Patents

Literature

133 results about "Firing order" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The firing order is the sequence of power delivery of each cylinder in a multi-cylinder reciprocating engine. This is achieved by sparking of the spark plugs in a gasoline engine in the correct order, or by the sequence of fuel injection in a Diesel engine. When designing an engine, choosing an appropriate firing order is critical to minimizing vibration, to improve engine balance and achieving smooth running, for long engine fatigue life and user comfort, and heavily influences crankshaft design.

Multi-stage variable displacement engine

InactiveUS20070131183A1Improve efficiencyReduce fuel consumptionInternal combustion piston enginesCylinder headsCurrent loadFiring order

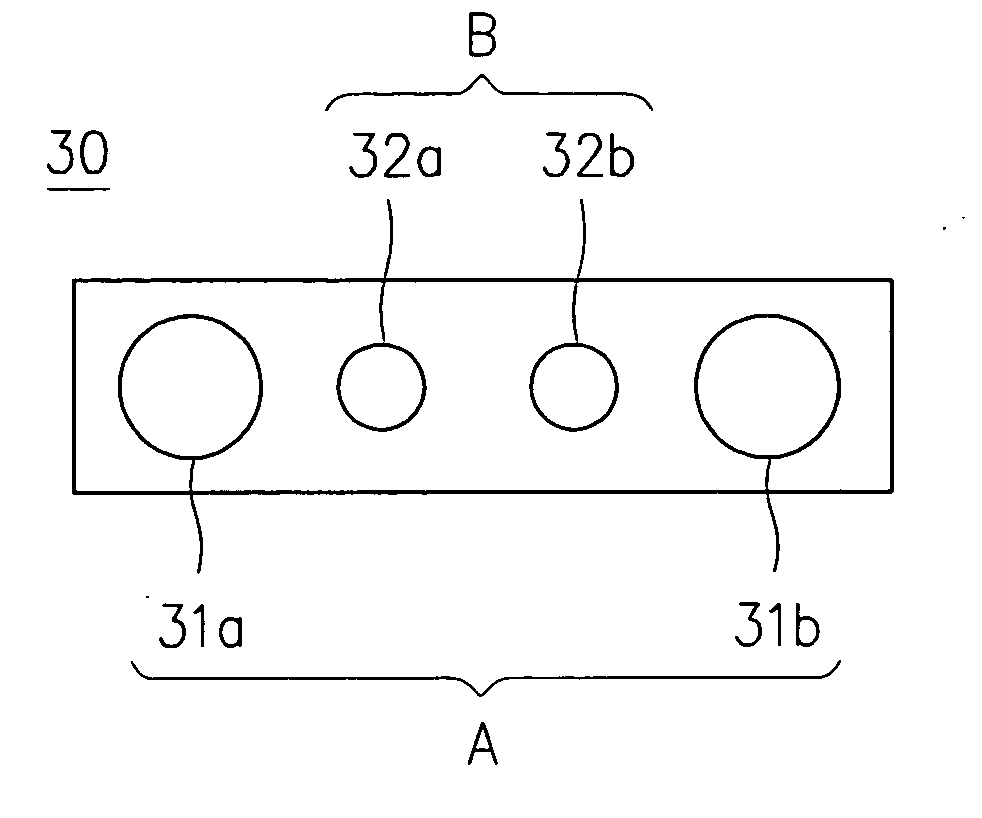

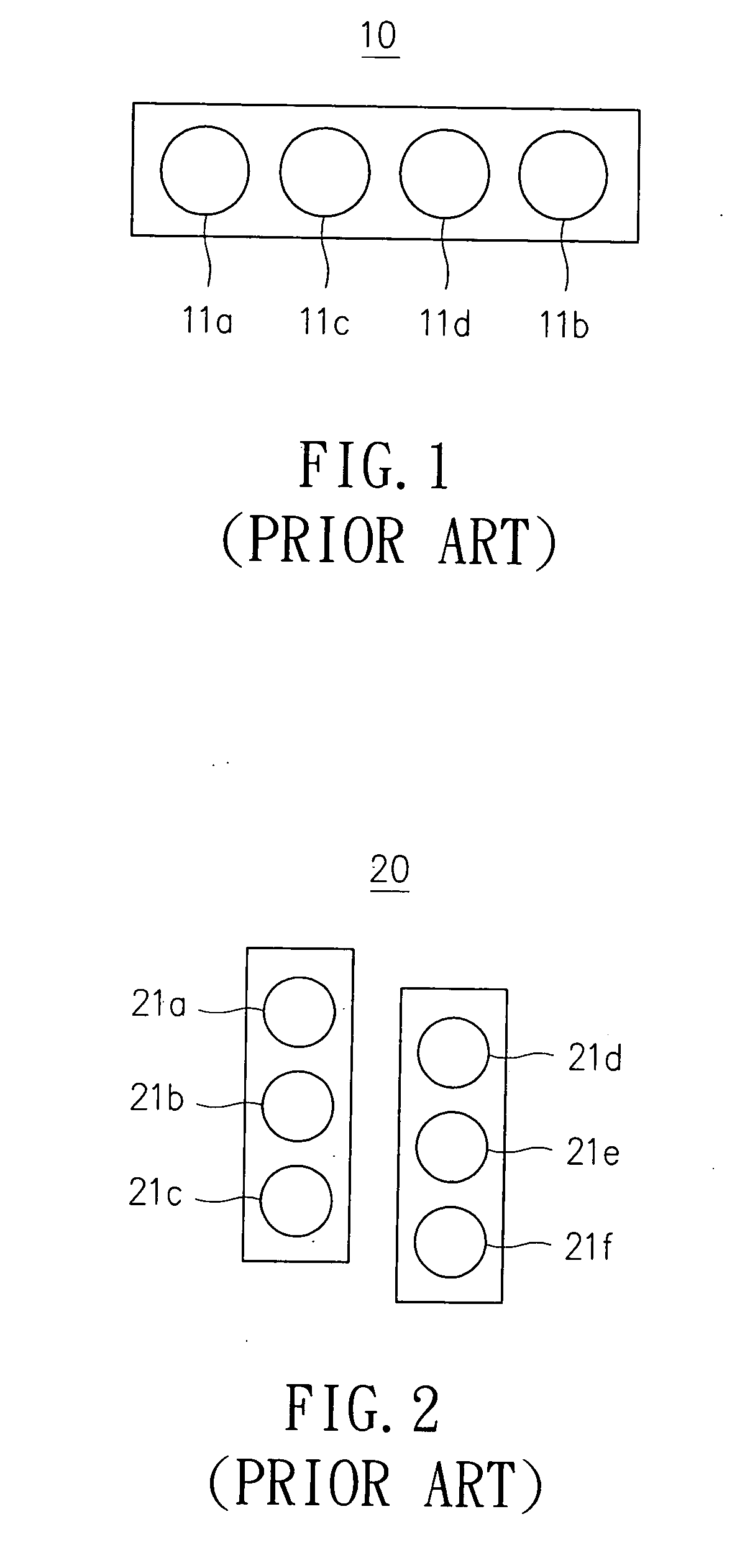

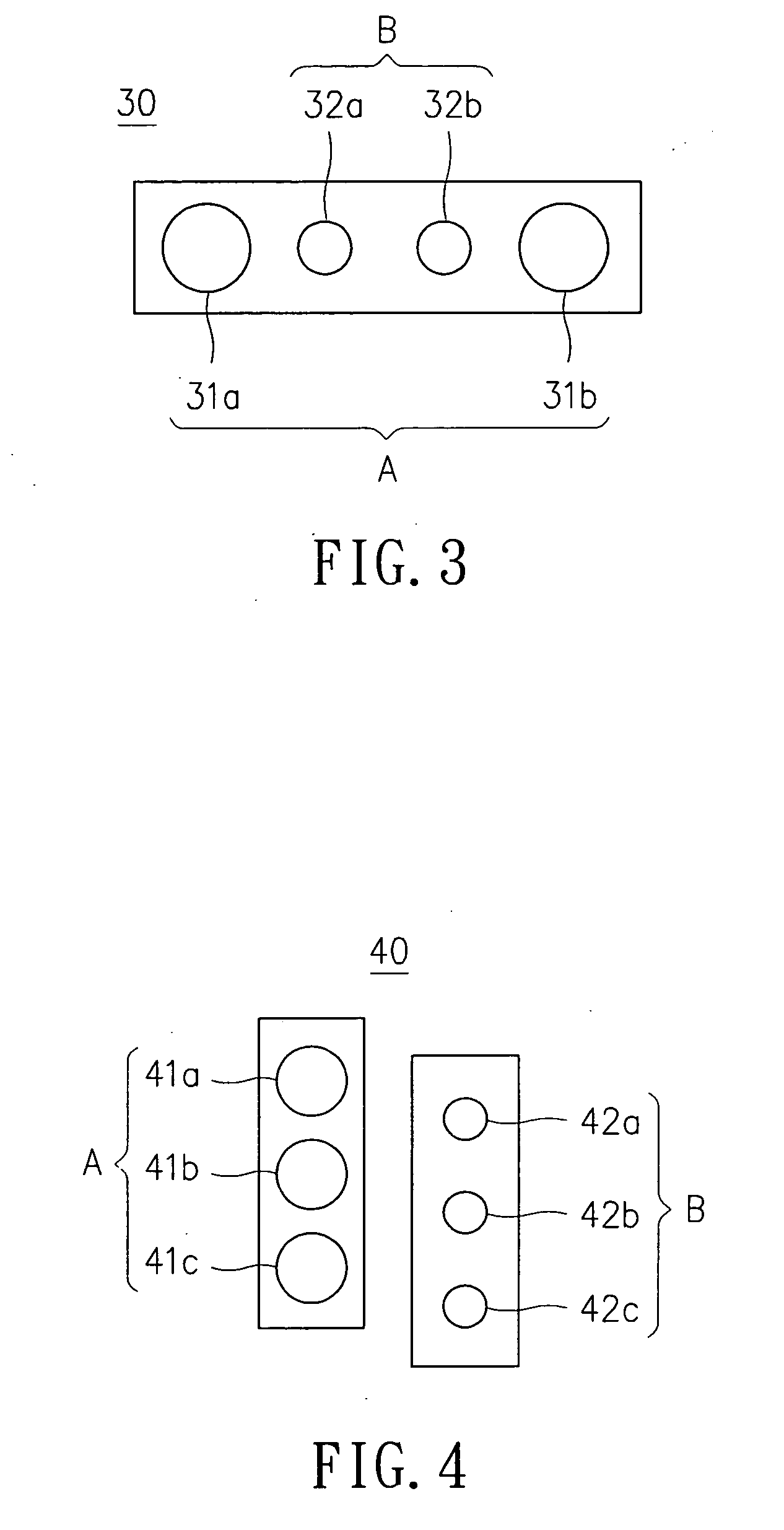

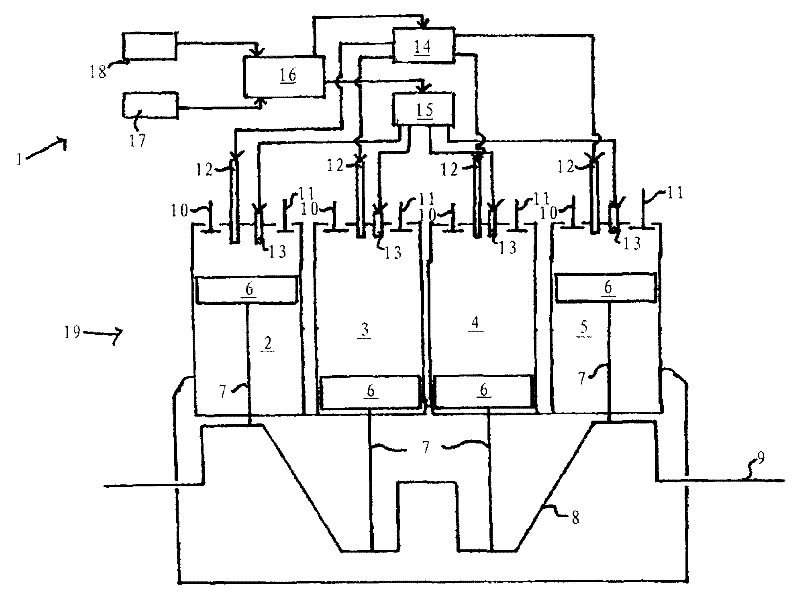

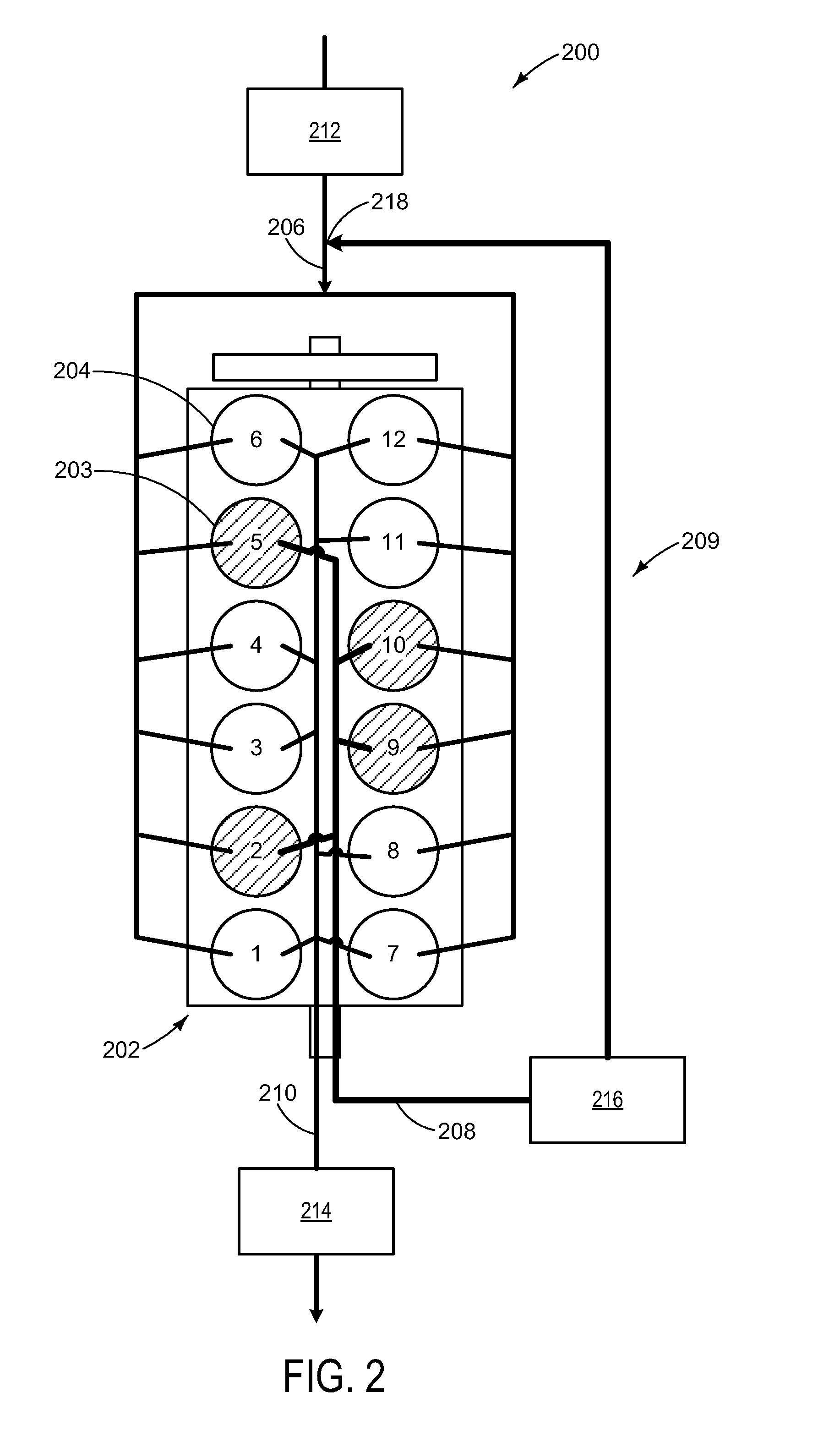

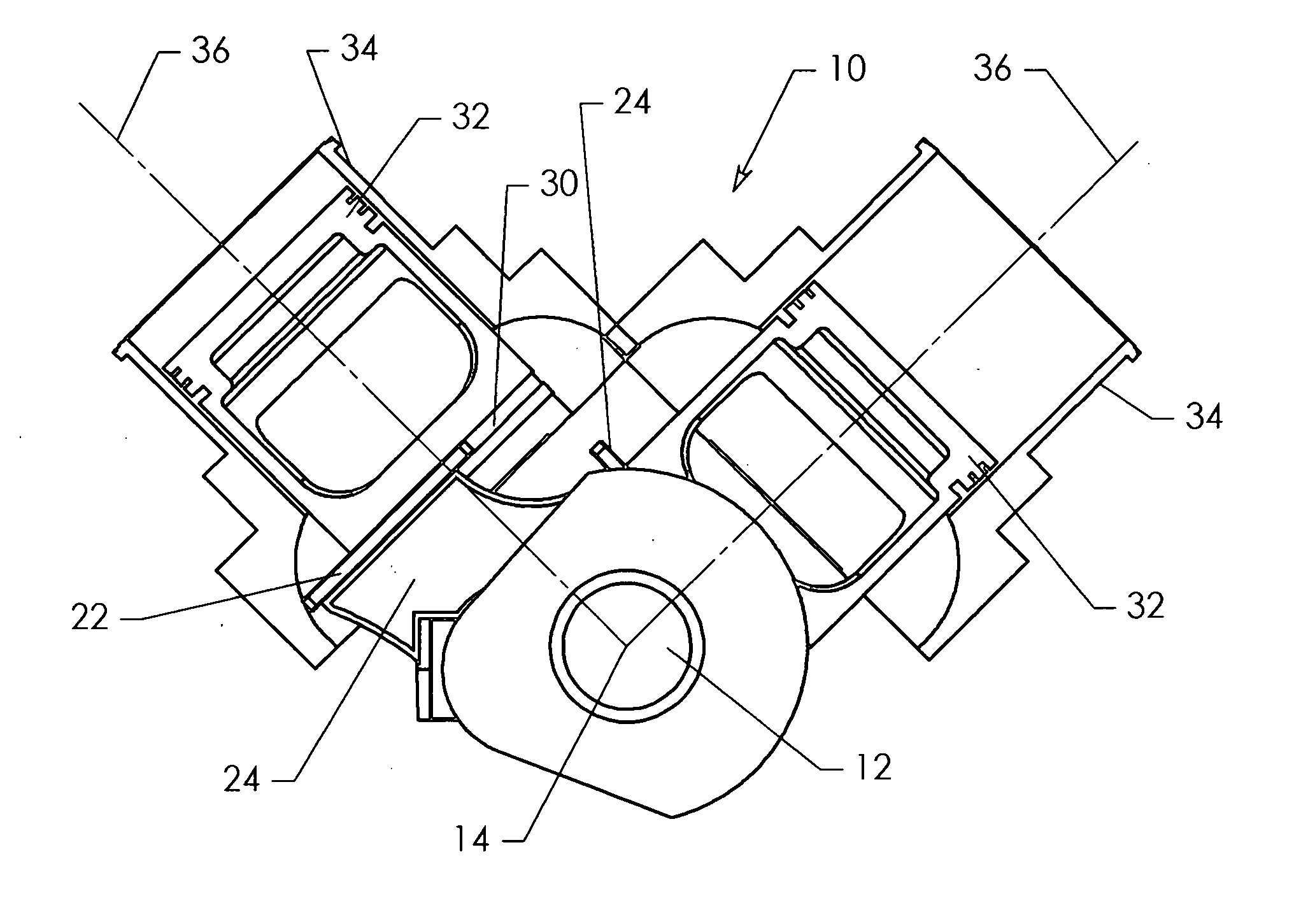

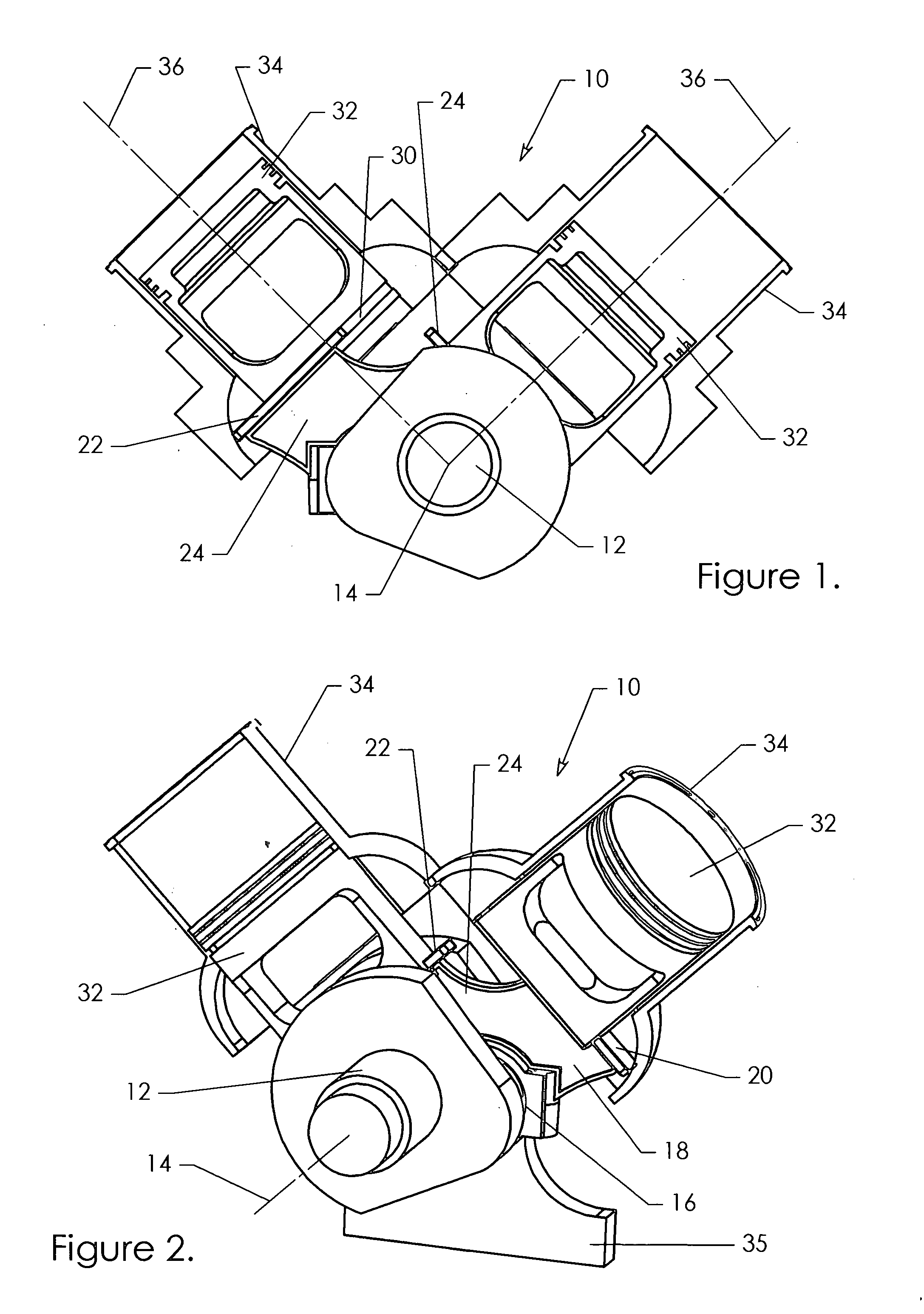

The present invention relates to an uneven cylinder displacement arrangement of a multi-stage variable displacement engine. By arranging a plurality of cylinders of at least two different cylinder bores or at least two different strokes in an engine while grouping the plural cylinders into at least two cylinder groups, e.g. grouping odd-numbered cylinders in an ignition sequence of the engine into a first group while grouping even-numbered cylinders in an ignition sequence of the engine into a second group, the engine is enabled to have multi-stage displacement capability adapted to various operation speeds for reducing fuel consumption since the displacement of the engine can be varied by using the ignition sequence to control and select which groups are to be ignited for matching the current load of the engine. In a preferred embodiment of the invention, there are two kinds of cylinders of different cylinder bores arranged in an engine which are grouped into two cylinder groups by the control of the ignition sequence of the engine, whereas the cylinder bore of a cylinder grouped in one of the two cylinder group is the same as another cylinder of the same cylinder group, but is different to those grouped in another cylinder group.

