Patents

Literature

3227 results about "Injection pump" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

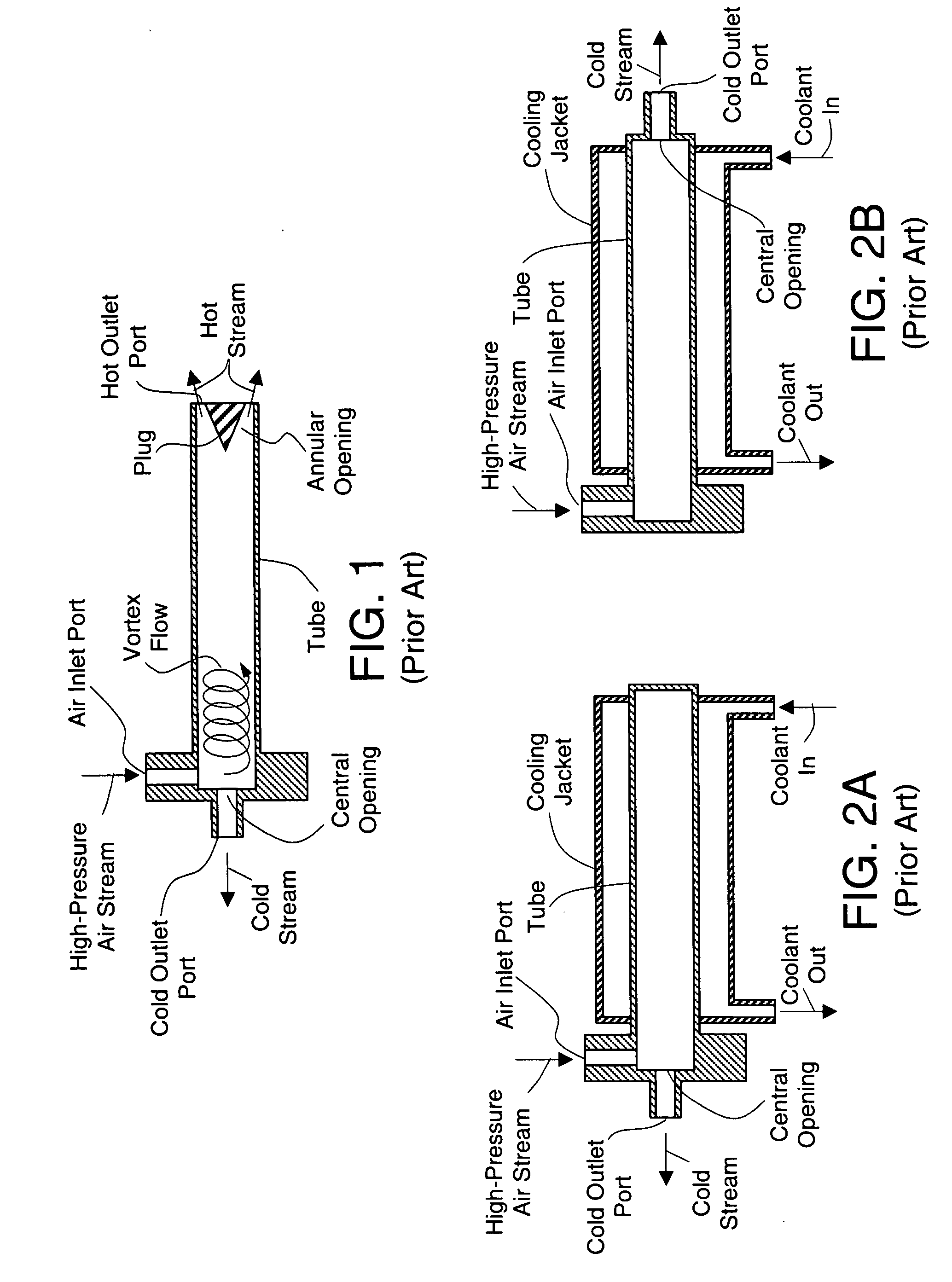

An Injection Pump is the device that pumps diesel (as the fuel) into the cylinders of a diesel engine. Traditionally, the injection pump is driven indirectly from the crankshaft by gears, chains or a toothed belt (often the timing belt) that also drives the camshaft. It rotates at half crankshaft speed in a conventional four-stroke diesel engine. Its timing is such that the fuel is injected only very slightly before top dead centre of that cylinder's compression stroke. It is also common for the pump belt on gasoline engines to be driven directly from the camshaft. In some systems injection pressures can be as high as 620 bar (8992 psi) .

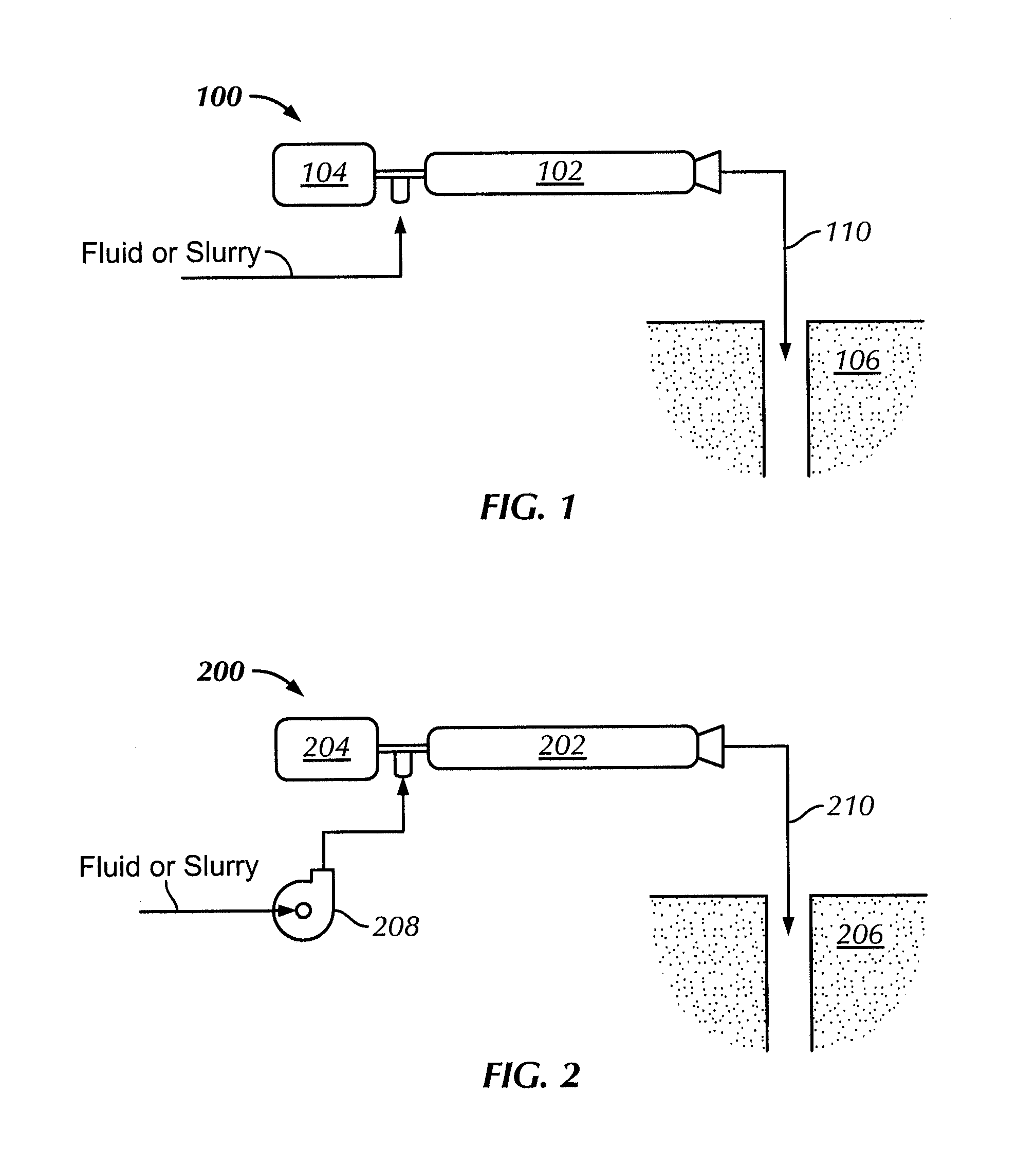

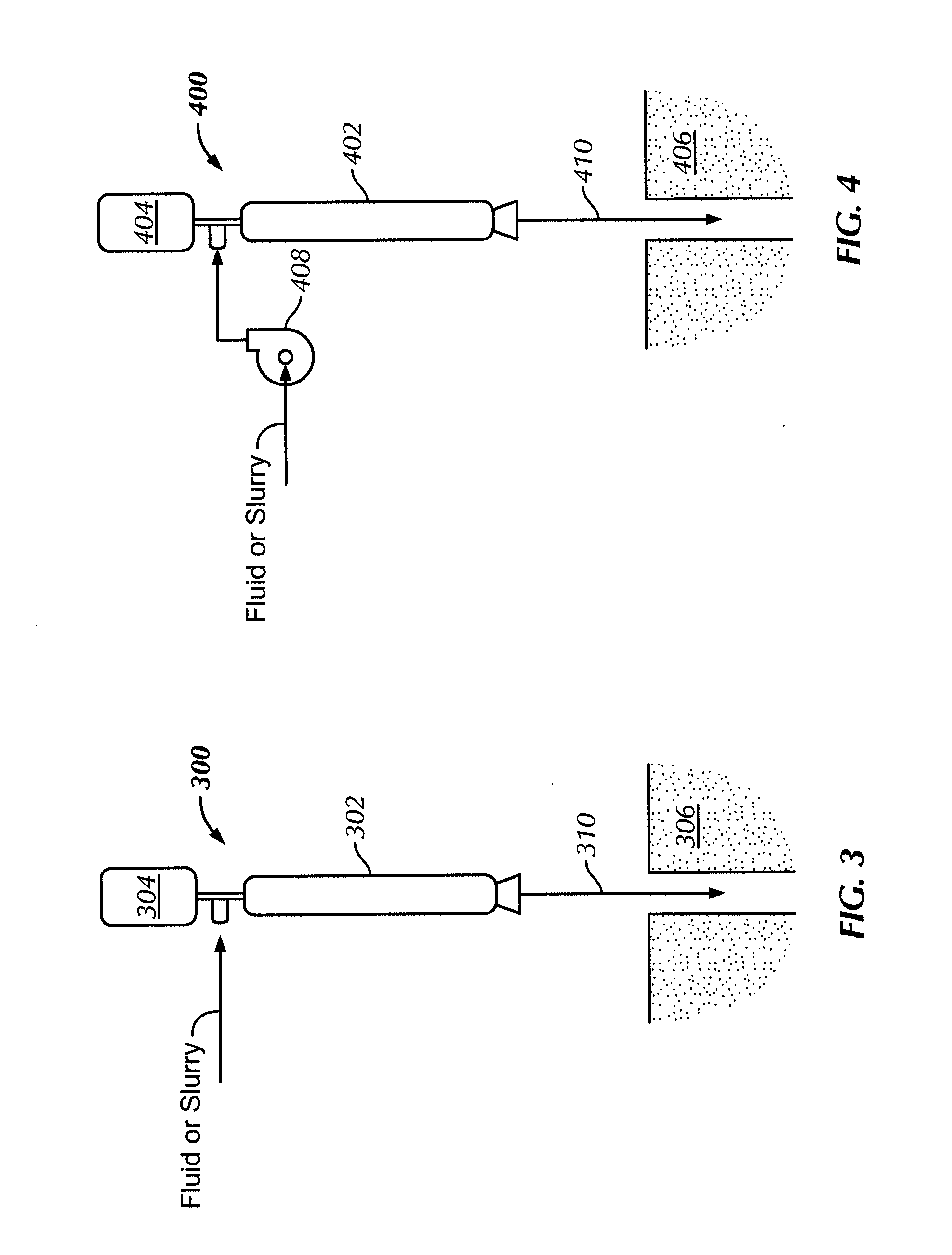

Method and system for injection of viscous unweighted, low-weighted, or solids contaminated fluids downhole during oilfield injection process

A system for injecting a fluid into a formation including a fluid, and at least one injection pump configured to receive the fluid, the at least one pump including a centrifugal pump having at least two stages configured to increase the pressure of the received fluid is disclosed. The system further includes a drive device coupled to the injection pump. A method of injecting a fluid downhole including providing a fluid to an injection pump, the injection pump including a centrifugal pump having at least two stages, pumping the fluid through the at least two stages of the centrifugal pump, thereby increasing the pressure of the fluid, and injecting the fluid from the injection pump into a wellbore is also disclosed.

Owner:MI

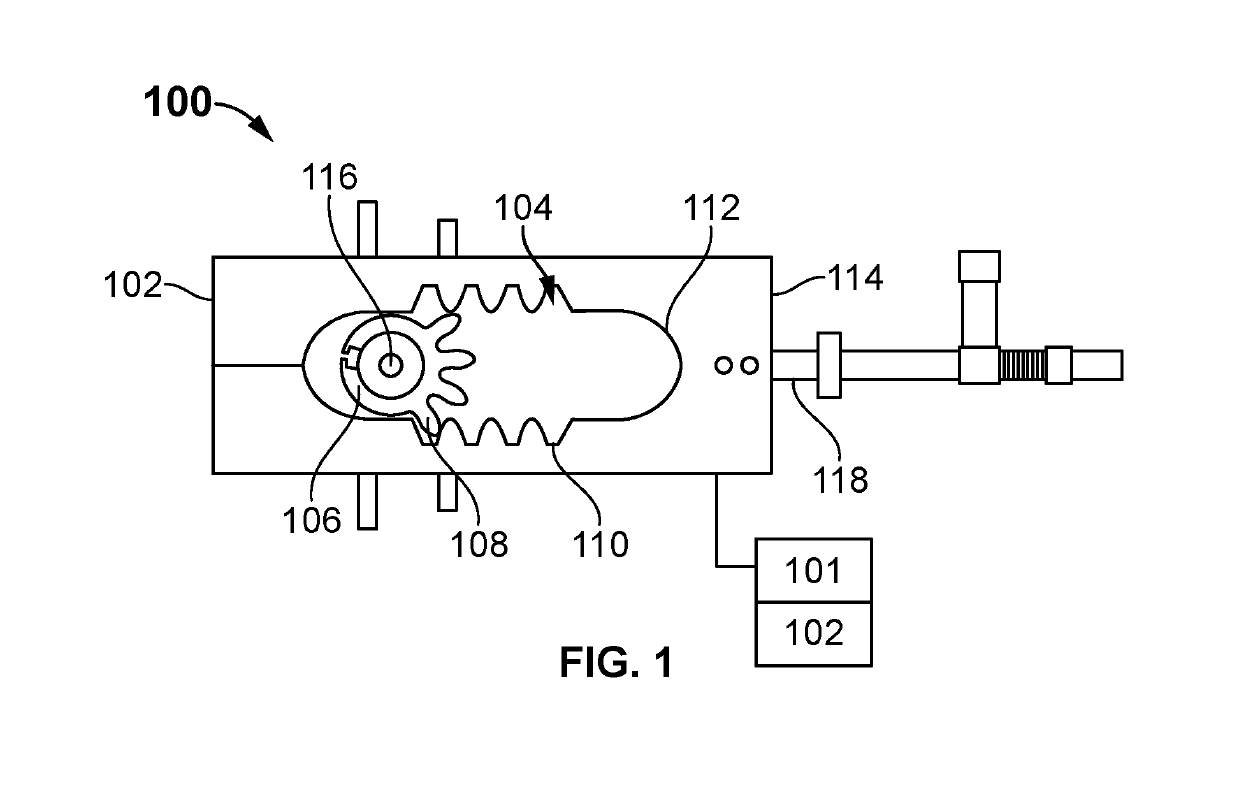

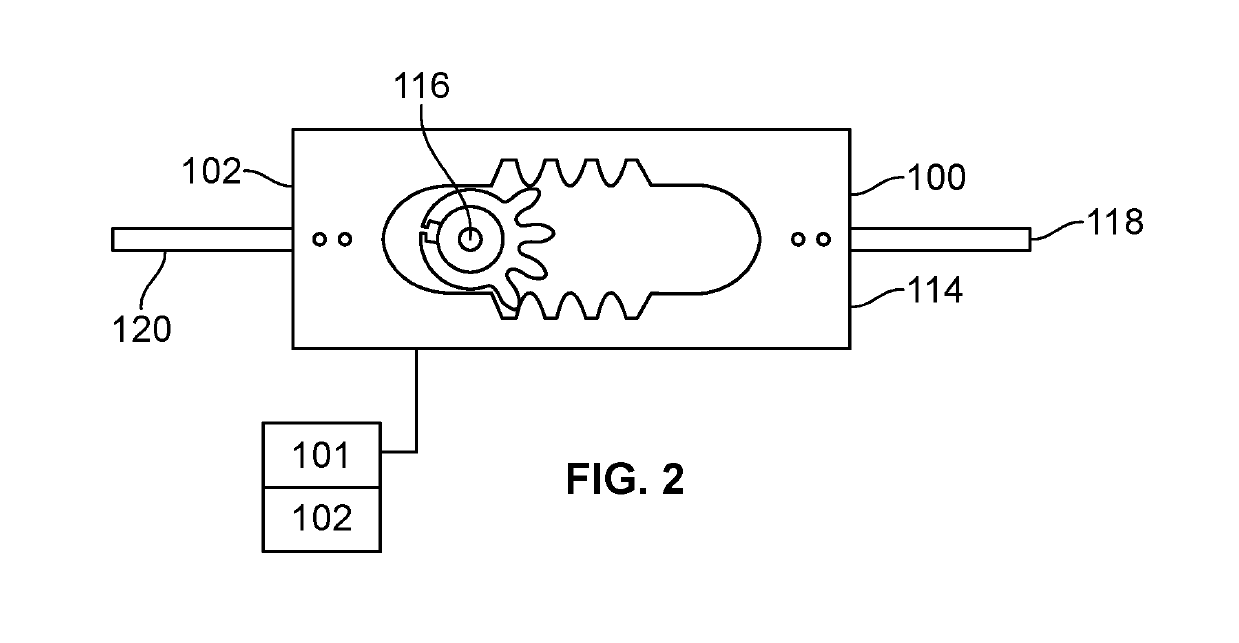

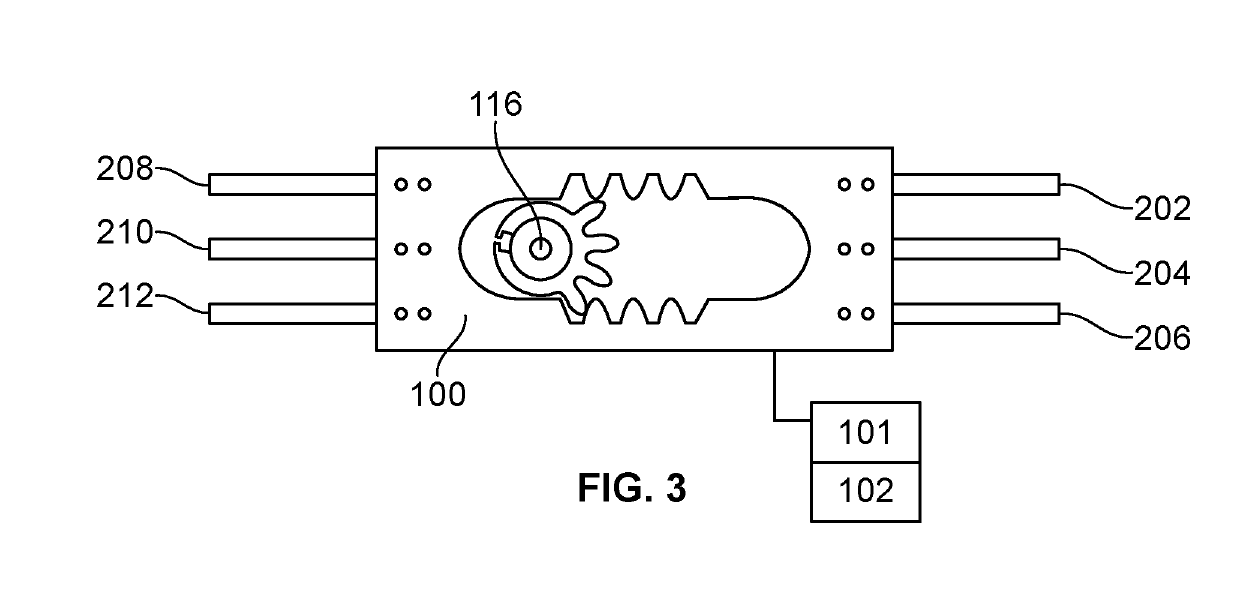

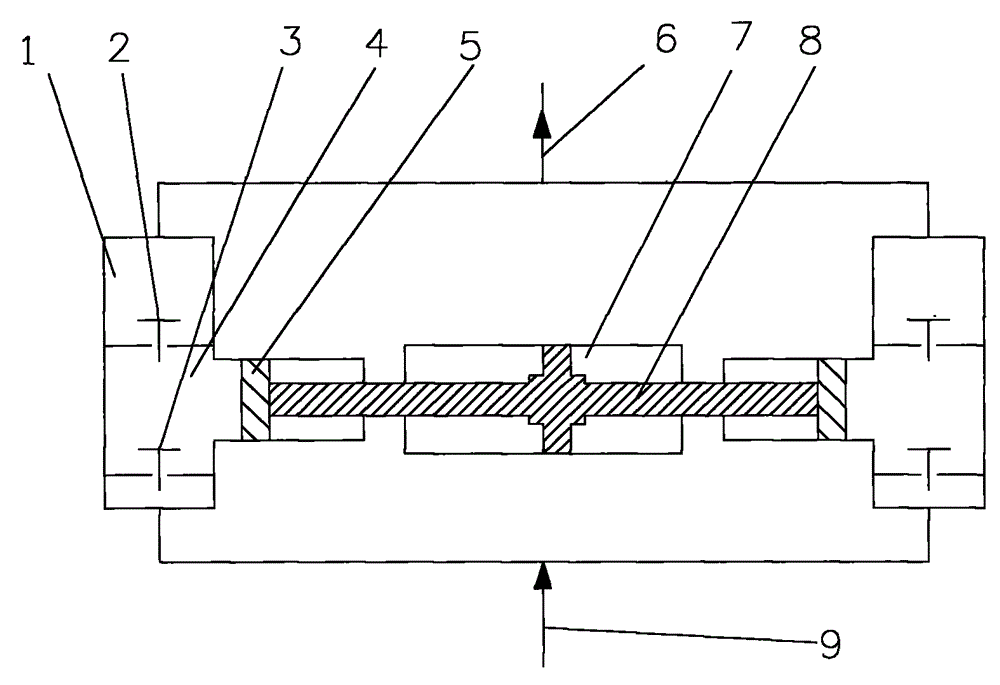

System and Method for a Reciprocating Injection Pump

A reciprocating injection pump is disclosed including but not limited to a reciprocating block driven by a rotating gear, the gear having a substantially circular shape with four gear teeth formed on the rotating gear along approximately one fourth of the substantially circular shape, the rotating gear is attached to a rotating motor, the rotating motor having a right-angle motor shaft.

Owner:PREDOMINANT PUMPS & AUTOMATION SOLUTIONS LLC

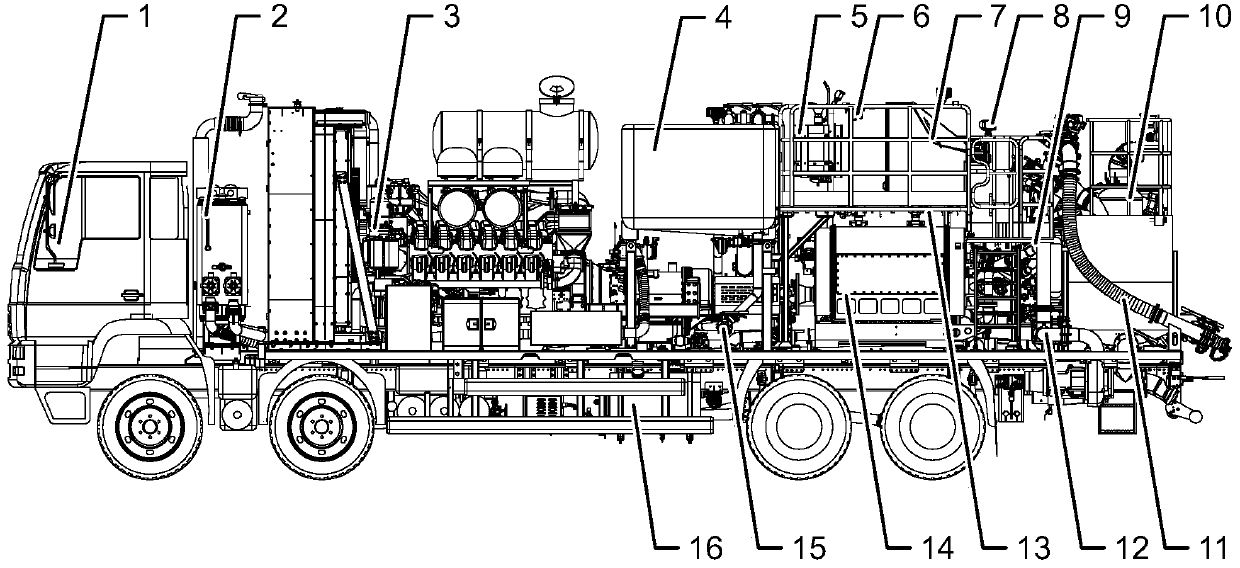

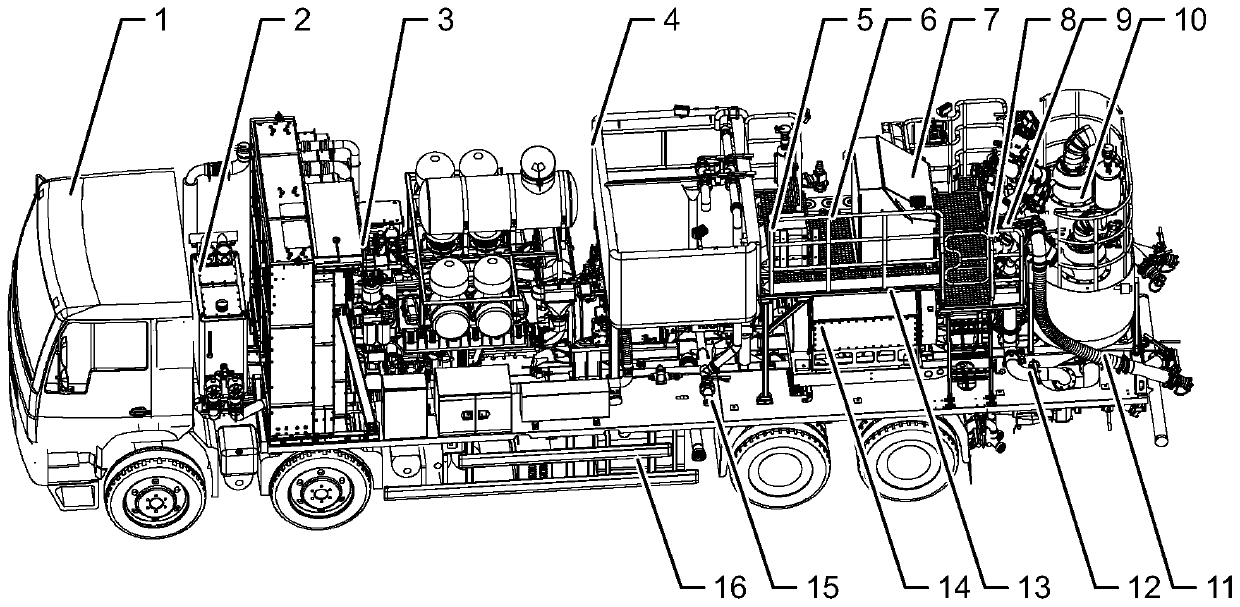

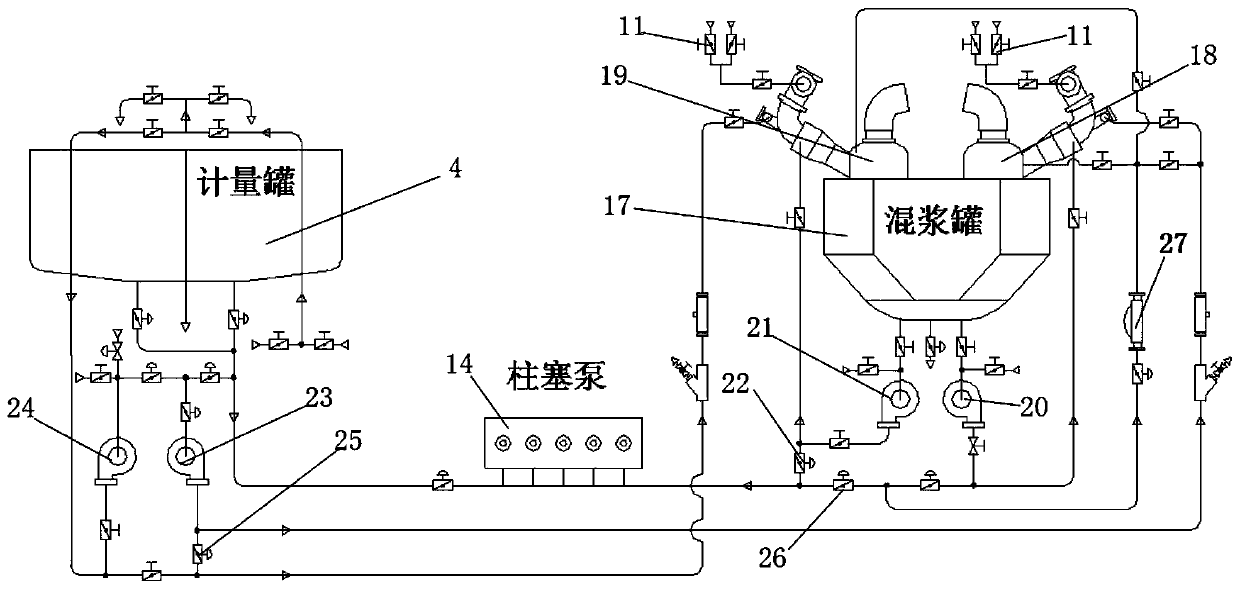

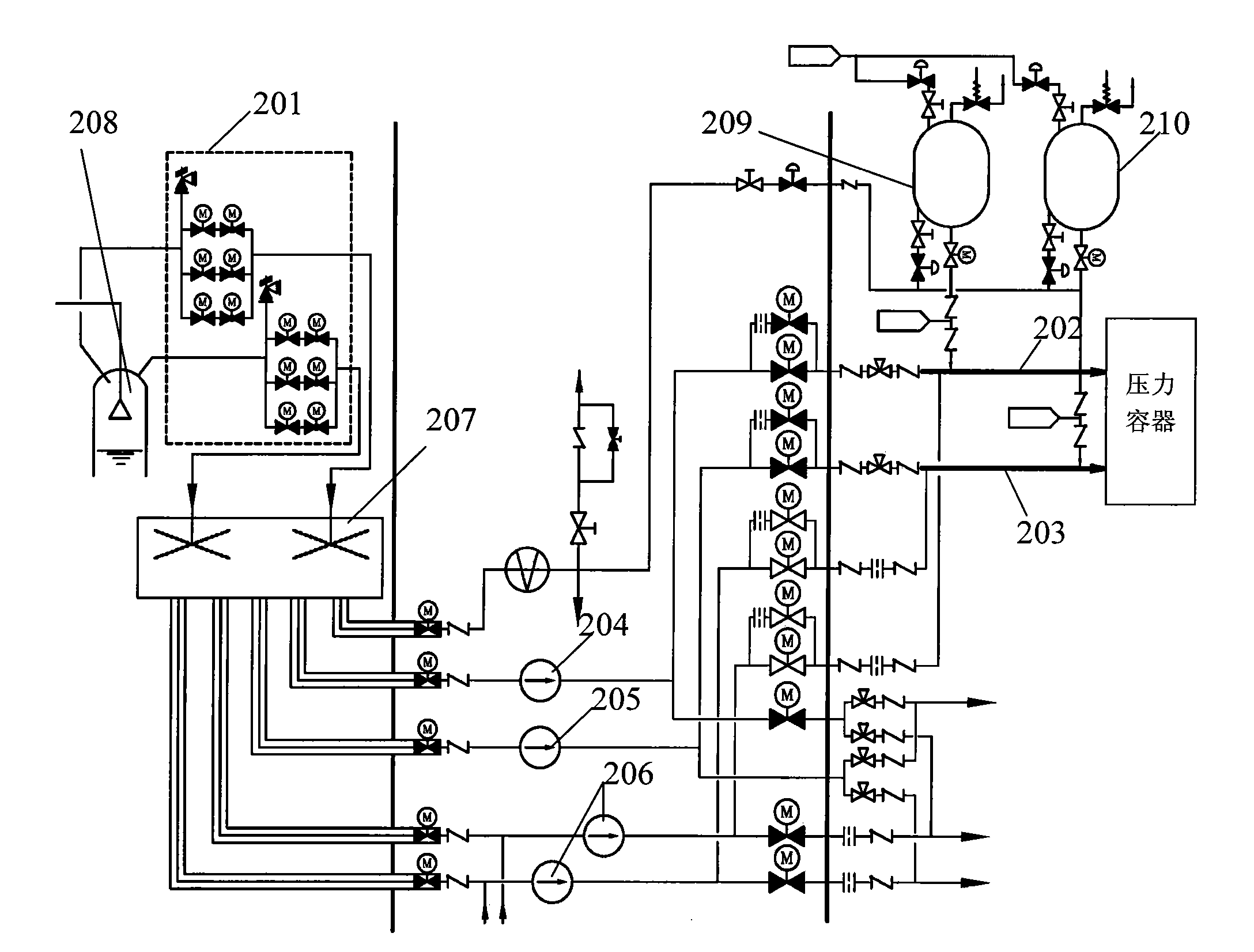

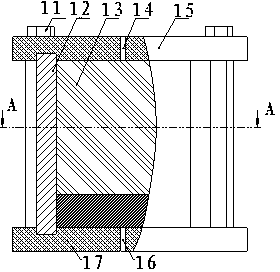

Novel ultra-large-displacement ultrahigh-pressure well cementing equipment

PendingCN111173476AIncrease pressureIncrease displacementItem transportation vehiclesSealing/packingUltra high pressureDrivetrain

The invention discloses novel ultra-large-displacement ultrahigh-pressure well cementing equipment. The novel ultra-large-displacement ultrahigh-pressure well cementing equipment comprises a loading carrier. A hydraulic system, a power transmission system, a metering tank, an electrical system, an air path system, a control system, an operating platform, a plunger pump, a clean water manifold, a mud manifold, a high-pressure manifold, a mixing system and an ash feeding manifold are mounted on the loading carrier, wherein the plunger pump is a five-cylinder plunger pump. The five-cylinder plunger pump is adopted to increase the pressure and displacement of the well cementing equipment, and the requirements of high pressure and large displacement are met; slurry mixing is carried out by double mixing devices, the mixing efficiency is improved, the stability of the slurry mixing density is improved, and the requirement of long-time uninterrupted operation is guaranteed; a mixing system pipeline is optimized, multiple sets of mixing systems are integrated on one slurry mixing tank, and the stability of the equipment is improved; and the clean water manifold is optimized, so that watersupply requirements of the multiple mixing devices can also be met at the same time by using one injection pump, and the requirement of large displacement is met.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

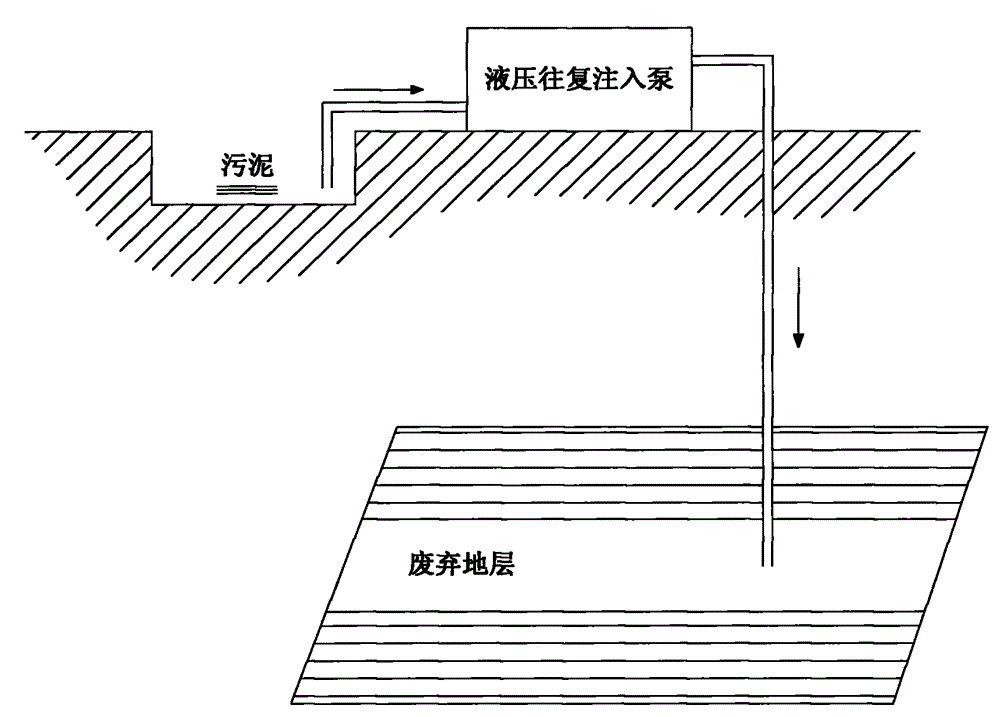

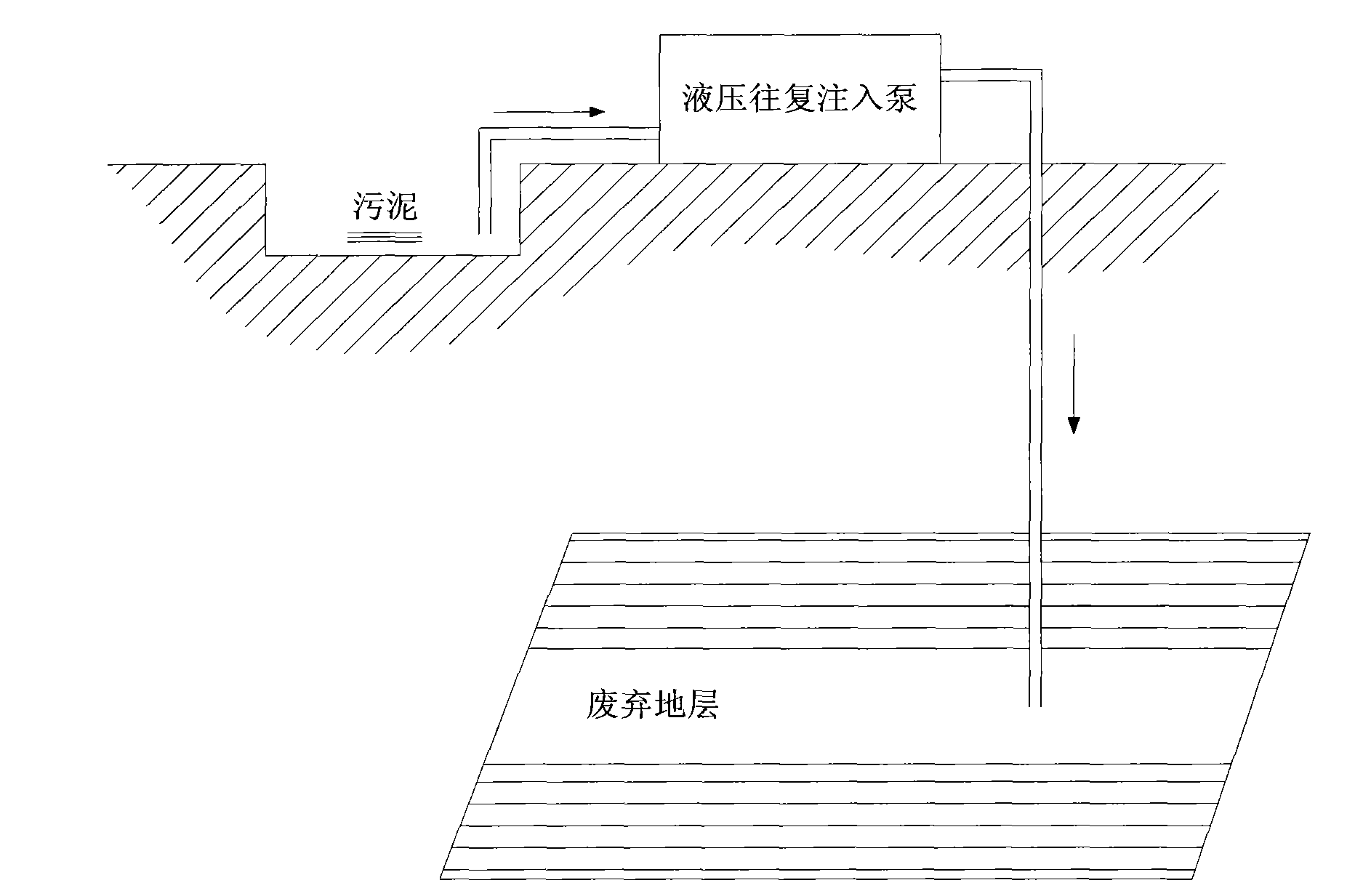

Harmless treatment method for reinjection of oil mining sludge

Relating to the technical field of harmless treatment of petroleum exploitation sludge, the invention provides a harmless reinjection treatment method for petroleum exploitation sludge. By means of a pump station composed of several hydraulic injection pumps in parallel connection, the sludge generated in petroleum exploitation is sent to an abandoned layer of an oil field. The method provided in the invention employs the hydraulic injection pumps with long stroke, low stroke frequency and high pressure to inject the sludge into the abandoned layer of the oil field, therefore, the treatment problem of oilfield exploitation sludge is solved, and simultaneously the sludge is returned to underground, thus realizing recycling of petroleum resources in the sludge, enhancing the petroleum recovery rate of the oil field, and changing the waste petroleum exploitation sludge into things of value.

