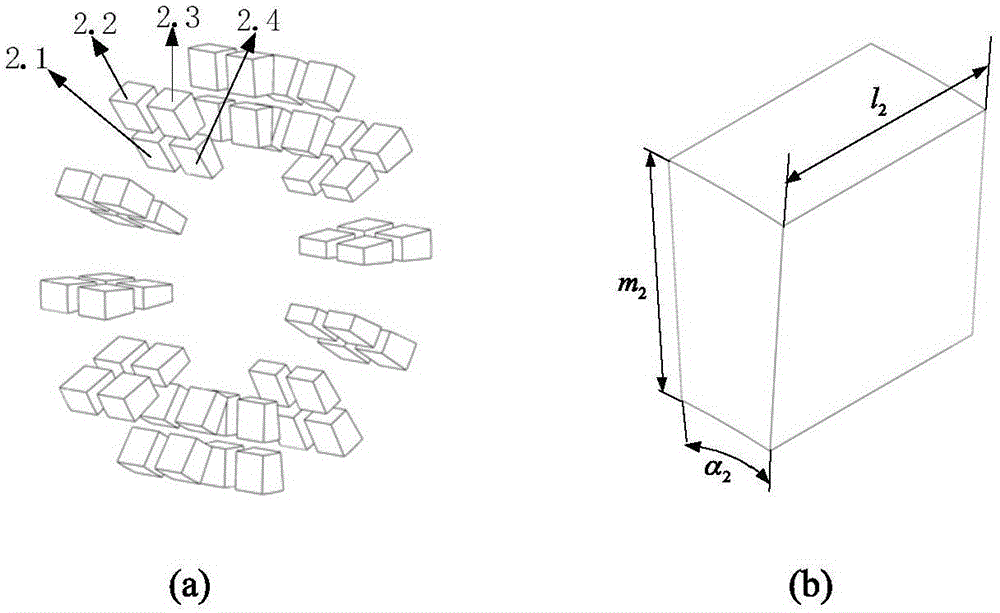

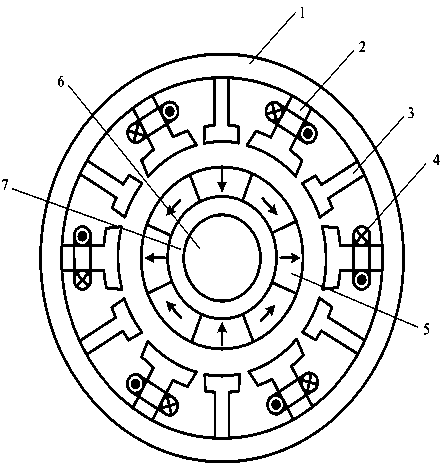

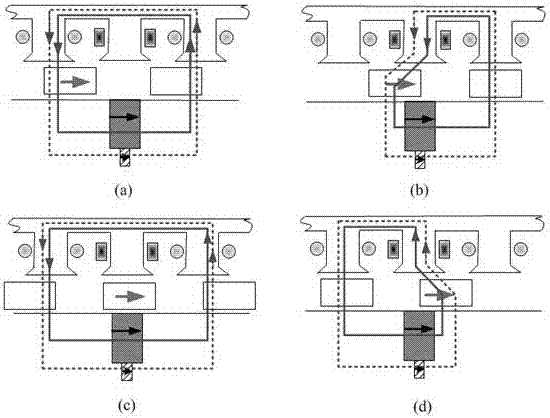

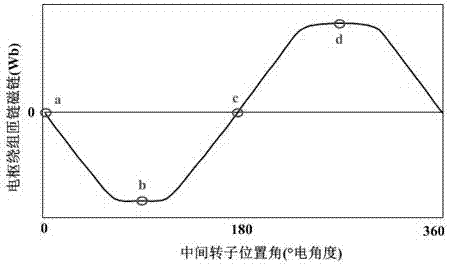

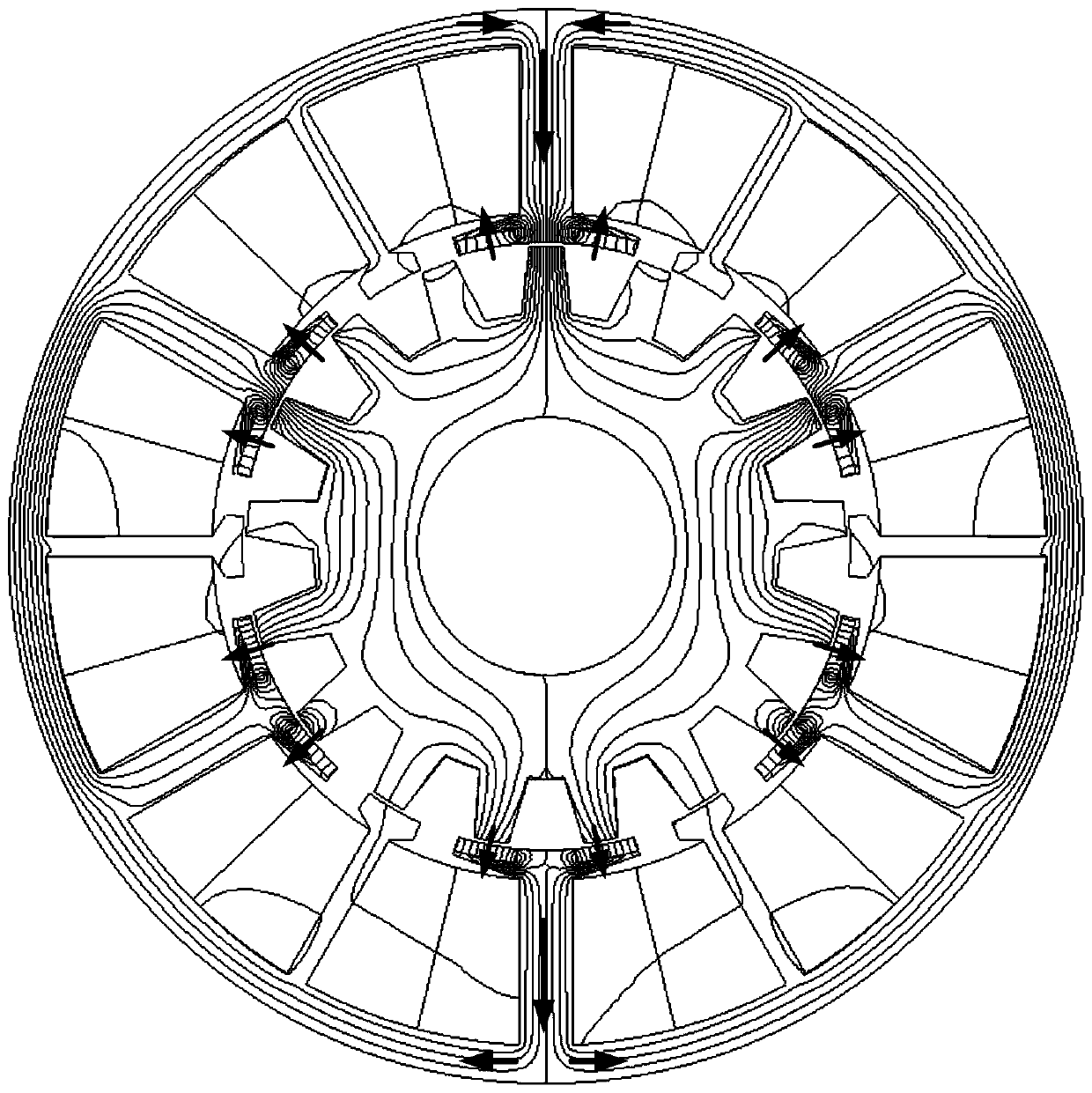

Magnetic flux switching type permanent magnet memory motor

ActiveCN103051139ASimple structureStable structureSynchronous machinesMagnetic circuit stationary partsElectric machineMemory motor

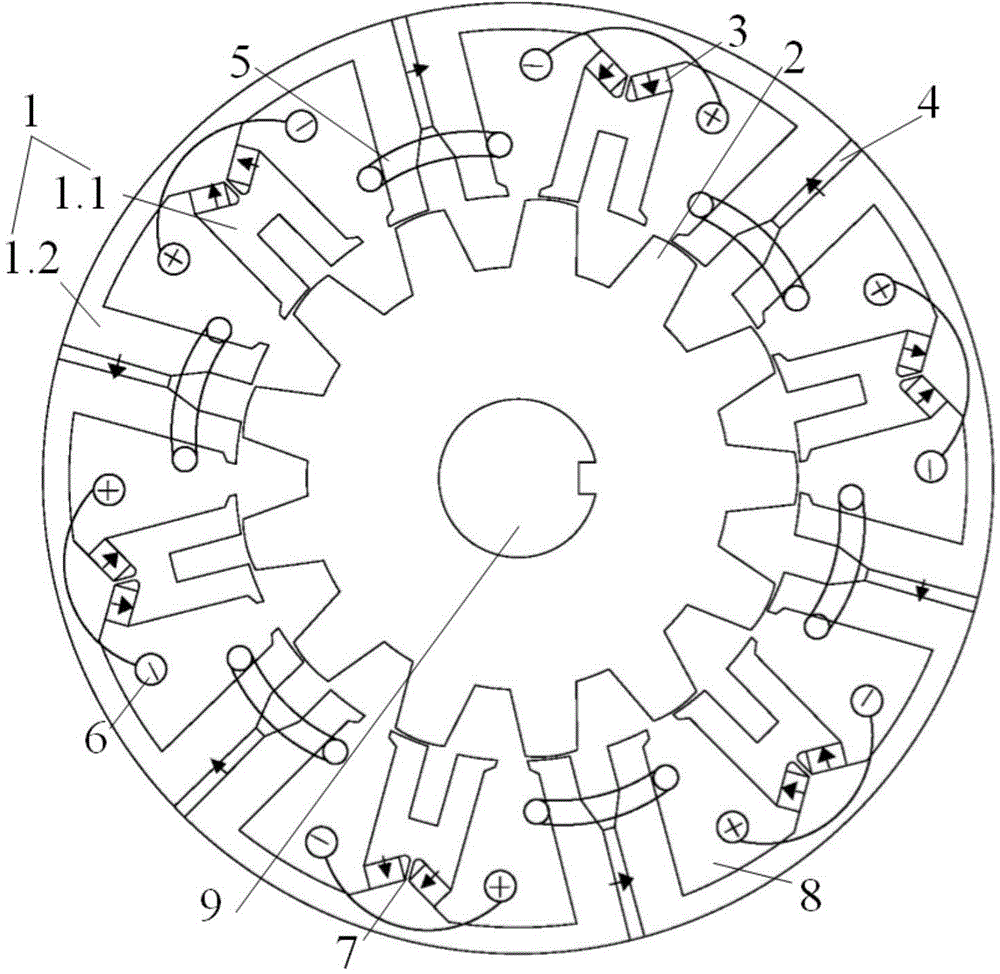

The invention discloses a magnetic flux switching type permanent magnet memory motor comprising an enclosure, a stator contained in the enclosure, a rotor (2) and a non-magnetic rotary shaft (8). The magnetic flux switching type permanent magnet memory motor is characterized in that the stator (1) is arranged at the outer part of the rotor (2); the rotor (2) is fixedly arranged on the non-magnetic rotary shaft (8) and is in a convex pole type; the rotor (2) comprises a rotor main body part and rotor teeth which protrude from the main body part to a direction which is far away from the center of the rotor; the stator comprises a stator iron core (1), a permanent magnet (3), a three-phase armature winding (4) and a pulse winding (5); the stator iron core (1) comprises a plurality of stator yokes and stator teeth (1.1) which protrude from the stator yokes to the direction of the center of the stator iron core; and the three-phase armature winding (4) is wound on the stator teeth (1.1). According to the magnetic flux switching type permanent magnet memory motor disclosed by the invention, a motor no-load gap magnetic field is adjustable, and the weak magnetism capability and the rotary speed operation speed of the motor are improved; and meanwhile, the torque and the power density of the motor are improved and the copper consumption of the motor is reduced.

Owner:SOUTHEAST UNIV

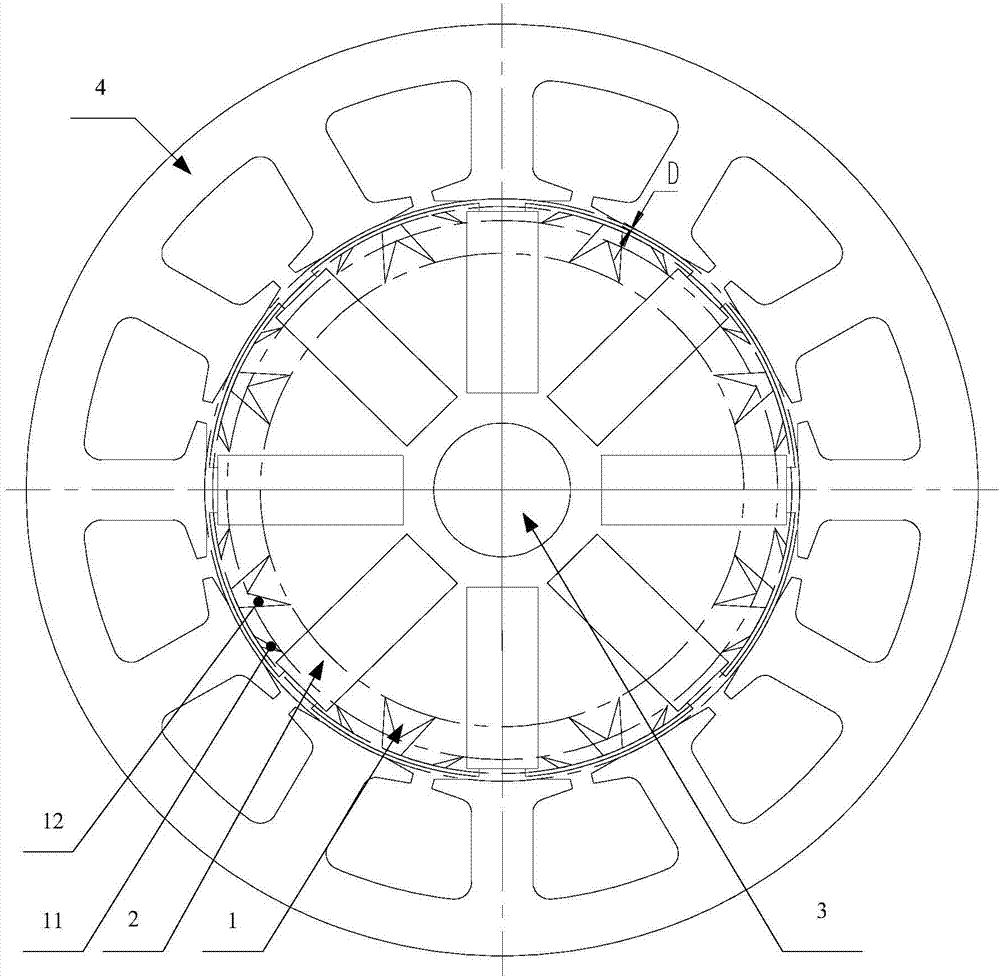

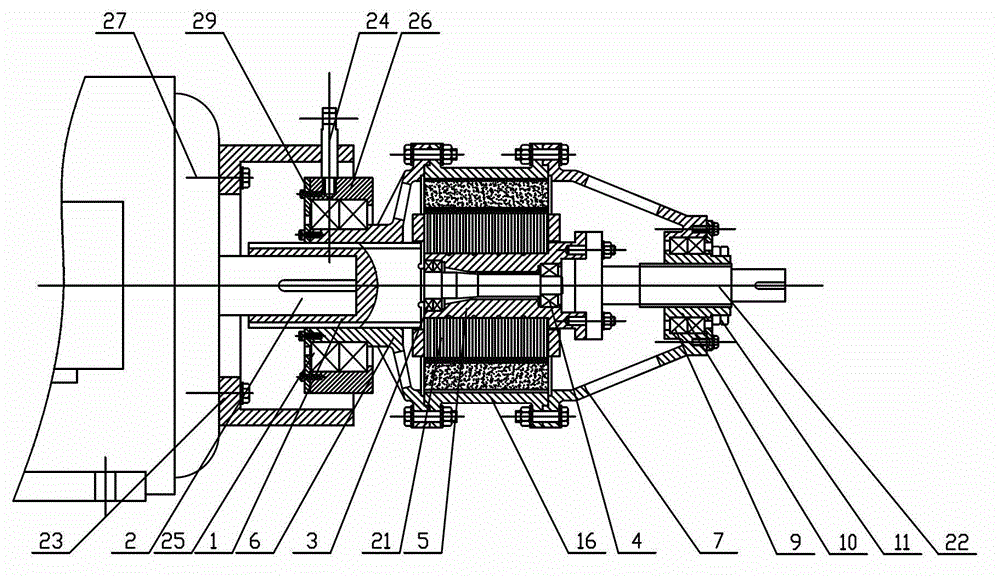

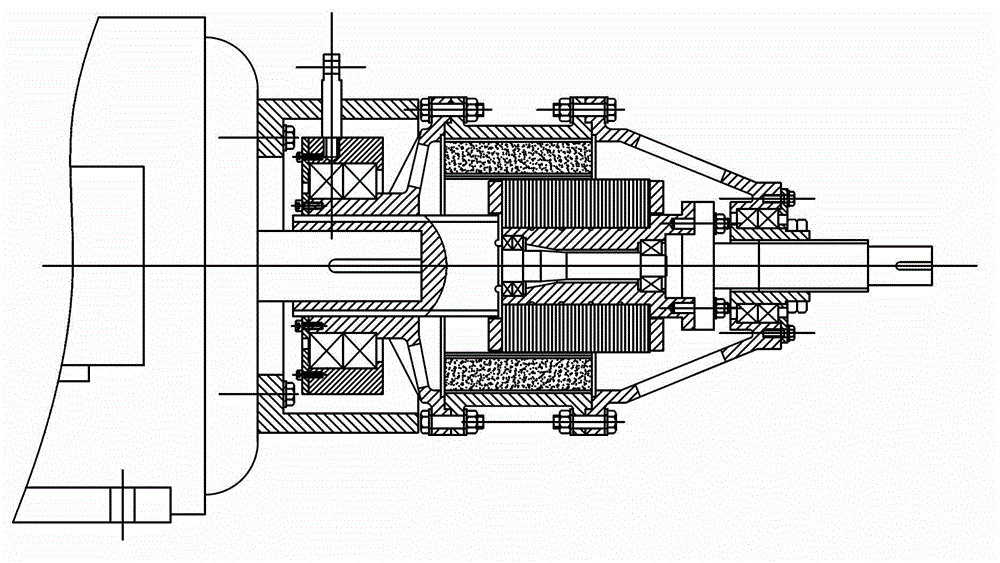

Directly driving mixed excitation dual stator wind power dynamotor

InactiveCN101017998AImprove power densitySmall leakage reactanceMagnetic circuit rotating partsWind energy generationWind drivenExcitation current

The dc-drive hybrid-excitation dual-stator wind-driven generator comprises: the dual-stator part including an inner / outer stator (4, 1) and inner stator frame (5), the excitation winding part including a winding (12) and winding frame (10), and a rotor including a cup rotor (8), an inner / outer permanent magnet (3, 2), a rotor yoke (11), and a rotation shaft (7). This invention cancels gear box, can adjust air gap magnetic field conveniently, and benefit to catch the maximal wind energy.

