Patents

Literature

295 results about "Run-flat tire" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A run-flat tire is a pneumatic vehicle tire that is designed to resist the effects of deflation when punctured, and to enable the vehicle to continue to be driven at reduced speeds - under 56 mph (90 km/h) - and for limited distances - generally between 10 mi (16 km) to 50 mi (80 km), depending on the type of tire.

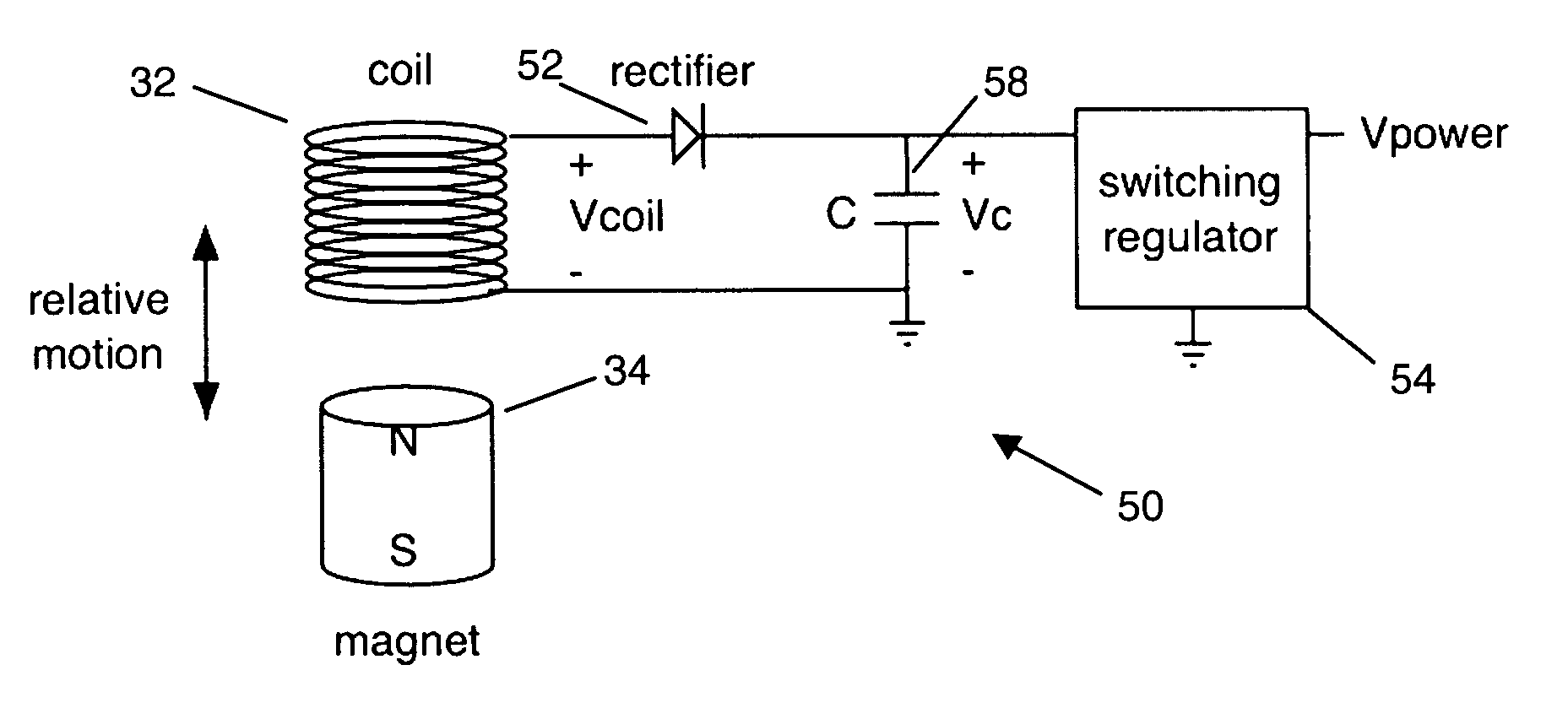

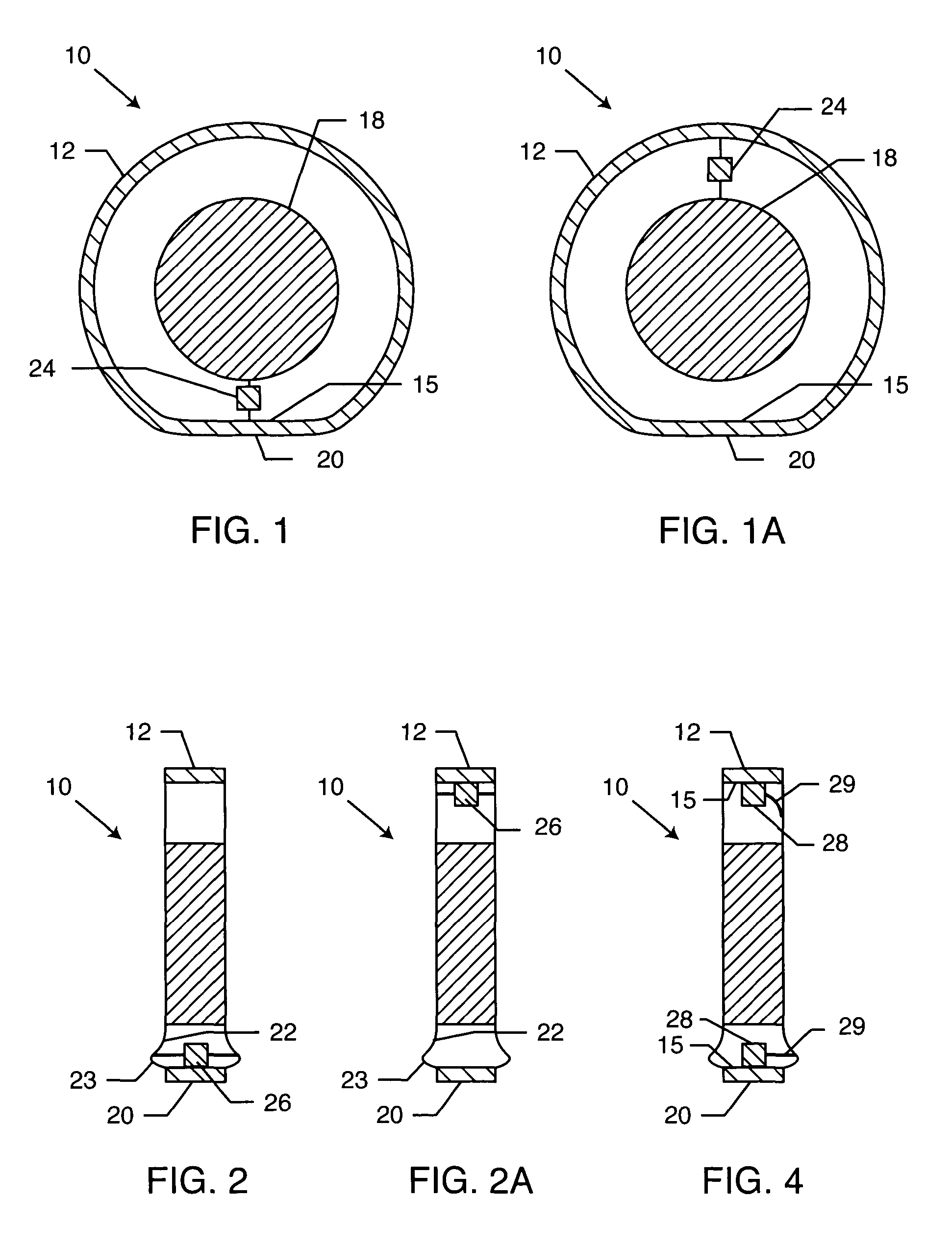

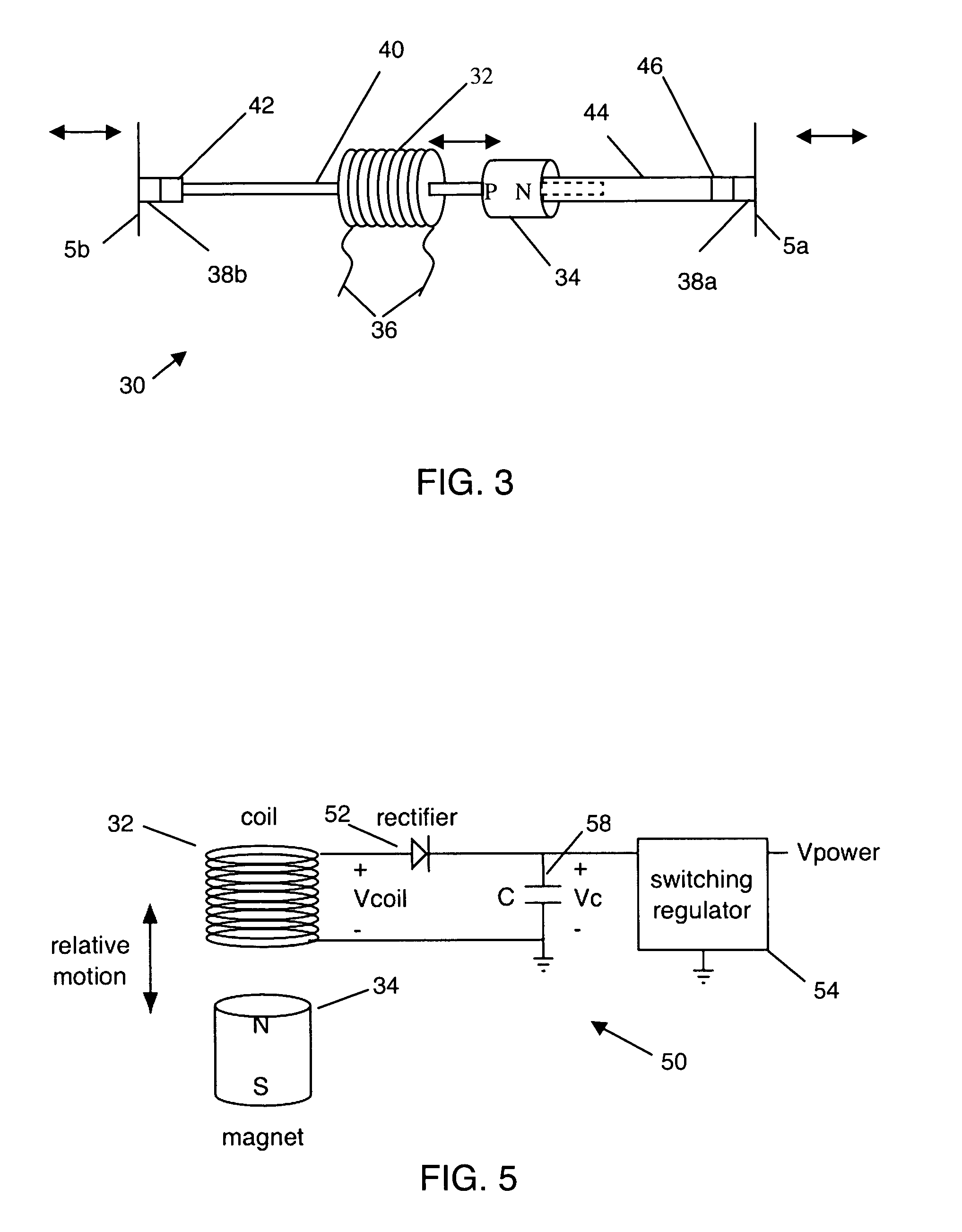

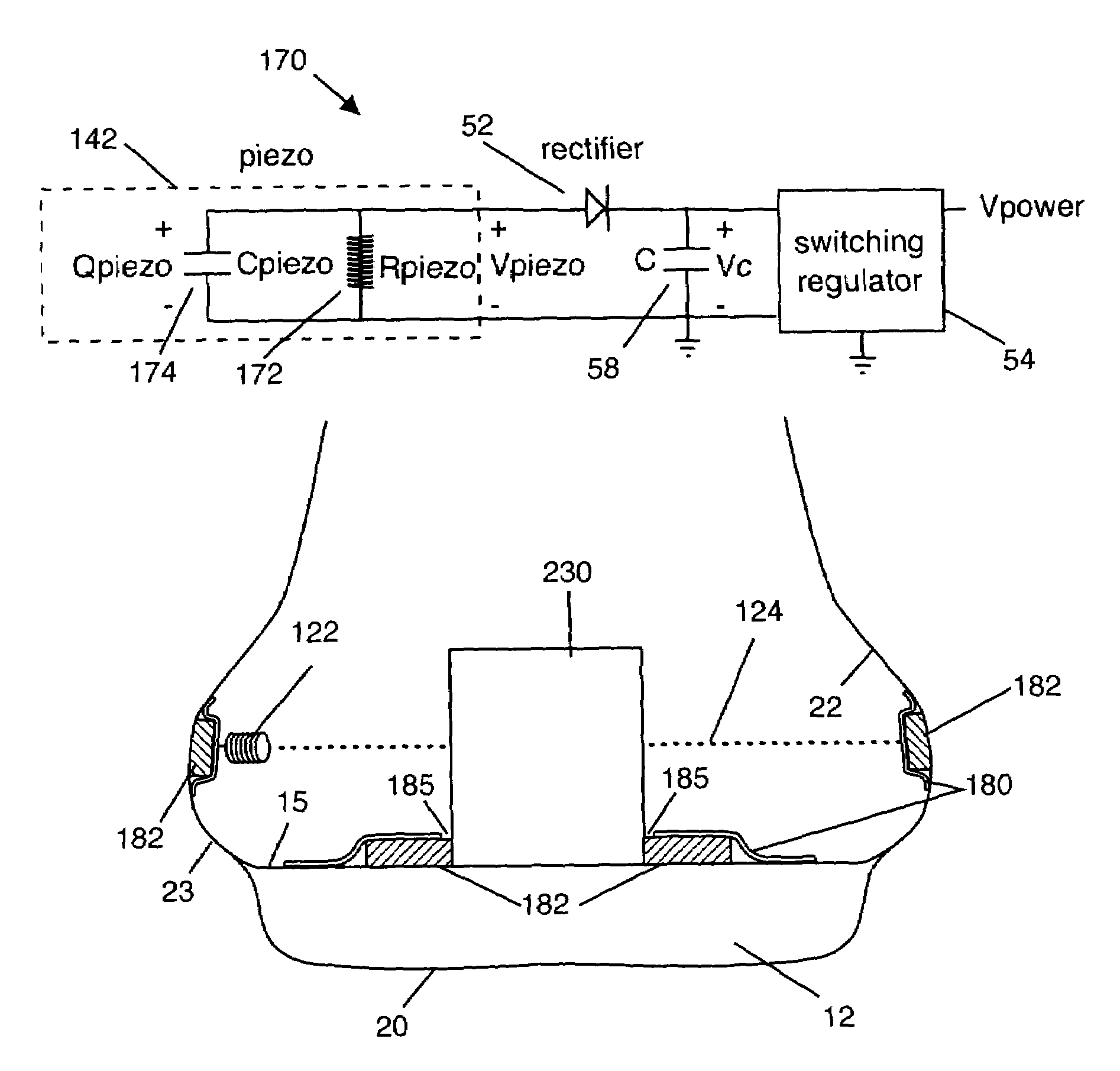

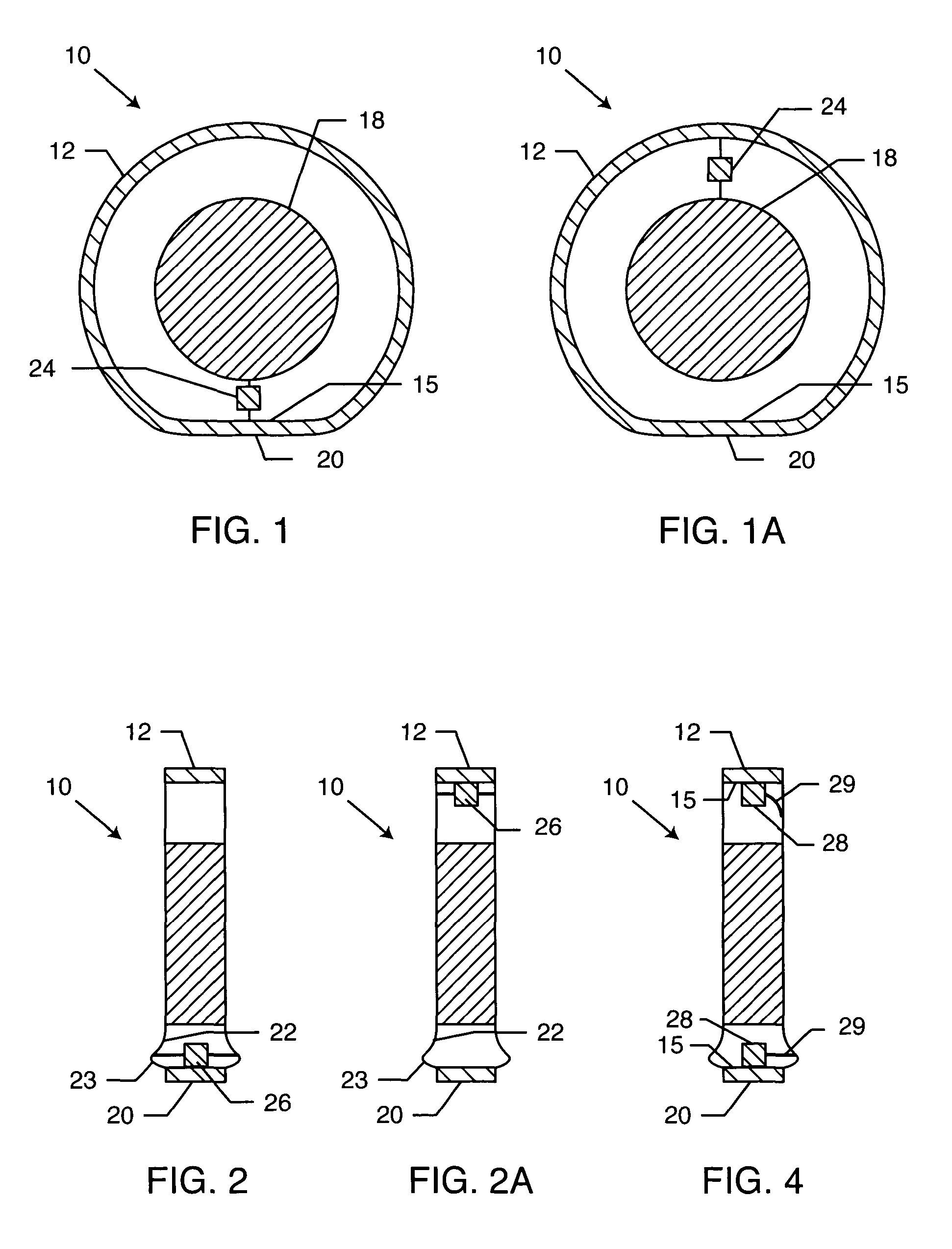

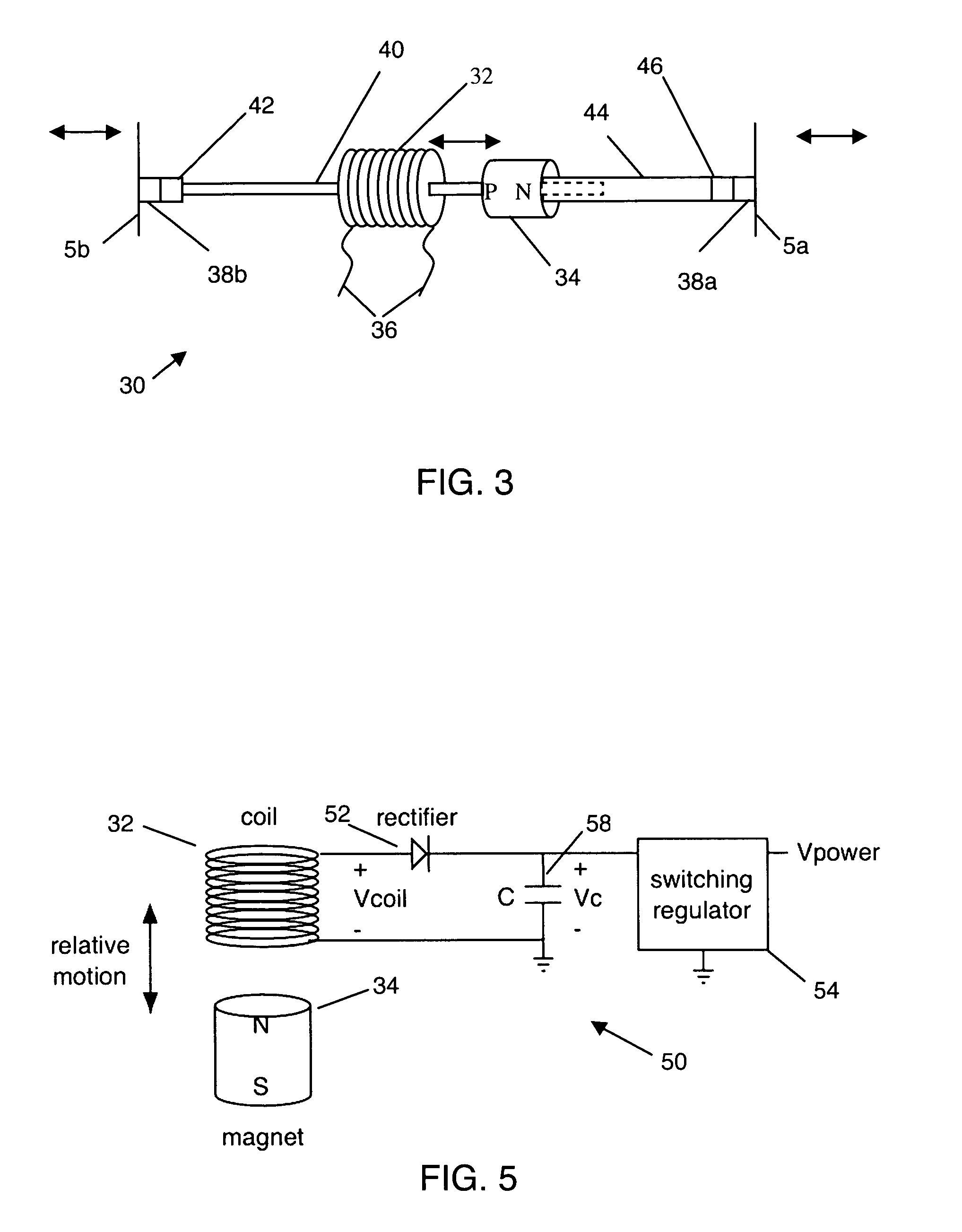

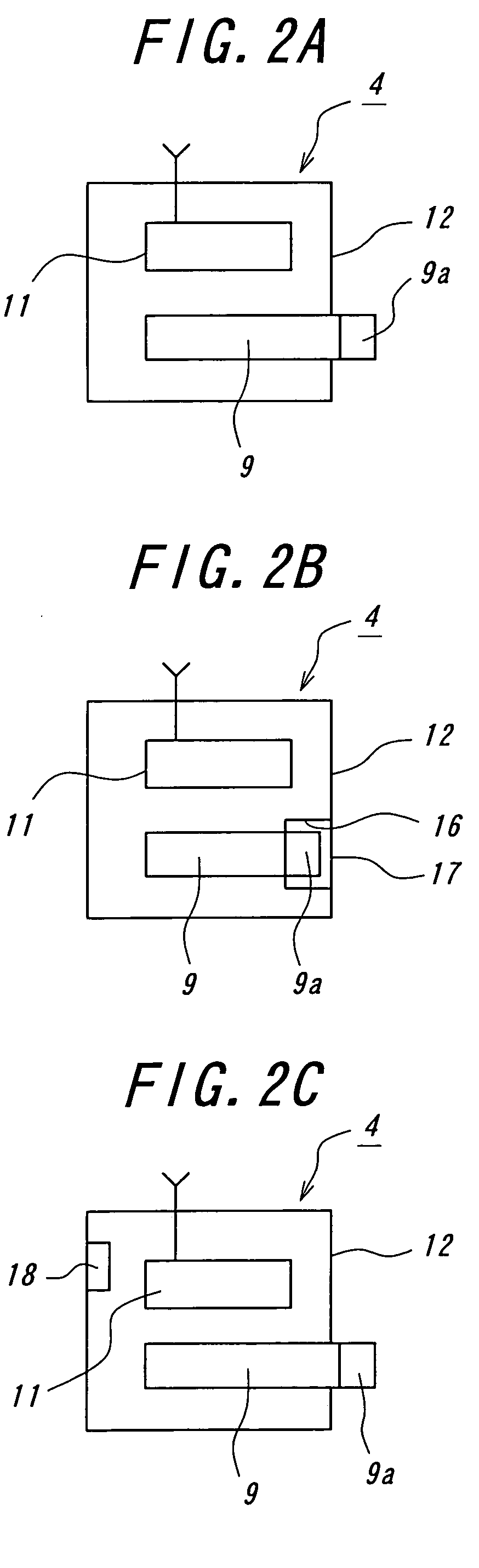

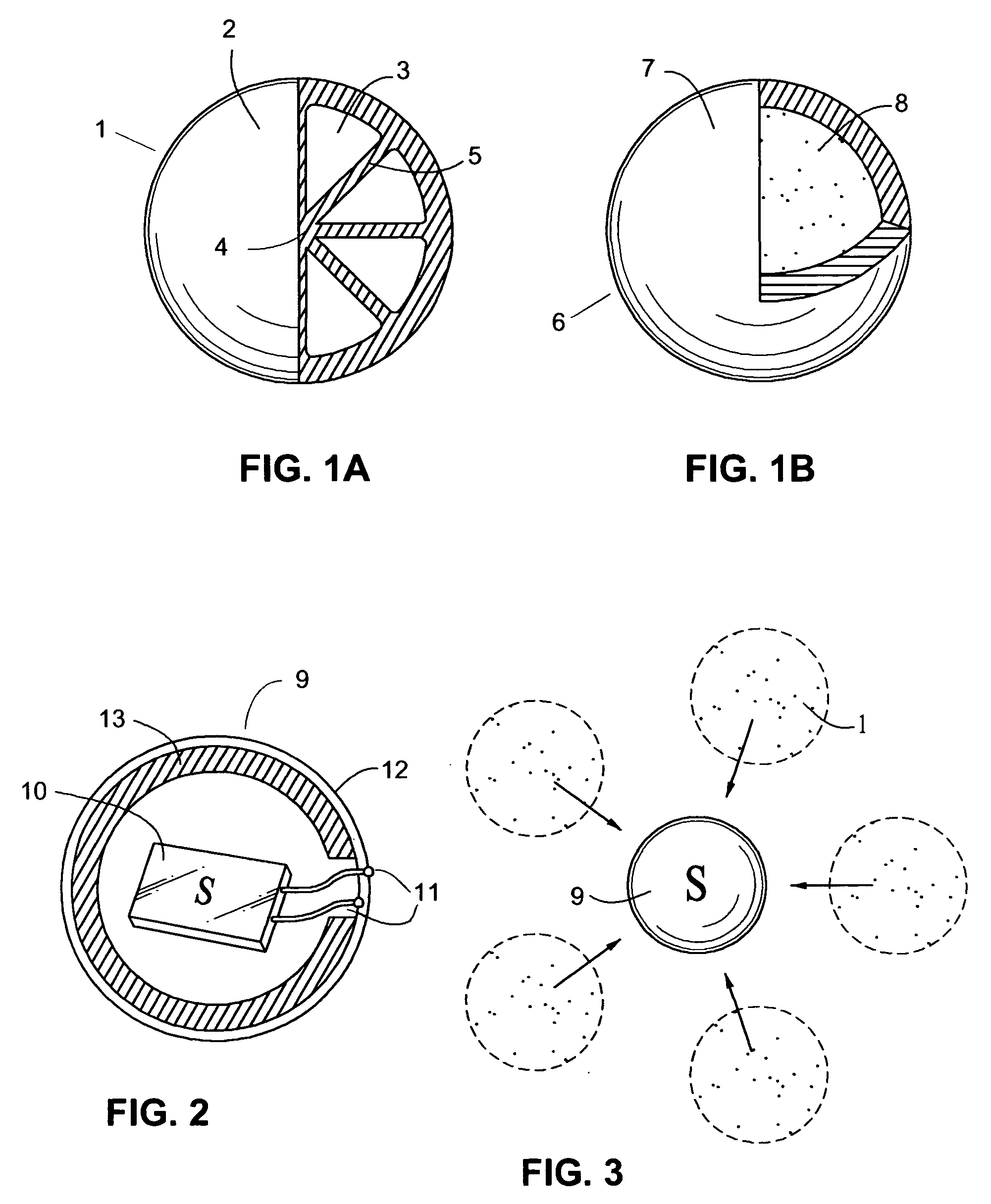

Apparatus and method for energy generation within a tire

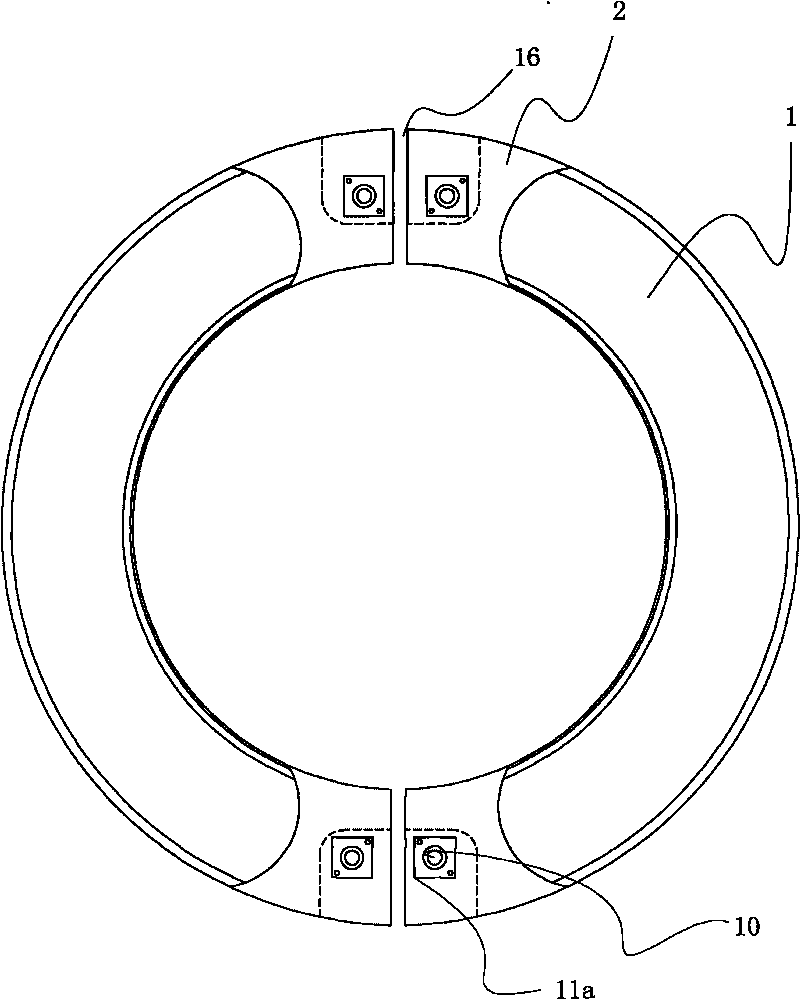

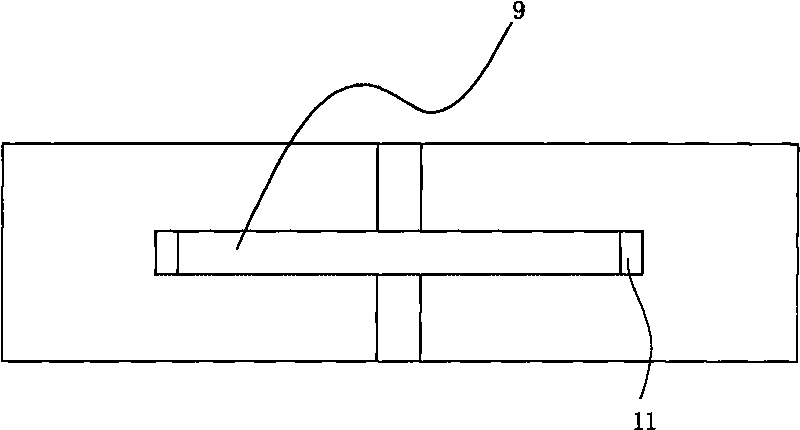

InactiveUS20040100100A1No damageNot to damageFlexible wall reciprocating enginesTyre measurementsCapacitanceRotary pump

Energy for in-tire use is generated from the load induced reciprocating deflection of the tire inner walls above the tire-to-road contact patch adjacent to the shoulder of the tire. This energy is used to power in-tire monitoring electronics. For pulsatile energy generation with capacitive capture, the capacitor is optimally selected in real-time as a function of pulse width to maximize energy capture, or as a function of the pulse-captured energy. The resulting energy pulses are also used to measure the time duration of the contact patch from which the contact patch length is determined thus providing real-time tire geometry and, with tire pressure, real time tire load and, with temperature, tire air molar content. The loads on all tires provide real time vehicle mass and mass distribution. For electrical energy generation, magnet-coil, piezo-electric, and other power conversions are applicable. For non-electric energy generation, fluid bellows, rotary pump, and other power conversions are applicable. Further, run flat tires are designed with a cutout to accommodate and protect electronic devices mounted on an inner surface when running flat.

Owner:WILSON KITCHENER CLARK

Apparatus and method for energy generation within a tire

InactiveUS7285868B2Sufficient powerEliminate needFlexible wall reciprocating enginesTyre measurementsCapacitanceRotary pump

Energy for in-tire use is generated from the load induced reciprocating deflection of the tire inner walls above the tire-to-road contact patch adjacent to the shoulder of the tire. This energy is used to power in-tire monitoring electronics. For pulsatile energy generation with capacitive capture, the capacitor is optimally selected in real-time as a function of pulse width to maximize energy capture, or as a function of the pulse-captured energy. The resulting energy pulses are also used to measure the time duration of the contact patch from which the contact patch length is determined thus providing real-time tire geometry and, with tire pressure, real time tire load and, with temperature, tire air molar content. The loads on all tires provide real time vehicle mass and mass distribution. For electrical energy generation, magnet-coil, piezo-electric, and other power conversions are applicable. For non-electric energy generation, fluid bellows, rotary pump, and other power conversions are applicable. Further, run flat tires are designed with a cutout to accommodate and protect electronic devices mounted on an inner surface when running flat.

