Patents

Literature

2182 results about "Common rail" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Common-rail direct fuel injection is a direct fuel injection system for diesel engines. On diesel engines, it features a high-pressure (over 100 bar or 10 MPa or 1,500 psi) fuel rail feeding solenoid valves, as opposed to a low-pressure fuel pump feeding unit injectors (or pump nozzles). Third-generation common-rail diesels now feature piezoelectric injectors for increased precision, with fuel pressures up to 2,500 bar (250 MPa; 36,000 psi).

Acid-free quaternized nitrogen compounds and use thereof as additives in fuels and lubricants

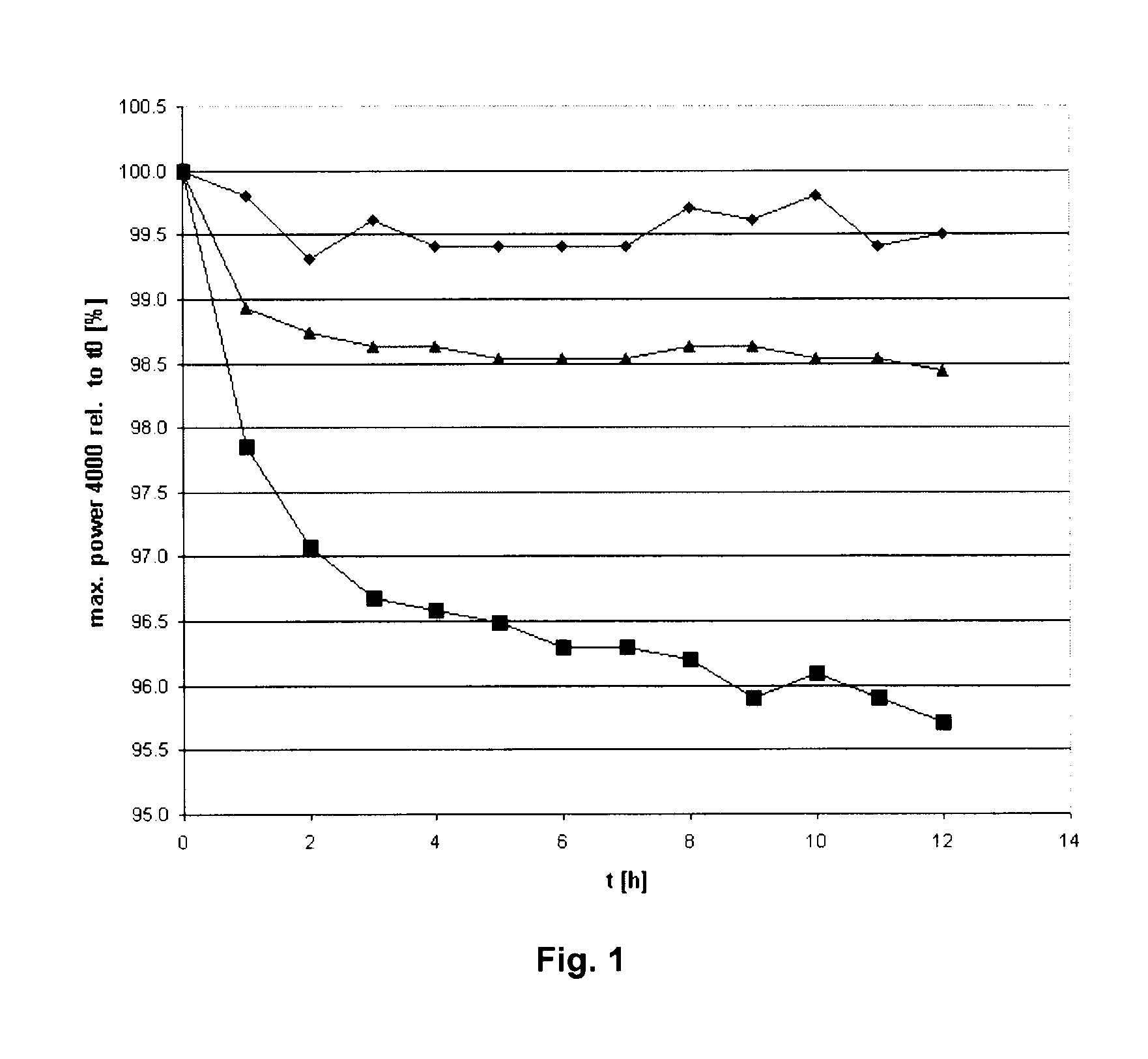

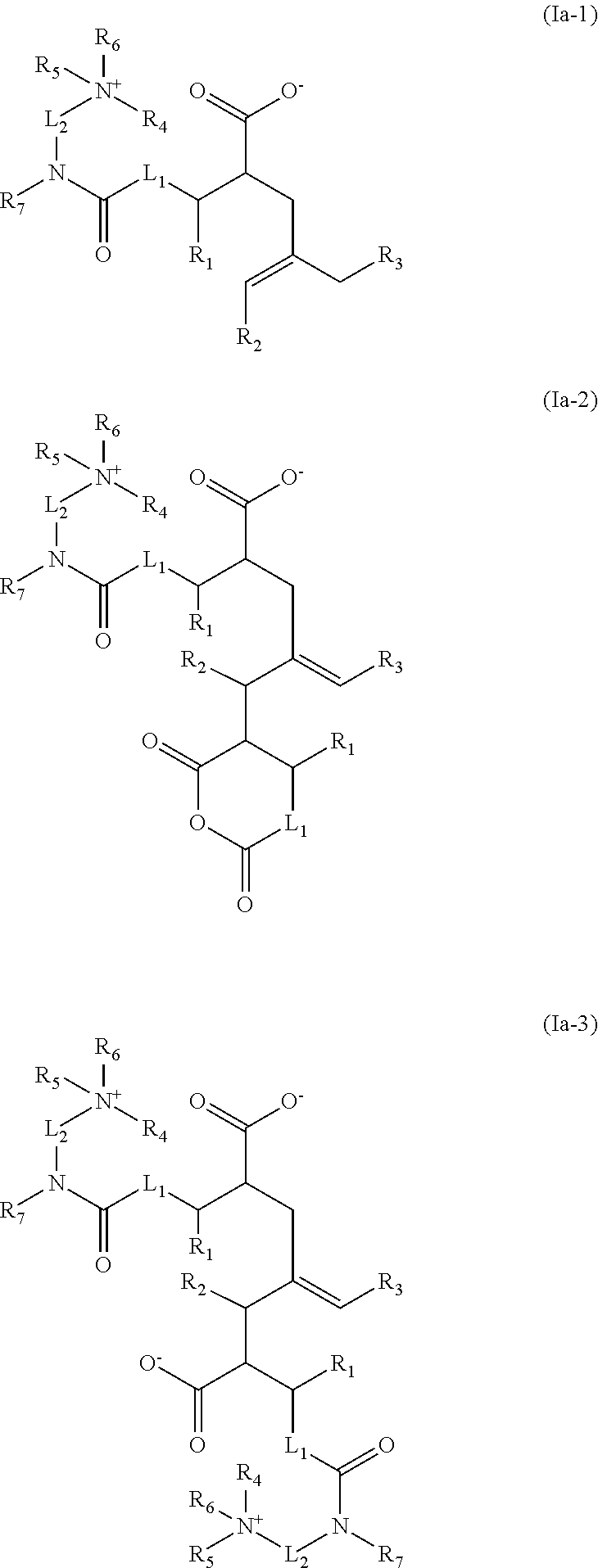

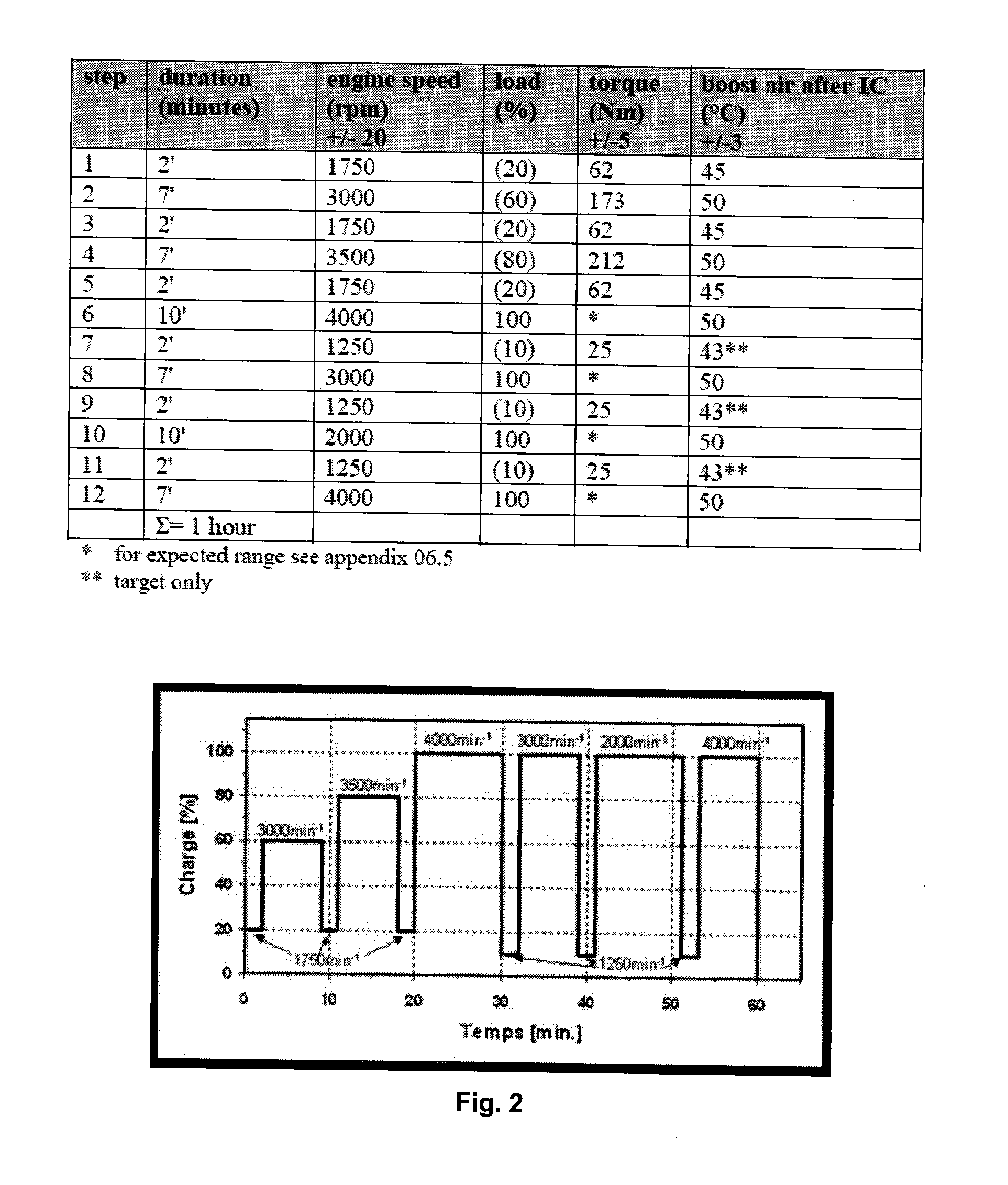

The present invention relates to novel acid-free quaternized nitrogen compounds, to the preparation thereof and to the use thereof as a fuel and lubricant additive, more particularly as a detergent additive, as a wax antisettling additive (WASA) or as an additive for reducing internal diesel injector deposits (IDID); to additive packages which comprise these compounds; and to fuels and lubricants thus additized. The present invention further relates to the use of these acid-free quaternized nitrogen compounds as a fuel additive for reducing or preventing deposits in the injection systems of direct-injection diesel engines, especially in common-rail injection systems, for reducing the fuel consumption of direct-injection diesel engines, especially of diesel engines with common-rail injection systems, and for minimizing power loss in direct-injection diesel engines, especially in diesel engines with common-rail injection systems.

Owner:BASF AG

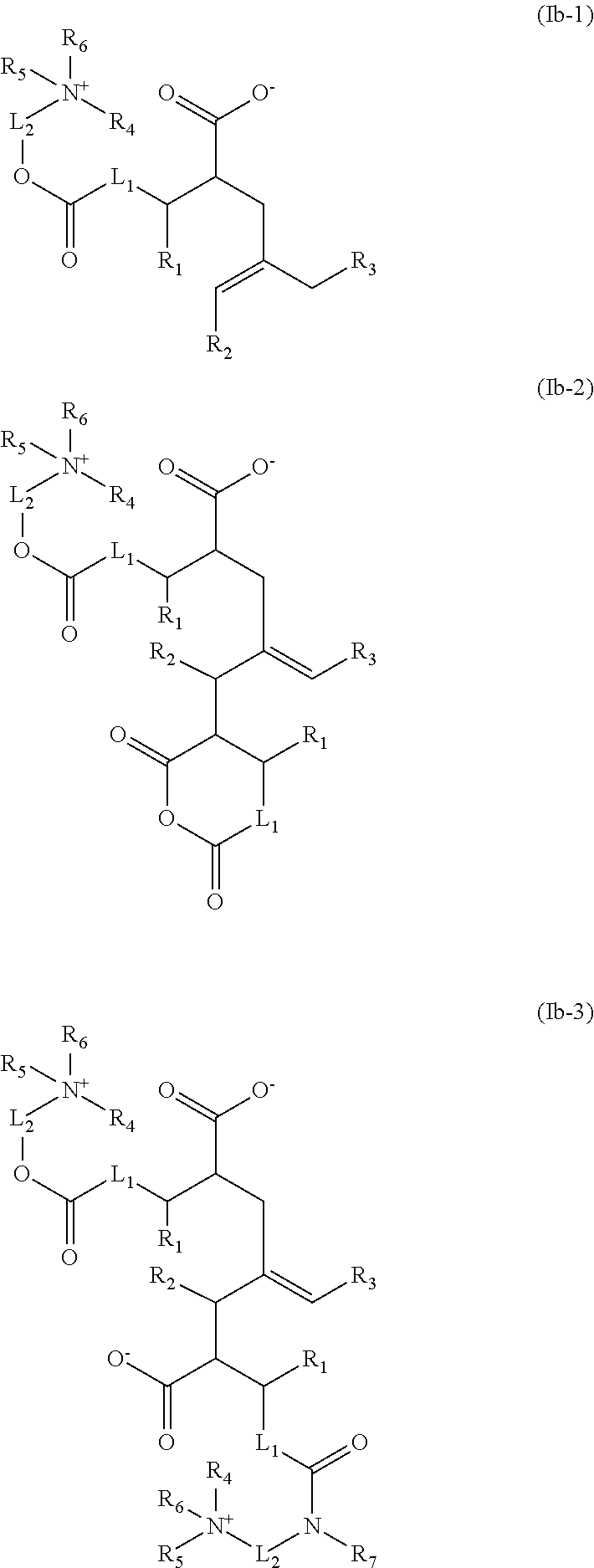

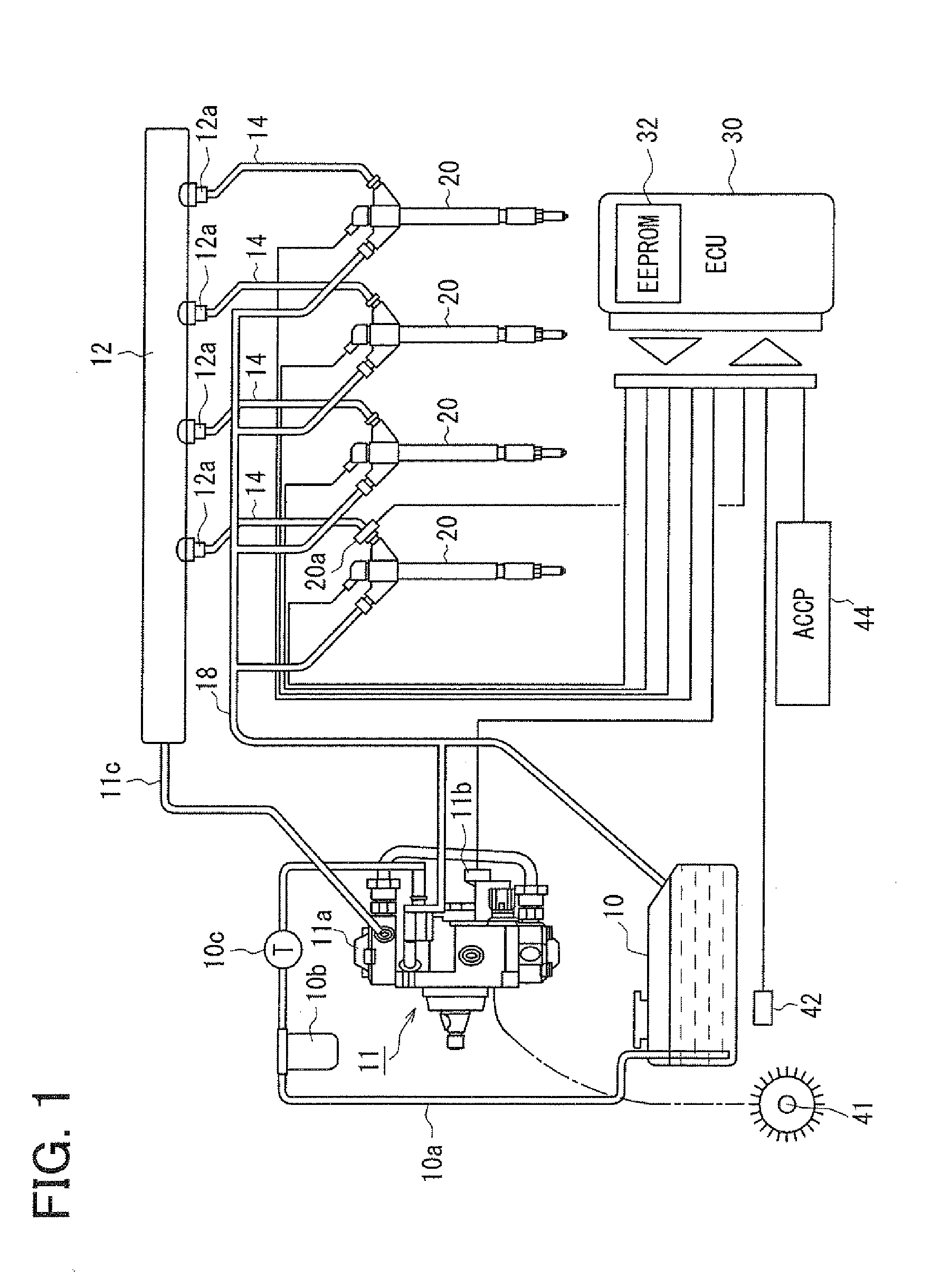

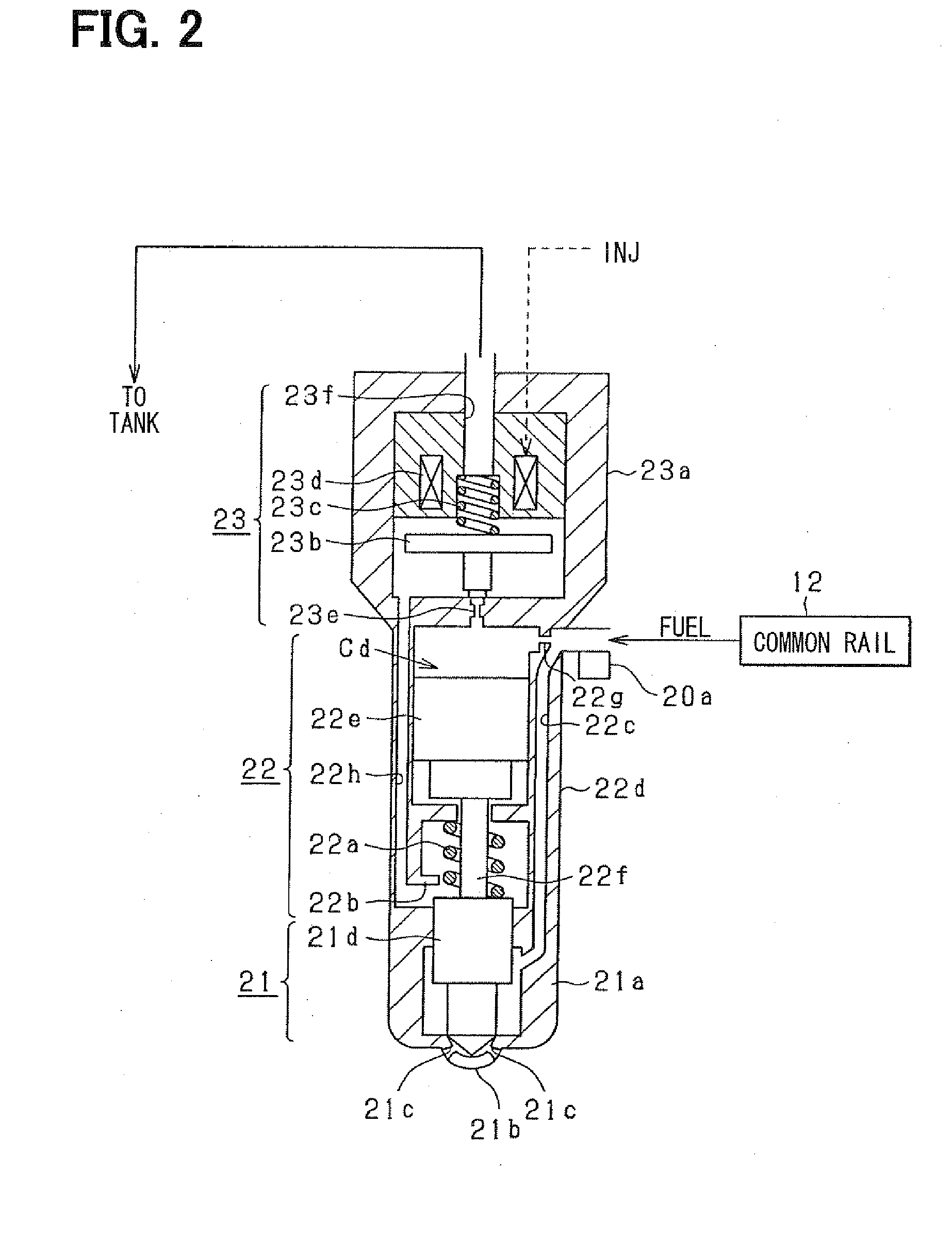

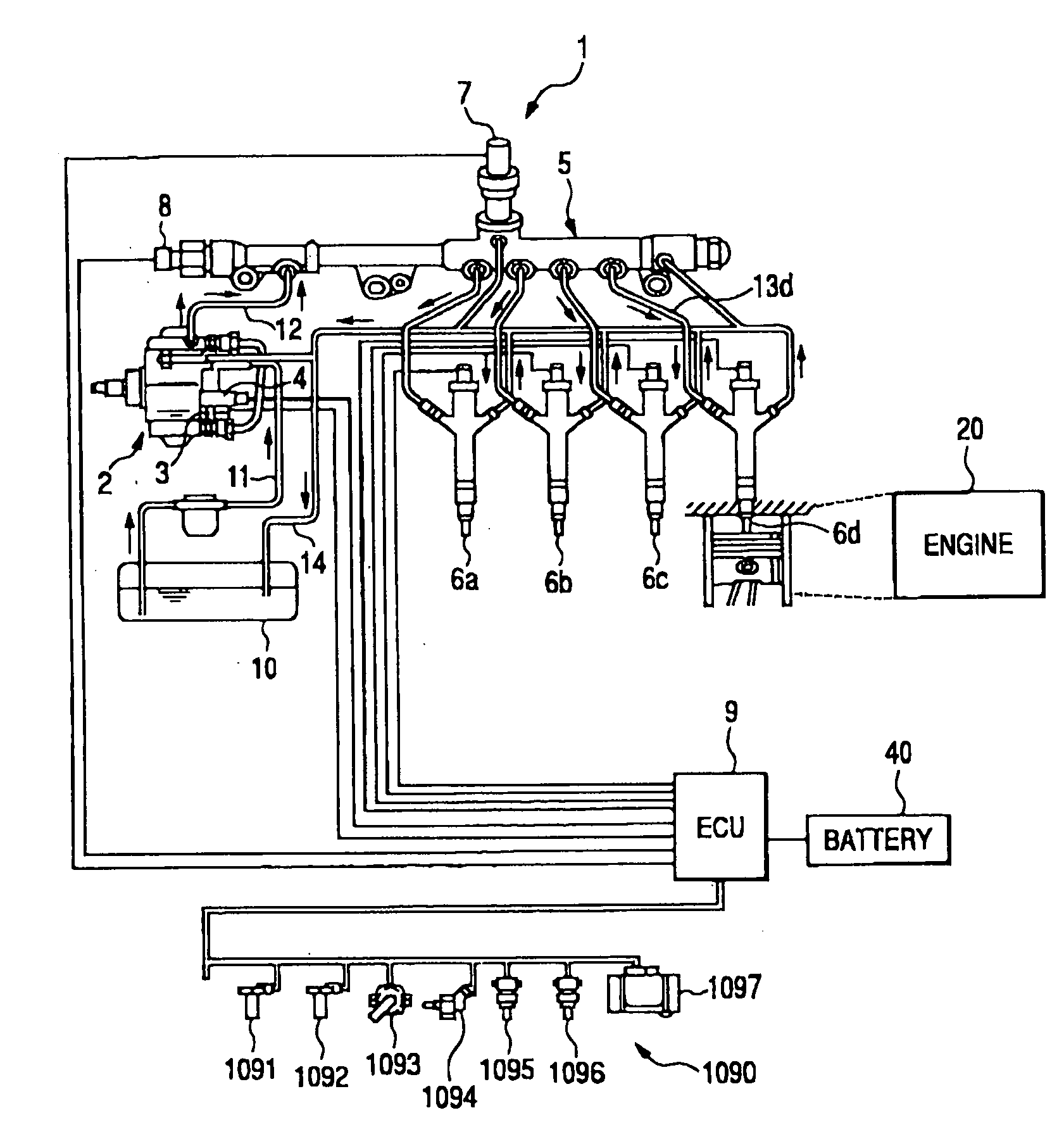

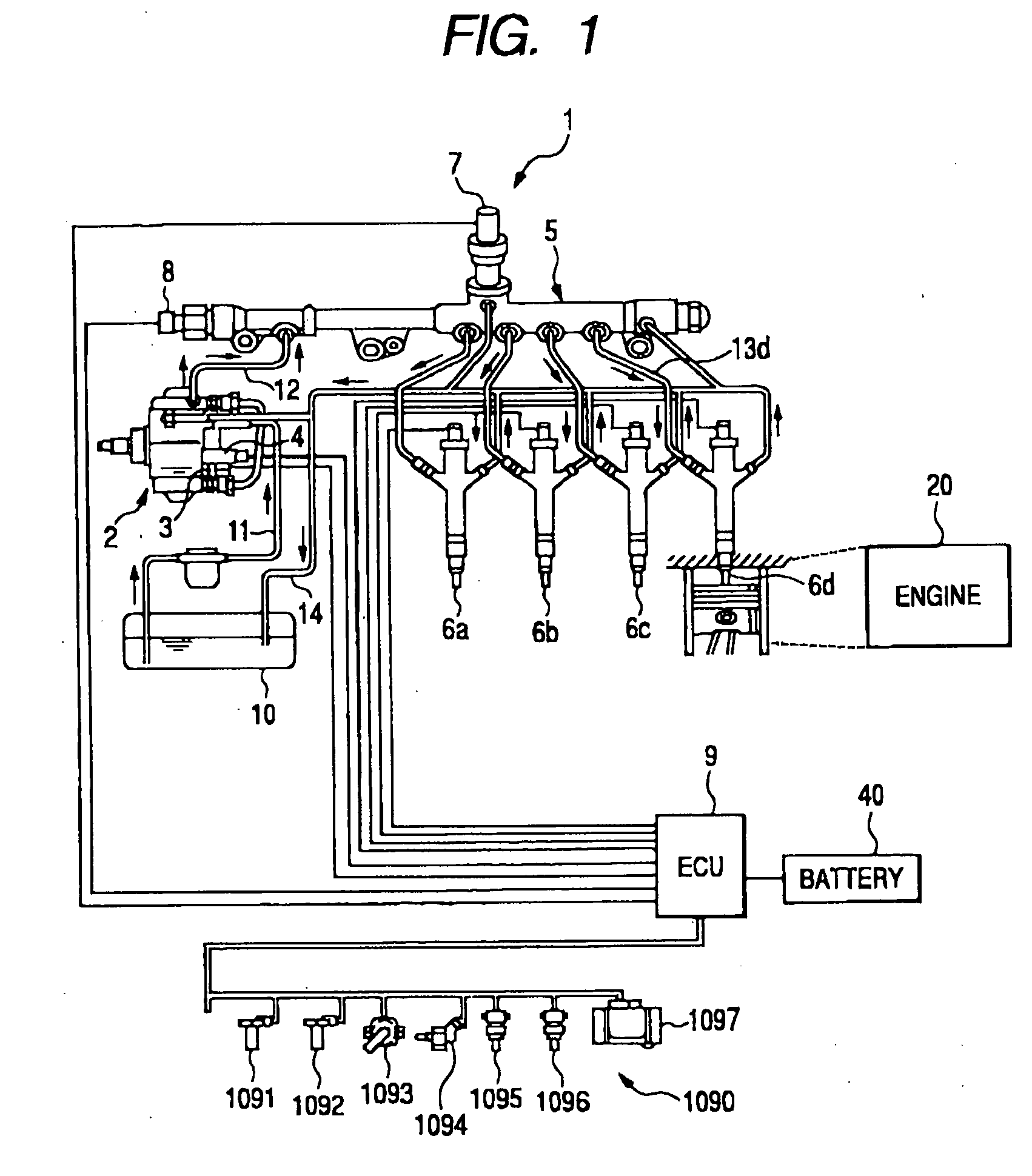

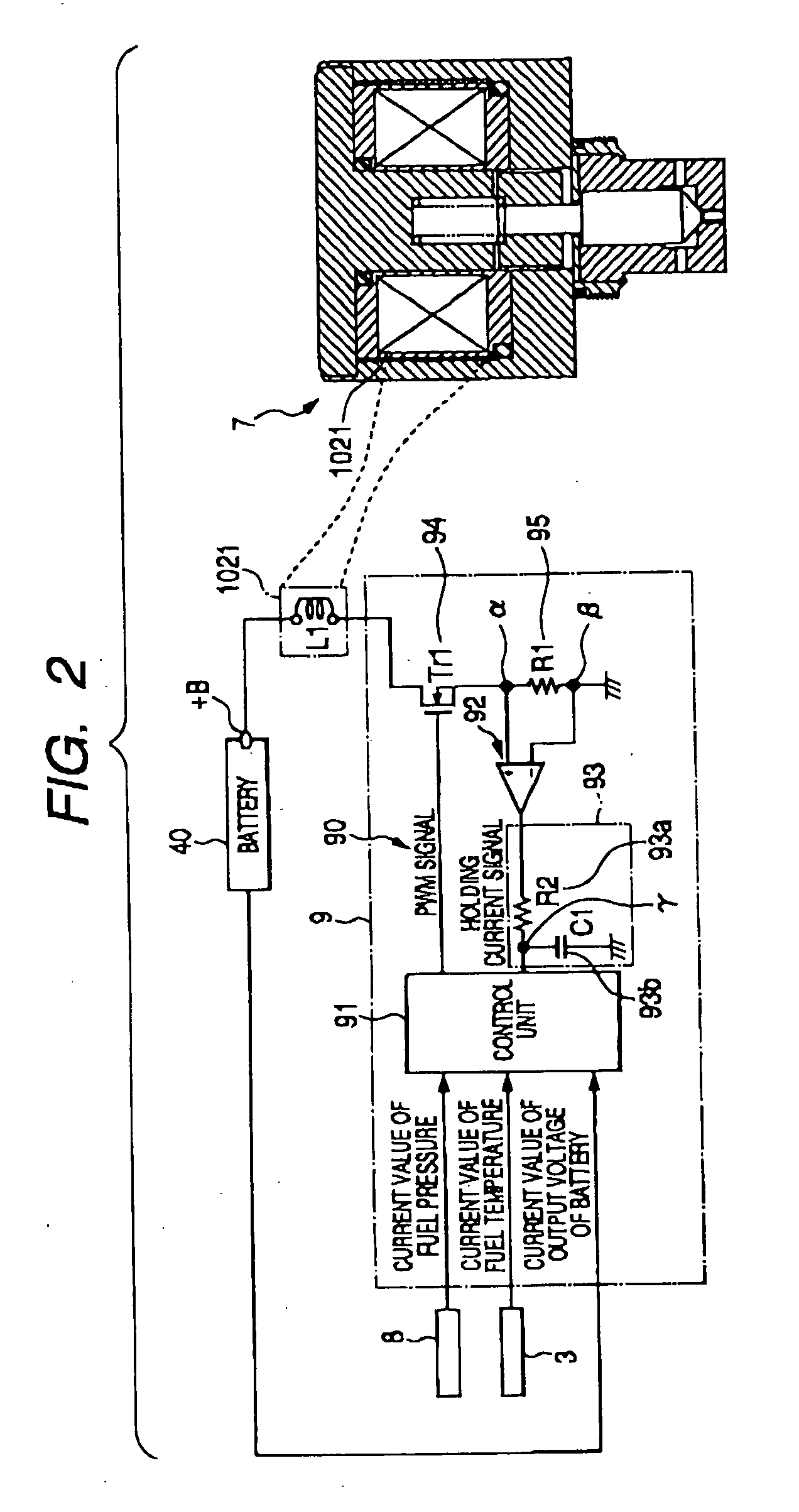

Fuel injection device and adjustment method thereof

ActiveUS20080228374A1Improve accuracyAccurate inductionInternal-combustion engine testingElectrical controlCommon railForce sensor

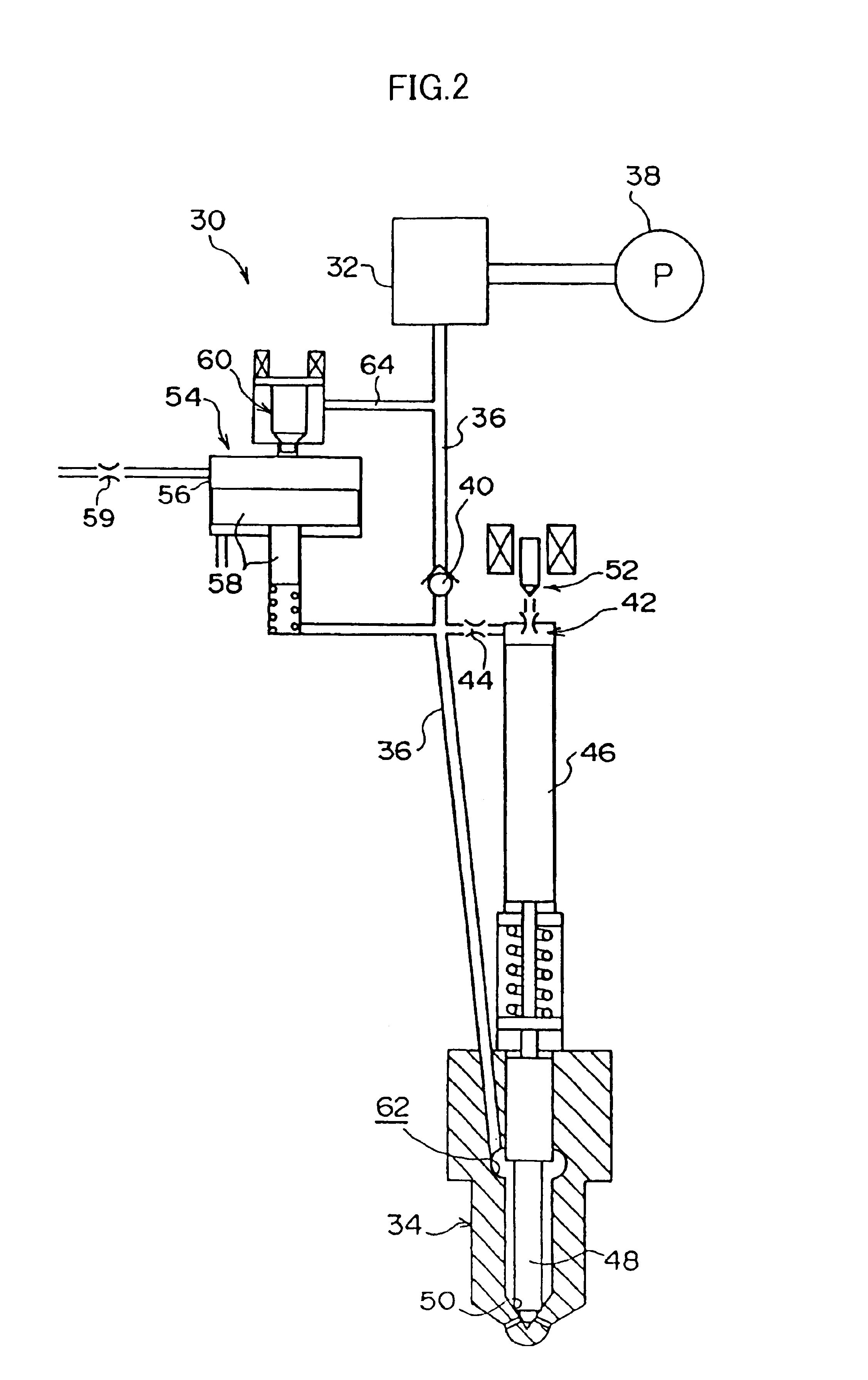

A fuel injection device (fuel supply system) of a common rail type fuel injection system for an engine includes a pressure sensor disposed in a fuel inlet of an injector for measuring a fuel pressure at a position where the sensor is disposed and an ECU for sensing various kinds of pressure fluctuations associated with the injection including a pressure leak due to an injection operation of the injector and waving characteristics due to actual injection thereof based on sensor outputs from the pressure sensor. The ECU serially obtains the sensor outputs from the pressure sensor at intervals of 20 μsec.