Owner:IND TECH RES INST

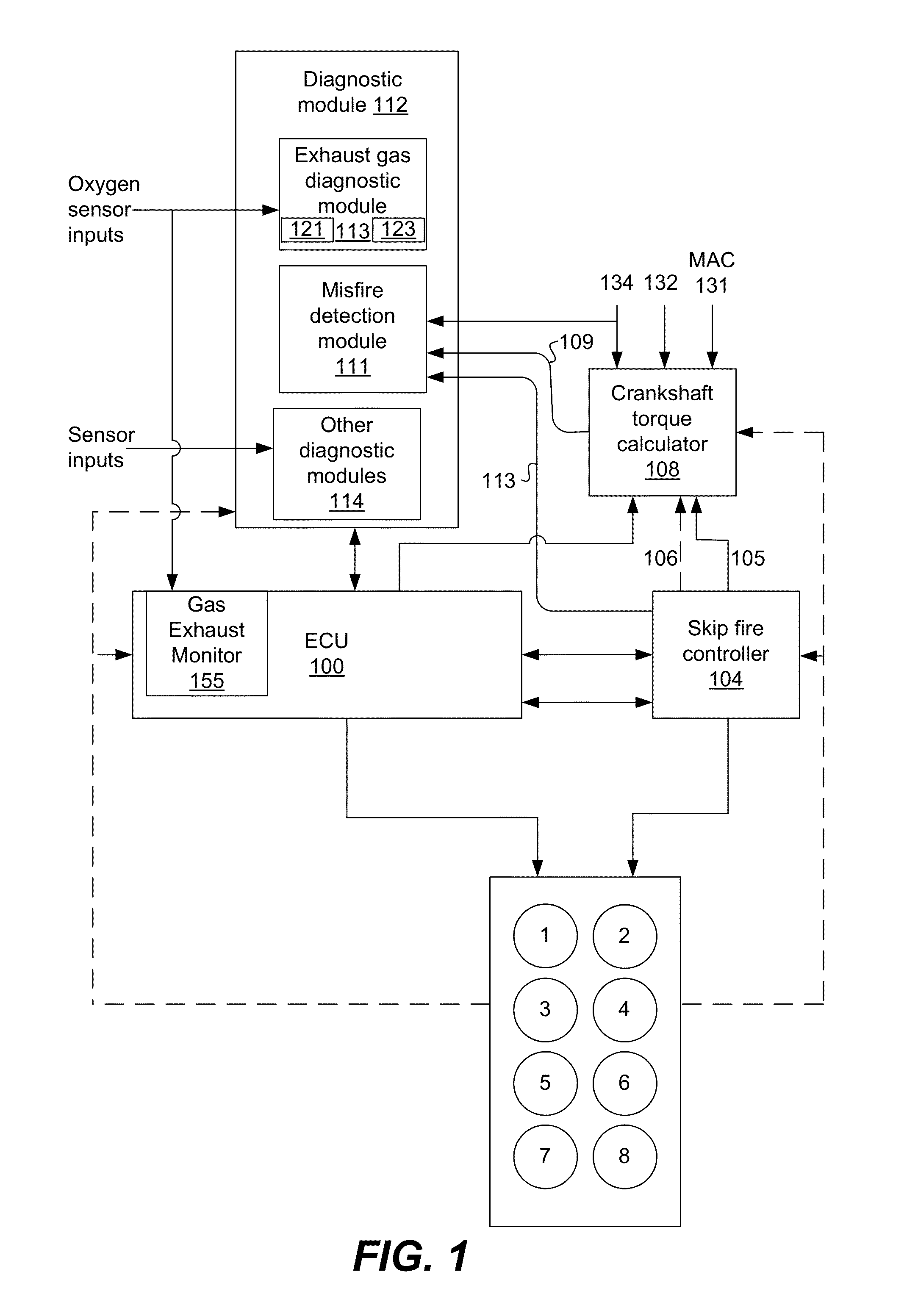

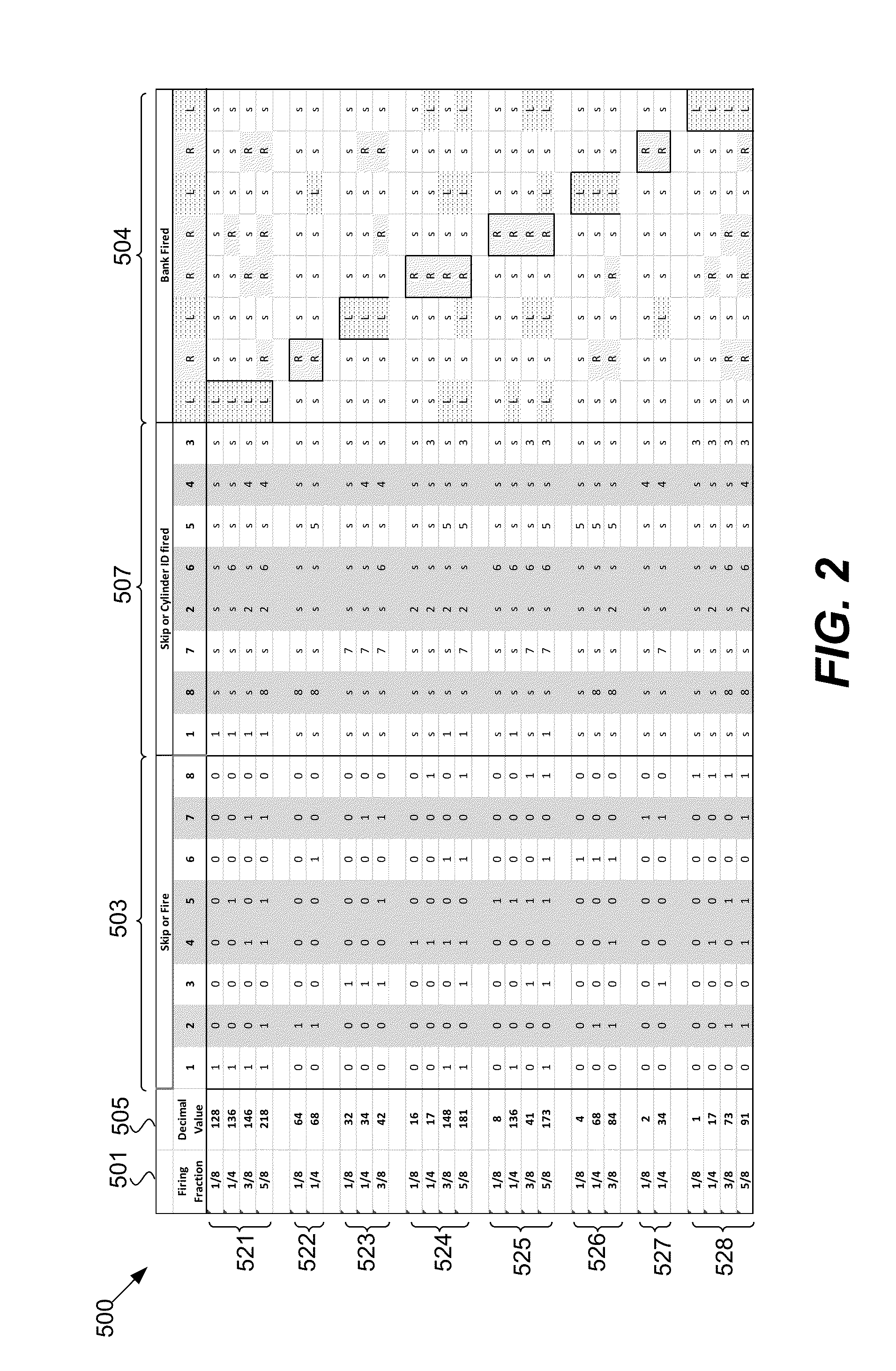

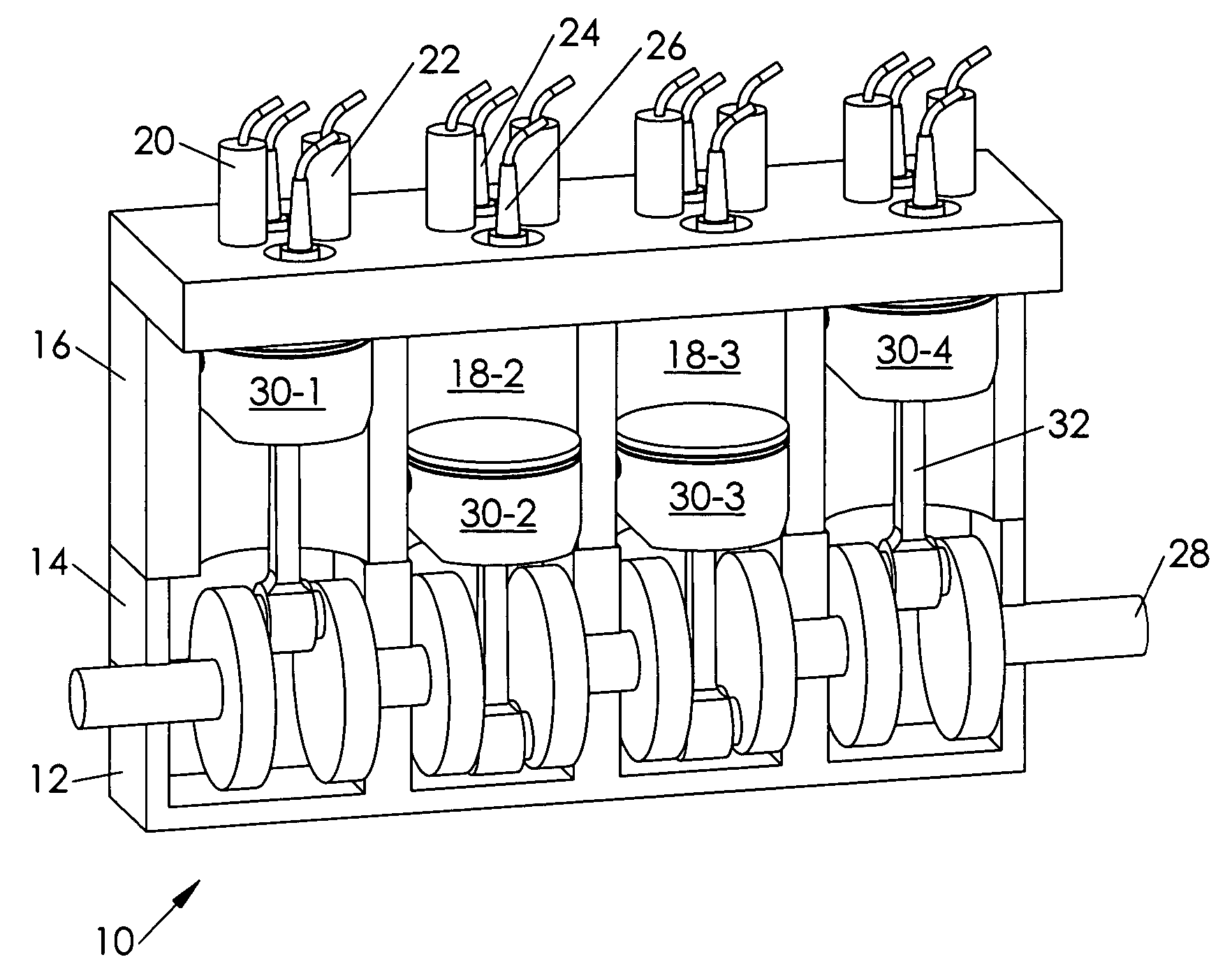

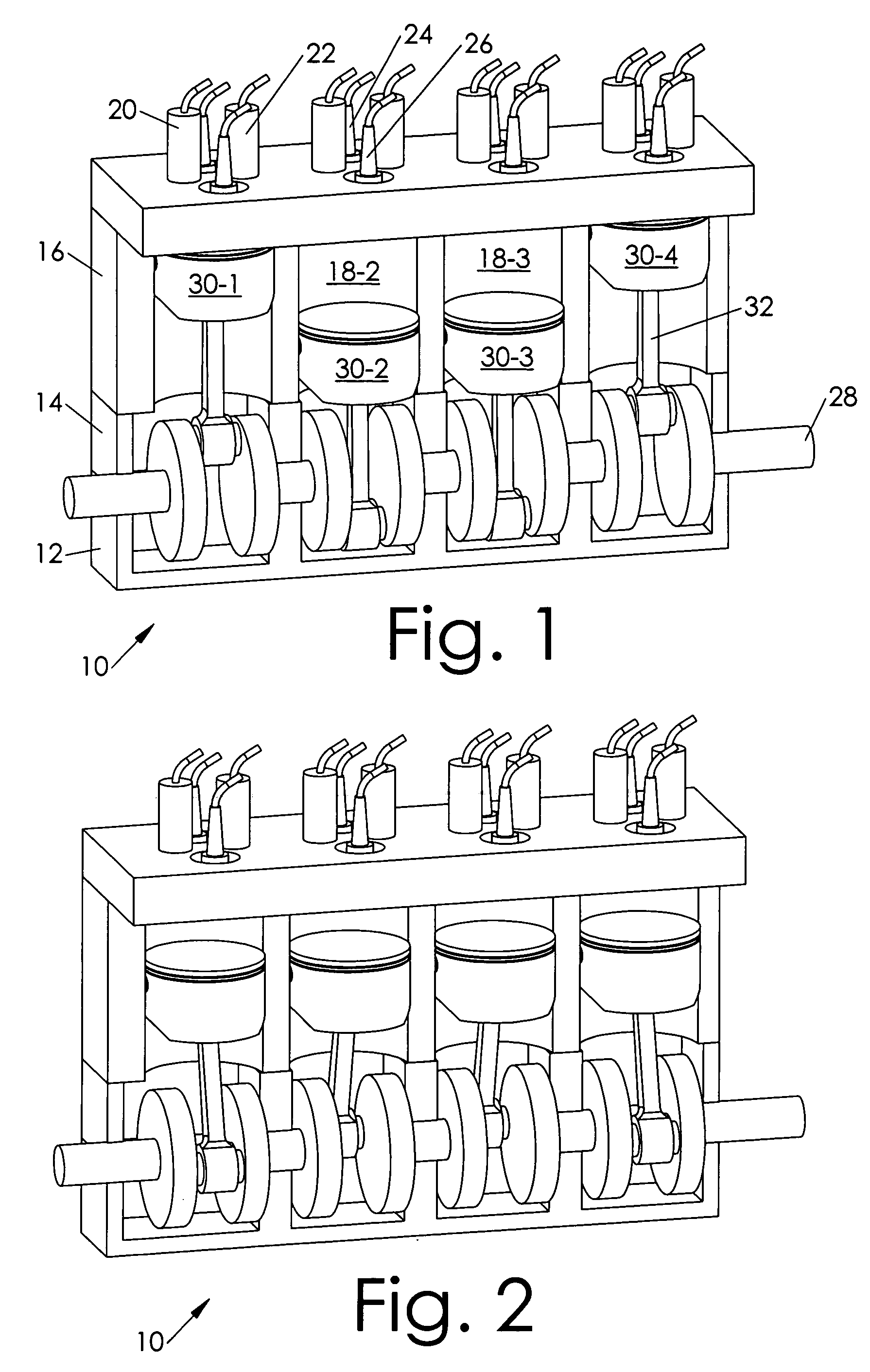

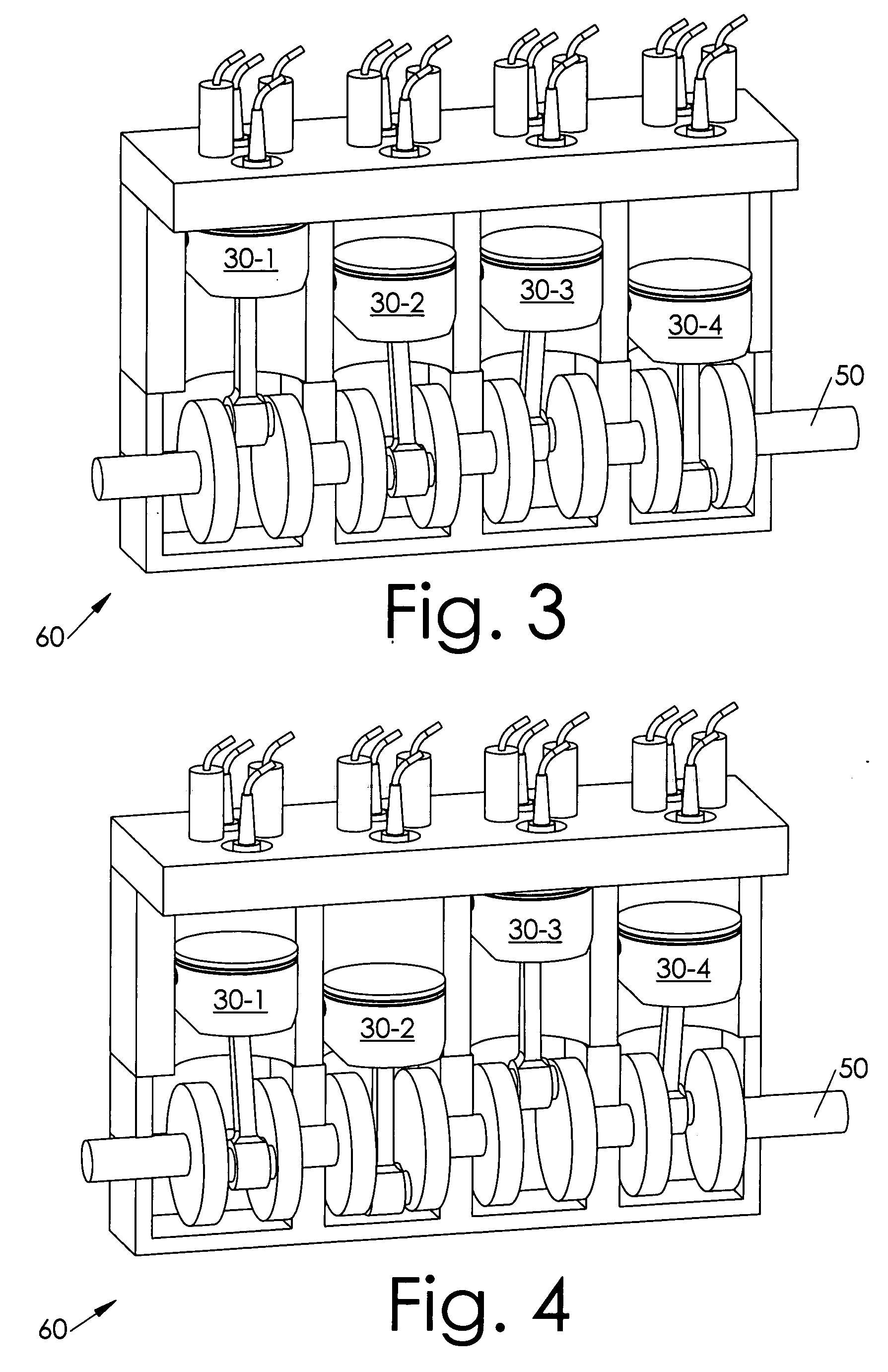

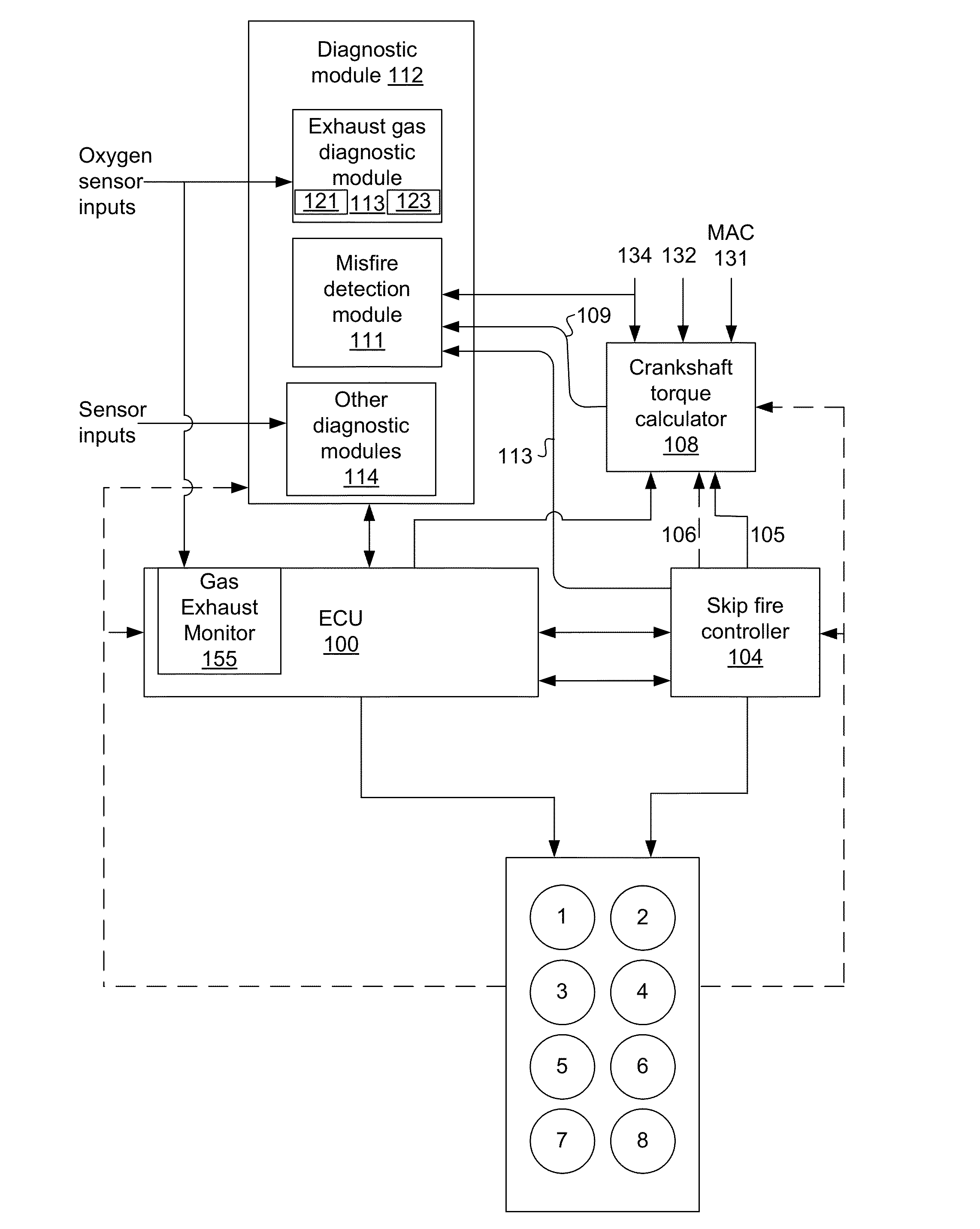

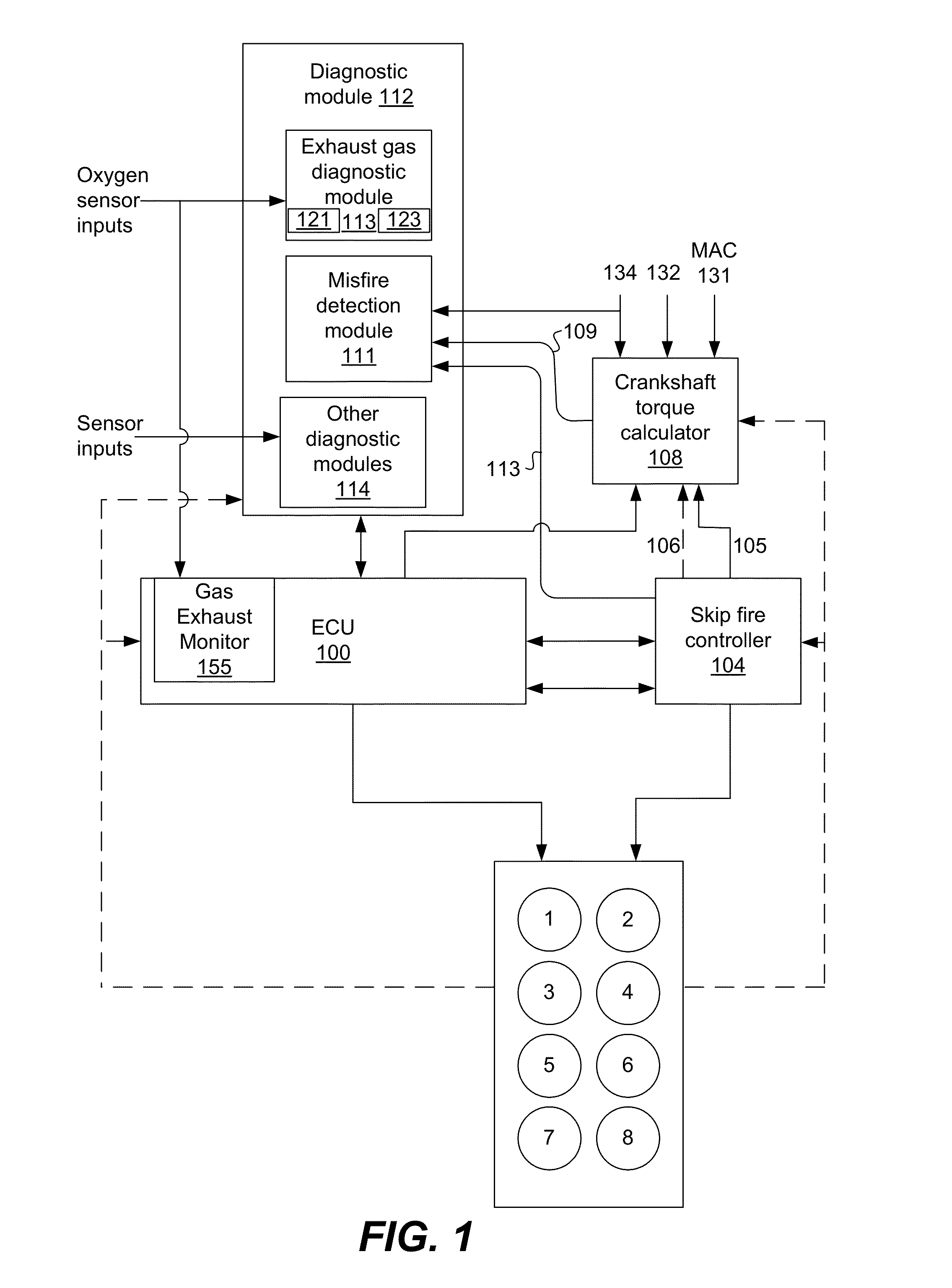

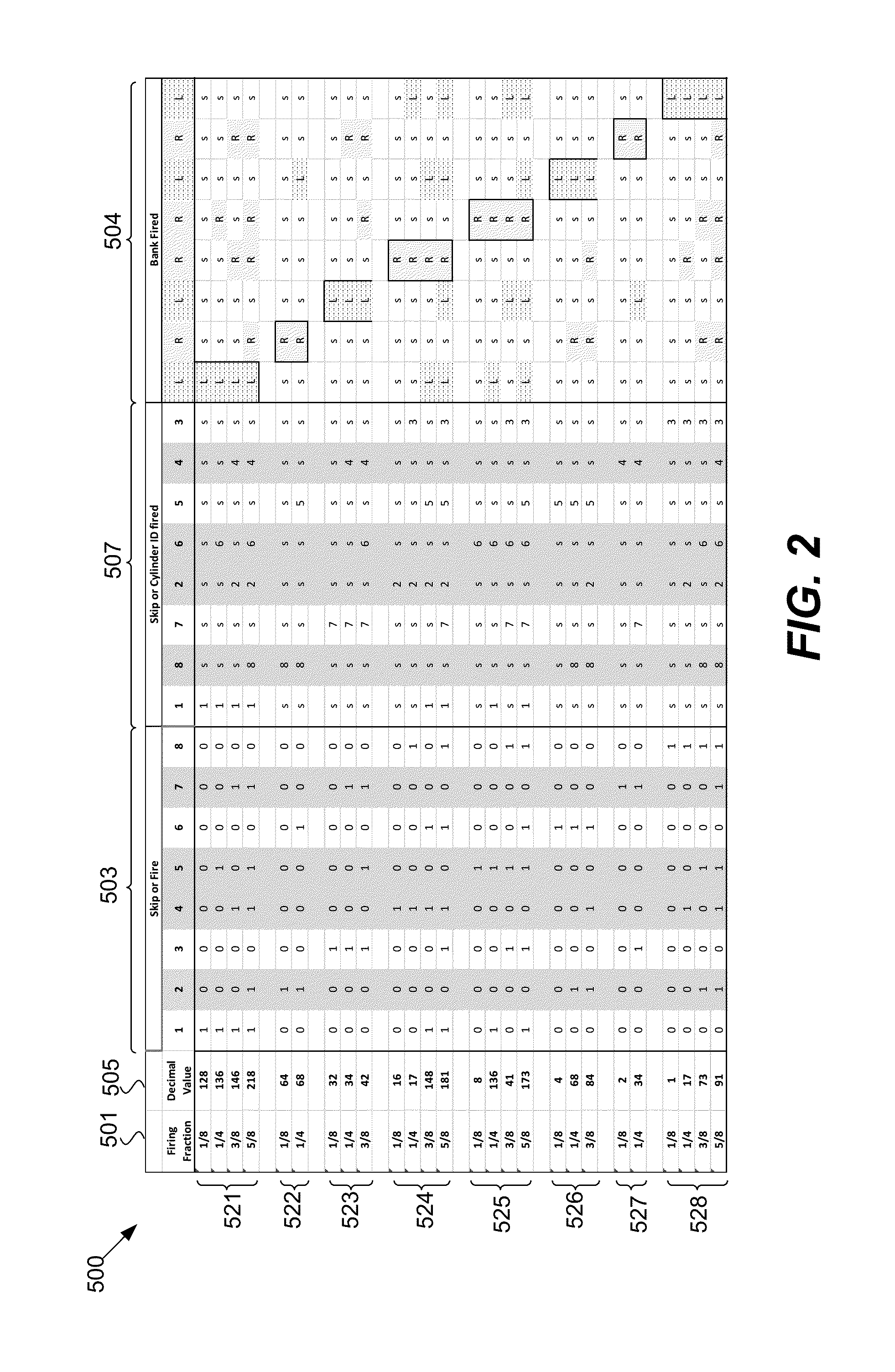

Engine diagnostics with skip fire control

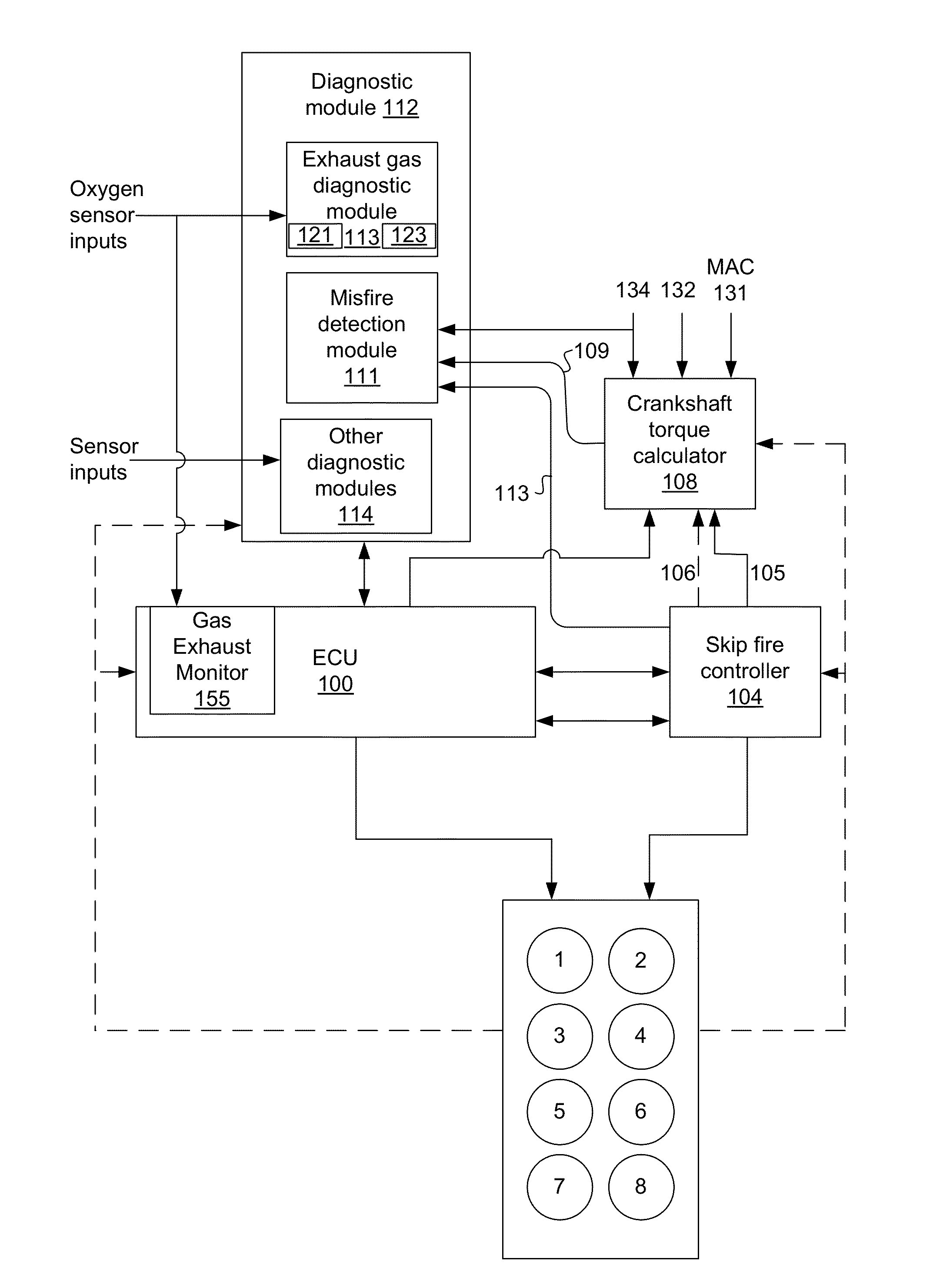

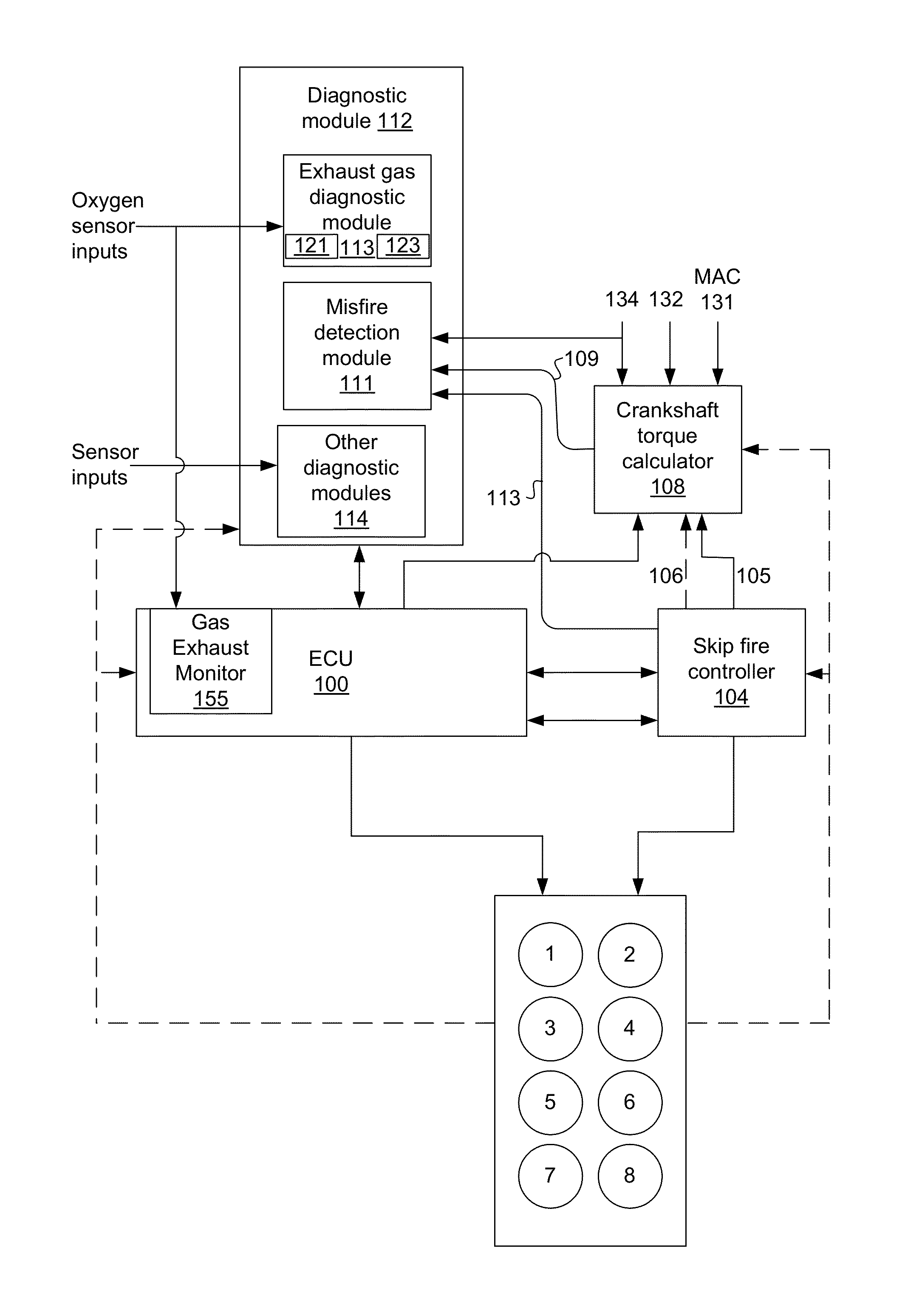

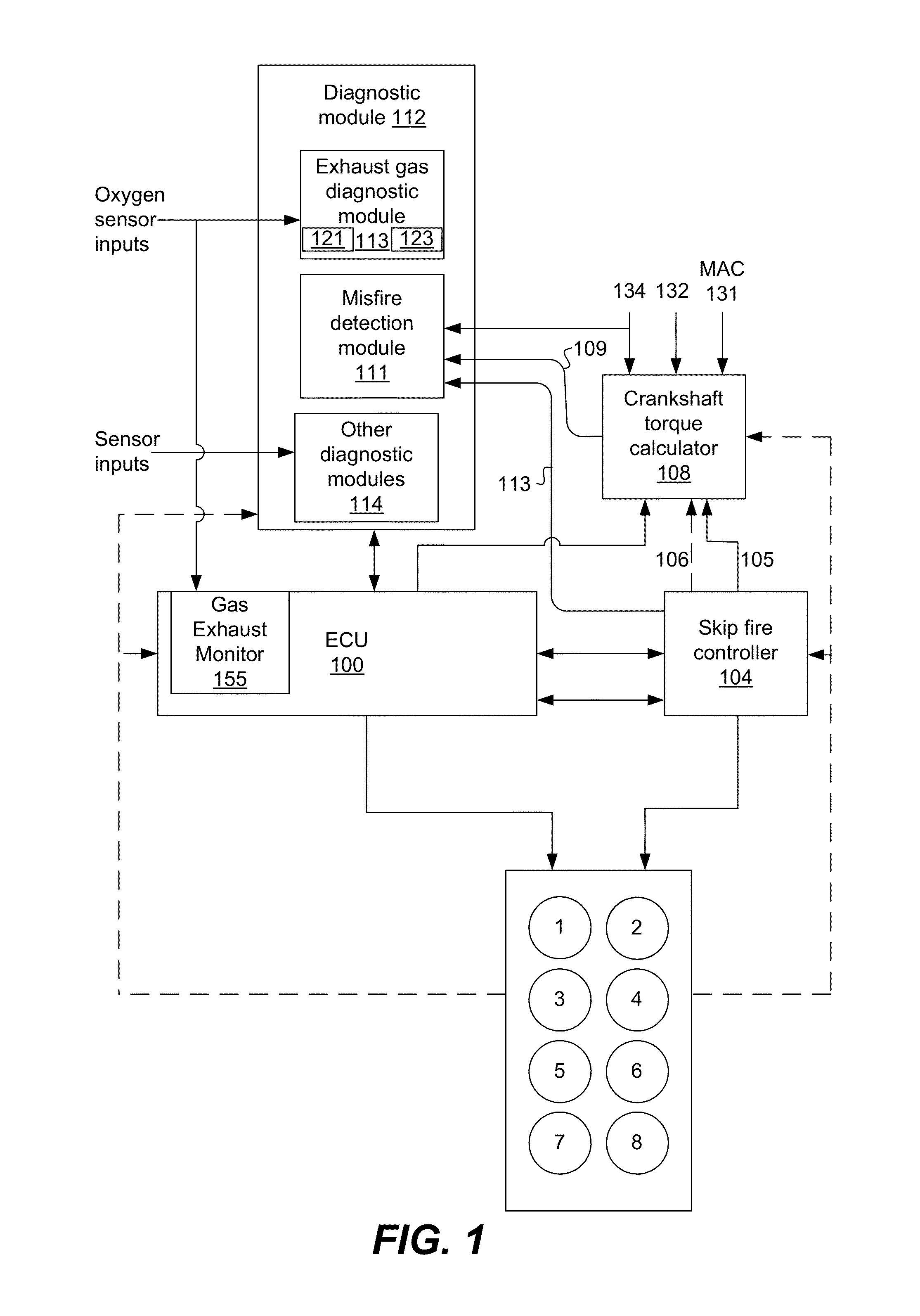

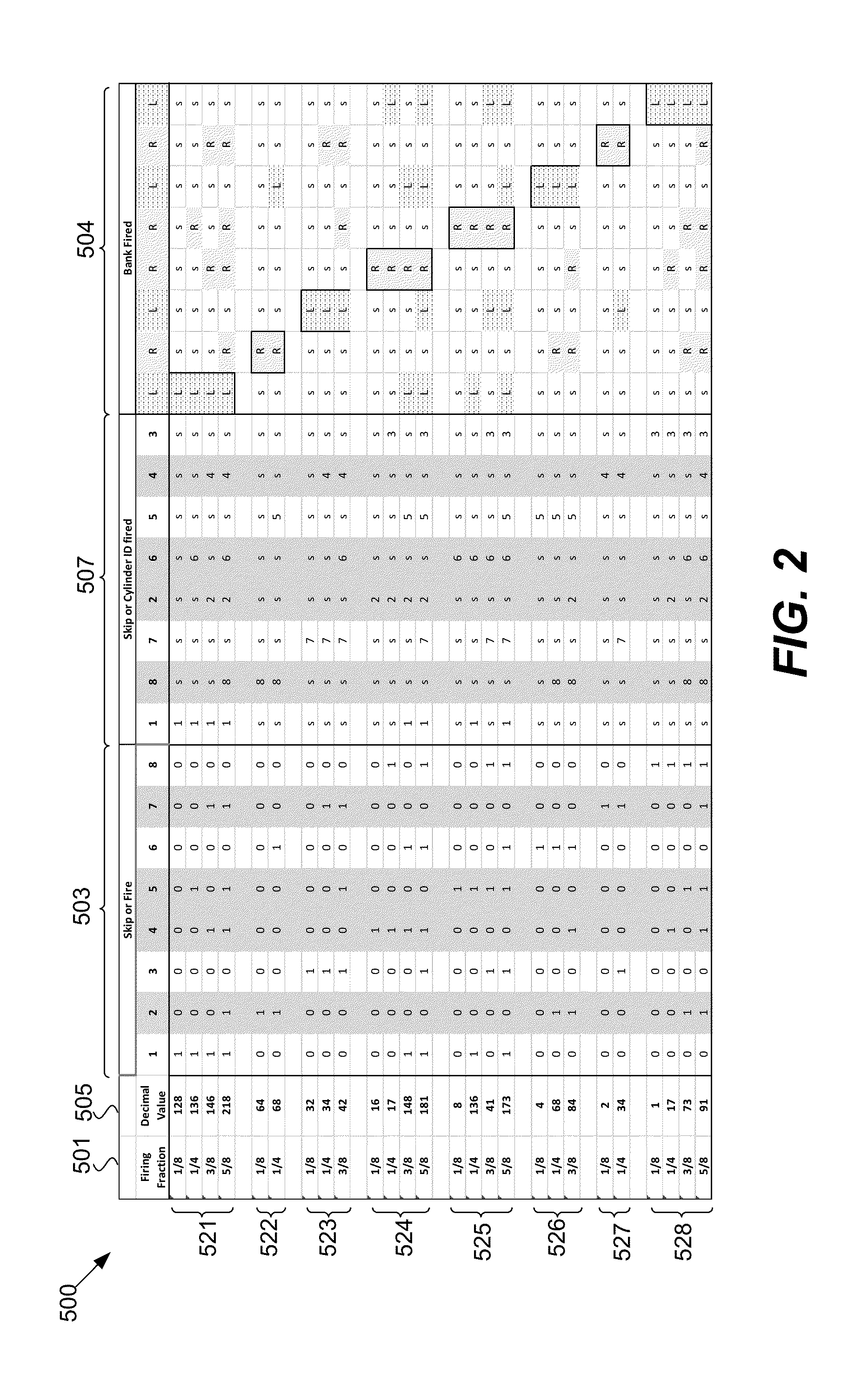

Methods and devices are described for performing engine diagnostics during skip fire operation of an engine while a vehicle is being driven. Knowledge of the firing sequence is used to determine appropriate times to conduct selected diagnostics and / or to help better interpret sensor inputs or diagnostic results. In one aspect, selected diagnostics are executed when a single cylinder is fired a plurality of times in isolation relative to a sensor used in the diagnosis. In another aspect, selected diagnostics are conducted while the engine is operated using a firing sequence that insures that no cylinders in a first cylinder bank are fired for a plurality of engine cycles while cylinders in a second bank are at least sometimes fired. The described tests can be conducted opportunistically, when conditions are appropriate, or specific firing sequences can be commanded to achieve the desired isolation or skipping of one or more selected cylinders.

Owner:TULA TECH INC

Engine control apparatus and method for transitioning cylinder operation modes of a multiple cylinder internal combustion engine

Owner:GM GLOBAL TECH OPERATIONS LLC

Engine diagnostics with skip fire control

Methods and devices are described for performing engine diagnostics during skip fire operation of an engine while a vehicle is being driven. Knowledge of the firing sequence is used to determine appropriate times to conduct selected diagnostics and / or to help better interpret sensor inputs or diagnostic results. In one aspect, selected diagnostics are executed when a single cylinder is fired a plurality of times in isolation relative to a sensor used in the diagnosis. In another aspect, selected diagnostics are conducted while the engine is operated using a firing sequence that insures that no cylinders in a first cylinder bank are fired for a plurality of engine cycles while cylinders in a second bank are at least sometimes fired. The described tests can be conducted opportunistically, when conditions are appropriate, or specific firing sequences can be commanded to achieve the desired isolation or skipping of one or more selected cylinders.

