Run-flat tire

A run-flat tire and bead technology, applied in tire parts, tire rims, tire sidewalls, etc., can solve the problems of poor ride comfort, increased tire weight, and thick thickness, and optimize ride comfort. performance, improve design efficiency, and improve durability

Inactive Publication Date: 2017-05-31

SAILUN GRP CO LTD

View PDF6 Cites 12 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0007] The self-supporting solution is mainly to add a certain thickness of supporting rubber on the sidewall to support the vehicle load when the tire is deflated. Fuel consumption increases, and under normal inflation conditions, the tires are very rigid and the driving comfort is poor

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0046] have figure 1 Run-flat tires with a size of 225 / 55R17 of the basic structure were produced according to the specifications in Table 1, and the run-flat durability and ride comfort performance of each trial tire were tested.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

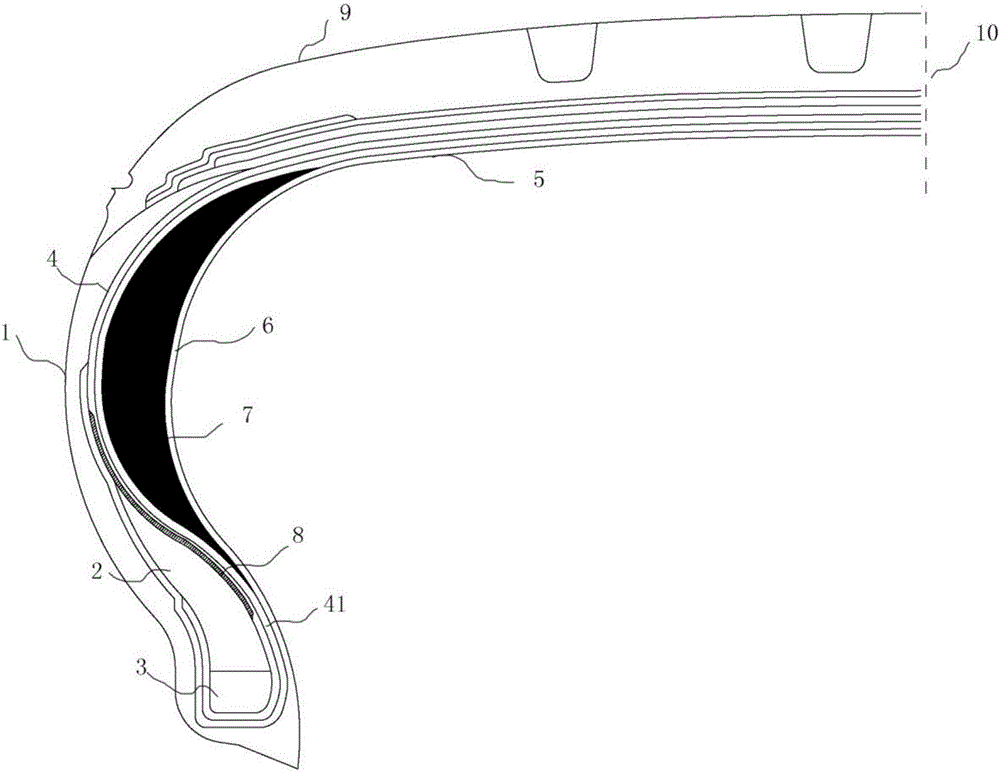

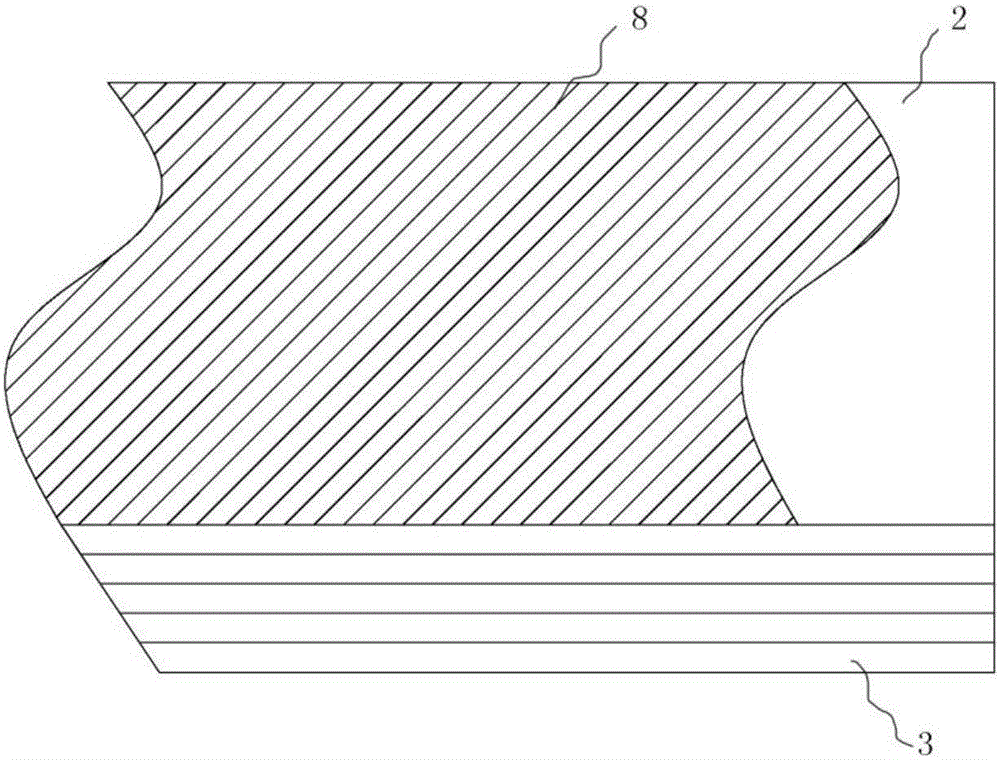

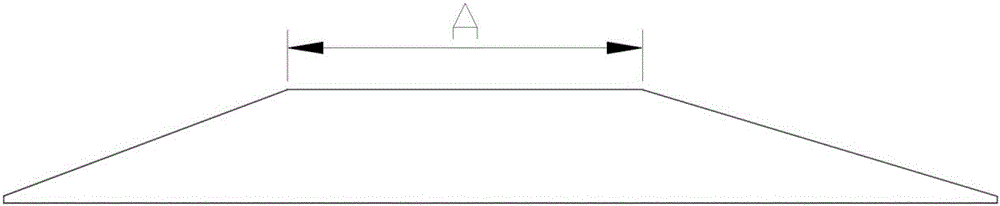

The invention relates to the field of tires, in particular to a run-flat tire. The run-flat tire comprises a tire bead, wherein the tire bead is internally filled with triangular rubber; a bead ring is arranged at the bottom end of the triangular rubber; a tire body layer is arranged around the tire bead; the tire body layer is turned back from the inner side to the outer side of the tire; a belt beam layer is arranged on the outer side of the tire body layer in the radius direction and inside a tire tread part; a tire sidewall supporting rubber layer is arranged between the tire body layer at a tire sidewall and a lining layer; and a tire bead reinforcing layer is arranged on the side surface of the tire bead. Compared with the ordinary run-flat tire, the run-flat tire disclosed