Rotor and motor

A rotor and rotor core technology, applied in the direction of magnetic circuit rotating parts, magnetic circuit shape/style/structure, etc., can solve the problems of poor magnetic flux leakage reduction, complicated assembly process, and complicated rotor structure, etc., to improve the effective utilization The effect of improving the efficiency, improving the overall performance and simplifying the assembly process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

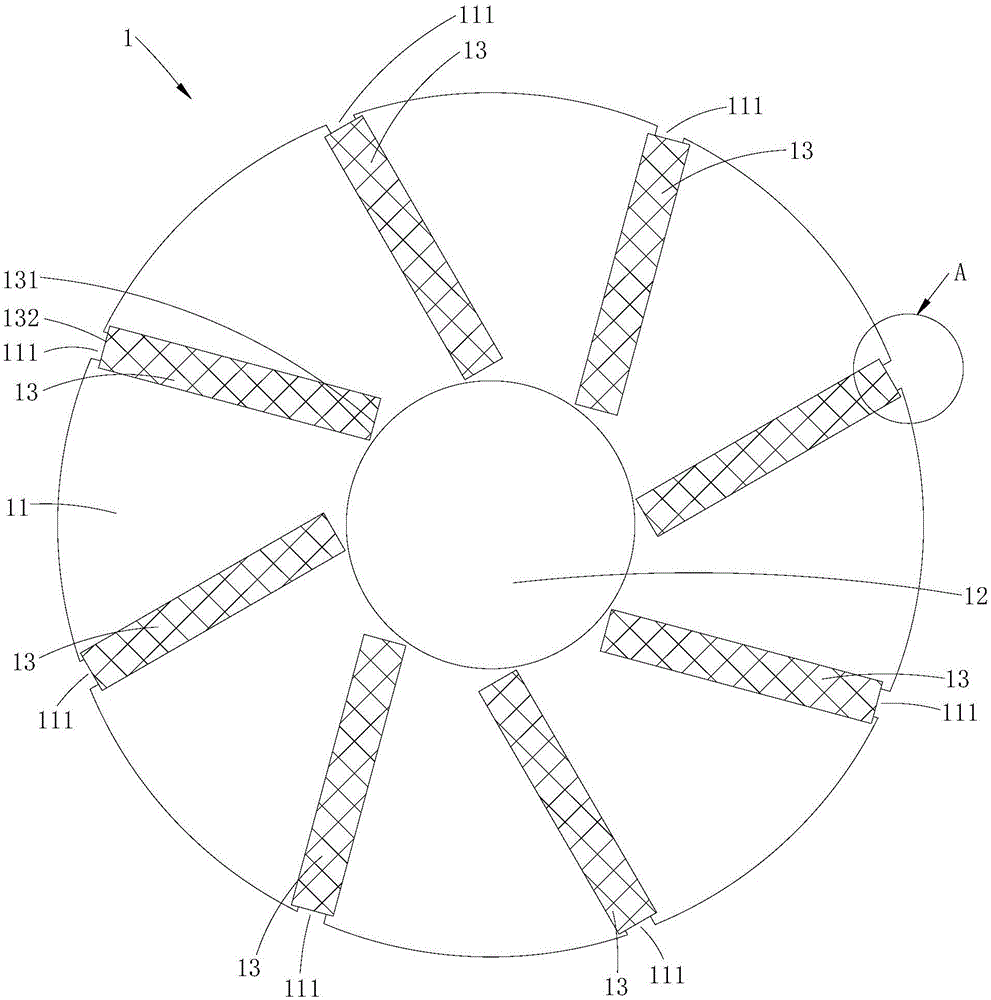

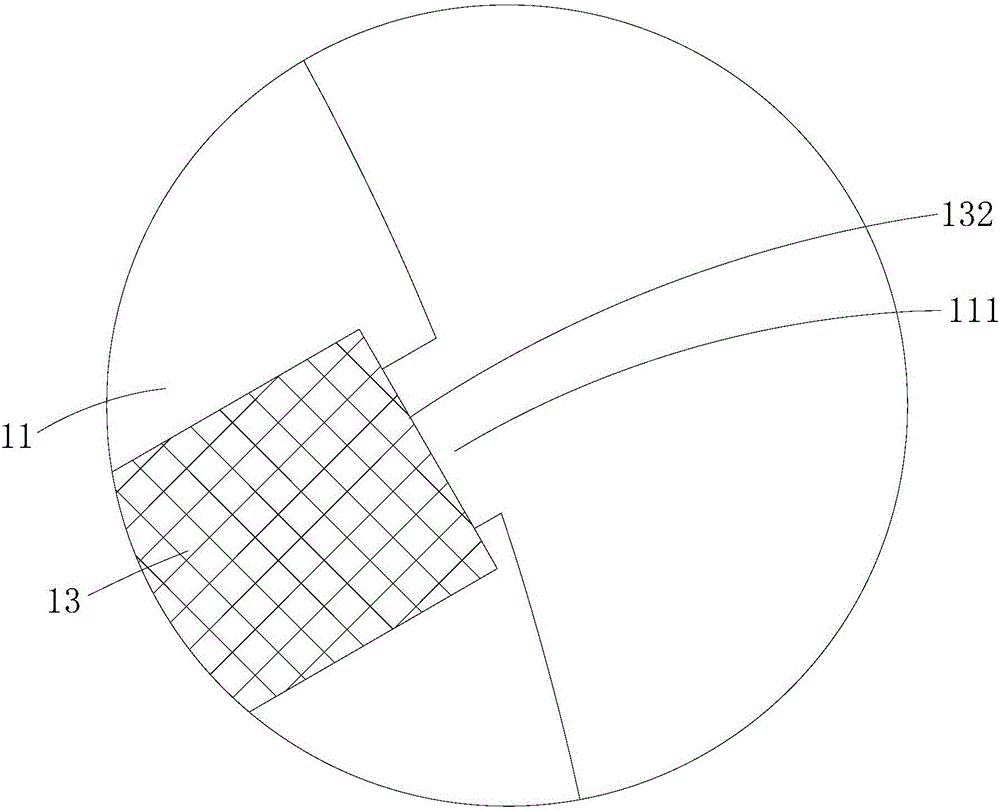

[0033] Such as figure 1 and figure 2 As shown, the rotor 1 provided by Embodiment 1 of the present invention includes a rotor core 11, a rotating shaft 12 installed at the center of the rotor core 11, and several magnets embedded in the rotor core 11 at intervals along the circumferential direction. Steel 13, the rotor core 11 is provided with several magnetic steel grooves for the accommodation and positioning of the magnetic steel 13, each magnetic steel 13 has an inner end 131 close to the rotating shaft 12 and an outer end 132 far away from the rotating shaft 12, the rotor iron core 11 There are also several outer magnetic bridge notches 111 recessed from the outer edge of the rotor core 11 and extending to the outer ends 132 of the magnetic steels 13 respectively. The rotor 1 provided in this embodiment cancels the setting of the magnetic isolation sleeve, thereby effectively simplifying the structure of the rotor 1, and because the assembly process of the magnetic isol...

