Patents

Literature

2419results about "Industrial buildings" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

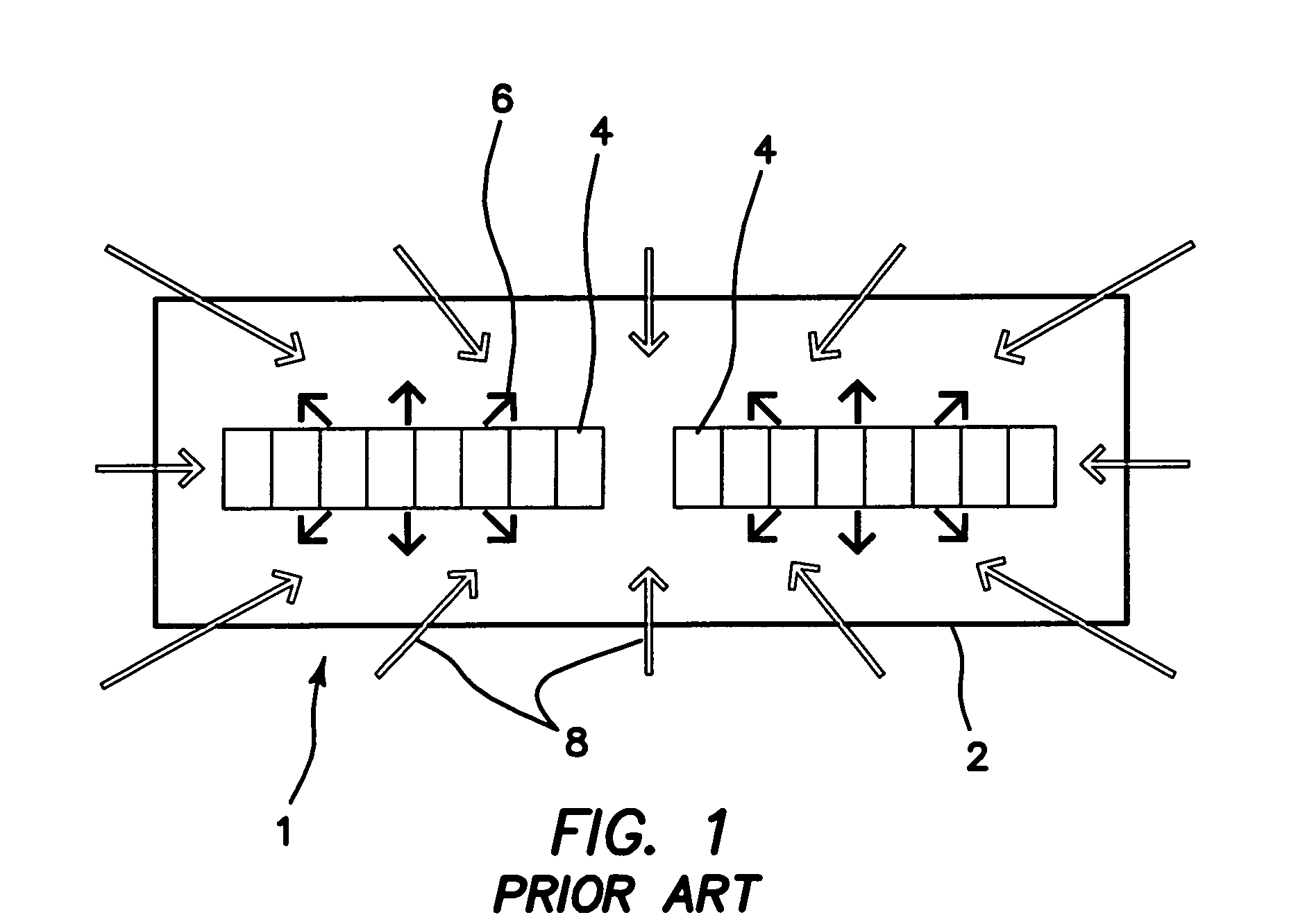

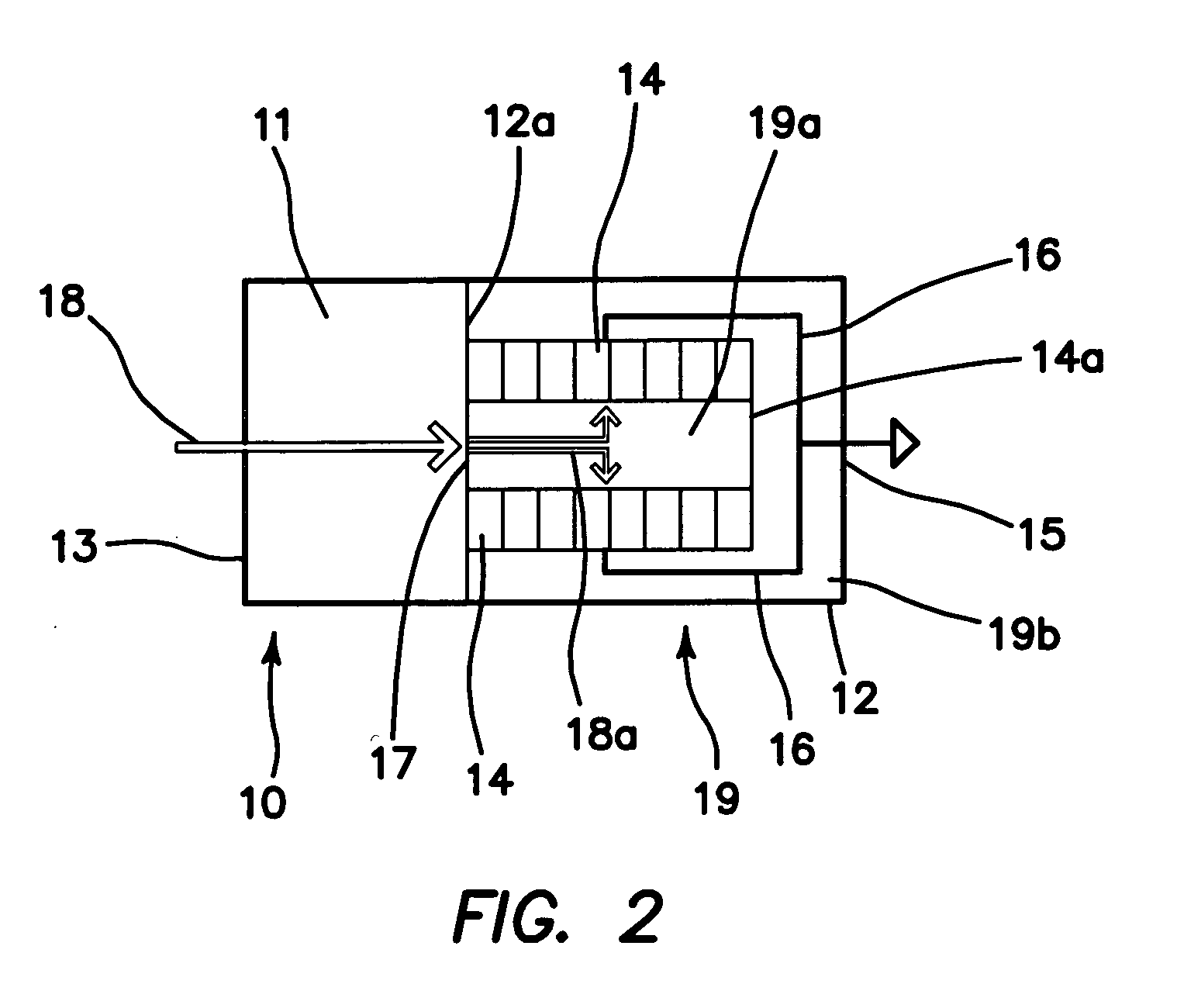

Data center cooling system

InactiveUS6859366B2Reduce mixProduce cool airSemiconductor/solid-state device detailsSolid-state devicesData centerEngineering