by the invention has the advantages as follows: the hardness of tire sidewall supporting rubber is relatively reduced, so that the driving comfort is optimized to a certain extent; under the condition of the same rigidity, the thickness of the tire sidewall supporting rubber is reduced, so that the weight reduction of the tire is facilitated; during to reinforcement of a reinforcing material on a seam allowance position, the flexible deformation of the seam allowance position is relatively small in a run-flat state, and in combination with the reduction in the thickness of the supporting rubber, heat generation at the tire sidewall is reduced and heat dissipation is facilitated, so that improvement on the durability of the tire is facilitated.

Description

technical field [0001] The invention relates to the field of tires, in particular to a run-flat tire. Background technique [0002] Tires are very important to the safety of the car. Once the tire leaks, it will deform and shrink, the car will lose its balance, and the driver cannot control the direction and braking, which can easily lead to traffic accidents, especially when driving at high speeds. Therefore, maintaining the normal tire pressure of the car tires is very important for the safe driving of the car. Many tire manufacturers are aware of this problem and have invested in the research of run-flat tires. [0003] The so-called run-flat tires refer to car tires that can still travel a certain distance at a set speed when the car is punctured and the tire pressure drops to zero. Generally, when the tire loses tire pressure, the tire can be separated from the hub like mud in the blink of an eye, and only the hub can contact the ground. The biggest difference betwee...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B60C13/00B60C15/04B60C15/06

CPCB60C13/00B60C15/04B60C15/06

Inventor 朱作勇赵猛黄宗茂毛德政

Owner SAILUN GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com