Owner:SOUTHEAST UNIV

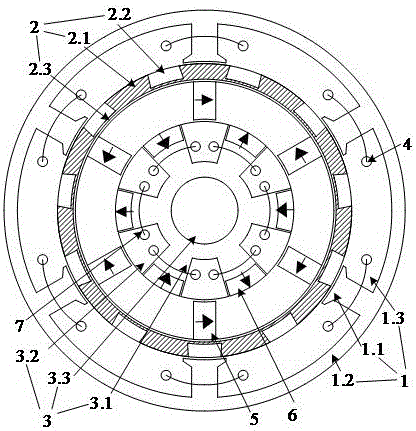

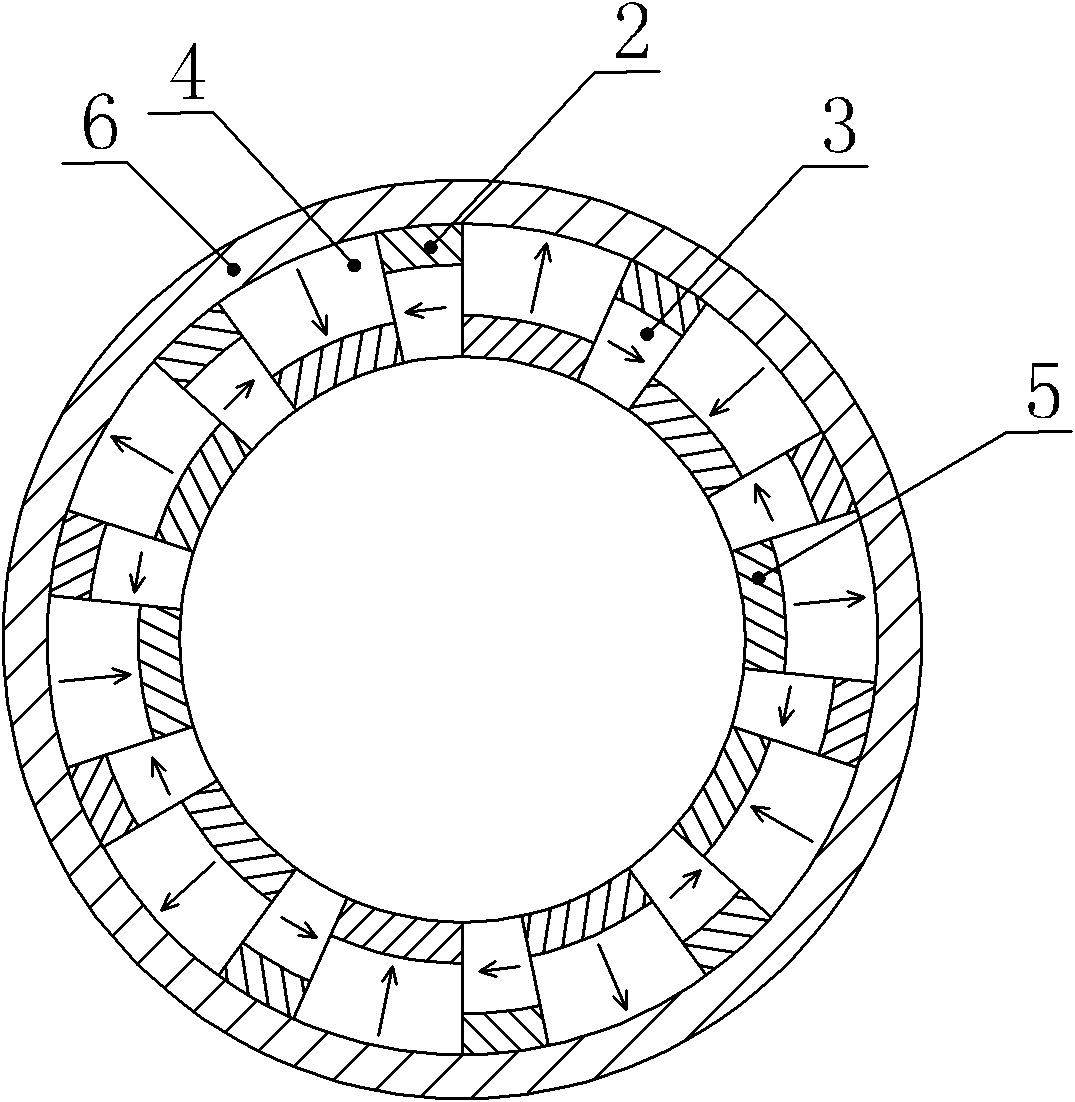

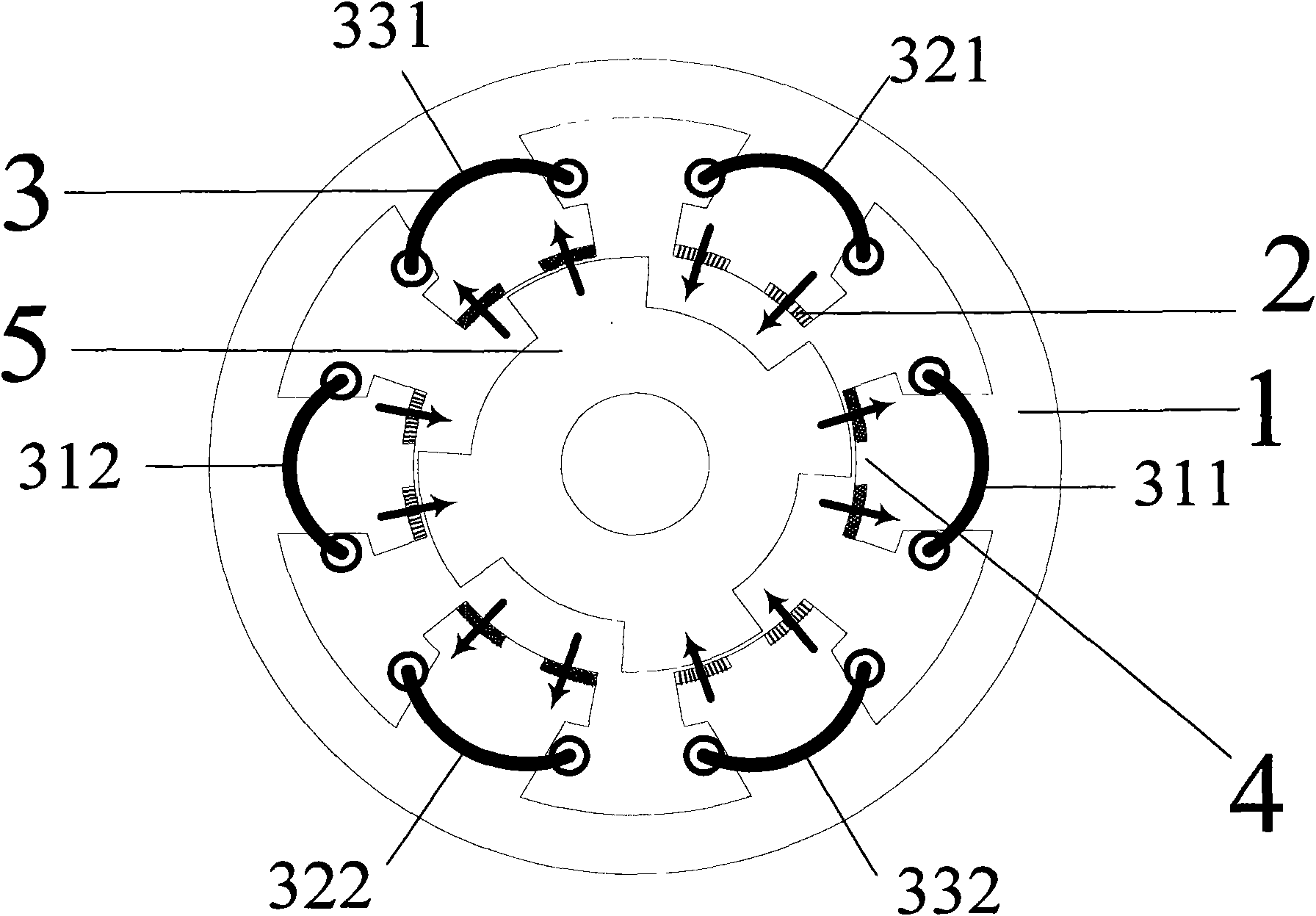

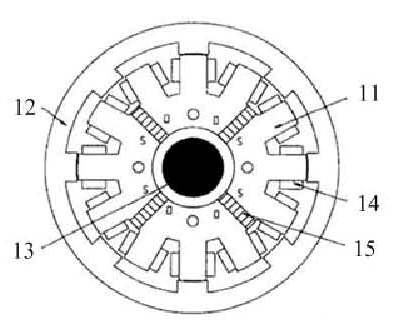

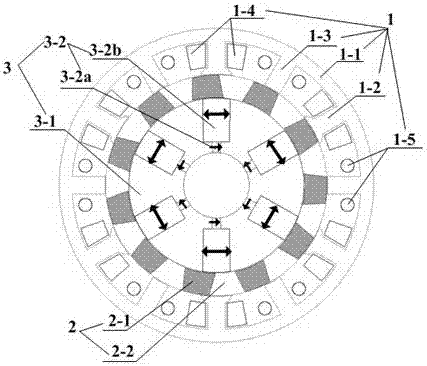

Magnetic gear type double-stator hybrid permanent magnet memory motor

InactiveCN105141092ASimple structureImprove space utilizationMagnetic circuit rotating partsMagnetic circuit stationary partsEpoxyElectric machine

The invention discloses a magnetic gear type double-stator hybrid permanent magnet memory motor. The motor comprises an external stator, a rotor and an internal stator which are coaxially arranged and sleeved from outside to inside in turn. The external stator comprises armature iron core teeth, stator yokes and armature windings which are arranged on the armature iron core teeth. The internal stator comprises an internal stator iron core provided with internal slots, neodymium iron boron permanent magnets, aluminum nickel cobalt permanent magnets and pulse magnetic regulating windings which are arranged in the internal slots of the internal stator. The two types of co-excitation permanent magnets are arranged in a "U" shape. The number of single permanent magnets on the internal stator is equal to that of external stator armature teeth. The whole rotor has an annular cup-shaped structure. Rotor iron blocks are fixed in a non-magnetic-conductive epoxy resin sleeve. The rotor iron blocks are connected via magnetic conductive bridges. Disadvantages that a conventional single stator has multiple internal excitation sources which are mutually hindered in space and torque density is relatively low can be solved. Besides, high power density is realized by arrangement of double-stator hybrid permanent magnets, and residual magnetization intensity and magnetization direction of the permanent magnets are regulated by applying pulse current so that motor magnetic field high-efficiency regulation is realized, and rotating speed operation range is enhanced.

Owner:SOUTHEAST UNIV

Outer rotor magnetic flux collecting magnetic gear

ActiveCN102312986AIncreased torque transfer capabilityIncrease air gap flux densityGearingMagnetic fluxCondensed matter physics

The invention discloses an outer rotor magnetic flux collecting magnetic gear. The magnetic gear has an axial structure, and the section of the magnetic gear comprises a magnetic gear outer rotor, a magnetic flux adjusting ring and a magnetic gear inner rotor from outside to inside in sequence; the magnetic gear outer rotor, the magnetic flux adjusting ring and the magnetic gear inner rotor are coaxial and are independent of one another; an outer air gap (3) is formed between the magnetic gear outer rotor and the magnetic flux adjusting ring; an inner air gap (6) is formed between the magnetic flux adjusting ring and the magnetic gear inner rotor; the magnetic gear outer rotor and the magnetic gear inner rotor freely rotate and are connected with a driving or driven component to perform torque transfer respectively; and the middle magnetic flux adjusting ring is in a stationary state and is fixed at the two axial ends. Through the outer rotor magnetic flux collecting magnetic gear, the torque transfer capacity of the magnetic gear can be improved.

