High-thrust short-travel voice coil motor

A technology of voice coil motor and short stroke, which is applied in the direction of electrical components, electromechanical devices, etc. It can solve the problems of thrust fluctuation and small thrust of voice coil motor, so as to reduce the volume of the yoke, increase the average thrust, and increase the magnetic density of the air gap Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

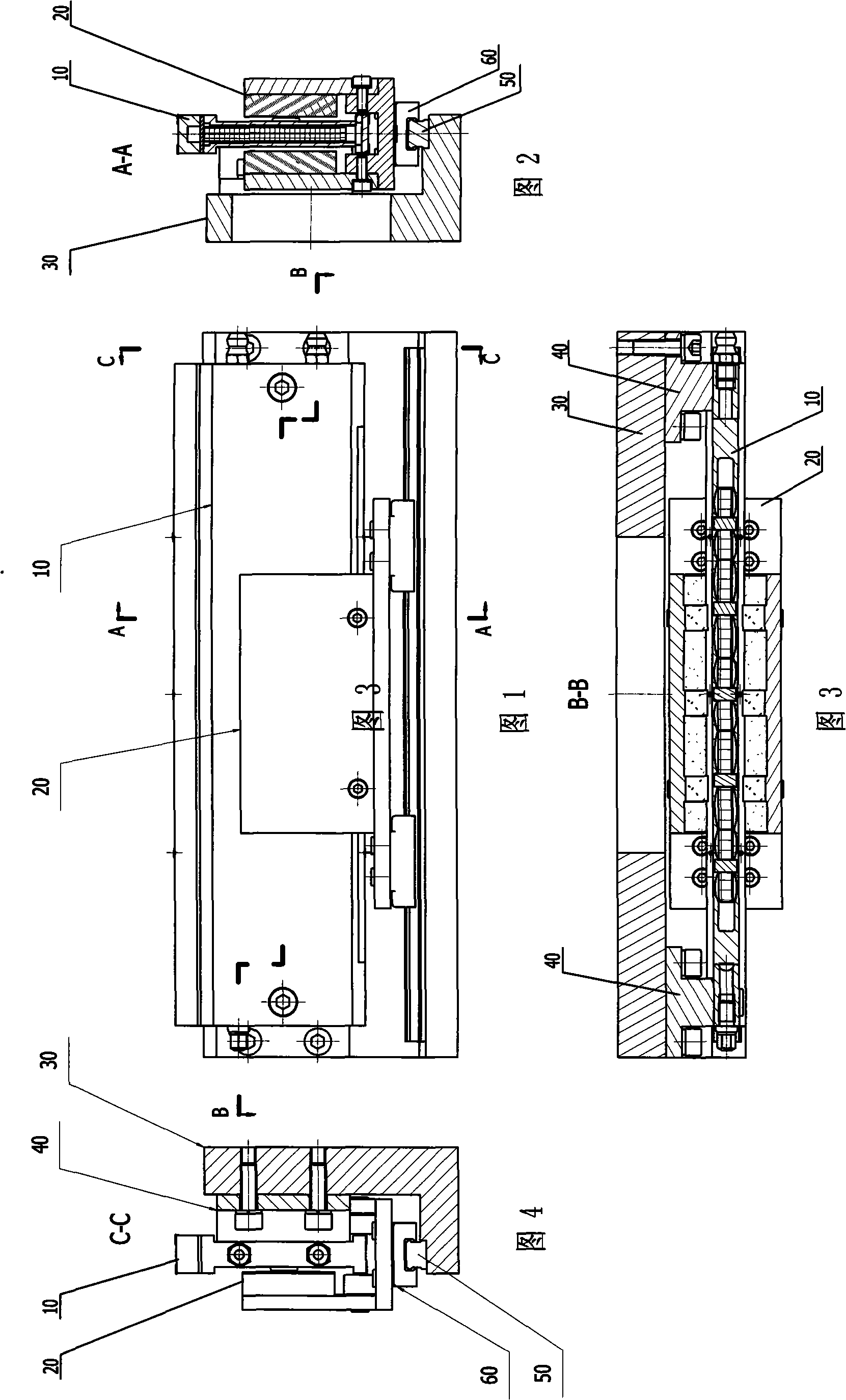

[0009] Specific embodiment one: in conjunction with Fig. 1 to Figure 12 Describe this embodiment, this embodiment is composed of stator 10 , mover 20 , motor base 30 , stator bracket 40 , guide rail 50 and slider 60 .

