Patents

Literature

130results about How to "Reduce magnetic flux leakage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

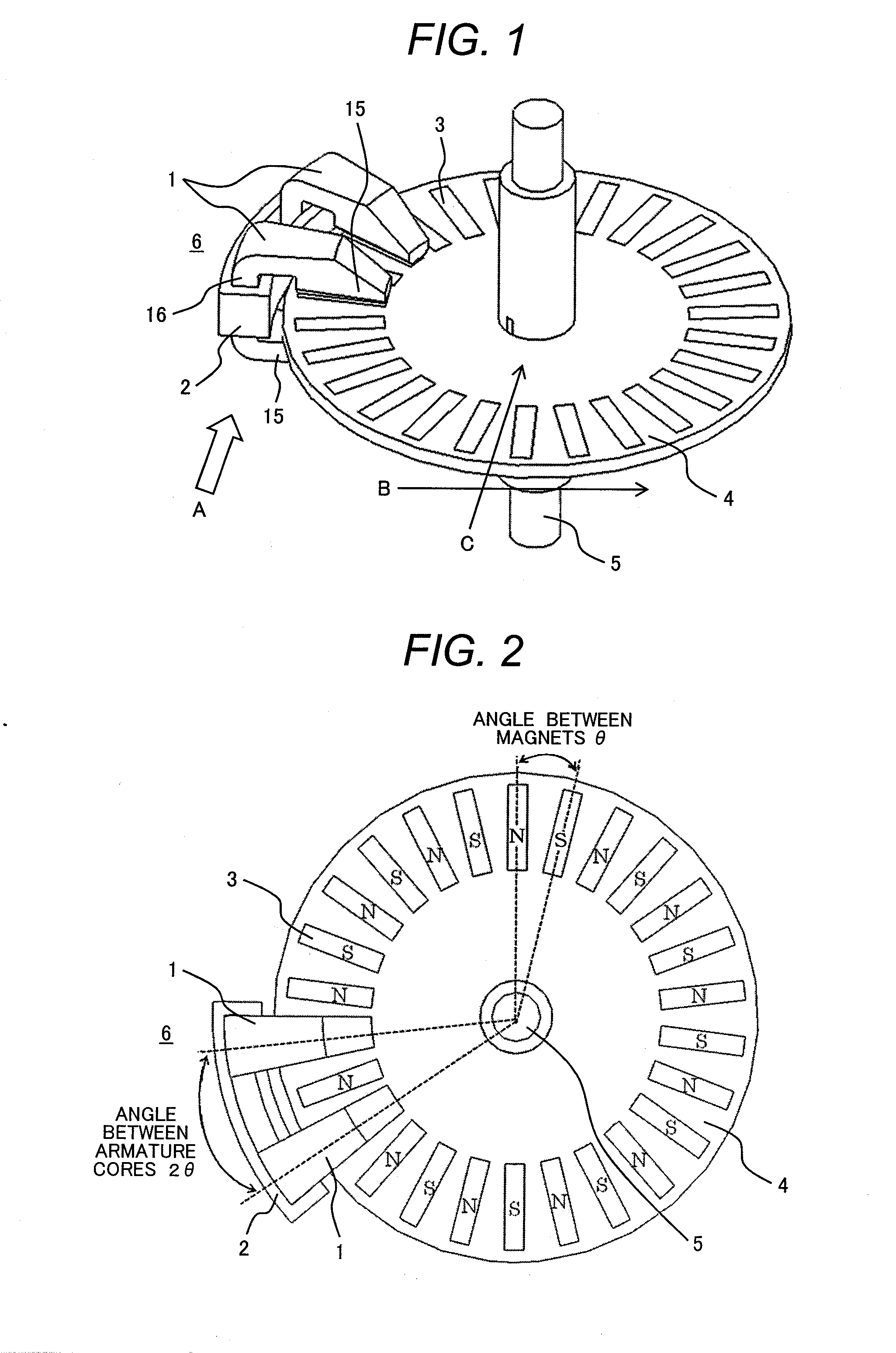

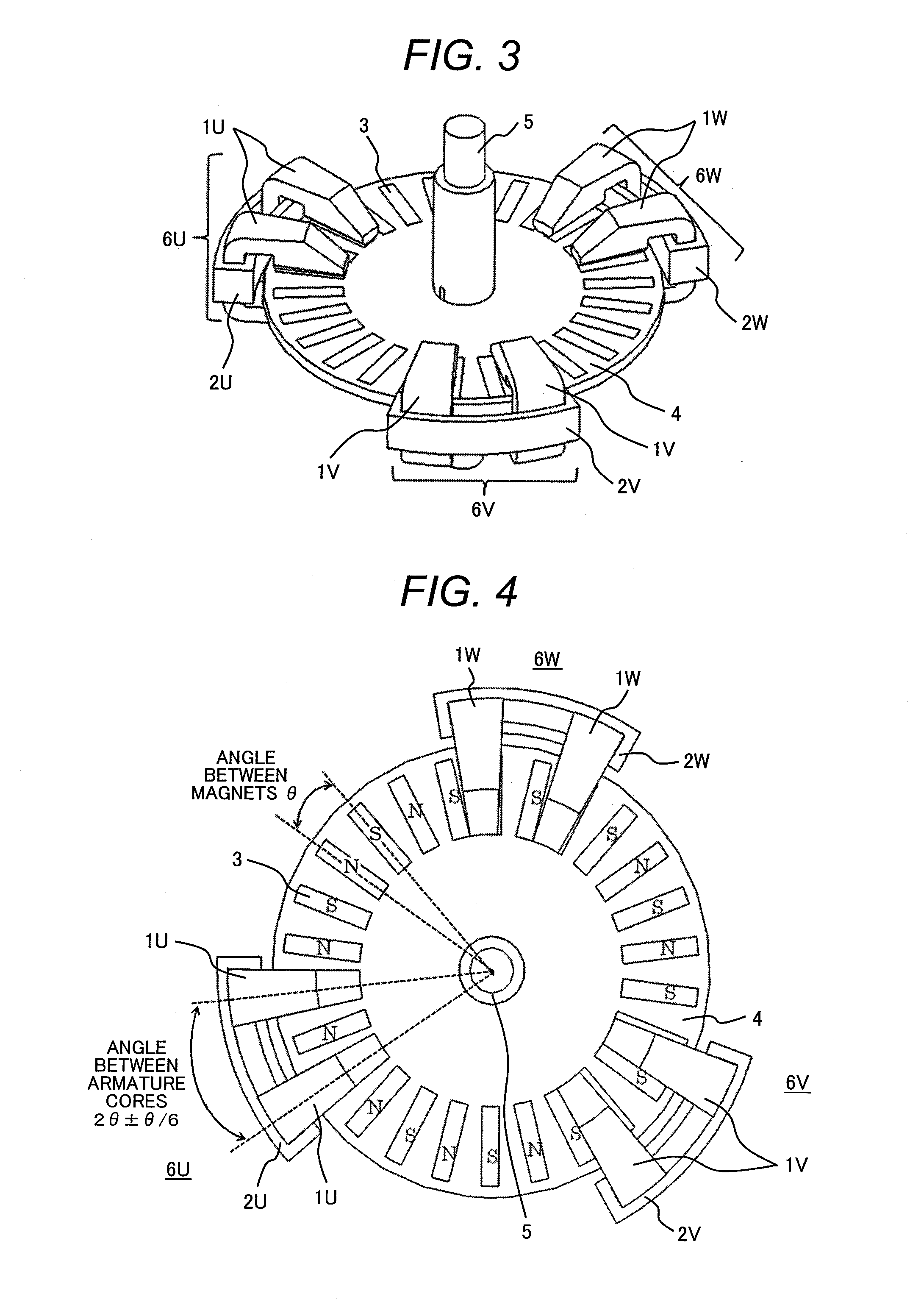

Rotary electrical machine

ActiveUS20110109190A1Reduce magnetic flux leakageSpacing intervalMagnetic circuit stationary partsSynchronous machines with stationary armatures and rotating magnetsMagnetic fluxHigh torque

When a conventional technology is employed, it is difficult to manufacture a magnet row because magnets are disposed so that N-poles face each other while S-poles face each other. Further, magnetic reluctance is increased because a generated magnetic flux obliquely crosses an air gap in which the magnets are disposed. Furthermore, the conventional technology is at a disadvantage in that magnetic flux interference occurs between neighboring magnetic poles. The present invention has been made to address the above problems and provide a rotary electrical machine capable of generating high torque at low speed. The rotary electrical machine includes a rotor disc and an armature. The rotor disc is configured so that plural rectangular magnets whose longitudinal direction crosses the direction of rotor disc rotation are disposed on the rotor disc, and that the polarities of neighboring magnets differ from each other. The armature is configured so that plural armature cores are disposed to sandwich the magnets, which are mounted on the rotor disc and provided with a particular magnetic pole, and that a winding is commonly wound between the armature cores.

Owner:HITACHI LTD +1

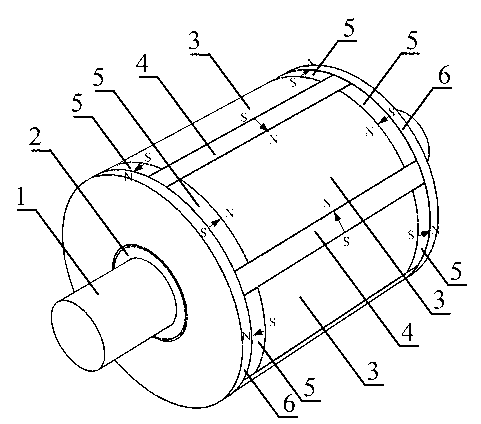

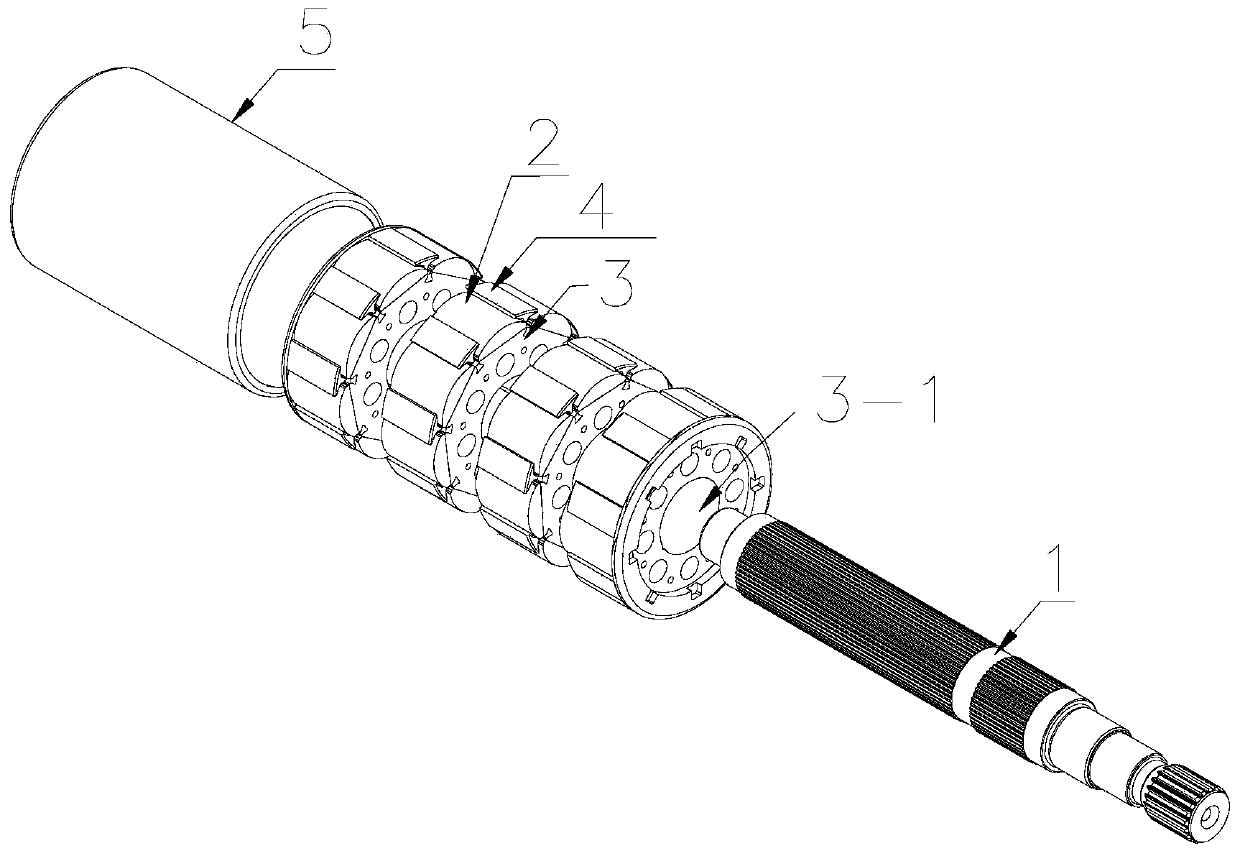

Permanent-magnetic rotor with non-magnetic-permeable distance sleeve and method for manufacturing permanent-magnet rotor

InactiveCN102761211AIncrease profitImprove electromagnetic compatibilityMagnetic circuit rotating partsManufacturing stator/rotor bodiesPermanent magnet rotorWork performance

The invention discloses a permanent-magnetic rotor with a non-magnetic-permeable distance sleeve and a method for manufacturing the permanent-magnetic rotor. The method includes sleeving the non-magnetic-permeable distance sleeve made of a non-magnetic-permeable material on a rotor shaft at first when iron cores of the rotor are mounted on the rotor shaft; then manufacturing the iron cores of the rotor into fan-shaped iron cores; uniformly distributing and fixedly mounting the fan-shaped iron cores of the rotor on the non-magnetic-permeable distance sleeve; encircling four surfaces, except for the arc-shaped upper end surface and a contacting surface with the non-magnetic-permeable distance sleeve, of each fan-shaped iron core, which is fixedly mounted on the non-magnetic-permeable distance sleeve, of the rotor by permanent magnets made of permanent magnetic materials in an attached manner; and arranging attached surfaces of the permanent magnets and the fan-shaped iron cores of the rotor properly so that magnetic polarities of the attached surfaces of the permanent magnets and the fan-shaped iron cores are identical correspondingly. The permanent-magnetic rotor has the advantages that the permanent-magnetic rotor is compact in structure, high in interference resistance, stable in work performance and long in service life, flux leakage at axial ends and flux leakage interference of the rotor are low, magnetic efficiency and utilization rate of each permanent magnet are high, and the like.

Owner:LINQUAN AEROSPACE MOTOR CO LTD

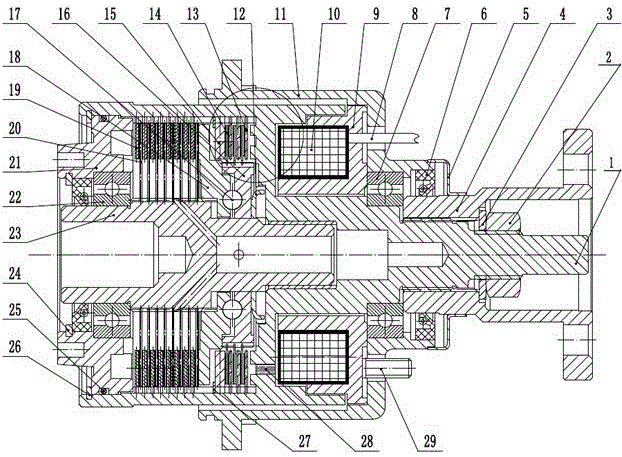

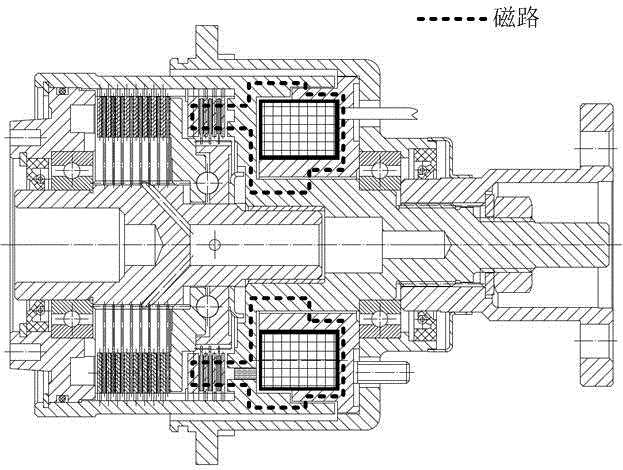

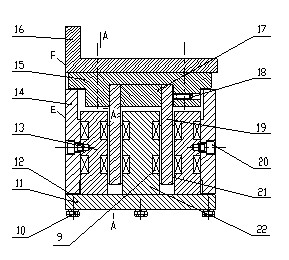

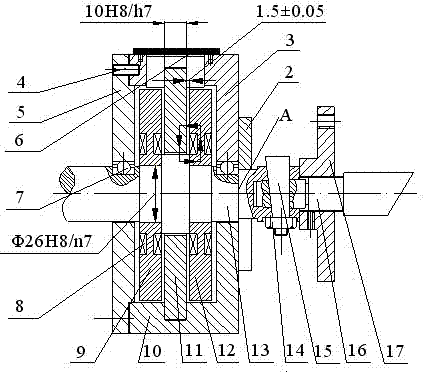

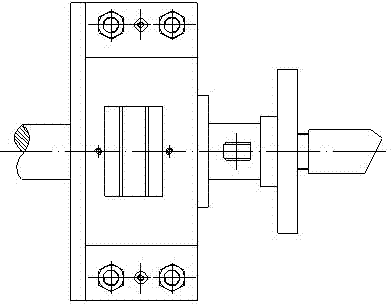

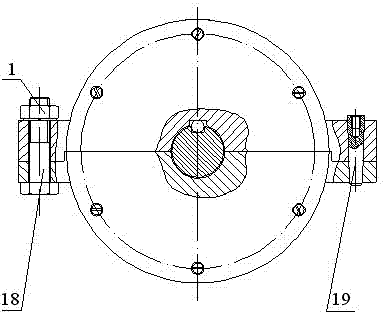

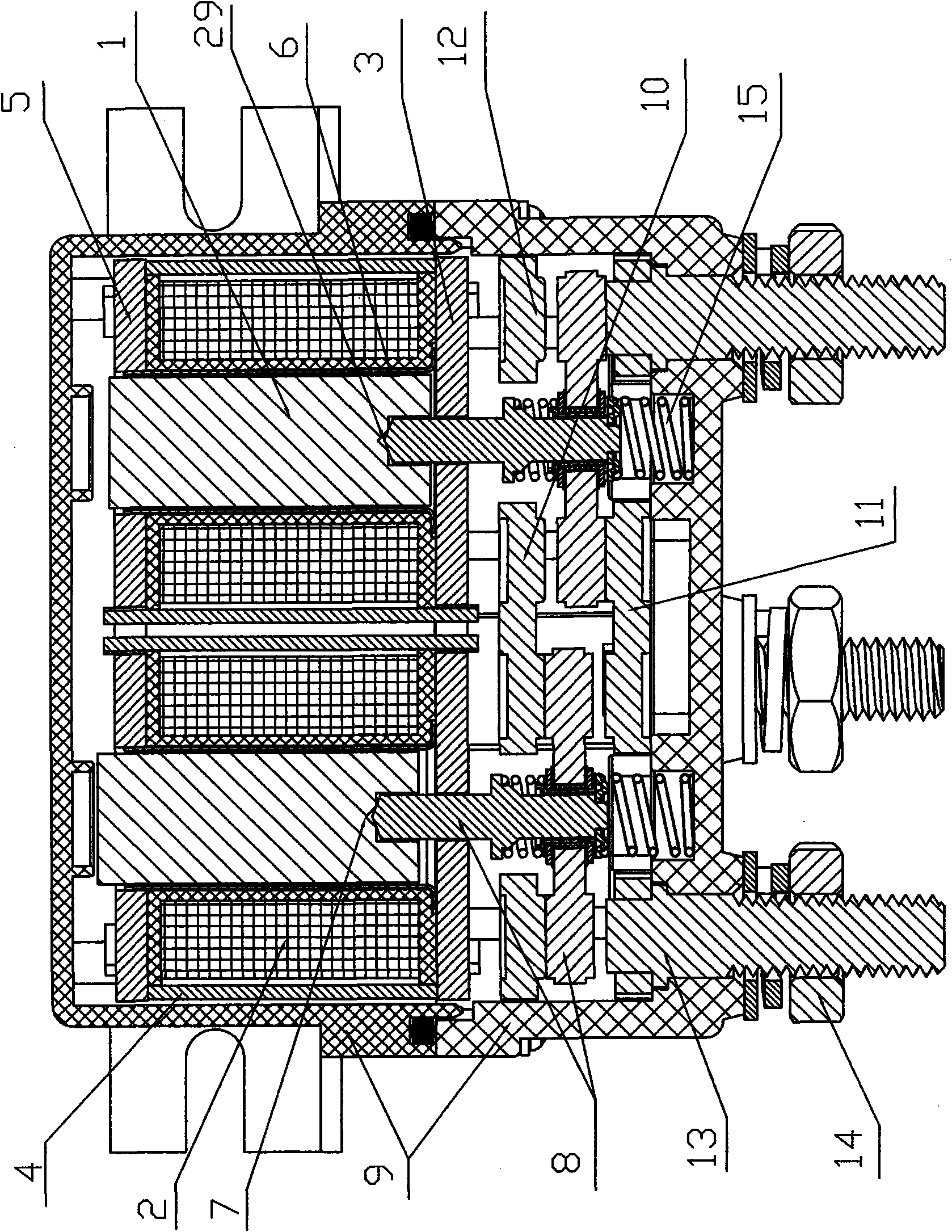

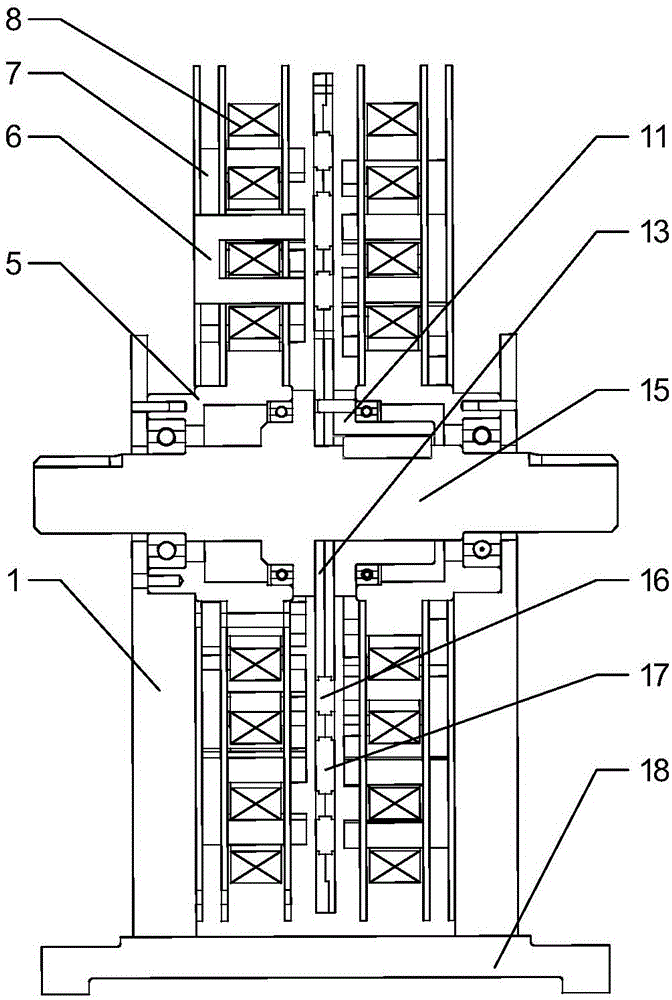

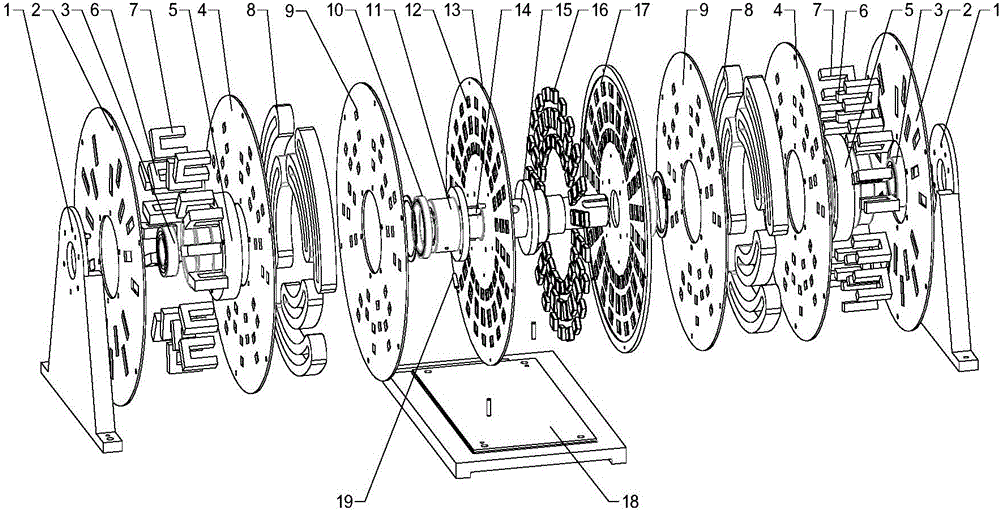

Two-stage multi-sheet electromagnetic clutch

ActiveCN105156503AReduce magnetic flux leakageAvoid disadvantagesMagnetically actuated clutchesControl devicesElectromagnetic clutchCam

The invention relates to a power cutting off and combination device, in particular to a two-stage multi-sheet electromagnetic clutch. The two-stage multi-sheet electromagnetic clutch comprises an input shaft with a left sleeve and a right sleeve, an output shaft pivoted to the input shaft, an electromagnet assembly pivoted to the input shaft, a primary clutch portion, a cam force increasing mechanism and a main clutch portion. Compared with the prior art, the two-stage multi-sheet electromagnetic clutch is simple in structure, fewer parts are used, and a series of problems of purchasing, management, machining, manufacturing and the like of the clutch are solved.

Owner:LONGKOU ZHONGYU MACHINERY

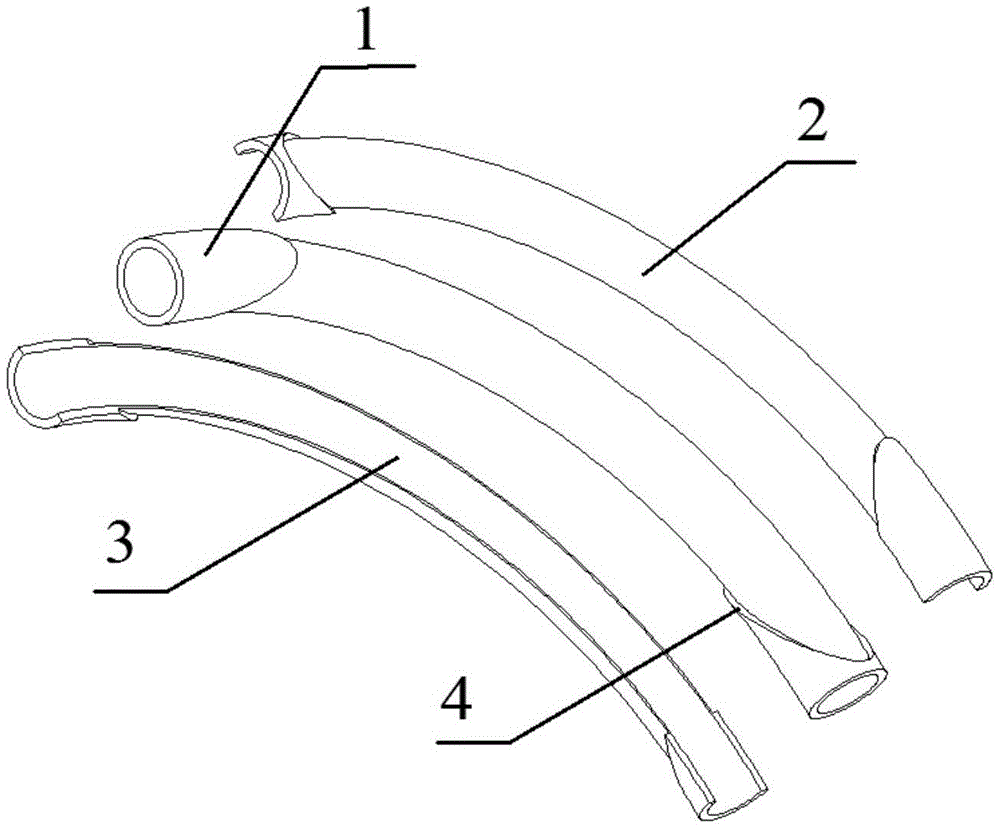

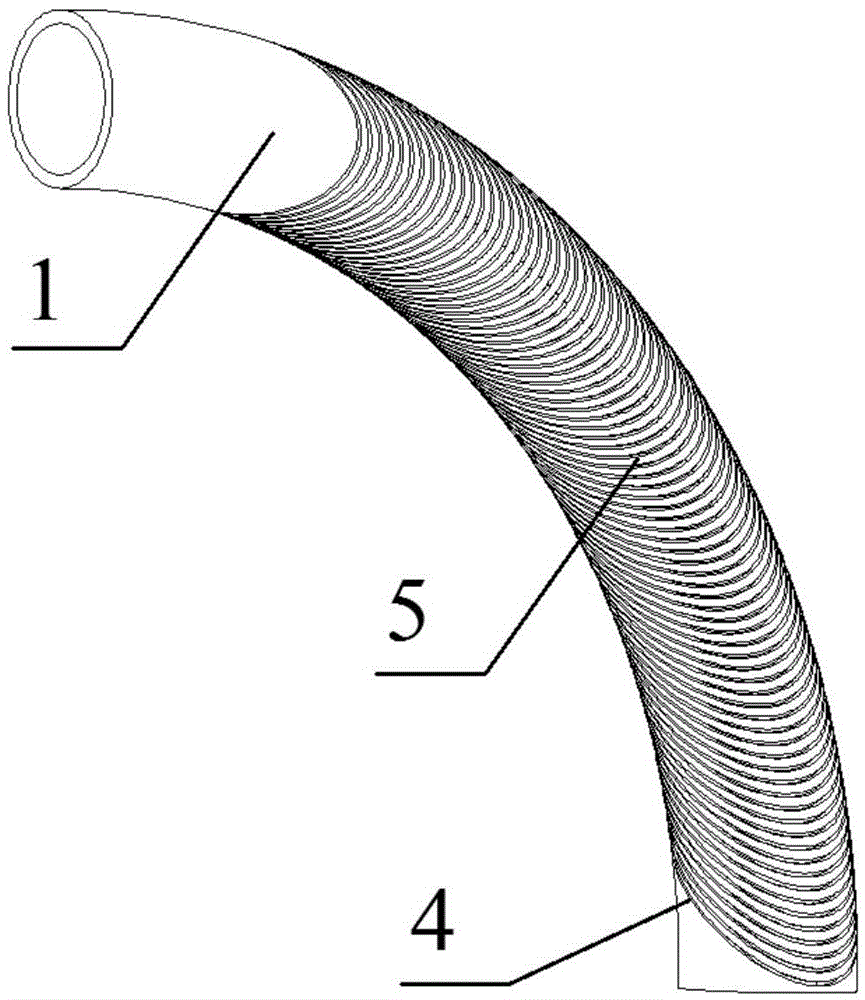

High temperature superconducting bending magnet structure appropriate for superconducting rotary rack technology

ActiveCN105469926ASmall sizeReduce weightSuperconducting magnets/coilsBending magnetsElectrical conductor

The invention discloses a high temperature superconducting bending magnet structure appropriate for a superconducting rotary rack technology. The high temperature superconducting bending magnet structure comprises a YBCO high temperature superconductor of a special structure, an inner coil and an outer coil which are coaxially nested, an outer conductor fixed layer, a conductor insulating layer, a stainless steel support layer, a clamping groove, a double cooling structure, an iron yoke beam magnetic layer and an aluminum shell. According to the high temperature superconducting bending magnet structure, deflection of ion beams in the superconducting rotary rack bending magnet can be realized, and the size, weight and cost of the bending magnet are effectively reduced; moreover, the requirements such as low temperature cooling, structural strength and quenching protection during the operation of the high temperature superconducting magnet can be realized; and a stable high-strength magnetic field can be generated in an iron beam conveying area by using the special YBCO superconductor structure and a winding manner. Finally, the miniaturization, light weight and low cost of the magnet structure are finally realized, and the development of the high temperature superconducting magnet in the medical field of ion beams is promoted.