Owner:TULA TECH INC

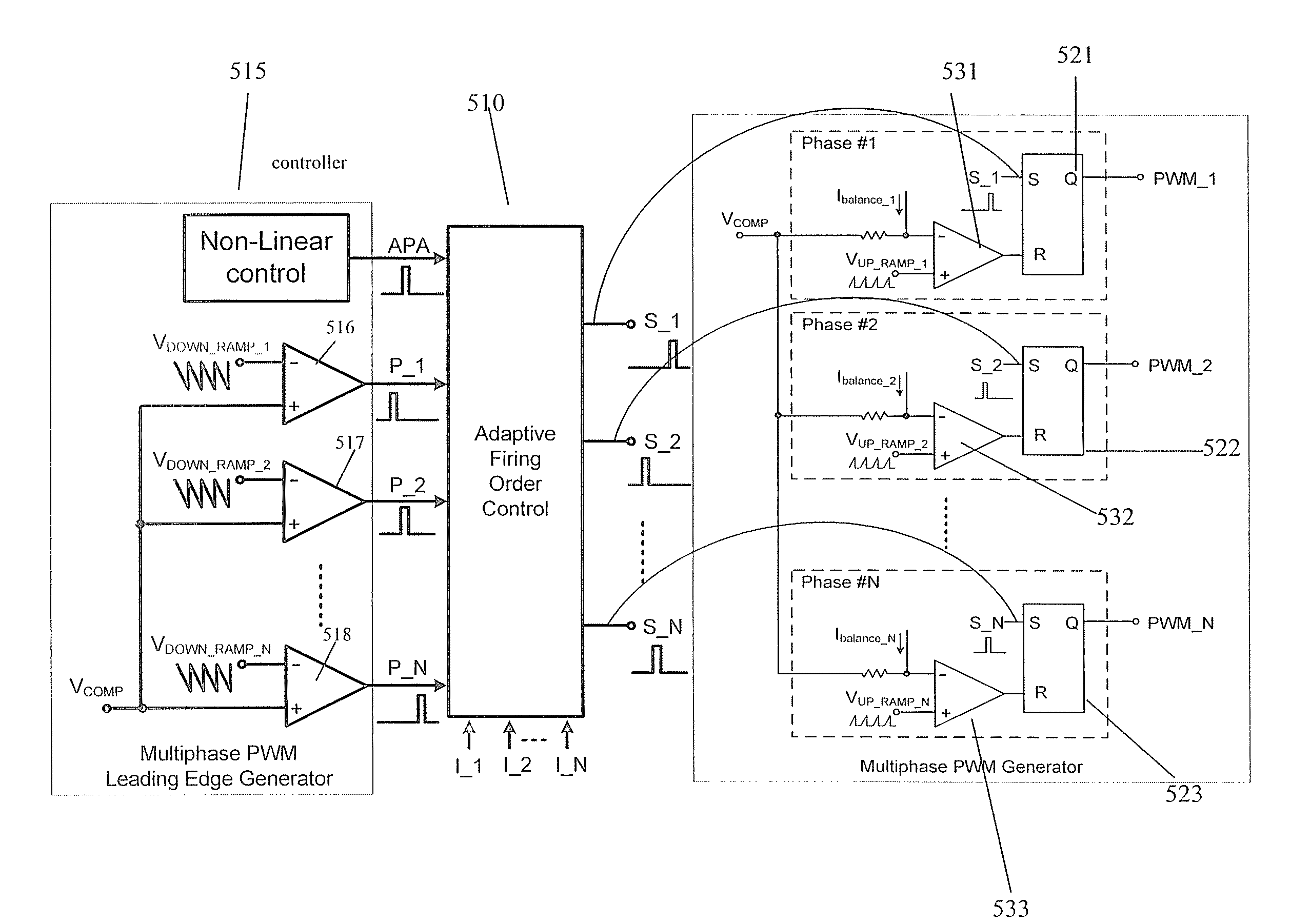

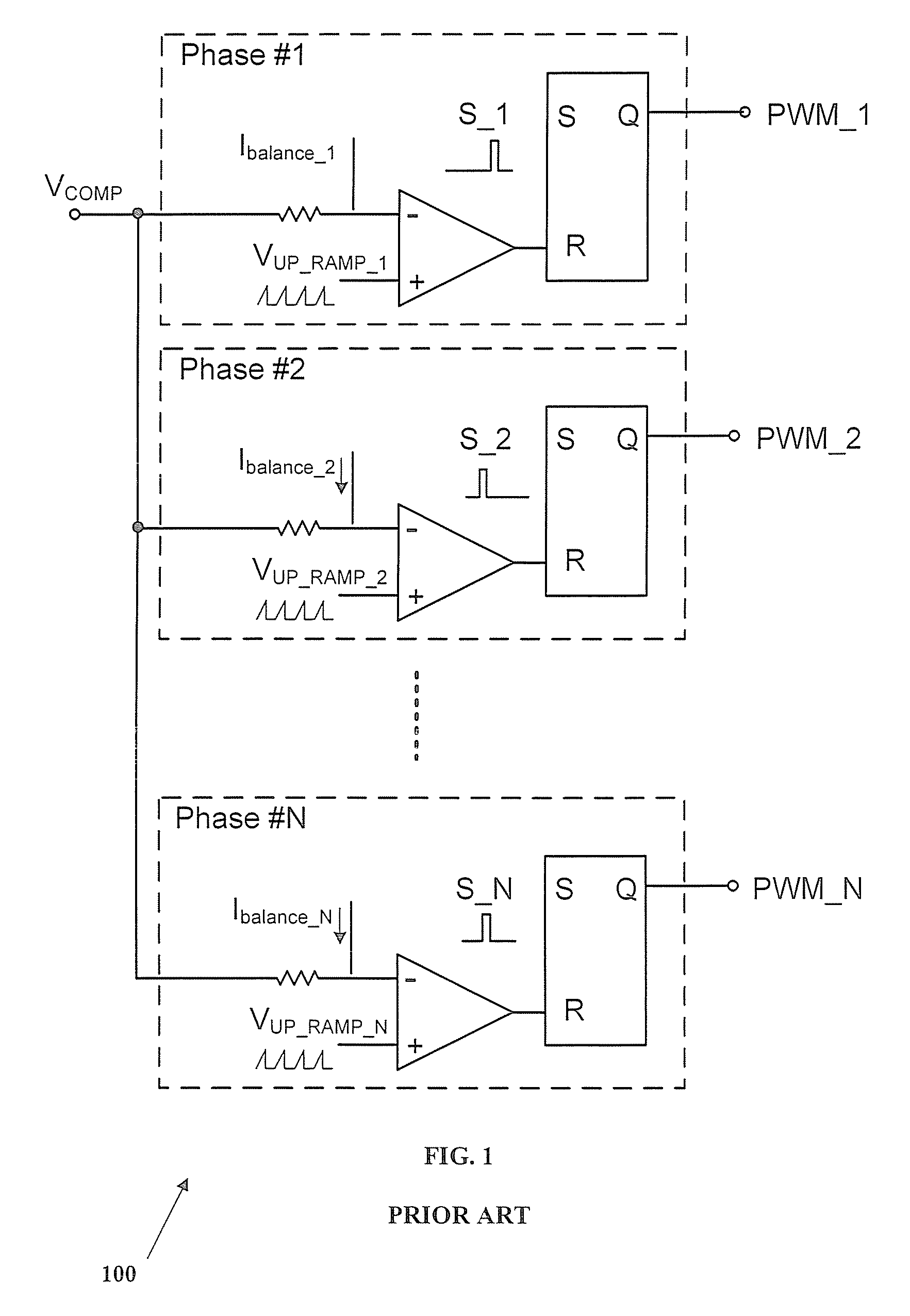

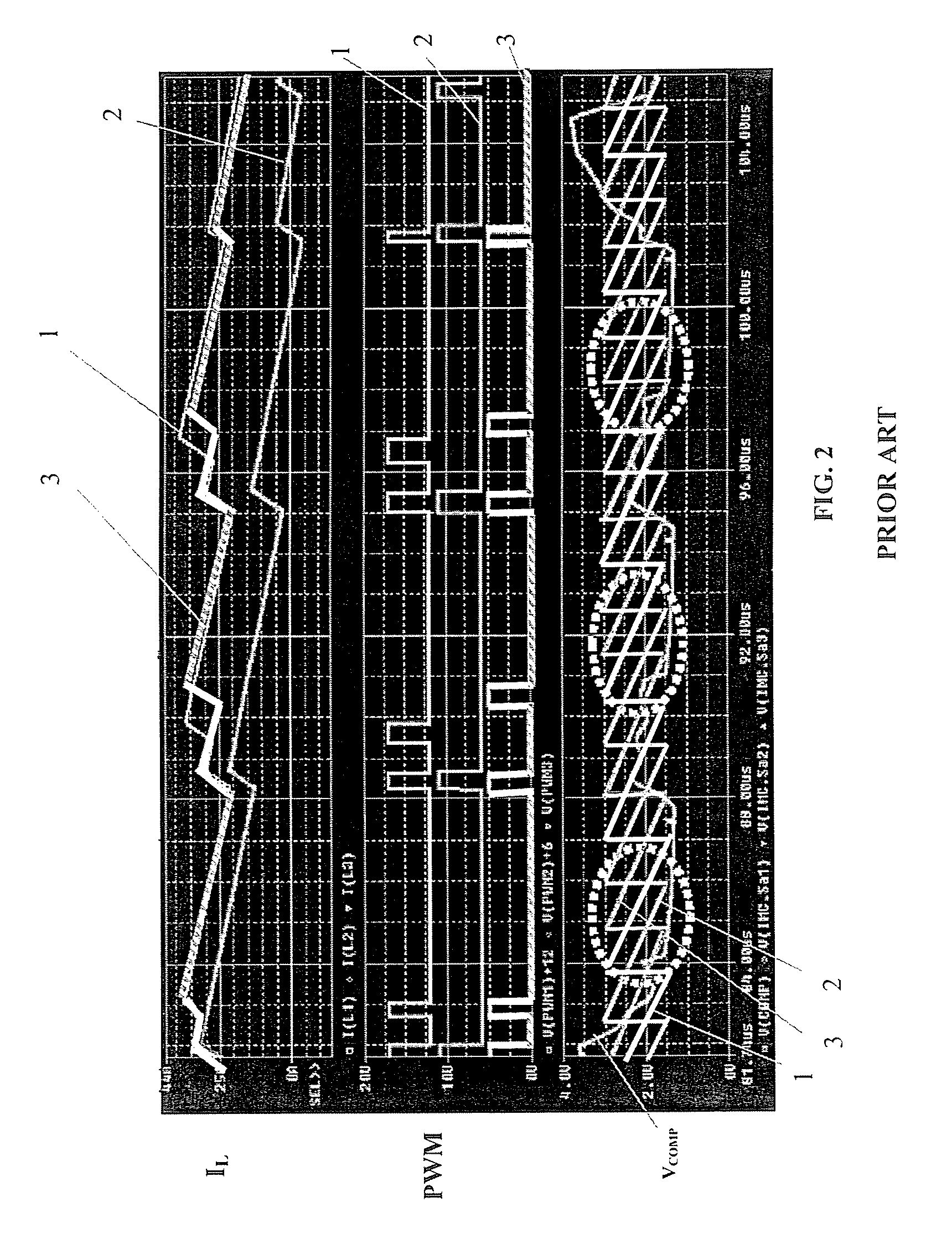

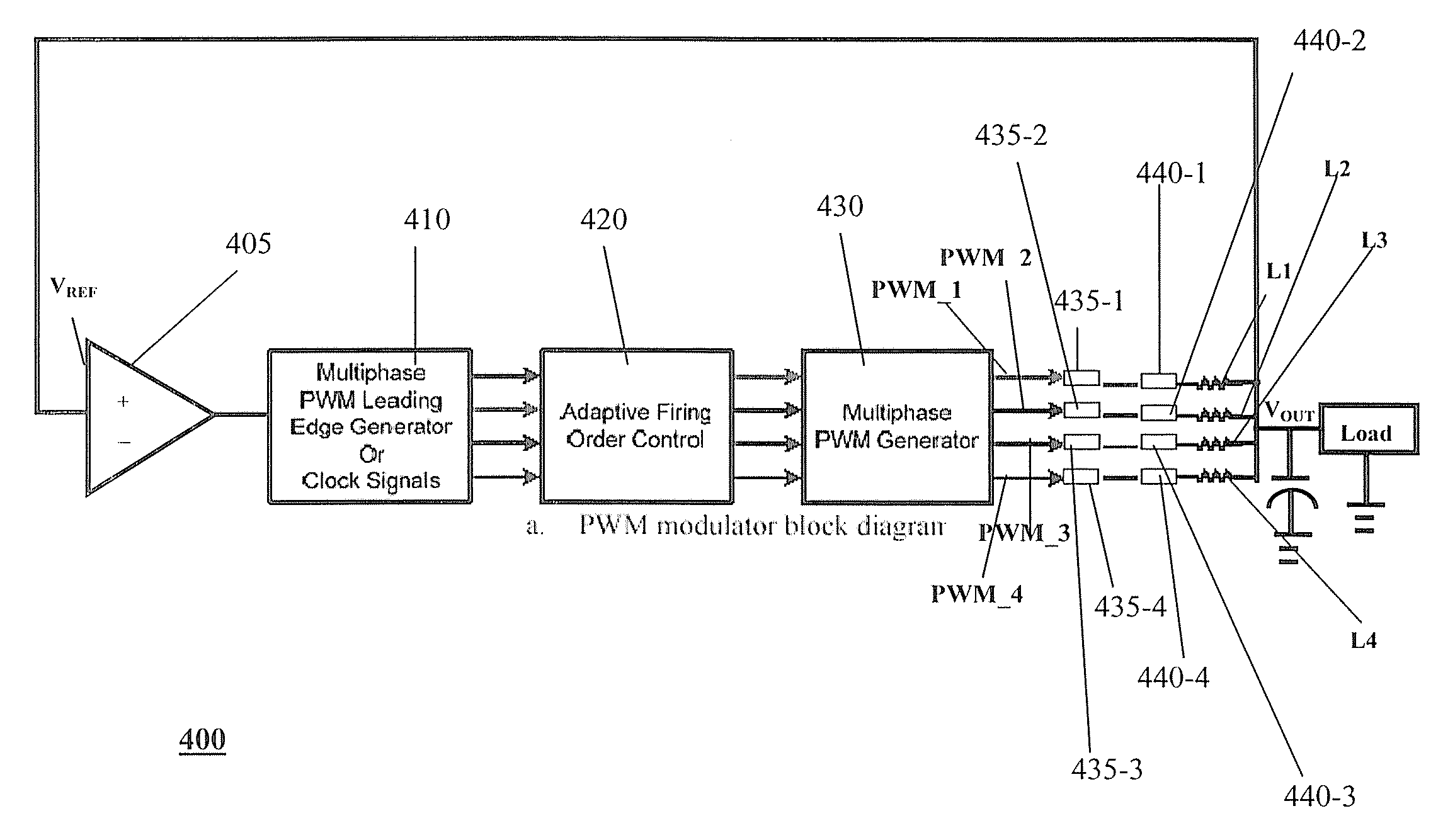

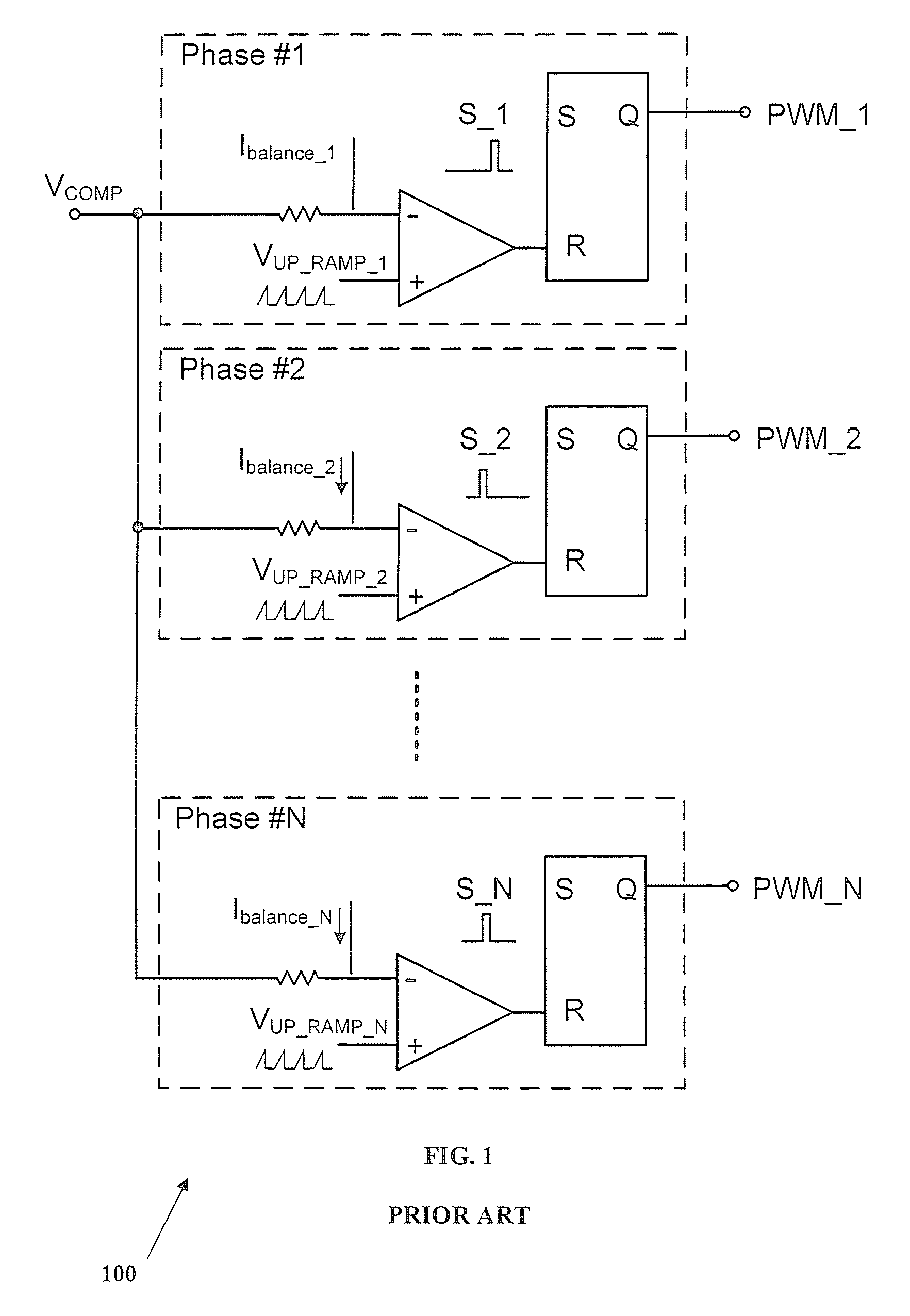

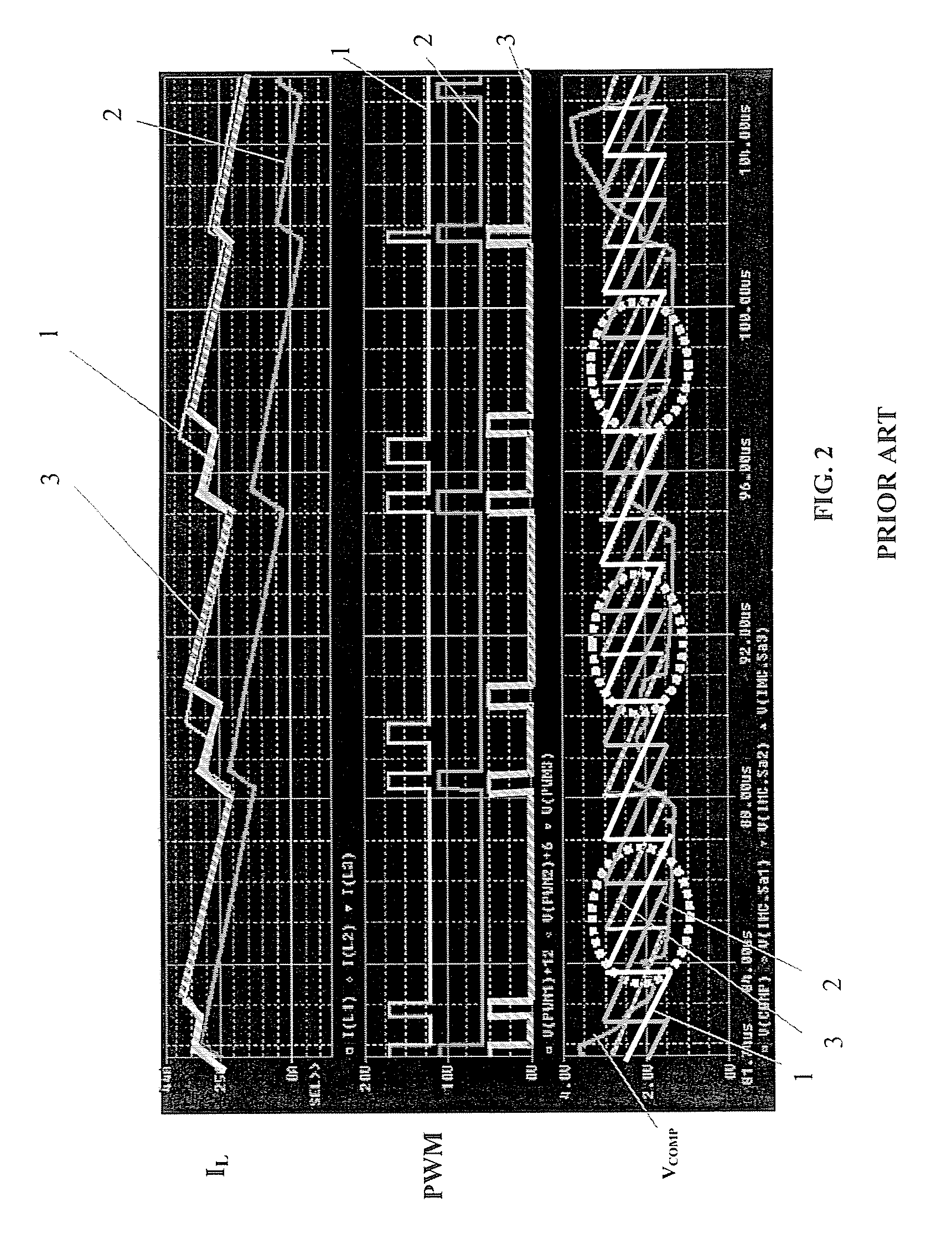

Adaptive firing order control for dynamic current balance of multiphase voltage regulators

A pulse width modulation (PWM) modulator for a multiphase power converter and related adaptive firing order (AFO) method includes a multiphase leading edge generator having pulse generating circuitry associated with each of the regulator phases, wherein the pulse generating circuitry generates phase pulses associated with each of the phases. An adaptive firing order (AFO) controller having circuitry including a mixer receives and sums the phase pulses into a summing signal and uses the summing signal to generate a series of turn-on pulses therefrom. A multiphase PWM generator has inputs coupled to an output of the AFO controller coupled to receive the series of turn-on pulses, the multiphase PWM generator having circuitry for generating said PWM signals therefrom. An adaptive firing order (AFO) controlled multi-phase power converter includes a plurality of parallel connected regulator phases controlled by respective pulse width modulation (PWM) signals provided by the PWM modulator.

Owner:INTERSIL INC

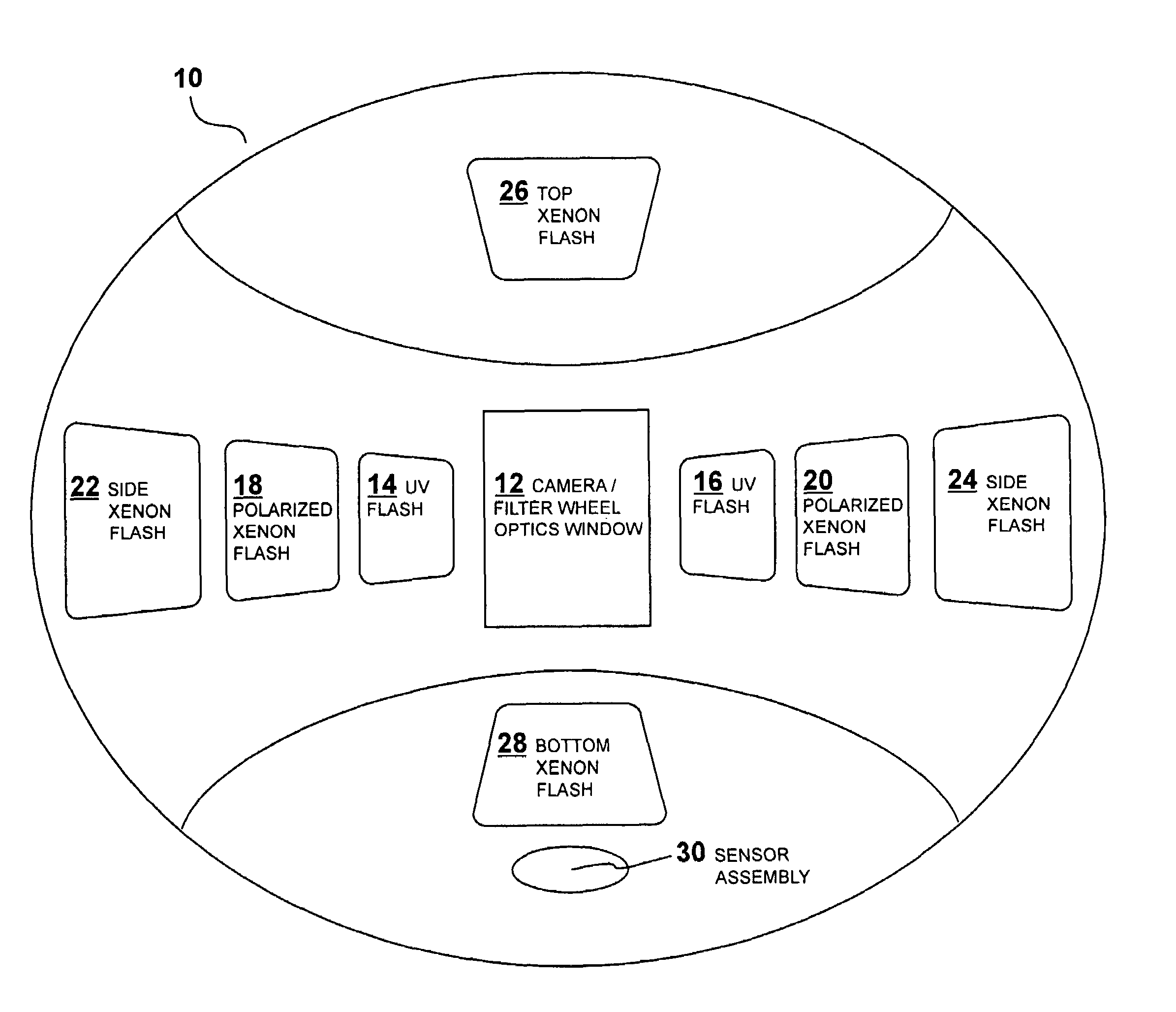

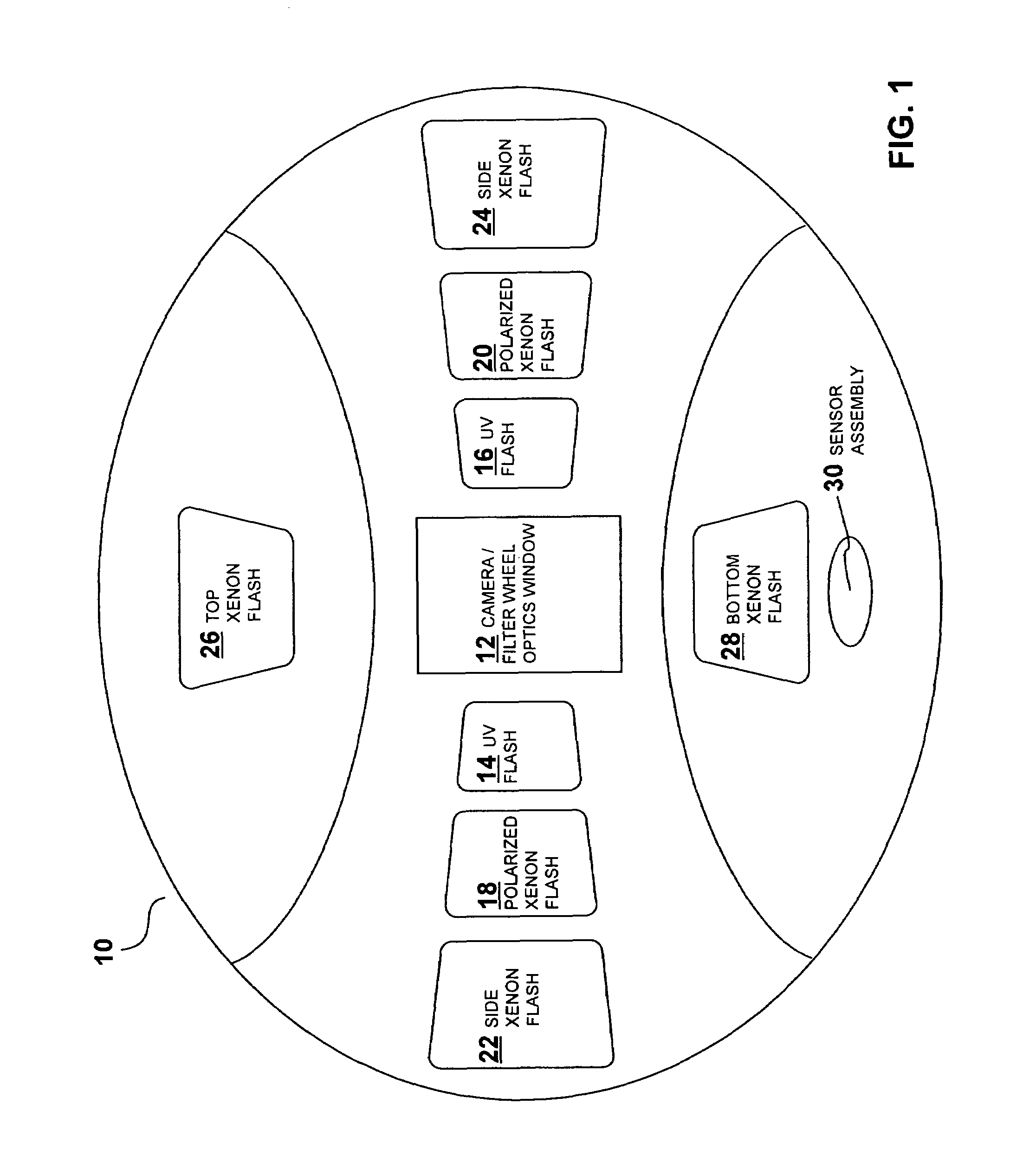

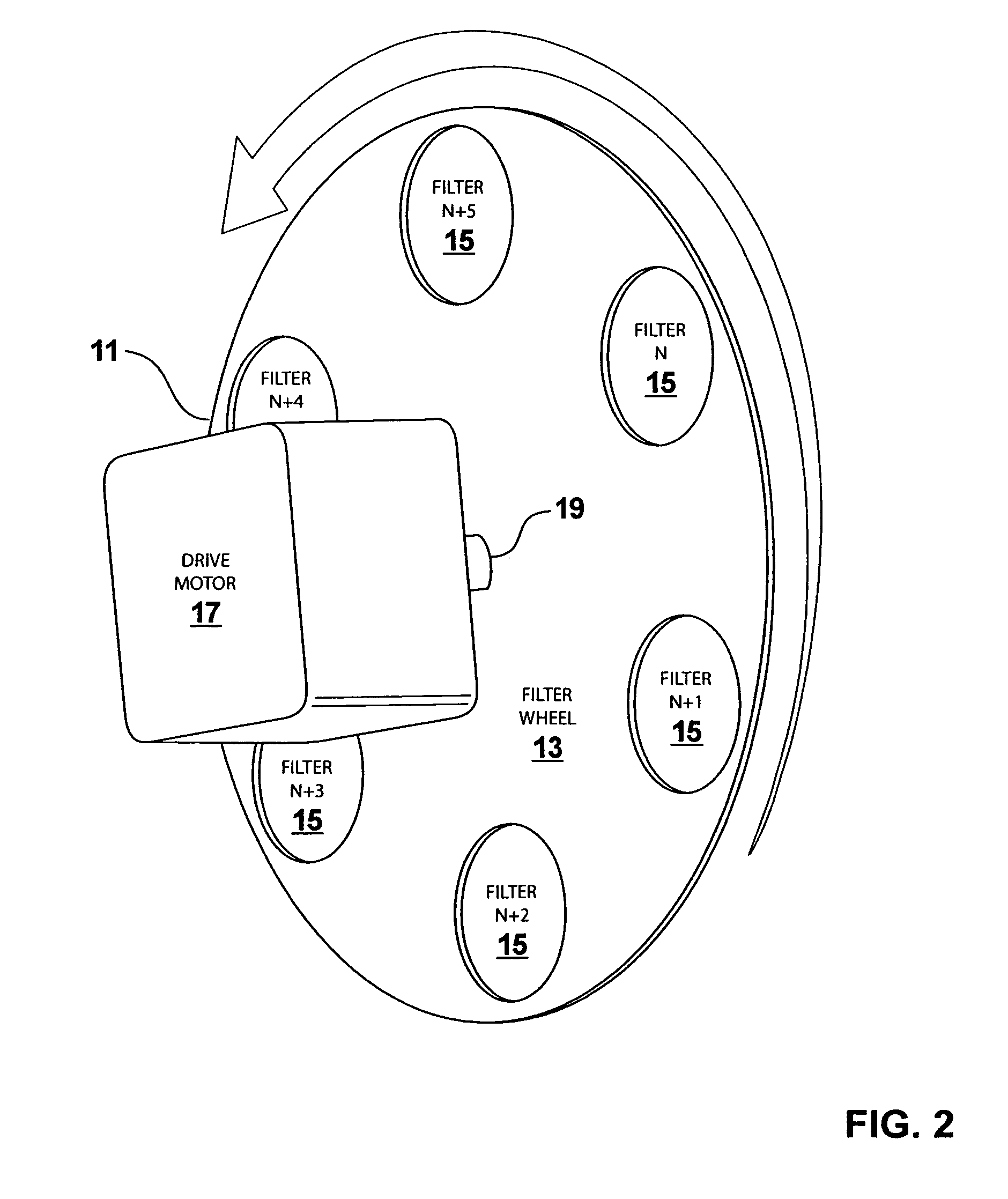

Programmable, multi-spectral, image-capture environment

ActiveUS7603031B1Enhance specific attributeImprove attributesTelevision system detailsDiagnostics using lightFiring orderSubject specific

A multi-flash photography system provides a dynamically-configurable lighting environment for a single exposure that is created and shaped through the sequentially firing of various light sources with different lighting characteristics controlled in accordance with both a programmed template specifying the flash type, position, firing order, and output intensity, as well as optical processing requirements such as filtering, polarizing, etc., and a shared photometric detector located sufficiently close to the subject being photographed to ensure that the light seen by the detector is substantially the same as the light received at the subject.

Owner:CANFIELD SCI

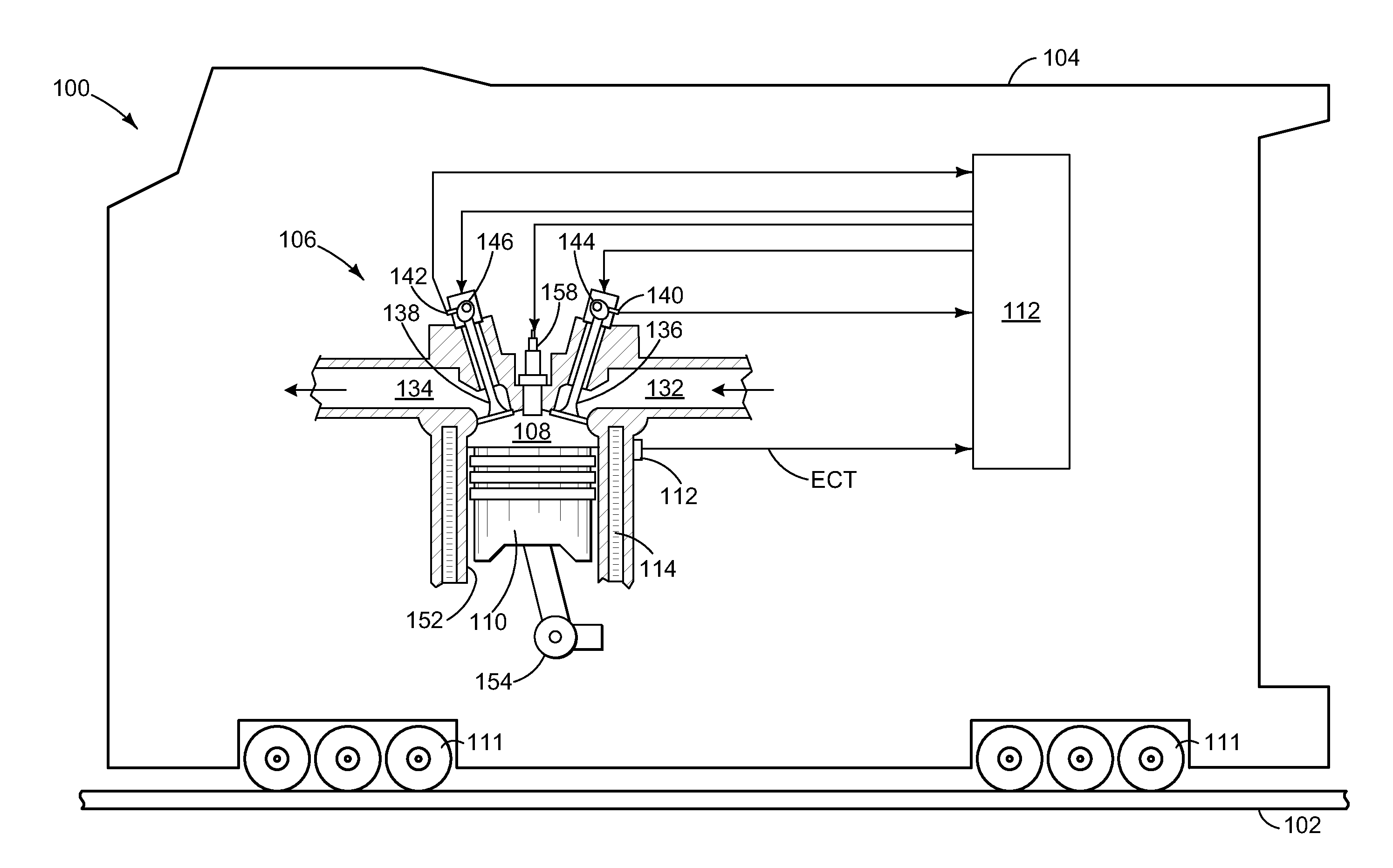

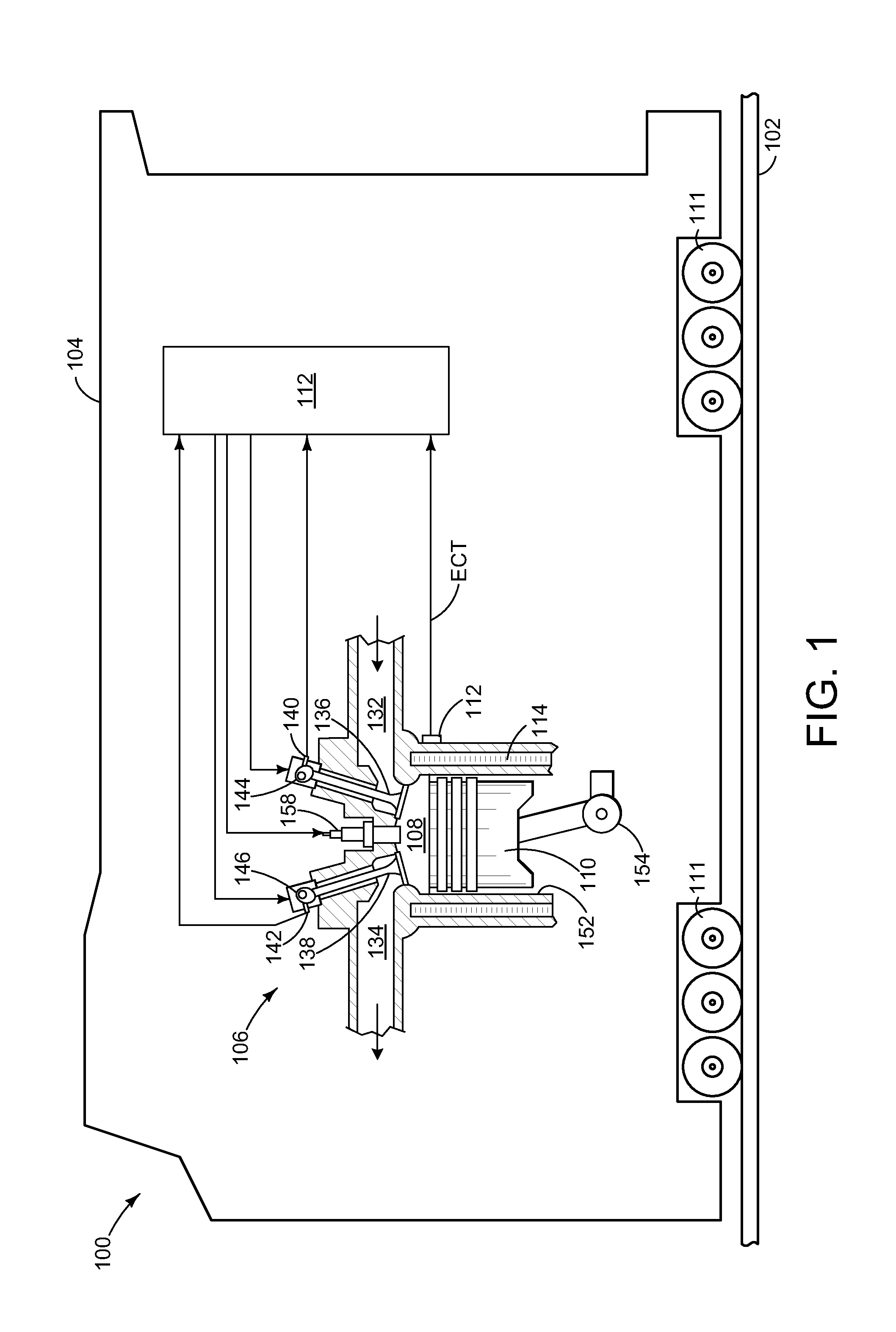

Methods and systems for an engine

InactiveUS20120222659A1Emission reductionReduce volatilityInternal combustion piston enginesNon-fuel substance addition to fuelFiring orderEngineering

Various methods and systems are provided for operating an exhaust gas recirculation engine having a plurality of exhaust gas donor cylinders and a plurality of non-donor cylinders. One example method includes firing each of the engine cylinders in a cylinder firing order, including firing at least one of the non-donor cylinders between every donor cylinder firing of the engine cycle.

