Inner supporting body for run-flat tire

An inner support, run-flat technology, applied in tire parts, transportation and packaging, vehicle parts, etc., can solve problems affecting vehicle safety and comfort, increase environmental burden, reduce service life, etc. Smoothness, improved safety and comfort, low density effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

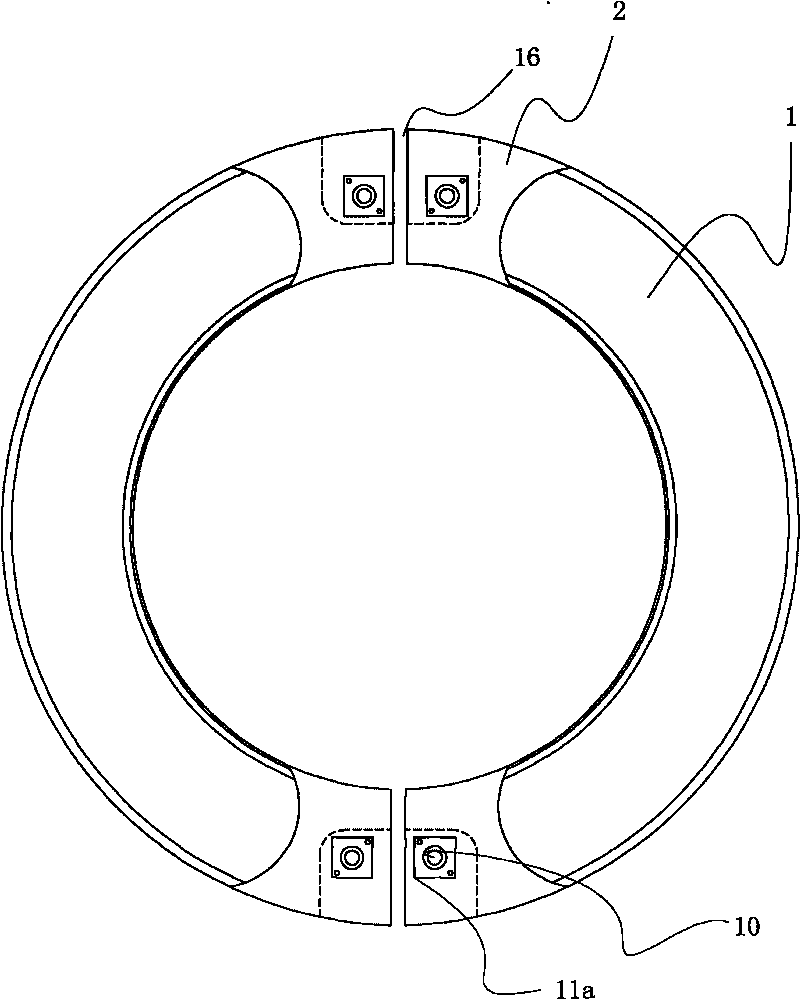

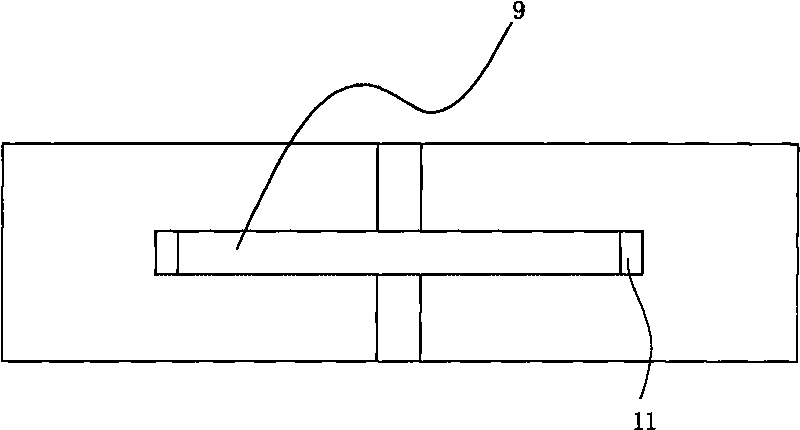

Embodiment 1

[0039] This embodiment describes the joint structure of the butt-joint magnesium alloy inner support body. The structure of the butt joint inner support body is as follows: image 3 As shown, its connectors include lock block 7, bolt 8, lock ring 9 and special nut 10 (such as Figure 4 , 7 , 8, 9, 10, 11), the connectors are prepared with 45# steel, the butt joint 2 is provided with a lock ring groove 11 corresponding to the lock ring 9, the above lock ring 9 and the lock The distance between the sides of the ring groove 11 is 5mm, so as to ensure that the lock ring 9 is convenient for positioning and installation, and at the same time avoid the collision between the two during use and affect the safety and comfort of the system. The contact surface of the lock ring 9 and the lock ring groove 11 passes through Tolerance matching dimensions ensure smooth installation. The lock ring 7 is provided with a bolt hole 12 and a lock block hole 13. The opposite joint is respectively ...