Owner:WILSON KITCHENER CLARK

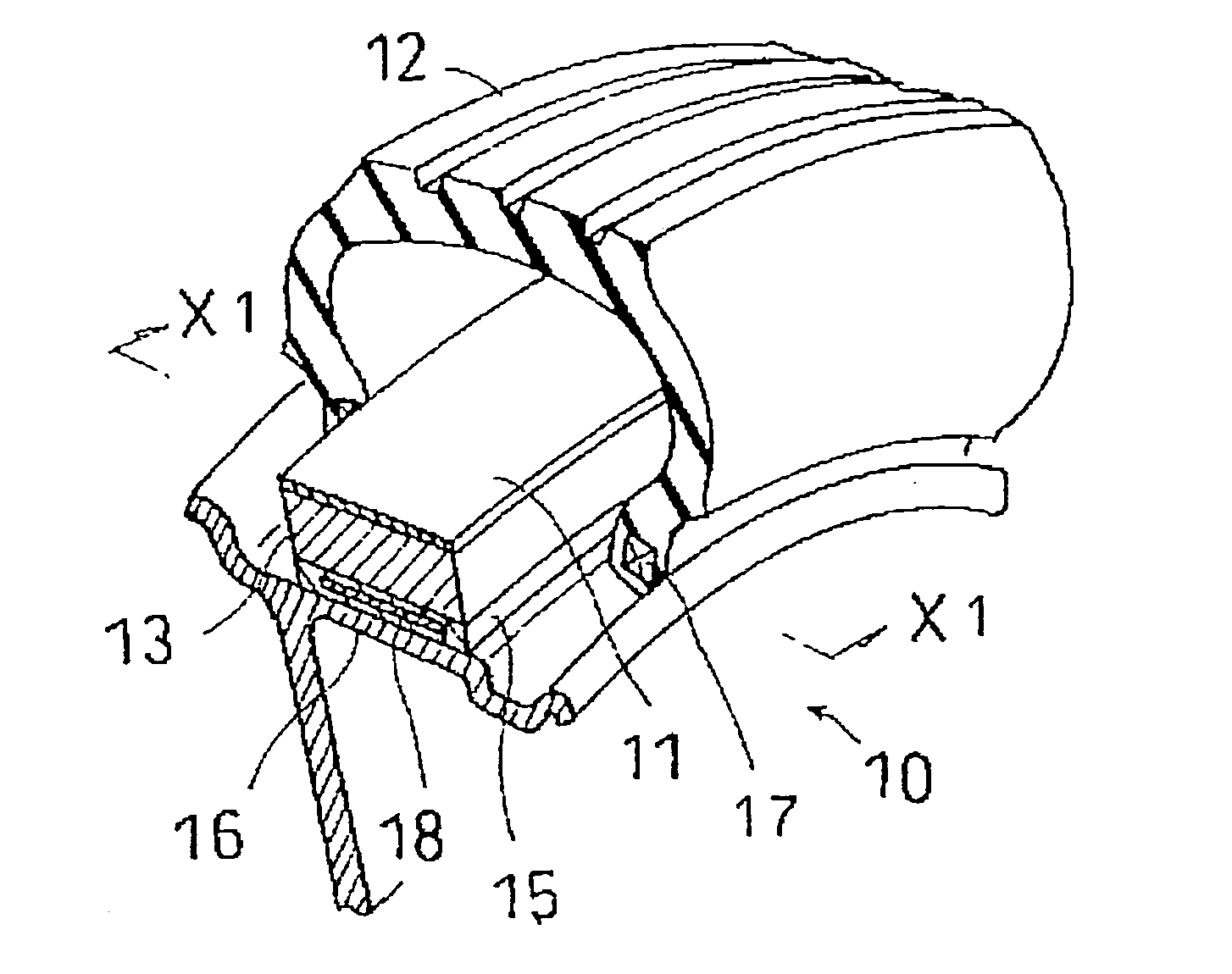

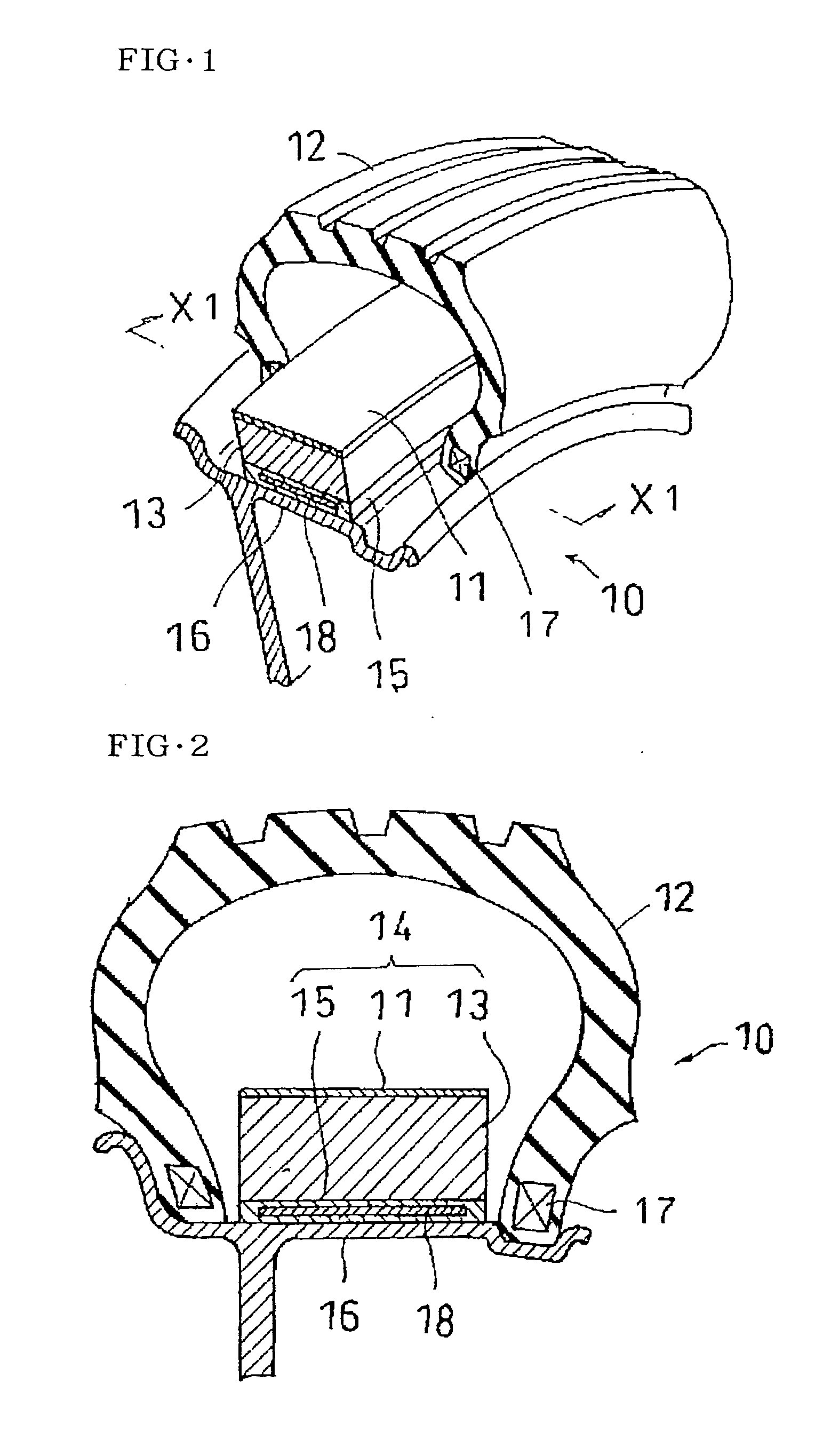

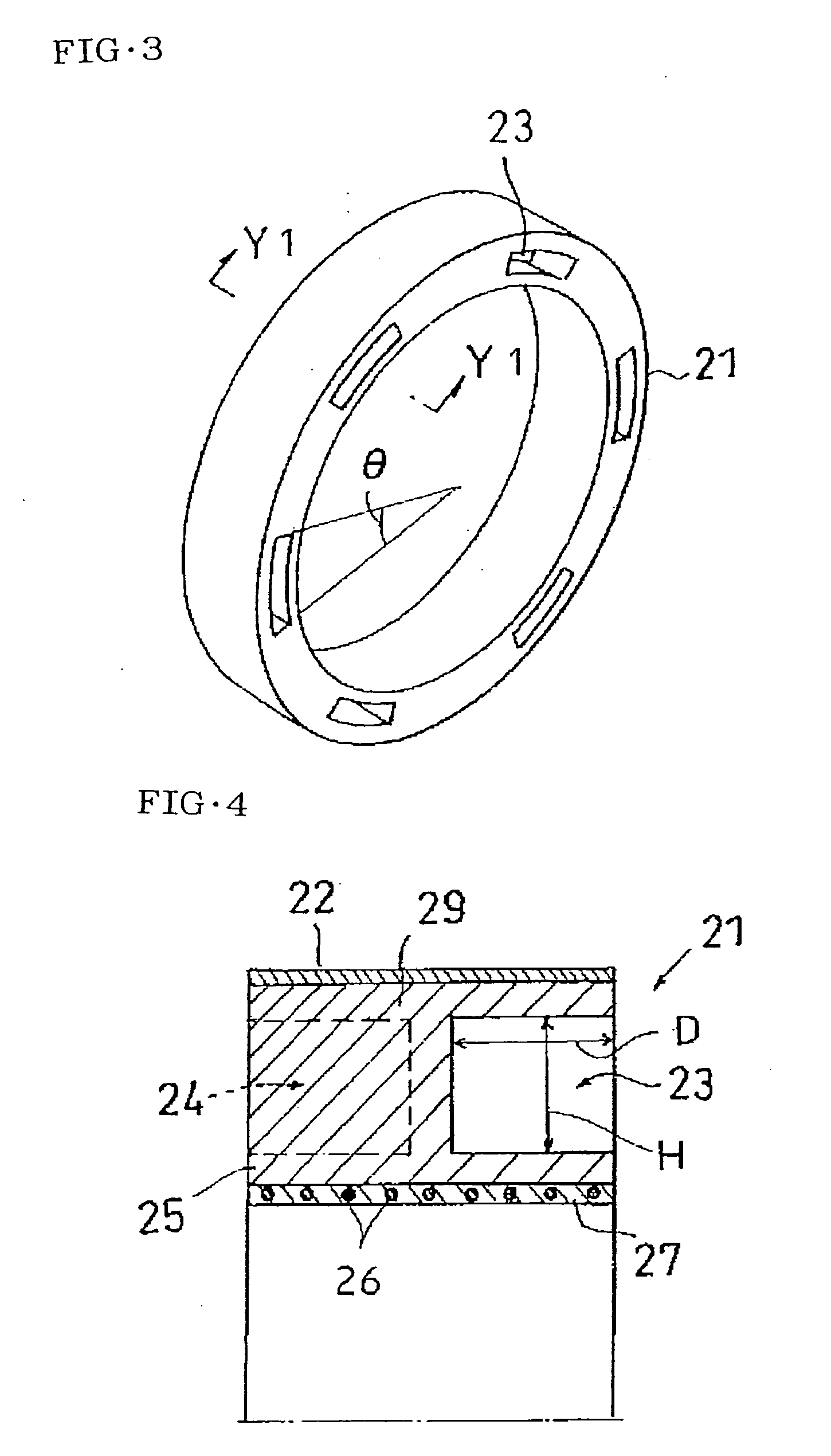

Run-Flat Tire Support, Manufacturing Method Therefor, and a Run-Flat Tire with the Run-Flat Tire Support Fixedly Mounted Thereto

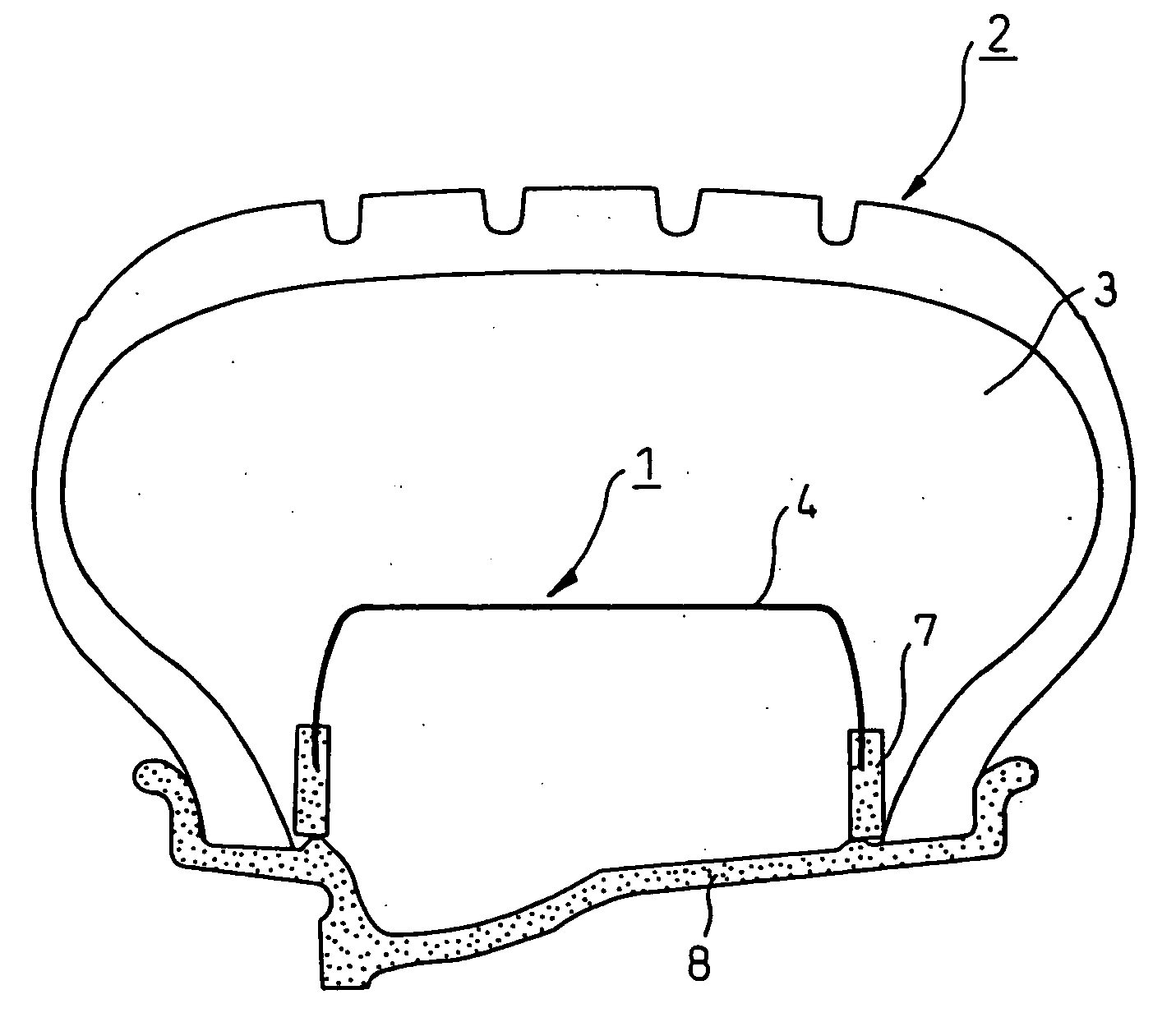

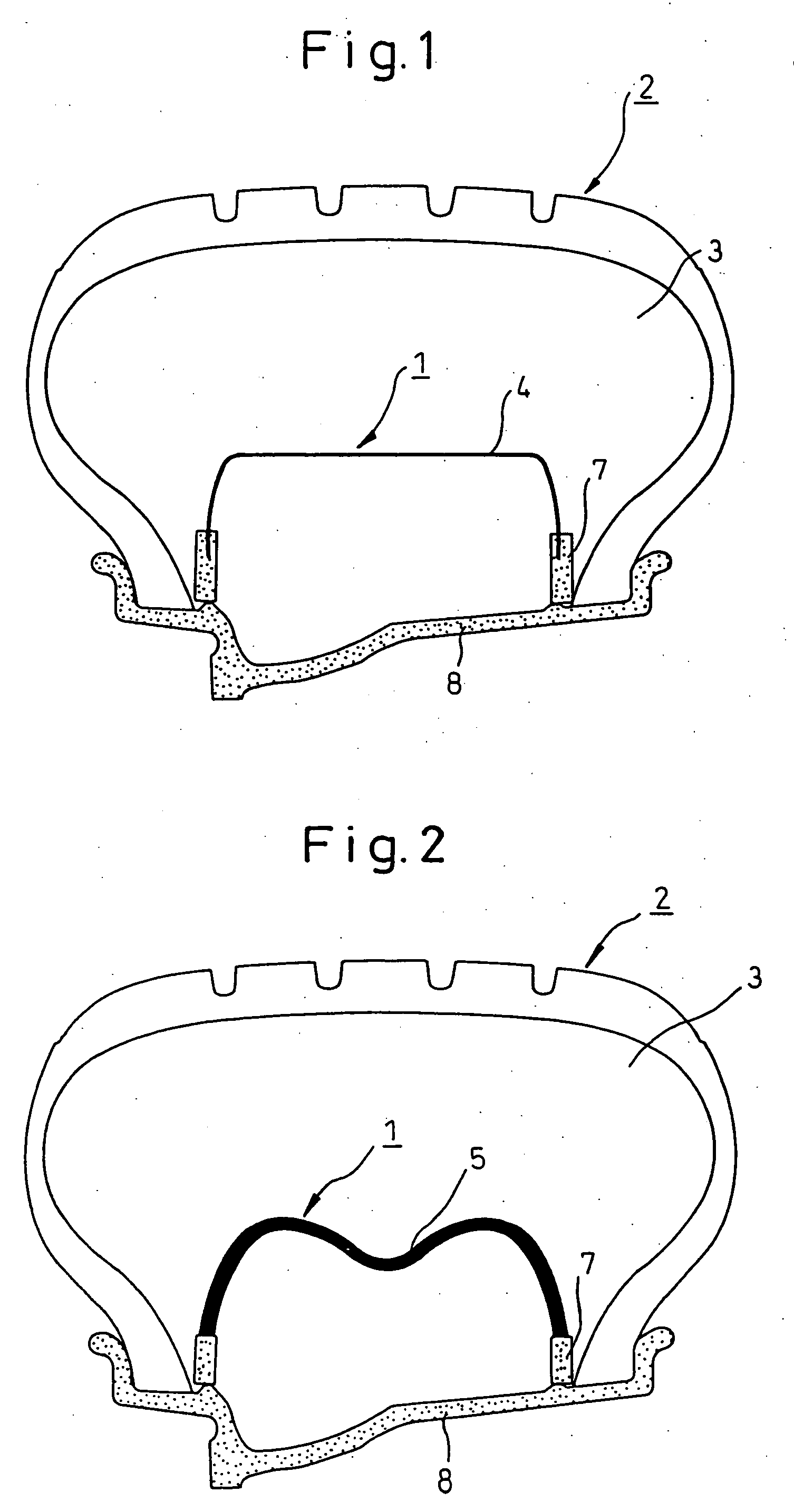

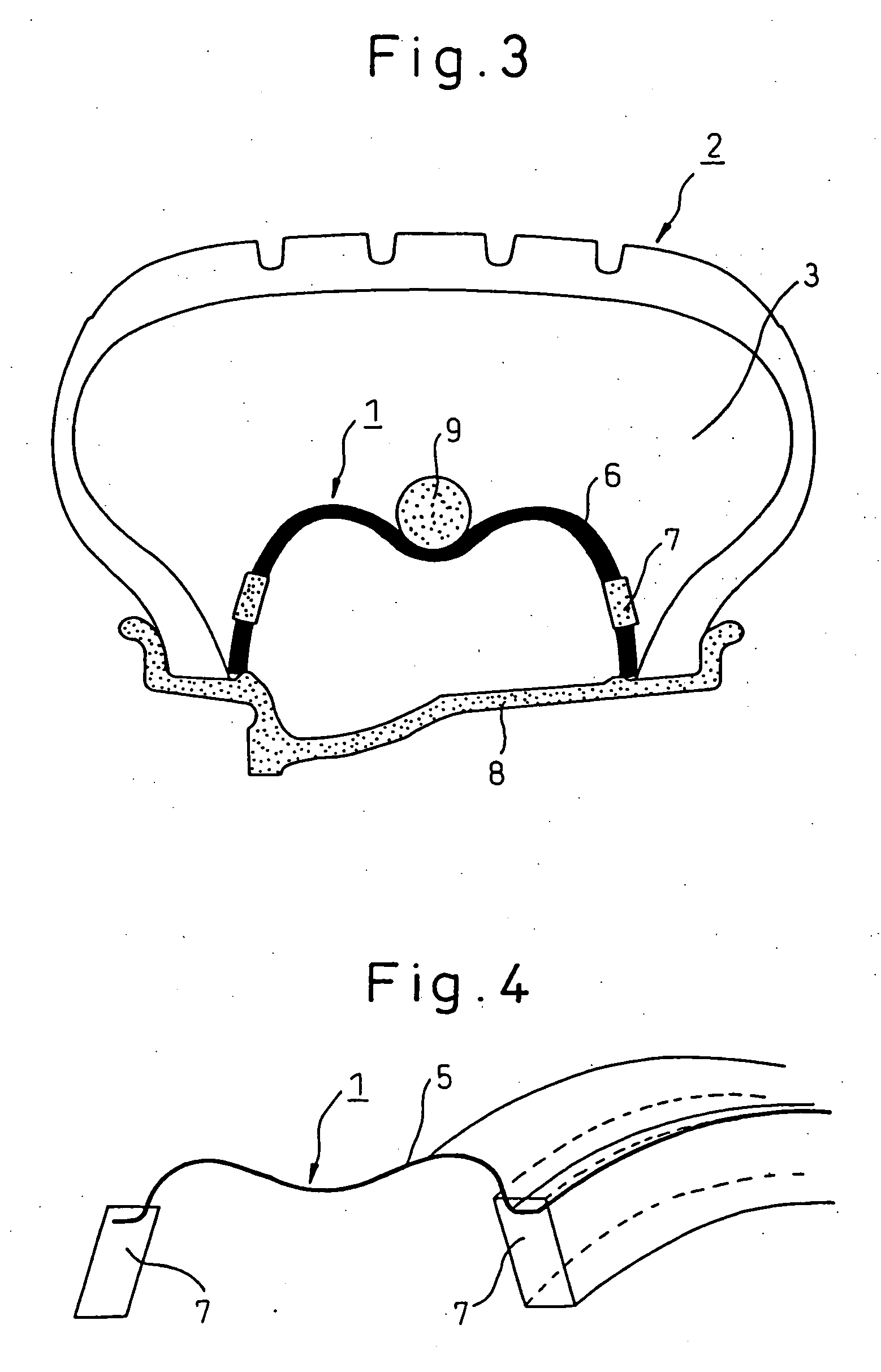

A run flat tire support body, a method of manufacturing the run flat tire support body, and a run flat tire on which the run flat tire support body is fixedly mounted. The run flat tire support body (14) enabling a reduction in weight and the suppression of the wear of the outer surface thereof by the sliding thereof on the inner surface of a tire when the tire runs in a run flat state comprises a base material part (13) having an inner diameter allowing the support body to be fitted to a rim (16) and formed of a resin foam body of 0.3 to 0.9 g / cm3 in density, a reinforcement part (15) installed on the inner peripheral part of the base material part (13), and a non-foam resin outer layer (11) covering at least the outer peripheral surface of the base material part (13).

Owner:TOYO TIRE & RUBBER CO LTD

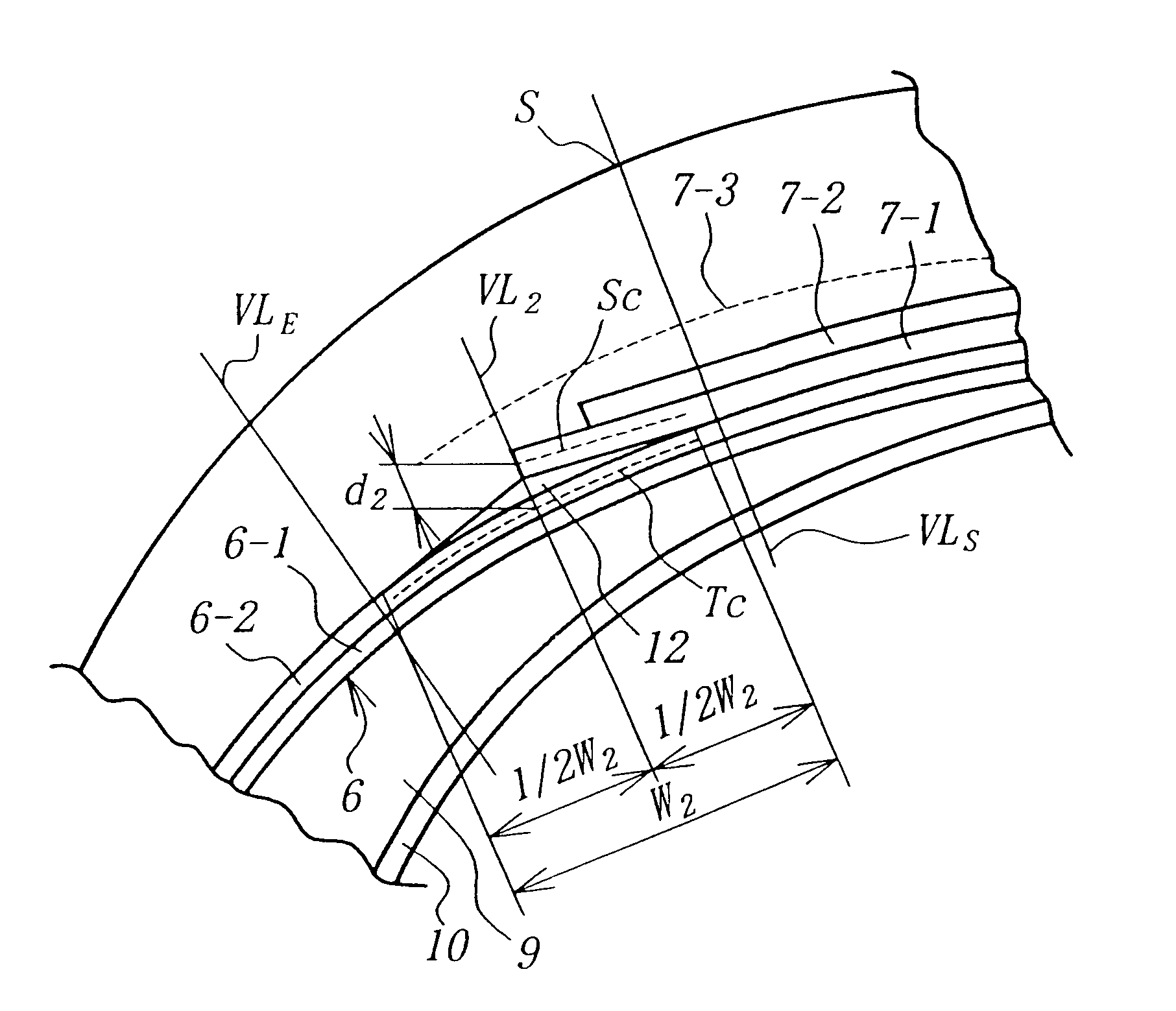

Pneumatic radial tire for passenger vehicles

InactiveUS20130042953A1Improve fuel efficiencyReduction factorSpecial tyresPneumatic tyre reinforcementsFlat tireRun-flat tire

A run-flat tire of the present invention is a pneumatic radial tire for passenger vehicles which has a carcass composed of plies of radially arranged cords toroidally extending between a pair of bead portions, and the a W / L ratio of the section width W to the outer diameter L of the tire is 0.25 or less.

Owner:BRIDGESTONE CORP

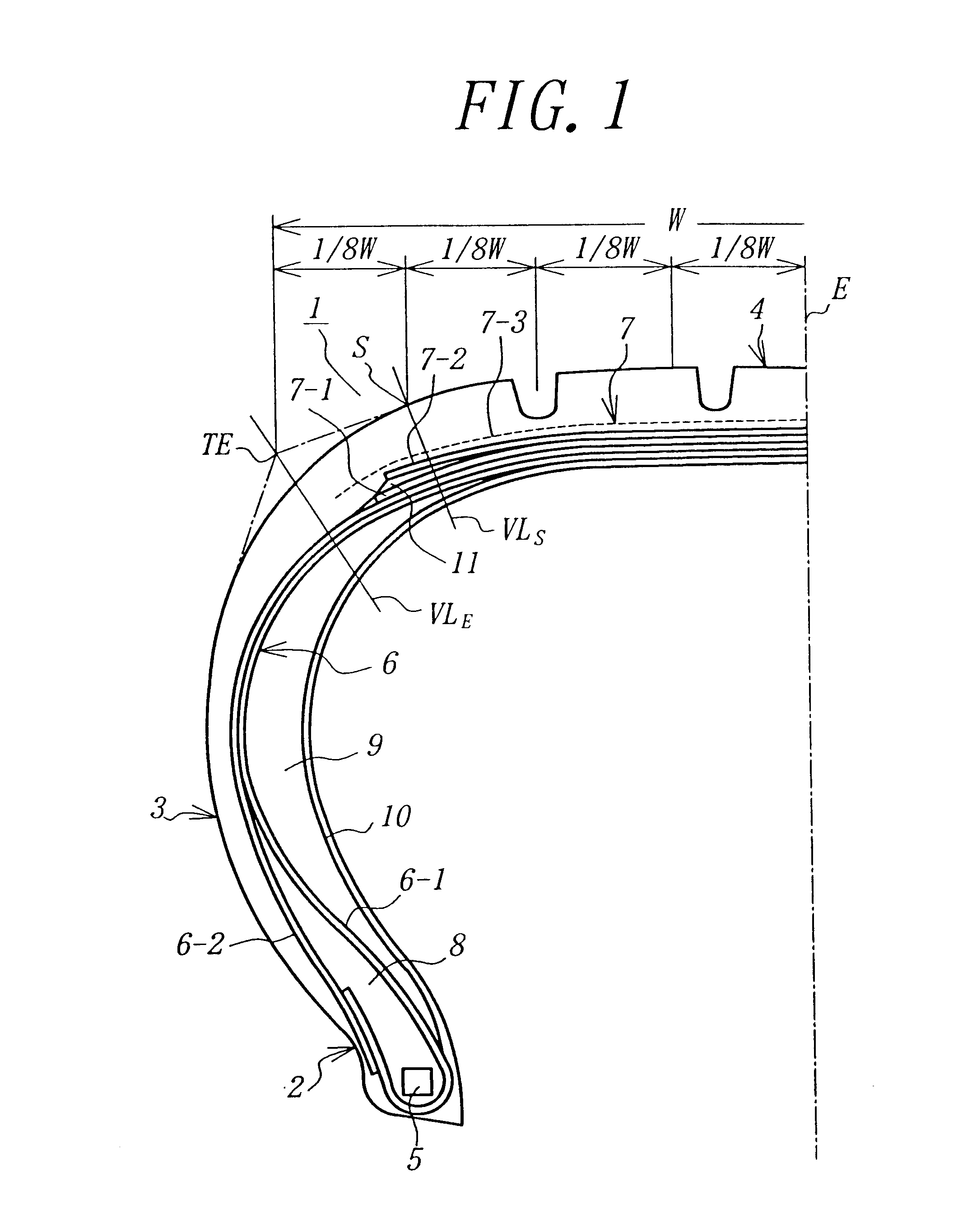

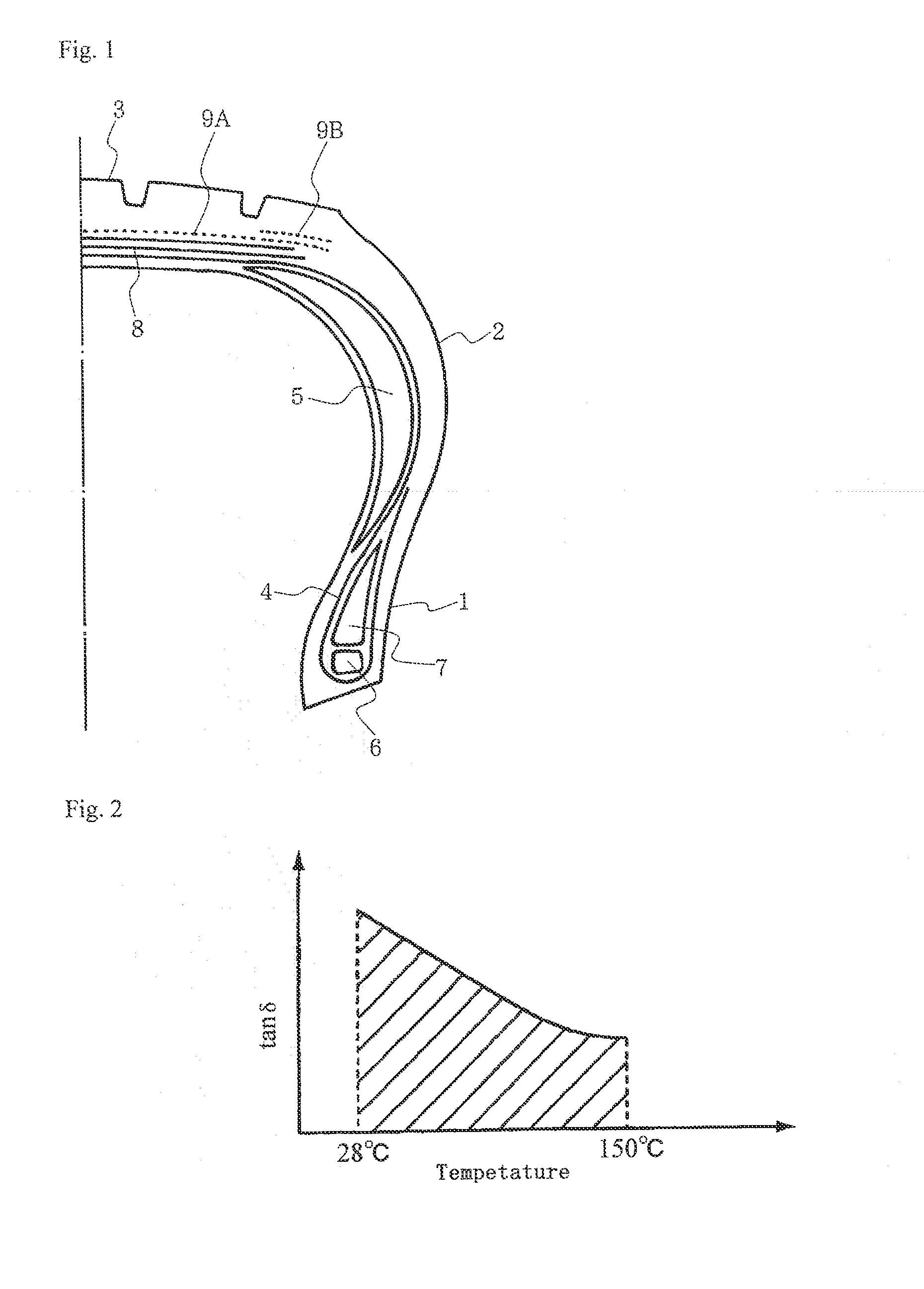

Run flat pneumatic tire with shoulder cushion rubber layer loss tangent less than carcass coating rubber loss tangent

InactiveUS6619354B1Excessive vibrationImprove vibrationSpecial tyresPneumatic tyre reinforcementsShoulder regionEngineering

There is provided a pneumatic tire having an aspect ratio of not less than 60 and considerably improving run flat durability as compared with the conventional type of the run flat tire, wherein at least one cushion rubber layer having a loss tangent lower than a loss tangent (tan delta) of a coating rubber for cords of a carcass ply is arranged between an end portion of a belt and a reinforcing rubber layer in a shoulder region and between mutually adjacent tire constitutional members. And also, when the carcass is comprised of plural plies, at least one ply is separated off in a zone beneath the belt, whereby the ride comfort against vibrations can be more improved.

