Patents

Literature

434results about How to "Improve cooling conditions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

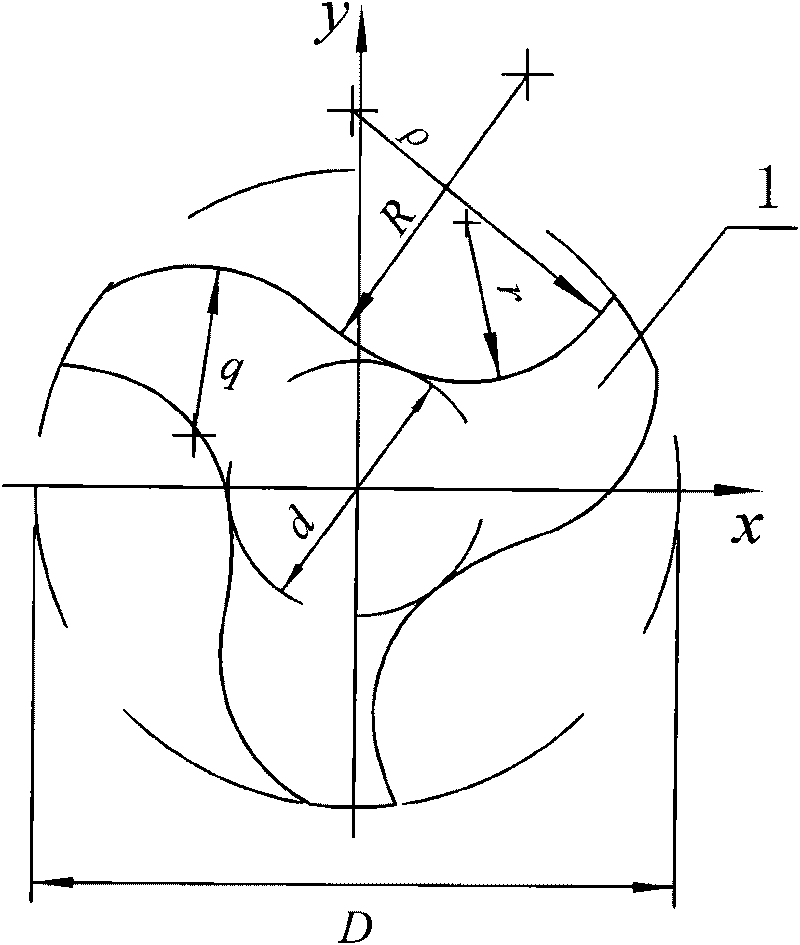

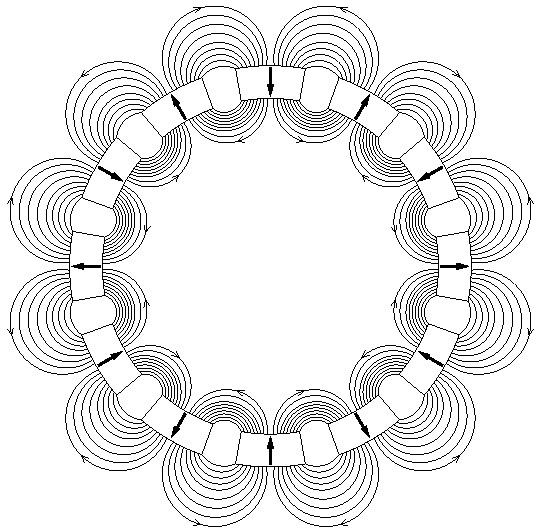

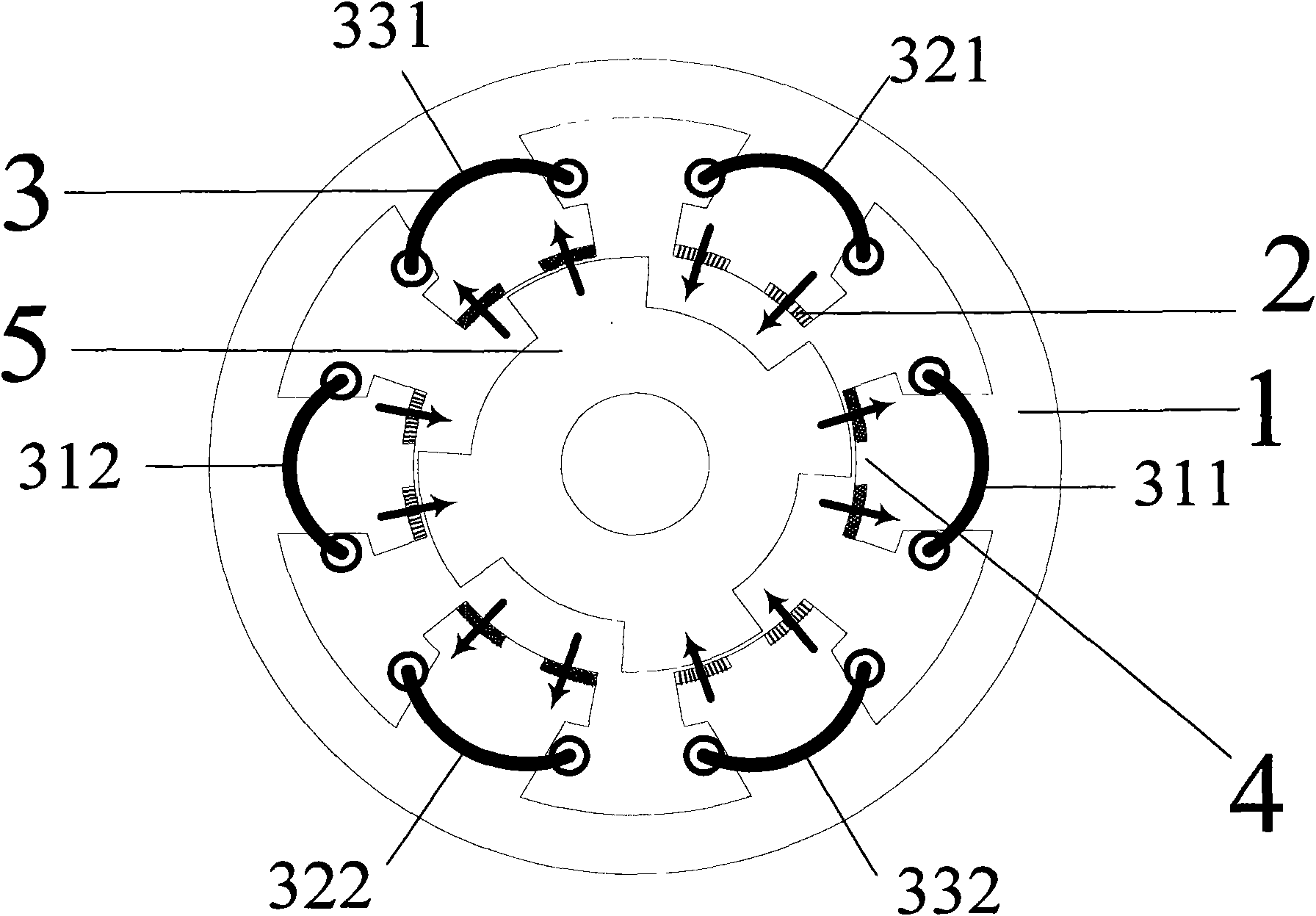

Permanent-magnet eddy current retarder based on Halbach array

InactiveCN102497085AImprove utilization efficiencyIncrease the magnetic field strength of the working air gapPermanent-magnet clutches/brakesOptical axisCoupling

Rotors are installed on a transmission shaft; the transmission shaft is installed in a central hole of a fixing plate; two ends of a bidirectional screw shaft are installed inside holes above the central hole of the fixing plate; two ends of each of three linear optical shafts are fixed into holes in front of, behind and below the central hole of the fixing plate; each of the two rotors consists of a Halbach-array permanent-magnet ring and a retaining rack; an outer cylindrical surface of the permanent-magnet ring is fixed inside a center hole of the retaining rack; a radial clearance is formed between an inner cylindrical surface of the permanent-magnet ring and an outer cylindrical surface of each rotor; four installing holes are uniformly distributed on the retaining rack; an upper installing hole is matched with the bidirectional screw shaft through a screw nut; the other three installing holes are matched with the linear optical shafts through linear bearings; and a servo motor is connected whit the bidirectional screw shaft through a shaft coupler. In the radial-array permanent-magnet eddy current retarder, the utilization ratio of a magnet is high, the brake moment is large, the response is quick, the heat dissipating conditions are good and the stepless regulation of the brake moment is realized.

Owner:ZHEJIANG UNIV

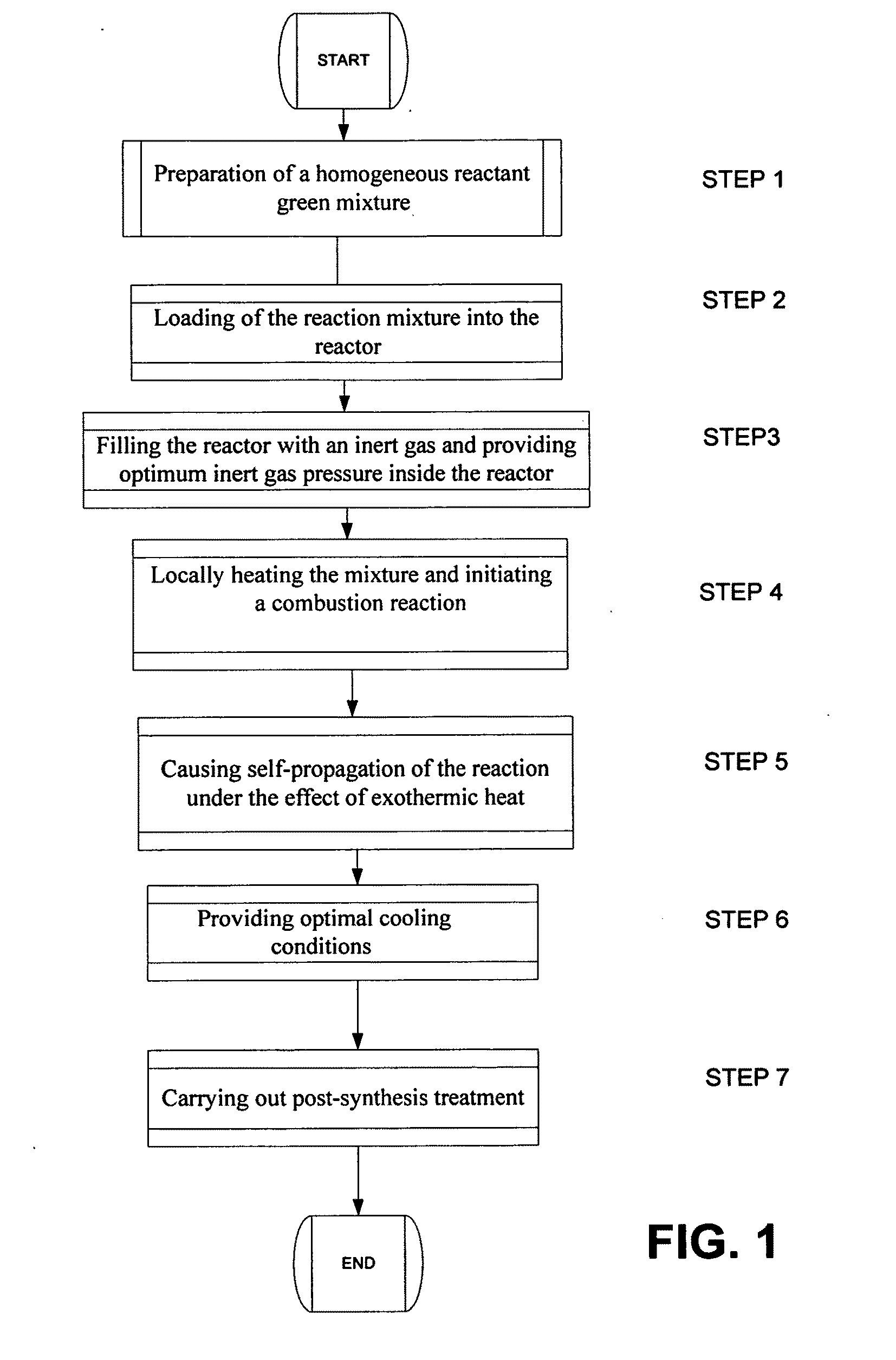

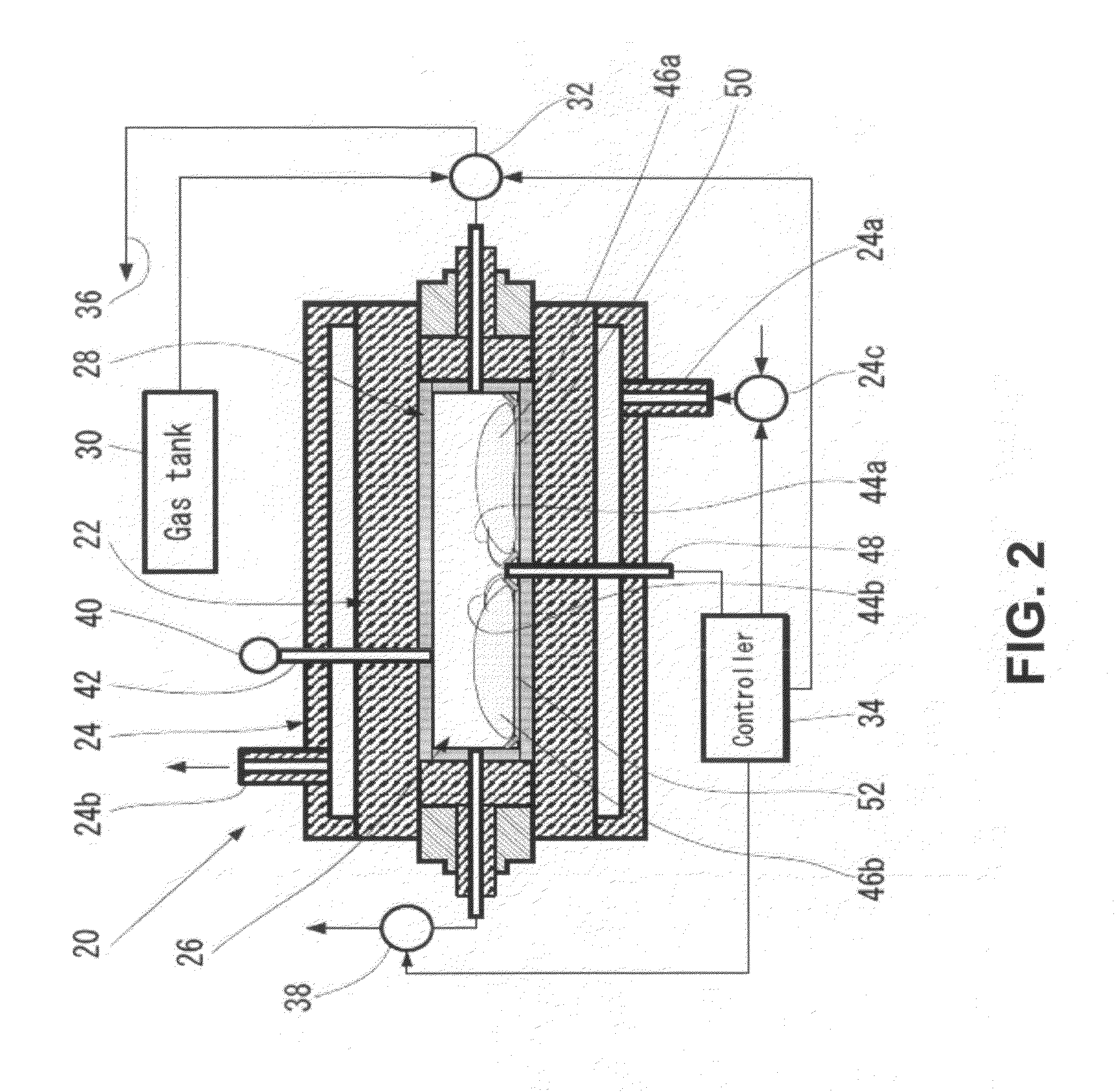

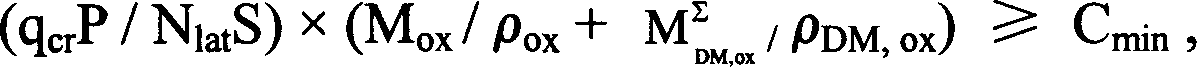

Method of manufacturing high-surface-area silicon

InactiveUS20110085960A1High purityReduce the amount requiredNanotechSiliconCombustion frontSilicon dioxide

A method for synthesis of high surface-area (>100 m2 / g) and nanosized (≦100 nm) silicon powder by initiation of self-sustained combustion reaction in a mixture of silicon dioxide and magnesium powders in a sealed reactor chamber under pressurized inert gas atmosphere. A specific feature of the method is rapid cooling of the product at a rate of 100 K / s to 400 K / s in the area directly behind the combustion front.

Owner:MUKASYAN ALEXANDER +2

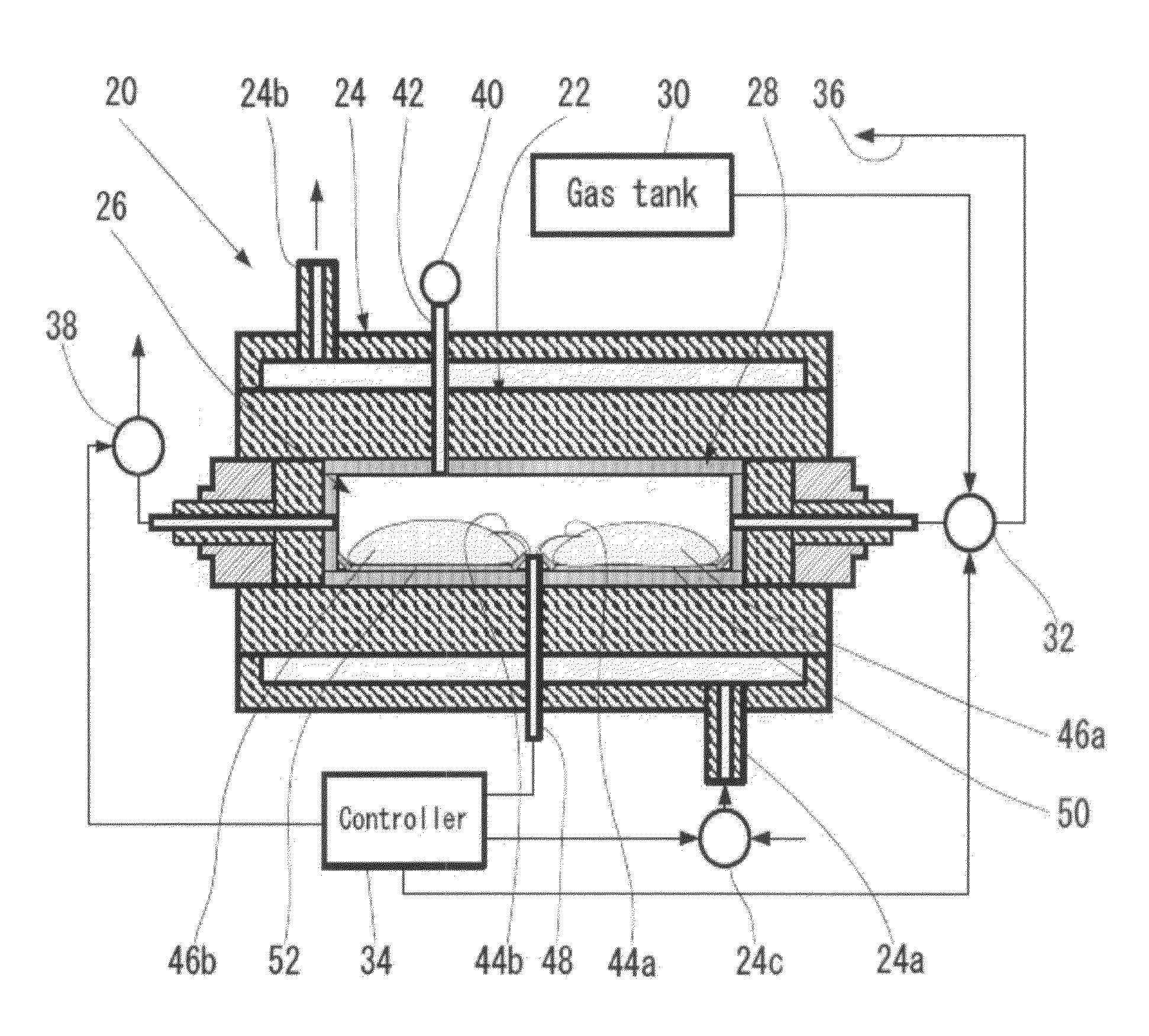

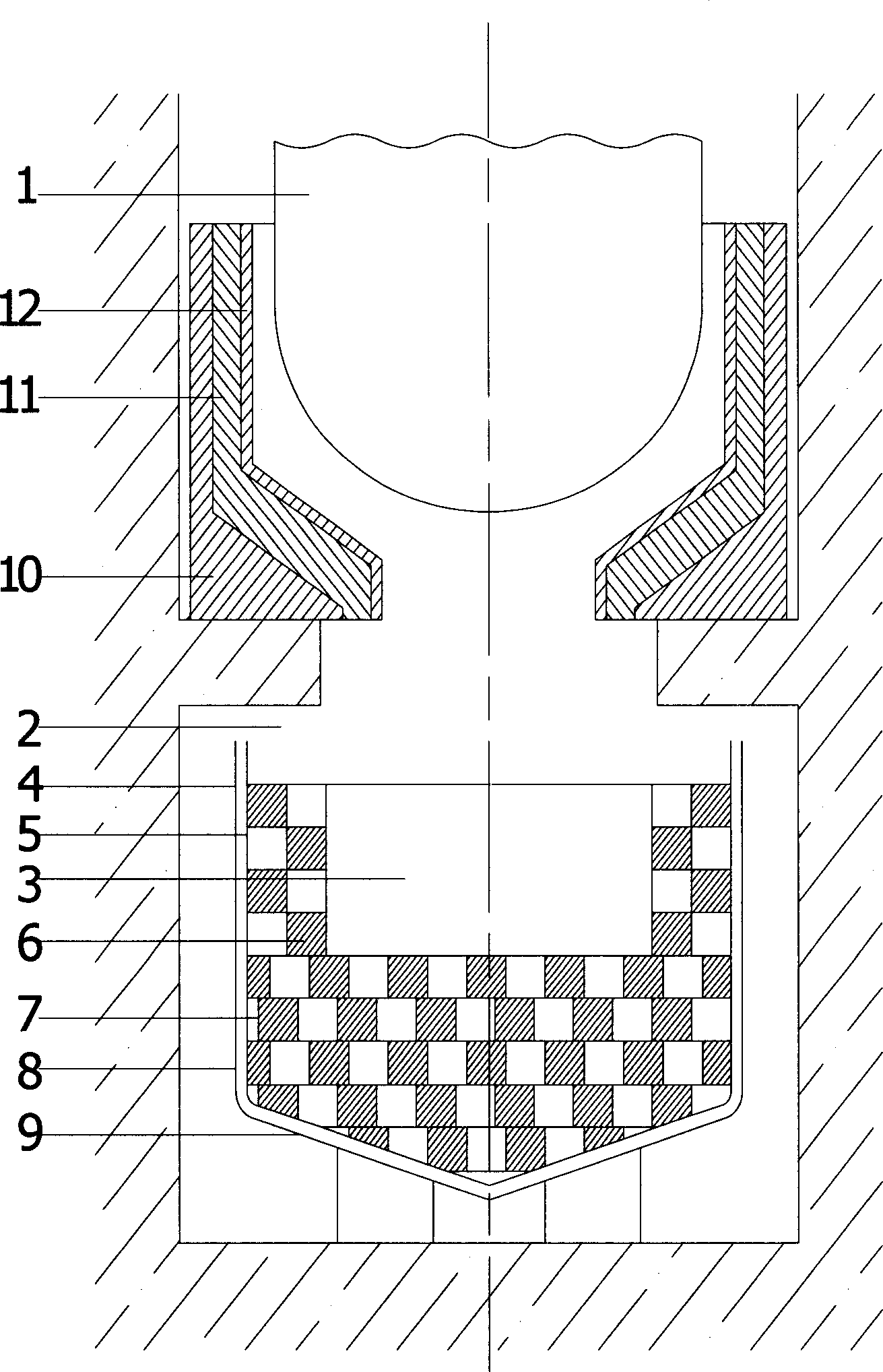

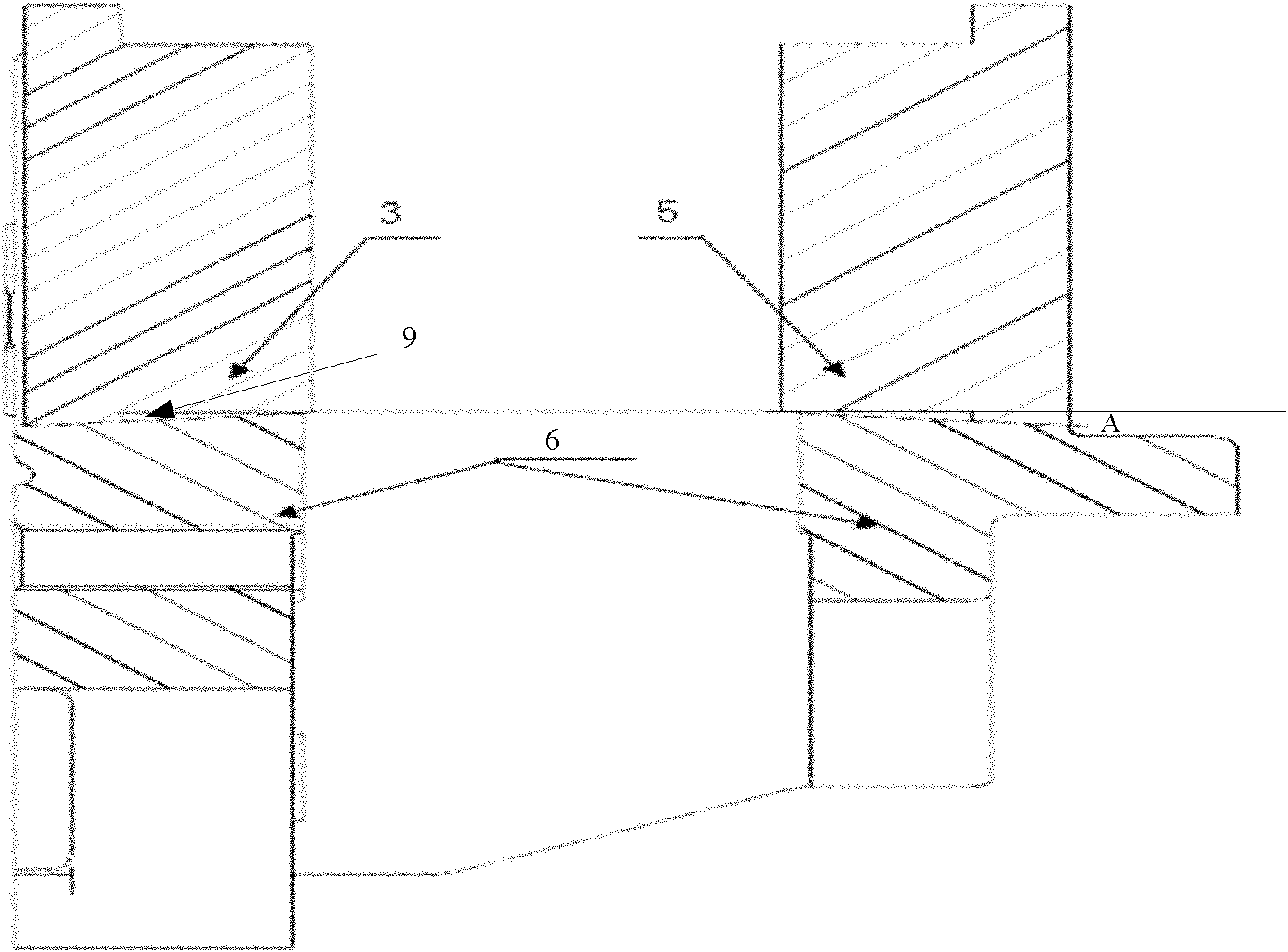

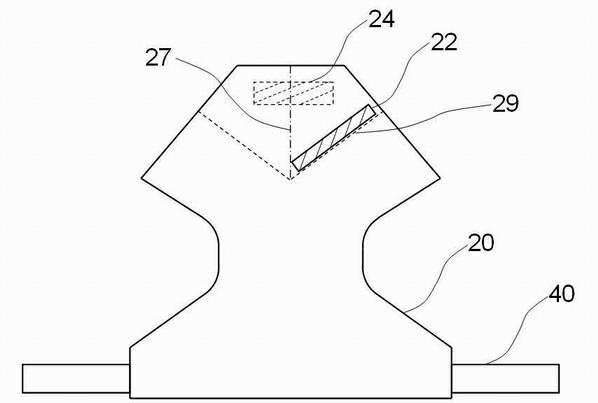

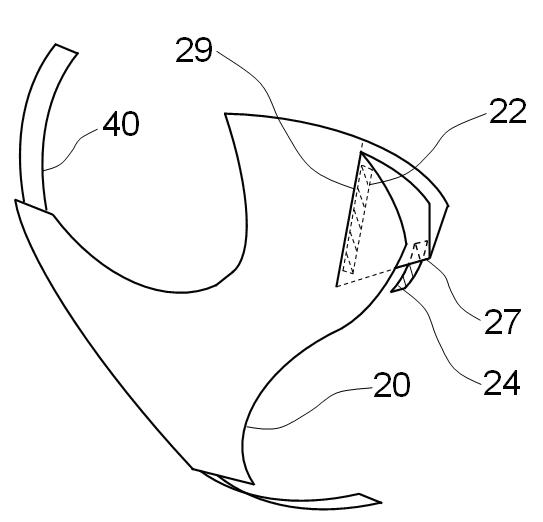

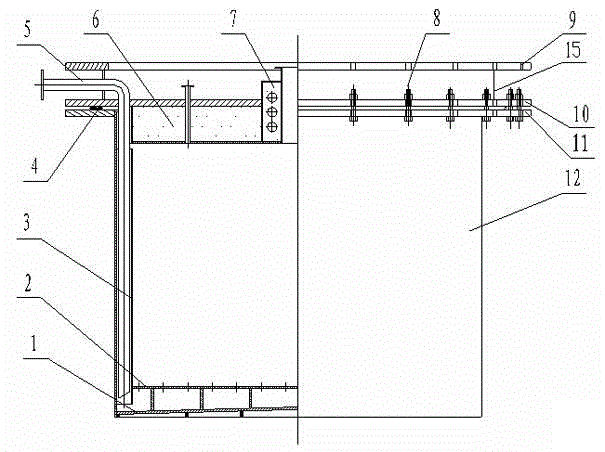

Apparatus for positioning and cooling lining layer of damaged LWR nuclear reactor

InactiveCN1585034AImprove melt fluidityImprove cooling conditionsNuclear energy generationEmergency protection arrangementsCore catcherNuclear reactor

The invention relates to apparatus for positioning and cooling melting lining layer when the melting lining layer flows out of the reactor shell during accident. The improvements of invention are described as following: the design of the cooling lining layer trap which has steel basket shell and arranged in sub-reactor, wherein sacrifice material is filled in the steel basket for diluting the component containing uranium and steel component of the lining layer; the shape (arrangement) of the sacrifice material in reactor core; the choice for optimum number of the sacrifice material; installation of guiding device used for the lining layer flowing into the reactor core trap. Especially, the thickness of bottom of the cooling jacket is larger than the thickness of the side wall thereof for no less than 30%, and the cooling jacket inclines to its center for 10 to 20 degree; the diluent and sacrifice material is made into blocks packed in steel shell.