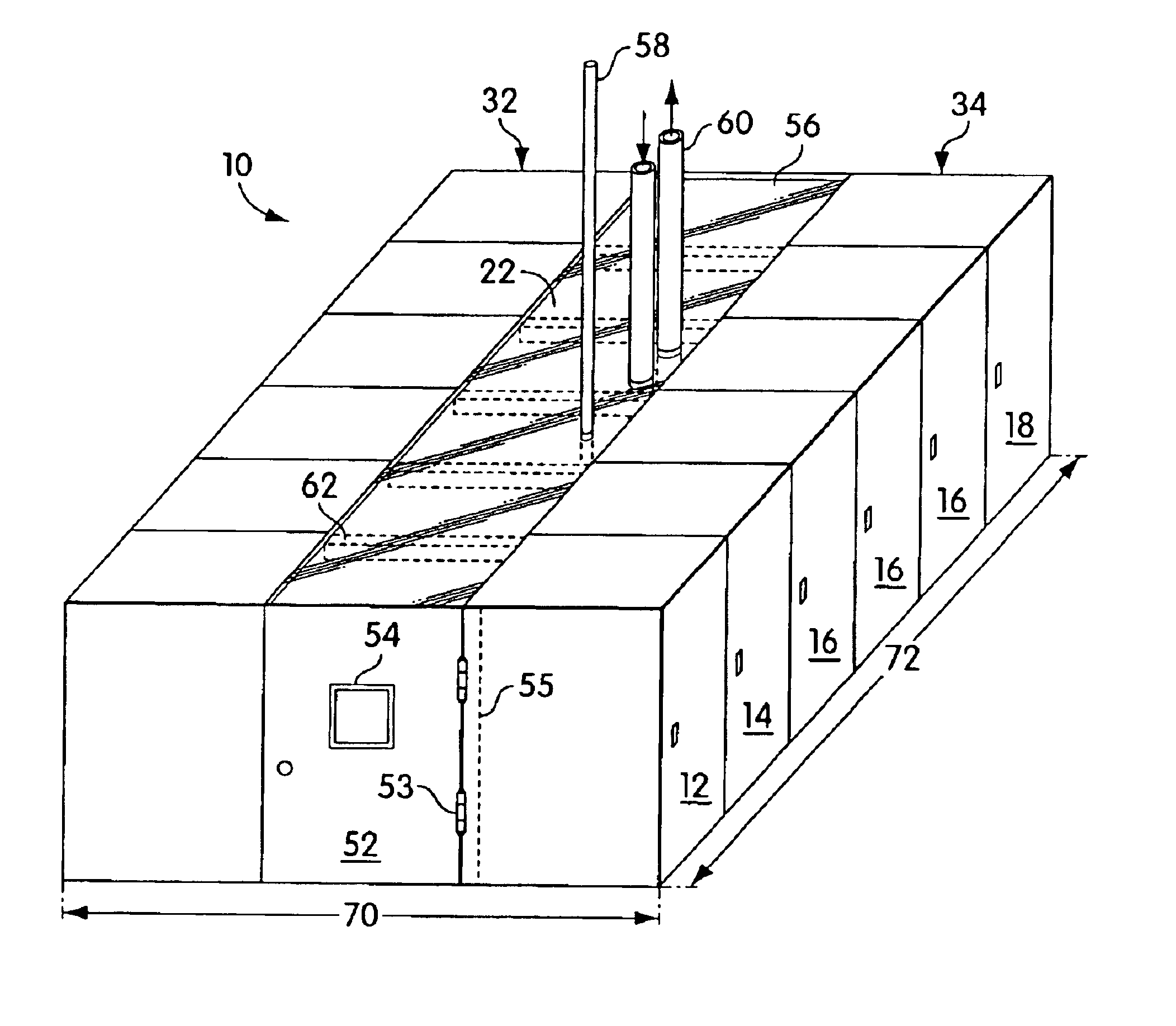

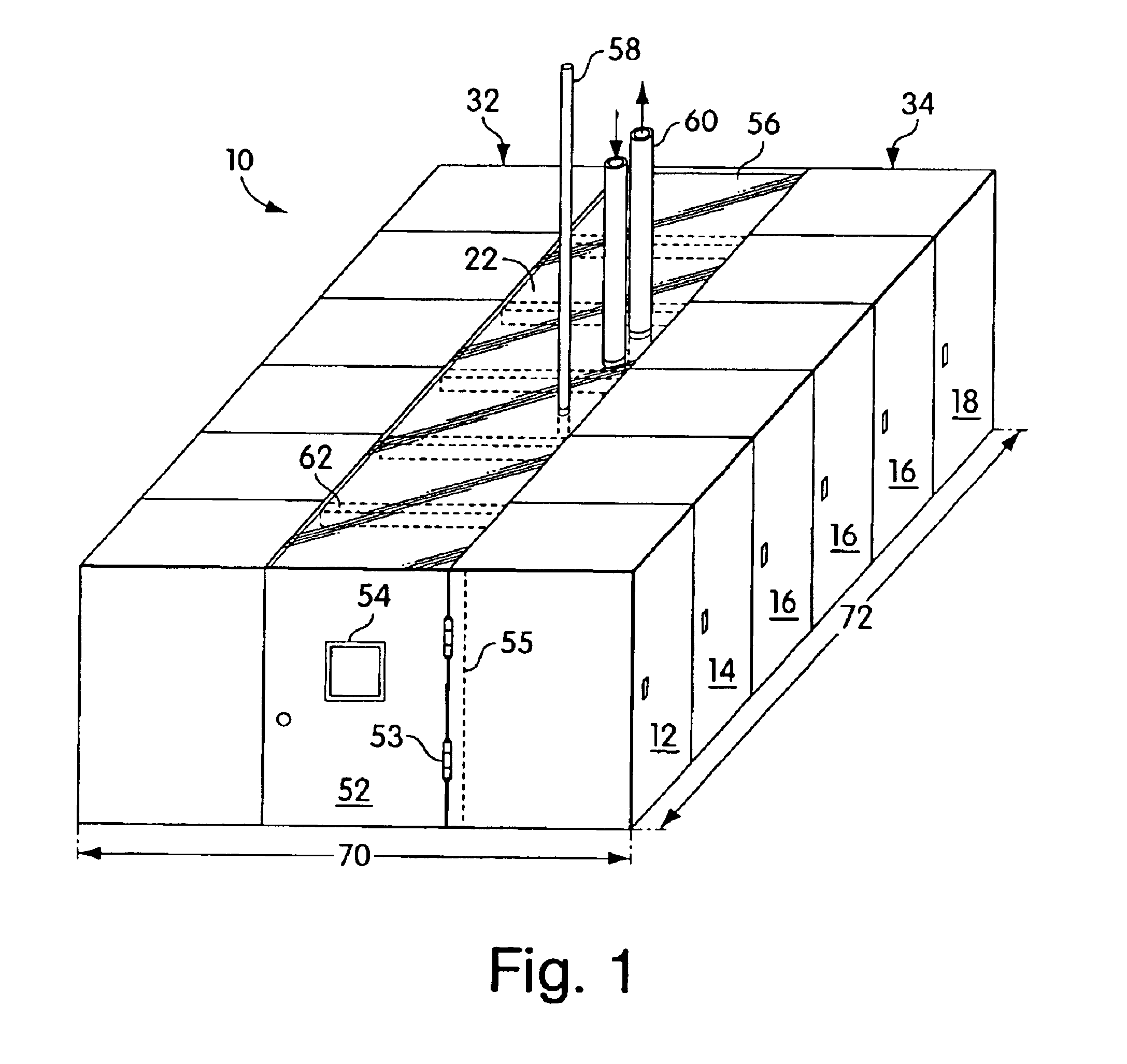

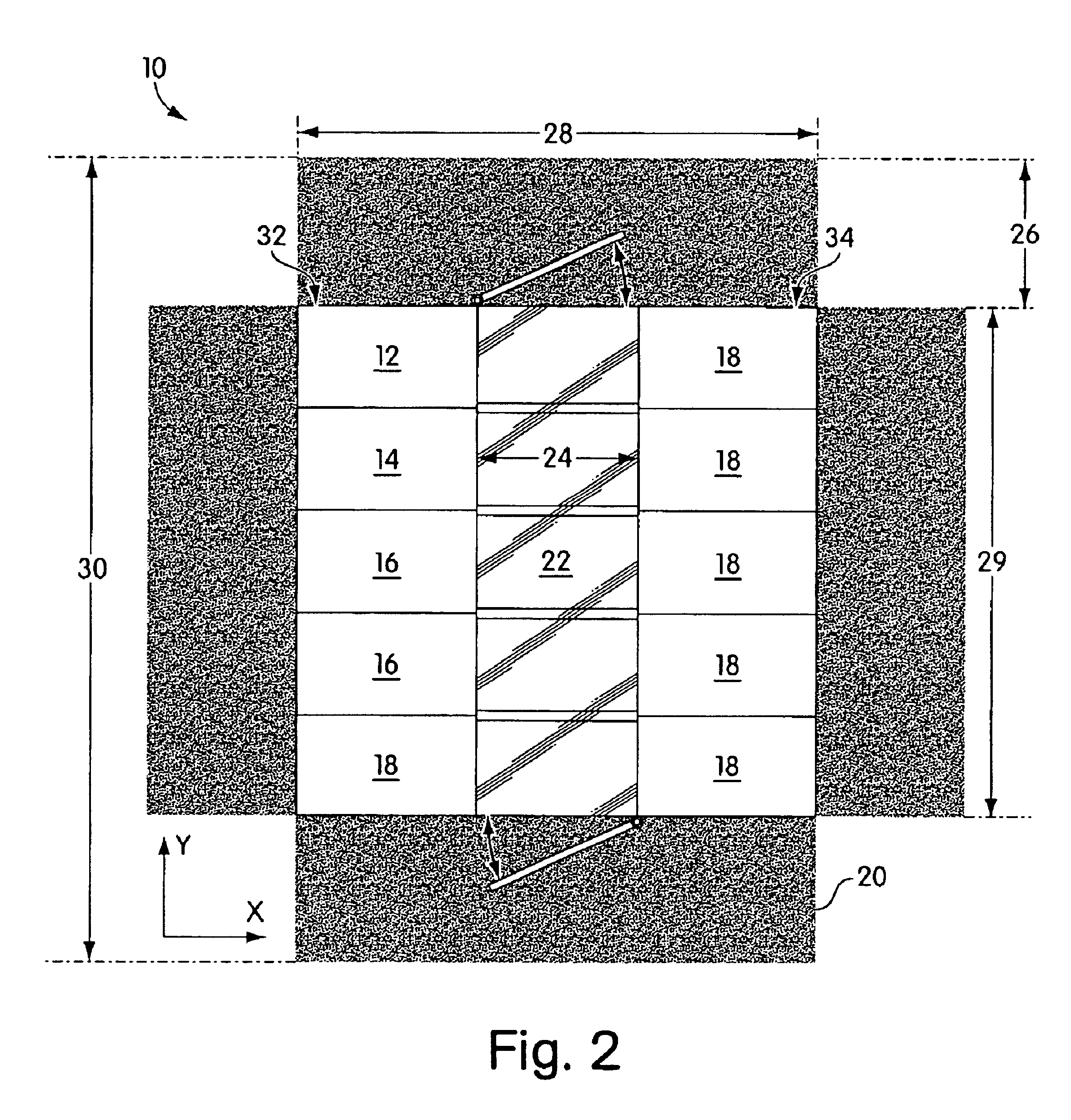

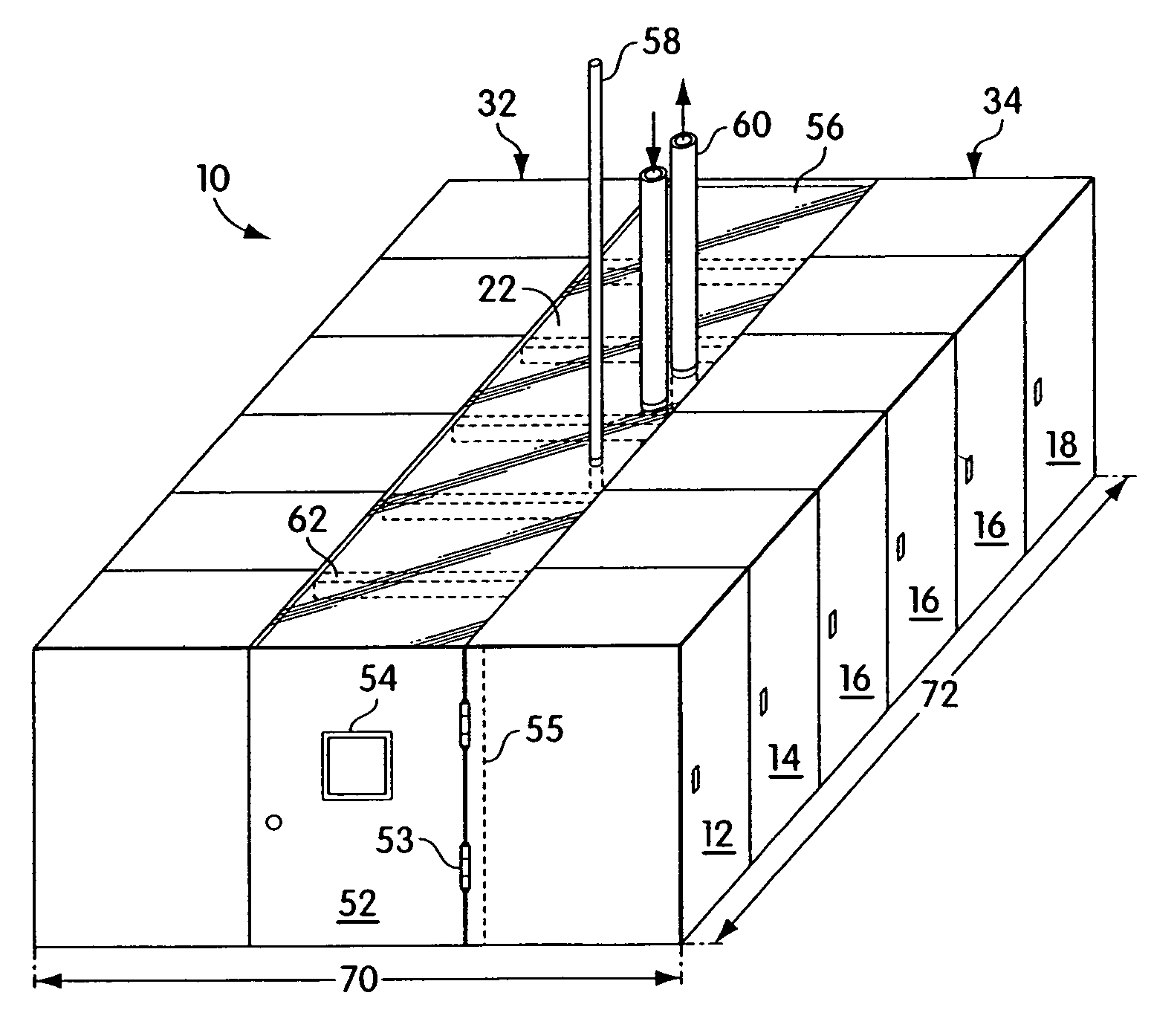

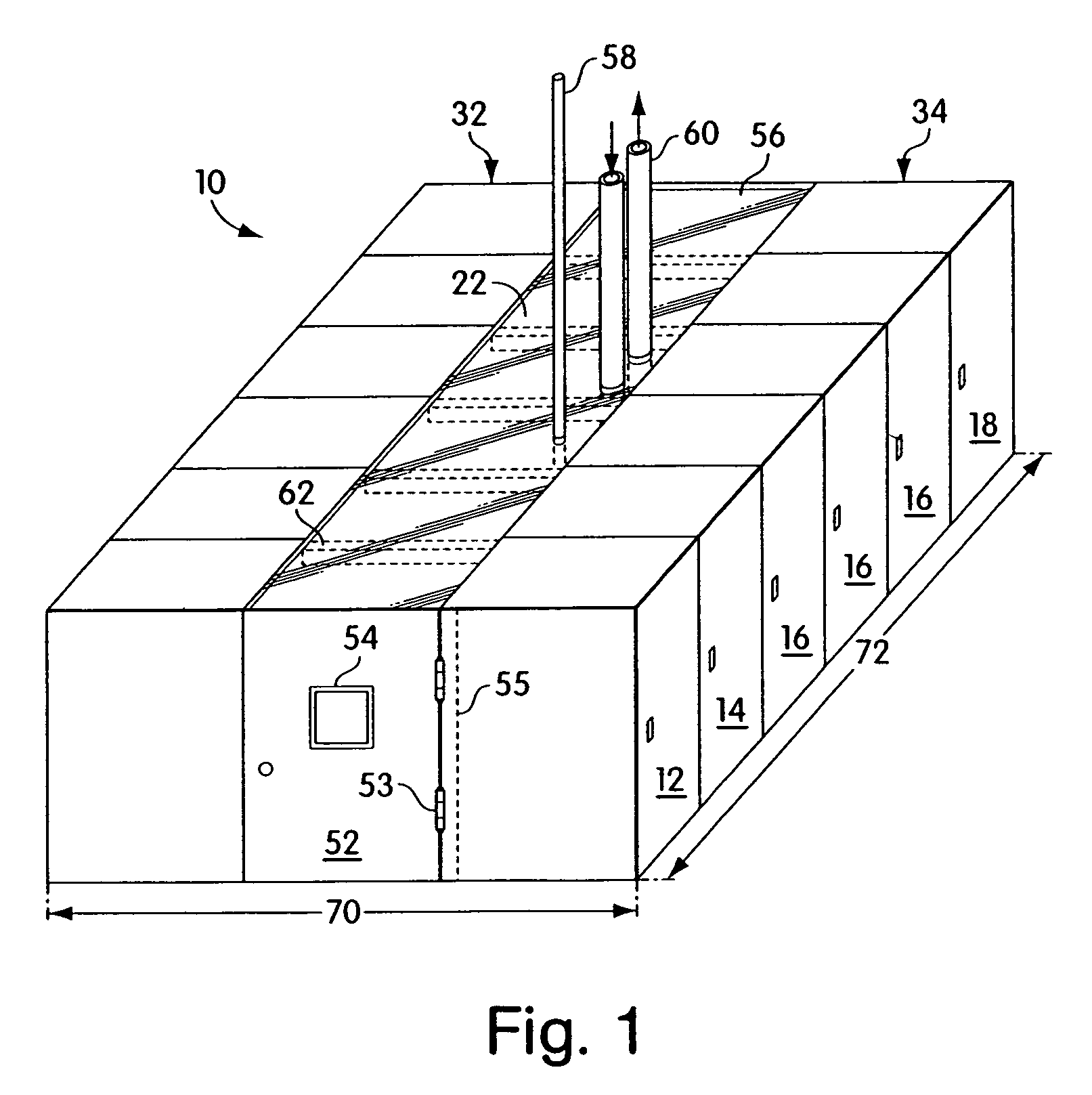

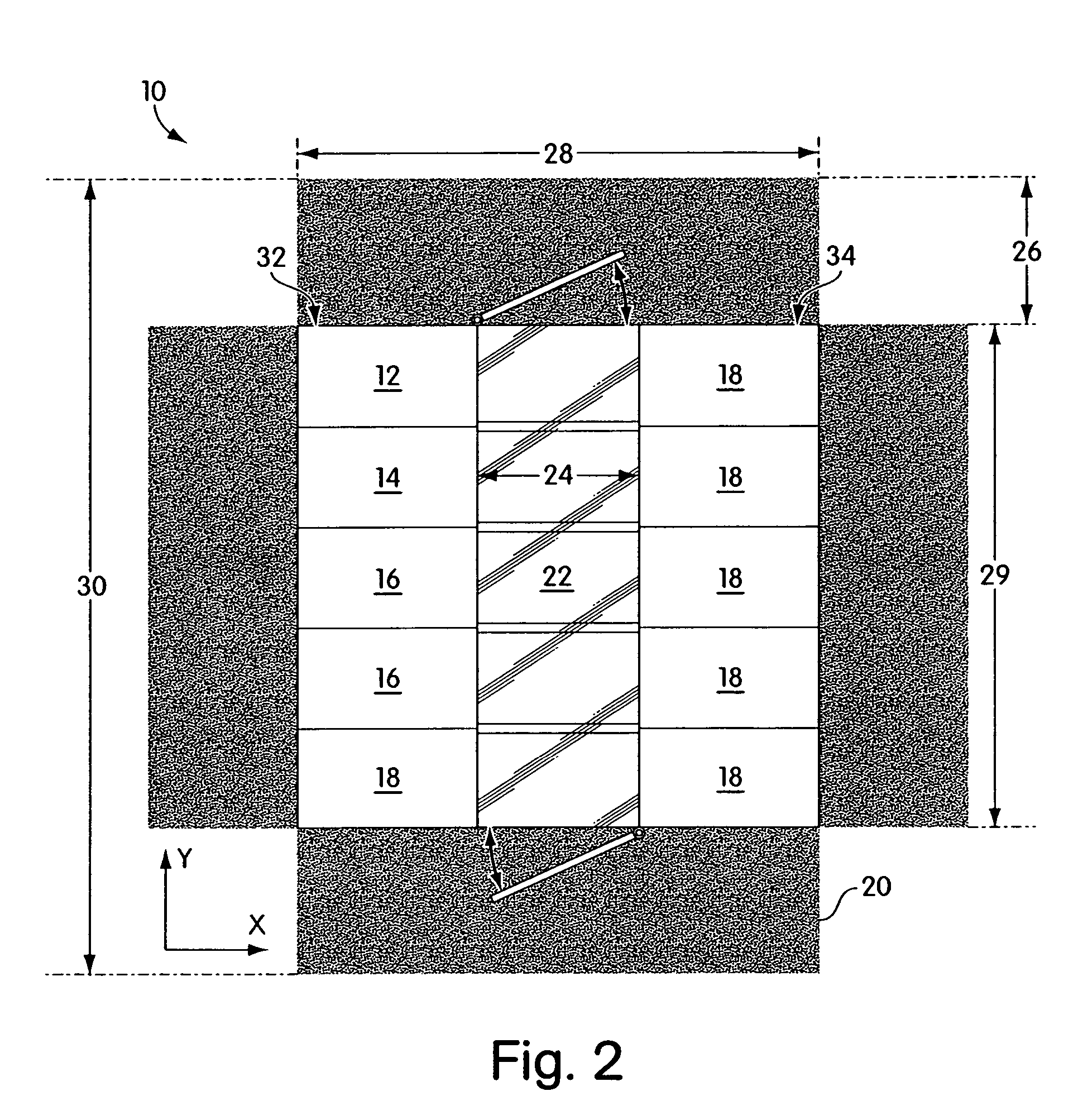

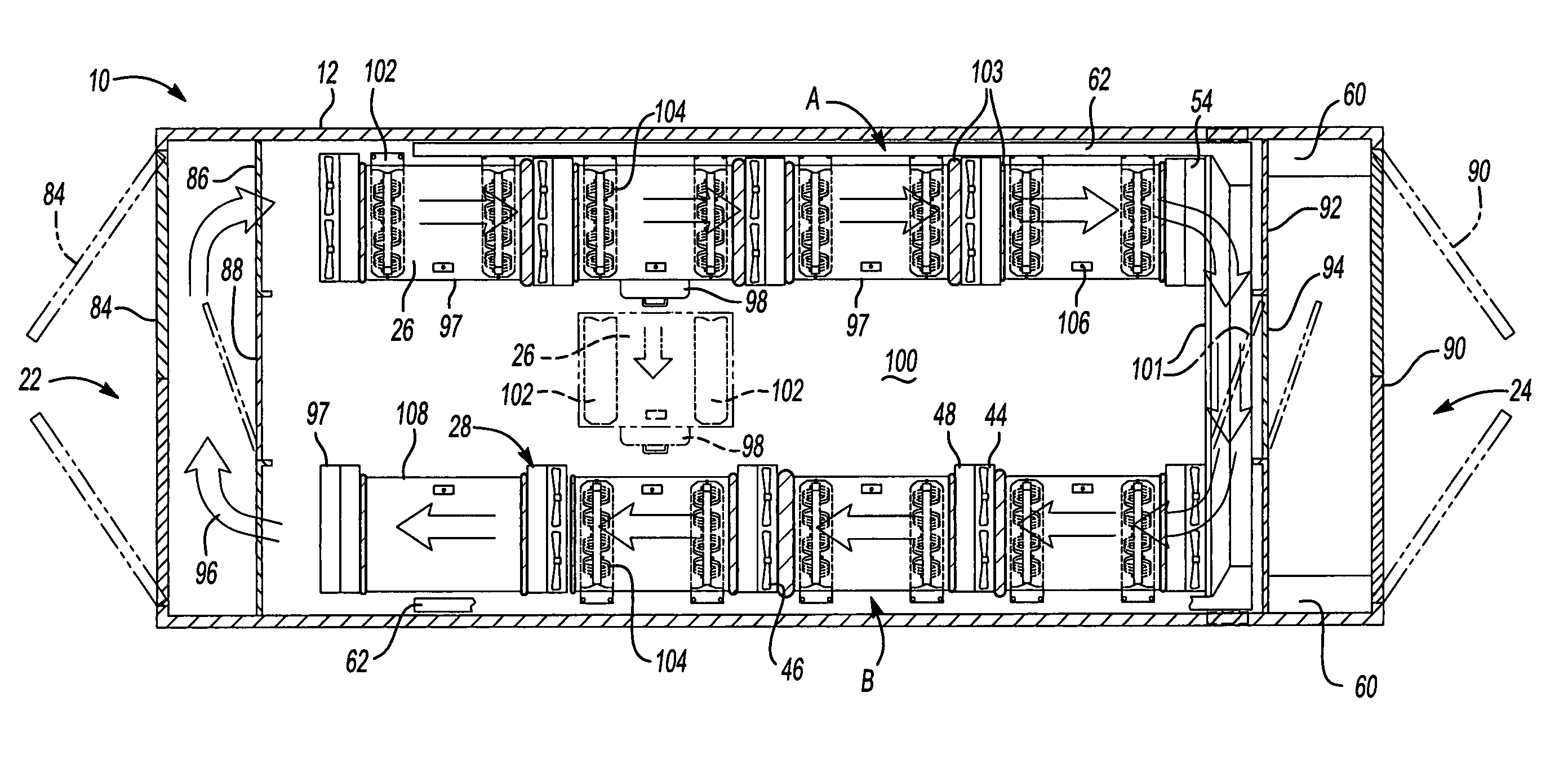

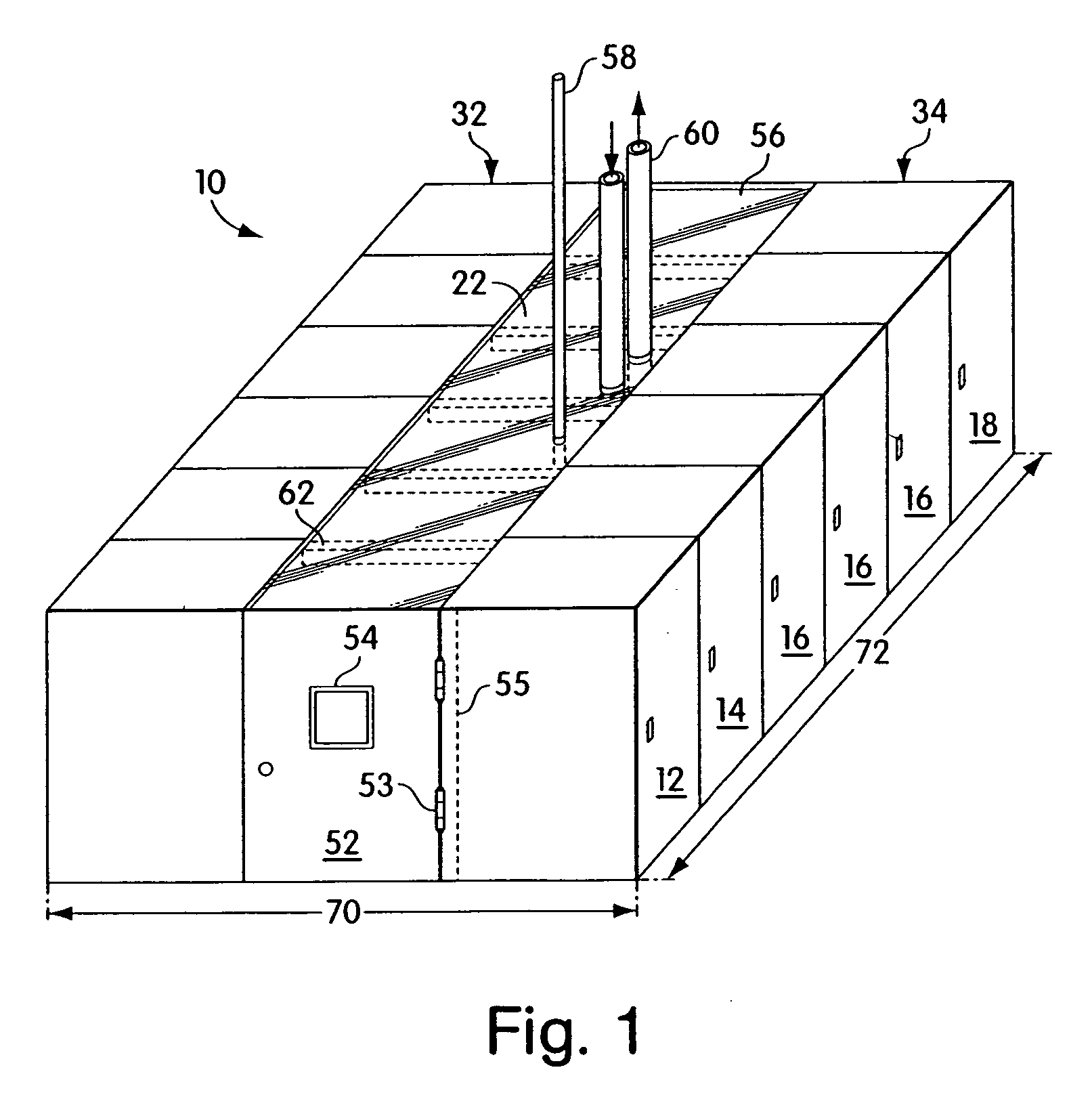

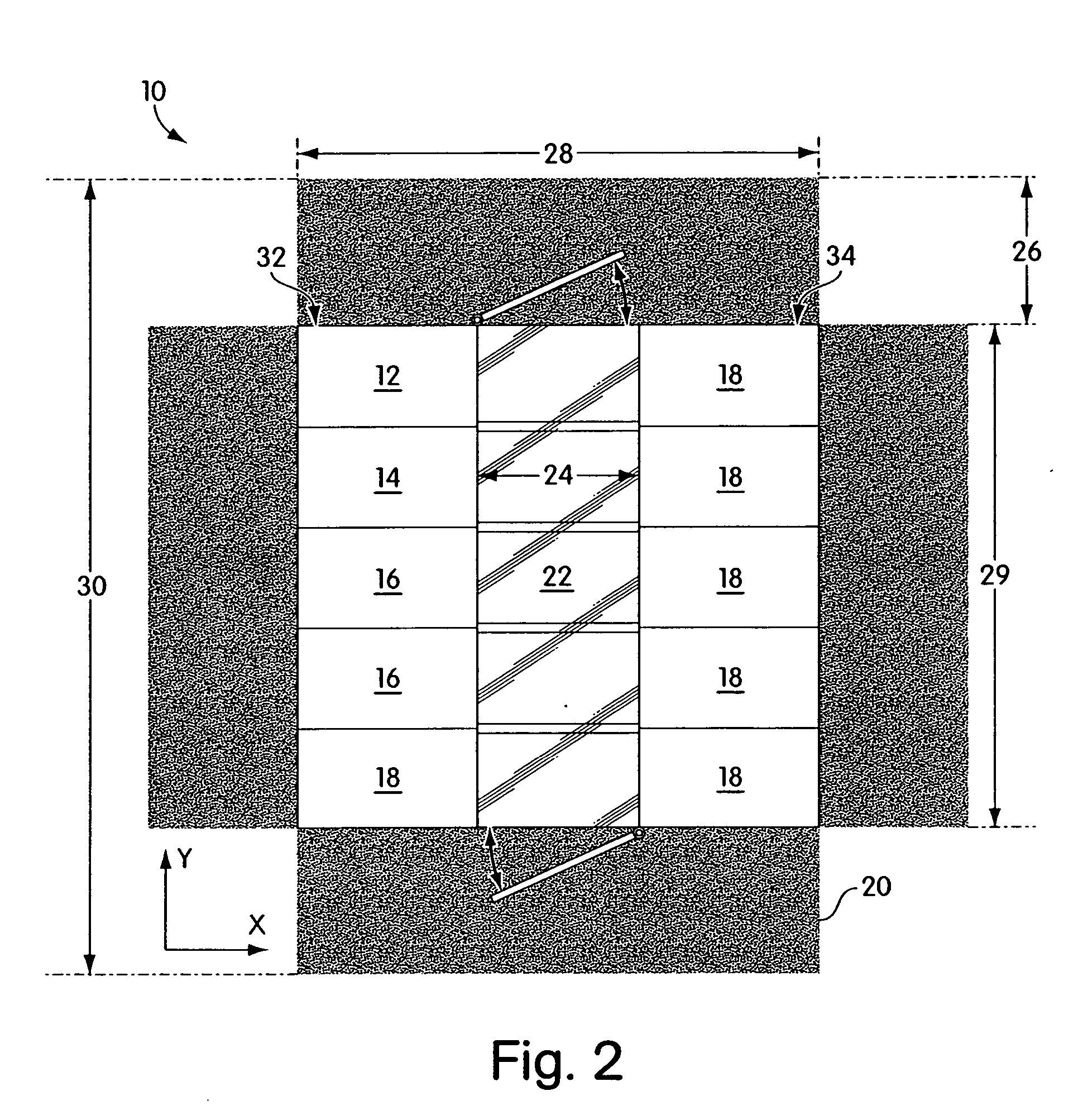

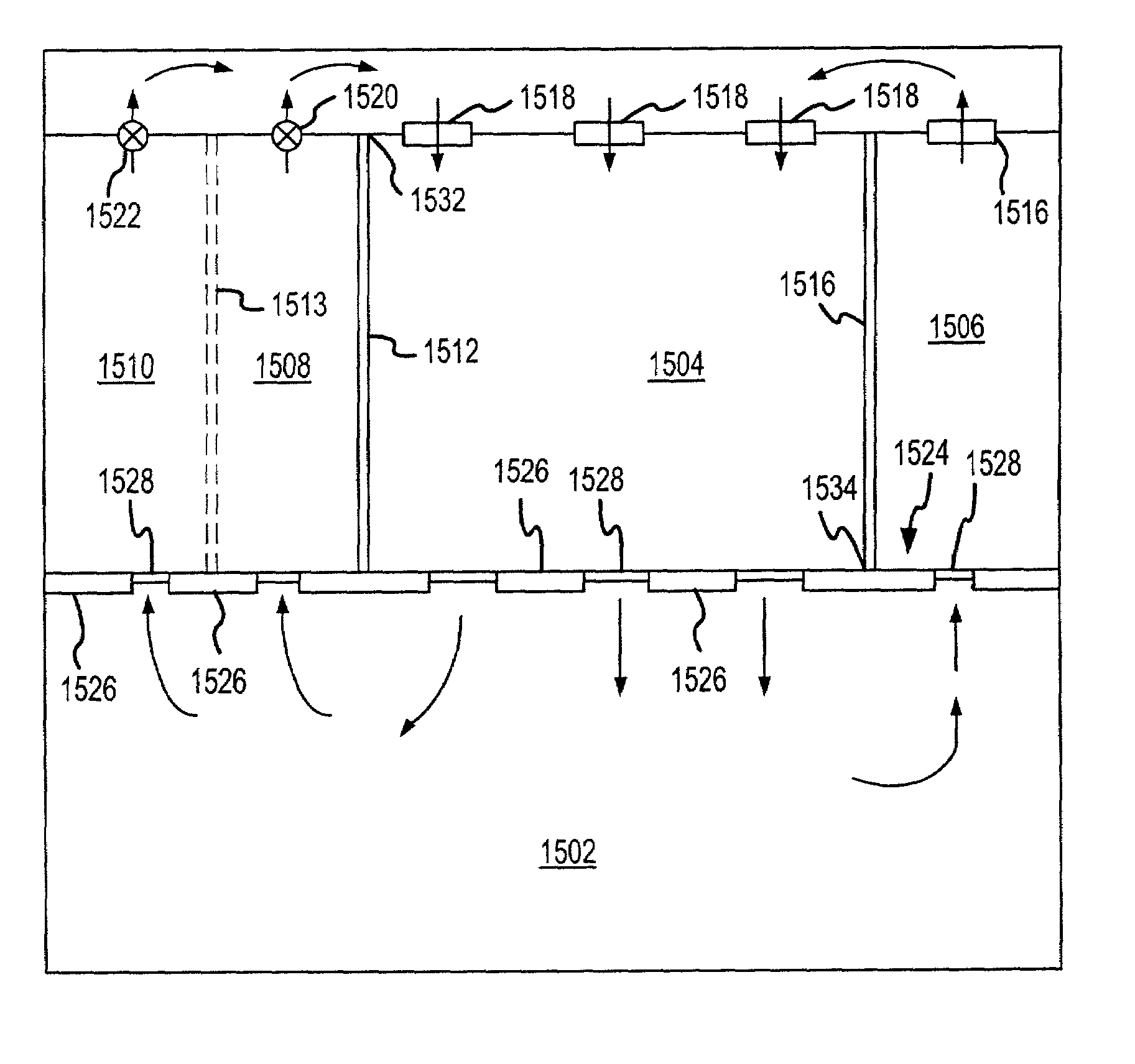

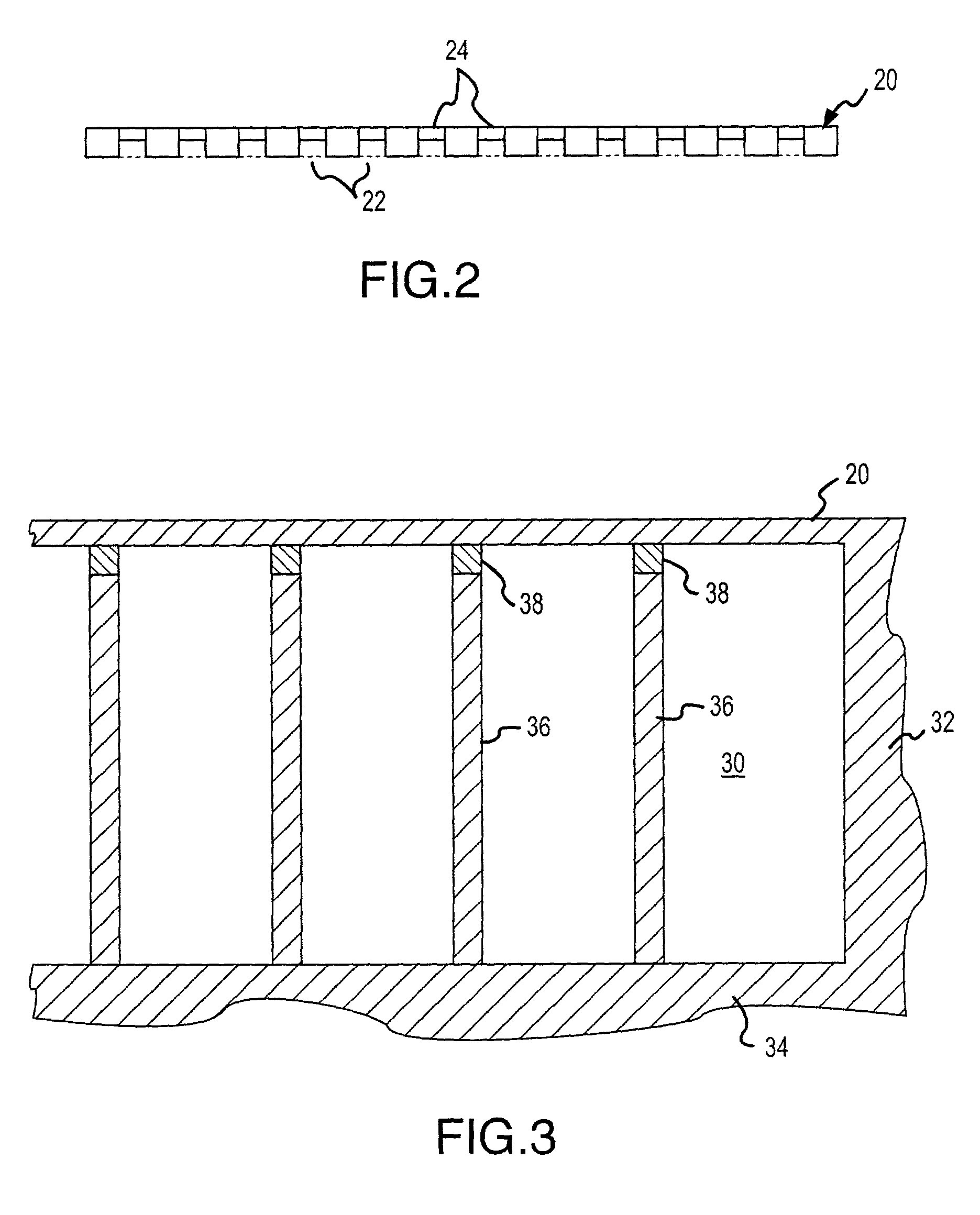

A cooling solution is provided for a modular data center. The modular data center includes a plurality of racks, each of the racks having a front face and a back face, wherein the plurality of racks is arranged in a first row and a second row, such that the back faces of racks of the first row are facing the second row, and the back faces of the racks of the second row are facing the first row, a first end panel coupled between a first rack of the first row and a first rack of the second row, the first end panel having a bottom edge and a tope edge, a second end panel coupled between a second rack of the first row and a second rack of the second row, the second end panel having a top edge and a bottom edge, and a roof panel coupled between the top edge of the first panel and the top edge of the second panel. Cooling equipment within at least one of the equipment racks draws hot air from between the rows of racks and delivers cooled air out of the front face of one of the racks.

Owner:SCHNEIDER ELECTRIC IT CORP

Data center cooling system

InactiveUS6980433B2Sufficient powerSemiconductor/solid-state device detailsSolid-state devicesData centerEngineering

A modular data center includes a plurality of racks, each of the racks having a front face and a back face, wherein the plurality of racks is arranged in a first row and a second row, such that the back faces of racks of the first row are facing the second row, and the back faces of the racks of the second row are facing the first row, a first end panel coupled between a first rack of the first row and a first rack of the second row, the first end panel having a bottom edge and a tope edge, a second end panel coupled between a second rack of the first row and a second rack of the second row, the second end panel having a top edge and a bottom edge, and a roof panel coupled between the top edge of the first panel and the top edge of the second panel.

Owner:SCHNEIDER ELECTRIC IT CORP

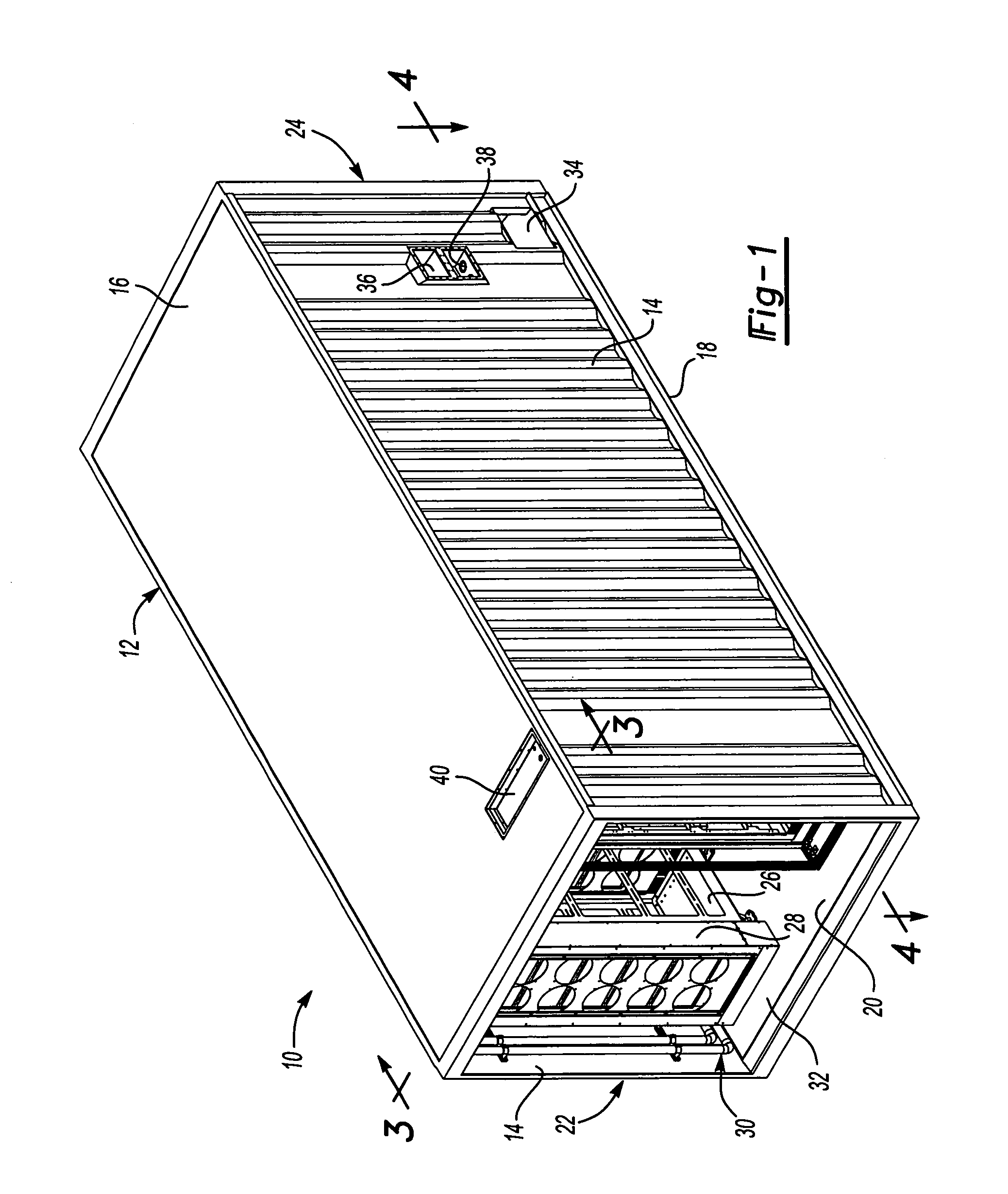

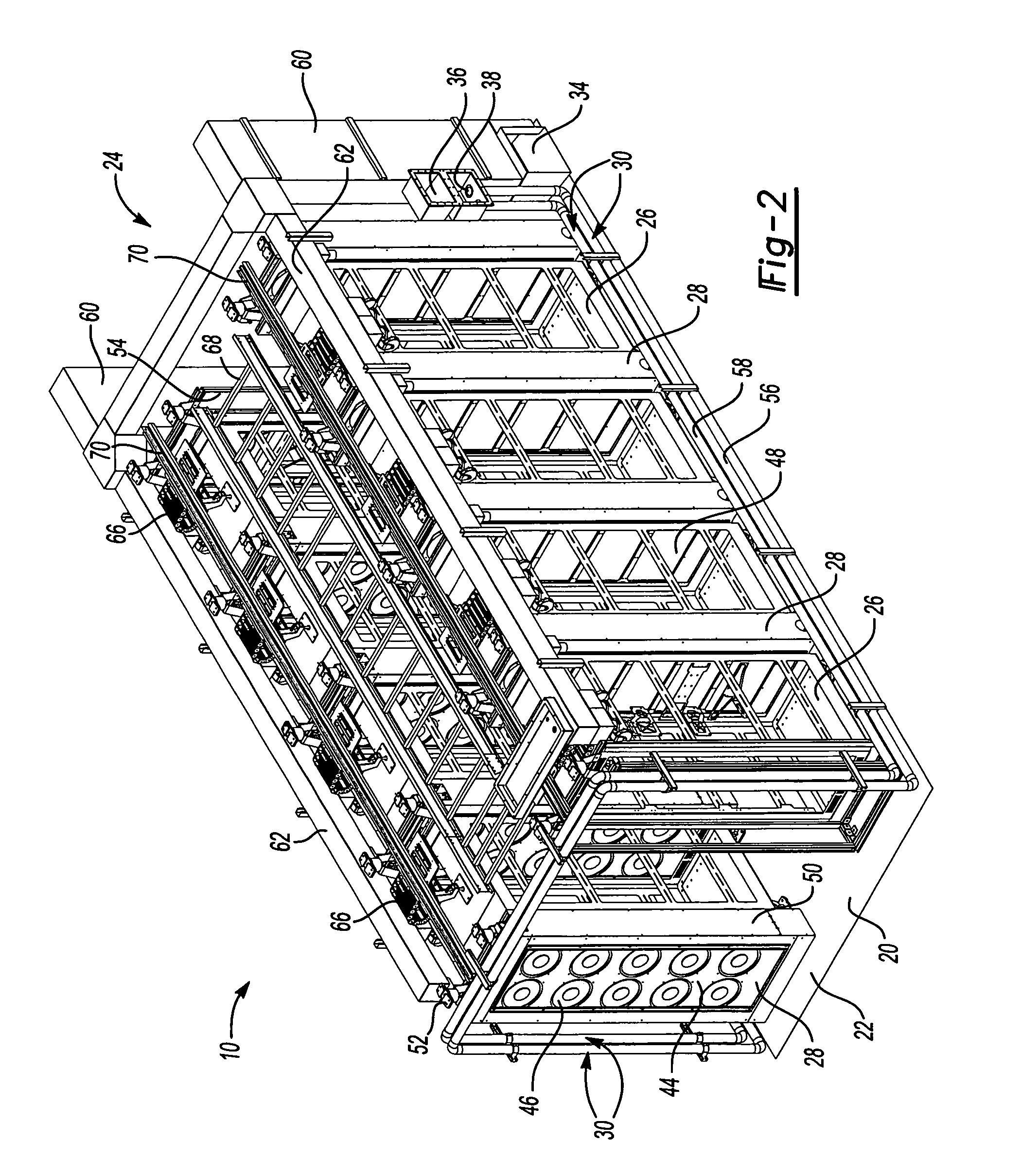

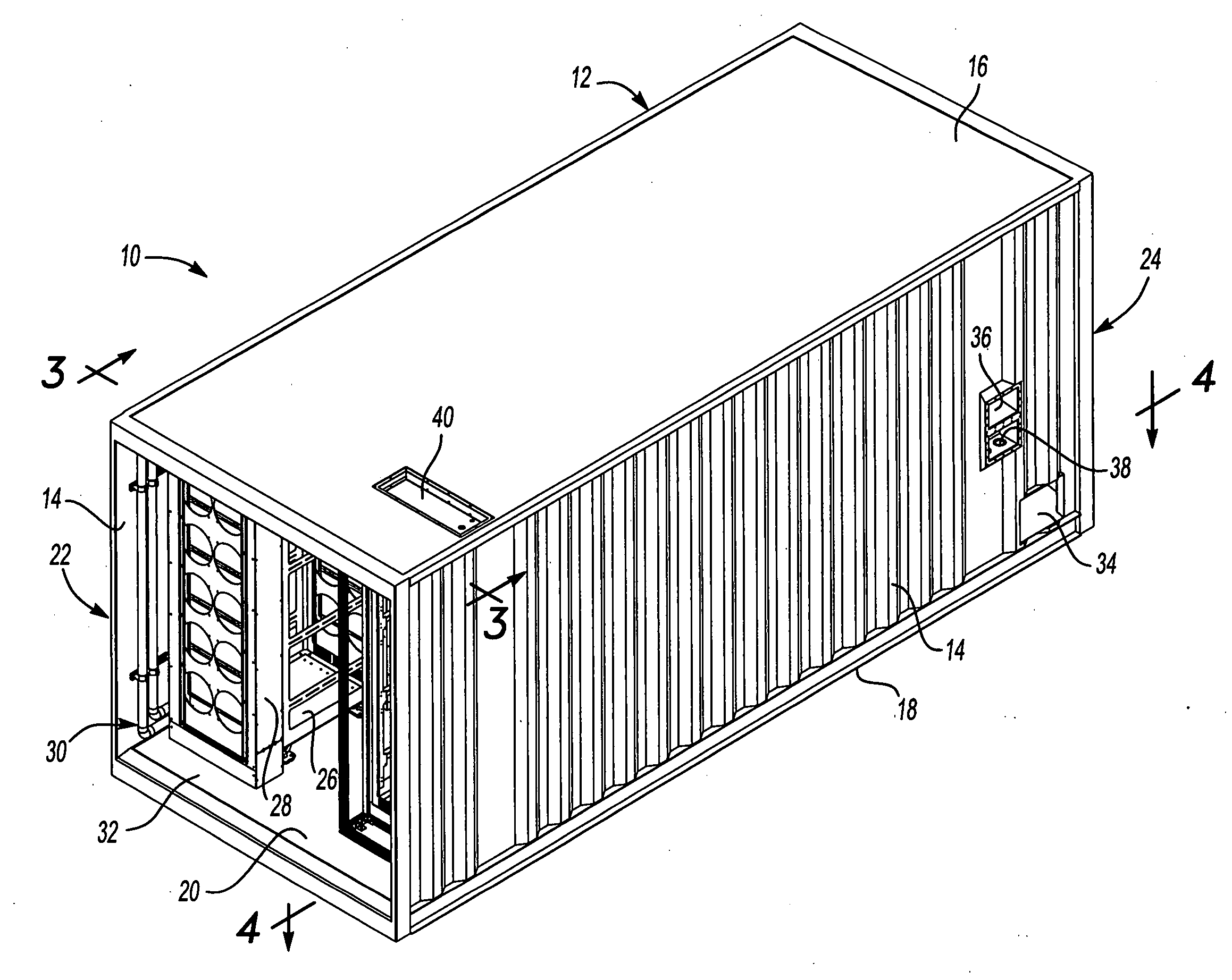

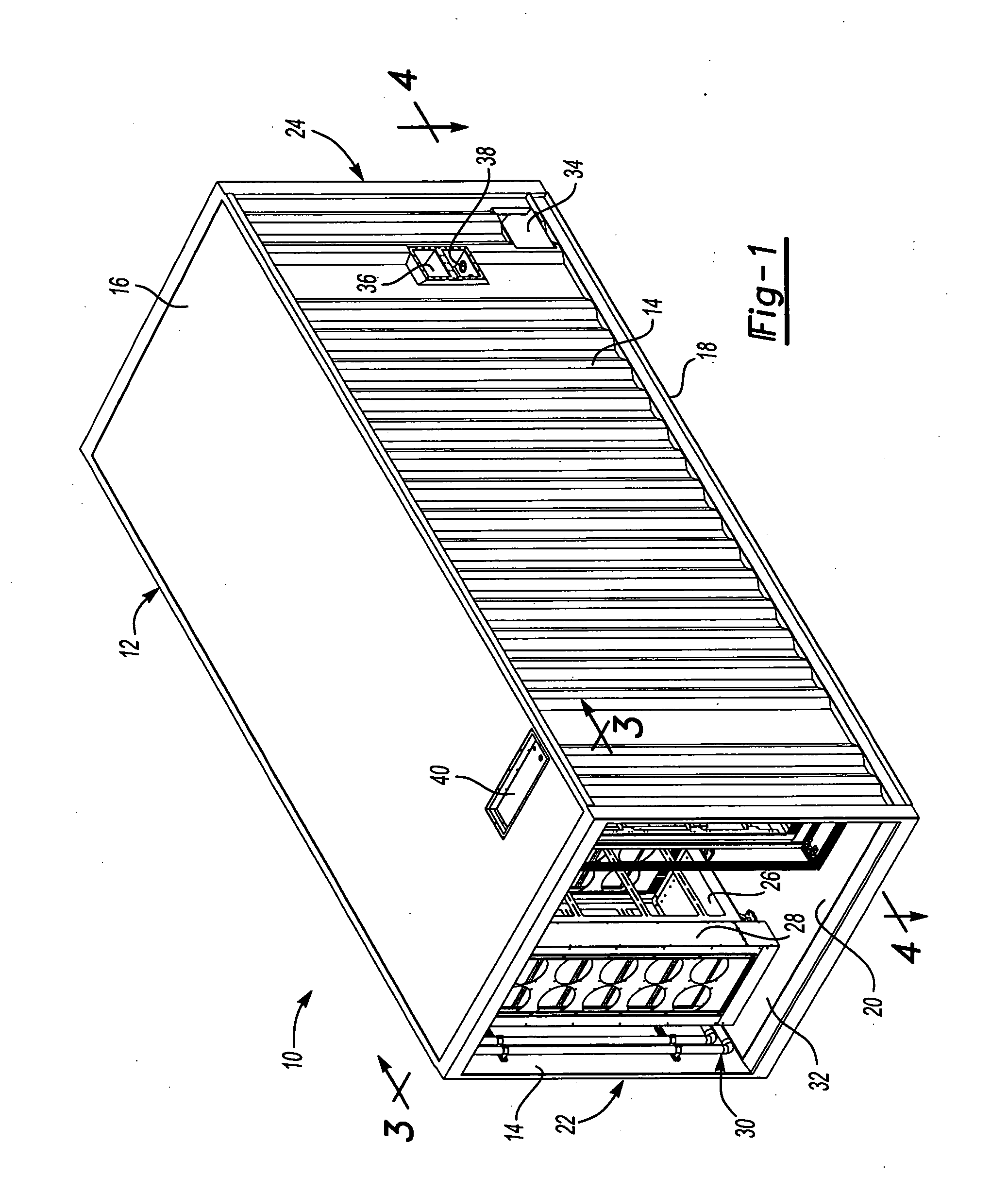

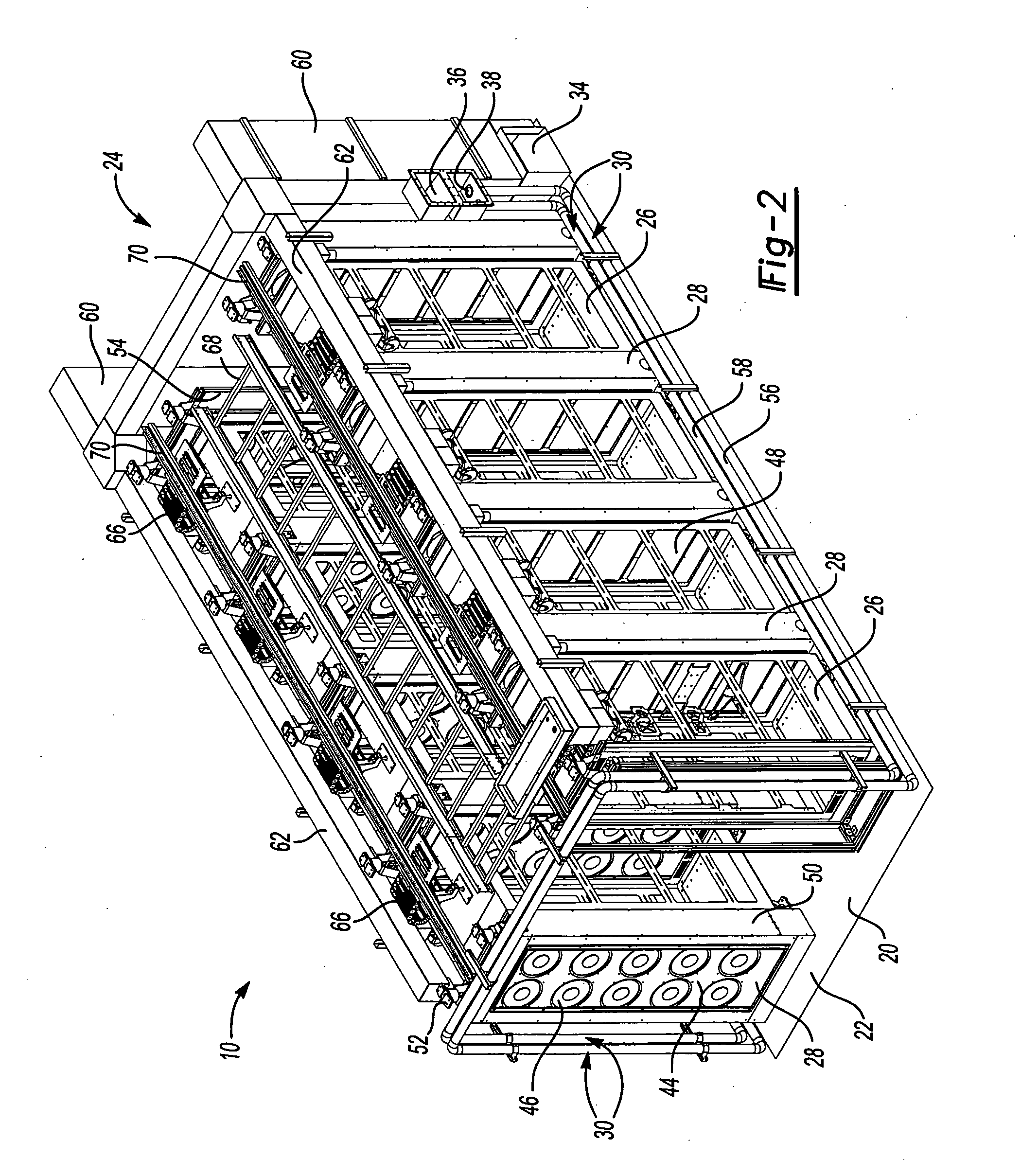

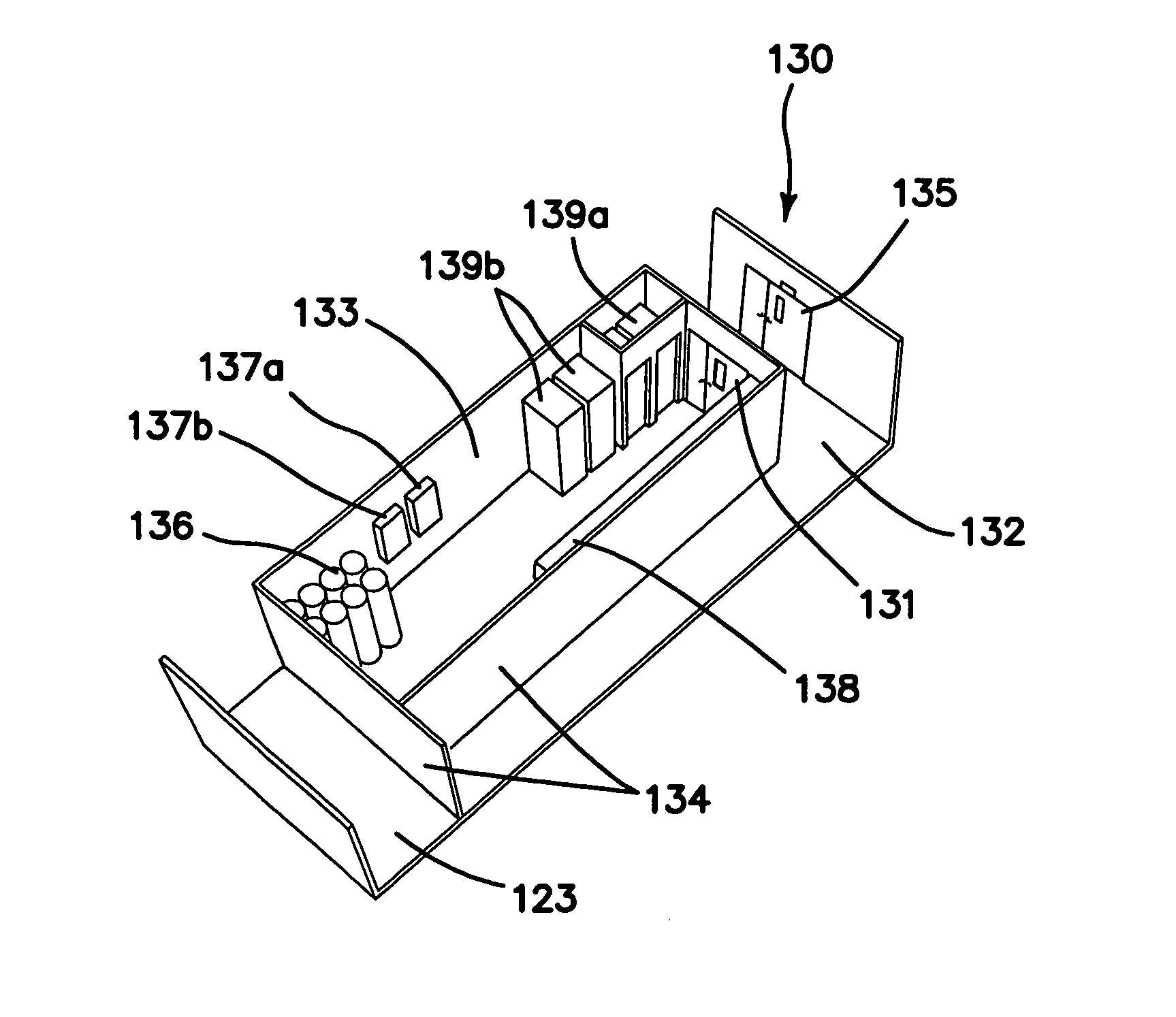

Server rack service utilities for a data center in a shipping container

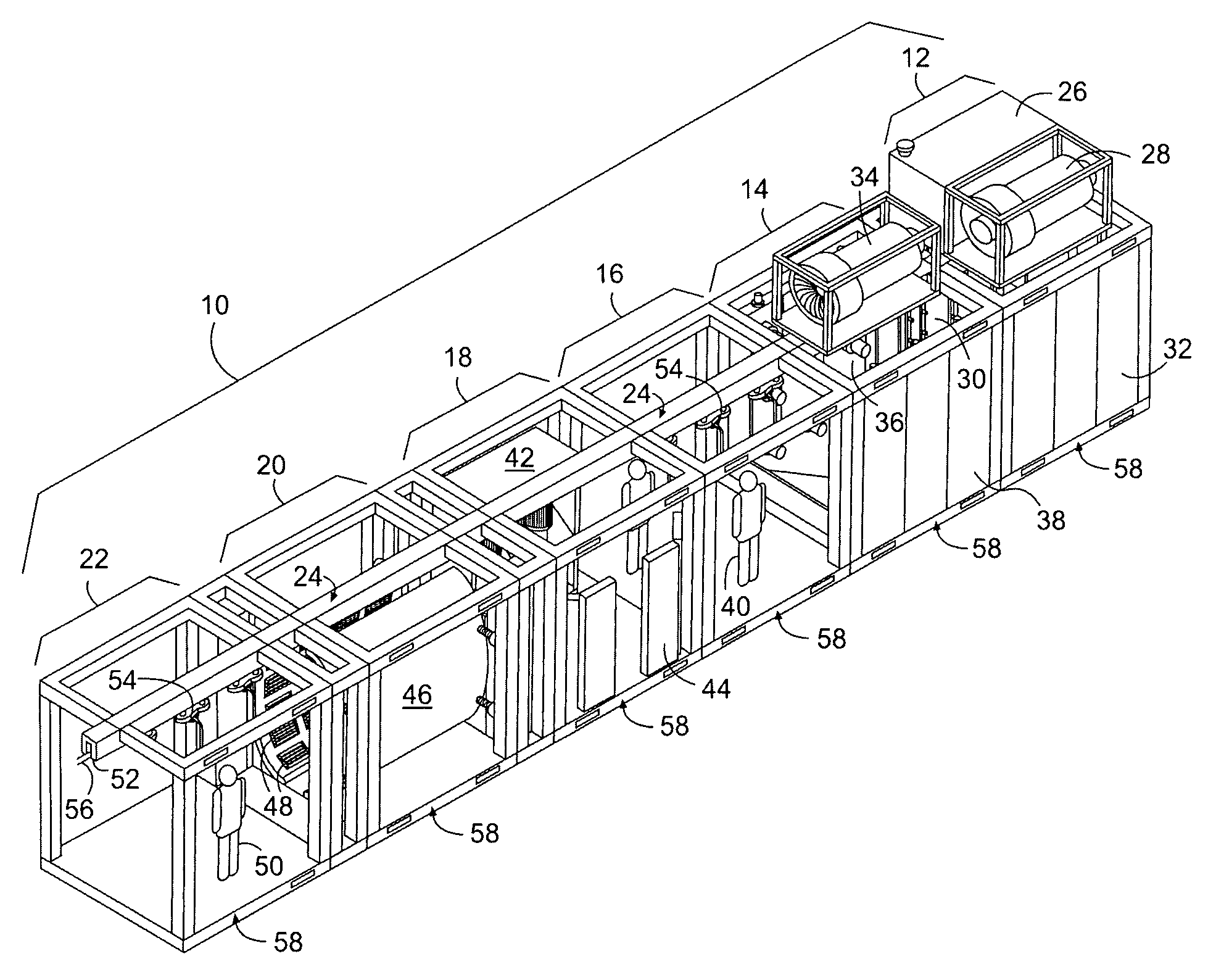

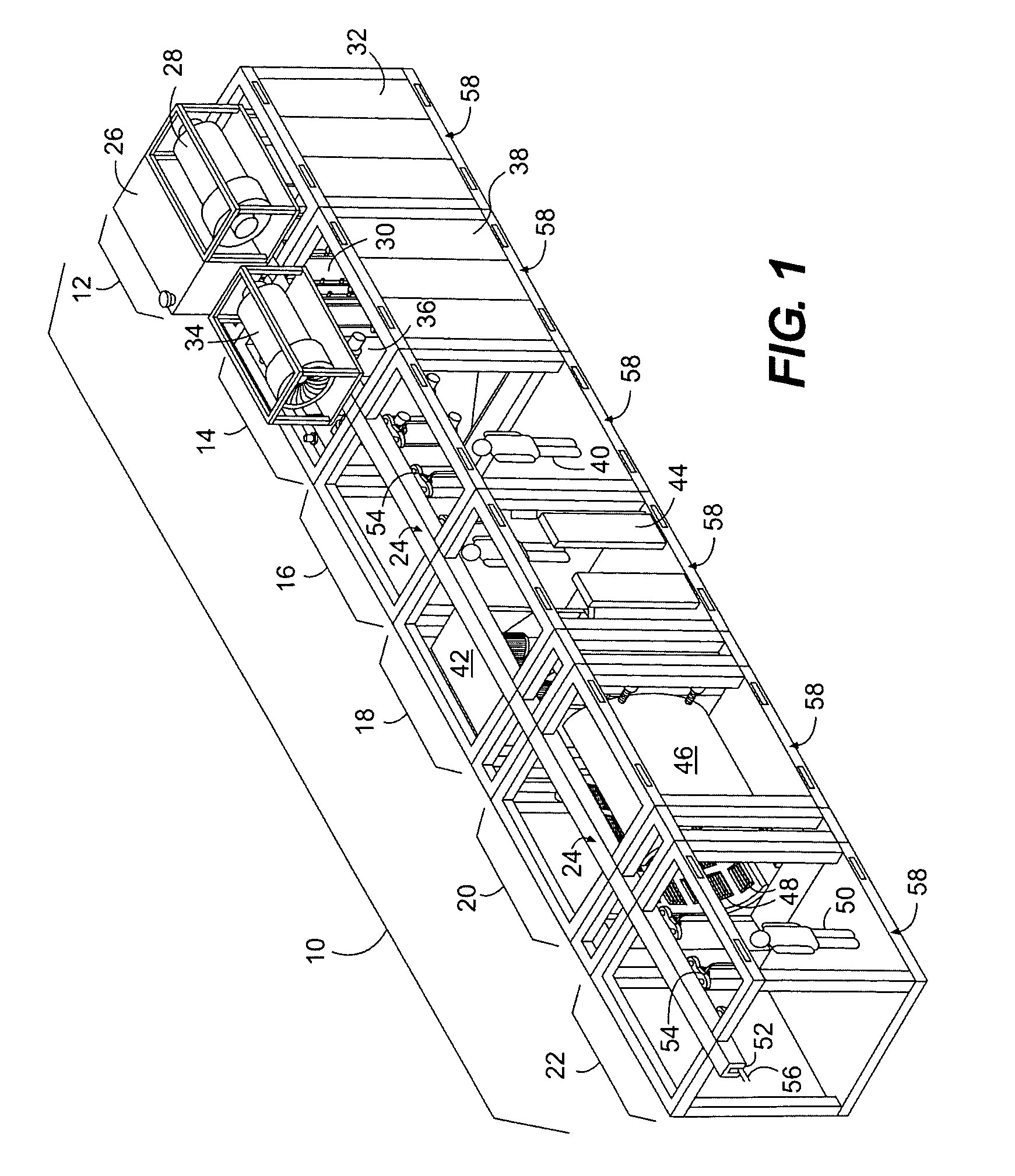

A movable data center comprising a portable enclosure in which a data processing module is operatively disposed. The data processing module is assembled onto a rack located in the enclosure that is movable between and operative position and a service position. A heat exchange module is arranged in the enclosure in air flow communication with the data processing module on the rack. The rack may be moved from the operative position in which the rack is in air flow communication with the heat exchange module to the service position in which the rack is not in air flow communication with the heat exchange module.

Owner:ORACLE INT CORP

Server rack service utilities for a data center in a shipping container

A movable data center comprising a portable enclosure in which a data processing module is operatively disposed. The data processing module is assembled onto a rack located in the enclosure that is movable between and operative position and a service position. A heat exchange module is arranged in the enclosure in air flow communication with the data processing module on the rack. The rack may be moved from the operative position in which the rack is in air flow communication with the heat exchange module to the service position in which the rack is not in air flow communication with the heat exchange module.