Owner:SOUTHEAST UNIV

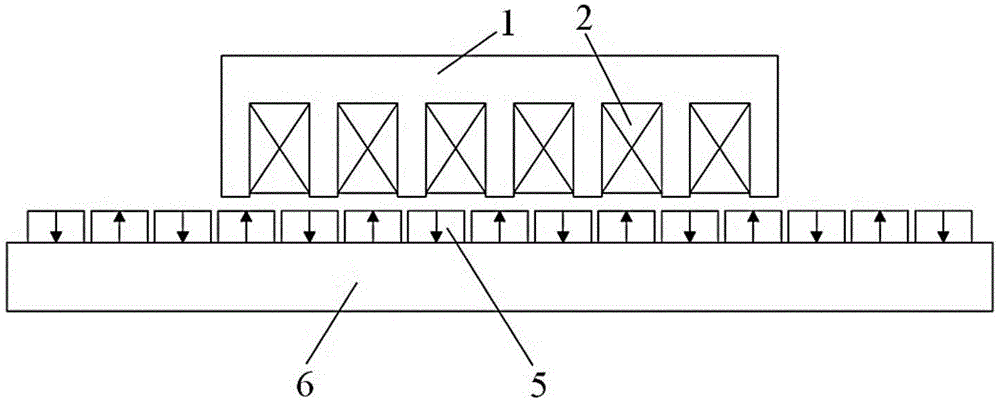

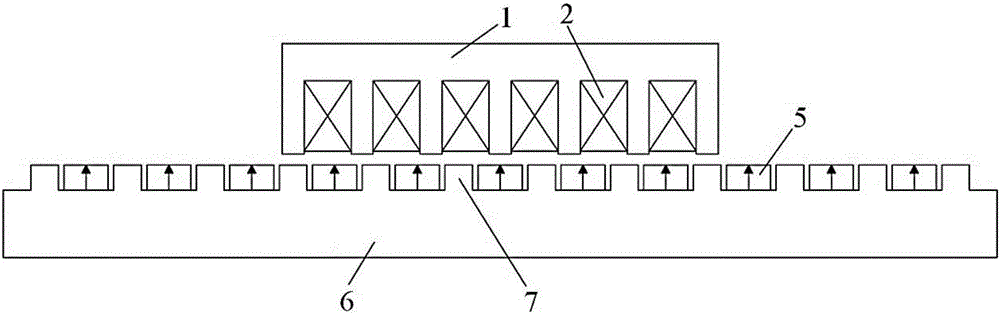

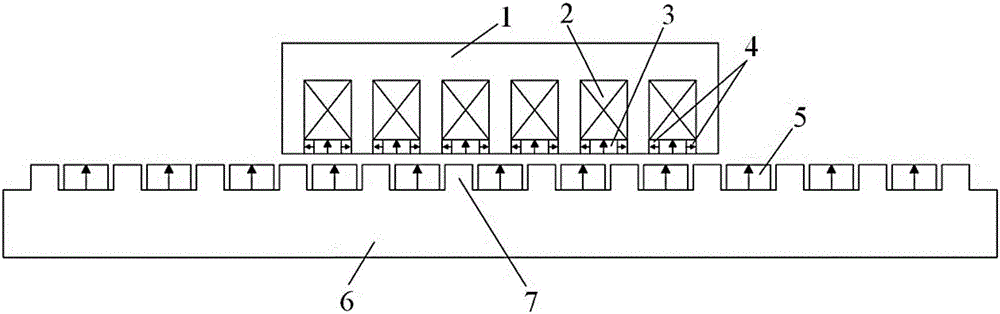

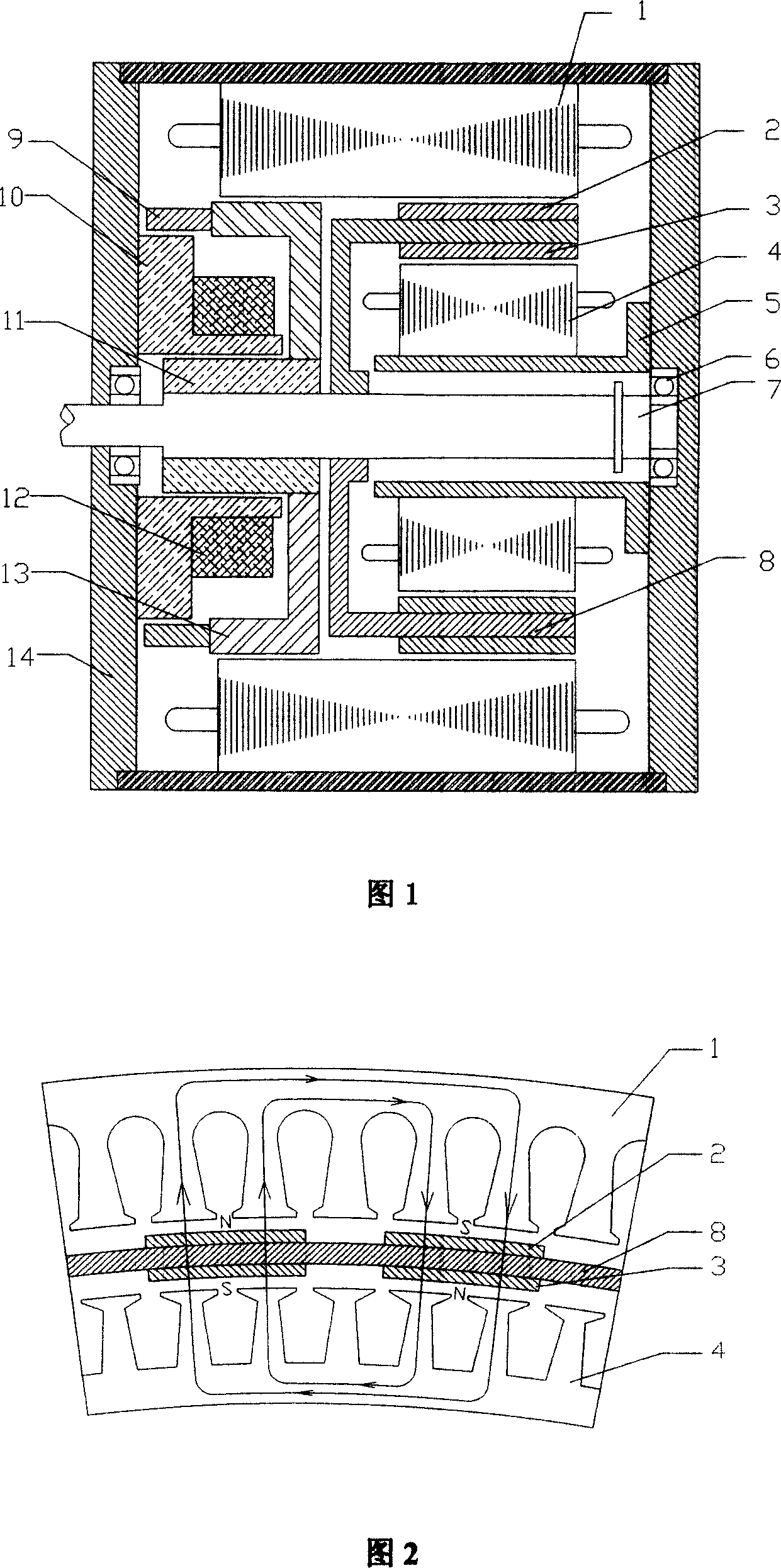

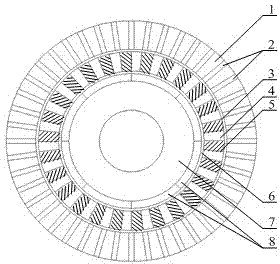

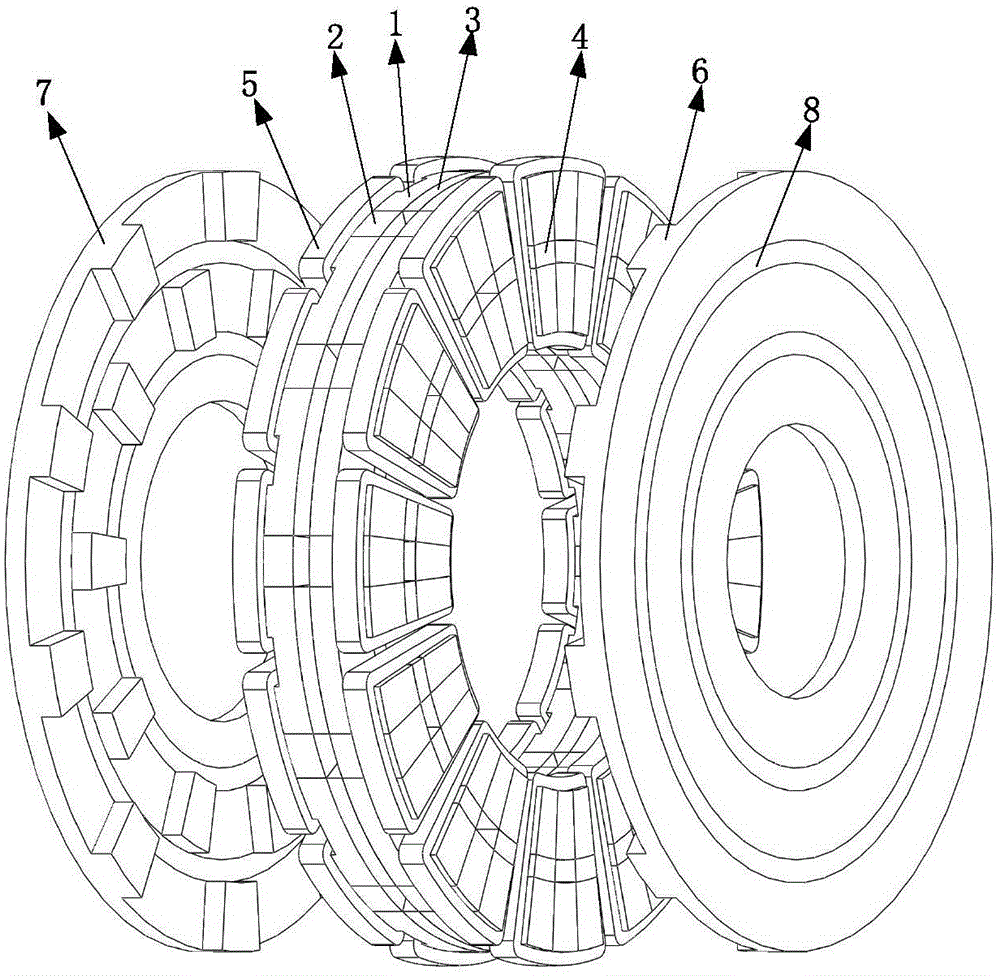

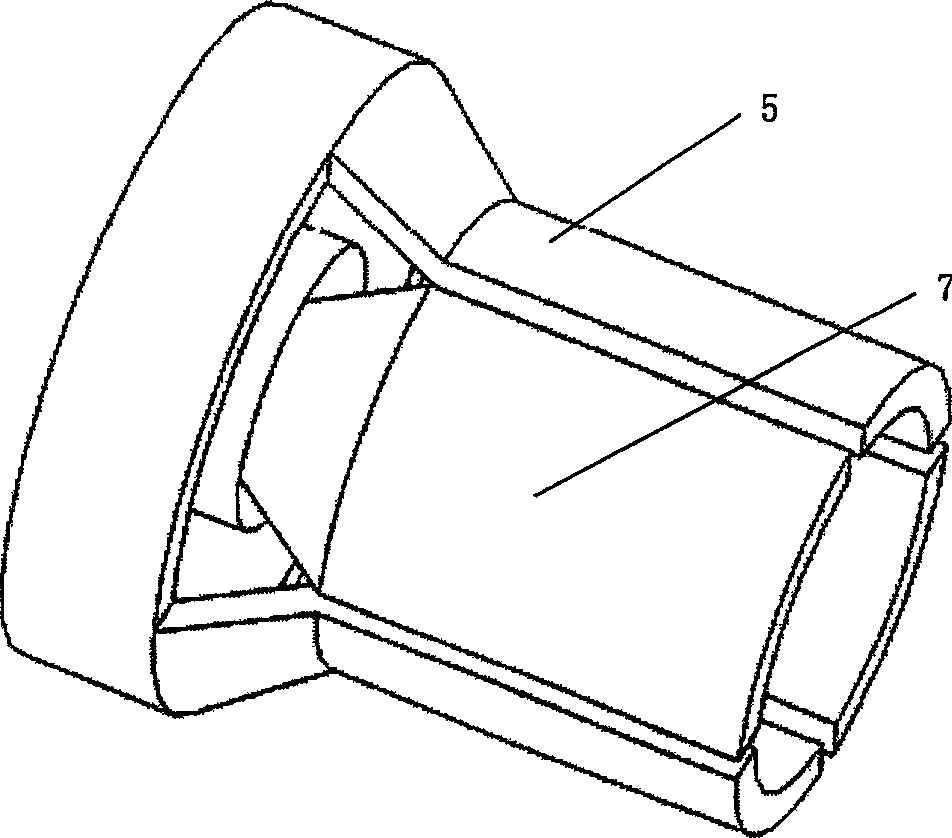

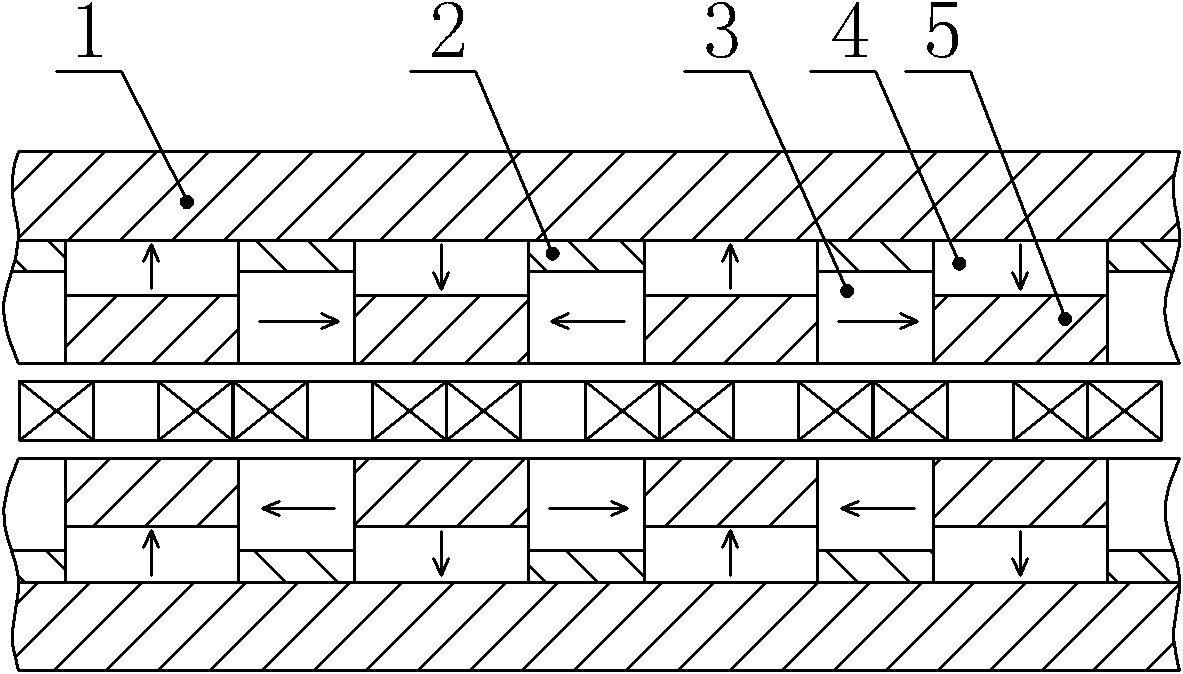

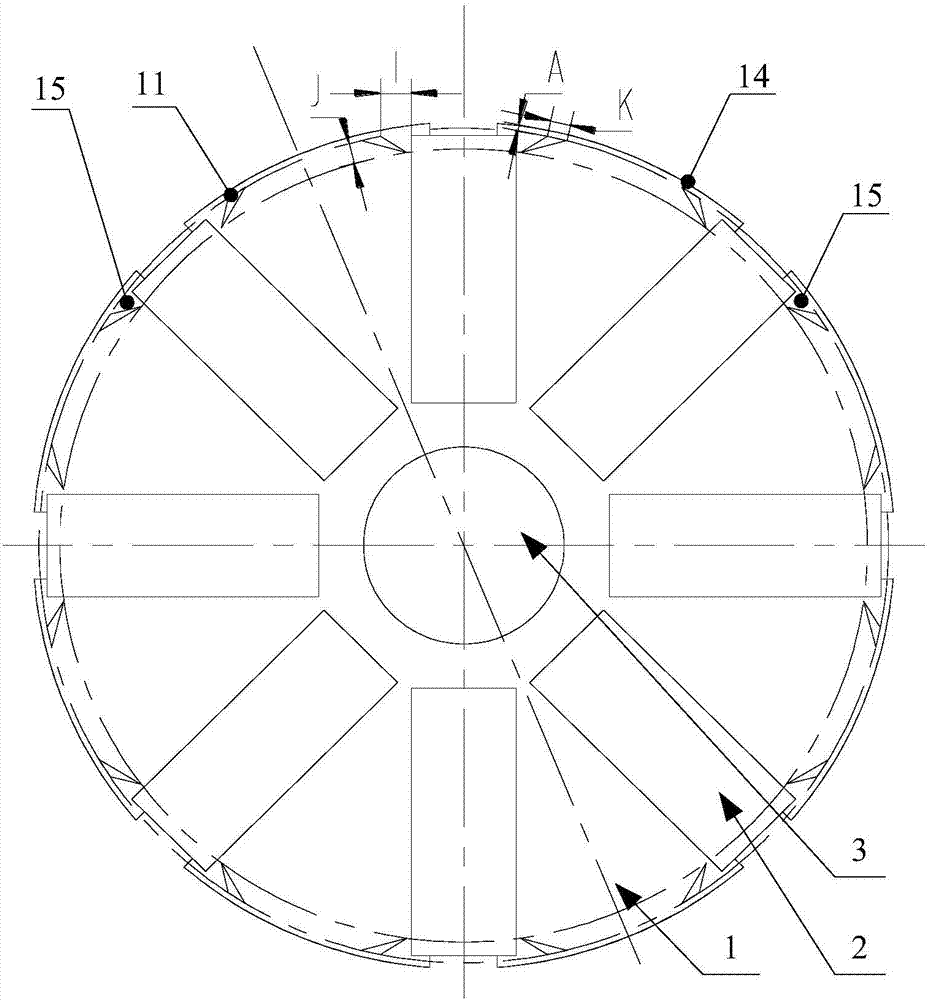

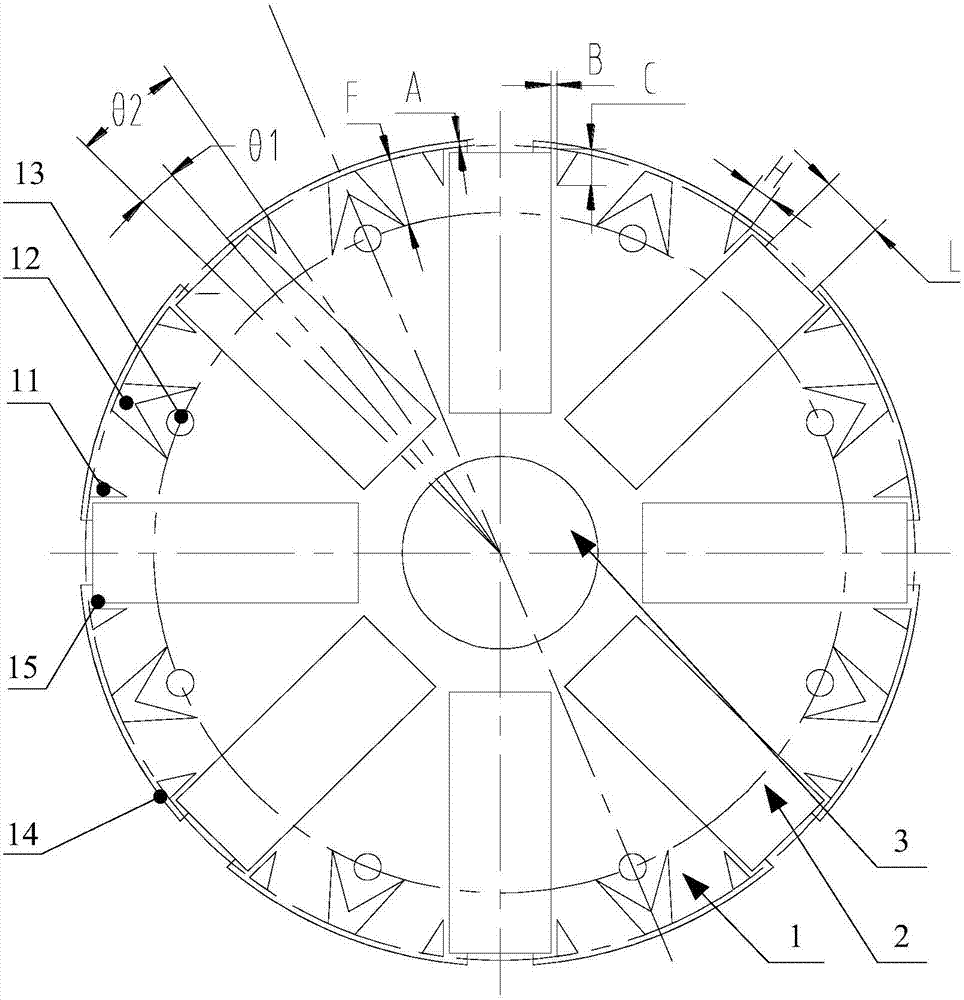

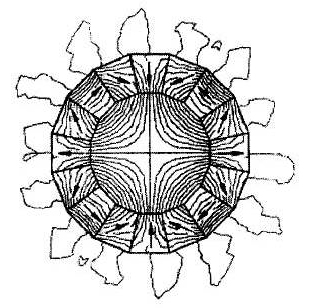

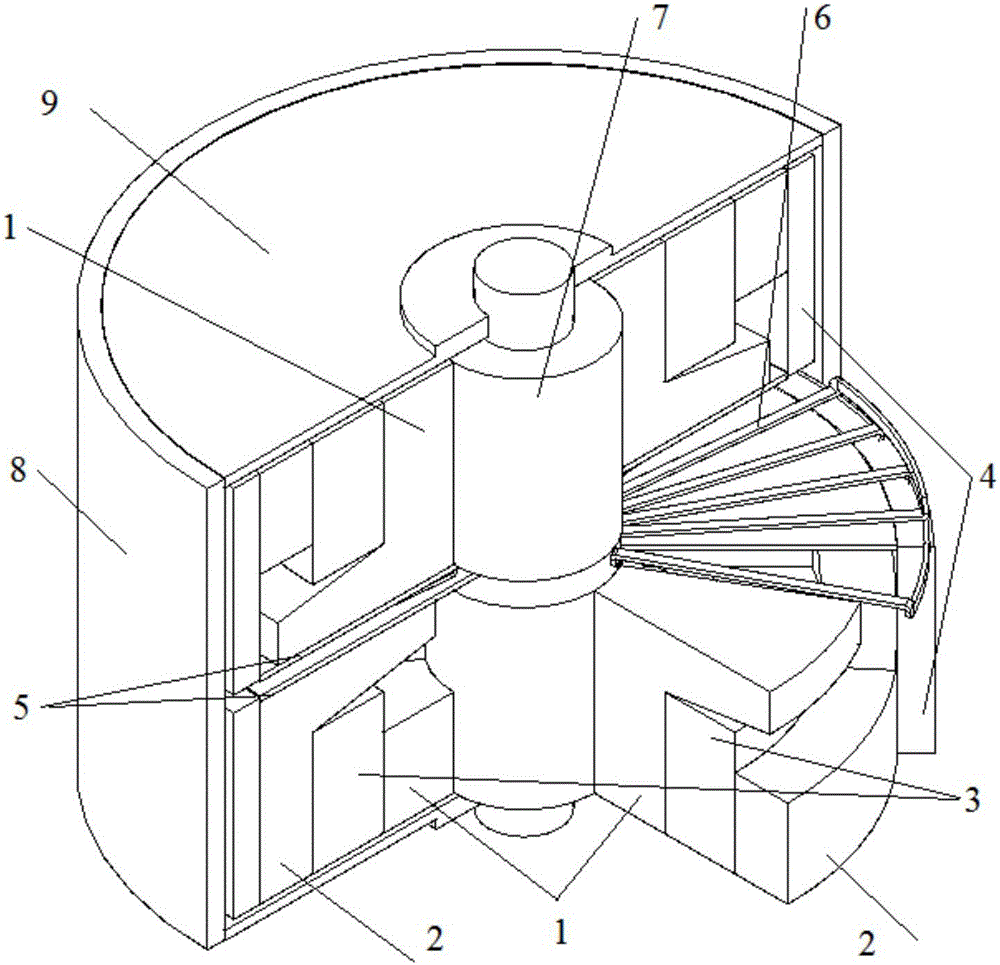

Magnetism-increasing decoupling axial-flux switching dual-rotor motor

ActiveCN105024508AReduce axial sizeImprove power densityMagnetic circuit rotating partsMagnetic circuit stationary partsCouplingMoment of inertia

The invention discloses a magnetism-increasing decoupling axial-flux switching dual-rotor motor. A rotor of the motor adopts a disc-type salient pole structure, and a stator is embedded between a first rotor and a second rotor, is of a salient pole structure and comprises a stator core, a tangential permanent magnet, a magnetism-increasing permanent magnet, a radial permanent magnet and an armature winding. In the magnetism-increasing decoupling axial-flux switching dual-rotor motor, the magnetism-increasing permanent magnet is additionally arranged on the central surface of the stator core of the motor, the whole magnetic path of the motor is divided into a left part and a right part, the magnetism-increasing permanent magnet plays a role in suppressing coupling of the left rotor magnetic path and the right rotor magnetic path, the coupling of the left rotor magnetic path and the right rotor magnetic path can be reduced to a certain extent, and thus, the left rotor and the right rotor have abilities of independent running. Meanwhile, a magnetism gathering effect is generated among the magnetism-increasing permanent magnet, the tangential permanent magnet and the radial permanent magnet, the gap flux density of the motor is further increased, and the power density of the motor is improved. No winding and no permanent magnet are arranged on the rotors, the magnetism-increasing decoupling axial-flux switching dual-rotor motor has the characteristics of simplicity in structure, low cost and small rotational inertia, is applicable for running at a high speed, and can be rapidly started, and a few iron core materials are required for the disc-type structured rotor.