Owner:V·B·哈本斯基 +17

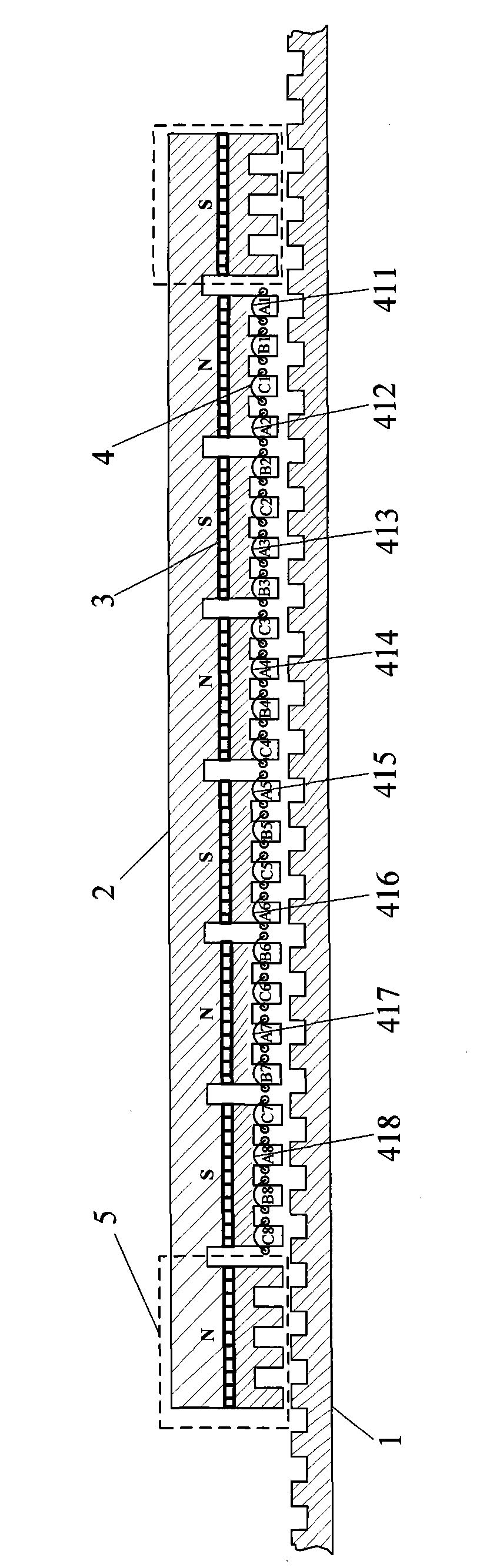

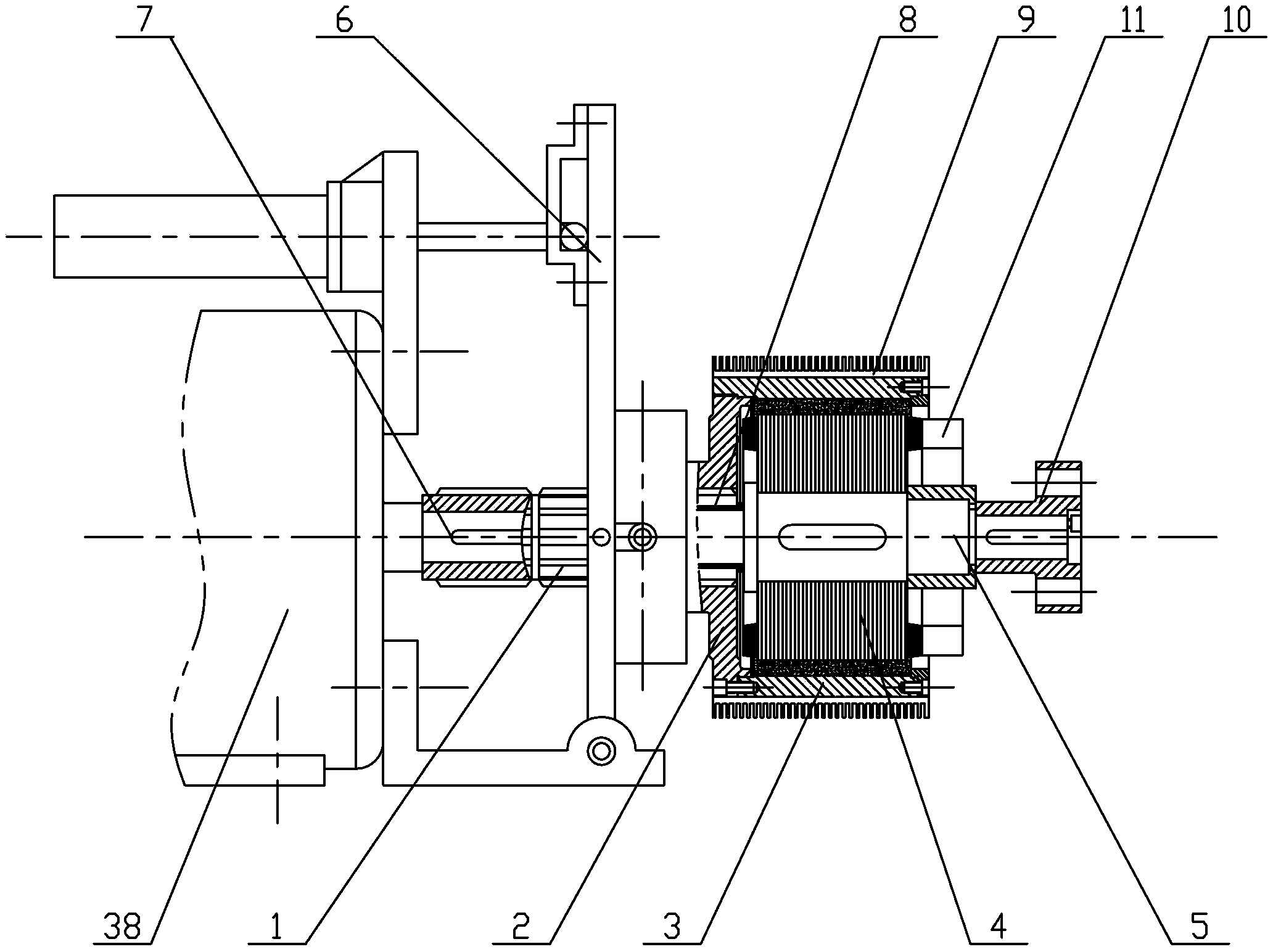

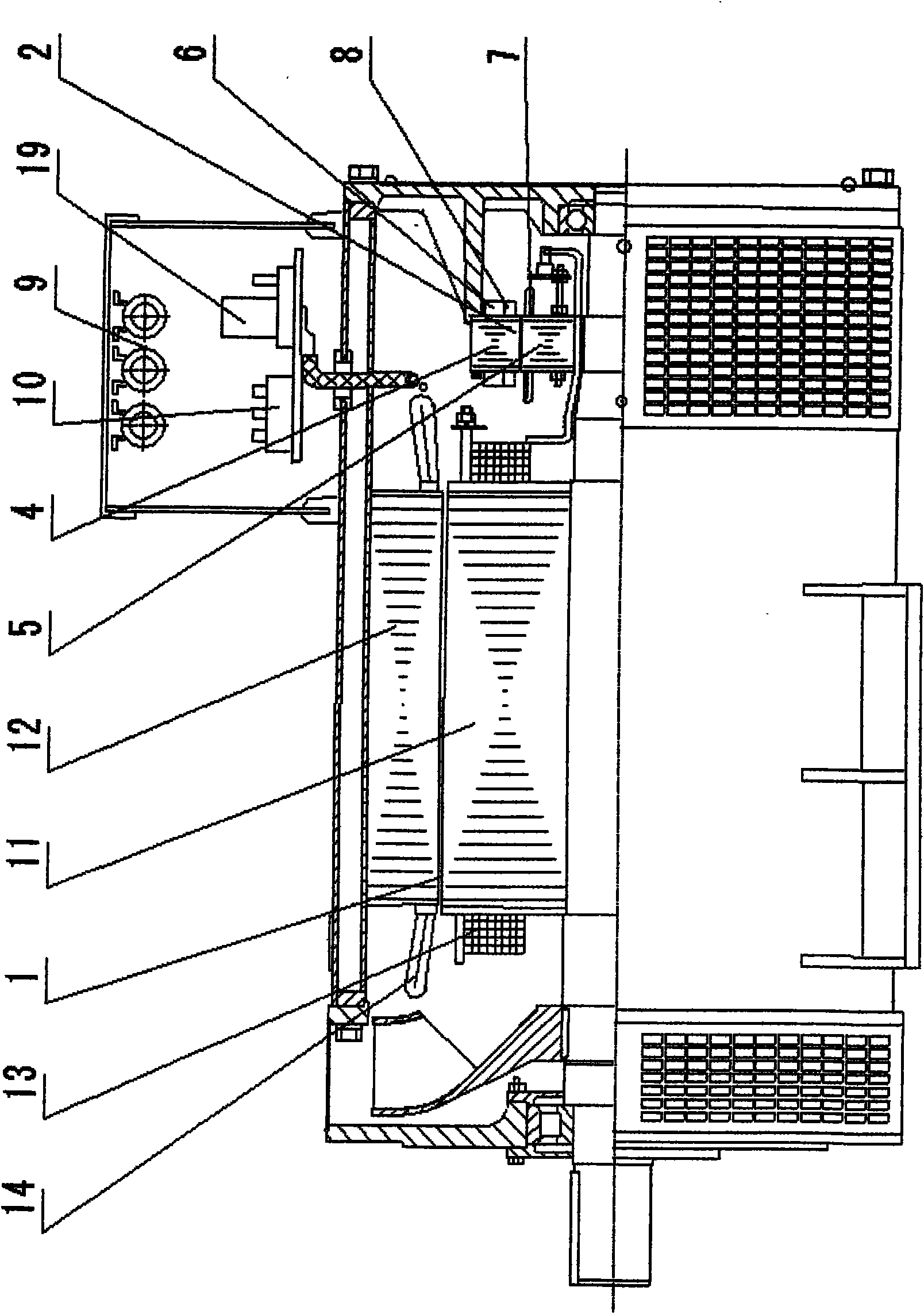

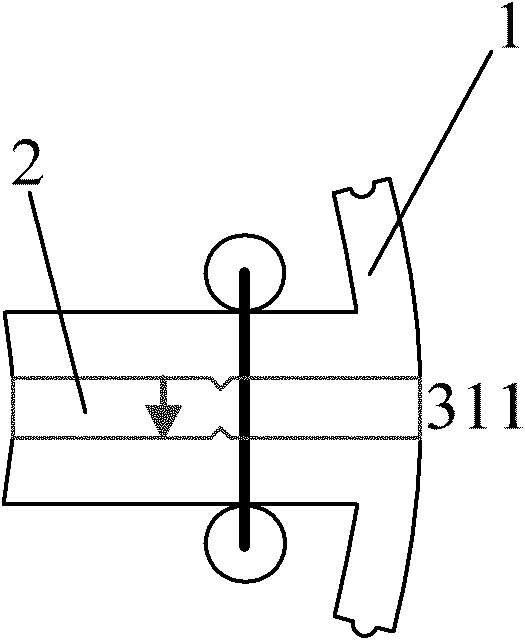

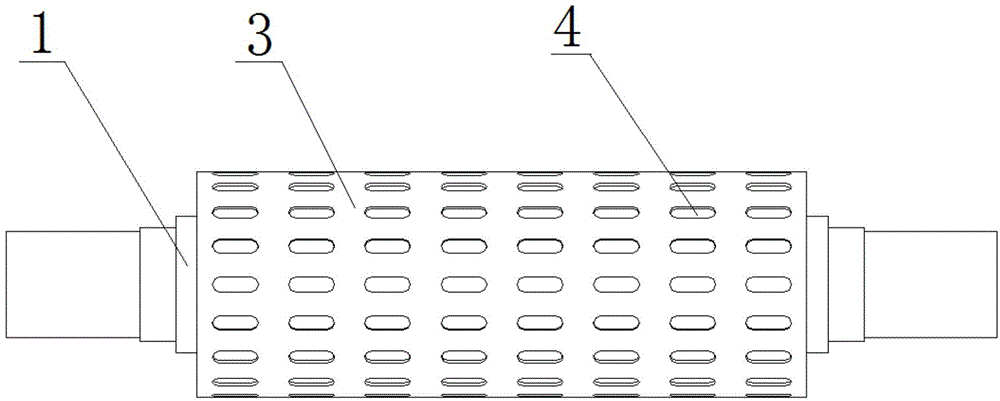

Multiphase long-stator primary permanent magnet linear motor

ActiveCN101783573AImprove cooling conditionsCompact structureMagnetic circuit rotating partsMagnetic circuit stationary partsPrimary permanentElectric machine

The invention relates to a multiphase long-stator primary permanent magnet linear motor which has the advantages of simple structure, firmness, stronger output thrust, higher power density and smaller thrust fluctuation. The motor comprises a stator (1), an air gap and rotors (2), wherein each rotor (2) comprises permanent magnets (3), a concentrated winding (4) and additional teeth (5); both the stator and the rotors are double-salient pole single-edges or double-edge flat-panel structures, and all concentrated winding coils of any phase are positioned in a rotor iron core slot; adjacent permanent magnets (3) form a serial magnetic circuit; the number of the permanent magnets (3) is NPM=2k*m+2, wherein k is a positive integer, and the number m of motor phases is not smaller than 3; both end parts of each rotor (2) are respectively provided with a permanent magnet which is an additional permanent magnet of each motor; the number of windings of the rotors is Nmt=(NPM-2)(m+1); and the central distance of adjacent teeth of the rotors is tau p.

Owner:SOUTHEAST UNIV

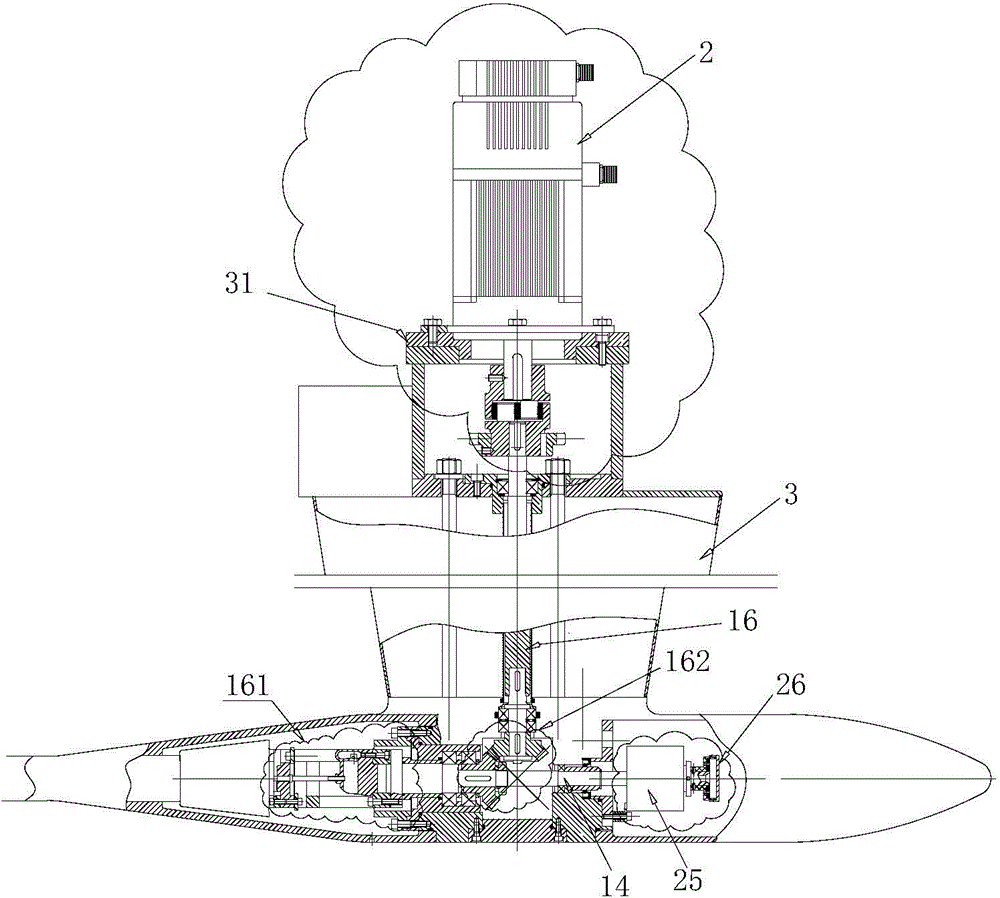

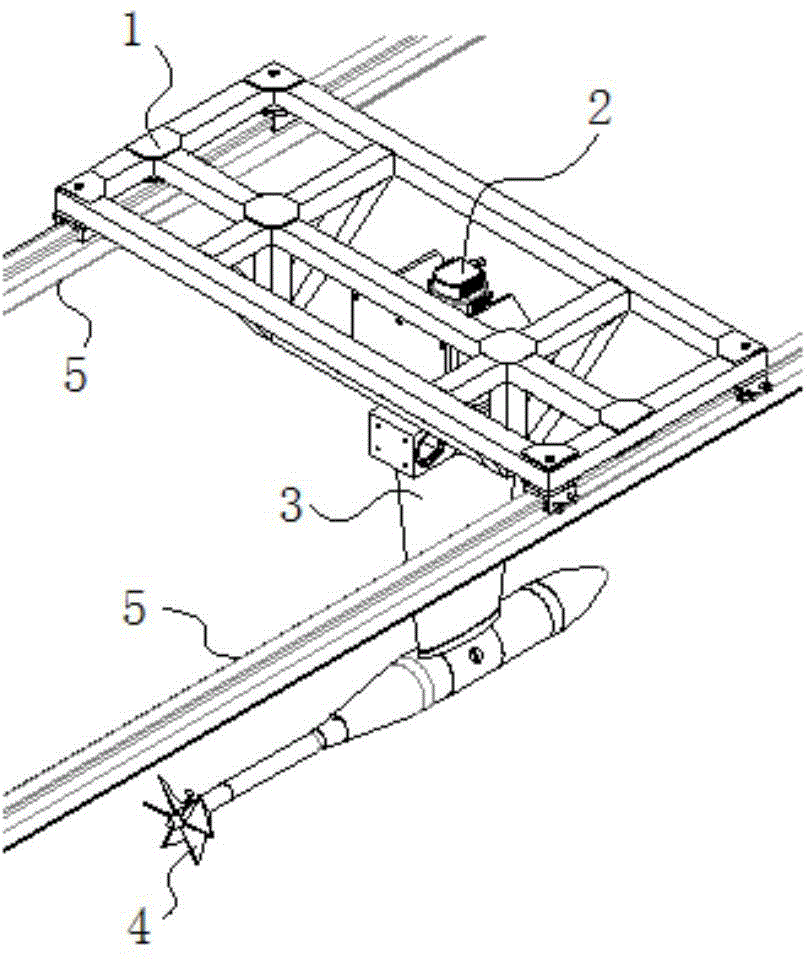

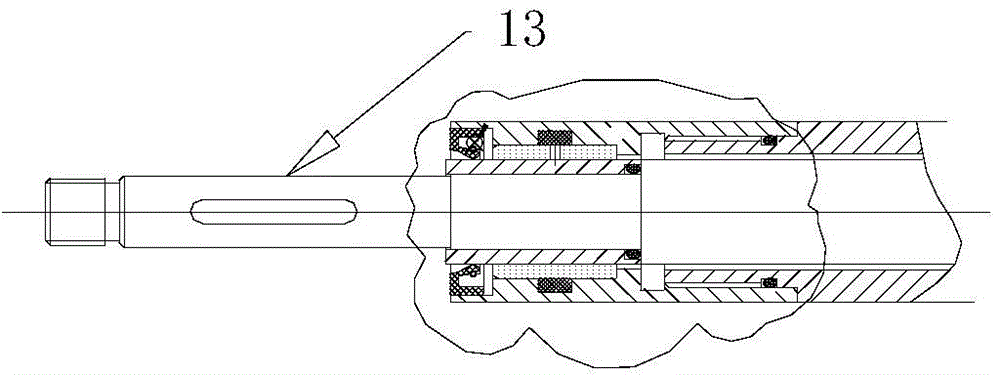

Strain propeller electric test dynamometer

ActiveCN103604600AEasy to assembleLow costMachine part testingForce measurementHorizontal transmissionStress conditions

The invention discloses a strain propeller electric test dynamometer which comprises a support, a servo motor arranged above the support, a vertical transmission shaft in transmission connection with the servo motor, and a horizontal transmission shaft in meshed transmission with the vertical transmission shaft through a gear set, wherein one end of the horizontal transmission shaft is connected with a thrust / torque sensing device; the thrust / torque sensing device is connected with a propeller through a horizontal spindle; a junction box is arranged at the other end of the horizontal transmission shaft through a sliding ring. The immersion depth tested by the dynamometer is 500mm, the dynamometer has high water tightness and normally operates at the temperature of 0-40 DEG C, the stress conditions of an underwater propeller in an operating state can be accurately measured, and the error is controlled to be 0.5 percent.