Owner:BRIDGESTONE CORP

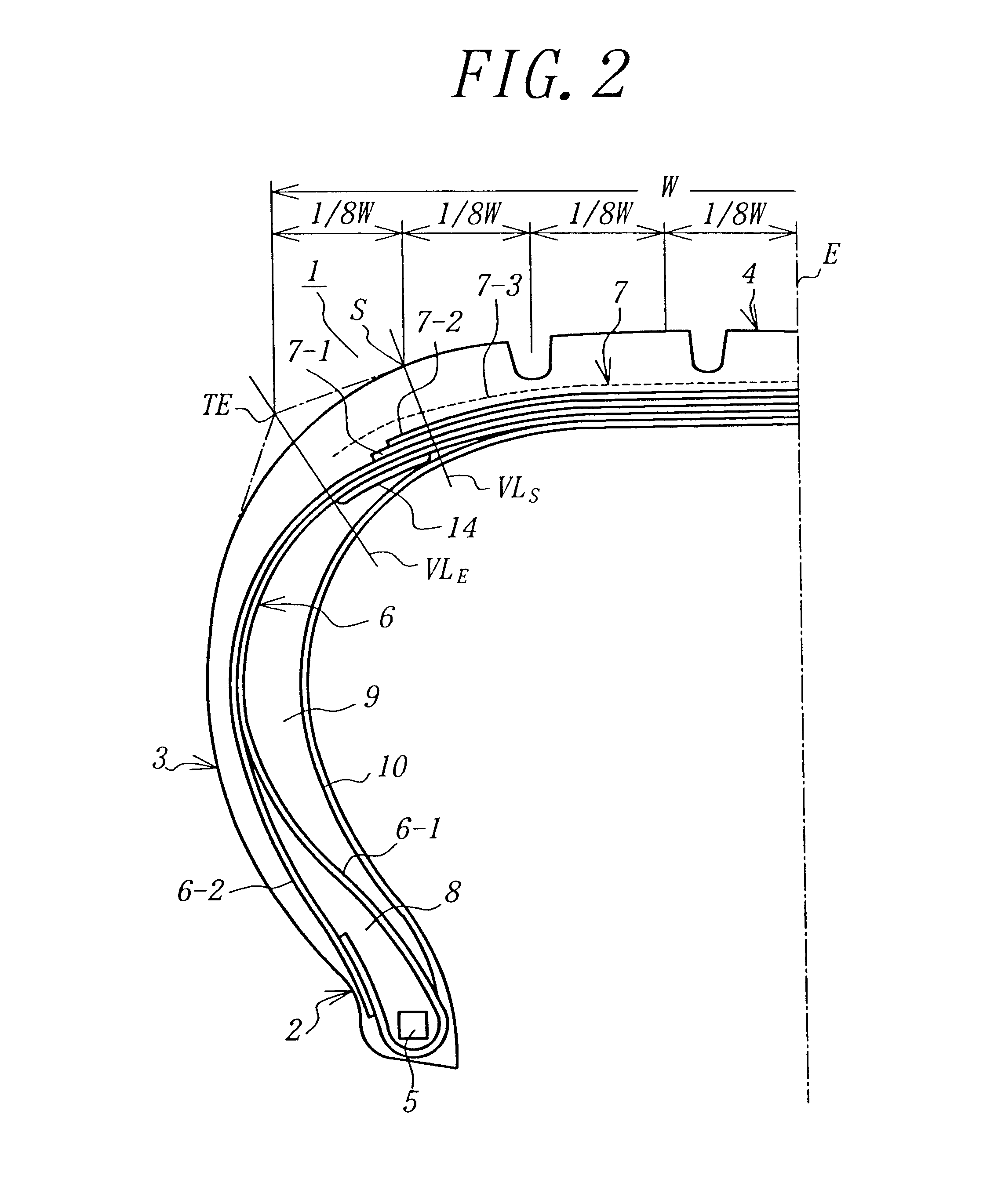

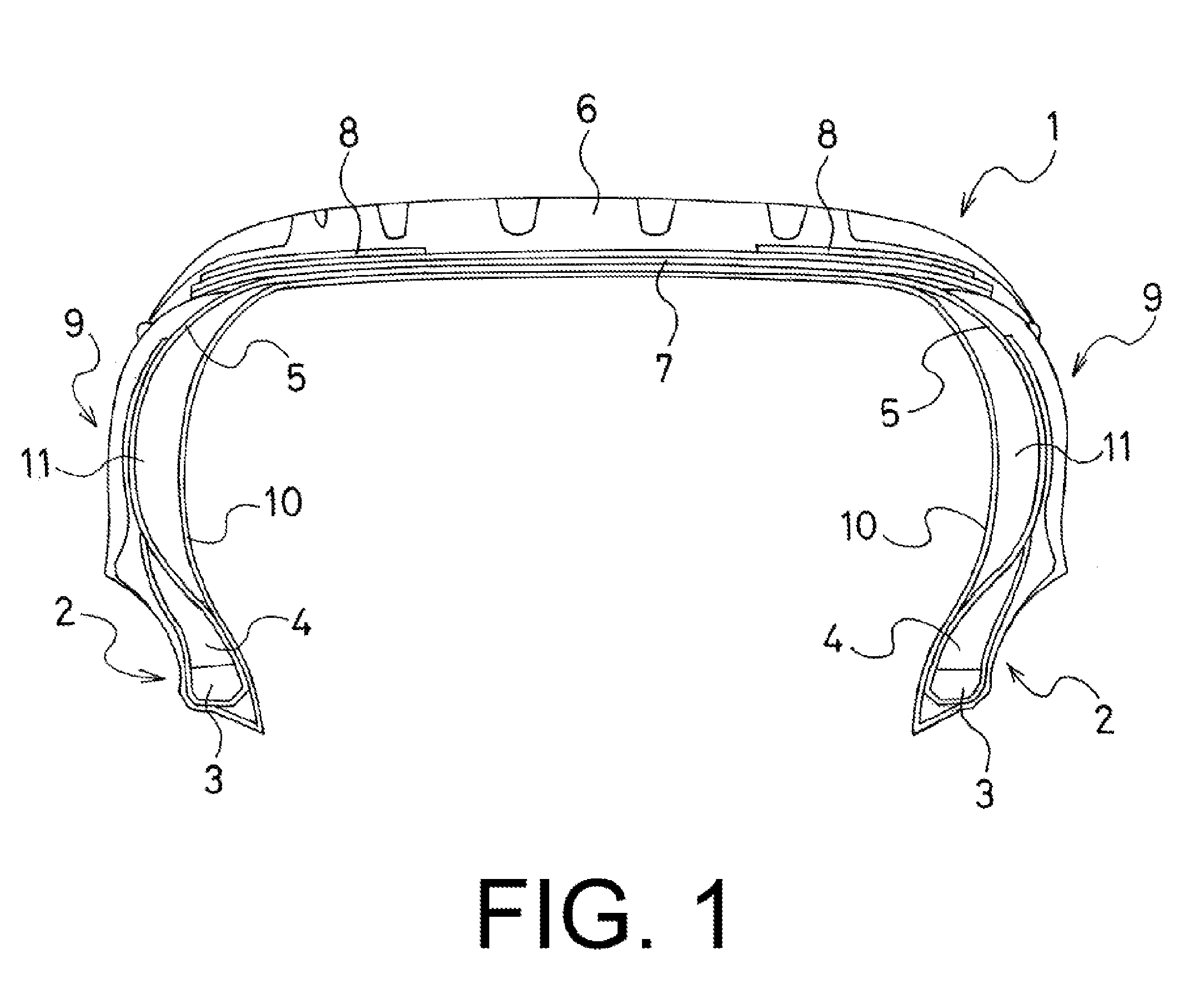

Run flat tire

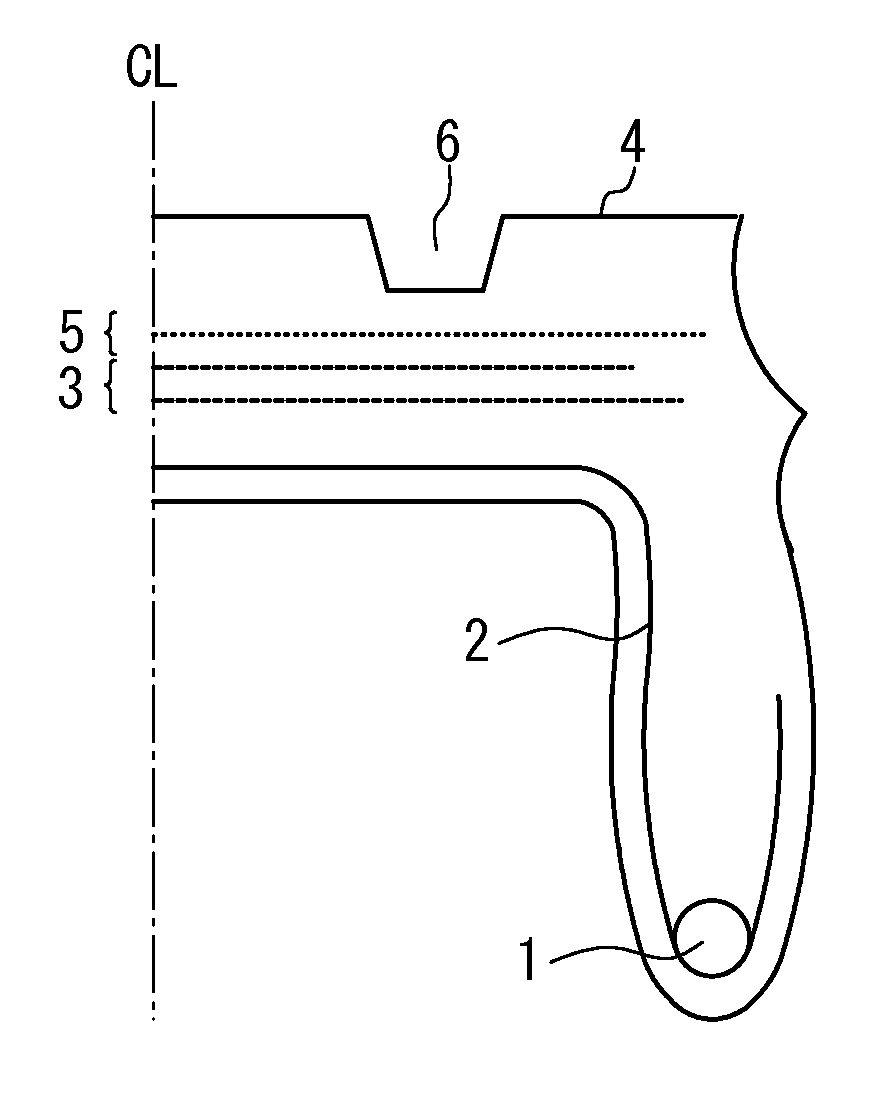

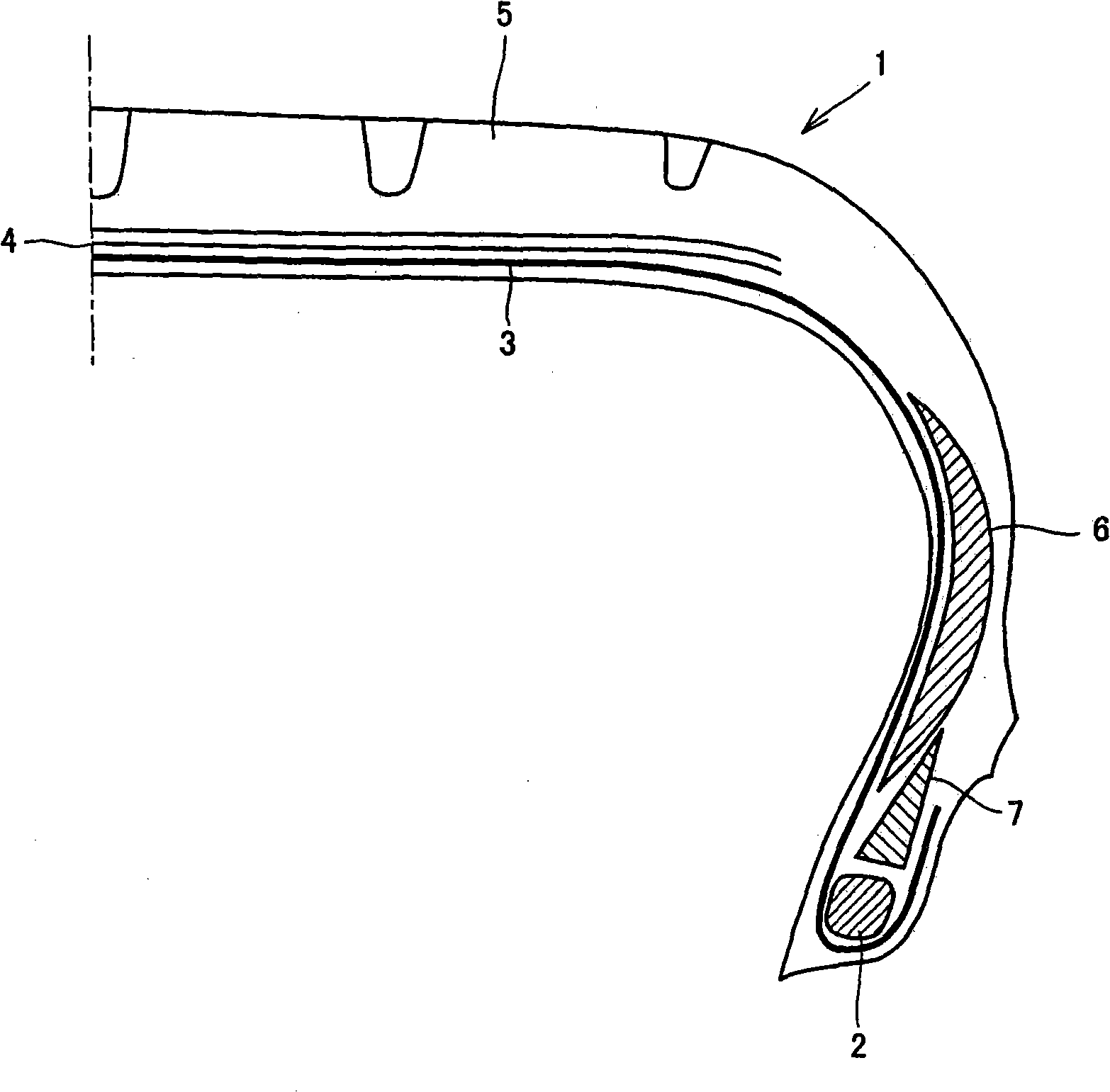

InactiveUS20120152425A1Suppressing vertical stiffnessImprove compatibilityPneumatic tyre reinforcementsYarnCellulose fiberReinforced rubber

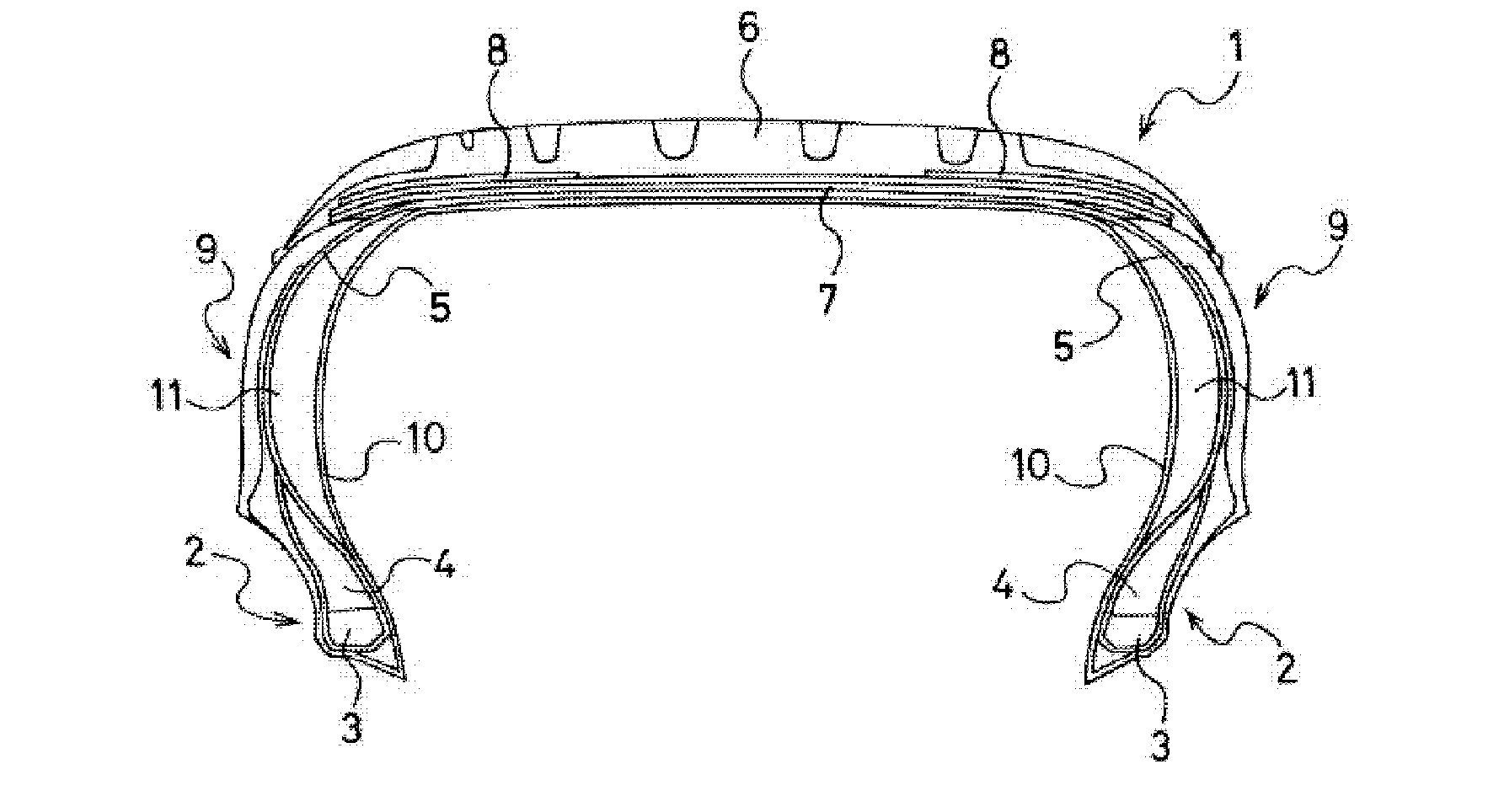

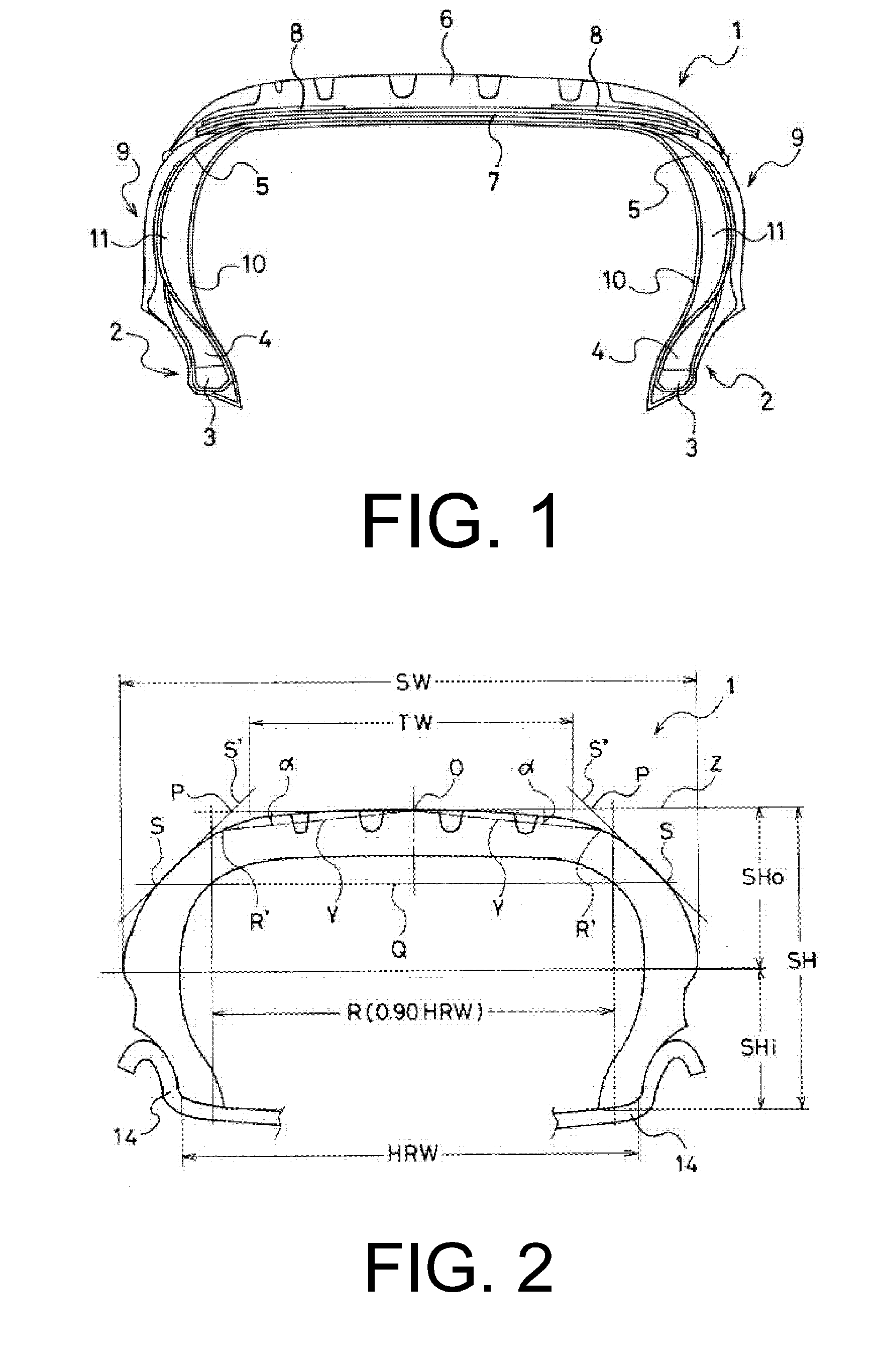

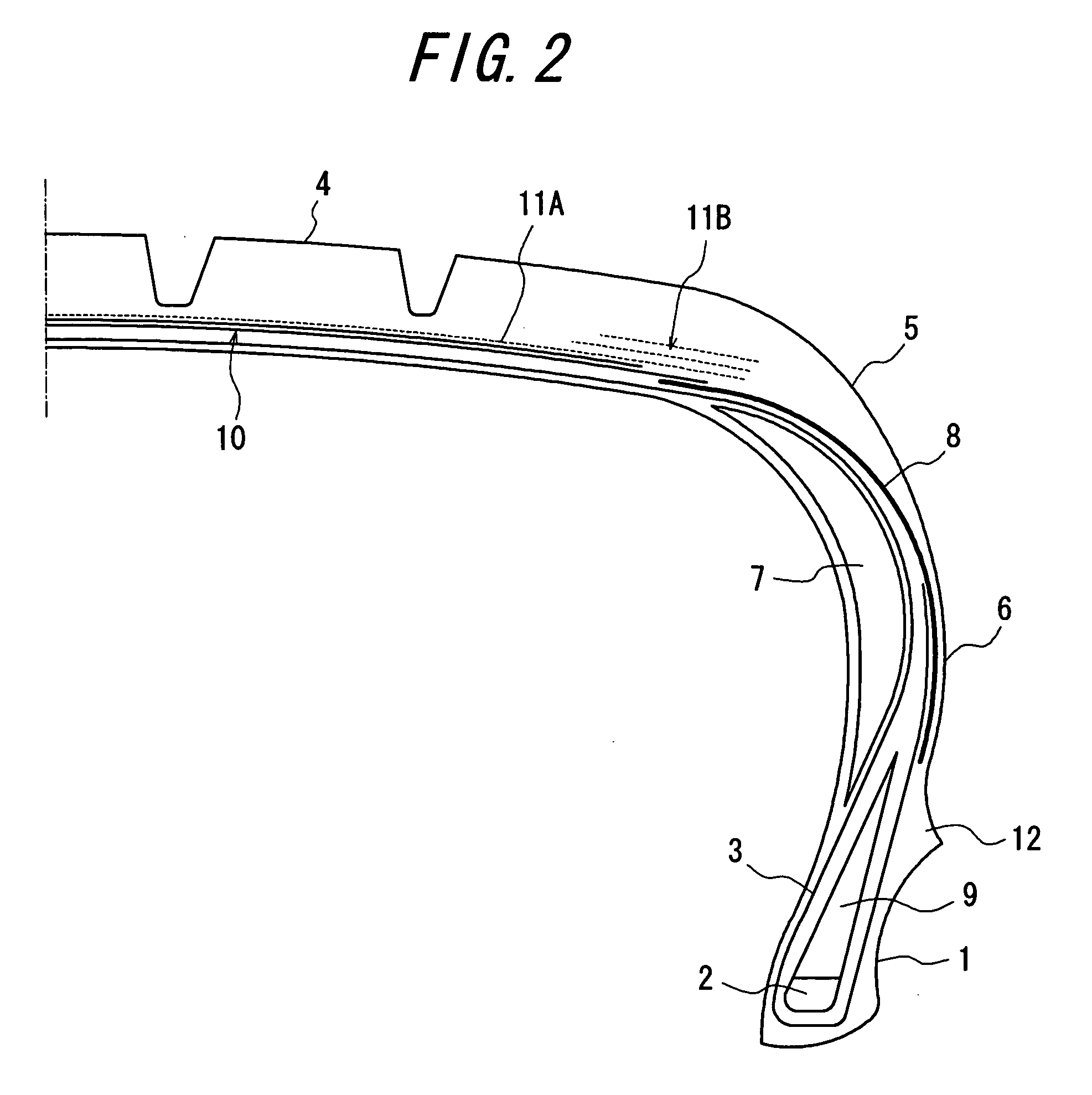

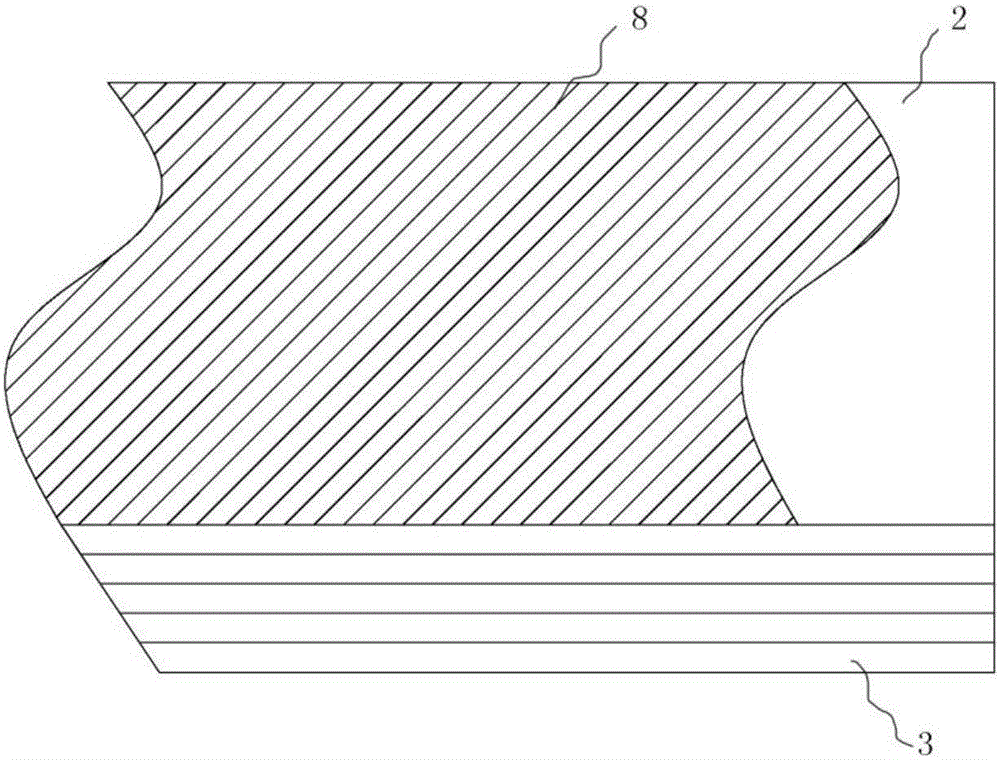

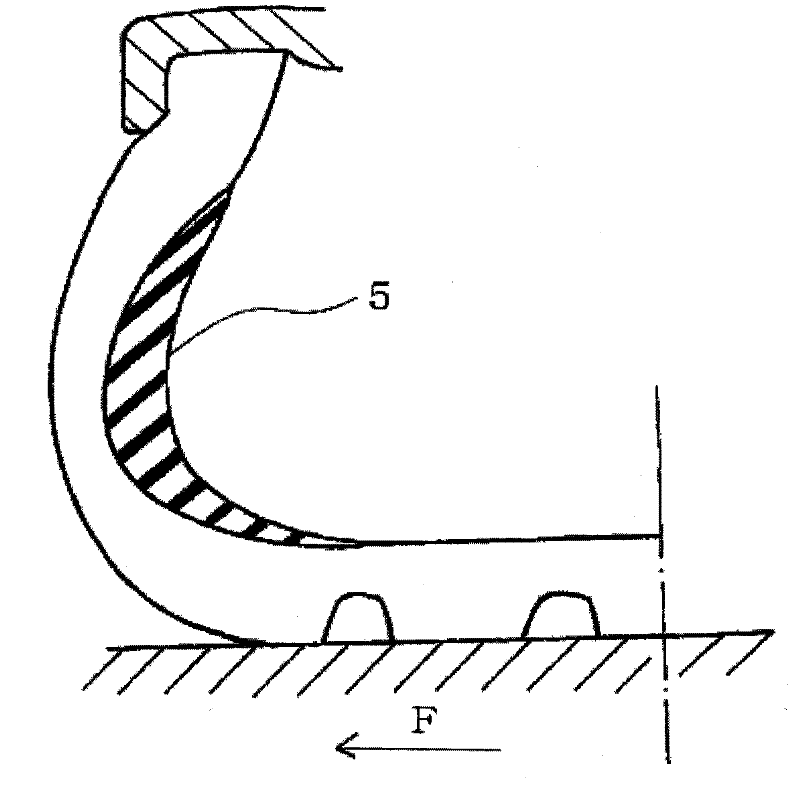

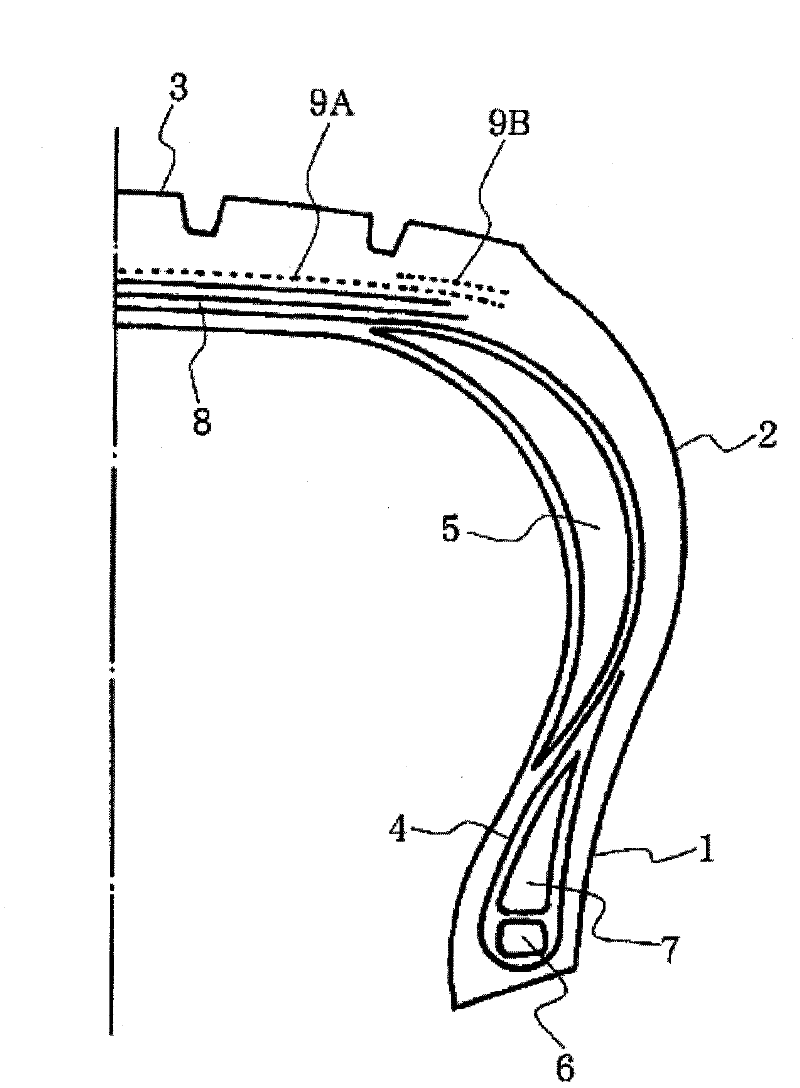

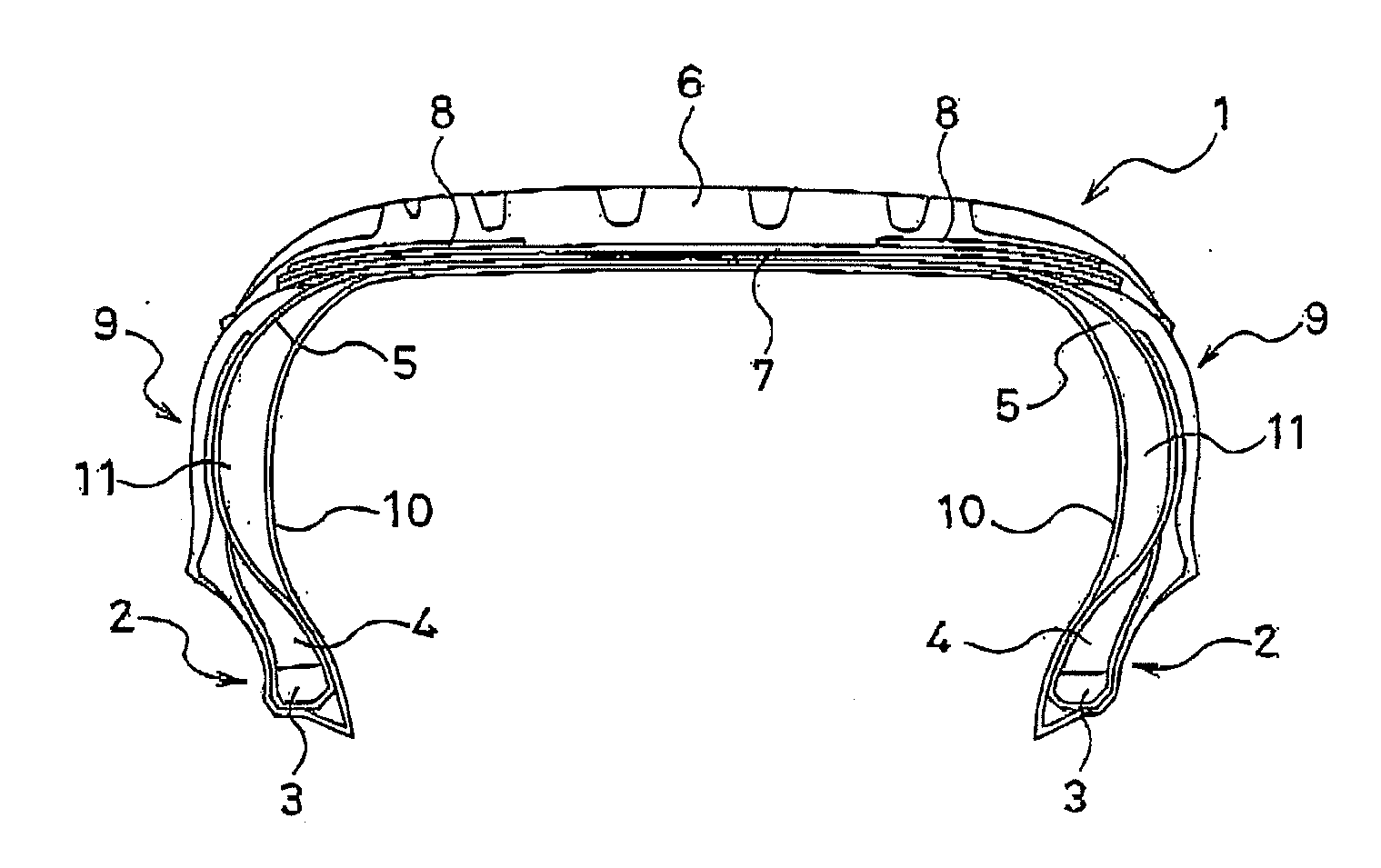

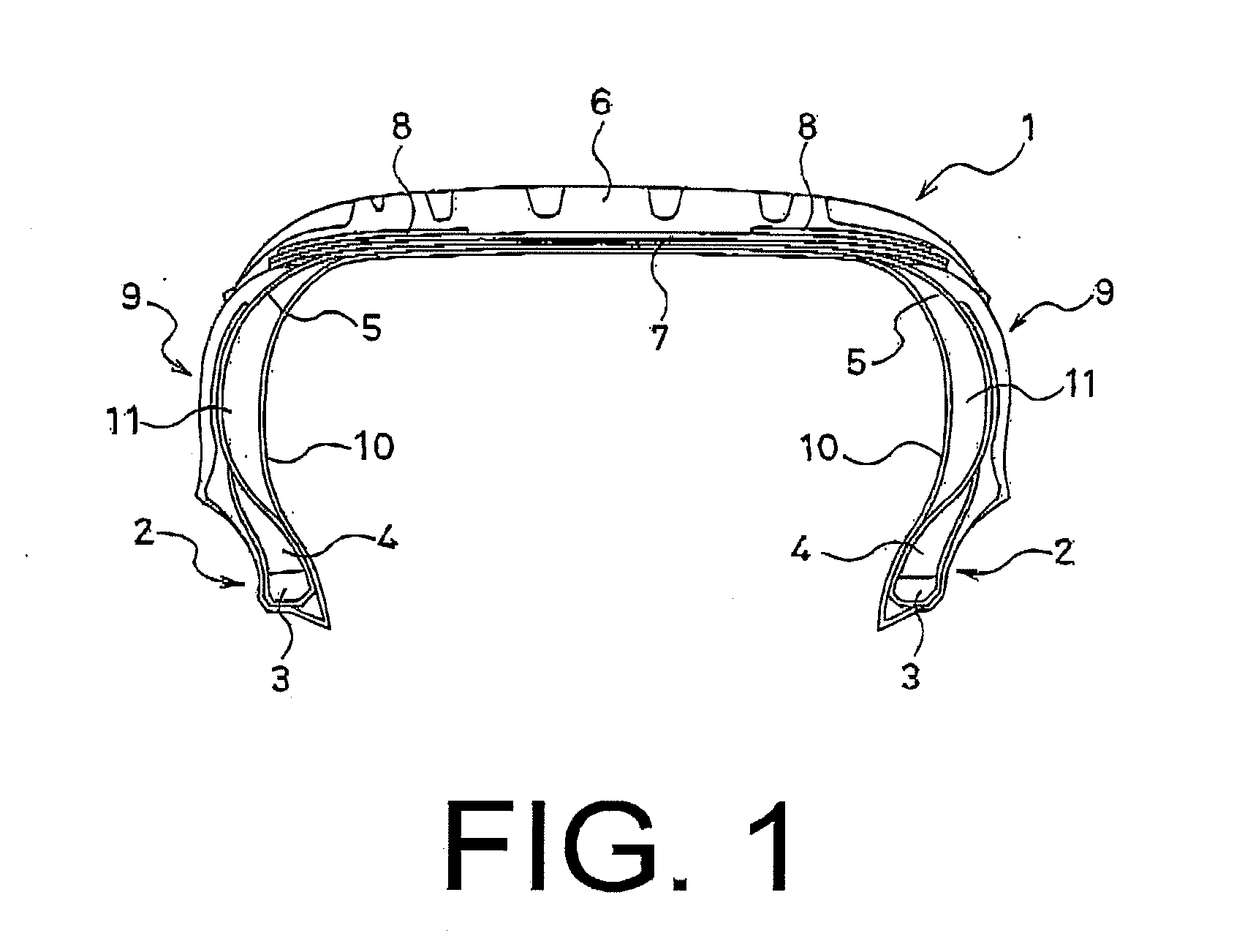

Provided is a run-flat tire in which a higher compatibility between the riding comfort and the run-flat travel durability during normal travelling can be attained.Provided is a run-flat tire comprising a bead portion 1, a side wall portion 2, a tread portion 3, a carcass 4 composed of one or more carcass plies extending toroidally between the pair of bead portions to reinforce these portions, and a side reinforcing rubber layer 5 having a crescent cross-sectional shape arranged on the inside of the carcass at the side wall portion.The carcass ply cord is a hybrid cord formed by twisting a filament composed of cellulose fibers and a filament composed of nylon, the thermal shrinkage stress (cN / dtex) of the hybrid cord at 177° C. after an adhesive treatment is not less than 0.20 cN / dtex, and the thermal shrinkage stress (cN / dtex) of the hybrid cord at 177° C. drawn from a tire product is not less than 0.10 cN / dtex.