Owner:ORACLE INT CORP

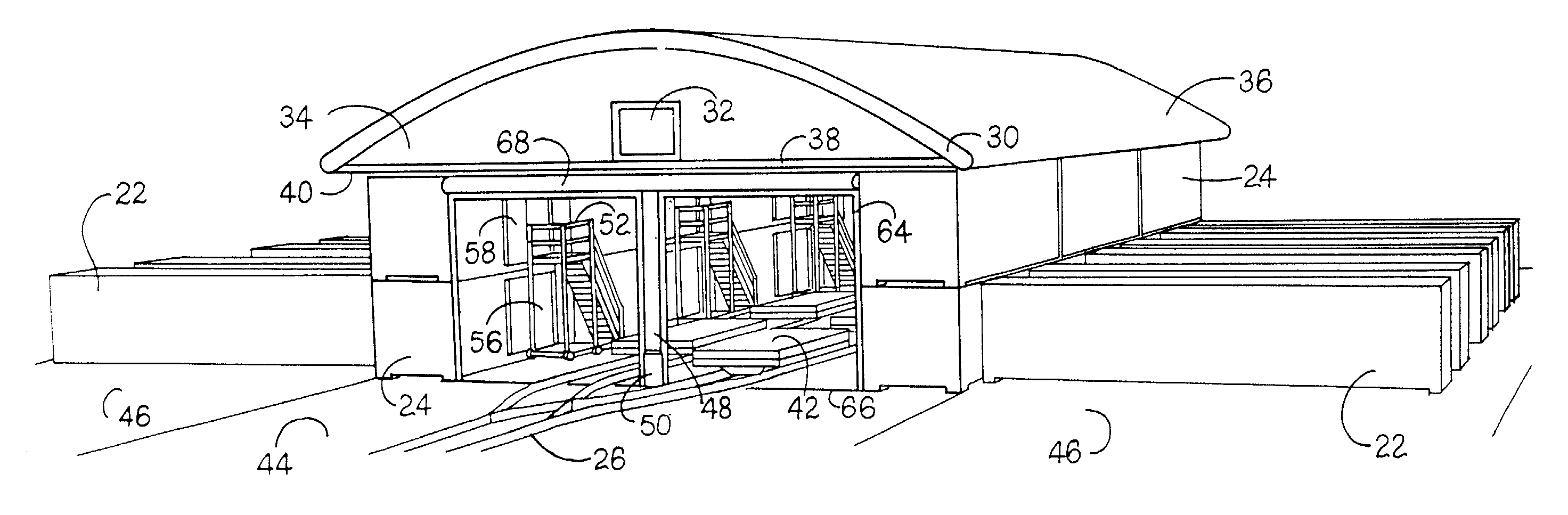

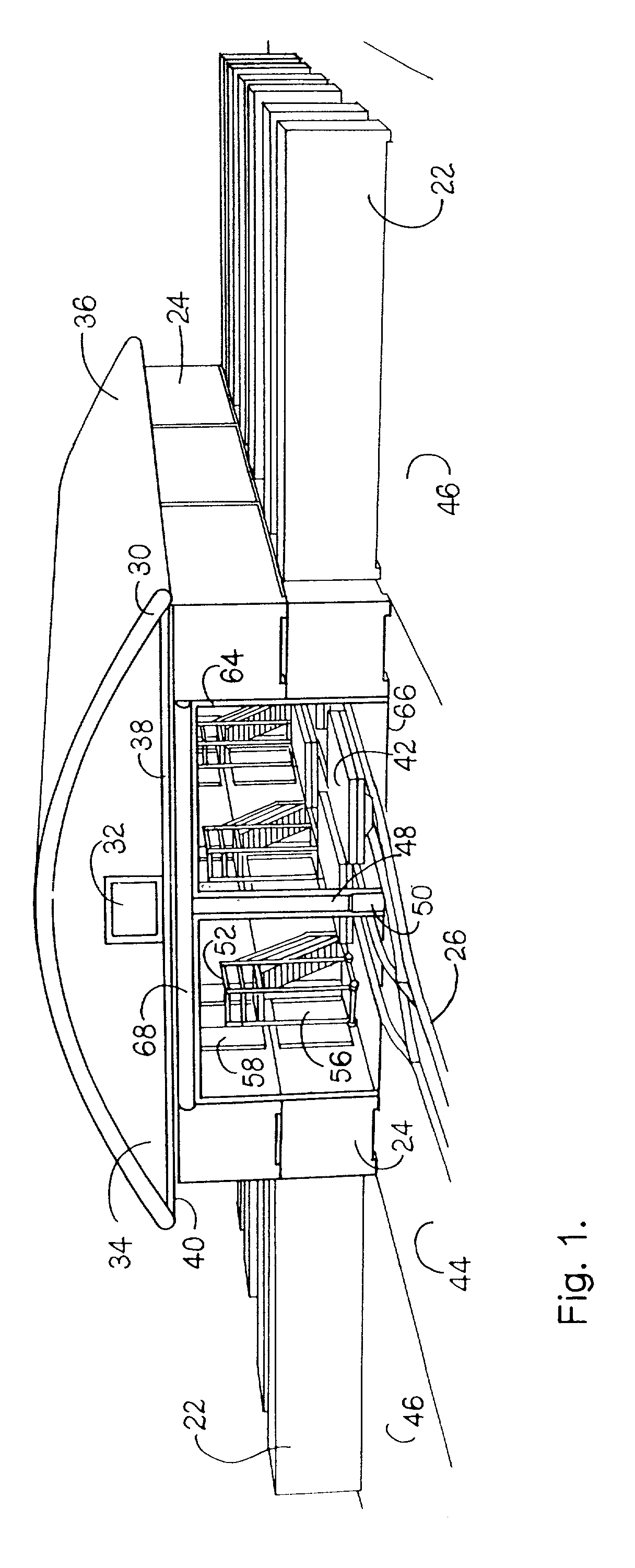

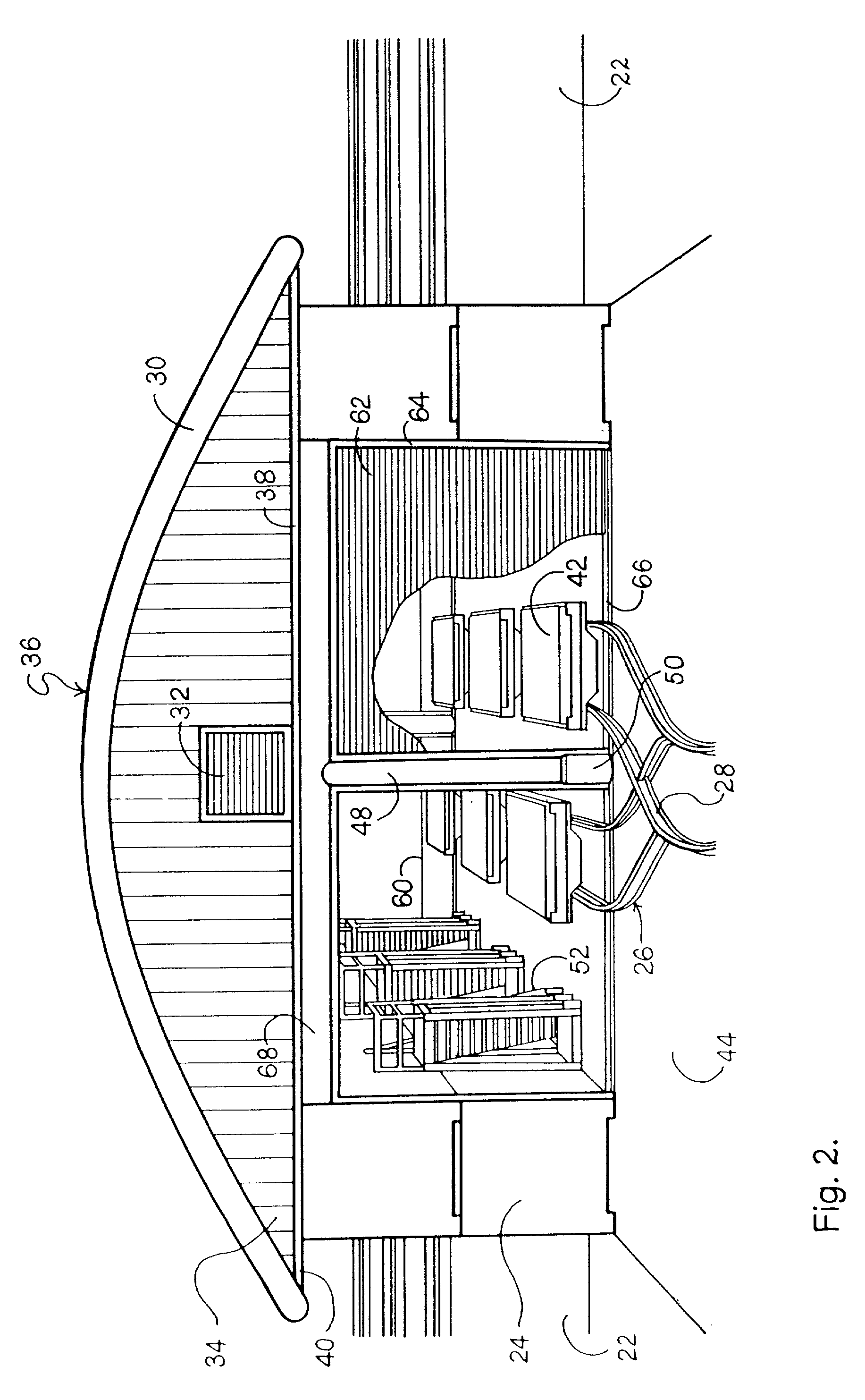

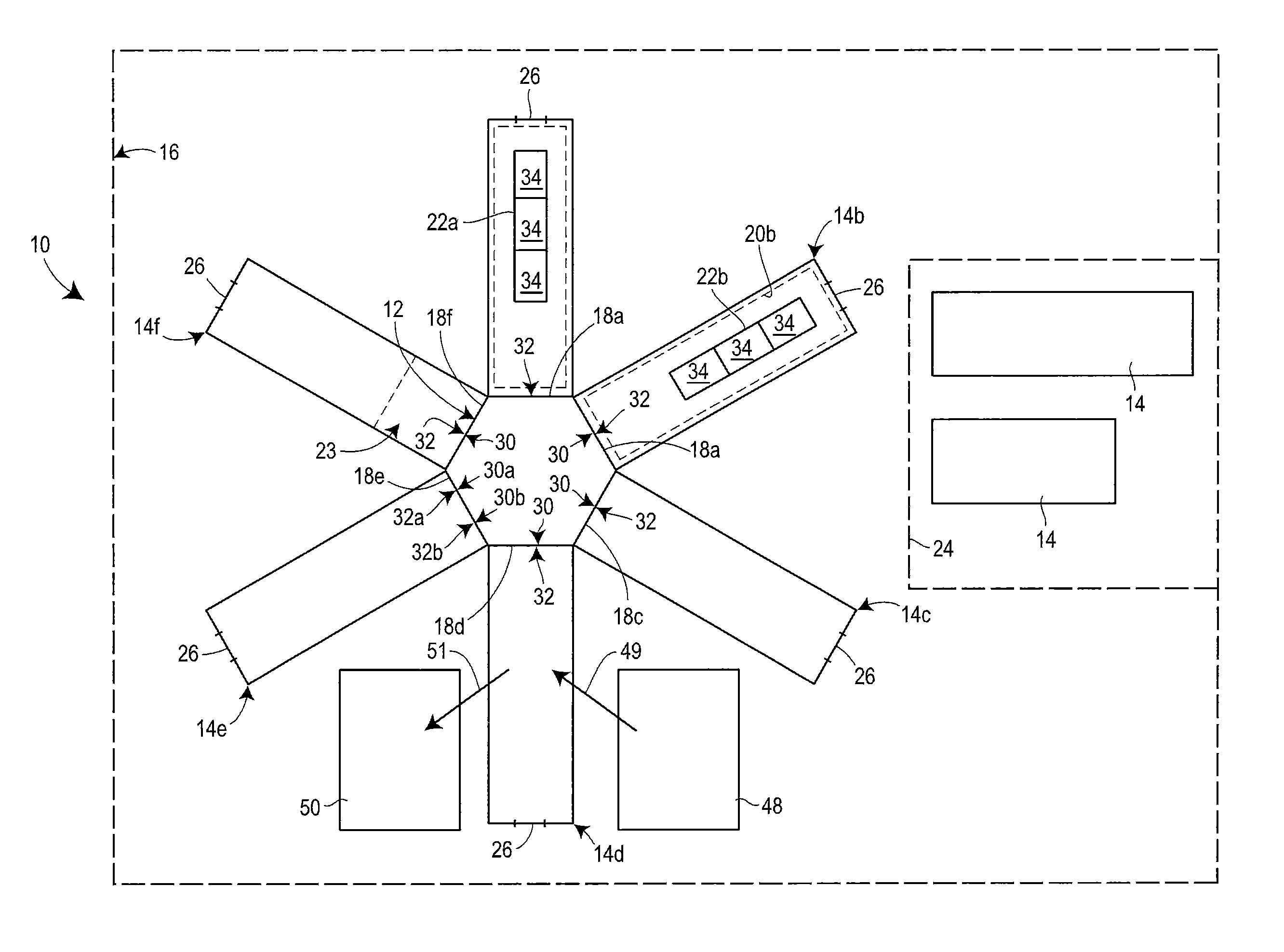

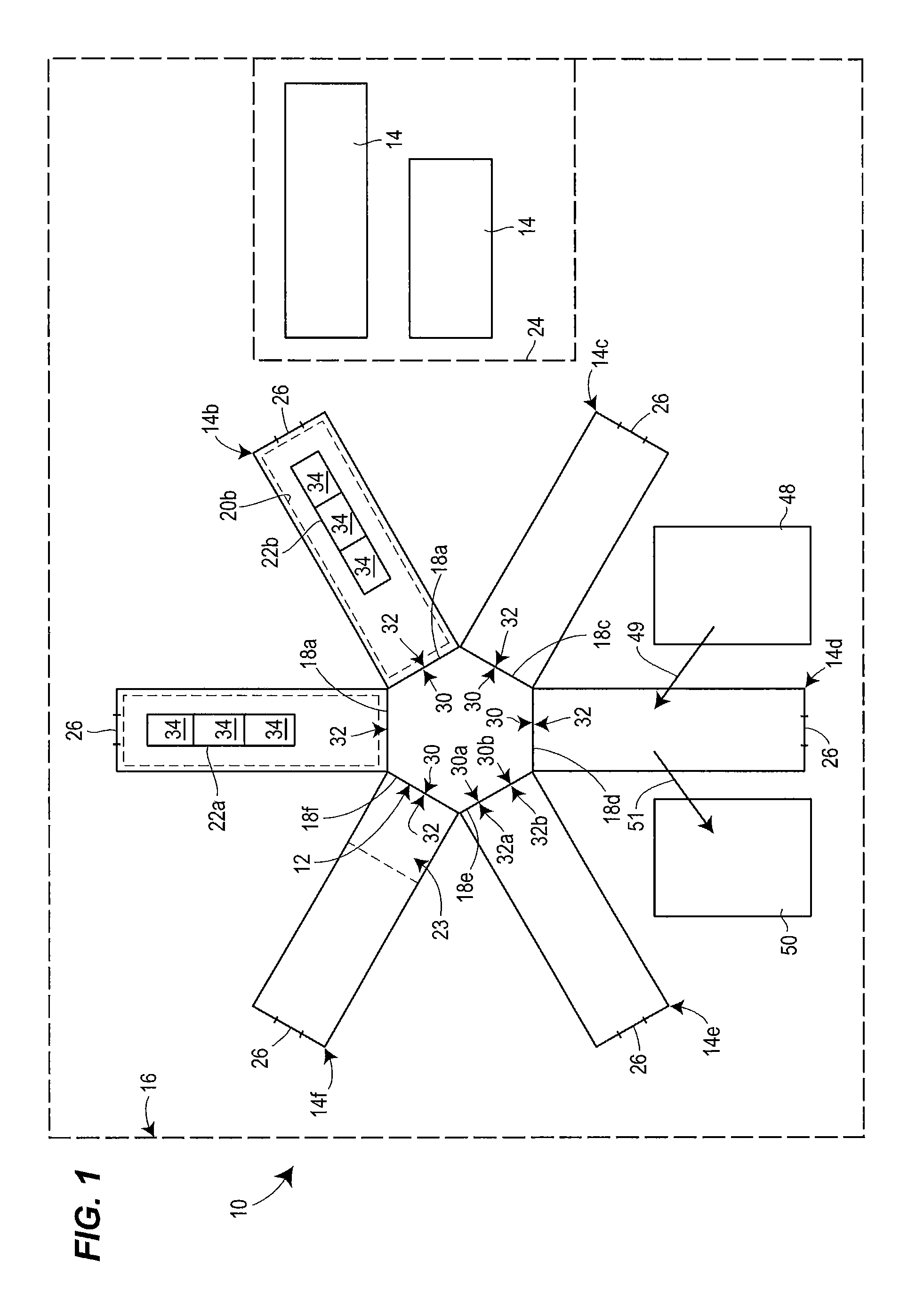

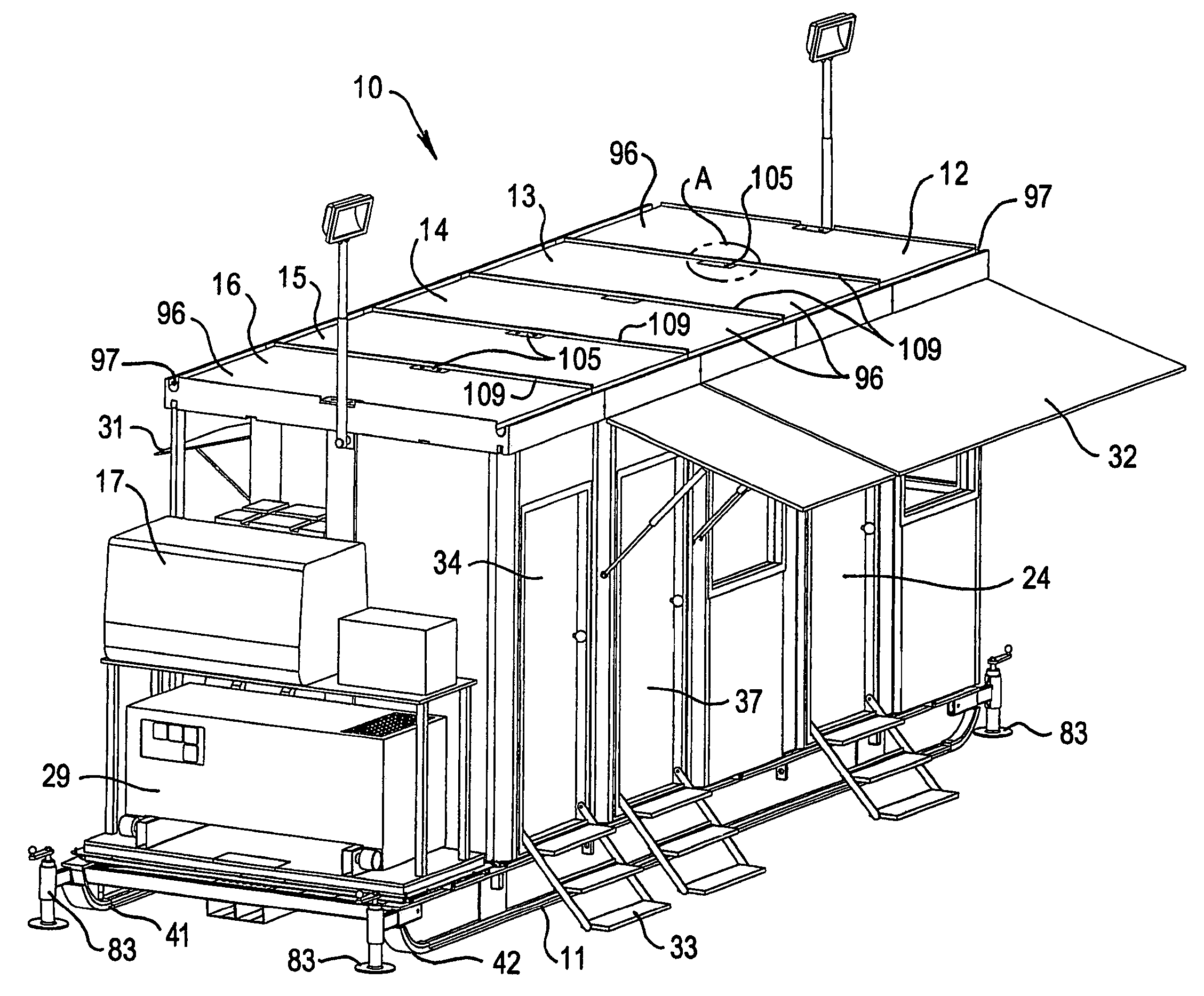

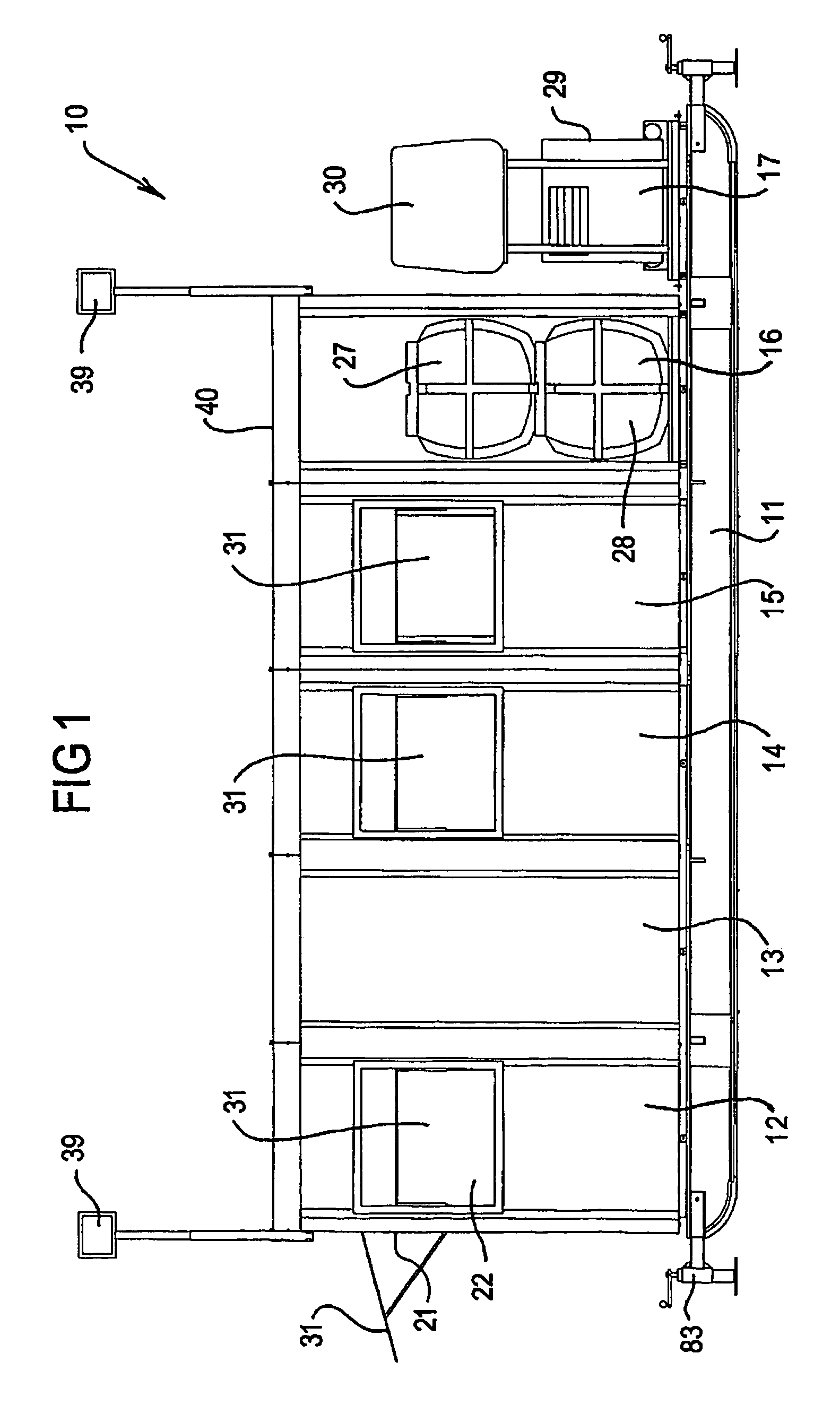

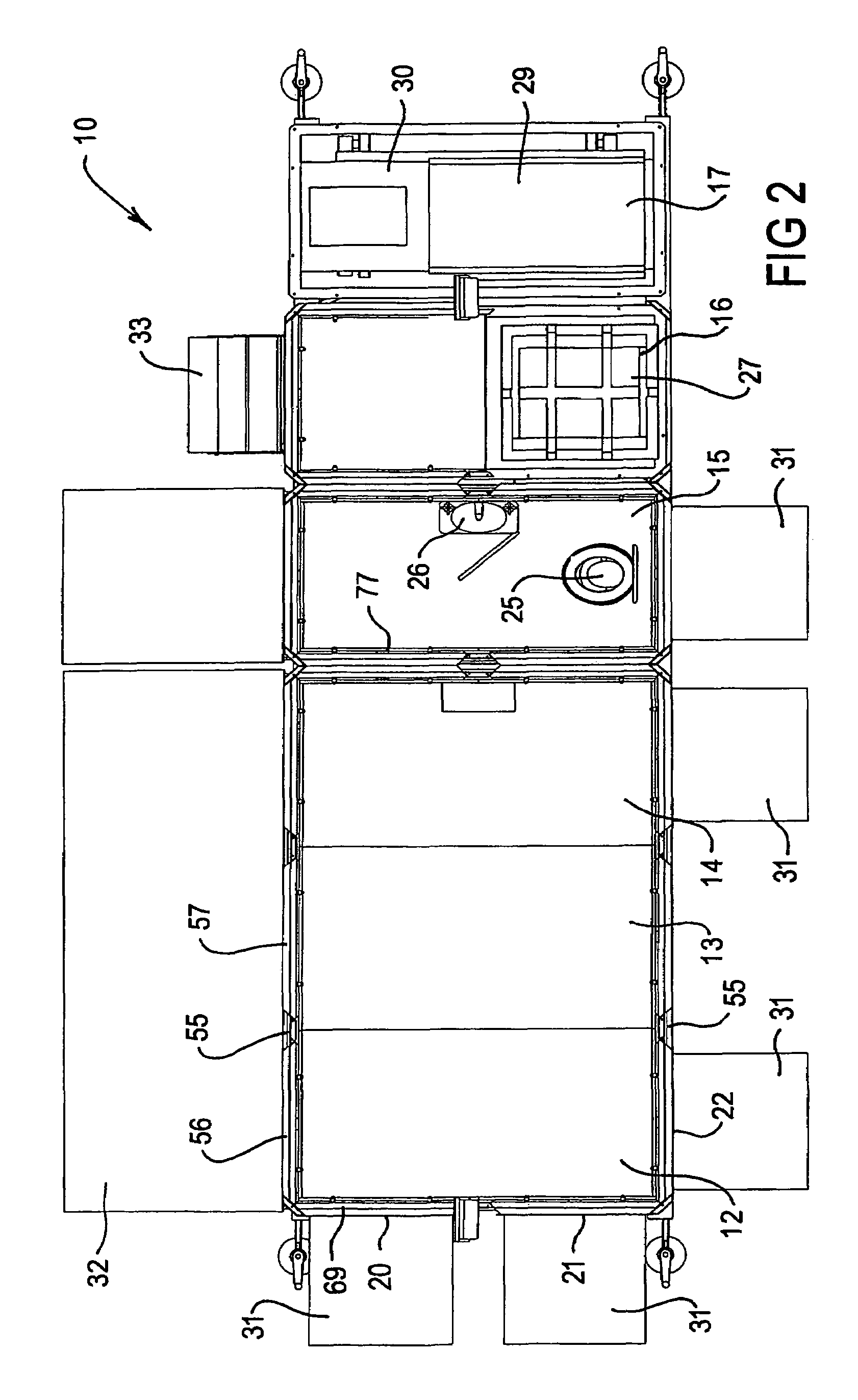

Portable modular factory structure and method of constructing same

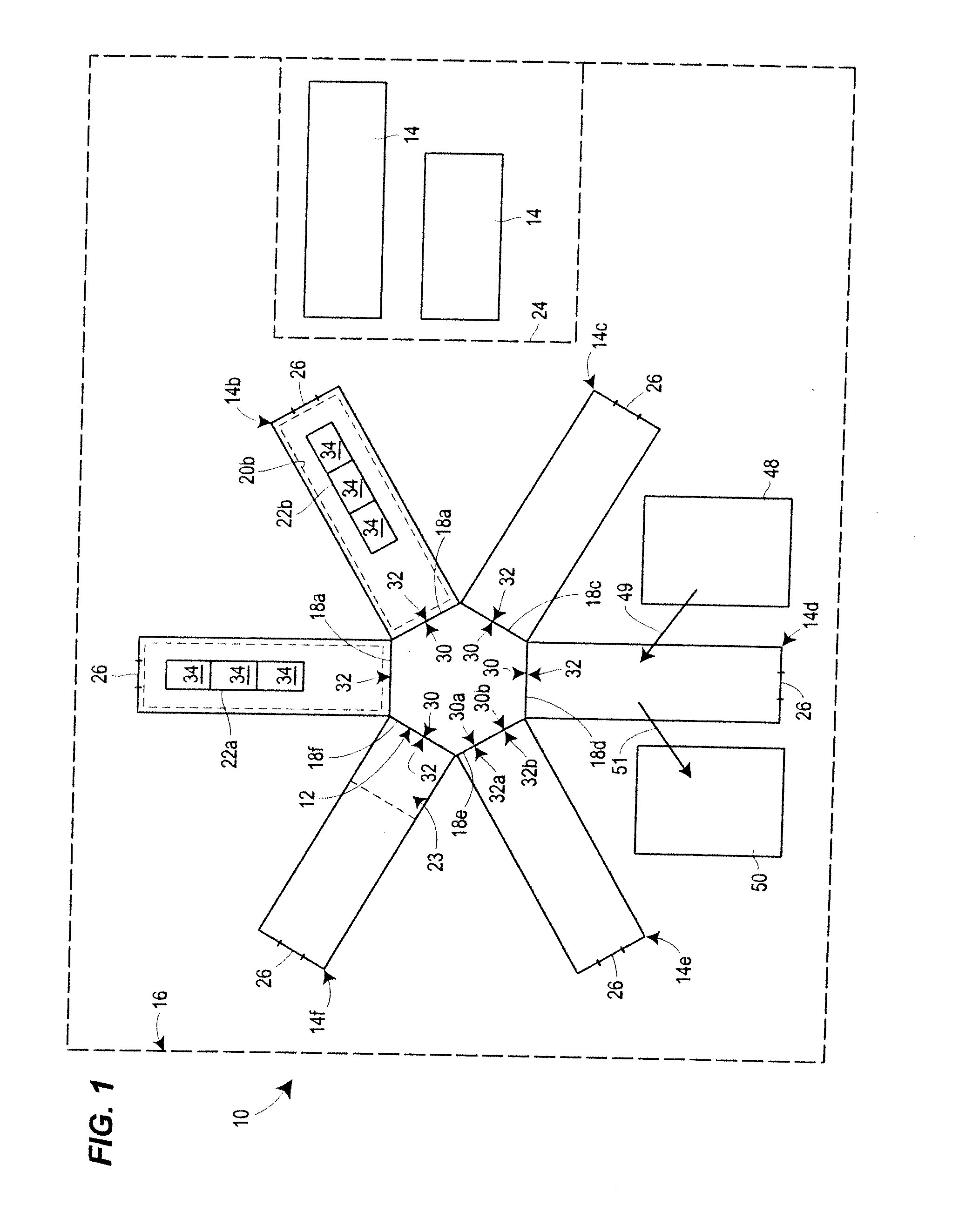

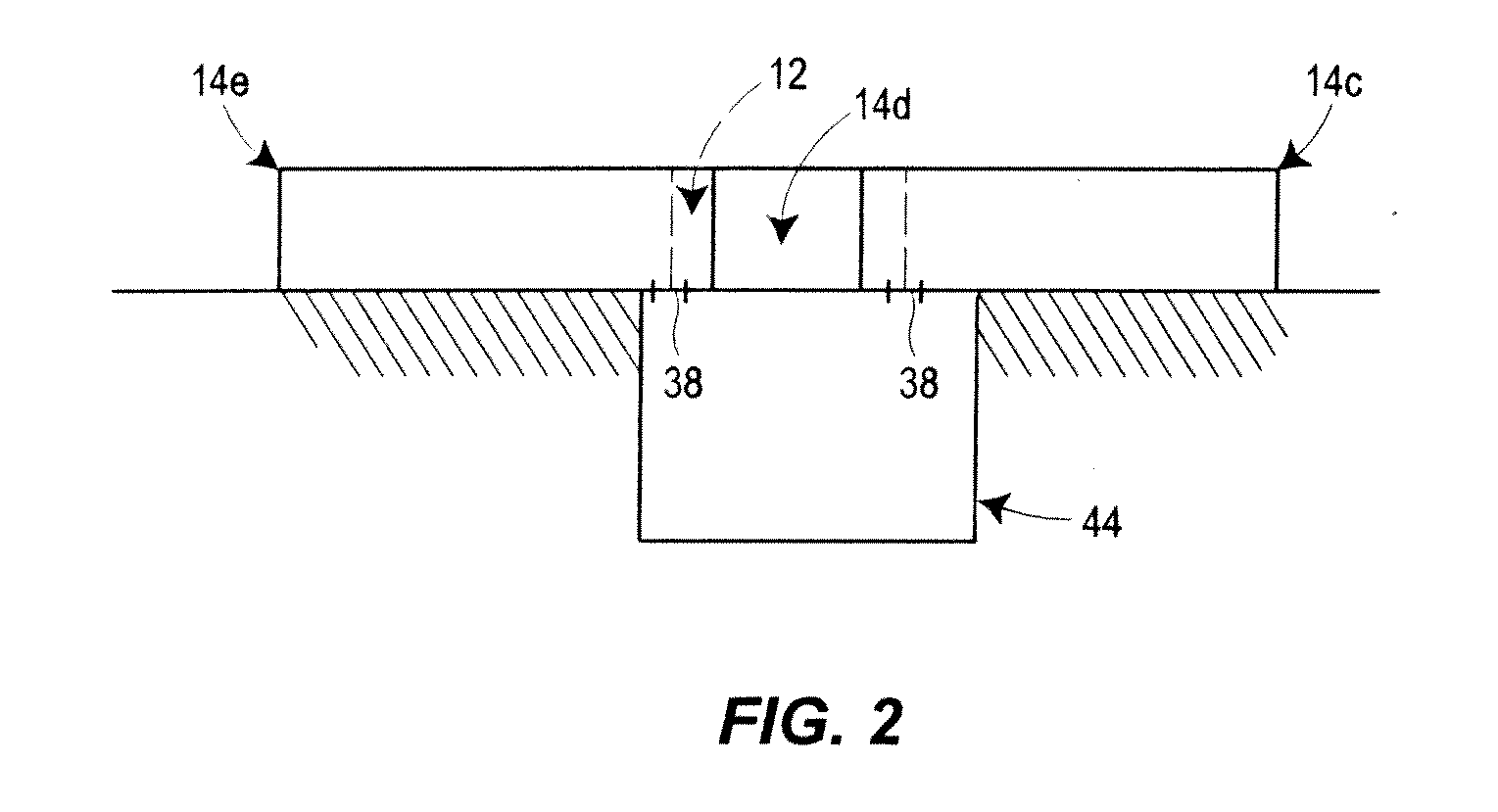

InactiveUS20020129566A1Easy to disassembleGuaranteed continuous supplyPublic buildingsBuilding repairsShipping containerBuilding material

A method of converting shipping containers containing factory equipment into a modular portable factory which comprises transporting the shipping containers to the factory site and aligning the containers in a side-by-side relation with their facing walls, to define the walls of the factory and floor of the factory. A roof structure spans over the top of the container to form top closure for the factory and access doors and stairways are provided in the factory. Shipping containers (main storage units) containing building materials are mounted on a foundation with the supply containers placed perpendicular, parallel or angled to the main storage units. The supply containers are movable by a supply track and the product moved by an assembly track, respectively, and turntables at the end of each of these tracks are operatively connected to the tracks to move the supplies or products in a desired direction. The invention also provides a novel portable modular factory which can be assembled on one site and readily disassembled for relocation to another site.

Owner:PICCOLO ROBERT +1

Data center cooling system

InactiveUS20050099770A1Sufficient powerData processing centersCooling/ventilation/heating modificationsData centerEngineering

A modular data center includes a plurality of racks, each of the racks having a front face and a back face, wherein the plurality of racks is arranged in a first row and a second row, such that the back faces of racks of the first row are facing the second row, and the back faces of the racks of the second row are facing the first row, a first end panel coupled between a first rack of the first row and a first rack of the second row, the first end panel having a bottom edge and a tope edge, a second end panel coupled between a second rack of the first row and a second rack of the second row, the second end panel having a top edge and a bottom edge, and a roof panel coupled between the top edge of the first panel and the top edge of the second panel.

Owner:SCHNEIDER ELECTRIC IT CORP

Superimposed Computer Room Building and Process for Cooling this Building

InactiveUS20110138708A1Easy temperature controlLower overall pressure dropTemperature control without auxillary powerRoof covering using slabs/sheetsHot zoneEngineering

