Patents

Literature

59results about How to "Reduce positioning force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

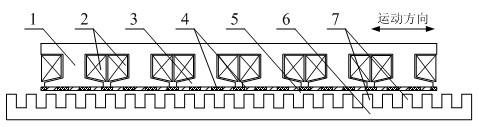

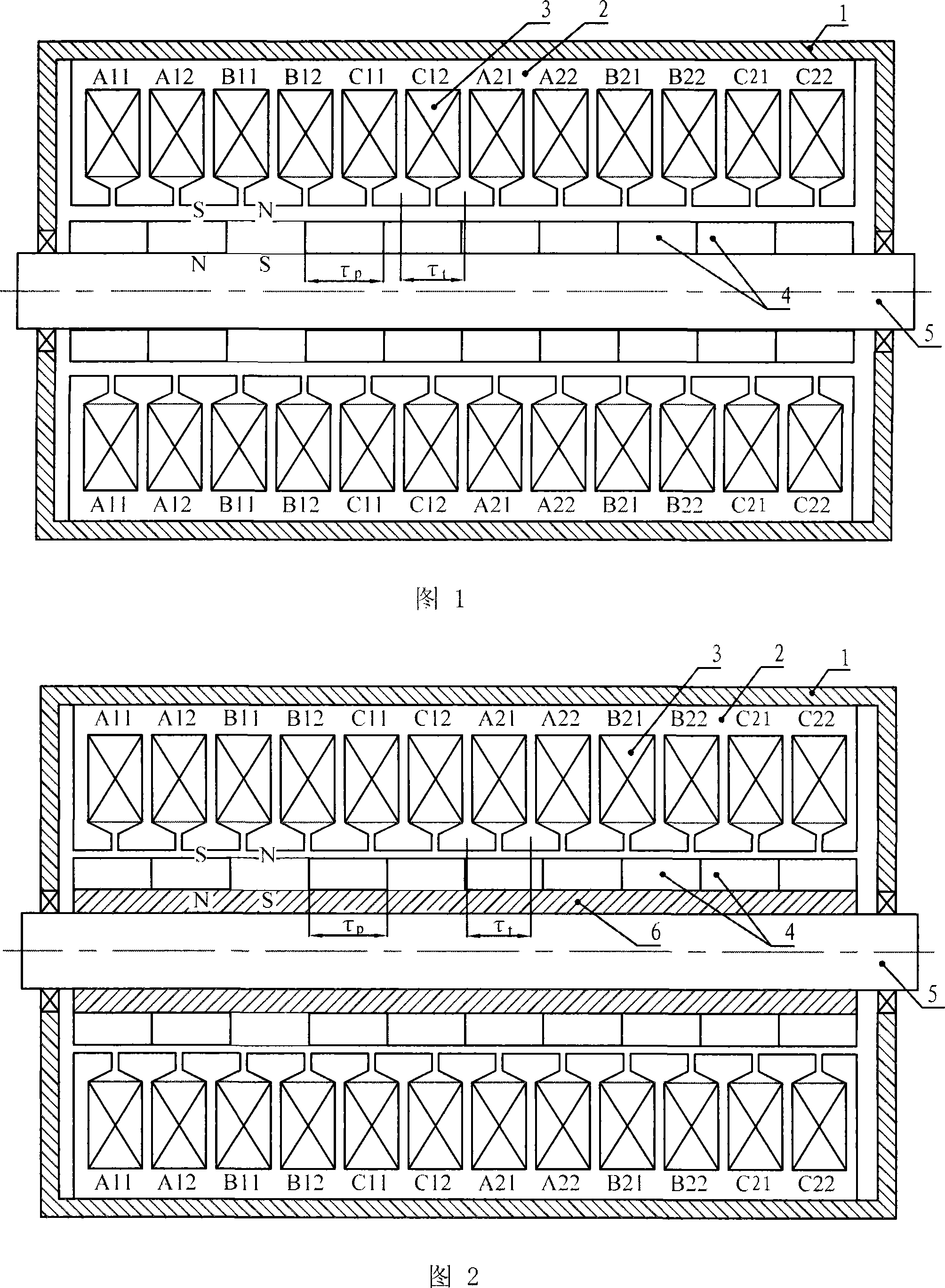

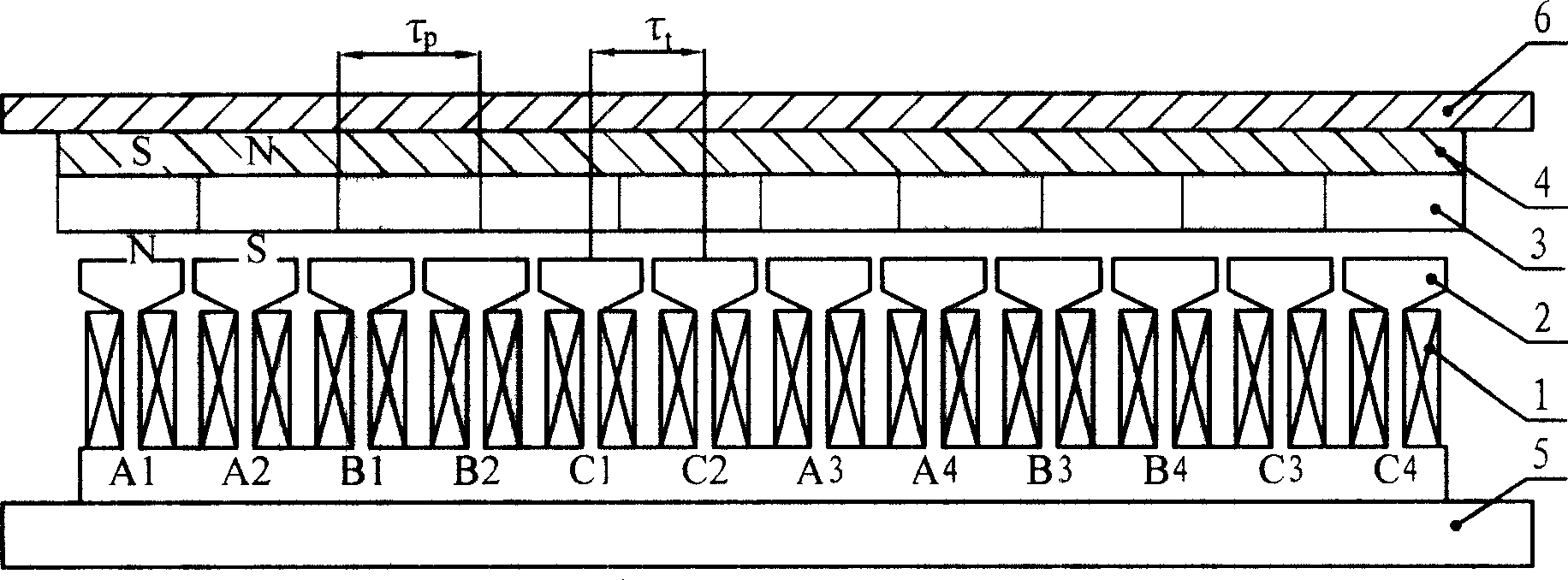

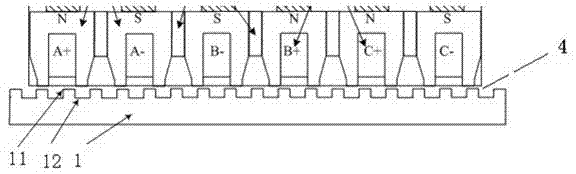

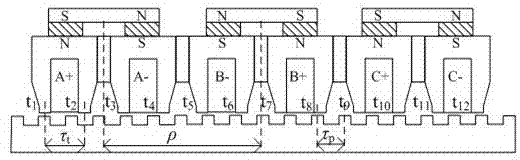

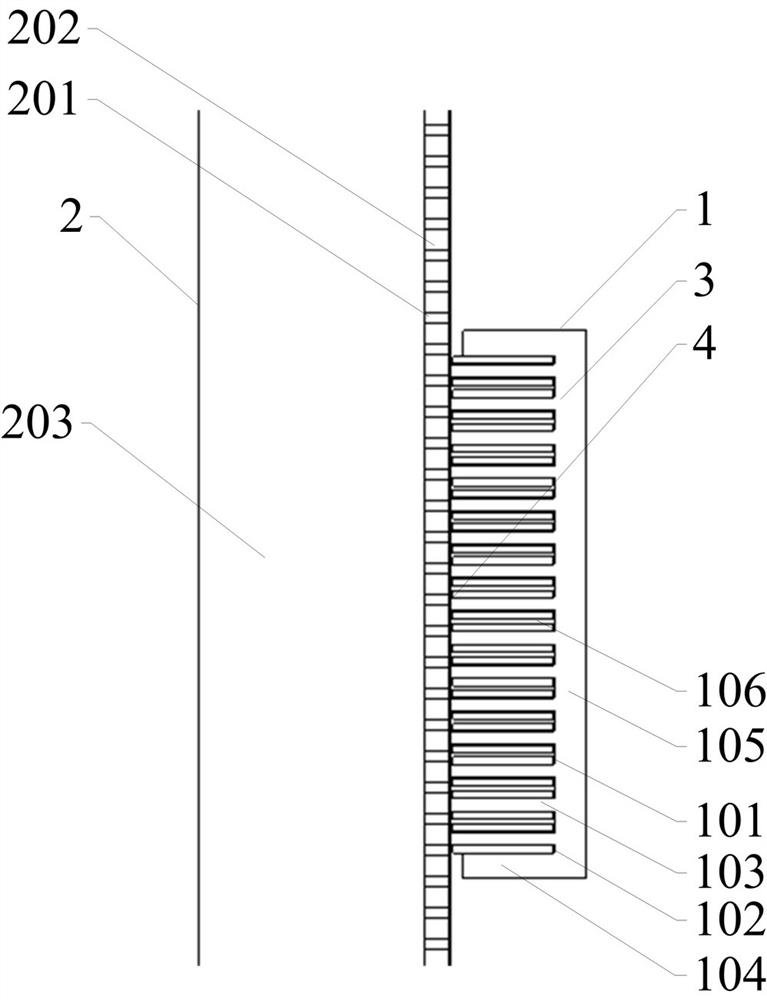

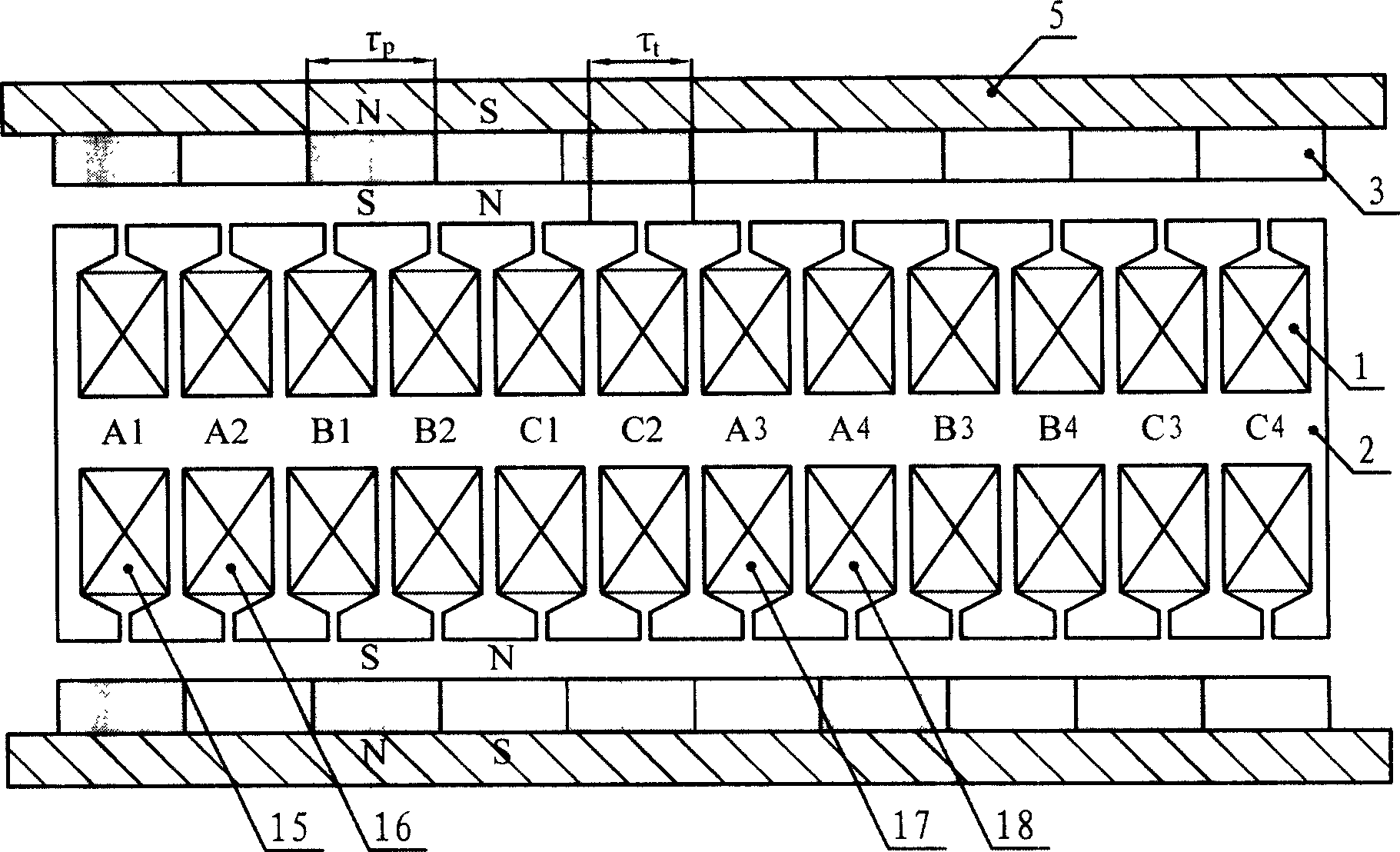

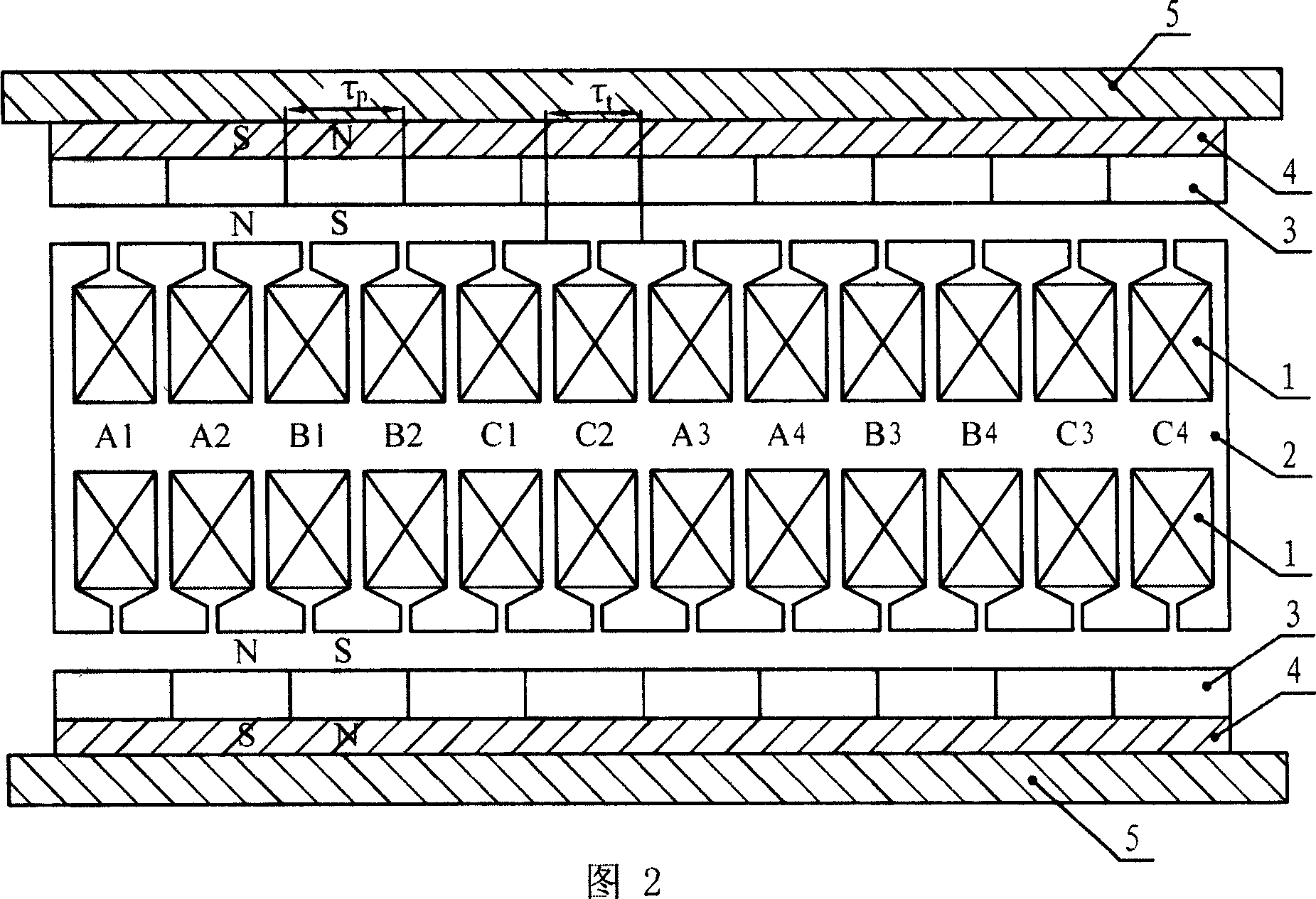

Multiphase long-stator primary permanent magnet linear motor

ActiveCN101783573AImprove cooling conditionsCompact structureMagnetic circuit rotating partsMagnetic circuit stationary partsPrimary permanentElectric machine