Owner:INST OF PLASMA PHYSICS CHINESE ACAD OF SCI

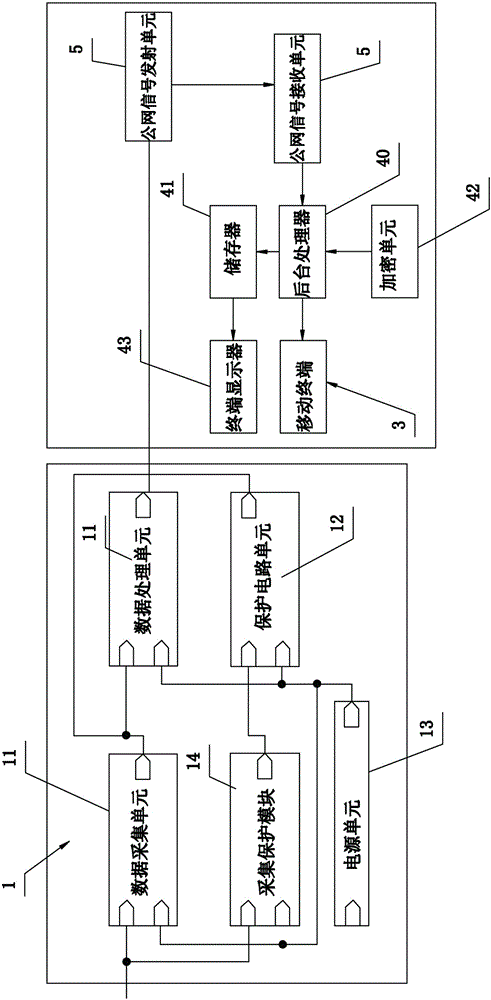

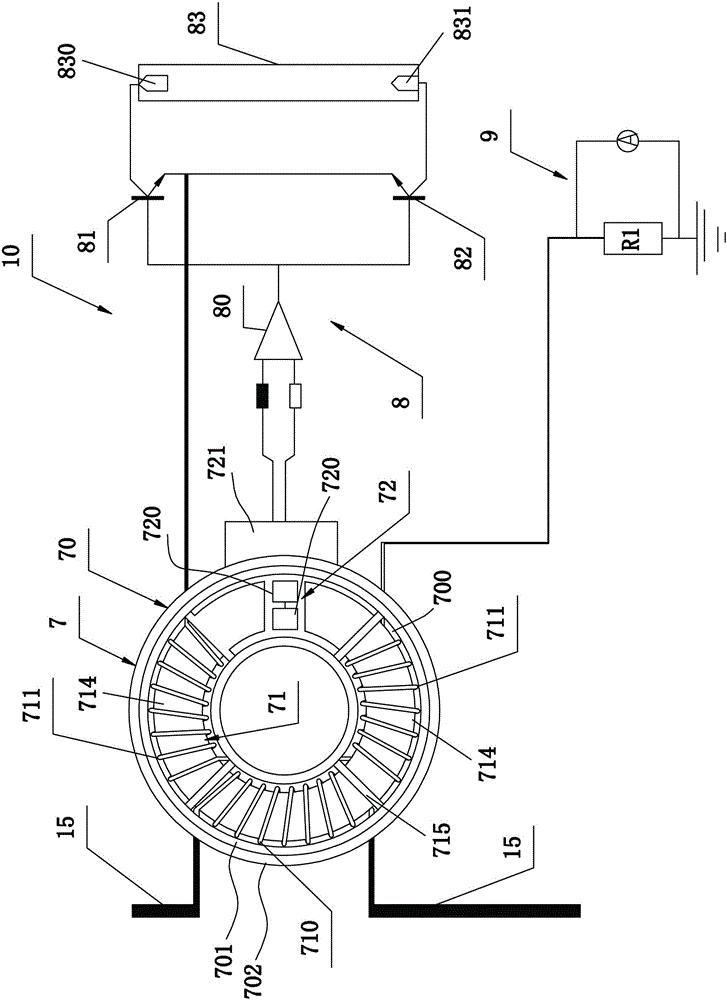

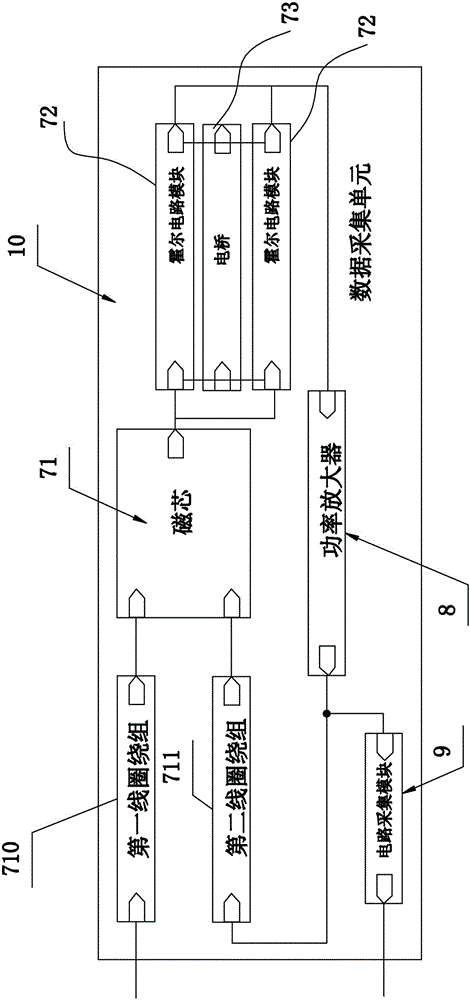

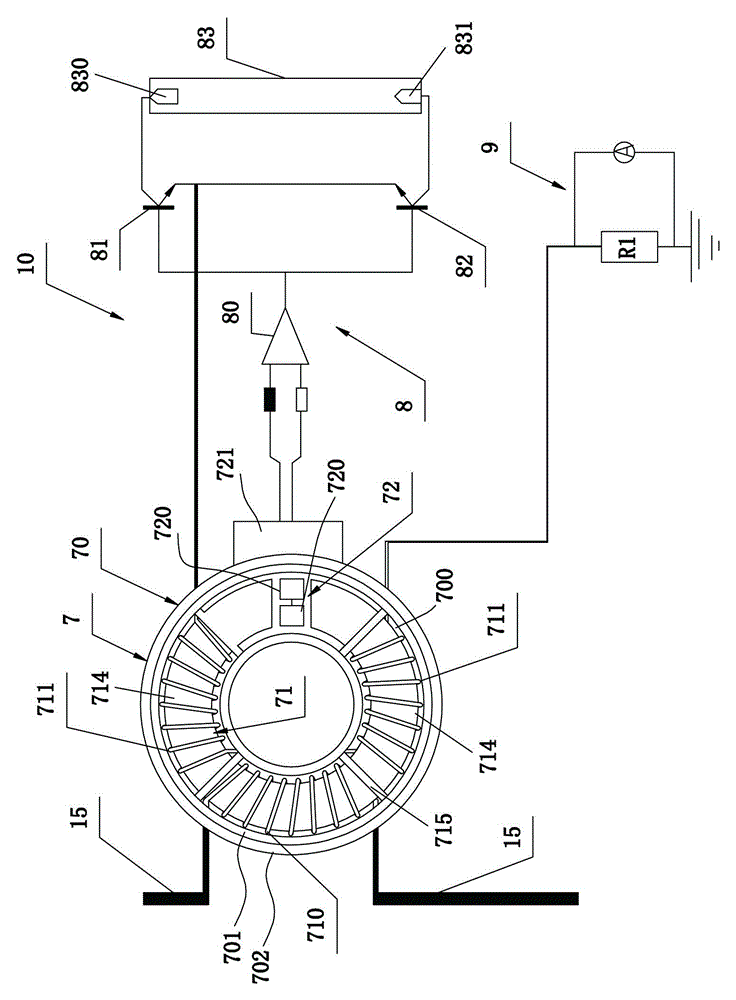

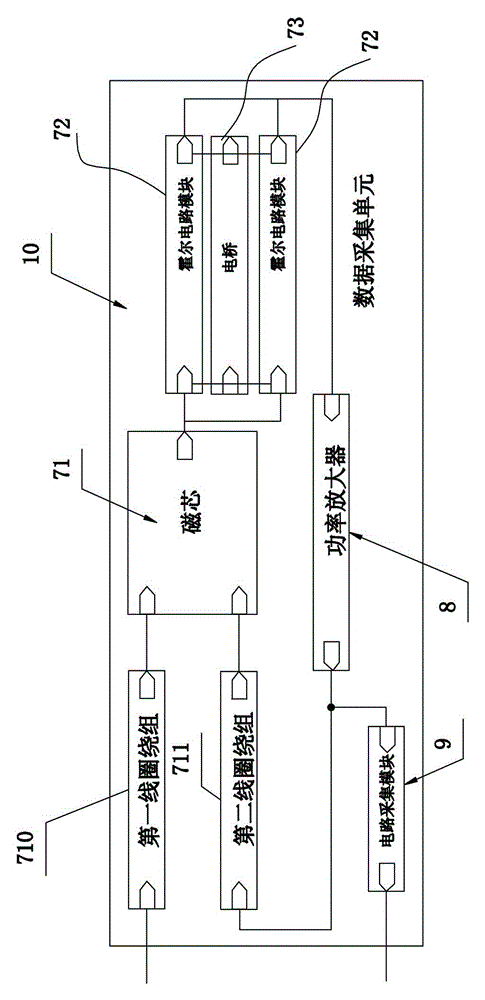

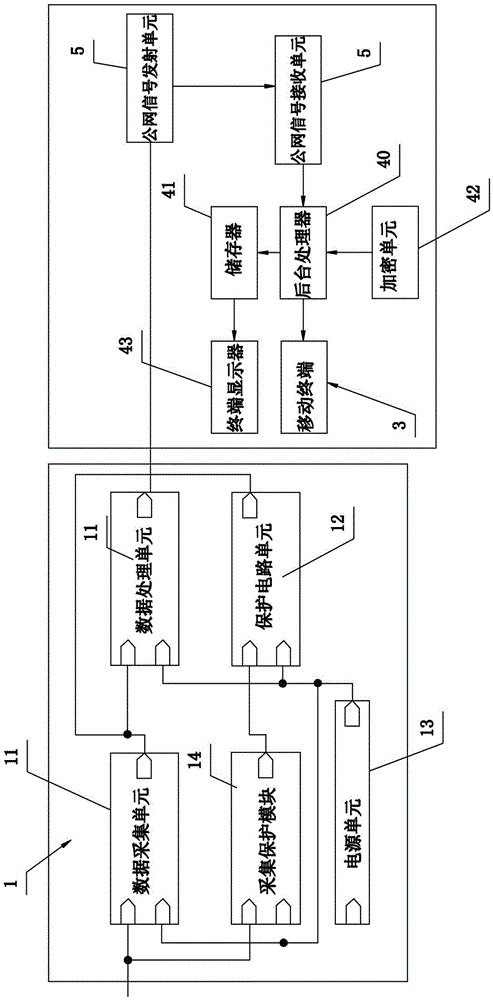

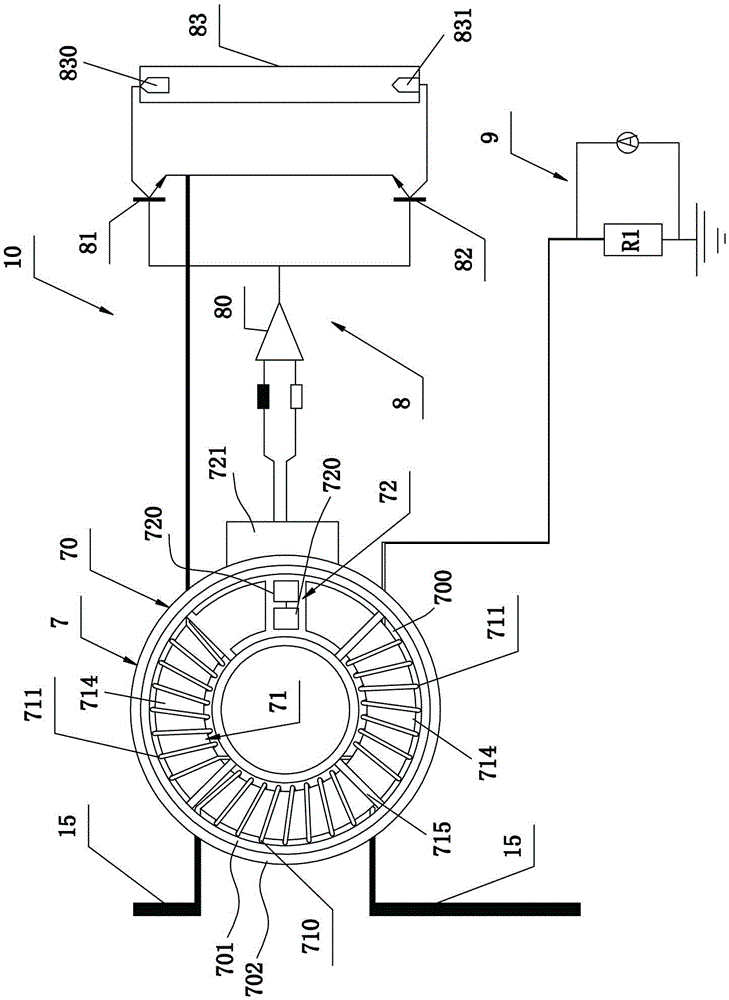

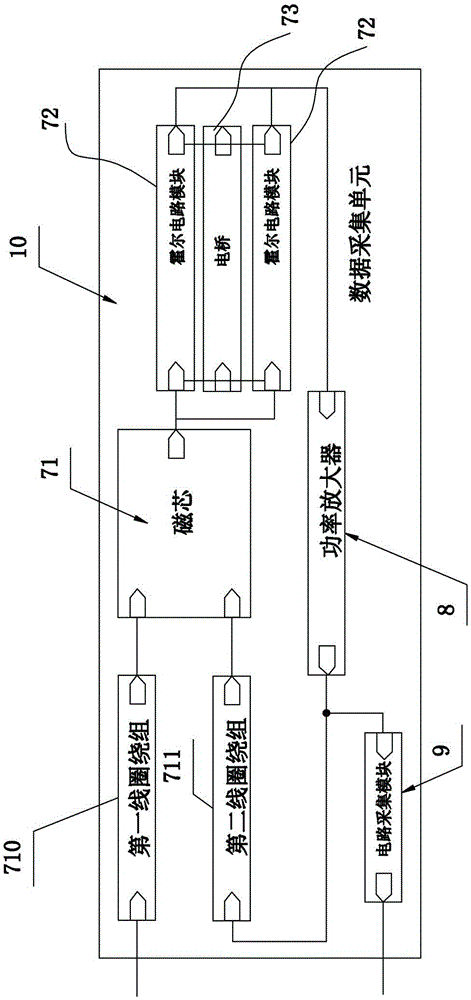

Acquisition unit for leak current of ultra high voltage direct-current arrester based on two Hall elements

ActiveCN105158543AGuaranteed uptimeImprove pressure resistanceCurrent/voltage measurementUltra high voltageCurrent sensor

The invention discloses an acquisition unit for leak current of an ultra high voltage direct-current arrester based on double Hall elements. The acquisition unit comprises a current sensor, a power amplifier and a circuit acquisition module, wherein the current sensor comprises an annular shell, a magnetic core arranged in a C shape and two Hall circuit modules; an accommodating space is formed inside the annular shell; a first coil winding and a second coil winding are respectively wound on the magnetic core, and the magnetic core is installed inside the accommodating space; and the magnetic flux density direction produced by the second coil winding is opposite to that of the first coil winding. The acquisition unit acquires the leak current of the arrester by adopting the two Hall circuit modules, so that the nonlinearity and the position error of the sensor can be greatly reduced, and the anti-interference capability and the range limit of the sensor are improved.

Owner:RED PHASE INC

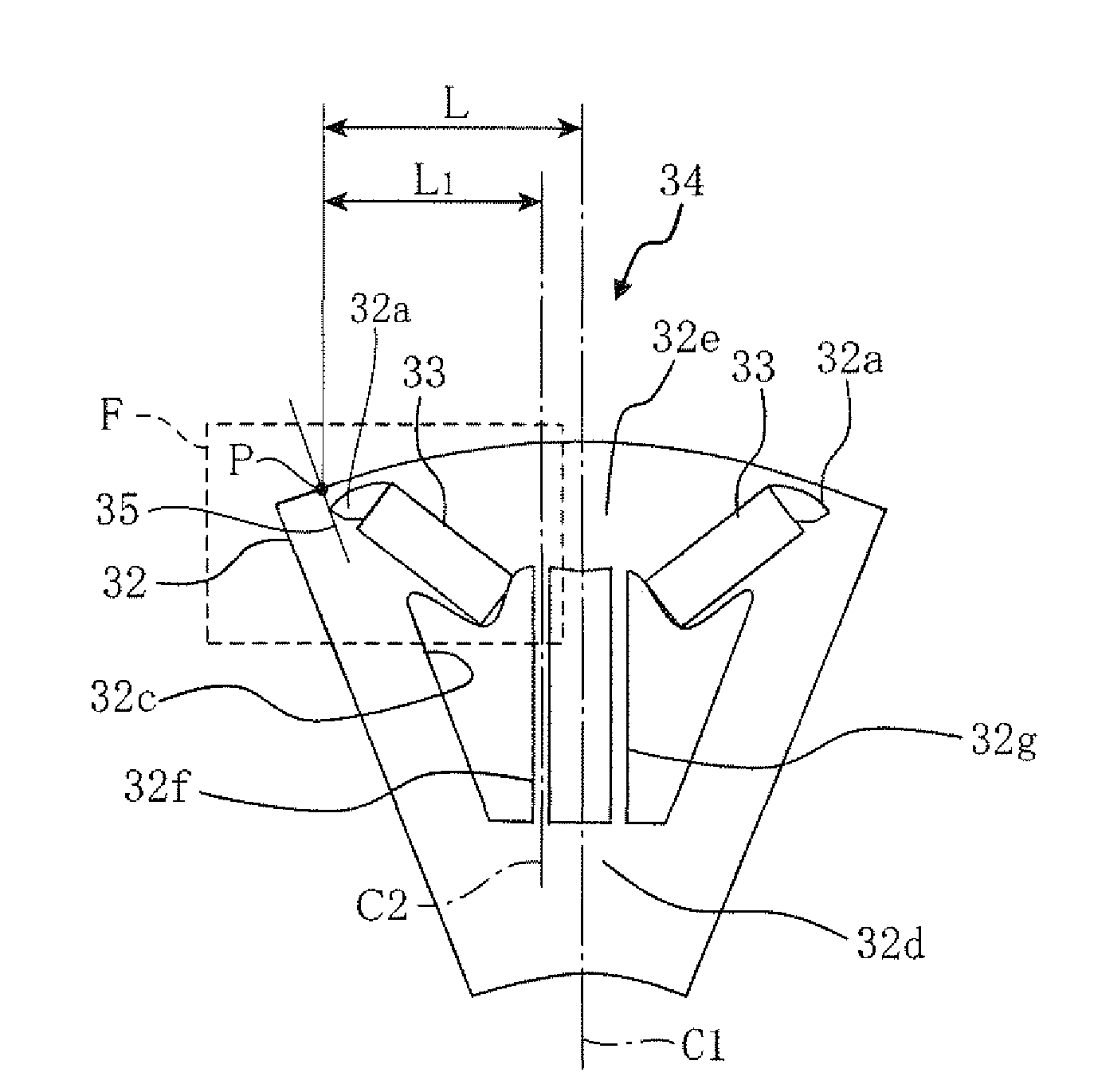

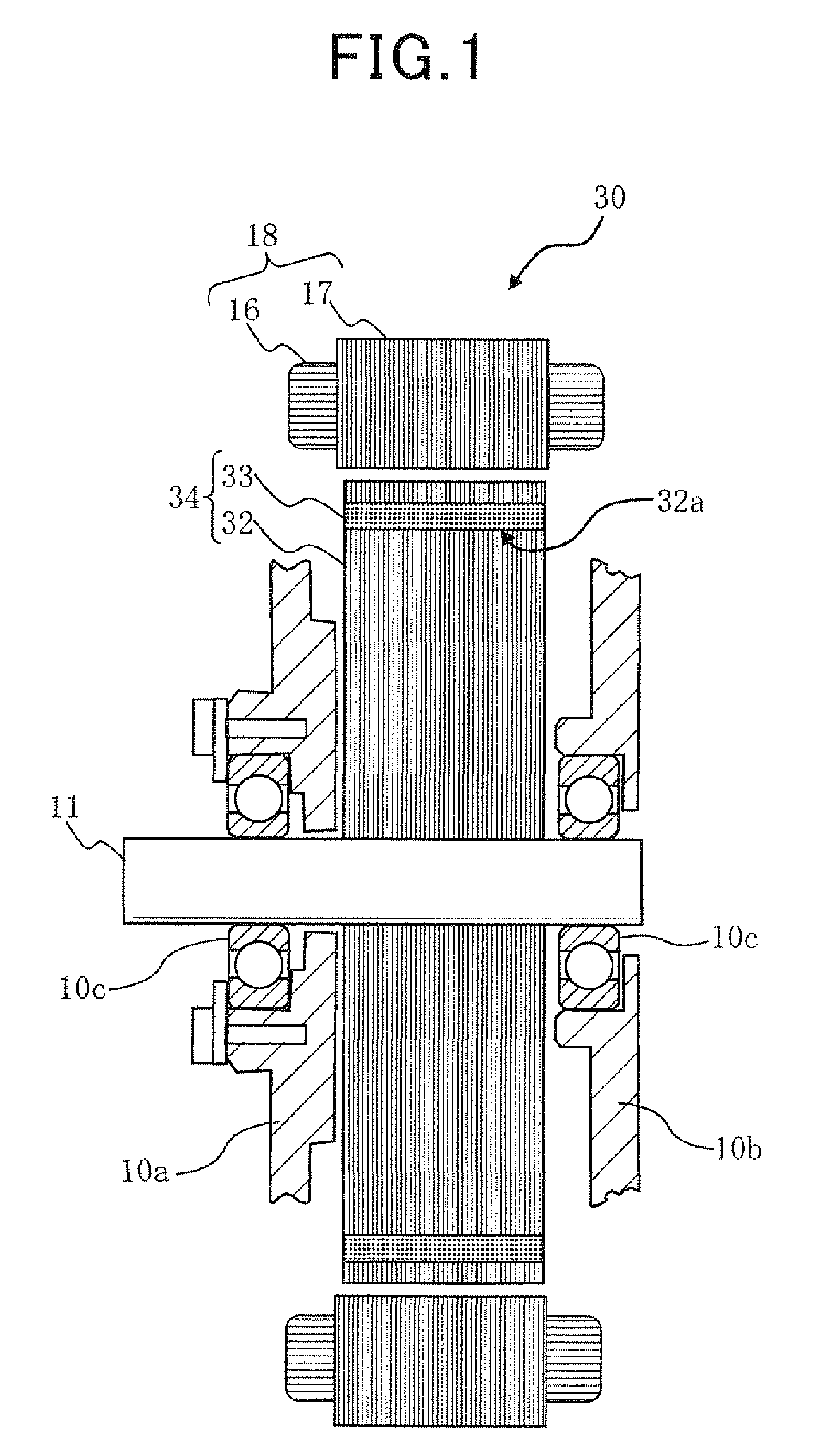

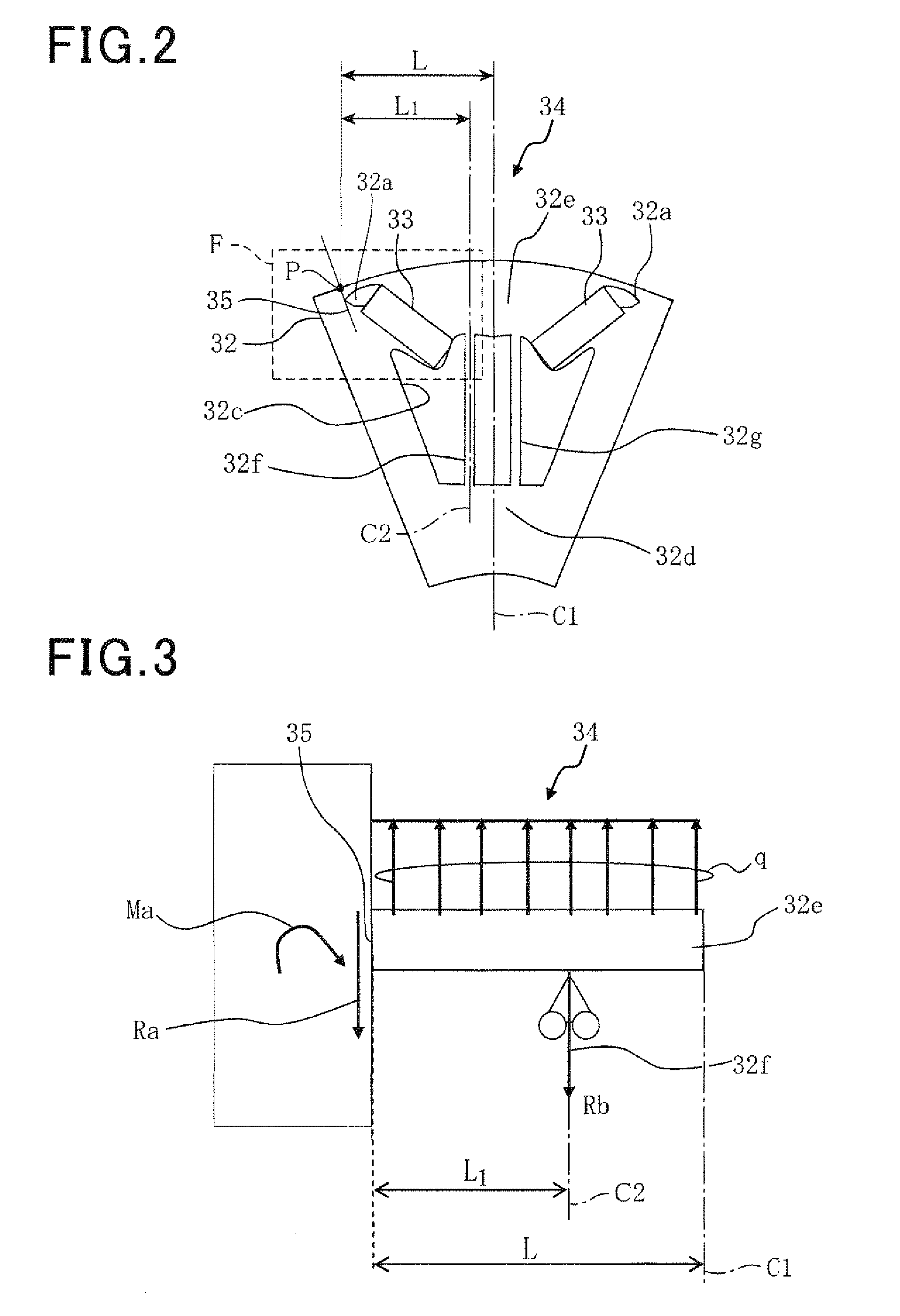

Rotor for electric rotating machine

ActiveUS20110278977A1Reduce magnetic flux leakageMagnetic reluctanceMagnetic circuit rotating partsSynchronous machines with stationary armatures and rotating magnetsEngineeringMagnetic poles

A rotor includes a hollow cylindrical rotor core and permanent magnets embedded in the rotor core to form a plurality of magnetic poles on the radially outer periphery of the rotor core. The rotor core has a plurality of openings each of which extends in the axial direction of the rotor core so as to penetrate it. When viewed along the axial direction, each of the openings is symmetrically positioned with respect to the centerline of a corresponding one of the magnetic poles. For each of the openings, there are provided n reinforcing portions, where n is an integer not less than 2. The n reinforcing portions extend to connect a pair of radially-inner and radially-outer peripheral portions of the rotor core, thereby partitioning the opening into (n+1) parts. The n reinforcing portions are symmetrically arranged with respect to the centerline of the corresponding magnetic pole.