Owner:JIANGSU UNIV

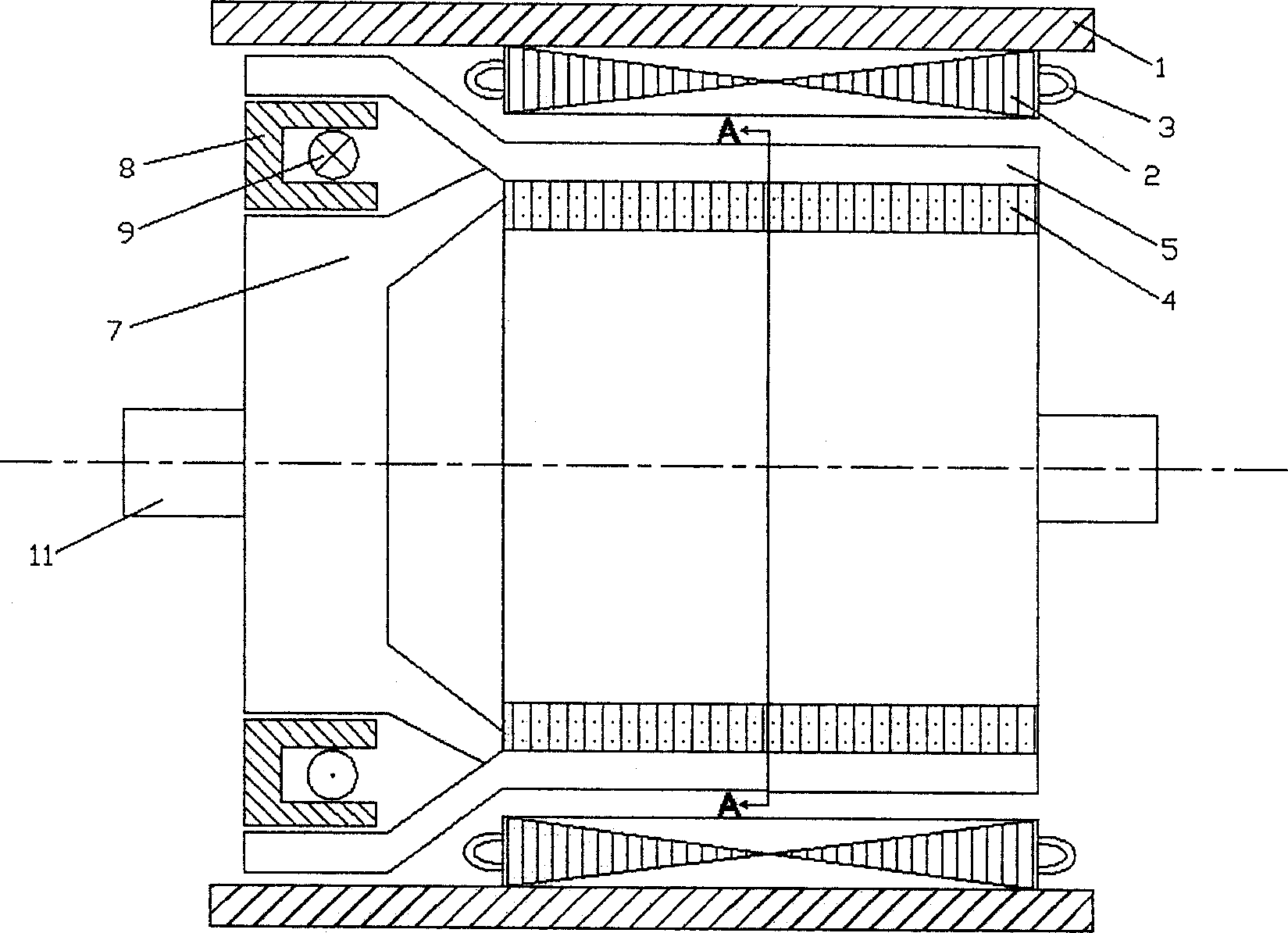

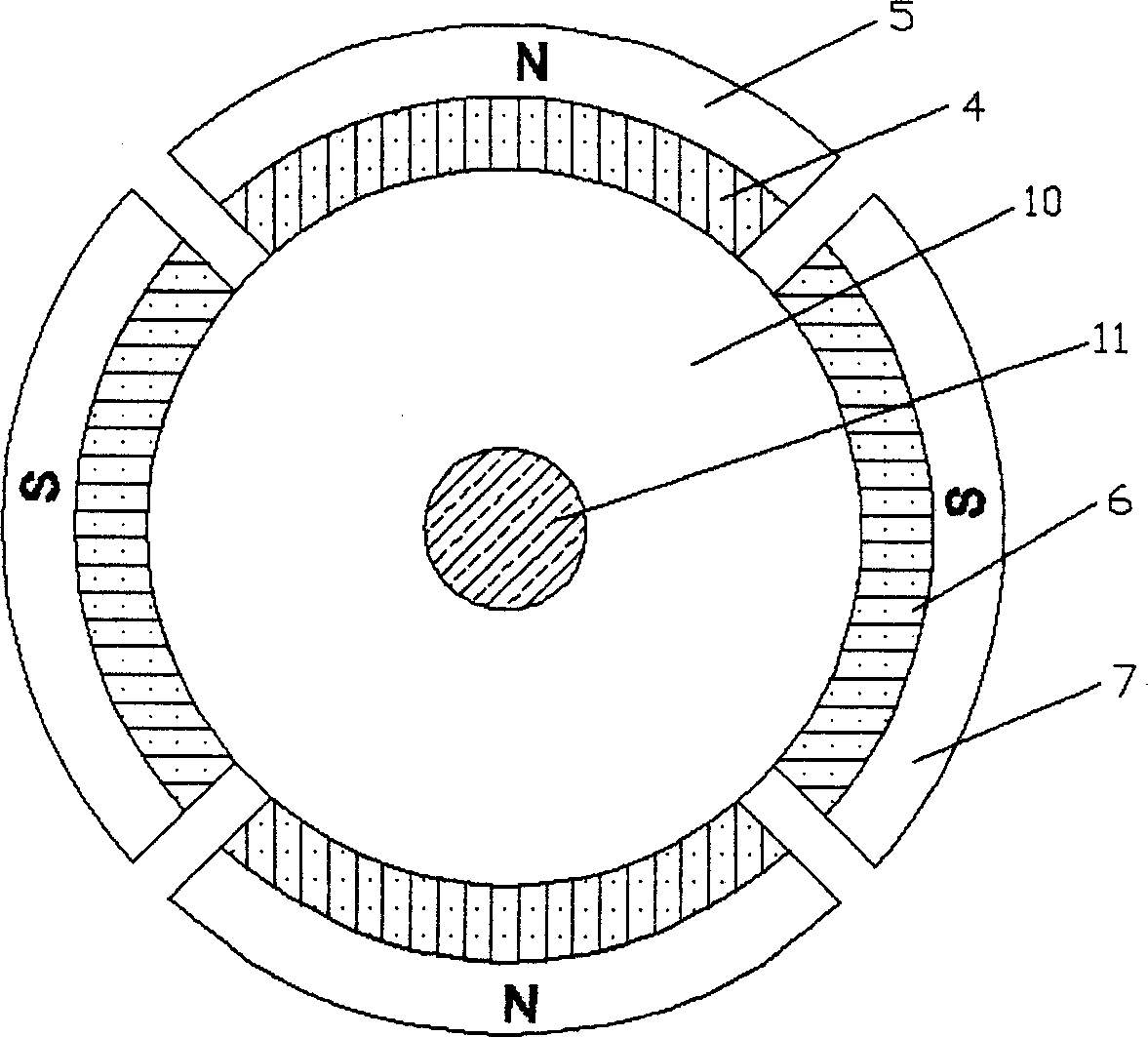

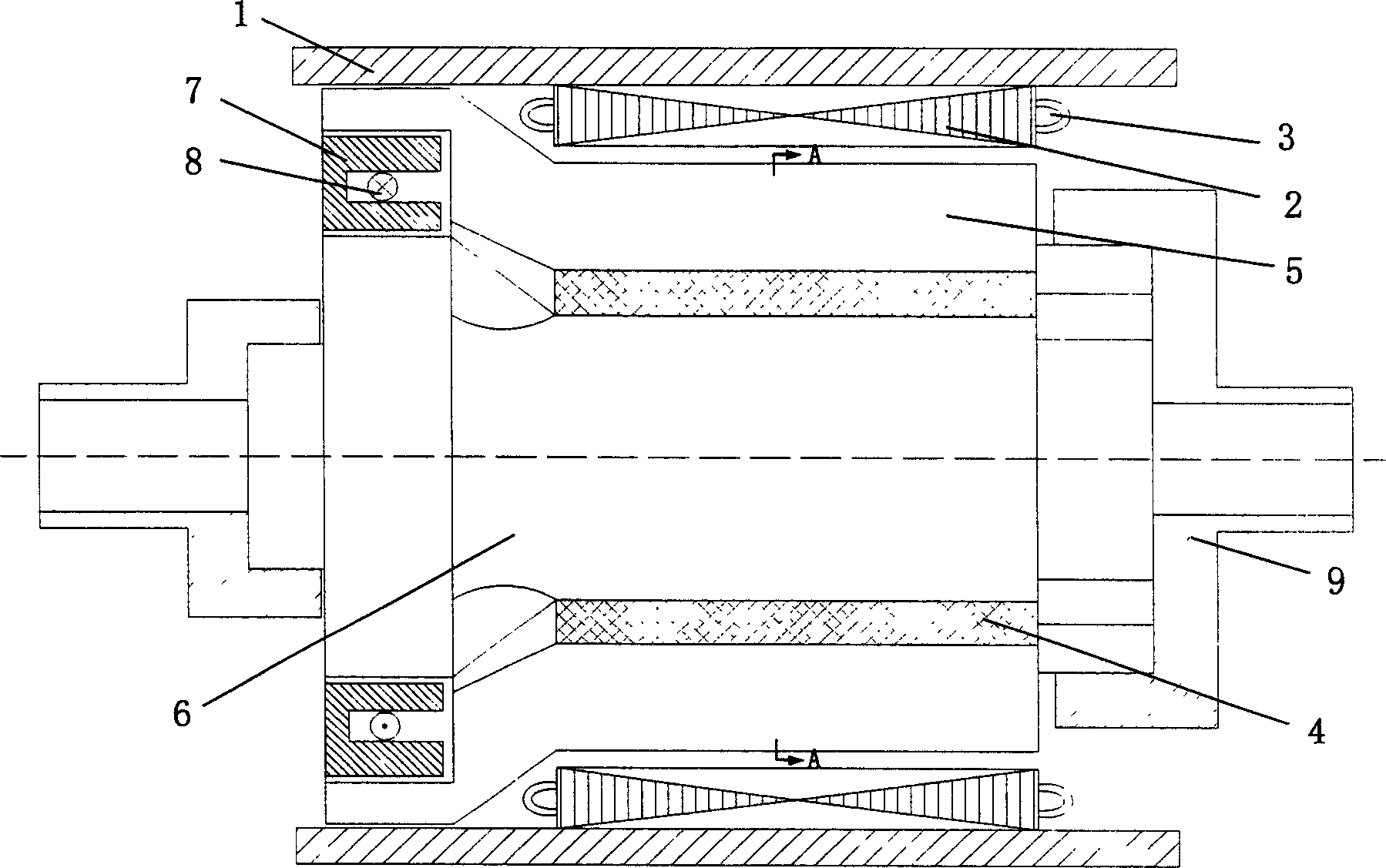

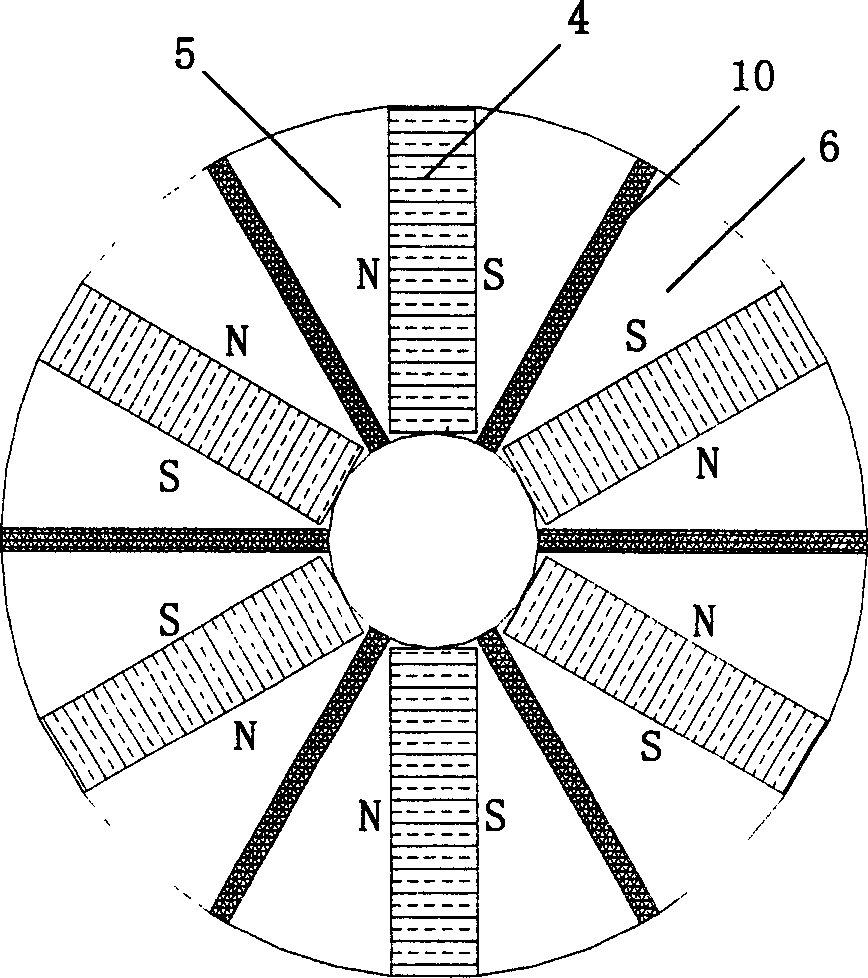

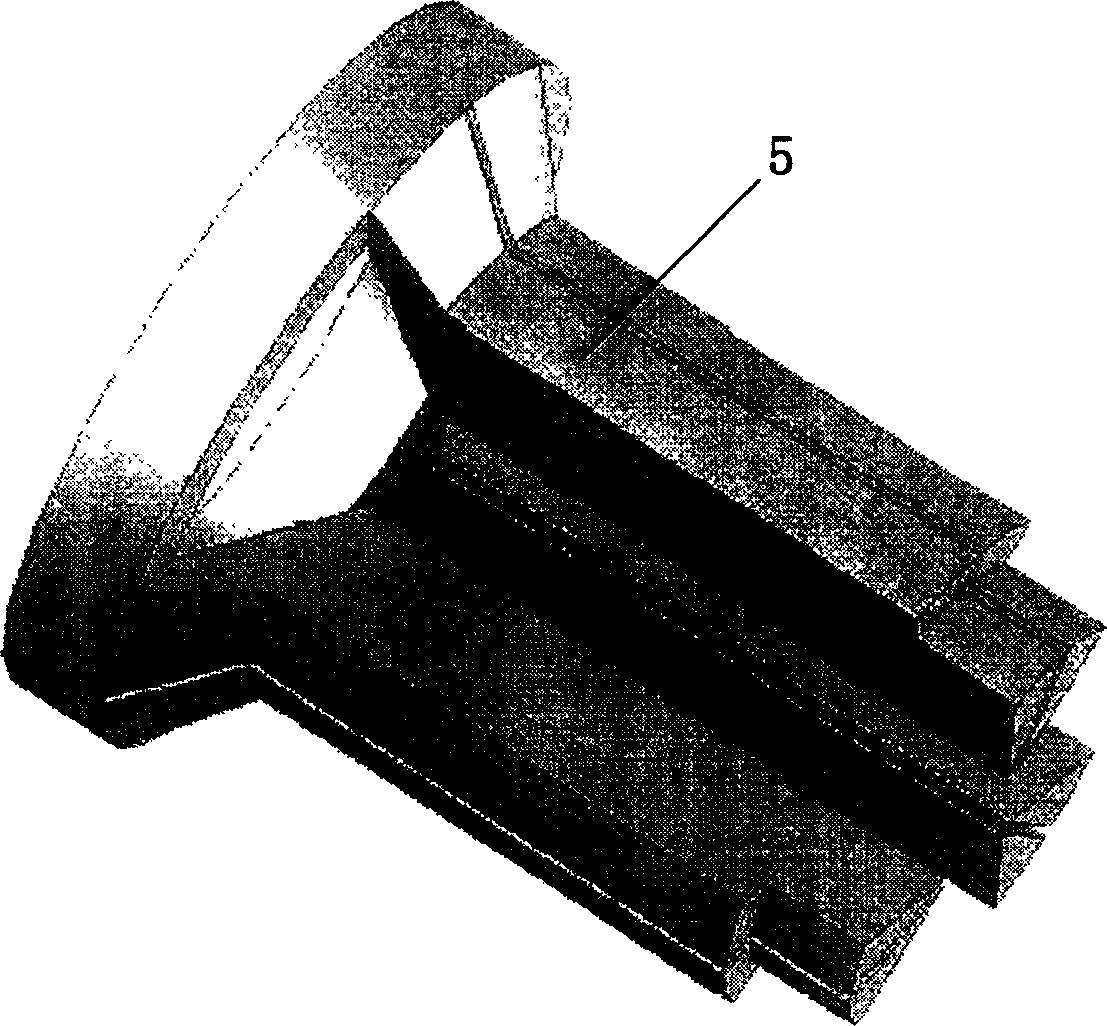

Mixed excitation synchronous motor with radial structure

InactiveCN1767316AAxial magnetic circuit shortenedReduce volumeMagnetic circuit rotating partsSynchronous machinesSynchronous motorPhysics

The invention relates to a radial structure mixed exciter synchronic motor which comprises: a stator formed by armature core 2 inside the casing 1 and the armature coil group 3 and a rotor formed by rotating shaft 11, rotor core 10, N-pole permanent magnet 4 and S-pole permanent magnet 6; the radial structure permanent magnet synchronic motor is formed by the stator and the rotor; the N-pole permanent magnet and the S-pole permanent magnet of the rotor are separately adhered 5 and 7 and makes the N-pole annex magnet and the S-pole annex magnet to extent with the same direction. The extent part of the rotor arranges an exciting coil group 9 and a ring-type exciting magnetic bridge 8.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