Owner:DENSO CORP

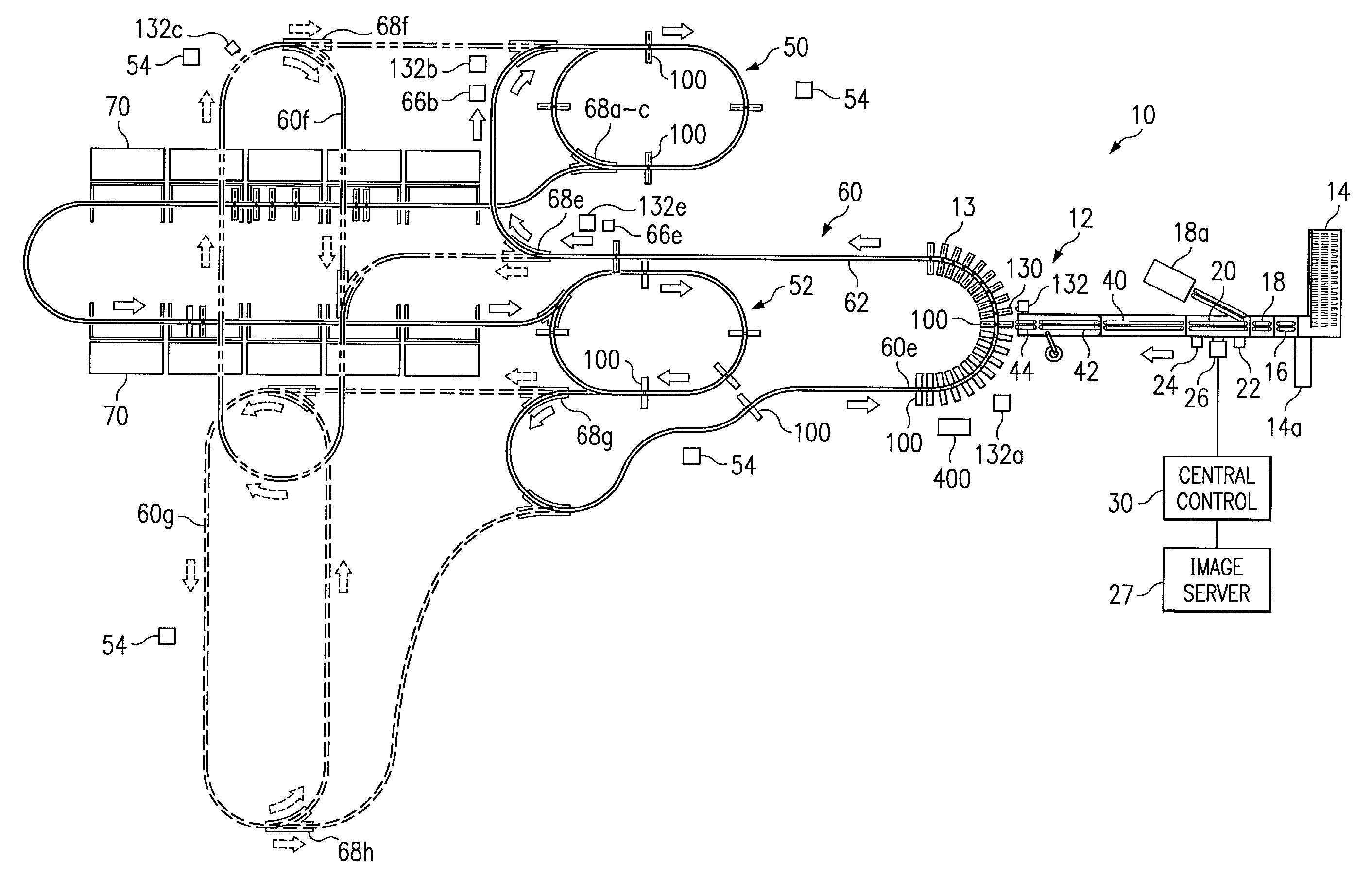

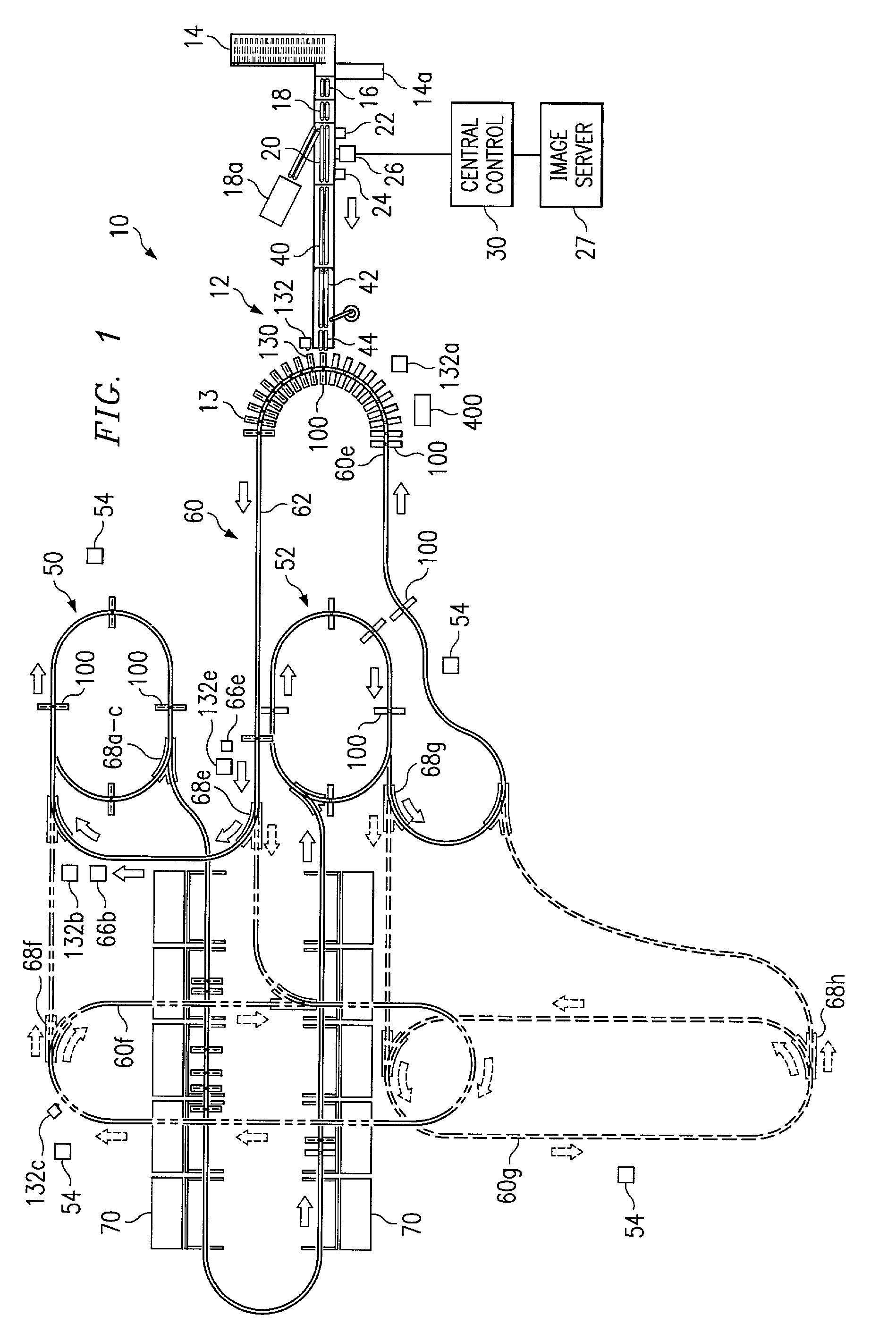

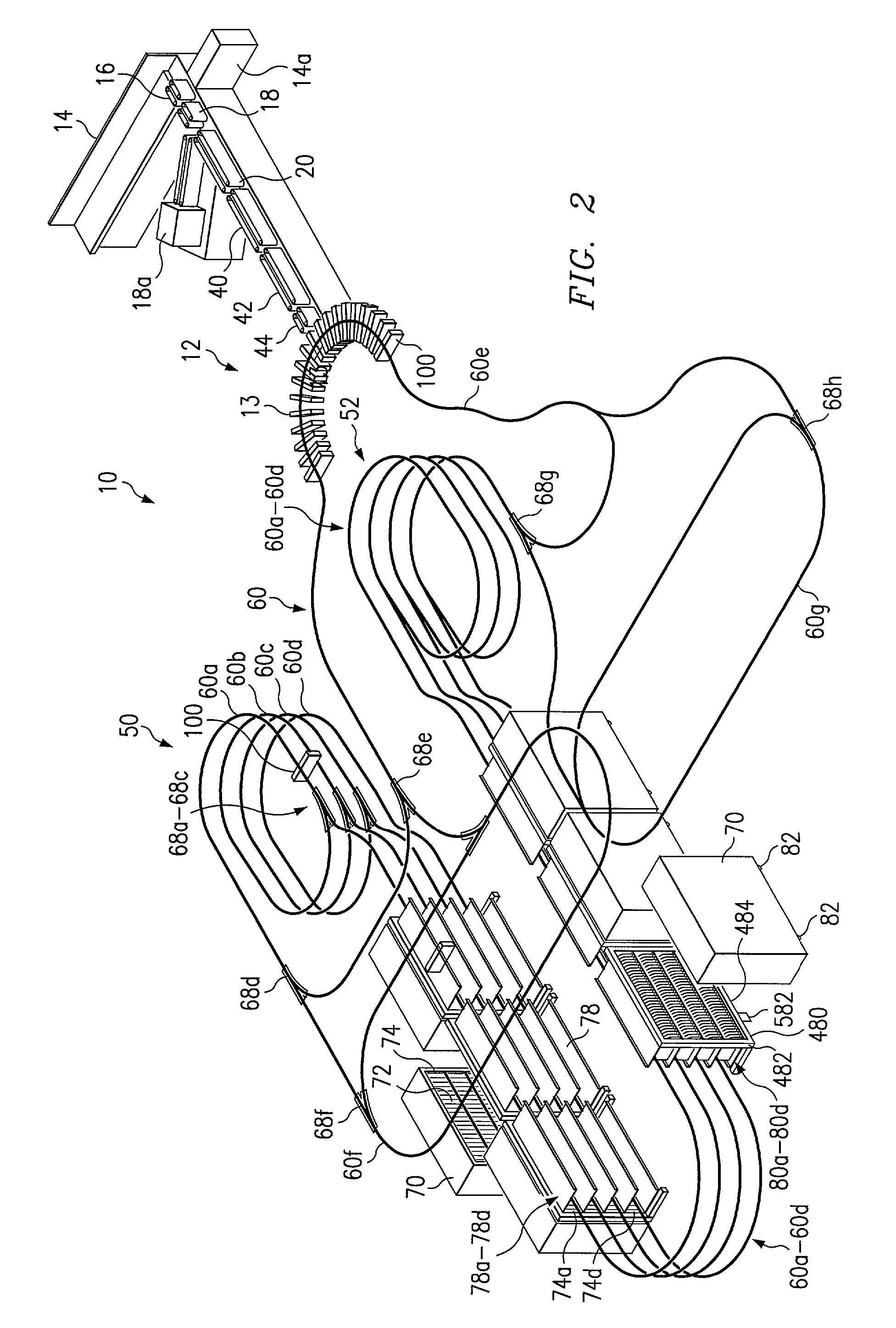

Apparatus and method for mail sorting

InactiveUS7138596B2Efficient drawingReduce capacityDigital data processing detailsSeparation devicesCommon railEngineering

A method for sorting mail to a case having a plurality of slots is described, wherein each slot corresponds to a destination. The method includes steps of loading a mail piece to be sorted into a delivery robot, determining for the mail piece a destination slot the mail piece is to be delivered to, moving the delivery robot along a rail disposed at the front of the case near the slots into proximity with an open end of the destination slot, inserting the mail piece from the delivery robot into the associated slot, and returning the delivery robot to a loading station whereby the cycle may be repeated. Such a method, when using a large number of robots moving along a common rail system, can sort a large volume of mail in carrier delivery order.

Owner:SIEMENS LOGISTICS LLC

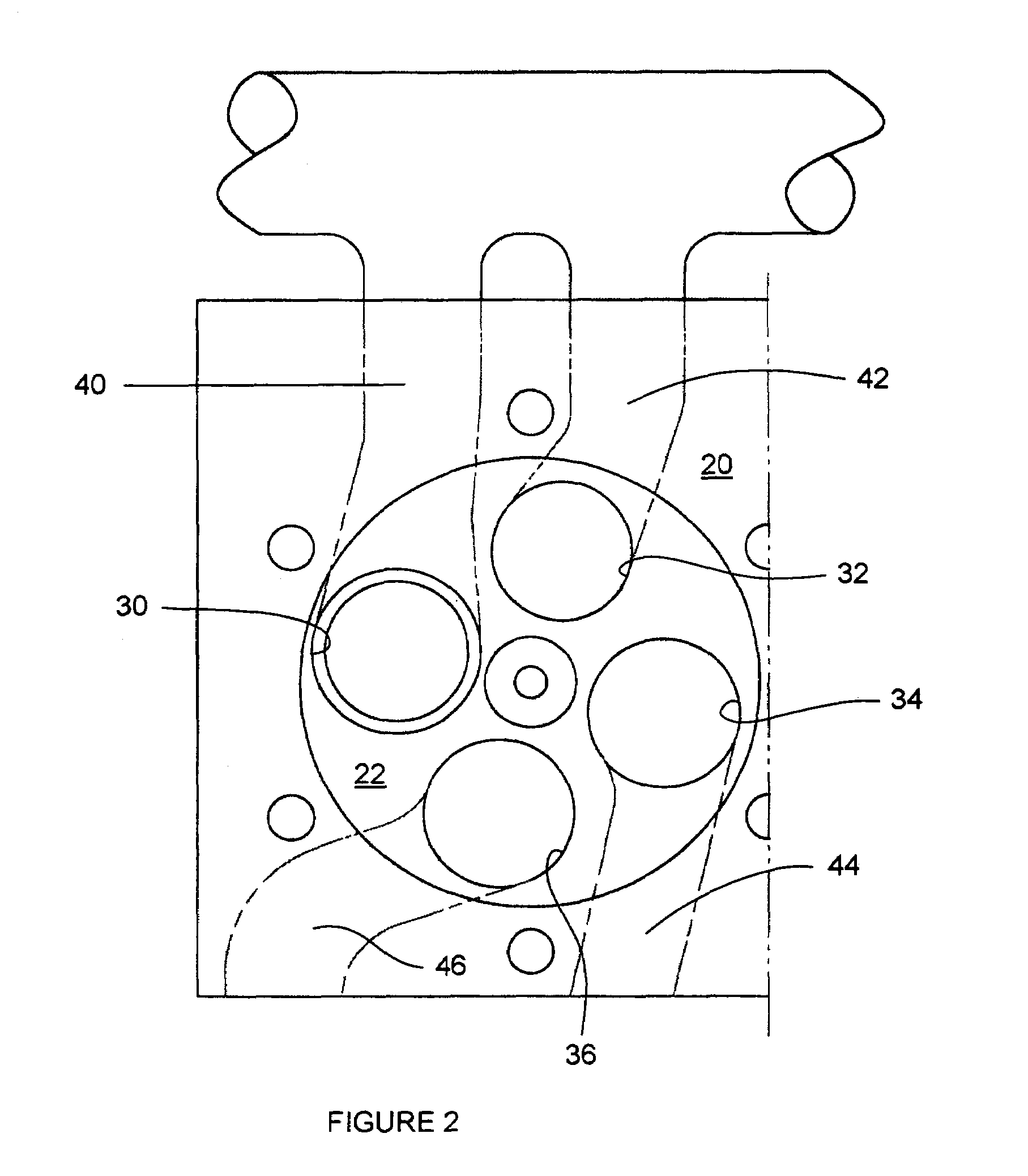

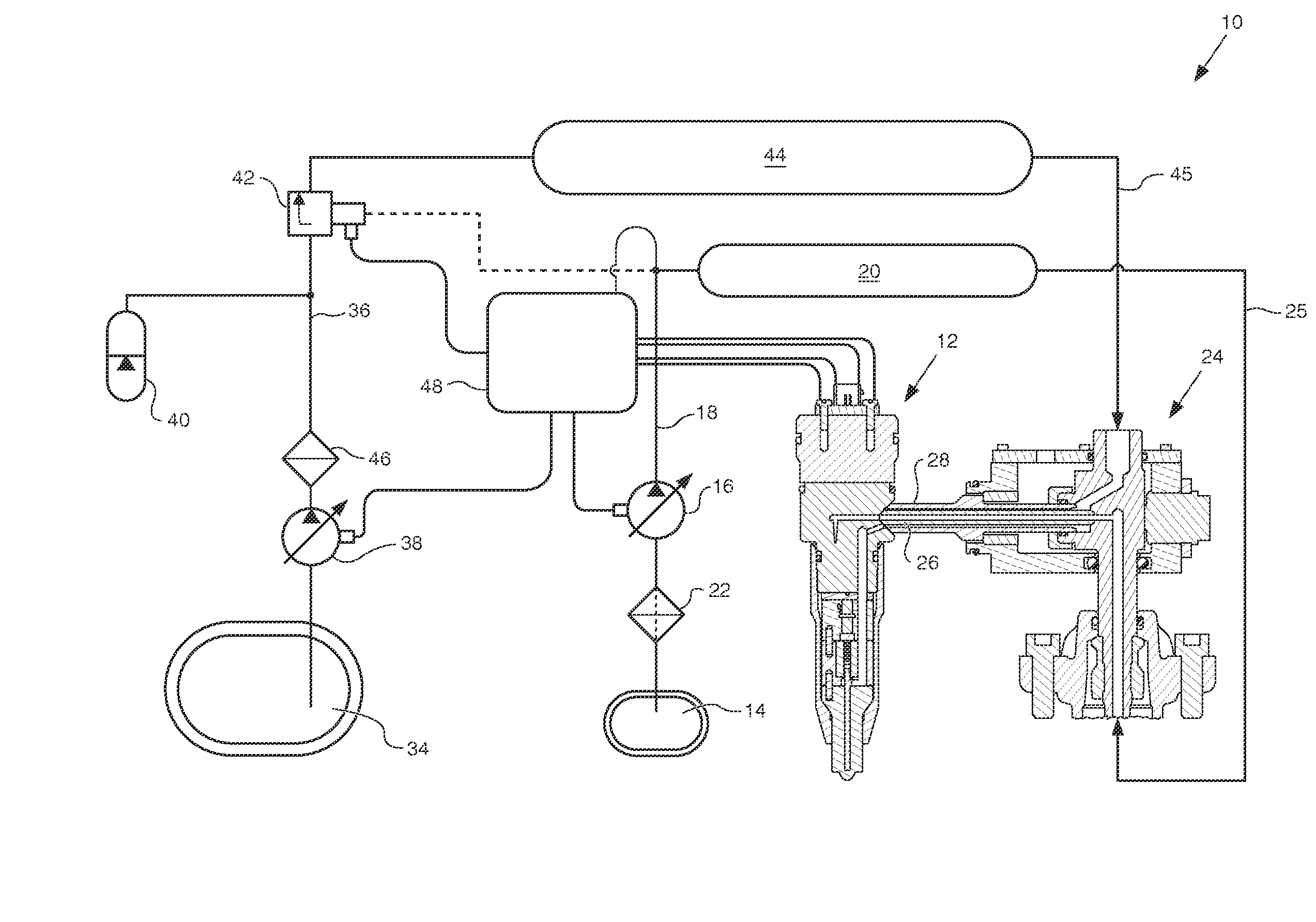

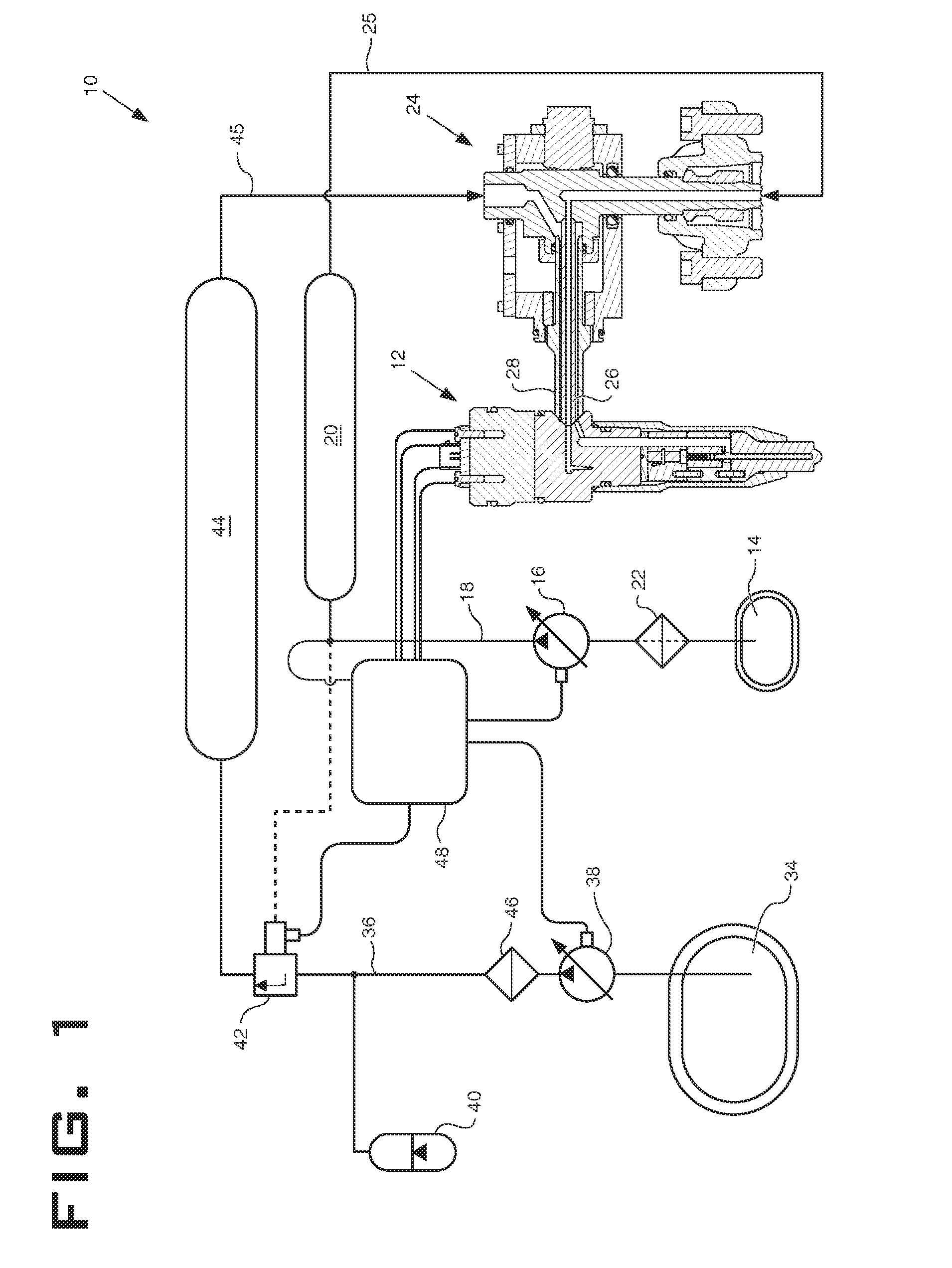

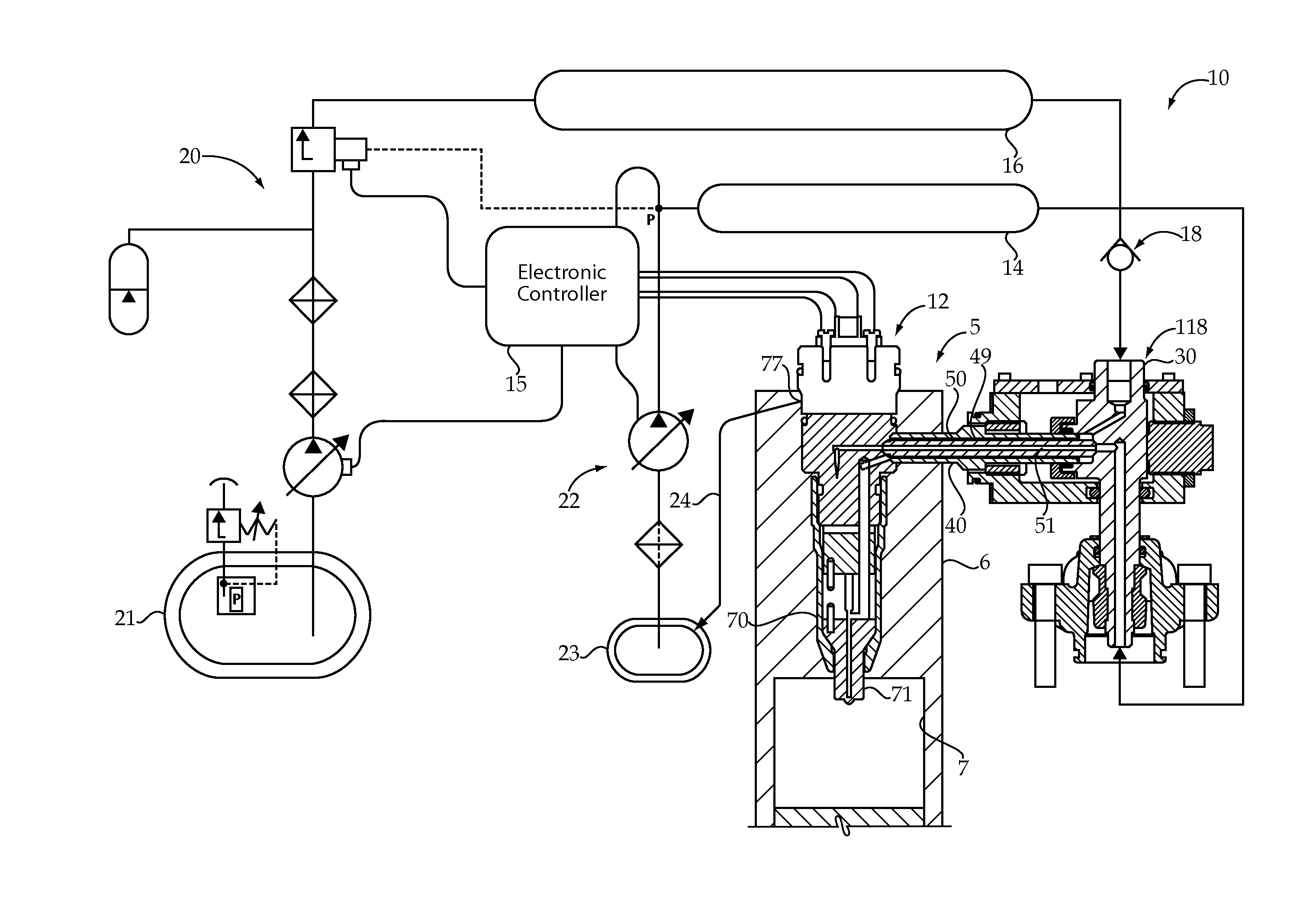

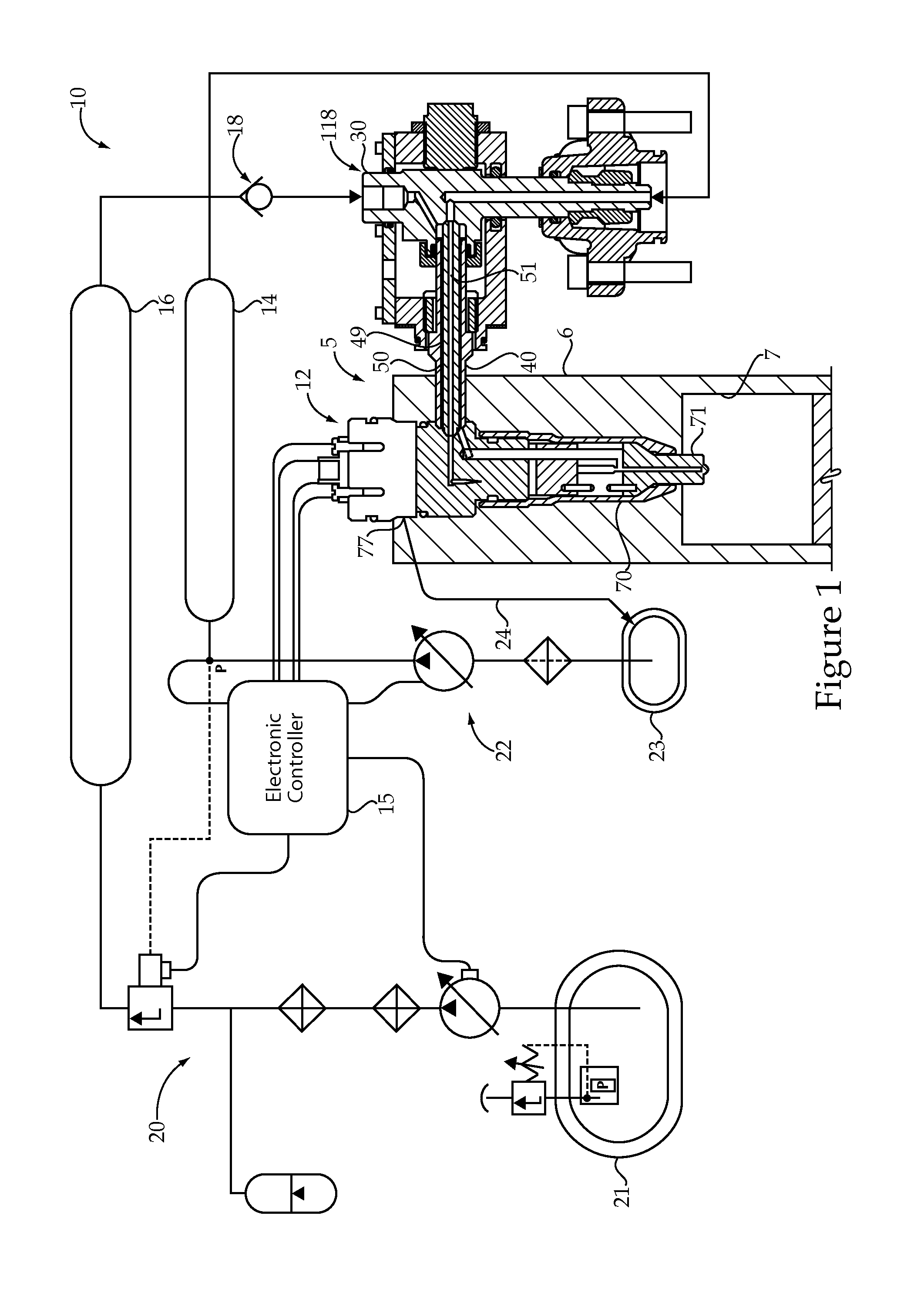

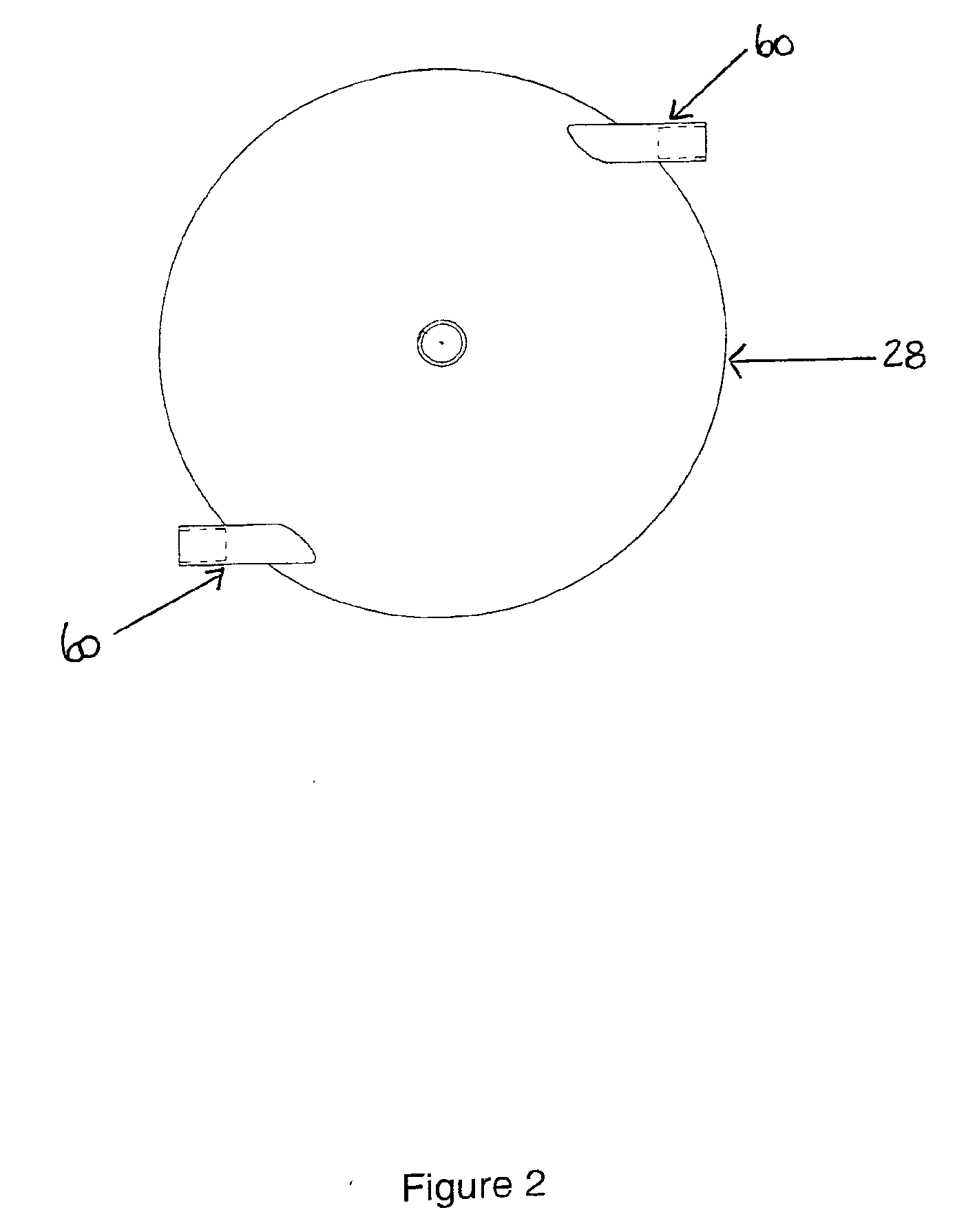

Common rail fuel pump with combined discharge and overpressure relief valves

ActiveUS20110126804A1Reduce system costIncrease flexibilityCheck valvesEqualizing valvesCommon railPump chamber

A high pressure piston fuel pump having a discharge check valve between the pumping chamber and a pressurized fuel reservoir and a pressure relief valve between the fuel reservoir and a passageway in the housing, wherein the discharge check valve and the pressure relief valve are contained within a single fitting assembly affixed at the pump housing. A first end flow passage is in fluid communication with the pumping chamber and provides an inlet to the discharge check valve and an outlet from the pressure relief valve. A second end flow passage is in fluid communication with the fuel reservoir and provides an outlet for the discharge check valve and an inlet for the pressure relief valve. Advantages include the ability to pre-test the outlet check and pressure relief prior to assembly into the pump housing, and improved flexibility of the outlet fitting location.