Embodiment 2

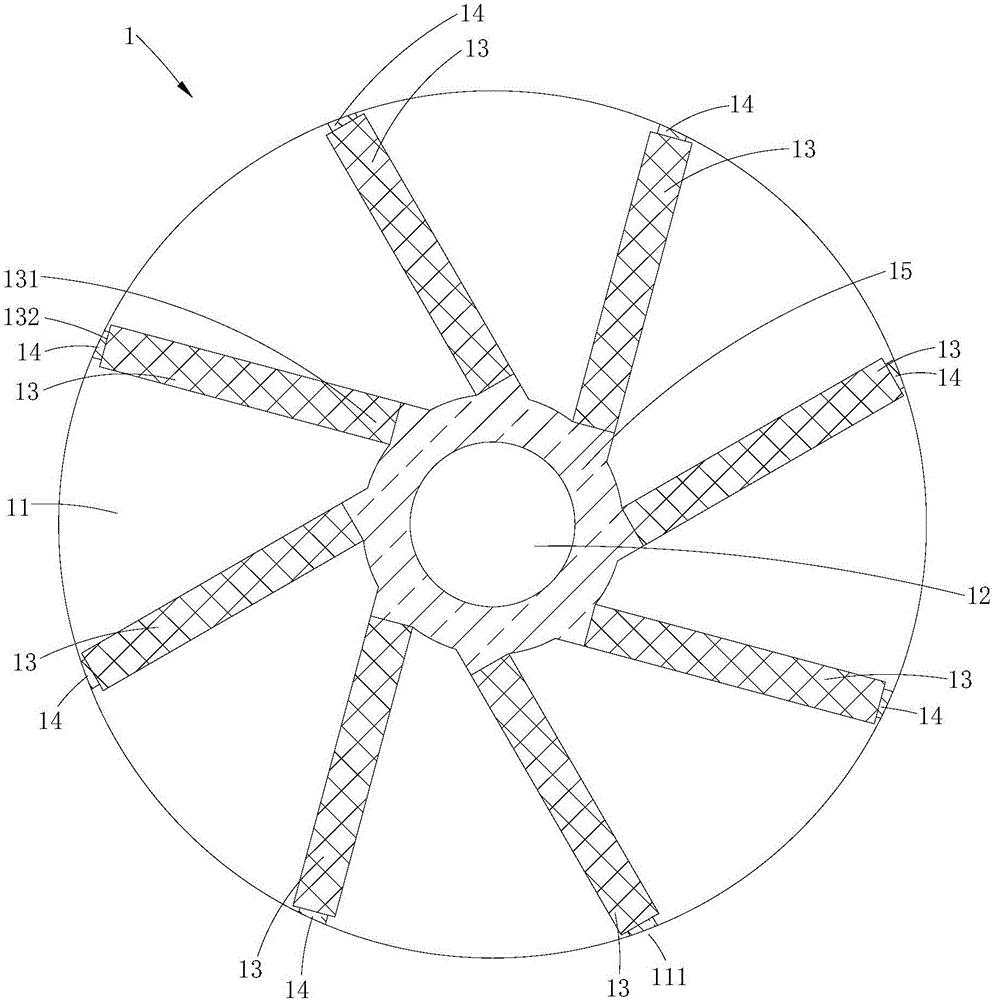

[0040] Such as image 3 and Figure 4 As shown, the same as the first embodiment, the rotor 1 provided by this embodiment also includes a rotor core 11, a rotating shaft 12 and several magnetic steels 13, each magnetic steel 13 also has an inner end 131 close to the rotating shaft 12 and an inner end 131 away from the rotating shaft 12. The outer end 132 of the rotating shaft 12 and the rotor iron core 11 are also provided with several magnetic steel grooves and a plurality of outer magnetic bridge gaps 111 recessed from the outer edge of the rotor iron core 11 and extending to the outer ends 132 of each magnetic steel 13; Different from Embodiment 1, the rotor core 11 of this embodiment is also provided with an inner magnetic bridge gap 112 located between the magnetic steel 13 and the rotating shaft 12, and the inner magnetic bridge gap 112 is injected and filled with an inner injection molded part 15 The outer magnetic bridge notch 111 is injected and filled with the outer...

Embodiment 3

[0044] Such as Figure 5 As shown, the same as the first embodiment, the rotor 1 provided by this embodiment also includes a rotor core 11, a rotating shaft 12 and several magnetic steels 13, each magnetic steel 13 also has an inner end 131 close to the rotating shaft 12 and an inner end 131 away from the rotating shaft 12. The outer end 132 of the rotating shaft 12 and the rotor iron core 11 are also provided with several magnetic steel grooves and a plurality of outer magnetic bridge gaps 111 recessed from the outer edge of the rotor iron core 11 and extending to the outer ends 132 of each magnetic steel 13; Different from the first embodiment, the rotor core 11 of this embodiment is also provided with a number of magnetic isolation bridges 114 distributed between the magnetic steel 13 and the rotating shaft 12 at intervals along the circumferential direction, so that through the magnetic isolation bridges 114 Setting, on the one hand, can further reduce the amount of magnet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com