Owner:DEZHOU UNITED GASOLINEEUM MACHINERY

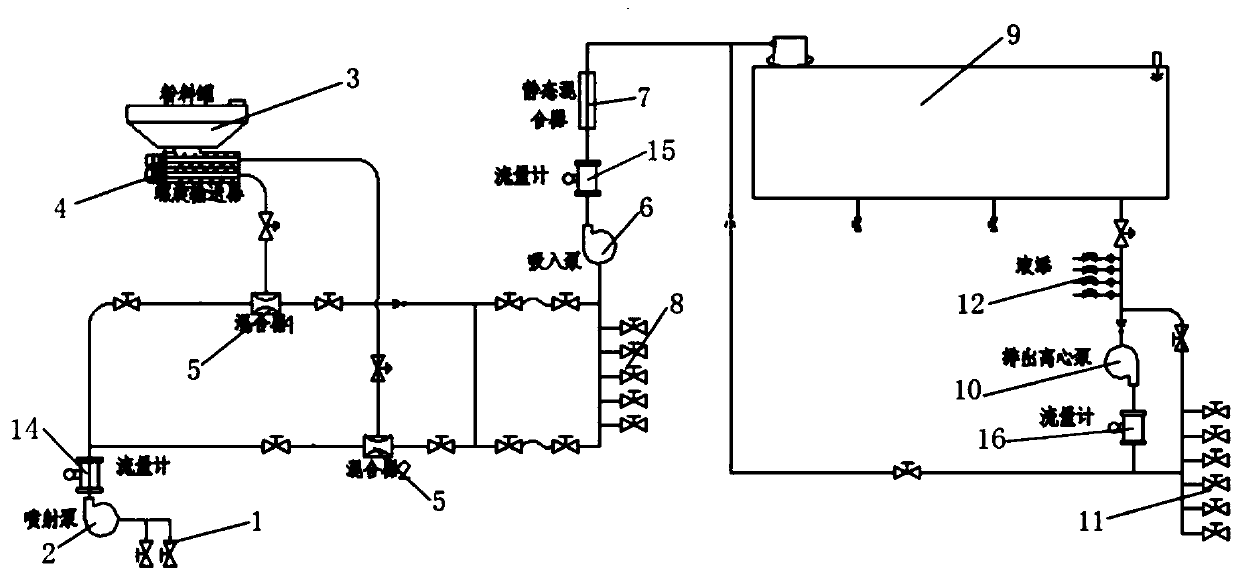

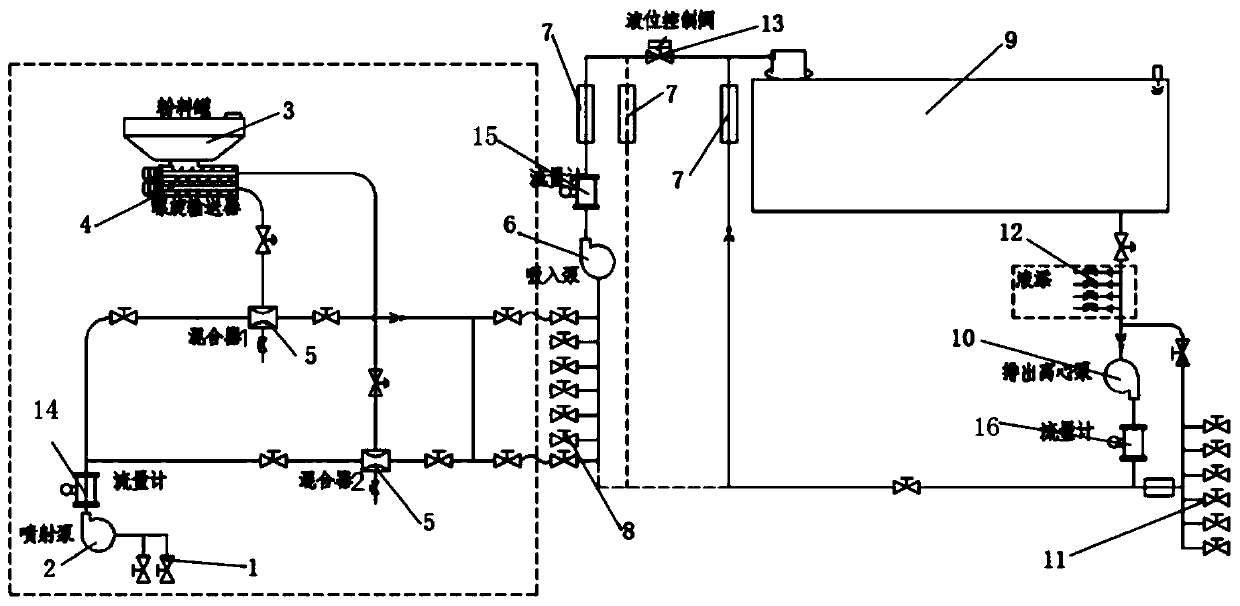

Mixing system

PendingCN110787667AImprove mix qualityImprove mixing efficiencyTransportation and packagingMixing methodsEngineeringStatic mixer

The invention discloses a mixing system. The mixing system comprises a mixing module and an output module, the mixing module comprises a first liquid inlet header, an injection pump, a powder tank anda mixer, the first liquid inlet header is connected with the injection pump, the injection pump is connected with the mixer, and the powder tank provides powder for the mixer; the output module comprises a second liquid inlet header, a suction pump, a second flowmeter, a static mixer, a mixing tank and a liquid discharge manifold, and the second liquid inlet header, the section pump, the second flowmeter, the static mixer, the mixing tank and the liquid discharge manifold are sequentially connected; an outlet of the mixer of the mixing module is connected with an inlet of the suction pump ofthe output module through a valve, and the mixing module and the output module can be used respectively or used in combination as a complete set. The mixing system has the beneficial effects that thesecond liquid inlet header and the static mixer are arranged, mixing with large discharge capacity and high quality can be completed with low energy consumption; and the mixing system is flexible in disassembly and assembly.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

Harmless reinjection treatment method for petroleum exploitation sludge

Relating to the technical field of harmless treatment of petroleum exploitation sludge, the invention provides a harmless reinjection treatment method for petroleum exploitation sludge. By means of a pump station composed of several hydraulic injection pumps in parallel connection, the sludge generated in petroleum exploitation is sent to an abandoned layer of an oil field. The method provided in the invention employs the hydraulic injection pumps with long stroke, low stroke frequency and high pressure to inject the sludge into the abandoned layer of the oil field, therefore, the treatment problem of oilfield exploitation sludge is solved, and simultaneously the sludge is returned to underground, thus realizing recycling of petroleum resources in the sludge, enhancing the petroleum recovery rate of the oil field, and changing the waste petroleum exploitation sludge into things of value.

Owner:DEZHOU UNITED GASOLINEEUM MACHINERY

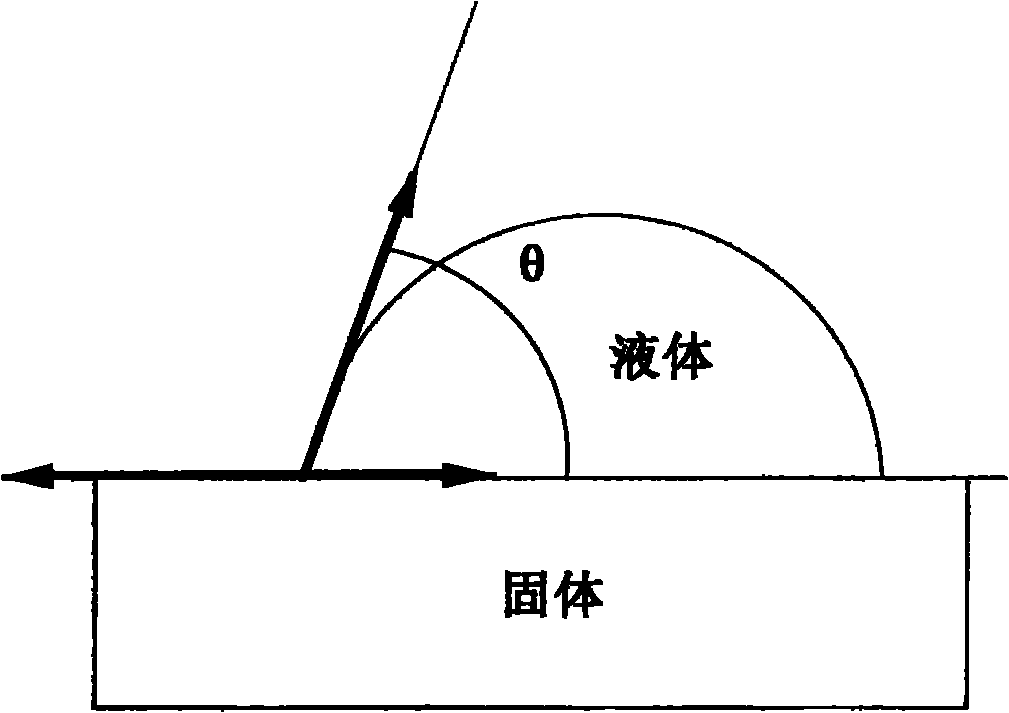

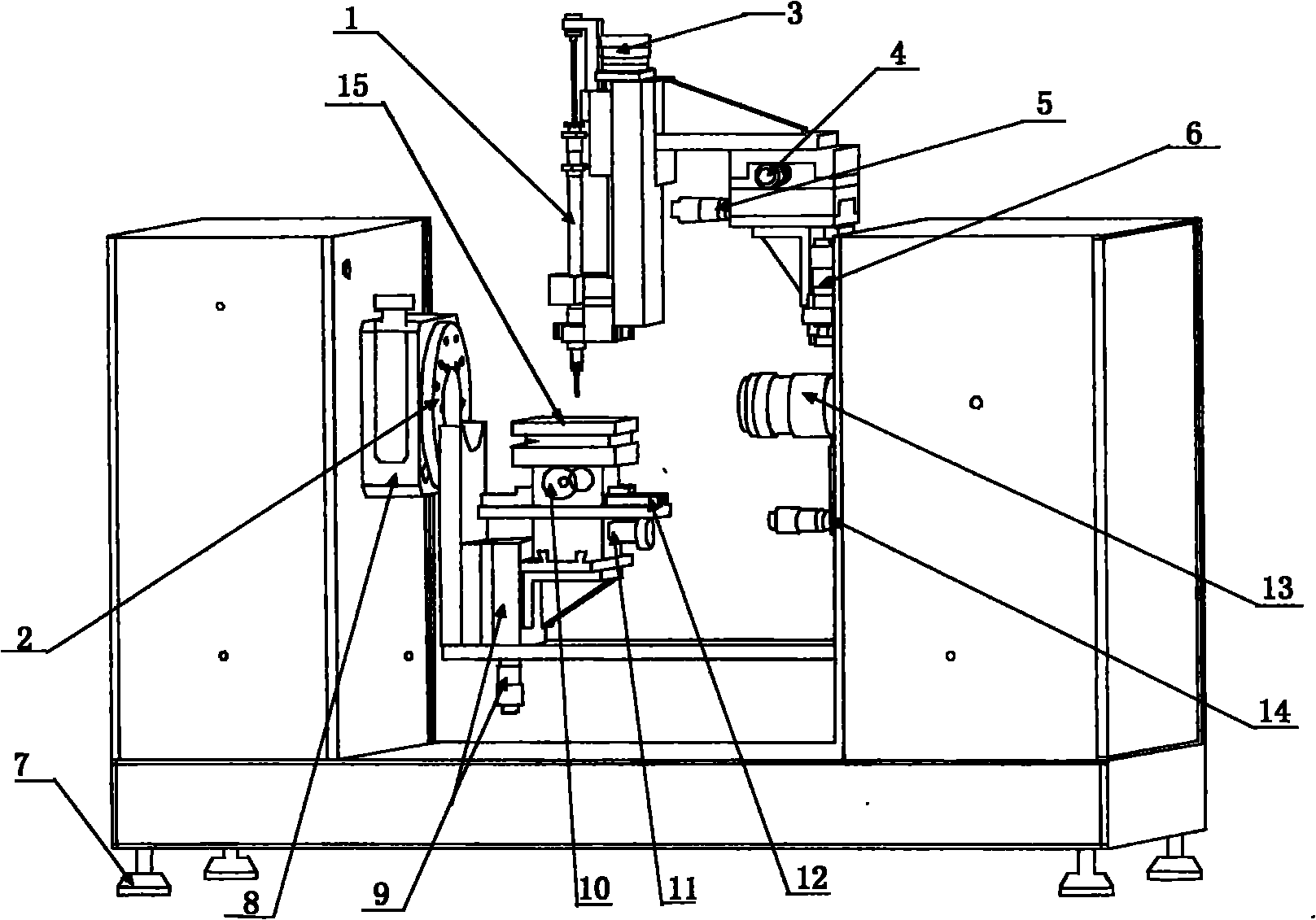

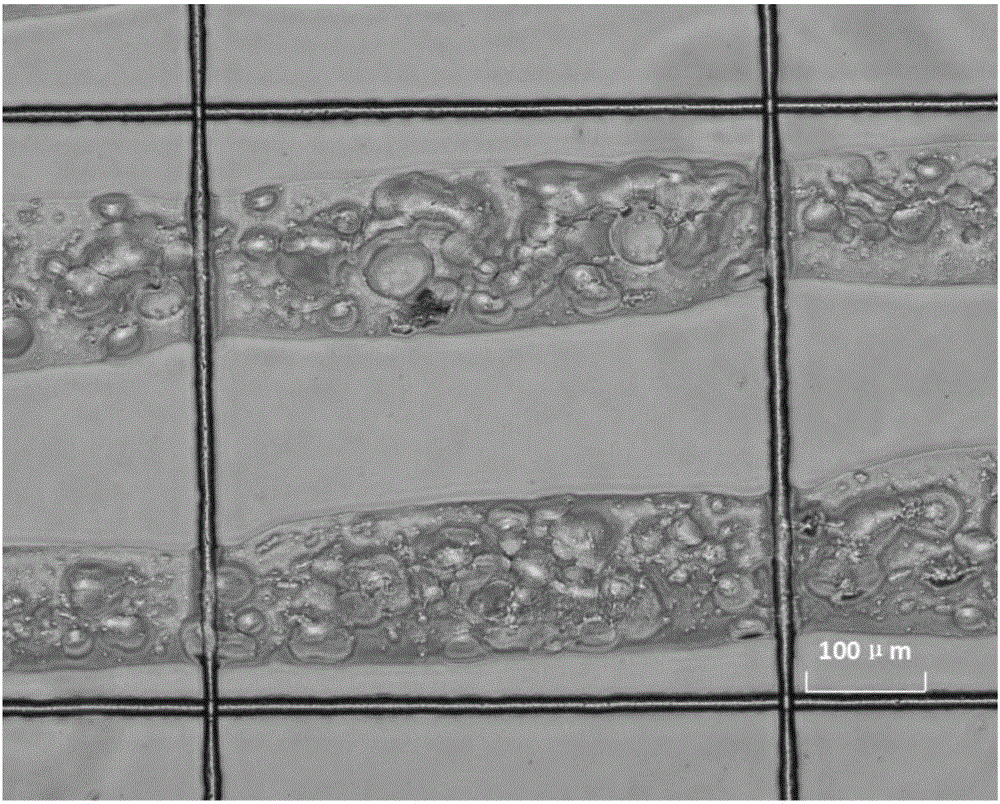

Apparatus and method for testing solid-liquid dynamic and static contact angles by actual liquid droplet method

InactiveCN101865807AHigh precisionEasy to operateSurface tension analysisPeristaltic pumpSmall droplet

The invention discloses an apparatus and a method for testing solid-liquid dynamic and static contact angles by an actual liquid droplet method. The method comprises the following steps of: during the testing, placing a solid phase sample on a sample table; controlling X, Y and Z of the sample table to move to a focusing position of a lens; sucking the liquid phase sample into a micro sample injector, injection pump or peristaltic pump; controlling the X, Y and Z of the sample injector to move to the focusing position; dripping a small droplet of the liquid and adsorbing the droplet to a needle head; moving the needle head to the surface of the solid phase sample until the liquid phase sample is adsorbed to the surface of the solid; making a software system control an optical imaging system (CCD) to capture a real-time picture and analyzing the picture by using the actual liquid droplet method; and displaying calculated solid-liquid contact angle value, solid surface free energy value and adhesion work value and managing the values by a database. The apparatus and the method can completely improve the accuracy of the analysis of the solid-liquid interfacial tension, are simple to operate, can be widely applied and have high popularization value.

Owner:上海梭伦信息科技有限公司

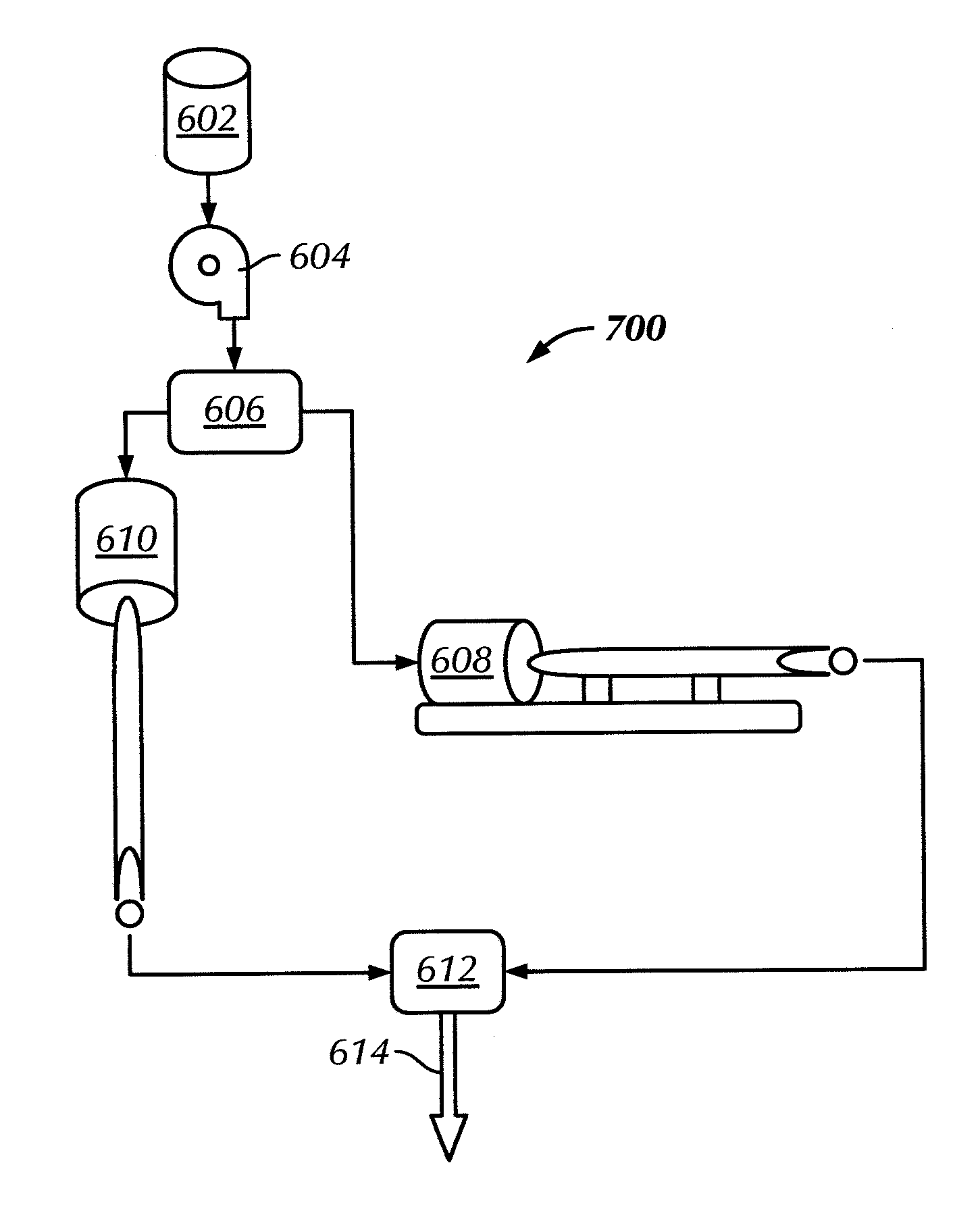

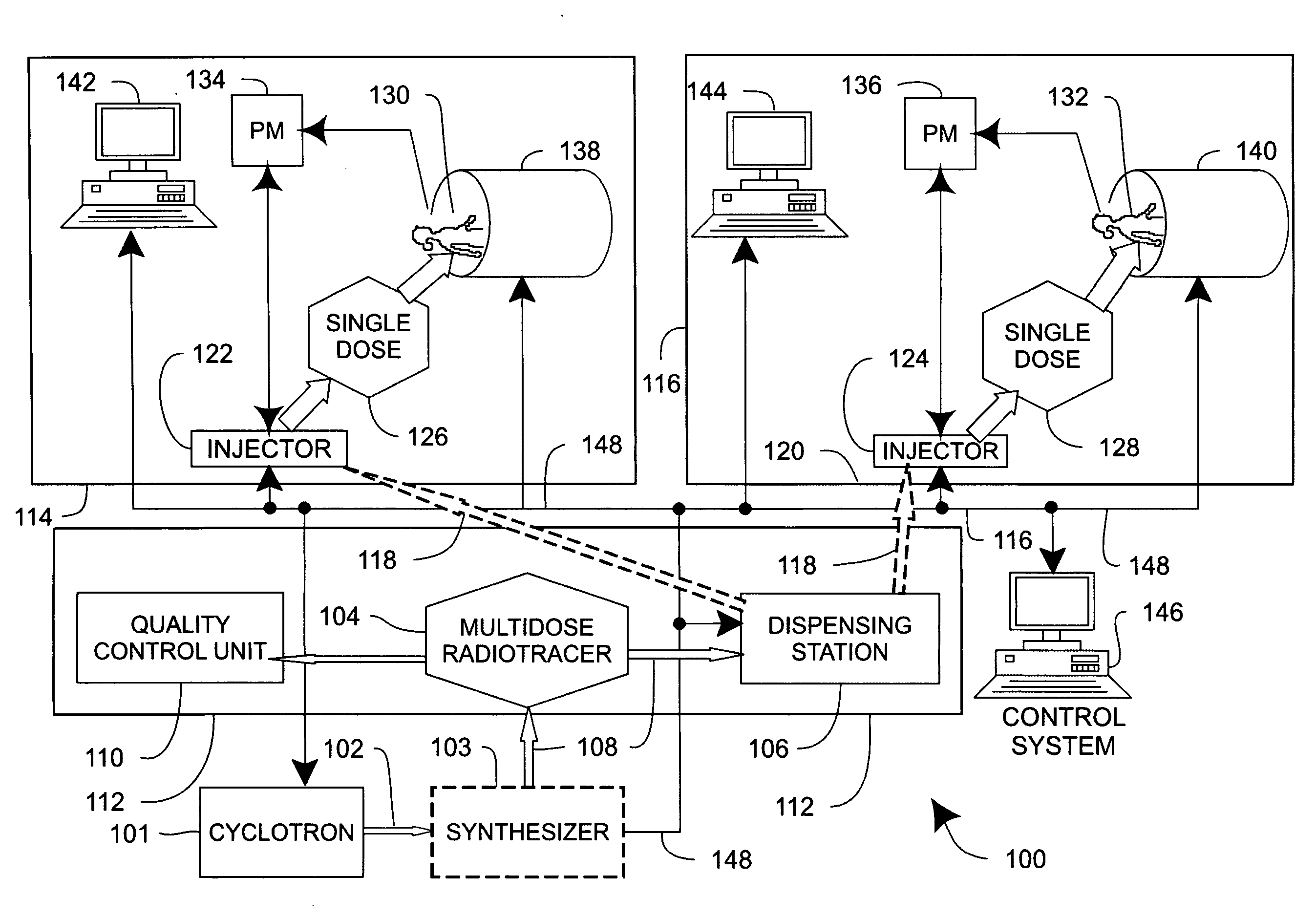

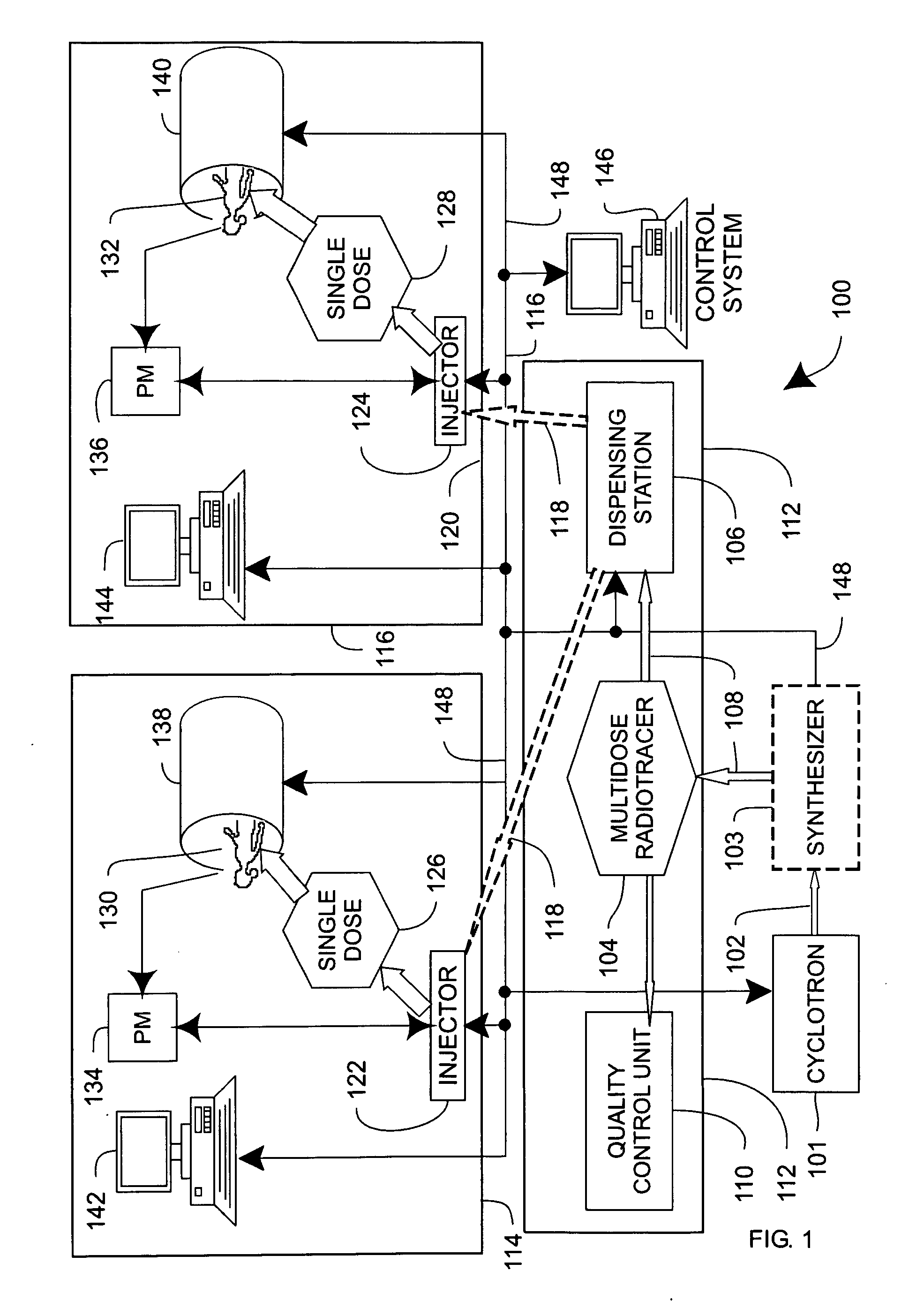

Systems, methods and apparatus for infusion of radiopharmaceuticals

ActiveUS20080242915A1Economy of scaleImprove distributionMechanical/radiation/invasive therapiesDrug and medicationsIntravenous needlesRadioactive tracer

Systems, apparatus and methods are provided through which an injector system automates a process of injecting an individual dose from a multiple dose of a radiotracer material. In some embodiments, the injector system includes a first dose calibrator system that receives a multidose vial of a radiotracer, a second dose calibrator system, an injection pump and an intravenous needle. In some embodiments, the first dose calibrator system and the multidose vial have an integrated shape. In some embodiments, the first dose calibrator system includes a pneumatic arm that receives the multidose vial.