[0010] The lower platform of the stator support 40 is provided with a guide rail 50, and the slider 60 connected to the guide rail 50 is arranged on the lower bottom surface of the mover 20, the stator 10 is placed in the U-shaped groove of the mover 20, and the two stator supports 40 One end is respectively fixed on the two ends of the stator 10, and the other end of the two stator supports 40 is fixed on the two ends of the vertical plate of the motor base 30, and the stator 10 is supported by the stator supports 40 fixed on the motor base 30. The sub 20 is supported by two slide blocks 60 fixed on the guide rail 50 of the motor base 30 . When the coil in the stator 10 is energized, it is subjected to the electromagnetic force of the magnet steel of the move...

specific Embodiment approach 2

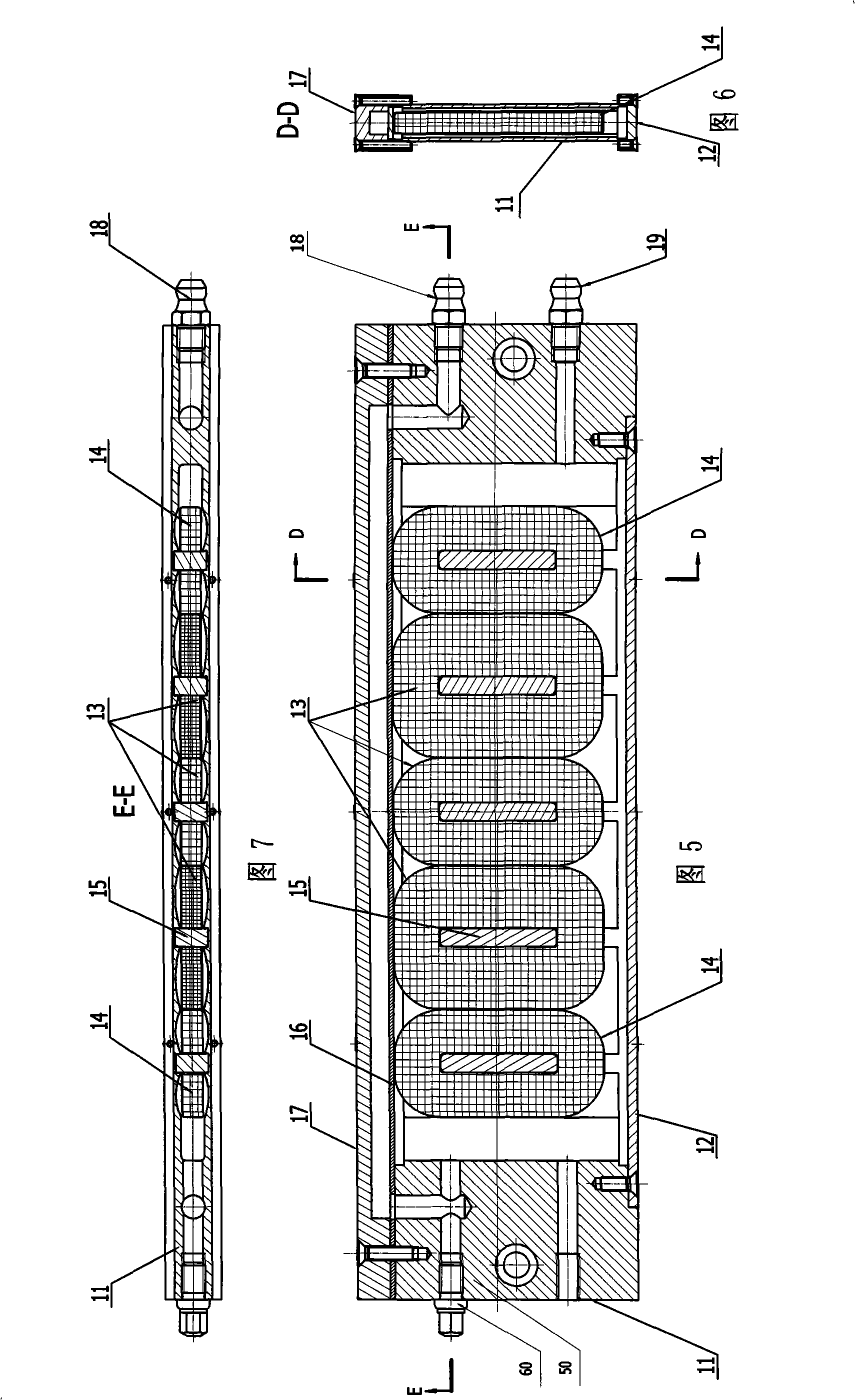

[0014] Specific embodiment 2: This embodiment is described in conjunction with Fig. 5 to Fig. 7. The difference between this embodiment and specific embodiment 1 is that the stator 10 also includes a stator lower cover 12, a stator upper cover gasket 16, and a stator upper cover 17. , water outlet 18 and water inlet 19; stator lower cover plate 12, stator upper cover plate gasket 16, stator upper cover plate 17, water outlet 18 and water inlet 19 are arranged on the stator coil frame 11, and the stator coil of the stator coil is placed The channels of the frame 11 are connected, the stator lower cover plate 12 is arranged on the bottom of the channel of the stator coil frame 11 and is airtightly connected with the stator coil frame 11, the stator upper cover plate gasket 16 and the stator upper cover plate 17 are arranged on the stator coil frame The top of the channel of 11 is airtightly connected with the stator coil frame 11, and a sealed cooling chamber is formed by the sta...