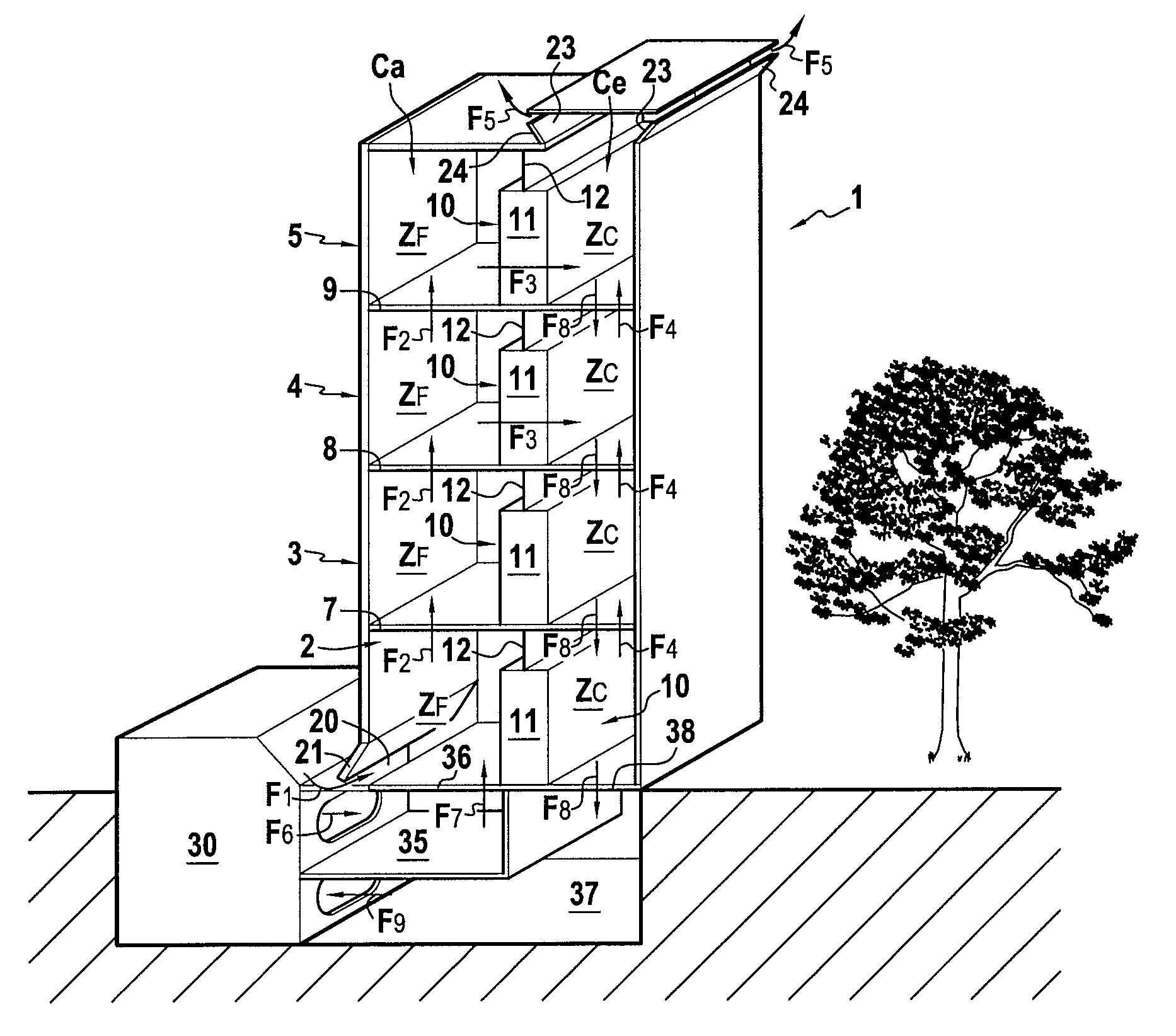

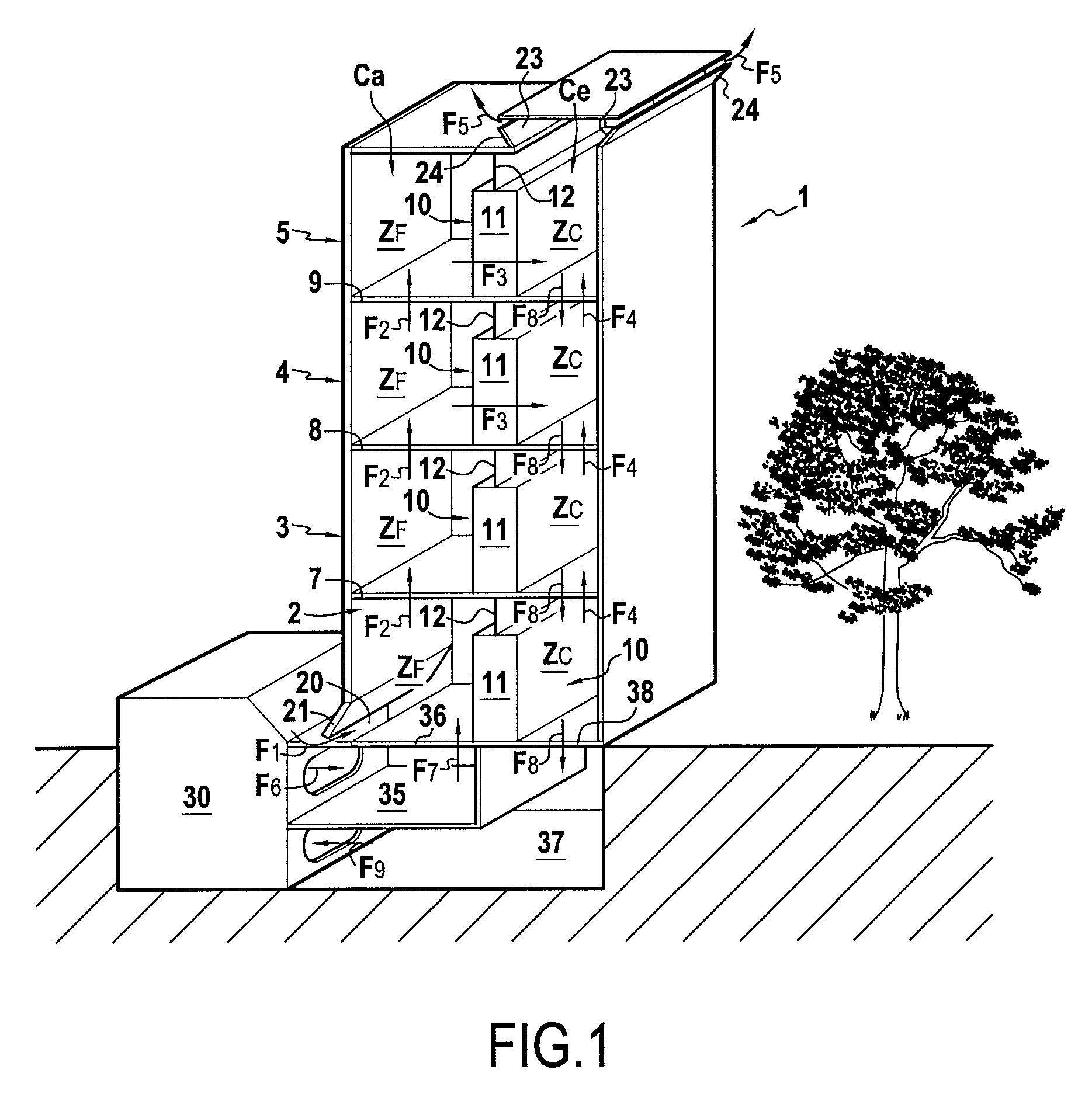

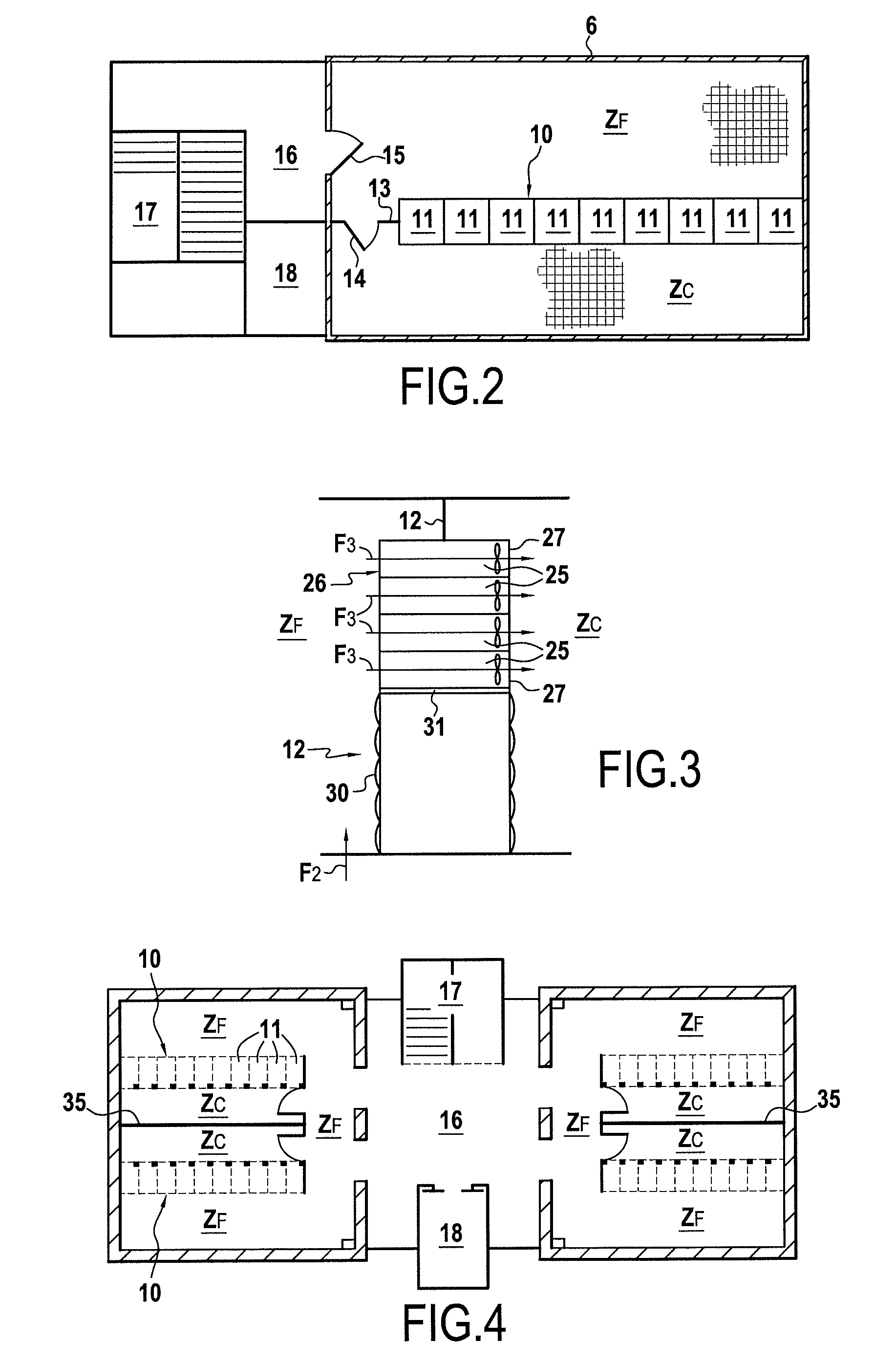

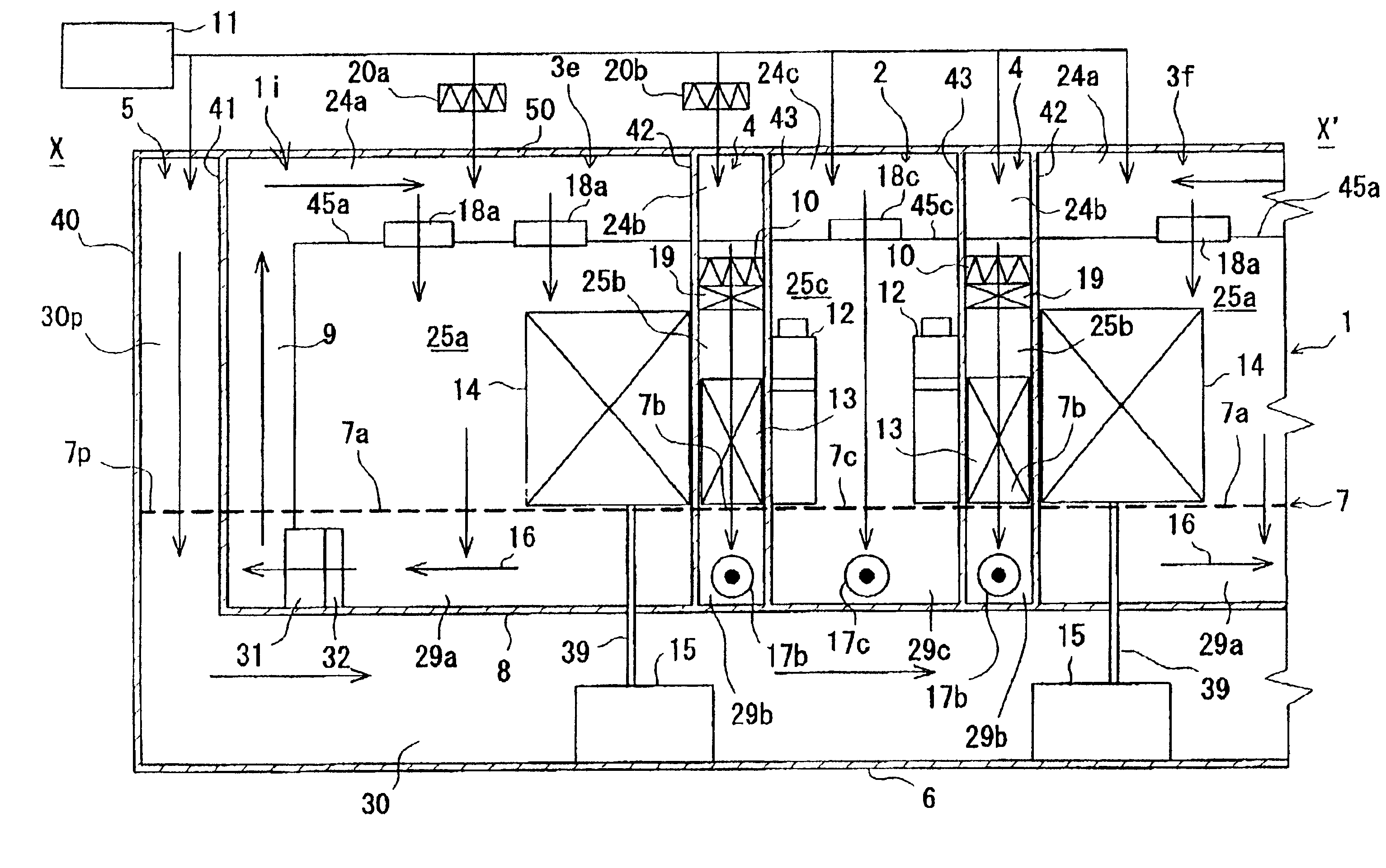

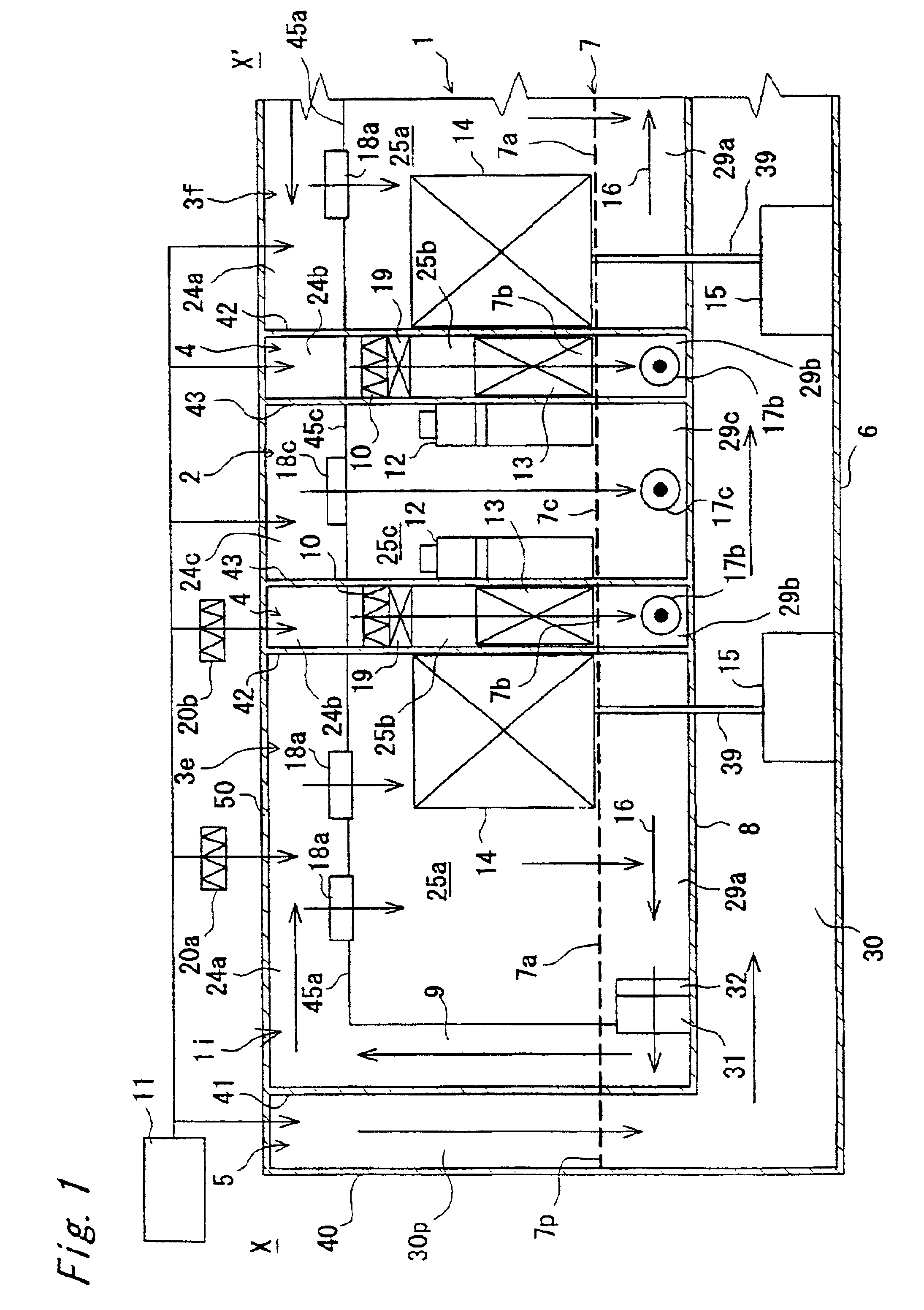

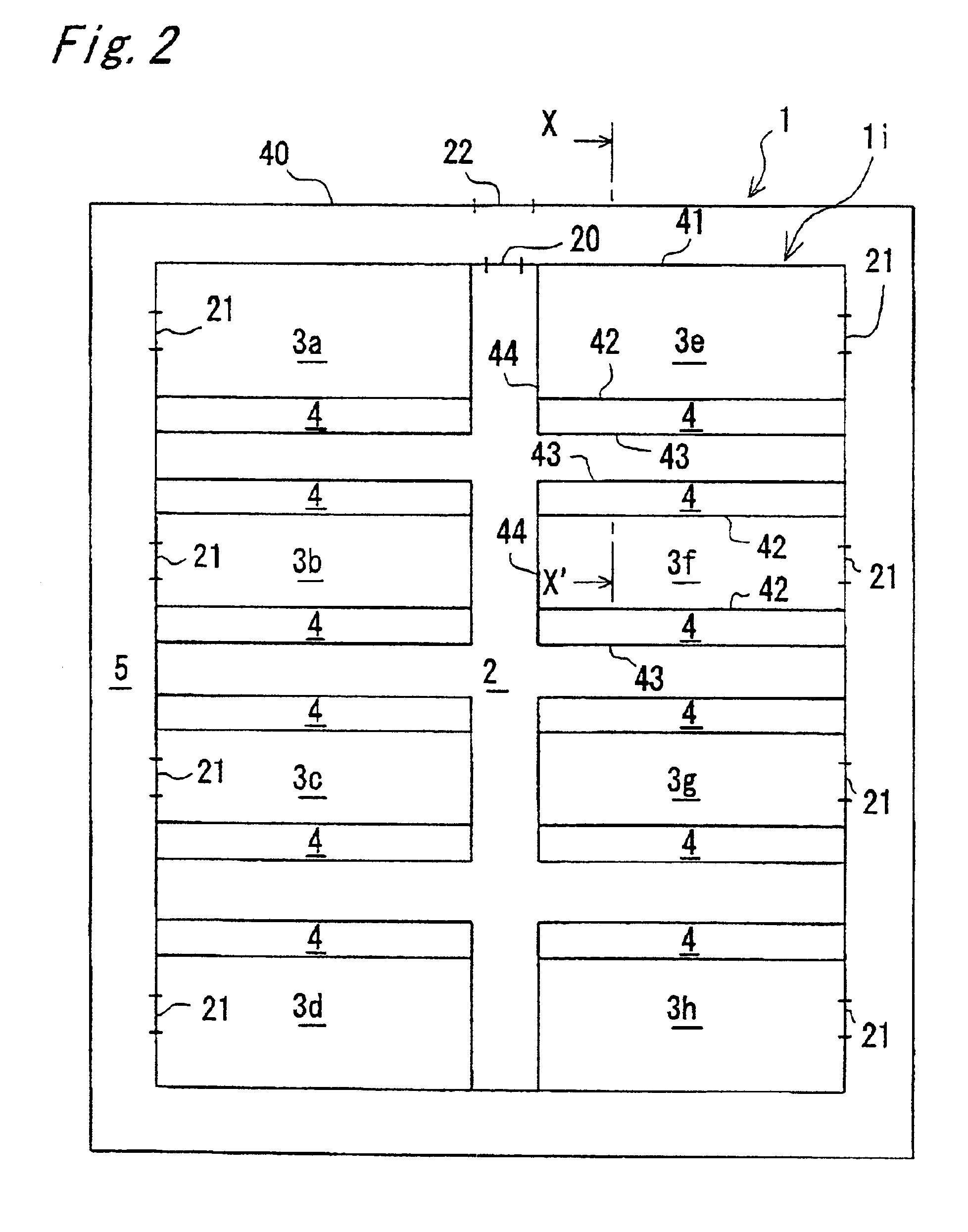

Building comprising at least two vertically superimposed computer rooms 2, 3, 4, 5 each limited by a peripheral wall 6 and separated from each other by an intermediate floor 7 and which each contain computer cabinets 11 for computer or electronic equipment 25. The building is characterised in that: each computer room 2, 3, 4, 5 comprises at least one interior wall 10 formed in part or less by the computer cabinets 11 and which separates the interior volume of each computer room into a hot zone Zc and a cold zone Zf, since the air cannot flow between the hot zone Zc and the cold zone Zf without passing through the computer cabinets 11; each intermediate floor 7, 8, 9 is perforated to allow free circulation of air, all cold zones Zf are superimposed and forming a supply column of fresh air Ca and all the hot spots are superimposed forming an exhaust column of hot air Ce; the floors 7, 8, 9, the perimeter walls 6 and interior walls 10 are adapted to prevent a direct flow of air between the supply column Ca and the exhaust column Ce, and the building comprises fresh air means 20, 30 in the supply column Ca and means for evacuating 23, 30 hot air from the exhaust column Ce.

Owner:ENIA ARCHITECTES +1

Portable modular manufacturing system

A modular manufacturing station is provided. The modular manufacturing station has a plurality of beams forming a skeleton and being capable of extension and retraction. The modular manufacturing station also has at least one utility connection for receiving external utilities. Additionally, the modular manufacturing station has at least one piece of manufacturing equipment. Furthermore, the modular frame has a control system configured to regulate operation of the manufacturing equipment.

Owner:CATERPILLAR INC

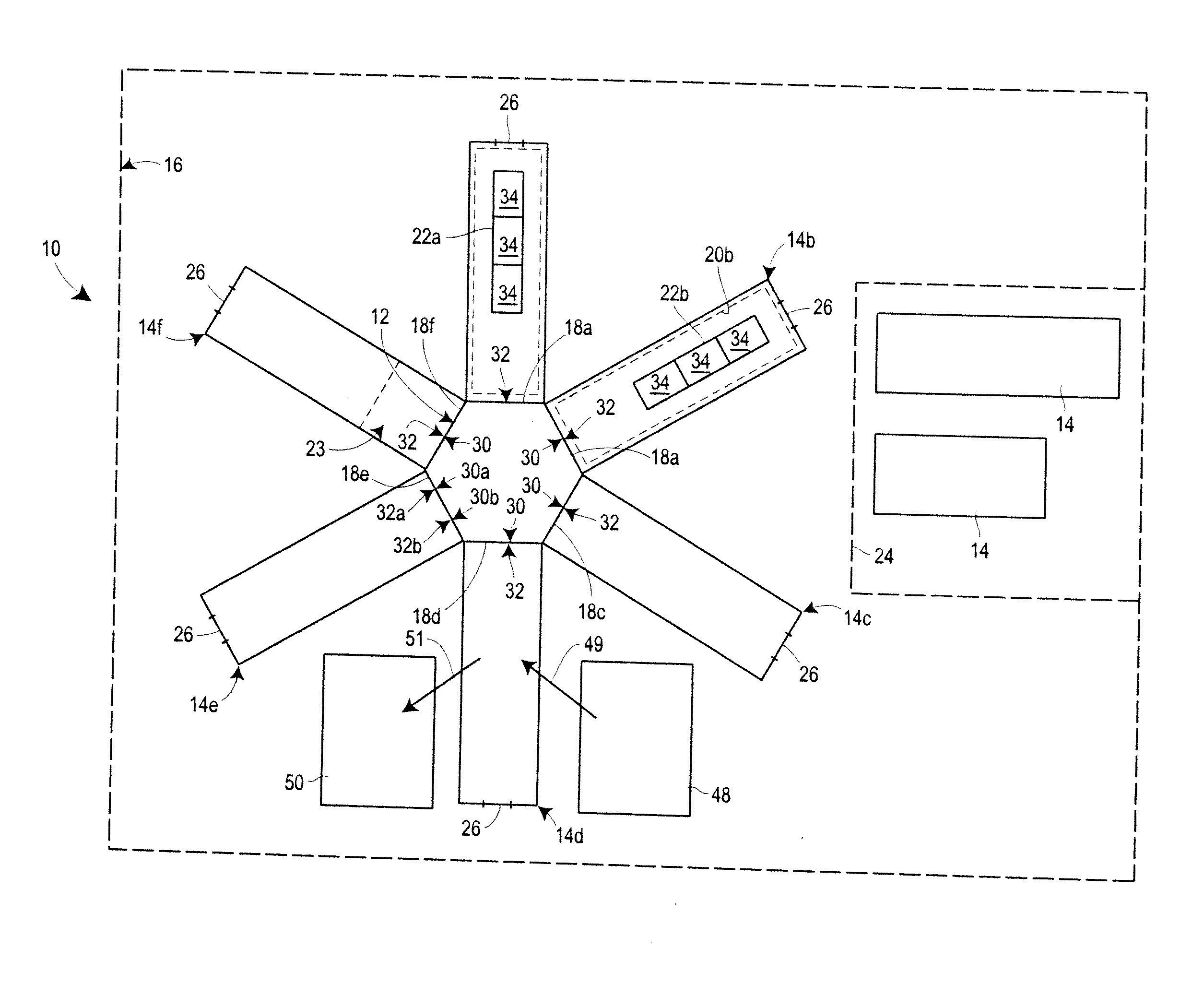

Data centre

ActiveUS8514572B2Facilitating correct positioningImprove efficiencyDomestic cooling apparatusTemperatue controlMaximum dimensionAir cycle

A data center (100) includes at least one rack room (in for example module 140) having a floor and a plurality of rack storage areas on the floor, each rack storage area being arranged to accommodate a plurality of racks (143) in which a plurality of rack-mountable electronic components may be housed, one or more controllable air circulation systems (in for example module 122), one or more cold aisles (144) in the rack room, each cold aisle being adjacent to a rack storage area, and one or more hot aisles (145) in the rack room, each hot aisle being adjacent to a rack storage area. There may be a large air duct, in the form of a personnel corridor (123), for transporting, under the control of the one or more air circulation systems, cooling air, above the floor, to the one or more cold aisles. The air supply corridor / duct (123) may have a height greater than 1.5 m above the floor and a cross-sectional area of at least 2 m2 and a maximum dimension in the plane of the cross-section of less than 3 m.

Owner:BRIPCO

Flexible manufacturing system

ActiveUS20110258837A1High capacity supplyDischarging wasteTreatment involving filtrationChemoinformaticsFlexible manufacturing systemEngineering

Owner:XOMA US

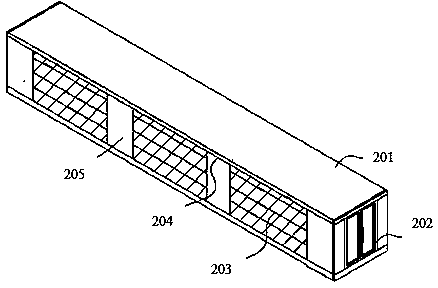

Container based data center solutions

A cooling container comprises a container housing with a chilled water storage tank including a first interface for receiving chilled water. The chilled water tank has a plurality of straight pipes joined by elbows connections to provide a folded path, the full path length being greater than the length of the container housing, and a second interface for outputting the chilled water. A number of interfaces within the container housing are configured to receive a chiller module or a free cool unit.

Owner:SCHNEIDER ELECTRIC IT CORP

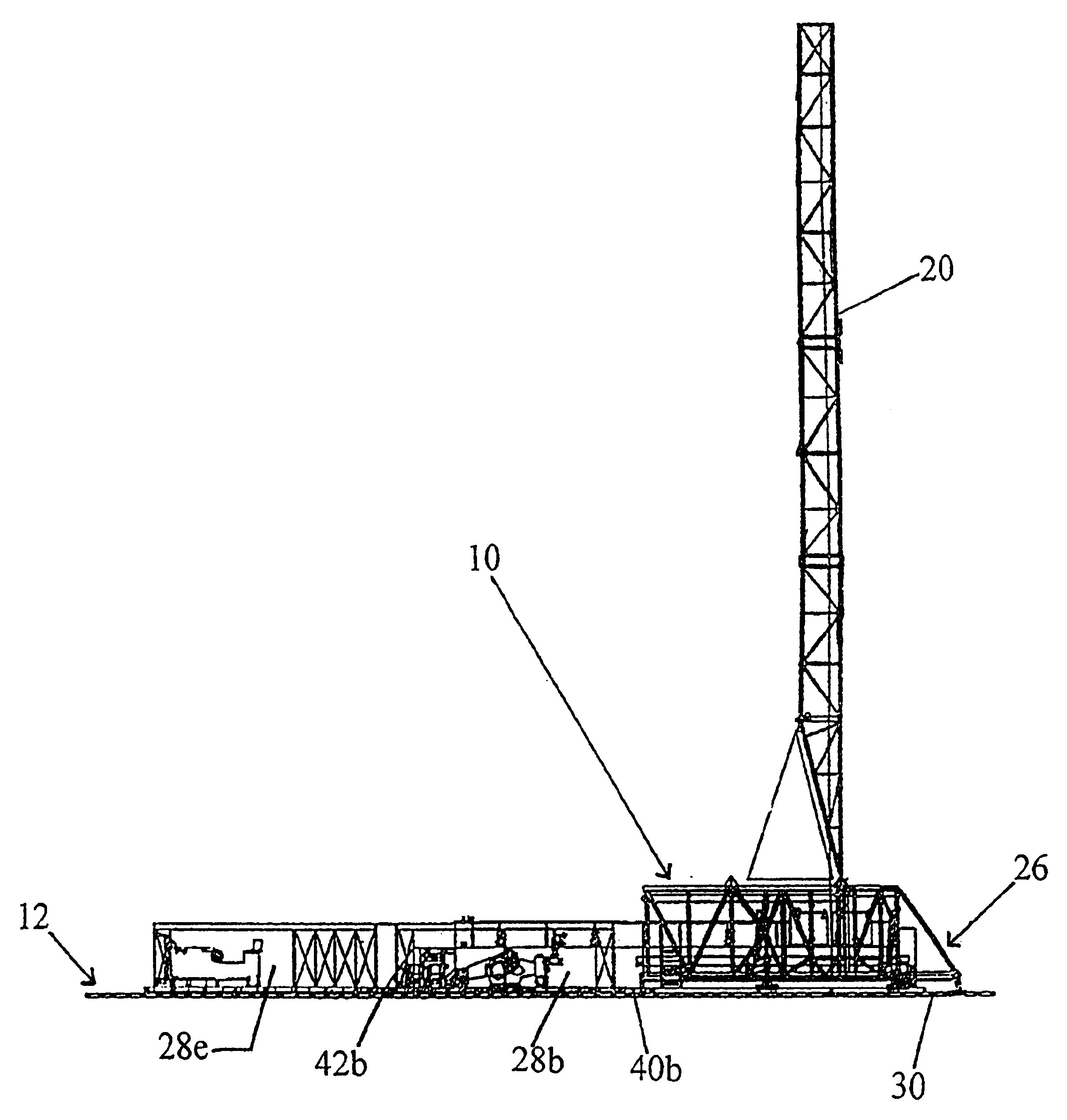

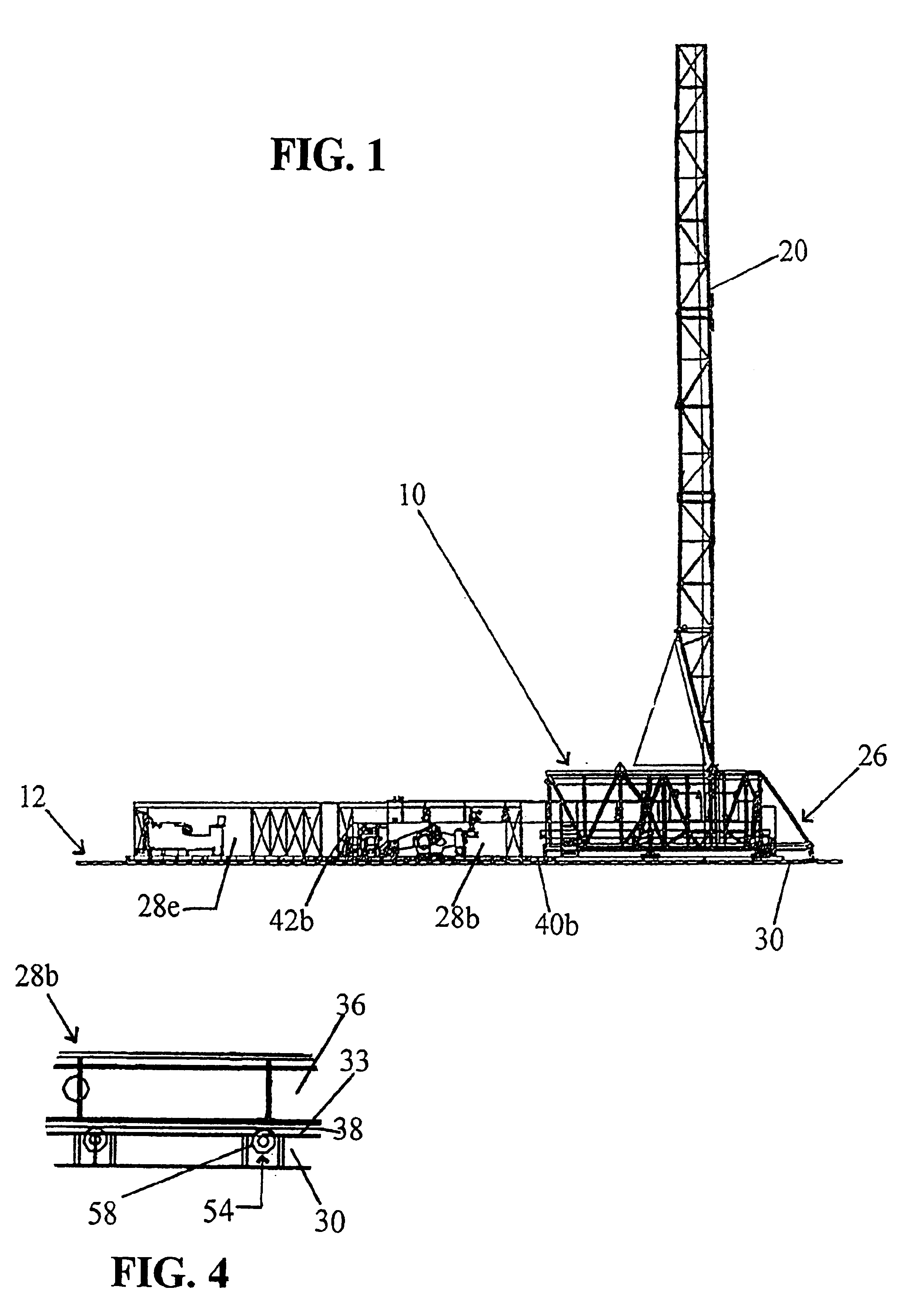

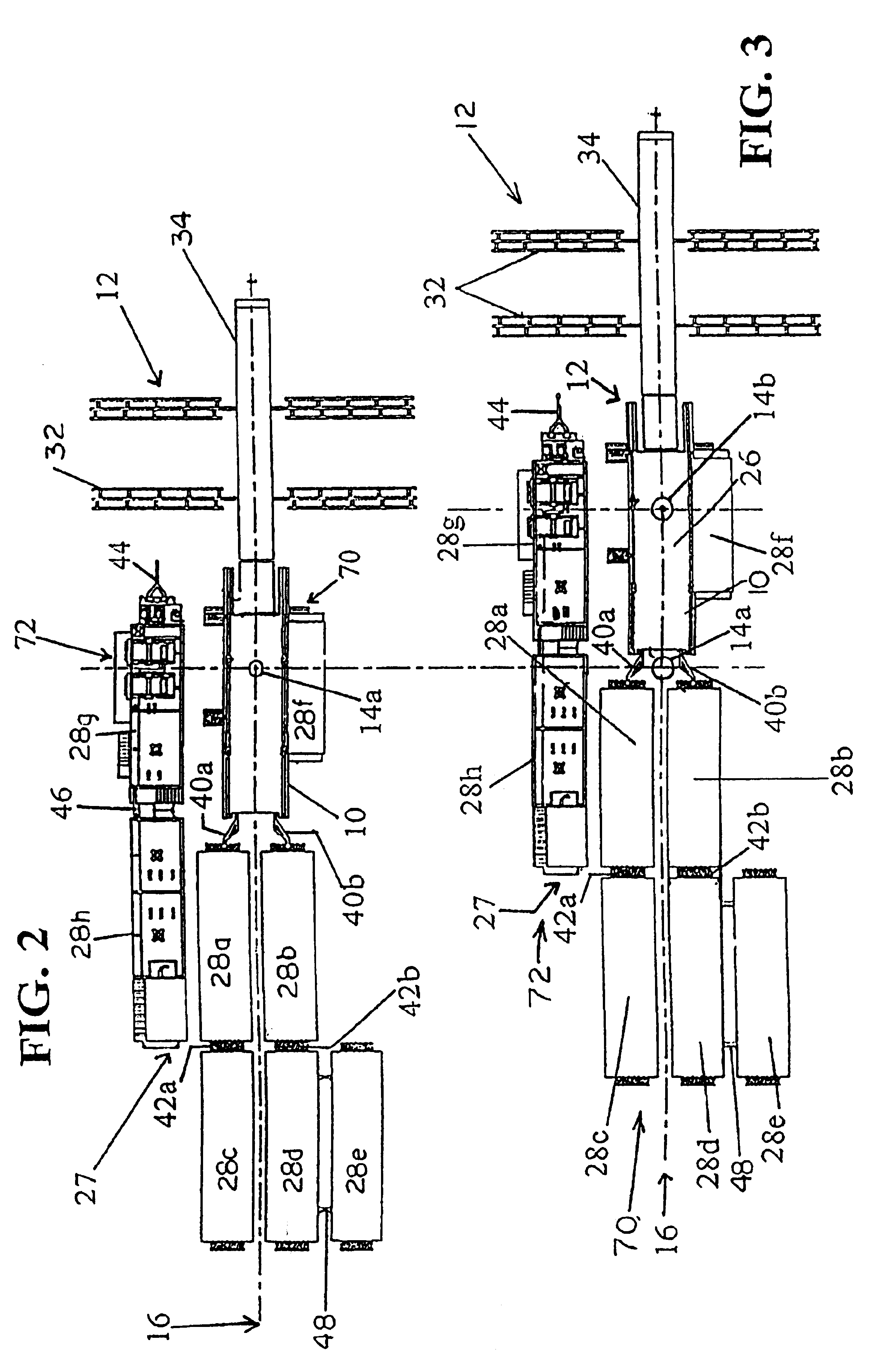

Method and apparatus for interconnected, rolling rig and oilfield building(s)

A conventional land drilling rig is interconnected to the substructure for an oilfield pad location. The interconnected drilling rig is placed on top of matting. The matting has embedded rollers to facilitate movement of the drilling rig as a “convoy” across the mat from one wellhead to another wellhead. The buildings in the mud tank system may also be interconnected and move in a separate convoy but in tandem with the first convoy.