Owner:DENSO CORP

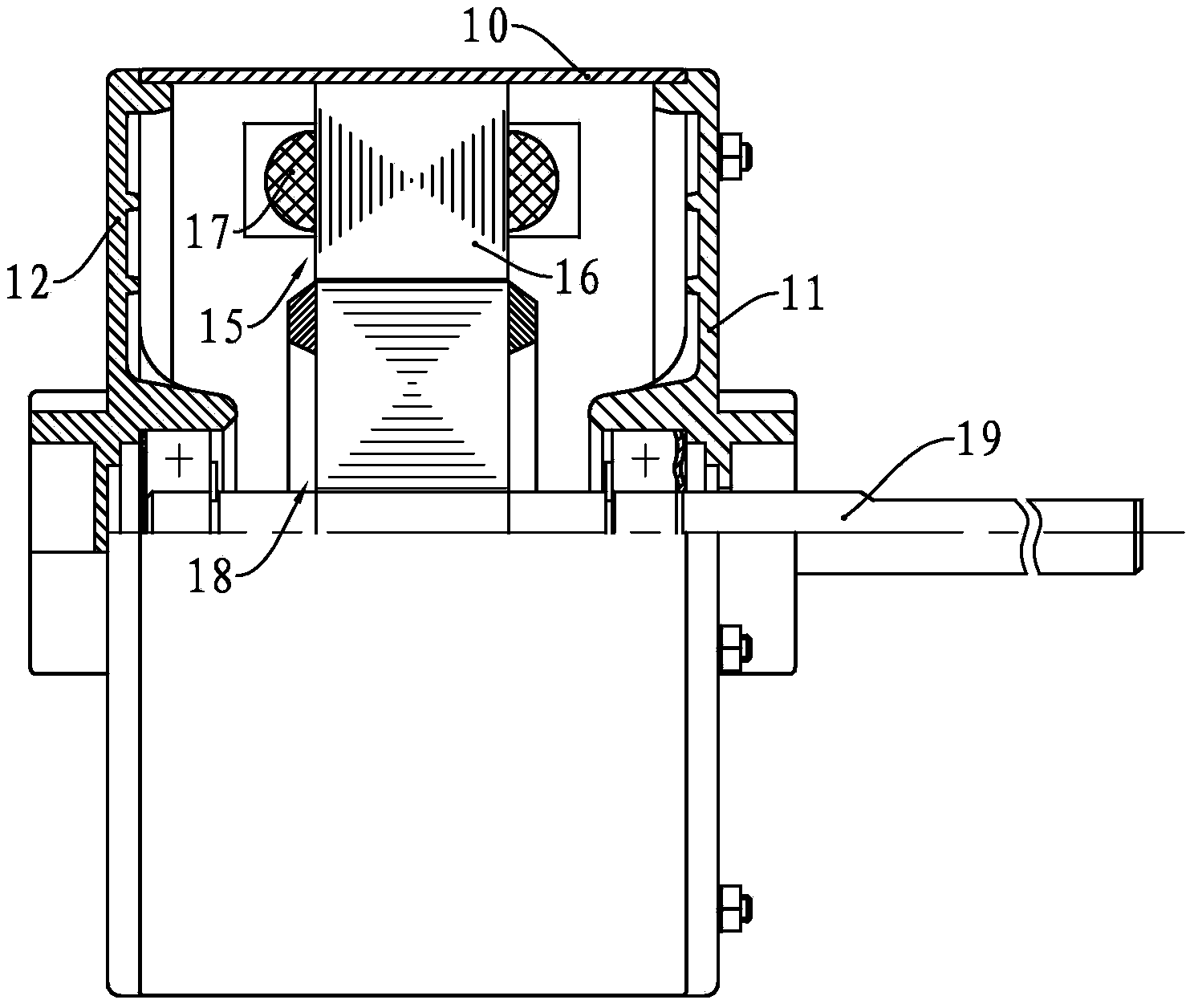

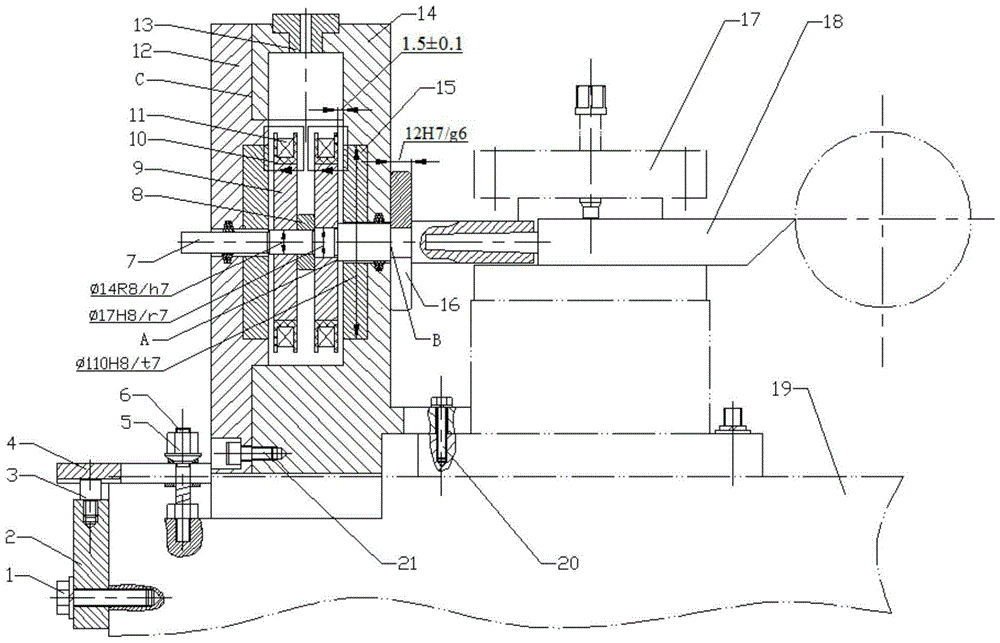

Magnetorheological vibration reduction system based on shearing work mode for cylindrical turning vibrations

InactiveCN102179534AImprove work efficiencyReduce magnetic flux leakageNon-rotating vibration suppressionAuxillary equipmentInterference fitMagnetic poles

The invention relates to a magnetorheological vibration reduction system based on a shearing work mode for cylindrical turning vibrations. An upper spacing groove is adjustably connected below a connecting plate inside a sliding magnetic pole assembly; two upper magnetic poles are fixedly connected below the upper spacing groove through upper partition plates; a lower spacing groove inside a fixed magnetic pole assembly is fixedly connected with a lower box body in a positioning way; the lower spacing groove is internally connected with a middle lower magnetic pole in an interference fit way;the inner side surface of the box body is fixedly connected with two side lower magnetic poles; magnet exciting coils are transversely wound in square grooves positioned on the outer surfaces of the side lower magnetic poles and the middle lower magnetic pole, and magnetorheological fluids are injected between the upper magnetic poles and the lower magnetic poles; an acceleration transducer is arranged on the front end of a lathe cross slide and sequentially connected with a charge amplifier, a computer and a program-controlled DC power supply through cables; and the program-controlled DC power supply is connected with the magnet exciting coils. The magnetorheological vibration reduction system has important application values to effectively enhancing the processing quality and the production efficiency of cylindrical turning, especially the cylindrical turning of slender axle parts, prolonging the lives of cutters and reducing turning noises.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

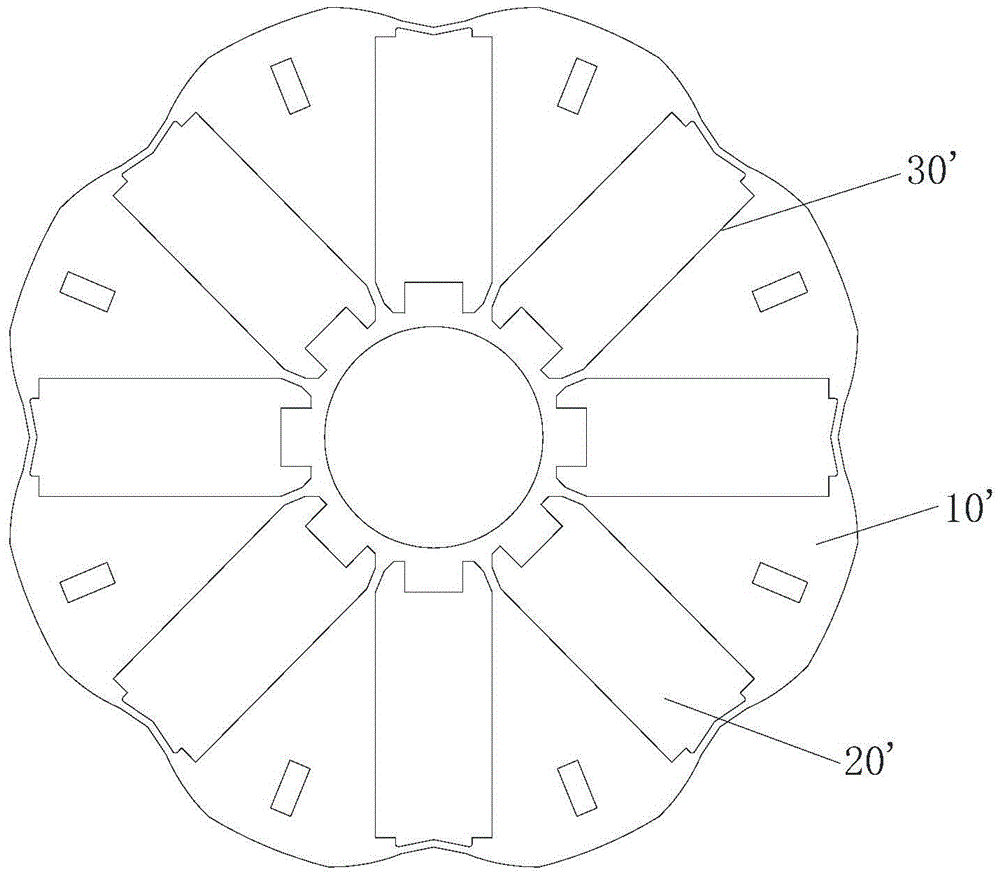

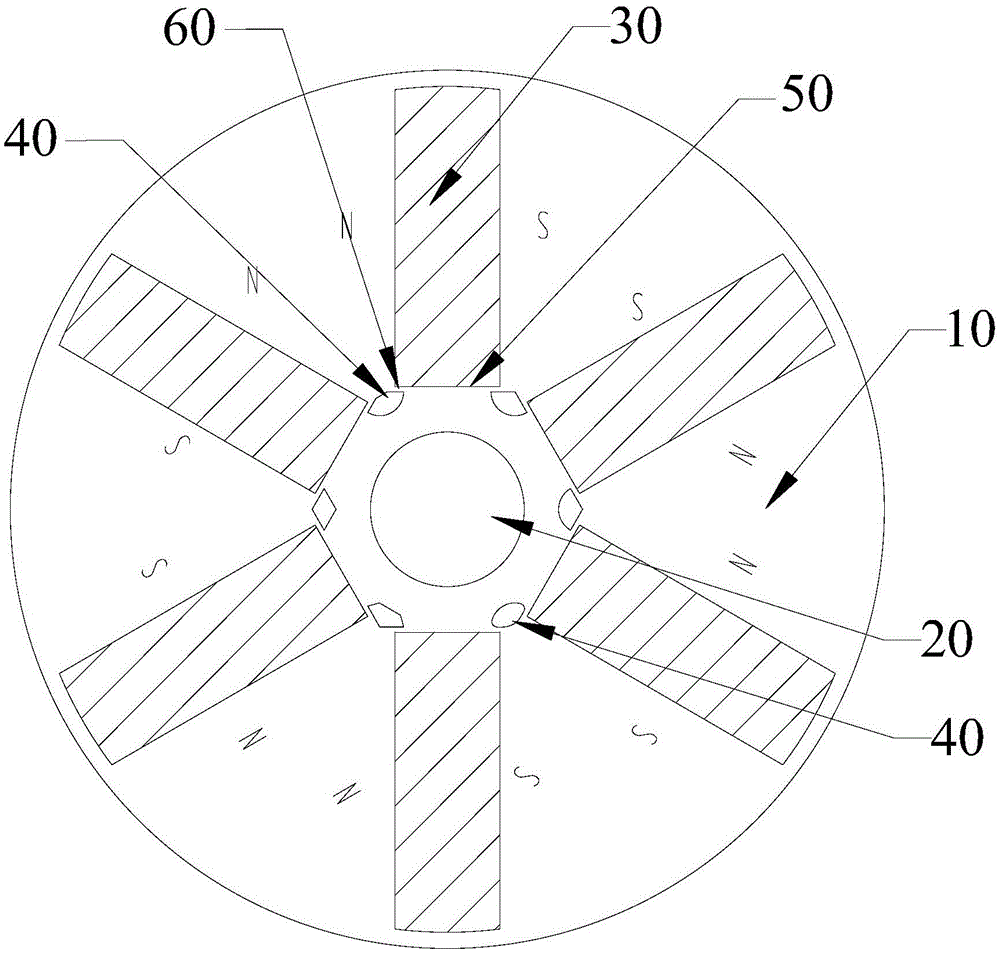

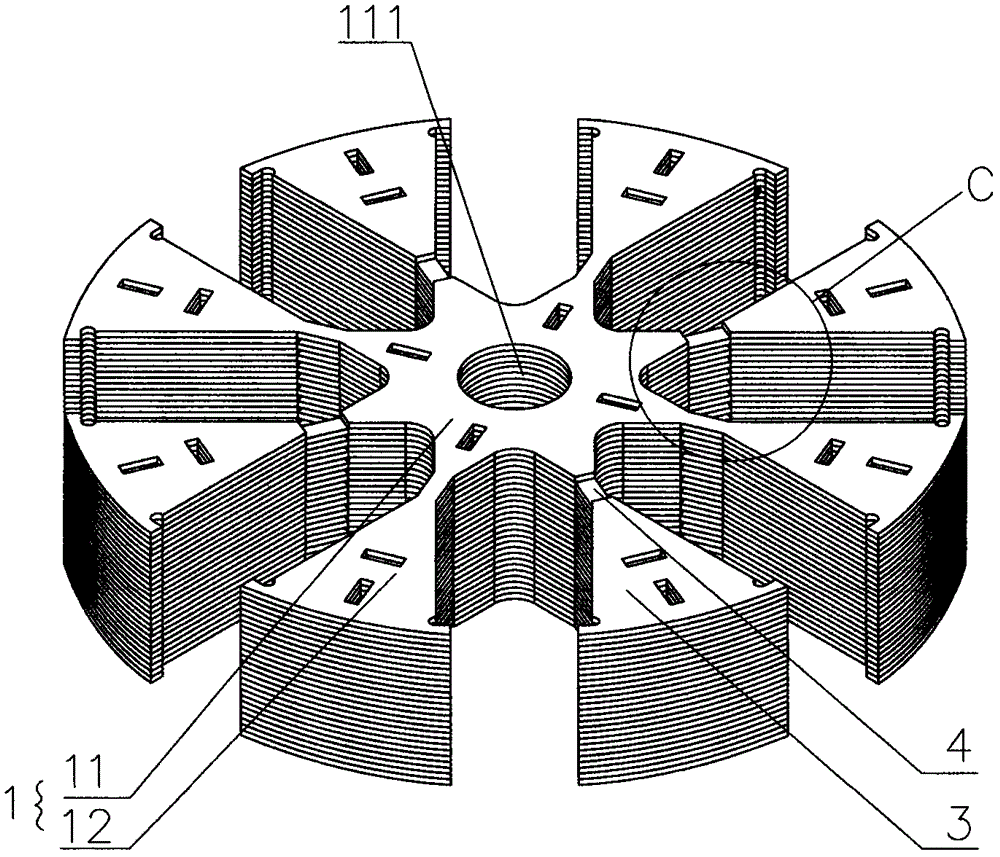

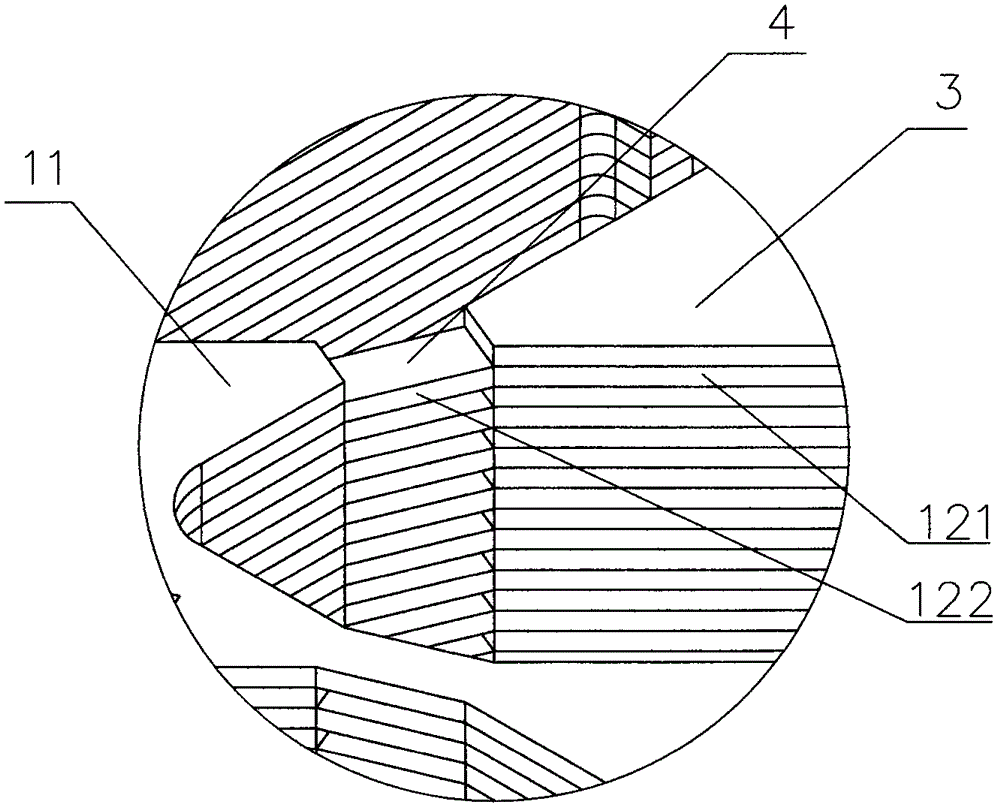

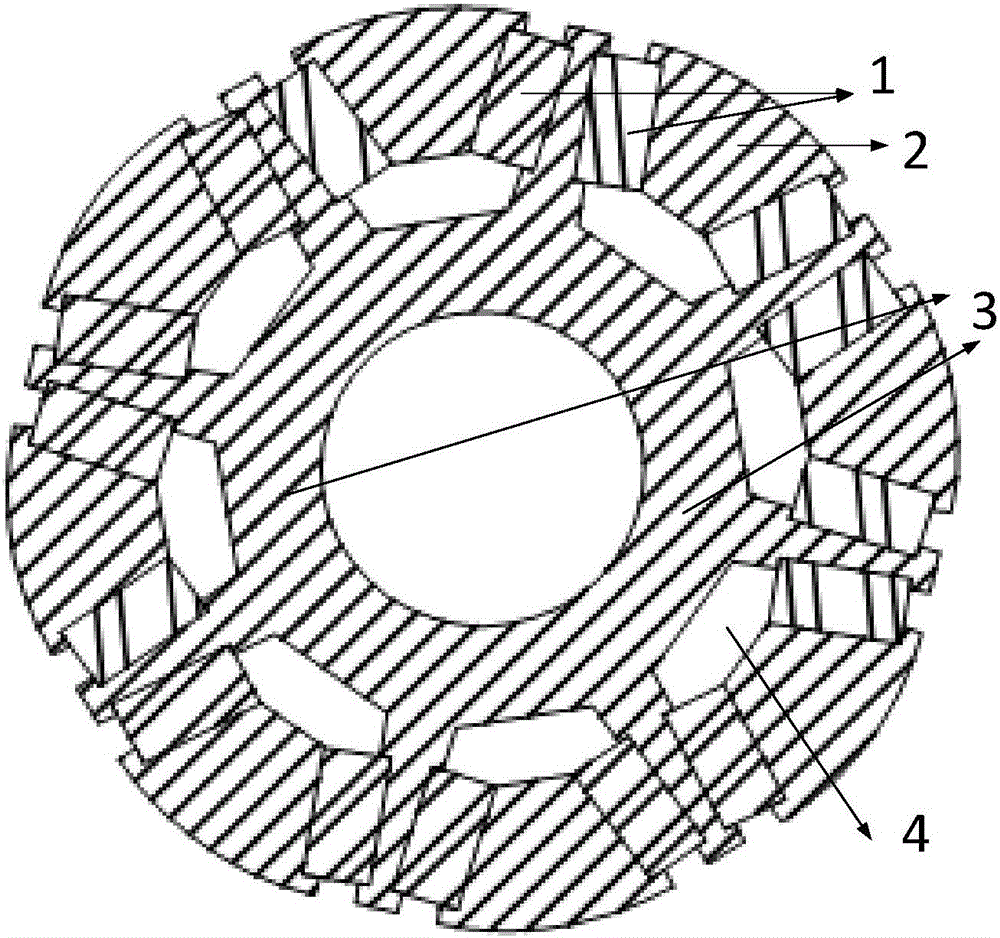

Rotor iron core and motor equipped with same

ActiveCN105471140AReduce Flux LeakageReduce magnetic flux leakageMagnetic circuit rotating partsElectric machineMetallurgy

The invention provides a rotor iron core and a motor equipped with the same. The rotor iron core comprises an iron core body, multiple magnetic steel grooves and multiple magnetic steels, wherein the multiple magnetic steel grooves are formed in the iron core body and are formed at intervals along the circumferential direction of the iron core body; each magnetic steel groove extends in a radial direction of the iron core body; each magnetic steel groove is provided with a first end close to the rotor iron core center and a second end far from the rotor iron core center; the multiple magnetic steels are arranged in the multiple magnetic steel grooves in a one-to-one correspondence manner, wherein the first ends of a part of the multiple magnetic steel grooves are spaced at intervals to form connecting bridges while the first ends of the other magnetic steel grooves are connected. Magnetic field flux leakage occurs from the connecting bridges; according to the technical scheme of the rotor iron core and the motor equipped with the same, the first ends of a part of the multiple magnetic steel grooves are connected but not spaced at intervals to form the connecting bridges, so that the number of the connecting bridges among the magnetic steels is reduced, and the flux leakage phenomenon is reduced as well; and therefore, the rotor iron core and the motor equipped with the same can reduce flux leakage and improve the equipment performance.

Owner:GREE ELECTRIC APPLIANCES INC +1

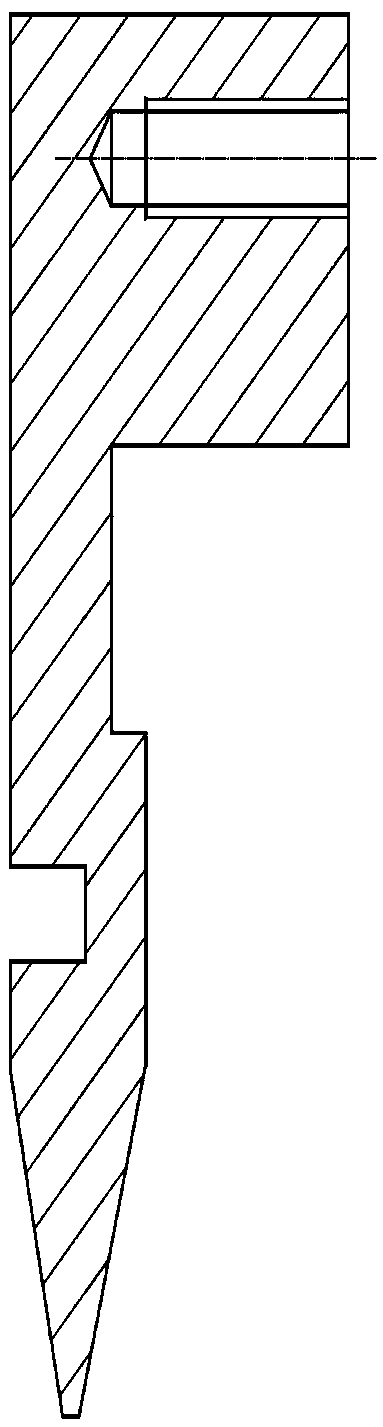

Dynamic vibration-absorption turning tool based on extruding working mode of magnetorheological fluid

InactiveCN103962883ASuppress chatterSuppresses turning chatterSpringsNon-rotating vibration suppressionMagnetic currentMagnetic poles

The invention relates to a dynamic vibration-absorption turning tool based on an extruding working mode of magnetorheological fluid. The dynamic vibration-absorption turning tool comprises a main vibration component and a magnetorheological dynamic vibration-absorption component, wherein the main vibration component is fixedly connected with a normal turning tool, and the magnetorheological dynamic vibration-absorption component is hung on the normal turning tool. The dynamic vibration-absorption turning tool is characterized in that the main vibration component and the magnetorheological dynamic vibration-absorption component are supported and connected by virtue of the magnetorheological fluid and roll balls, wherein the rigidity and damp of the magnetorheological can be changed under a magnetic field, the roll balls are mounted on key slots in two sides of a cutter bar shaft of the main vibration component, and the magnetorheological fluid is filled in a round disc magnetic pole, upper tank body, lower tank body and end cover of the magnetorheological dynamic vibration-absorption component as well as an axial gap between first and second disc-shaped iron cores of the main vibration component. According to the dynamic vibration-absorption turning tool, the magnetorheological fluid is used as a regulating-executing medium, and the parameters such as the damp and inherent frequency of the magnetorheological dynamic vibration-absorption component are changed in real-time and online manners by regulating the magnetic induction intensity aiming at vibration frequencies under different turning working conditions, so that the vibration energy in the turning tool of a main vibration system is maximally absorbed, and the turning vibration is effectively restrained.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

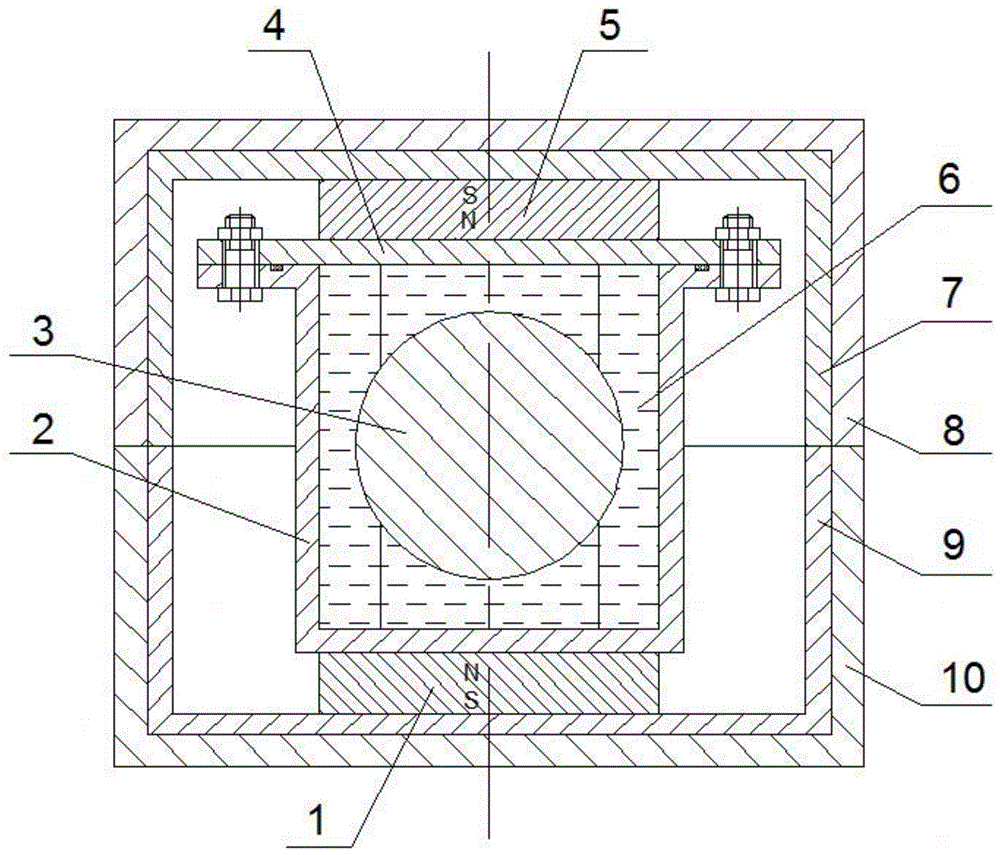

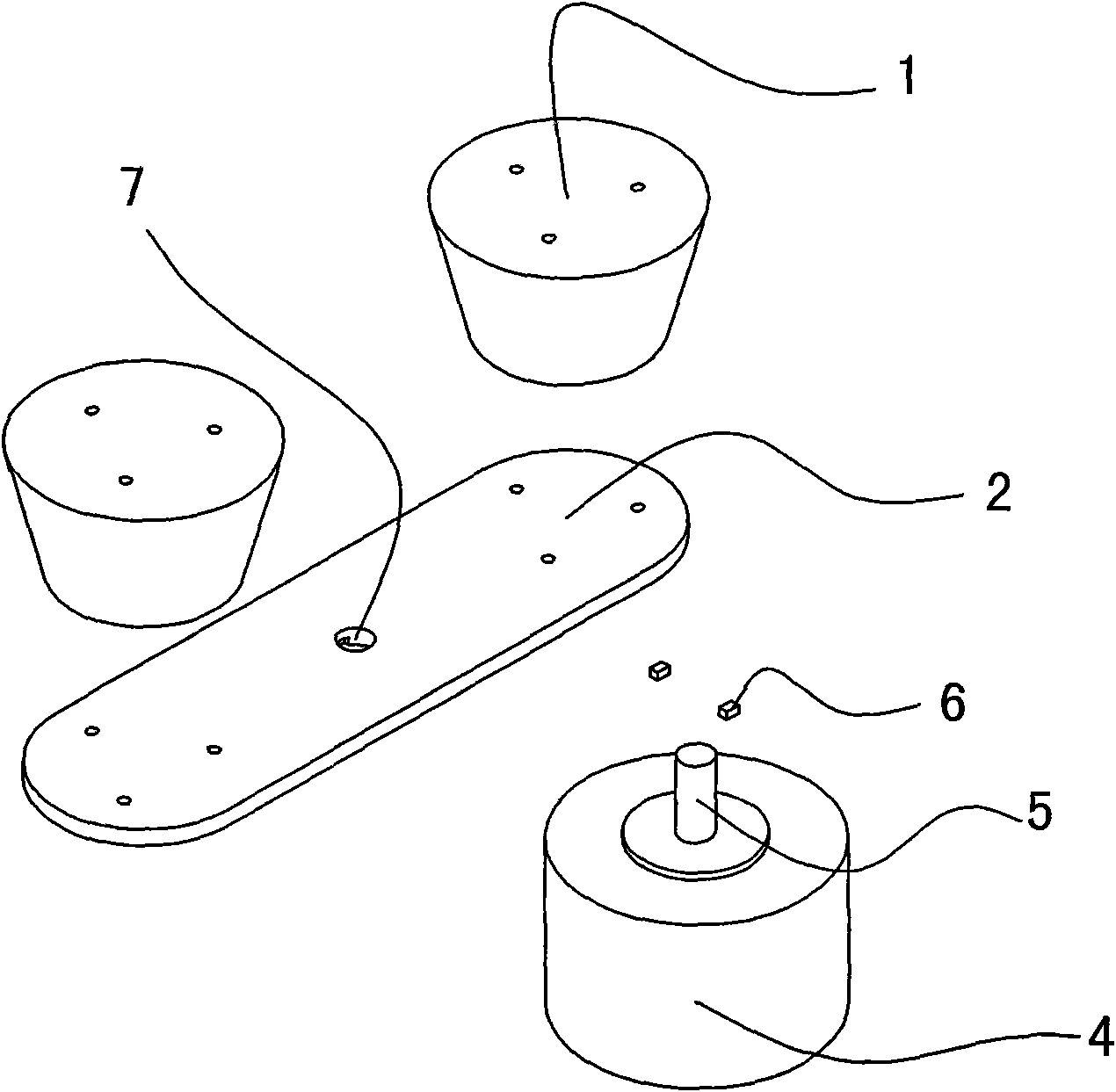

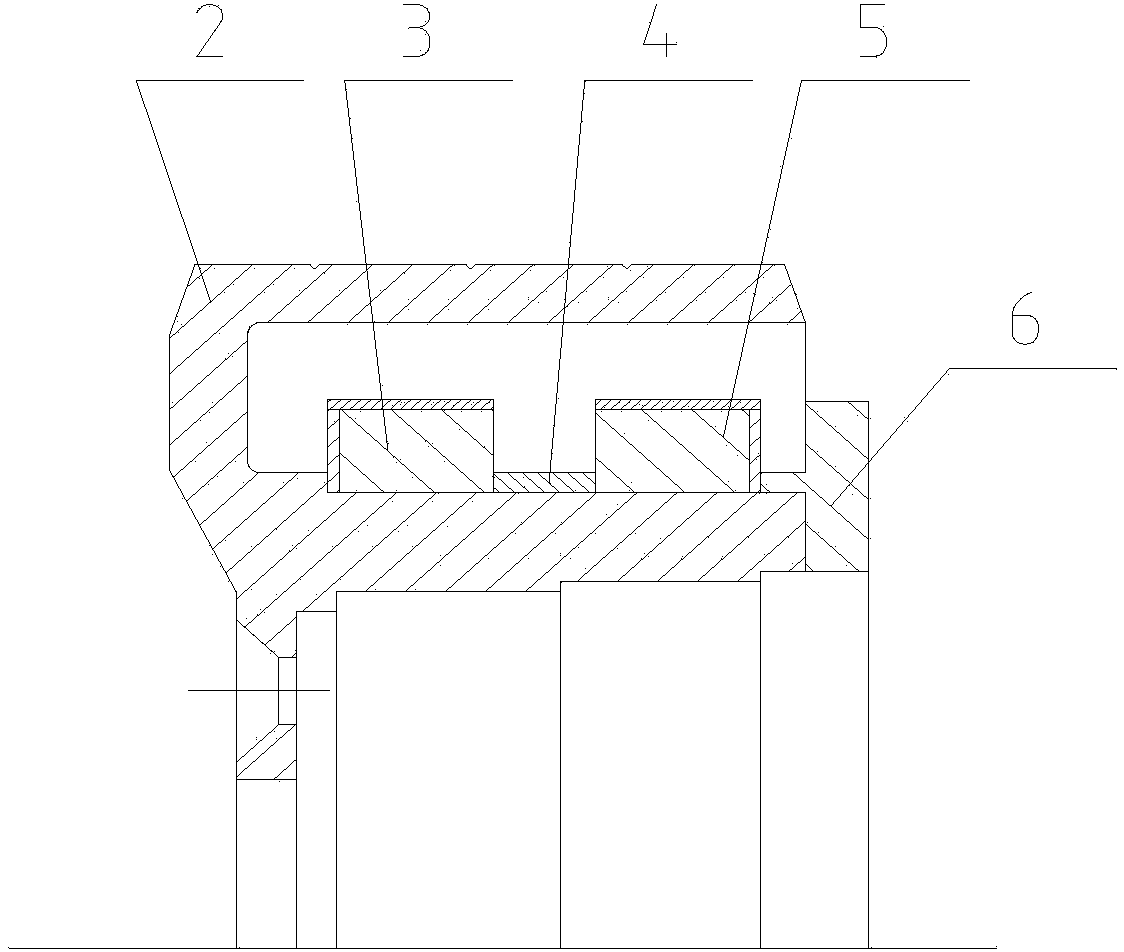

First-order buoyancy principle based magnetic liquid damping shock absorber with magnetic shielding covers

InactiveCN104948627ASuspension stabilityAvoid liquidityVibration dampersMagnetic springsStructural ProblemAbsorbed energy

The invention relates to a first-order buoyancy principle based magnetic liquid damping shock absorber with magnetic shielding covers, belongs to the field of mechanical engineering vibration, and successfully solves the problem that the existing magnetic liquid damping shock absorbers cannot be applied in engineering practice due to various structural problems. The absorber comprises a first permanent magnet (1), a housing (2), a mass (3), an end cap (4), a second permanent magnet (5), magnetic fluid (6), an upper magnetic inner sleeve (7), an upper magnetic shielding outer sleeve (8), a lower magnetic inner sleeve (9) and a lower magnetic shielding outer sleeve (10). When the external vibration occurs, a non-magnetic ball moves in a chamber, the magnetic fluid flows in a recess of the housing (2) to absorb energy, first-order buoyancy formed within the magnetic fluid by the first permanent magnet (1) and the second permanent magnet (5) allows frequency difference to be formed between the mass (3) and the housing (2), so that the maximum vibration damping efficiency is achieved, and the upper and lower magnetic shielding covers effectively prevent magnetic flux leakage of the permanent magnets.