Owner:SHANGHAI ORIENTAL MARITIME ENG TECH CO LTD

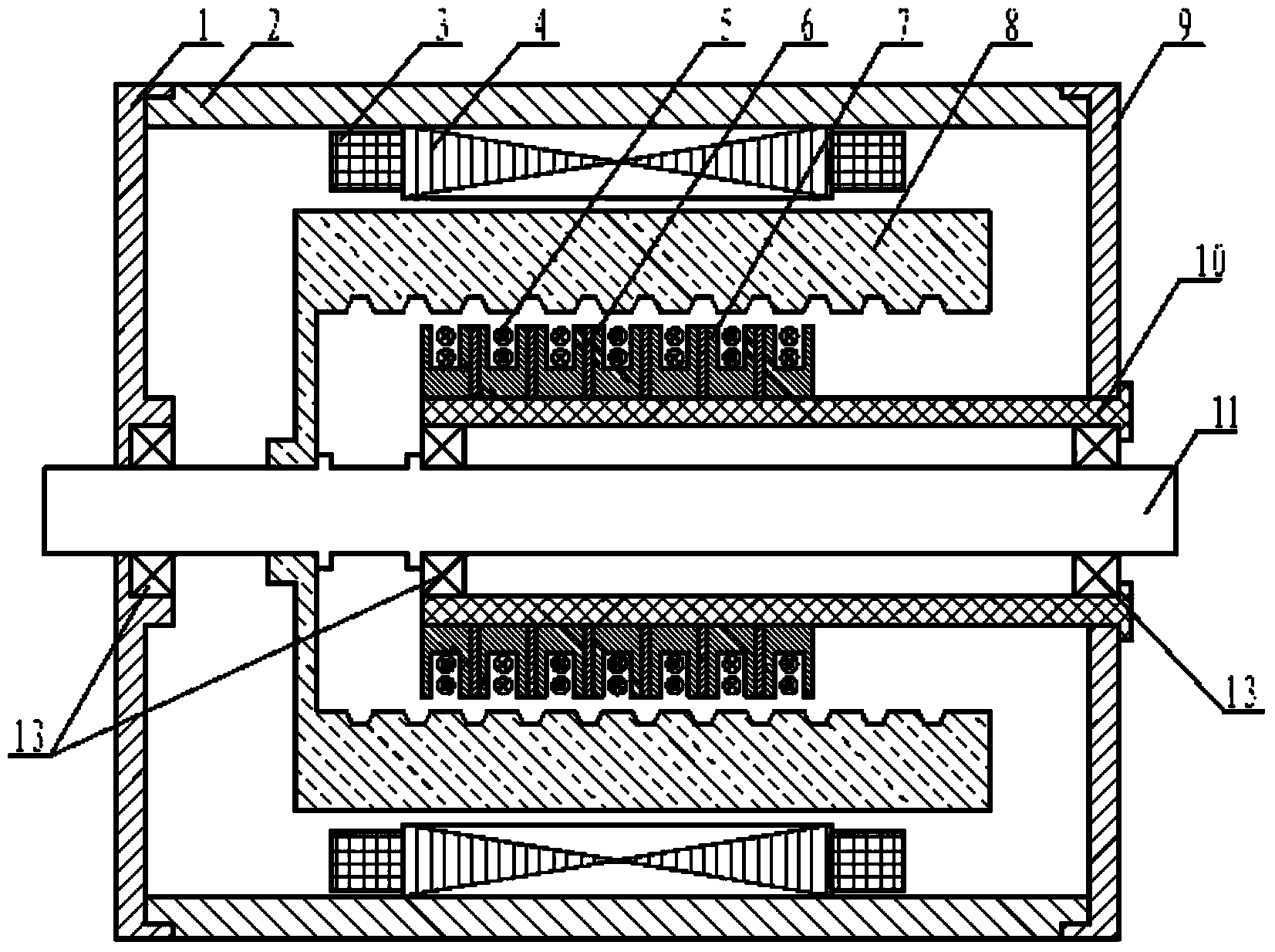

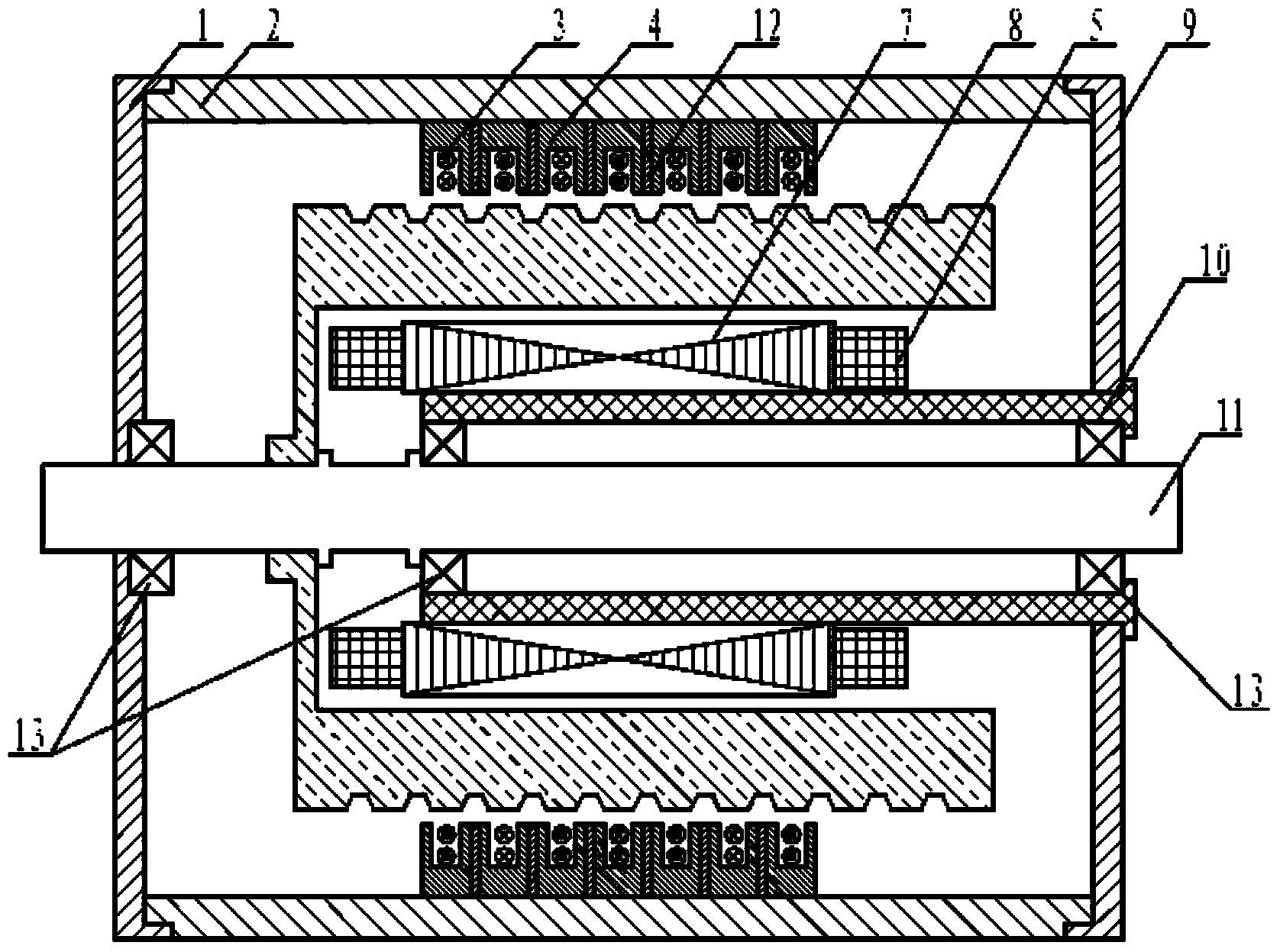

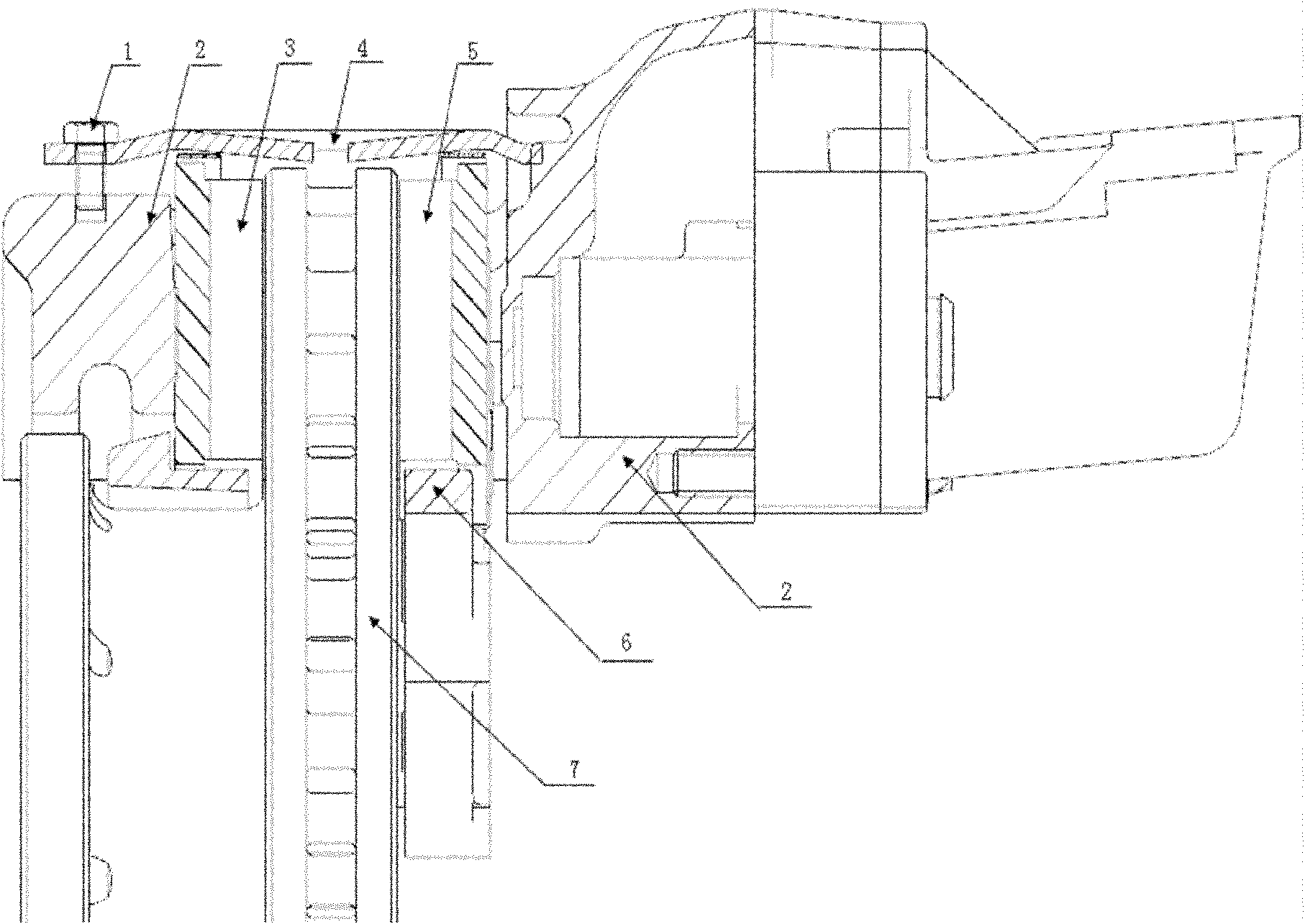

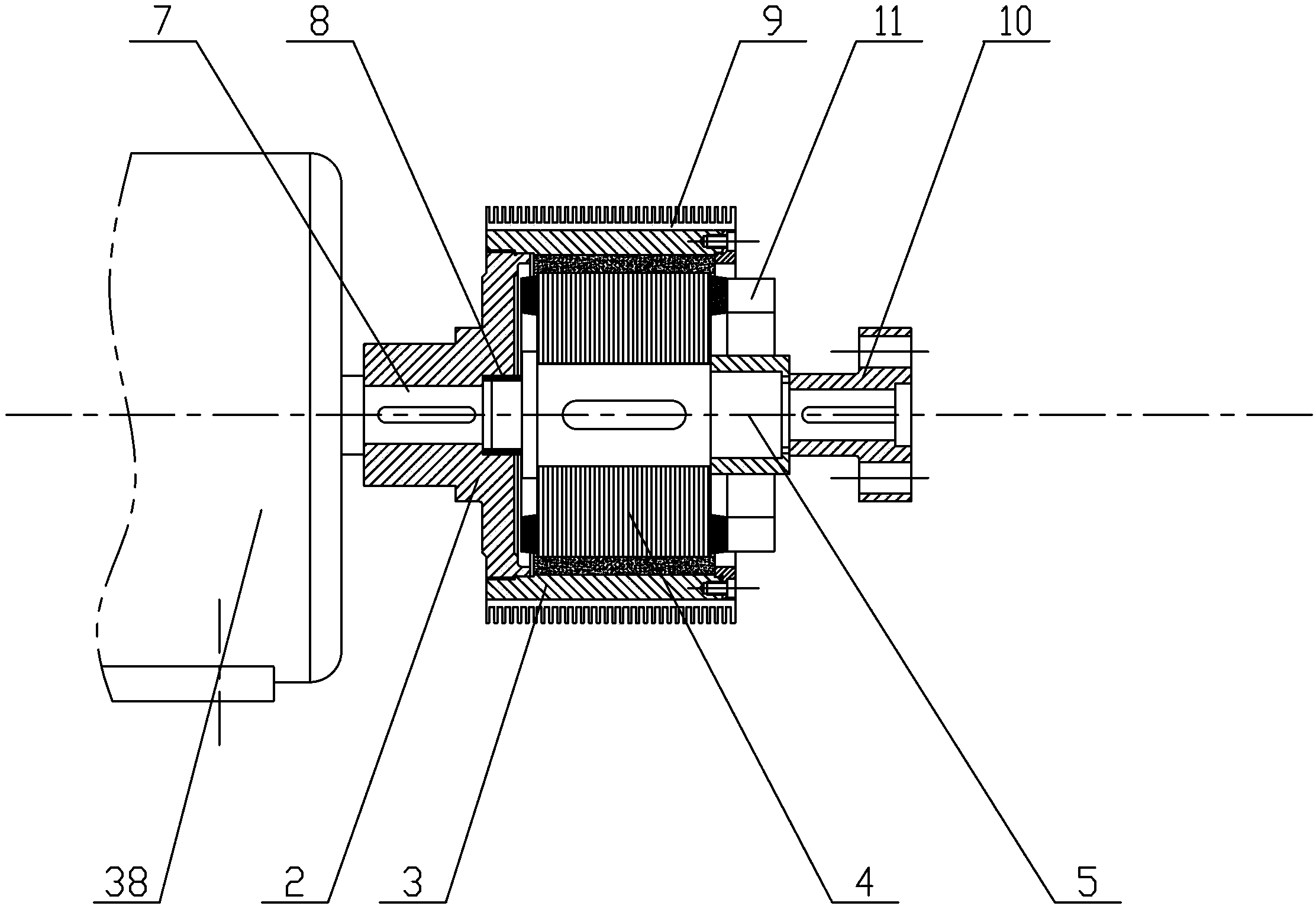

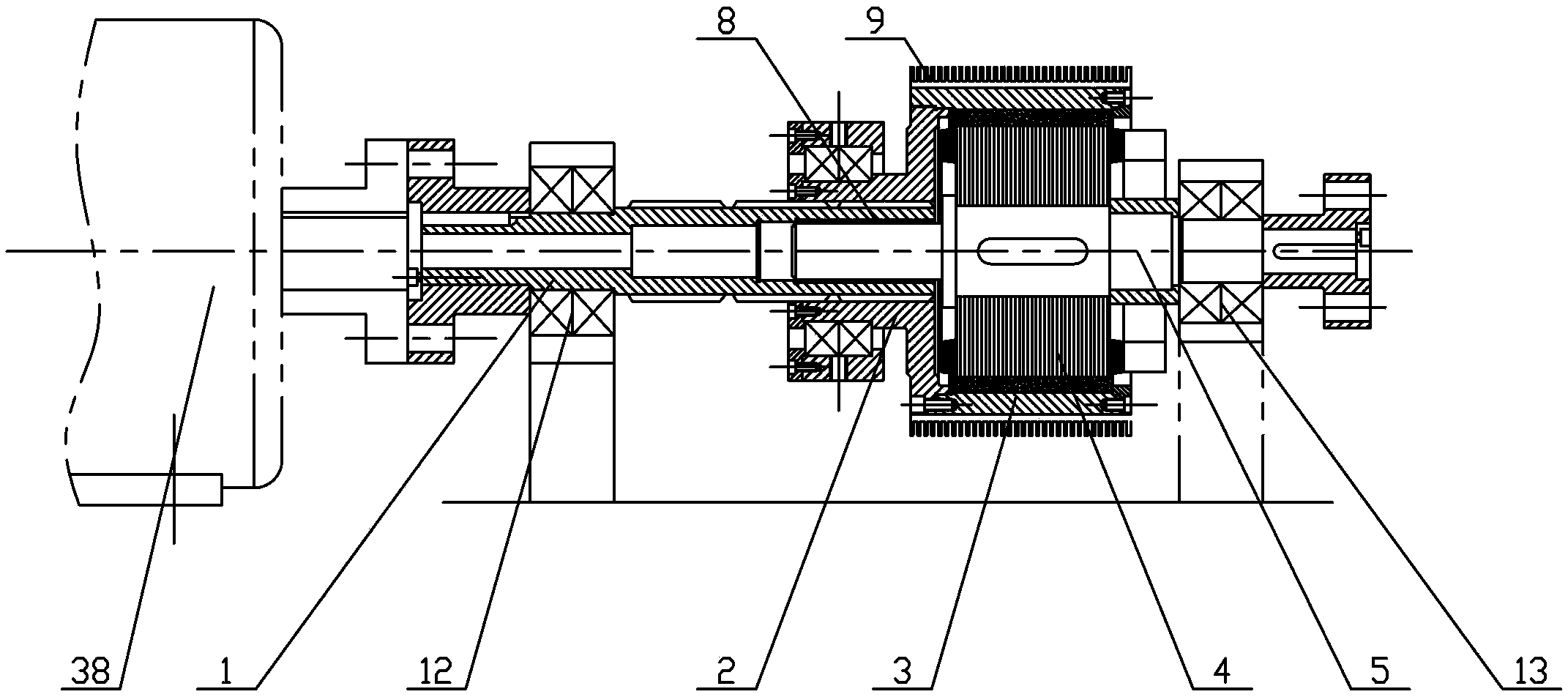

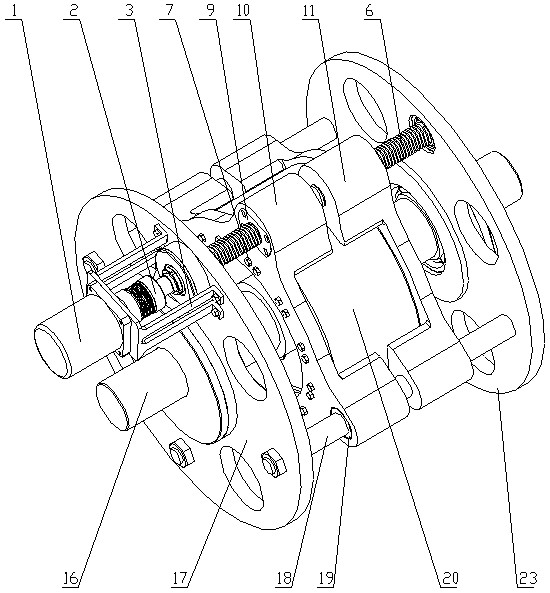

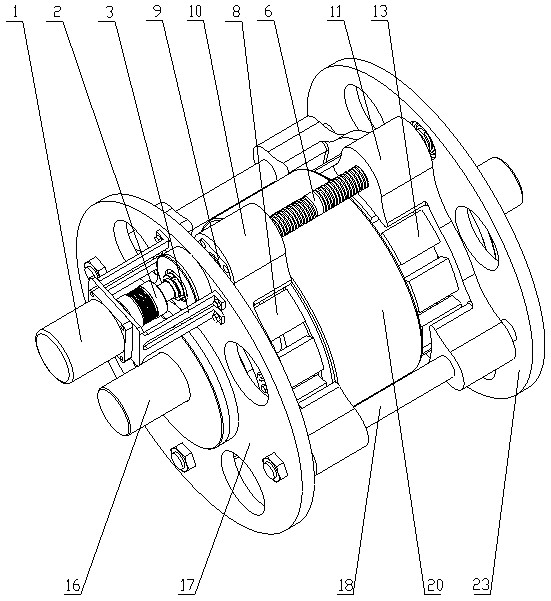

Linear rotation permanent magnet motor

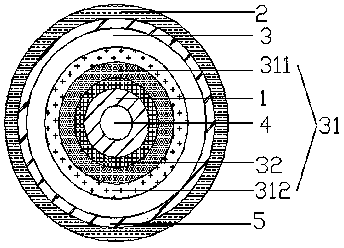

InactiveCN103475178AReduce volumeEasy to implement decoupled controlDynamo-electric machinesCouplingPermanent magnet motor

The invention discloses a linear rotation permanent magnet motor. The linear rotation permanent magnet motor comprises an inner stator, an outer stator, a rotor located between the inner stator and the outer stator, a left end cover (1), a machine shell (2), an outer stator winding (3), an outer stator iron core (4) with a groove, an inner stator winding (5), an inner stator permanent magnet (6), an inner stator iron core (7) with a groove, a rotor (8), a right end cover (9), an inner stator support (10), a rotation shaft (11), an outer stator permanent magnet (12) and a bearing (13), wherein the left end cover (1), the machine shell (2) and the right end cover (9) form a cavity, the inner stator support (10) is arranged in the cavity, and one end of the inner stator support (10) is connected with the right end cover (9). According to the linear rotation permanent magnet motor, the structure of the linear rotation two-freedom-degree motor is simplified, the size and the weight of the motor are reduced, magnetic coupling of linear and rotary motion units is eliminated, and the control difficulty of linear and rotary motions is lowered.

Owner:SOUTHEAST UNIV

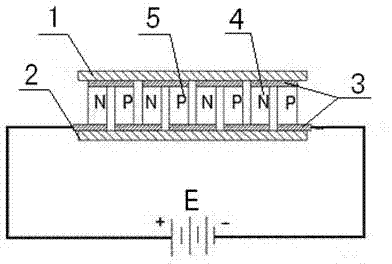

Semiconductor refrigeration or heating module and manufacturing method thereof

InactiveCN102297544AImprove cooling conditionsImprove cooling efficiencyMachines using electric/magnetic effectsMetal sheetSemiconductor

The invention discloses a semiconductor refrigeration or heating module and a manufacturing method thereof. In the invention, each N-type semiconductor and P-type semiconductor are arranged on the first insulating ceramic sheet and the second insulating ceramic sheet at intervals without contacting each other. Between, fix at least 1 conductive metal sheet on the first insulating ceramic sheet, fix at least 2 conductive metal sheets on the second insulating ceramic sheet, the conductive metal sheet fixed on the second insulating ceramic sheet is more than that fixed on the first insulating ceramic sheet There is one more conductive metal sheet on the ceramic sheet, and one N-type semiconductor and one P-type semiconductor are fixed on each conductive metal sheet on the first insulating ceramic sheet, and will be fixed on the same conductive metal sheet on the first insulating ceramic sheet The other ends of the N-type semiconductor and the P-type semiconductor on the chip are respectively fixed on different conductive metal sheets on the second insulating ceramic chip. The invention has the advantages of high refrigeration or heating efficiency, energy saving, simple structure, easy manufacture, stable work, long service life and the like.

Owner:陈志明 +2

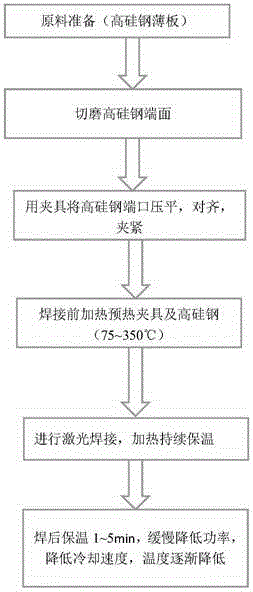

Laser welding method of high silicon steel

ActiveCN106041305ARealize welding formingImprove cooling conditionsWelding/soldering/cutting articlesLaser beam welding apparatusAlloySlow cooling

The invention belongs to the field of the metallurgy technology and material science, and aims at providing a laser welding process method of brittle high silicon steel. Quick welding of strip tension rolling in the rolling preparation process of a high silicon steel thin strip is met. According to the mass ratio, an adopted alloy is prepared from 93%-96.5% of Fe and 3.5%-7% of Si; and the thickness ranges from 0.1 mm to 3.5 mm. According to the method, laser welding and a supplementary heat source are combined, and double-face or single-face welding is adopted; preheating carried out before welding is utilized for controlling the temperature rise speed, and heat preservation during welding and heat preservation carried out after welding are utilized for slow cooling to control the temperature reduction speed; and the temperature gradient and welding stress in the weld joint cooling process are reduced, and welding forming of the brittle high silicon steel is achieved. By means of the adoption of the method, cracks generated by the too high welding stress of the brittle high silicon steel can be avoided well, and the yield and the mechanical performance of the brittle high silicon steel are increased.

Owner:UNIV OF SCI & TECH BEIJING

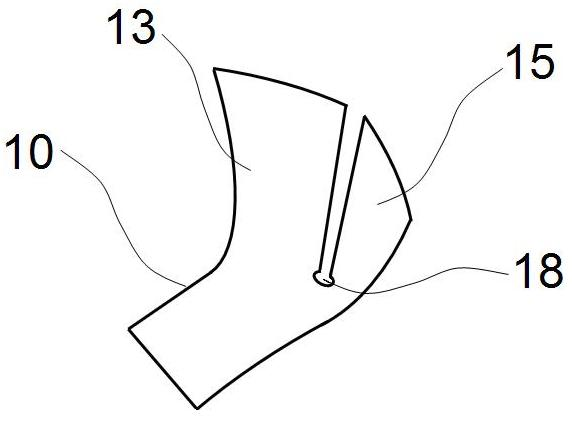

Disc brake with friction block return structure

The invention discloses a disc brake with a friction block return structure. The disc brake comprises a brake disc, friction blocks located at two sides of the brake disc, a clamp body bracket supporting the friction blocks, a clamp body pushing the friction block along the axial direction of the brake disc and a friction block pressing plate at one side of the friction blocks, and the middle part of the friction block pressing plate is provided with an elastic element which is inclined towards the axis of the brake disc and can deform elastically along the direction vertical to the axis of the brake disc. The disc brake enables the friction blocks to return to the original position in time after brake removal, and ensures that the radiation condition is improved and the delayed friction between the friction blocks and the brake disc can be avoided.

Owner:DONGFENG MOTOR CORP HUBEI

Magnetic coupler

ActiveCN103401398ASmall moment of inertiaImprove reliabilityDynamo-electric gearsElectric machineControl theory

The invention discloses a magnetic coupler which comprises a power input shaft, connecting flanges, permanent magnet outer rotor assemblies, cage type inner rotors, a power output shaft and a mechanical speed adjustment device, wherein the permanent magnet outer rotor assemblies have hollow cup-shaped structures, are sleeved outside the cage-type inner rotors and realize transmission of torque under the coupling action of an air gap magnetic field between the permanent magnet outer rotor assemblies and the cage-type inner rotors; the mechanical speed adjustment device can change axial air gap areas between the permanent magnet outer rotor assemblies and the cage-type inner rotors according to a lever theory, thus realizing stepless speed variation for load rotating speed. According to the magnetic coupler, a method for designing the number of pole pairs of the permanent magnet outer rotor assemblies is provided on the basis of a minimum torque ripple rule, so that the thickness of yokes and the rotating inertia of the coupler are reduced. The cage-type inner rotors can adopt structures which are the same as or similar to that of the conventional motor cage rotor iron core. The magnetic coupler disclosed by the invention can be coaxially connected with a load and can be used as a belt wheel adapter matched with a belt wheel.