Owner:BRIDGESTONE CORP

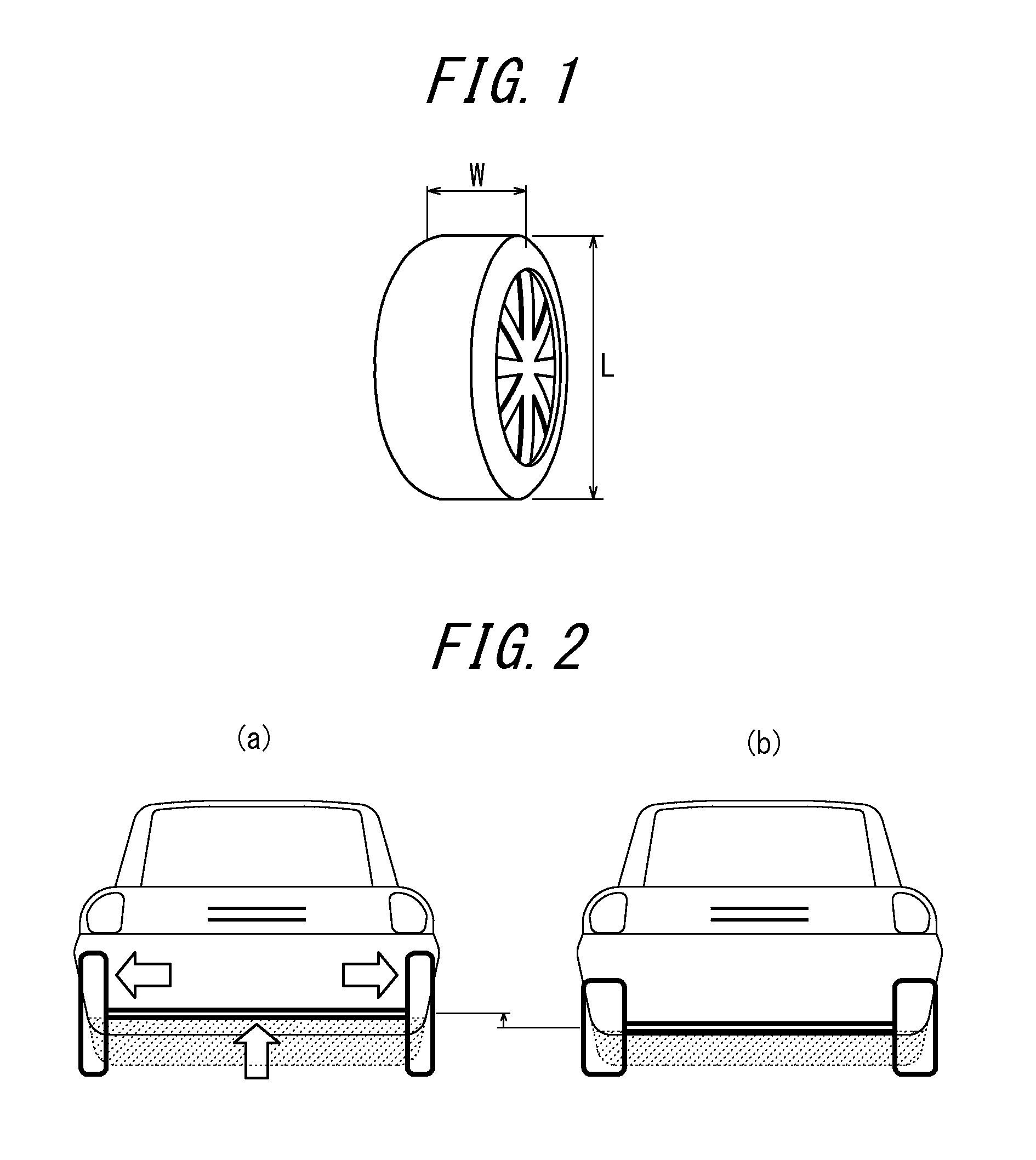

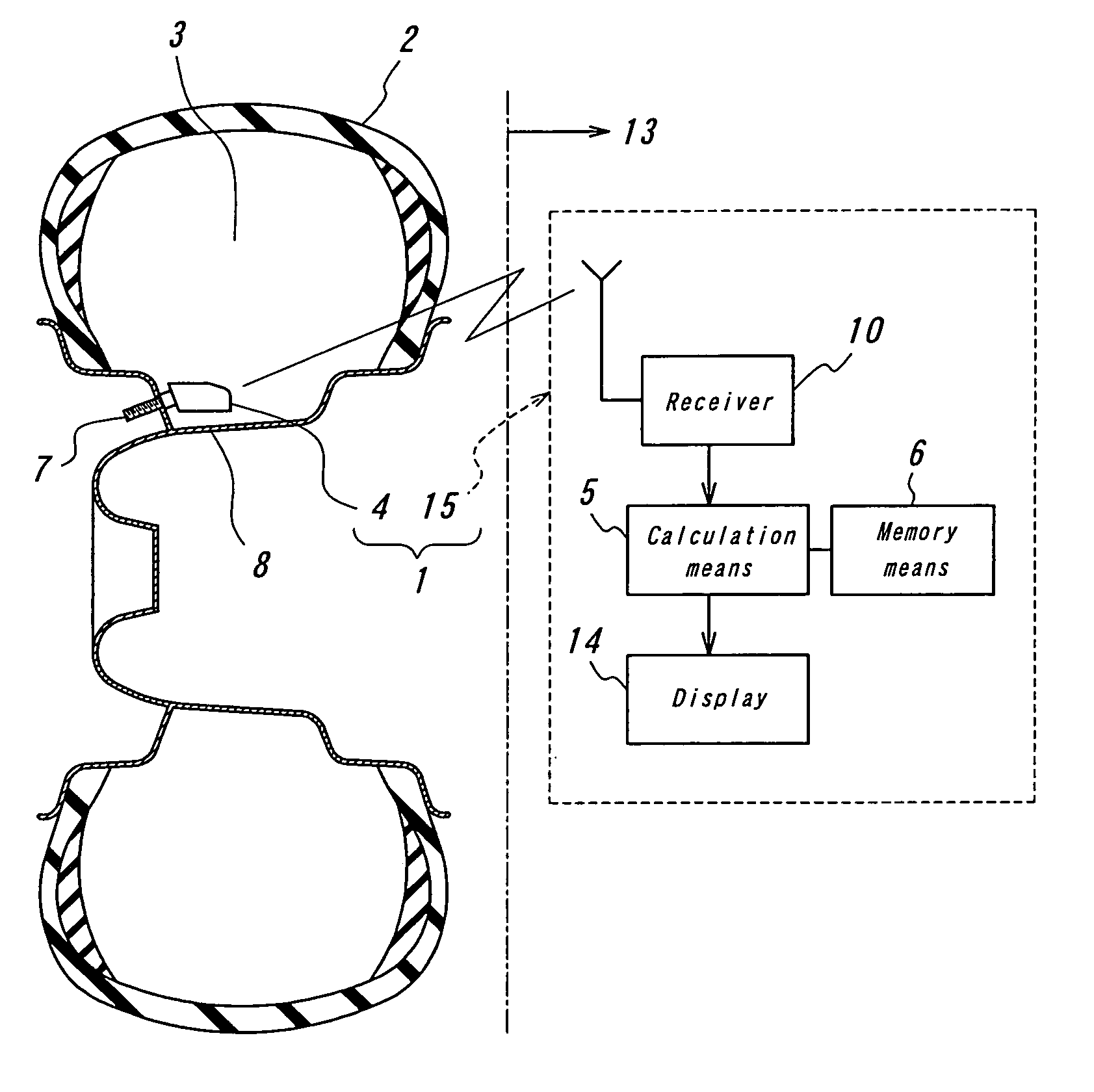

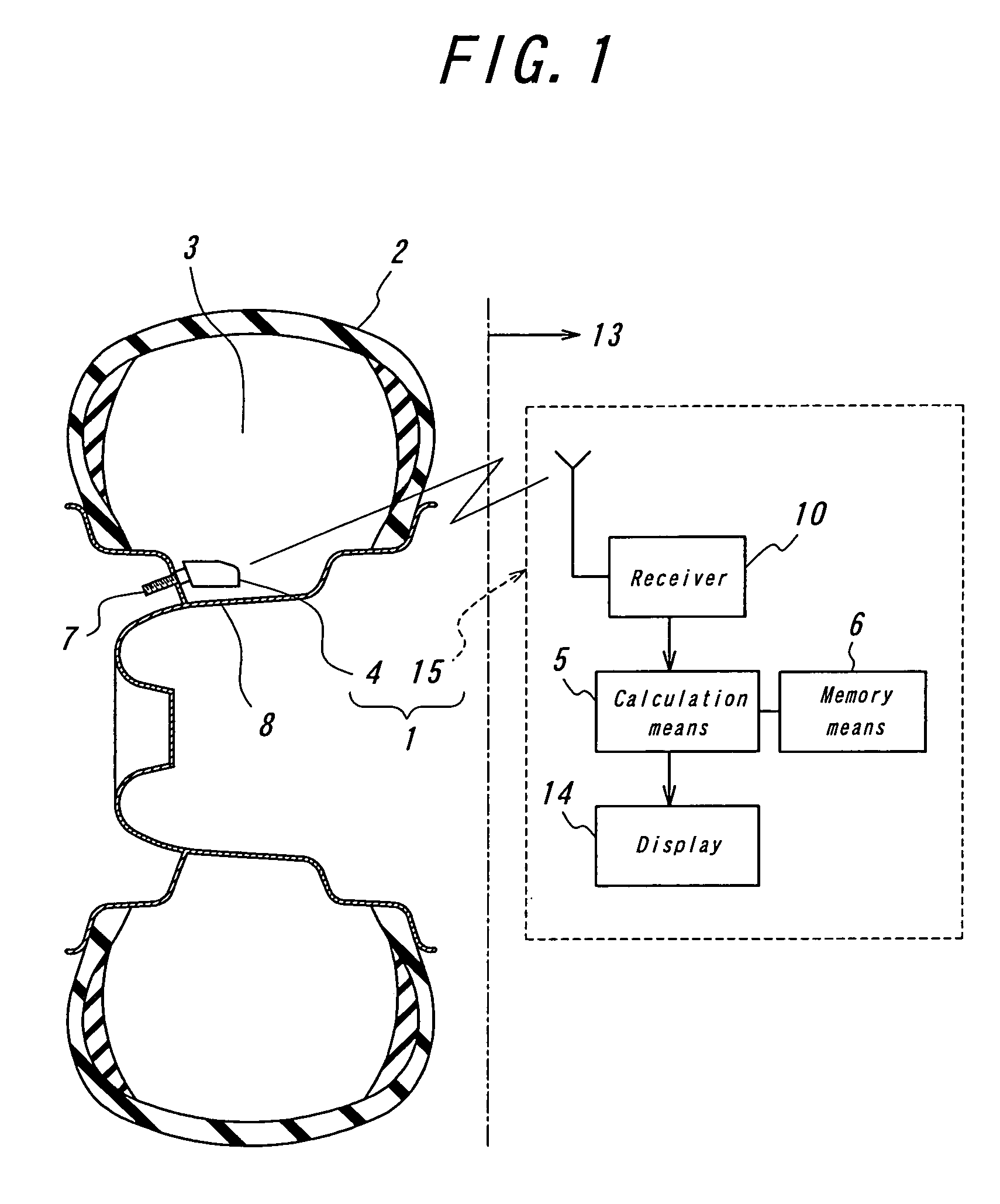

Method device and recording medium where program is recorded, for deciding residual travel life and end of life of run-flat tire that continues traveling in run-flat condition

InactiveUS20060093015A1Improve relationshipConvenient ArrangementThermometer detailsWeather/light/corrosion resistanceInternal pressureEnd stages

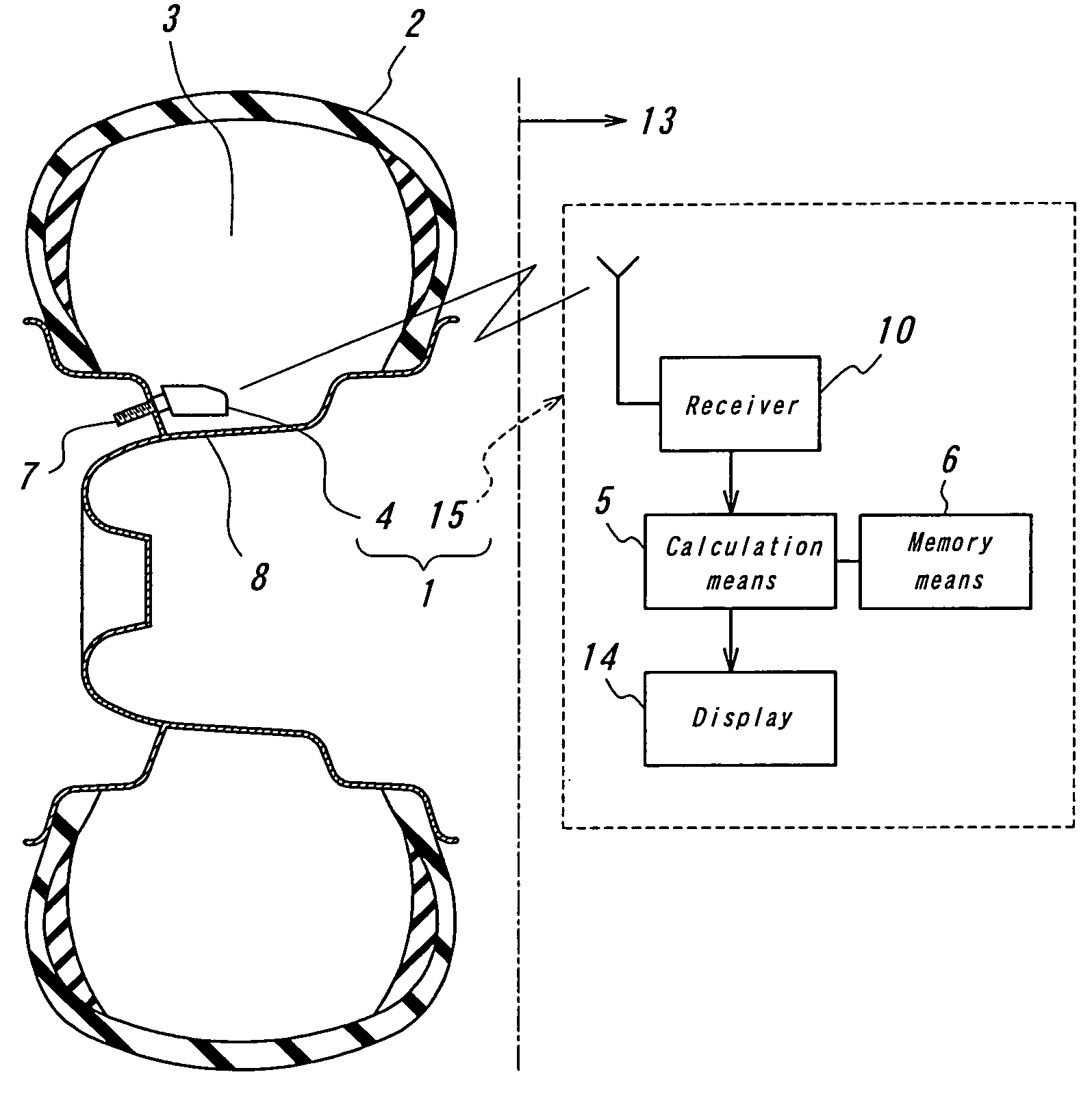

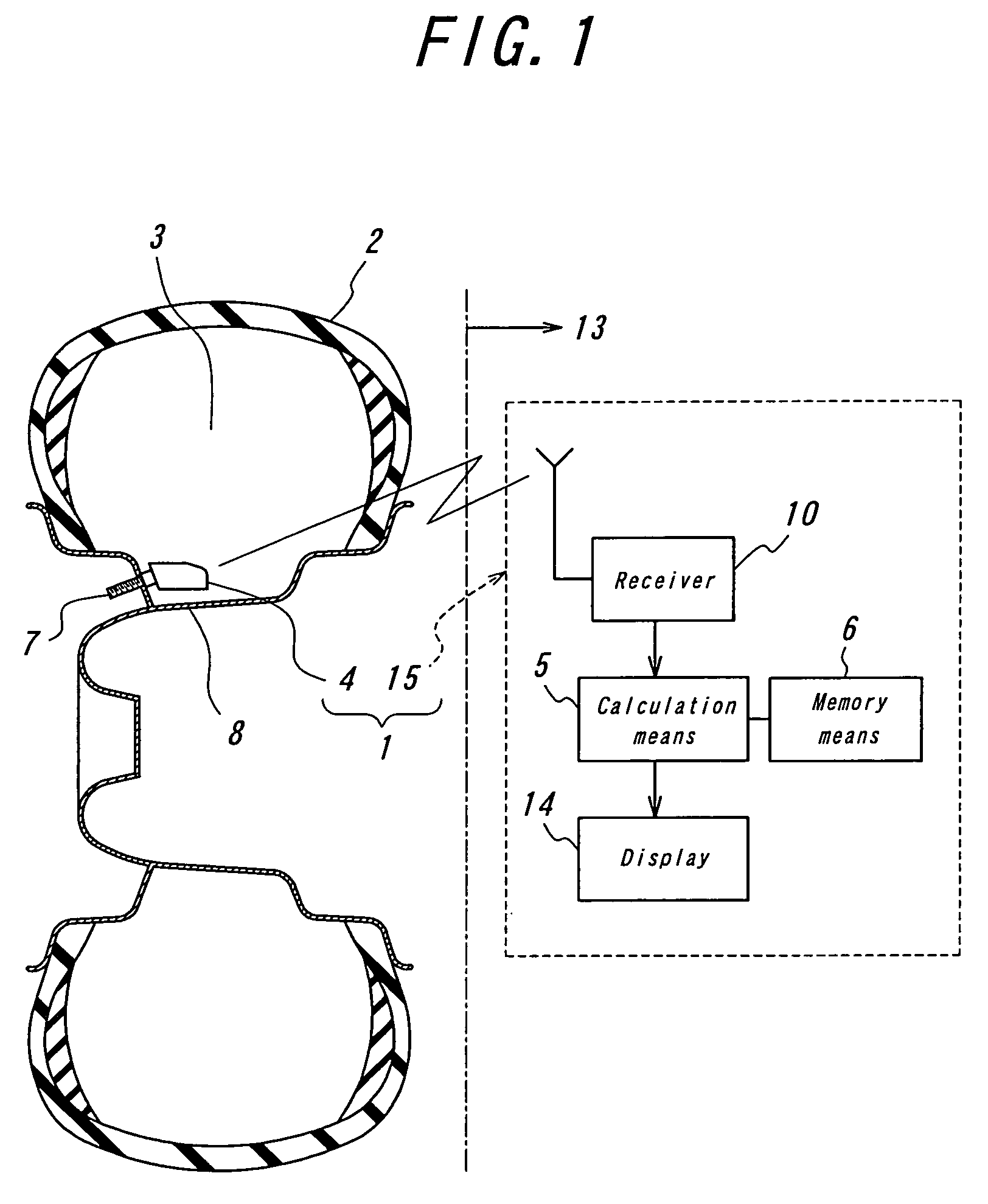

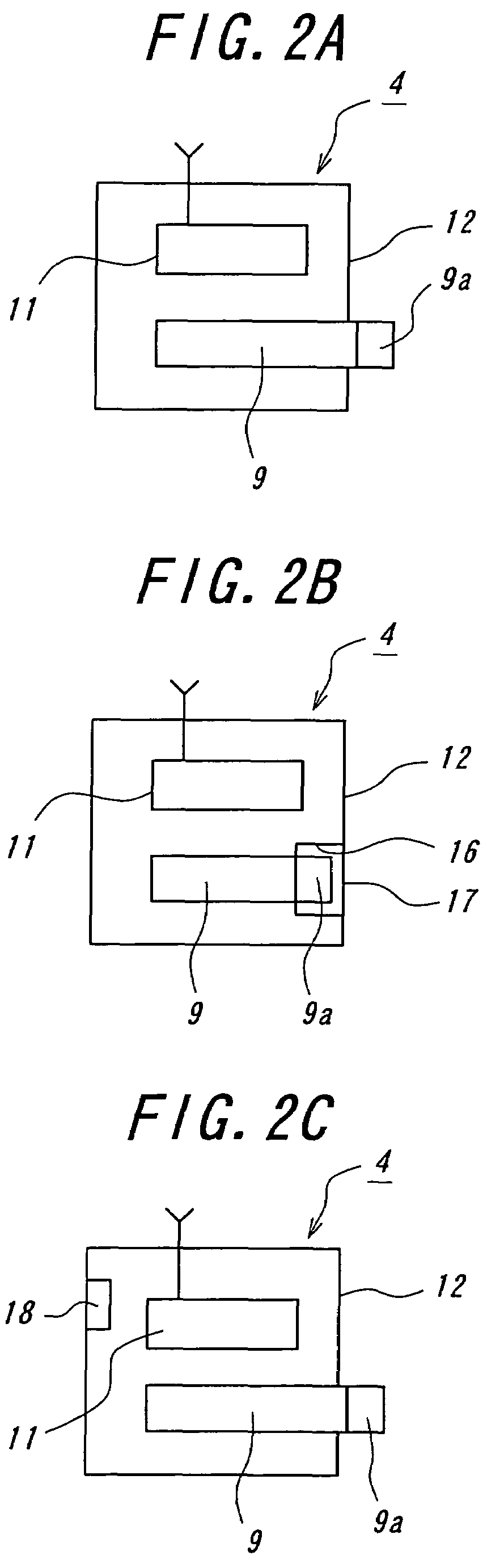

There are provided a process and the like for judging a residual lifetime of a run-flat tire and an end stage of the residual lifetime thereof during continuous running at a run-flat state. The process for judging the residual lifetime of the tire of the invention is characterized in that in a vehicle equipped with a run-flat tire system comprising run-flat tires 2 and detection units 4 each arranged in the respective tire 2 and capable of measuring an atmosphere temperature in at least an interior 3 of the tire 2, when the tire 2 is continuously run at the run-flat state by an extreme lowering of an internal pressure accompanied with the occurrence of puncture or the like, after a limit temperature being statistically an occurrence of trouble is previously set, the atmosphere temperature inside tire of the run-flat tire continuously running at the run-flat state is measured, and a runnable time and / or distance until the run-flat tire results in trouble is predicted by using the atmosphere temperature inside tire measured and data calculated therefrom.

Owner:BRIDGESTONE CORP

Self-supporting pneumatic tire

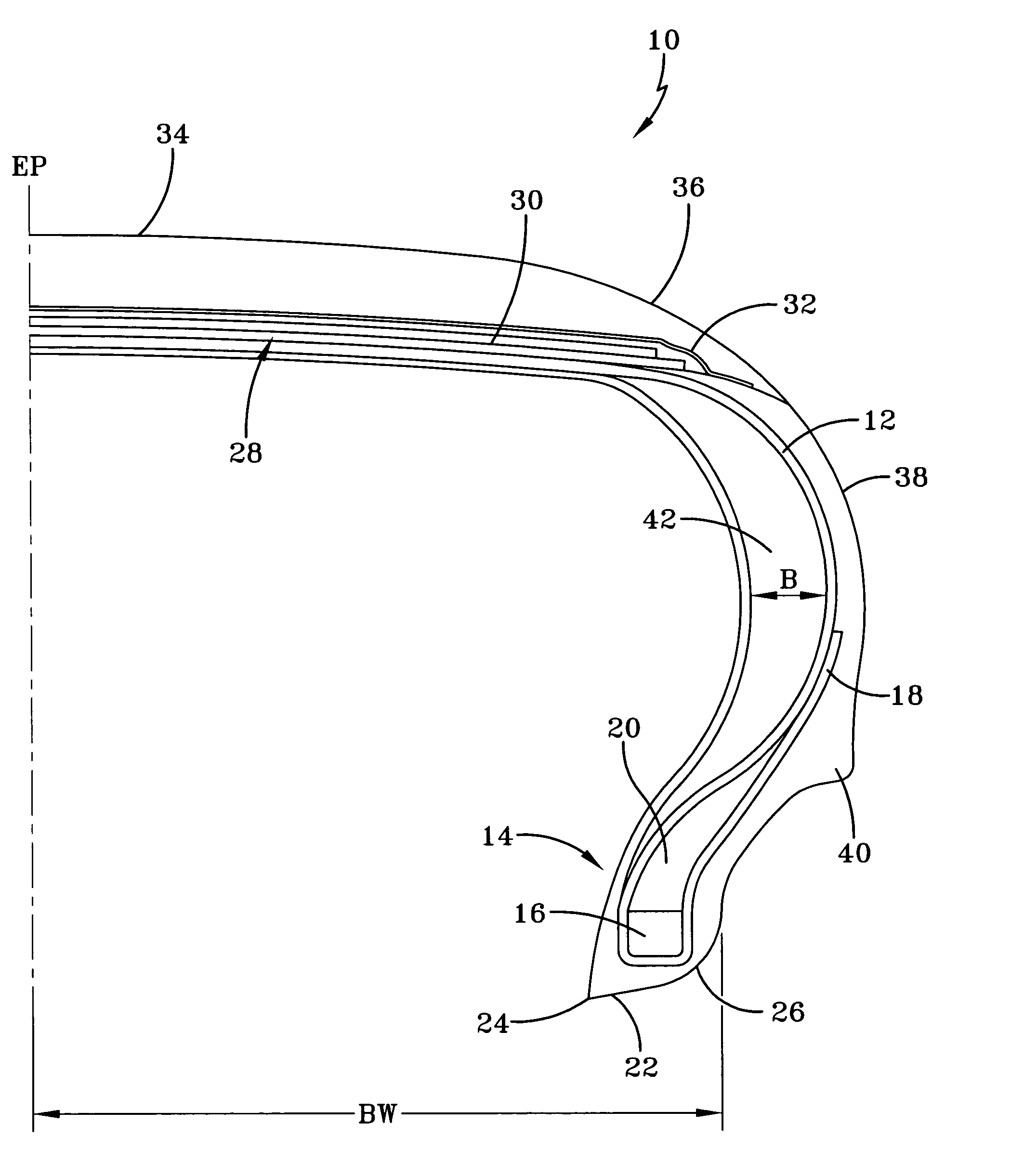

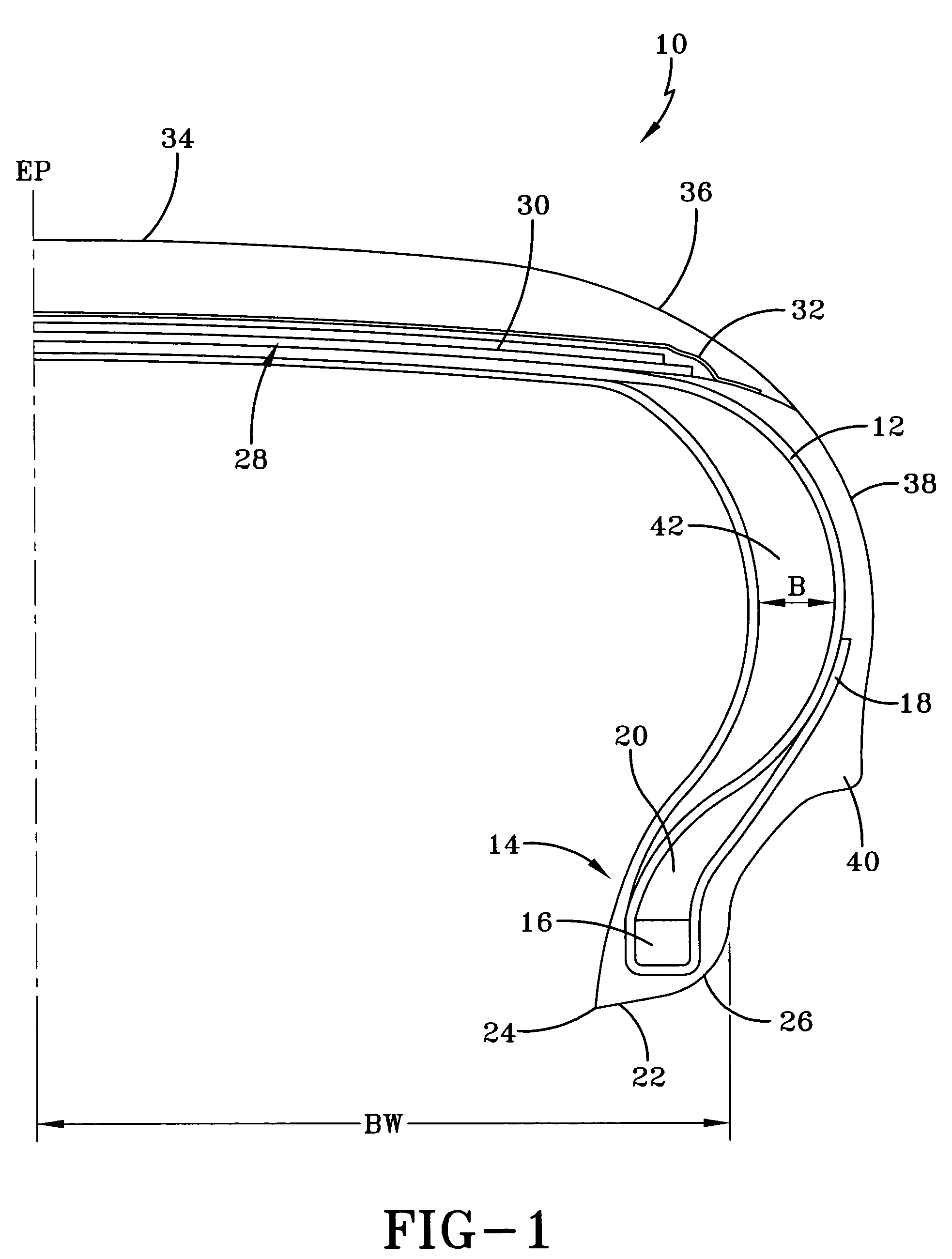

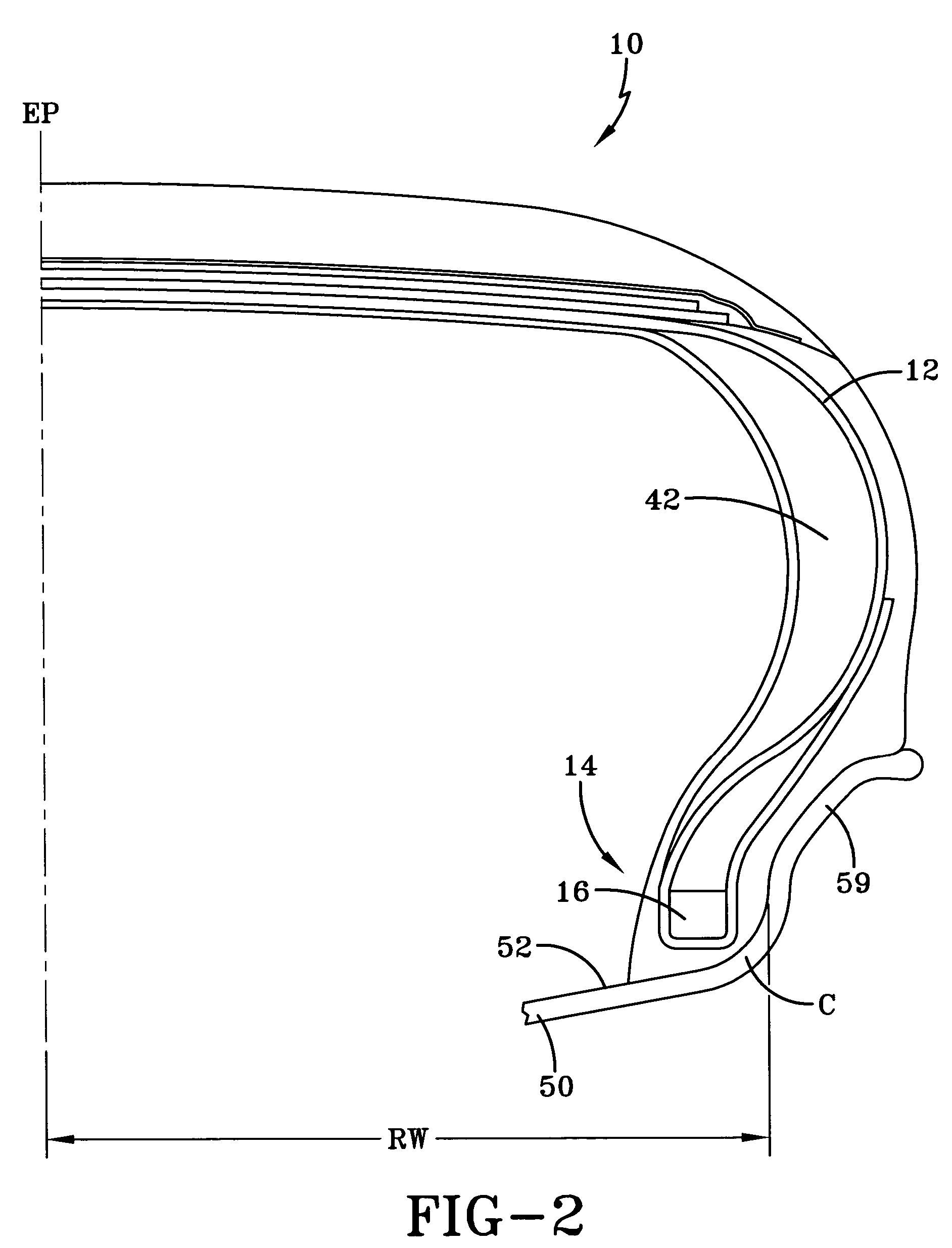

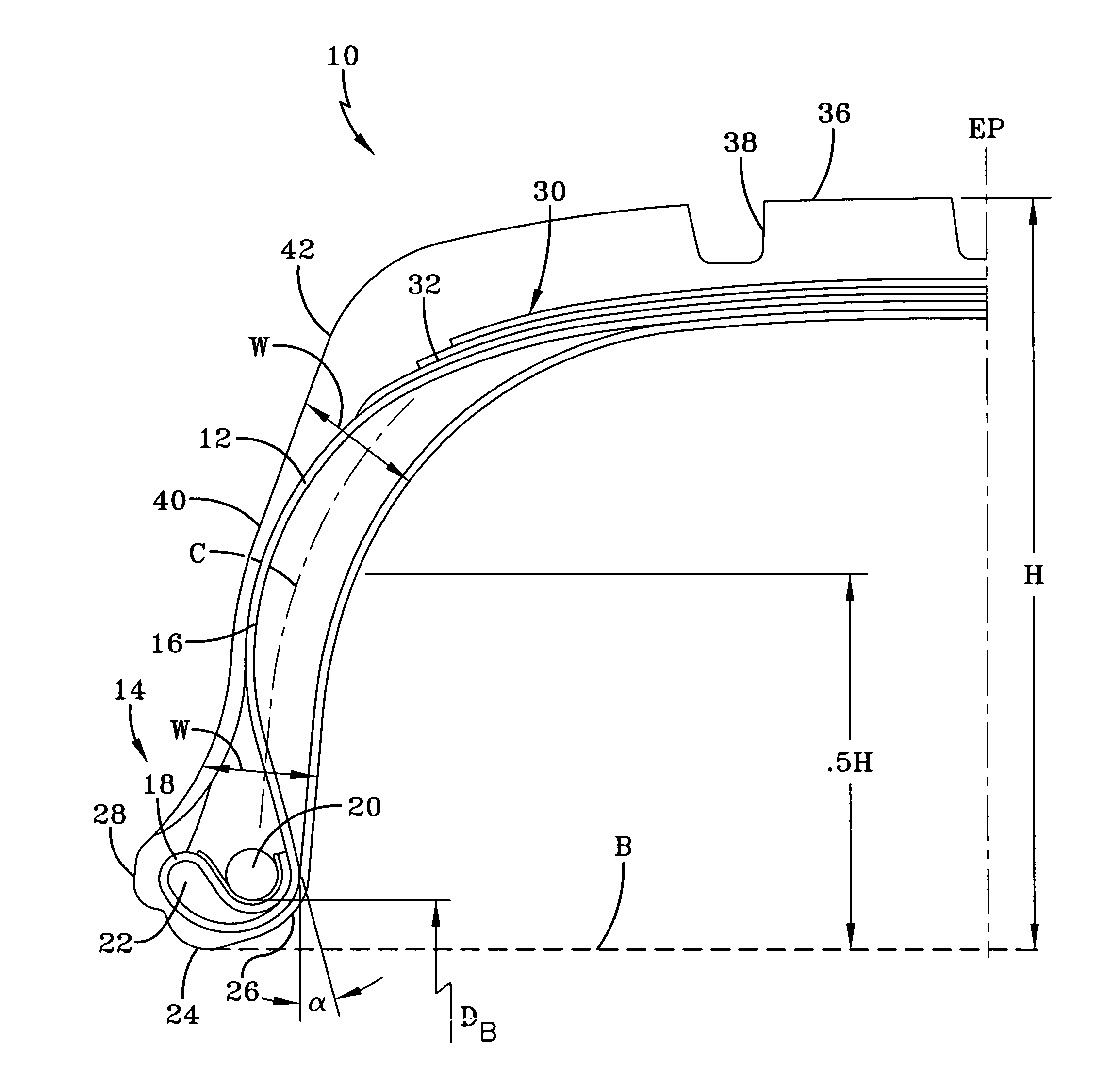

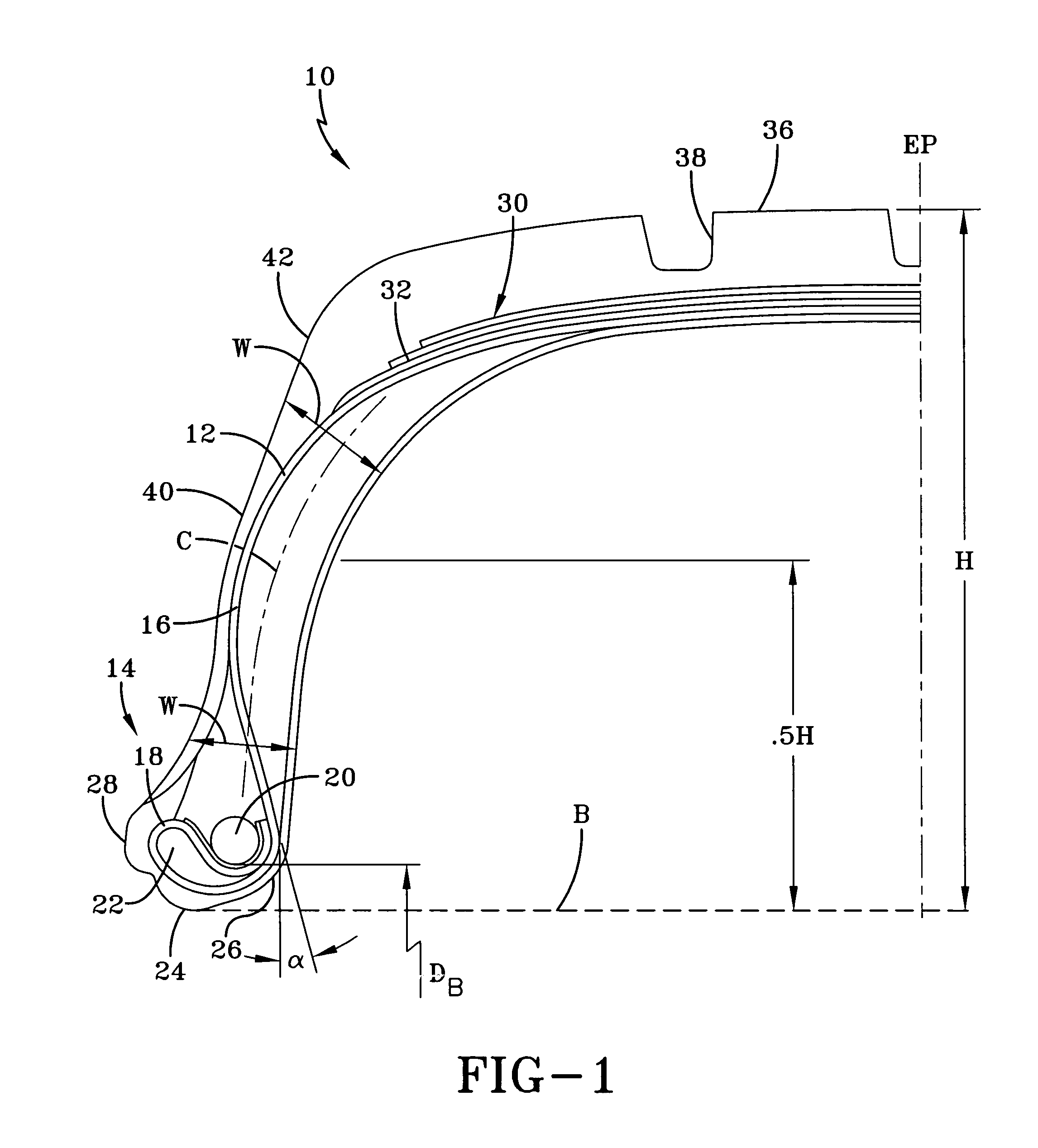

InactiveUS7093633B2Ride comfort is improvedIncreased durabilityWithout separate inflatable insertsRimsStrain energyEngineering

A self-supporting pneumatic tire is molded in such a manner that ride comfort is improved, durability is increased, and a greater run-flat capability can be achieved. The self-supporting run-flat tire is molded such that the molded bead base width is equal or less than the rim width of the intended rim upon which the tire is to be mounted. By molding the tire with a bead width less than or equal to the rim width, the sidewall inserts are not subjected to additional stress during and after inflation of the tire and the strain energy is more evenly distributed through the sidewall pillar construction.