Owner:WEATHERFORD CANADA

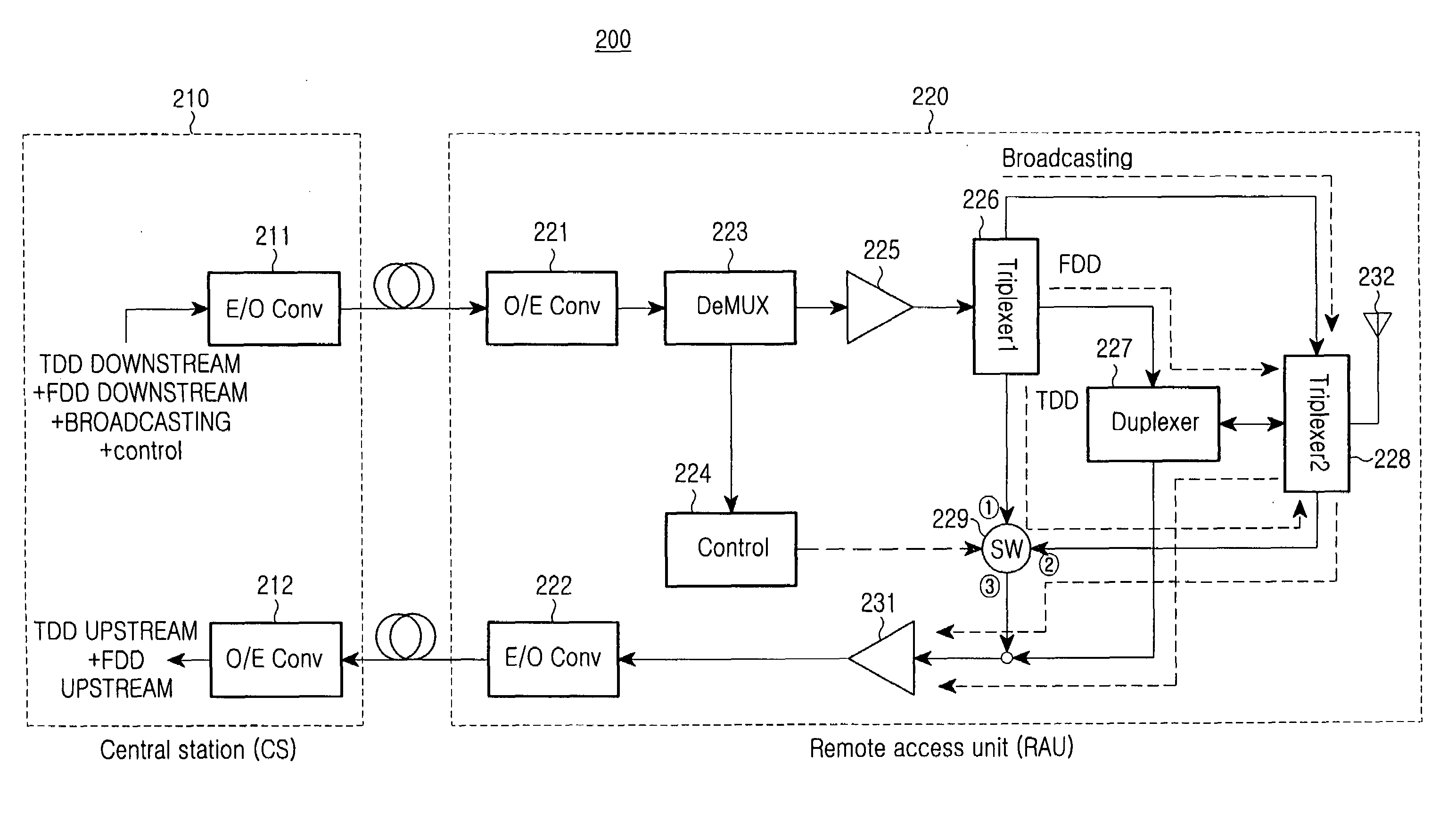

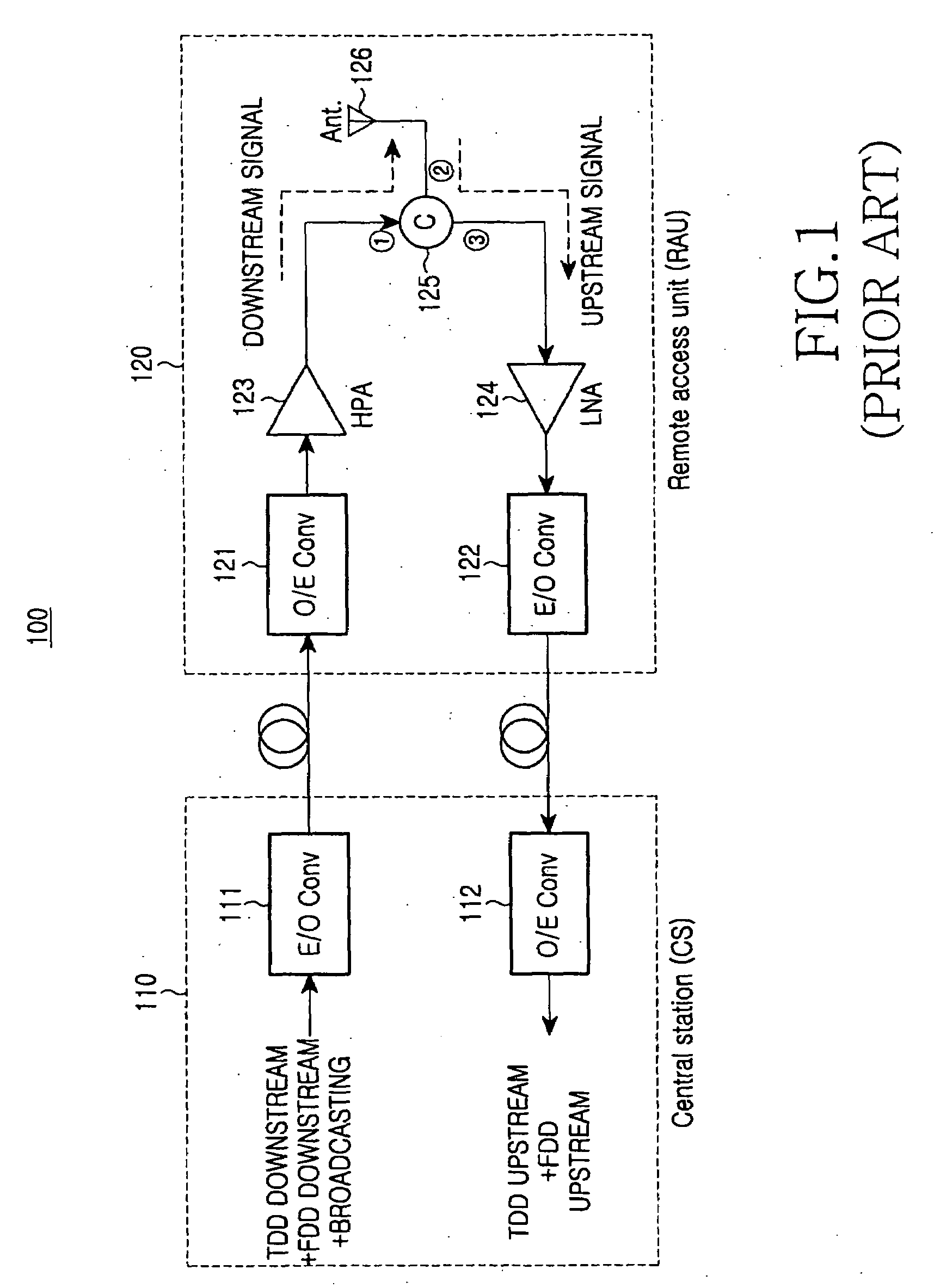

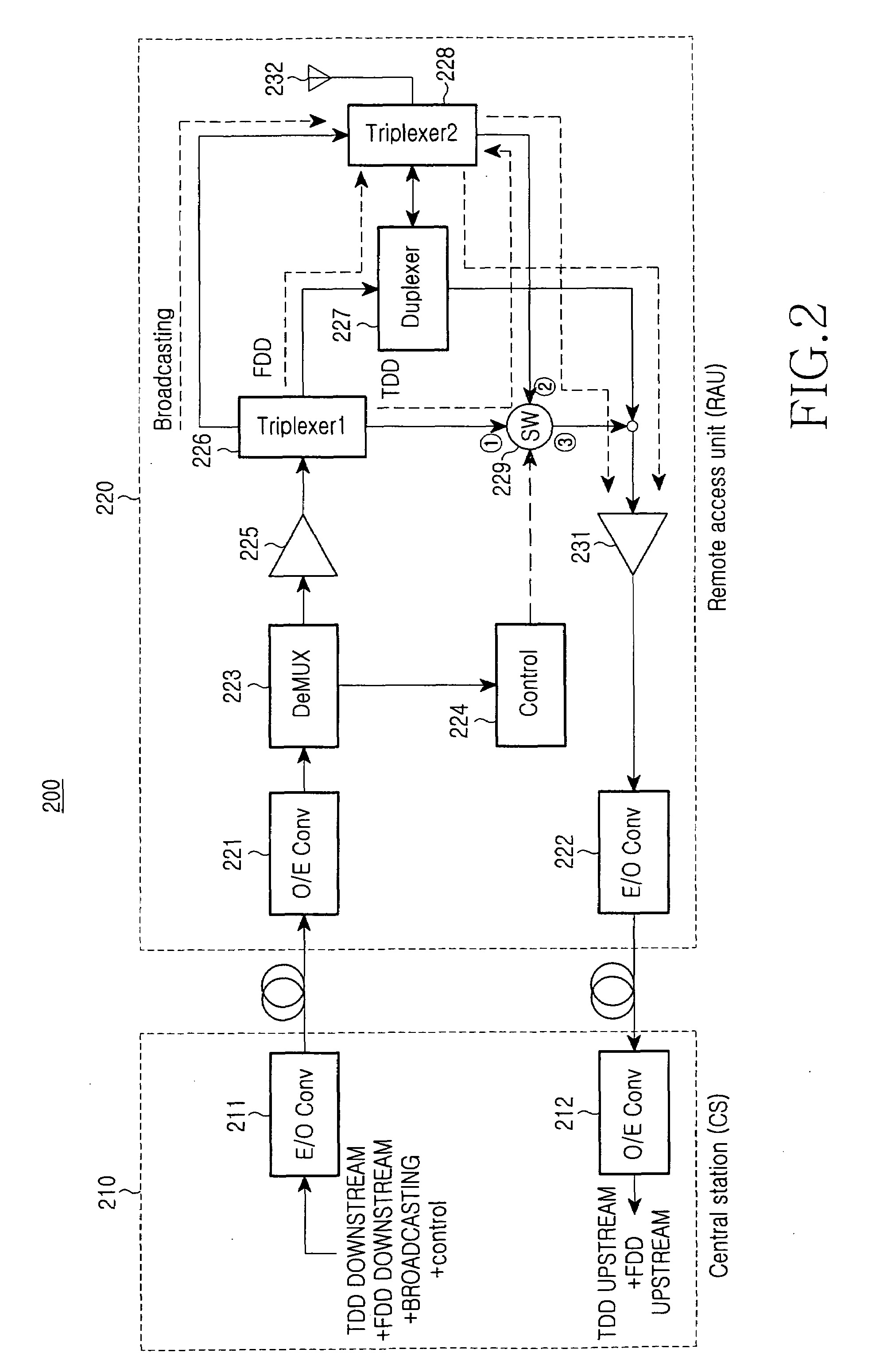

Optical network for bi-directional wireless communication

InactiveUS20070174889A1Prevent degradationTwo-way working systemsSelective content distributionRadio frequencySignal transition

Owner:SAMSUNG ELECTRONICS CO LTD

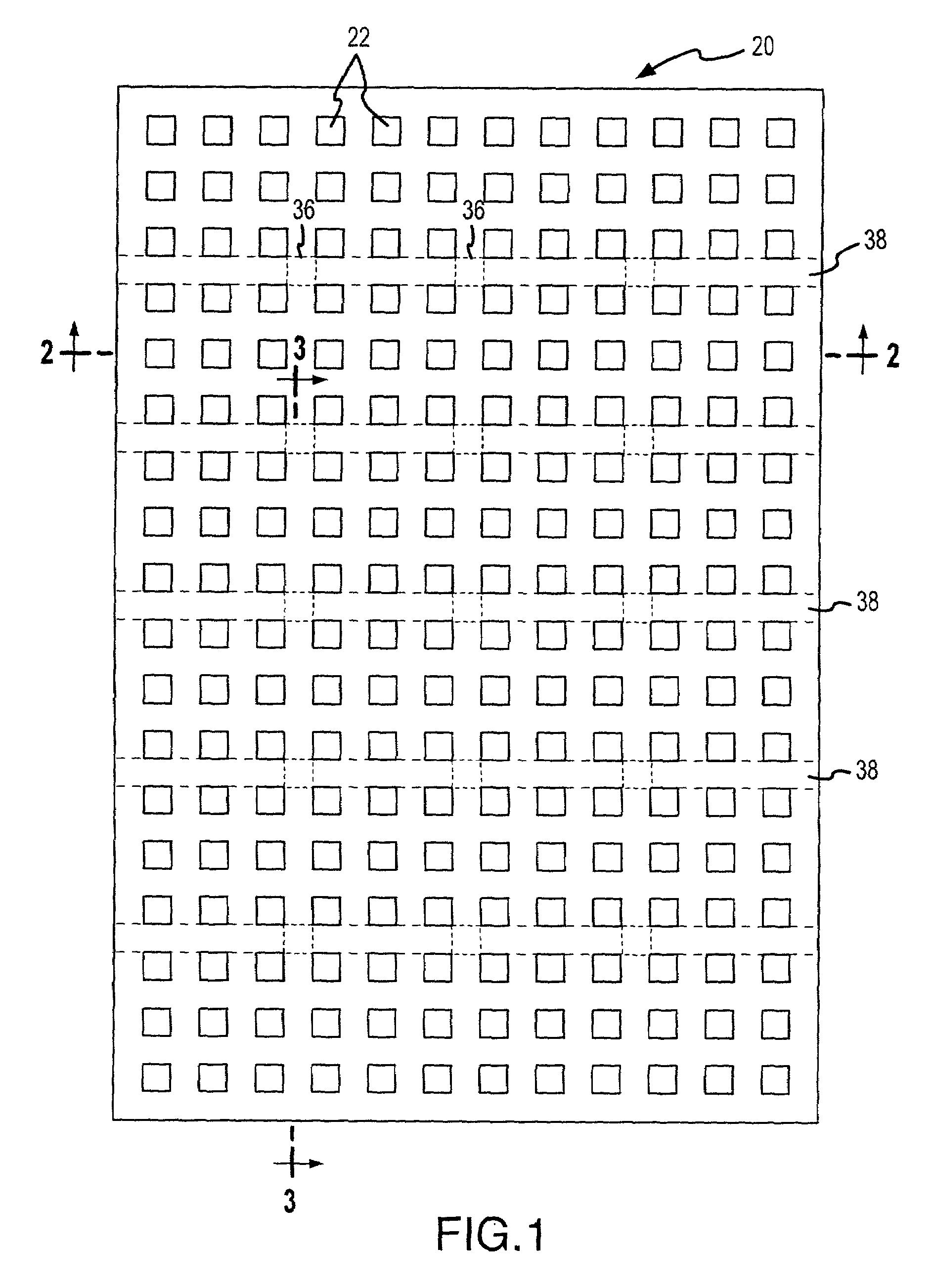

Clean room for semiconductor device

InactiveUS6869457B2Minimize turbulenceReduce runningCombination devicesMechanical apparatusProcess regionProcess engineering

A clean room has an equipment installation area where an apparatus for treating an object to be treated such as a semiconductor wafer is installed, a process area 4 where the object is loaded in or unloaded from the apparatus, and an operation area where operations of the apparatus are executed. The equipment installation area, the process area and the operation area are arranged horizontally in the above-stated order and separated by partitions. These areas are air-conditioned independently of one another. The clean room is thus capable of preventing contamination of the object and a running cost of chemical filters in the clean room is reduced.

Owner:SHARP KK

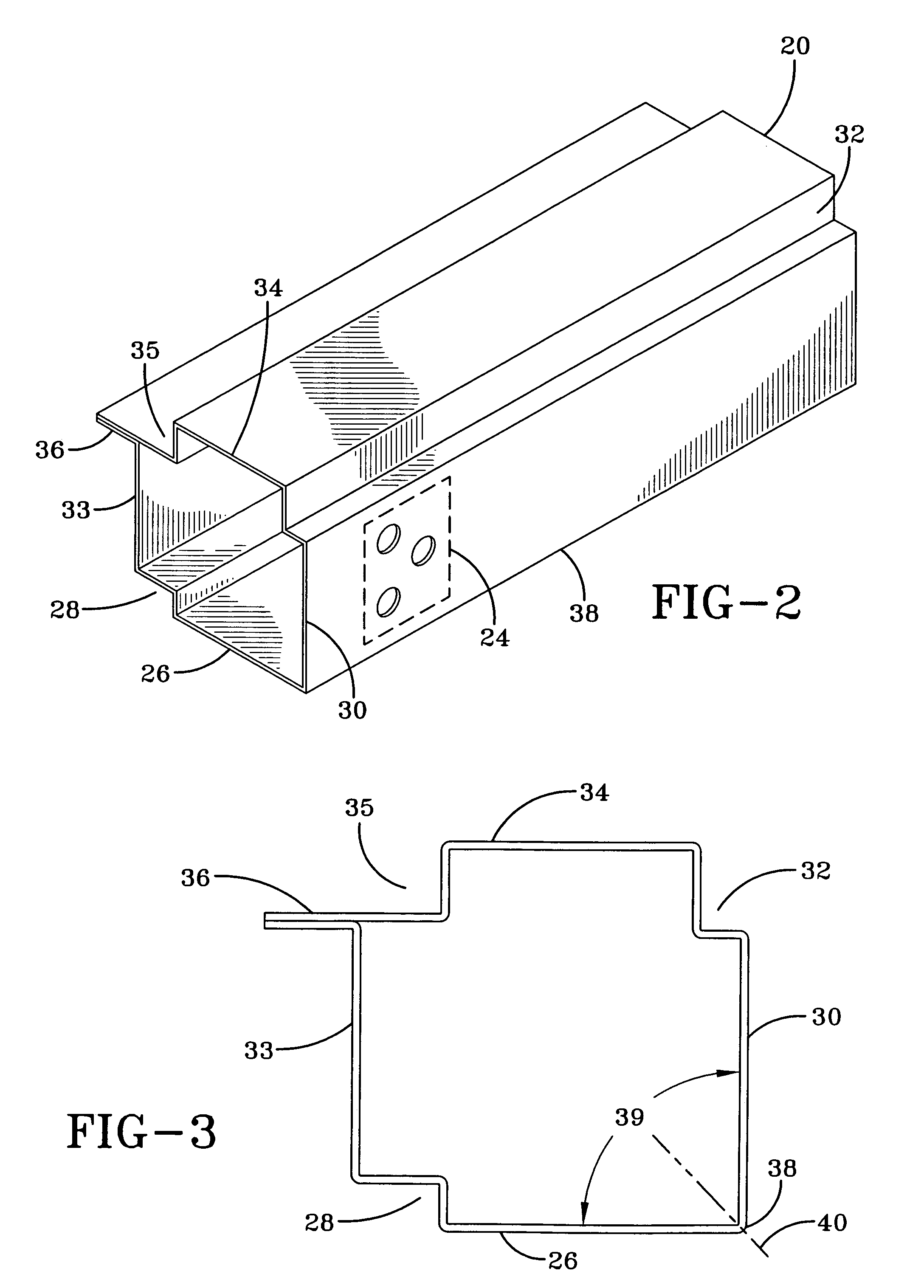

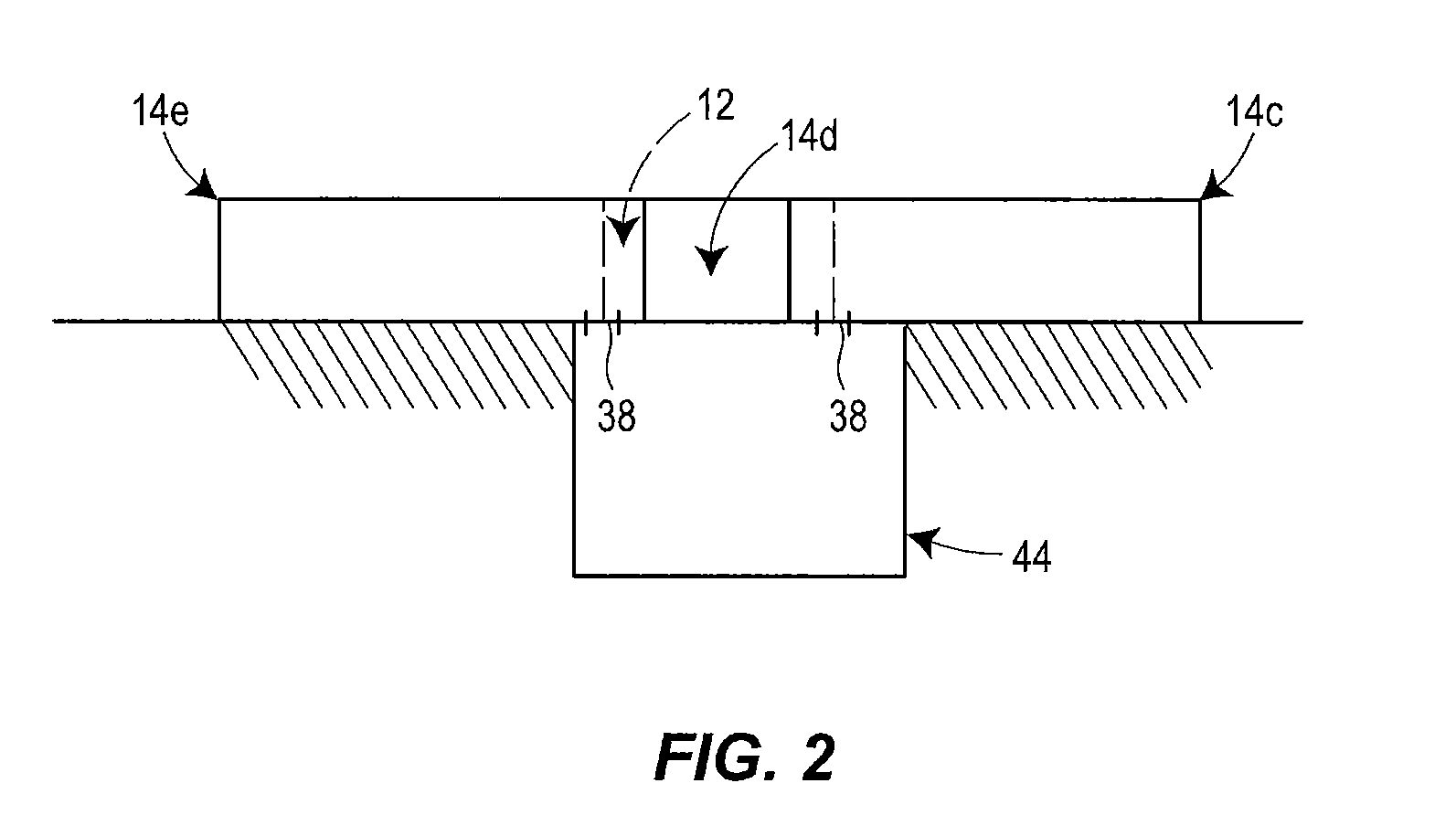

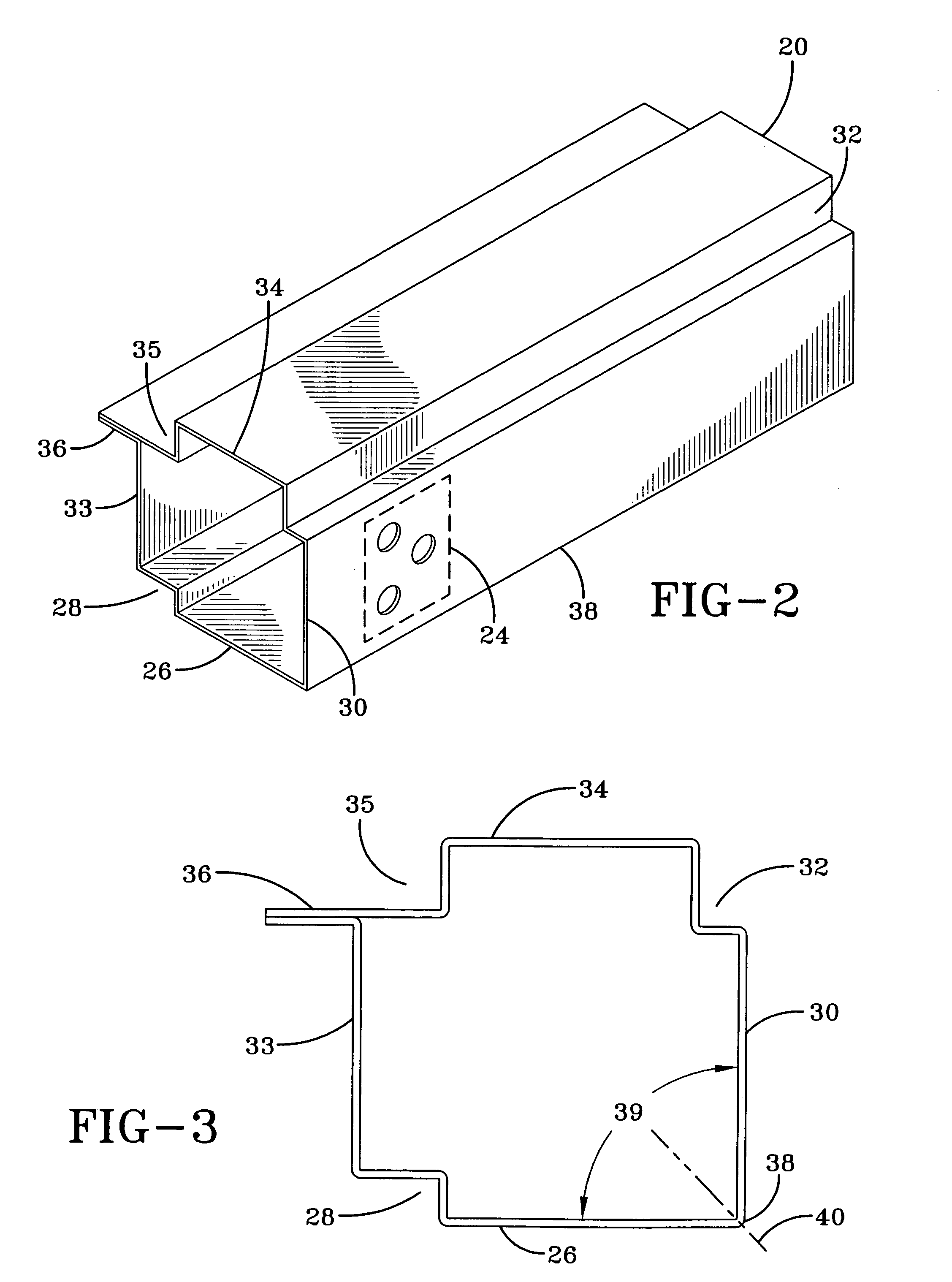

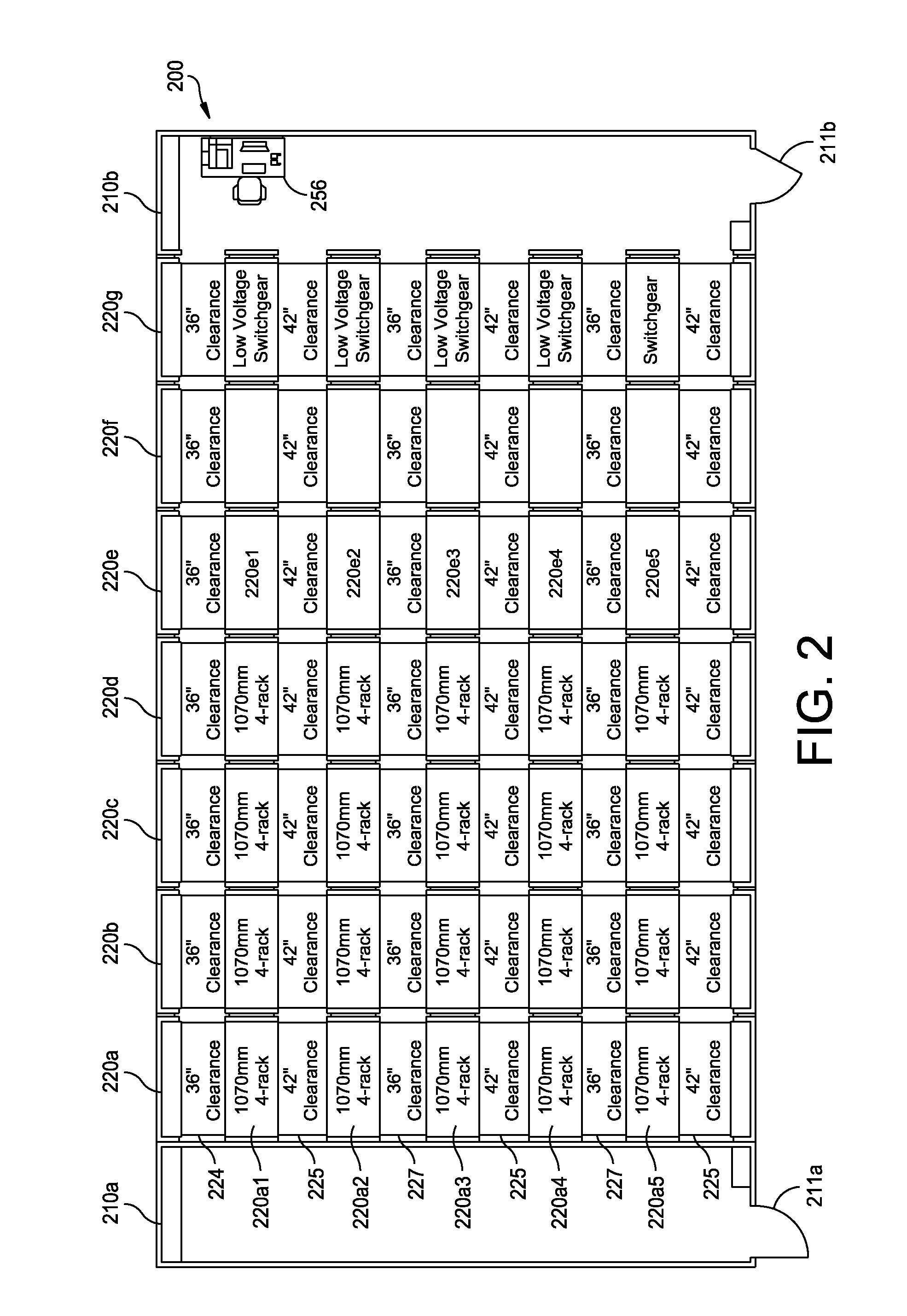

Raceway construction for an air handling unit

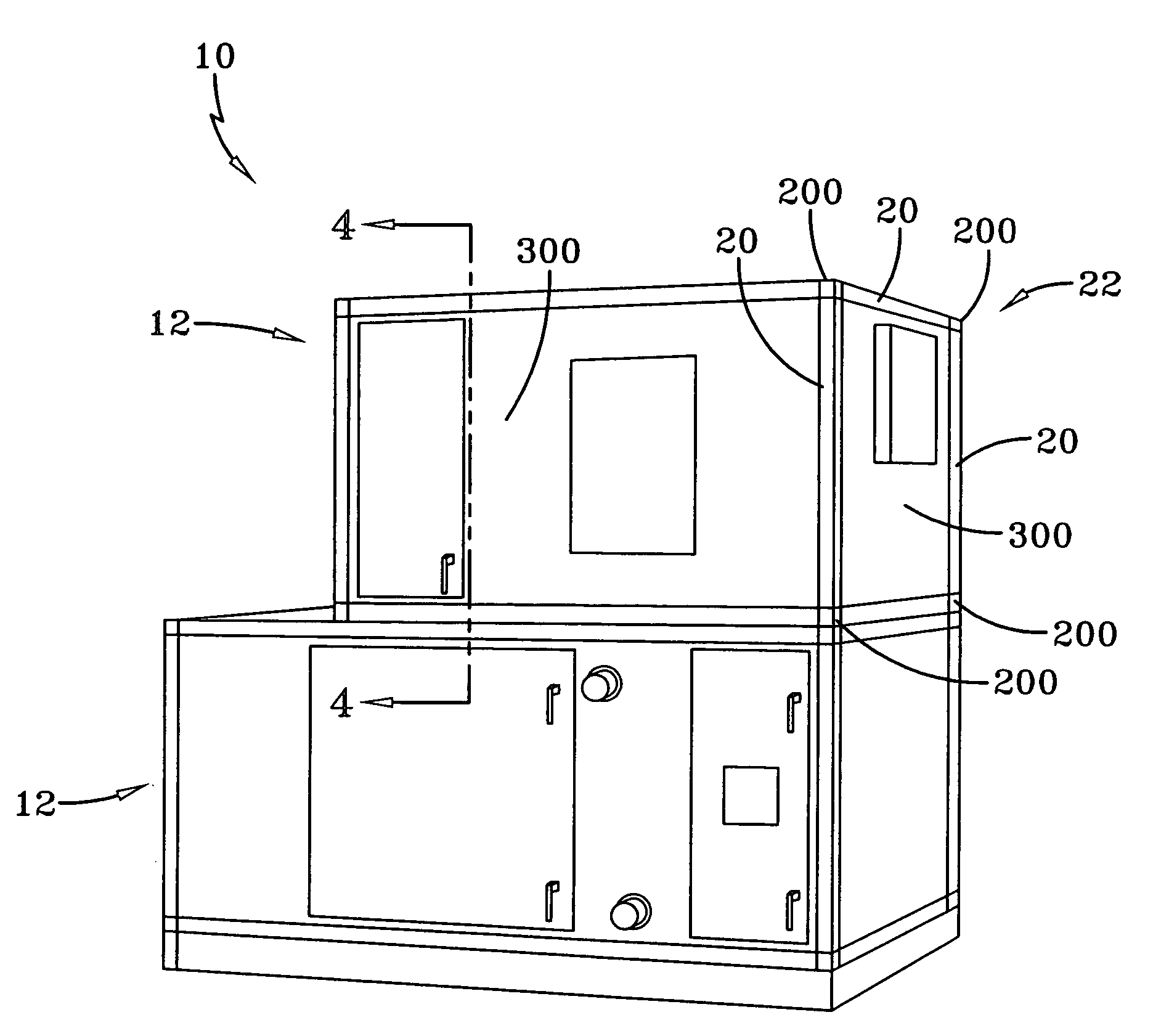

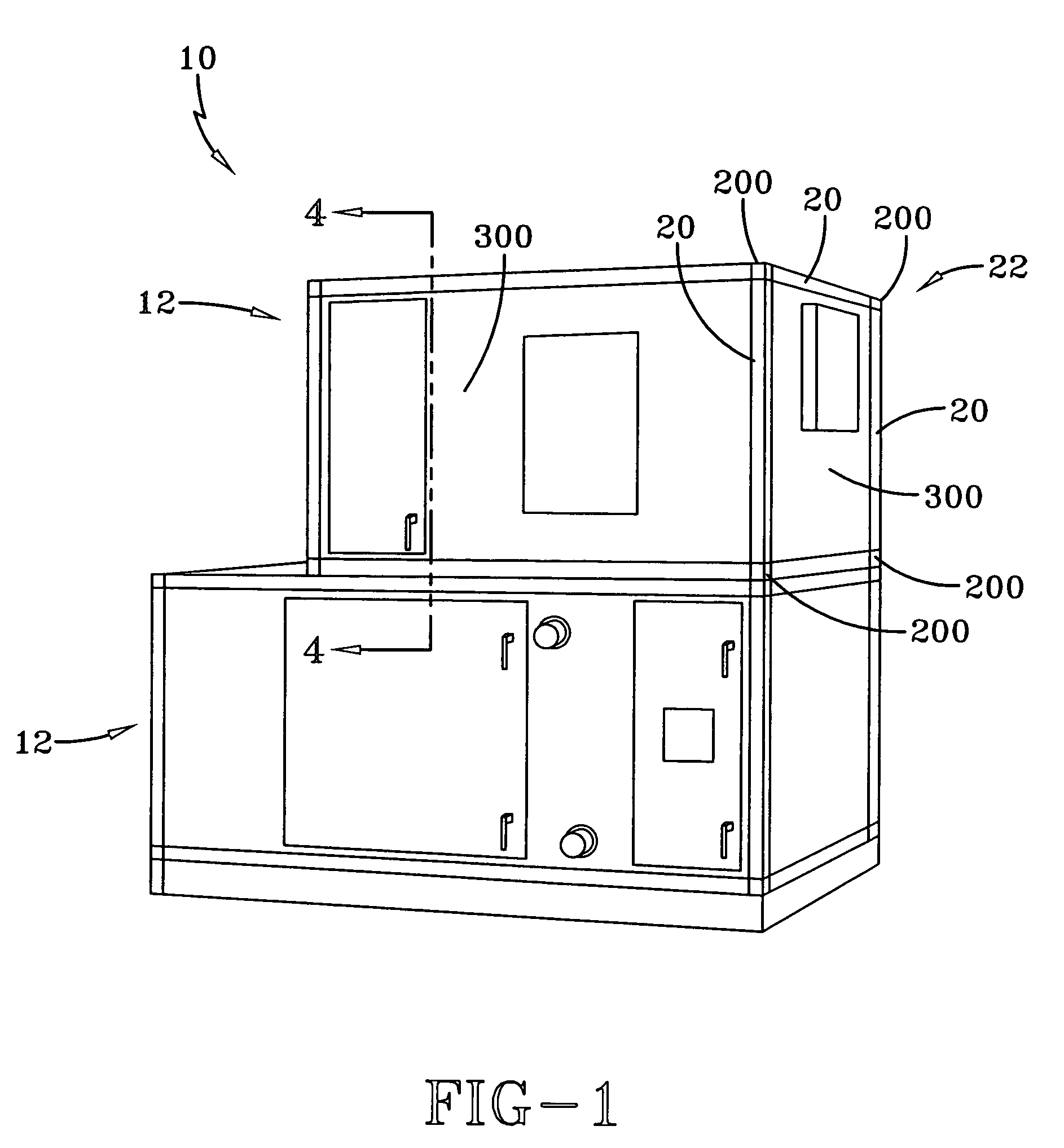

InactiveUS7334377B2Avoid collectingLow thermal conductivityLighting and heating apparatusWallsAir treatmentArchitectural engineering

An air handling unit (AHU) for housing a number of components used in a heating or cooling system to provide forced air for climate control in a particular structure includes a single raceway construction having both low thermal conductivity and enhanced mechanical properties for use with lifting the AHU; a single insulated panel construction having a minimum number of components as well as enhanced mechanical properties for use as the floor in an AHU compartment; to minimize costs associated with fabrication and installation.

Owner:YORK INT CORP

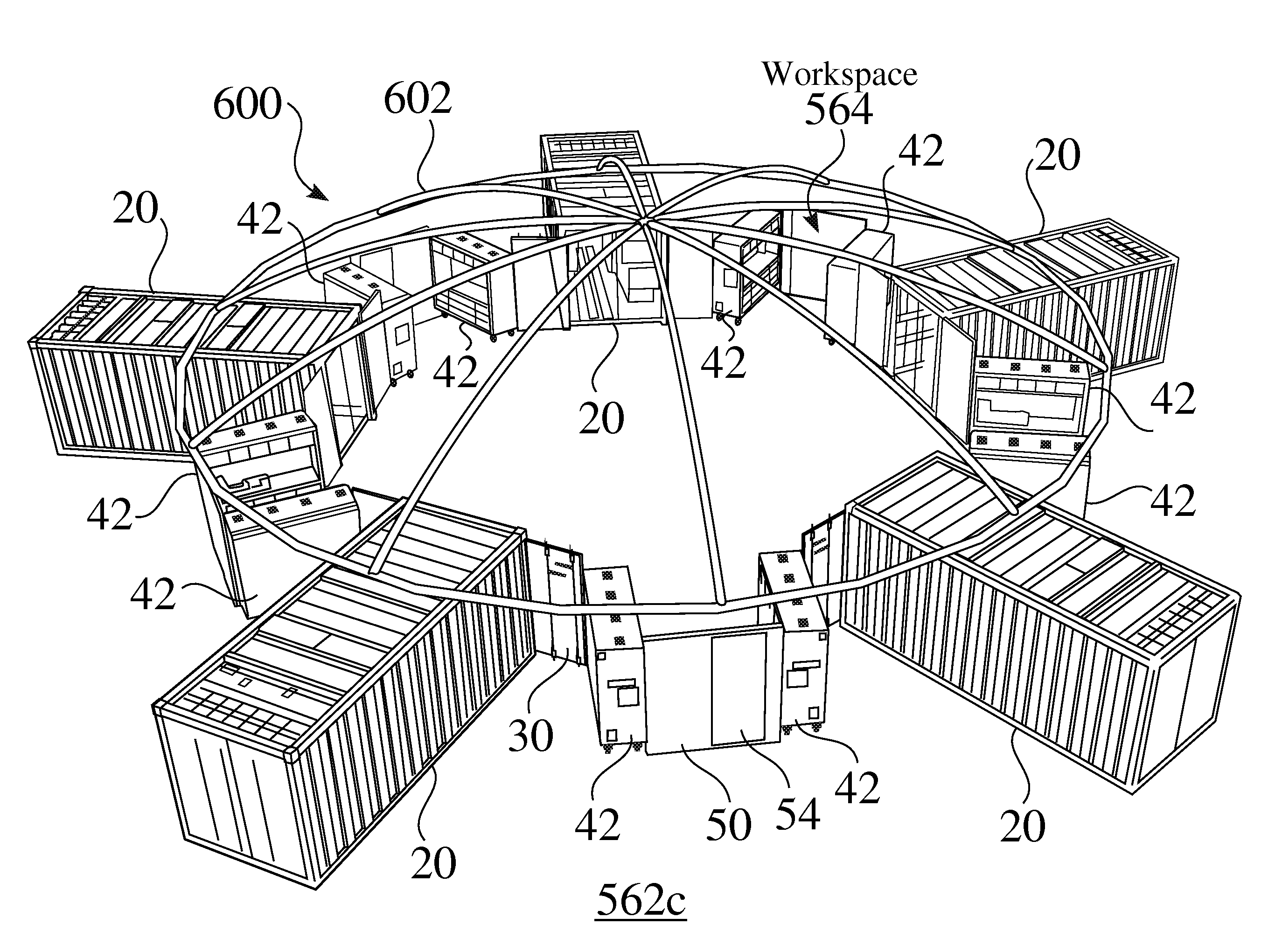

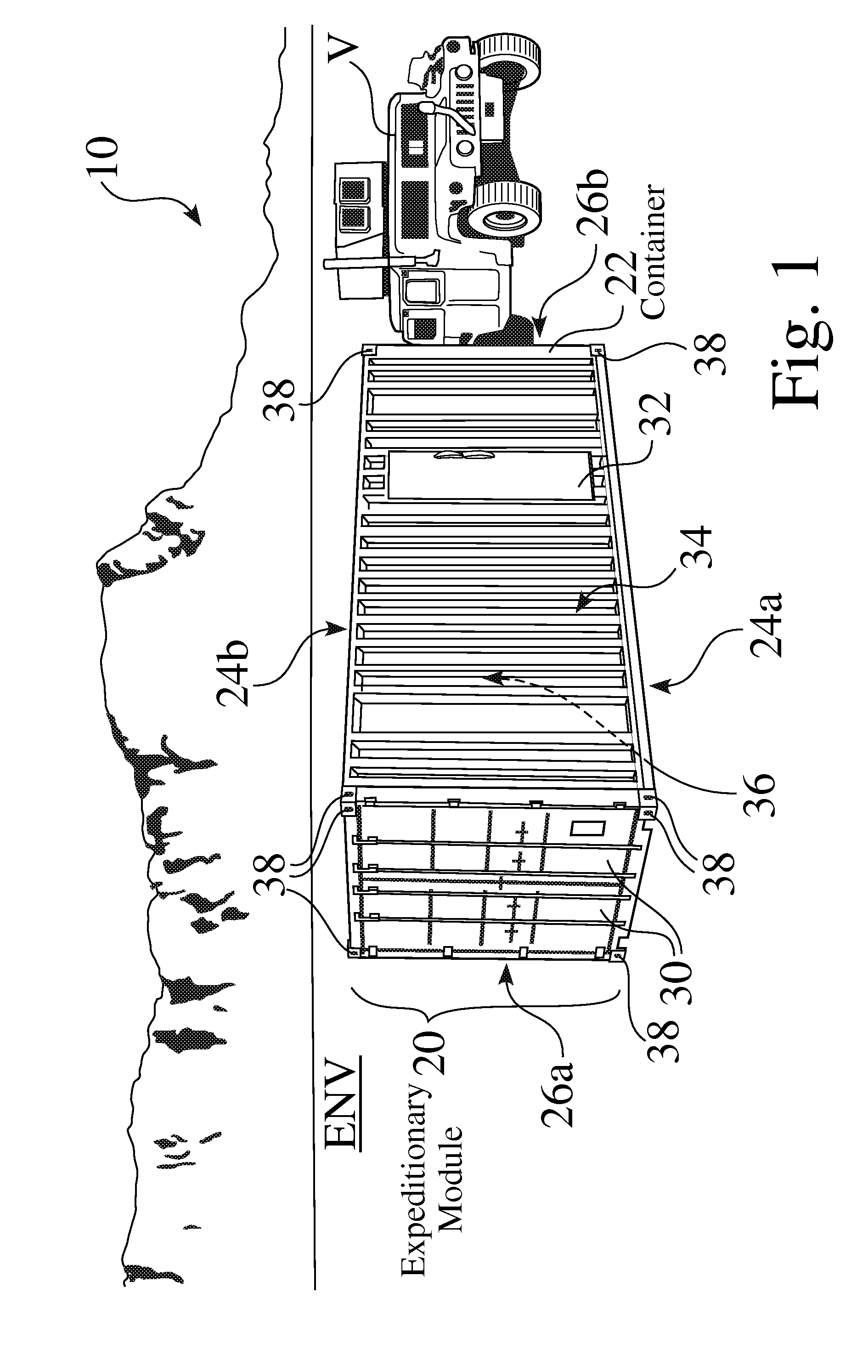

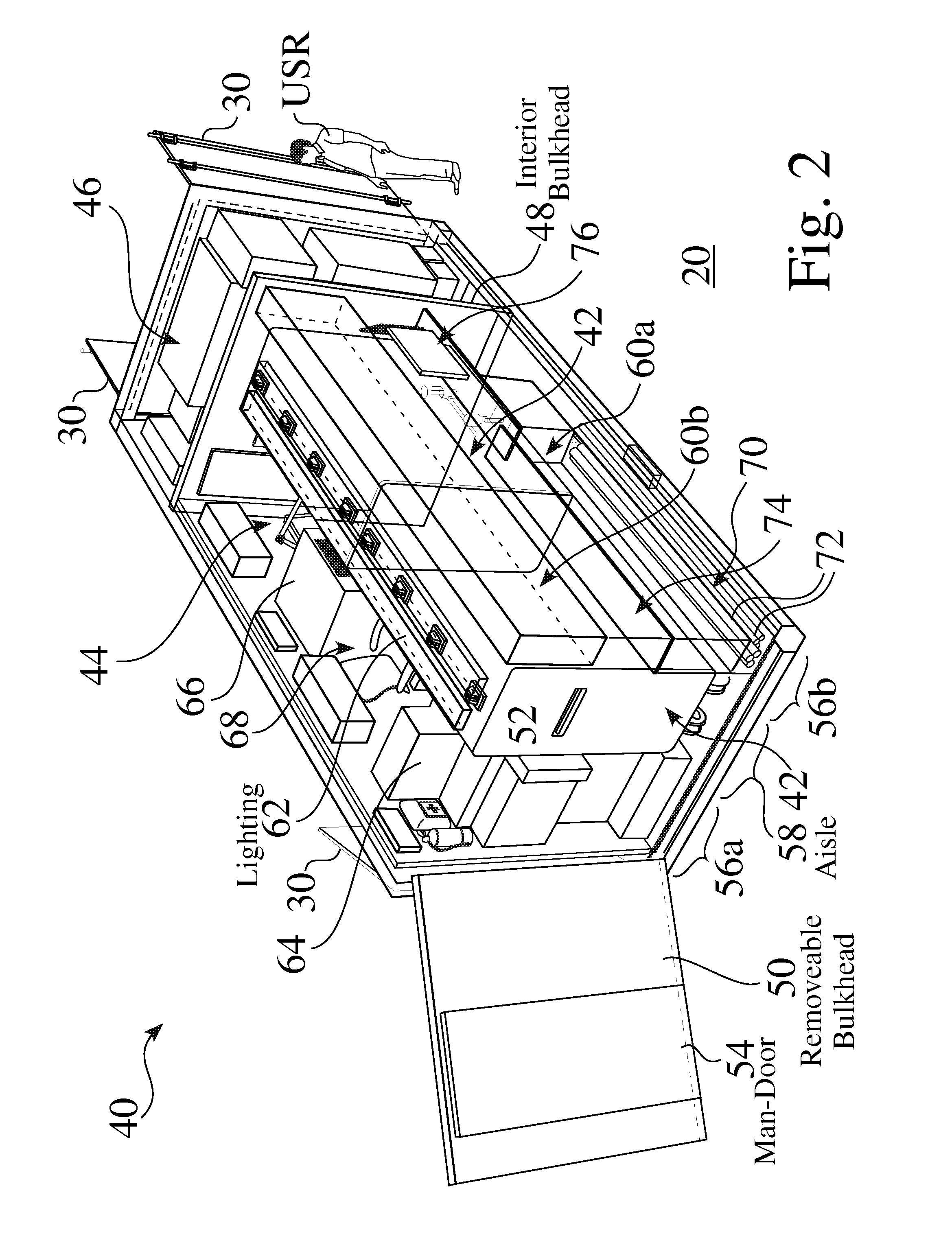

Expeditionary modules, systems and processes having reconfigurable mission capabilities packages

ActiveUS20140008359A1Increase capacityEasy loadingLarge containersArticle unpackingGeneral purposeSupporting system

An expeditionary module comprises one or more mission capabilities package (MCP) carts, to provide a self-contained mission support system, such as in remote and austere environments. The exterior structure of the expeditionary module may to preferably comprise a standard shipping container. One or more MCP carts are stowable within the exterior structure, such as on a U-channel track and I-Beam rail system that runs longitudinally along the floor and ceiling of the exterior structure. The expeditionary module typically comprises a suite of standard equipment, to provide general-purpose functionality. Prior to deployment, one or more MCP carts may preferably be selected for an operation, and are loaded into the expeditionary module, via the U-channel track and I-Beam rail system. Upon arrival at the operation location, personnel readily unload the MCP carts. Additional structures allow personnel to configure one or more MCP carts and containers in a variety of configurations.