Owner:STANDYNE INC

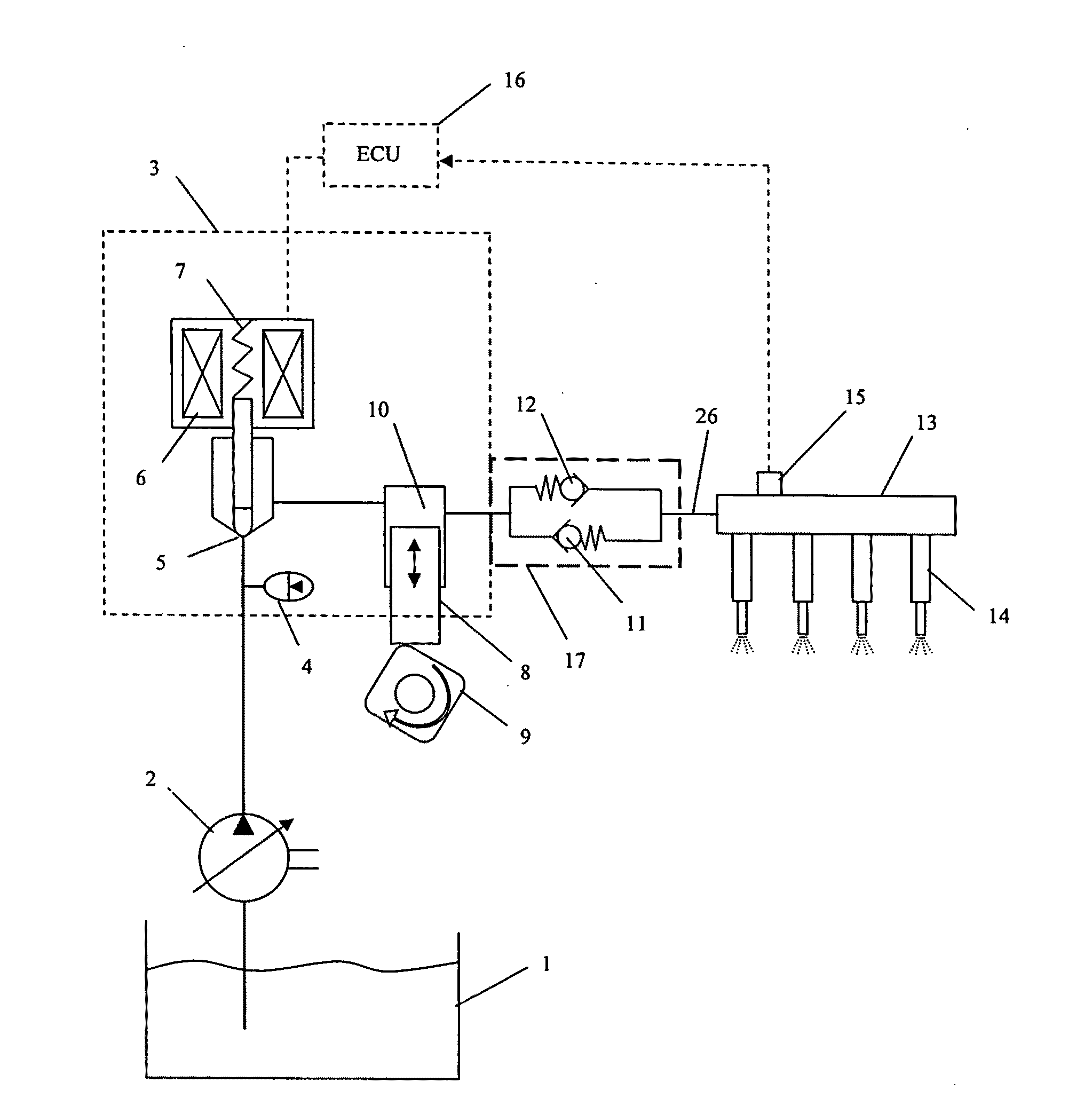

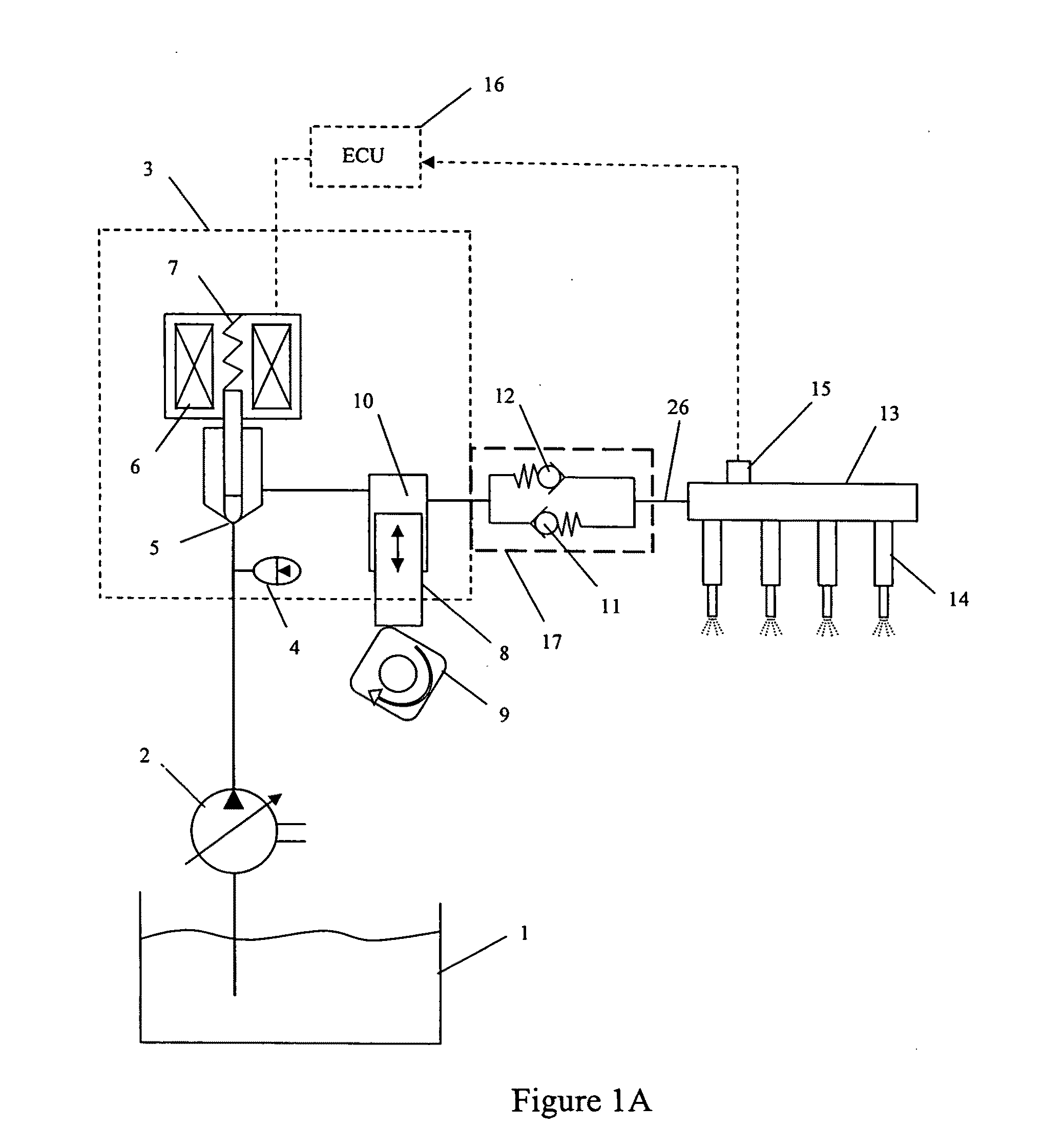

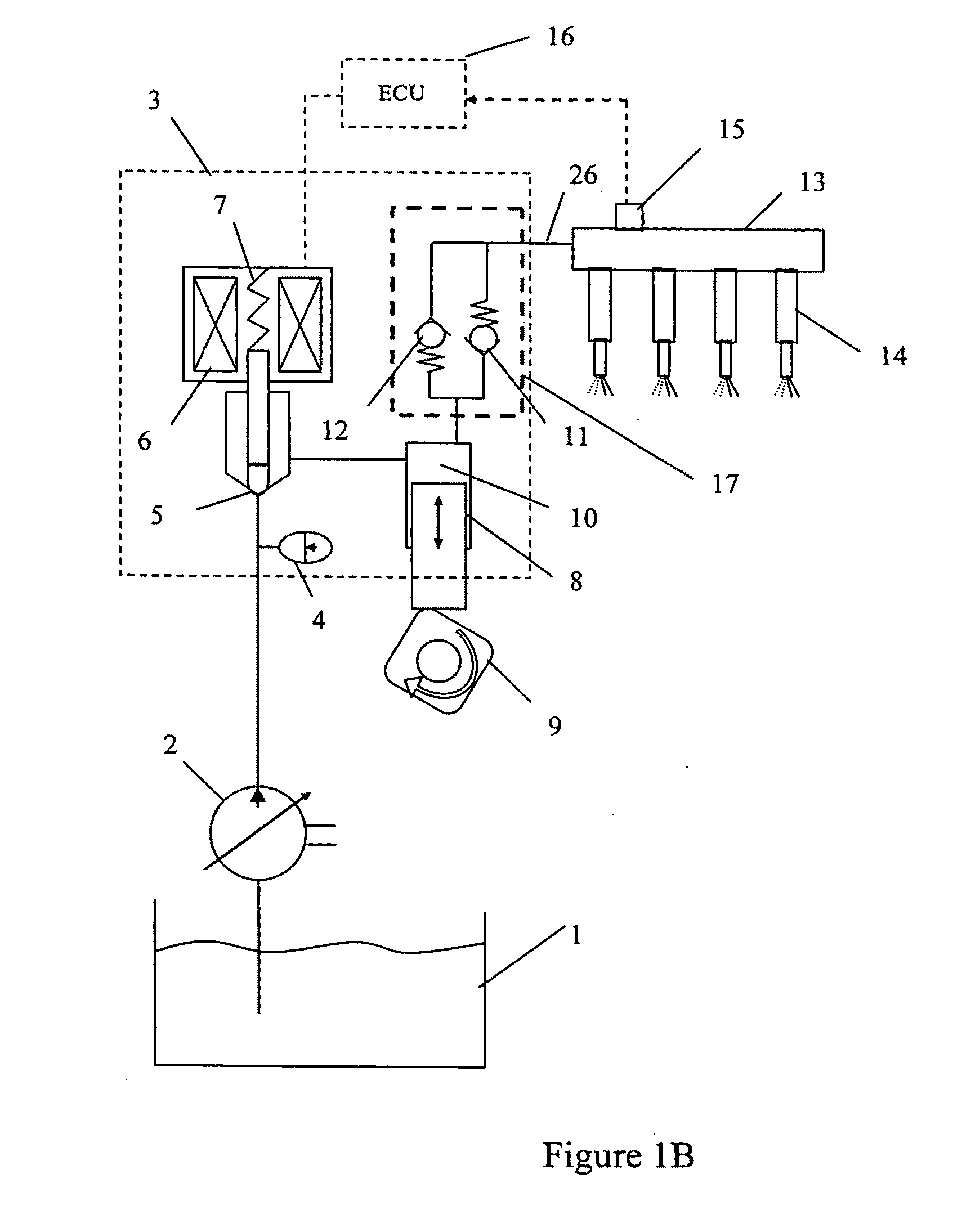

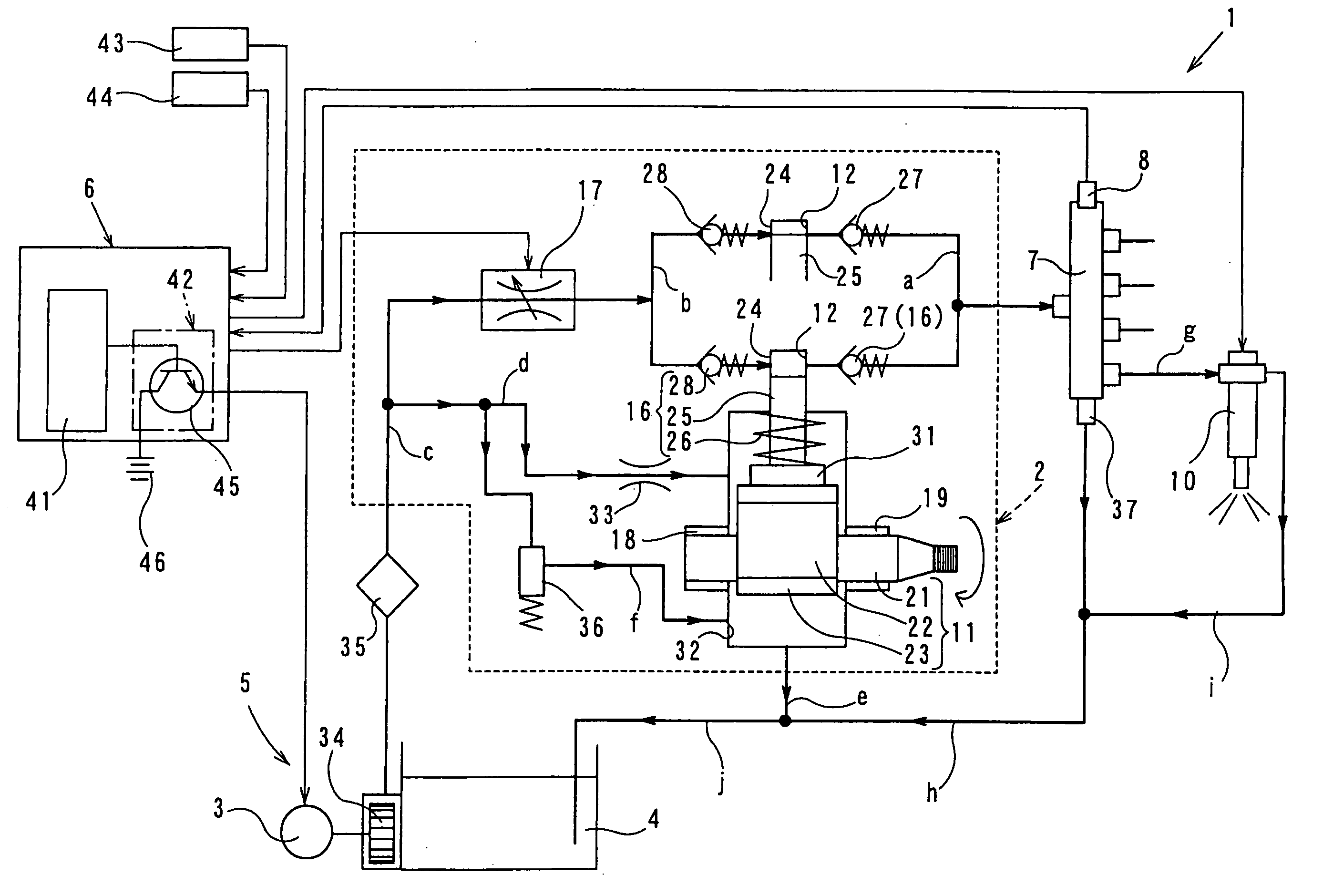

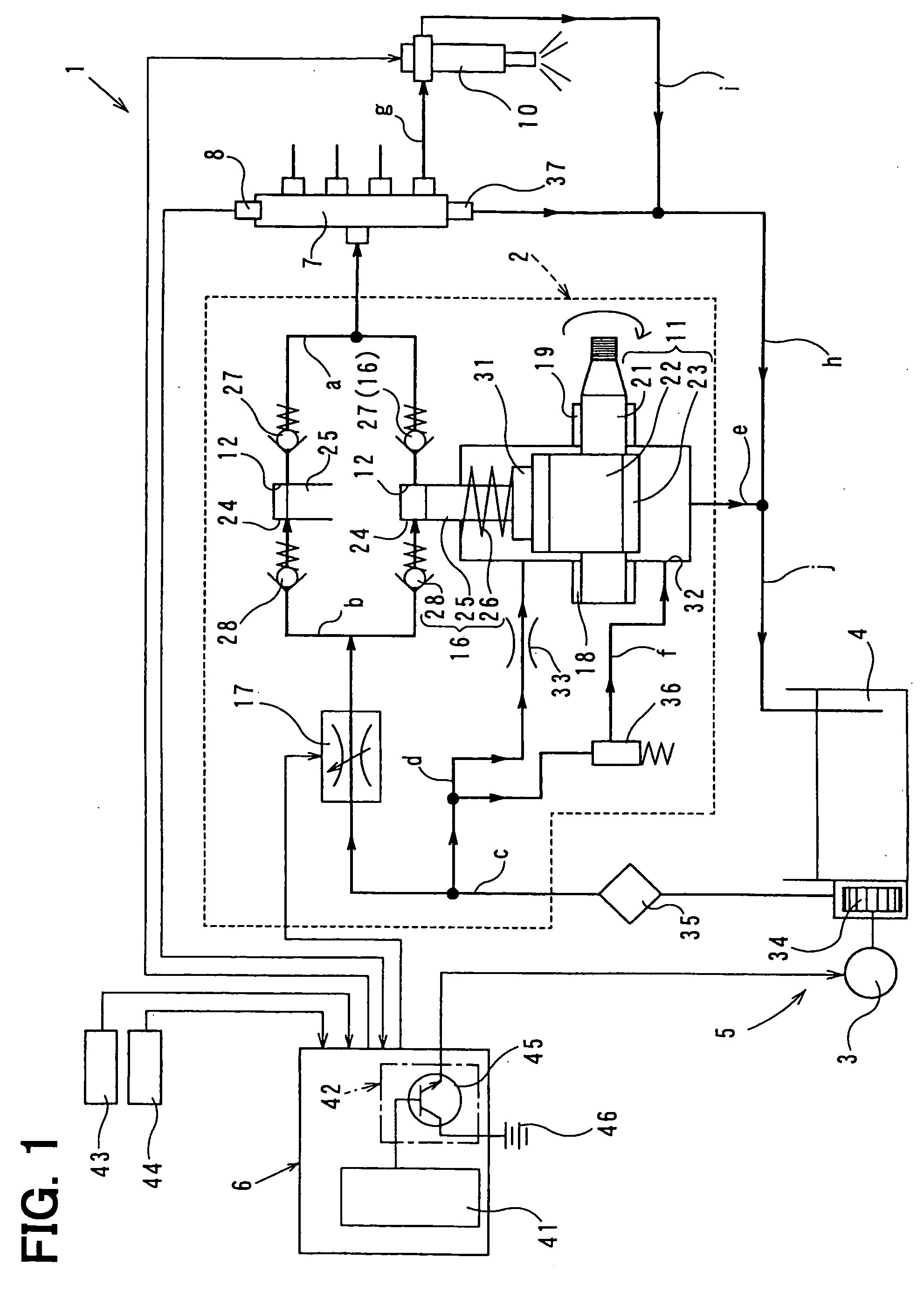

Fuel injection device

InactiveUS20090326788A1Accurate calculationPrecision injectionElectrical controlDigital data processing detailsDifferential pressureCommon rail

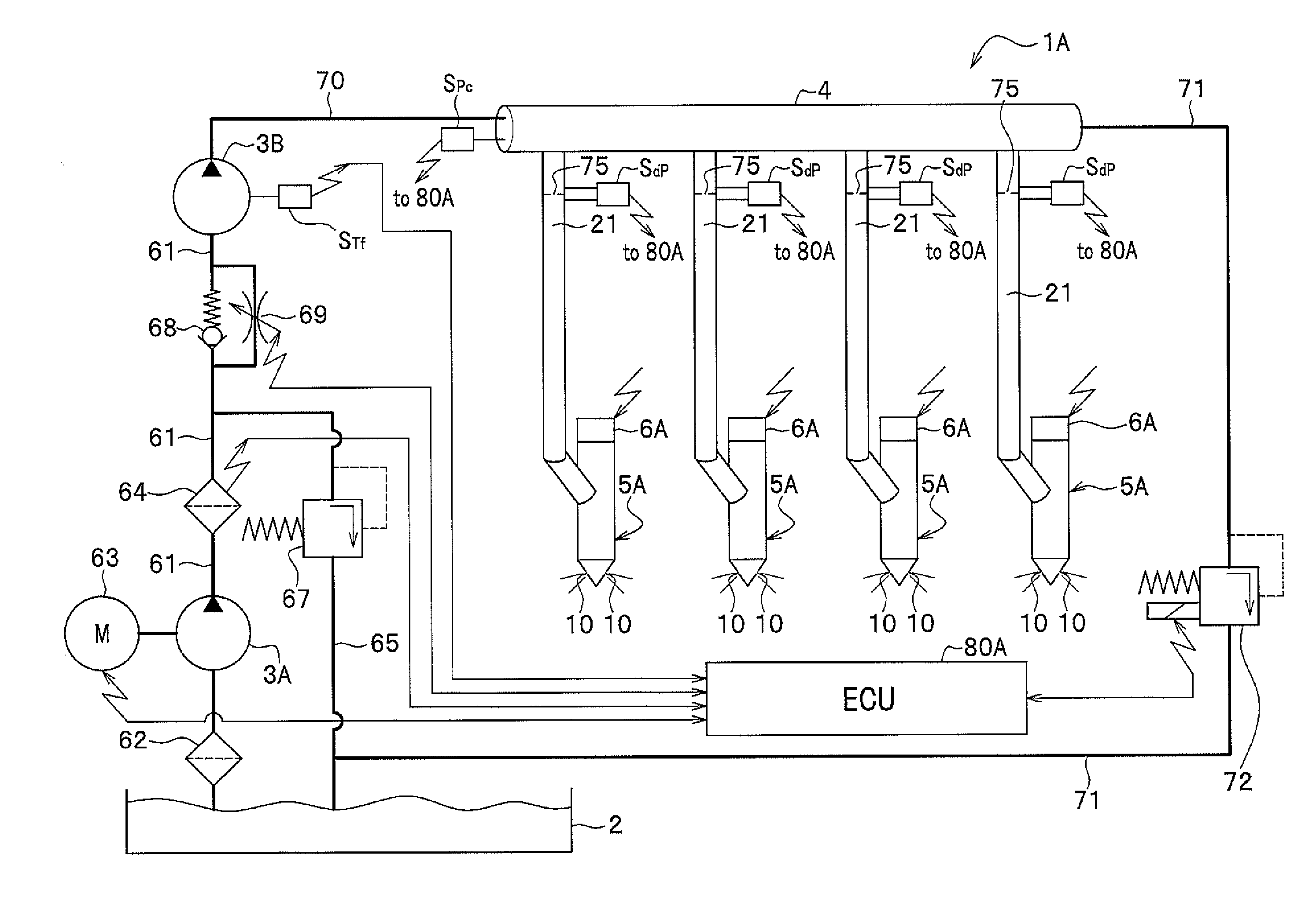

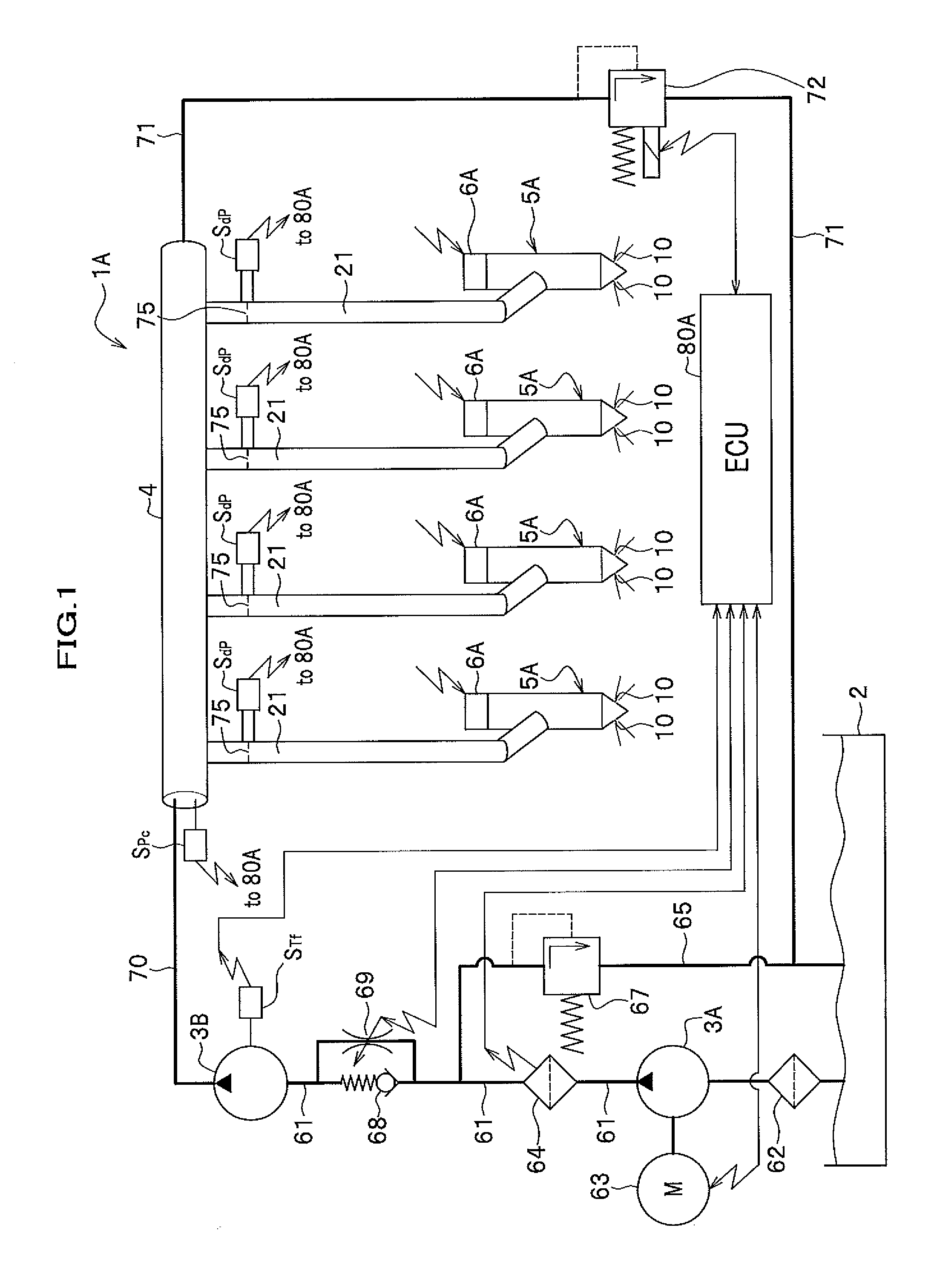

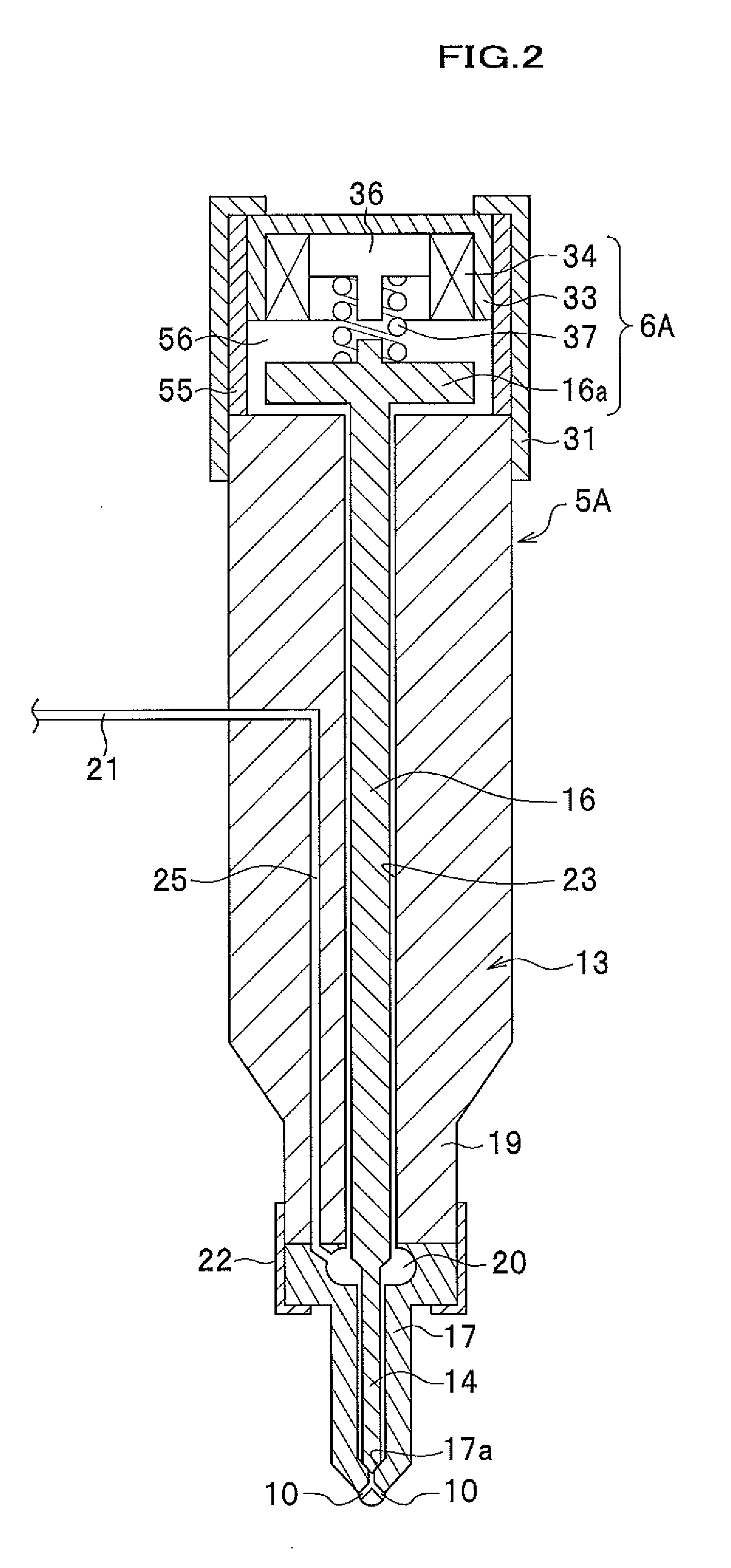

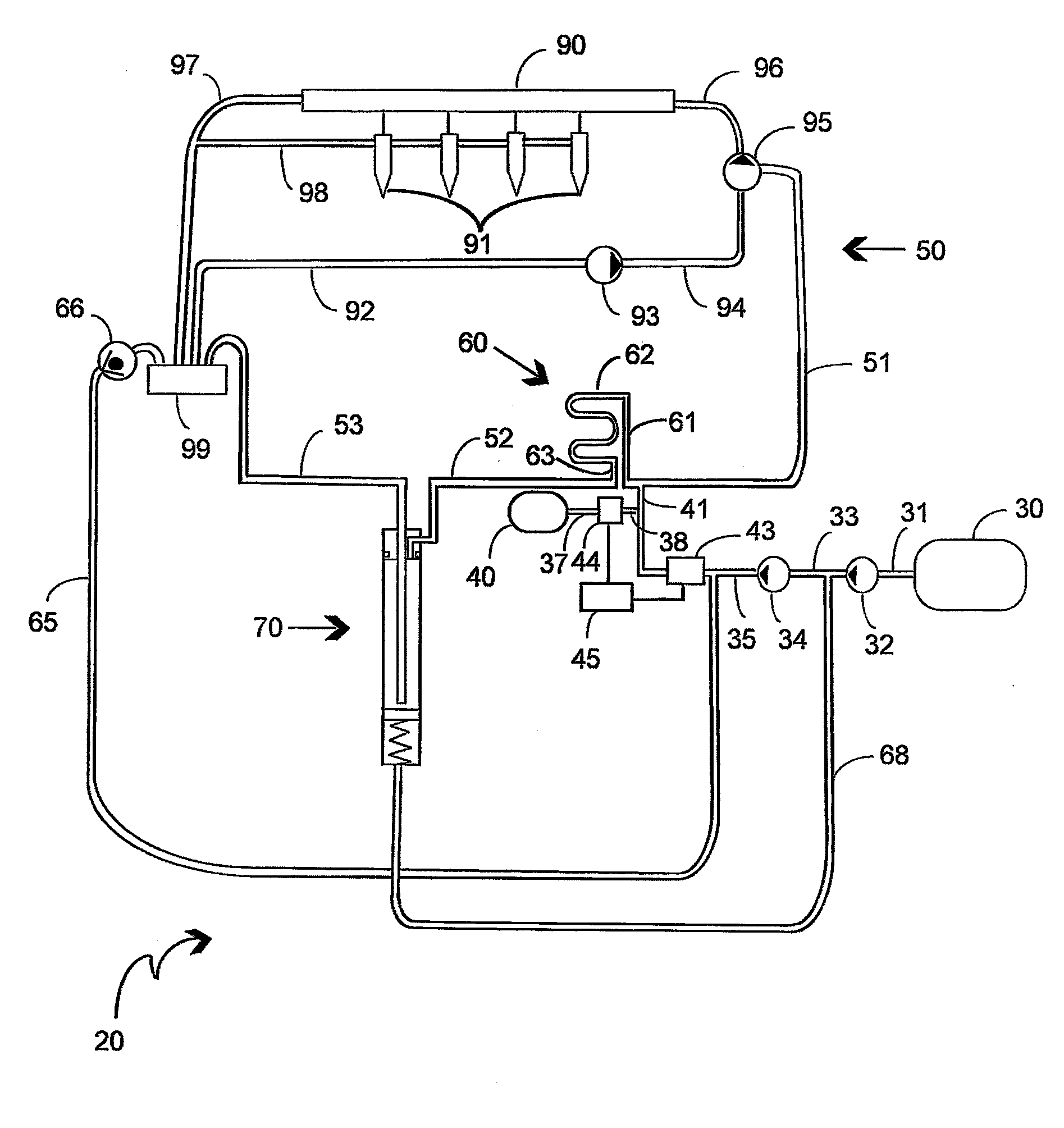

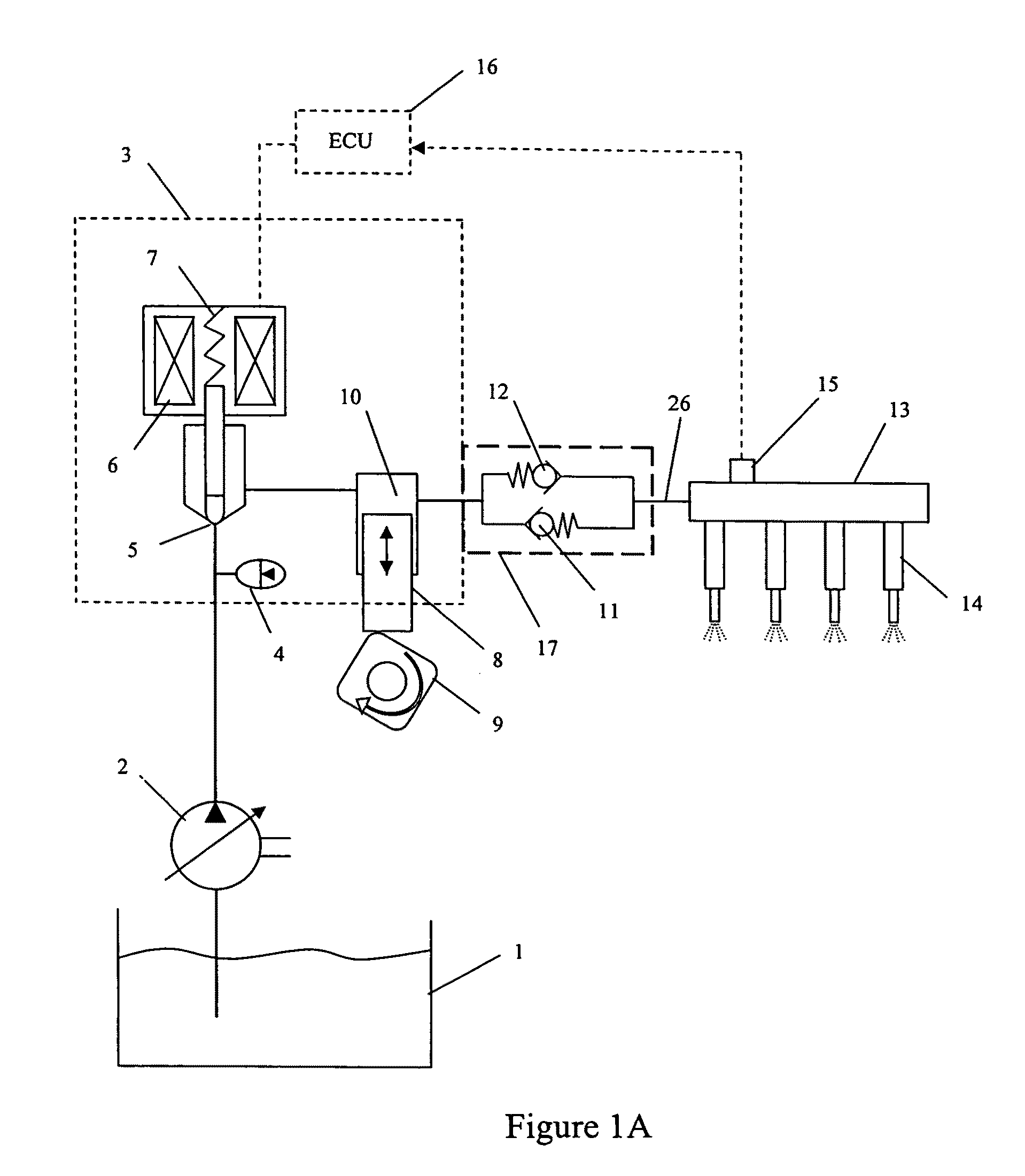

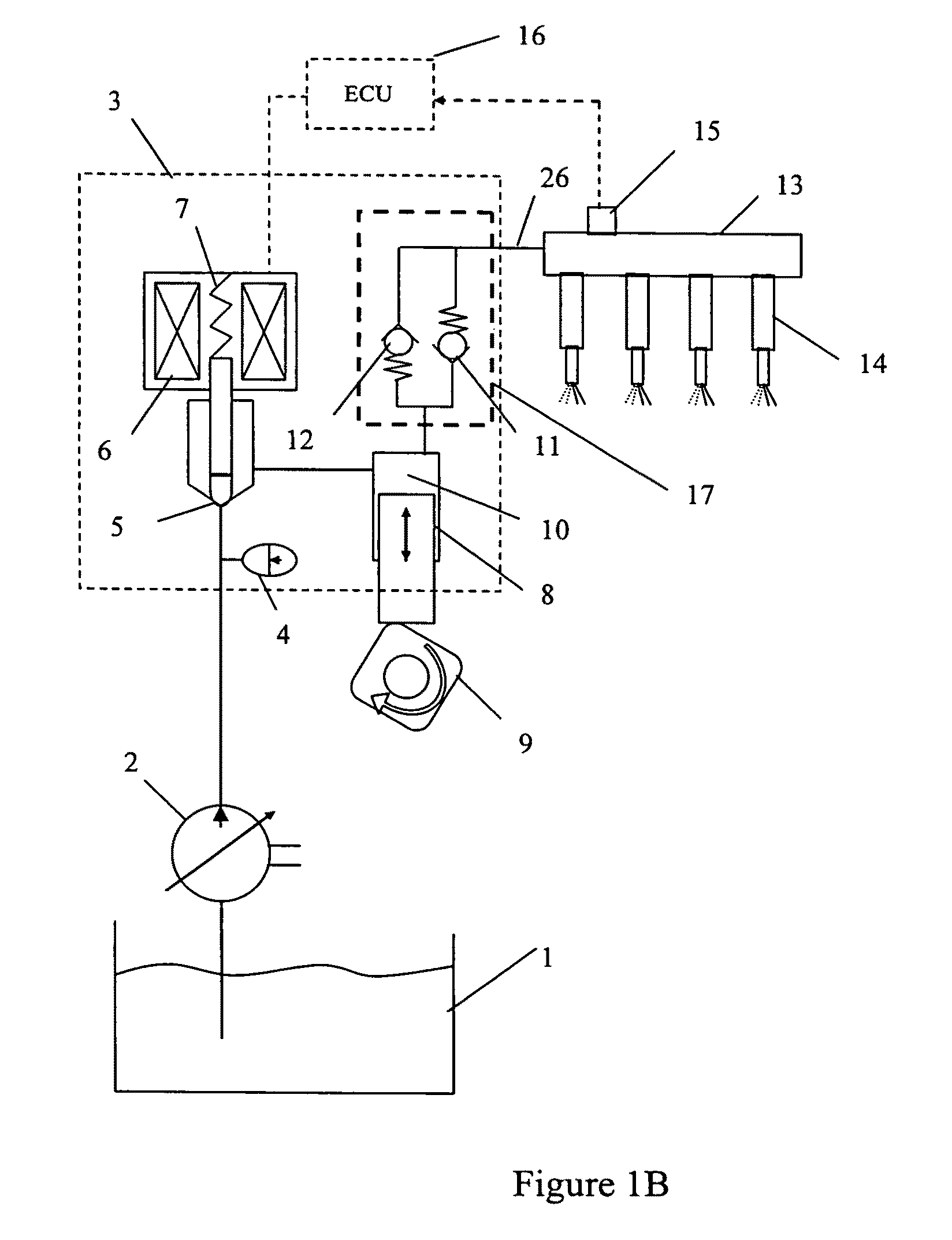

A fuel injection device 1A which includes a common rail 4 for accumulating fuel delivered by a high pressure pump 3B in a pressure-accumulated state, an injector for injecting in a cylinder of the diesel engine fuel supplied through a high pressure fuel supply passage 21 branched from the common rail 4, and an ECU 80A for outputting an injection command signal for injecting the fuel from the injector 5A. The fuel injection device 1A further includes an orifice 75 in the high pressure fuel supply passage 21 on the side of the common rail 4, and a differential pressure sensor SdP for detecting the pressure difference of the pressures on the upstream and downstream sides of the orifice 75. The ECU 80A calculates an actual fuel supply amount that passes the orifice 75 based on a signal from the differential pressure sensor SdP.

Owner:HONDA MOTOR CO LTD

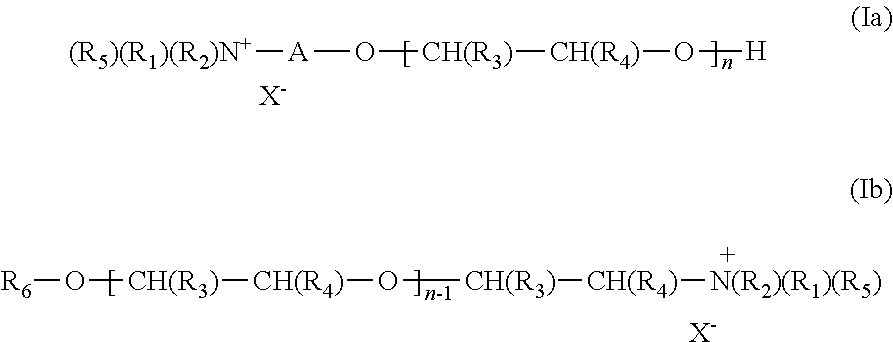

Quaternized polyether amines and their use as additive for fuels and lubricants

InactiveUS20130225463A1Organic compound preparationLiquid carbonaceous fuelsGasoline fuelCommon rail

The present invention relates to novel quaternized polyetheramines and to the preparation thereof. The present invention further relates to the use of these compounds as a fuel and lubricant additive. More particularly, the invention relates to the use of these quaternized nitrogen compounds as a fuel additive for reducing or preventing deposits in the injection systems of direct injection diesel engines, especially in common rail injection systems, for reducing the fuel consumption of direct injection diesel engines, especially of diesel engines with common rail injection systems, and for minimizing power loss in direct injection diesel engines, especially in diesel engines with common rail injection systems. The invention also provides additive packages comprising these polyetheramines; and fuels and lubricants additized therewith. The invention further relates to the use of these quaternized nitrogen compounds as an additive for gasoline fuels, especially for improving the intake system cleanliness of gasoline engines.