Owner:DALIAN JIAOTONG UNIVERSITY

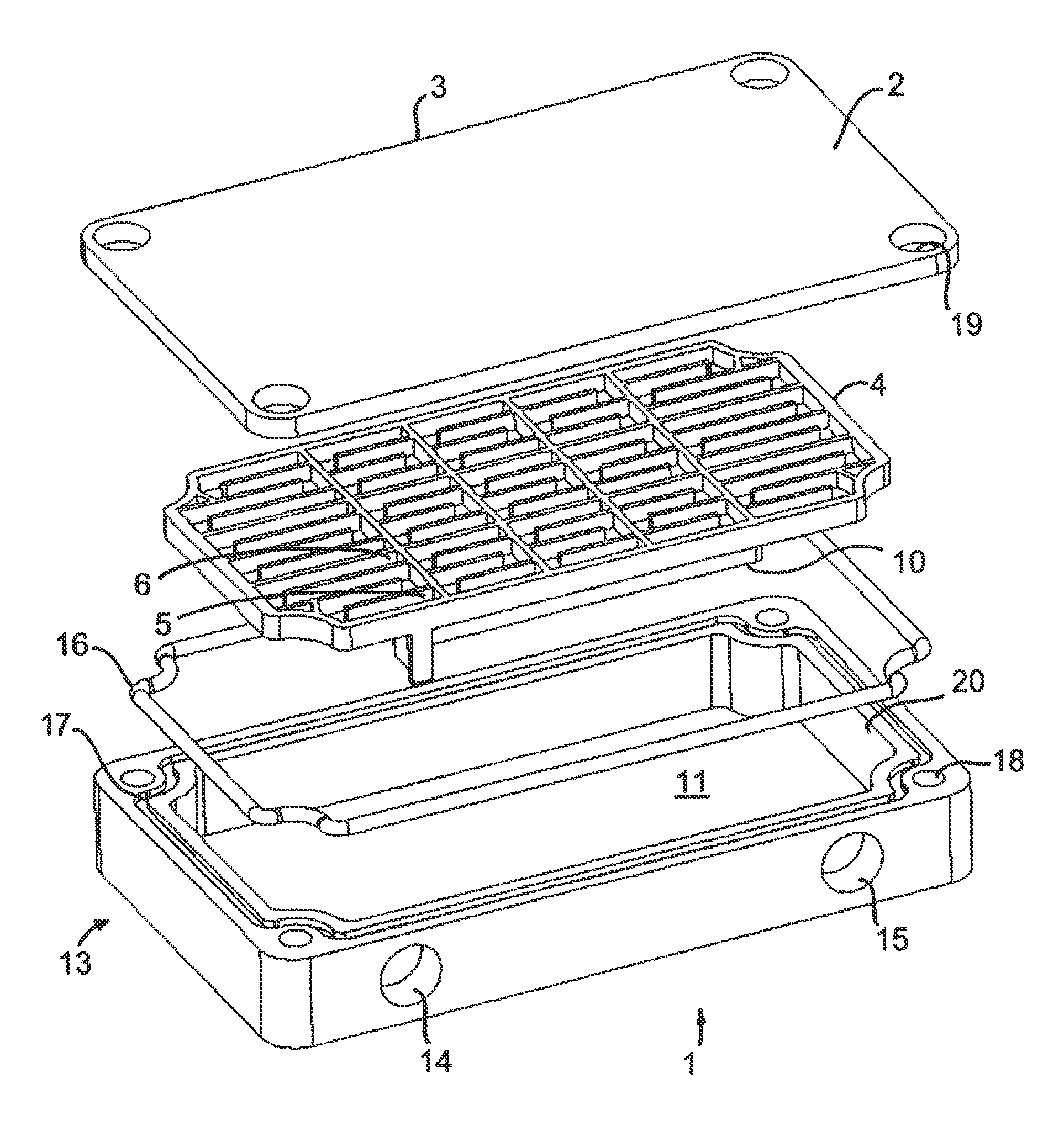

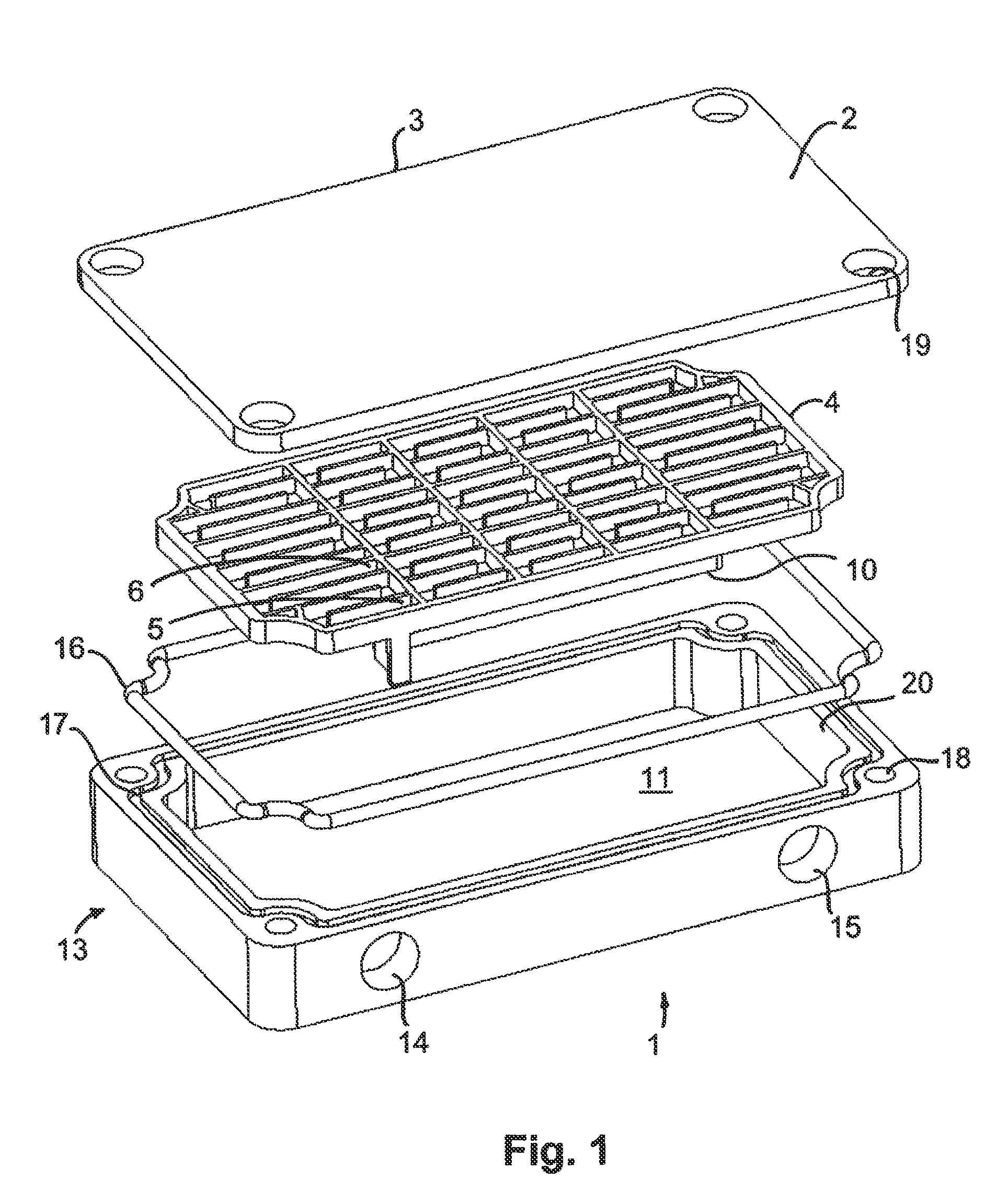

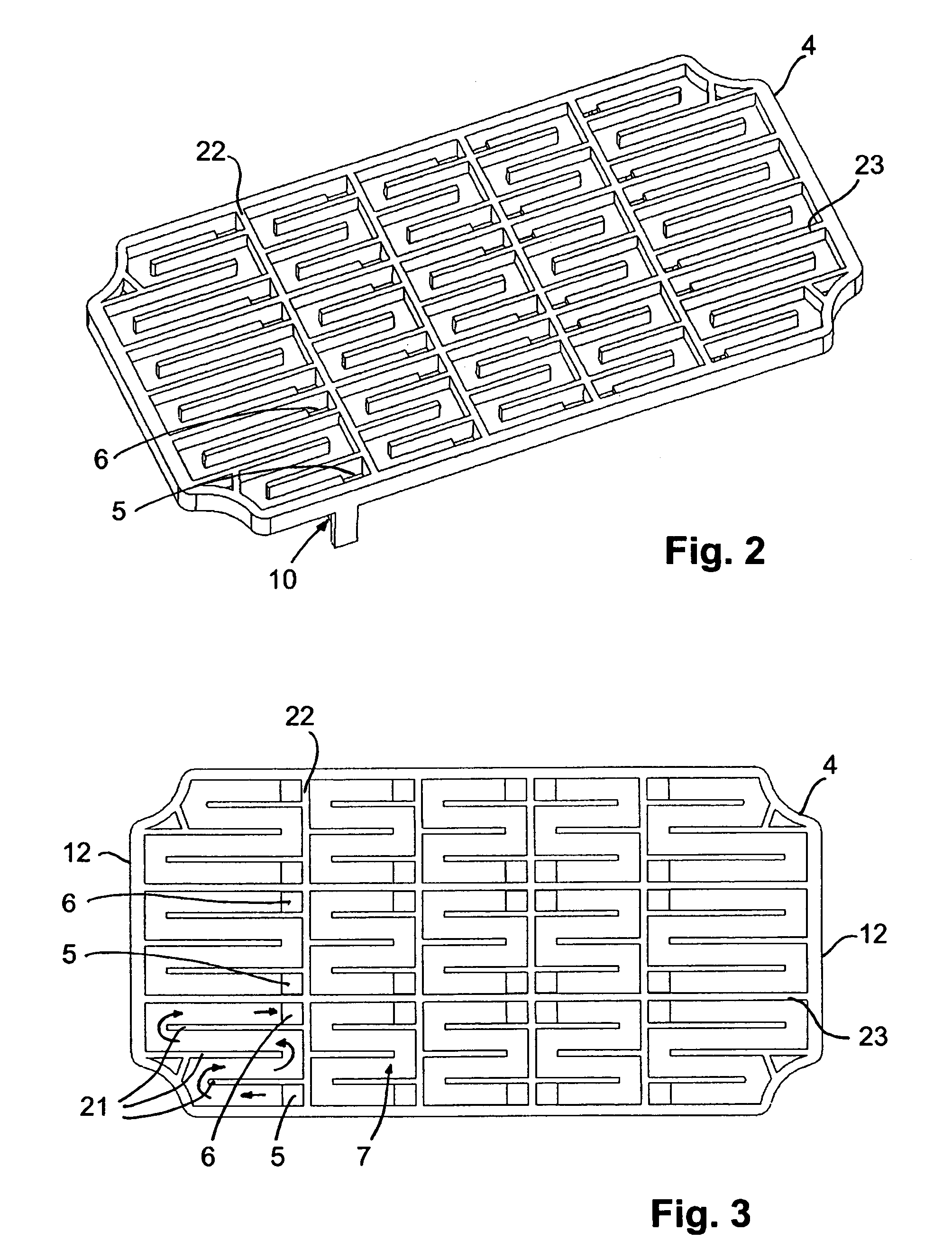

Cooling unit and flow distributing element for use in such unit

ActiveUS7339788B2Improve cooling conditionsInternal temperatureSemiconductor/solid-state device detailsSolid-state devicesEngineeringCooling power

A liquid-cooled power semiconductor unit has components to be cooled arranged on the upper side of a plate. The bottom side of the plate is cooled by liquid, which is guided along the plate by means of a distributing element, and the liquid inlet and the liquid outlet of the distributing element are preferably arranged perpendicular to the plate. The distributing element is divided into cells, where each cell has a liquid inlet and a liquid outlet perpendicular to the cooled plate, and the distributing element has multiple cells along the plate.

Owner:DANFOSS SILICON POWER

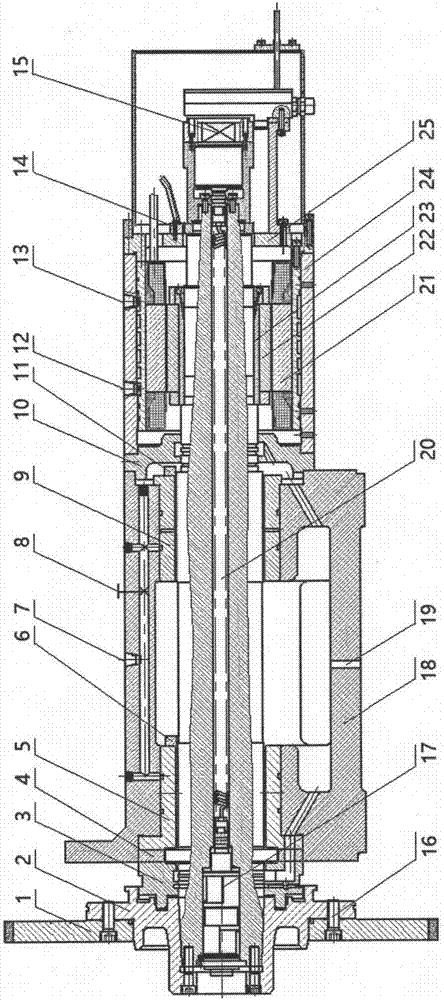

High-speed high-precision built-in dynamic and static piezoelectric main shaft

ActiveCN106984836ASmall amount of thermal deformationImprove output accuracyLarge fixed membersMaintainance and safety accessoriesNumerical controlElectricity

The invention relates to a high-speed high-precision built-in dynamic and static piezoelectric main shaft. The high-speed high-precision built-in dynamic and static piezoelectric main shaft is characterized in that the main shaft comprises a box body, a front bearing and a rear bearing are arranged in the box body through a front bearing end cover and a rear bearing end cover correspondingly, and the front bearing and the rear bearing jointly bear a main shaft body internally provided with an online dynamic balancing head; the box body is provided with an oil inlet and an oil outlet, the oil inlet communicates with the oil outlet through an oil way, the oil way is divided into two parts, and one part enters the front bearing and the rear bearing through the oil inlet to suspend the main shaft body in a gap between the front bearing and the rear bearing to form pure liquid lubrication; and the other part is fed to the front bearing and the front bearing end cover to make the main shaft body achieve axial positioning, and a grinding wheel is arranged on the front bearing end cover through a flange disc. The high-speed high precision built-in dynamic and static piezoelectric main shaft is simple in structure, good in dynamic performance, large in rotation number of the main shaft, high in rotation precision and small in heat deformation and can be widely applied to grinding wheel electric main shafts of precise grinding machines, main shafts of numerical control machining centers and precise lathes and the like.

Owner:DONGHUA UNIV

Paper diaper

ActiveCN102090953AIncrease activity spaceImprove cooling conditionsAbsorbent padsCoatingPulp and paper industry

The invention discloses a paper diaper. The front end of an absorption core layer of the paper diaper is provided with at least one branch, and the branches can be combined and folded to form a three-dimensional structure. A coating and the front end of base cloth can also be folded into a three-dimensional structure. The three-dimensional structure at the front end of the paper diaper can provide a space for the scrotum of a baby boy and is favorable for heat dissipation of the testis. The rear end of the paper diaper can be folded to form a three-dimensional structure to accommodate the excrement of the infant. The paper diaper, only the rear end of which is provided with the three-dimensional structure, can be used for a baby girl. The paper diaper can be used as an adult paper diaper.

Owner:NANJING MEIXIAOJIA TECH CO LTD

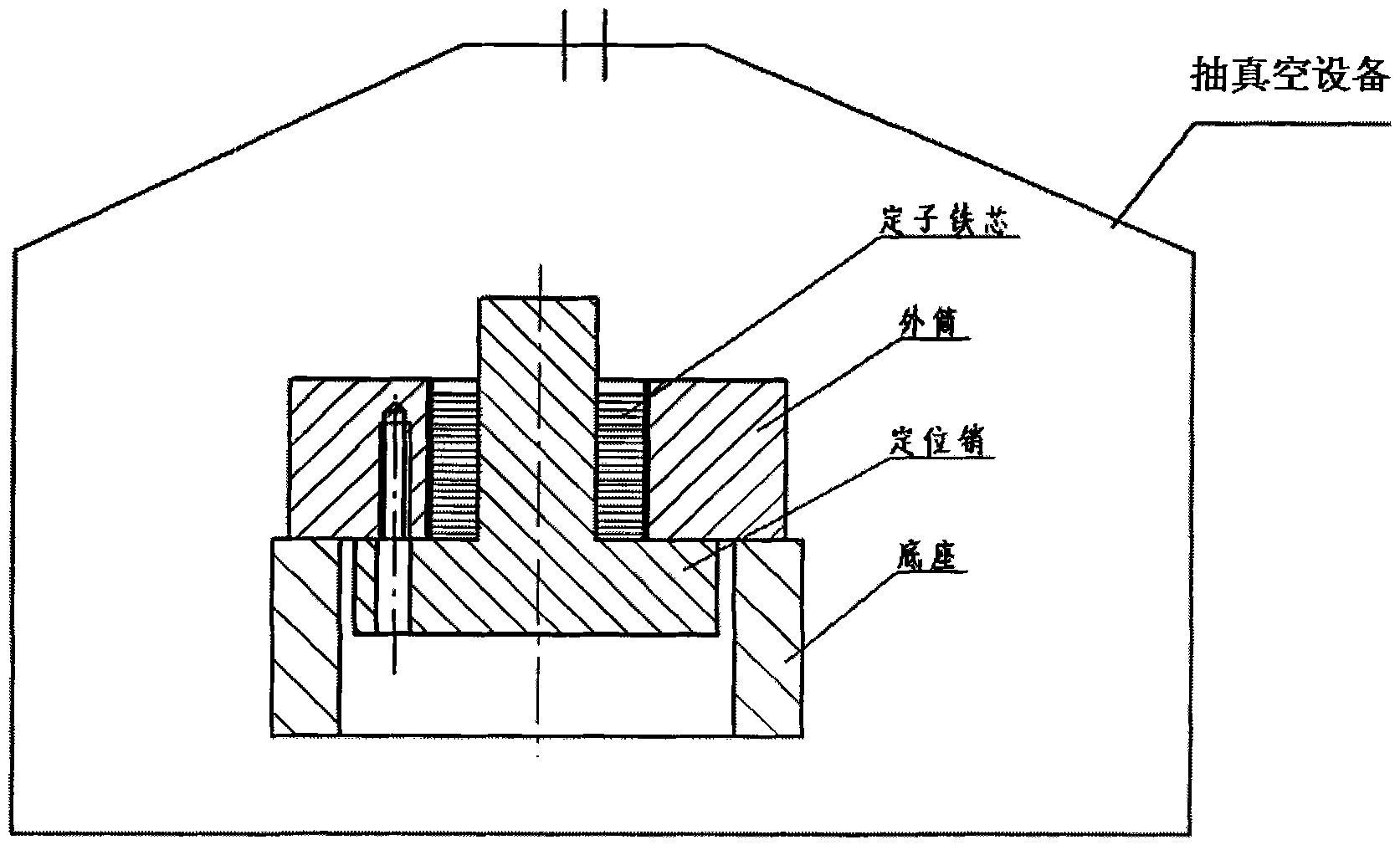

Adhesive filling and grinding processing method for stator-rotor iron core component of motor

InactiveCN101895176ASolve the problem of inner and outer conicityIncreased resistance to deformationManufacturing stator/rotor bodiesAdhesiveRoom temperature

The invention discloses an adhesive filling and grinding method for a stator-rotor iron core component of a motor. The method comprises the processes of gluing the iron core component through lamination, grinding an iron core by a benchwork, filling an adhesive, removing adhesive layers on two end faces by the benchwork, grinding an inner hole and an excircle of the iron core by a grinder, removing a potting adhesive and the like. The method is characterized in that: when the adhesive is filled, the potting adhesive is placed into a container, stirred and heated to a temperature of between 120 and 130 DEG C; the potting adhesive is poured into an pre-heated iron core groove immediately; a die is vacuumized in a vacuum chamber, so that bubbles are removed from the die, wherein the vacuum degree is 10 to 300Pa and the time is 5 to 20 minutes; and the die is taken out and cooled at the room temperature, so that the potting adhesive is solidified. Compared with the prior art, a profiled groove part of the stator-rotor iron core component forms an entity through the adhesive filling process so that deformation resistance of the stator-rotor iron core component is enhanced and interrupted cut is avoided; and at the same time, the grinding process solves the problems of crack, swelling, poor coaxiality and the like caused by internal and external conicity of the stator-rotor iron core component and temperature distortion of the adhesive layers of the iron core component.

Owner:FLIGHT AUTOMATIC CONTROL RES INST

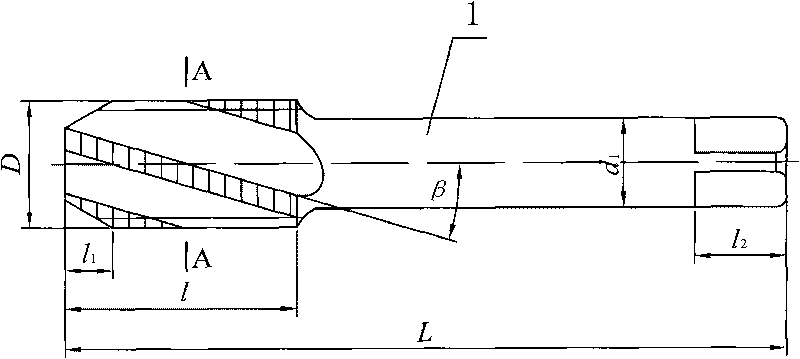

Spiral fluted tap and method for processing same

The invention discloses a spiral fluted tap and a method for processing the same. The spiral fluted tap comprises a tap body provided with a plurality of uniformly distributed spiral flutes on a front cut part, wherein the spiral flute is an S-shaped smooth curved groove formed by sequentially connecting four sections of tangential circular arcs end to end; and the four sections of tangential circular arcs are a cutting circular arc, a chip curling circular arc, a chip accommodating circular arc and a blade back circular arc respectively. The method for processing the spiral fluted tap comprises the following steps of: (1) preparing before processing; (2) processing the spiral flute by a special tool: fitting a blade shape of a cutter by a computer, and then manufacturing the cutter according to the fitted cutter blade shape so as to process the spiral flute; and (3) carrying out subsequent treatment by using a machining process so as to obtain a finished product of the tap body. The spiral fluted tap processed by the method has simple structure and can be molded in one step. Moreover, the processing method is suitable for different processing materials, particularly for processing fluted taps made of light alloys, such as an aluminum alloy and the like.