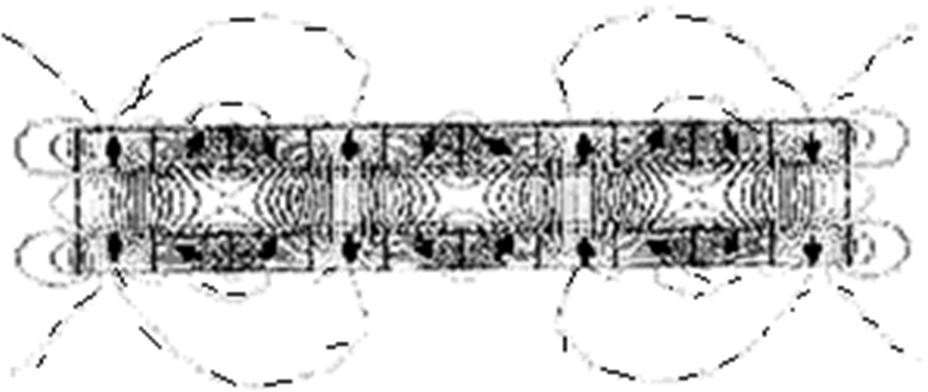

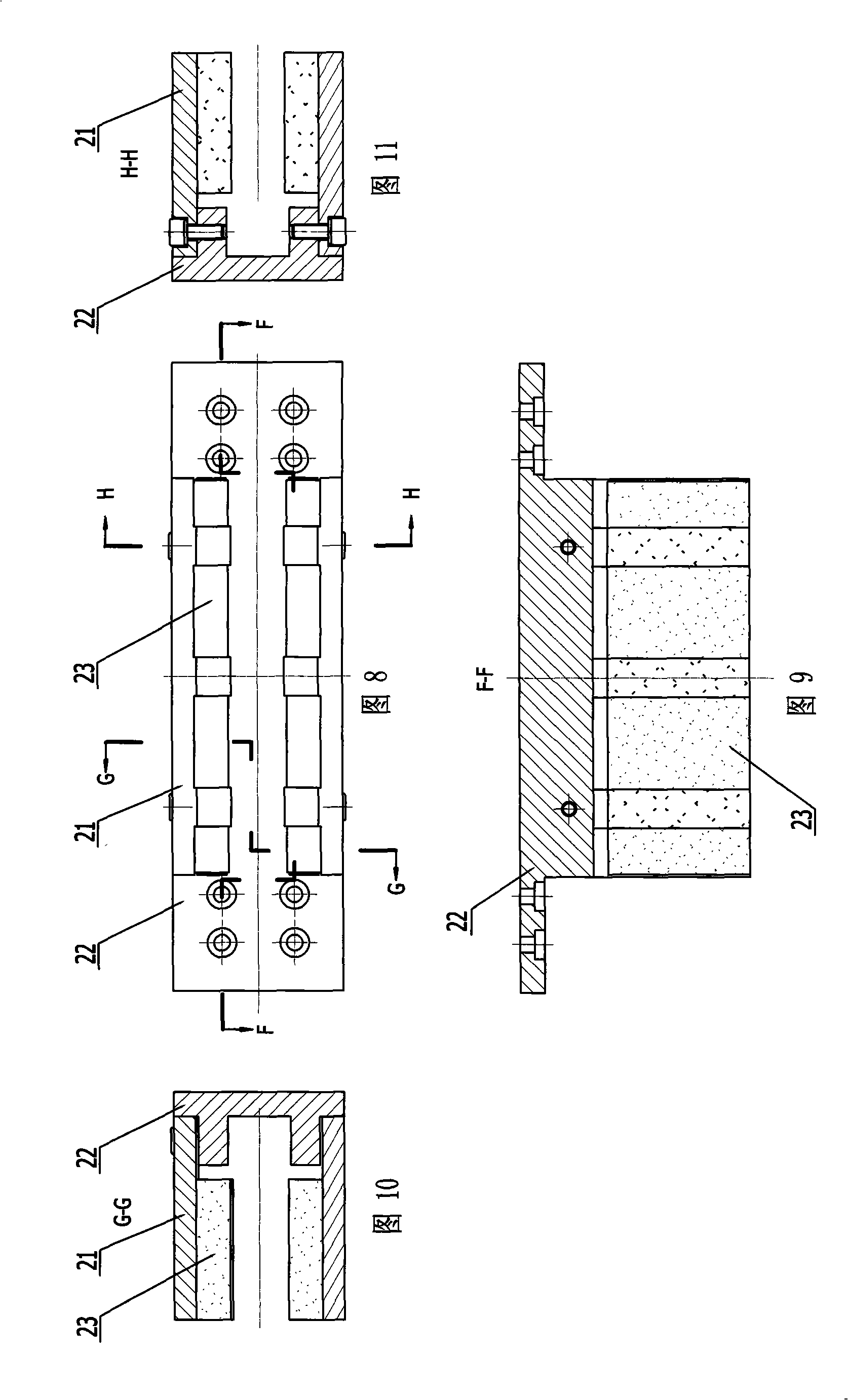

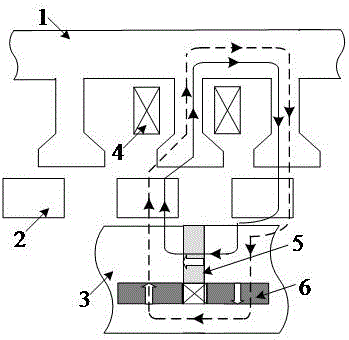

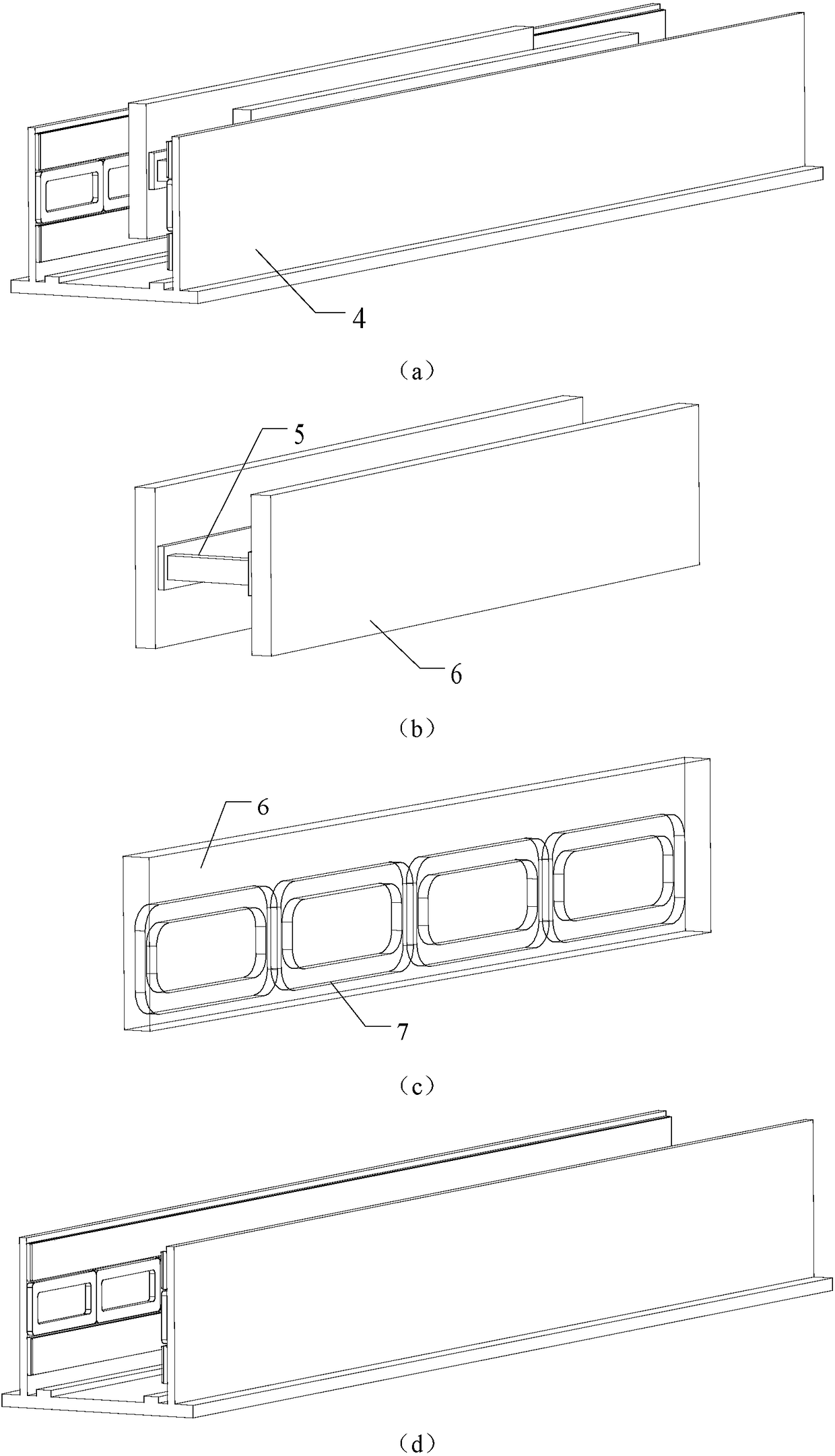

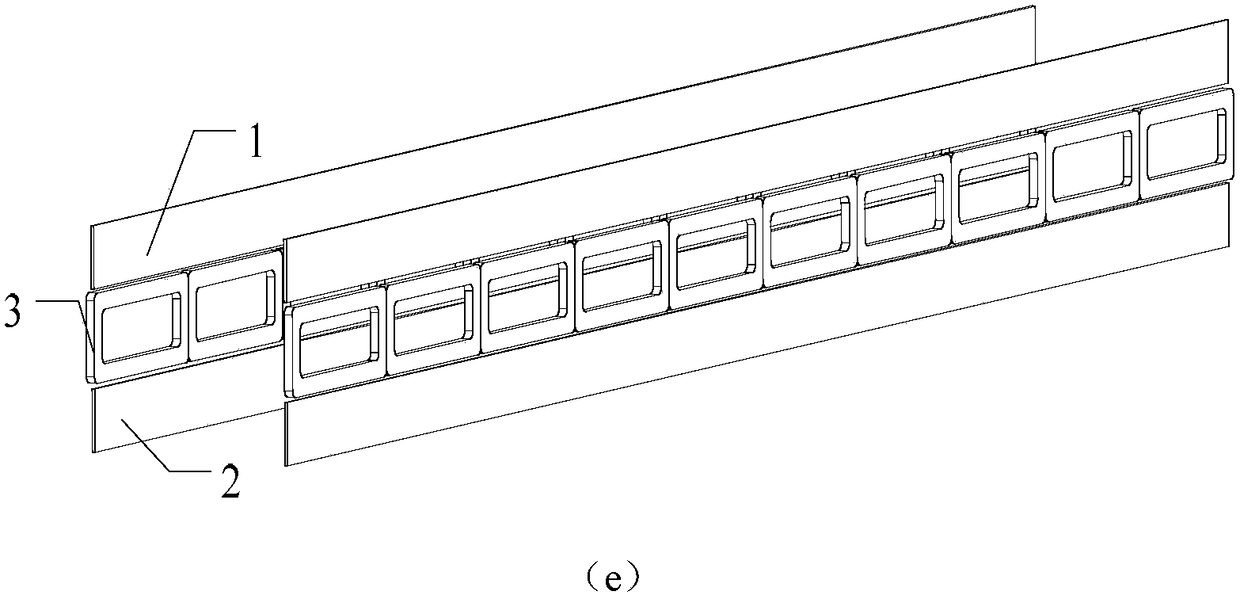

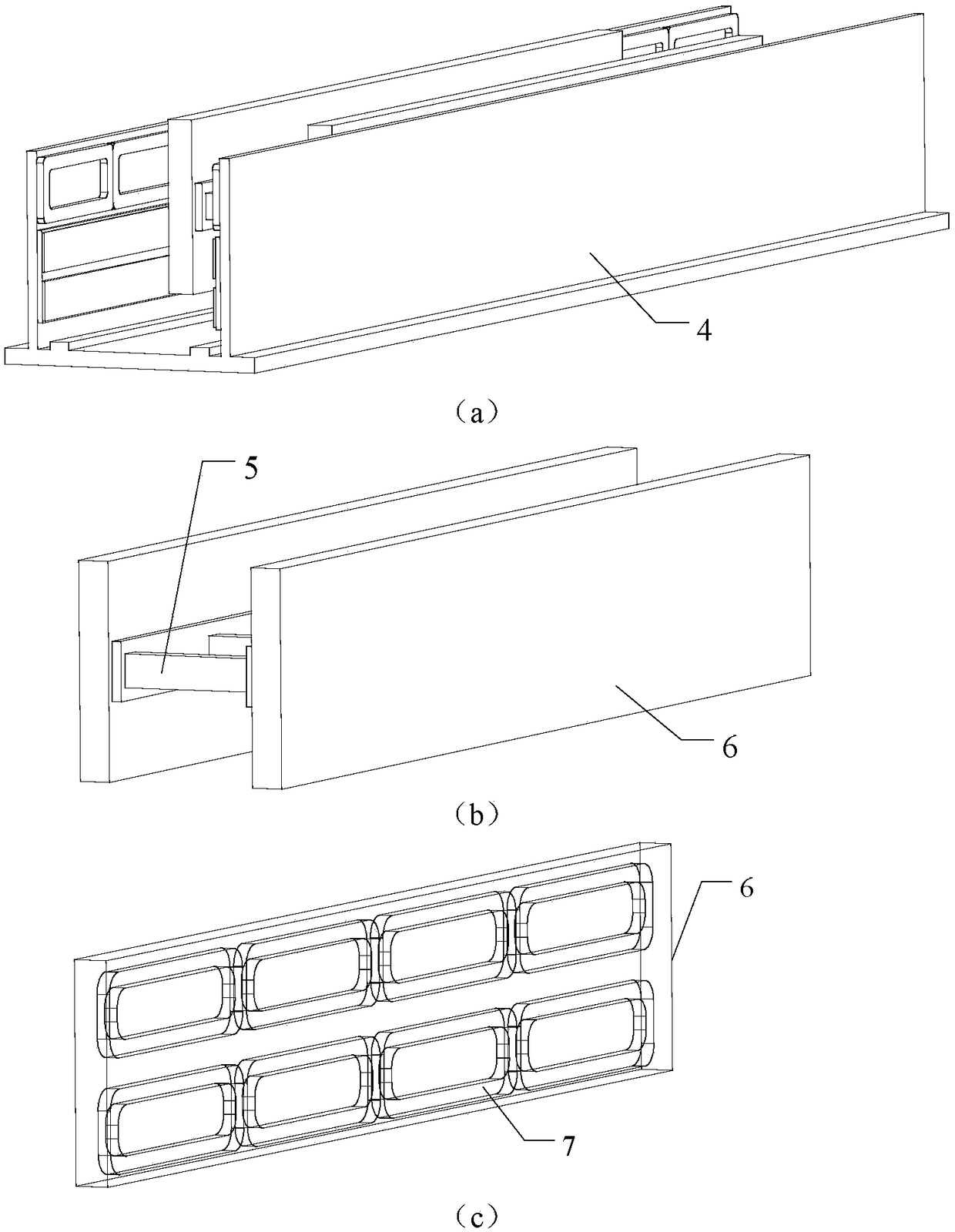

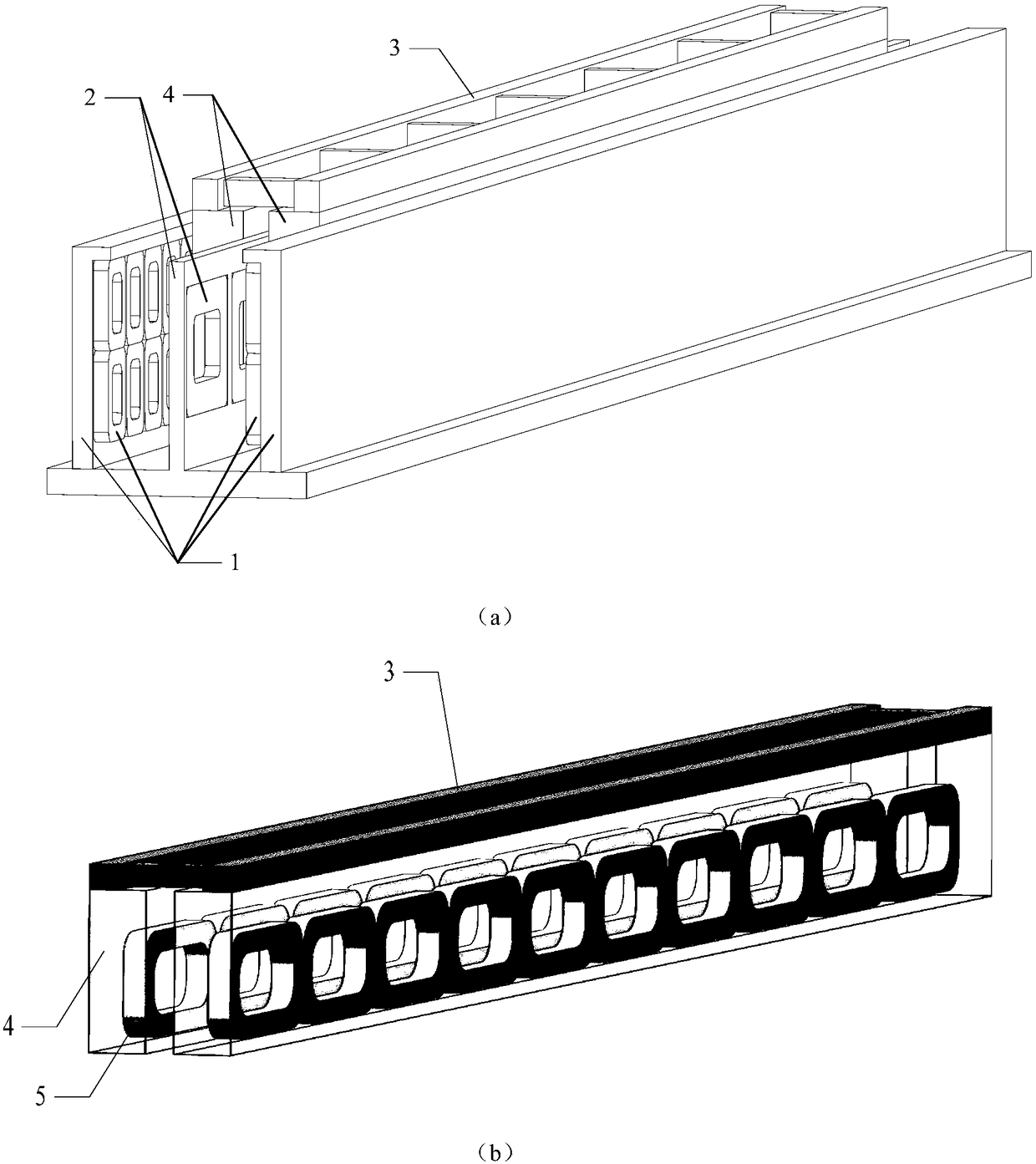

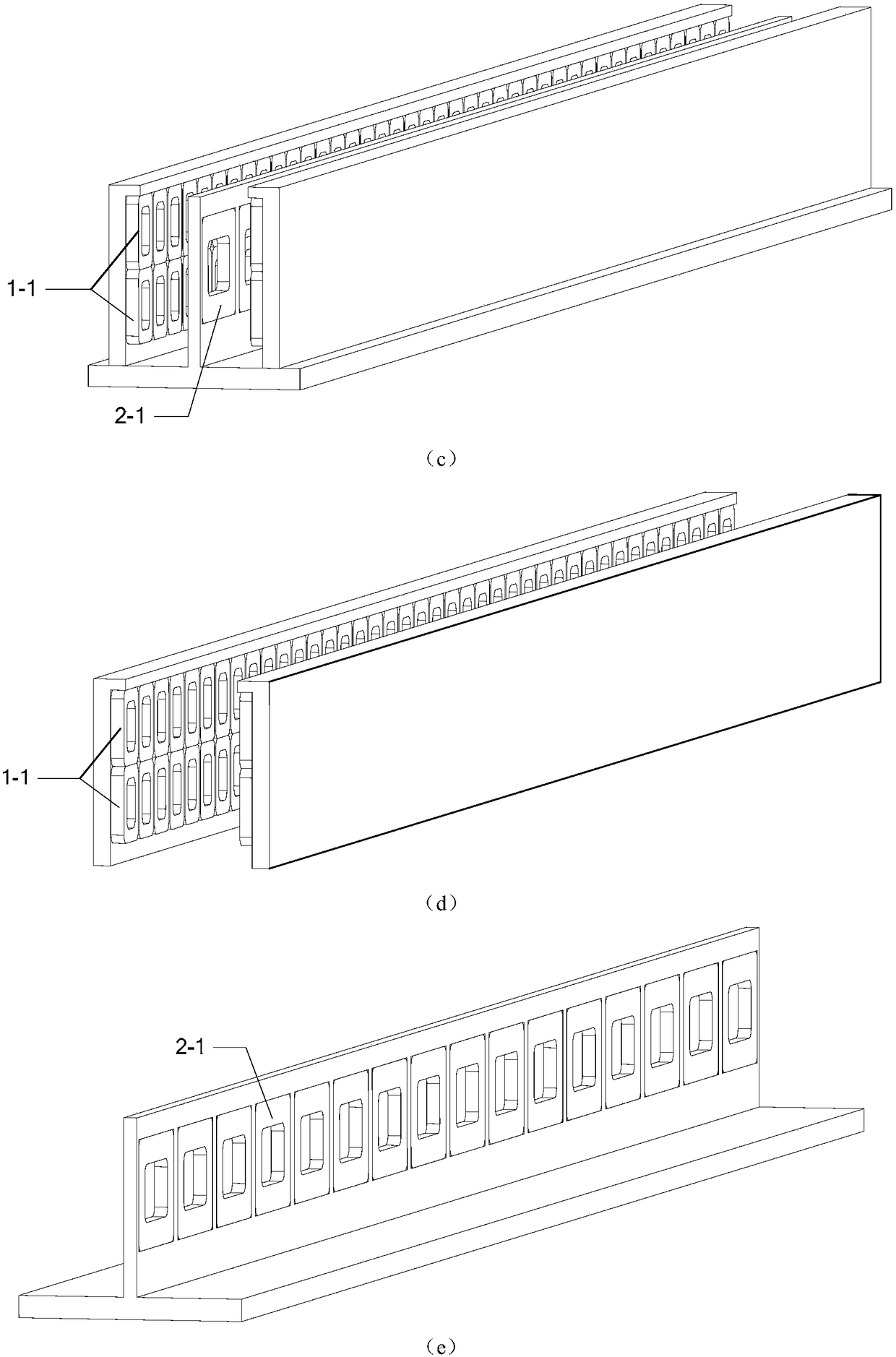

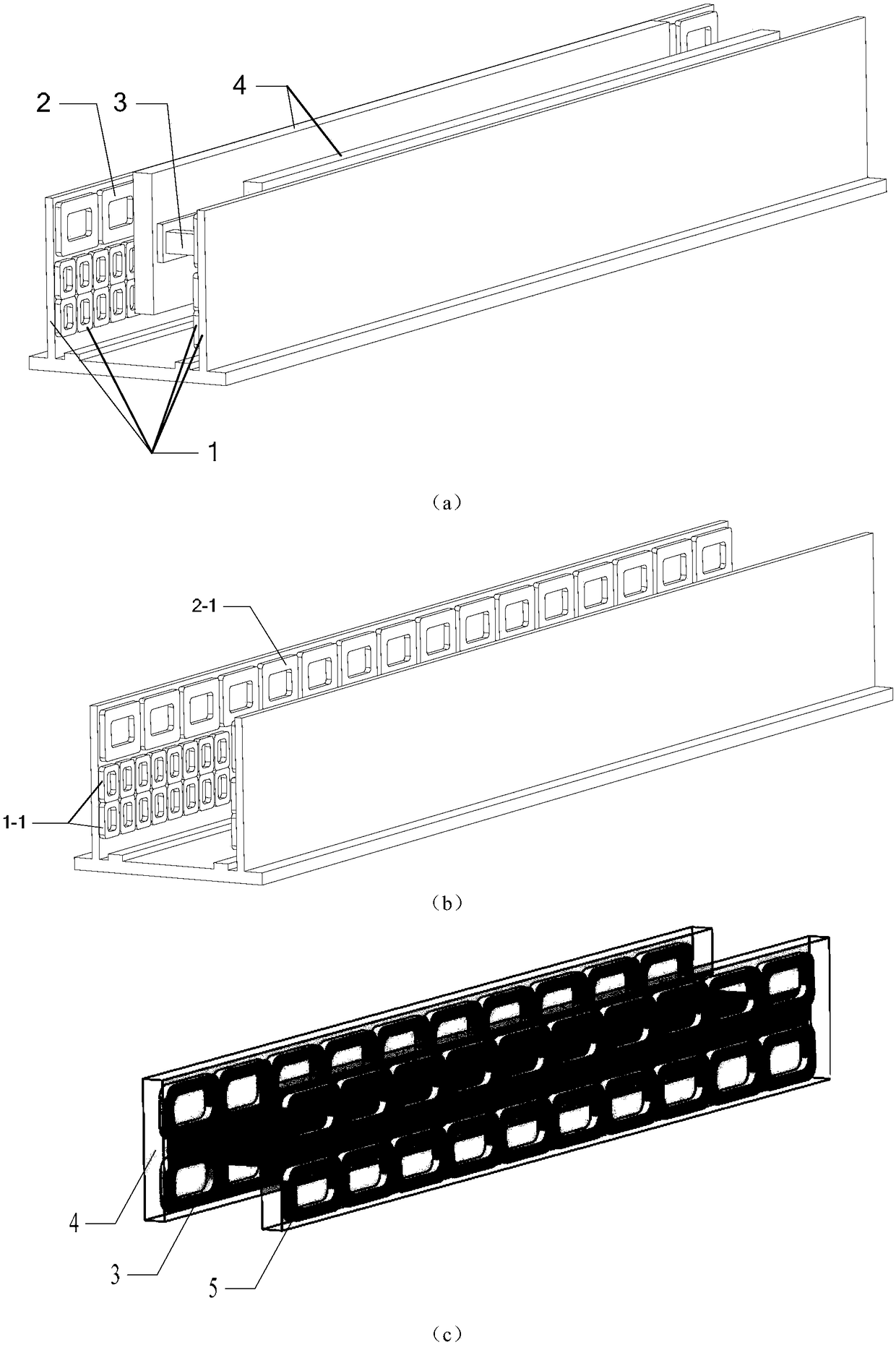

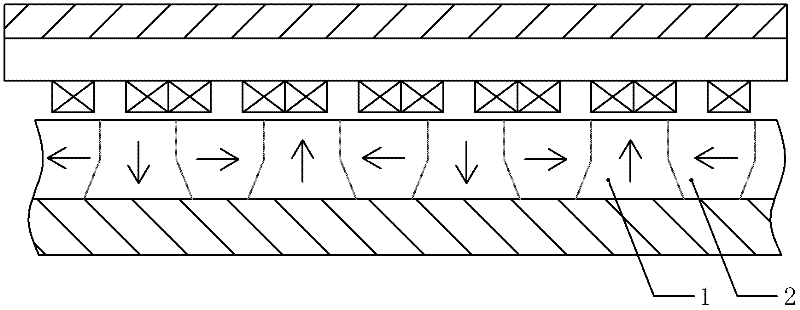

High-speed magnetic levitation linear electromagnetic propulsion system

ActiveCN108306477ARealize automatic suspensionImplementation orientationPropulsion systemsMagnetic holding devicesLevitationElectric machine

The invention relates to a high-speed magnetic levitation linear electromagnetic propulsion system and belongs to the electric motor field. The invention aims to solve the problem of serious magneticflux leakage due to the openness of a magnetic field and the problems of small levitation height, large levitation control difficulty and high requirements for lines of a normal conducting magnetic levitation technology due to large weight of vehicles. The high-speed magnetic levitation linear electromagnetic propulsion system of the invention a primary unit and a secondary unit; the primary unitis mounted on the ground, is of a bilateral structure and is arranged symmetrically on the left side and right side of the secondary unit; air gaps are left between the primary unit and secondary unit; the primary unit comprises a levitation guide primary unit and a propulsion primary unit; each primary structure at each side of the propulsion primary unit includes a primary coil and a primary substrate, wherein the primary coil is fixed at the inner side of the primary substrate; each primary structure at each side of the levitation guide primary unit includes an upper conductor plate and a lower conductor plate, wherein the upper conductor plate and the lower conductor plate are juxtaposed in a vertical direction; the propulsion primary unit is arranged between the upper conductor platesand the lower conductor plates; two columns of magnetic poles of the primary unit are respectively fixed at two sides of a skid; and each column of magnetic poles simultaneously serves as levitationguide magnetic poles and propulsion magnetic poles.