Owner:BASF AG

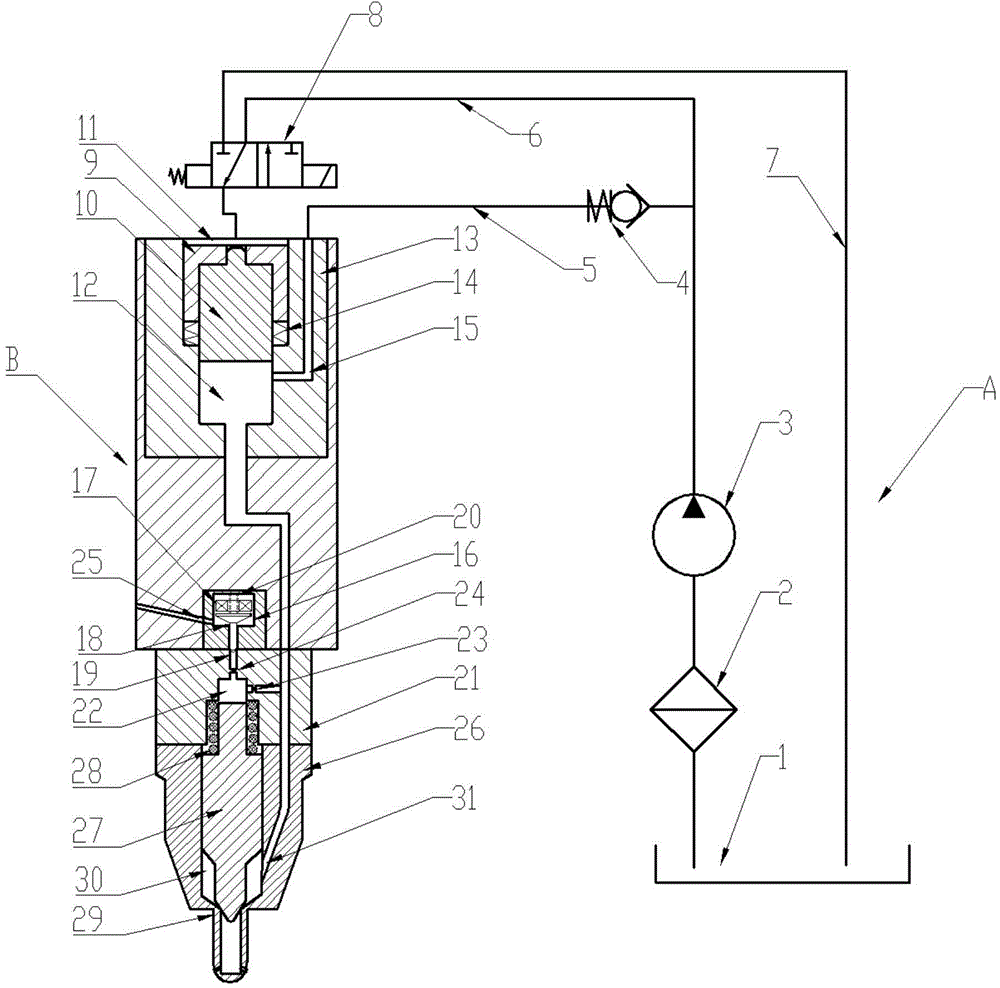

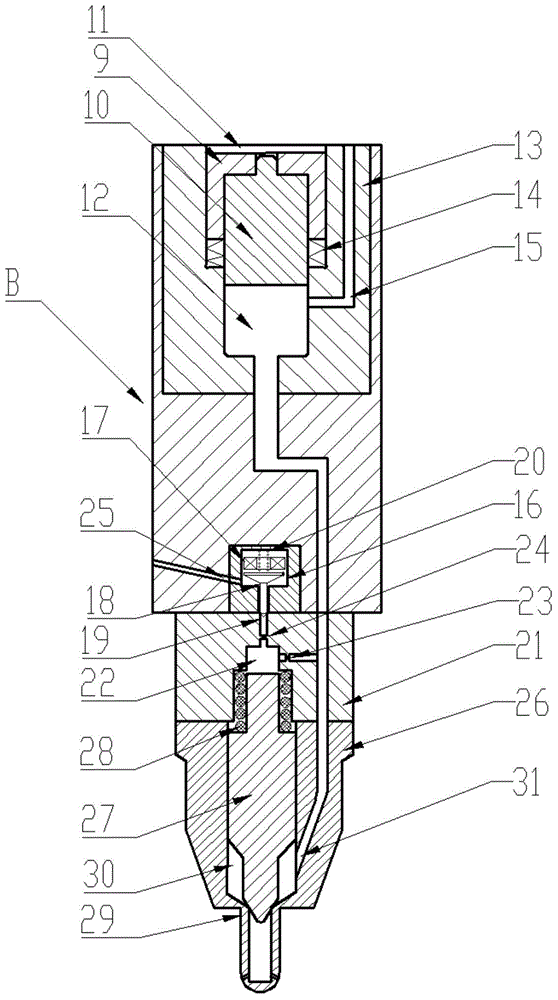

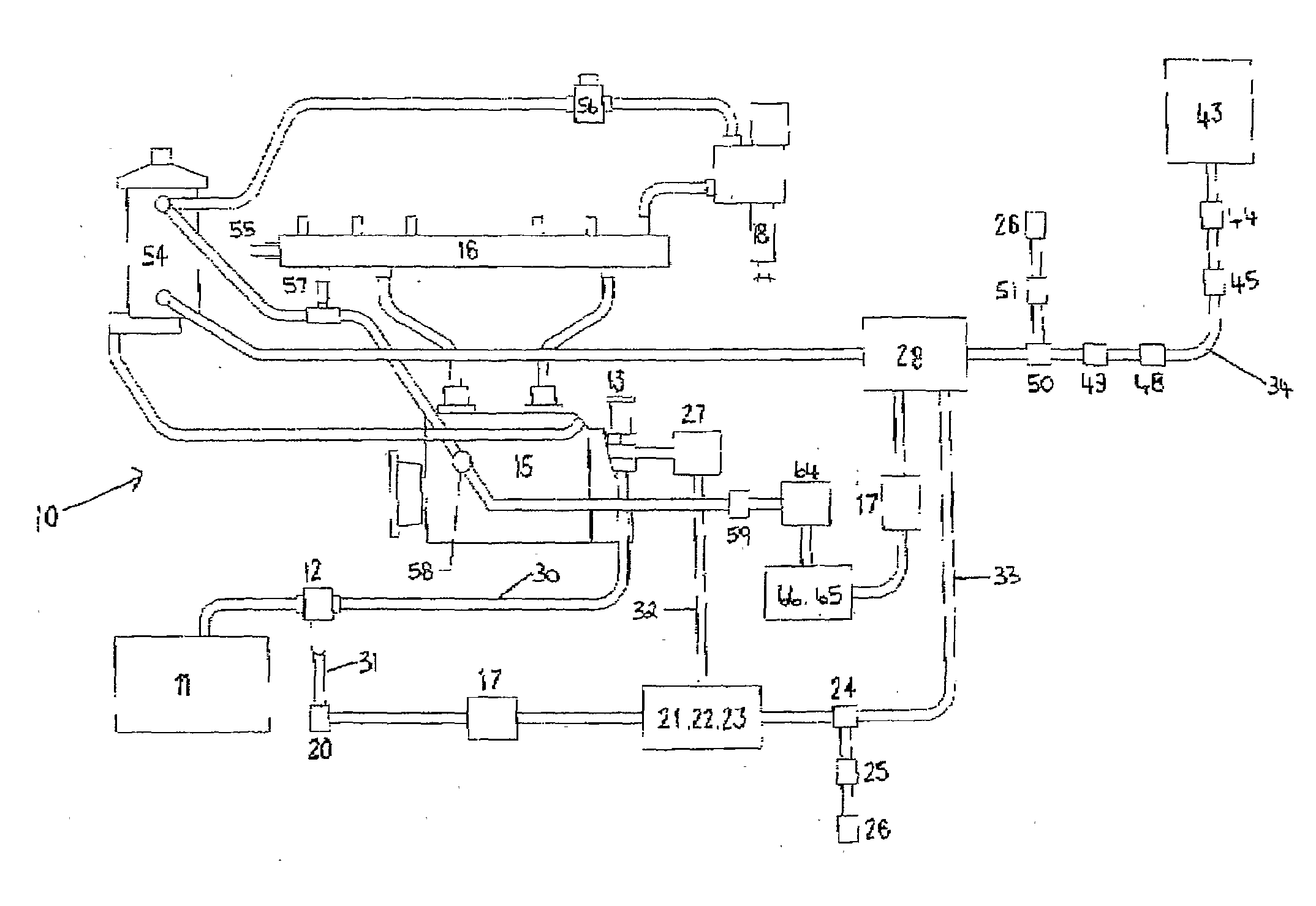

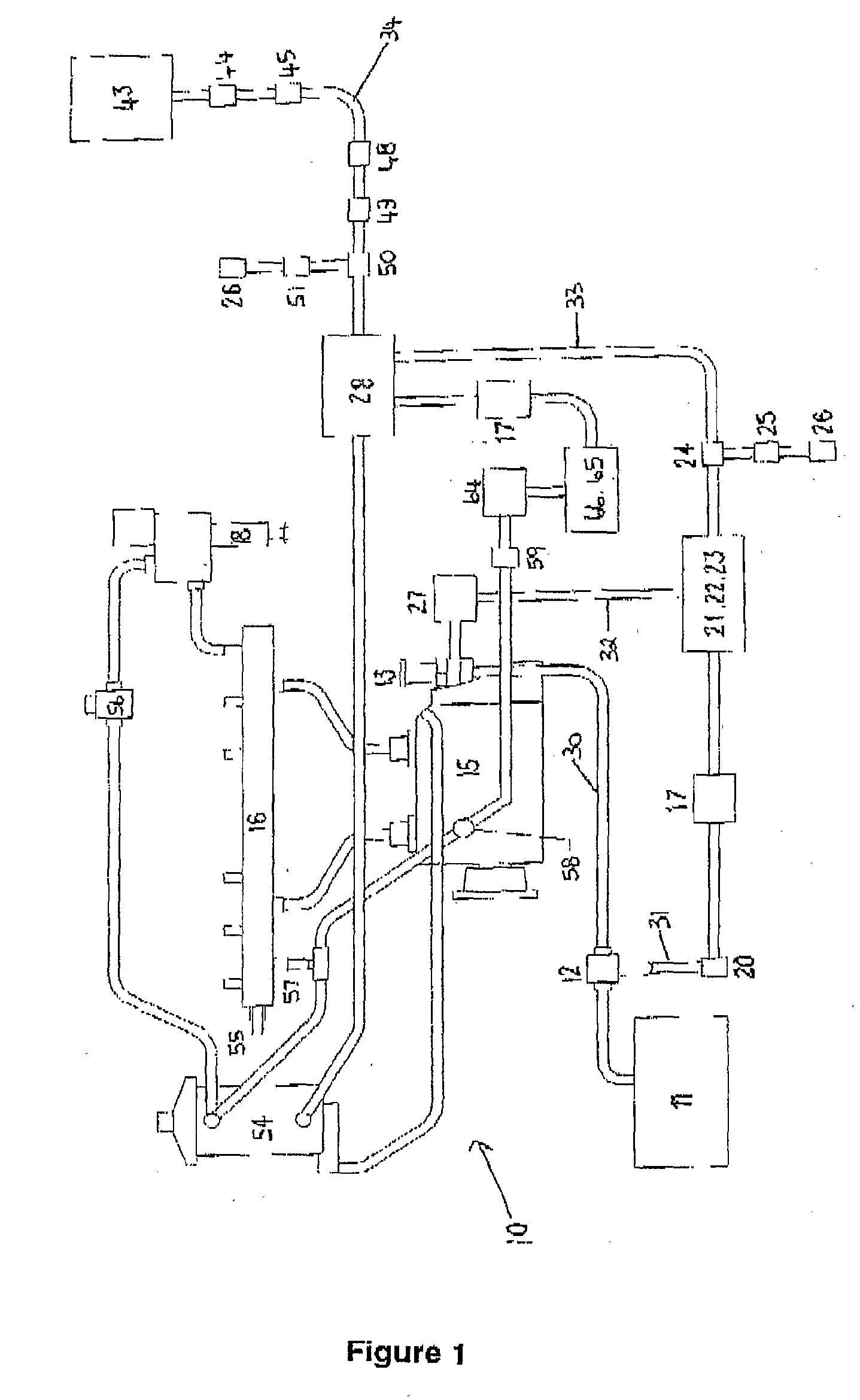

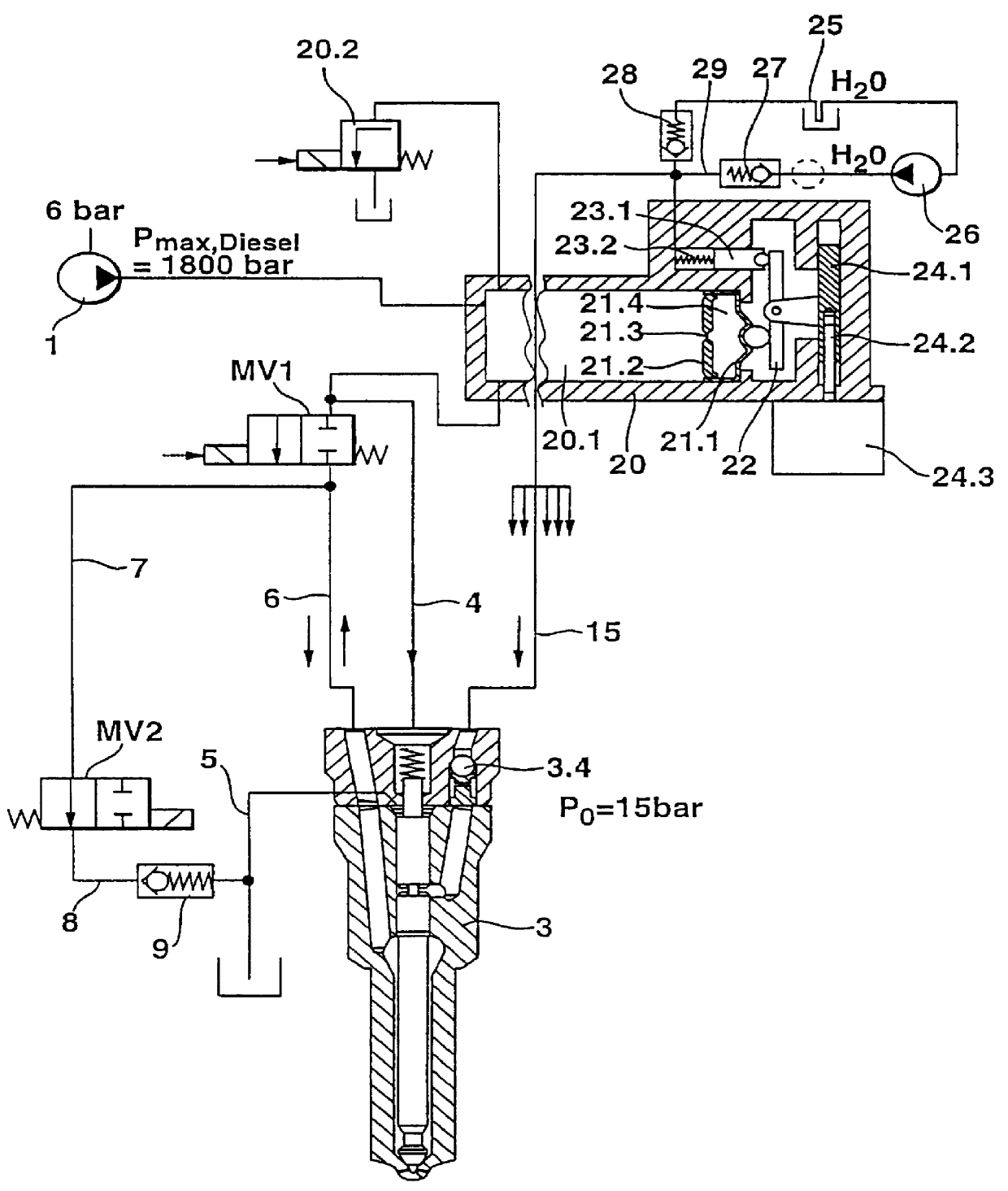

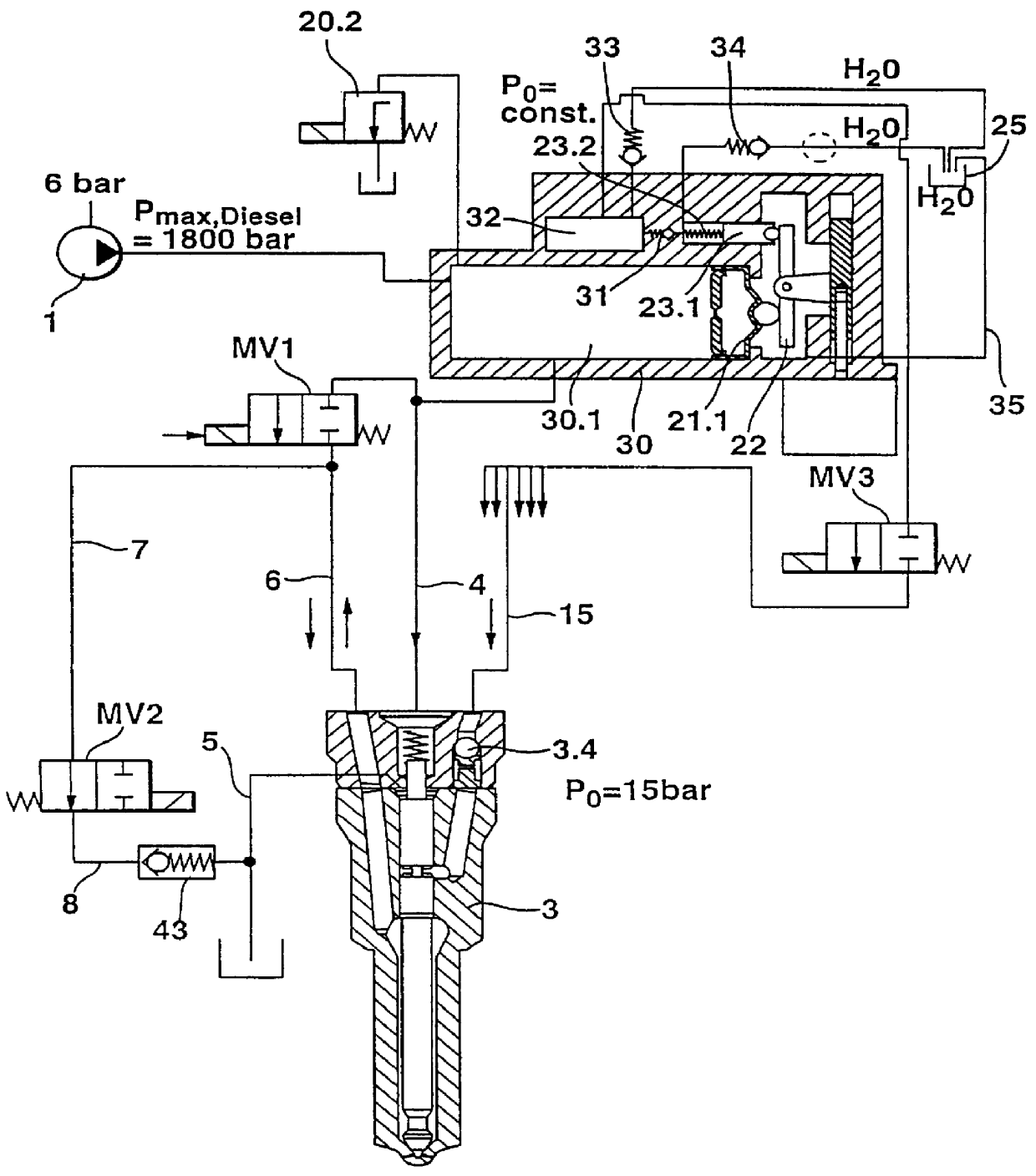

Common-rail fuel oil jet system controlled by double electromagnetic valves and applied to low-speed diesel engine for ship

InactiveCN104632485ASimple structureReduce processing costsFuel injection apparatusMachines/enginesLow speedCommon rail

The invention provides a common-rail fuel oil jet system controlled by double electromagnetic valves and applied to a low-speed diesel engine for a ship. The common-rail fuel oil jet system comprises a fuel oil supply portion and a common-rail jet device. The fuel oil supply portion supplies fuel oil and servo oil to the common-rail jet device. In the common-rail jet device, an upper pressurizing piston cavity and a lower pressurizing piston cavity are formed between a pressurizing piston and a pressurizing piston body, and the pressurizing piston control valve controls the fuel oil supply portion to be communicated or not communicated with the upper pressurizing piston cavity, so that fuel oil pressurization or fuel oil suction is achieved; the electromagnetic fuel oil jet control valve conducts fuel oil-working-condition accurate flexible control over fuel oil jet timing and the circulation jet amount, a pressurized high-pressure fuel oil path in the lower pressurizing piston cavity is divided into two paths, one path reaches a control cavity, and the other path reaches a fuel oil containing groove. According to the common-rail fuel oil jet system, the two electromagnetic valves are used for control, fuel oil is used as fuel and servo oil at the same time, the structure is simplified, cost is reduced, mutual independence between fuel oil pressurization and jet and repeated jet are achieved, fuel oil jet timing, the fuel oil jet rule and the circulating fuel oil jet amount are more accurately controlled, the fuel oil economical efficiency and the emission performance of the diesel engine are improved.

Owner:HUDONG HEAVY MACHINERY +2

Solenoid valve for an electrically controlled valve

InactiveUS6161813APrevent reverberationOperating means/releasing devices for valvesFluid pressure injection controlCommon railSolenoid valve

PCT No. PCT / DE97 / 02723 Sec. 371 Date Oct. 28, 1998 Sec. 102(e) Date Oct. 28, 1998 PCT Filed Nov. 20, 1997 PCT Pub. No. WO98 / 38426 PCT Pub. Date Sep. 3, 1998A solenoid valve comprising a magnet armature which is embodied as having multiple parts and has an armature disk and an armature bolt. The magnet armature is guided in a slider. A damping device is provided in order to prevent post-pulse oscillation of the armature after a closing of the solenoid valve. The required short switching times of the solenoid valve can be exactly maintained with a device of this kind. The solenoid valve is designated for use in injection systems with a common rail.

Owner:ROBERT BOSCH GMBH

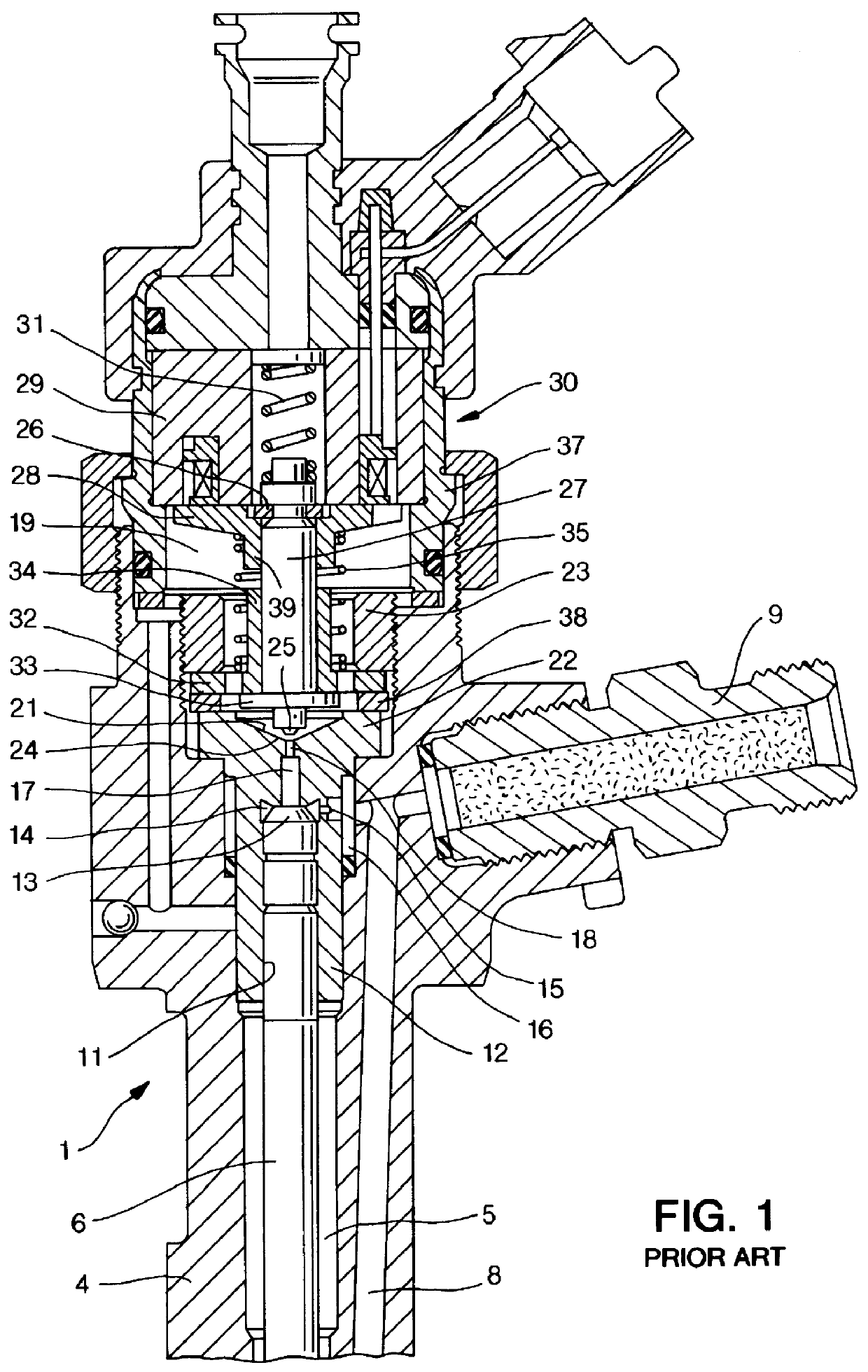

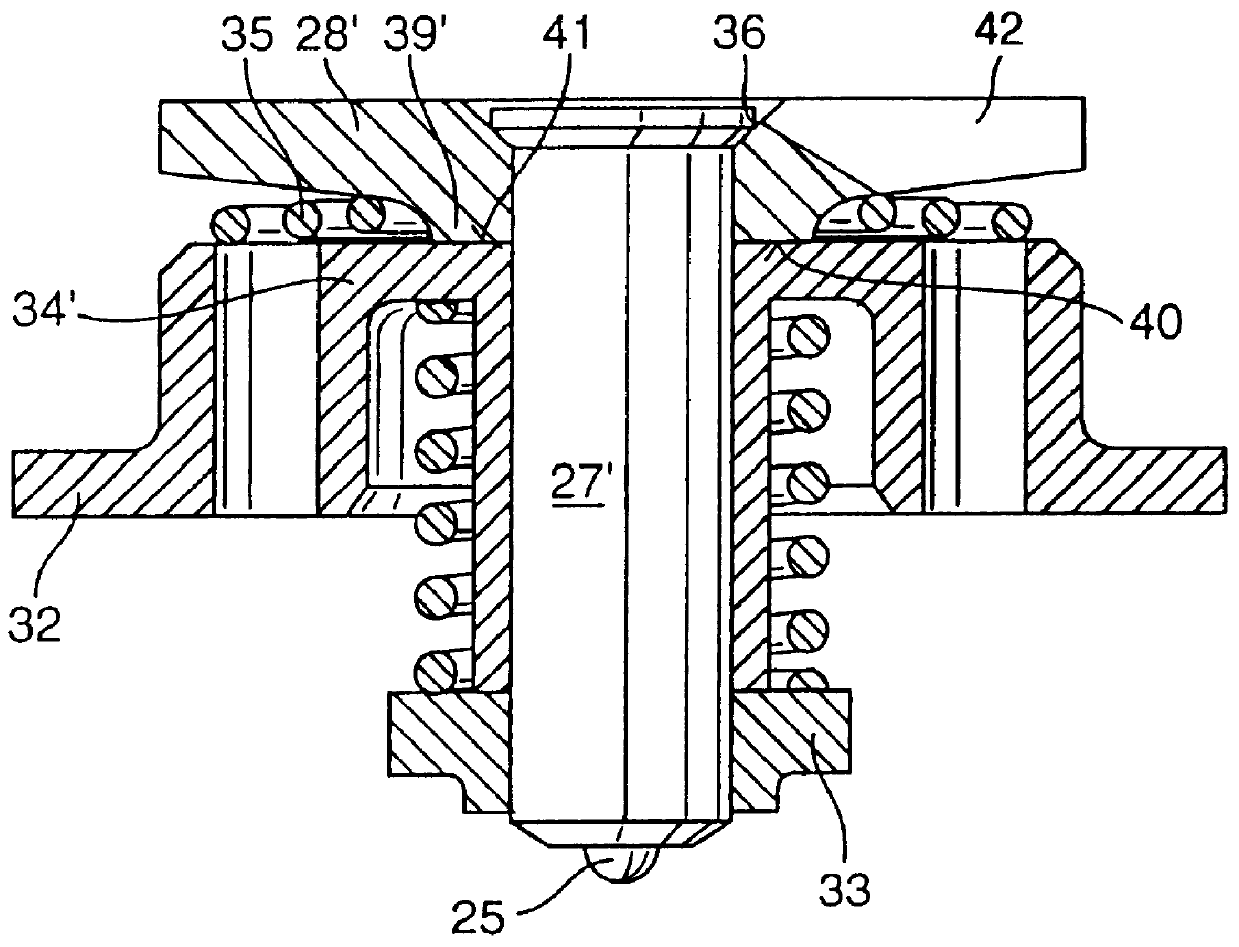

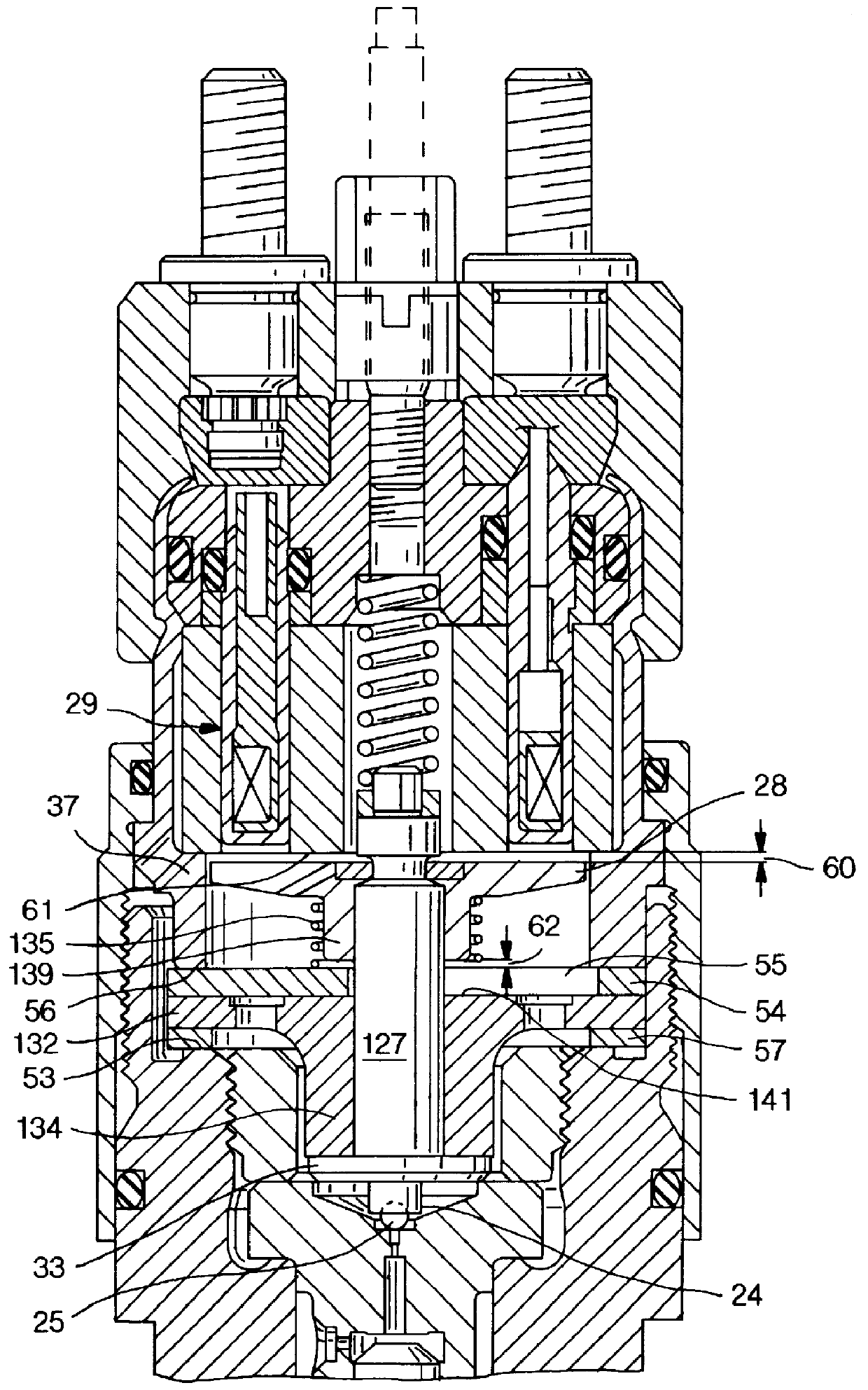

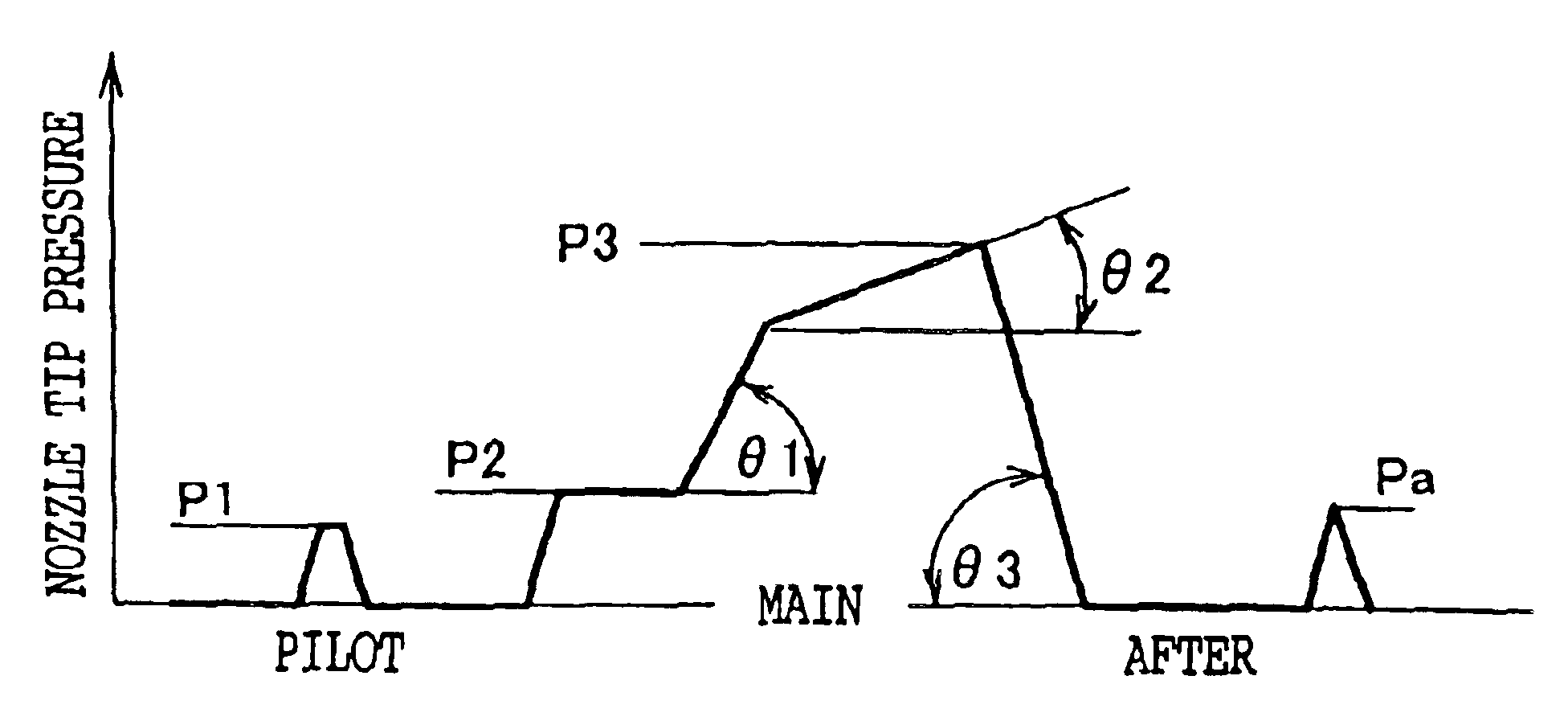

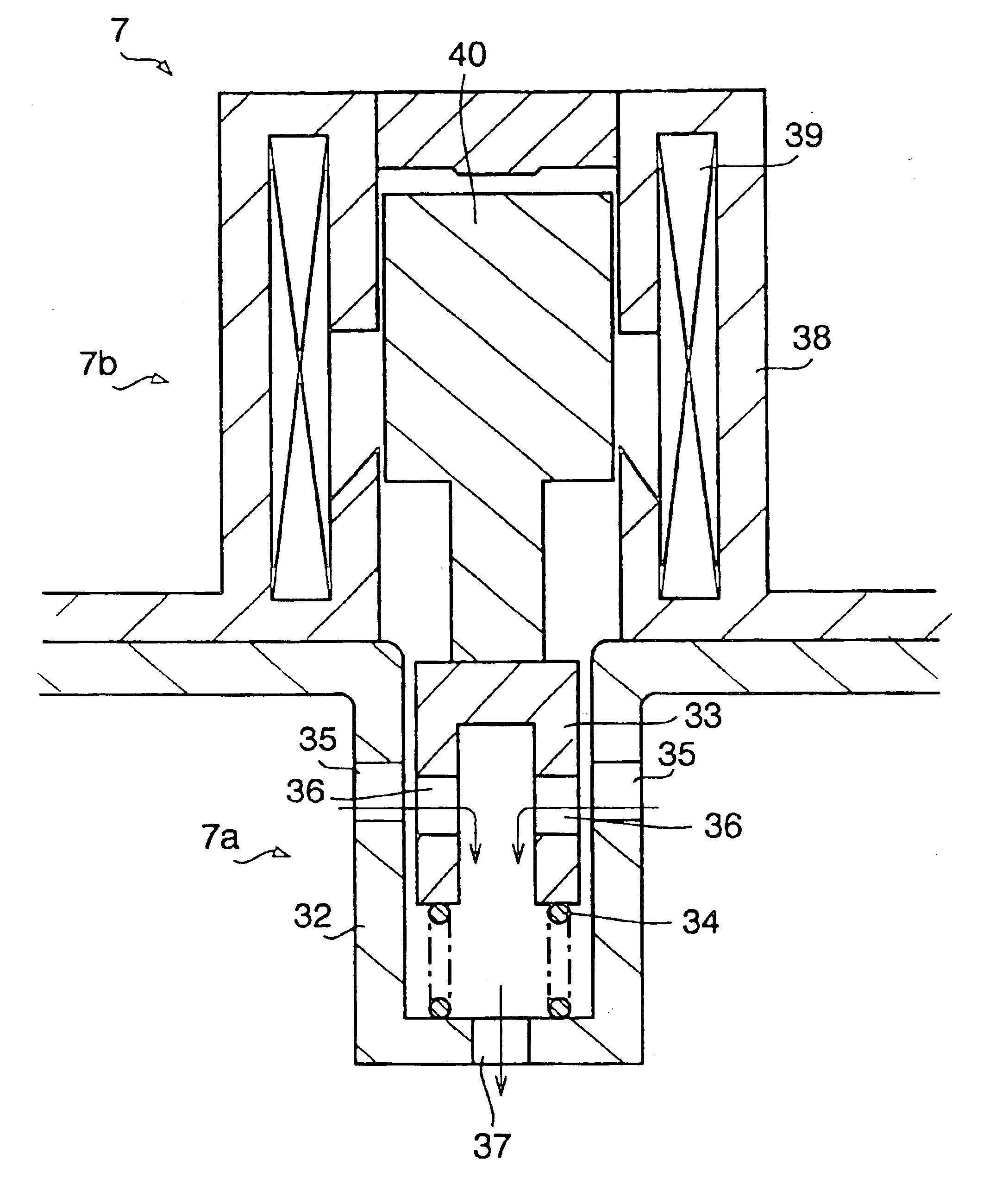

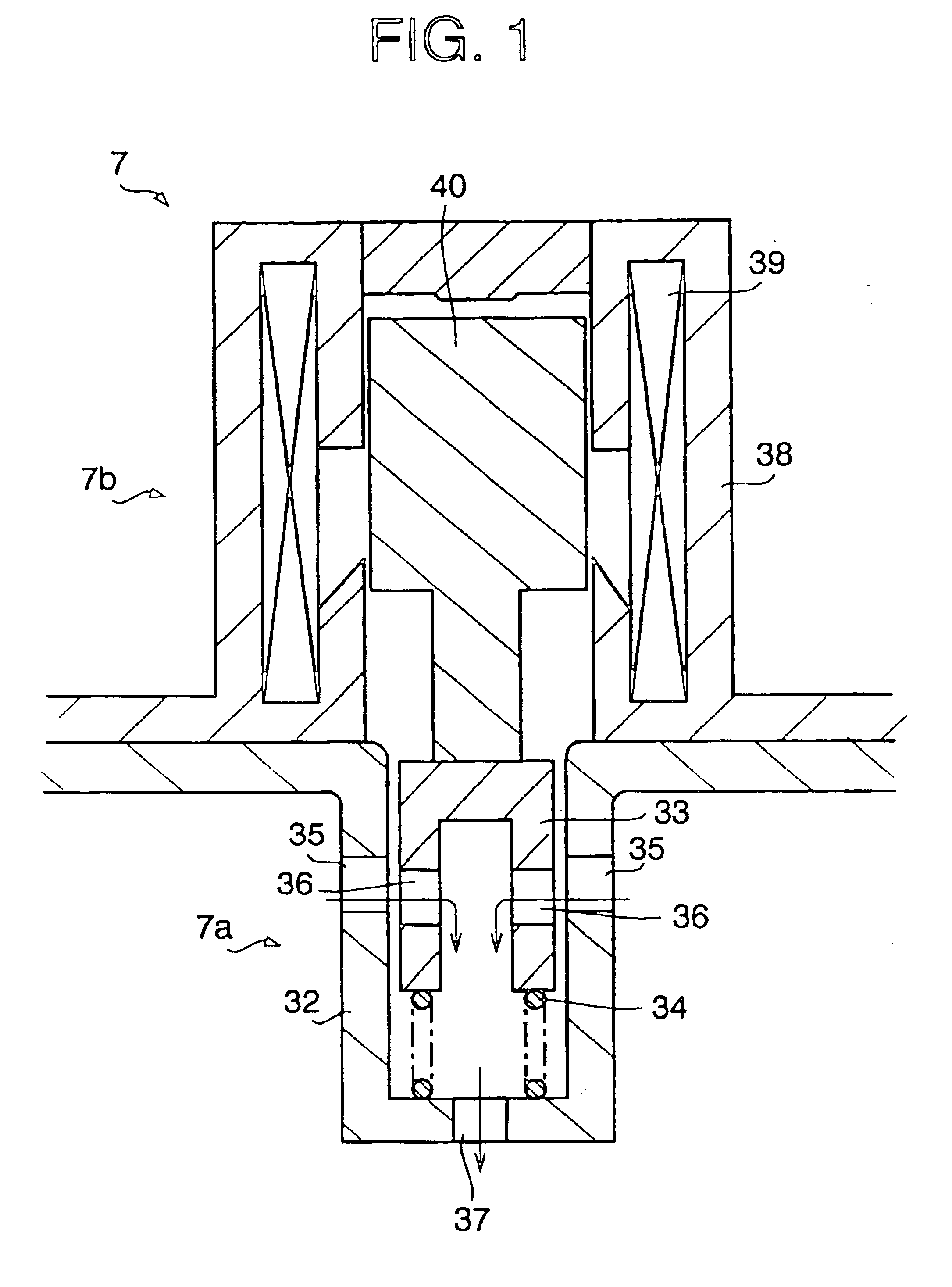

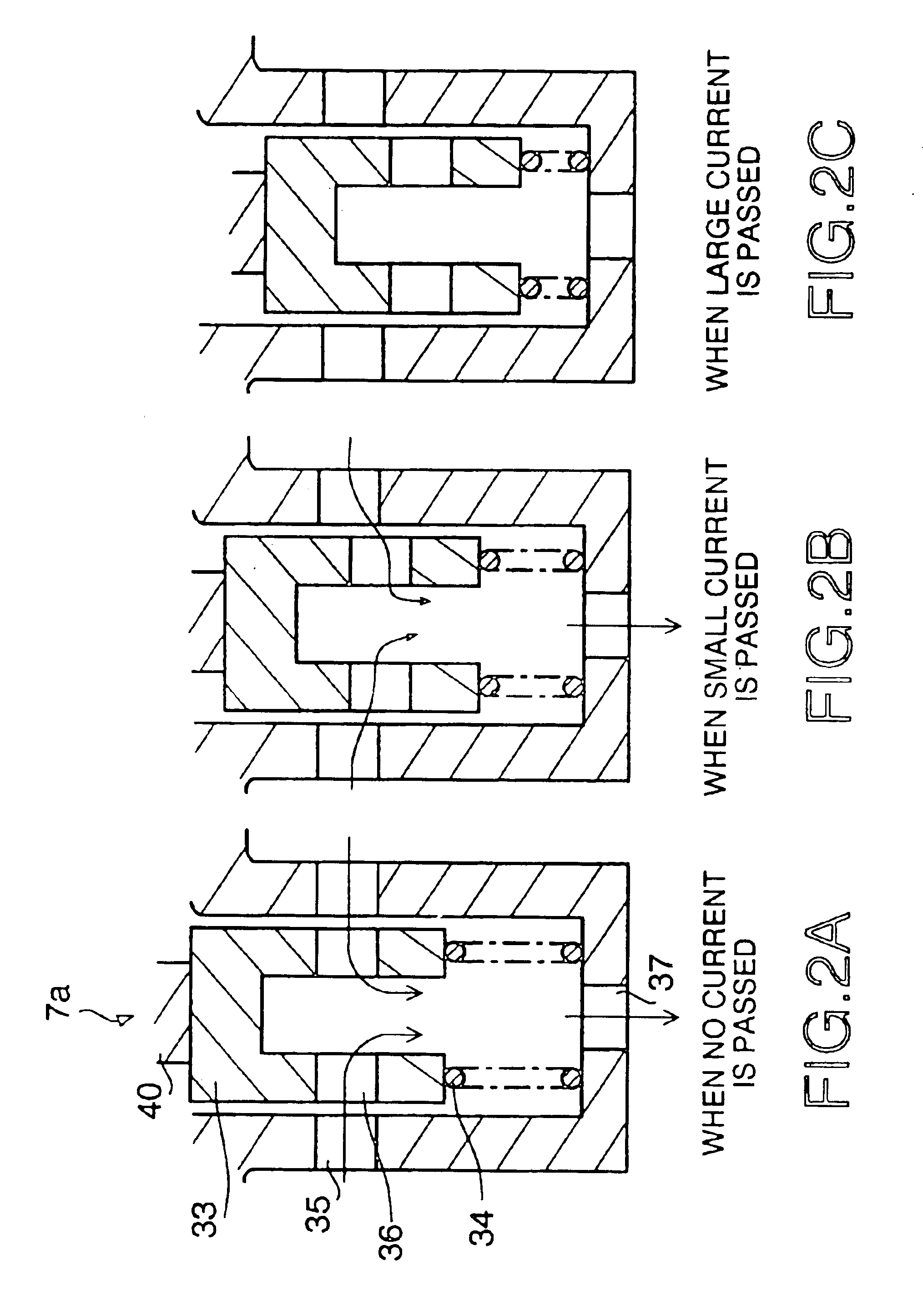

Fuel injection method in fuel injector

InactiveUS6904893B2Increase freedomRealize the structureElectrical controlInternal combustion piston enginesPhase differenceEngineering