Owner:XIAN TECHNOLOGICAL UNIV

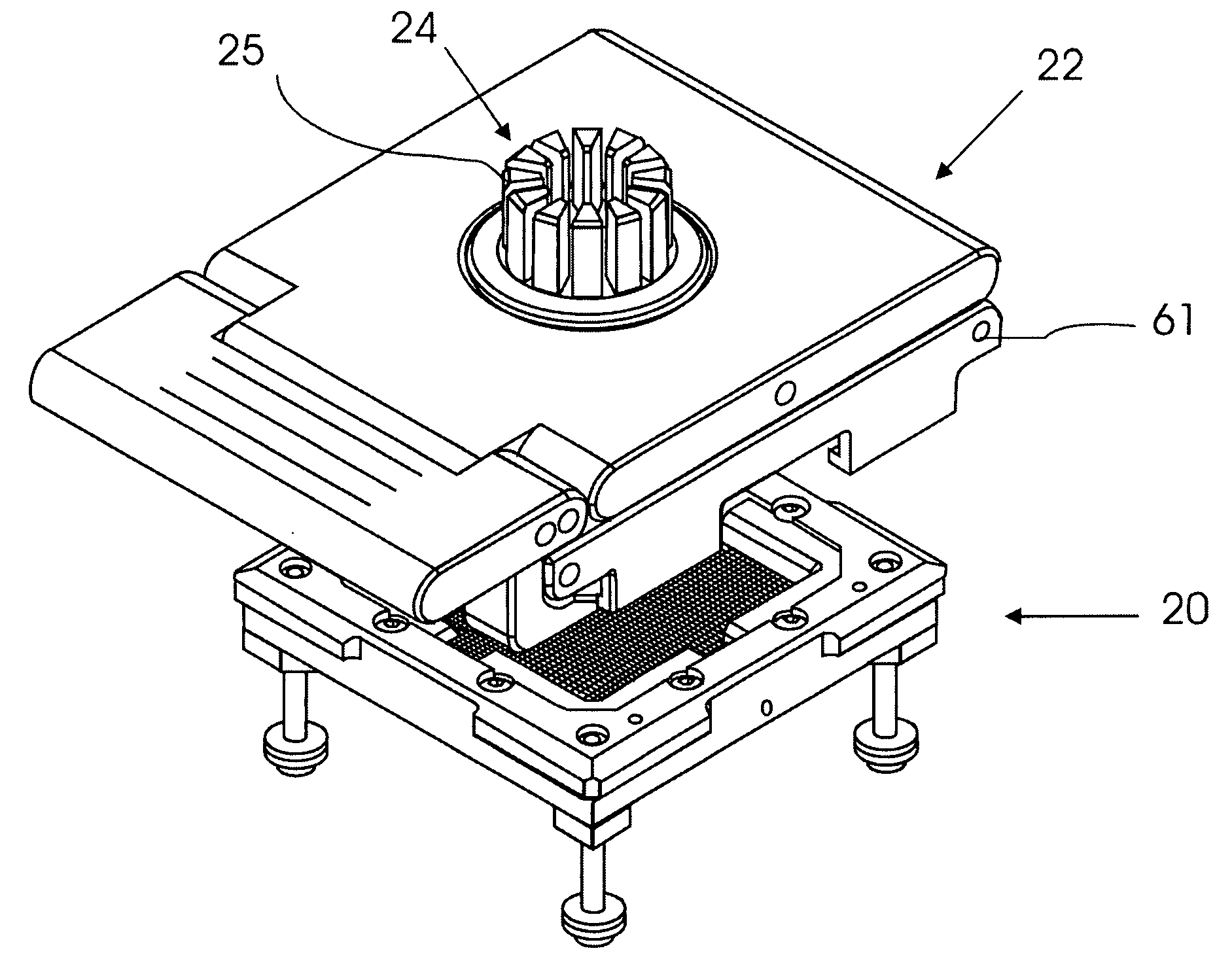

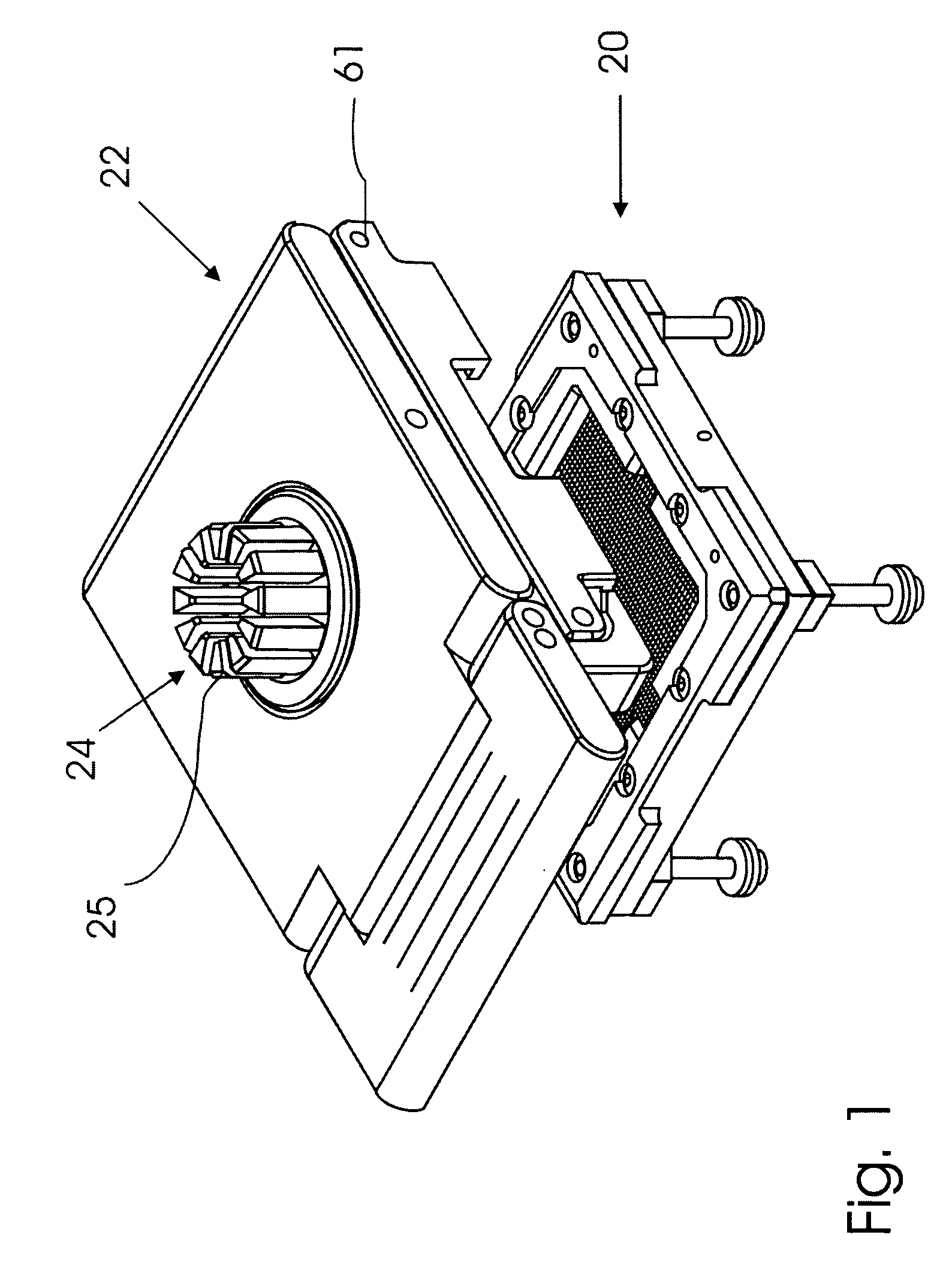

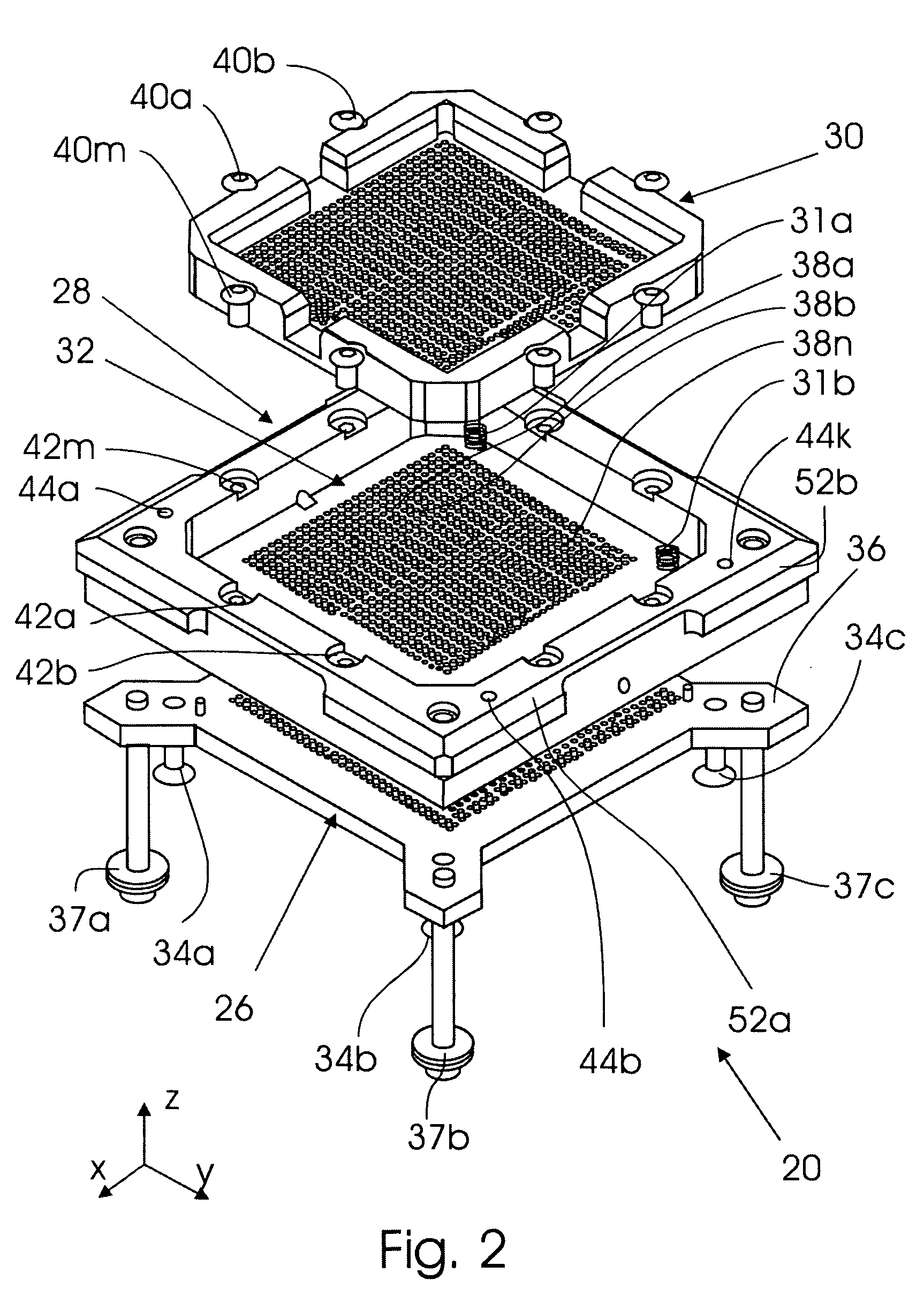

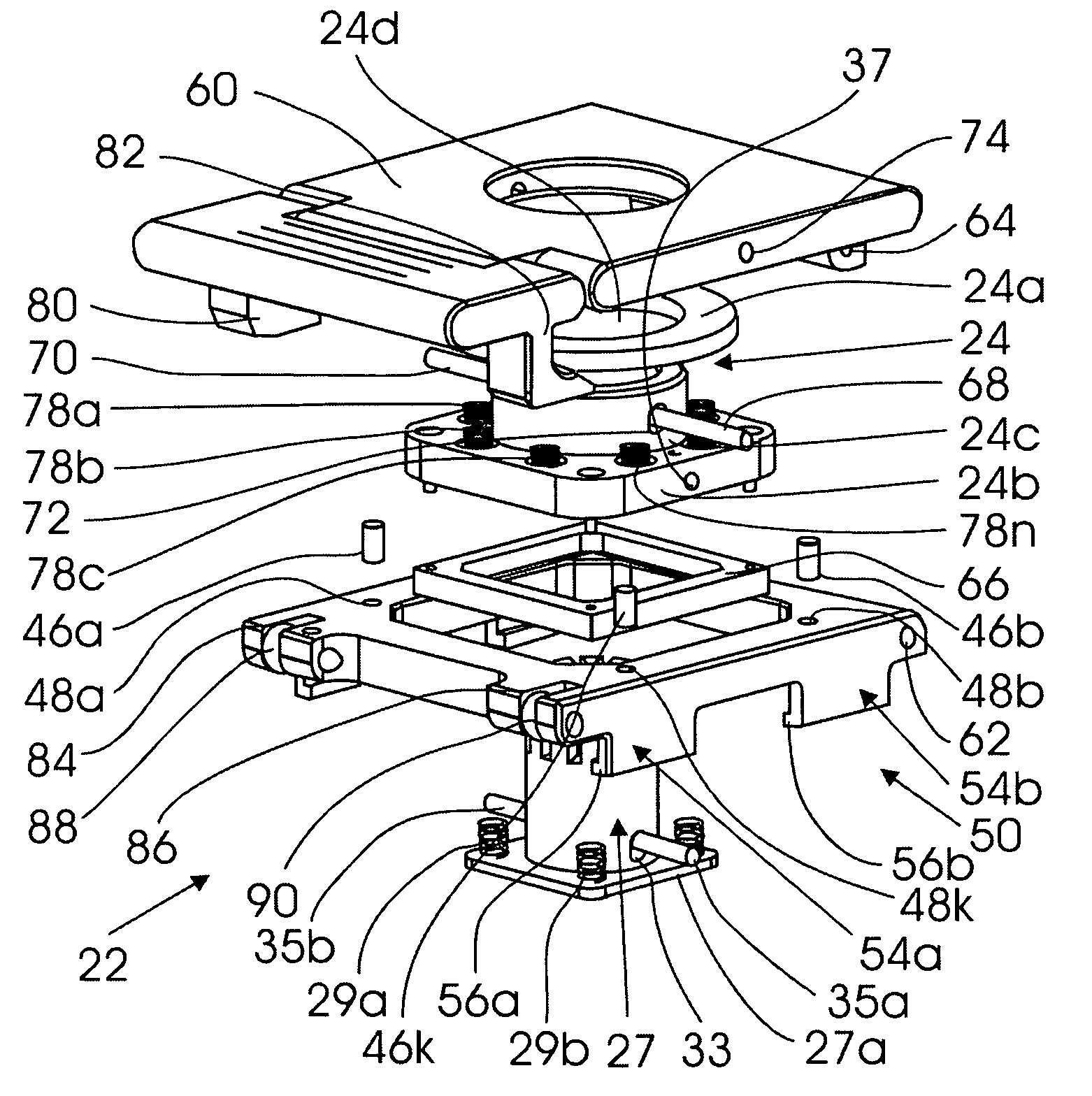

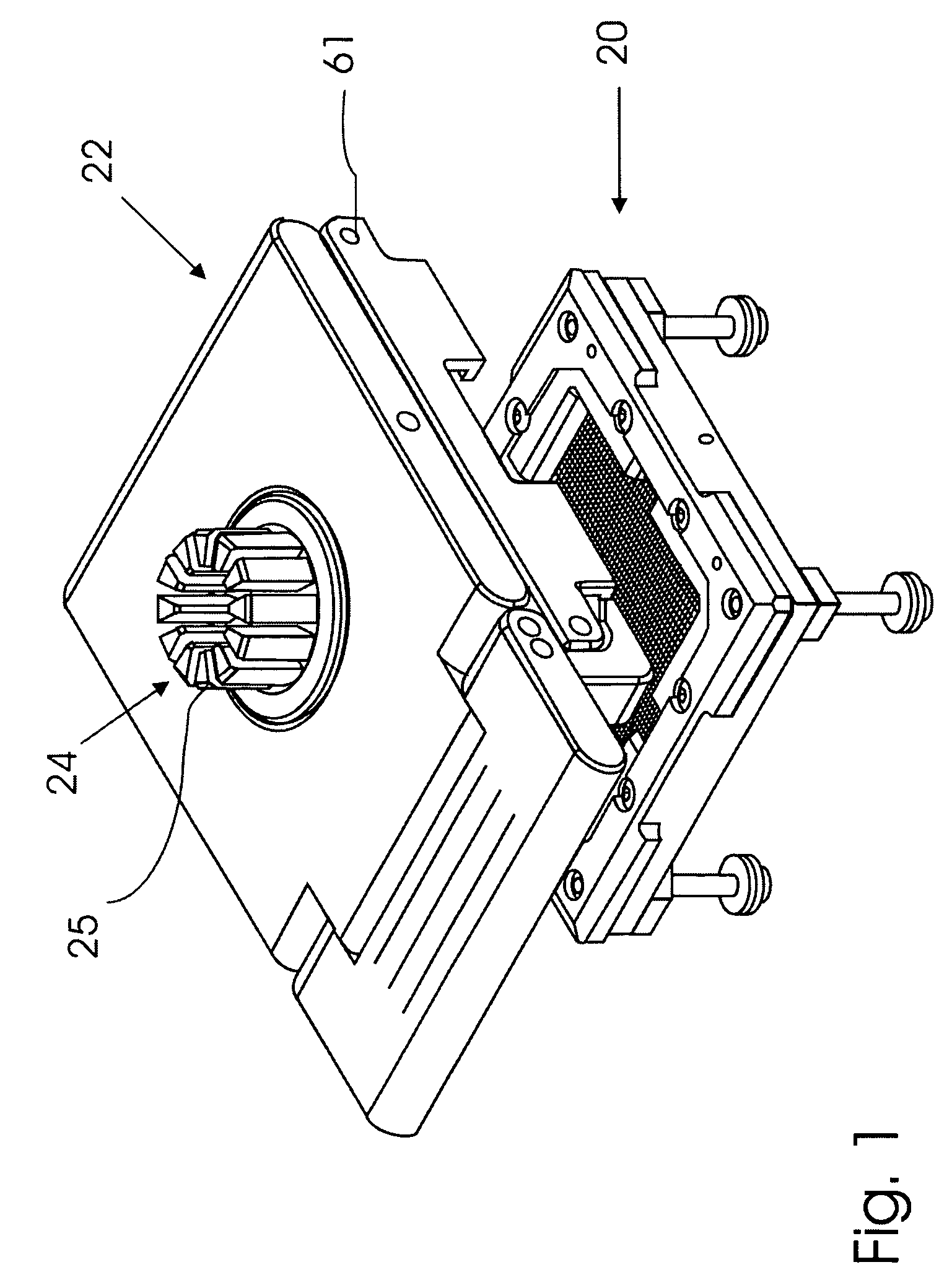

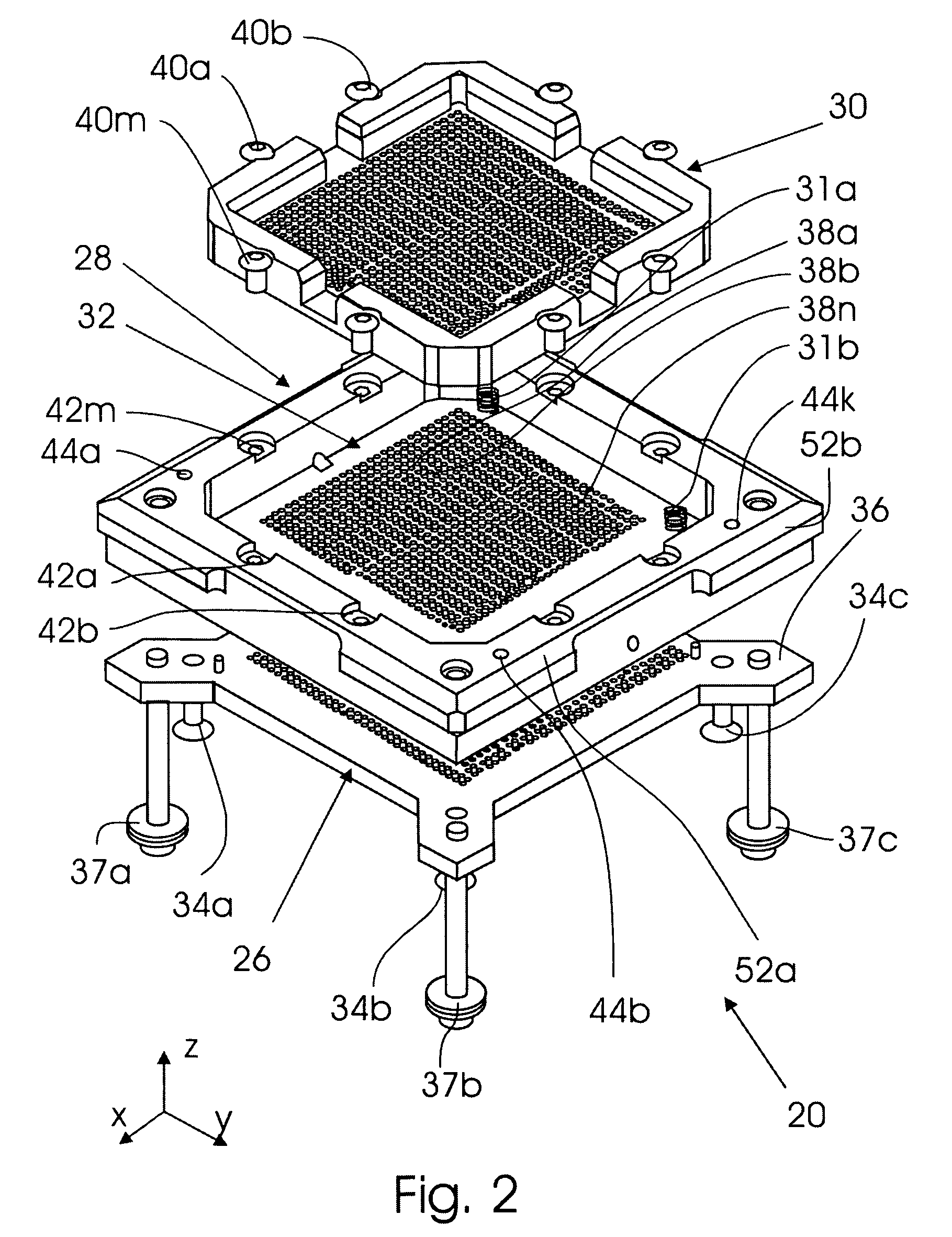

Test socket-lid assembly

InactiveUS20080020623A1Uniform clamping forceUniform heat transferEngagement/disengagement of coupling partsCoupling contact membersComposite structureBiomedical engineering

A test socket-lid assembly for testing electronic devices such as IC chips consists of a socket sub-assembly and a lid-sub-assembly, which is separated from the socket sub-assembly. In the lid sub-assembly, the lid is pivotally connected to the frame and supports a spring-loaded pusher that can slide in a vertical direction relative to the lid and can perform rocking movements relative to the lid. The assembly is distinguished from existing devices of this type in that the IC chip is supported and clamped in the lid sub-assembly and in that the entire lid sub-assembly together with the clamped and spring-loaded pusher is attached to the socket by guiding the lid sub-assembly in a transverse direction along the socket guide to the position wherein the spring plungers are locked into their respective openings on the surface of the socket. In one embodiment the pusher is a single part that has three degrees of freedom relative to the IC chip; in another embodiment, the pusher is of a composite structure and has five degrees of freedom.

Owner:PROTOS ELECTRONICS

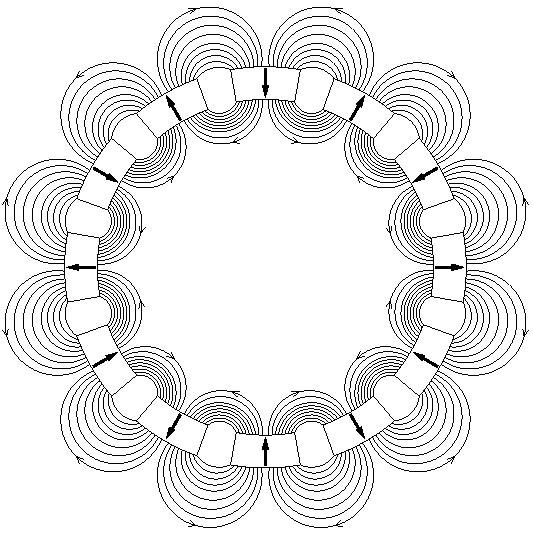

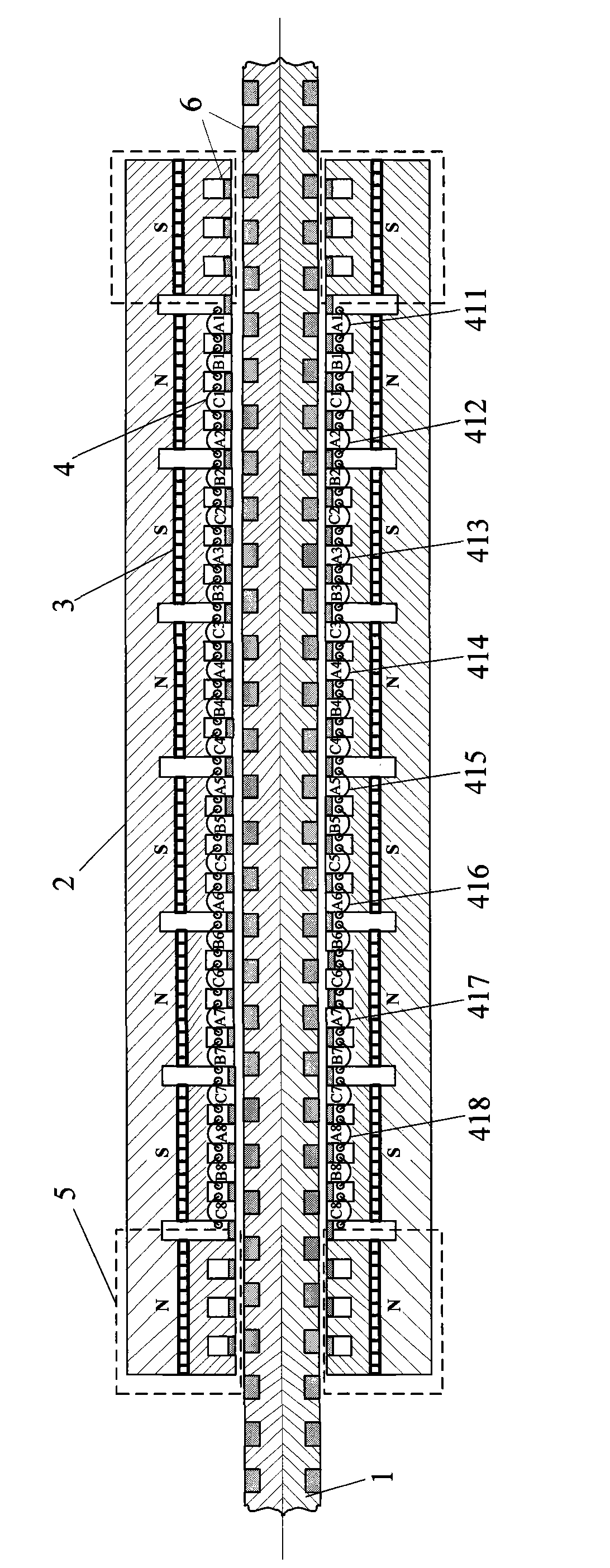

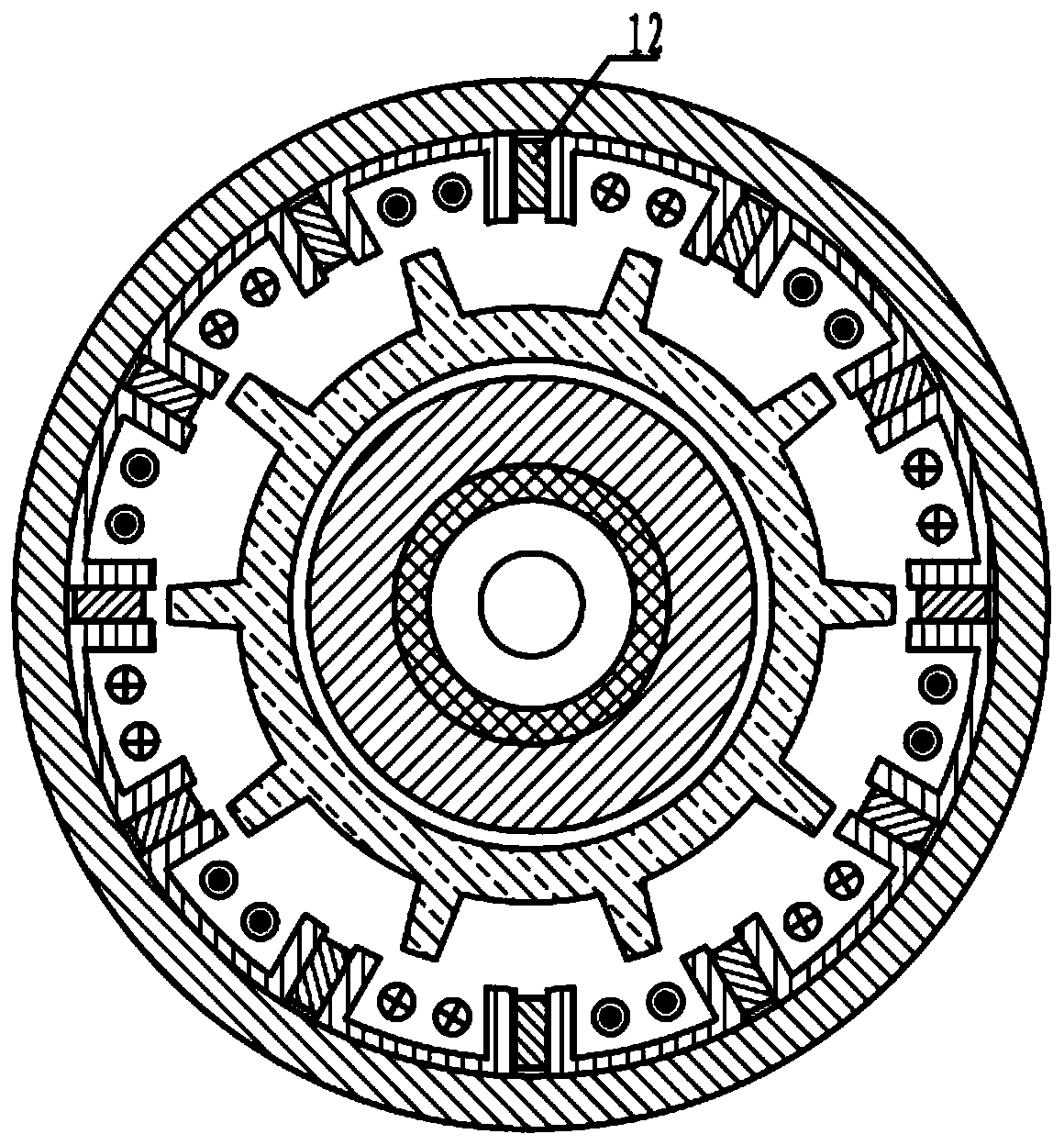

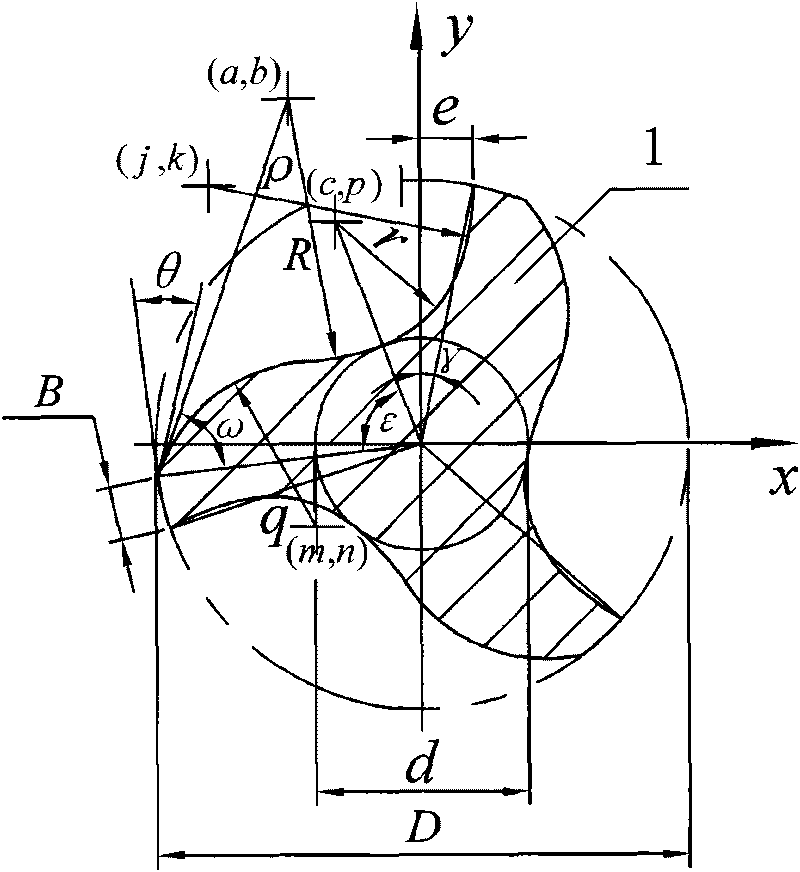

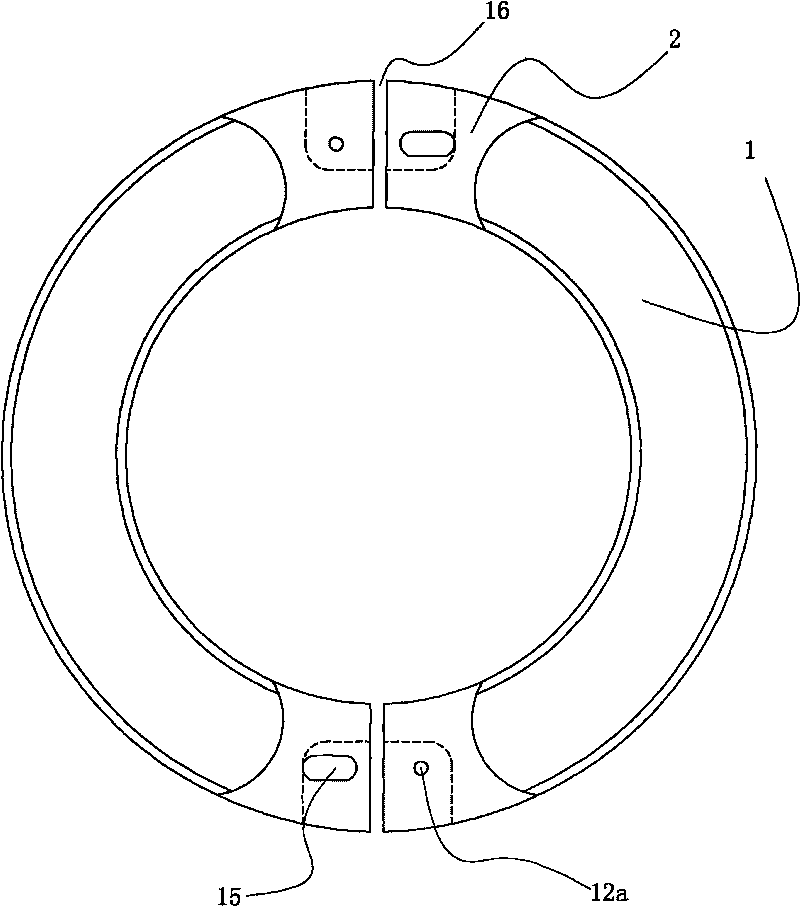

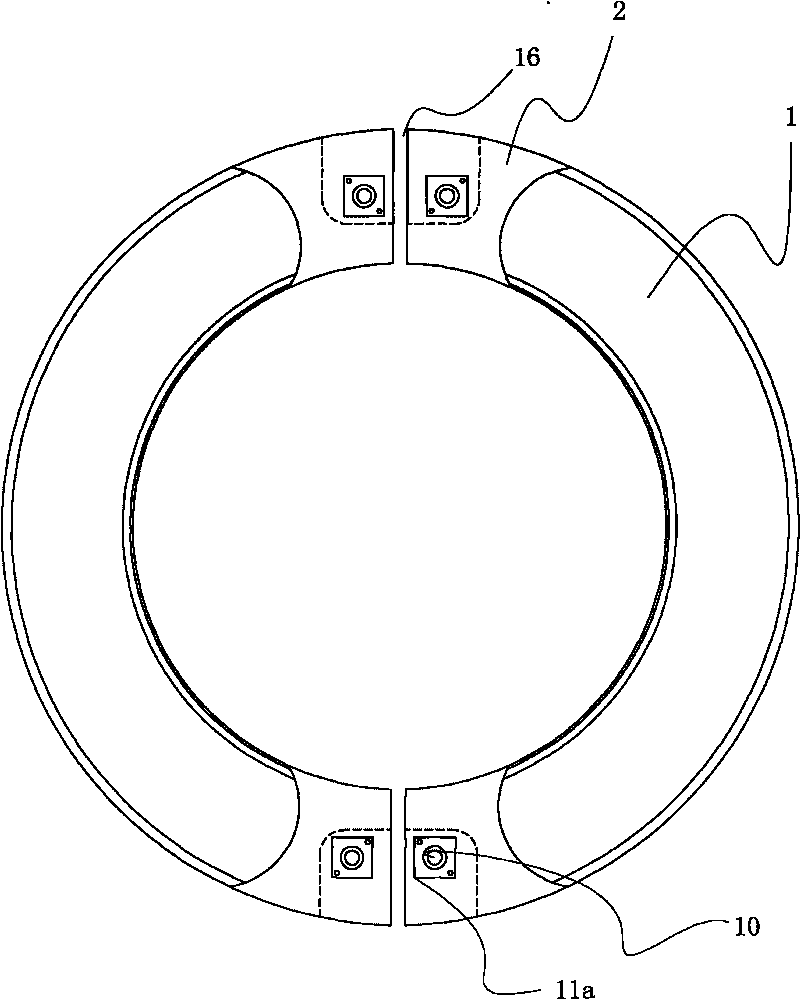

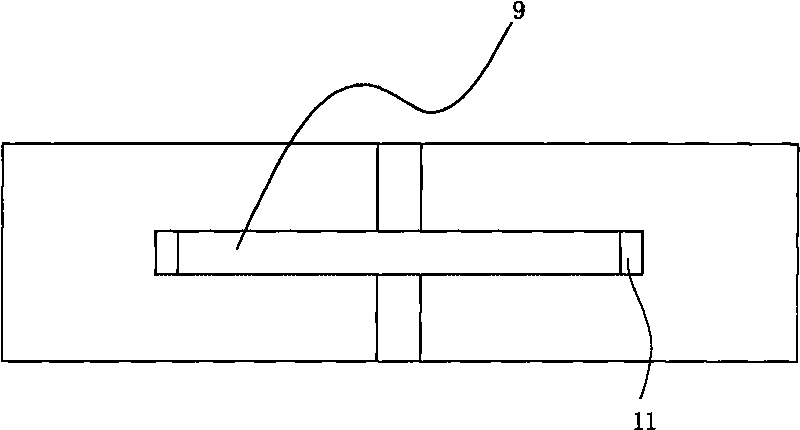

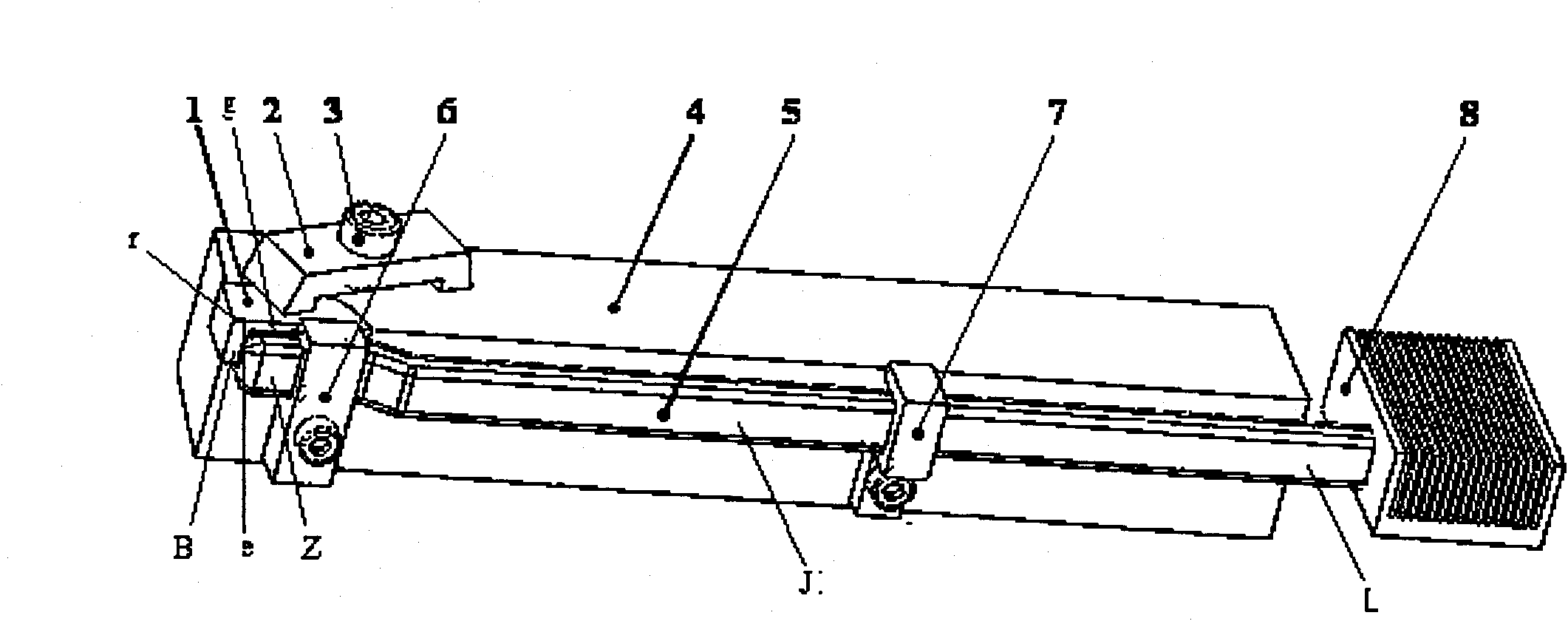

Radial-array permanent-magnet eddy current retarder

InactiveCN102497084AIncrease profitIncrease braking torquePermanent-magnet clutches/brakesOptical axisDrive shaft