Owner:APPLIED MINDS

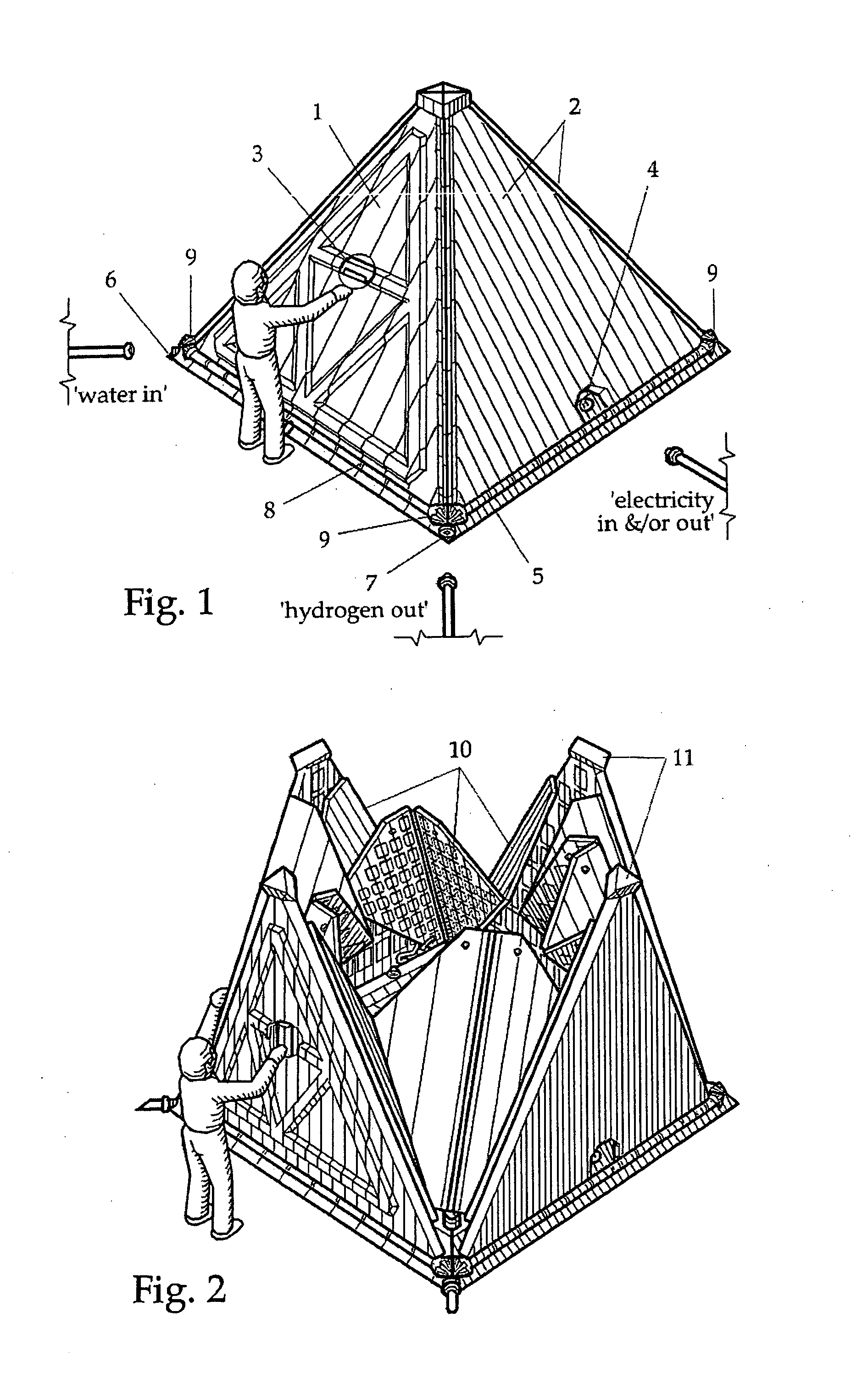

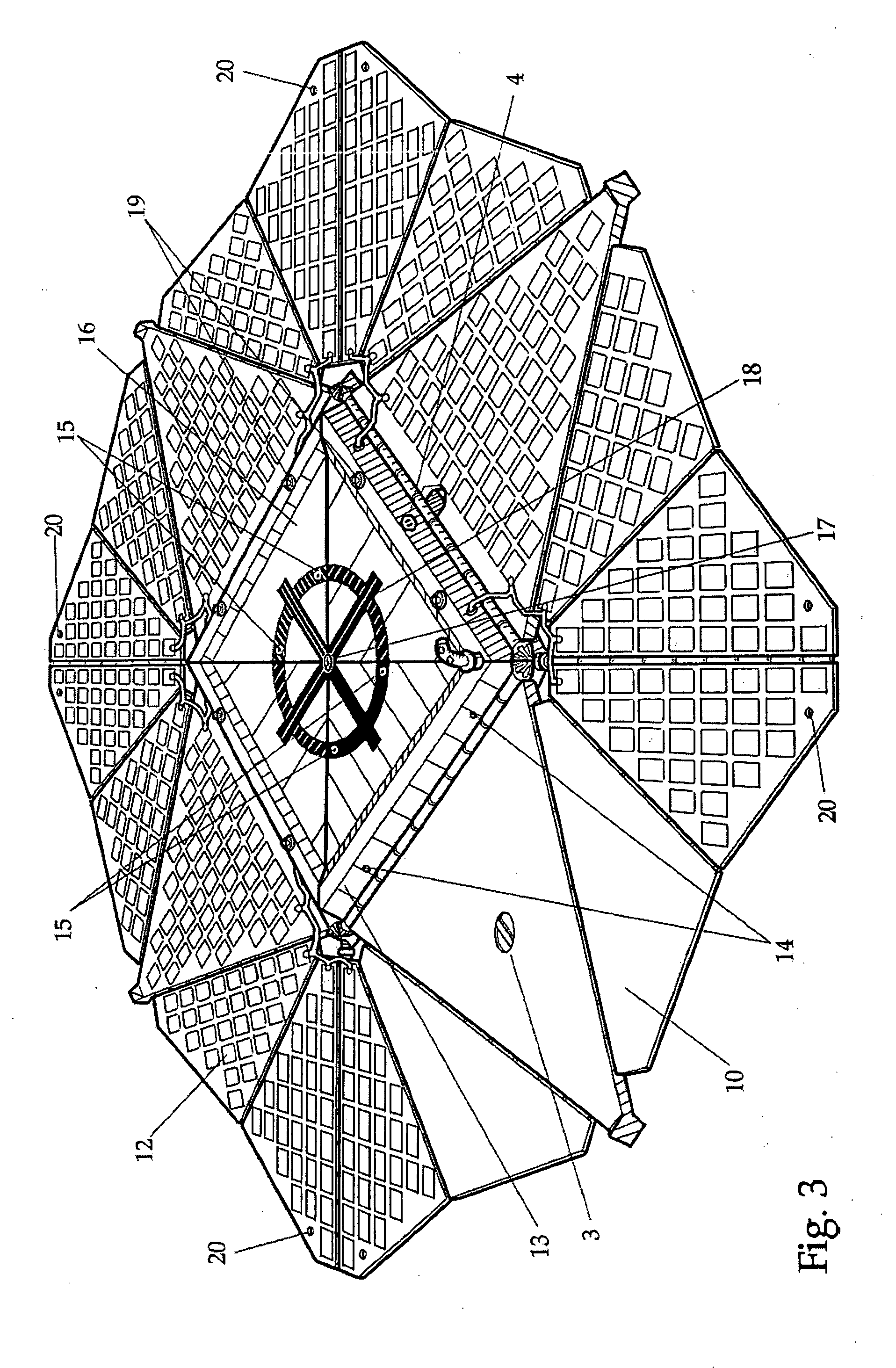

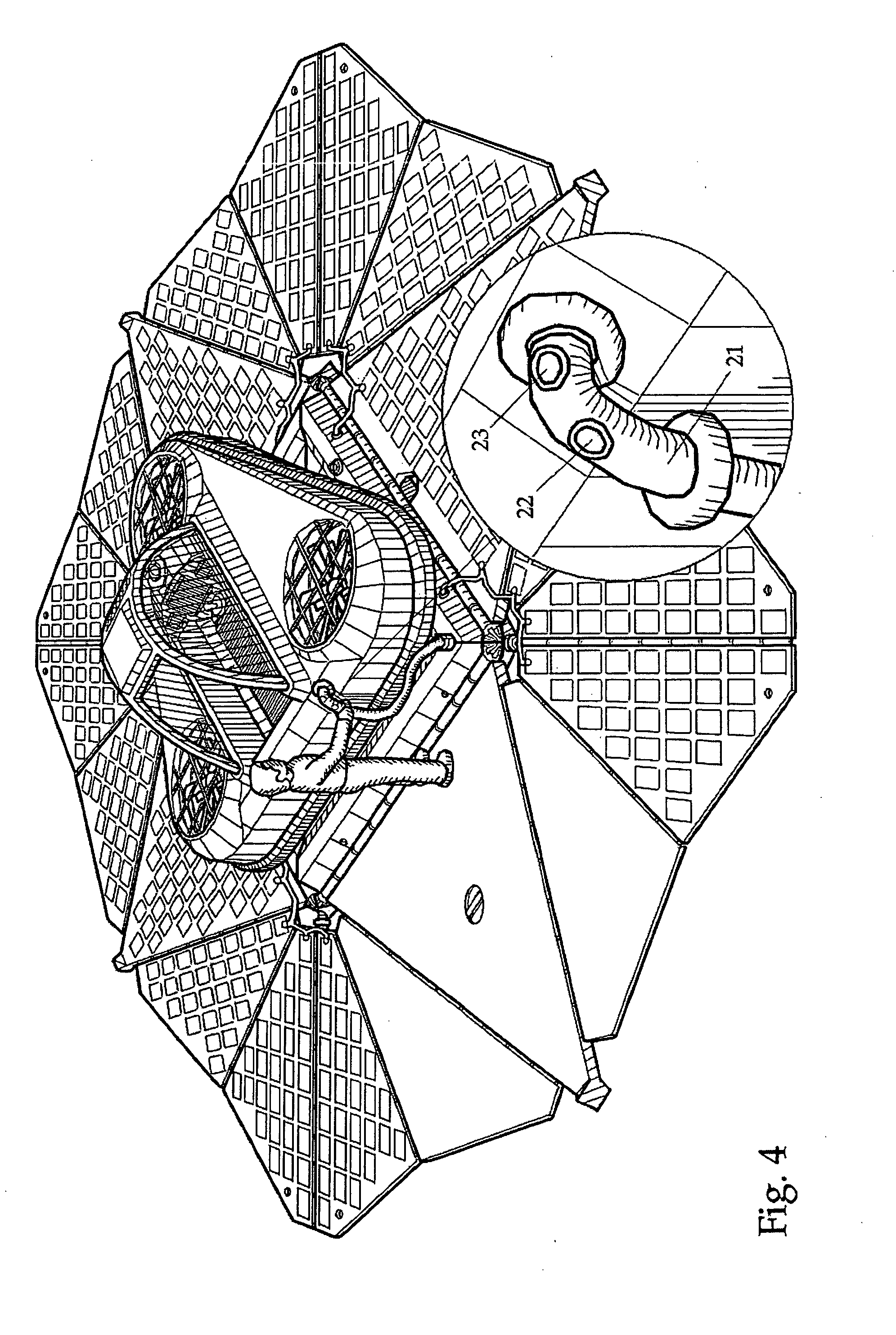

Personal renewable-energy fueling & storage station for electric-powered vehicles

InactiveUS20050231157A1Avoid delayAvoid traffic congestionBatteries circuit arrangementsRailway vehiclesExternal energyHydrogen fuel cell

A personal refueling station for a personal-sized electric vehicle has a polygonal base structure housing a refueling system and a plurality of flat panels hinged thereto which open to form a flat surface and close up to an upright pyramid for storage. The flat panels have solar PV arrays mounted on their inside surfaces which generate electricity from sunlight in the open position. The electricity is used to generate hydrogen for hydrogen-fuel-cell vehicles, or is stored for recharging non-hydrogen electric vehicles. Alternatively, hydrogen or electricity may be provided from an external renewable power source. The station can also have utility hookups to provide excess hydrogen or electricity to an external energy usage, such as a home, business, or other station. The personal refueling station has a compact design that can be installed at home or business locations. It is designed to accommodate a personal-use electric vehicle such as an electric car or cart or a personal VTOL hovercraft. It can be used in a stationary location or transported for remote use, as well as operated by remote control.

Owner:UFOZ

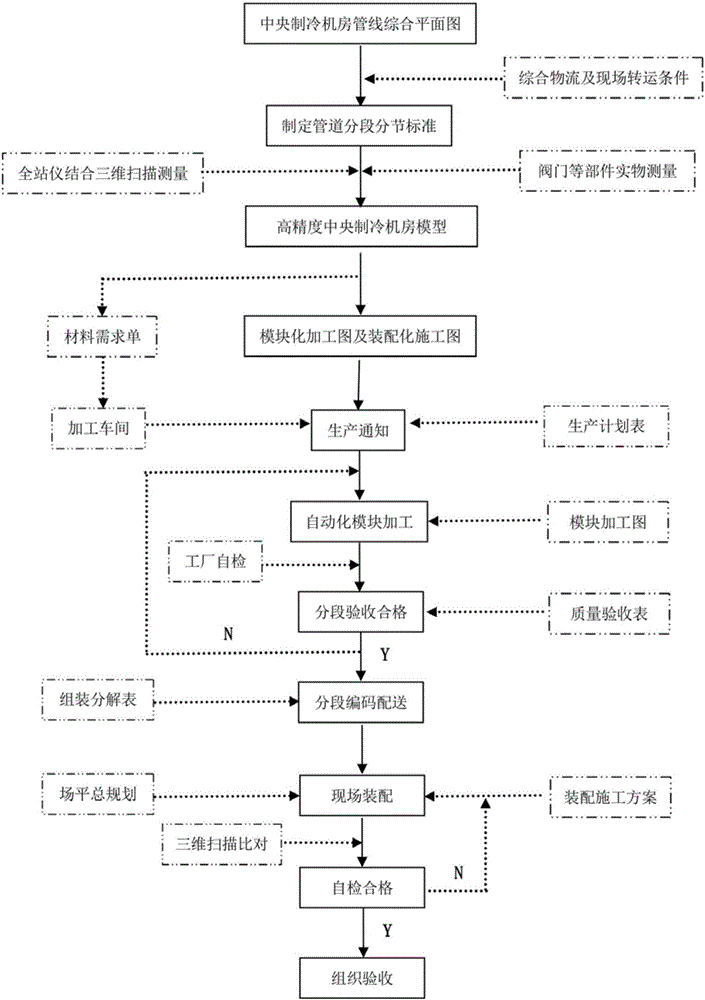

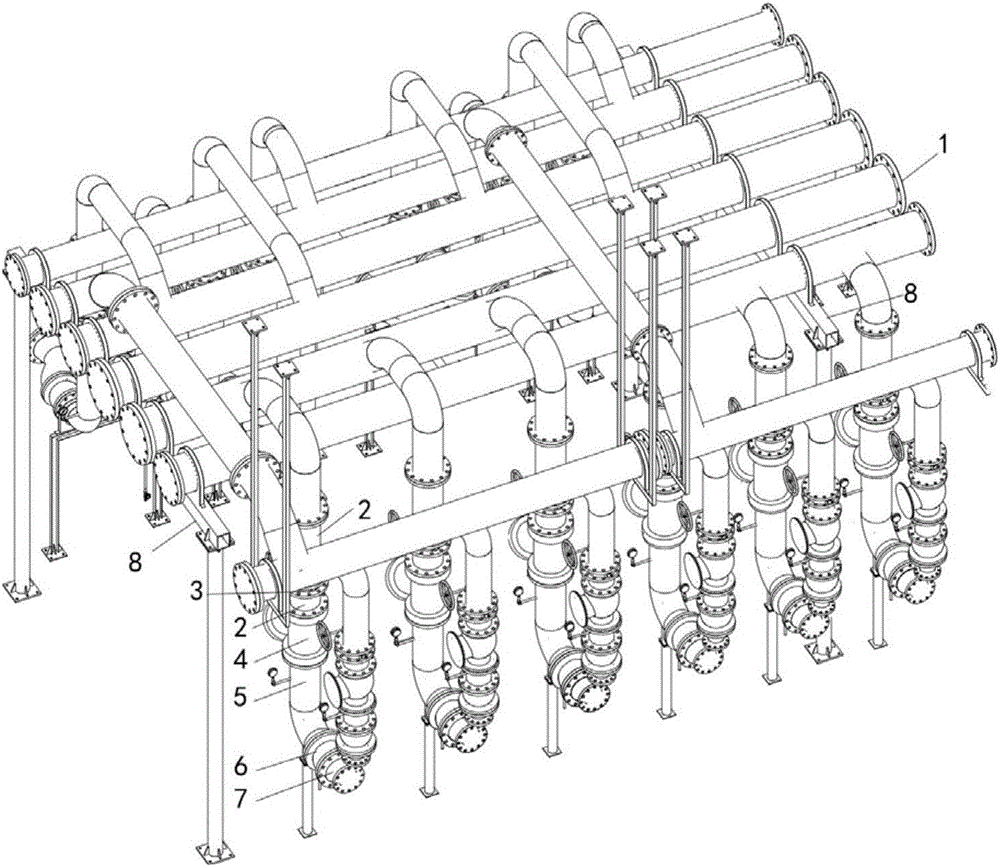

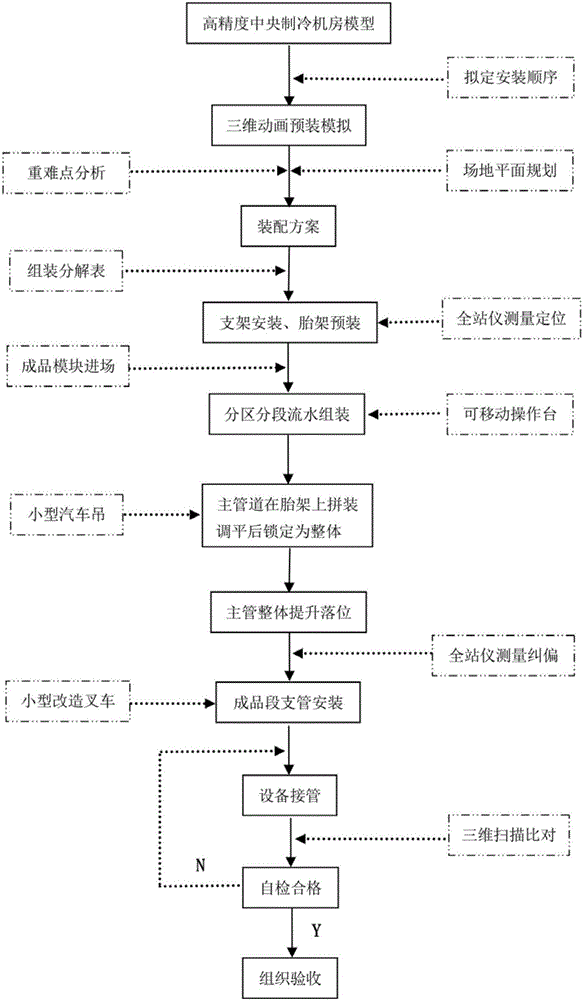

Central refrigeration machine room modular prefabrication and assembled construction method

ActiveCN105888317AError controllableImprove assembly efficiencyGeometric CADSpecial data processing applicationsComputer moduleRefrigeration

The invention discloses a central refrigeration machine room modular prefabrication and assembled construction method. The method comprises: refrigeration machine room standard family storehouse establishment, digital module design, three-dimensional precision control, factory full-automation prefabrication and assembled construction. A standard family storehouse is a central refrigeration machine room complete device, valve and component family storehouse created based on the size of an entity. A digital module is generated after a high-precision BIM model is subjected to scientific segmented encoding. The three-dimensional precision control comprises: rechecking and measuring a central refrigeration machine room building structure, constructing an absolute coordinate system, and ensuring that the model design precision, the processing precision and the field assembly precision are controlled uniformly and reliably. The factory full-automation prefabrication comprises factory production performed according to a digital module processing diagram. The assembled construction comprises segmented flange connection, and integrated lifting and mounting. The central refrigeration machine room modular prefabrication and assembled construction method has the advantages that mounting efficiency of a central refrigeration machine room can be improved, mounting quality and precision are improved, the reproduction and transplantation performances of a standard module design are high, and industrial production conditions are met.

Owner:THE SECOND CONSTR ENG CO LTD OF CHINA CONSTR THIRD ENG BUREAU

Flexible manufacturing system

ActiveUS8584349B2Increase supplyDischarging wasteSpace heating and ventilationTreatment involving filtrationFlexible manufacturing systemProcess engineering

Owner:XOMA (US) LLC

Raceway construction for an air handling unit

InactiveUS20050034390A1Avoid collectingLow thermal conductivityWallsLighting and heating apparatusAir treatmentForced-air

An air handling unit (AHU) for housing a number of components used in a heating or cooling system to provide forced air for climate control in a particular structure includes a single raceway construction having both low thermal conductivity and enhanced mechanical properties for use with lifting the AHU; a single insulated panel construction having a minimum number of components as well as enhanced mechanical properties for use as the floor in an AHU compartment; to minimize costs associated with fabrication and installation.