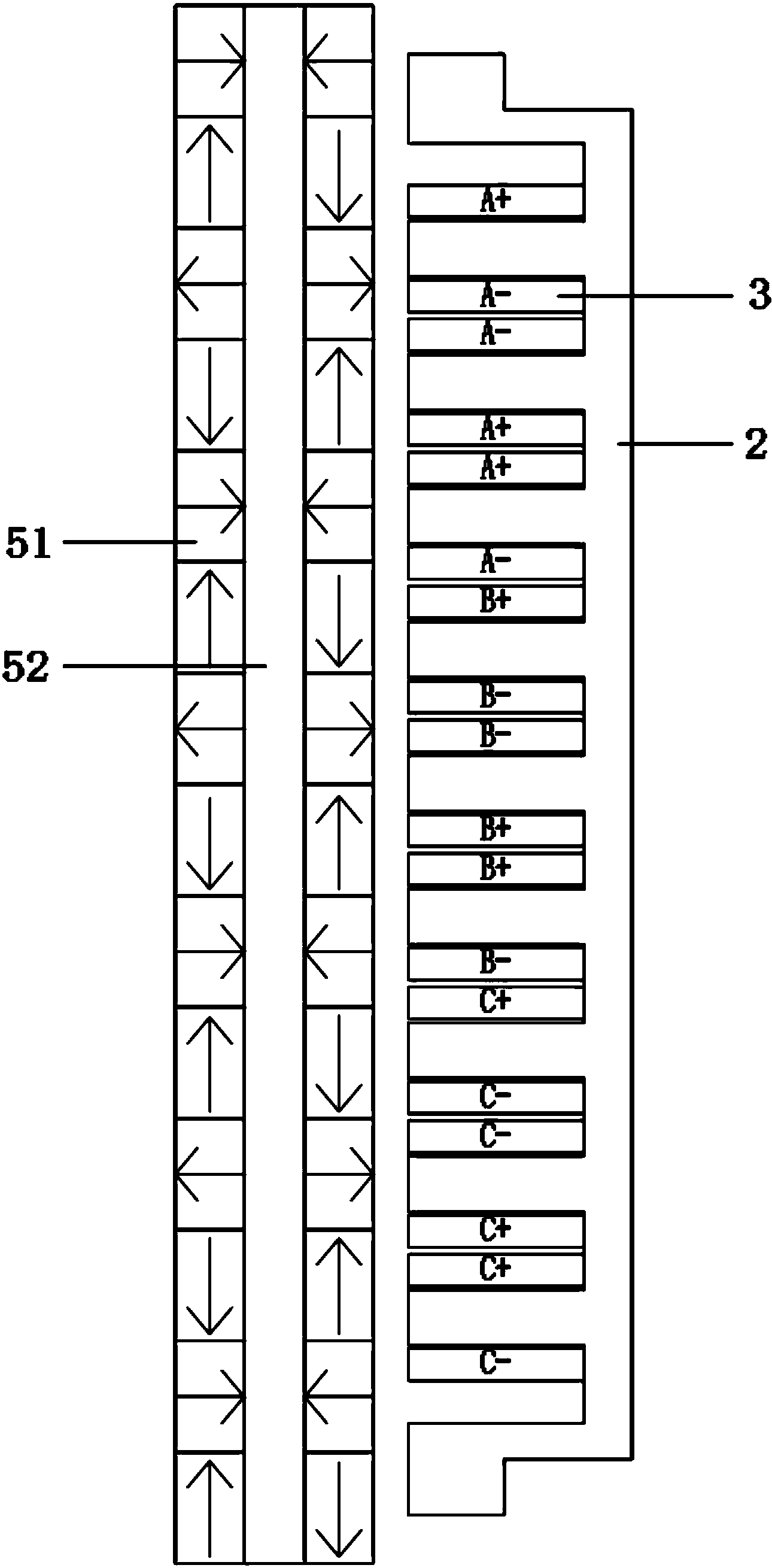

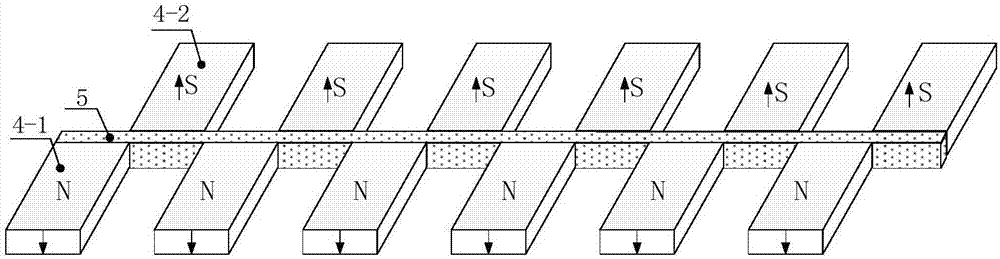

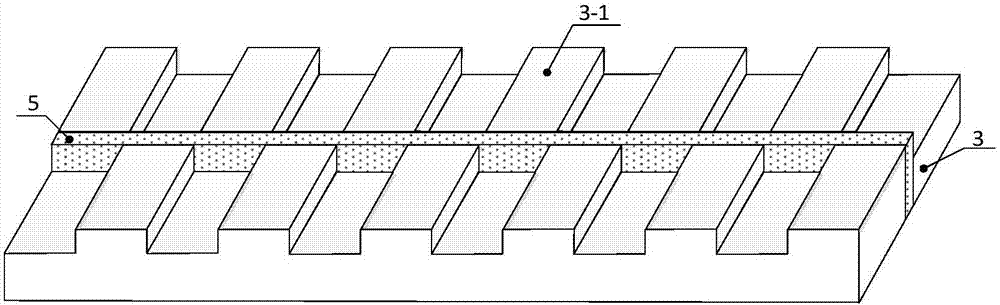

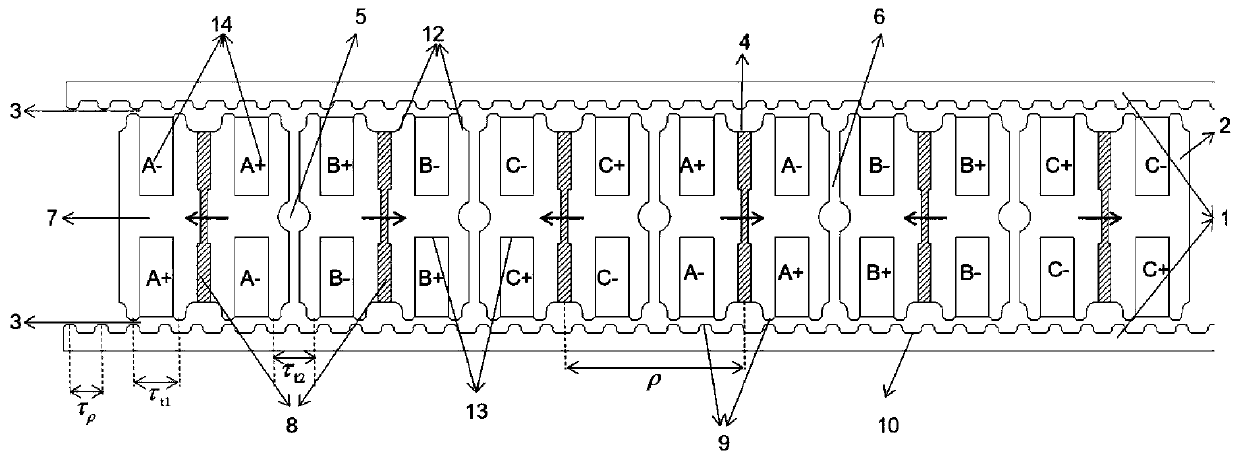

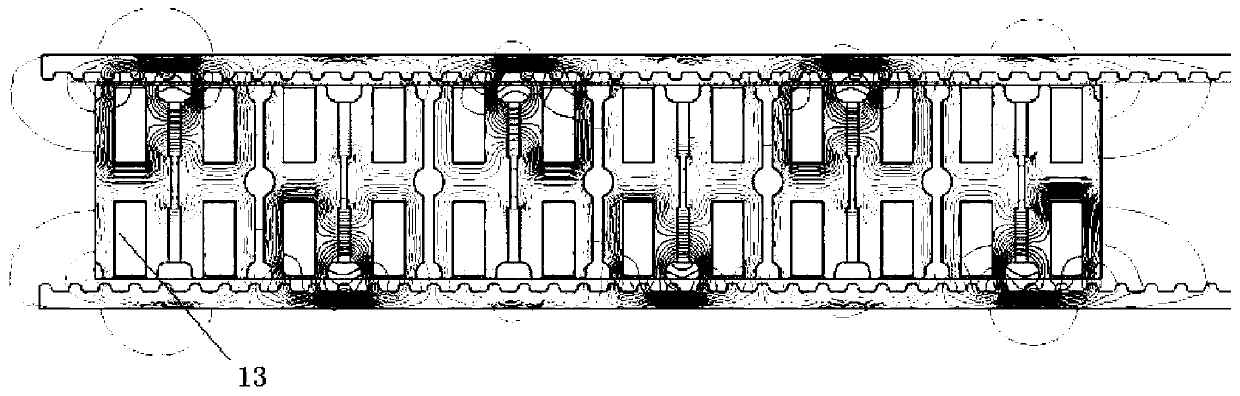

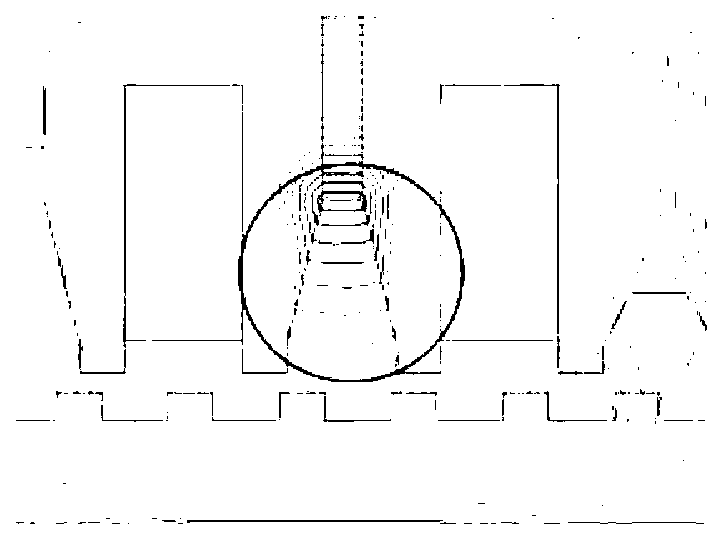

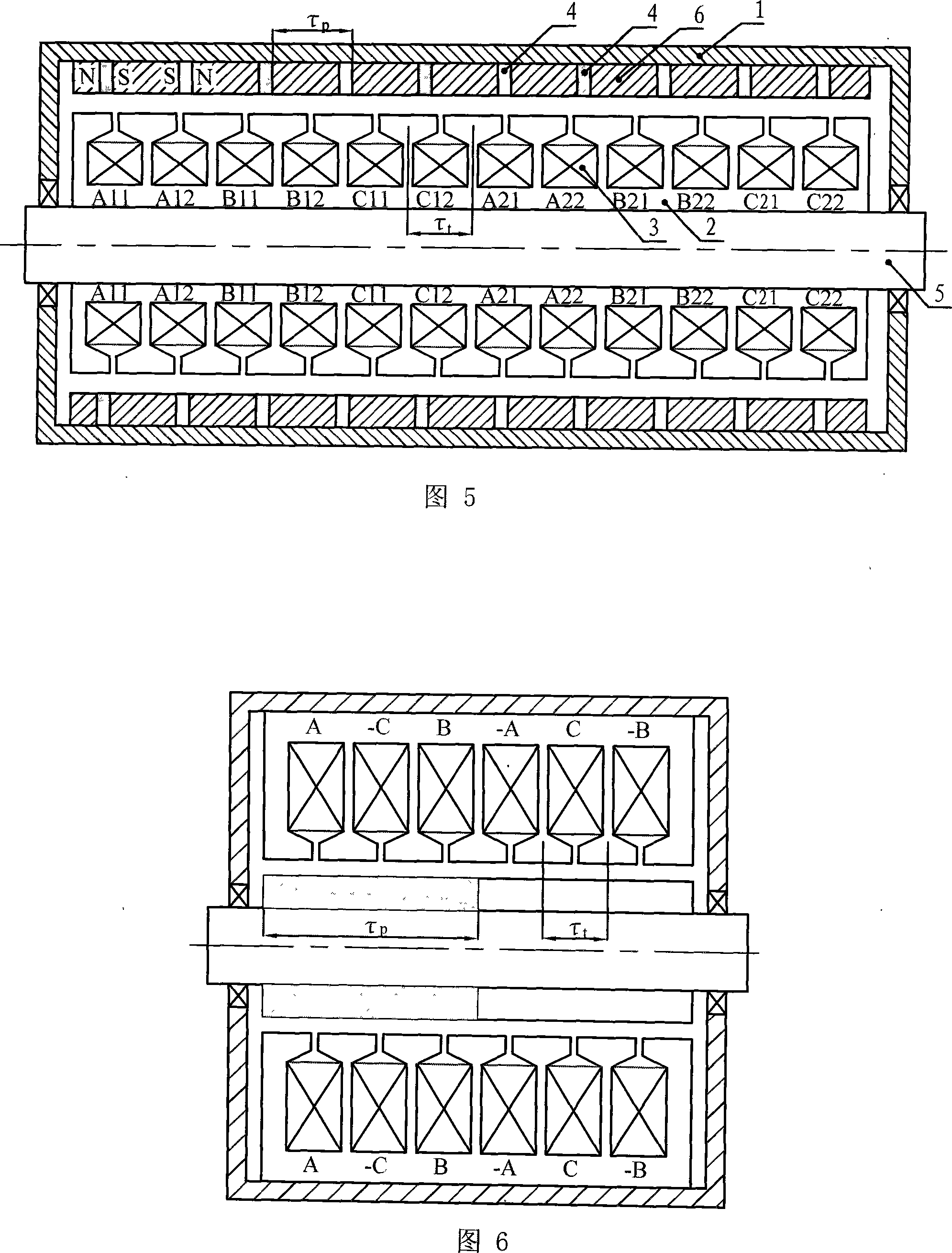

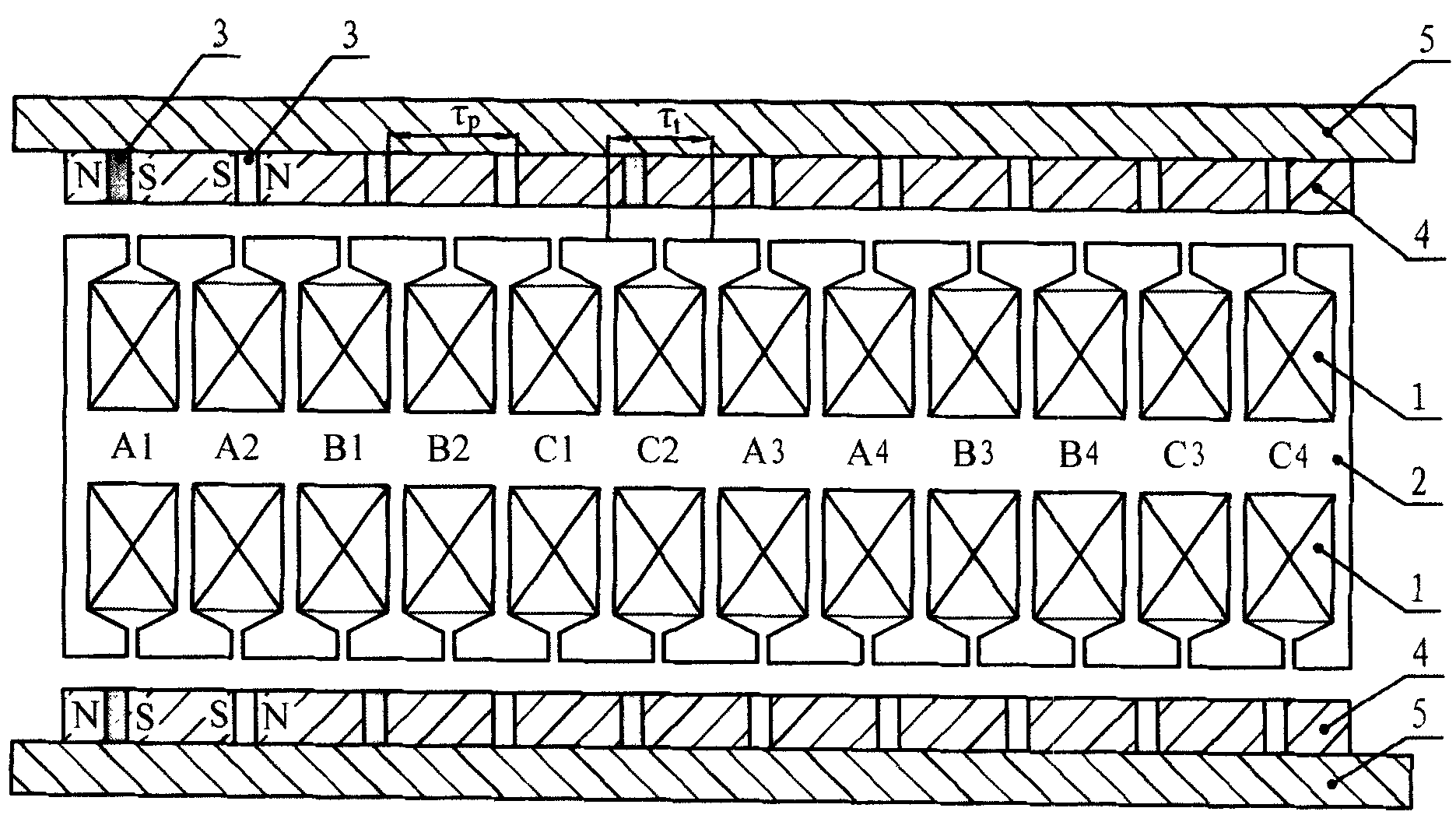

The invention relates to a multiphase long-stator primary permanent magnet linear motor which has the advantages of simple structure, firmness, stronger output thrust, higher power density and smaller thrust fluctuation. The motor comprises a stator (1), an air gap and rotors (2), wherein each rotor (2) comprises permanent magnets (3), a concentrated winding (4) and additional teeth (5); both the stator and the rotors are double-salient pole single-edges or double-edge flat-panel structures, and all concentrated winding coils of any phase are positioned in a rotor iron core slot; adjacent permanent magnets (3) form a serial magnetic circuit; the number of the permanent magnets (3) is NPM=2k*m+2, wherein k is a positive integer, and the number m of motor phases is not smaller than 3; both end parts of each rotor (2) are respectively provided with a permanent magnet which is an additional permanent magnet of each motor; the number of windings of the rotors is Nmt=(NPM-2)(m+1); and the central distance of adjacent teeth of the rotors is tau p.

Owner:SOUTHEAST UNIV

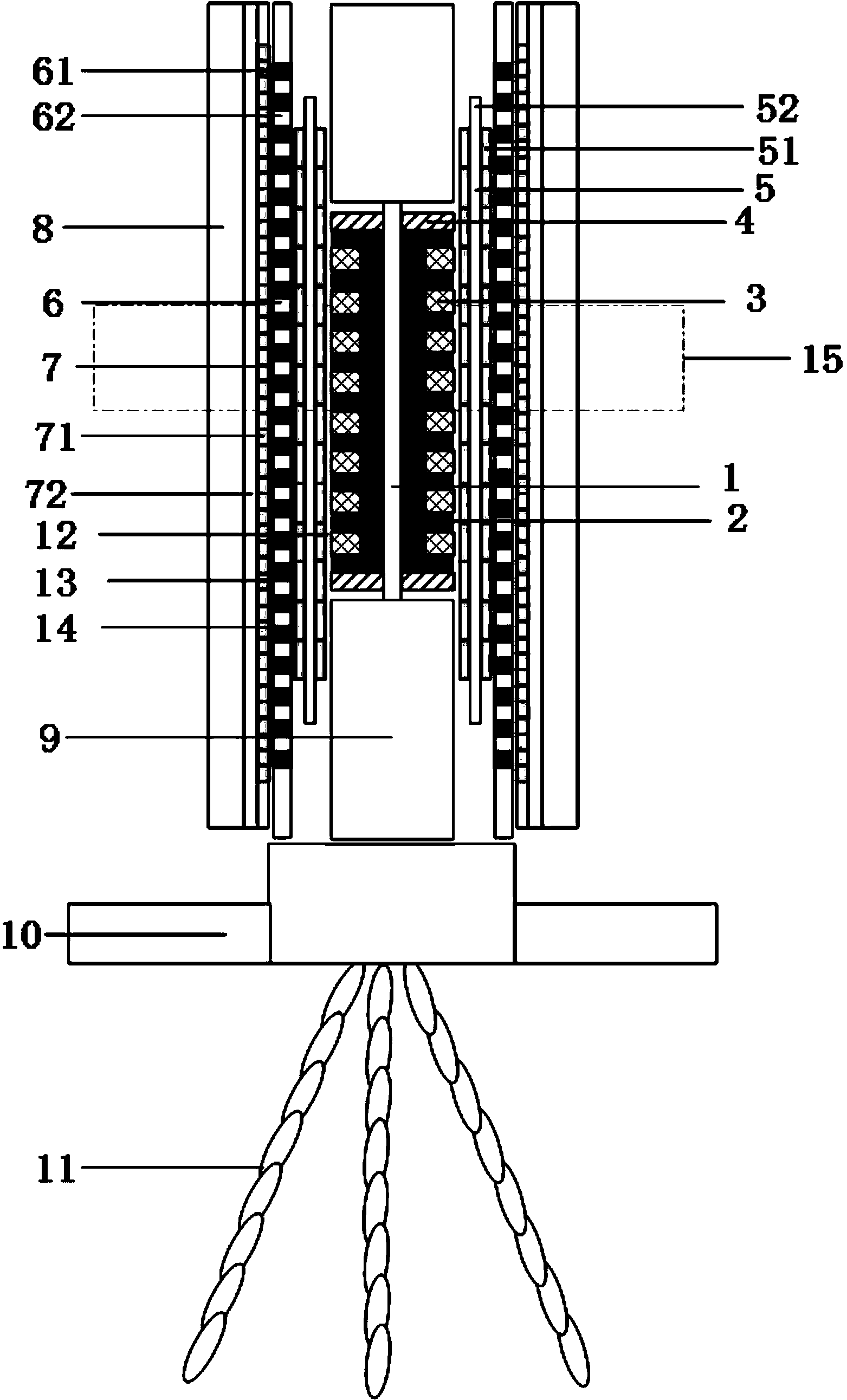

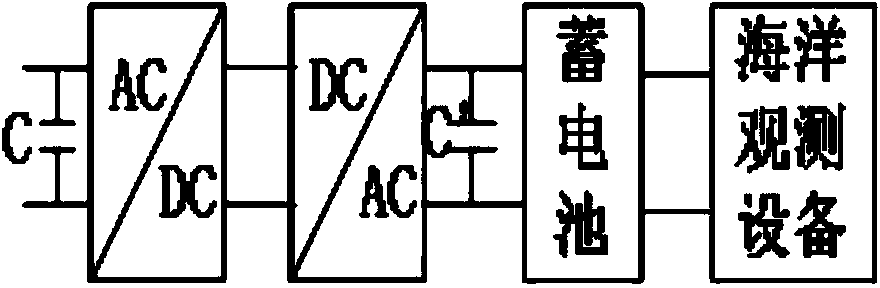

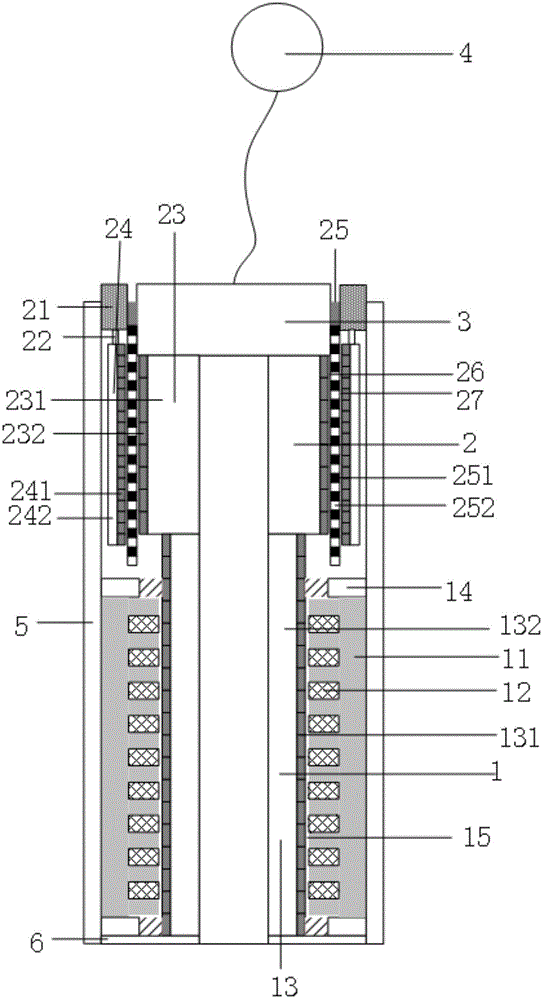

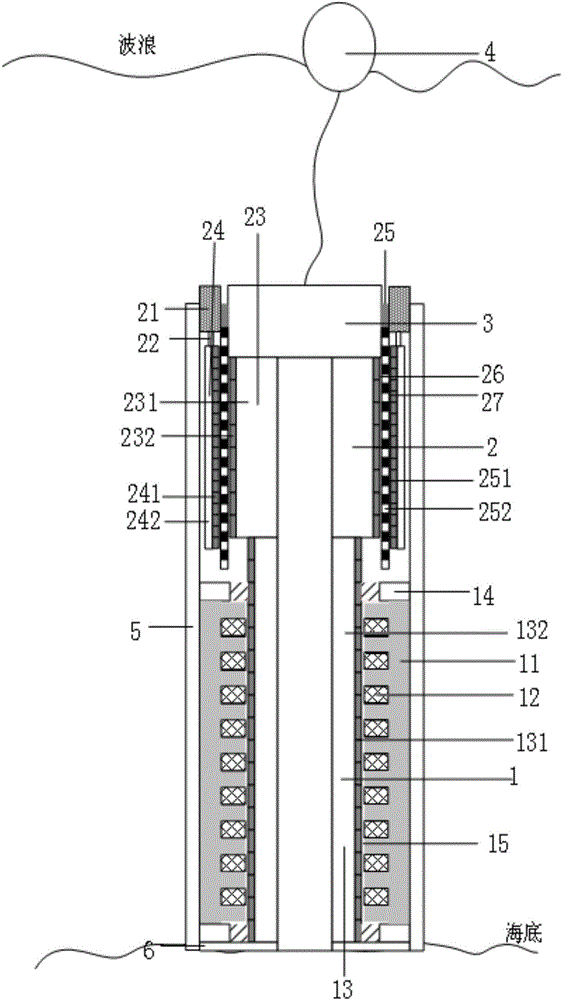

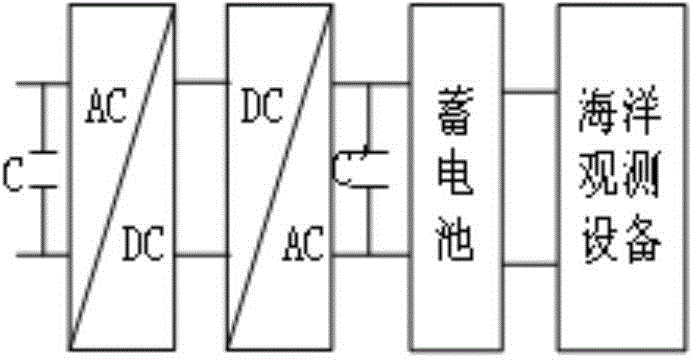

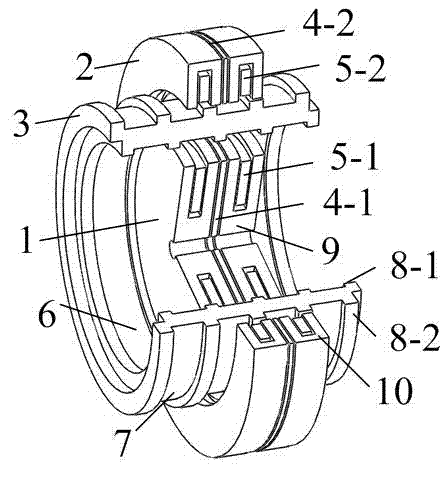

Wave power generation device based on linear magnetic gear motor

InactiveCN103807085AImprove power generation efficiencySimple structureMachines/enginesEngine componentsWave power generationLow speed

The invention discloses a wave power generation device based on a linear magnetic gear motor. The wave power generation device comprises a motor stator core, a motor converter, a magnetism regulating ring, a magnetic gear low-speed moving part, an inner floating barrel and an outer floating barrel. The motor stator core is sleeved with the motor converter, the motor converter is sleeved with the magnetism regulating ring, the magnetism regulating ring is sleeved with the magnetic gear low-speed moving part, the magnetic gear low-speed moving part is sleeved with the inner floating barrel, and the inner floating barrel is sleeved with the outer floating barrel. A first air gap is formed between the motor stator core and the motor converter, a second air gap is formed between the motor converter and the magnetism regulating ring, and a third air gap is formed between the magnetism regulating ring and the magnetic gear low-speed moving part. A motor stator shaft and the magnetism regulating ring are fixed in position, and the magnetic gear low-speed moving part and the inner floating barrel are fixed in position. The wave power generation device has the advantages that no huge speeders need to be additionally arranged, the size is small, energy capture and power generation efficiency is high, and convenience is brought to design, debugging and maintenance of an electrical control system through the whole floating suspended structure.