Owner:GENERAL ELECTRIC CO

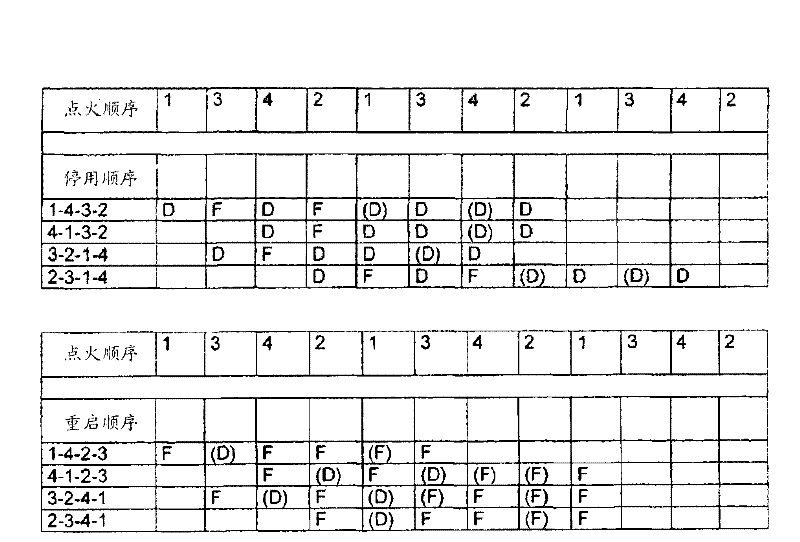

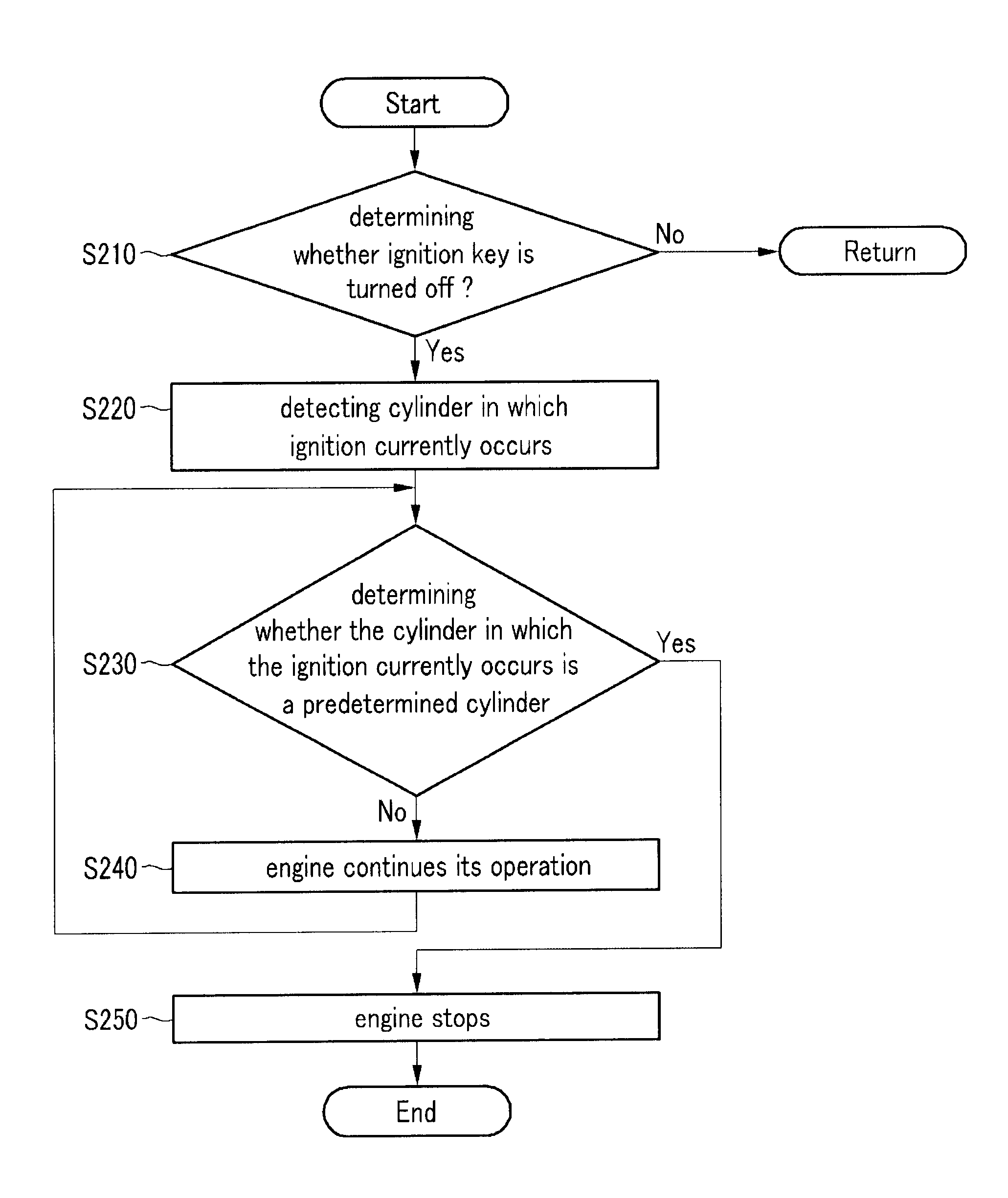

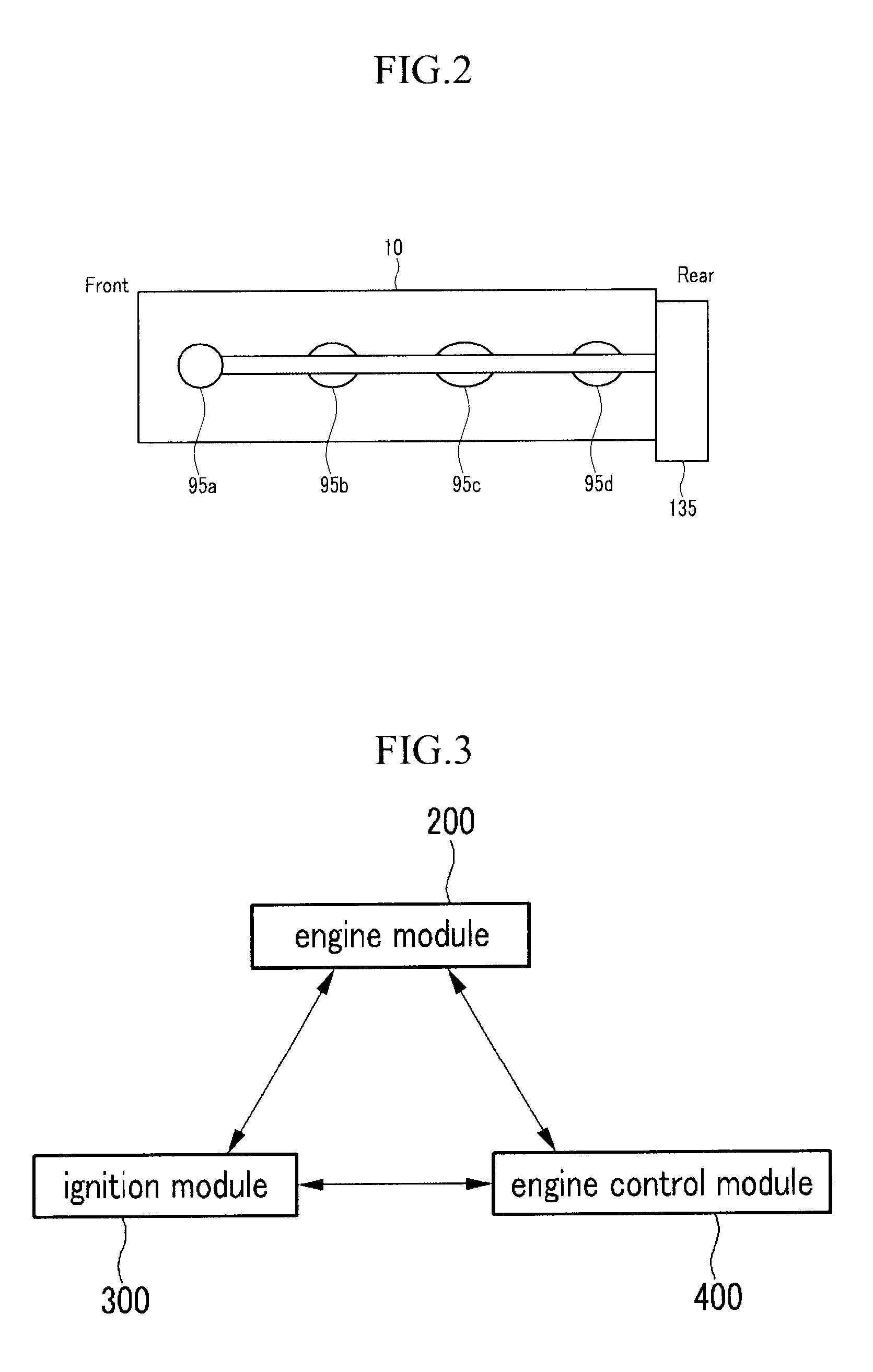

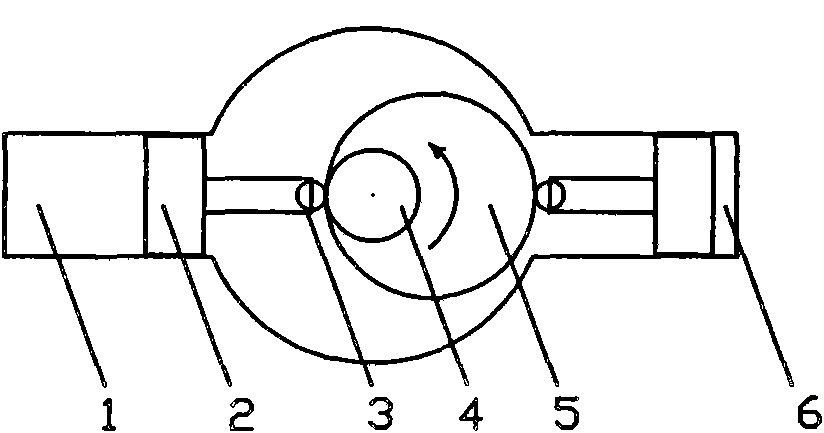

Vibration reducing system at key-off and method thereof

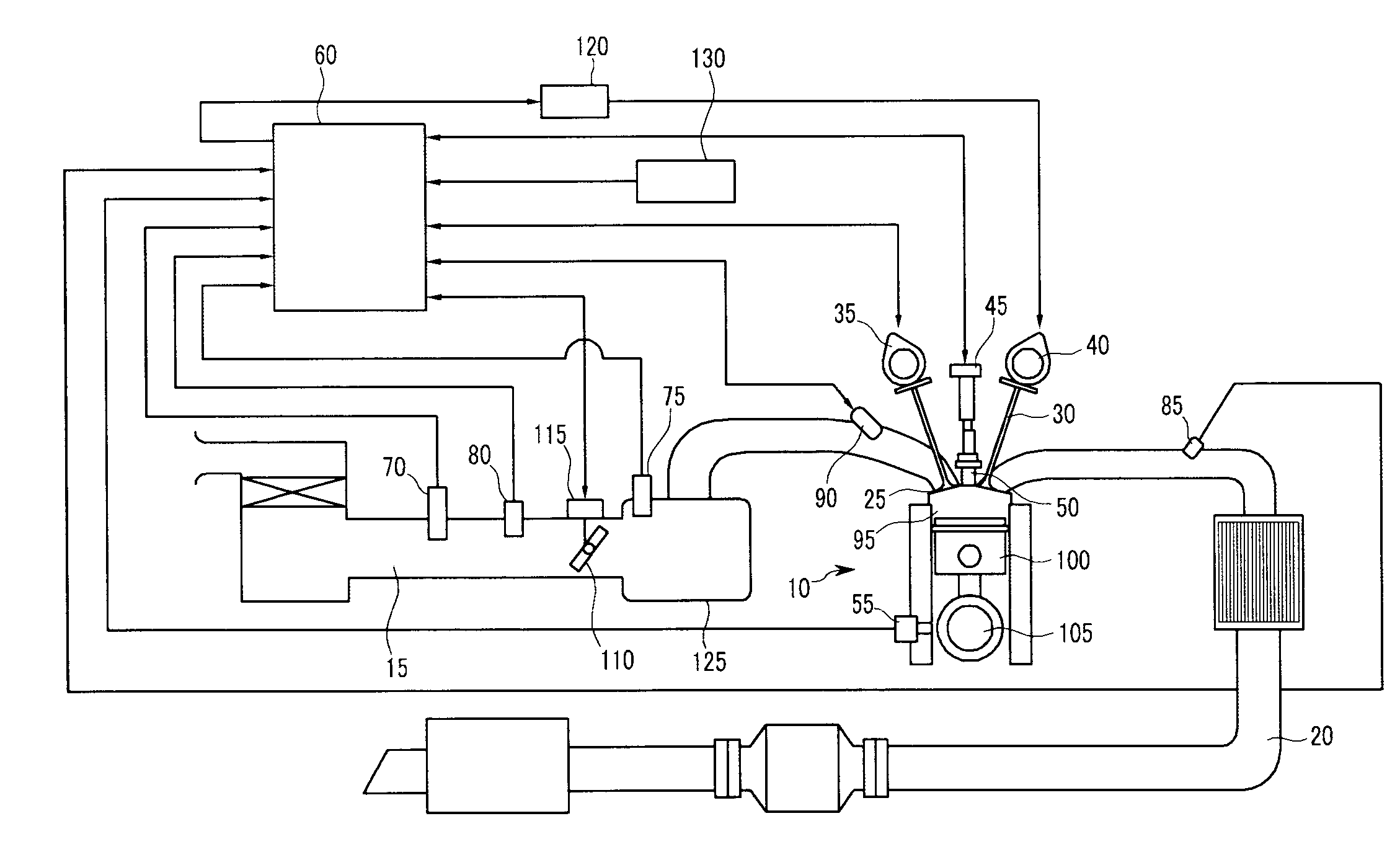

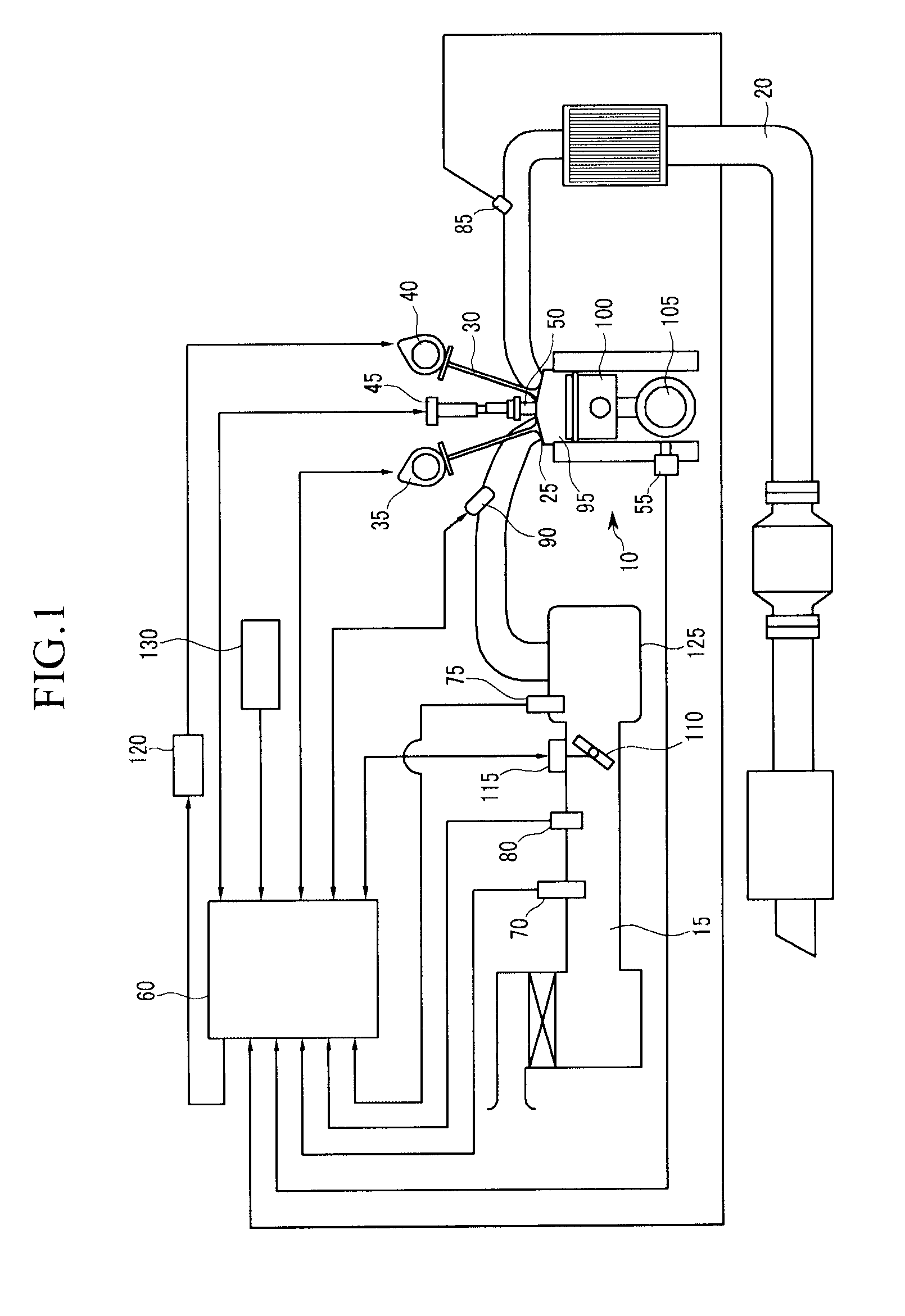

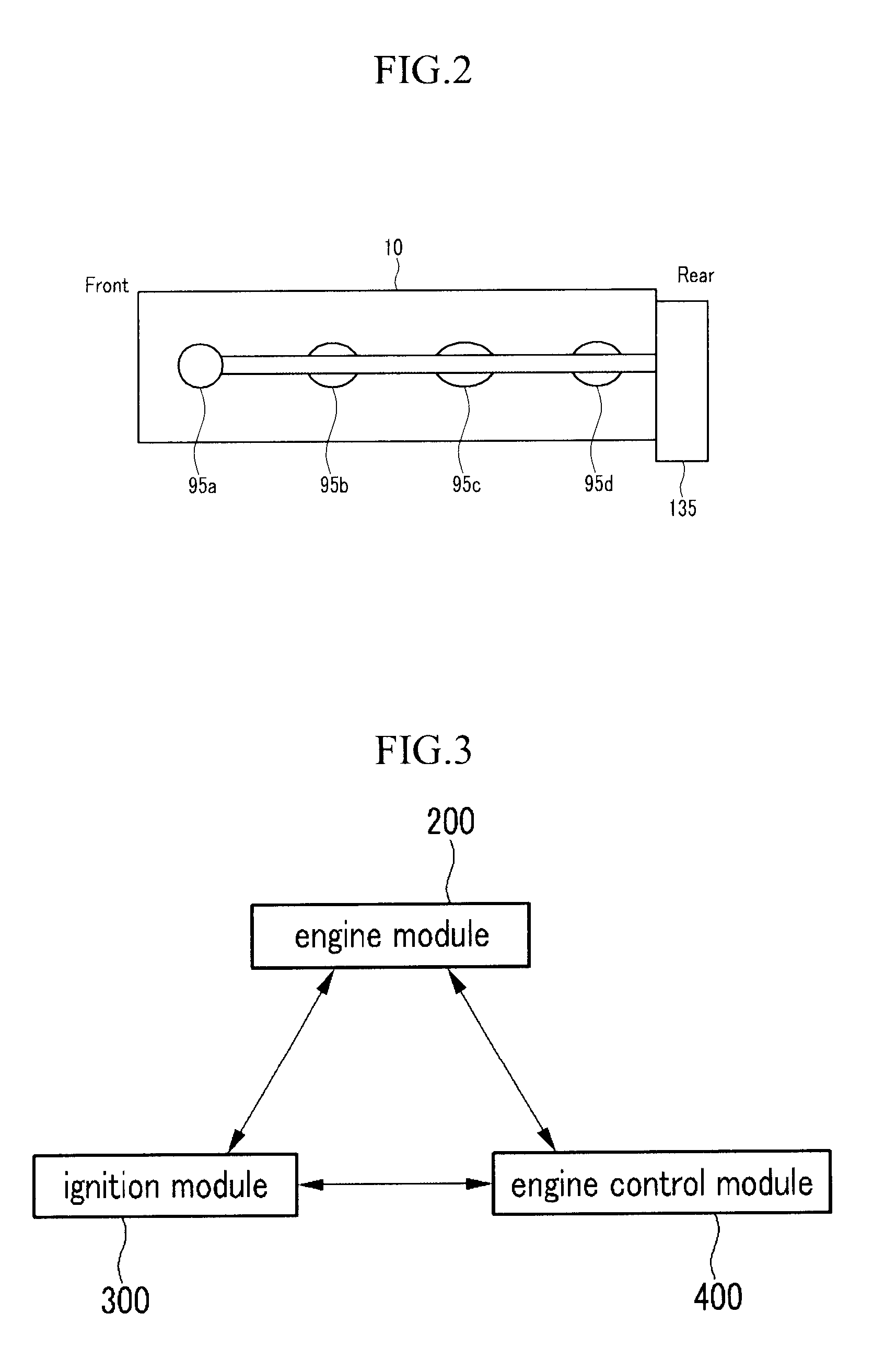

A system and method for controlling engine shutoff at vehicle ignition key-off. An ignition module performs ignition in the engine's cylinders according to a predetermined ignition sequence. An engine module detects the cylinder in which ignition currently occurs. An engine control module controls the engine to stop operating only after a predetermined condition is satisfied after key-off. The predetermined condition may be that the cylinder in which ignition currently occurs is a preselected cylinder, such as the cylinder closest to a flywheel. The method determines whether an ignition key is turned off, detects the cylinder in which ignition currently occurs if the ignition key is turned off, determines whether the cylinder in which ignition currently occurs is a preselected cylinder, and controls the engine to stop only if the cylinder in which ignition currently occurs is the preselected cylinder. The preselected cylinder may be closest to a flywheel.

Owner:HYUNDAI MOTOR CO LTD +1

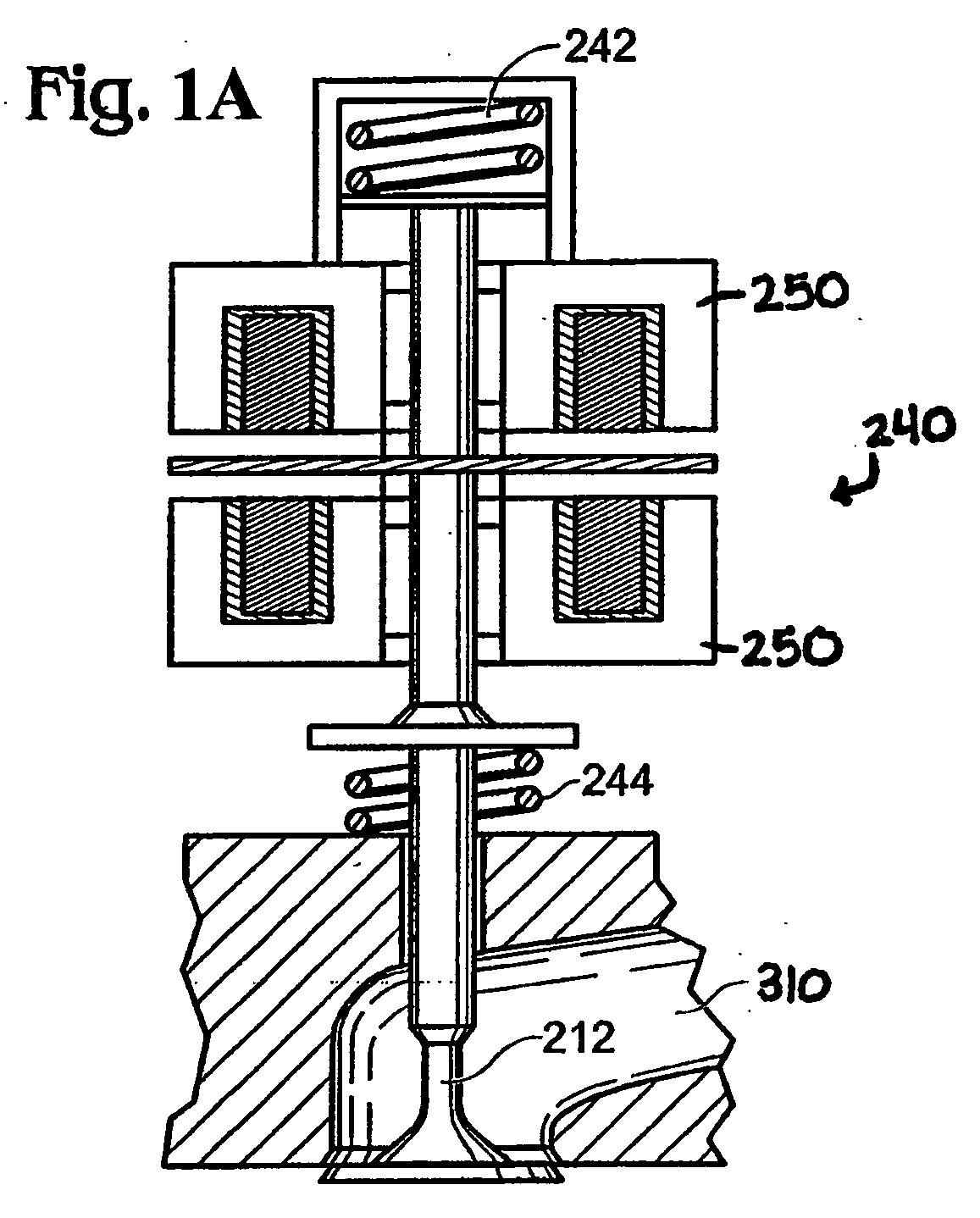

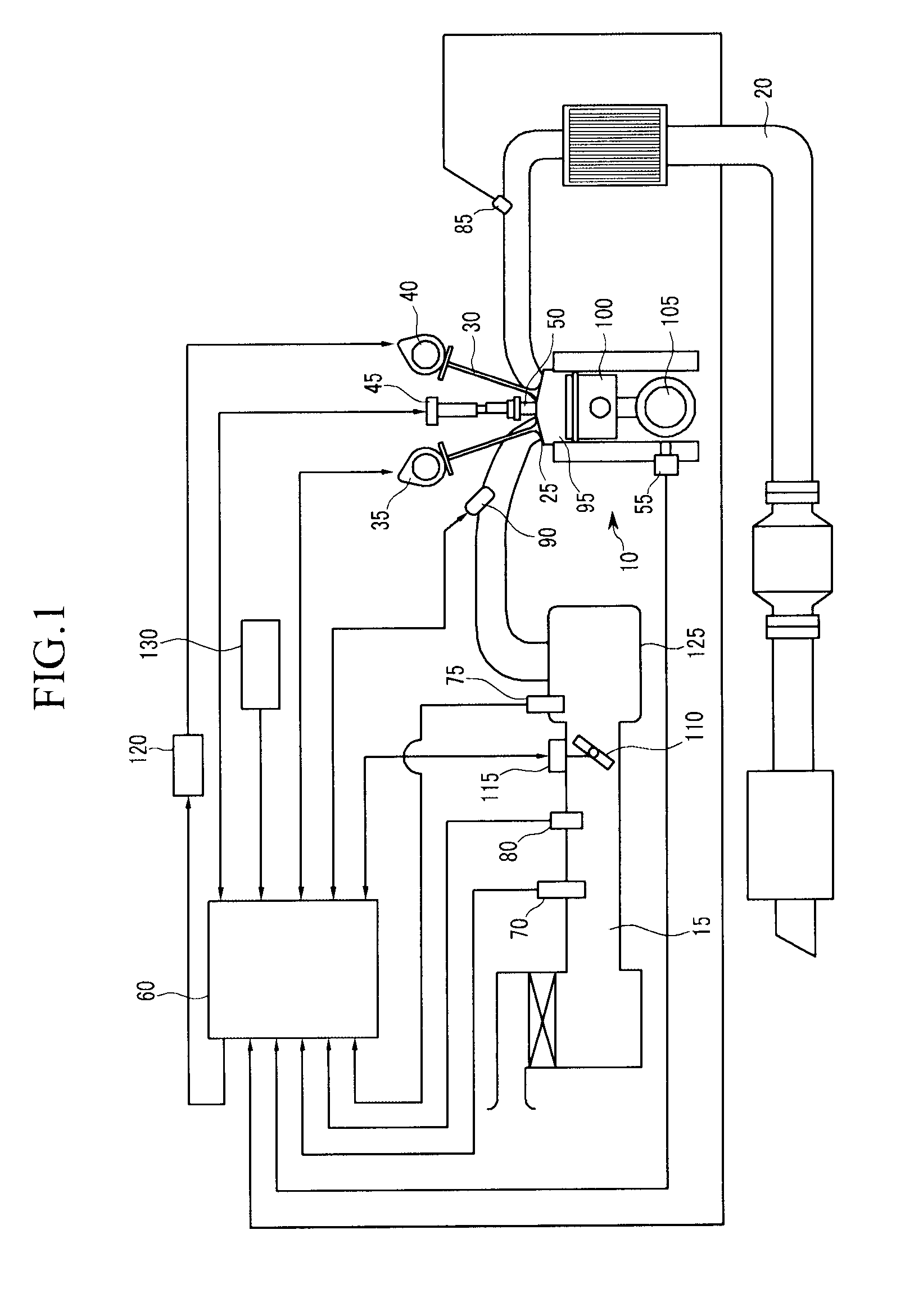

Engine starting for engine having adjustable valve operation

ActiveUS20060254550A1Increased starting torqueEasy to startElectrical controlInternal combustion piston enginesFiring orderVALVE PORT

A method for controlling an engine having at least two cylinders, at least one of which having at least an adjustable valve, the method comprising before engine rotation closing electrically actuated valves in at least a first and a second cylinder; fueling at least said first cylinder with a first fuel amount and said second cylinder with a second fuel amount; and performing a first spark in at least one of said first cylinder and said second cylinder; and after engine rotation, firing each cylinder of the engine in a sequential firing order without changing a number of strokes in any cylinder of the engine.

Owner:FORD GLOBAL TECH LLC

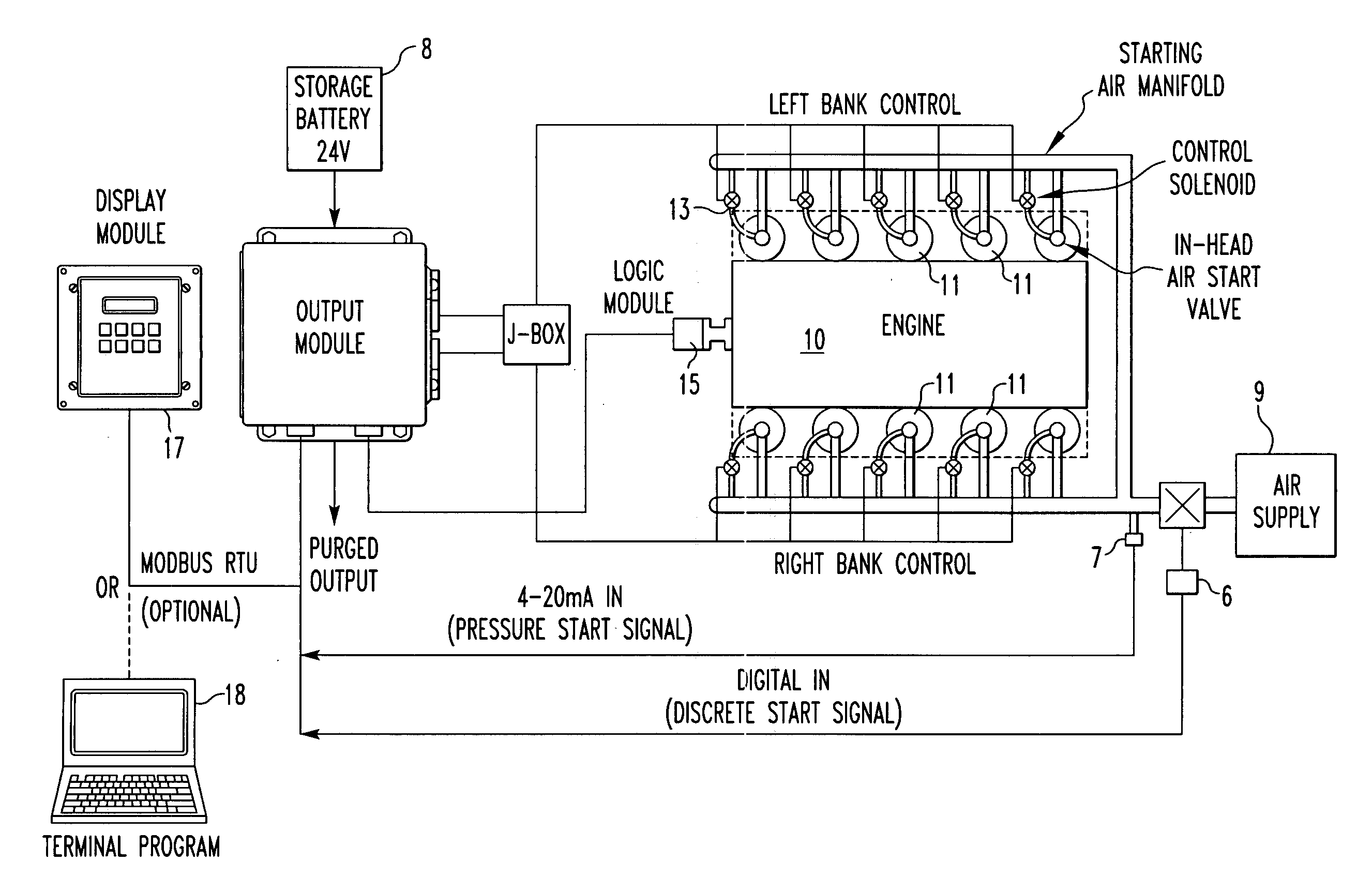

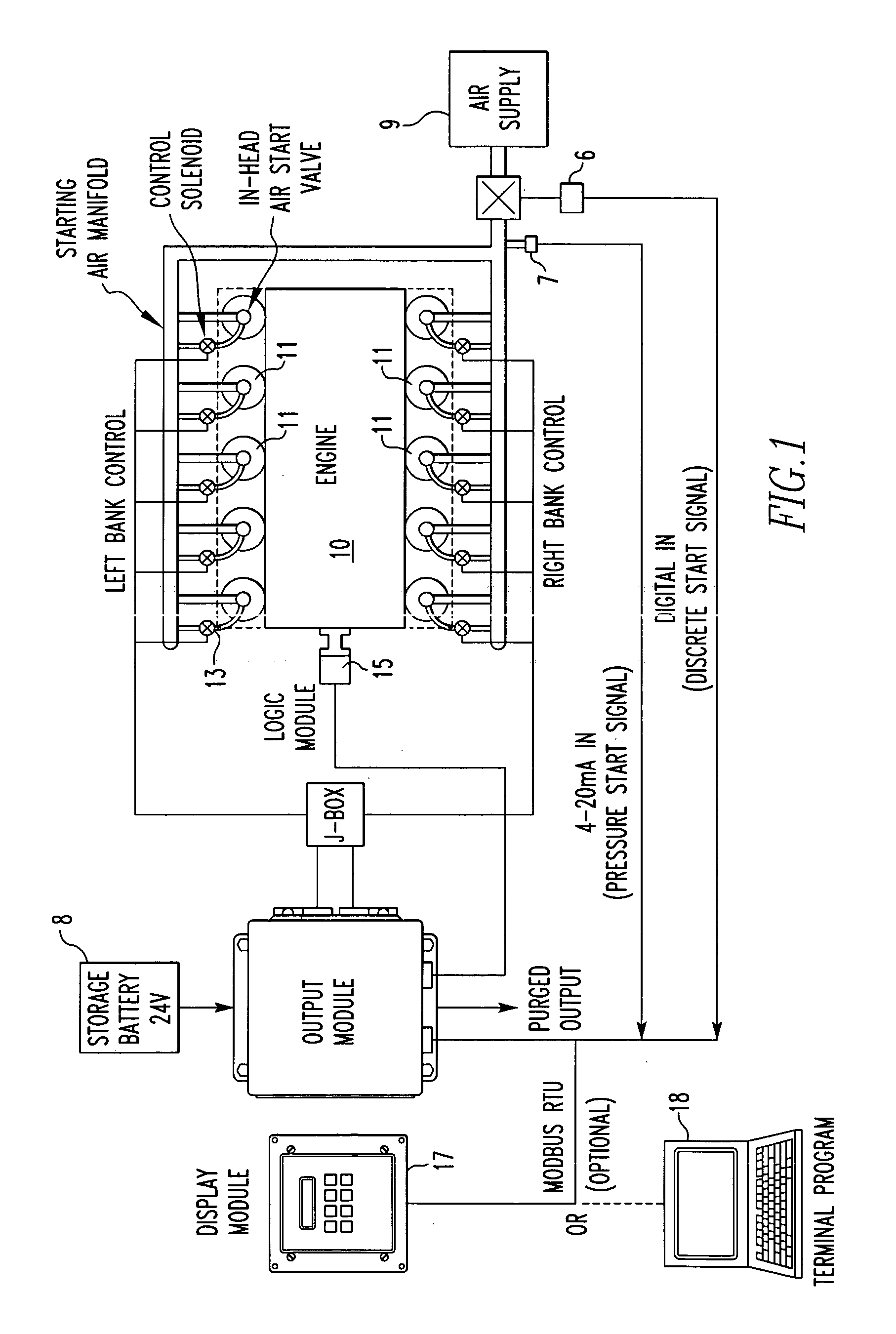

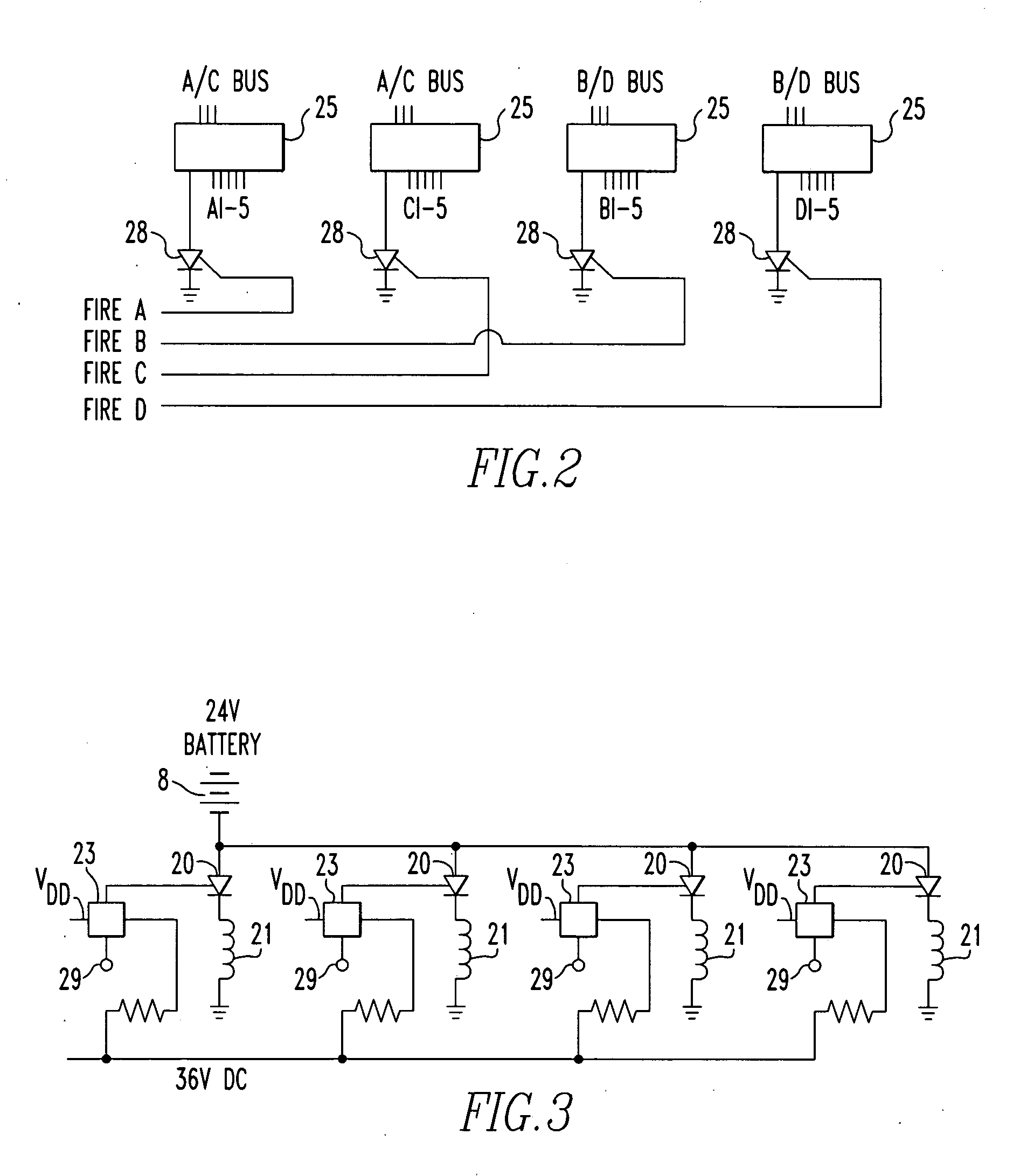

Air starter and electronic control therefor

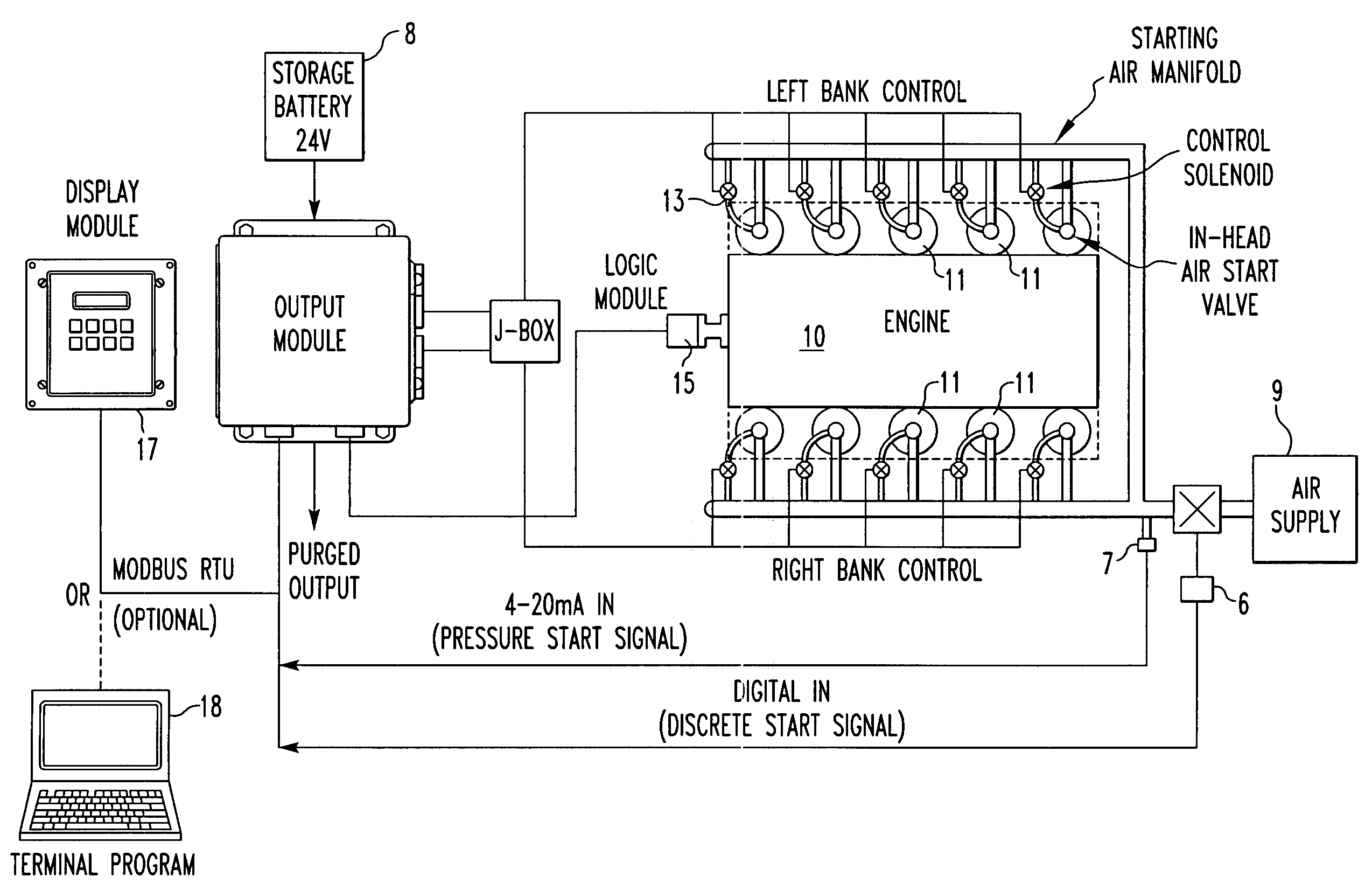

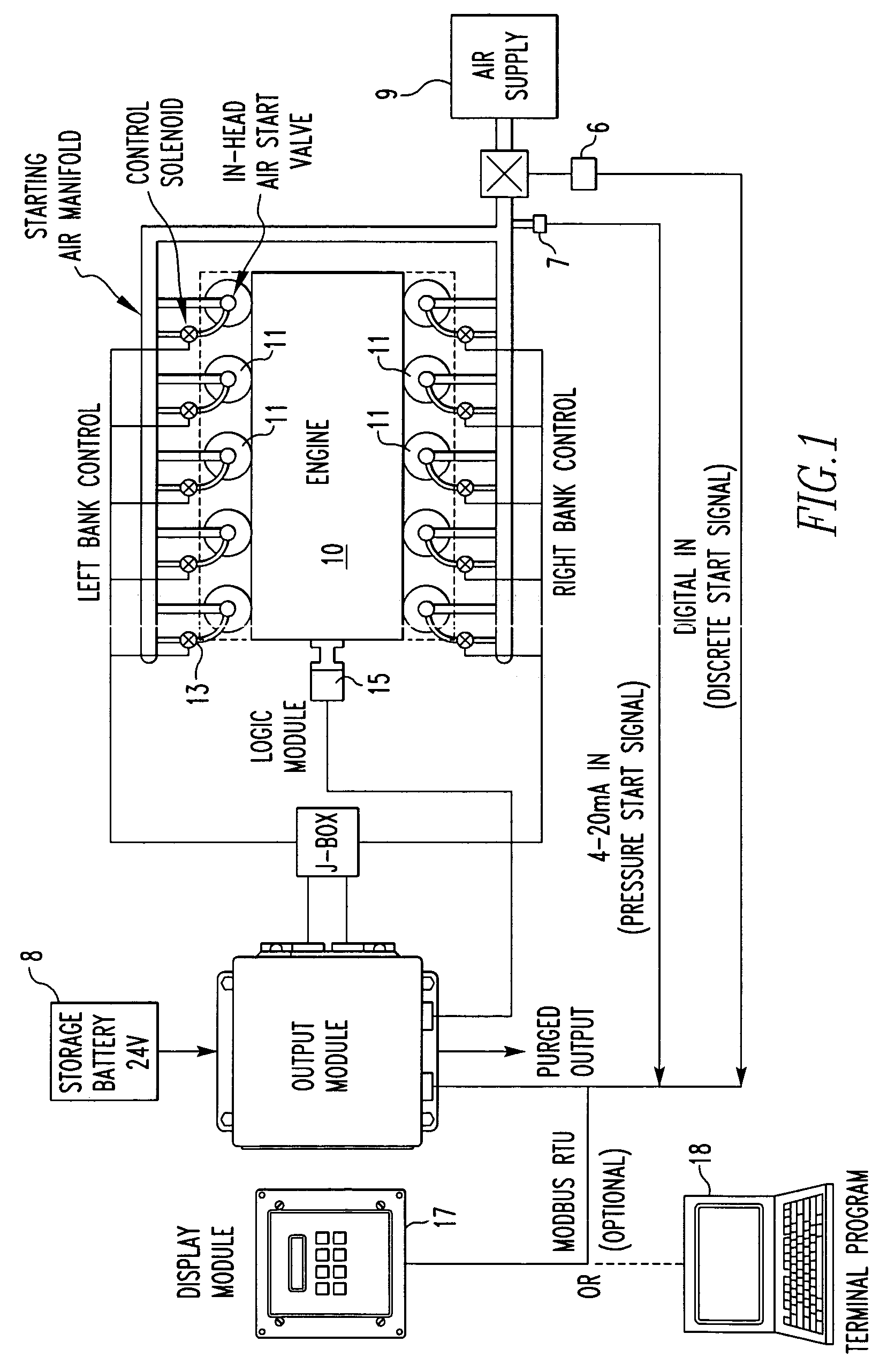

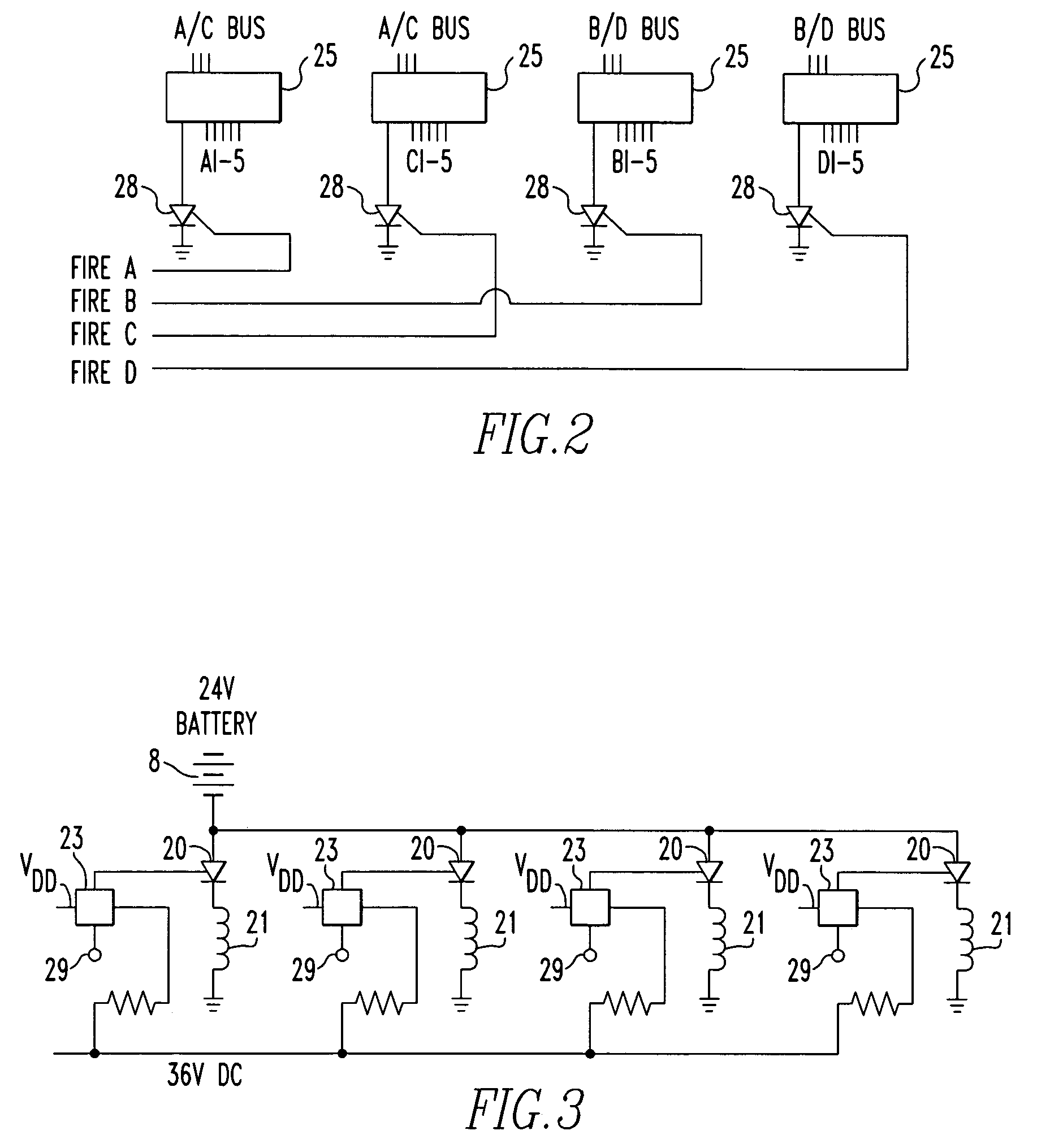

ActiveUS20070005222A1Analogue computers for vehiclesPower operated startersTop dead centerFiring order

An in-head compressed air start-up system for an internal combustion engine comprises an absolute angular position detector for the crankshaft outputting an electrical signal indicative of the angular position, a computer for storing a table of the firing order of the cylinders and the angular position of the crankshaft at which each piston reaches a desired angular position relative to top dead center (TDC), wherein the computer means compares the signal indicative of angular position of the crankshaft to the firing order table and generates a plurality of signals sequentially open and close solenoid valves to cause rotation of the crankshaft.

