Safety injection system

A safety injection and safety injection pump technology, which is applied in the field of improving the structure of the safety injection system of nuclear power plants, can solve the problems of insufficient accident handling capacity of the safety injection system, and achieve the goals of enhancing the mitigation ability of severe accidents, simplifying the system composition, and simplifying the operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The preferred embodiments of the present invention will be described in detail below with reference to the drawings.

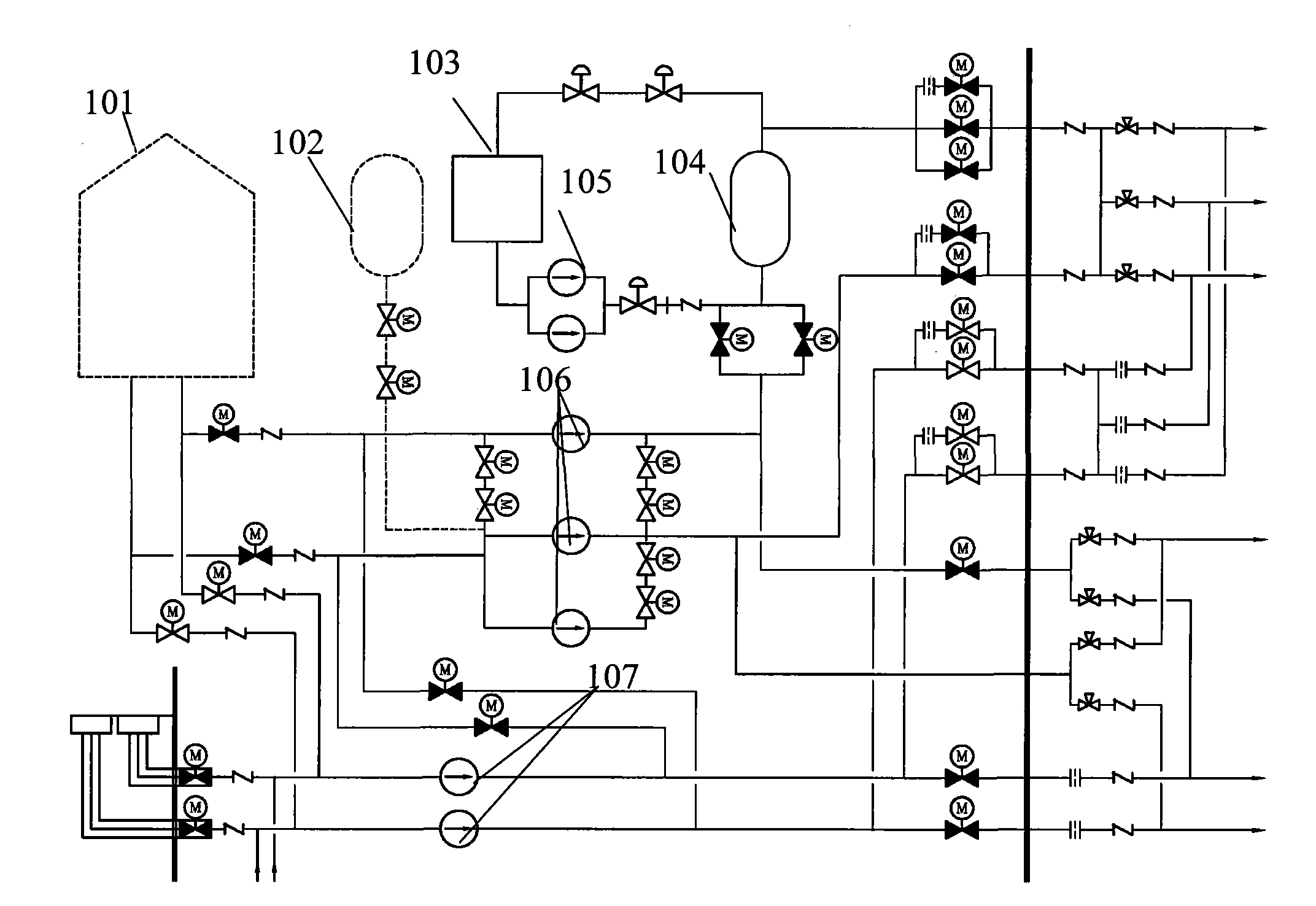

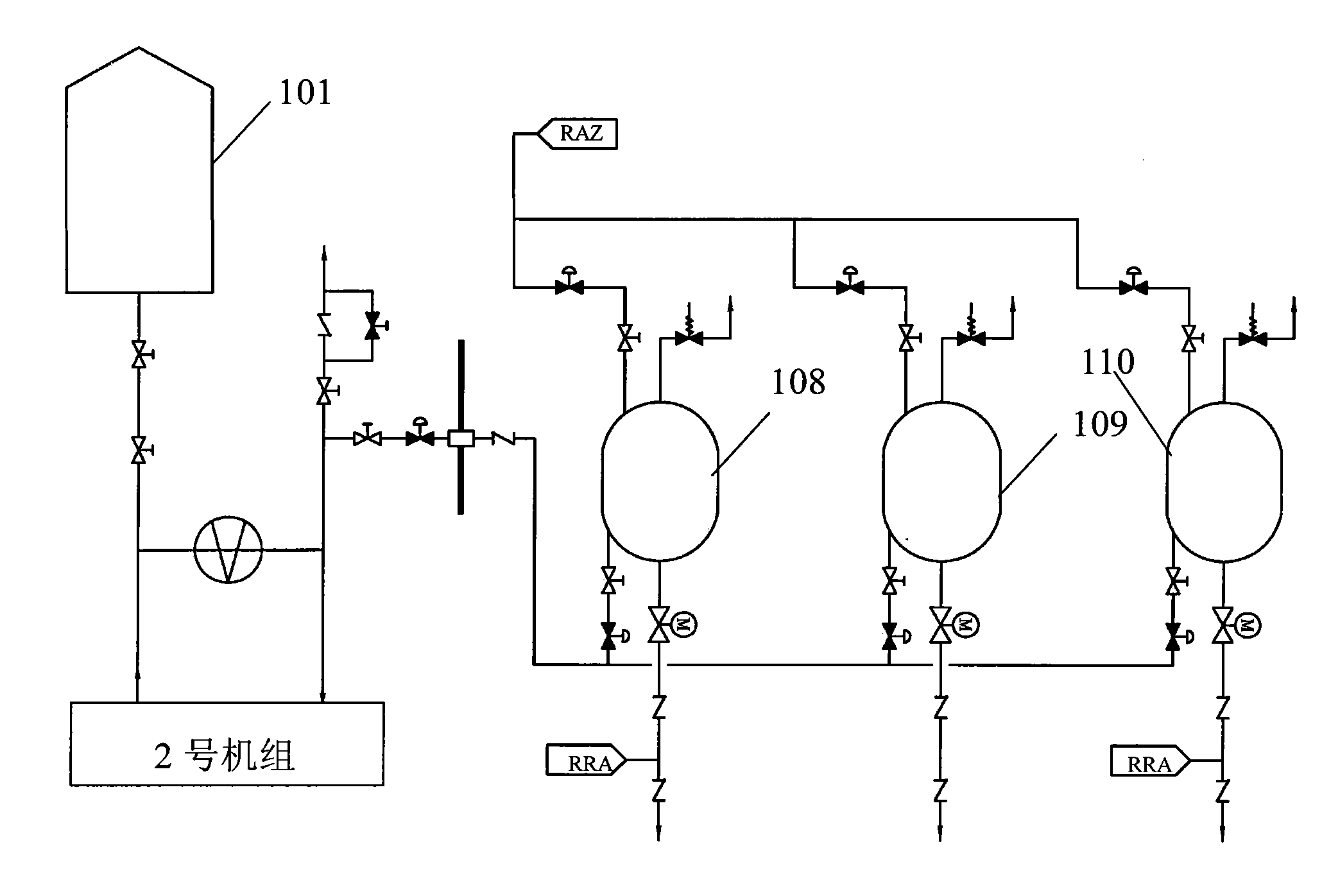

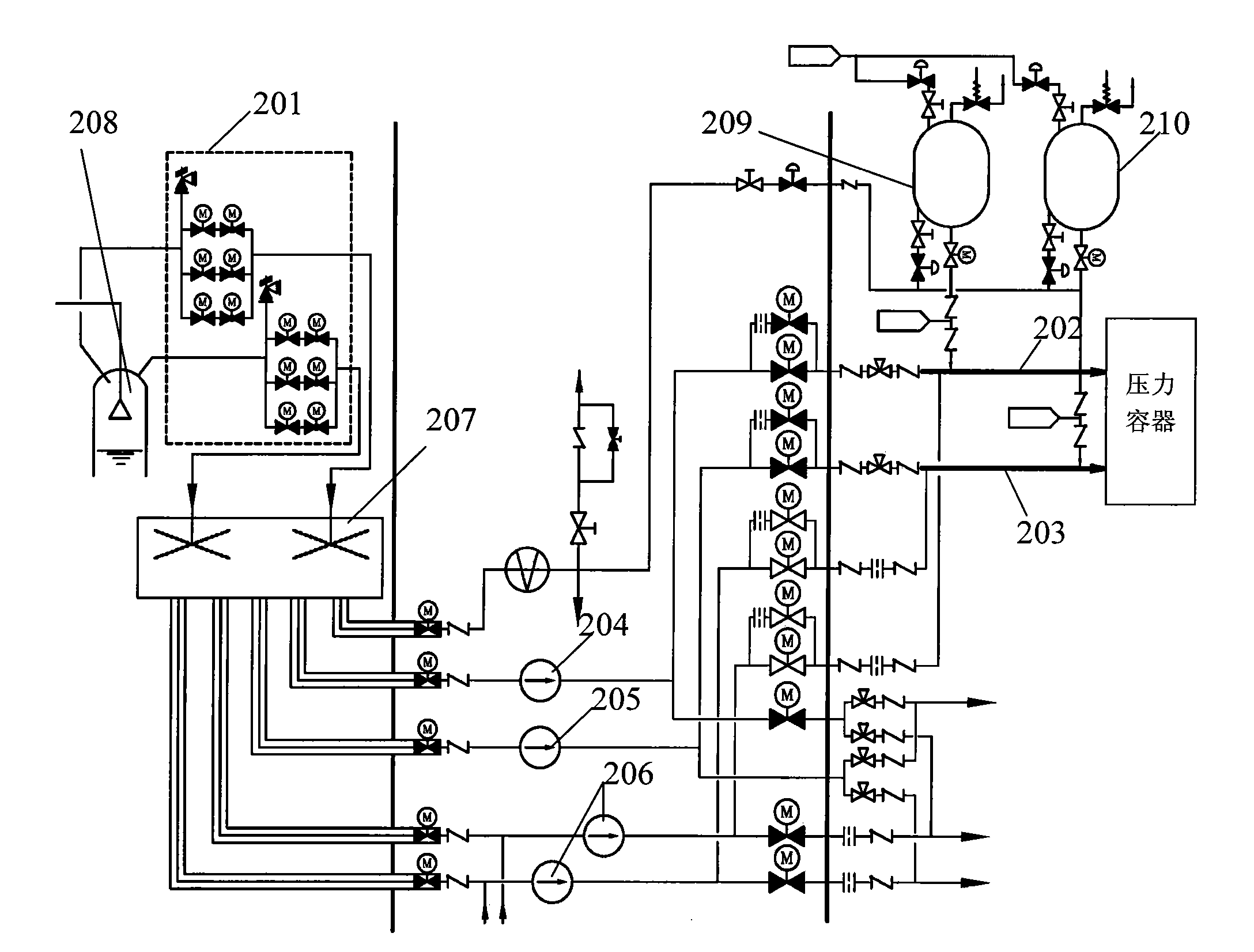

[0029] The structural diagram of the safety injection system of the nuclear power plant in the embodiment of the present invention is as follows: image 3 As shown, compared with the original system, the improved safety injection system still adopts the safety injection method under three pressure levels of high, medium and low, but the composition of the system is greatly simplified. The improved safety injection system mainly includes a high-pressure safety injection pump, a low-pressure safety injection pump 206, a safety injection tank, and a refueling water tank 207 for accommodating safety injection water. Among them, the high-pressure safety injection pump can be connected to the refueling water tank 207 and the direct pressure vessel injection pipeline through a pipeline provided with a control valve, such as image 3 shown. The low-pressure s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com