Owner:HARBIN INST OF TECH +1

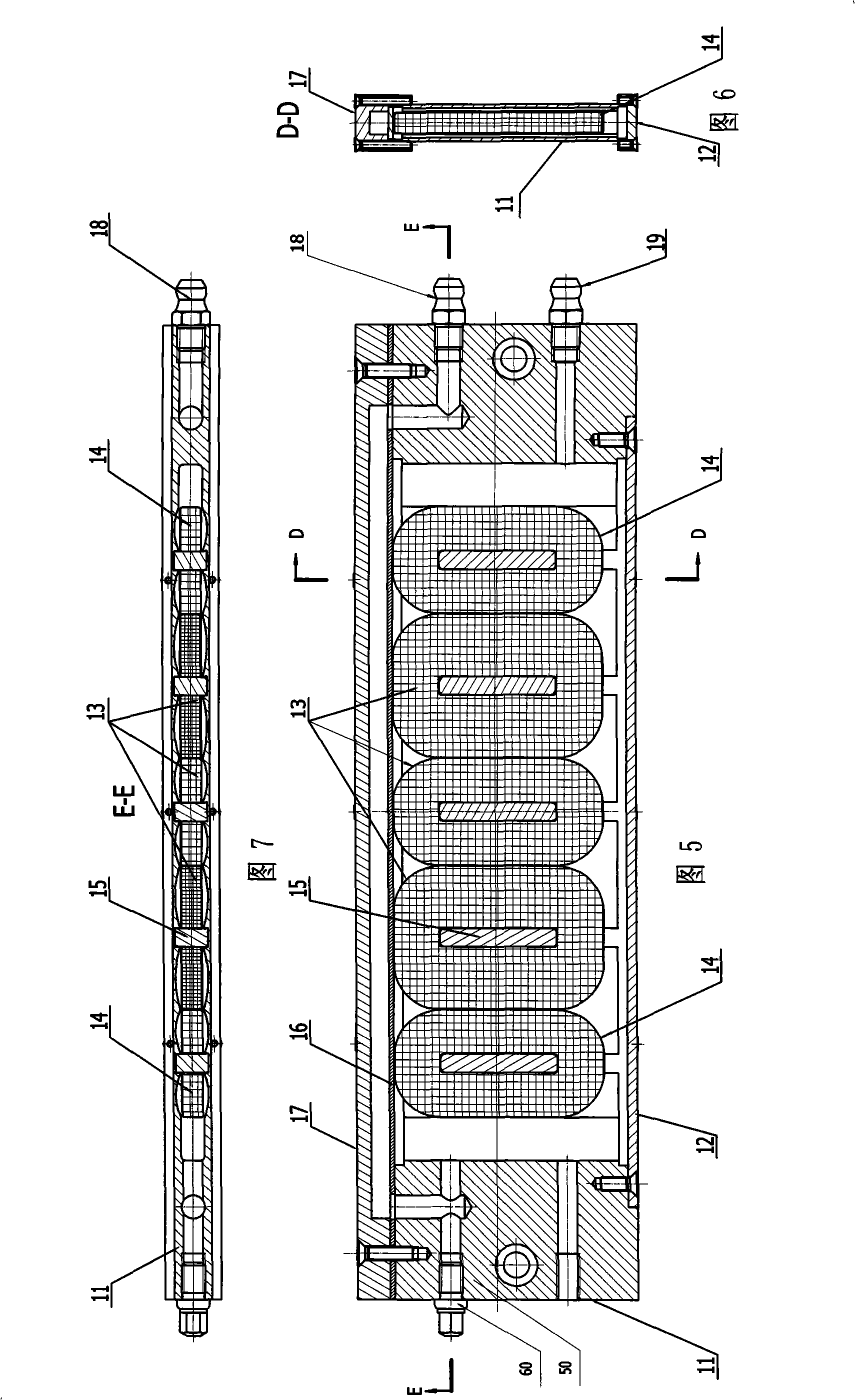

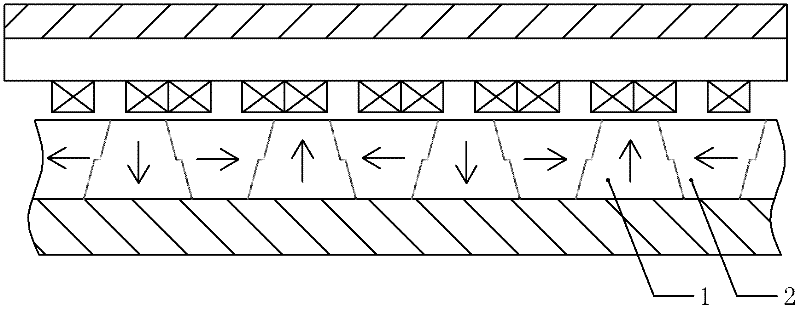

High-power density permanent magnet motor

ActiveCN101969261AIncrease air gap flux densityIncrease Electromagnetic ThrustPropulsion systemsElectric machineWave form

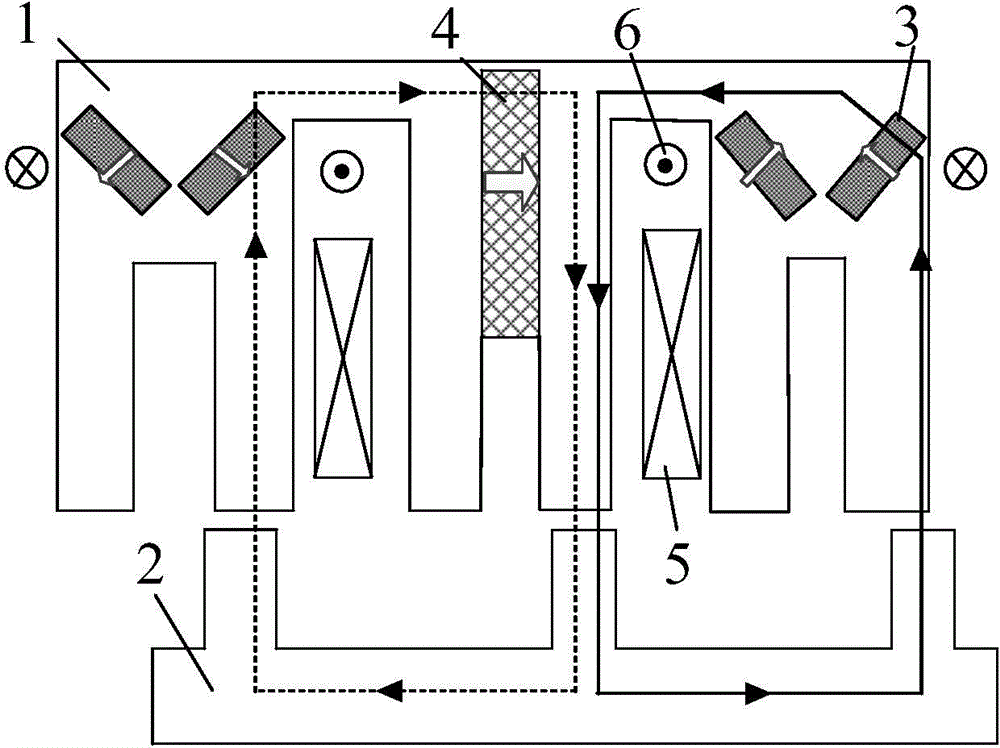

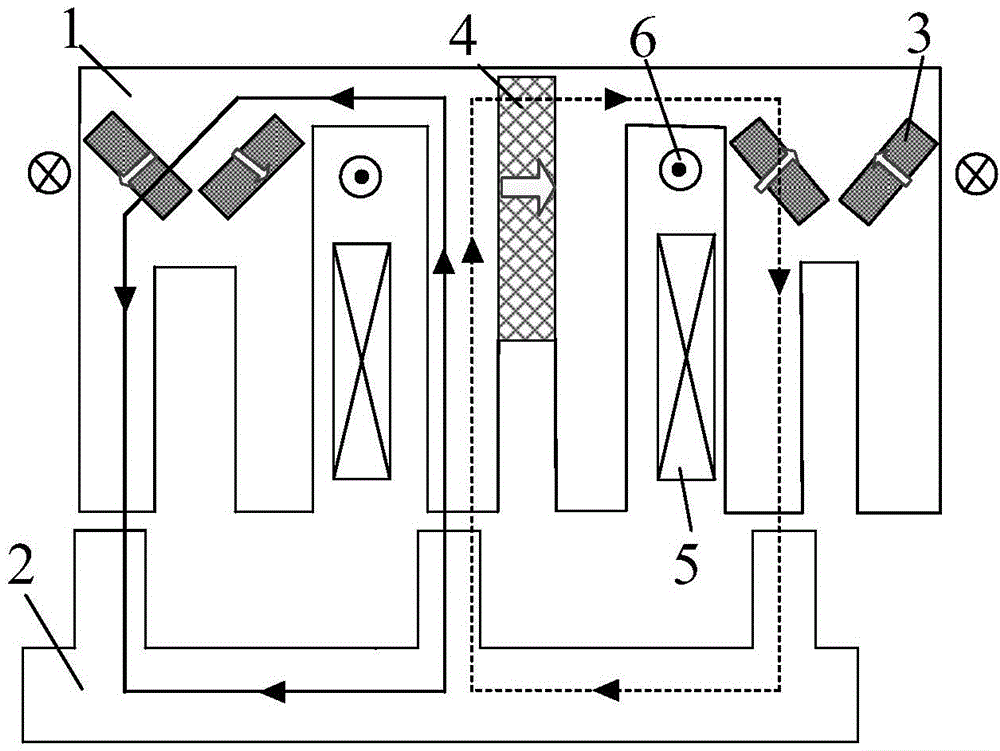

The invention relates to a high-power density permanent magnet motor belonging to the field of motors. The invention solves the problems of low efficiency and thrust density, large thrust fluctuation and high vibration and noises of the traditional double-edge ironless straight line permanent magnet synchronous motor, which are caused by low air gap magnetic density and poor sine degree of air gap magnetic density wave forms. An air gap is positioned between a primary pole and a secondary pole of a straight line motor; main permanent magnets and isolated magnets are sequentially arranged on the inner wall of a yoke plate at intervals; the inner sides of the main permanent magnets are provided with assembling magnets which have same widths along a motion direction; the inner sides of the isolated magnets are provided with auxiliary permanent magnets which have same widths along the motion direction; the outer side surfaces of m auxiliary permanent magnets and m assembling magnets are positioned on a same plane; the main permanent magnets are parallelly magnetized in magnetizing directions perpendicular to the motion directions of active cells, and every two adjacent main permanent magnets are in reverse magnetizing directions; the auxiliary permanent magnets are parallelly magnetized in the magnetizing directions parallel to the motion directions of the active cells, and every two adjacent auxiliary permanent magnets are in reverse magnetizing directions.

Owner:HARBIN INST OF TECH

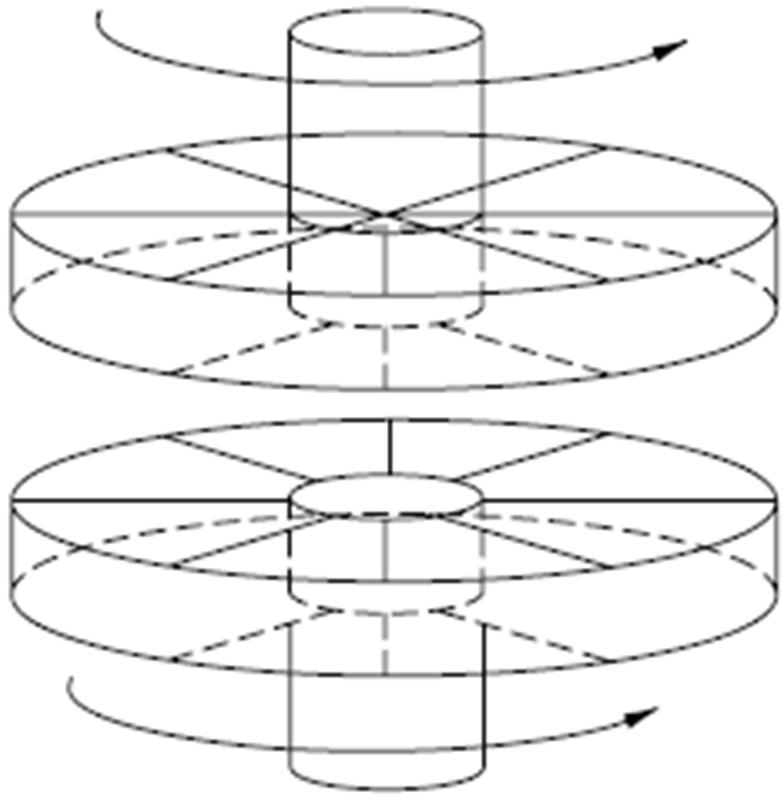

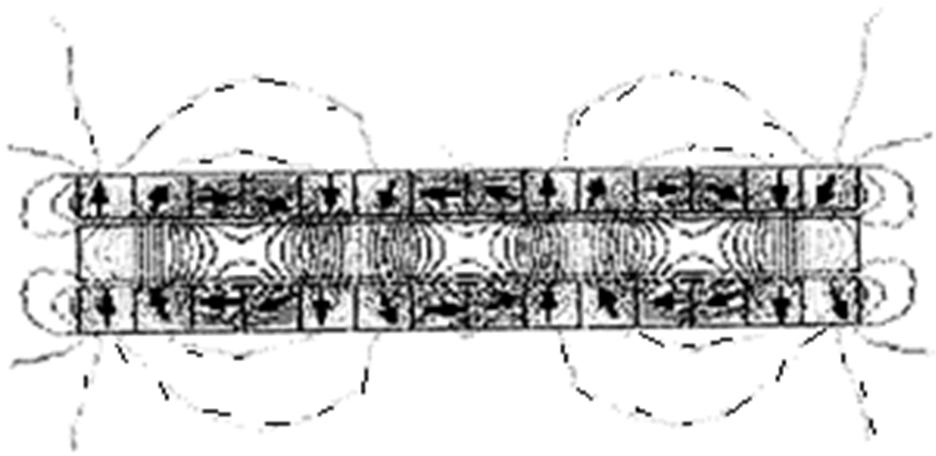

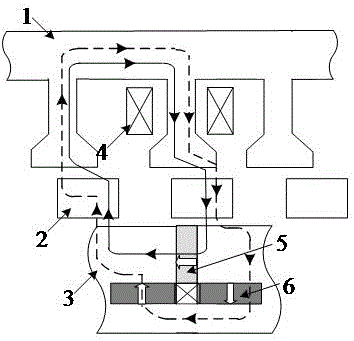

Super-conduction magnetic suspension linear electromagnetic propelling system

ActiveCN108448873ARealize independent designImplementation orientationDynamo-electric machinesMagnetic holding devicesElectromagnetic propulsionEngineering

The invention discloses a super-conduction magnetic suspension linear electromagnetic propelling system, relates to the field of a motor, and aims to solve the problems as follows: the magnetic fieldformed by a super-conduction magnet of the existing magnetic suspension propelling system is open on a vehicle, which causes severe magnetic leakage and high magnetic field shielding difficulty; the vehicle is high in weight and the conventional conduction magnetic suspension technology is relatively low in suspension height, which causes high suspension control difficulty, and relatively high requirements on circuit flatness, roadbed sinkage and turnout junction structure. The invention provides the super-conduction magnetic suspension linear electromagnetic propelling system; and by adoptionintegrated suspension, guiding winding and series magnetic path super-conductor excitation, automatic suspension and guiding of the high-speed linear propelling system mover is realized, and independent design of the propelling winding is achieved.

Owner:HARBIN INST OF TECH +1

Stator surface mounted doubly salient permanent magnet motor with auxiliary salient pole

ActiveCN101651371AImprove cooling conditionsSimple and strong structureMagnetic circuit rotating partsMagnetic circuit stationary partsConstant powerSurface mounting

The invention relates to a stator surface-mounted doubly salient permanent magnet motor with an auxiliary salient pole which has simple and firm structure, and constant power, wide speed-regulation operation range and higher power density; the motor comprises a stator (1) and a rotor (5), the rotor (5) is arranged at the inner part or outer part of the stator (1), the stator (1) and the rotor (5)are in a doubly salient structure, and a concentrated winding (3), a permanent magnet (2) and an auxiliary salient pole (4) are arranged on the stator (1), wherein, each concentrated winding coil of any one phase of the concentrated winding (3) is arranged in an iron core groove of the stator (1), and the coils of each a phase winding are connected serially or in parallel; the permanent magnet (2)is arranged on the salient pole of the stator (1), the outer surface of each stator tooth, facing to air gap, is mounted with two permanent magnets (2), and the polarity of two magnetic steels, belowthe same tooth, is the same, and the magnetism of the magnetic steel, below the adjacent stator tooth, is opposite.