Owner:ALTRONIC

Vibration reducing system at key-off and method thereof

Owner:HYUNDAI MOTOR CO LTD +1

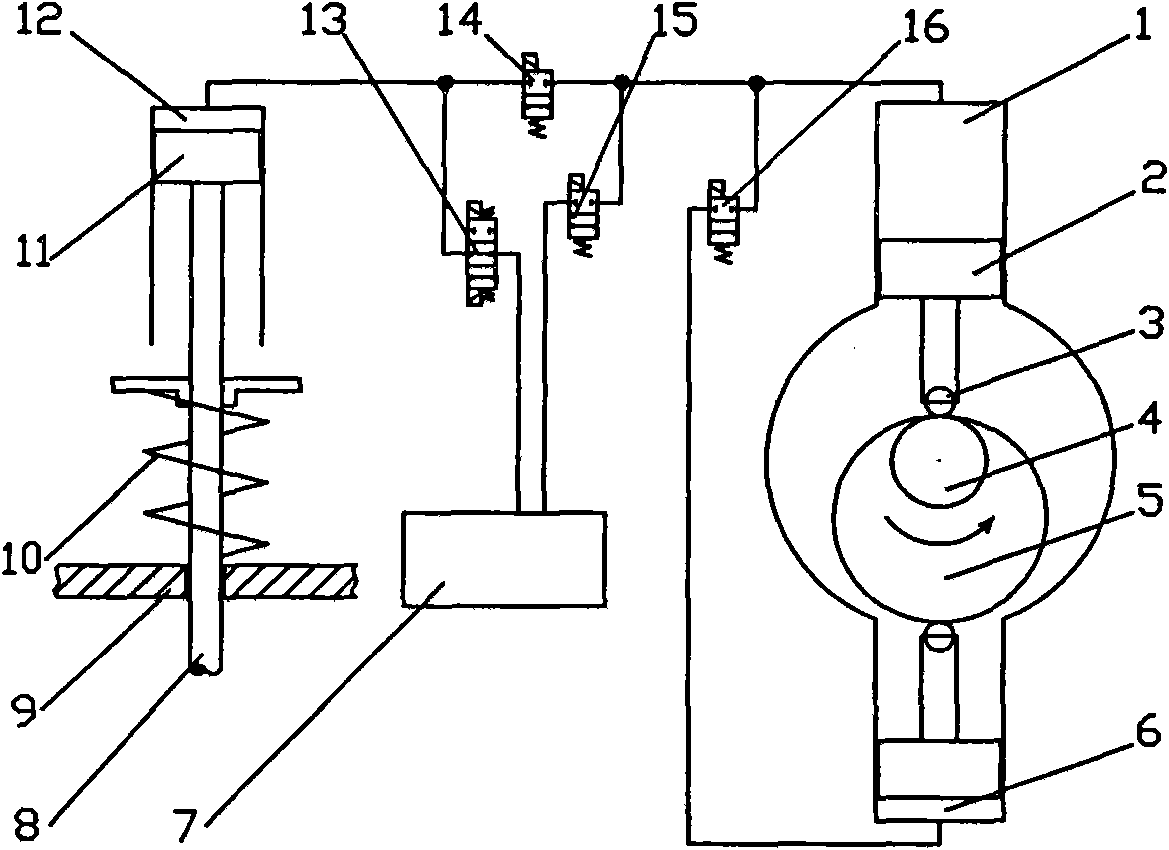

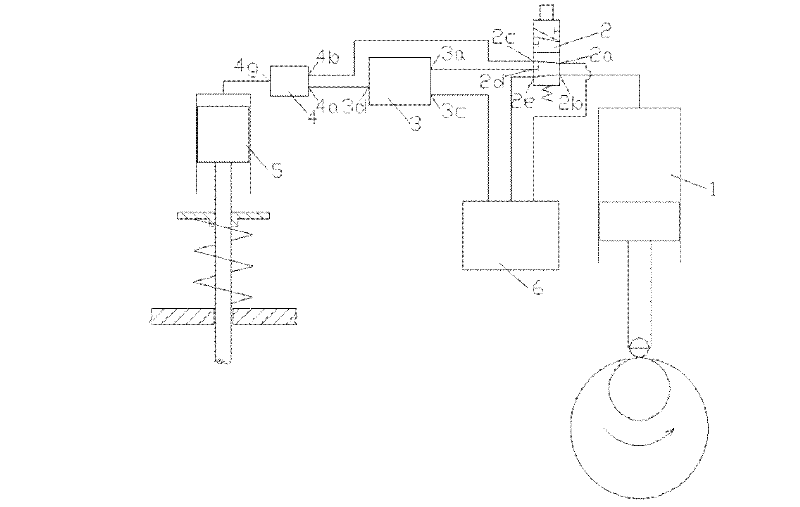

Cam oil-supply type electro-hydraulic valve driving system

InactiveCN101936198ASave energyClose fastMachines/enginesNon-mechanical valveExhaust valveFiring order

The invention discloses a cam oil-supply type electro-hydraulic valve driving system and belongs to a variable-valve cam oil-supply type electro-hydraulic valve driving system of an engine. The cam oil-supply type electro-hydraulic valve driving system mainly comprises an oil supplier, a valve driving mechanism, an oil tank, a connection oil line and an electromagnetic valve. An opposed cam-plunger oil supplier is designed according to the number of cylinders of the engine and the ignition order, and hydraulic oil can be provided for all intake / exhaust valve driving mechanisms of the engine by using only two oil suppliers. A variable intake / exhaust valve can be realized and energy required by valve drive can be reduced by controlling a first electromagnetic valve between an oil supply oil cavity and a driving oil cavity. The secondary opening of the exhaust valve is realized by controlling a fifth electromagnetic valve. Energy consumption for charging the oil supply oil cavity can be reduced by matching a second electromagnetic valve between the oil supply cavity and the oil tank with a fourth electromagnetic valve between a forward oil supply oil cavity and a reverse oil supply oil cavity. When a third electromagnetic valve is used, a valve seat buffer and a valve gap regulator are saved, the valve closing speed is increased and the valve closing range is broadened.

Owner:DALIAN UNIV OF TECH

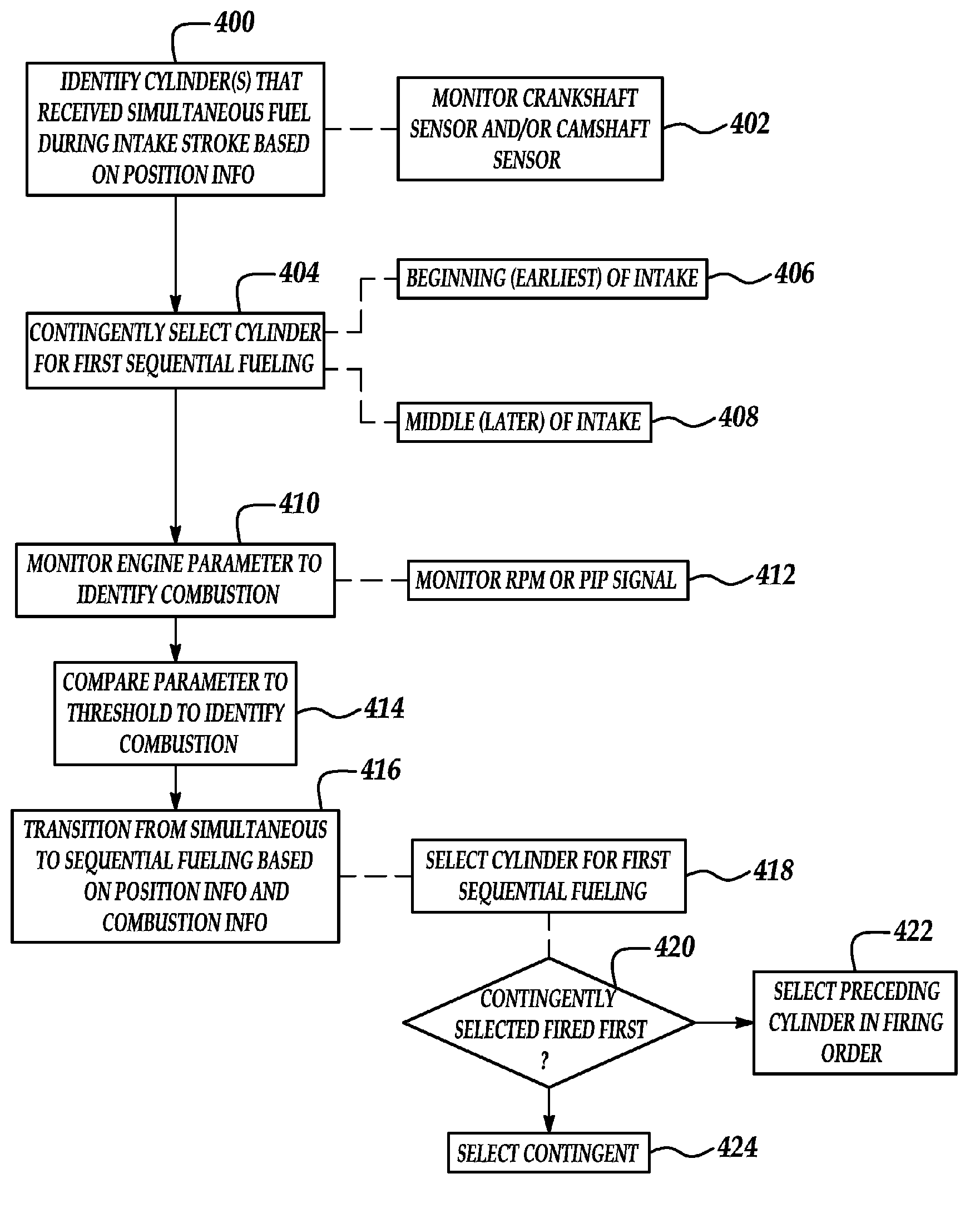

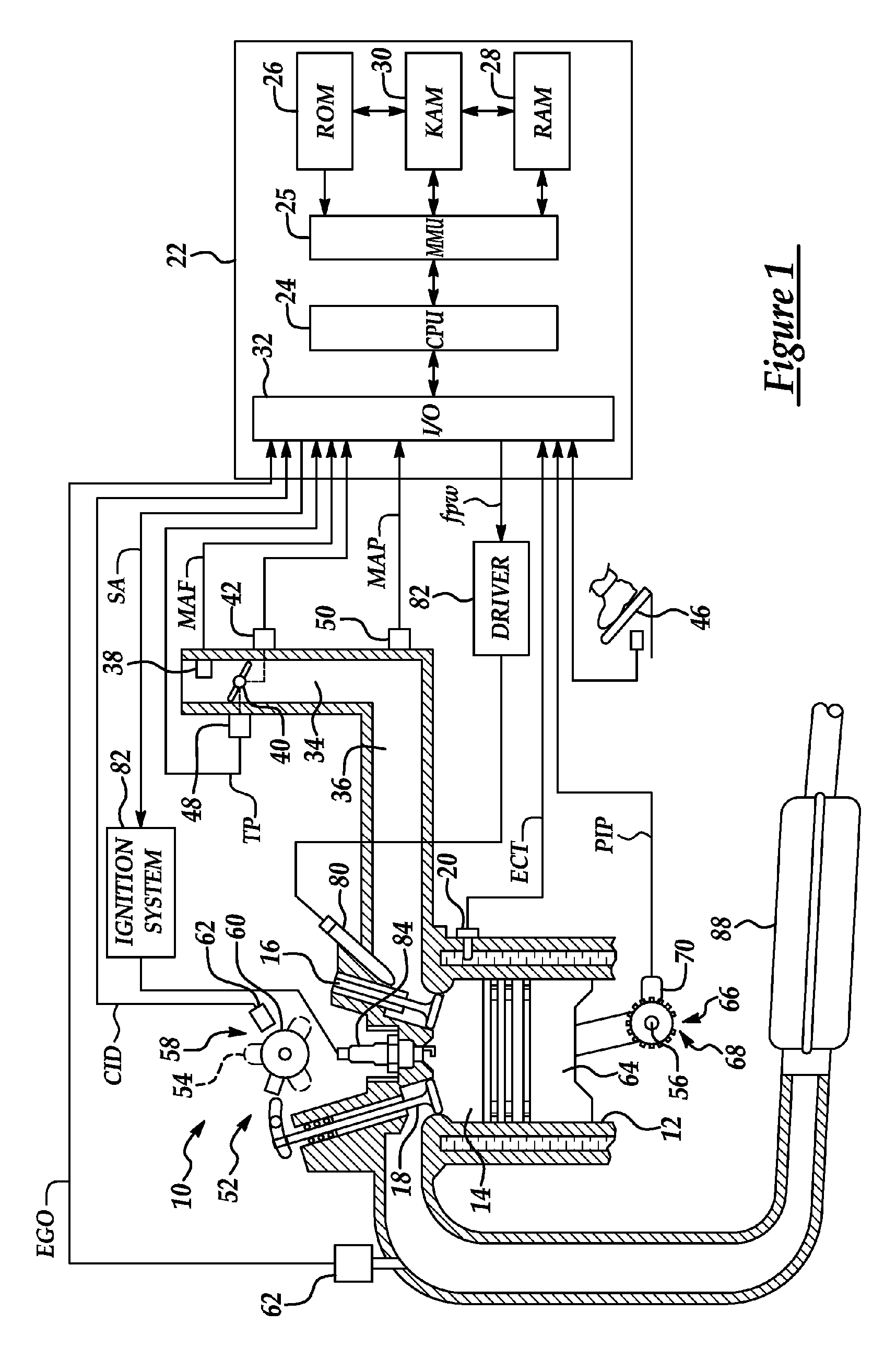

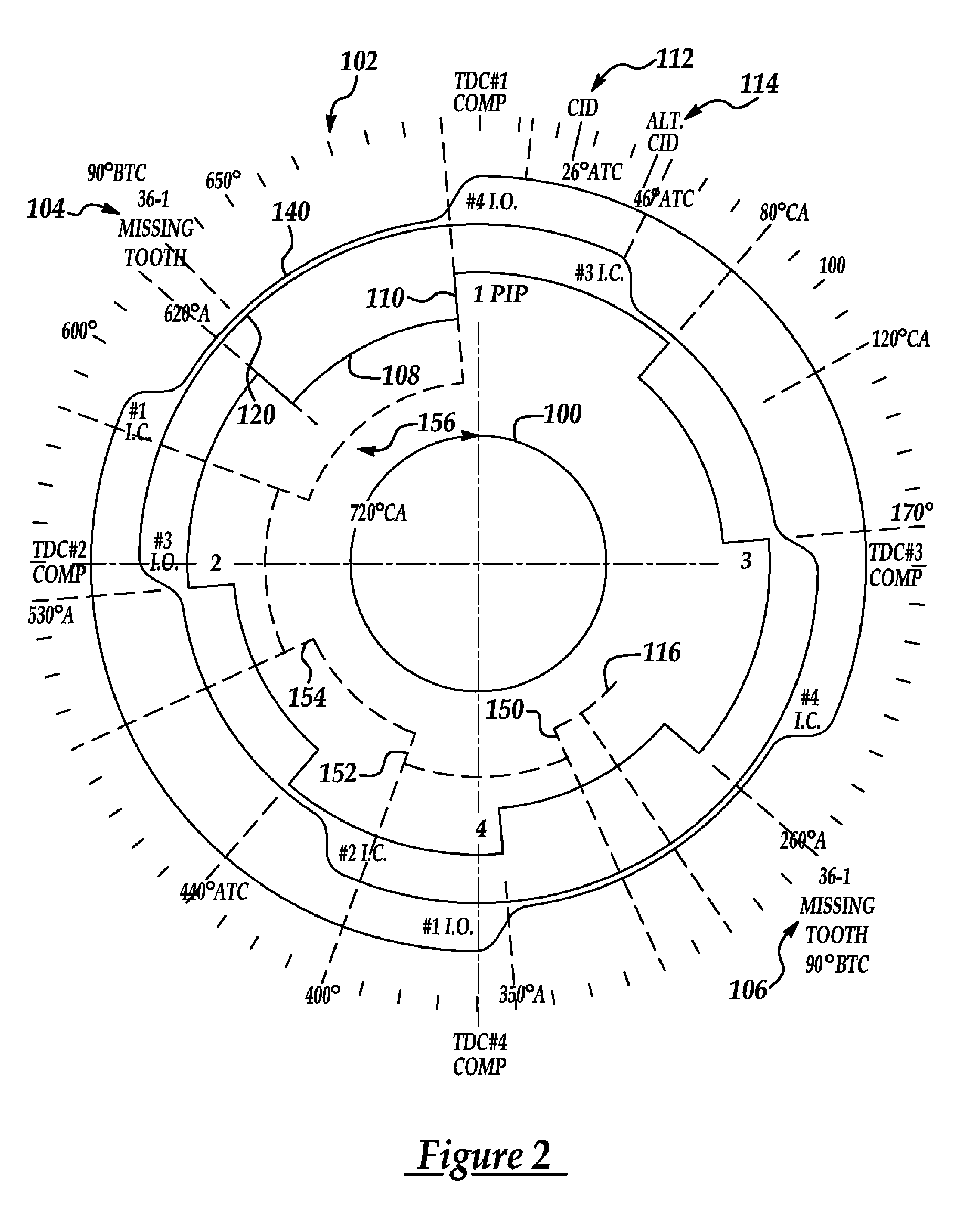

System and method for starting sequential fuel injection internal combustion engine

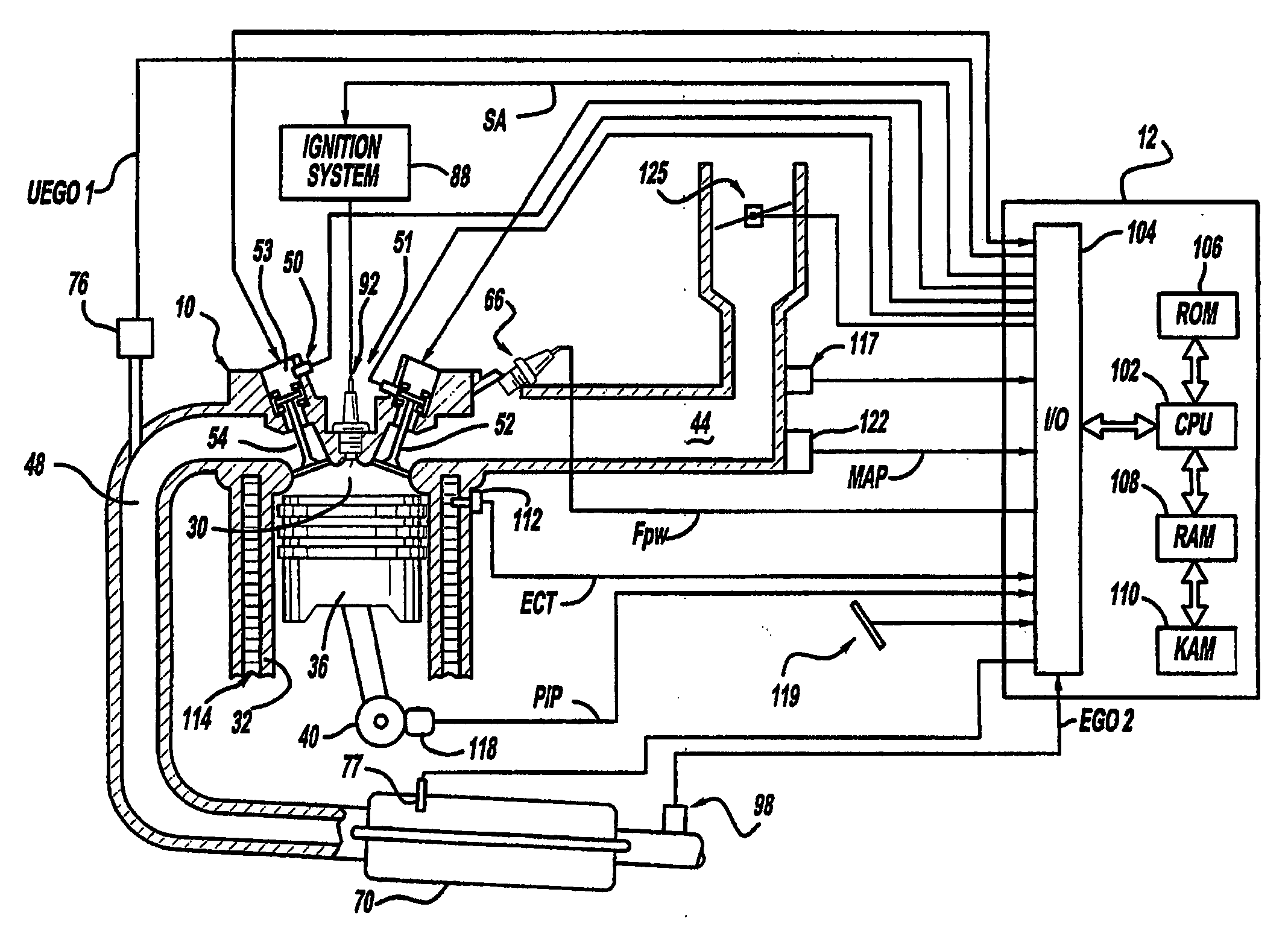

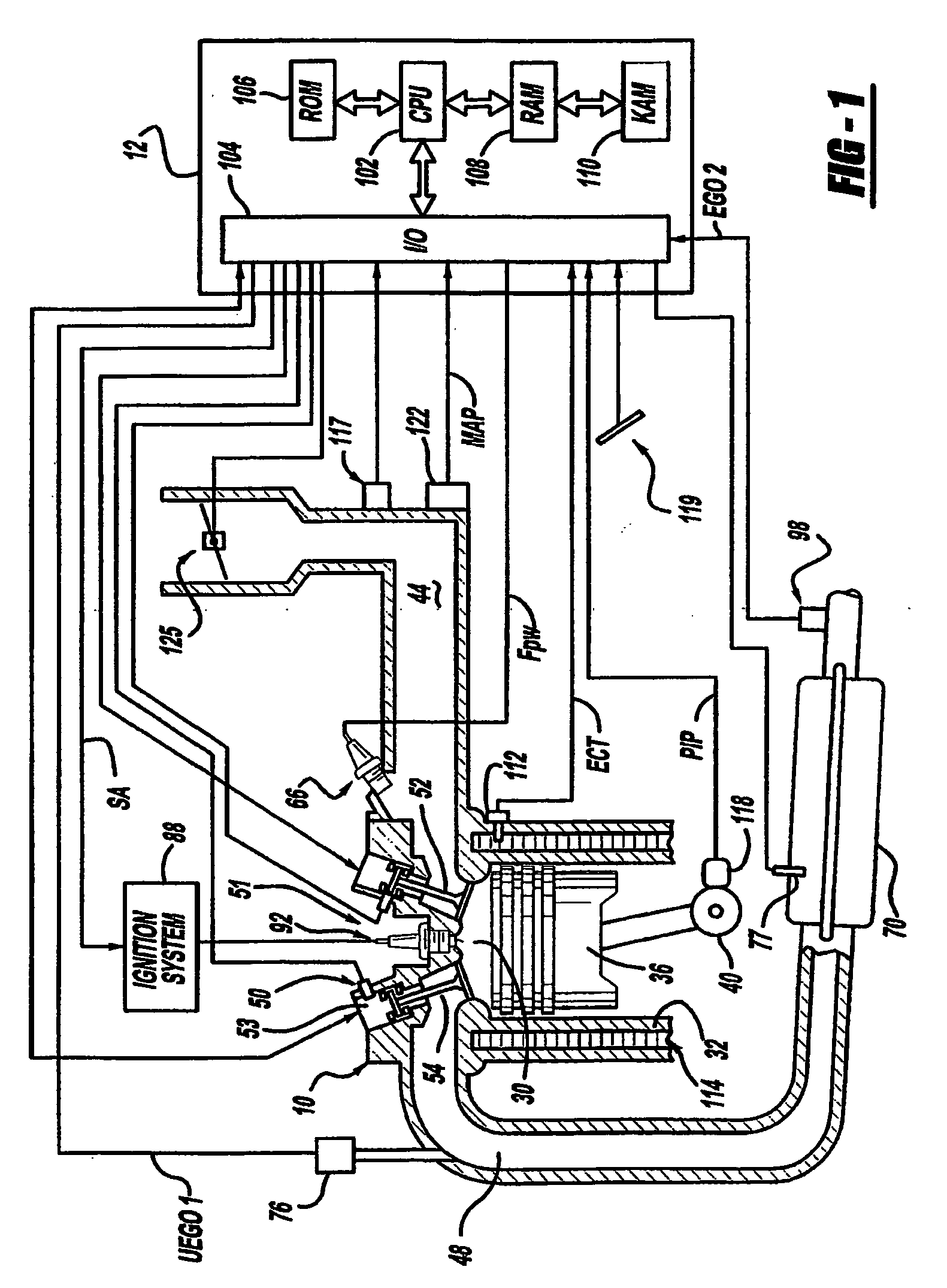

ActiveUS7124743B2Reduces and eliminates misfireAvoids over fuelingElectrical controlDigital data processing detailsCombustionFiring order

A system and method for controlling an internal combustion engine during starting use position sensor information in addition to cylinder combustion information to transition from simultaneous fueling to sequential fueling by selecting a cylinder to receive a first sequential fuel injection. Embodiments include a system and method for controlling a sequentially fueled port injected internal combustion engine that contingently select a cylinder to receive a first sequential fuel injection based on position information indicating that the cylinder received a simultaneous fuel injection during its intake stroke. Engine rotational speed is monitored to detect combustion and determine which cylinder fired first. A first sequential fueling pulse is provided to the contingently selected cylinder unless a preceding cylinder in the firing order fires first.

Owner:FORD GLOBAL TECH LLC

Adaptive firing order control for dynamic current balance of multiphase voltage regulators

InactiveUS20080197824A1Improved dynamic current balanceDc-dc conversionElectric variable regulationEngineeringPwm signals

A pulse width modulation (PWM) modulator for a multiphase power converter and related adaptive firing order (AFO) method includes a multiphase leading edge generator having pulse generating circuitry associated with each of the regulator phases, wherein the pulse generating circuitry generates phase pulses associated with each of the phases. An adaptive firing order (AFO) controller having circuitry including a mixer receives and sums the phase pulses into a summing signal and uses the summing signal to generate a series of turn-on pulses therefrom. A multiphase PWM generator has inputs coupled to an output of the AFO controller coupled to receive the series of turn-on pulses, the multiphase PWM generator having circuitry for generating said PWM signals therefrom. An adaptive firing order (AFO) controlled multi-phase power converter includes a plurality of parallel connected regulator phases controlled by respective pulse width modulation (PWM) signals provided by the PWM modulator.

Owner:INTERSIL INC

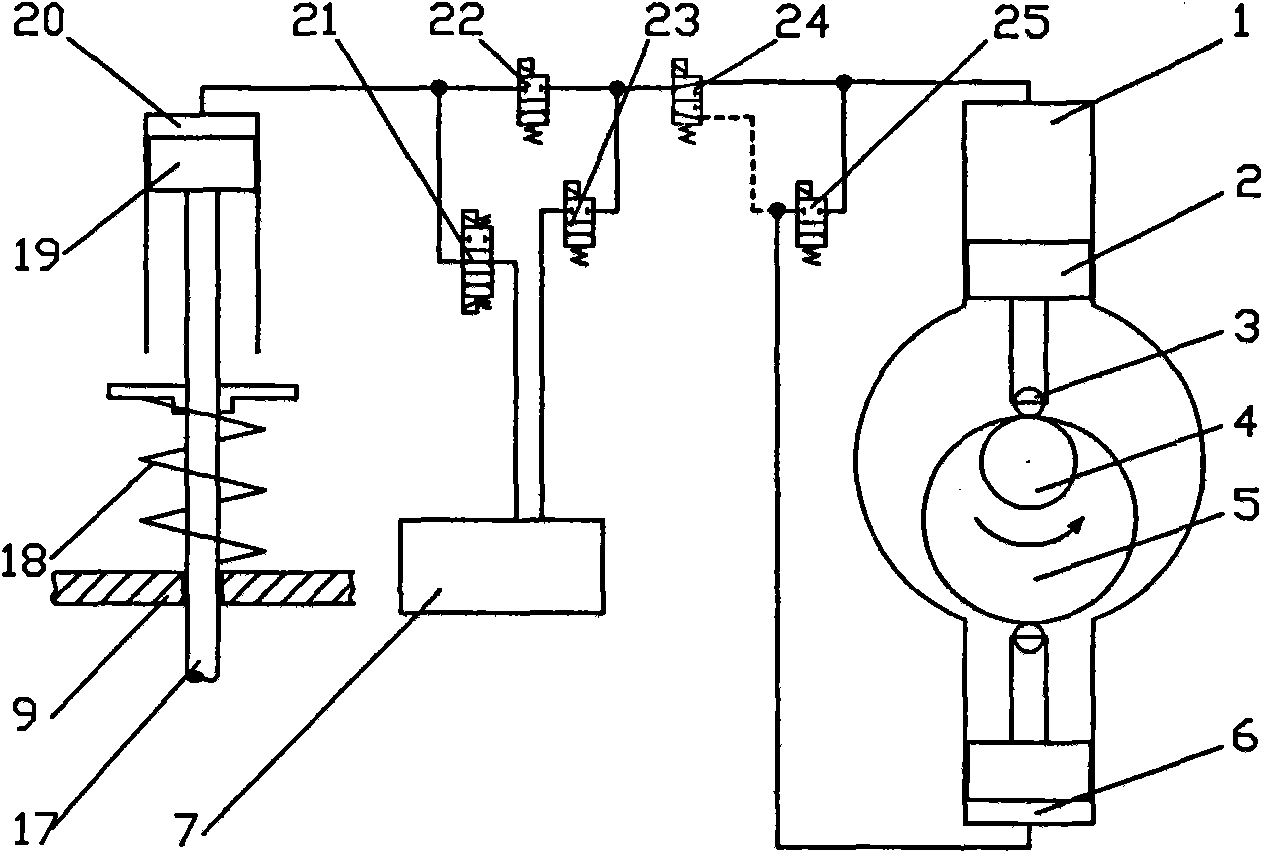

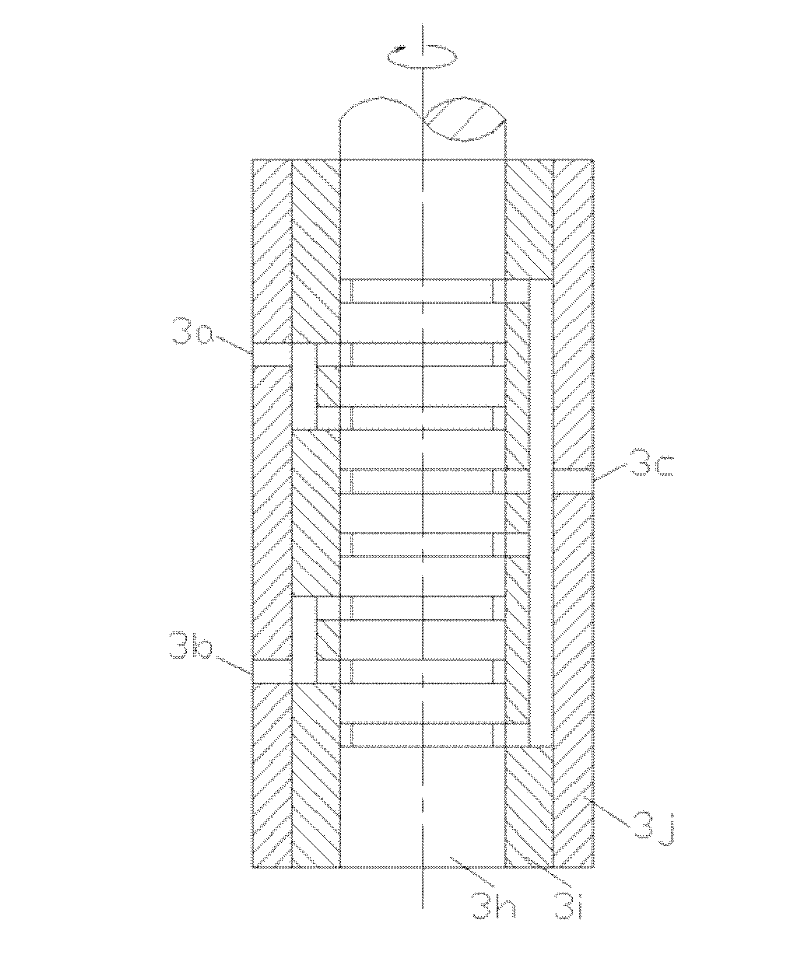

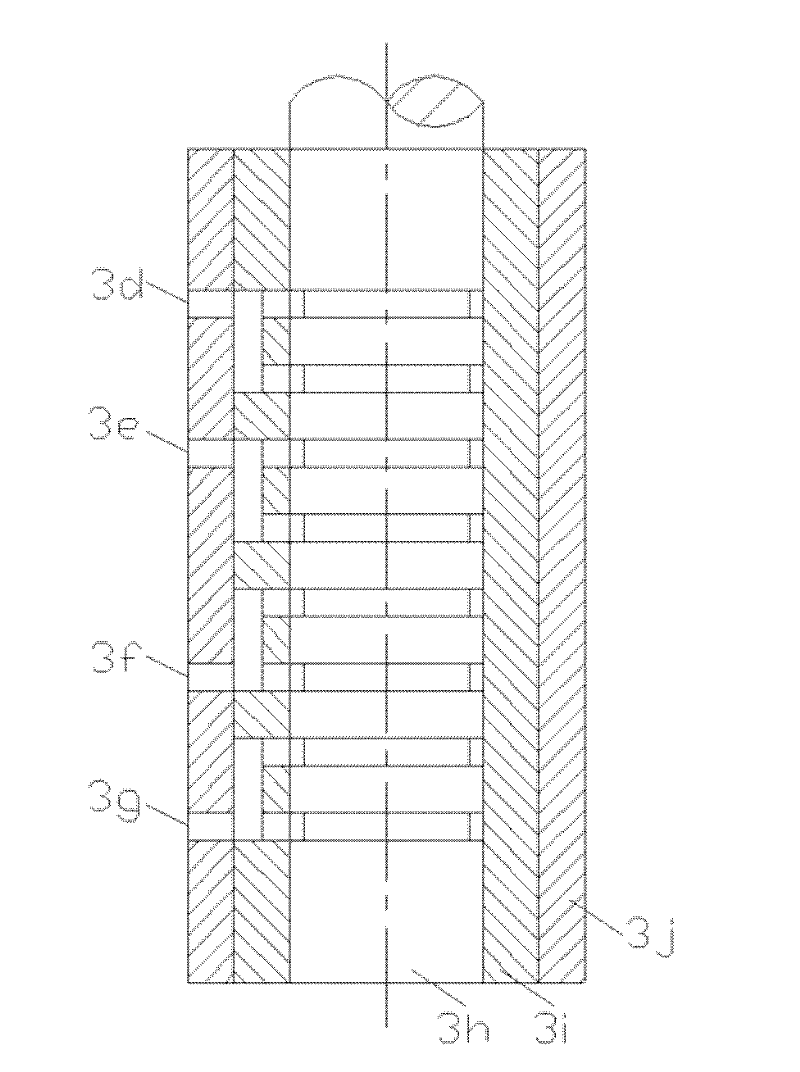

Double-mode type full-variable valve driving system for four-cylinder internal combustion engine

InactiveCN102444440AReduce in quantityHigh acceptanceValve drivesMachines/enginesCombustionExternal combustion engine

The invention relates to a double-mode type full-variable valve driving system for a four-cylinder internal combustion engine, belonging to the field of the variable valve driving system of the internal combustion engine. The double-mode type full-variable valve driving system mainly comprises a mode converter, a driving circulator, a forward oil supply device, a reverse oil supply device, valve driving mechanisms of all cylinders, a forward high-speed valve, a reverse high-speed valve, an oil tank, oil pipes and the like. The invention provides the mode converter and the driving circulator with a three-layer embedding type structure according to the number of the engine cylinders and the ignition sequence, not only can achieve the purpose that all inlet (exhaust) valve driving mechanismscan be completely and flexibly driven by only using two electromagnetic valves to realize a variable valve event required by a driving mode of the internal combustion engine as a power source and a braking mode of the internal combustion engine as a consuming source, can be used as a gas distributing system and an auxiliary braking system of the internal combustion engine, realizes powerful functions with extremely-low cost, can be applied to natural gas-suction type or turbo-supercharging type internal combustion engines by only needing to exchange a communication object of the two oil pipes, and is good in model adaptability and wide in application range.