Owner:GENERAL ELECTRIC CO

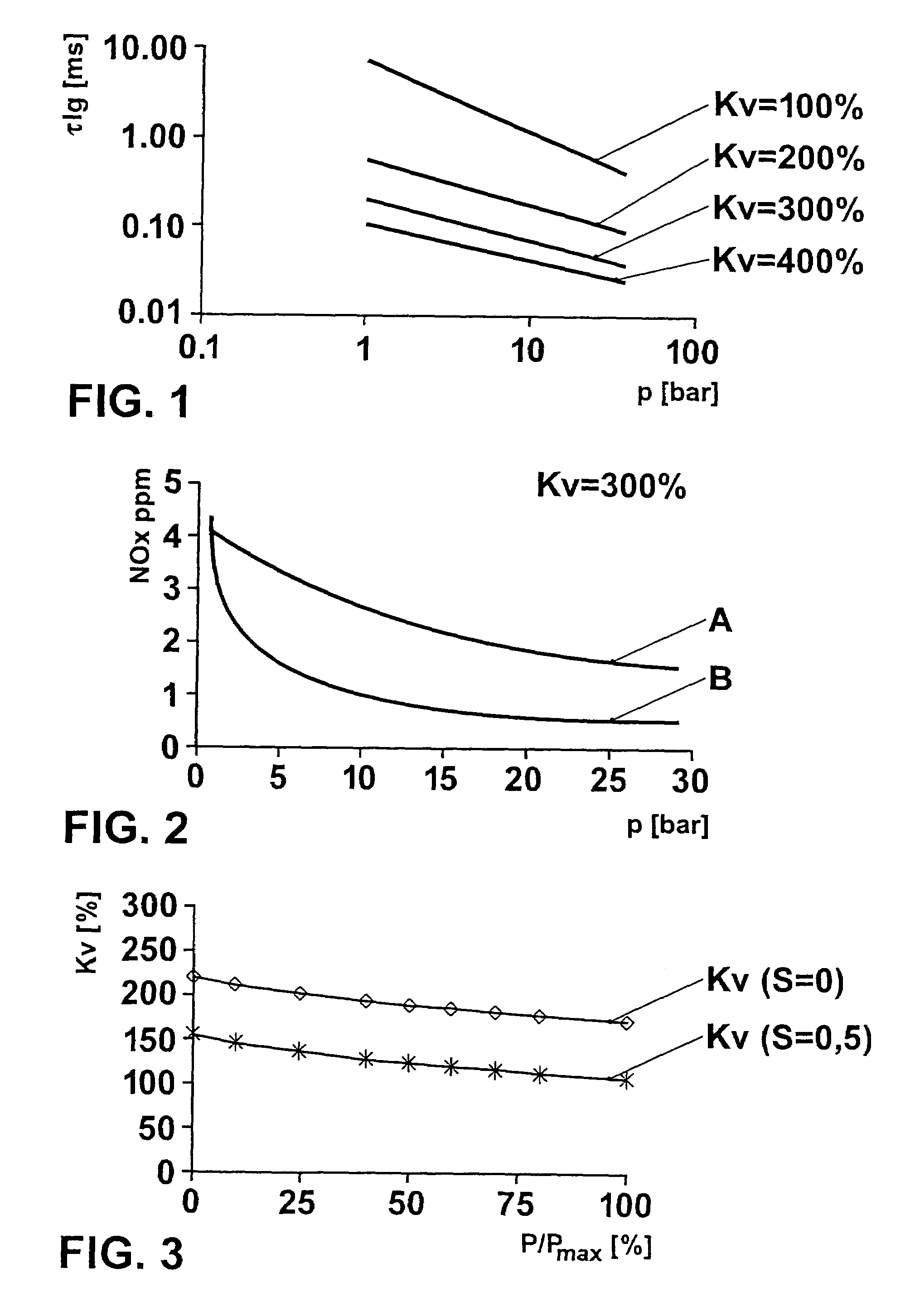

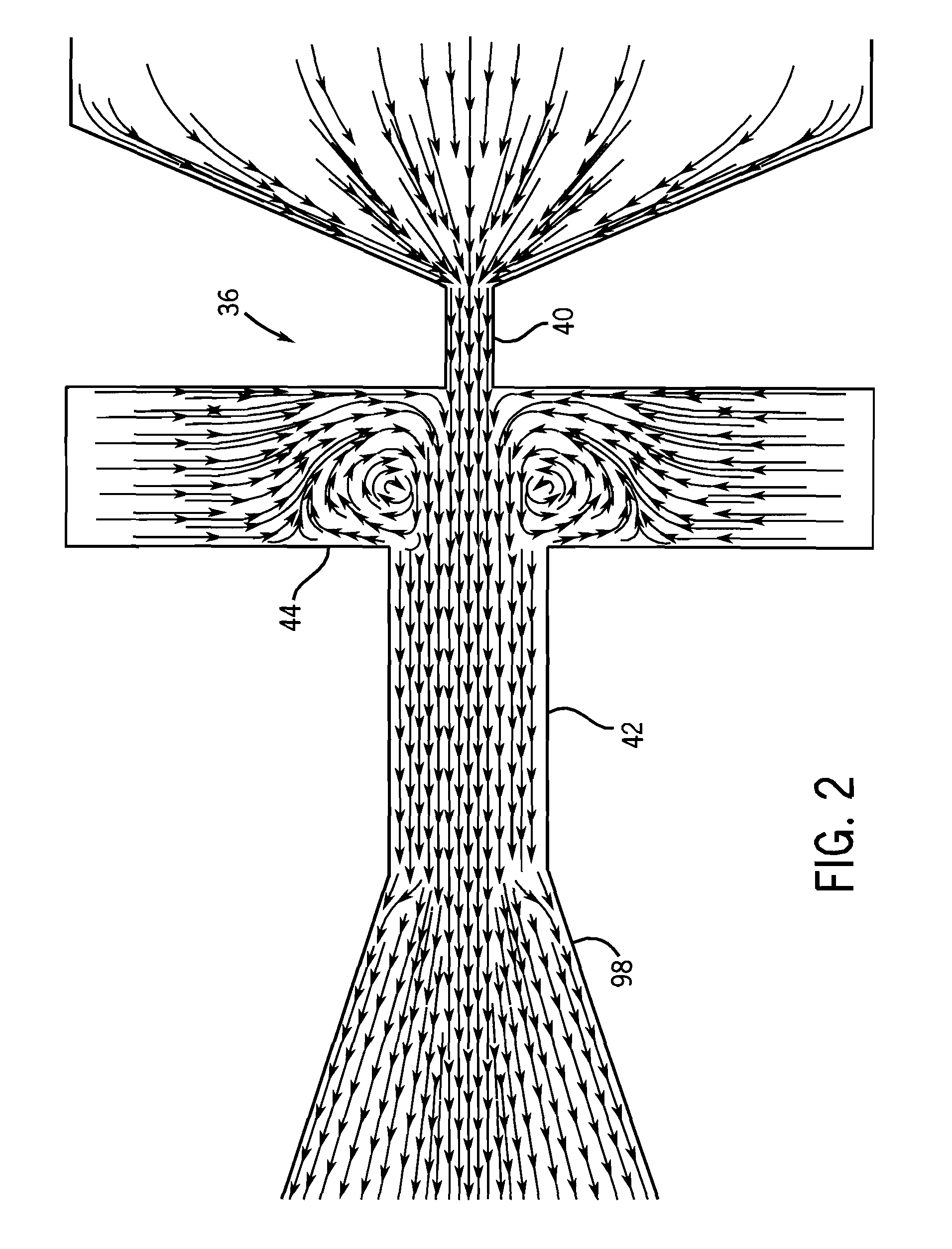

Method for combustion of a fuel

InactiveUS7363756B2Increase speedAccelerated dilutionContinuous combustion chamberGas turbine plantsCombustion chamberFront velocity

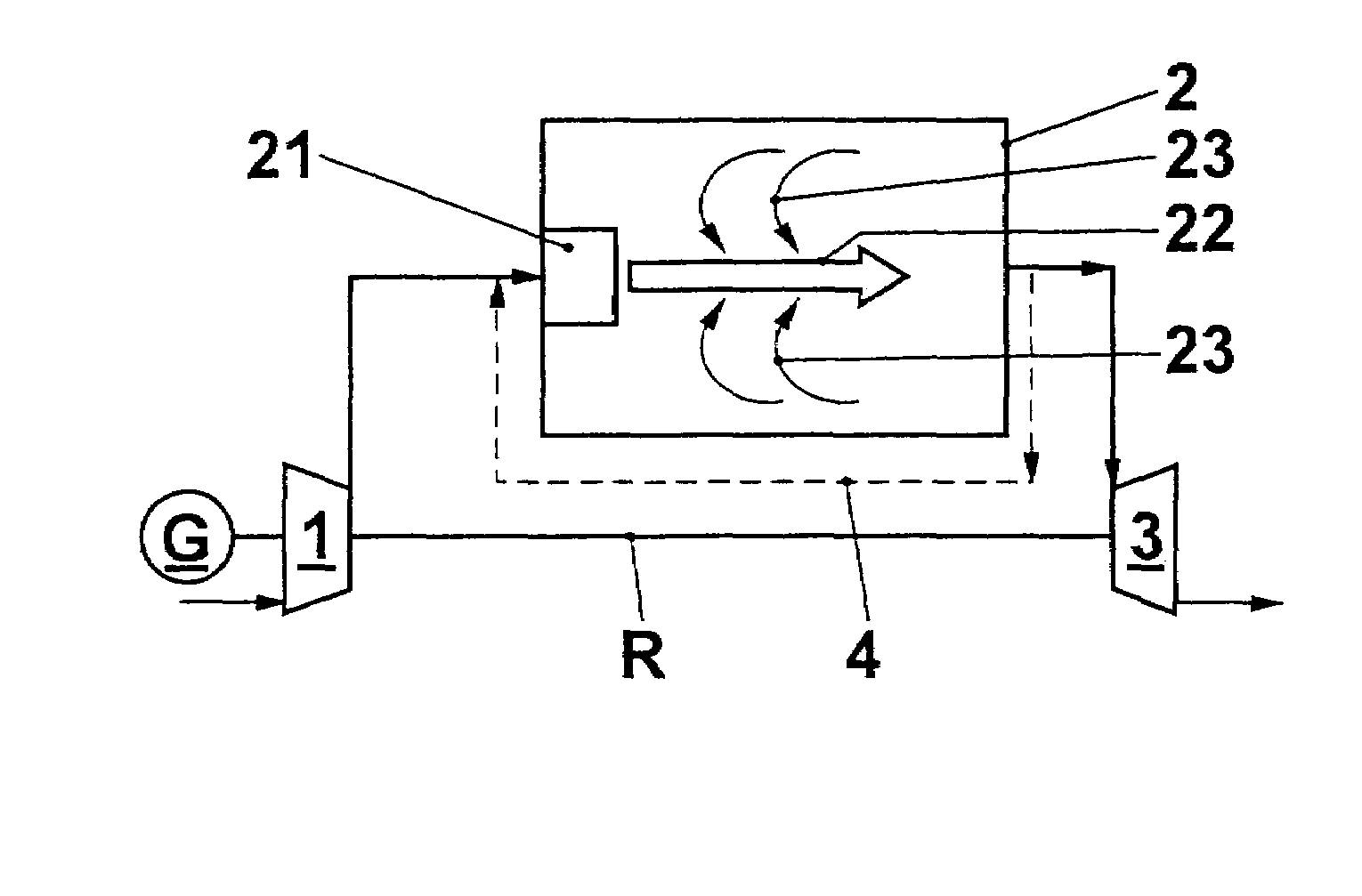

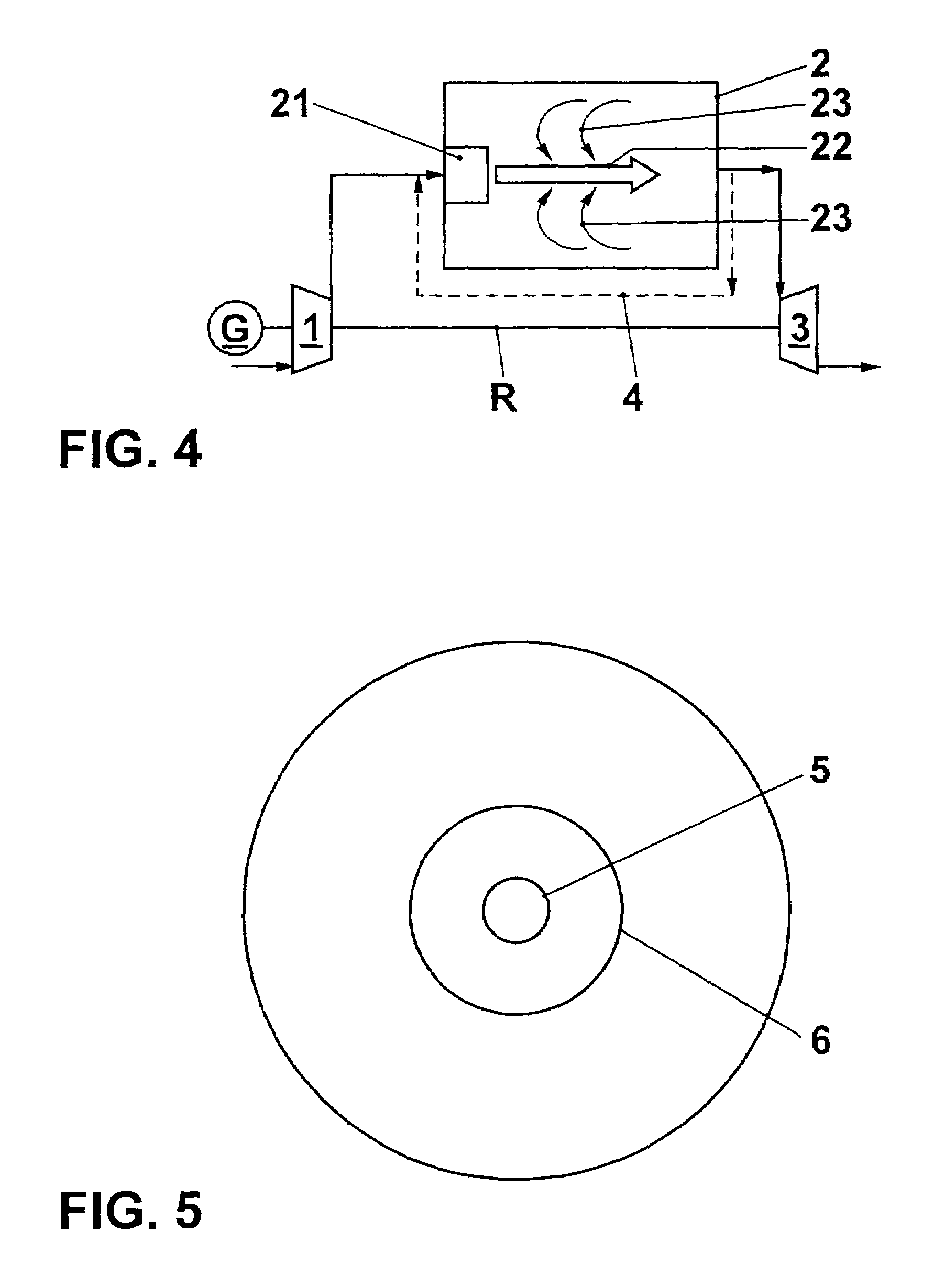

In a method for the combustion of a fuel, a fuel or a premixed combustible mixture is introduced into a combustion space as a combustible fluid open jet. The velocity of the open jet is selected in such a way that it is impossible for a stable flame front to form, i.e. is in any event greater than the flame front velocity, and that, on account of a jet pump effect, flue gas is mixed into the combustible fluid jet from the combustion chamber in a jet-induced recirculation internally within the combustion chamber. The admixed flue gas dilutes and heats the combustible fluid. The heating causes the spontaneous ignition temperature to be exceeded, and a low-pollutant volumetric flame is formed in a highly dilute atmosphere.

Owner:ANSALDO ENERGIA SWITZERLAND AG

Apparatus and method for producing electrolyzed water

An apparatus for producing electrolyzed water includes an electrochemical cell and a solution reservoir containing a solution and having an outlet. An injection pump has an input end in fluid communication with the outlet of the solution reservoir and an output end in fluid communication with the electrochemical cell, wherein the injection pumps an amount of the solution from the solution reservoir to mix with a water solution and enter the electrochemical cell. A current feedback sensor senses a cell current in the electrochemical cell. A current control unit in data communication with the current feedback sensor and the injection pump wherein the current control unit compares the cell current with a preselected current and adjusts the amount of solution pumped from the injection pump responsive to the comparison. The apparatus may also include an automatic control feedback system to monitor and adjust pH.

Owner:EAU TECH

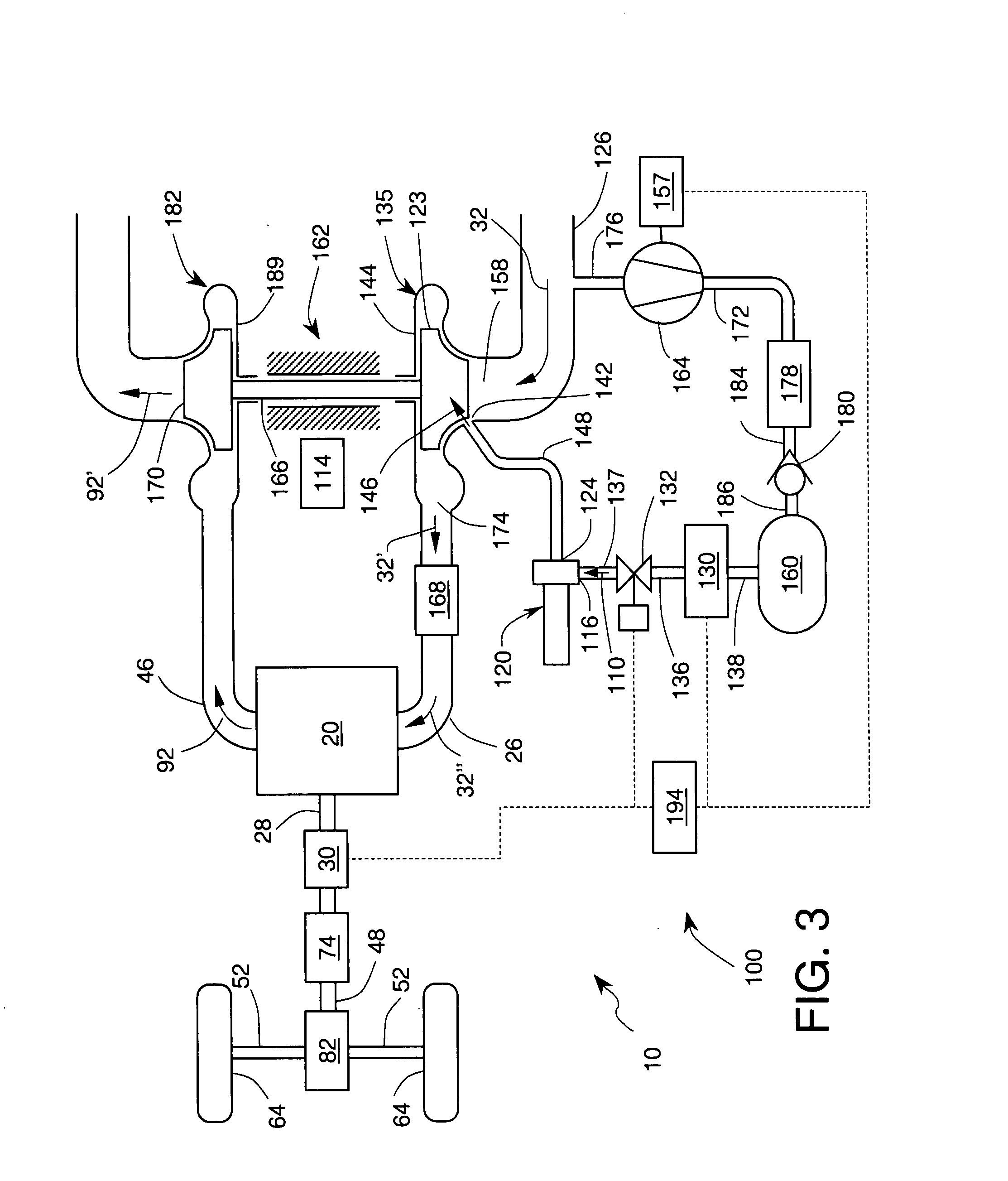

Turbocharged internal combustion engine system

InactiveUS20080133110A1Increase compressor surge limitIncrease compressor speedElectrical controlInternal combustion piston enginesCold airImpeller

The present invention relates to a turbocharged internal combustion engine (ICE) system having fast response to increased power demand and reduced response time lag. The system includes a vortex tube for delivering cold air into the turbocharger compressor where it may be used to cool the impeller, and / or accelerate the impeller rotational speed, and / or favorably shift the compressor surge line at low speeds and high loads. Cold air from the vortex tube may be also used to operate an ejector pump in the intake duct which further compresses intake air and increases engine charge weight during periods of high power demand. In addition to increasing engine output power, delivery of cold air into engine intake also reduces engine pre-ignition (knocking) thereby reducing emissions. The invention also relates to a method for operating a turbocharged internal combustion engine.

Owner:AGWEST

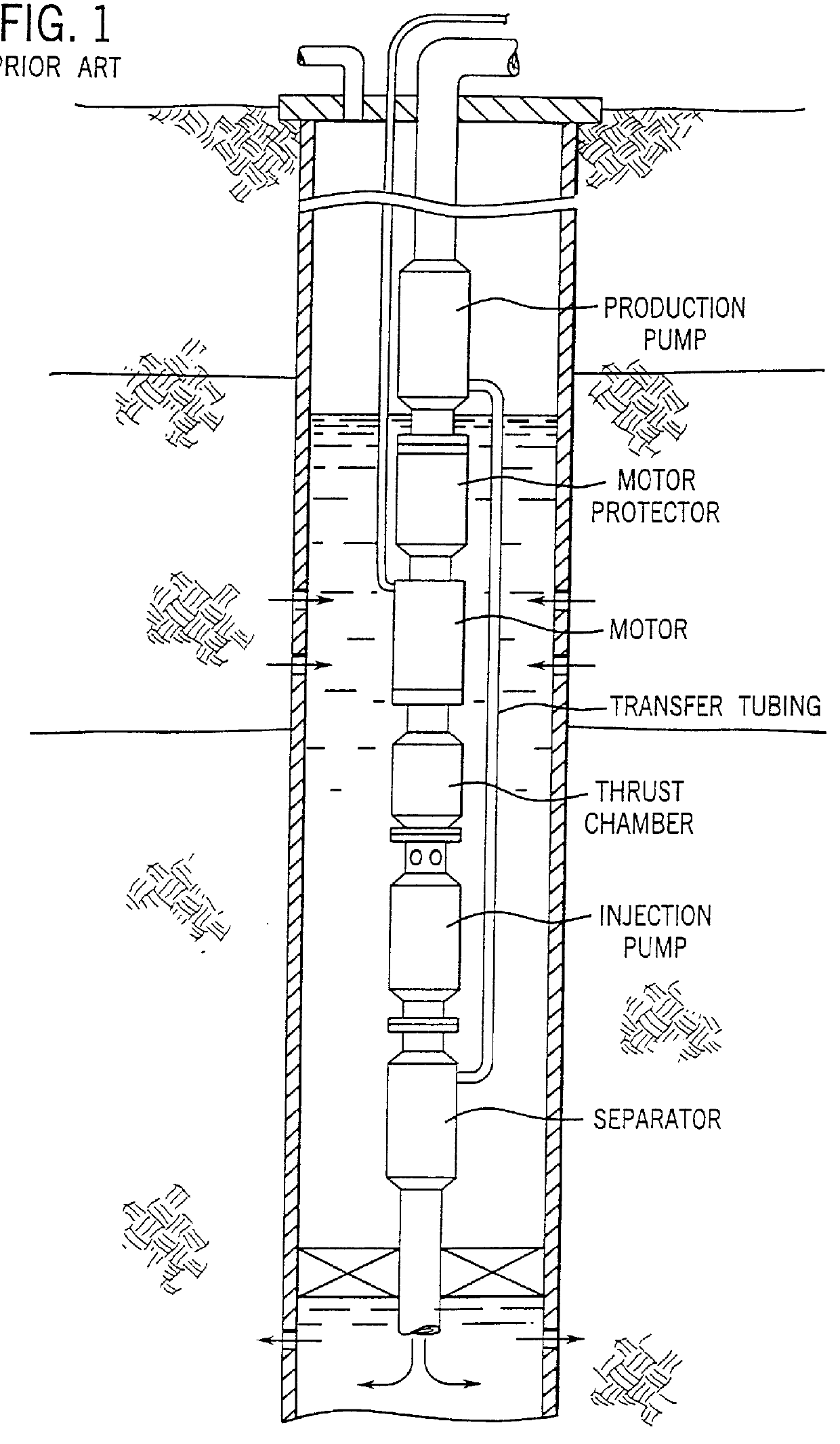

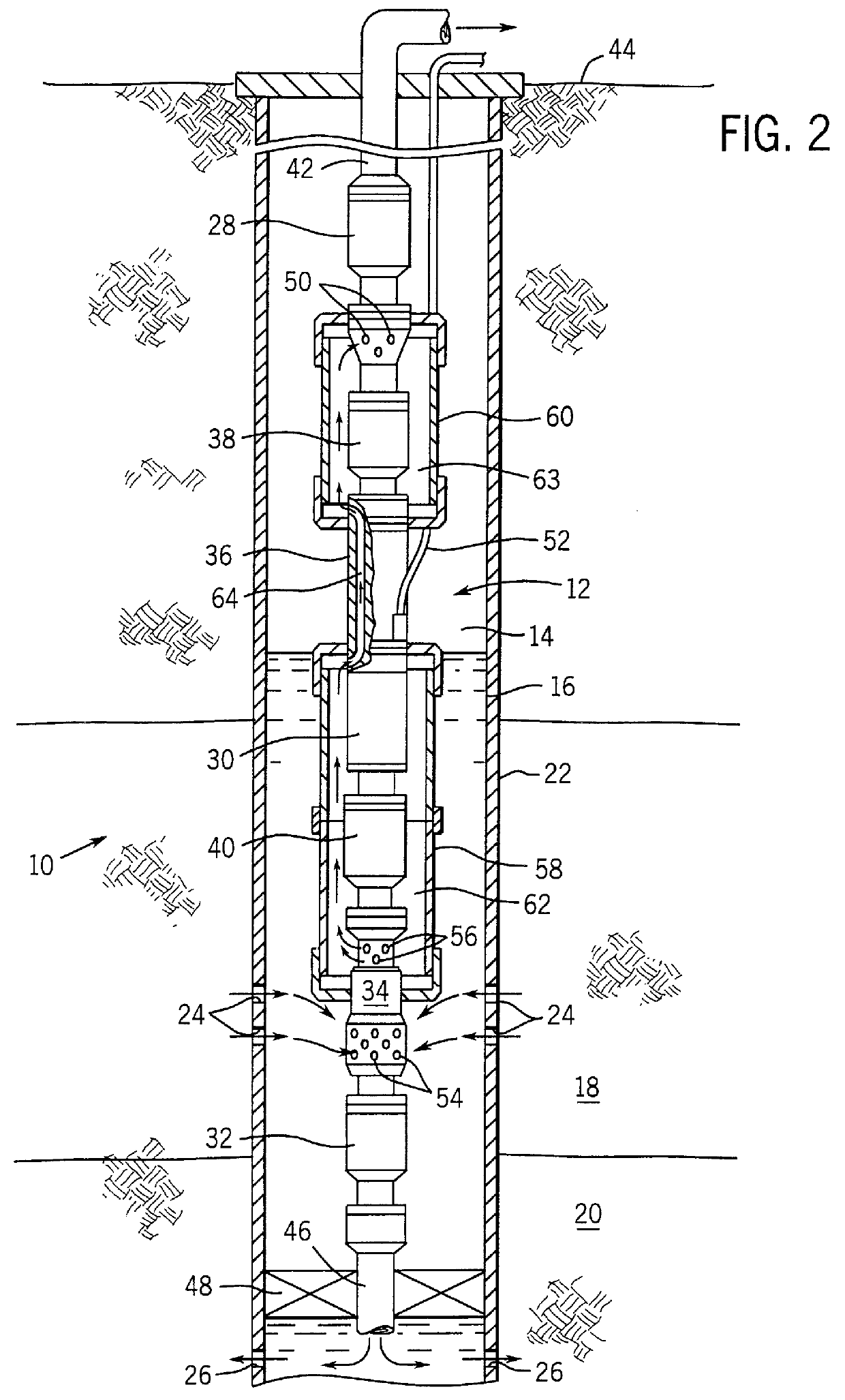

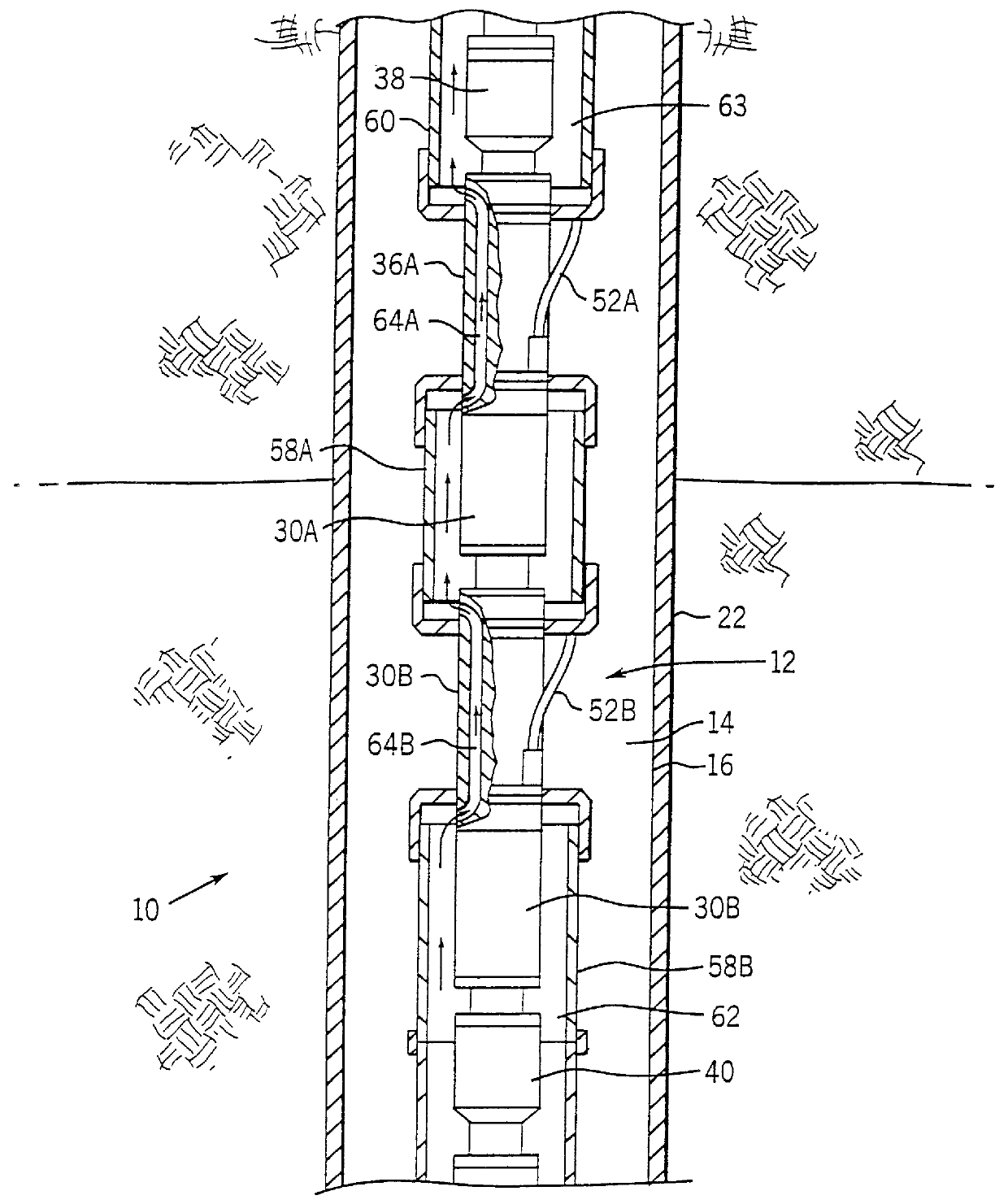

Downhole fluid separation system incorporating a drive-through separator and method for separating wellbore fluids

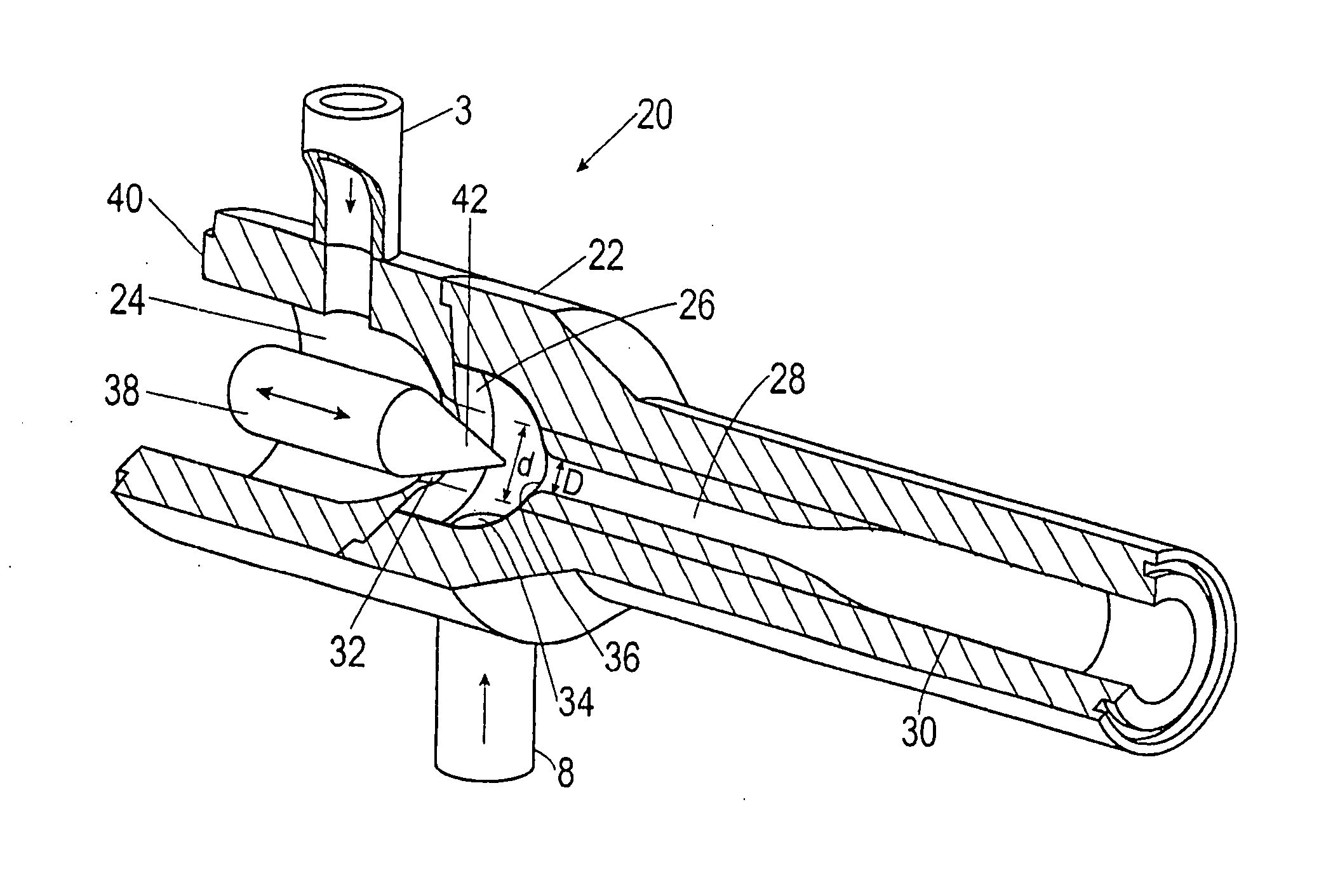

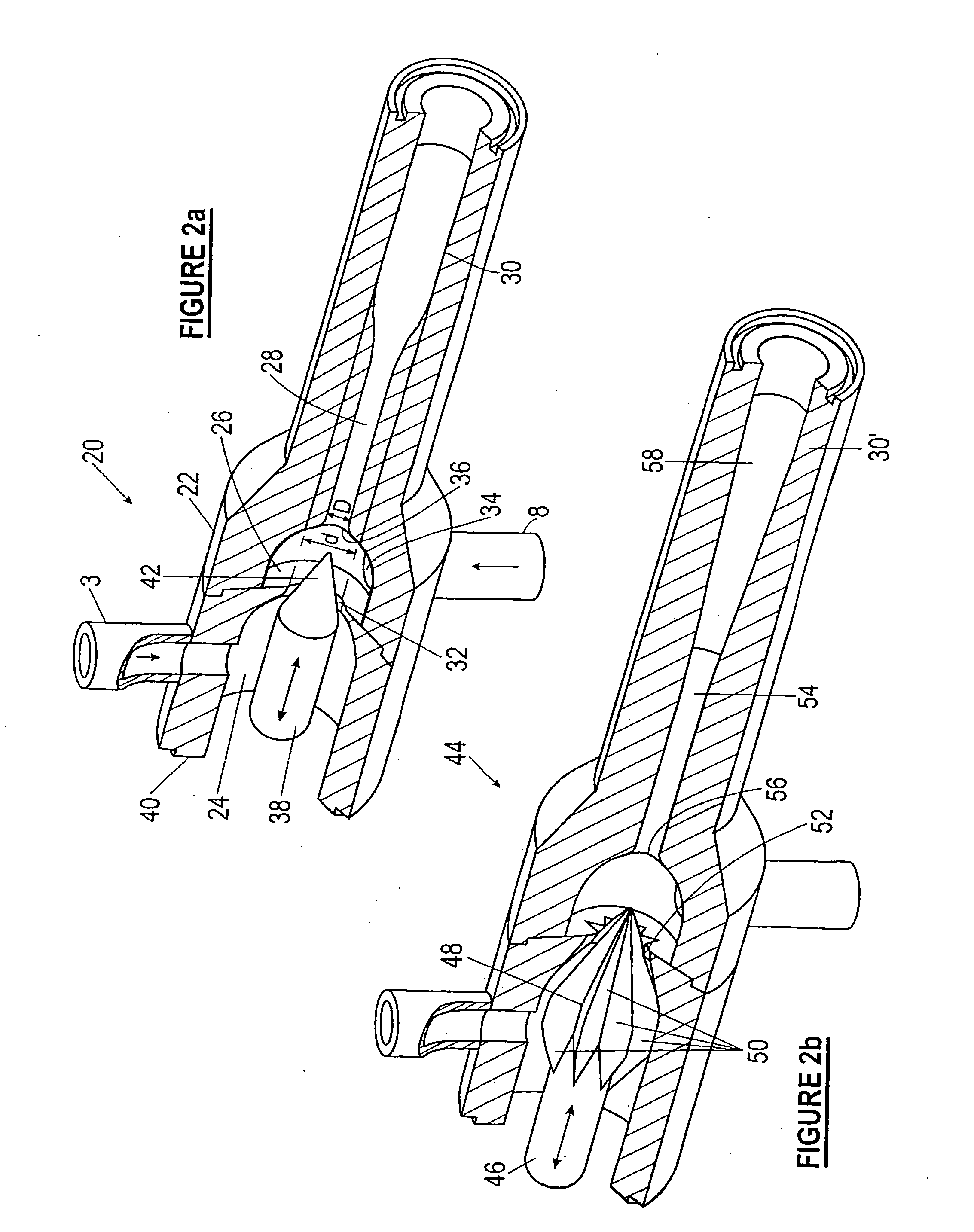

A fluid separation system is provided for separating wellbore fluids into production fluids and non-production fluids. The system includes a separator adapted for transmitting mechanical power between a drive motor and at least one pump. The separator includes one or more separation units, such as hydrocyclone separators. A drive train traversing the separator is interfaced with drive elements, such as a submergible electric motor, and driven elements such as an injection or production pump. Wellbore fluids are channeled through the separator in either a push-through or pull-through manner. Production fluids are then transferred from the separator to the production pump for removal from the well. Non-production fluids are transmitted from the separator either to the injection pump for reinjection into a subterranean discharge zone, or directly into the discharge zone from the separator. The drive train elements traversing the separator are supported by antifriction bearings in interface plates on either end of the separator. The ability to transmit mechanical power through the separator facilitates assembly of pumping system components in various configurations as well as piping fluid communication paths between the pumping system components.