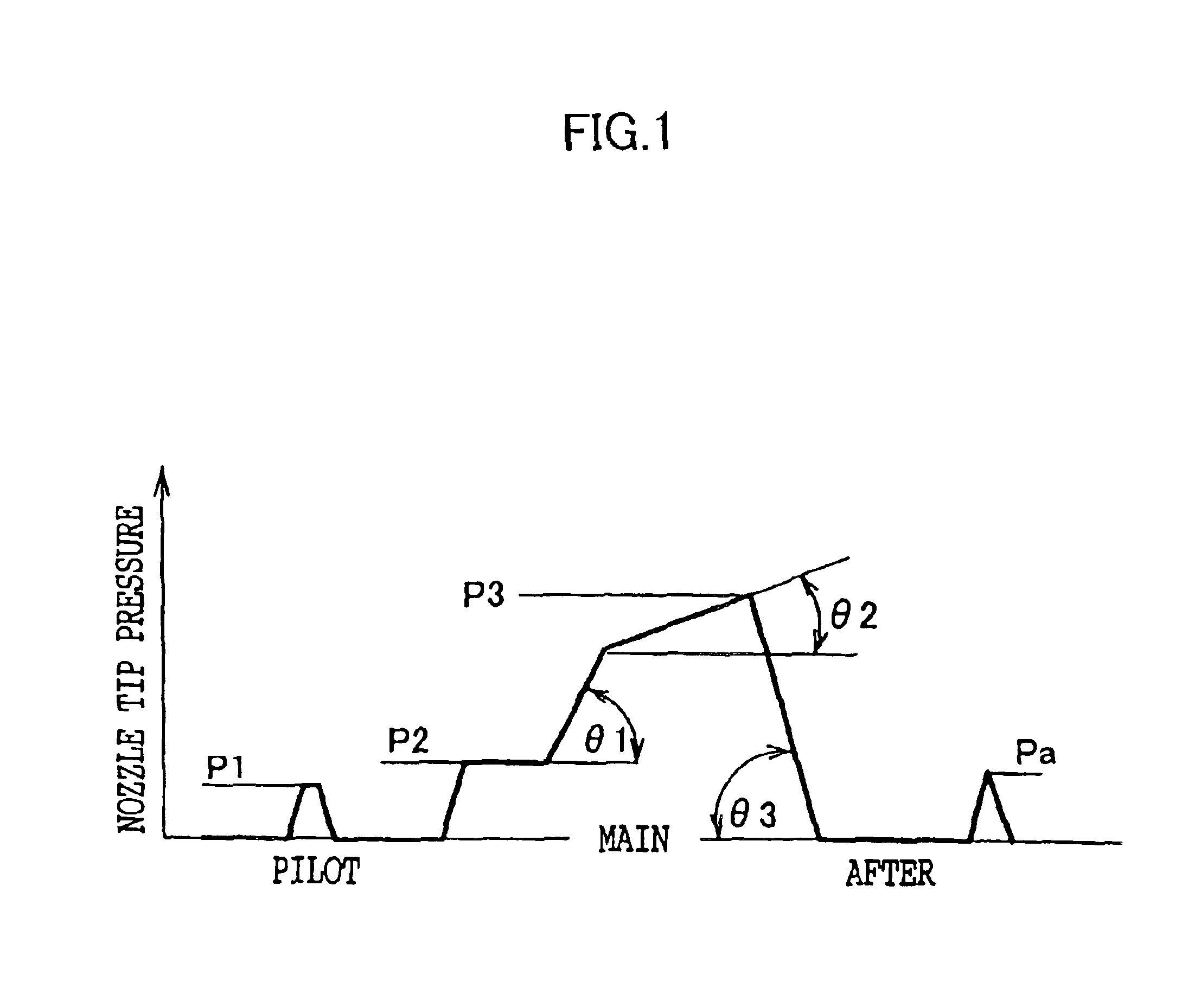

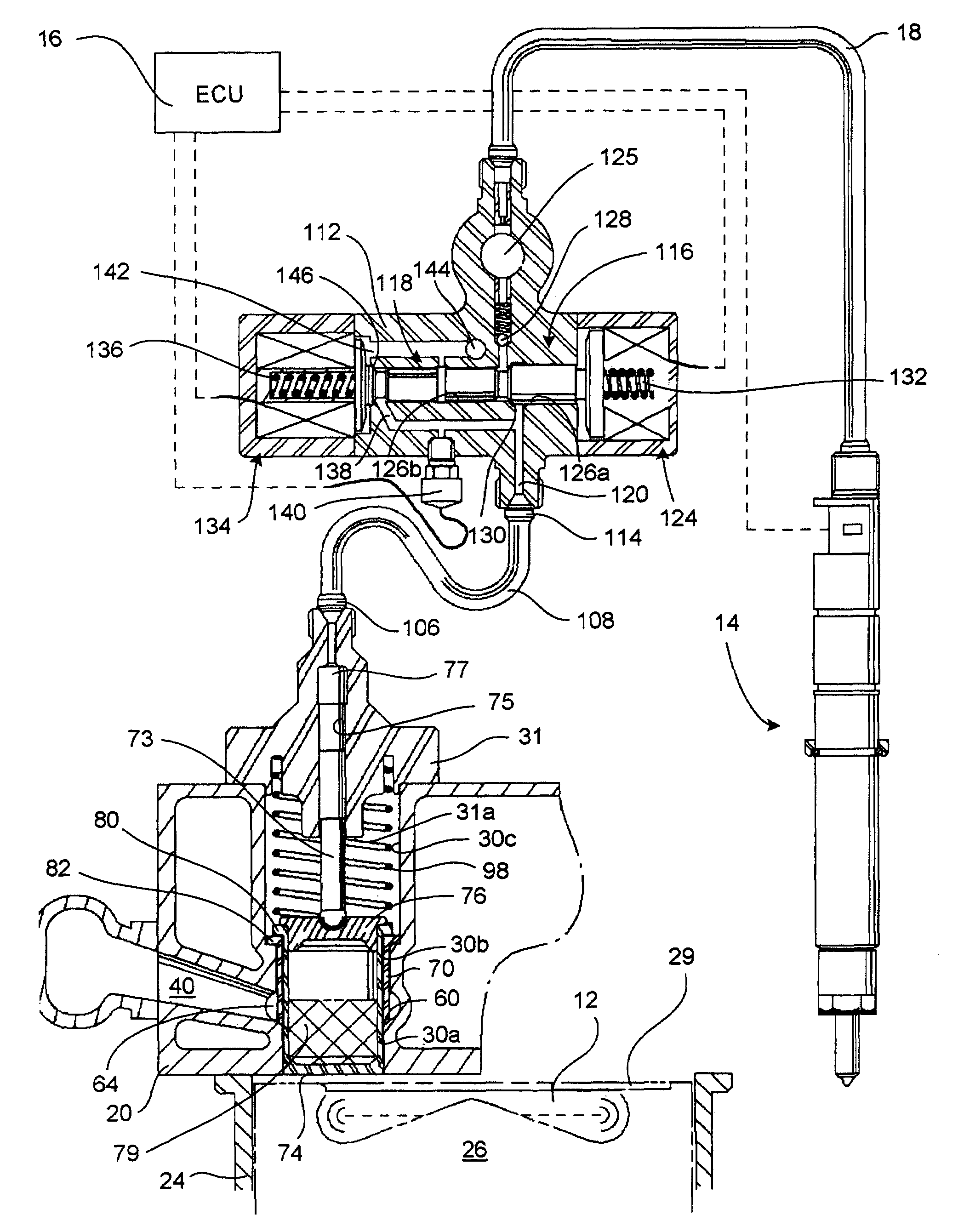

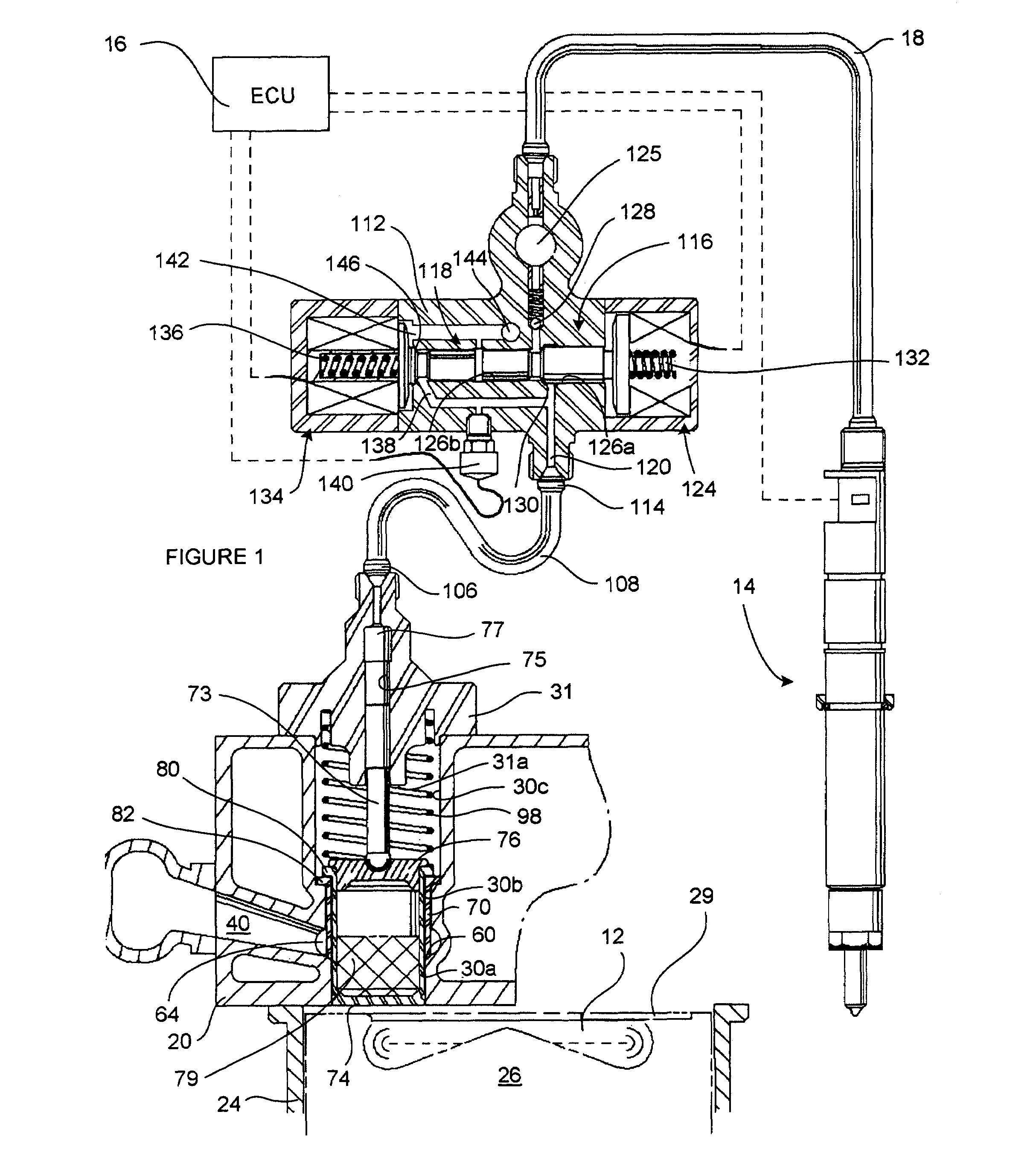

In fuel injector including an accumulator and an intensifier, fuel is injected such that an injection control valve and a piston control valve are individually controlled, an operational phase difference therebetween is regulated, and at least one of a maximum injection pressure, a rate of increase of an injection pressure at the start of an increase of pressure, a rate of decrease of the injection pressure at the completion of injection, a pilot injection pressure, and an after injection pressure of fuel injected from a fuel injection nozzle is arbitrarily changed. Namely, a pressure during a movement from a base common rail pressure of the accumulator to a static maximum pressure statically determined by an operation of the intensifier is positively used as a control factor of injection, whereby a fuel injection pattern can be implemented with an extremely high degree of freedom.

Owner:TOYOTA JIDOSHA KK

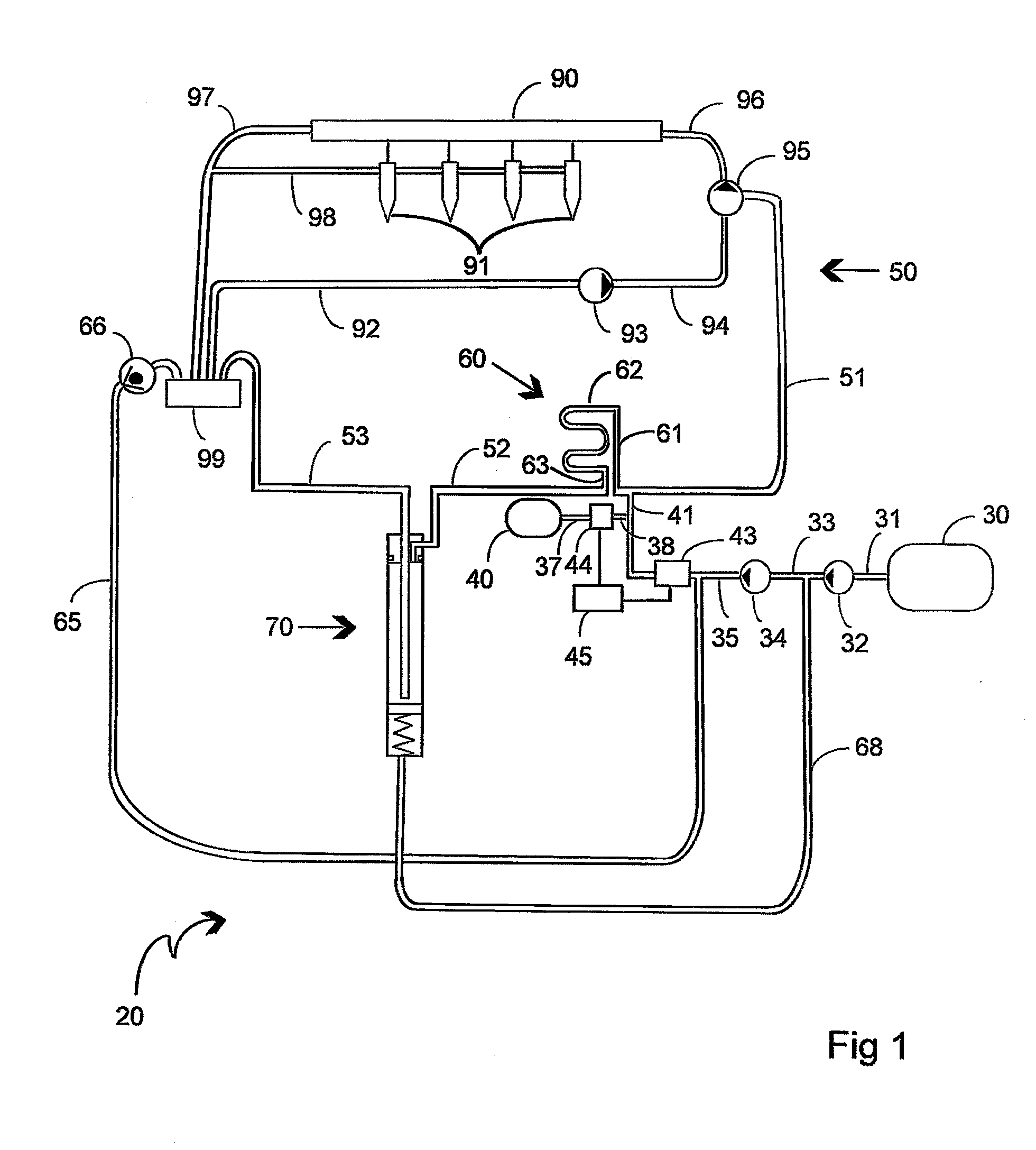

Exhaust valve arrangement and a fuel system incorporating an exhaust valve arrangement

InactiveUS7533656B2Small diameterSecure attachmentMachines/enginesFuel injecting pumpsCombustion chamberExhaust valve

Owner:DELPHI INT OPERATIONS LUXEMBOURG S A R L

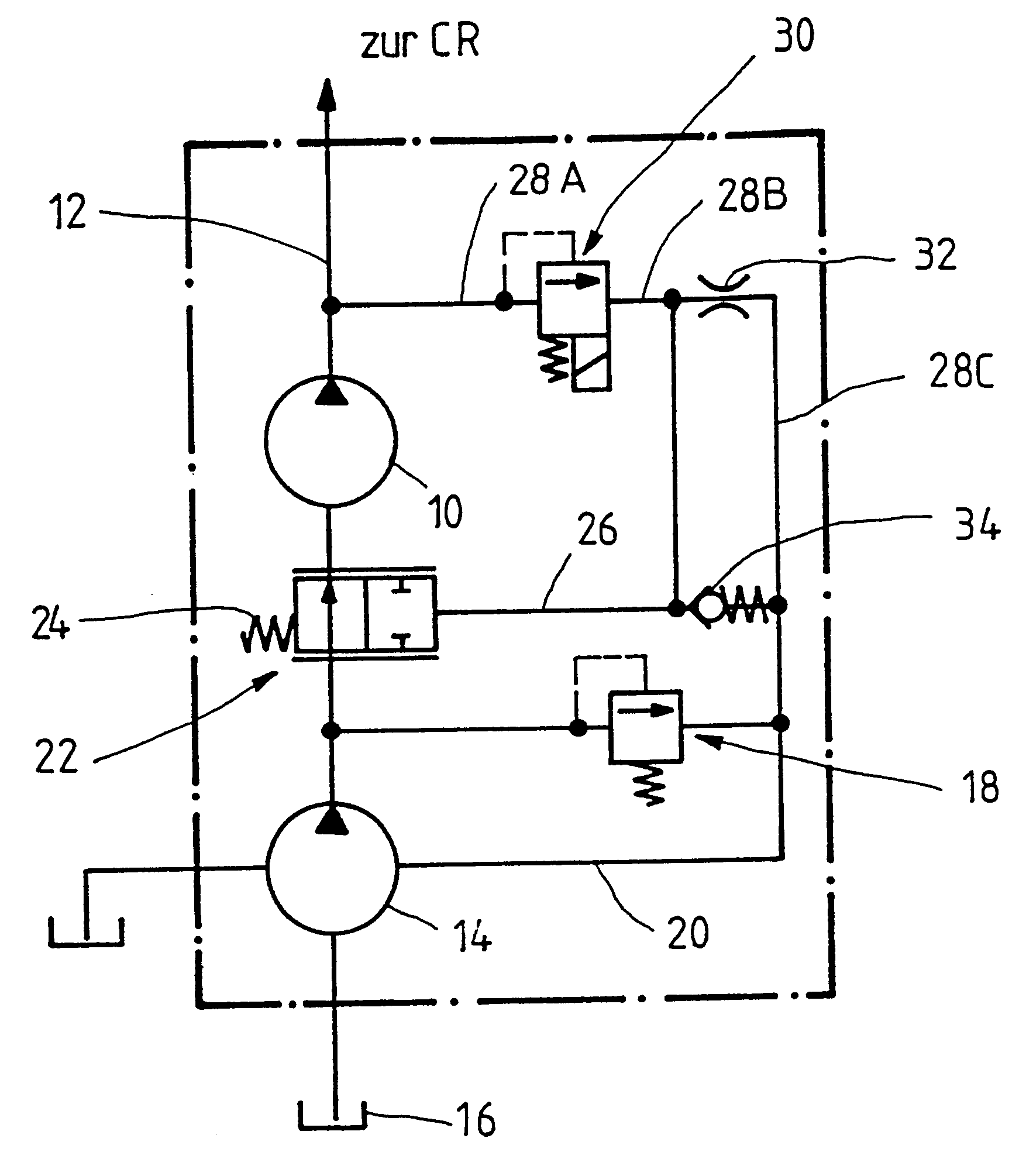

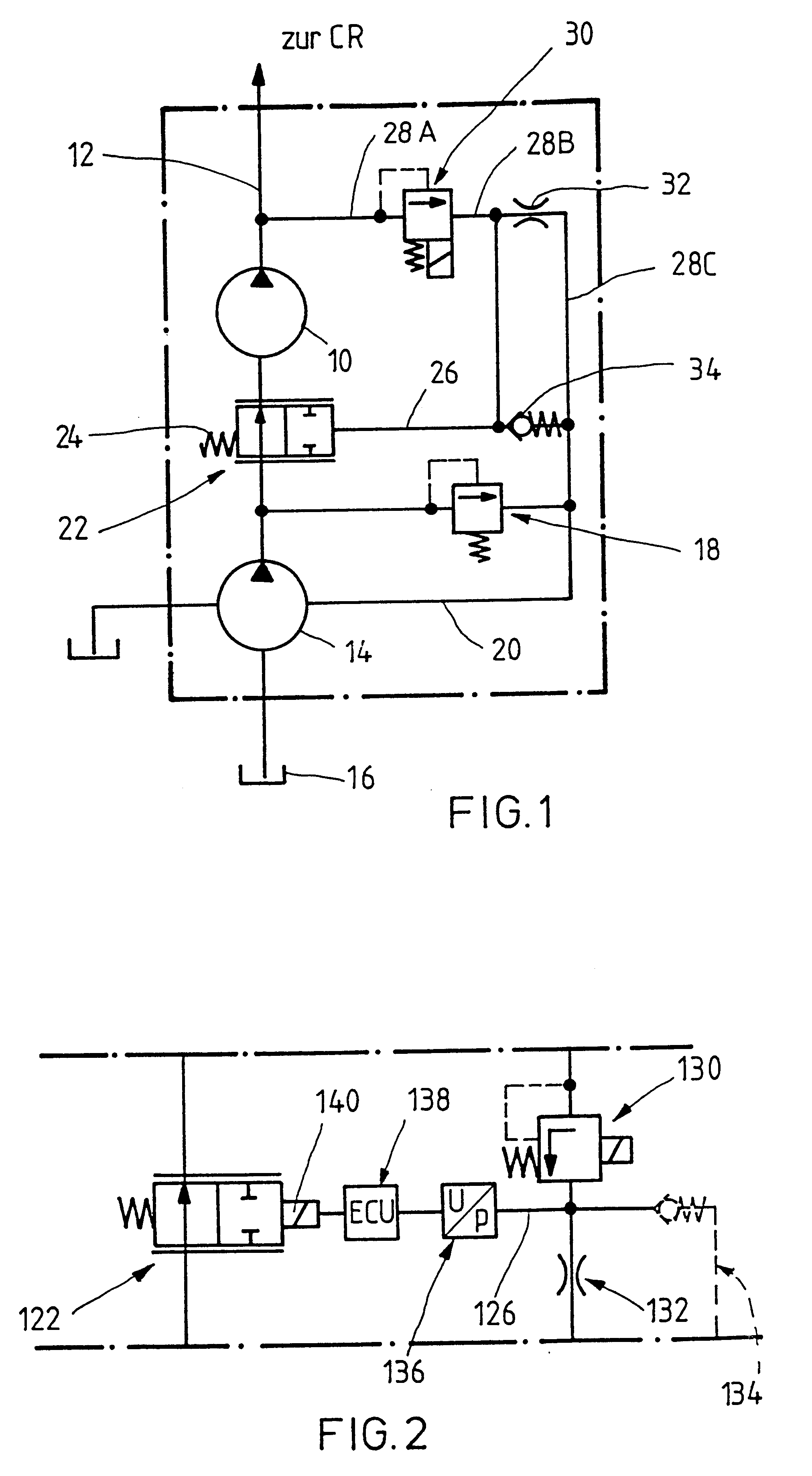

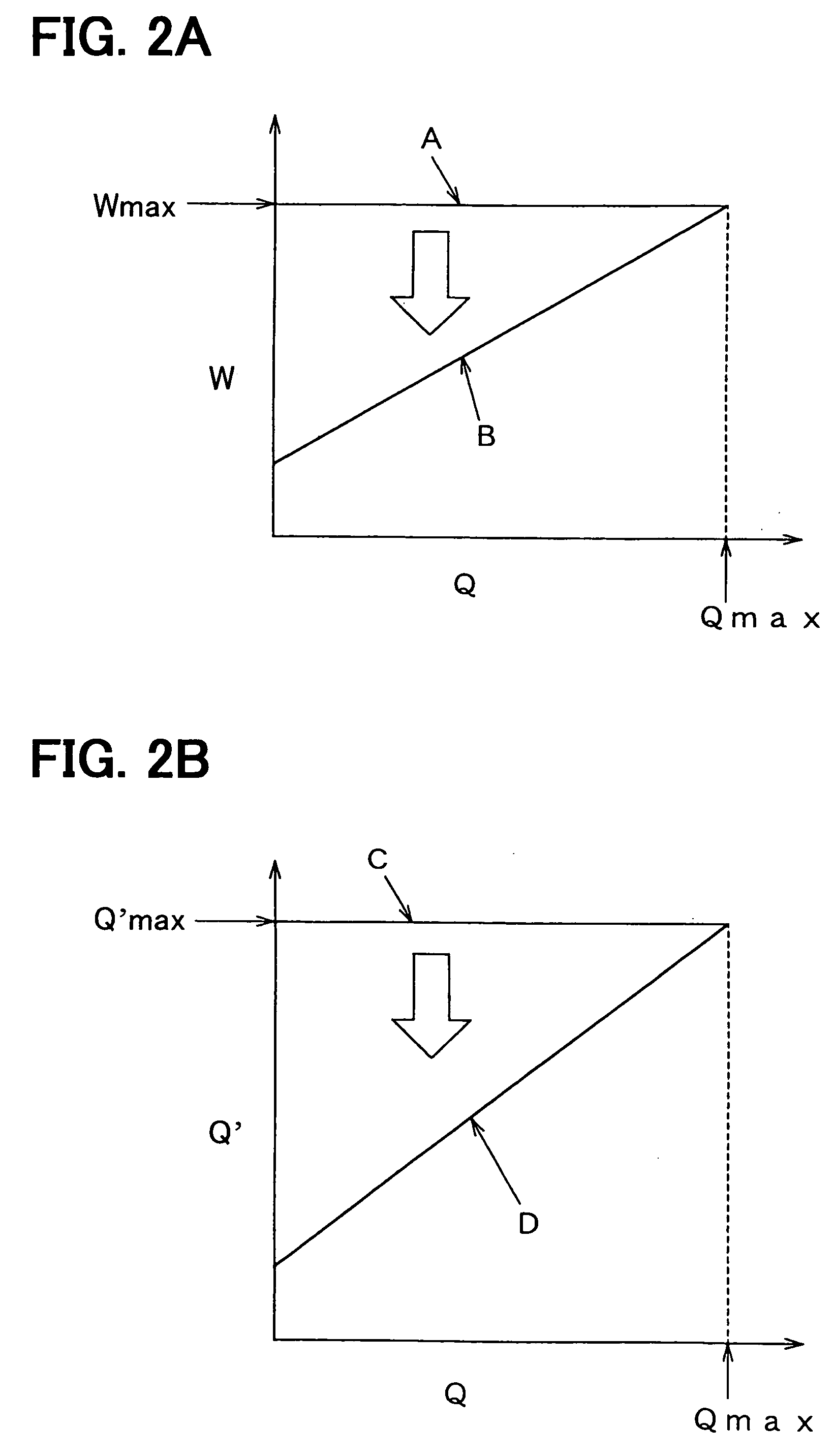

Control for a fluid pressure supply system, particularly for high pressure in a fuel injection system

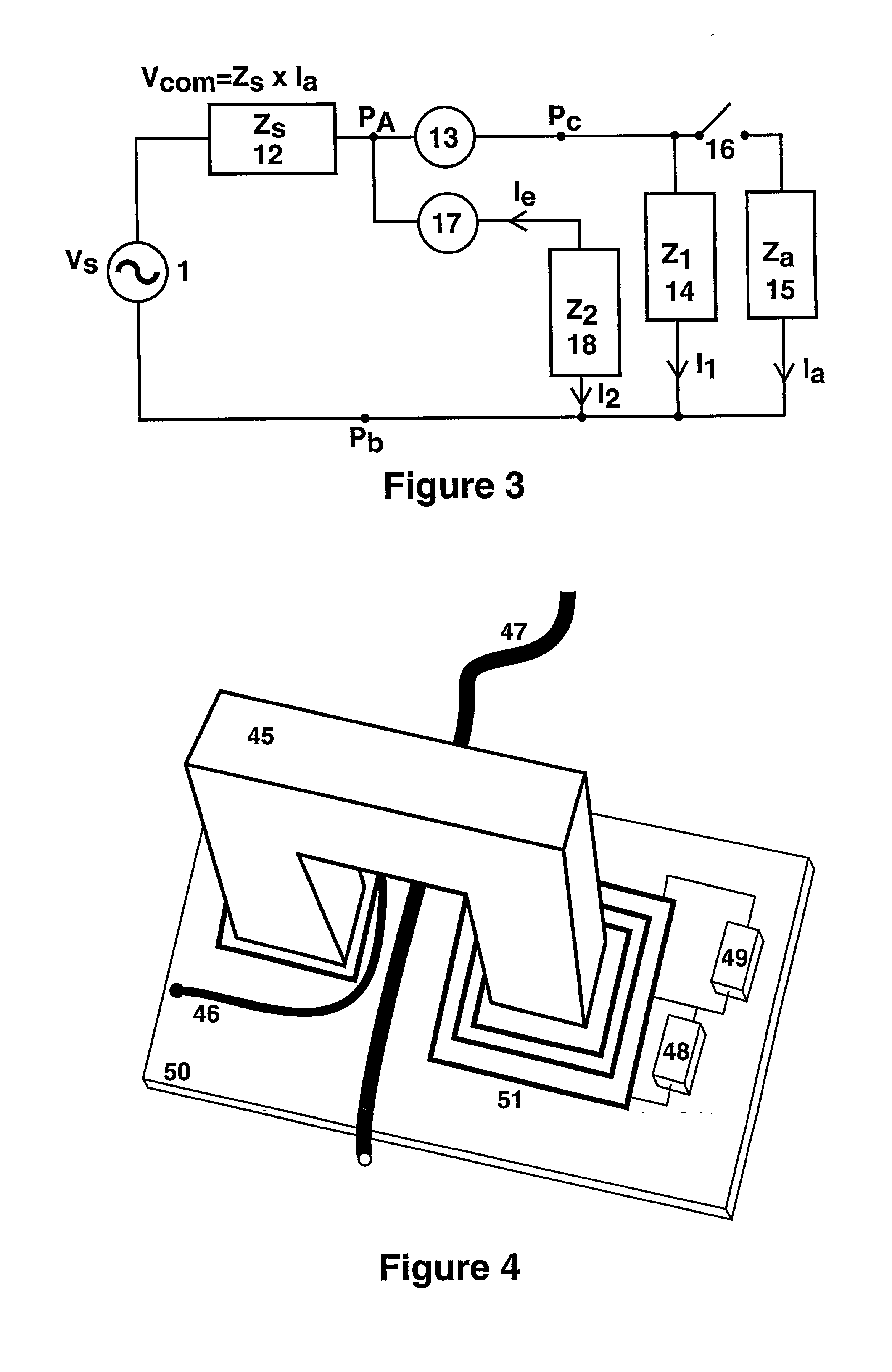

InactiveUS6293253B1Control system can be kept considerably shorterReduce energy lossFluid parameterElectrical controlEngineeringThroughput

A control for a pressure fluid supply system is described, in particular for the high pressure in a fuel injection system, for example for an internal combustion Diesel engine, by means of which the pressure in a common high-pressure line supplied by a high-pressure pump, i.e. in the common rail, to which individual consumers are connected, is controlled in accordance with the instantaneous pressure fluid requirements. For adapting the pressure in the common high-pressure line to the pressure fluid requirements of the consumers, i.e. the injection nozzles, a device for limiting the amounts of fluids conveyed is associated with the high-pressure pump, which has at least on adjusting element which can be changed by means of an adjusting signal representing the instantaneous pressure fluid supply situation in the common rail. To avoid an elaborate pressure sensor device in the common rail and for the simultaneous improvement of the reaction behavior of the control, in particular when reducing the high pressure in the common rail, the adjusting signal is derived from the amount of fluid throughput in the delivery line of a pressure control valve connected to the common rail. The pre-conveying pressure or the pre-conveying amount available to the high-pressure pump is affected by means of this adjusting signal in the sense of a regulation of the pressure in the common rail.

Owner:CONTINENTAL AUTOMOTIVE GMBH

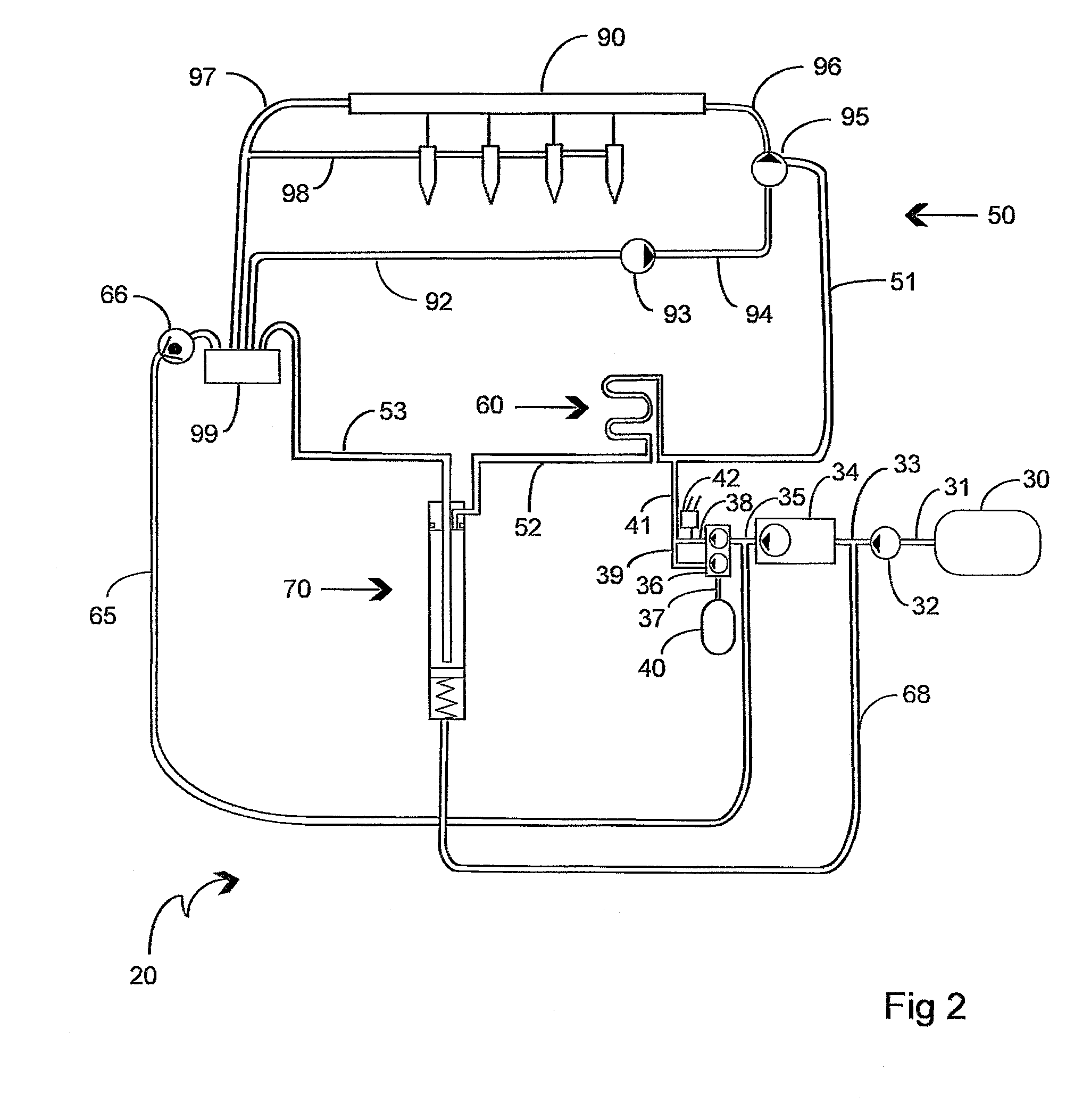

Fuel injection method and device for engines

InactiveUS6102009AInhibit deteriorationIncrease blockingElectrical controlInternal combustion piston enginesCommon railElectrical and Electronics engineering

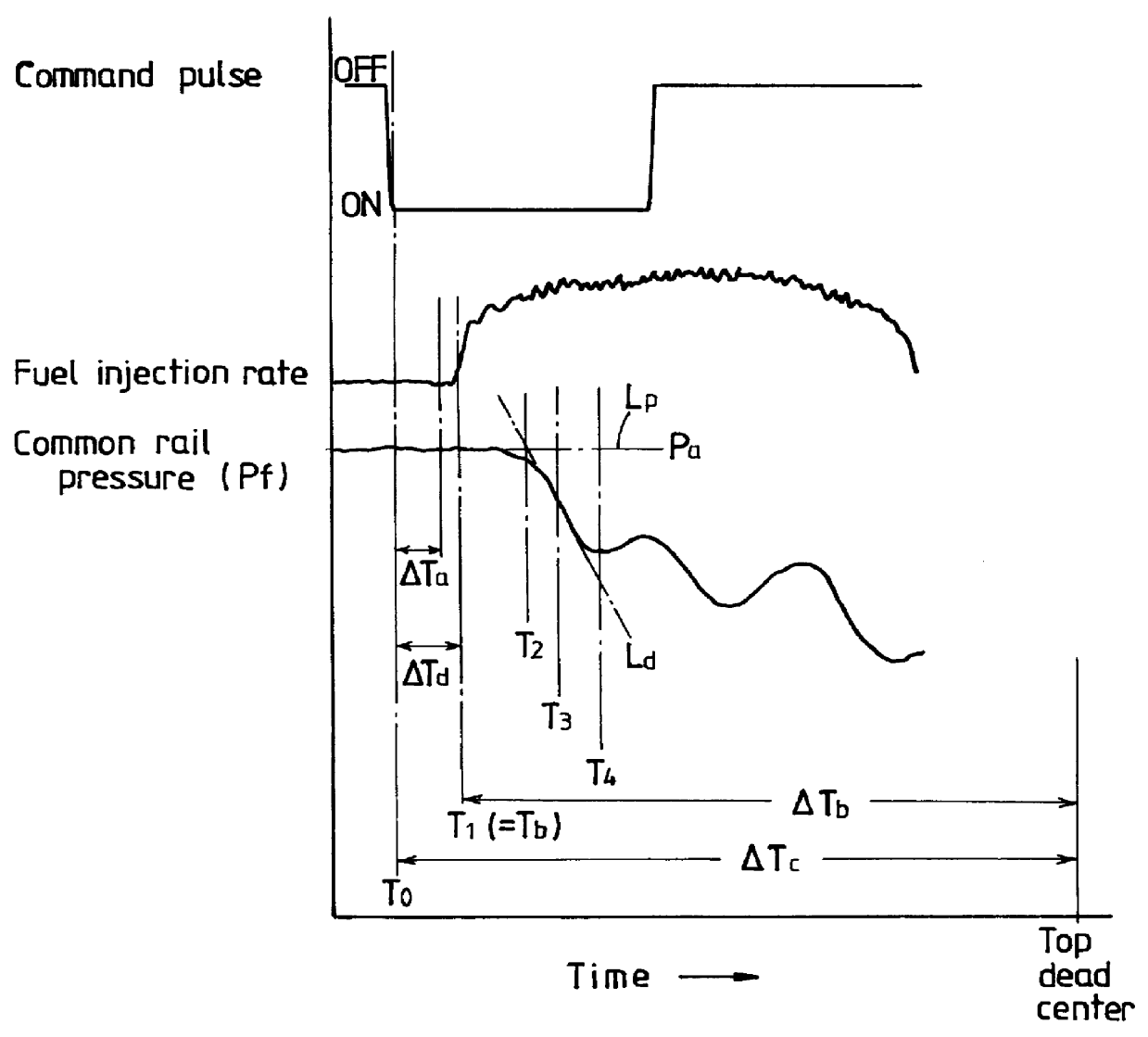

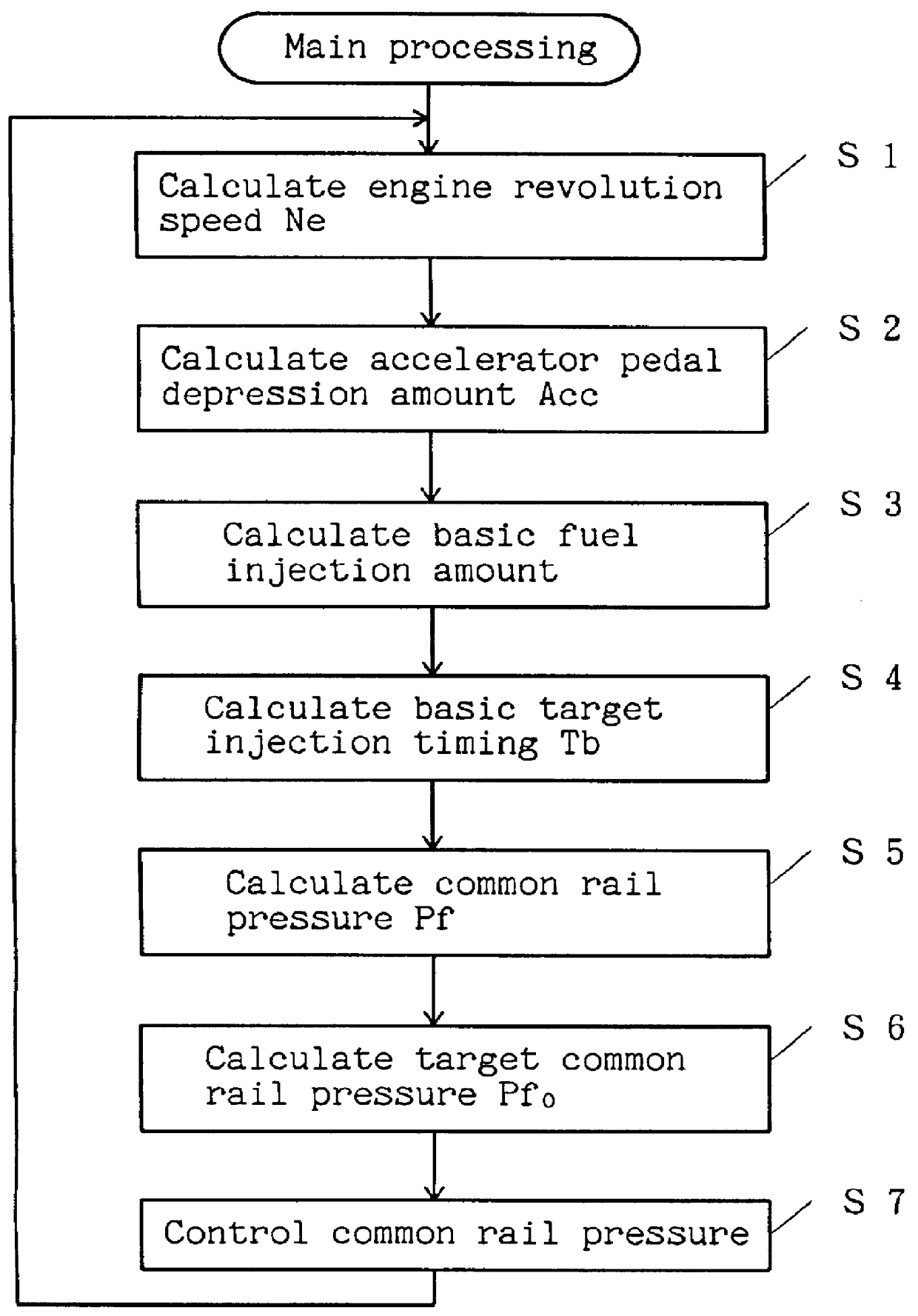

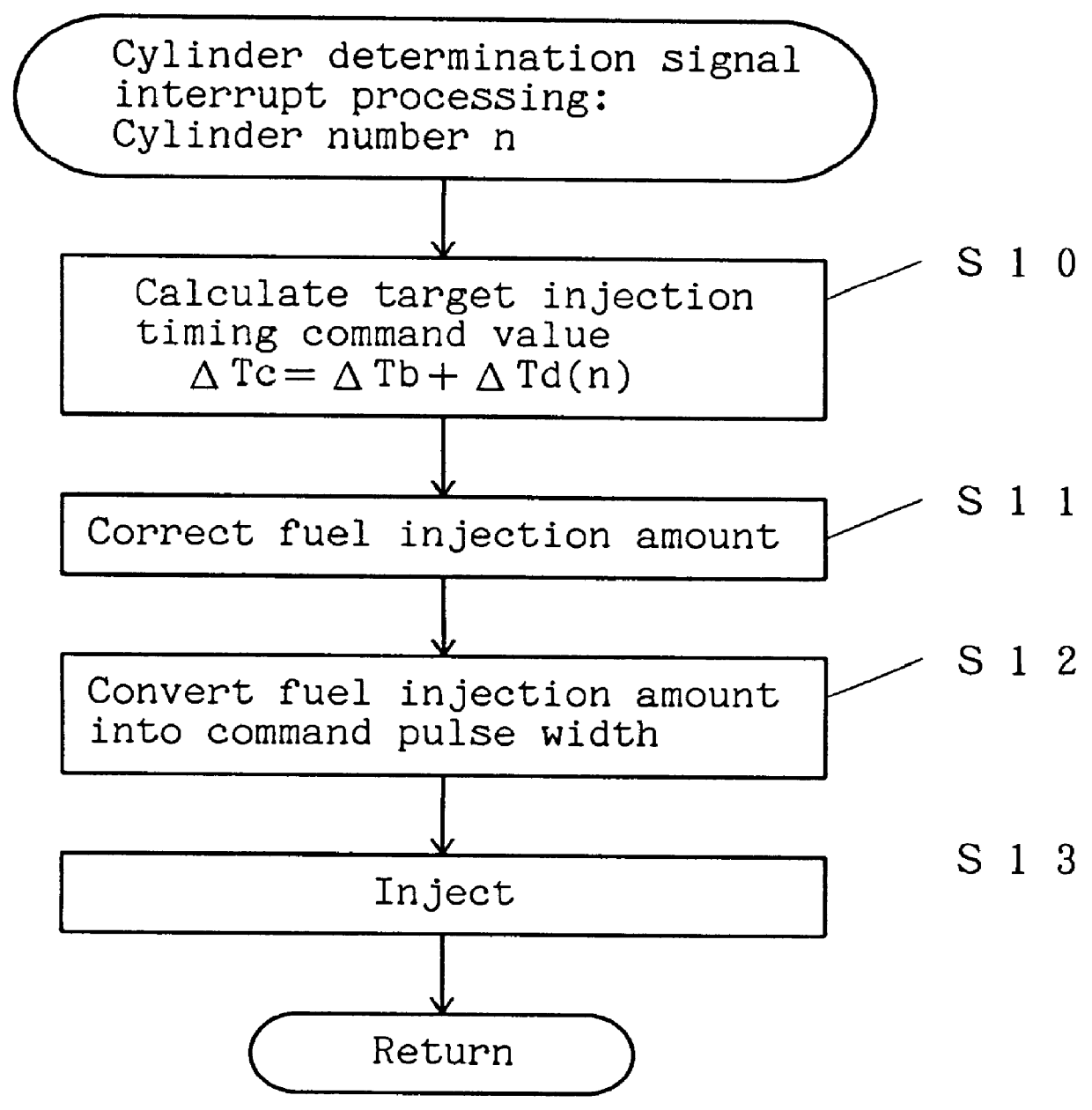

This invention determines the output timing of the injection command signal to each of the injectors so that the fuel injection timing agrees with the basic target injection timing even when there are variations in the fuel injection timing among the injectors, and thereby improves the exhaust emission performance of the engine. The time T2 of an intersection between the straight line Lp representing an average Pa of the common rail pressure before it starts to fall and the first-degree approximation straight line Ld having a maximum inclination of fall of the common rail pressure is determined as the timing at which the common rail pressure starts to fall. Based on the time T2 and the average pressure Pa, the delay time DELTA Td which elapses from the output timing T0 of the injection command signal to each of the injectors to the actual fuel injection timing T1 is calculated. The output timing T0 for the injection command signal is determined as an instant the delay time DELTA Td before the basic target injection timing Tb, which is determined from the operating state.