Owner:BEIJING JIAOTONG UNIV

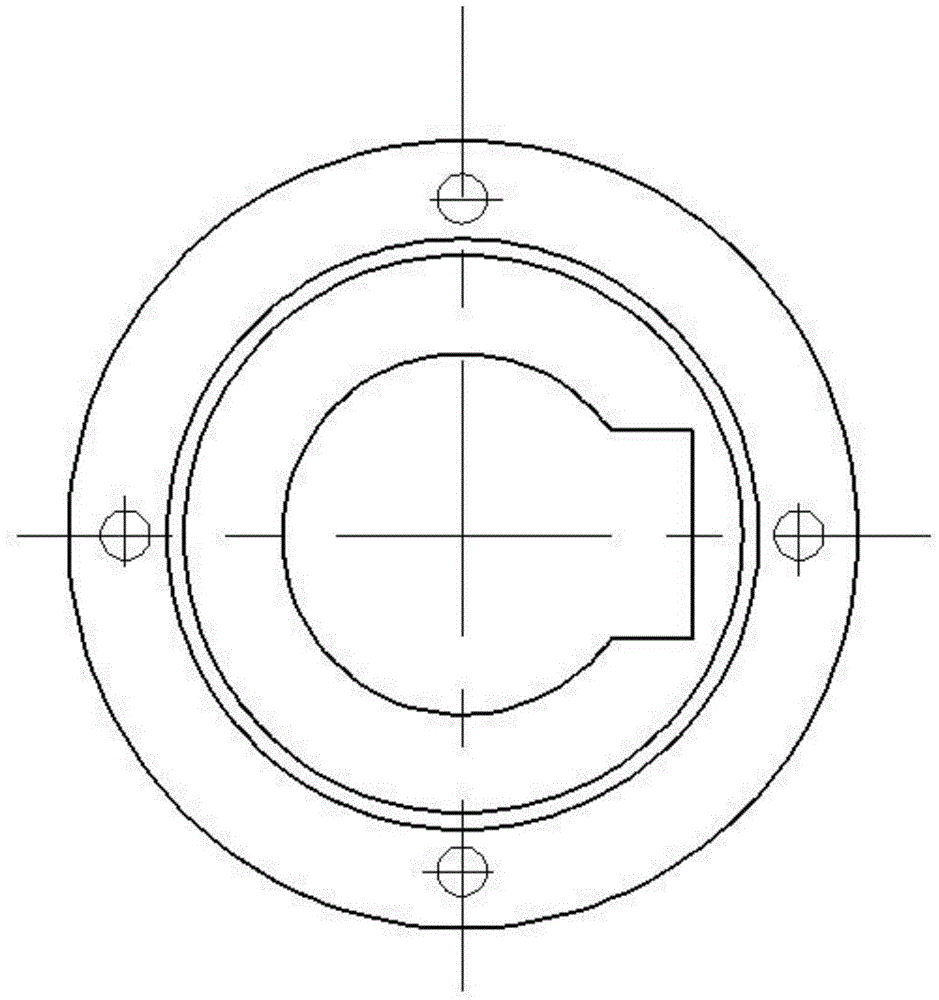

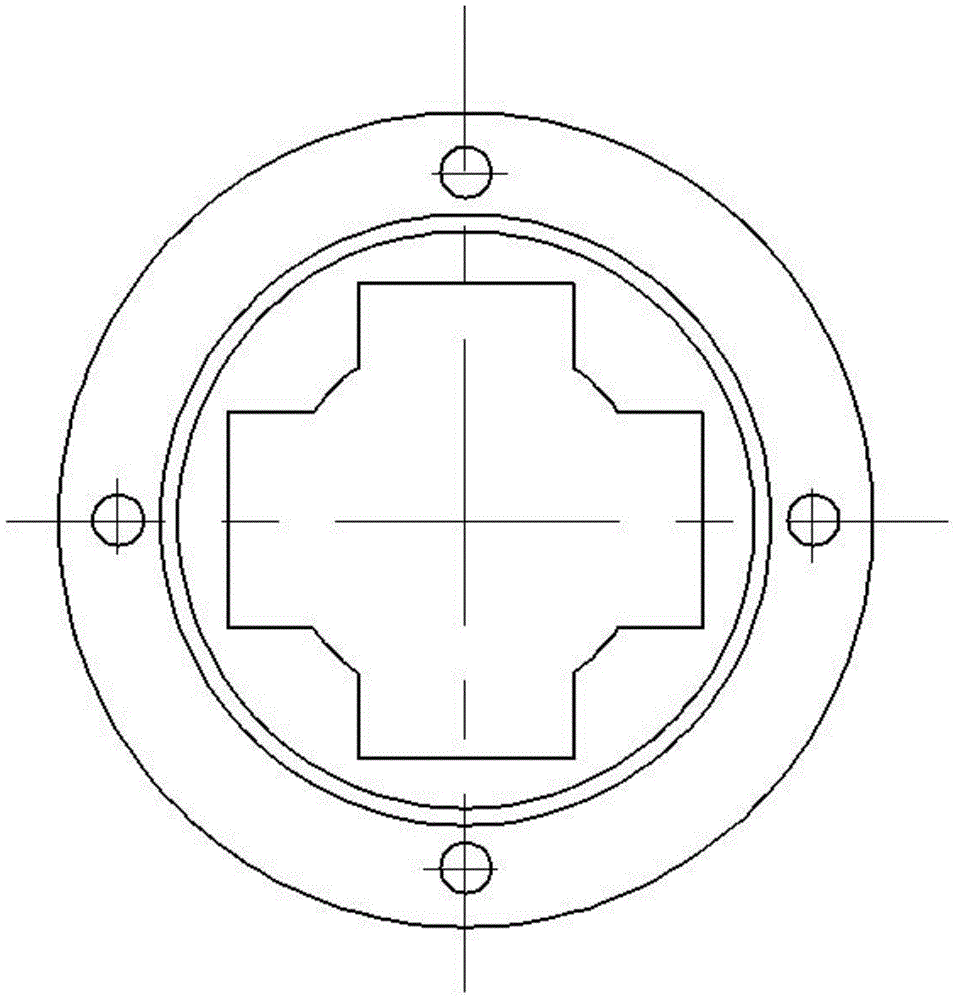

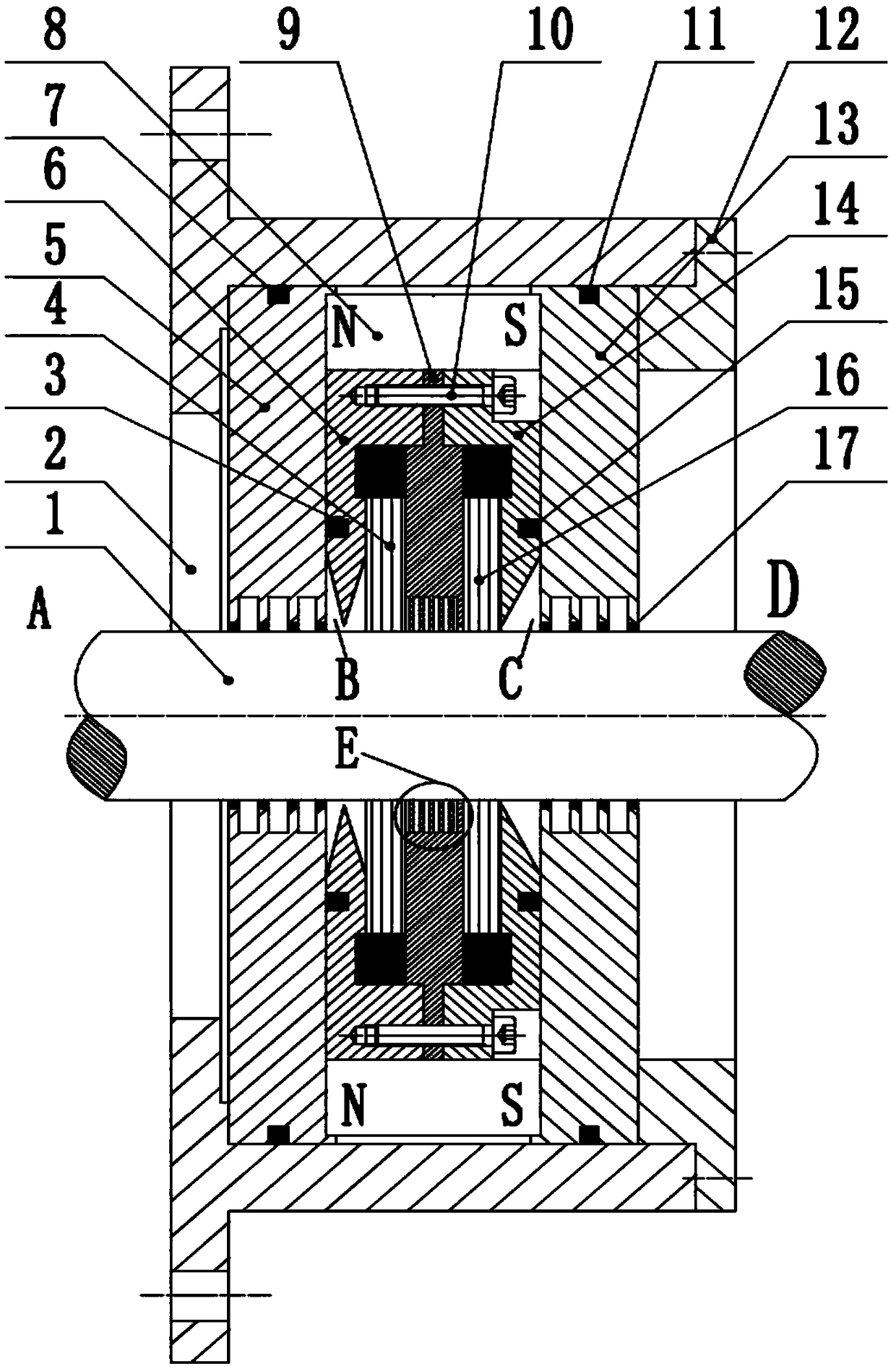

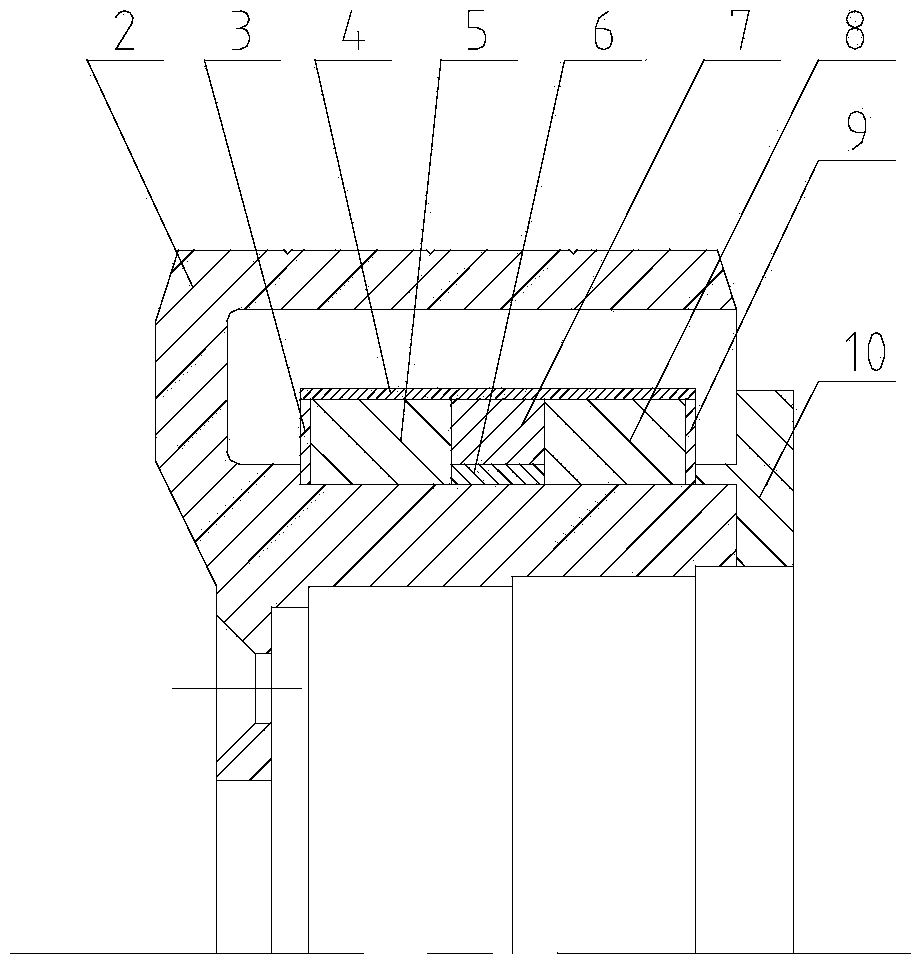

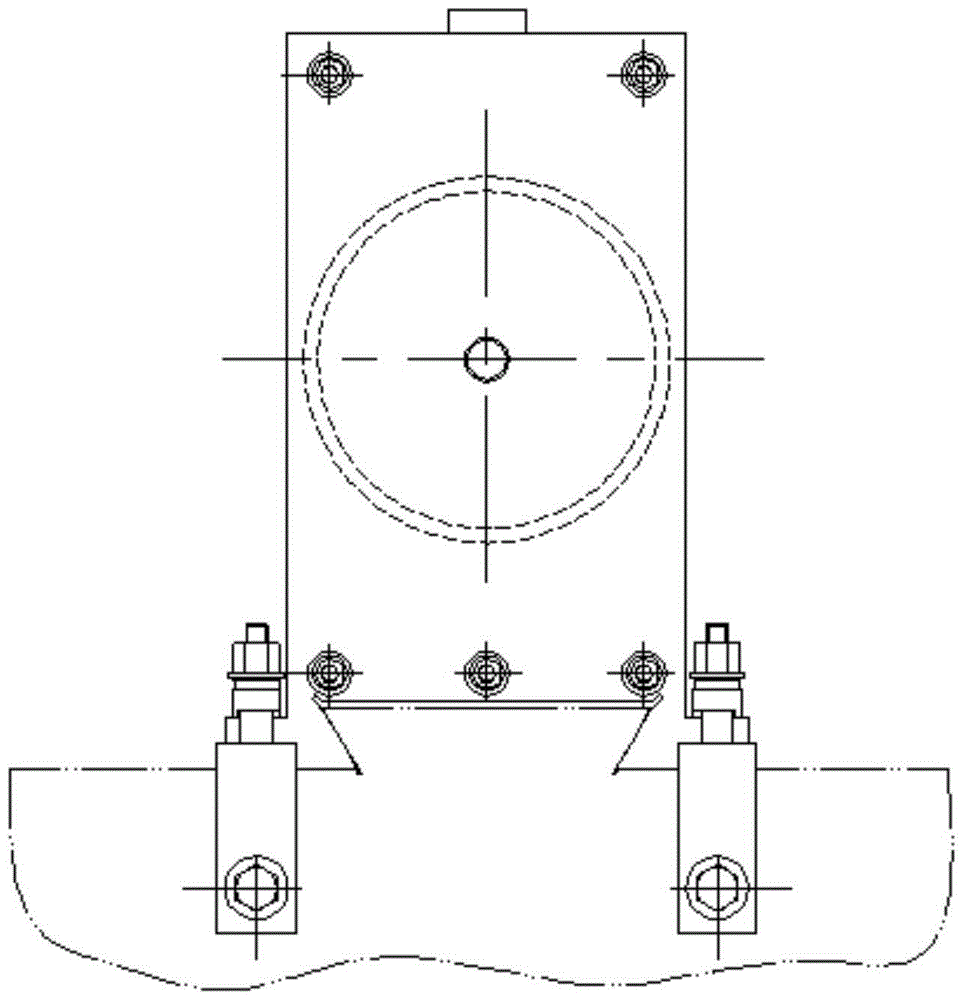

Magnetic liquid sealing and brush type sealing composite device

InactiveCN108953614AReduce magnetic flux leakageImprove work efficiencyEngine sealsEngineeringMagnetic liquids

The invention discloses a magnetic liquid sealing and brush type sealing composite device, and belongs to the field of mechanical engineering sealing. The composite device solves the problem that in the case of an existing magnetic liquid seal, under the condition that the pressure fluctuation of a sealing medium is large, after the pressure of the sealing medium exceeds the limit pressure resistance value of the magnetic liquid seal and efficiency is lost, a large number of sealing medium leaks. According to the magnetic liquid sealing and brush type sealing composite device, a front baffle plate (6), a middle baffle plate (9) and a rear baffle plate (14) are made of non-magnetic materials, so that the effect of magnetic isolation rings is achieved, and the flux leakage of a permanent magnet can be effectively reduced; a labyrinth sealing structure with flat teeth or high-low teeth is machined in the middle baffle plate (9), the height of a gap between the tooth top of each labyrinthsealing tooth of the middle baffle plate (9) and a rotating shaft is 0.15-0.3 mm, and labyrinth sealing can further prevent leakage of the sealing medium to the outside D; and in the case of the composite device, a gap between a left pole shoe (5) and a right pole shoe (13) is utilized, therefore, the axial length and the radial height of the sealing device are not increased, the impact resistanceand reliability of the magnetic liquid seal are improved, and the application range of the magnetic liquid seal is further expanded.

Owner:BEIJING JIAOTONG UNIV

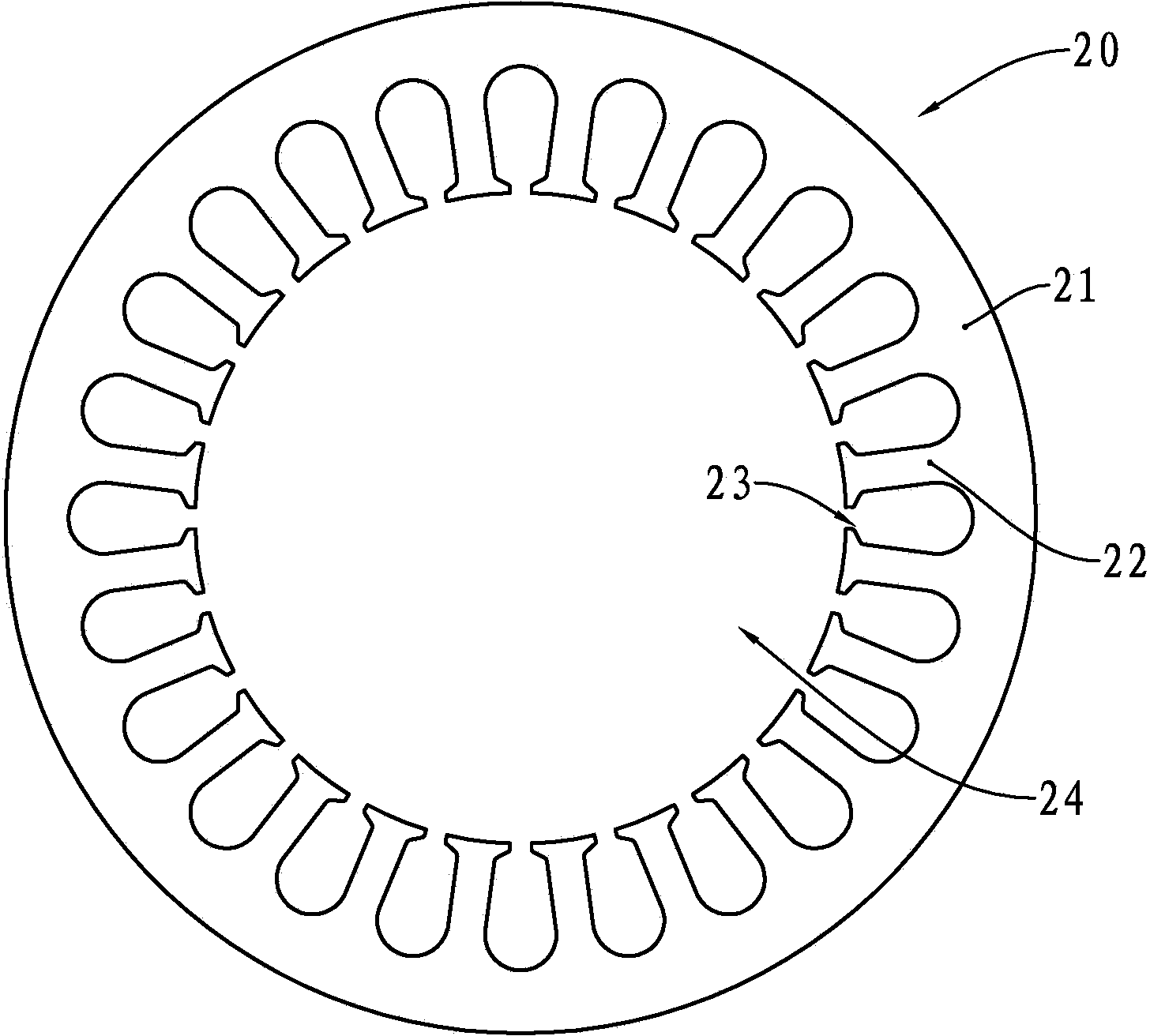

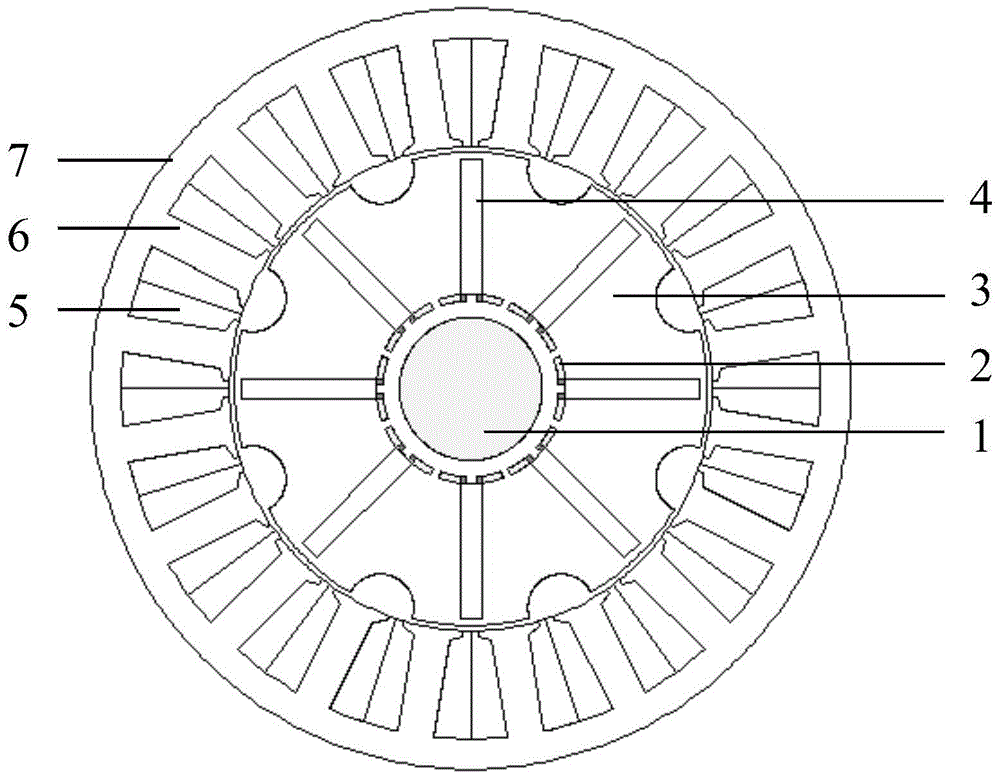

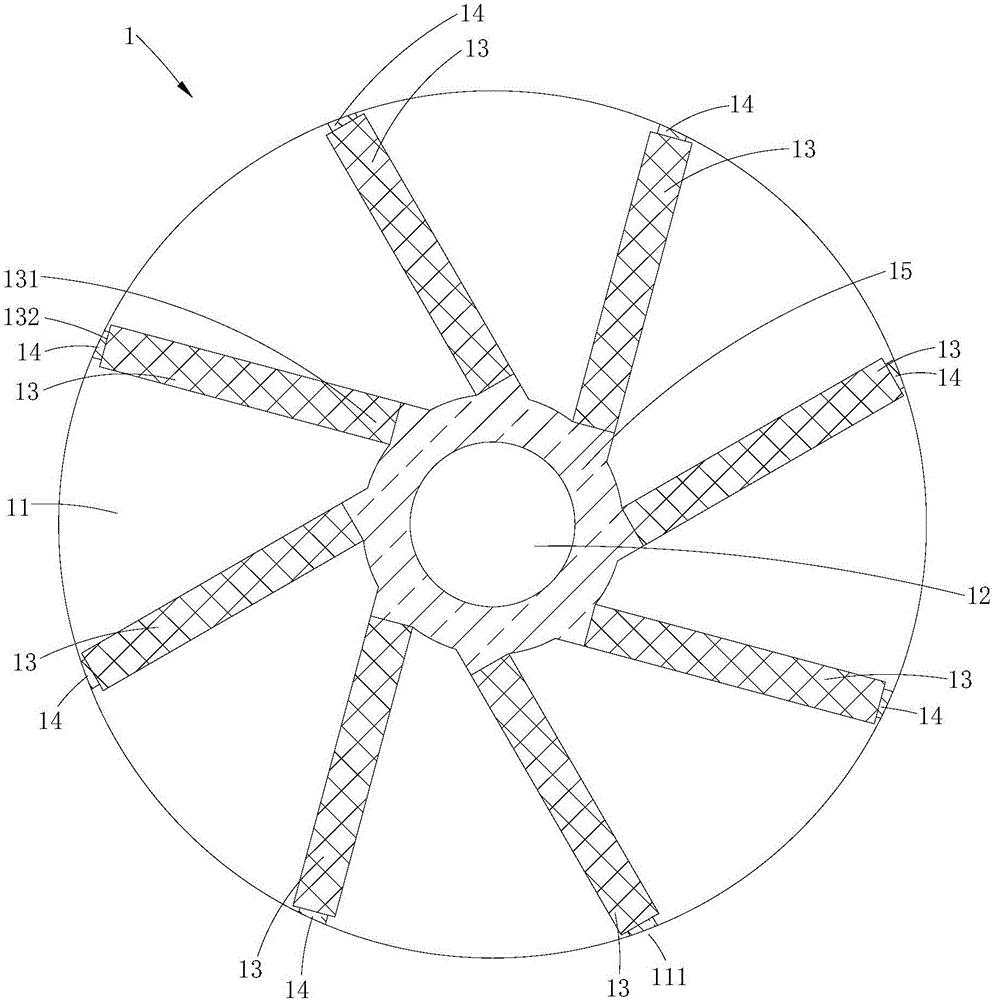

Stator punching piece, stator core and motor

InactiveCN103457365AAvoid breakingSimple structureMagnetic circuit stationary partsPunchingEngineering

The invention provides a stator punching piece, a stator core and a motor. The stator punching piece is provided with an annular yoke part and a tooth part detachably connected with the yoke part. The tooth part is located in the yoke part, a plurality of teeth are circumferentially arranged on the tooth part, tooth roots of every two adjacent teeth are connected through a bridge part, every bridge part is provided with an inner arc close to the circle center of the tooth part and an outer arc far away from the circle center of the tooth part, inner arcs of a plurality of bridge parts are located on a first circumference, outer arcs of the plurality of bridge parts are located on a second circumference, and the first circumference and the second circumference are concentric circles with the circle center of the tooth part serving as the circle center. The stator core is provided with a first tooth part formed by stacking the stator punching pieces. The motor is provided with a stator and a rotor, and the stator comprises the stator core. Flux leakage of the stator core can be reduced, breakage of the stator punching piece from the bridge parts is avoided, and quality of the stator punching piece is improved.