Owner:CAMCO INT

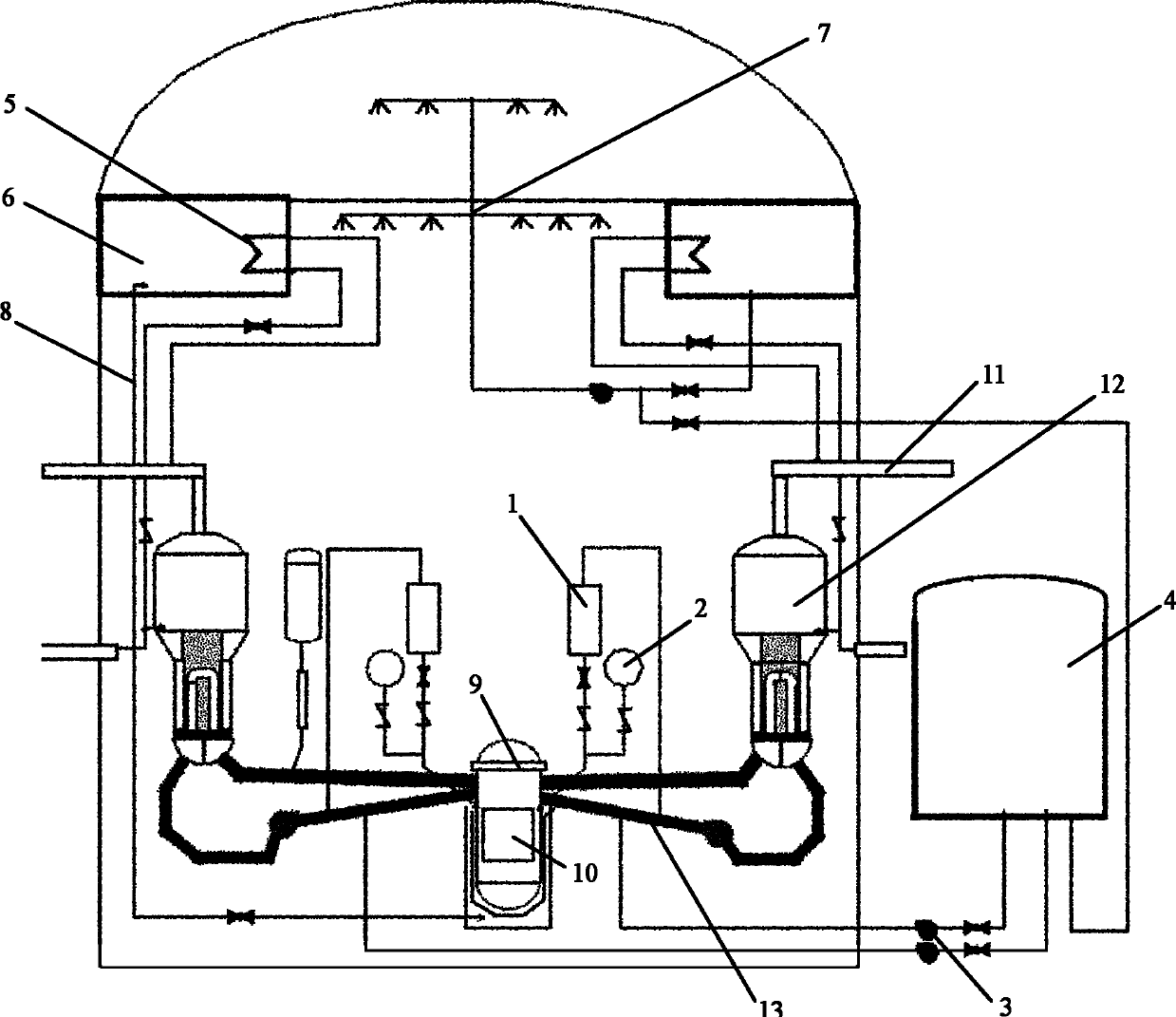

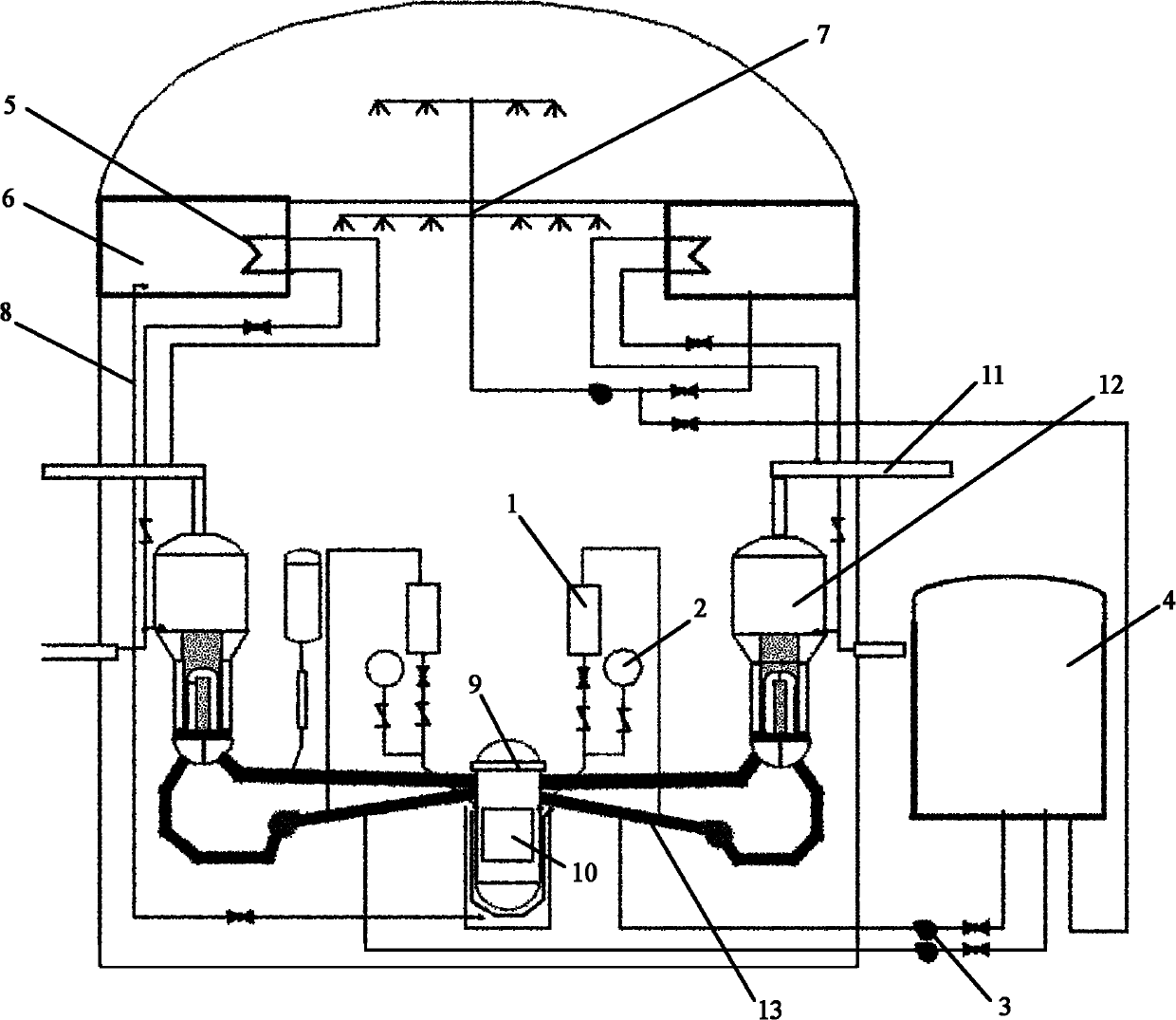

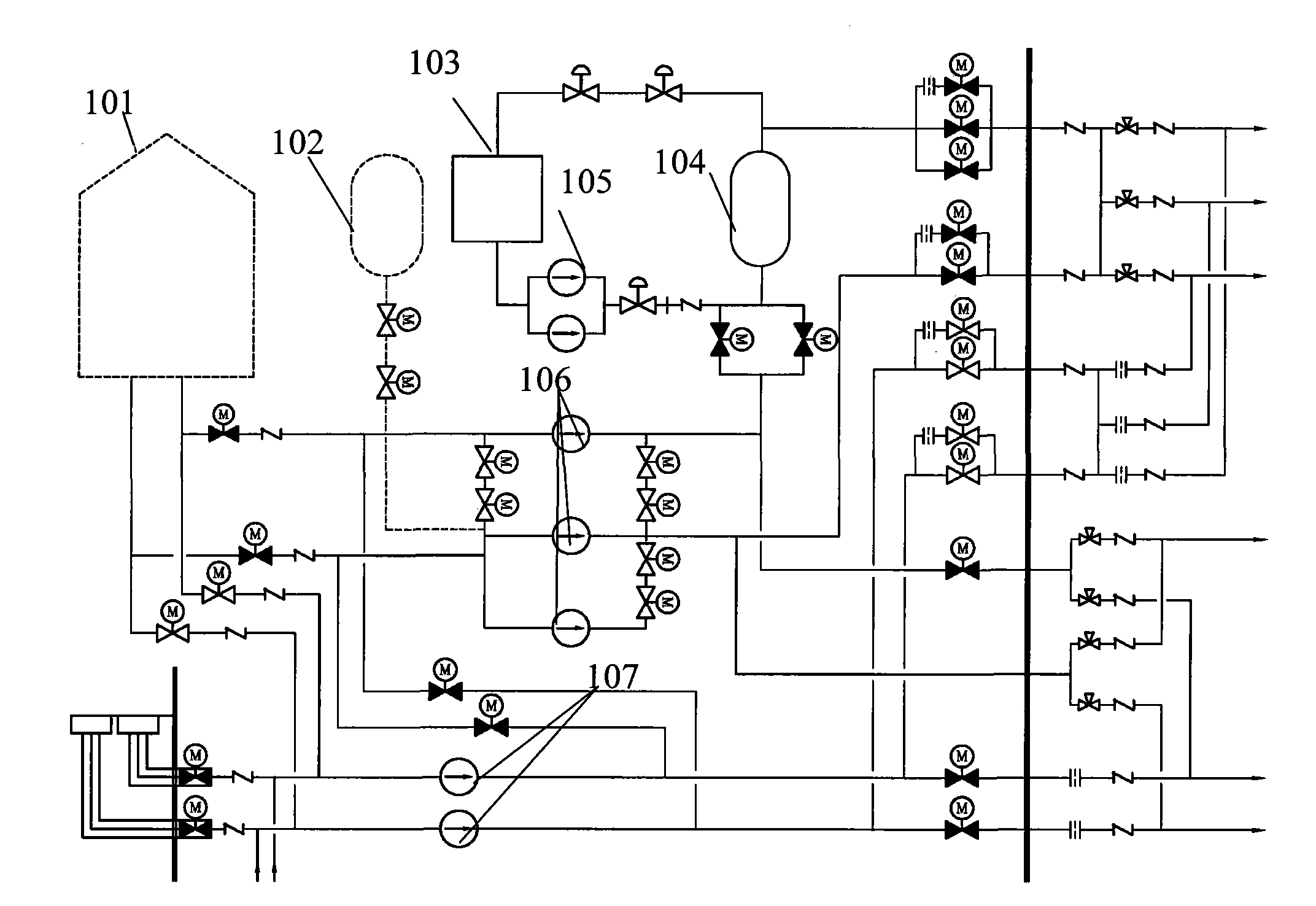

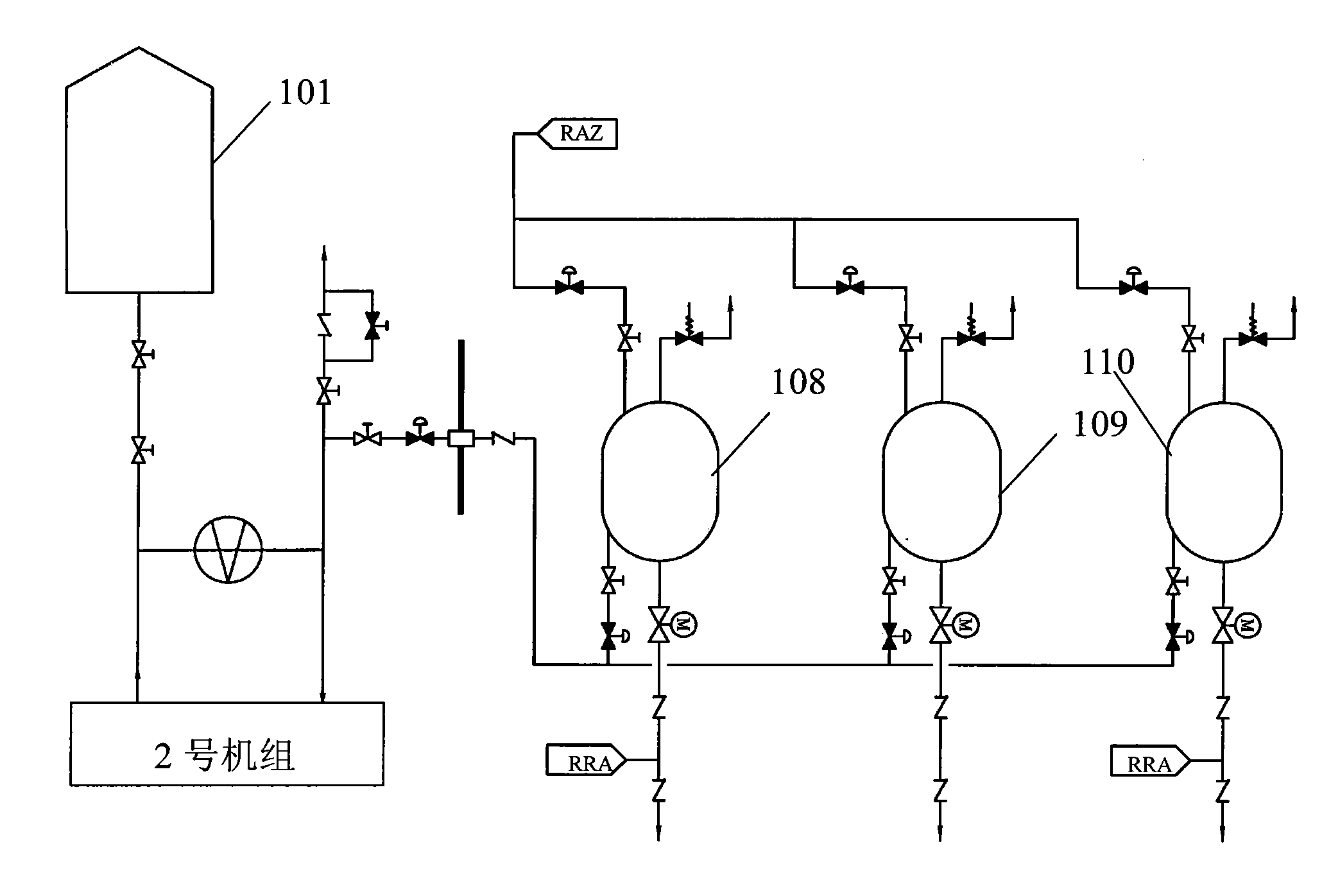

Passive and active combined special safety system for nuclear power plant

InactiveCN102169733AImprove securityReduced risk of serious accidentsNuclear energy generationCooling arrangementActive safetyNuclear power

The invention belongs to safety equipment for a nuclear power plant, in particular to a passive and active combined special safety system for the nuclear power plant. The system comprises a passive high-pressure core water supply tank, an accumulator, a low-pressure safety injection pump, a refueling water tank, a secondary-side passive residual heat removal heat exchanger, a vapor condensation water tank, a containment spray system, a passive reactor cavity water injection system, related valves and related pipes. When the nuclear power plant has a design basis accident or beyond design basis accident, through a series of passive and active safety facilities used in all steps, the circuit of a reactor and the core can be cooled effectively, so that the nuclear power plant can enter a safe cold shutdown condition smoothly; and thus, the serious accident consequence of the reactor is inhibited or relieved, damage caused by accidents is relieved, and the safety of the nuclear power plant is improved.

Owner:CHINA NUCLEAR POWER ENG CO LTD

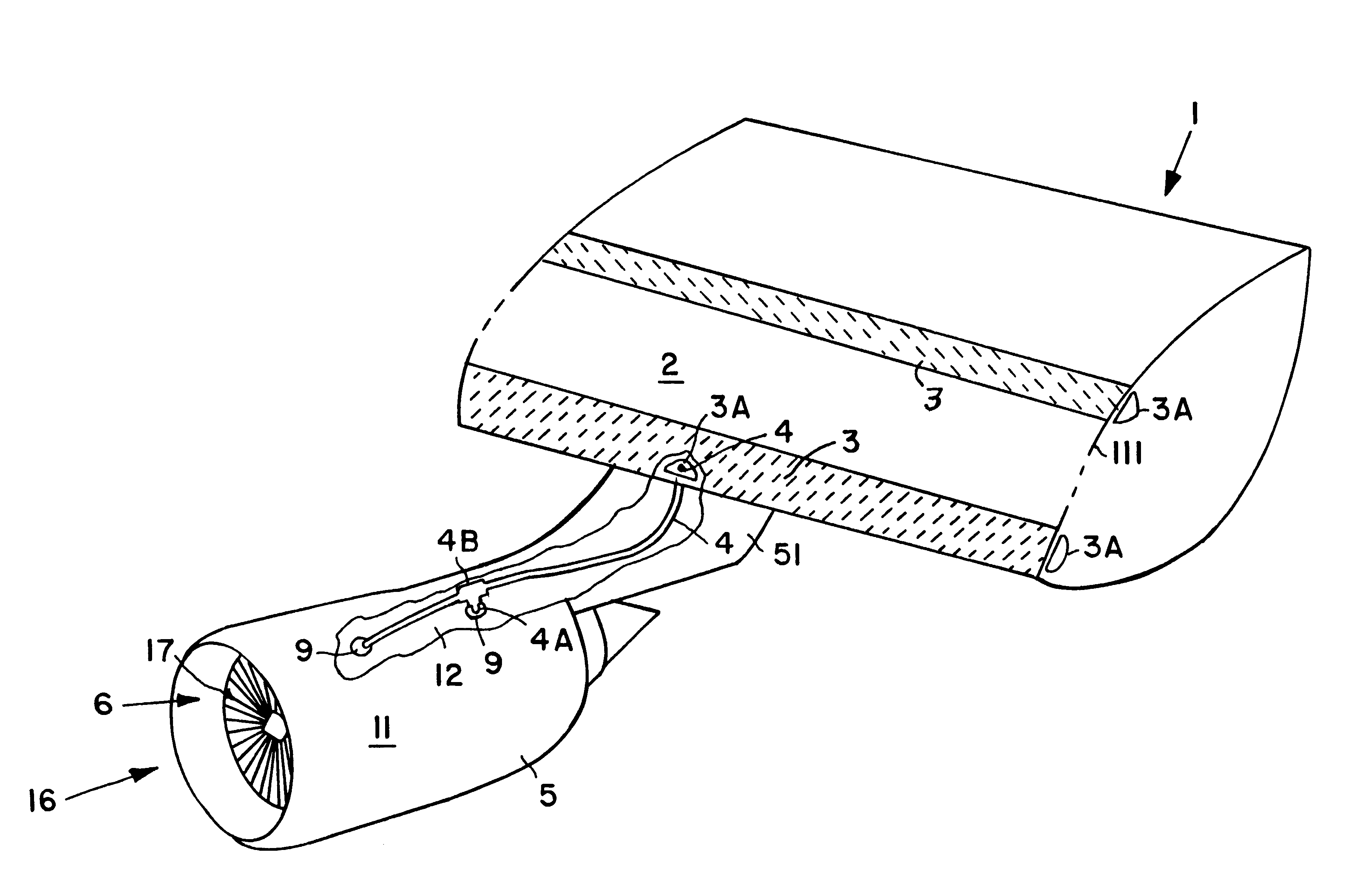

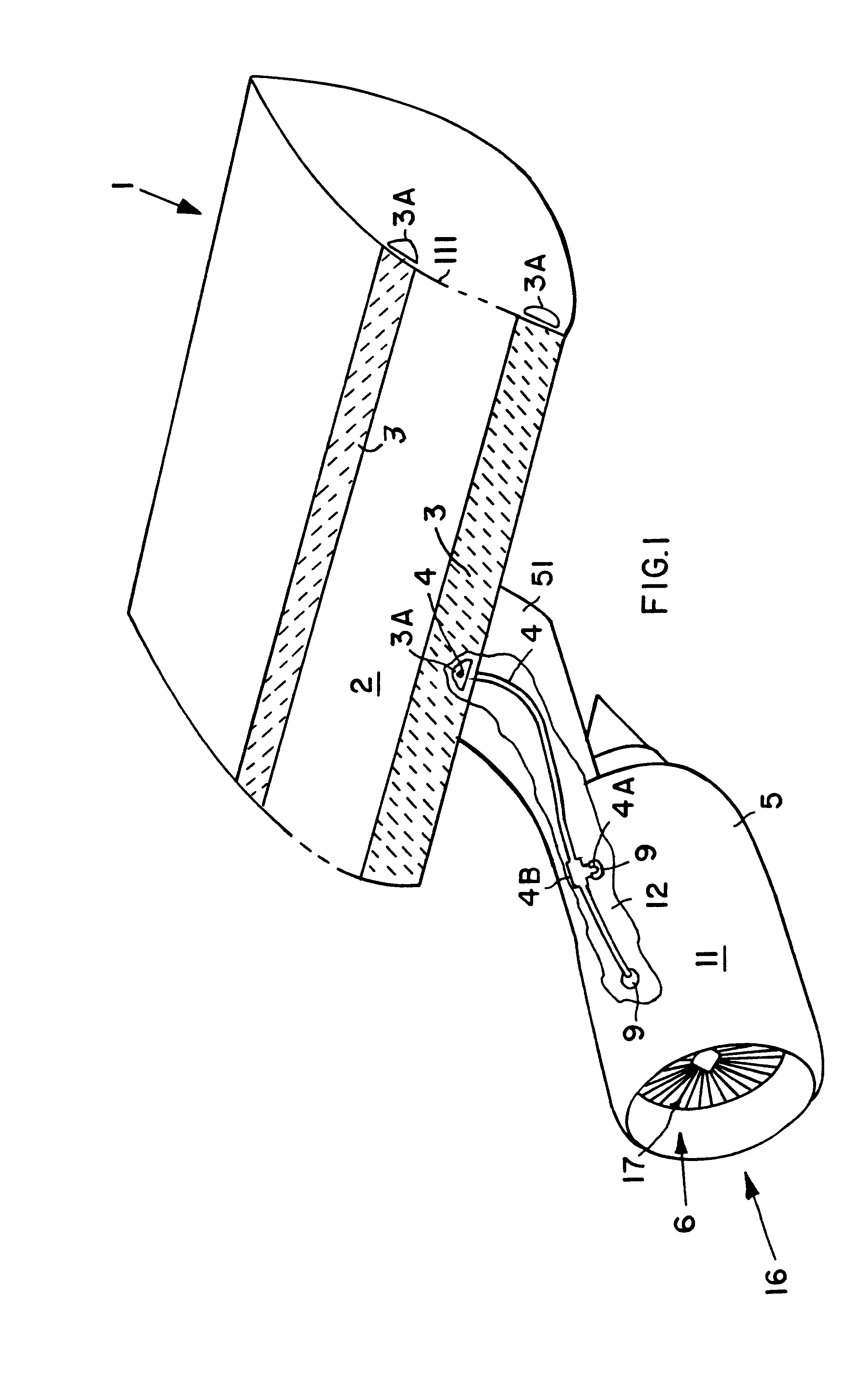

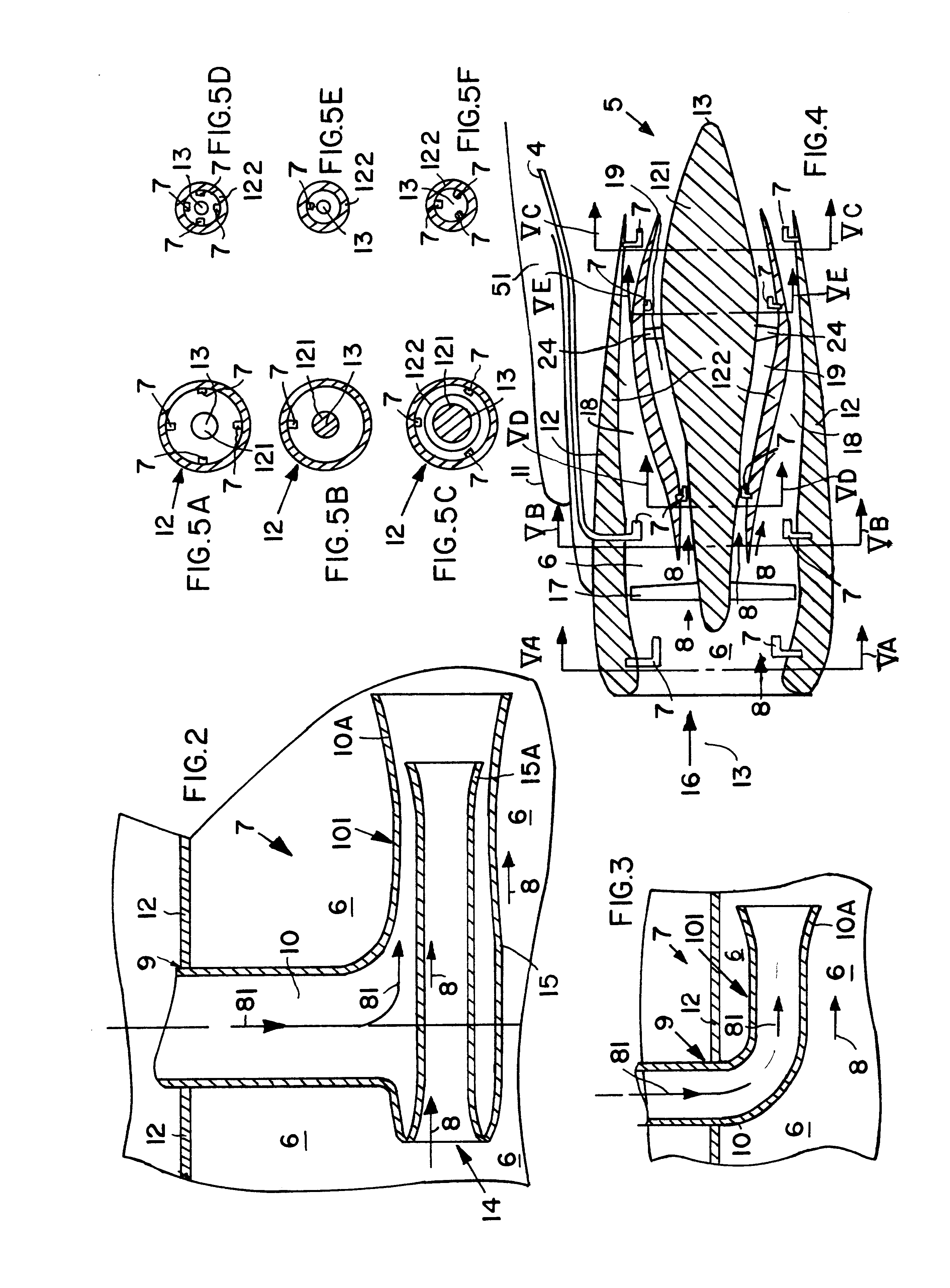

Suction device for boundary layer control in an aircraft

InactiveUS6216982B1Increase consumptionFree and reliable failureEngine fuctionsBoundary layer controlsTurbineGuide tube

A system for achieving a boundary layer control by sucking at least a portion of the boundary layer air flow through perforated or porous suction areas on the outer skin of the wings or other areas of the aircraft, includes one or more jet pumps (7) arranged in the bypass engine (5) of the aircraft, and a system of suction conduits (4) connecting the jet pumps (7) to suction channels (3A) communicating with the perforated or porous suction areas (3). Each jet pump (7) includes an ejector pipe (101) that is driven by an external surrounding driving jet (8) or by an internal driving jet (8) flowing through an internal jet pipe (15). The jet pumps (7) are arranged at selected locations in the air intake upstream of the fan, in the bypass channel (18) just downstream of the fan, in the bypass channel near the outlet end thereof, in the core hot gas channel (19) upstream of a compressor assembly, and / or in the core channel downstream of a turbine assembly. The jet pumps (7) provide an efficient, maintenance-free, reliable, and easily installable suction generator system.