The invention discloses a radial-array permanent-magnet eddy current retarder. Rotors are installed on a transmission shaft; the transmission shaft is installed in a central hole of a fixing plate; two ends of a bidirectional screw shaft are installed inside holes above the central hole of the fixing plate; two ends of each of three linear optical shafts are fixed into holes in front of, behind and below the central hole of the fixing plate; each of the two rotors consists of a radial-array permanent-magnet ring and a retaining rack; an end surface of one side of the permanent-magnet ring is fixed on an end surface of the retaining rack through bolts; radial clearances are formed between an inner cylindrical surface and an outer cylindrical surface of the permanent-magnet ring and an inner cylindrical surface and an outer cylindrical surface of an annular groove of each rotor; four installing holes are uniformly distributed on the retaining rack; an upper installing hole is matched with the bidirectional screw shaft through a screw nut; the other three installing holes are matched with the linear optical shafts through linear bearings; and a servo motor is connected whit the bidirectional screw shaft through a shaft coupler. In the radial-array permanent-magnet eddy current retarder, the utilization ratio of a magnet is high, the brake moment is large, the response is quick, and the stepless regulation of the brake moment is realized.

Owner:ZHEJIANG UNIV

Inner supporting body for run-flat tire

The invention discloses an inner supporting body for a run-flat tire, which is characterized in that: the inner supporting body is made of a magnesium alloy serving as a raw material, and adopts a two-block split structure; the split parts comprise a main body and a joint respectively; and the joints between the split parts are connected by a connection piece. The inner supporting body has the advantages of high rigidity, good heat stability and light weight, and the inner supporting body adopts the magnesium alloy to improve the radiating condition fundamentally, prevent rubber and engineering plastics from softening due to quick and massive deformation, eliminate the ,thermal explosion, phenomenon in the process of using the inner supporting body, improve the safe driving distance after a vehicle has a flat tire, and prolong the service life.

Owner:NO 52 INST OF CHINA NORTH IND GRP CORP

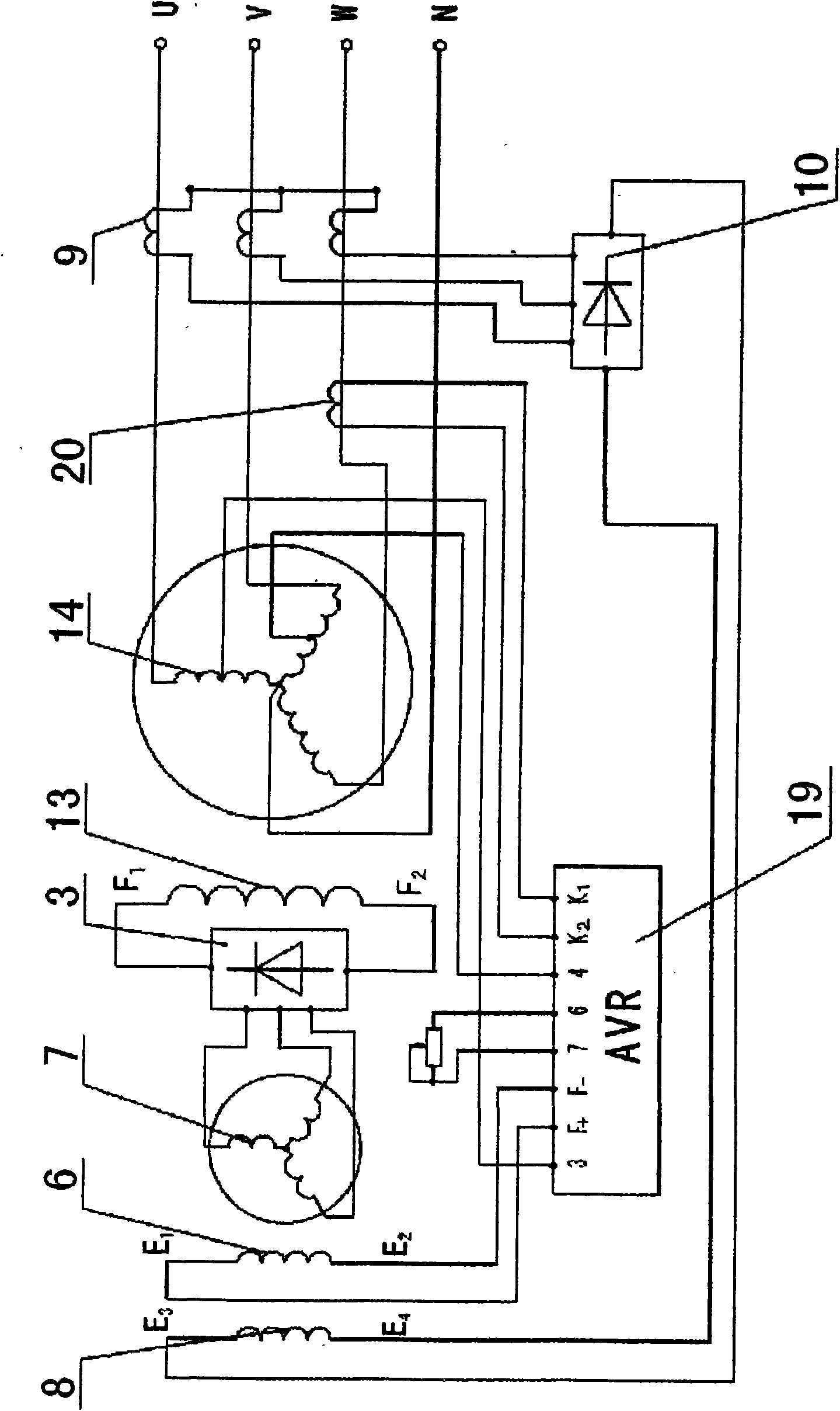

Overall salient type intermediate-frequency brushless excitation synchronous generator

InactiveCN101795040AThe voltage is basically constantStator magnetic field enhancementSynchronous generatorsCooling/ventillation arrangementIntermediate frequencyTransformer

The invention relates to an overall salient type intermediate-frequency brushless excitation synchronous generator, which comprises a main generator, an exciter, an excitation regulating system. The excitation regulating system consists of a compound excitation device, a rotating rectifier and an AVR automatic voltage regulator, wherein the compound excitation device consists of a compound excitation winding, a compound excitation current transformer and a three-phase rectifier bridge, the stator of the main generator adopts a fractional slot type short-range winding, the slot number per pole and per phase q is a fractional value, the rotor of the main generator is formed by lamination of multi-pole rotor core laminated pieces, the rotor core of the main generator is of an overall salient type rotor core structure and is formed by overall punching and lamination of rotor core laminated pieces, each rotor core laminated piece is formed with a magnetic pole and a magnetic yoke integrated, and an axial air-cooling hole is arranged at the magnetic yoke. The generator realizes the brushless excitation intermediate-frequency generation, outputs the single-phase or three-phase intermediate-frequency voltage, and has the advantages of excellent performance, stable and reliable operation and high output power.

Owner:上海强辉电机有限公司

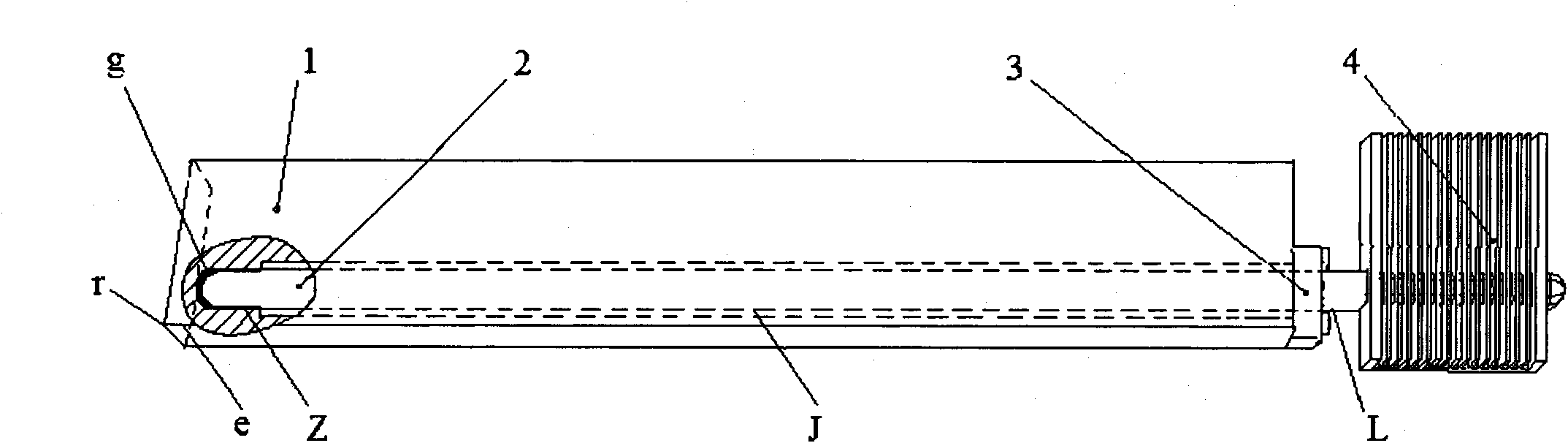

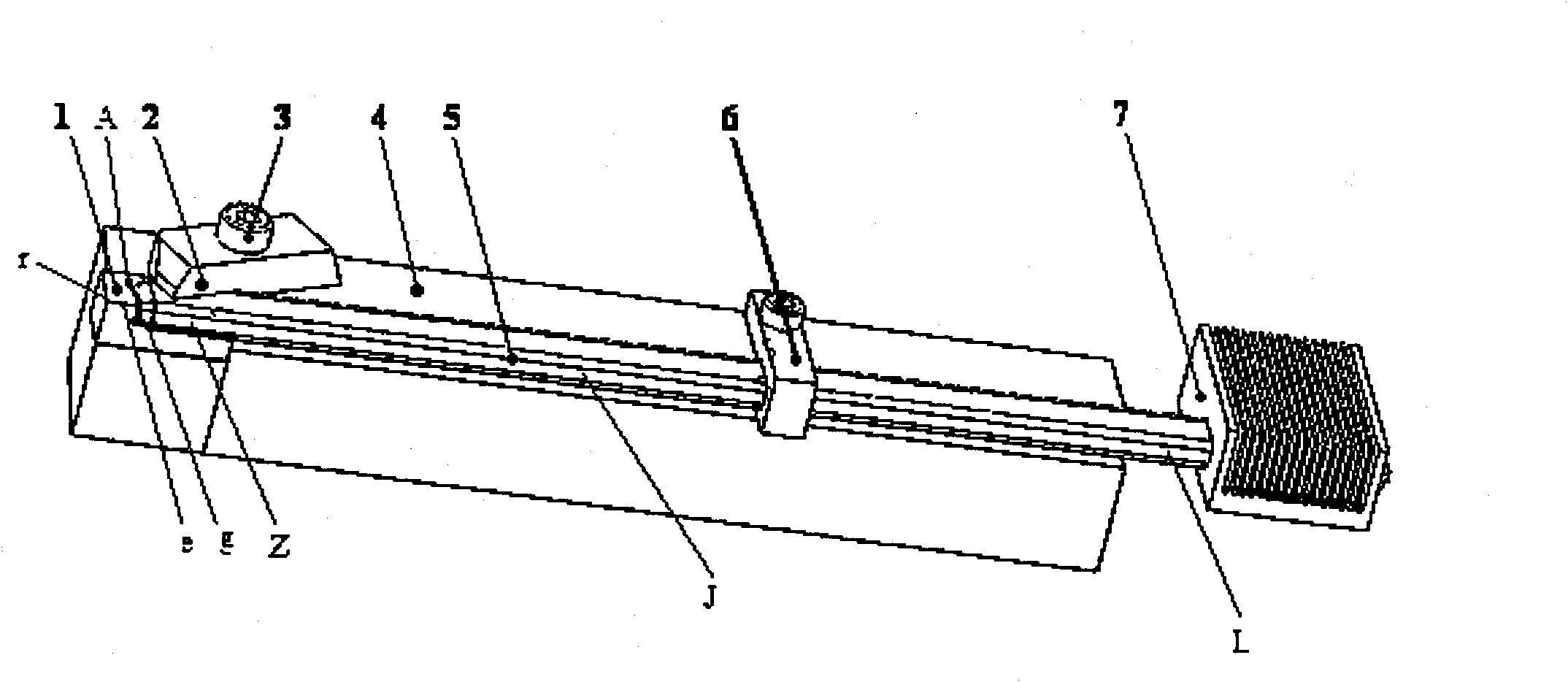

Heat pipe cutter and method for improving radiation of cutting tool by using heat pipe

InactiveCN101885077AImprove cooling conditionsReduce the temperature of the cutter headTurning toolsThermal insulationPhase transition

The invention discloses a heat pipe cutter and a method for improving radiation of a cutting tool by using the heat pipe. The heat pipe cutter comprises a cutter body, a heat pipe and a fixing device, wherein the heat pipe is axially divided into an evaporation section, a thermal insulation section and a condensation section in turn along the heat pipe; the heat pipe is arranged on the cutter body through the fixing device; the evaporation section of the heat pipe is positioned on a main blade and at the rear end of the cutter point; the evaporation section of the heat pipe is in close contact with the cutter; a space is formed between the thermal insulation section of the heat pipe and the cutter; and the condensation section of the heat pipe is arranged on the outer side of the cutter. The heat mainly produced by the cutter head is conducted to the evaporation section of the heat pipe through the cutter head, the working medium in the evaporation section of the heat pipe absorbs the heat and is boiled, and after phase transition, the high-pressure vapor carrying heat arrives the condensation section after passing through the thermal insulation section and is condensed at the condensation section to release the latent heat, and the capillary attraction liquid depending on a liquid absorption core flows back to the evaporation section again to finish a heat transfer process of one period; and the steps are repeated so that the heat produced by the cutting of the cutter head is constantly transferred to the condensation section from the evaporation section of the heat pipe to be diffused, and thus the temperature rise of the cutter head is effectively avoided.

Owner:SOUTH CHINA UNIV OF TECH

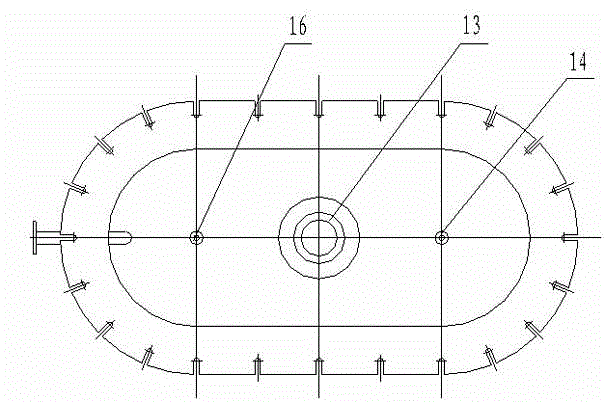

Sponge titanium reduction distillation reactor and production technique thereof

The invention relates to a sponge titanium reduction distillation reactor which is formed by connecting a tank body and a large cover through a flange rubber cushion and a bolt set, wherein the tank body comprises a bottom plate, a sieve plate, a magnesium chloride discharge casing, a tank body flange and a waist-type cylinder; the large cover comprises a magnesium chloride discharge pipe, a thermal insulation layer, an internal heating device, a large cover upper flange, a large cover lower flange, a central pipe, a charging casing 1, a short cylinder and a charging casing 2; the integral reactor is in a stereoscopic waist circular structure; and the bottom plate is a sloping plate positioned on the lowest part of the whole reactor, and is matched with the waist-type cylinder to form an open stereoscopic waist-type tank body. The integral effective width of the reactor is 1.2-1.5 meters, the height is 1.5-2.5 times of the width, and the length is 2-3 times of the width. The reactor for producing sponge titanium can change the sponge titanium structure, solve the problem of compactness, greatly enhance the overall charging rate, simplify the distillation process and greatly shorten the period.

Owner:罗时雨

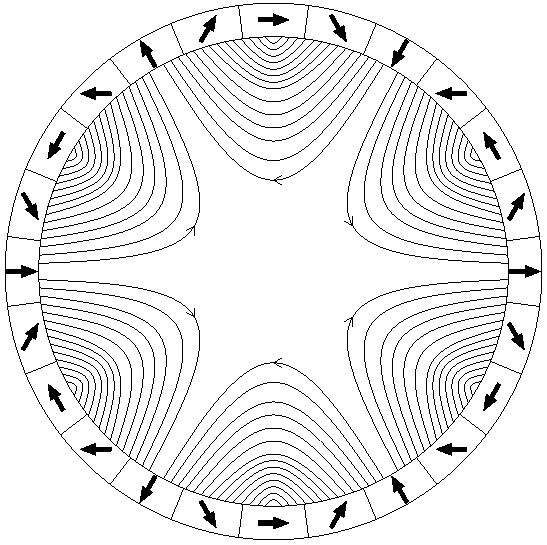

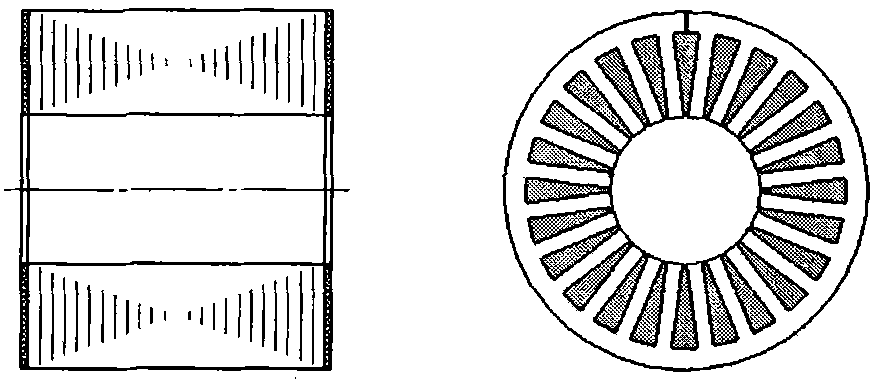

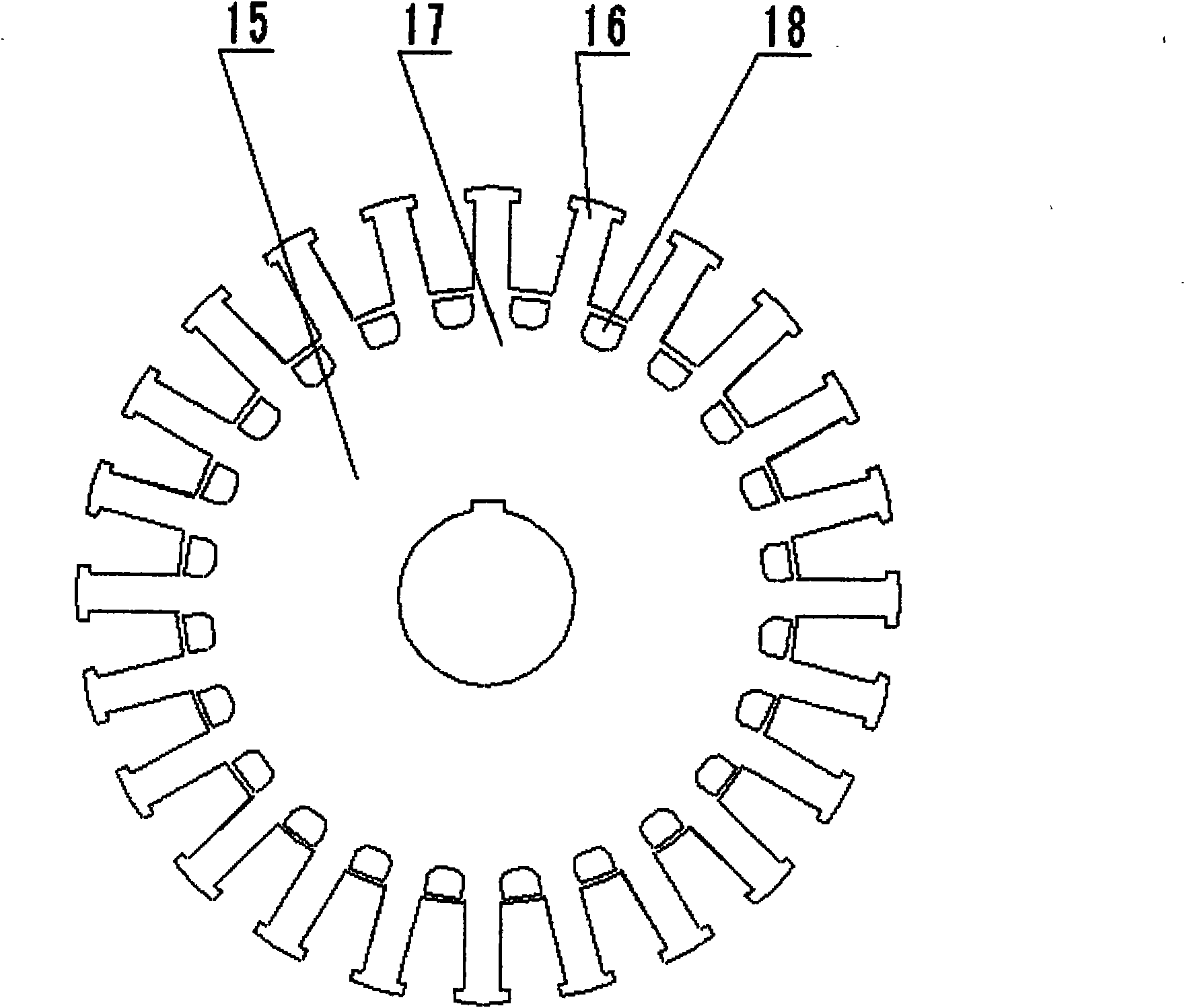

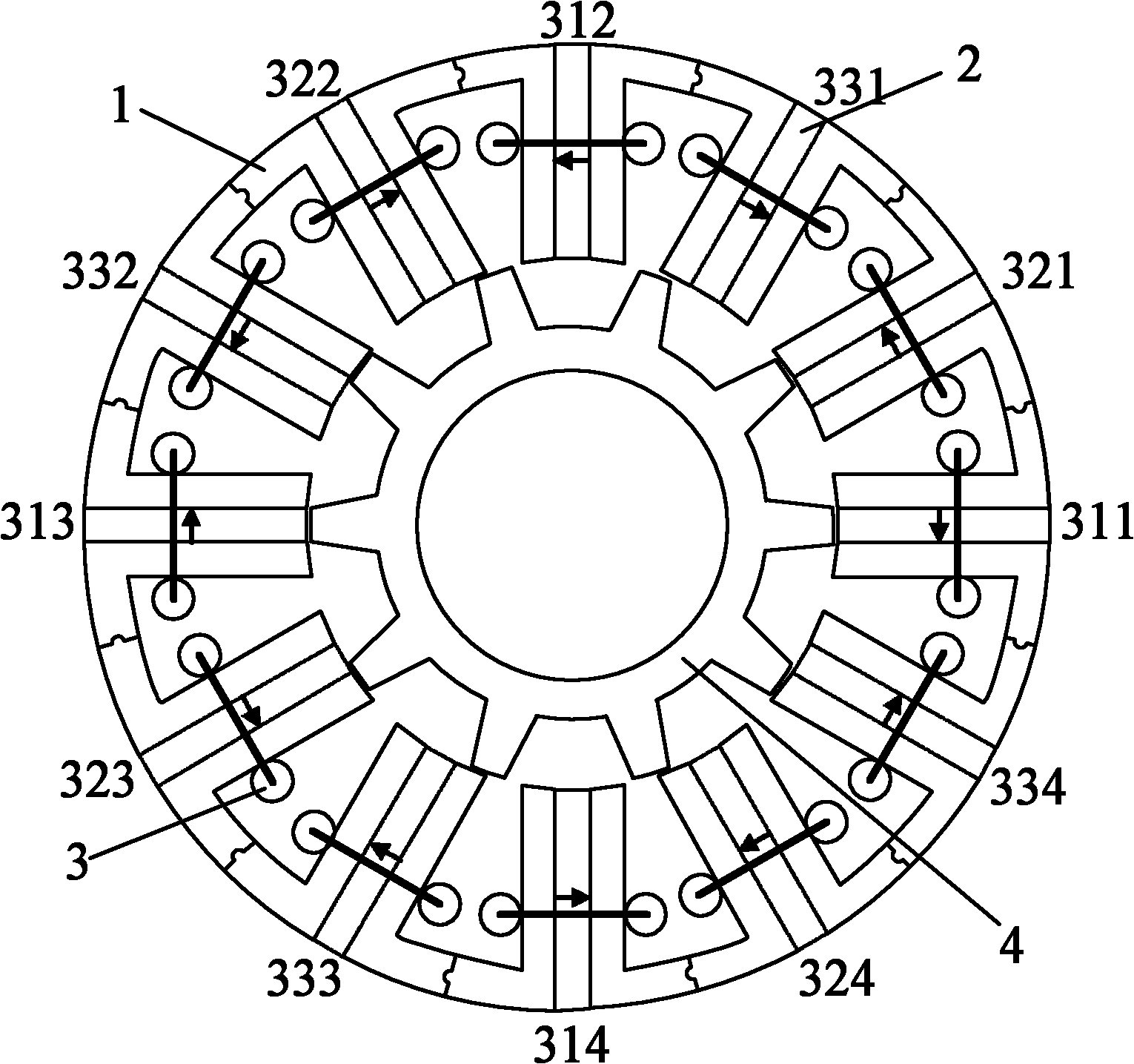

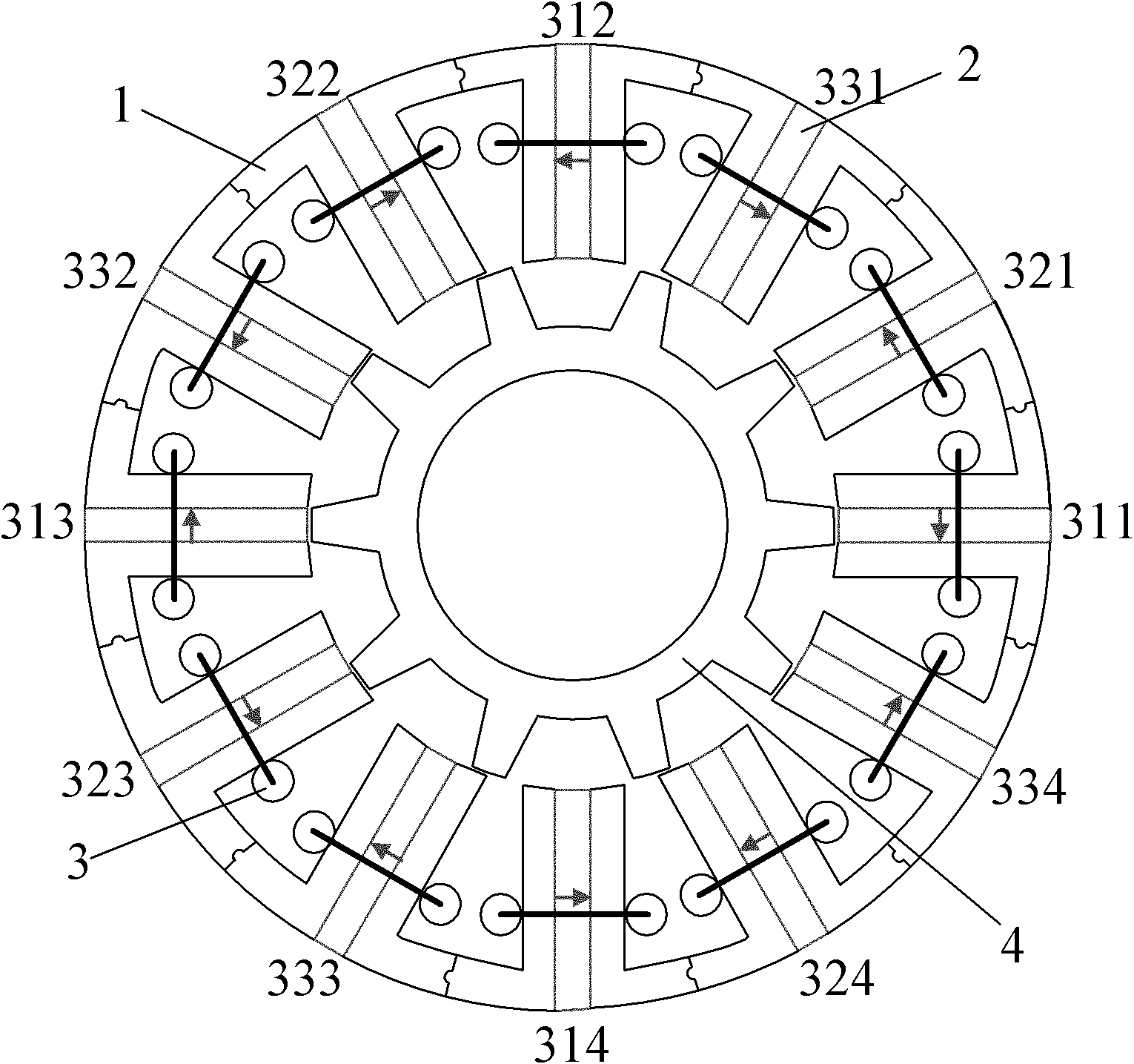

Modularized flux switching permanent magnet (FSPM) motor

InactiveCN102157993AImprove cooling conditionsSimple and strong structureMagnetic circuit rotating partsMagnetic circuit stationary partsElectrical resistance and conductanceElectric machine