Owner:GREE ELECTRIC APPLIANCES INC +4

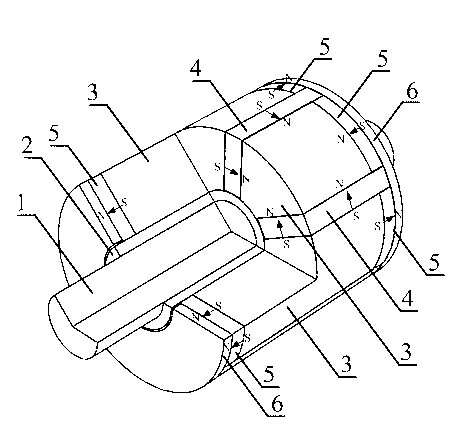

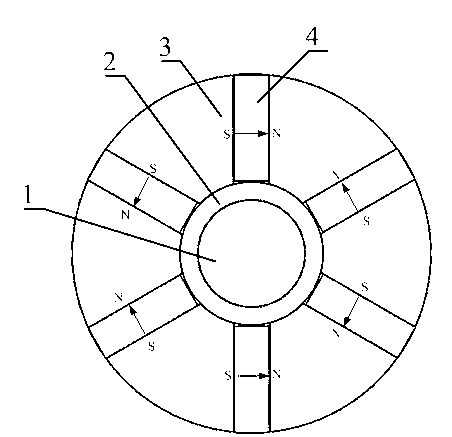

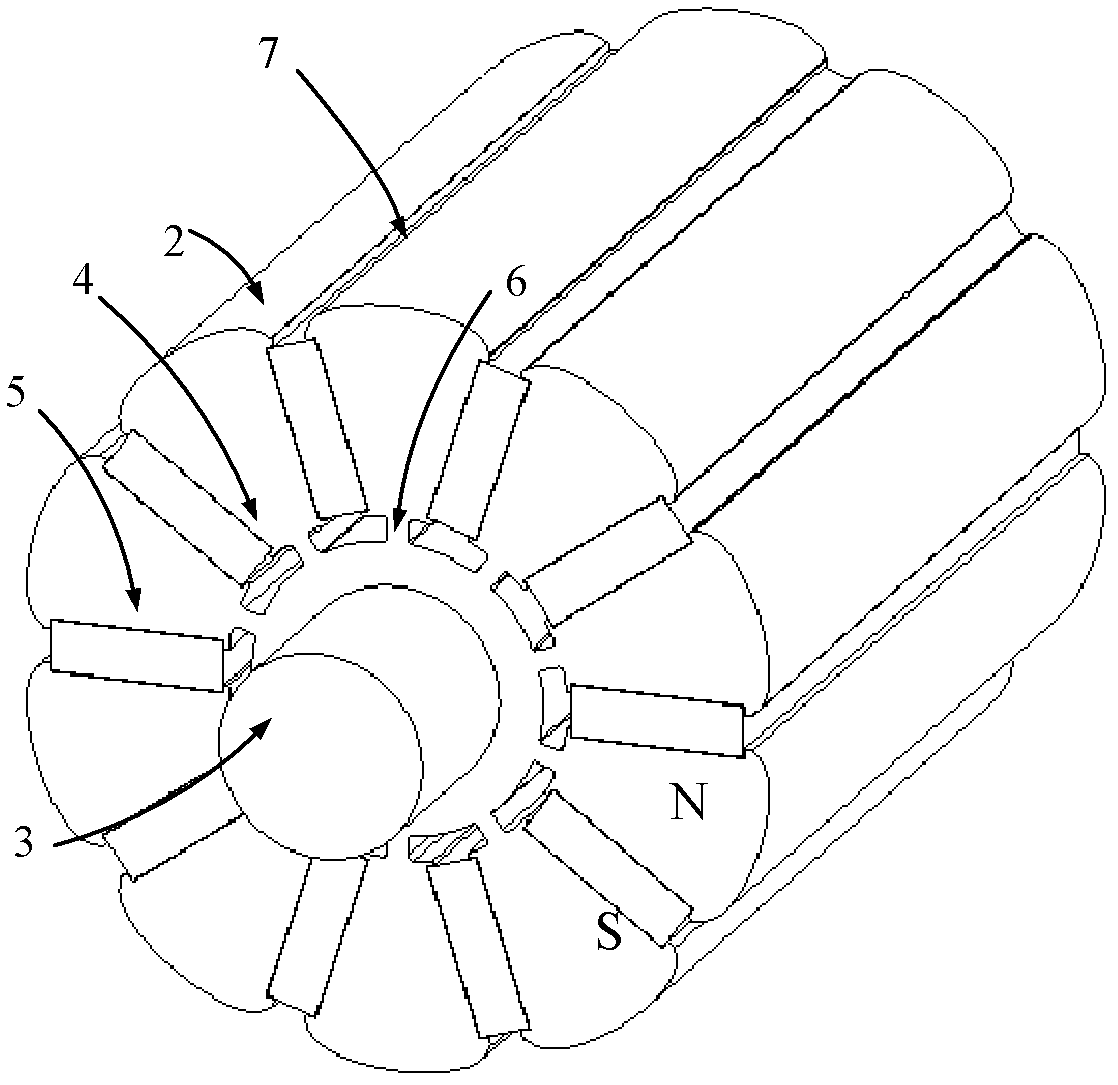

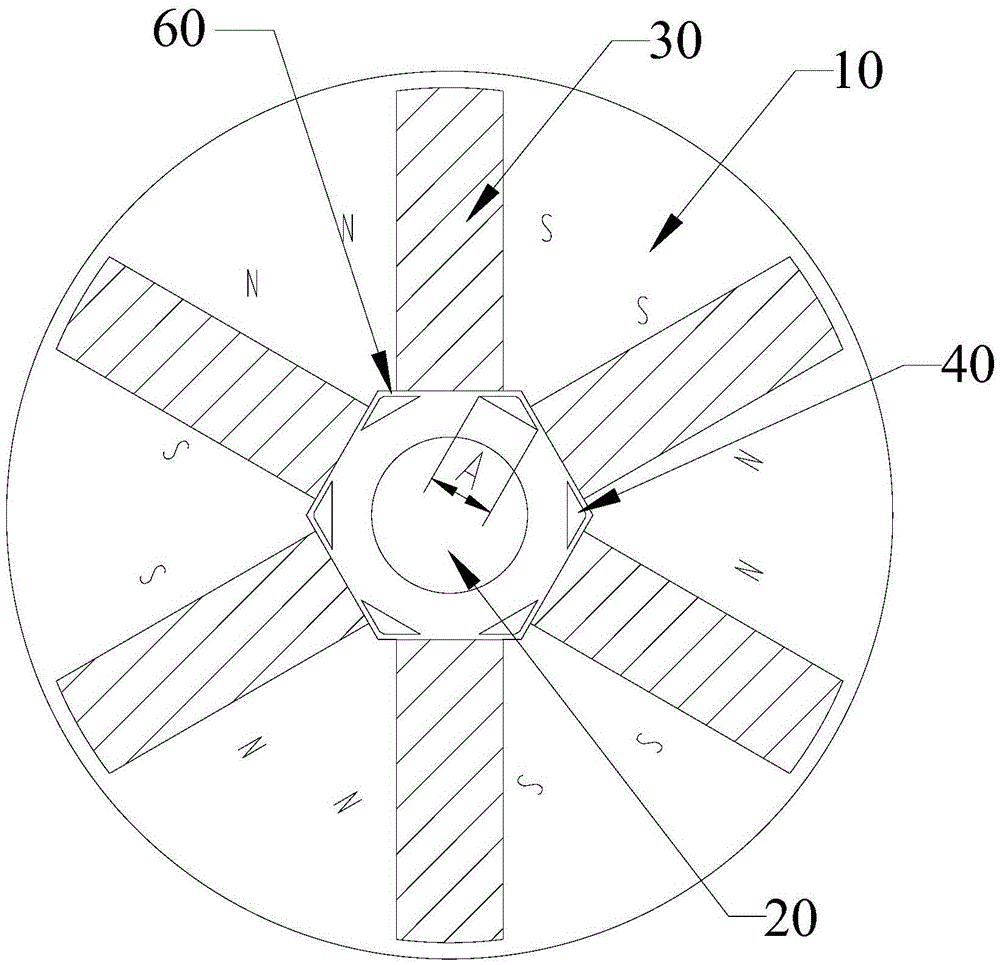

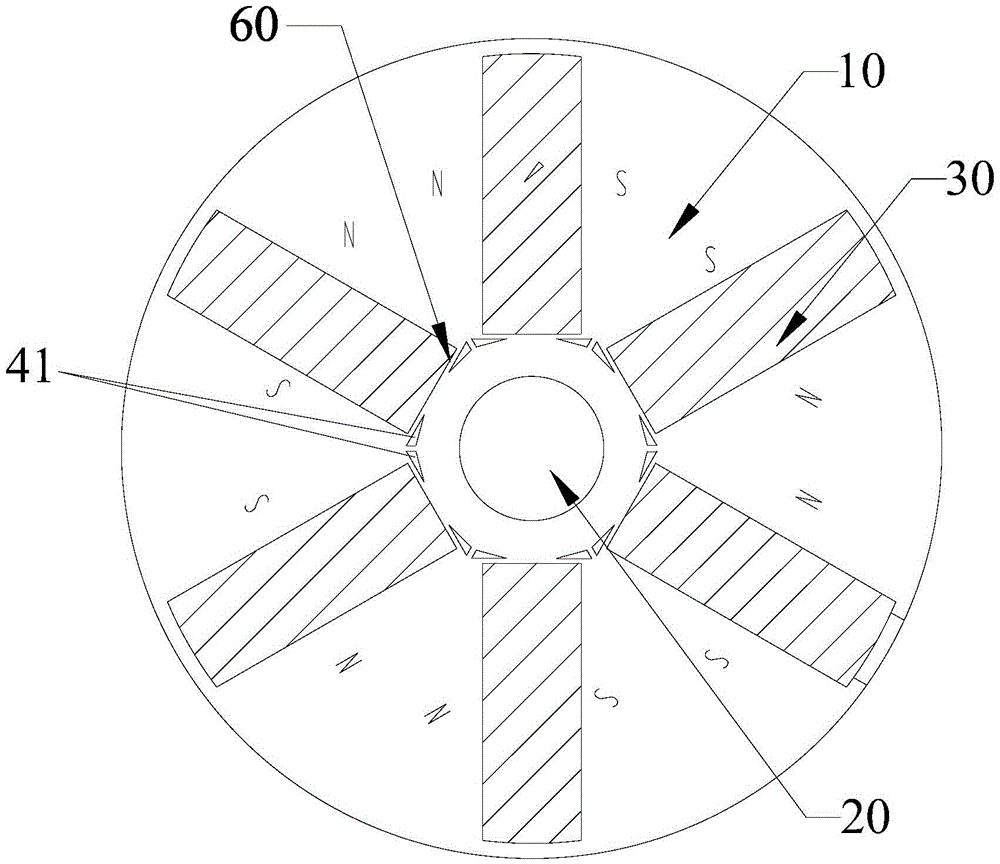

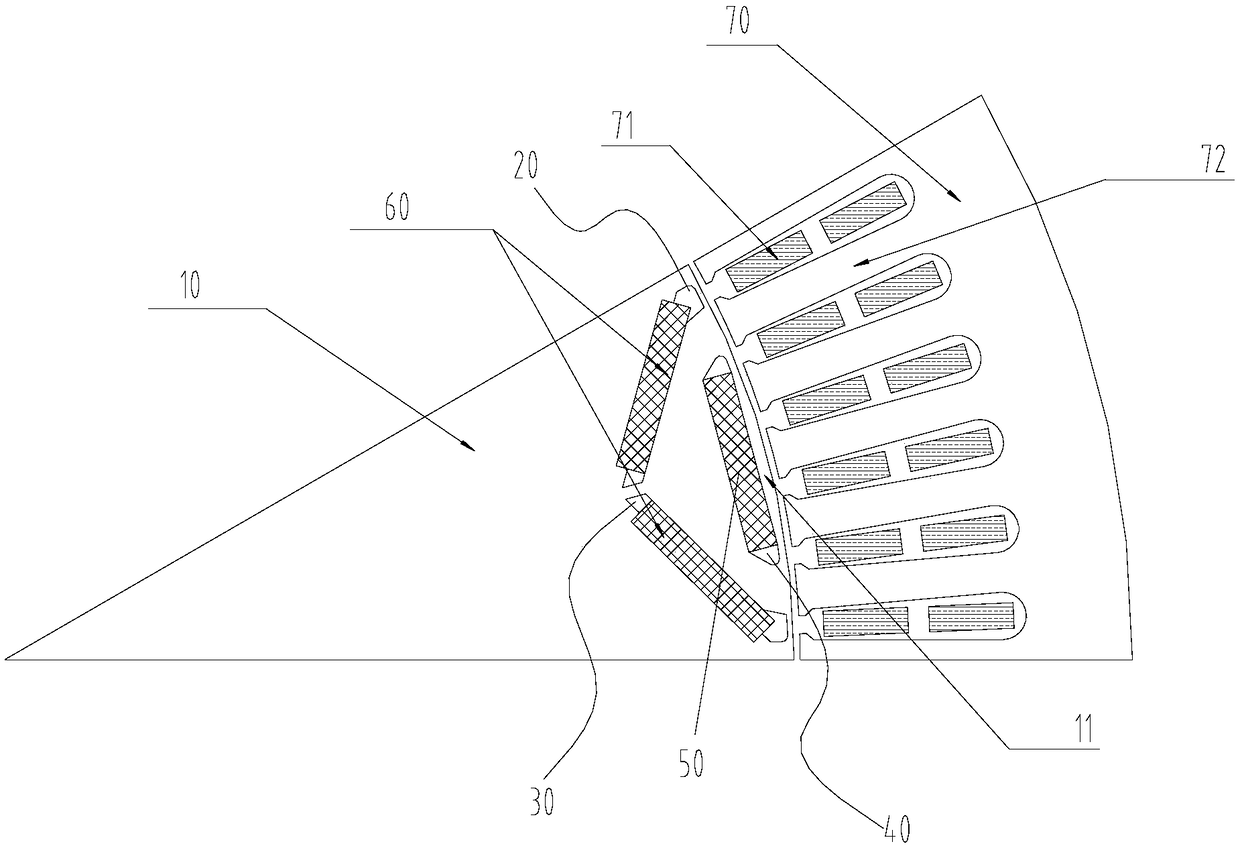

Tangential rotor for rotating motor

InactiveCN102545433AReduce magnetic flux leakageIncrease profitMagnetic circuit rotating partsElectric machineMagnetic poles

The invention discloses a tangential rotor for a rotating motor. The tangential rotor comprises rotor consisting of a revolving shaft and laminated iron cores, wherein a plurality of permanent magnetic pole parts which rotate along the axis of the revolving shaft and are magnetized along the circumferential direction of the rotor relative to the axis are arranged in the laminated iron cores; the permanent magnetic pole parts are embedded into the laminated iron cores through permanent magnetic grooves; one sides of the permanent magnetic grooves which are close to air gaps are connected with or disconnected from the laminated iron cores; the spacing circumferential widths among one sides of the permanent magnetic grooves which are close to the revolving shaft are 0.1-5 millimeters; the polarities of adjacent permanent magnetic pole parts are reverse; and the spacing circumferential widths among one sides of the permanent magnetic grooves which are close to the revolving shaft are 0.4-3 millimeters. In the tangential rotor, the permanent magnetic grooves for embedding the permanent magnetic pole parts are formed on the laminated iron cores, and the polarities of adjacent permanent magnetic parts are reverse, so that the structure is simple and reasonable, the phenomenon of magnetic leakage of a magnet can be avoided, the utilization ratio of the magnet is increased, the problem that the revolving shaft is made of a stainless steel material or a magnetic insulating copper sleeve is solved, and the manufacturing cost is effectively lowered.

Owner:MIDEA WELLING MOTOR TECH SHANGHAI

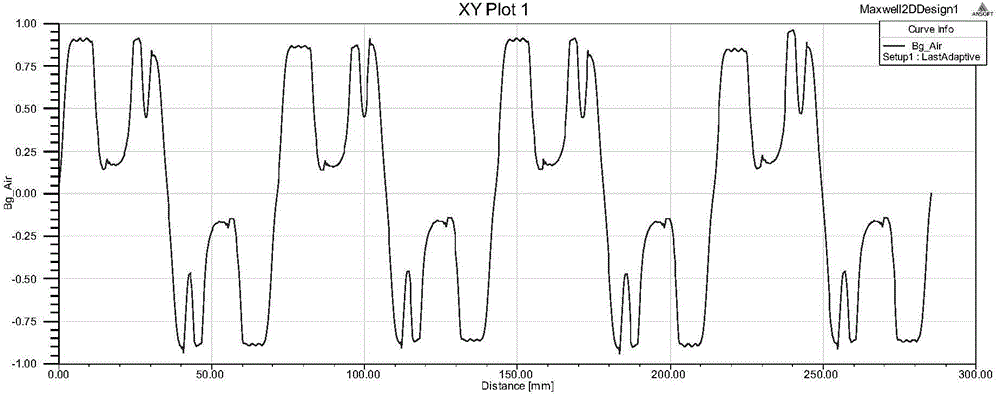

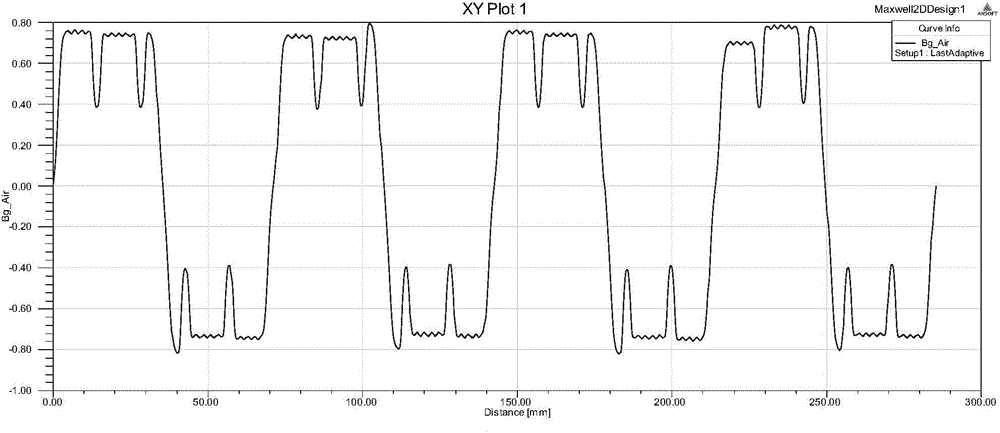

Five-phase permanent magnet synchronous motor with high torque density

InactiveCN104883017AIncreased third harmonic contentImprove utilizationMagnetic circuit rotating partsSynchronous machines with stationary armatures and rotating magnetsPermanent magnet synchronous motorPermanent magnet synchronous generator

The invention discloses a five-phase permanent magnet synchronous motor with high torque density. A motor body comprises a stator and a rotor, wherein the stator comprises a stator core and a five-phase fractional slot concentrated winding; and the stator comprises a slotted rotor core and built-in permanent magnets. The outer side of the rotor is provided with grooves which are alternatively arranged along the circumferential direction. The motor disclosed by the invention has the characteristics that the appropriate groove width is selected, and a third-harmonic air gap magnetomotive force can be increased, so that characteristics of a five-phase permanent magnet motor are sufficiently used, that is, fundamental current and third-harmonic current can be injected into the stator winding simultaneously, thereby increasing the current control freedom degree, improving the motor torque density and also being capable of reducing the motor magnetic field saturation.

Owner:SHANDONG UNIV

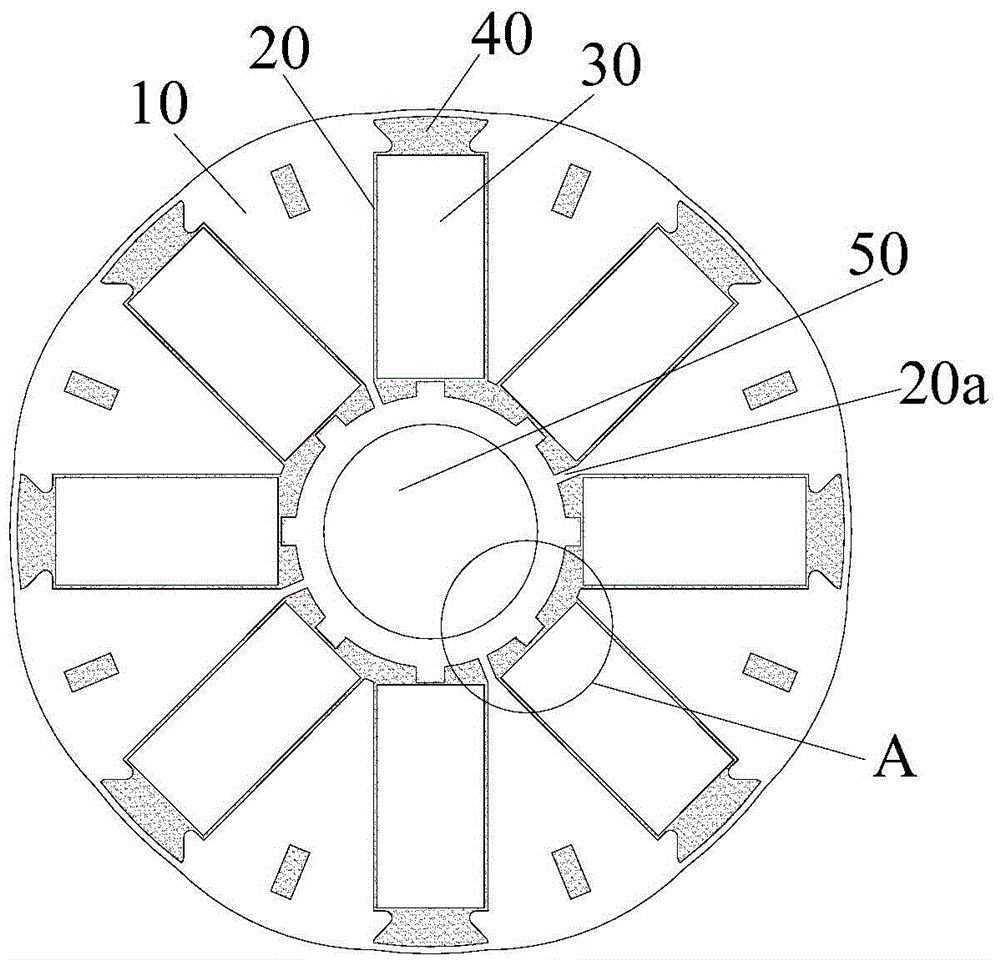

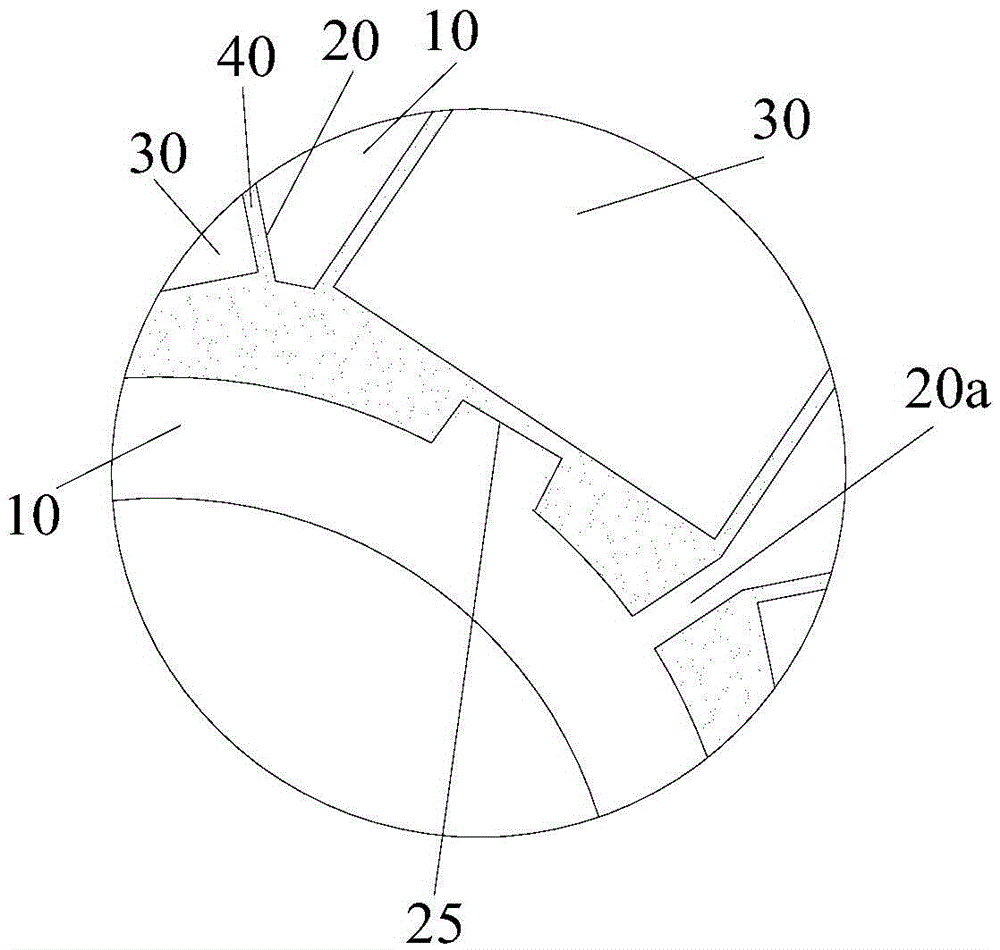

Rotor and motor

ActiveCN105071569ASimple structureReduce Flux LeakageMagnetic circuit rotating partsRotor fluxEngineering

The invention is suitable for the field of motors, and discloses a rotor and a motor. The rotor comprises a rotor core, a rotating shaft passing through the center of the rotor core, and a plurality of magnet steels which are embedded in the rotor core at intervals in a circumferential direction. The rotor core is provided with a plurality of magnet steel grooves which are used for the storage and positioning of the plurality of magnet steels. Each magnet steel is provided with an inner end close to the rotating shaft, and an outer end far from the rotating shaft. The rotor core is also provided with a plurality of outer magnetic bridge gaps which extend from the edge of the rotor core to the outer ends of the magnet steels in a concave manner. The rotor gets rid of a magnetic isolation sleeve, thereby effectively simplifying the structure of the rotor and the assembly technology of the rotor. Meanwhile, the outer edge of the rotor core is additionally provided with the outer magnetic bridge gaps, thereby opening an outer magnetic bridge of the rotor core, enabling more magnetic chains of the magnet steels to pass through a stator winding linkage, reducing the magnetic leakage of the rotor, greatly improving the effective utilization rate of the magnetic flux of the rotor, and finally achieving a purpose of improving the output capability of the motor.

Owner:GUANGDONG WELLING ELECTRIC MACHINE MFG +1

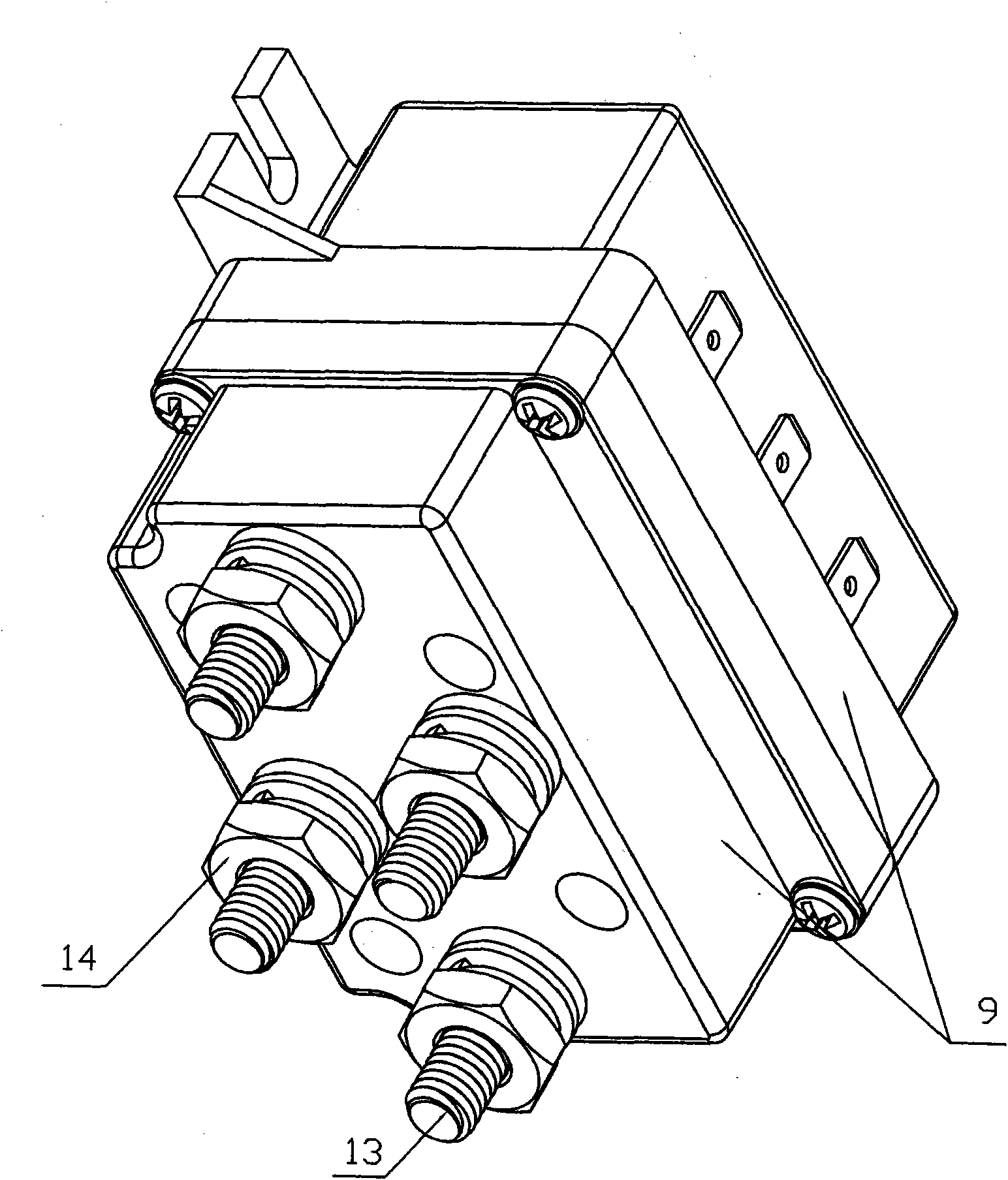

Reversing contactor

ActiveCN101976635AReduce magnetic flux leakageReduce magnetic lossElectromagnetic relay detailsNon-polarised relaysEngineeringElectromagnetism

The invention discloses a reversing contactor, which is composed of an electromagnetic construction member, a movable contact bridge construction member (8), an upper contact bridge (10), a lower contact bridge (11), a curve contact bridge (12), a curved bridge stud (13), a reset spring (15) and a shell (9), wherein, the electromagnetic construction member comprises an iron core (1), a coil (2) and a lower magnet conducting plate (3), wherein, a magnet conducting outer ring (4) is arranged at the periphery of the coil (1); the magnet conducting outer ring (4) and the lower magnet conducting plate (3) surround the coil (2) and the iron core (1) in a U-shaped square manner; and an upper magnet conducting plate (5) is arranged above the coil (1). The upper magnet conducting plate, the magnetconducting outer ring and the lower magnet conducting plate wholly encase the coil and the iron core in a full surround type, so as to lead the coil and the iron core to have less leaked magnetism quantity and less magnetic loss when in operation, thereby improving the utilization of the electromagnetism, and promoting the quality of the product.

Owner:RUIAN ZHIGUANG ELECTRIC CO LTD

Sounding device

ActiveCN110166907AAvoid damageImprove the vibration effectElectrical transducersLoudspeakersSound productionEngineering

The invention relates to a sounding device. The device has a first shell provided with a first accommodating space, a first magnet contained in the first shell, a second shell oppositely arranged in aspaced mode, the second shell being provided with a second containing space, an elastic piece connected with the first shell and the second shell and elastically supporting the first shell, and a second magnet and a coil contained in the second shell. The second shell comprises a bottom wall and a magnetic conductive column which extends from the center of the bottom wall to the direction of thefirst shell and is located in the second containing space, the coil is coupled to the magnetic conductive column, and the second magnet is arranged on the peripheral side of the coil. The sounding device has the beneficial effects that the integration of the sound production device with other equipment and structures is realized, the structure is simple, and the manufacturing cost is low.

Owner:AAC MICROTECH CHANGZHOU

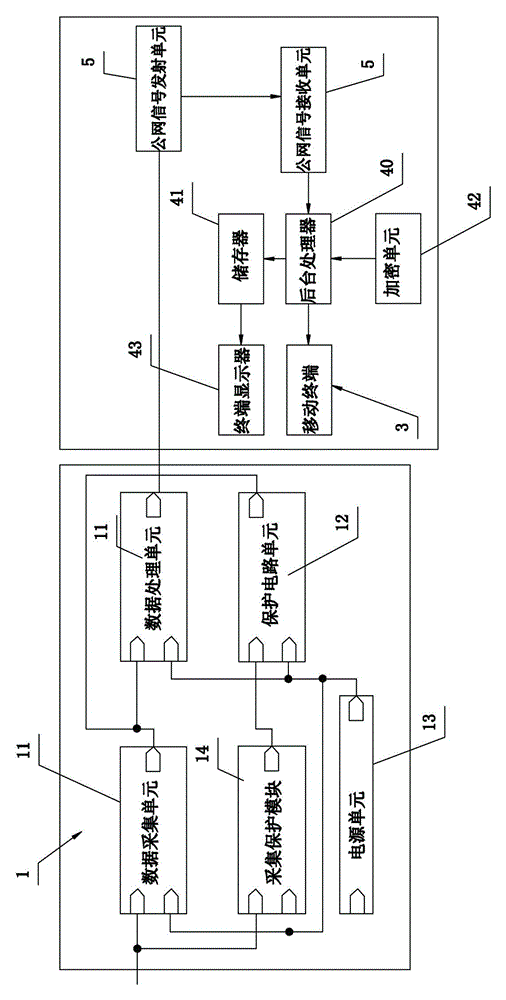

Ultrahigh voltage DC arrester state detection device with Hall sensor acting as framework

ActiveCN105182044AGuaranteed uptimeImprove pressure resistanceCurrent/voltage measurementCurrent sensorData treatment

The invention provides an ultrahigh voltage DC arrester state detection device with a Hall sensor acting as a framework. The ultrahigh voltage DC arrester state detection device comprises a data acquisition unit, a data processing unit, a protection circuit unit and a power supply unit. The data acquisition unit comprises a current sensor, a power amplifier and a circuit acquisition module. The current sensor comprises an annular shell, a magnetic core which is arranged in a C shape, and two Hall circuit modules. A first coil winding and a second coil winding are respectively wound on the magnetic core, and the magnetic core is installed in an accommodating space. An electrical bridge is connected between the two Hall circuit modules. The magnetic flux density direction generated by the second coil winding is opposite to the magnetic flux density direction of the first coil winding. Double Hall circuit modules are adopted to acquire arrester leakage current so that nonlinearity and position error of the sensor can be greatly reduced, and anti-interference capability and the scope of measuring range of the sensor can be enhanced.