Owner:YIXING DALONG POWER TECH

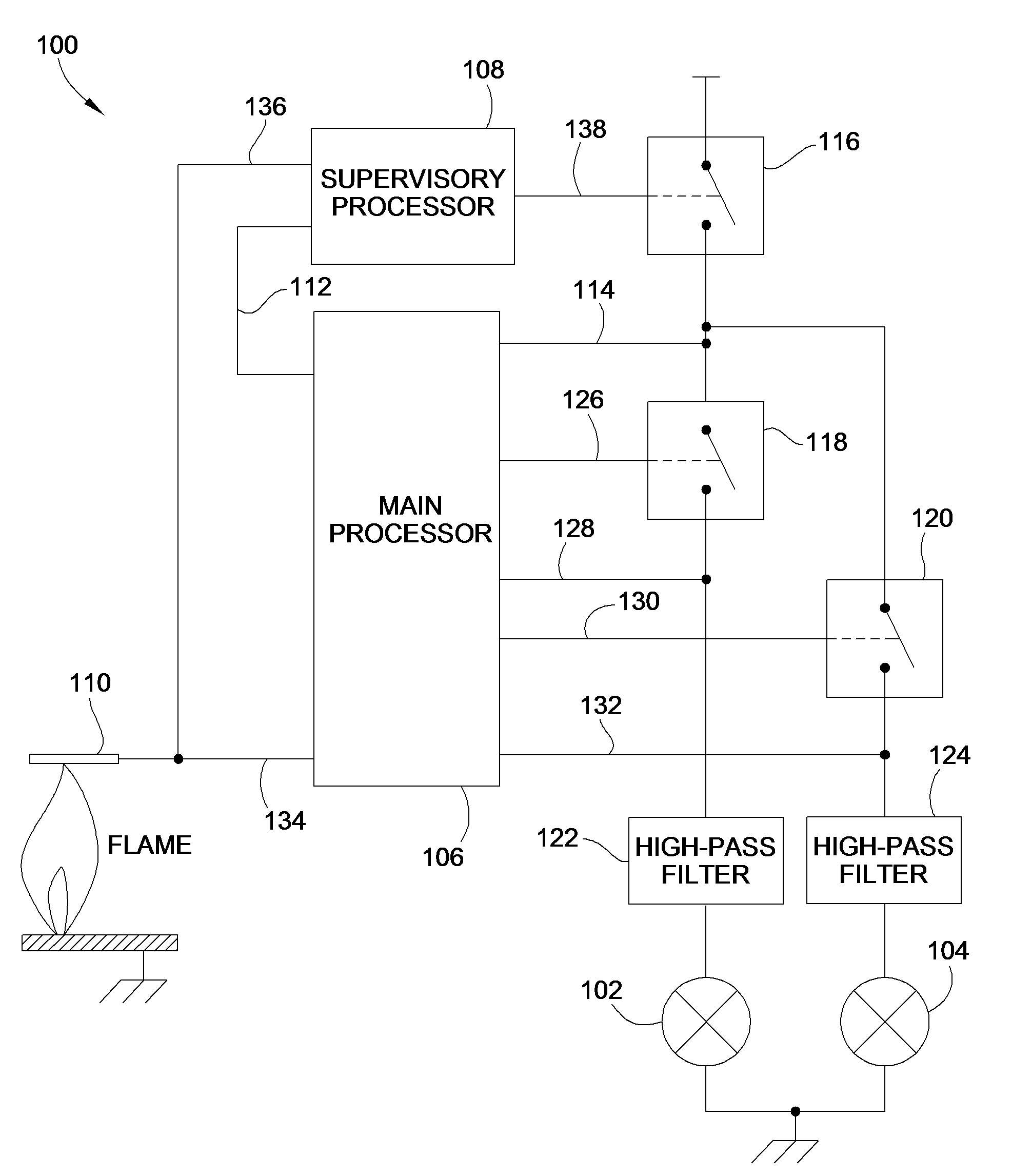

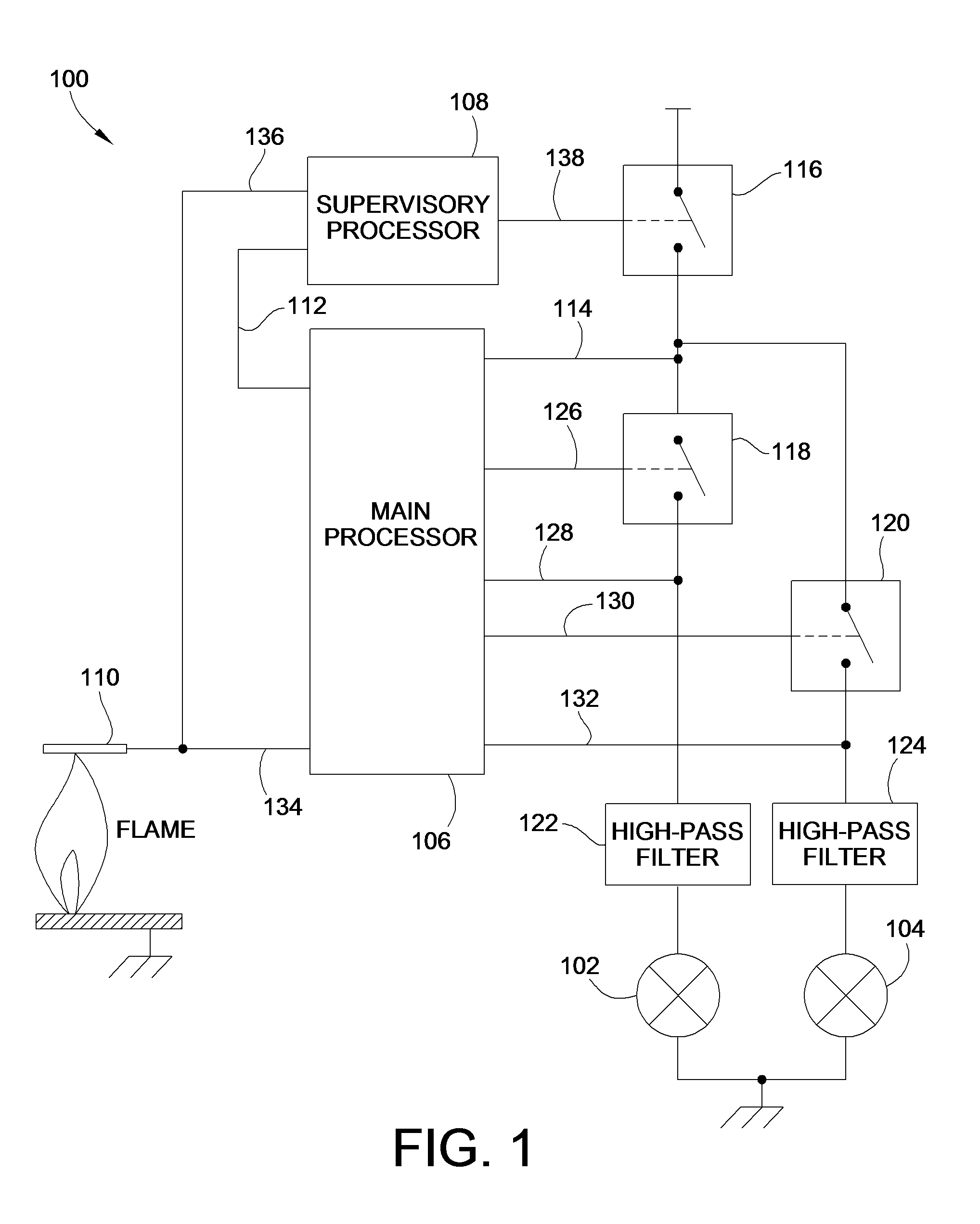

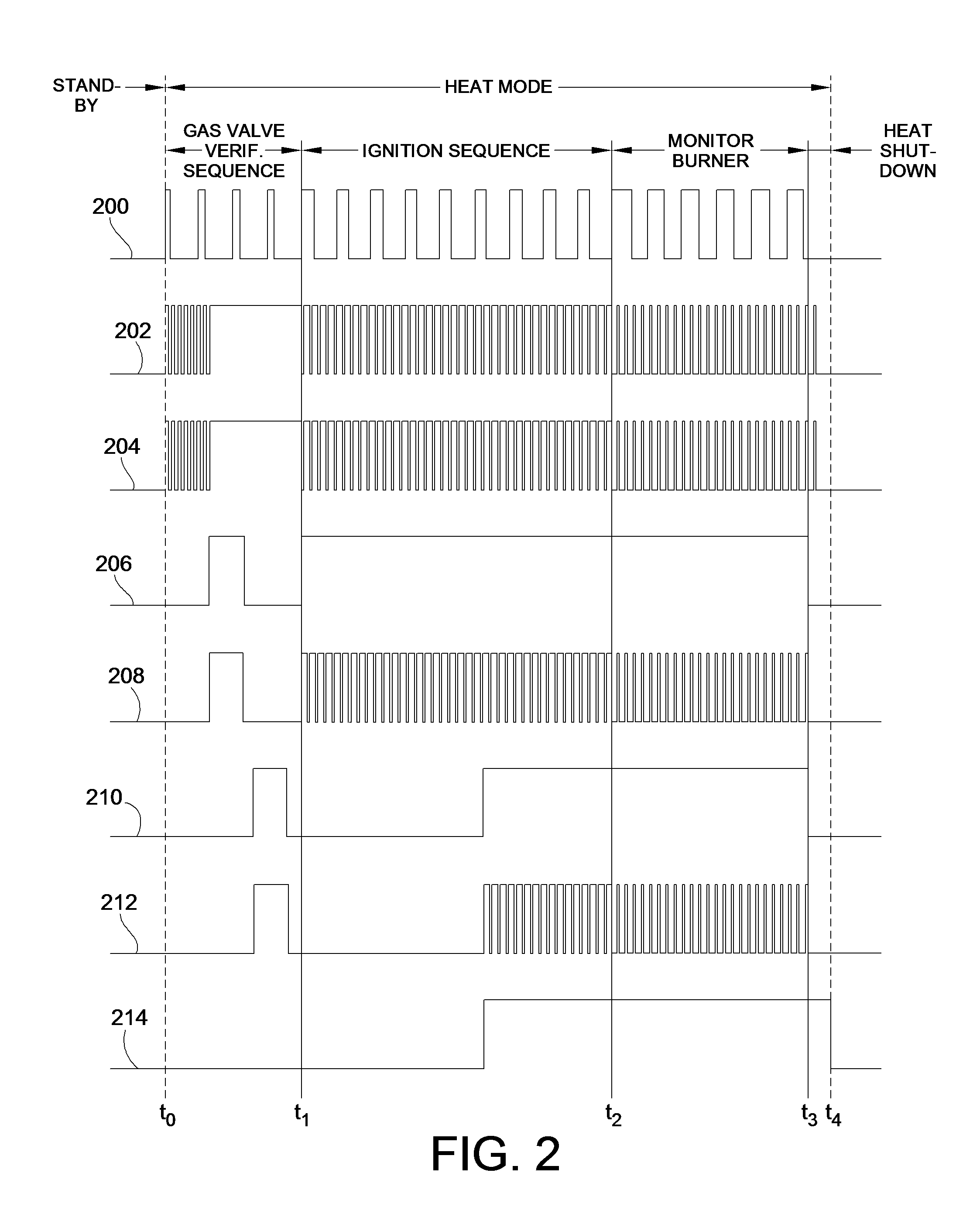

Redundant Ignition Control Circuit and Method

InactiveUS20100075264A1Simplified communication techniqueMinimize resourceElectric spark ignitersPilot flame ignitersEngineeringIgnition control

A redundant ignition control system and method for gas burning appliances is provided. The system utilizes a main processor and a supervisory processor to provide the redundant, fail safe operation of both the pilot valve and the main gas valve of the appliance. Three switching elements under the control of the two processors, as well as the use of high pass filters to block DC from the gas control valves provide redundant, fail safe operation. The use of variable duty cycle or frequency pulse width modulated signals enables use in low power applications and ensures system safety. Inclusion of a gas valve verification sequence, ignition sequence, burner monitoring sequence, and heat shutdown and standby sequences ensures safe, low power operation during normal control, and fail safe operation upon the failure of any component of the system.

Owner:ROBERTSHAW CONTROLS CO

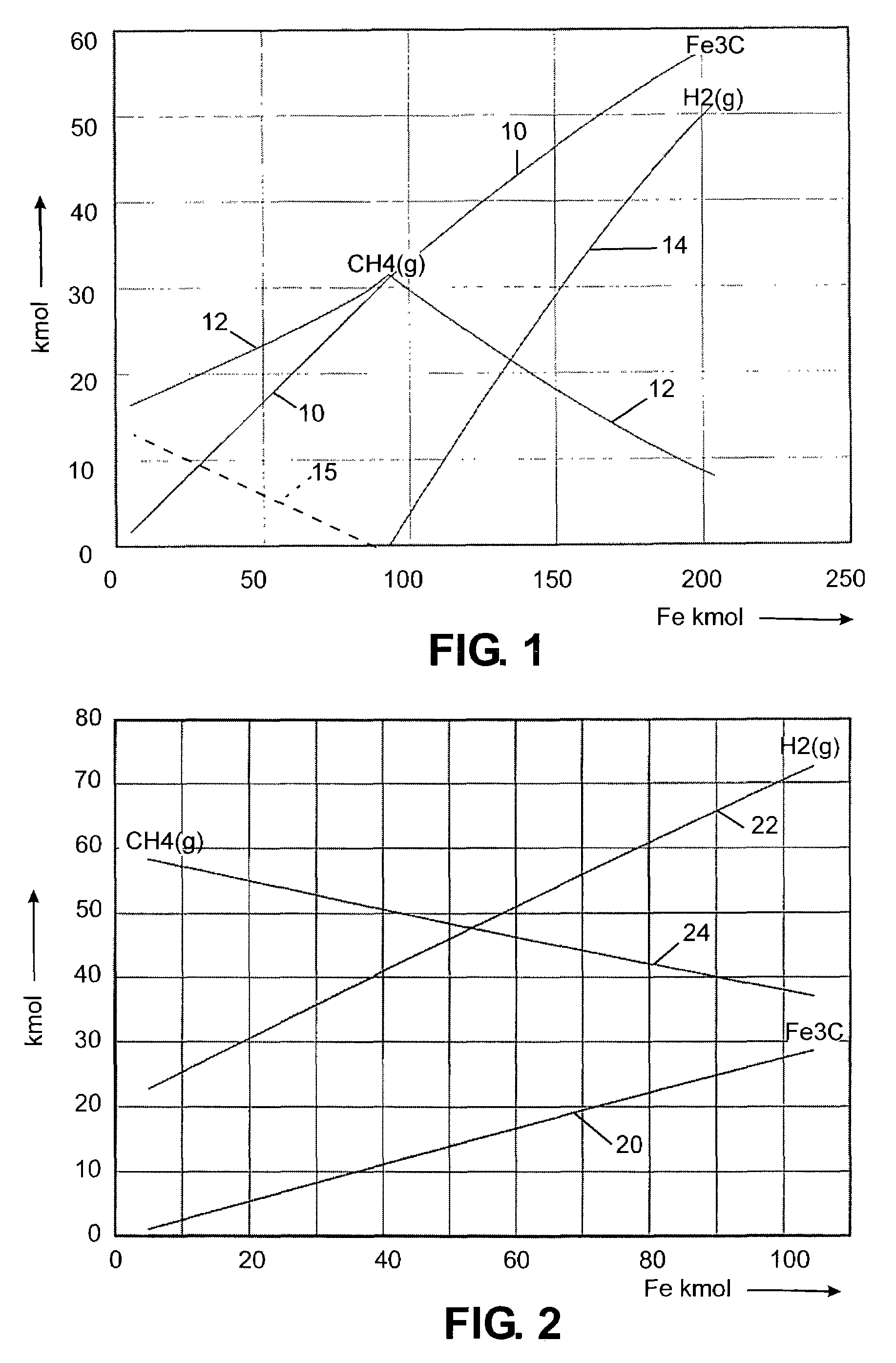

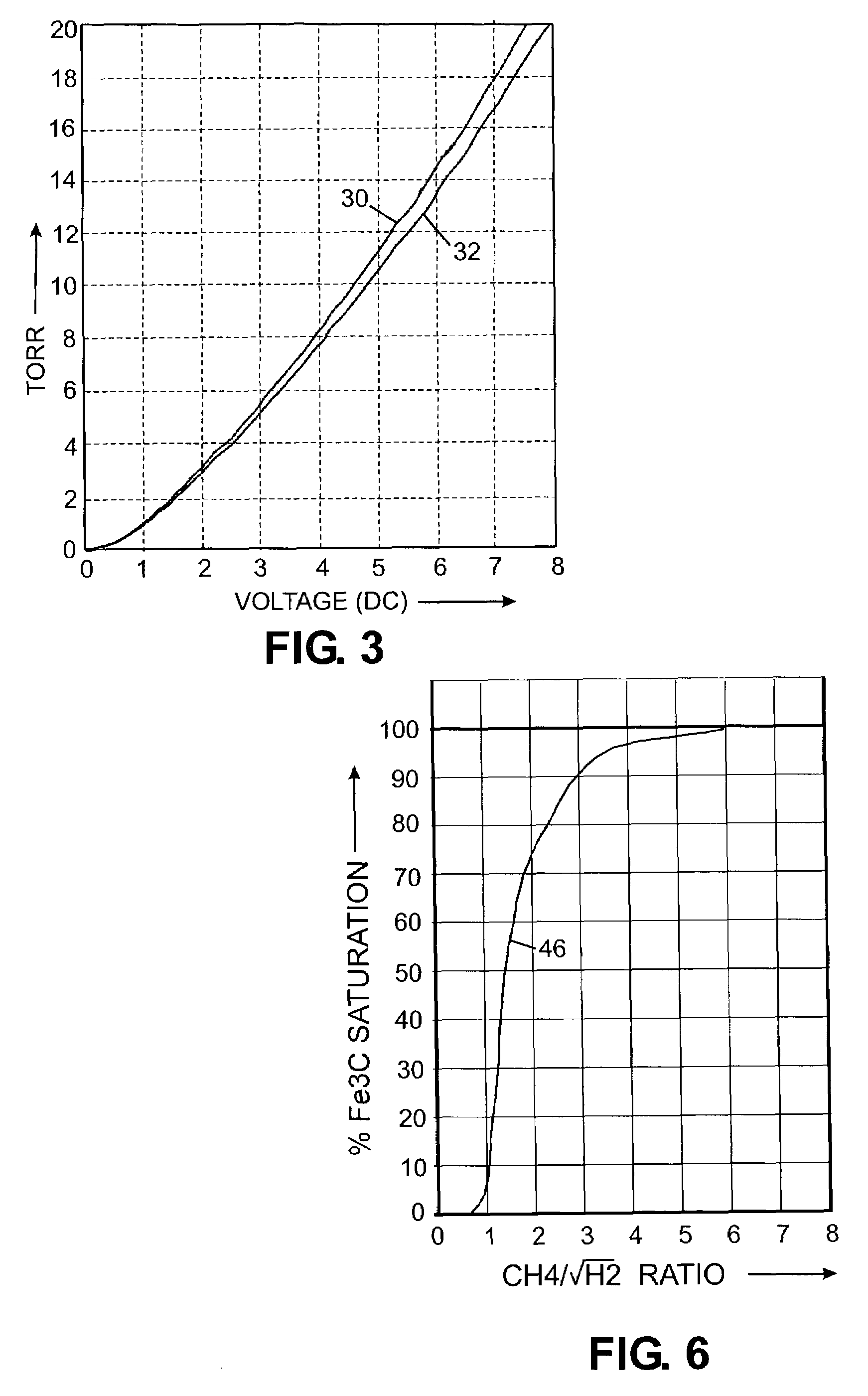

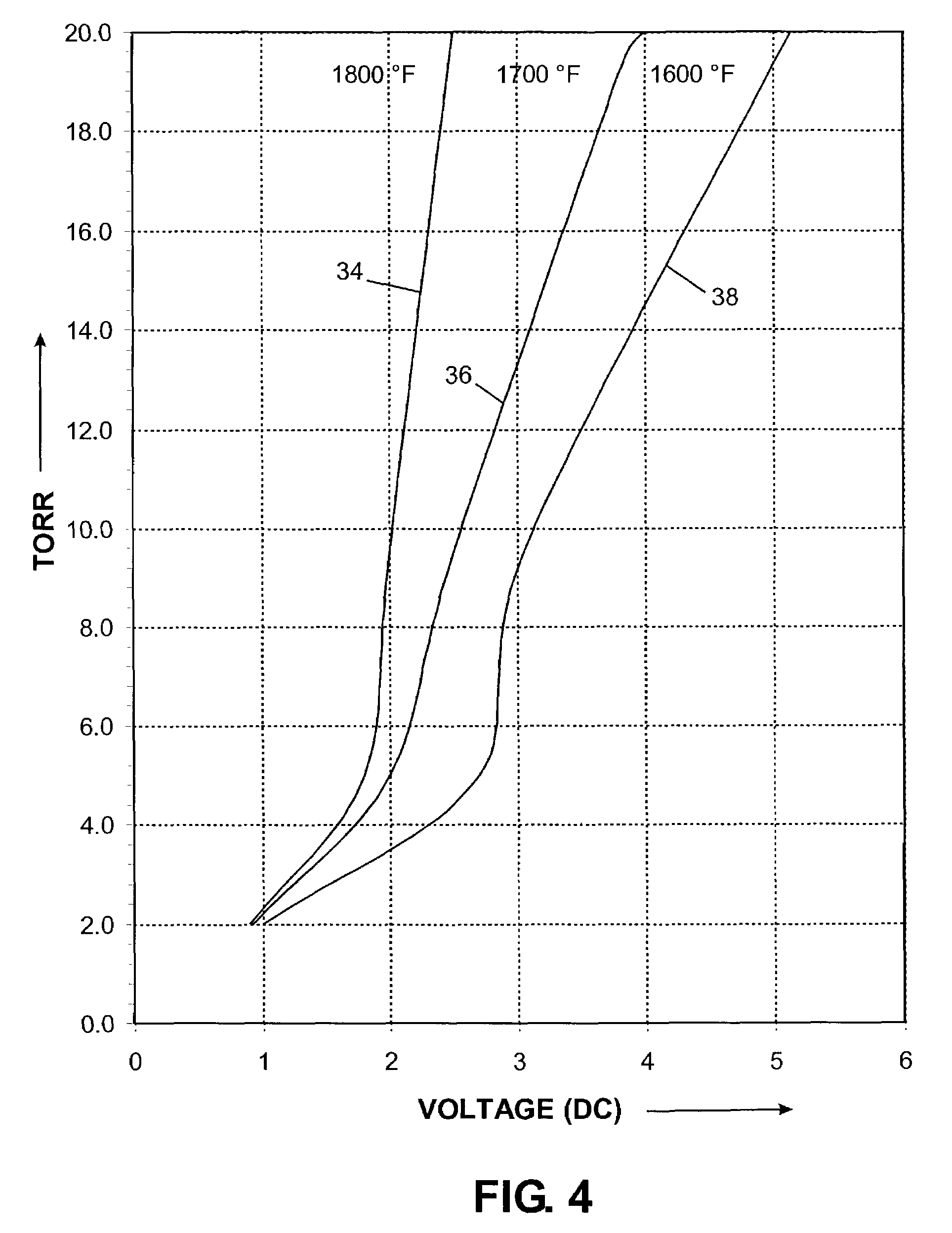

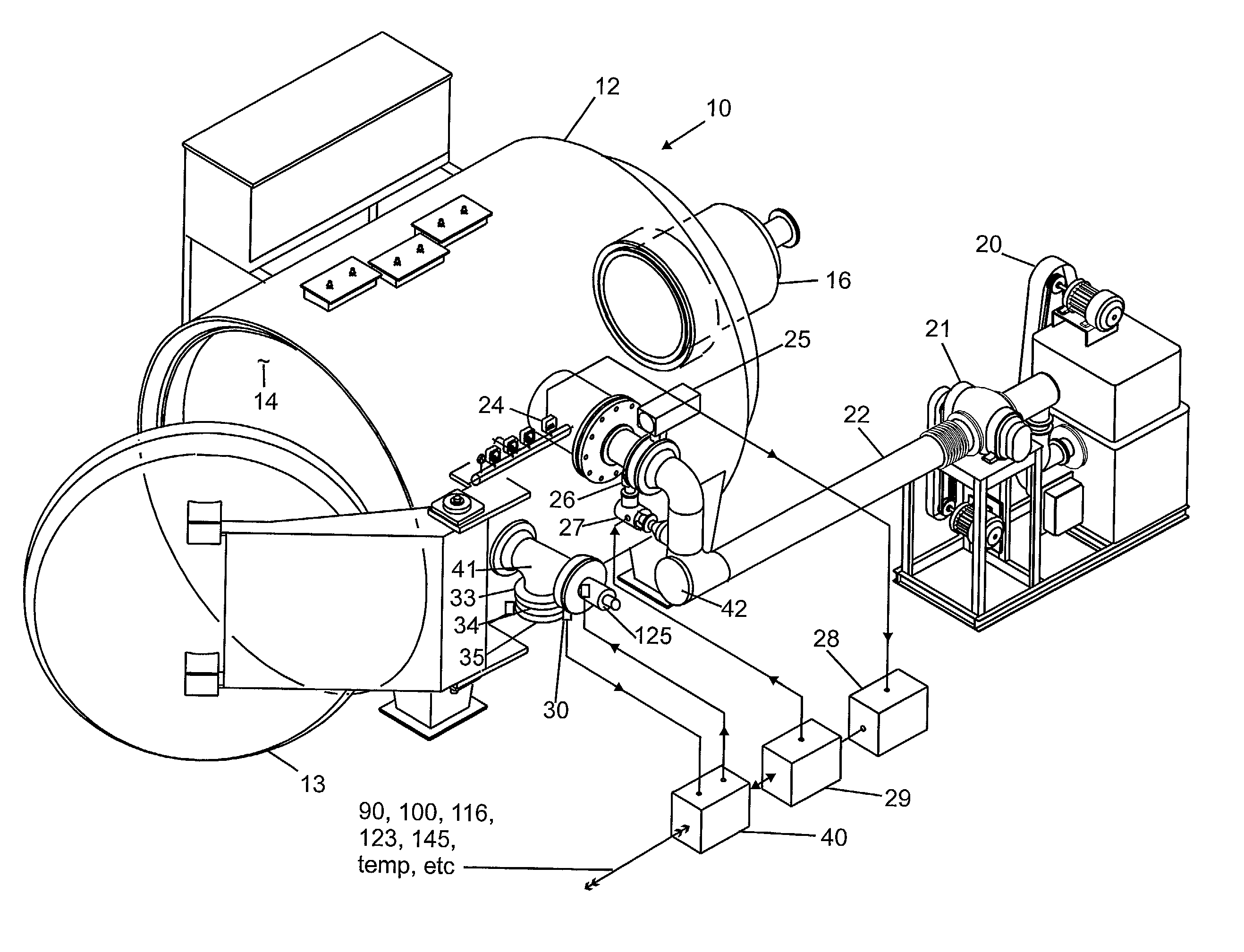

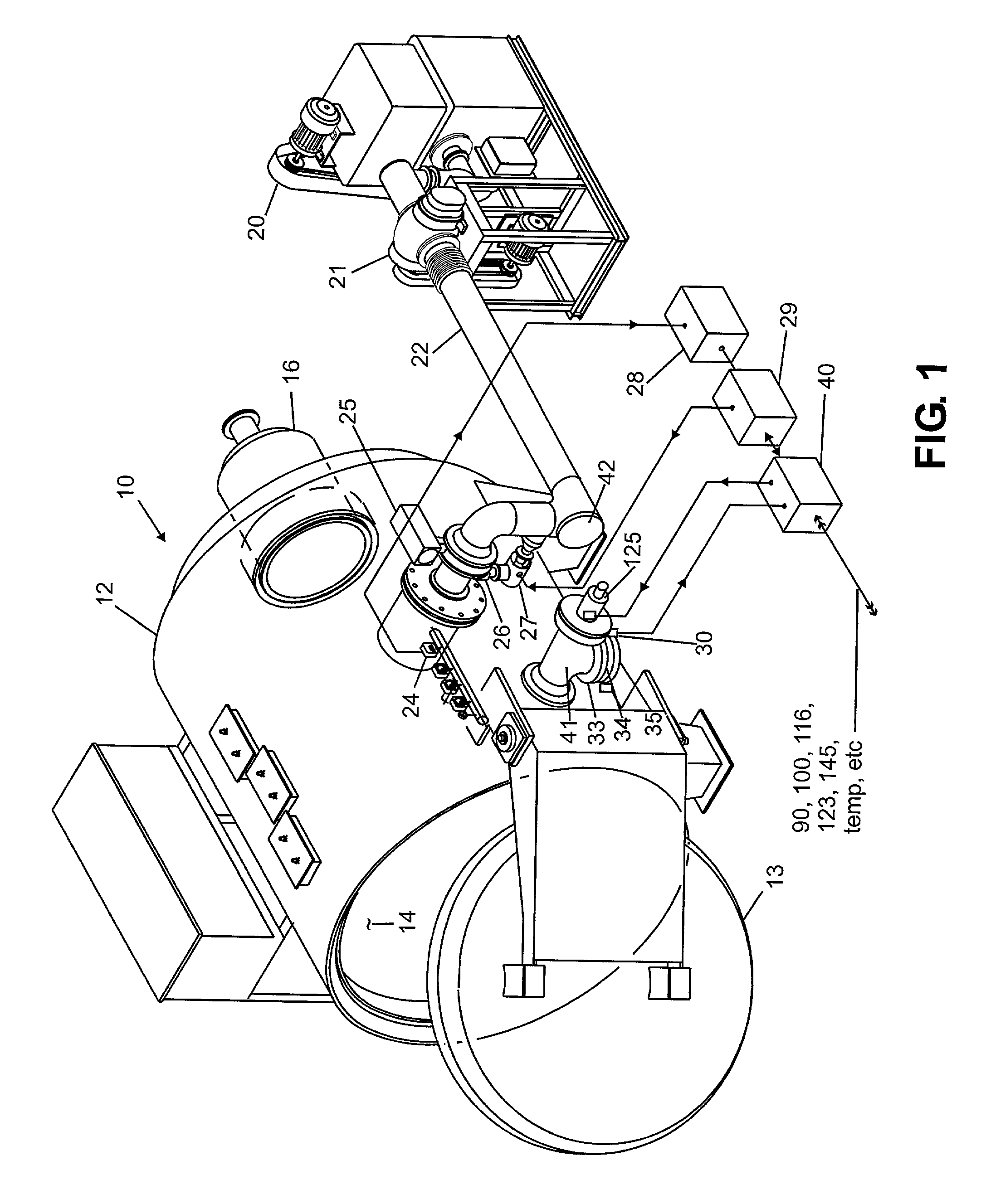

Vacuum carburizing with napthene hydrocarbons

InactiveUS6991687B2Easy to controlAccurate repeatabilitySolid state diffusion coatingHeat treatment process controlCarbon potentialCarbon deposit

Vacuum carburizing of ferrous workpieces is performed at low pressure in a vacuum furnace using a napthene hydrocarbon as the carburizing medium. The furnace is constructed to be generally transparent to the napthene so that cracking tends to occur at the workpiece which functions as a catalyst to minimize carbon deposits. The napthene is supplied in liquid form to fuel injectors which inject the liquid napthene as a vapor at duty cycles and firing orders to produce a uniform dispersion of the hydrocarbon gas about the work resulting in uniform carburizing of the workpieces. An in-situ methane infrared sensor controls the process. Hydrogen is added to the napthene to either assure full carbon potential and produce methane or to perform variable carburizing.

Owner:SURFACE COMBUSTION

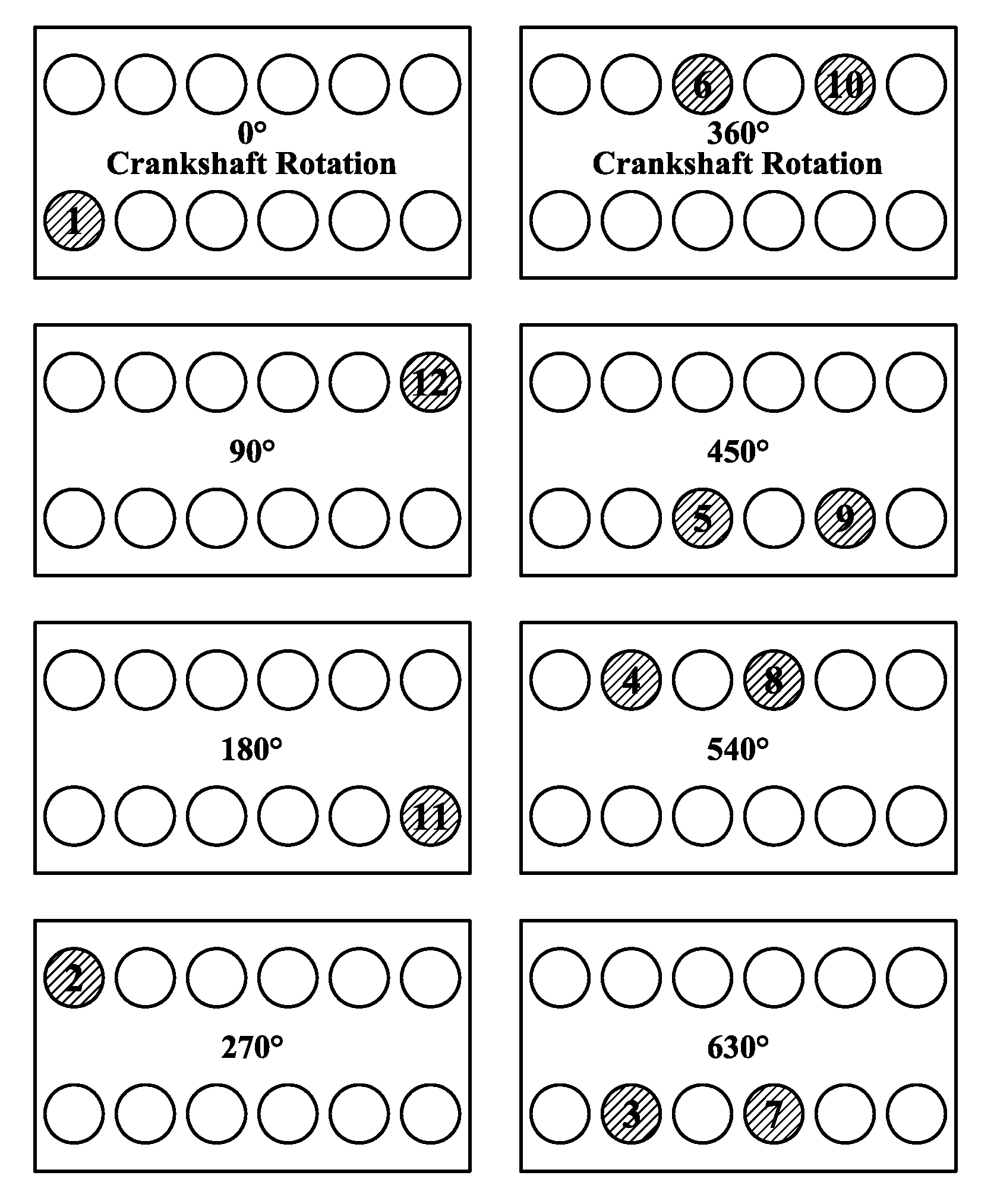

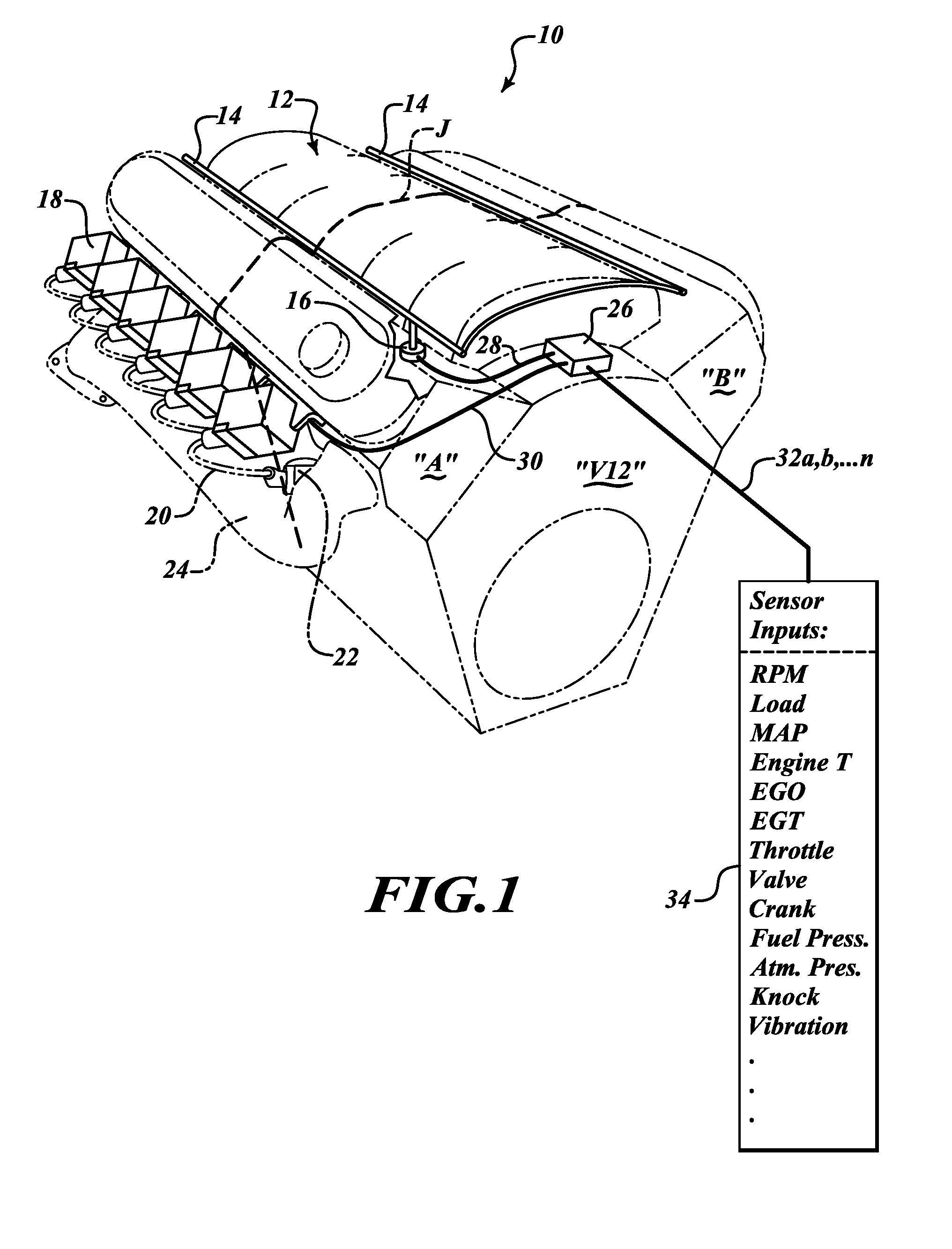

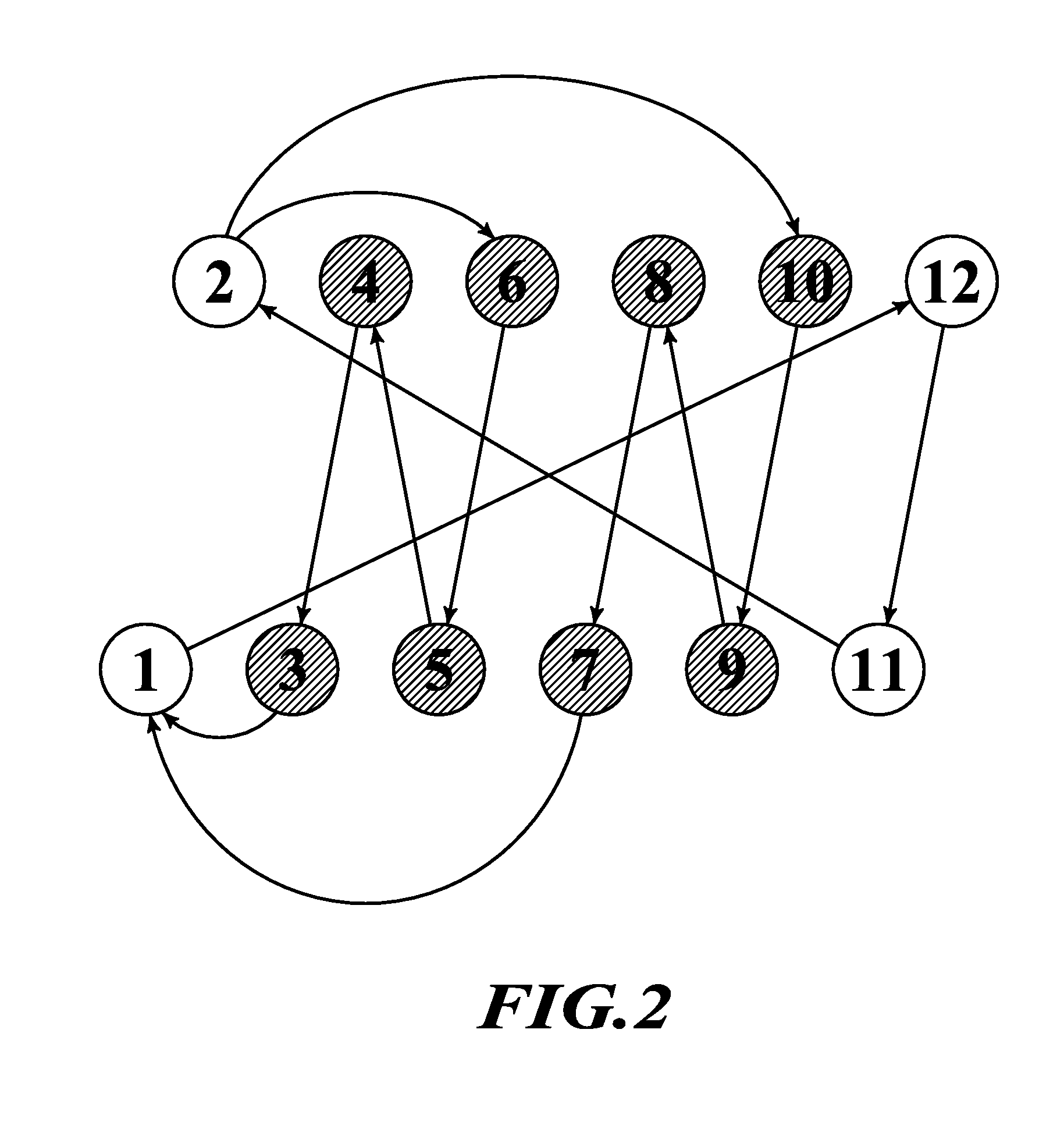

Even fire 90°V12 IC engines, fueling and firing sequence controllers, and methods of operation by PS/P technology and IFR compensation by fuel feed control

InactiveUS7979193B2Raise the ratioImproved engine compartment layoutElectrical controlDigital data processing detailsFiring orderIndustrial equipment

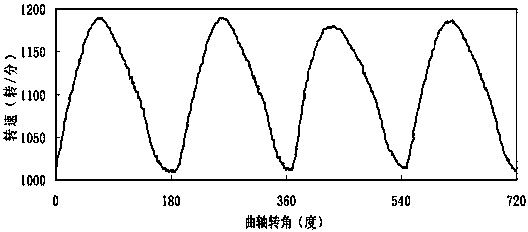

90°V12 reciprocating, EFI / DIS fueled / fired, IC engines having a PCM controller operating the engine in an Even Fire ignition mode, in a novel fueling and firing sequence called Progressive Single / Pair (PS / P) firing, wherein the cylinders of each of a set of four pairs of internal cylinders are simultaneously fueled and fired in parallel to produce a pump-gas fueled power curve greatly improved over V6 and V8 engines. The inherent imbalance-induced transitory vibration in IFR RPM is compensated-for by fuel feed control, namely, leaning one cylinder of each pair-fired cylinder pair. The inventive 90°V12 retro-fits into the engine compartment of conventional vehicles and can use any liquid or gaseous fuel. The inventive 90°V12 has use in the exemplary fields of: automotive engines; heavy military and industrial equipment and vehicle engines; marine engines; aircraft engines; and stationary power sources; in both 2-cycle and 4-cycle modes, and in normally aspirated, super-charged and turbo-charged configurations.

