Run flat pneumatic tire with shoulder cushion rubber layer loss tangent less than carcass coating rubber loss tangent

a pneumatic tire and shoulder cushion technology, applied in the field of pneumatic tires, can solve the problems of unavoidable tires, increased cost, and difficulty in assembling tires onto wheels, so as to improve ride comfort against vibration, and damage the effect of ride comfor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

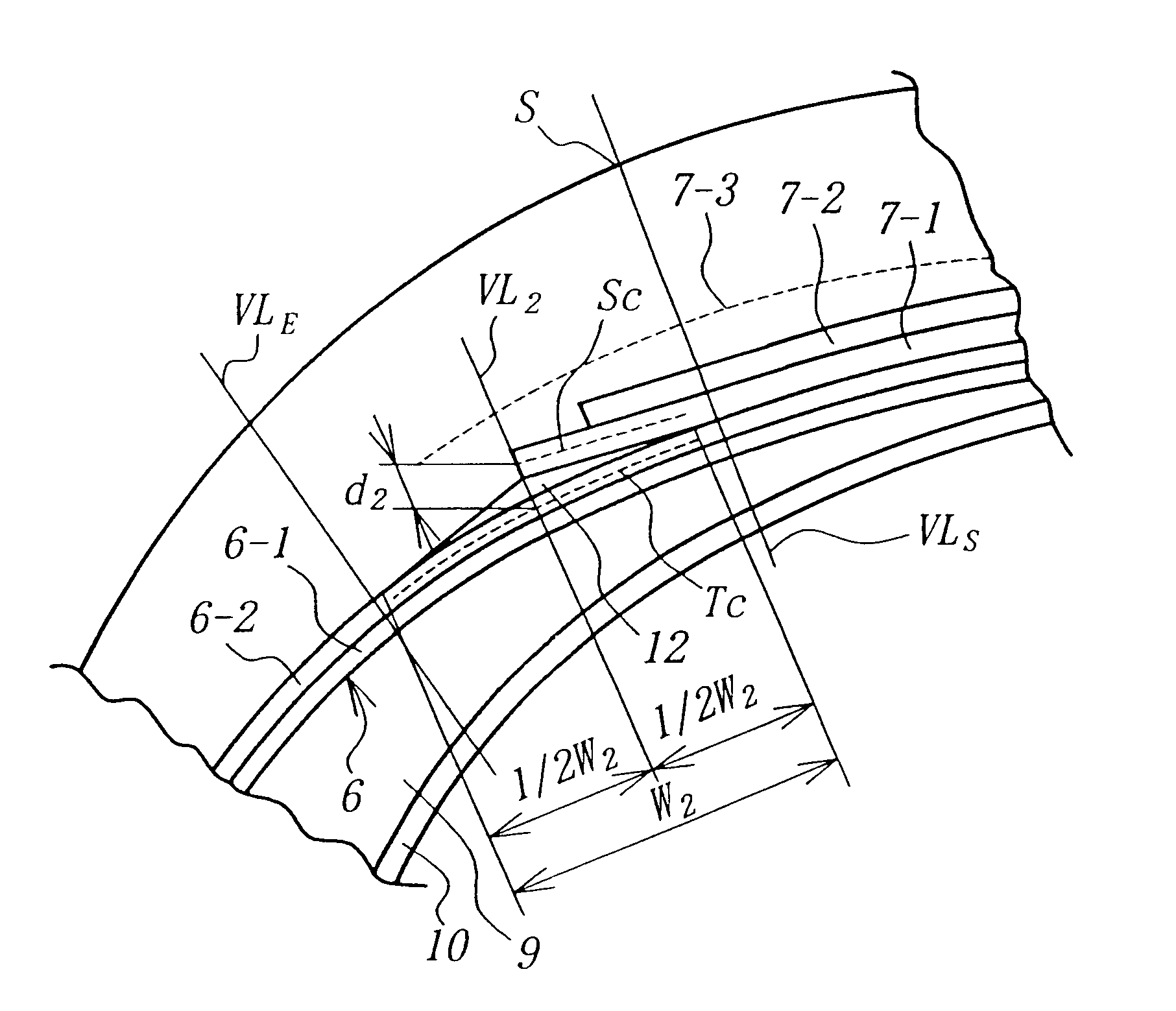

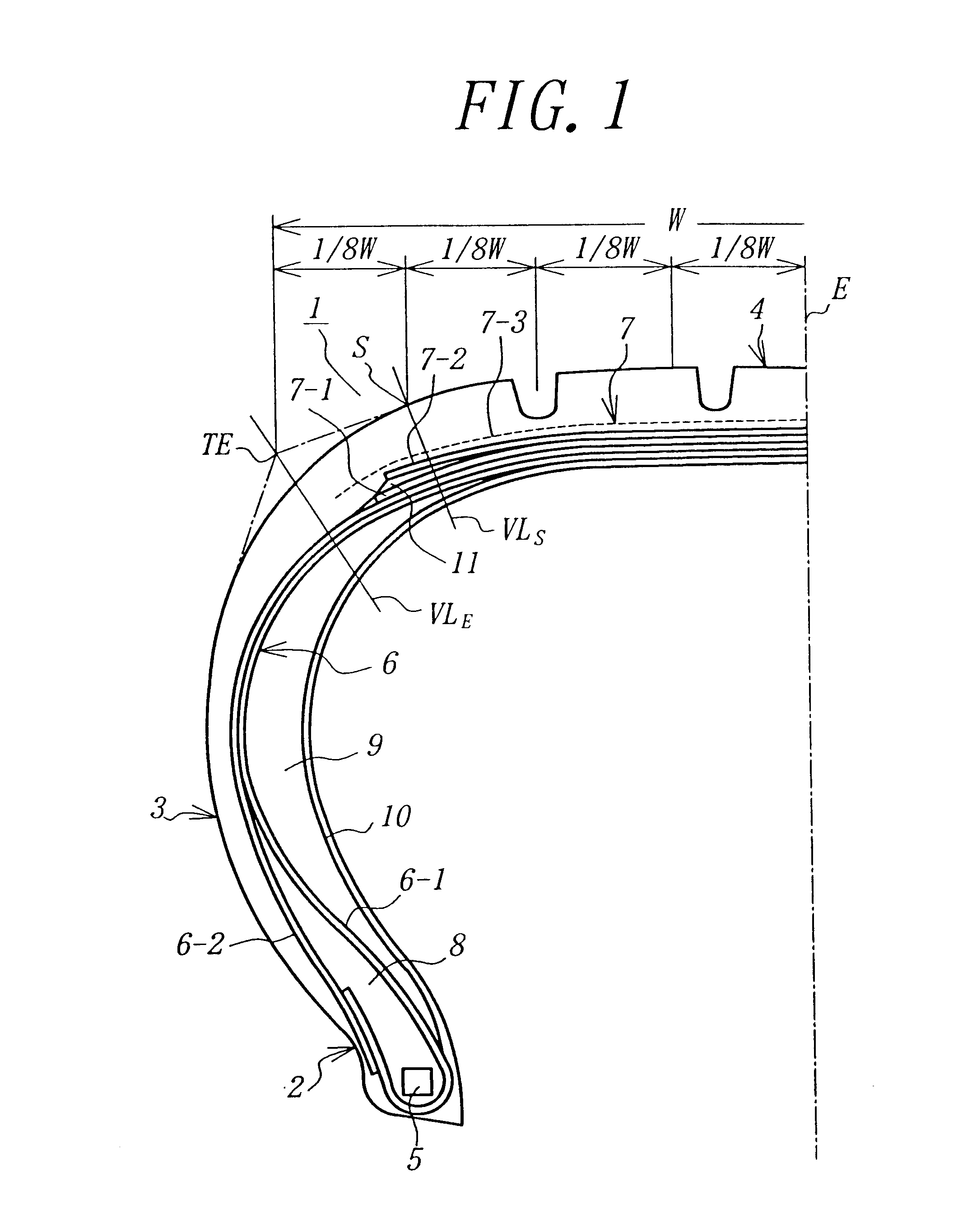