Owner:RED PHASE INC

Permanent magnet rotor and permanent magnet motor

InactiveCN105490415AReduce demagnetizationReduce riskMagnetic circuit rotating partsPermanent magnet rotorElectric machine

The invention discloses a permanent magnet rotor and a permanent magnet motor. The permanent magnet rotor comprises a rotor core and a rotating shaft positioned in middle of the rotor core, wherein multiple mounting grooves distributed in a radial direction of the rotor core are formed in the rotor core; a permanent magnet is mounted in each mounting groove; multiple flux-insulation grooves are formed in the regions, between the rotating shaft and the corresponding permanent magnets, of the rotor core; each flux-insulation groove is formed between two adjacent permanent magnets; and flue-insulation bridges are formed in the parts, between the corresponding flux-insulation grooves and the corresponding groove bottoms, close to the rotating shaft, of the adjacent mounting grooves, of the rotor core. The problems of degradation of motor performance, excitation loss of the permanent magnets and impossibility of motor operation caused by the reason that the parts, close to the rotating shaft, of the permanent magnets cannot be fully magnetized to reach a saturated state in the prior art are effectively solved by the permanent magnet rotor and the permanent magnet motor.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

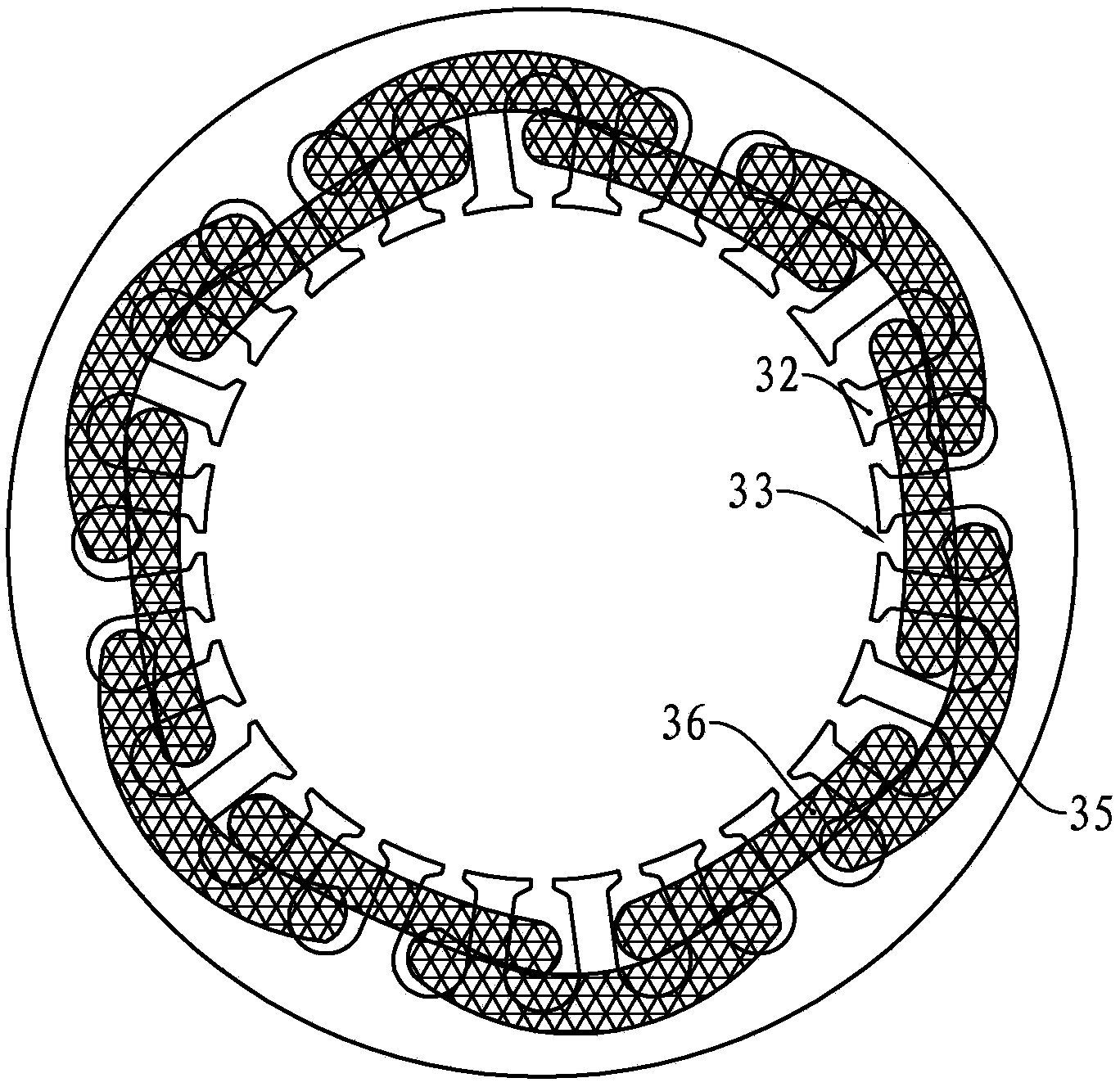

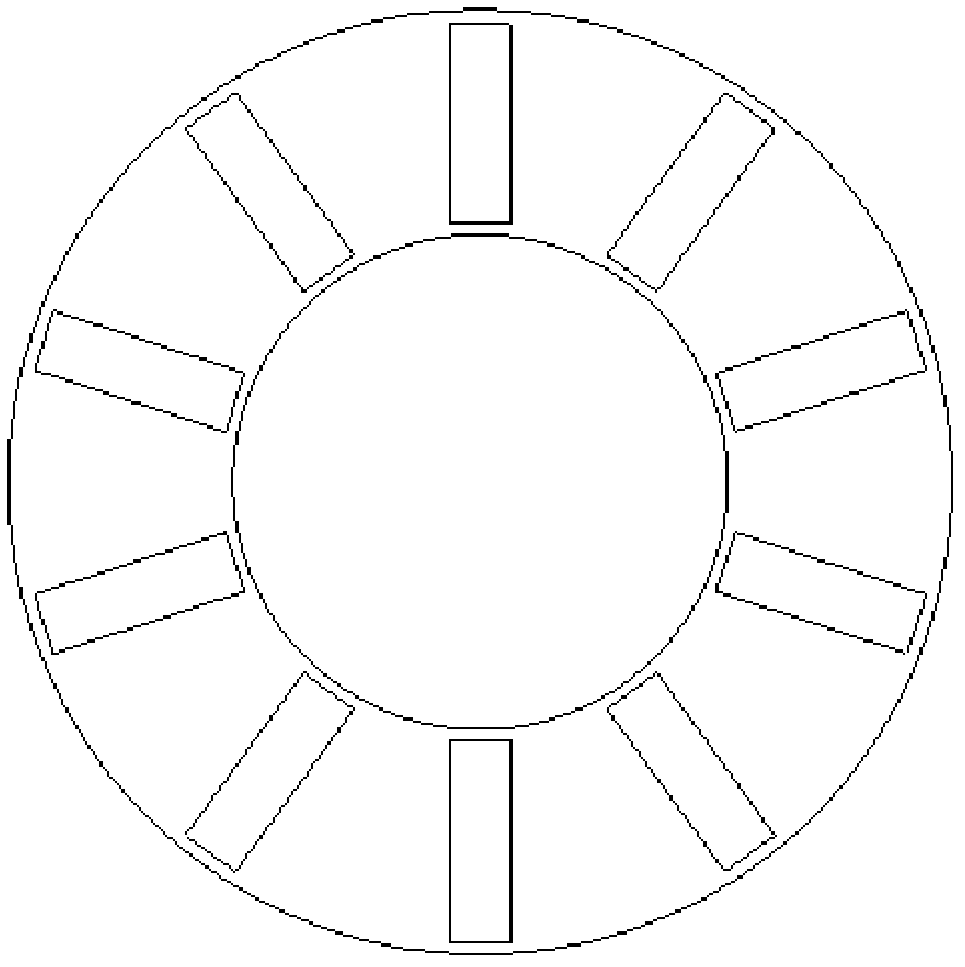

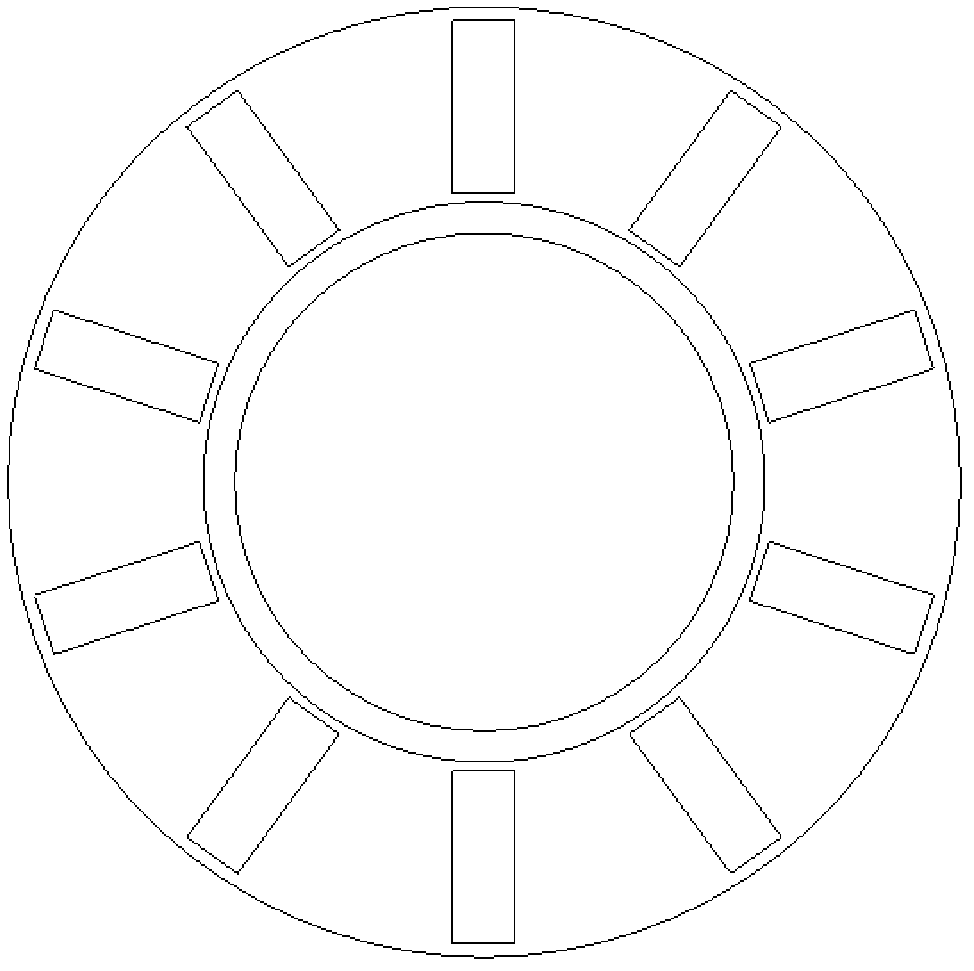

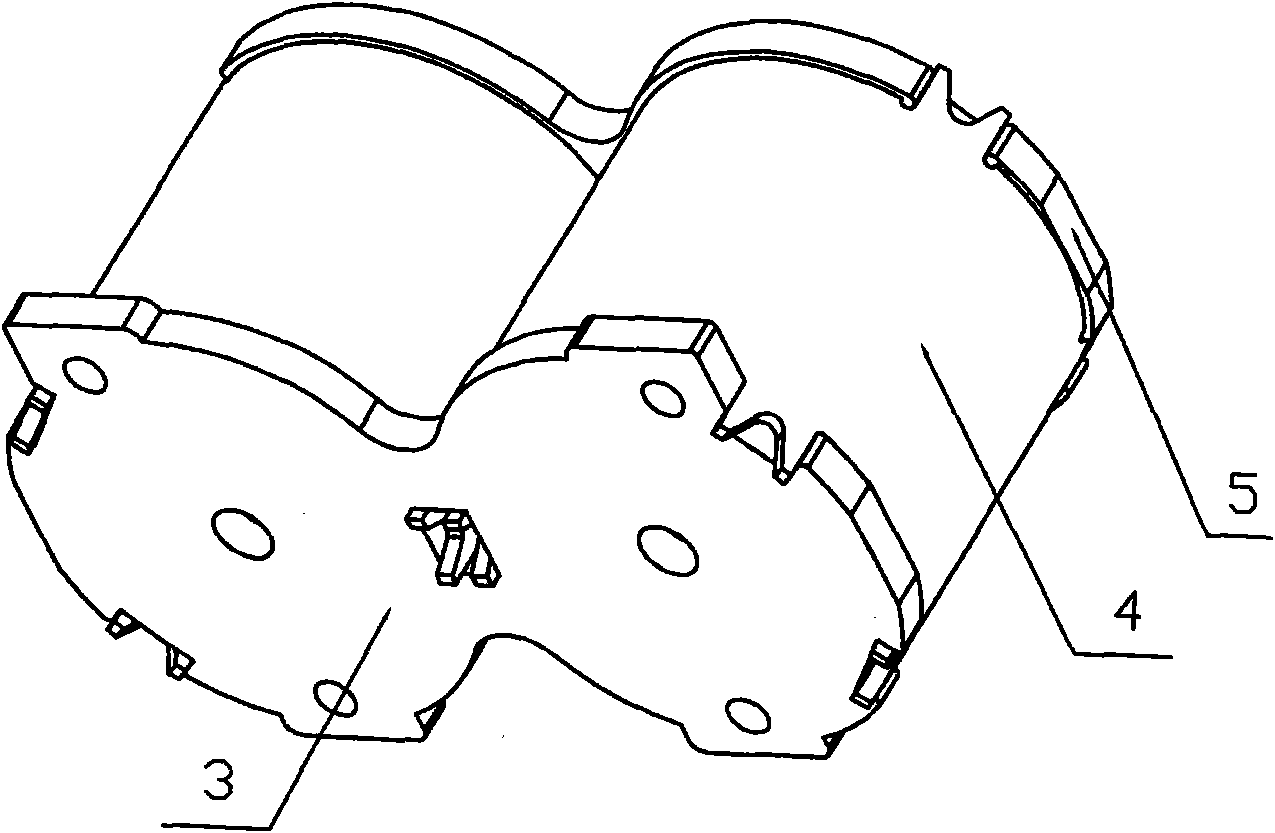

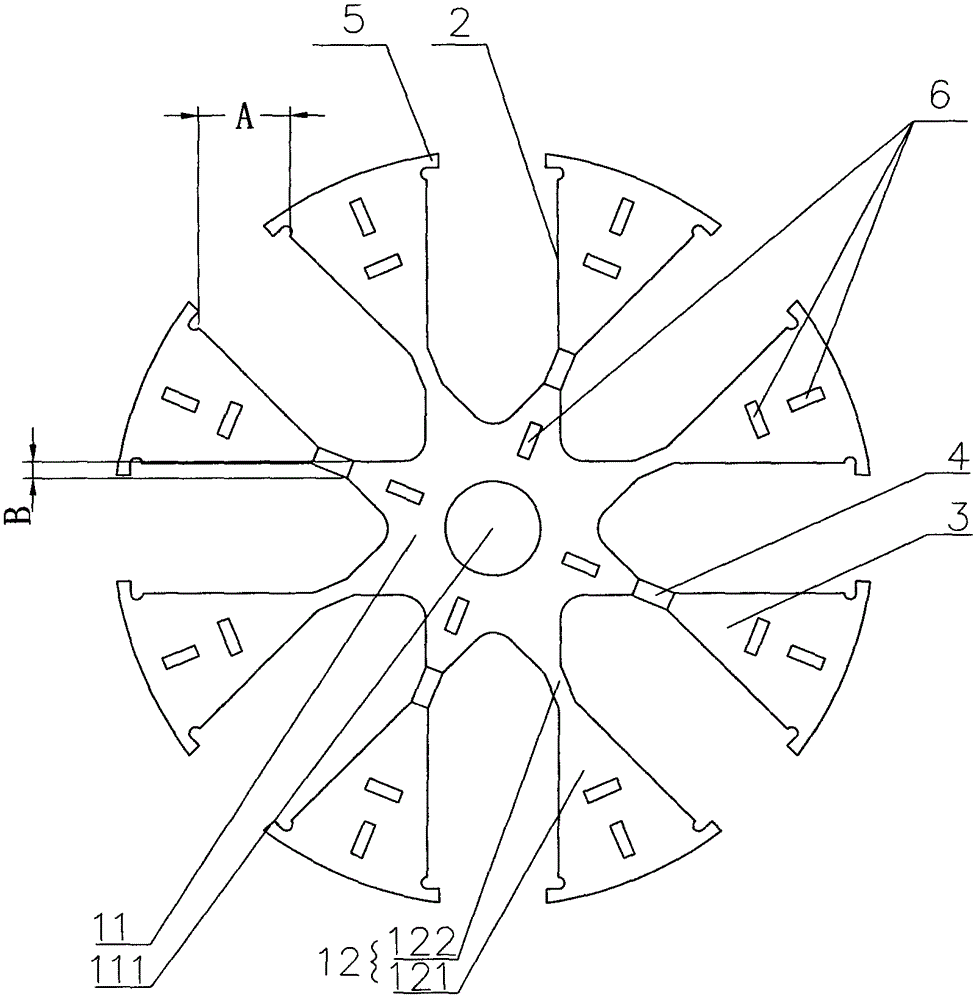

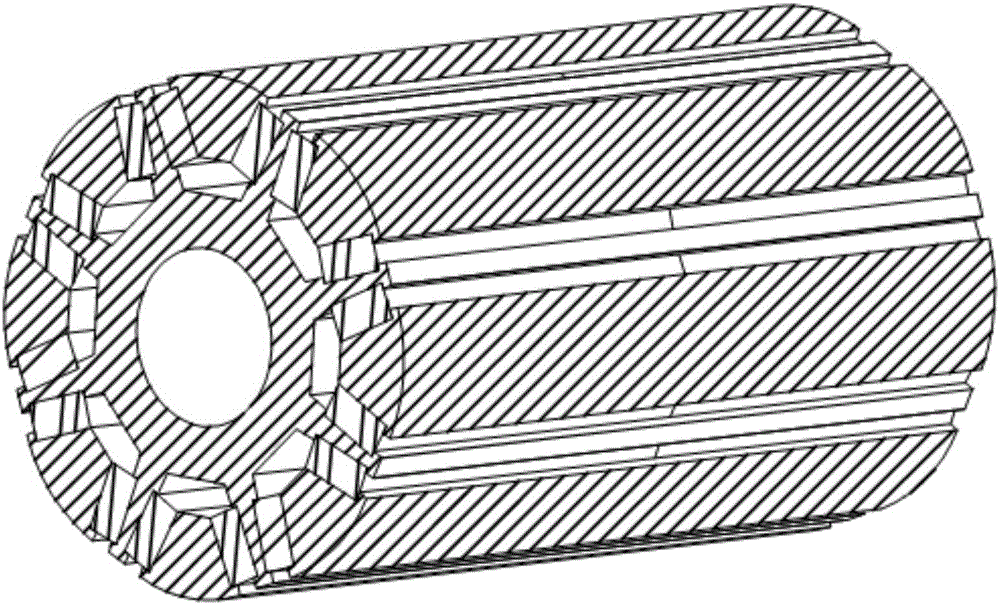

Rotor core of brushless motor

PendingCN105871096AImprove efficiencyReduce the temperatureMagnetic circuit rotating partsManufacturing stator/rotor bodiesBrushless motorsMagnetic flux leakage

The invention discloses a rotor core of a brushless motor and belongs to the field of motors. The rotor core of the brushless motor solves the technical problem that the magnetic flux leakage phenomenon of a rotor of a brushless motor in the prior art is serious, and comprises a core body. The core body comprises laminated rotor stamped sheets. Each rotor stamped sheet comprises a body, core sheets arranged at intervals in the circumferential direction of the body, and splicing blocks located between the adjacent core sheets, wherein magnetic shoe grooves are formed between the splicing blocks and the core sheets, and the splicing blocks and the body are spaced to form broken bridges. Besides, for every two adjacent rotor stamped sheets, the core sheets on the lower layer rotor stamped sheet are located under the splicing blocks on the upper layer rotor stamped sheet.

