Cam oil-supply type electro-hydraulic valve driving system

A drive system and fuel supply technology, applied in the direction of engine components, machines/engines, and non-mechanically actuated valves, can solve the problems of low valve flexibility and inability to realize the secondary opening of exhaust valves, etc., to achieve The effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

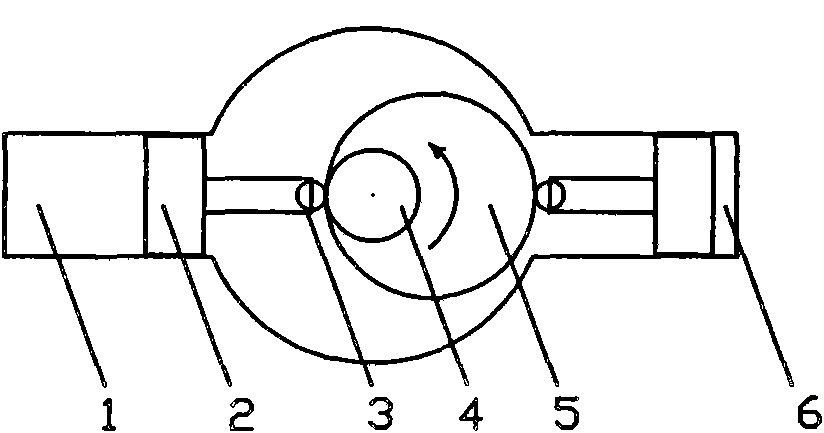

[0015] figure 1 A structure of an opposed cam-plunger oiler is shown. Since each cylinder of a four-stroke engine is always carried out in the order of intake, compression, work, and exhaust, the order of each cylinder's intake and exhaust is consistent with the ignition sequence of the engine. The opposed cam-plunger oiler is designed according to the number of cylinders and firing order of the engine. The oil feeder mainly includes a forward oil supply oil chamber 1, two oil supply plungers 2, two rollers 3, an oil supply camshaft 4, an oil supply cam 5 and a reverse oil supply oil chamber 6. As the oil supply camshaft 4 rotates, the oil supply cam 5 pushes the oil supply plunger 2 to move up and down, so that the forward oil supply oil chamber 1 and the reverse oil supply oil chamber 6 are alternately supplied with oil.