Owner:SOUTHEAST UNIV

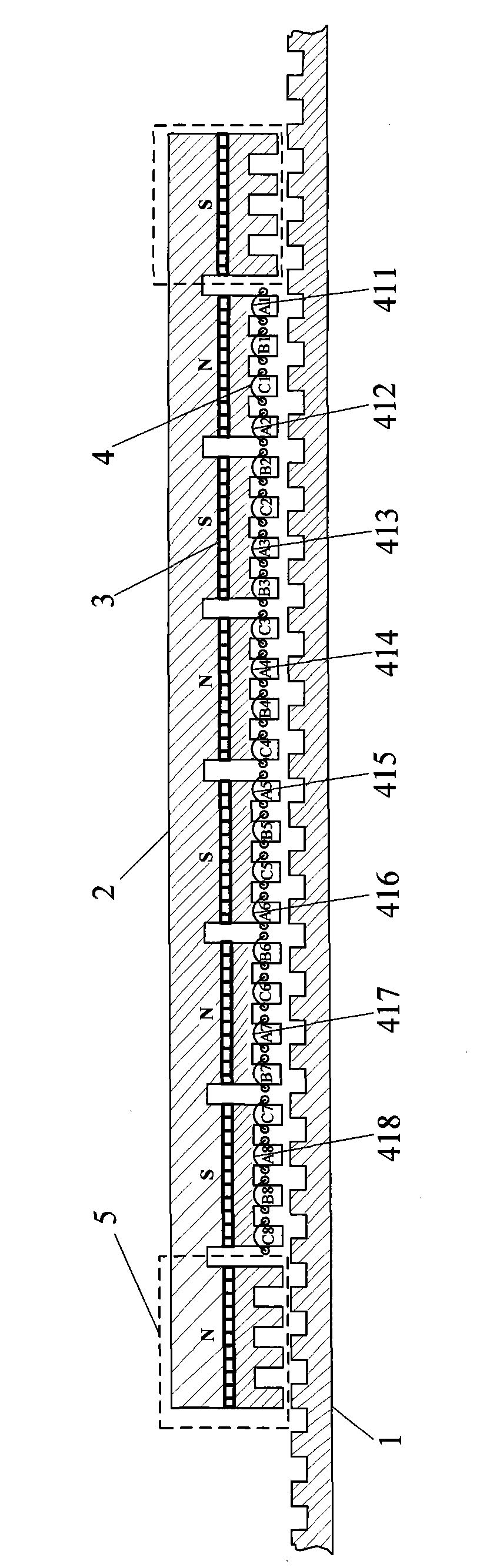

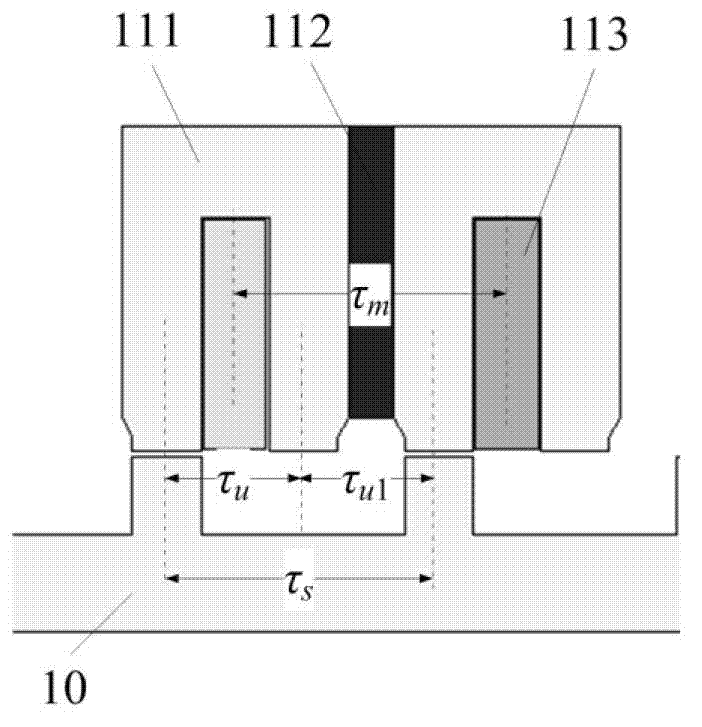

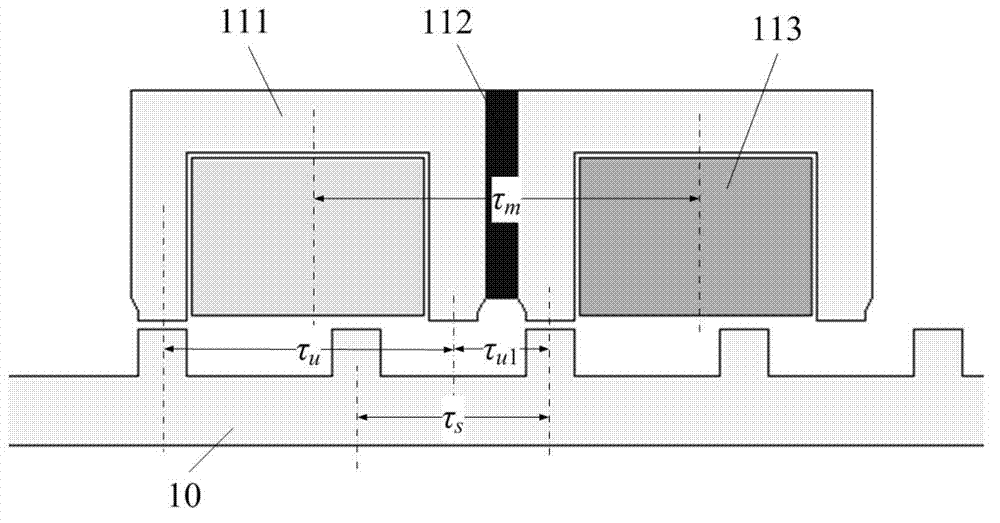

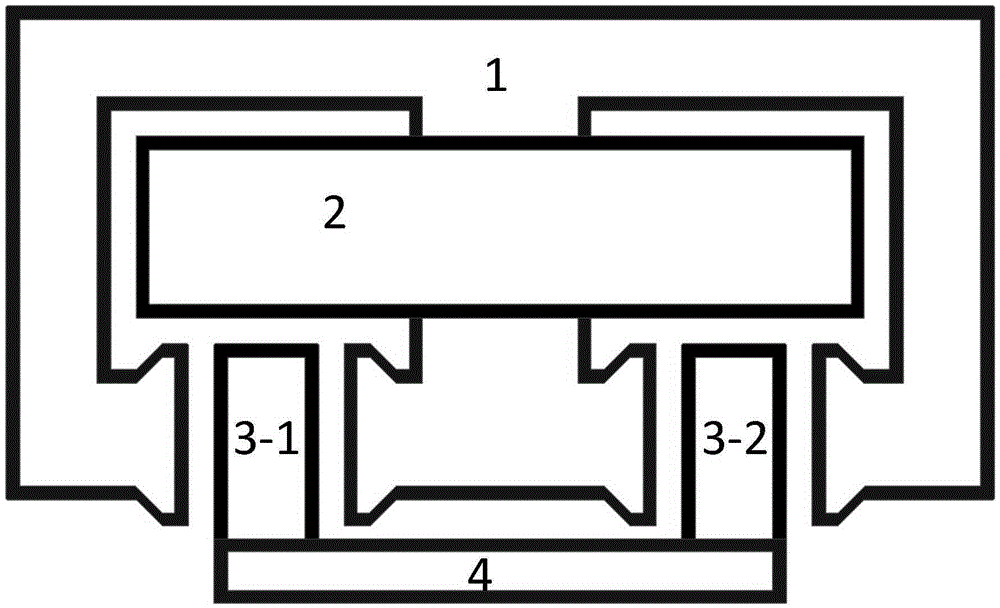

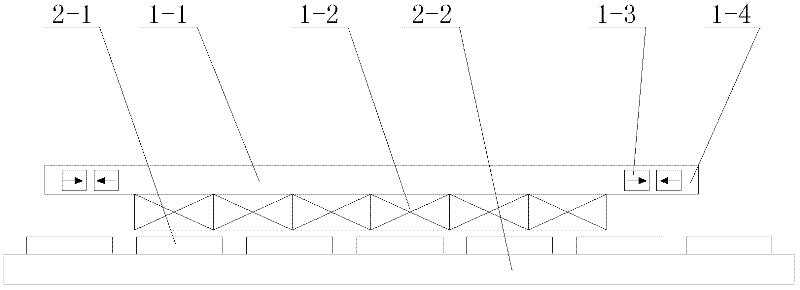

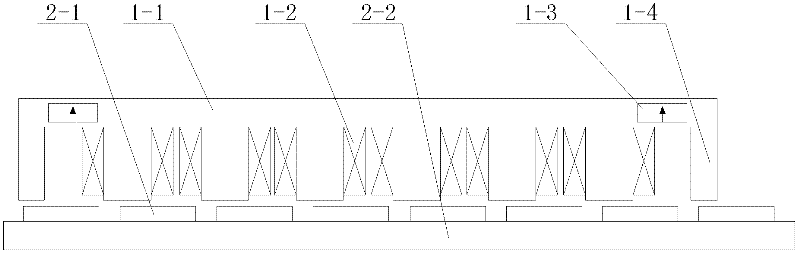

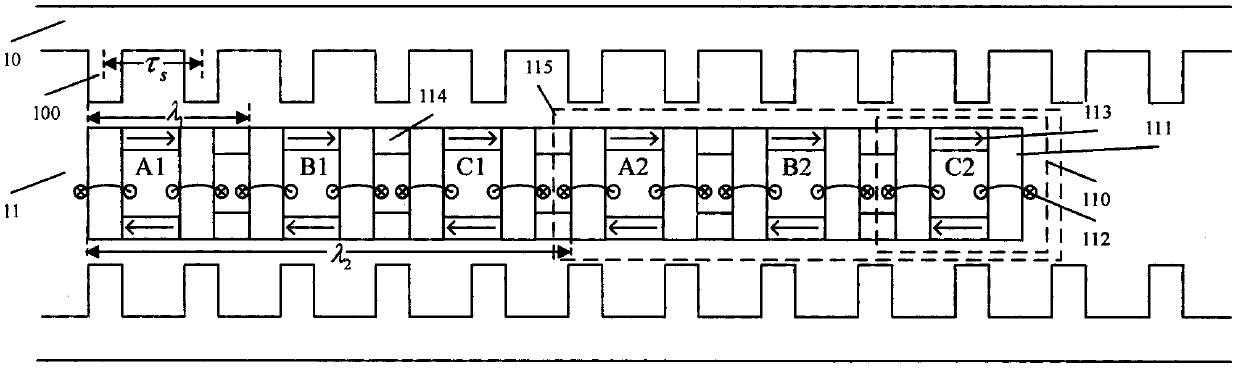

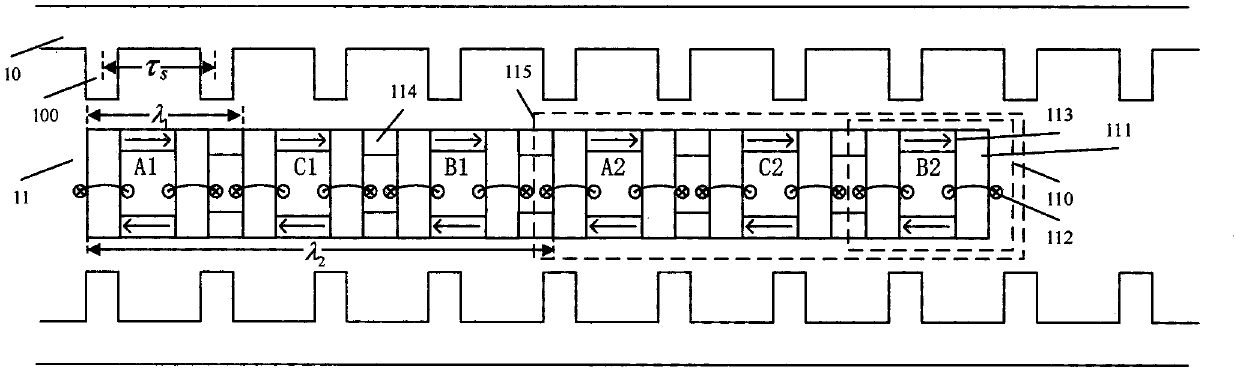

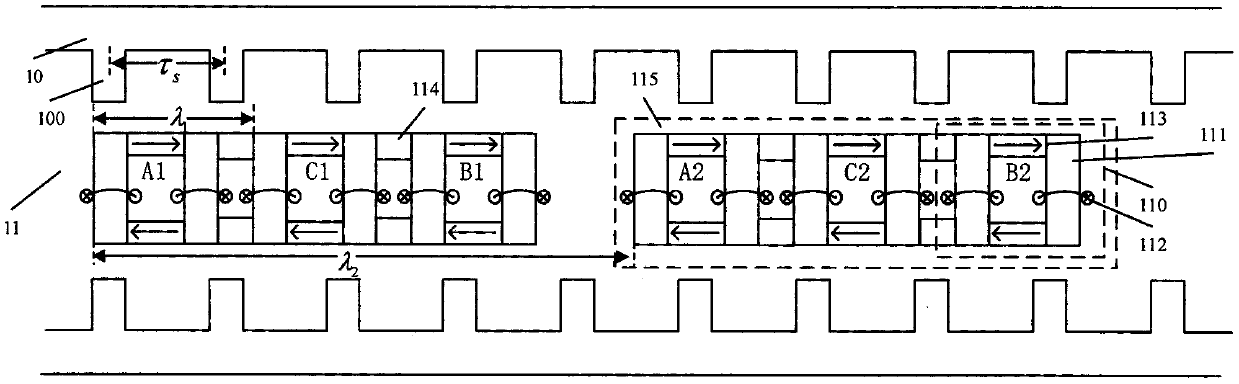

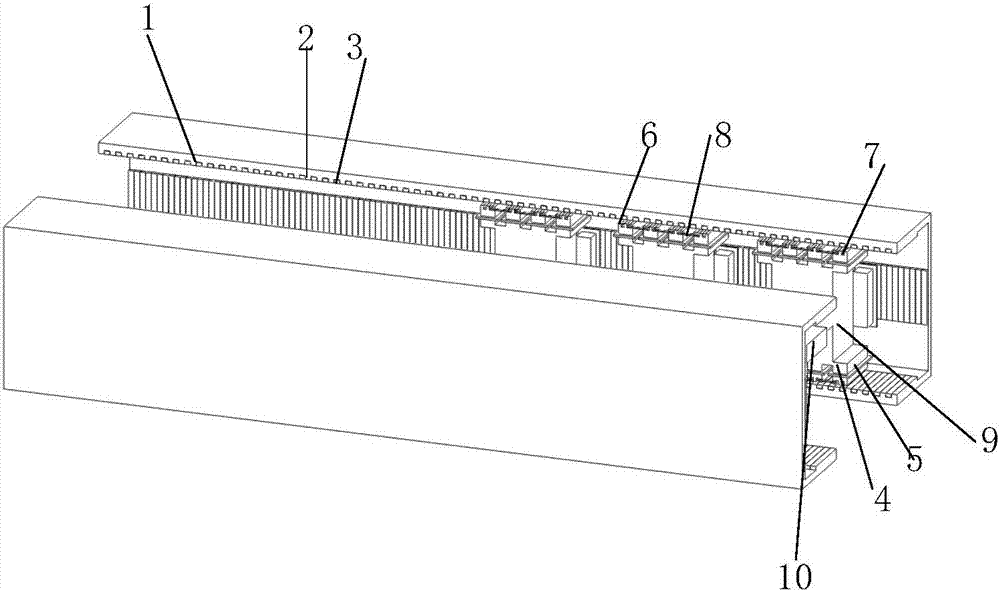

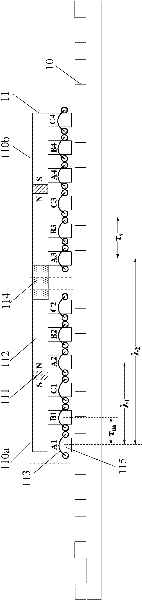

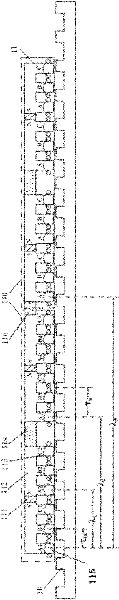

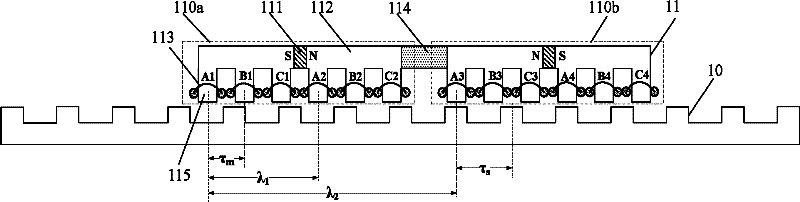

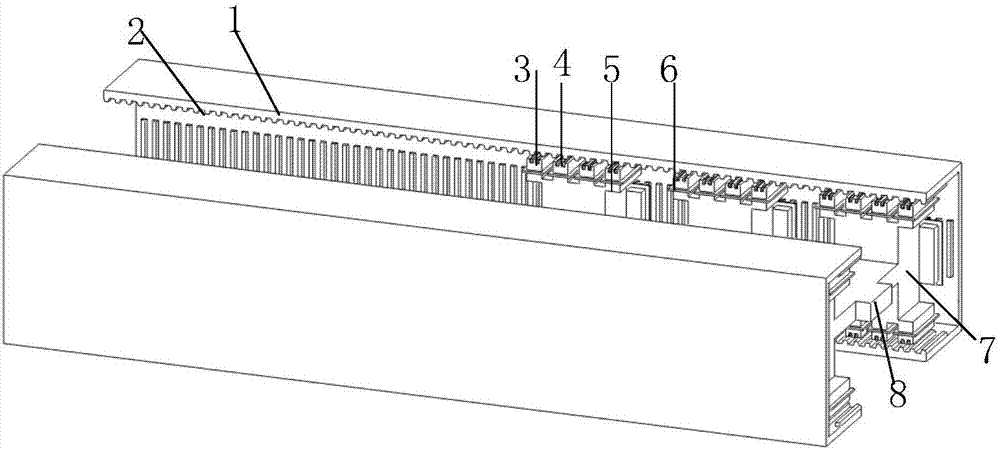

Modular primary permanent magnetic linear motor and motor module consisting of same

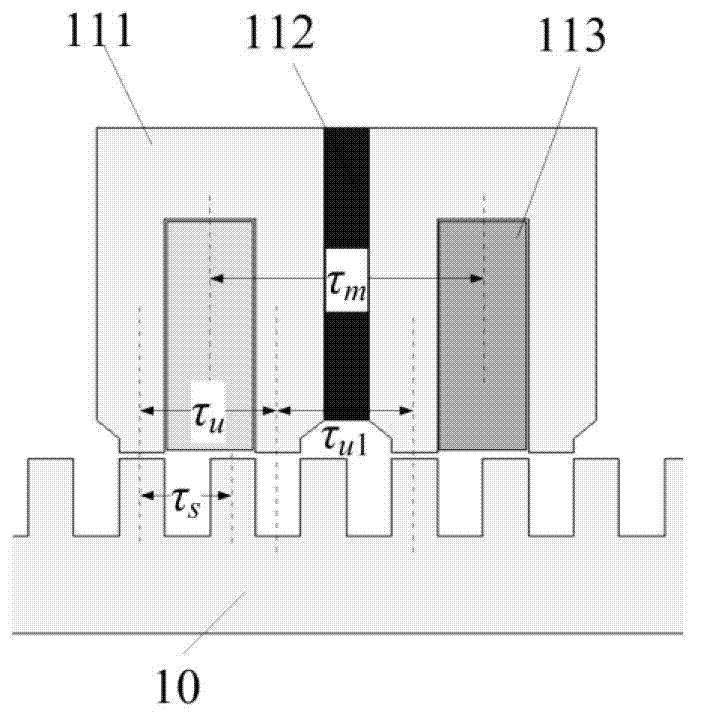

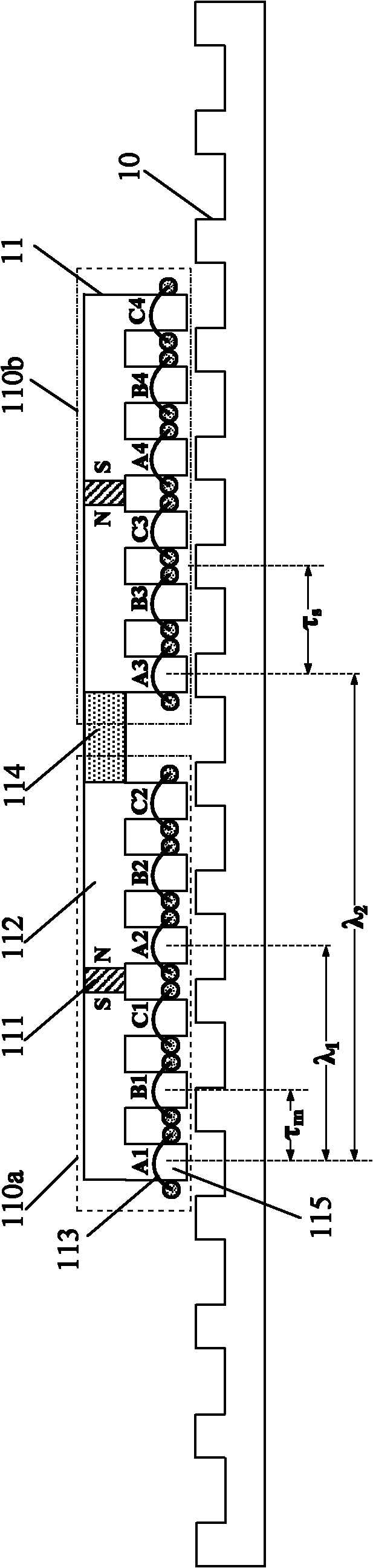

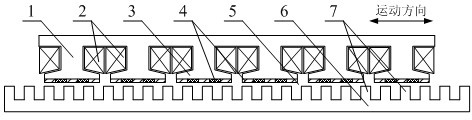

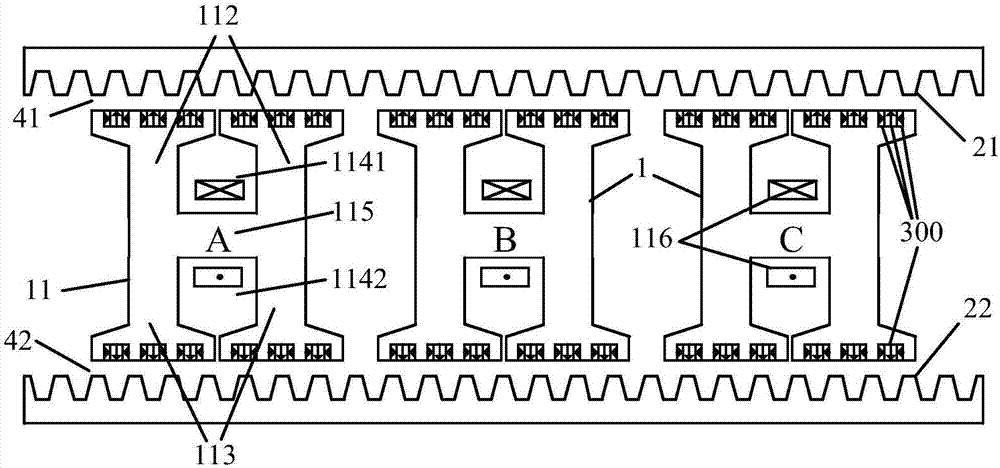

ActiveCN103051148AOffset positioning forceSimple structurePropulsion systemsRelative displacementPrimary permanent

The invention discloses a modular primary permanent magnetic linear motor and a motor module consisting of the modular primary permanent magnetic linear motor. The modular primary permanent magnetic linear motor comprises a primary and a secondary, wherein the primary comprises m or 2m primary modules; each primary module comprises two U-shaped magneto-conducting materials and a permanent magnet between the U-shaped magneto-conducting materials; and taum, taus, tauul, tauu, wmt and wst satisfy the following relational expressions that tm is equal to or approximate to ktaus, tauul is equal to or approximate to (j+0.5) taus, tauul is equal to taum-tauul, and wmt is less than or equal to wst. Relative displacement between two primary modules which belong to the same phase is lambda1 which is equal to (n+ / -0.5)taus or lambda1 which is equal to ntaus, and relative displacement between two primary modules which belong to different phases is lambda2 which is equal to (i+ / -1 / m)taus or lambda2 which is equal to [i+ / -(0.5-1 / m)]taus. The motor and the motor module have the advantages of symmetric counter potential, relatively low sine and positioning force, small thrust ripple and the like, and are applied to the places where a long secondary structure linear motor is applied.