Embodiment 2

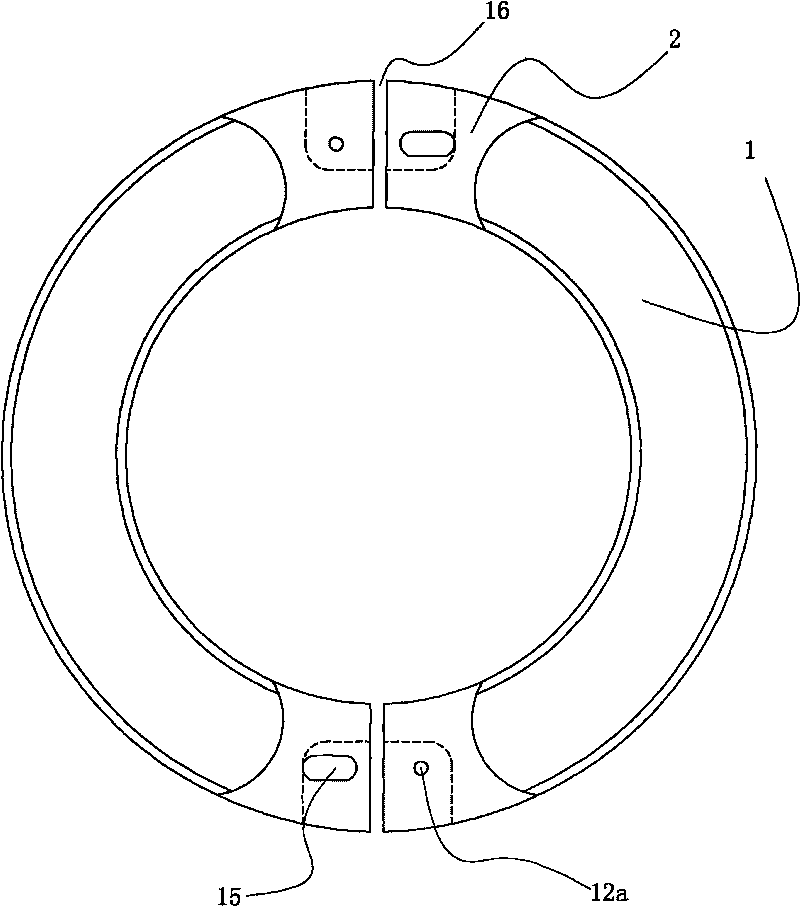

[0041] This embodiment describes the joint structure of the lap-joint magnesium alloy inner support body.

[0042] The joint structure of the lap joint inner support body is as follows: Figure 14 As shown, the connectors include lock blocks 7, bolts 8 and special nuts 10 (such as Figure 7 , 8 , 9, 10, and 11), the connecting piece is prepared by 45# steel, and one split joint 2 that fits each other has a fitting surface 14 corresponding to the other split joint 2, and the The joints of the fitted joints 2 touch face to face, and the overall rigidity is better after tightening. The above-mentioned mutually fitted joints 2 are also provided with a locking block hole 15 corresponding to the locking block 7, and the locking block 7 is inserted into the locking block hole 15, the above-mentioned lock block 7 is provided with a bolt hole, and the two splits pass through the bolt hole at the lock block 7 through the bolt 8 and are connected and fixed with a special nut 10. Conne...

Embodiment 3

[0044] This embodiment describes the joint structure of the plug-in magnesium alloy inner support body.

[0045] The structure of the plug-in inner support body joint is as follows: Figure 15 As shown, the connectors include lock blocks 7, bolts 8 and special nuts 10 (such as Figure 7 , 8 , 9, 10, and 11), the connecting piece is prepared by 45# steel, a slot 18 is provided at 2 of the split joints that are inserted into each other, and a slot 18 is provided at 2 of the other split joints corresponding to the slot 18. The protruding fast 19, the contact surface 17 of the joint joints that are inserted into each other has a larger area, and the overall rigidity is better after tightening. The above-mentioned joints 2 that are inserted into each other are also provided with a lock block hole 15 corresponding to the lock block 7. The lock block 7 is put into the lock block hole 15, and the above lock block 7 is provided with a bolt hole, and the two splits pass through the bo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com