Owner:HARBERT RICHARD H

Vacuum carburizing with unsaturated aromatic hydrocarbons

ActiveUS7033446B2Easy to controlAccurate repeatabilitySolid state diffusion coatingAlkaneCarbon potential

Vacuum carburizing of ferrous workpieces is performed at low pressure in a vacuum furnace using an unsaturated aromatic such as benzene as the carburizing medium. The unsaturated aromatic is gas phase hydrogenated into a napthenes, such as cyclohexane, which is metered into the furnace chamber proper and functions as the carburizing gas. The furnace is constructed to be generally transparent to the napthenes so that cracking tends to occur at the workpiece which functions as a catalyst to minimize carbon deposits. The unsaturated aromatic is supplied in liquid form to fuel injectors which inject the liquid aromatic as a vapor at duty cycles and firing orders to produce a uniform dispersion of the hydrocarbon gas about the work resulting in uniform carburizing of the workpieces. An in-situ methane infrared sensor controls the process. Excess hydrogen beyond what is required to hydrogenate the aromatic is added to the furnace chamber to either assure full carbon potential and produce methane or to perform variable carburizing. Hydrogenation occurs in a hydrogenation coil in fluid communication with the furnace chamber with temperature for the reaction set by the position of the hydrogenation coil in the furnace insulation.

Owner:SURFACE COMBUSTION

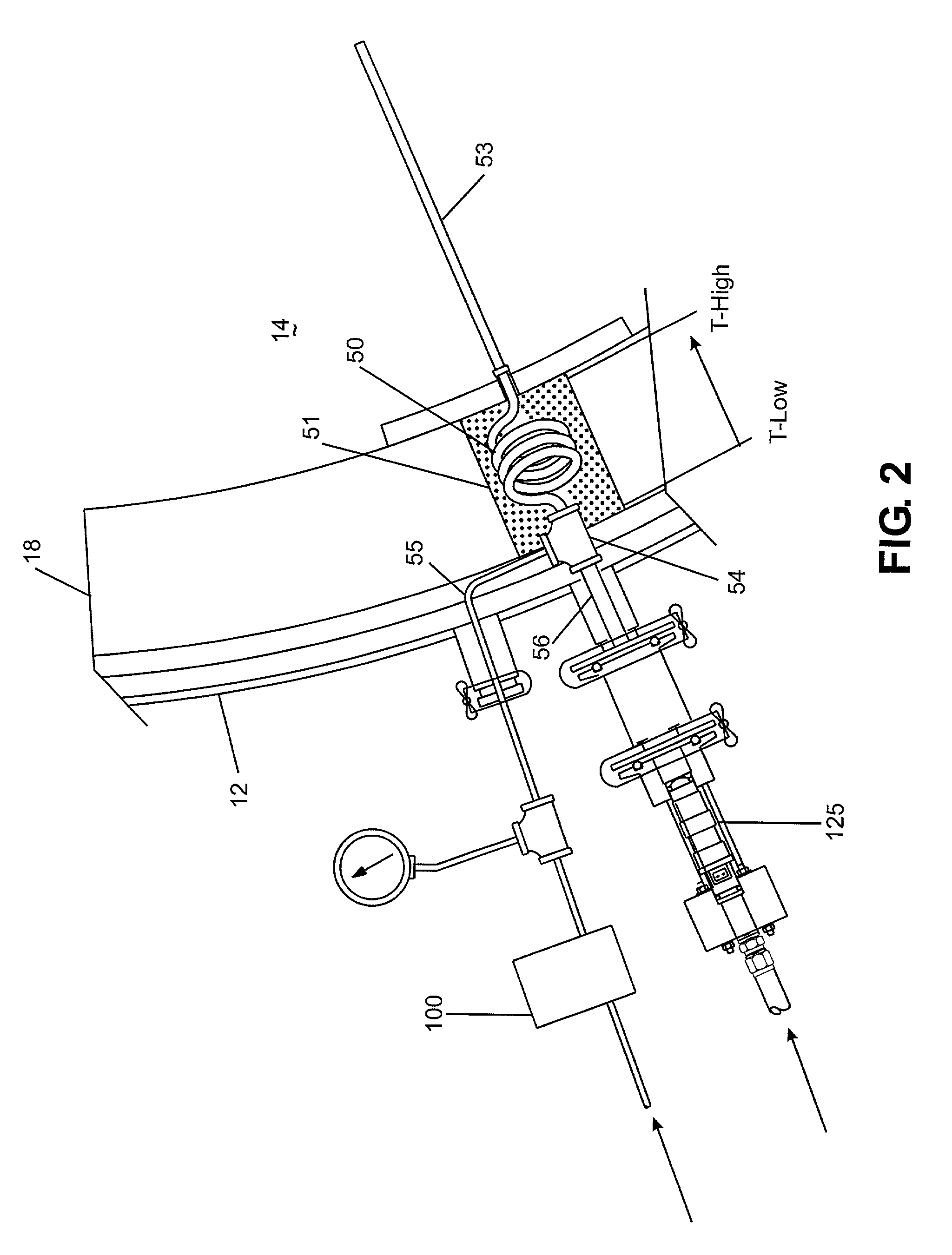

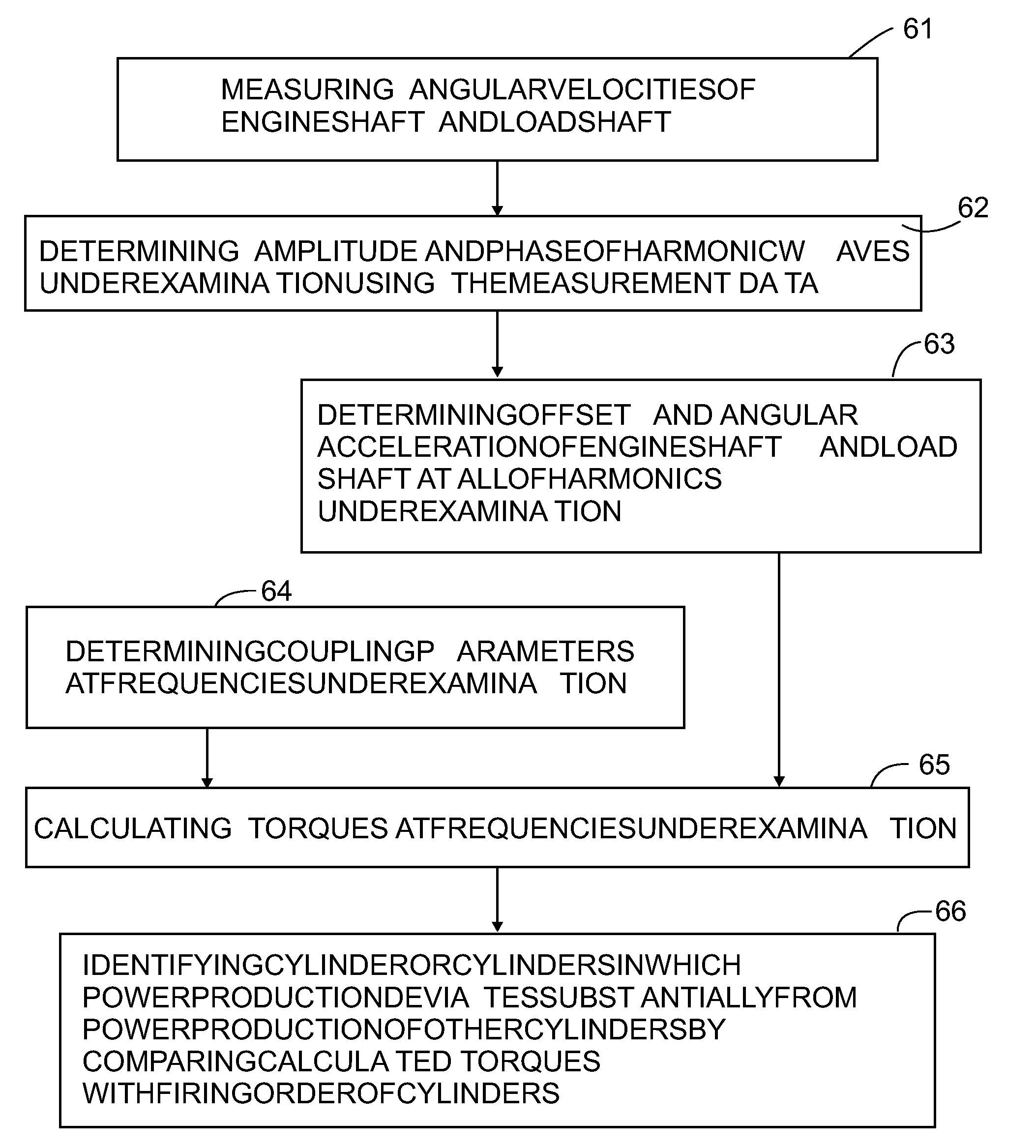

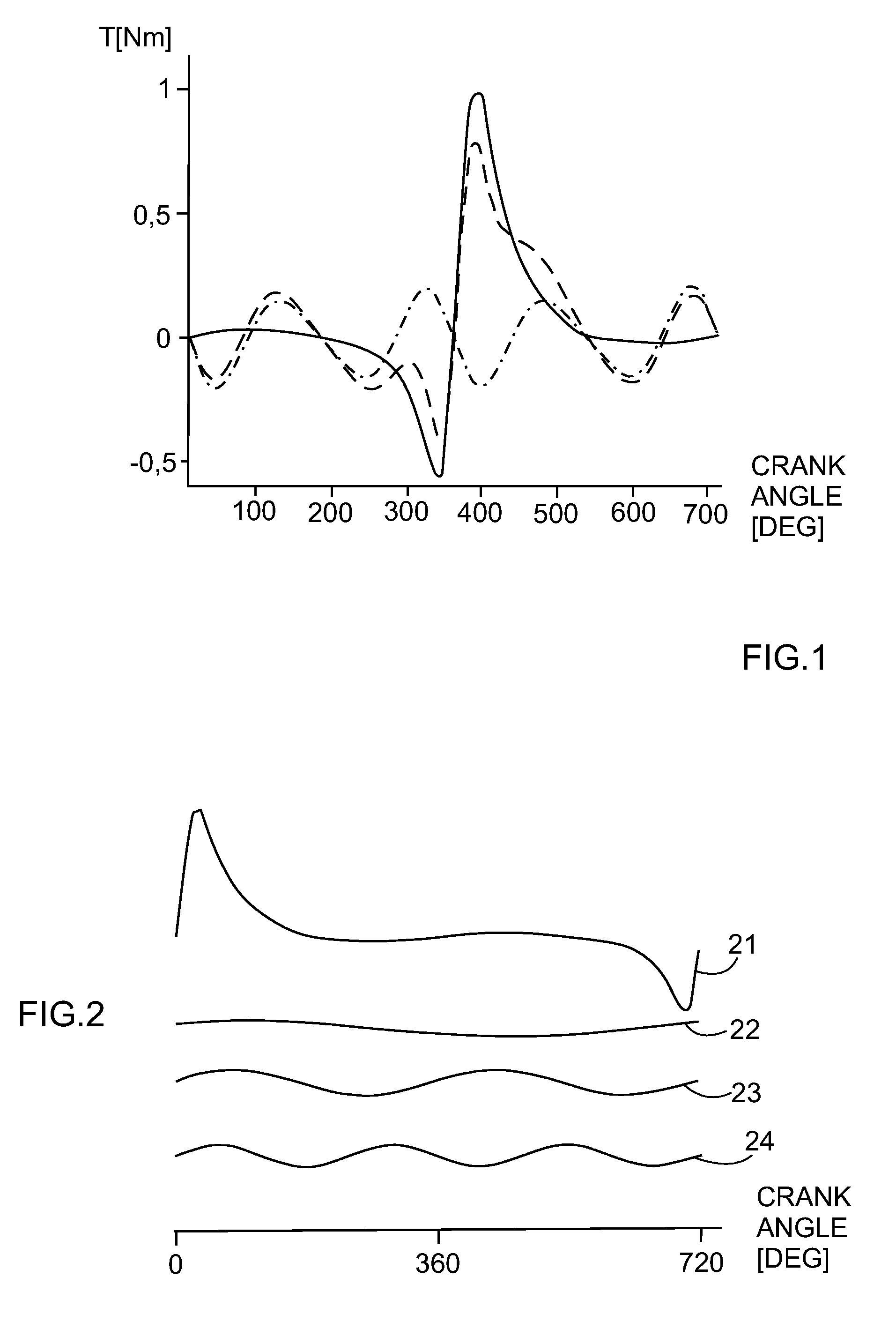

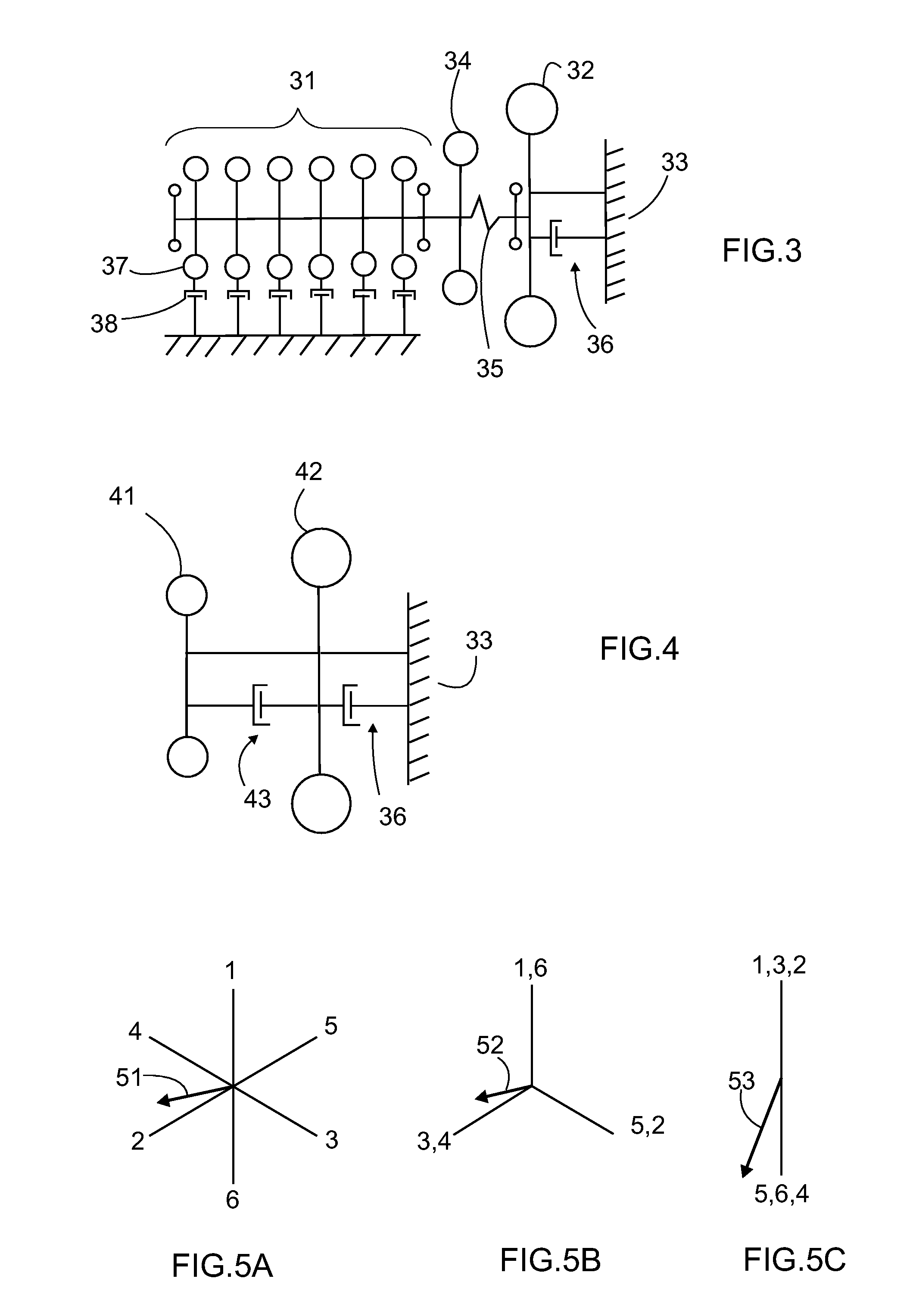

Apparatus for Identifying a Non-Uniform Share of Cylinder Power in an Internal Combustion Piston Engine System

The invention utilizes the firing order of the cylinders within the engine to identify the cylinder or cylinders that mainly contribute or, alternatively, contribute as little as possible to the production of certain harmonic frequencies in the engine's torque. In order to use the engine's torque for this purpose, the calculation of torque must take into account the non-linearities of the engine system. Thus the calculation of torque takes into account not only the properties of the engine but also the properties of the load and the shaft.

Owner:WARTSILA FINLAND OY

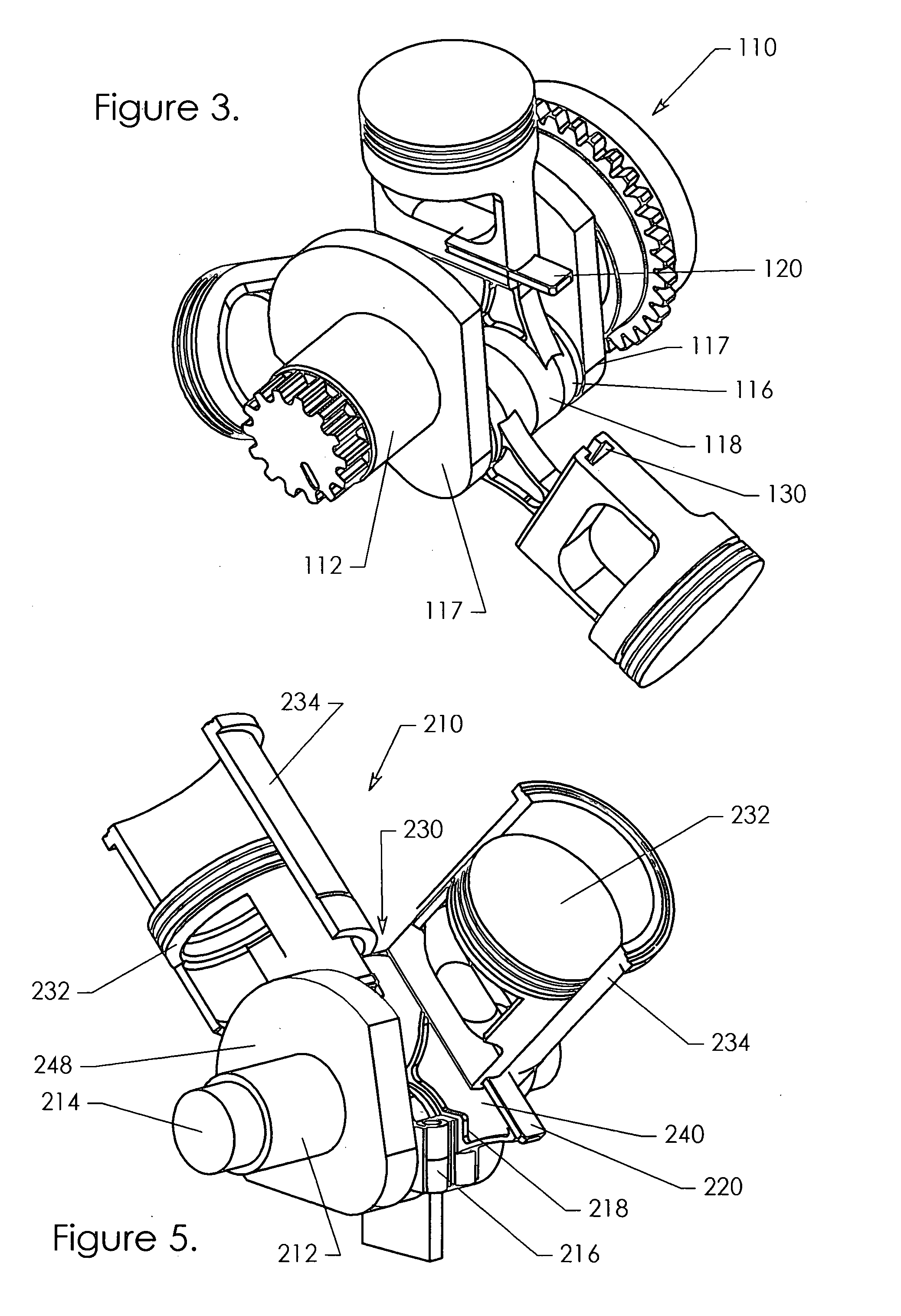

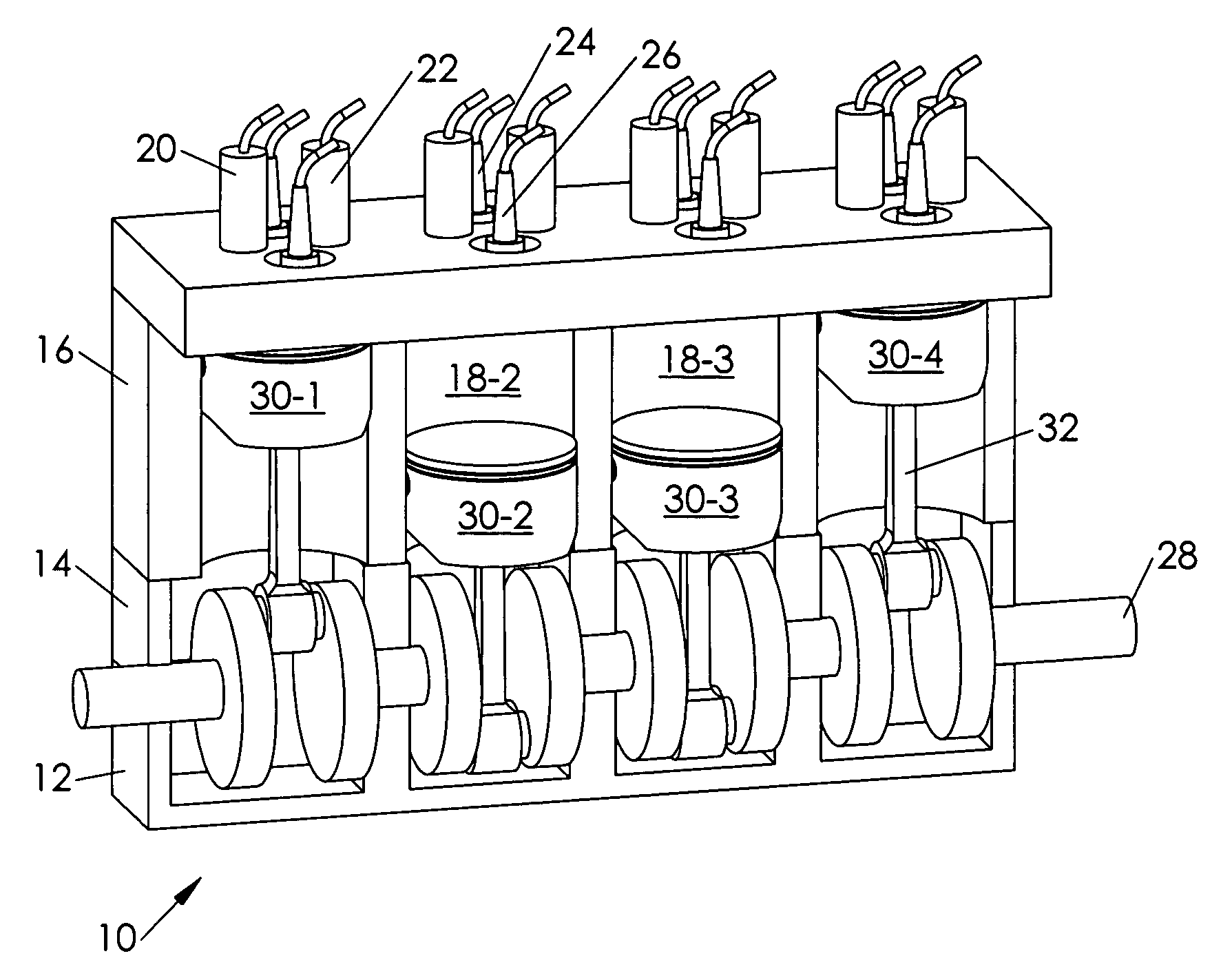

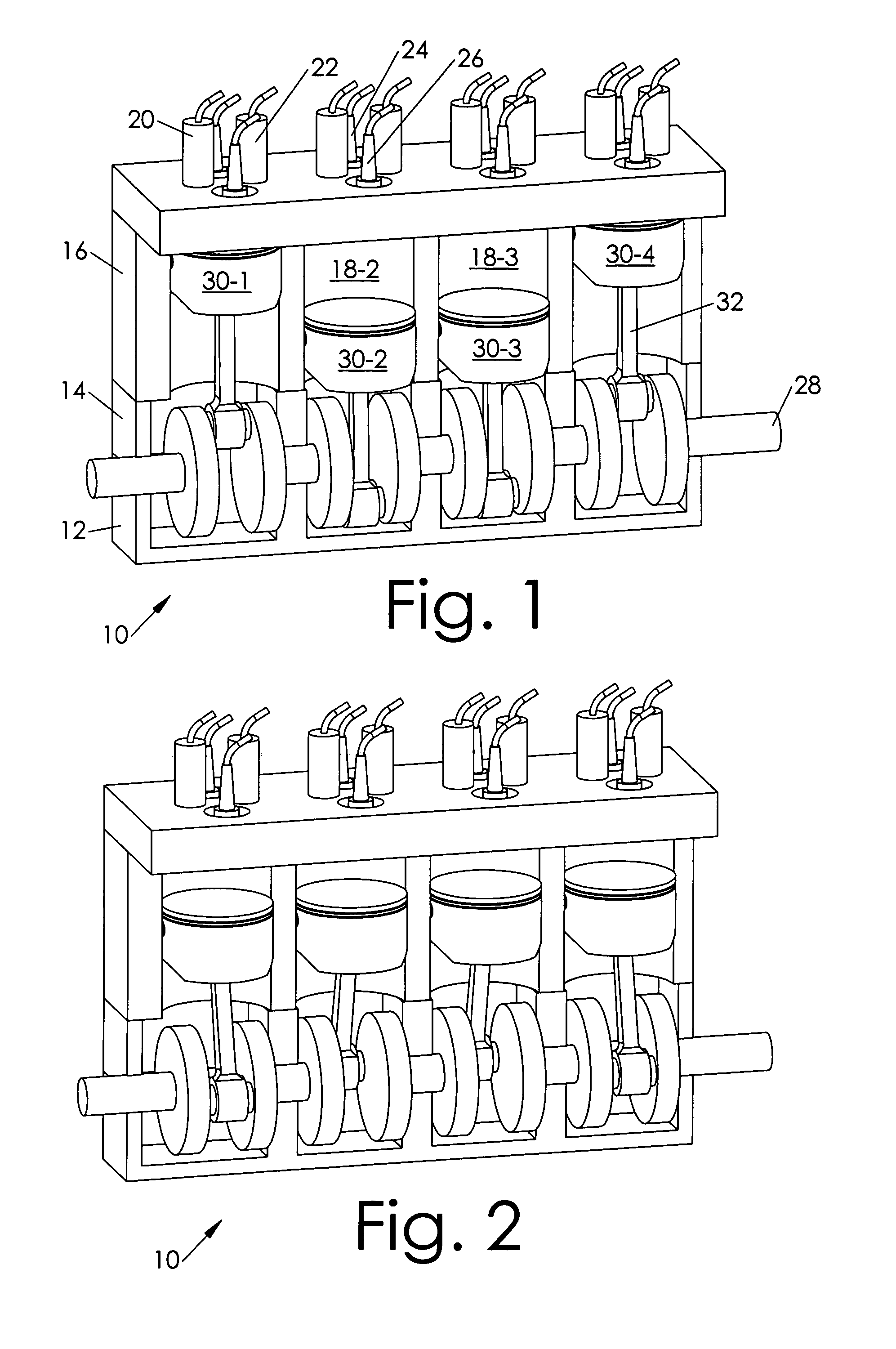

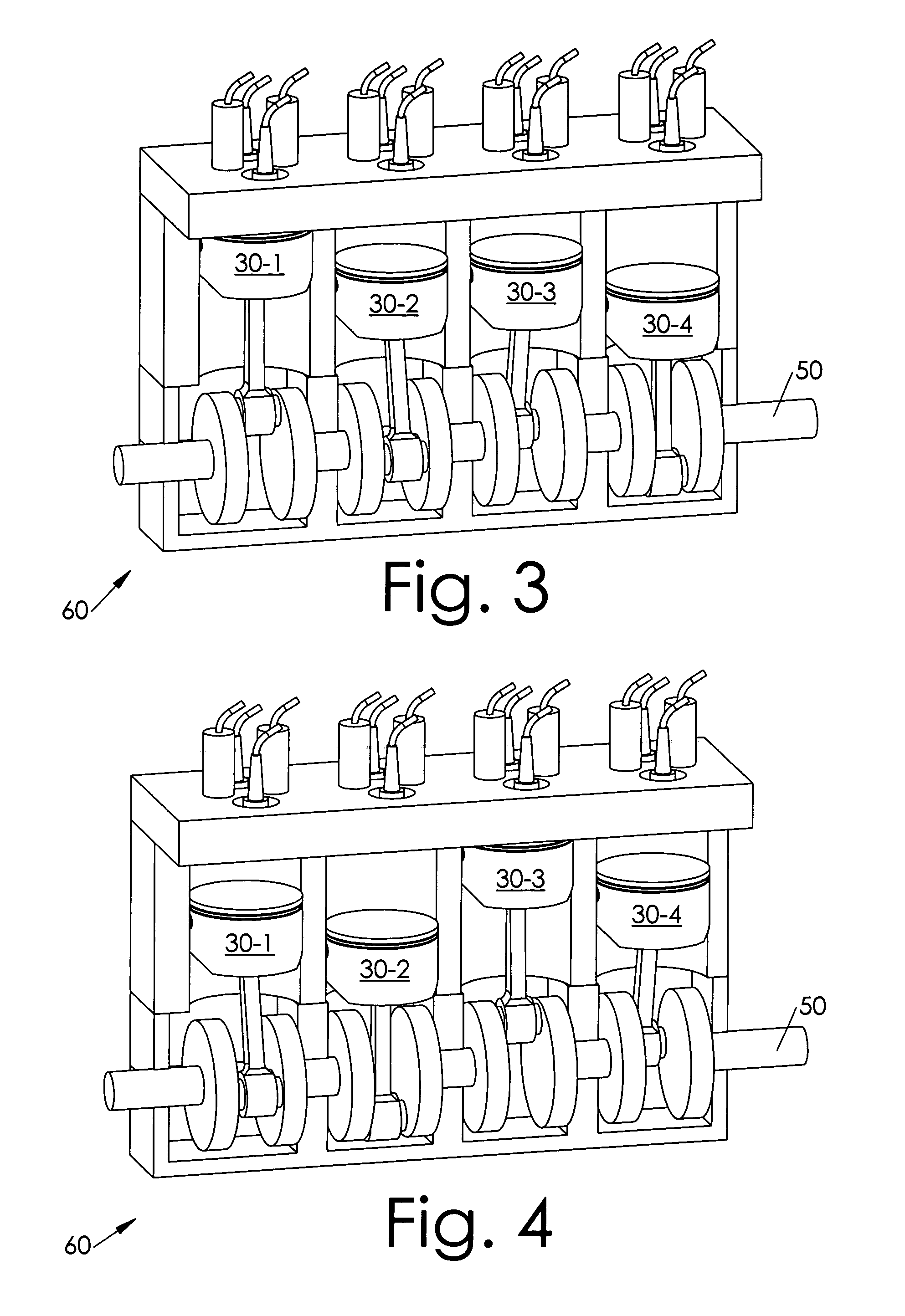

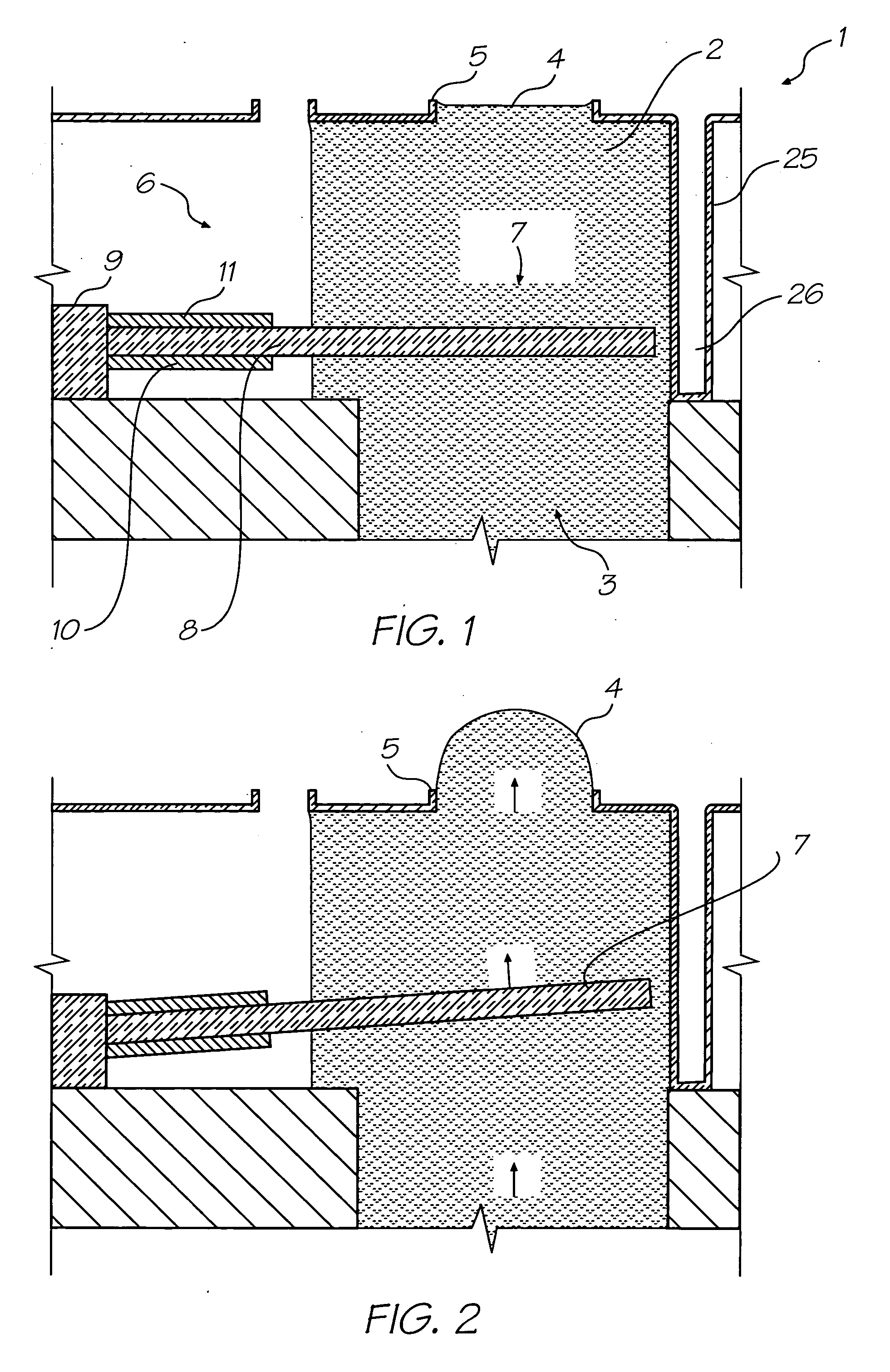

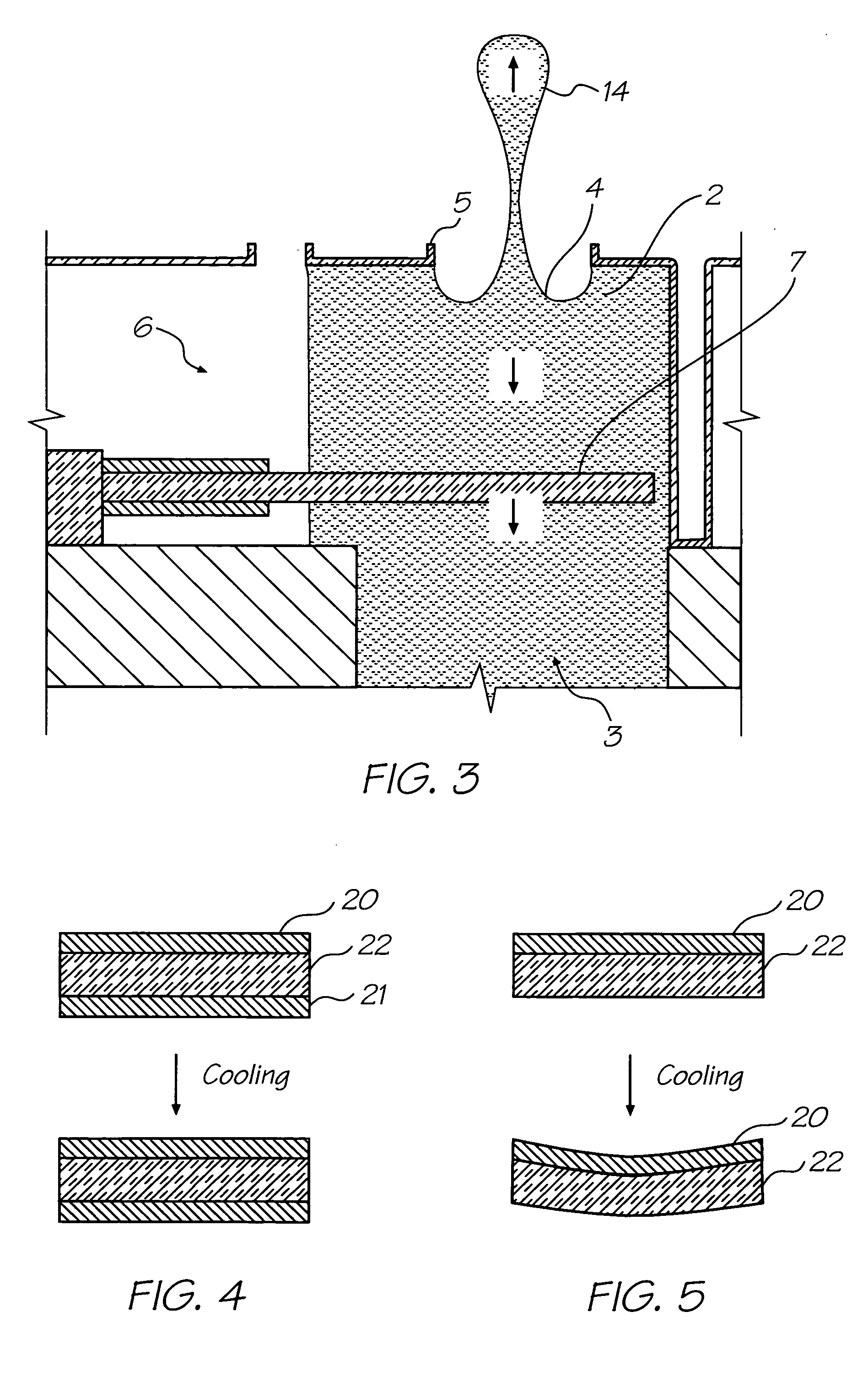

Piston engine with selectable firing order

InactiveUS20060102124A1Internal combustion piston enginesElectric ignition installationFiring orderInternal combustion engine

A multi-cylinder four-stroke internal combustion engine enabling a method for on-the-fly switching between two or more firing orders. Switching to the new firing order is done without requiring any tear-down of the engine such as to swap camshafts. Switching can be triggered by the rider, or it can be triggered automatically per conditions such as selected gear, RPM range, track location, velocity, and the like.

Owner:MOTOCZYSZ

Engine diagnostics with skip fire control

ActiveUS20160061127A1Electrical controlInternal combustion piston enginesFiring orderMechanical engineering

Methods and devices are described for performing engine diagnostics during skip fire operation of an engine while a vehicle is being driven. Knowledge of the firing sequence is used to determine appropriate times to conduct selected diagnostics and / or to help better interpret sensor inputs or diagnostic results. In one aspect, selected diagnostics are executed when a single cylinder is fired a plurality of times in isolation relative to a sensor used in the diagnosis. In another aspect, selected diagnostics are conducted while the engine is operated using a firing sequence that insures that no cylinders in a first cylinder bank are fired for a plurality of engine cycles while cylinders in a second bank are at least sometimes fired. The described tests can be conducted opportunistically, when conditions are appropriate, or specific firing sequences can be commanded to achieve the desired isolation or skipping of one or more selected cylinders.