Owner:ISUZU MOTORS LTD

Homogenizing fuel enhancement system

A homogenizing fuel enhancement system involves at least one circulation loop existing outside of the injection system for continuously circulating and maintaining the homogeneity of a multi-fuel mixture apart from any demands by or delivery to the engine's injection system (whether mechanical injection or a common rail), and at least one infusion tube configured within the at least one circulation loop for providing a volumetric expansion wherein the fuel mixture is infused and thereby rendered more homogeneous.

Owner:EXEN HLDG

Fuel injection system having electric low-pressure pump

InactiveUS20050199219A1Reducing wasteful fuel supplyReduce decreaseElectrical controlMachines/enginesCommon railFuel supply

Controlling means of a fuel injection system regulates an energization amount of an electric motor in accordance with a sensing signal outputted from common rail pressure sensing means. Thus, the controlling means controls a fuel supply quantity of a low-pressure pump. Thus, power consumption of the electric motor driving the low-pressure pump can be regulated in accordance with a pressure-feeding quantity of a high-pressure pump. As a result, the power consumption of the electric motor can be reduced and wasteful fuel supply of the low-pressure pump can be reduced.

Owner:DENSO CORP

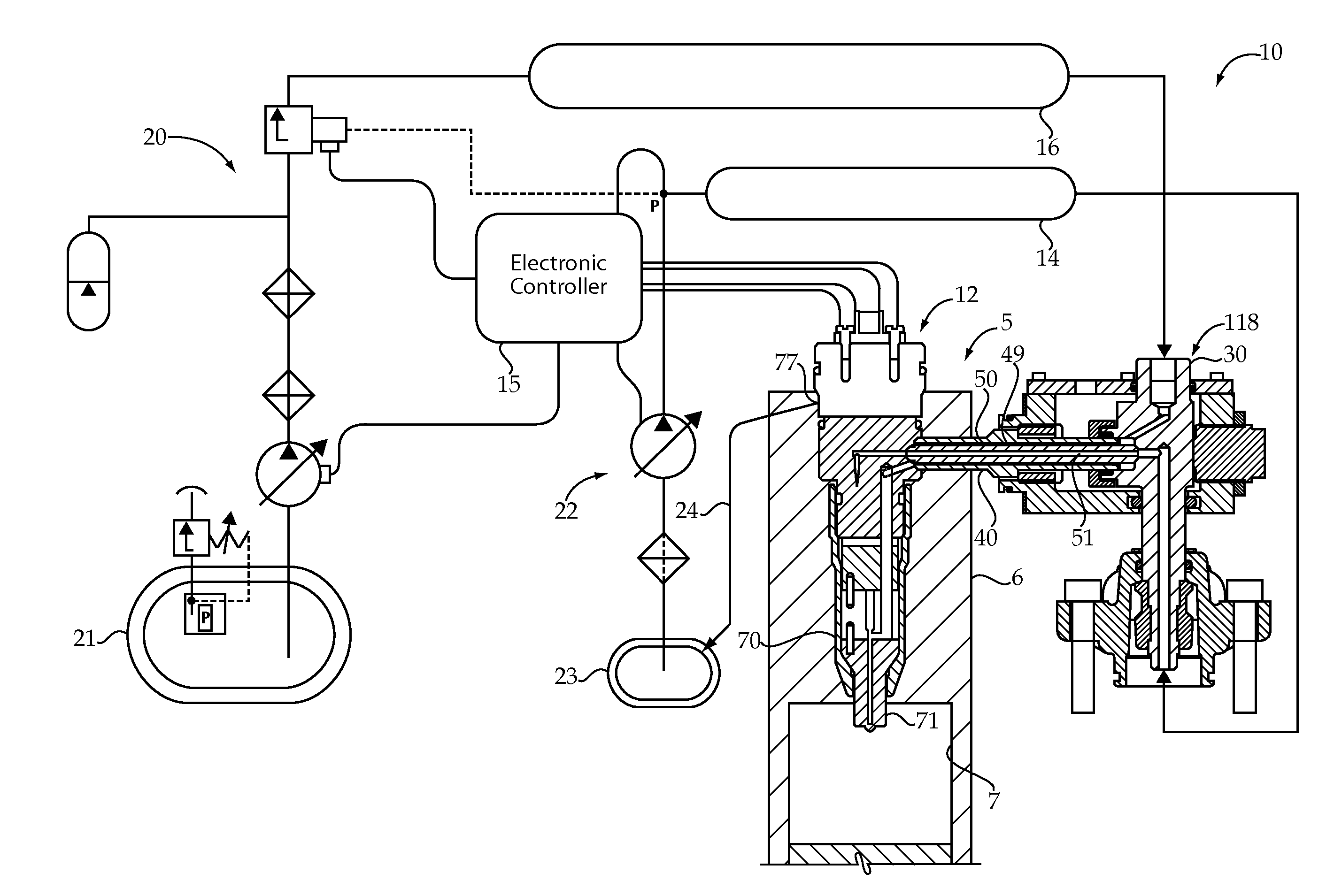

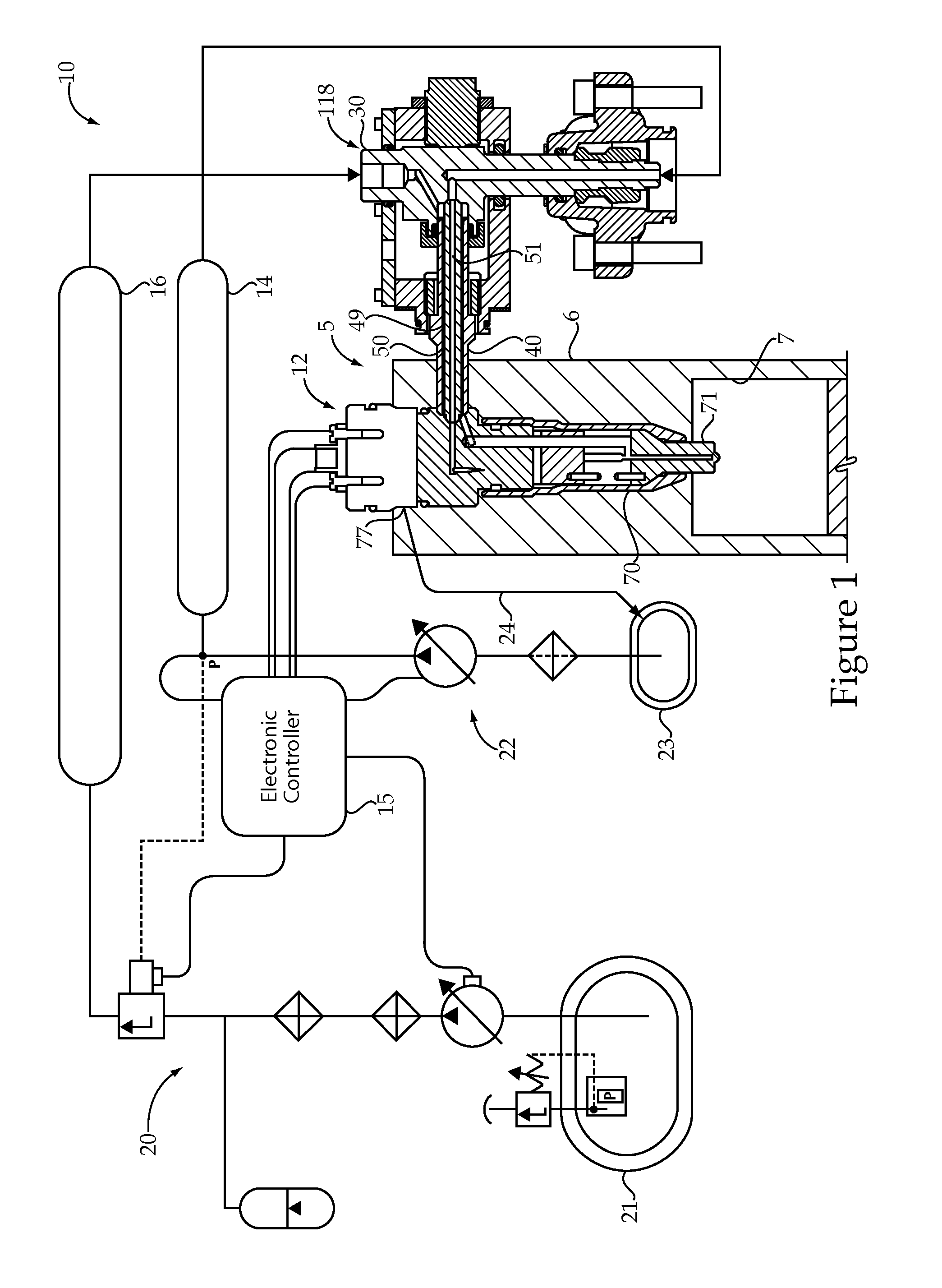

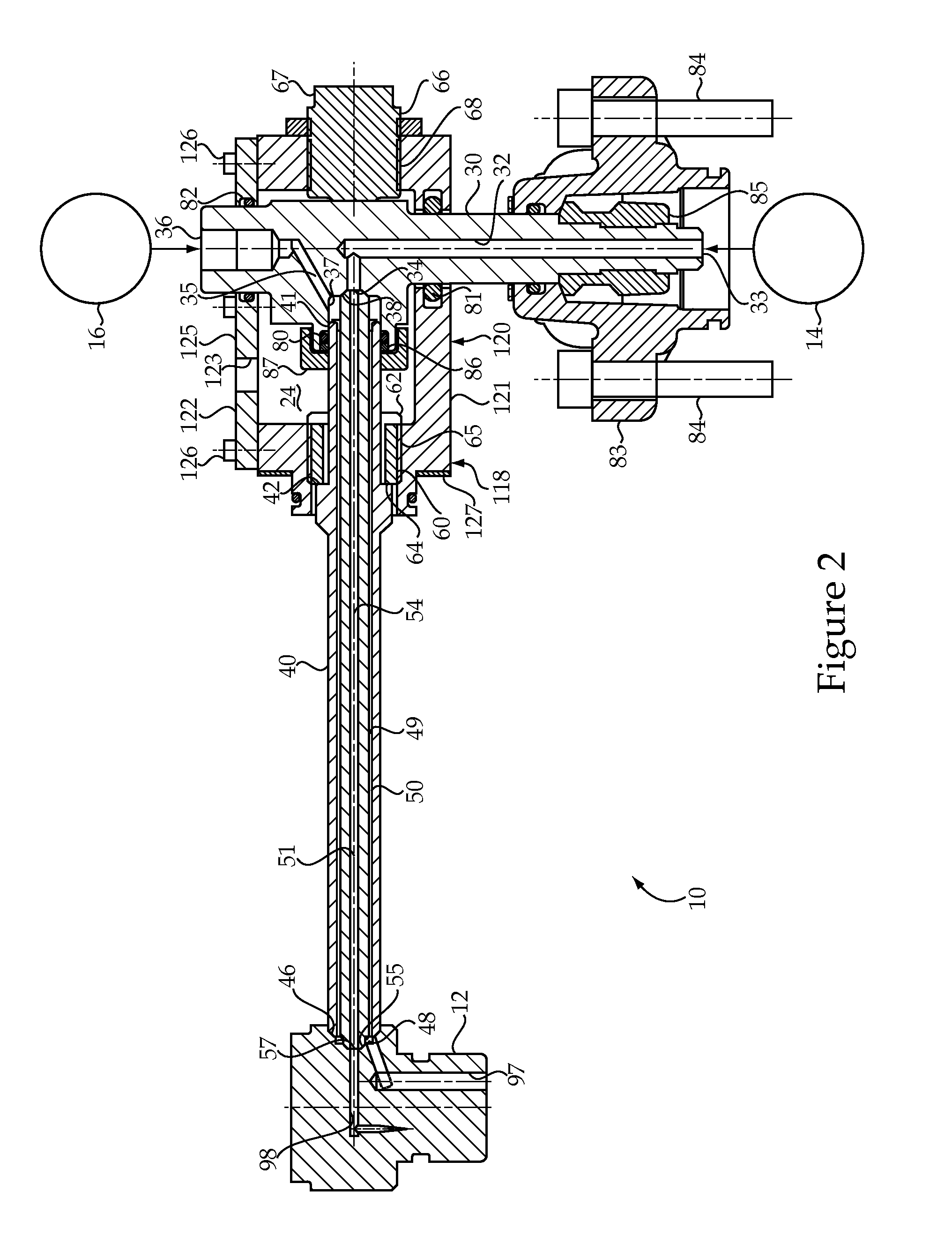

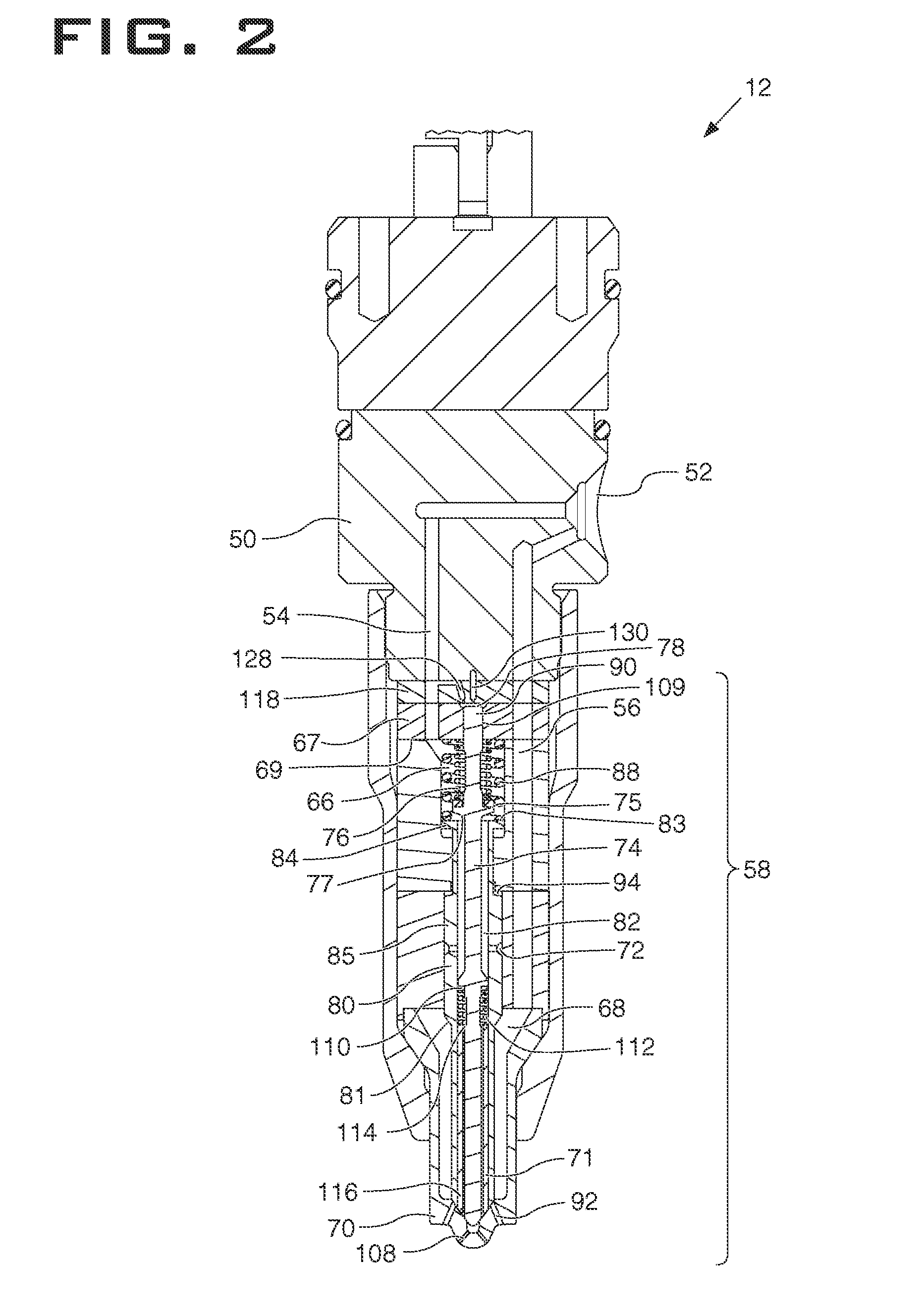

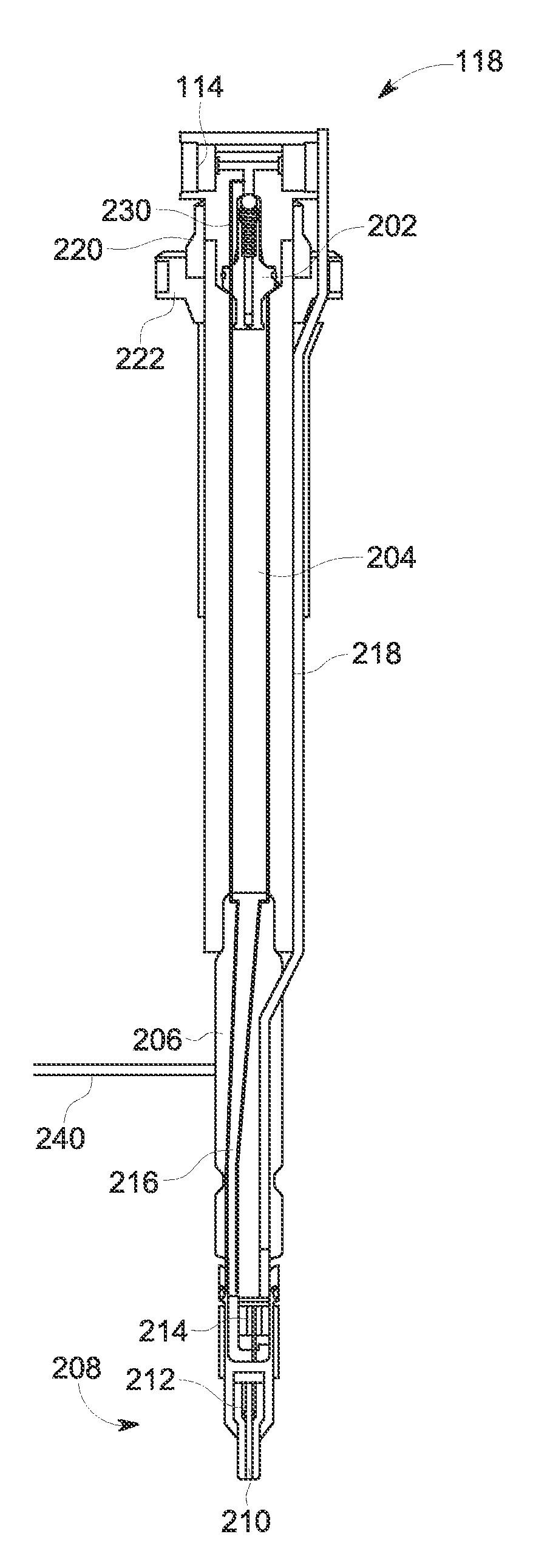

Fuel Injector For Dual Fuel Common Rail System

InactiveUS20130047964A1Improve the lubrication effectInhibit migrationInternal combustion piston enginesEngine controllersCommon railNuclear engineering

A duel fuel system includes a plurality of fuel injectors that have a non-injection configuration, a liquid fuel injection configuration, a gaseous fuel injection configuration and a combined fuel injection configuration. Each of the fuel injectors is fluidly connected to a gaseous fuel common rail and a liquid fuel common rail. Each of the fuel injectors includes a three way gas control valve and a three way liquid control valve that move along a common centerline. A gas control chamber of each fuel injector is fluidly connected to the liquid fuel common rail by two passages in parallel when the gas control valve member is in a first position corresponding to the non-injection configuration. The liquid control chamber of each fuel injector is also fluidly connected to the liquid fuel common rail by two passages in parallel when the liquid control valve is in a first position, again corresponding to the non-injection configuration.

Owner:CATERPILLAR INC

Method and apparatus for pressure reducing valve to reduce fuel pressure in a common rail

InactiveUS20080059039A1Lower closing pressureIncrease pressureAnalogue computers for vehiclesElectrical controlCommon railDelayed time

It is a objective of the present invention to provide a control apparatus which is capable of compensating a delay time for opening a pressure reducing valve since an electronic control unit sends a command signal for driving the pressure reducing valve so as to discharge high pressure fuel in a fuel accumulating device of a fuel injection system for the internal combustion engine. The delay time control apparatus for opening a pressure reducing valve has a potential for avoiding an overshoot phenomenon in which an actual pressure of fuel accumulated in the fuel accumulating device overshoots a target value of fuel pressure during the increase the fuel pressure of the fuel accumulating device.

Owner:DENSO CORP

Dual fuel injector having fuel leak seals

InactiveUS20130160741A1Prevent leakageInternal combustion piston enginesLow pressure fuel injectionCommon railLiquefied natural gas

A dual fuel common rail fuel injector includes a first and second check needle used to selectively inject two different fuels such as diesel and liquefied natural gas. The fuel injector includes a fuel separator disposed in the interior cavity of the first check needle and is in sealing contact with the nozzle. The fuel separator is configured to prevent commingling of the diesel fuel and the liquefied natural gas. The fuel injector also includes at least one sealing member that is configured to prevent the diesel fuel from leaking from the diesel fuel check cavity into a gaseous fuel orifice.

Owner:CATERPILLAR INC

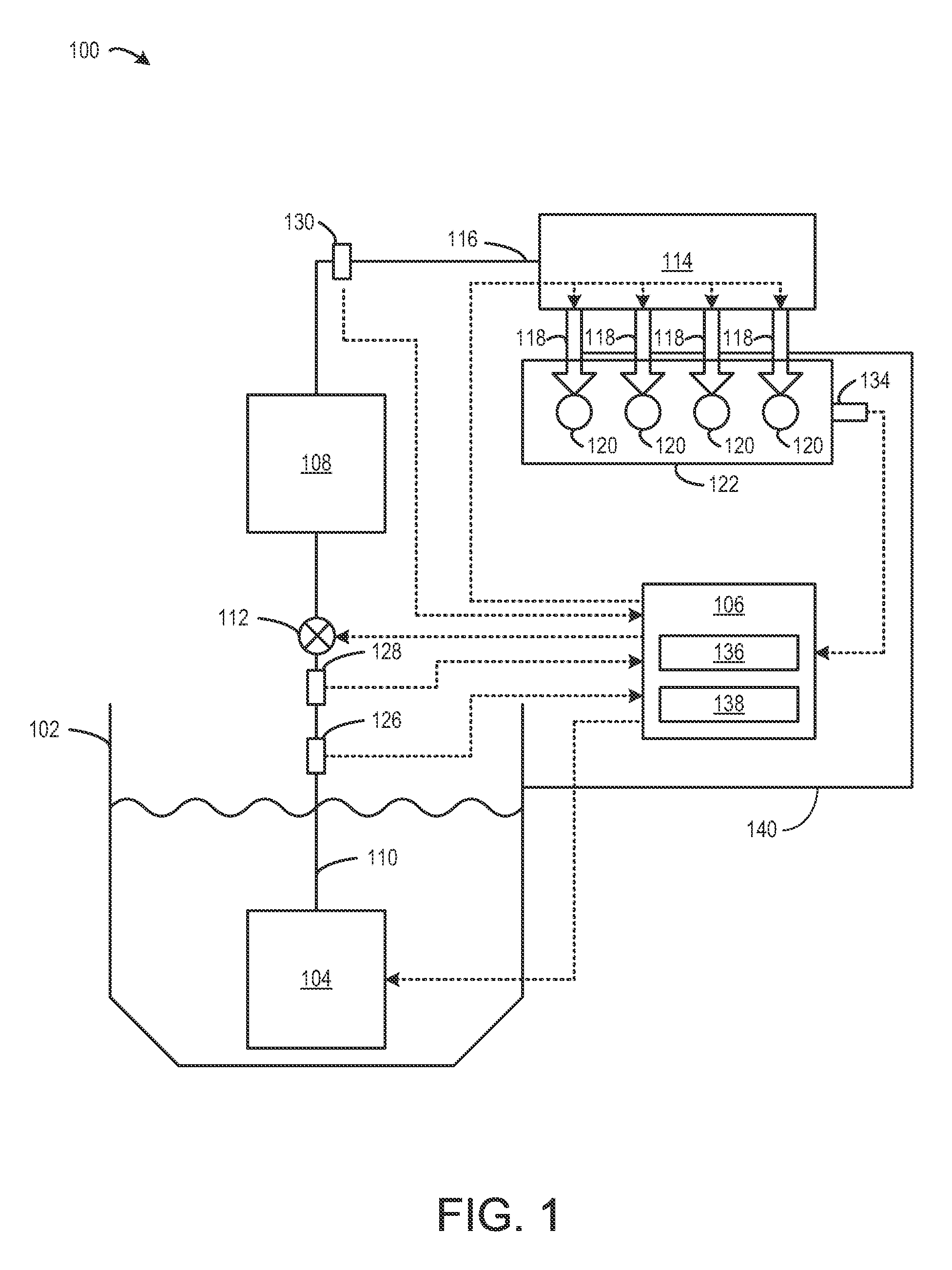

Method and systems for a leakage passageway of a fuel injector

ActiveUS9234486B2Reduce stepsReduce componentsMachines/enginesFuel injection with fuel accumulatorsCommon railAutomotive engineering

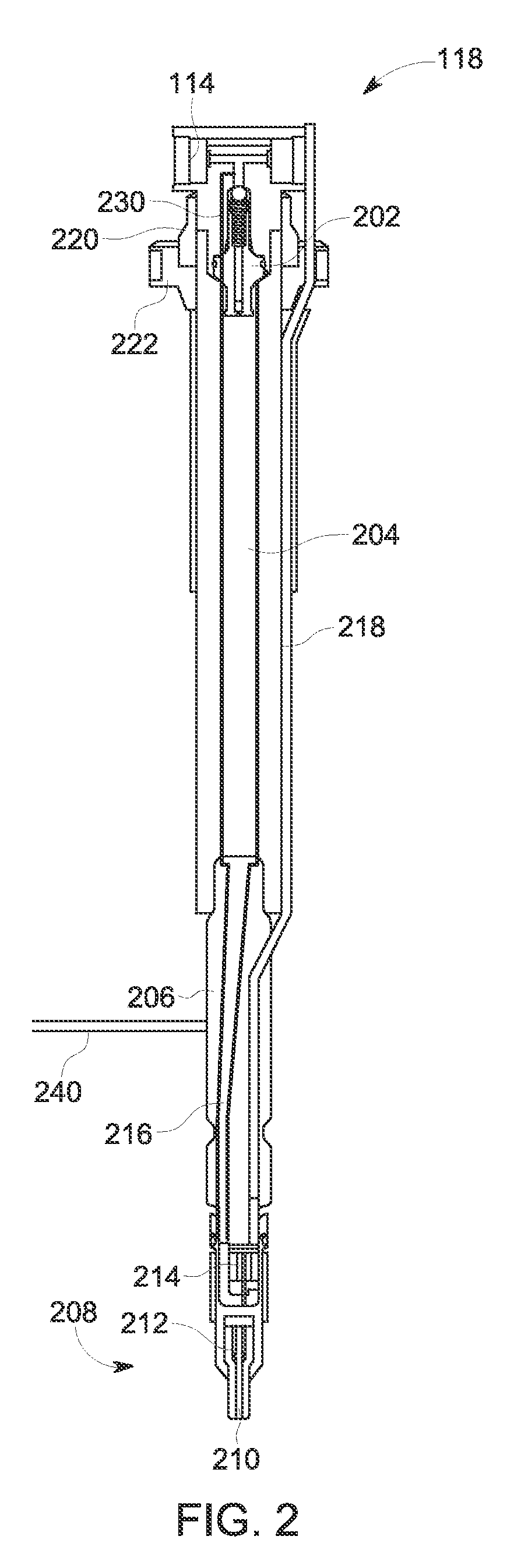

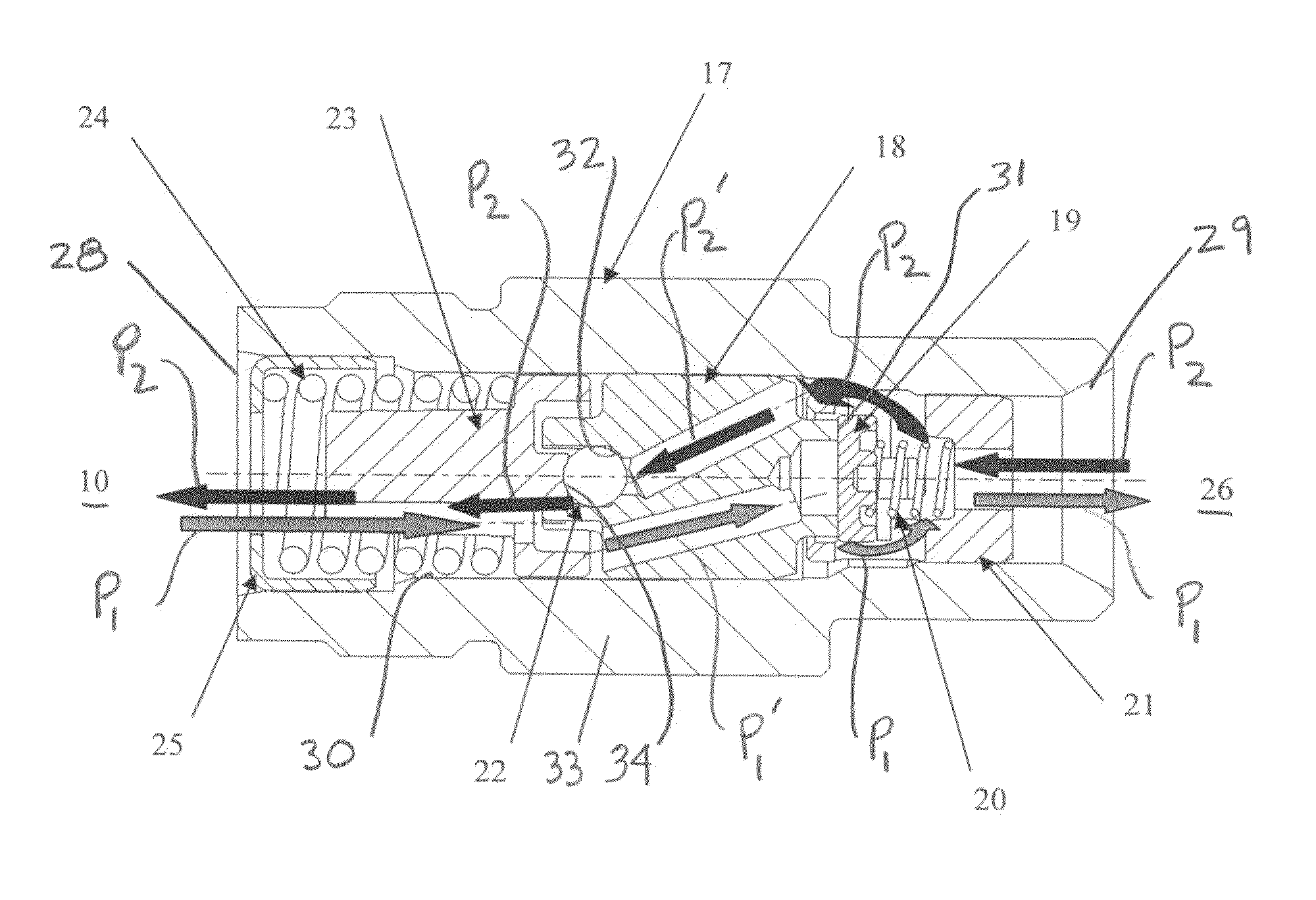

Various methods and systems are provided for a leakage passageway for a fuel injector of a common rail fuel system. In one embodiment, a fuel injector for an engine comprises an injector accumulator, an injector flow limiter valve configured to control a flow of fuel from a common fuel rail and into the injector accumulator, and a leakage passageway coupled between the injector accumulator and an inlet of the injector flow limiter valve, the leakage passageway bypassing the injector flow limiter valve.

Owner:GE GLOBAL SOURCING LLC

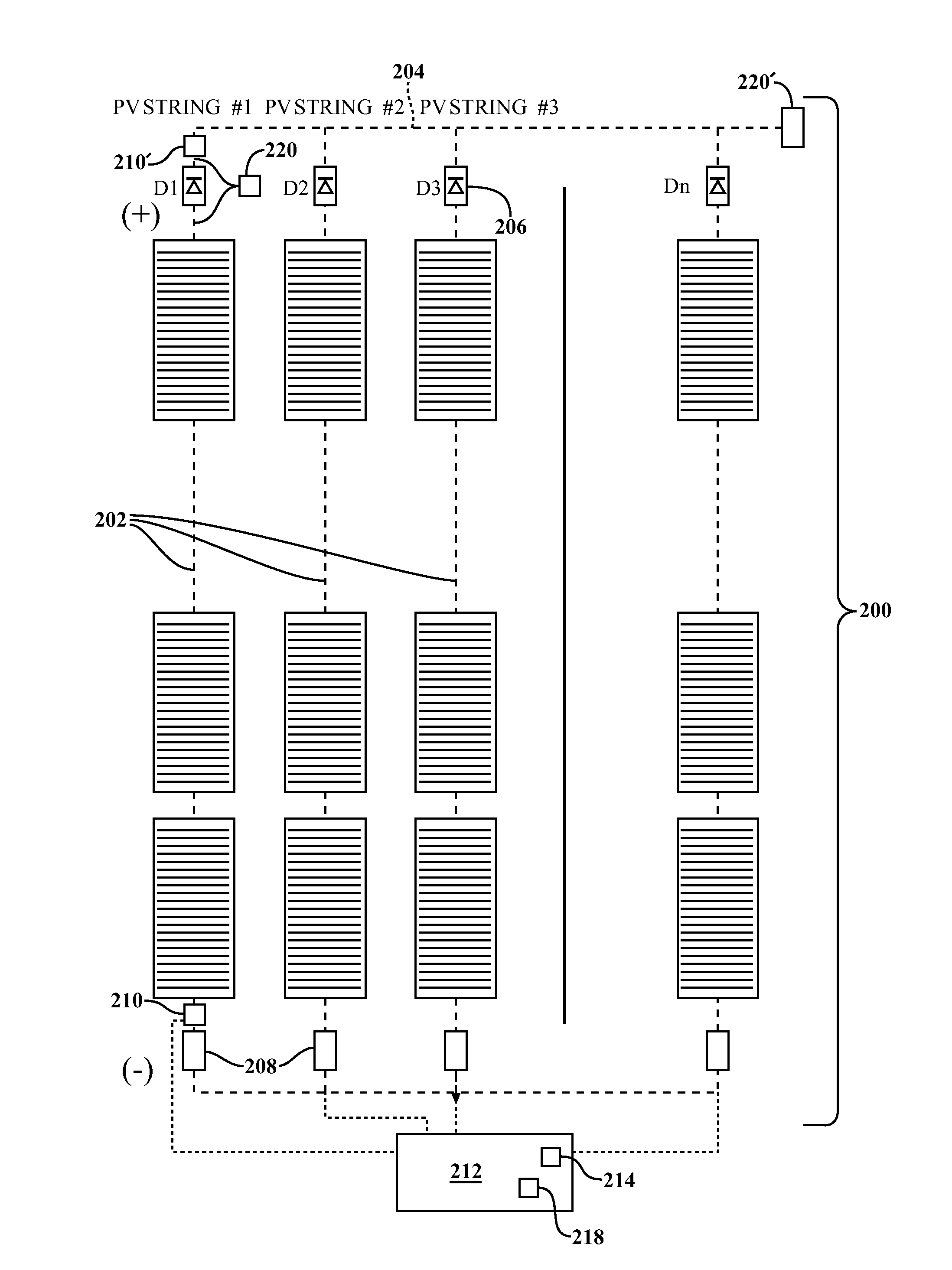

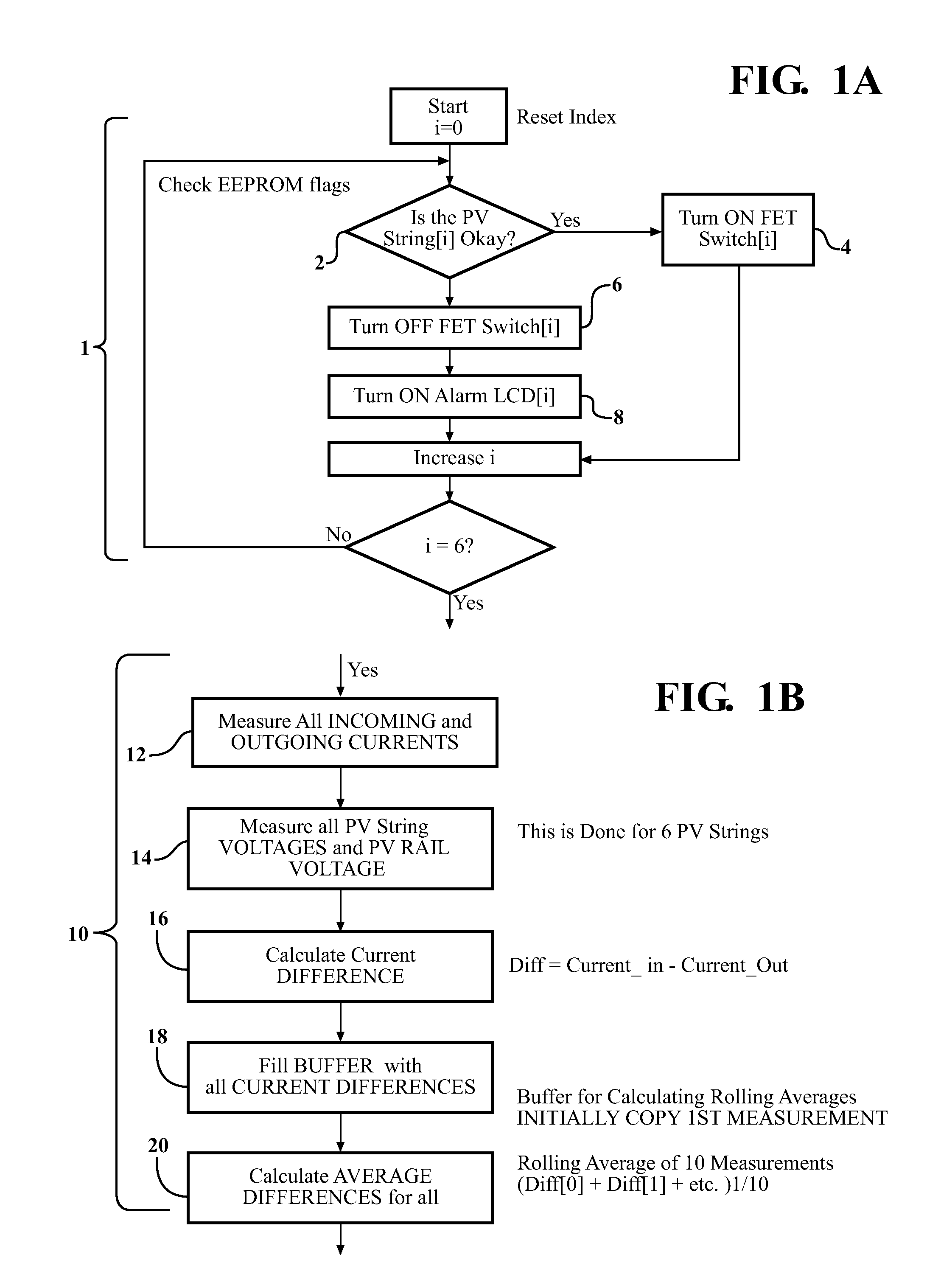

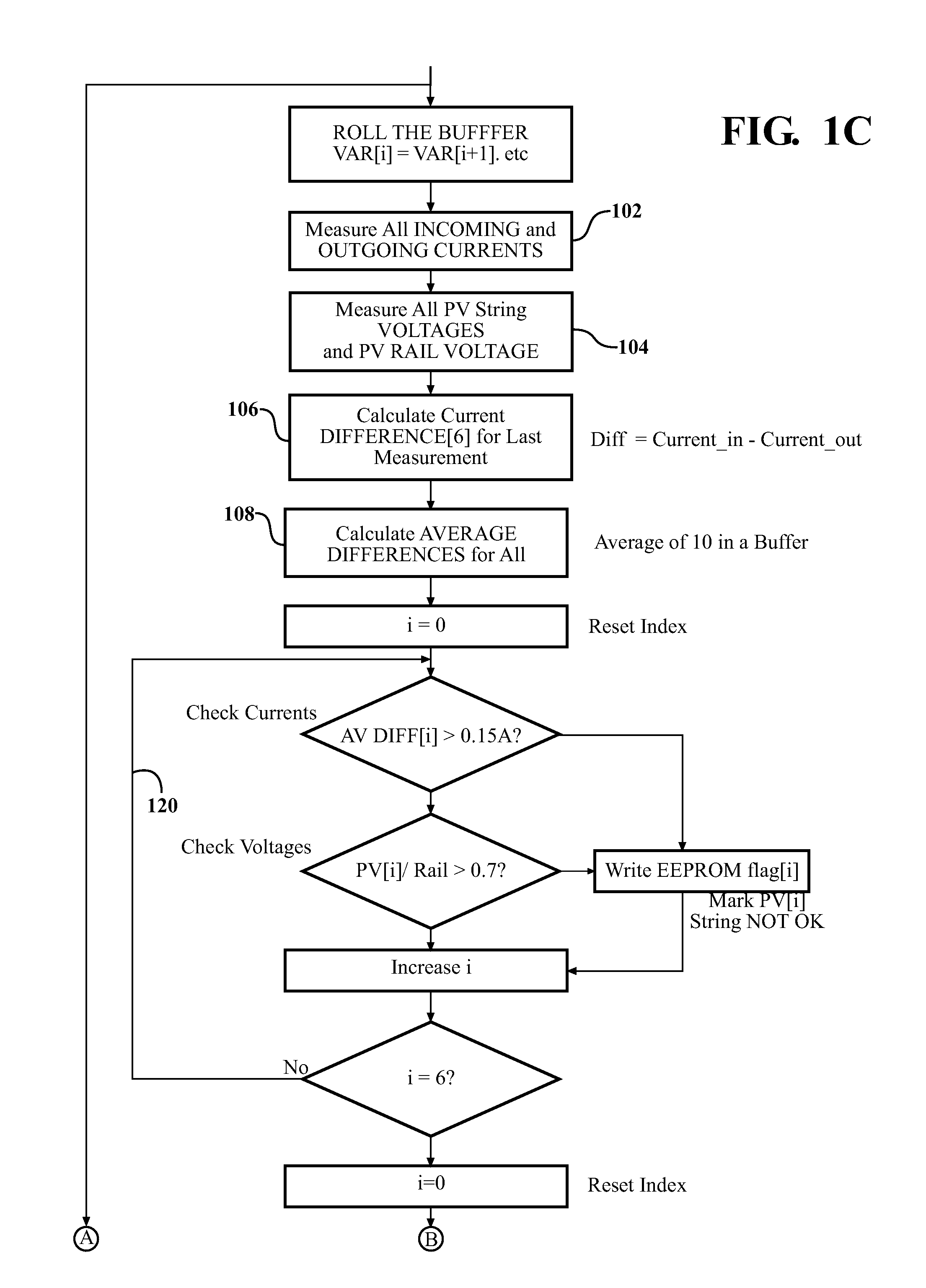

Failure detection system for photovoltaic array

InactiveUS20130015875A1Prevent backfeedingPromote repairPhotovoltaic monitoringPhotovoltaic energy generationPower flowCommon rail

A process for detecting and terminating a fault in a photovoltaic device is provided that operates in the millisecond or faster timescale. A process includes measuring a current or voltage in each of a plurality of strings relative to a common rail. When the voltage or current from a string is outside a predetermined threshold, a flag is generated indicating the presence of a fault in the string. A control unit will detect the flag and disconnect the faulty string from the system through a switch. The use of continuously rolling averages of baseline currents and voltages as well as a series of measurements averaged to measure the difference of current or voltage at each step provides a process and a fault detection system that does not suffer from false fault detections thereby providing a reliable and efficient system for detecting and terminating faults in photovoltaic devices.