Owner:THE GOODYEAR TIRE & RUBBER CO

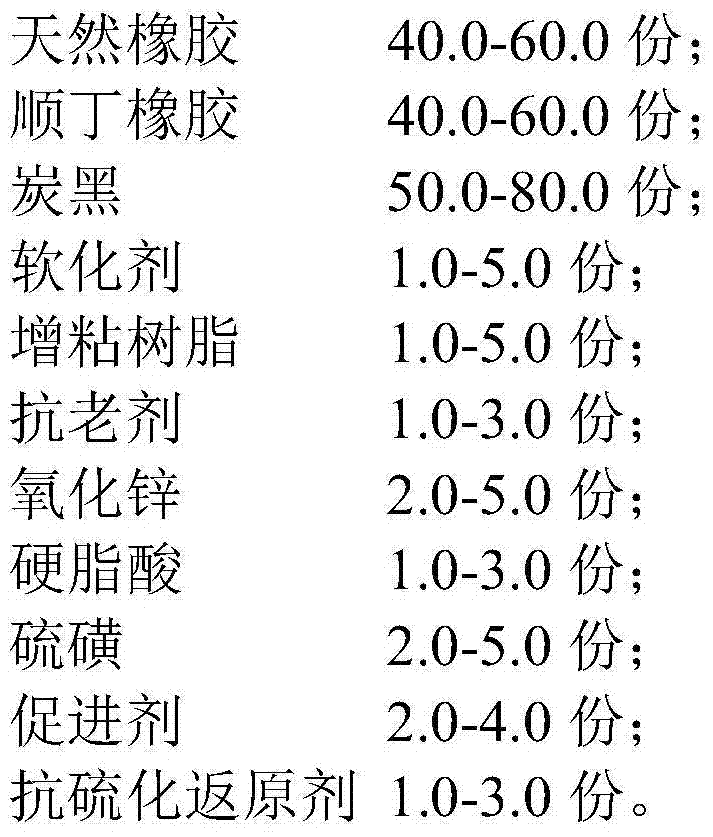

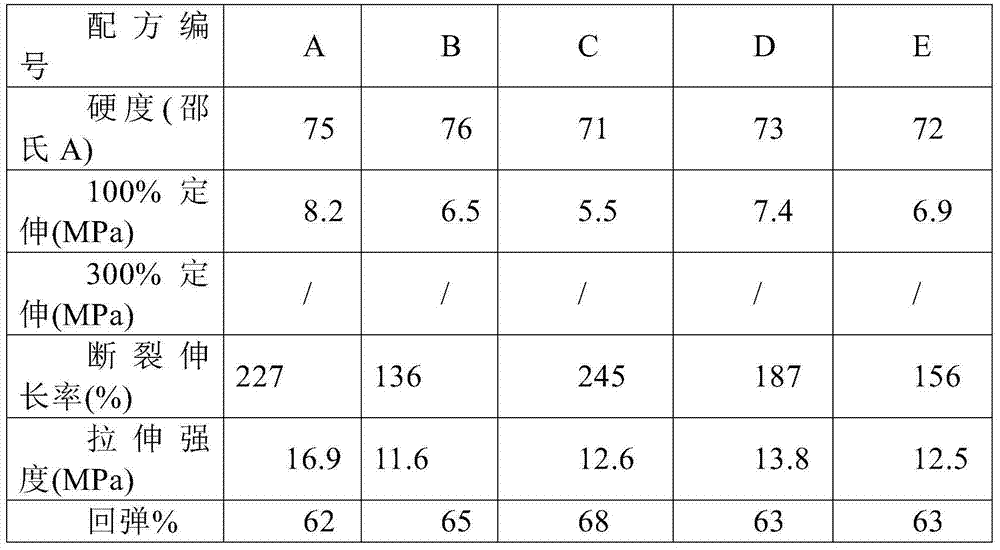

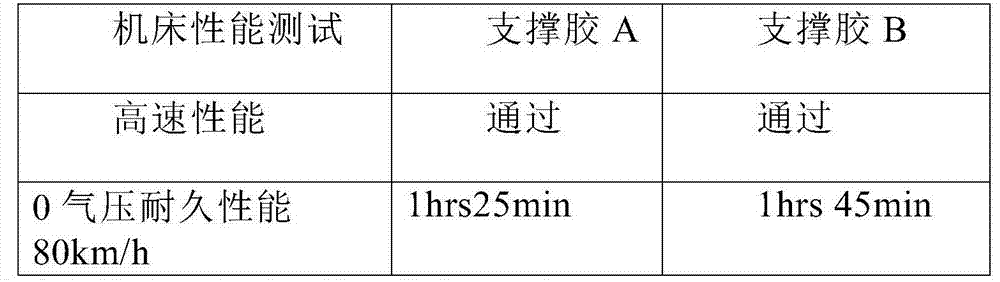

Rubber composition for run-flat tire sidewall part of car

Owner:特拓(青岛)轮胎技术有限公司

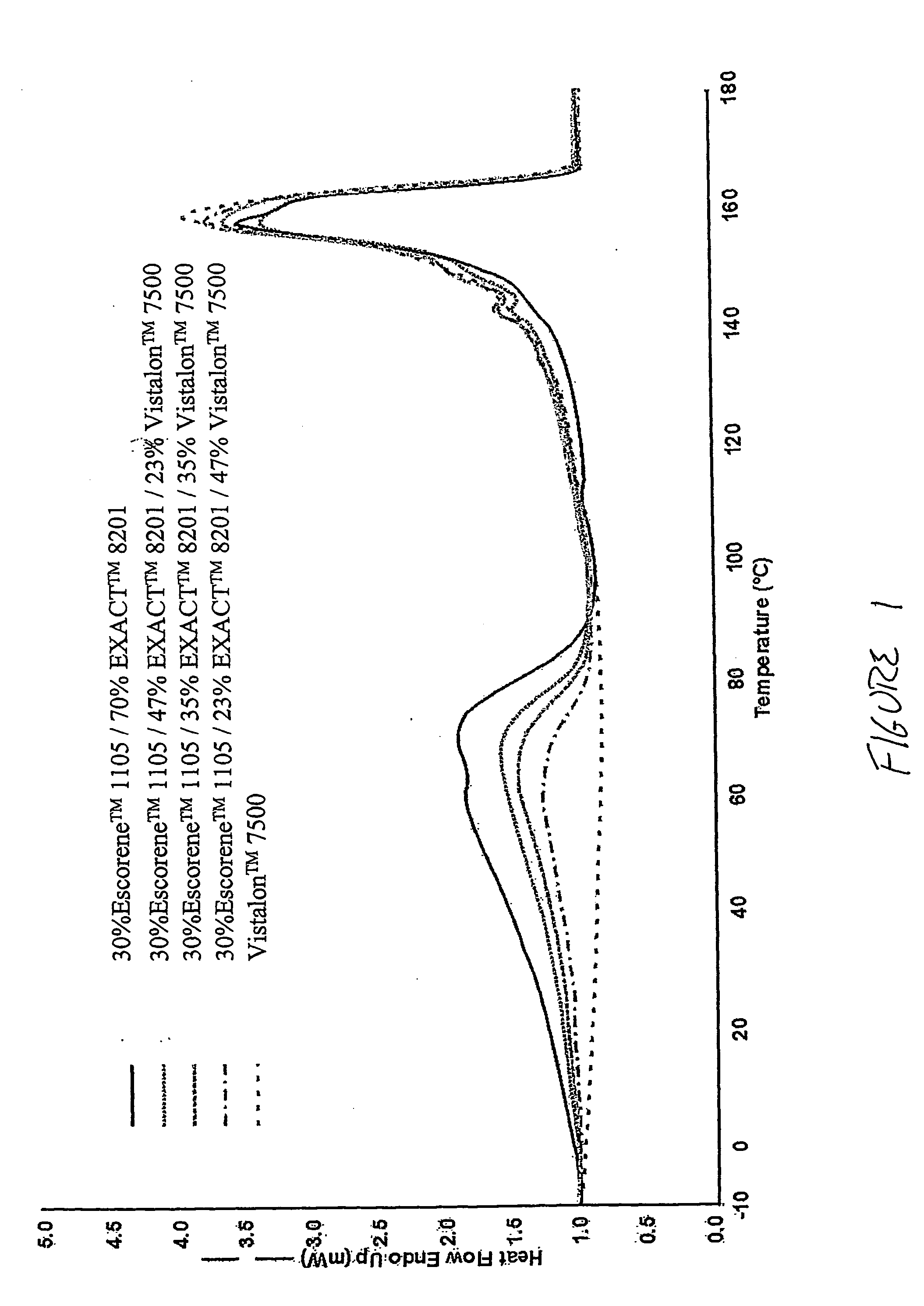

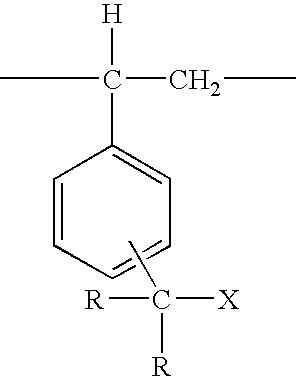

Thermoplastic vulcaninates for run-flat tires

This invention relates generally to run-flat tires. More specifically, this invention relates to compounds comprising thermoplastic vulcanizates that are suitable for use in run-flat tire inserts.

Owner:EXXONMOBIL CHEM PAT INC

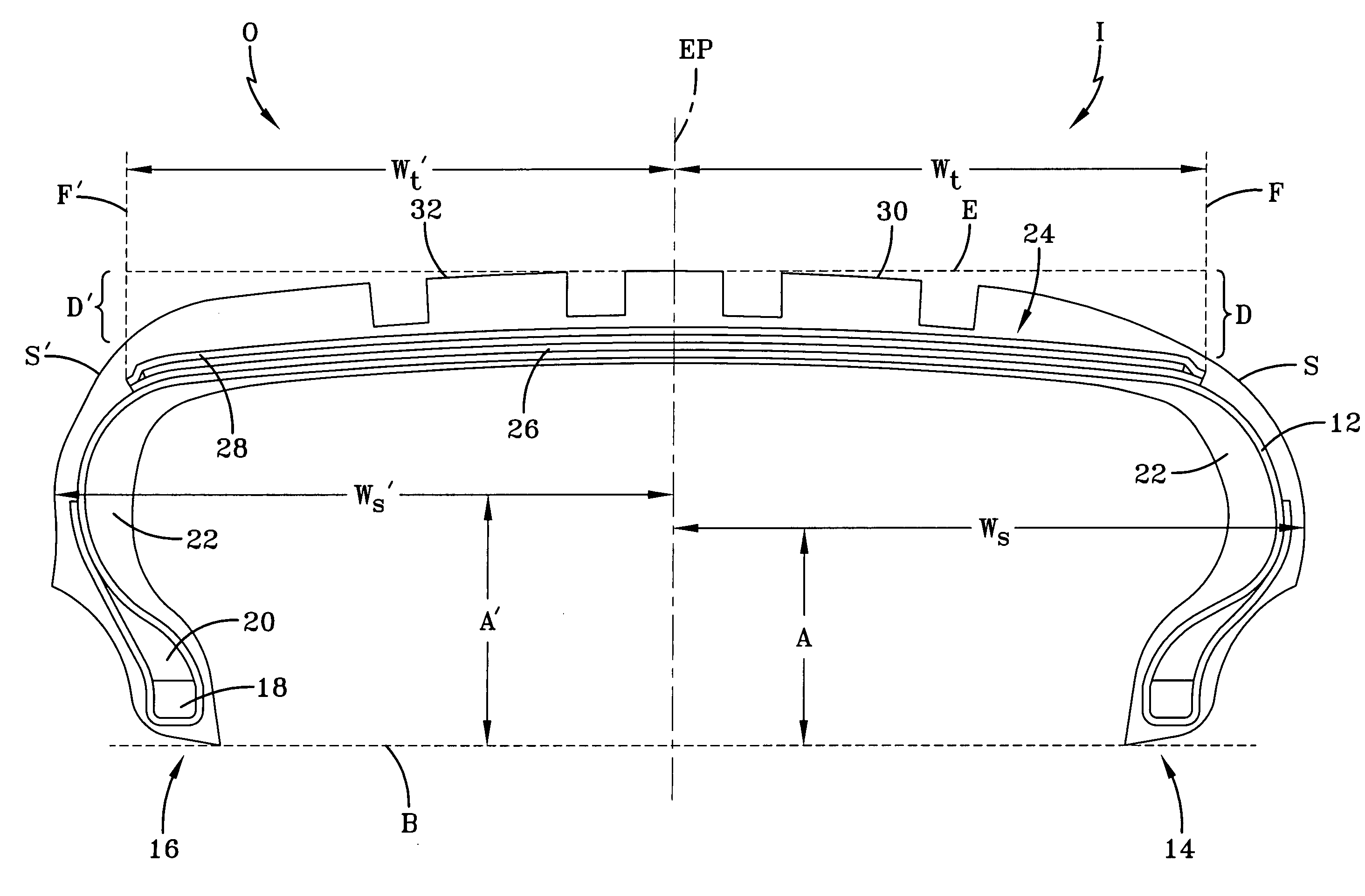

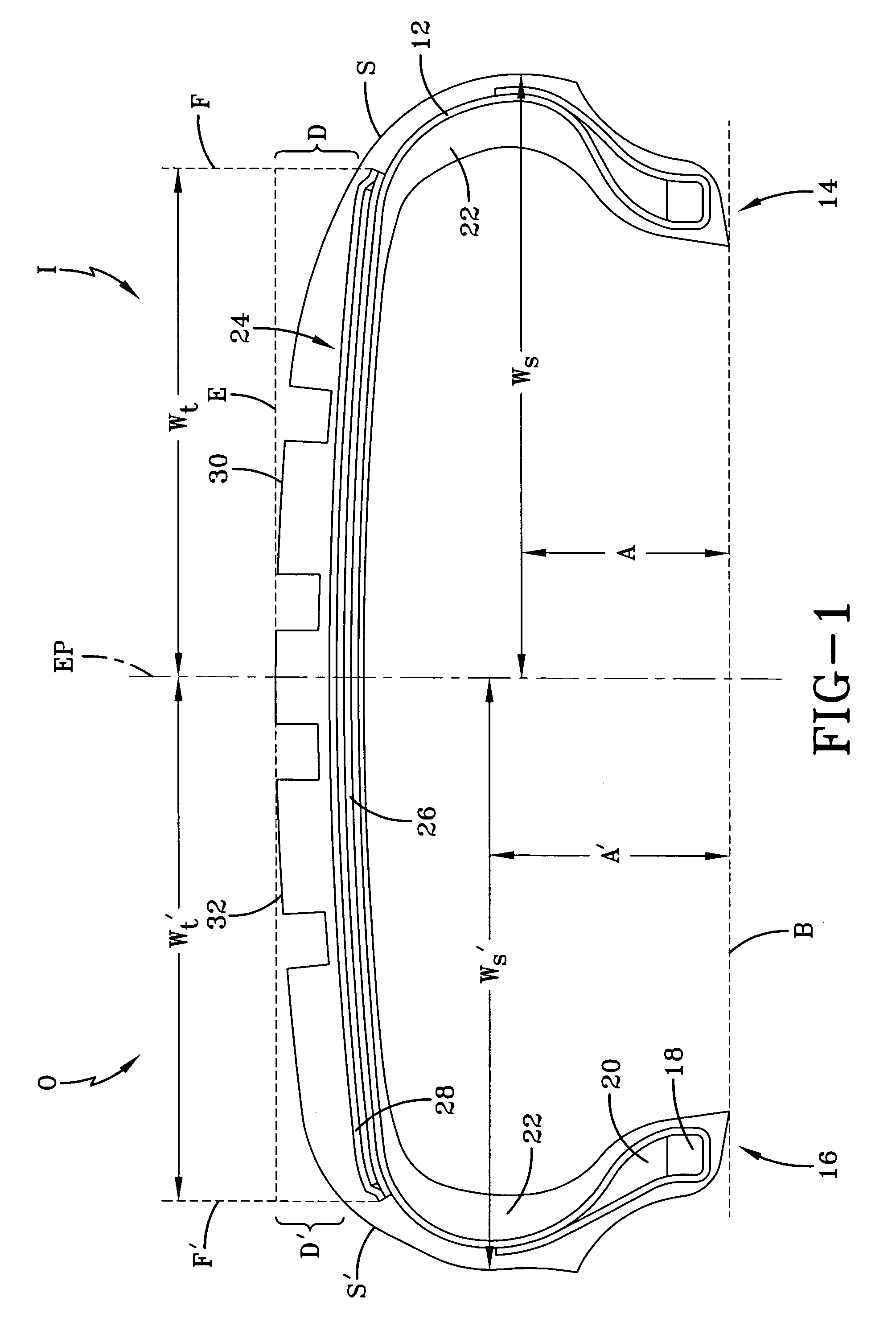

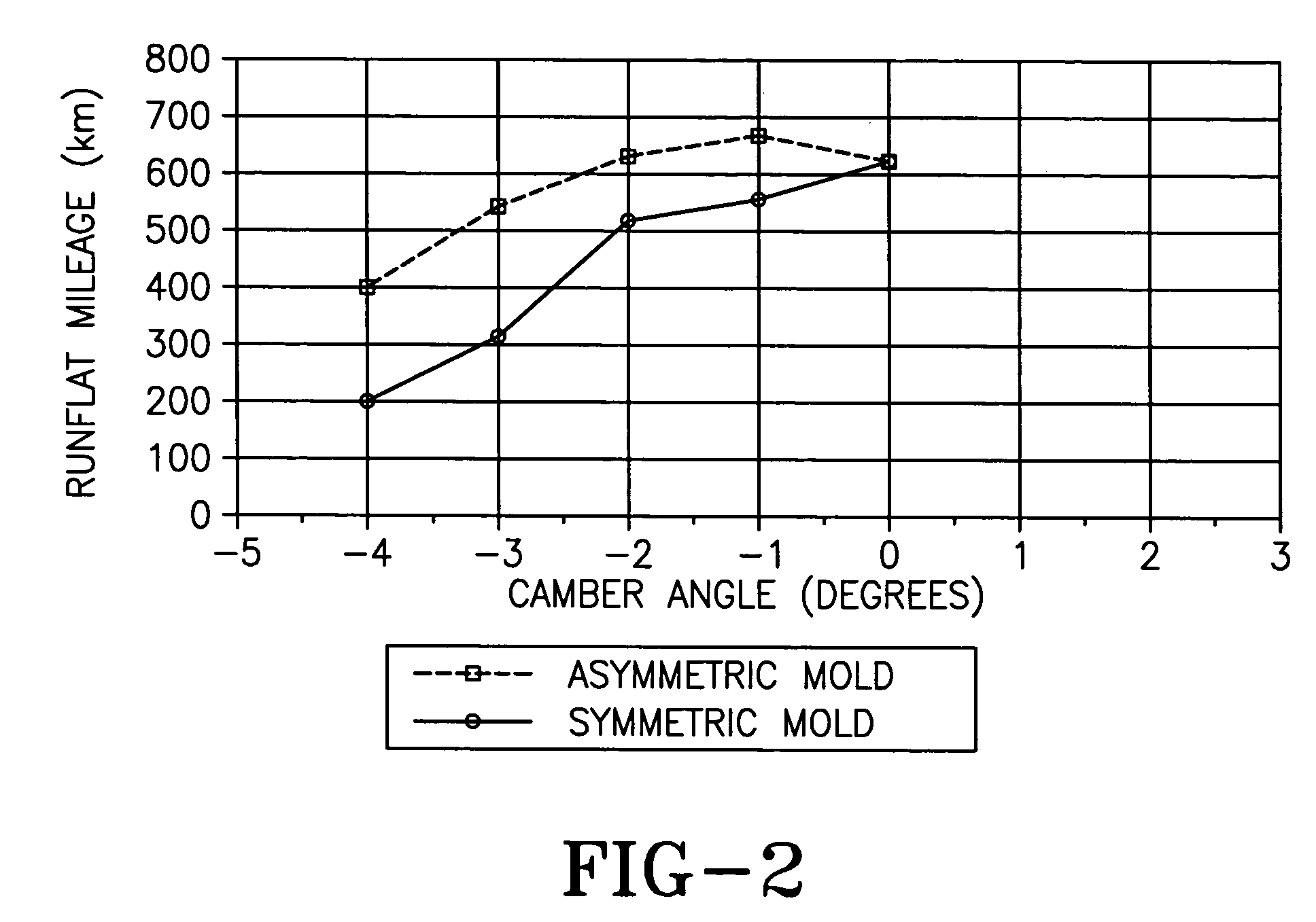

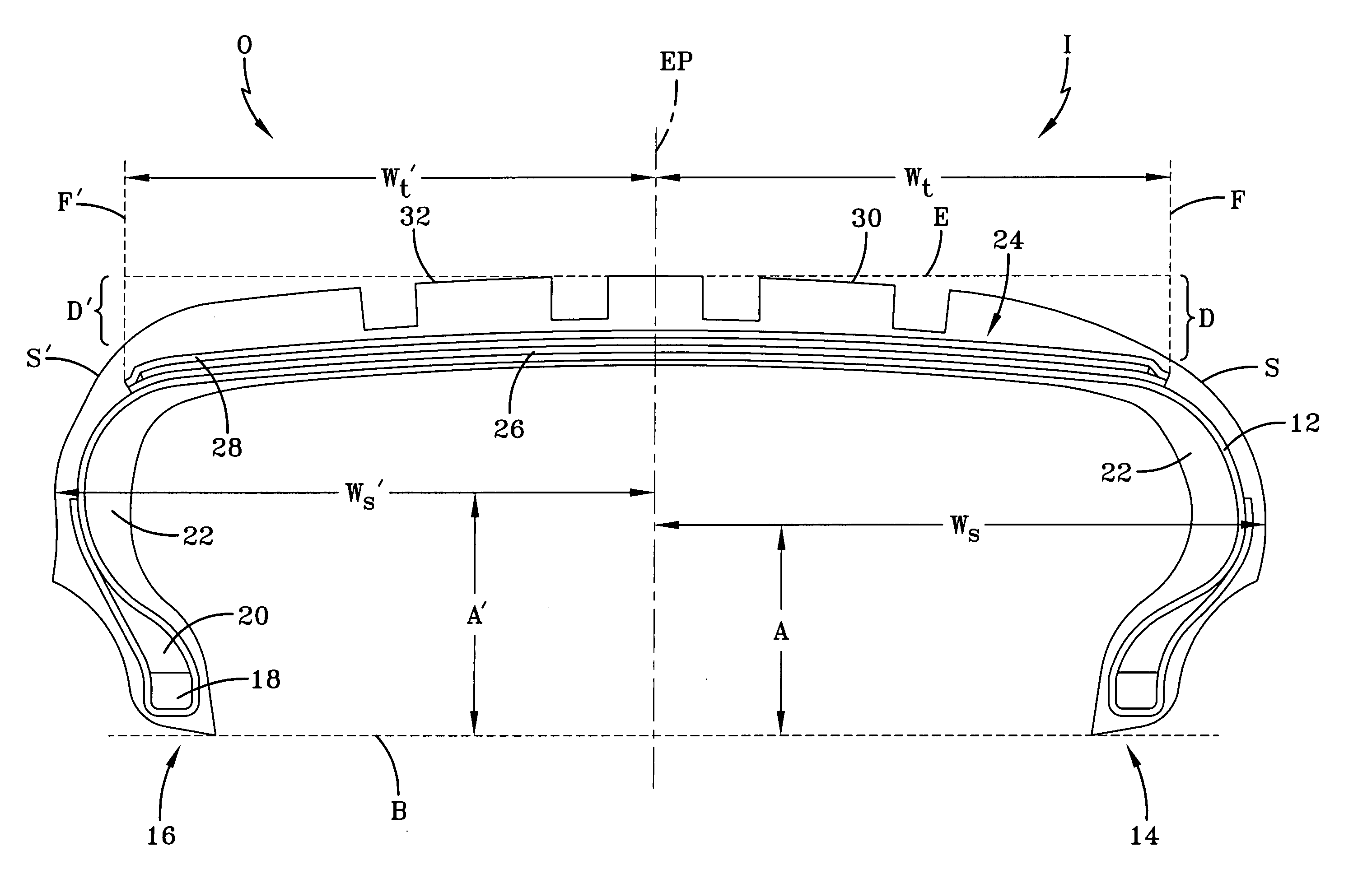

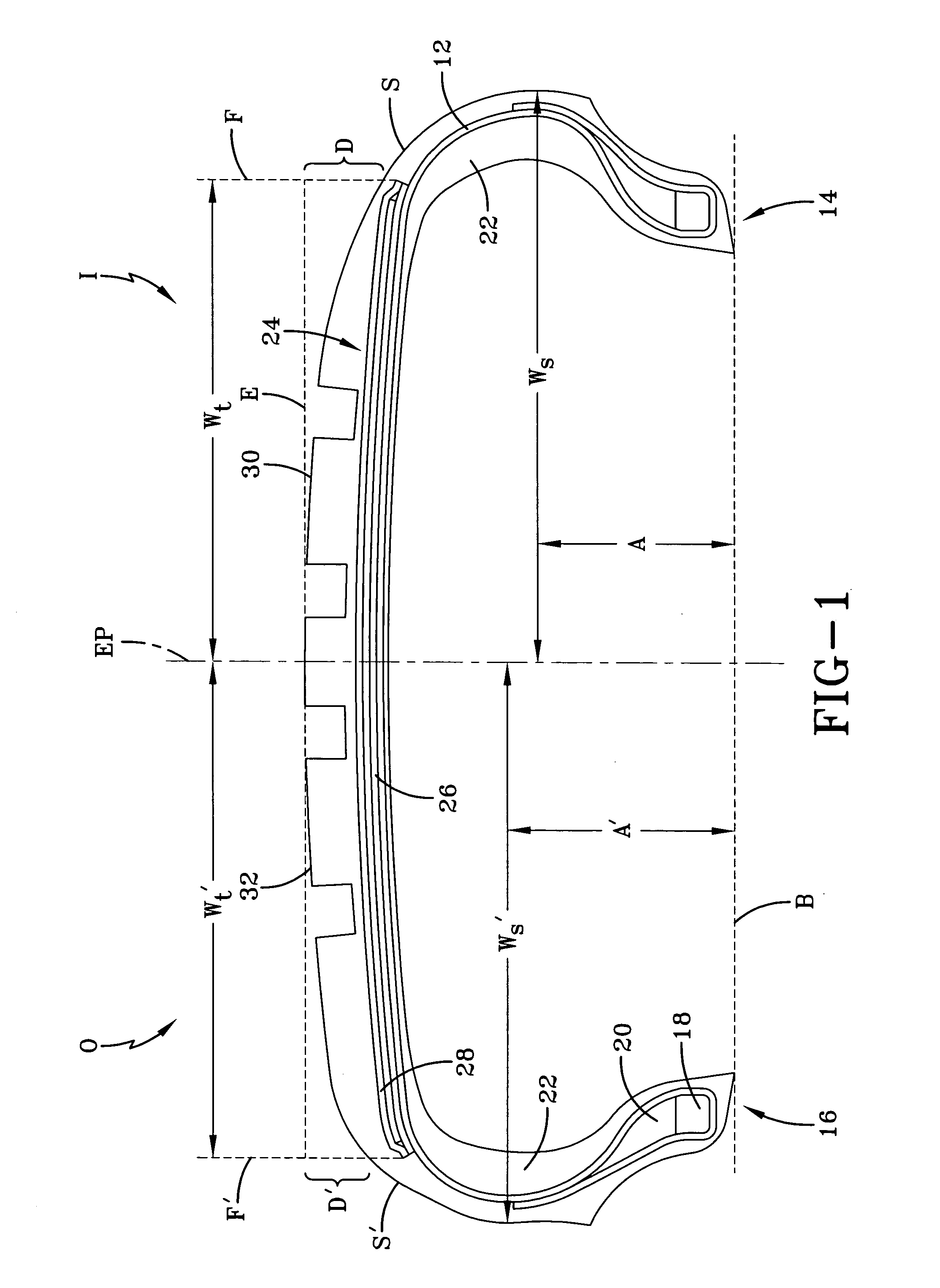

Asymmetrical pneumatic run-flat tire

InactiveUS7278455B2Difference in stiffnessIncreased durabilityTyresSpecial tyresEngineeringMechanical engineering

Owner:THE GOODYEAR TIRE & RUBBER CO

Pneumatic tire

ActiveUS20100193102A1Reduce the temperatureIncreased travel resistanceInflatable tyresTyre sidewallsMechanical engineeringRun-flat tire

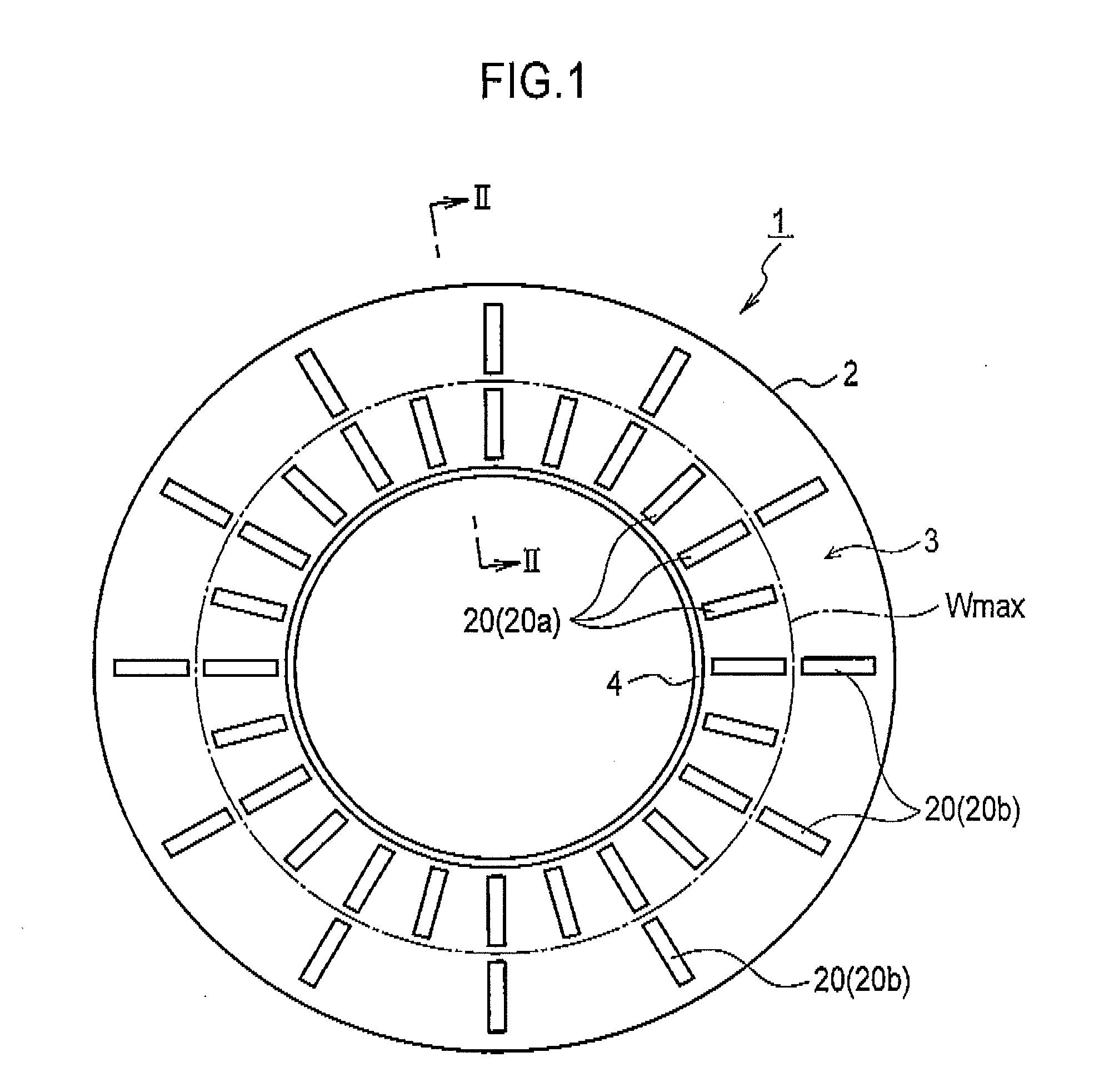

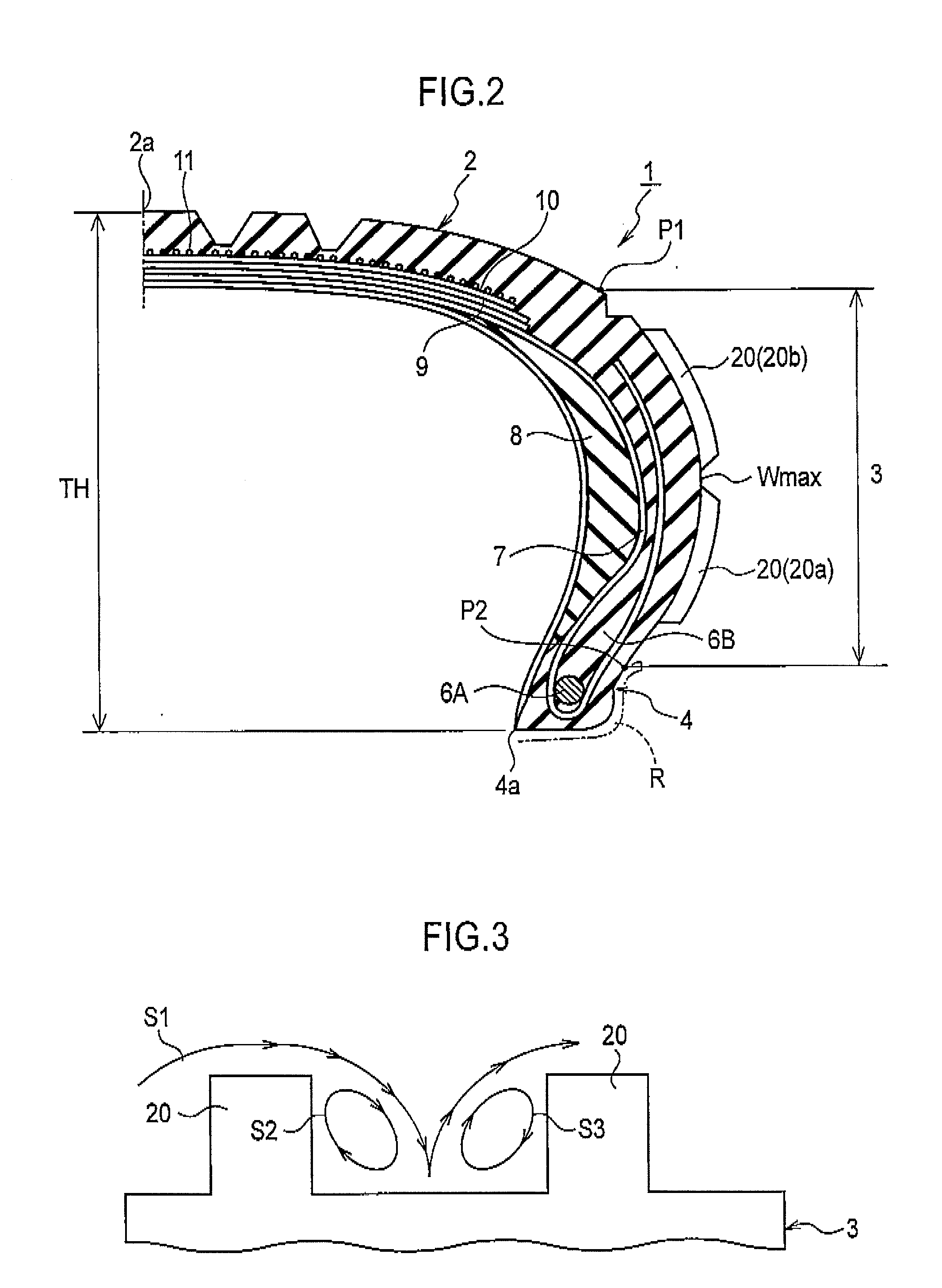

The present invention includes a run-flat tire 1 comprising a plurality of turbulence generation ridges 20 which extend on a surface of a tire side portion 3 in a tire-radial direction and which are arranged at a pitch in a tire-circumferential direction and relationship Si>So is satisfied. Si is the sum of sidewall areas of all the turbulence generation ridges located at the inner side, in the tire-radial direction, of a maximum width position of the pneumatic tire. So is the sum of sidewall areas of all the turbulence generation ridges located at the outer side, in the tire-radial direction, of the tire maximum width position.

Owner:BRIDGESTONE CORP

Rubber composition for sidewall reinforcing layer or sidewall, and tire

The present invention aims to provide a rubber composition for a sidewall reinforcing layer or a sidewall, which has sufficient thermal conductivity and low heat build-up property as well as excellent rigidity and run-flat durability. The present invention also aims to provide a pneumatic tire such as a run-flat tire, which has a sidewall reinforcing layer or sidewall that is produced using the rubber composition.The present invention relates to a rubber composition for a sidewall reinforcing layer or a sidewall, which contains a diene rubber and a coal-pitch based carbon fiber.

