Common-rail fuel oil injection system injector failure diagnosing method

A fuel injection system and fault diagnosis technology, which is applied to fuel injection devices, charging systems, instruments, etc., can solve the problems of not being able to apply the common rail fuel injection system and increase costs, and achieve easy implementation, low cost, and reliable judgment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific implementation, working principle and preferred embodiment of the fuel injector fault diagnosis method of the present invention will be described in detail below in conjunction with the accompanying drawings.

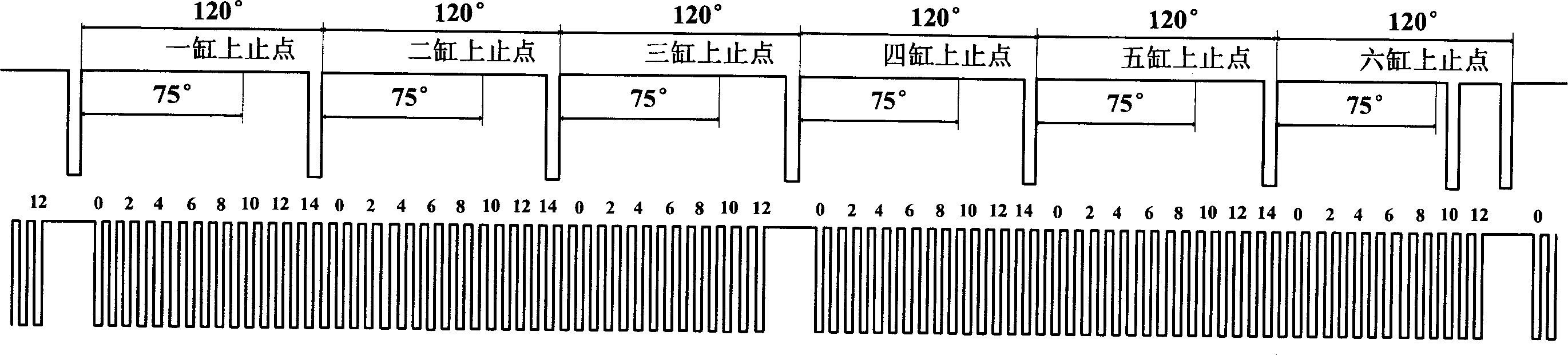

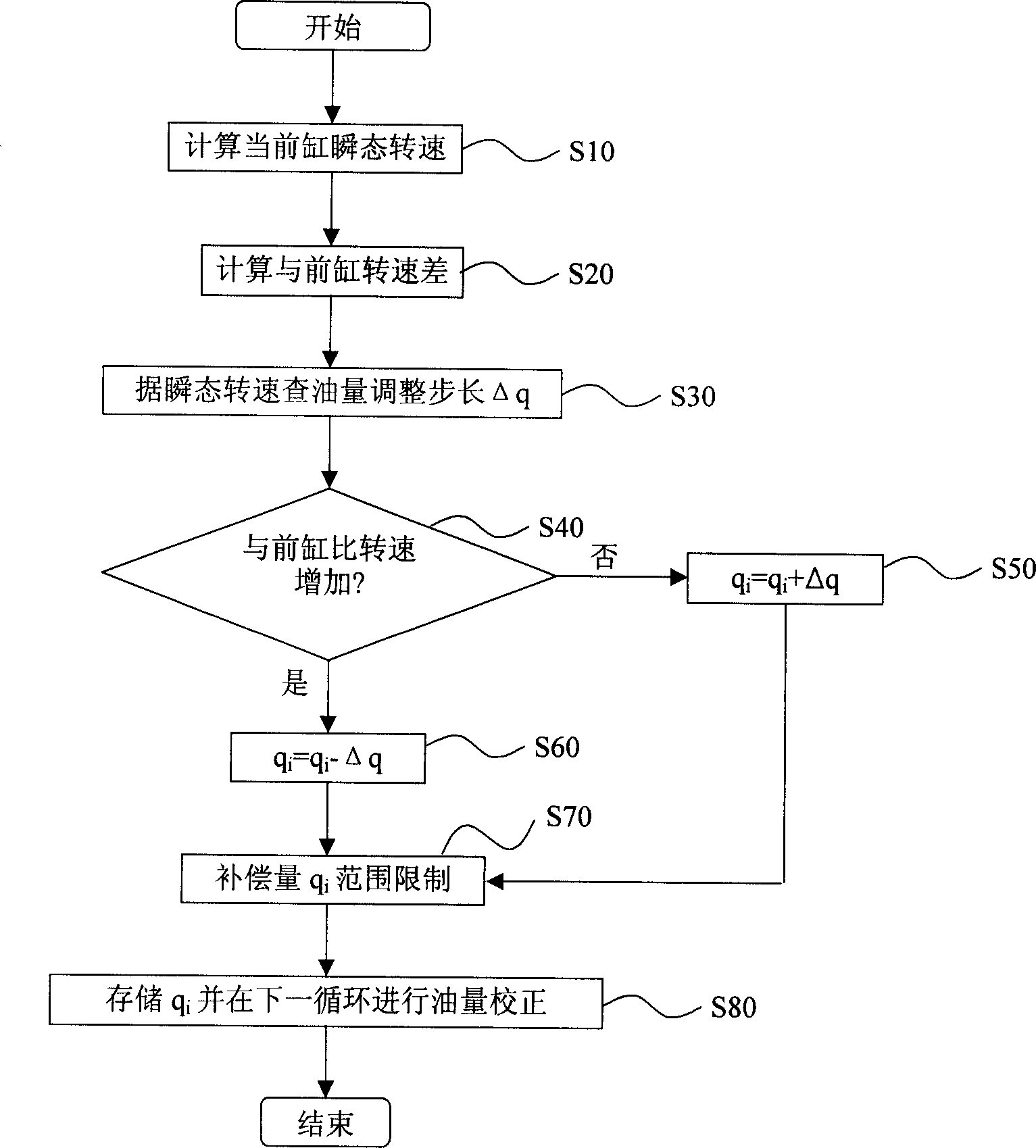

[0017] The accompanying drawing takes a six-cylinder four-stroke common rail diesel engine as an example, and the ignition sequence of the engine is 1-5-3-6-2-4. The crankshaft (or flywheel) chainring used to measure the instantaneous speed of the engine has a structure of 48 missing 3 teeth. The pulse signal tooth plate installed on the high-pressure oil supply pump to identify the cylinder has a 6+1 tooth structure. figure 1 Indicates the phase relationship between the engine crankshaft and the high-pressure fuel pump speed pulse signal. exist figure 1 Among them, the compression top dead center of the corresponding cylinder is located at about 75° crankshaft angle after the cylinder signal is judged. In order to make the collected signal reflec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com