The invention discloses a modularized flux switching permanent magnet (FSPM) motor, which is used for solving the problem of such a motor in which a permanent magnet is placed in a rotor. The motor comprises a stator and a rotor and adopts an inner rotor mode or an external rotor mode. The stator and the rotor are respectively a convexo-convex pole and slot structure. A magnetic module and a centralized armature winding are arranged on the stator; the magnetic module comprises one male concentrating flux iron core and one female concentrating flux iron core of the stator as well as a permanent magnet embedded in the stator; and the rotor is not provided with a permanent magnet and a winding. The motor has the beneficial effects that the structure is simple, compact and stable, and the volume is small; the windings are high in slot fullness, the resistance and the copper consumption are decreased and the efficiency is higher; the linear charge density, the torque output capacity and the power density are improved; the magnetic flux gathering effect exists, and the no-load air gap magnetic density is higher; and the armature reaction flux is vertical to the permanent magnet flux in space, and the stronger demagnetization-resisting capacity is ensured.

Owner:DALIAN MINGYANG IND +1

Test socket-lid assembly

InactiveUS7338295B2Uniform clamping forceEasy to useEngagement/disengagement of coupling partsCoupling contact membersThree degrees of freedomDegrees of freedom

A test socket-lid assembly for testing electronic devices such as IC chips consists of a socket sub-assembly and a lid-sub-assembly, which is separated from the socket sub-assembly. In the lid sub-assembly, the lid is pivotally connected to the frame and supports a spring-loaded pusher that can slide in a vertical direction relative to the lid and can perform rocking movements relative to the lid. The assembly is distinguished from existing devices of this type in that the IC chip is supported and clamped in the lid sub-assembly and in that the entire lid sub-assembly together with the clamped and spring-loaded pusher is attached to the socket by guiding the lid sub-assembly in a transverse direction along the socket guide to the position wherein the spring plungers are locked into their respective openings on the surface of the socket. In one embodiment the pusher is a single part that has three degrees of freedom relative to the IC chip; in another embodiment, the pusher is of a composite structure and has five degrees of freedom.

Owner:PROTOS ELECTRONICS

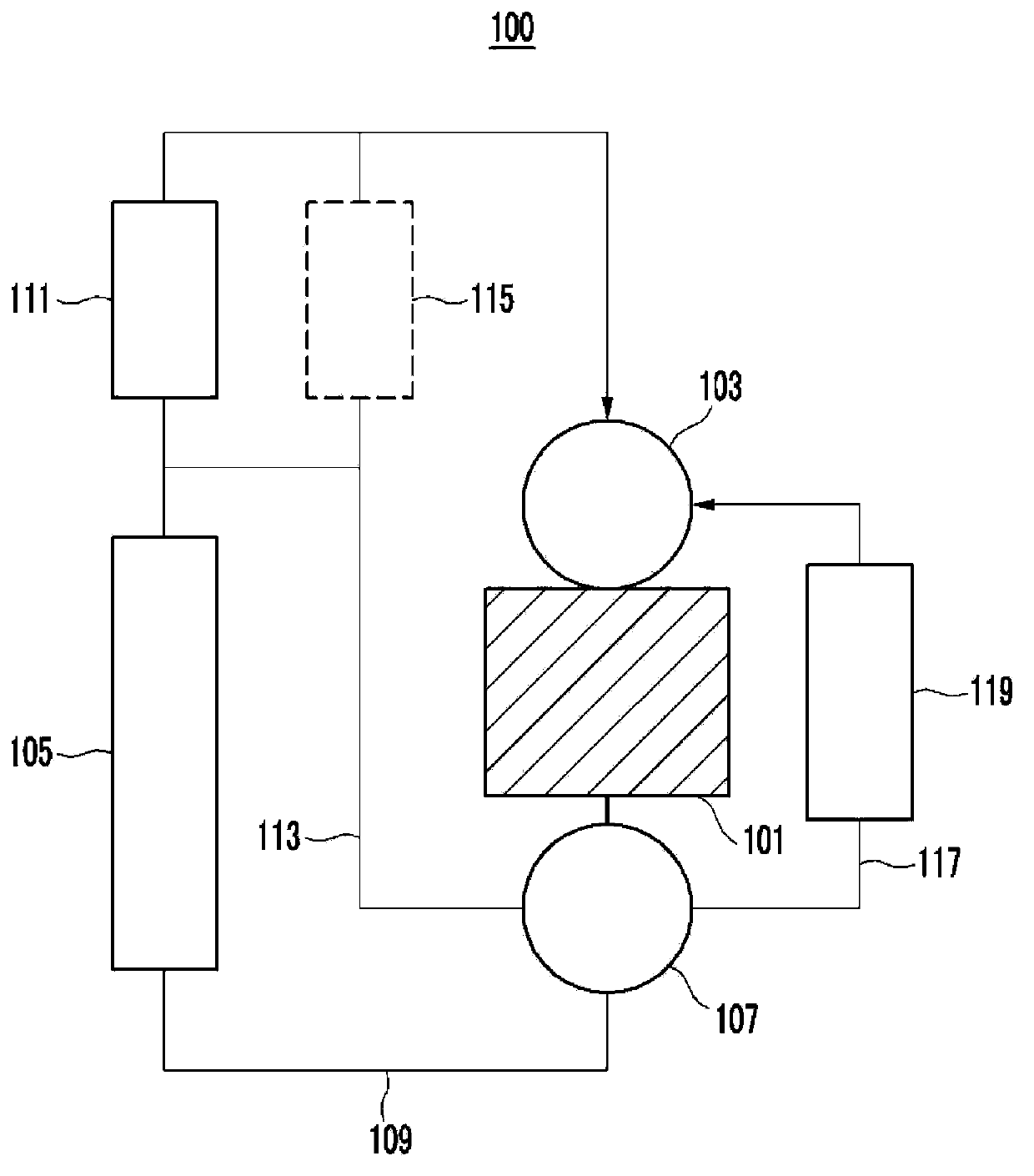

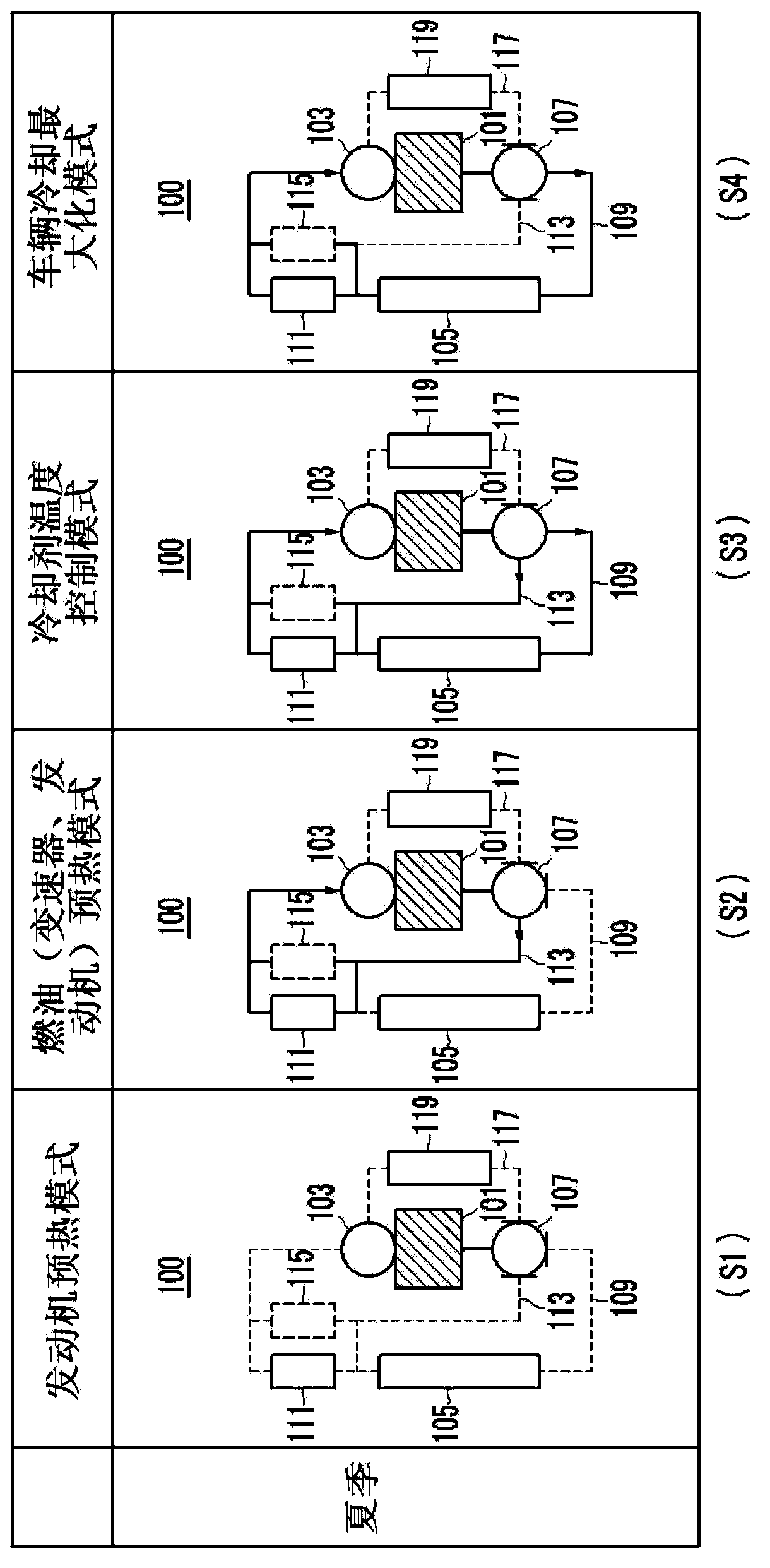

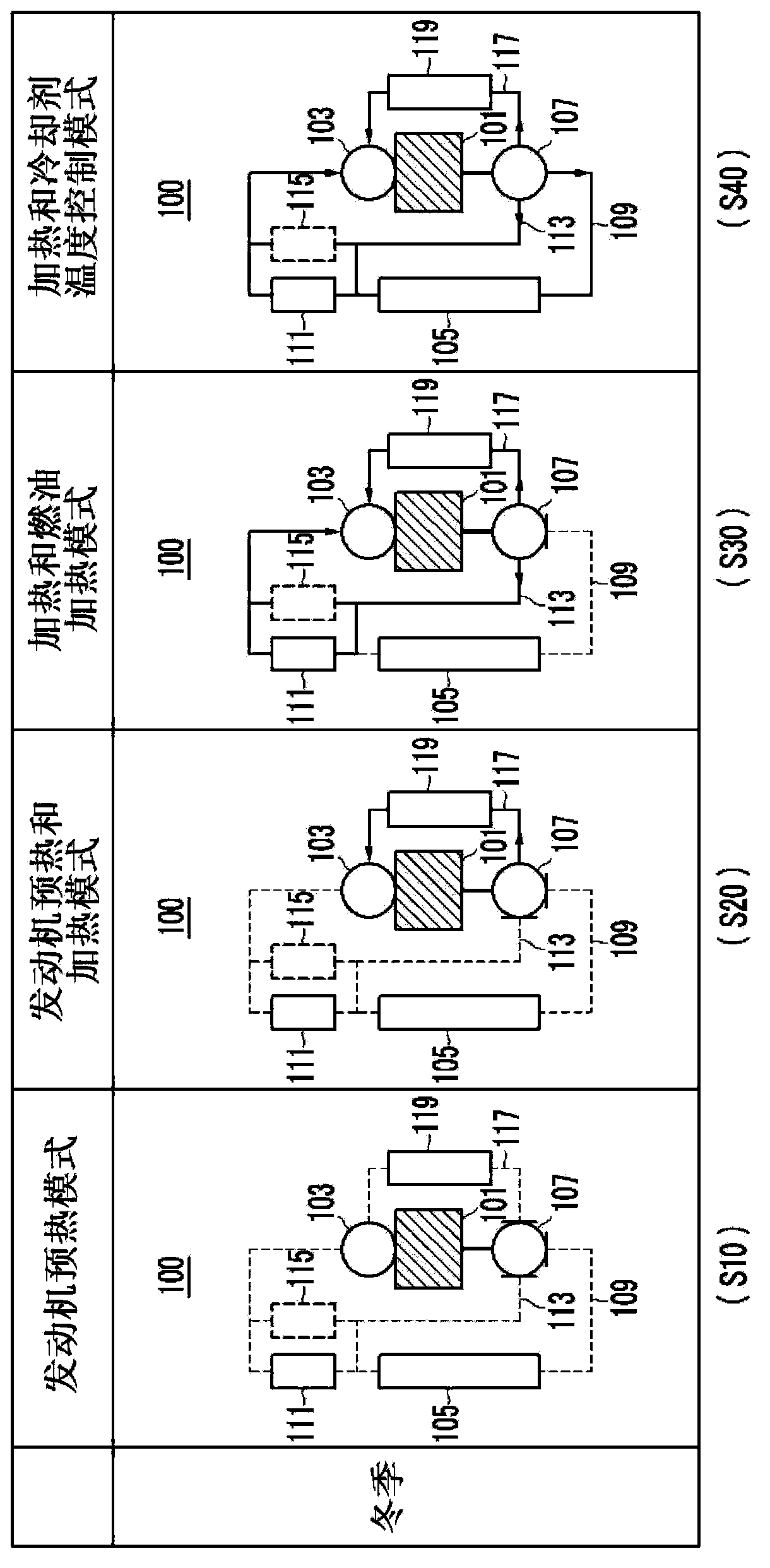

Engine cooling system for vehicle and control method of the same

InactiveCN103867281AImprove cooling effectImprove air conditioning performanceLiquid coolingCoolant flow controlControl flowEngineering

An engine cooling system for a vehicle includes a water pump disposed to supply an engine with a coolant and a radiator disposed to cool heated coolant of the engine by exchanging heat with outside air. The system may include: a control valve that is disposed at one side of the engine to control flow rate and flow passage of coolant; a first passage that connects the control valve with the radiator and connects the radiator with the water pump; a TOC that is disposed between an outlet of the radiator and the water pump to be connected through the first passage; a second passage that connects the TOC with the control valve and directly supplies the TOC with the coolant exhausted from the engine; and a heater that is disposed in a third passage that bypasses the engine to connect the control valve with the water pump.

Owner:HYUNDAI MOTOR CO LTD

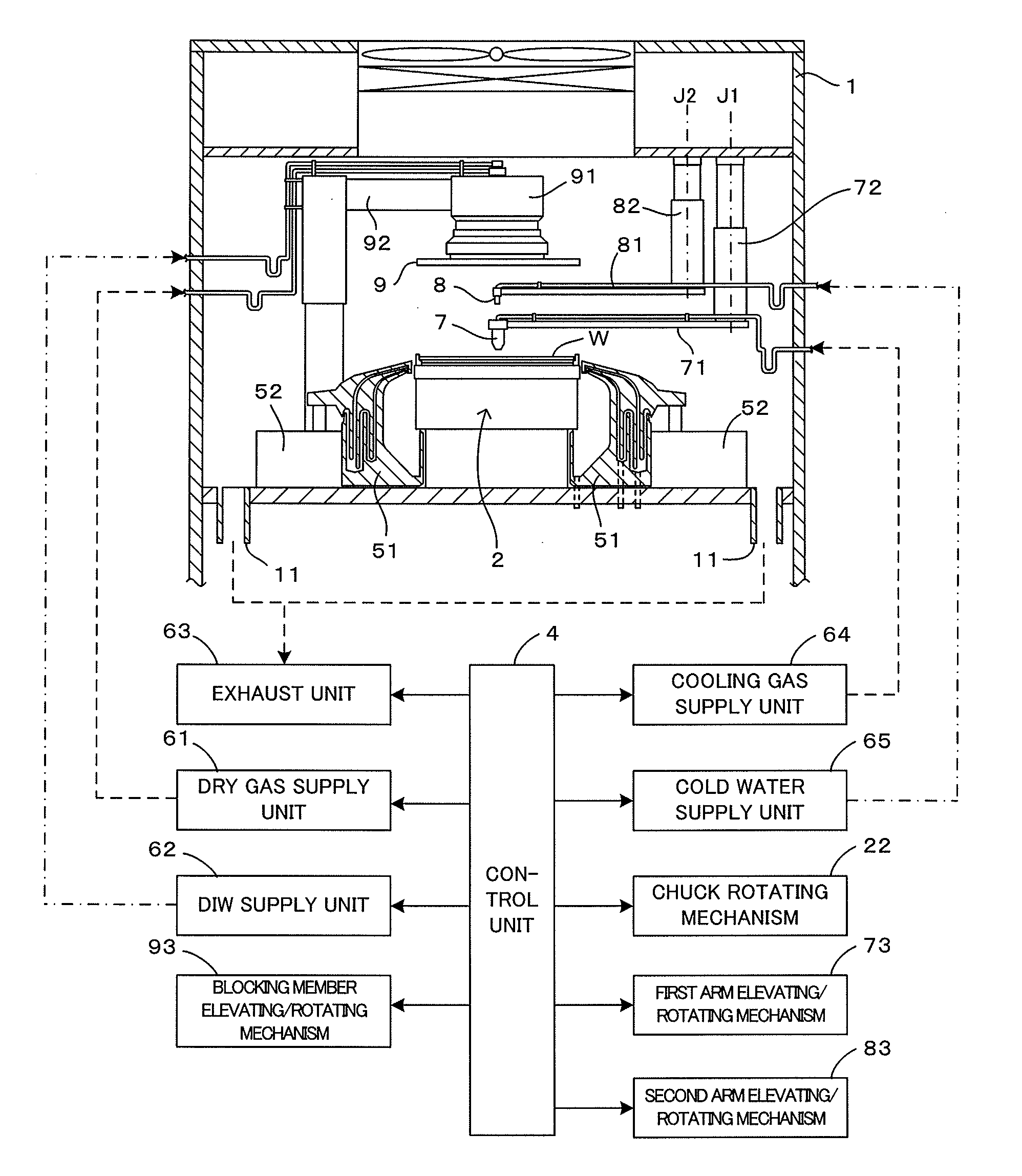

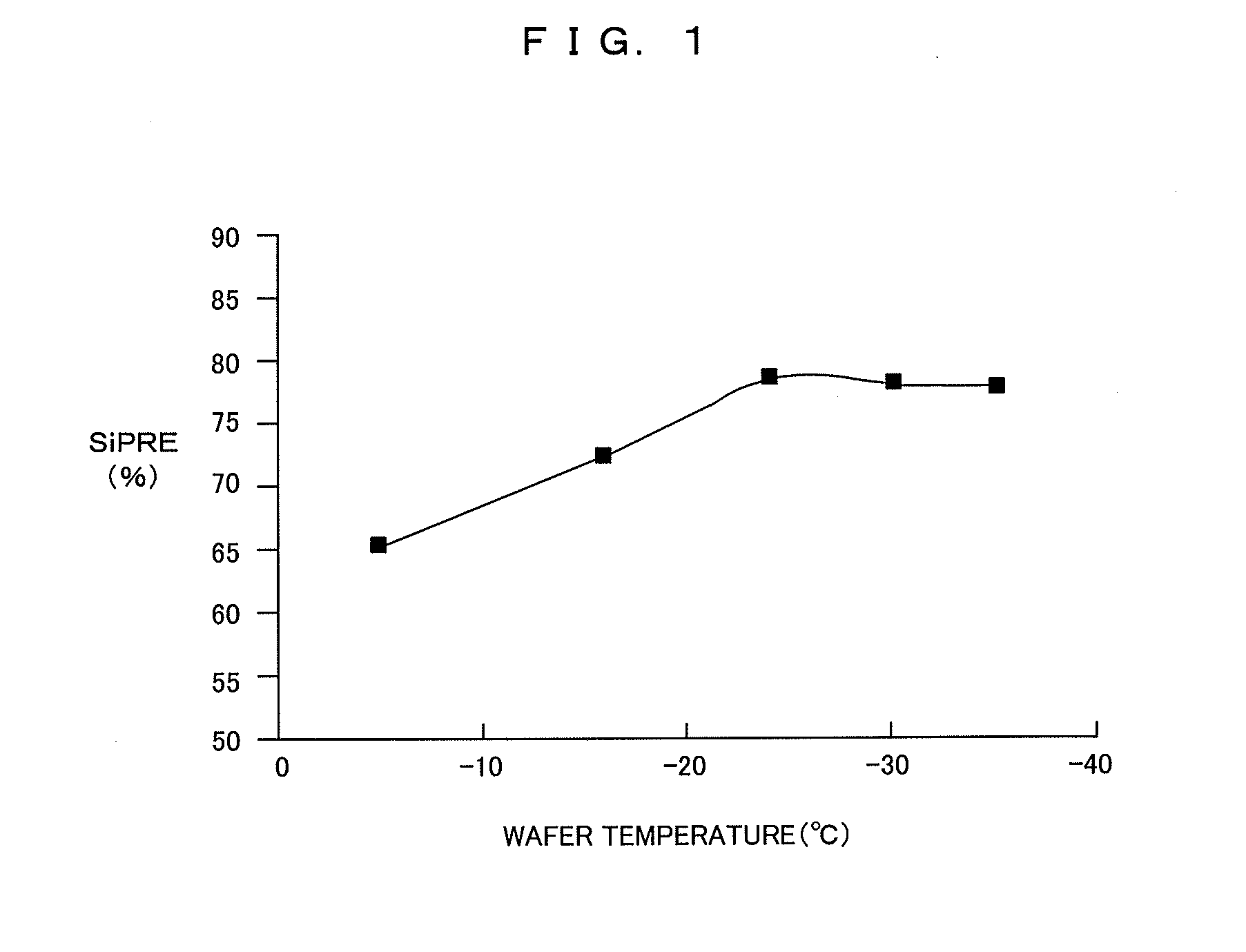

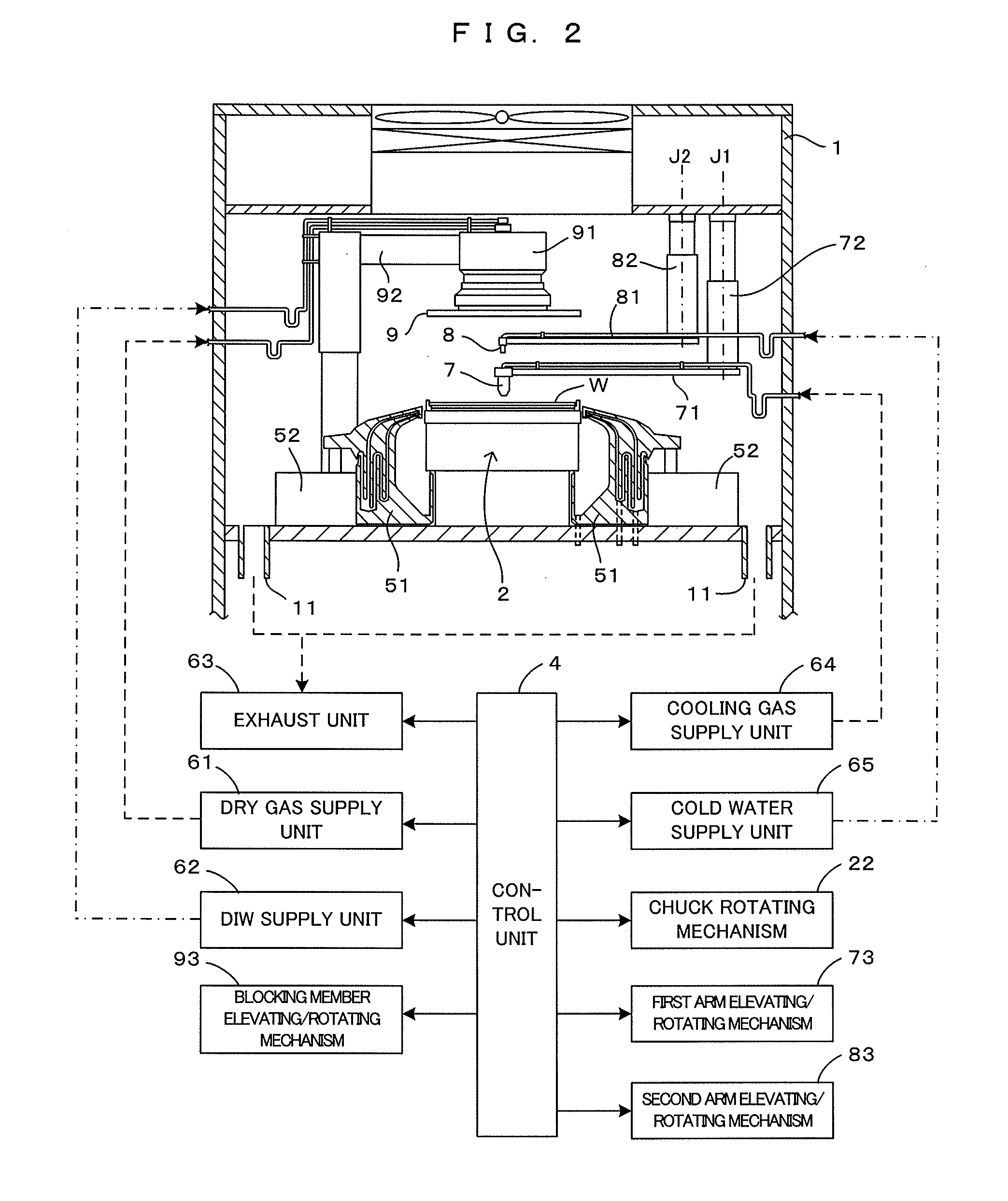

Substrate processing method and substrate processing apparatus

ActiveUS20120186275A1Reduce the temperatureIncrease ratingsLighting and heating apparatusSemiconductor/solid-state device manufacturingEngineeringSubstrate surface

A cooling gas discharge nozzle 7 is arranged above an initial position P(Rin) distant from a rotation center P(0) of a substrate W toward the outer edge of the substrate W and supplies a cooling gas to the initial position P(0) of the rotating substrate W to solidify DIW adhering to an initial region including the initial position P(Rin) and the rotation center P(0). Following formation of an initial solidified region FR0, a range to be solidified is spread toward the outer edge of the substrate W and all the DIW (liquid to be solidified) adhering to a substrate surface Wf is solidified to entirely freeze a liquid film LF.