Owner:SUMITOMO RUBBER IND LTD

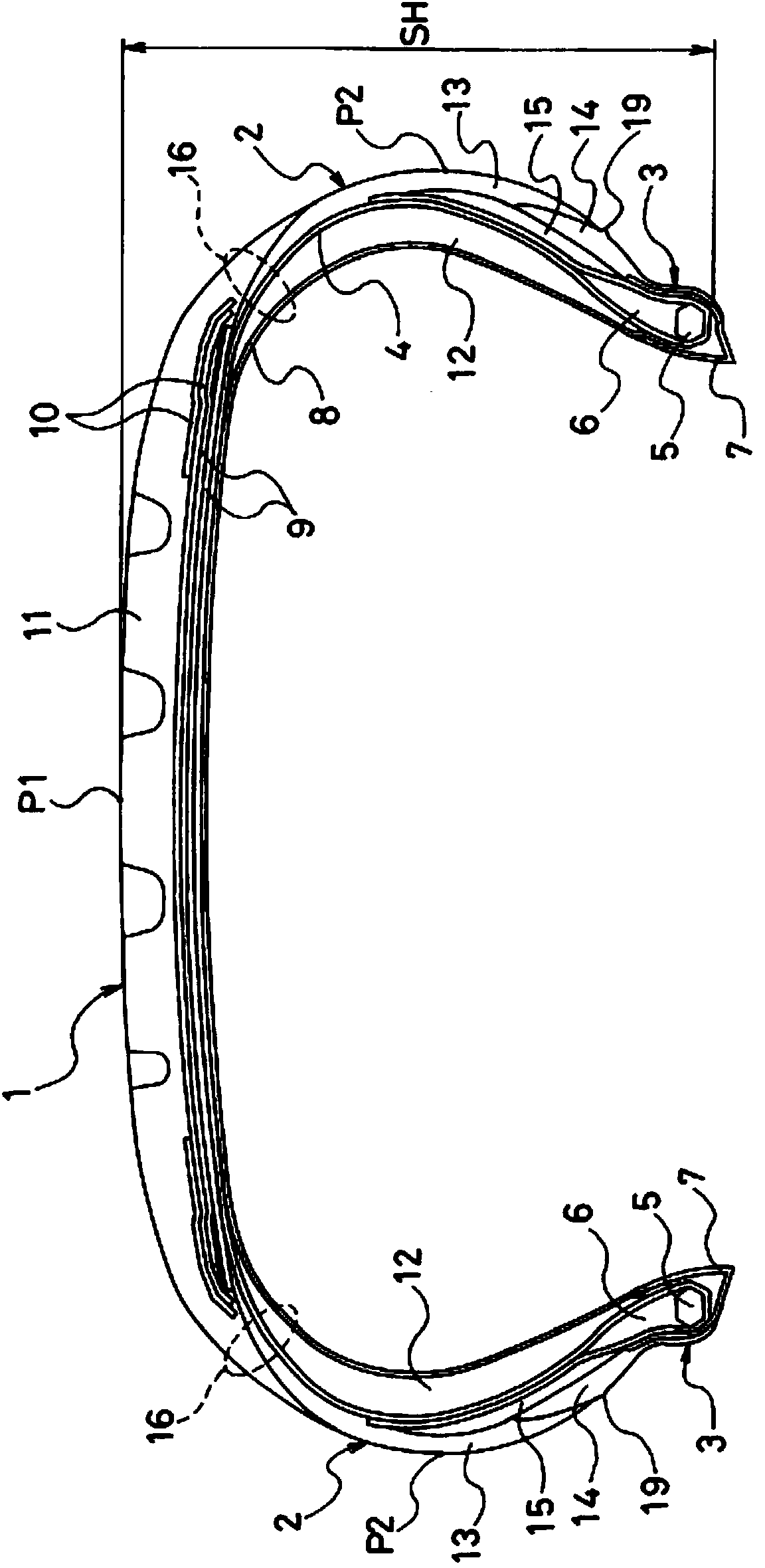

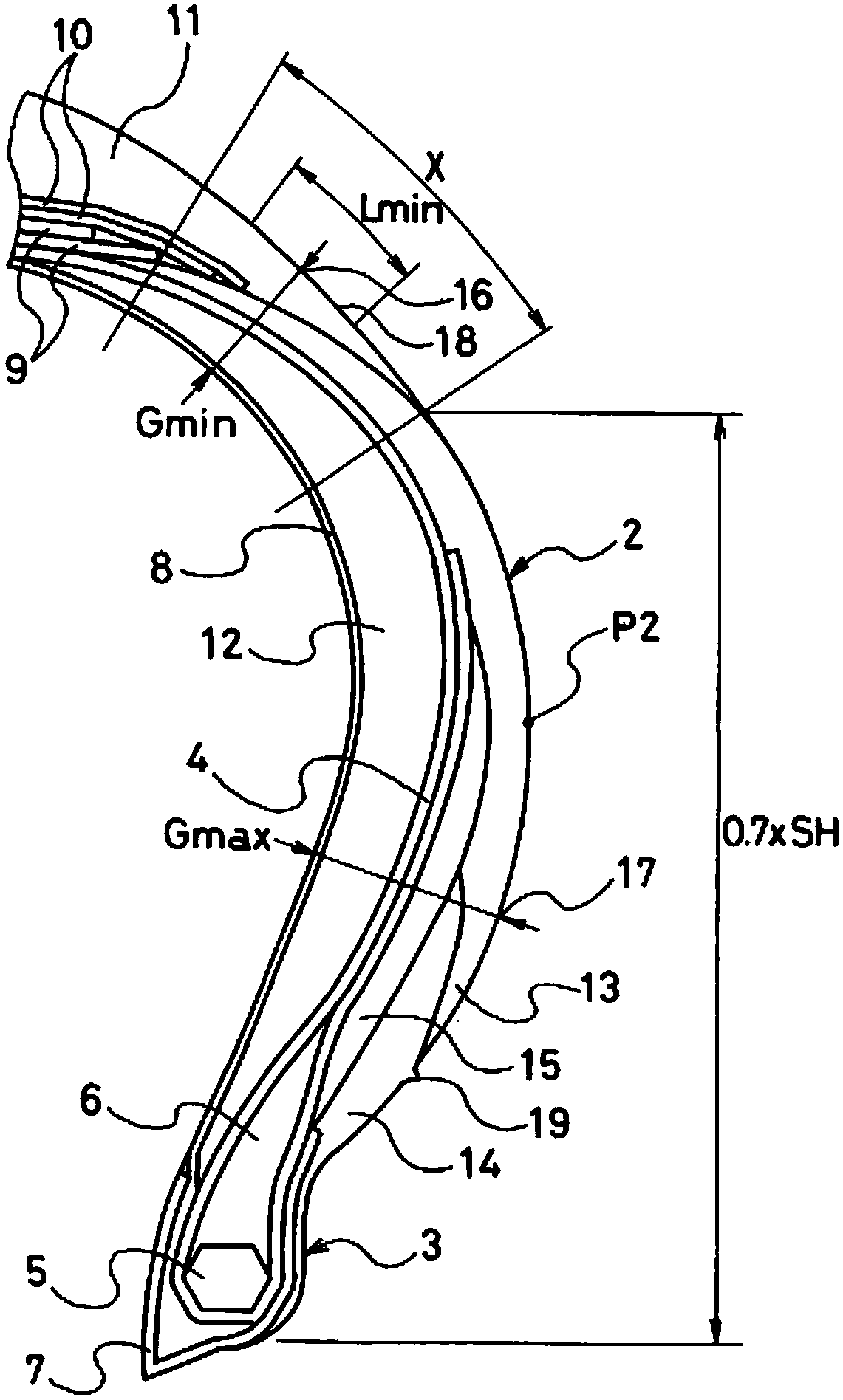

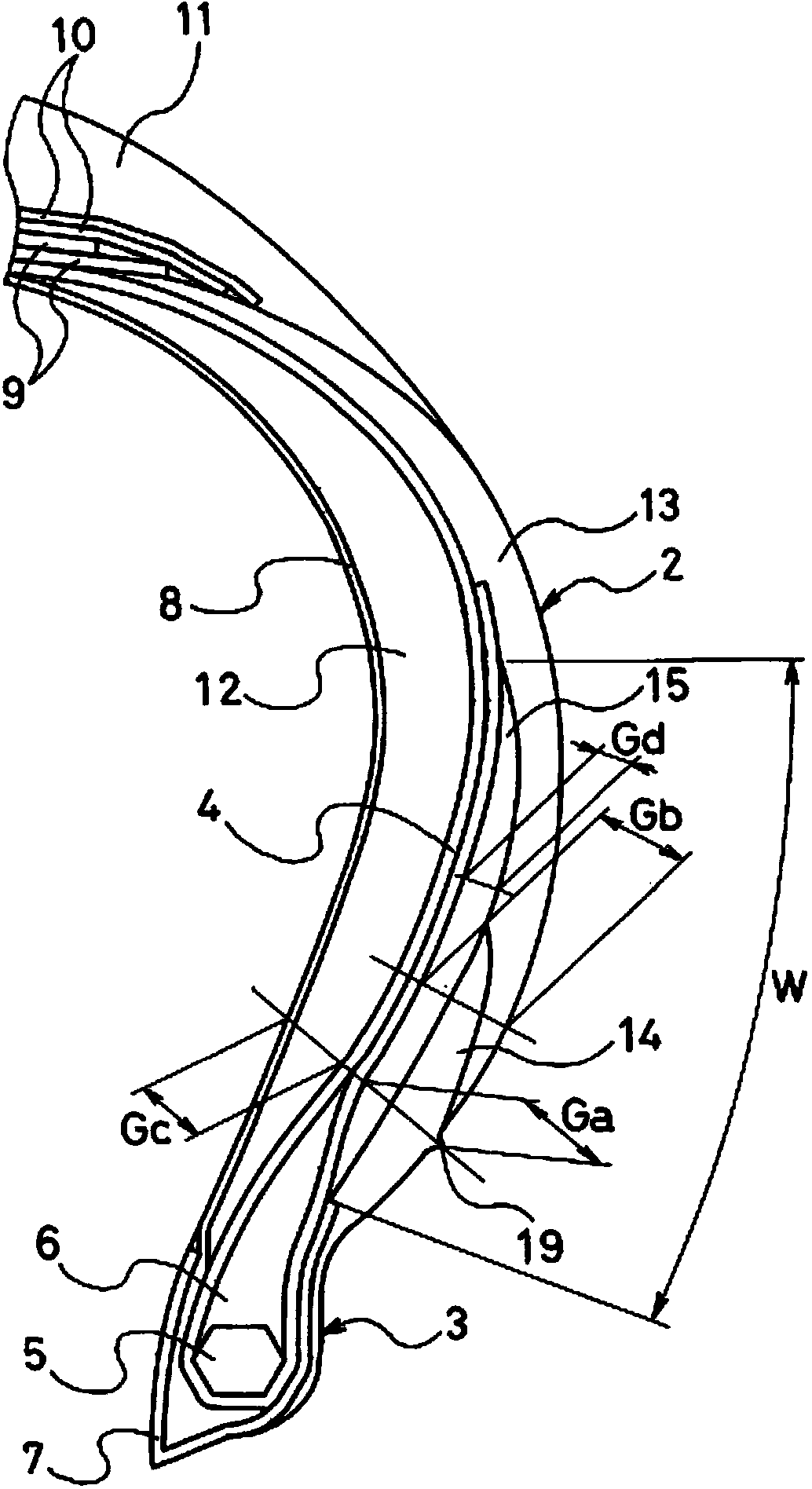

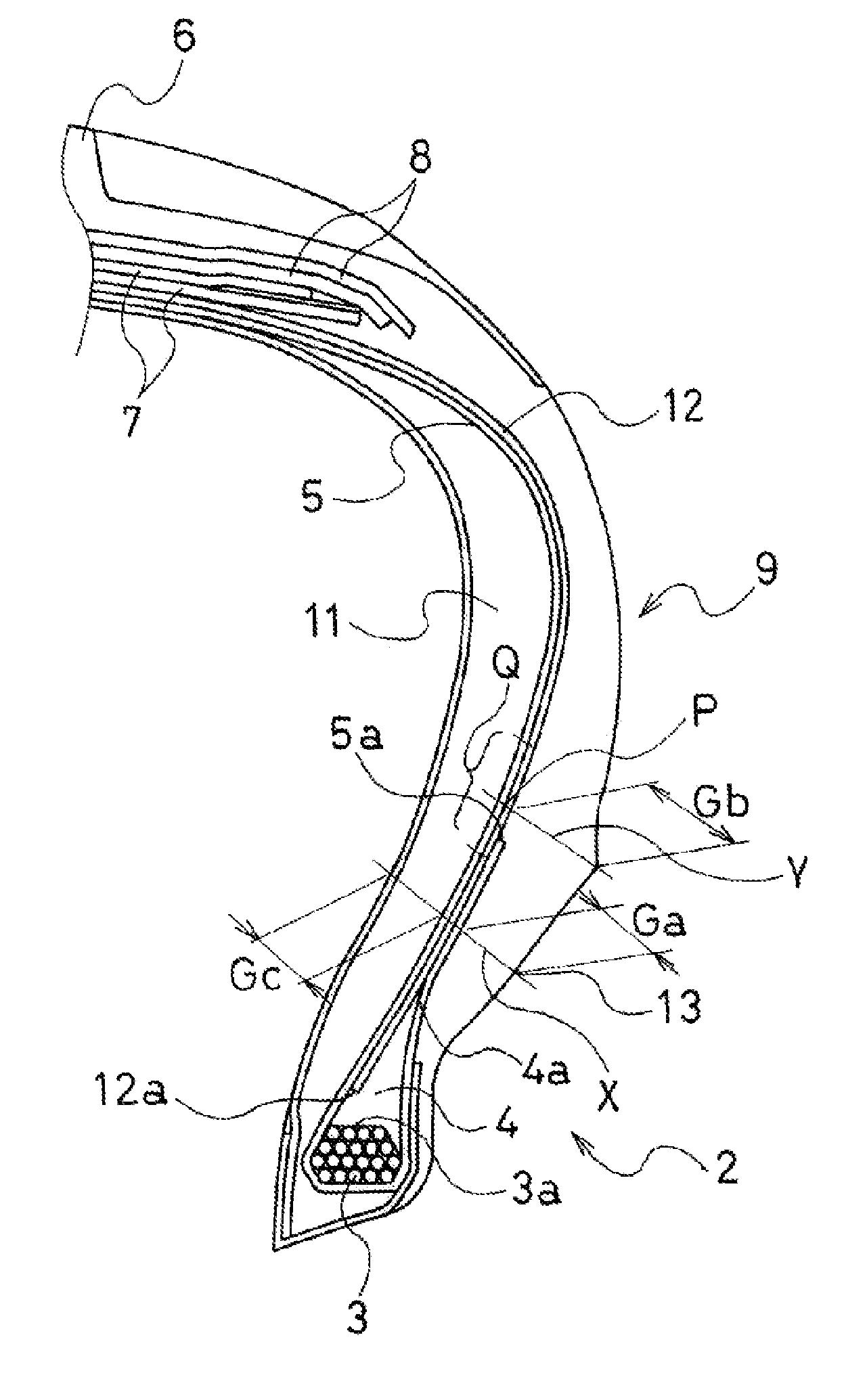

Run-flat tire

ActiveCN104321209AAvoid breakingIncreased durabilitySpecial tyresPneumatic tyre reinforcementsEngineeringRun-flat tire

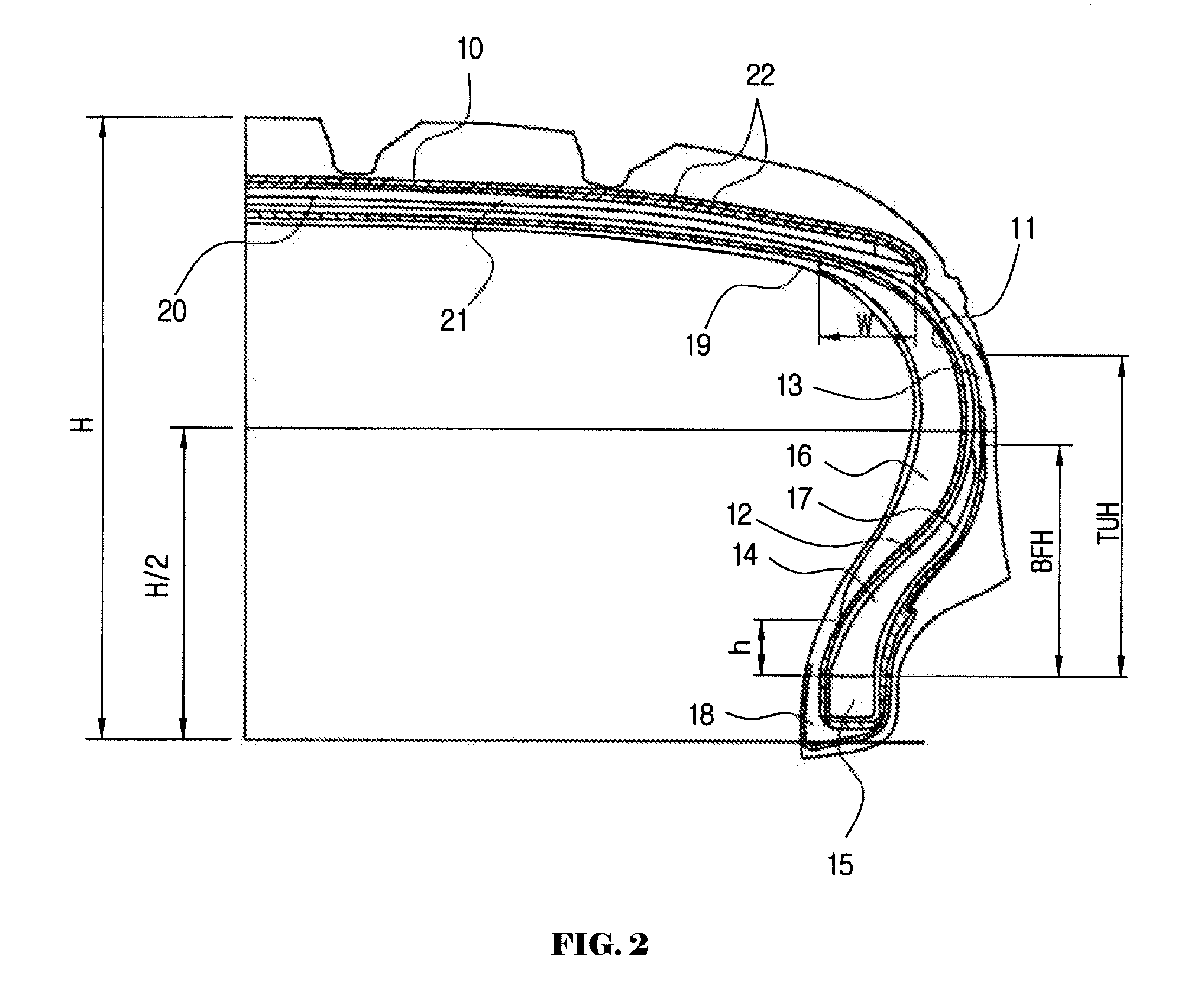

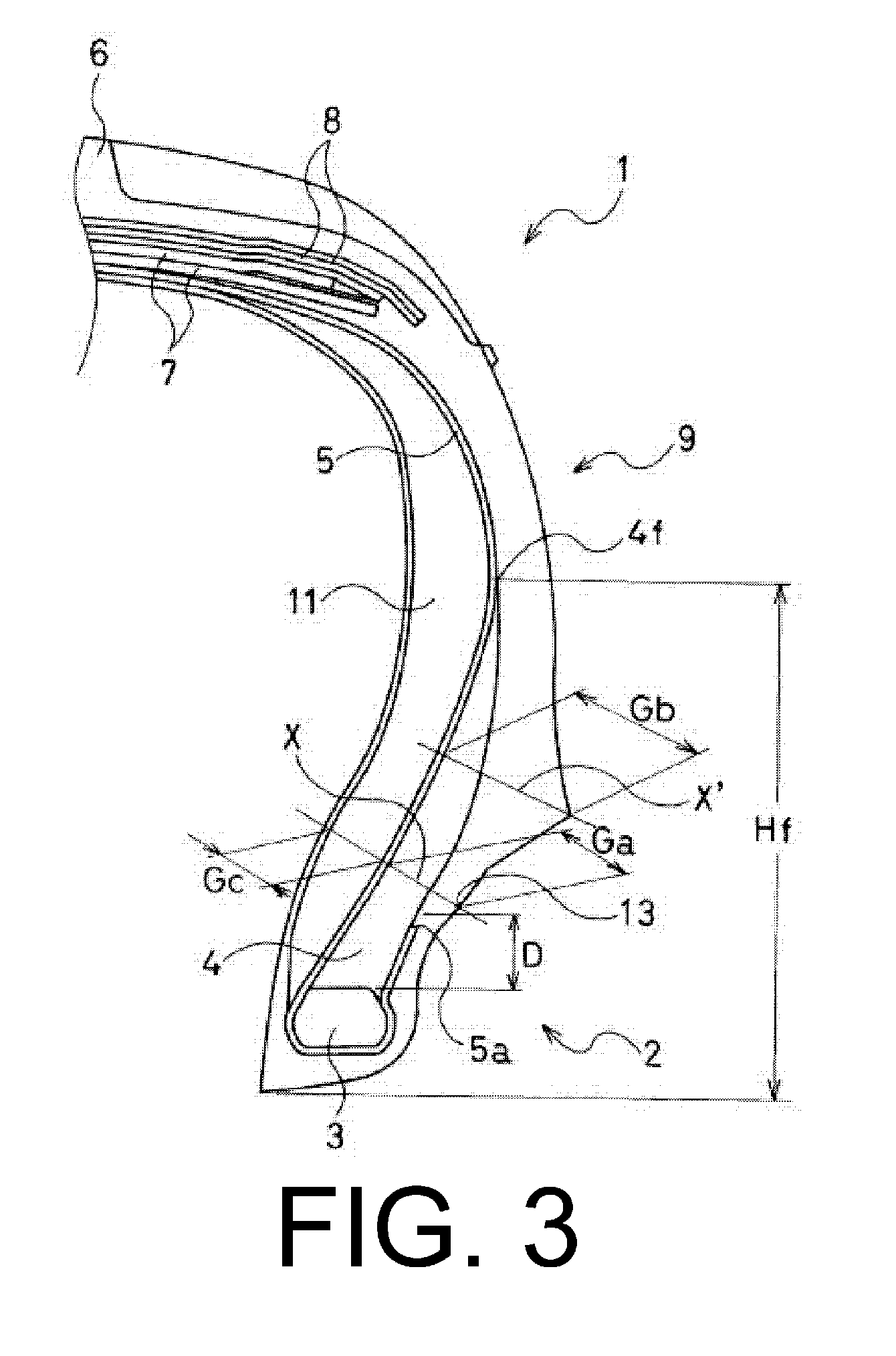

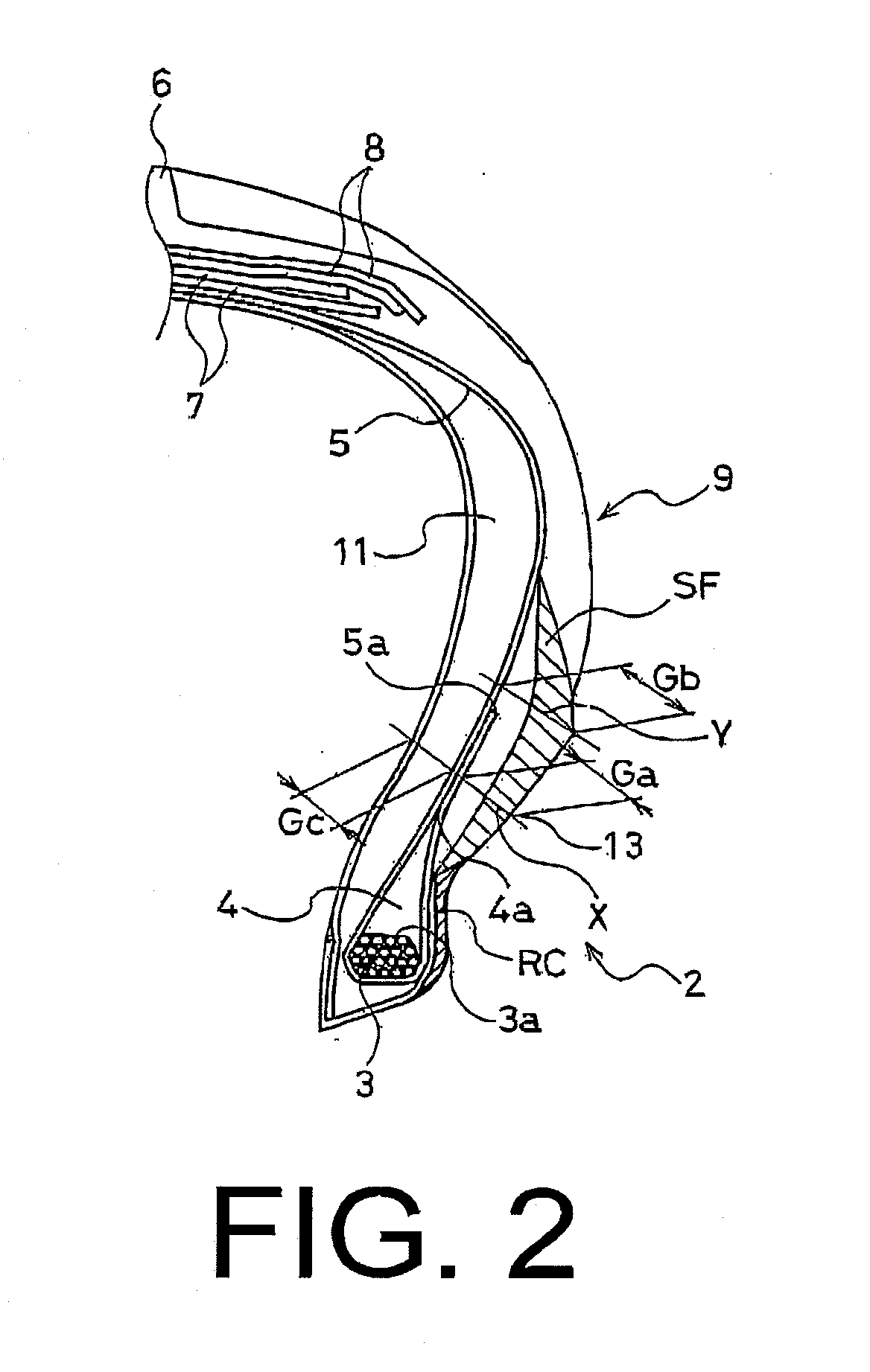

Provided is a run-flat tire that achieves high levels of both run-flat durability and ride comfort, and minimizes weight increase. In a sidewall-reinforced run-flat tire, the minimum thickness section being positioned between the belt layer end section and the tire cross-sectional height (SH) 70% position, the relationship between the thickness (Gmin) of the minimum-thickness section and the thickness (Gmax) of the maximum thickness section (17) is defined as 0.5 × Gmax ≤ Gmin ≤ 0.8 × Gmax; the relationship between the length (Lmin) of the thin region and the tire cross-sectional height (SH) is defined as 0.18 × SH ≤ Lmin ≤ 0.26 × SH; the relationship between the weight (Wr) of the sidewall-reinforcement layer, the tire total weight (Wt), and the tire oblateness (R) is defined as 0.08 × Wt × (1 - 0.2 × (1 - R / 50)) ≤ Wr ≤ 0.18 × Wt × (1 - 0.2 × (1 - R / 50)); the relationship between the thickness (Ga) at the rim-check line of the outer-side rubber portion outward of the carcass layer, and the maximum thickness (Gb) thereof, is defined as 0.8 × Gb ≤ Ga ≤ 1.0 × Gb; and the relationship between the thickness (Gc) at the rim-check line of the inner-side rubber portion inward of the carcass layer and the thickness (Ga) is defined as 0.7 × Ga ≤ Gc ≤ 1.0 × Ga.

Owner:THE YOKOHAMA RUBBER CO LTD

Inner supporting body for run-flat tire

The invention discloses an inner supporting body for a run-flat tire, which is characterized in that: the inner supporting body is made of a magnesium alloy serving as a raw material, and adopts a two-block split structure; the split parts comprise a main body and a joint respectively; and the joints between the split parts are connected by a connection piece. The inner supporting body has the advantages of high rigidity, good heat stability and light weight, and the inner supporting body adopts the magnesium alloy to improve the radiating condition fundamentally, prevent rubber and engineering plastics from softening due to quick and massive deformation, eliminate the ,thermal explosion, phenomenon in the process of using the inner supporting body, improve the safe driving distance after a vehicle has a flat tire, and prolong the service life.

Owner:NO 52 INST OF CHINA NORTH IND GRP CORP

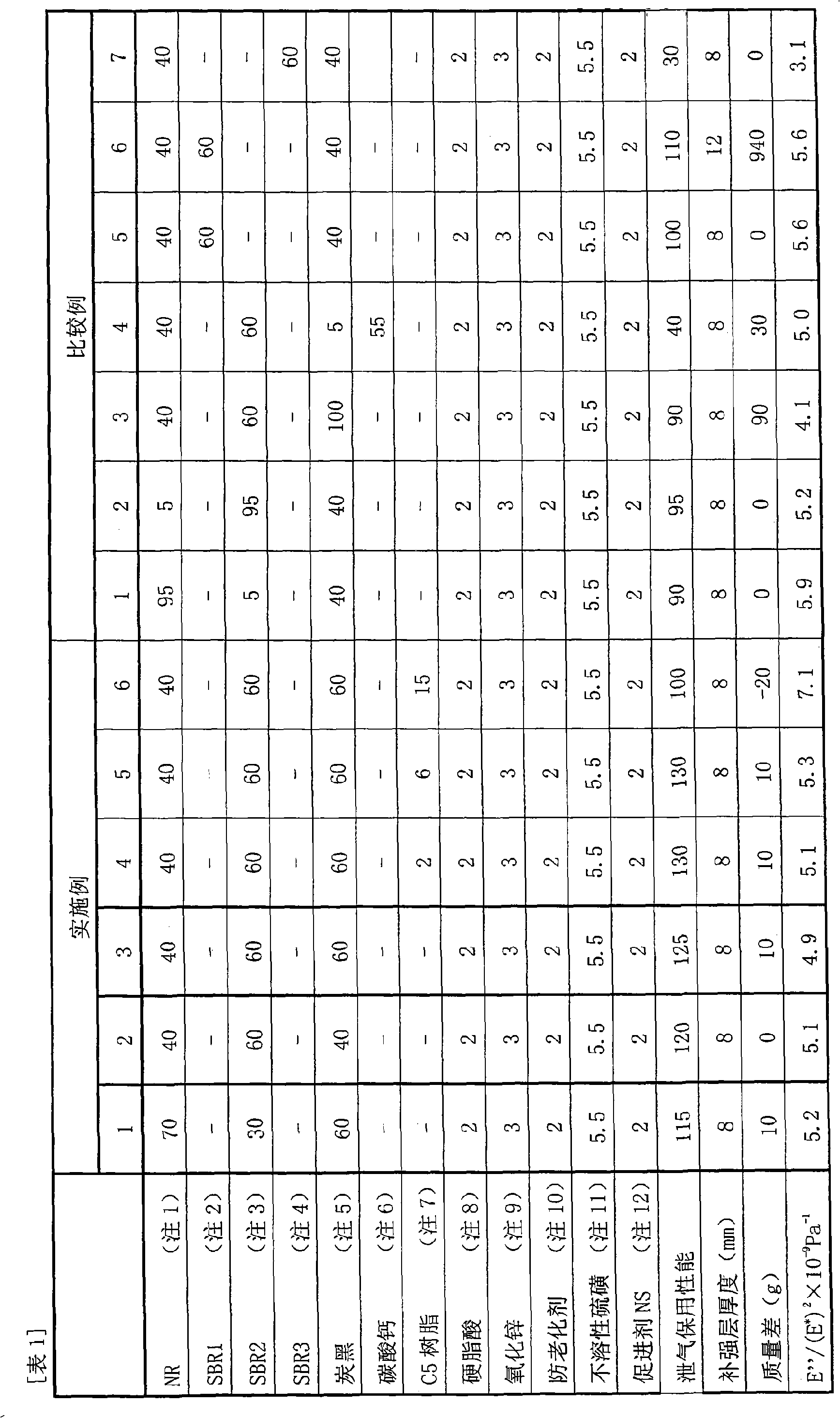

Rubber composition and run flat tire using the same

Owner:SUMITOMO RUBBER IND LTD

Self-supporting type pneumatic run-flat tire, and insert and bead rubber composition for run-flat capability

InactiveUS20070006956A1High expansion capacityReduce weightWithout separate inflatable insertsSpecial tyresMechanical engineeringPolybutadiene

A self-supporting type pneumatic run-flat tire is optimized in location and gauge of insert rubber at sidewalls, thereby enhancing run-flat and expansion capabilities. The self-supporting type pneumatic run-flat tire comprises an insert and bead rubber composition which comprises syndiotactic 1,2-polybutadiene in order to enhance run-flat capability.