Owner:SOUTHEAST UNIV

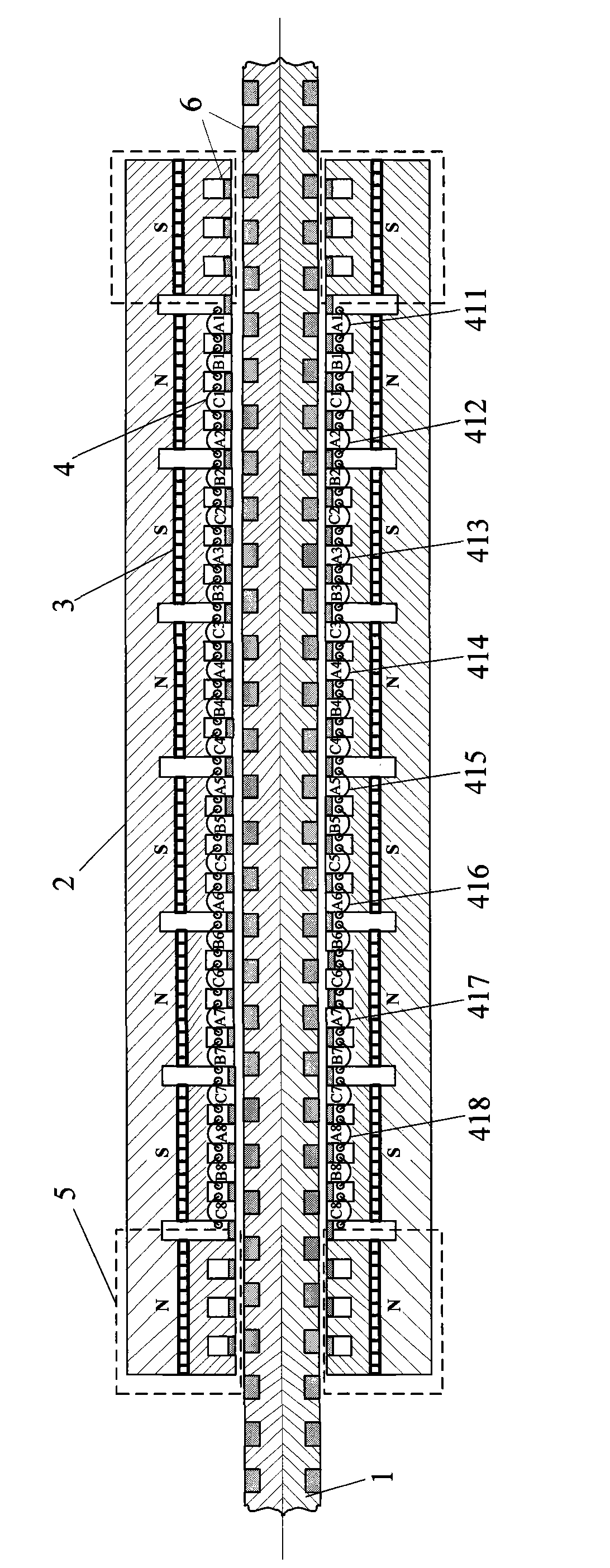

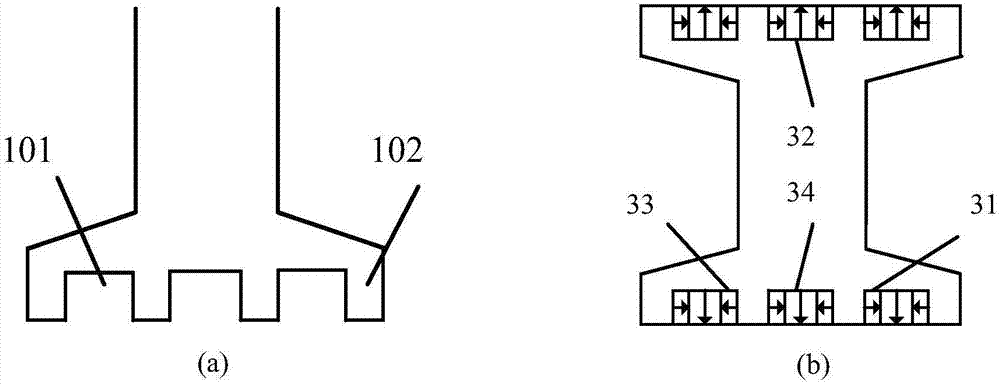

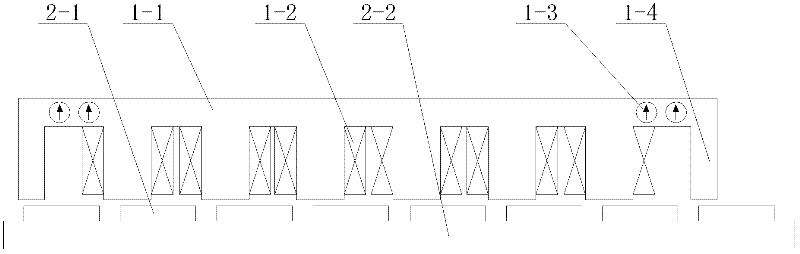

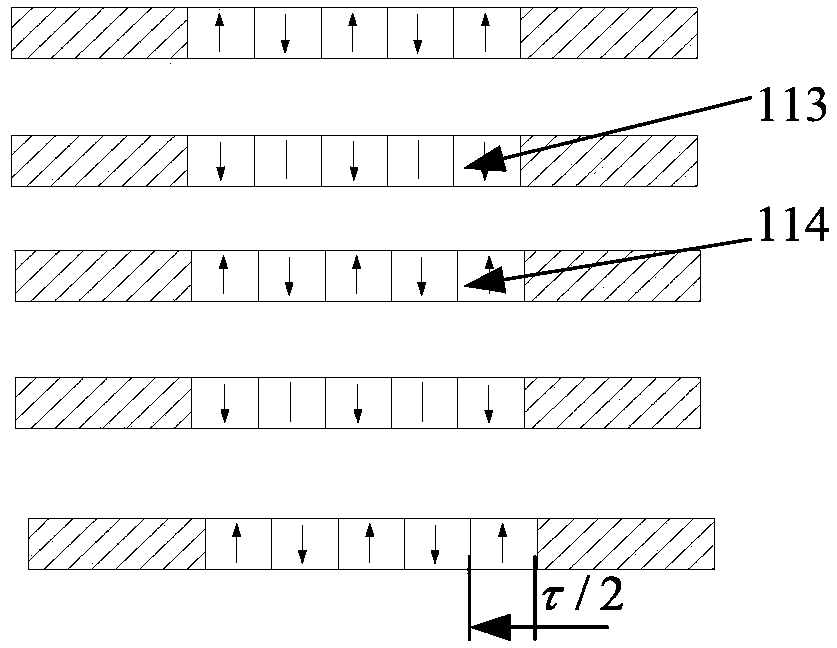

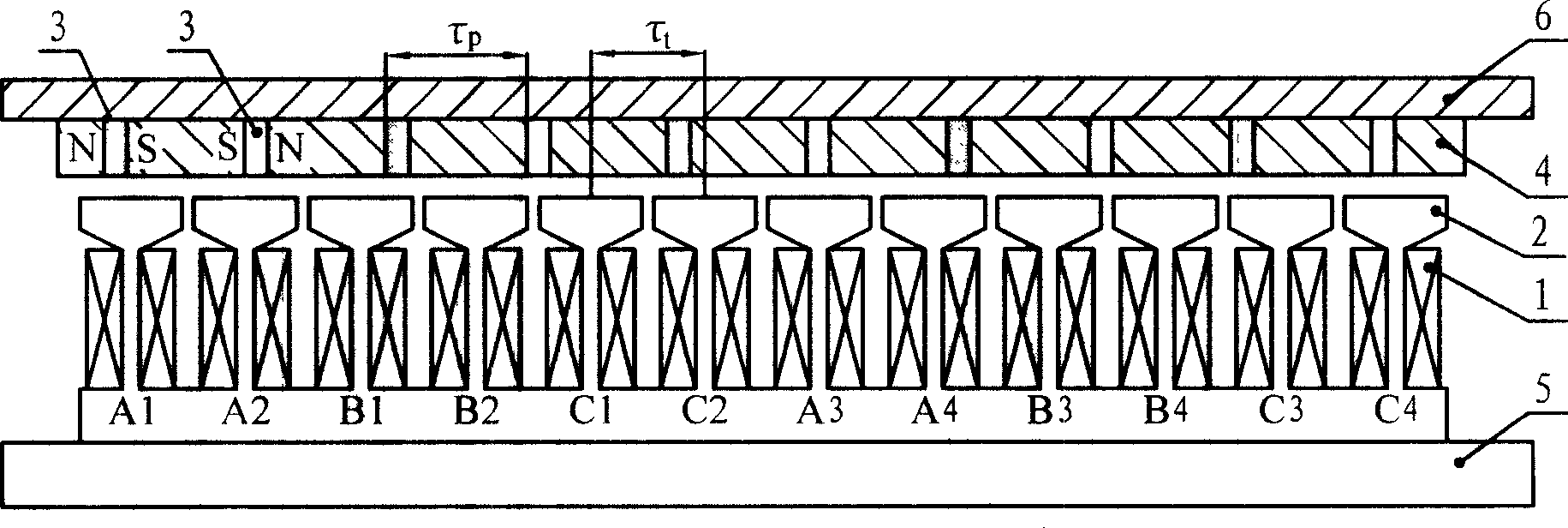

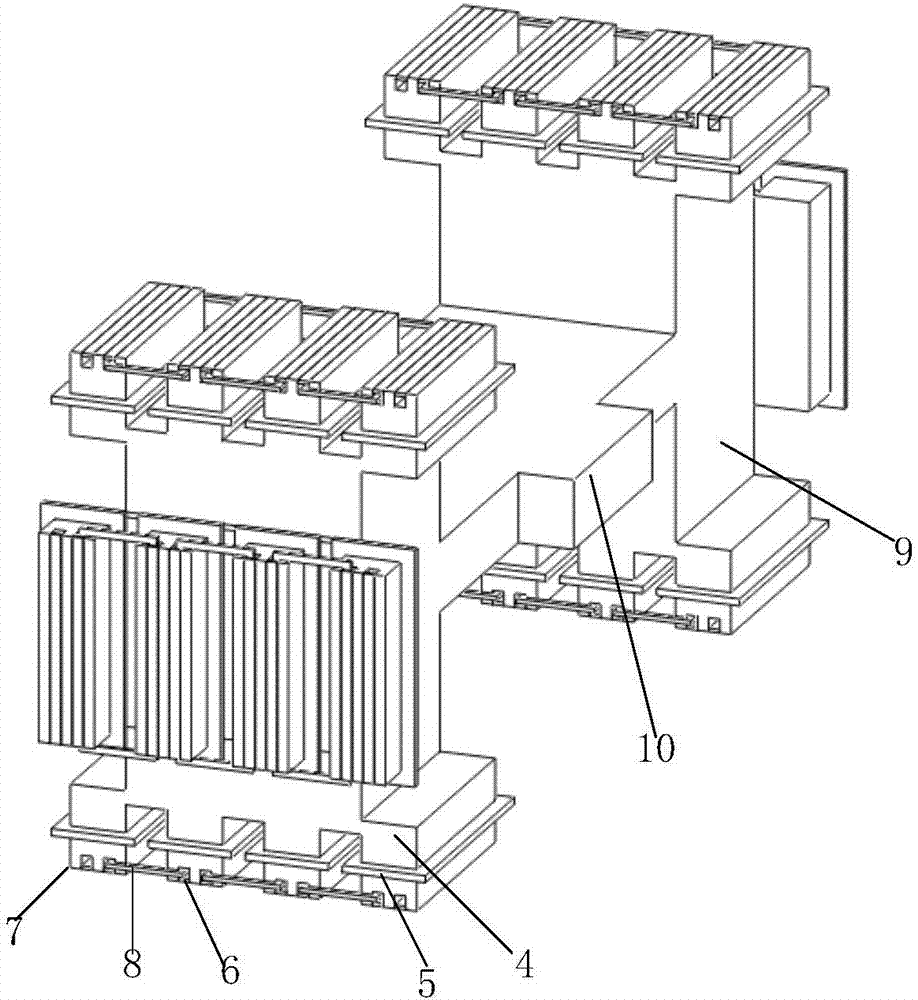

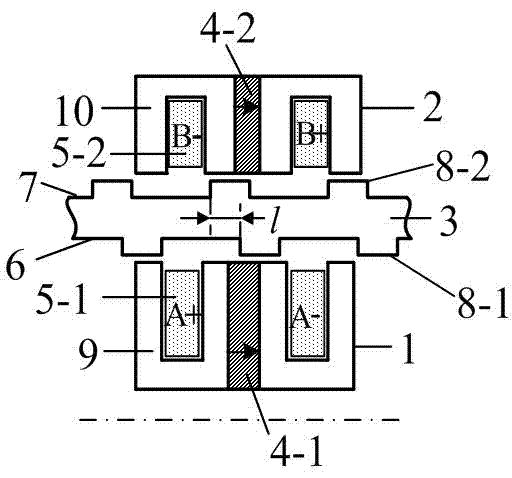

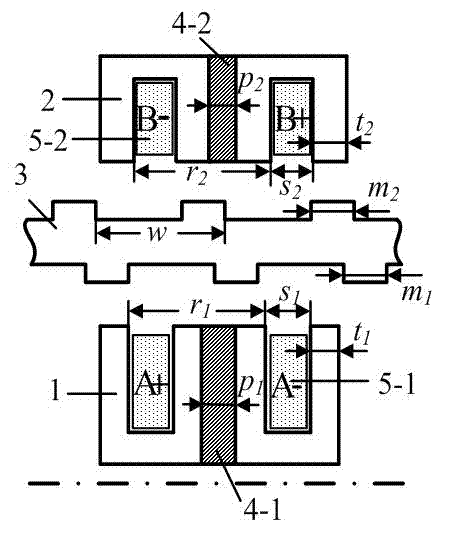

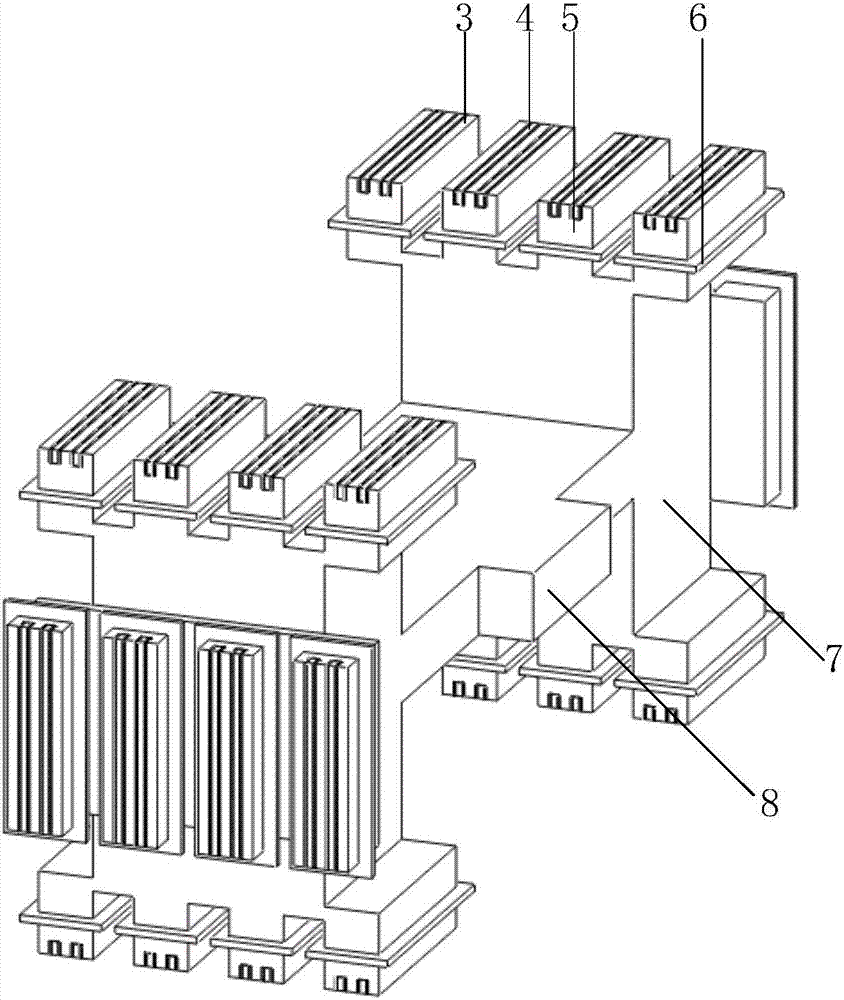

Modular complementary type primary permanent magnet linear motor and motor module formed thereby

The invention discloses a modular complementary type primary permanent magnet linear motor and a motor module formed thereby. The primary permanent magnet linear motor comprises a primary level and a secondary level; the primary level and the secondary level are respectively in a salient-pole structure, and an air gap is formed between the two levels; the primary level comprises a rotor module which comprises a first module and a second module; a first non-magnetic material is arranged between the first module and the second module; the first module and the second module both comprise two salient-pole magnetic materials and a permanent magnet arranged between the two salient-pole magnetic materials; the salient-pole magnetic material is provided with m numbered primary teeth, and a central armature winding is arranged on the primary teeth; the relative displacement between the first module and the second module is calculated as follows: lambda2=(k+ / -0.5) tau s; the relative displacement between the adjacent two salient-pole magnetic materials is calculated as follows: lambda1=m*tau m; and the ratio of the primary polar distance to the secondary polar distance is as follows: tau m: tau s=(m+ / -1):m. The invention has the advantages of symmetric back electromotive force, relatively small positioning force, low thrust fluctuation and the like and is applicable to the application occasion of a linear motor with a long-stator structure.

Owner:SOUTHEAST UNIV

Wave energy power generating device based on serial connection linear magnetic gear motor

InactiveCN104061116AImprove power generation efficiencySimple structureDynamo-electric gearsMachines/enginesElectric machinePermanent magnet linear motor

The invention discloses a wave energy power generating device based on a serial connection linear magnetic gear motor, and belongs to a power generating device combining a linear magnetic gear and a permanent-magnet linear motor through serial connection. The wave energy power generating device comprises a permanent-magnet linear motor part, a linear magnetic gear part, a floating tube, a floater, an external encapsulation device and a base, wherein an outer rotor is driven by a driving motor and a mechanical transmission part to move in a certain moving range, the goal of variable transmission ratio is achieved, and the whole set of device has the advantages that the additional arrangement of a huge accelerator is not needed, the size is smaller, the energy capturing and power generating efficiency is high, no terminal winding is adopted, no radial force is exerted on a bearing, and the like.

Owner:SOUTHEAST UNIV

High-thrust permanent magnet direct drive linear electric motor

InactiveCN102082490ARealize the effect of speed-upIncrease thrust densityPropulsion systemsElectric machineMagnetic reluctance

The invention relates to a high-thrust permanent magnet direct drive linear electric motor, comprising a motor primary and a motor secondary, wherein the motor primary comprises a primary iron core (1) with a slot, an armature winding (2), primary pole shoes (3) and permanent magnets (4), wherein the armature winding (2) is embedded into the slot of the primary iron core (1); the permanent magnets (4) are arranged on the surfaces of the primary pole shoes (3); the motor secondary comprises a secondary iron core (6) and secondary salient poles (7); an air gap (5) exists between the motor primary and the motor secondary; and the motor primary is fixed, and the motor secondary linearly moves along with the motion direction of a motor. The motor comprises a unilateral flat-plate structure, a bilateral flat-plate structure, and a cylindrical structure. In the high-thrust permanent magnet direct drive linear electric motor, the special structures of the motor are utilized to modulate the air gap reluctance distribution of the motor. When the motor is in operation, the movement velocity of a permanent magnetic flux in the motor primary is multiplied of that of a permanent magnetic flux in the motor secondary, thus realizing the speed-raising effect. The high-thrust permanent magnet direct drive linear electric motor is applied to low-speed direct drive application occasions, and has the characteristics of high power density, large rated thrust and the like.

Owner:SOUTHEAST UNIV

Magnetic field modulation permanent magnet linear motor capable of improving winding utilization rate and optimum design method thereof

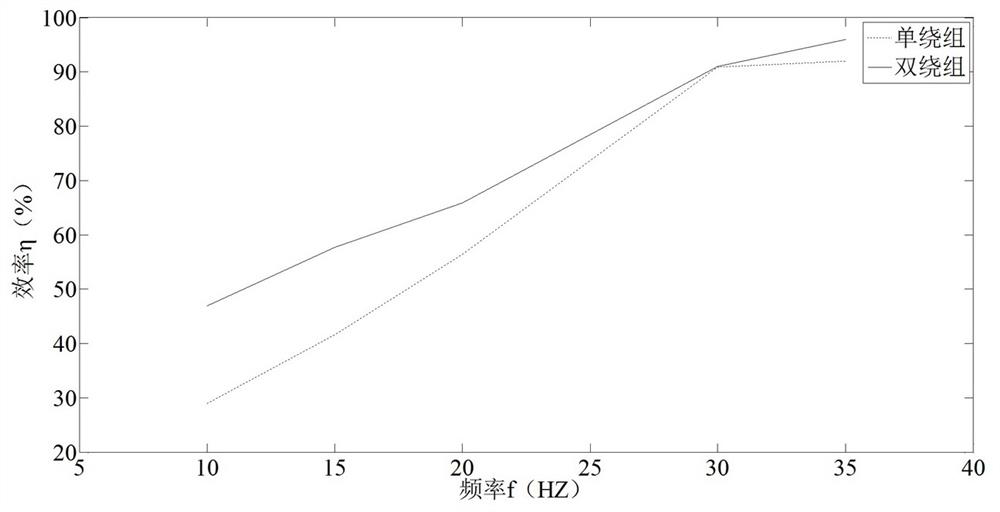

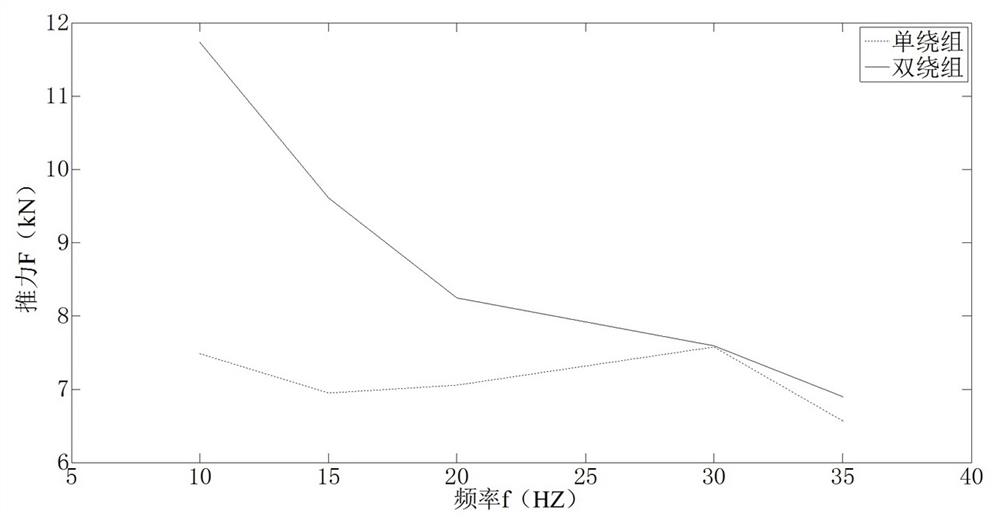

ActiveCN106992655AImprove fault toleranceImprove stabilityPropulsion systemsEngineeringPerformance index

The invention discloses a magnetic field modulation permanent magnet linear motor capable of improving winding utilization rate and an optimization design method thereof, and belongs to the field of a permanent magnetism motor. The permanent magnet linear motor comprises a single primary side and double secondary sides. An air gap is arranged between the single primary side and each of the double secondary sides. The single primary side is formed by three unit modules. Each unit module is slotted in the sides close to the air gaps to form four primary teeth and two primary slots. The tooth end of each primary tooth is provided with a plurality of virtual slots and virtual teeth in the motor motion direction, wherein the number of the virtual teeth is larger by one than that of the virtual slots, and each virtual slot is embedded by a magnetic concentrating unit formed by three permanent magnets. Three phases of windings in the primary slots are wounded on yoke portions of the three primary unit modules respectively; and each phase of winding can cut magnetic force lines generated by the permanent magnets on the four primary teeth in the corresponding module simultaneously. The permanent magnet linear motor improves winding utilization rate, reduces half of the winding use amount and reduces copper consumption under the condition of ensuring that performance indexes of no-load counter potential, thrust output, permanent magnet use amount and fault-tolerant capability and the like are not influenced.

Owner:常熟市董浜科技创业投资发展有限公司

Double-permanent-magnet lateral magnetic flux linear permanent magnet motor

InactiveCN105356720ACompact structureEasy to assemblePropulsion systemsElectric machinePermanent magnet motor

The invention discloses a double-permanent-magnet lateral magnetic flux linear permanent magnet motor, and the motor comprises a primary mechanism and a secondary mechanism. The primary mechanism comprises a plurality of primary units in the same structure, and each primary unit comprises a magnetic conduction part and an armature winding. The magnetic conduction part is provided with three projection parts: a main magnetic tooth and auxiliary magnetic teeth located at two sides of the main magnetic tooth. The armature winding is wound around the periphery of the main magnetic tooth. The secondary mechanism comprises a permanent magnet fixing plate and a permanent magnet matrix, wherein the permanent magnet matrix comprises a plurality of permanent magnets which are arranged in parallel. The two rows of permanent magnets are sequentially fixed at two sides of the permanent magnet fixing plate in a one-one corresponding manner. There are gaps between the magnetic conduction part and the permanent magnets. The motor can achieve a purpose that one iron core lamination is corresponding to two parallel magnetic flux loops of one armature winding, is simple in structure, is short in each magnetic loop, is higher in force density, and is smaller in output force fluctuation. The shorter magnetic loop can reduce the eddy-current loss of the motor, improves the efficiency of the motor, and improves the utilization rate of the permanent magnets.

Owner:SHANDONG UNIV

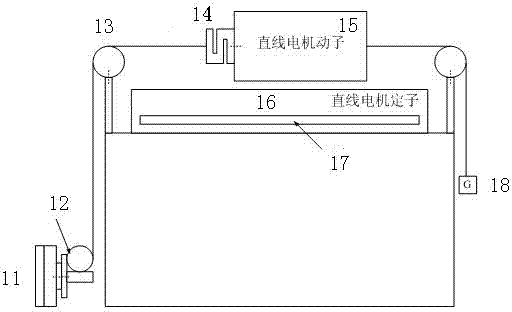

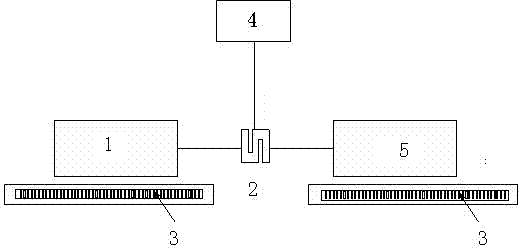

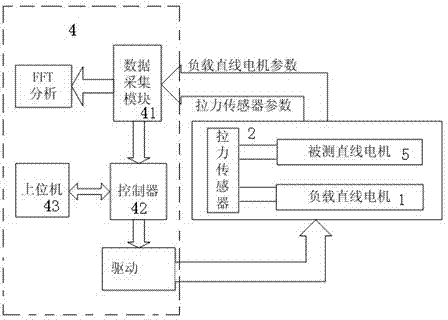

Electromagnetic thrust of linear motor and thrust fluctuation test apparatus

InactiveCN102353492AFrictionlessReduce positioning forceApparatus for force/torque/work measurementDynamo-electric machine testingElectric machineLinear motor

The invention discloses an electromagnetic thrust of a linear motor and a thrust fluctuation test apparatus. The apparatus comprises a load linear motor, a drawing force transducer, a raster ruler and a data processor. Besides, one end of the drawing force transducer is connected with the load linear motor and the other end of the drawing force transducer is connected with a to-be-detected linear motor; a signal output terminal of the drawing force transducer is connected with the data processor; the load linear motor and the to-be-detected linear motor are arranged on the raster ruler; and the load linear motor is a gullet-free linear motor with magnetic suspension. According to the invention, the structure is simple and the testing precision is high; therefore, the apparatus is suitable for an electromagnetic thrust of a linear motor and a thrust fluctuation test; and the apparatus can also be applied to a test on a dynamic performance of a motor.