Owner:TULA TECH INC

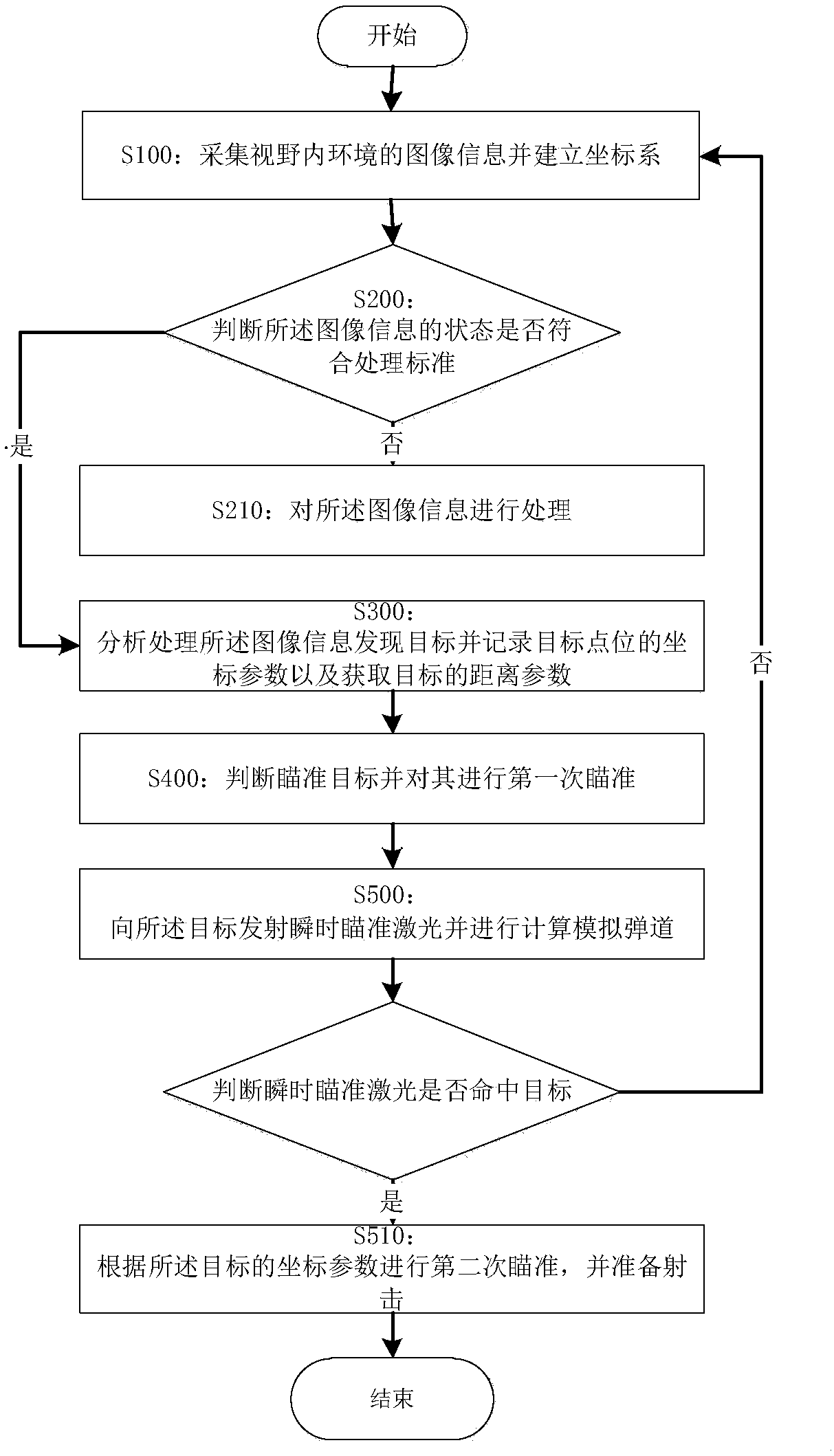

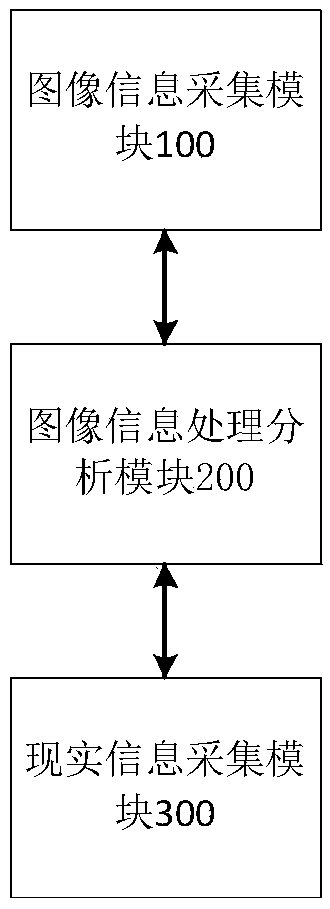

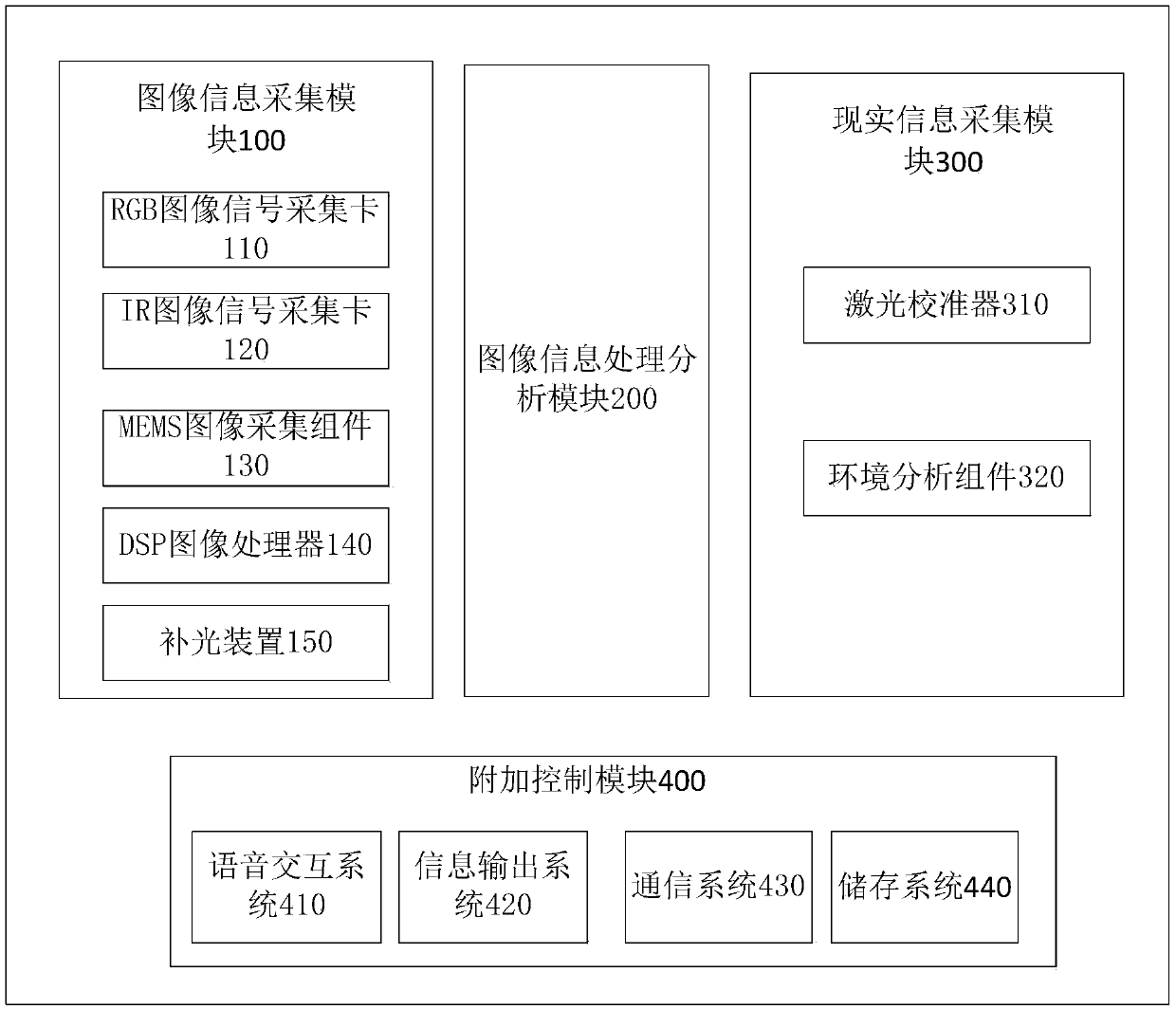

Artificial intelligent accurate aiming method and system

ActiveCN107741175AEasy to identifyImprove aimingImage analysisSighting devicesBiological bodyFiring order

The embodiment of the invention relates to the technical field of automatic identification and aiming for organisms, in particular to an artificial intelligent accurate aiming method and system. The method comprises the following steps of collecting image information, and establishing a coordinate system; recording the coordinate parameter of a target point location, and obtaining the distance parameter of a target; conducting the first-time aiming; emitting instantaneous aimed laser to the target, and calculating and simulating a ballistic trajectory; if the instantaneous aimed laser hits thetarget, conducting the second-time aiming according to the coordinate parameter of the target, and readying to fire; if the instantaneous aimed laser does not hit the target, conducting the steps again. Compared with the prior art, the method can conduct high-precision identification and aiming for the target, and can also automatically calculate the importance degree of the target so as to select the firing order. Particularly, the method simulates the ballistic trajectory through the instantaneous aimed laser, the automatic firing percentage in the prior art can be greatly increased, and therefore the practicality of the method is greatly improved.

Owner:JEWXON INTELLIGENT TECHWUHANCO LTD

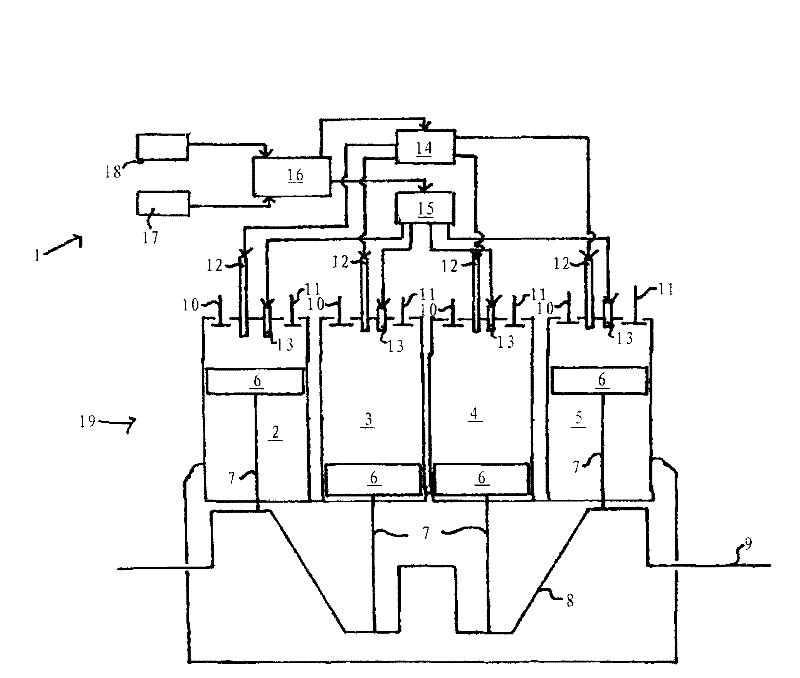

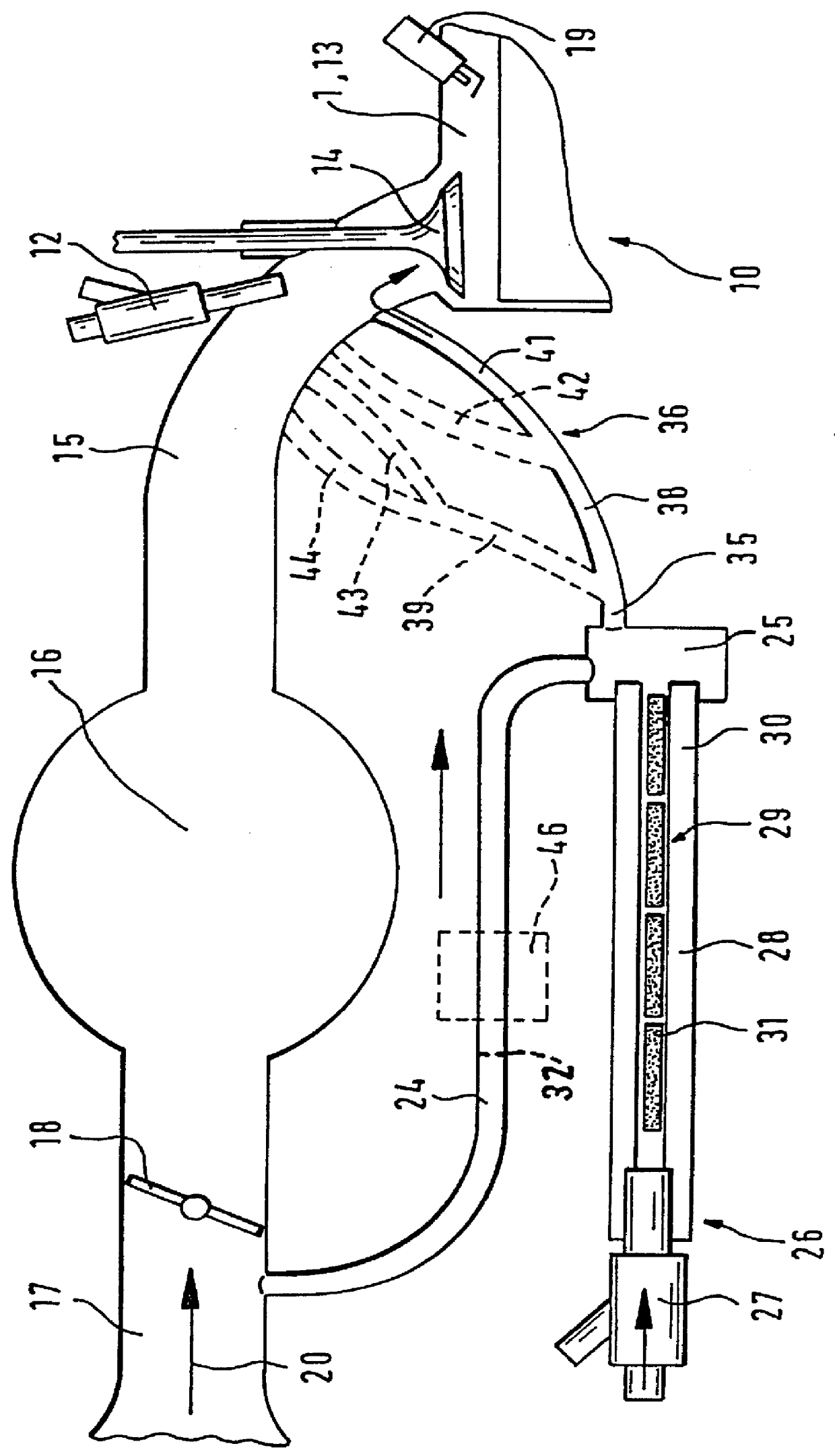

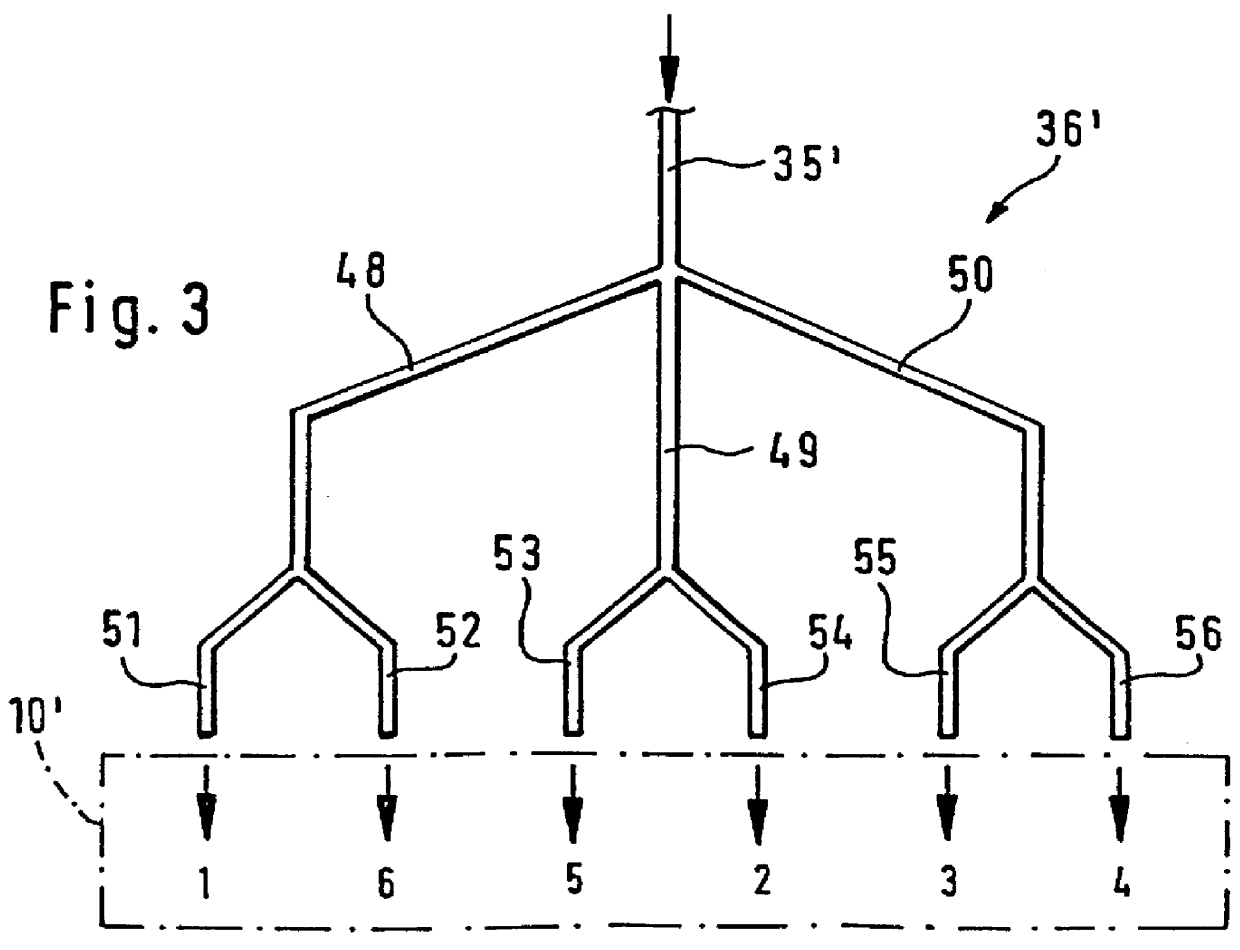

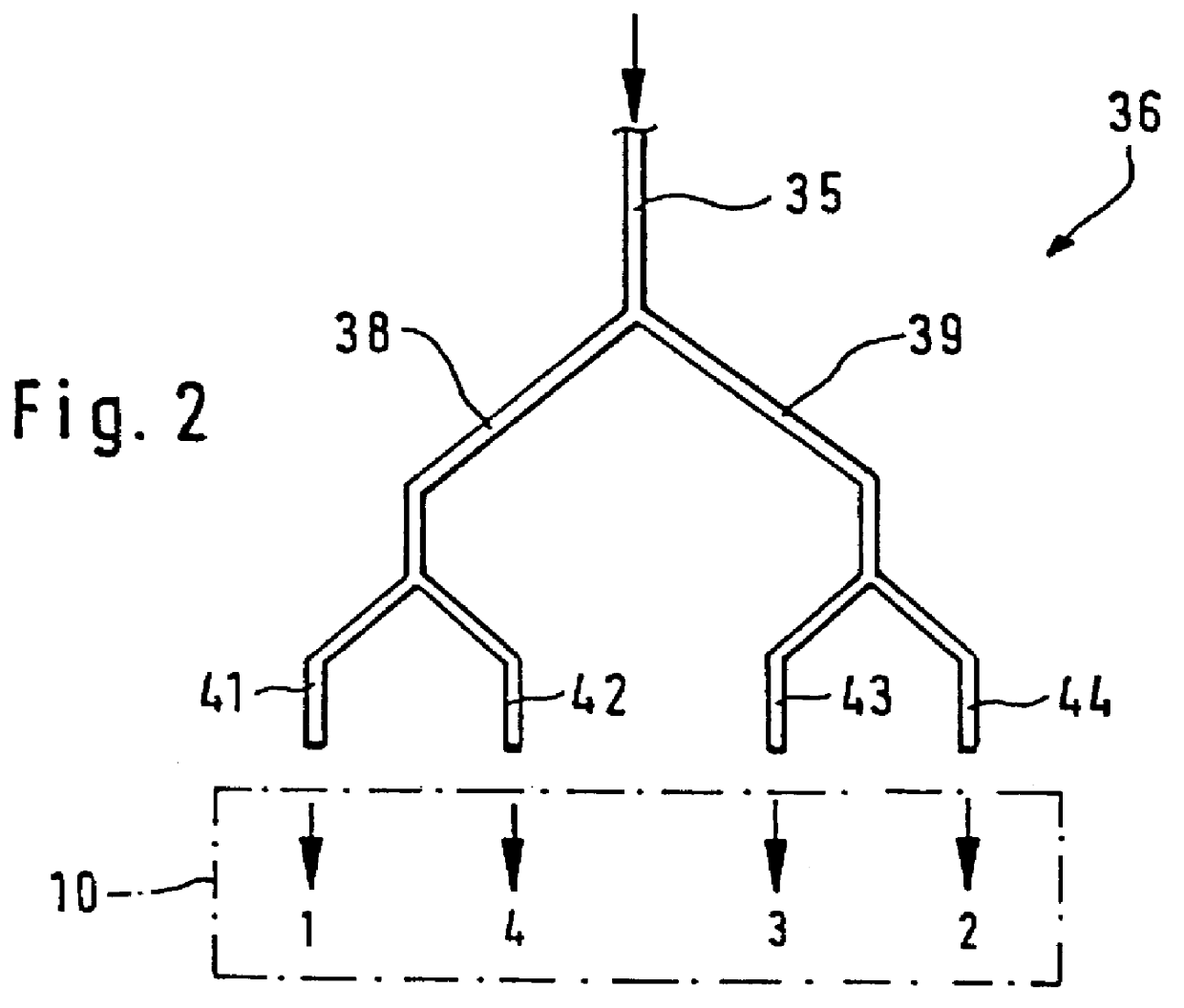

Multicylinder internal combustion engine with externally supplied ignition

InactiveUS6058915AGuaranteed uptimeSolution value is not highNon-fuel substance addition to fuelInternal combustion piston enginesMobile vehicleCombustion chamber

This disclosure is directed to a multicylinder internal combustion engine with externally supplied ignition, which has a fuel vaporizing device which is connected to individual intake tubes of the engine via a line system. The line system is embodied as branching in such a way that only respective combustion chambers which are not operated in direct ignition sequence (1-3-4-2) are connected in pairs to each other and jointly via a central line to the fuel vaporizing device. The multicylinder internal combustion engine with externally supplied ignition, is provided for motor vehicles.

Owner:ROBERT BOSCH GMBH

Internal combustion engine

InactiveUS20070079787A1High pressureInternal combustion piston enginesPistonsCombustion chamberFiring order

The invention has many aspects. One aspect is that of an internal combustion engine (8010) that has a piston (8020) within a cylinder (8022) and has a crankcase (8012), defining a combustion chamber (8024) and crank volume (8026). A passageway (8032 and 8034) links the combustion chamber (8024) and the crank volume (8026). There is provided valve means (8038) for selectively closing the linking passageway and valve means (8030) for selectively closing and inlet to the crank volume (8026). In another aspect, there is an improvement to a scotch yoke fluid device. A displaceable member for relieving pressure in a variable volume chamber in the cylinder where combustion is occurring is provided. The invention includes a method of varying power output of a scotch yoke device, by choosing cylinder angle, pin angle and firing order in various ways. The invention also deals with other aspects of scotch yoke designs.

Owner:RAFFAELE PETER ROBERT +1

Method for diagnosing faults of diesel engine based on instant rotary speed clustering analysis

ActiveCN103900824AFast convergenceEasy to implementInternal-combustion engine testingSpecial data processing applicationsTime domainTop dead center

The invention provides a method for diagnosing faults of a diesel engine based on instant rotary speed clustering analysis. Instant rotary speed signals in the process of diesel engine operation are collected, the collected signals are filtered, noise interference is eliminated, main shaft instant rotary speed data are resolved according to a top dead center signal and a firing order of air cylinders, and the instant rotary speed information corresponding to each air cylinder is obtained; time domain analysis and frequency domain analysis are conducted on the processed signals, time domain features and frequency domain features of the instant rotary speed signals are obtained, and therefore a two-dimensional array is formed; clustering analysis is conducted through the random restarting K-means algorithm, the performance states of the air cylinders of the multi-cylinder diesel engine are horizontally compared, the different classification number K is set, clustering is conducted repeatedly, and the most significant clustering result is selected to serve as a final diagnosis result, so that the faulted air cylinder is diagnosed. When the random restarting K-means algorithm is used for clustering, a large number of experiential parameters do not need to be set and influence caused by the experiment parameters on the clustering result is avoided; the faulted air cylinder can be rapidly and accurately positioned.

Owner:HARBIN ENG UNIV

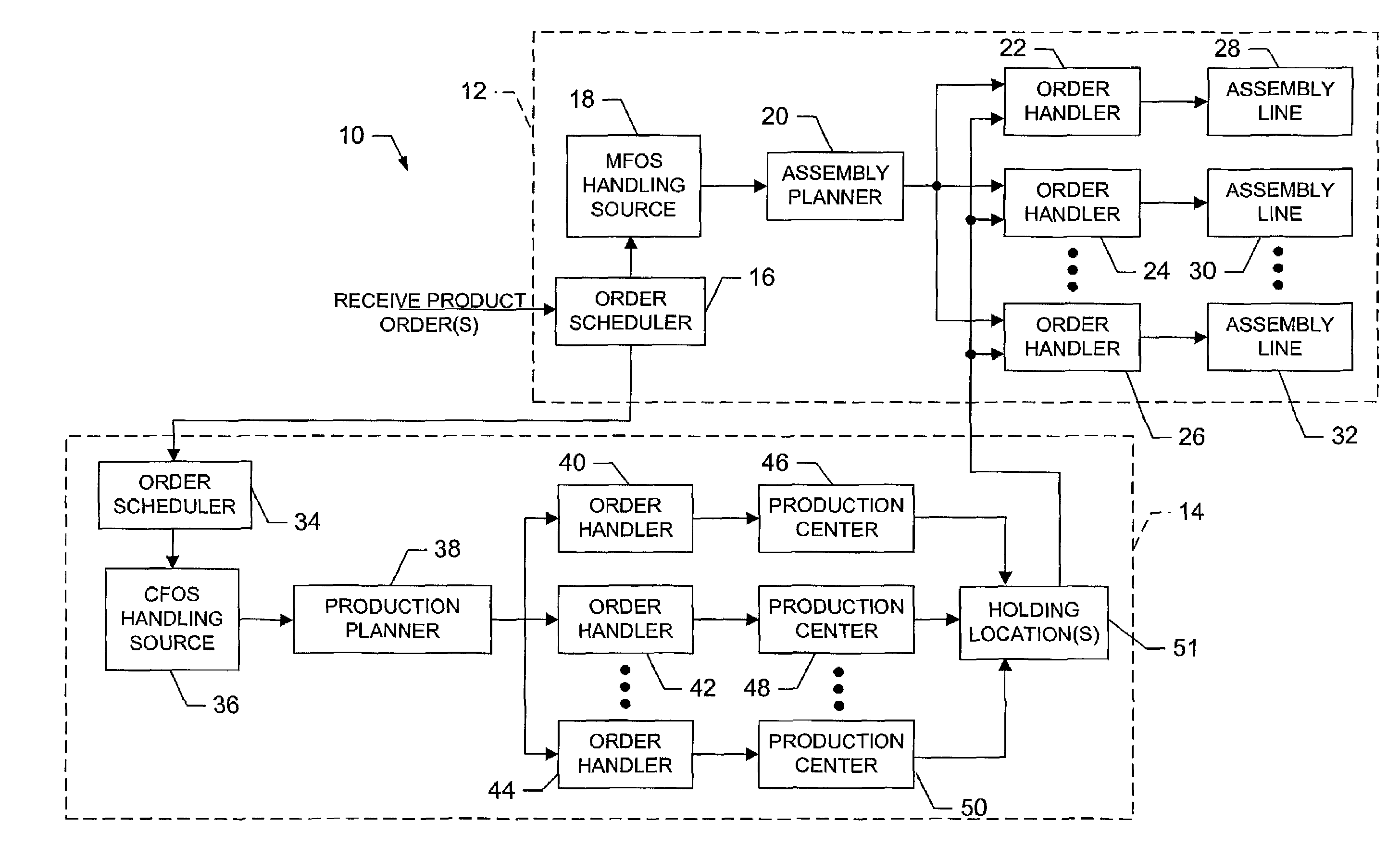

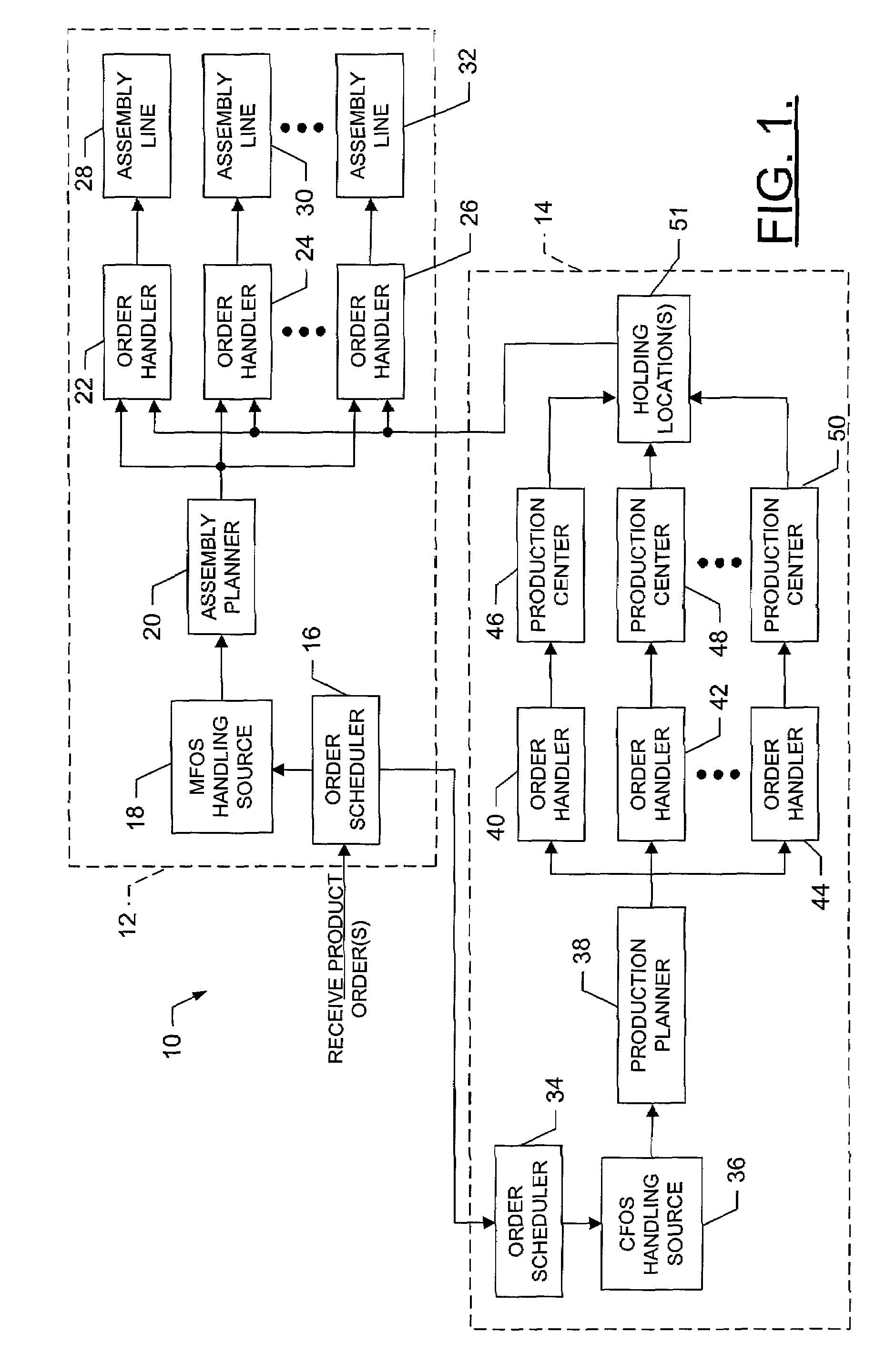

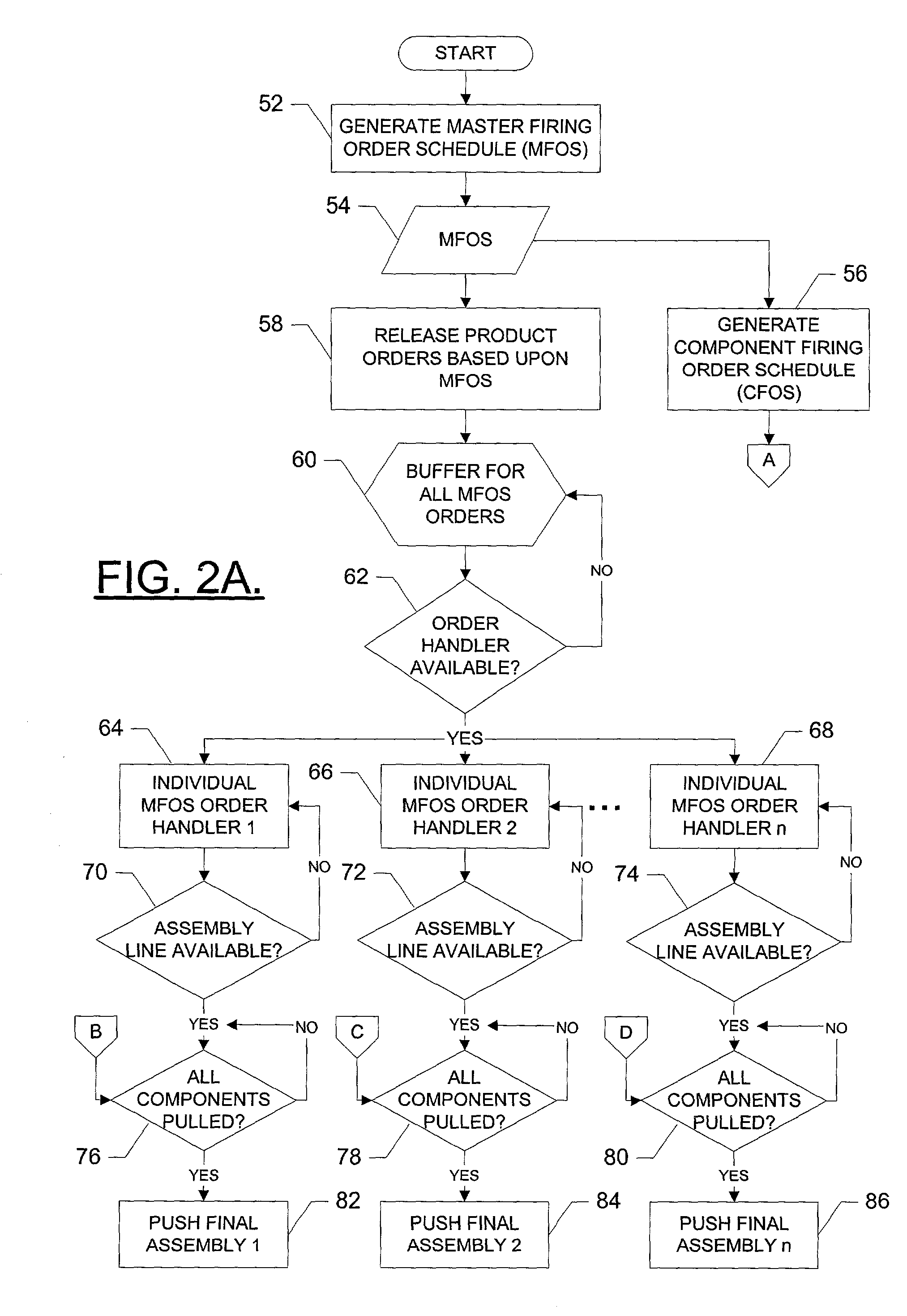

Systems and methods for manufacturing a product in a pull and push manufacturing system and associated methods and computer program products for modeling the same

InactiveUS6983189B2Increase the number ofShorten assembly timeResourcesSpecial data processing applicationsFiring orderAssembly line

A system of manufacturing a product in a pull and push manufacturing system is provided, where the product comprises at least one model and each model includes at least one component. The system includes an order scheduler, a component scheduler, a make-to-order (MTO) portion and an assemble to order (ATO) portion. The order scheduler is capable of receiving order(s) for model(s) of the product, and the component scheduler is capable of generating a component firing order schedule (CFOS) for the components corresponding to the models ordered. The MTO portion can release each component and thereafter produce the components. And the ATO portion can release each order and thereafter assemble the orders released from the produced components at a number of assembly lines. Advantageously, a number of system parameters can be determined based upon modeling the manufacturing system.

Owner:THE BOEING CO

Piston engine with selectable firing order

InactiveUS7063059B2Internal combustion piston enginesOutput powerExternal combustion engineFiring order

A multi-cylinder four-stroke internal combustion engine enabling a method for on-the-fly switching between two or more firing orders. Switching to the new firing order is done without requiring any tear-down of the engine such as to swap camshafts. Switching can be triggered by the rider, or it can be triggered automatically per conditions such as selected gear, RPM range, track location, velocity, and the like.

Owner:MOTOCZYSZ

Air starter and electronic control therefor

ActiveUS7203593B2Analogue computers for vehiclesPower operated startersTop dead centerSolenoid valve

An in-head compressed air start-up system for an internal combustion engine comprises an absolute angular position detector for the crankshaft outputting an electrical signal indicative of the angular position, a computer for storing a table of the firing order of the cylinders and the angular position of the crankshaft at which each piston reaches a desired angular position relative to top dead center (TDC), wherein the computer means compares the signal indicative of angular position of the crankshaft to the firing order table and generates a plurality of signals sequentially open and close solenoid valves to cause rotation of the crankshaft.

Owner:ALTRONIC

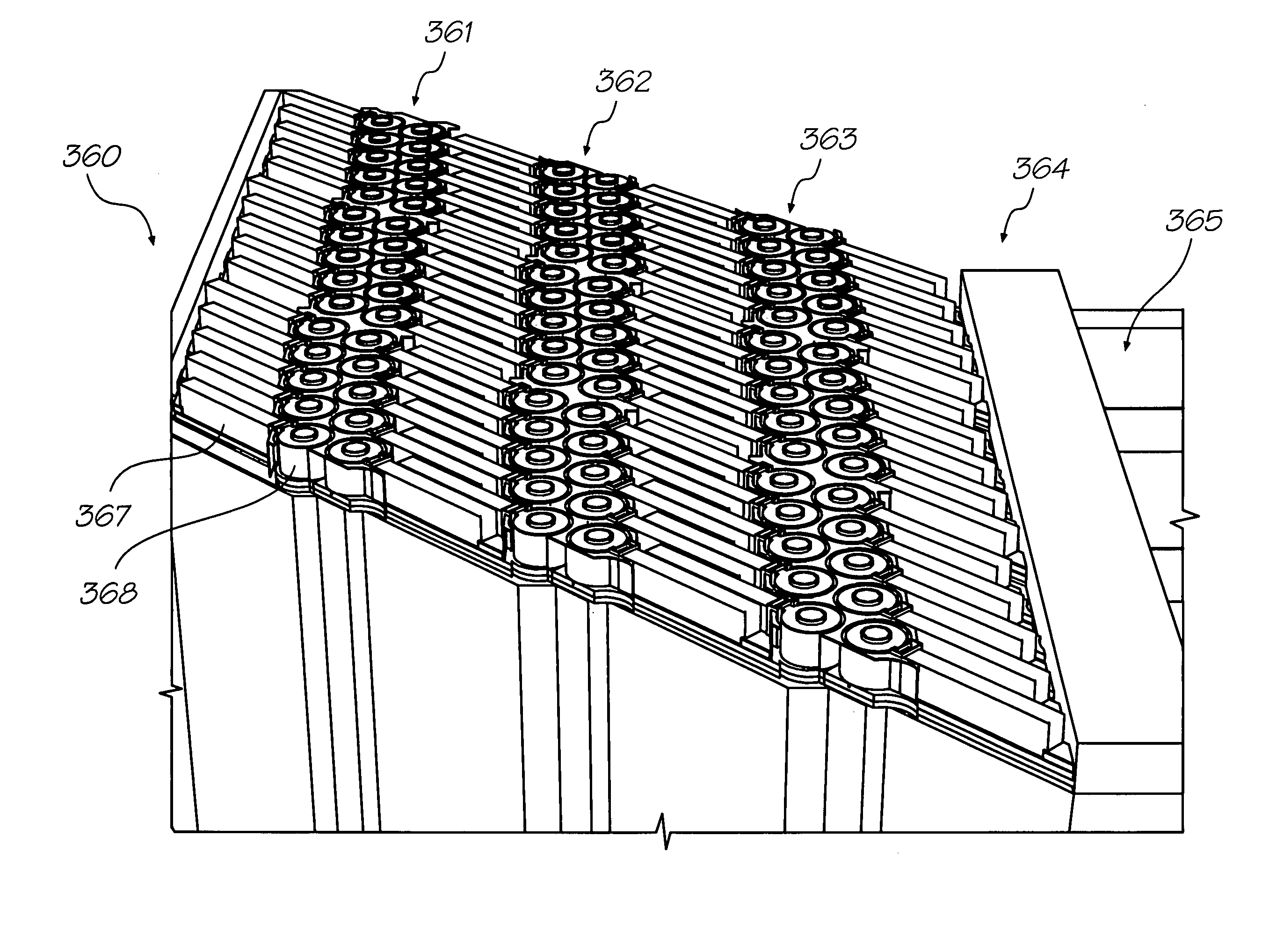

Printhead

The present invention relates to a printhead for ejecting ink. The printhead comprises a first row of nozzle pods, and each nozzle pod comprises a plurality of nozzles arranged in rows and ranks. There is also provided a first ink supply for storing a first type of ink. The first ink supply is in fluid communication with the nozzles in the first row. The printhead also comprises a printhead controller for controlling the firing of the nozzles. In one embodiment, the printhead controller controls the firing order of the nozzles.

Owner:SILVERBROOK RES PTY LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com