Owner:DAINIPPON SCREEN MTG CO LTD

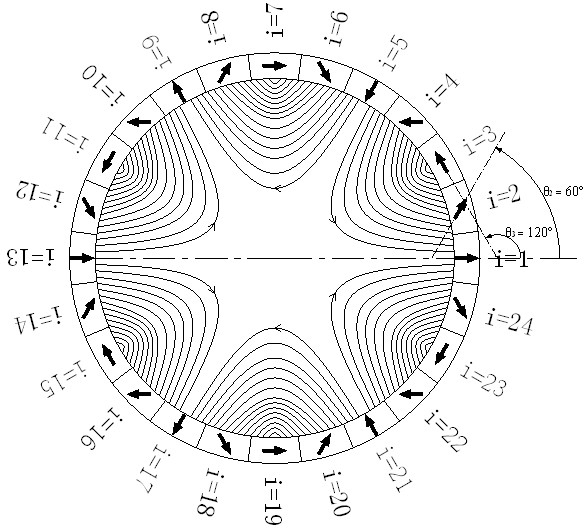

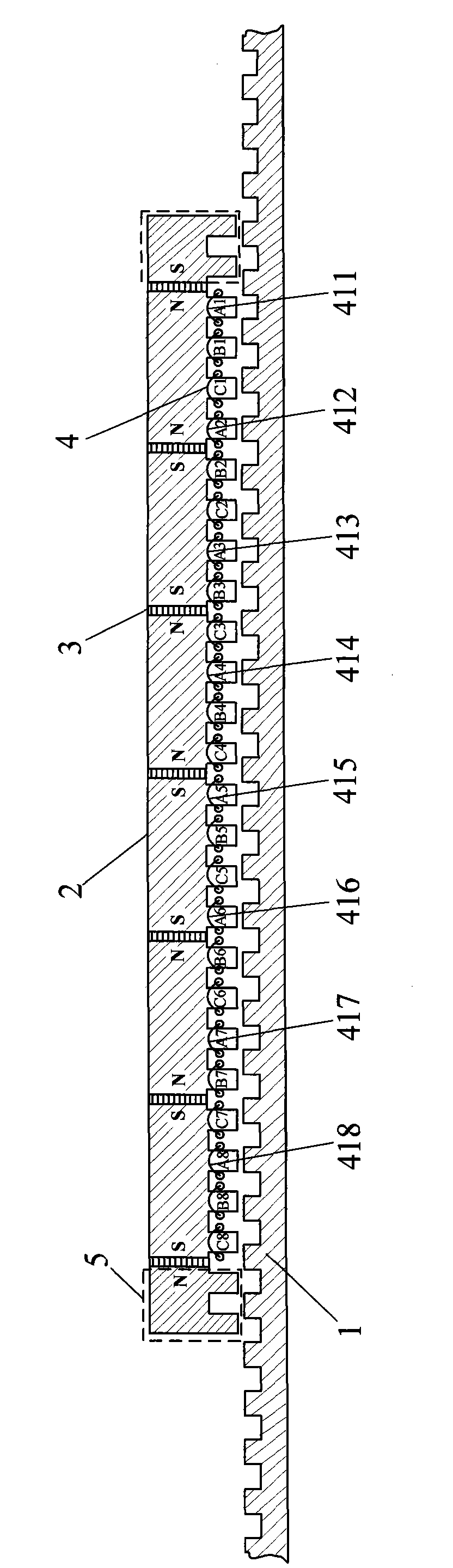

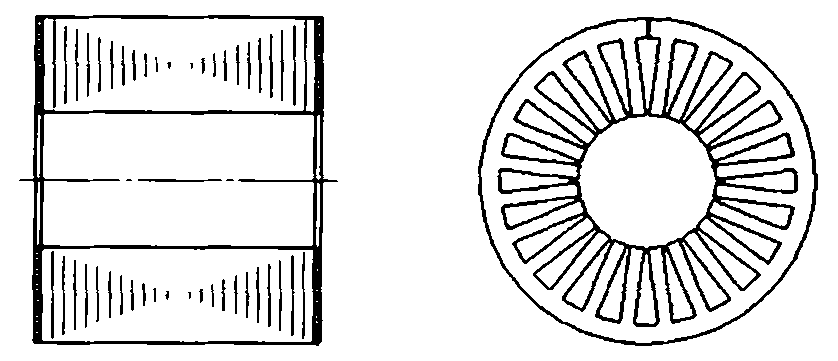

Stator surface mounted doubly salient permanent magnet motor with auxiliary salient pole

ActiveCN101651371AImprove cooling conditionsSimple and strong structureMagnetic circuit rotating partsMagnetic circuit stationary partsConstant powerSurface mounting

The invention relates to a stator surface-mounted doubly salient permanent magnet motor with an auxiliary salient pole which has simple and firm structure, and constant power, wide speed-regulation operation range and higher power density; the motor comprises a stator (1) and a rotor (5), the rotor (5) is arranged at the inner part or outer part of the stator (1), the stator (1) and the rotor (5)are in a doubly salient structure, and a concentrated winding (3), a permanent magnet (2) and an auxiliary salient pole (4) are arranged on the stator (1), wherein, each concentrated winding coil of any one phase of the concentrated winding (3) is arranged in an iron core groove of the stator (1), and the coils of each a phase winding are connected serially or in parallel; the permanent magnet (2)is arranged on the salient pole of the stator (1), the outer surface of each stator tooth, facing to air gap, is mounted with two permanent magnets (2), and the polarity of two magnetic steels, belowthe same tooth, is the same, and the magnetism of the magnetic steel, below the adjacent stator tooth, is opposite.

Owner:SOUTHEAST UNIV

Circular shielding insulating bus and machining method thereof

ActiveCN103366872AReduce skin effectReduce power lossSingle tube conductorsInsulated cablesElectrical conductorEngineering

The invention relates to a circular shielding insulating bus, which has the advantages of high carrying capacity, good heat dissipation, low temperature rise, strong electric insulation performance, no environmental disturbance and high reliability. The circular shielding insulating bus comprises a circular conductor and an outer layer sheath, wherein a plurality of insulating shielding layers are arranged between the circular conductor and the outer layer sheath and consist of insulating layers and shielding layers; each insulating layer comprises two polytetrafluoroethylene layers and a thermal shrinkage sheath from inside to outside; and silicone oil is uniformly brushed between the polytetrafluoroethylene and the thermal shrinkage sheath.

Owner:JIANGSU SHILIN ELECTRIC EQUIP

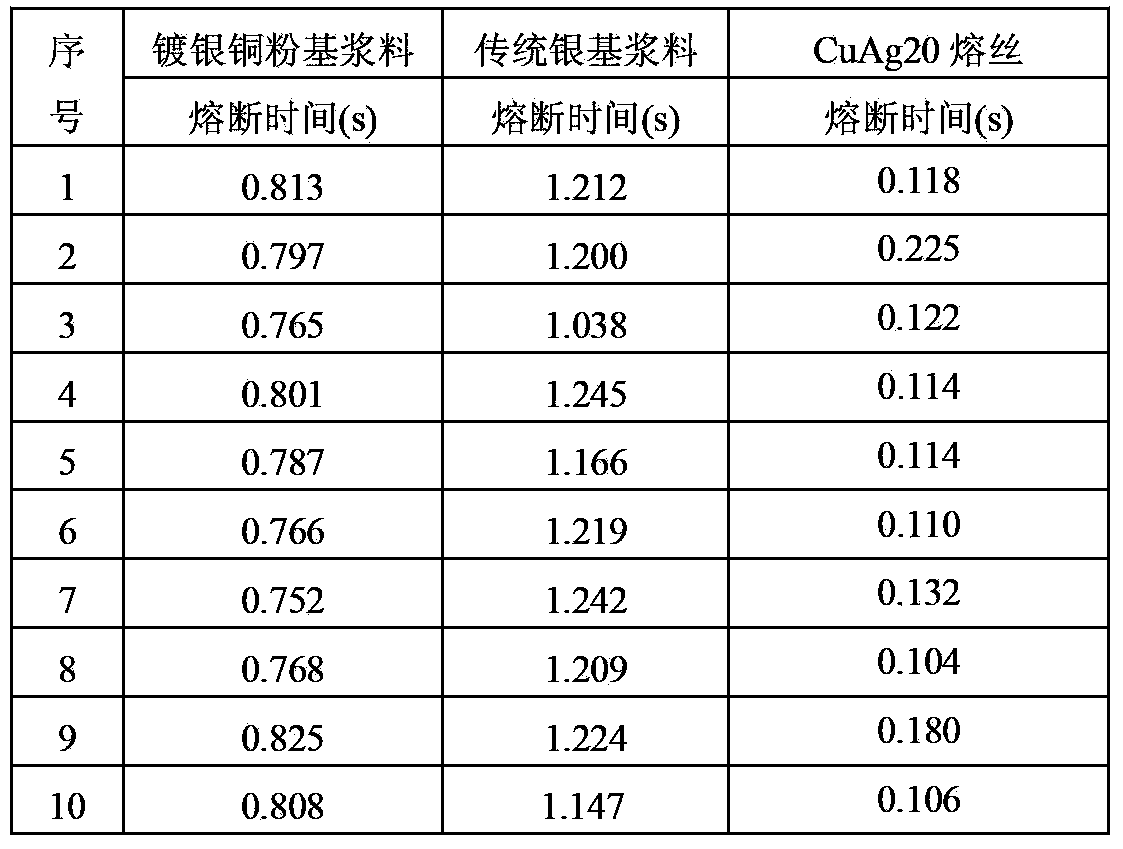

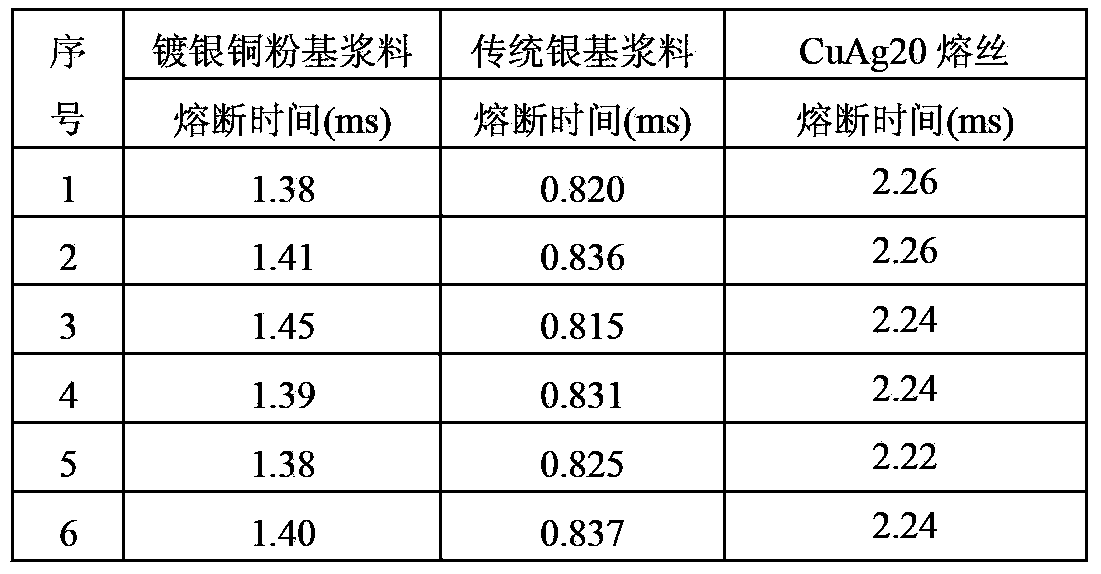

Electronic paste for fuse link of surface-mount fuse and preparation method thereof

ActiveCN103413591AImprove anti-pulse abilityPrevent oxidationNon-conductive material with dispersed conductive materialEmergency protective devicesWater bathsSilver paste

The invention relates to electronic paste and a preparation method of the electronic paste. The electronic paste comprises, by weight, 30-70% of silver-plated copper powder or silver-plated nickel powder, 0-40% of nano-silver powder, 3-15% of organic solvent, 5-12% of macromolecule resin and 2-10% of inorganic additive. The preparation method of the electronic paste comprises the steps of (1) weighing the macromolecule resin and the organic solvent in proportion, placing the macromolecule resin and the organic solvent into a container, placing the container into a thermostatic water bath, evenly mixing the macromolecule resin and the organic solvent to obtain an organic carrier, and (2) weighing the silver-plated copper powder or the silver-plated nickel powder, the nano-silver powder and the inorganic additives in proportion, adding the silver-plated copper powder or the silver-plated nickel powder, the nano-silver powder and the inorganic additives to the organic carrier obtained in the step (1), carrying out grinding and rolling to meet the requirement of the fineness to achieve even distribution of the solid-phase powder in the organic carrier. The preparation method of the electronic paste is simple, high in production efficiency and low in cost. When the obtained electronic paste is used for printing a fuse link structure of a surface-mount fuse, and compared with traditional silver paste, the pulse resistant capacity is greatly improved.

Owner:NANJING SART SCI & TECH DEV

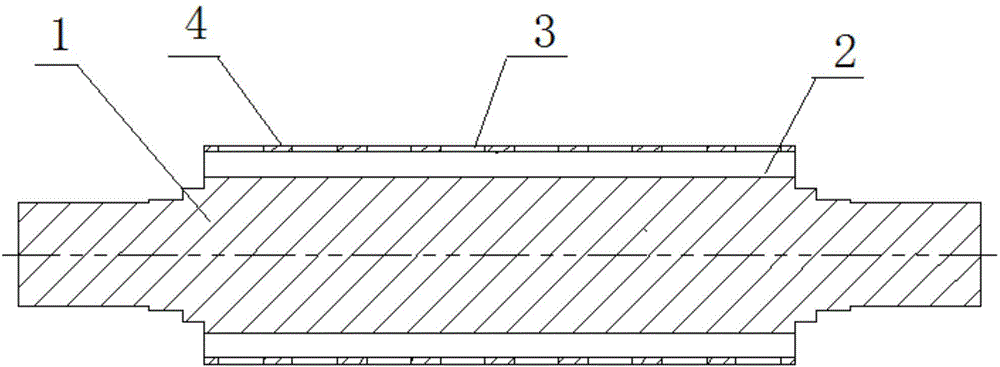

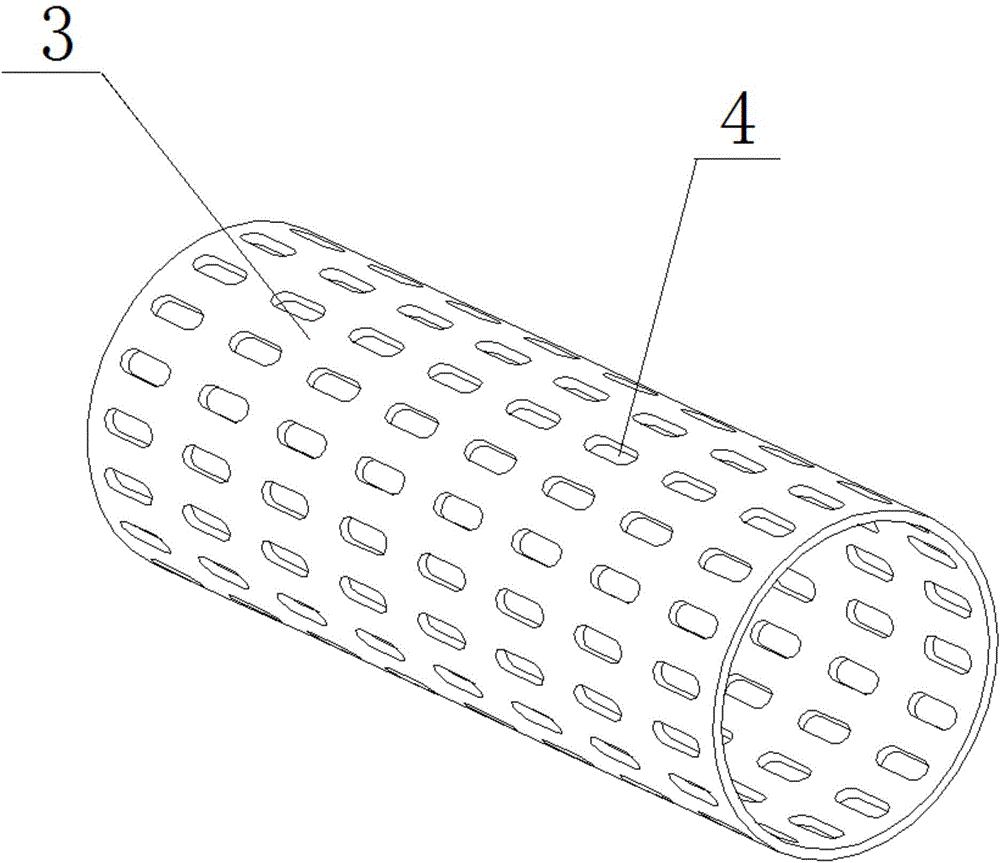

Sheath of high-speed permanent magnet motor rotor

InactiveCN104917318AReduce volumeReduce areaMagnetic circuit rotating partsPermanent magnet rotorPermanent magnet motor

The invention discloses a sheath of a high-speed permanent magnet motor rotor. A high-speed permanent magnet motor comprises a permanent magnet and a revolving shaft, wherein the permanent magnet is attached to the revolving shaft. The sheath of the high-speed permanent motor rotor tightly fixes the permanent magnet on the revolving shaft; the sheath is made of a non-magnetically-conductive alloy; the sheath is of a cylindrical structure; the cylindrical wall of the cylindrical structure is provided with grooves which are distributed uniformly; and the sheath is used for reducing the eddy current loss of the rotor and dissipating heat. Through the grooves, the size of the alloy sheath is reduced, and the formation of large-area eddy current is blocked, so that the eddy current loss in the alloy sheath can be effectively reduced. When the alloy sheath rotates at a high speed along with the permanent magnet rotor, gap air is driven to form strong turbulence, so that heat generated by the permanent magnet rotor is directly taken away, and the heat dissipation condition of the high-speed permanent magnet rotor is improved.

Owner:HARBIN INST OF TECH

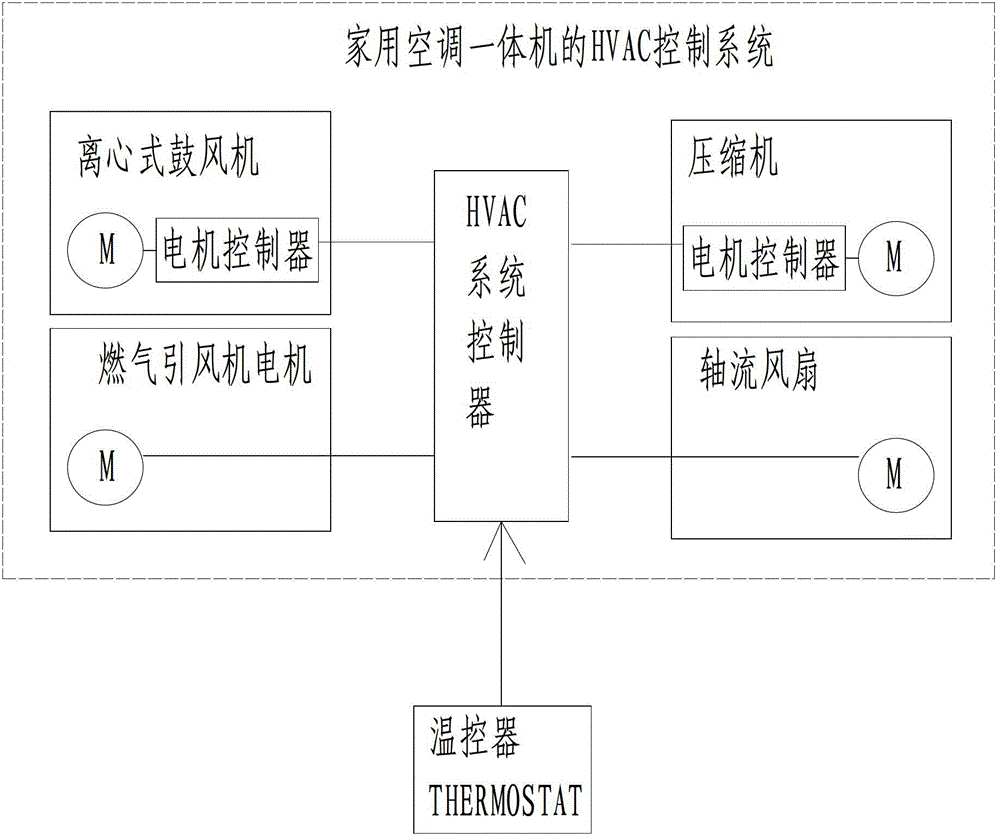

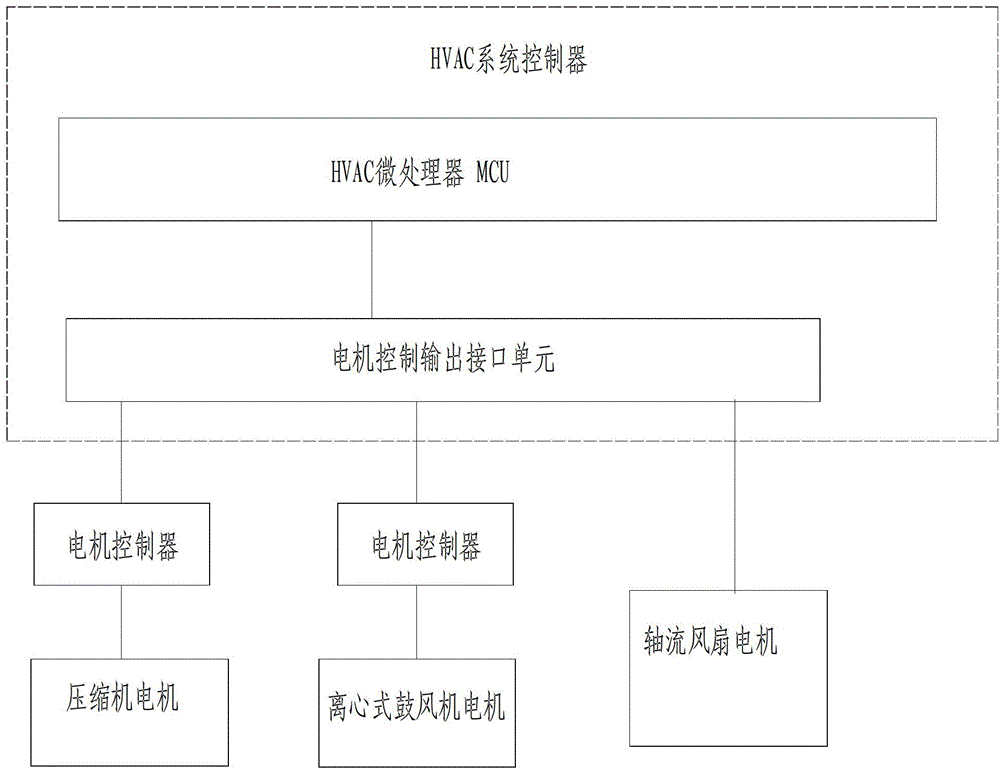

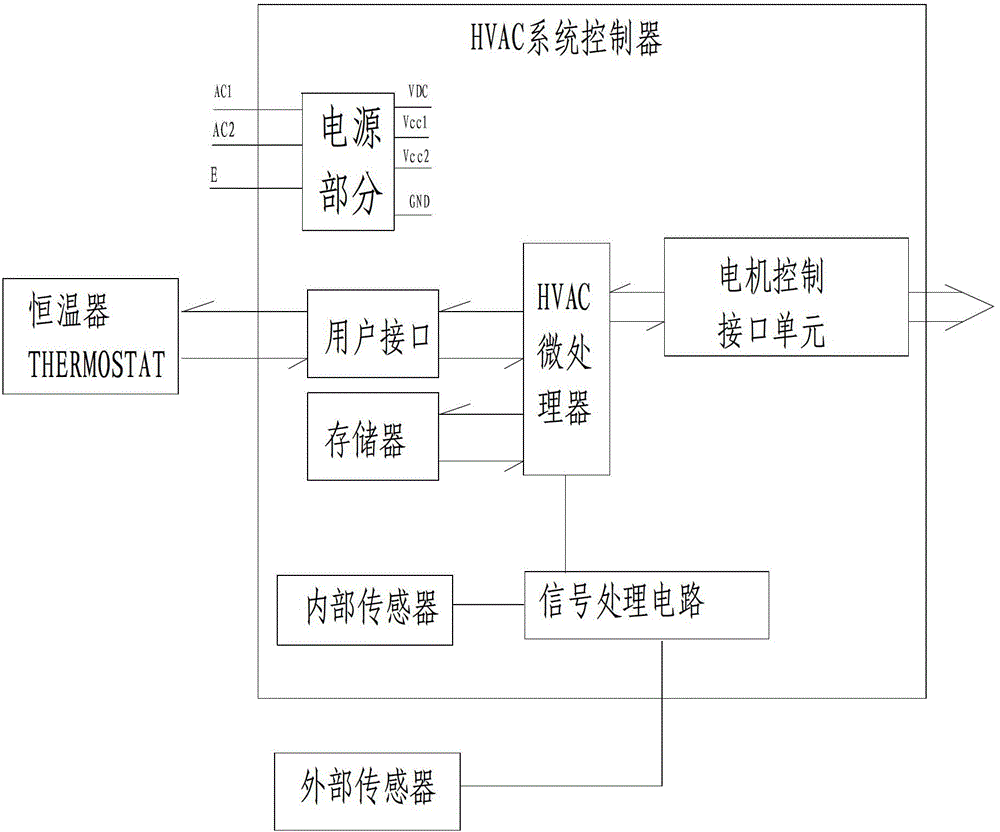

HVAC (heating ventilation and air conditioning) control system of household central air conditioner

ActiveCN102748834AImprove cooling conditionsSimple structureMechanical apparatusElectric motor controlSignal processing circuitsElectric machine

The invention relates to an HVAC (heating ventilation and air conditioning) control system of a household central air conditioner, comprising an HVAC system controller, a centrifugal blower motor, a compressor motor, and an axial fan motor, wherein the HVAC system controller comprises an HVAC microprocessor, a sensor, a motor control interface unit and a power supply portion; the power supply portion is used to supply power for circuits of various parts; the sensor transmits a detection signal to the HVAC microprocessor through a signal processing circuit, wherein at least one of the centrifugal blower motor, the compressor motor and the axial fan motor is a permanent magnet synchronous motor without a motor controller; the motor control interface unit comprises an inverter unit and a rotor position detecting unit; the HVAC microprocessor drives the permanent magnet synchronous motor without the motor controller through the inverter unit; the rotor position detecting unit transmits a rotor position signal of the permanent magnet synchronous motor without the motor controller to the HVAC microprocessor to process. According to the invention, overlapped circuit configuration is removed, circuit structures are simplified, product cost is reduced greatly, and resource waste is reduced.

Owner:ZHONGSHAN BROAD OCEAN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com