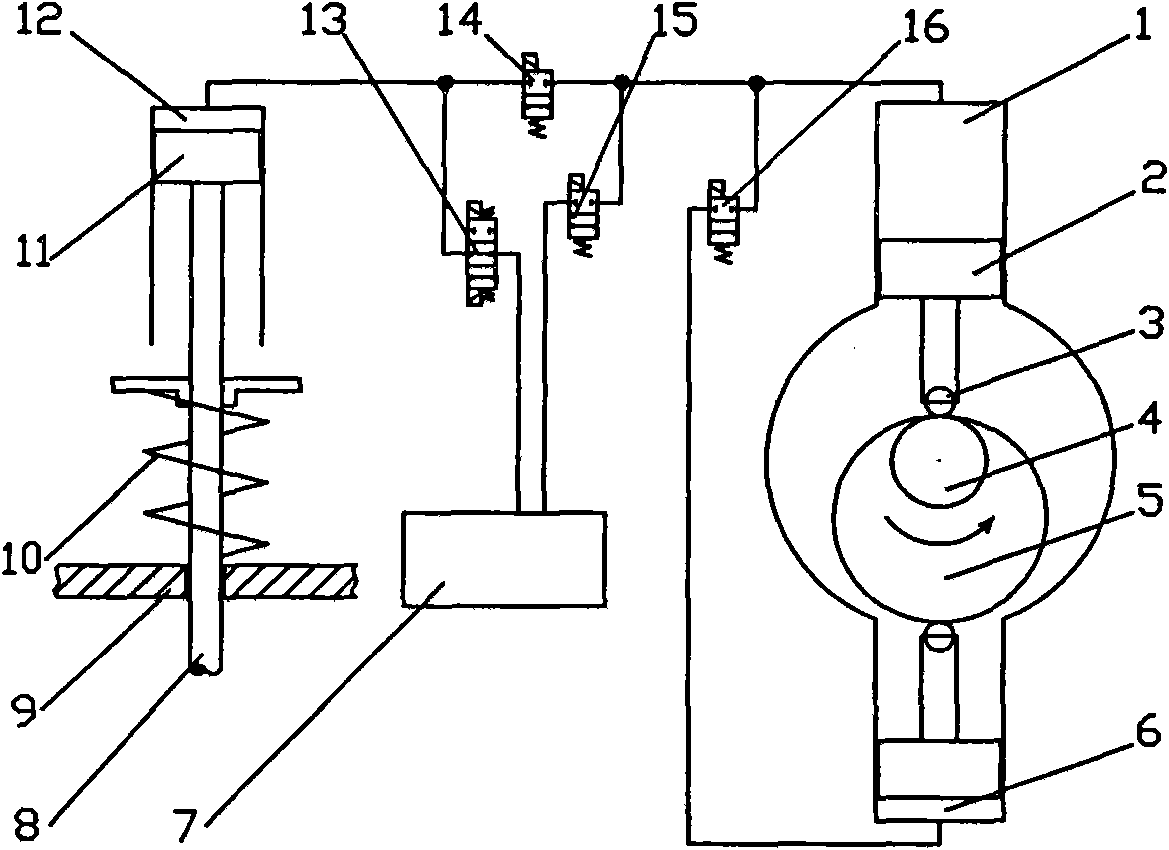

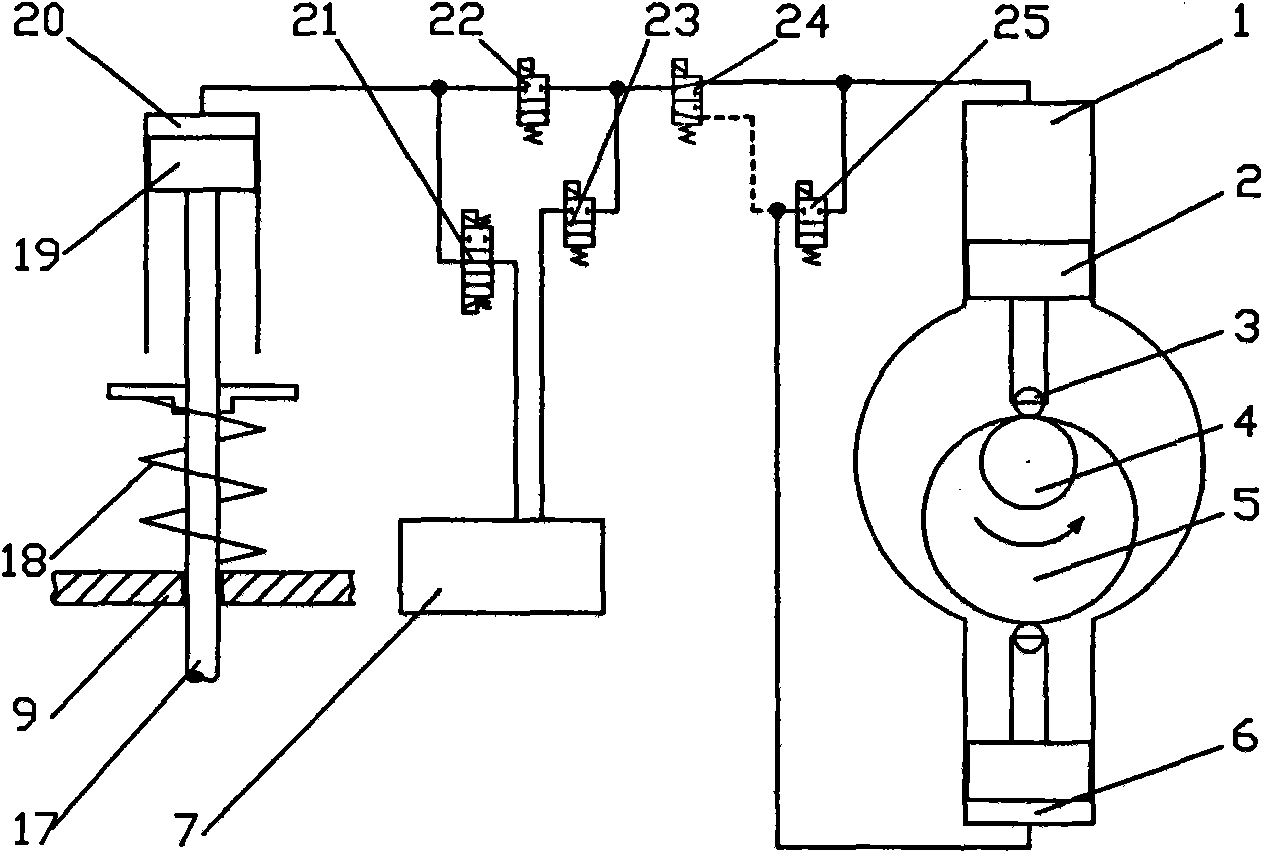

[0016] figure 2 A schematic diagram showing the working principle of the cam oil-fed electro-hydraulic valve actuation system for a single intake valv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com