Owner:DAIMLER CHRYSLER AEROSPACE AIRBUS

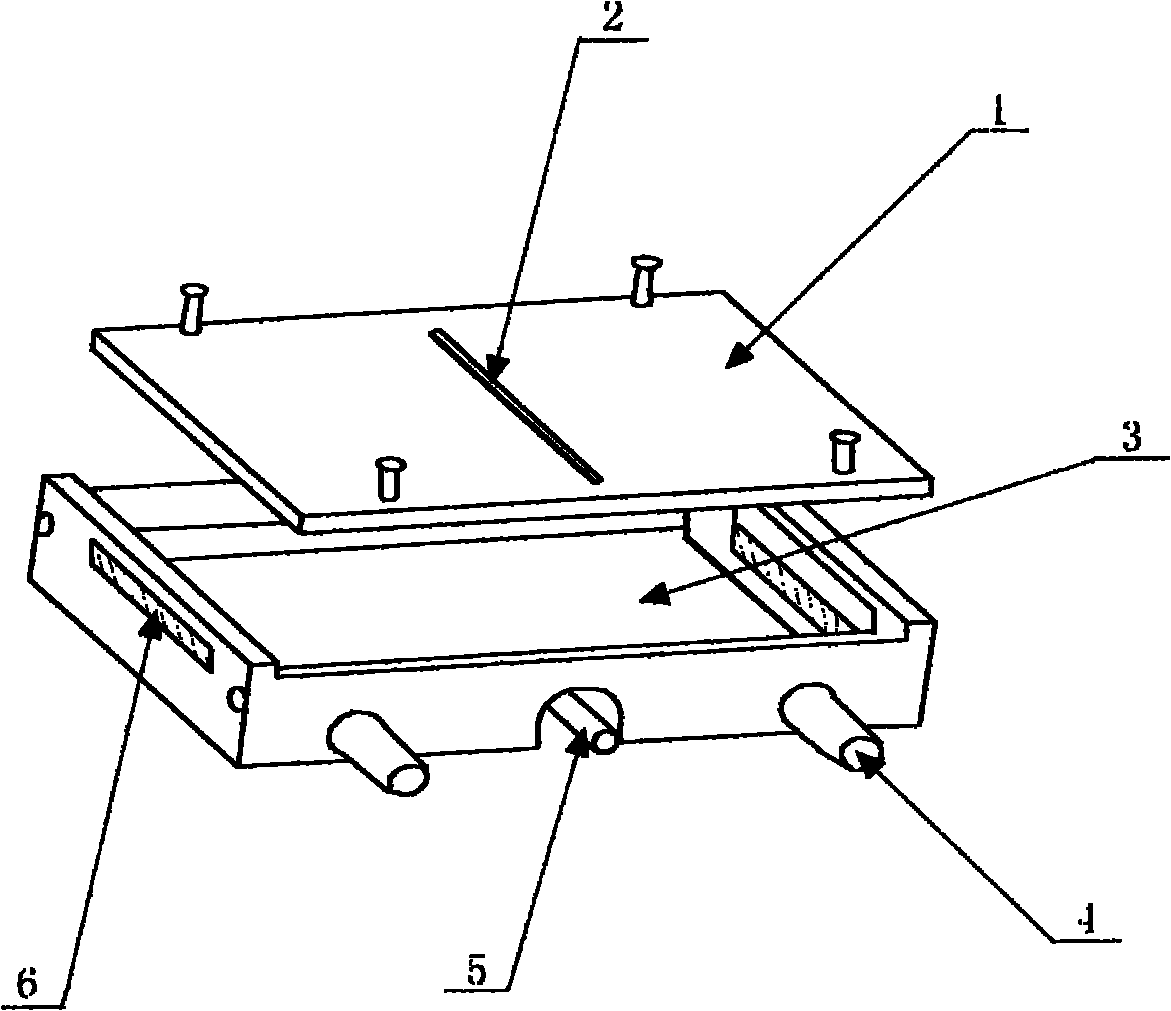

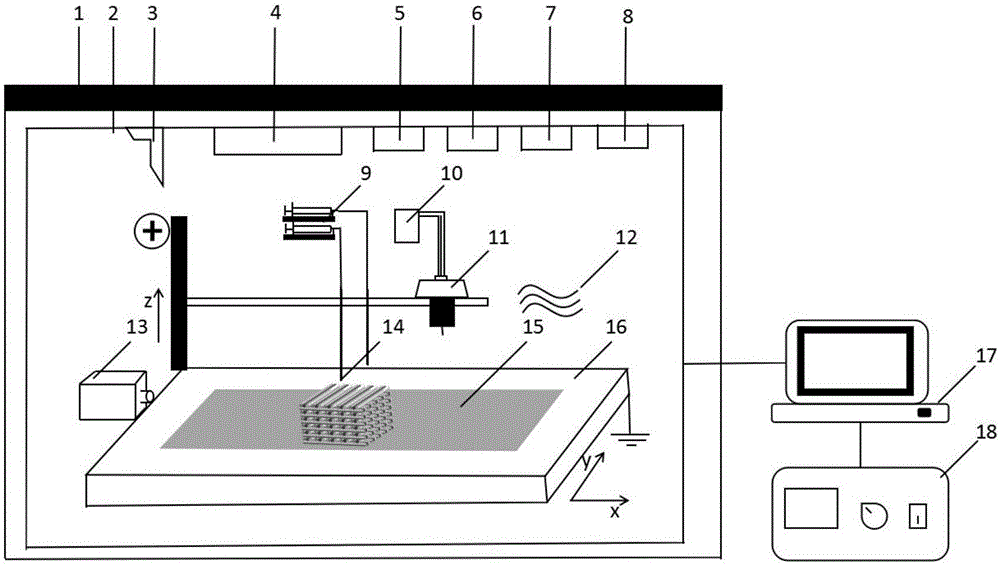

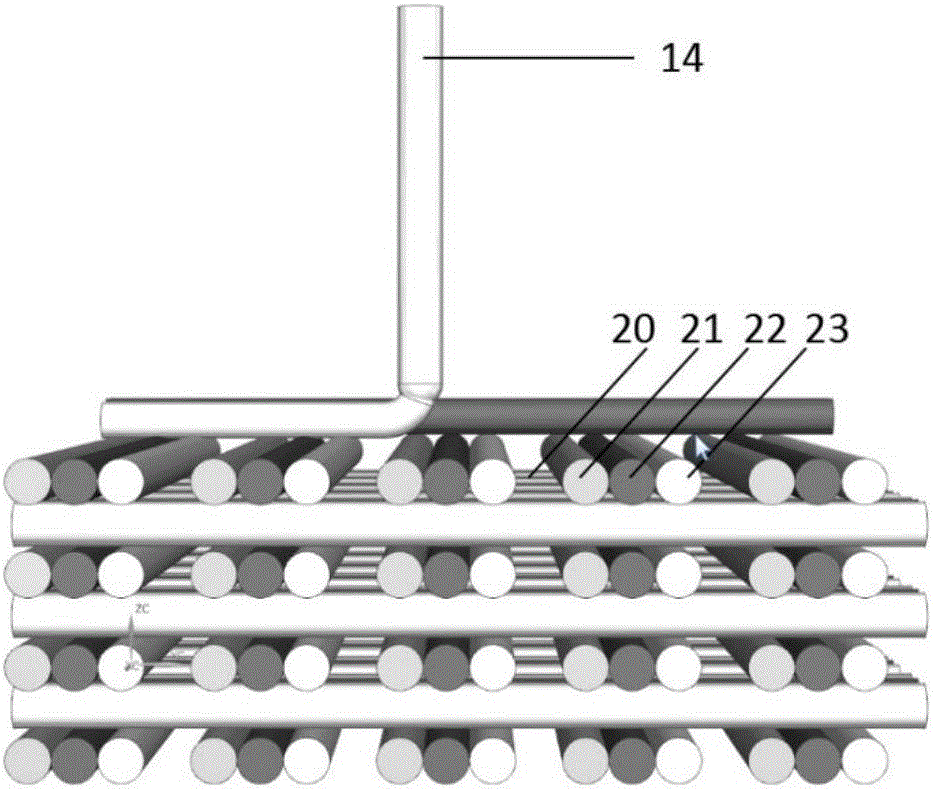

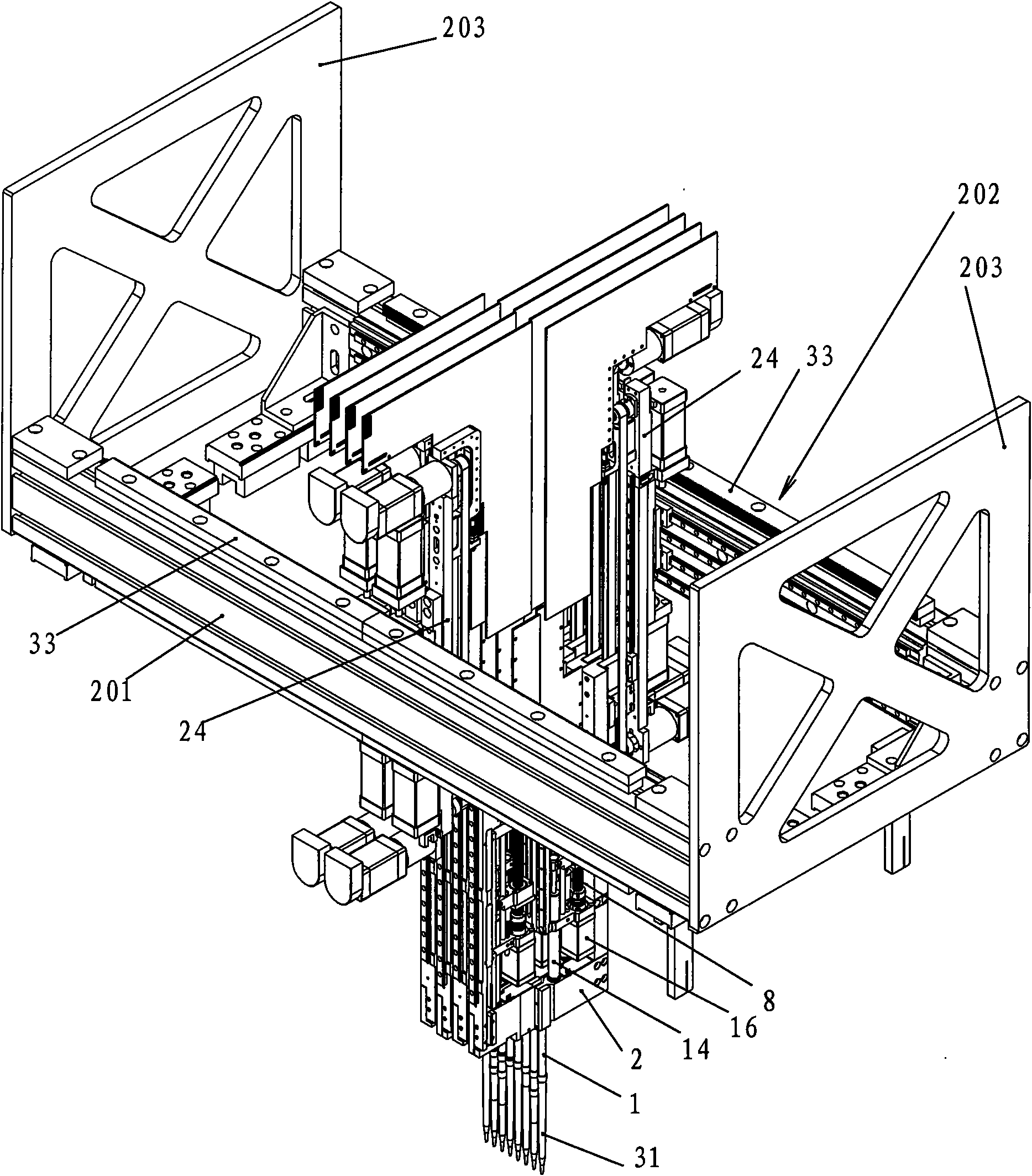

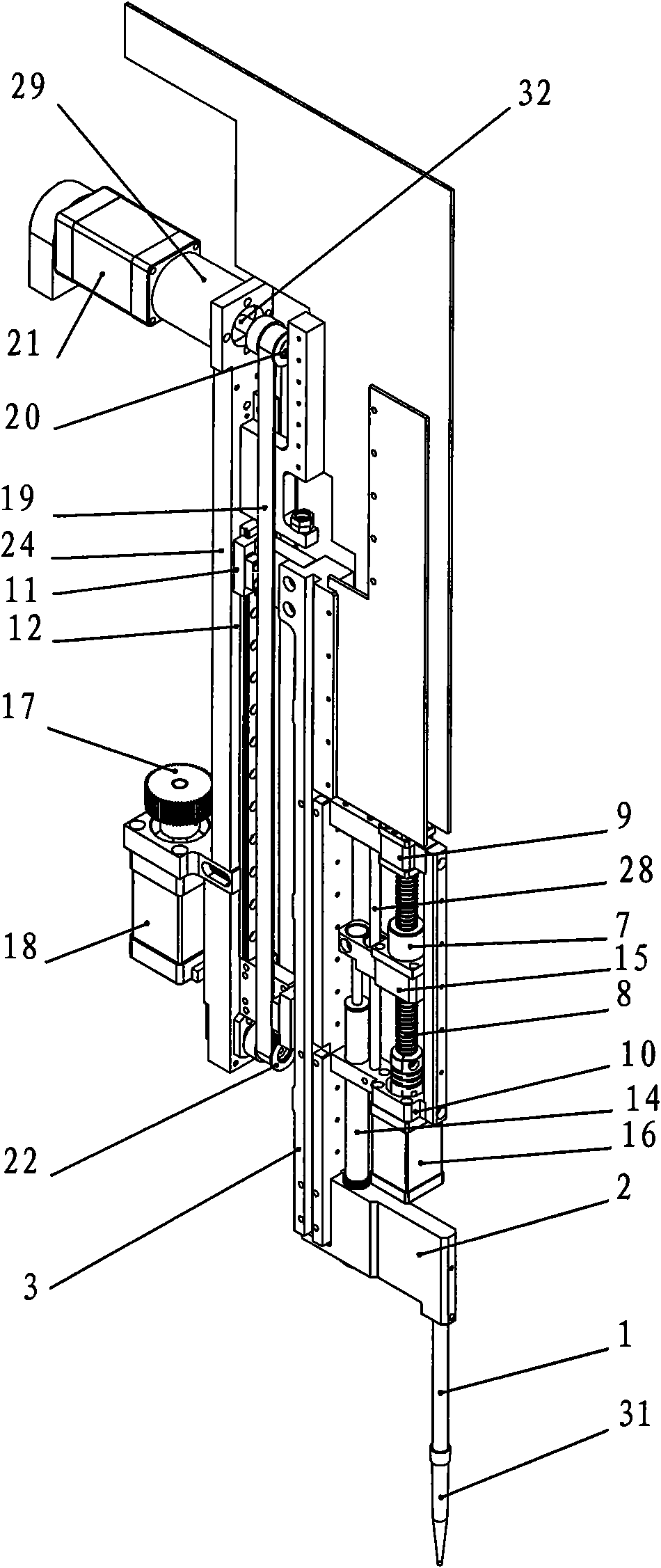

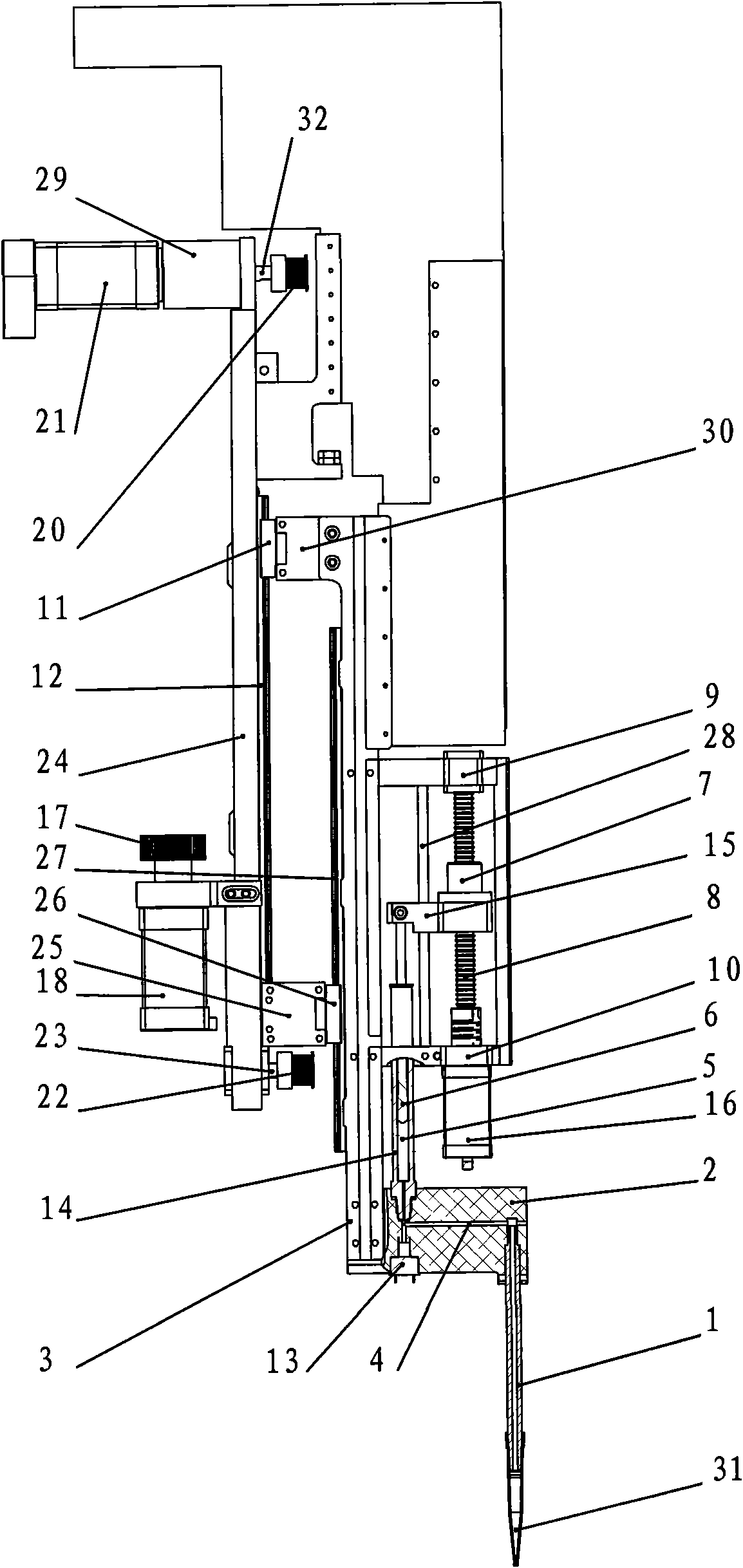

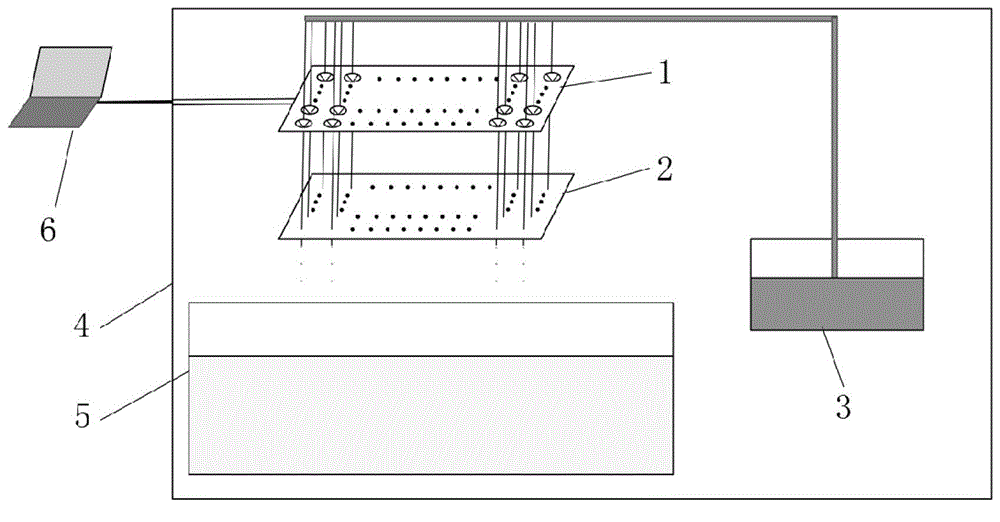

High-precision bio-compound 3D printing device and printing method

ActiveCN106222085AStable Composite PrintingHigh precisionAdditive manufacturing apparatusTissue/virus culture apparatusRefluxHigh-voltage direct current

The invention discloses a high-precision bio-compound 3D printing device and a printing method. The high-precision bio-compound 3D printing device comprises a cell printing spraying head and an electrostatic direct writing device which are arranged above a collection platform and are connected with a motion control module, wherein the cell printing spraying head is connected with an ultra-precision injection pump; the electrostatic direct writing device is connected with a reflux heating device; a main unit and a high-voltage direct current power supply are arranged outside an ultra-clean experiment table; the electrostatic direct writing device, the cell printing spraying head and the high-voltage direct current power supply are connected with the main unit. The printing method comprises the following steps: the main unit automatically switches the cell printing spraying head and the electrostatic direct writing device to print a cell-containing gel / biological scaffold / micro-channel compound structure; after the printing of one layer is completed, the cell printing spraying head and the electrostatic direct writing device move a distance equal to the thickness of one layer in the Z-axis direction for printing of the next layer, and repeating till all tissue organs to be printed are completed in printing. The high-precision bio-compound 3D printing device can stably and precisely print compounds of various cells and submicron or nano-level biological scaffolds.

Owner:XI AN JIAOTONG UNIV

Multi-channel loading device

ActiveCN101596469AImprove applicabilityImprove interchangeabilityBurettes/pipettesPush and pullEngineering

A multi-channel loading device comprises a beam, a plurality of sampler injector fixing rods are arranged on the beam, a sample placing pad is arranged below the beam, each sampler fixing rod is provided with a sampler comprising a sampling pin which is hollow and arranged vertically, the lower part of each sampling pin is intercalated with a suction end, each sampling pin is arranged on an injection pump base and connected with an injection pipeline in the injection pump base, each injection pipeline is respectively provided with a pressure sensor used for measuring the pressure in each injection pipeline, the upper part of each injection pump is provided with a push-and-pull rod inserted into a solution cavity vertically, the top of each push-and-pull rod is connected with a leadscrew nut which is rotationally mounted on a leadscrew vertically. The invention aims at providing the multi-channel sampling device with high accuracy and good stability of solution suction and separation, strong adaptability and capacity in reducing and avoiding cross infection among samples.

Owner:YANTAI ADEKANG BIOTECHNOLOGY CO LTD

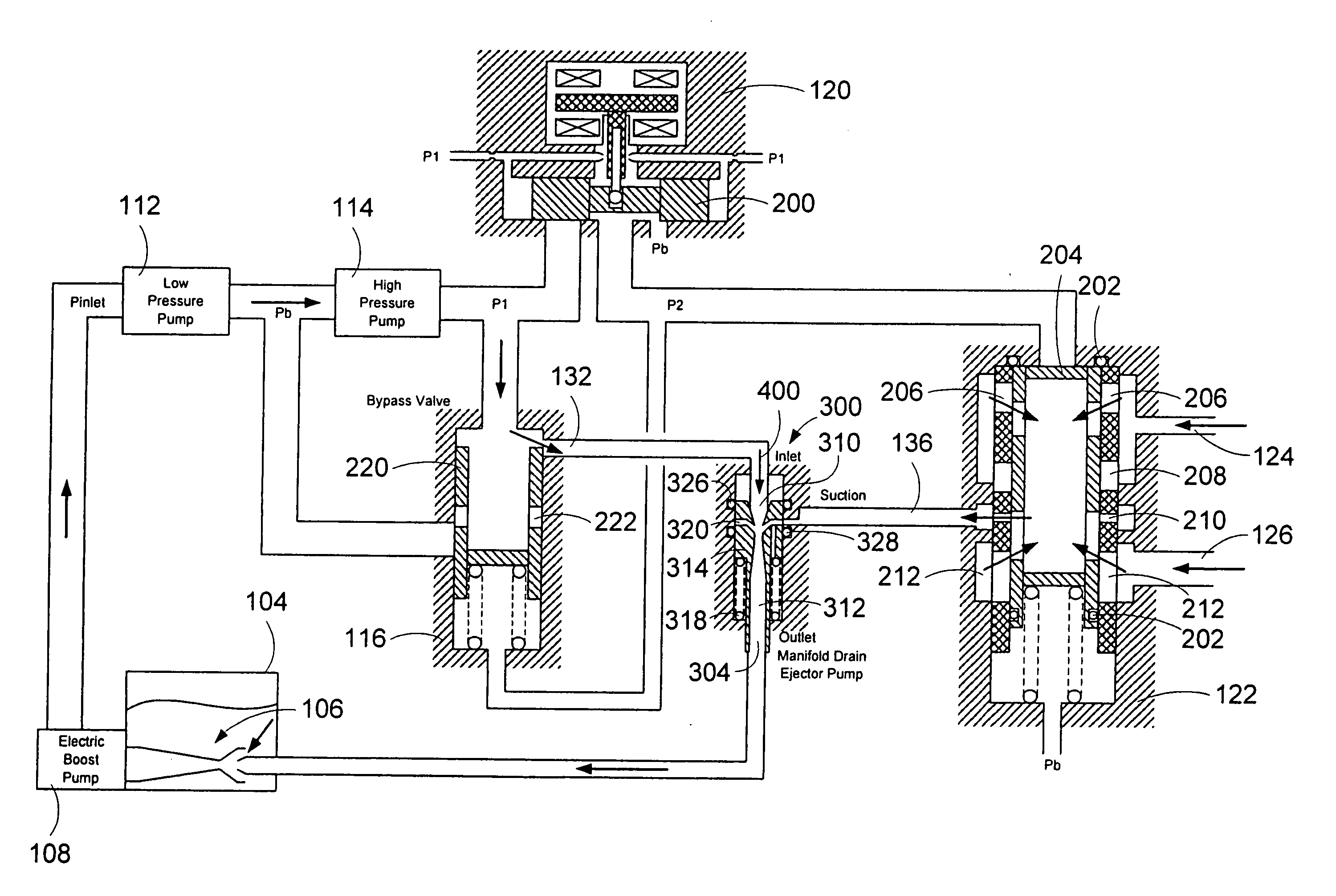

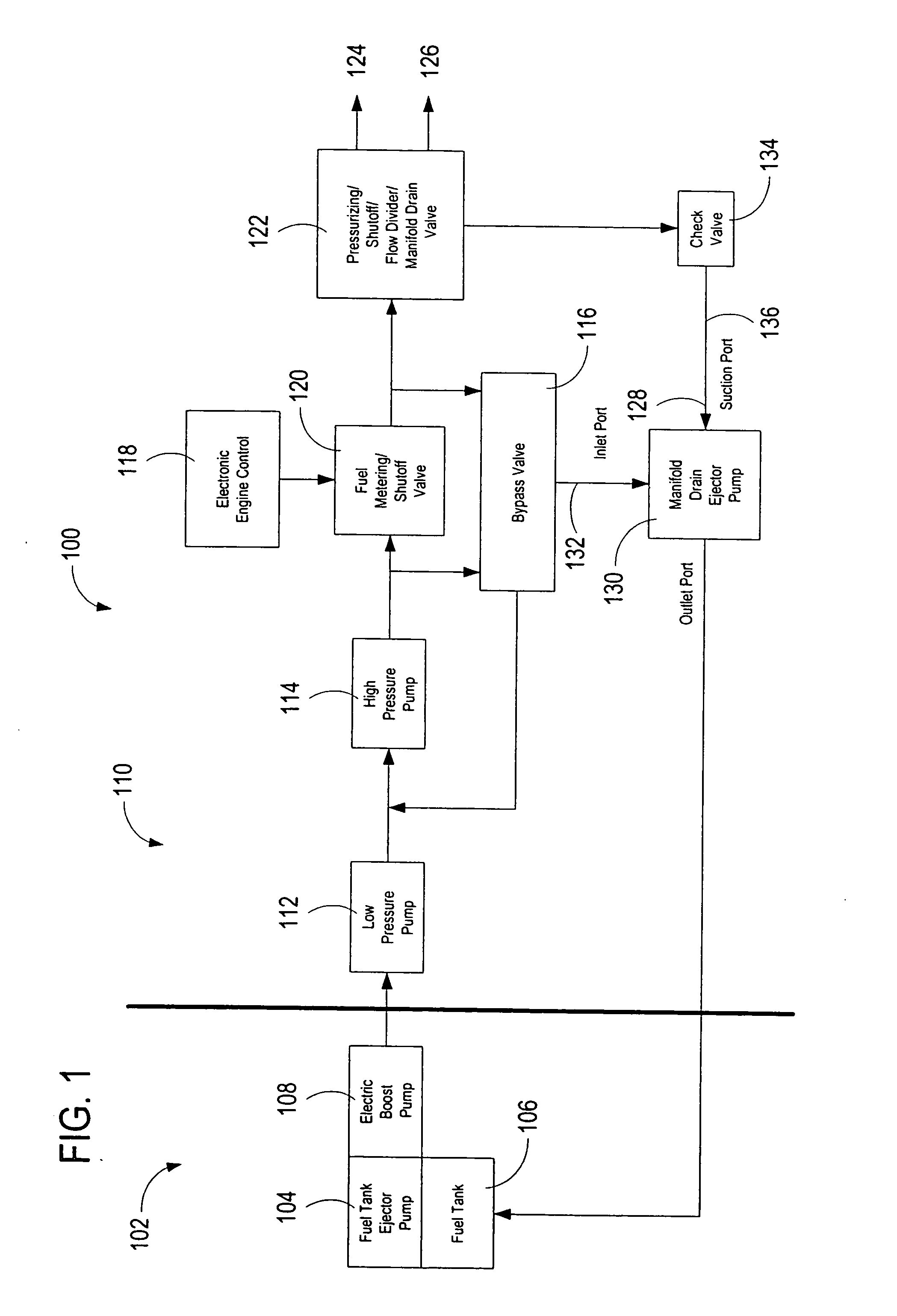

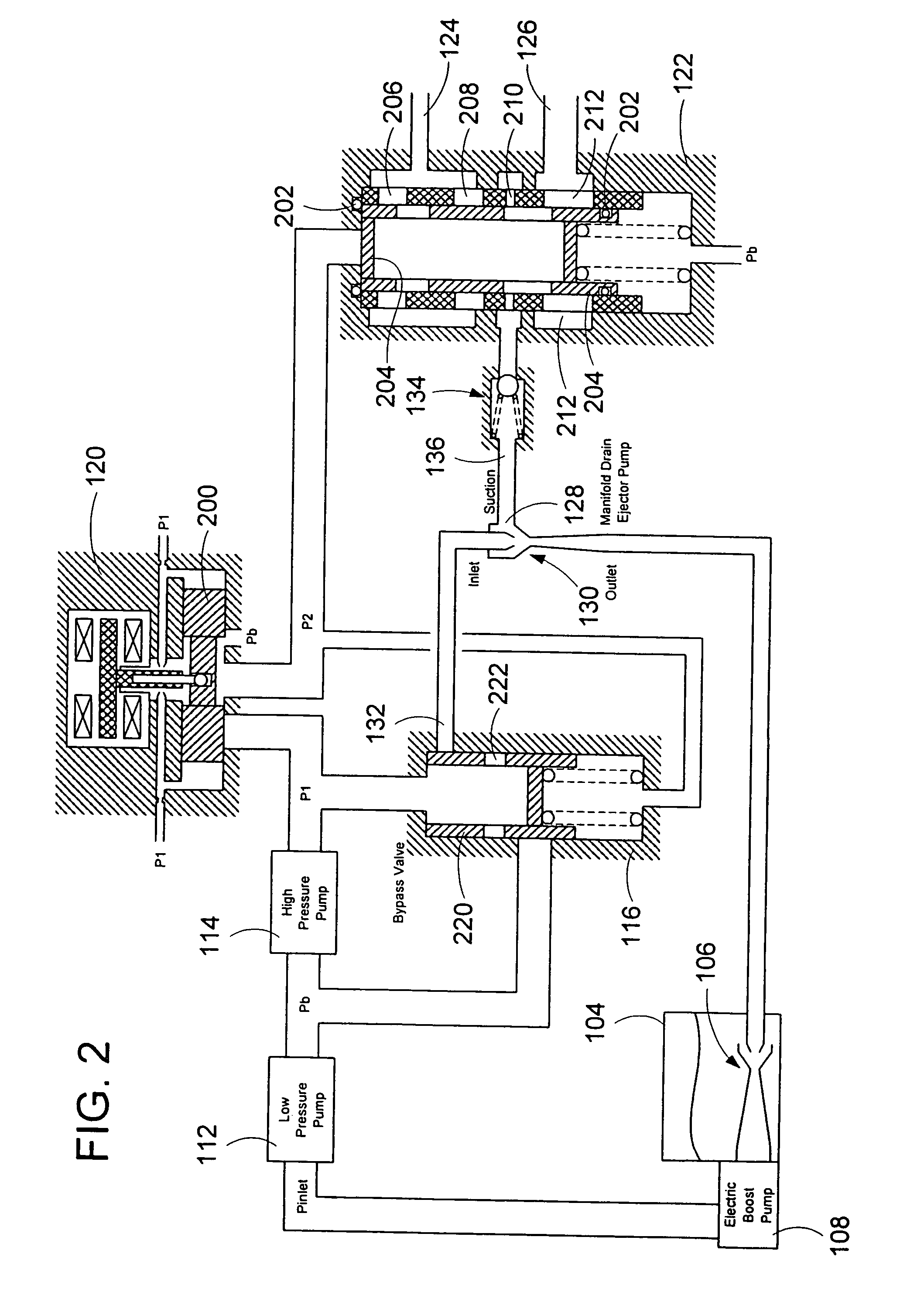

Method to transfer fuel in a fuel system for a gas turbine engine

InactiveUS20050279079A1Eliminate needTurbine/propulsion fuel deliveryTurbine/propulsion fuel valvesFuel tankCheck valve

A system for automatically transferring the fuel from one or more engine fuel manifolds directly to the engine fuel tank(s) during engine shutdown using an ejector pump has been presented. A checkvalve, which may be integrated with the ejector pump, is also used. A metering valve initiates fuel flow shutoff and is used in the draining of the fuel manifolds, thereby eliminating the need for an additional solenoid dedicated mainly to the shutoff function. The shutoff and pressurizing valve provides flow division between manifolds and manifold drain for systems having multiple manifolds. The bypass valve is used to turn the motive flow and / or manifold drain functions on and off as a function of engine speed at start and shutdown.

Owner:WOODWARD GOVERNOR CO

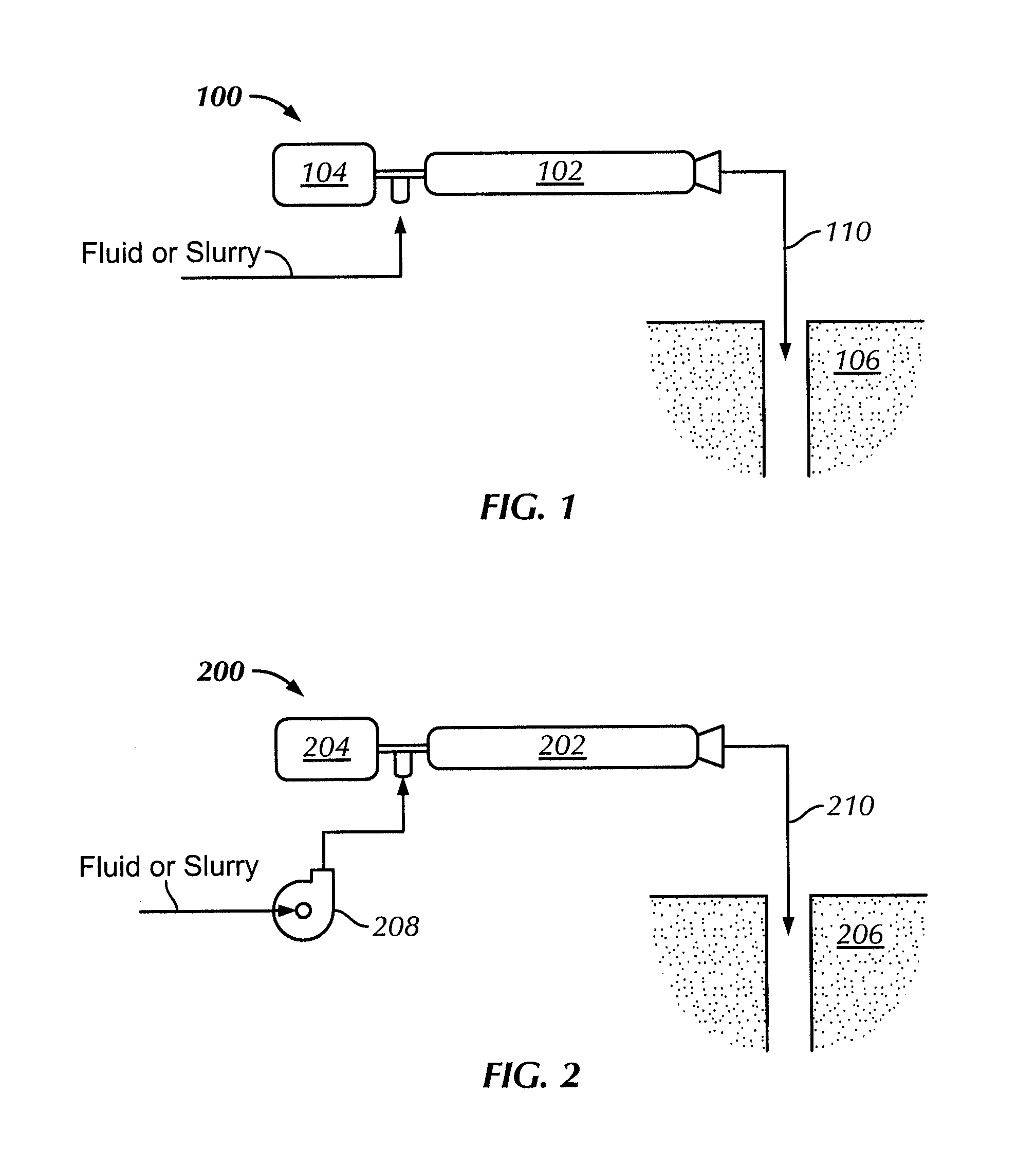

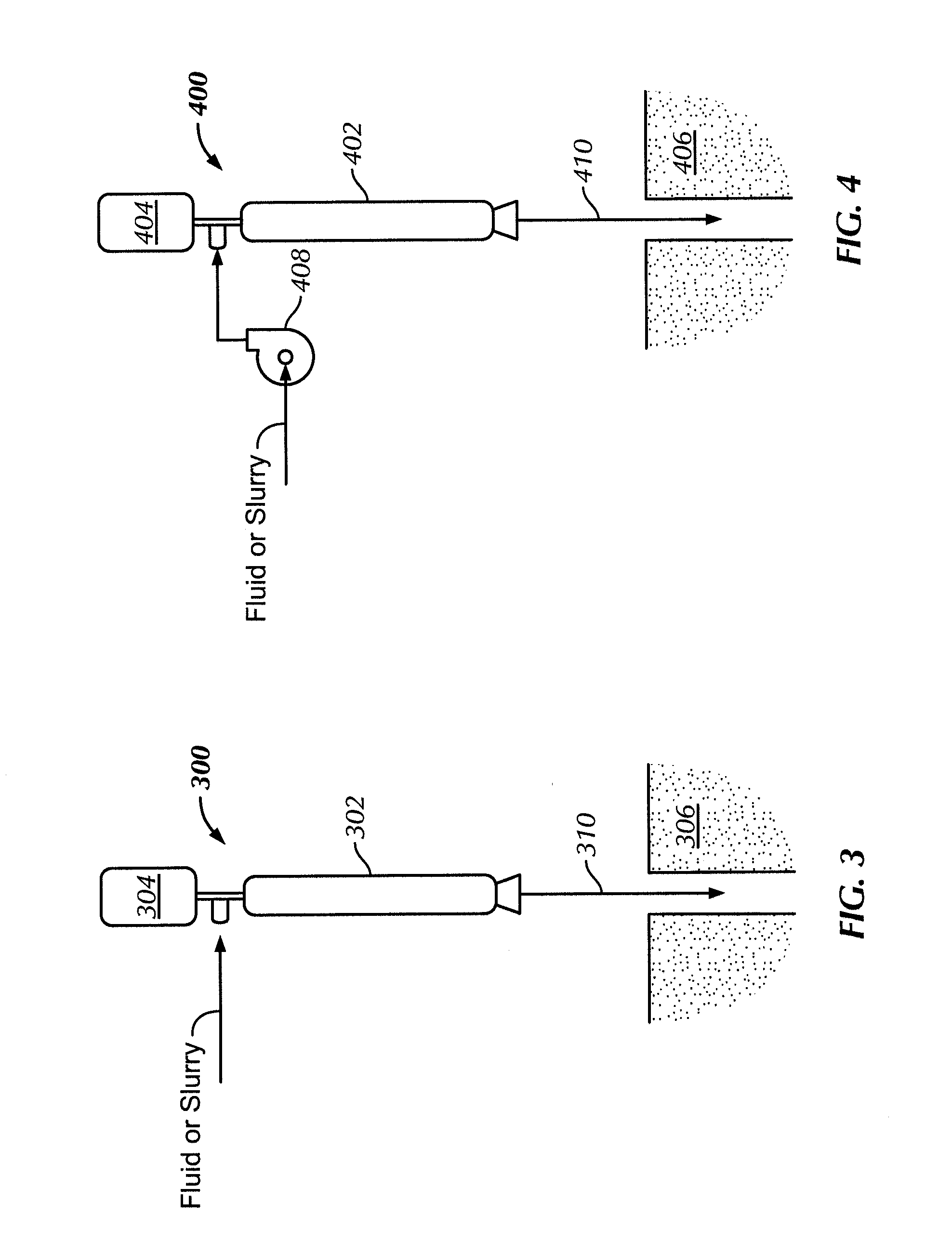

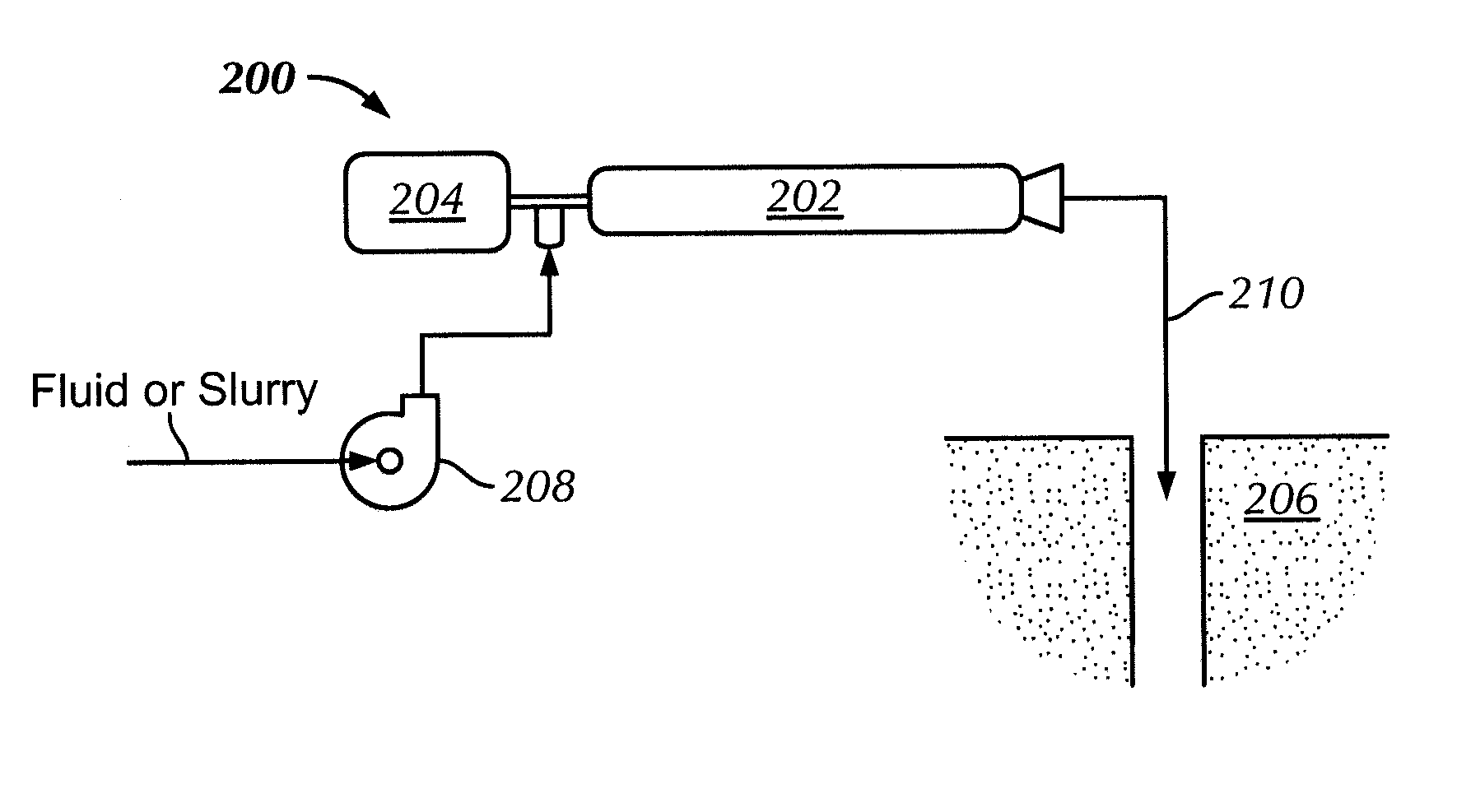

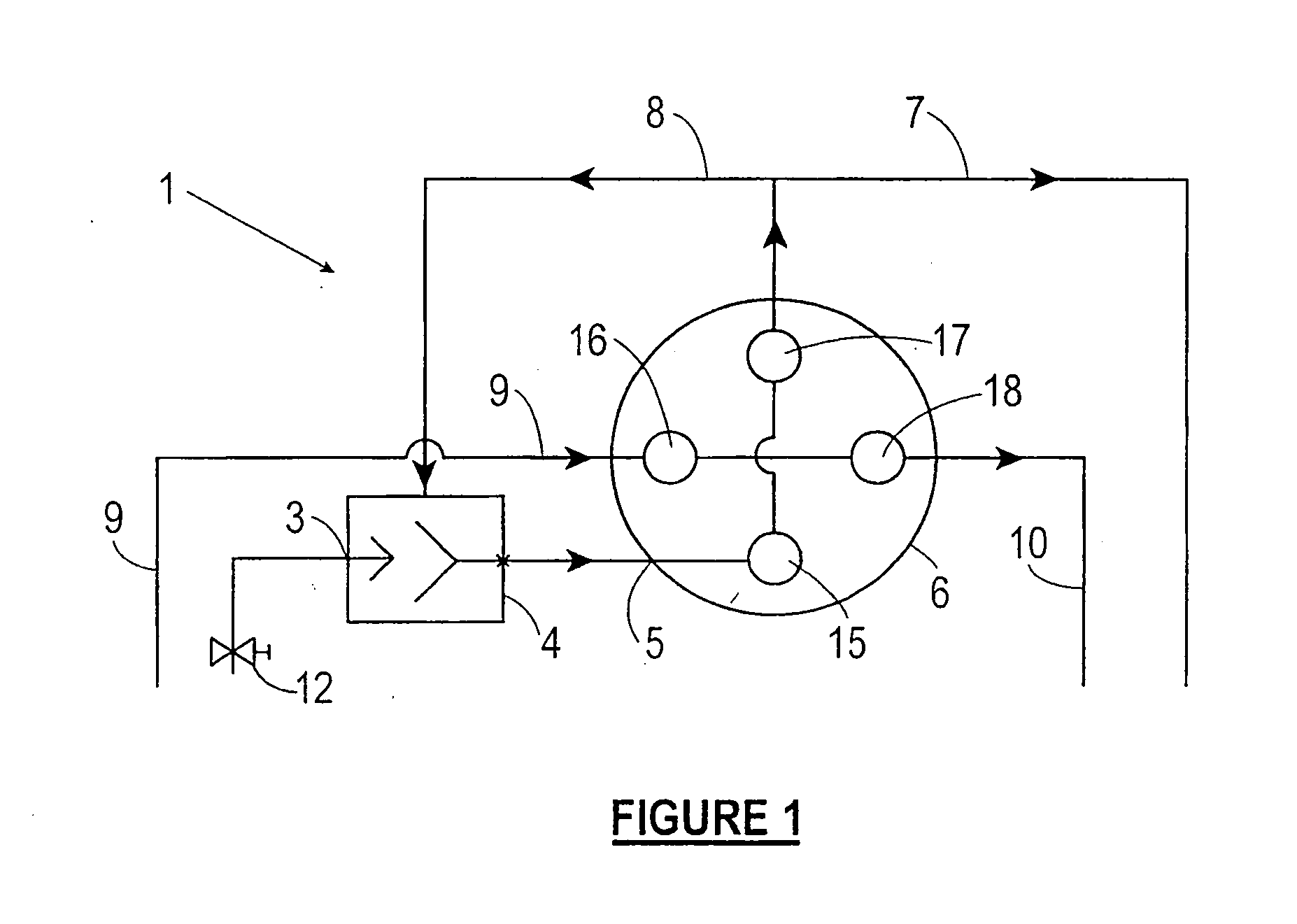

Method and system for injection of viscous unweighted, low-weighted, or solids contaminated fluids downhole during oilfield injection process

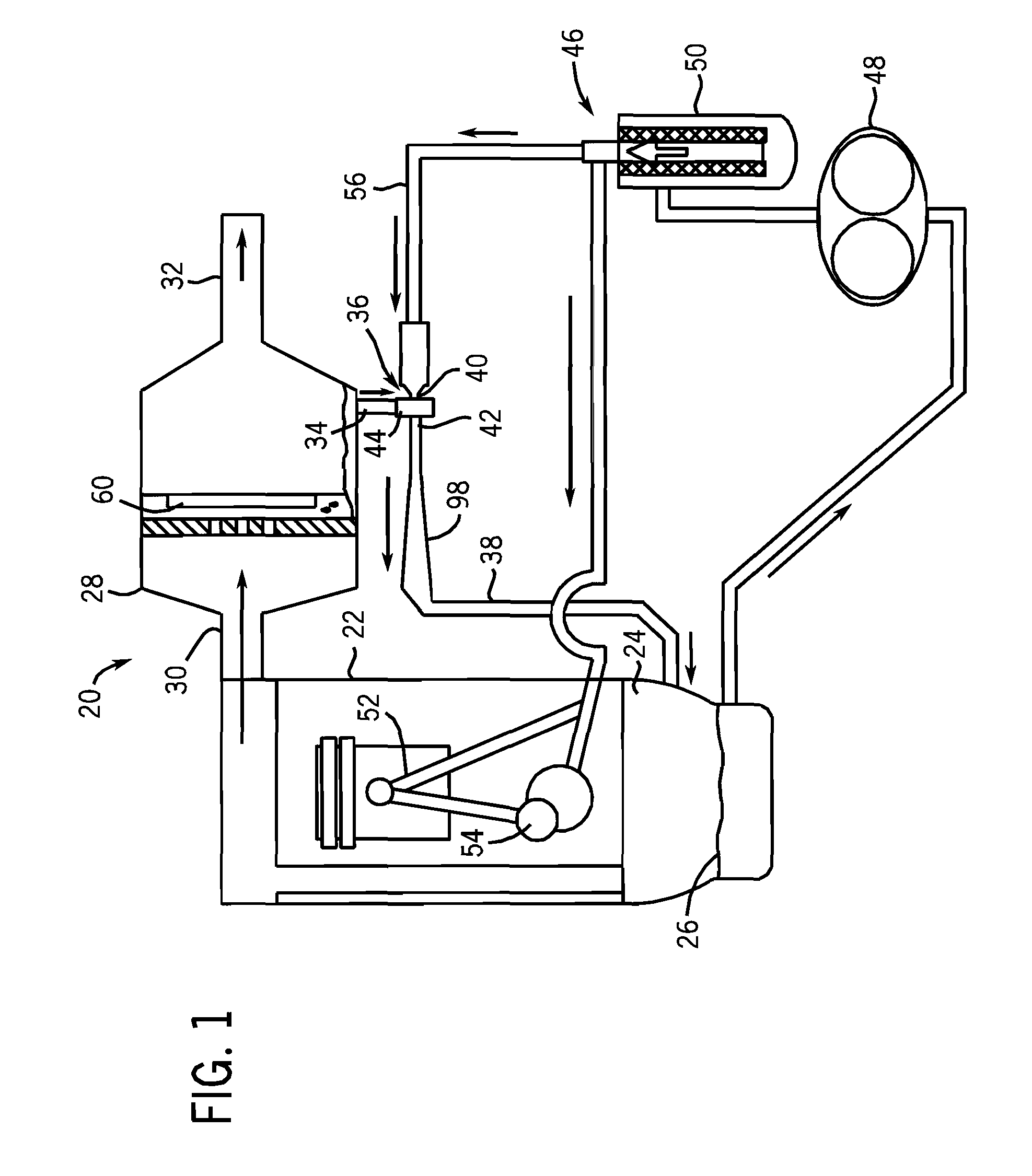

InactiveUS20090260826A1Increase pressureFluid removalPump installationsBiomedical engineeringInjection pump

A system for injecting a fluid into a formation including a fluid, and at least one injection pump configured to receive the fluid, the at least one pump including a centrifugal pump having at least two stages configured to increase the pressure of the received fluid is disclosed. The system further includes a drive device coupled to the injection pump. A method of injecting a fluid downhole including providing a fluid to an injection pump, the injection pump including a centrifugal pump having at least two stages, pumping the fluid through the at least two stages of the centrifugal pump, thereby increasing the pressure of the fluid, and injecting the fluid from the injection pump into a wellbore is also disclosed.