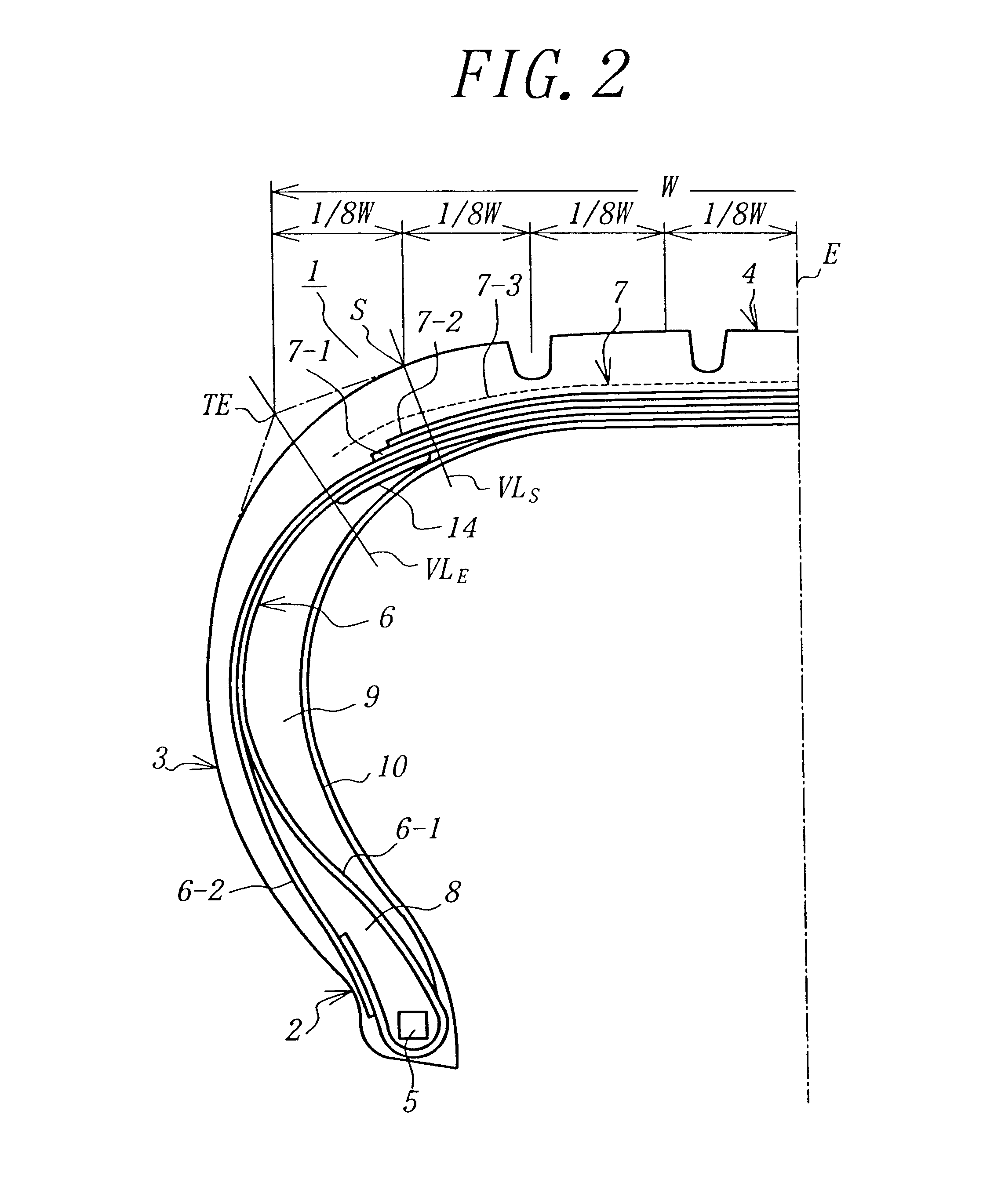

Image

Examples

examples 40

OMPARATIVE EXAMPLES 2.about.3

In this example, the melting point of fiber for the cord of the carcass ply through DSC is a peak temperature of a melting curve measured through DSC made by Dunlop under conditions that a temperature rising rate is 10.degree. C. / min and a sample weight is about 5 mg.

The tensile stress of rubber composition used in the reinforcing rubber layer, coating rubber for the cord of the carcass ply and the like is measured according to JIS K6301-1995.

The tensile strength and elongation at break of the cord of the carcass ply are measured according to JIS L1017-1983.

The tire performances are measured by the following methods.

(1) Ride Comfort Against Vibrations

A test tire adjusted to an internal pressure of 2.0 kg / cm.sup.2 is trained on a drum having an outer diameter 2000 mm and provided on one place with a semi-circular iron projection having a radius of 5 mm at a speed of 80 km / h under a load of 570 kg for 20 minutes, and thereafter the internal pressure is rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com