Owner:浙江希尔富电气股份有限公司

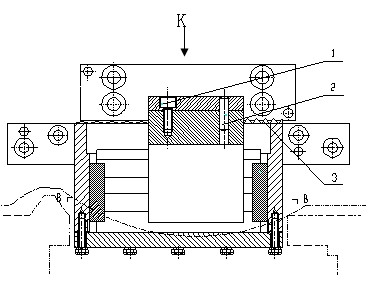

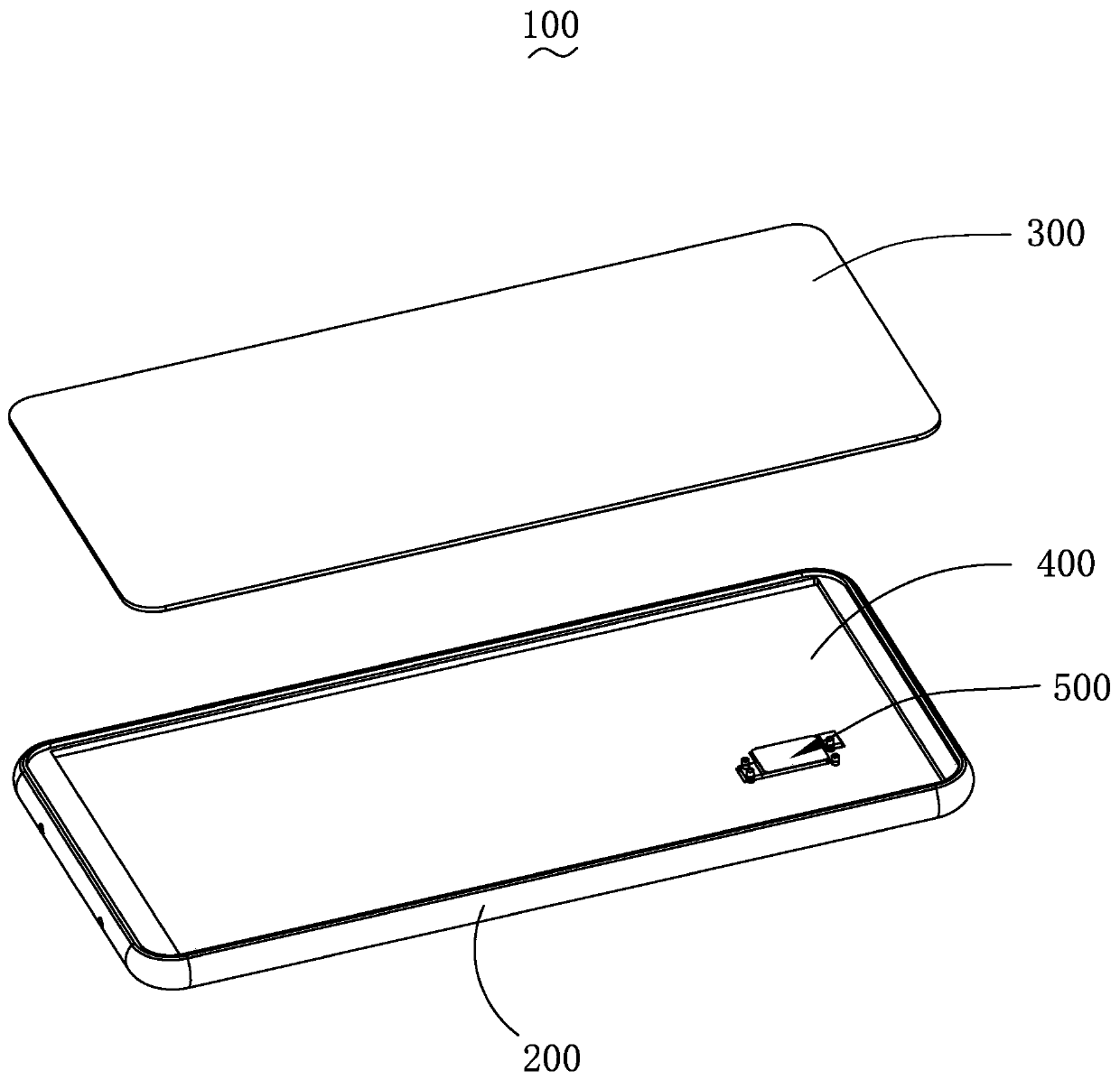

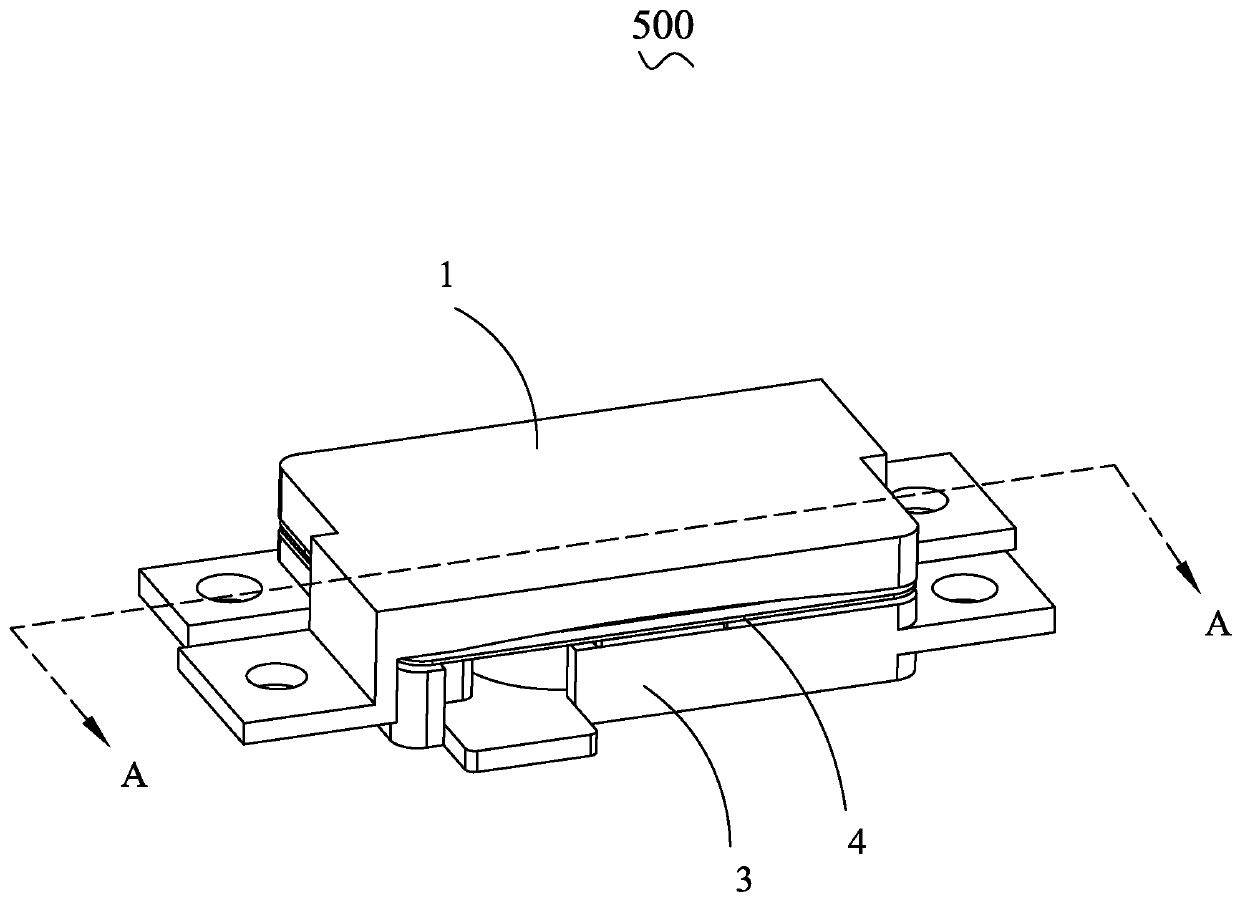

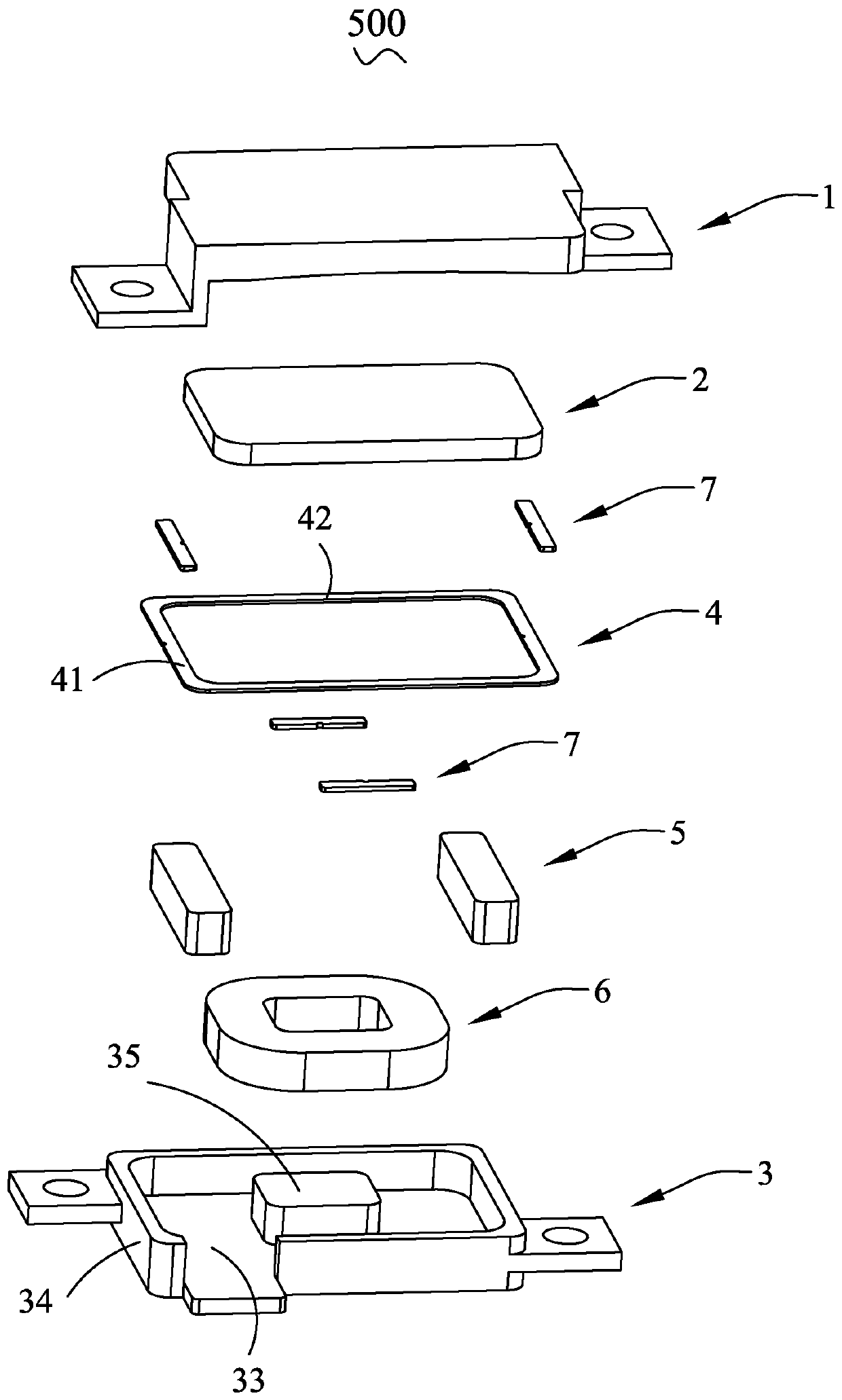

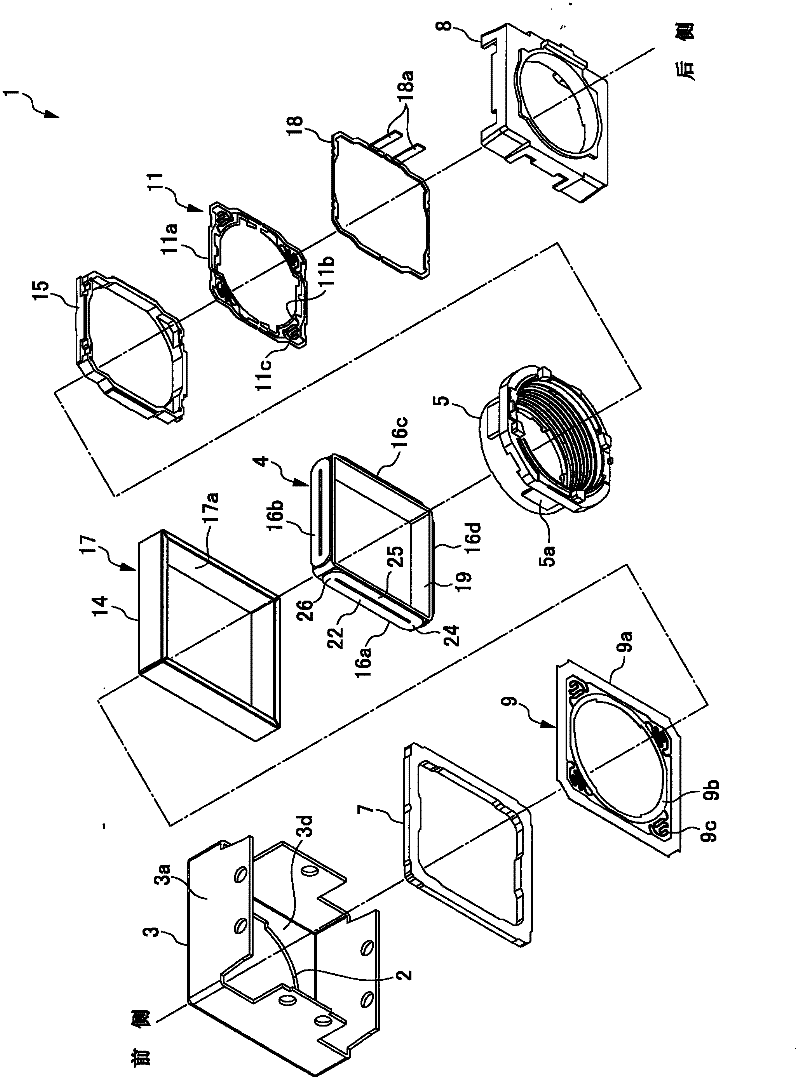

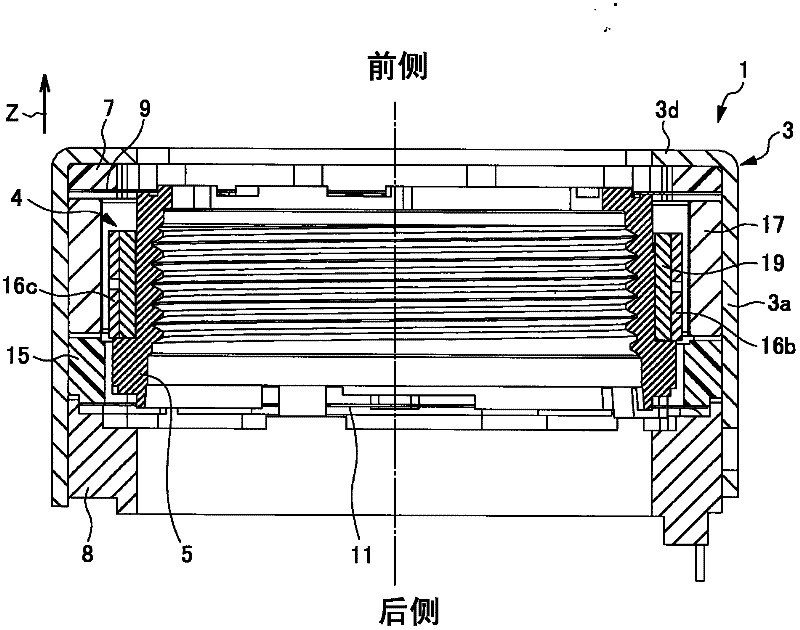

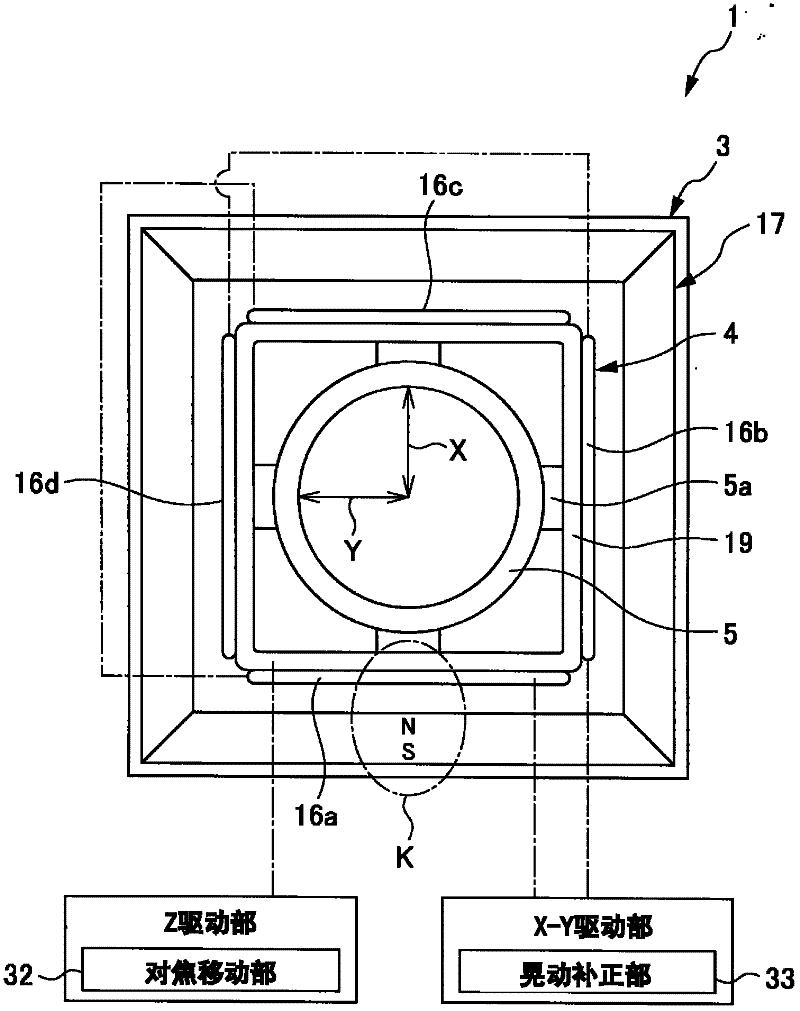

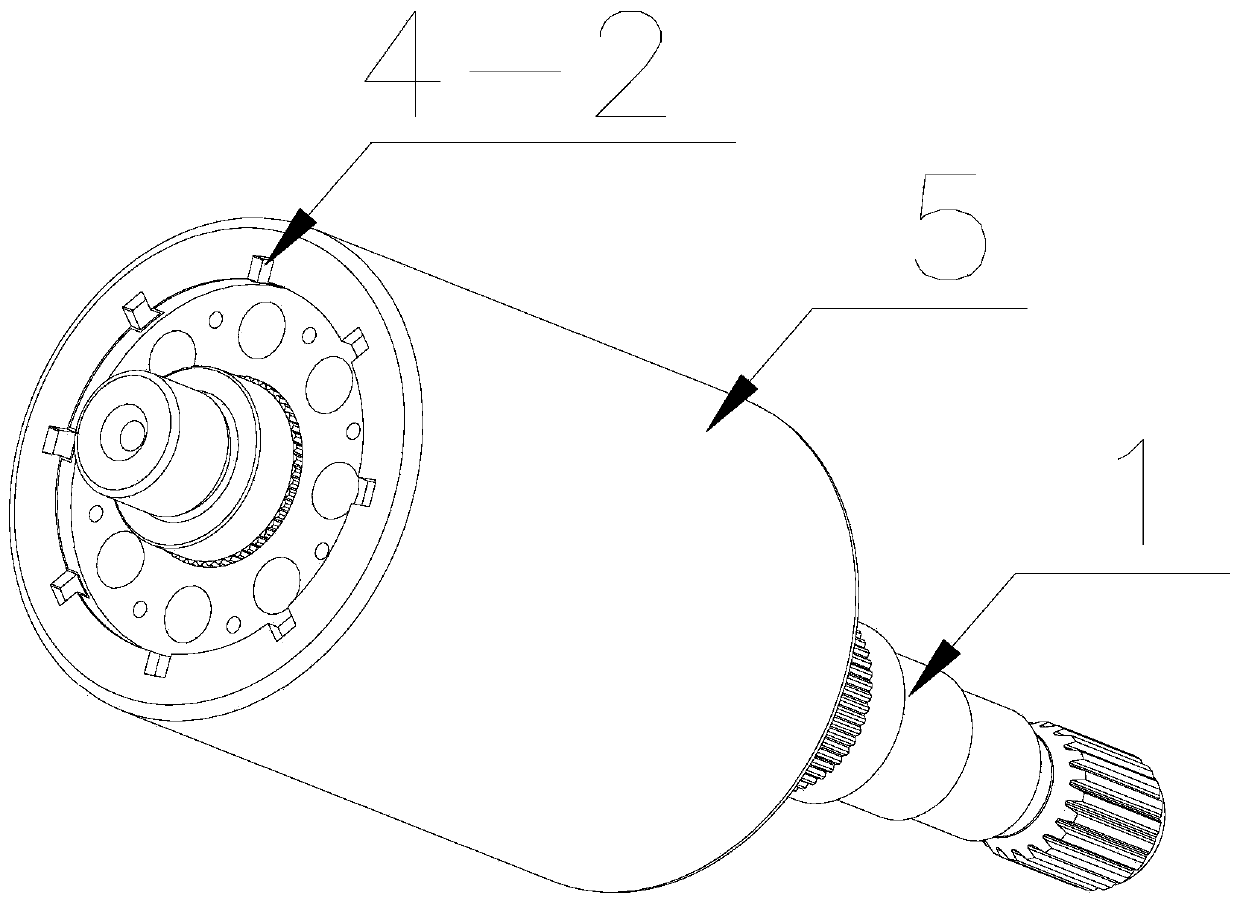

Lens driving device, auto-focusing camera, and mobile terminal device with camera

The invention provides a simple-structured lens driving device, an auto-focusing camera, and a mobile terminal device with a camera capable of moving the lens support body towards the optical axis direction and correcting the shaking by the moving. A first coil 19 is winded on the outer periphery of the lens support body 5, the plane of the first coil is in the shape of four corners, viewed from the optical axis side. The second coils 16a -16d are disposed on the outer periphery at the interval of 90degrees. When the first coil forms the four-corner shape, viewed from the radial direction of the lens support body 5, the second coils are in the annular shape. A first magnet 17 is disposed oppositely to each side of the first coil 19, and the inner peripheral plane can be configured to have the same pole, at the same time, the first coil is opposite to the positions of the second coils 16a-16d. When the lens support body moves towards the optical shaft, the first coil 19 is powered on, when towards the X-Y direction, the second coils 16a-16b are provided with a certain quantity of current.

Owner:NEW SHICOH MOTOR CO LTD

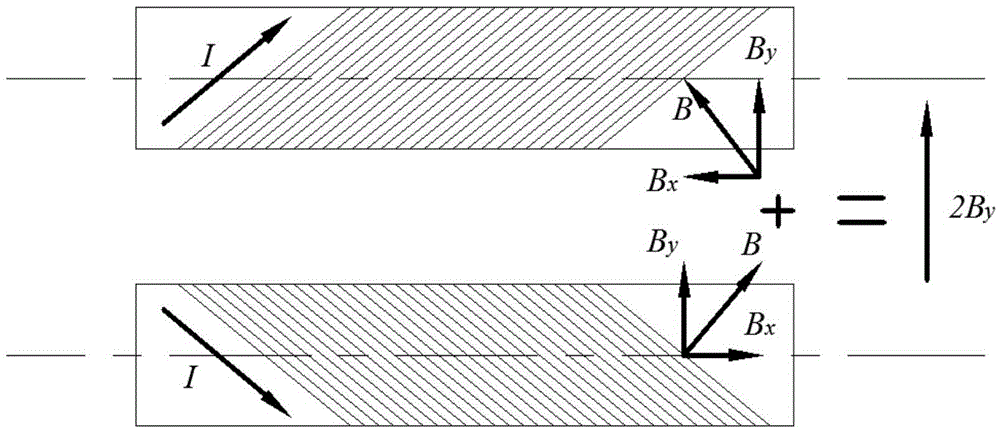

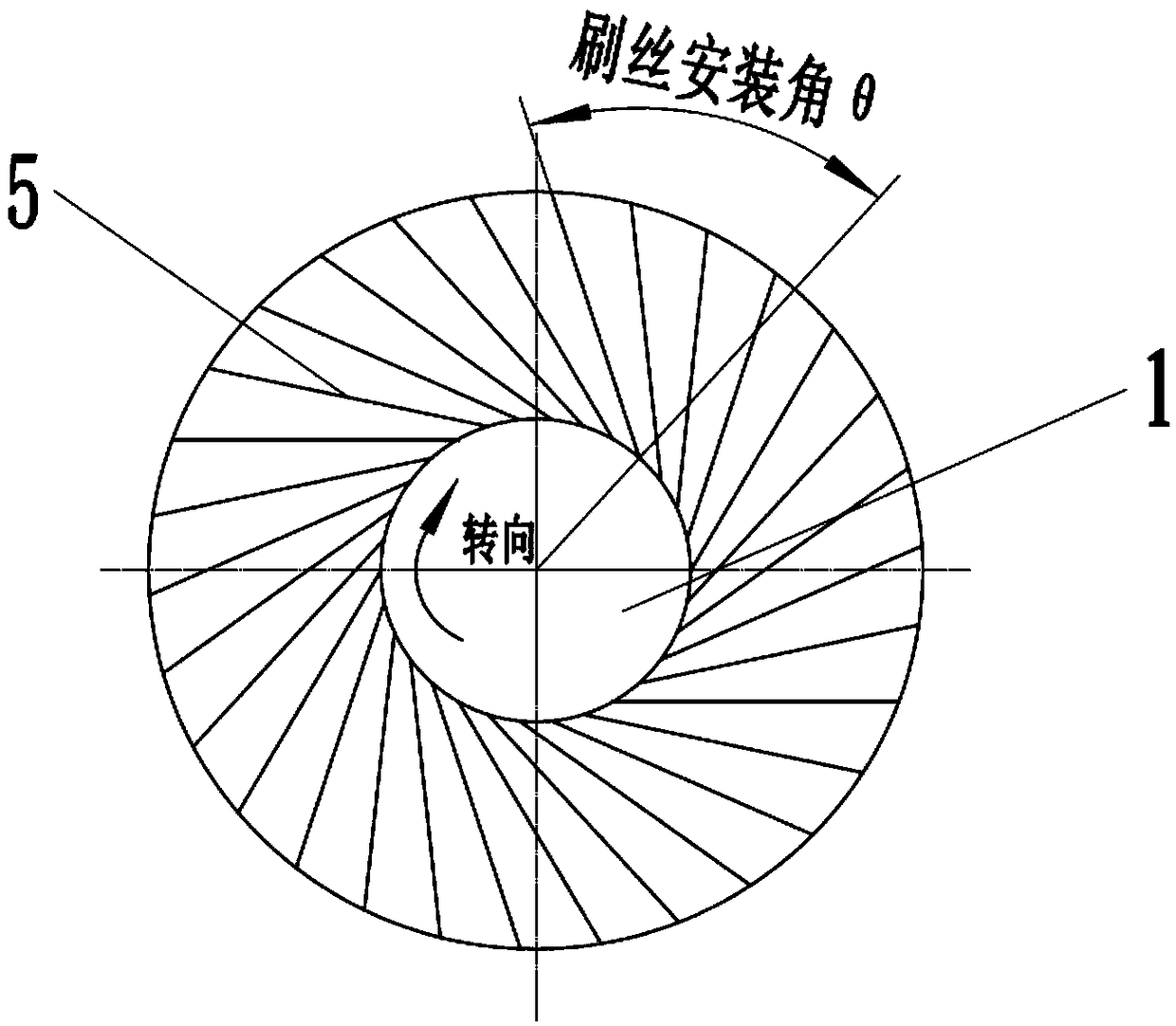

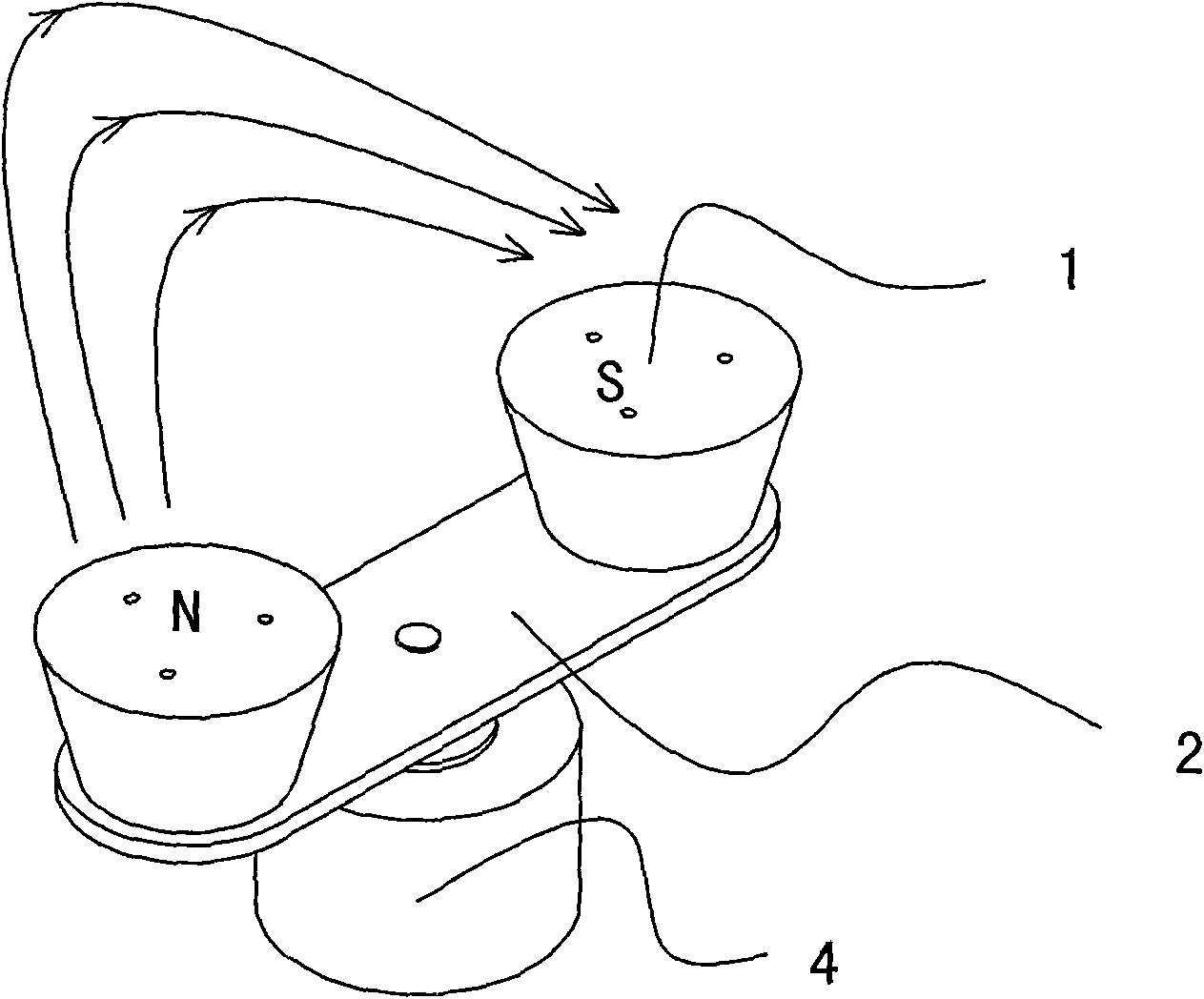

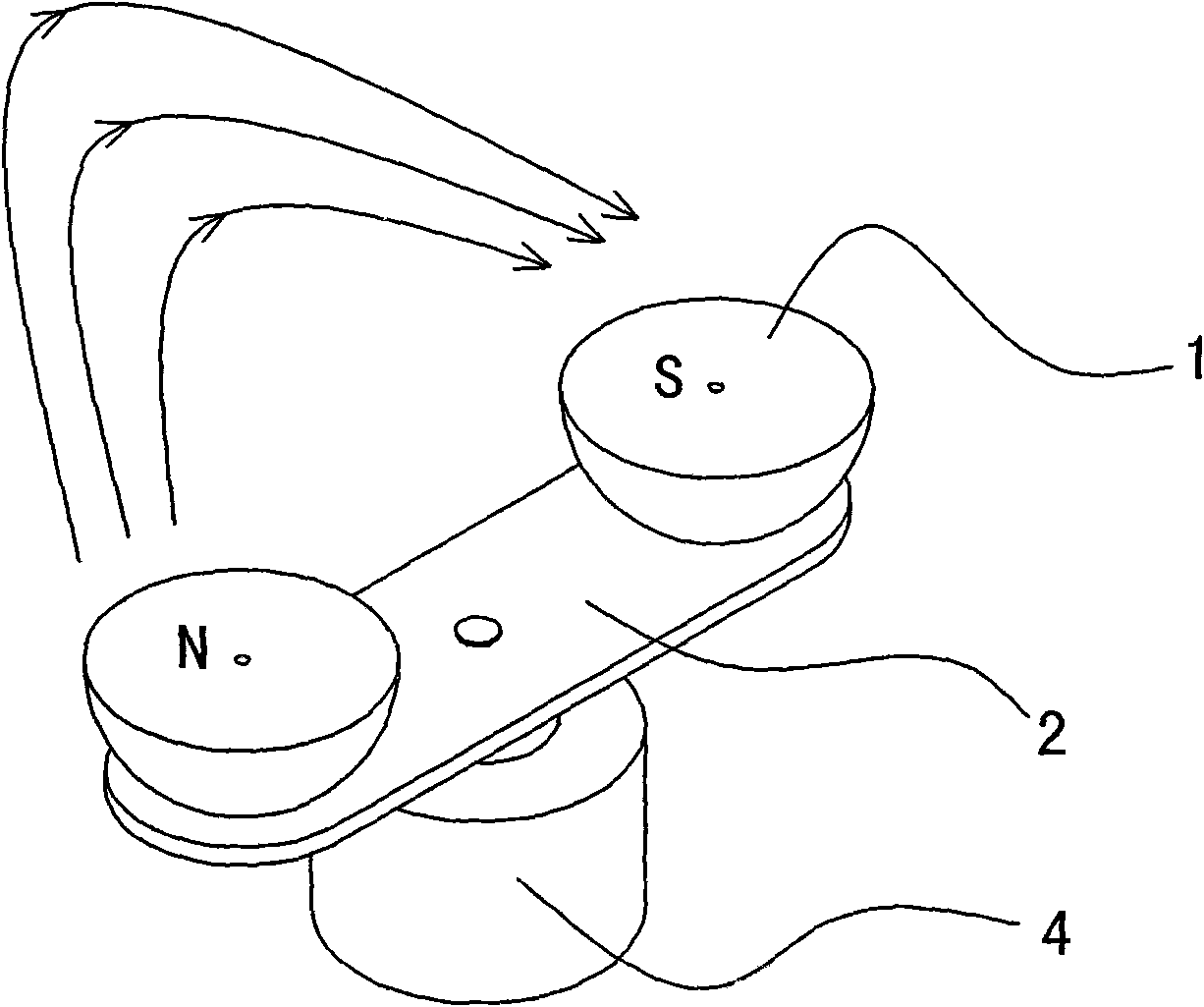

Method for realizing low-frequency rotary constant high-intensity magnetic field

InactiveCN101640094AReduce Flux LeakageReduce dosageElectrotherapyPermanent magnetsMagnetic polesTherapeutic effect

The invention discloses a method for realizing a low-frequency rotary constant high-intensity magnetic field. More than two high-intensity magnetic bodies with an even number and a magnetic spiral armare arranged; each high-intensity magnetic body is symmetrically and fixedly mounted on the same side of the magnetic spiral arm; the magnetic poles of a free surface of the two symmetrical high-intensity magnetic bodies are opposite to each other; the area of the free surface of the high-intensity magnetic body is greater than the area of a connecting surface; the cross section of the high-intensity magnetic body is an edge-free geometric shape; and a rotating device drives the magnetic spiral arm and the high-intensity magnetic body to rotate. The invention can prevent flux leakage of the magnetic body around so that a magnetic line is centralized to emit upwards without flux leakage in other directions, thereby ensuring the intensity of the magnetic field in a usable direction, effectively preventing interference on other electric appliances and ensuring the highest upward emitting height of the magnetic line, the strongest magnetic line and the best magnetic therapy effect.

Owner:深圳市恒安鸿源磁科技有限公司

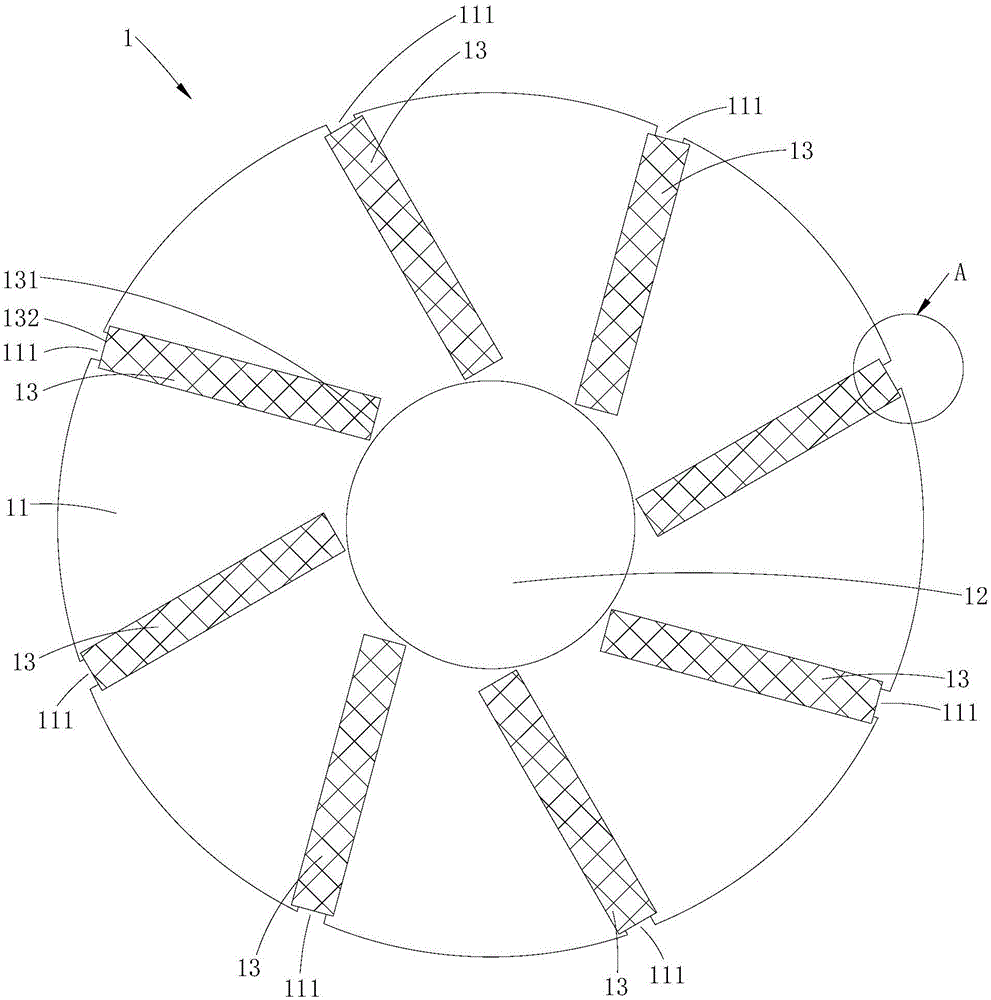

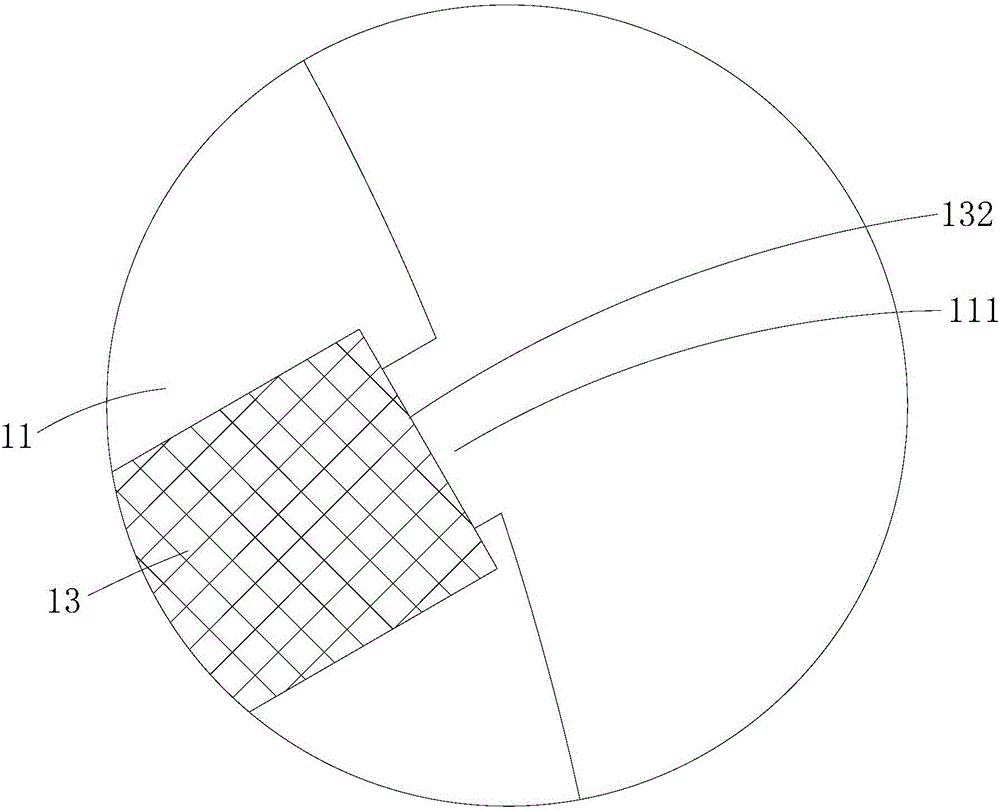

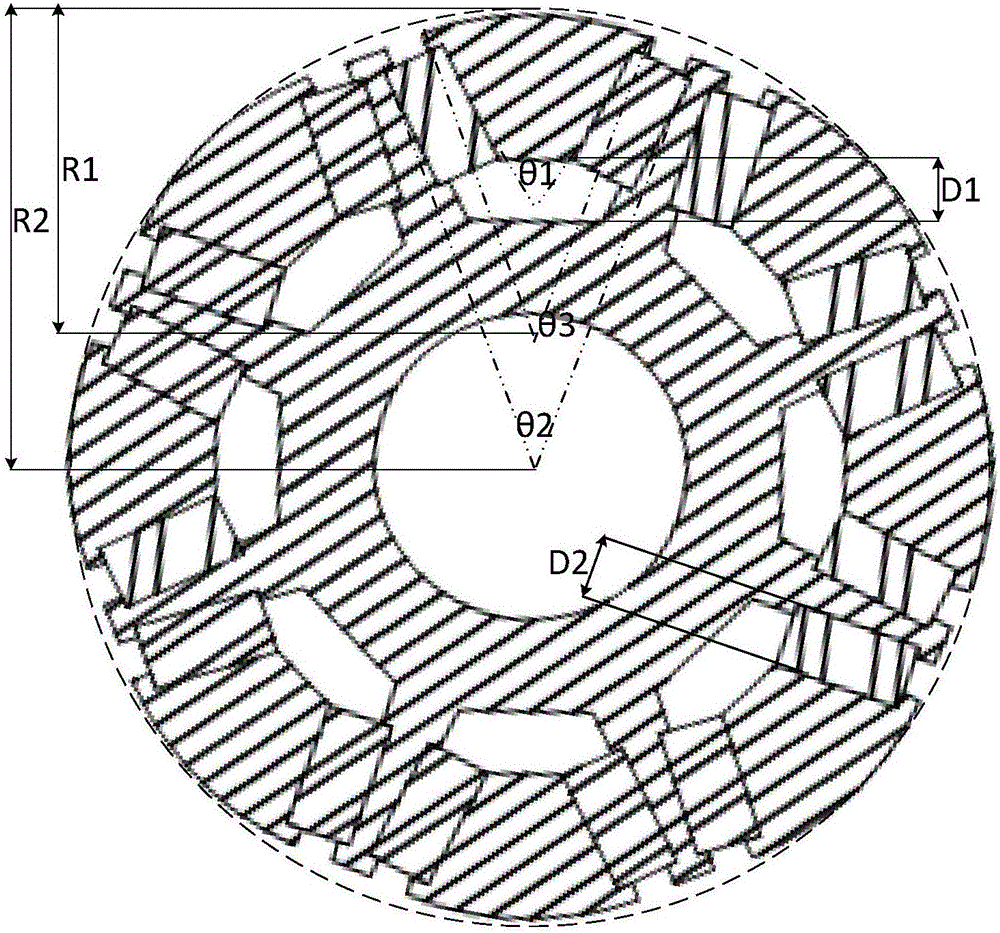

Rotor with quasi-V-shaped magnetic steel structures and suitable for high-performance motor

InactiveCN106411007AIncrease air gap flux densityReduce positioning forceMagnetic circuit rotating partsTemperature controlAir gap flux density

The invention discloses a rotor with a quasi-V-shaped magnetic steel structures and suitable for a high-performance motor. The rotor comprises a main rotor core, quasi-V-shaped magnetic steel and auxiliary rotor cores, the quasi-V-shaped magnetic steel and auxiliary rotor cores are arranged in the outer side of the main rotor core, the main rotor core of a hollow structure is provided with multiple toothed portions in the outer side, each quasi-V-shaped magnetic steel structure composed of the quasi-V-shaped magnetic steel and the auxiliary rotor core is arranged between two adjacent toothed portions, and a cooling channel exists between each quasi-V-shaped magnetic steel structure and the external surface of the main rotor core. Compared with a present rotor of a permanent magnetic motor, the air-gap magnetic flux density is high, the gullet torque is small, and harmonic waves are low; the salient rate is high, and convenience is provided for field weakening control; a short magnetic circuit is avoided effectively, and magnetic flux leakage is little; and the cooling channels are provided to improve temperature control.