Owner:MI

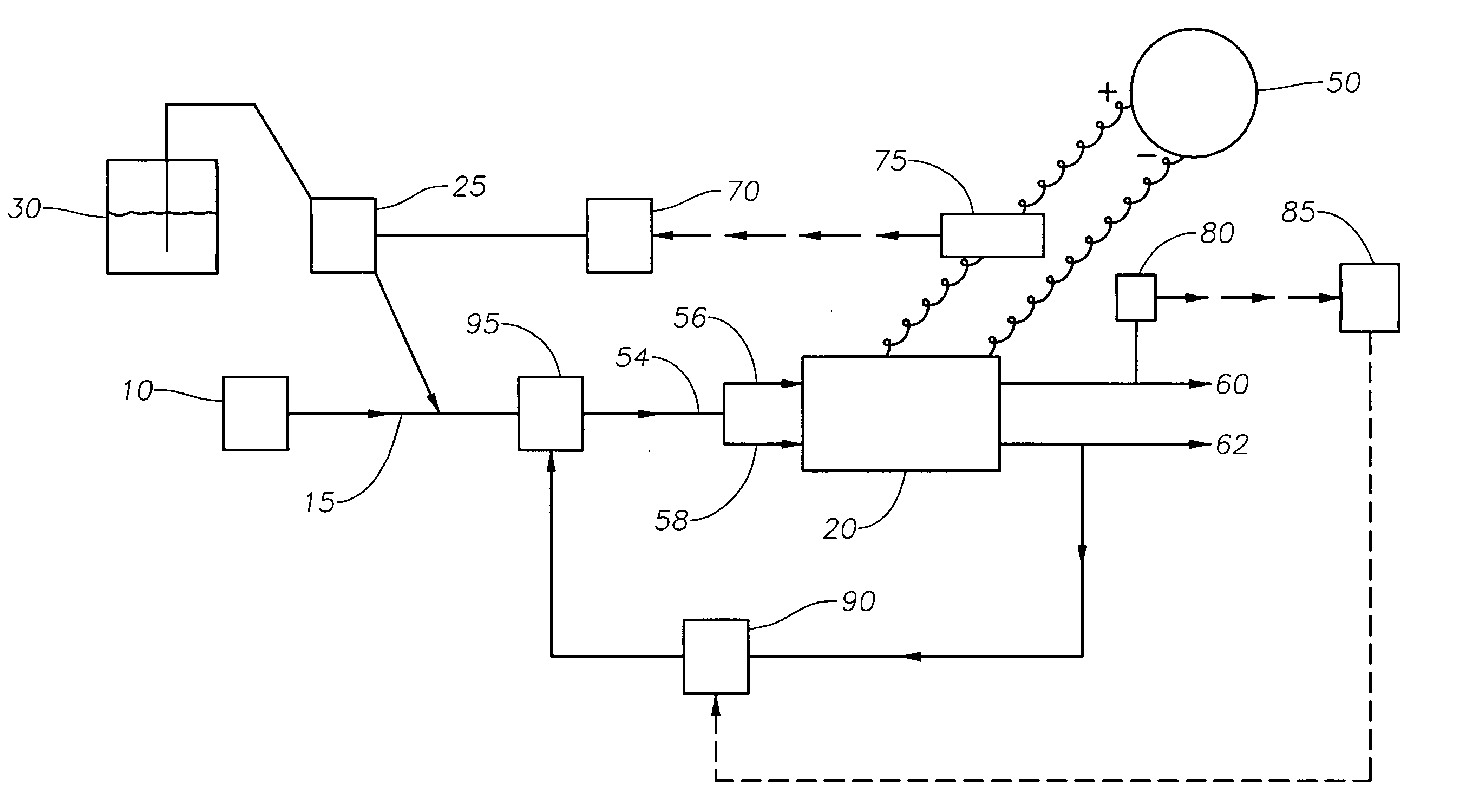

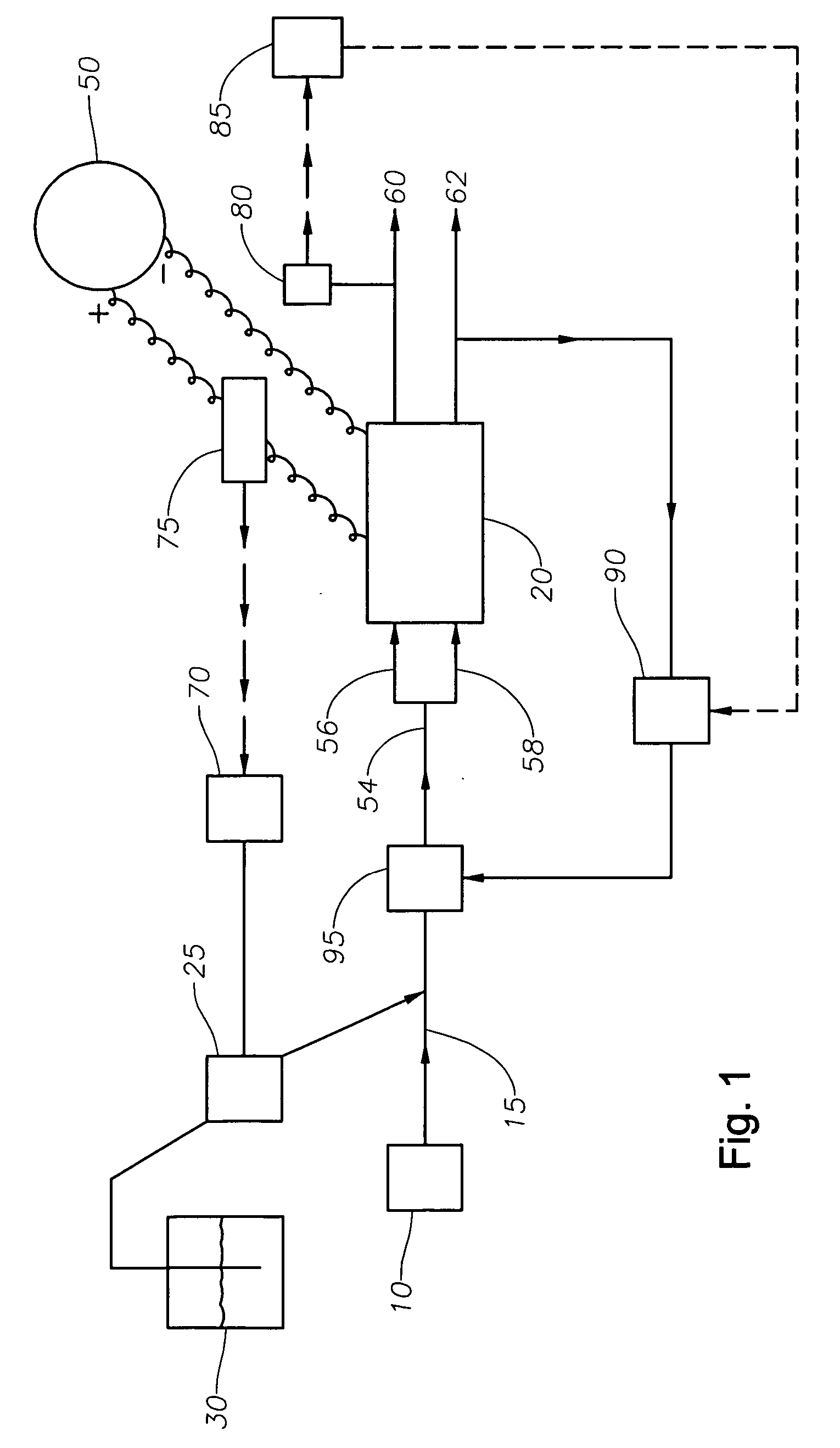

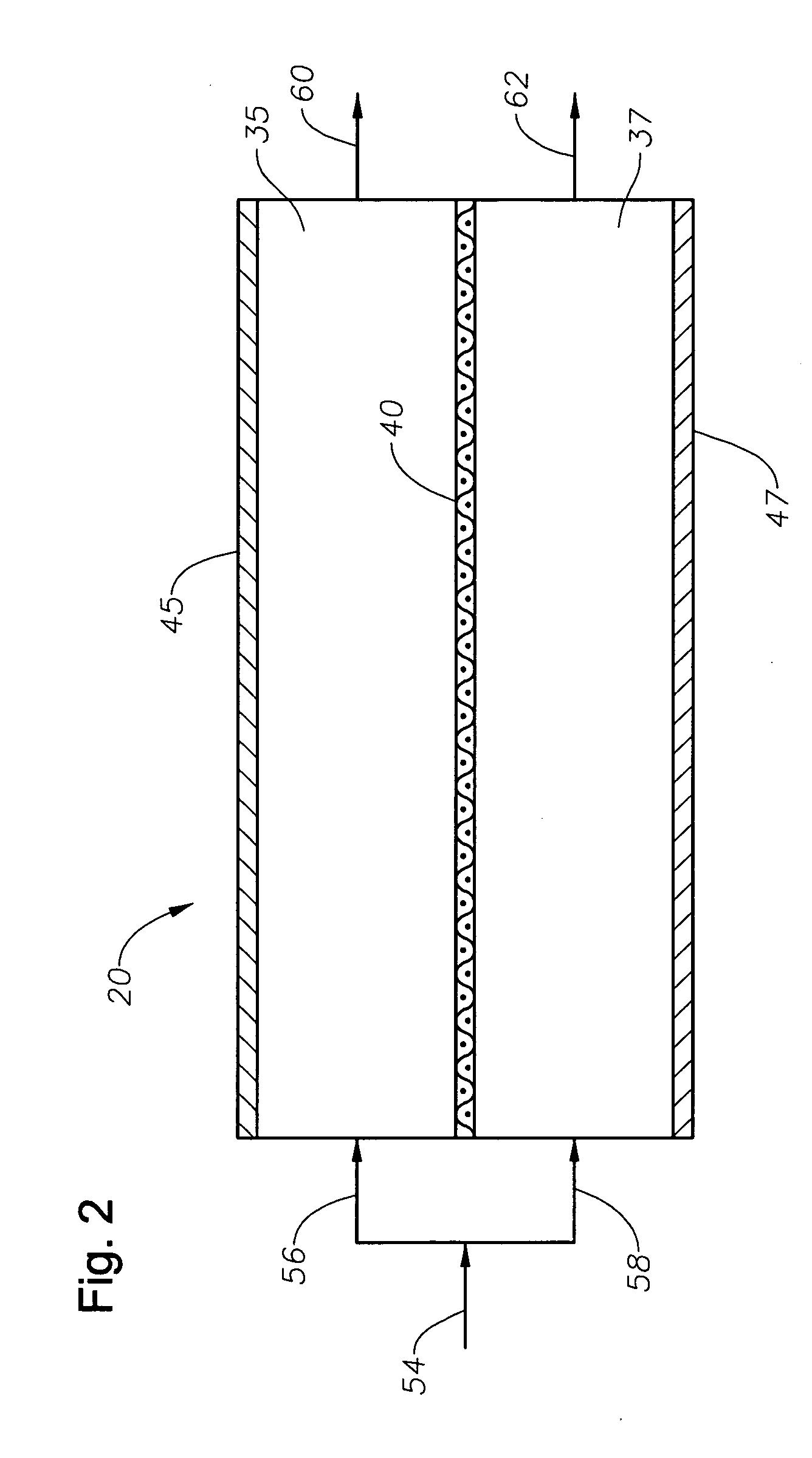

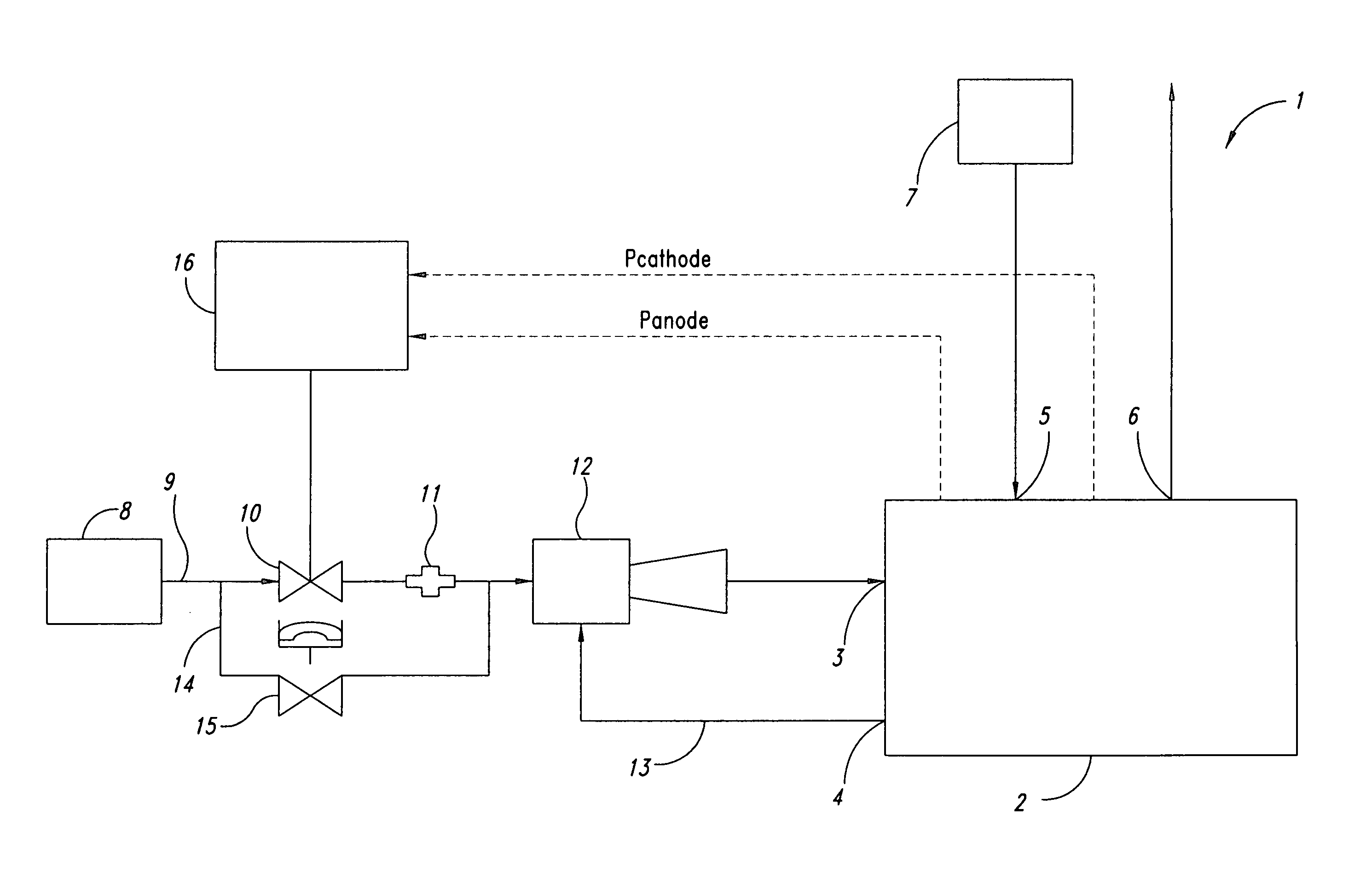

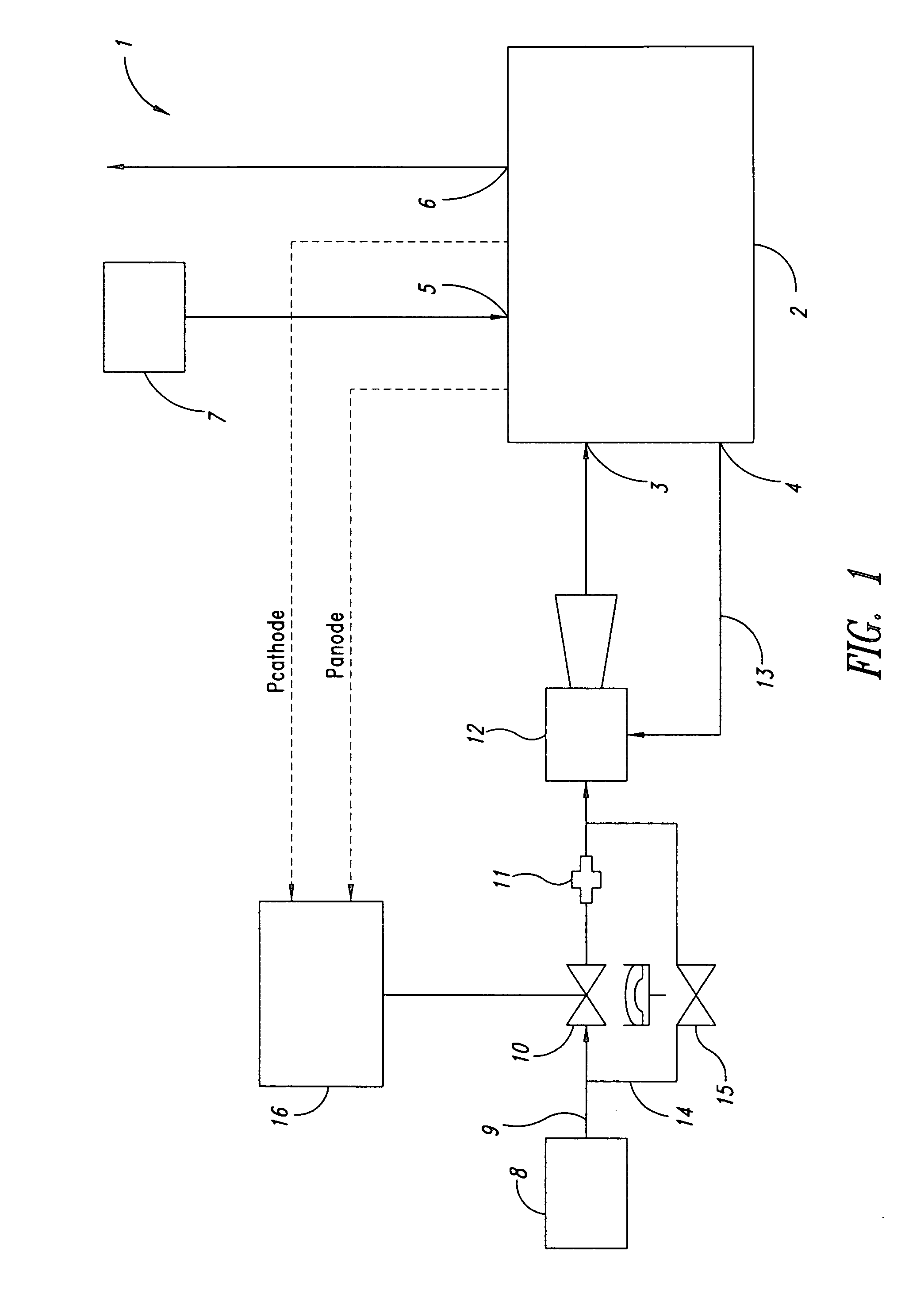

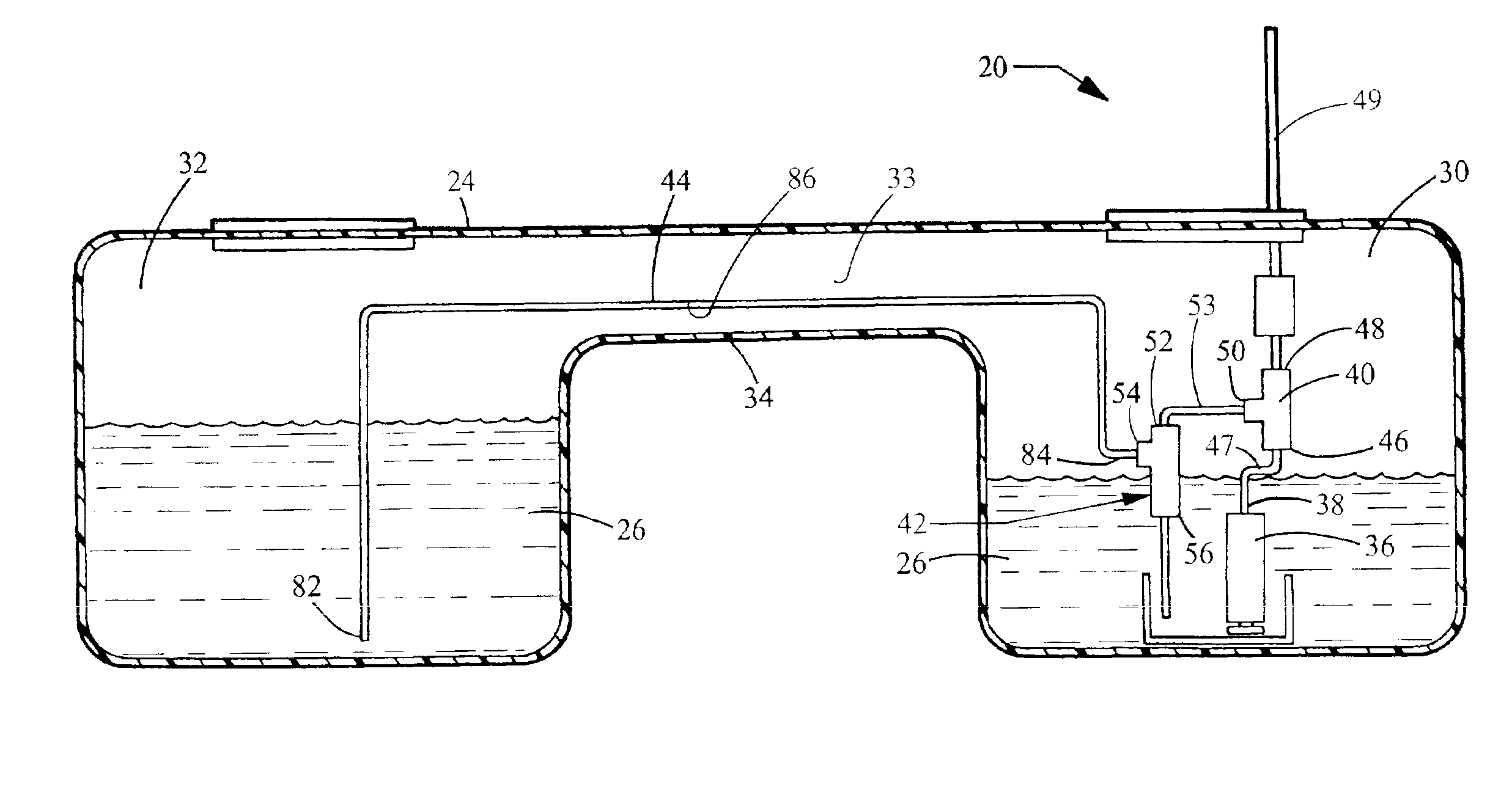

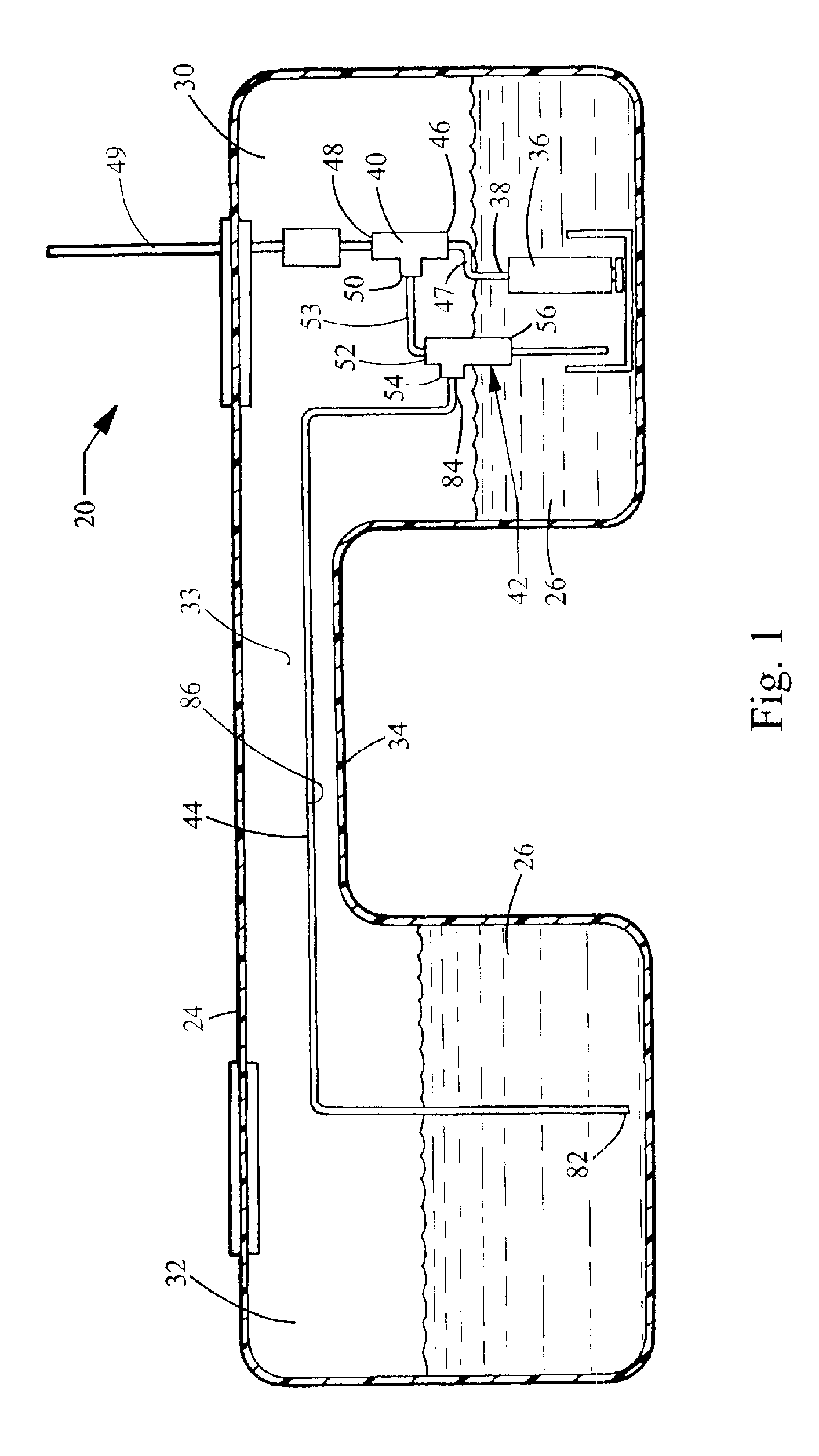

Fuel cell system with improved fuel recirculation

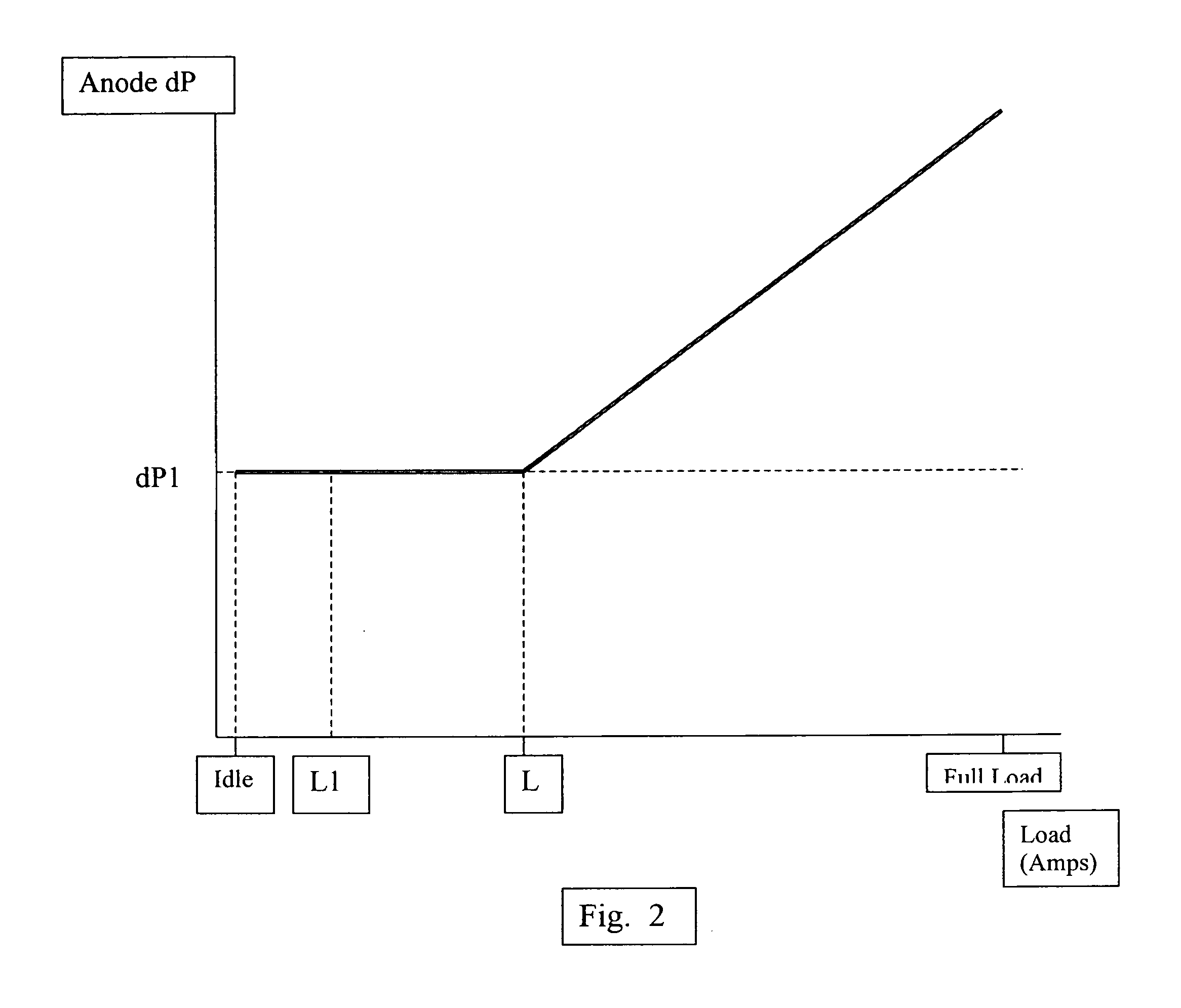

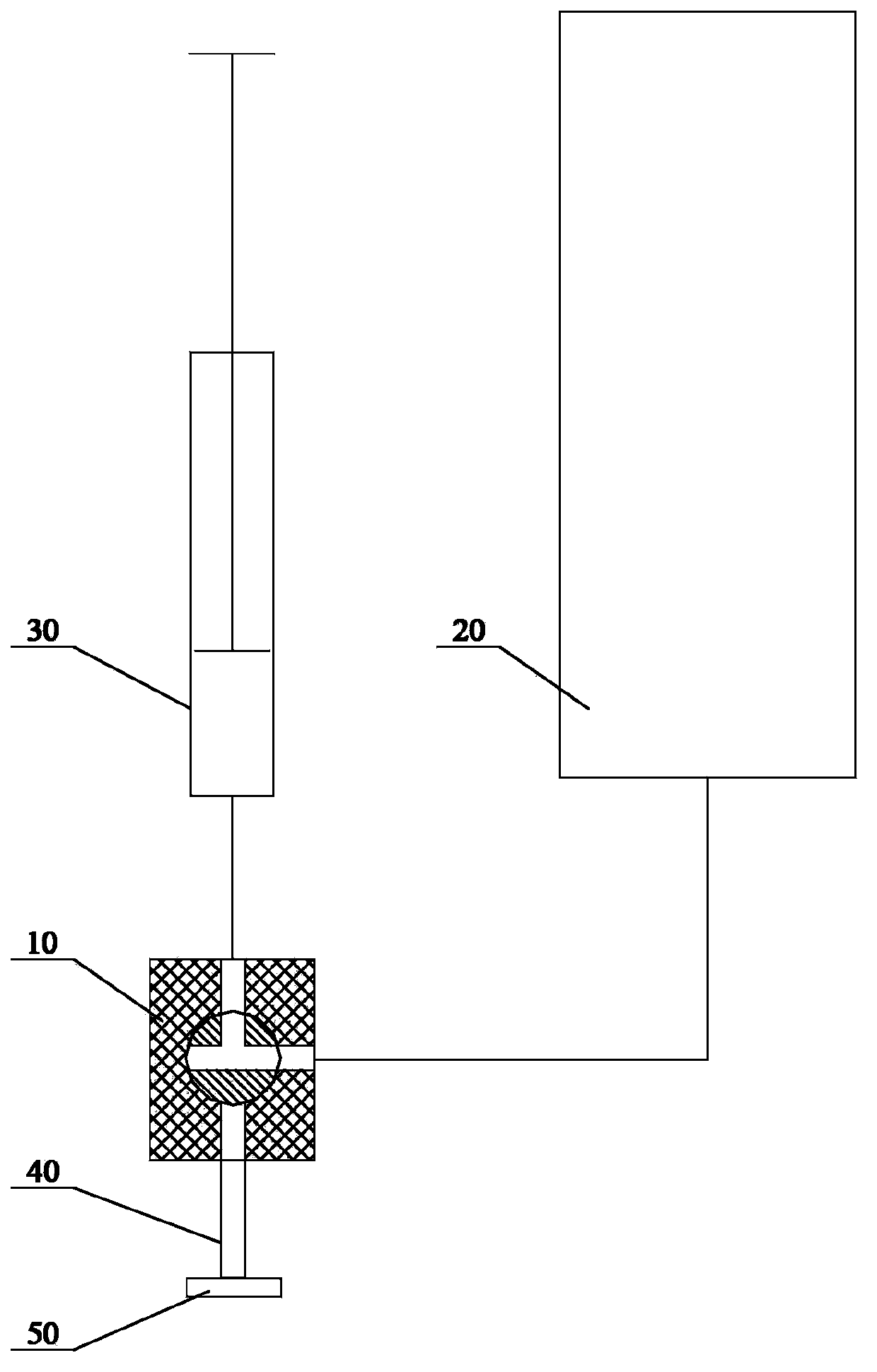

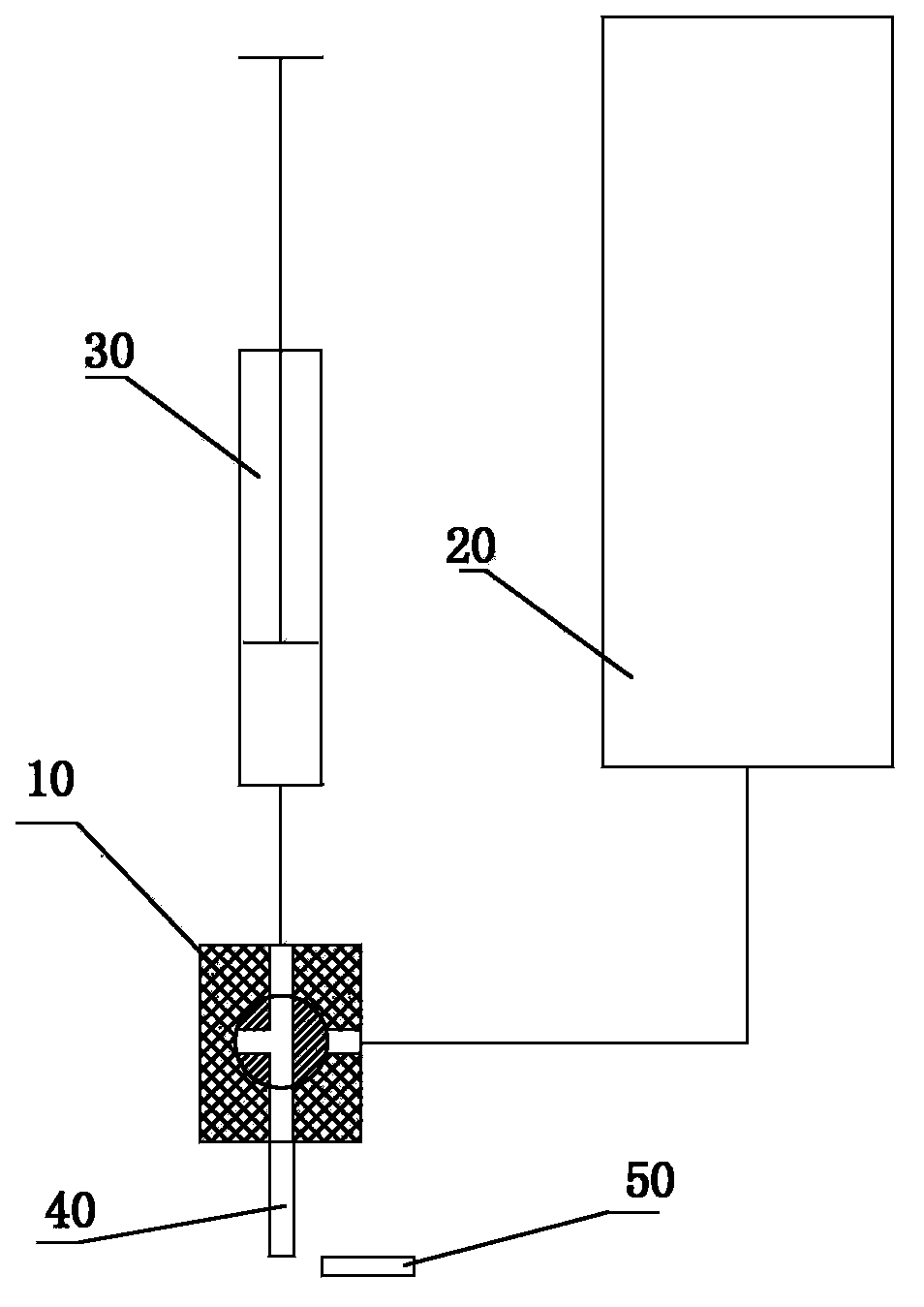

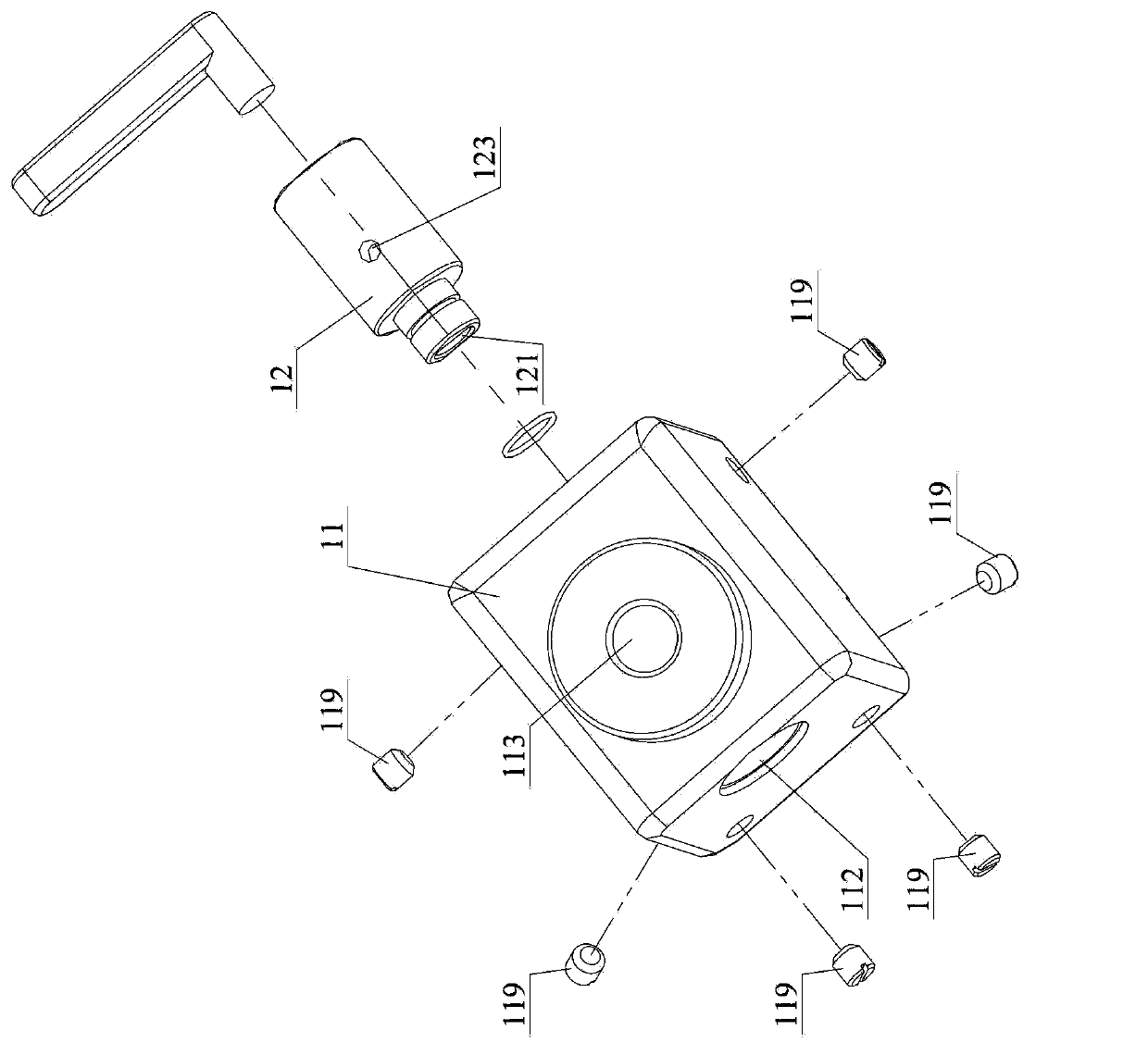

ActiveUS20070248858A1Improves fuel recirculationIncreased recirculationFuel cells groupingFuel cell auxillariesFuel cellsLow load

A fuel cell system comprising a fuel cell stack, a fuel recirculation line provided with a jet pump and a valve controlled by a control unit based on the anode-cathode pressure differential such that the valve is closed to reduce or stop fuel supply when the anode-cathode pressure differential reaches a predetermined value, and opened again to circulate more fuel through the jet pump when the pressure differential is below a predetermined value, to create a pulsed fuel supply that improves the fuel recirculation at low loads and ensures adequate water removal from the anode flow field channels.

Owner:BALLARD POWER SYSTEMS

Color mixer and reversing valve device thereof

ActiveCN103968106ASolve the phenomenon of color paste dryingSolve the problem of color paste depositionPlug valvesTransportation and packagingInjection pumpPhysics

The invention discloses a reversing valve device. A first opening on a valve body is used for being communicated with a colorant container while a second opening on the same is used for being communicated with an injection pump, a valve core is arranged in an internal valve cavity of the valve body in a pivoted manner, an internal passage and a first colorant injection hole are arranged on the valve core, the internal passage is communicated with the second opening of the valve body, one end of the first colorant injection hole is communicated with the internal passage while the other end of the same is arranged on the peripheral surface of the valve core, a third opening on the valve body is formed on the inner wall of the internal valve cavity, a first passage is communicated with the first opening and the third opening, a fourth opening is formed on the lower end face of the valve body and communicated with the internal valve cavity, the first colorant injection hole can switch working positions along with rotating of the valve core, and the first colorant injection hole is exposed out of the fourth opening when being at a first colorant injection working position and communicated with the third opening when being at a non-colorant-injection position. By structural optimization, the phenomenon that colorant appears at a colorant outlet can be completely avoided. On the basis, the invention further provides a color mixer with the reversing valve device.

Owner:ZHENGZHOU SANHUA TECH & IND

Safety injection system

ActiveCN101847451AReduce headReduce cross pipeNuclear energy generationCooling arrangementNuclear engineeringControl valves

The invention relates to a safety injection system, which is used for mitigating an accident and protecting the safety of a reactor core of a nuclear power plant and comprises a high-pressure safety injection pump, a low-pressure safety injection pump, a safety injection tank and a refueling water tank for containing safety injection water, wherein the refueling water tank is positioned in a safety shell of the nuclear power plant; the safety injection tank is connected on a direct pressure vessel injection pipeline by a pipeline provided with a control valve; the high-pressure safety injection pump is connected between the refueling water tank and the direct pressure vessel injection pipeline by a pipeline provided with a control valve; and the low-pressure safety injection pump is connected between the refueling water tank and the direct pressure vessel injection pipeline by a pipeline provided with a control valve. The safety injection system has the advantages of reducing cross pipelines of the system, realizing continuous operation, simplifying the system operation, also strengthening mitigating capability of the system for the serious accident and improving safety of the nuclear power plant.

Owner:中广核工程有限公司 +1

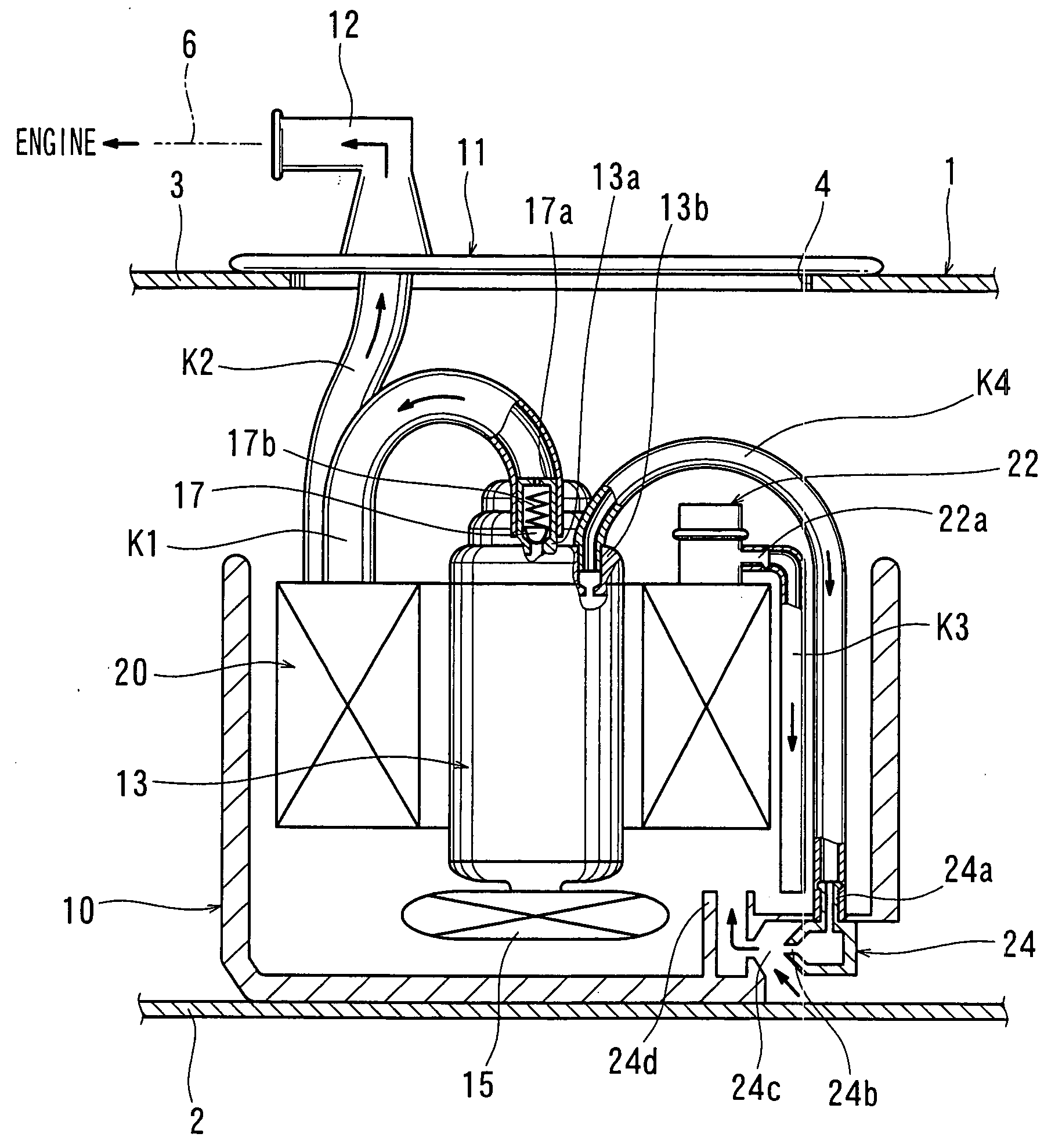

Fuel delivery systems

ActiveUS20050045159A1Reduce manufacturing costImprove spraying effectJet pumpsMachines/enginesFuel tankFuel supply