Owner:UNITED SOLAR OVONIC

Dual Fuel Injector With Hydraulic Lock Seal And Liquid Leak Purge Strategy

InactiveUS20130098333A1Inhibit migrationPrevent movementInternal combustion piston enginesFuel supply apparatusCommon railEngineering

A dual fuel system includes a dual fuel injector that has disposed therein a gaseous nozzle chamber fluidly connected to a gaseous fuel inlet, and a liquid nozzle chamber fluidly connected to the liquid fuel inlet. The dual fuel injector also includes a hydraulic lock seal with an annular volume of liquid fuel surrounding a guide segment of a gas needle valve member for inhibiting migration of gaseous fuel into the liquid fuel. A liquid fuel common rail is fluidly connected to a liquid fuel inlet. A check valve is fluidly positioned between the gaseous fuel common rail and the gaseous nozzle chamber of the dual fuel injector for blocking liquid fuel leaked into a gaseous nozzle chamber through the hydraulic lock seal from entering the gaseous fuel common rail.

Owner:CATERPILLAR INC

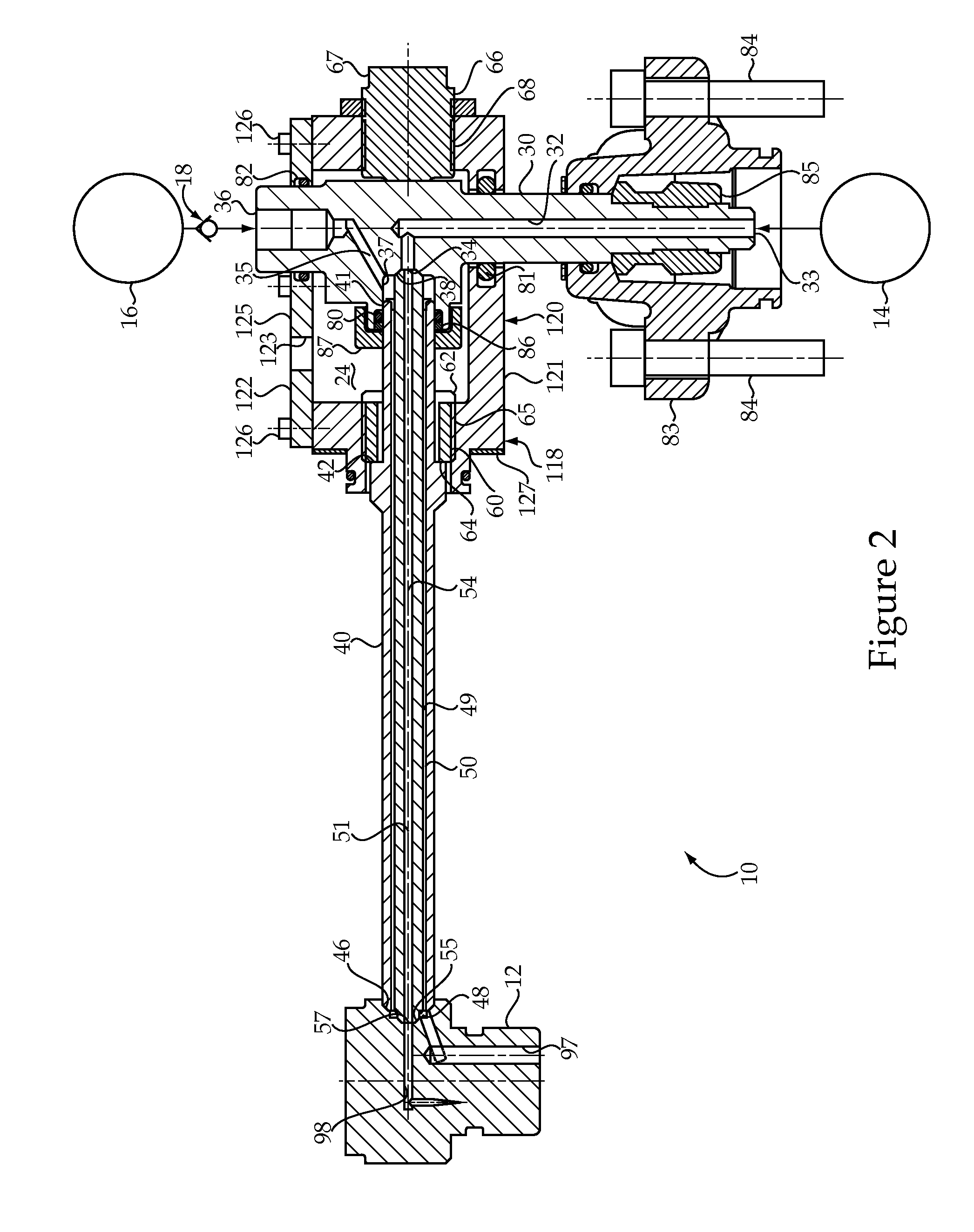

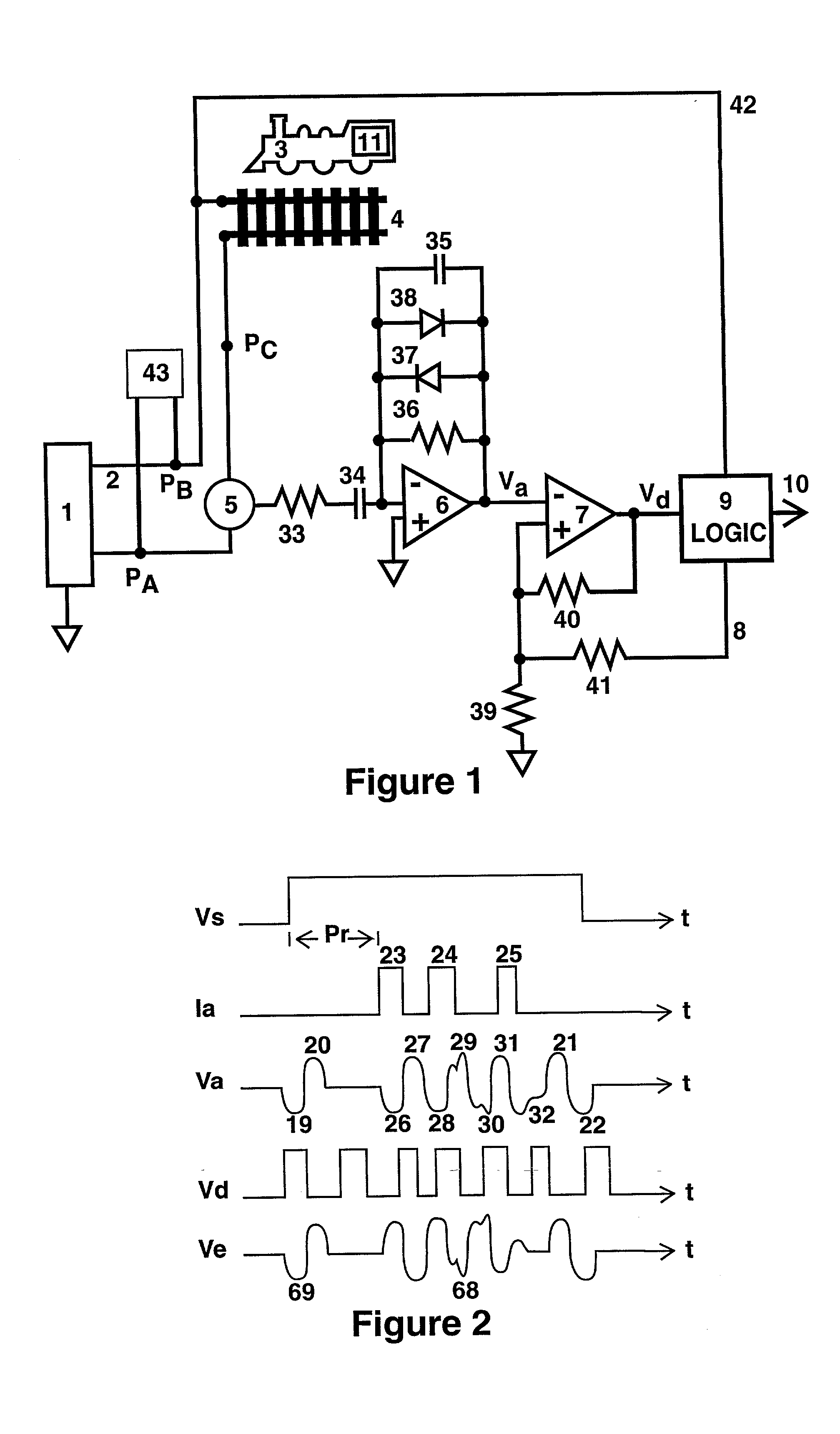

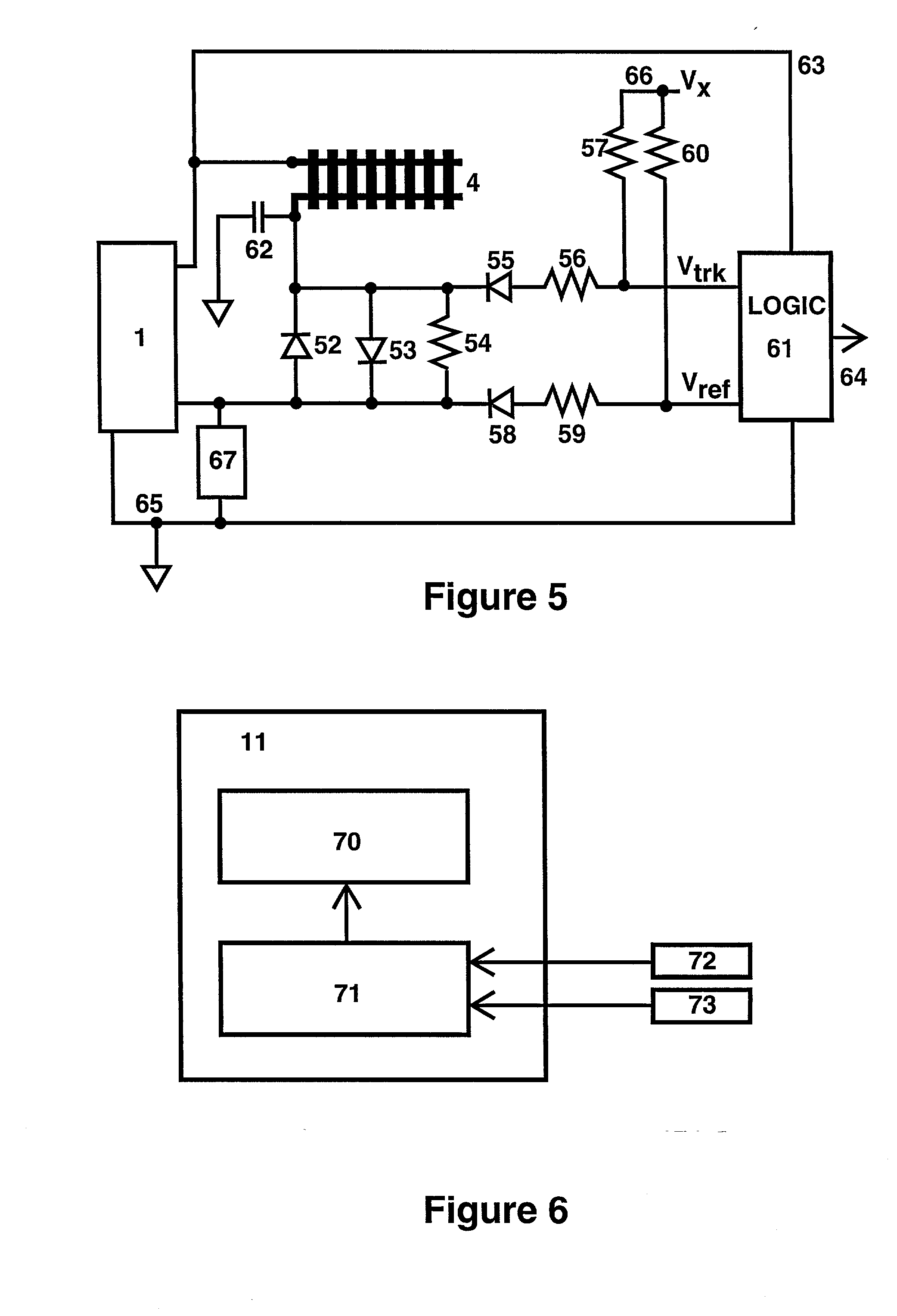

Model railroad occupancy detection equipment

InactiveUS20010005001A1Simple designReduce the possibilityRailway signalling and safetyModel railwaysScale modelCapacitance

Owner:IRELAND ANTHONY JOHN

Dual fuel system

InactiveUS20090320786A1Internal combustion piston enginesFuel supply apparatusCombustion chamberOperational costs

The present invention is directed to a dual fuel system and a dual fuel system assembly where liquid LPG and diesel are mixed and then distributed via the common rail to the combustion chambers. The liquid fuel mixture remains in a liquid state and under pressure for introduction to the combustion chambers. With the preferred embodiment of the dual fuel system, only minor changes are required to the diesel engine without altering the manufactures specifications and voiding the manufacturer's warranties. The resultant combustion of the liquid fuel mixture provides a cleaner emission and relatively cheaper vehicle operational costs.

Owner:DGC IND

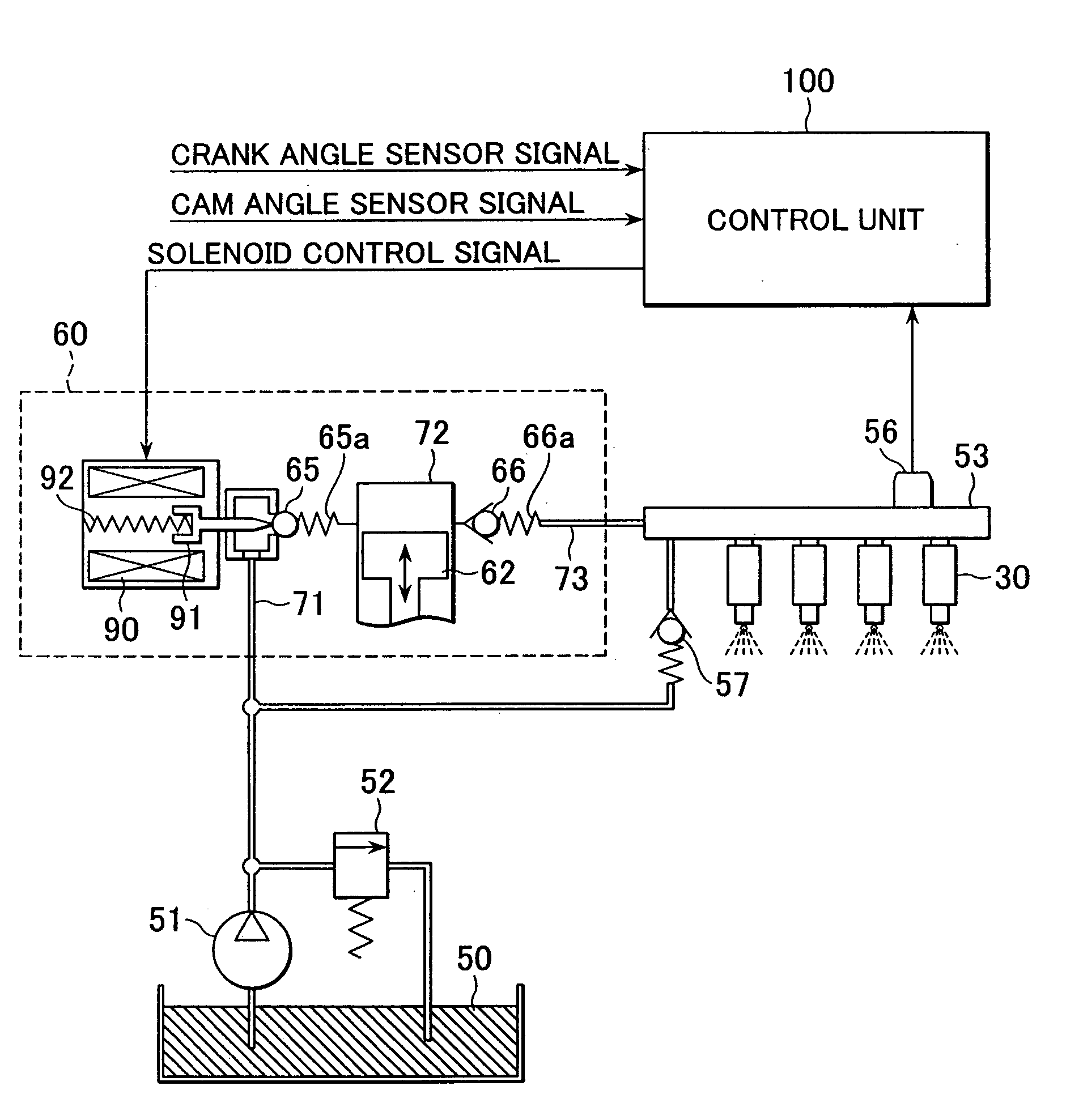

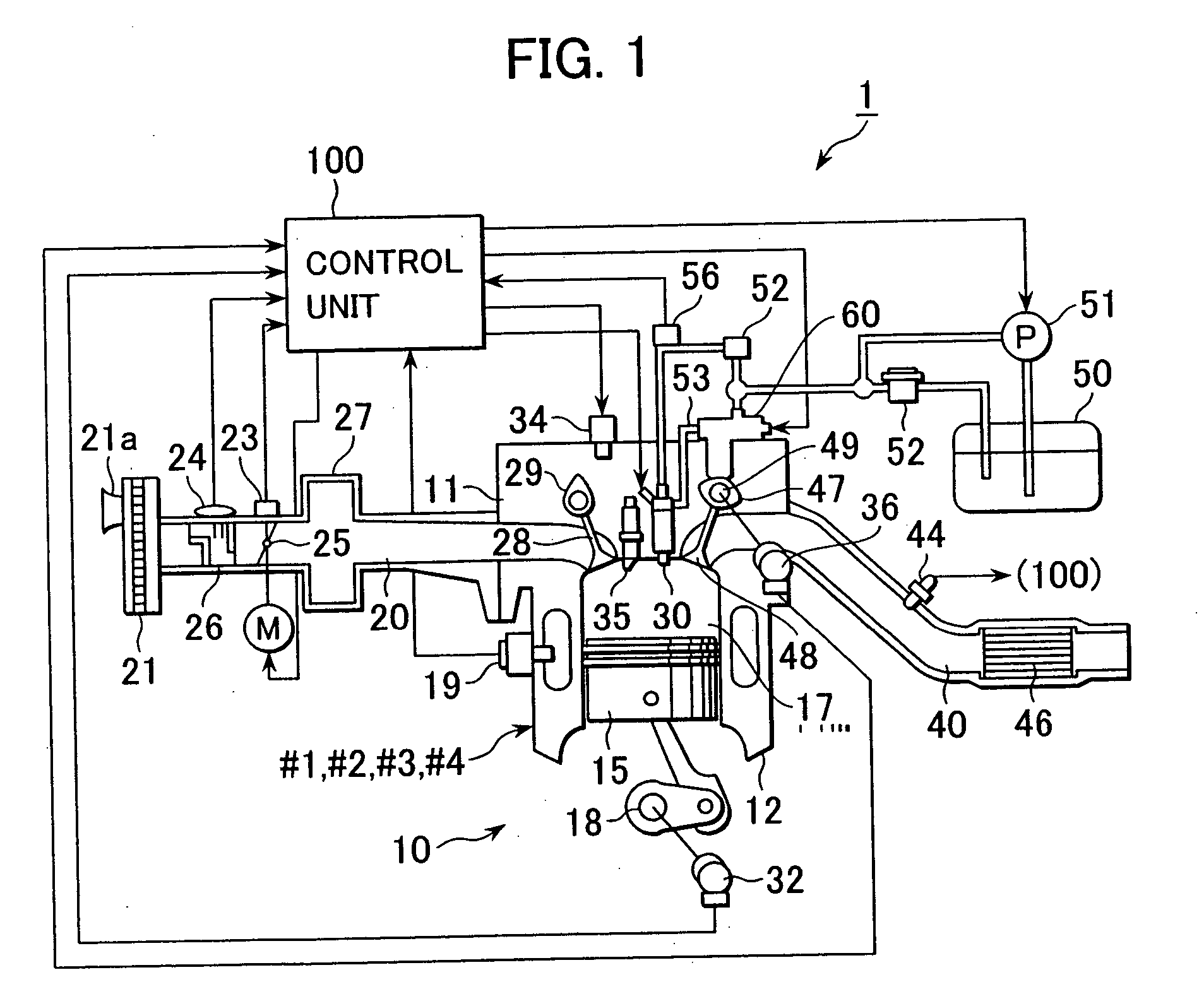

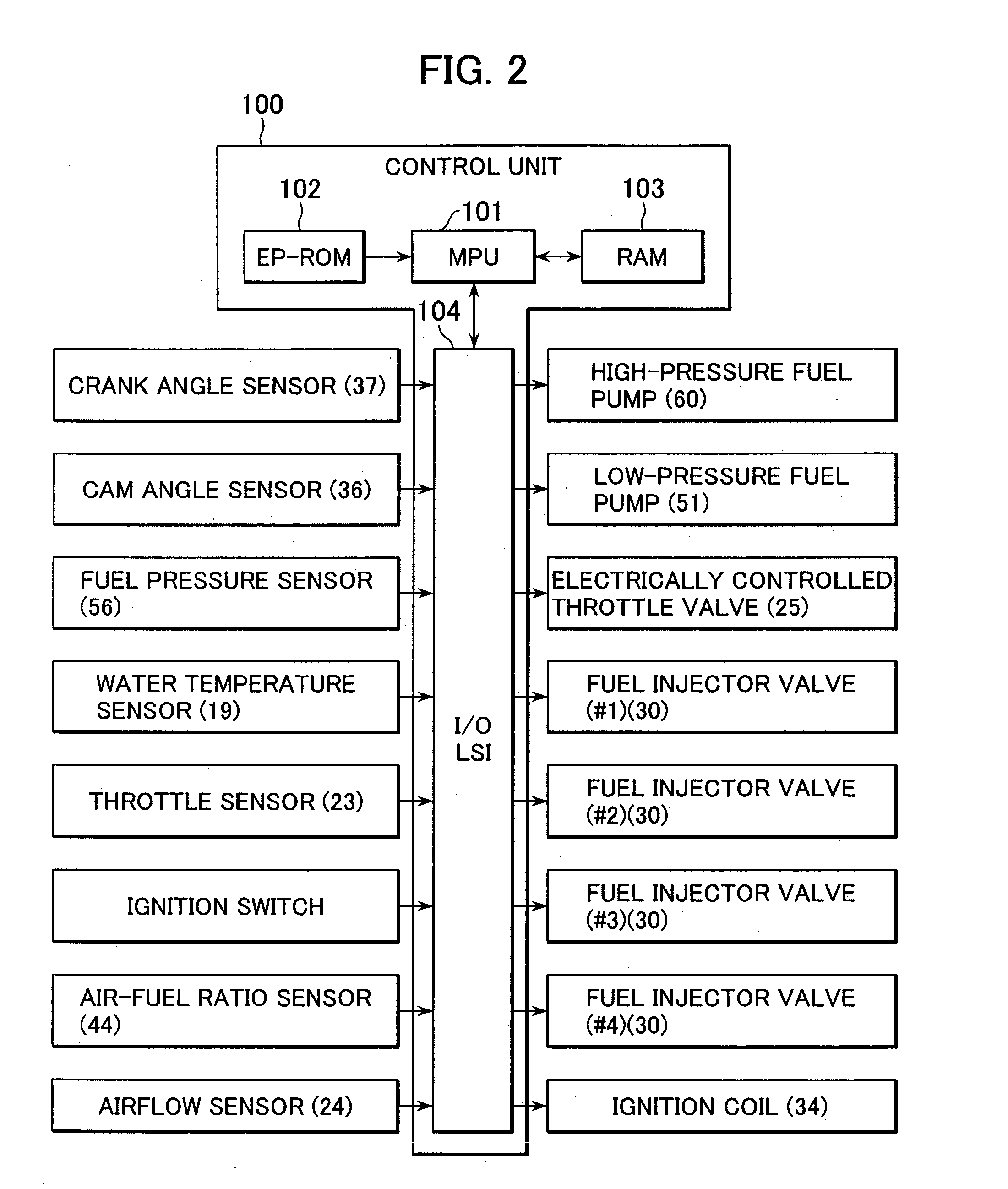

High-pressure fuel pump control device for engine

ActiveUS20050126539A1Satisfactory combustionImprove robustnessElectrical controlMachines/enginesCombustion chamberCommon rail

A high-pressure fuel pump control device capable of reducing current consumption, increasing pump durability, and promoting a rise of fuel pressure from startup. The high-pressure fuel pump control device comprises a fuel injector valve for directly injecting fuel in a common rail into a combustion chamber and a high-pressure fuel pump for feeding the fuel under pressure to the common rail. The high-pressure fuel pump comprises a pressurization chamber, a plunger for pressurizing the fuel in the pressurization chamber, a fuel passage valve disposed in the pressurization chamber, and an actuator for actuating the fuel passage valve. The control device includes a control unit for executing output control of a drive signal for the actuator to vary a discharge rate of the high-pressure fuel pump. The control unit starts outputting of the actuator drive signal during a period from operation start to a point in time at which the actuator drive signal becomes able to issue in a predetermined crank angle phase, and sets timing of stopping the outputting of the actuator drive signal to a point in time at which the fuel pressure in the common rail has boosted over a predetermined value per unit time.

Owner:HITACHI ASTEMO LTD

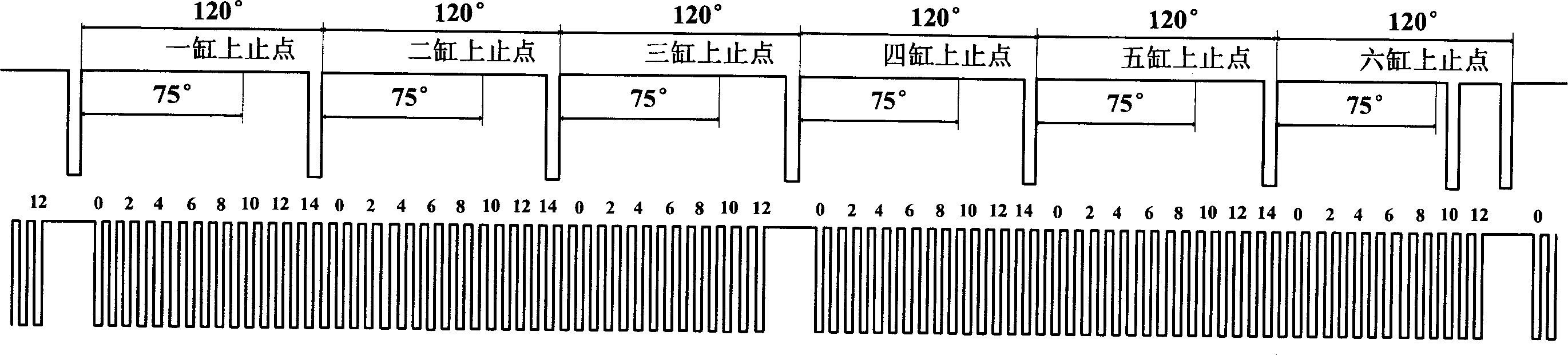

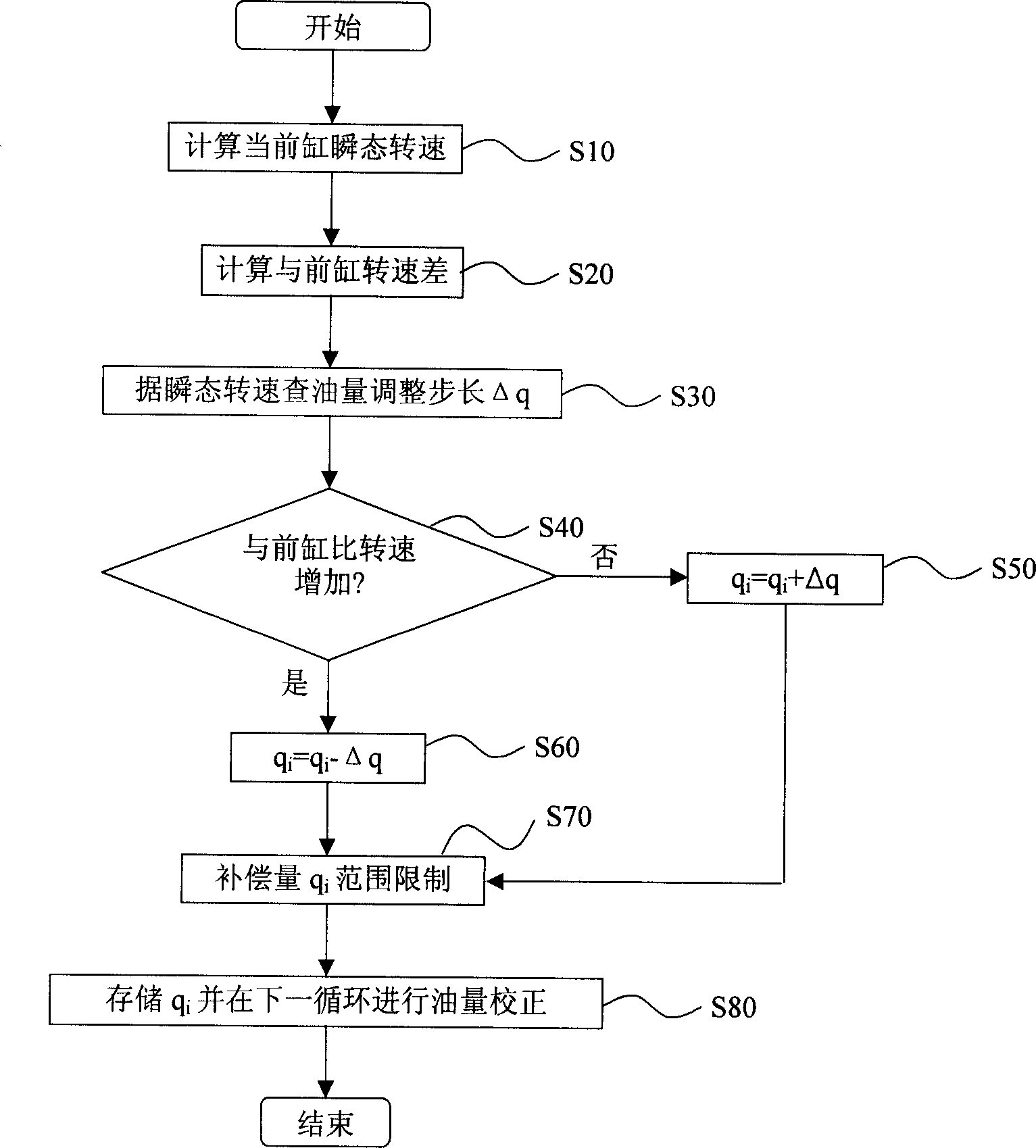

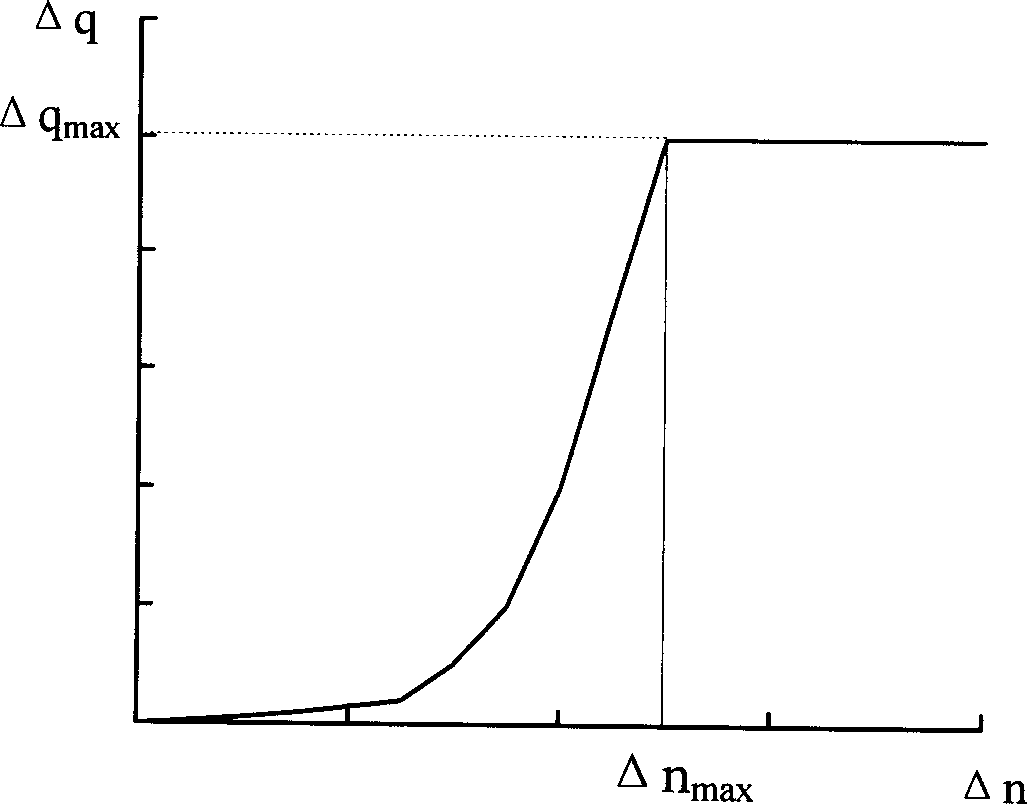

Common-rail fuel oil injection system injector failure diagnosing method

ActiveCN1773101AAvoiding Insufficient Fault JudgmentReliable diagnosisEngine testingFuel injection apparatusCommon railFuel oil

The present invention relates to a diagnostic method of injector failure in common rail fuel injection system. Said method includes the following steps: firstly, utilizing acquisition and analysis of transient rotational speed of engine, then utilizing the injection compensation quantity obtained according to engine inter-cylinder balanced algorithm to make statistical analysis of compensation quantity variable tendency and adopting probability statistic method to judge the failure of injection system, so that it can greatly raise the accuracy of failure judgment of fuel injection system.