Owner:SOUTHEAST UNIV +1

Positioning force compensating type linear permanent magnet synchronous motor

ActiveCN102403872ARestraint end positioning forceDoes not affect the outputPropulsion systemsSurface mountingPermanent magnet synchronous motor

The invention relates to a positioning force compensating type linear permanent magnet synchronous motor which belongs to the technical field of motors and solves the problems that the existing method for reducing the fluctuation of the push force of the linear motor only can restrain the fluctuation of the motor to a certain extent and simultaneously reduces the effective push force of the motor. An air gap is arranged between a primary and a secondary of the motor, the primary comprises an armature iron core and an armature winding and is in a structure of surface mounted armature winding or a cogging structure, the positioning force generated by the interaction of compensating parts and a secondary permanent magnet and the positioning force generated by interaction of the primary iron core and the secondary permanent magnet can be mutually counteracted through the addition of the compensating parts at the yoke parts of two ends of the armature iron core of the primary and using permanent magnets to perform magnetism isolation, so that the acting forces at the front end part and the rear end part of the motor are mutually counteracted. The detent force compensating type linear permanent magnet synchronous motor is suitable for linear permanent magnet synchronous motors.

Owner:HARBIN INST OF TECH

Fault-tolerate primary permanent magnetic vernier linear motor

The invention discloses a fault-tolerate primary permanent magnetic vernier linear motor, which is applied to the field of high-reliability linear driving and comprises a primary winding, a secondary winding and an armature winding; the secondary winding is a simple salient pole structure with ladder-shaped teeth and is longer than the primary winding, an air gap exists between the primary and secondary windings, armature teeth with even number are uniformly distributed on the primary winding, a set of concentrated winding is wound on each armature tooth, a fault-tolerate tooth is arranged between adjacent two armature teeth, a permanent magnet with the magnetizing direction being parallel to the central symmetrical axis of the armature is attached to the lower face of each armature tooth, the permanent magnets are uniformly distributed on each armature tooth, the magnetizing direction of each permanent magnet is in N-S and S-N alternative arrangement, and the magnetizing directions of the permanent magnets on all armature tooth are same in arranging sequence; and the height of the fault-tolerate tooth is equal to the sum of the heights of the armature tooth with the face being attached to the permanent magnetic and the permanent magnet. The fault-tolerate primary permanent magnetic vernier linear motor is simple in structure, large in pushing force, small in pushing force pulse, high in reliability and strong in the running property of the motor with the fault and fault-tolerate property.

Owner:江苏良基集团有限公司

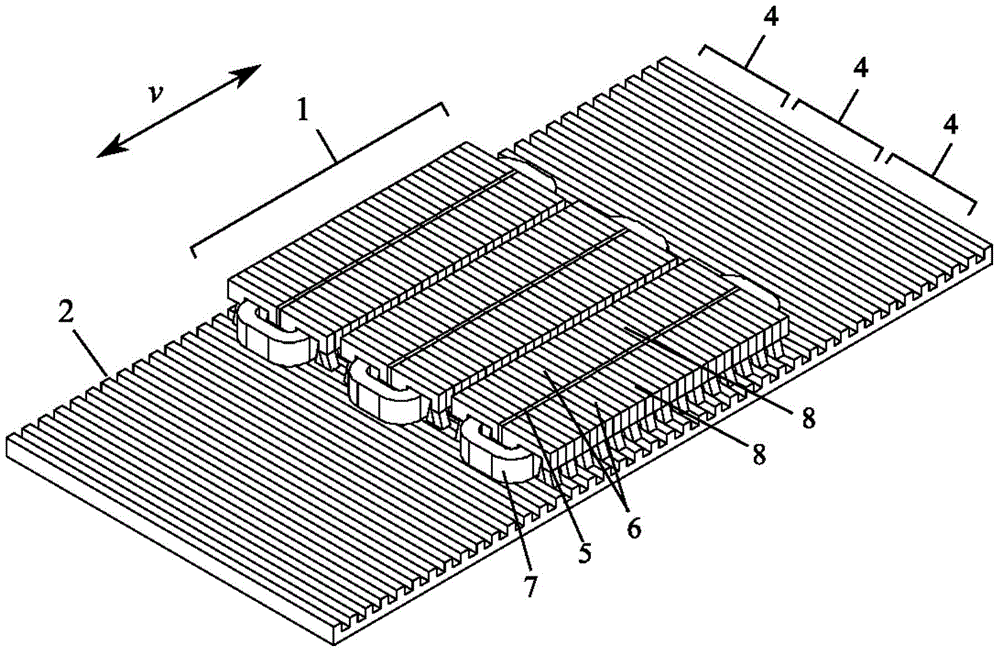

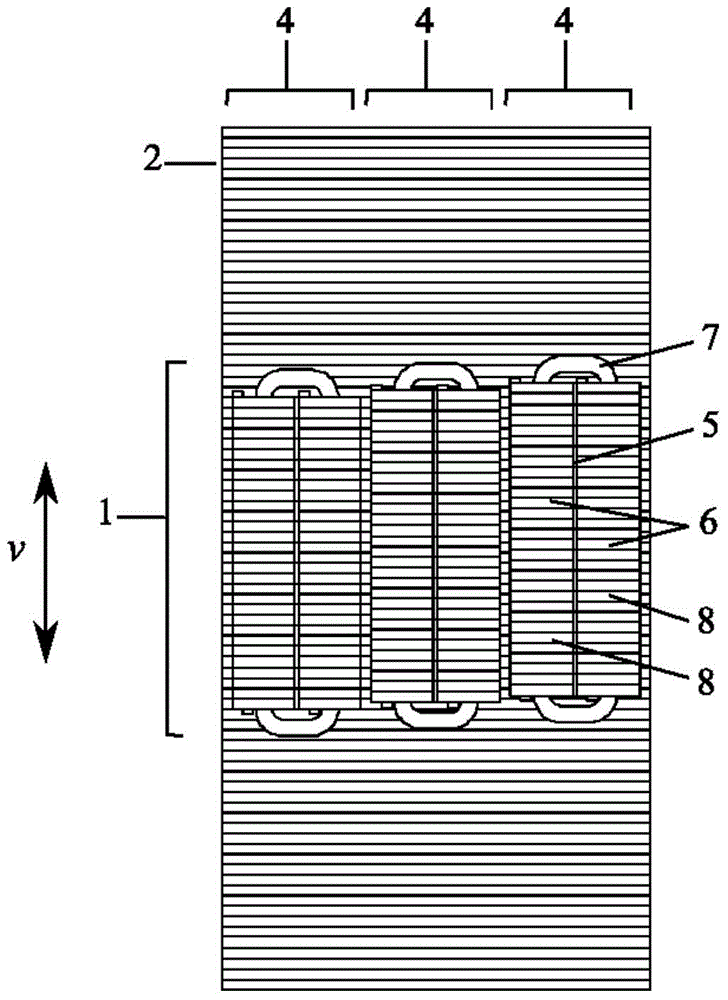

Flat-plate-type transverse magnetic flux switching permanent magnet linear motor

InactiveCN104167897AEasy to processIncrease production capacityPropulsion systemsElectrical steelElectric machine

The invention discloses a flat-plate-type transverse magnetic flux switching permanent magnet linear motor. The motor comprises a flat-plate-type motor primary and a flat-plate-type motor secondary, wherein the motor primary and the motor secondary are oppositely installed, an air gap face is arranged between the motor primary and the motor secondary, and permanent magnets and windings are installed on the motor primary and operate based on a magnetic flux switching principle. The motor is characterized in that the motor primary further comprises one or more primary units, each primary unit comprises a primary unit iron core, each primary unit iron core is composed of two primary unit iron core blocks perpendicular to the moving direction v, and the primary unit iron core blocks are formed by overlapping primary electrical steel sheets in the moving direction v; the motor secondary is formed by overlapping secondary electrical steel sheets in the moving direction v. The motor has the advantages that the structure and the production technology are simple, the primary and the secondary can be overlapped for reducing iron loss, the utilization rate of the permanent magnets and the windings is high, a permanent magnetic circuit is even in magnetic conductance and small in positioning force and eddy current, power thrust is only related to the length of the motor, and rapid designing in batches can be performed.

Owner:SOUTHEAST UNIV

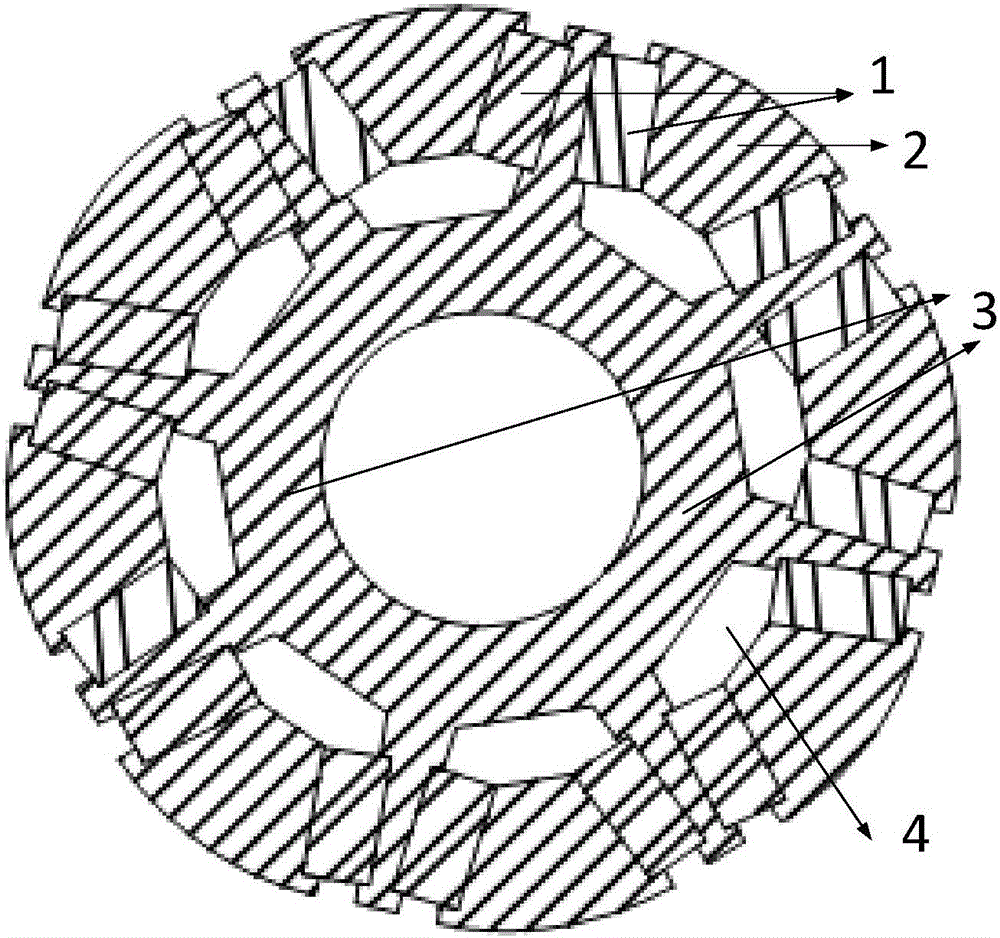

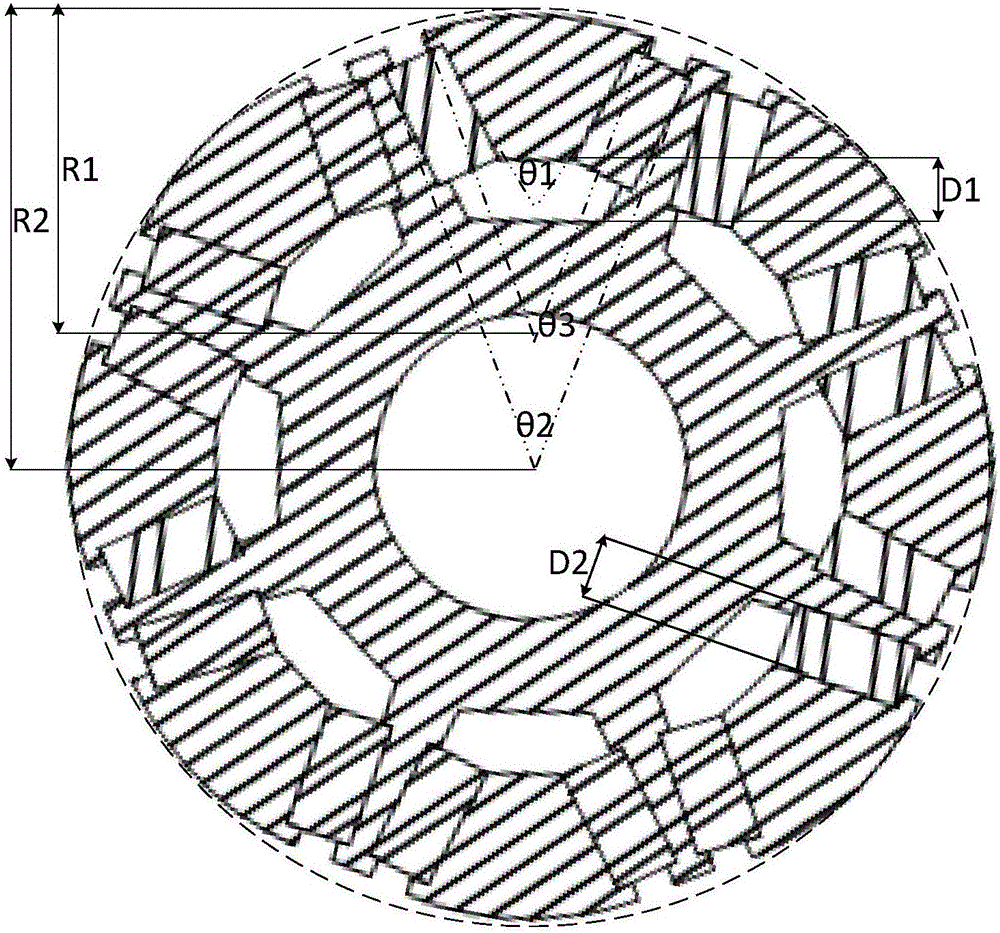

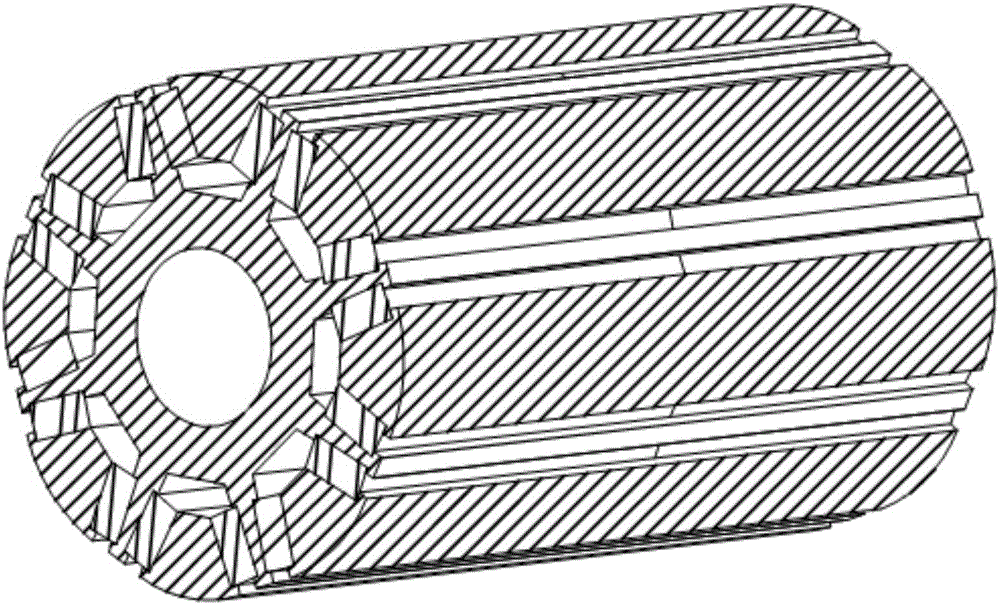

Rotor with quasi-V-shaped magnetic steel structures and suitable for high-performance motor

InactiveCN106411007AIncrease air gap flux densityReduce positioning forceMagnetic circuit rotating partsTemperature controlAir gap flux density

The invention discloses a rotor with a quasi-V-shaped magnetic steel structures and suitable for a high-performance motor. The rotor comprises a main rotor core, quasi-V-shaped magnetic steel and auxiliary rotor cores, the quasi-V-shaped magnetic steel and auxiliary rotor cores are arranged in the outer side of the main rotor core, the main rotor core of a hollow structure is provided with multiple toothed portions in the outer side, each quasi-V-shaped magnetic steel structure composed of the quasi-V-shaped magnetic steel and the auxiliary rotor core is arranged between two adjacent toothed portions, and a cooling channel exists between each quasi-V-shaped magnetic steel structure and the external surface of the main rotor core. Compared with a present rotor of a permanent magnetic motor, the air-gap magnetic flux density is high, the gullet torque is small, and harmonic waves are low; the salient rate is high, and convenience is provided for field weakening control; a short magnetic circuit is avoided effectively, and magnetic flux leakage is little; and the cooling channels are provided to improve temperature control.

Owner:SOUTHEAST UNIV

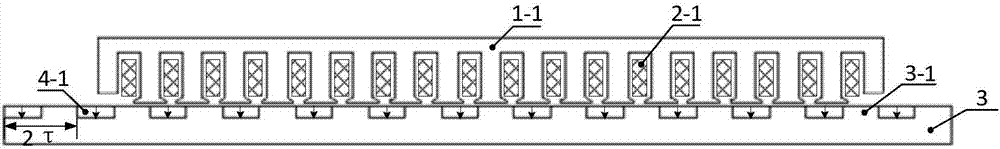

Staggered continuous pole permanent magnet synchronous linear motor

The invention discloses a continuous staggered pole permanent magnet synchronous linear motor which comprises a primary, a secondary and an air gap formed between the primary and the secondary. The primary comprises multi-tooth primary iron cores and primary armature windings. The secondary comprises a secondary back yoke iron core, a permanent magnet-iron pole array, and a magnetic isolation material. The permanent magnet-iron pole array is arranged at the upper surface of the secondary back yoke iron core and is laterally divided into two groups with a same length, each group of iron pole and secondary back yoke iron core are integratedly formed, and a magnetic isolation material is arranged between the two groups. The polarities of one group are alternately arranged according to a sequence of N-iron pole-N, the polarities of the other group are alternately arranged according to a sequence of iron pole-S-iron pole, permanent magnets used by the two groups have opposite polarities and are arranged in staggered way, the distance between adjacent secondary permanent magnets is 2tau, and an array is formed according to a cycle of 2tau. Compared with a conventional permanent magnet synchronous linear motor, the continuous staggered pole permanent magnet synchronous linear motor has the advantages of less permanent magnets, a high utilization ratio of the permanent magnets, good thrust performance, high economy and practicability and can be applied in industrial occasions with low speed movement.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

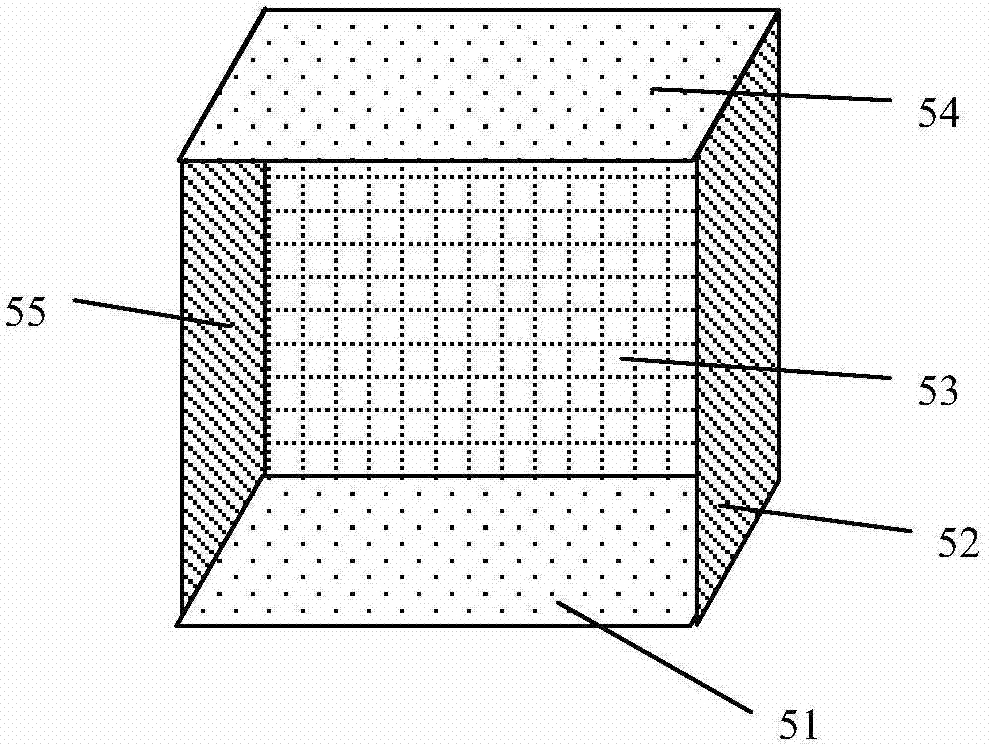

Three-dimensional magnetic flux permanent magnet linear motor of multi-air-gap independent winding structure

InactiveCN103915971AIncrease thrust densityIncrease the air gap areaPropulsion systemsElectric machinePermanent magnet linear motor

The invention provides a three-dimensional magnetic flux permanent magnet linear motor of a multi-air-gap independent winding structure and belongs to the technical field of motors. The three-dimensional magnetic flux permanent magnet linear motor comprises a primary assembly, a secondary assembly and multiple air gaps. The primary assembly comprises n primary units and armature windings, and the primary units are arranged perpendicular to the horizontal direction. An array composed of 2m+1 permanent magnets arrayed in a polarity staggering mode is arranged on each primary unit, the width of each permanent magnet is T / 2 (T is polar distance), and two rectangular grooves are formed by annular magnetic permeability iron cores arranged at the two ends of each permanent magnet and the permanent magnet, and the armature windings are arranged in two grooves in the vertical direction and are the same in phase. The secondary assembly is composed of n-1 secondary units, wherein the secondary units and the primary units are arrayed perpendicular to the horizontal direction in a staggered mode, and non-magnetic-permeability grooves or magnetism isolation bridges are arranged periodically arranged on secondary unit iron cores. The non-magnetic-permeability grooves of the adjacent secondary units are staggered by T / 2 distance in the horizontal direction. The motor is provided with 2n-2 air gaps. A three-dimensional magnetic circuit is adopted for the motor, high electromagnetic loads can be effectively achieved, and the motor has the advantages of being high in thrust density and reliability.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