A fuel delivery system for delivering fuel from a fuel tank to an engine includes a reservoir disposed within the fuel tank and a fuel pump, such as an electrically driven fuel pump, operable to draw fuel from within the reservoir. The fuel pump has a first port and a second port that independently discharge the fuel from the fuel pump. A first jet pump is operable to draw the fuel within the fuel tank into the reservoir. A first flow path communicates between the first port and the engine. A second flow path communicates between the second port and the first jet pump, so that the fuel within the fuel tank is transferred into the reservoir due to the flow of the fuel supplied to the first jet pump via the second flow path.

Owner:AISAN IND CO LTD

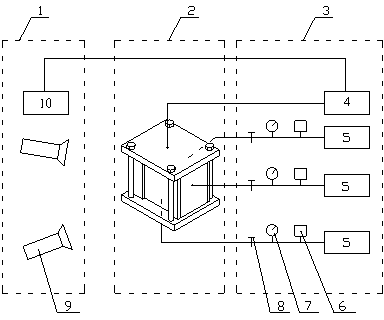

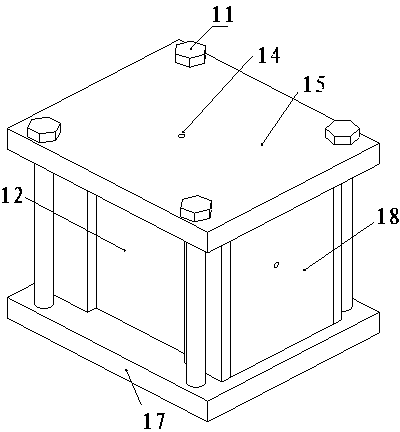

System and method for visualization fracturing simulation experiment

The invention relates to a system and method for a visualization fracturing simulation experiment. According to the technical scheme, the system comprises a visualization fracturing simulation experiment device, a pressure control module and a data acquisition module, wherein the visualization fracturing simulation experiment device is a square container, the pressure control module comprises a servo control injection pump, a confining pressure pump and the like, and the data acquisition module comprises a pressure data recorder and a high-definition high-frequency vidicon. Through combination of the visualization fracturing simulation experiment device and transparent specimens, crack initiation characteristics and expanding dynamic states of hydraulic fractures in interiors of the experiment specimens can be clearly known by researchers, and study of crack initiation mechanisms and expanding rules of the hydraulic fractures are deepened. According to the experiment method, crack initiation and expanding dynamic state videos of the fractures can be obtained, crack initiation and the expanding rules of the fractures can be clearly showed, storage of video data is simple, spreading is convenient, and the method can help the researchers to exchange experiment achievements across regions.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

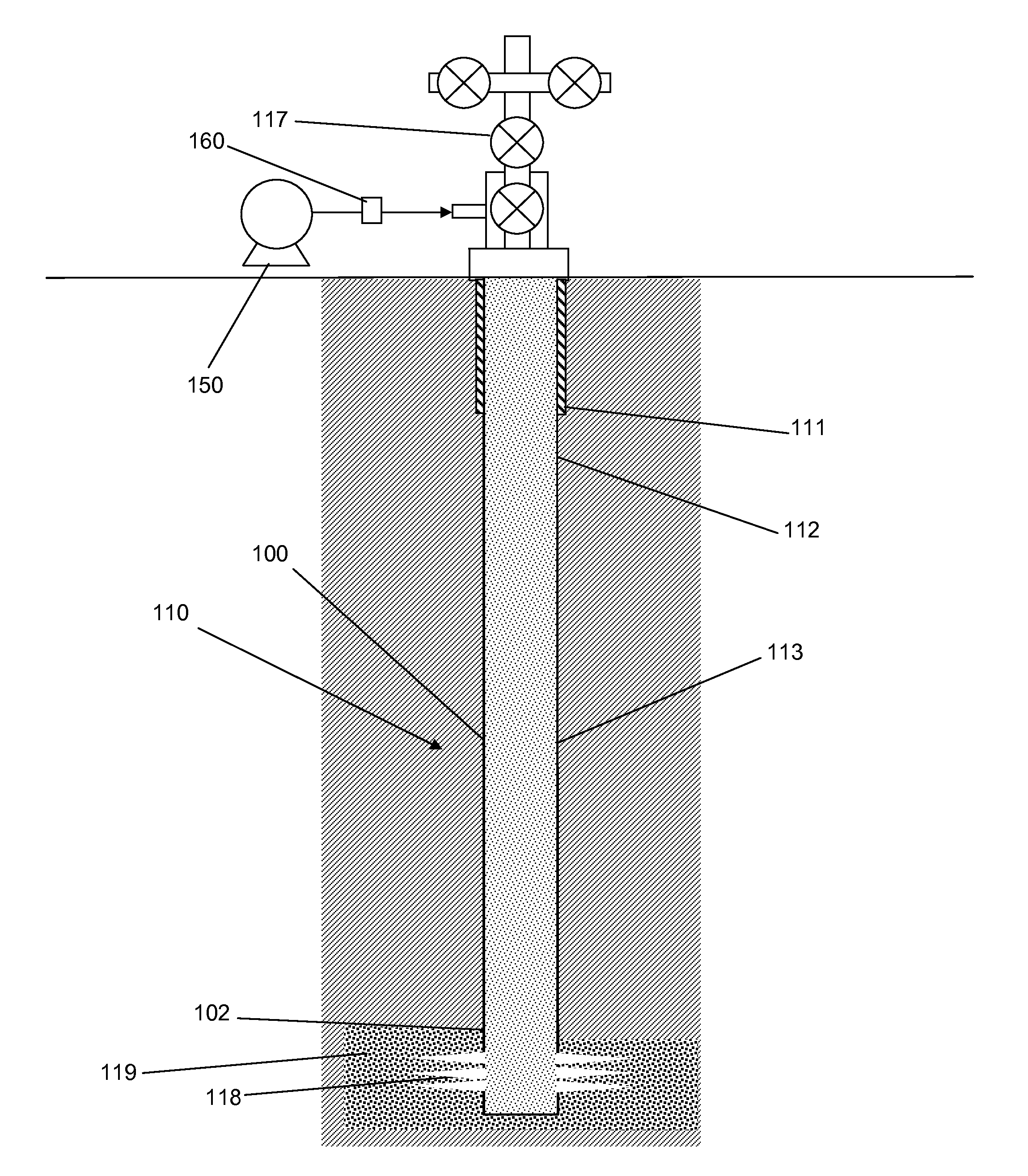

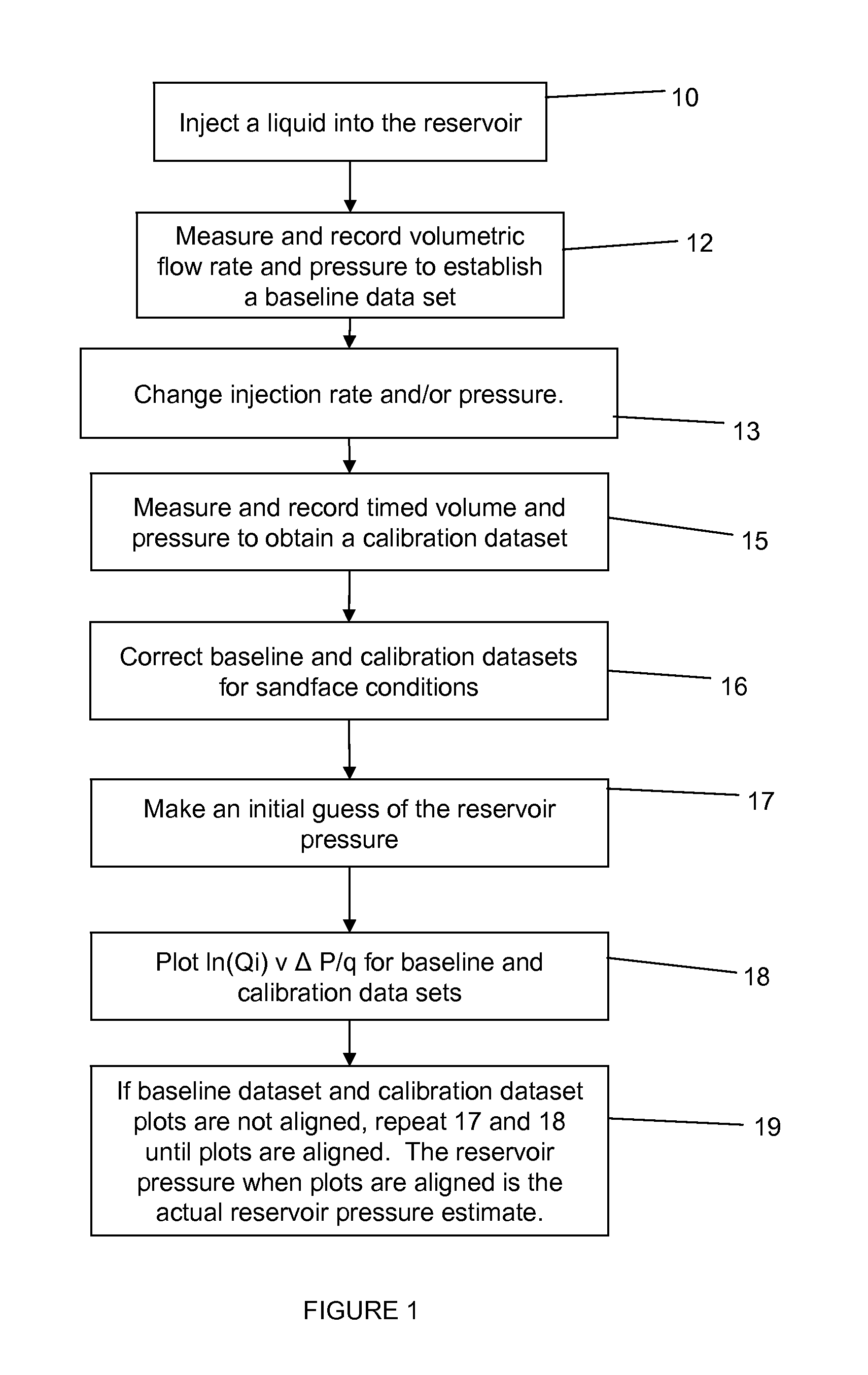

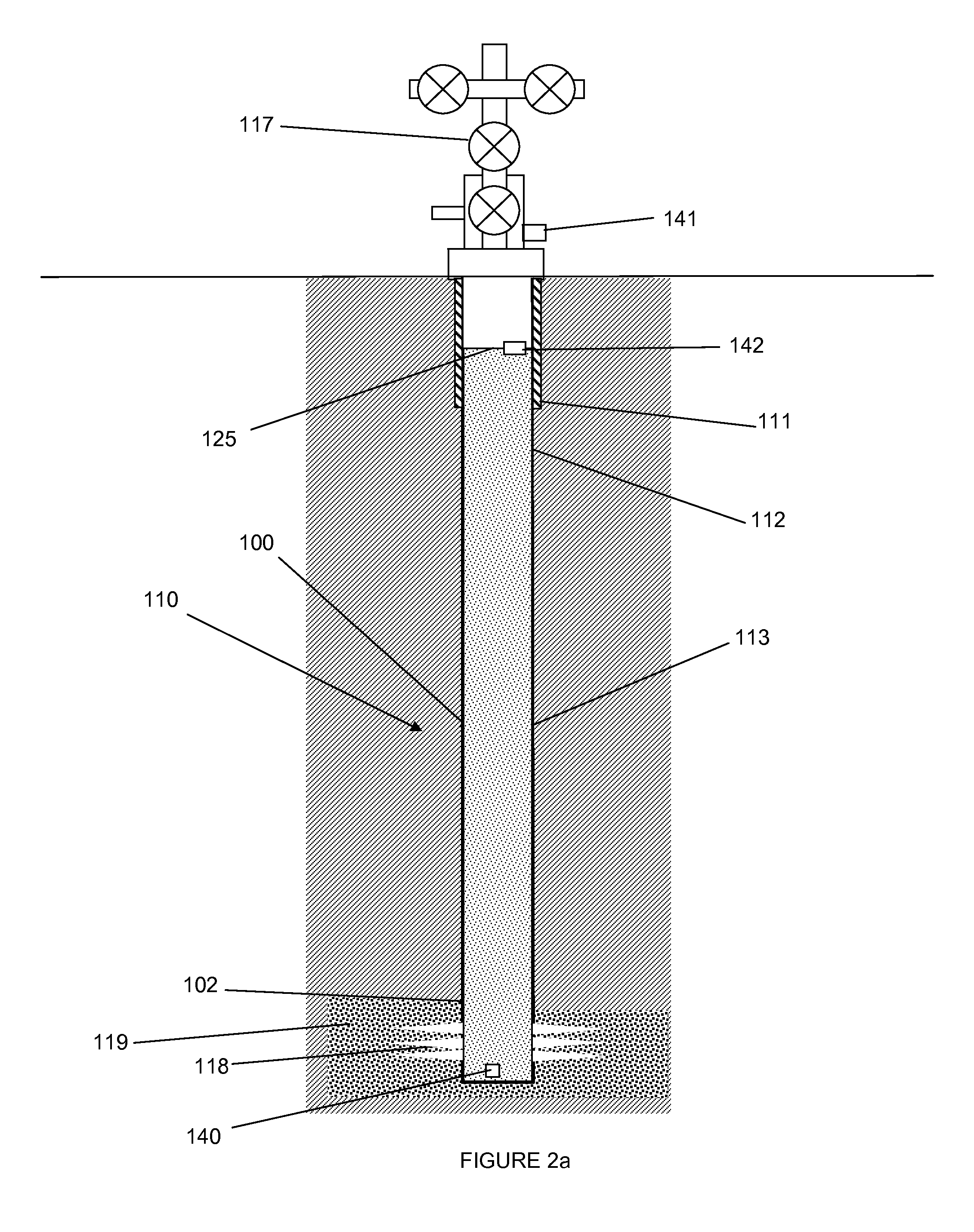

Method of determining reservoir pressure

ActiveUS20120158310A1Reduce penetrationElectric/magnetic detection for well-loggingSurveyBaseline dataInjection pressure

A new approach is disclosed for measuring the pressure of tight gas reservoirs, using information obtain from continuous injection prior to hydraulic fracture stimulation. The technique can be obtained utilizing either bottom-hole or surface pressure gauges and properly instrumented surface injection pumps. The analysis is completed by plotting injection and rate data in a specialized form from terms arranged in Darcy's radial flow equation to obtain a curve or trend. The key component to proper application of this technique is to obtain both baseline and one or more calibration data sets. These calibration data sets are obtained by either increasing or decreasing the injection pressure and / or rate from the baseline data. Initial reservoir pressure is assumed, but the calibration data indicates if the guess was too high or low. Accurate estimates of reservoir pressure may be obtained in a few iterations.

Owner:BP CORP NORTH AMERICA INC

Fuel cell system and method for recycling exhaust

InactiveUS20060251935A1Increase the cross-sectional areaReduce riskFuel cells groupingFuel cell auxillariesFuel cellsEngineering

A fuel cell system includes a primary fuel line to the fuel cell assembly, a jet pump in the primary fuel line and adapted to be driven by the flow of primary fuel, the jet pump having a nozzle, an entrainment chamber downstream of the nozzle and a mixing tube downstream of the entrainment chamber, a fuel exhaust recycle line from the fuel cell assembly opening to the entrainment chamber for supply of fuel exhaust thereto, and a mass flow control device in the primary fuel line upstream of the jet pump for controlling the primary fuel flow rate to the jet pump. The nozzle of the jet pump has an adjustable cross-sectional area to provide a variable area flow of the primary fuel so that the ratio of fuel exhaust entrained by the primary fuel in the entrainment chamber can be varied.

Owner:CERAMIC FUEL CELL LTD

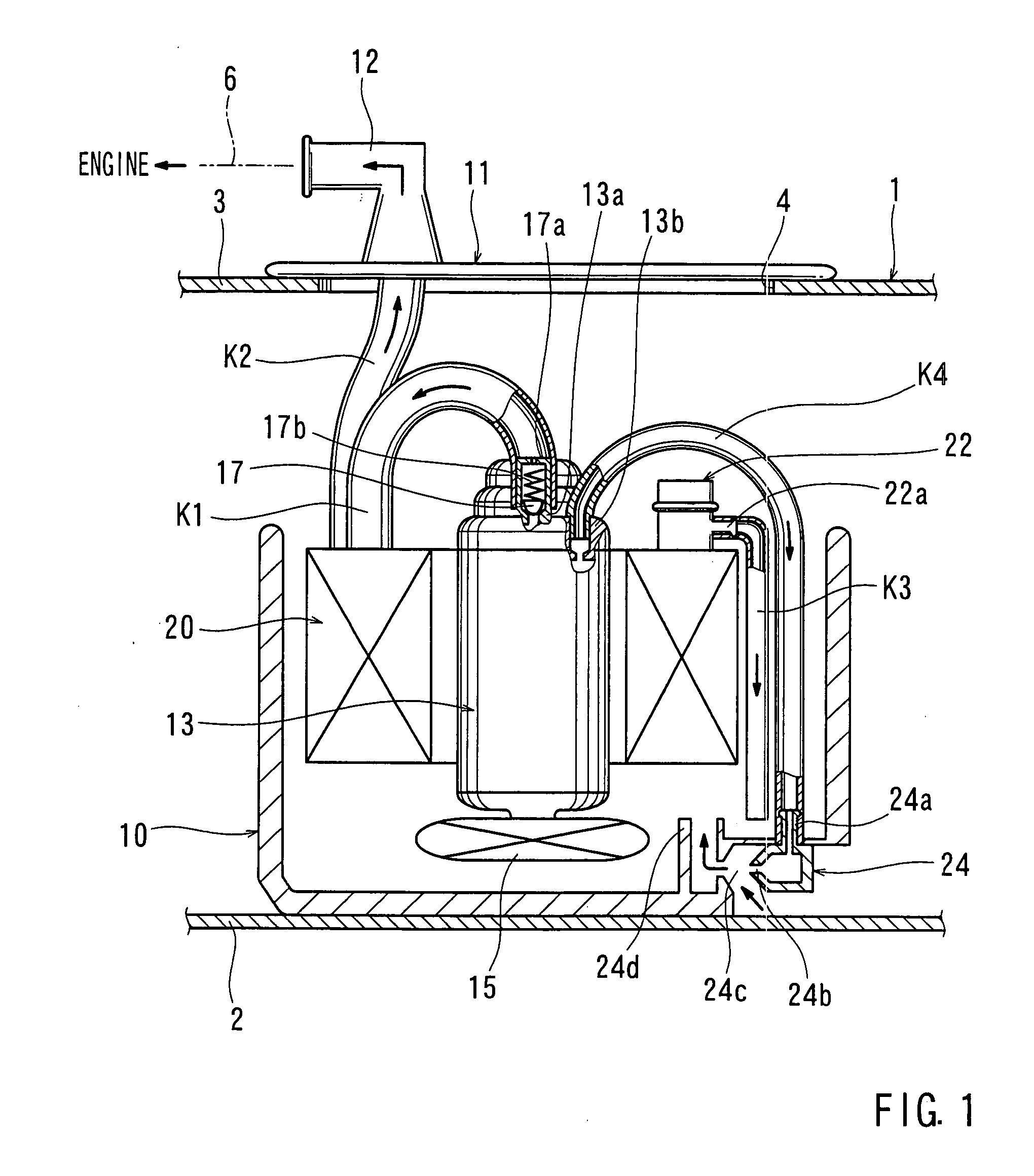

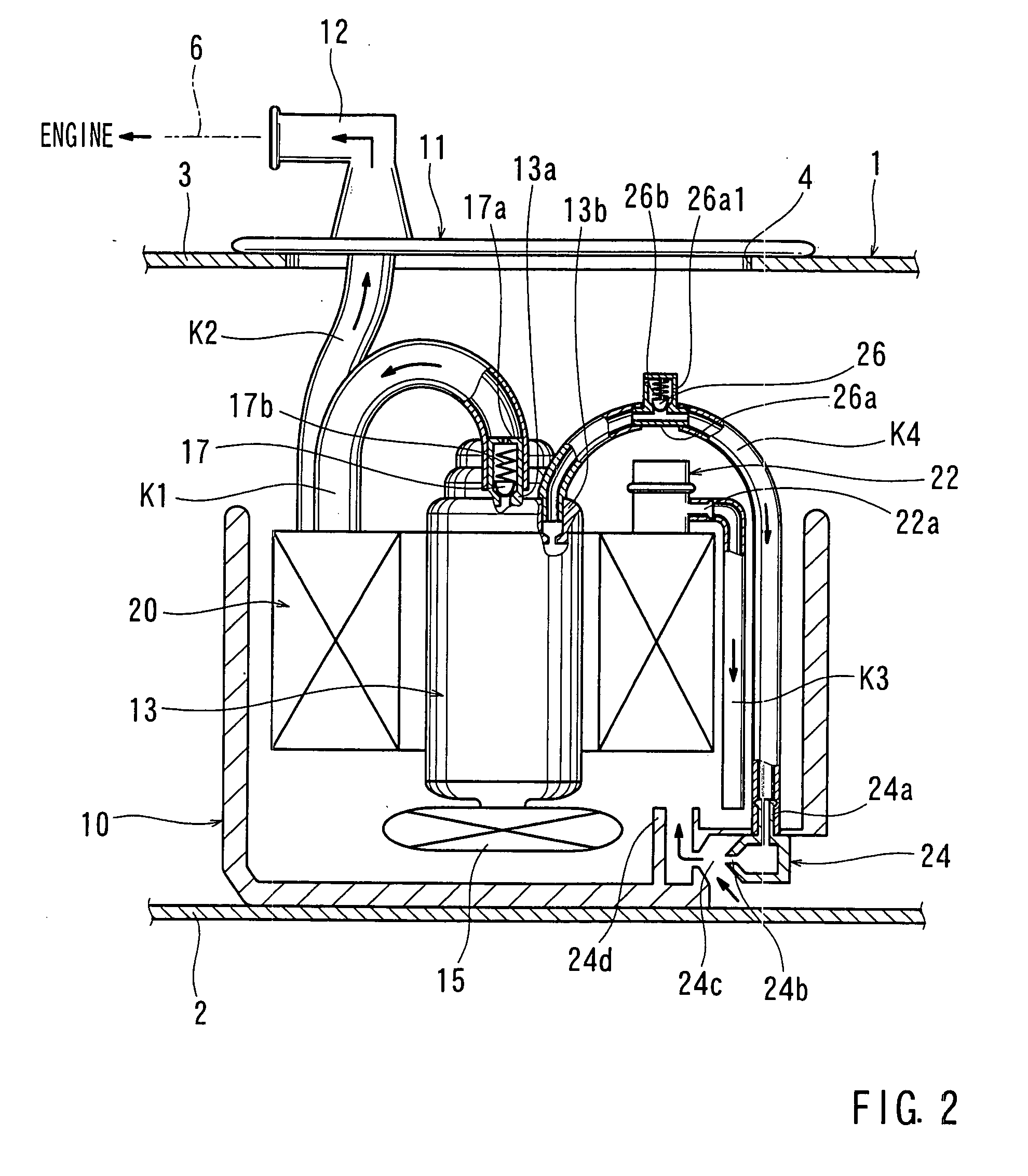

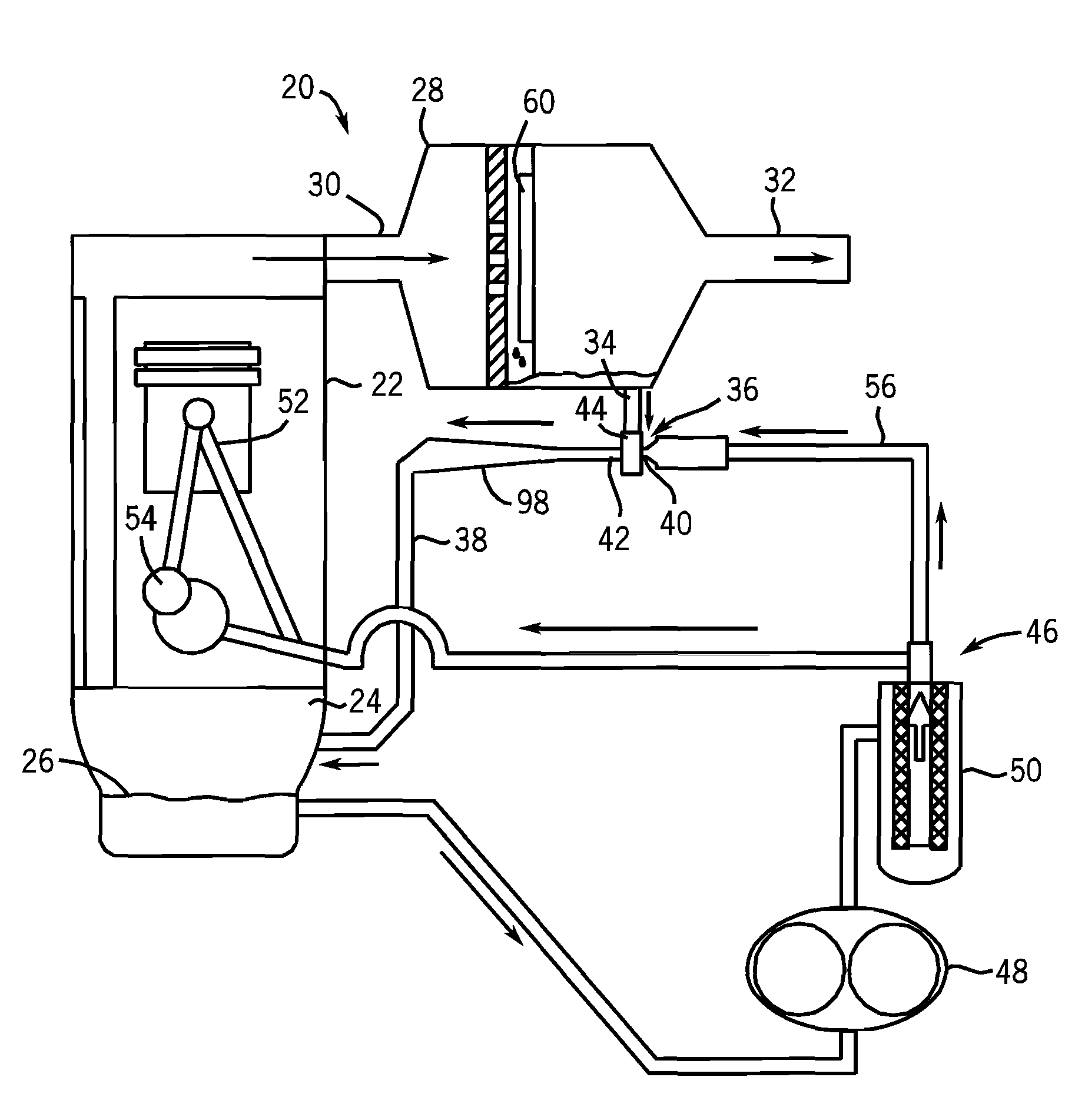

Crankcase Ventilation System with Pumped Scavenged Oil

ActiveUS20090025662A1Simple wayThe process is simple and effectiveDispersed particle filtrationCombustion enginesExternal combustion engineInjection pump

A crankcase ventilation system for an internal combustion engine has a jet pump suctioning scavenged separated oil from the oil outlet of an air / oil separator and pumping same to the crankcase.