Owner:HANKOOK TIRE WORLDWIDE

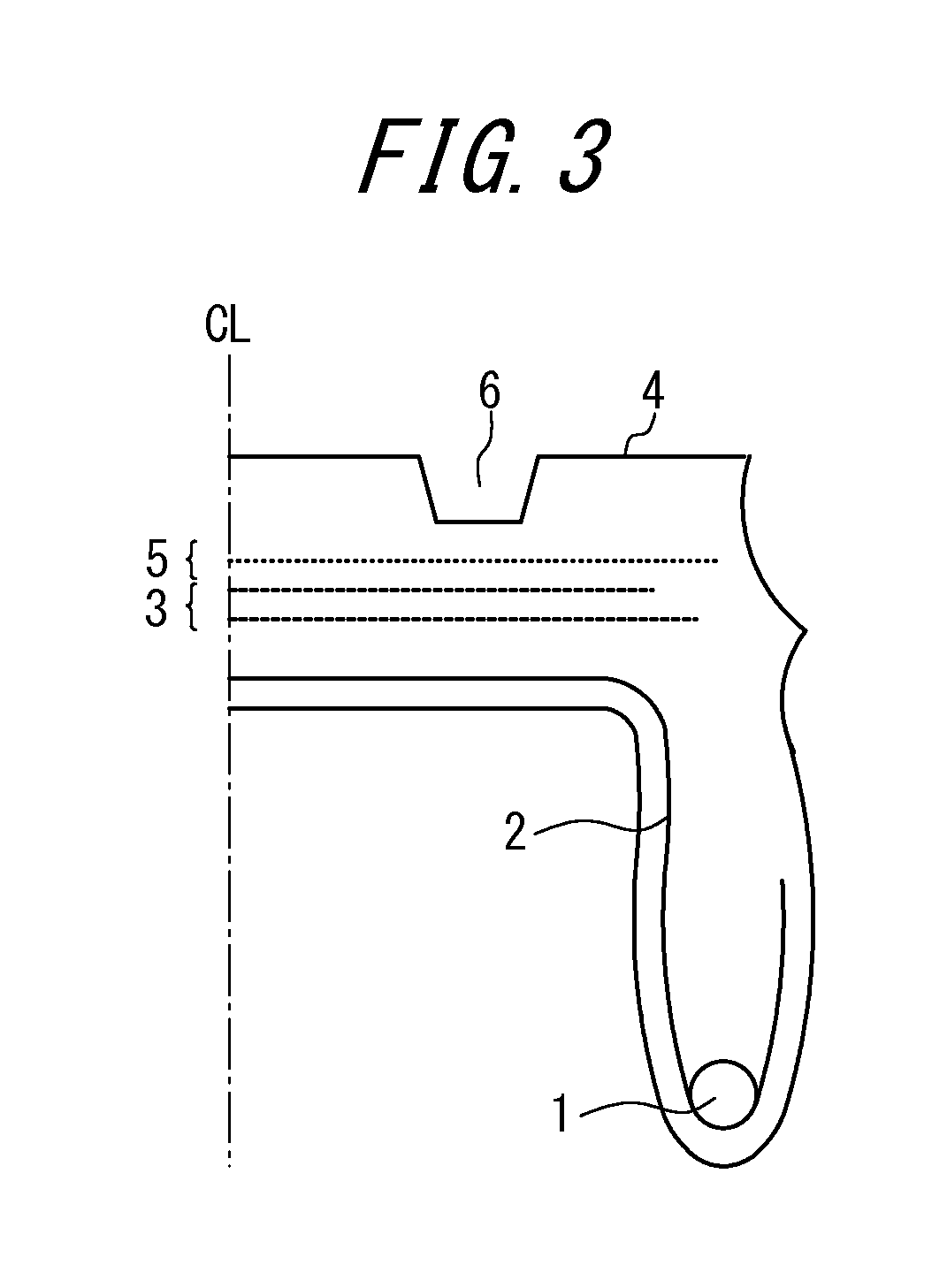

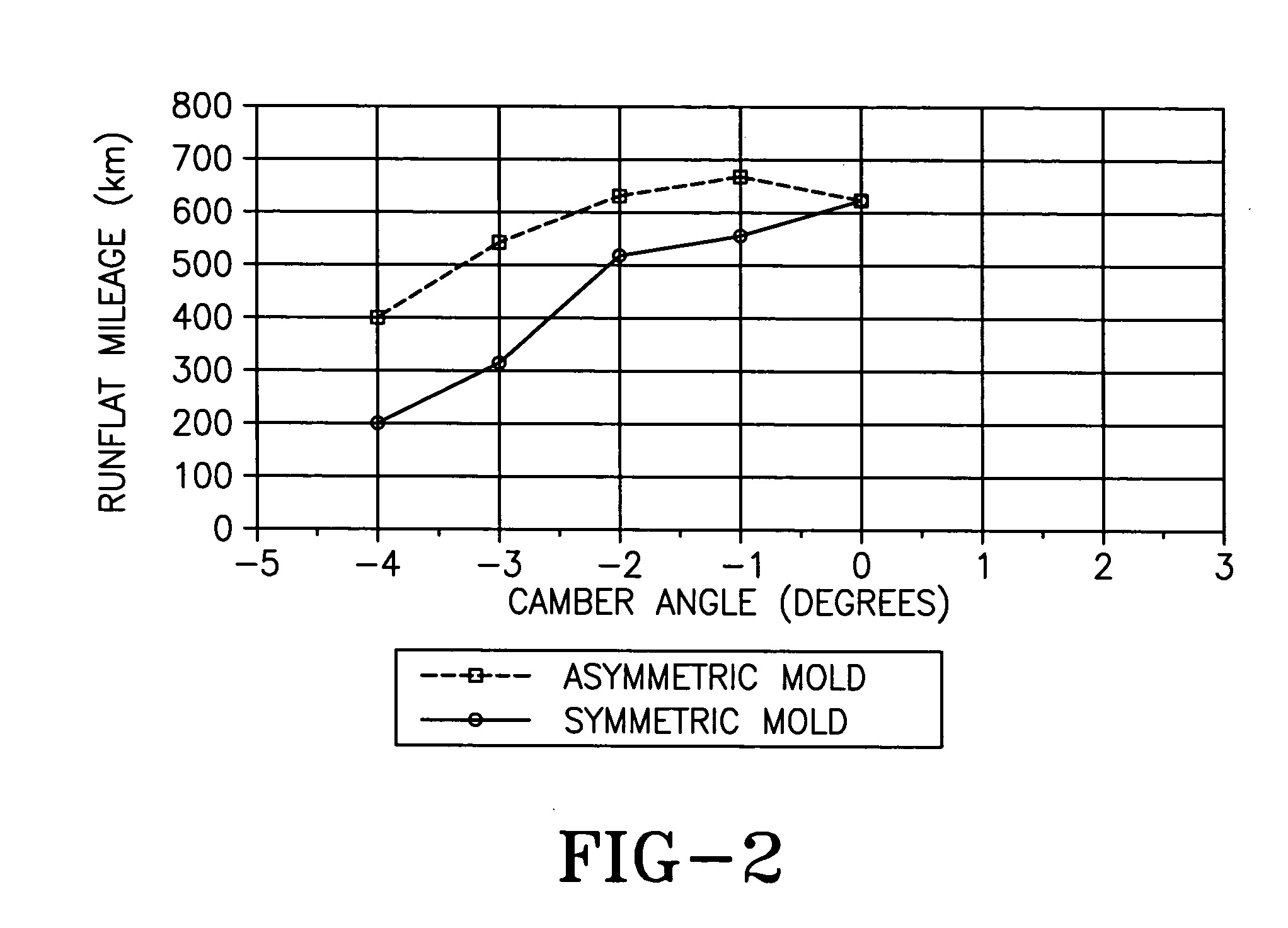

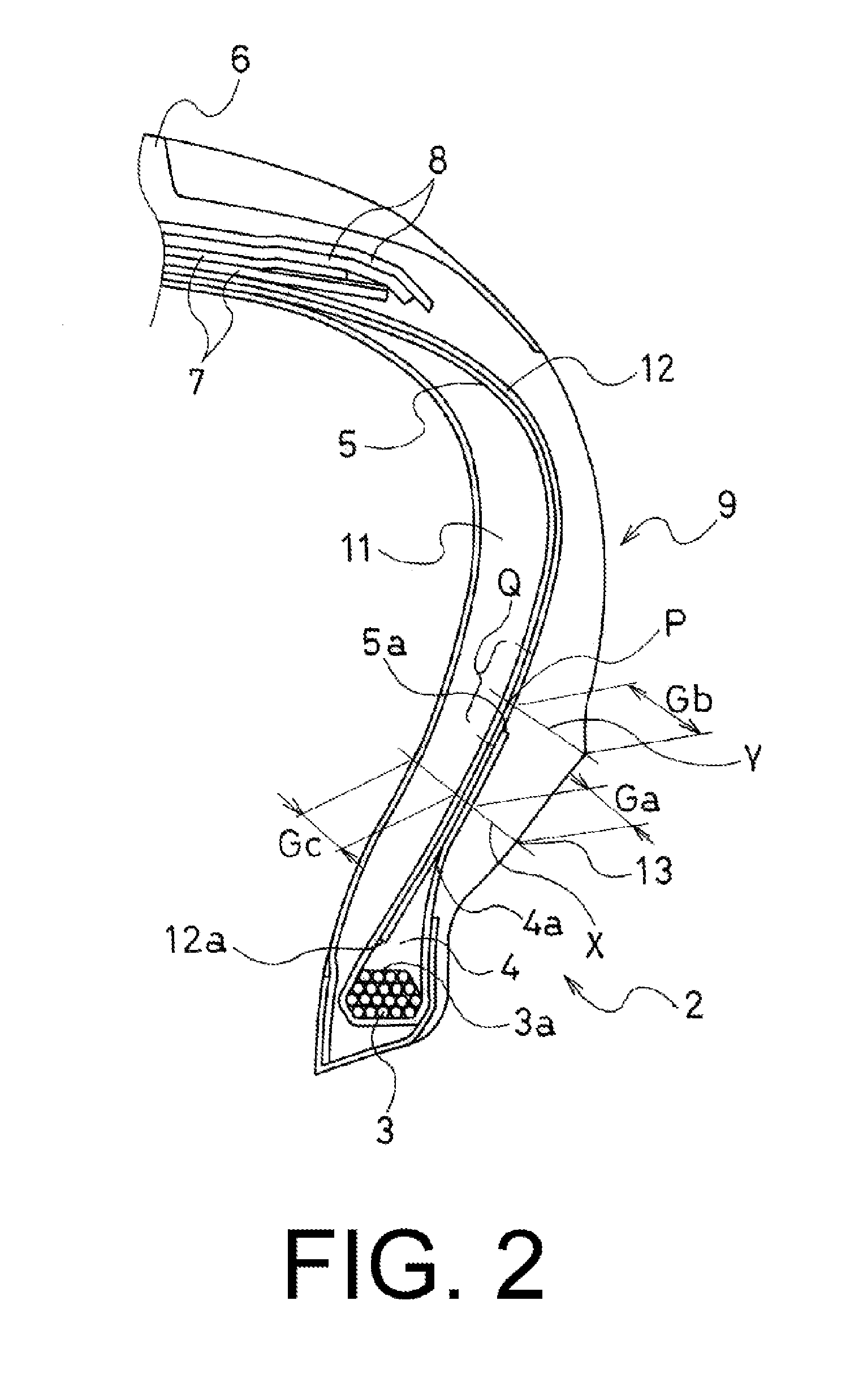

Run flat tire

InactiveUS20120132338A1Increased durabilityRide-comfort can be improvedSpecial tyresPneumatic tyre reinforcementsEngineeringAtmospheric pressure

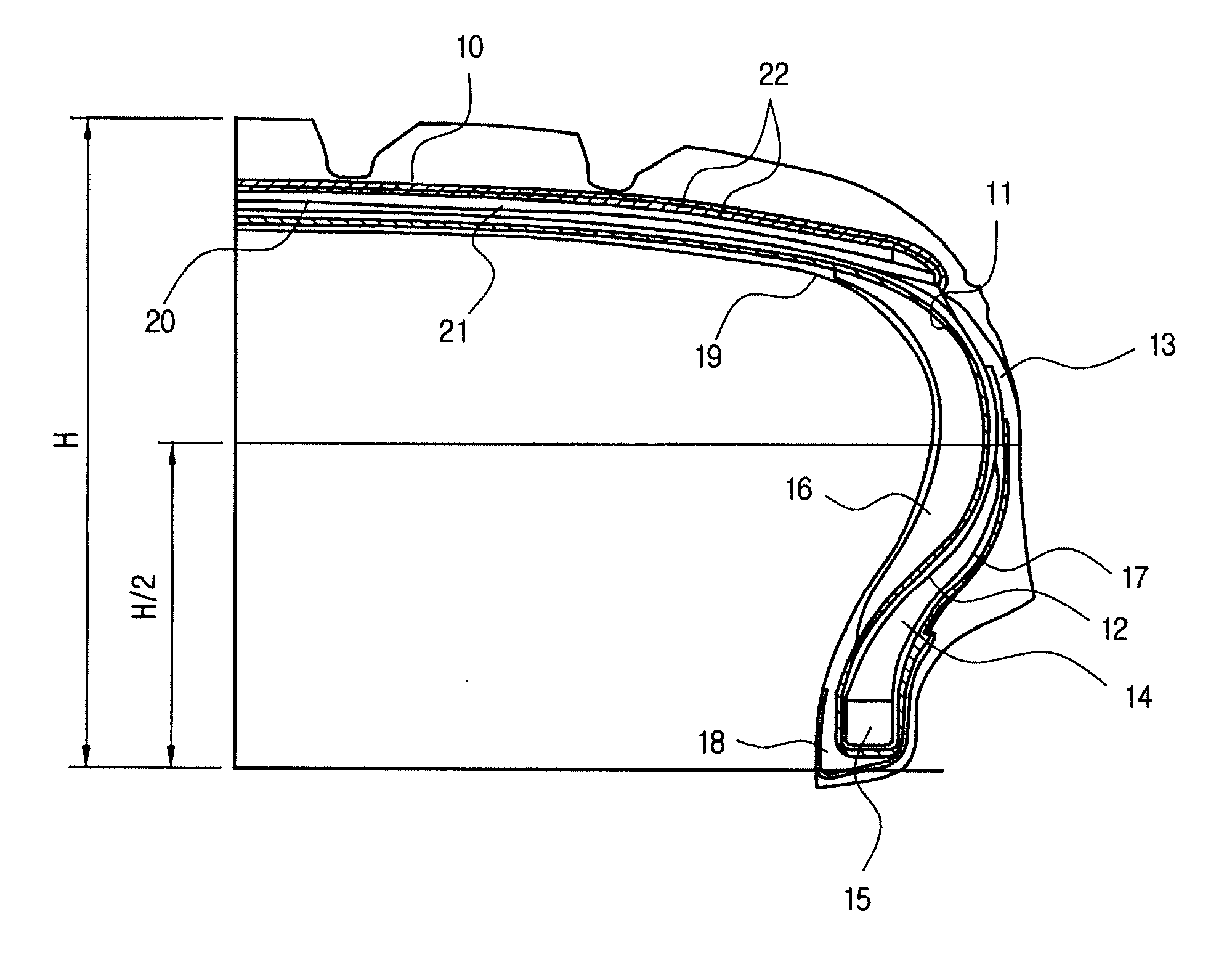

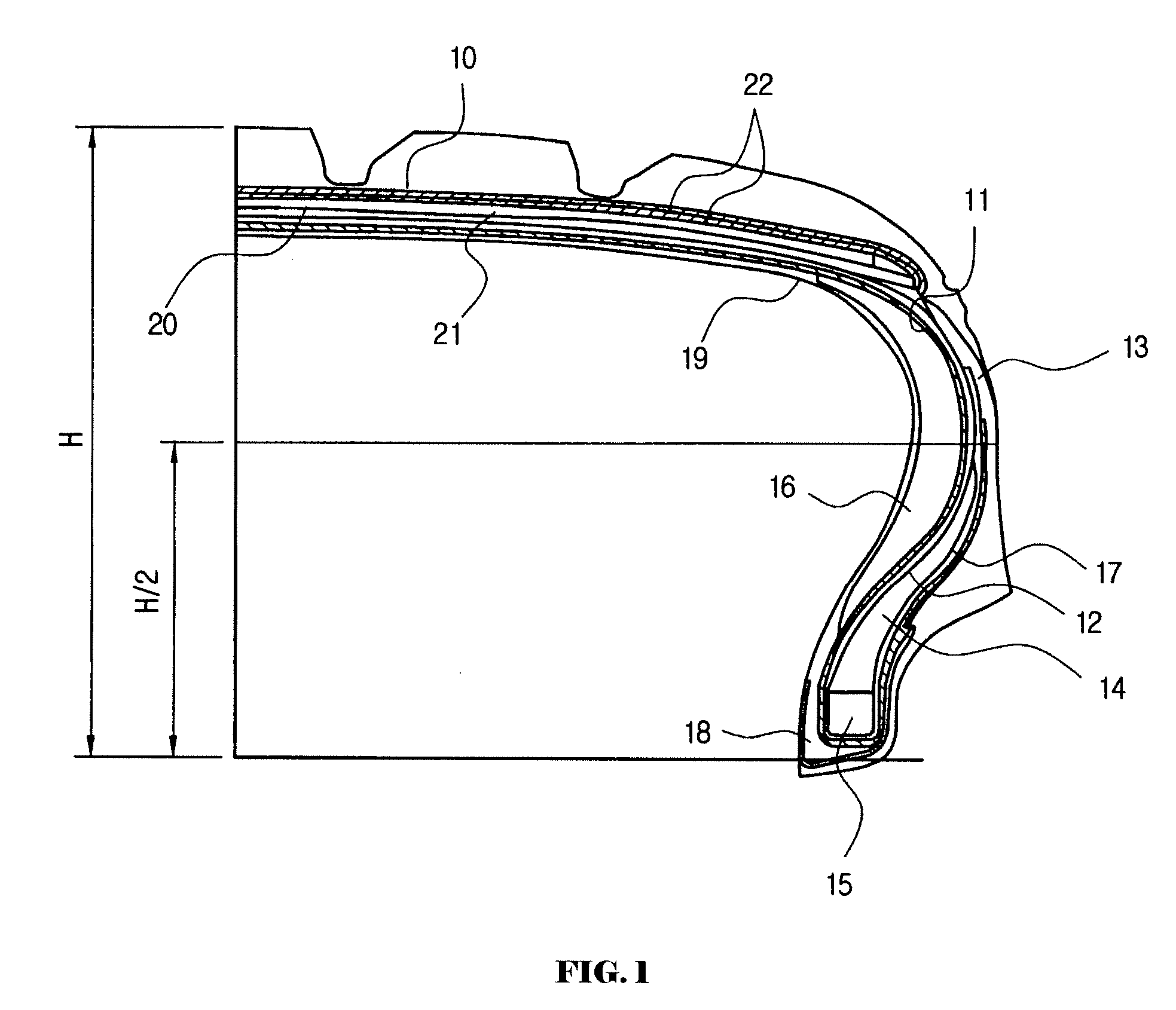

A run flat tire where: the ratio of the cross-sectional height on the inner side in the radial direction to the cross-sectional height on the outer side in the radial direction, having the maximum tire width in a state inflated to an air pressure as a boundary; the inclination angle of the outer wall in the upper region of the side wall portion; the curving form of the tread surface; the position of the carcass folded over end; the height of the bead filler; the relationship between the thickness of the outer side rubber taken on a line normal to the rim line and the maximum thickness of the outer side rubber in an upper region of the bead portion; and the relationship of the thickness of the inner side rubber and the thickness of the outer side rubber taken on a line normal to the rim line are stipulated.

Owner:THE YOKOHAMA RUBBER CO LTD

Run-Flat Tire

InactiveUS20080156409A1Increased durabilityWithout separate inflatable insertsSynthetic resin layered productsTire beadPolyketone

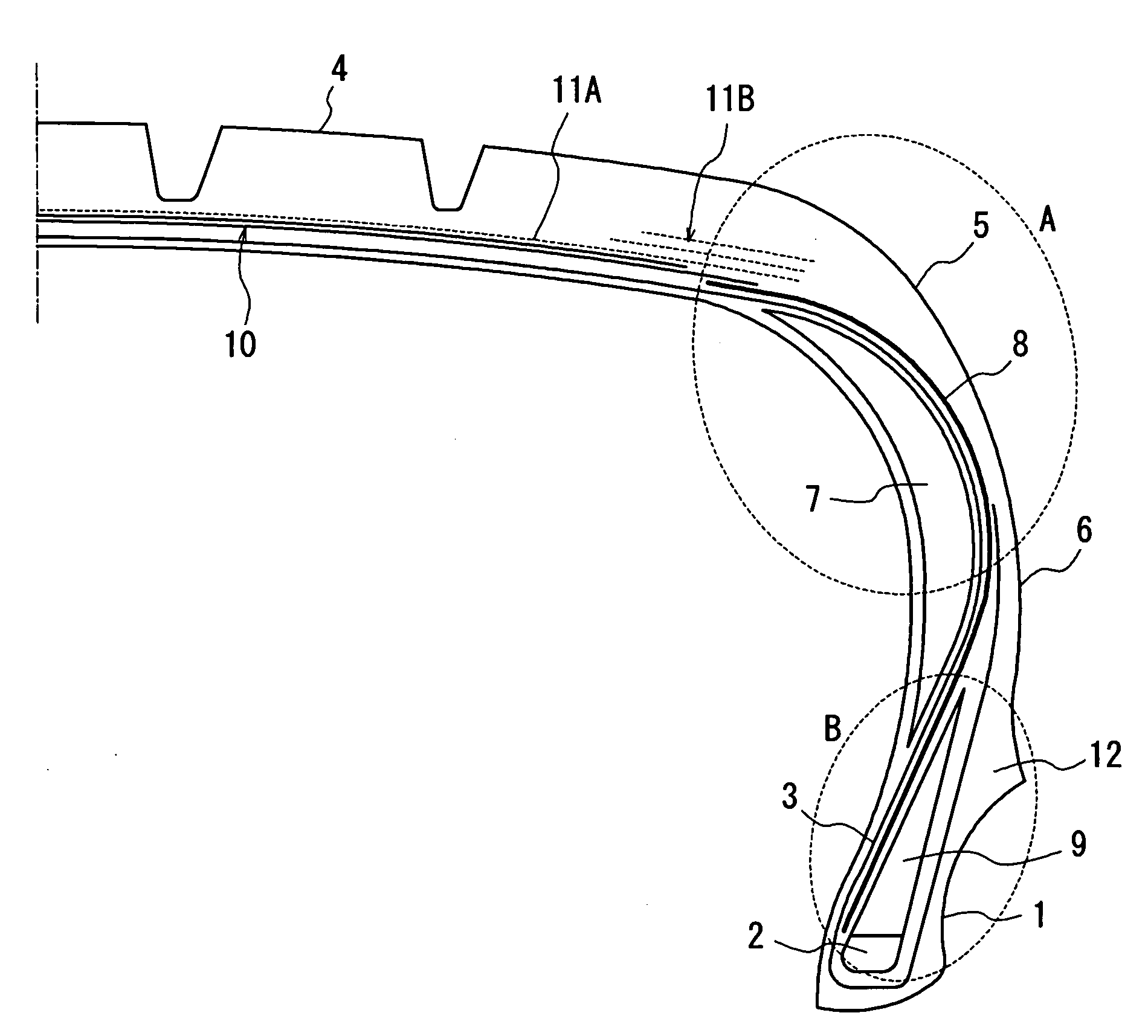

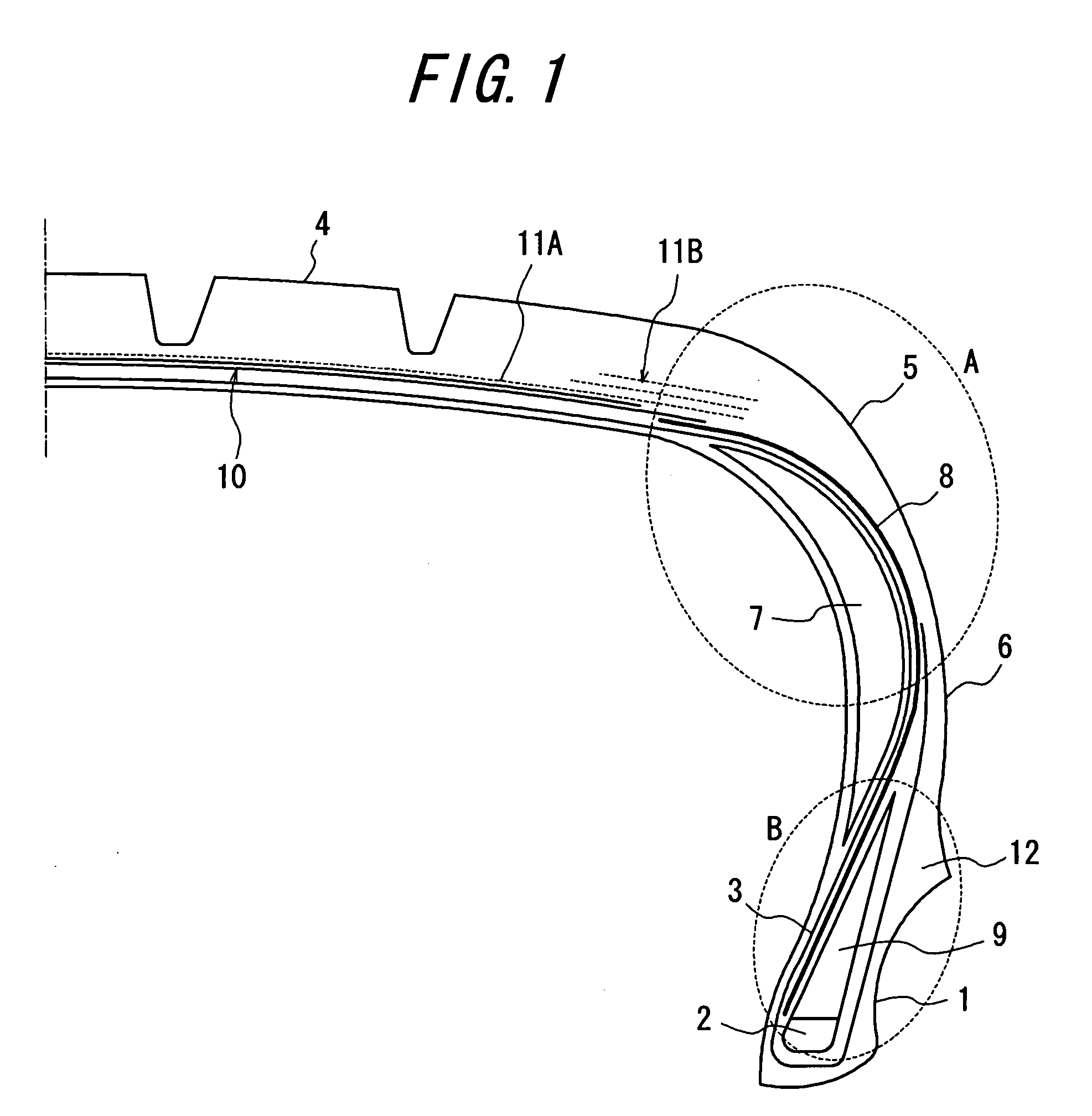

This invention relates to a tire having an improved durability in the run-flat running without damaging the ride comfort in the usual running, and more particularly to a run-flat tire comprising a sidewall portion provided with a side reinforcing rubber layer having a crescent shape at section wherein a cord layer including a polyketone fiber cord satisfying the following conditions of the following equations (I) and (II):σ≧−0.01×E+1.2 (I)σ≧0.02 (II)[wherein σ is a thermal shrinkage stress at 177° C. (cN / dtex) and E is an elastic modulus at 25° C. under a load of 49 N (cN / dtex)] is disposed in at least a part of a region A ranging from a belt end to a maximum width part of a tire side portion and a region B ranging from a neighborhood of a bead core to a bead filler.

Owner:BRIDGESTONE CORP

Method device and recording medium where program is recorded, for deciding residual travel life and end of life of run-flat tire that continues traveling in run-flat condition

InactiveUS7563021B2Improve relationshipConvenient ArrangementThermometer detailsThermometers using mean/integrated valuesInternal pressureEnd stages

There are provided a process and the like for judging a residual lifetime of a run-flat tire and an end stage of the residual lifetime thereof during continuous running at a run-flat state. The process for judging the residual lifetime of the tire of the invention is characterized in that in a vehicle equipped with a run-flat tire system comprising run-flat tires 2 and detection units 4 each arranged in the respective tire 2 and capable of measuring an atmosphere temperature in at least an interior 3 of the tire 2, when the tire 2 is continuously run at the run-flat state by an extreme lowering of an internal pressure accompanied with the occurrence of puncture or the like, after a limit temperature being statistically an occurrence of trouble is previously set, the atmosphere temperature inside tire of the run-flat tire continuously running at the run-flat state is measured, and a runnable time and / or distance until the run-flat tire results in trouble is predicted by using the atmosphere temperature inside tire measured and data calculated therefrom.

Owner:BRIDGESTONE CORP

Run-flat tire

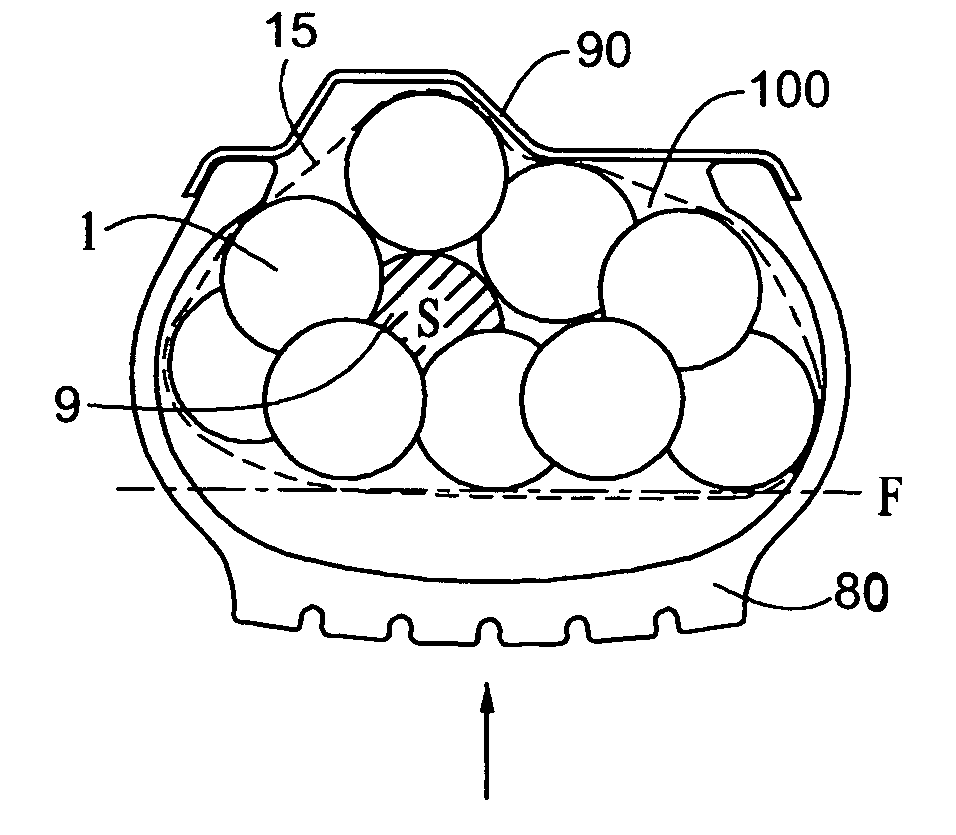

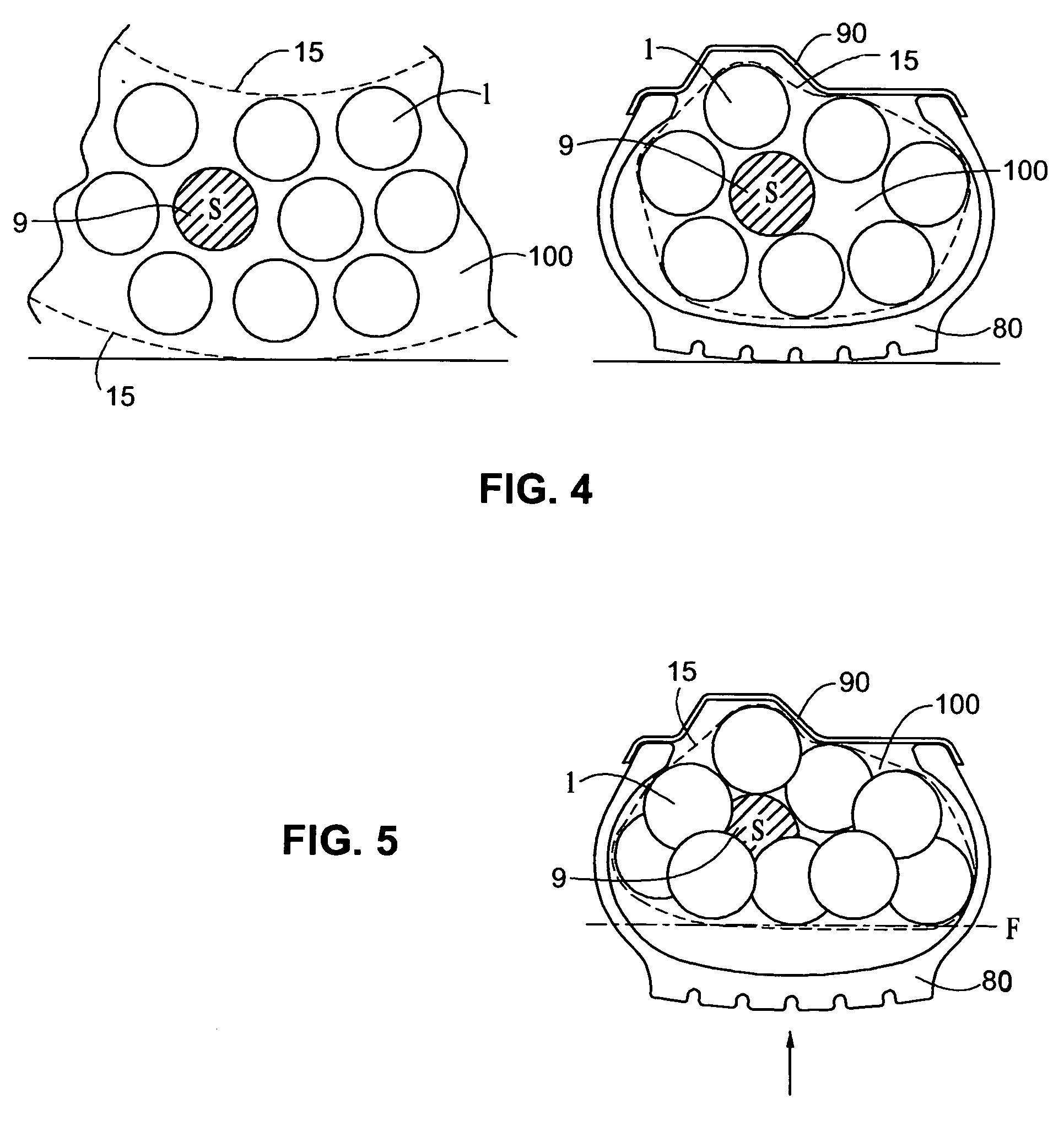

InactiveUS20050051249A1Eliminate the problemWith separate inflatable insertsWith multiple inflatable chambersDriver/operatorEngineering

Disclosed is a run-flat tire and condition sensing assembly for vehicle tires. The assembly comprises plurality of rounded, support objects, wherein each object comprises an interior, an interior surface, and an outer shell. There is also at least one rounded, sensor object comprising an interior, an interior surface, and an outer shell. A pressure sensor, which detects pressure and transmits a corresponding signal, is situated within the sensor object. A net houses the plurality of rounded, support and sensor objects. The interiors of the support objects can be filled with pressurized helium gas, an elastic material or contain a support structure. Accordingly, during deflation of the tire, the sensor alerts the driver of the deflation while the plurality of support objects prevents radical deformation of the tire and allows the driver to operate the vehicle to safety.

Owner:LEE GUL NAM

Run-flat tire

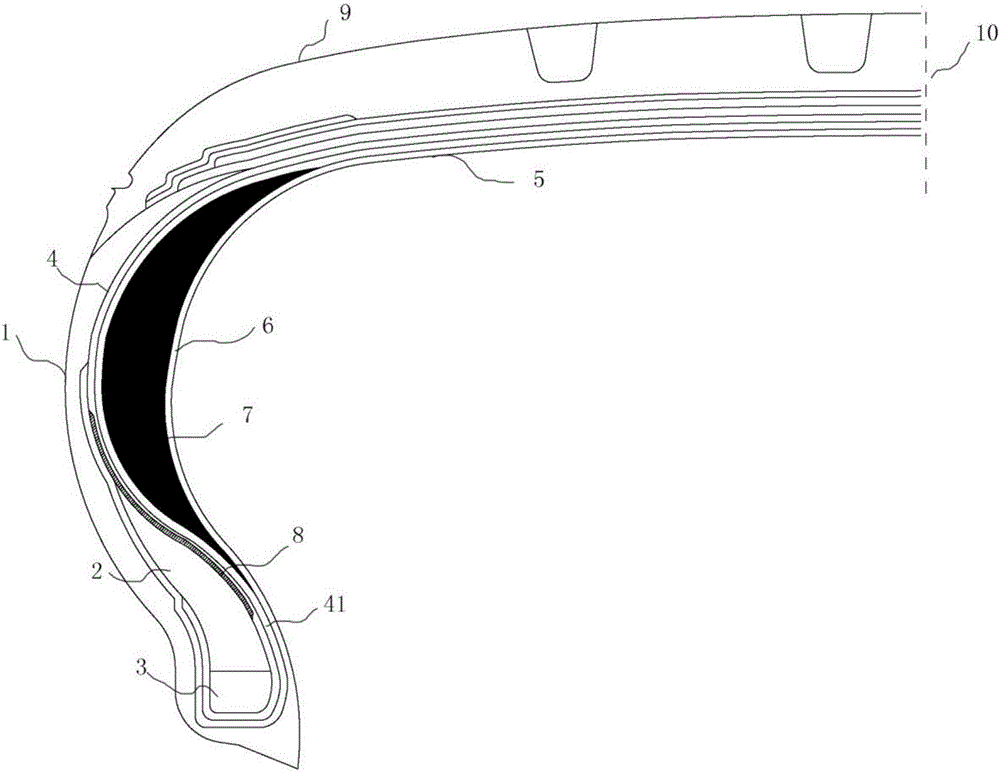

The invention relates to the field of tires, in particular to a run-flat tire. The run-flat tire comprises a tire bead, wherein the tire bead is internally filled with triangular rubber; a bead ring is arranged at the bottom end of the triangular rubber; a tire body layer is arranged around the tire bead; the tire body layer is turned back from the inner side to the outer side of the tire; a belt beam layer is arranged on the outer side of the tire body layer in the radius direction and inside a tire tread part; a tire sidewall supporting rubber layer is arranged between the tire body layer at a tire sidewall and a lining layer; and a tire bead reinforcing layer is arranged on the side surface of the tire bead. Compared with the ordinary run-flat tire, the run-flat tire disclosed by the invention has the advantages as follows: the hardness of tire sidewall supporting rubber is relatively reduced, so that the driving comfort is optimized to a certain extent; under the condition of the same rigidity, the thickness of the tire sidewall supporting rubber is reduced, so that the weight reduction of the tire is facilitated; during to reinforcement of a reinforcing material on a seam allowance position, the flexible deformation of the seam allowance position is relatively small in a run-flat state, and in combination with the reduction in the thickness of the supporting rubber, heat generation at the tire sidewall is reduced and heat dissipation is facilitated, so that improvement on the durability of the tire is facilitated.

Owner:SAILUN GRP CO LTD

Pneumatic run-flat tire

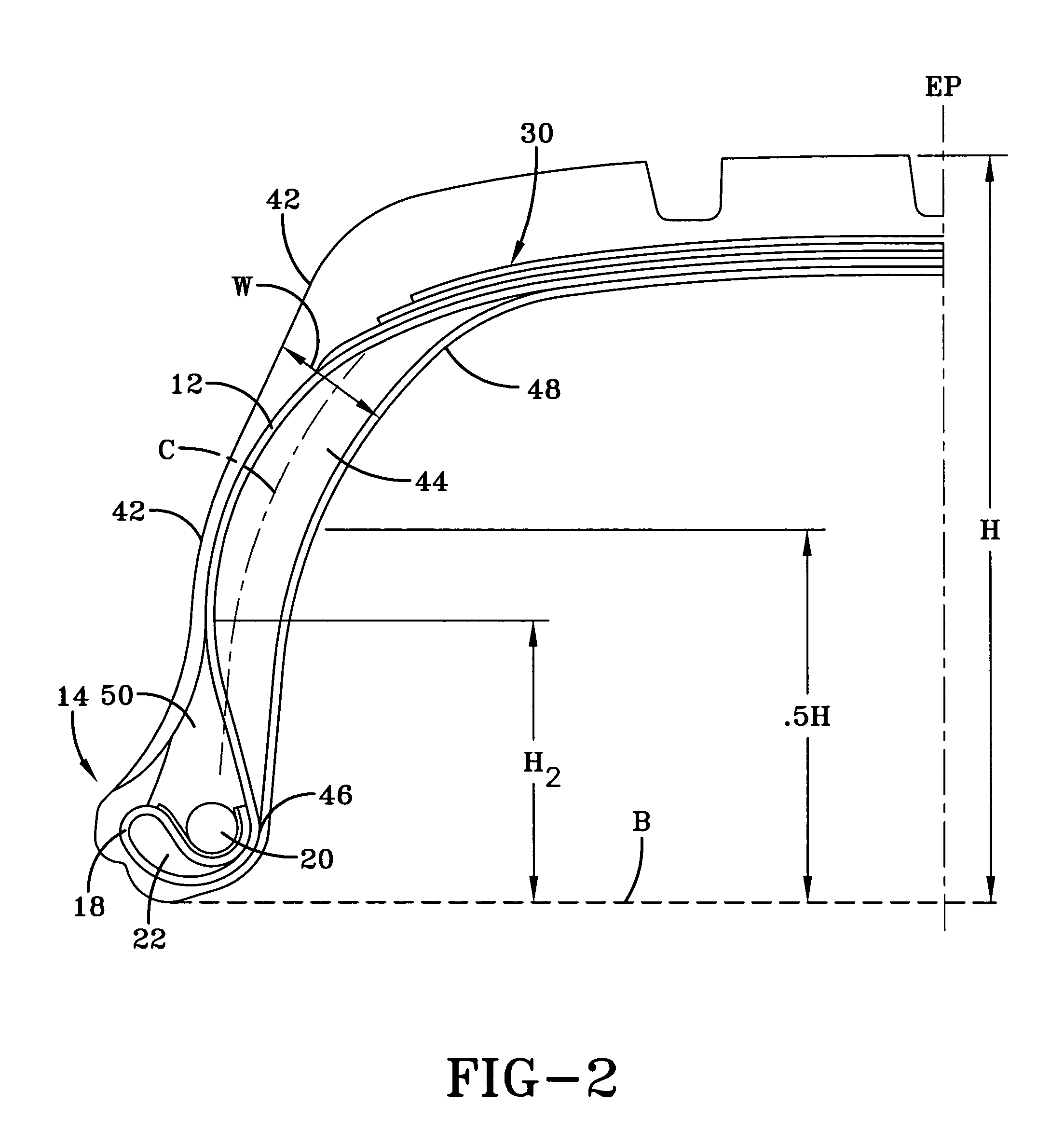

A pneumatic run-flat tire has a bead configuration wherein the axially inner end is radially inward of the axially outer end of the bead. The sidewall of the tire, from the bead region to the upper sidewall is reinforced to form a pillar support in the sidewall. The bead configuration and the pillar reinforcement enable the tire to lock itself onto a tire rim during low pressure operation and be self-supporting.