Owner:YORK INT

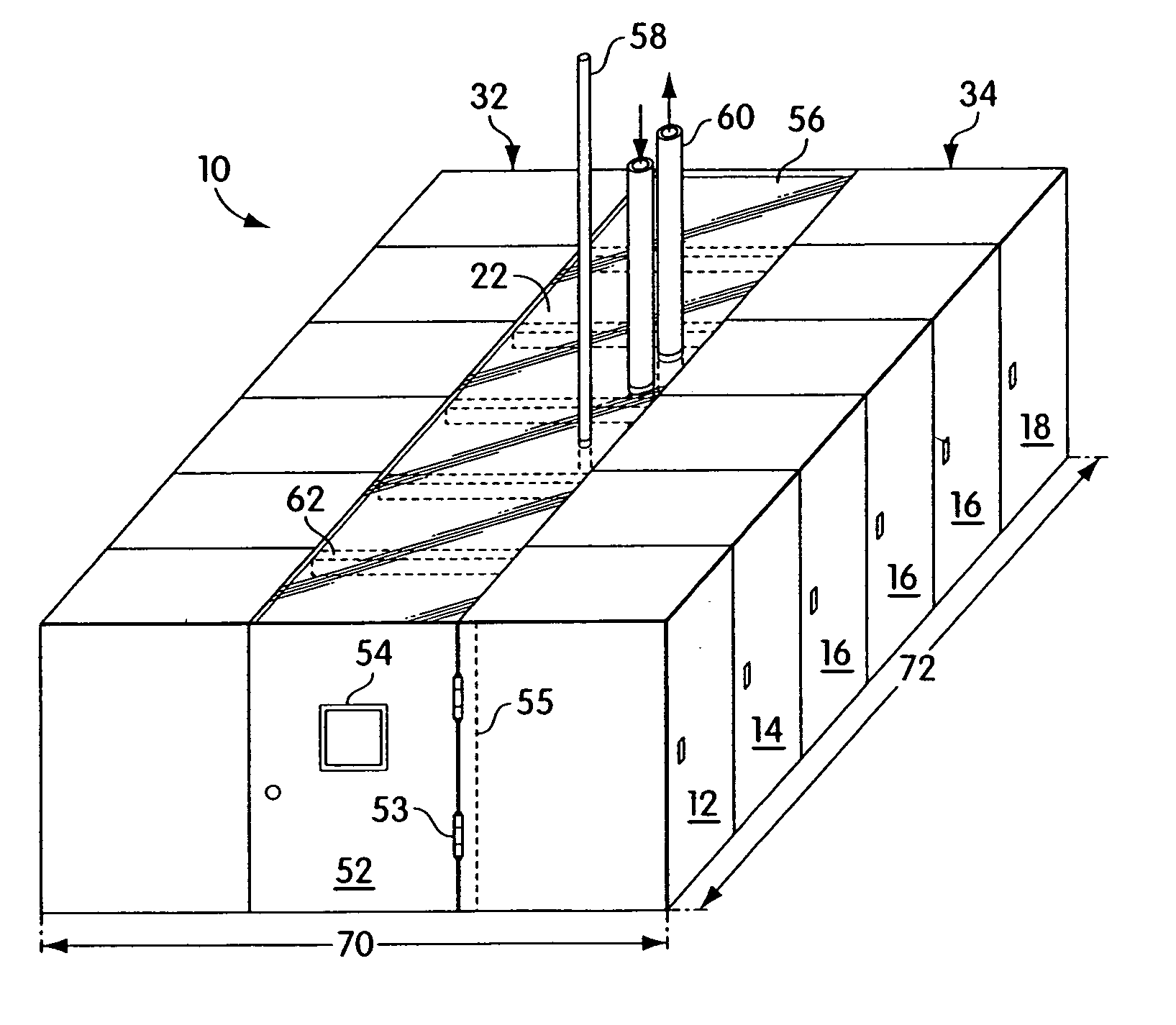

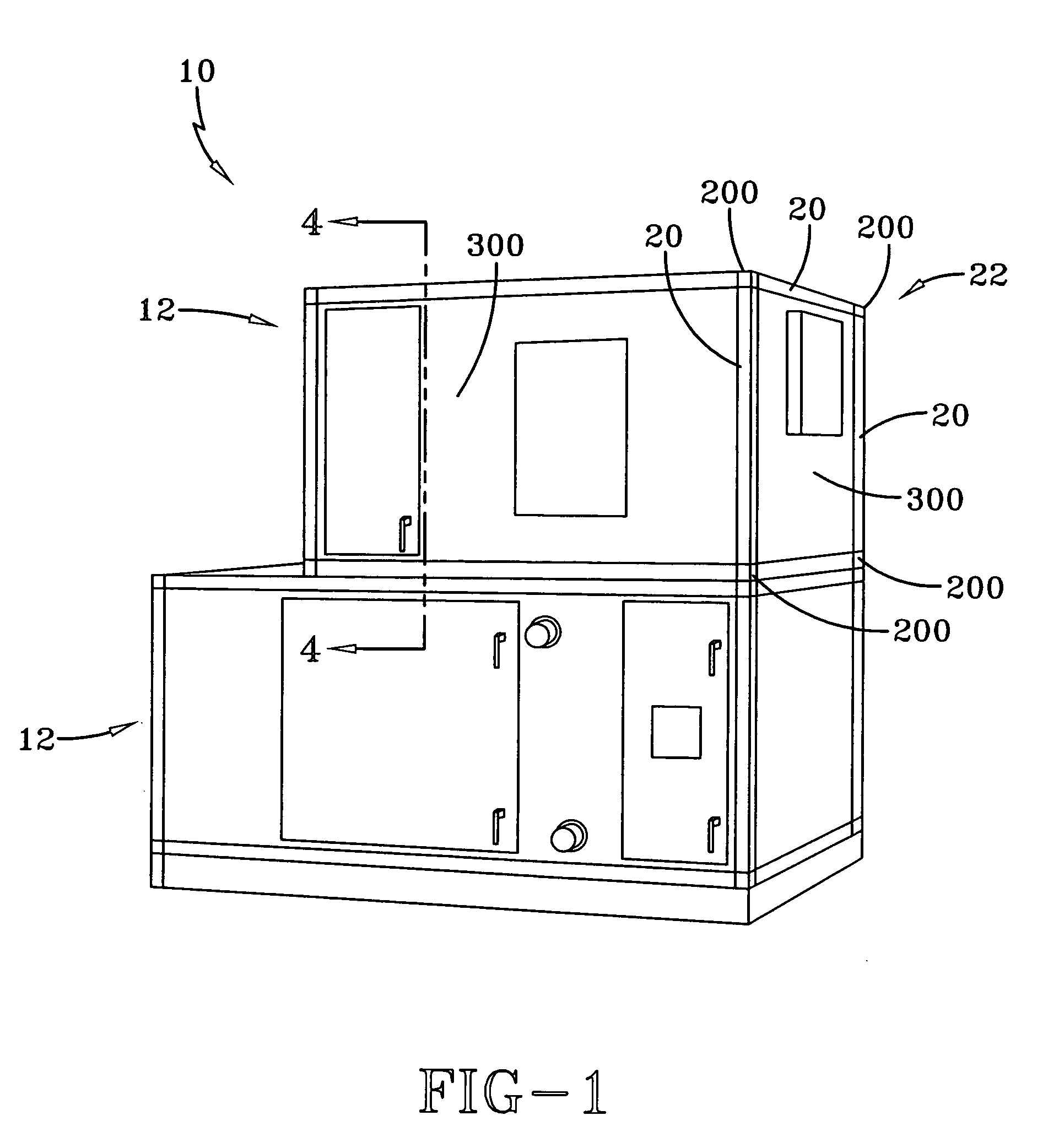

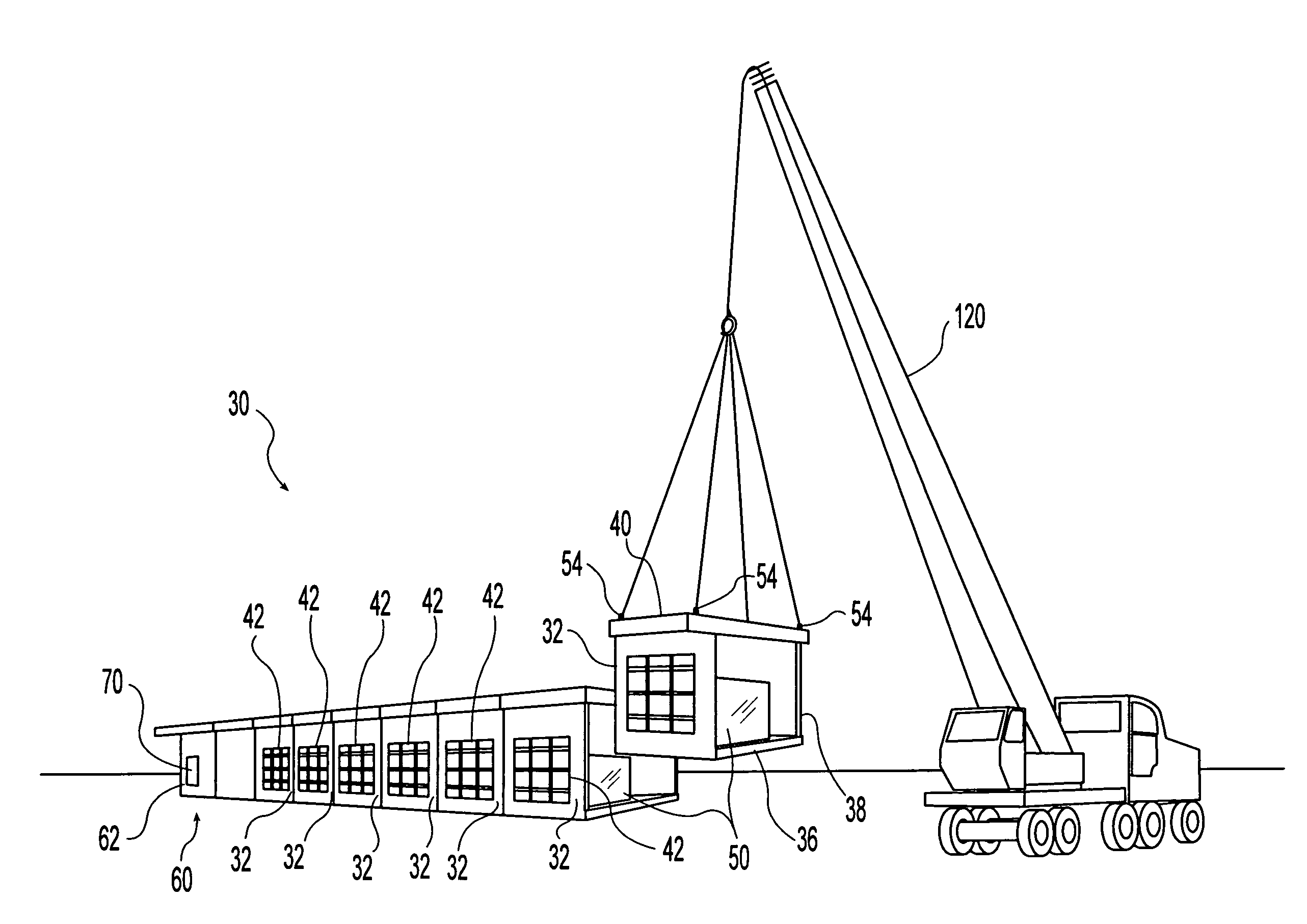

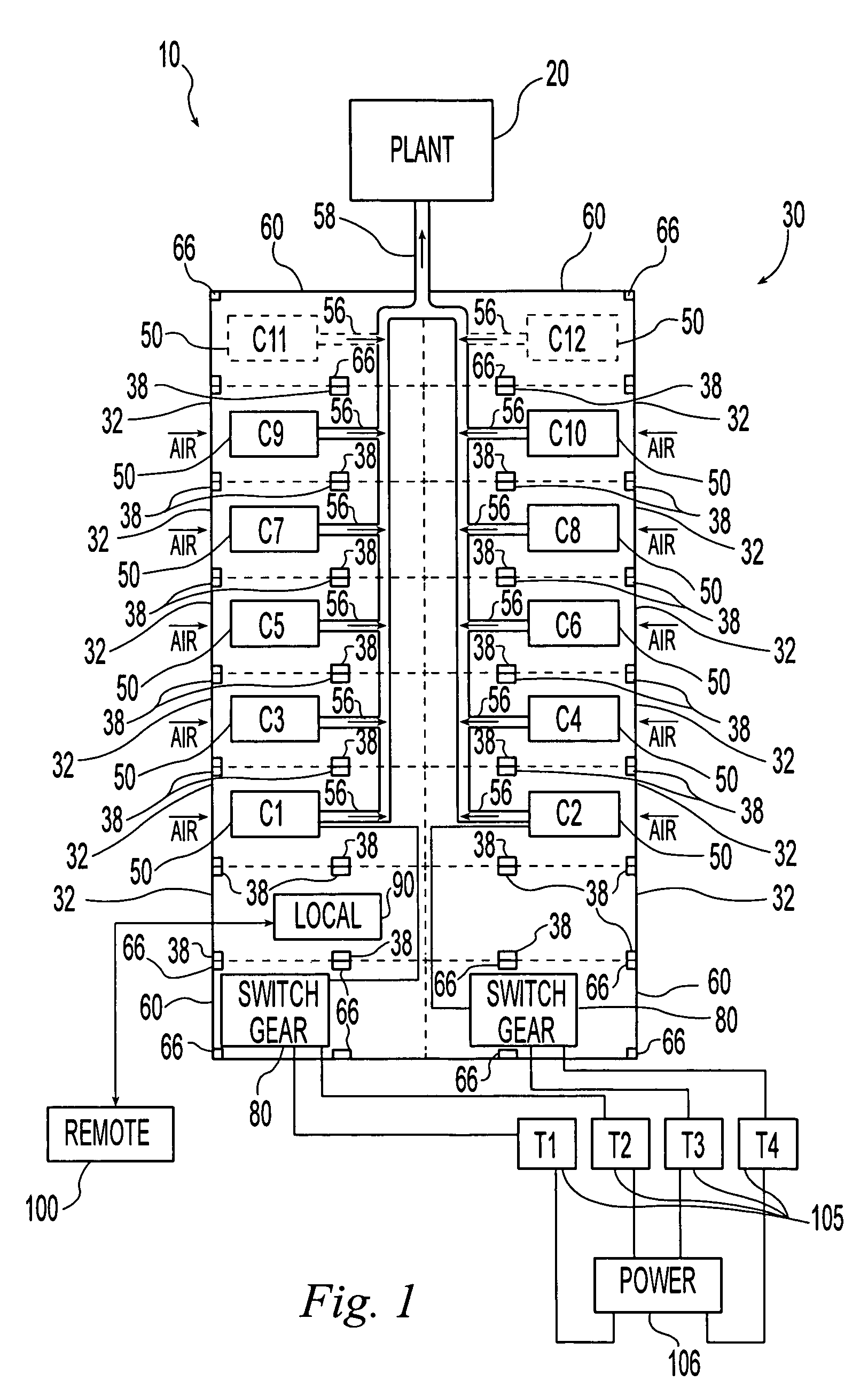

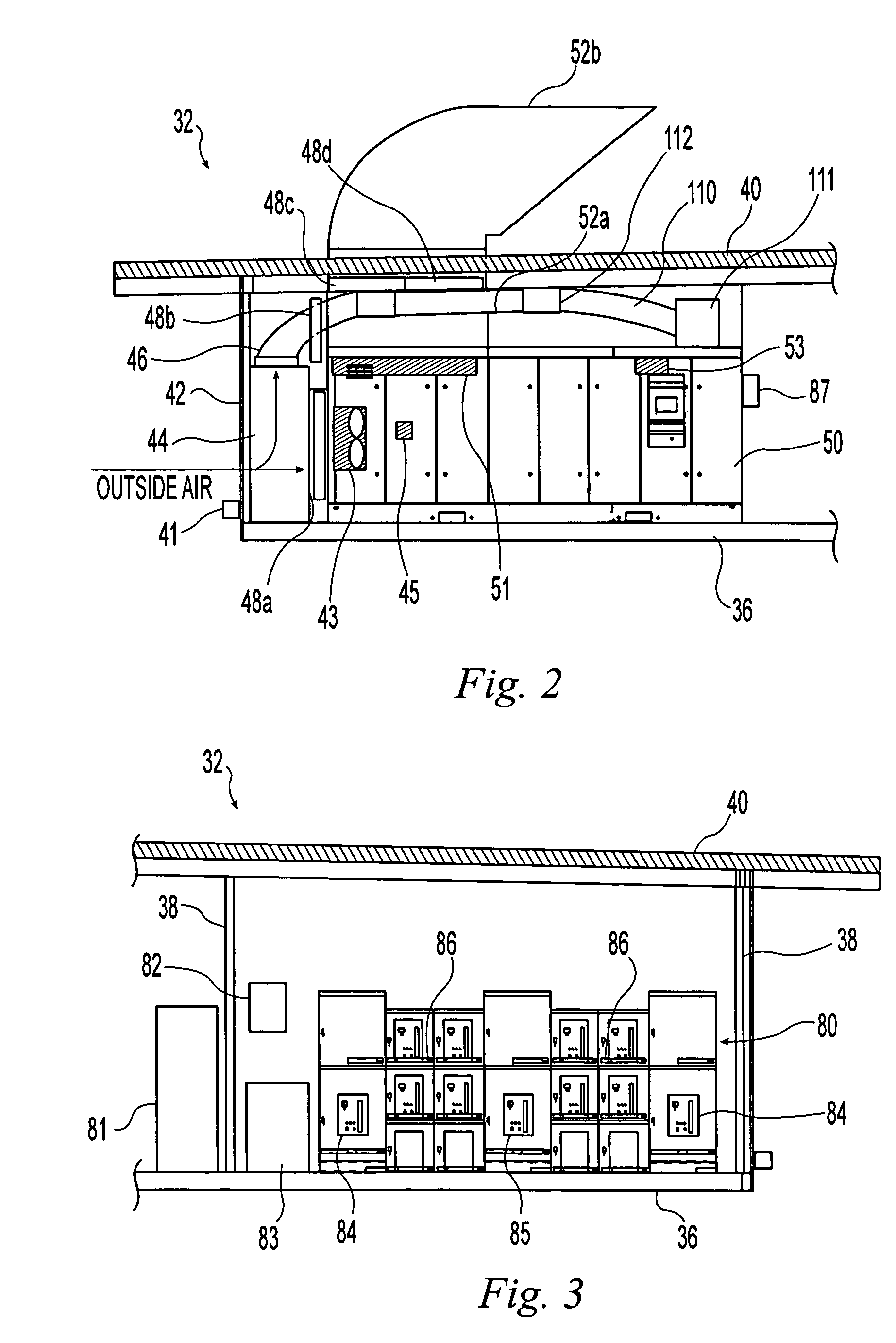

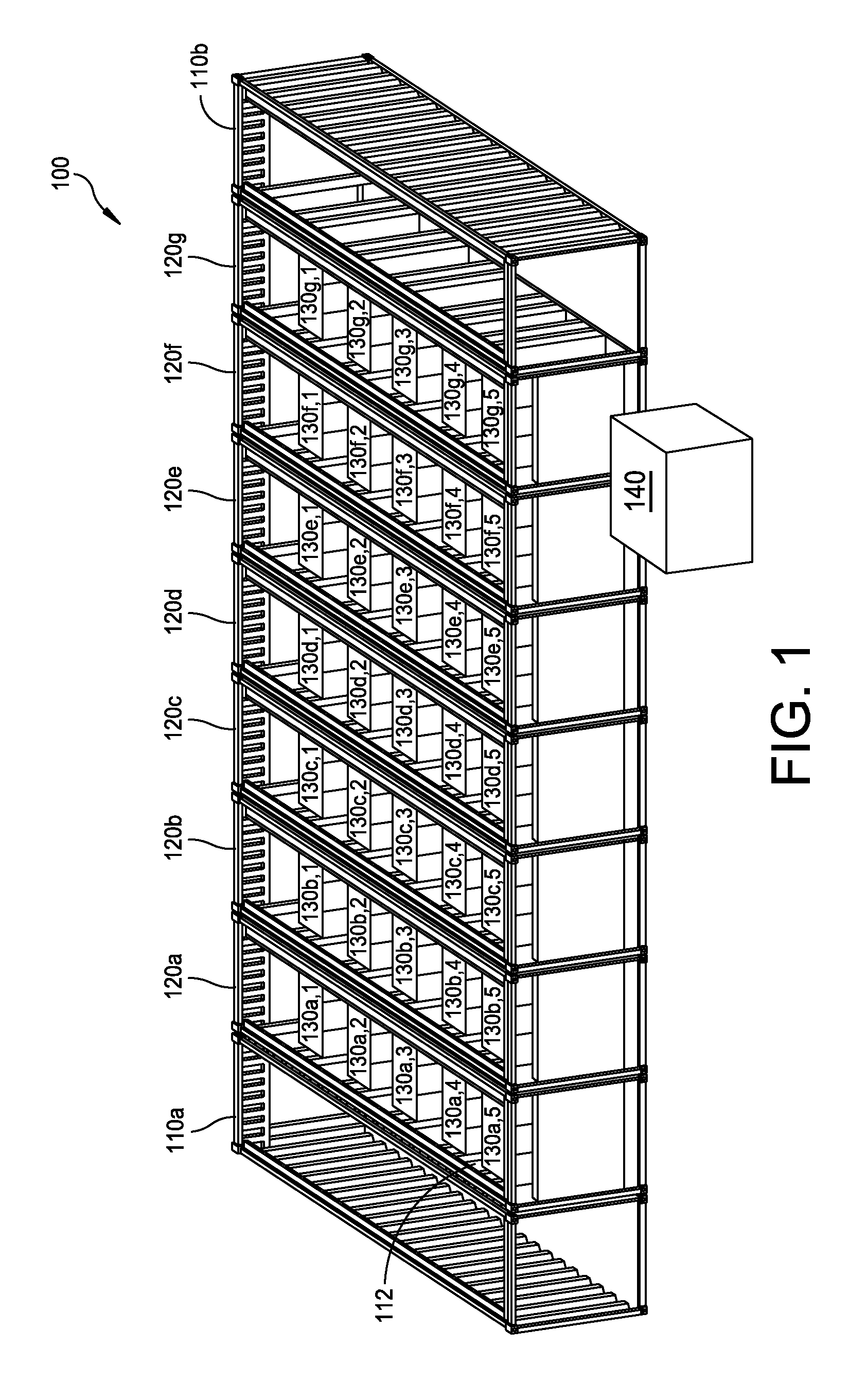

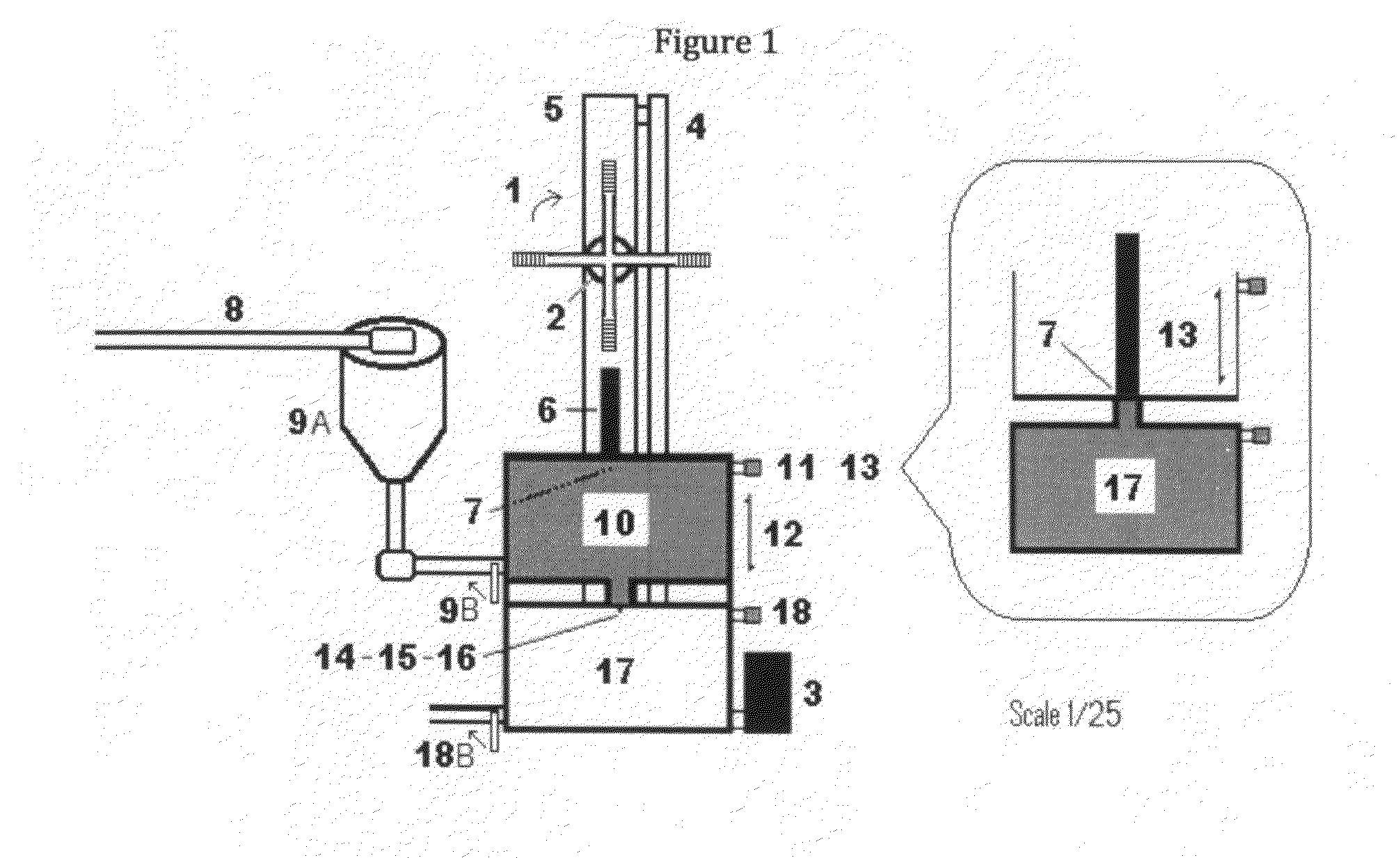

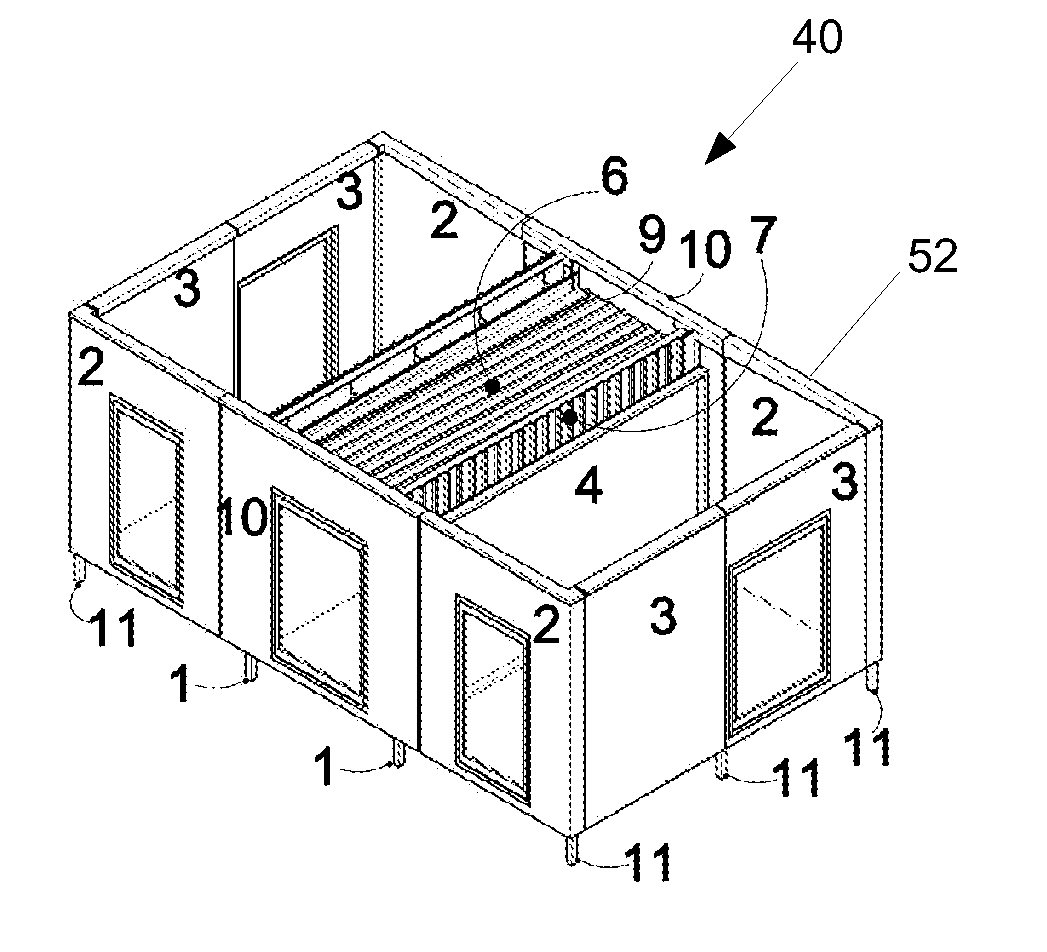

Modular industrial equipment facility

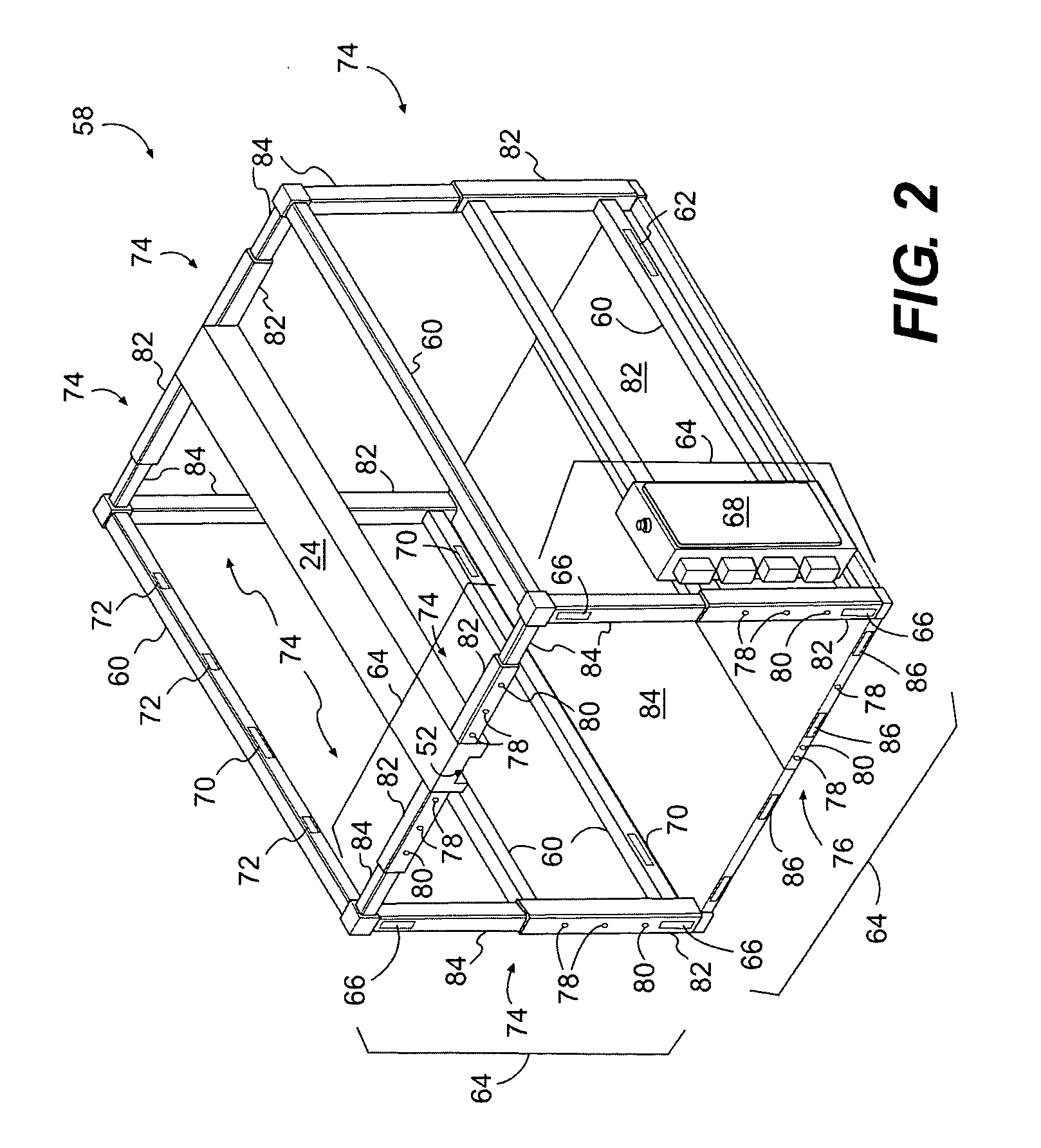

InactiveUS20070094946A1Output of the industrial equipment facility of this invention may be increased or reducedPublic buildingsSpecial buildingControl systemIndustrial equipment

A modular industrial equipment facility is provided. This facility includes a plurality of pre-assembled, portable modules that may further include a plurality of internal modules, and a plurality of terminal modules for connecting to the plurality of internal modules, wherein each module may be configured to operate either in combination with or independent of the other modules. These modules are typically intended for use with heavy, industrial grade equipment. The internal modules and terminal modules may be arranged to form a single, integrated structure that has the appearance of a permanent, non-modular building. This invention may also include a computerized monitoring and control system that may further include a local component that monitors and controls the operation of equipment that may be housed in the various modules; and a remote monitoring and control component that is capable of monitoring and controlling the operation of the equipment in the various modules. Pre-installed ductwork and computerized air handling allow the facility to be expanded or contracted without significant structural modifications.

Owner:OHIO TRANSMISSION CORP

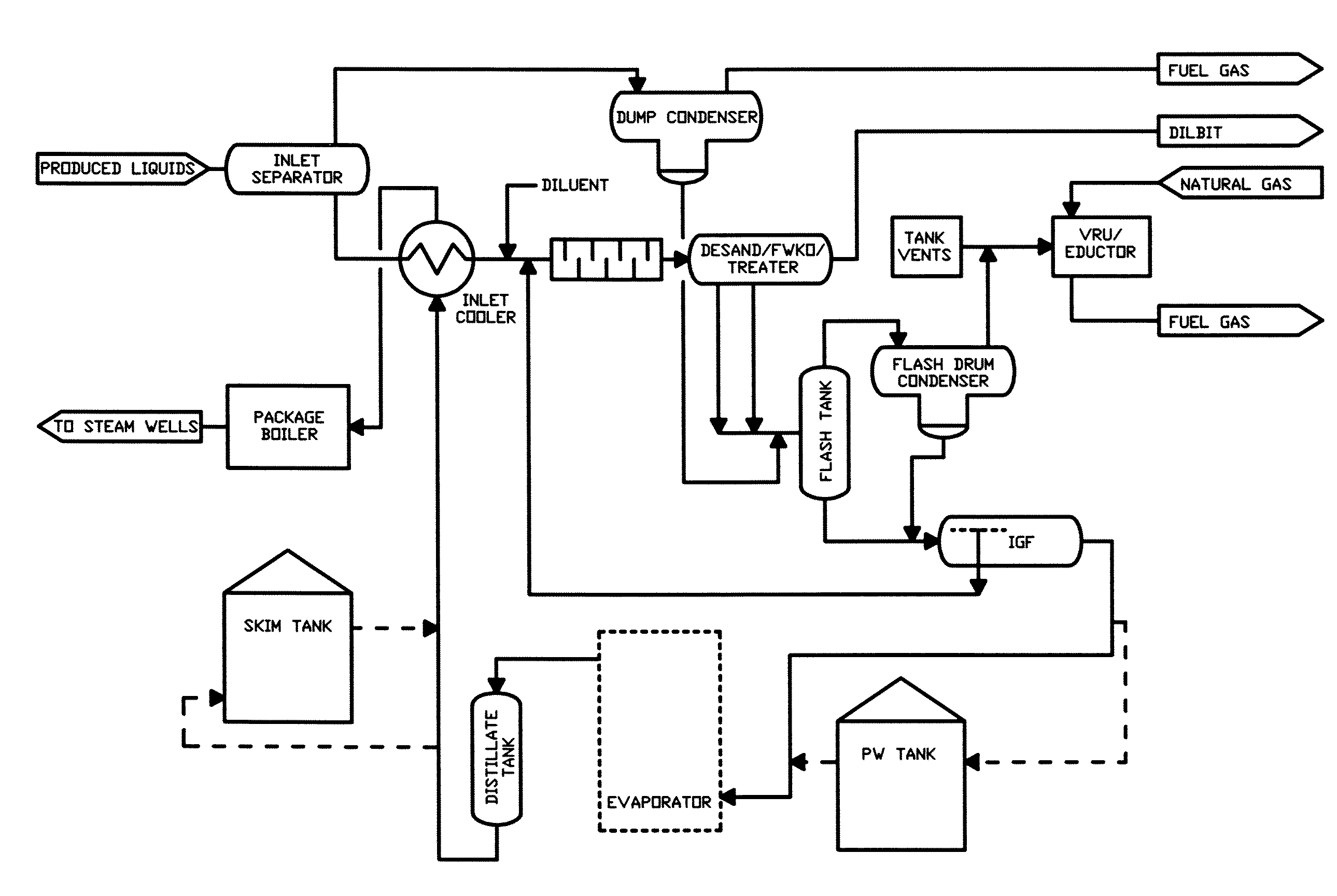

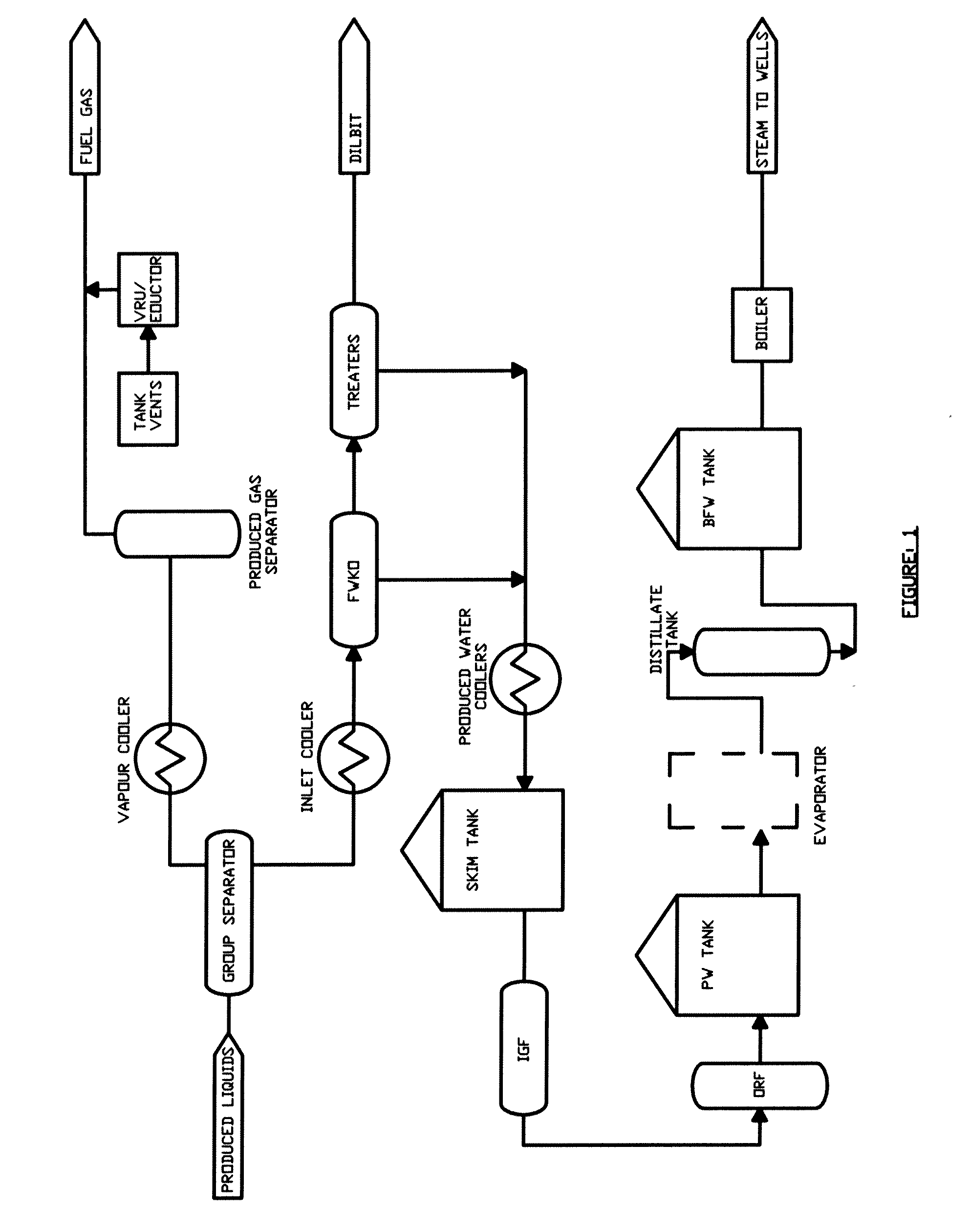

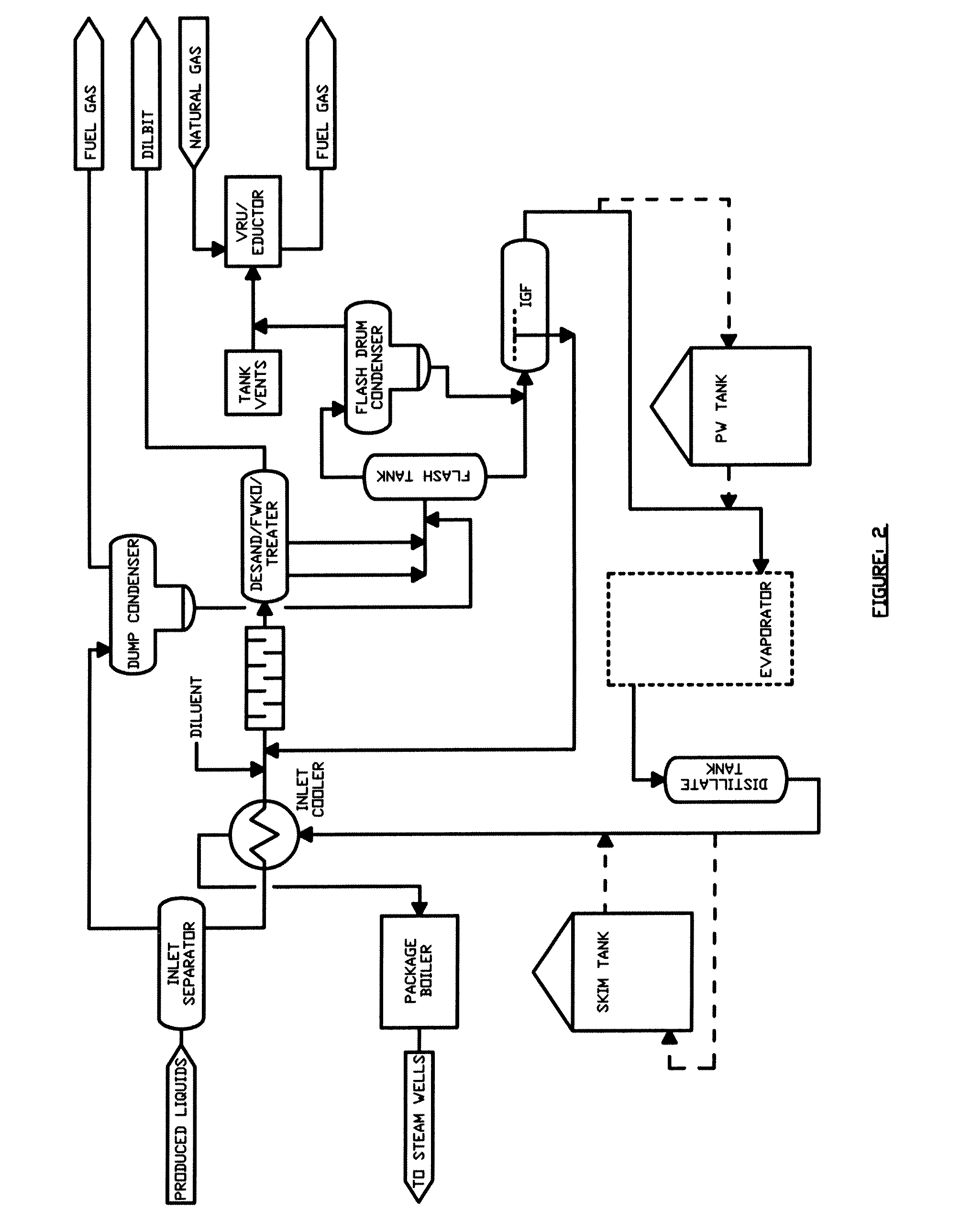

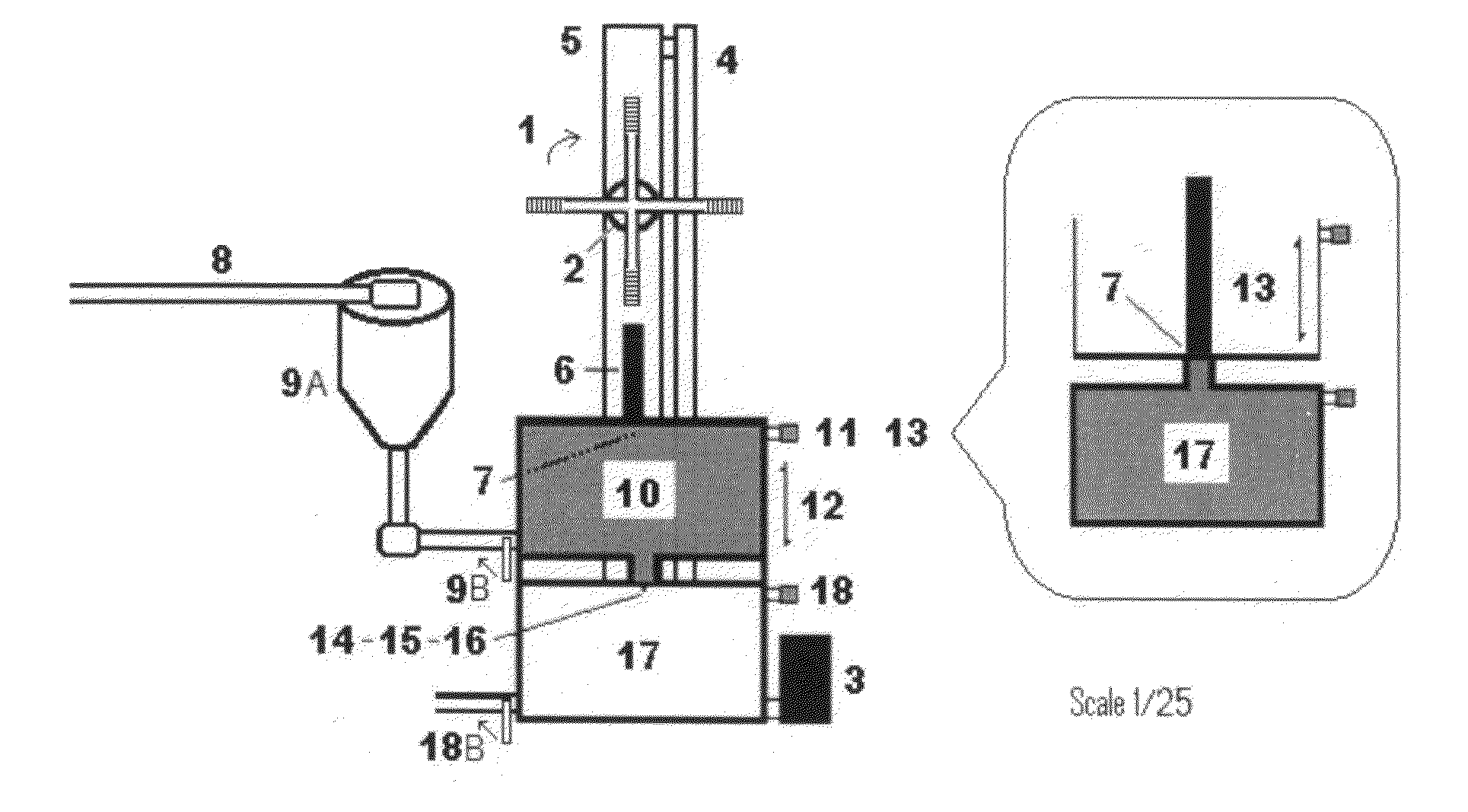

Modular Transportable System For SAGD Process

InactiveUS20120193093A1Easy interconnectionSmall sizeDrilling rodsInsulationProcess moduleSteam-assisted gravity drainage

A transportable modular process for exploiting a remote heavy oil resource or the like using steam assisted gravity drainage technology or the like. Said process comprising transportable preassembled and commissioned modules which when interconnected adjacent said remote heavy oil resource provide the ability to exploit said heavy oil resource or the like. Each module being preassembled and commissioned at the time of manufacture with the necessary piping and electrical wiring and other essential equipment for each module prior to being transported to adjacent the resource. Each module being, when transported to adjacent said resource, able to be readily interconnected with other process modules to enable an entire SAGD process or the like to be constructed adjacent said resource.

Owner:1NSITE TECH

Clean room facility and construction method

InactiveUS7083515B2Area of clean can be expanded and reducedReduce transmissionBuilding roofsMechanical apparatusMechanical engineeringEngineering

Owner:NOVELLUS SYSTEMS

Container based data center solutions

A cooling container comprises a container housing with a chilled water storage tank including a first interface for receiving chilled water. The chilled water tank has a plurality of straight pipes joined by elbows connections to provide a folded path, the full path length being greater than the length of the container housing, and a second interface for outputting the chilled water. A number of interfaces within the container housing are configured to receive a chiller module or a free cool unit.

Owner:SCHNEIDER ELECTRIC IT CORP

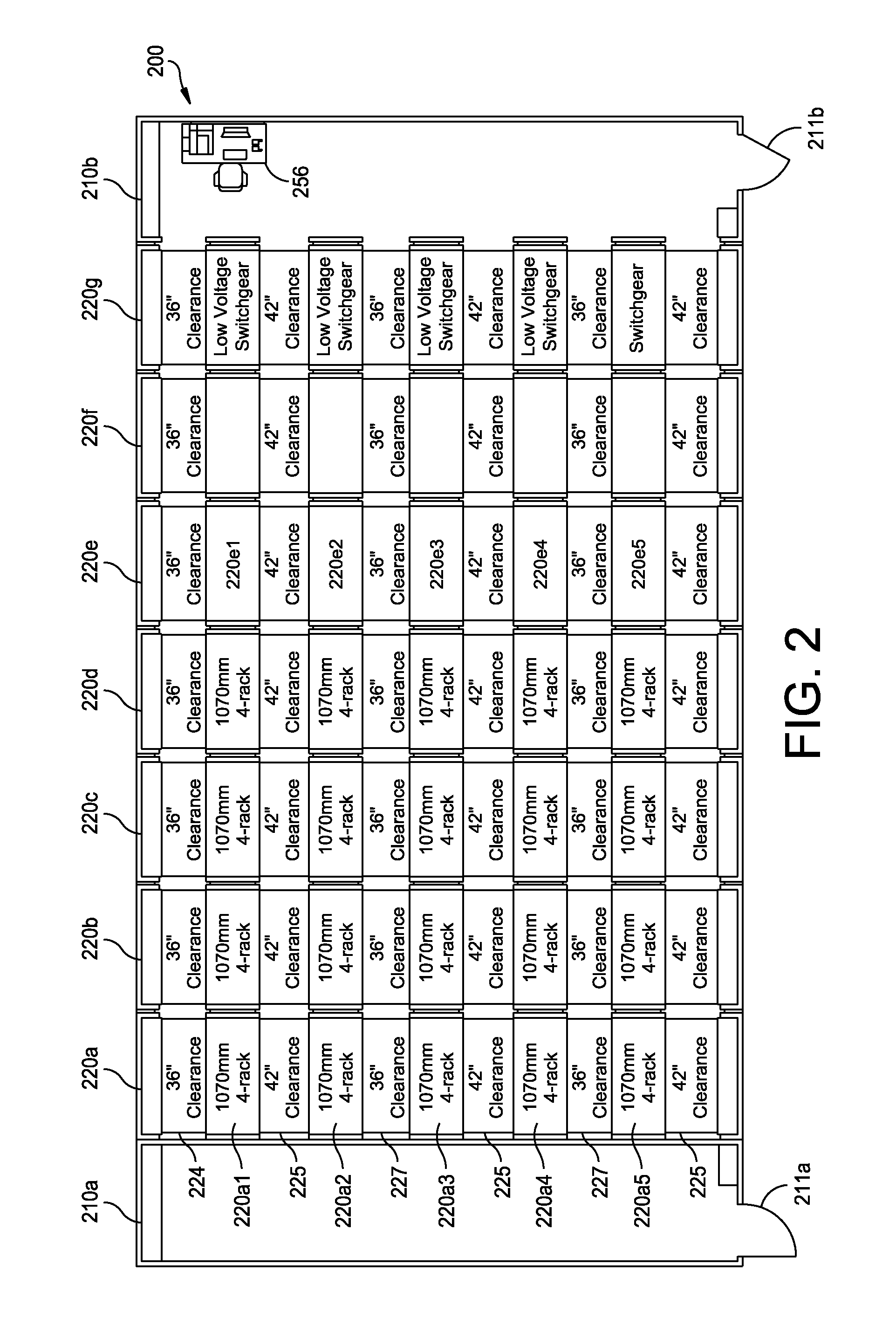

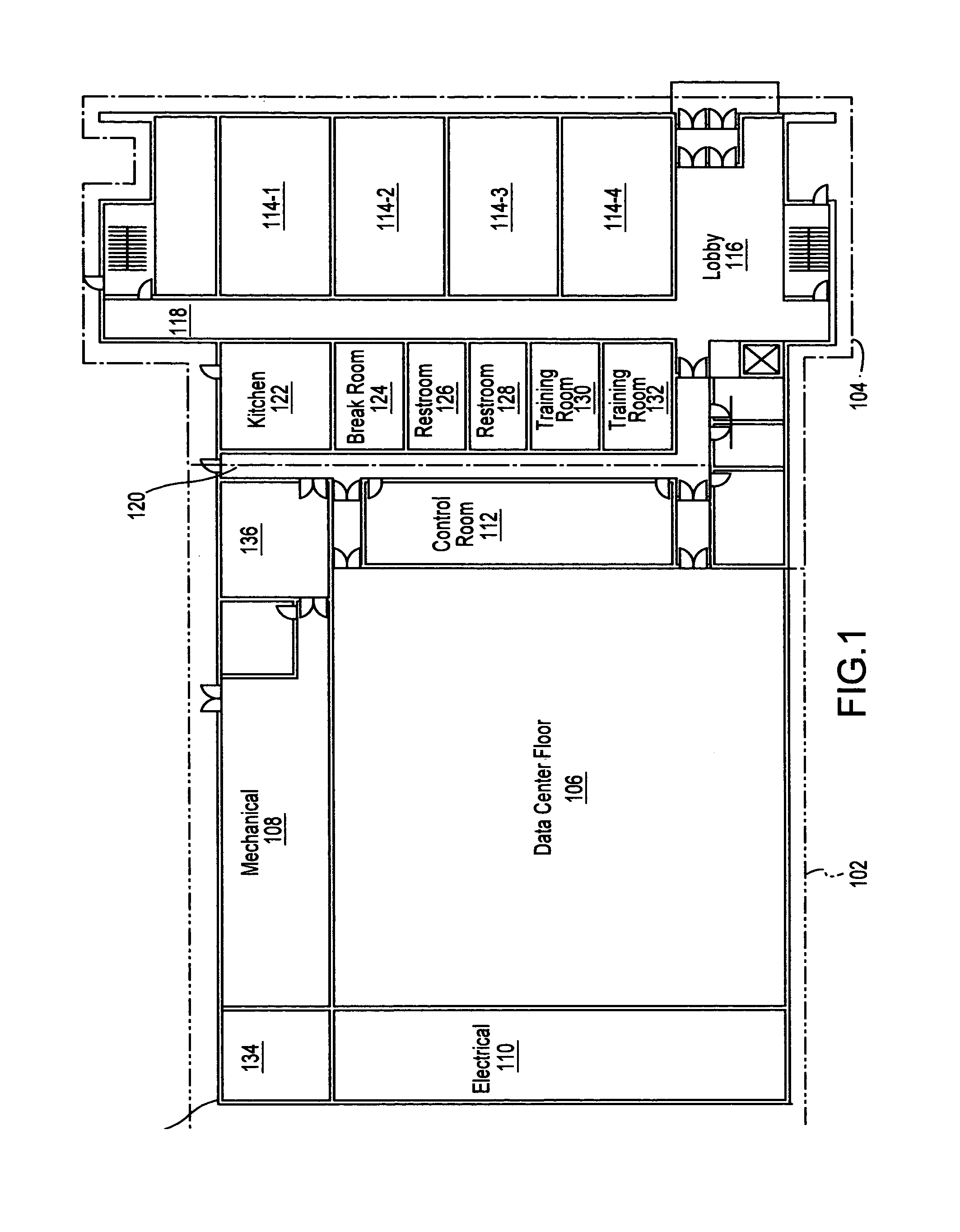

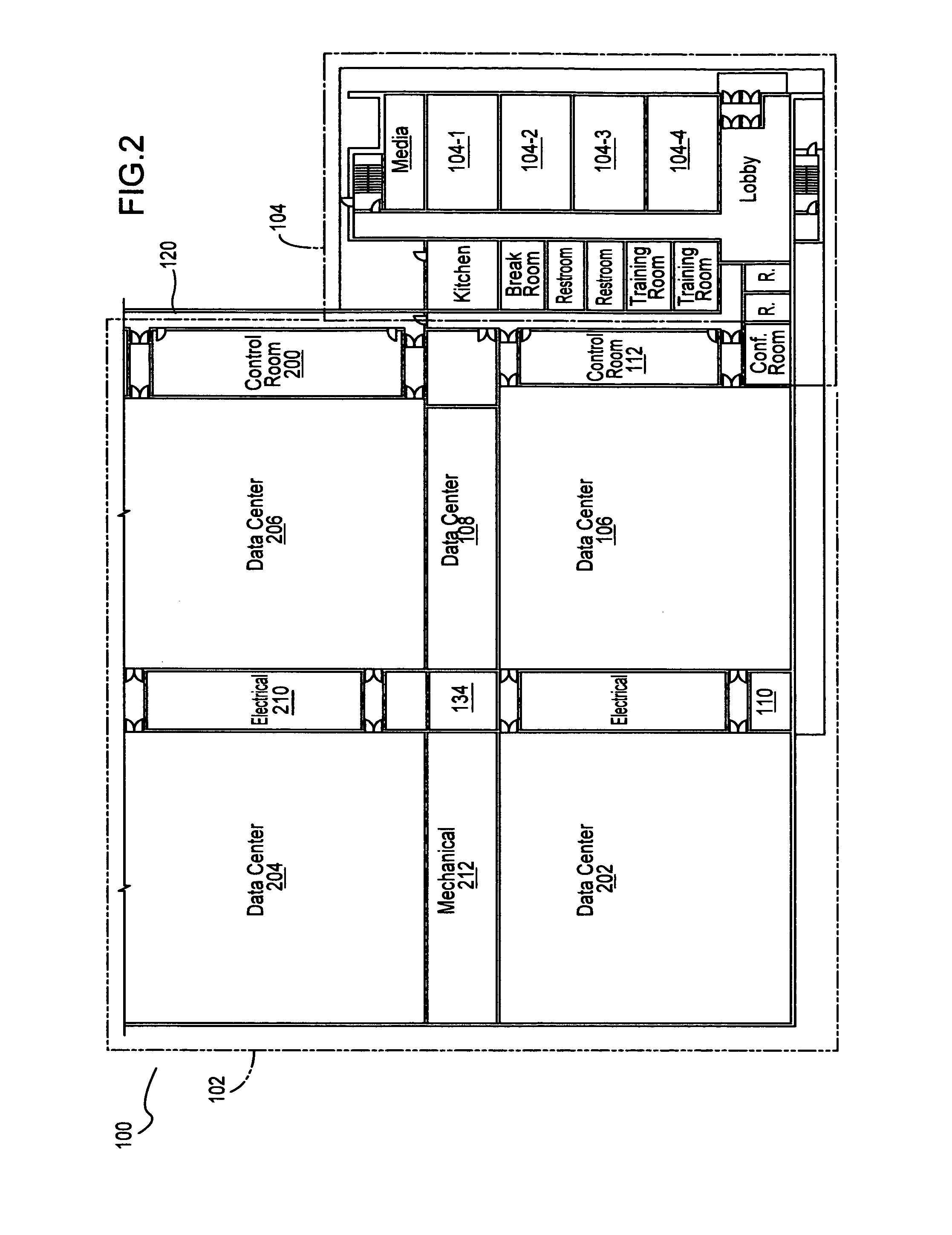

Data center having expandable or multipurpose configuration

InactiveUS20110023388A1Without serviceWithout spaceRoof covering using slabs/sheetsRoof covering using tiles/slatesData centerControl room

A building includes a data center to house computing equipment including computers and servers. The data center stores data. The building also includes a multipurpose center that houses office spaces, conference rooms and meeting rooms. The data center and multipurpose center differ in function but share resources. The data center is expandable using a configuration of a control room, an electrical room and a mechanical room. Additional data center floors adjoin existing structures to increase available space in a linear manner.