Owner:SOUTHEAST UNIV

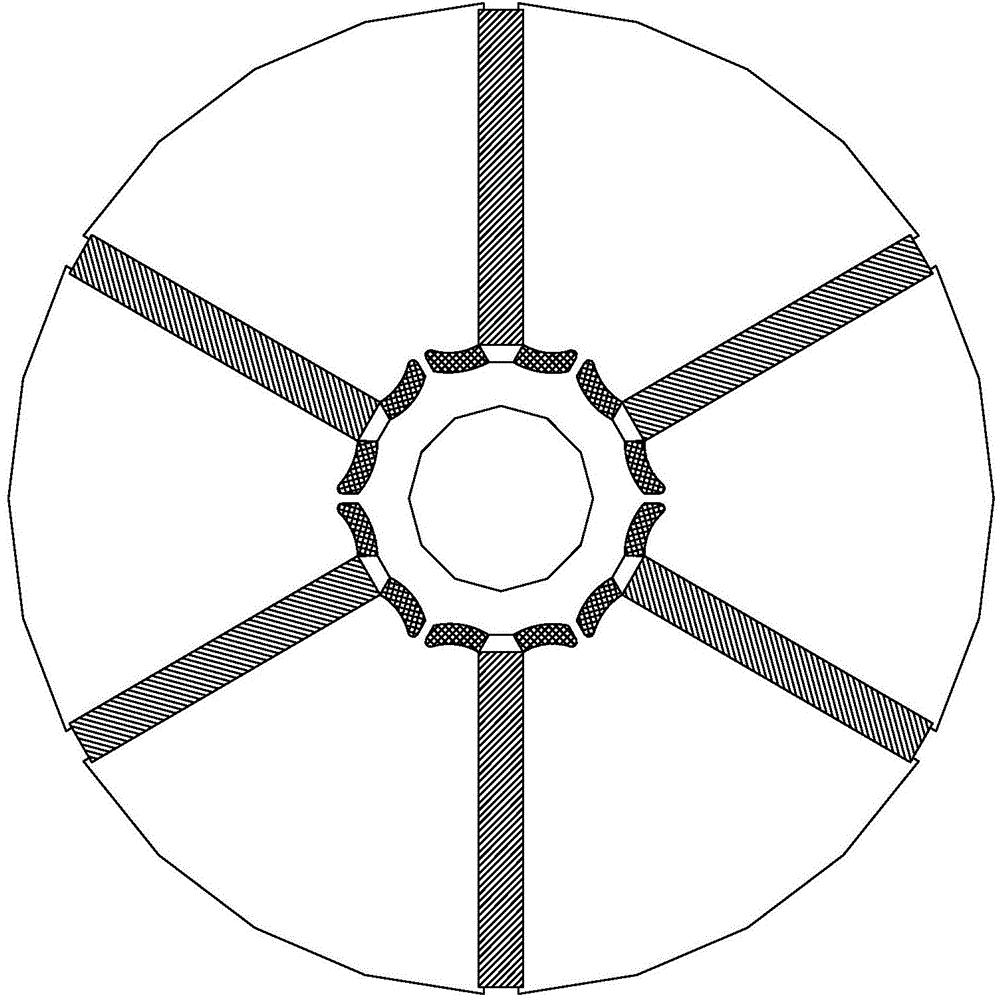

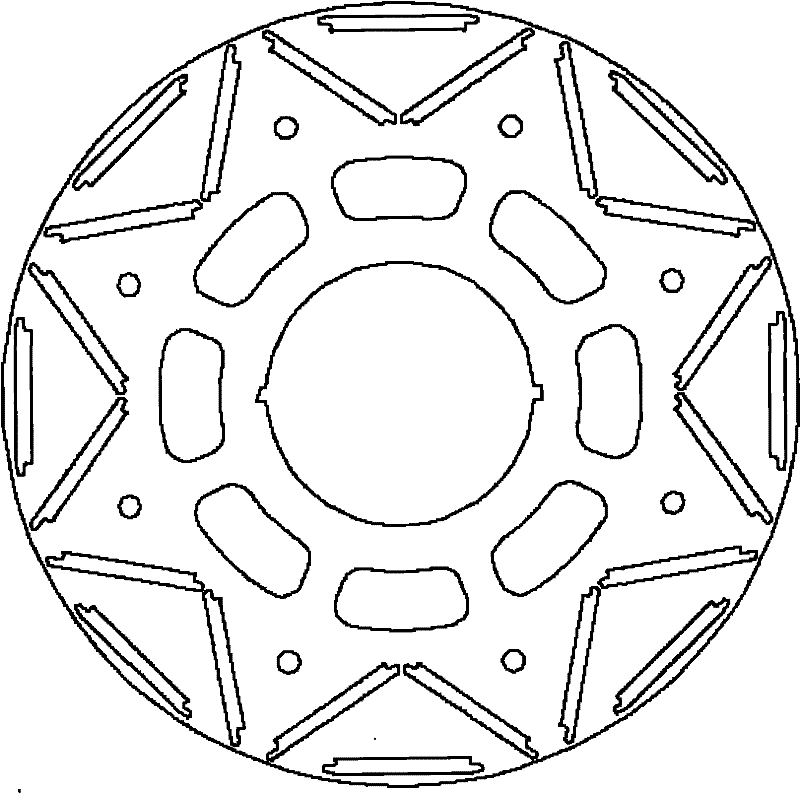

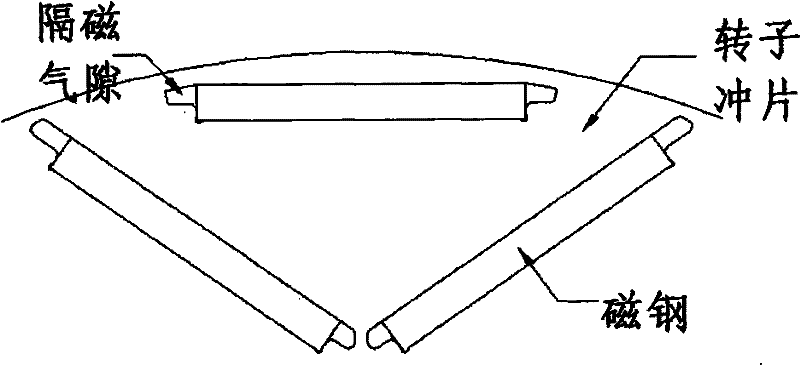

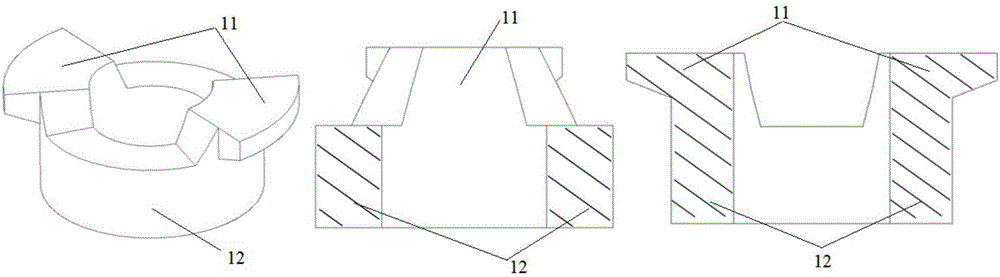

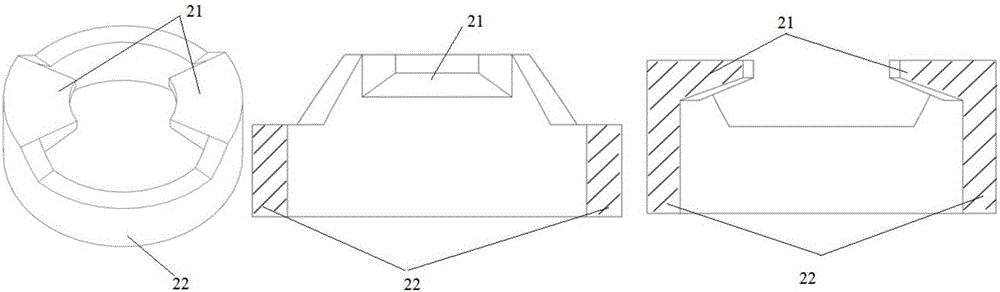

Tangential motor, tangential motor rotor and rotor core of tangential motor rotor

ActiveCN107240975AEnsure the magnetic isolation effectUniform thicknessMagnetic circuit rotating partsElectric machinesElectric machineMagnetic poles

The invention discloses a tangential motor, a tangential motor rotor and a rotor core of the tangential motor rotor. The rotor core comprises a rotor body (1) and magnetic steel grooves (2) which are formed in the rotor body (1), 2N magnetic isolation holes (11) are formed in a rotor magnetic pole between two adjacent magnetic steel grooves (2), and the 2N magnetic isolation holes (11) are symmetrically formed in two sides of the magnetic pole center axis of the rotor magnetic pole; the widths of the magnetic isolation holes (11) increase from the circle center of the rotor body (1) to the outer side of the rotor body (1), and the outer side hole surfaces, close to the outer side of the rotor body (1), of the magnetic isolation holes (11) are arc-shaped surfaces which are concentrically arranged with the rotor body (1). The rotor core reduces the vibration noise of the motor and improves the efficiency of the motor.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

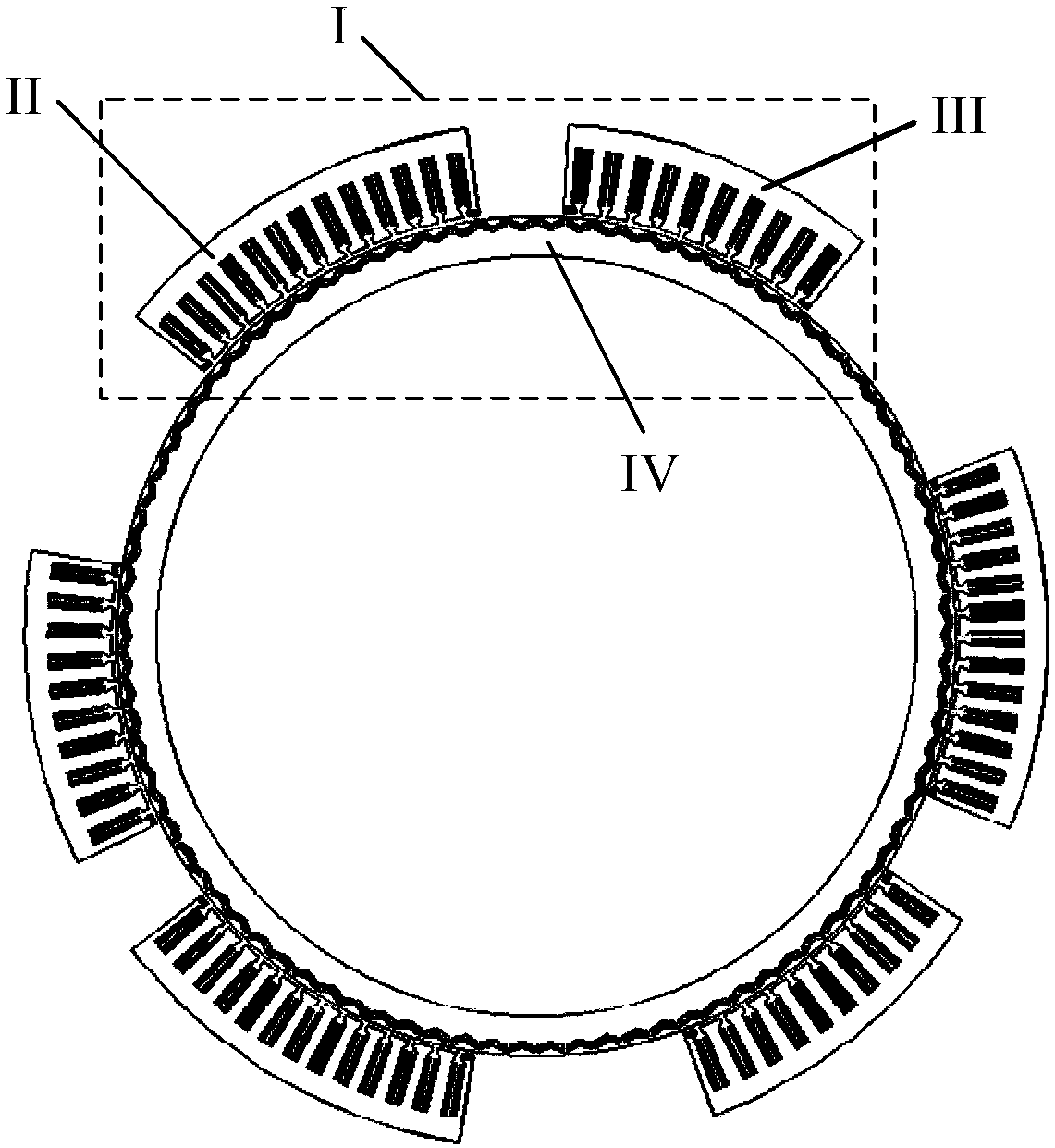

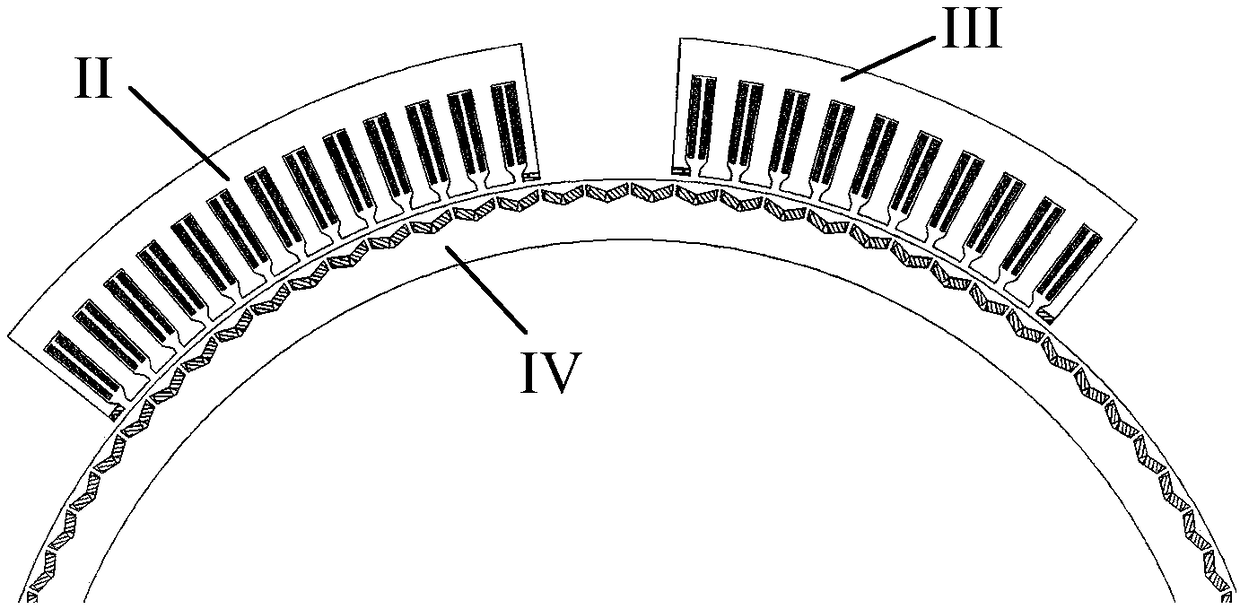

Asymmetric double three phase camber line permanent-magnet synchronous electrical machine

ActiveCN108429420AIncreased torque densityImprove power densityMagnetic circuit rotating partsMagnetic circuit stationary partsMagnetic effectLow speed

The invention discloses an asymmetric double three phase camber line permanent-magnet synchronous electrical machine. The electrical machine comprises two parts that are stator combinations (I) and arotor (IV), wherein the three stator combinations (I) form a camber line structure on a circumference outside the rotor (IV), each stator combination (I) comprises a 12-slot stator module (II) and a 9-slot stator module (III) arranged side by side on the circumference outside the rotor (IV), the 12-slot stator module (II) and the rotor (IV) form a 12-slot 10-pole unit motor, the 9-slot stator module (III) and the rotor (IV) form a 9-slot 8-pole unit motor, the stator combinations (I) and the rotor (IV) together form the two-phase three phase electrical machine, permanent magnets are arranged in the rotor in an embedded manner in such a way that a V shape structure is formed, strong assembled magnetic effects are exerted, main magnetic flux can be effectively improved, torque density of theelectrical machine can be improved, the permanent magnets form 120 pairs of electrodes, the electrical machine is enabled to be characterized by low speed and large torque, and the electrical machineis applied to low speed and large torque direct driving occasions and large aperture astronomical telescope driving occasions.

Owner:SOUTHEAST UNIV

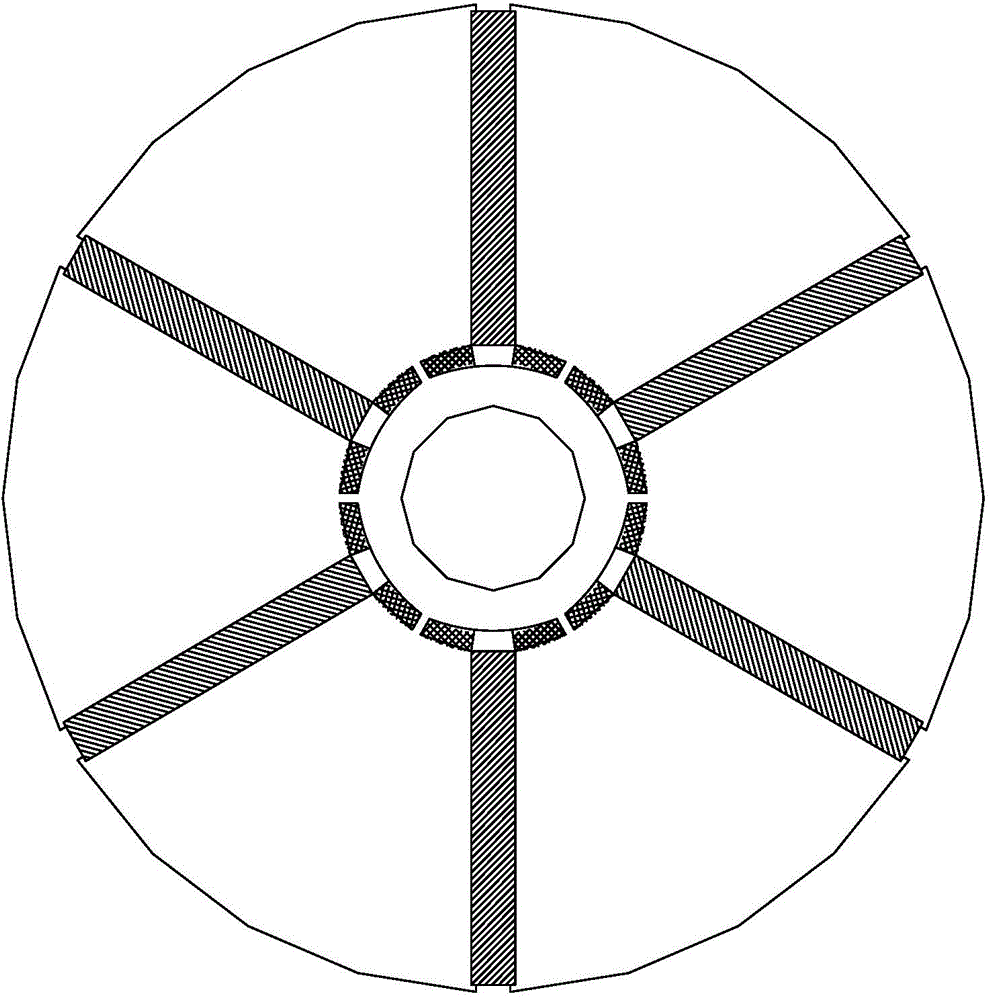

Halbach outer rotor doubly salient motor

InactiveCN102005835AIncrease the air gapIncrease air gap flux densityMagnetic circuit rotating partsMagnetic circuit stationary partsMagnetic sourceElectric machine

The invention provides a magnetizing outer rotor doubly salient motor with a radial structure, which is characterized by comprising a stator, a rotor, an air gap between the stator and the rotor, a rotating shaft and the like, wherein, the stator comprises a stator permanent magnet support arranged around the rotating shaft, permanent magnets arranged around the stator permanent magnet support, and a stator core arranged around the permanent magnet; the permanent magnets adopt a radial magnetizing or parallel magnetizing mode; the stator core is composed of stator core components; air gaps exist among the stator core components; and the permanent magnets and the stator core components are contacted with each other and have equal number. The magnetizing outer rotor doubly salient motor takes the magnetizing body with a radial / parallel structure as a magnetic source and has simple manufacturing process and less magnetic leakage on an end part; and the magnetizing outer rotor doubly salient motor can be widely applied to fields such as wind power generation, an automobile hub and the like.

Owner:SHANGHAI DIANJI UNIV

Synchro motor of mixed exitation of tangential magnet steel possessing divided magnetic circuit

InactiveCN1761131AAxial magnetic circuit shortenedReduce volumeMagnetic circuit rotating partsSynchronous machines with stationary armatures and rotating magnetsAviationSynchro

The disclosed synchro motor includes stator and rotor. The stator is composed of case, armature core, armature winding. The rotor consists of shaft, pole shoe of N pole, pole shoe of S pole, and tangential magnetized permanent magnet. Character is that pole shoe of N pole, pole shoe of S pole are extended to same direction; and annular excitation bridge with excitation winding being embedded is setup between annular pole shoes at extended end of the pole shoes of rotor. Comparing with prior art, the invention possesses advantages of large magnetic density at air slot, high efficiency of electric excitation, short axial magnetic circuit etc. The disclosed synchro motor can be used as generator or motor, having high efficiency of permanent magnet motor, and controllable excitation of electric excitated motor. The invention is applicable to start up system and power generation system in aviation, spaceflight and vehicles as well as servo system in mechanical industry.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

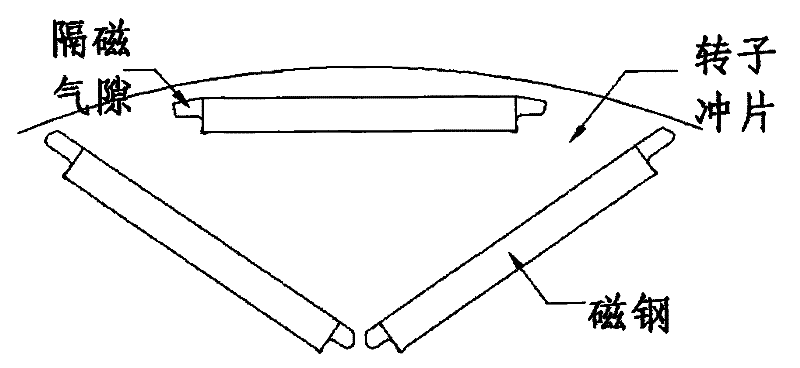

Novel multi-layer structure of rotor core

InactiveCN102214963AIncrease in sizeGuaranteed normal outputMagnetic circuit rotating partsWave formEngineering

The invention relates to a novel multi-layer structure of a rotor core. The novel multi-layer structure of the rotor core is formed by laminating punched silicon-steel sheets and embedding magnetic steel. During the design of a rotor, a double-layer structure is adopted, wherein the first layer comprises a piece of linear magnetic steel; and the second layer of magnetic steel has a V-shaped structure. Magnetic flux can be output to a largest extent by reasonably designing the length of the magnetic steel and distances between the respective magnetic steel, and the similarity of a counter potential wave form and a sine wave reaches 1.02 to 1.04. In a novel multi-layer embedded rotor sheet, on the basis of reserving the conventional advantages that a motor smoothly operates at a speed of 8,000 rpm, by the unique multi-layer structure of the rotor, the output of the magnetic flux of each electrode can be guaranteed to a largest extent, and the volume of the magnetic steel cannot be greatly increased.