Owner:CUMMINS FILTRATION IP INC

Saddle tank fuel delivery system

InactiveUS6907899B2Efficient workLess componentsPump componentsUsing liquid separation agentFuel tankDelivery system

Owner:FORD GLOBAL TECH LLC

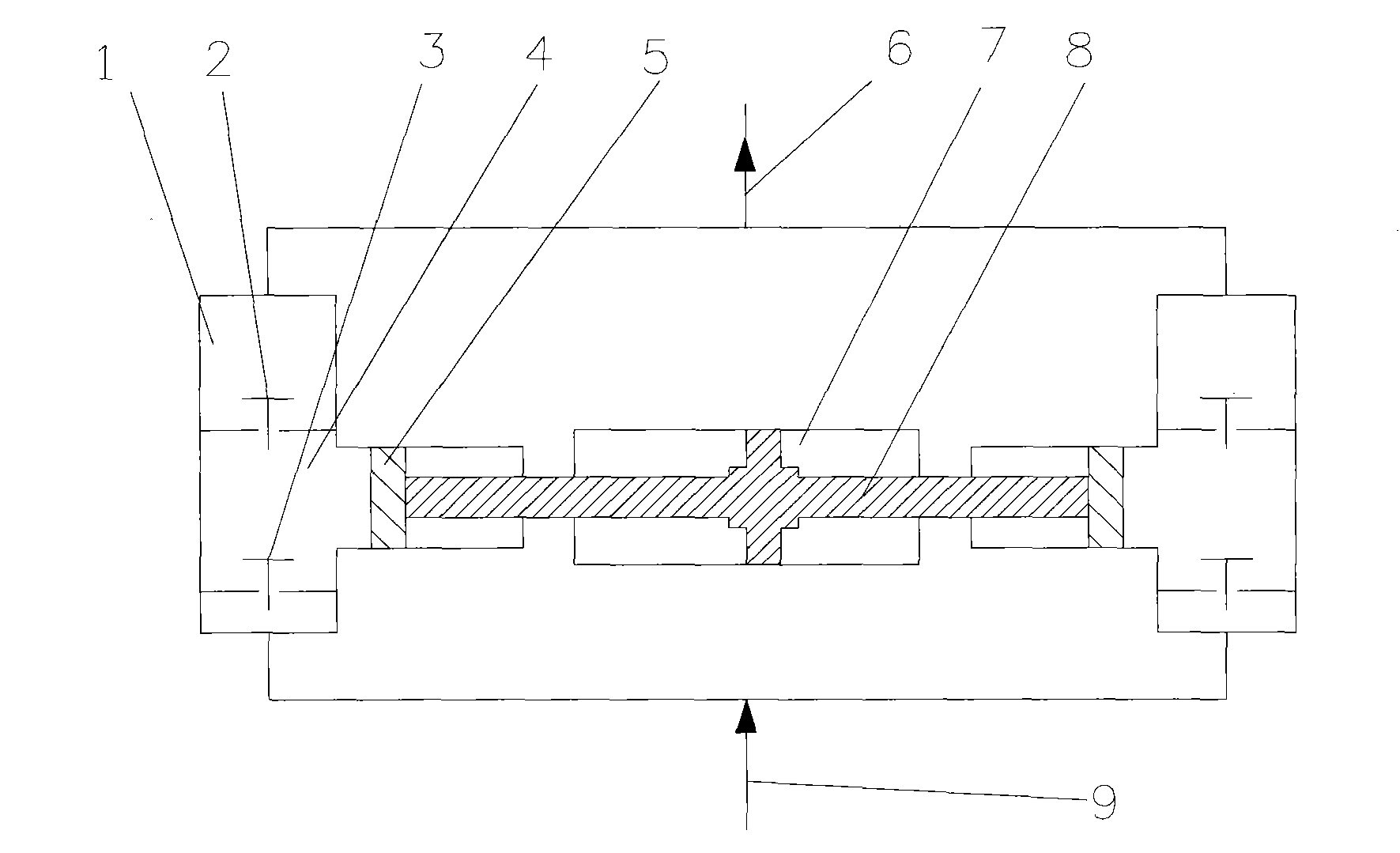

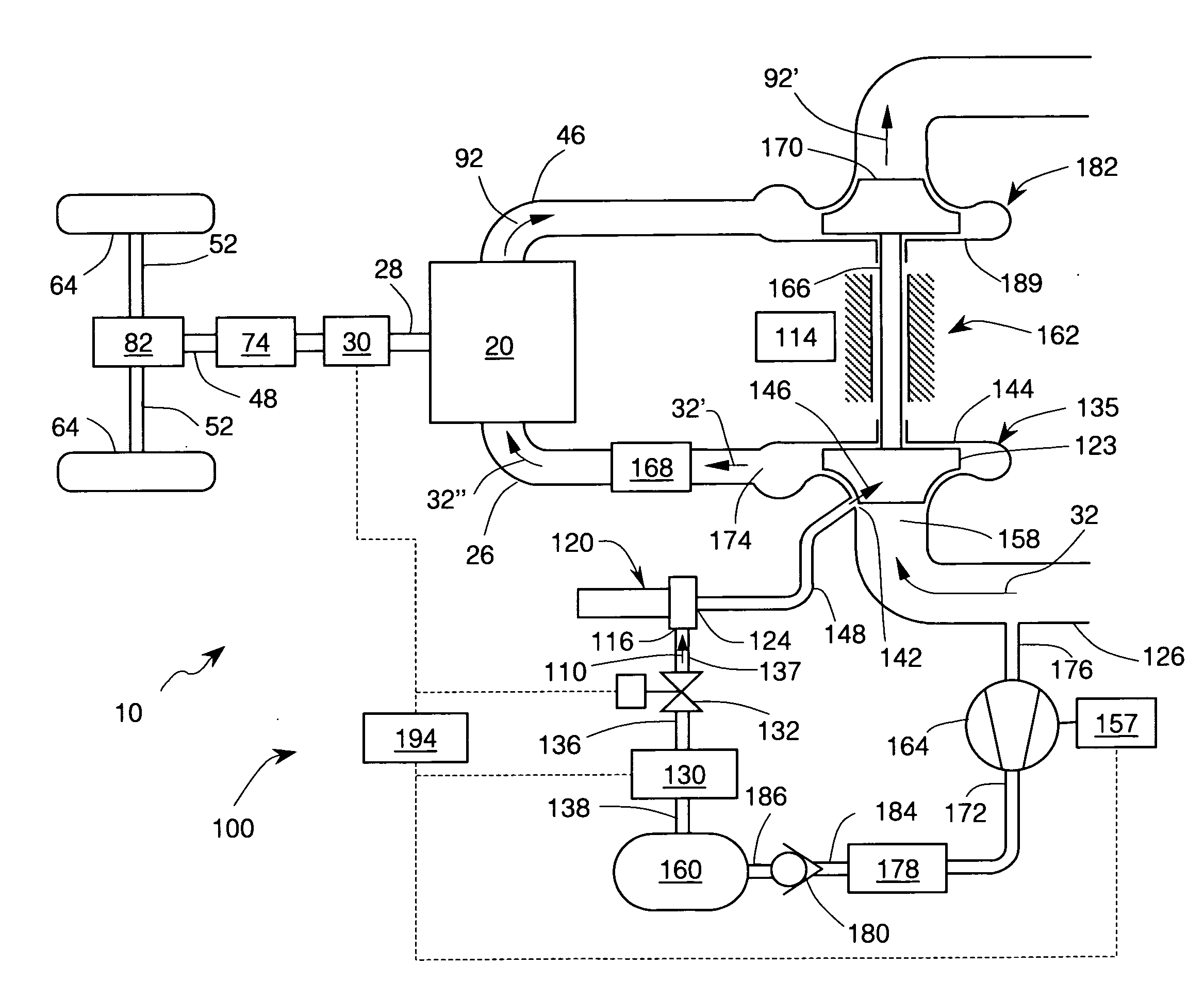

Method and apparatus for metering injection pump flow

InactiveUS6135719AReliable indicatorValve arrangementsFlow control using electric meansControl flowReciprocating motion

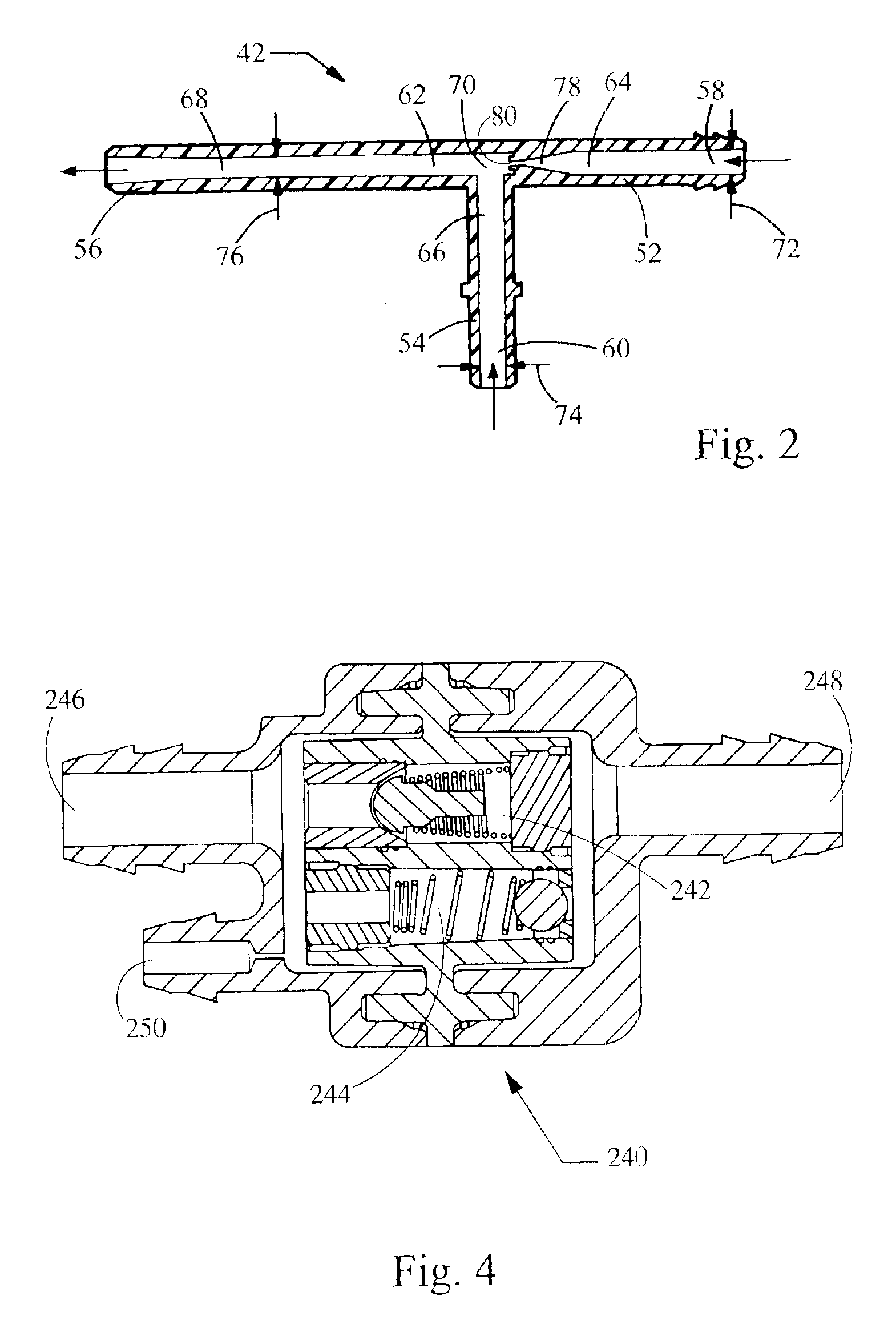

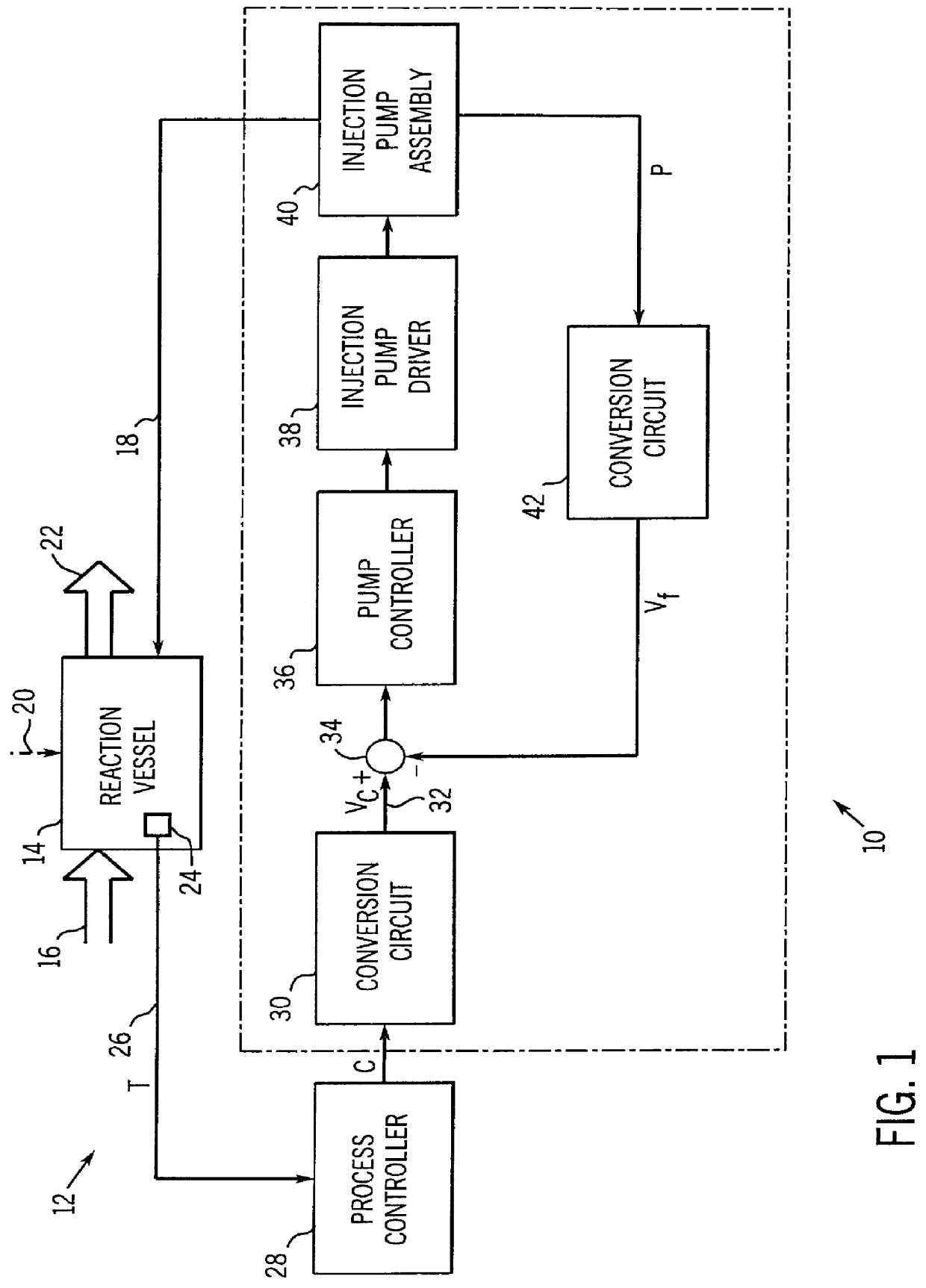

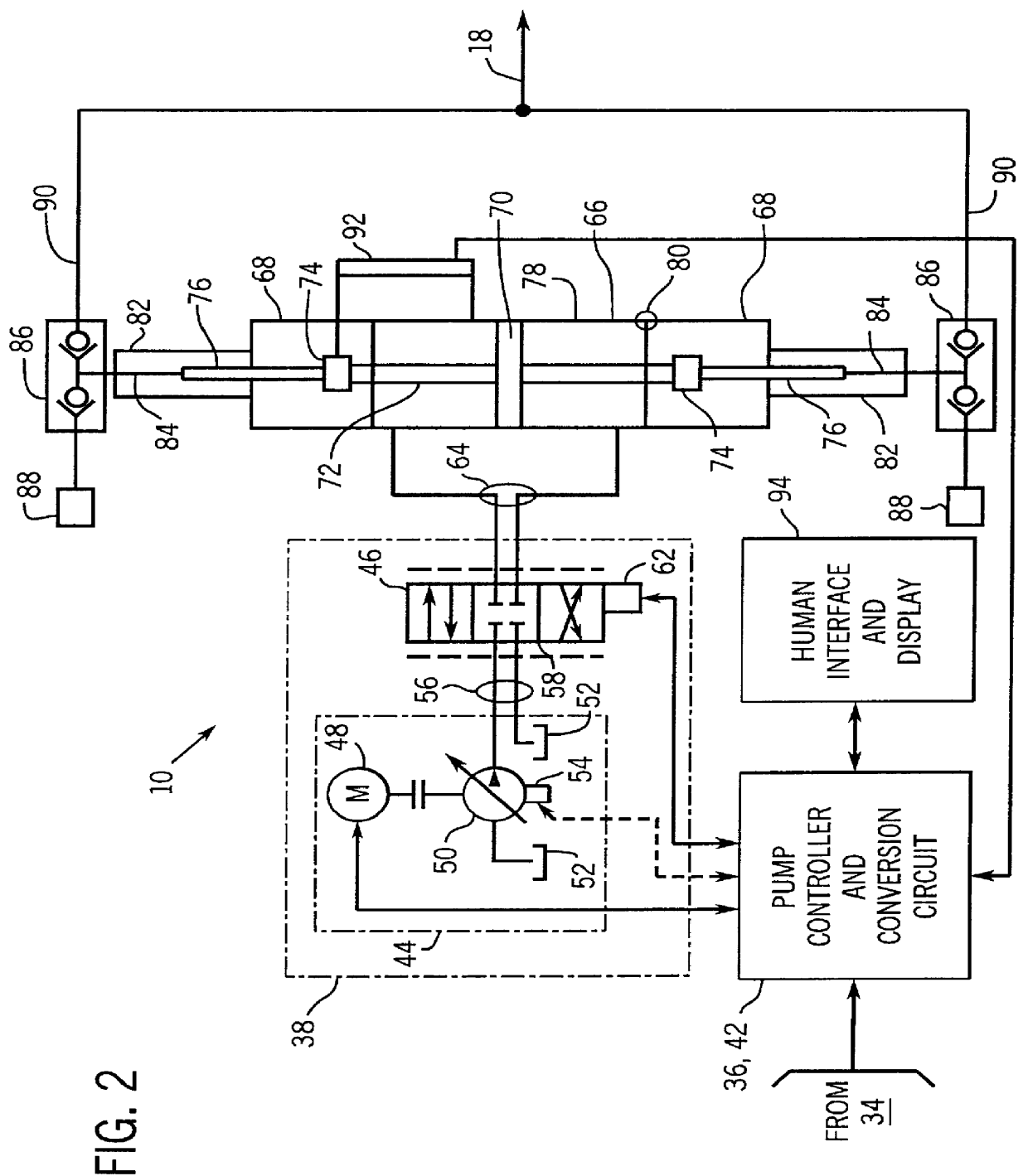

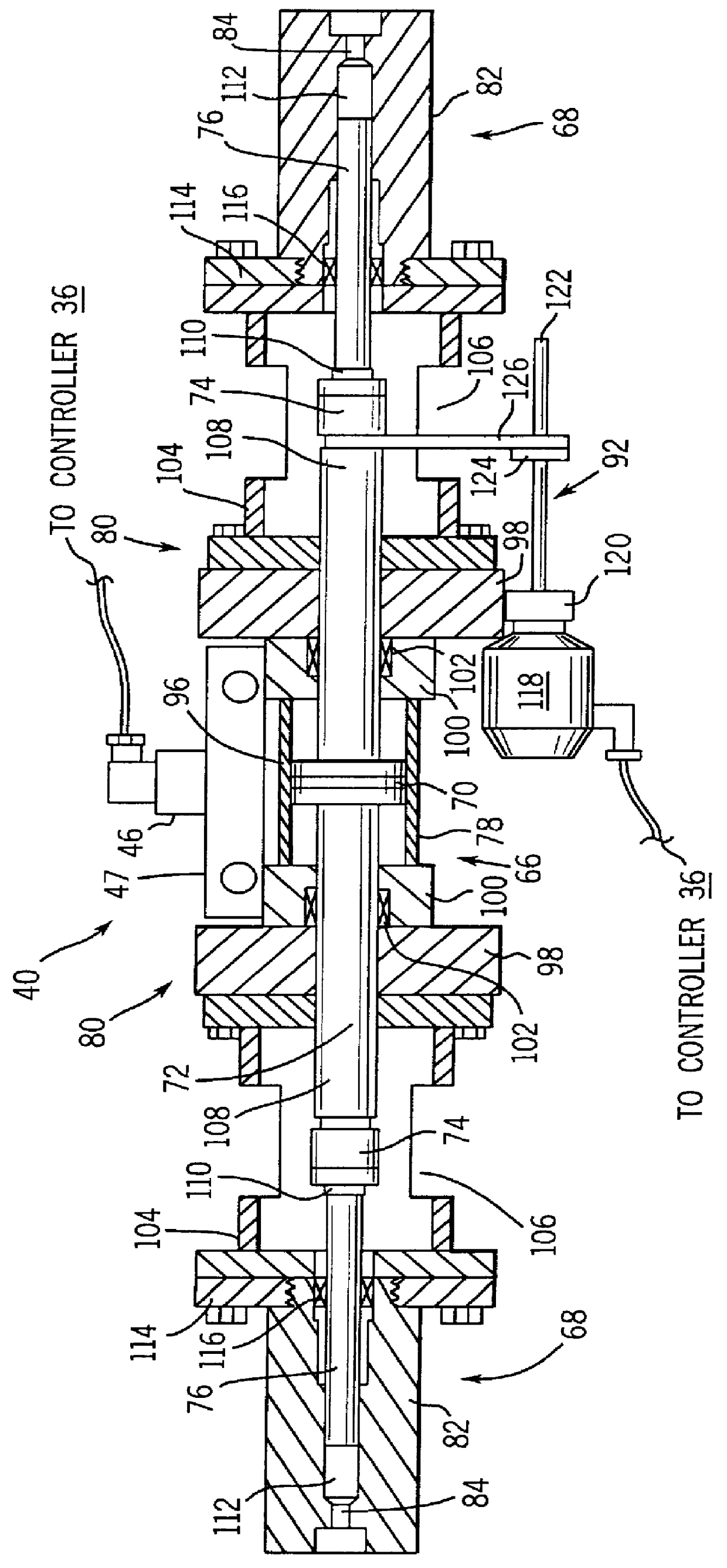

A system for metering a fluid, such as a catalyst in an industrial chemical process plant, includes a controller, a drive pump assembly and an injection pump assembly. The drive pump assembly forces reciprocation of the injection pump assembly via a controlled flow of hydraulic fluid. The injection pump assembly includes a drive cylinder and at least one injection section. The drive cylinder receives pressurized fluid from the drive pump assembly and causes metered fluid to be drawn into and expelled by the injection section. The position of reciprocating components of the injection pump assembly is detected between stroke limits and converted to a velocity signal. Closed-loop control of the flow from the injection pump assembly is implemented by the controller via the drive pump assembly based upon the actual velocity of the reciprocating components of the injection pump assembly and a commanded velocity. The closed-loop injection rate control may be incorporated in a nested fashion with a process parameter control loop to maintain a desired level of a process parameter, such as temperature in a reaction vessel.

Owner:OILQUIP

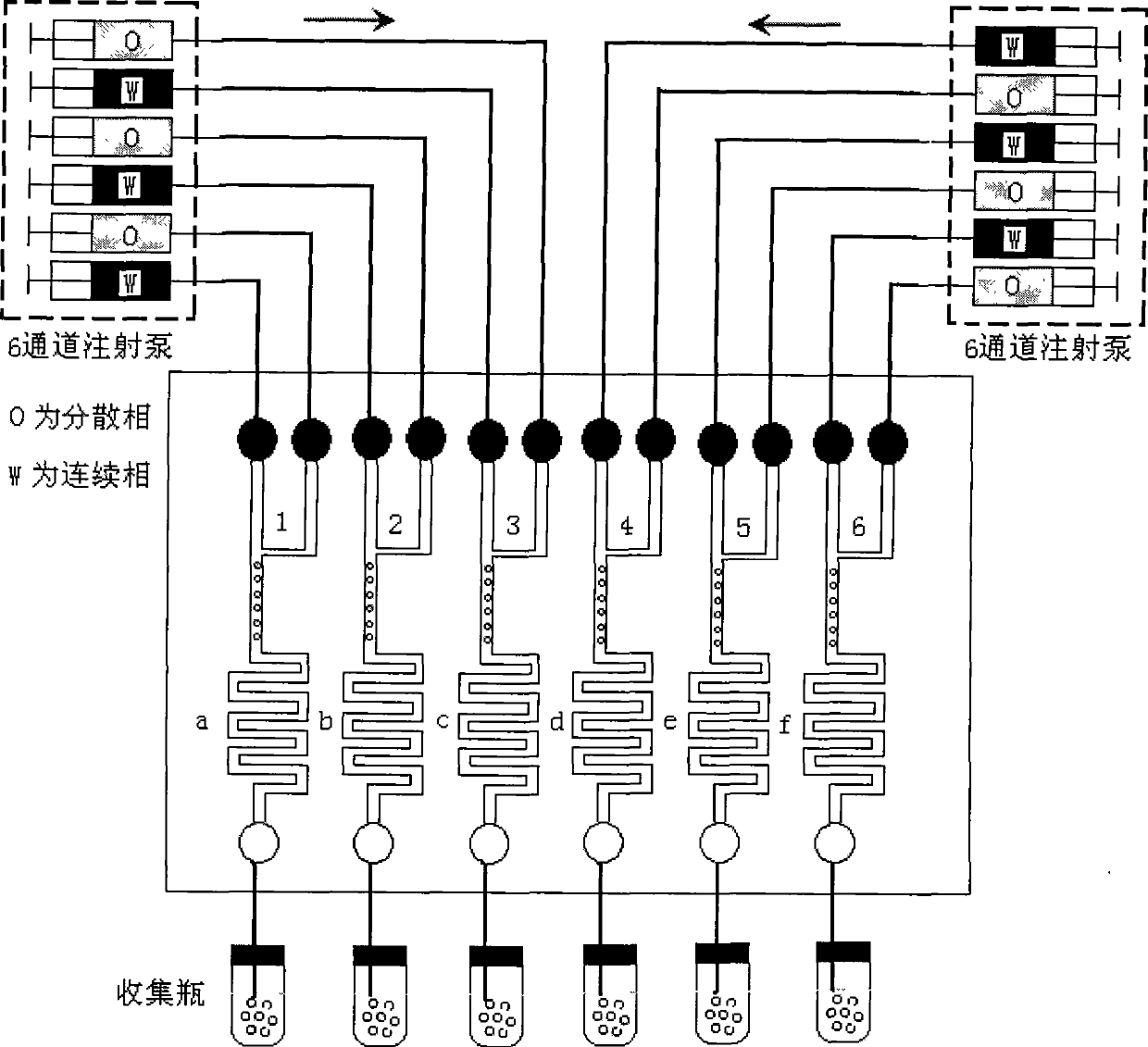

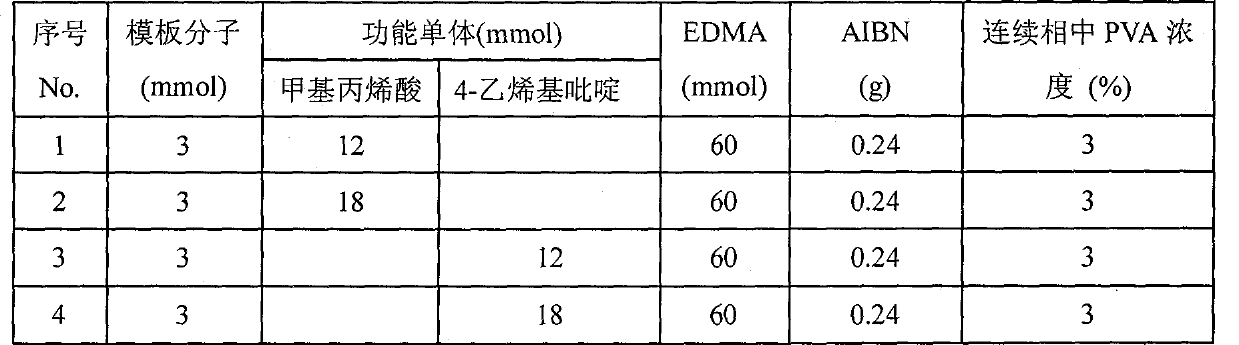

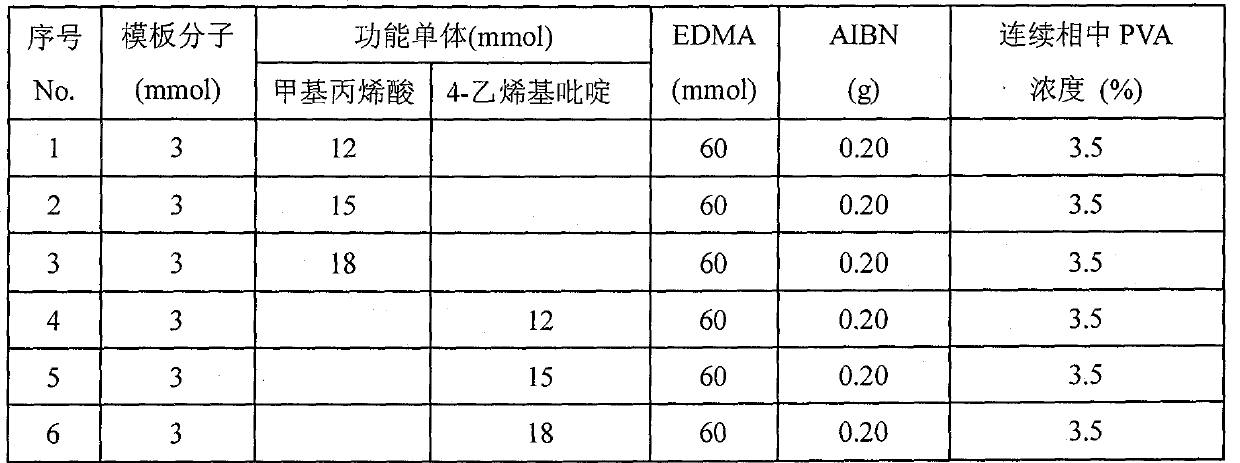

Molecular engram microspheres preparation method using micro-fluidic reactor

InactiveCN101507909AOther chemical processesChemical/physical/physico-chemical processesReactor systemMicrosphere

The invention relates to a method for combined synthesis of molecular engram microspheres through a micro-fluidic reactor, which is characterized in that a micro-fluidic reactor system comprises a fluid drive unit (an injection pump group), a liquid droplet or milk droplet forming unit and an ultraviolet illumination and polymerization unit, wherein the micro-fluidic reactor comprises n groups of '*'-shaped microchannels with the same structure, and can simultaneously prepare the molecular engram microspheres under n conditions or prepare the molecular engram microspheres of n template molecules; and dispersed phases and continuous phases are driven by injection pumps to enter respective microchannels and form milk droplets when encountering each other on crossings of the microchannels, and the prepared milk droplets arrive at the ultraviolet illumination unit for polymerization reaction.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Low-melting-point metal multi-dimensional structure liquid phase printing system and method

The invention provides a low-melting-point metal multi-dimensional structure liquid phase printing system. The low-melting-point metal multi-dimensional structure liquid phase printing system comprises an injection pump array, an injection needle array, a liquid metal tank, a thermostat, a thermostatic bath and a control unit. The injection pump array includes m*n of injection pumps and an inlet of every injection pump is connection with the liquid metal tank. Injection needles are perpendicular to the thermostatic bath and liquid inlets of the injection needles are connected to outlet ends of the injection pumps respectively. The control unit is connected to the injection pump array. A low-melting-point metal multi-dimensional structure liquid phase printing method uses the smart control mechanism of fluid for applying effective buffer, crushing and buoyancy actions to liquid metal injection droplets, and the liquid cooling treatment more efficient than a traditional gas cooling mode can be provided for enabling liquid metal injected into a liquid phase environment to be quickly solidified due to the large heat capacity, so that short-time forming of a multi-dimensional structure is achieved, and meanwhile the oxidation not easy to avoid in a traditional method is reduced.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com