Owner:THE GOODYEAR TIRE & RUBBER CO

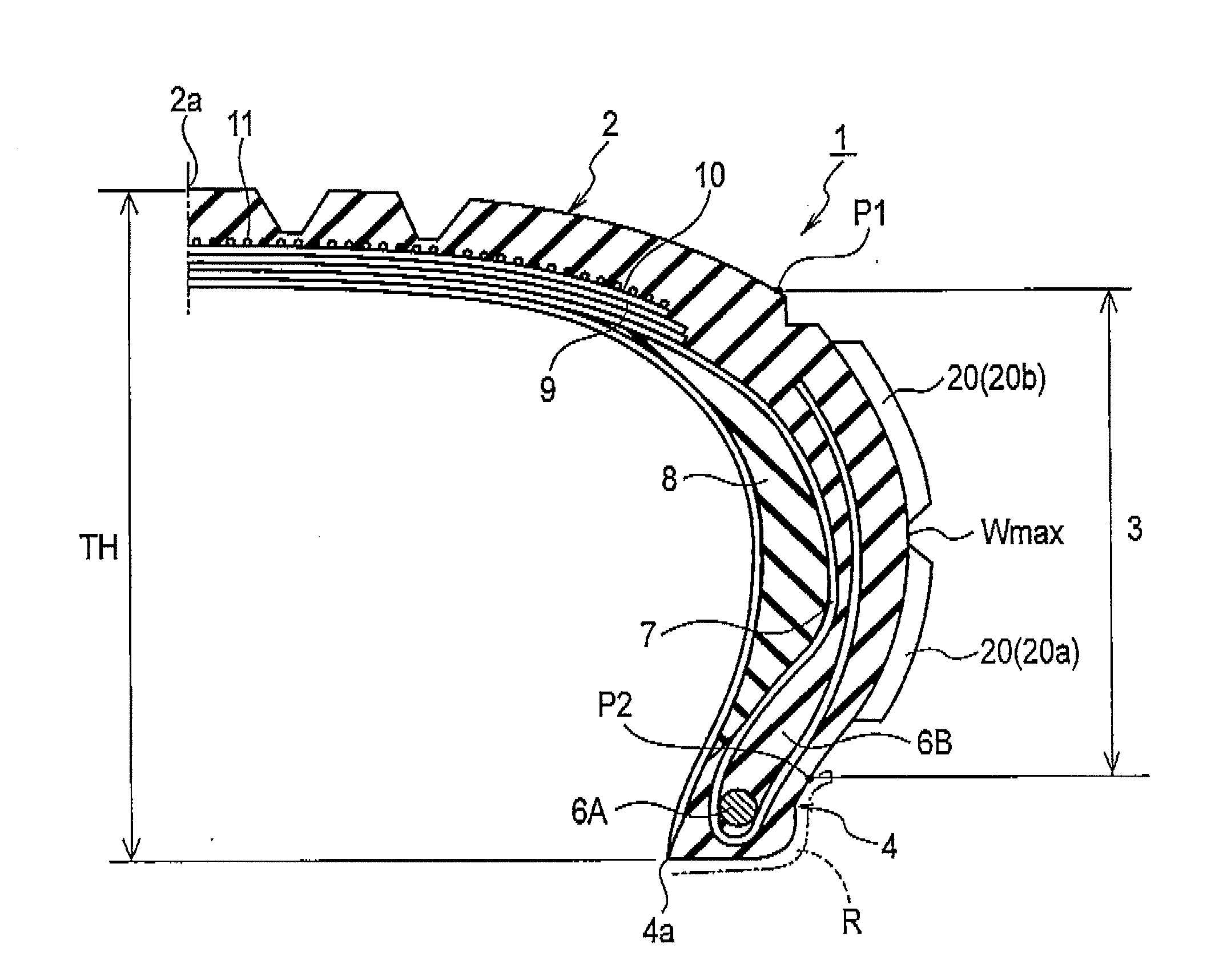

Pneumatic tire

ActiveUS20160236521A1Increased durabilityInhibit deteriorationNon-inflatable tyresPneumatic tyre reinforcementsMechanical engineeringRun-flat tire

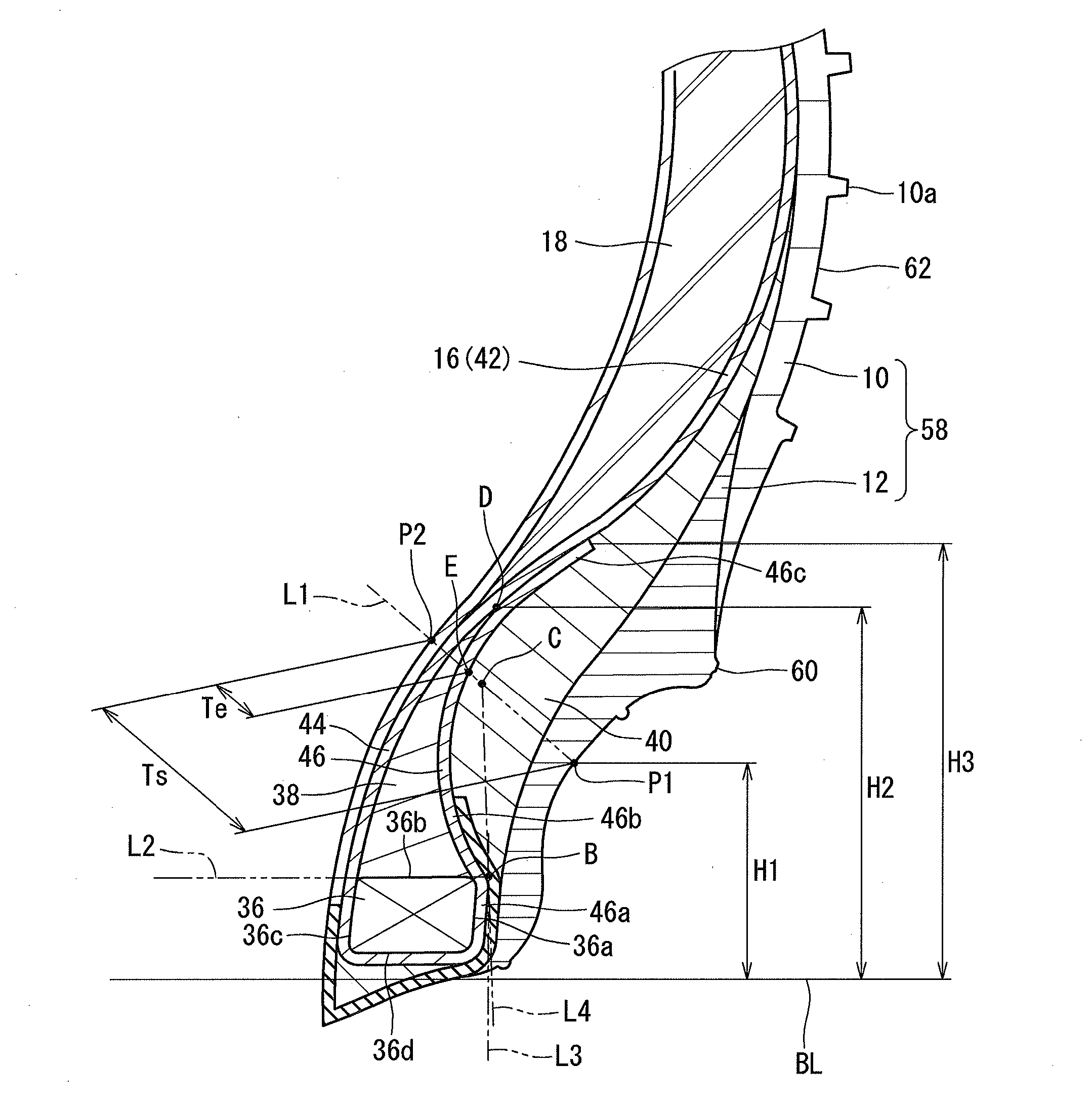

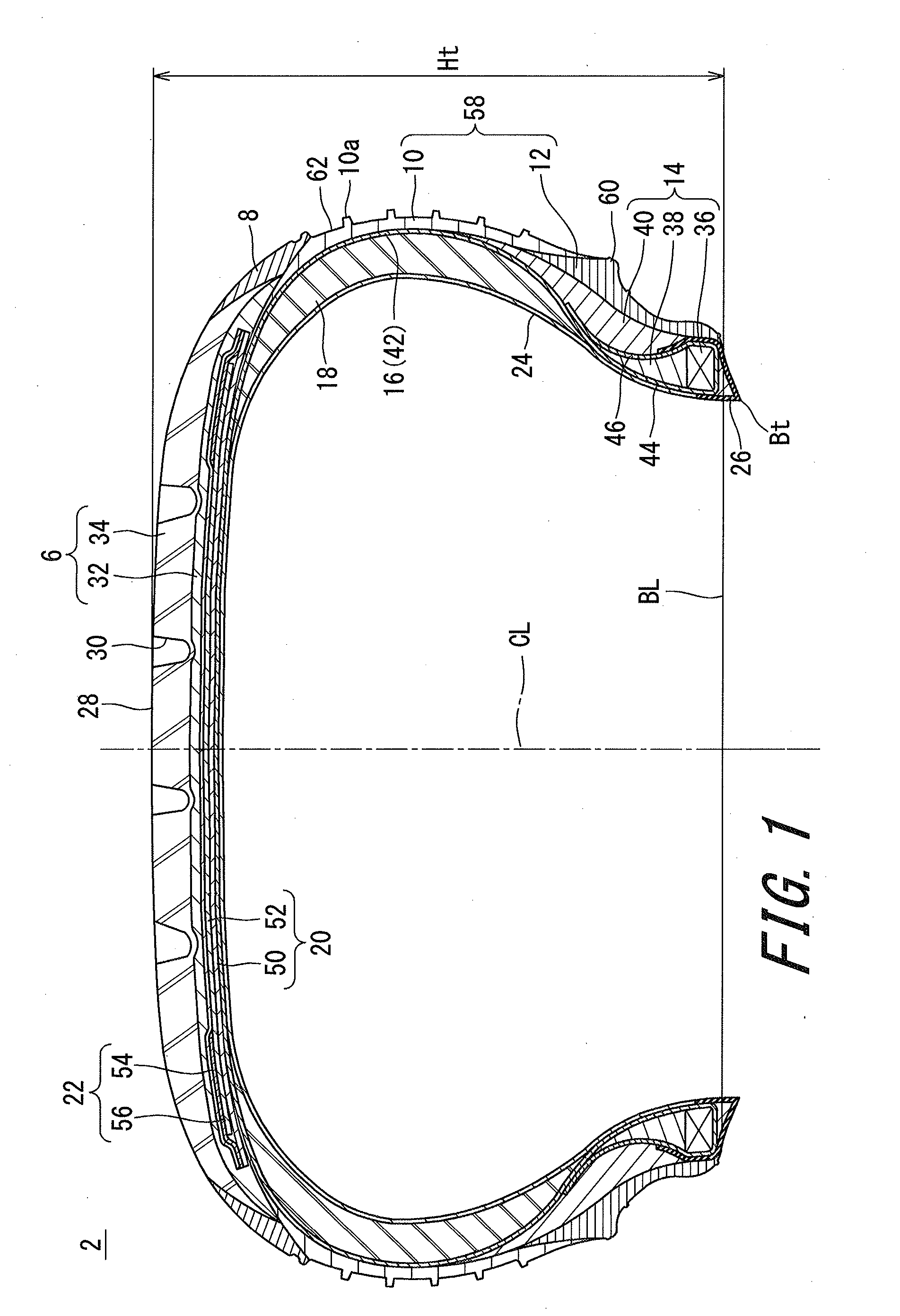

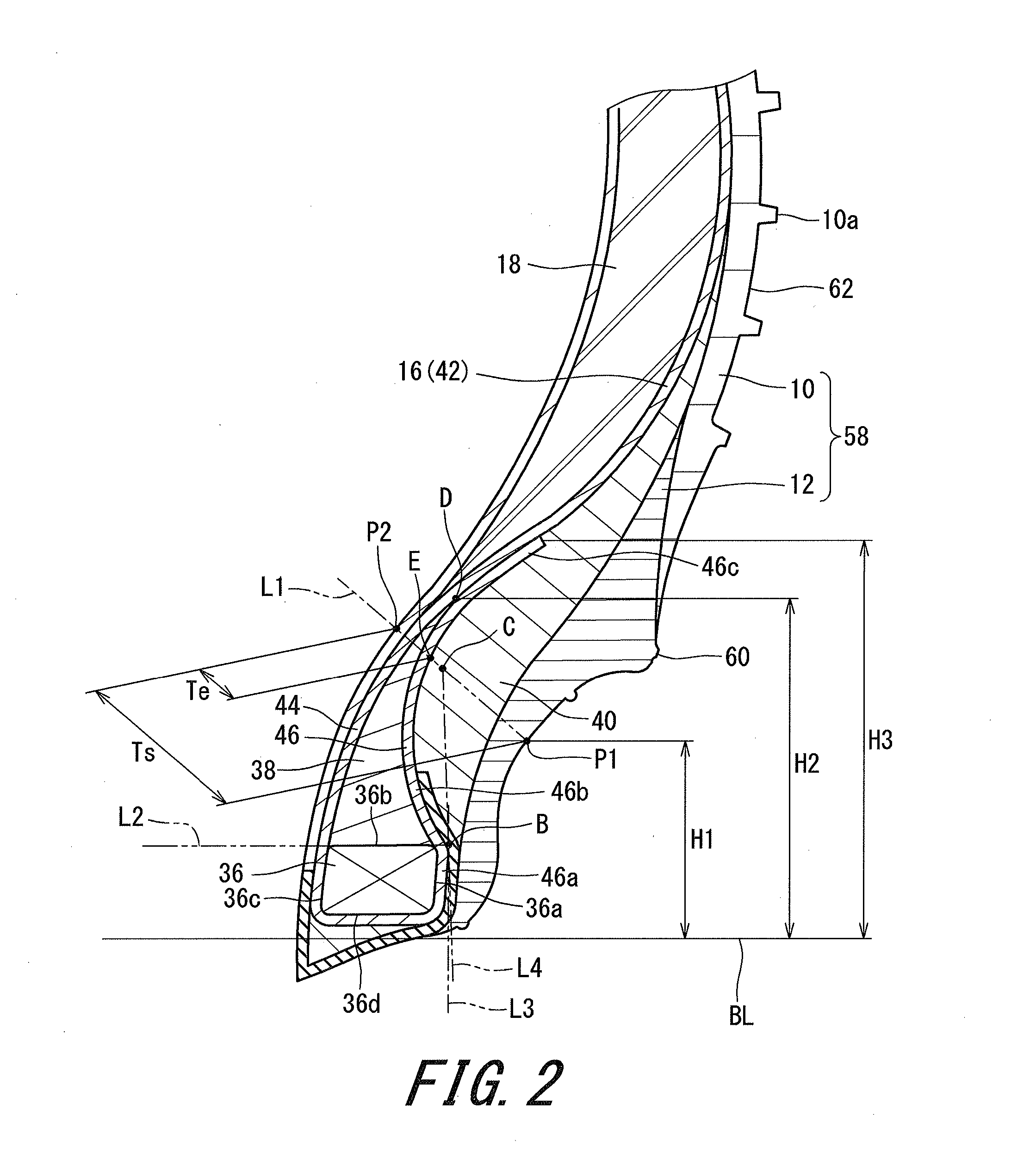

A run flat tire is provided having a line L1 connecting point P1 having height H1 of 17 mm; and point P2 at which a thickness from point P1 is minimum thickness Ts. Point C represents a point which is distant from point P2 on line L1 by a distance that is 0.4 times Ts. A point B represents a point of intersection of: line L2 that extends in the axial direction through radially outer end of core 36; and line L3 that extends in the radial direction through an axially outer end of core side portion 46a of turned-up portion 46. A line L4 passes through point C and point B. The thickness Ts is greater than or equal to 10 mm, and not greater than 17 mm. The turned-up portion 46 extends through a region surrounded by an axially outer surface of main portion 44, and lines L2-L4.

Owner:SUMITOMO RUBBER IND LTD

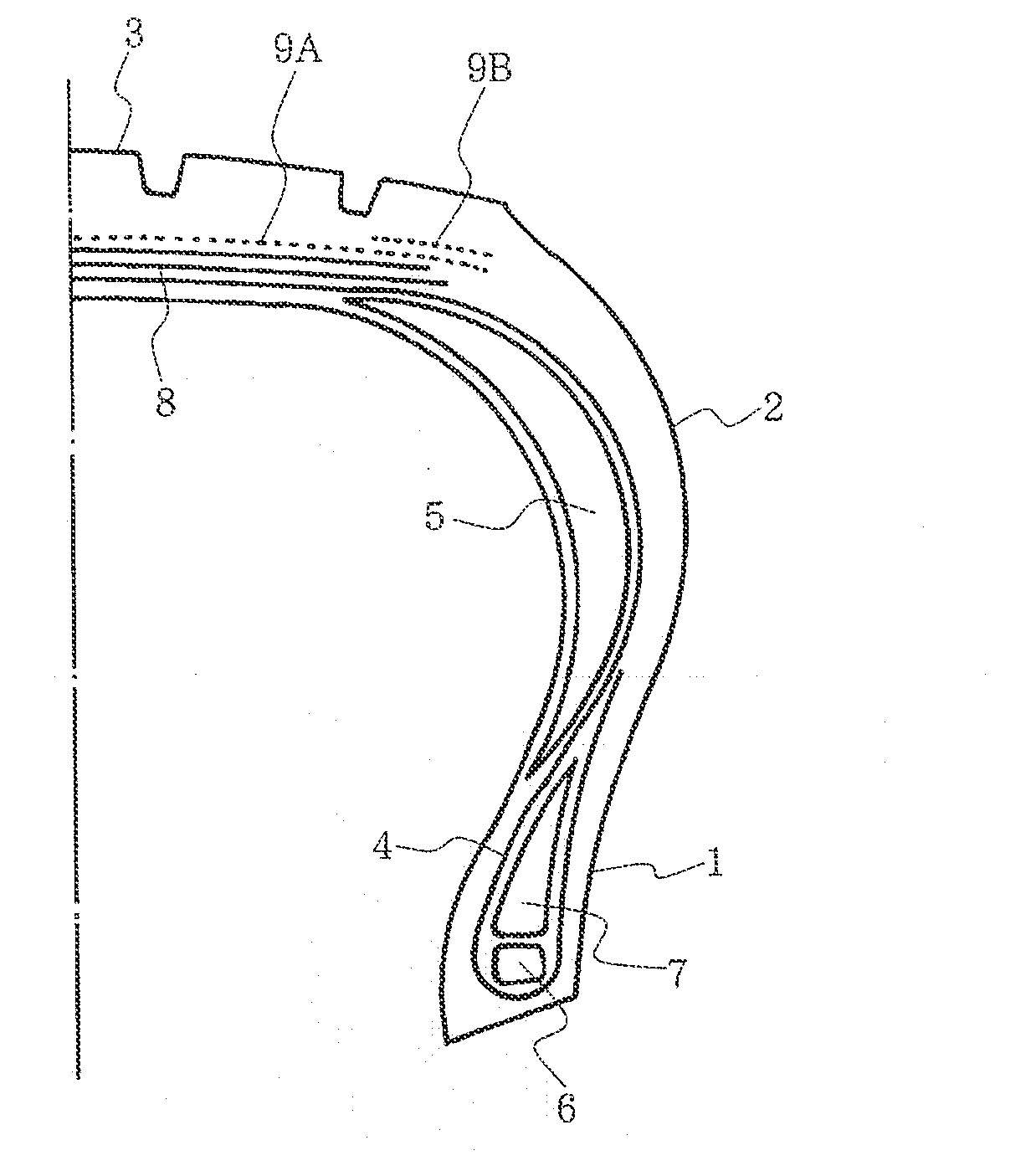

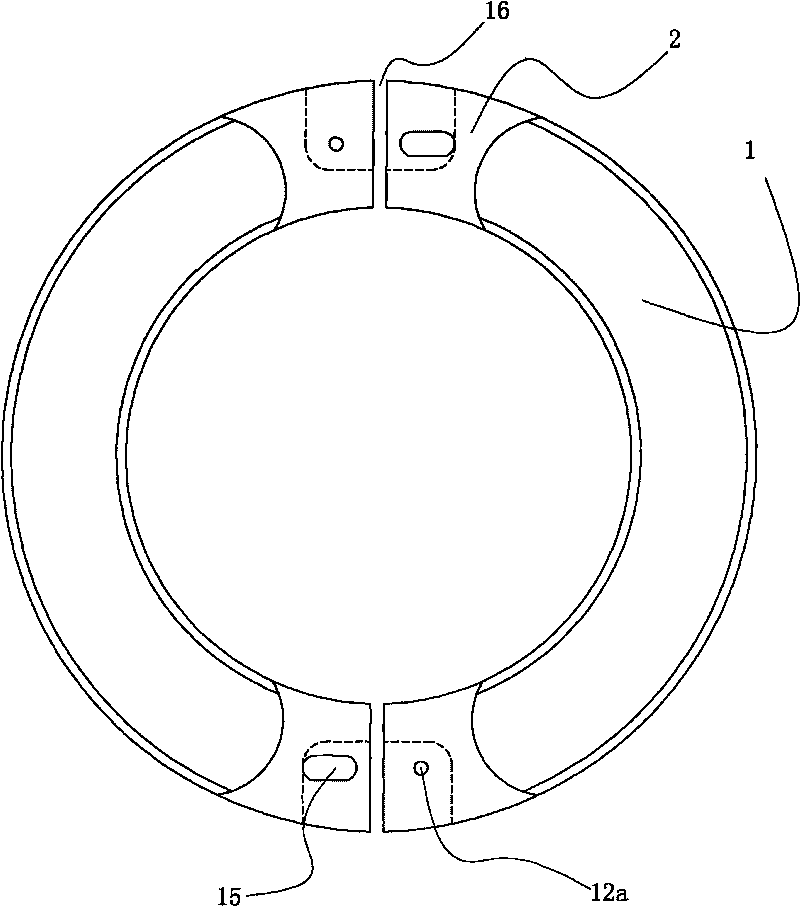

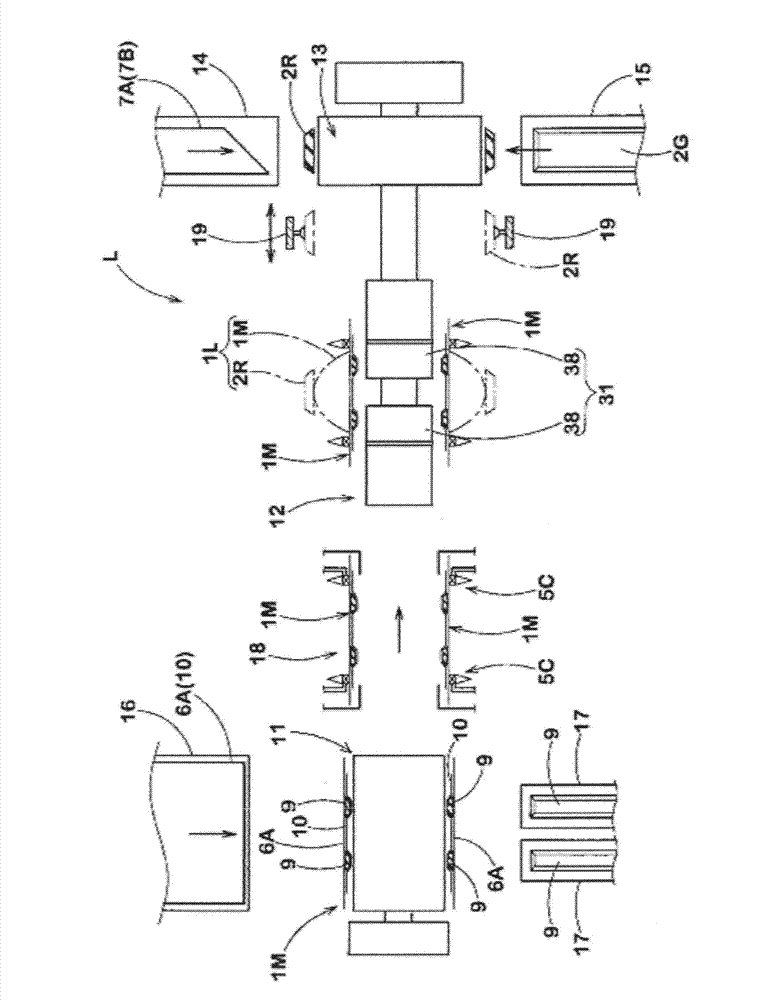

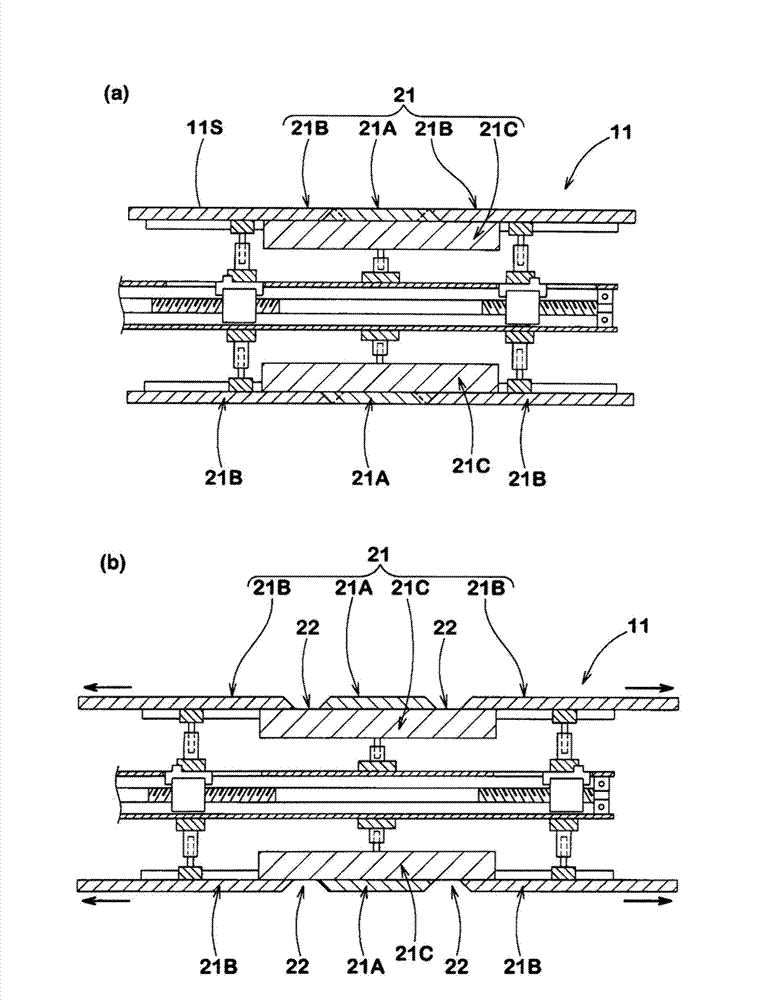

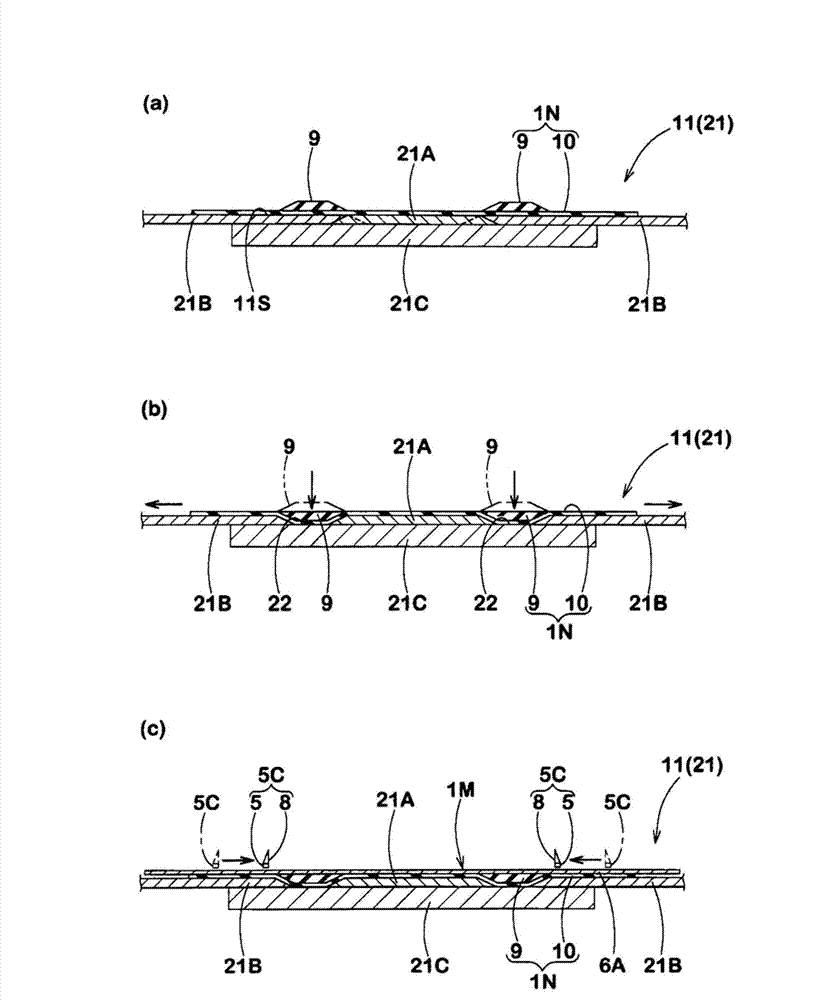

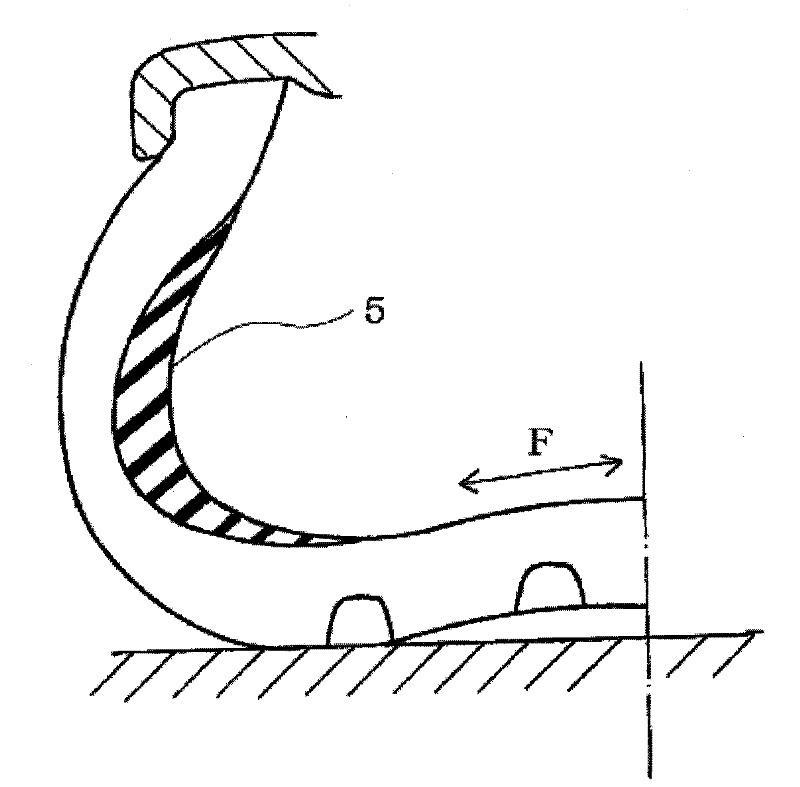

Run-flat tire forming device

InactiveCN102774024APrevent poor vulcanizationImprove productivityTyresTire beadMechanical engineering

Provided is a run-flat tire (1) forming device (12) for expanding and deforming a tire body base body (1M) with a pair of bead cores (5), a tire body cord fabric layer (6A) and a rubber reinforcing layer (9). The forming device (12) comprises a pair of bead locking units (32) for clamping the tire body cord fabric layer (6A) through expanding to keep the bead cores (5) from the inner side and moving to an axial direction; a pair of tire side plates (38) capable of extending and shrinking diameters, located in an axial inner side of the bead locking units (32) and capable of supporting a tire side part (3) of the tire body base body (1M) from the inner side. The peripheral surfaces of the tire side plates (38) form a peripheral groove (45) matching with a section shape of the rubber reinforcing layer (9).

Owner:SUMITOMO RUBBER IND LTD

Run-flat tire

InactiveCN102056754AExcellent run-flat performanceExcellent high-speed straight running stabilitySpecial tyresPneumatic tyre reinforcementsWire rodDynamic storage

Provided is a run-flat tire which has an excellent run-flat performance as well as a high high-speed straight running stability in the non-punctured state, a high steering stability on both of a dry road surface and a wet road surface and a good fuel efficiency. A run-flat tire which comprises at least two cross belt layers formed by rubberizing a steel cord and a tread rubber located successively, wherein a reinforcing rubber is provided inside a carcass. The above-described steel cord has a single twisted structure or a core / single layered sheath structure consisting of 6 to 10 steel strands having a strand diameter of 0.10 to 0.20 mm. The density of the implanted steel cords is 40 cords / 50 mm or more and the distance between the adjacent steel cords in the belt layer is 0.3 mm or longer. Moreover, the dynamic storage modulus E' (MPa) at 30 DEG C of the tread rubber and tand at 60 DEG C of the same respectively satisfy the relationships represented by the formulae: 5.0<=E' and 0.050<=tand<=0.240.

Owner:BRIDGESTONE CORP

Run flat tire

InactiveUS20130037193A1Increase the itineraryRelieve pressurePneumatic tyre reinforcementsTyre beadsEngineeringHardness

A run flat tire with reinforced sides, wherein inner and outer rubber thickness ratios centered on a carcass layer in a side wall portion are stipulated and a side filler extending in the tire radial direction is embedded on the outer wall surface side of the side wail portion. In this run flat tire, the modulus of the side filler / modulus of a side reinforcing layer, the modulus of a rim cushion / a modulus of the side filler, the cross-sectional area of a bead filler / cross-sectional area of the side filler, the cross-sectional area of the side filler / cross-sectional area of the side reinforcing layer, the rubber hardness of the side reinforcing layer, and the material of belt cover layers are each stipulated.

Owner:YOKOHAMA RUBBER CO LTD

Tire wheel assembly

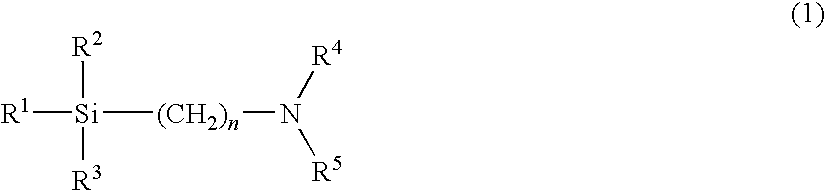

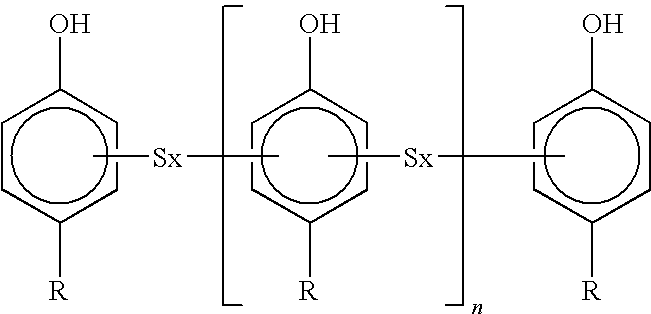

InactiveUS20070084537A1Improve adhesionReduce processSpecial tyresInflatable tyresEngineeringSilicon dioxide

A run flat tire wheel assembly having a run flat support member formed by a ring-shaped metal shell and rubbery elastic members in an inside cavity of a tire / rim, wherein the rubbery elastic member comprises a rubber composition including (A) 100 parts by weight of a diene-based rubber and (B) (i) 0.1 to 5 parts by weight of cobalt acetyl acetonate and / or (B) (ii) (a), as a reinforcing filler, 40 to 90 parts by weight of carbon black / silica in a ratio of 10 / 1 to 1 / 2 (weight ratio) and (b) 1 to 20% by weight based upon the weight of the silica, of a silane coupling agent, whereby the bondability between the ring-shaped metal shell and rubbery elastic members is improved.

Owner:YOKOHAMA RUBBER CO LTD

Asymmetrical pneumatic run-flat tire

InactiveUS20060130951A1Difference in stiffnessIncreased durabilityTyresSpecial tyresMechanical engineeringRun-flat tire

Owner:THE GOODYEAR TIRE & RUBBER CO

Run flat tire

InactiveUS20110284143A1Increase stiffnessImprove steering stabilityPneumatic tyre reinforcementsTyre beadsEngineeringMechanical engineering

A side wall reinforced run flat tire, wherein a second carcass layer that does not reach a bead core is disposed along the outer peripheral surface of a carcass layer. A position of an outer peripheral edge of a bead filler, a relationship between a rubber thickness Gc of the inner side and a rubber thickness Ga of an outer side taken on the line X normal to the rim line and centered on the carcass layer, a relationship between the rubber thicknesses Ga and Gb of the side wall rubber in an upper region of a bead portion, and a position of a folded up end of the carcass layer are each stipulated.

Owner:THE YOKOHAMA RUBBER CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com