Owner:CHINA FIRST AUTOMOBILE

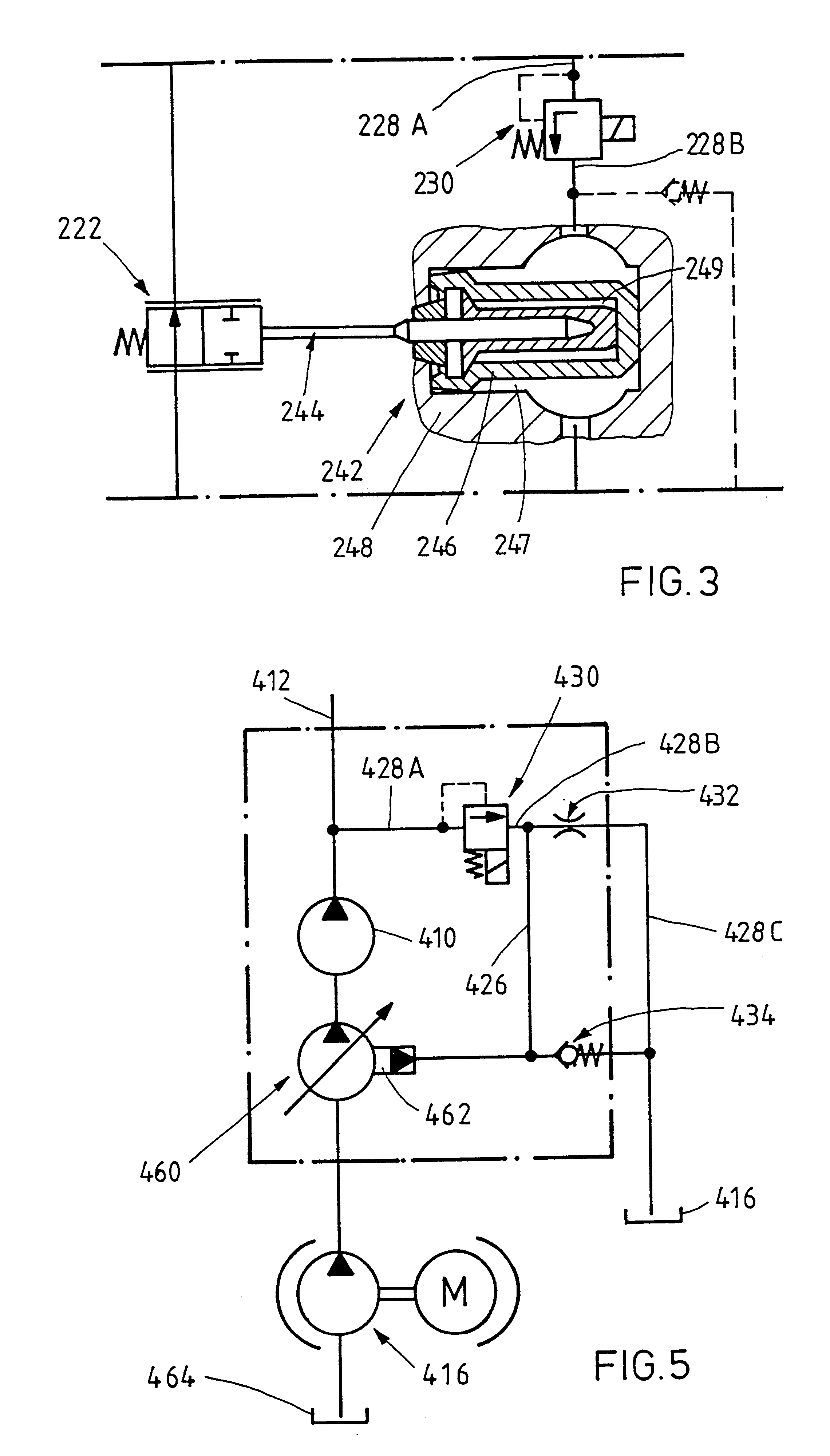

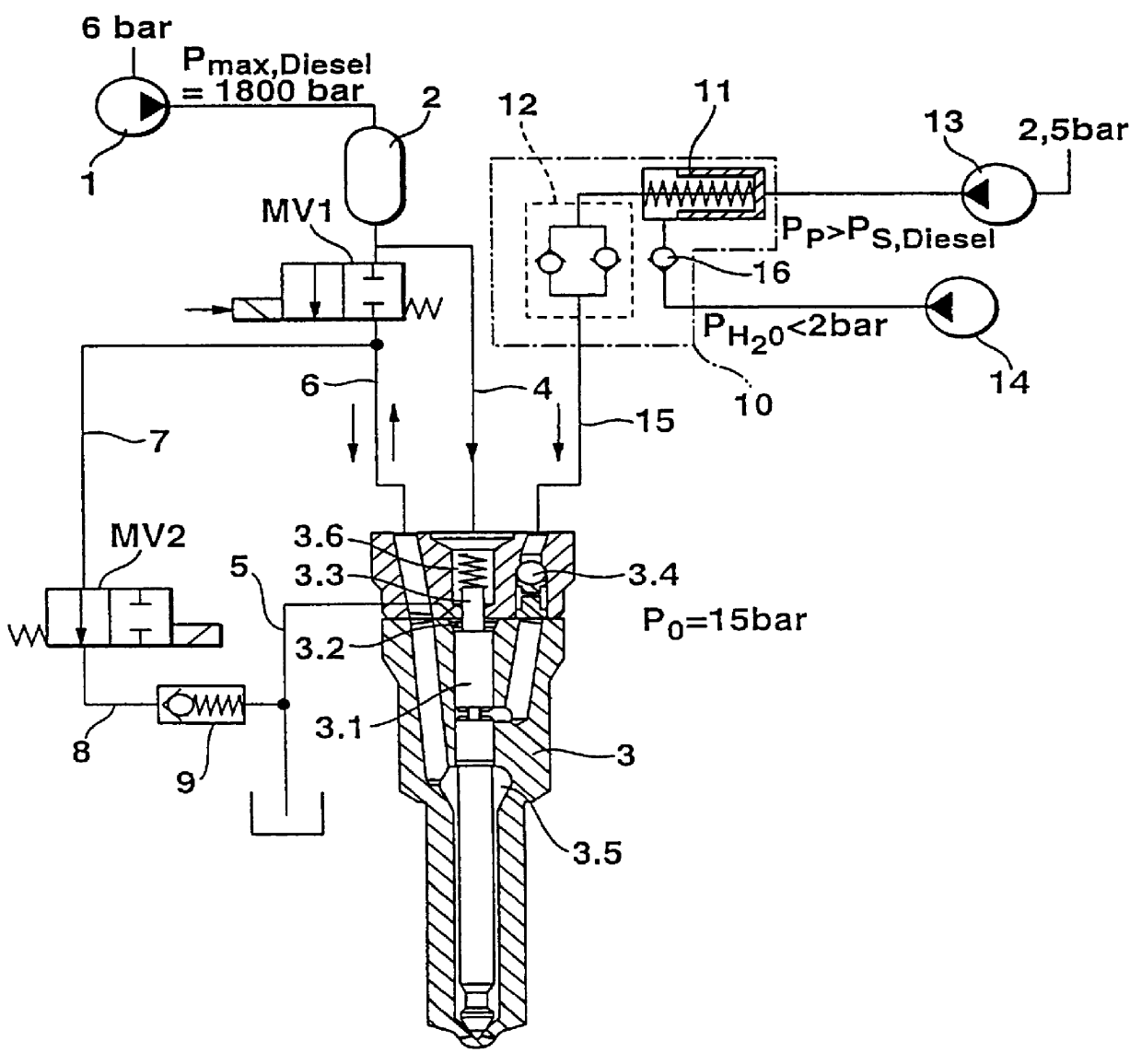

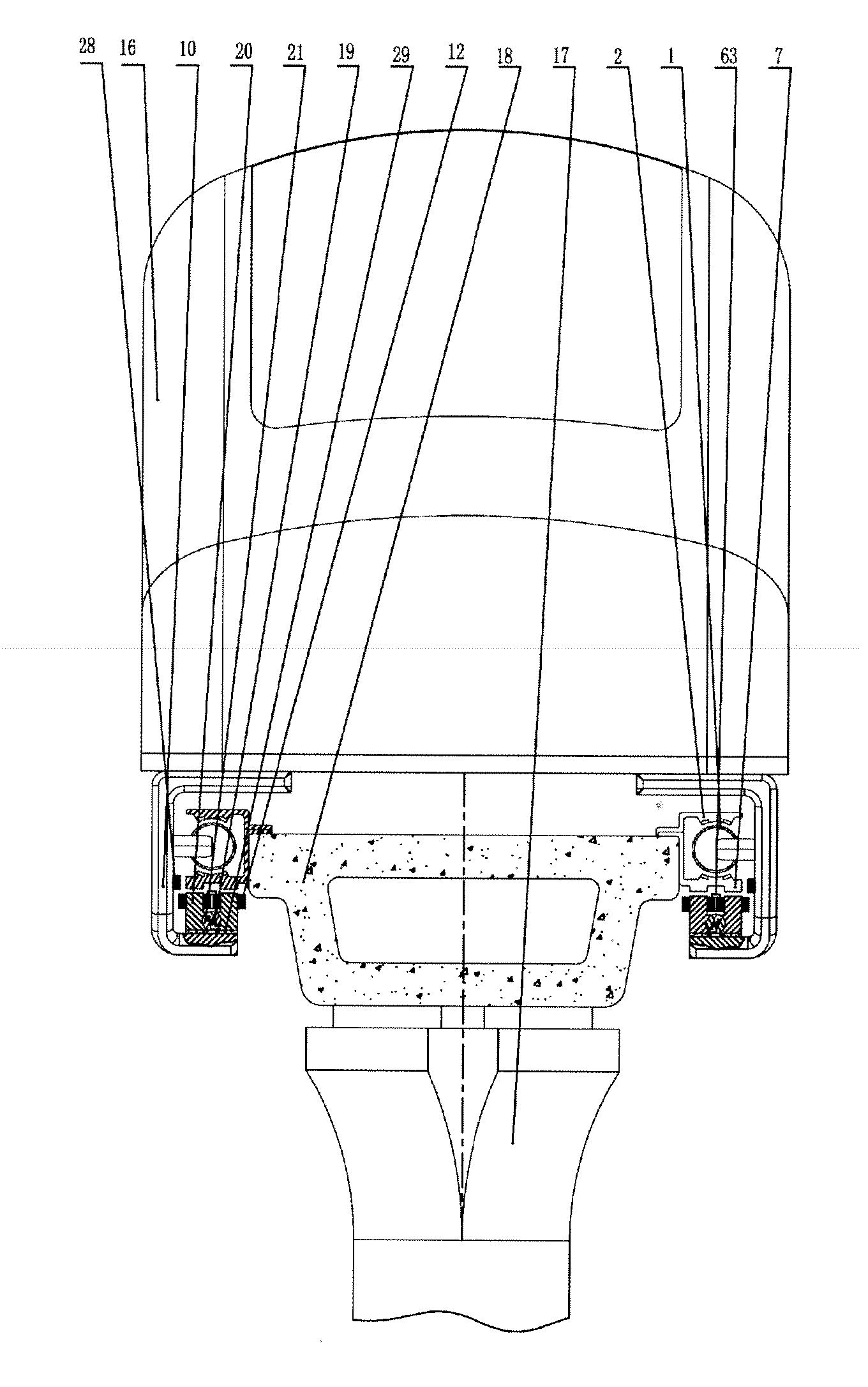

Fuel injection system for an internal combustion engine

InactiveUS6067964AAccurate supervisionHigh degreeCombustion enginesFuel injecting pumpsCommon railEngineering

PCT No. PCT / DE98 / 02771 Sec. 371 Date Jul. 23, 1999 Sec. 102(e) Date Jul. 23, 1999 PCT Filed Sep. 18, 1998 PCT Pub. No. WO99 / 20893 PCT Pub. Date Apr. 29, 1999A fuel injection system having a common rail pressure reservoir filled with high-pressure fuel and having a dual-fuel injector for a bi-fluid injection of fuel and an additive fluid into an internal combustion engine. The system includes a first 2 / 2-way valve in the injection line between the common rail pressure reservoir and a pressure chamber encompassing the injector needle of the dual-fuel injector as well as a second 2 / 2-way valve, whose inlet is connected via a supply line to the injection line at a point between the first 2 / 2-way valve and the pressure chamber, and whose outlet is connected to the low-pressure fuel side by way of an outlet line. As a result, the otherwise conventional 3 / 2-way solenoid control valves, which are significantly more complex technically, can be replaced by more reasonably priced 2 / 2-way valves. At the same time, this raises the possibility of shifting the quantity metering for additive fluid to a single metering valve that serves an entire group of injectors.

Owner:ROBERT BOSCH GMBH

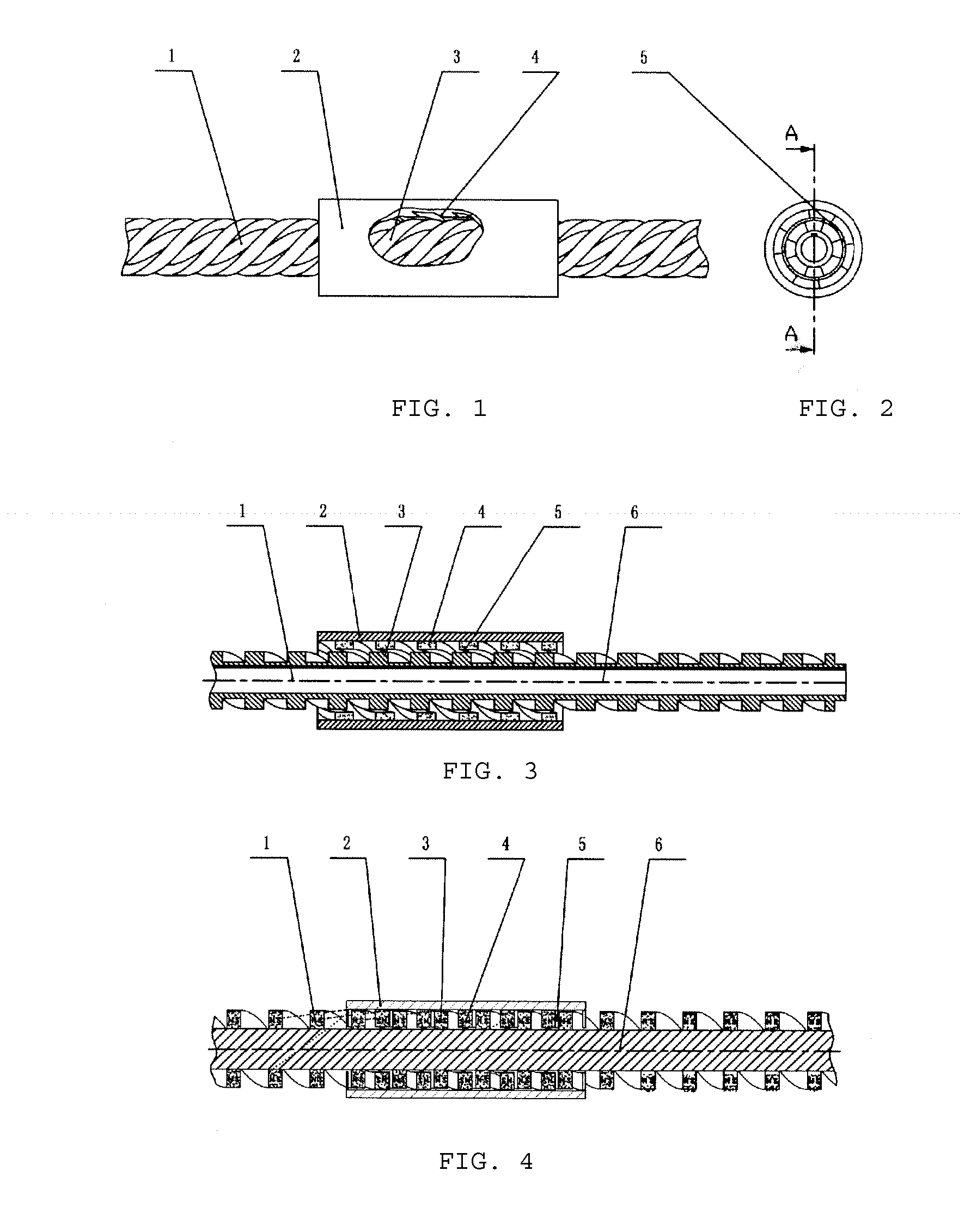

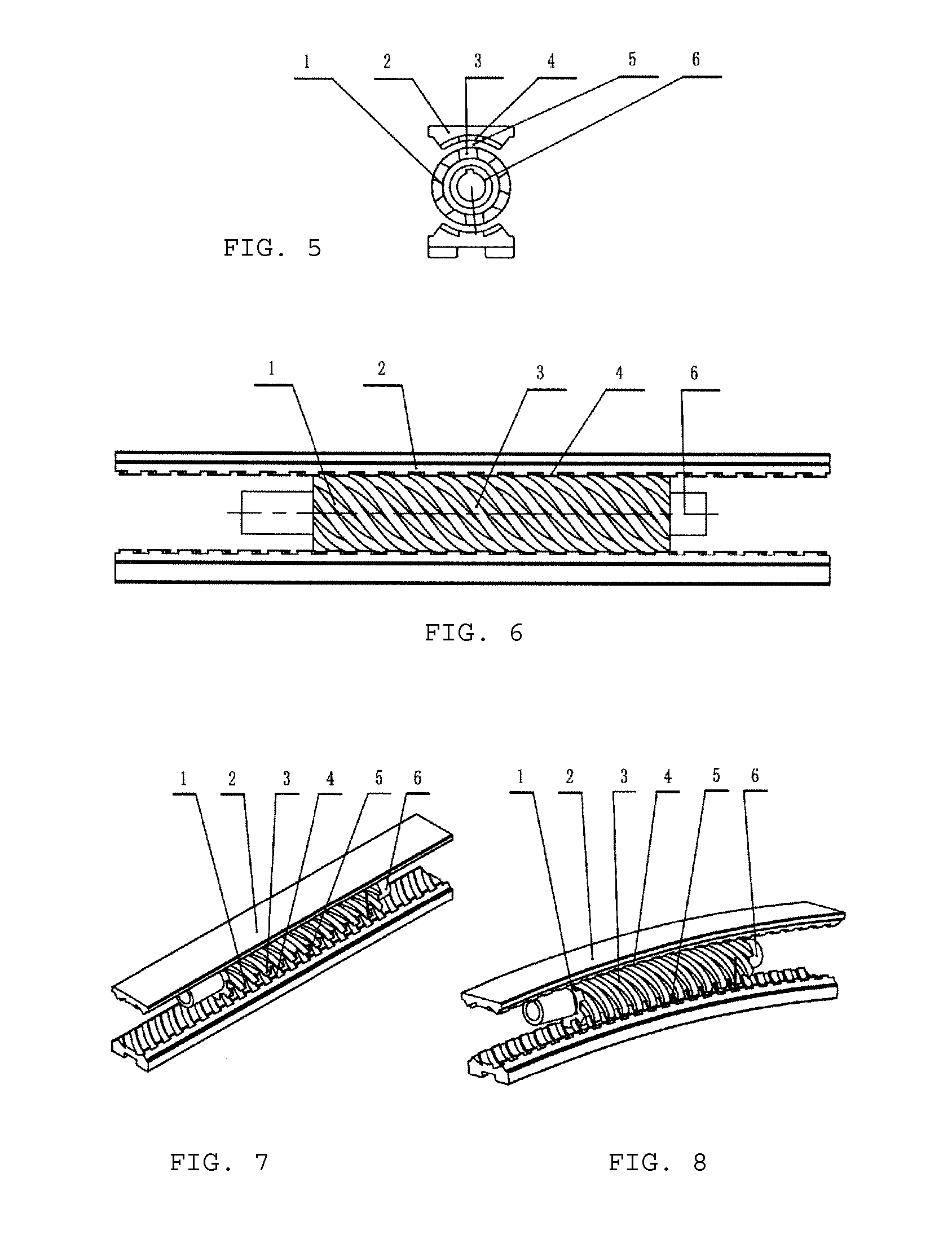

Linear permanent magnet drving system and permanent magnet driving and magnetic suspension roadway system

InactiveUS20110271867A1Improve transmission efficiencyMaximum effectivenessRail devicesRailway componentsLinear motionLow speed

The invention relates to a linear permanent magnet driving system and a permanent magnet driving maglev train rail system, the linear permanent magnet driving system comprises spiral rotors and stators, wherein at least one of the spiral rotor and the stator adopts the structure having a permanent magnet while the other one adopts the structure having the permanent magnet or a magnetizer; when the spiral rotors are driven by an engine to rotate, linear motion of the spiral rotors is achieved by means of the magnetic force between both, and speed of the linear motion of the spiral rotors can reach supersonic speed at most. By applying the linear permanent magnet driving system to the permanent magnet driving maglev train rail system, the entire rail can avoid the use of both permanent magnet and driving coil, and the construction cost of maglev train rail is equivalent to that of the current high-speed wheel / rail. The permanent magnet driving maglev train can save energy by 60 to 90% compared with wheel / rail train when traveling at low speed below 80 kilometers per hour and save energy by about 50% compared with high-speed wheel / rail train when traveling at high speed above 200 kilometers per hour. The invention can realize the interchangeability of maglev rail and common rail, leading the maglev rail to universality, networkability and compatibility in modern transportation.

Owner:LIU ZHONGCHEN

Common rail fuel injection control device

InactiveUS6840220B2Achieve traceabilityAvoid stickingElectrical controlLow pressure fuel injectionCommon railEngineering

The common rail fuel injection control device in accordance with the present invention computes a base duty (A) equivalent to a base target opening degree of a metering valve and a correction coefficient (B) based on the engine operation state, adds the value obtained by multiplying an oscillation duty (C) which oscillates periodically by the correction coefficient (B) to the base duty (A), and determines the final duty (D) equivalent to a final target opening degree of the metering valve.

Owner:ISUZU MOTORS LTD

Method and device for fuel injection for engines

InactiveUS6105554AAvoiding degradation of exhaust emission characteristicReduce speedElectrical controlInternal combustion piston enginesCommon railNOx

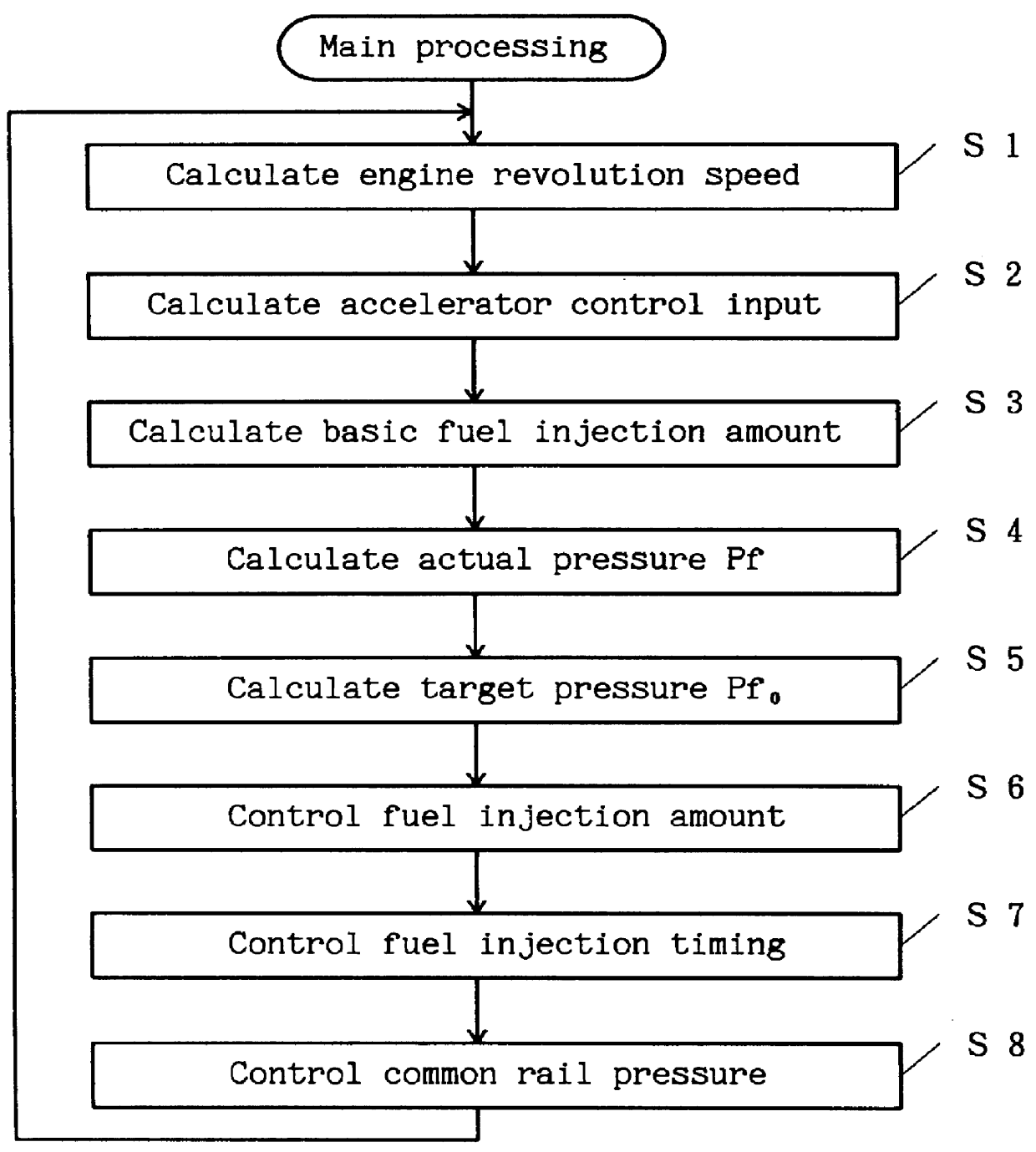

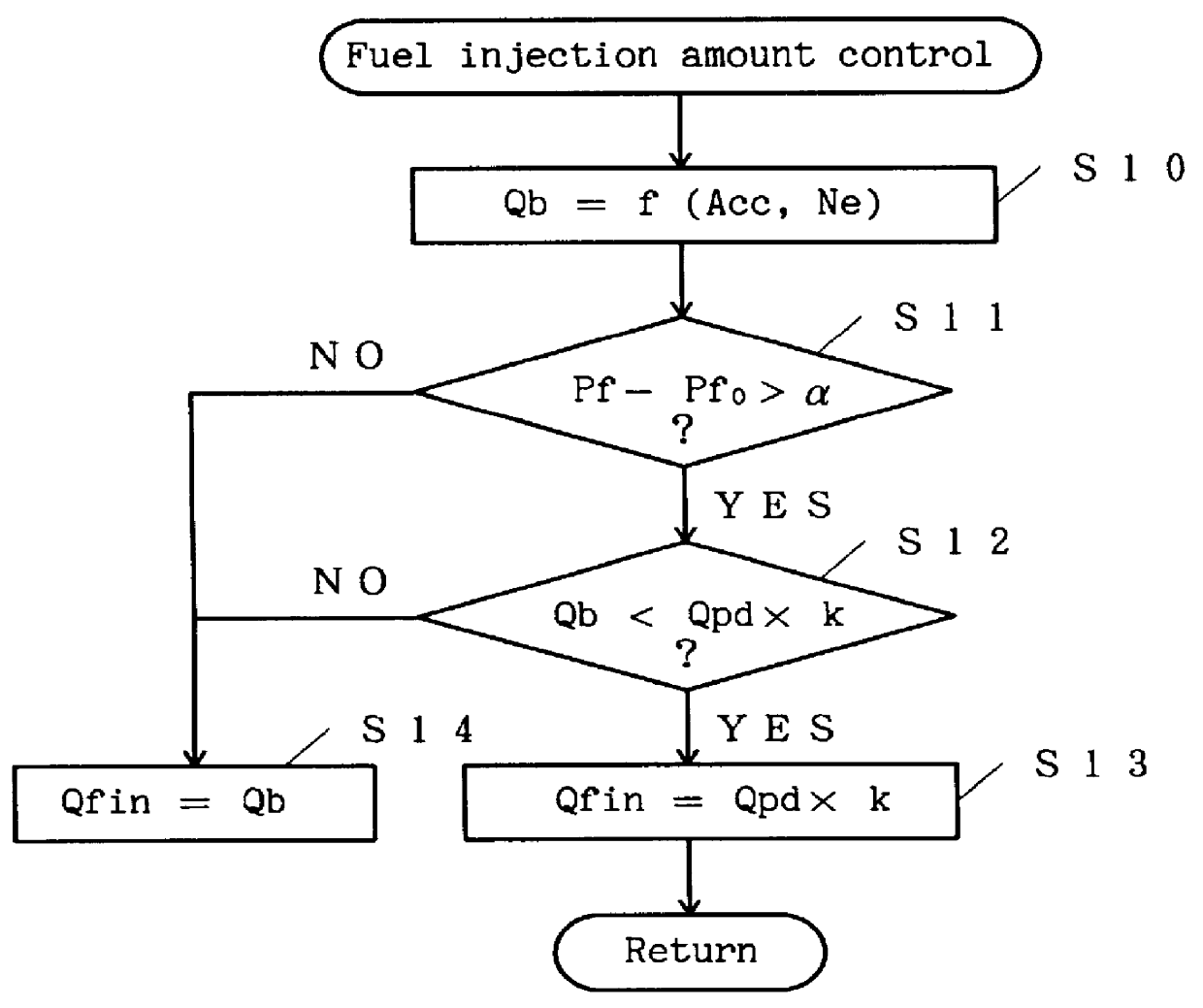

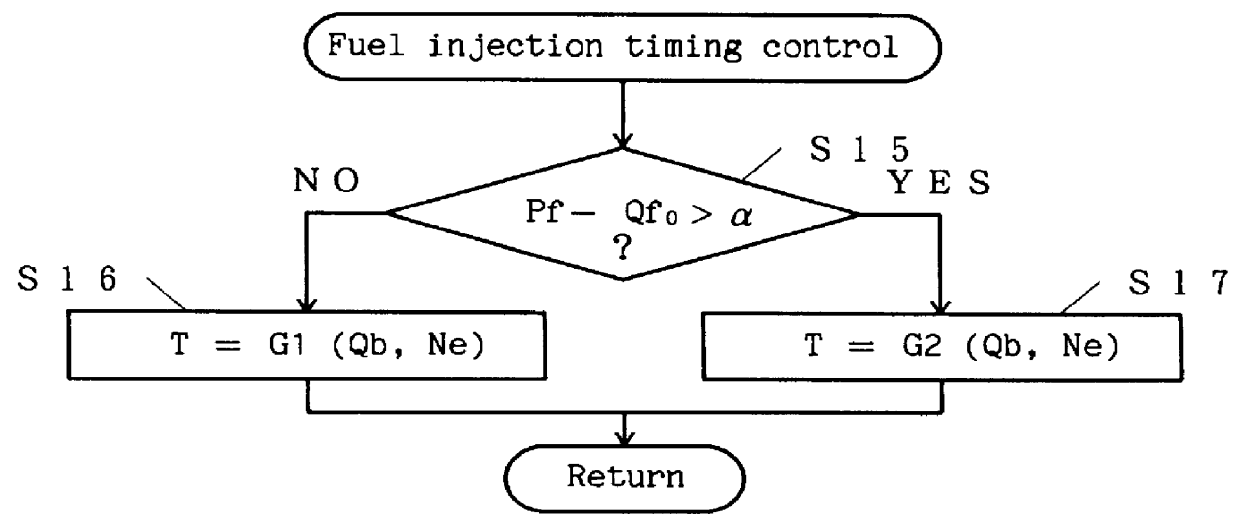

The common-rail type fuel injection method of this invention injects a small amount of fuel during the deceleration of engine to swiftly accomplish reductions in the common rail pressure and the engine revolution speed, thus reducing the amount of NOx at the end of the deceleration. The basic fuel injection amount Qb is determined from the accelerator control input Acc and the engine revolution speed Ne (step S10). When the actual pressure Pf of the common rail is higher than the target pressure Pf0 by more than a predetermined value alpha (step S11) and also the basic fuel injection amount Qb is smaller than the second fuel injection amount, which is equal to a smaller-than-one factor k times the first fuel injection amount Qpd that stabilizes the engine revolution speed during no-load operation (step S12), then the final fuel injection amount Qfin is set to the second fuel injection amount (step S13) to lower the common rail pressure in order to avoid fuel injection at high pressure when the accelerator is depressed again.

Owner:ISUZU MOTORS LTD

Common rail fuel pump with combined discharge and overpressure relief valves

ActiveUS8132558B2Increase flexibilityReduce system costCheck valvesEqualizing valvesCommon railPump chamber

A high pressure piston fuel pump having a discharge check valve between the pumping chamber and a pressurized fuel reservoir and a pressure relief valve between the fuel reservoir and a passageway in the housing, wherein the discharge check valve and the pressure relief valve are contained within a single fitting assembly affixed at the pump housing. A first end flow passage is in fluid communication with the pumping chamber and provides an inlet to the discharge check valve and an outlet from the pressure relief valve. A second end flow passage is in fluid communication with the fuel reservoir and provides an outlet for the discharge check valve and an inlet for the pressure relief valve. Advantages include the ability to pre-test the outlet check and pressure relief prior to assembly into the pump housing, and improved flexibility of the outlet fitting location.

Owner:STANADYNE OPERATING CO LLC

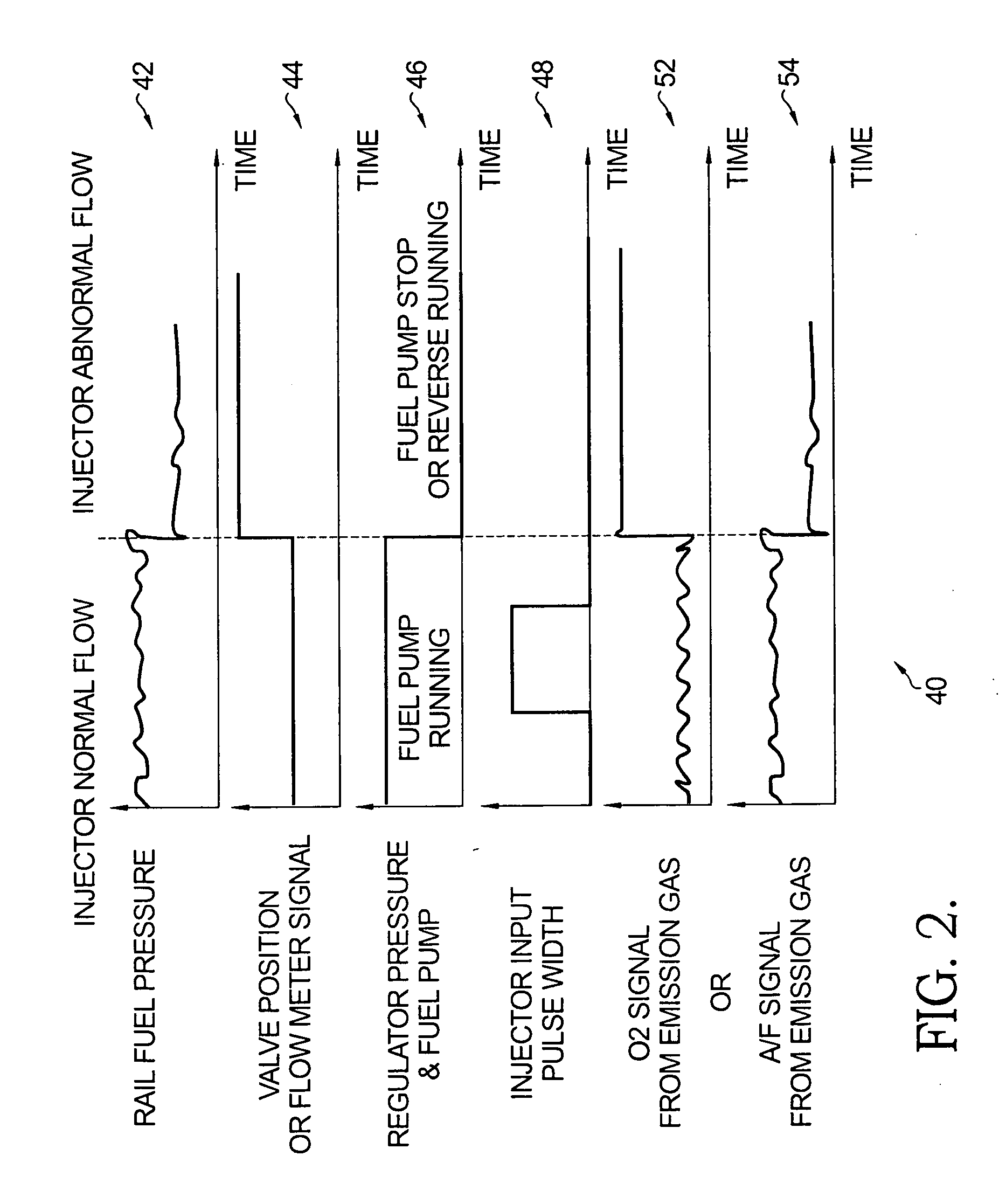

Flow sensing fuel system

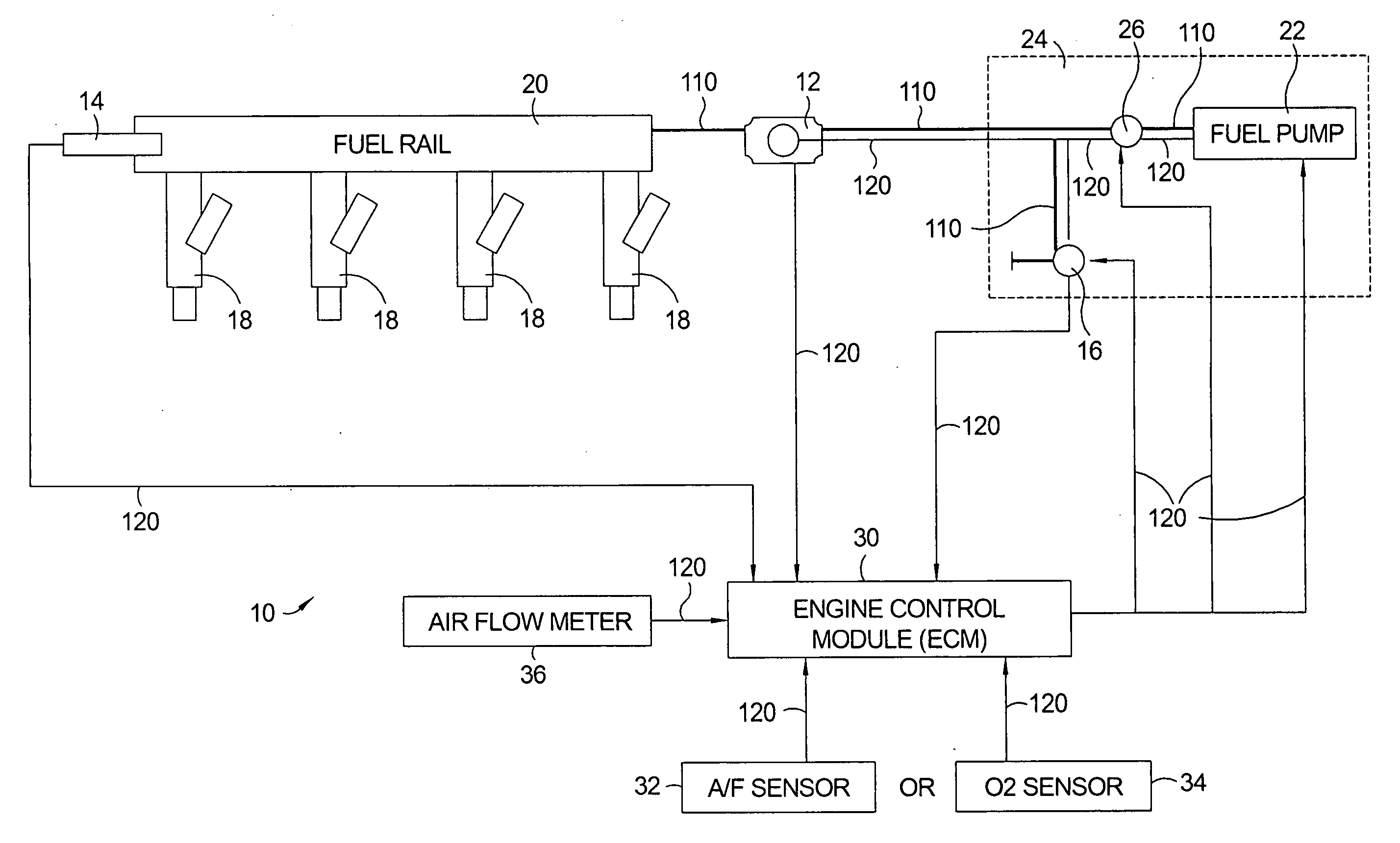

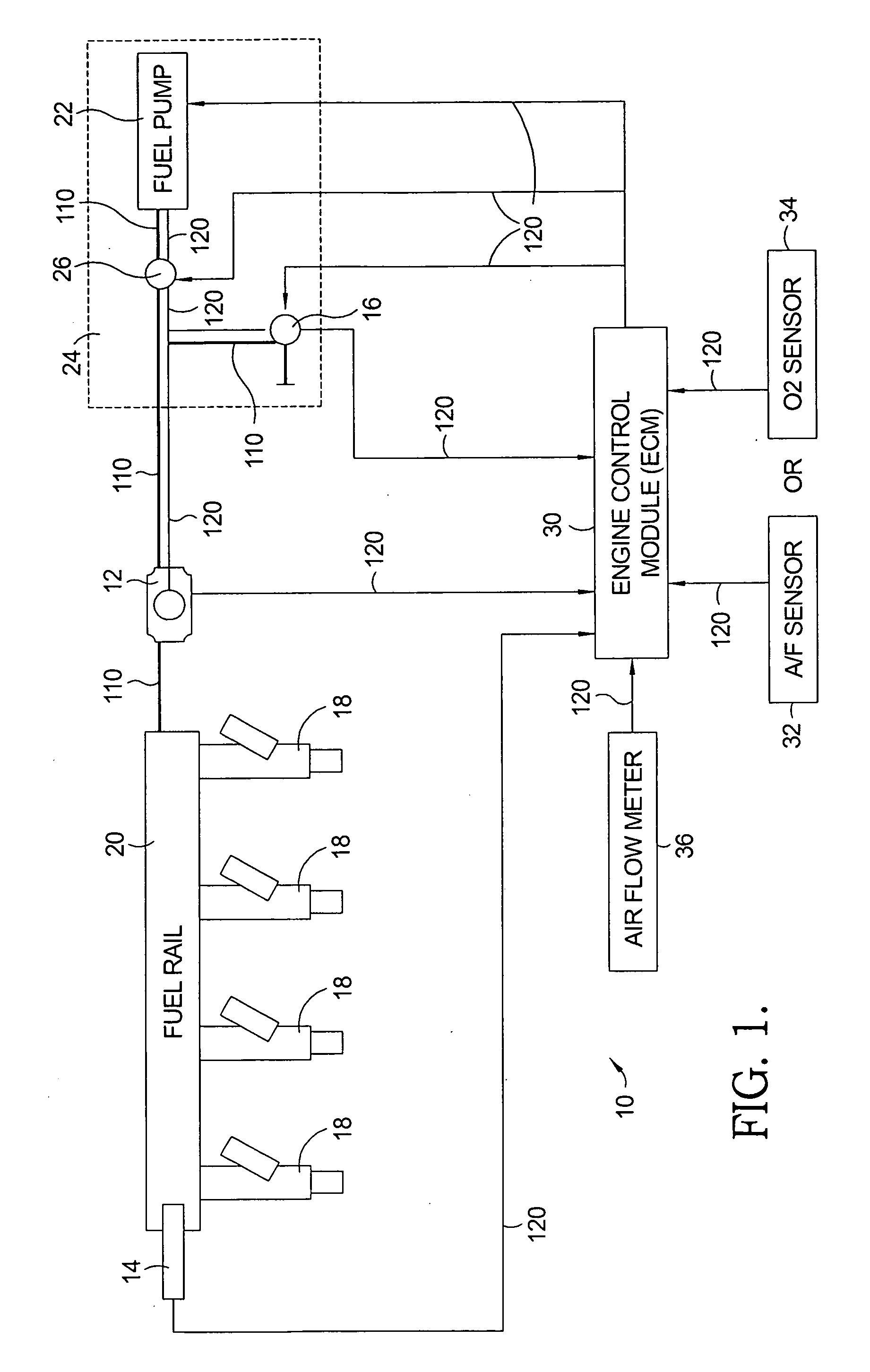

InactiveUS20090250038A1Prevent fuel leakagePrevent leakageAnalogue computers for vehiclesElectrical controlGasoline direct injectionPort fuel injection

A flow sensing fuel system for multiple port fuel injection gasoline engines, gasoline direct injection engines, or common rail diesel engines include a flow monitoring device positioned in a fuel flow passage between a fuel pump and a fuel rail, a fuel pressure sensor in fluid communication with said fuel rail, and a controllable pressure regulator closing to a fuel tank. By integrating flow monitoring device, fuel pressure sensor, and controllable pressure regulator in existing fuel systems, a flow sensing fuel system is provided that protects the engine and limits the fuel leaking into the environment in case of a stuck open condition or sealing problem of one or more injectors or in case of a leak in the fuel rail assembly. The flow sensing fuel system enables monitoring the fuel flow during engine start-up, during engine operation, and after engine shut down.

Owner:DELPHI TECH INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com