Sheath of high-speed permanent magnet motor rotor

A technology of permanent magnet motors and sheaths, which is applied to the rotating parts of the magnetic circuit, the shape/style/structure of the magnetic circuit, etc., which can solve the problems of difficult cooling and heat dissipation of the rotor, high loss density of the rotor, etc., to reduce the volume and area, reduce the Eddy current loss, effect of improving heat dissipation conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing:

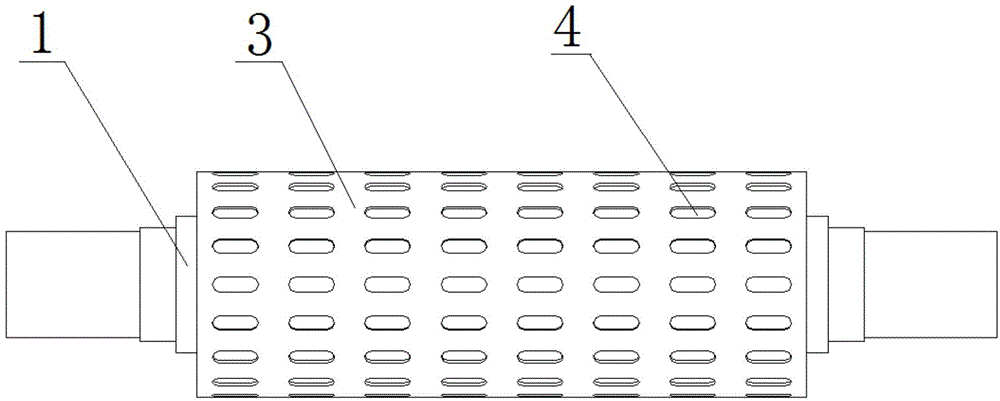

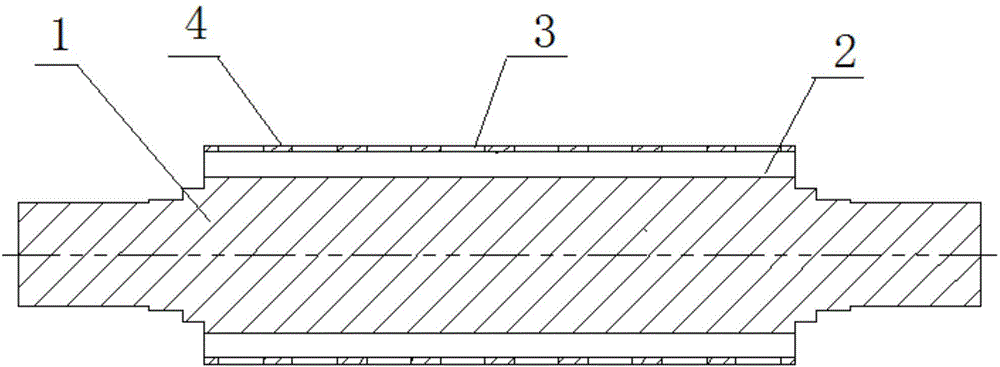

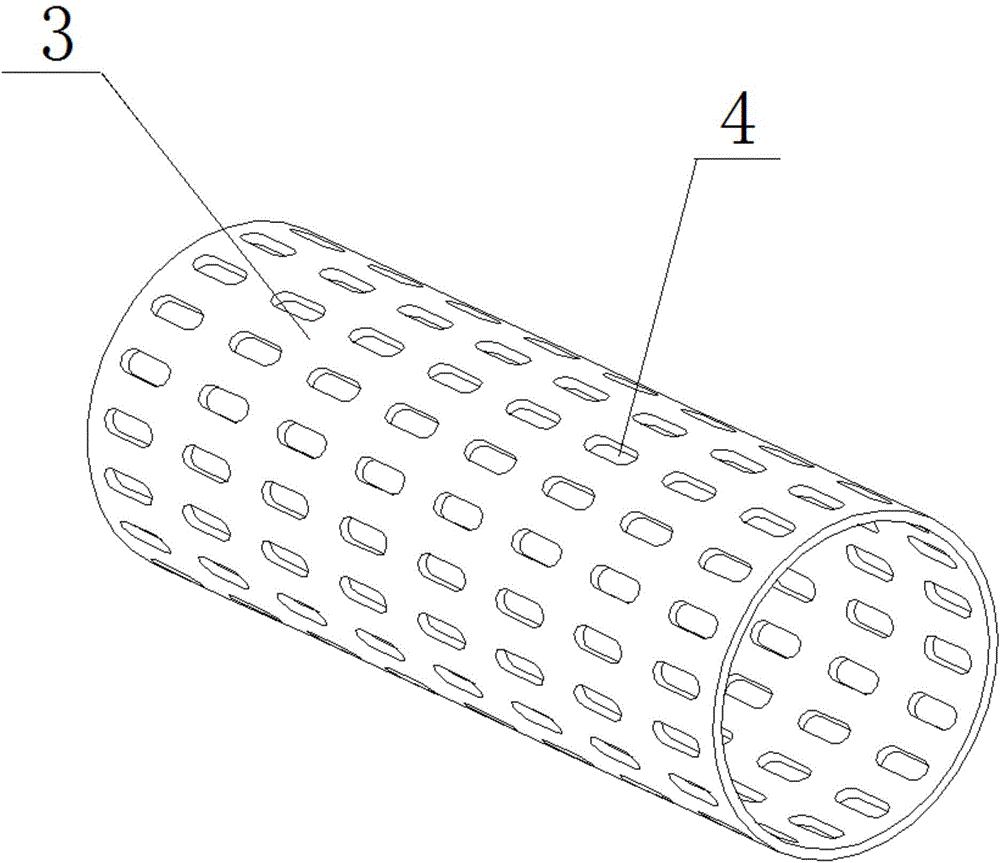

[0020] like figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, a sheath of a high-speed permanent magnet motor rotor, the high-speed permanent magnet motor includes a permanent magnet 2 and a rotating shaft 1, the permanent magnet 2 is attached to the rotating shaft 1, and the sheath 3 of the high-speed permanent magnet motor rotor The permanent magnet 2 is tightly fixed on the rotating shaft 1; the material of the sheath 3 is a non-magnetic alloy, and the sheath 3 is a cylindrical structure, and the wall of the cylindrical structure is opened with uniform Distributed grooves 4; the sheath 3 is used to reduce the eddy current loss of the rotor and dissipate heat. The grooves on the cylinder wall can be impermeable grooves 4 or transparent grooves 4 . The principle of uniform distribution of grooves is: two adjacent rows or columns of grooves 4 are loc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com