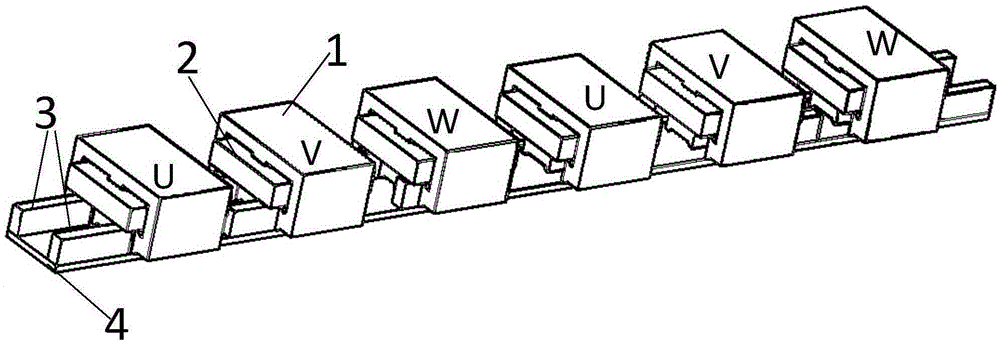

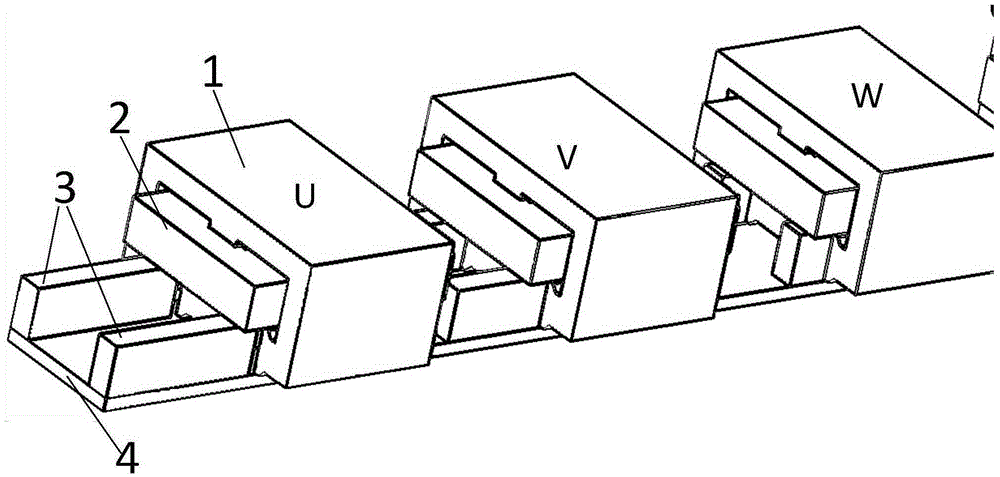

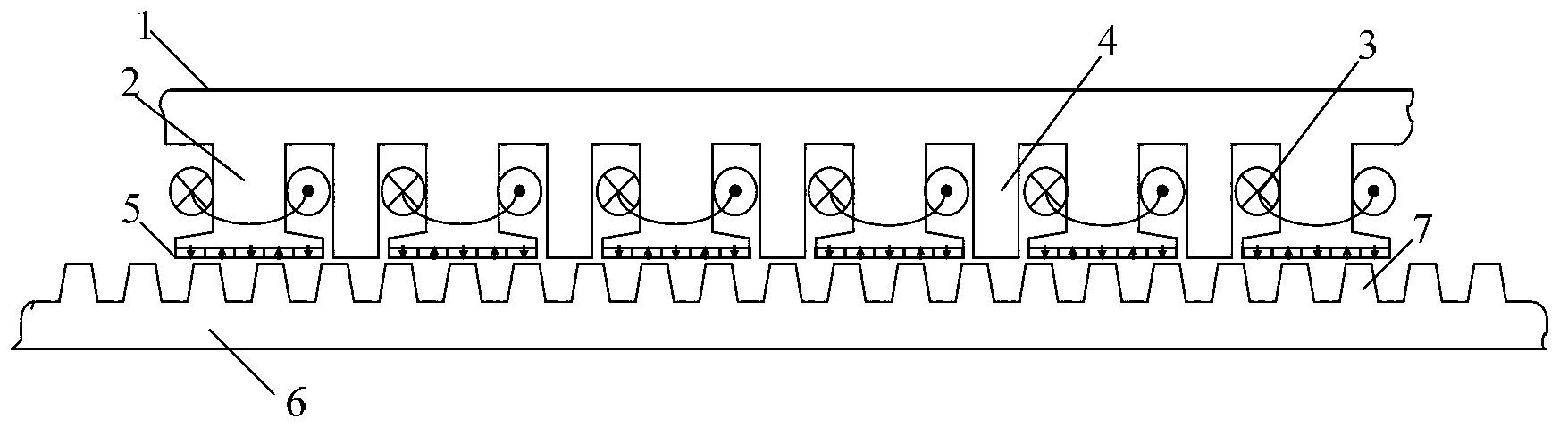

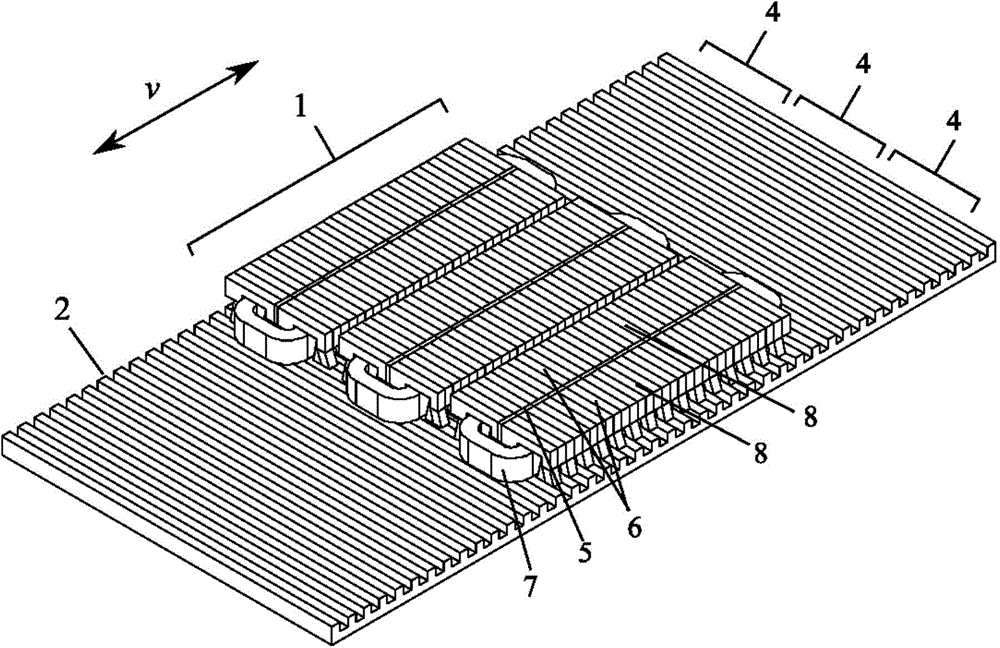

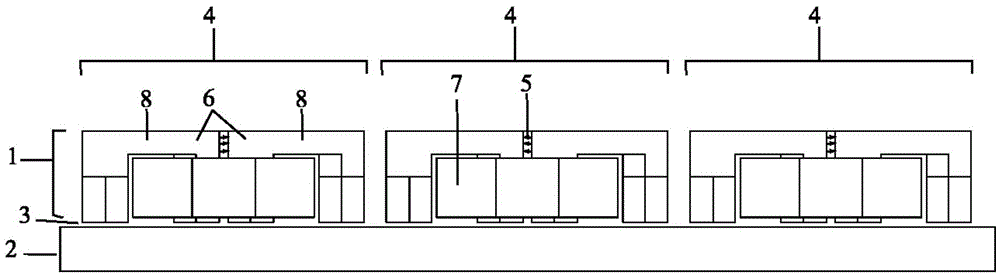

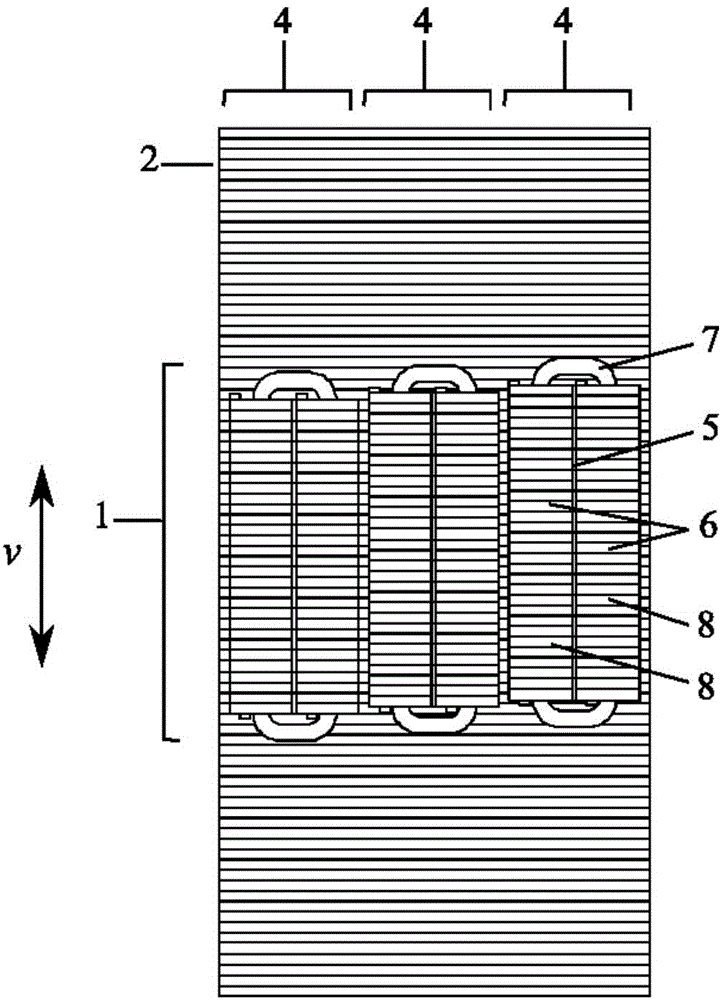

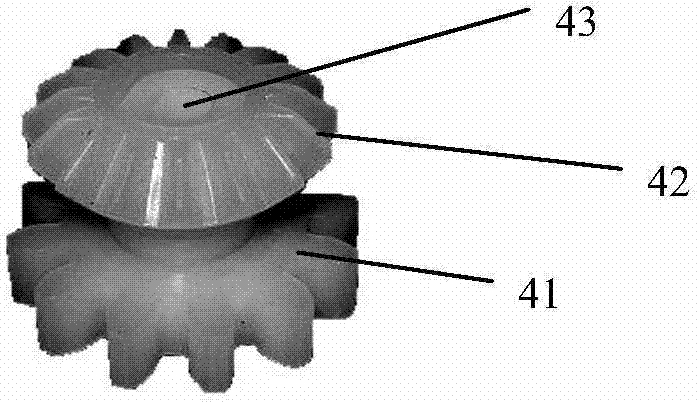

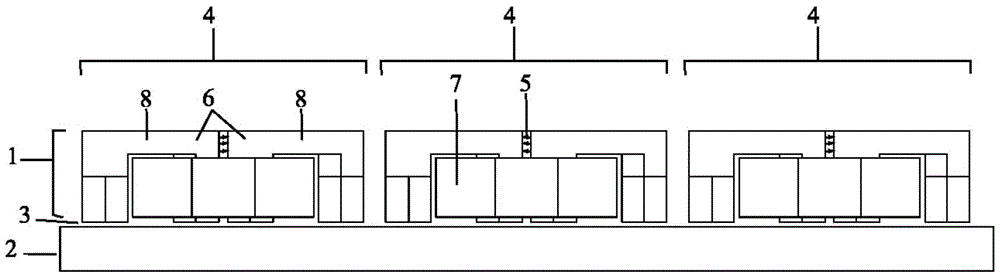

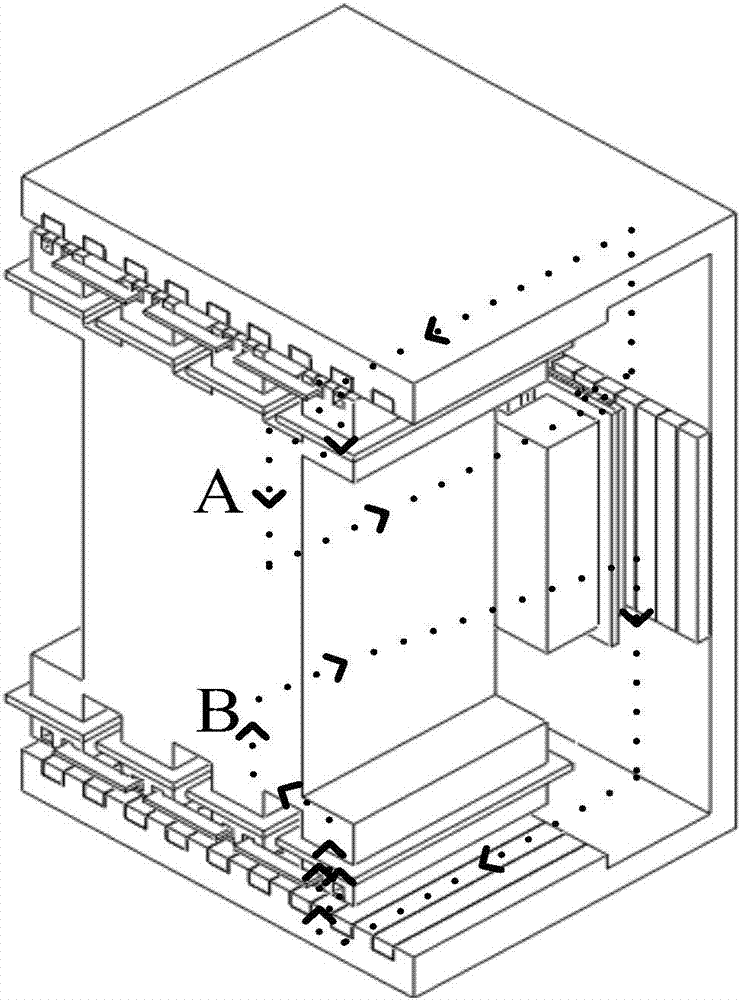

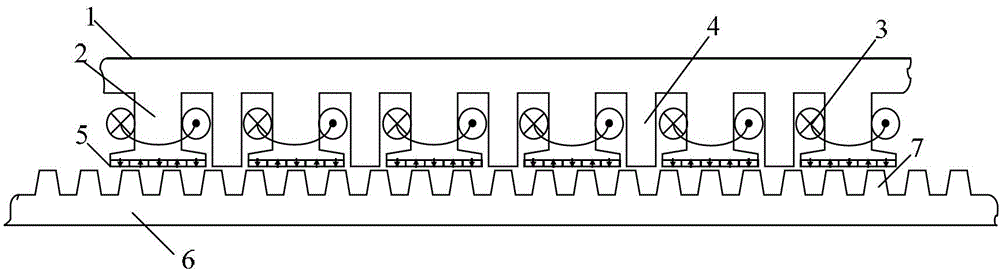

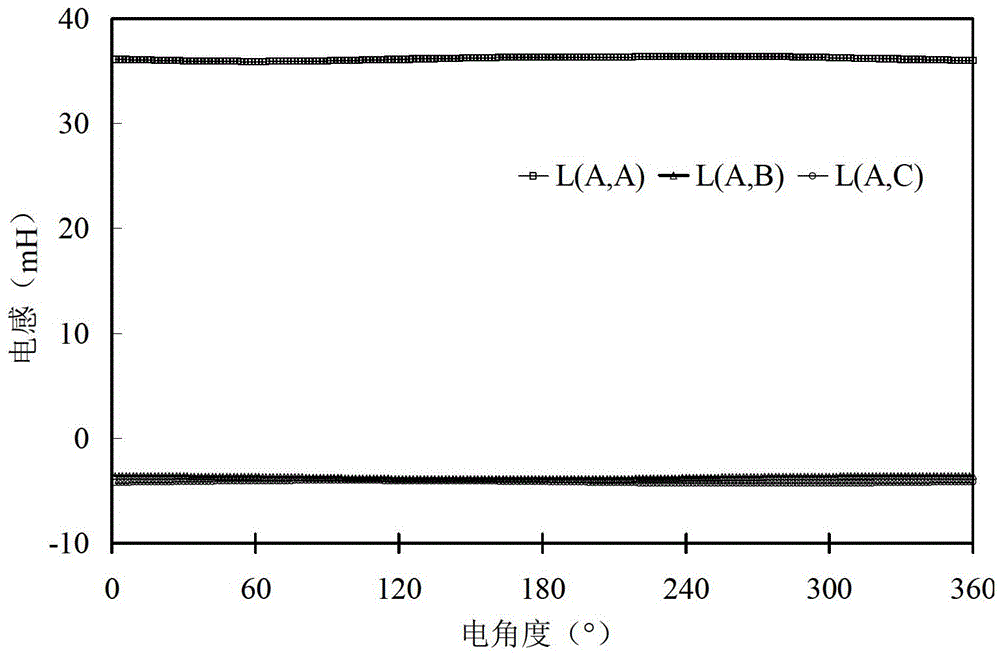

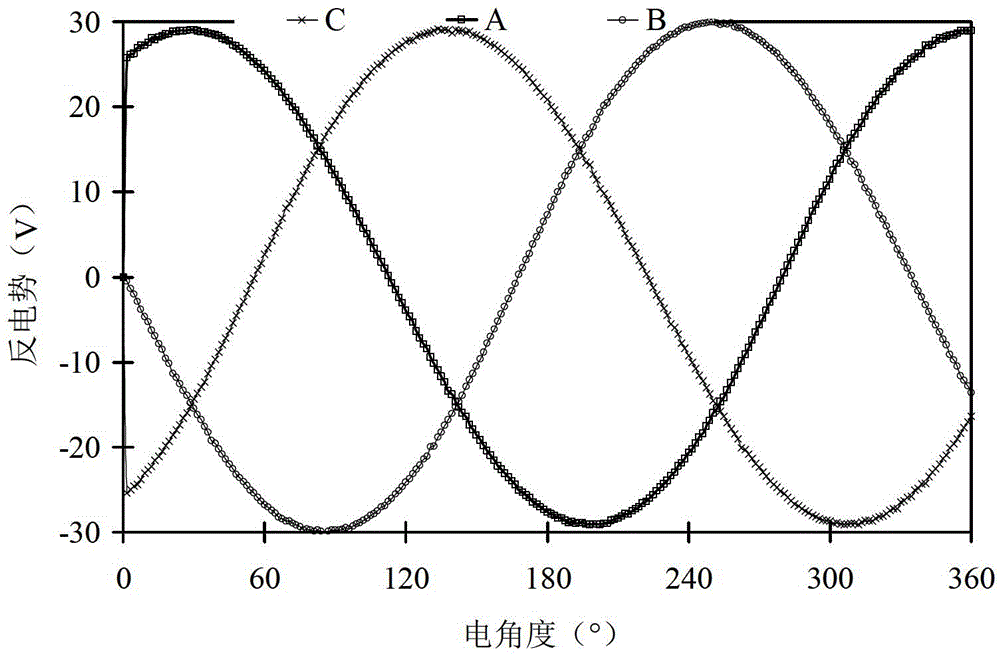

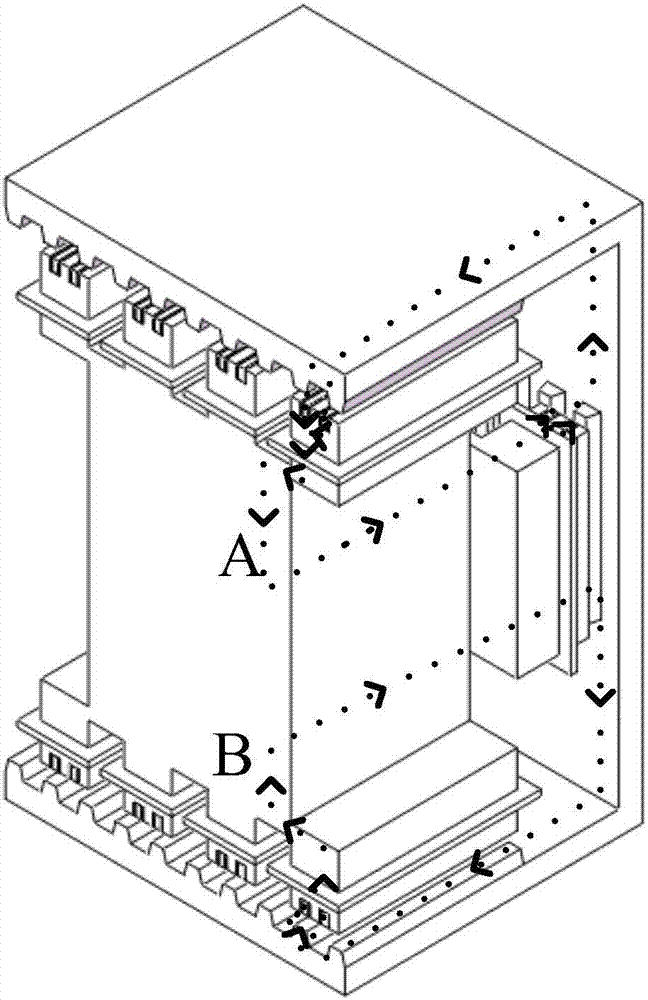

Modular primary permanent magnet bilateral switched reluctance linear motor

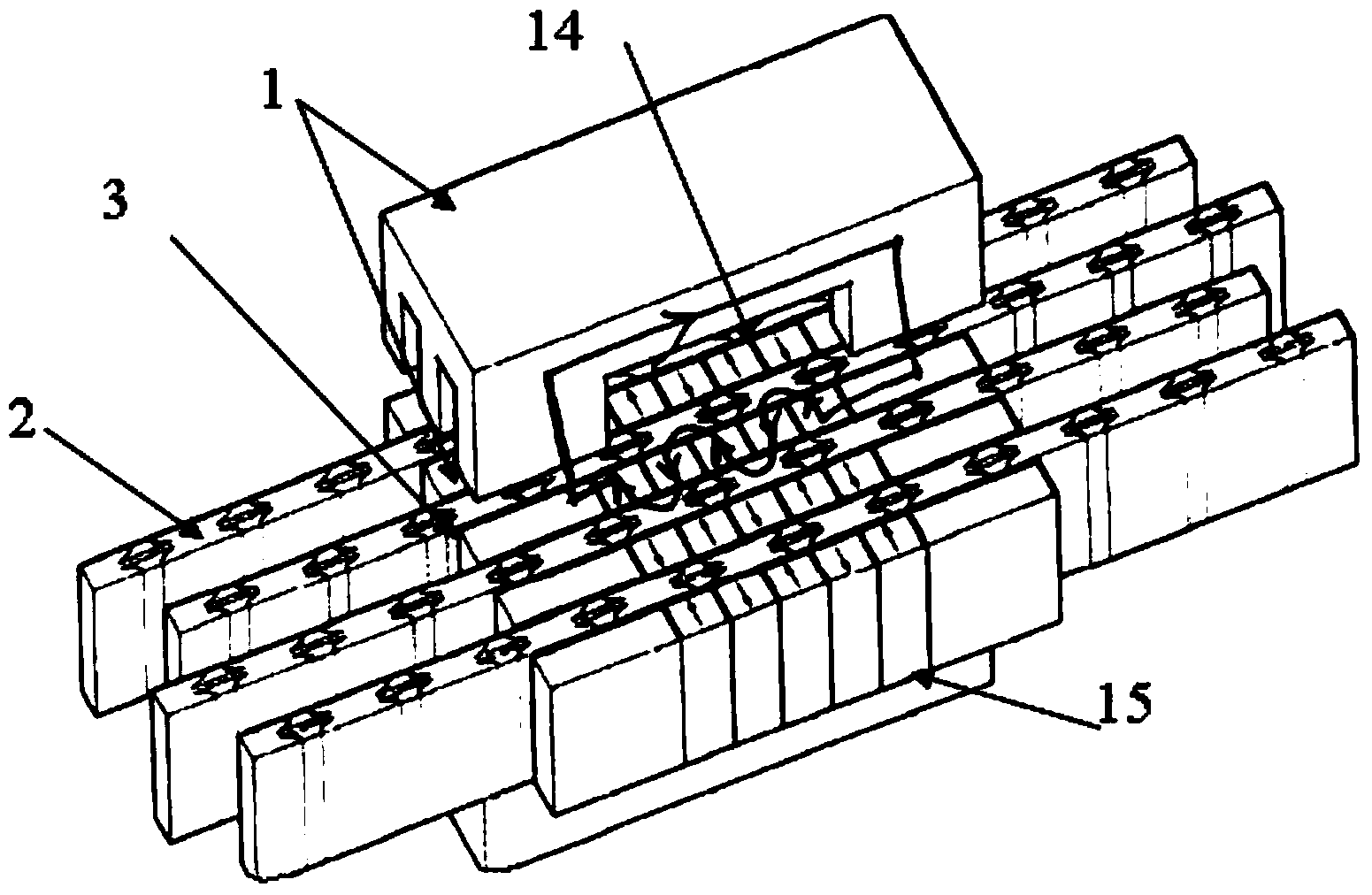

PendingCN110011513AReduce positioning forceReduce thrust fluctuationPropulsion systemsForce linesPrimary permanent

The invention discloses a modular primary permanent magnet bilateral switched reluctance linear motor. The primary side of the motor is modularized. Each primary module is composed of a magnetically permeable material, an armature winding and permanent magnets distributed in the vertical direction between two magnetic conducting blocks. The secondary side is composed of a magnetically permeable material. The permanent magnets are magnetized in parallel. The permanent magnets corresponding to the adjacent primary modules have the same magnetization direction. The upper and lower corresponding permanent magnets belonging to the same primary module have opposite magnetization directions. In a no-load state, a permanent magnet magnetic circuit is short-circuited by the primary magnetic conducting blocks, and the magnetic force lines hardly pass through an air gap and the secondary side, which reduces the positioning force. In a loaded state, a series magnetic circuit is formed between theprimary magnetic conducting blocks and the bilateral secondary side to generate electromagnetic force. In addition, the modular primary permanent magnet bilateral switched reluctance linear motor hasa simple secondary-side structure and large thrust density, and the permanent magnets are placed in the short primary side to reduce the cost of the motor. The modular primary permanent magnet bilateral switched reluctance linear motor can be applied to long secondary-side occasions such as an elevator driving system.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Bilateral magnetic flux switching permanent magnet linear motor

ActiveCN110957876AReduce weightWeight, reducing the cost of motor manufacturingMagnetic circuit rotating partsPropulsion systemsElectric machinePermanent magnet linear motor

The invention discloses a bilateral magnetic flux switching permanent magnet linear motor. The linear motor comprises bilateral secondary stators and a primary rotor arranged between the stators, theprimary rotor comprises six primary rotor units, connecting bridges exist between the primary rotor units, each primary rotor unit comprises two H-shaped magnetic conductive iron cores, and a permanent magnet is arranged between the two H-shaped magnetic conductive iron cores; a plurality of secondary teeth are formed on the secondary stators at intervals, secondary grooves are formed between thesecondary teeth, yoke parts are formed at the bottoms of the secondary grooves, magnetic conductive teeth are formed on the H-shaped magnetic conductive iron core opposite to the secondary teeth, andwinding mounting grooves are formed between the magnetic conductive teeth on the same side; the bilateral secondary stators are used as fixed parts, the primary rotor is used as a moving part, and theprimary rotor does linear motion in the middle of the bilateral secondary stators to form a motor with a bilateral flat plate structure. The linear motor has the advantages of the high utilization rate, the low magnetic flux leakage and the like.