Owner:SOUTHEAST UNIV

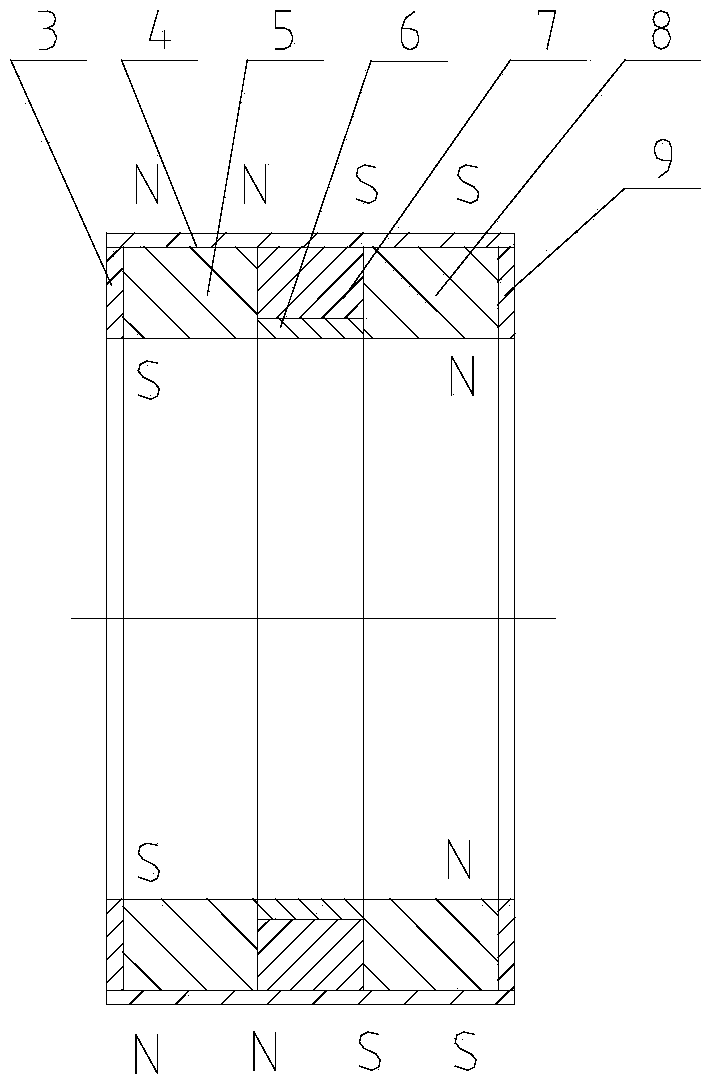

Hybrid magnetic-circuit torquer and flexible gyroscope comprising the same

ActiveCN104038009AImprove work efficiencyReduce unevennessRotary gyroscopesDynamo-electric machinesMotor speedGyroscope

The invention discloses a hybrid magnetic-circuit torquer and a flexible gyroscope comprising the same. The hybrid magnetic-circuit torquer of the invention is a three-row magnet steel hybrid magnetic-circuit torquer, in which a three-row permanent magnet steel ring forms a moving coil portion of the torquer which is fixedly connected with a flywheel rotor to rotate at high speed, and a fixed coil of the torquer is combined with a sensor to be secured to a gyro case. As such, the magnetic flux density B of the operating airgap magnetic field is increased, and the torque coefficient of the gyroscope is also increased, resulting in a maximum tracking angle rate above 600degrees / s of the gyroscope. With the flexible gyroscope using the hybrid magnetic-circuit torquer, the gyroscope's angular momentum H is decreased by setting the rotation speed of the motor properly. A low friction torque bearing C2206094JK is used in the gyro motor in order to reduce the friction toque. Also, by reducing the operating gap between the stator and the rotor, choosing the operating site properly, and maximizing the starting torque of the driving motor, the sync time of the gyroscope is made to be less than 5S and reduced to less than 2S in a high-voltage start-up and low-voltage operation mode, so as to meet high-speed operation requirements.

Owner:BEIJING INST OF AEROSPACE CONTROL DEVICES

Rotor structure and motor thereof

InactiveCN108462272AImprove resistance to demagnetizationReduce lossMagnetic circuit rotating partsSynchronous machines with stationary armatures and rotating magnetsNon magneticMagnet

The present invention provides a rotor structure and a motor thereof. The rotor structure comprises a rotor body, the rotor body is provided with a magnet steel slot group, the magnet steel slot groupcomprises a plurality of magnet steel slots which are independently arranged, and one magnetic conductive channel is formed between each two adjacent magnet steel slots. The extension lines of the magnet steel slots in a radial direction encircle a triangle. The arrangement mode of the magnet steel slots can effectively increase the length of a non-magnetic bridge formed on the rotor body, can reduce the leakage flux amount of a switching structure and can improve the demagnetization resisting capacity of the rotor, namely improves the utilization of a rotor field and reduces the loss of therotor. The rotor structure and the motor thereof can improve the demagnetization resisting capacity of the motor rotor, can improve the safety factor, is simple in assembling and can decrease the manufacturing cost, and the arrangement mode of the triangular magnet steel slots can increase the corresponding reluctance torque and can allow the motor to be easily flux weakening so as to allow the motor to achieve a higher rotation speed.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

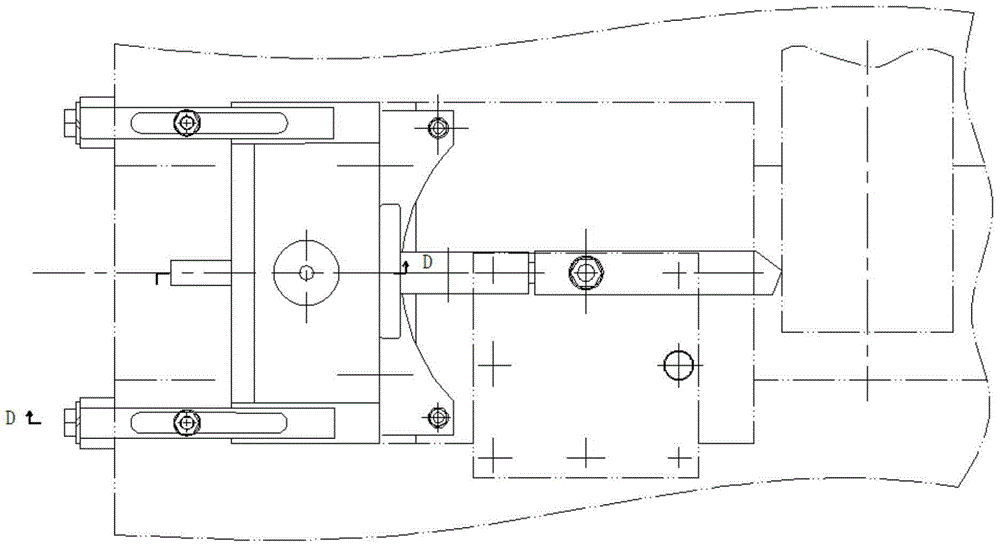

Semi-active turning flutter magneto-rheological damping device based on extrusion operation mode

ActiveCN105240443ARealize online real-time controlQuick responseNon-rotating vibration suppressionAuxillary equipmentSemi activeInterference fit

The invention relates to a semi-active turning flutter magneto-rheological damping device based on an extrusion operation mode. The damping device comprises a fixed magnetic pole component and a vibrated magnetic pole component, wherein an end cover in the fixed magnetic pole component is fixedly connected with a box body; two fixed magnetic pole plates are connected with the end cover and a cylindrical hole in the inner side of the box body in an interference fit manner respectively; a dabber in the vibrated magnetic pole component is matched and connected with a homemade lathe tool through a Morse's cone; the space between the end cover and the box body is filled with a magnetorheological fluid; two disk-shaped iron cores are placed in the space between the end cover and the box body, and are connected with the dabber in an interference fit manner; and magnet exciting coils wind cylindrical skeletons of the disk-shaped iron cores. By the adoption of the characteristics that the magnetorheological fluid is fast in response under an external magnetic field, and different damping forces can be provided in transformation from liquid to solid, and on-line continuous real-time control of power parameters (damping, stiffness and the like) of a lathe saddle system is realized; and the damping device is mounted on a lathe sliding box, so that the adjustment is convenient, and flutter in cylindrical turning can be effectively inhibited.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Ultrahigh voltage DC lightning arrester leakage current online detection method by using cloud technology

ActiveCN105301323AGuaranteed uptimeImprove pressure resistanceCurrent/voltage measurementElectrical testingHarmonicOrder of magnitude

The invention provides an ultrahigh voltage DC lightning arrester leakage current online detection method by using a cloud technology. The following steps are respectively completed by using a detection system: a. whether signal acquisition of current is performed is judged; b. signal acquisition of current is performed; c. the acquired signals are processed and then current value data are formed and outputted; d. the acquired current data are wirelessly transmitted to a central monitoring device to be summarized; and e. the central monitoring device displays the current data and allocates and transmits the current data to the mobile terminals of corresponding lightning arrester managers simultaneously. Online acquisition of the microampere order of magnitude of weak circuit signals can be performed, and change of leakage current, harmonic wave and static electricity in the DC lightning arresters can be monitored anytime via the central monitoring device by depending on the cloud technology so that damage and casualties of buildings and people and animals can be effectively eliminated, and the service life of the lightning arresters can be prolonged.

Owner:RED PHASE INC

Permanent magnet motor rotor structure and mounting method

PendingCN110277850AReduce running noiseEasy to fixMagnetic circuit rotating partsManufacturing stator/rotor bodiesPermanent magnet motorMechanical engineering

The invention discloses a permanent magnet motor rotor structure. The structure comprises a rotating shaft, a magnetic steel, a rotor iron core, magnetic steel fixing parts and a rotor sheath, wherein a through hole is formed at the center of the rotor core, the section of the rotor core is a regular polygon, and the periphery of the rotor iron core is provided with a magnetic isolation groove at the junction of the side edges. The magnetic steel fixing parts are partially injected into the magnetic isolation grooves, and the magnetic steel fixing parts are T-shaped; the magnetic steel is inserted into a cavity formed by the surfaces of every two adjacent T-shaped magnetic steel fixing parts and the surface of the rotor iron core, the rotating shaft is pressed into a central through hole of the rotor iron core, and the magnetic steel fixing parts further comprise side baffle rings arranged on the two sides of the rotor iron core; the rotor sheath is cylindrical, one side of the rotor sheath is provided with a closing opening which is preset to be closed up towards the circle center, and the closing opening is annular; the rotor core is sleeved by the rotor sheath, one side of the shell nosing is located on the shaft extension side, the other side of the rotor sheath is also folded towards the circle center, and the shell nosing is annular. The magnetic flux leakage rate is low, the materials are saved, and the working efficiency is high.

Owner:NIDEC KAIYU AUTO ELECTRIC JIANGSU

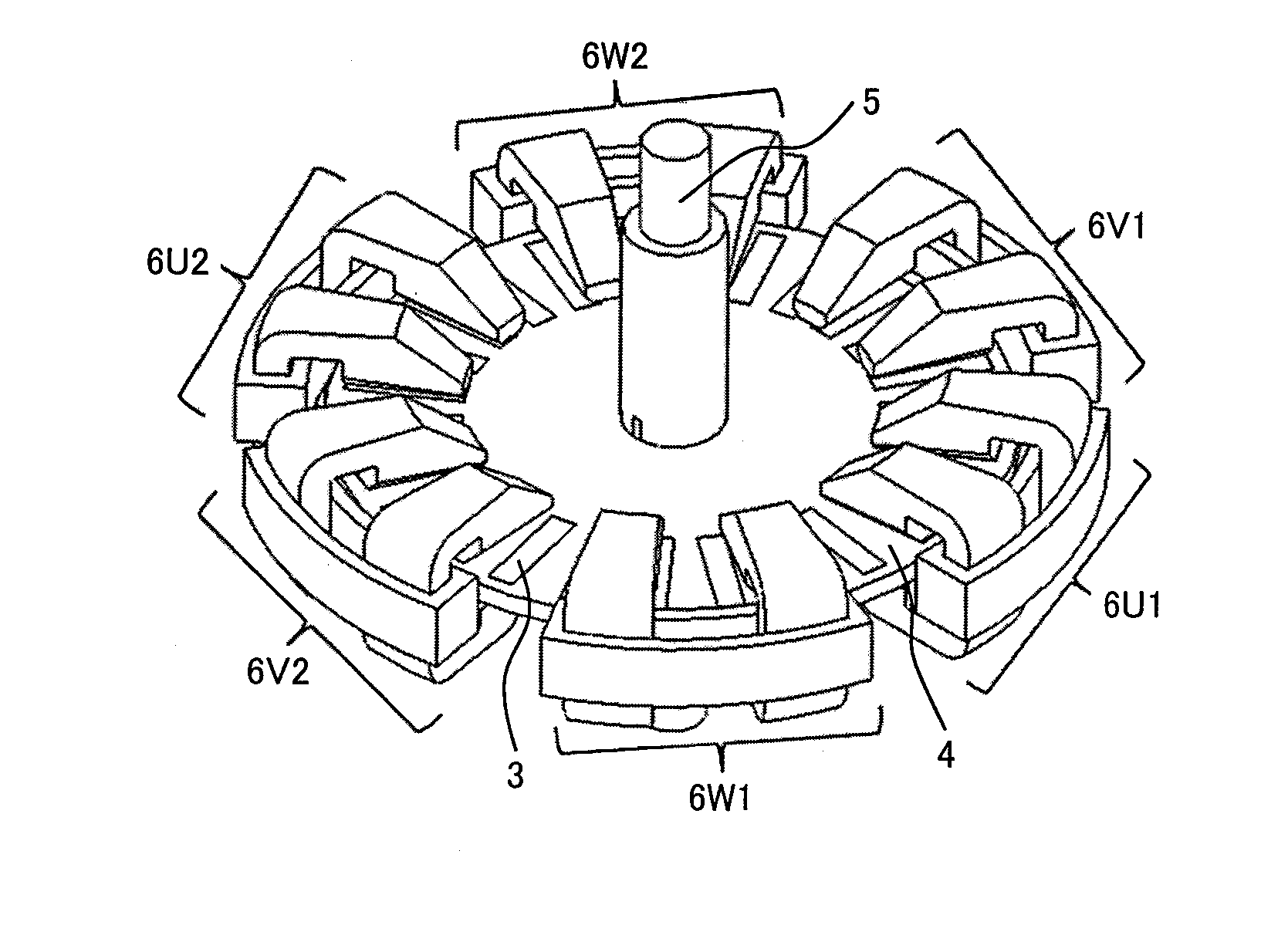

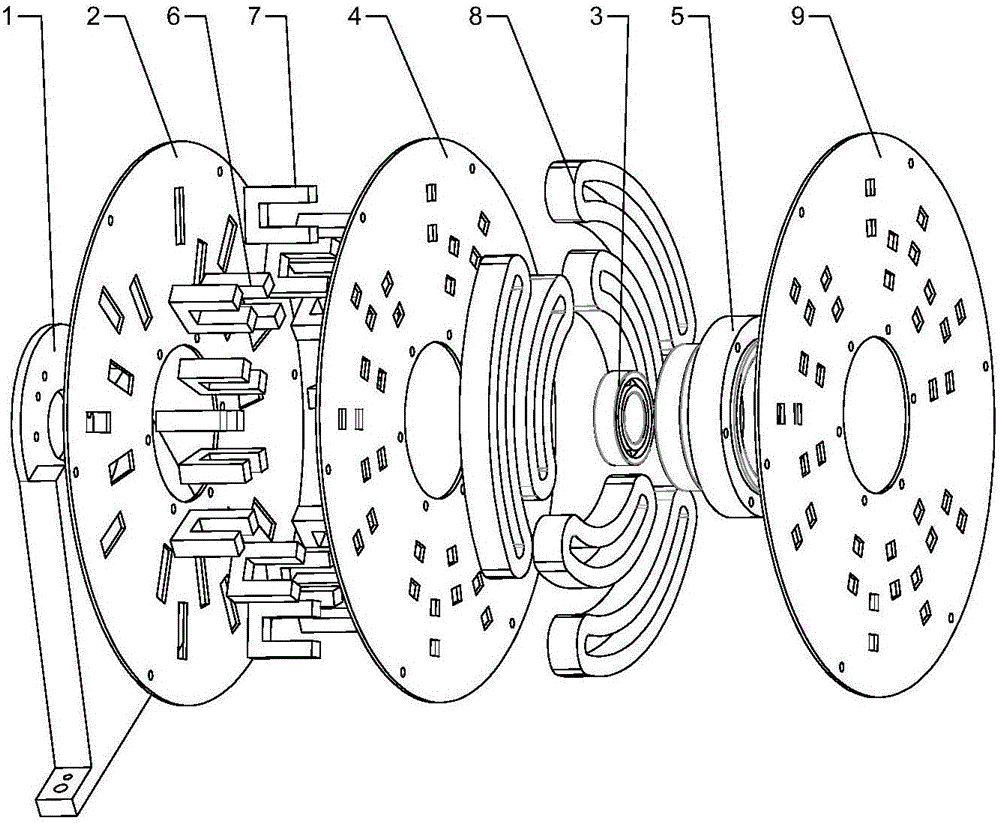

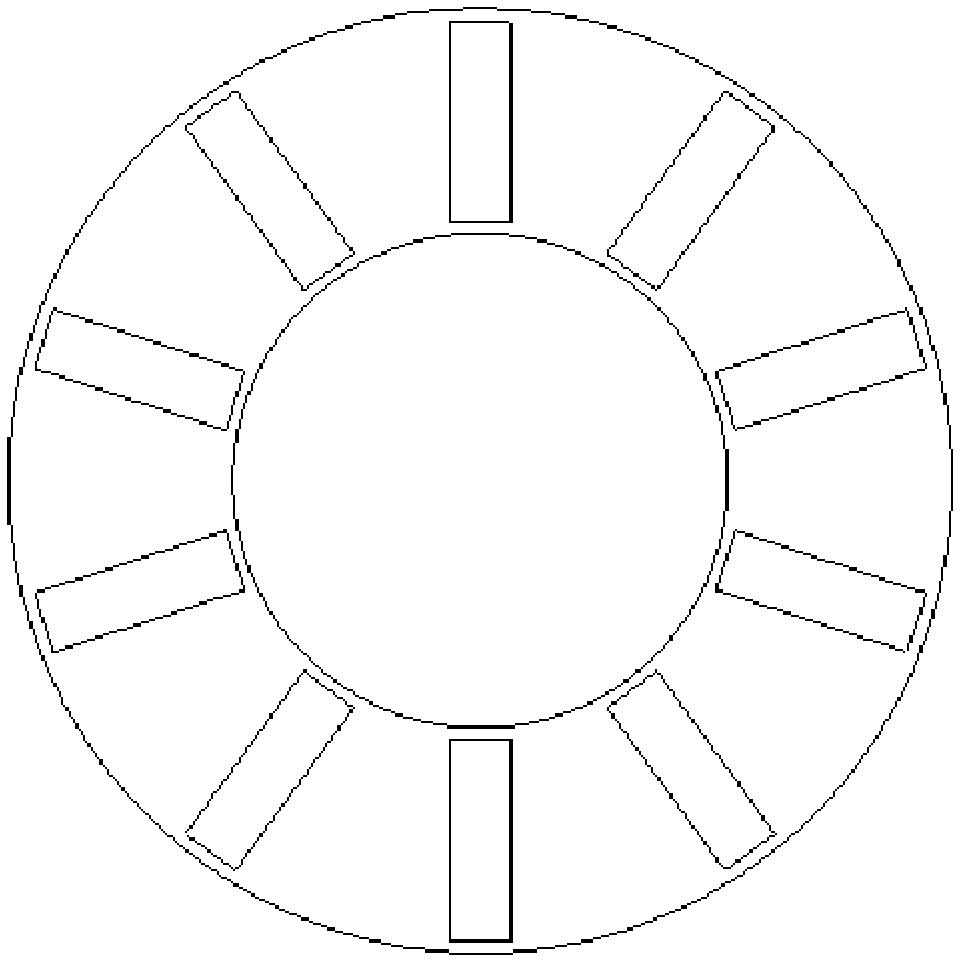

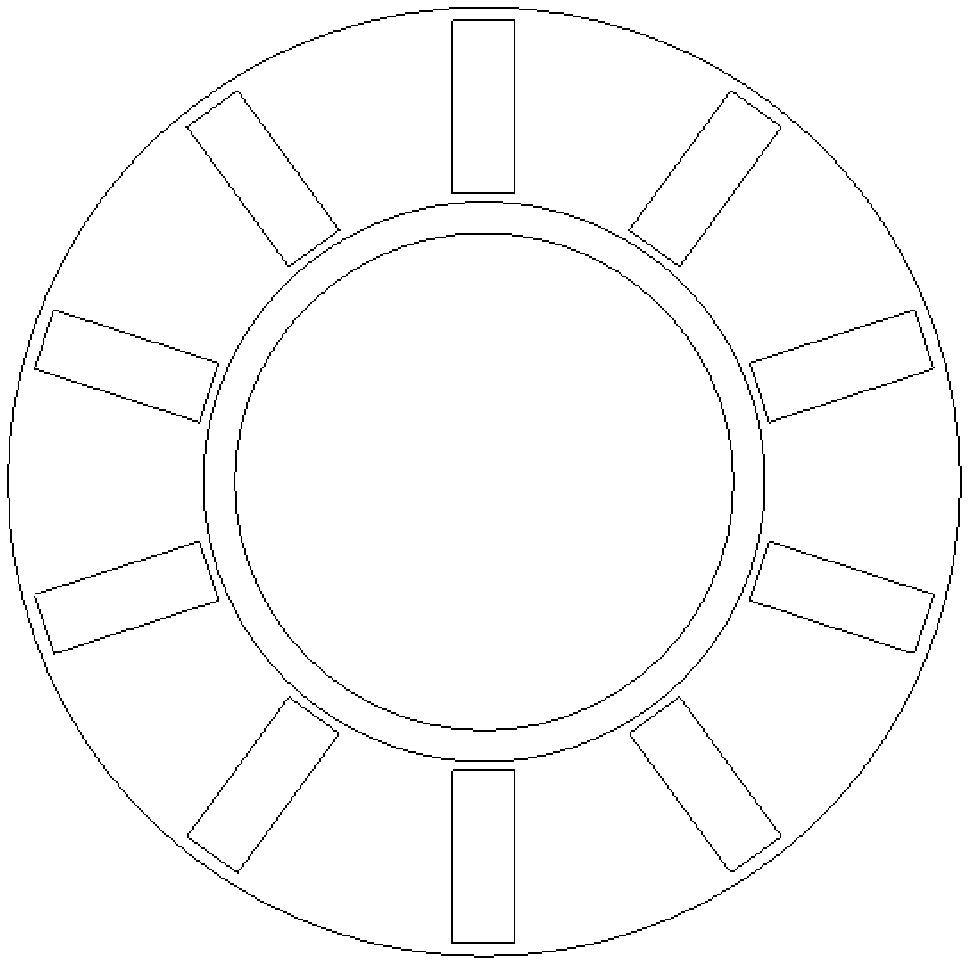

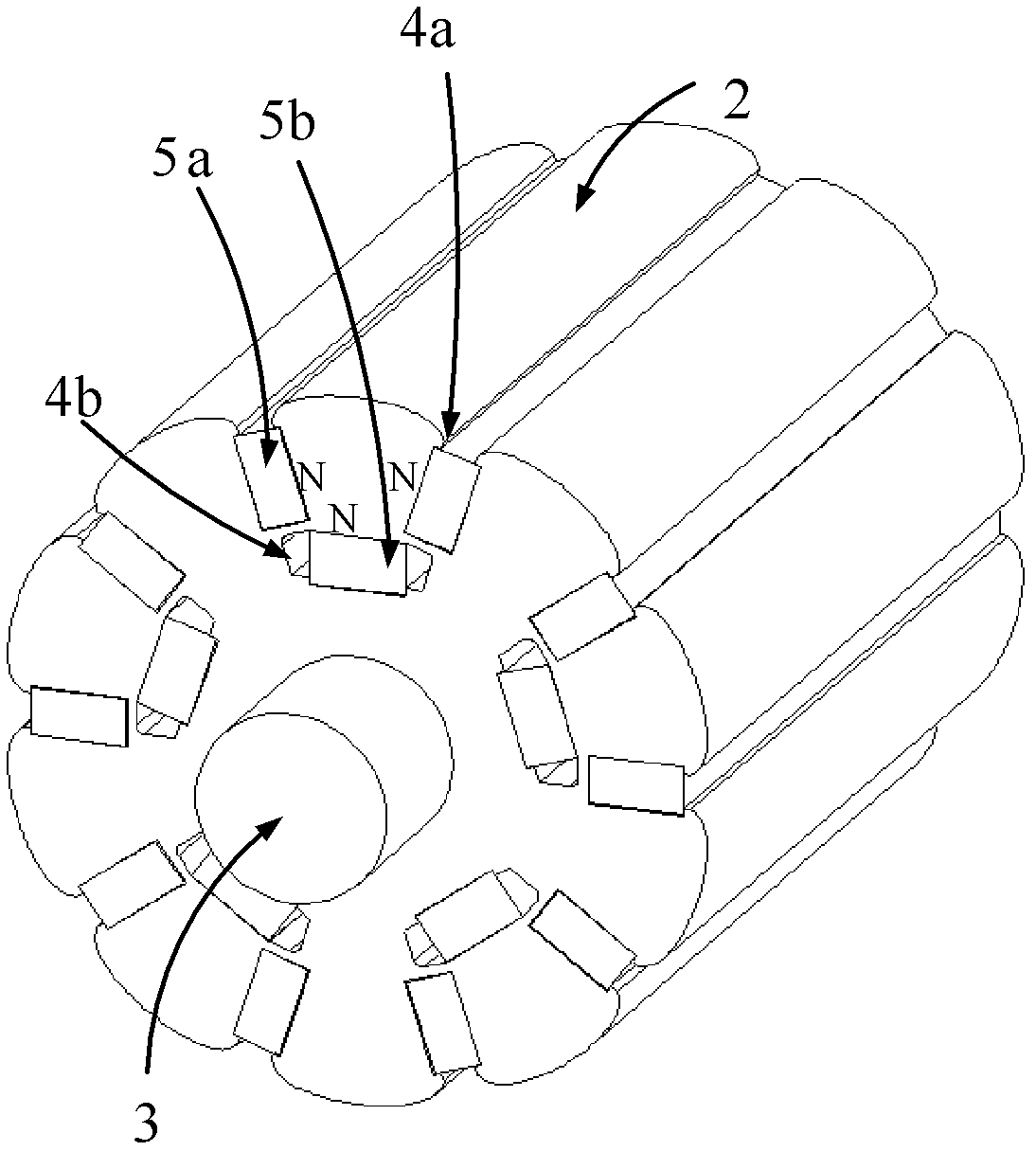

Disc-type double-cross-chain magnetic-concentrating transverse magnetic field motor

ActiveCN106341016AImproved torque stabilityEasy to installSynchronous machine detailsMagnetic circuit rotating partsTransverse magnetic fieldConductor Coil

The invention discloses a disc-type double-cross-chain magnetic-concentrating transverse magnetic field motor. The motor is formed by one rotor and two stators whose two sides differ a 360 / 2P mechanical angle. The P is a motor pole pair number. The motor rotor is formed by two divided rotor discs provided with step holes, a permanent magnet and a shaft sleeve. Each motor stator is formed by an armature winding, a primary C-type silicon steel lamination and a secondary C-type silicon steel lamination which are reversely connected in series. The primary C-type silicon steel lamination and the secondary C-type silicon steel lamination differ the 360 / 2P mechanical angle along an axial direction. A periphery of an inner ring winding of the armature winding and an inner circumference of an outer ring winding are placed in tooth grooves of the primary C-type silicon steel lamination and the secondary C-type silicon steel lamination respectively along a radial direction. The stators and a support are positioned through a pin. The support and a motor seat are positioned and fixedly connected through the pin. In the motor structure, a difference angle of each phase of primary and secondary stator cores is the same with a circumferential difference angle of a rotor permanent magnet. Each pole of the permanent magnet of the rotor is used, a leakage flux of the motor is effectively reduced and a permanent magnet utilization rate is increased.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Pole-following rotor of rotary motor

InactiveCN102570662AReduce magnetic flux leakageReduce utilizationMagnetic circuit rotating partsElectrical polarityPole piece

A pole-following rotor of a rotary motor comprises a rotor consisting of a rotating shaft and a laminated core, wherein a plurality of first permanent magnet pole pieces rotating along the axis of the rotating shaft and magnetized in the circumferential direction of the rotor relative to the axis are arranged in the laminated core; a plurality of second permanent magnet pole pieces rotating along the axis of the rotating shaft and magnetized in the radial direction of the rotor relative to the axis are also arranged in the laminated core; the quantity of the second permanent magnet pole pieces is half of that of the first permanent magnet pole pieces; the polarities of the adjacent first permanent magnet pole pieces are opposite, and the polarities of the second permanent magnet pole pieces are the same; the polarity of the second permanent magnet pole pieces is the same as the opposite polarity of the rotor; and the first permanent magnet pole pieces are embedded into the laminated core through first permanent magnet slots, and the second permanent magnet pole pieces are embedded into the laminated core through second permanent magnet slots. The pole-following rotor provided by the invention has a simple and reasonable structure, reduces magnetic leakage of a magnet, improves the utilization ratio of the magnet, solves the problem that the rotating shaft has to be made of stainless steel or a magnetism isolating copper sleeve, and has effectively reduced production cost.

Owner:MIDEA WELLING MOTOR TECH SHANGHAI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com