Owner:TIANJIN SANTROLL ELECTRIC SCI & TECH

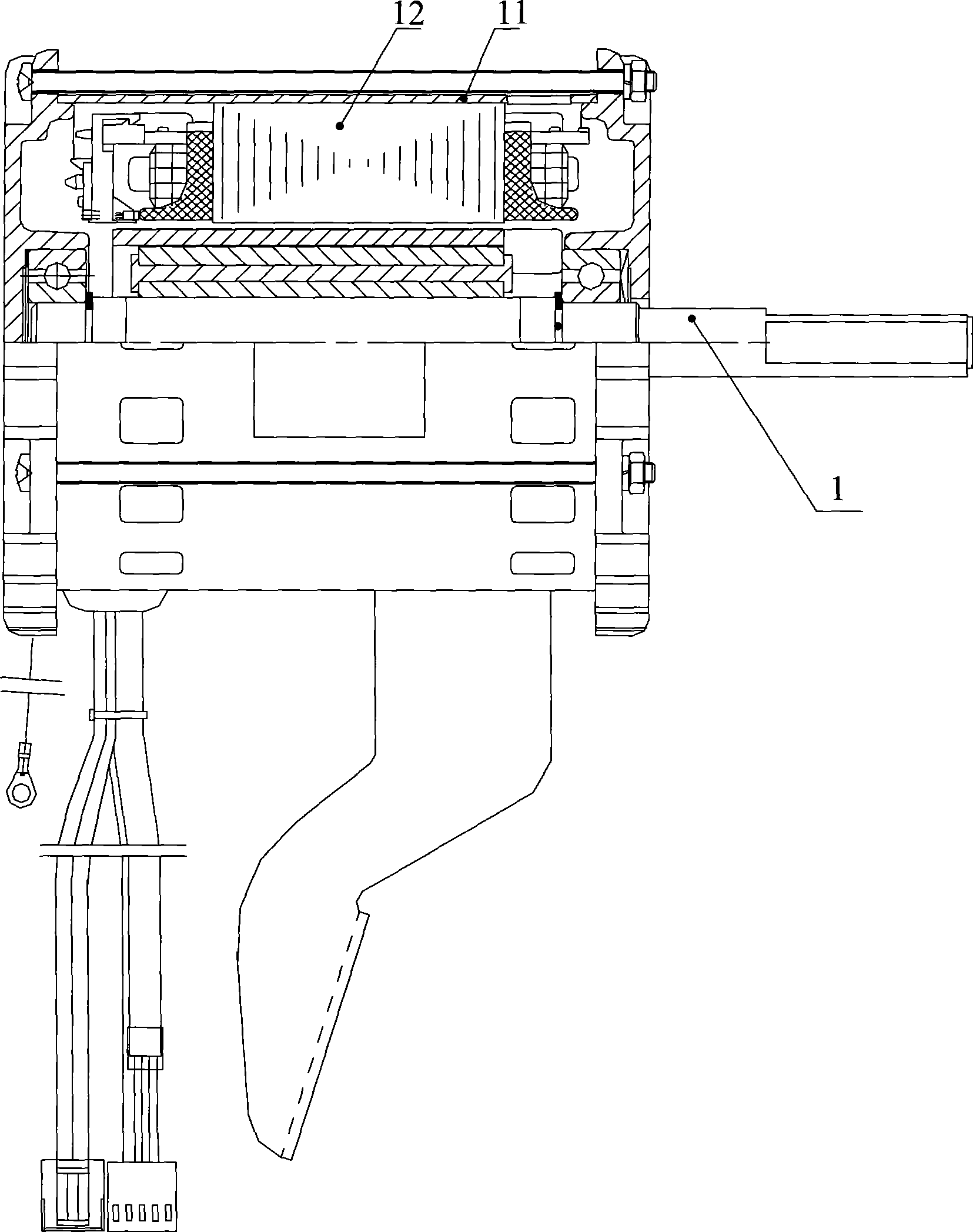

Low noise fast response permanent magnet DC brushless motor for constant wind control

InactiveCN101459370AImprove qualityReduce torque fluctuationMagnetic circuit rotating partsMagnetic circuit stationary partsLow noiseBrushless motors

The invention provides a low noise fast response permanent magnet direct current brushless motor for controlling constant air volume, which comprises a shell, a stator and a rotor in the shell, wherein the stator comprises a stator iron core and a stator winding which are fixed on the inner wall of the shell, the rotor comprises a main shaft and a rotor iron core, the external circumferential direction of the rotor iron core is evenly fixed with rotor magnetic poles which comprise radial magnetized magnetic steel and tangential magnetized magnetic steel, the radial magnetized magnetic steel is a main magnetic pole, and the tangential magnetized magnetic steel which is arranged between adjacent main magnetic poles is a side magnetic pole. Or, the inner circumferential direction of the rotor iron core is evenly embedded with built-in radial magnetized rectangular strip magnetic steel which is the main magnetic pole, and the tangential magnetized magnetic steel which is arranged between adjacent main magnetic poles is the side magnetic pole. The low noise fast response permanent magnet direct current brushless motor gathers magnetic through two ways of radial and tangential direction, thereby observably increasing the air gap flux density, greatly reducing the mechanical time constant, increasing fast response, controlling the constant air volume in a high performance, which leads a motor to steadily operate in high efficiency, saving energy, low fluctuation, low noise, frequent starting and rapid response, and the low noise fast response permanent magnet direct current brushless motor can achieve the miniaturization and lightening of the motor.

Owner:苏州和鑫电气股份有限公司

Fault-tolerant type single-winding bearing-less permanent magnet motor

InactiveCN103929035ACompact structureShort endsMagnetic holding devicesSynchronous machines with stationary armatures and rotating magnetsShortest distancePermanent magnet motor

The invention discloses a fault-tolerant type single-winding bearing-less permanent magnet motor. A stator magnet yoke is in a cylinder shape and is placed on the outermost portion of the permanent magnet motor. A rotating shaft and the stator magnet yoke are coaxial, the rotating shaft is placed in the middle in the stator magnet yoke, a rotor iron core coaxial with the rotating shaft is fixed on the outer periphery surface of the rotating shaft, and a plurality of permanent magnets which are evenly distributed on the outer surface of the rotor iron core in a Halbach array structure to form a cylinder shape are fixed on the outer periphery surface of the rotating shaft. Six armature teeth and six fault-tolerant teeth which are arranged in an alternating mode in the periphery direction are fixed evenly on the inner periphery face of the stator magnet yoke. Each armature tooth is provided with a set of an armature winding which generates torque and radial suspension force at the same time in a winding mode. Each set of armature winding is of a concentrating short-distance winding structure. Each phase control current is formed by overlapping of a torque winding control current component and a suspension force winding control current component. According to the fault-tolerant type single-winding bearing-less permanent magnet motor, only one set of armature winding is needed, the structure is simple, motor weight is lowered, and the suspension operation capacity with fault of the motor is improved.

Owner:JIANGSU UNIV

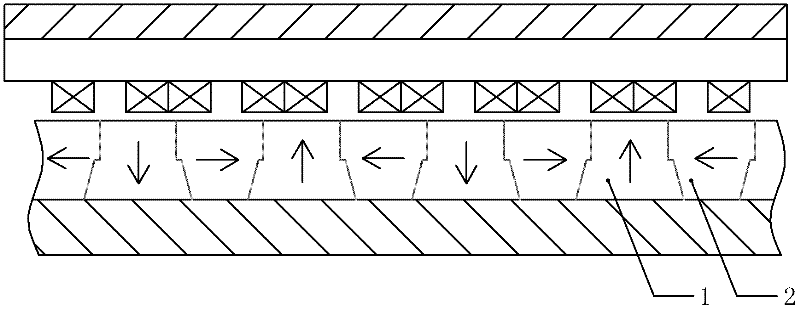

High-power density permanent magnet motor

InactiveCN102594086AReduce thrust fluctuationLow costMagnetic circuit rotating partsPropulsion systemsWave shapeRelative motion

The invention relates to a high-power density permanent magnet motor, belonging to the field of motors, solving a problem of poor sine degree of an air gap flux density waveform in a conventional motor. The cross section of each main permanent magnet body in a linear electric motor secondary unit is in a shape of bilaterally symmetric hexagon or octagon, the bottom edge of the hexagon or octagon, close to an air gap side is shorter than the bottom edge far away from the air gap side, the main permanent magnet bodies are magnetized in parallel in a direction vertical to relative motion direction of a primary unit and the secondary unit, auxiliary permanent magnet bodies are magnetized in parallel in the relative motion direction of the primary unit and the secondary unit, and the main permanent magnet bodies and the auxiliary permanent magnet bodies are alternately and closely arranged and fixed on the air gap side of a conductive magnetic yoke. According to the high-power density permanent magnet motor disclosed by the invention, the cross section of each main permanent magnet body in the linear electric motor secondary unit is in the shape of radially symmetric octagon, and the length of the edge of the octagon at the air gap side is smaller than the length of the edge far away from the air gap side; the main permanent magnet bodies are magnetized radially or in parallel, and the auxiliary permanent magnet bodies are magnetized tangentially; and the main permanent magnet bodies and the auxiliary permanent magnet bodies are alternately and closely arranged in the circumferential direction and fixed on the surface of the air gap side of a rotor yoke drum.

Owner:HARBIN INST OF TECH

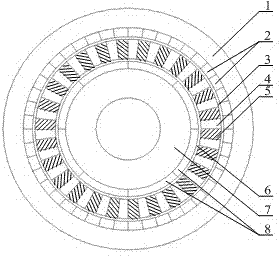

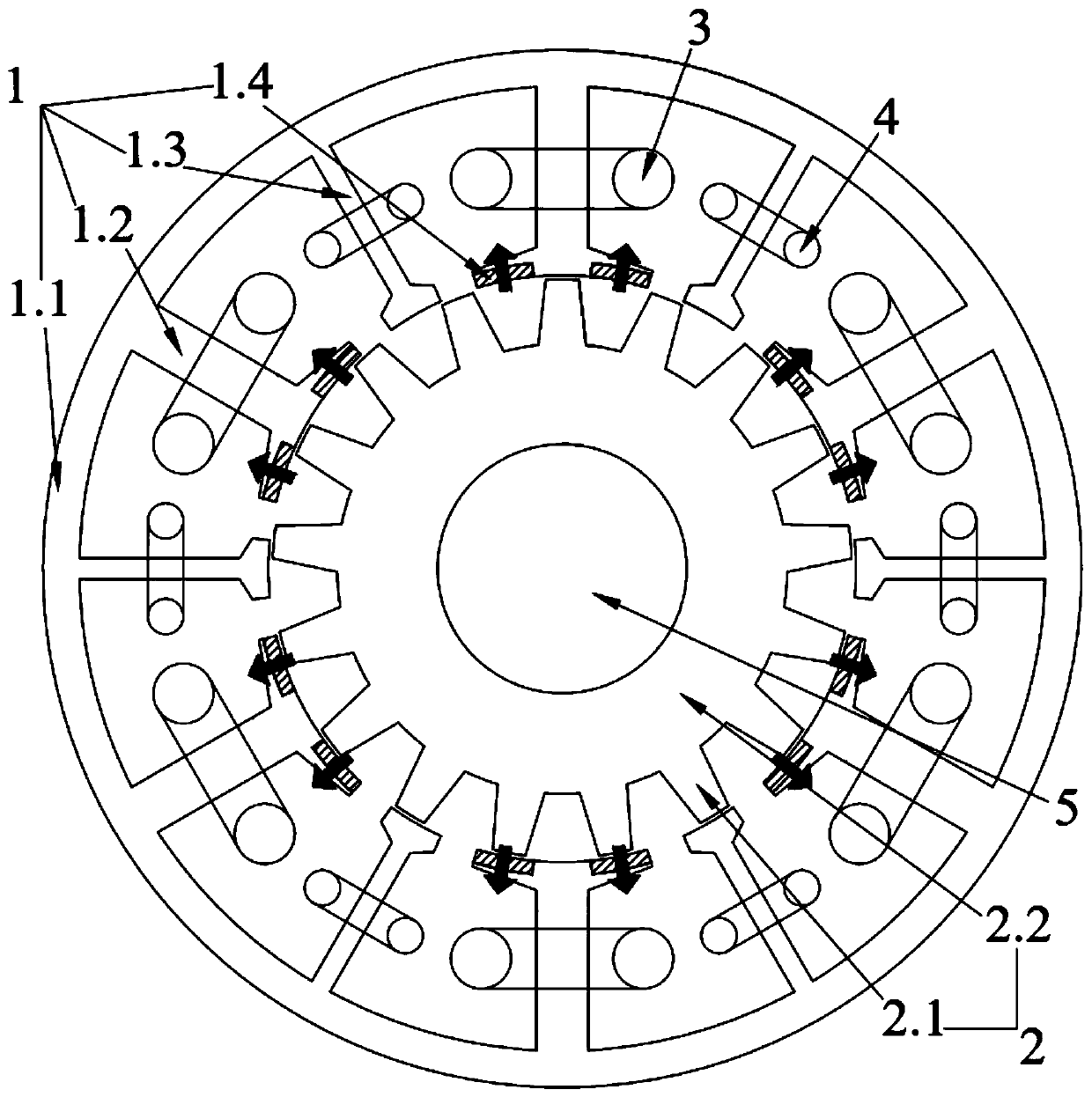

Less-rare-earth multi-excitation-source double-stator flux-switching memory motor

InactiveCN106911237AAchieve separationSolve mutual problemsMagnetic circuit rotating partsMagnetic circuit stationary partsRare earthEngineering

The invention discloses a less-rare-earth multi-excitation-source double-stator flux-switching memory motor, which belongs to the technical field of motor body design and operating principles. Coaxial outer stators, rotors and inner stators are sleeved together in turns from outside to inside to compose the memory motor, wherein a radial air gap exists between the outer stators and the rotors, the rotors and the inner stators, the outer stators are composed of armature core teeth, fault-tolerant teeth and stator yokes, and the rotors are composed of a rotor support, a magnetic silicon steel block and a magnetic insulation block, and meanwhile, the inner stators are composed of the inner stator core and a combined permanent-magnet cell block. The double-stator structure of the motor realizes the separation of armature winding and permanent magnet and solves the problem that multiple excitation sources inside the traditional flux-switching permanent magnet motors restrain each other, thereby easily increasing motor power density and torque density. The memory motor maintains high air-gap flux density and ensures of the motor power density and the torque density, meanwhile, the consumption of rare-earth permanent-magnetic materials is effectively lowered. On the other side, the memory motor can realize flexible adjustment of a motor air-gap field and expand the range of speed operation.

Owner:YANGZHOU UNIV

Permanent-magnet axial-flux semi-hollow pulse power generator

ActiveCN106505765AImprove efficiencyImprove reliabilityMagnetic circuit rotating partsMagnetic circuit stationary partsMagnetic polesConductive materials

The invention belongs to the field of pulse power generators and discloses a permanent-magnet axial-flux semi-hollow pulse power generator comprising a rotor, a stator, a rotating shaft, a housing, and an end cap. The rotor comprises inner and outer magnetic poles, a permanent magnet and a compensation plate. The permanent magnet is arranged between the inner and outer magnetic poles of the rotor. The inner and outer magnetic poles cooperate with the permanent magnet to convert radial flux into axial flux. The compensation plate covers the tops of the inner and outer magnetic poles. The rotor rotates together with the rotating shaft. The stator is formed by pouring non-magnetic material on a winding and is fixed on the housing. The magnetic conductive material of the rotor and the non-magnetic conductive material of the stator form a semi-hollow structure. The semi-hollow pulse power generator simplifies a motor excitation system, reduces excitation loss, and increases motor efficiency. Brushless structure increases the reliability of the motor.

Owner:HUAZHONG UNIV OF SCI & TECH

Hybrid excitation type flux reversing motor with asymmetric stator poles

ActiveCN110829770AImprove cooling effectSimple structureSynchronous machine detailsMagnetic circuit rotating partsElectric machineEngineering

The invention discloses a hybrid excitation type flux reversing motor with asymmetric stator poles. The motor comprises a stator, a rotor, three-phase armature windings, single-phase excitation windings, and a non-magnetic rotating shaft. The rotor comprises rotor teeth and a rotor yoke. The rotor yoke is fixed on the non-magnetic rotating shaft. The rotor teeth are uniformly arranged along the circumferential direction of the rotor yoke. The stator is positioned outside the rotor teeth of the rotor, and a certain gap is formed between the stator and the rotor teeth. The stator comprises a stator yoke, stator armature teeth, stator excitation teeth, and permanent magnets. The stator armature teeth and the stator excitation teeth are alternately arranged in the circumferential direction ofthe stator, and two permanent magnets with the same polarity are arranged at the lower end of each stator armature tooth and located on the two sides of a stator armature tooth iron core. The three-phase armature windings are wound around the stator armature teeth, and the single-phase excitation windings are wound around the stator excitation teeth. According to the invention, a doubly salient structure is adopted, and the motor has a simple structure and strong robustness and is suitable for AC brushless operation. Meanwhile, because of the introduction of hybrid excitation, the air gap fluxcan be adjusted, and the speed range of the motor is improved.

Owner:SOUTHEAST UNIV

Cage-shaped rotor magnetic coupling capable of regulating speed

InactiveCN102916558AImprove reliabilityImprove operational efficiencyAsynchronous induction clutches/brakesCouplingMagnetic poles

The invention discloses a cage-shaped rotor magnetic coupling capable of regulating speed. The cage-shaped rotor magnetic coupling comprises a power input shaft, a connection device, a permanent magnet outer rotor assembly, a cage-shaped inner rotor assembly, a power output shaft and a mechanical speed regulating device, the permanent magnet outer rotor assembly is sleeved outside the cage-shaped inner rotor assembly, and even air gaps are arranged between the permanent magnet outer rotor assembly and the cage-shaped inner rotor assembly. A layout mode of permanent magnets in the permanent magnet outer rotor assembly adopts a radial layout mode or a circumferential layout mode. The cage-shaped rotor magnetic coupling adopts an inside-outside-inside sleeved mode, an outer rotor adopts a structure with alternative magnetic poles, an inner rotor adopts a squirrel-cage rotor structure in an asynchronous motor, a rotating magnetic field produced by rotation of the outer rotor is used, induced current is produced in a squirrel-cage guide strip of the inner rotor, and the rotating magnetic field and the induced current drive the inner rotor to rotate under effects of ampere force. The magnetic coupling is high in reliability and operating efficiency, and reduces design and production cost.

Owner:葛研军

Rotor and motor

ActiveCN105071569ASimple structureReduce Flux LeakageMagnetic circuit rotating partsRotor fluxEngineering

The invention is suitable for the field of motors, and discloses a rotor and a motor. The rotor comprises a rotor core, a rotating shaft passing through the center of the rotor core, and a plurality of magnet steels which are embedded in the rotor core at intervals in a circumferential direction. The rotor core is provided with a plurality of magnet steel grooves which are used for the storage and positioning of the plurality of magnet steels. Each magnet steel is provided with an inner end close to the rotating shaft, and an outer end far from the rotating shaft. The rotor core is also provided with a plurality of outer magnetic bridge gaps which extend from the edge of the rotor core to the outer ends of the magnet steels in a concave manner. The rotor gets rid of a magnetic isolation sleeve, thereby effectively simplifying the structure of the rotor and the assembly technology of the rotor. Meanwhile, the outer edge of the rotor core is additionally provided with the outer magnetic bridge gaps, thereby opening an outer magnetic bridge of the rotor core, enabling more magnetic chains of the magnet steels to pass through a stator winding linkage, reducing the magnetic leakage of the rotor, greatly improving the effective utilization rate of the magnetic flux of the rotor, and finally achieving a purpose of improving the output capability of the motor.

Owner:GUANGDONG WELLING ELECTRIC MACHINE MFG +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com