Owner:SHIJIAZHUANG TIEDAO UNIV

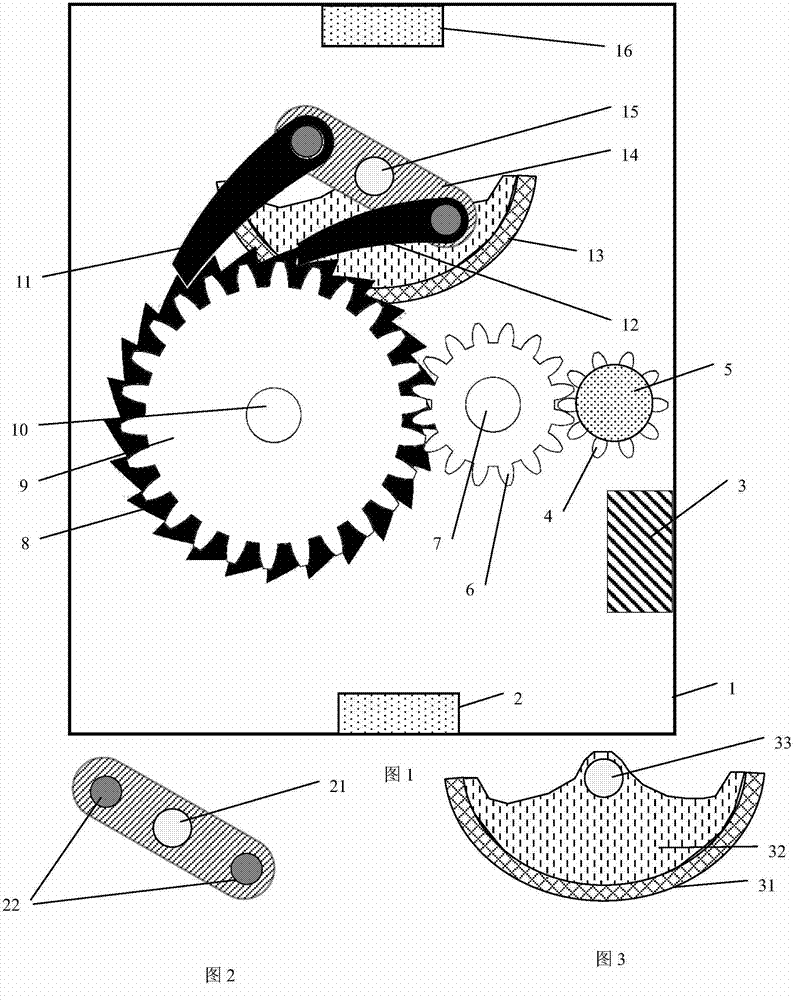

Vehicle vibration power generation device with USB interface

ActiveCN103715827AHigh vibration pickup efficiencyImprove electromechanical conversion efficiencyElectrical storage systemEnergy storageWorking lifeIn vehicle

The invention relates to a vehicle vibration power generation device with a USB interface. The device adopts a heavy hammer and a double-acting type ratchet wheel as a vibration pickup mechanism, a gear set is a vibration mechanical energy transmission mechanism, a direct current permanent magnet generator is an electromechanical energy conversion mechanism, and an electric energy processing circuit with a USB interface processes irregular direct current electric energy, and supplies power to a vehicle-mounted electronic device. The vehicle vibration power generation device uses the double-acting type ratchet wheel mechanism for vibration pickup, converts rectilinear motion in vehicle running to rotational motion, and drives the low damping permanent magnet direct current generator to work through the efficient gear mechanism, and compared with a common linear type vibration power generation device, the transmission and conversion efficiency of vibration mechanical energy can be significantly improved. The vehicle vibration power generation device with the USB interface generates power by renewable energy, the vibration pickup efficiency, and the energy transmission and conversion efficiency are high, the working life is long, the USB interface is adopted to be suitable for the use of most vehicle-mounted electronic devices, and the universality is strong.

Owner:天津融承科技有限公司

Cylinder-shaped polyphase linear permanent-magnet synchronous generator

InactiveCN101159408ASimple processing technologyReduce positioning forcePropulsion systemsPhysicsUnit volume

A cylindrical multi-phase linear permanent magnet synchronous motor relates to the motor field. The motor resolves the question that the Taut of a teeth space of an iron core (Taut) is contained and limited with of the Taup of a pole space of a permanent magnet. The motor comprises a primary structure, a secondary structure and an air gap. And the primary structure includes the circular iron core and a winding of an armature embedded in the iron core slot of the armature. The secondary structure includes the circular permanent magnet. The teeth space of the iron core Taut and the pole space of the permanent magnet Taup can meet following correlation requirement: Taup is more than and equal to 0.8 Taut, but less than and equal to 1.2 Taut, and Taut is not equal Taup. The teeth space of the iron core Taut and the pole space of the permanent magnet (Taup) can be selected practically, with small difference therebetween. The invention reduces the positioning force caused by the slot effect, and upgrades the output of pulling force in unit volume. In addition, the motor can be utilized as a linear motor, as well as a linear generator.

Owner:HARBIN INST OF TECH

Permanent-magnet linear motor based on arc-shaped and inner-step shaped hybrid structure of stator

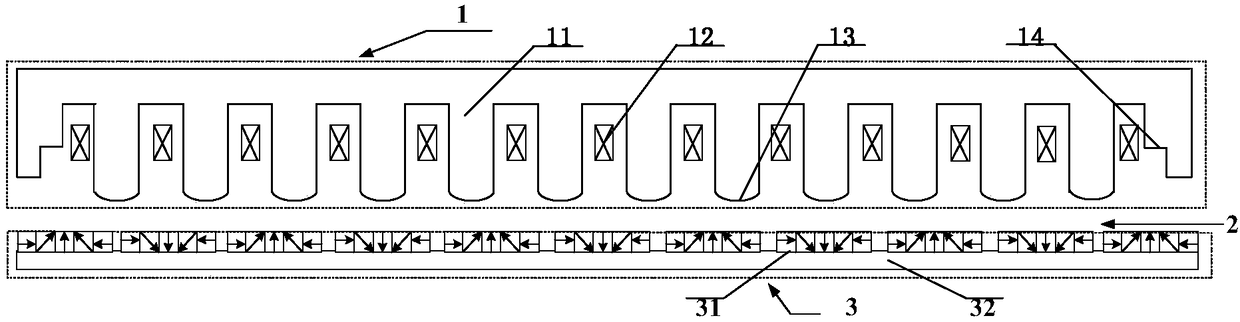

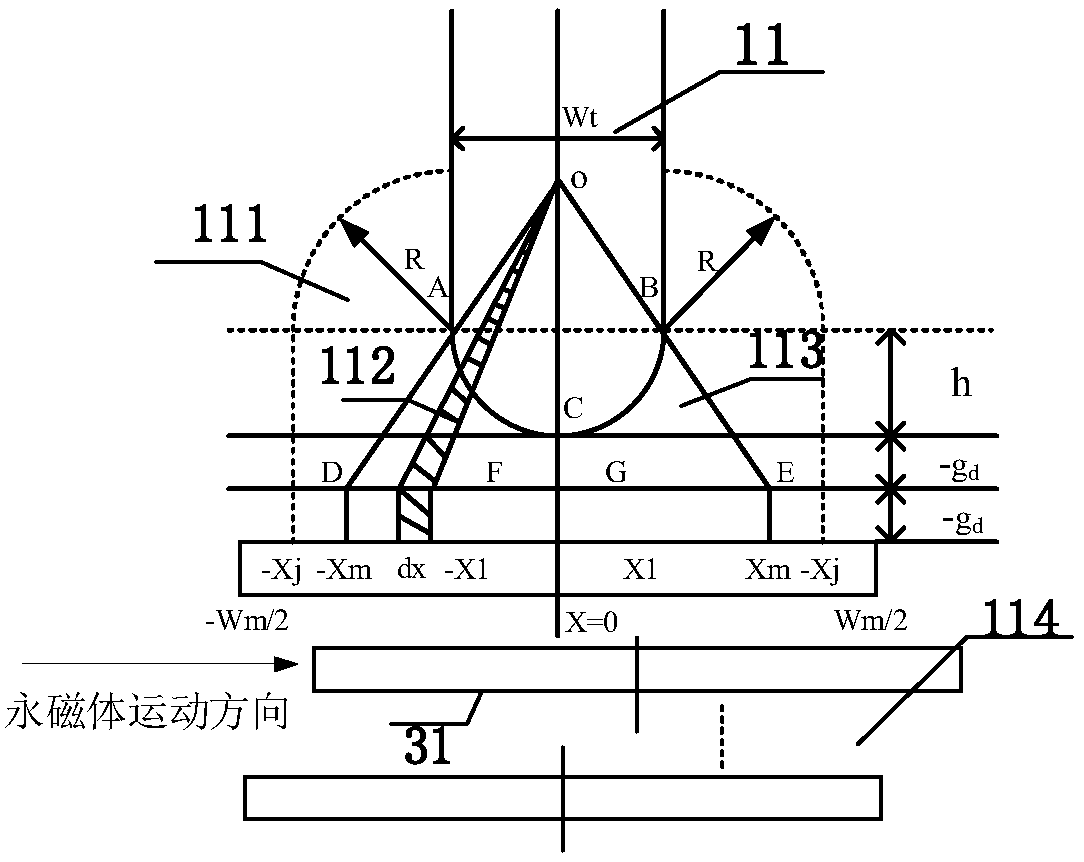

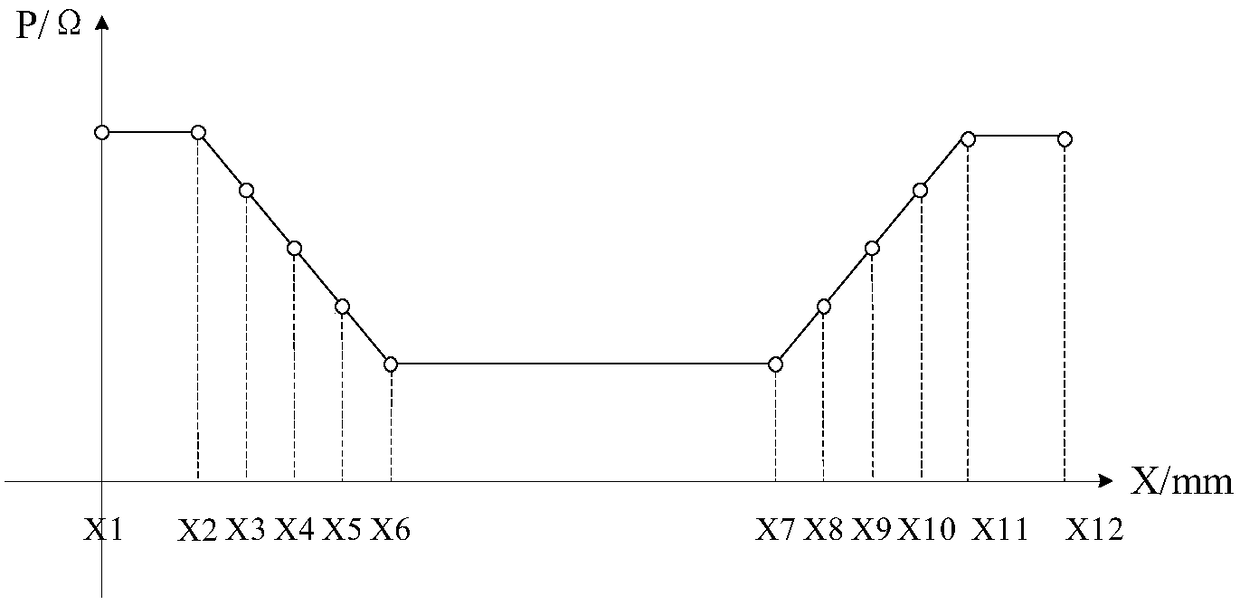

ActiveCN108258877AReduce thrust fluctuationImprove power densityDesign optimisation/simulationPropulsion systemsPermanent magnet linear motorConductor Coil

The invention discloses a permanent-magnet linear motor based on an arc-shaped and inner-step shaped hybrid structure of a stator. The motor comprises a stator armature primary side and a Halbach permanent-magnet mover secondary side, the stator armature primary side is located on the outer side of the permanent-magnet mover secondary side, the stator armature primary side is formed by a stator iron core and an armature winding, inner-step shaped structures are adopted by the ends of two sides of the stator iron core, and arc-shaped structures are adopted by inner teeth of the stator iron core; the permanent-magnet mover secondary side is formed by a mover iron core and a permanent magnet adhering to the surface the of the iron core, and a Halbach array structure is adopted by the permanent magnet. By means of the motor, air gap magnetic flux larger than a conventional magnet can be obtained, the motor has a better magnetic shielding effect, and the thickness of a magnetic conductive yoke of the mover can be reduced. The invention provides an analysis model of an arc-shaped tooth structure, and the magnitude of magnetic conductance and a magnetic conductance-position variation curve can be derived by means of the model. The optimal structure of the motor is obtained by adopting a Taguchi optimization algorithm.

Owner:SOUTHEAST UNIV

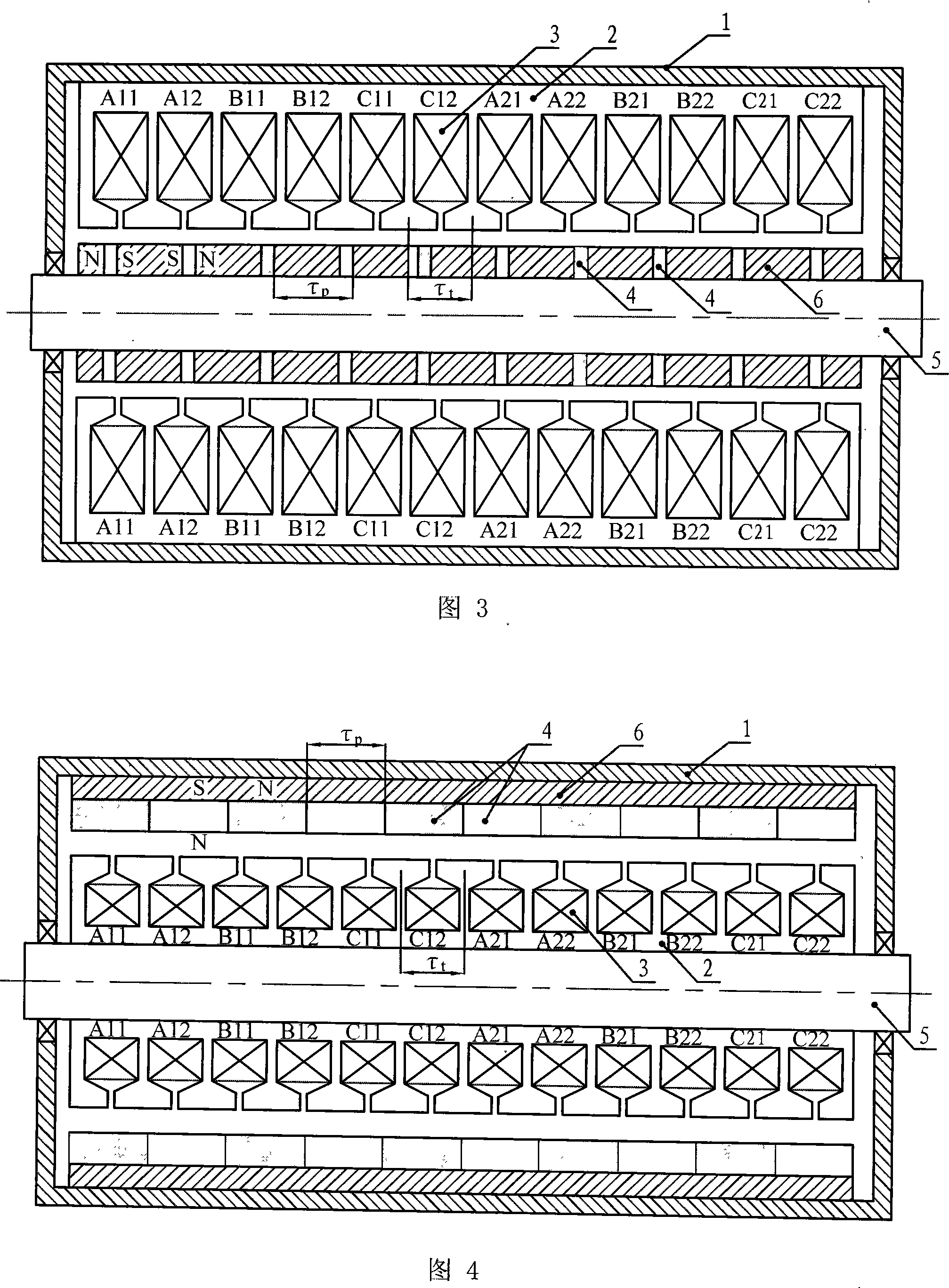

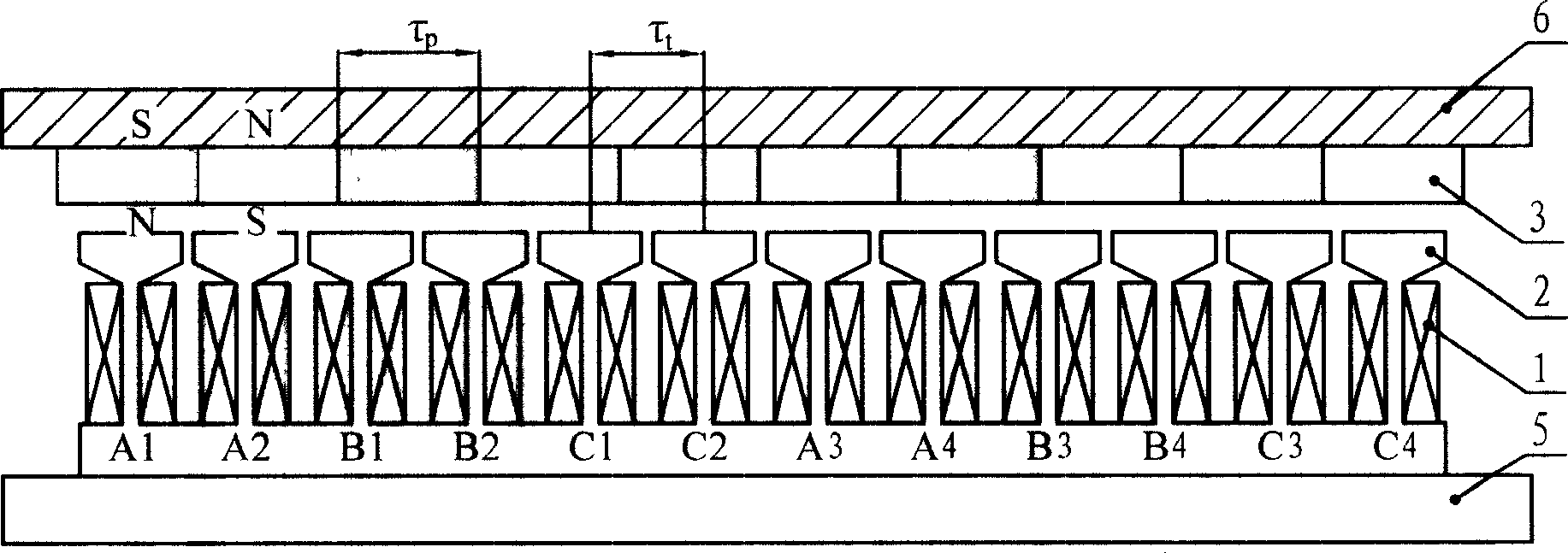

Flat plated three-phase linear permanent-magnet synchronous motor

InactiveCN101013843BSimple preparation processSimple insulationPropulsion systemsSynchronous motorPermanent magnet synchronous motor

The invention relates to a flat plated three-phase linear permanent-magnet synchronous motor, belonging to the motor field. The invention overcomes the problems in the prior flat plated three-phase linear permanent-magnet synchronous motor that the designs of a pitch tau t and a polar distance tau p are not easy considerate, the winding end parts are long and mutual cross, the insulation of the windings is complex, and the production cost is high and so on. The flat plated three-phase linear permanent-magnet synchronous motor comprises an armature part and a permanent-magnet excitation part, wherein, these two parts have gas gap therebetween; the armature part is composed of an armature winding and an armature iron core; the permanent excitation part is composed of a permanent-magnet part and a permanent-magnet yoke; the armature iron core pitch tau t and the permanent-magnet polar distance tau p satisfy the following formula as 3ntau t=(3n+-1)tau p, wherein n is a natural number. The invention not only can be used as the linear motor with high performance, but also can be used as the linear generator with high performance, thereby having wide application prospect.

Owner:HARBIN INST OF TECH

A Flat Type Transverse Flux Switching Permanent Magnet Linear Motor

InactiveCN104167897BEasy to processIncrease production capacityPropulsion systemsTransverse fluxElectrical steel

The invention discloses a flat type transverse magnetic flux switching permanent magnet linear motor, comprising a flat type motor primary and a flat type motor secondary, the motor primary and the motor secondary are installed oppositely, an air gap surface is left in the middle, and the motor primary is installed with a Permanent magnets and windings work on the principle of magnetic flux switching; it is characterized in that: the motor primary includes more than one primary unit, the primary unit includes a primary unit iron core, and the primary unit iron core consists of two primary unit cores perpendicular to the direction of motion v Composed of unit core blocks, the primary unit core block is formed by laminating primary electrical steel sheets along the moving direction v; the secondary of the motor is formed by laminating secondary electrical steel sheets along the moving direction v. The motor provided by the invention has a simple structure and production process, both primary and secondary can be laminated to reduce iron loss, high utilization rate of permanent magnet and winding, uniform permeance of permanent magnet magnetic circuit, small positioning force, small eddy current, and electric thrust only It is related to the length of the motor and can be designed in rapid batches and other beneficial effects.

Owner:SOUTHEAST UNIV

Transverse flux magnetic field modulation type linear motor

ActiveCN106961203AImprove space utilizationSimple structurePropulsion systemsTransverse fluxPower flow

The invention discloses a transverse flux magnetic field modulation type linear motor. The linear motor comprises primary bodies and secondary bodies. The two secondary bodies are in a C-shaped, mirror image arrangement, and three air gaps are arranged among the primary body and the secondary bodies. The inner sides of the secondary bodies are provided with a plurality of secondary grooves and a plurality of secondary teeth at equal intervals, and secondary permanent magnets are disposed in the secondary grooves. Each of the primary bodies comprises two same primary iron cores and a connecting beam used for connecting the two primary iron cores. The upper surfaces and the lower surfaces of the primary iron cores and the surfaces of the primary iron cores back to the connecting beams are provided with salient pole teeth, which are arranged at equal intervals, and are the same. The salient pole teeth are provided with salient armature windings in a coiled manner, and are provided with virtual teeth, and virtual grooves are arranged among adjacent virtual teeth, and in addition, virtual groove permanent magnets are disposed in the virtual grooves. Virtual groove armature windings are disposed in the virtual grooves. The three phases of the primary bodies are provided with three phases of armature windings. The armature winding of the same primary body is used to form one phase, and the armature windings of the three primary bodies are used to form three phases, and a difference among currents flowing through the three phases is 120degrees. The transverse flux magnetic field modulation type linear motor adopts modularization design, and has advantages of simple structure, and ability of improving fault-tolerant performance.