specific Embodiment approach 3

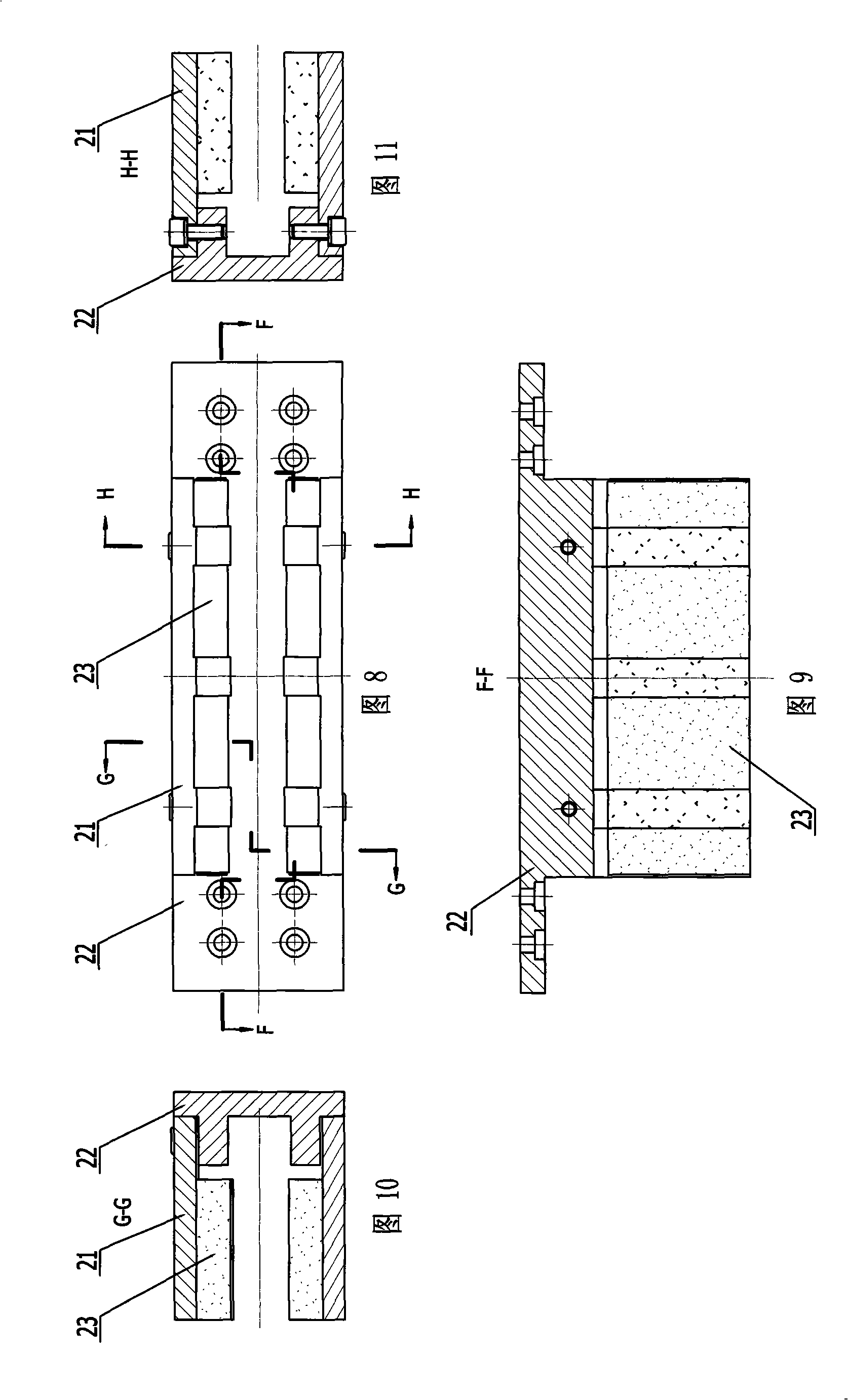

[0015]Specific embodiment three: The difference between this embodiment and specific embodiment one is that the stator coil 13 and the stator additional coil 14 have adopted alcohol-soluble self-adhesive enameled wire, and when winding the coil, smear the alcohol with a concentration of 90%, and put it into an electric oven Heating and setting reduces the volume of the coil skeleton. Other compositions and connection methods are the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com