Owner:TONG S DAVID +1

Demountable building

InactiveUS7021010B2Easy to installEasy to removeVehicle body-frame connectionsSuperstructure subunitsEngineering

Owner:AARON SMITH PTY LTD

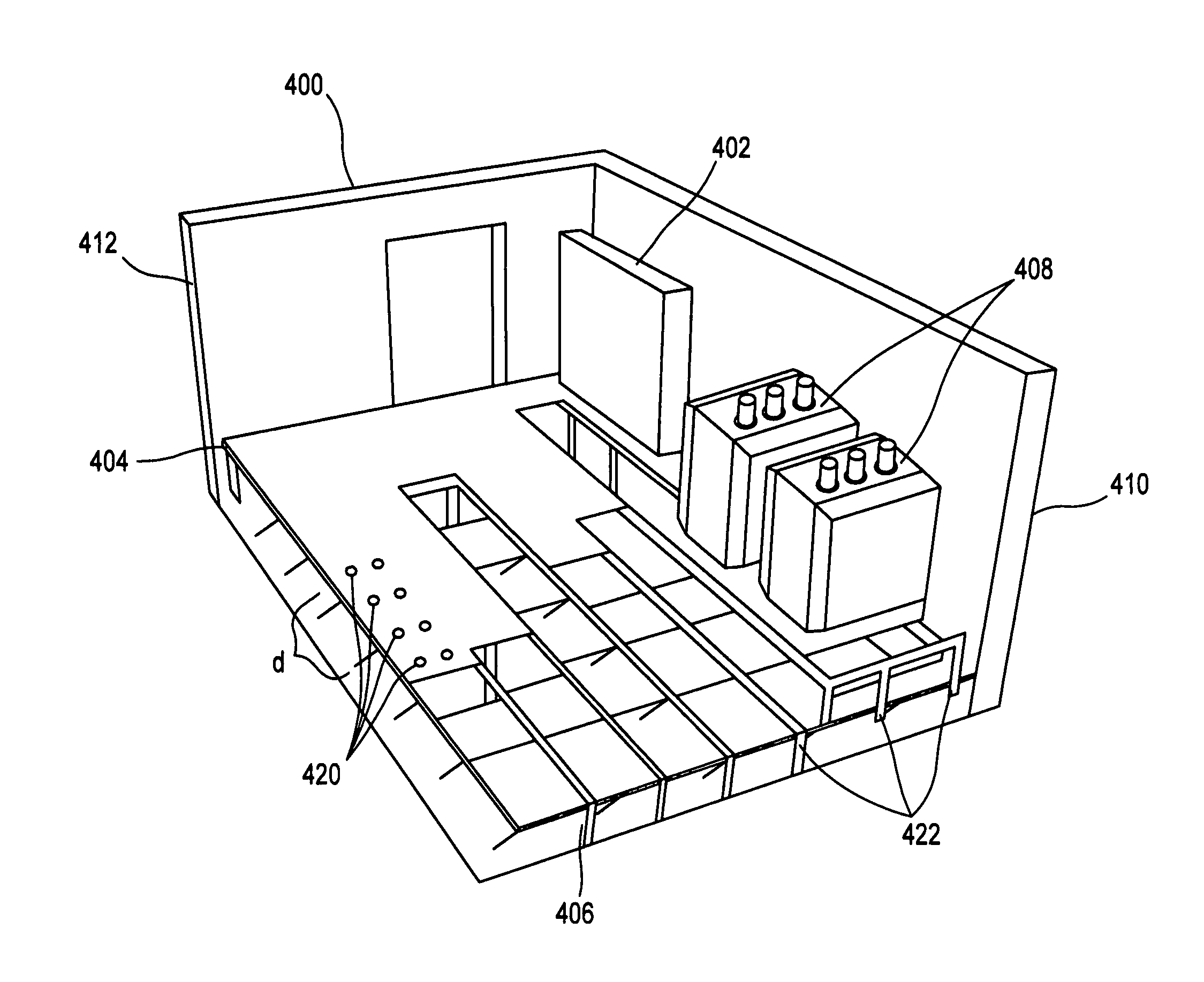

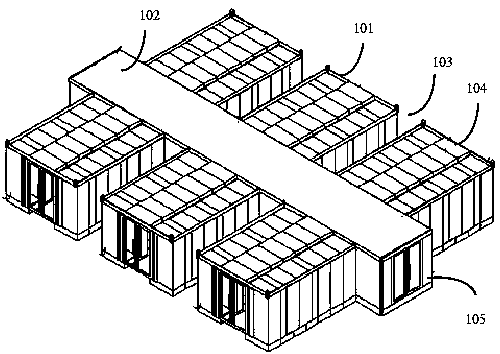

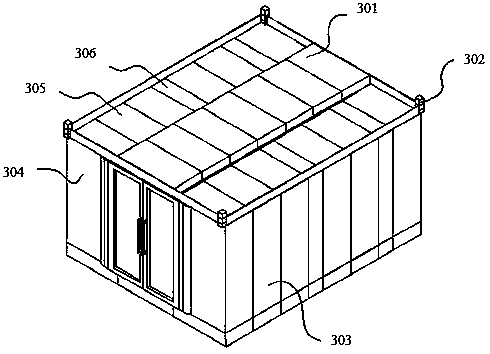

Modularized data center machine room provided with sealed channels

ActiveCN103806704AImprove construction efficiencyShort construction periodCooling/ventilation/heating modificationsIndustrial buildingsWater leakageData center

The invention discloses a modularized data center machine room provided with sealed channels. A wire routing channel and a pipe routing channel are arranged, so that factory prefabrication and productization installation are achieved, a construction period is shortened, and construction efficiency of a data center system is improved. By the adoption of hidden wire routing and pipe routing, the data center system is clean and tidy. Besides, the data center system is divided into a cold channel area, a hot channel area and a work maintenance channel area, wherein the cold channel area, the hot channel area and the work maintenance channel area are mutually isolated, the temperature of the three areas can be effectively controlled, comfortable environment is provided for workers, and the utilization rate of cool air is improved. A horizontal pipe routing channel is provided for a refrigerating unit, the water leakage risk is reduced, and engineering maintenance difficulty is reduced.

Owner:SHENZHEN XBROTHER TECH

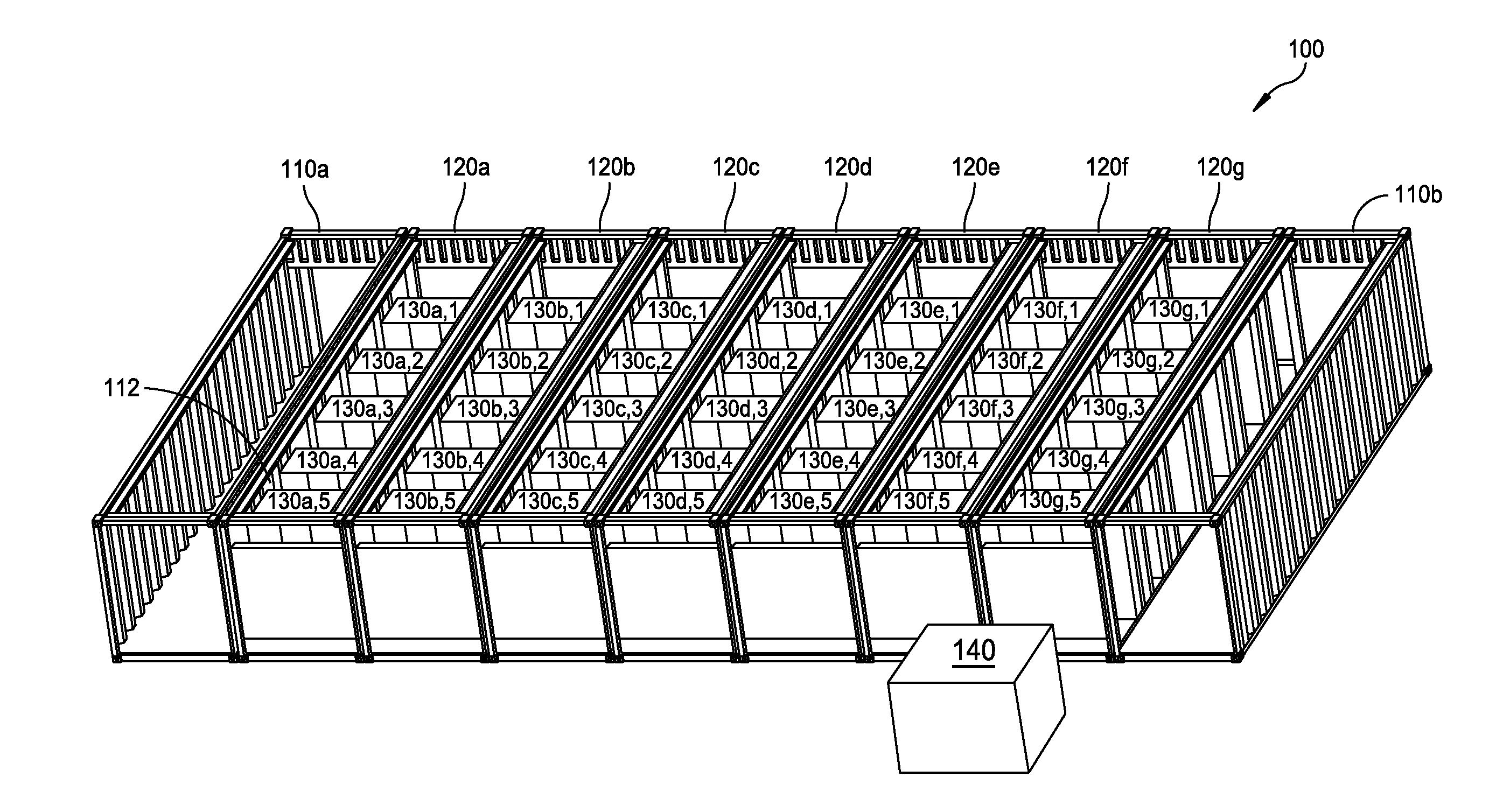

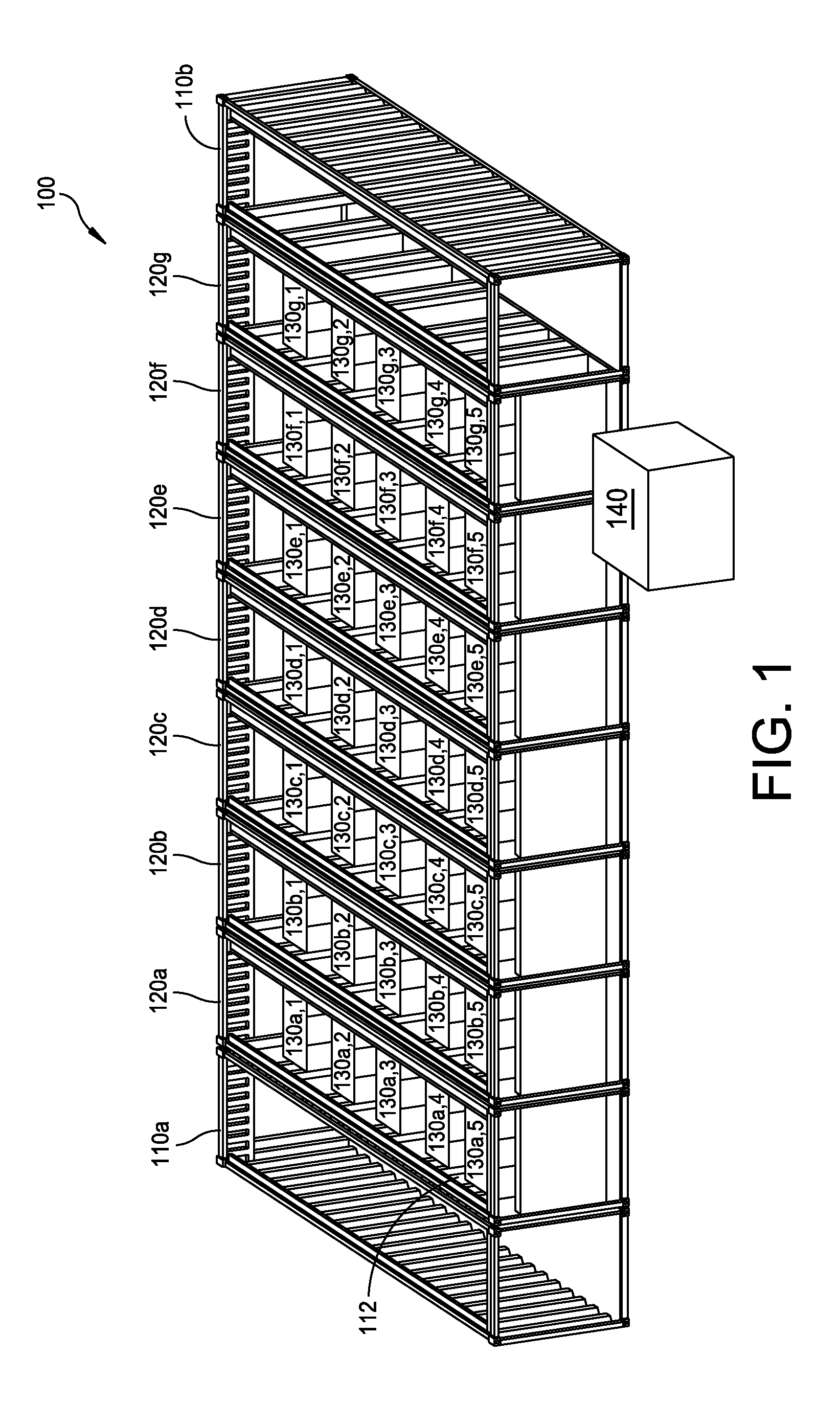

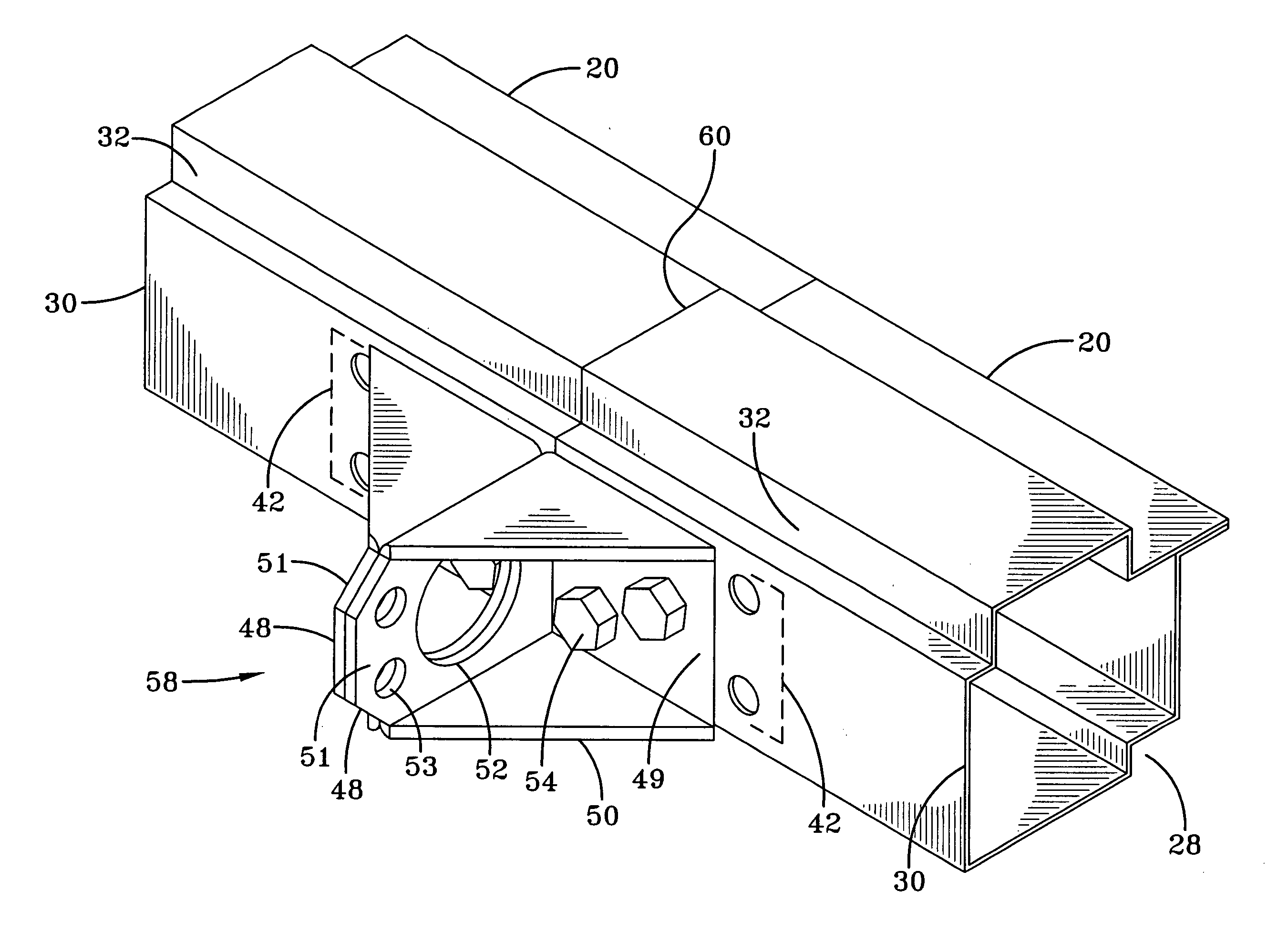

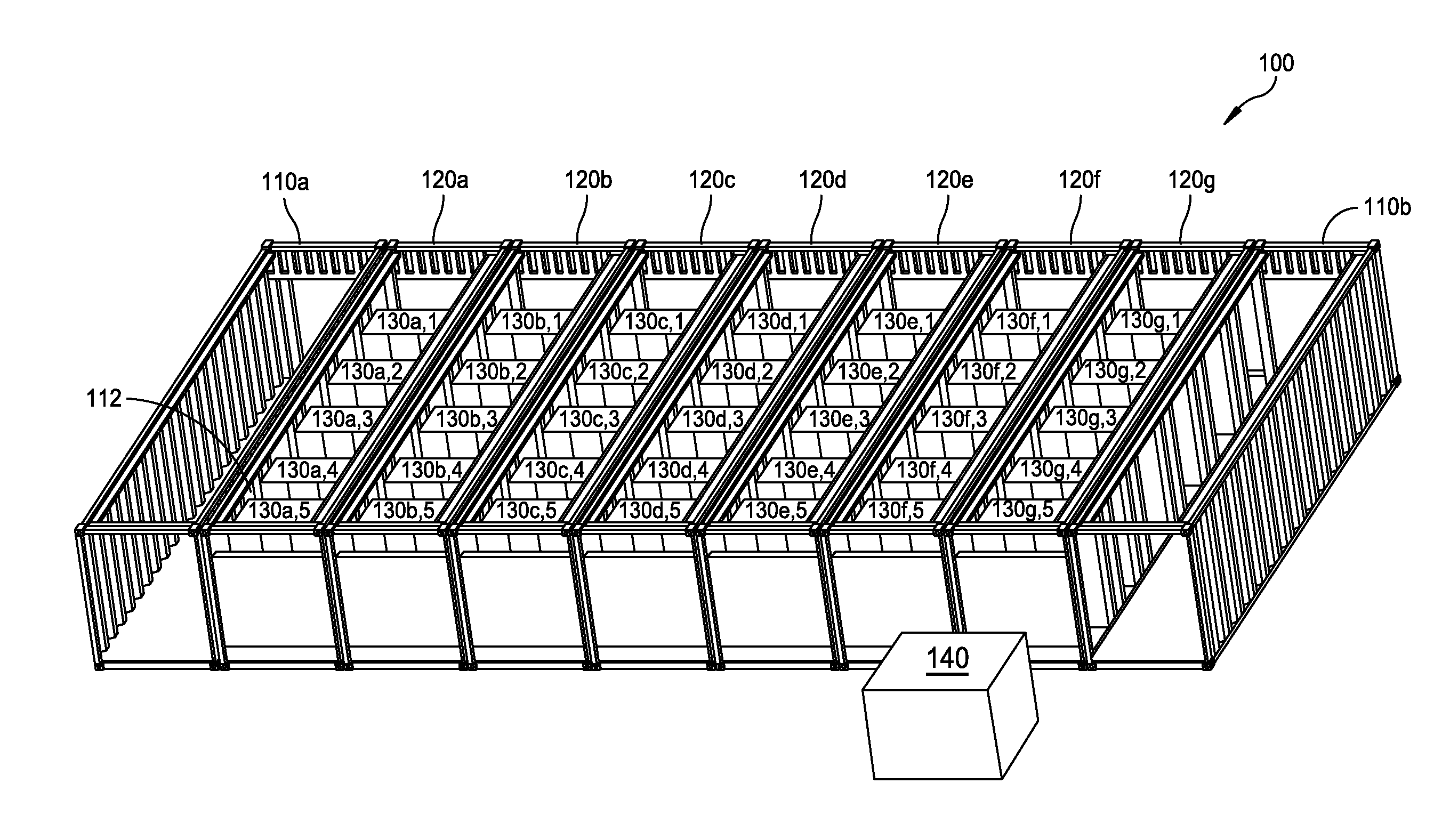

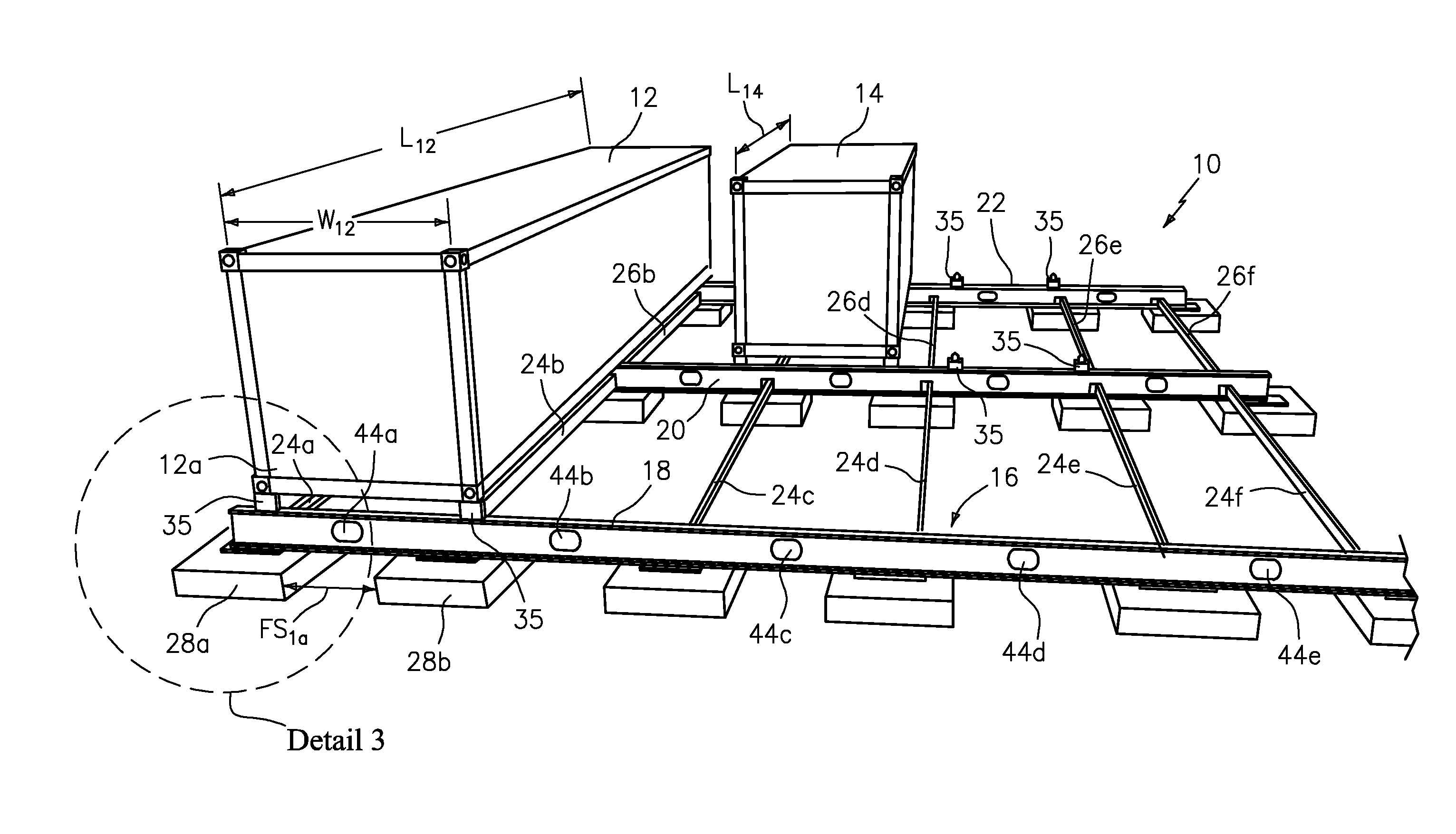

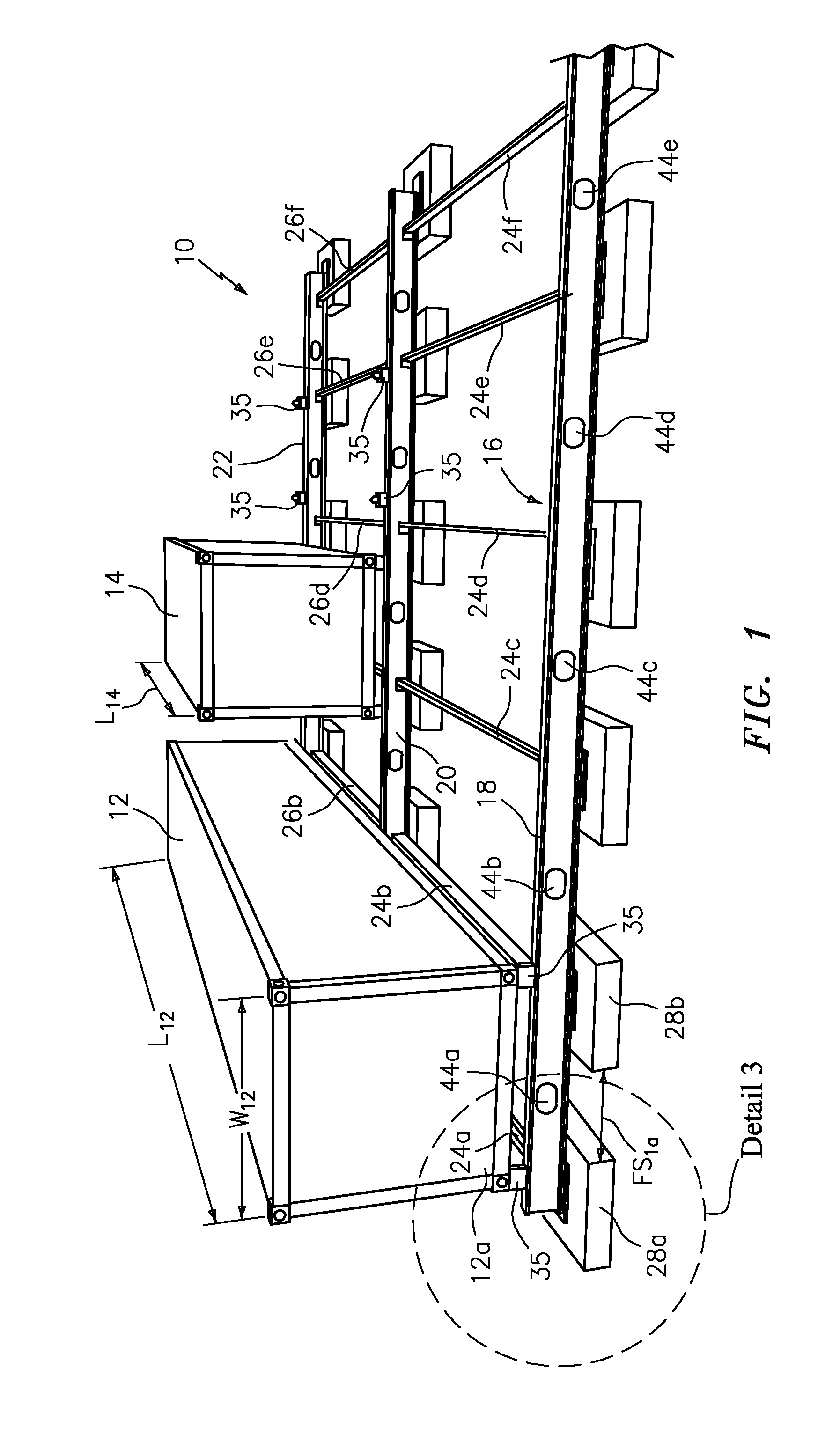

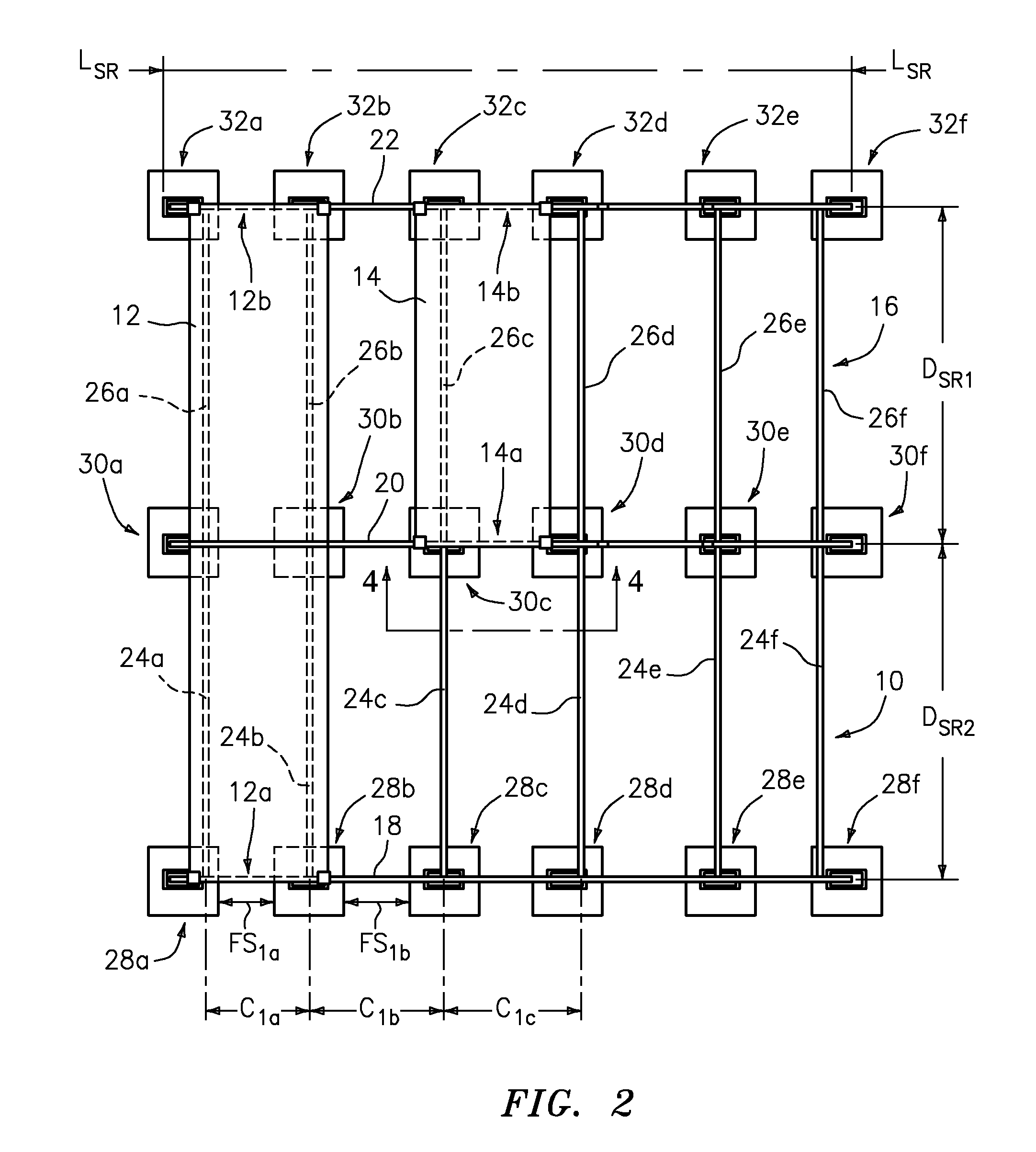

Frames for supporting service cells

A frame for supporting one or more cells that provide one or more services to a site. The frame includes a plurality of footings disposed on the site and a frame assembly disposed on the footings. The frame assembly includes a plurality of support rails, a plurality of connecting rails extending between and joined to the support rails, and a plurality of locking mechanisms disposed on the frame assembly. Each of the locking mechanisms selectively retains a portion of at least one of the cells to the frame assembly. The footings and the frame assembly contribute to define a service area between a lower surface of the cells and grade of the site. In one embodiment, one or more of the support rails includes one or more through-holes. The through-holes are configured to receive conduits for providing one or more services to and between the one or more cells.

Owner:TURNER LOGISTICS

Non ionic groups of amphoteric polysaccharide linear or branched alkyl or acid and base distillation reservoir liquid or gas mechanically refined and Nano particle dispersion and recovery basin in vacuum processing for Building Materials and High Wear-Heat Resistant Parts Brushes; Windings; Coils; Battery Cells; Brake Pads; Bushings; 2.5 Phase Extrusions Die Cast Molding; Refrigeration; Polarized Glass; and Central Processing Unit Processors.

Manufacture process scientific formula mechanically refined and nanoparticle dispersion preform slurry non ionic or electrolyte carbon nanofoam CNFs with or without ionic suspension elements manufactured, Preform slurry high wear-heat resistant parts electronic component composite coils, composite windings, drawn, annealing, spun, coils, windings, wire, woven textile mesh, shielding, brushes, inductors, antinode couplers, electric rheostats, starters, motors, alternators, generators, ionic suspension element enhanced composite coils, composite windings, drawn, annealing, spun, coils, windings, wire, woven textile mesh, shielding, brushes, capacitors, battery cells, rheostats, electronic resistors, transformers, transducers, rectifiers, power supplies, or heat sinks, Preform slurry carbon nanofoam CNFs extrusion high wear-heat resistant parts aerospace, automotive, and transportation brake calipers, rotors, pads, washers, spacers, and bushings, Preform slurry carbon nanofoam CNFs extrusion high wear-heat resistant parts precision casting molds manufacturing highly pure metal, Super Alloy, acid-solid, alkaline, glass, acrylic, halide, alkalide, or ceramics specializing in 2.5 phase die cast molding.

Owner:MATTHEWS ROBERT RICHARD

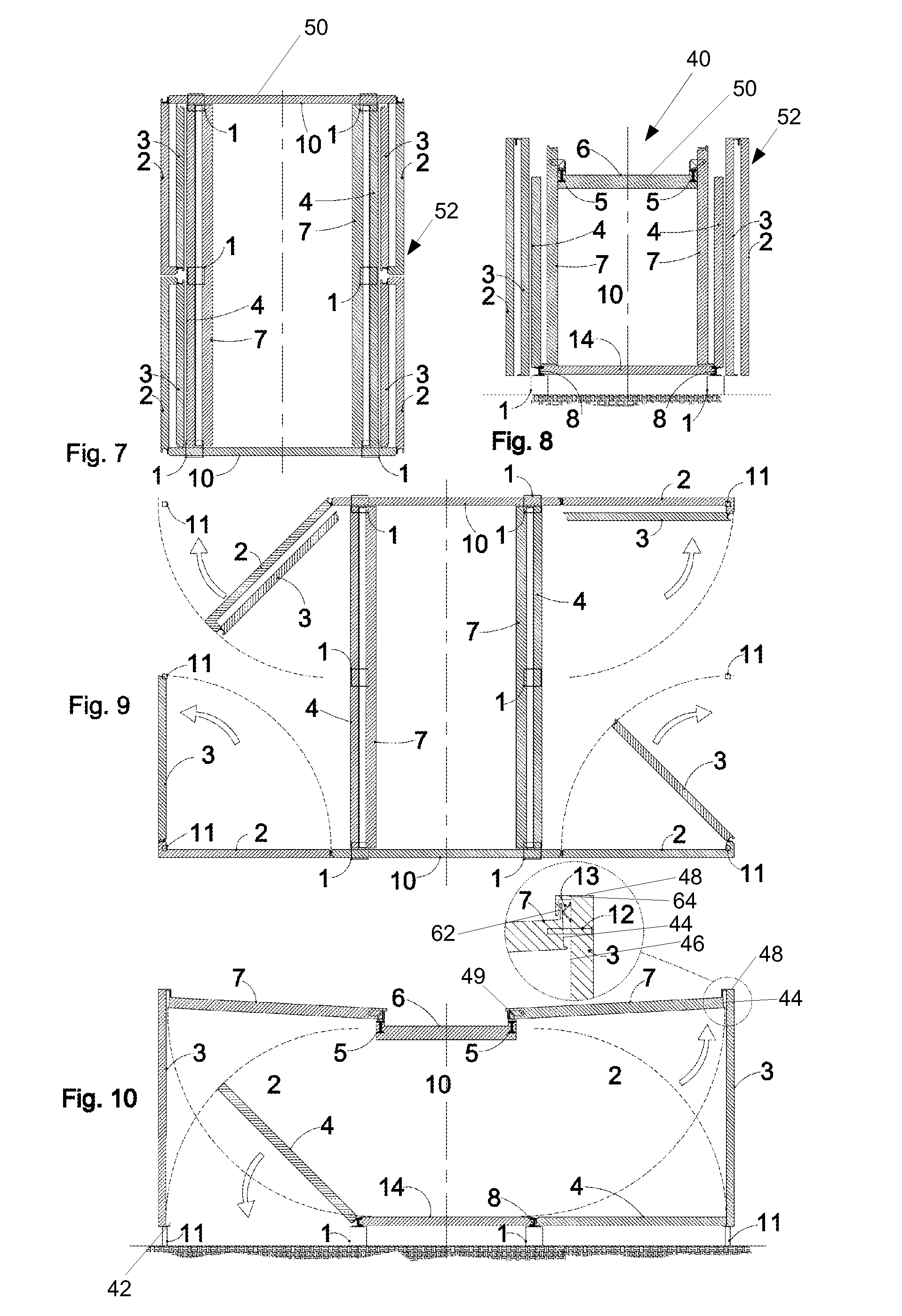

Prefabricated foldable building module

ActiveUS20160069062A1Convenient for storage and transportQuick installationHospitalsSpecial buildingFloor slabWall mount

Owner:DYNON MATTHEW

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com