Owner:湖南天友精密技术有限公司

Fault Tolerant Primary Permanent Magnet Vernier Linear Motor

Owner:江苏良基集团有限公司

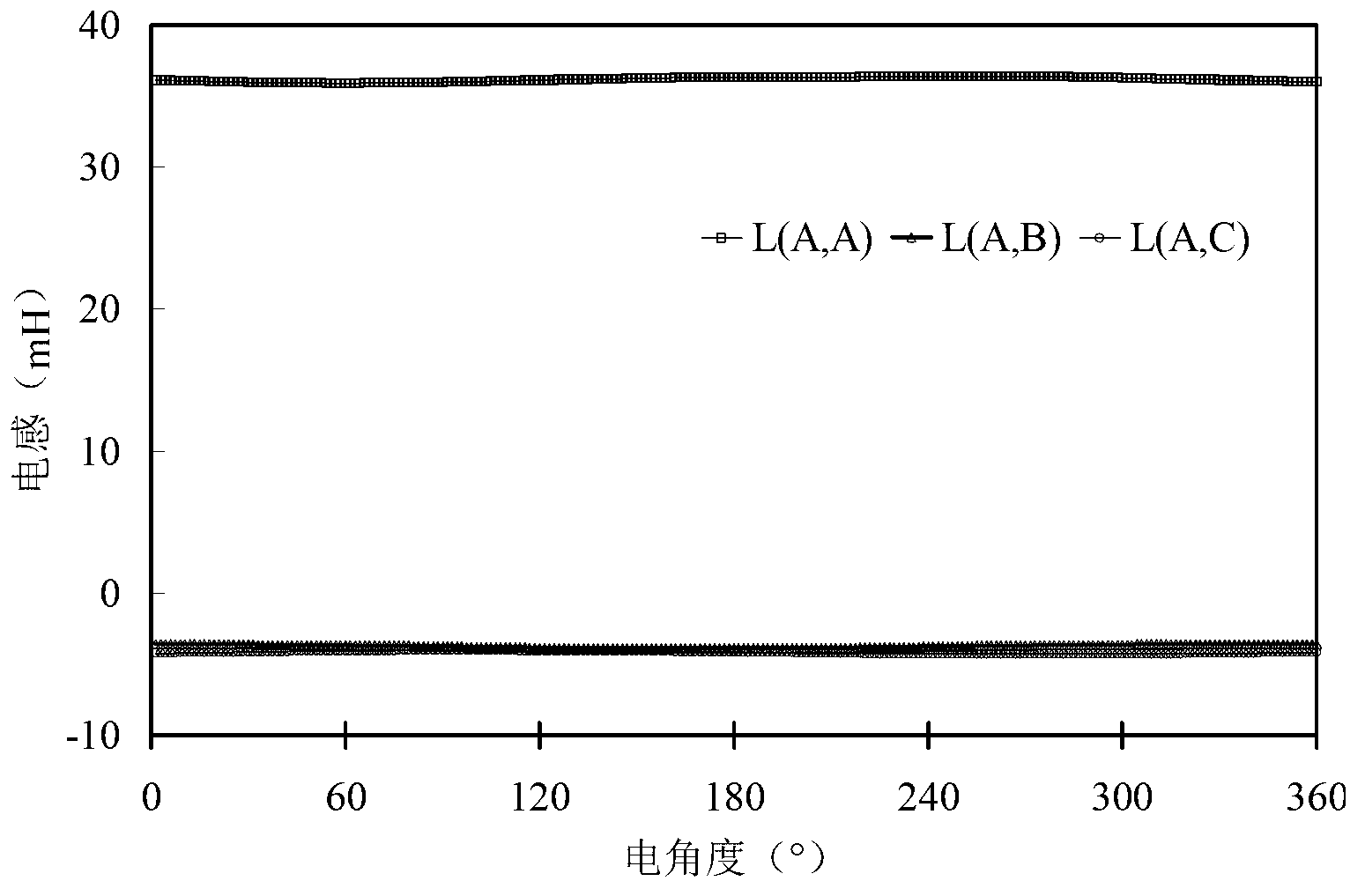

Modular complementary type primary permanent magnet linear motor and motor module formed thereby

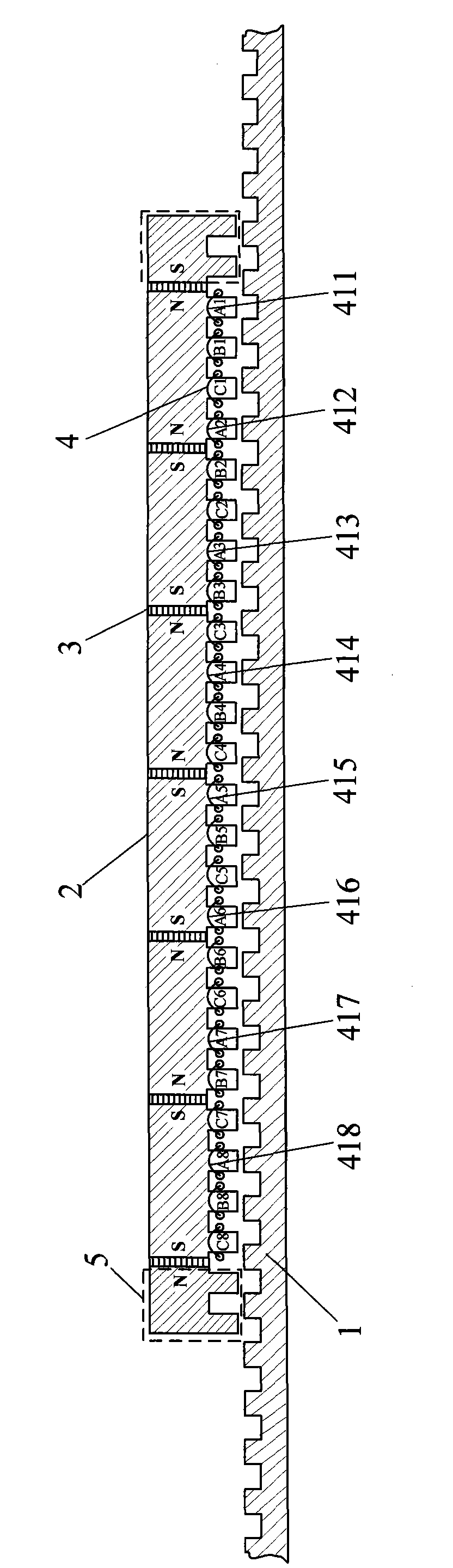

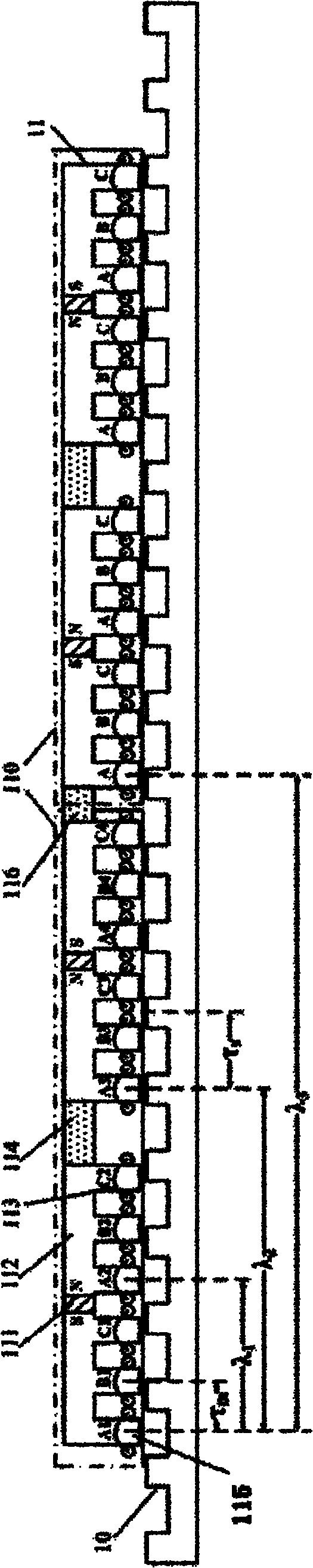

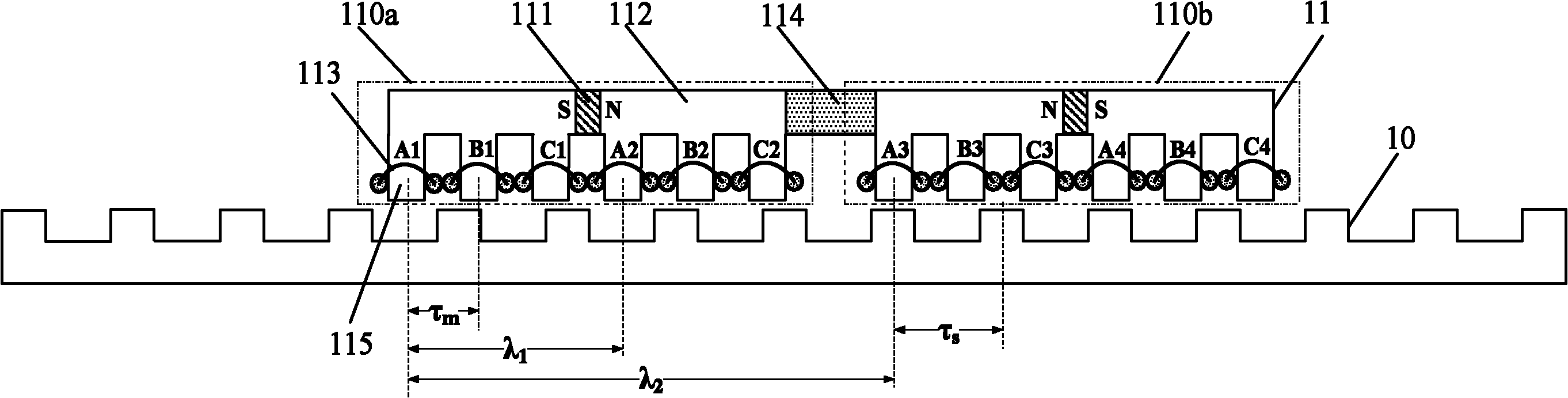

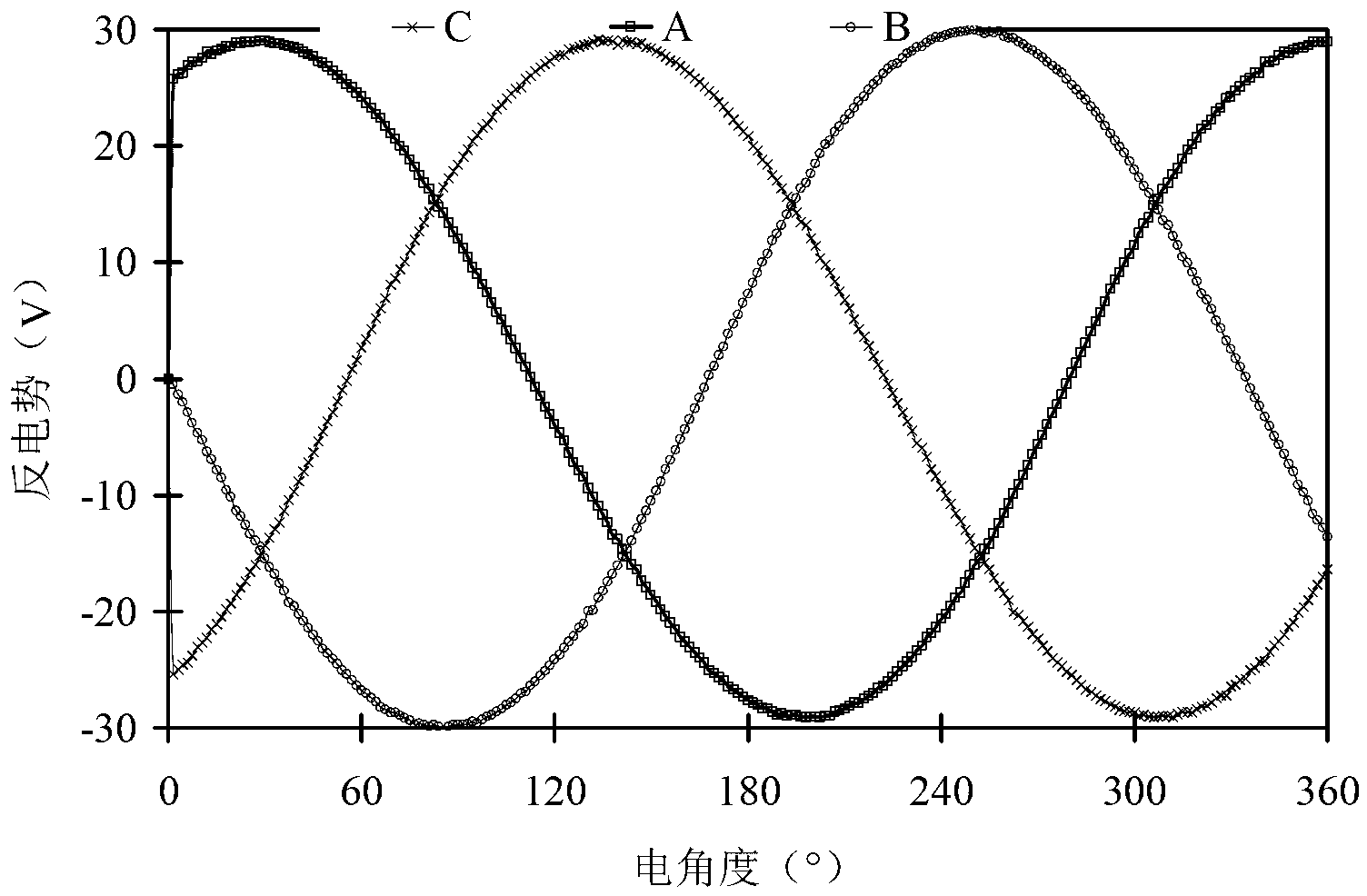

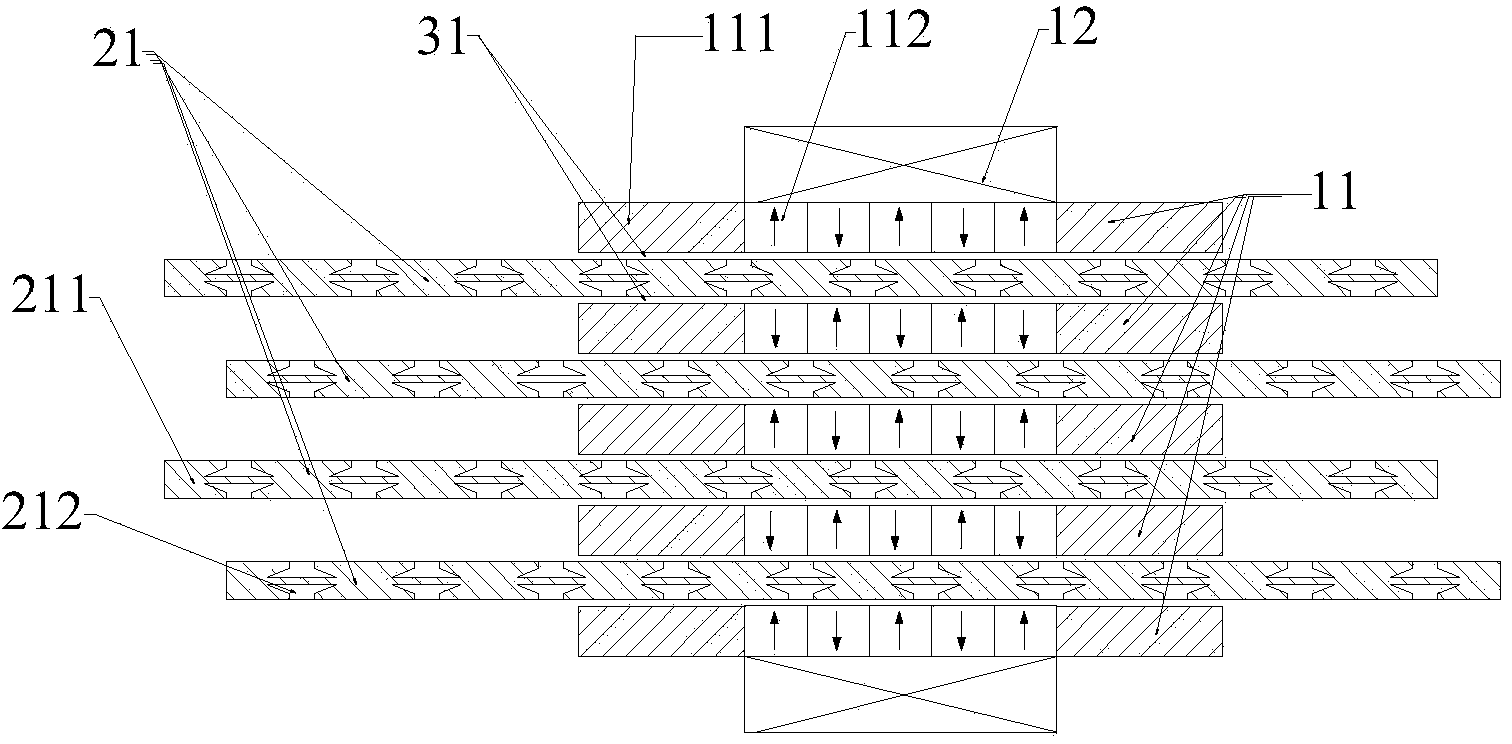

ActiveCN102013786BImprove fault toleranceLow costPropulsion systemsPrimary permanentElectromotive force

The invention discloses a modular complementary type primary permanent magnet linear motor and a motor module formed thereby. The primary permanent magnet linear motor comprises a primary level and a secondary level; the primary level and the secondary level are respectively in a salient-pole structure, and an air gap is formed between the two levels; the primary level comprises a rotor module which comprises a first module and a second module; a first non-magnetic material is arranged between the first module and the second module; the first module and the second module both comprise two salient-pole magnetic materials and a permanent magnet arranged between the two salient-pole magnetic materials; the salient-pole magnetic material is provided with m numbered primary teeth, and a central armature winding is arranged on the primary teeth; the relative displacement between the first module and the second module is calculated as follows: lambda2=(k+ / -0.5) tau s; the relative displacement between the adjacent two salient-pole magnetic materials is calculated as follows: lambda1=m*tau m; and the ratio of the primary polar distance to the secondary polar distance is as follows: tau m:tau s=(m+ / -1):m. The invention has the advantages of symmetric back electromotive force, relatively small positioning force, low thrust fluctuation and the like and is applicable to the application occasion of a linear motor with a long-stator structure.

Owner:SOUTHEAST UNIV

Positioning force complementary double-stator cylindrical linear motor

ActiveCN102694444BTake advantage ofImprove power densityDynamo-electric machinesProsthesisGroove widthLinear motor

The invention discloses a positioning force complementary double-stator cylindrical linear motor; an inner stator ring or an outer stator ring comprises a permanent magnet and two circular U-shaped teeth which have the same structure and have the U-shaped grooves being towards a dynamic ring; the permanent magnets are excited along an axial direction and are clamped between the two circular U-shaped teeth; two sets of circular armature windings are inlaid in the two U-shaped grooves of the circular U-shaped teeth; the tooth pitch between the salient pole teeth of every two inner side surfaces on the inner side circular surface of the dynamic ring is the same with that between the salient pole teeth of every two outer side surfaces on an outer side surface of the dynamic ring, and all the salient pole teeth on the inner side surface and all the salient pole teeth on the outer side surface are staggered by one-fourth teeth pitch; the U-shaped groove width, the tooth width and the permanent magnet width of the circular U-shaped teeth of the inner stator ring and those of the circular U-shaped teeth of the outer stator ring are different; and the positioning force variation frequency on the inner side and that on the outer side of the dynamic ring are twice of reverse potential variation frequency, the positioning force on the inner side and on the outer side is complementary, and the positioning force is reduced.

Owner:指南者品牌管理(苏州)有限公司

Linear switch magnetic flux permanent magnet motor with low location force and high thrust

InactiveCN102255471BReduce intermediate mechanical lossImprove reliabilityPropulsion systemsNumerical controlMagnetization

The invention discloses a linear plate type switch magnetic flux permanent magnet motor. The motor comprises a secondary stator and a primary rotor. The primary rotor comprises U-shaped iron cores with U-shaped sections, permanent magnets, a non-magnetic conductor interval, a magnetic conduction bridge and a primary three-phase winding. The non-magnetic conductor interval is arranged between the two adjacent U-shaped iron cores. The non-magnetic conductor interval and the U-shaped iron cores are same in thickness. The magnetic conduction bridge is arranged on the tops of the U-shaped iron cores. Two permanent magnets which are same in thickness and opposite in magnetization direction are installed between the two U-shaped iron cores of same phase and the magnetic conduction bridge. The secondary stator is provided with an electrode and a groove on the surface which is just opposite to the primary rotor. The electrode and the groove can be precisely located and controlled by a controller driven by sine-wave current. A gas clearance is arranged between the U-shaped iron core of the primary rotor and the secondary rotor. The motor disclosed by the invention is used in a direct drive type alternating-current transmission system; and an intermediate transmission structure and a speed changing device are unnecessary. The motor can be used as a direct drive motor of a feeding drivingsystem of a numerical control machine. The motor can also be applicable to a translation transmission system with a locating function.

Owner:JIANGSU ZHONGRONG ELECTRIC +1

Transverse magnetic flux magnetic field modulation type linear motor

ActiveCN106998126AImprove space utilizationSimple structurePropulsion systemsElectric machineSecondary stage

The invention discloses a transverse magnetic flux magnetic field modulation type linear motor. The transverse magnetic flux magnetic field modulation type linear motor comprises primary stages and secondary stages; the two secondary stages are C-shaped and arranged in a mirror image manner; secondary stage grooves and secondary stage teeth are distributed on three surfaces on the inner side of the C shape in an equally spaced manner; three surfaces of air gaps exist between the primary stages and the secondary stages; each primary stage comprises two same primary stage iron cores and a connecting beam for connecting the two primary stage iron cores; same salient pole teeth in equally spaced distribution are arranged on the upper surfaces, the lower surfaces, and the surfaces, opposite to the connecting beam, of the primary stage iron cores; equidistant virtual teeth are arranged at the ends, close to the air gaps, of the salient pole teeth; the salient pole teeth are wound with armature windings; the adjacent armature windings are connected end to end; the winding direction of the armature windings on the upper surface of the salient pole teeth is opposite to that of the armature windings on the lower surface of the salient pole teeth; the winding direction of the armature windings on the surfaces, opposite to the connecting beam, of the salient pole teeth is the same as that of the armature windings on the lower surface of the salient pole teeth; the armature windings of the salient pole teeth on the three surfaces are connected in series to form one phase of windings; and permanent magnets are arranged at the ends, close to the air gaps, of the salient pole teeth.

Owner:东莞希思克传动科技有限公司

Low-speed high-thrust density double-layer fractional slot winding cylindrical linear motor

InactiveCN108683319BReduce pole distanceThrust density hasPropulsion systemsWindings conductor shape/form/constructionElectric machineEngineering

The invention provides a low-speed high-thrust-density double-layer fractional slot winding cylindrical linear motor which belongs to the technical field of a linear motor. The low-speed high-thrust-density double-layer fractional slot winding cylindrical linear motor comprises a motor primary stage, a motor secondary stage, a primary iron core, an air gap, a primary wire duct, a primary half wireduct, primary teeth, primary edge teeth, a primary yoke, a cake-shaped winding, a permanent magnet, a magnet guiding ring, etc. A double-layer factional slot winding structure is utilized. A motor polar distance is reduced, and working frequency is effectively increased, thereby improving motor efficiency, and realizing a certain speed adjusting range of the motor. The width of an edge trough isset to one half of that of a normal primary trough, and the thickness of the primary edge trough is smaller than that of the primary tooth. Furthermore the effective length of the motor primary pole is equal with (n+1 / 2)*tau, and a remarkable inhibition effect is performed on motor thrust force fluctuation. A motor fixing force is reduced so that higher stability and higher reliability are realized in motor operation. The low-speed high-thrust-density double-layer fractional slot winding cylindrical linear motor has advantages of simple structure, relatively low cost, high efficiency, relatively large speed adjusting range, high thrust force density, high operation stability, high operation reliability, etc. The low-speed high-thrust-density double-layer fractional slot winding cylindricallinear motor is suitable for a low-speed large-thrust-force occasion.

Owner:HARBIN UNIV OF SCI & TECH +2

A dual-edge plane three-phase linear permanent magnetic synchronization motor

ActiveCN101009454BSimple preparation processEasy insulation processPropulsion systemsThree-phaseLinear motor

A kind of two-sized flat three phase beeline permasyn motor, it relates to field of motor. Aiming at resolve problem that pitch Taut and polar distance Taup design is not easy to give attention to, every ends are across with each other, ends of coil is long, the copper cost is big, insulation of coil is complex, cost of manufacture is high of current flat three phase beeline permasyn motor, the invention designs a kind of two-sized flat three phase beeline permasyn motor. The invention includes armature part and permanent-magnet excitation parts; the armature part is nipped between the permanent-magnet excitation parts which are parallel with each other, two gases are between the armature part and two permanent-magnet excitation parts, thereinto the armature part mainly composes armature winding and armature iron core; the permanent-magnet excitation parts composes permanent-magnet. Iron core pitch Taut of the armature and polar distance Taup of the permanent-magnet fulfills the relation 3nTaut=(3n+-1)Taup, thereinto n is natural number. The beeline motor of the invention can be used as beeline motor, but also as the beeline generator, it possesses wide application foreground.

Owner:HARBIN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com